Patents

Literature

410 results about "Hydroxypropyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-hydroxypropyl methacrylate is an enoate ester that is the 1-methacryloyl derivative of propane-1,2-diol. It has a role as a polymerisation monomer. It has a role as a polymerisation monomer. It derives from a propane-1,2-diol and a methacrylic acid .

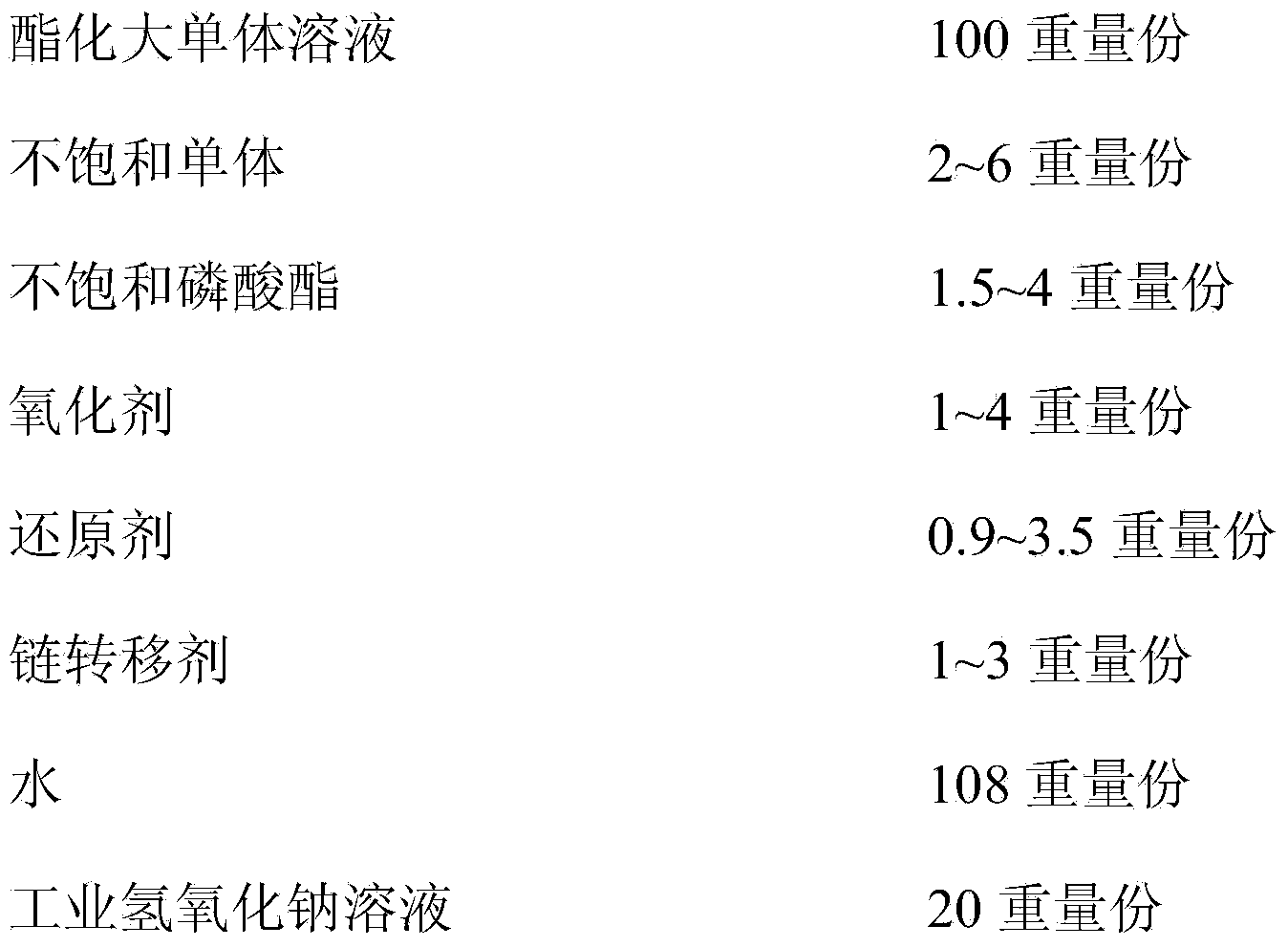

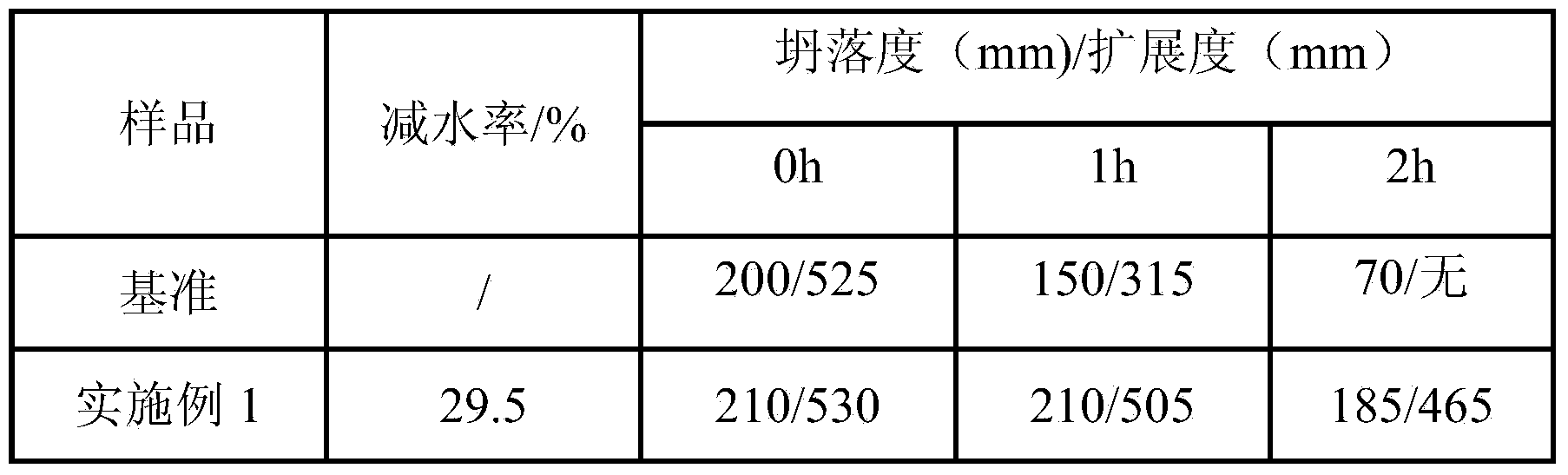

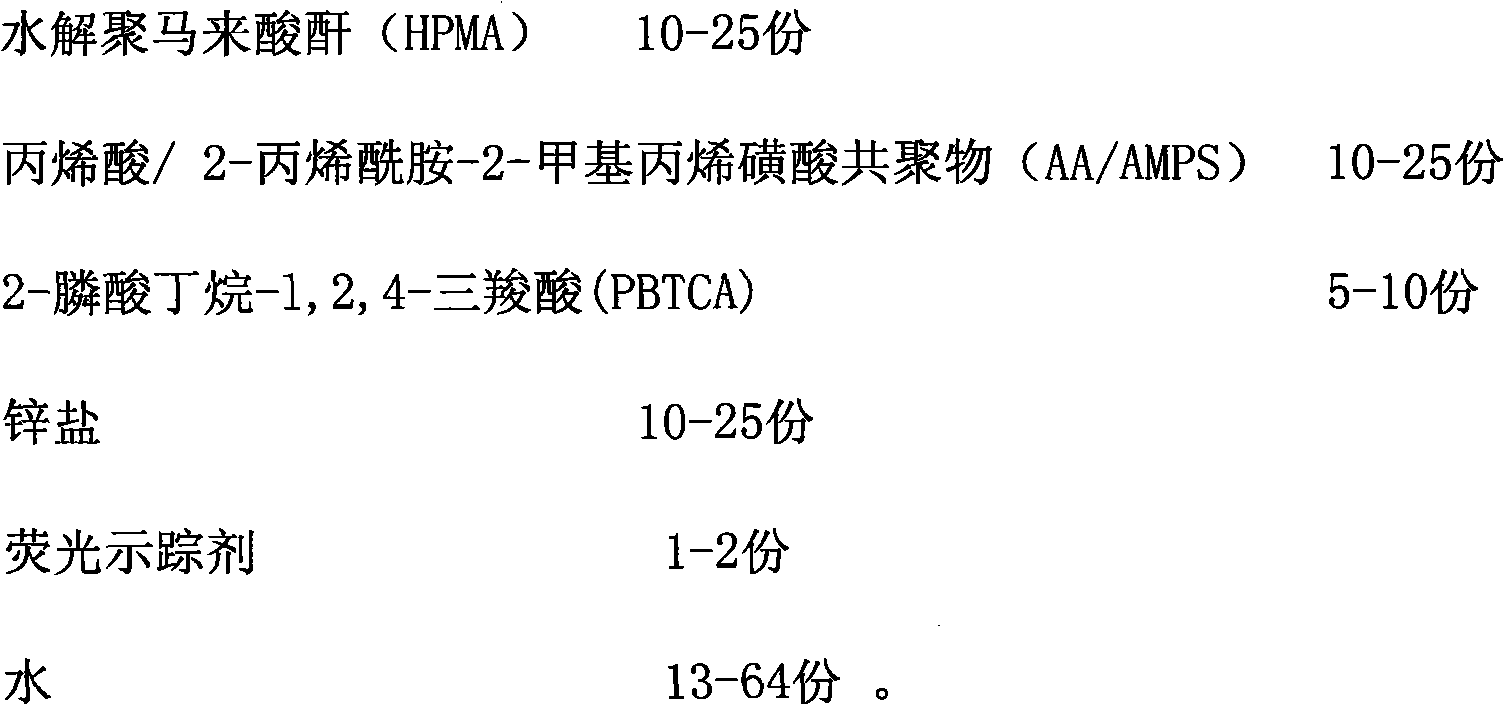

Ester slump retaining type polycarboxylate water reducer and preparation method thereof

The invention discloses an ester slump retaining type polycarboxylate water reducer and a preparation method thereof. The ester slump retaining type polycarboxylate water reducer is made from raw materials comprising the following components in parts by weight: 100 parts of esterified macromer solution by weight, 2-6 parts of unsaturated monomer by weight, 1.5-4 parts of unsaturated phosphate by weight, 1-4 parts of an oxidizing agent by weight, 0.9-3.5 parts of a reducing agent by weight, 1-3 parts of a chain transfer agent by weight, 108 parts of water by weight, and 20 parts of industrial sodium hydroxide solution by weight, wherein the concentration of the esterified macromer solution is 75-85%, and a solute thereof is the mixture of methoxy polyethylene glycol methacrylate, crosslinking monomers triethylene glycol dmethylacrglate and methyl methacrylate; the unsaturated monomer is methacrylic acid, acrylic acid, hydroxyethyl methylacrylate, hydroxyethyl acrylate, hydroxypropyl methacrylate or hydroxypropyl acrylate. The ester slump retaining type polycarboxylate water reducer provided by the invention has good slump retaining performance, good dispersibility, good adaptability and low cost.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

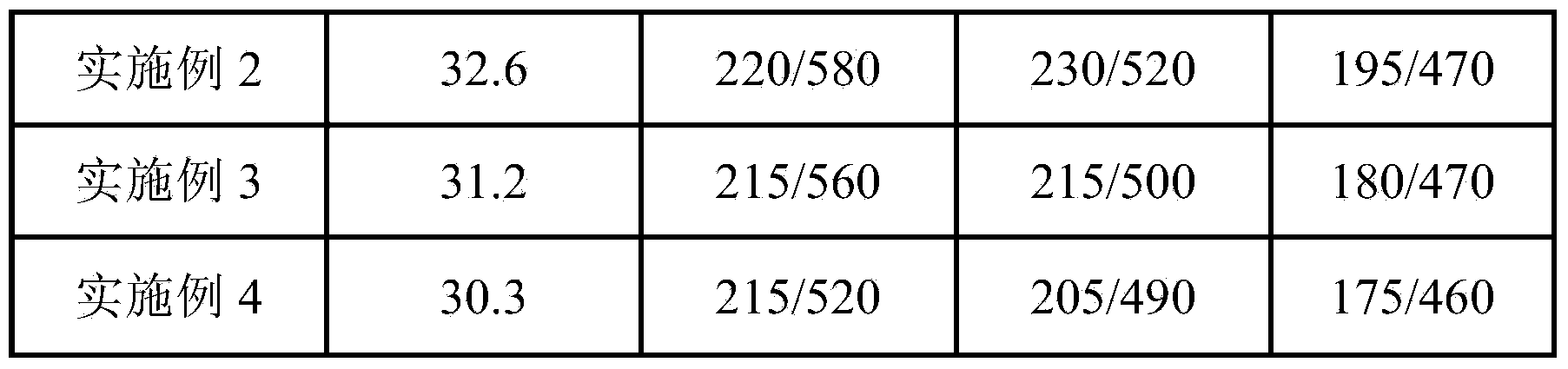

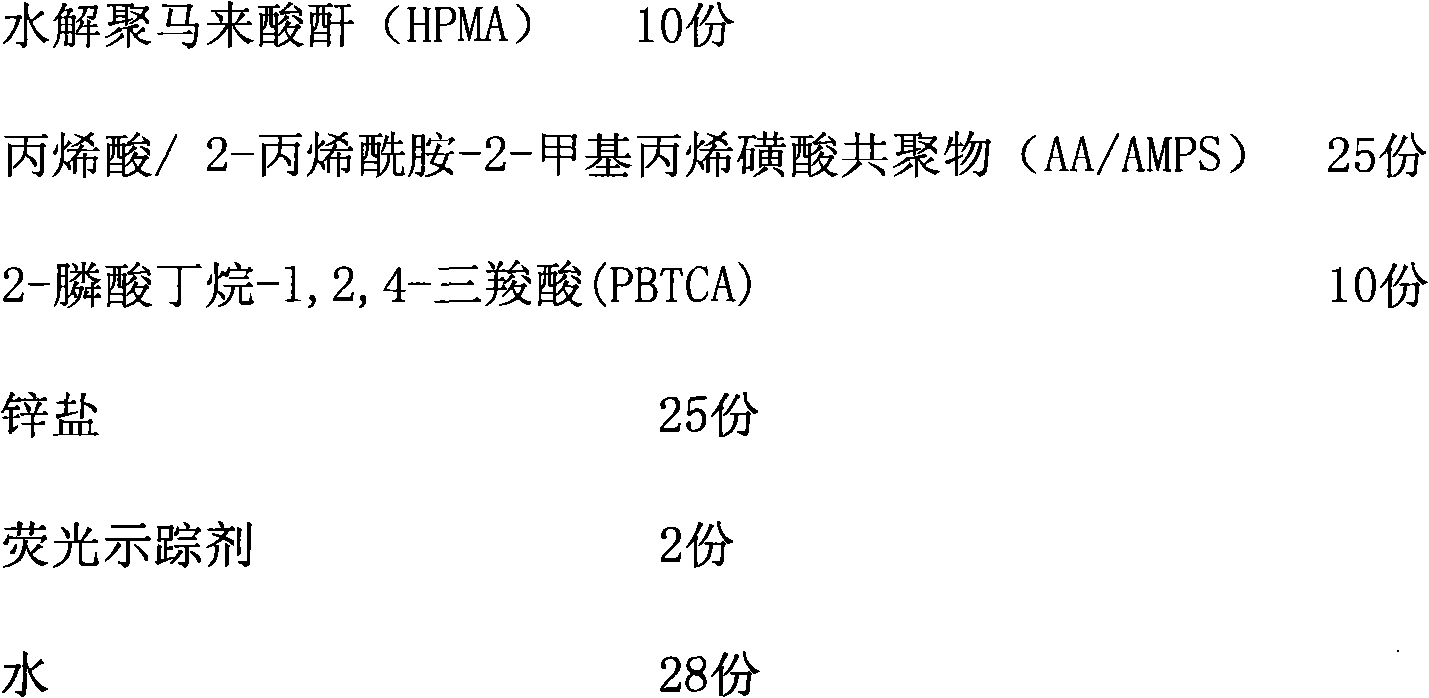

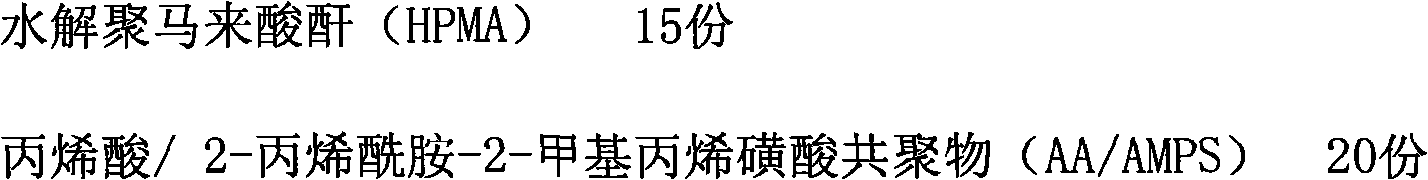

Composite low-phosphorus corrosion and scale inhibitor and application thereof

InactiveCN102674570ALow A phosphorus contentReduce dosageScale removal and water softeningTricarboxylic acidGluconic acid

