Patents

Literature

244results about How to "Fast removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

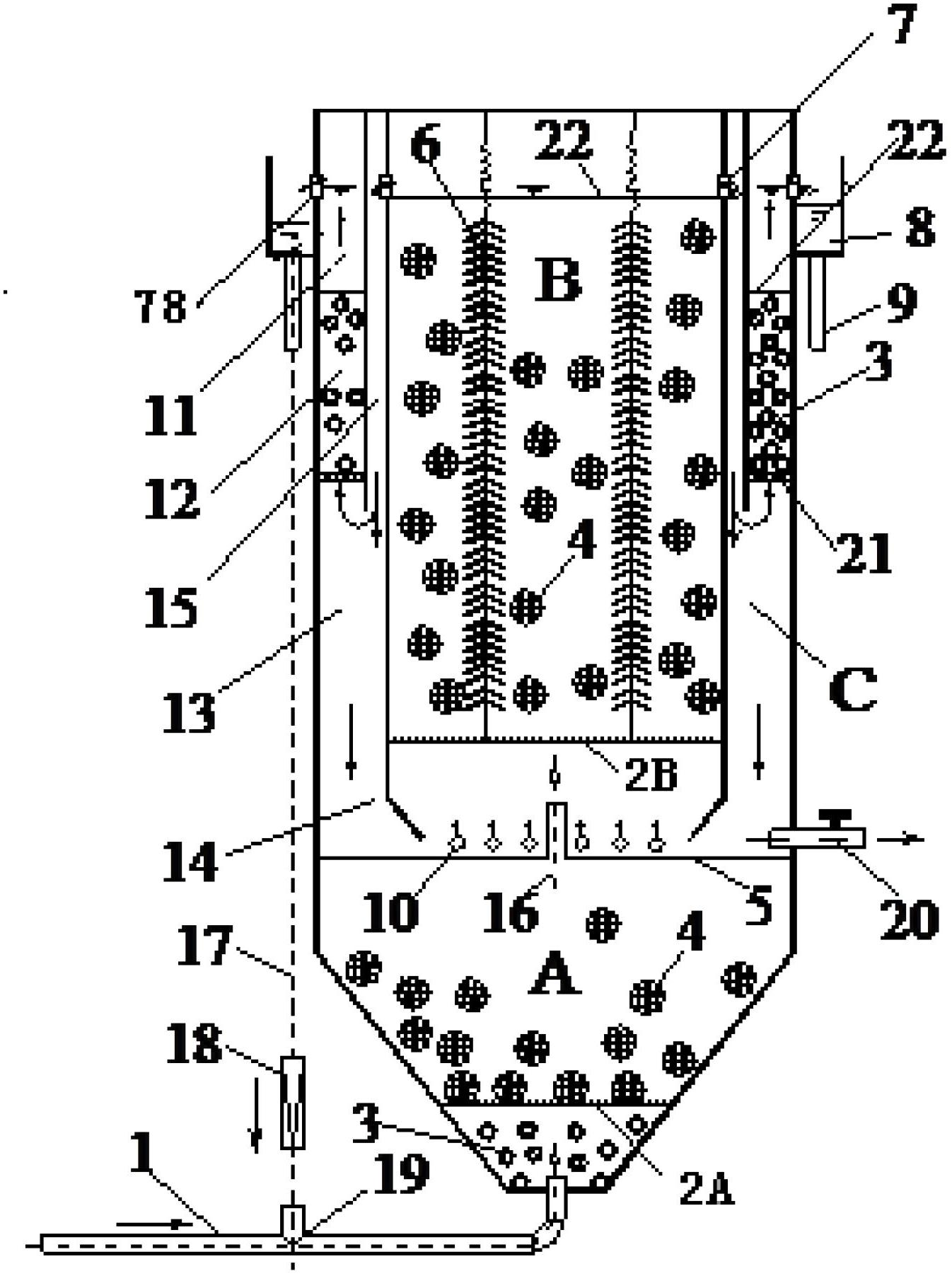

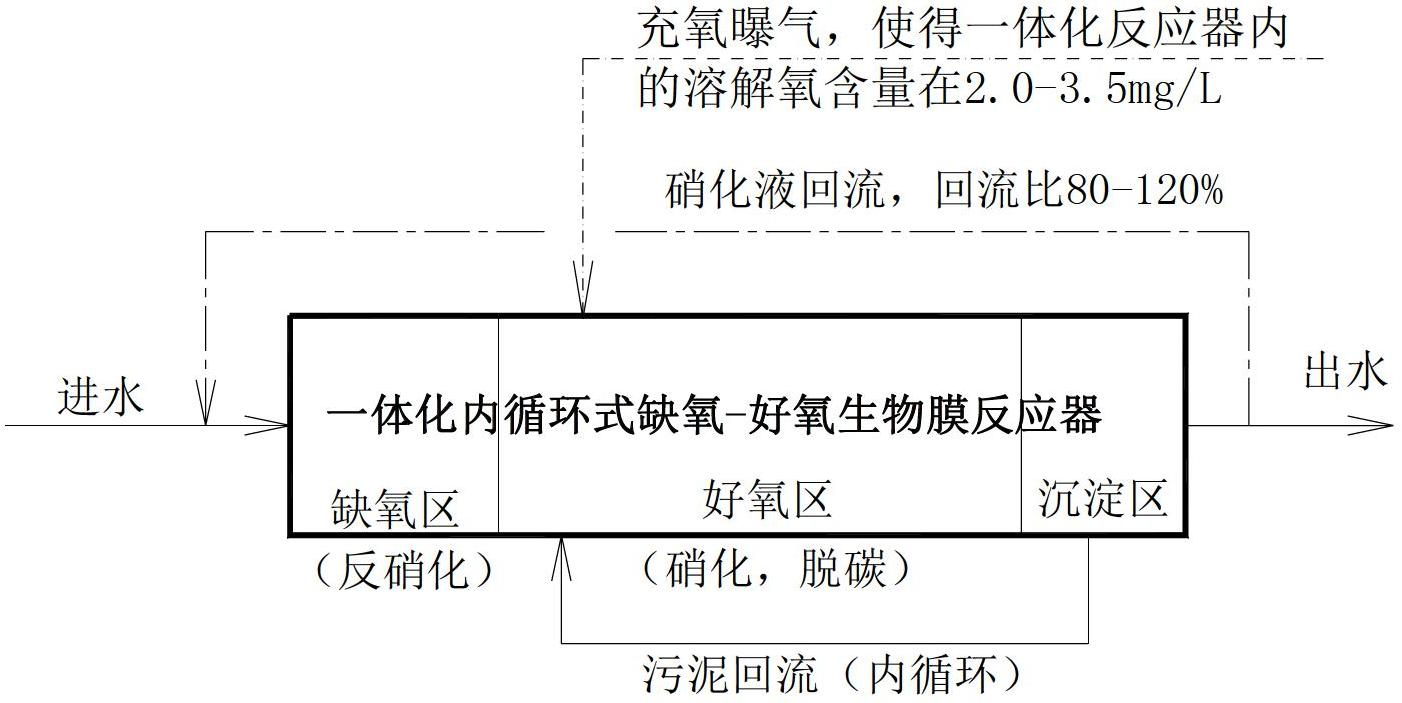

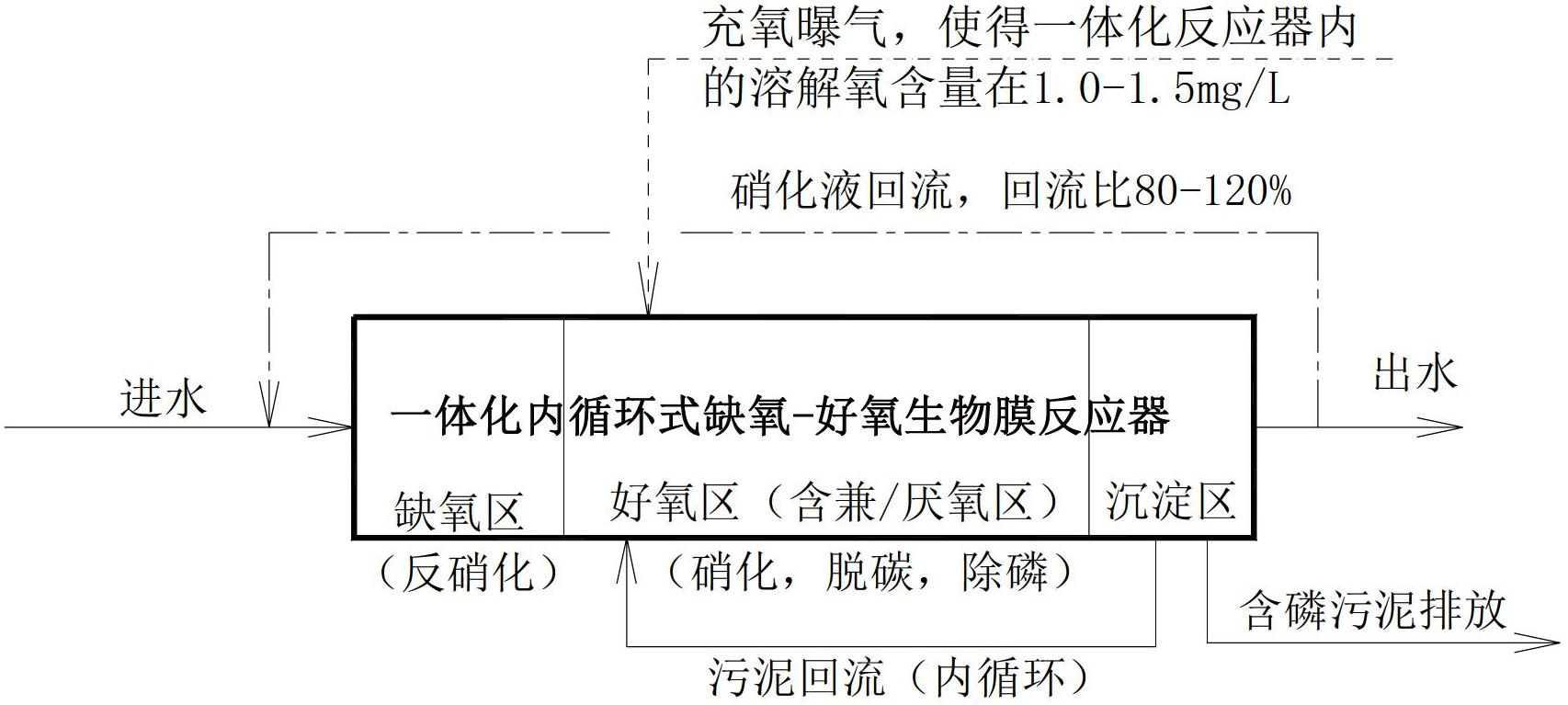

Integrated internal circulation type denitrification and decarburization bio-membrane reactor and operating method thereof

InactiveCN102659244AEfficient removalEfficient nitrogen and carbon removalTreatment with aerobic and anaerobic processesSludgeMembrane reactor

The invention provides an integrated internal circulation type denitrification and decarburization bio-membrane reactor and an operating method thereof. The main body of the reactor consists of an anoxic zone on the lower part, an aerobic zone on the upper part and a settling zone on the periphery of the aerobic zone; a composite filler is filled in the anoxic zone, and a water inlet pipe is communicated with the bottom of the anoxic zone; the aerobic zone is partitioned into a filler zone for adding a carrier on the upper part and a mud-water mixing zone on the lower part by adopting an orifice plate, the anoxic zone and the aerobic zone are partitioned through an impermeable partition plate, and a plurality of aeration pipes are arranged at the bottom of the aerobic zone and provided with air inlet pores; and the settling zone consists of three parts, namely a clean water zone, a contact settling zone and a sludge returning zone which are sequentially arranged from top to bottom, wherein the bottom of the sludge returning zone is provided with a sludge returning seam and communicated with the bottom of the aerobic zone. The reactor realizes zero power consumption in sludge returning, and is compact in structure; and a back flushing system is not required in the contact settling zone, and additional agents and carbon sources are not required, so that the reactor is low in running cost.

Owner:SUZHOU UNIV OF SCI & TECH

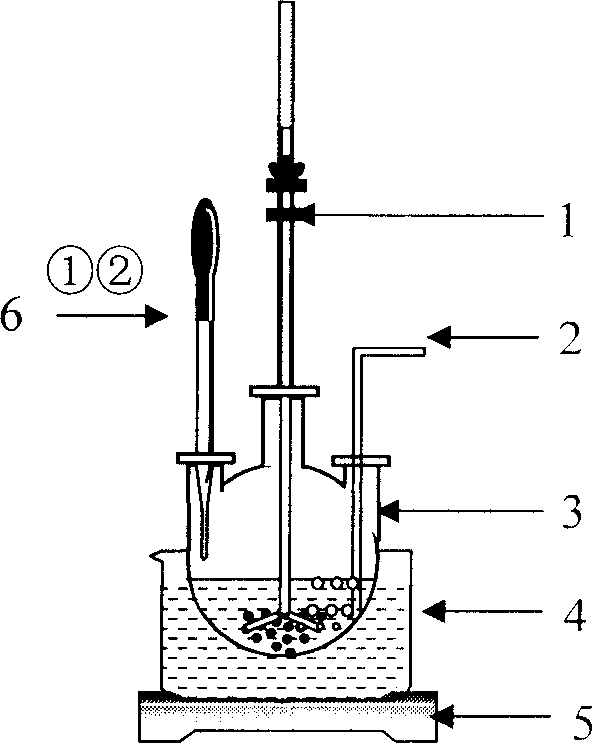

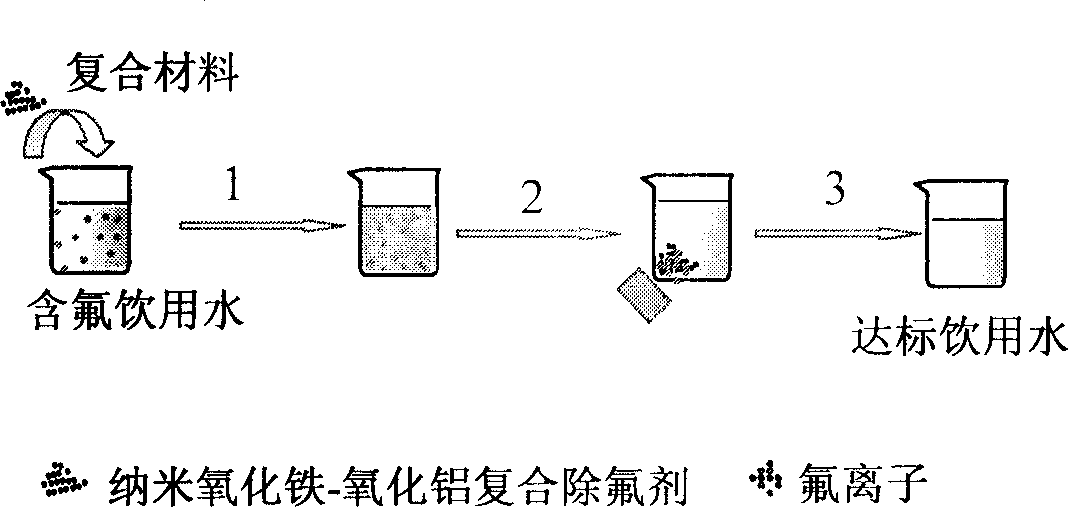

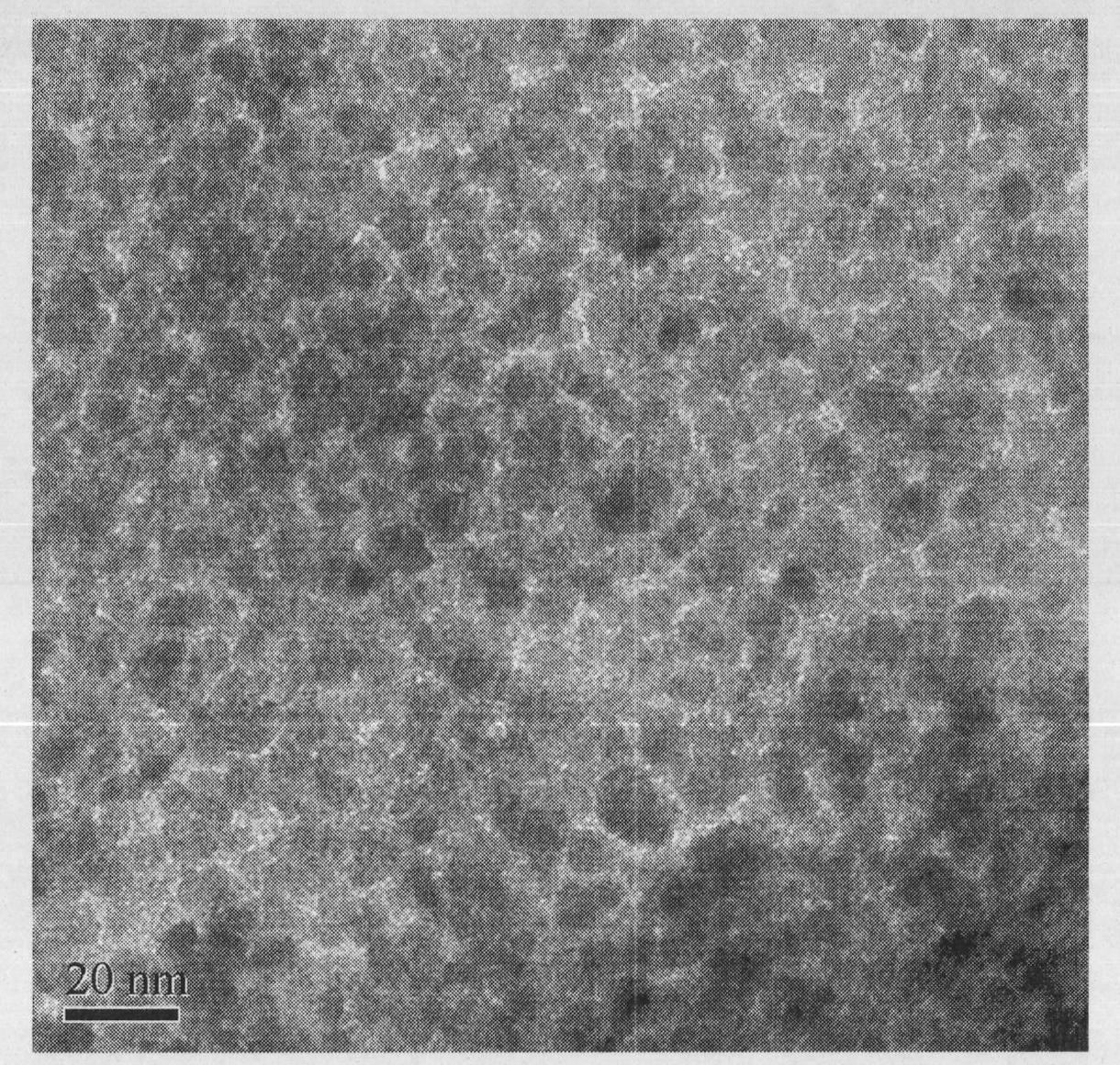

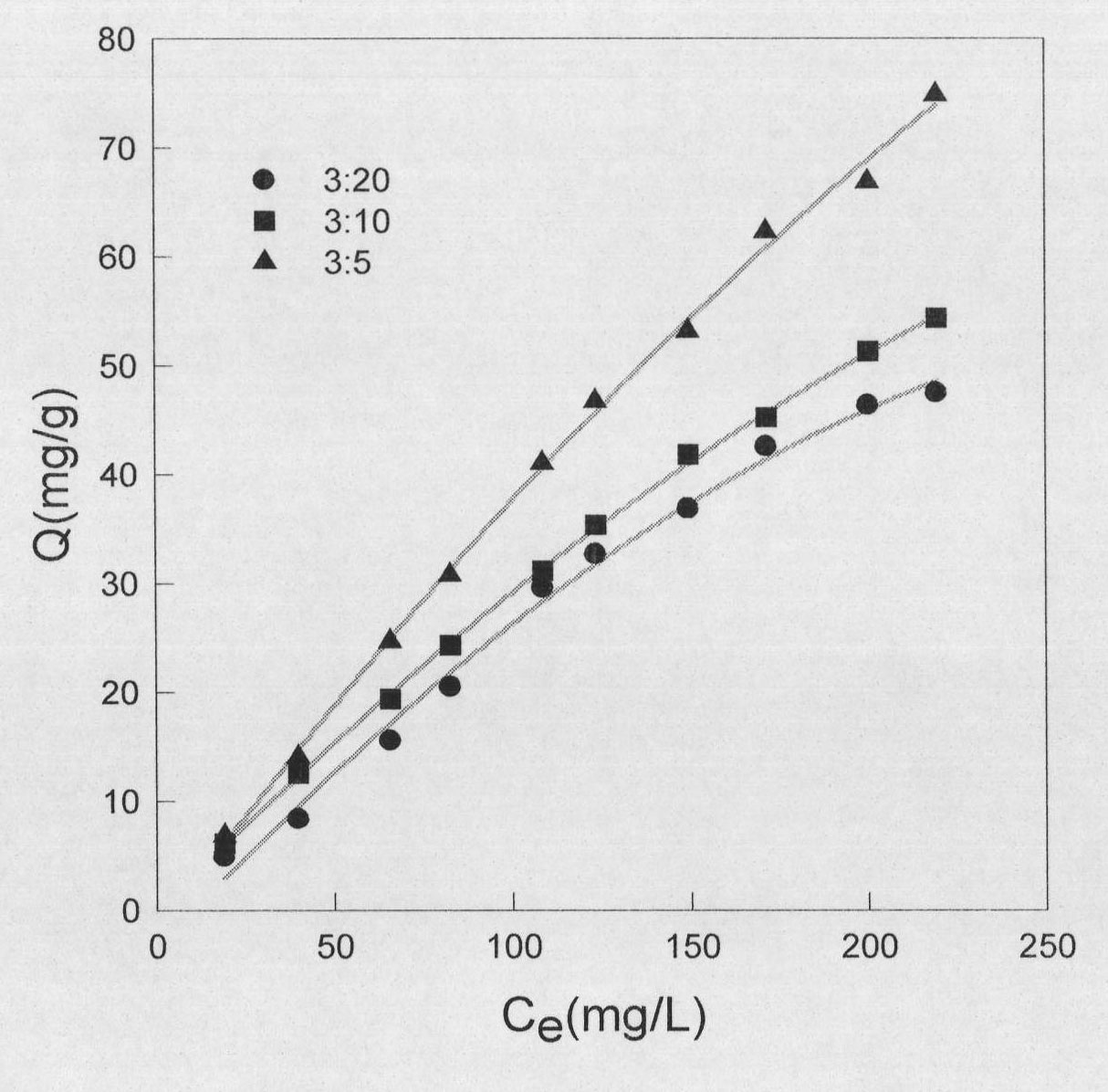

Preparing and applications of ferric oxide-alumina compound nanophase defluoridation material

InactiveCN101229504AReduce dosageImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionSorbentAlumina composite

The invention pertains to the field of chemical analysis test equipment, relating to a novel composite material of nano iron oxide-alumina which is used as an sorbent for removing fluoride from water to remove the fluoride from the large amount of drinking water; the fluorin content after the treatment is lower than the content of national standard; compared with the traditional defluorinating agent, the invention has the advantages of simple structure, low cost, high sorption capacity and fast removing speed. As a novel magnetic nano material, the defluorinating agent can realize the separation of extraction agent and base solution under the condition of external magnetic field. The surface of the nano iron oxide is coated with a layer of Al(OH)3; F<-> and Al<3+> in the water to form a complex compound which settles down to realize the effect of defluorination; 1L of water sample only consumes the defluorinating agent of 0.1g; to high fluorin content water with concentration of 20mg / L, the concentration after defluorination can be less than 1mg / L, which can well meet requirement with the reproducibility of analysis result RSD being less than 7 percent.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

