Curable resin composition for encapsulating optical semiconductor and cured product thereof

A curable resin and composition technology, applied in the direction of semiconductor devices, epoxy resin glue, adhesive type, etc., can solve the problems of LED product illumination reduction durability, sealing part depression, and alicyclic epoxy resin volatilization problems such as problems, to achieve the effect of excellent coloring resistance and excellent corrosion gas resistance

Inactive Publication Date: 2011-01-12

NIPPON KAYAKU CO LTD

View PDF14 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As a result, the sealing portion of the surface-mounted LED product is dented, which sometimes causes failure

In addition, depending on the degree of the depression, the electric wire portion that supplies current to the LED chip may be exposed, and in this case, the function as a sealing material may no longer be realized.

Therefore, this cycloaliphatic epoxy resin also has a problem in volatilization during heating and curing.

In addition, in recent years, LED products have become brighter for lighting or TV backlights, and LED lighting has begun to generate a lot of heat. Therefore, resin compositions using this alicyclic epoxy resin are also used in LED chips. Coloration is caused on the surface, and the final LED product has a decrease in illuminance and a problem in durability (Patent Document 3)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

Synthetic example 1

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Login to View More

Abstract

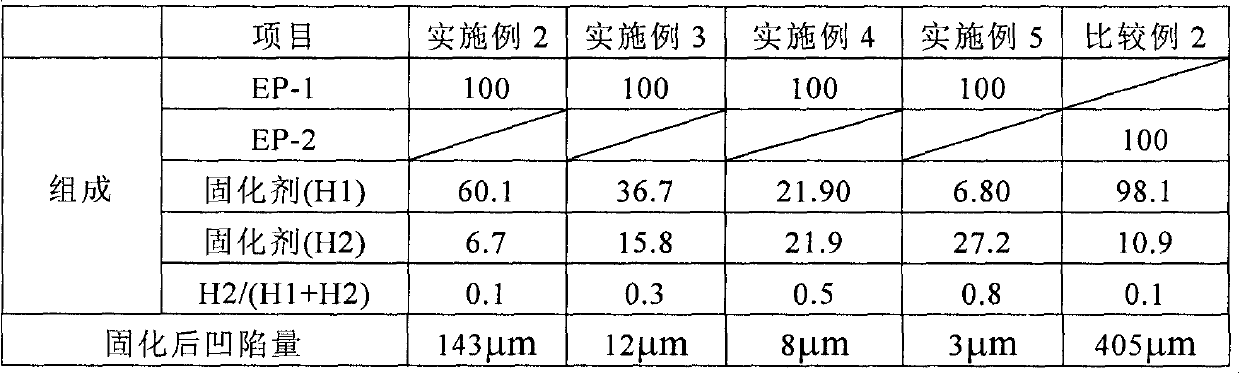

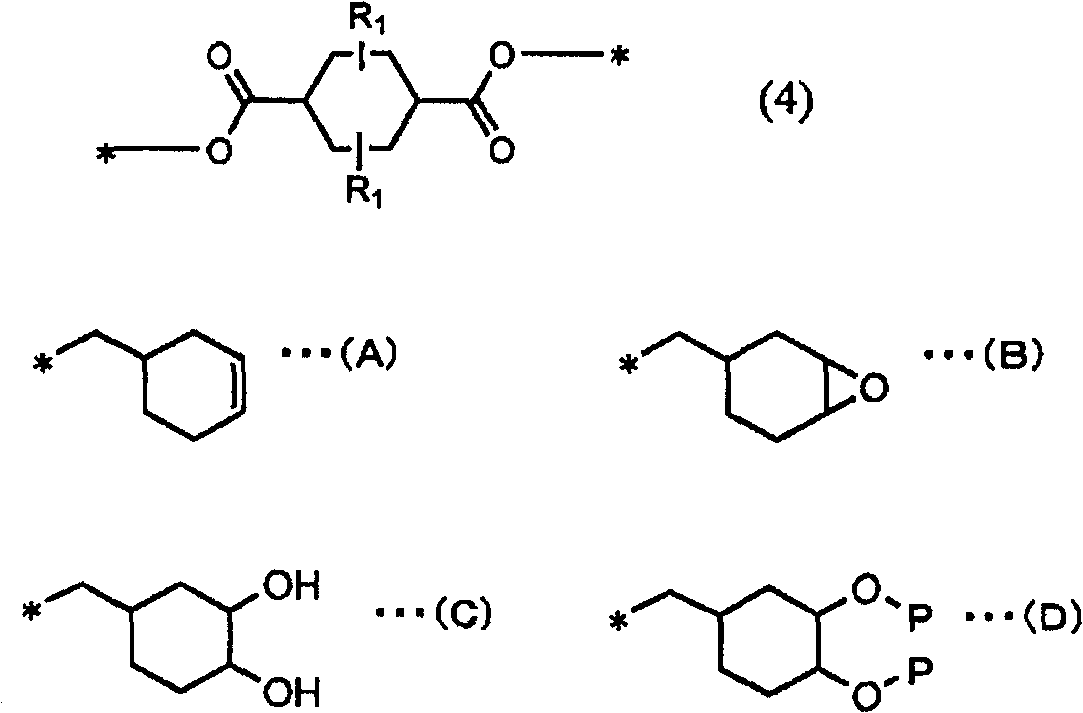

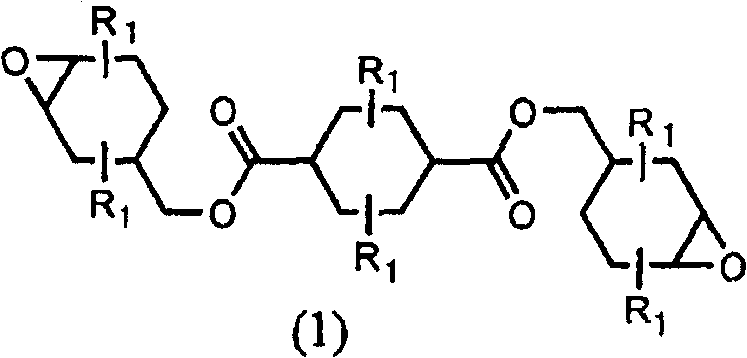