The invention provides a composite low-phosphorus corrosion and scale inhibitor and application thereof. The composite low-phosphorus corrosion and scale inhibitor is prepared from a corrosion and scale inhibitor A and a corrosion and scale inhibitor B, wherein the corrosion and scale inhibitor A is prepared from 20-40 parts of polyepoxysuccinic acid (PESA), 20-40 parts of sodium gluconate and 20-60 parts of water; and the corrosion and scale inhibitor B is prepared from 10-25 parts of hydroxypropyl methacrylate (HPMA), 10-25 parts of acrylic acid / 2-acrylamido-2-methylacrylsulfonic acid copolymer (AA / AMPS), 5-10 parts of 2-phosphonobutyl-1,2,4-tricarboxylic acid (PBTCA), 10-25 parts of zinc salt, 1-2 parts of fluorescent tracer and 13-64 parts of water. The technical scheme is as follows: the corrosion and scale inhibitor A and the corrosion and scale inhibitor B in a weight ratio of 1:2 are compounded with water. The composite low-phosphorus corrosion and scale inhibitor has excellent corrosion and scale inhibition effects, and thus, the phosphorus content in the product is low, thereby reducing the phosphorus discharge and having favorable environmental protection performance.

Owner:CHINA PETROLEUM & CHEM CORP

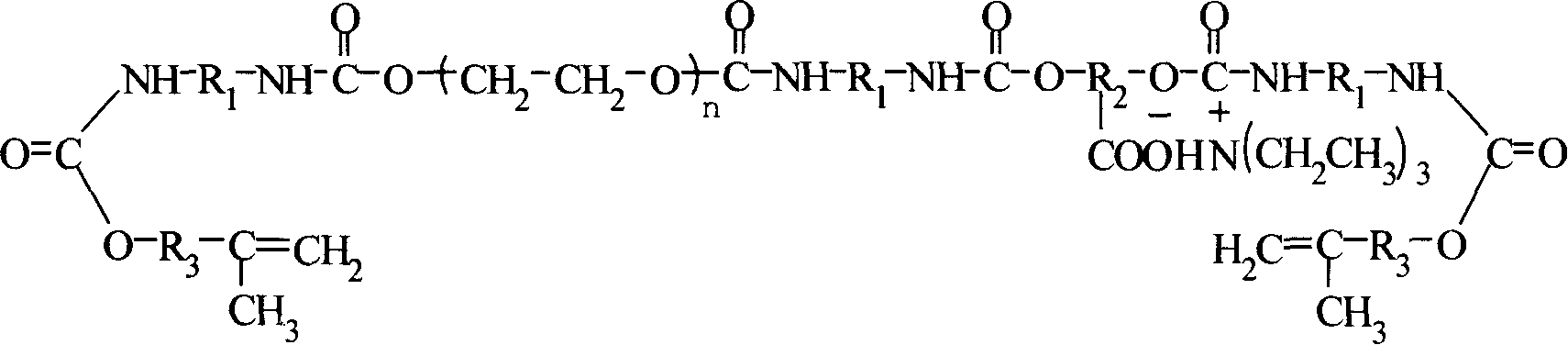

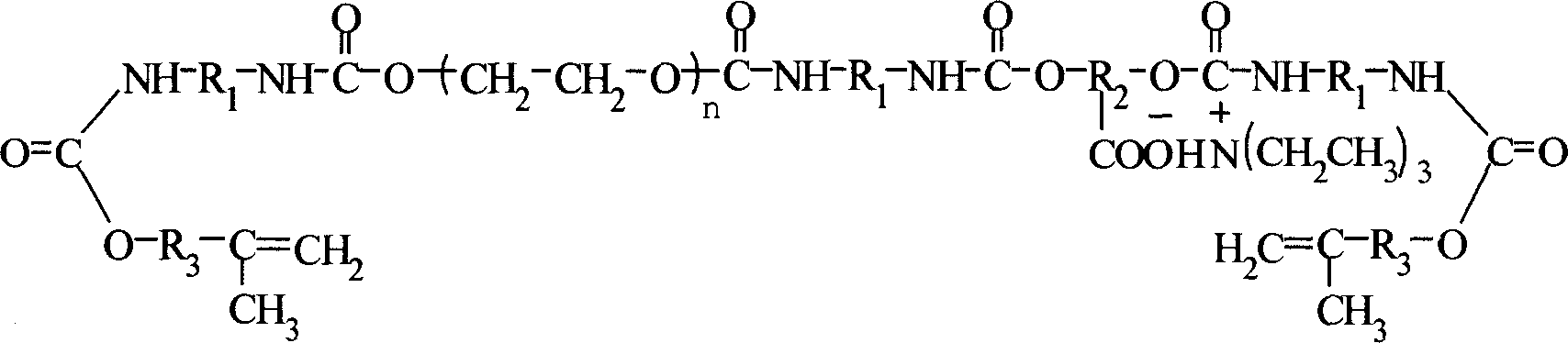

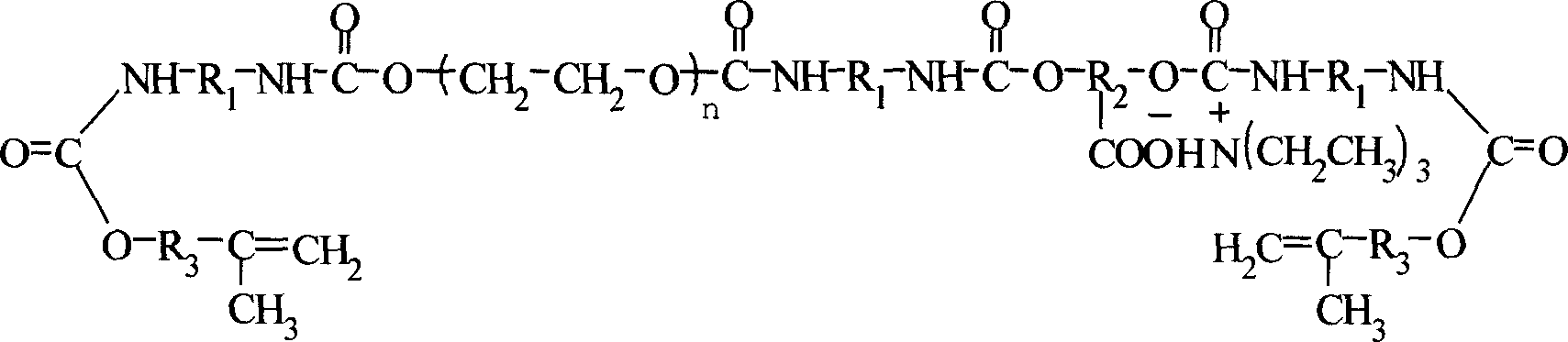

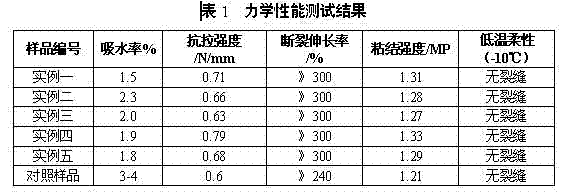

Ultraviolet light solidfication water polyurethane acrylate paint resin and its preparation method

InactiveCN1869139AThe molecular structure is well controlledImprove performancePolyurea/polyurethane coatingsSolubility(Hydroxyethyl)methacrylate

The invention relates to an ultraviolet light solidified water urethane acrylate coating resin. It is mainly made up of aromatic diisocyanate, polyethylene glycol, polyhydroxy-carboxylic acid, dihydric alcohol, hydroxyethyl methacrylate ethyl ester, and tri-ethylamine. It is prepared by adding the above materials orderly. It has the advantages of good water solubility, pliability, and stability.

Owner:SHANTOU UNIV +1

Preparation method of polyacrylate emulsion containing silicon, fluorine and phosphate group

The invention relates to a preparation method of polyacrylate emulsion containing silicon, fluorine and a phosphate group. The polyacrylate emulsion is widely applied in the fields of leather, paper and architectural decoration and finishing paint due to excellent caking property, film-forming property and mechanical properties. According to the preparation method provided by the invention, butyl acrylate, methyl methacrylate, styrene, hydroxypropyl methacrylate, vinyl triethoxy silane, phosphate functional monomer and dedecafluoroheptyl methacrylate are taken as polymerization monomers, lauryl sodium sulphate and fatty alcohol-polyoxyethylene ether are taken as emulsifiers, peroxysulphate is taken as an initiator, and a pre-emulsification seeded emulsion polymerization process is adopted for preparing the polyacrylate emulsion. According to the polyacrylate emulsion obtained by adopting the preparation method provided by the invention, fluorine, silicon and the phosphate group are introduced into a molecular structure, flame retardance, low temperature resistance, corrosion resistance, water resistance, anti-scouring property, mechanical properties and adhesiveness with materials such as metal and cement of a polymer emulsion film are obviously improved, and the obtained polyacrylate emulsion can be applied to leather, textile, metal antirust paints and decorative finish paints for an internal wall and an external wall of a building material and has good development prospect.

Owner:南京紫鸿生物科技有限公司 +1

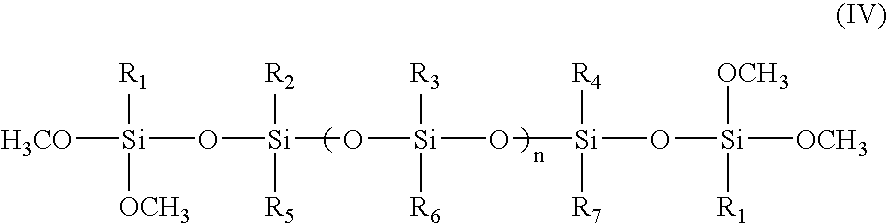

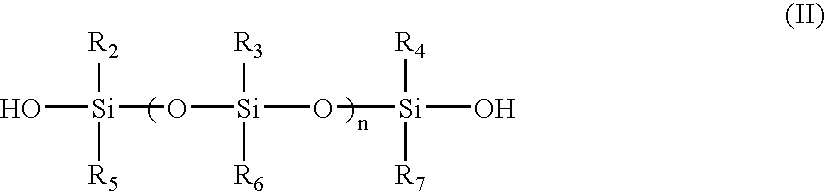

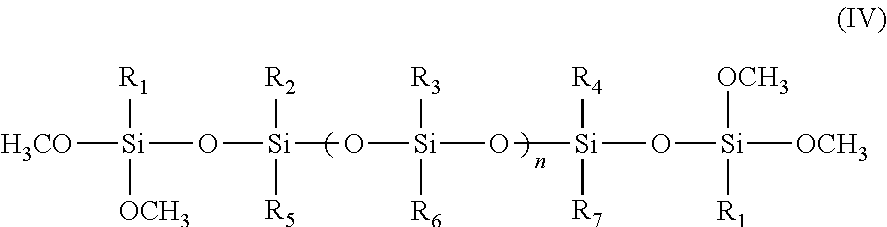

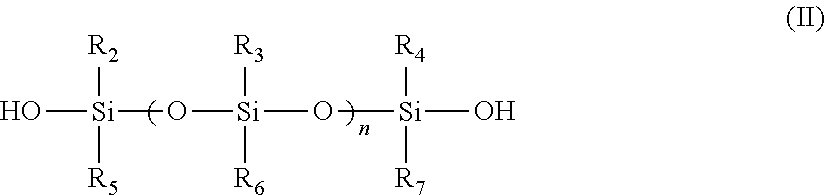

Room temperature-curable polymers

Methods of making room temperature-curable polymers. Reactants include siloxane-terminated polymers and silanols. The reactants are mixed, and the polymerization allowed to proceed in air at room temperature. The polymers are exceptionally useful because they allow for the incorporation into the polymers themselves of one or more therapeutic compounds. Thus, medical devices from which controlled drug release is desirable (for either local or systemic delivery) can be coated with therapeutic compound-containing polymers of the invention. In a preferred embodiment, a polymer of poly(MPCw:LAMx:HPMAy:TSMAz) where w, x, y, and z represent the molar ratios of monomers used in the feed for preparing the polymer; MPC represents the unit 2-methacryoyloxyethylphosphorylcholine, LMA represents the unit lauryl methacrylate, HPMA represents the unit 2-hydroxypropyl methacrylate, and TSMA represents the unit 3-trimethoxysilylpropyl methacrylate is reacted with polydimethylsiloxane. In another preferred embodiment, a therapeutic compound is incorporated into the polymer, such as dexamethasone.

