Ester slump retaining type polycarboxylate water reducer and preparation method thereof

A slump-preserving, polycarboxylic acid technology, which is applied in the field of building materials, can solve the problems of excessive slump loss, prolonged setting time, and high cost of slump-preserving agents, and achieves improved dispersing ability, increased steric hindrance effect, and improved slump retention. good for dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

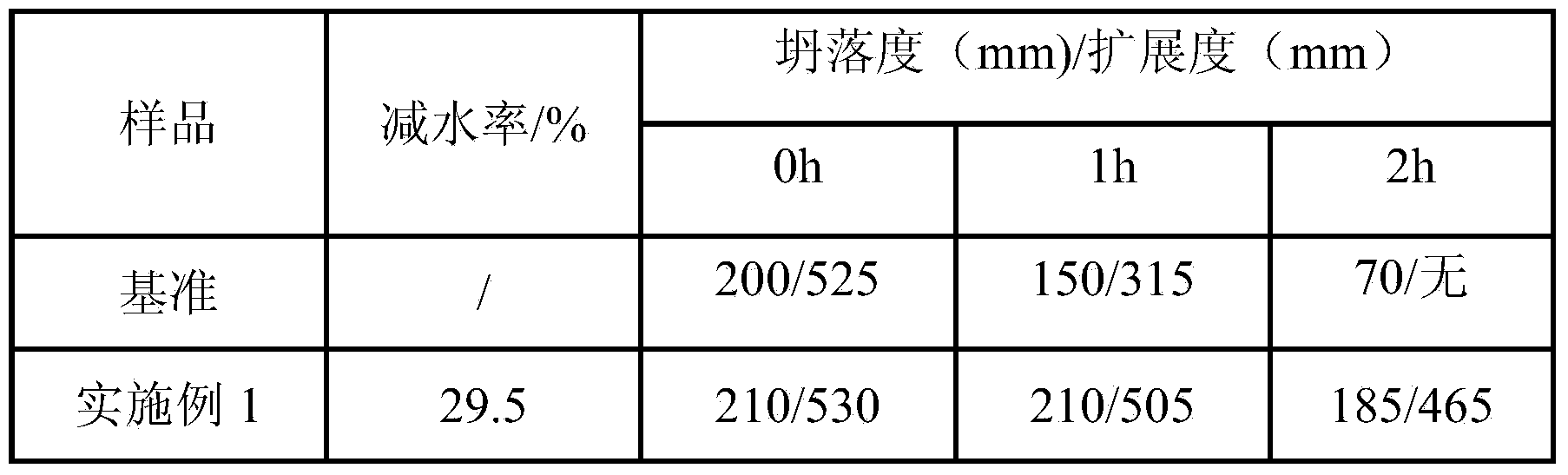

Embodiment 1

[0034] (1) Preparation of the esterified macromonomer: polyethylene glycol monomethyl ether, triethylene glycol, methyl methacrylate, n-butyl titanate and mixed polymerization inhibitor with a molecular weight of 600 at 100 : 2:27:1:0.6 mass ratio, mix well, add to the reactor equipped with condensing device, under nitrogen atmosphere, react at constant temperature at 80°C for 6 hours, cool down to 50°C after the reaction, add 32.4 parts of water Adjust the concentration to 80% to obtain the esterified macromonomer solution, the solute polyethylene glycol monomethyl ether methacrylate, the crosslinking monomer triethylene glycol bismethyl The mixture of base acrylate and methyl methacrylate; The mixed polymerization inhibitor is a mixture of hydroquinone and hydroquinone monomethyl ether, and the mass ratio of the two is 2:1;

