Patents

Literature

307results about How to "Improve stirring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

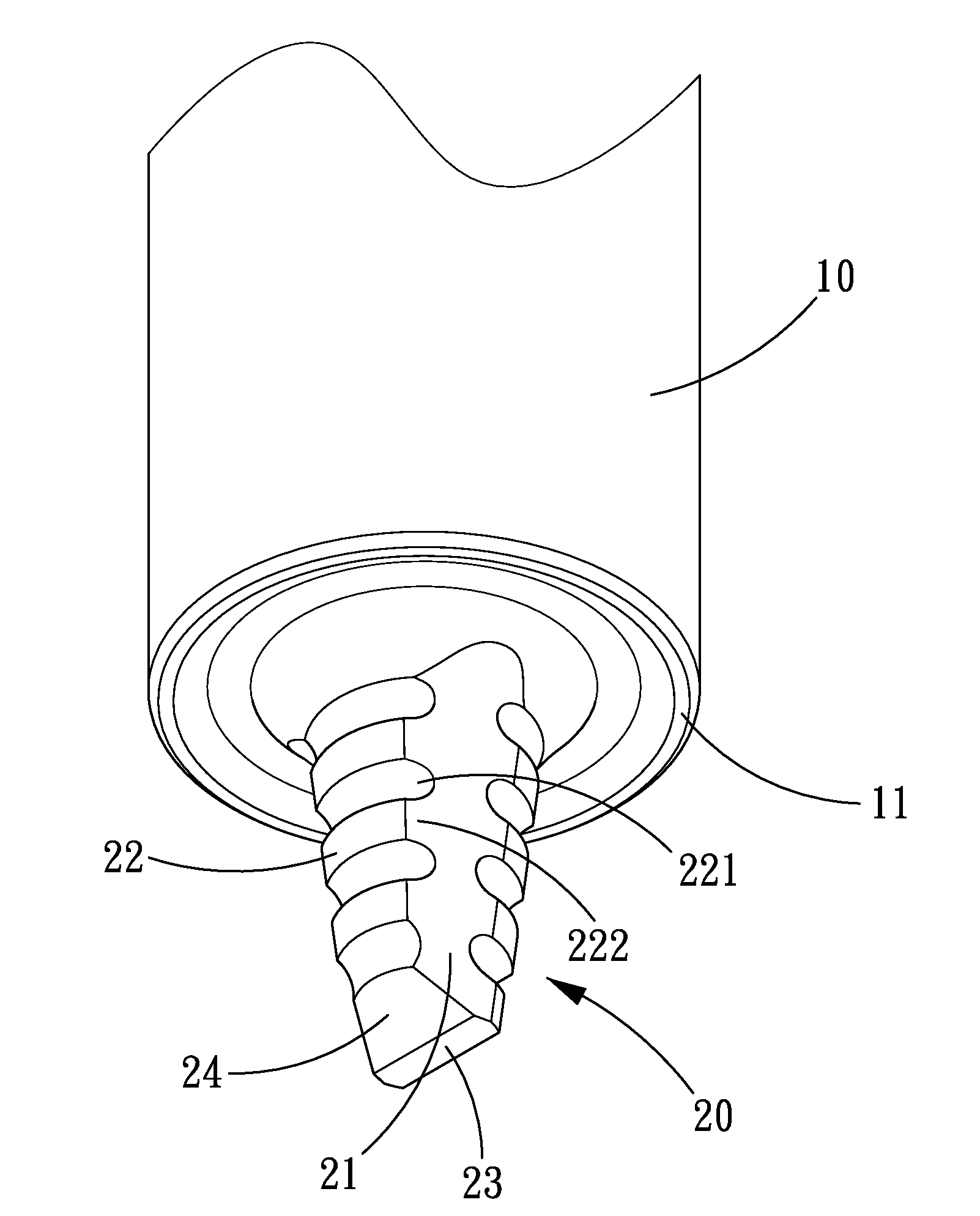

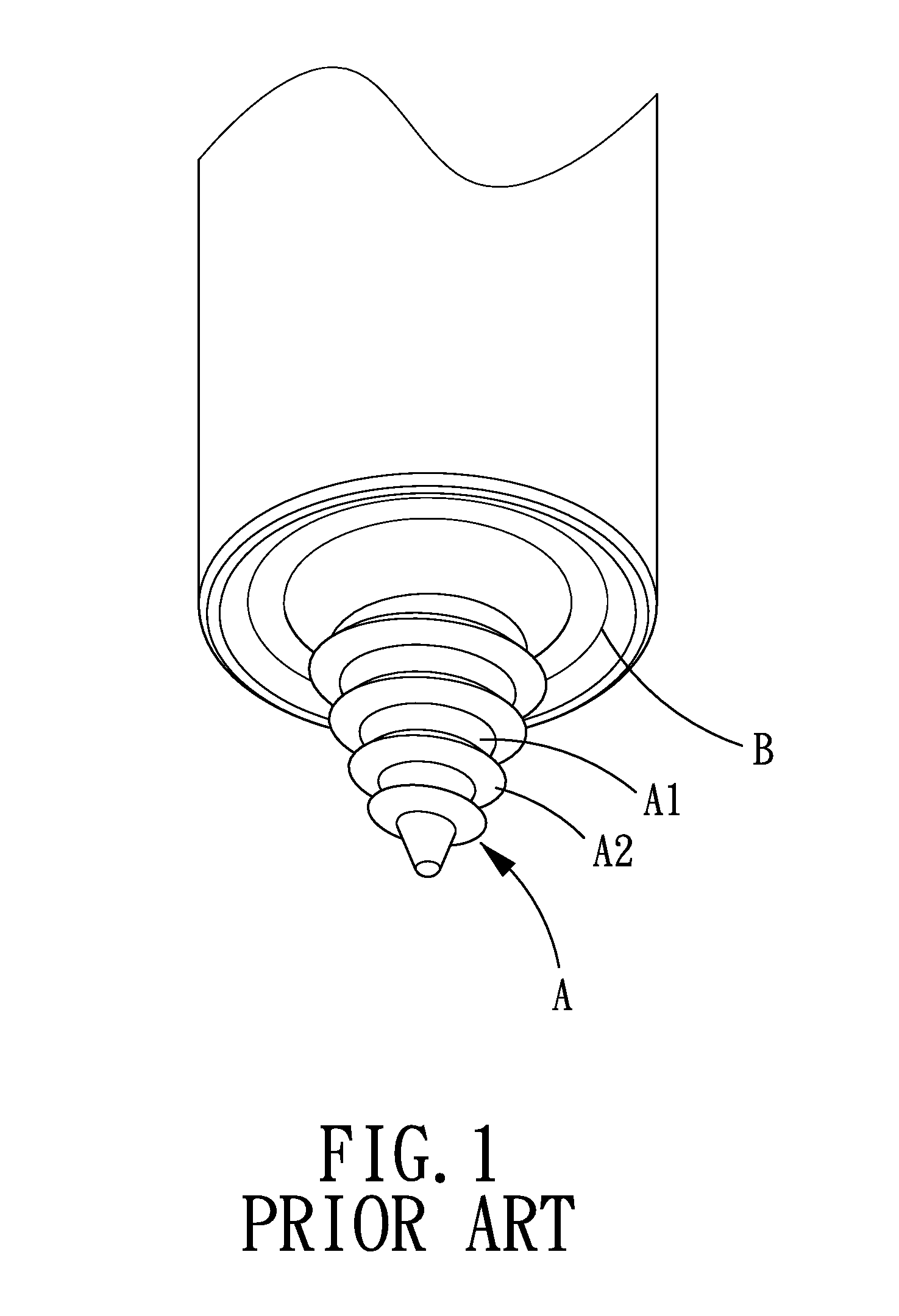

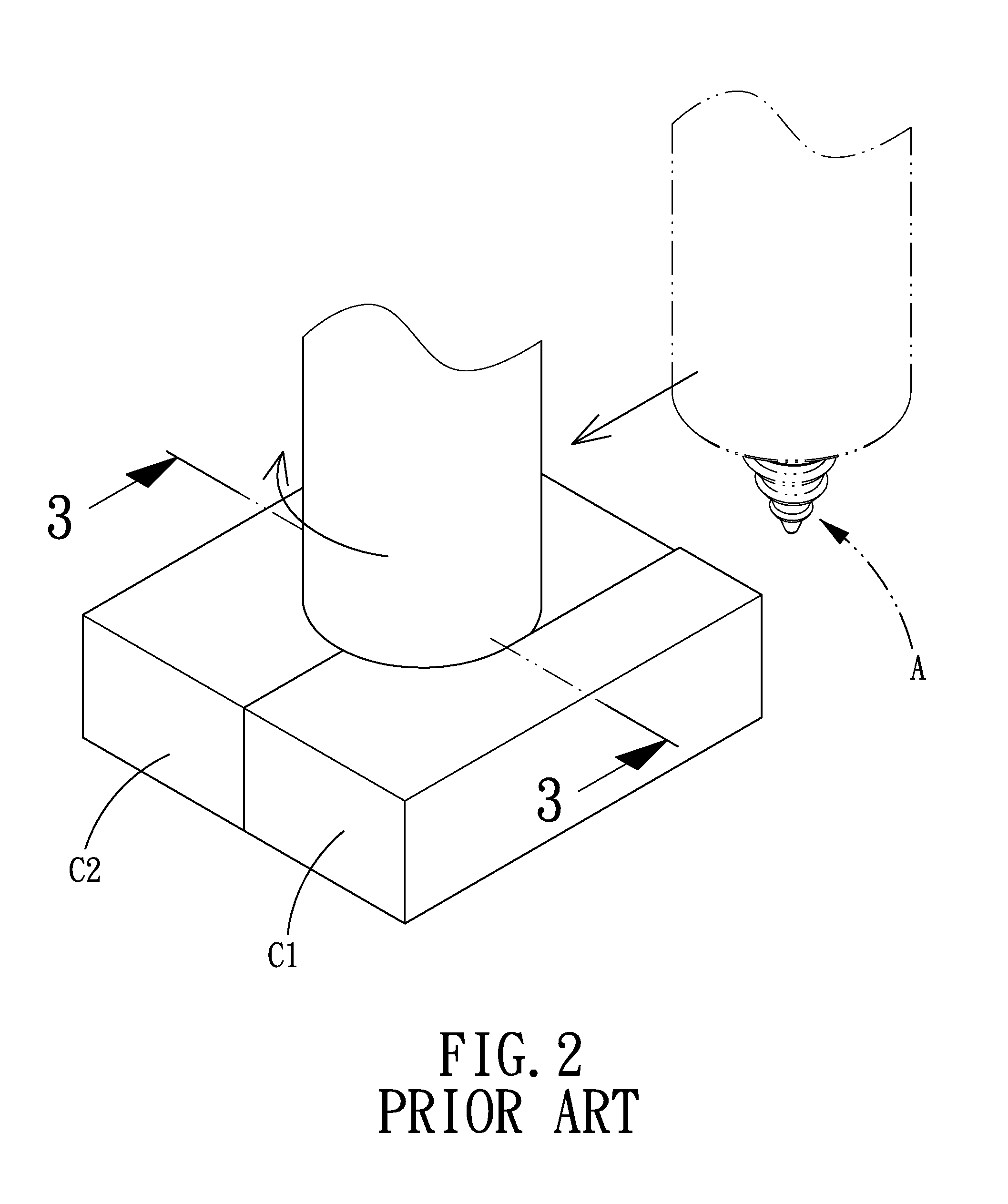

Friction Stir Welding Tool and Weld Metal Structure with Plural Onion Rings

InactiveUS20100081005A1High strengthAvoid defect formationWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

A friction stir welding tool and weld metal structure with plural onion rings, in which the tool is formed on the tool head with three surfaces, which are connected to one another through three spaced surfaces. An eccentrical axis of the tool head deviates from a central axis of the tool handle. One of the three surfaces is a deviation cutting surface which is a flat surface formed by cutting off a wall thickness from one side of an outer peripheral surface of the tool head toward the central axis of the tool handle. Each of the three spaced surfaces is alternately formed with plural notches and plural protrusions. The above welding tool is used to perform a stir friction welding operation to two metals to form the weld metal structure with the same number of onion rings as the protrusions and notches of each of the spaced surfaces.

Owner:AEROSPACE INDUSTRIAL DEVELOPMENT CORPORATION

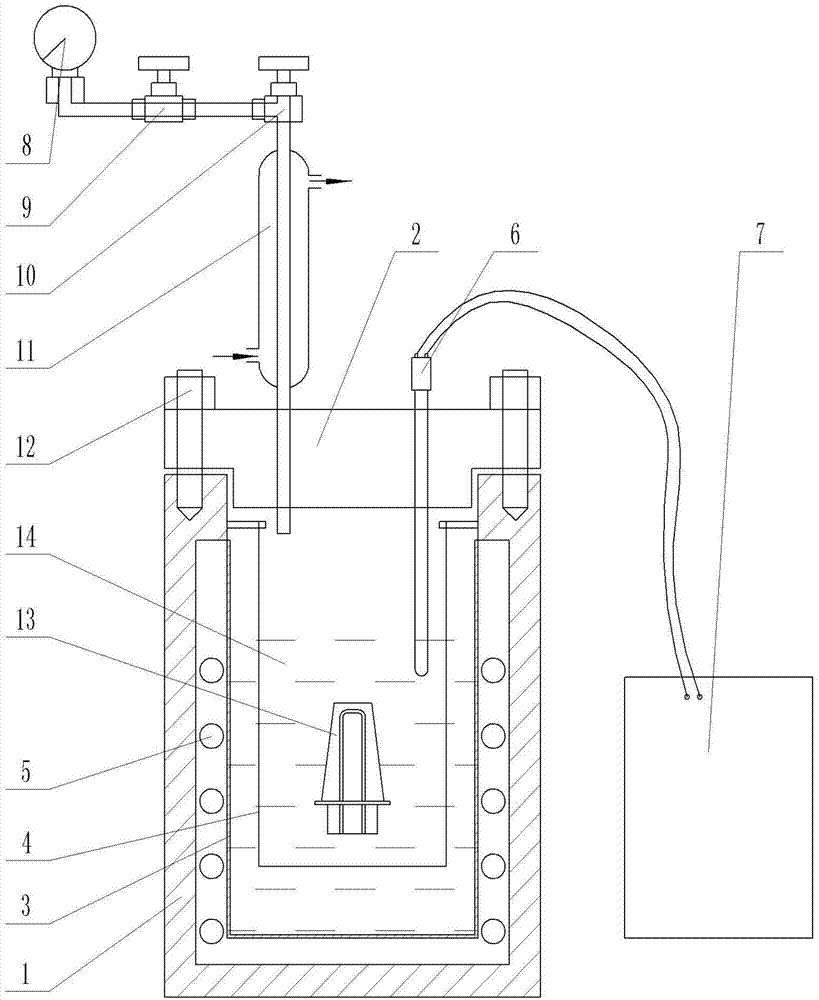

Alumina-based ceramic core removal method and special device thereof

Disclosed are an alumina-based ceramic core removal method and a special device thereof. The method includes placing a hollow blade with an alumina-based ceramic core into a reaction kettle fully filled with lye, and then sealing the reaction kettle; heating the reaction kettle in high-temperature, high-pressure and airtight environment; decreasing the pressure of the reaction kettle till being lower than the saturated vapor pressure of the lye, allowing the lye to be boiled to enter channels of the hollow blade for 10 to 30 seconds; recovering the pressure in the reaction kettle to stop boiling the lye and recover stable statues; removing residual lye and removed ceramic core from the hollow blade, and finally utilizing acid to neutralize residual lye on the hollow blade, and washing with water. The method has the advantages that reacted waste lye in the cavity of the hollow blade can be discharged rapidly through high temperature and increasing and decreasing the pressure repeatedly, good stirring effect is provided by periodically boiling the lye, the lye is guaranteed contacting with the alumina-based ceramic core fully, reacting efficiency is improved, and removal speed of the alumina-based ceramic core is increased significantly.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

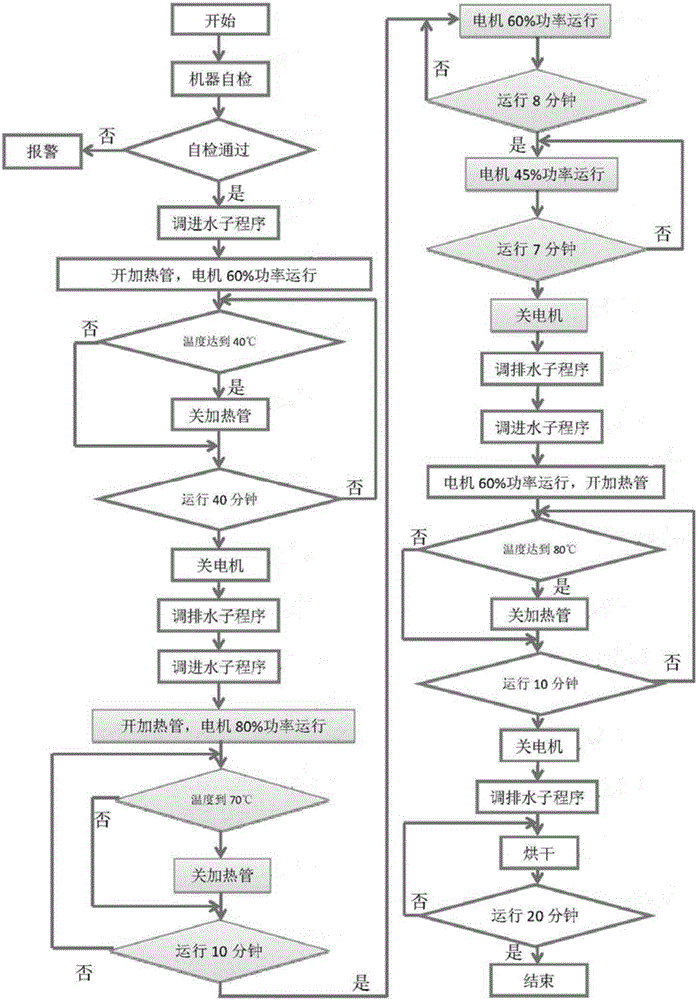

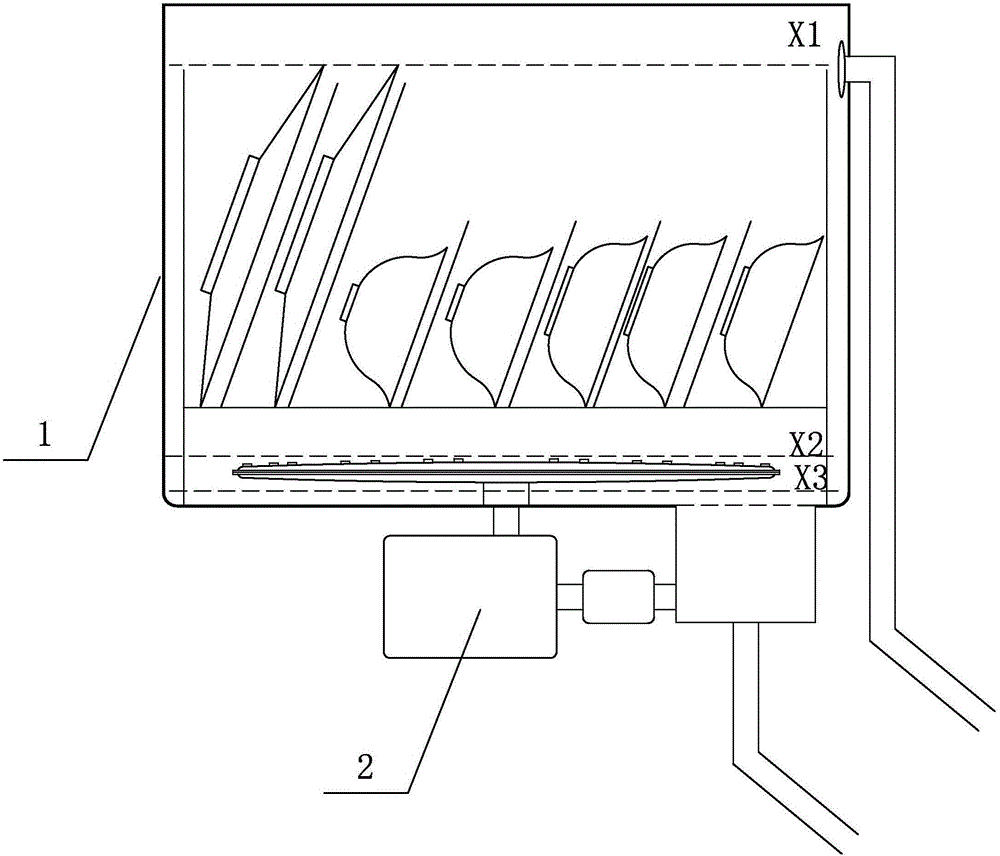

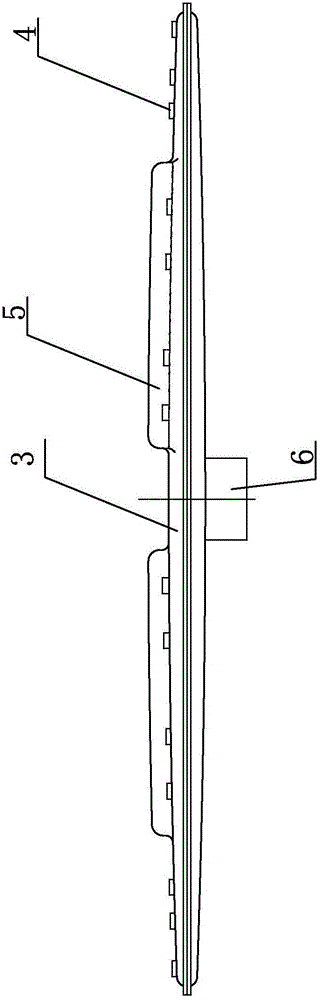

Washing method for water tank type dish washer

ActiveCN104983379AAvoid collisionIncrease flushing powerTableware washing/rinsing machinesHome appliance efficiency improvementElectricityPulp and paper industry

The invention discloses a washing method for a water tank type dish washer. The method includes the following steps that firstly, at the prewashing stage, water is injected, heating is started when the amount of injected water reaches a preset water amount, a circulating water pump starts running at the power accounting for 50% to 60% of the rated power, and eddy stirring is conducted through fins arranged on the upper surfaces of rotating spraying arms; secondly, at the main washing stage, the amount of injected water is controlled to be the preset water amount below the rotating spraying arms, heating is started, and the rotating spraying arms are driven to conduct spraying of different spraying strengths and different spraying angles in a segmented mode by setting the rated power of the circulating water pump in a segmented mode and setting the execution time in a segmented time; thirdly, at the rinsing stage, the amount of injected water is controlled to be the preset water amount below the rotating spraying arms, heating is started, and the rotating spraying arms are driven to conduct rinsing spraying. The washing method for the water tank type dish washer can solve various problems of Chinese style dishes, the washing efficiency can be effectively improved, more water and electricity are saved, and a mixing program is obtained.

Owner:NINGBO ZHONGWU DONGFANG OPTOELECTRONICS TECH CO LTD

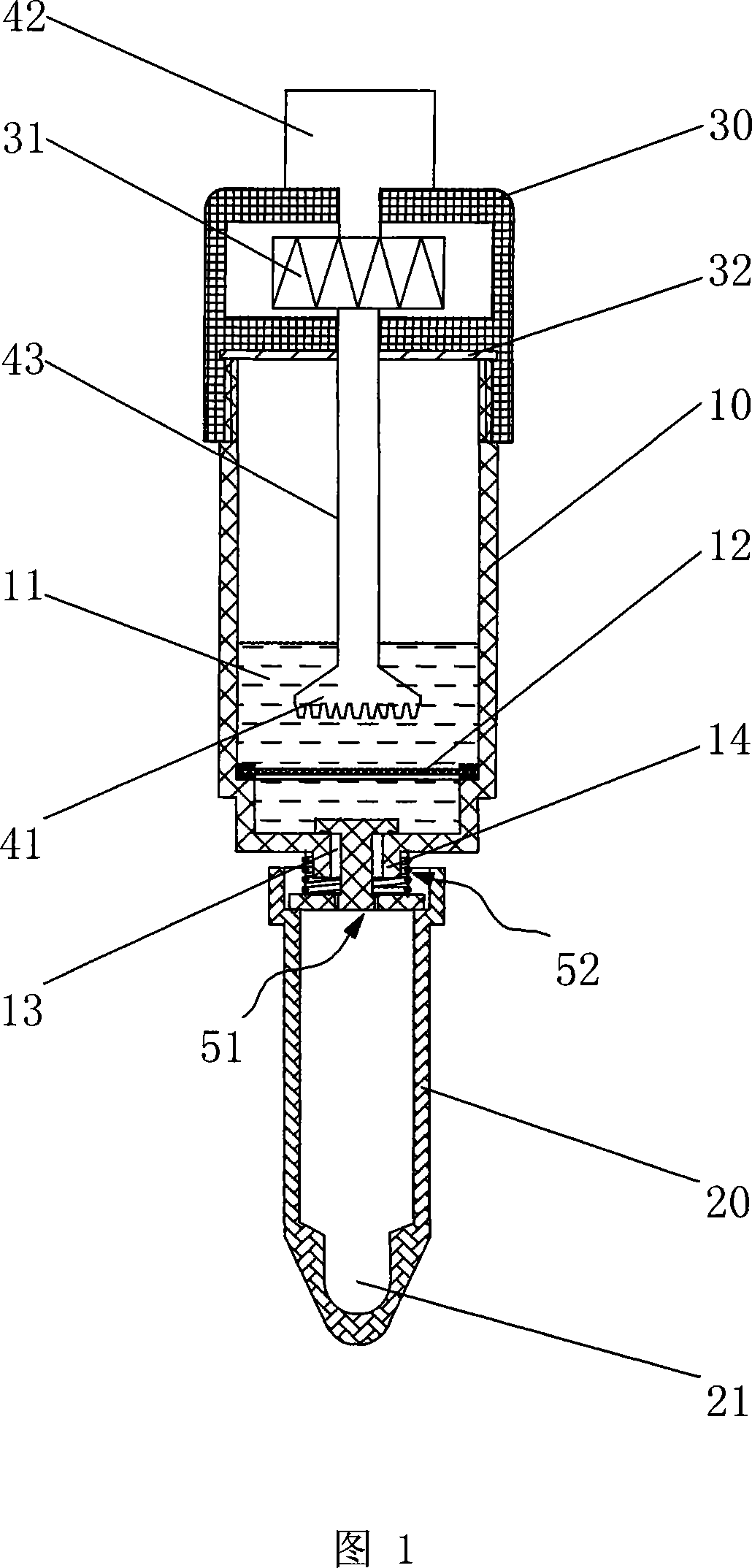

Specimen sampling equipment

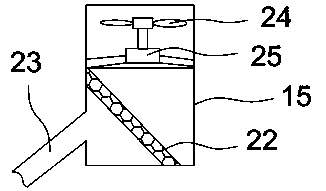

InactiveCN101078675AEasy to storeEasy to carryWithdrawing sample devicesPreparing sample for investigationTorsion springTesting equipment

The invention relates to a specimen sampling device, belonging to the medical sampling testing equipment field. Bottle cover for sealing is set at the upper of liquid accommodating bottle with test reagent in it. Round-role rod body of sampling rod passes through the bottle cover to extend downward to inner of liquid accommodating bottle and rotary sealing matching is set between the rod body and the bottle cover. The sampling end of sampling rod immerges under the liquid level of test reagent. Handhold end of sampling rod is set at the outside of bottle cover. The head of bottle cover is hollow cavity and a torsion spring matched on rod body of sampling rod is set in the hollow cavity. One end of torsion spring is fixed on the rod body and the other end is fixed on the bottle cover. An open port is set at the bottom of liquid accommodating bottle. Check valve for sampling liquid moving downward is set at the position of open port. The invention can collect, store and take fences sample conveniently and easily translates fences into sampling liquid which can be tested directly. Transfers of sampling liquid and continuous tests are convenient so that it makes doctor and patient convenience greatly.