Owner:ABBOTT LAB INC

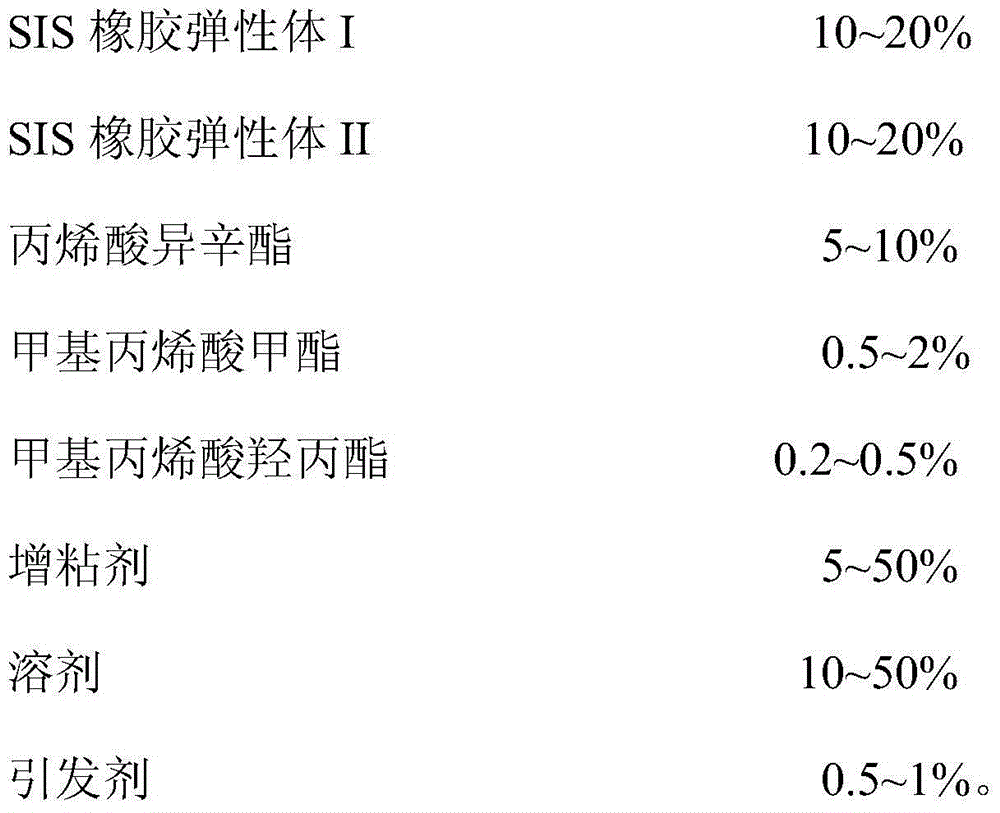

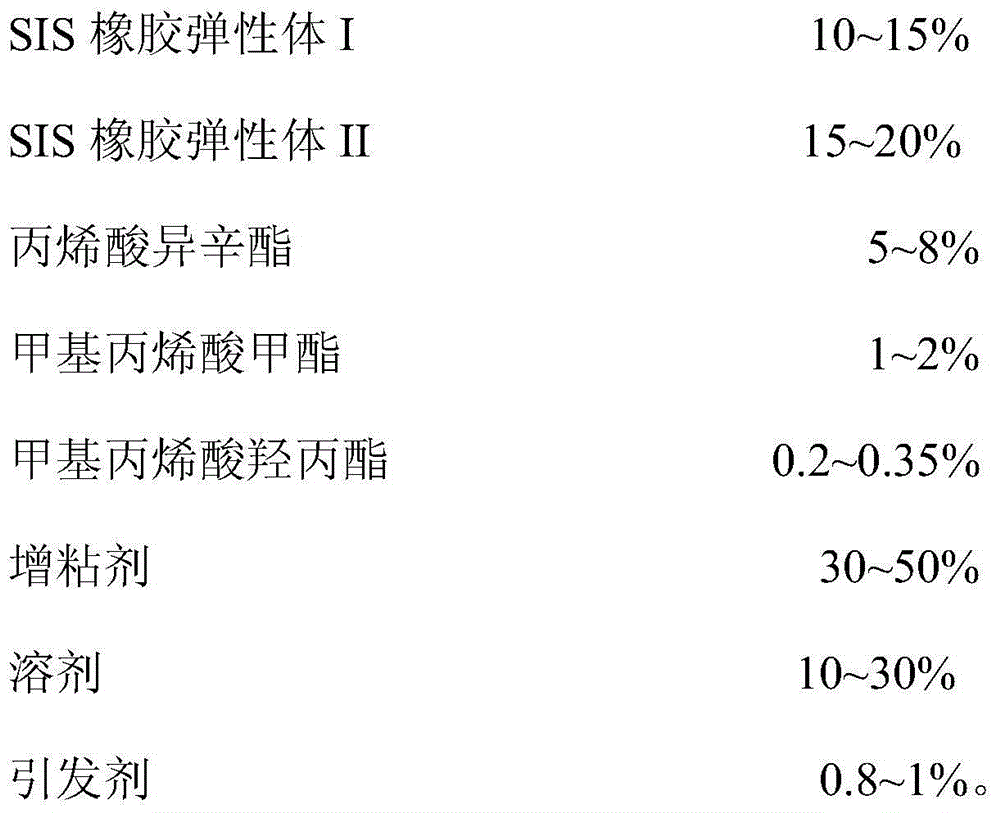

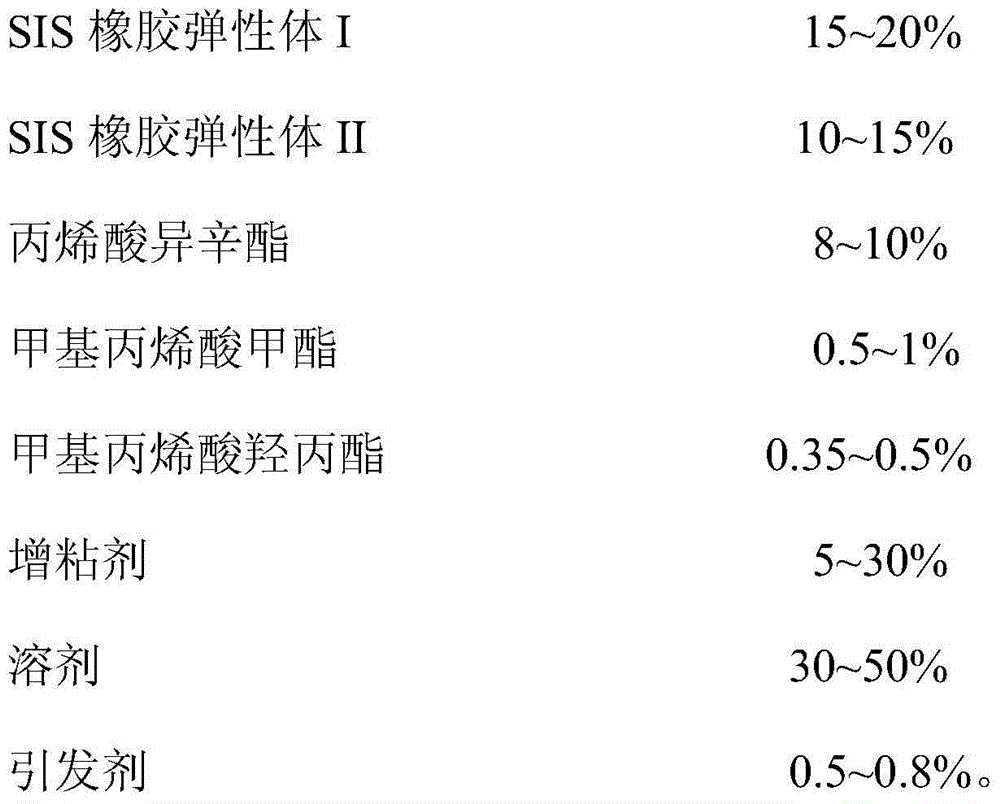

Acrylic acid modified hot-melt pressure-sensitive adhesive for bearing adhesive tape and preparation method of acrylic acid modified hot-melt pressure-sensitive adhesive

The invention relates to an acrylic acid modified hot-melt pressure-sensitive adhesive for a bearing adhesive tape. The acrylic acid modified hot-melt pressure-sensitive adhesive comprises the following raw materials in percentage by weight: 10-20 percent of an SIS rubber elastomer I, 10-20 percent of an SIS rubber elastomer II, 5-10 percent of 2-ethylhexyl acrylate, 0.5-2 percent of methyl methacrylate, 0.2-0.5 percent of hydroxypropyl methacrylate, 5-50 percent of a tackifier, 10-50 percent of a solvent, and 0.5-1 percent of an initiator. The acrylic acid modified hot-melt pressure-sensitive adhesive is high in cohesion, high in adhesion stress, high in ageing resistance, strong in adhesive force on a substrate, and wide in application range. A preparation method of the acrylic acid modified hot-melt pressure-sensitive adhesive comprises the following steps: the materials are weighed: the SIS rubber elastomer I, the SIS rubber elastomer II and a solvent account for the total amount of the solvent are added in a first reaction kettle, and 2-ethylhexyl acrylate, methyl methacrylate, hydroxypropyl methacrylate, the initiator and the rest of the solvent are added in a second reaction kettle to form a mixed solution; the mixed solution is slowly added in the first reaction kettle; the tackifier is added in the first reaction kettle, and the solvent is distilled out; the materials are discharged in heating, and the finished product is obtained. The preparation method is simple in process, and high in the production efficiency and yield.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

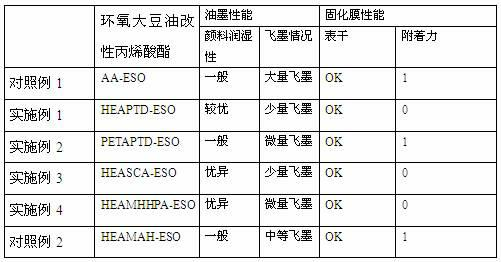

Acrylic acid ester modified epoxy soybean oil, its preparation method and application thereof

ActiveCN102660387ANovel structureImprove adhesionOrganic chemistryFatty acid chemical modificationPolymer scienceMeth-

The invention discloses an acrylic acid ester modified epoxy soybean oil, its preparation method and an application thereof. According to the preparation method of the acrylic acid ester modified epoxy soybean oil, acrylate monomer bearing a hydroxyl group reacts with acid anhydride to obtain a half-ester intermediate, and the half-ester intermediate reacts with epoxy soybean oil to obtain the acrylic acid ester modified epoxy soybean oil. The acrylate monomer bearing a hydroxyl group is hydroxyethyl acrylate, hydroxyethyl methacrylate, pentaerythritol triarylate, hydroxypropyl acrylate, hydroxypropyl methacrylate, trimethylol propane diacrylate or trimethylol propane dimethacrylate. Acid anhydride is o phthalic anhydride, succinic anhydride, methyl hexahydrophthalicanhydride, hexahydrophthalic anhydride or tetrahydrophthalic anhydride. The acrylic acid ester modified epoxy soybean oil has a novel structure. When applied in paper printing ink, the acrylic acid ester modified epoxy soybean oil can improve adhesive force of a cured film and also can improve wetability of pigments and remarkably minimize occurrence of misting. The preparation method helps widen the application range of the modified epoxy soybean oil.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

Nanometer SiO2 modifying process of ultraviolet ray cured adhesive

InactiveCN1887972AGood compatibilityGood dispersionNon-macromolecular adhesive additivesPigment treatment with organosilicon compounds(Hydroxyethyl)methacrylateAdhesive

The present invention discloses nanometer SiO2 modifying process of UV ray cured adhesive. The long chain polyether silane coupler in the general expression of (R1O)3SiCH2CH2CH2O(CH2CH2O)a(CH2CH(CH3)O)bC=OC(R2)=CH2 is first used in surface modifying SiO2 of grain size of 5-50 nm inside isopropyl alcohol dispersing medium; the obtained composite pre-polymer is then mixed with epoxy acrylate, hydroxyethyl methacrylate or hydroxypropyl methacrylate, trimethylopropane-3ethoxyl -triacrylic ester, acrylic cid or acrylate with acid functional radical, photoiniitator, KH570, triethanolamine and maleic acid through stirring to obtain the UV adhesive product. The present invention has improved SiO2 dispersivity and stability, and the UV adhesive product has greatly raised adhesion performance.

Owner:ZHEJIANG UNIV +1

Preparation method of core-shell acrylic acid elastic emulsion containing phosphate group

InactiveCN102757523ASimple processEasy to operateAnti-corrosive paintsPolymer scienceFunctional monomer

