Hole tamping method of circuit board

A circuit substrate and circuit board technology, which is applied in the direction of the electrical connection of printed components, can solve the problems of board surface depression, bubble rupture, and lower circuit board yield, so as to prevent board explosion, prevent depression, and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method for plugging holes of the circuit substrate provided by the technical solution will be further described in detail below with reference to the drawings and embodiments.

[0021] The plugging method of the circuit substrate provided by the technical solution comprises the steps of:

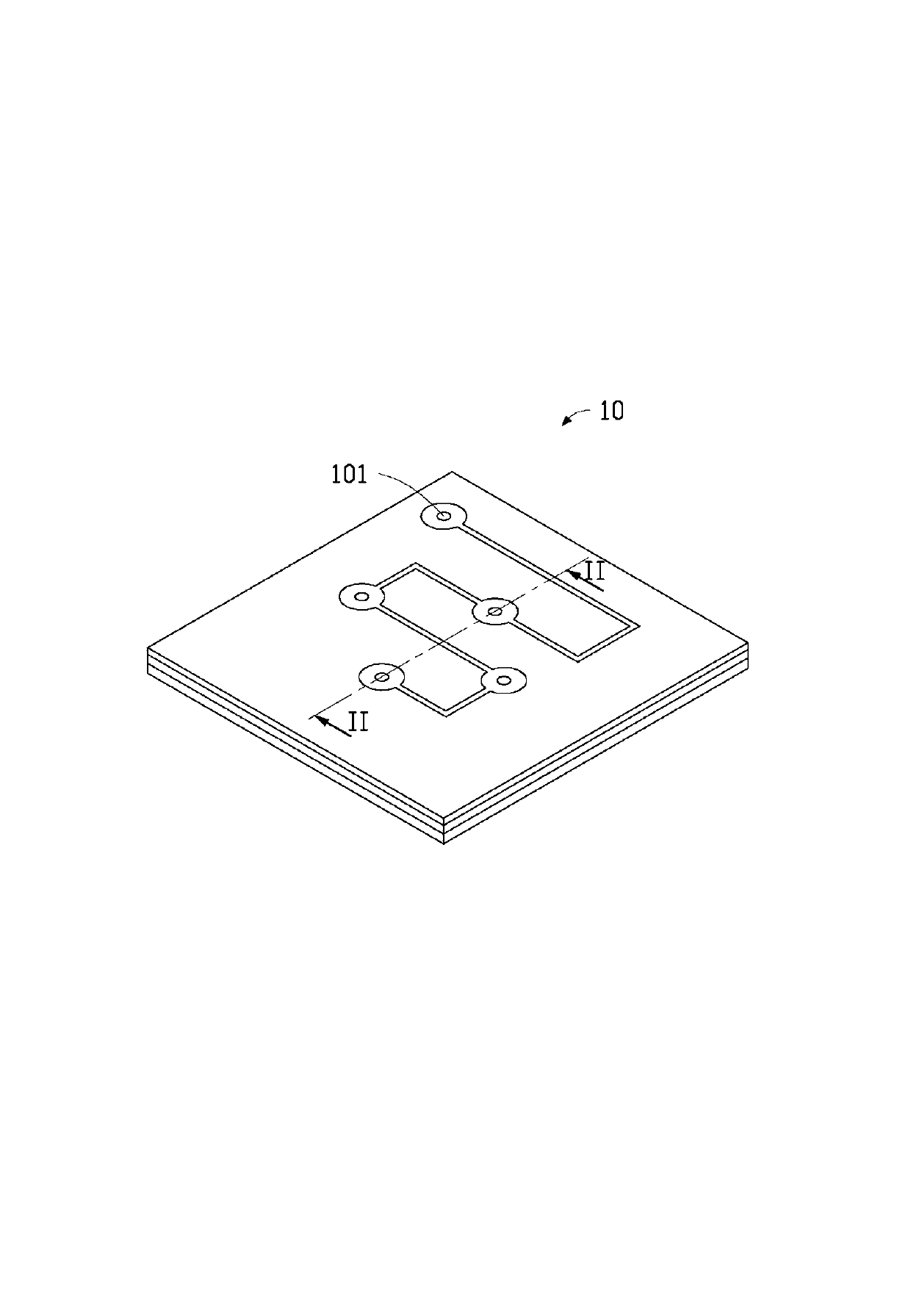

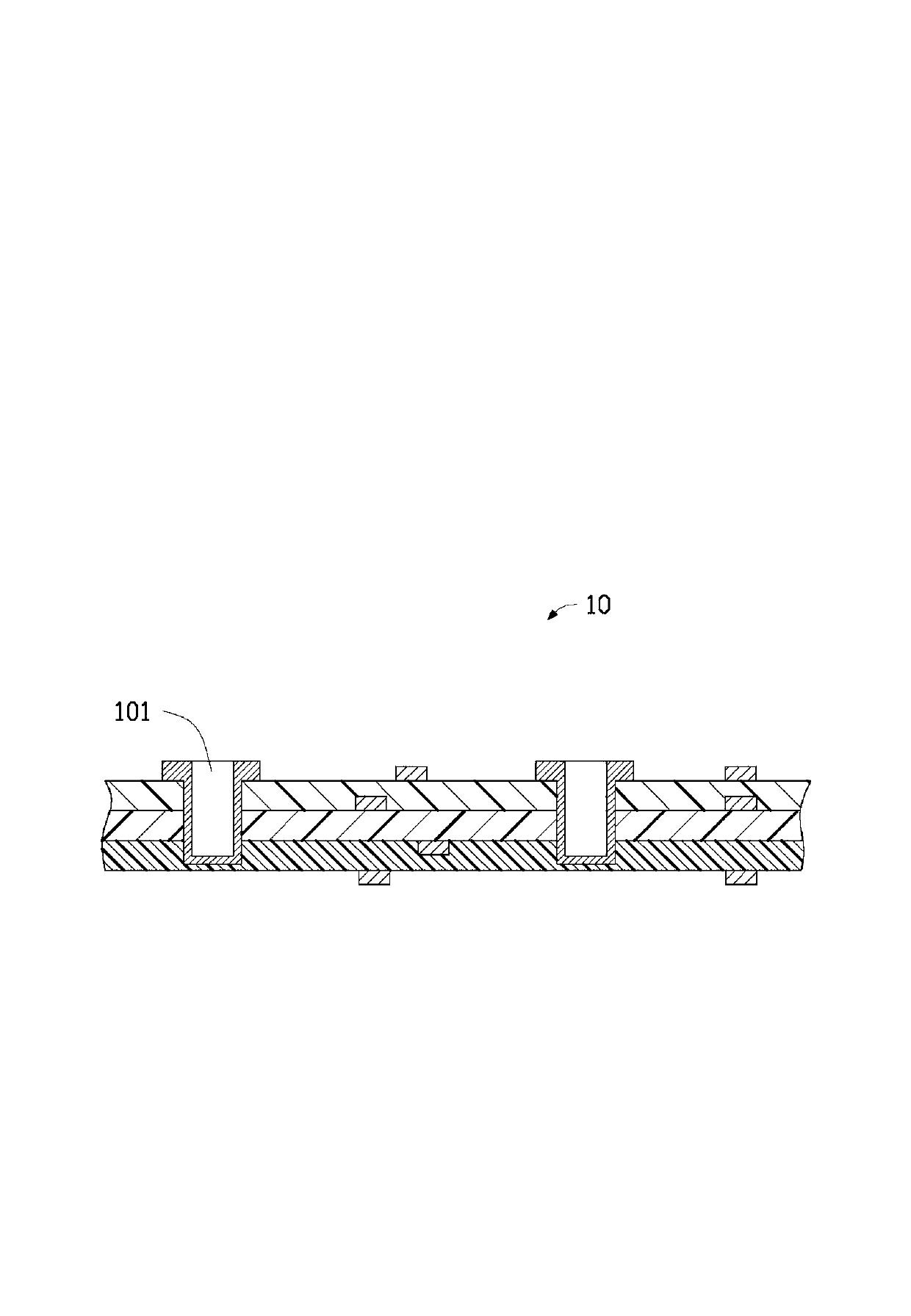

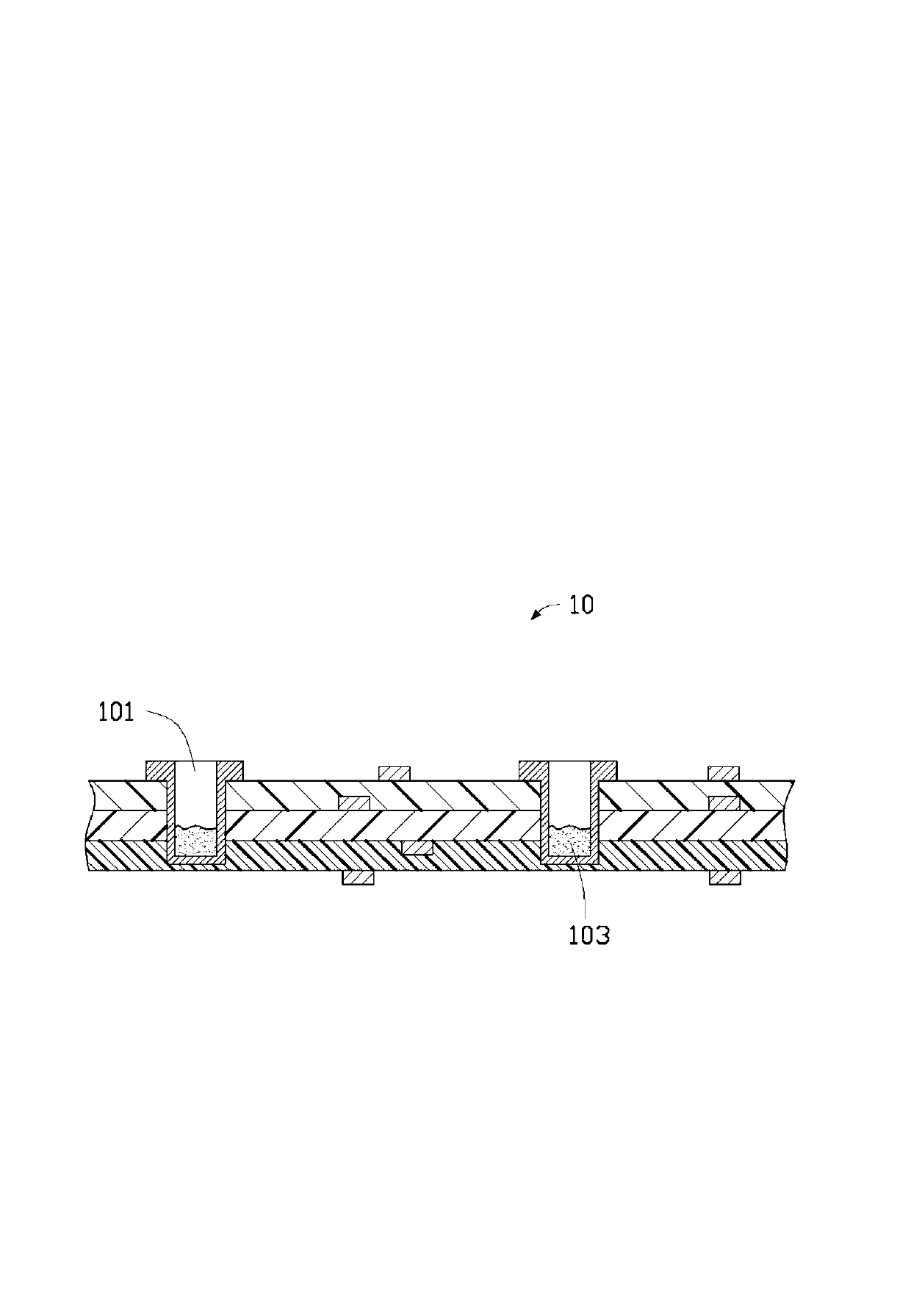

[0022] For a first step, see figure 1 and figure 2 , providing a circuit substrate 10 . The circuit substrate 10 is a structure including at least one insulating layer and at least one circuit layer. The circuit substrate 10 has a plurality of conductive holes 101 , the depth of each conductive hole 101 is greater than 3 mm, and the ratio of the thickness of the circuit substrate 10 to the depth of the conductive holes 101 is greater than or equal to 8. In this embodiment, the circuit substrate 10 is a four-layer circuit board, which includes three insulating layers and four circuit layers, the conductive hole 101 is a conductive blind hole, and the ratio of the thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com