Owner:合肥新月电子技术有限责任公司

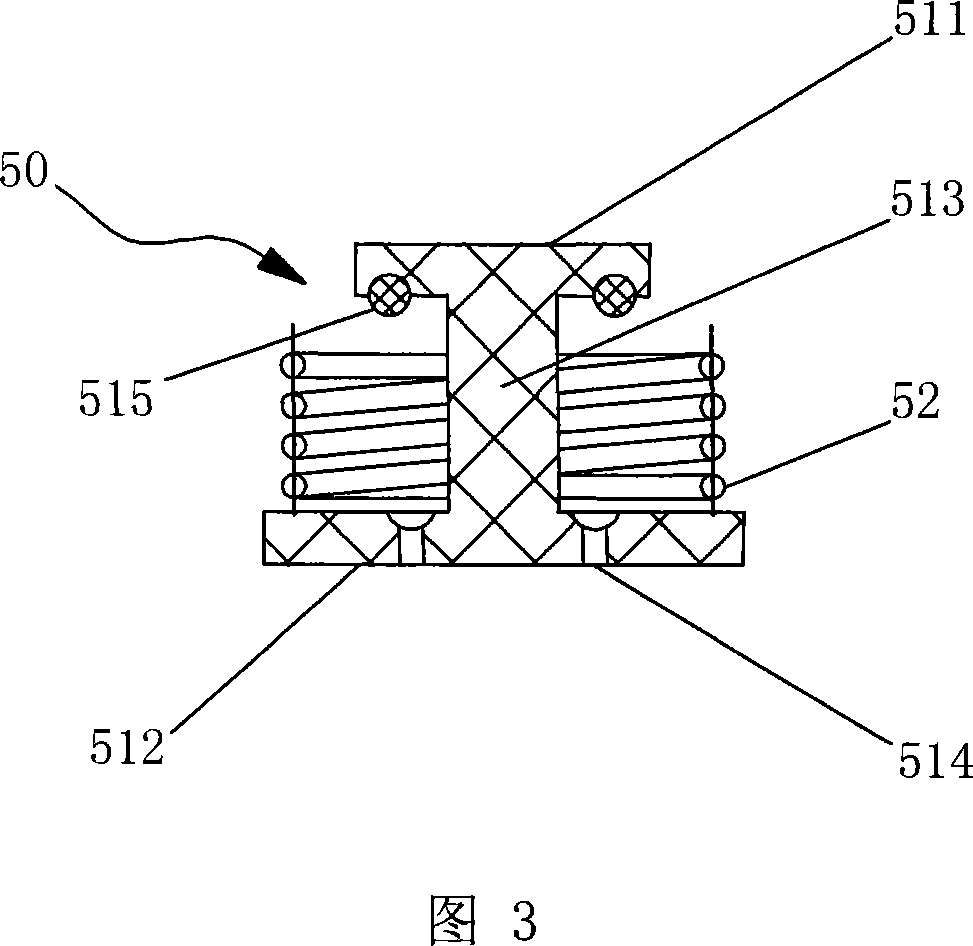

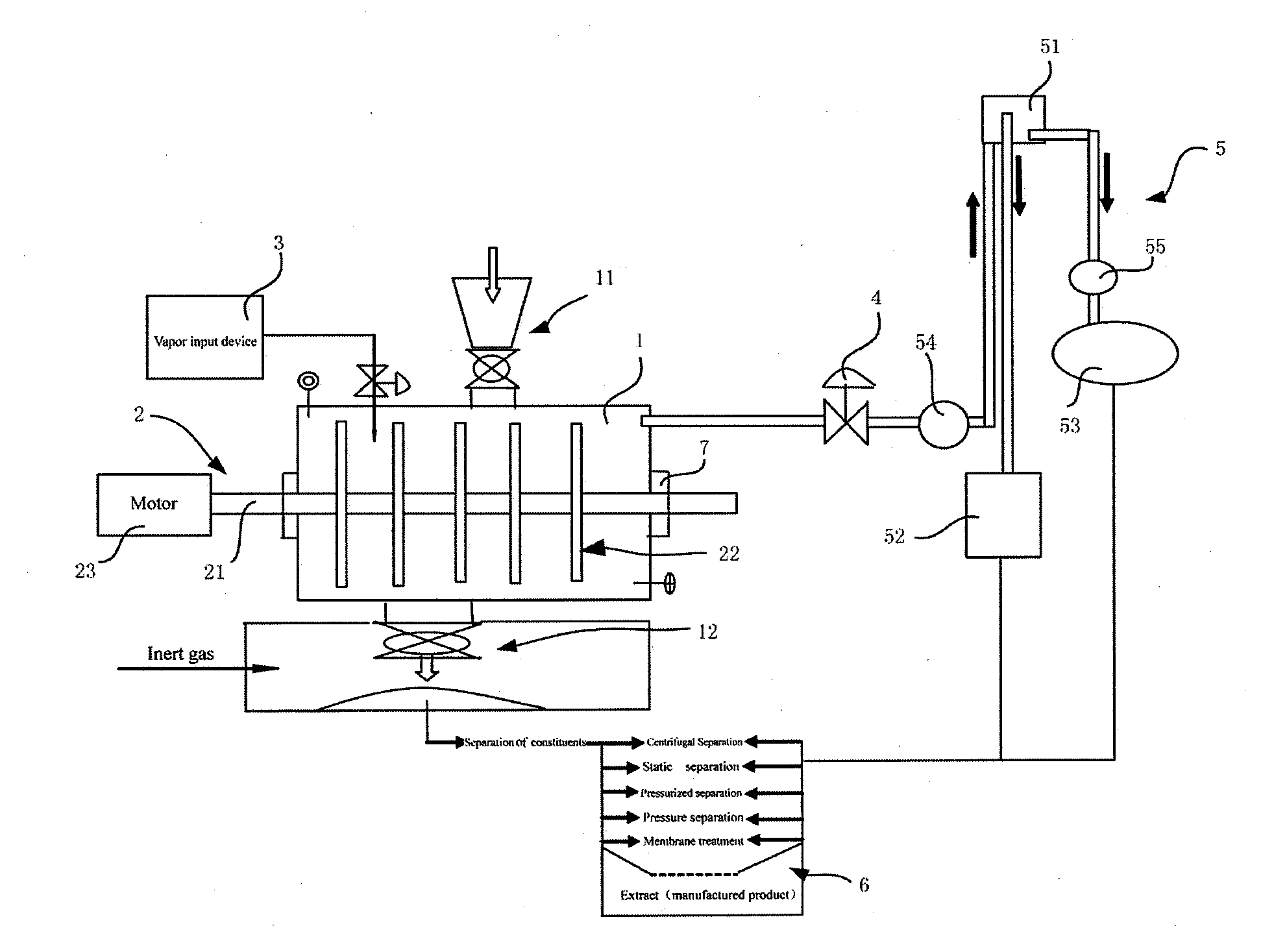

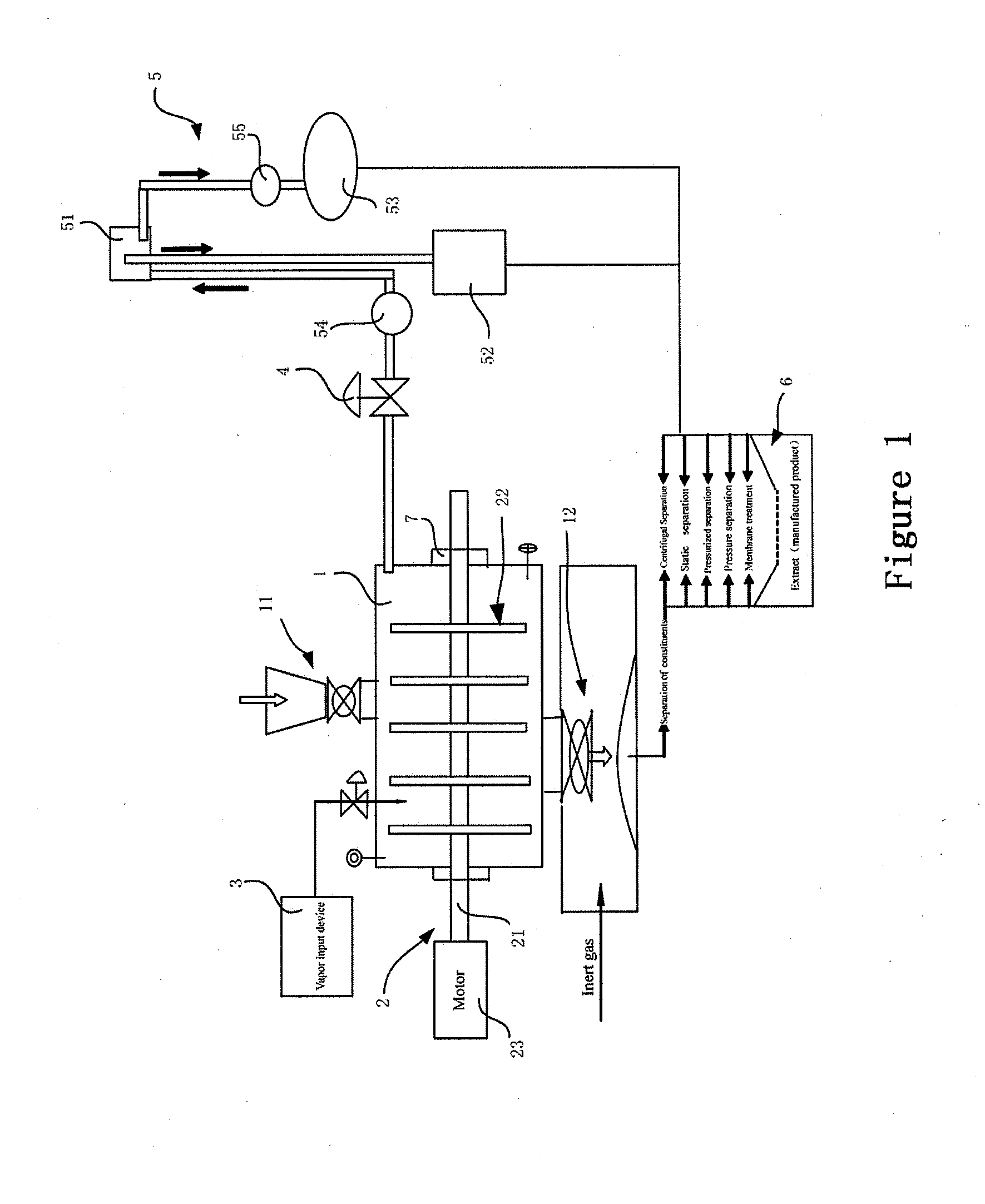

Method and device for biogenic waste treatment

ActiveUS20110192791A1Increase added valueFull recoveryThermal non-catalytic crackingPressurized chemical processWater vaporDecreased pressure

The present discloses a method and a device for biogenic waste, or bio-waste treatment, and said method is as follows: Firstly, the biogenic waste is evenly mixed with water vapor, or steam, heating and pressurizing so that the temperature reaches 130-190° C. and the pressure reaches 1.5-1.9 MPa after mixture, and this state is maintained for 1-25 minutes; Then, the pressure of the mixture of said biogenic waste and water vapor is reduced to normal pressure, such as atmospheric pressure so as to conduct low-molecularization, such as decreasing or reduction of molecular weight of the biogenic waste to obtain a low-molecularized mixture, such as a low molecular weight mixture; finally, the low-molecularized mixture, such as low-molecular weight mixture is separated so as to obtain the final products. Said device includes reaction vessel, stirring device, vapor input device, pressure-reducing regulator and separation device.

Owner:YANG JUN

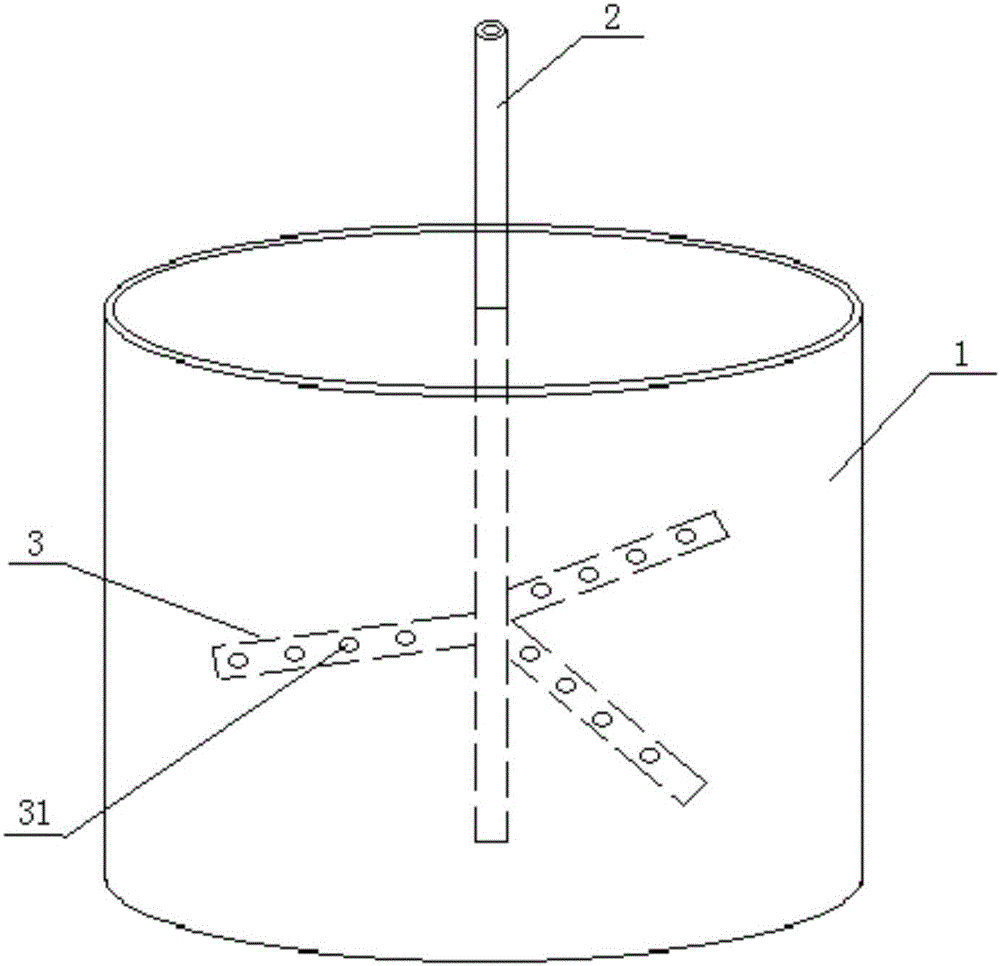

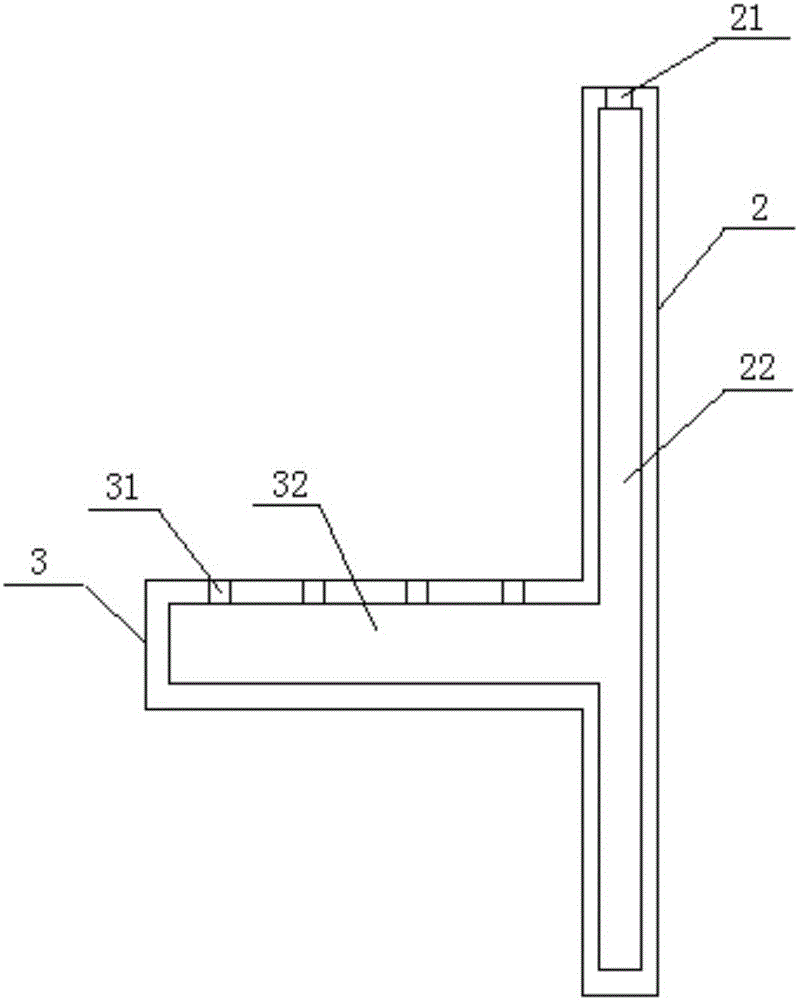

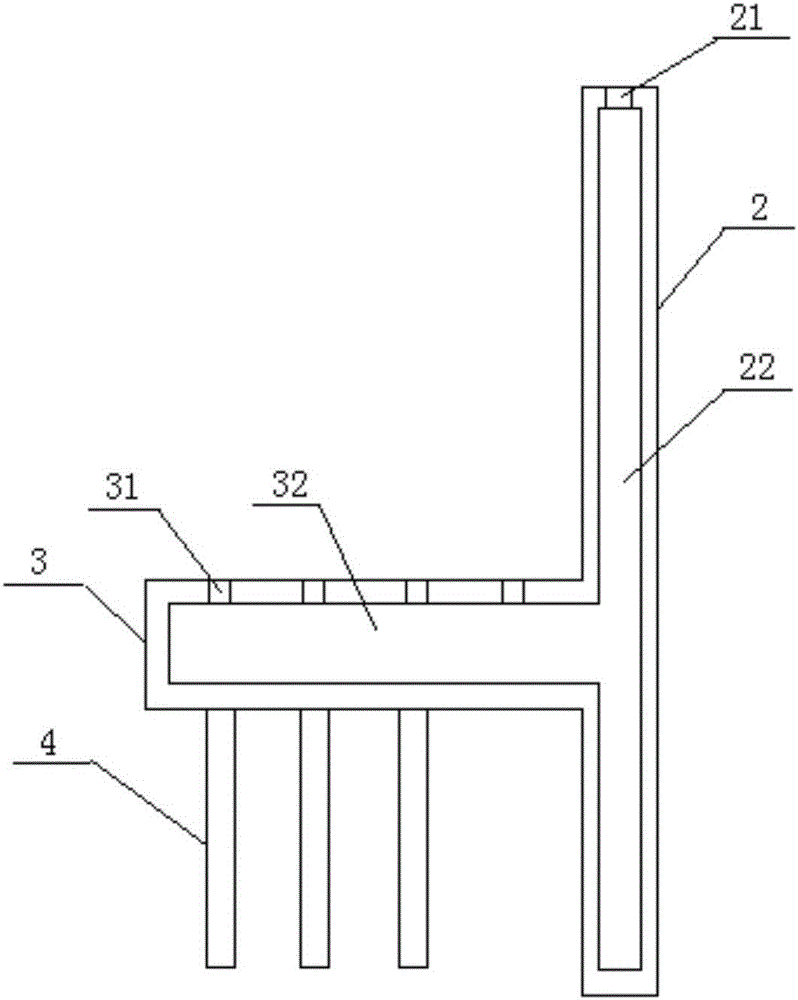

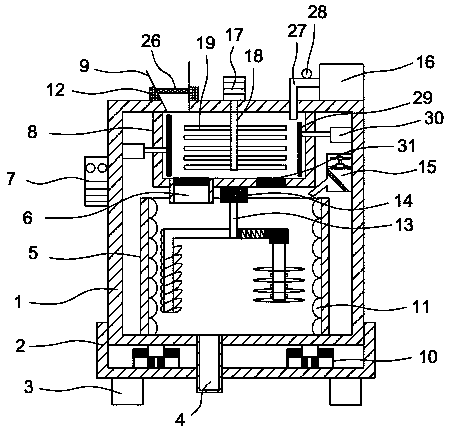

Stirring device

ActiveCN104984681AStir wellWater evenlyRotary stirring mixersClay mixing apparatusEngineeringCavity wall

The invention discloses a stirring device. The stirring device comprises a box body with an opening in the upper end, a stirring shaft and a stirring paddle, wherein the stirring shaft is connected with the stirring paddle, the stirring shaft comprises a first hollow cavity, and a water injection port is formed in the cavity wall of the first hollow cavity; the stirring paddle comprises a second hollow cavity, the second hollow cavity is communicated with the first hollow cavity, and a plurality of water outlet holes are formed in the cavity wall of the second hollow cavity. The stirring device disclosed by the invention can greatly improve the stirring uniformity.

Owner:ZHANJIANG JIANKE ENG QUALITY TESTING CENT CO LTD

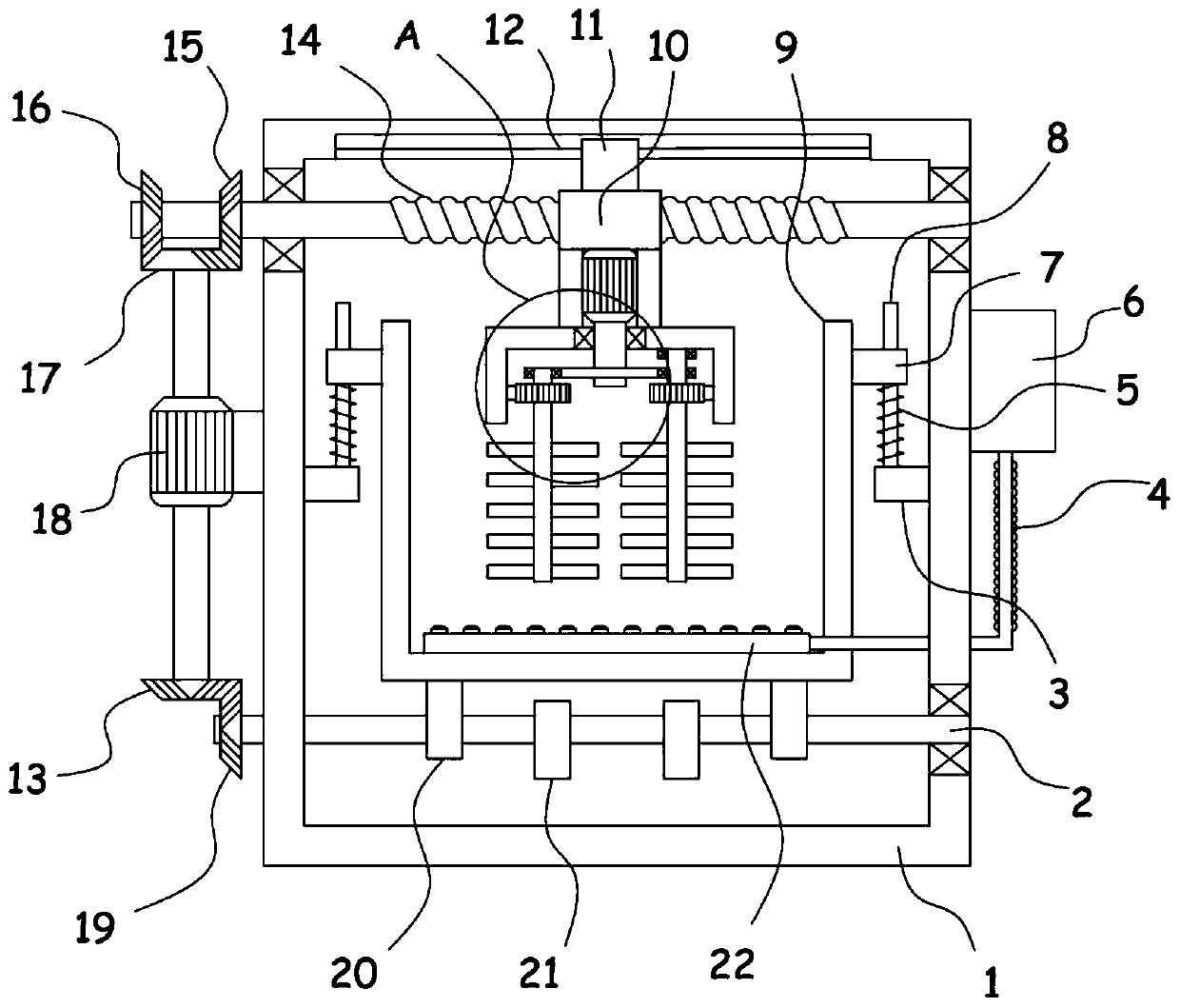

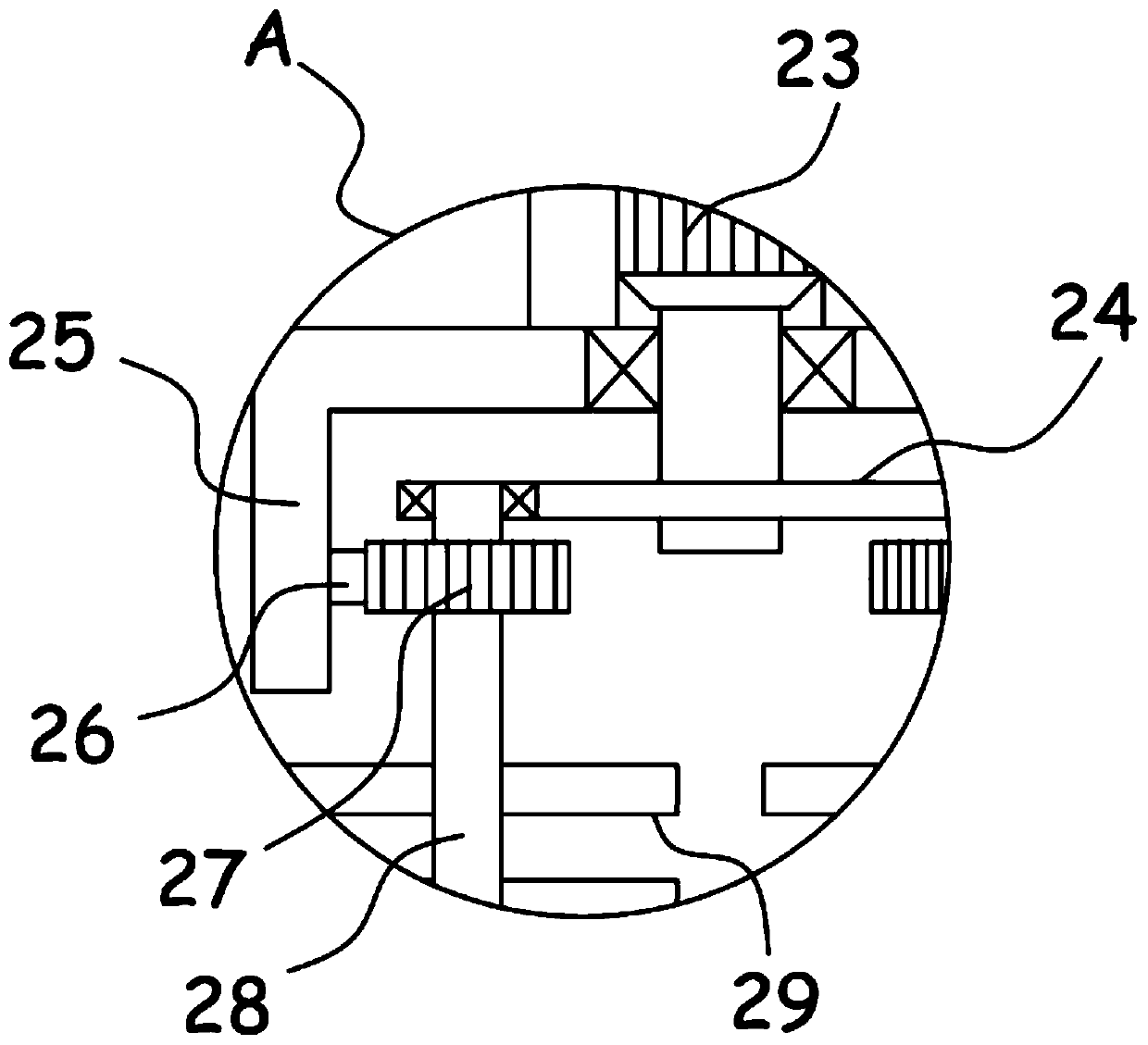

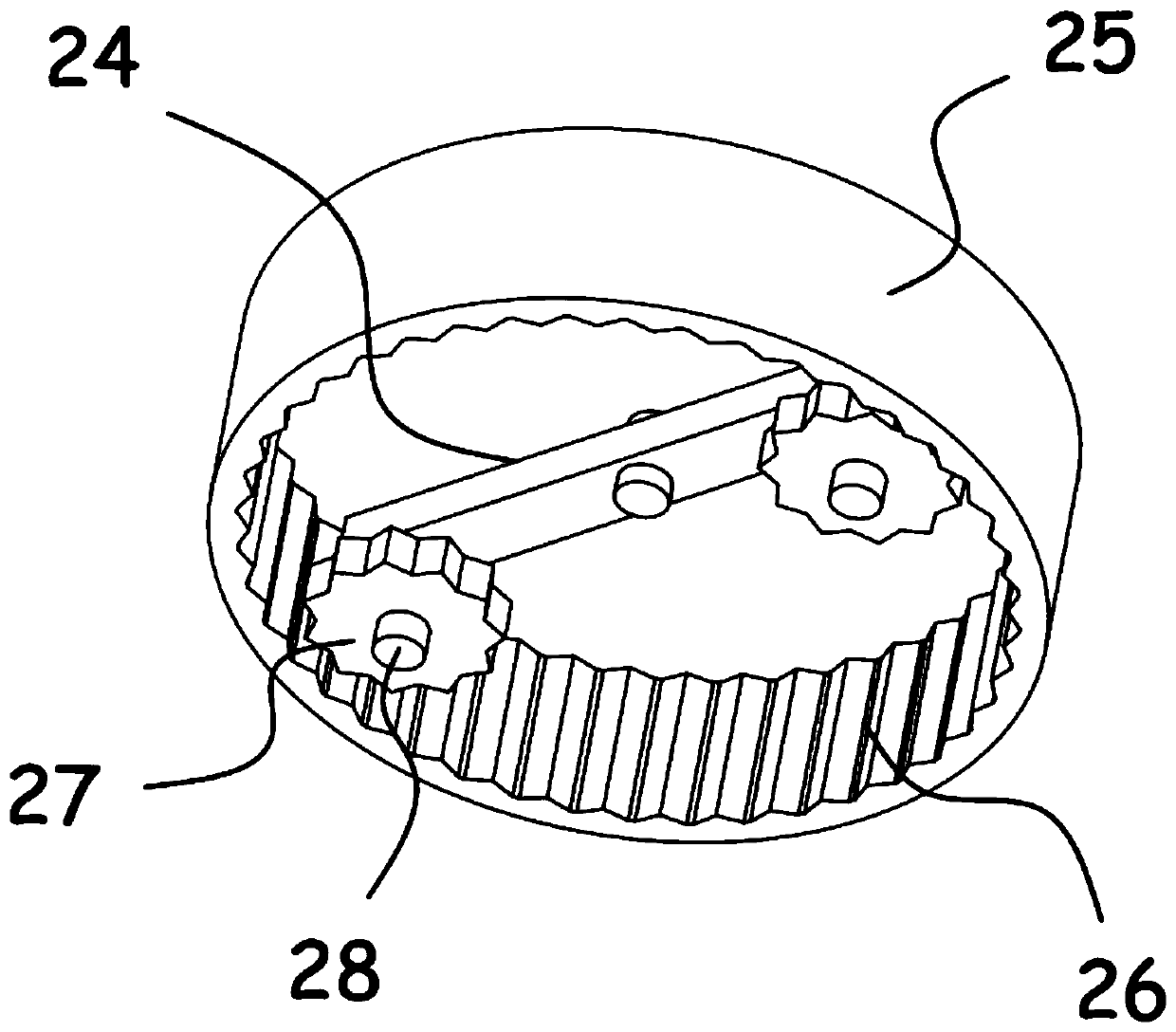

Stirring device for glue used for electronic processing

InactiveCN110935369AStir wellStir thoroughlyShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionAdhesive glue

The invention discloses a stirring device for a glue used for electronic processing, and relates to the technical field of electric power processing. The stirring device comprises a fixed frame, wherein a stirring groove is arranged in the fixed frame; a stirring mechanism driven by a transverse translation mechanism to stir the glue in the stirring groove is arranged in the fixed frame; and a pushing mechanism used for driving the stirring groove to vertically reciprocate is arranged on the fixed frame. According to the invention, through arrangement of the stirring mechanism, the glue in thestirring groove is rotationally stirred; through arrangement of a transmission shaft, stirring blades can be driven to rotate around the rotation center of a connecting plate; meanwhile, the stirringblades can be driven to rotate around the transmission shaft; through arrangement of the transverse translation mechanism, the stirring mechanism can be driven to move back and forth at a horizontalposition, so the glue at different positions in the stirring groove can be fully stirred, and the glue is stirred more fully; and through arrangement of the pushing mechanism, the stirring groove canbe driven to reciprocate up and down relative to the stirring mechanism, so the glue is stirred fully, thoroughly and efficiently.