Owner:BEIJING UNIV OF CHEM TECH

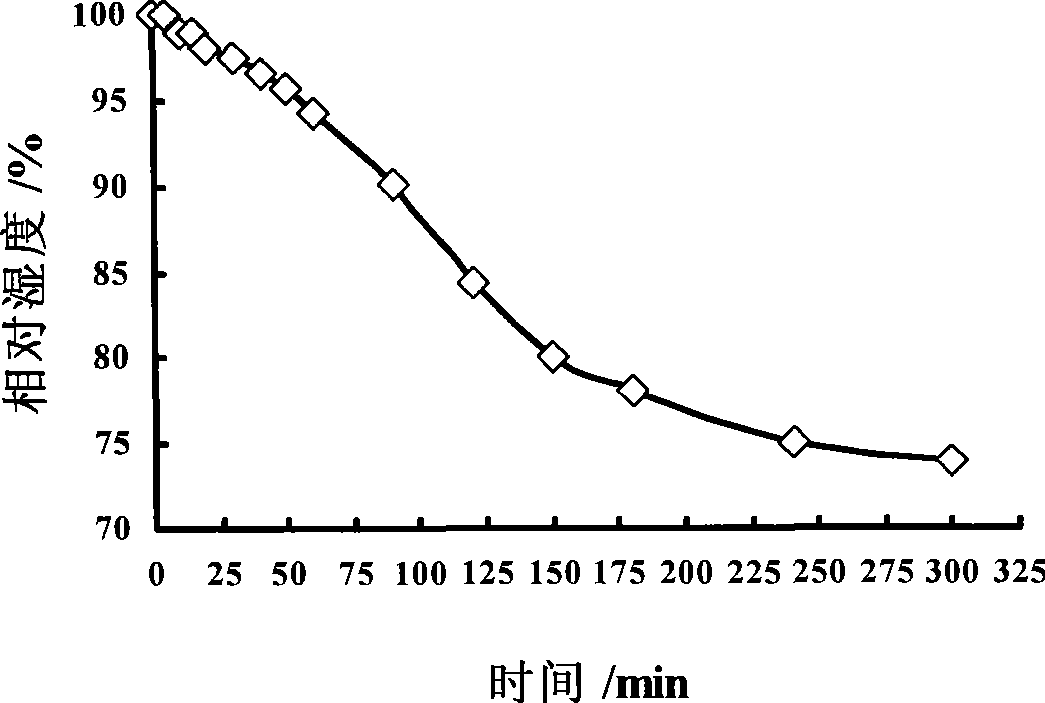

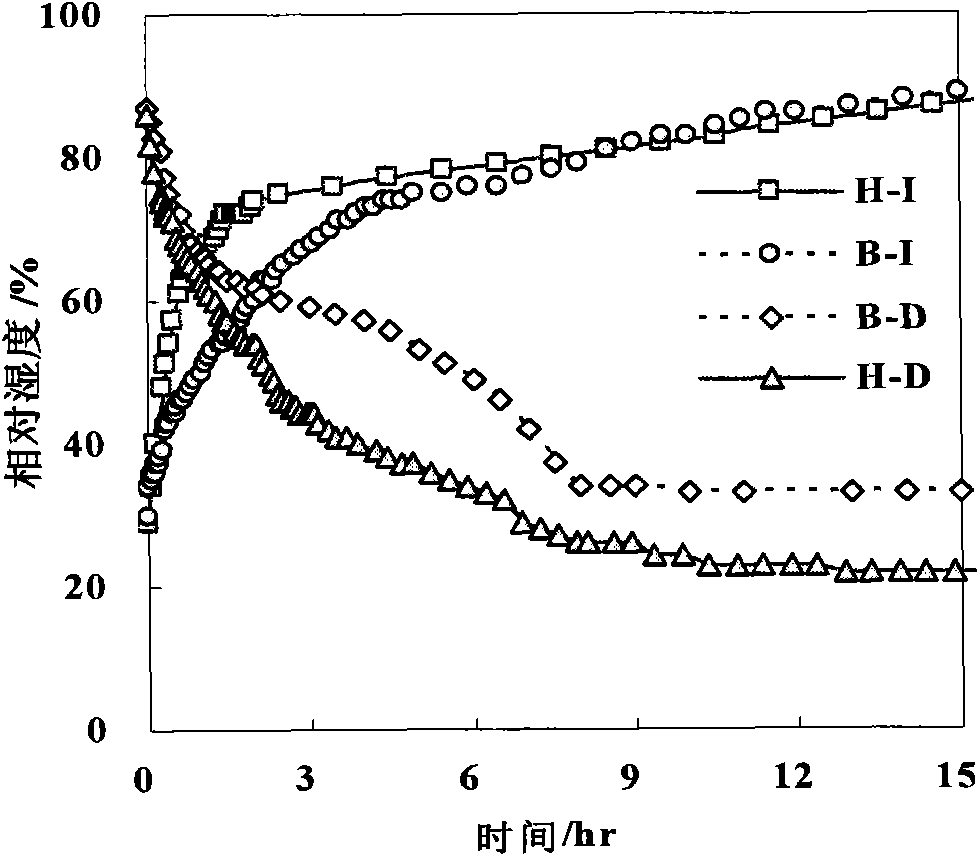

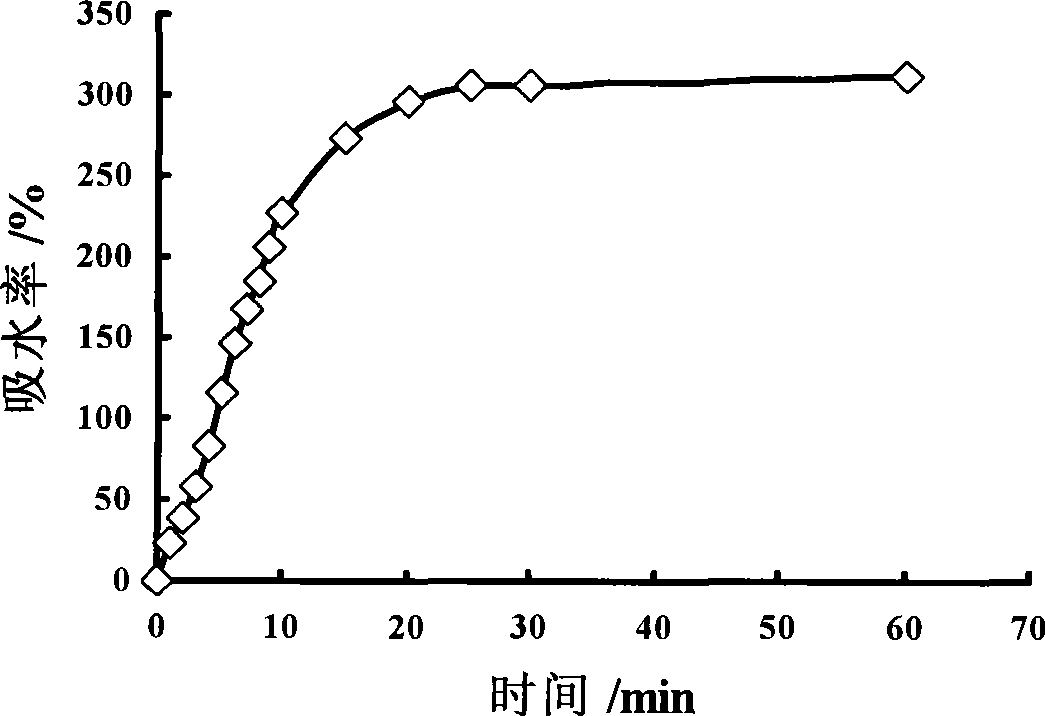

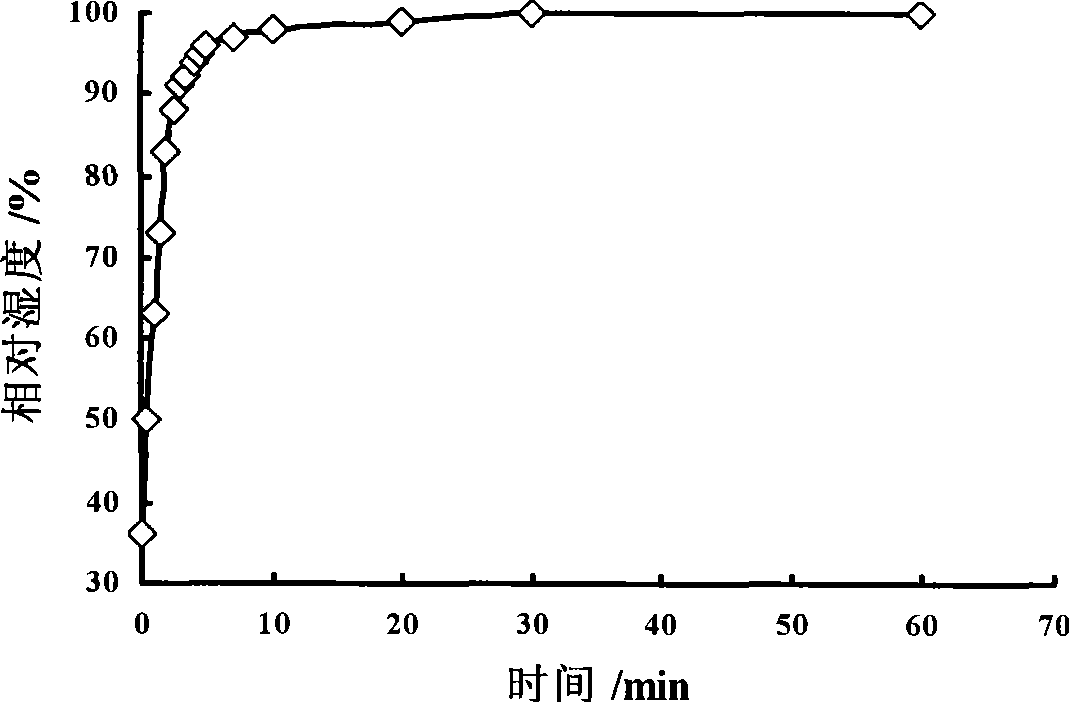

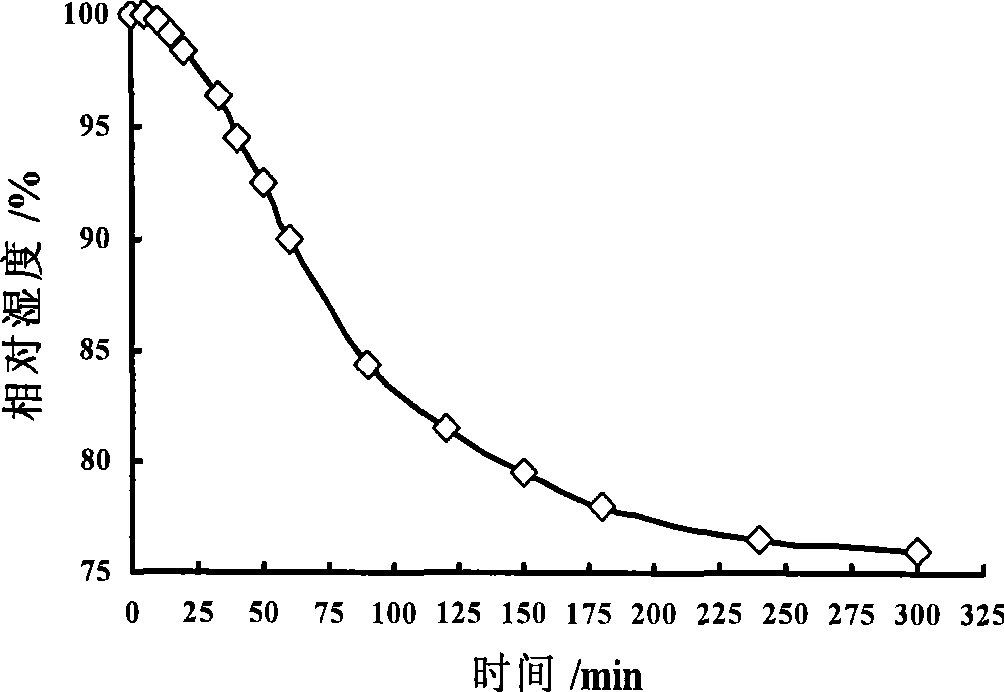

Soap-free core-shell emulsion type amphiphilic polymer resin and preparation and application thereof in preparation of function humidity controlling coating

InactiveCN101423581AGood lookingImprove water resistanceCoatingsPolymer science(Hydroxyethyl)methacrylate

The invention provides a nonsoap nuclear shell latex type amphipathic polymer resin, which is polymerized from methyl methacrylate, styrene, methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, hydroxyethyl methacrylate, acrylamide, diacetone acrylamide and other monomers. The nonsoap nuclear shell latex type amphipathic polymer resin is used as a main film forming material for a paint and is combined with various inorganic macromolecular fillers to prepare the paint; the prepared paint integrates decoration, dampness regulation, permeability, heat insulation, dewing resistance, water and alkali resistance, antisepsis and the like, and can also prevent a coating film from falling off caused by various leakage and water condensation of a wall body so that the coating film is more lasting and durable; and the paint contains no organic solvent and no emulsifier, is safer and more environment-friendly, and has more superior coating property.

