Polishing solution for ceramic bonded sapphire polishing, and preparation method thereof

A technology of sapphire and polishing fluid, which is applied in the field of sapphire polishing, can solve the problems of low polishing efficiency and high surface roughness of wafers, and achieve the effects of saving production costs, improving polishing efficiency and polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

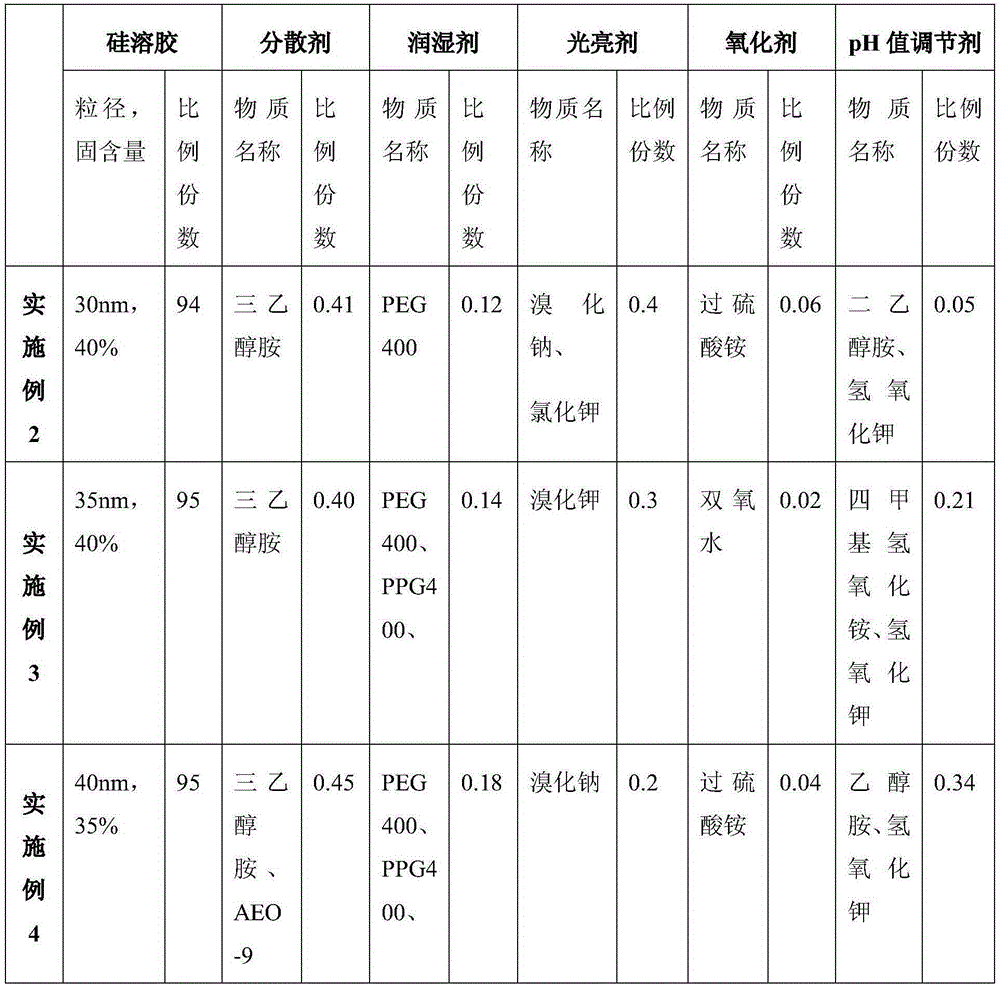

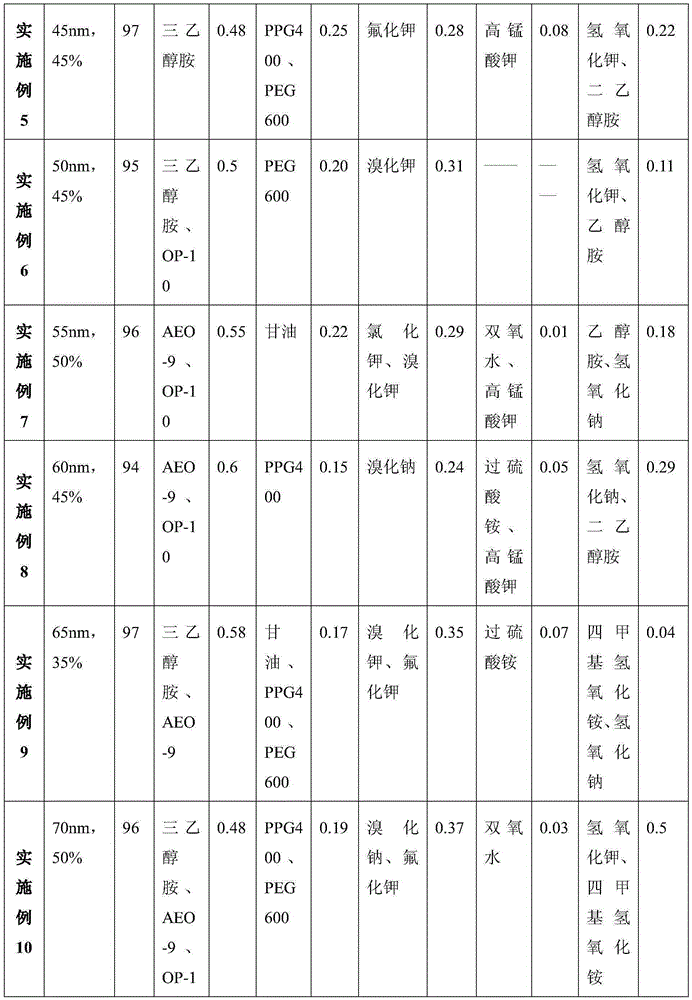

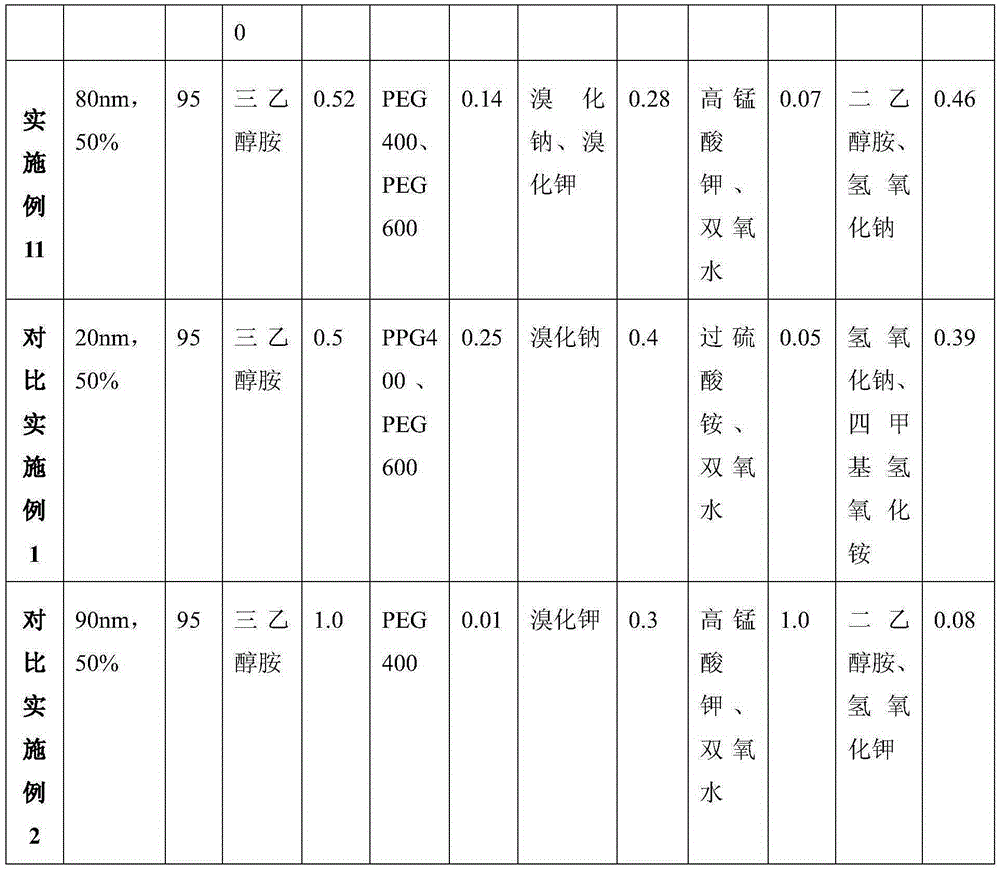

[0029] Formula (weight percentage):

[0030] 94-97 parts of silica sol, 0.4-0.6 parts of dispersant, 0.1-0.25 parts of wetting agent, 0.2-0.4 parts of brightener, 0-0.08 parts of oxidizing agent, 0.04-0.5 parts of pH value regulator, and the balance Deionized water.

[0031] The preparation is completed by the following process steps:

[0032] A. Weigh an appropriate amount of brightener and dissolve it in a small amount of water. After it is fully dissolved, add a dispersant and a wetting agent to make a mixed solution, stir and mix evenly and then stand still to obtain reagent 1;

[0033] B. Weigh an appropriate amount of oxidant, slowly add a small amount of water, stir to make it fully dissolved, and then stand still to obtain reagent 2;

[0034] C. Use a 500-mesh screen filter system to remove impurity particles in the silica sol raw material, and add it to the cleaned reactor along with the pumping equipment;

[0035] D. Stir the filtered 35-50wt% silica sol at a rotation speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com