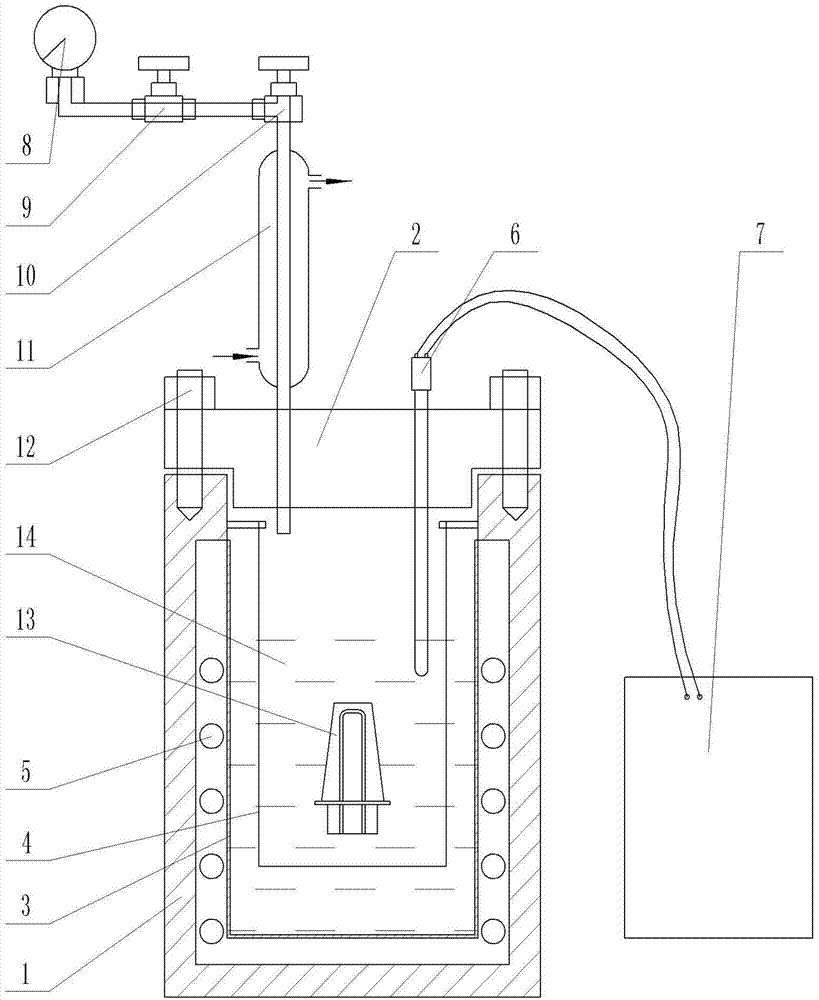

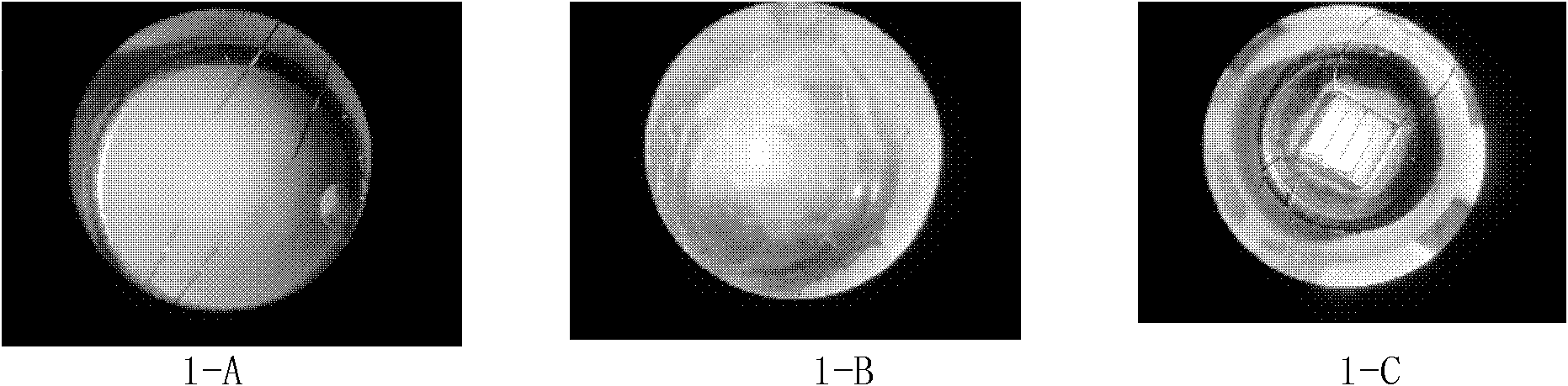

Alumina-based ceramic core removal method and special device thereof

Disclosed are an alumina-based ceramic core removal method and a special device thereof. The method includes placing a hollow blade with an alumina-based ceramic core into a reaction kettle fully filled with lye, and then sealing the reaction kettle; heating the reaction kettle in high-temperature, high-pressure and airtight environment; decreasing the pressure of the reaction kettle till being lower than the saturated vapor pressure of the lye, allowing the lye to be boiled to enter channels of the hollow blade for 10 to 30 seconds; recovering the pressure in the reaction kettle to stop boiling the lye and recover stable statues; removing residual lye and removed ceramic core from the hollow blade, and finally utilizing acid to neutralize residual lye on the hollow blade, and washing with water. The method has the advantages that reacted waste lye in the cavity of the hollow blade can be discharged rapidly through high temperature and increasing and decreasing the pressure repeatedly, good stirring effect is provided by periodically boiling the lye, the lye is guaranteed contacting with the alumina-based ceramic core fully, reacting efficiency is improved, and removal speed of the alumina-based ceramic core is increased significantly.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

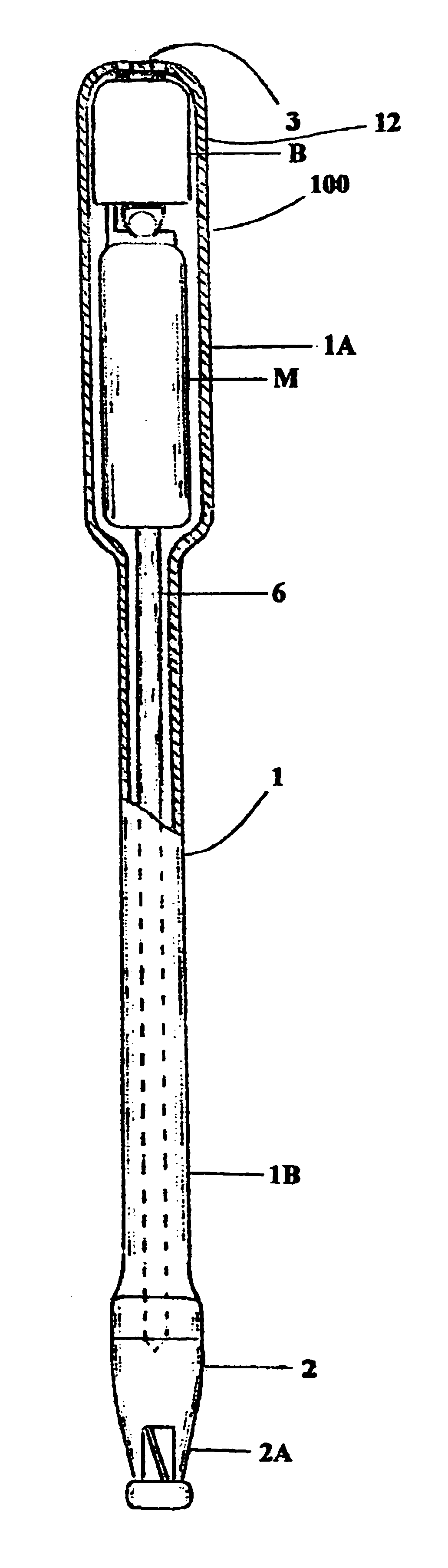

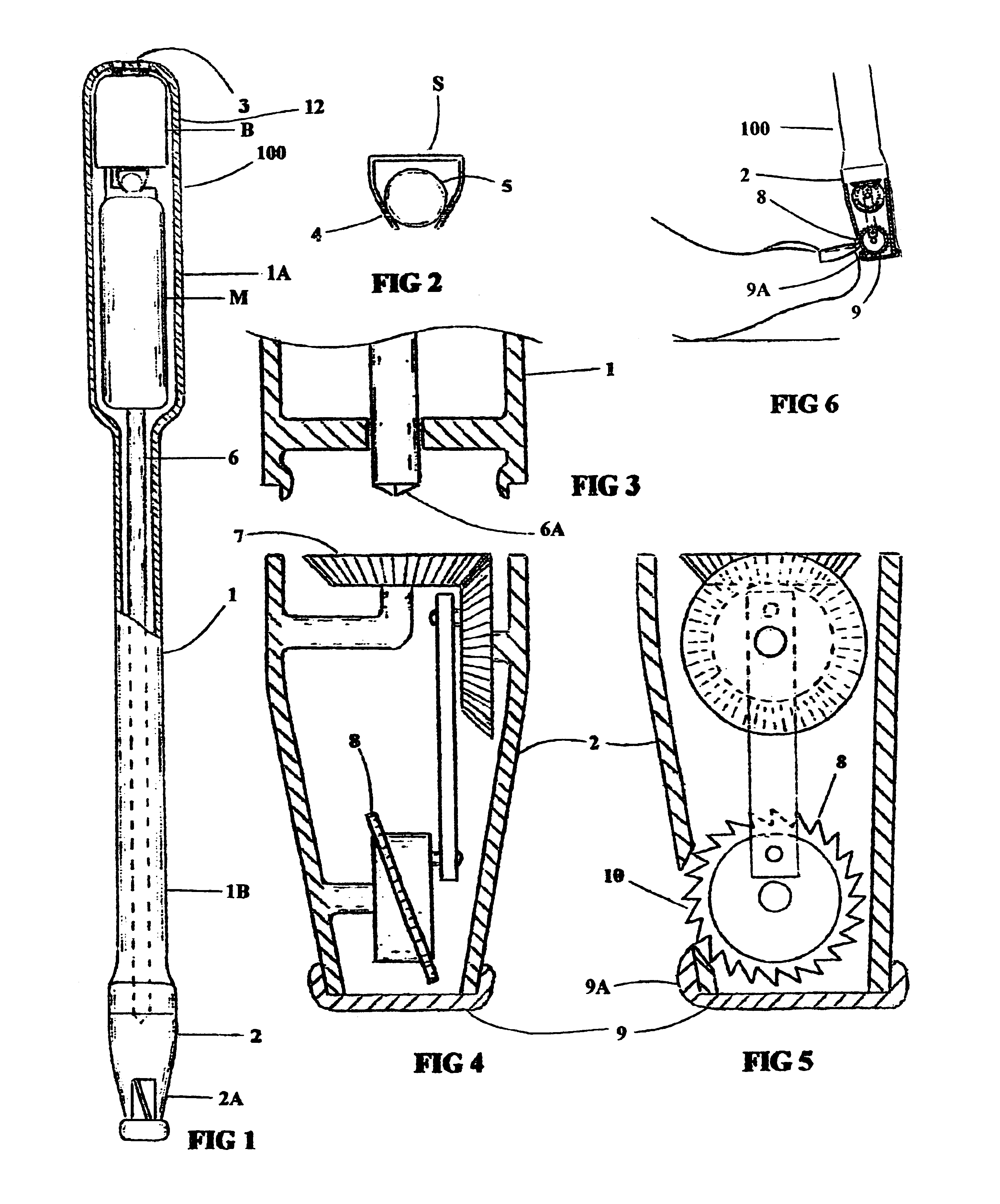

Nail trimmer

InactiveUS6865812B1Sufficient forceComfortable postureManicure/pedicureMetal working apparatusGear wheelEngineering

A nail trimmer for enabling a person to comfortably trim toenails without having to take on an awkward or uncomfortable posture. The nail trimmer has a long extension housing, which has a handle at its upper end and a trimmer unit at its lower end. A battery operated motor and on / off switch are incorporated into the handle end. A detachable trimmer unit is connected at the lower end. A dado cutting blade and a gear unit are enclosed in the trimmer unit. An opening in the trimmer unit housing provides access to the cutting edge of the blade.

Owner:MARTIN JR ROY C

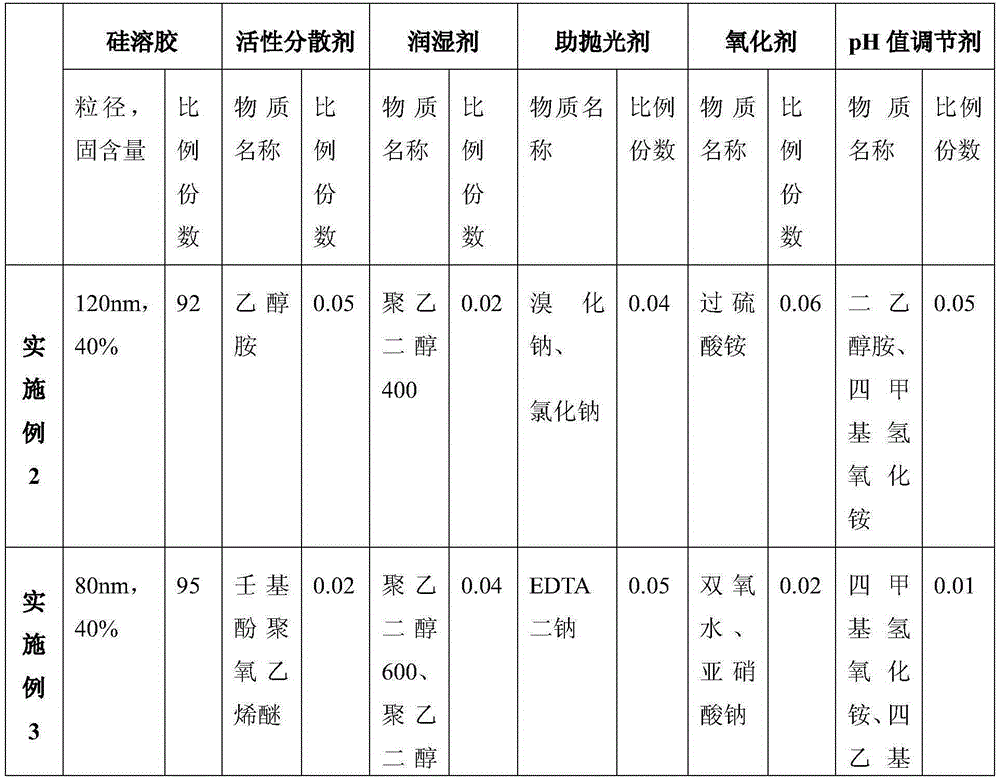

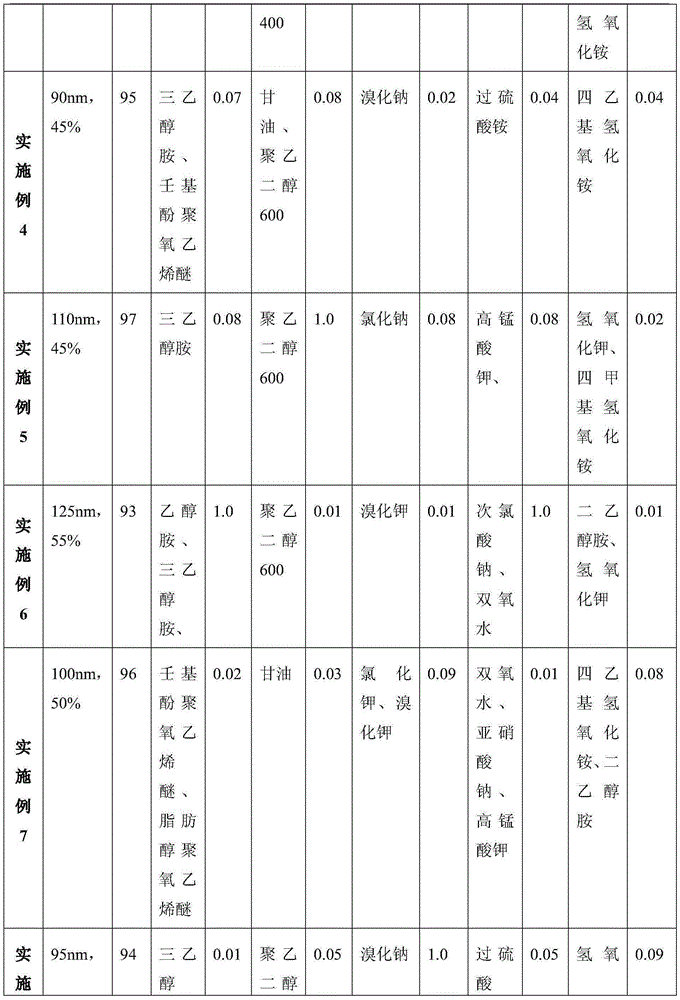

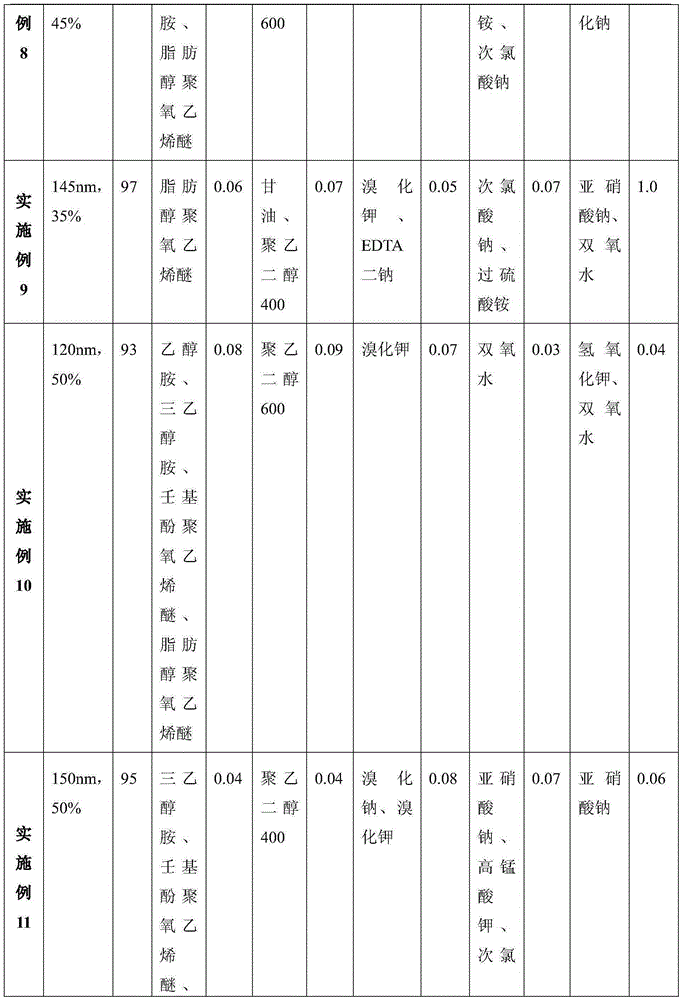

Polishing solution for A orientation sapphire polishing, and preparation method thereof

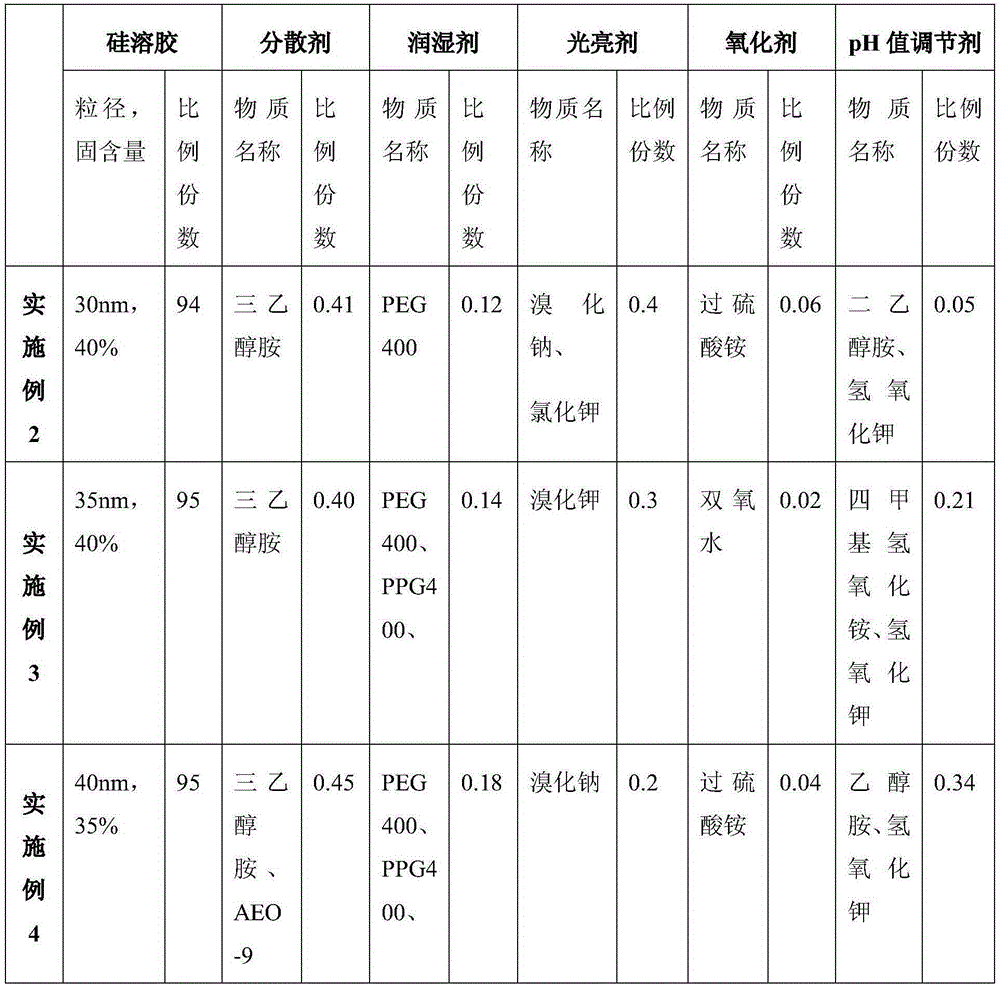

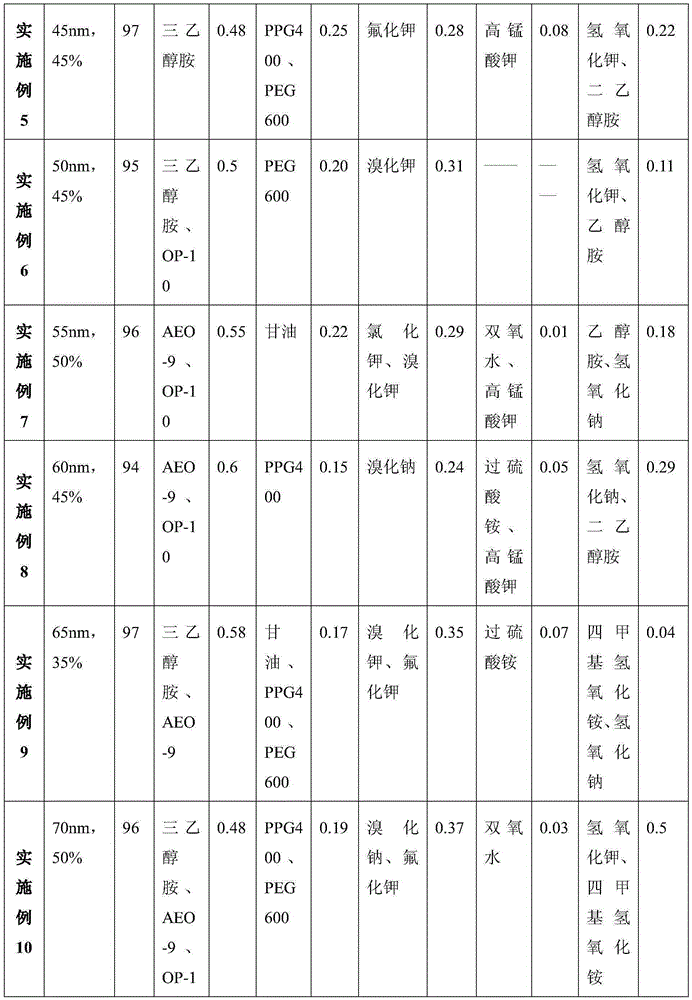

InactiveCN105385357AAverage Apparent Yield ImprovementImprove polishing efficiencyPolishing compositions with abrasivesMachining processLubrication

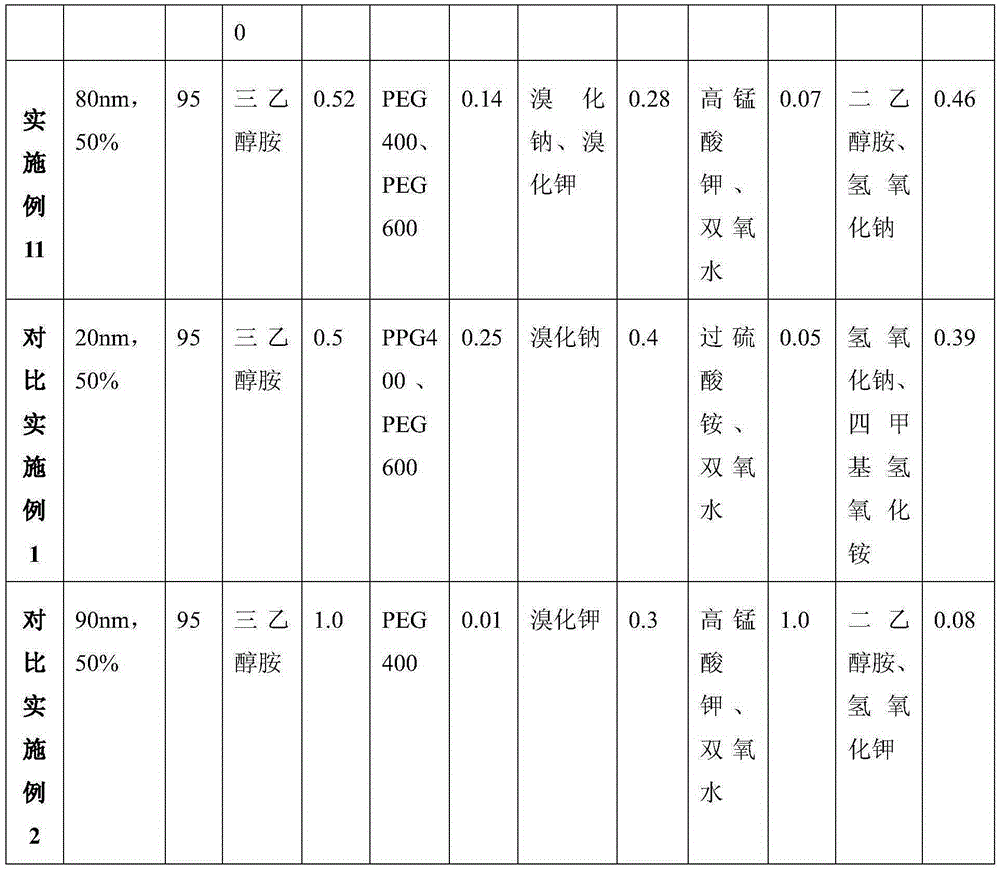

The invention provides a polishing solution for A orientation sapphire polishing, and a preparation method thereof. The polishing solution comprises, by mass, 92-97 parts of silica sol, 0.01-1 part of an active dispersant, 0.01-1 part of a wetting agent, 0.01-2 parts of a polishing aid, 0.01-1 part of an oxidant, 0.01-2 parts of a pH adjusting agent, and the balance of deionized water. The polishing solution prepared in the invention has the advantages of good removal rate, excellent lubrication effect, good quality of the surface of a processed product in the sapphire polishing processing process, simple processing and preparation method, and facilitation of industrial popularization.