Owner:NORTHWEST NORMAL UNIVERSITY

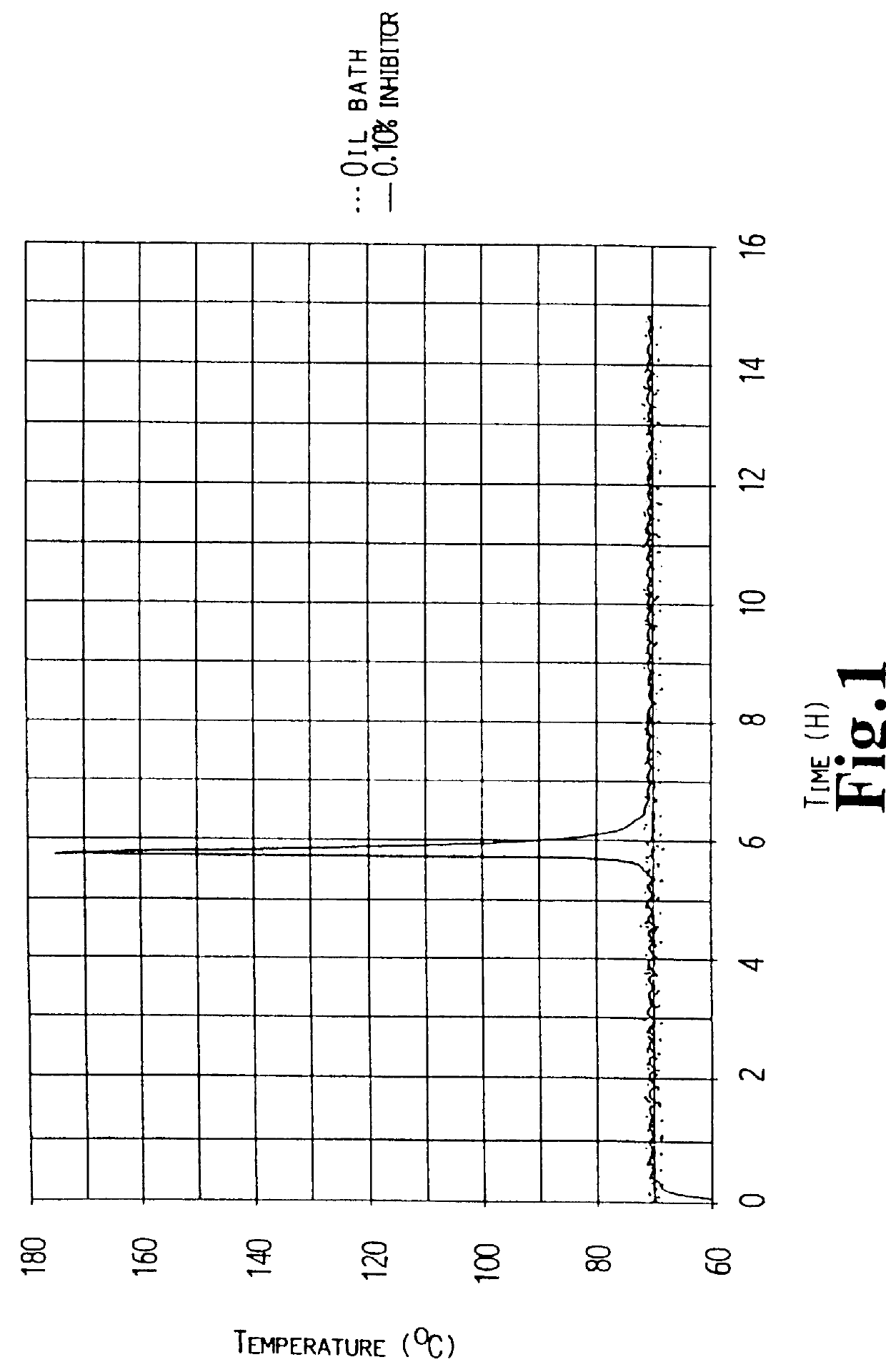

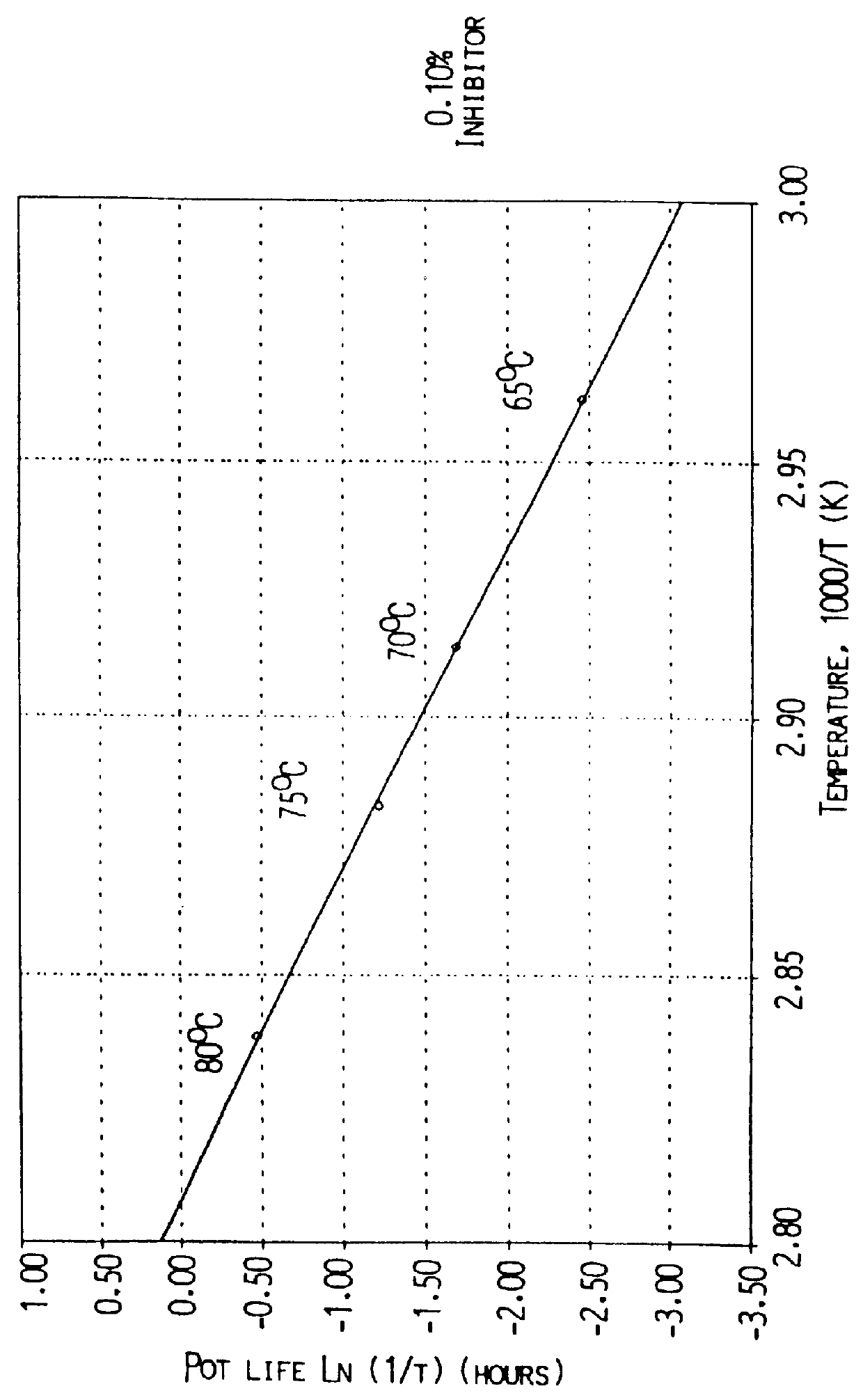

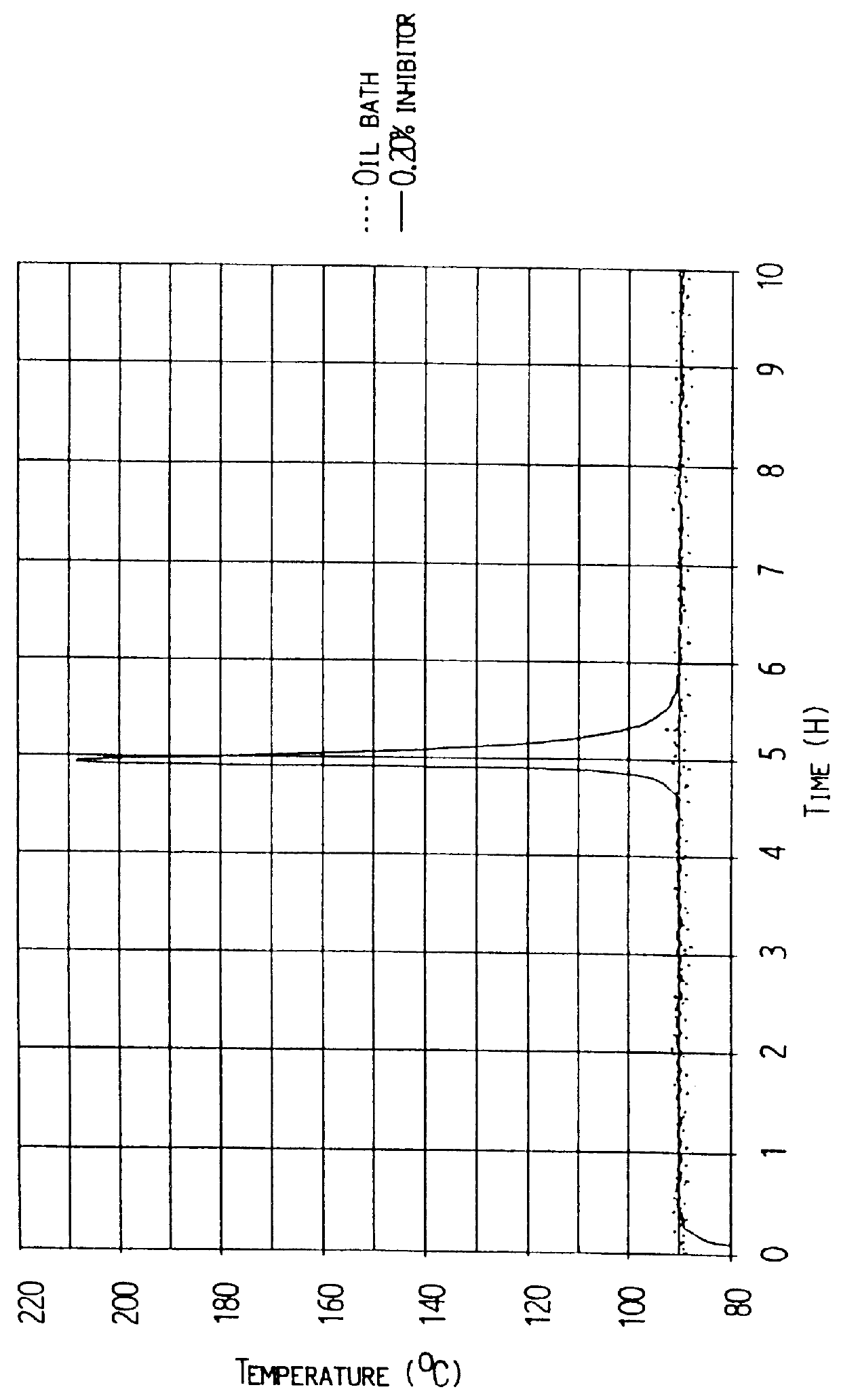

Means and method for the preparation of sealings in oil and gas wells

PCT No. PCT / NO96 / 00255 Sec. 371 Date Apr. 23, 1998 Sec. 102(e) Date Apr. 23, 1998 PCT Filed Oct. 25, 1996 PCT Pub. No. WO97 / 15746 PCT Pub. Date May 1, 1997Agent and method for establishing different types of zone sealings particularly in oil wells and gas wells, wherein the zone to be sealed is supplied with a composition comprising: monomers, an initiator for heat-induced production of free radicals, a pot life extending inhibitor for stabilization of free radicals, and optionally other additives. The composition is subjected to radical polymerization induced by heat in the well zone and at a temperature of 5-120 DEG C., and establishes a cured mass, particularly at temperatures in the range of 65-100 DEG C. The composition is supplied with an at least partly unsaturated prepolymer selected from the group consisting of polyester and epoxy vinylester, including one or more vinyl-containing co-monomers selected from the group consisting of styrene, vinyltoluene, 2-hydroxyethyl-methacrylate and 2-hydroxypropyl-methacrylate. The prepolymer is present in a quantity of 15-75 weight parts and the vinyl-containing co-monomers are added in a quantity of 75-15 weight parts. The composition is particularly suited for low temperature applications.

Owner:WELLCEM

Instant-dissolved cationic polyacrylamide capsulation agent and preparing method thereof

The invention belongs to the field of cationic polymer capsulation agents, and relates to an instant-dissolved low-molecular-weight polyacrylamide capsulation agent and a preparing method thereof. The capsulation agent is prepared from three monomers in a copolymerization mode, wherein the first monomer is one of acrylamide and sodium acrylate, the second monomer is one of cationic monomers including dimethyl diallyl ammonium chloride, diethyl diallyl ammonium chloride, acryloxyethyl ethyl dimethyl benzyl ammonium chloride, methacryloyl oxyethyl dimethyl-benzyl ammonium chloride and methacryloyloxyethyl trimethyl ammonium chloride, and the third monomer is one of hydroxyethyl methylacrylate and hydroxypropyl methacrylate. The molecular structures of the monomers contain hydroxyl, the hydroxyl can interact with drilling cuttings, and the capsulation inhibiting performance is improved. According to the capsulation agent, the inverse emulsion polymerization technology is adopted, the aftertreatment technology is simple, the granular product can be conveniently stored for a long time and transported, the dissolving time is short in use, convenience is brought to site utilization, the capsulation inhibiting effect is good, and the performance of a drilling fluid system can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phosphorus-free composite corrosion and scale inhibitor for bitter circulating water and preparation method thereof

ActiveCN104891684AGood synergyNo distractionScale removal and water softeningWater treatmentCorrosion

The invention relates to a phosphorus-free composite corrosion and scale inhibitor for bitter circulating water and a preparation method thereof, belonging to the technical field of water treatment. The phosphorus-free composite corrosion and scale inhibitor for bitter circulating water is prepared from the following raw materials in percentage by weight: 5-20% of sodium molybdate, 5-20% of urotropine, 10-30% of polyepoxysuccinic acid, 1-5% of azole derivative, 5-20% of hydroxypropyl methacrylate, 5-15% of acrylic acid-acrylate-sulfonate terpolymer, 5-15% of sodium humate, 0.1-1% of fluorescent tracer, 0.5-2% of caustic soda flakes and the balance of deionized water. The phosphorus-free composite corrosion and scale inhibitor for bitter circulating water can not interfere with other water treatment agents, is free of phosphorus, zinc and other components harmful to the environment, and can effectively solve the problems of corrosion and scales in the bitter-based high-salt-content high-pH system. The invention also relates to a simple and convenient preparation method.

Owner:INLEN CHEM TECH +1

Emulsion type amphiphilic polymer resin and preparation and application thereof in preparation of coating

InactiveCN101423582AImprove adhesionAvoid disadvantagesCoatings(Hydroxyethyl)methacrylateEthylene Glycol Methacrylate

The invention provides a latex type amphiphilic polymer resin, which is formed by polymerizing unsaturated acid alkyl, methyl methacrylate, styrene, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, ethylene glycol methacrylate, acrylamide, diacetone-acryloamide and other monomers. The paint which takes the latex type amphiphilic polymer resin as a main film forming material and combines with inorganic polymer stuffing integrates with decorative property, humidifying property, permeability, heat preservation, condensation prevention, water and alkali resistance, bacterium resistance and so on, and can prevent the paint film from dropping off due to multiple kinds of seepage and water condensation of a wall body, so that the paint film is more durable; in addition, the paint has no organic solvent, and is safe and environment friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

