Alumina-based ceramic core removal method and special device thereof

A special equipment and alumina technology, which is applied in the field of high-temperature alloy hollow blade removal, can solve the problems of low removal efficiency and achieve the effects of increased removal speed, improved reaction efficiency, and good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

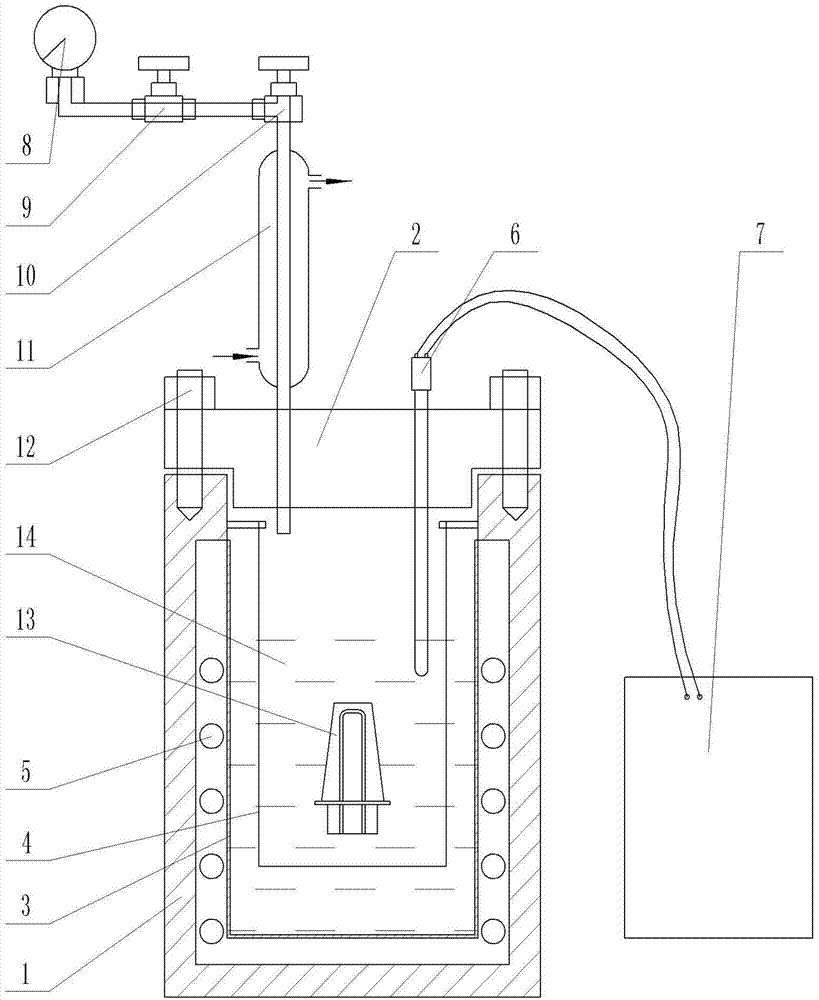

Image

Examples

Embodiment 1

[0039] Step 1, filling the reactor with KOH with a concentration of 45%, then placing the hollow blade with the alumina-based ceramic core in the parts basket, and then sealing the reactor;

[0040] Step 2, through the high temperature and high pressure closed environment, the temperature is controlled at 300 ° C, the pressure is controlled at 3.5 MPa, and the reactor is heated, so that KOH can penetrate into all the gaps of the hollow blade with alumina-based ceramic core, and corrosion occurs React for 10 minutes;

[0041] Step 3, reduce the pressure in the reactor to 2.0MPa, make the lye boil and roll into the channel of the hollow blade, and the process lasts for 15s;

[0042] Step 4, restore the pressure in the reactor, stop the lye from boiling, and return to a stable state;

[0043]Repeat steps 2 to 4 6 times until the alumina-based ceramic core is completely removed;

[0044] Step 5, remove the residual lye and the removed ceramic residual core from the hollow chip, ...

Embodiment 2

[0046] Step 1, filling the reactor with NaOH with a concentration of 40%, then placing the hollow blade with the alumina-based ceramic core in the parts basket, and then sealing the reactor;

[0047] Step 2, through the high temperature and high pressure closed environment, the temperature is controlled at 200 ° C, the pressure is controlled at 1.5 MPa, and the reactor is heated to make NaOH penetrate into all the gaps of the hollow blade with the alumina-based ceramic core, and corrosion occurs React for 15 minutes;

[0048] Step 3, the pressure in the reactor is reduced to 0.5MPa, so that the lye boils and rolls into the channel of the hollow blade, and the process lasts for 20s;

[0049] Step 4, restore the pressure in the reactor, stop the lye from boiling, and return to a stable state;

[0050] Repeat steps 2 to 4 12 times until the alumina-based ceramic core is completely removed;

[0051] Step 5, remove the residual lye and the removed ceramic residual core from the h...

Embodiment 3

[0053] Step 1, filling the reactor with KOH with a concentration of 60%, then placing the hollow blade with the alumina-based ceramic core in the parts basket, and then sealing the reactor;

[0054] Step 2, through the high temperature and high pressure airtight environment, the temperature is controlled at 150°C, the pressure is controlled at 0.5MPa, and the reactor is heated to make KOH penetrate into all the gaps of the hollow blade with alumina-based ceramic core, and corrosion occurs React for 30 minutes;

[0055] Step 3, the pressure in the reactor is reduced to 1.5MPa, so that the lye boils and rolls into the channel of the hollow blade, and the process lasts for 30s;

[0056] Step 4, restore the pressure in the reactor, stop the lye from boiling, and return to a stable state;

[0057] Repeat steps 2 to 4 10 times until the alumina-based ceramic core is completely removed;

[0058] Step 5, removing the residual lye and the removed ceramic residual core from the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com