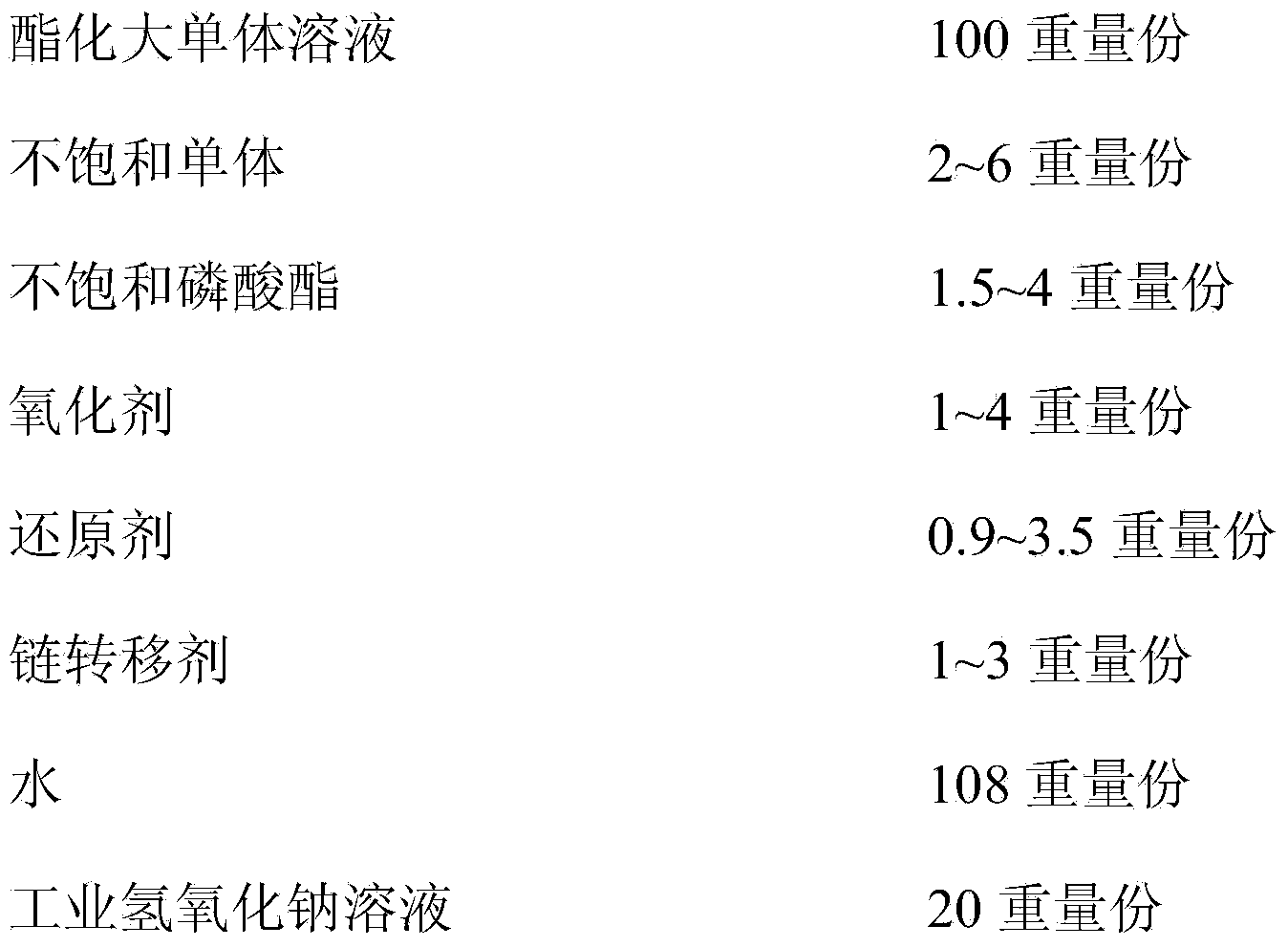

[0035] (2) Take by weighing 100 parts by weight of esterified macromer solution, 2 parts by weight of methacrylic acid, 3 parts by weight of hydroxypro...