Owner:LENS TECH CHANGSHA

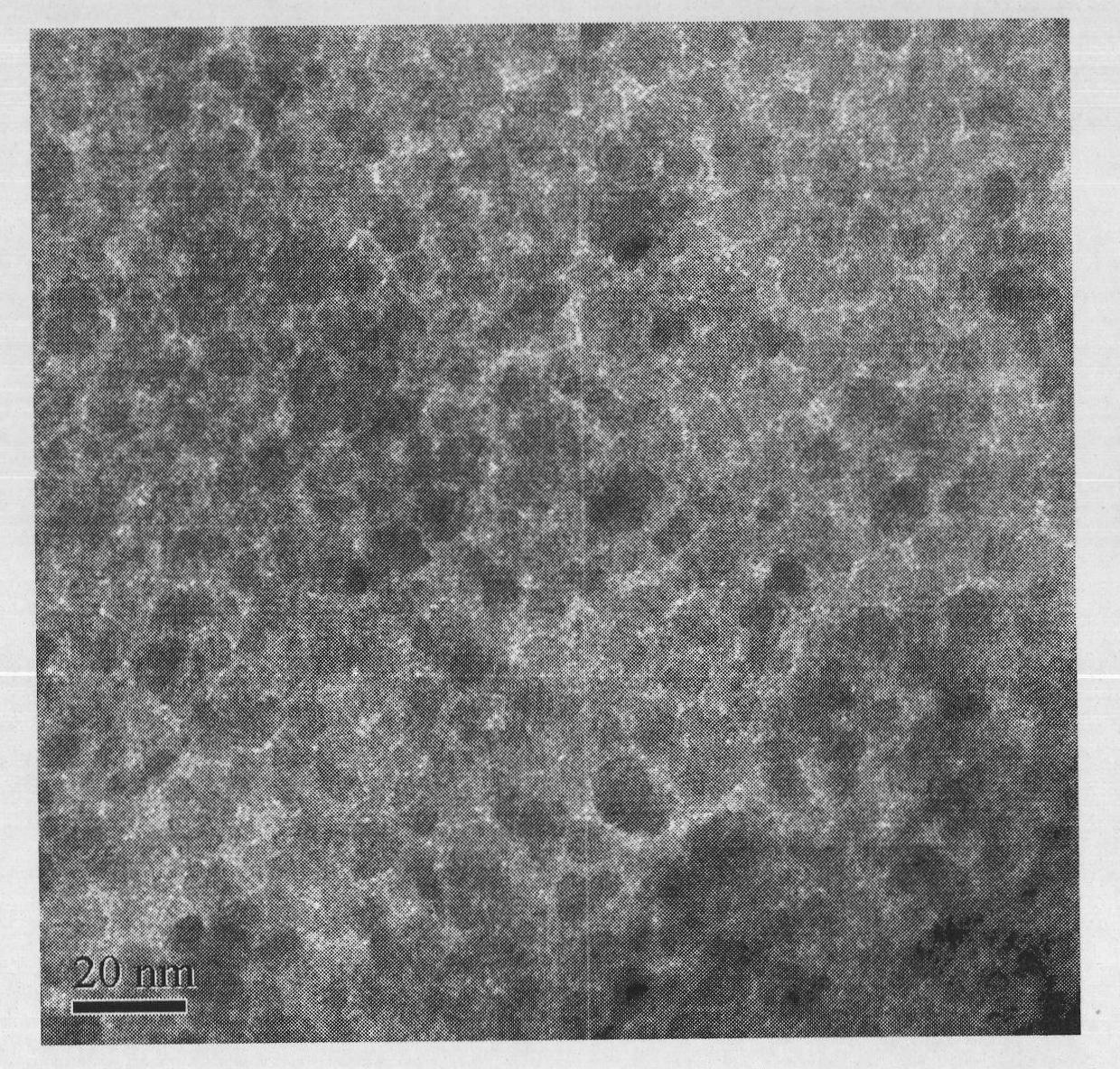

Method for preparing Fe3O4@ZrO(OH)2 magnetic nano-adsorbing material for high-efficient fluoride removal from drinking water

InactiveCN101811020AShort adsorption pathMagneticOther chemical processesWater contaminantsMicrosphereReaction temperature

The invention discloses a method for preparing an Fe3O4@ZrO(OH)2 magnetic nano-adsorbing material for high-efficient fluoride removal from drinking water. The method comprises the following steps: (1) preparing magnetic nano-Fe3O4 microspheres by using a coprecipitation method; and (2) adding the magnetic nano-Fe3O4 microspheres and deionized water into a reaction vessel; adding a certain amount of solution of zirconium salt dropwise into the reaction vessel under the condition of mechanical stirring; adding the solution of NaOH into the reaction vessel dropwise; and separating and washing by utilizing an externally-applied magnetic field after heating, refluxing and reacting for 1 to 3 hours so as to obtain the magnetic nano-Fe3O4@ZrO(OH)2 composite microspheres. The method has the following advantages that: 1, adsorption capacity is large, so the method is suitable for advanced treatment of large volume of drinking water; 2, the removal speed is high, and the adsorption paths of nano-particles are short; and 3, the preparation is simple because the overall preparation process has no need of complex reaction process, special reaction equipment or harsh reaction temperature, the operation is simple and easy to implement, and the reproducibility is high.

Owner:NANCHANG HANGKONG UNIVERSITY

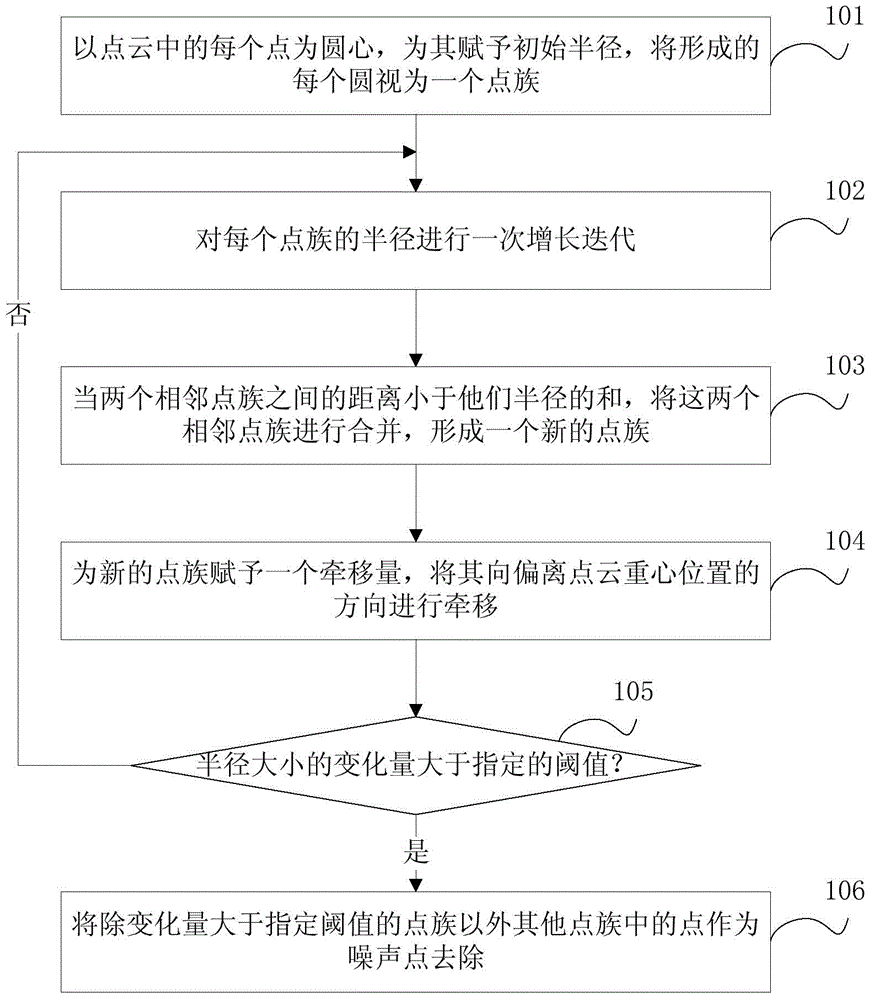

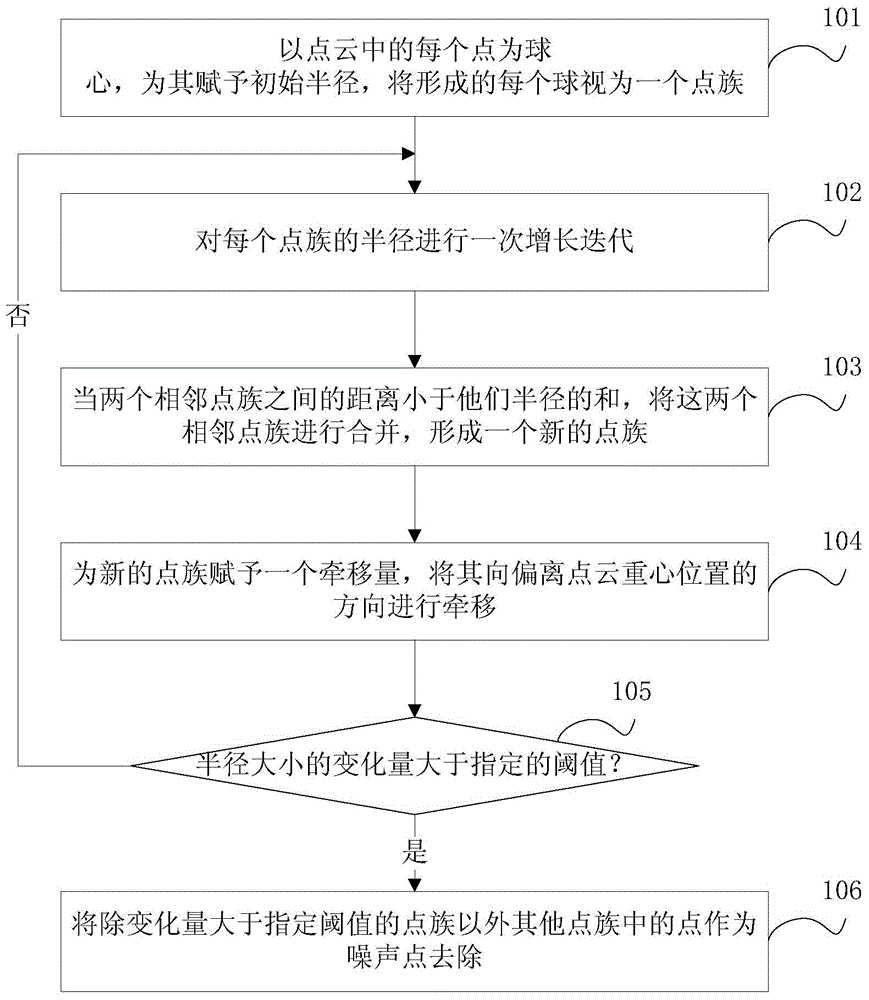

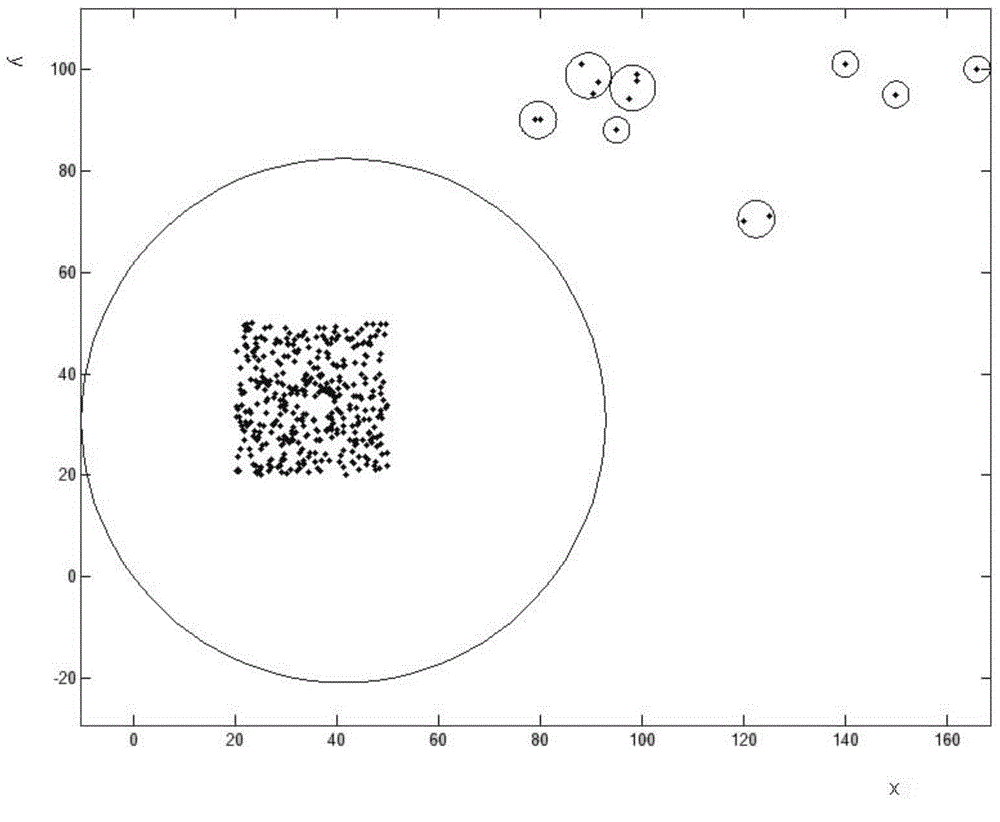

Removal method for point cloud noise points

The invention discloses a removal method for point cloud noise points. The method is used for removing the noise point in a point cloud. The removal method comprises the steps that the initial radius is given to the point cloud with each point in the point cloud as the circle center or the ball center, and each formed circle or ball is regarded as a point group; the radius of each point group is increased and iterated for one time; when the distance between two adjacent point groups is smaller than the sum of the radiuses of the two adjacent point groups, the adjacent point groups are merged and form a new point group; pulling amount is given to the new point group, and the point group is pulled towards the direction deviating from the gravity center position of the point cloud; when all the current point groups are sorted according to the radiuses of the point groups, the change amount of the radius corresponding to each point group is calculated, if the change amount is larger than the specified threshold value, iteration is finished, and otherwise, returning to iteration of next time is carried out; finally, the points in the other point groups except for the point groups with the change amount larger than the specified threshold value are regarded as the noise points and removed. The removal method effectively improves the removal efficiency of the point cloud noise points.

Owner:ZHEJIANG UNIV OF TECH

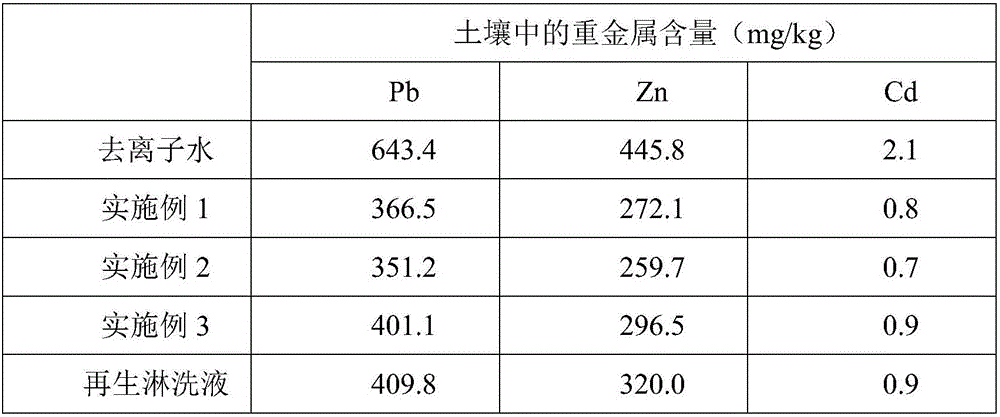

Compound chemical leaching method for efficient remediation of heavy metal contaminated soil

The invention relates to the field of soil remediation, in particular to a compound chemical leaching method for efficient remediation of heavy metal contaminated soil. Natural organic acid and iron salt are used as main raw materials to prepare a compound leacheate, and the technical problems that an existing soil remediation eluent is high in cost and low in efficiency and can cause secondary pollution easily are solved. According to the compound chemical leaching method, the heavy metal contaminated soil is remediated, the heavy metal content in the soil can be reduced quickly, and a good remediation effect is achieved. Waste liquid generated after leaching is disposed through a regenerant, and the primary regeneration efficiency can reach 80% or over.

Owner:东莞中科土壤科技开发有限公司

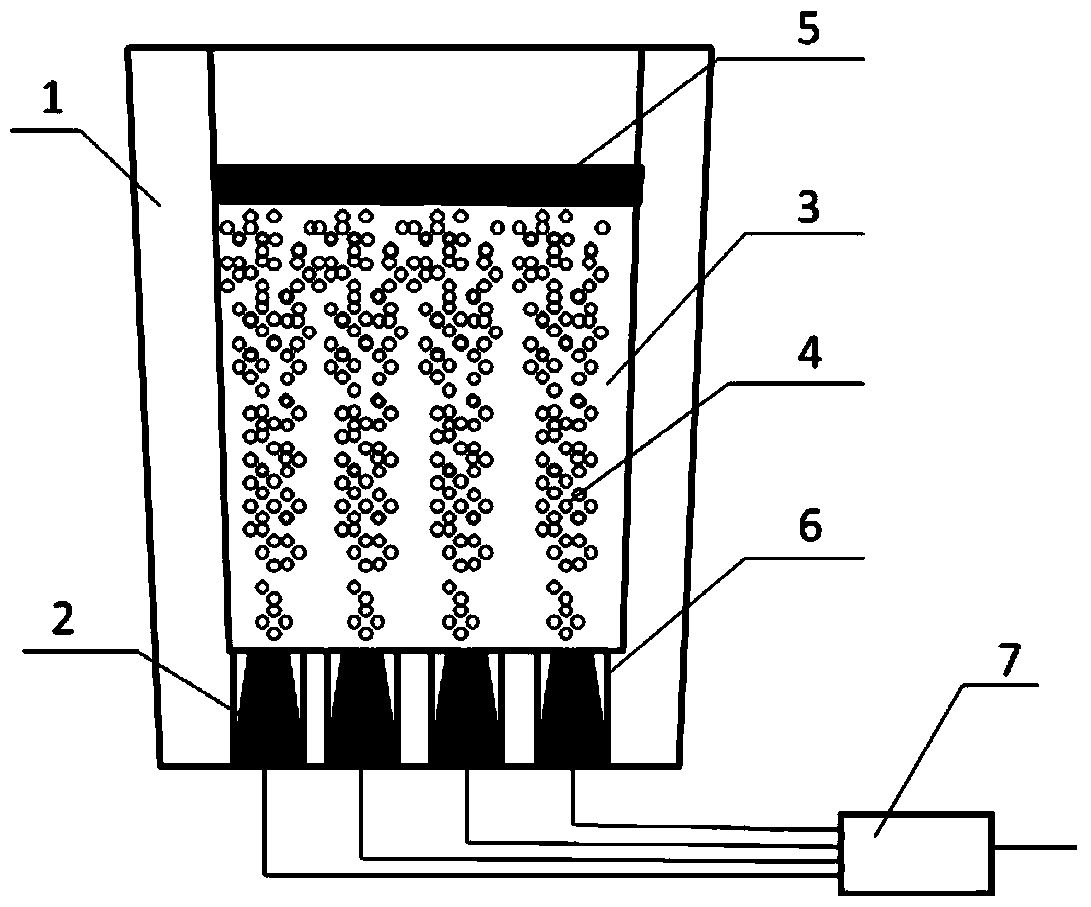

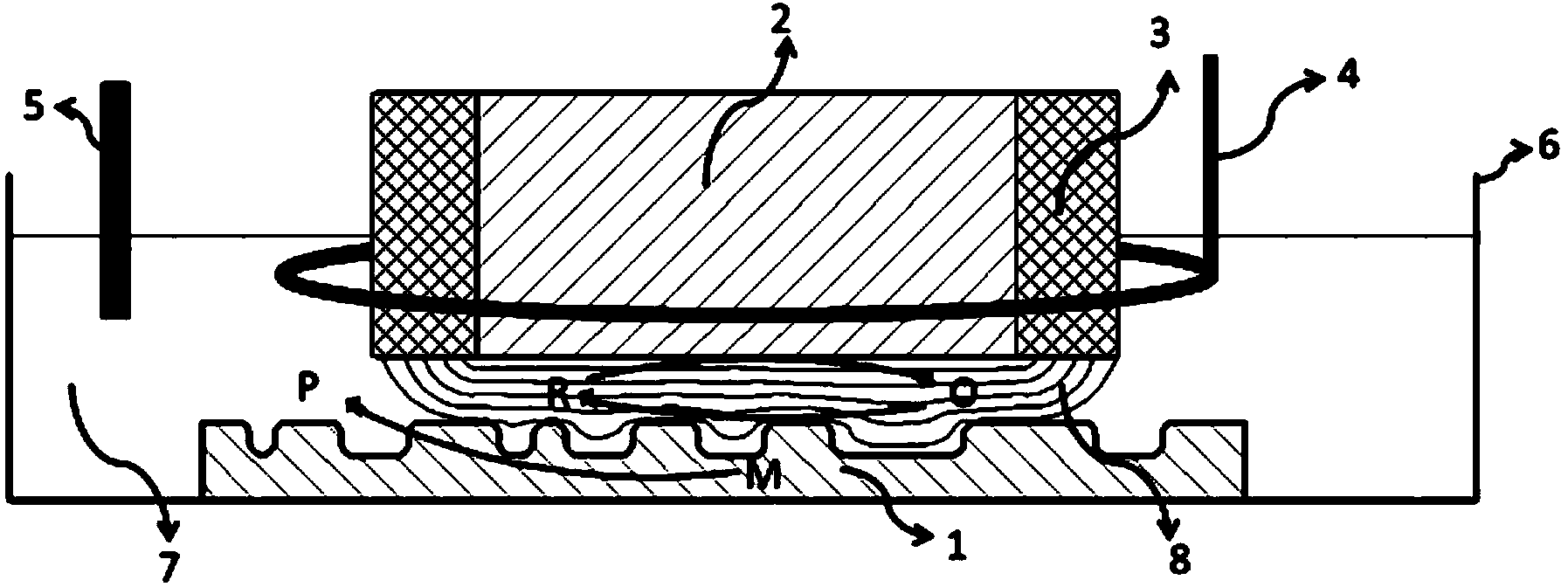

Device and method for quickly removing occluded foreign substances in molten steel

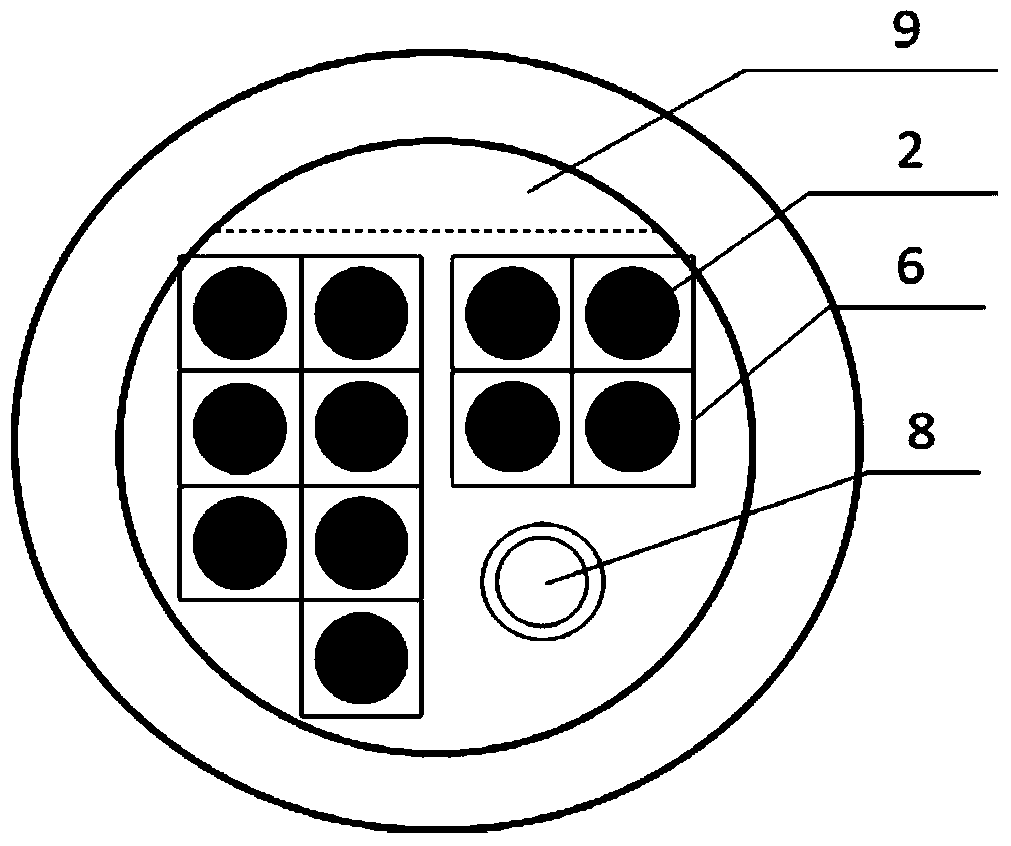

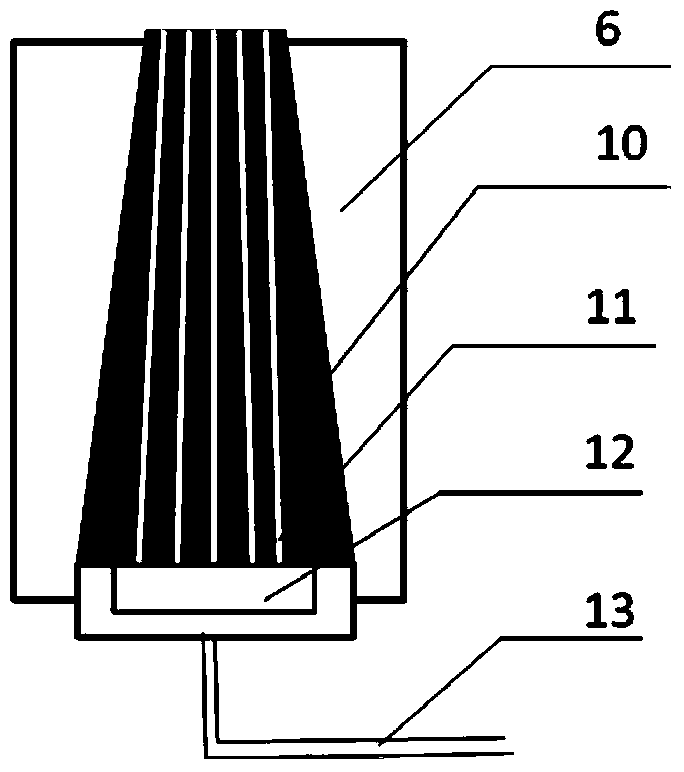

The invention discloses a device and a method for quickly removing occluded foreign substances in molten steel, and relates to the field of production of a high-quality steel product. The basic principle is that high-purity argon is blown at the bottom of a molten steel container; a certain amount of specific ventilating elements are arranged according to the demands; a lot of tiny bubble areas are generated in the molten steel which is primarily melted or refined; the molten steel is subjected to purification treatment; the occluded foreign substances in the molten steel are efficiently and quickly promoted to enter inside top residue to be removed in catching and rising manners. The device is composed of a container (steel ladle or tundish) (1) of containing the molten steel, a plurality of specific conical bottom blowing elements (2), a guard brick (6), a bottom blowing gas adjusting system (7) and the like. The device has the advantages of being large in dispersed bubble coverage area of bottom air supply in the molten steel, fast in removal rate of the occluded foreign substances, and high in gas utilization rate; a specific air supply element has the convertibility and the like; the refining requirements of high-quality steel can be met.

