Patents

Literature

631results about How to "Improve polishing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

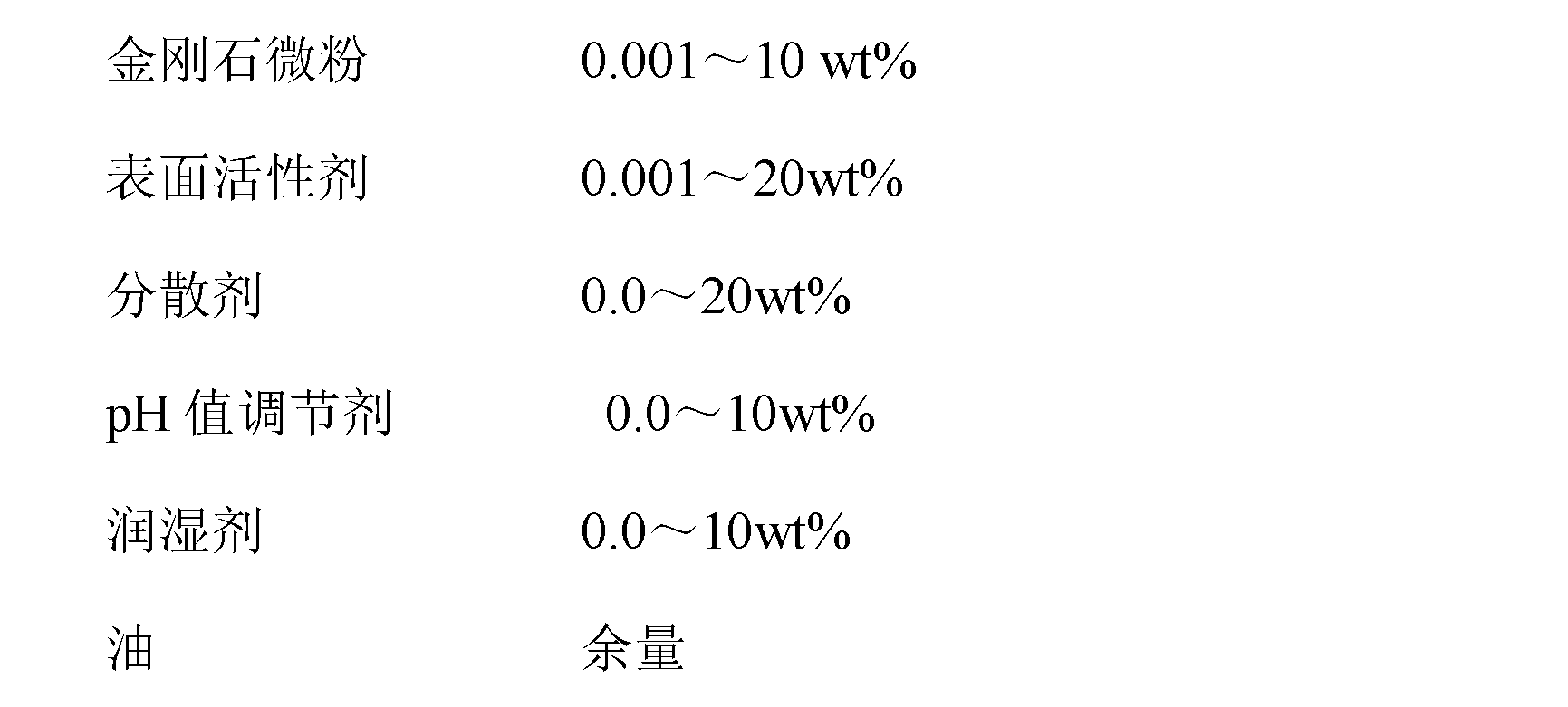

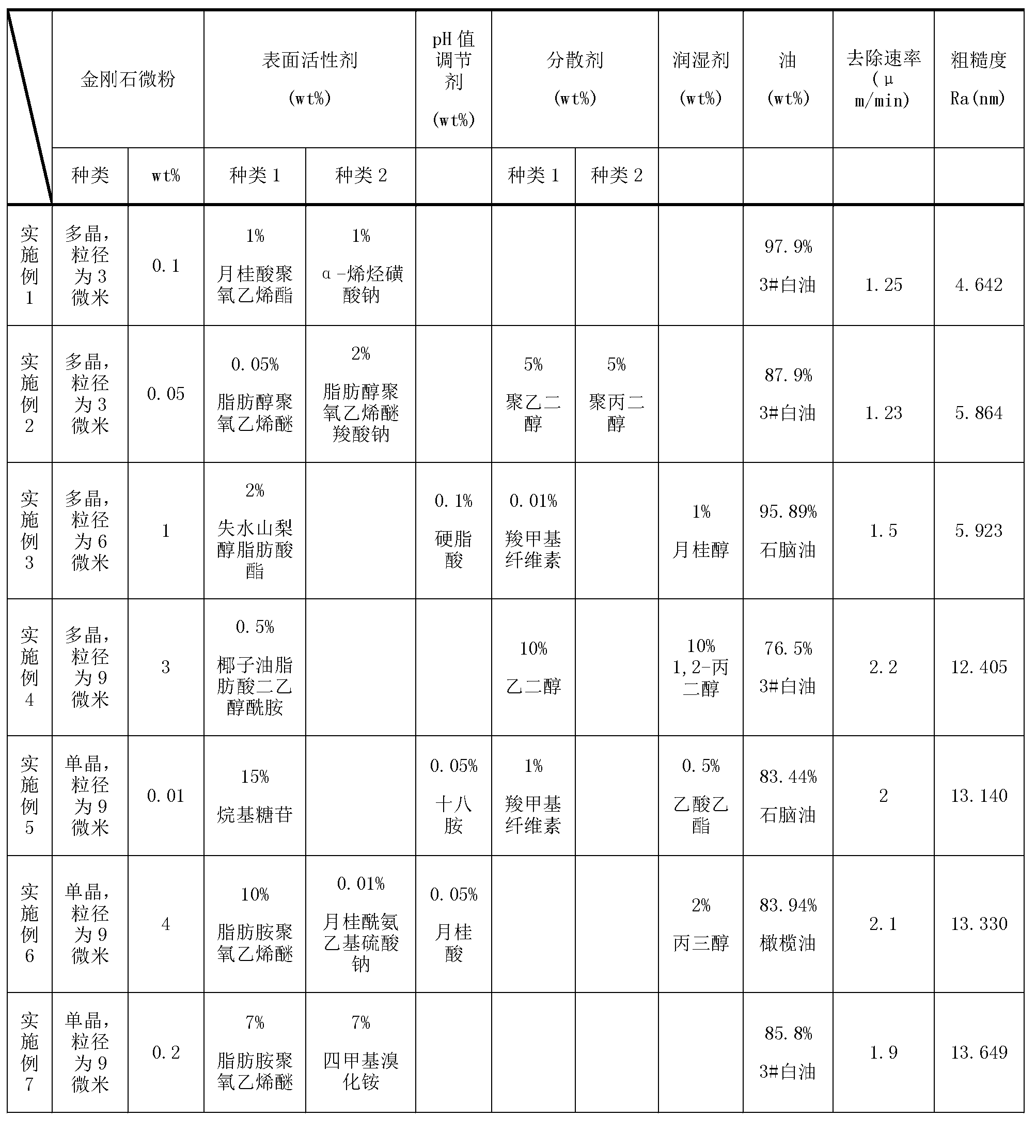

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

Method for polishing wheet from sisal fiber

InactiveCN1562570ARich varietyVarious ventilation structuresFlexible-parts wheelsPlant fibreSisal fiber

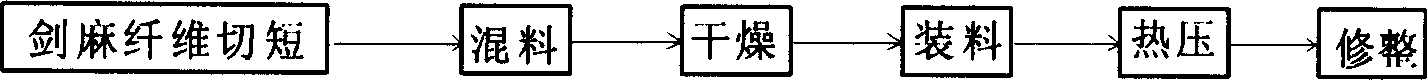

A polishing wheel is made up of short sisal hemp fibres, synthetic resin, plant fibres and inorganic compound through proportionally mixing, drying, hot die pressing and trimming.

Owner:黄焕仪 +1

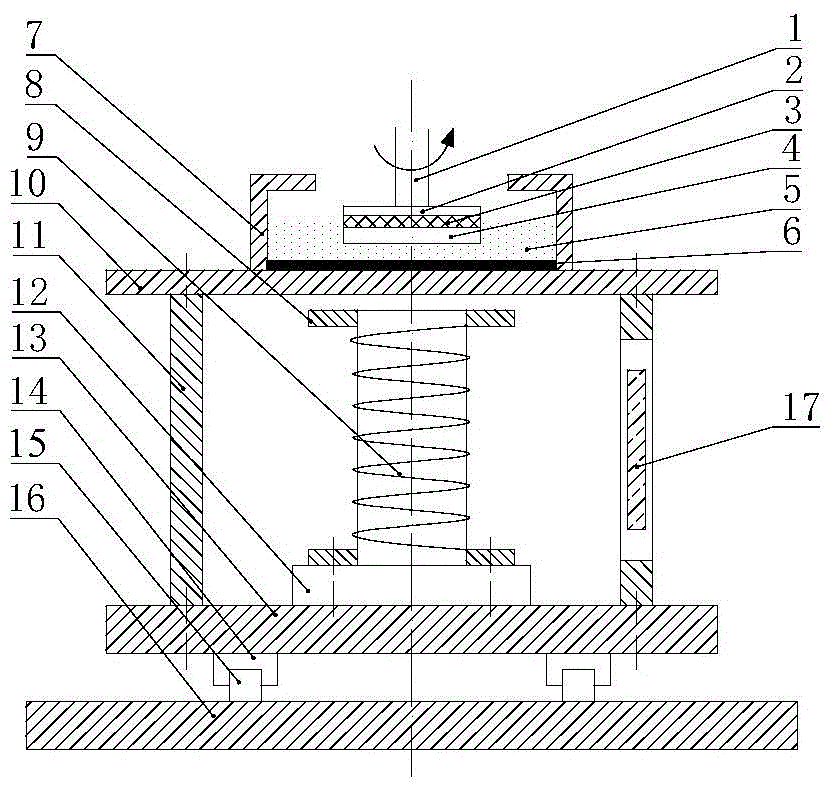

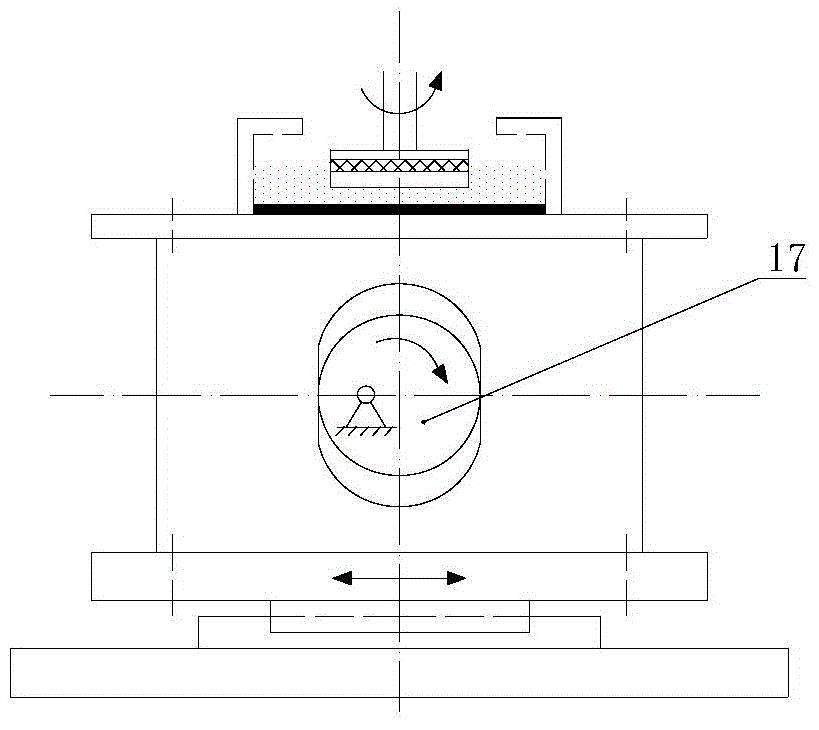

Magnetorheological polishing device and method

ActiveCN104308671ANo need to increase sizeIncrease cycle exchangeReciprocating motionMagnetorheological fluid

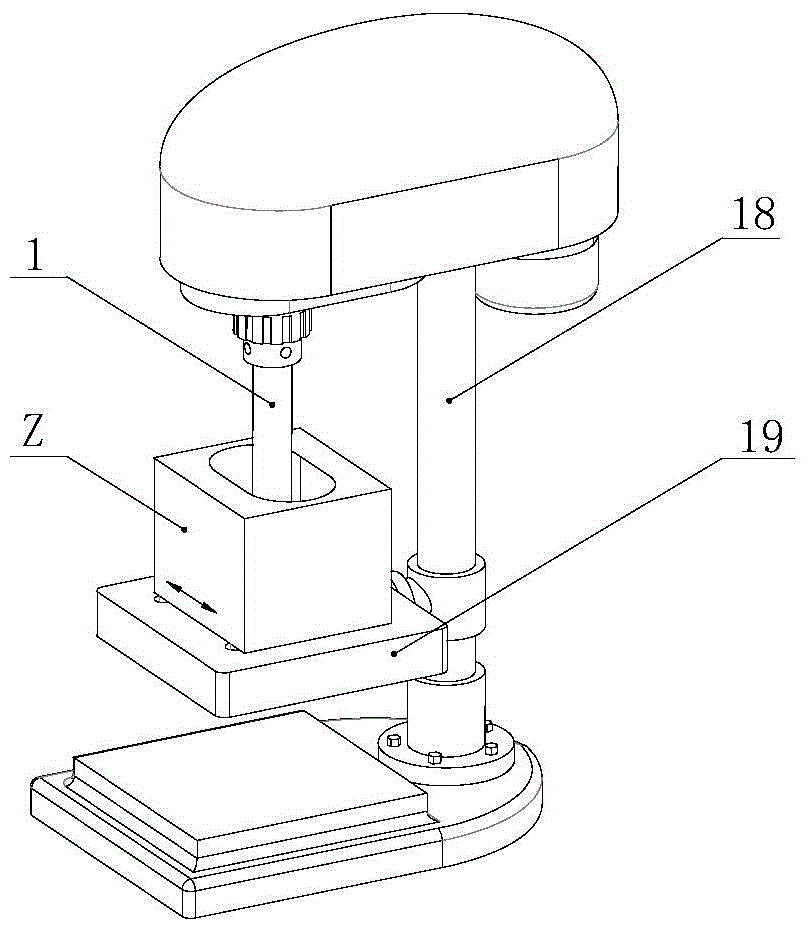

The invention discloses a magnetorheological polishing device. A polishing head consists of a workpiece shaft, a nonmagnetic fixture fixed at the lower end of the workpiece shaft and a soft magnetic plate arranged between the nonmagnetic fixture and the workpiece shaft; a fluid carrying groove containing magnetorheogical fluid is positioned below the polishing head; the bottom of the fluid carrying groove is provided with a polishing pad; an electromagnet is positioned below the fluid carrying groove and is kept 12-18mm away from a workpiece; the electromagnet and the fluid carrying groove are driven by a reciprocating transmission mechanism and linearly reciprocate parallel to the polished surface of the workpiece. The device is used for magnetorheological polishing, the flux density of the electromagnet is 0.1-0.4T, the reciprocating travel is slightly greater or equal to the workpiece polishing length, and the reciprocating speed is 0.5-5mm / s. A surface material of the workpiece is removed under the compound motion of translational motion of a magnetic field and rotation of the workpiece. The device has the advantages of good homogenization of the magnetic field, smooth exchange of the magnetorheogical fluid in a polishing area, easy discharge of processing scraps, good homogenization of micro textures of the polished surface of the workpiece and the like, and is particularly suitable for grinding and polishing large-plane surfaces of narrow and long workpieces.

Owner:NORTHEASTERN UNIV

Quick polishing equipment for steel pipe surfaces for industry

ActiveCN106863102AImprove polishing qualityQuality improvementGrinding carriagesPolishing machinesSteel tubeBolt connection

The invention relates to polishing equipment for steel pipe surfaces, and particularly relates to quick polishing equipment for steel pipe surfaces for industry. The invention aims to provide the quick polishing equipment for the steel pipe surfaces for the industry, which has the advantages of high polishing quality, less polishing risk, time saving and labor saving in polishing. In order to solve the technical problem, the invention provides the quick polishing equipment for the steel pipe surfaces for the industry. The quick polishing equipment comprises a bottom plate, a first sliding rail, a first sliding block, a movable plate, a fixed plate, a first bearing seat, a rotary rod, a fixed block, a cranking bar, a guide rail and a movable block, wherein the first sliding rail is installed in the left side of the bottom plate in a bolt connecting mode, the first sliding block is connected to the interior of the first sliding rail in a sliding mode, the movable plate is installed on the upper end of the first sliding block in a welding mode, and the fixed plate is installed on the upper right part of the bottom plate in a welding mode. The quick polishing equipment has the effects of high polishing quality, less polishing risk, time saving and labor saving in polishing.

Owner:新昌县承慧机电设备有限公司

Automatic stainless pan polishing equipment

InactiveCN103273410ANo pollutionNo harmPolishing machinesGrinding work supportsElectrical controlEngineering

The invention belongs to the technical field of polishing and particularly relates to automatic stainless pan polishing equipment. The automatic stainless pan polishing equipment is characterized in that the equipment comprises an electrical control device, a workbench, fixing clamps, supports and polishing devices, the fixing clamps are mounted on the workbench through a rotating device, the workbench is connected with a workbench motor and driven by the same to rotate, the polishing devices are mounted on the supports through a moving device, and the electrical control device is connected with and controls the polishing devices, the rotating device, the workbench motor and the moving device. The automatic stainless pan polishing equipment is reasonable in structural design and high in working efficiency, polished products are shining, dust pollution and damages to human bodies cannot be caused in the process of operating, labor intensity of workers is reduced, production cost is lowered, and a brand-new automatic polisher equipment capable of replacing manpower is provided.