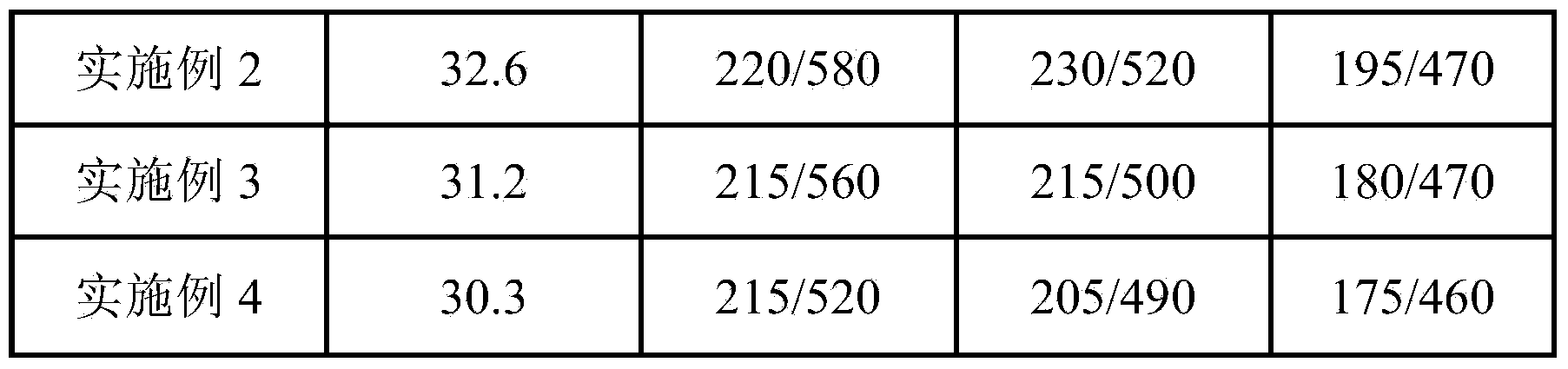

Embodiment 2

[0043] (1) Preparation of the esterified macromonomer: polyethylene glycol monomethyl ether, triethylene glycol, methyl methacrylate, 4-dimethylaminopyridine and mixed polymerization inhibitor with a molecular weight of 1200 The mass ratio of 100:0.5:17.5:0.2:0.3 was mixed evenly, added to the reactor equipped with a condensing device, and reacted at a constant temperature of 70°C for 5 hours under a nitrogen atmosphere. After the reaction was completed, the temperature was lowered to 50°C, and 29.6 parts of Adjust the concentration to 80% with water to obtain the esterified macromonomer solution, the solute polyethylene glycol monomethyl ether methacrylate, the crosslinking monomer triethylene glycol bis A mixture of methacrylate and methyl methacrylate; the mixed polymerization inhibitor is a mixture of hydroquinone and hydroquinone monomethyl ether, and the mass ratio of the two is 2:1;

[0044] (2) Weigh 100 parts by weight of esterified monomer solution, 3 parts by weight...

Embodiment 3

[0052] (1) Preparation of the esterified macromonomer: polyethylene glycol monomethyl ether, triethylene glycol, methyl methacrylate, dibutyltin oxide and mixed polymerization inhibitor with a molecular weight of 2000 at 100 The mass ratio of :1:17:1.5:0.4 is mixed evenly, added to the reactor equipped with a condensing device, and reacted at a constant temperature of 90°C for 5 hours under a nitrogen atmosphere. After the reaction is completed, the temperature is lowered to 50°C, and 29.6 parts of water are added. Adjust the concentration to 80% to obtain the esterified macromonomer solution, the solute polyethylene glycol monomethyl ether methacrylate, the crosslinking monomer triethylene glycol bismethyl The mixture of base acrylate and methyl methacrylate; The mixed polymerization inhibitor is a mixture of hydroquinone and hydroquinone monomethyl ether, and the mass ratio of the two is 2:1;

[0053] (2) Weigh 100 parts by weight of esterified monomer solution, 6 parts by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com