Owner:CENT IRON & STEEL RES INST

Polishing solution for ceramic bonded sapphire polishing, and preparation method thereof

InactiveCN105385358AAverage Apparent Yield ImprovementImprove polishing efficiencyPolishing compositions with abrasivesMachining processLubrication

The invention provides a polishing solution for ceramic bonded sapphire polishing, and a preparation method thereof. The polishing solution comprises, by mass, 94-97 parts of silica sol, 0.4-0.6 parts of a dispersant, 0.1-0.25 parts of a wetting agent, 0.2-0.4 parts of a brightener, 0-0.08 parts of an oxidant, 0.04-0.5 parts of a pH adjusting agent, and the balance of deionized water. The polishing solution for ceramic bonded sapphire polishing has the advantages of good removal rate in the processing process,, excellent lubrication effect, good quality of the surface of a processed product, simple processing and preparation method, low cost, high polishing efficiency and low roughness.

Owner:LENS TECH CHANGSHA

Formaldehyde scavenging agent and formaldehyde scavenging method thereof

InactiveCN105771627AImprove comfortFast removalDispersed particle separationDeodrantsAir cycleSodium Bentonite

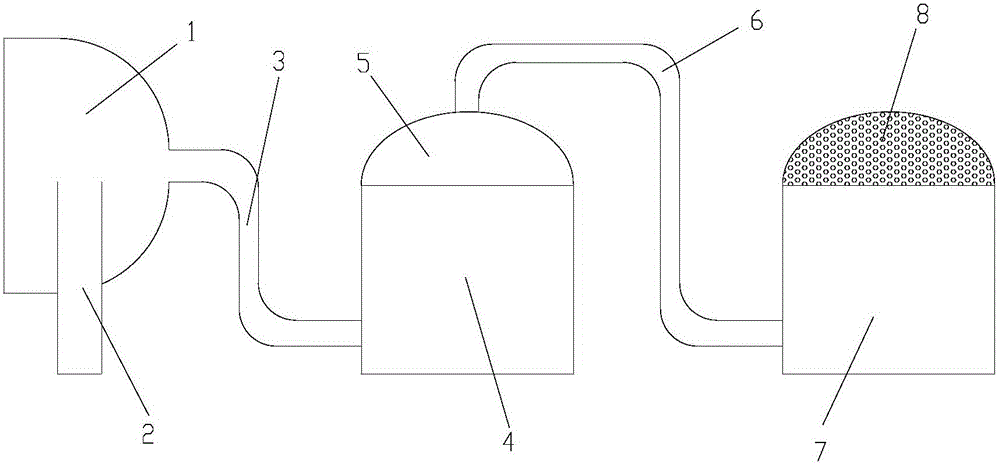

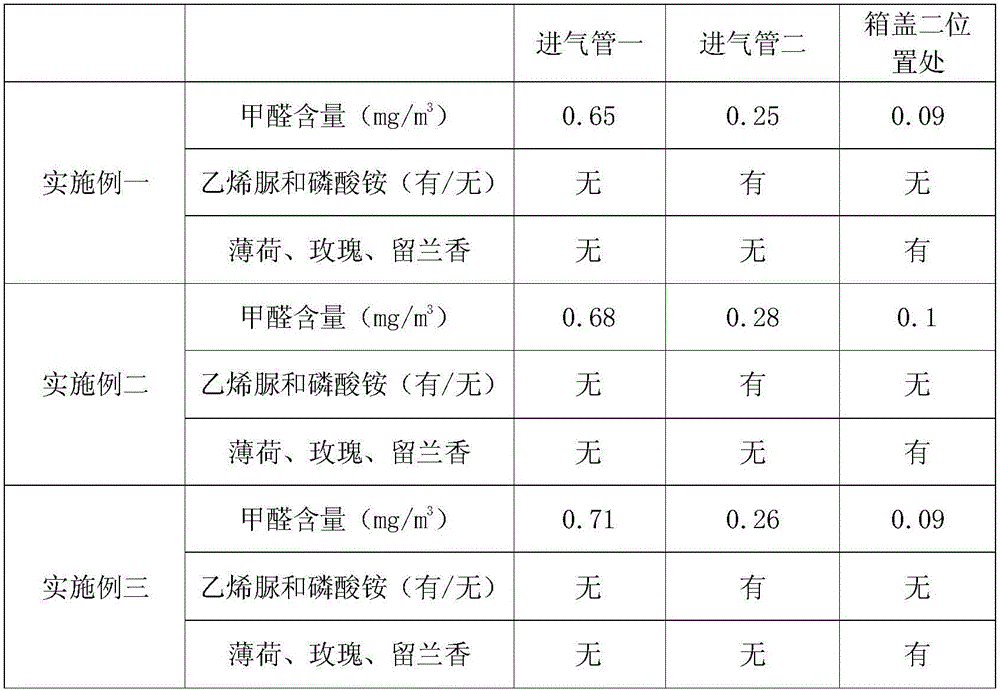

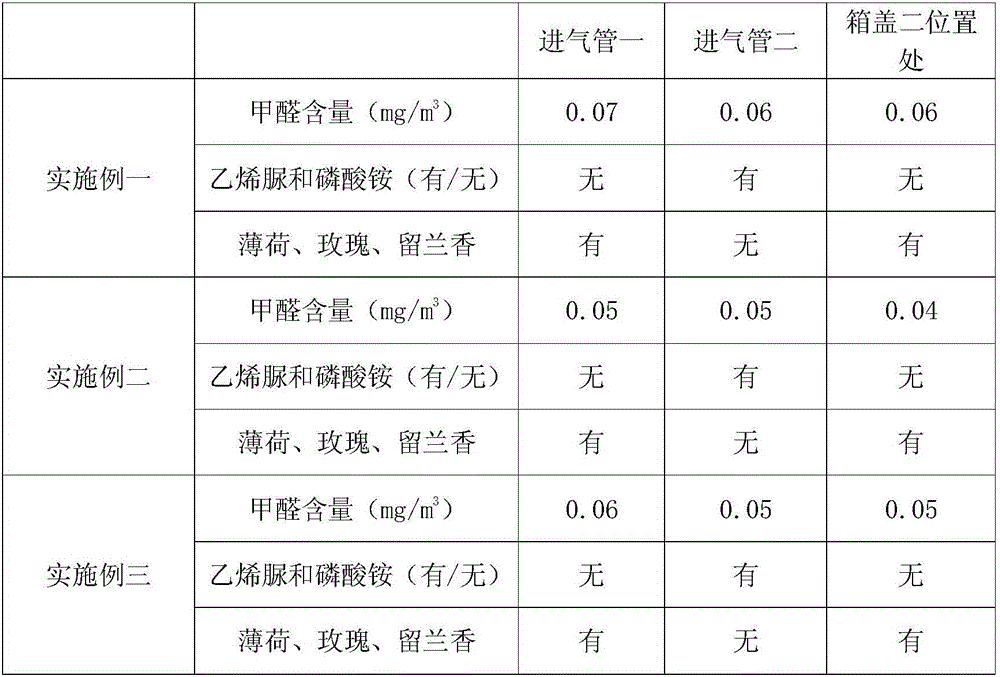

The invention discloses a formaldehyde scavenging agent and a formaldehyde scavenging method thereof. The formaldehyde scavenging agent comprises a plant component A, an essential oil component B and an adsorption component C, wherein the plant component A is prepared from, by weight, 3-8 parts of Chlorophytum comosum (Thunb.) Baker, 3-9 parts of Epipremnum aureum, 3-7 parts of Hedera nepalensis var. Sinensis (Tobl.) Rehd, 2-6 parts of aloe, 1-7 parts of Agave americana L., 2-5 parts of Sansevieria trifasciata Prain and 1-8 parts of Commelina communis; the essential oil component B is prepared from, by weight, 10-20 parts of ethanol, 5-15 parts of distilled water, 3-5 parts of peppermint oil, 1-2 parts of rose essential oil and 2-3 parts of spearmint oil; the adsorption component C is prepared from, by weight, 1-3 parts of attapulgite and 3-5 parts of bentonite by means of uniform mixing. In the formaldehyde scavenging method, a formaldehyde scavenging device is used for scavenging formaldehyde circularly. The formaldehyde scavenging agent and the formaldehyde scavenging method have the advantages of good formaldehyde scavenging effect and capabilities of improving air quality after formaldehyde scavenging and accelerating formaldehyde scavenging.

Owner:ANHUI ZHONGHONG TECH DEV CO LTD

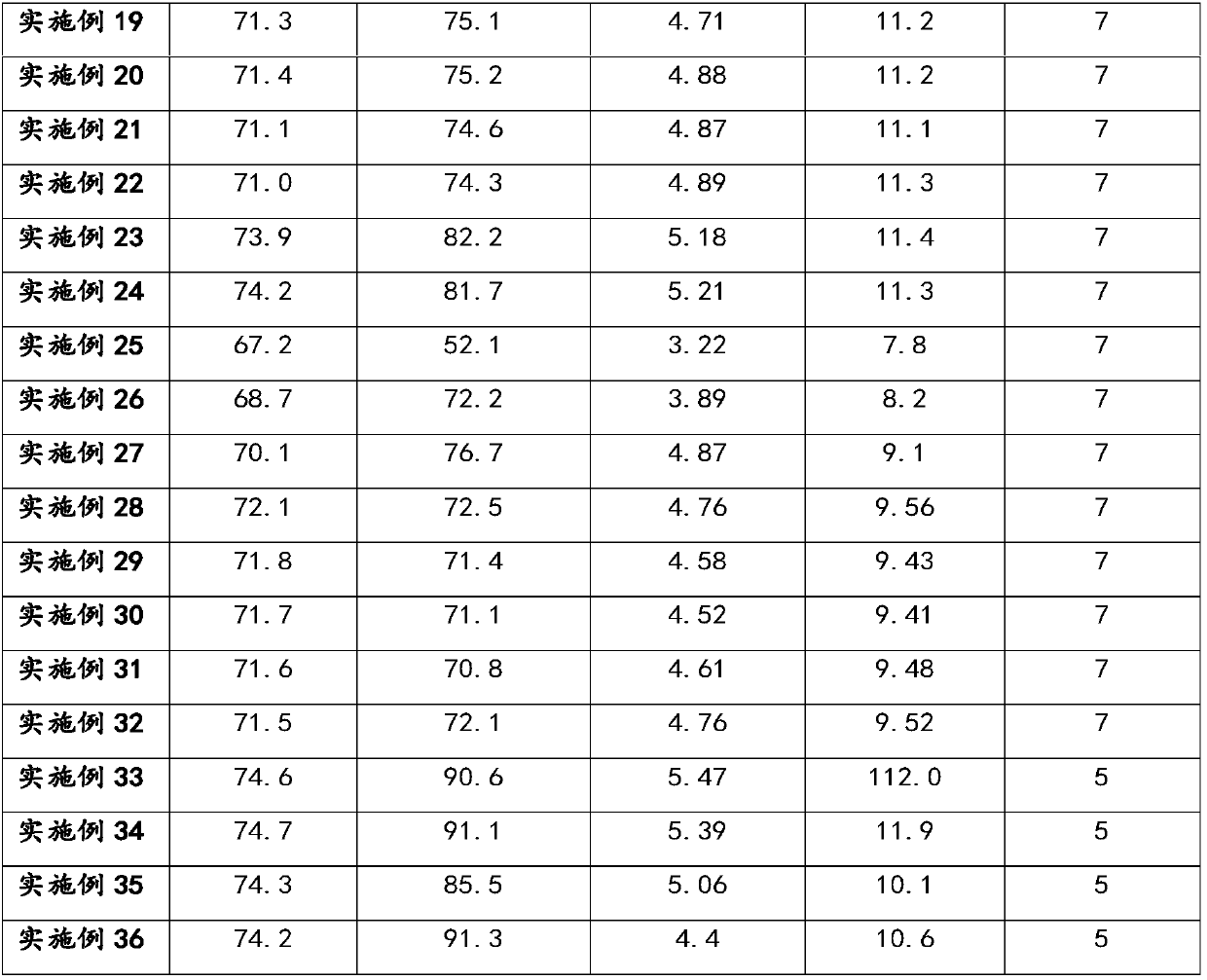

Cement-based stone-like curb stone as well as preparation method and molding equipment thereof

InactiveCN109986678AFast removalHigh removal rateDischarging arrangementMouldsVacuum pumpingWork in process

The invention relates to the technical field of artificial stones, in particular to a cement-based stone-like curb stone as well as a preparation method and molding equipment thereof. The cement-basedstone-like curb stone comprises the following components of, in percentage by weight, 14-16% of cement, 26-28% of yellow sand, 45-55% of gypsum and 6-8% of water. The preparation method comprises thefollowing steps of a) fully mixing, in percentage by weight, 14-16% of cement, 26-28% of yellow sand, 45-55% of gypsum and 6-8% of water to obtain a concrete mixed wet material; (b) placing the concrete mixed wet material into the molding equipment, closing a mold, wherein the closing pressure is 100-160 MPa, and performing negative pressure vacuum pumping on a cavity, wherein the vacuum degree value of the vacuum pumping is 0.8-1.0 MPa, the closing and pressure maintaining time and the vacuum pumping time are less than or equal to 5 minutes, and the concrete mixed wet material quickly loses90% of moisture and is initially solidified and formed into a curb stone semi-finished product; and (c) carrying out mold opening and demolding by the molding equipment, transferring the semi-finishedcurb stone product out of the mold for stacking to obtain a finished cement-based stone-like curb stone product. The molding equipment is adopted, the manufacturing efficiency is high, the strength of the curb stone is high, the production efficiency is high, and the production cost is reduced.

Owner:CHANGZHOU INST OF LIGHT IND TECH

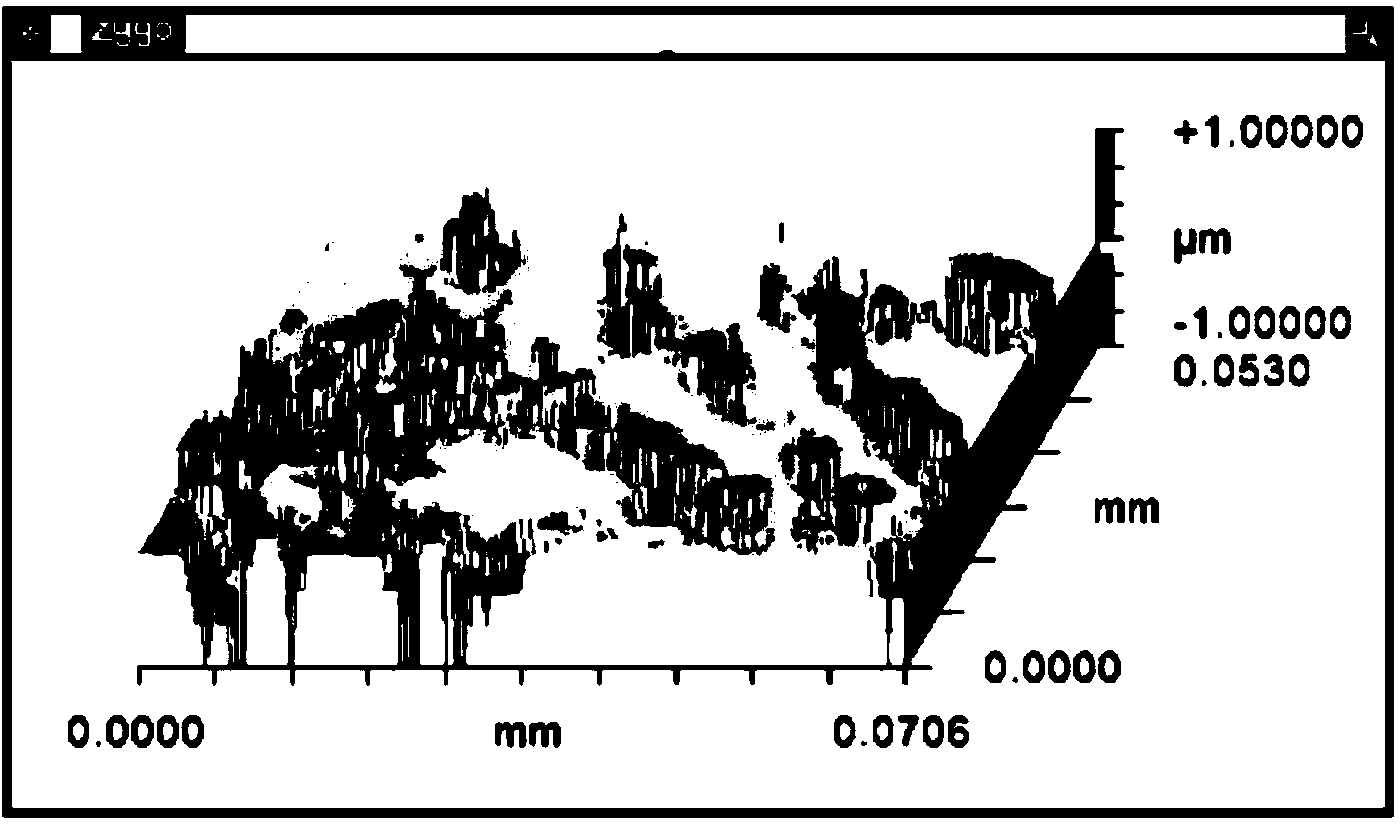

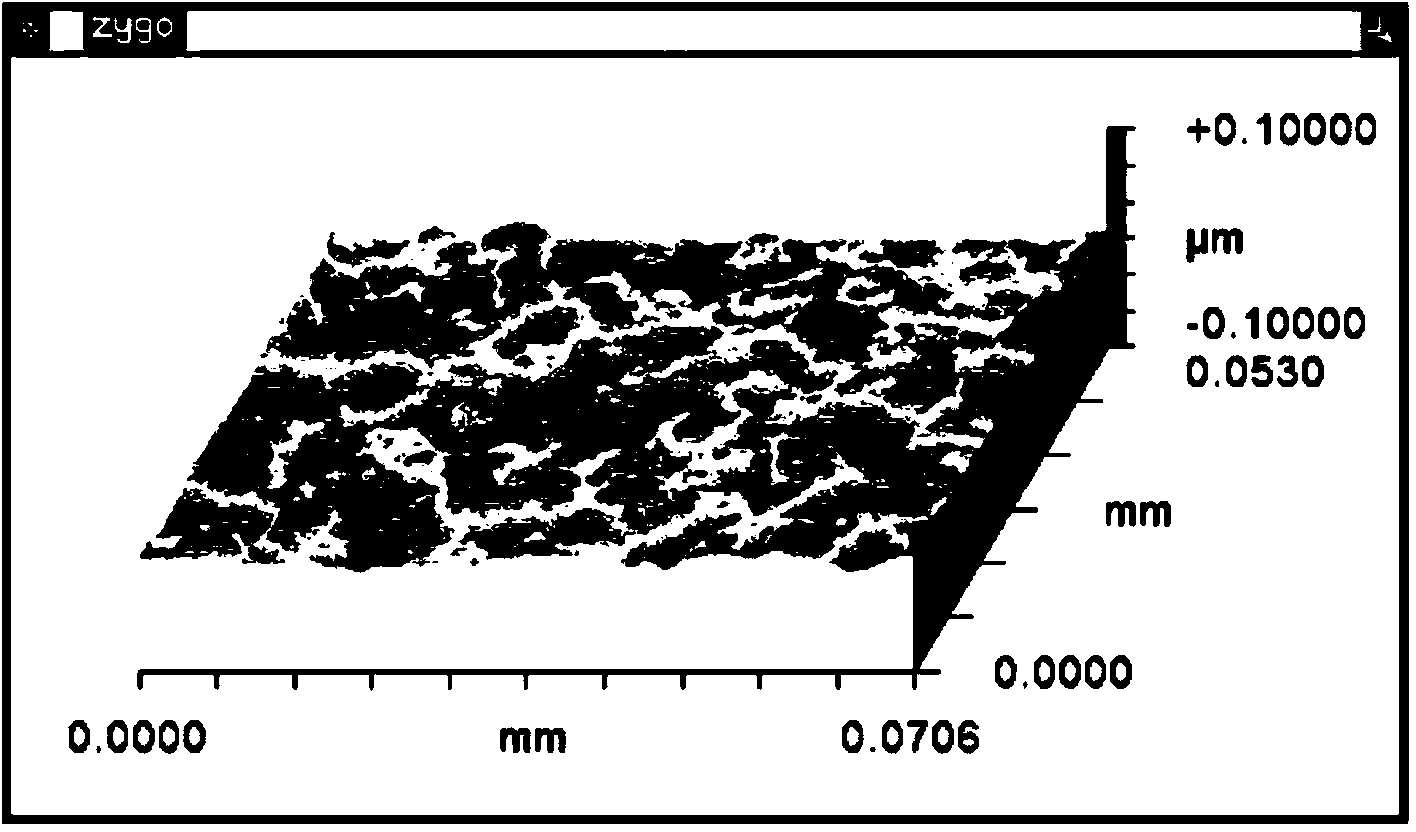

Electrogenerated chemical polishing method

ActiveCN103924287AAbility to selectively removeMethod steps scienceSemiconductor/solid-state device manufacturingMicro nanoElectrochemical response

The invention provides an electrogenerated chemical polishing method which comprises the following steps: preparing a working solution which contains an electroactive mediator, a pH regulating agent, a viscosity regulating agent and an inhibiting agent; parallelly and oppositely arranging the working surface of a working electrode and the surface of a workpiece, wherein the working surface of the working electrode has smoothness less than 1 micrometer; and immersing the working surface of the working electrode and the surface of the workpiece into the working solution, and regulating the spacing between the working surface of the working electrode and the surface of the workpiece to 0.05-20 micrometers through a micro-nano composite feeding mechanism. According to the method, a power supply is started to electrify the working electrode and an auxiliary electrode, the electroactive mediator near the working surface of the working electrode generates an etching agent through electrochemical reaction, and a local high point positioned on the surface of the workpiece is selectively etched in such a way that the etching agent is dispersed to the surface of the workpiece and generates diffusion controlled etching reaction, so that the unstressed polishing on the surface of the workpiece is realized.

