Patents

Literature

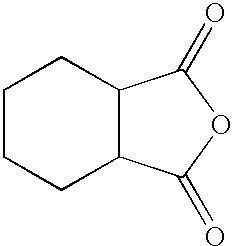

214 results about "Hexahydrophthalic anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer dielectric medium with low dielectric constant and low loss and preparation method of polymer dielectric medium

InactiveCN103980664AGood dispersionImprove thermal conductivitySynthetic resin layered productsEpoxyHeat conducting

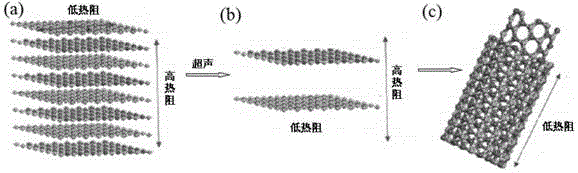

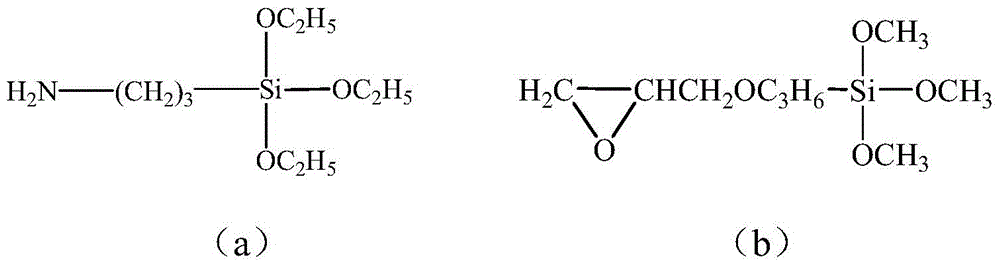

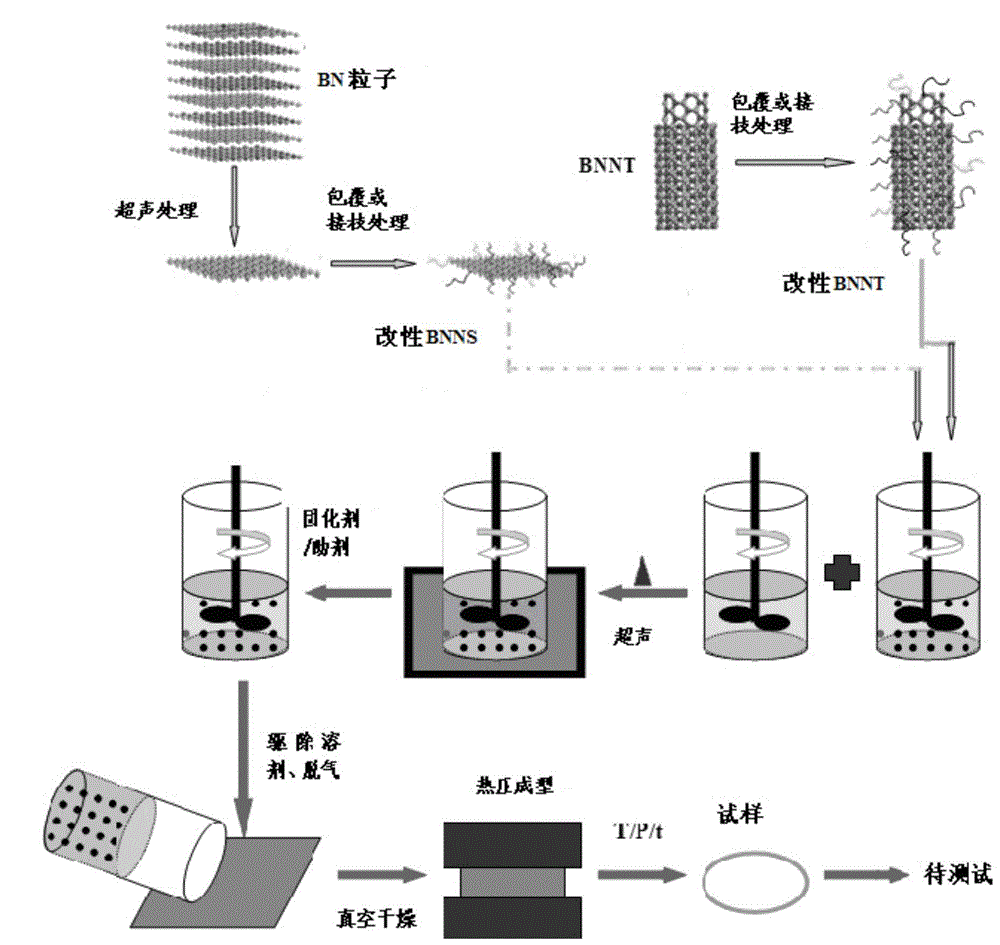

The invention discloses a polymer dielectric medium with low dielectric constant and low loss and a preparation method of the polymer dielectric medium. The polymer dielectric medium comprises the following raw materials: 50-60% of epoxy resin system, and 40-50% of mixed boron nitride nanoparticles, wherein the mixed boron nitride nanoparticle is a mixture of a boron nitride nanotube and a boron nitride nanotube; the epoxy resin system is formed by 100phr of epoxy resin E-51, 85phr of methyl hexahydrophthalic anhydride and 1phr of benzyl dimethylamine in a mixing manner. The thermal breakdown voltage of the polymer dielectric medium is significantly improved by the polymer dielectric material with high heat conductivity and high electric breakdown, the service life is prolonged, the dielectric constant and loss and the heat expansion coefficient are reduced, the mechanical strength and the tenacity are improved, the highest heat conductivity can be up to 5.26W / mK, the volume resistivity is about 1014ohm.cm, the thermal breakdown voltage is about 2-3kV / mm higher than that of the similar heat-conducting polymer dielectric medium, and the dielectric constant and the loss are a little lower than those of pure resin.

Owner:XIAN UNIV OF SCI & TECH

Acrylic acid ester modified epoxy soybean oil, its preparation method and application thereof

ActiveCN102660387ANovel structureImprove adhesionOrganic chemistryFatty acid chemical modificationPolymer scienceMeth-

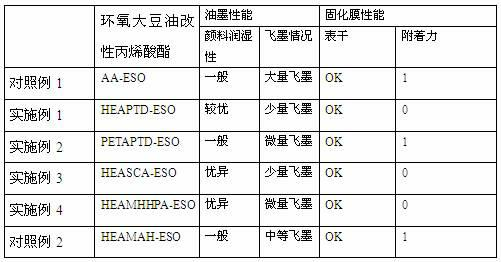

The invention discloses an acrylic acid ester modified epoxy soybean oil, its preparation method and an application thereof. According to the preparation method of the acrylic acid ester modified epoxy soybean oil, acrylate monomer bearing a hydroxyl group reacts with acid anhydride to obtain a half-ester intermediate, and the half-ester intermediate reacts with epoxy soybean oil to obtain the acrylic acid ester modified epoxy soybean oil. The acrylate monomer bearing a hydroxyl group is hydroxyethyl acrylate, hydroxyethyl methacrylate, pentaerythritol triarylate, hydroxypropyl acrylate, hydroxypropyl methacrylate, trimethylol propane diacrylate or trimethylol propane dimethacrylate. Acid anhydride is o phthalic anhydride, succinic anhydride, methyl hexahydrophthalicanhydride, hexahydrophthalic anhydride or tetrahydrophthalic anhydride. The acrylic acid ester modified epoxy soybean oil has a novel structure. When applied in paper printing ink, the acrylic acid ester modified epoxy soybean oil can improve adhesive force of a cured film and also can improve wetability of pigments and remarkably minimize occurrence of misting. The preparation method helps widen the application range of the modified epoxy soybean oil.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

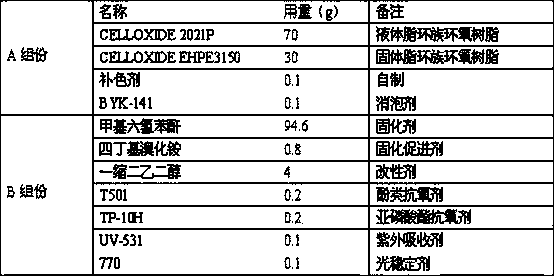

LED-packaging epoxy resin composition

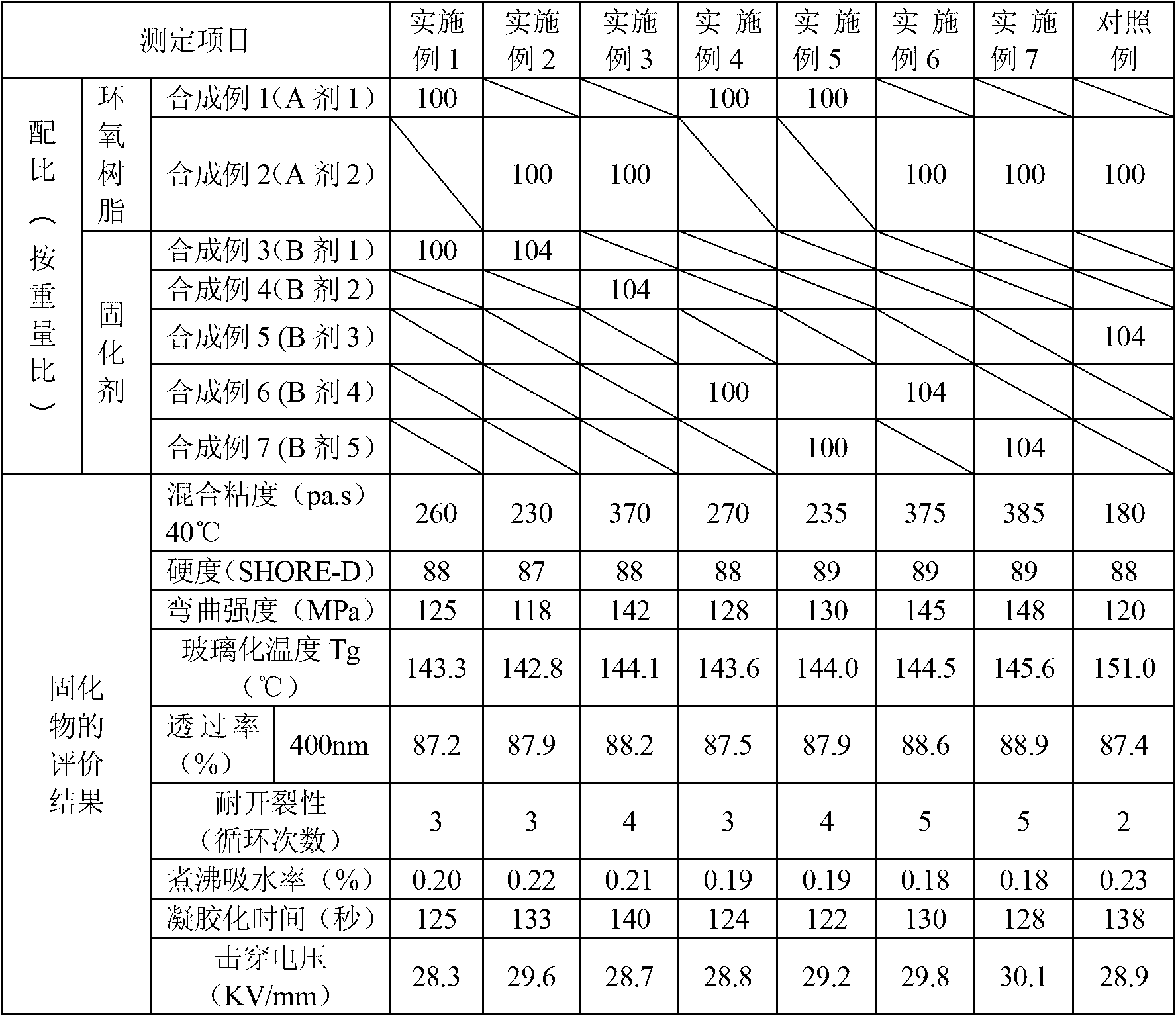

InactiveCN102746487AGuaranteed crack resistanceGuaranteed craftsmanshipNon-macromolecular adhesive additivesEpoxy resin adhesivesPhosphonium saltPhosphate

The invention discloses a method for improving the performance of a large-power high-light-transmittance LED packaging epoxy resin composition. The composition is composed of a component A and a component B. The composition has excellent UV resistance and yellowing resistance. The composition is advantaged in good manufacturability, good light transmittance, and low light failure. The composition can be used in white-light and blue-light LED packaging. Compared with organosilicon, the composition is advantaged in low price. Innovatively, the component A of the composition is composed of liquid cycloaliphatic epoxy resin, solid cycloaliphatic epoxy resin, and hydrogenated bisphenol A epoxy resin. An anti-forming agent, a color complementary agent, and a dispensing agent are adopted in auxiliary. The system does not contain benzene ring, and yellowing is not easy to occur. The component B is prepared through the steps that: methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride are subjected to a polymerization reaction with promoting agents or cationic initiators such as quaternary phosphonium salt, quaternary ammonium salts, DBU salt, and imidazole; with added phosphate antioxidant, a thermal yellowing capacity is improved. With the applications of an ultraviolet absorber and a light stabilizer, a UV yellowing resisting effect is further improved.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS +1

