Preparation method of polyacrylate emulsion containing silicon, fluorine and phosphate group

A technology of polyacrylate emulsion, fluorine and phosphoric acid groups, which is applied in the field of preparation of polyacrylate emulsion, and can solve the problem that flame retardancy, corrosion resistance and low temperature resistance do not coexist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

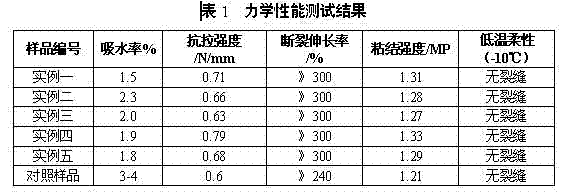

Examples

Embodiment 1

[0016] 1) Preparation of pre-emulsion

[0017] In parts by mass, 10 parts of deionized water, 0.4 parts of sodium lauryl sulfate, 1.2 parts of AEO-9, 3.5 parts of hydroxypropyl methacrylate, 4 parts of PAM-100, 3.5 parts of vinyltriethoxy Silane and 3 parts of dodecafluoroheptyl methacrylate were put into the reaction kettle, and the temperature was raised to 45°C under high-speed stirring, and then a mixture consisting of 33 parts of butyl acrylate, 10 parts of styrene and 5 parts of methyl methacrylate 90% of the body was slowly added to the reaction kettle, stirred for 30 minutes, and a stable milky white pre-emulsion was obtained, which was removed for subsequent use;

[0018] 2) Preparation of polyacrylate emulsion

[0019] In parts by mass, add 0.1 part of sodium lauryl sulfate, 0.2 part of AEO-9, 0.1 part of n-octanol, 0.1 part of sodium bicarbonate and 15 parts of deionized water into the reactor, stir, and heat up to 80 °C, Add 5 parts of the initiator solution and ...

Embodiment 2

[0022] 1) Preparation of pre-emulsion

[0023] In parts by mass, 15 parts of deionized water, 0.6 parts of sodium lauryl sulfate, 1.6 parts of Pingpingjia O-15, 2.5 parts of hydroxypropyl methacrylate, 3.5 parts of PAM-100, 3.8 parts of vinyl triethyl Oxysilane and 4 parts of dodecafluoroheptyl methacrylate were put into the reaction kettle, and the temperature was raised to 50°C under high-speed stirring, and then a mixture of 39 parts of butyl acrylate, 14 parts of styrene and 8 parts of methyl methacrylate was added 90% of the mixed monomers were slowly added to the reactor, stirred for 34 minutes to obtain a stable milky white pre-emulsion, which was removed for later use;

[0024] 2) Preparation of polyacrylate emulsion

[0025] In parts by mass, add 0.2 parts of sodium lauryl sulfate, 0.4 parts of Pingpingjia O-15, 0.5 parts of n-octanol, 0.5 parts of disodium hydrogen phosphate and 25 parts of deionized water into the reactor, stir, and heat up to 85 After 10°C, add 1...

Embodiment 3

[0028] 1) Preparation of pre-emulsion

[0029] In parts by mass, 12 parts of deionized water, 0.45 parts of sodium lauryl sulfate, 1.3 parts of Pingpingjia O-20, 2.9 parts of hydroxypropyl methacrylate, 3.7 parts of PAM-200, 4 parts of vinyl triethyl Oxysilane and 3.5 parts of dodecafluoroheptyl methacrylate were put into the reaction kettle, and the temperature was raised to 47°C under high-speed stirring, and then a mixture of 36 parts of butyl acrylate, 11 parts of styrene and 9 parts of methyl methacrylate was added 90% of the mixed monomers were slowly added to the reactor, stirred for 35 minutes to obtain a stable milky white pre-emulsion, which was removed for later use;

[0030] 2) Preparation of polyacrylate emulsion

[0031] In parts by mass, add 0.12 parts of sodium lauryl sulfate, 0.20 parts of Pingpingjia O-20, 0.2 parts of sodium bicarbonate, 0.2 parts of dodecyl mercaptan and 18 parts of deionized water into the reactor, stir, and heat up to 84 After ℃, add 7 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com