Room temperature-curable polymers

Owner:ABBOTT LAB INC

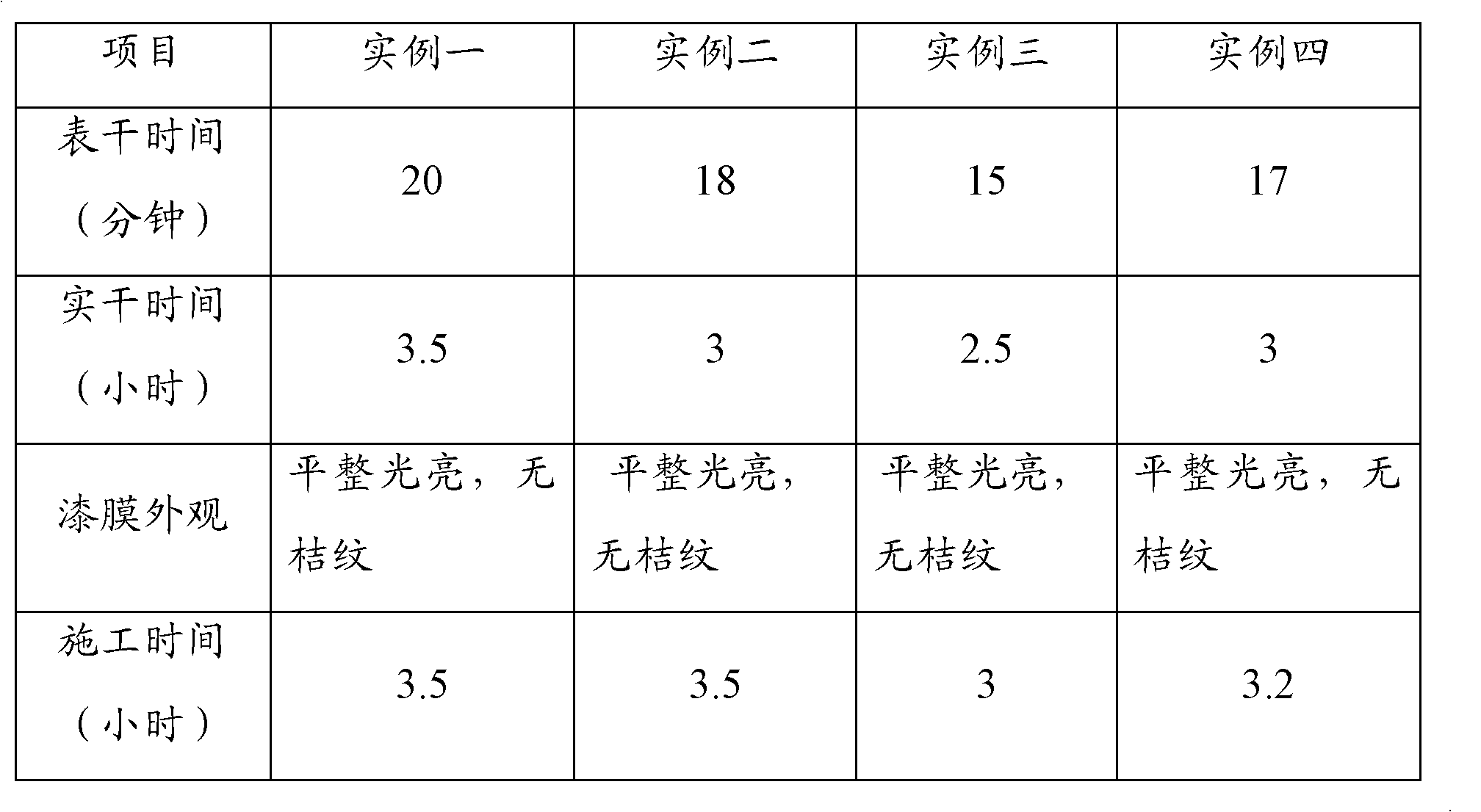

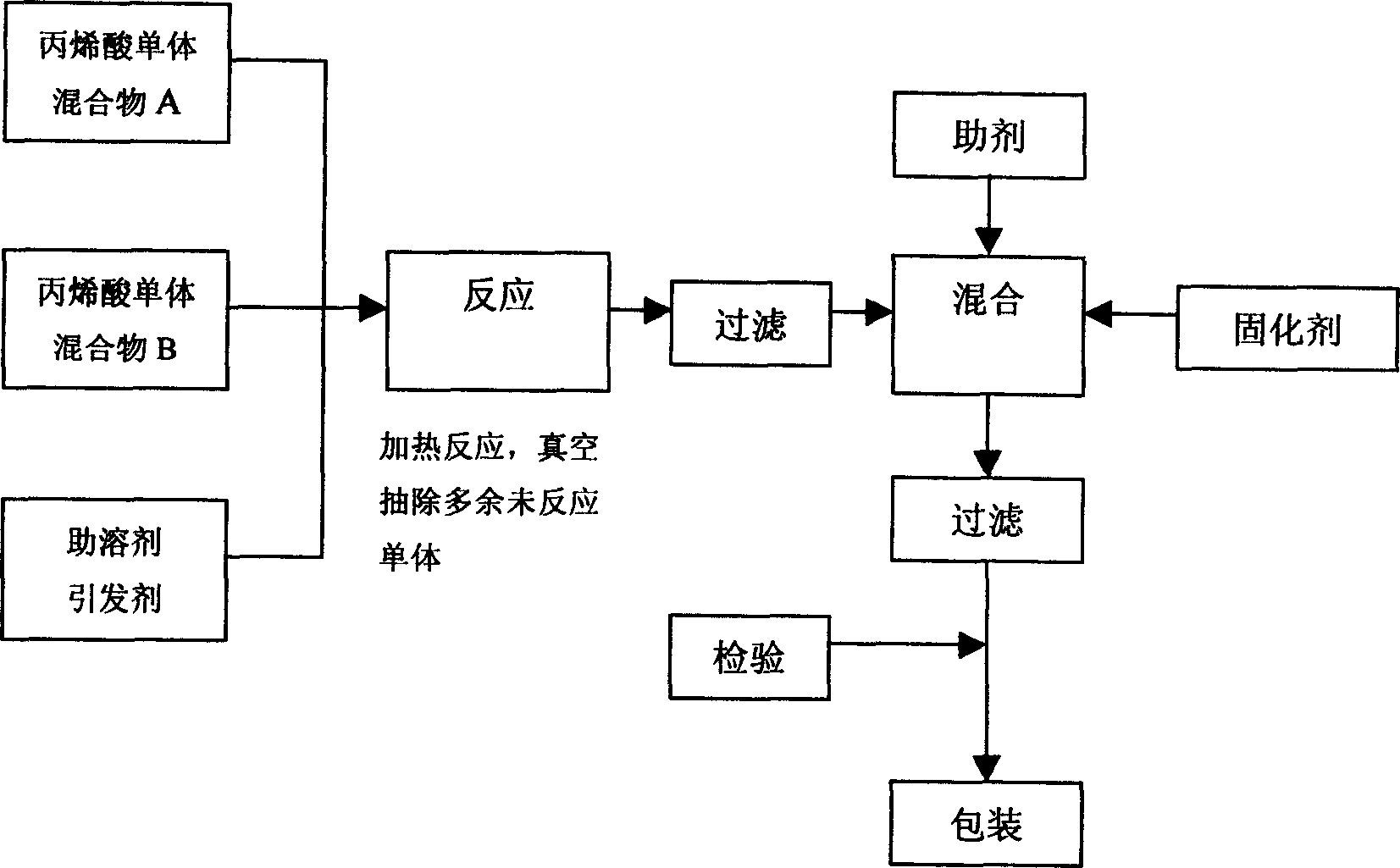

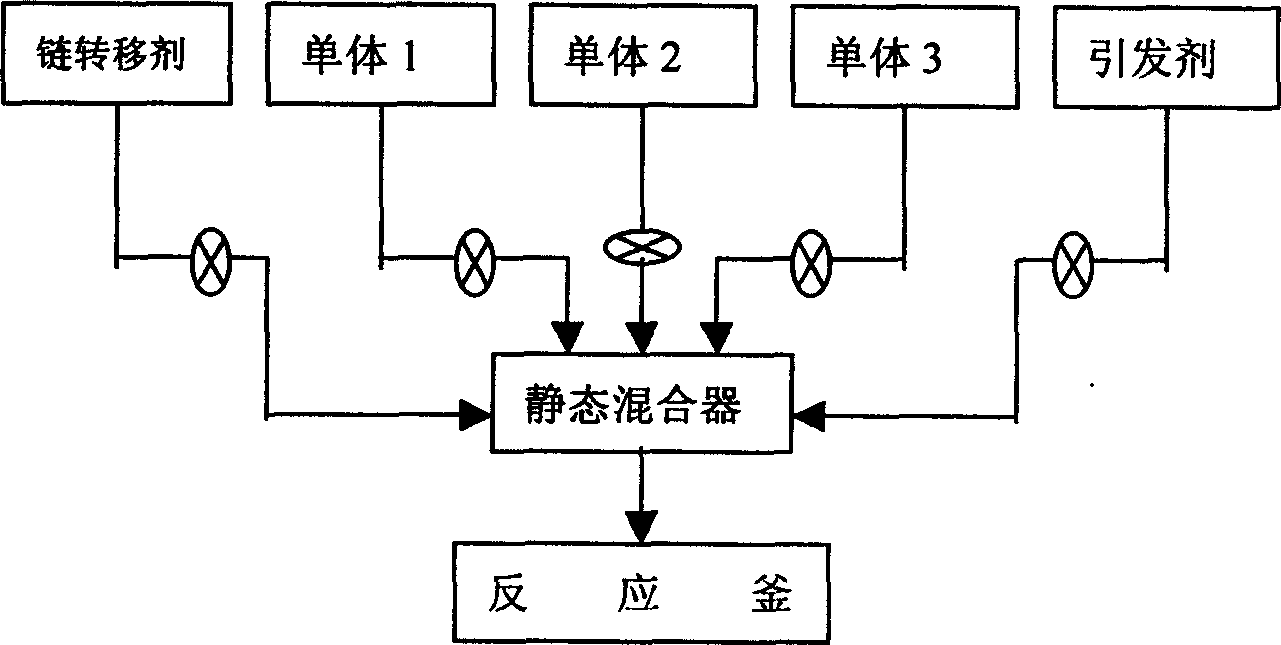

Hydroxy acrylic resin for ultra-fast dry automobile varnish and preparation method thereof

InactiveCN102153691AHas ultra-fast drying and curing propertiesImprove the level ofCoatingsPolymer scienceAcrylic resin

The invention discloses a preparation method of hydroxy acrylic resin for ultra-fast dry automobile varnish. The preparation method comprises the following steps of: 1) putting a material A into a reaction kettle, and heating the material A to the temperature of between 140 and 160 DEG C; 2) dripping a material B for 3 to 4 hours, and controlling the temperature in the reaction kettle at 140 to 160 DEG C; 3) after the dripping is finished, preserving the heat for 3.5 to 4.5 hours at the temperature of between 140 and 160 DEG C; 4) adding a material C, and performing heat preservation reactionfor 3.5 to 4.5 hours; and 5) cooling the reaction product to be less than 80 DEG C, and filtering the reaction product, wherein the material A comprises 10 to 15 weight parts of dimethyl benzene and 28 to 32 weight parts of trimethyl benzene; the material B comprises 20 to 25 weight parts of styrene or alpha-styrene, 12 to 15 weight parts of sec-butyl methacrylate or tert-butyl methacrylate, 10 to 12 weight parts of propyl methacrylate or ethyl methacrylate or ethyl acrylate, 2 to 4 weight parts of methyl acrylic acid, and 0.3 to 1.0 weight part of maleic anhydride or fumaric acid; and the material C is 6 to 9 weight parts of initiator. The hydroxy acrylic resin is applied to the varnish, and has ultra-fast dry curing property, good construction performance and varnish film appearance.

Owner:同宇新材料(广东)股份有限公司

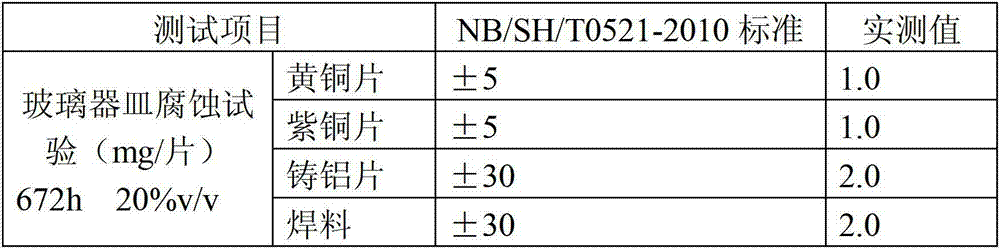

1,2-propanediol antifreezing cooling liquid

ActiveCN102732232AGood corrosion resistanceGood additionHeat-exchange elementsCooling towerCavitation

The invention discloses a 1,2-propanediol antifreezing cooling liquid which comprises the following components in percentage by mass: 0.5-3.0% of decanedioic acid, 0.25-1.5% of succinic acid, 0.1-0.9% of benzotriazole, 0.05-0.3% of hydroxypropyl methacrylate, 0.0004-0.005% of defoaming agent and the balance of 1,2-propanediol. The 1,2-propanediol antifreezing cooling liquid composite formula system disclosed by the invention has the characteristics of no water, persistent effect, environmental protection and durable corrosion resistance; the antifreezing agent is the non-toxic 1,2-propanediol capable of being naturally degraded; the formula technology mainly uses the organic acids; the 1,2-propanediol antifreezing cooling liquid can provide long-acting protection for the cooling system, and implement temperature rise of the antifreezing cooling liquid without pressurized conditions; and the 1,2-propanediol antifreezing cooling liquid can almost completely eliminate liner pitting corrosion, aluminum pump cavitation corrosion and other technical problems when being used in heavy-load engines, and can widely use automobiles, ships, large-size cooling towers, solar energy and the like as the heat-conducting media of the cooling system.

Owner:张家港迪克汽车化学品有限公司

Method for preparing antibacterial fiber membrane

ActiveCN105839295AUniform pore sizeExcellent stable membrane fluxHollow filament manufactureElectro-spinningYarnCellulose diacetate

The invention discloses a method for preparing an antibacterial fiber membrane. The method comprises the following steps: preparing a complex antibacterial agent by using N-(4-hydroxy-3-methoxybenzyl)acrylamide, 2-hydroxypropyl methacrylate, N, N- (dimethylamino)ethyl methacrylate, and vinyltriethoxysilane-modified nano zinc oxide; adding polyacrylonitrile, cellulose diacetate and glucose to a mixed solvent to obtain a mixed solution; adding the complex antibacterial agent, poly vinyl alcohol, laponite, silver ion loaded zeolite molecular sieve, nano titanium dioxide, alumina sol, calcium chloride and dilauryl thiodipropionate to water to be uniformly mixed, adding the mixed solution and then conducting electrostatic spinning to obtain a raw yarn, putting the raw yarn in water to be soaked and dried. The method for preparing the antibacterial fiber membrane provided by the invention has the advantages of simple process, mild conditions, good antibacterial properties, excellent stain resistance, high mechanical strength and toughness, and long service life.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

Potato starch graft emulsion, preparation and application thereof

InactiveCN101906189AOvercome the disadvantage of high energy consumptionInhibit sheddingCoatings(Hydroxyethyl)methacrylatePotato starch

The invention provides a potato starch graft emulsion which is formed by carrying out monomer graft polymerization on potato starch, unsaturated alkyl acid, styrene, methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, hydroxy-ethyl methacrylate, acrylic amide, diacetone acrylamide and the like. The potato starch graft emulsion is taken as main film forming matter of paint and is added with conventional inorganic polymer filler which is adopted for preparing the paint, so that the prepared paint has the functions of decoration, humidity adjustment, permeability, heat preservation, moisture condensation prevention, water and alkali resistance, antibiosis and the like; meanwhile, the invention also can prevent a coating from falling off caused by various leakage and water condensation of a wall body, thus ensuring the coating to be more durable; and the potato starch graft emulsion does not contain organic solvent and is safer and more environment-friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

Acroleic acid/polyurethane transparent anode electrophoresis coating and its preparation method

InactiveCN1807528AControl molecular weightIncrease the degree of effective responsePaints for electrolytic applicationsMethacrylateSurface-active agents

The invention relates to an acroleic acid / polyurethane transparent anode electrophoresis coating and its preparation method, comprising the following raw materials (by weight ratio): cationic acrylic polymer 52-85, closed isocyanate cross linking agent 14.5-23.5, non-ionic or / and cationic surface active agent 4.6-8, catalyst 0.6-1.1, chain-transferring agent 0.5-0.8, deionized water 26-51. The cationic acrylic polymer comprises the following raw materials (by weight portions): isobutyl methacrylate 35-55, methyl acrylic ester 23-43, methyl methacrylic hydroxyl propyl ester 15-26, dimethyl amido propyl ester methacrylamide 13.5-23, 2-ethylhexyl methacrylate 13-28, azo-diisobutyronitrile 0.5-1.2, and dimethyl carbinol 35-89.