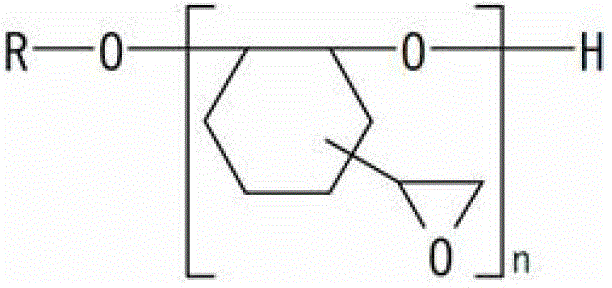

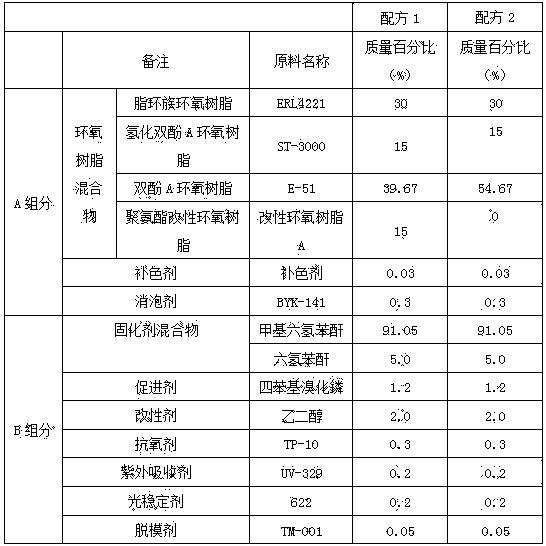

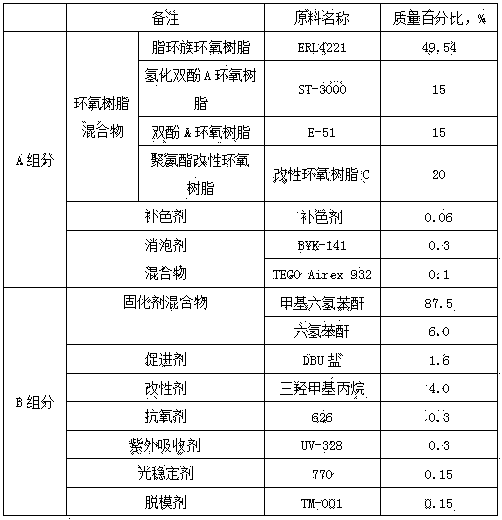

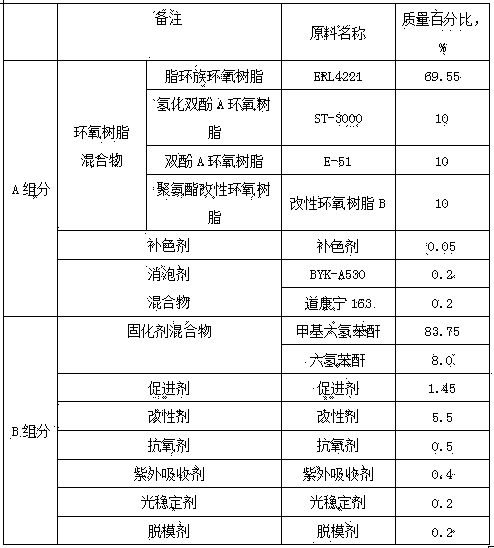

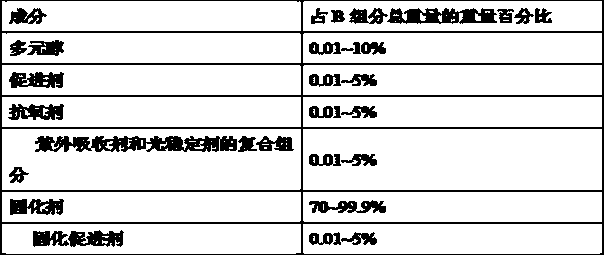

Preparation method of high-performance epoxy resin composition for LED (light-emitting diode) packaging

ActiveCN104403277AImprove brittlenessReduce internal stressSemiconductor devicesAntioxidantLight-emitting diode

The invention discloses a preparation method of a high-performance epoxy resin composition for LED (light-emitting diode) packaging, which comprises the steps of raw material preparation, proportional mixing, vacuum degassing and curing. In the raw material preparation step, the epoxy resin composition is composed of a component A and a component B, wherein the component A comprises an epoxy resin mixture, a defoaming agent and a color complementing agent; the epoxy resin is composed of an alicyclic epoxy resin, a hydrogenated bisphenol A epoxy resin, a bisphenol A epoxy resin and a polyurethane modified epoxy resin; the component B comprises a curing agent mixture, a modifier, an antioxidant, an ultraviolet absorbent, a light stabilizer, an accelerator and a mold release agent; and the curing agent mixture is composed of methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride. The method improves the brittleness of the epoxy resin, lowers the internal stress of the material, enhances the low-temperature resistance of the finished product, and improves the aging resistance, yellowing resistance and ultraviolet resistance of the LED product.

Owner:无锡嘉联电子材料有限公司

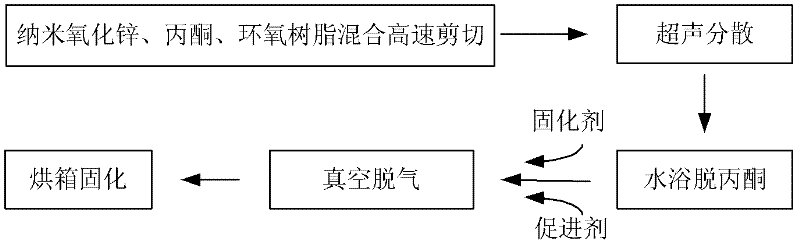

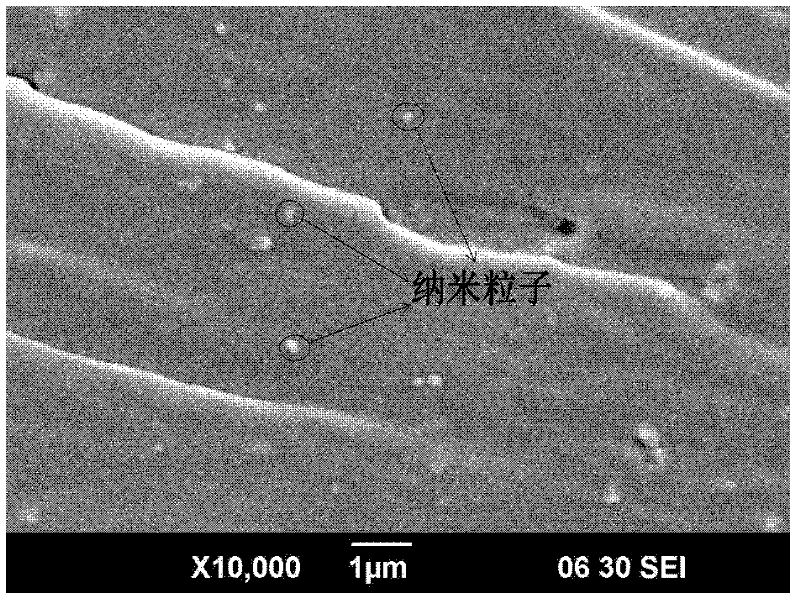

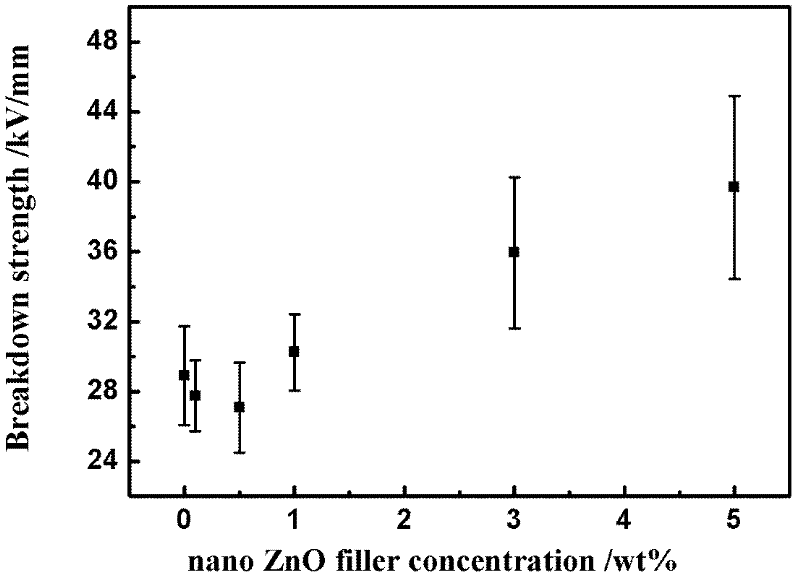

Epoxy resin matrix nano-zinc oxide composite material and preparation method thereof

The invention relates to an epoxy resin matrix nano-zinc oxide composite material and a preparation method of the epoxy resin matrix nano-zinc oxide composite material. The epoxy resin matrix nano-zinc oxide composite material comprises matrix resin, curing agent, accelerating agent and additive, wherein the matrix resin is epoxy resin, the curing agent is methy hexahydrophthalic anhydride, the accelerating agent is N, N- methylbenzylamine, and the additive is nano-zinc oxide; the epoxy resin matrix nano-zinc oxide composite material comprises the components in part by weight: 100 parts of the epoxy resin, 70-120 parts of the methy hexahydrophthalic anhydride, 1-4 parts of the N, N- methylbenzylamine, and 0.5-10 parts of the nano-zinc oxide; the preparation method of the epoxy resin matrix nano-zinc oxide composite material comprises the steps of: mixing the nano-zinc oxide, acetone, the epoxy resin, carrying out high-speed shearing and ultrasonic dispersion on the obtained mixture, removing the acetone by water bath, carrying out vacuum degassing after the curing agent and the accelerating agent are added, and curing by an oven. The epoxy resin matrix nano-zinc oxide composite material has the advantages of being excellent in dielectric property and especially strong in power frequency breaking down field strength. The preparation method of the epoxy resin matrix nano-zinc oxide composite material has the characteristic of low cost.

Owner:XI AN JIAOTONG UNIV

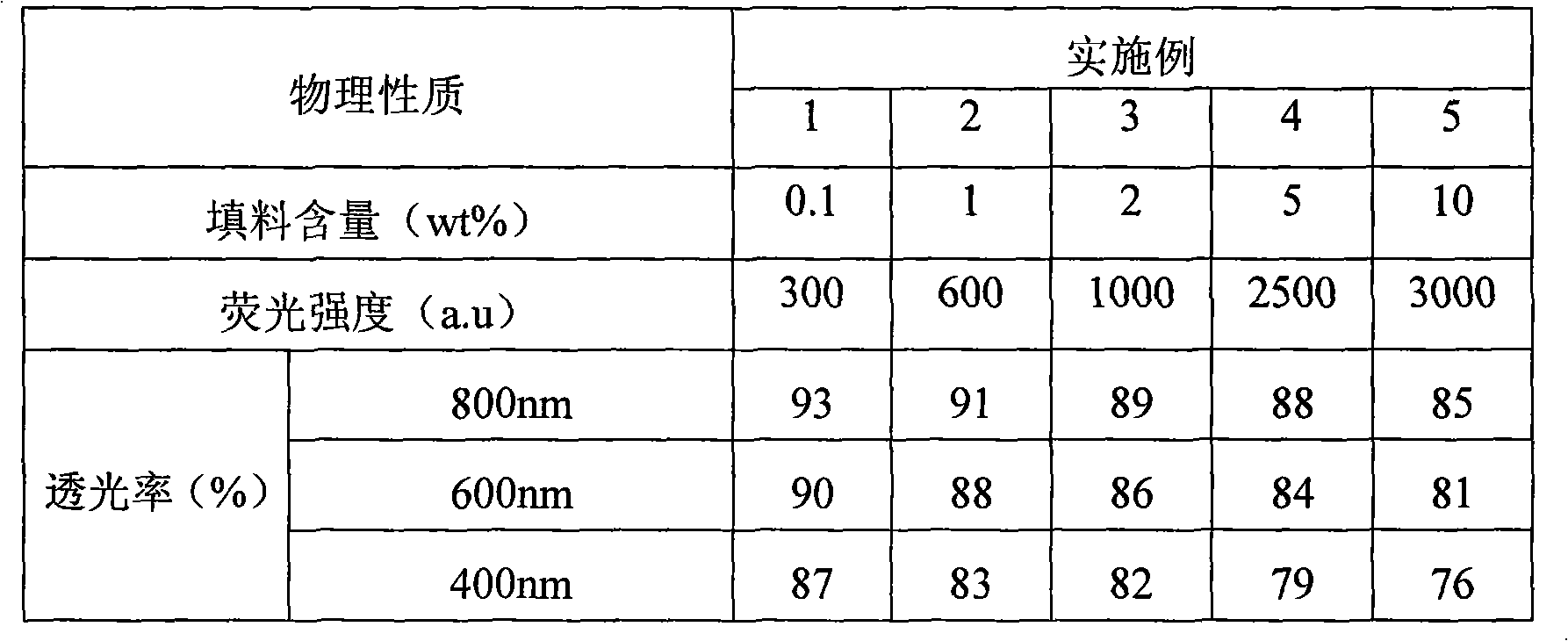

Photoluminescent transparent epoxy nanometer composite material, preparation method and application thereof

InactiveCN101338187APhotoluminescence achievedHigh light transmittanceLuminescent compositionsPhotoluminescenceHexahydrophthalic anhydride

The invention relates to a photoluminescence transparent epoxy nanometer composite material, a manufacturing method and the usage. The composite material comprises transparent epoxy resin matrix material and photoluminescence inorganic nanometer fillers uniformly dispersed in the epoxy resin matrix material; the transparent epoxy resin matrix material comprises epoxy resin and acid anhydrides epoxy curing agent. The epoxy resin is alicyclic epoxy resin, bisphenol A type epoxy resin or hydrogenated bisphenol A type epoxy resin. The acid anhydrides epoxy curing agent is methyl hexahydro-pthalic anhydride or hexahydrophthalic anhydride containing 1.0-5.0wt percent of curing accelerator. The curing accelerator is amine curing accelerator or imidazole curing accelerator. The composite material of the invention is provided with good transparency and photoluminescence, can be used for substituting the traditional sealing mode of phosphor adding packaging material and can be directly applied to the sealing of LED luminescence semiconductor devices, large outdoor neon lamps, etc.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

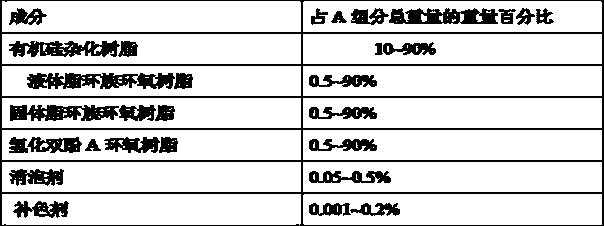

Novel high quality LED packaging material

InactiveCN104232007ANon-macromolecular adhesive additivesEpoxy resin adhesivesPhosphonium saltUltraviolet

The invention discloses a LED organosilicon hybrid resin doping cycloaliphatic epoxy resin packaging glue used for increasing large power. A compound is composed of a part A and a part B. The part A is composed of organosilicon hybrid resin, liquid cycloaliphatic epoxy resin, solid epoxy resin and hydrogenated bisphenol A, and is cooperated with an antifoaming agent, a complementary color agent and a diffusion agent; nonsaturated chemical bond is not contained in a system, and anti-yellowing performance is excellent. The part B is composed of methylhexahydrophthalic anhydride and hexahydrophthalic anhydride, and is cooperated with promoters or cation catalysts such as quaternary phosphonium salt, quaternary ammonium salt, DBU salt and imidazoles, and phenols and phosphite anti-oxidant and an ultraviolet absorbent and a light stabilizer are added for increasing the anti-yellowing capability. The organosilicon hybrid resin doping cycloaliphatic epoxy resin packaging glue has the advantages of excellent ultraviolet resistance and yellowing-resistance performance, good manufacturability, high light transmittance, little light decay, and sulfuration pollution resistance. Compared with the organosilicon, the packaging glue has price advantage, also can overcome the disadvantages of brittleness and high hygroscopicity of a pure cycloaliphatic epoxy system, and is more suitable for packaging high-end LED, large power LED or ultraviolet-based white light or blue light LED.