Owner:DALIAN UNIV OF TECH +1

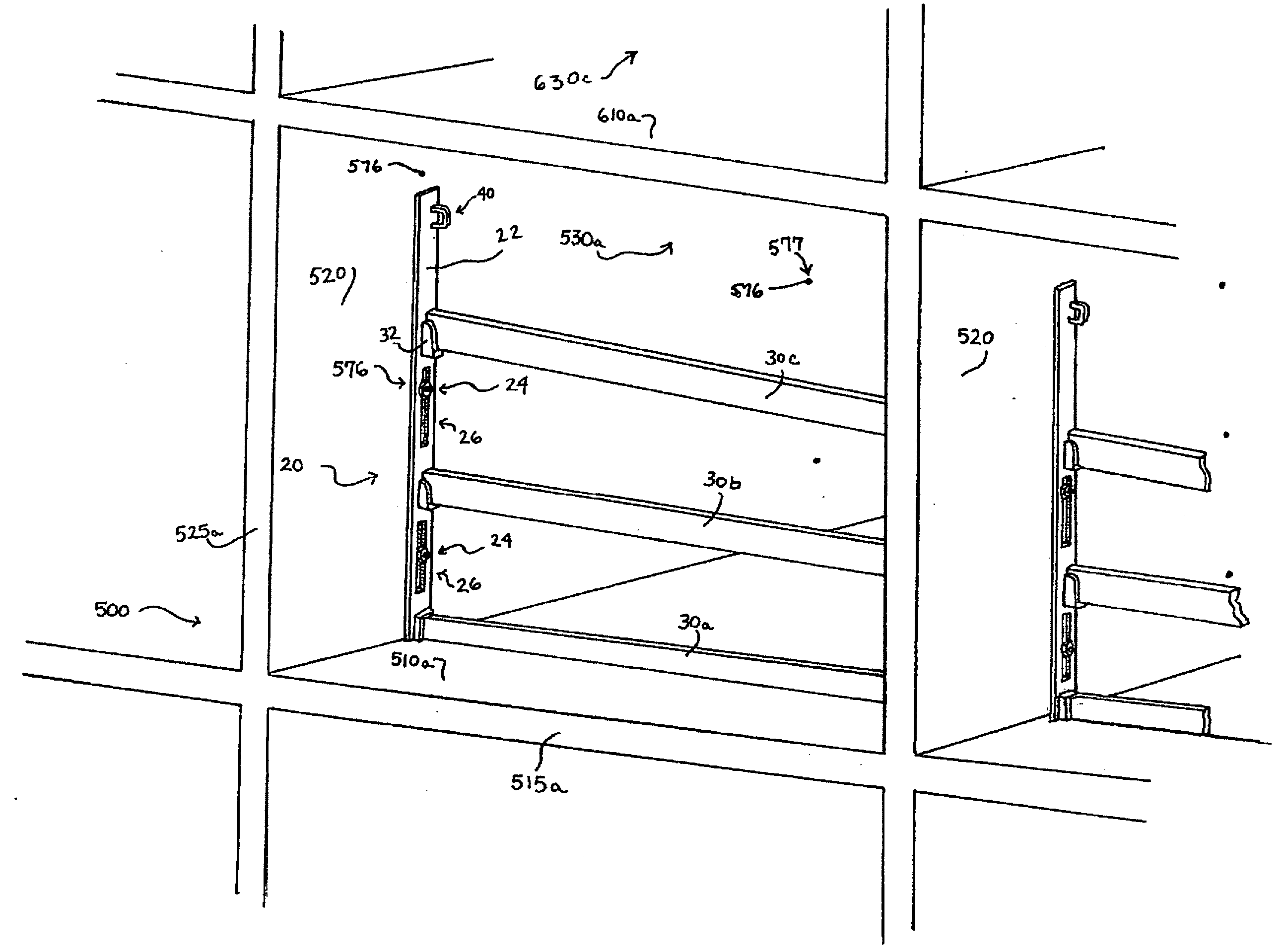

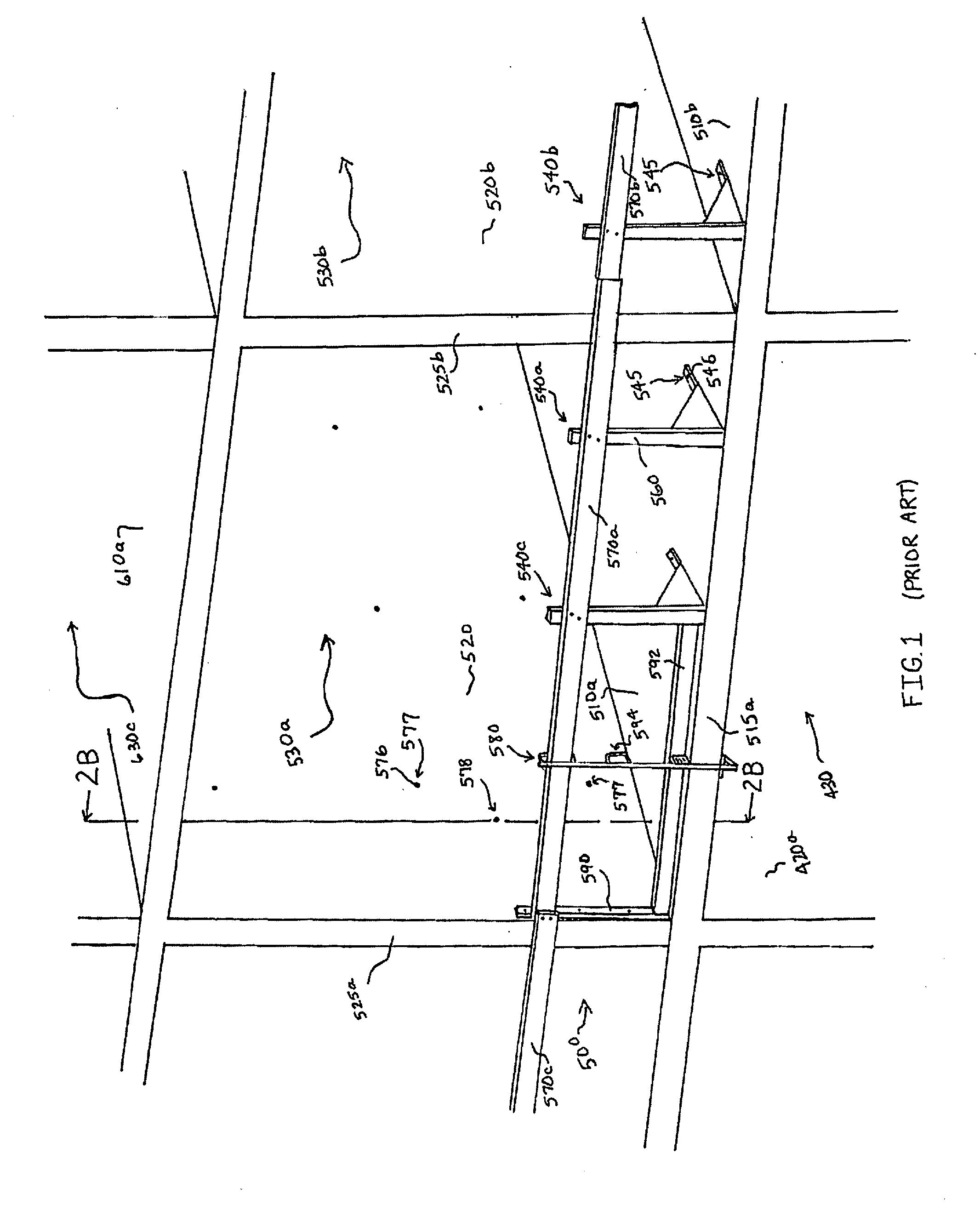

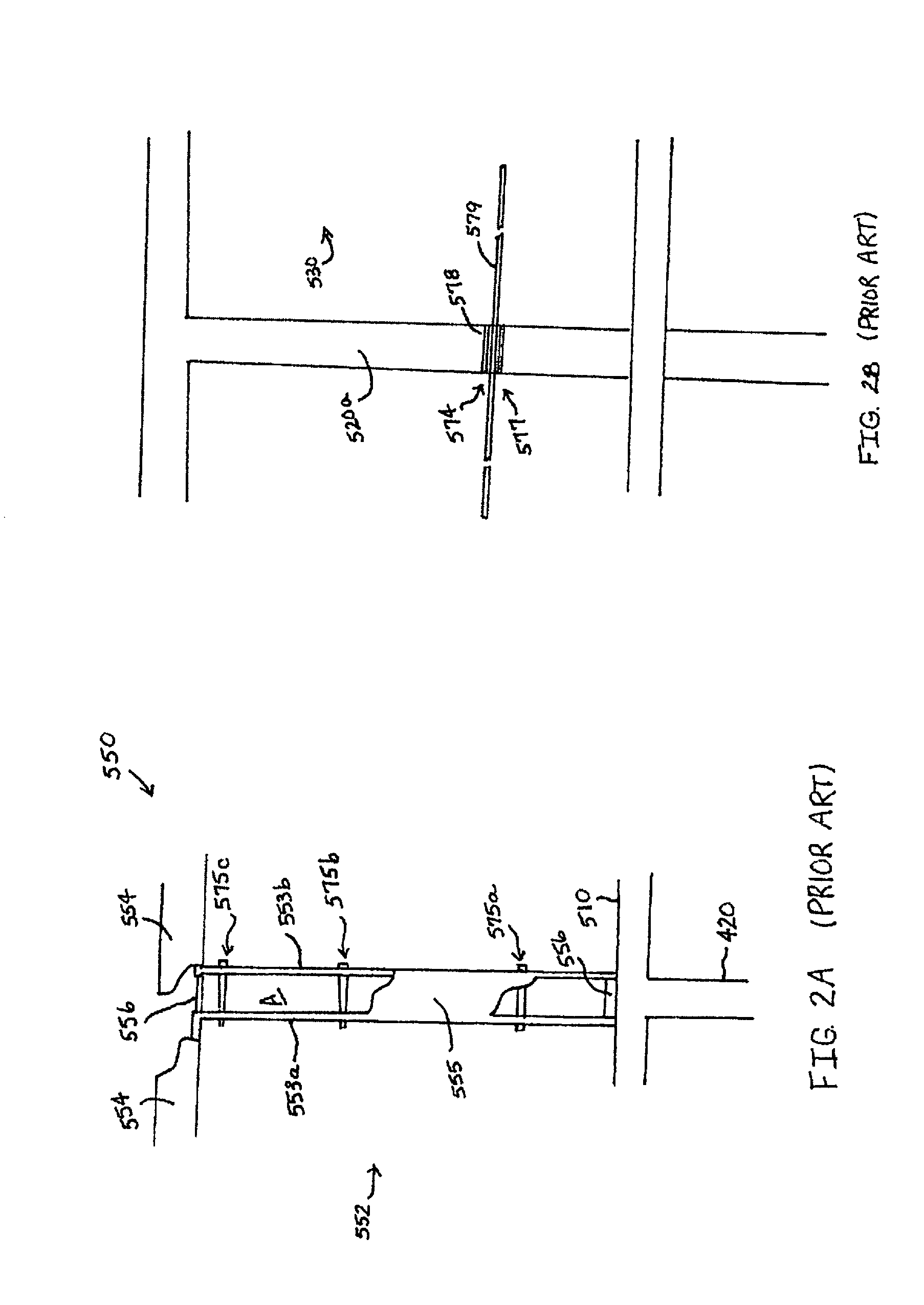

Guardrail stanchion and system

ActiveUS20140373360A1Avoid damageFast removalMetal-working apparatusDomestic articlesPre-existingFastener

A guardrail system (20) and method comprises utilizing at least one through-hole (577) of a poured concrete wall (520) of a structure (500) to affix a stanchion (22, 122, 222) to the wall inside a bay (530) of the structure. The stanchion allows for a guardrail (30) or a gate to be conveniently and securely positioned within the bay (530) without damage to the structure and without covering an edge (515, 525) of the structure (500). A fastener (24) inserts through the through-hole (577) which is a pre-existing tie-hole (576) resulting from formation of the wall (520). In one optional aspect a guardrail stanchion (222) includes a base segment (50) having at least two slots (26) for receiving fasteners (24) which insert through two tie-holes (576) of the wall (520), and at least one side segment (52) having at least one adjustment port (56), the side segment (52) extending generally perpendicular to the base segment (50). A pair of stanchions (22, 122, 222) may be affixed to opposing walls within the bay, and guardrails (30) affixed thereto and spanning across the bay (530). The system (20) may also include a cable system (80) having a cable (579) operate as a guardrail (30) to be tightened by utilizing a stanchion (22, 122, 222) in accordance with the invention. Additional aspects are also presented for utilizing timber stanchions (22, 122, 222) and nylon straps (30), among other aspects.

Owner:OUICANDUIT

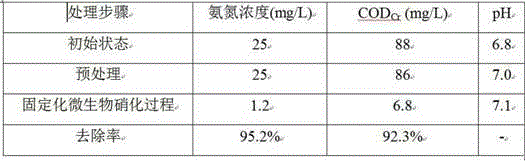

Preparing and using method for immobilized photosynthetic bacteria for treating aquaculture waste water

InactiveCN104944712AImprove stabilityRetain activityMultistage water/sewage treatmentOn/in organic carrierAmmoniacal nitrogenNitrogen removal

The invention discloses a preparing and using method for immobilized photosynthetic bacteria for treating aquaculture waste water. The immobilized photosynthetic bacteria are formed by natural polymer sodium alga acid hydrogel of a grid structure, and active photosynthetic bacteria fixed in grids. The invention further discloses the using method for the immobilized photosynthetic bacteria for treating the aquaculture waste water. According to the preparing and using method for the immobilized photosynthetic bacteria for treating the aquaculture waste water, the COD removing rate can reach 90%, the ammonium-nitrogen removal rate can reach 95%, and the operation of using photosynthetic bacterium particles for treating the aquaculture waste water is easy and convenient to implement, and the pollutant removing rate is high.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

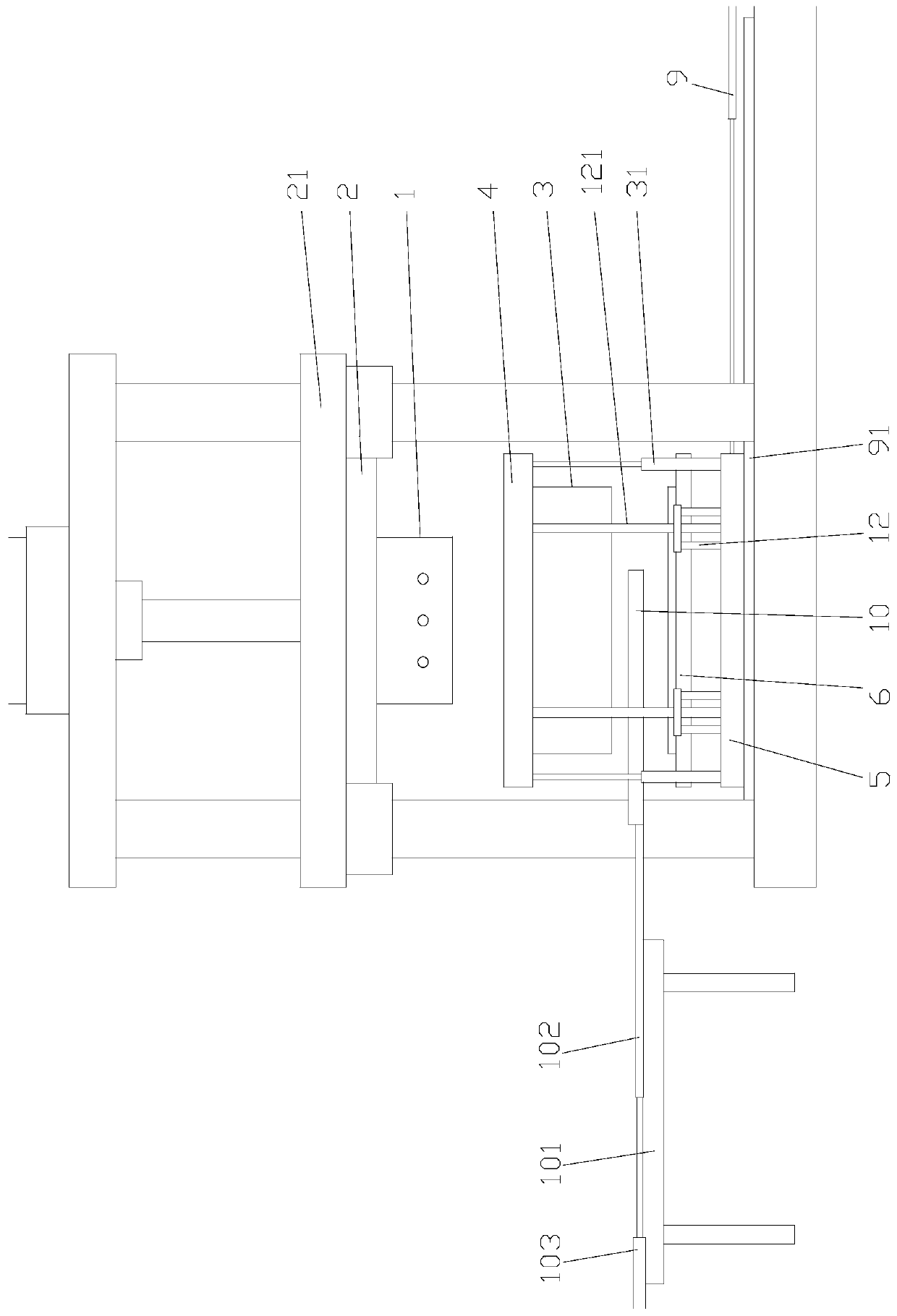

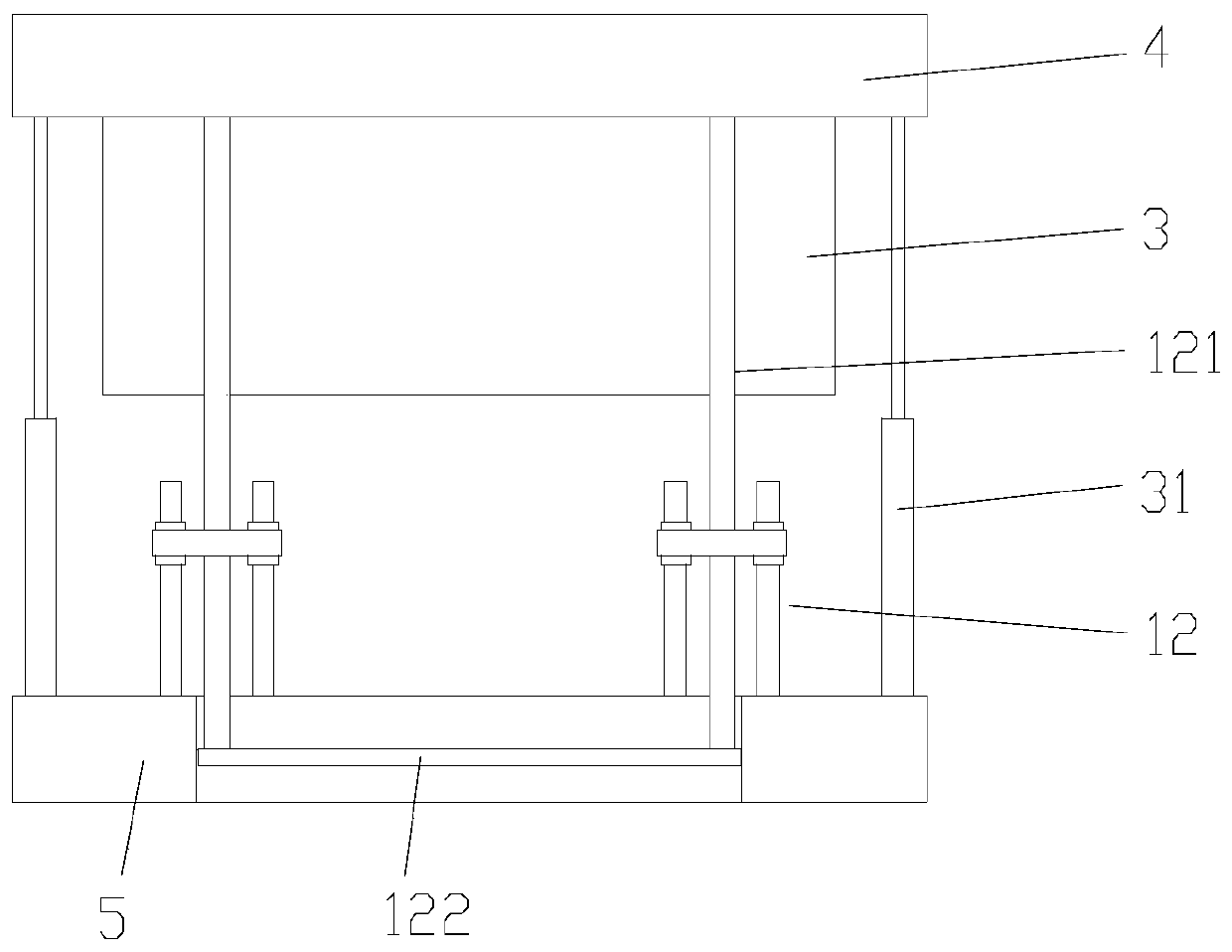

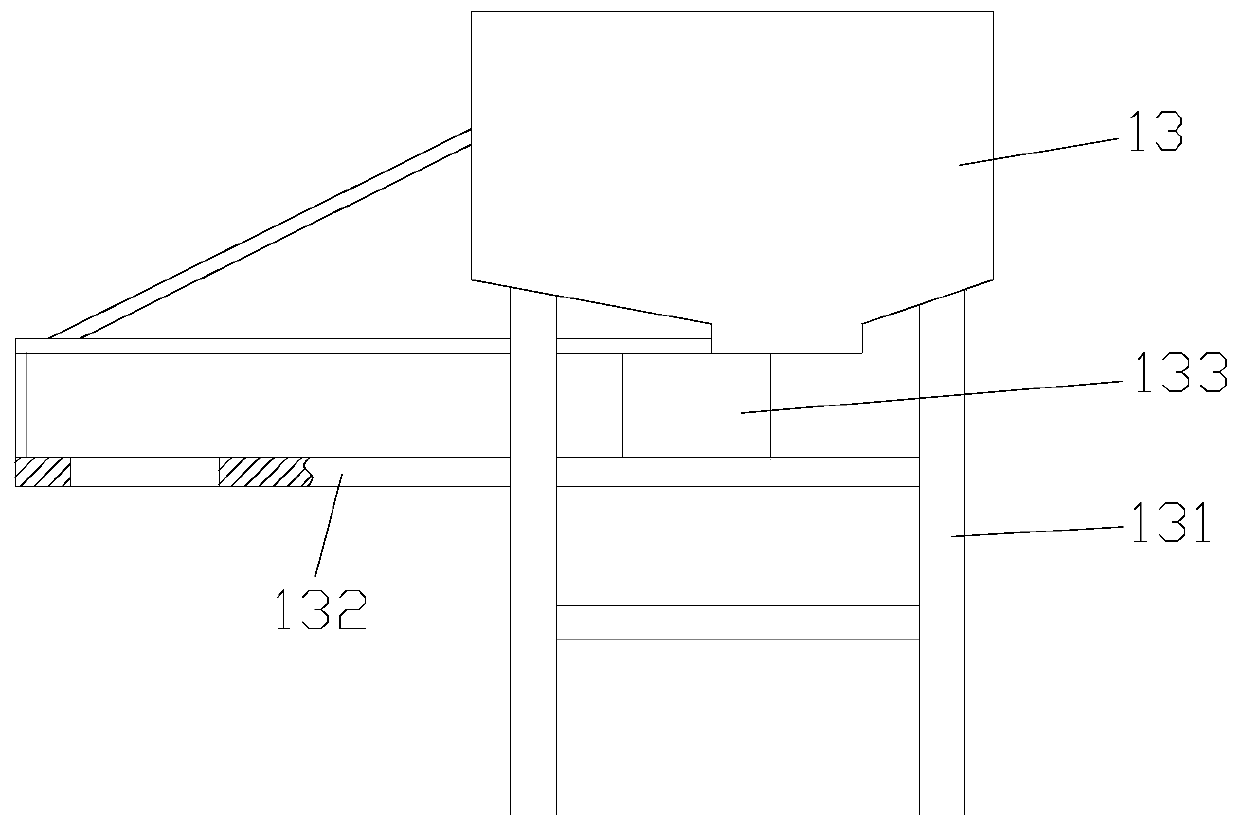

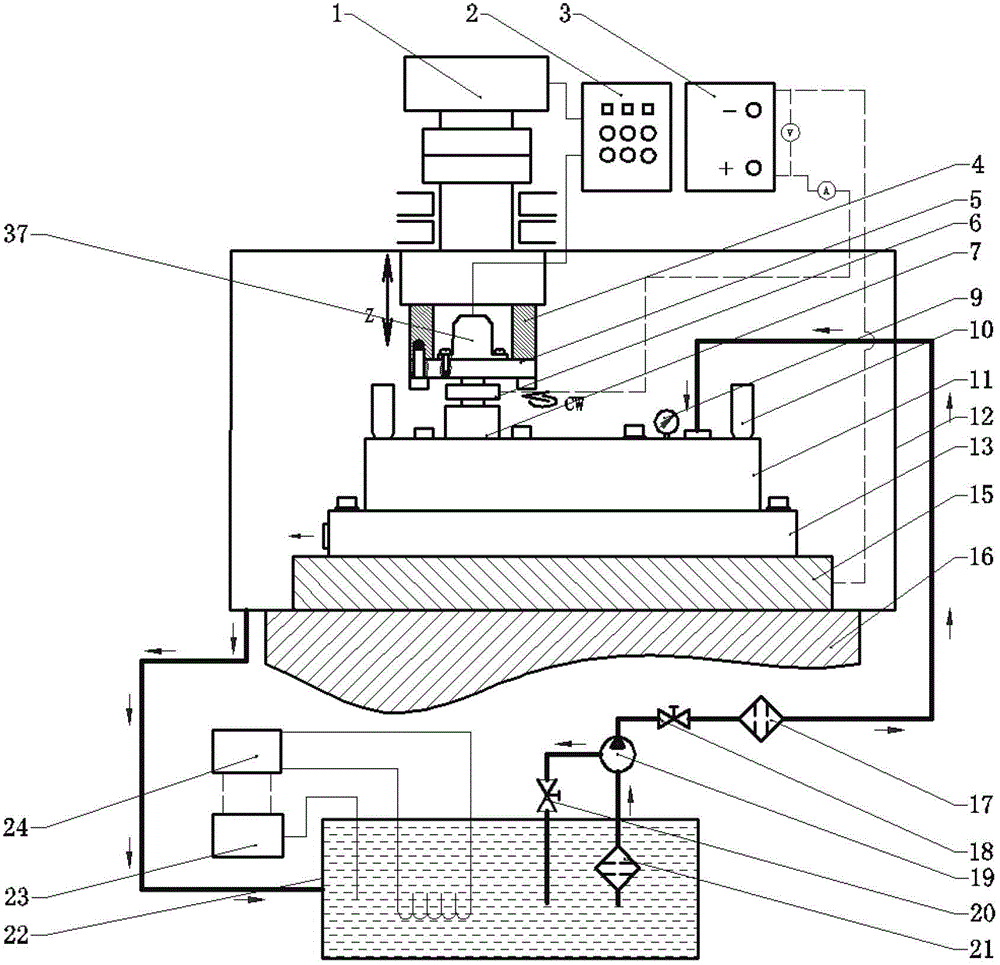

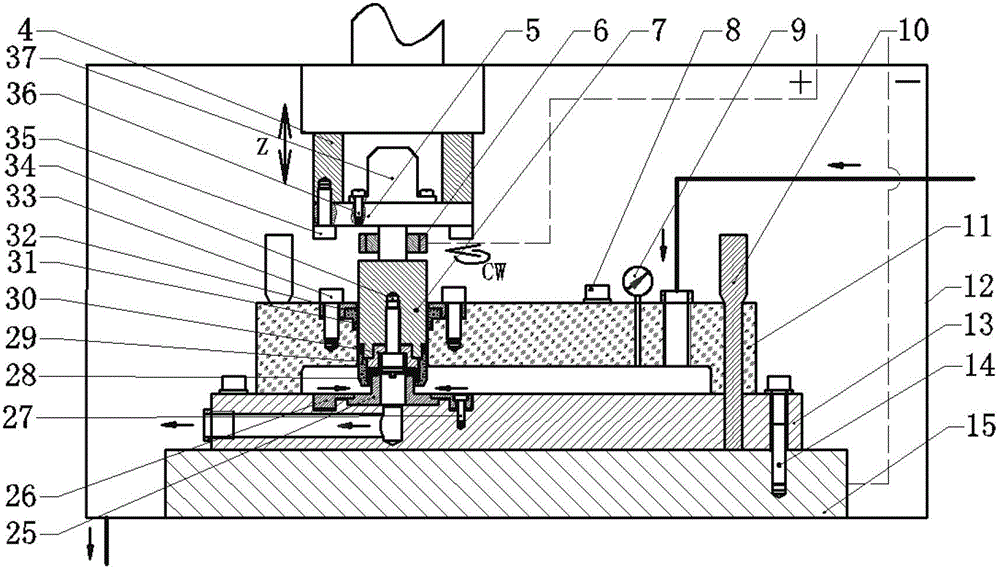

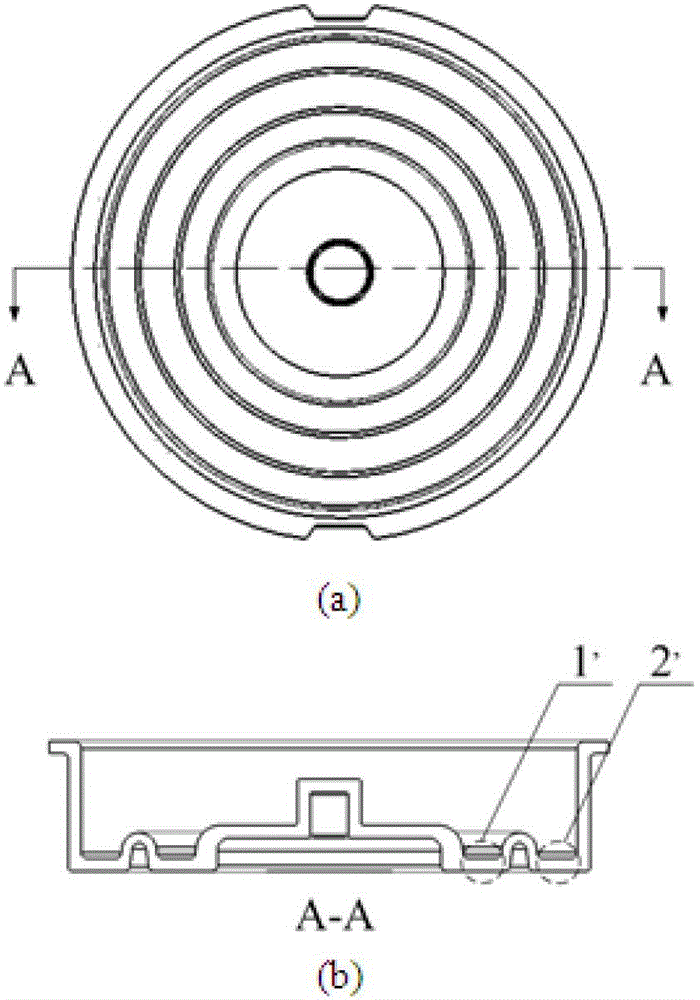

Thinning and electrolytic machining device for inner wall of static cutter cover of shaver and machining process method of device