Owner:江西诺驰科技咨询有限公司

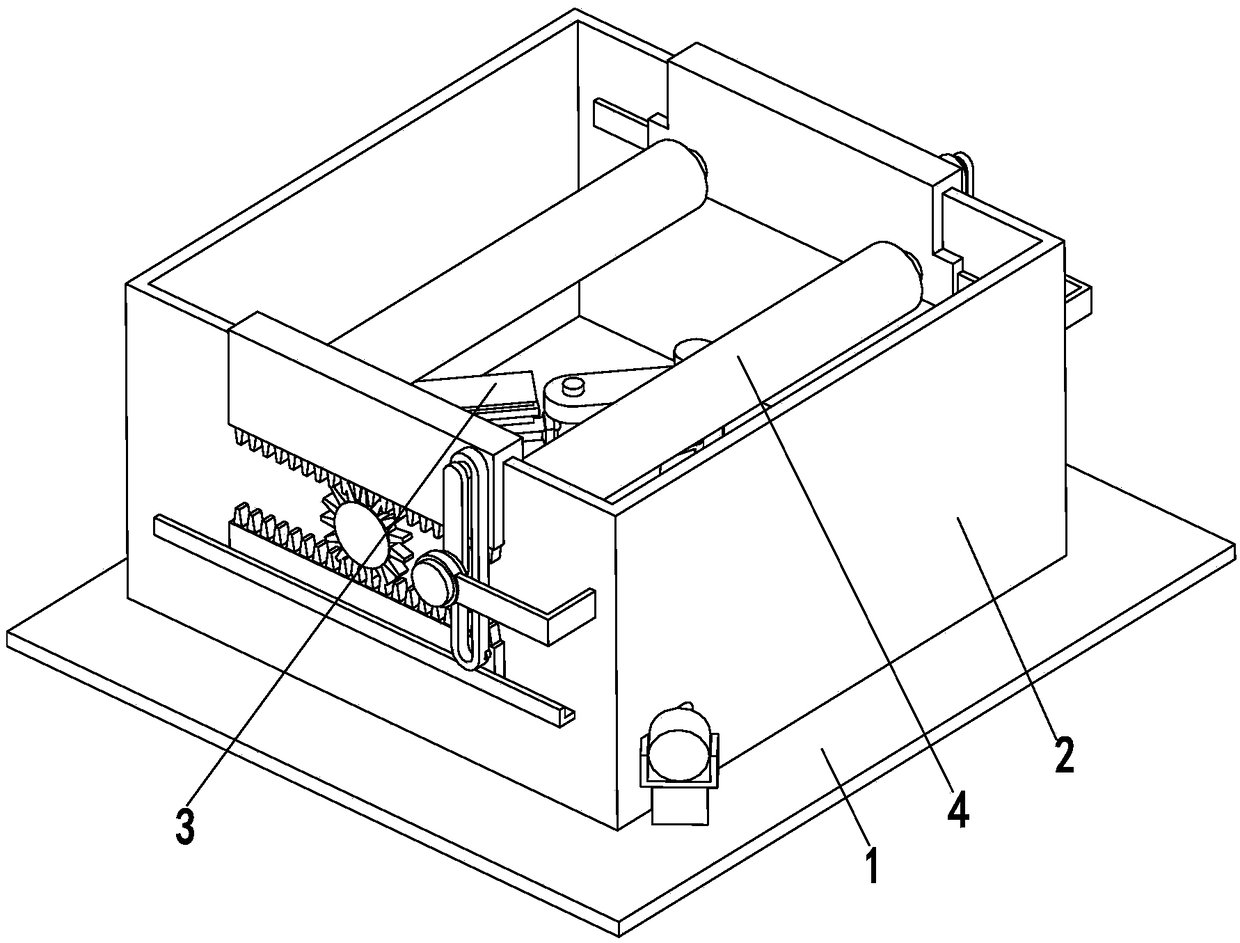

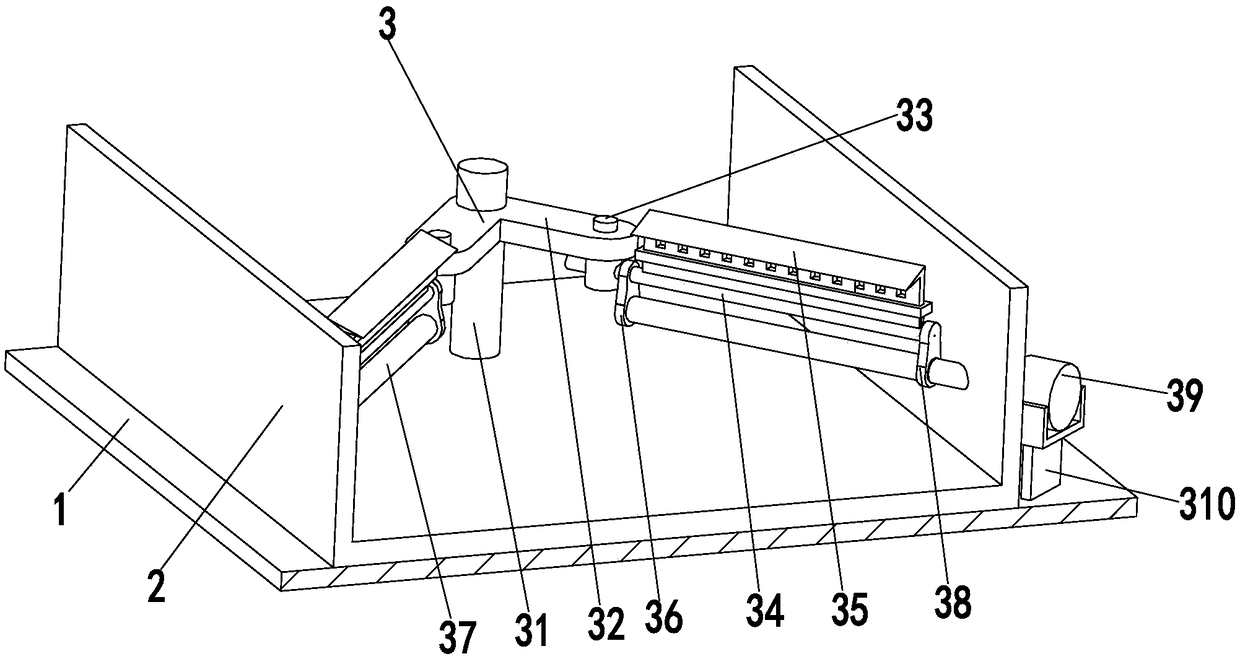

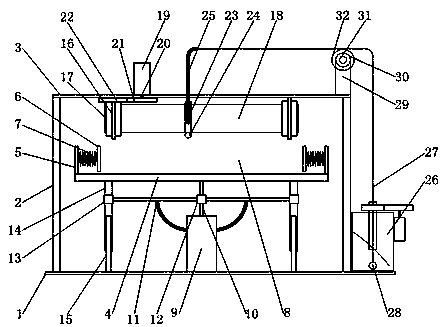

Cement flattening compacting device for road construction

PendingCN108385481AImprove stirring effectAvoid cloggingRoads maintainenceEngineeringMechanical engineering

The invention discloses a cement flattening compacting device for road construction. The cement flattening compacting device comprises a rack and a base. The rack is mounted on the base, and the rackis provided with a material box, a conveying mechanism, a transmission device and a transmission frame. The transmission device comprises a sliding bar, the sliding bar is vertically mounted on the rack, a top plate and a bottom plate are mounted on the sliding bar, the top plate and the bottom plate are mounted on the sliding bar through sliding sleeves, the top ends of the top plate and the bottom plate are provided with a first transmission link for connecting the two, the front ends of the top plate and the bottom plate are provided with a second transmission link for connecting the two, the transmission frame is mounted at the rear end of the rack, a sliding frame is mounted inside an inner cavity in the transmission frame, sliding blocks are mounted at the upper and lower ends of thesliding frame, the upper and lower sides of the inner wall of the transmission frame are provided with sliding rails, and the sliding blocks are limited in the sliding rails. The cement flattening compacting device has high stability and high operation consistency, can perform fully automated operation, and can save a lot of human resources.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

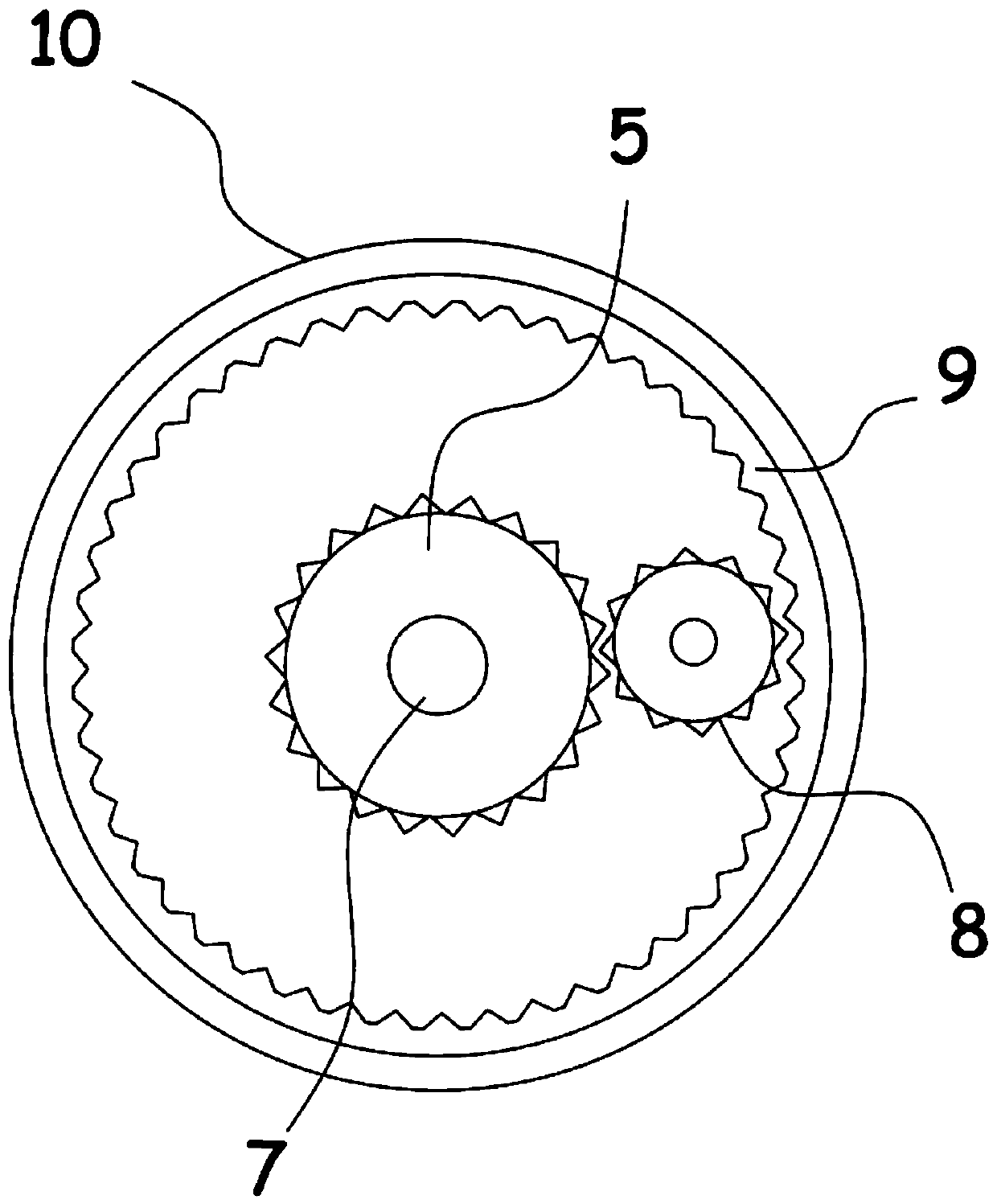

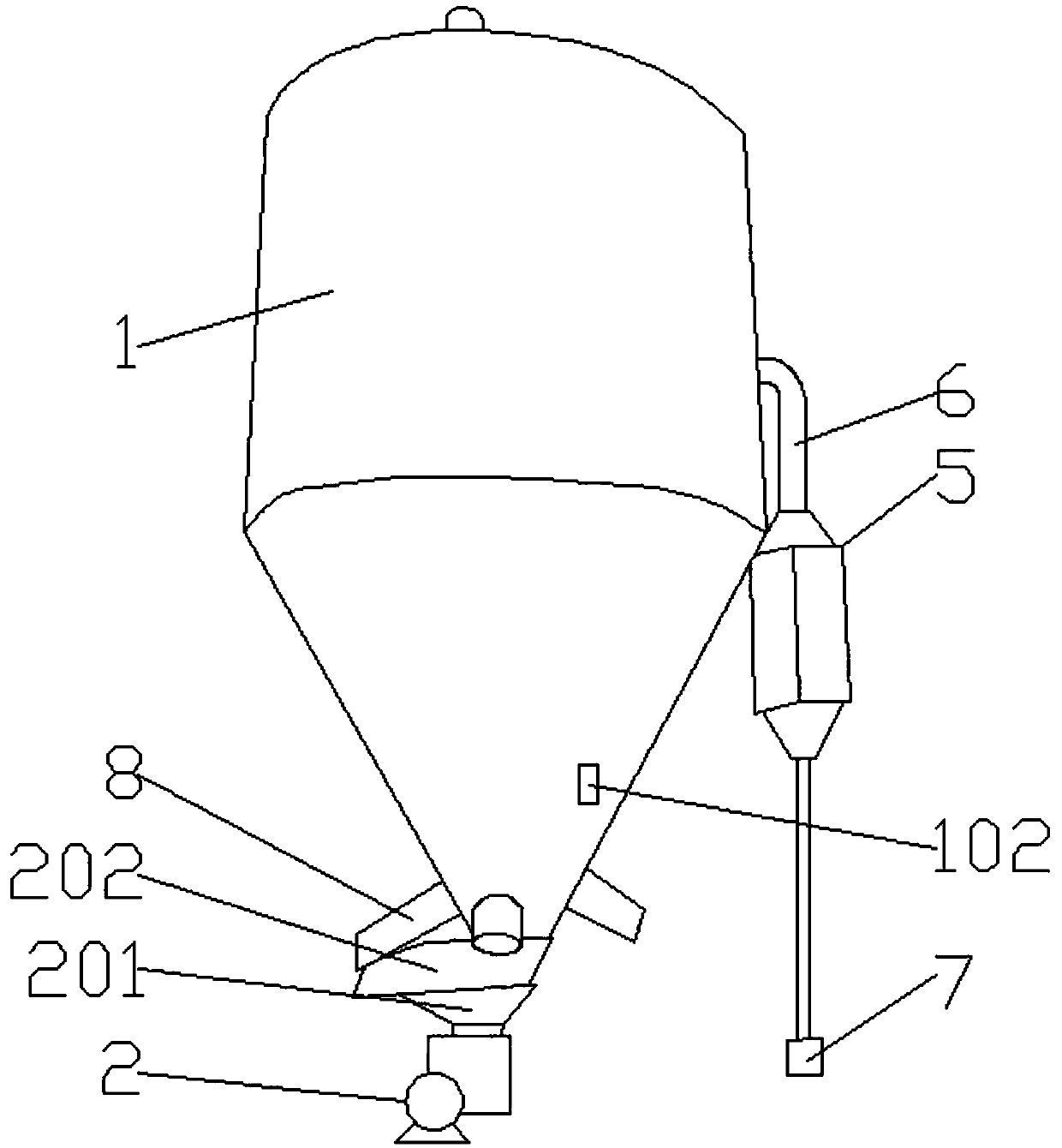

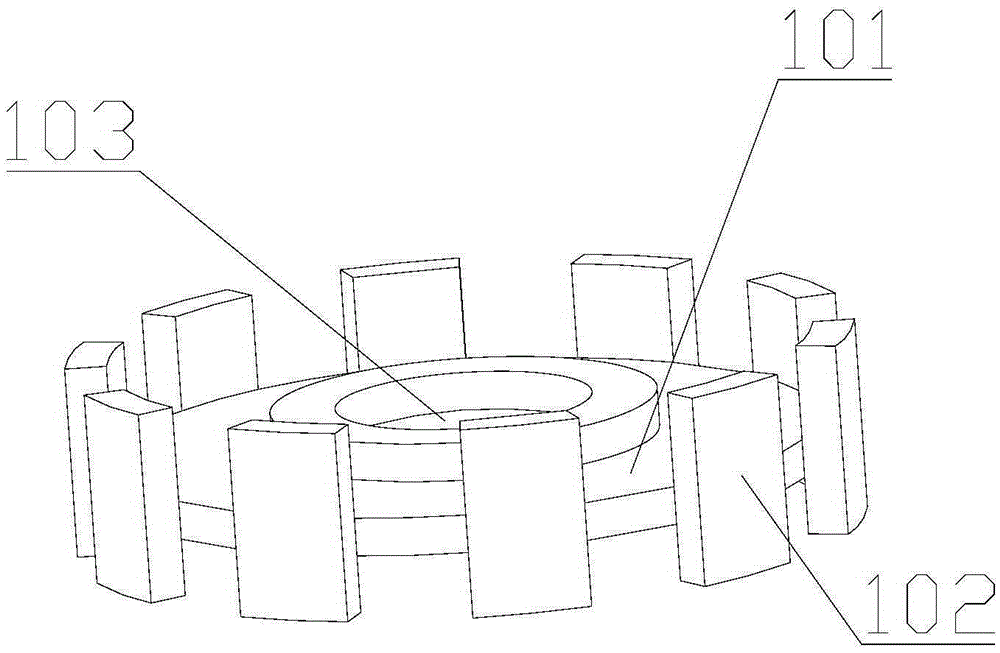

Anti-blocking switch gear of discharge bin

ActiveCN105346876AAvoid blocking problems such as archingIncrease the output speedLarge containersEngineeringMechanical engineering

The invention discloses an anti-blocking switch gear of a discharge bin, the anti-blocking switch gear is arranged above a discharge hole in the bottom of the discharge bin, and the cross section of the discharge hole is circular. The anti-blocking switch gear comprises a discharge mechanism, an arch breaking mechanism and a rotary mechanism, wherein the discharge mechanism comprises a baffle plate, an air cylinder and a circular ring; the circular ring is connected with a motor, so that the motor drives the circular ring to rotate for driving the air cylinder and the baffle plate to rotate; the arch breaking mechanism comprises a circular-ring-shaped base and a cylindrical supporting base; the base is hinged with the baffle plate to realize linkage; the side edge of the upper surface of the supporting base is provided with a plurality of spiral pawls which are in upward right-handed rotation, so that a plurality of spiral openings are formed; the rotary mechanism comprises an outer rod, an inner rod extending into a space formed by the pawls, and a plurality of blades, wherein one blade is blocked into one opening, so that the corresponding blade is driven to rotate in a rotary process of the supporting base. The anti-blocking switch gear has the advantages of being capable of effectively preventing the discharge hole from arching, uniform in discharge of the discharge bin, simple in structure, high in working efficiency and the like.

Owner:GUANGXI SHENTA MACHINERY EQUIP CO LTD

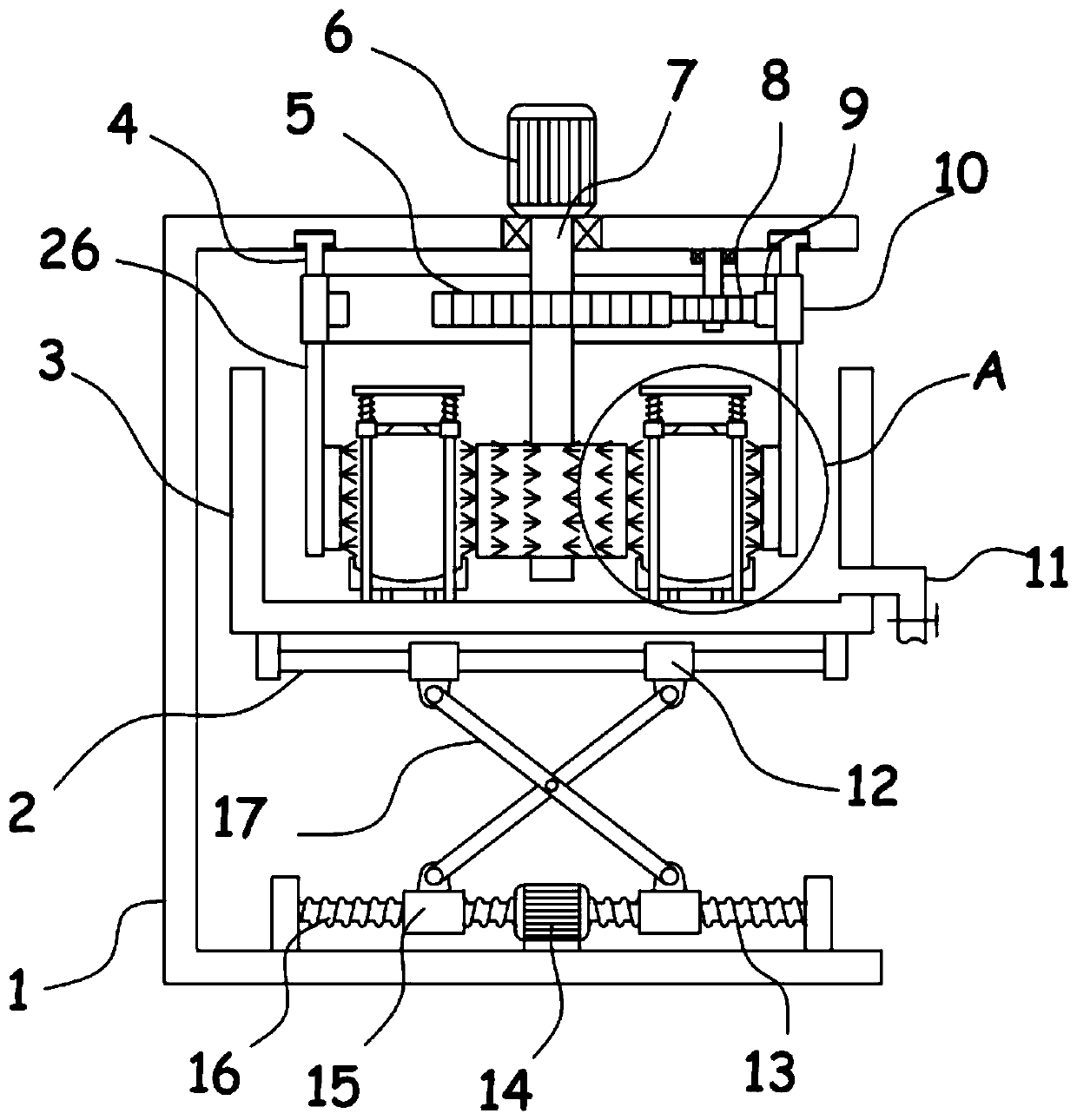

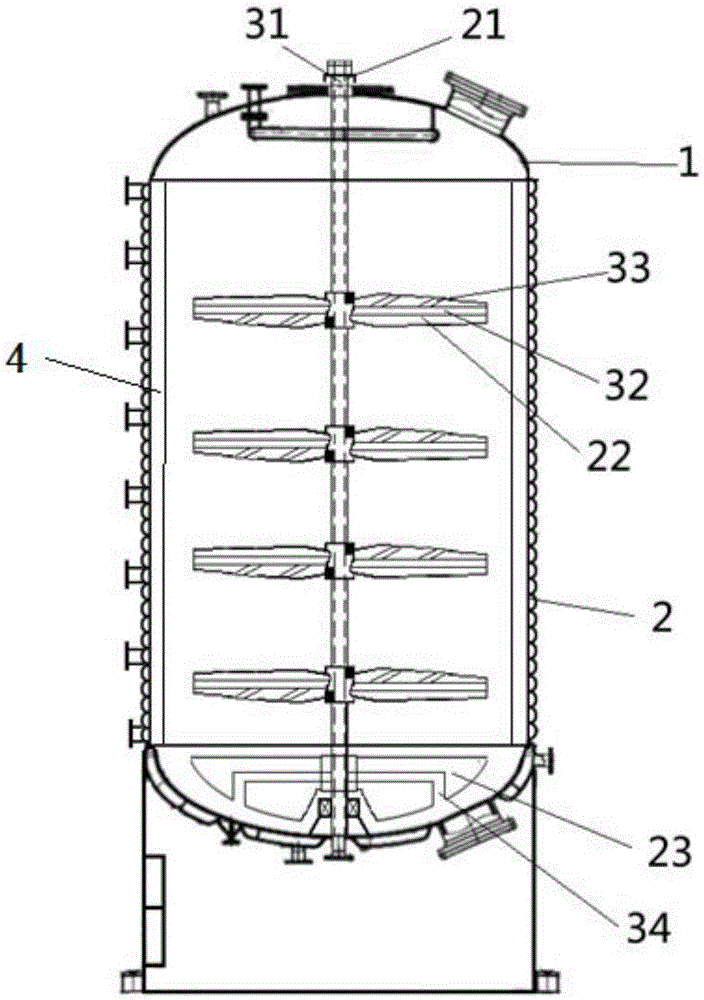

Reaction kettle suitable for intermittent mixed acid nitration

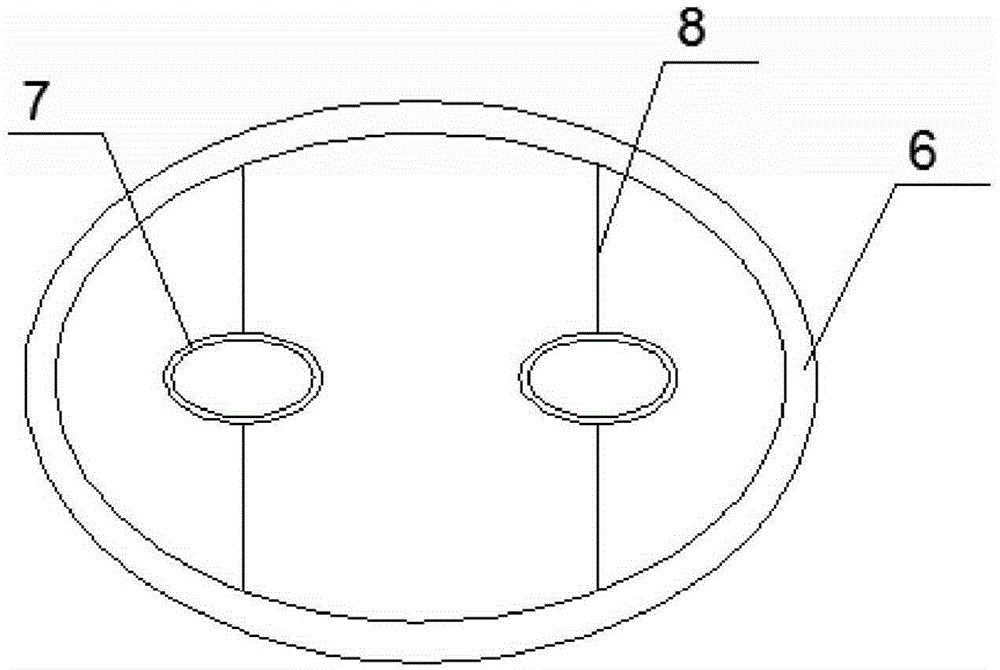

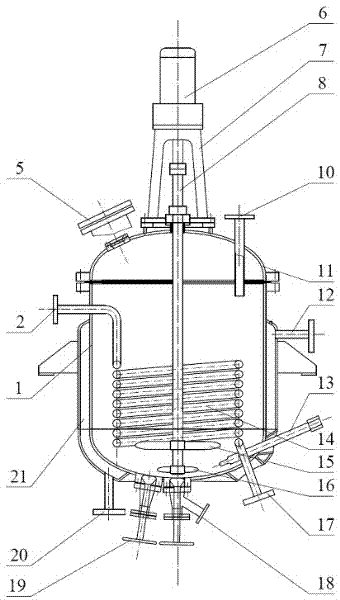

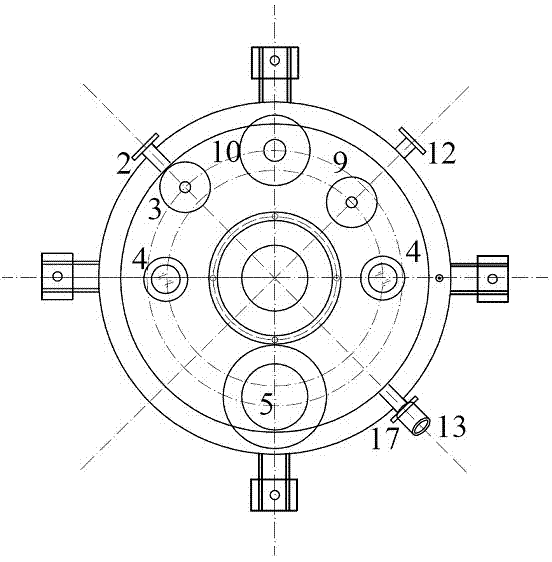

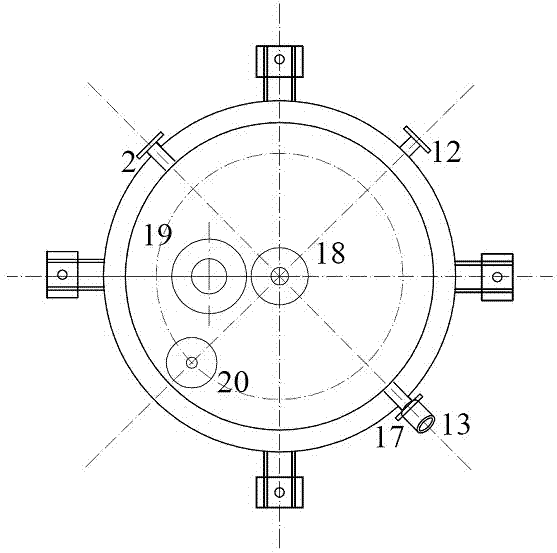

InactiveCN102580654AAvoid contactUniform concentrationChemical/physical/physico-chemical stationary reactorsNitrationEngineering

The invention discloses a reaction kettle suitable for intermittent mixed acid nitration. The reaction kettle is characterized in that a kettle cover is a standard ellipsoidal head and is provided with a liquid charging hole, view monitors, a hand hole, a thermometer hole and a vent; a shaft base is arranged at the top of the kettle cover; a stirring motor is arranged on the shaft base; the stirring motor is connected with the upper end of a stirring shaft; a main stirring paddle and an auxiliary stirring paddle are fixed on the stirring shaft; a coil pipe outlet and a thermometer connector are arranged on the sides of a kettle body; a coil pipe inlet, a material outlet and an emergent discharge hole are arranged at the bottom of the kettle body; jackets are arranged on the periphery of the kettle body and are provided with a jacket outlet and a jacket inlet; a coil pipe is arranged in the kettle body; and the two ends of the coil pipe are respectively connected with the coil pipe outlet and the coil pipe inlet. The reaction kettle has the following beneficial effects that materials can be fully stirred when the liquid level in the kettle is low by adding the small auxiliary stirring paddle at the bottom of the kettle, thus ensuring the heat and mass transfer effects; and the vent extends into the kettle and vacuumizes the interior of the kettle during solid charging, thus preventing the solids from agglomeration as the solids become damp under the effect of acid mist.