Owner:大连芯拓光电有限公司

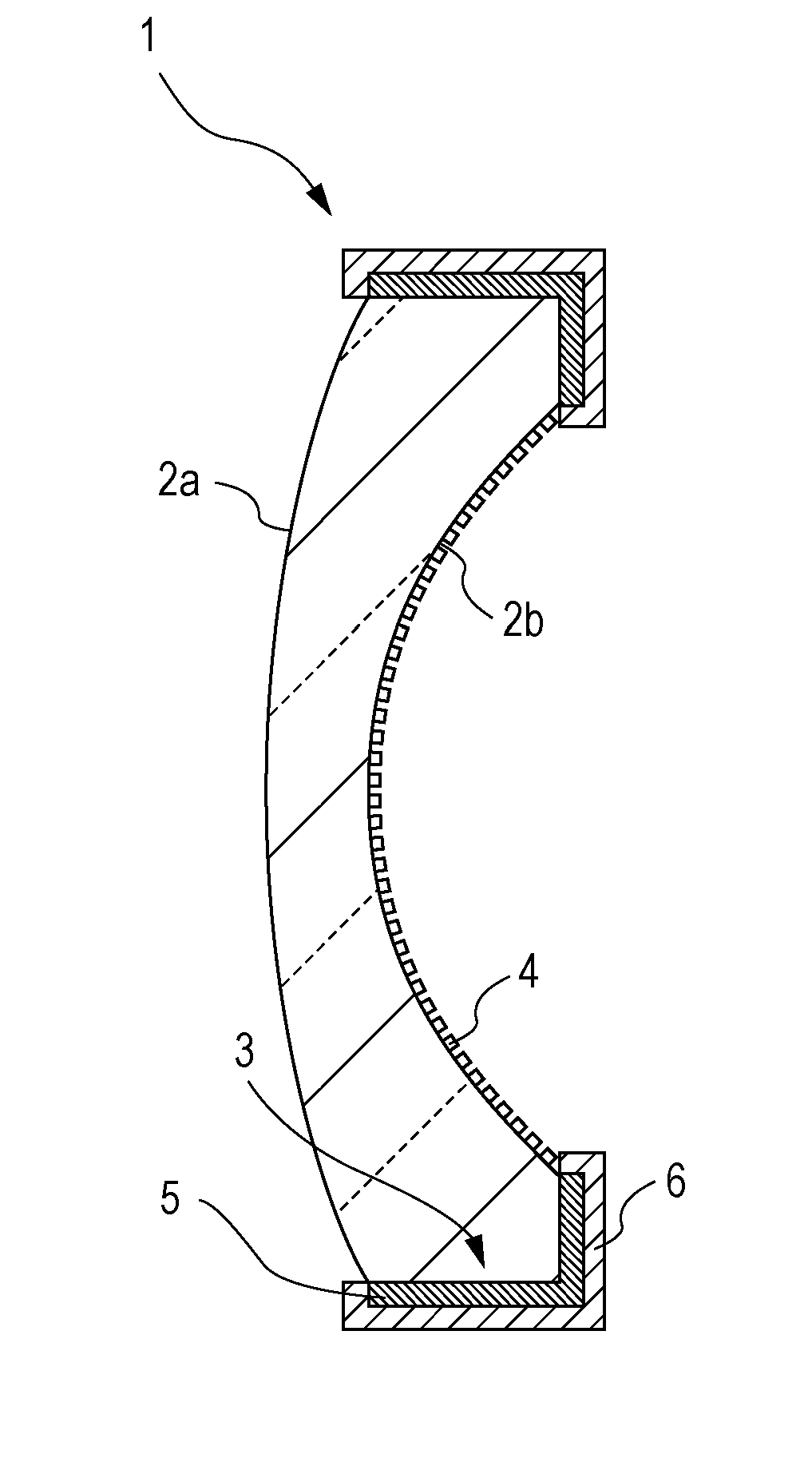

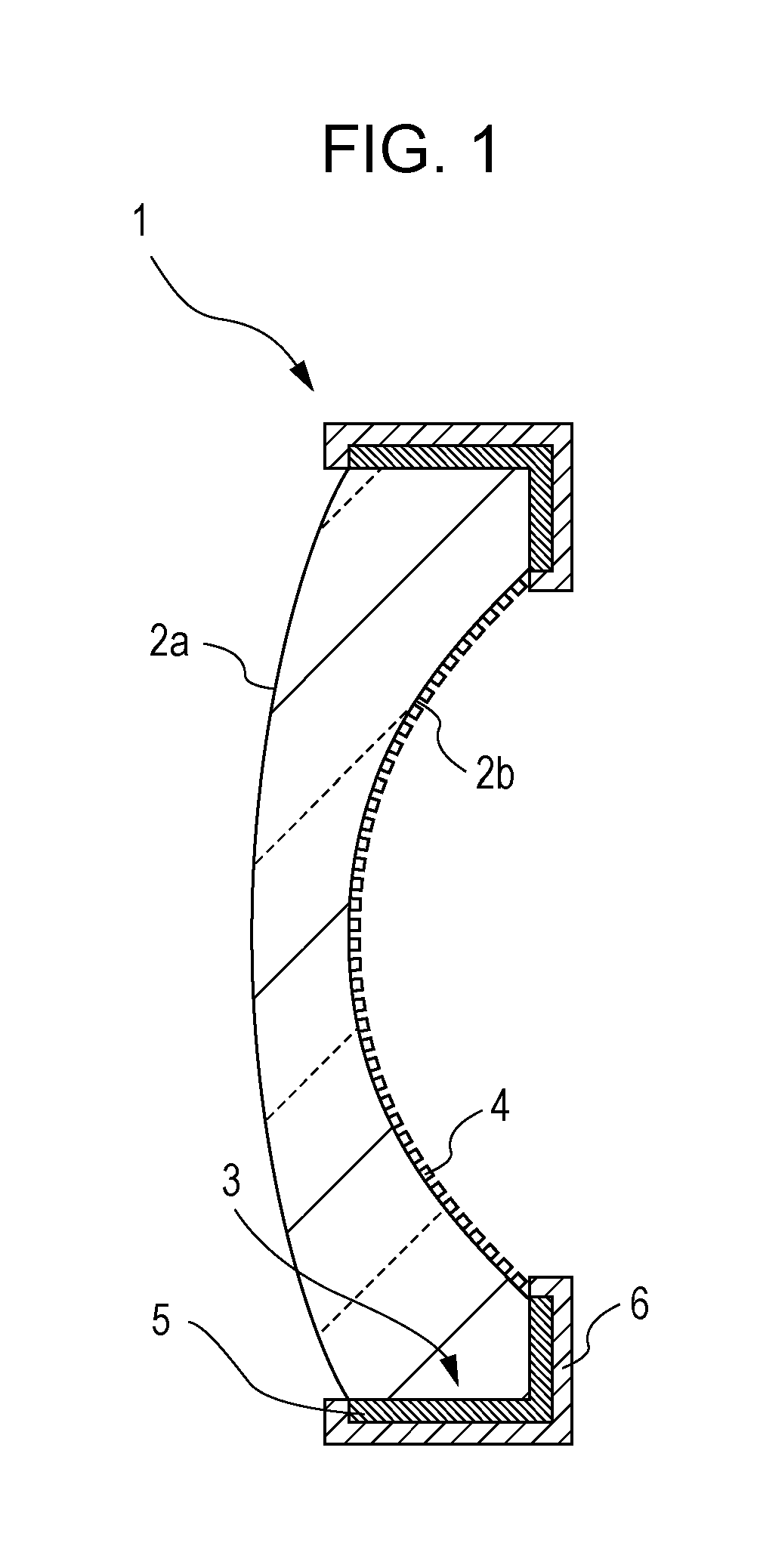

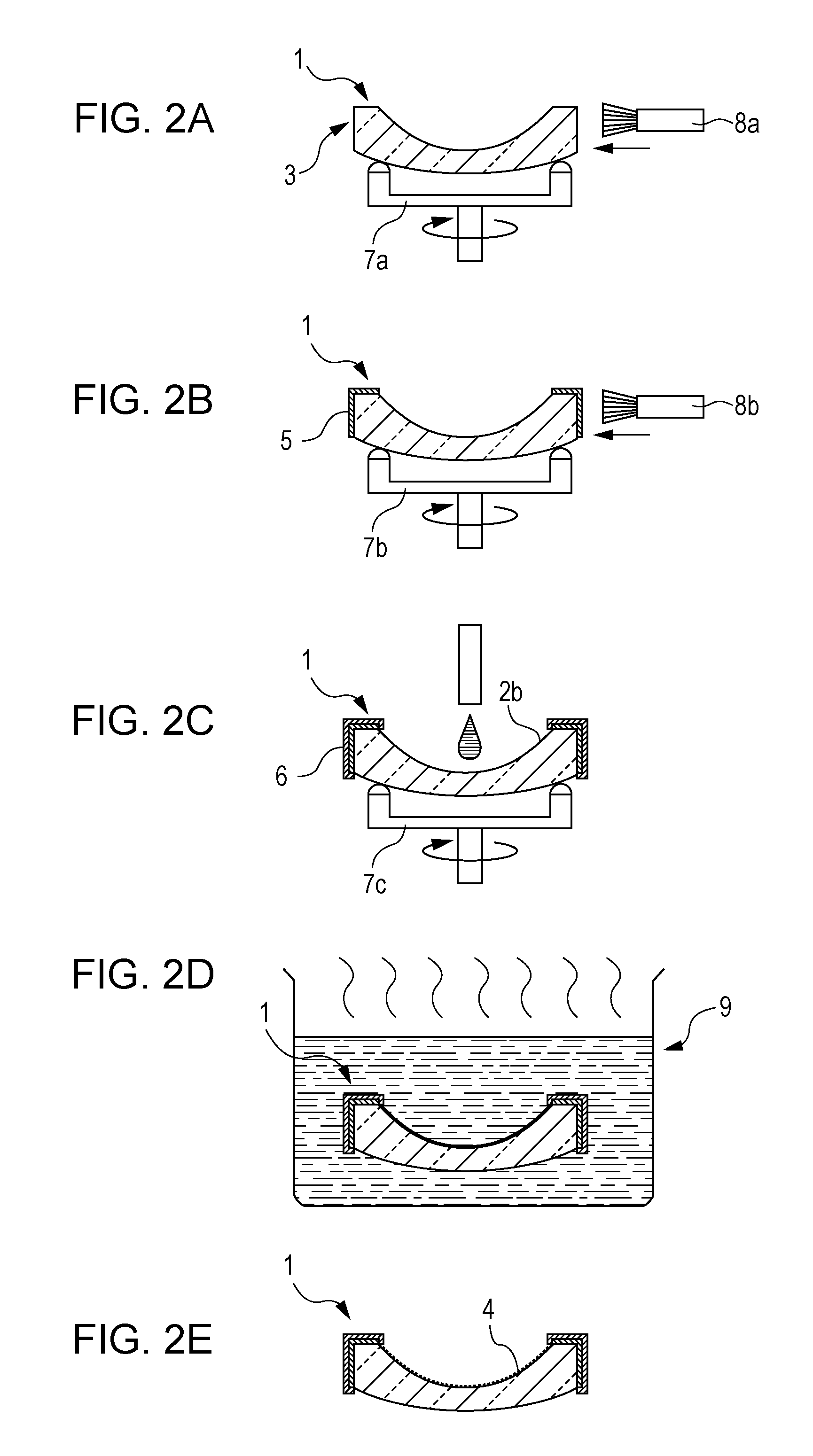

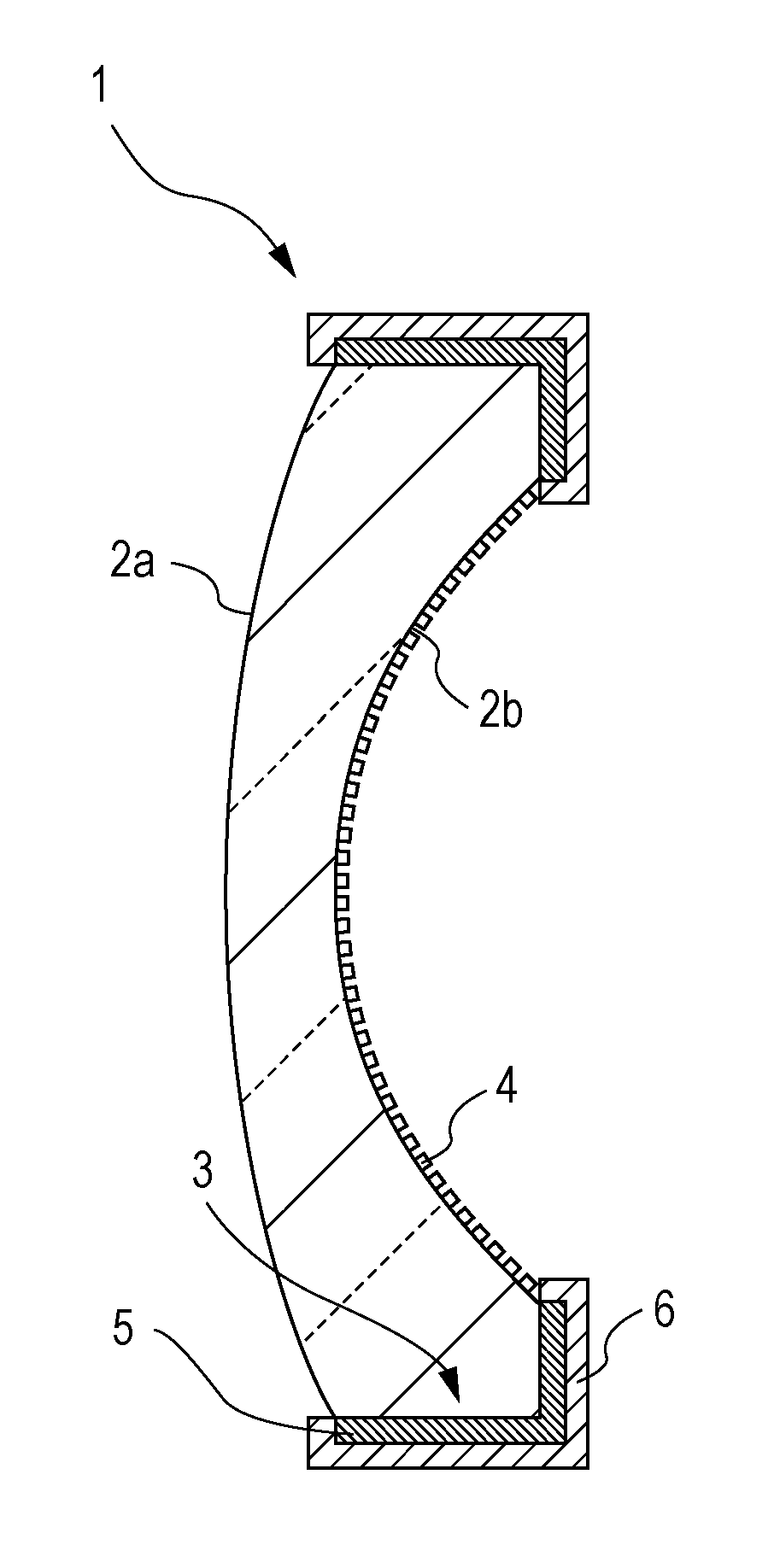

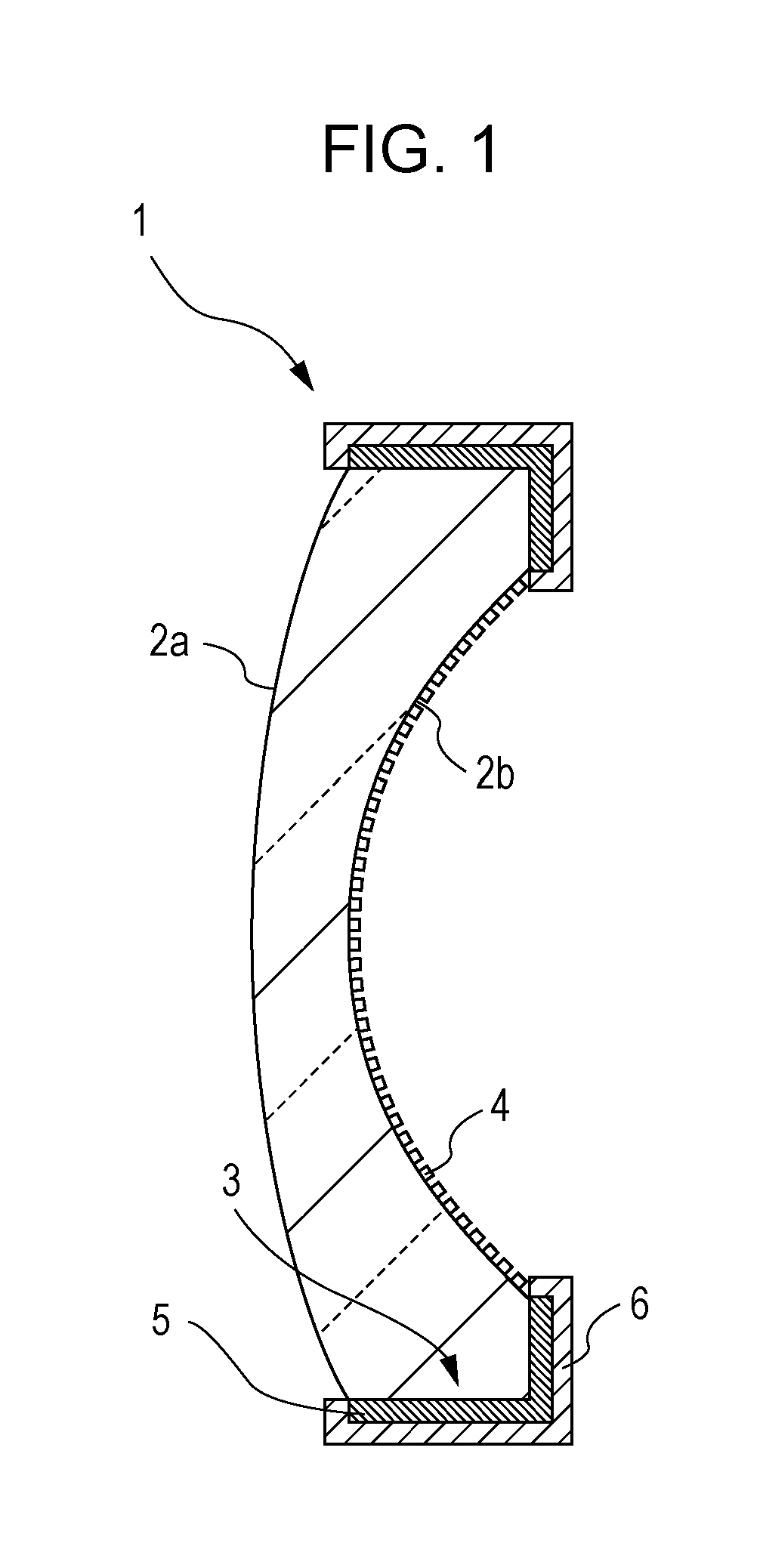

Optical element, method of manufacturing optical element, and imaging optical system

InactiveUS20110176216A1Increase flexibilityIncrease resistanceSpecial surfacesCoatingsHexahydrophthalic anhydrideMethylhexahydrophthalic acid

An optical element includes an optically effective area and an optically ineffective area partly or entirely coated with a coating opaque at wavelengths used. The opaque coating contains a cured product prepared from an epoxy resin and a curing agent containing an alicyclic acid anhydride. The alicyclic acid anhydride is preferably methylhexahydrophthalic anhydride or hexahydrophthalic anhydride.

Owner:CANON KK

Liquid epoxy resin composition for packaging LED (Light Emitting Diode)

InactiveCN102702682AGood flexibilityImprove crack resistanceSemiconductor devicesCrack resistanceHexahydrophthalic anhydride

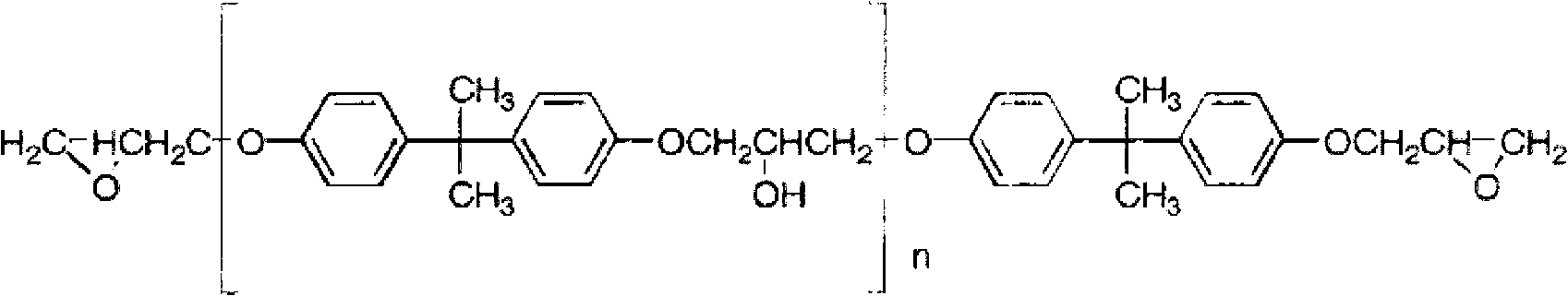

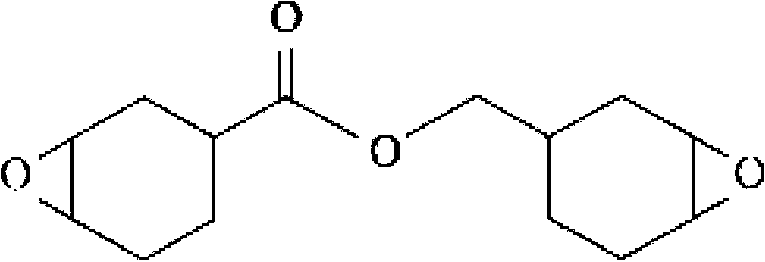

The invention discloses a liquid epoxy resin composition for packaging an LED (Light Emitting Diode). The liquid epoxy resin composition consists of an agent A and an agent B, wherein the agent A comprises 97-99 percent by weight of epoxy resin composition and 1-3 percent by weight of defoaming agent; the agent B comprises 94-97 percent by weight of alicyclic anhydride, 0.02-0.1 percent by weight of antioxidant, 0.02-0.1 percent by weight of ultraviolet absorber, 2-5 percent by weight of toughening modifier and 0.5-1.5 percent by weight of accelerator; and the weight ratio of the agent A to the agent B is 100:(100-105). The epoxy resin composition in the agent A is bisphenol-A epoxy