Owner:冯会民

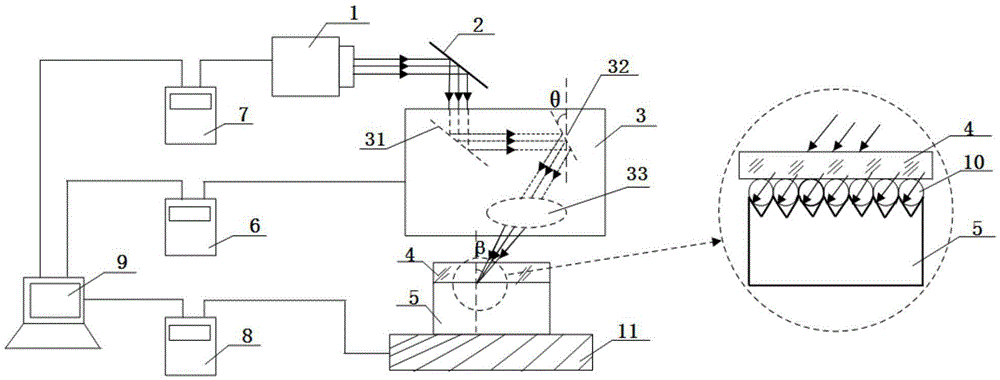

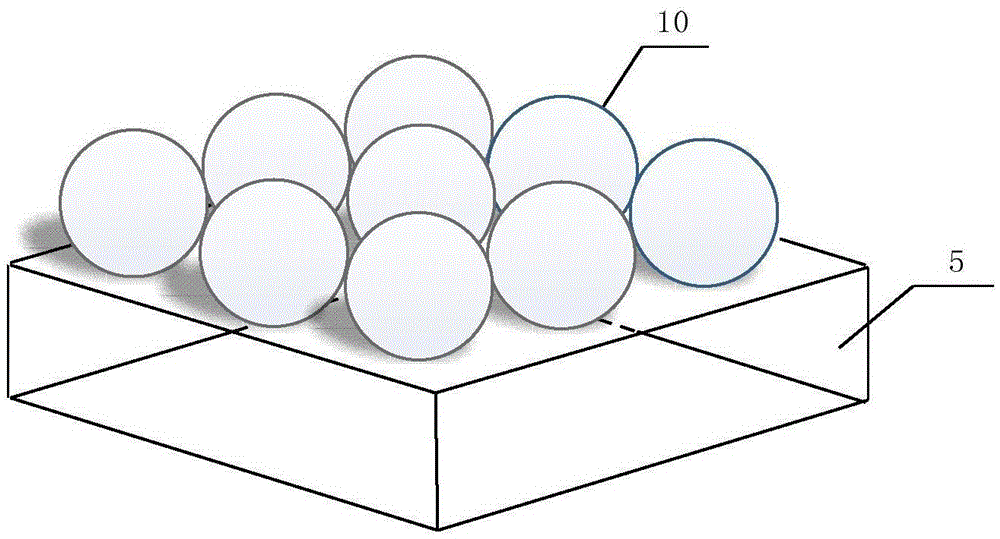

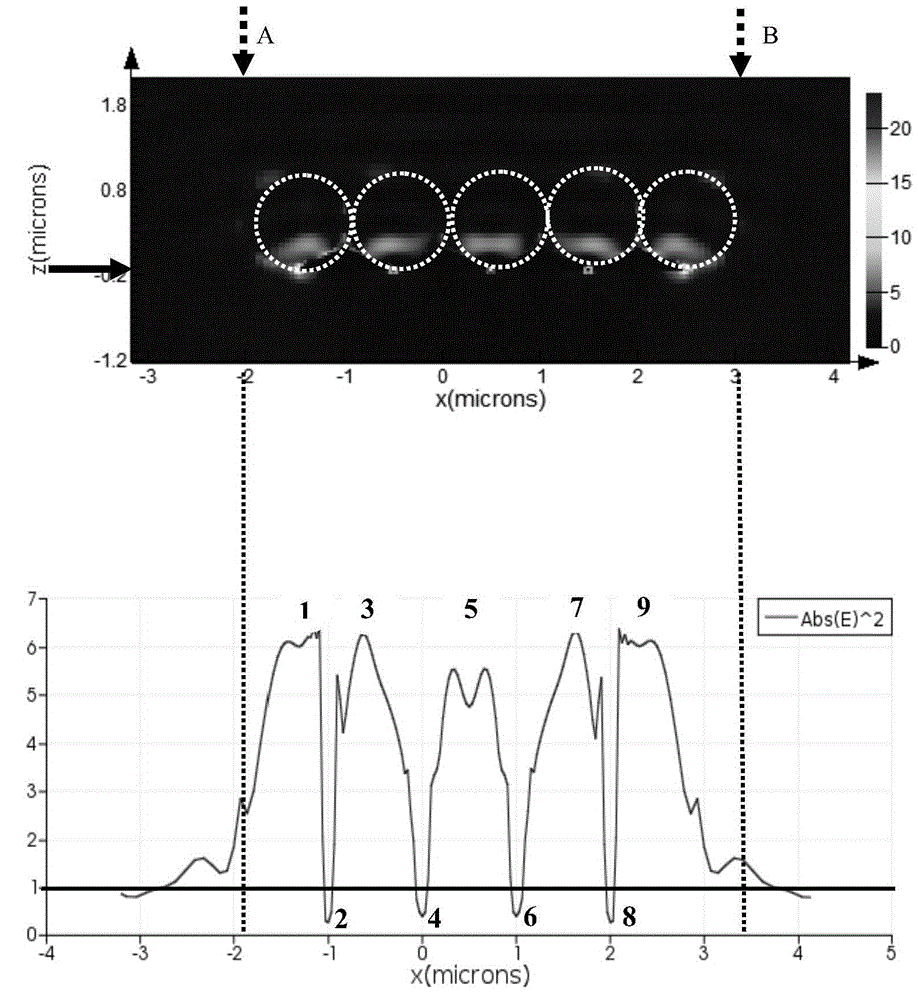

Precise laser polishing device and method thereof

InactiveCN105583524AEasy to buildEasy to polishLaser beam welding apparatusMicro nanoNanoscopic scale

The invention provides a precise laser polishing device and a method thereof. According to the method, a glass pane coated with micro-nano particles is attached to the surface of a work-piece to be polished, the micro-nano particles are located between the glass pane and the work-piece to be polished, a pulsed laser device emits pulse lasers, focused pulse light beams radiate the glass pane coated with the micro-nano particles, the micro-nano particles serve as a focusing lens, energy around the micro-nano particles is enhanced after the lasers are focused by the micro-nano particles, the surface of the work-piece to be polished protrudes or the tip part of the work-piece to be polished gets fused, and therefore the polishing effect is realized. According to the precise laser polishing device and the method thereof, the pulse lasers converge and act on the surface of material through the micro-nano particles, and the laser polishing technology within the micro-nano scale range is realized through the local field enhancement effect of the micro-nano particles. The polishing device is convenient to construct, simple and practicable; for work-pieces with complex shapes and appearances to be polished, the polishing effect is still good through the method.

Owner:JIANGSU UNIV

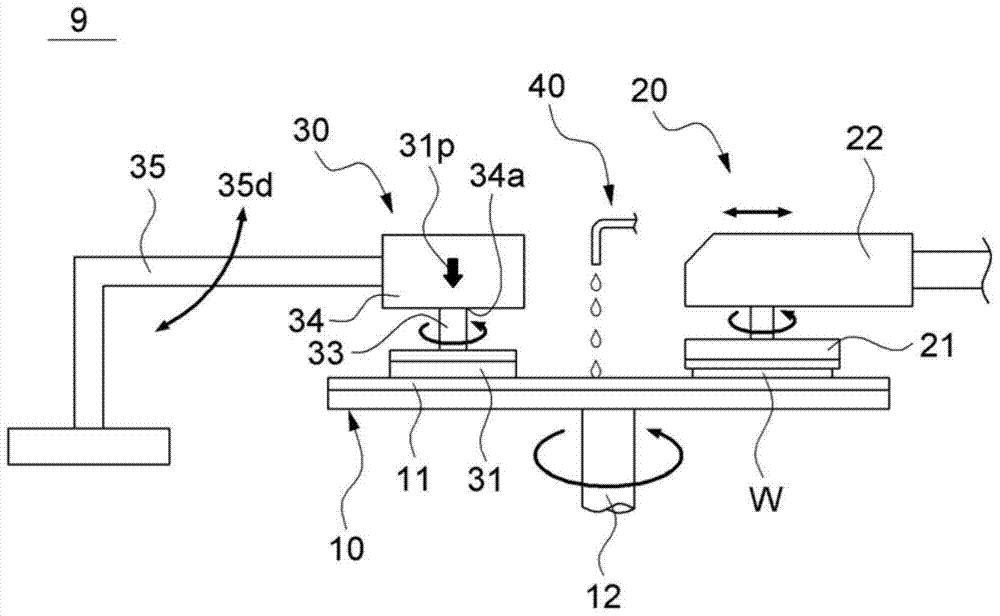

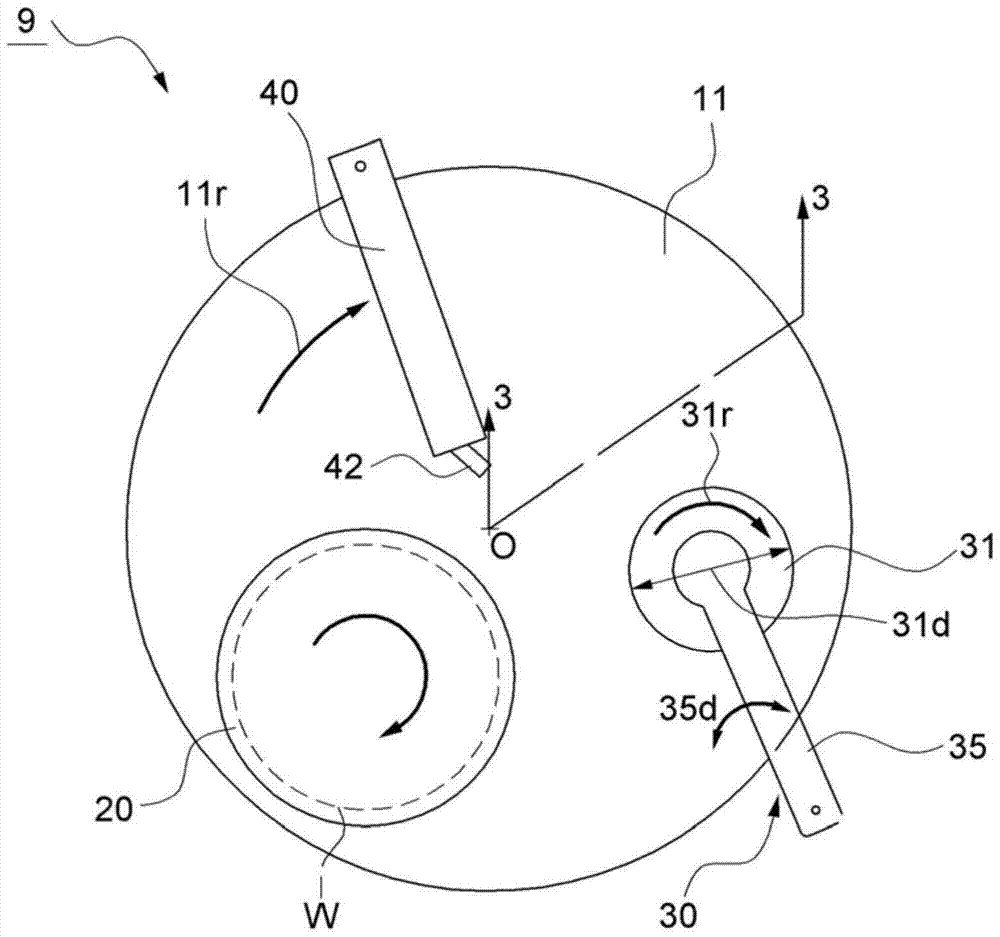

Chemical mechanical polishing apparatus and method thereof

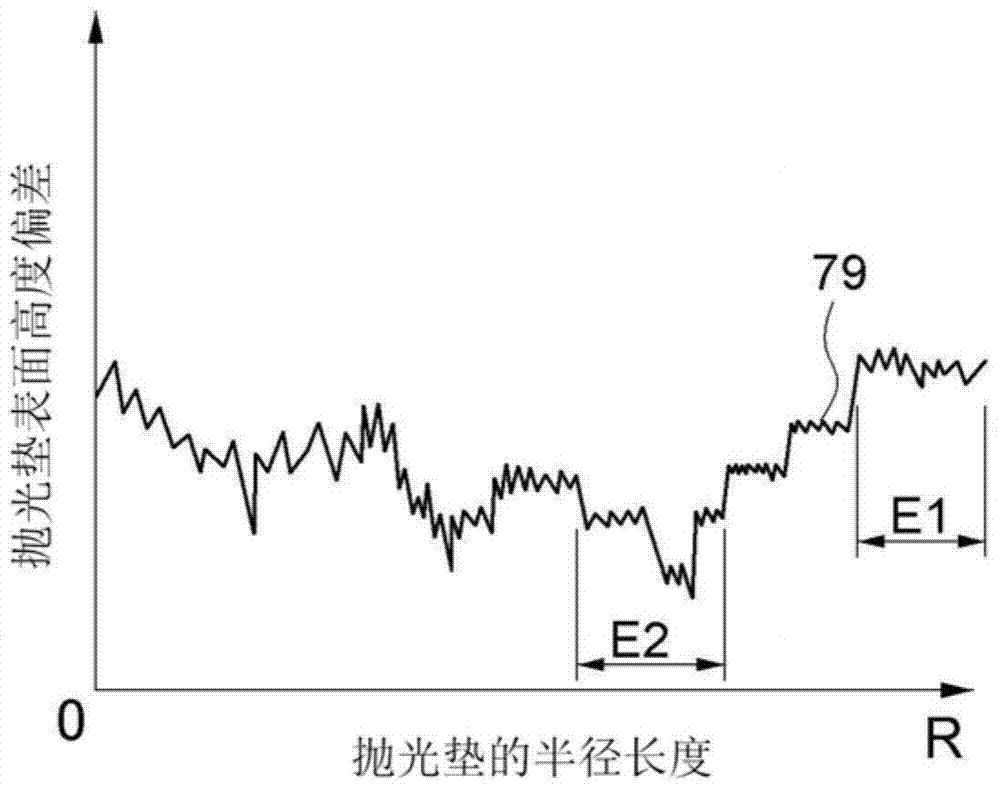

The invention relates to a chemical mechanical polishing apparatus and a method thereof. The apparatus comprises a polishing head for pressing and rotating a wafer in a state where the wafer is on a lower side; a height measuring portion for obtaining a height deviation in the radial direction of a polishing pad during the chemical mechanical polishing; a regulating device having an arm portion and an adjusting disc, the arm being rotated about a hinge axis to rotate at a predetermined angle, and the adjusting disc pressing the polishing pad against the lower side of the arm portion and rotating; and a control portion for adjusting the rotational speed of the arm portion with a second rotation speed at a second position, the height of the polishing pad at the second position being higher than the height at the first position, and the second rotational speed being smaller than the first rotational speed, such that, by adjusting the rotational speed of the adjusting disc, it is possible to alleviate the height deviation of the polishing pad at different positions. Therefore, even if the same pressure is applied to the wafer, the friction amount is different depending on the height deviation of the polishing pad, so that the polishing amount per hour of the wafer can be adjusted in each region.