Owner:ZHEJIANG UNIV

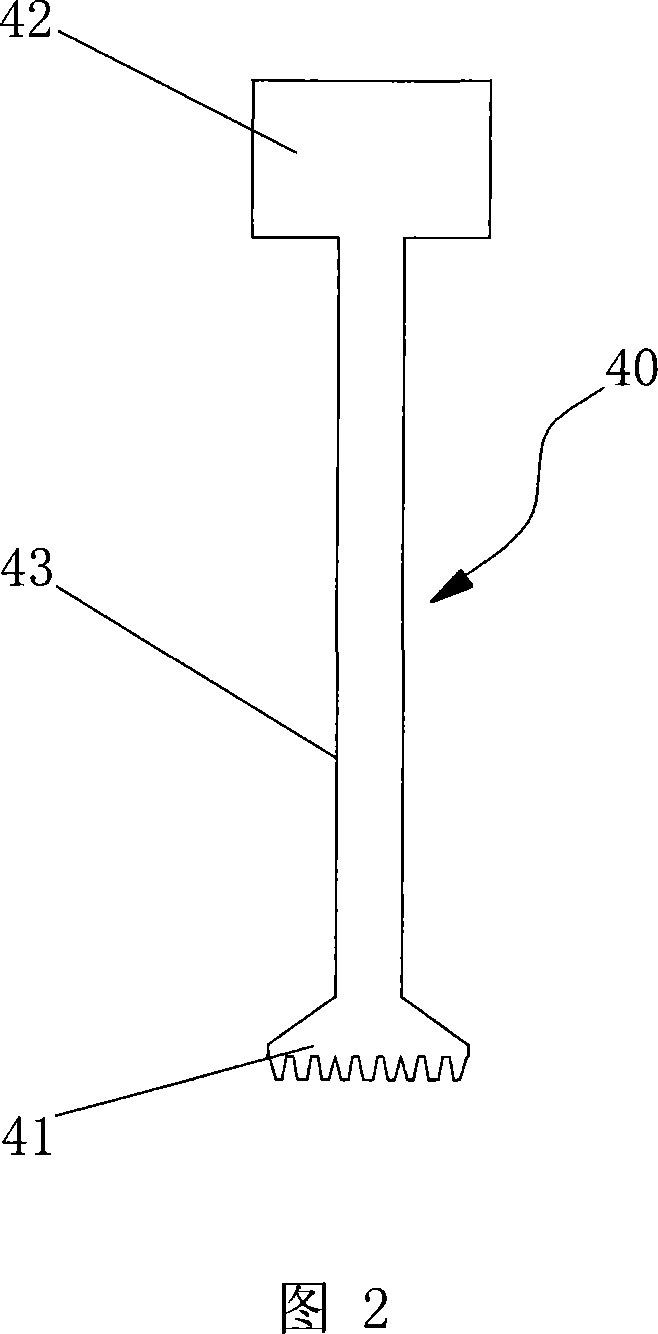

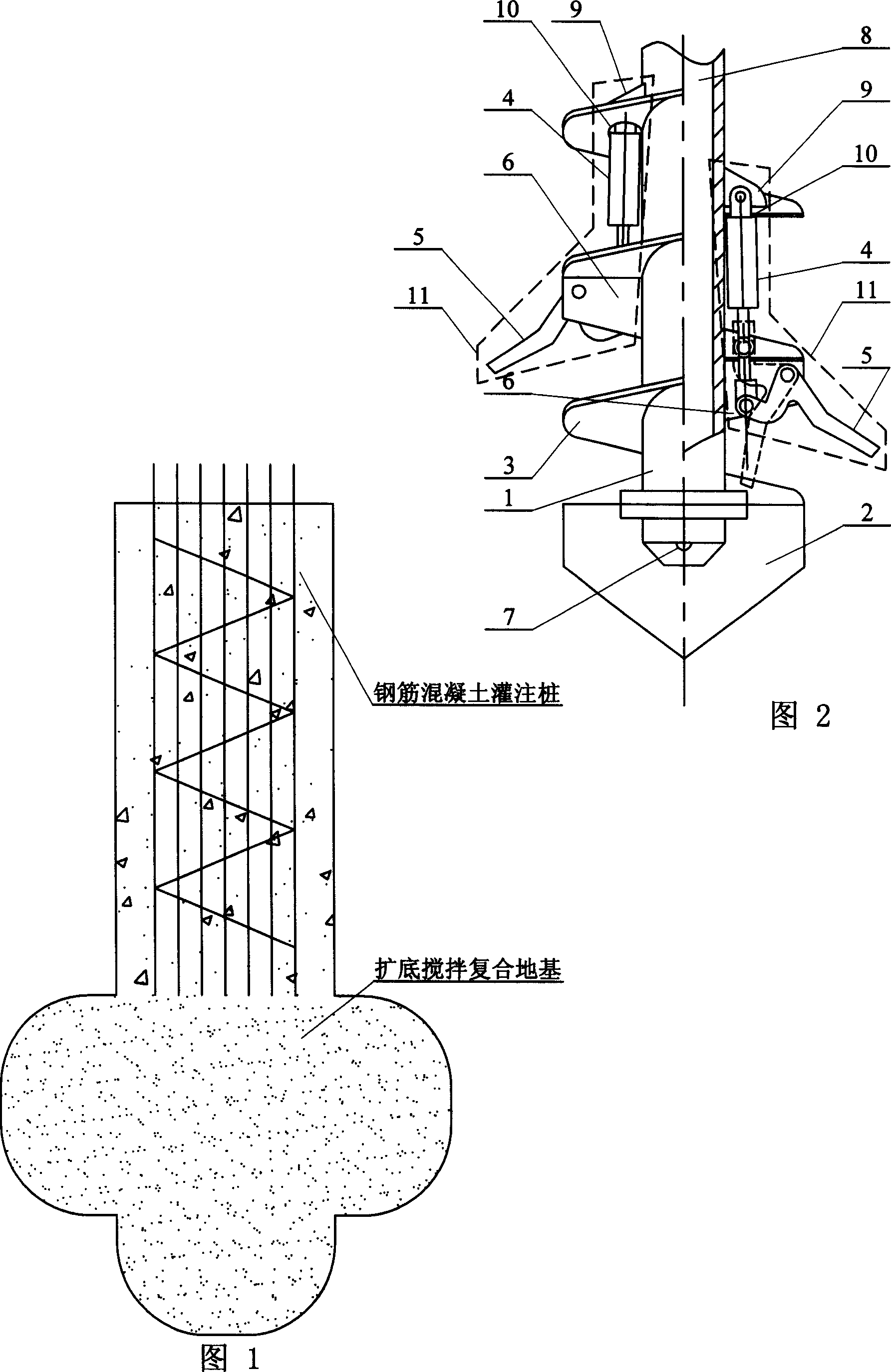

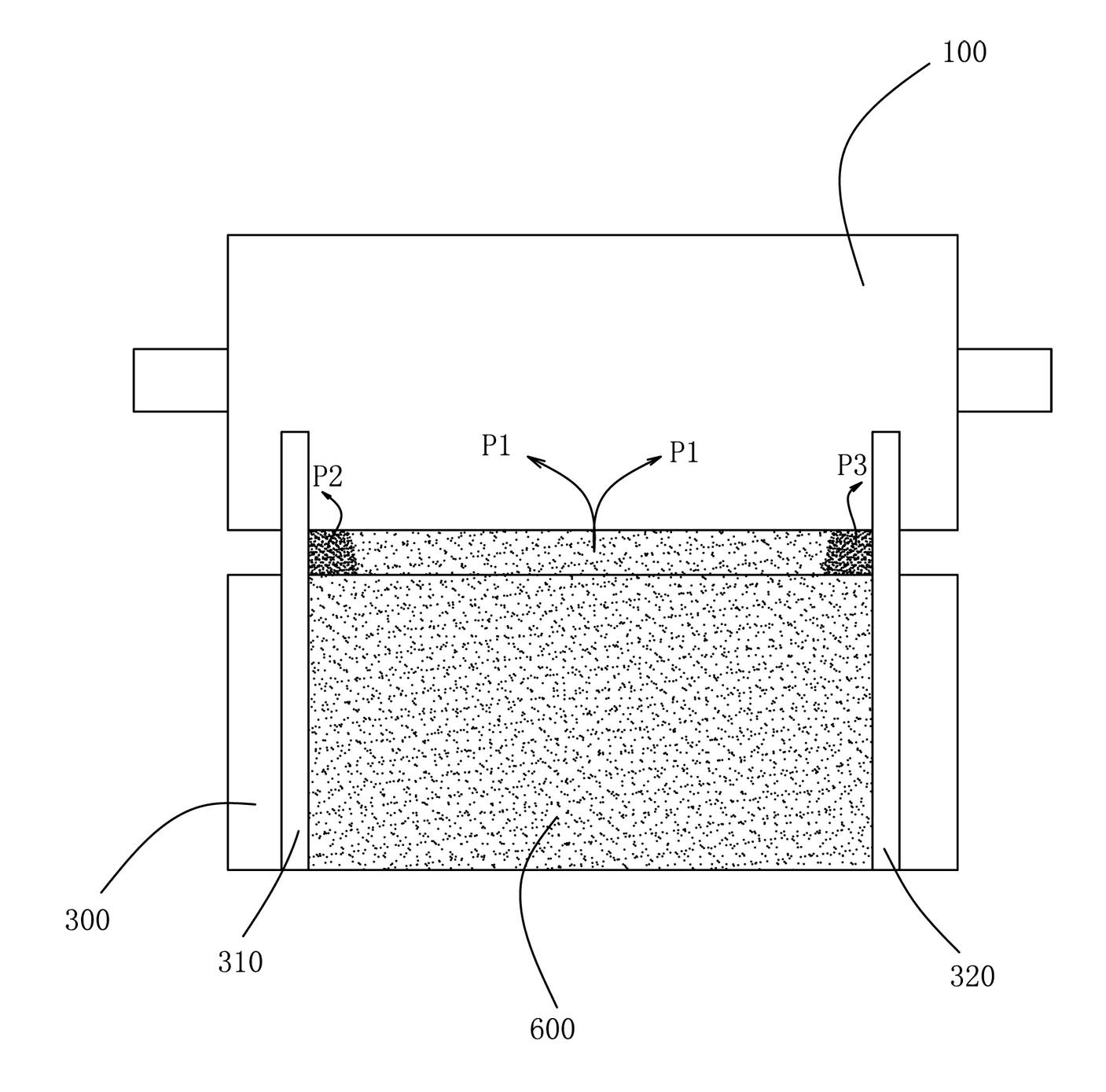

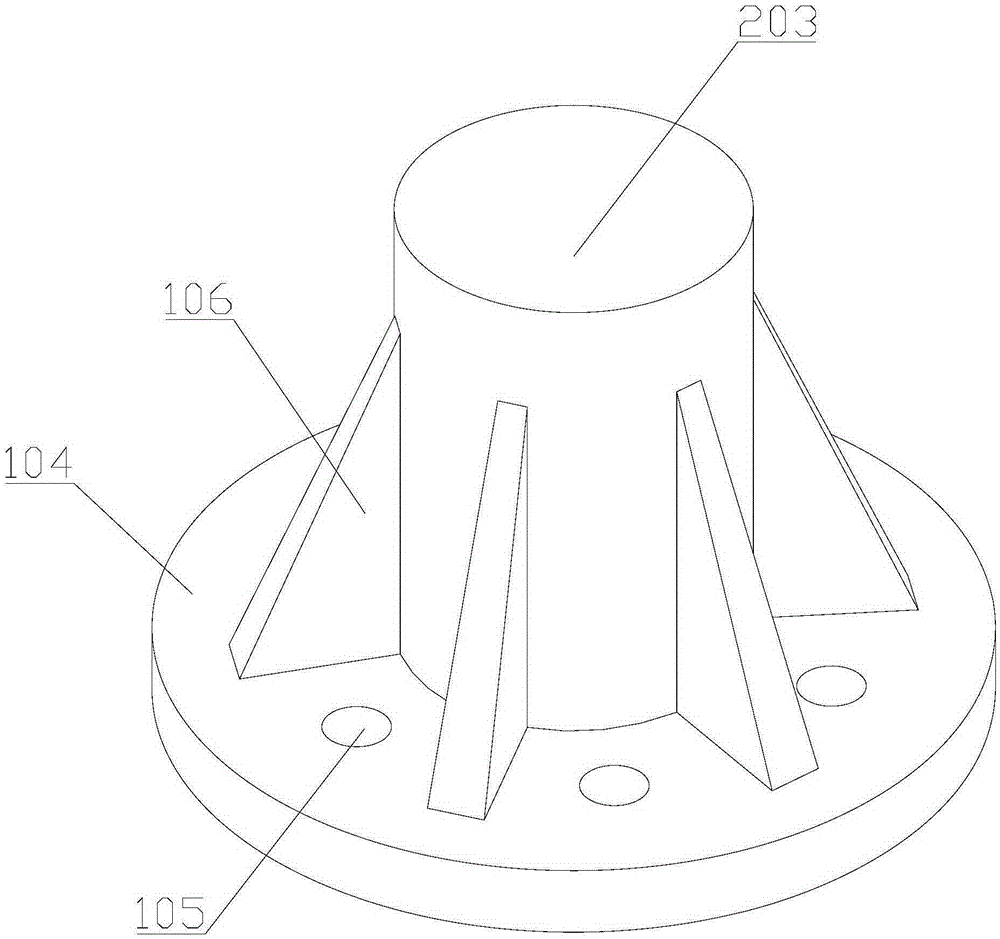

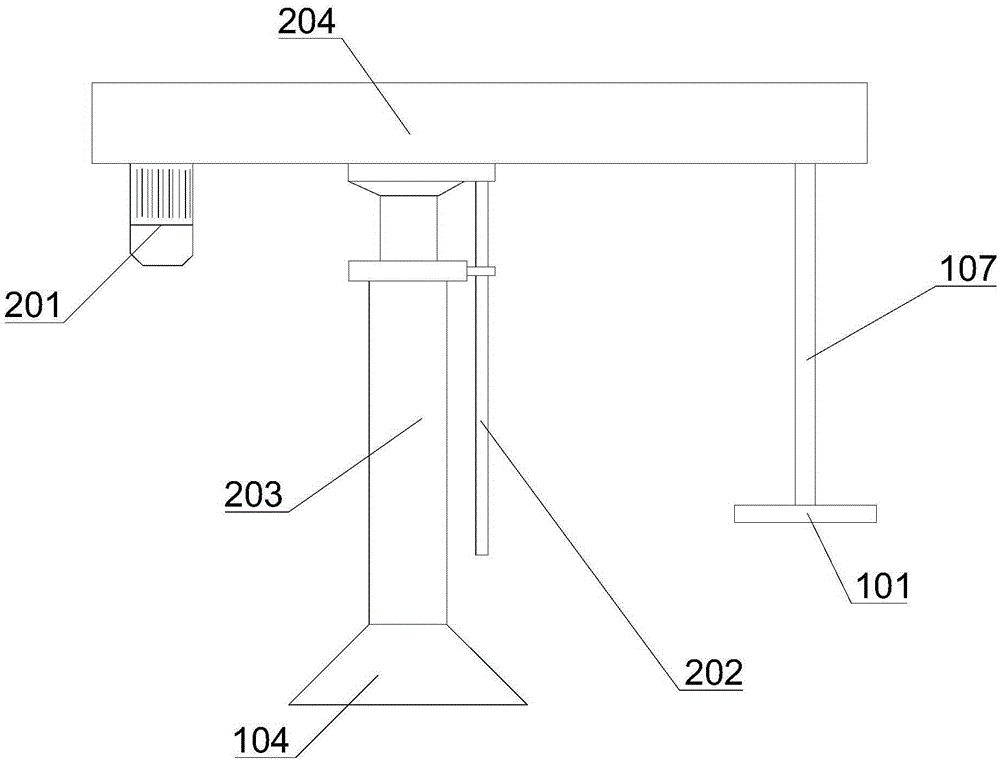

Method of constructing enlarged based composite foundation for stirring concrete filling pile

InactiveCN1600997ASimple construction methodEasy constructionEarth drilling toolsBulkheads/pilesCement slurryCement mortar

The invention discloses a kind of construction method and its device of composite base of concrete filling pile enlarged base disturbing. It relates to the production method and the construction and device of the base. In the invention, the drilling tool is lifting with its circumrotation. The mixing head disturb the earth and cement slurry or cement mortar which comes from the spreading of the bottom hole and form composite base of concrete filling pile enlarged base disturbing. The slurry muzzle interconnected with the slurry channels is set under the drill pipe; the flex mixing head is set on the side of drill pipe. The construction method in the invention has advantages of easy construction technique, quick construction speed, and strong adaptability to the complex geology and many times increasing the under stress of individual pile. The construction device in the invention has advantages of easy structure, good disturbing effect, and no big noise and no pollution to the stratum and environment.

Owner:翟向滨

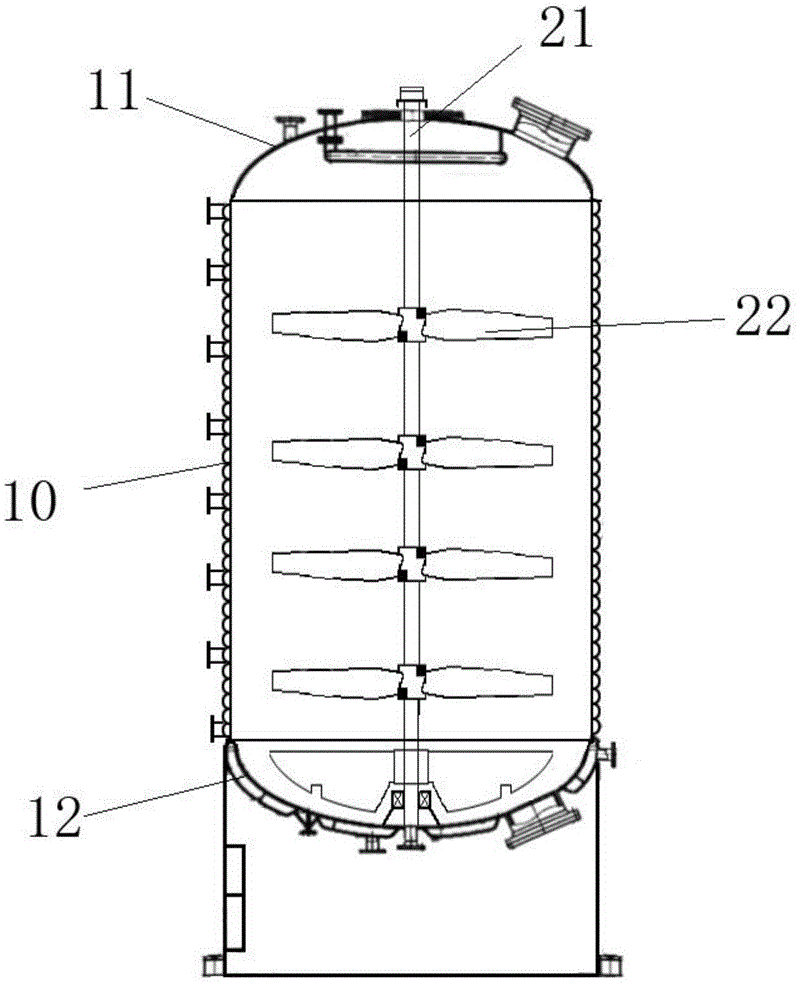

Reaction container

ActiveCN104923145AIncrease profitUniform particle sizeMixersChemical/physical/physico-chemical stationary reactorsEngineeringNoise reduction

The invention relates to a reaction container. Steam firstly enters a steam introduction cavity from an opening, then enters a steam buffer cavity through a first through hole and passes through a second through hole in the outer wall of the buffer cavity and finally enters a tank body. In the process that the steam passes through the steam introduction cavity and the steam buffer cavity, a steam disperse part carries out noise reduction treatment on the steam. Moreover, the steam is dispersed into a plurality of small streams of steam through the first and second through holes and plays a role of stirring a liquid mixture in the tank body, so that the stirring effect is improved. When the small streams of steam move in the liquid mixture, the steam releases heat and is liquefied to become a part of the liquid mixture, so that heat contained in the steam is fully transferred into the liquid mixture, and therefore, the utilization ratio of the heat energy and the steam is increased. As the stirring effect is improved, the grain size or the molecular weight of high-molecular polymers produced by adopting the reaction container is uniform and the proportion of the high-molecular polymers with large grain size or high molecular weight is reduced.

Owner:ZHEJIANG TIANCHEN PLASTIC IND

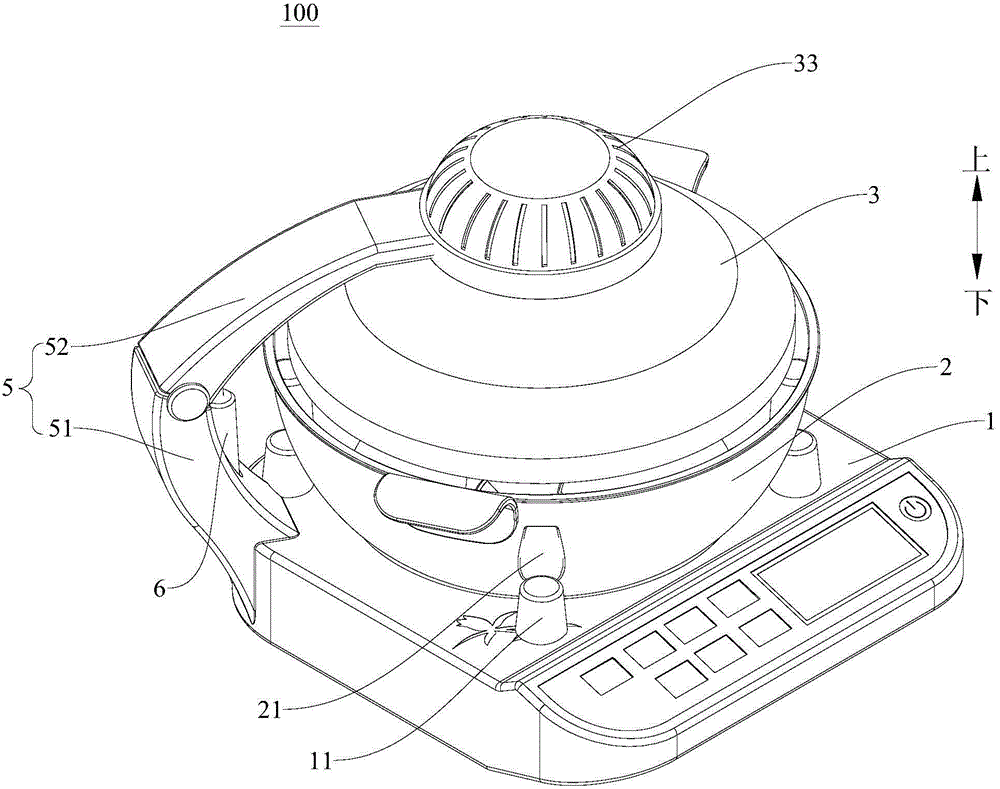

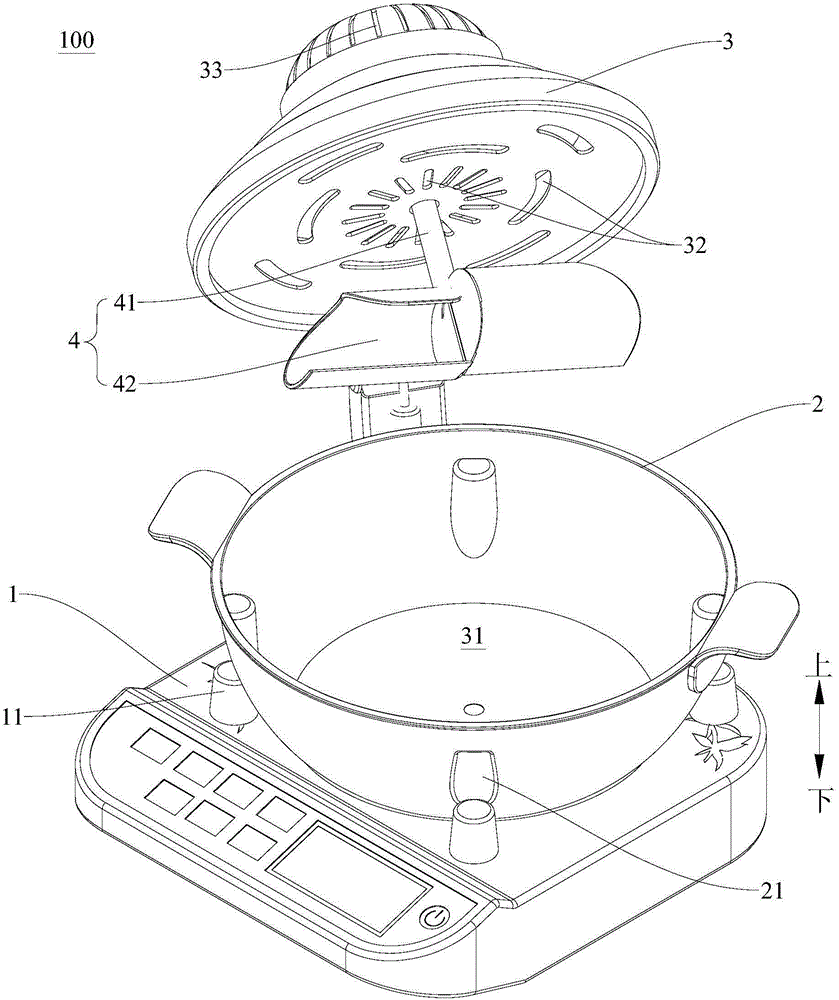

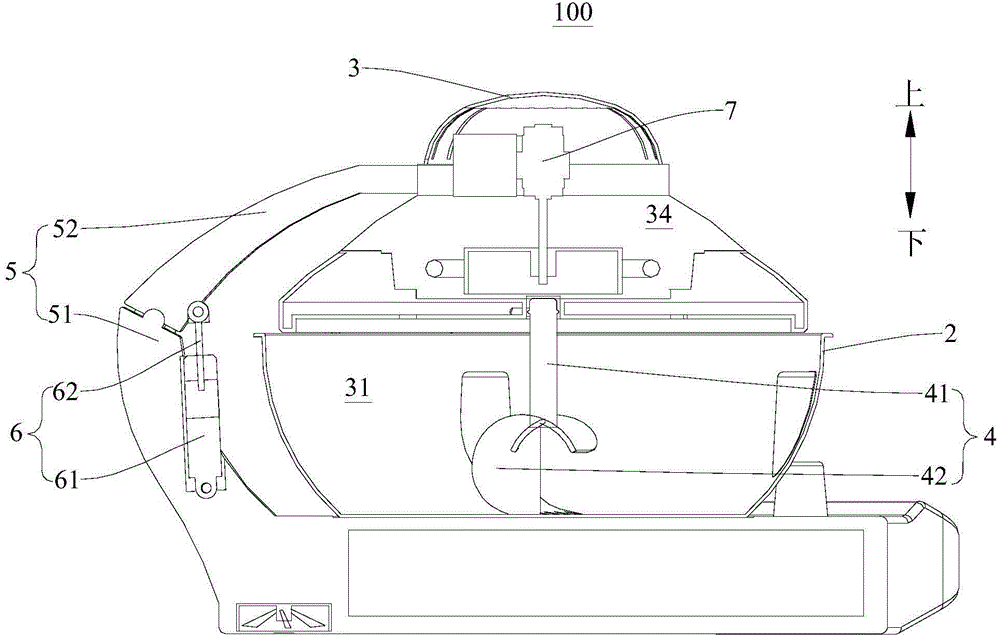

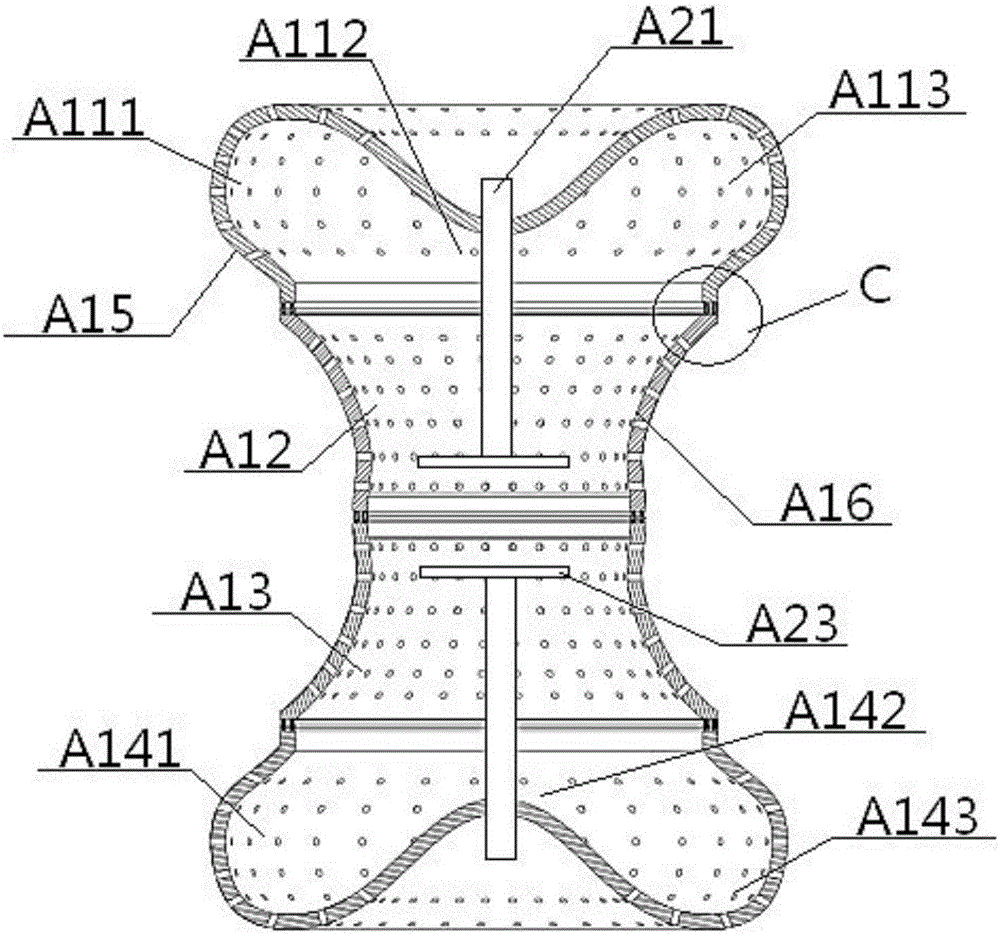

Stirring device for cooking device

The invention provides a stirring device for a cooking device. The stirring device comprises a motor and a stirring assembly, wherein the stirring assembly comprises a rotation shaft which is rotated under driving of the motor and also comprises overturning blades; the overturning blades are connected to the rotation shaft; and the cross section of the overturning blades roughly forms a C shape, and openings of the overturning blades are roughly horizontal and upward. According to the embodiment of the invention, the stirring device for the cooking device has the advantages of a rational structure and good stir-frying effects.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

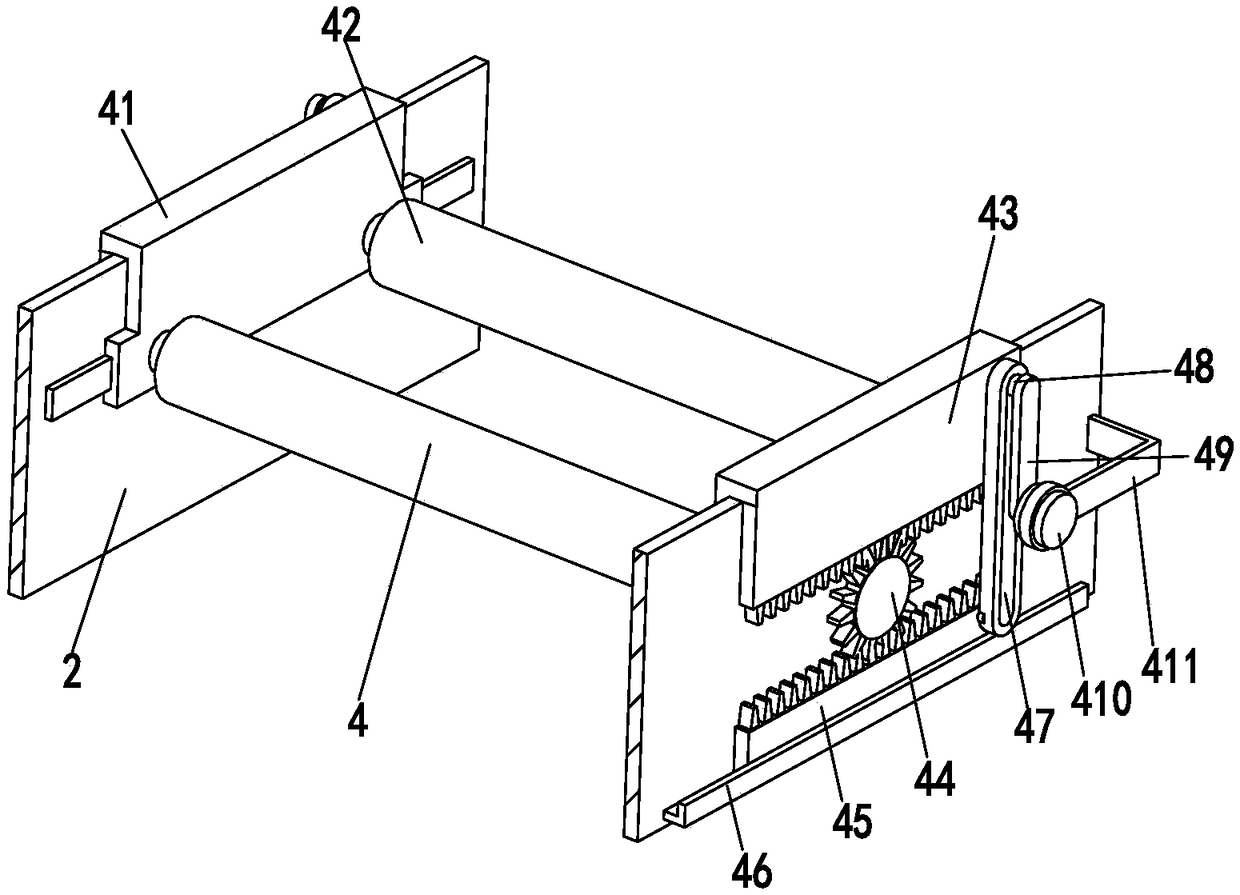

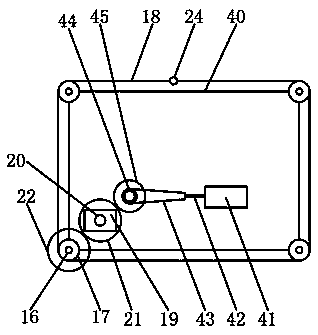

Dye vat for jig dyeing of textiles and automatic dye stirring technology

ActiveCN108754949AGuaranteed to proceed normallyExpand the scope of workLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsEngineeringFixed Slide

The invention relates to a dye vat for jig dyeing of textiles and an automatic dye stirring technology. The dye vat comprises a bottom plate, a tank, a stirring mechanism and an oscillating mechanism,the tank is mounted on the bottom plate, the stirring mechanism is mounted at the bottom of the tank, and the oscillating mechanism is mounted on sidewalls of the tank. The stirring mechanism comprises a fixed column, a sliding rack, connection columns, stirring racks, first connection plates, rotating shafts, second connection plates, a stirring motor and a fixed support. The oscillating mechanism comprises oscillating racks, auxiliary rollers, oscillating racks, gears, auxiliary racks, fixed slide grooves, working racks, protruding columns, rotating racks, rotating motors and mounting racks. The dye vat solves the problems of uneven dye distribution, uneven dyeing and the like of an existing jig dyeing process, can automatically stir dye in the dye vat and has the advantages of even dyedistribution, dyeing evenness and the like.