InactiveCN102941383AHigh quality processingEfficient processingMachining electrodesElectrical-based machining electrodesThinningMachining process

The invention relates to a thinning and electrolytic machining device for the inner wall of a static cutter cover of a shaver and a machining process method of the device and belongs to the technical field of machining of the static cutter cover of the shaver. The thinning and electrolytic machining device is based on an electrolytic machining principle and adopts a tool cathode to carry out thinning and machining forming on the inner wall of a blank of the static cutter cover; and in the process of carrying out electrolytic machining on the blank of the static cutter cover, the blank of the static cutter cover rotates around the axis of the blank of the static cutter cover when linearly fed relative to the tool cathode, and electrolyte required for the electrolytic machining flows through a machining gap formed by the blank of the static cutter cover and the tool cathode continuously at a high speed (10 m / s to 20 m / s). The thinning and electrolytic machining device not only has a high machining efficiency, a stable machining process and a high accuracy, but also realizes high-quality and high-efficiency machining on the inner wall of the static cutter cover.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

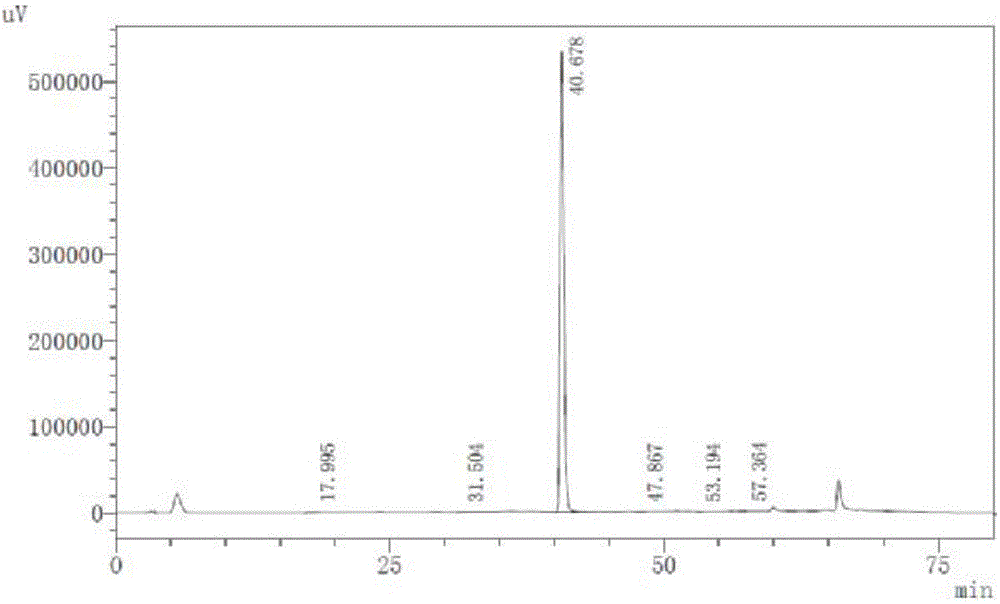

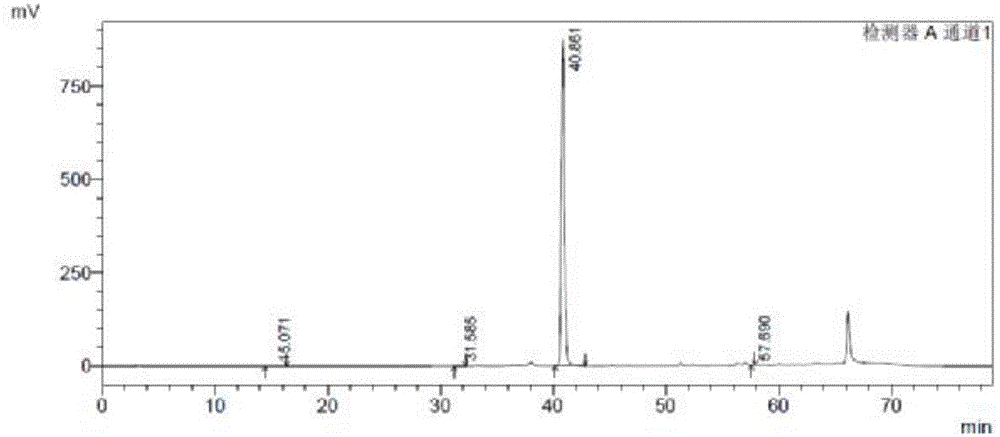

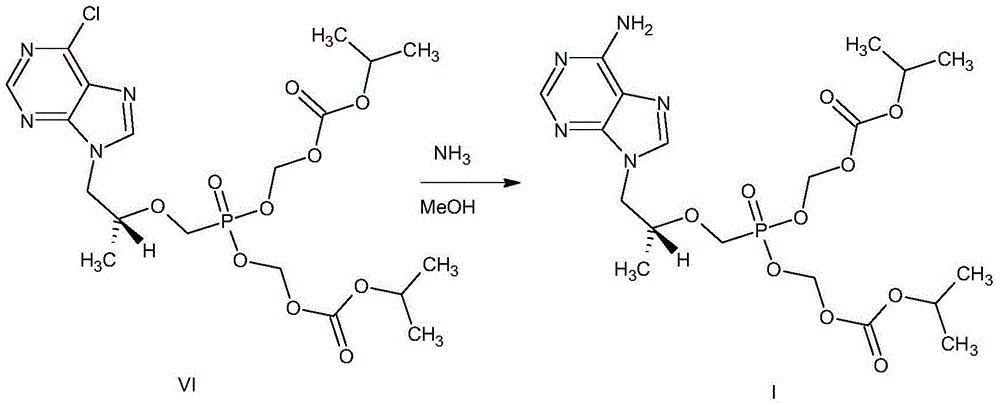

Tenofovir disoproxil salt preparation method

InactiveCN104130288AHigh yield and purityFast removalGroup 5/15 element organic compoundsDecompositionEvaporator

The invention relates to a tenofovir disoproxil salt preparation method; first tenofovir or tenofovir monohydrate is used as a starting material for condensation reaction with chloromethyl isopropyl carbonate in a strong polar organic solvent in the presence of a phase transfer catalyst to prepare tenofovir disoproxil, then the tenofovir disoproxil is salified with succinic acid and fumaric acid to prepare a tenofovir disoproxil salt; in the stage of esterification reaction for removing the organic solvent, a thin film evaporator is used for distillation for removing rapidly the solvent at low temperature, the material flows through the evaporator in a very short time about 10 seconds, the problems of reactant decomposition caused by too high distillation temperature and long heating time in the prior art can be avoided, and the product purity and yield are greatly improved. The final finished product HPLC (high performance liquid chromatography) is more than or equal to 99.85%, the single impurity content is less than 0.1%, and the yield is 62%-67%.

Owner:NINGBO MENOVO PHARMA

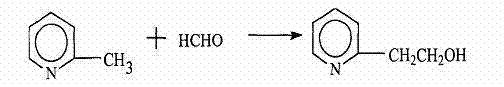

Preparation method of 2-ethoxyl pyridina

InactiveCN102731372ALow equipment requirementsReduce manufacturing costOrganic chemistryPyridineParaformaldehyde

The invention discloses a preparation method of 2-ethoxyl pyridina, which comprises the steps of: (1) using tetrahydrofuran as a solvent, enabling 2-methyl pyridine and organic alkali to completely react in the solvent at -60-60 DEG C to prepare a reaction liquid; (2) adding paraformaldehyde into the reaction liquid, agitating and reacting for 0.5-5 hours at 10-60 DEG C, then dropping water into the mixture under the reaction condition, and agitating continuously and reacting for 0.5-1 hours at 10-60 DEG C after dropping water to prepare a product liquid; and (3) removing water in the product liquid, then removing tetrahydrofuran in the product liquid to obtain the 2-ethoxyl pyridine. The method provided by the invention is simple in process operation, short in synthesizing time of product, low in production cost, high in production efficiency, less in secondary reaction, high in product yield and high in purity.

Owner:SHANDONG TIANYI CHEM

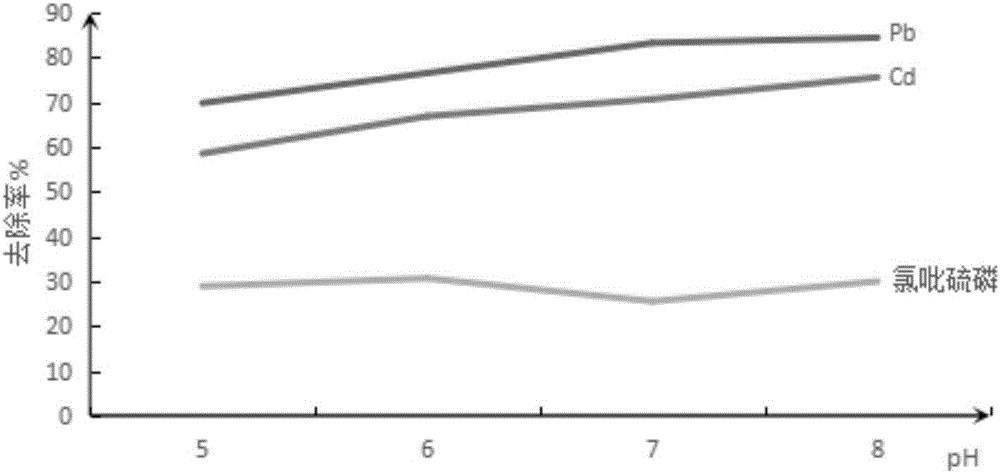

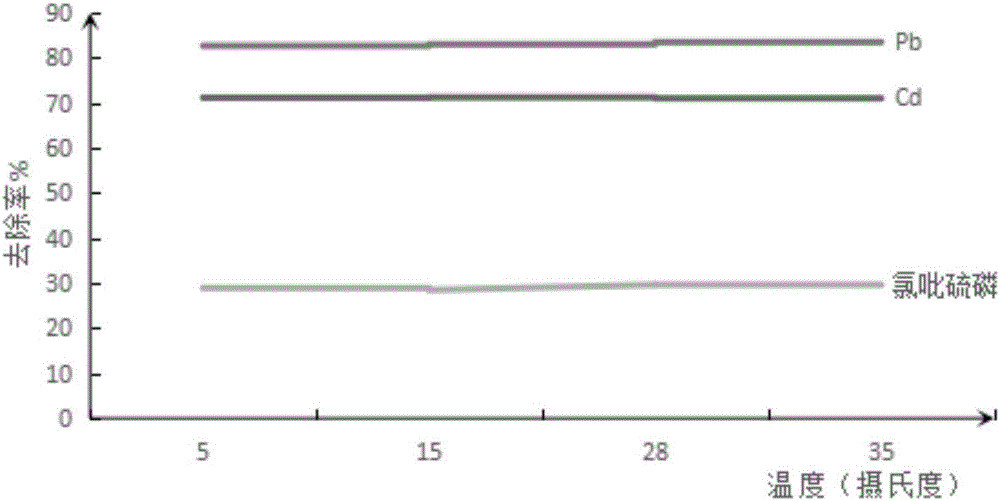

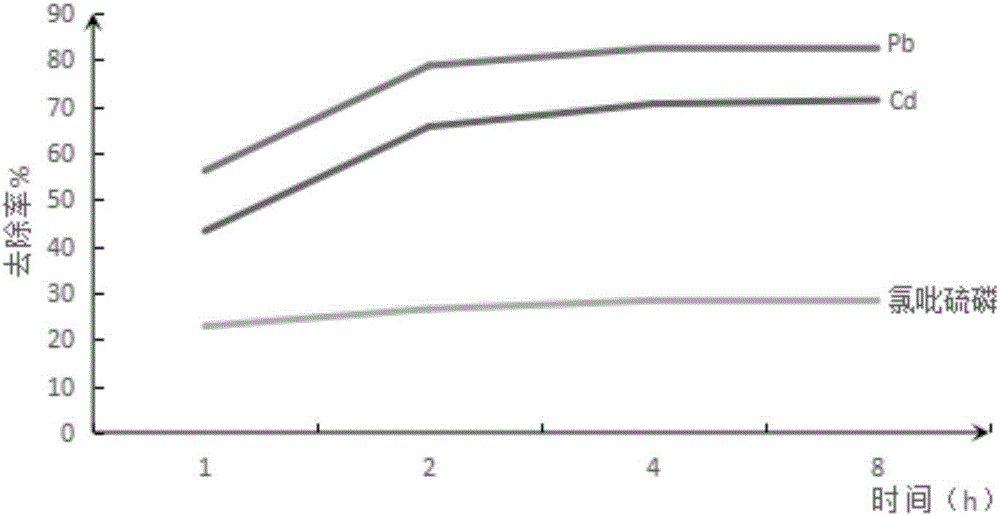

Treatment and reutilization method of organic and inorganic compound polluted loess leaching liquid

ActiveCN107175065ALow costAbundant resourcesOther chemical processesWater contaminantsChlorpyrifosClay minerals

The invention discloses a treatment and reutilization method of organic and inorganic compound polluted loess leaching liquid. The treatment and reutilization method comprises the following steps: putting an organic and inorganic compound body, a loess ferromanganese nodule and losses clay mineral into a granulating machine according to the mass ratio of (10 percent to 40 percent) to (10 percent to 40 percent) to (10 percent to 40 percent) and granulating; in a granulating process, adding a gypsum solution to prepare an adsorbent for carrying out adsorption treatment on the organic and inorganic polluted loess leaching liquid containing organic chlorpyrifos pesticide and inorganic heavy metal Pd / Cd. According to the treatment and reutilization method disclosed by the invention, the concentration of Pb and Cd in an adsorbed solution is detected; after the concentration reaches the standard, the solution can be directly reused for agricultural irrigation and drop irrigation and the aim of recycling and reutilizing the chlorpyrifos pesticide and other nutrients in the solution is realized. The adsorbent obtained by precipitation and centrifugal separation is safely backfilled or used in other ways, such as a road construction axillary material and a building axillary material.

Owner:SHAANXI UNIV OF SCI & TECH

Immobilized nitrifying bacteria capable of removing ammonia nitrogen in aquarium and preparation method of immobilized nitrifying bacteria

InactiveCN104803487AImprove stabilityRetain activityPisciculture and aquariaBiological water/sewage treatmentWater solubleNitrifying bacteria

The invention discloses immobilized nitrifying bacteria for removing ammonia nitrogen in an aquarium and a preparation method of the immobilized nitrifying bacteria. The immobilized nitrifying bacteria comprises polymeric hydrogel with a grid structure and activated nitrifying bacteria fixed in the grids. The polymeric hydrogel is formed through free radical polymerization of water-soluble acrylate monomers. The invention further discloses a using method of the immobilized nitrifying bacteria in the aquarium, and further provides a using position of immobilized nitrifying bacteria in the aquarium. According to the immobilized nitrifying bacteria for removing ammonia nitrogen in the aquarium, provided by the embodiment of the invention, the ammonia nitrogen removal rate reaches 95%. Ammonia nitrogen in the aquarium can be treated by using nitrifying bacteria particles, high simpleness and convenience and high easiness in implementation are achieved, and the ammonia nitrogen removal rate is high.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

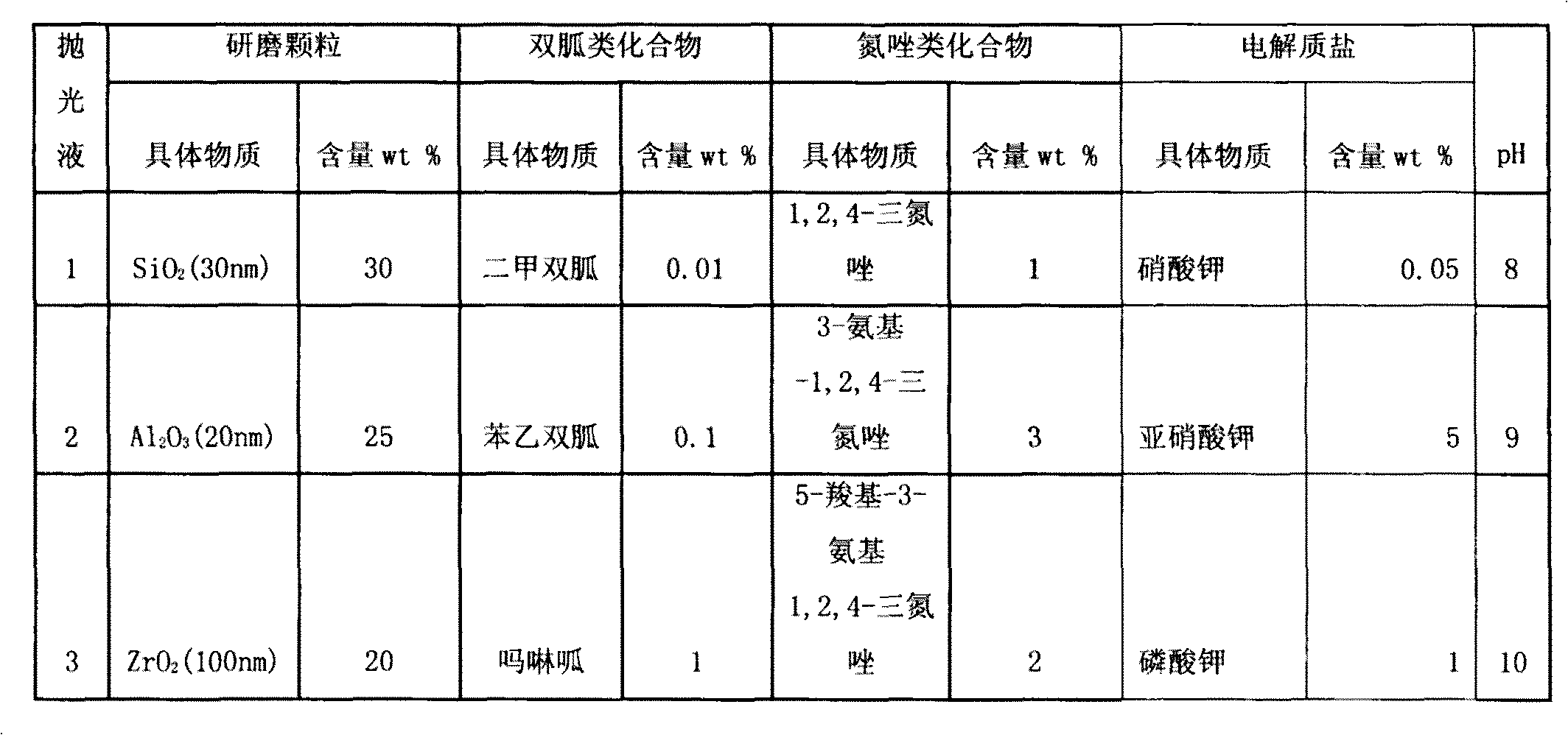

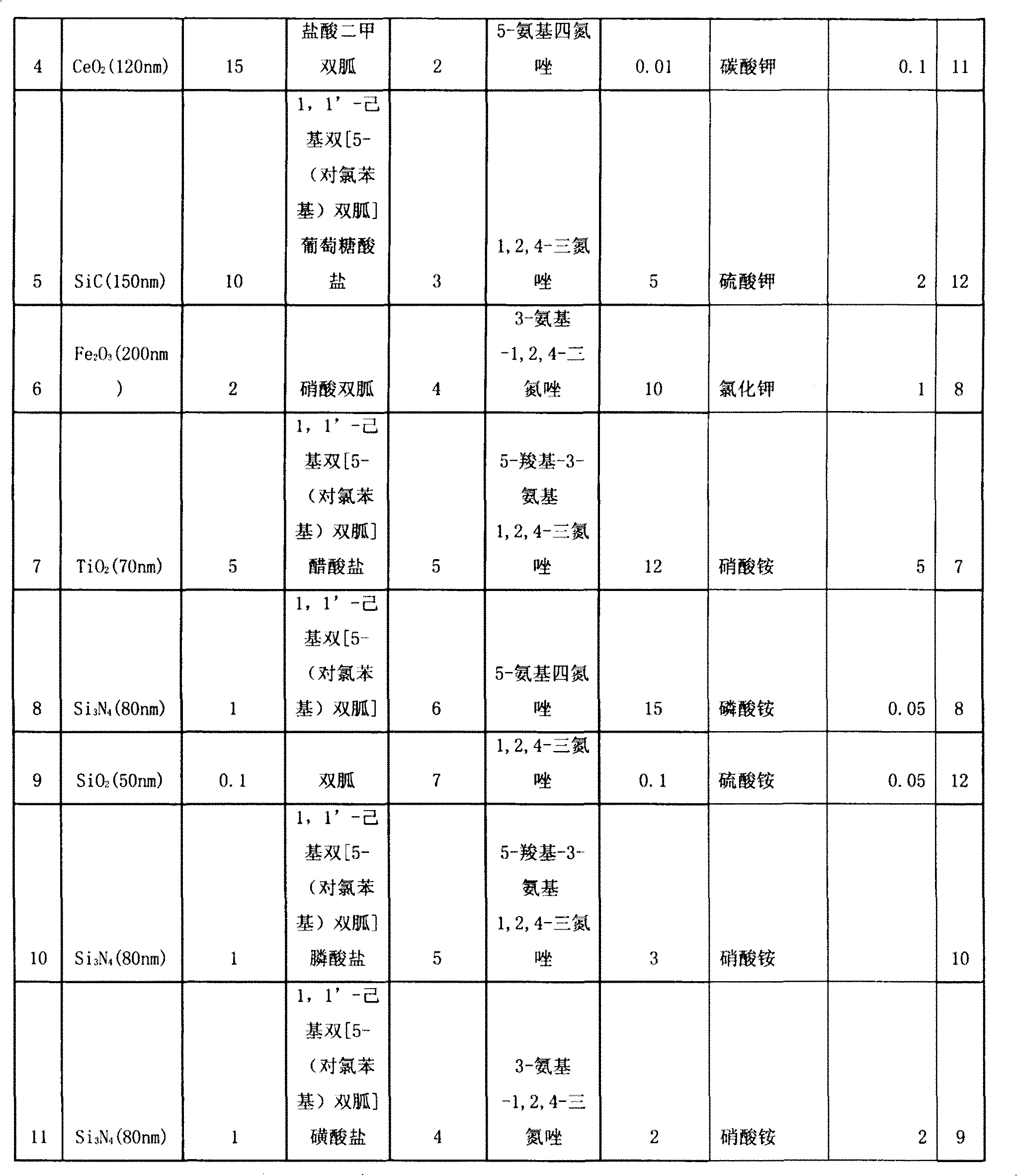

Chemical mechanical polishing solution

ActiveCN101665663AImprove removal rateFast removalPolishing compositions with abrasivesCompound (substance)Physical chemistry

The invention discloses chemical mechanical polishing solution, which comprises polishing particles and water, as well as bis-biguanide compounds, azole compounds and electrolyte. The bis-biguanide compounds and the azole compounds simultaneously contained in the polishing solution have synergic effect, and are associated with the added electrolyte, so the polishing solution can remarkably improve the velocity of removing polycrystalline silicon.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

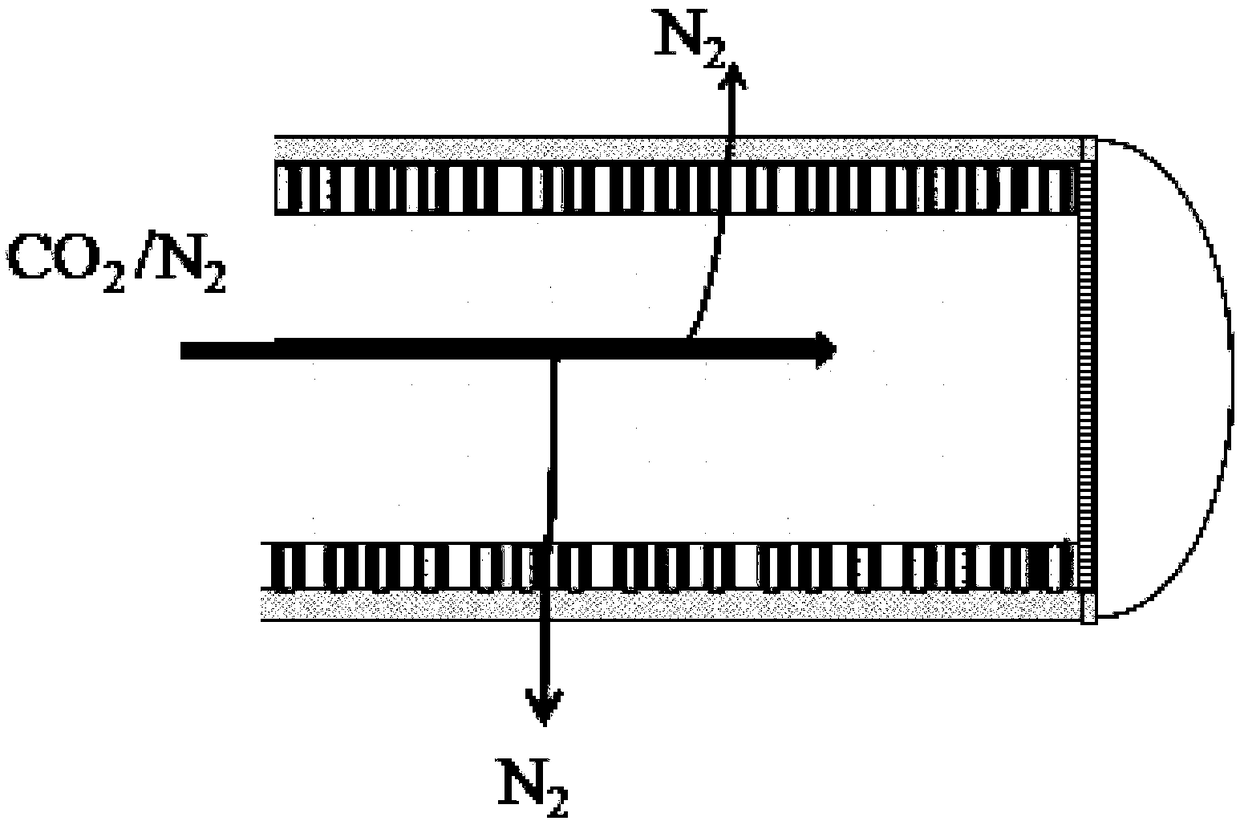

Solid amine adsorbent, preparation method thereof, and CO2 adsorption assembly containing same

ActiveCN109174017ALarge specific surface areaLarge pore volumeGas treatmentOther chemical processesHollow fibreFiber

The invention provides a solid amine adsorbent, a preparation method thereof, and a CO2 adsorption assembly containing the same. The solid amine adsorbent comprises hollow fibers and an organic aminesupported on the inner surface of the hollow fibers. The hollow fibers have a conveniently-adjusted pore structure, and can accommodate introduction groups with different structures and different molecular sizes to make the selection range of the organic amine wide; and a regular finger-like structure in the finger-like porous layer of the hollow fibers makes the organic amine uniformly distributed in pores to form an organic amine film, so the surface area of a CO2 adsorption reaction is greatly improved, and the removal rate of CO2 is significantly improved.