resin and 3,4-epoxy cyclohexylmethyl and 3,4-epoxycyclohexyl carboxylate; and the alicyclic anhydride in the agent B is at least one of methyl tetrahydrophthalic anhydride, methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride; and the toughening modifier is neopentyl glycol. The neopentyl glycol has a structure of a branched chain, so that the flexibility and the cracking resistance of the cured epoxy resin are remarkably improved.

Owner:JIAXING JIAGANG SYNTHETIC MATERIALS

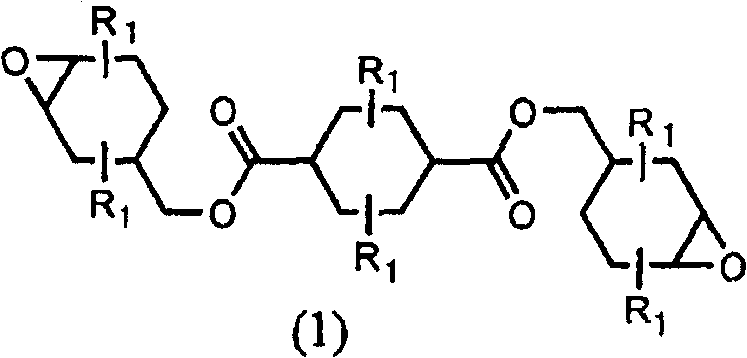

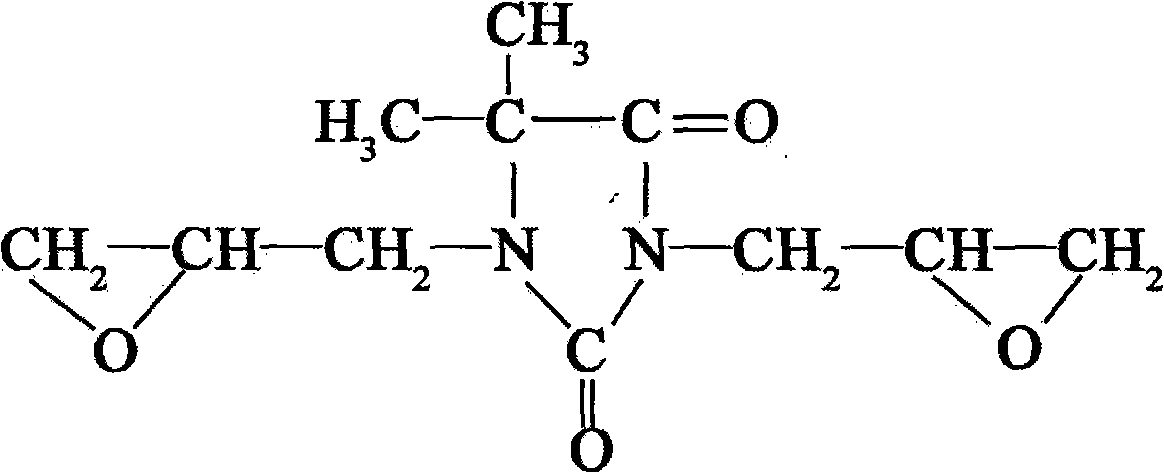

Curable resin composition for encapsulating optical semiconductor and cured product thereof

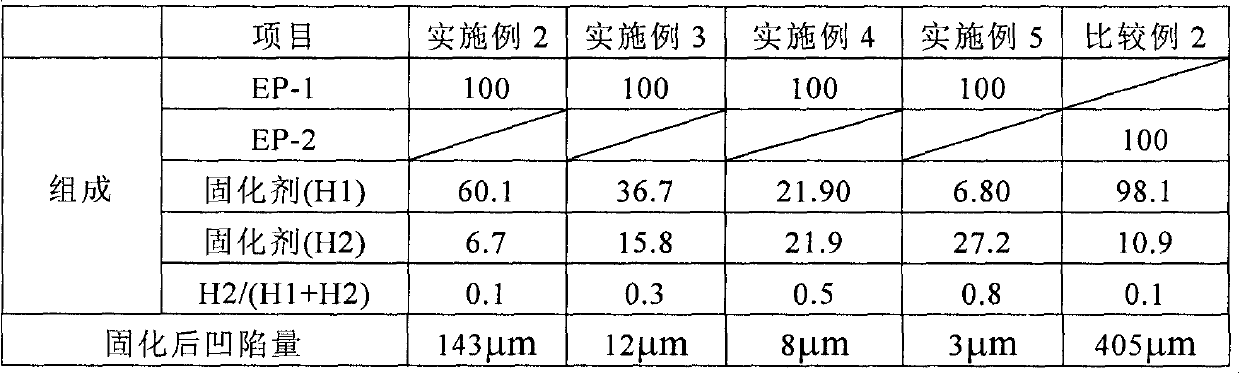

InactiveCN101942073AAvoid dentsExcellent resistance to corrosive gasesSolid-state devicesEpoxy resin adhesivesEpoxyHydrogen atom

The invention aims to provide a curable resin composition for encapsulating an optical semiconductor and a cured product thereof, which can prevent sinking after curing and have excellent property of etchant gas resistance and excellent dyeing resisting property. The curable resin composition contains epoxy resin, solidifying agent and / or solidifying booster expressed by formula (1) (in the formula, a plurality of R1 can be same or different and can independently present hydrogen atom or methyl). The curable resin composition of the invention, used as the optimized solidifying agent cyclohexane-1, 3, 4-triformic-3, 4-anhydride and methyl hexahydrophthalic anhydride, has particular effect in preventing sinking after curing.

Owner:NIPPON KAYAKU CO LTD

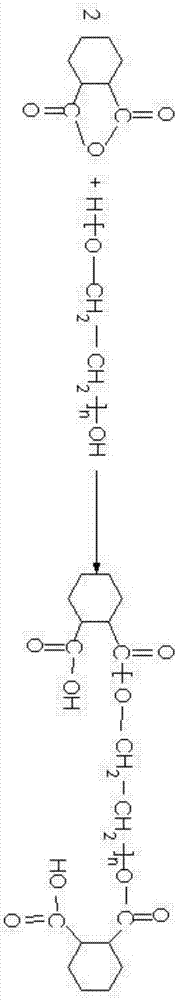

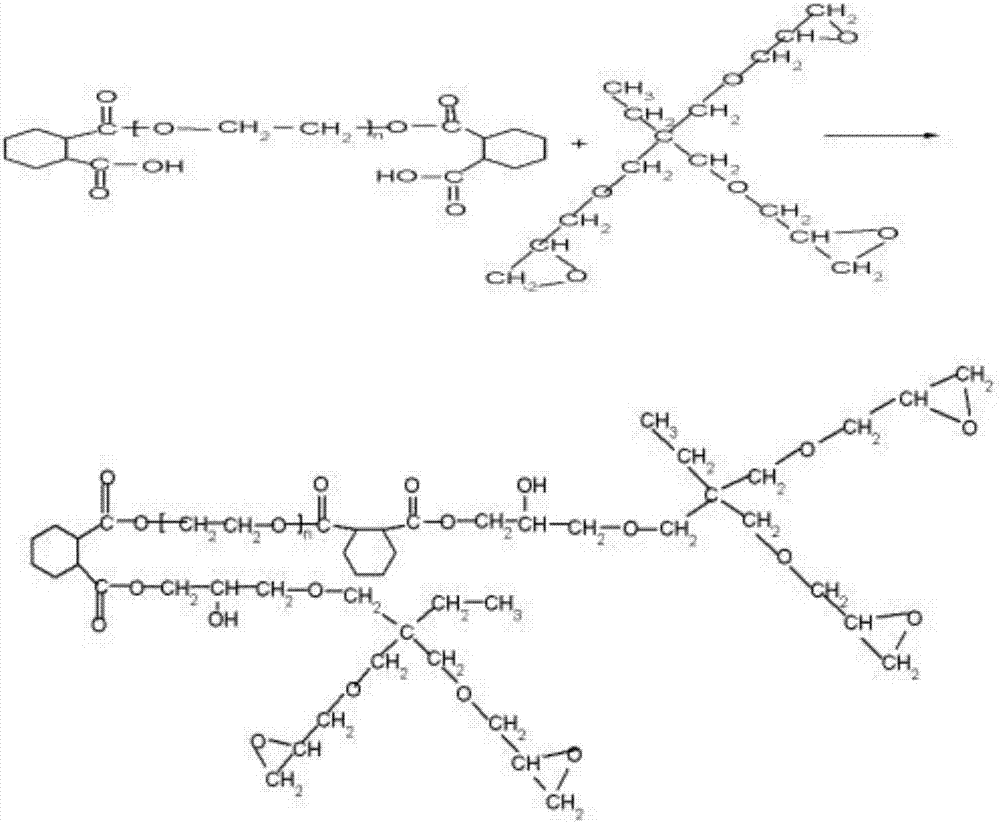

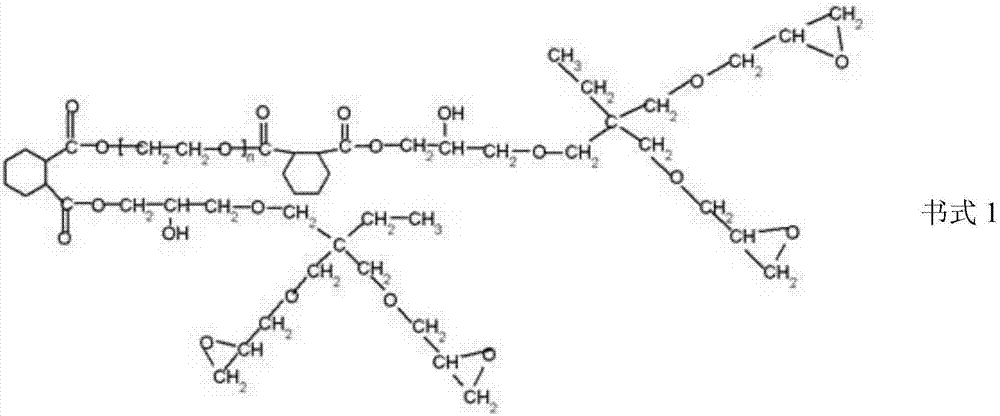

Nonionic epoxy active emulsifier, preparation method of nonionic epoxy active emulsifier and waterborne epoxy resin emulsion