Owner:K C TECH

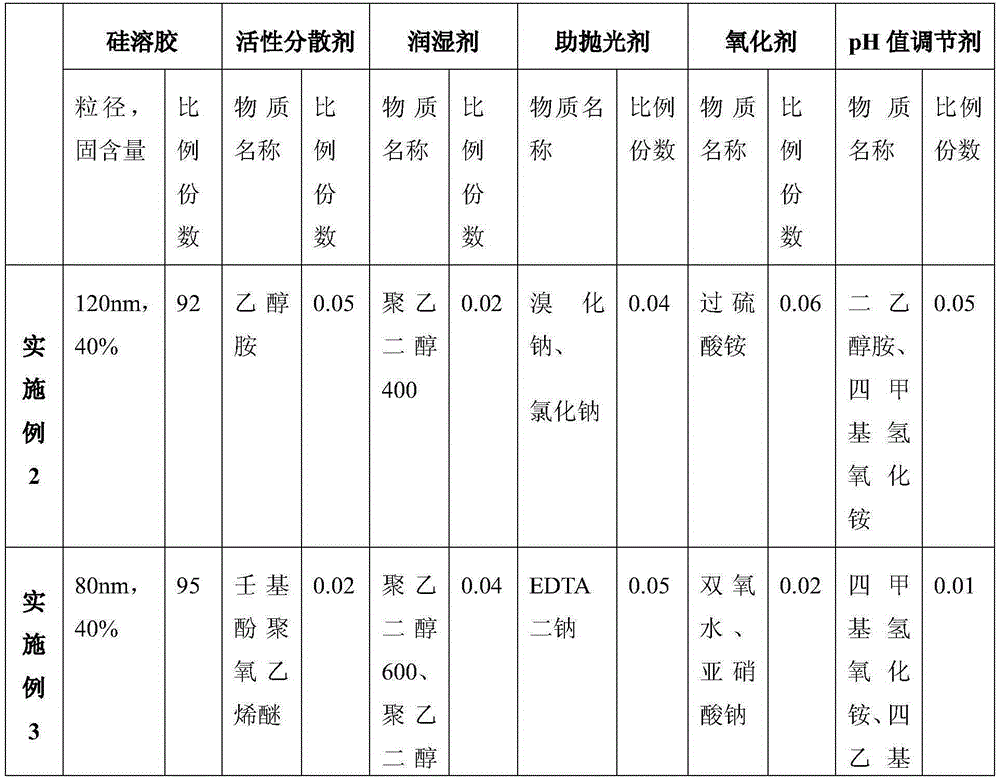

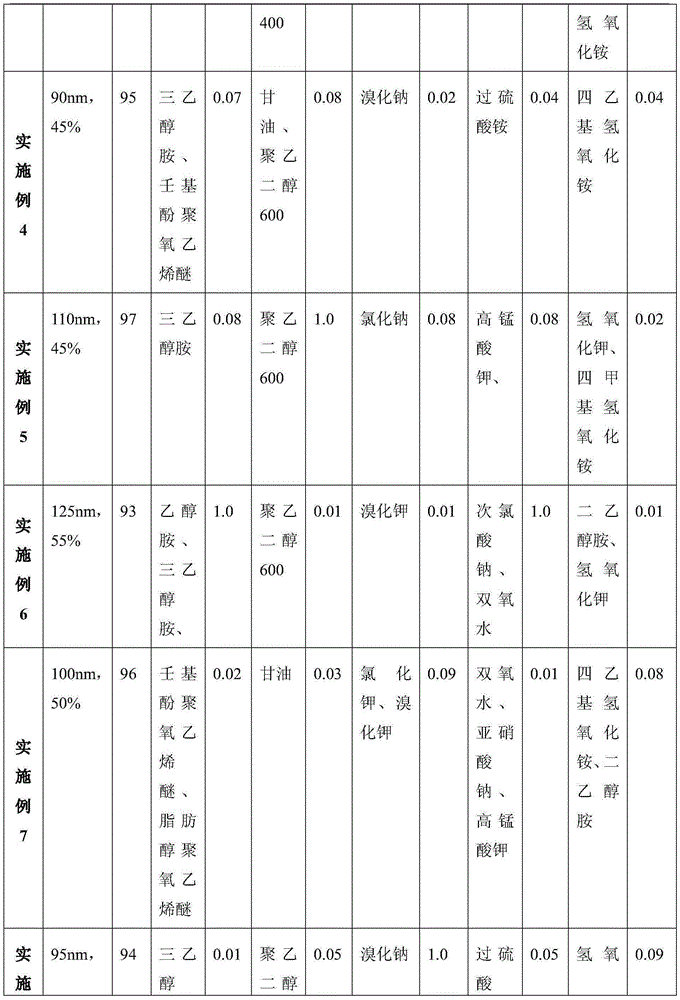

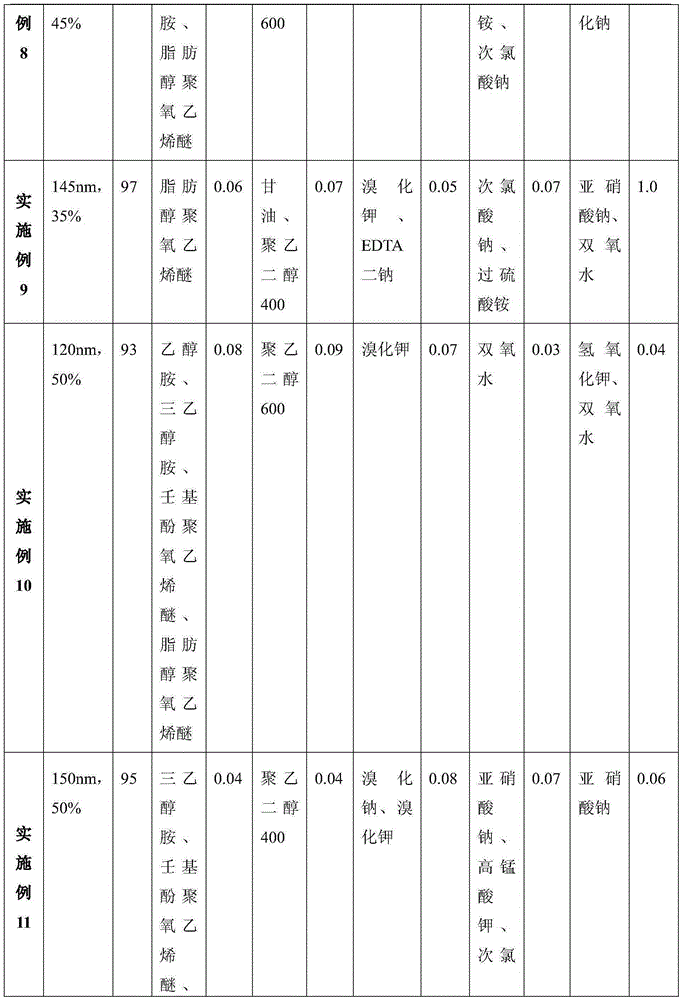

Polishing solution for A orientation sapphire polishing, and preparation method thereof

InactiveCN105385357AAverage Apparent Yield ImprovementImprove polishing efficiencyPolishing compositions with abrasivesMachining processLubrication

The invention provides a polishing solution for A orientation sapphire polishing, and a preparation method thereof. The polishing solution comprises, by mass, 92-97 parts of silica sol, 0.01-1 part of an active dispersant, 0.01-1 part of a wetting agent, 0.01-2 parts of a polishing aid, 0.01-1 part of an oxidant, 0.01-2 parts of a pH adjusting agent, and the balance of deionized water. The polishing solution prepared in the invention has the advantages of good removal rate, excellent lubrication effect, good quality of the surface of a processed product in the sapphire polishing processing process, simple processing and preparation method, and facilitation of industrial popularization.

Owner:LENS TECH CHANGSHA

Sapphire substrate polishing agent used for double-side polishing machine

InactiveCN104109480AEasy to cleanImprove polishing qualityPolishing compositions with abrasivesChemistryNonionic surfactant