Owner:冯国贤

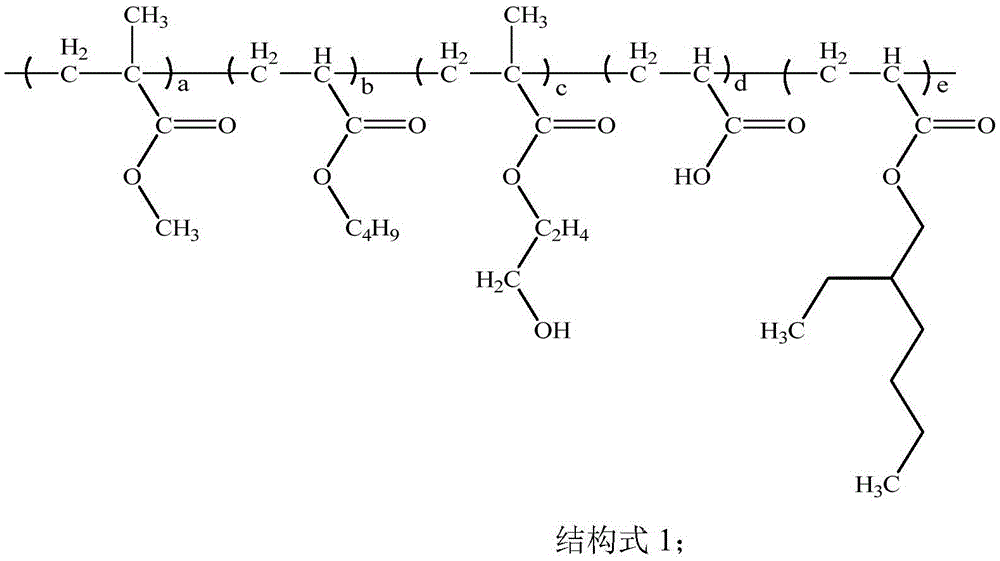

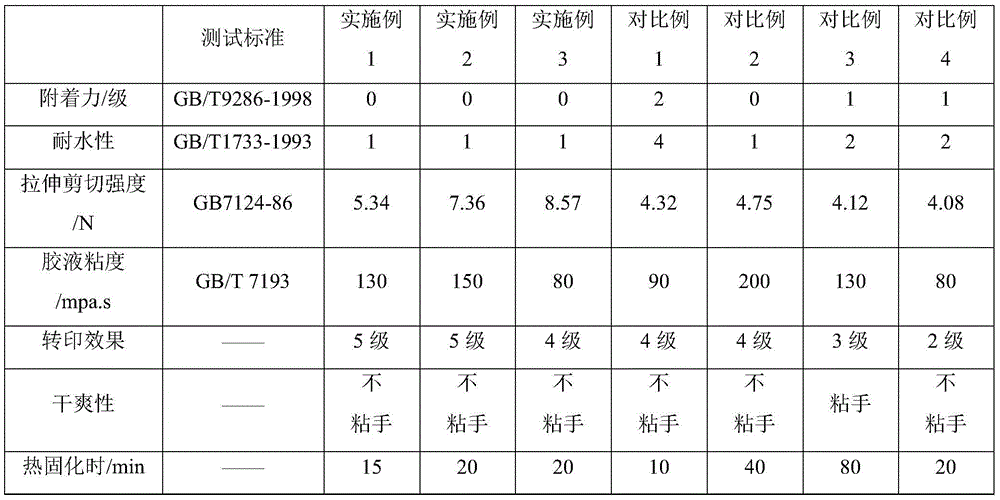

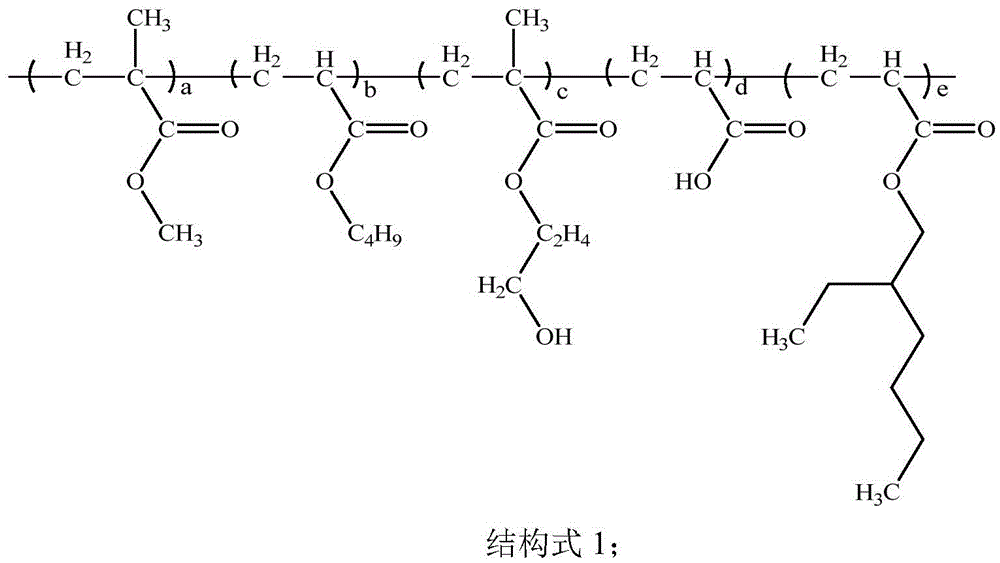

Ultraviolet light curing transfer printing glue and preparation method and application thereof

ActiveCN105602515AHigh glass transition temperatureHigh tensile shear strengthDuplicating/marking methodsPolyureas/polyurethane adhesivesIsooctyl acrylateUltraviolet lights

The invention discloses an ultraviolet light curing transfer printing glue composition for a transfer printing film. The ultraviolet light curing transfer printing glue composition comprises the following components in parts by weight: 20-40 parts of modified acrylate, 20-40 parts of epoxy resin, 10-30 parts of reactive diluent, 3-8 parts of photoinitiator, 5-15 parts of adhesion promoter, 2-5 parts of silane coupling agent and 0-1 part of auxiliary, and the modified acrylate is prepared by modifying pentapolymer prepared from methyl methacrylate (MMA), n-butyl acrylate ((i)n( / i)-BA), hydroxypropyl methacrylate (HMPA), acrylic acid (AA) and 2-ethylhexyl acrylate (EHA) through free radical copolymerization by using polyurethane containing isocyanato. The prepared ultraviolet light curing transfer printing glue has good adhesion to a glass base material, and is good in water resistance, high in tensile strength and excellent in transfer printing effect.

Owner:GUANGDONG UNIV OF TECH

Soap-free emulsion type amphiphilic polymer resin and preparation and application thereof in production of intelligent breathing coating

InactiveCN101423583AImprove humidity control performanceImprove performanceCoatings(Hydroxyethyl)methacrylateEthylene Glycol Methacrylate

The invention provides a soap free latex type amphiphilic polymer resin, which is formed by polymerizing unsaturated acid alkyl, styrene, methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, ethylene glycol methacrylate, acrylamide, diacetone-acryloamide and other monomers. The paint which takes the soap free latex type amphiphilic polymer resin as a main film forming material and combines with multiple kinds of inorganic polymer stuffing integrates with decorative property, humidifying property, permeability, heat preservation, condensation prevention, water and alkali resistance, bacterium resistance and so on, and can prevent the paint film from dropping off due to multiple kinds of seepage and water condensation of a wall body, so that the paint film is more durable; in addition, the paint has no organic solvent, and is more safe and environment friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

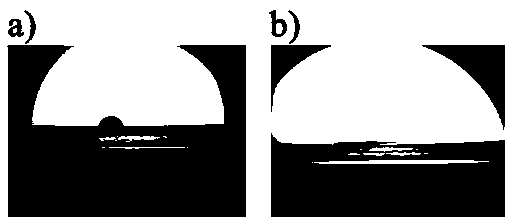

Organic-silicon modified acrylic acid resin superhydrophilic antifogging coating and preparation method thereof

ActiveCN109135487ALow preparation temperatureImprove stabilityChemical industryCoatingsGlycidyl methacrylateN dimethylformamide

The invention relates to the field of coating preparation, and discloses an organic-silicon modified acrylic acid resin superhydrophilic antifogging coating and a preparation method thereof. The primary reaction raw materials comprises, by weight, 6.3-10.7% of methymethacrylate, 4.5-7.9% of butyl acrylate, 8.8-15.3% of gamma-methacryloxypropyl trimethoxysilane, 8.1-13.9% functional monomer hydroxyethyl methylacrylate, 16.0-27.0% of the reaction produict of diethanol amine and glycidyl methacrylate 3-(bis(2-hydroxyethyl)amino)-2-hydroxypropyl methacrylate and 7.4-12.8% of 2-acrylamide-2-methylpropionic sulfonic acid, the using amount of the azobisisobutyronitrile is 0.2%-0.4%, and the reaction solvent is N, N-dimethylformamide which takes up the 25.3%-45.6% of the total amount. The coatinghas the advantages of lower preparation temperature, good stability, simple production process, the purpose of energy saving is achieved, invested equipment is less, the coating is transparent leveledand has high adhesion force, -40 DEG C low temperature fog resisting and 80 DEG C high-temperature fog resisting can be achieved, the coating does not wrinkle, there exists no crack, and the coatingcan be repeatedly used for over 100 times.

