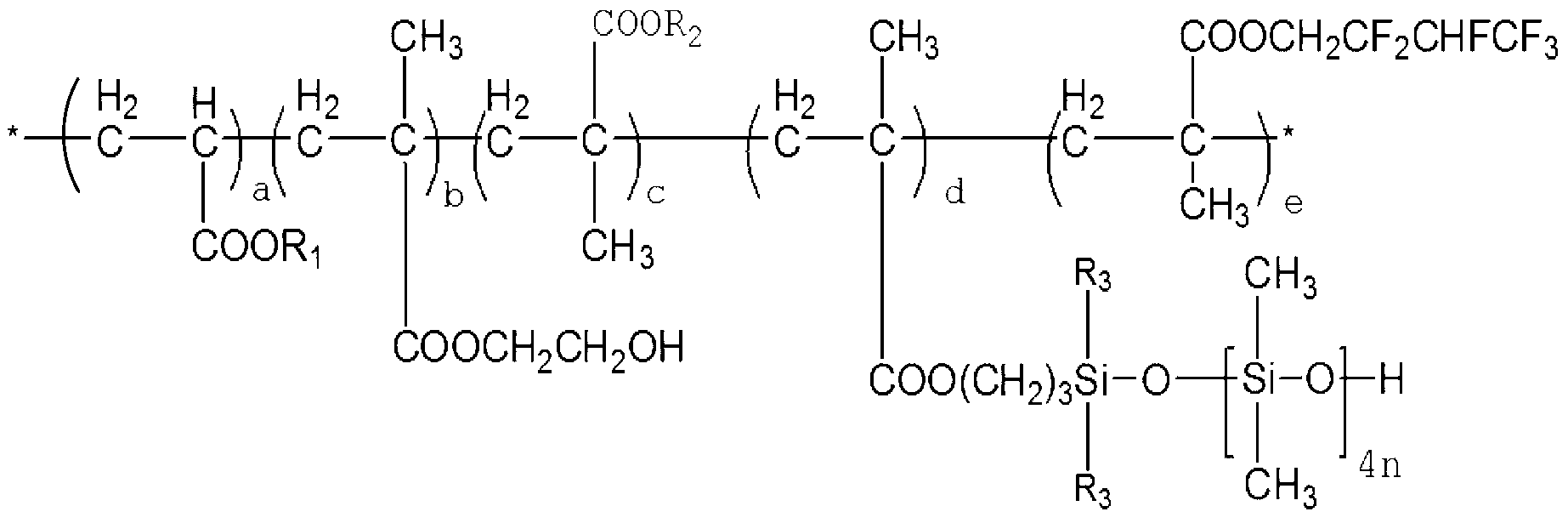

Modified acrylic resin for weather-resistant coating and preparation method for same

A technology of acrylic resin and acrylic resin, applied in the direction of coating, etc., can solve the problems of environmental pollution, limited application, increased cost, etc., and achieve the effect of less equipment investment, increased utilization rate, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