Owner:天津西美半导体材料有限公司

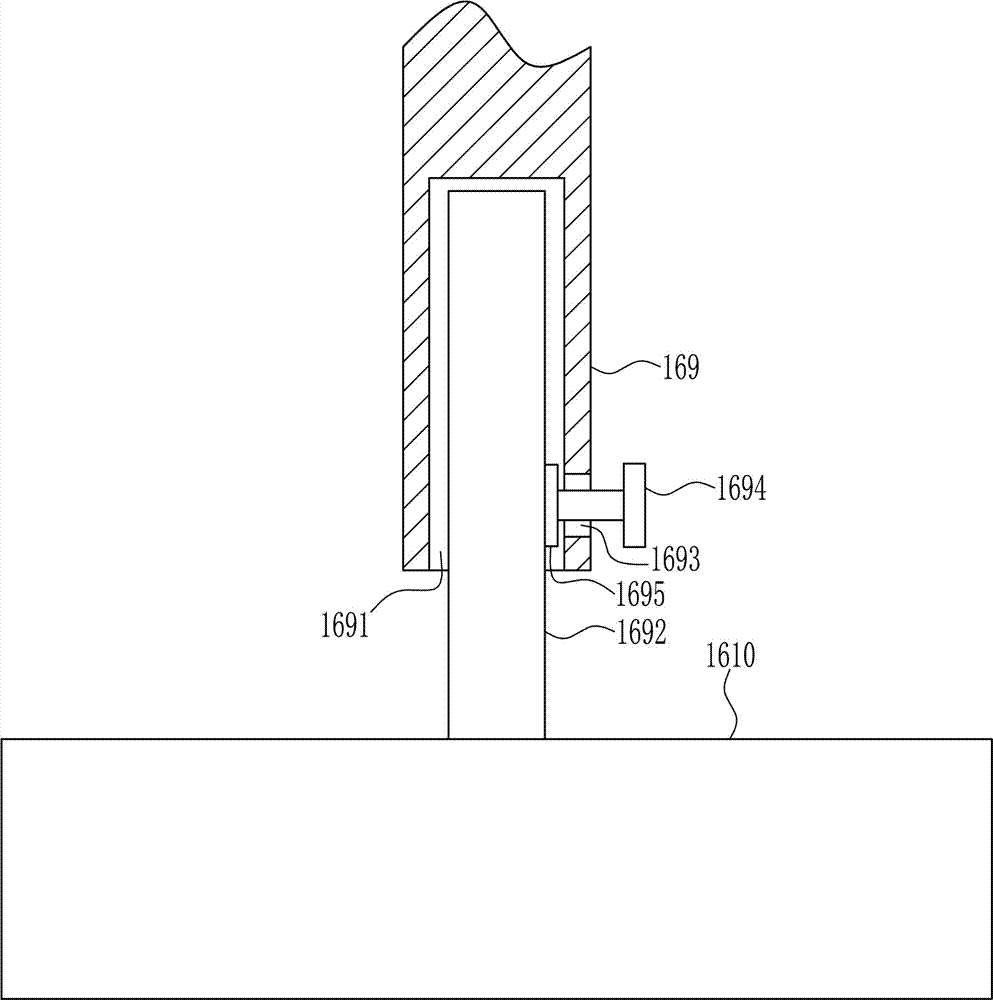

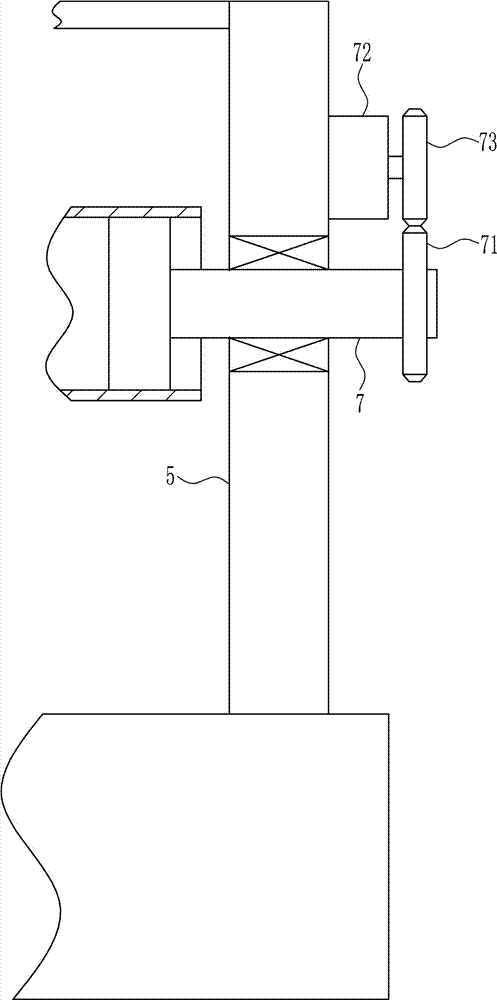

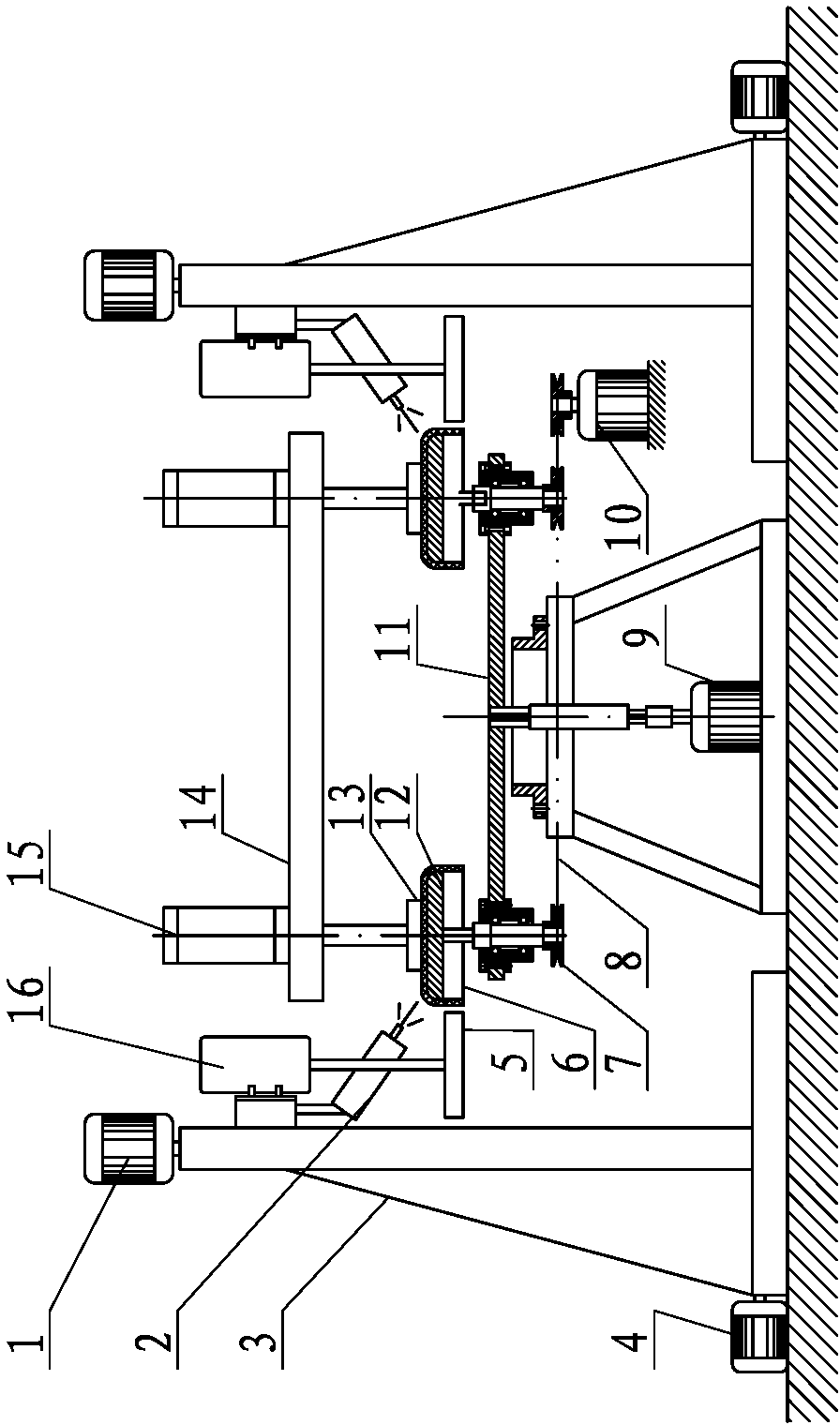

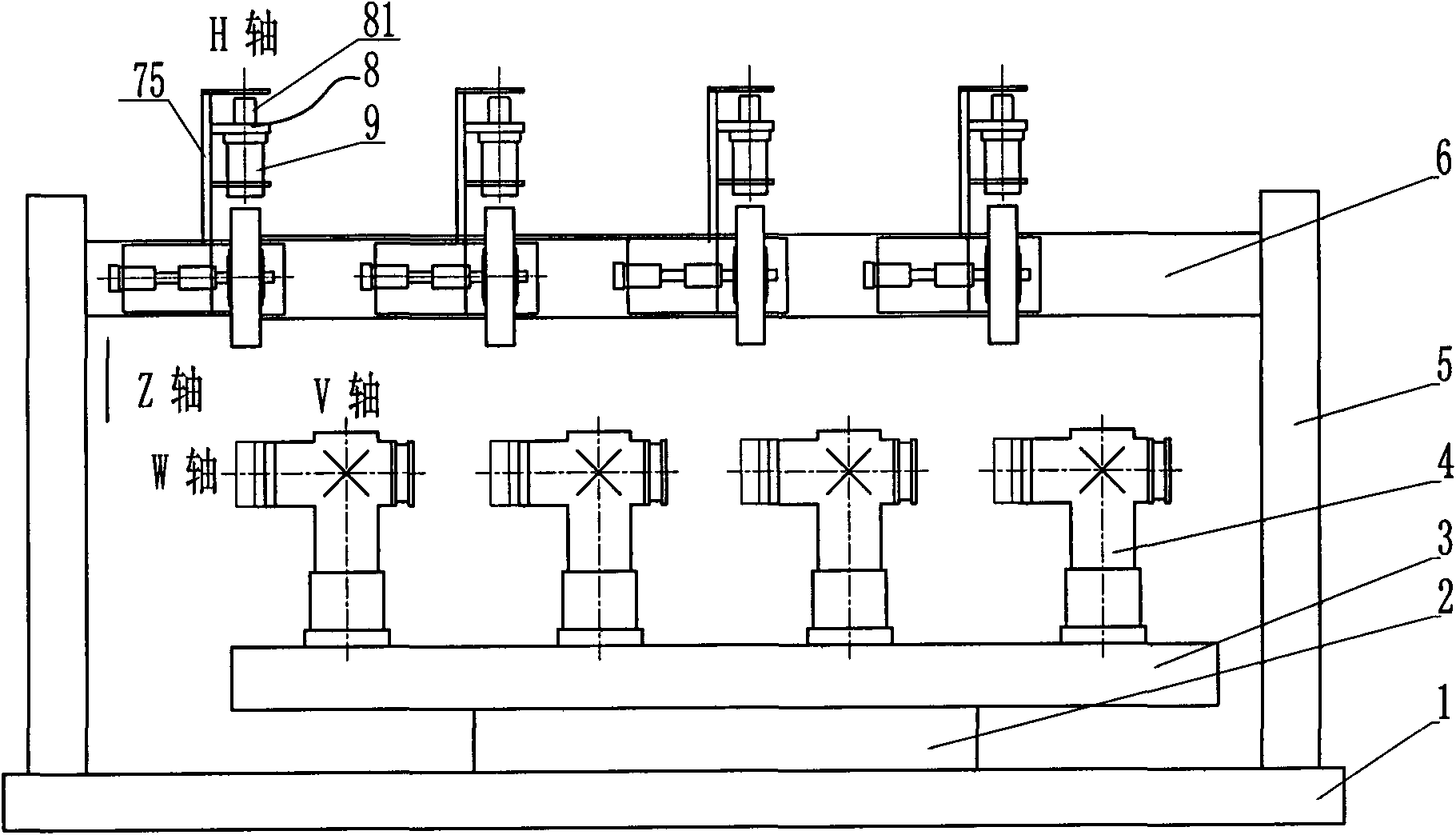

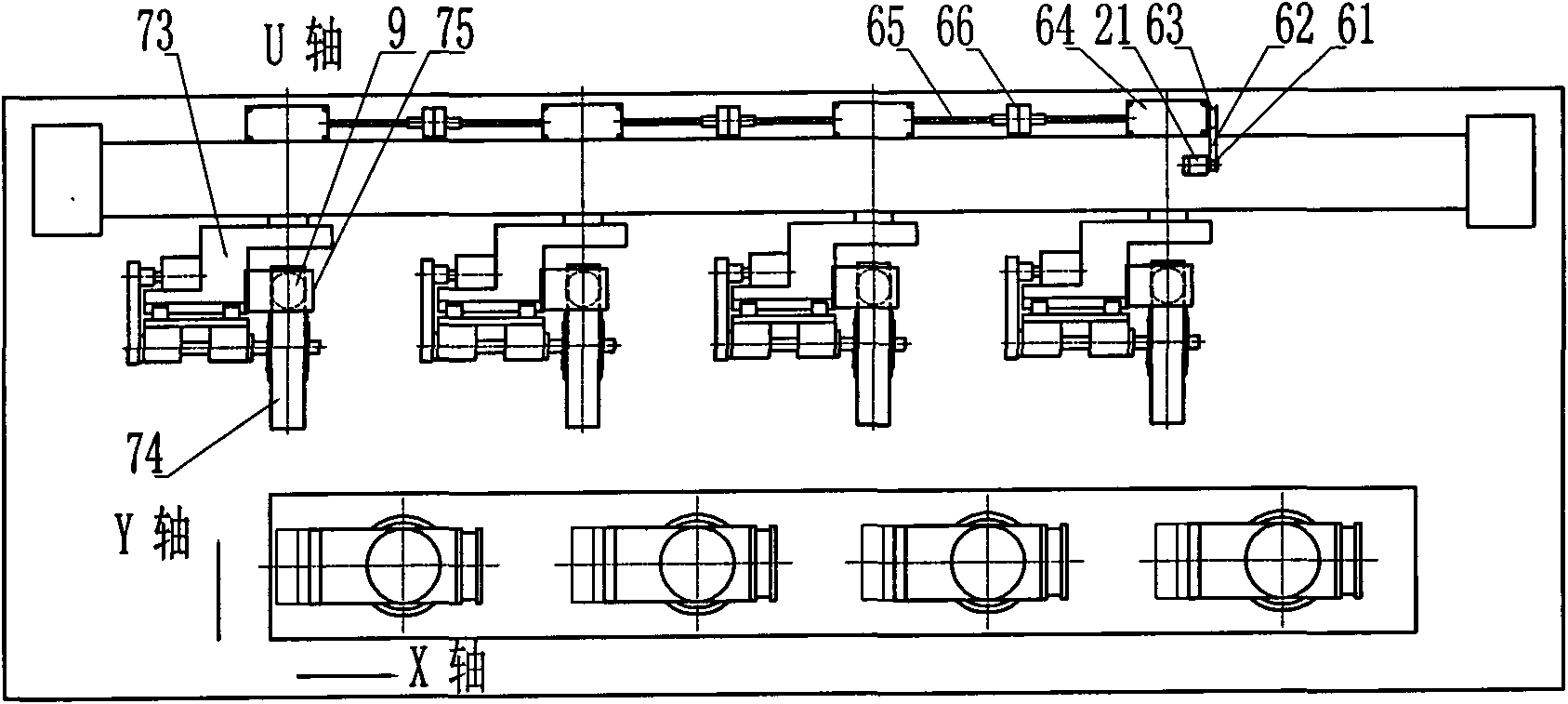

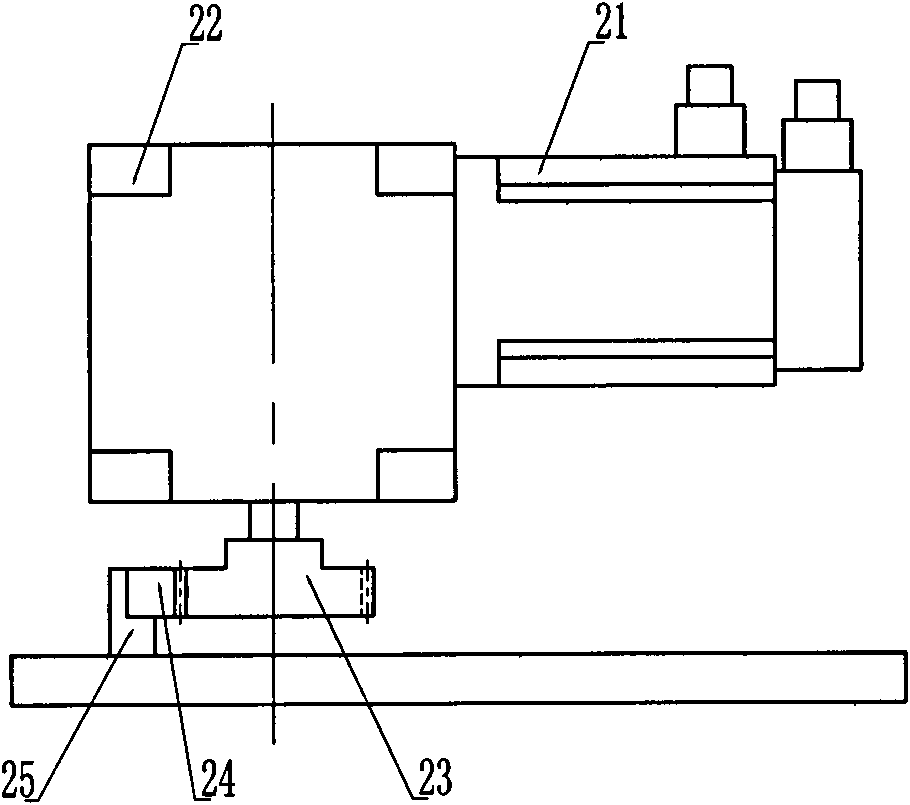

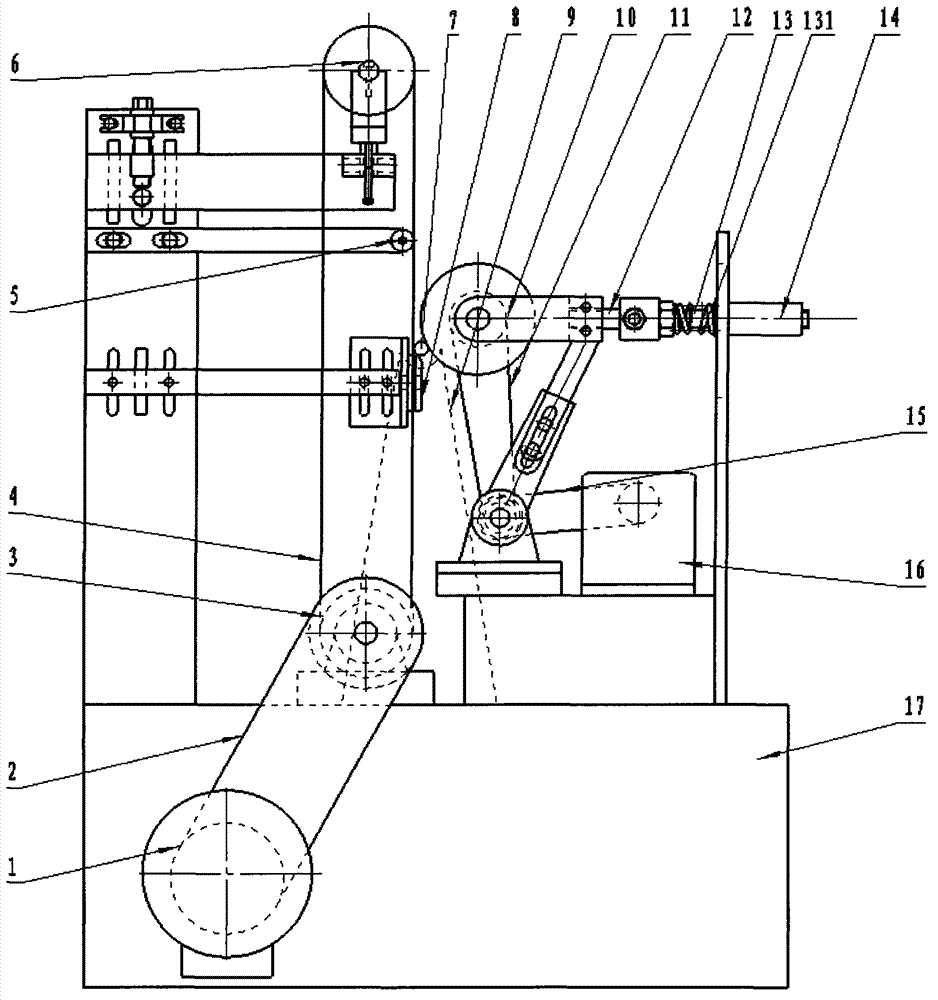

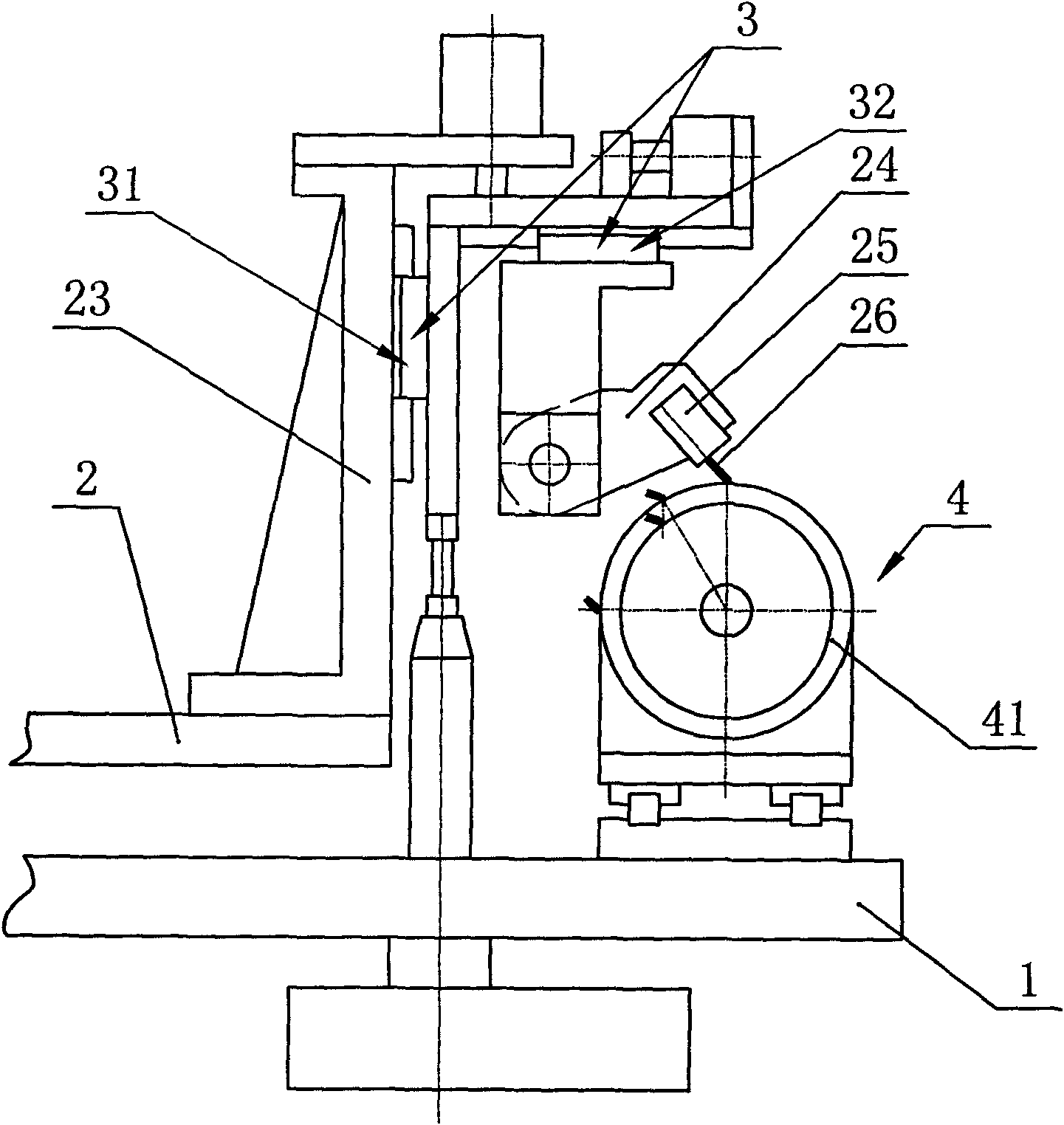

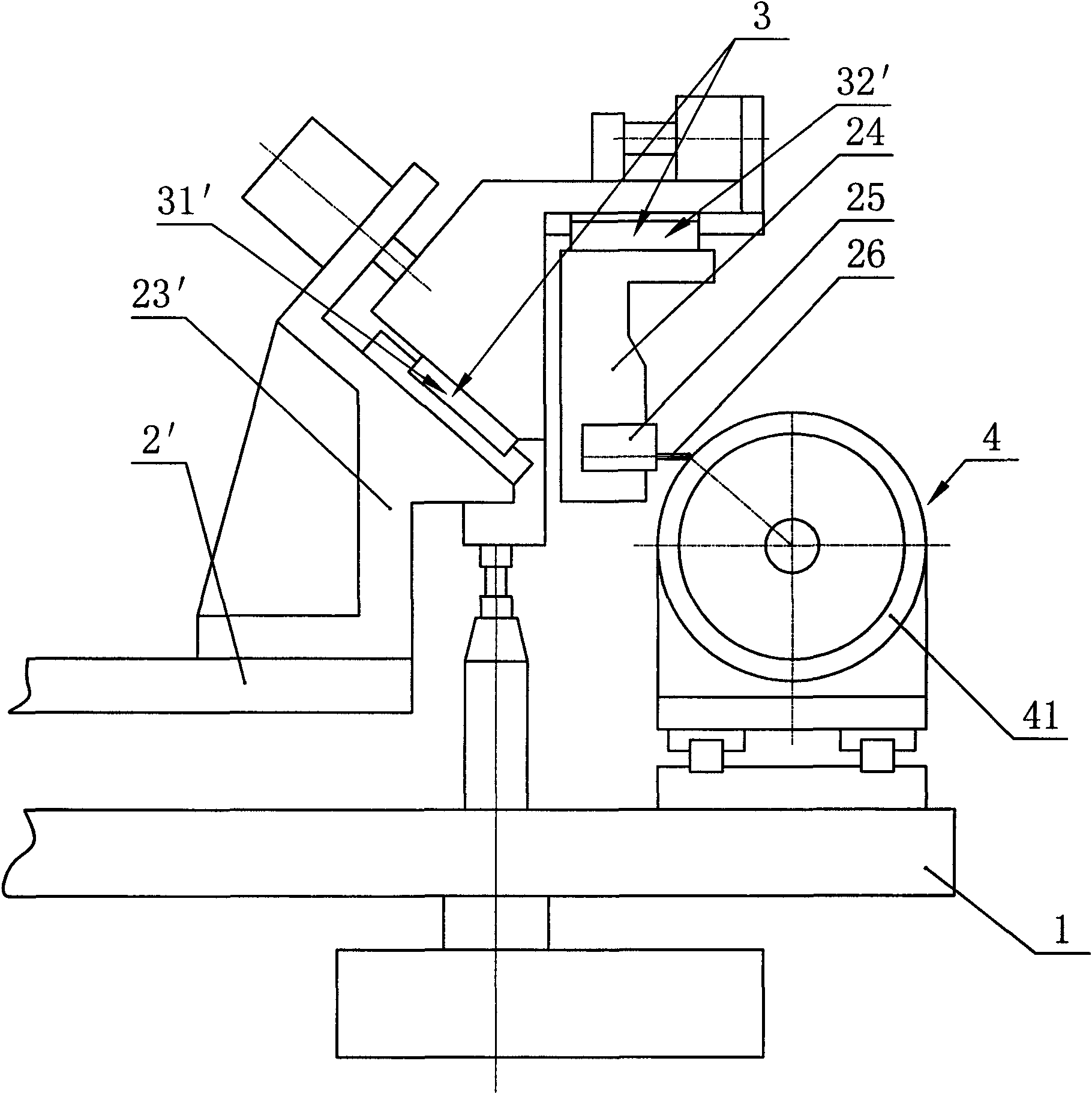

Seven-axis linkage numerical control polishing machine

InactiveCN101607380AImprove polishing qualityImprove stabilityPolishing machinesNumerical controlMechanical engineering