Owner:CHONGQING UNIV

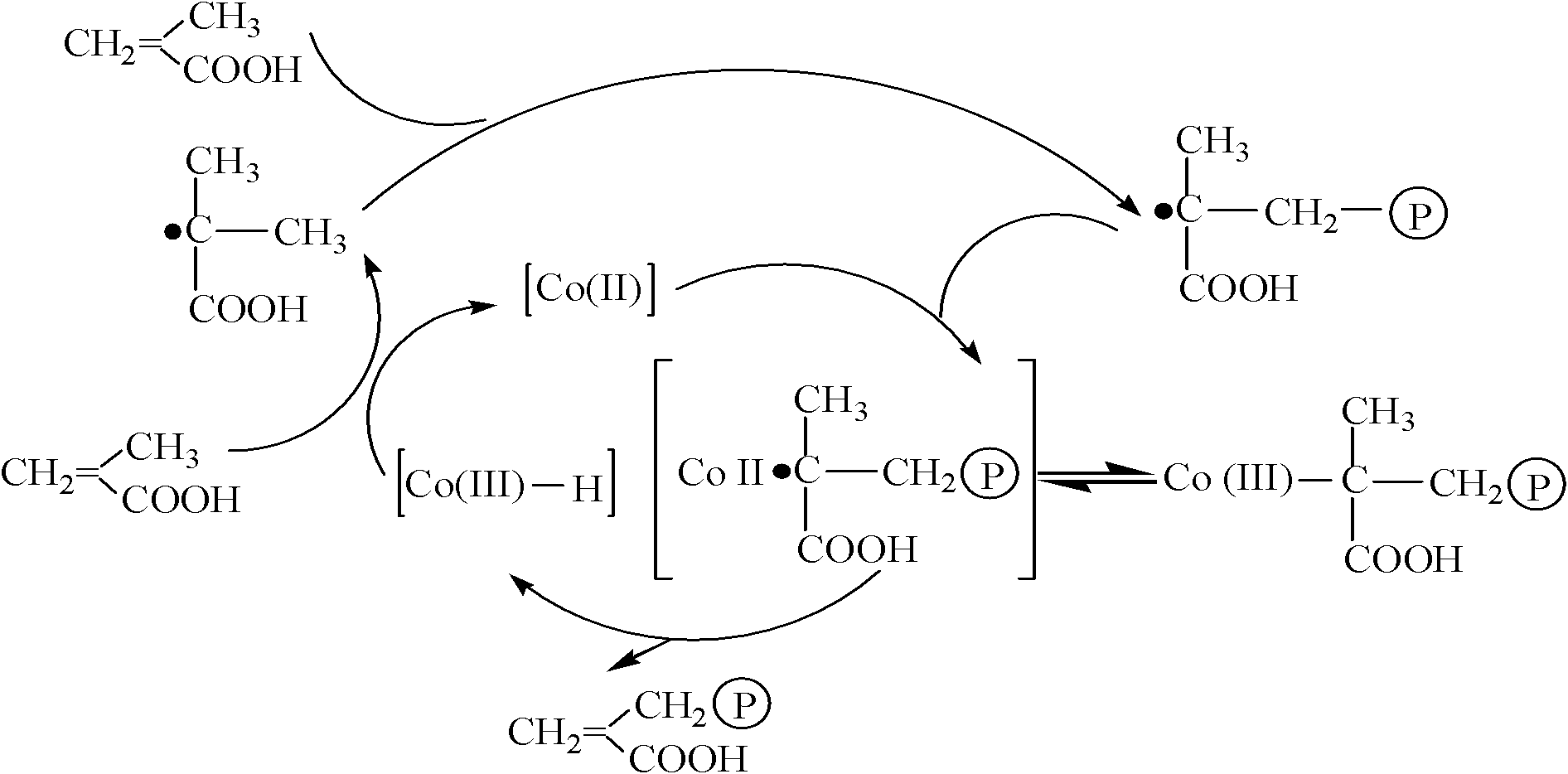

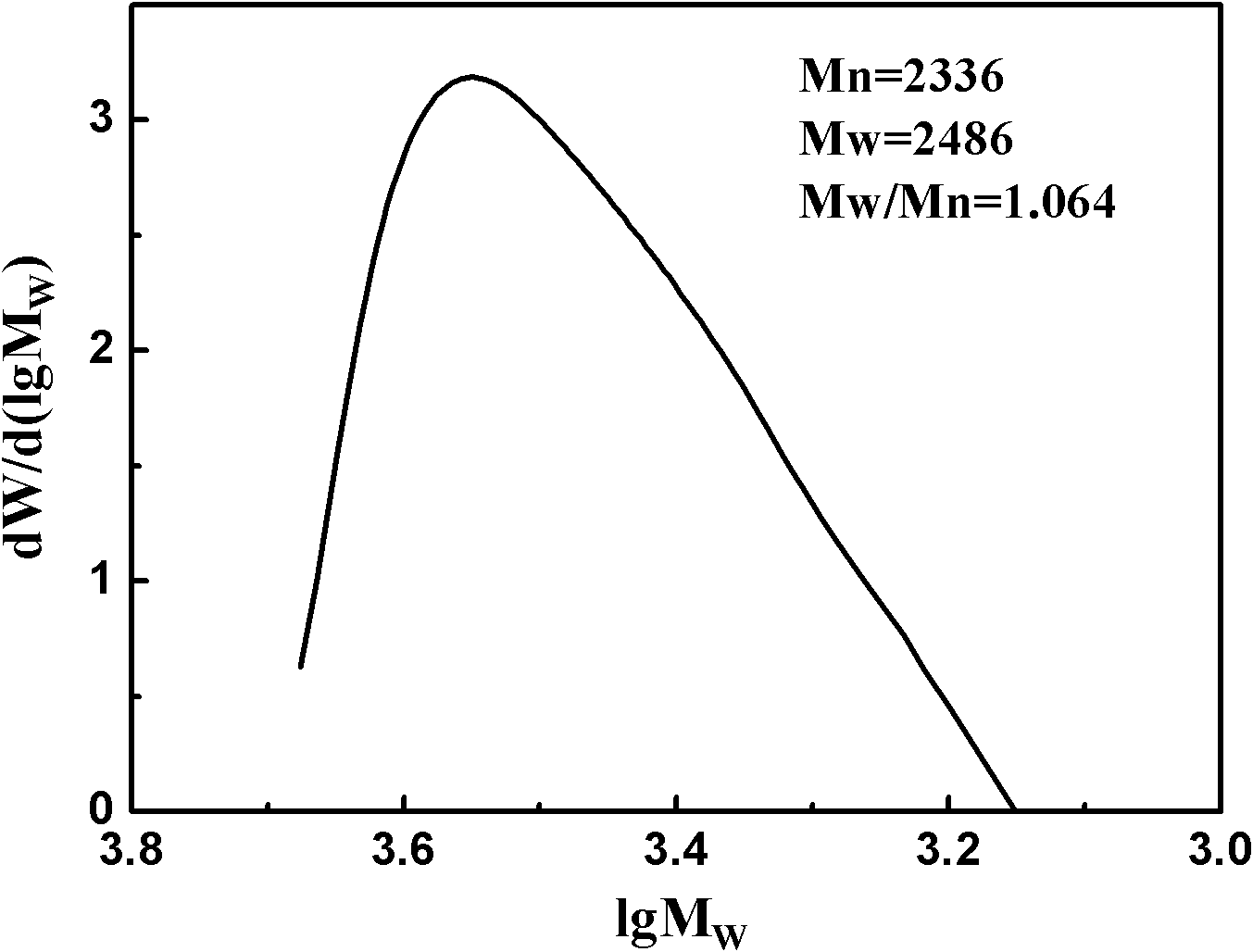

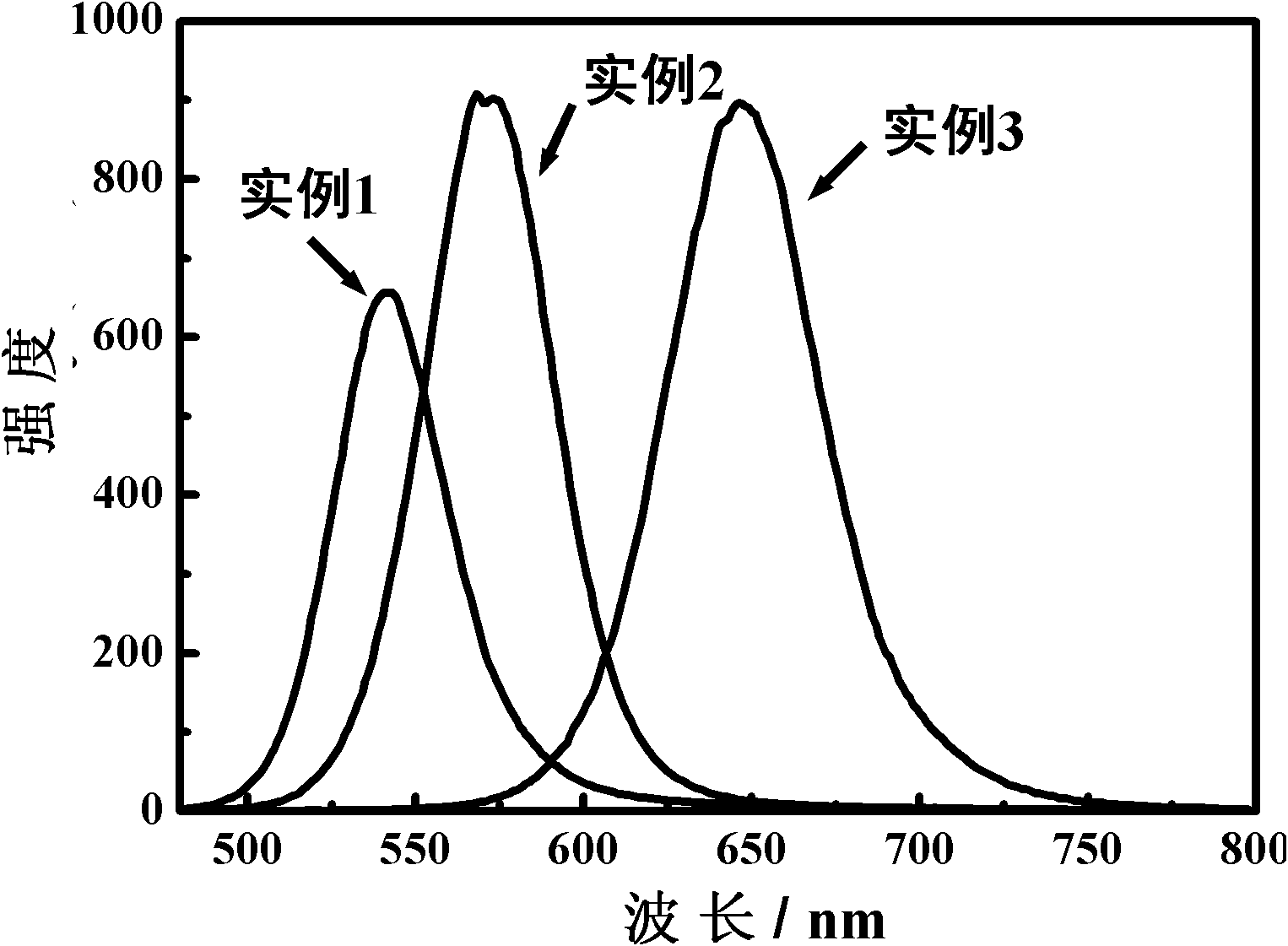

Quantum dots modified by macromolecular monomer, preparation method for quantum dots and application of quantum dots

ActiveCN102492068ALaunch stableGood fluorescence stabilityLuminescent compositionsSemiconductor devicesQuantum yield(Hydroxyethyl)methacrylate

The invention discloses quantum dots modified by a macromolecular monomer. According to the quantum dots, the macromolecular monomer which is prepared through catalytic chain transfer polymerization is taken as a ligand; and the quantum dots have the characteristics of narrower fluorescence emission spectrum, high luminous efficiency and high stability. Particle sizes of the quantum dots modified by the macromolecular monomer are 2 to 20nm, the quantum dots are water-soluble, the quantum yield is 20 to 95 percent, the half-peak width of a photoluminescence spectrum is 20 to 80nm, and the fluorescent quantum dots are one of ZnxCd1-xS, ZnxCd1-xTe and ZnxCd1-xSe, wherein x is more than or equal to 0 and less than or equal to 1; and the macromolecular monomer used as the ligand is one of polymethylacrylic acid, polyacrylic acid, poly(hydroxyethyl methacrylate), poly(2-Hydroxypropyl methacrylate) or a polymethylacrylic acid-b-poly(butyl acrylate) block copolymer, and the molar ratio of the macromolecular monomer to metal ions is (0.5:1)-(5:1).

Owner:江苏康纳思光电科技有限公司

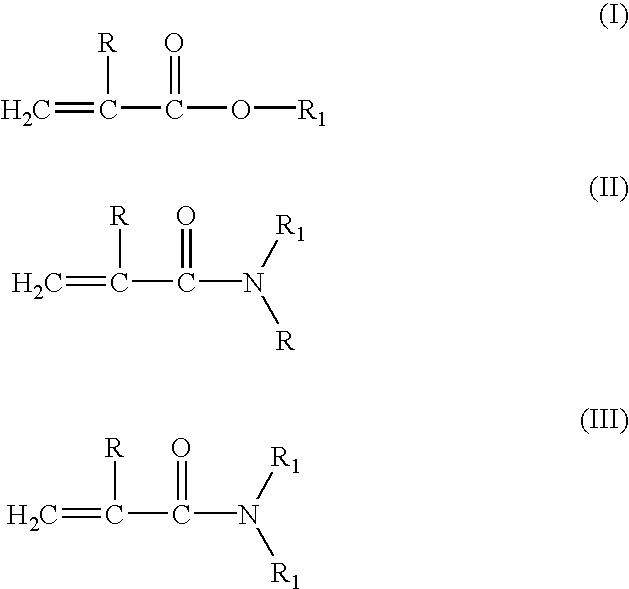

A kind of betaine type amphoteric thickener based on guar gum derivative and preparation method thereof

ActiveCN102277141AImprove solubilityPrevent coagulationDrilling compositionBetaineHydroxypropyl methacrylate

The invention relates to a guar derivative-based betaine-type amphoteric thickening agent with a structural formula (I) and a preparation method thereof, wherein R is selected from hydroxypropyl, hydroxyethyl, carboxymethyl, 2-hydroxypropyl-N,N,N-trimethyl; R1 and R2 represent C1-C4 alkyl respectively, and R3 represents a carboxylic group COO- or a sulfonic group SO3-; the substitution degree of R is 0.02-0.6, and the substitution degree of the betaine-type amphoteric ion pair is 0.02-0.6.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Releasing agent used for casting

InactiveCN102329686AGood release effectReduce manufacturing costFoundry mouldsFoundry coresSilanesTalc

The invention discloses a production formula of a releasing agent used for casting and a preparation method thereof. The releasing agent is composed of hydroxypropyl methacrylate, crylic acid, butyl acrylate, styrene, ammonium persulphate, an emulsifying agent OP, deionized water, calcium stearate, calcium carbonate, talc powder, titanium pigment, sodium polyacrylate, alcohol ester 12 and silane.During production, a synthesis emulsion is prepared with an emulsion polymerization method; the synthesis emulsion is put into a high-speed dispersion machine; and then, the sodium polyacrylate, the talc powder, the titanium pigment, the calcium carbonate, the calcium stearate, the alcohol ester 12 and the silane are added into the dispersion machine to obtain the releasing agent used for casting. The releasing agent has the advantages of good releasing effect and low production cost, and does not corrode castings, and the castings can not generate mildew, corrosion and the like even if beingstored for more than a half year.

Owner:王崇高

Inorganic gel profile control technology

InactiveCN104989347AImprove water flooding efficiencyImprove water absorptionFluid removalDrilling compositionActive agentCross linker

The invention discloses an inorganic gel profile control technology. Various profile control water shutoff agents are used and comprise a weak gel profile control agent, an inorganic gel profile control agent, a pre-crosslinking particle profile control agent and an oil-displacing agent, wherein the weak gel profile control agent comprises cross-linked polymers HPMA (hydroxypropyl methacrylate), a cross-linking agent, a stabilizing agent and a delay agent; the cross-linked polymers HPMA are partially hydrolyzed polyacrylamides; the cross-linking agent is a composite system of formaldehyde and resorcinol; the inorganic gel profile control agent is an inorganic mixing body using metasilicic acids as main ingredients and is matched with the pre-crosslinking particle profile control agent to be used in the profile control process; the pre-crosslinking particle profile control agent is a synthetic flexible macromolecule material containing a great number of hydrophilic groups; and the oil-displacing agent is a surfactant with amphiphiles. The inorganic gel profile control technology has the advantages that various profile control water shutoff agents using the inorganic gel as a main body extend to the inside of an oil reservoir to block a high-permeability zone, so that the direction of fluid is converted; injected water affects medium-low-permeability zones which are not affected in the prior art; the displacement effect is improved; and the recovery ratio is improved.

Owner:YANAN YUHAN PETROLEUM ENG TECH SERVICE CO LTD

Tire with component of rubber composition comprised of silica reinforcement and emulsion polymerization derived terpolymer rubber of diene/vinyl aromatic compound which contains pendant hydroxyl groups

InactiveUS20020173560A1Enhance elastomer reinforcing effectEnhances rubber reinforcement aspectSpecial tyresElastomerPolymer science

This invention relates to a tire having at least one component of a silica reinforced rubber composition comprised of an emulsion polymerization derived terpolymer rubber which contain pendant hydroxyl groups, particularly derived from diene hydrocarbon and vinyl aromatic compound monomers, particularly a hydroxyalkyl methacrylate. Preferably the hydroxyalkyl methacrylate is a hydroxypropyl methacrylate (HPMA). Preferably at least one additional elastomer is blended with the terpolymer rubber. The rubber composition is prepared by blending a coupling agent therewith subsequent to the addition said silica reinforcement. Said tire component may be, for example, a tire tread.

Owner:THE GOODYEAR TIRE & RUBBER CO

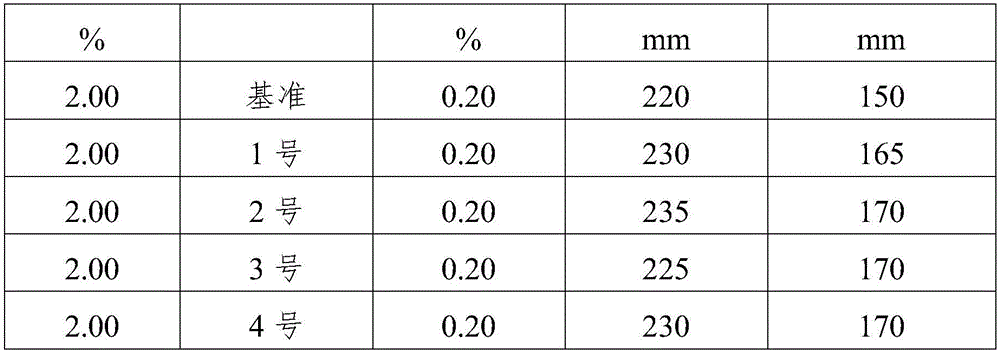

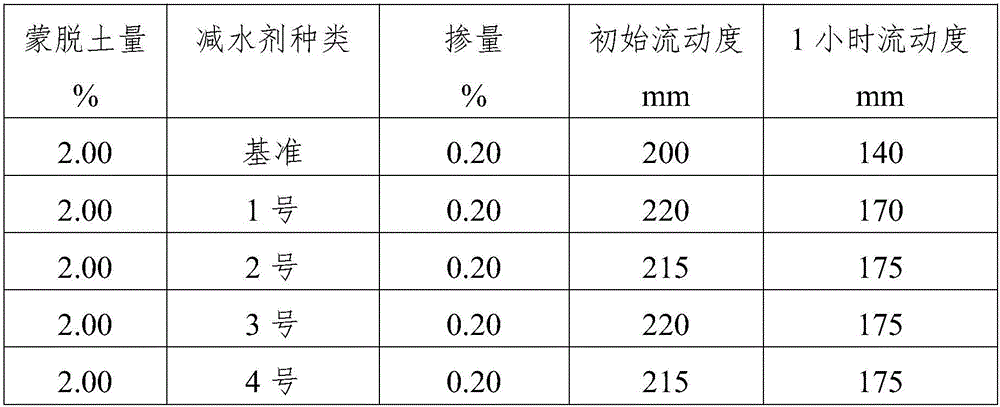

Polycarboxylic cationic anti-mud agent, and preparation method and application thereof

The invention discloses a polycarboxylic cationic anti-mud agent, and a preparation method and application thereof, belonging to the technical field of concrete additives. According to the invention, hydroxypropyl methacrylate with poor hydrophilicity is employed to replace side-chain monomer with good hydrophilicity for synthesis of monomer with a part of cationic charges; and acrylic acid and sodium methallyl sulfonate are used as anionic adsorption monomers for synthesis of a micromolecular polymer through free radical polymerization. Experimental results show that under the condition of same mud content of aggregates, a polycarboxylate superplasticizer with the anti-mud agent has obviously improved dispersion effect, improves the initial fluidity of concrete, reduces slump loss, enables the compressive strength of concrete to be increased by 1.5 to 3 MPa, exerts good inhibitory effect on mud content and is suitable for industrial large-scale production.

Owner:萧县沃德化工科技有限公司

Medical adhesive

The invention discloses a medical adhesive, comprising the following substances in parts by weight: 65-80 parts of alpha-N-butylcyanoacrylate, 5-8 parts of hydroxypropyl methacrylate, 3-5 parts of sulfur dioxide, 1-2 parts of hydroquinone, 0.5-2 parts of polyurethane, 0.5-1.5 parts of agar, 0.8-1.2 parts of fibrin glue, 2-3 parts of water soluble phenol-formaldehyde resin, and 20-25 parts of deionized water. The medical adhesive has the beneficial effects that the medical adhesive provided by the invention is low in thrill, and excellent in bonding persistence; compared with the traditional common adhesive, the persistence of the medical adhesive can be up to 1.5-3 times; and animal experiments show that the toxic and side effects are small.

Owner:台山市弘毅医疗用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com