Owner:TIANJIN POLYTECHNIC UNIV +1

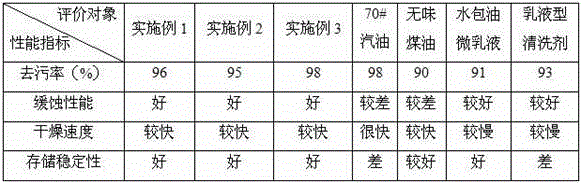

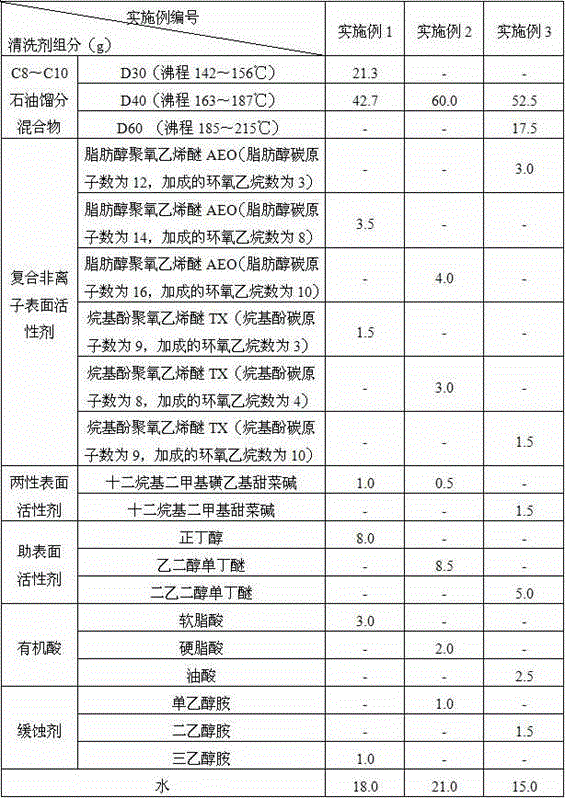

Water-in-oil microemulsion printing ink cleaning agent and preparation method thereof

ActiveCN106398375AStrong cleaning powerDiffusion is fastChemical paints/ink removersOrganic acidChemistry

The invention relates to a water-in-oil microemulsion printing ink cleaning agent and a preparation method thereof. The cleaning agent is prepared from a C8-C10 petroleum fraction mixture, a composite nonionic surfactant, an ampholytic surfactant, a cosurfactant, organic acid, a corrosion inhibitor and water. The preparation method comprises the steps that the composite nonionic surfactant, the ampholytic surfactant and the cosurfactant are added into the C8-C10 petroleum fraction mixture in sequence, all the materials are stirred for 20-40 min, then a mixture of organic acid and the corrosion inhibitor is added, water is added, stirring is conducted for 20-40 min till the mixture is clear and colorless, and the cleaning agent is obtained. The cleaning agent is high in printing ink stain removing speed, good in effect, high in corrosion inhibition, high in drying speed and good in stability; the cleaning agent has the advantages of being high in flashing point and noncombustible and not polluting the environment, the safety performance is good, the cost is low, and the cleaning agent can be widely used for cleaning of printing machines, ink rollers and rubber blankets; the method is easy to implement and low in energy consumption, and microemulsion can be formed by means of self-emulsification at room temperature.

Owner:HUNAN NORMAL UNIVERSITY

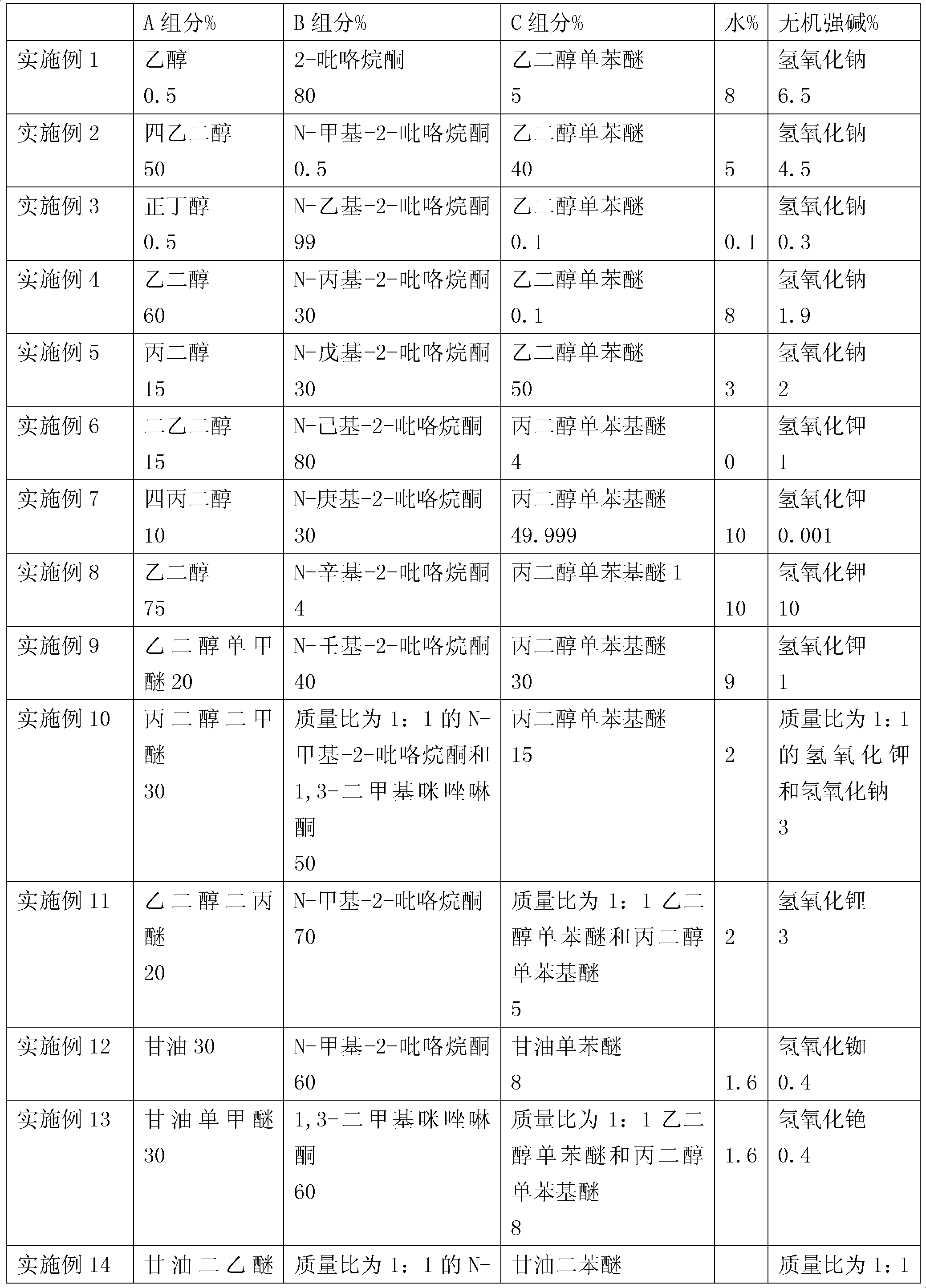

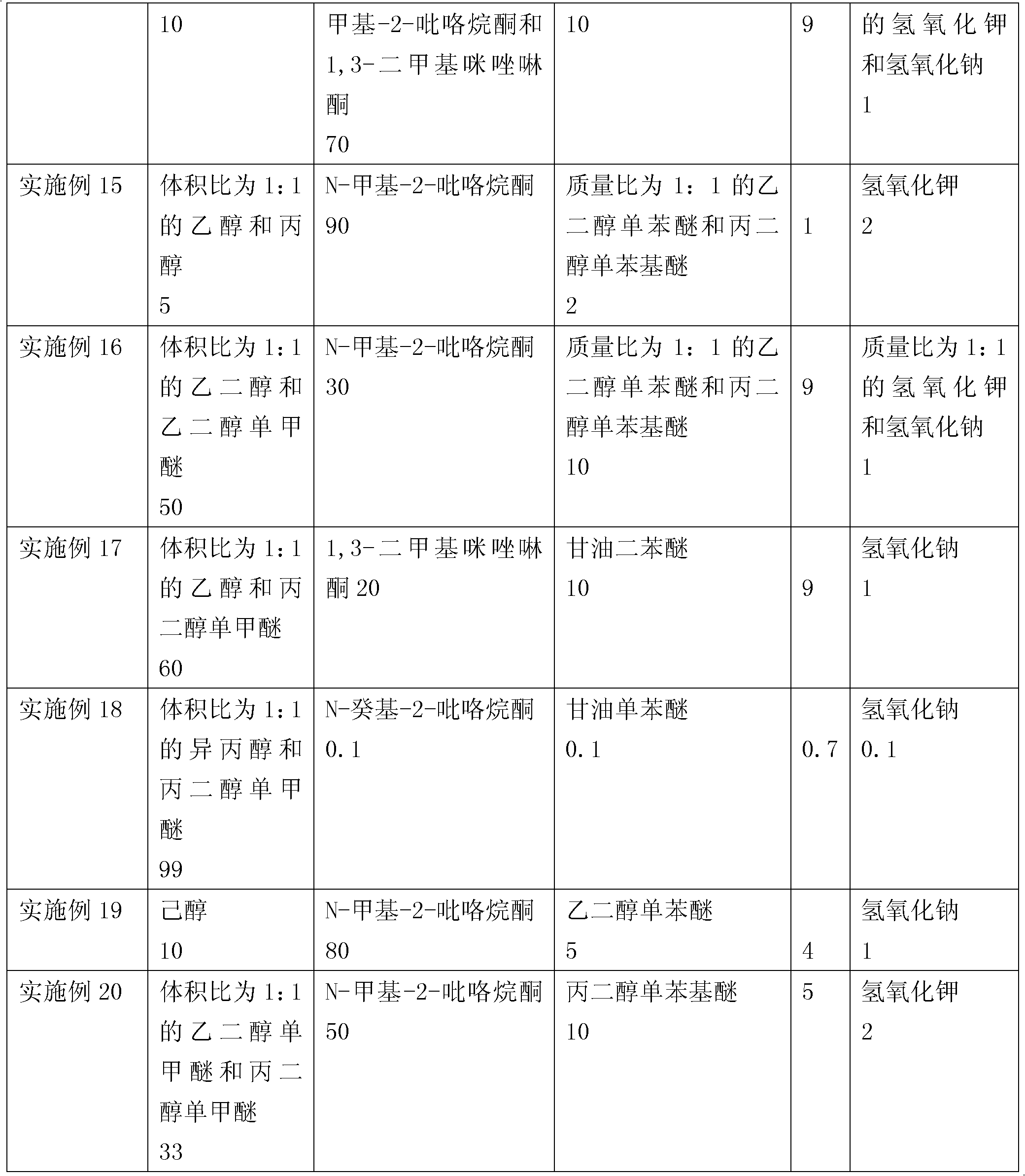

Epoxy resin and silicon resin cured coating and package removing agent and preparation method thereof

ActiveCN102433043ALow toxicityReduce volatilityChemical paints/ink removersEpoxy resin coatingsEpoxyDiphenyl ether

The invention discloses an epoxy resin and silicon resin cured coating and package removing agent, which consists of a component A, a component B, a component C, water and an inorganic strong alkali, wherein the component A may be at least one of aliphatic monohydric alcohol, aliphatic dihydric alcohol, aliphatic dihydric alcohol condensation product, ether formed by aliphatic dihydric alcohol and aliphatic monohydric alcohol, aliphatic trihydric alcohol and aliphatic ether of aliphatic trihydric alcohol; the component B may be at least one of pyrrolidone compound and / or 1,3-dimethyl imidazolidinone; and the component C may be at least one of monobenzyl ether of aliphatic dihydric alcohol, monobenzyl ether of aliphatic trihydric alcohol and diphenyl ether of aliphatic trihydric alcohol. When the removing agent disclosed by the invention is used, cured epoxy resin and organic silicon resin on the surface of an object can be dissolved and removed, the removal is quick and complete, and the surface of the substrate such as electronic element and circuit board can be protected from any damage; and the removing agent can be repeatedly used. The removing agent disclosed by the inventionis low in toxicity and volatility, the use temperature range is wide, the cost is low, and the removing agent is environment-friendly.

Owner:TECORE SYNCHEM

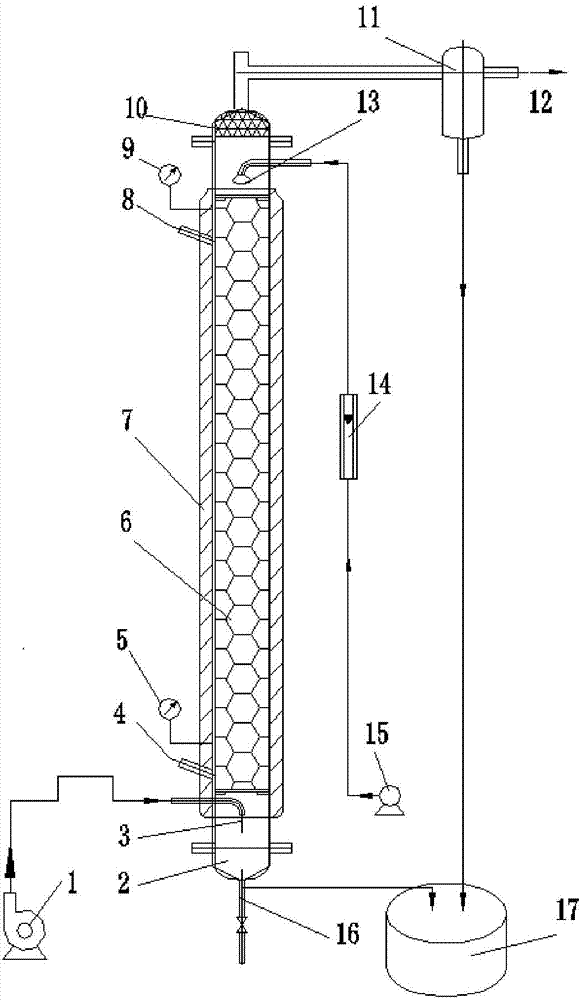

Apparatus for removing nitrous acid in reprocessing feed solution

InactiveCN104332210AIncrease processing scaleGood removal effectRadioactive decontaminationSteam distillationPUREXContinuous operation

The invention, which belongs to the technical field of nuclear fuel reprocessing, discloses an apparatus for removing nitrous acid in reprocessing feed solution in the nuclear fuel reprocessing Purex process. The apparatus comprises a removal tower, an air generator and a feed solution receiving tank, wherein a feed solution inlet is arranged on the top end of the removal tower, an air inlet is arranged on the lower end of the removal tower, a feed solution outlet is arranged on the bottom of the removal tower, and a heater is arranged on the external wall of the removal tower; the feed solution receiving tank is connected with the feed solution outlet of the bottom of the removal tower through a feed solution output pipe; packing is arranged in the removal tower, and feed solution to be treated enters the removal tower via the feed solution inlet of the removal tower to be in countercurrent contact with the air entering the air inlet. The apparatus has the advantages of good nitrous acid removal effect, high speed, continuous operation and high treatment capability.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Spraying agent for removing formaldehyde and method for preparing same

The invention provides a method for preparing a spraying agent for removing formaldehyde. The method comprises the following steps of: mixing dandelion, isatis roots and cordate houttuynia, and extracting by refluxing to obtain an extract; mixing licorice, folium artemisiae argyi and dried orange peels, and extracting by distilling to obtain an essential oil; mixing the extract and the essential oil, and adding an essence and an additive to obtain the spraying agent for removing the formaldehyde. The spraying agent prepared by adopting the method disclosed by the invention can be used for removing the formaldehyde at a high rate and a high speed without causing secondary pollution.

Owner:胡正义

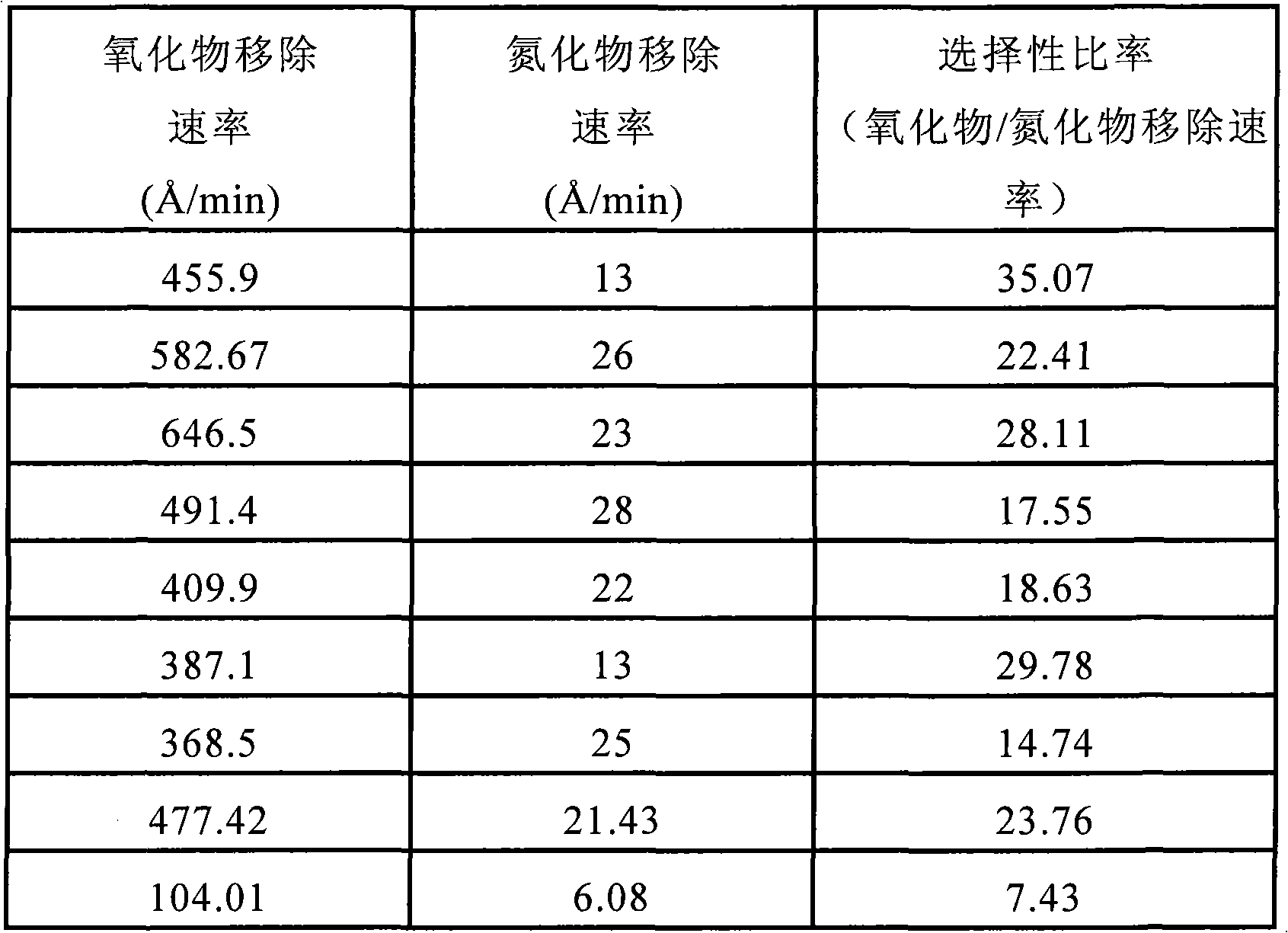

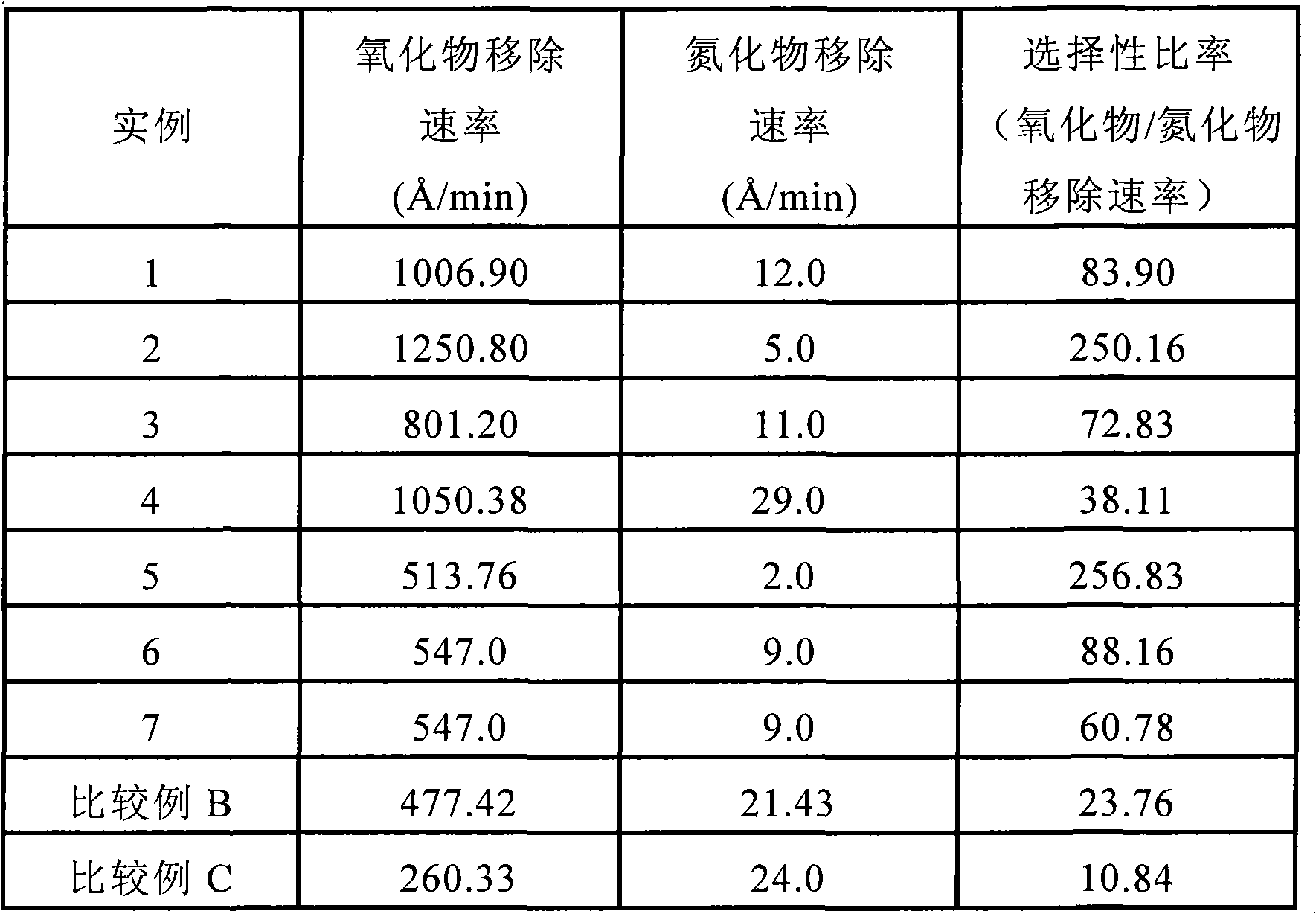

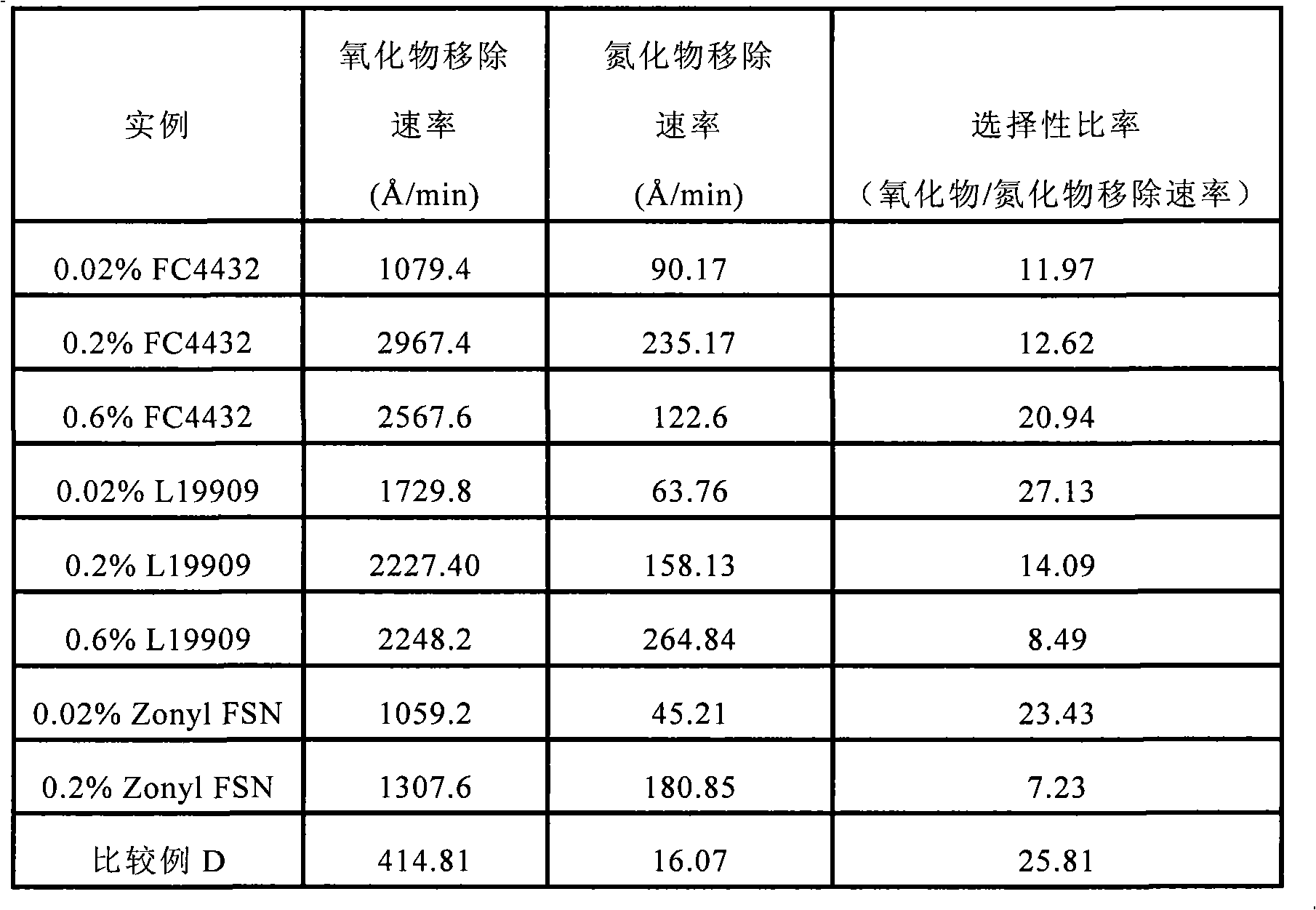

Chemical mechanical planarization composition, system, and method of use

InactiveCN101568613APreserve optionalityEnhanced chemical-mechanical planarization performanceOther chemical processesSemiconductor/solid-state device manufacturingSURFACTANT BLENDNitride

The disclosure relates to chemical mechanical planarization (CMP) polishing compositions including proline and a fluorochemical surfactant. The wafer polishing composition may be used as a solution substantially free of abrasive particles, the composition of which can be adjusted to control Oxide Removal Rate and oxide over nitride Selectivity Ratio in Shallow Trench Isolation (STI) processing ofsemiconductor wafers using a fixed abrasive CMP process. In certain embodiments, the disclosure provides a working liquid for fixed abrasive CMP including proline and a fluorochemical surfactant at apH from 9 to 11. When used in a fixed abrasive CMP system and method for STI, exemplary working liquids may yield an Oxide Removal Rate of at least 500 angstroms per minute, and an oxide over nitrideSelectivity Ratio of at least 5.