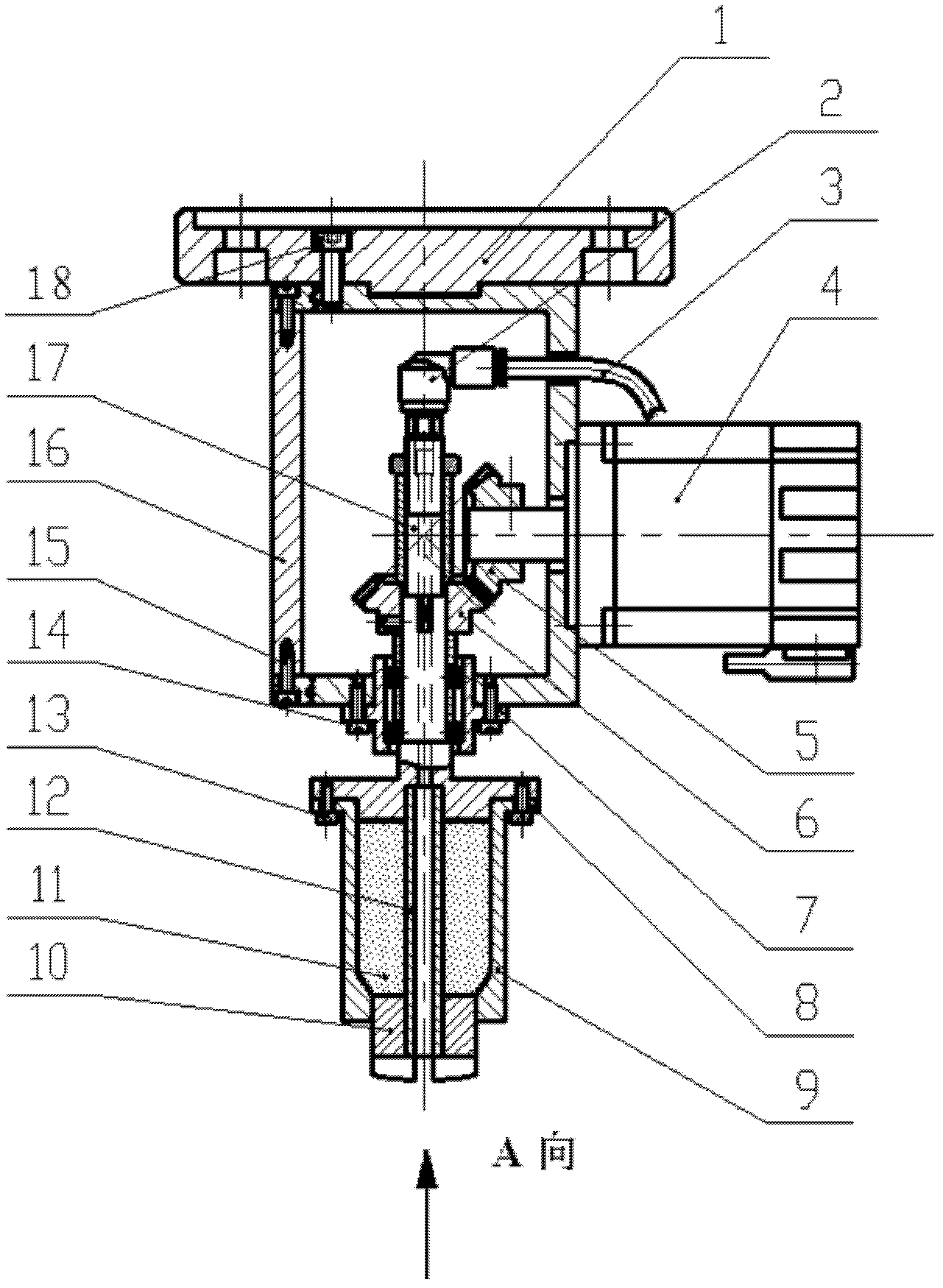

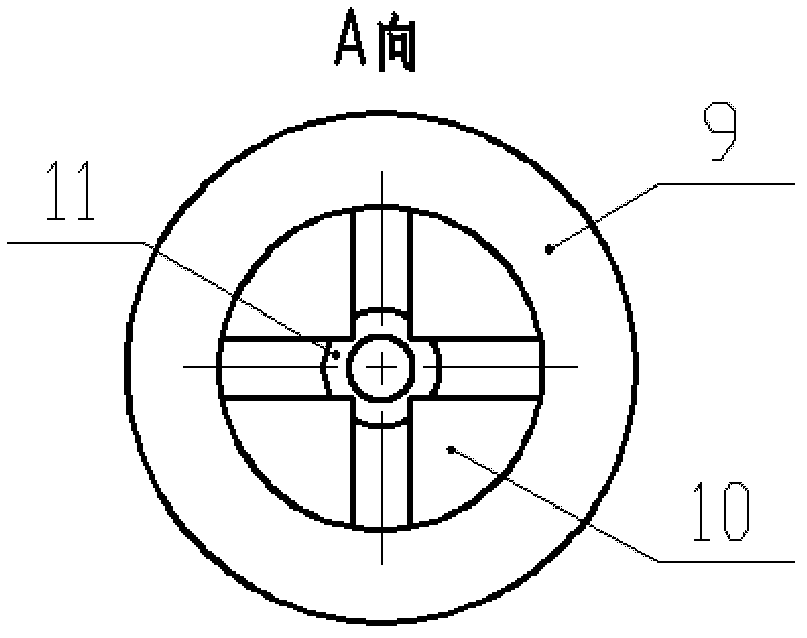

The invention relates to a seven-axis linkage numerical control polishing machine comprising a large base, a movable base, a worktable, a tee revolving base, upright posts, a beam and a head frame, wherein a polishing wheel is installed on the head frame; a working piece is installed on the tee revolving base; the movable base makes straight movement along the X-axis direction on the large base through a driving mechanism; the worktable makes straight movement along the Y-axis direction on the movable base through the driving mechanism; the tee revolving base rotates around a V axis on the worktable, and the working piece is clamped on the tee revolving base and rotates around a W axis; the beam arranged between the left upright post and the right upright post does straight movement along the Z-axis direction through the driving mechanism; the head frame for installing the polishing wheel rotates around a U axis; the movements in the six directions are all driven by independent servo motors and numerically controlled for the whole process by a servo system; the head frame is provided with an automatic wax-polishing device for polishing wax to the polishing wheel; and a wax rod arranged on the automatic wax-polishing device is driven by a feeding motor to rotate around an H axis. The polishing machine adopting the structure has stable processing quality and effectively improves the production efficiency and the economic benefit.

Owner:霍彩红

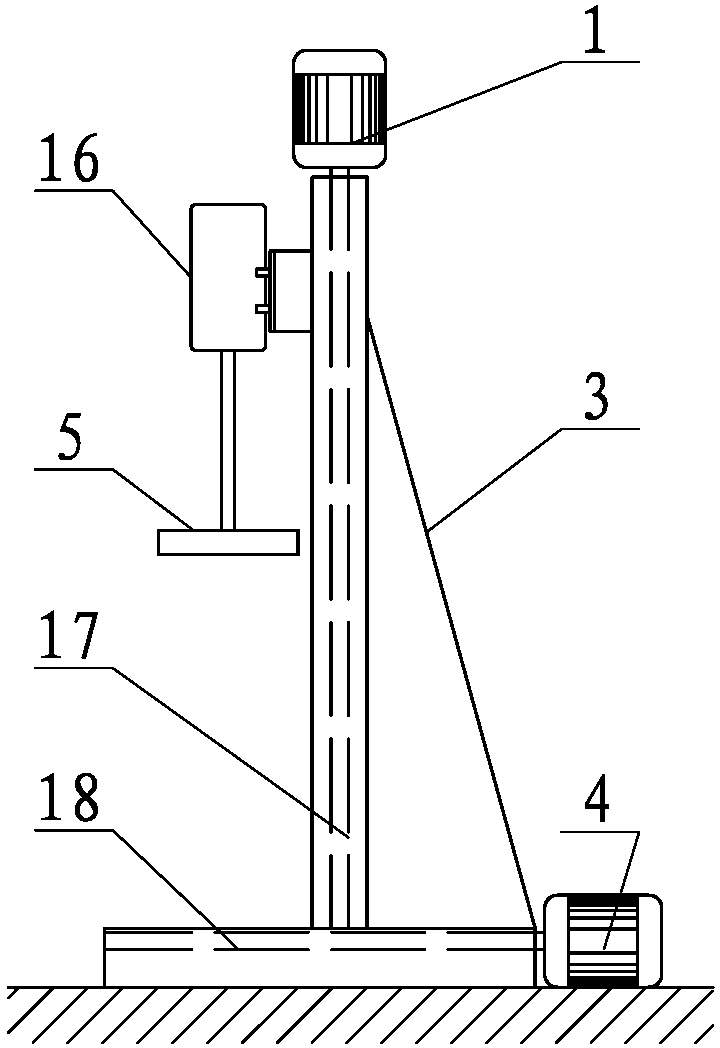

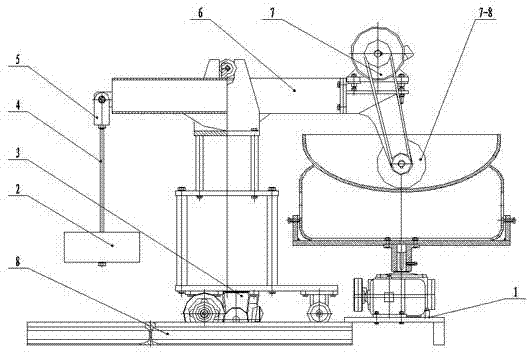

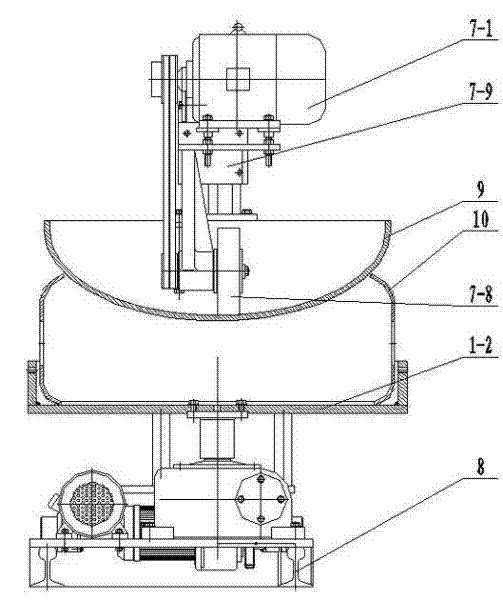

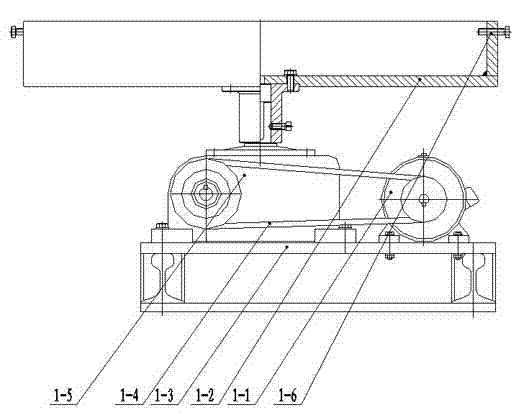

Capped end polishing machine

InactiveCN102513907AReasonable structureImprove efficiencyPolishing machinesSurface finishMechanical equipment

The invention relates to a polishing machine, in particular to a capped end polishing machine for polishing capped ends, belonging to the field of mechanical equipment. The capped end polishing machine comprises a rail, a running mechanism capable of horizontally moving along the rail, a capped end rotation mechanism, an automatic lifting system and a polishing mechanism, wherein the capped end rotation mechanism for clamping a capped end and driving the capped end to rotate is arranged on one side of the rail; the automatic lifting system for driving the polishing mechanism to perform feed motion along the inner circular-arc face of the capped end comprises a cantilever mechanism and a balancing weight; one end of the cantilever mechanism is connected with the balancing weight, and the other end of the cantilever mechanism is fixed with the polishing mechanism; and the cantilever mechanism is fixed on the running mechanism through a supporting seat and is hinged with the supporting seat. The polishing machine disclosed by the invention has a reasonable structure and a high efficiency, is simple and convenient to operate, greatly improves the environmental condition for operators, has high polishing quality, and completely eliminates the defect that hand operation cannot ensure the uniformity of the smoothness of all surfaces.