Owner:浙江旺盛控股集团股份有限公司

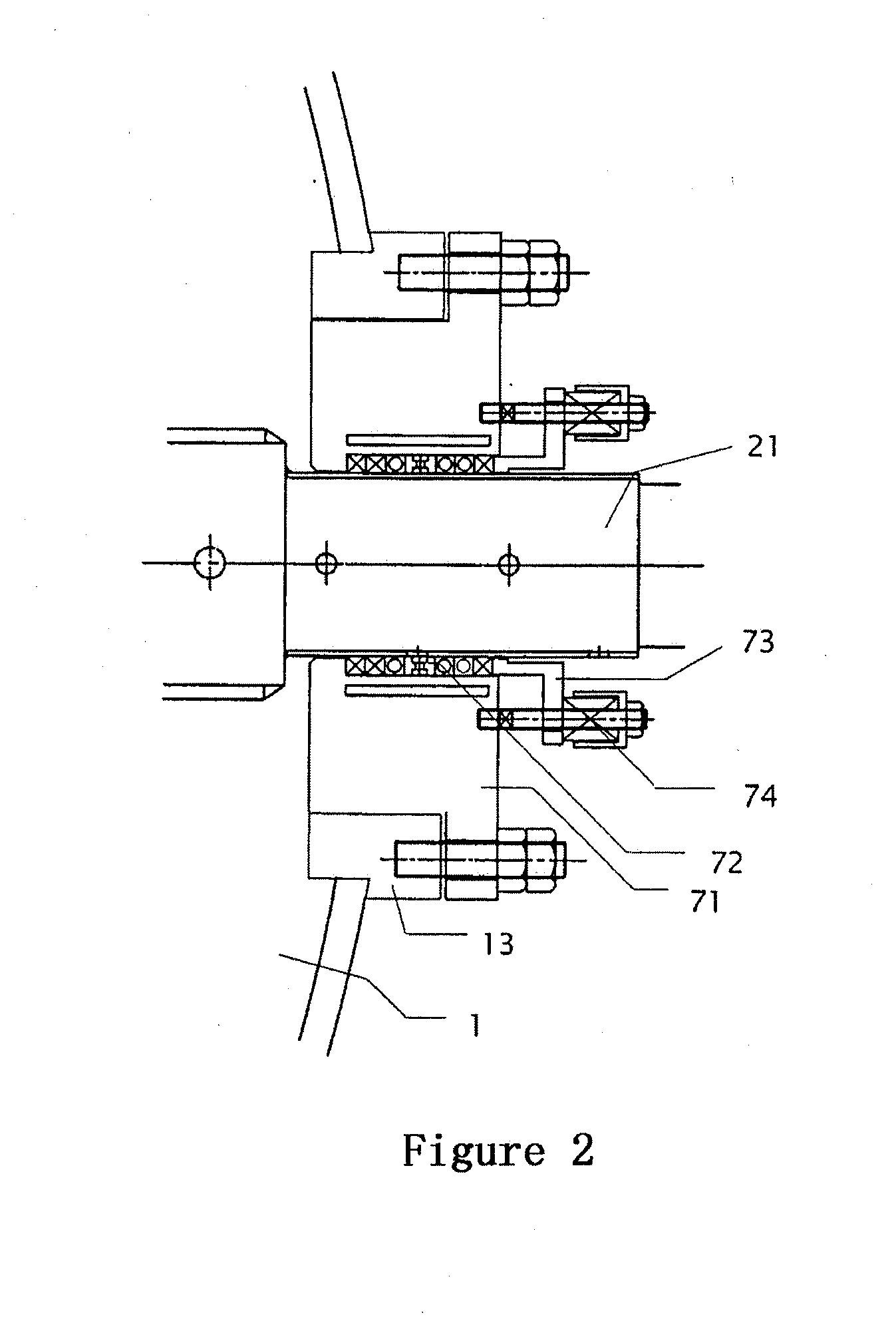

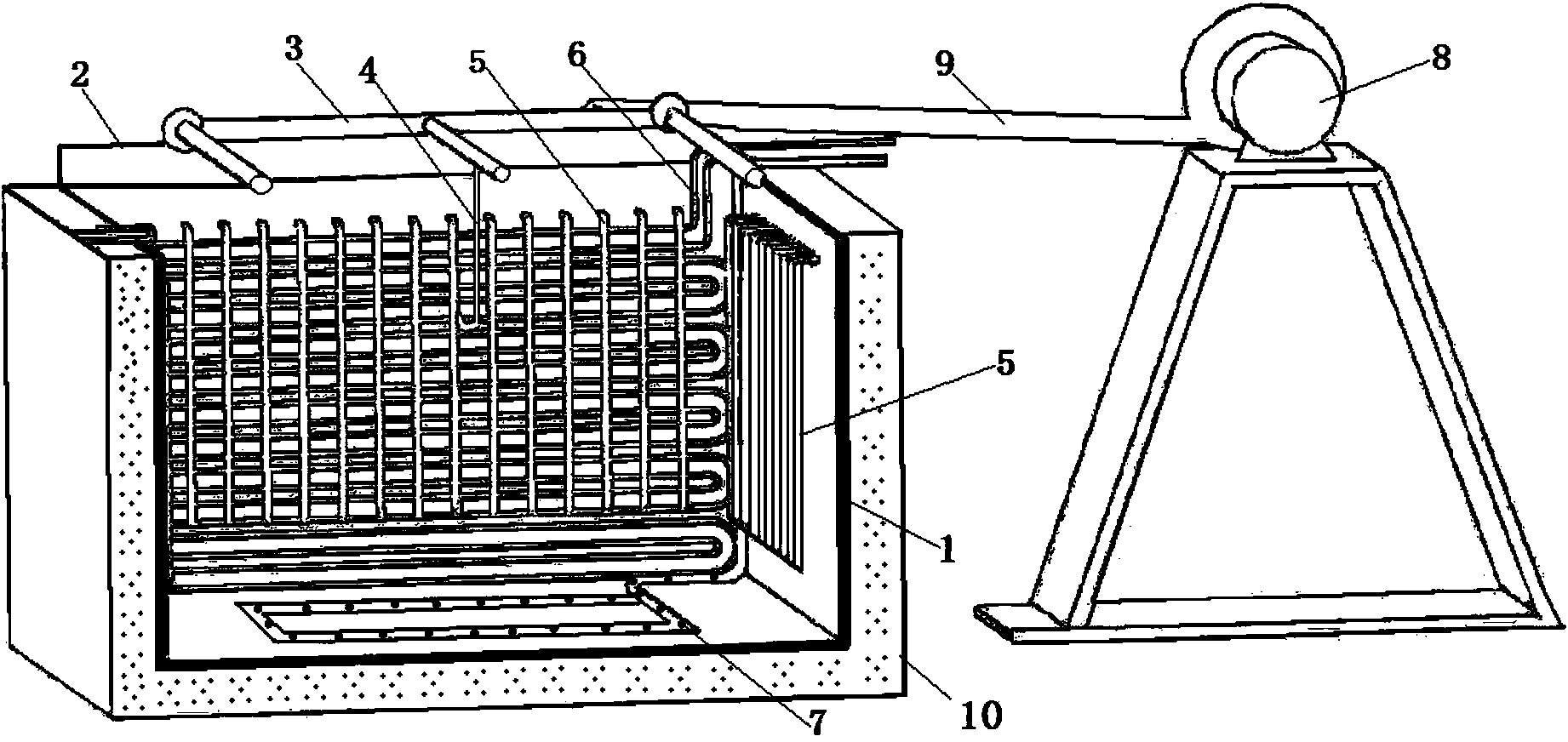

Internal heating and united stirring type isothermal quenching salt-bath device

ActiveCN103966406AImprove heating efficiency and heating speedImprove stabilityHeat treatment process controlQuenching devicesPipingQuenching

The invention provides an internal heating and united stirring type isothermal quenching salt-bath device which at least comprises a salt bath tank, wherein a work piece rack is arranged in the salt bath tank; an internal heating system, a cooling system, a united stirring system and a temperature control system are also arranged in the salt bath tank, wherein the internal heating system consists of heating rods which are uniformly distributed in the salt bath tank; the cooling system consists of two cooling water coil pipes which are respectively arranged on two opposite inner walls of the salt bath tank; the united stirring system consists of a swinging unit and an air stirring unit, wherein the swinging unit comprises a swinging mechanism, and rails which are arranged on two sides of the top of the salt bath tank; the air stirring unit is an air pipe which is arranged at the bottom of the salt bath tank; air vents distributed uniformly are formed in the air pipe; the temperature control system comprises a temperature meter, a pipeline pump and a controller. The internal heating and united stirring type isothermal quenching salt-bath device is uniform in temperature, also small in temperature fluctuation range and capable of realizing automatic control.

Owner:WUHAN TEXTILE UNIV

Bamboo shoot surface rotary cleaning device for agricultural and sideline product processing

InactiveCN110226763ARealize surface cleaning effectImprove cleanlinessFood treatmentDrive shaftWater flow

The invention discloses a bamboo shoot surface rotary cleaning device for agricultural and sideline product processing, and relates to the technical field of agricultural fertilization. The device includes a supporting rack; a drain pipe is installed on the lower sidewall of a cleaning tank; a driving shaft is fixedly sleeved a brush rotating roller; a cleaning mechanism opposite to the rotation direction of the brush rotating roller is fixedly installed at the bottom of a transmission collar; multiple clamping mechanisms located between the brush rotating roller and the cleaning mechanism areuniformly fixed in the cleaning tank; and the supporting rack is provided with an elevating mechanism used for adjusting the height of the cleaning tank. A rotary mechanism can be driven and rotatedby an arranged driving motor, so that the brush rotating roller can be driven to rotate by the driving shaft; the transmission collar drives hairbrush plates to rotate through arc plates, so that thecleaning effects on the surfaces of bamboo shoots stably clamped by the clamping mechanism can be realized; and the rotation directions of the hairbrush plates are opposite, the stirring effects of water flow at the internal of the cleaning tank can be promoted, the degree of cleaning the bamboo shoots can be higher, and cleaning efficiency can be effectively enhanced.

Owner:何明华

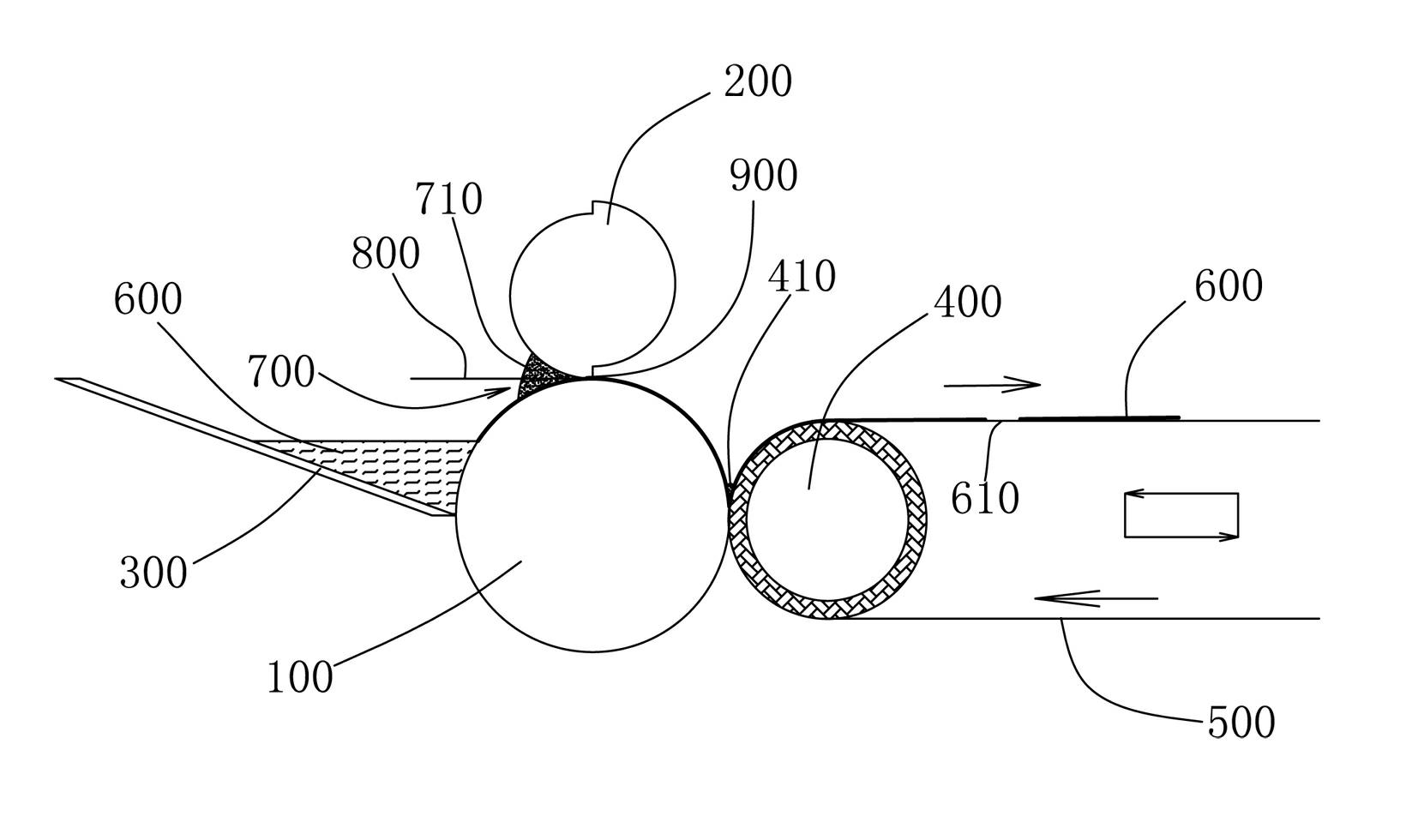

Interval type coating machine head

ActiveCN102357441AImprove uniformityHigh precisionLiquid surface applicatorsCoatingsPole pieceSlurry

An interval type coating machine head comprises a drive roll and a hopper located at one side of the drive roll and feeding the drive roll, an upper knife edge located above the drive roll, arranged along a same direction of the axial direction of the drive roll and used for evenly distributed slurry, a back roll used for delivering pole pieces and a reciprocate driving device used for driving the back roll and the drive roll to be in interval contact. The upper knife edge is a plate-type upper knife edge which comprises a three-dimensional hanging body, and a plate-type blade is arranged on the lower bottom face of the three-dimensional hanging body which is in a same plane with a coating line of the coating machine head. The interval type coating machine head is high in uniformity of coating piece thickness and accuracy, free of limitation of mounting position and height, capable of removing accumulated material pressure between included angles. Rotational speed of a feeding roll can be freely controlled, feeding amount on the curved surface of the drive roll is even and unanimous, the feeding roll has good stirring effect, the slurry can be avoided depositing in the hopper, andinfluences on the pole piece of dry materials are avoided. Two edges of the pole piece can not wrinkle.

Owner:SHENZHEN XINYUREN TECH

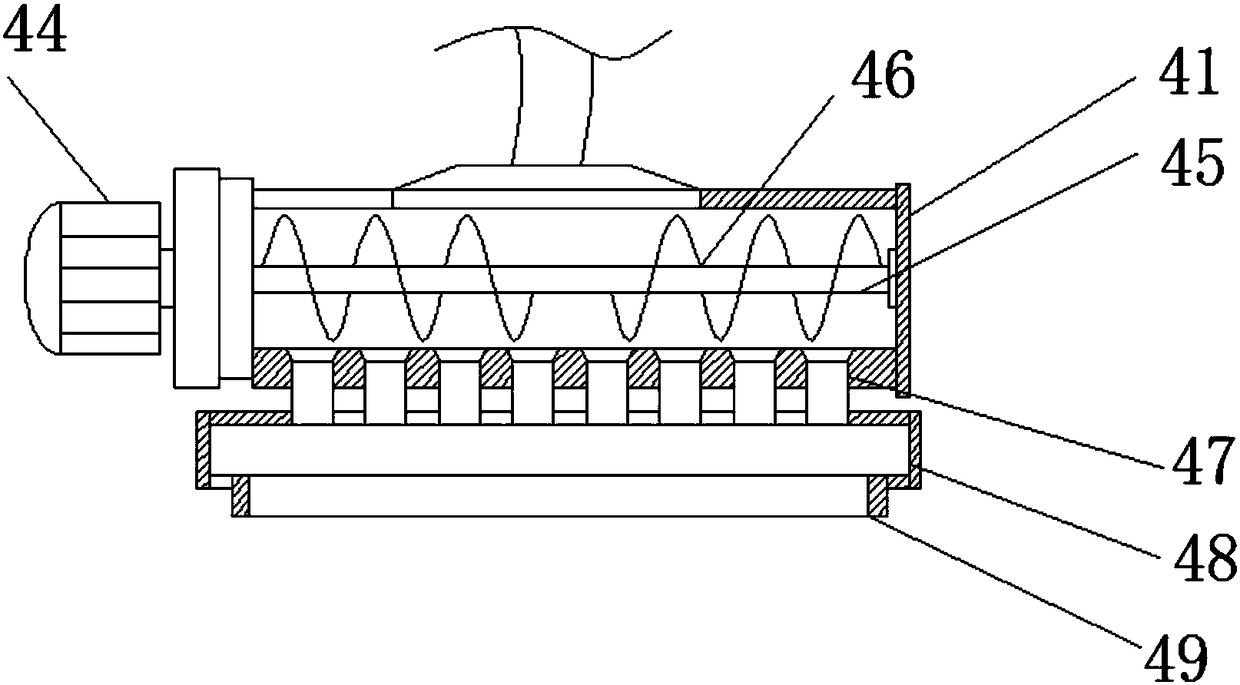

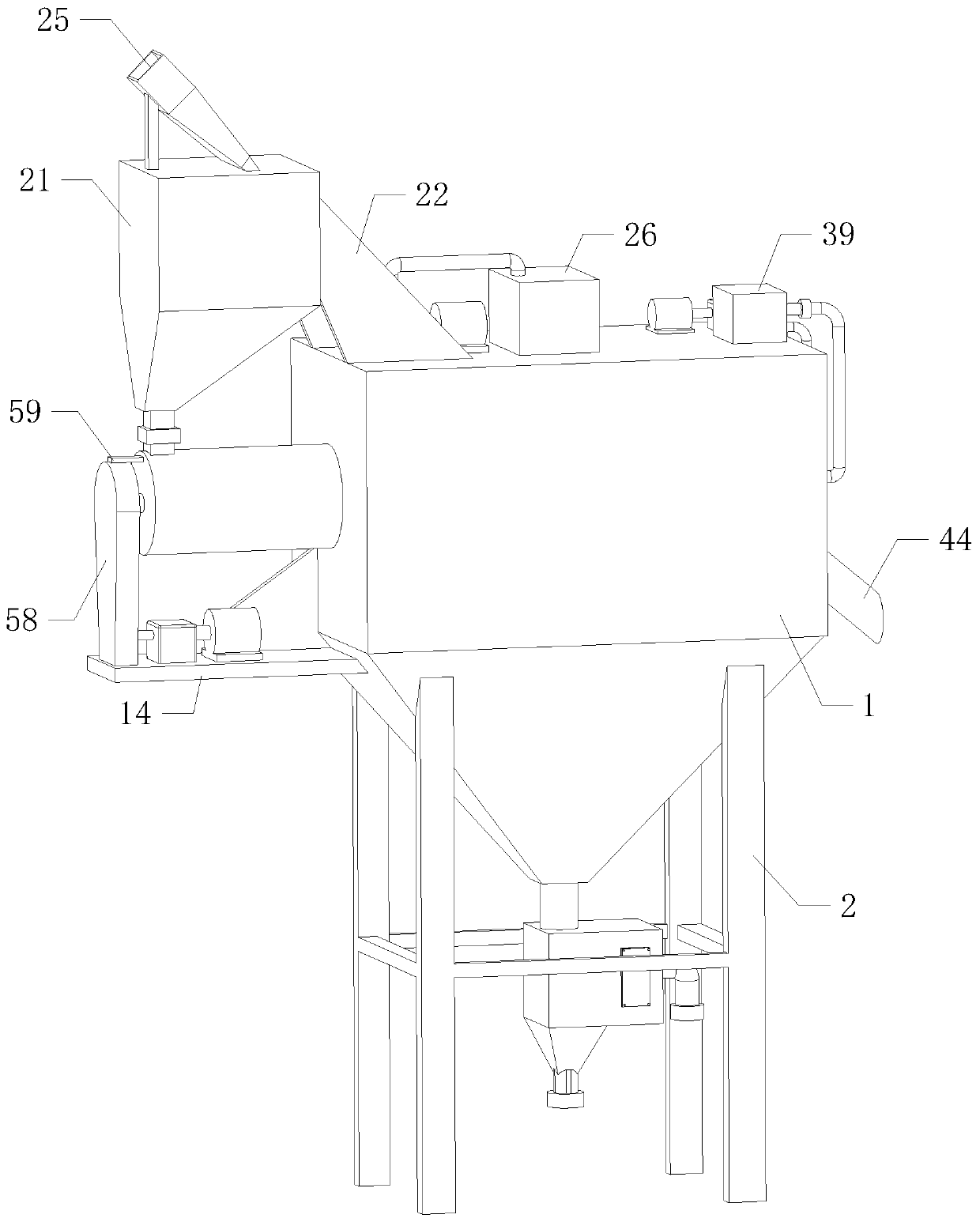

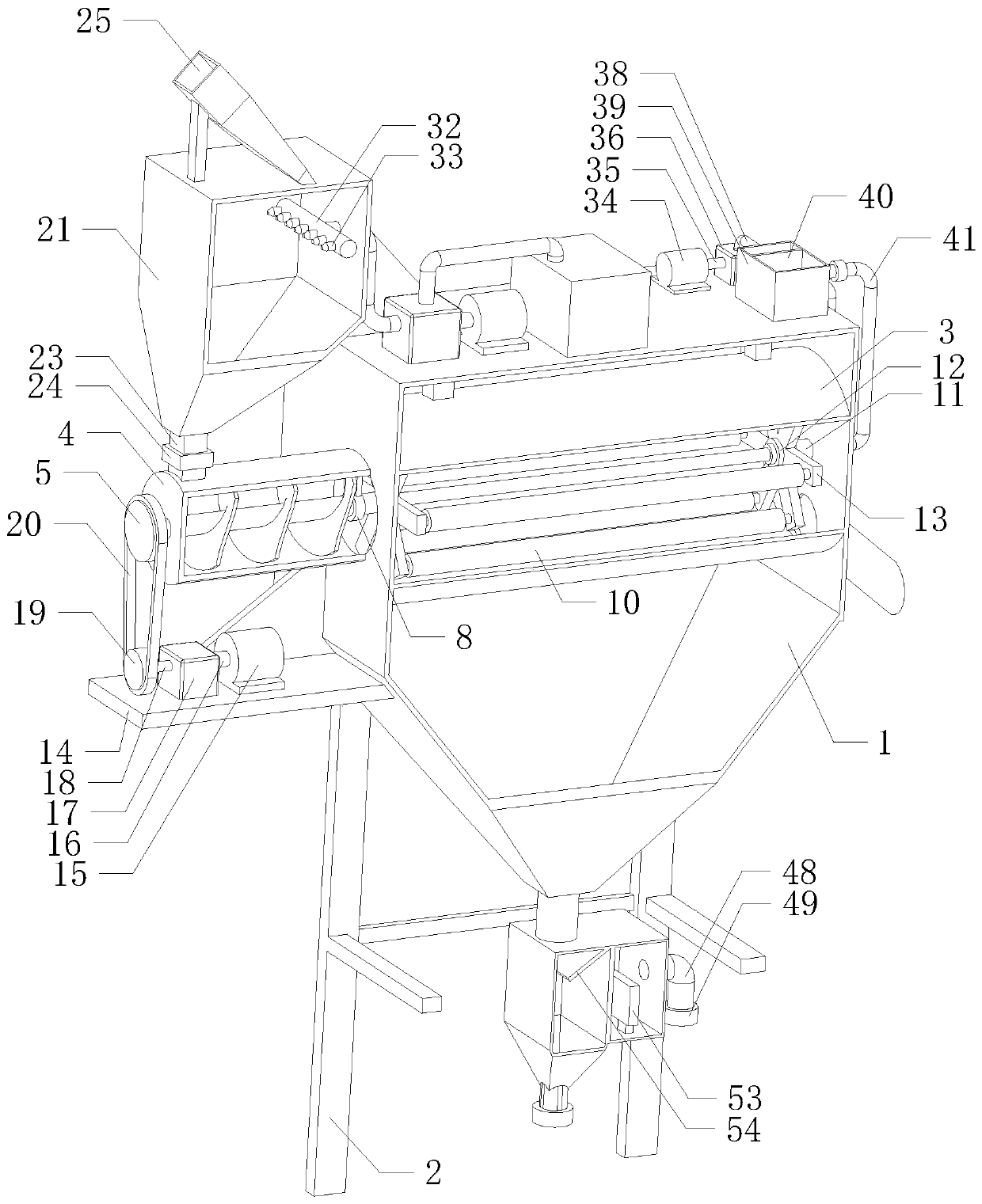

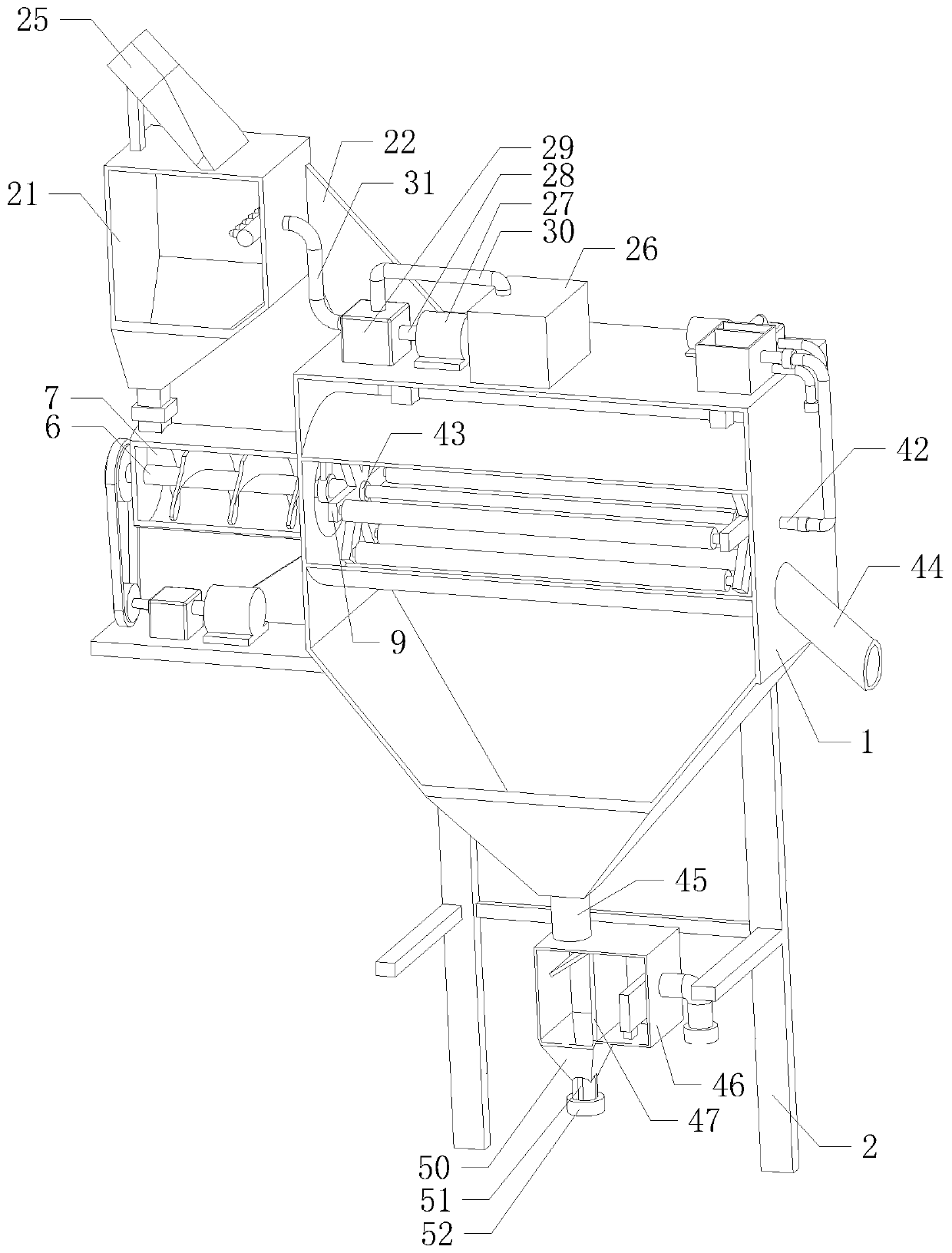

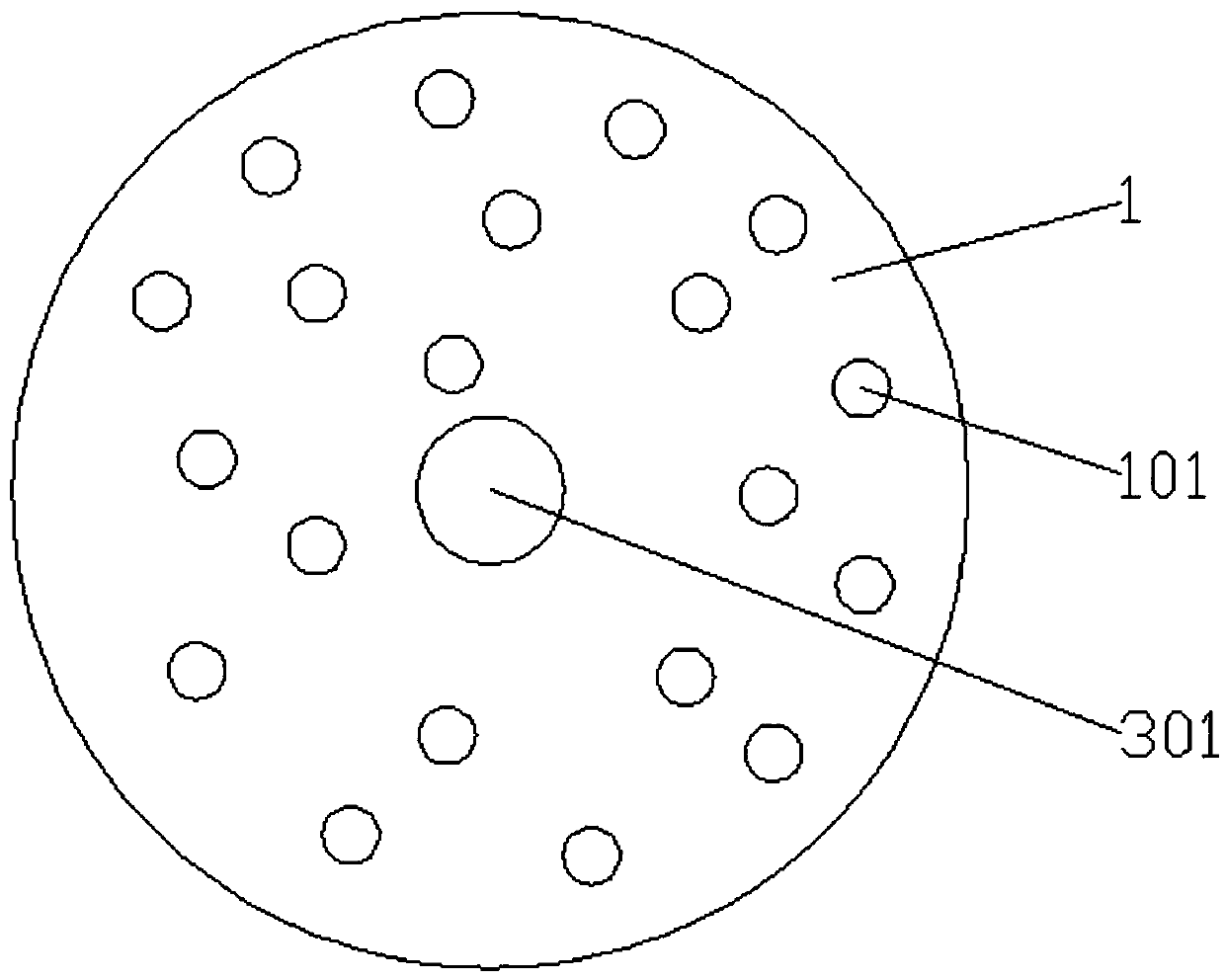

Novel rice polishing machine

ActiveCN110721759AAvoid enteringImprove protectionGrain huskingGrain polishingSpiral bladeAgricultural engineering

The invention relates to the technical field of mechanical equipment, in particular to a novel rice polishing machine. By the novel rice polishing machine, the polishing effect of rice is improved, the polishing yield of rice is improved, the damage amount of rice is increased, the purification treatment of rice is facilitated, the diversity of equipment functions is improved, and the practicability and reliability are improved by carrying out integrated polishing treatment on rice. The novel rice polishing machine comprises a guiding device, a polishing device, a power device, a wetting device, a separating device and a discharging device. The guiding device comprises a working bin, a first support, a screen barrel, a feeding bin, a first belt pulley, a transmission shaft, spiral blades and a second support. The lower side of the working bin is conical, and a first cavity is formed in the working bin; the outer side of the bottom end of the working bin is connected with the top end ofthe first support; the screen barrel is cylindrical, and a plurality of groups of screen holes are uniformly formed in the outer wall of the screen barrel; the right end of the screen barrel is hermetically connected with the upper side of the right end of the first cavity; and the left end of the screen barrel is in sealing connection with the upper side of the left end of the first cavity.