The invention relates to a preparation method of a novel structure nonionic epoxy active emulsifier and a preparation method of an emulsion. The preparation method comprises (1) adding hexahydrophthalic anhydride (HHPA) and a catalyst (p-toluenesulfonic acid) into polyethylene glycol (PEG1000-10000) in a nitrogen atmosphere, and carrying out a heating reaction process, (2) adding an appropriate amount of a trifunctional diluent trimethylolpropane triglycidylglyceride (TMPGE), and carrying out a heating reaction process to obtain a multi-block epoxy resin emulsifier (called as HHPA-P-TMPGE for short), and (3) mixing an appropriate amount of epoxy resin and the emulsifier at a certain temperature, adding deionized water into the mixture drop by drop at a certain flowing rate, carrying out high rate stirring until the system viscosity is suddenly reduced and phase inversion is produced in the system, and adding water into the reaction system to obtain a waterborne epoxy resin emulsion. The waterborne epoxy resin emulsion has the advantages of small average particle size, low dispersion degree and excellent dilution, centrifugation and storage performances. The preparation method provides a novel thinking for preparation of a high performance waterborne epoxy emulsion.

Owner:HAOLISEN CHEM TECH (JIANGSU) CO LTD

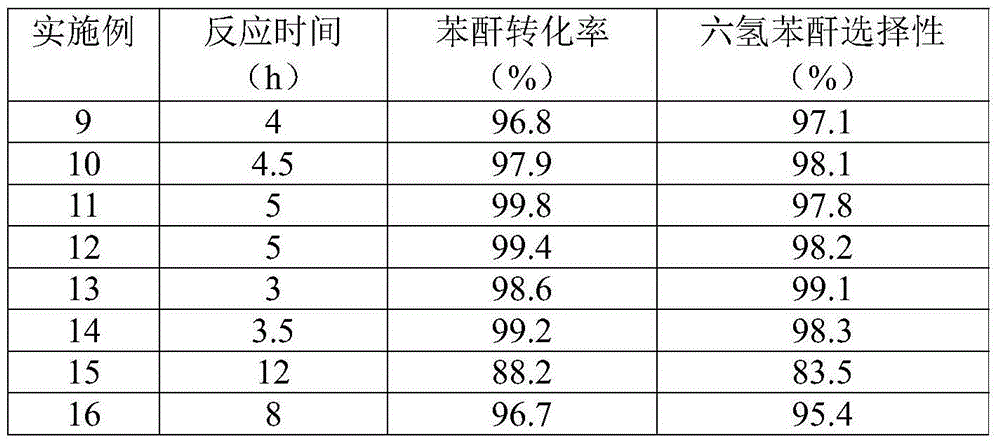

Hydrogenation catalyst, its preparation method and its application in preparation of hexahydrophthalic anhydride

ActiveCN104785250ALow costEasy to prepareOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHexahydrophthalic anhydridePorous carbon

The invention discloses a hydrogenation catalyst, and a preparation method of hexahydrophthalic anhydride. The catalyst adopts meso-porous carbon as a carrier and Ru as an active component, and the load amount of the active component is 0.5-10% of the mass of the catalyst. The preparation method of hexahydrophthalic anhydride is characterized in that hexahydrophthalic anhydride is produced through highly selective hydrogenation of phthalic anhydride as a raw material in the presence of a solvent and the hydrogenation catalyst. The method has the characteristics of low cost, high selectivity, few byproducts, and easy recovery of a precious metal in the catalyst.

Owner:SHANGYU SUNFIT CHEM

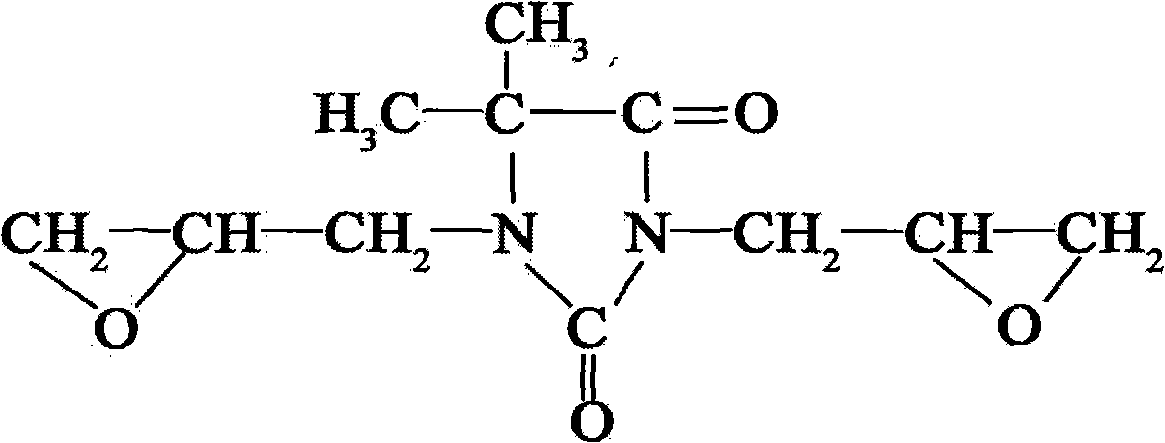

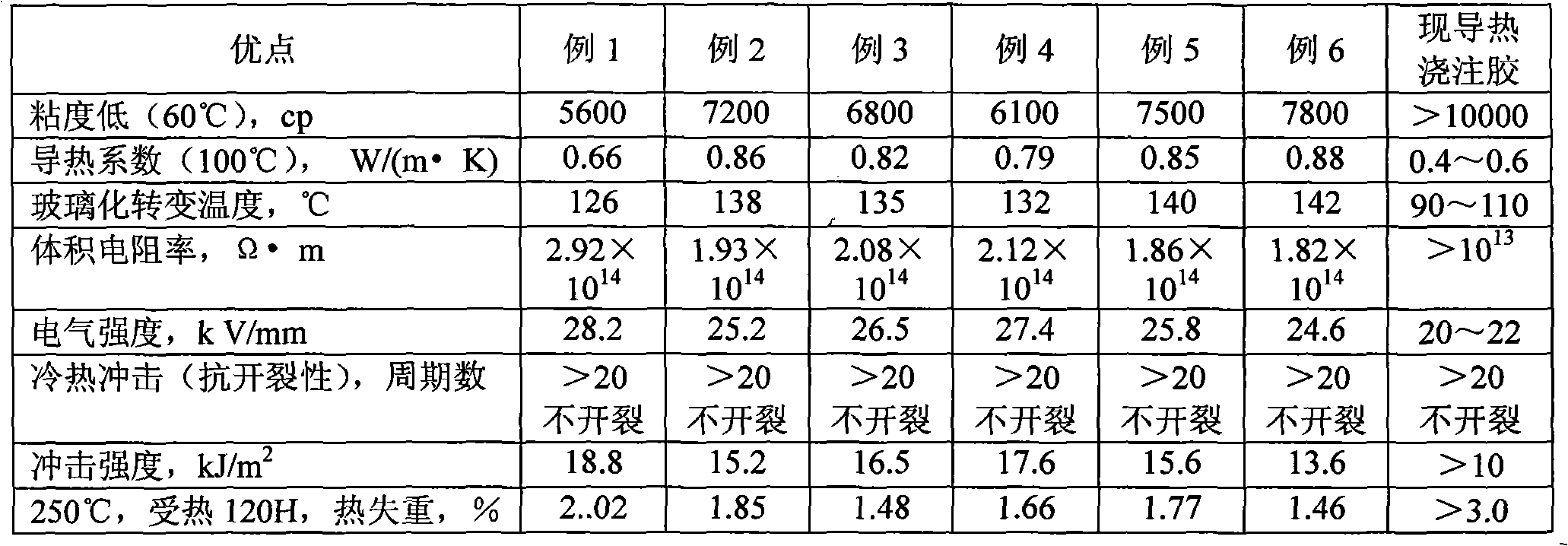

Heat conduction insulating casting glue and preparation method thereof

ActiveCN102093665ALow viscosityGood workmanshipInorganic insulatorsHeat-exchange elementsEpoxyTetrahydrophthalamic acid

The invention relates to a heat conduction insulating casting glue and a preparation method thereof. The casting compound comprises the following main components in parts by weight: (A) 100 parts of hydantoin epoxy resin, (B) 60-120 parts of anhydride curing agent, and (C) 200-400 parts of inorganic heat conductive filler, wherein the component A (per 100 weight parts) contains 10-15 weight partsof alcohol plasticizer; the component B is one or more of hexahydrophthalic anhydride, tetrahydrophthalic anhydride, methyltetrahydrophthalic anhydride, methylhexahydrophthalic anhydride and methylnadic anhydride; and the component C is one or more of silica micropowder, aluminum oxide, aluminum nitride and boron nitride in 300-900 meshes. The preparation method of the casting compound comprises the following steps: mixing A and B proportionally; soaking C in ethanol solution of silane coupling agent, dispersing at a high speed, filtering, and oven-drying; heating the mixture of A and B, adding C, mixing, and debubbling; and casing, and curing. The casting compound provided by the invention has low viscosity, greatly improved heat-conducting property and improved mechanical properties, and is convenient in casting. The preparation method of the casting compound is solvent-free, and has no pollution to the environment.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Epoxy resin glue for photoelectron attenuation-resistant packaging

InactiveCN102070875AImprove the attenuation effectImprove featuresSemiconductor devicesPolymer sciencePhosphonium salt

The invention relates to epoxy resin glue for photoelectron attenuation resistant packaging. The epoxy resin glue consists of glue A and glue B, wherein the glue A is a resin part mixed in parts by weight, and the glue B is a curing agent part mixed in parts by weight; the glue A consists of 10-70 parts of hydrobisphenol A epoxy resin, 20-60 parts of cycloaliphatic epoxide, 0-80 parts of bisphenol A epoxy resin, 0.02-2 parts of light stabilizer, 0.02-2 parts of antioxidant and 0,01-2 parts of defoamer; and the glue B consists of 40-100 parts of methyl hexahydrophthalicanhydride, 0-60 parts of hexahydrophthalic anhydride, 1-5 parts of organphosphorus compound, 0-4 parts of quaternary phosphonium salt complex and 0-3 parts of antioxidant. The epoxy resin glue prepared by using the glue A and the glue B on the spot has the characteristics of good attenuation resistance and aging resistance, namely, the existing product is yellowed after being aged for 20 hours at the temperature of 150 DEG C, but the product obtained by the invention has no obvious variation after being aged for 100 hours at the temperature of 150 DEG C, and the high-temperature luminous attenuation of the product obtained by the invention is far smaller than that of similar products within 2000 hours.

Owner:东莞市永固绝缘材料有限公司

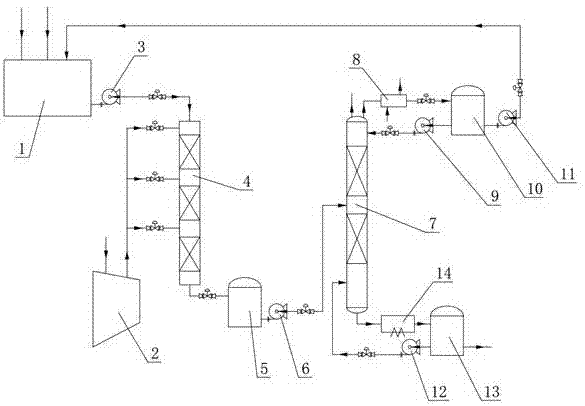

Process for preparing hexahydrophthalic anhydride (HHPA) by means of catalytic hydrogenation

ActiveCN107011304AReduce generationUniform and controllable response layoutOrganic chemistryHexahydrophthalic anhydrideMetal catalyst

The invention discloses a process for preparing hexahydrophthalic anhydride (HHPA) by means of catalytic hydrogenation. The process includes preparing Pd-NiO / SiO2 catalysts by the aid of impregnation processes by SiO2 used as a carrier; catalytically hydrogenating tetrahydrophthalic anhydride in a trickle-bed reactor to prepare the hexahydrophthalic anhydride (HHPA). The process has the advantages that the optimal reaction conditions and process parameters are explored; the SiO2-supported Pd and Ni binary-metal catalysts are adopted, the activity of the catalysts is appropriately deteriorated, the hydrogen partial pressures are increased, and accordingly the selectivity of the hexahydrophthalic anhydride (HHPA) which is a target product can be effectively improved; hydrogen can flow into the trickle-bed reactor from an upper location, a middle location and a lower location, accordingly, reaction layout is uniform and controllable, and side reaction can be reduced; heat generating reaction is carried out during catalyst hydrogenation, the internal circulation speed of the hydrogen in the reactor can be increased, the hydrogen is used as a heat transfer medium, accordingly, reaction heat can be timely transferred, local overheating phenomena can be effectively prevented, and the side reaction can be reduced.