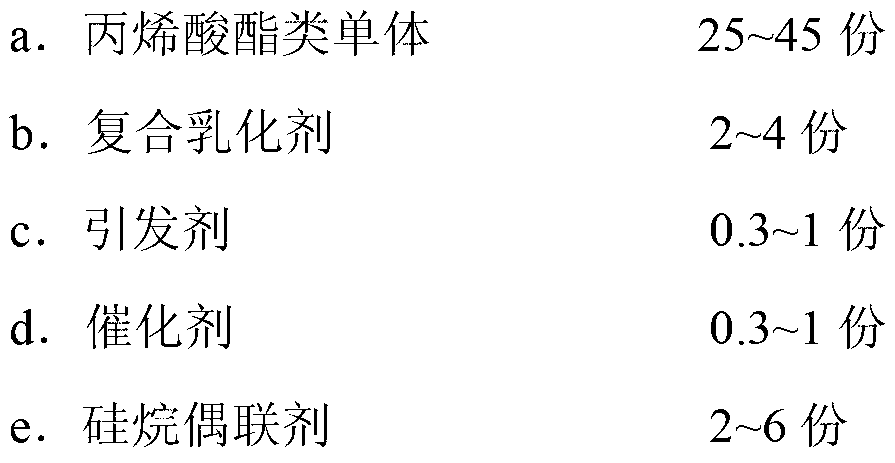

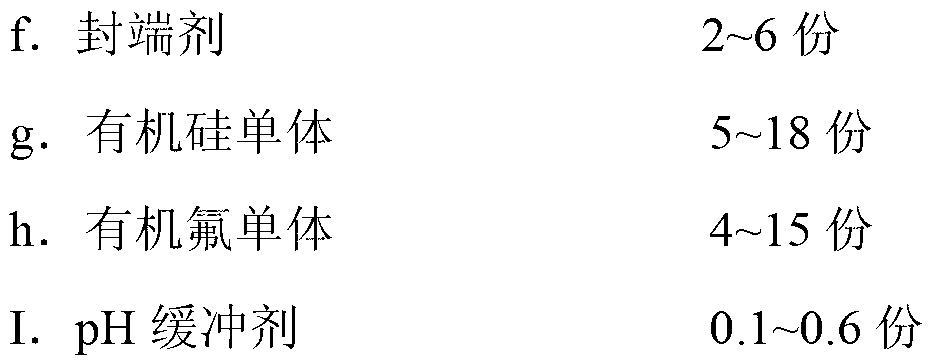

Method used

Image

Examples

Embodiment 1

[0046] Step 1) Dissolve 1g of alkylphenol polyoxyethylene ether, 1g of sodium lauryl sulfate, 0.3g of dodecylbenzenesulfonic acid, and 0.1g of sodium bicarbonate in 70g of water, and add it to a place equipped with a stirrer, a thermometer, Condenser, drop into the reactor of the device, stir and dissolve to form an emulsion;

[0047] Step 2) Nitrogen protection, raise the temperature to 90°C, add 2g of methacryloxypropyltrimethoxysilane, 2g of hydroxyethyl methacrylate, and 5g of octamethylcyclotetrasilicon to the reactor dropwise The mixed solution of oxane is incubated for 1h after the dropwise addition to obtain a silicone resin emulsion;

[0048] Step 3) When the temperature drops to 80°C, weigh 3g of acrylic acid, 12g of methyl methacrylate, and 10g of butyl acrylate to mix, and add 1 / 3 of the total amount to the silicone resin emulsion obtained in step 2), and place the rest In the dripping device;

[0049] Step 4) Dissolve 0.3g of ammonium persulfate in 5mL of water,...

Embodiment 2

[0055] Step 1) Dissolve 1.25g alkylphenol polyoxyethylene ether, 1.25g sodium dodecylsulfonate, 0.5g dodecylbenzenesulfonic acid, 0.25g sodium bicarbonate in 85g water, add to the , a thermometer, a condenser tube, and dropwise into the reaction vessel of the device, stirring and dissolving to form an emulsion.

[0056] Step 2) Nitrogen protection, raise the temperature to 70°C, add dropwise a mixture of 3g vinyltrimethoxysilane, 3g hydroxyethyl methacrylate, and 8g octamethylcyclotetrasiloxane into the reaction vessel , keep warm for 3h after the dropwise addition, to obtain a silicone resin emulsion;

[0057] Step 3) Adjust the temperature to 80°C, weigh 2g of acrylic acid, 15g of methyl methacrylate, and 13g of butyl acrylate to mix, and add 1 / 3 of the total amount to the silicone resin emulsion obtained in step 2), and place the rest in In the dripping device;

[0058] Step 4) Dissolve 0.5g of sodium persulfate in 8mL of water, add 1 / 5 of the aqueous solution of sodium p...

Embodiment 3

[0061] Step 1) Dissolve 1.5g alkylphenol polyoxyethylene ether, 1.5g sodium dodecylbenzenesulfonate, 0.7g dodecylbenzenesulfonic acid, 0.4g potassium bicarbonate in 100g water, add to a stirring Device, thermometer, and condenser are added dropwise to the reaction vessel of the device, stirred and dissolved to form an emulsion.

[0062] Step 2) Nitrogen protection, raise the temperature to 80°C, add dropwise a mixture of 4g vinyltriethoxysilane, 4g hydroxypropyl methacrylate, and 11g vinylcyclotetrasiloxane into the reactor, After the dropwise addition, the mixture was incubated for 1 hour to obtain a silicone resin emulsion.

[0063] Step 3) When the temperature drops to 80°C, weigh 2g of acrylic acid, 13g of methyl methacrylate, and 20g of butyl acrylate to mix, and add 1 / 3 of the total amount to the silicone resin emulsion obtained in step 2), and place the rest In the dripping device;

[0064] Step 4) Dissolve 0.7g ammonium persulfate in 5mL water, add 1 / 5 ammonium persu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com