Owner:3M INNOVATIVE PROPERTIES CO

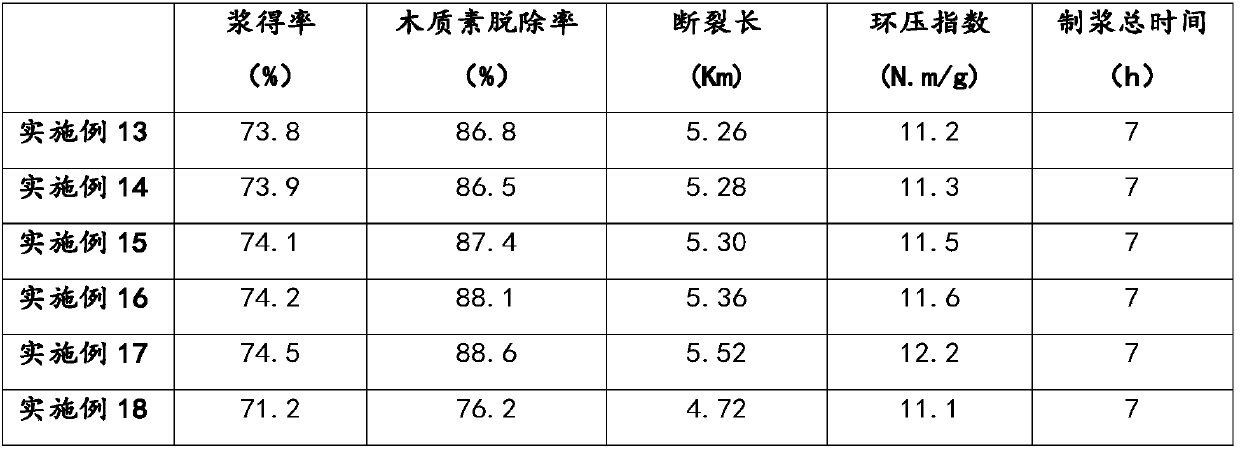

Lignin removing pulping agent and plant fiber lignin removing pulping method

ActiveCN107938411AFast removalResidue reductionCellulose treatment using microorganisms/enzymesFiberMicrobial agent

The invention provides a lignin removing pulping agent and a plant fiber lignin removing pulping method, and relates to the technical field of plant fiber pulping. The lignin removing pulping agent comprises a composite biological enzyme agent, a composite microbial agent and a chemical auxiliary agent, wherein the mass ratio of the composite biological enzyme agent to the composite microbial agent to the chemical auxiliary agent is (4-6):(2-3):(2-3). The composite biological enzyme agent comprises laccase, ligninase, hemicellulase, xylanase, glucosidase, lipoxygenase and coenzyme, wherein themass ratio of the laccase to the ligninase to the hemicellulase to the xylanase to the glucosidase to the lipoxygenase to the coenzyme is (3-5):(2-3):(1-2):(1-2):(1-2):(1-2):(1-2). The technical problem that pulping by using a microorganism preparation cannot meet the high-efficiency high-quality requirement of the papermaking industry at present is relieved; through the combination of the composite biological enzyme agent, the composite microbial agent and the chemical auxiliary agent, the removal rate of lignin from the plant fibers is accelerated, the pulping cycle is shortened, and the lignin residue in the papermaking slurry is reduced.

Owner:北京华通盛世科技有限公司

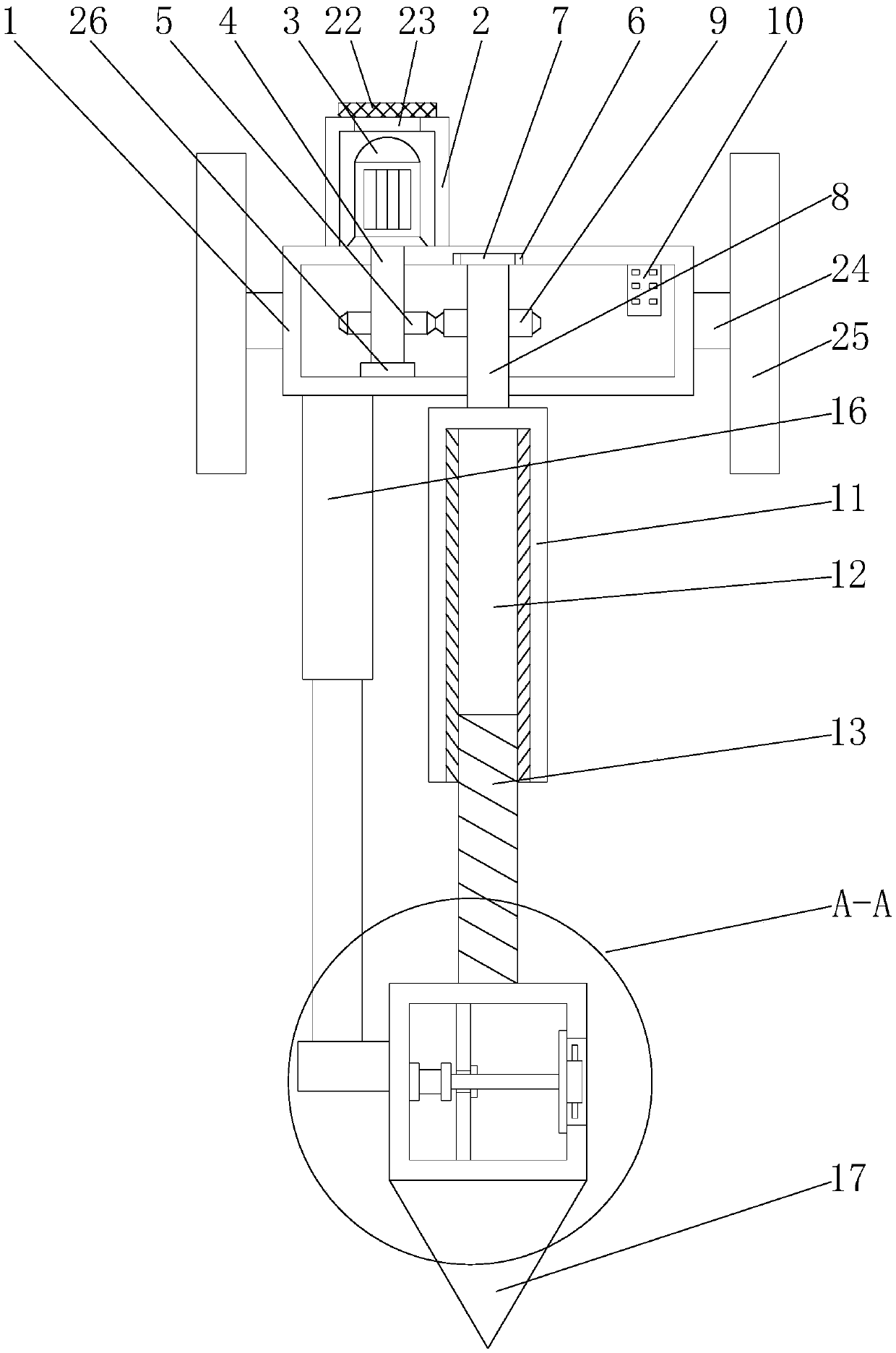

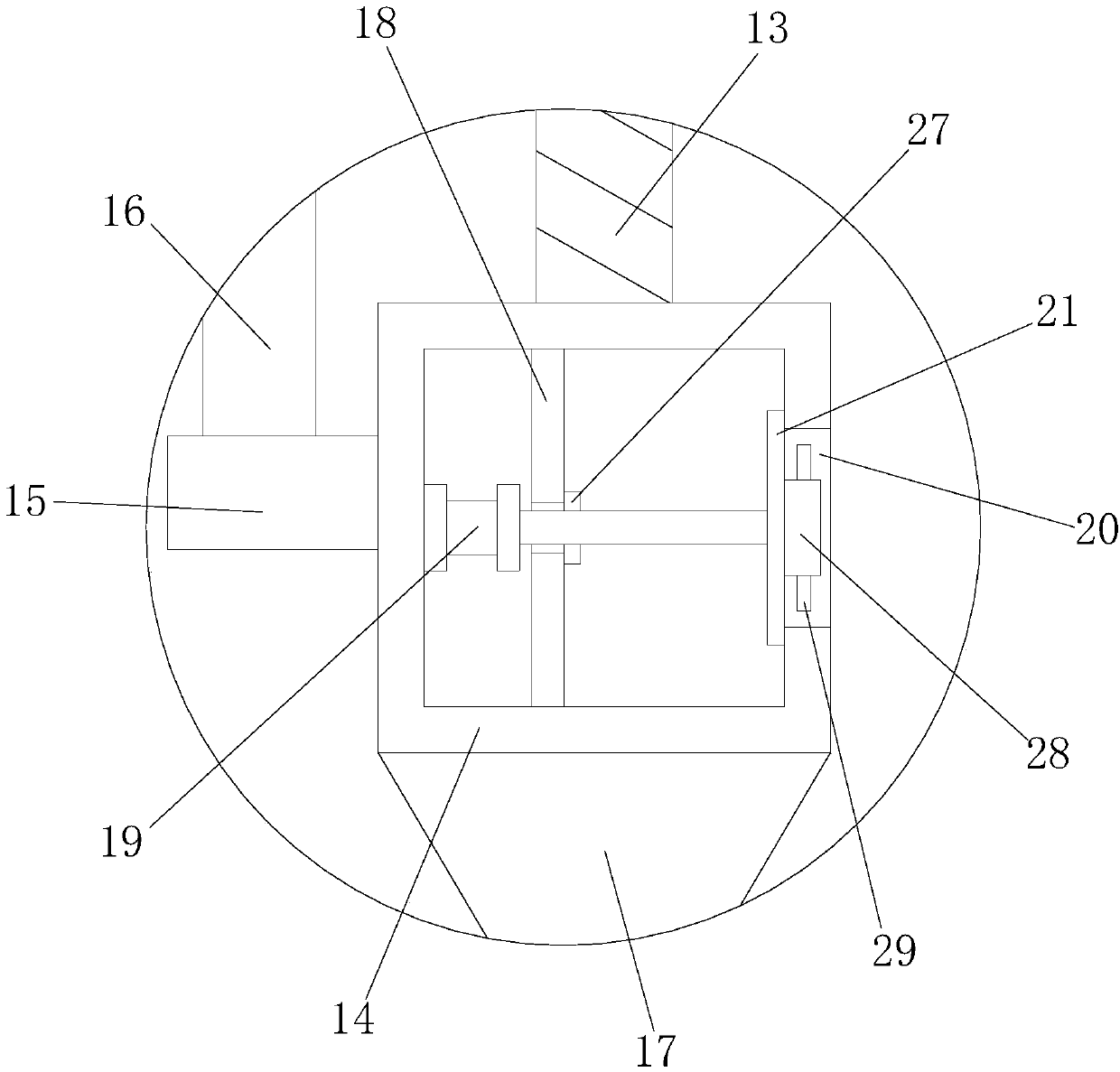

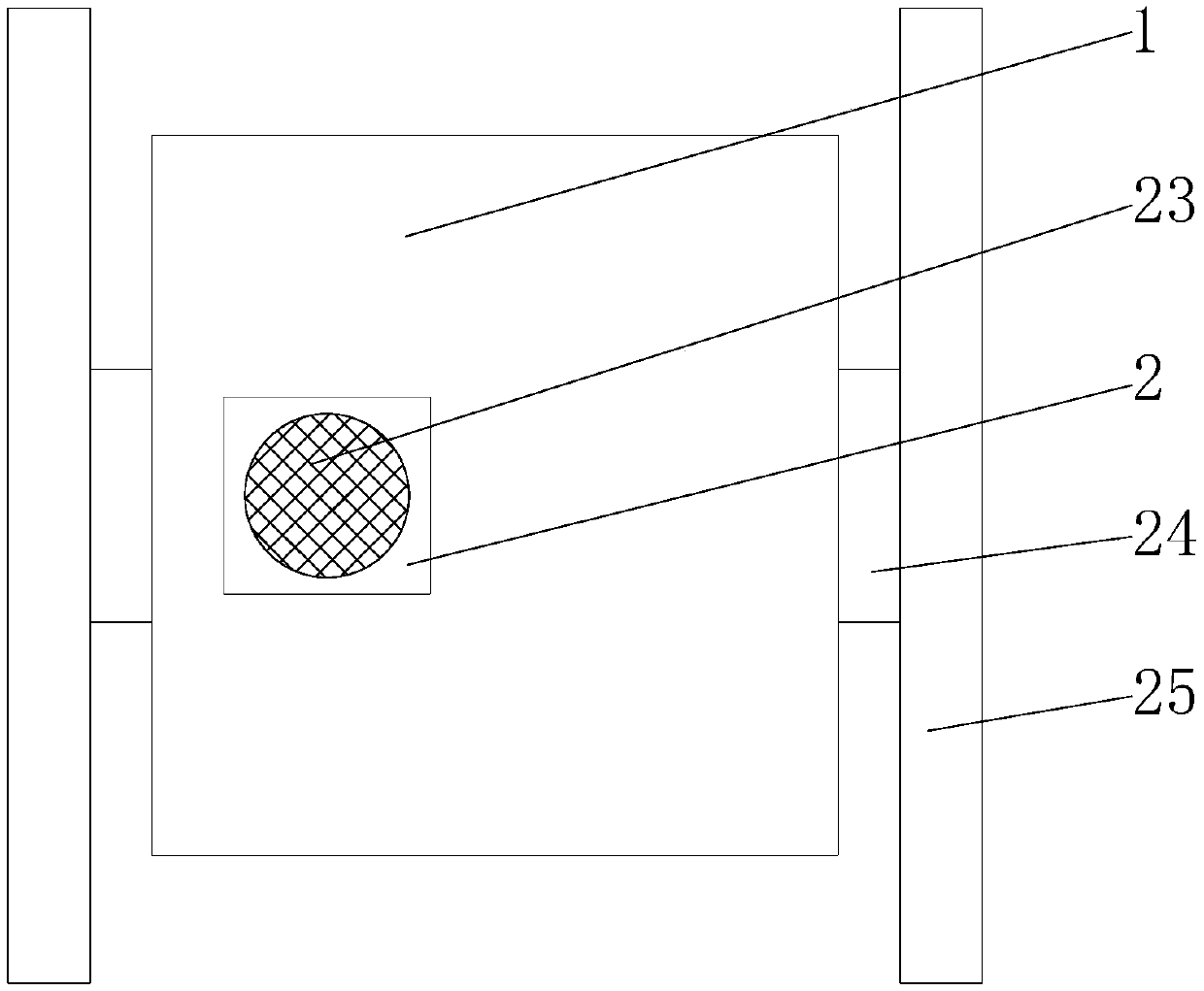

Microbial dredging device

The invention discloses a microbial dredging device, comprising a casing body. The top of the casing body is fixedly connected with a shell, and the top of the casing body is fixedly connected with adriving motor inside the shell. The microorganism is placed in the inner part of the box through the coordination of a driving motor, a driving shaft, a first gear, a rolling bearing, a rotating shaft, a second gear, a controller, a thread sleeve, a thread groove, a threaded rod, a box, a telescopic rod, a drill bit, a cylinder, a through groove and a baffle plate. The controller drives the driving shaft forward or backward by controlling the driving motor, the driving shaft drives the second gear to rotate through the first gear, and the second gear drives the thread sleeve to rotate throughthe rotating shaft. Due to the screw principle, the threaded rod drives the box to move upward or downward, and the microorganism can be applied to the mud at different depth positions. The speed of sludge removal is accelerated, and the sludge removal effect is ideal, which brings great convenience to the dredging work.

Owner:郭山河

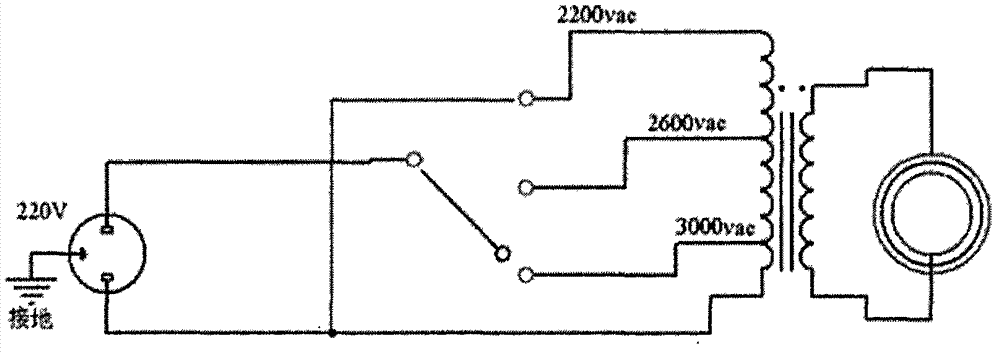

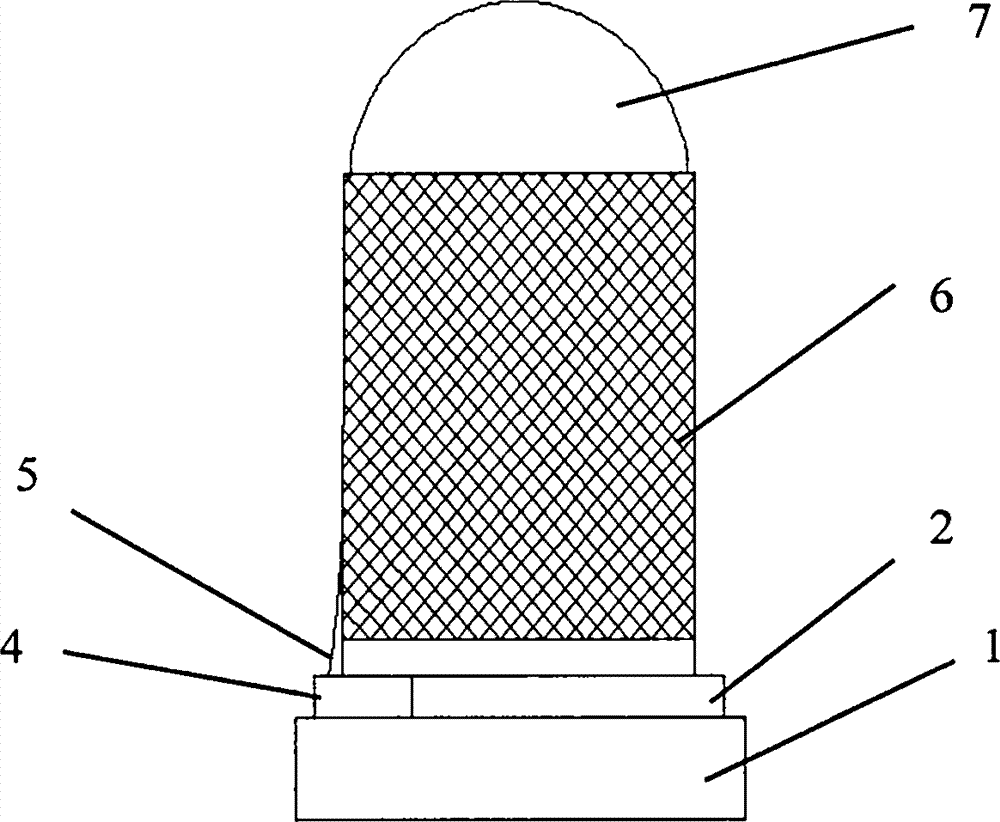

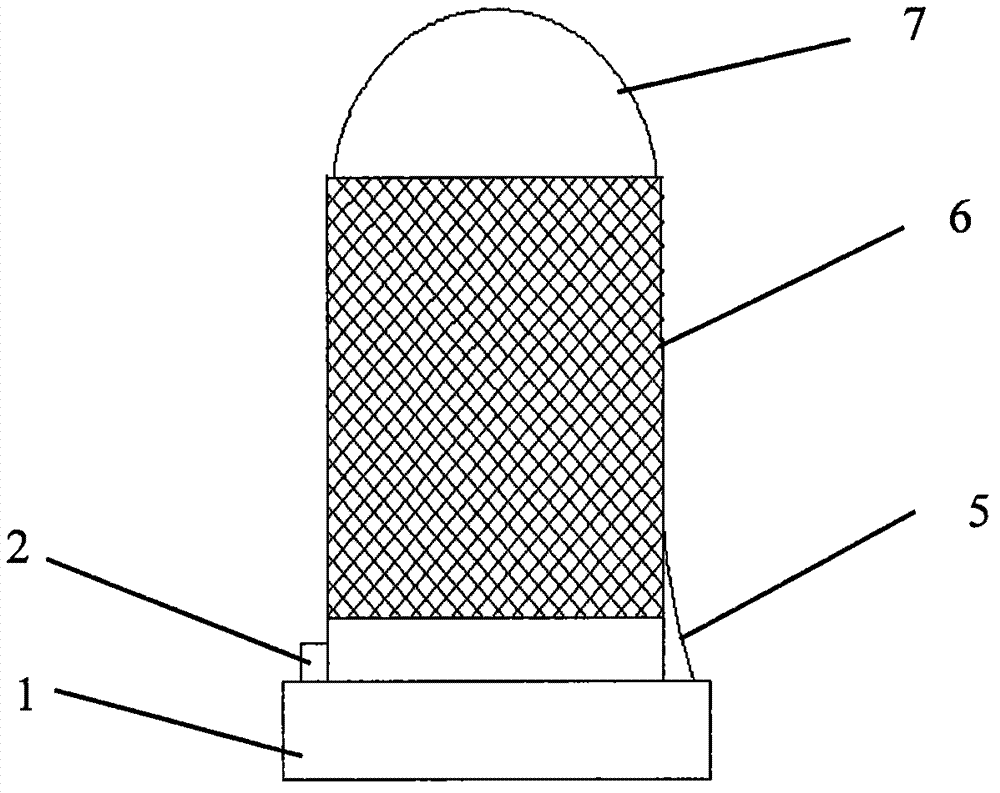

Plasma generator

InactiveCN104772011AQuality improvementEfficient decompositionDispersed particle separationDeodrantsPlasma generatorEngineering

The invention discloses a plasma generator, which is characterized by comprising a base, a control module, a display module, a formaldehyde detection module, an upper cover, an outer electrode, a glass tube, and an inner electrode. The glass tube is a cylindrical glass pipe with two opened ends and is vertically arranged on the base. The outer electrode is arranged in the inner side of the glass tube, the inner electrode is arranged in the inner side of the glass tube, the outer electrode does not contact the inner electrode directly, and the upper cover is arranged on the upper opening of the glass tube. The ends close to the base of the outer electrode and the inner electrode are respectively connected to two different conductive parts, which do not contact with each other. The control module and the formaldehyde detection module are parallelly arranged on the base, and the display module is arranged on the control module. The generator can measure the environmental temperature and humidity, can also measure the formaldehyde content, is capable of automatically adjusting the number of ions generated by the plasma generator according to the environmental formaldehyde content, and is very practical.

Owner:SHENZHEN LIDENG ENVIRONMENTAL PROTECTION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com