Owner:PUYANG SHENGYUAN ENERGY TECH

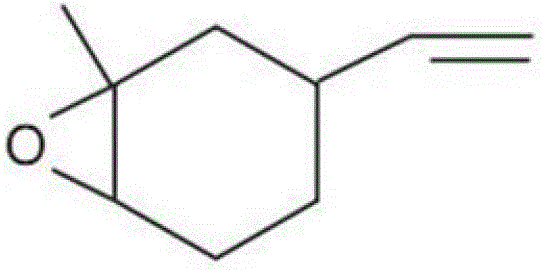

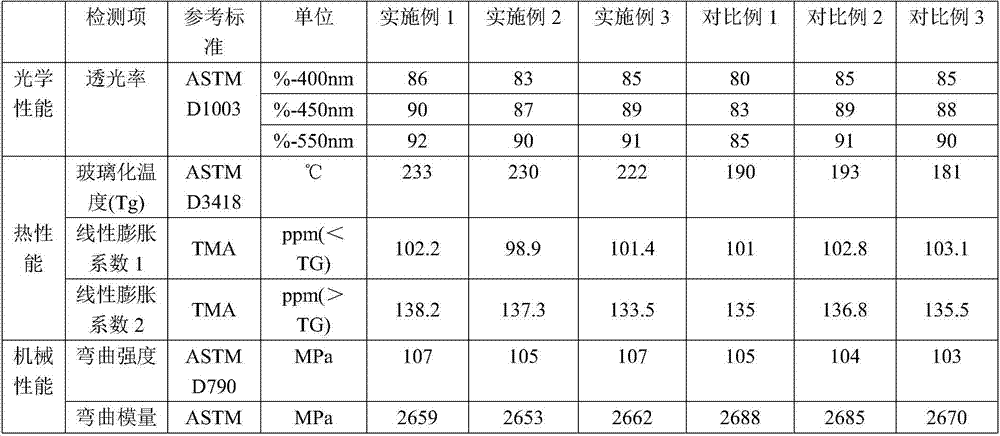

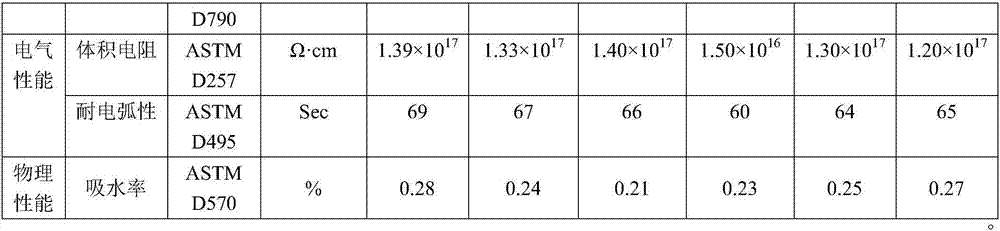

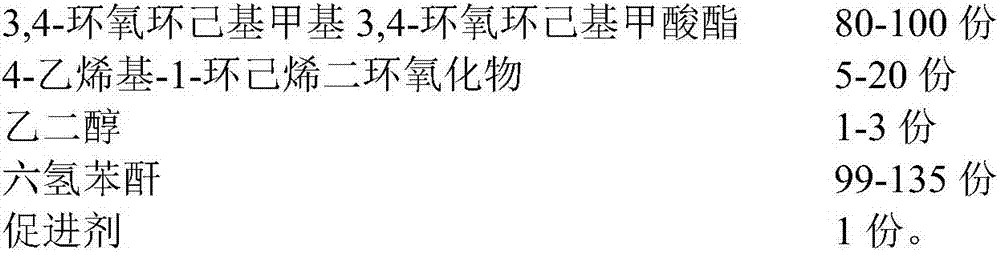

Heat-resistant alicyclic epoxy resin cured product and preparation method thereof

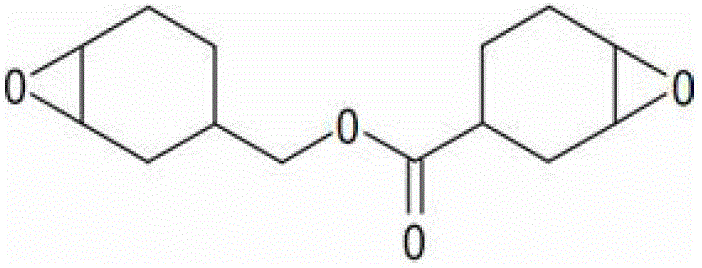

ActiveCN108003328AHigh light transmittanceHigh glass transition temperatureHexahydrophthalic anhydrideGlass transition

The invention relates to a heat-resistant alicyclic epoxy resin cured product. The cured product comprises the following raw materials in parts by weight: 80-100 parts of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexanecarboxylate, 5-20 parts of 4-vinyl-1-cyclohexene dioxide, 1-3 parts of ethylene glycol, 99-135 parts of hexahydrophthalic anhydride and 1 part of an accelerator. The invention also relates to a preparation method of the heat-resistant alicyclic epoxy resin cured product. According to the heat-resistant alicyclic epoxy resin cured product provided by the invention, the light transmittance and glass transition temperature (Tg) are obviously improved, and the properties such as volume resistance, arc resistance and the like are superior to the properties of prior alicyclic epoxyresin cured products.

Owner:JIANGSU TETRA NEW MATERIAL TECH

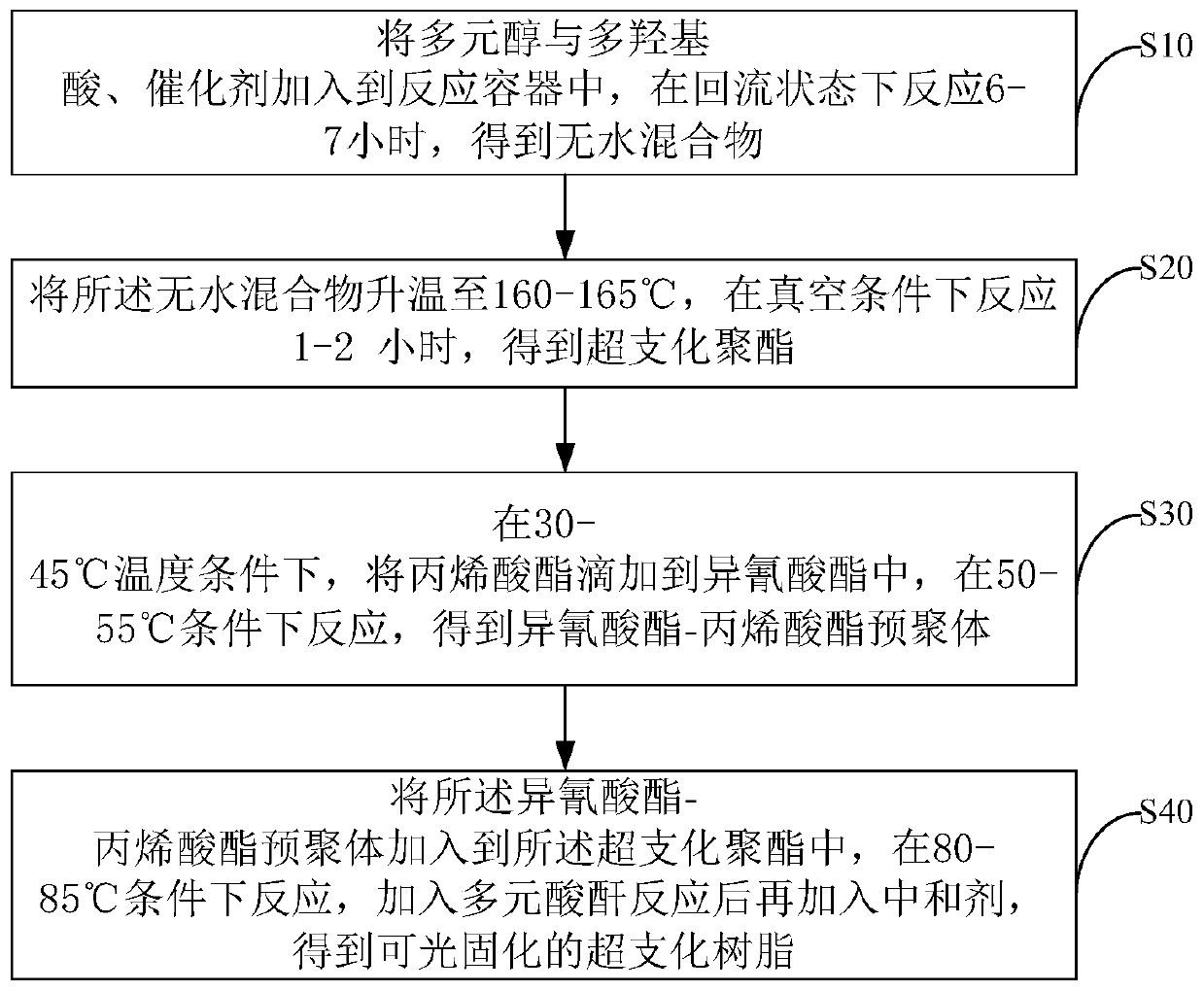

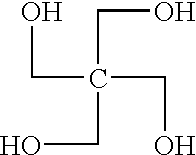

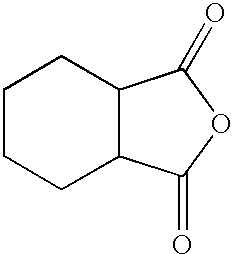

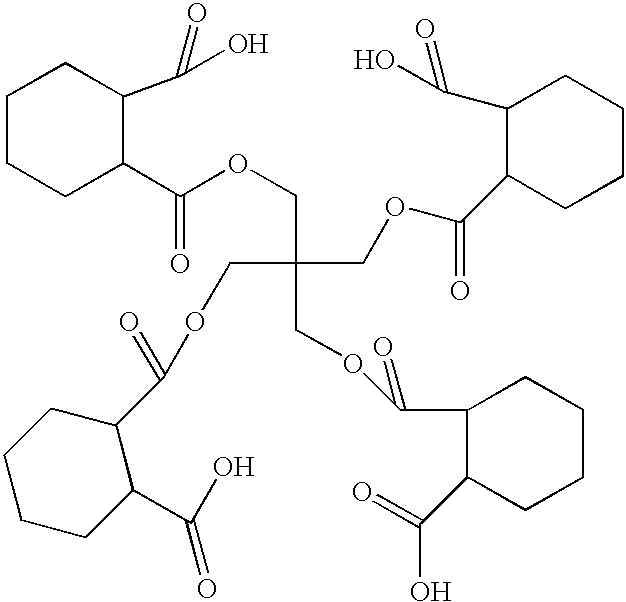

Photocurable waterborne hyperbranched resin and preparation method thereof

InactiveCN110669202AGood storage stabilityImprove water resistanceAntifouling/underwater paintsPaints with biocidesHydroxybutyric acidPolymer science

The invention discloses a photocurable waterborne hyperbranched resin and a preparation method thereof. The waterborne hyperbranched resin is synthesized through reacting 1-6 wt% of a polyol, 10-50 wt% of a polyhydroxy acid, 6-25 wt% of a polybasic acid anhydride, 10-45 wt% of isocyanate, 4-6 wt% of a neutralizer and 10-30 wt% of acrylate; the polyhydroxy acid is one or more of dimethylolpropionicacid, dihydroxybutyric acid, ethylenediamine butyl sulfonic acid and glycollic acid; and the polybasic anhydride is one or more of phthalic anhydride, maleic anhydride, trimellitic anhydride, tetrahydrophthalic anhydride, hexahydrophthalic anhydride, butanedioic anhydride and adipic acid anhydride. The photocurable waterborne hyperbranched resin has a good storage stability; and a film formed bythe resin under the action of a photoinitiator has excellent water resistance, hardness, aging resistance, chemical resistance and pollution resistance, also has the characteristics of high glossiness, good wear resistance, strong adhesion, high fullness, excellent impact resistance and the like, and is widely applied to surface radiation coating and protection of products such as wood plastic andthe like.

Owner:南雄市沃太化工有限公司

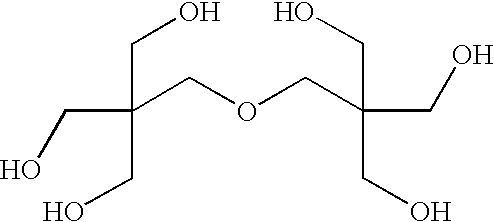

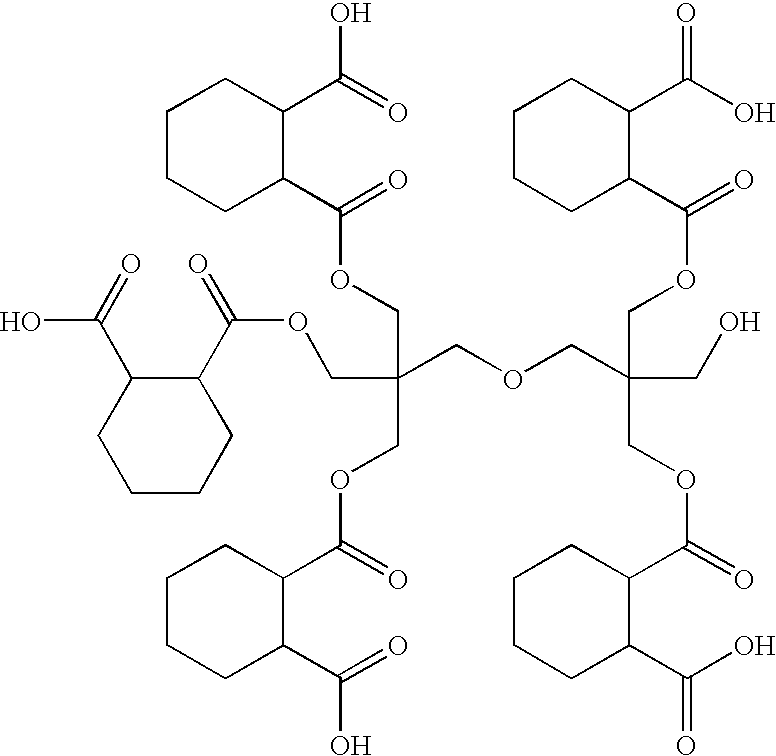

Polymeric pigment dispersant utilized as a grind resin for pigments and method of preparing the same

InactiveUS6657002B2Enough timeIncreased pigment-to-binder ratioTransportation and packagingOrganic dyesPolyesterPentaerythritol

The present invention is directed to a polyester carboxylate polymeric pigment dispersant to be used as a grind resin to incorporate inorganic pigment into a pigment dispersion for a coating composition. The polymeric pigment dispersant is the reaction product of pentaerythritol, hexahydrophthalic anhydride, glycidylneodecanoate, and dimethylethanolamine. The present invention is also directed to a method of preparing the polymeric pigment dispersant. In this method, the pentaerythritol and the hexahydrophthalic anhydride are polymerized to form an intermediate compound. Next, an epoxy group of the glycidylneodecanoate reacts with the intermediate compound, and then the dimethylethanolamine neutralizes the intermediate compound to form the completed polymeric pigment dispersant. The polymeric pigment dispersant is utilized for efficient wetting and grinding of the pigment.