Owner:扬州正大机械制造有限公司

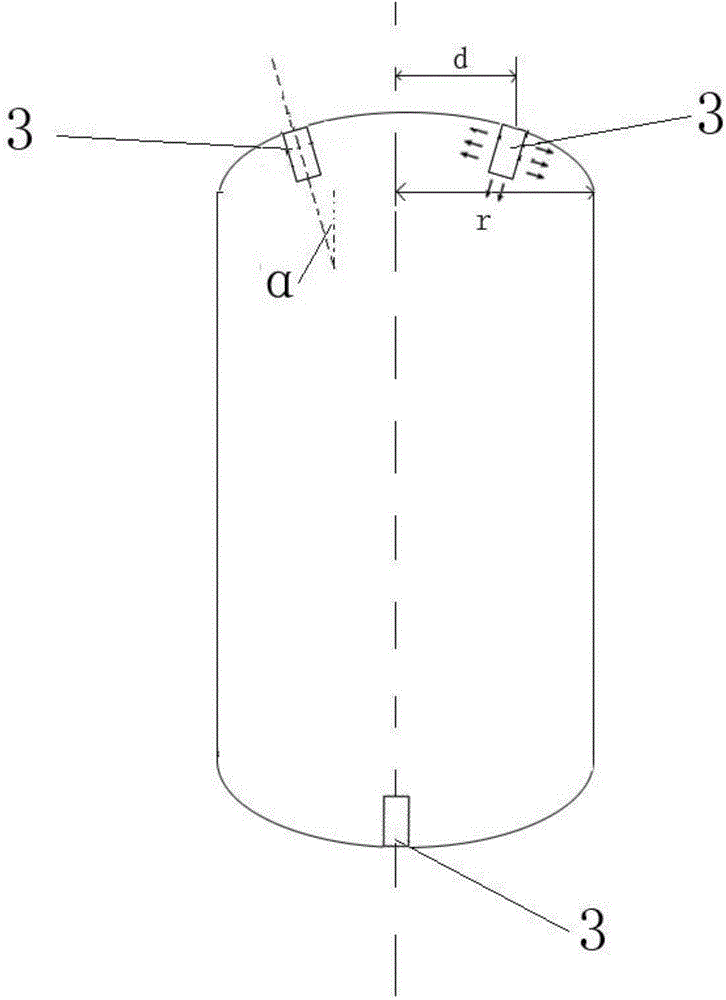

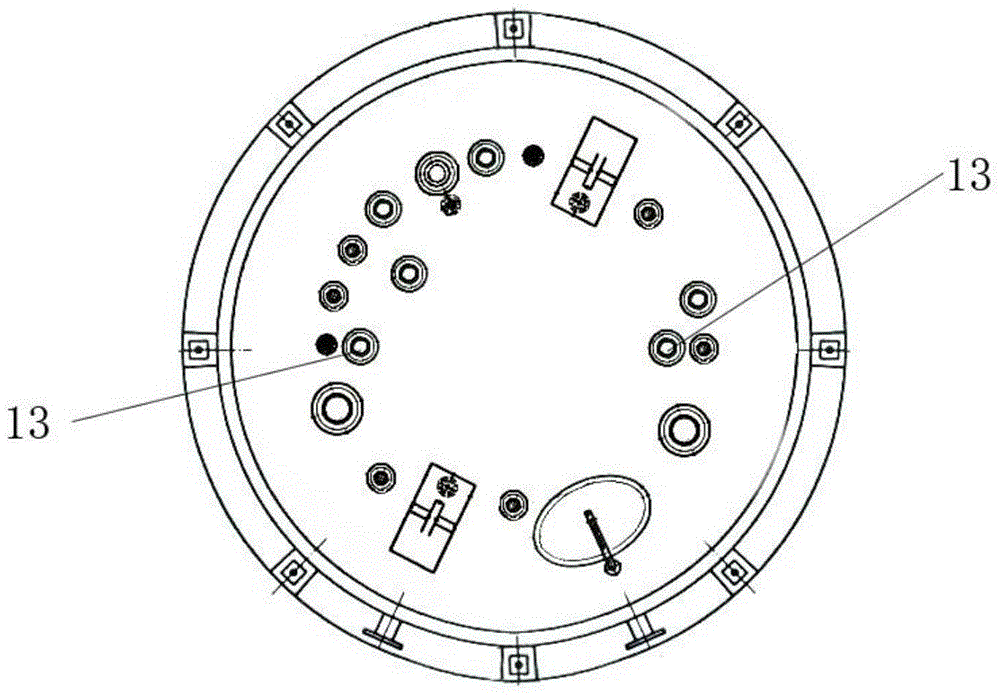

Reaction device

ActiveCN105536675AAdequate responseUniform responseTransportation and packagingMixer accessoriesSoft waterPulp and paper industry

The invention relates to a reaction device. According to the reaction device, a stirring device and a steam introduction mechanism are integrated, a high-temperature steam circulation channel is formed in the rotating shaft of the stirring device and blades, high-temperature steam is jetted through air jet holes in the blades, and the blades and the air jet holes are located in a tower body, so that on one hand, stream can be dispersed and is promoted to be liquefied on the tower body, heat of the stream is adequately released into the tower body, and soft water which is taken as a raw material for producing high-molecular polymers is formed after the liquefaction of steam; besides, the blades and the air jet holes can rotate along with the rotating shaft to further uniformly send stream to each part in the tower body, so that the stirring effect of high-temperature stream to the raw material of the high-molecular polymers in the tower body is improved, the reaction of the high-molecular polymers is relatively adequate and uniform, the content of un-reacted polymeric monomers is low, and the molecular weight of the high-molecular polymers is relatively uniform.

Owner:HEZE DIJADE CHEM CORP

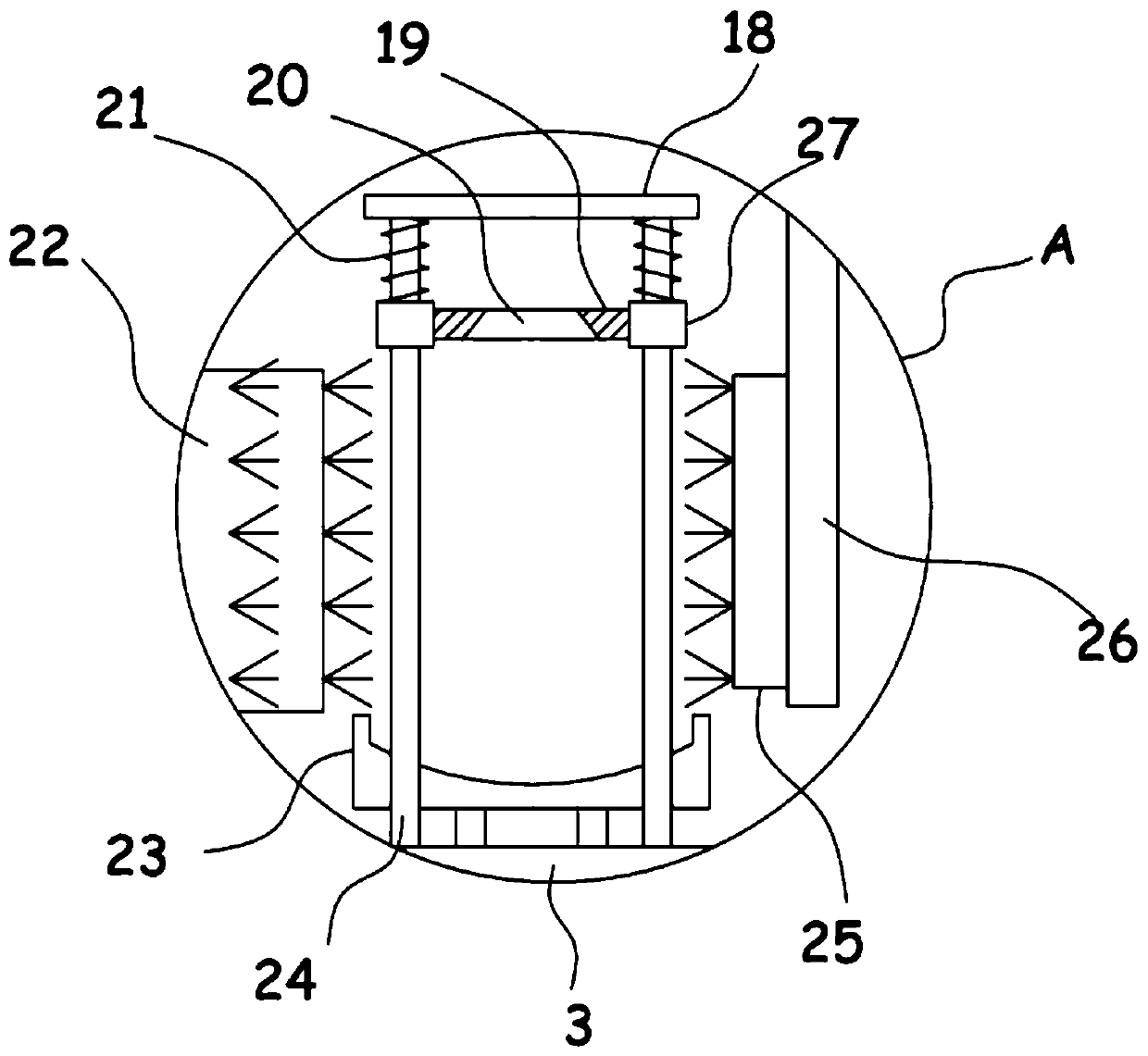

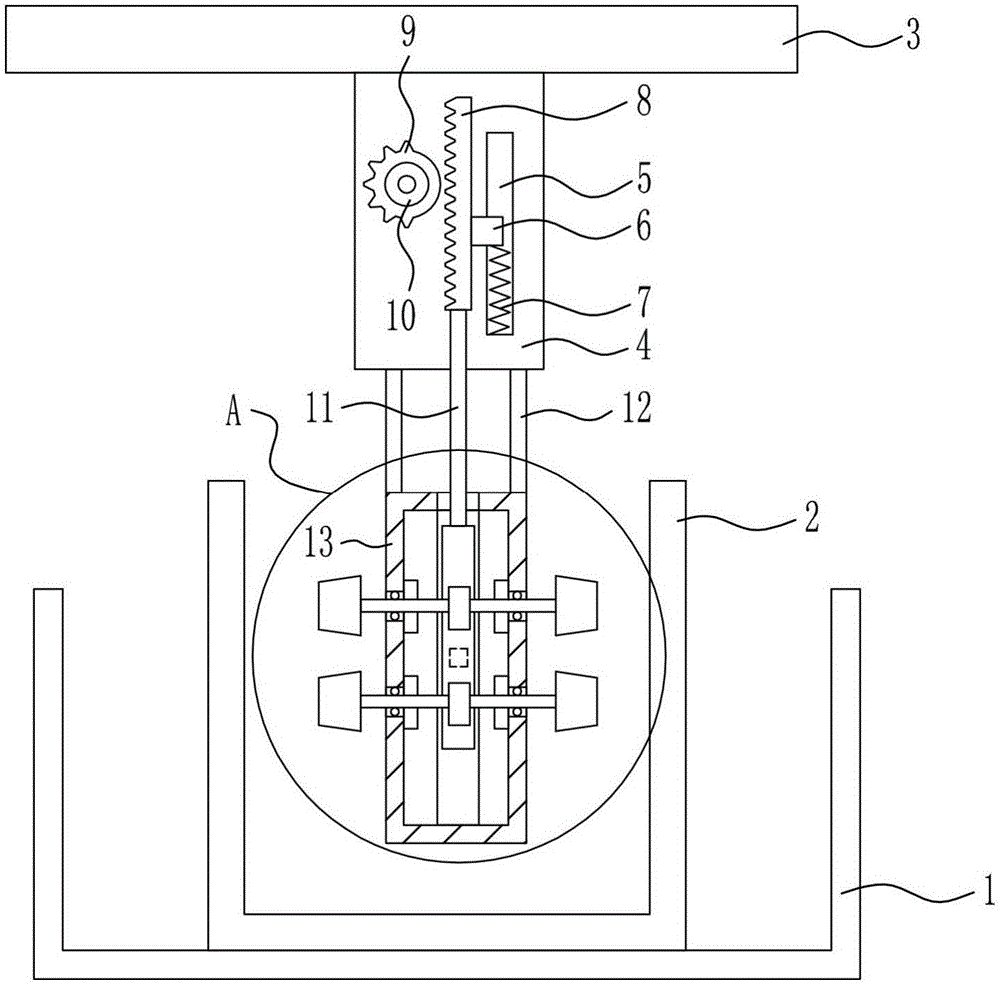

Anti-congealment pretreatment equipment for special printing ink for aluminum foil for medicine packaging

ActiveCN106626752AImprove stirring effectIncrease antifreeze effectShaking/oscillating/vibrating mixersTransportation and packagingPrinting inkElectrical and Electronics engineering

The invention relates to anti-congealment pretreatment equipment, in particular to the anti-congealment pretreatment equipment for special printing ink for aluminum foil for medicine packaging. The anti-congealment pretreatment equipment for the special printing ink for the aluminum foil for medicine packaging is good in anti-congealment effect and comprises a machine frame, a water bath barrel, a printing ink barrel, a top plate, a fixed plate, a first sliding rail, a first sliding block, a first spring, a first rack, a sector gear, a motor, a connecting rod and the like, wherein the water bath barrel is arranged on the machine frame, the printing ink barrel is placed inside the water bath barrel, and the top plate is connected to the machine frame in a welded mode and is located above the water bath barrel. According to the anti-congealment pretreatment equipment for the special printing ink for the aluminum foil for medicine packaging, the mode of combining water-bath heating with stirring is adopted for preventing the printing ink from being congealed, the anti-congealment effect is good, and workers place the printing ink into the printing ink barrel and control the motor to rotate clockwise.