Owner:ZHEJIANG KIN SHINE TECH

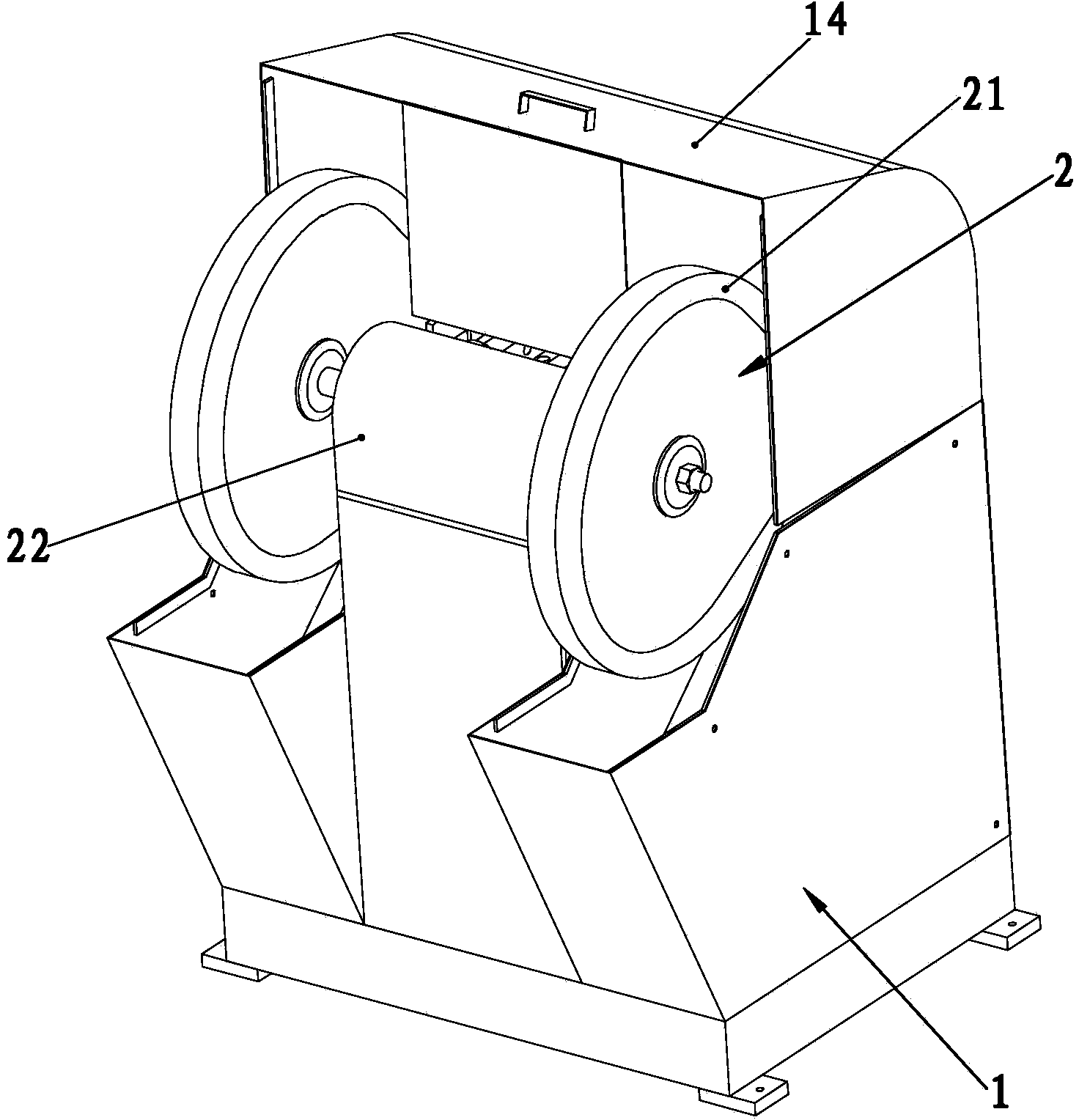

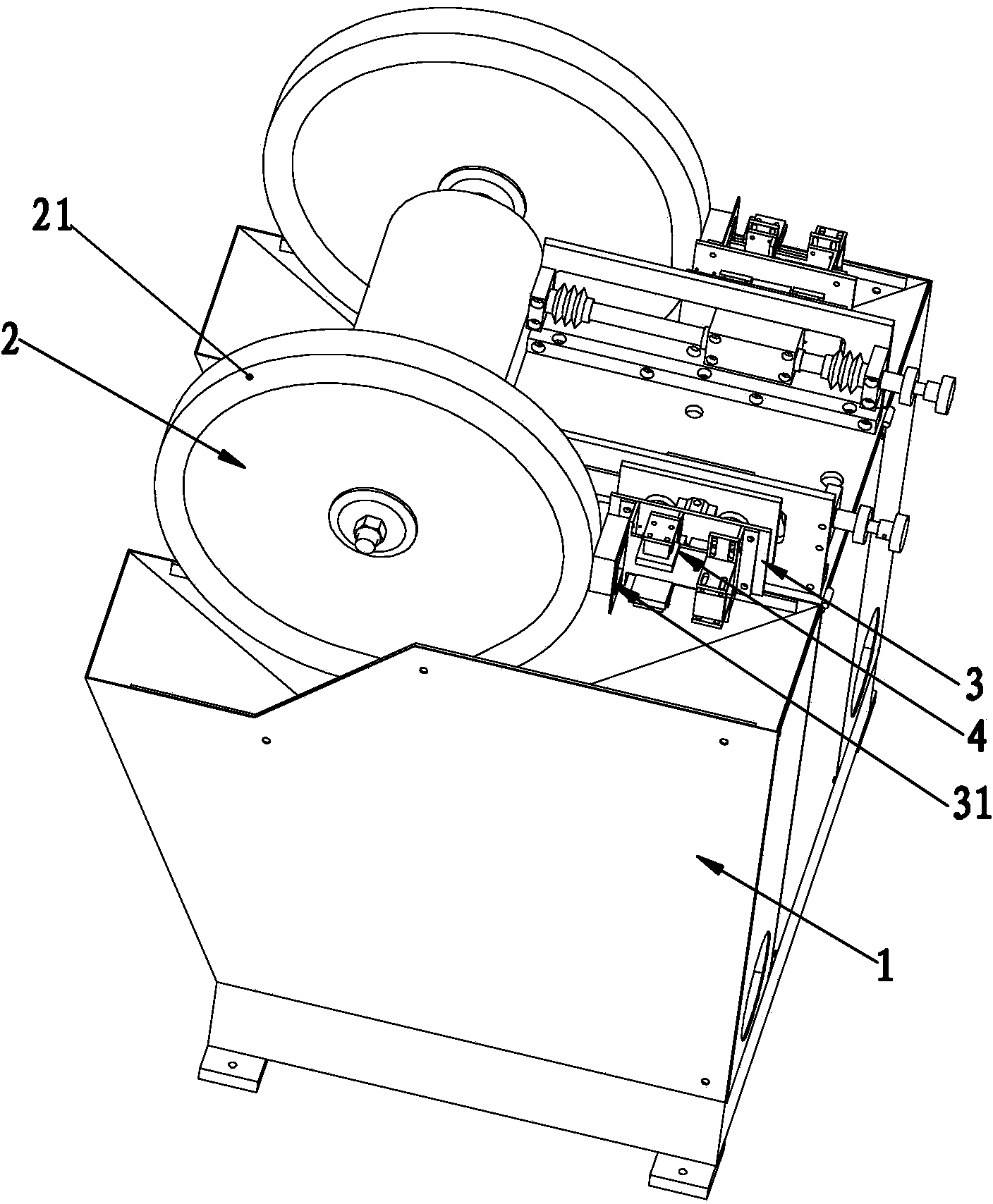

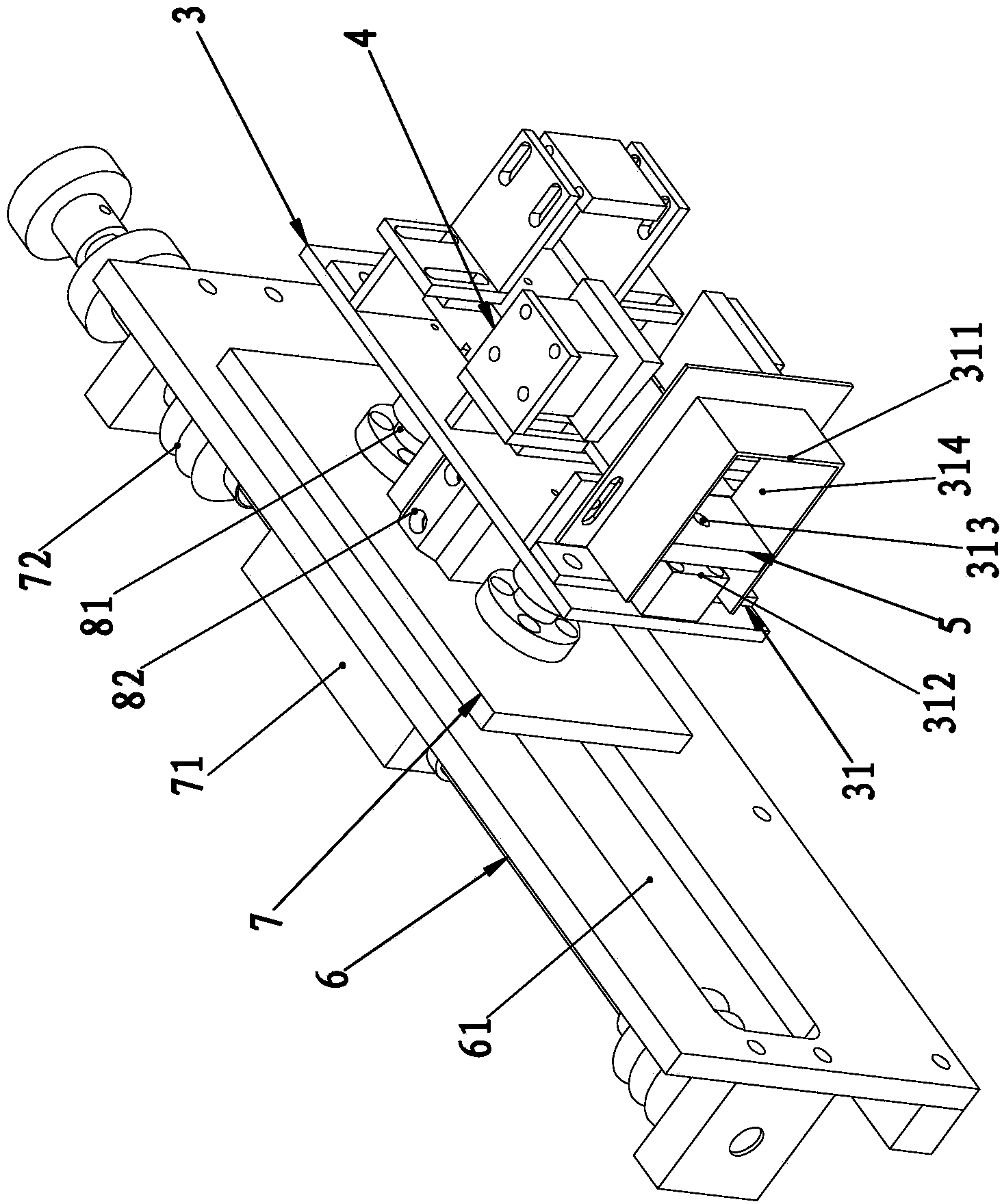

Variable cross-section outer cylinder surface sander suitable for timber

InactiveCN102765031AGood polishing qualityImprove polishing efficiencyBelt grinding machinesSanderDrive shaft

A variable cross-section outer cylinder surface sander suitable for timber mainly comprises an abrasive belt, a feeding plate, a receiving hopper, a press wheel mechanism, a rod end joint bearing, a screw and a spring. When the variable cross-section outer cylinder surface sander is in work, a workpiece placed on the feeding plate is pressed on the abrasive belt through a press wheel, the press wheel and the abrasive belt rotate clockwise to drive the workpiece to rotate in a counter-clockwise direction and be polished through the abrasive belt along the circumference, and simultaneously the workpiece is gradually contacted with the press wheel along the axial direction of the workpiece, moves along the feeding plate and is finally ejected out to the receiving hopper. When the workpiece section varies, on one hand, the press wheel, a press wheel horizontal support, the rod end joint bearing and the screw move horizontally relative to a machine frame, and on the other hand, the rod end joint bearing enables the press wheel and the press wheel horizontal support to perform tiny deflection relative to the screw, simultaneously a press wheel inclined support performs tiny deflection around a press wheel inclined support transmission shaft, so that the relative positions of the press wheel and the workpiece can automatically change, and polishing of the variable cross-section outer cylinder surface is achieved. The variable cross-section outer cylinder surface sander is good in polishing effect, strong in adaptability, simple in structure and simple and convenient to operate.

Owner:杨红艳

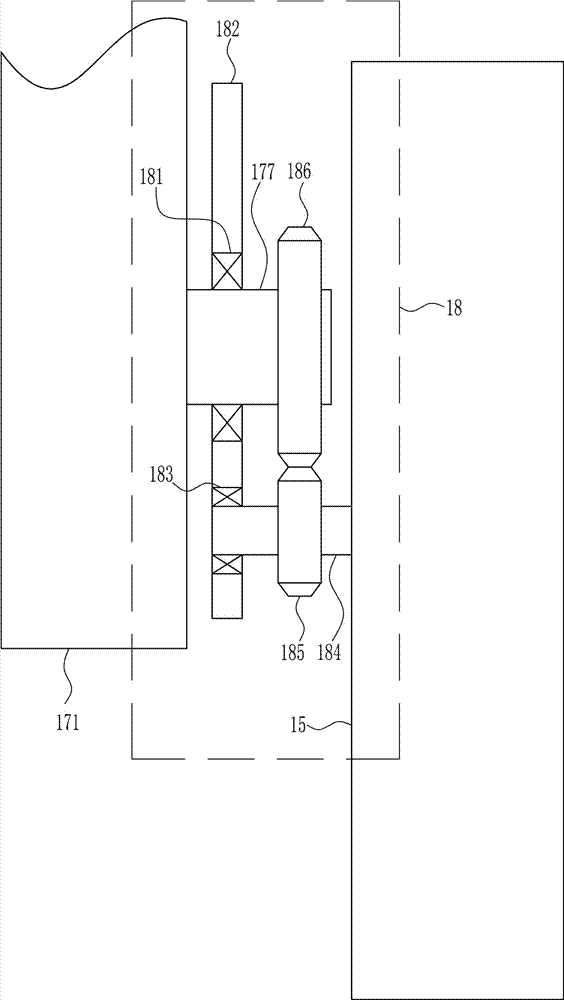

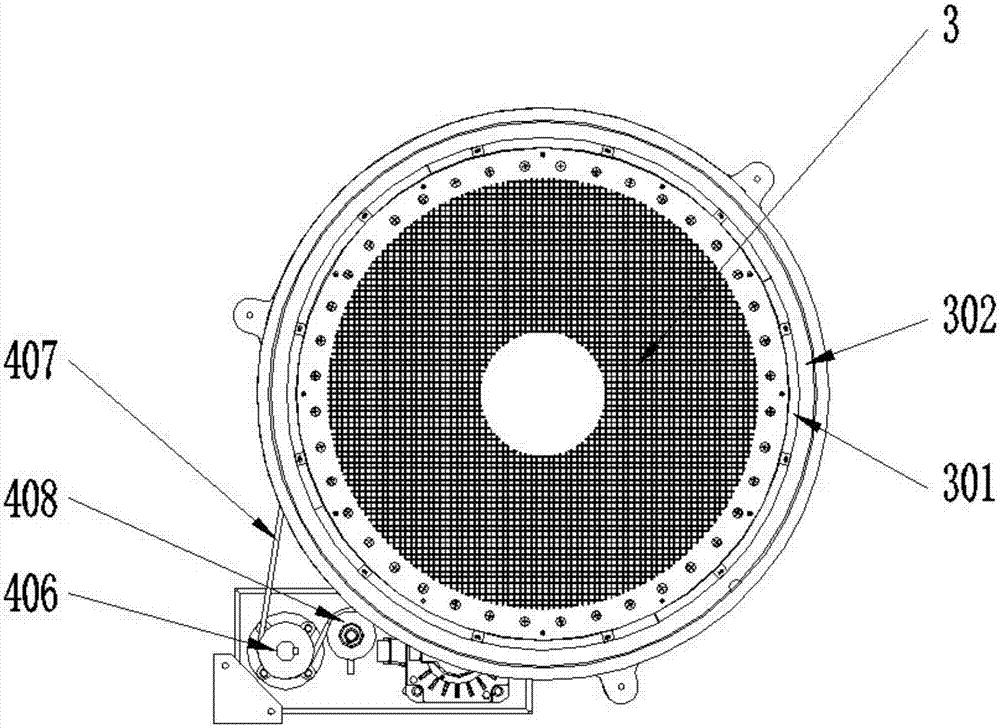

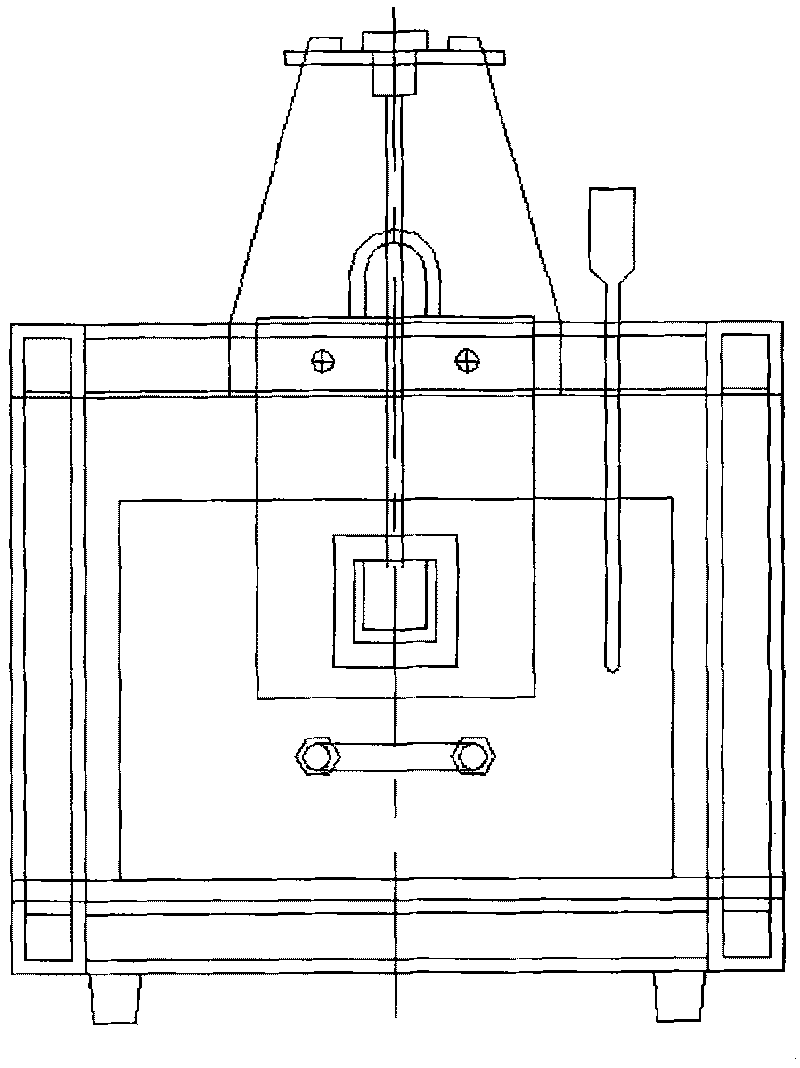

Magneto-rheological plane polishing device

The invention provides a magneto-rheological plane polishing device and relates to the technical field of ultra-precision machining. The magneto-rheological plane polishing device comprises a bracket. A platform is arranged at the top end of the bracket. A rotating seat is fixed to the platform. A polishing disc is arranged on the rotating seat. A polishing disc driving mechanism is connected to the rotating seat. A workpiece clamping mechanism is arranged above the polishing disc and provided with a chuck. A magnetic field generating mechanism is arranged below the platform. A plurality of permanent magnets are uniformly arranged along the uniform-speed spiral on a rotating disc with the center of the rotating disc as a starting point. According to the magneto-rheological plane polishing device, the permanent magnets are alternately arranged on the rotating disc along the uniform-speed spiral in the mode that the directions of magnetic poles are opposite, and magneto-rheological polishing fluid forms a flexible polishing surface under the rotating composite action of the polishing disc, a to-be-machined workpiece and the permanent magnets; and real-time rapid updating self-sharpening is achieved on abrasive materials in the magneto-rheological polishing fluid under the action of a pulsed magnetic field, so that the magneto-rheological polishing efficiency is improved, the abrasion rate of abrasive particles in the polishing fluid is decreased, the service life of the magneto-rheological polishing fluid is prolonged, and the polishing efficiency and quality are improved.

Owner:BEIJING JIAOTONG UNIV +1

Sapphire wafer polishing solution

ActiveCN104356950AEvenly distributedFully moistenedPolishing compositions with abrasivesReaction rateOrganic base

The invention discloses a sapphire wafer polishing solution which consists of the following components in percentage by weight: 20 to 30 percent of silica sol with solid content of 30 to 40 weight percent, 10 to 20 percent of alumina with a diameter of 80 to 200nm, 0.1 to 0.4 percent of organic base, 0.1 to 3 percent of a dispersing agent, 0.3 to 1 percent of nonylphenol polyethylene ether and the balance of de-ionized water. According to the sapphire wafer polishing solution, the silica sol and the alumina are compounded, so that the polishing speed is ensured, and machining scratches are avoided; furthermore, the nonylphenol polyethylene ether, the dispersing agent and the like are added to form a stable colloidal dispersion system to promote the full wetting of a polished wafer and a polishing pad and the stable and uniform distribution of the polishing solution between the polishing pad and the polishing wafer, so that the reaction rate of each part of the surface of the wafer can be balanced, and the polishing quality is ensured and improved; the sapphire wafer polishing solution can be used for the machining of a sapphire wafer.

Owner:临汾博利士纳米材料有限公司

Grinding and polishing tool for diamond, method for polishing diamond, and polished diamond, single crystal diamond and single diamond compact obtained thereby

InactiveUS20030091826A1Improve grinding effectEasy to operateEdge grinding machinesLayered productsRoom temperatureSingle crystal

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Stainless steel material polishing agent for mechanical equipment and preparation method of stainless steel material polishing agent

ActiveCN104194648ASignificant flatnessSignificant micro-prickling effectPolishing compositions with abrasivesSilica particleMonocalcium phosphate

The invention discloses a stainless steel material polishing agent for mechanical equipment and a preparation method of the stainless steel material polishing agent. Aiming at the defects existing in the conventional stainless steel polishing agent, the stainless steel material polishing agent is prepared from an inorganic acid, dicarboxylic acid compound, monocalcium phosphate, a stabilizer, a catalyst, an oxidizing agent, a water-soluble surfactant, glycerin, silica particles, a buffer agent and water according to a certain preparation method. The stainless steel material polishing agent for mechanical equipment disclosed by the invention has the advantage of high polishing quality, no dust is generated in the polishing process; and the polishing agent also has the advantages that the dispersibility of abrasive is good and the stability of the composition is good; the defects of the traditional stainless steel polishing agent are overcome; the stainless steel material polishing agent has obvious effect on glazed surface evenness and micro burring phenomenon of the stainless steel material of the mechanical equipment.

Owner:宁波宇精锁具科技有限公司

Polisher

ActiveCN103934743AEasy to operateOperation time savingPolishing machinesGrinding/polishing safety devicesWaxEngineering

The invention relates to a polishing device, in particular to a polisher which comprises a machine frame, a polishing wheel arranged on the machine frame, a polishing textile arranged on the polishing wheel in a sleeved mode and a drive motor driving the polishing wheel. A wax stone clamping seat and a clamping mechanism arranged on the wax stone clamping seat are arranged on the machine frame and located at the polishing wheel. The wax stone clamping seat is provided with a wax stone continuous conveying mechanism matched with the clamping mechanism. The polisher is convenient to operate, saves time, and improves polishing quality.