Owner:BASF CORP

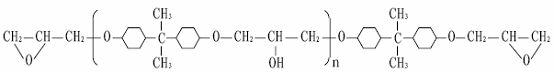

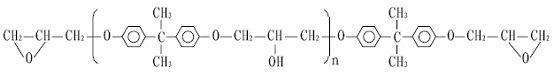

Epoxy resin suitable for pultrusion process and carbon fiber composite material thereof

The invention relates to an epoxy resin suitable for pultrusion process and a carbon fiber composite material thereof. The system comprises two components, a component A is compounded epoxy resin, anda component B is a curing agent. The weight ratio of the component A to the component B is 100:80-110; wherein the component A comprises matrix resin, a toughening agent and a diluent in a weight ratio of 50-70:5-20:10-30, and the matrix resin is one or more of bisphenol A type epoxy resin, bisphenol F type resin and novolac epoxy resin; the component B is an anhydride curing agent, which can beone or more of methyl tetrahydrophthalic anhydride, methyl hexahydrophthalic anhydride or methyl nadic anhydride. The epoxy resin system adopting the anhydride curing agent has the advantages of low viscosity, long working life and excellent cured product physical properties, and satisfies the requirements of pultrusion process for the properties of the resin system.

Owner:绍兴宝旌复合材料有限公司 +1

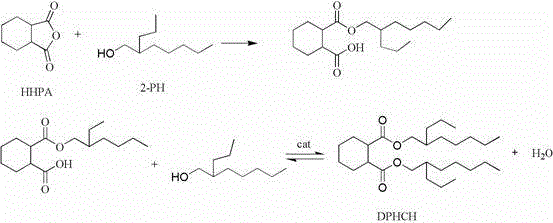

Preparation method of di(2-propylheptyl) cyclohexyl-1,2-diformate

InactiveCN104478722AImprove product qualityMeet the requirements of green environmental protectionOrganic compound preparationCarboxylic acid esters preparationSodium bisulfatePhthalate

The invention relates to a preparation method of di(2-propylheptyl) cyclohexyl-1,2-diformate, belonging to the field of synthesis of fine chemical engineering products. The preparation method comprises the following steps: carrying out esterification reaction on hexahydrophthalic anhydride and 2-propyl heptanol by using non-protonic acid as a catalyst; and after the esterification reaction finishes, neutralizing, washing with water, dealcoholizing, and drying to obtain the di(2-propylheptyl) cyclohexyl-1,2-diformate, wherein the esterification rate is up to 99% above. The non-acid catalyst is a composite catalyst composed of tetrabutyl titanate, sodium bisulfate monohydrate or tetrabutyl titanate and sodium bisulfate monohydrate, and accounts for 0.2-4 wt% of the acid anhydride; the raw material alcohol / acid mole ratio is (2.2-3.0):1; the esterification reaction temperature is controlled at 140-230 DEG C, and the reaction time is 3-12 hours; and when the acid number is lower than 1mg KOH / g, the reaction is finished, thereby obtaining the product with nearly no color and higher esterification rate. The method has the advantages of high utilization ratio of the raw materials, high product quality, high efficiency and environment friendliness; and the di(2-propylheptyl) cyclohexyl-1,2-diformate is free of benzene ring structure, can be substituted for the phthalate-type novel environment-friendly plasticizer product, and has broad market prospects.

Owner:JIANGNAN UNIV

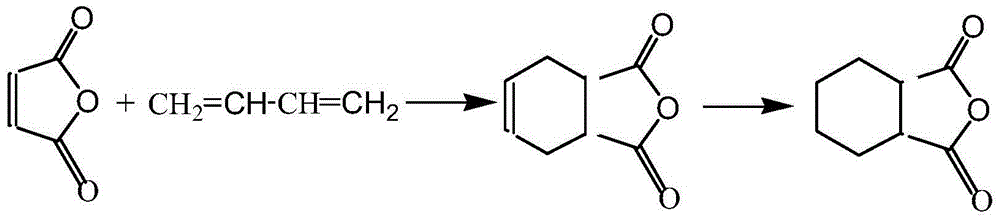

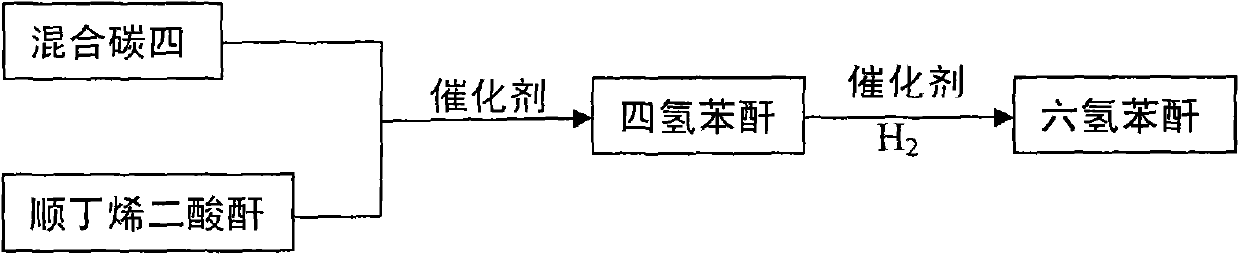

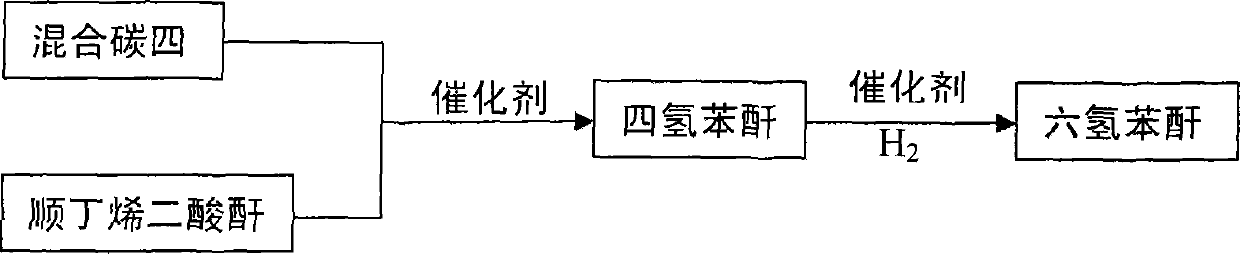

Method for producing hexahydrophthalic anhydride by using C4 mixture

ActiveCN101768143ALow reaction temperatureReduce pollutionOrganic chemistryHydroxybenzoate EthersHexahydrophthalic anhydride

The invention discloses a method for producing hexahydrophthalic anhydride by using C4 mixture and belongs to the field of organic synthesis. The method comprises the following steps: using maleic anhydride and C4 mixture, which mainly containing butadiene, as the raw materials; under the actions of the HC-200102P compound catalyst [p-hydroxyanisole and Cu2(PPh3)6(mu-OOCH)(ClO4), directly using maleic anhydride to absorb the C4 mixture to obtain tetrahydrophthalic anhydride; and carrying out catalytic hydrogenation on the tetrahydrophthalic anhydride by using the CC-1 compound catalyst (Pd / BaSO4 or Pd / BaCO3, and Cu4(C7H4NO4)2(dppm)4(NO3)2, thereby obtaining the hexahydrophthalic anhydride. The method enhances the reaction selectivity, reduces the production cost, reduces the environmental pollution and has industrialized popularization value.

Owner:PUYANG HUICHENG ELECTRONICS MATERIAL

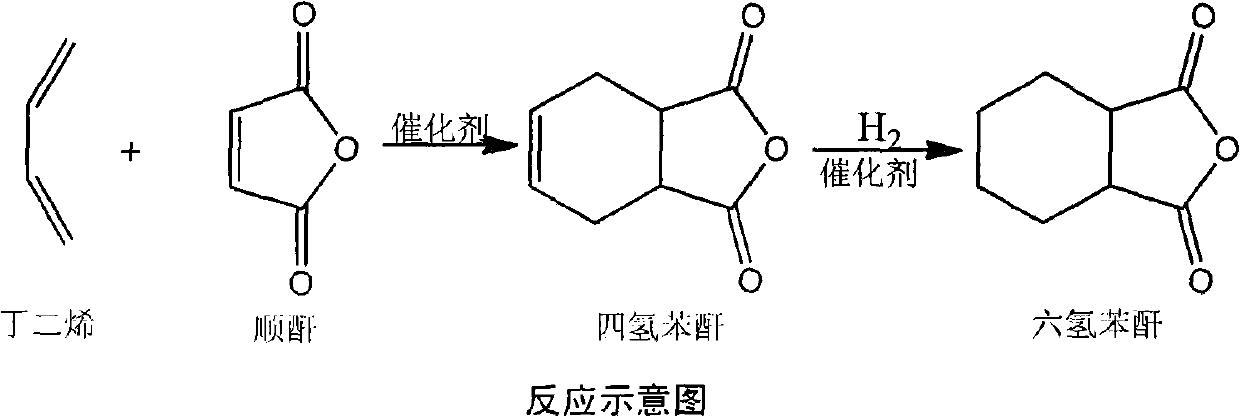

Epoxy resin encapsulation adhesive and use thereof

InactiveCN101372608AGood anti-light decay performanceImprove anti-agingOther chemical processesSemiconductor/solid-state device detailsPhosphoniumAntioxidant

The invention relates to an encapsulation adhesive used for an electronic device, in particular to an epoxy resin encapsulation material for encapsulating a light emitting diode. The encapsulation adhesive has the advantages of good anti-optical weaken performance, short curing time, not getting yellow of the color of cured resin, good aging resistance, long operative time, etc. The encapsulation adhesive comprises two parts of component A and component B which are mixed to be used. The component A is A-typed bisphenol epoxy resin. The component B comprises methyl hexahydrophthalic anhydride, ethyl triphenyl iodo phosphonium, triphenylphosphine and beta-(3, 5-di-tert-butyl-4-hydroxyphenyl) propanoic acid n-octadecanol antioxidant. The mass ratio of A to B is 1 to 0.8-1.