The invention aims to provide a curable resin composition for encapsulating an optical semiconductor and a cured product thereof, which can prevent sinking after curing and have excellent property of etchant gas resistance and excellent dyeing resisting property. The curable resin composition contains epoxy resin, solidifying agent and / or solidifying booster expressed by formula (1) (in the formula, a plurality of R1 can be same or different and can independently present hydrogen atom or methyl). The curable resin composition of the invention, used as the optimized solidifying agent cyclohexane-1, 3, 4-triformic-3, 4-anhydride and methyl hexahydrophthalic anhydride, has particular effect in preventing sinking after curing.

Description

technical field The present invention relates to a curable resin composition suitable for electrical and electronic material applications, particularly optical semiconductor applications, its cured product, and an optical semiconductor device including the cured product. Background technique Conventionally, an epoxy resin composition has been used in consideration of the balance between performance and economy as a sealing material for optical semiconductor elements such as LED products. Glycidyl ether-type epoxy resin compositions typified by bisphenol A-type epoxy resins that are particularly excellent in the balance of heat resistance, transparency, and mechanical properties are widely used. However, as a result of shortening the emission wavelength of LED products (indicating the situation of 480nm or less in LED products that mainly emit blue light), the sealing material is colored on the LED chip due to the influence of short-wavelength light, and the resulting LED pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G59/24C08G59/42C08G59/68C09J163/00H01L33/56

CPCH01L2924/0002H01L2924/00

Inventor 川田义浩中西政隆洼木健一宫川直房佐佐木智江青木静铃木瑞观小柳敬夫

Owner NIPPON KAYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com