Owner:滁州瑞林包装材料有限公司

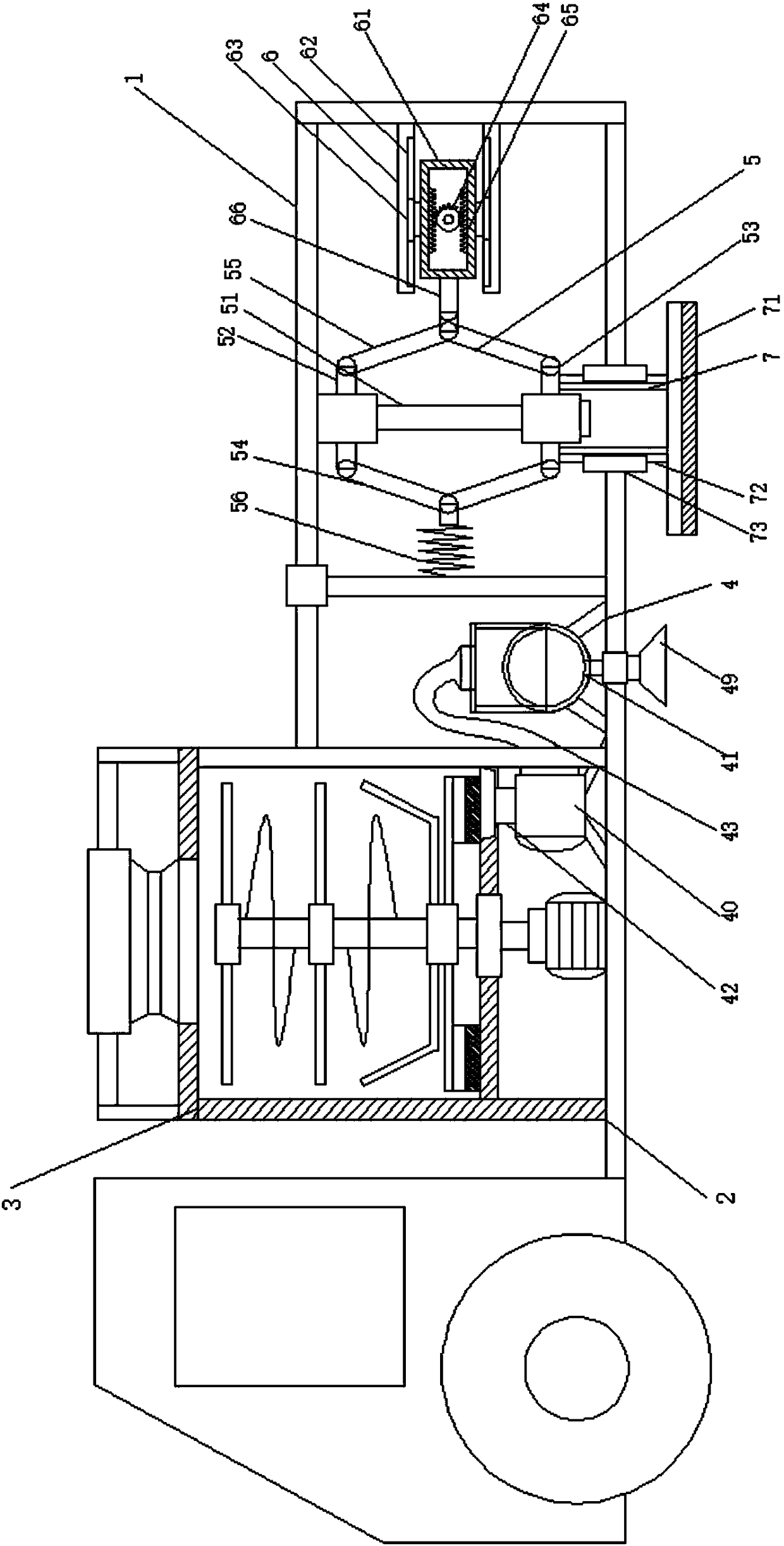

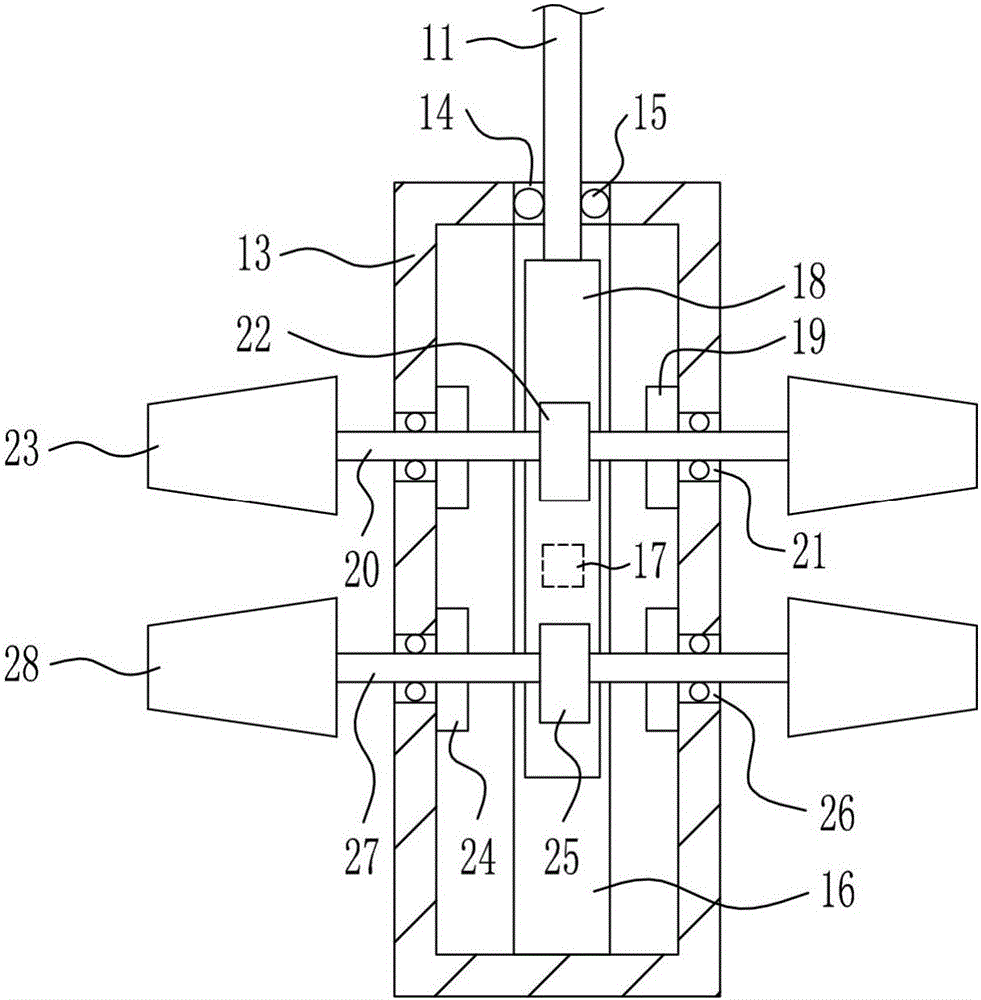

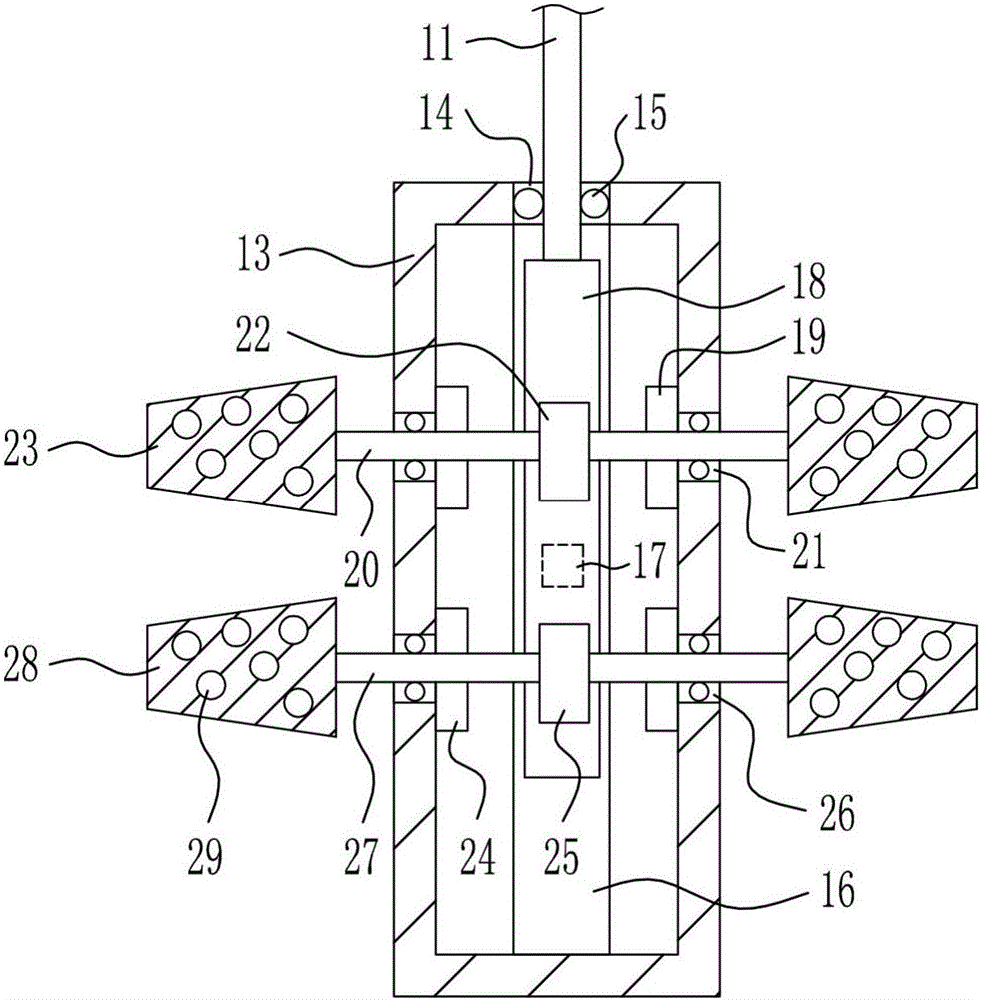

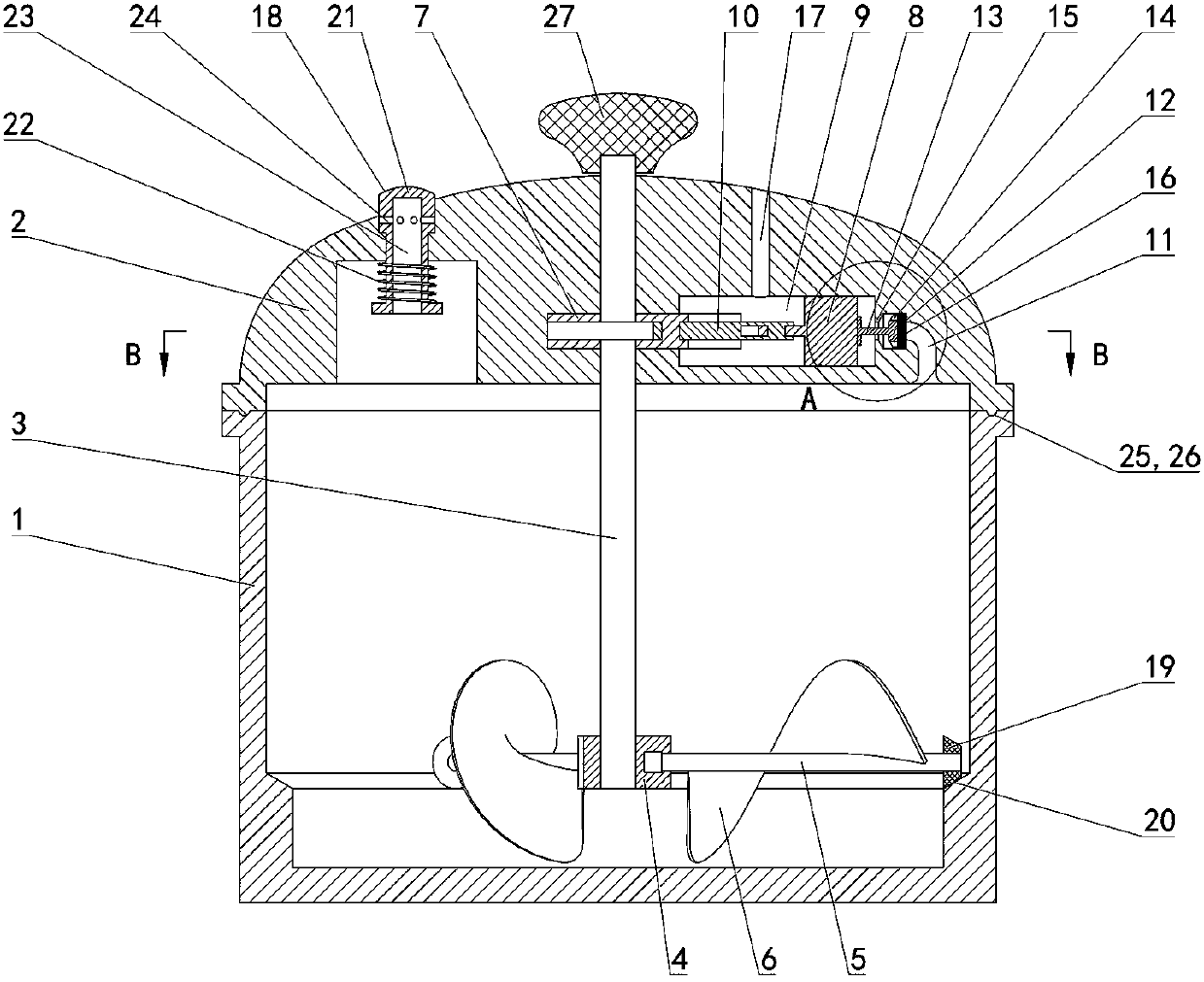

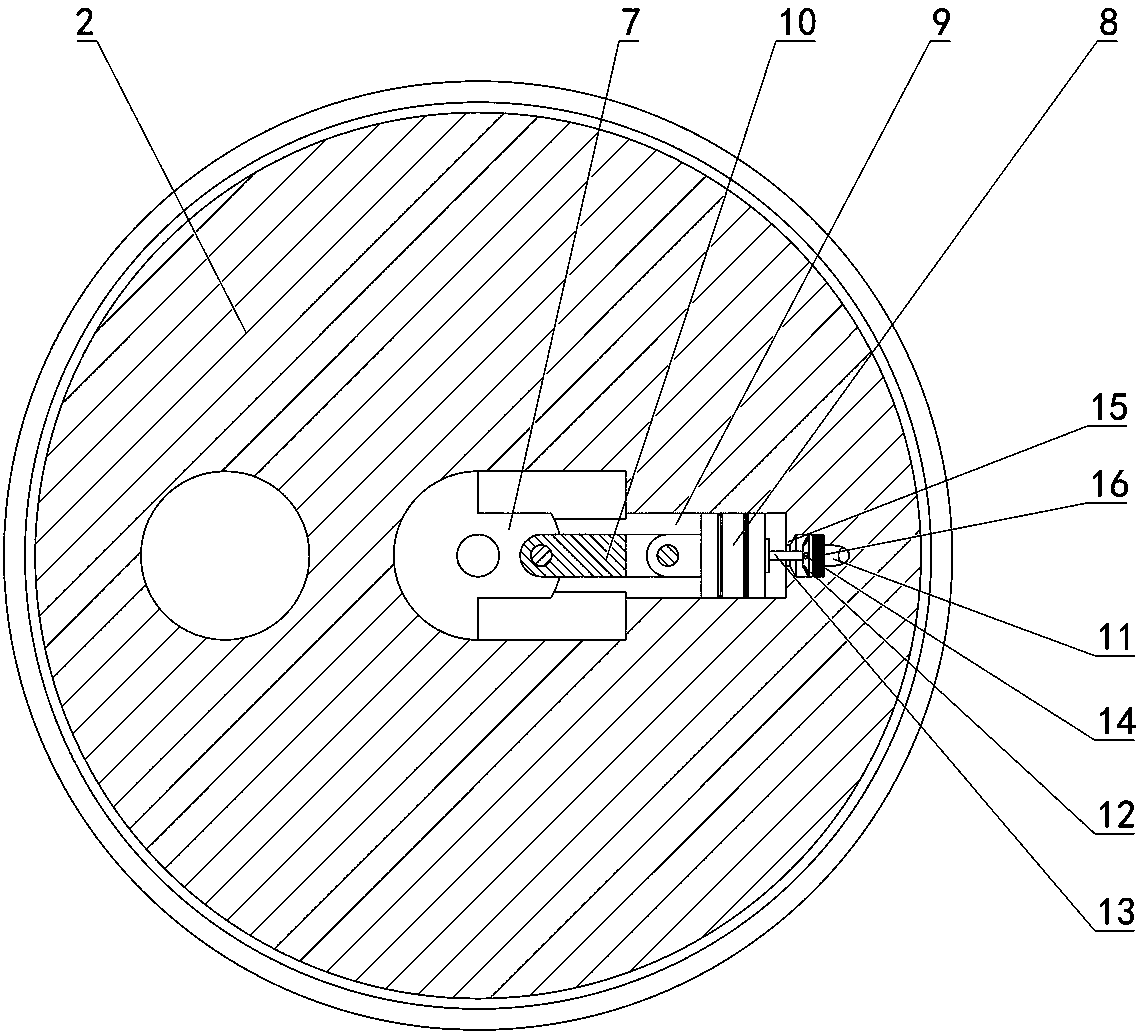

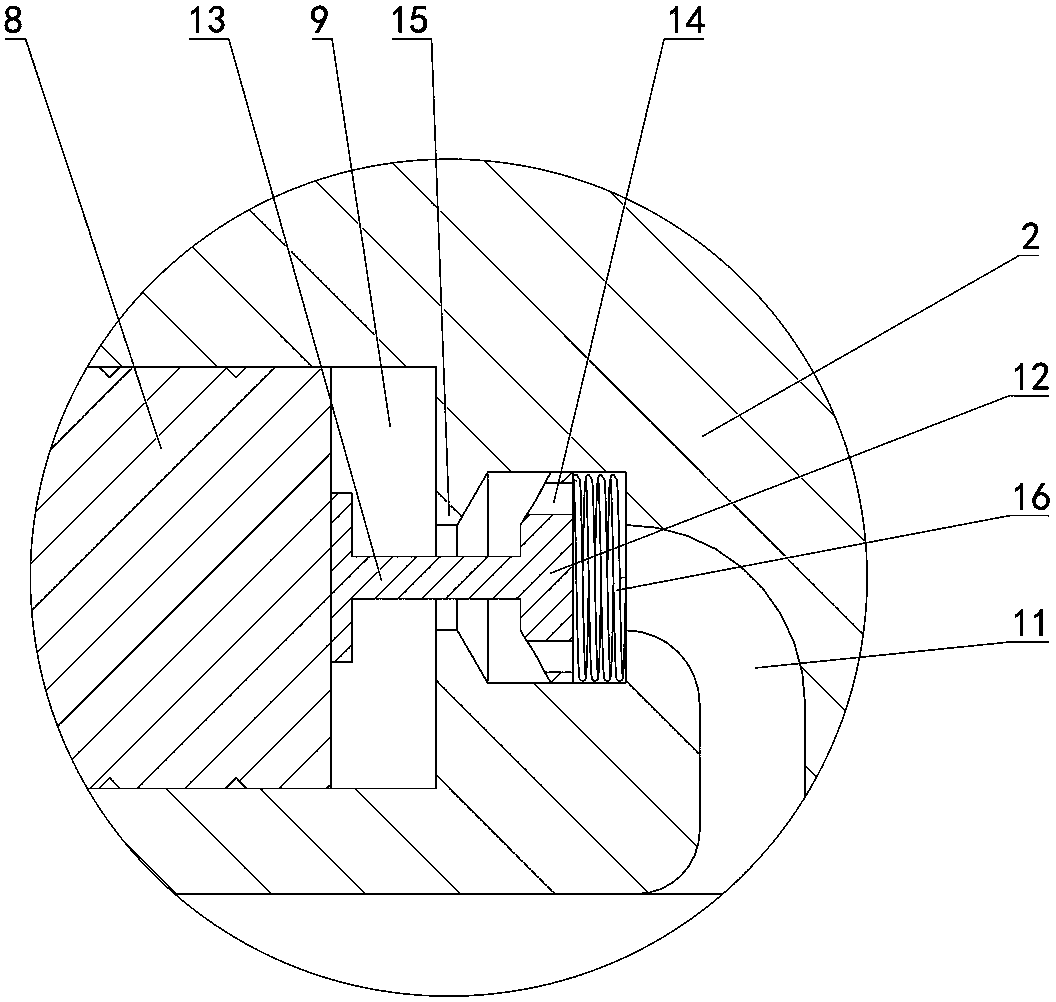

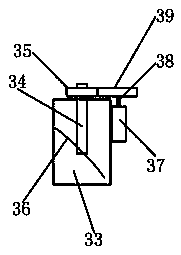

Pressure-controlled medicinal herb decocting device

ActiveCN107865775AImprove stirring effectFully contactedRotary stirring mixersTransportation and packagingEngineeringPressure controlled ventilation

The invention relates to a pressure-controlled medicinal herb decocting device. The pressure-controlled medicinal herb decocting device comprises a kettle body and a kettle cover, wherein a vertical revolving shaft is arranged on the kettle cover; a connecting block placed on the inner side of the kettle body is arranged on the revolving shaft; a plurality of fan blade shafts are arranged on the connecting block; spiral fan blades are arranged on the fan blade shafts; a crankshaft coaxially connected with the revolving shaft and a piston sliding horizontally are arranged in the kettle cover; asliding cavity matched with the piston is formed in the kettle cover; the crankshaft is hinged to the piston through a connecting rod; the kettle cover is provided with an air inlet hole which communicates the sliding cavity with the inner side space of the kettle body; an air inlet check block capable of sliding along the sliding direction of the piston is arranged on the kettle cover; a push rod is arranged on the air inlet check block; one end of the push rod is placed in the sliding cavity; the air inlet check block is provided with a through hole being consistent with the sliding direction of the air inlet check block; a spoiler corresponding to the position of the through hole is arranged on the kettle cover; the air inlet check block is connected with the kettle cover through a first spring; the kettle cover is provided with an exhaust hole which communicates with the sliding cavity; when the piston slides to a position being closest to the revolving shaft, the piston crosses the exhaust hole; a pressure relief valve is arranged on the kettle cover.

Owner:SUZHOU YUANLIAN SCI & TECH PIONEER PARK MANAGEMENT CO LTD

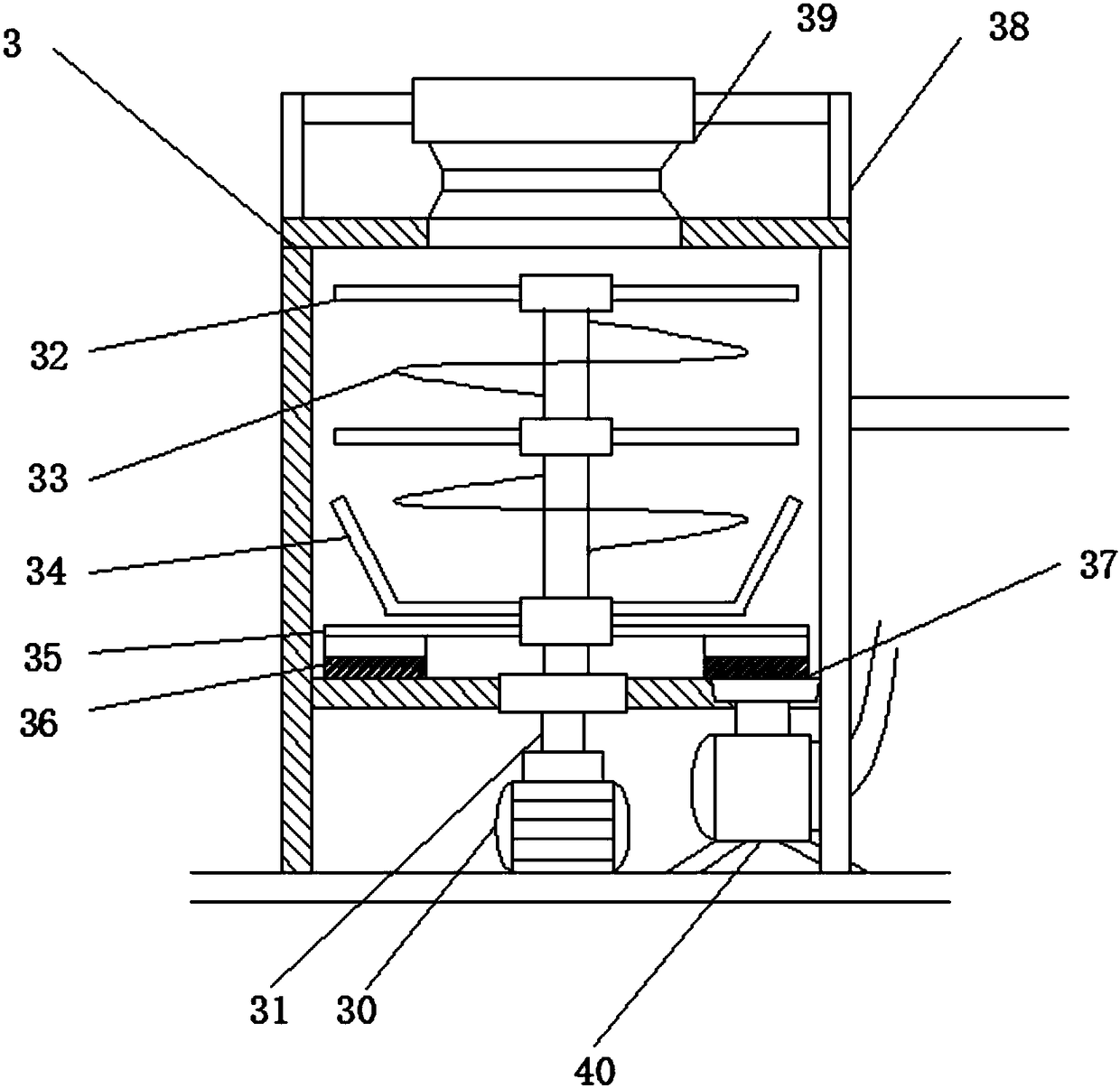

Broken plastic stirring device

The invention relates to the technical field of waste plastic reprocessing equipment and particularly discloses a broken plastic stirring device. The broken plastic stirring device comprises a material cylinder, a feeding device, a stirring device body, an air uniformizing device and a temperature increasing device. The feeding device comprises a feeding bin, feeding hoppers, a first screw rod, asecond screw rod, a first spiral blade and a second spiral blade, and the spiral direction of the second spiral blade is opposite to the spiral direction of the first spiral blade. The stirring devicebody comprises a stirring motor, a stirring shaft, a spiral stirring blade and a spreading disk, and the spiral stirring blade is of a structure gradually becoming larger from bottom to top on the stirring shaft. The air uniformizing device comprises a main air pipe, annular air uniformizing pipes and gourd-shaped air uniformizing nozzles. The temperature increasing device comprises a shell, twosupporting plates, insulating rings and heating pipes. The broken plastic stirring device has the characteristics that stirring is uniform, the manpower cost and the material resource cost are both low, and dust and moisture are easy to discharge.

Owner:德清意欣塑料制品有限公司

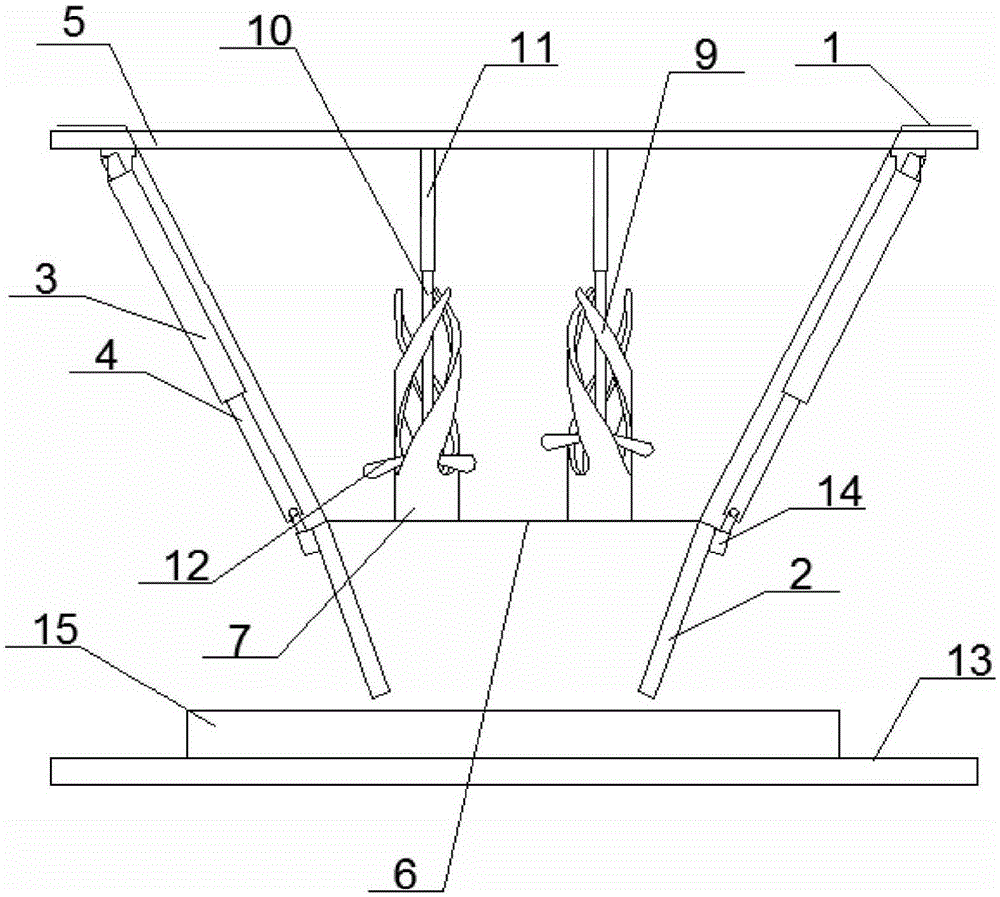

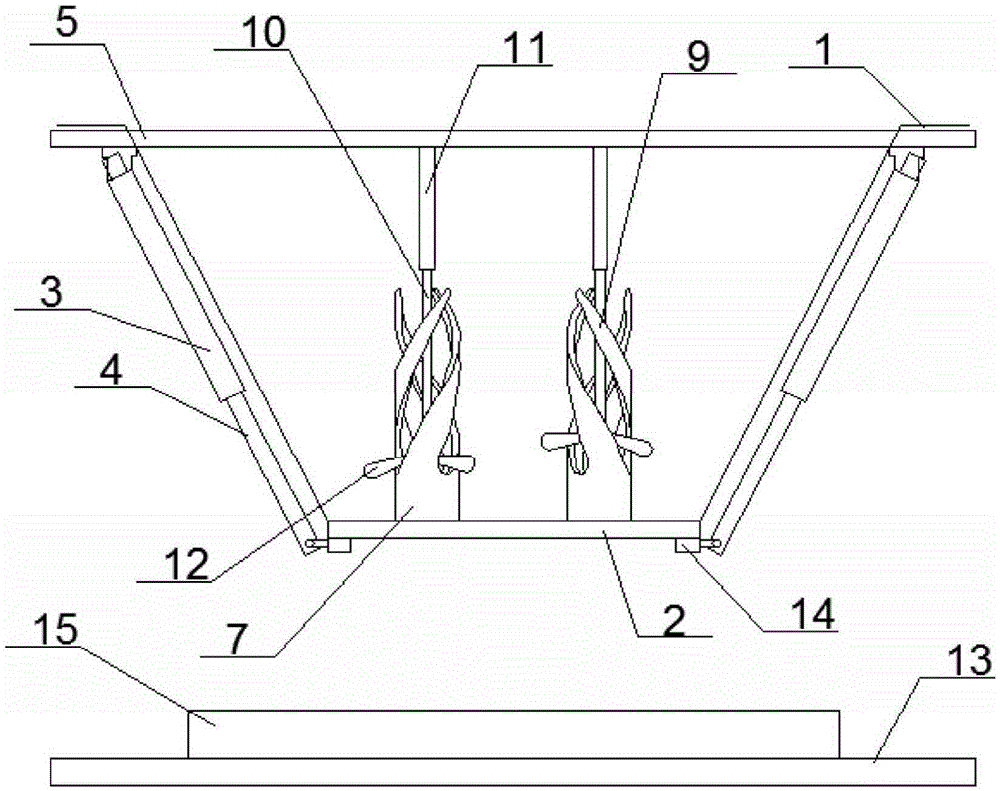

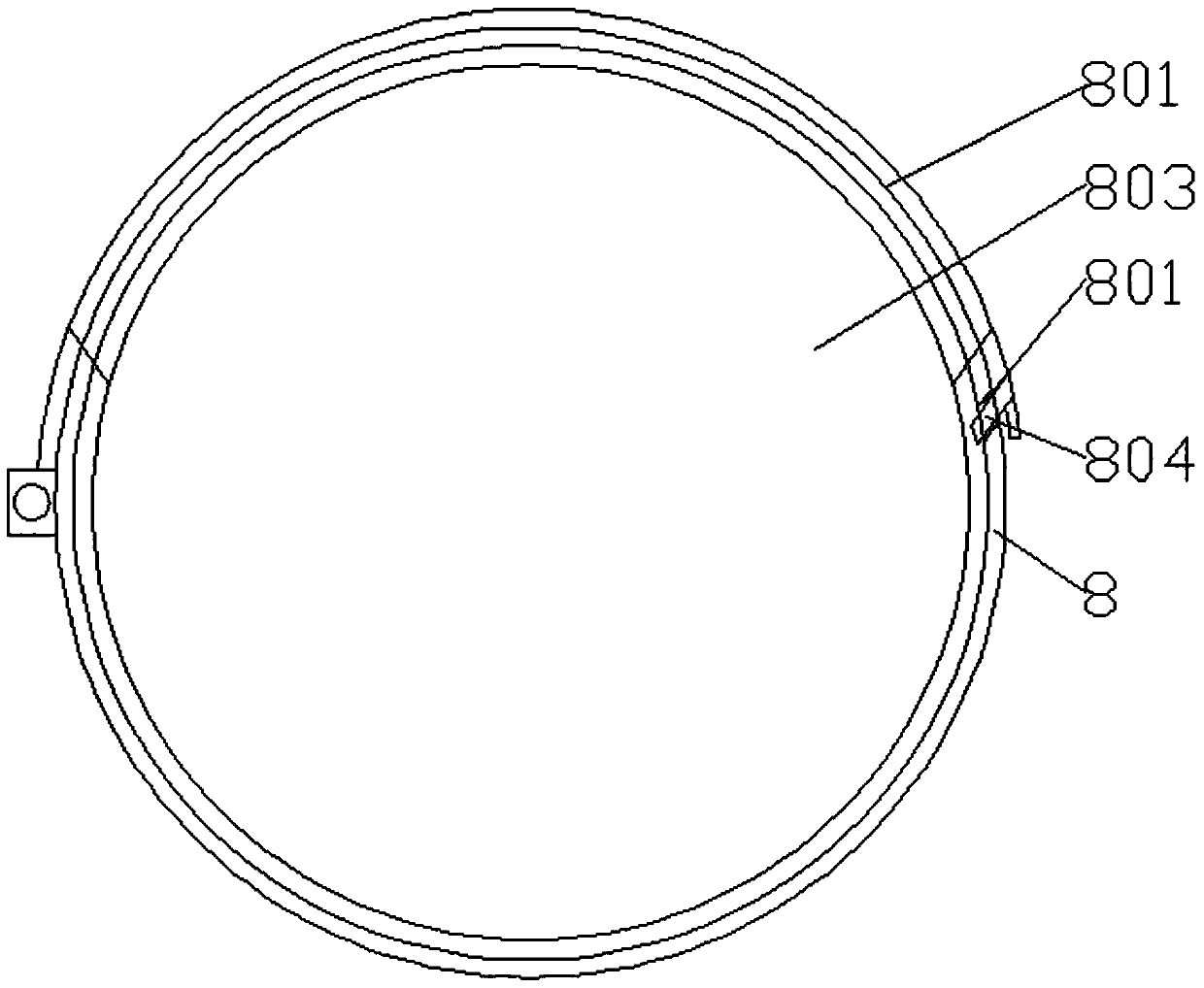

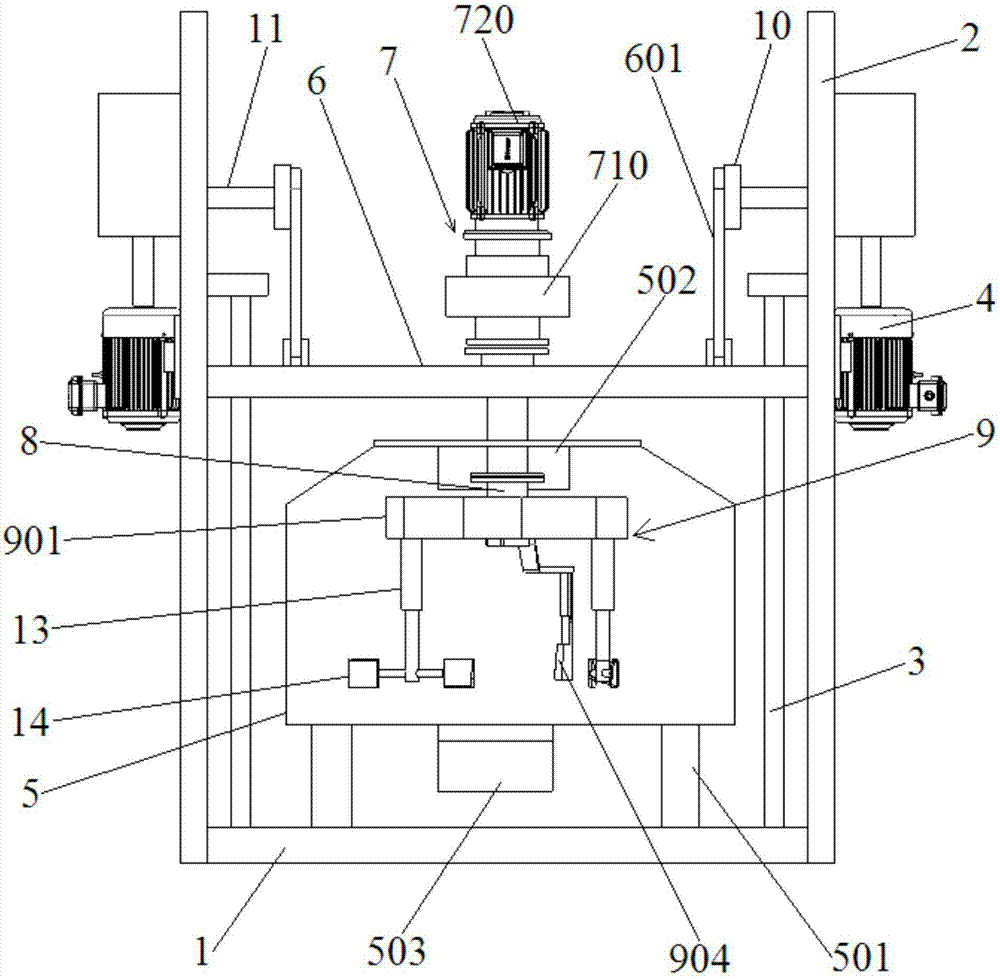

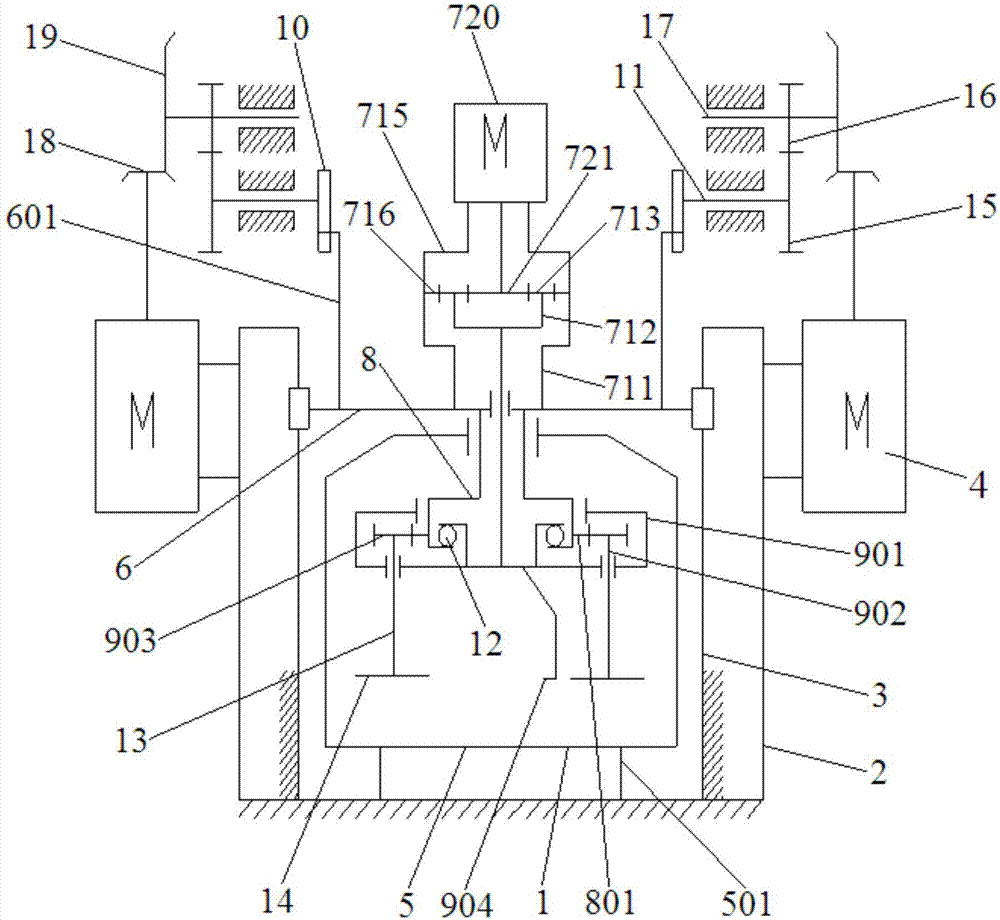

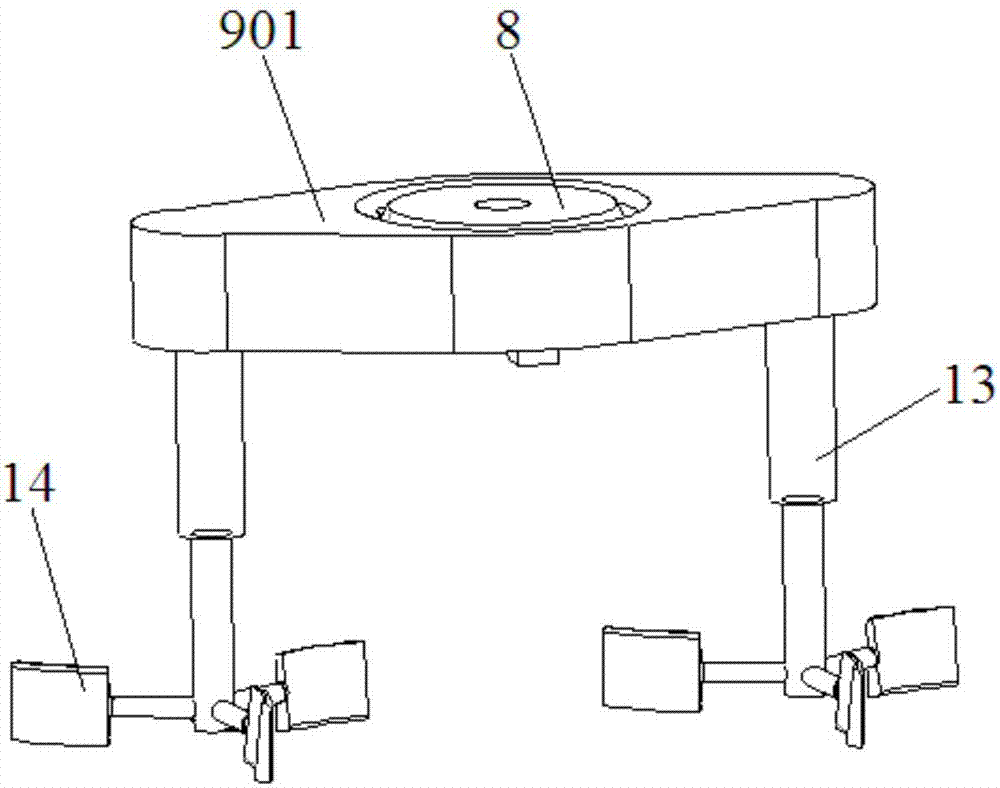

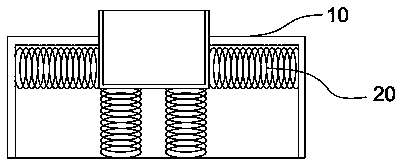

Vertical shaft planet stirring machine capable of lifting materials

InactiveCN106956363AReduce line speedInhibition of segregationCement mixing apparatusThrough transmissionEngineering

The invention provides a vertical shaft planet stirring machine capable of lifting materials. The machine comprises a base, a stirring cylinder, a stirring frame and a planet stirrer; stand columns are respectively arranged at two ends of the base; guide rods are arranged on the inner sides of the stand columns; lifting motors and lifting rotating shafts are arranged on the stand columns; one ends of the lifting rotating shafts are in transmission connection with the lifting motors through transmission systems; the other ends of the lifting rotating shafts are connected with lifting cranks; two ends of the stirring frame are slidingly matched with the guide rods through slide holes; the upper sides of two ends of the stirring frame are respectively hinged to connecting rods; the other ends of the connecting rods are hinged to the lifting cranks; a stirring driving device is arranged on the upper side of the middle part of the stirring frame; the lower side of the stirring frame is connected with a rotating support; the upper end of the planet stirrer is rotationally connected to the rotating support; and the lower end of the planet stirrer extends into the stirring cylinder. The vertical shaft planet stirring machine capable of lifting materials can perform a material lifting action, and reduces a diameter-height ratio of the stirring cylinder to prevent the segregation phenomenon of stirred materials caused by higher linear velocity of stirring blades during stirring.