Owner:大连芯拓光电有限公司

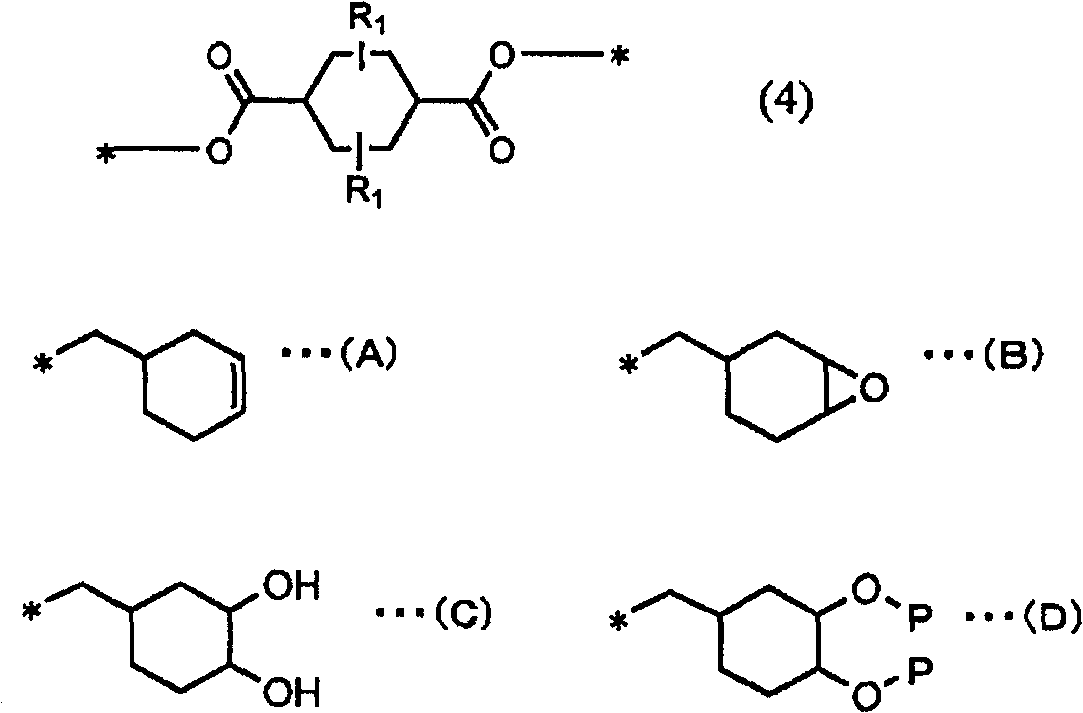

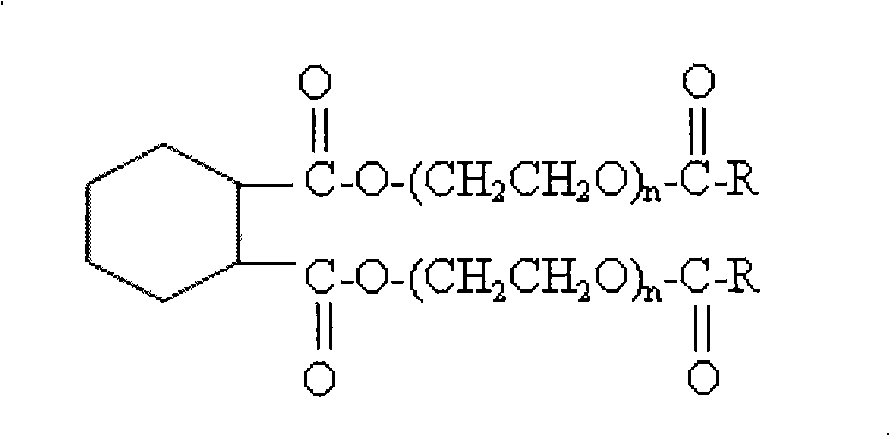

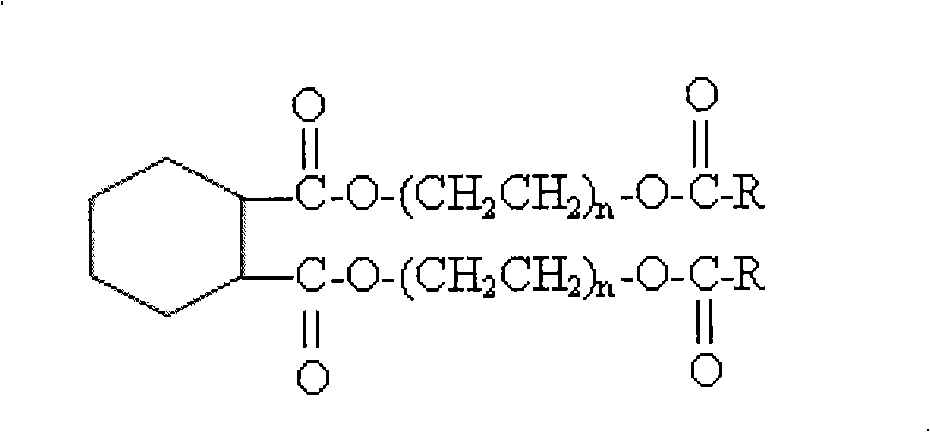

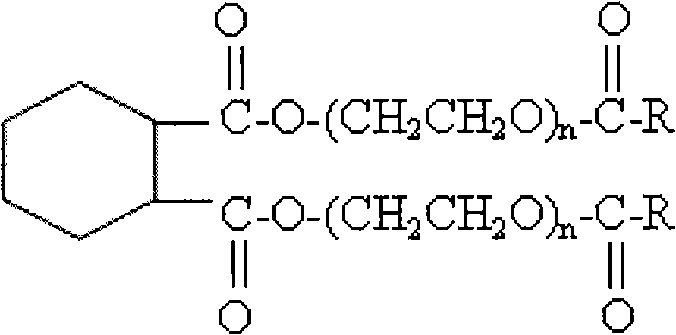

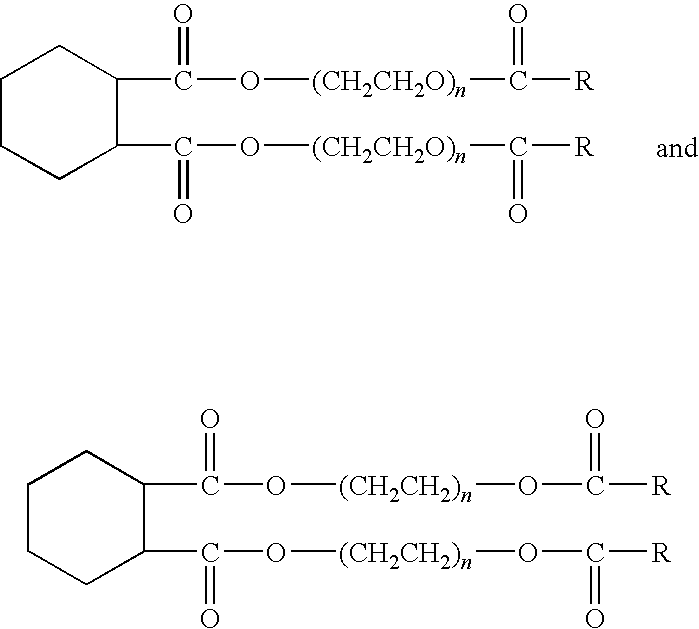

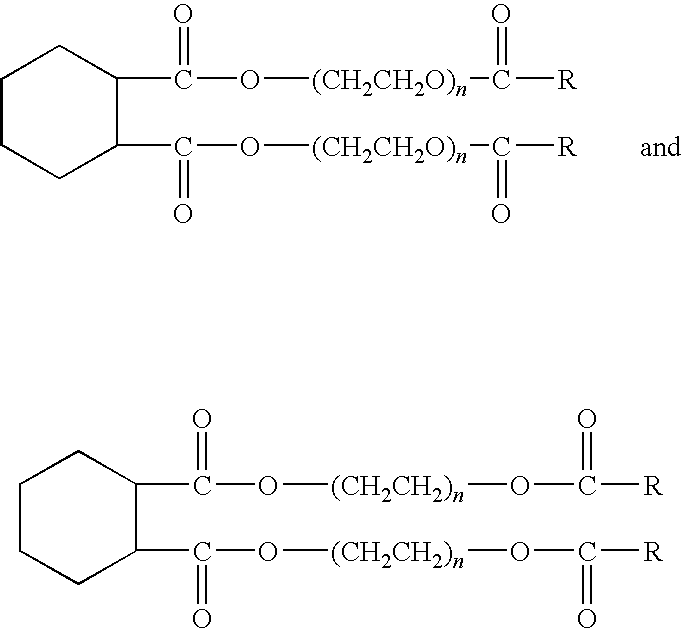

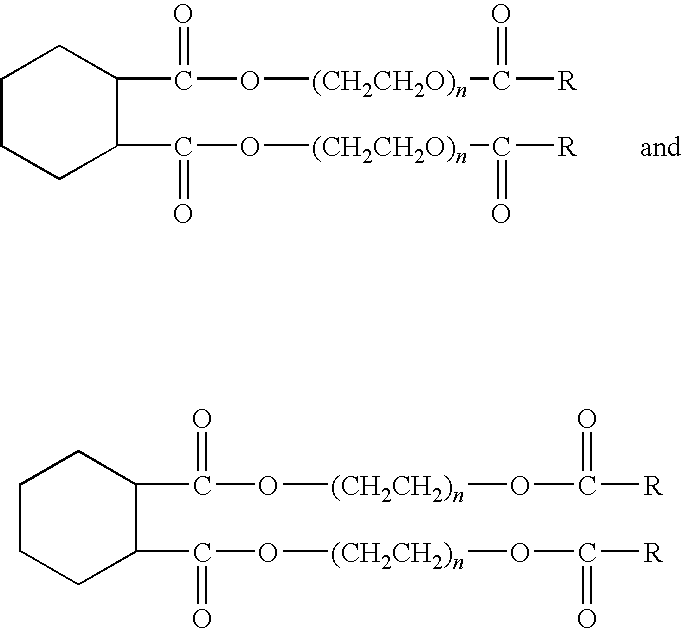

Hexa-hydrogen phthalate compound and preparation thereof

The invention relates to hexahydrophthalic acid ester compound used for preparing the plasticizer without phthalic acid and benzoic acid, which can not cause damage to the organism and the environment. The invention adopts the preparation method that firstly, the esterifying reaction is performed to hexahydrophthalic anhydride and diatomic alcohol and catalyzator, after acid radical is removed, the hexahydrophthalic acid ester alcohol is synthetized, then monoprotic acid is added into the synthetized hexahydrophthalic acid ester alcohol to continue the esterificating reaction, and finally, the hexahydrophthalic acid ester compound is produced.

Owner:NANYA PLASTICS CORP

Polyoxymethylene plastic plate

The invention discloses a polyoxymethylene plastic plate. The polyoxymethylene plastic plate comprises polyoxymethylene plastic and additives, wherein the additives comprise an antioxidant, a weather resistant agent, a crosslinking agent, a wear resistant agent, a high temperature resistant agent and a filling agent, the antioxidant is triphenyl phosphite, the weather resistant agent is [2-4-hydroxy-(octyloxy)phenyl]phenyl-methanone, the crosslinking agent is hexahydrophthalic anhydride, the wear resistant agent is silicon nitride, the high temperature resistant agent is polyimide, and the filling agent is talcum powder. A modified polyoxymethylene plastic plate product is all improved in high temperature resistance, oxidation resistance and weather resistance, so that the polyoxymethylene plastic plate has less possibility of being eroded in a use process, and is prolonged in service life; in addition, the crosslinking agent can be used for promoting the product production in a production process, so that the mechanical strength and wear resistance of the polyoxymethylene plastic plate are both improved.

Owner:SUZHOU IND PARK FANGYUAN METAL PROD

Manufacturing technology of epoxy resin for sensors

The invention provides a manufacturing technology of an epoxy resin for sensors. The manufacturing technology of the epoxy resin for the sensors is prepared by uniformly stirring the following materials in parts by weight: 100 parts of modified epoxy resin, 60 to 140 parts of liquid methyl hexahydrophthalic anhydride; 5 to 15 parts of xylene, ethanol or acetone, 1 to 2 parts of SPA-200 defoamer for latex paint, then adding a curing agent under a stirring state and heating to 85 to 90 DEG C, then adding a defoamer after the mixture is melted into liquid, continuing to stir for 10 to 30 minutes,and then obtaining the epoxy resin for the sensors after completion of stirring.

Owner:JIANGSHAN HAIWEI TECH

Polymeric pigment dispersant utilized as a grind resin for pigments and method of preparing the same

InactiveUS6849686B2Improve stabilityEffectively wettedOrganic chemistryOther chemical processesPolymer scienceHexahydrophthalic anhydride

The present invention is directed to a polymeric pigment dispersant to be used as a grind resin to incorporate pigment into a pigment dispersion for a coating composition. The polymeric pigment dispersant is the reaction product of dipentaerylthritol, hexahydrophthalic anhydride, glycidylneodecanoate, dimethylethanolamine, and polyphosphoric acid. The present invention is also directed to a method of preparing the polymeric pigment dispersant. In this method, the dipentaerythritol and the hexahydrophthalic anhydride are polymerized to form an intermediate compound. Next, an epoxy group of the glycidylneodecanoate reacts with the intermediate compound, and then the dimethylethanolamine salts the intermediate compound. Finally, the polyphosphoric acid is added to form the completed polymeric pigment dispersant. The polymeric pigment dispersant has improved stability in the pigment dispersion and is utilized for efficient wetting and grinding of the pigment in the pigment dispersion.

Owner:BASF CORP

Hybrid grafted oxidation-resistant and flame-retardant epoxy material and preparation method thereof

The invention discloses a hybrid grafted oxidation-resistant and flame-retardant epoxy material. The material is prepared from raw materials in parts by weight as follows: 3-4 parts of ammonium polyphosphate, 6-8 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 1-2 parts of vinyl trimethoxy silane, 0.1-0.2 parts of azobisisobutyronitrile, 2-3 parts of triglycidyl isocyanurate, a proper amount of dimethylformamide, 0.8-2 parts of 3-amino propyl triethoxysilane, 17-20 parts of a 10%-13% hydrochloric acid solution, 5-8 parts of methyl hexahydrophthalic anhydride, 100-120 parts of epoxy resin E40, 3-4 parts of dioctyl sebacate, 0.8-1 part of diisocyanate, 1-2 parts of diacetone acrylamide, a proper amount of ethanol, 0.4-1 part of tert-butyl hydroquinone, 3-5 parts of diniconazole, 2-3 parts of sodium myrastate and 1-2 parts of calcium borate. The added tert-butyl hydroquinone and the like can effectively improve the oxidation resistance of the finished material and improve the storage stability of the finished product.

Owner:倪群

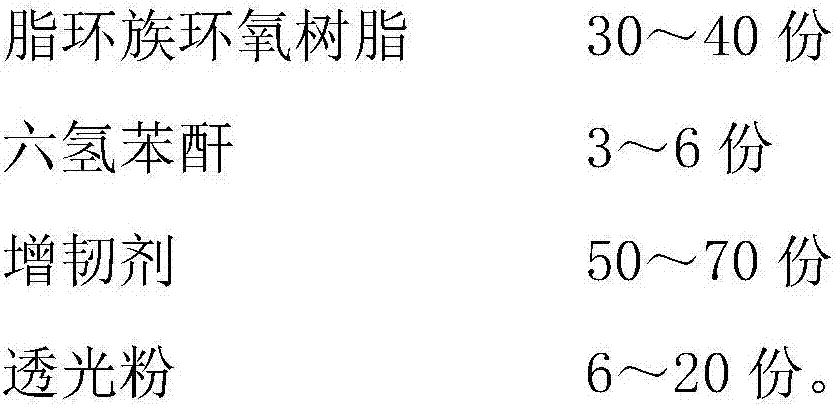

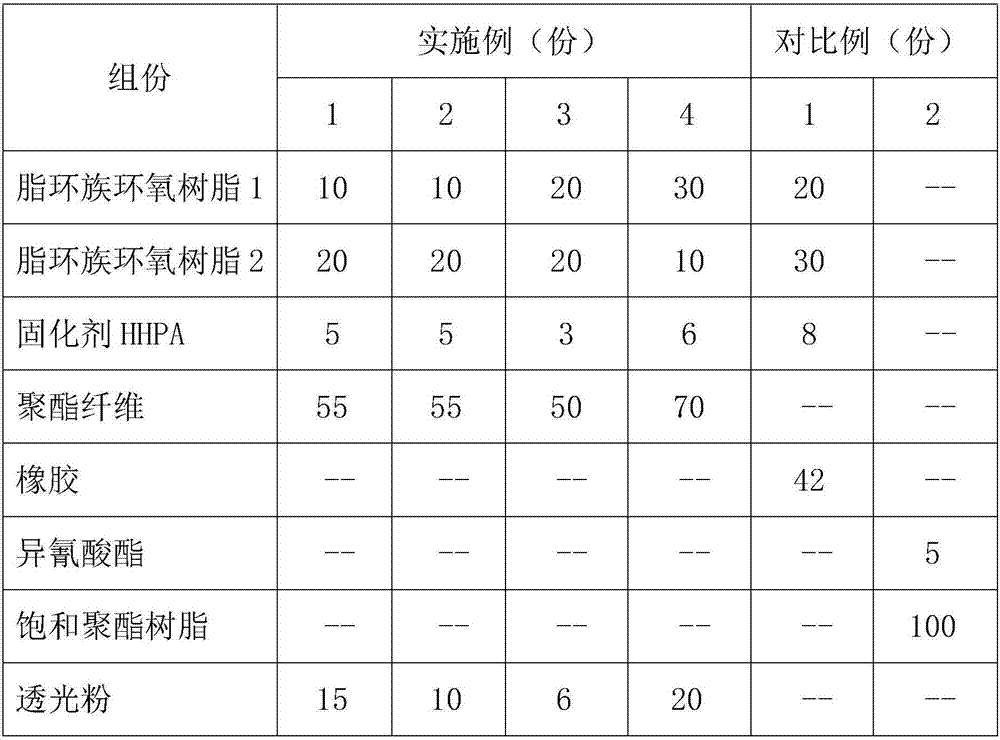

Transparent epoxy adhesive and application thereof

InactiveCN107400491AGood light transmissionLow epoxy equivalentNon-macromolecular adhesive additivesSynthetic resin layered productsPolyesterHeat resistance

The invention discloses a transparent epoxy adhesive and application thereof. The adhesive is prepared from the following components in parts by weight: 30 to 40 parts of aliphatic epoxy resin, 3 to 6 parts of hexahydrophthalic anhydride, 50 to 70 parts of toughening agent and 6 to 20 parts of translucent powder. By adopting the transparent epoxy adhesive, the influence of rubber on yellowing performance can be avoided; the influence of polyurethane on yellowing is avoided, and epoxy resin can be toughened. By adopting the transparent epoxy adhesive, an epoxy system and a flexible polyester system are combined together, the advantages of the epoxy system and the flexible polyester system are brought into full play, and the problems concerned with compatibility and yellowing resistance are solved; the flexible transparent adhesive has high transparency, high heat resistance and high bonding force.

Owner:ZHONGSHAN DONGYI HIGH TECH MATERIAL

Optical lens having sub-wavelength structure containing aluminum or aluminum oxide, method of manufacturing optical lens, and imaging optical system including optical lens

InactiveUS8905559B2Increase flexibilityIncrease resistanceOptical articlesCoatingsHexahydrophthalic anhydrideMethylhexahydrophthalic acid

Owner:CANON KK

Hexahydrophthalate based compound and process for producing the same

ActiveUS20090281349A1Quality improvementImproved processing physical propertyOrganic chemistryOrganic compound preparationBenzoic acidAlcohol

A hexahydrophthalate based compound is adapted to use as a plasticizer that contains no phthalic acid and benzoic acid, possess physical properties superior to DEHA and DINA in transparency and adhesion and is friendly to organisms and the environment; and a process for producing the hexahydrophthalate based compound includes esterifying hexahydrophthalic anhydride, a diol, and a catalyst for decarboxylation to get hexahydrophthalic alcohol, and adding a monoacid into the hexahydrophthalic alcohol for further esterification, thereby obtaining the hexahydrophthalate based compound.

Owner:NANYA PLASTICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com