Owner:ZHEJIANG KINGSTONE HOUSEWARES

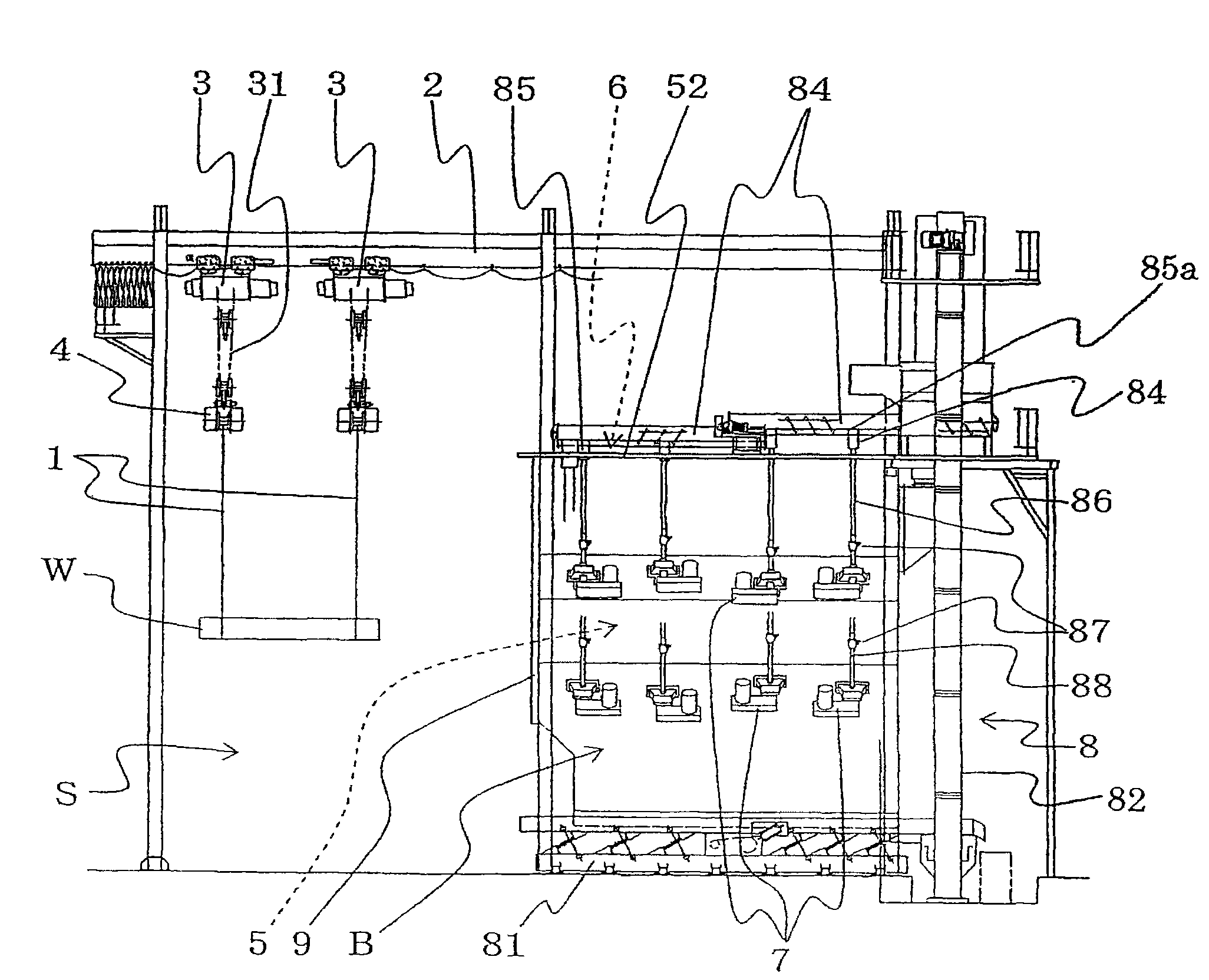

Shot-blasting machine

ActiveCN101687308ASmall volumeAvoid flyingAbrasive machine appurtenancesAbrasive blasting machinesEngineeringMechanical engineering

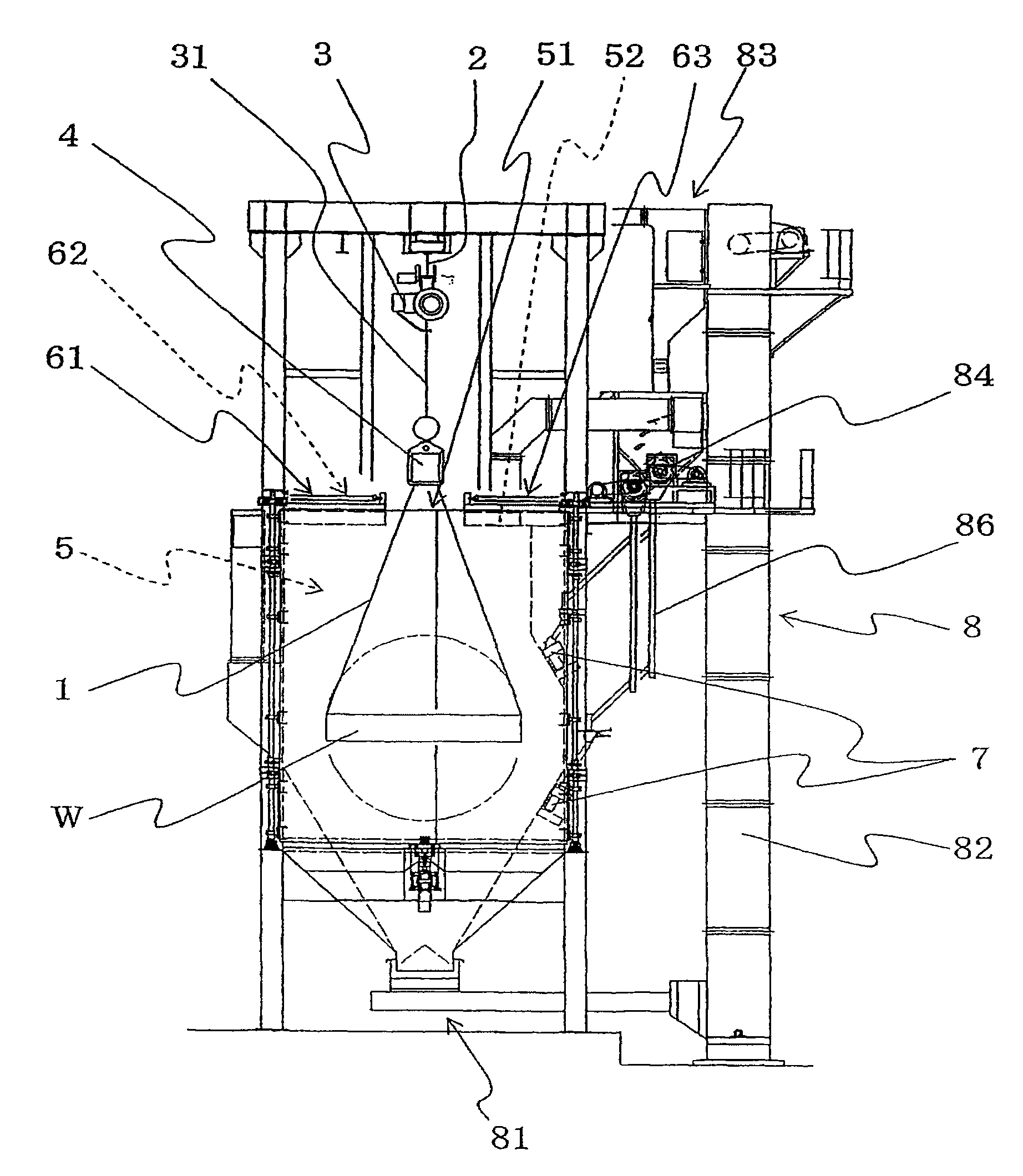

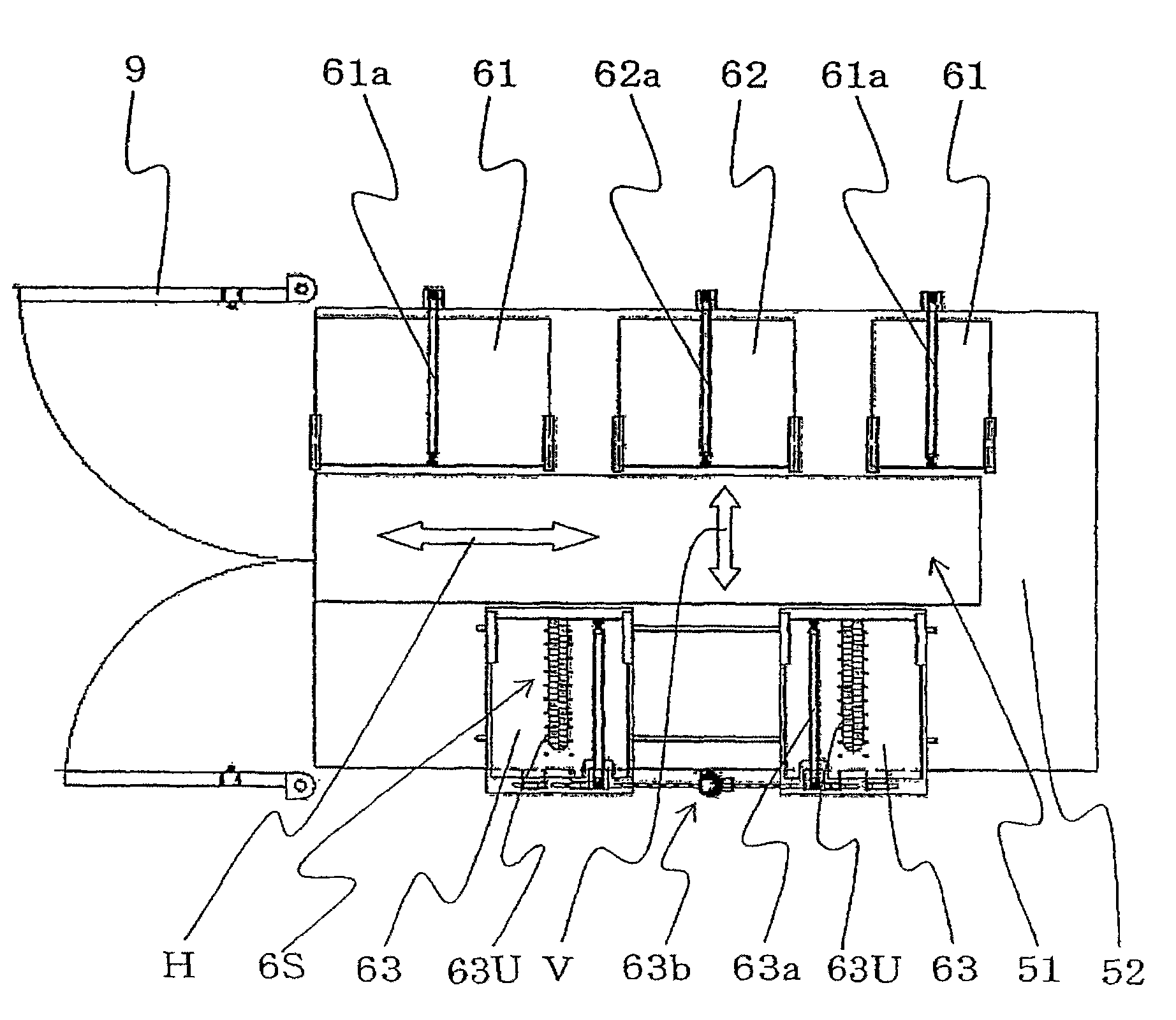

A shot-blasting machine for shot blasting a workpiece is disclosed. The shot-blasting machine comprises a rail 2 mounted on an upper part of the shot-blasting machine and extending in a horizontal direction, one or two hoists movable along the rail, and two inverting mechanisms 4. Each inverting mechanism 4 includes chain slings 1 for supporting one workpiece W at one end or the other end such that the workpiece W is suspended therefrom and includes a feeder for feeding the chain sling 1. An enclosure B in the shot-blasting machine has an entrance at one side and defines a projecting chamber 5therein. The upper surface of the enclosure B is provided with an elongated opening 51. The volume of the projecting chamber 5 is to allow the workpiece W supported by the chain slings 1 to be movedalong the direction that the rail 2 extends by running the hoist 3, while the workpiece W can be rotated about a rotating axis that is parallel to the direction that the rail 2 extends. The upper surface of the enclosure B is provided with a sealing mechanism 6 for preventing the shots from dispersing from the opening 51 by closing the opening 51 in which the chain slings 1 are inserted.