Owner:CHANGAN UNIV

Coating dispersion machine

ActiveCN105381749ASimple structureEasy to useTransportation and packagingRotary stirring mixersElectricityPulp and paper industry

The invention provides a coating dispersion machine, belonging to the technical field of coating production equipment. The coating dispersion machine comprises a power supply, a stirring motor, a stirring support frame, a stirring rod and a stirring plate; the stirring motor is arranged on the stirring support frame; the stirring motor is electrically connected with the power supply; one end of the stirring rod is connected with the output shaft of the stirring motor; the other end of the stirring rod is movably connected with the stirring plate. By using the dispersion machine, the coating of different depths in a container can be sufficiently mixed and the dispersion effect of the coating can be improved.

Owner:泰州市中山涂料有限公司

Production process for ultrasonic dissolved copper in electrolytic copper foil production

InactiveCN102146574AIncrease speedEnhanced mass transferCellsElectroforming processesElectrolysisDissolution

The invention discloses a production process for ultrasonic dissolved copper in electrolytic copper foil production. A copper raw material is placed in a dissolved copper tank filled with sulfuric acid solution. The process is characterized by comprising the following steps of: providing oxygen for the dissolved copper tank through an air delivery pipe, and simultaneously starting an ultrasonic generator on the dissolved copper tank, wherein the ultrasonic waves generated by the ultrasonic generator enables the solution in the dissolved copper tank to vibrate and provides heat for the dissolved copper tank when the solution vibrates, so that the copper sulfate generated by reaction of the copper raw material and the sulfuric acid solution is quickly peeled from the surface of the copper raw material and dissolution of the copper raw material is achieved. The energy consumption is low, the energy is saved, the production cost is reduced, and the copper dissolution rate can be greatly improved.

Owner:HUBEI ZHONGYI TECH

Solar cell panel fluorescent edge spraying device

ActiveCN110465429AGood stirring effectImprove stirring effectLiquid spraying apparatusFluorescenceSpray nozzle

The invention discloses a solar cell panel fluorescent edge spraying device. A base is included, and the two sides of the base are each provided with a side frame; the tops of the side frames are provided with a top frame; a lifting table is arranged on the base, and the two sides of the lifting table are each provided with a limiting plate; the positions of the surfaces, facing the interiors, ofthe limiting plates are provided with lock plates; lock springs are arranged between the lock plates and the limiting plates, and a lock cavity is arranged between the lock plates; the top frame is provided with a spraying mechanism which comprises suspended ceiling shafts, and the outer peripheral faces of the suspended ceiling shafts are sleeved with rotating wheels; a rotating belt is wound between the rotating wheels; the top frame is provided with a stepping motor, and a rotating shaft is arranged on the front portion of the stepping motor; the peripheral face of the rotating shaft is sleeved with a driving gear, and the upper end of one rotating wheel is provided with a rotating gear; the rotating gear is engaged with the driving gear; the rotating belt is provided with a positioningpipe, and the lower end of the positioning pipe is provided with a spraying nozzle. According to the solar cell panel fluorescent edge spraying device, fluorescent liquid can be conveniently sprayedat the edge position of a solar cell panel through the spraying nozzle, and therefore the fluorescent edge of the solar cell panel can be prepared and obtained.

Owner:江苏海川光电新材料有限公司

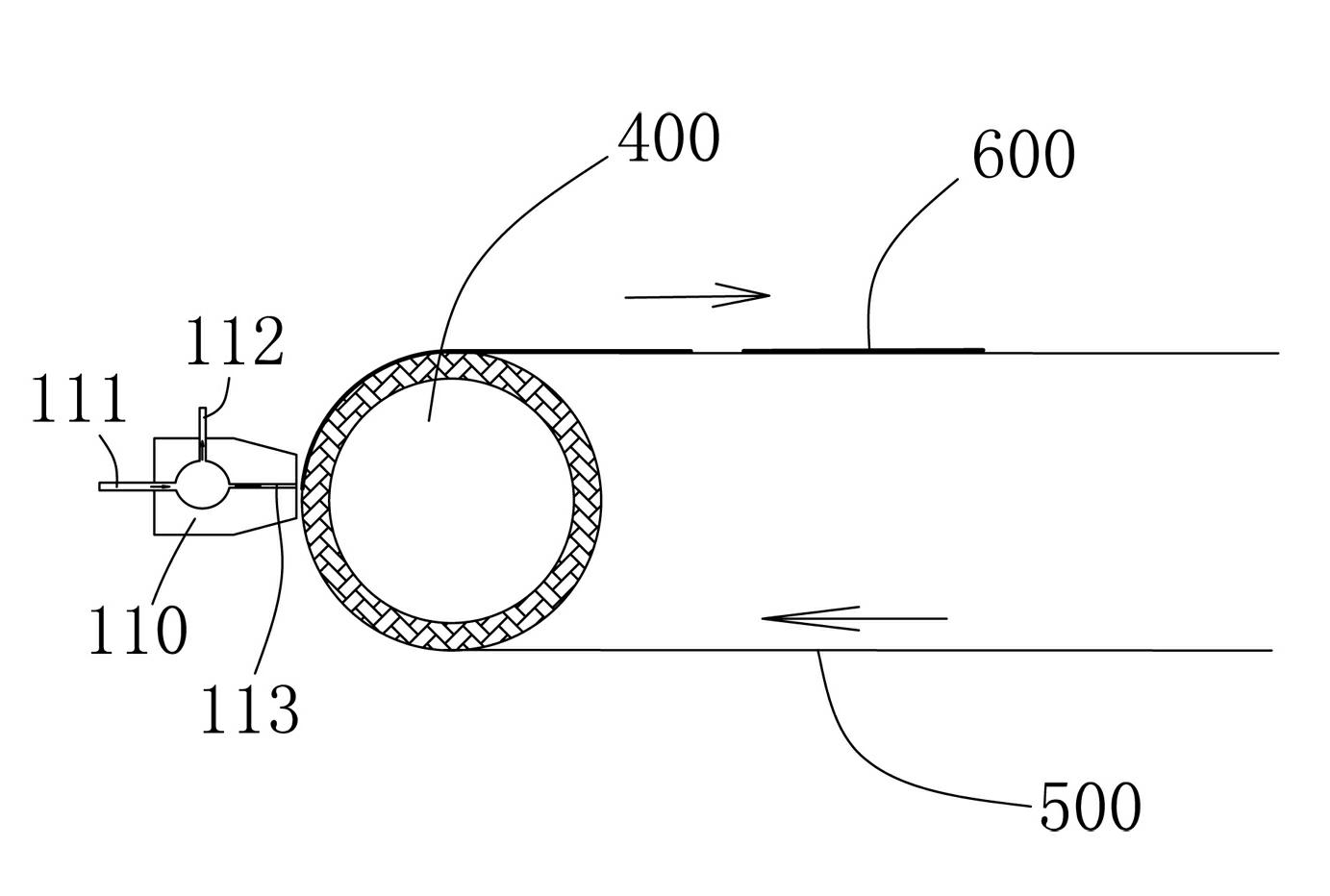

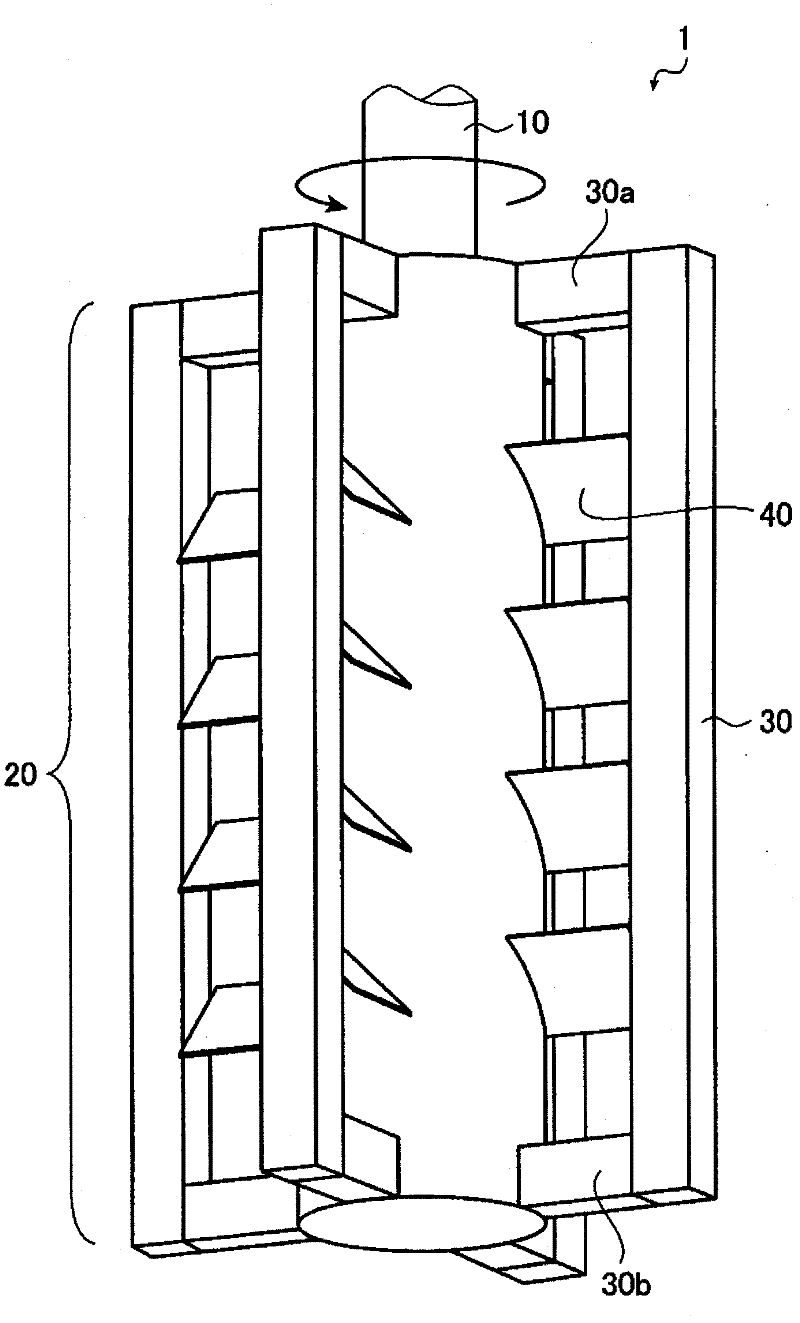

Molten glass stirring device

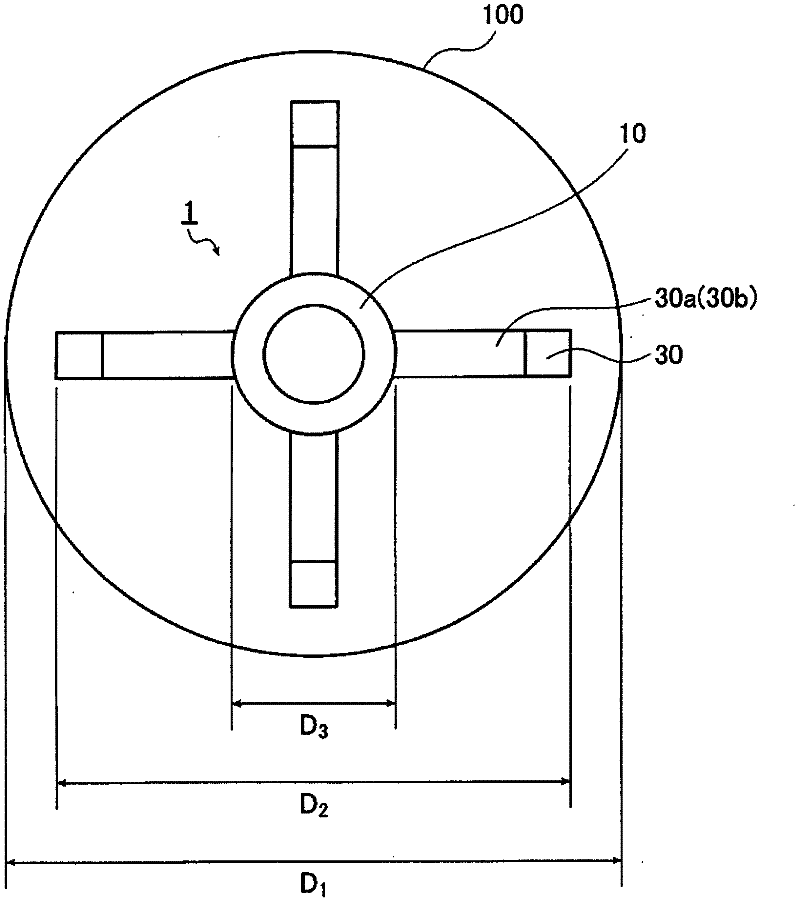

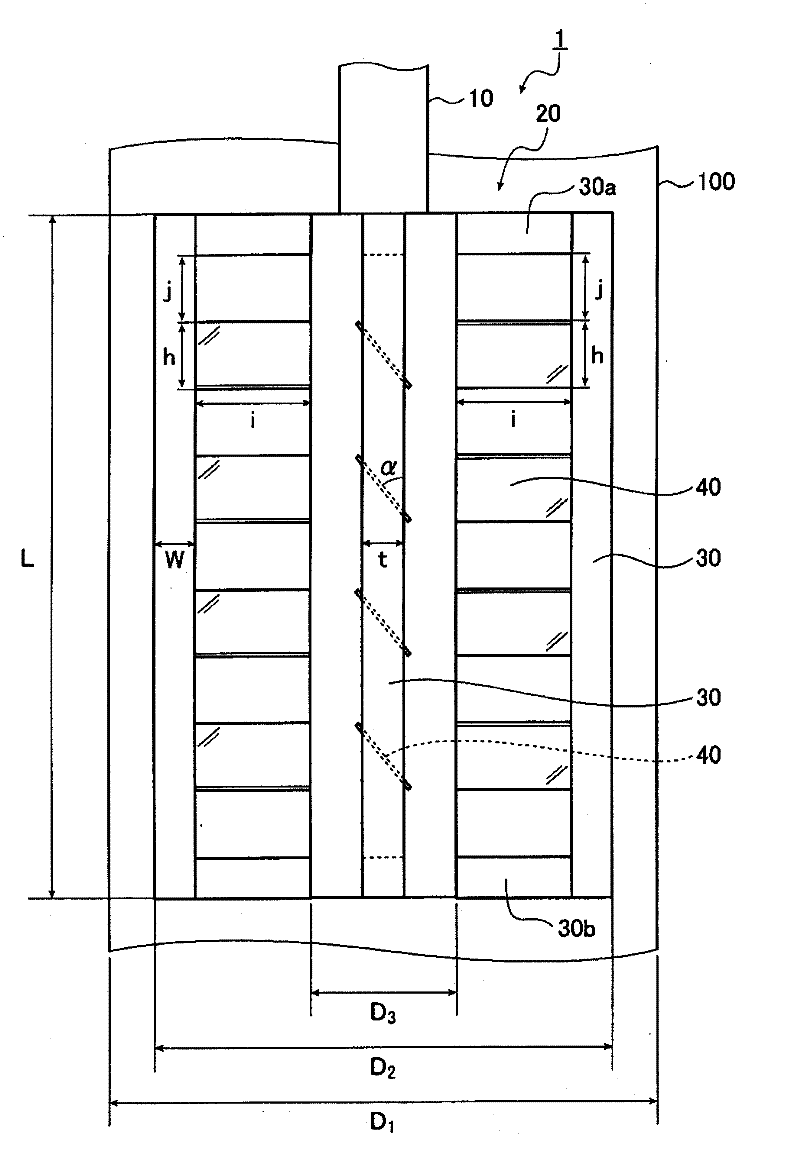

InactiveCN102300819AImprove homogeneityHigh transparencyGlass furnace apparatusRotary stirring mixersMaximum diameterViscosity

The present invention provides a molten-glass stirring device by which molten glass having a viscosity of 100-7,000 dPas is stirred in a molten-glass conveyance pipe through which the molten glass is conveyed at a rate of 1-50 m<3> / hr*S (wherein S is the sectional area of the conveyance pipe). The molten-glass stirring device is composed of a rotatable center shaft and a stirring part disposed on the center shaft. The stirring part is composed of lateral stirring blades and vertical stirring blades, each blade comprising a platy object. The lateral stirring blades have been disposed so that the longer sides are perpendicular to the center shaft and the shorter sides are inclined toward the axial direction of the center shaft at 10-70 degrees. The vertical stirring blades have been disposed so that the longer sides are parallel to the center shaft and are located in positions that define the periphery of the stirring part. When the diameter of the molten-glass conveyance pipe in the portion where the stirring part has been disposed is expressed by D1 (mm) and the maximum diameter of the periphery of the stirring part is expressed by D2 (mm), then D1 and D2 satisfy 0.8*D1 <= D2 <= 0.98*D1.

Owner:ASAHI GLASS CO LTD

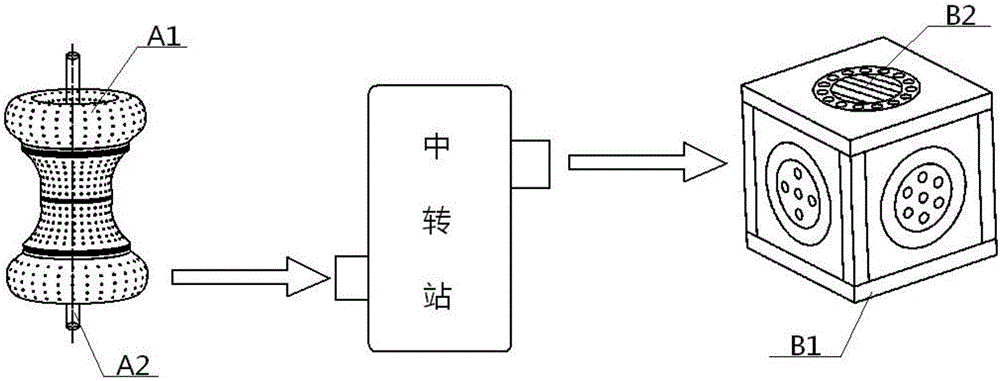

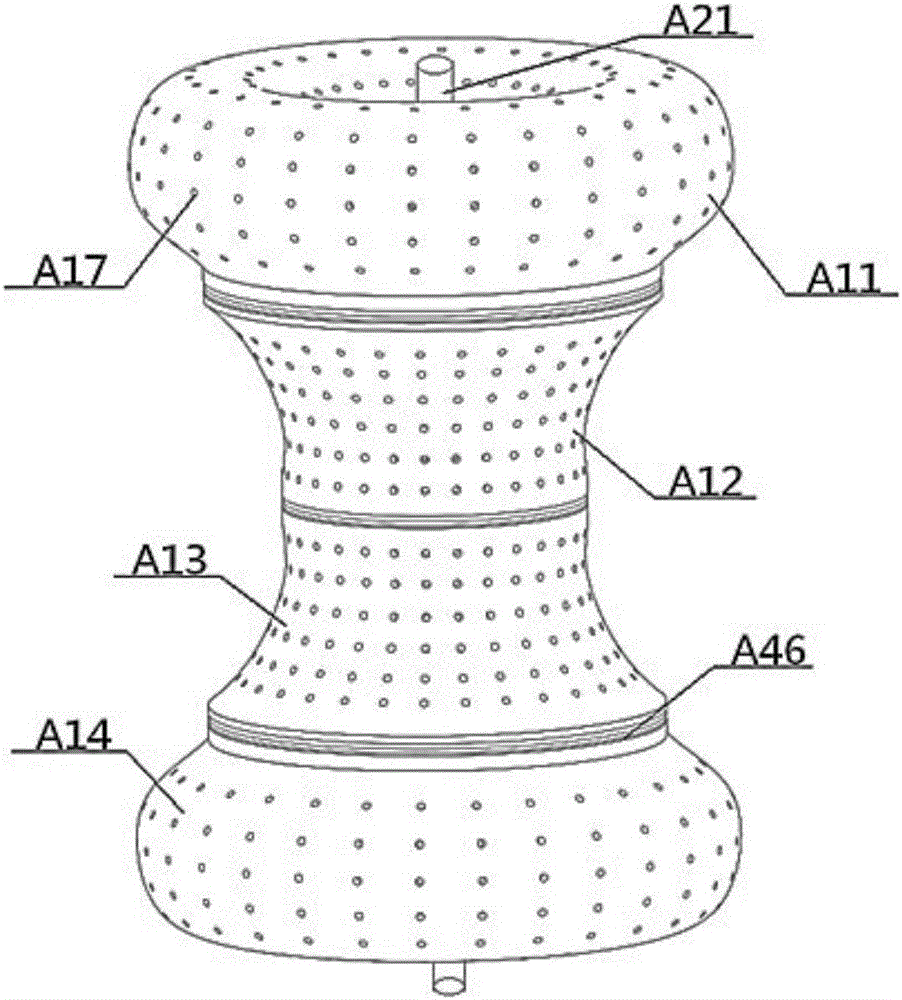

Refining and mixing system adopted in wet-process phosphoric acid refining process by solvent extraction method

ActiveCN106379879AImprove uniformityImprove stirring effectPhosphorus compoundsPhosphoric acidLubrication

A refining and mixing system adopted in a wet-process phosphoric acid refining process by a solvent extraction method is used for liquid-liquid mixing or liquid-powder mixing and comprises an A type mixing device, a transfer station and a B type mixing device which communicate with each other successively, wherein the A type mixing device has functions including that an external containing body can rotate, a heating body can be arranged and a rotating airflow can be generated, and a stirrer has three functions of body stirring, airflow stirring and enhanced stirring; the B type mixing device has functions including that an external containing body can generate a rotating airflow, a heating body can be arranged and a module can be replaced, and a stirrer has four functions of body stirring, airflow stirring, enhanced stirring, and midway addition of raw materials. The system can eliminate a fluid stagnation zone, can heat a mixed object, has the advantages of good mixing performance and high uniformity, can achieve rotation of an external container, strong lubrication effect, various stirring functions and midway addition, and has a wide range of application.

Owner:HUAZHONG NORMAL UNIV

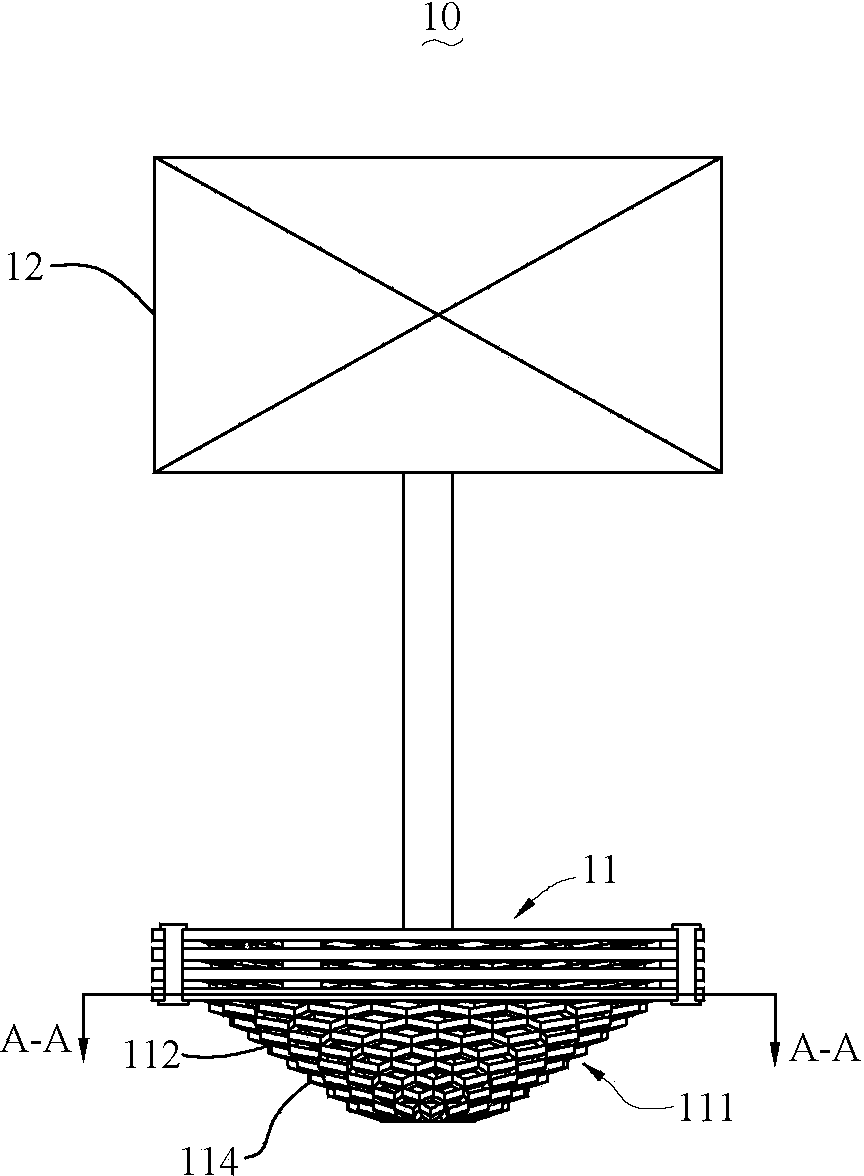

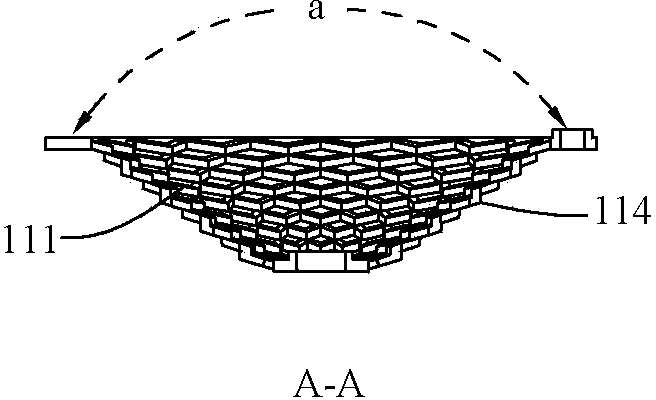

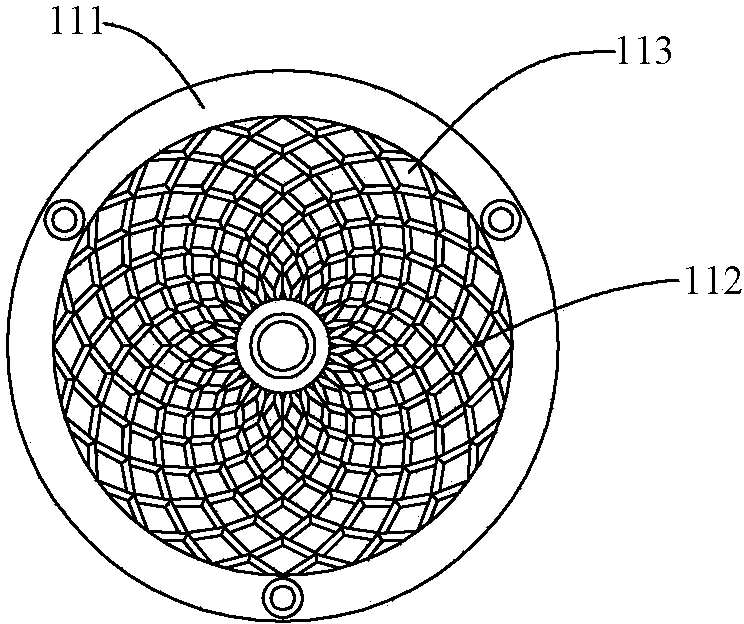

Household gas-liquid delivery device for rapidly preparing ozone water, and ozone water preparation device

ActiveCN103418257AHigh speedGuaranteed uniformityMixing methodsRotary stirring mixersEnvironmental engineeringWater resource management

The invention relates to a household gas-liquid delivery device for rapidly preparing ozone water, and an ozone water preparation device. The gas-liquid delivery device comprises a centrifugal gas-liquid mixing part with an inverted umbrella shape, and a rotation dynamic part used for driving the centrifugal gas-liquid mixing part to rotate rapidly. The rotation dynamic part is connected to the centrifugal gas-liquid mixing part through a rotation shaft. The centrifugal gas-liquid mixing part stirs water to flow fast, such that ozone water is drawn into water and bubbles are formed. The centrifugal gas-liquid mixing part comprises a plurality of separation ribs refining the bubbles. When the centrifugal gas-liquid mixing part with the inverted umbrella shape rotates, a negative-pressure absorption effect is formed, and ozone is absorbed into the inverted umbrella. Turbulence formed by rapid flow of water draws the ozone gas into water, such that speed for ozone to enter water is increased. Ozone bubbles in water meet the separation ribs, and are further refined into tiny ozone bubbles by the separation ribs. Therefore, contact area of ozone and water is increased, and dissolution efficiency is improved.

Owner:JOYOUNG CO LTD

Food processing stirrer

InactiveCN109550452APrevent Alternate ContaminationImprove mixing uniformityRotary stirring mixersTransportation and packagingEngineeringPower component

The invention discloses a food processing stirrer, which comprises a shell, wherein the side wall of the shell is provided with a control panel, a crushing box is arranged on the upper portion insidethe shell, a stirring box body is arranged on the lower end of the crushing box, pushing plates are arranged on the inner walls of both sides of the crushing box, the surface of the pushing plate is connected to the output end of an electric pushing rod arranged on the upper portion inside the shell, and one side of the bottom portion of the crushing box is provided with a weight sensor. Accordingto the present invention, the control panel is arranged on the side wall of the shell, and is used for controlling the intelligent operation of each power component in the device so as to improve theintelligent level of the device; the crushing box and the stirring box arranged in the shell are used for crushing and stirring the food; by arranging the weight sensor on the bottom portion of the crushing box, when the detected weight of the food accumulated on the side of the crushing box exceeds the preset value, the control panel starts the electric pushing rods to operate, and the pushing plates on both sides in the crushing box are pushed to the middle, such that the food accumulated on both sides are pushed to the middle portion of the crushing box to be crushed so as to increase thecrushing efficiency; and the food processing stirrer has advantages of simple structure and convenient operation, and is suitable for large-scale promotion.

Owner:嘉兴市爵拓科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com