Owner:SINTOKOGIO LTD

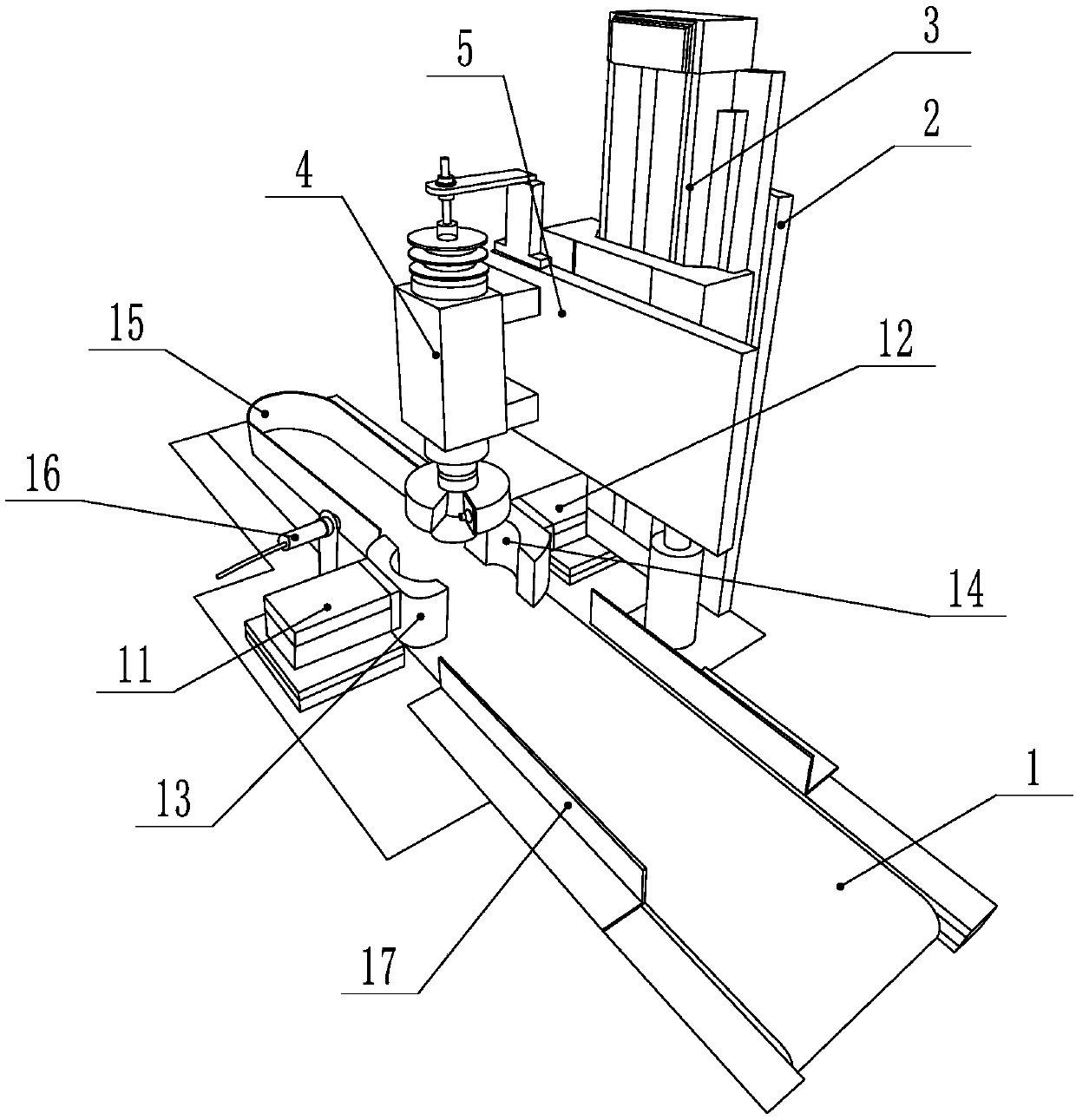

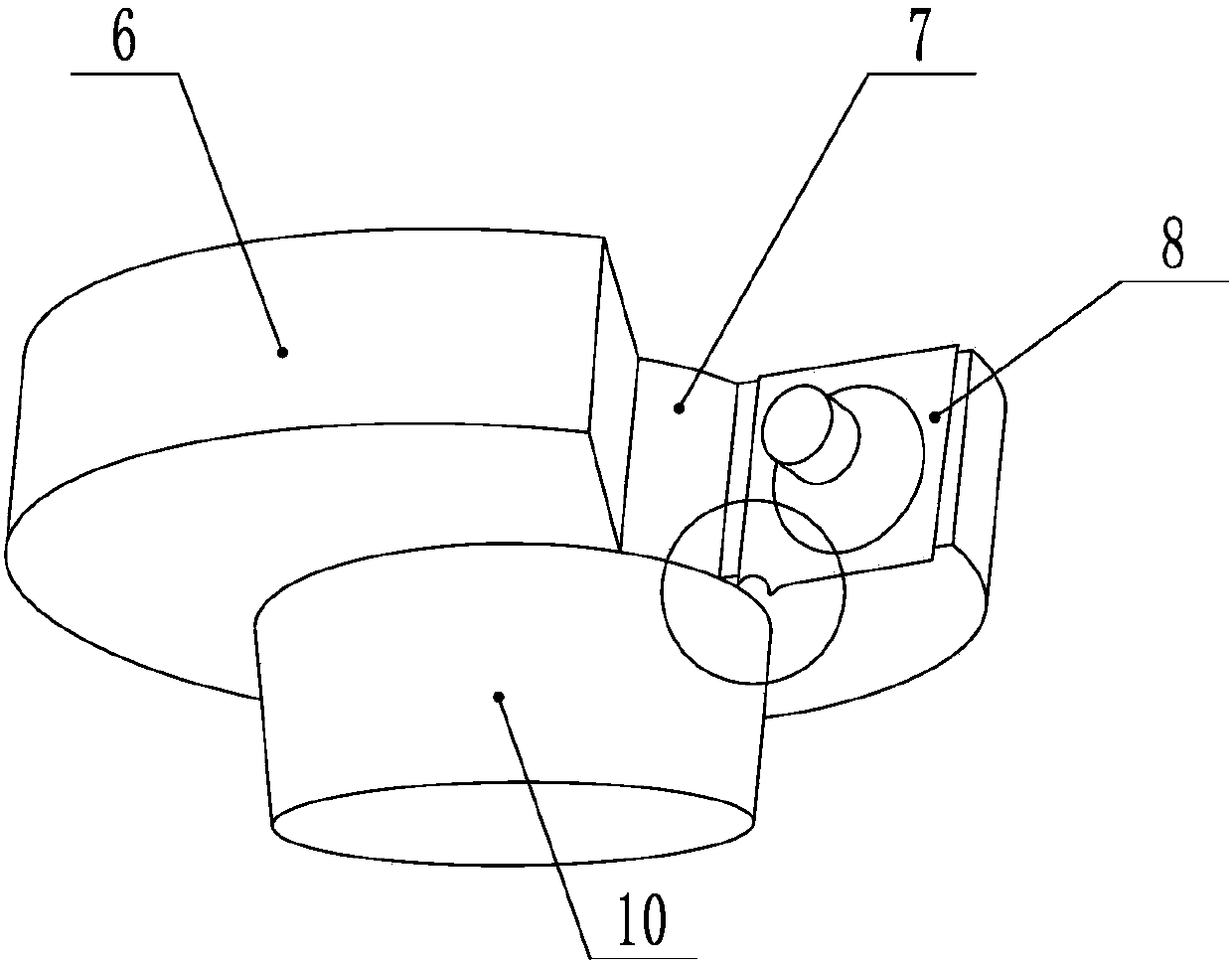

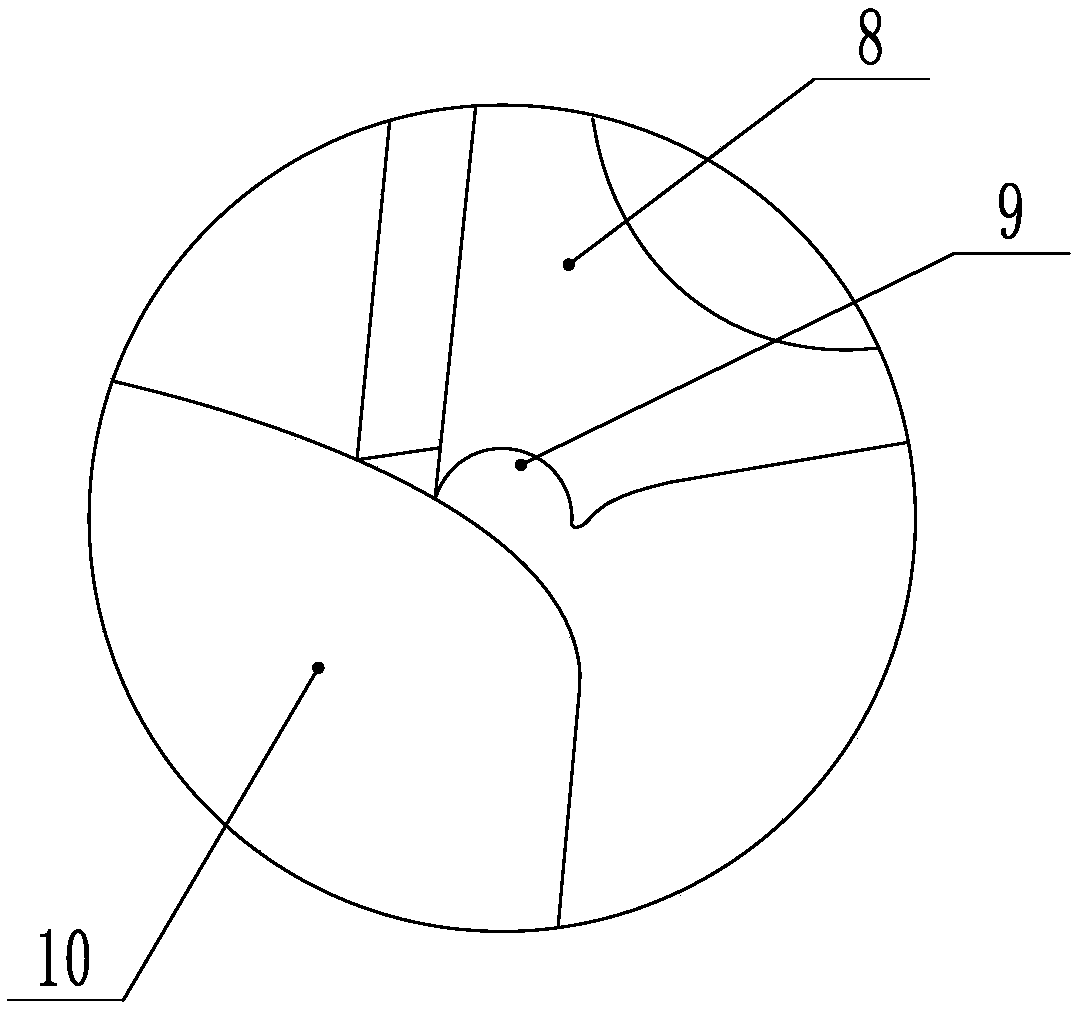

Magnetic grinding and polishing device for large curved surface

The invention discloses a magnetic grinding and polishing device for a large curved surface capable of continuously grinding and polishing a curved surface to obtain uniform surface quality finally. The magnetic grinding and polishing device comprises the following components: a main frame, a front-end supporting side plate, a side plate fixing bolt, a motor, a drive bevel gear, a driven bevel gear, a locating sleeve, a connecting bolt, a fastening bolt, a spindle, a magnetic pole, a grinding material and grinding liquid mixture conveying pipeline, a rotating joint, a magnetic shield, a flange disc, a flange locating bolt, a flange disc, a permanent magnet and a magnetic pole sleeve. The magnetic grinding and polishing device, provided by the invention, has the advantages of high processing efficiency, simple structure, low manufacturing cost and convenience for installation; the magnetic grinding and polishing device has an independent drive motor, convenience for connection with multiple processing equipment or devices, good university and no other external power. The magnetic grinding and polishing device can be widely applied to finish all kinds of curved surfaces, in particular to grind and polish a large-area complicated free curved surface. Technique grinding matched with the device has small temperature rise, high efficiency, difficulty in deformation of a processing work-piece, and no deterioration layer after processing.

Owner:UNIV OF SCI & TECH LIAONING

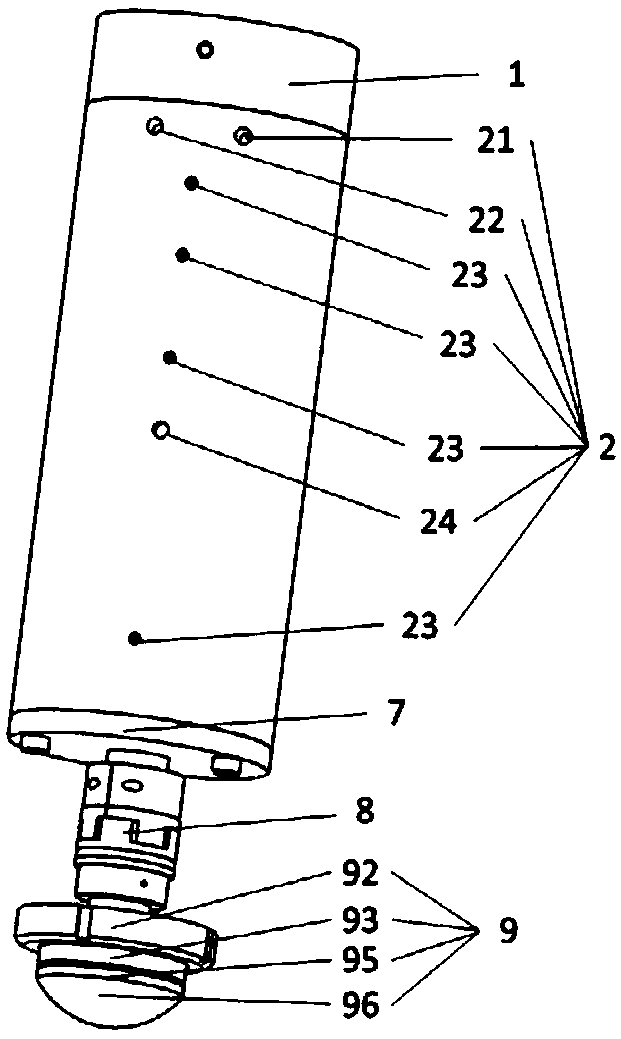

Magnetic rheology type flexible polisher with air bag

InactiveCN1663744AImproved Morphological AccuracyReduce weightGrinding machine componentsFlexible-parts wheelsDrive shaftAir cell

The invention relates to the magnetic rheo-gas cell flexible polishing tool. The said polishing tool comprises a gas cell with a polishing cloth in its front as the work face; an interlayer is in front of the said gas cell, which is filled with the magnetic rheological liquor; the said gas cell is equipped in the retainer; the said retainer is on the drive shaft with one or several pairs of electrical magnets at its front end; the said drive shaft socket joints a sleeving; the said sleeving and the drive shaft gas-tight joint; the said sleeving has outside gas entrance port and the overflow valve; the drive shaft in the sleeving opens the airflow channel that connects the said air cell. The flexibility of the polishing tool head can be controlled online, the contacting area of polishing is big, and the curve face polishing has high efficiency, well adaptation to the curvature change, which can be profiling remembered.

Owner:ZHEJIANG UNIV OF TECH

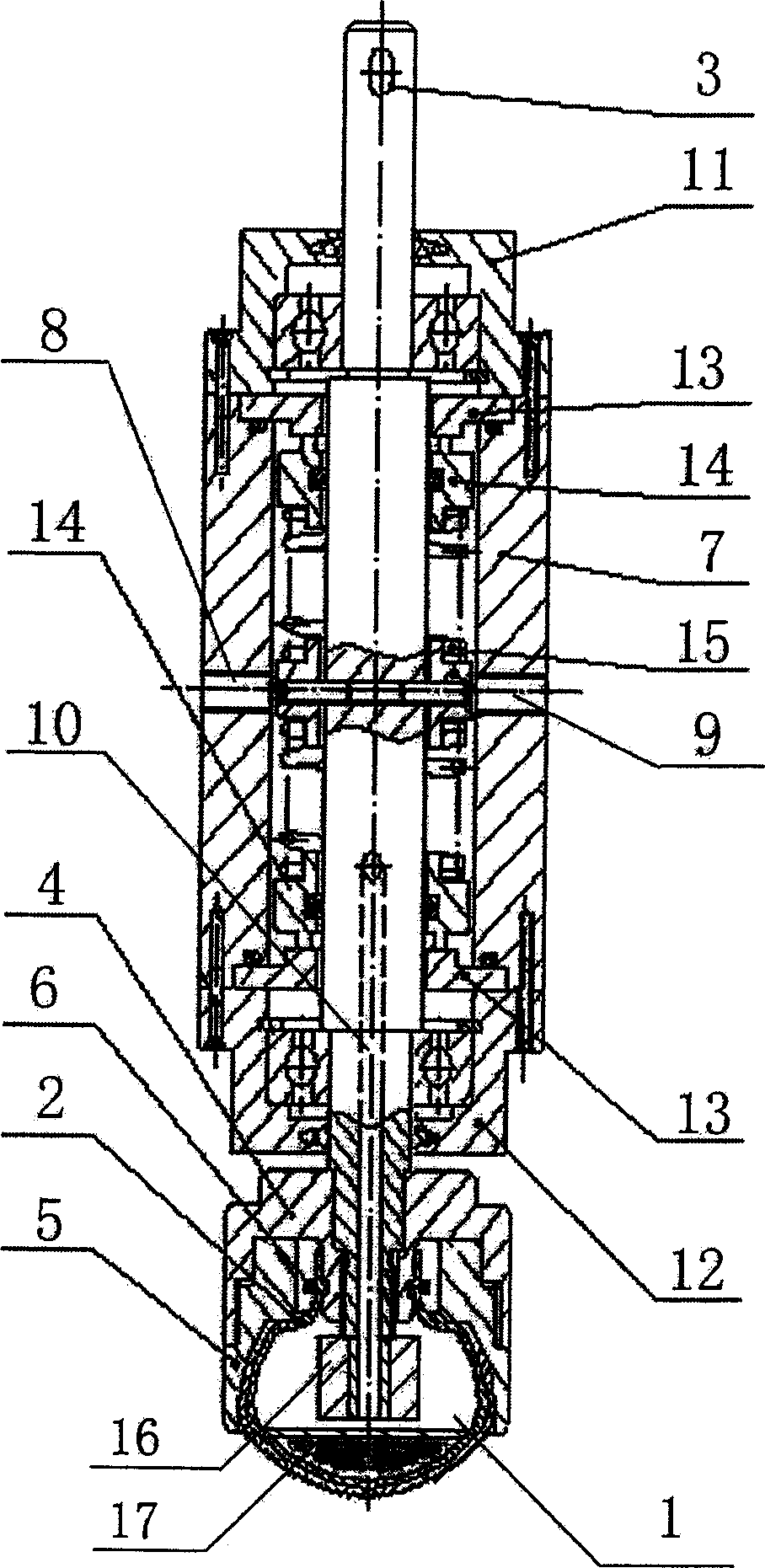

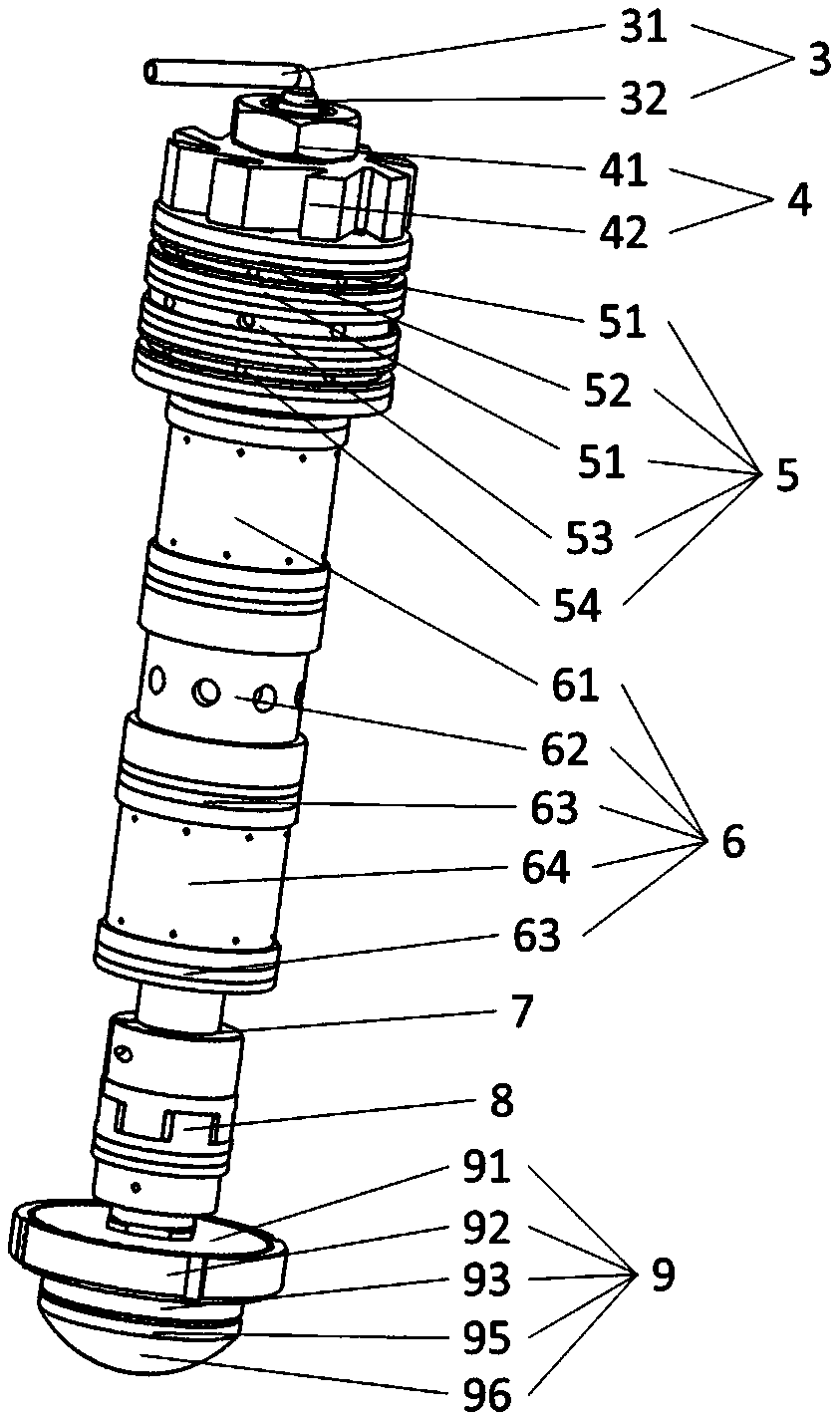

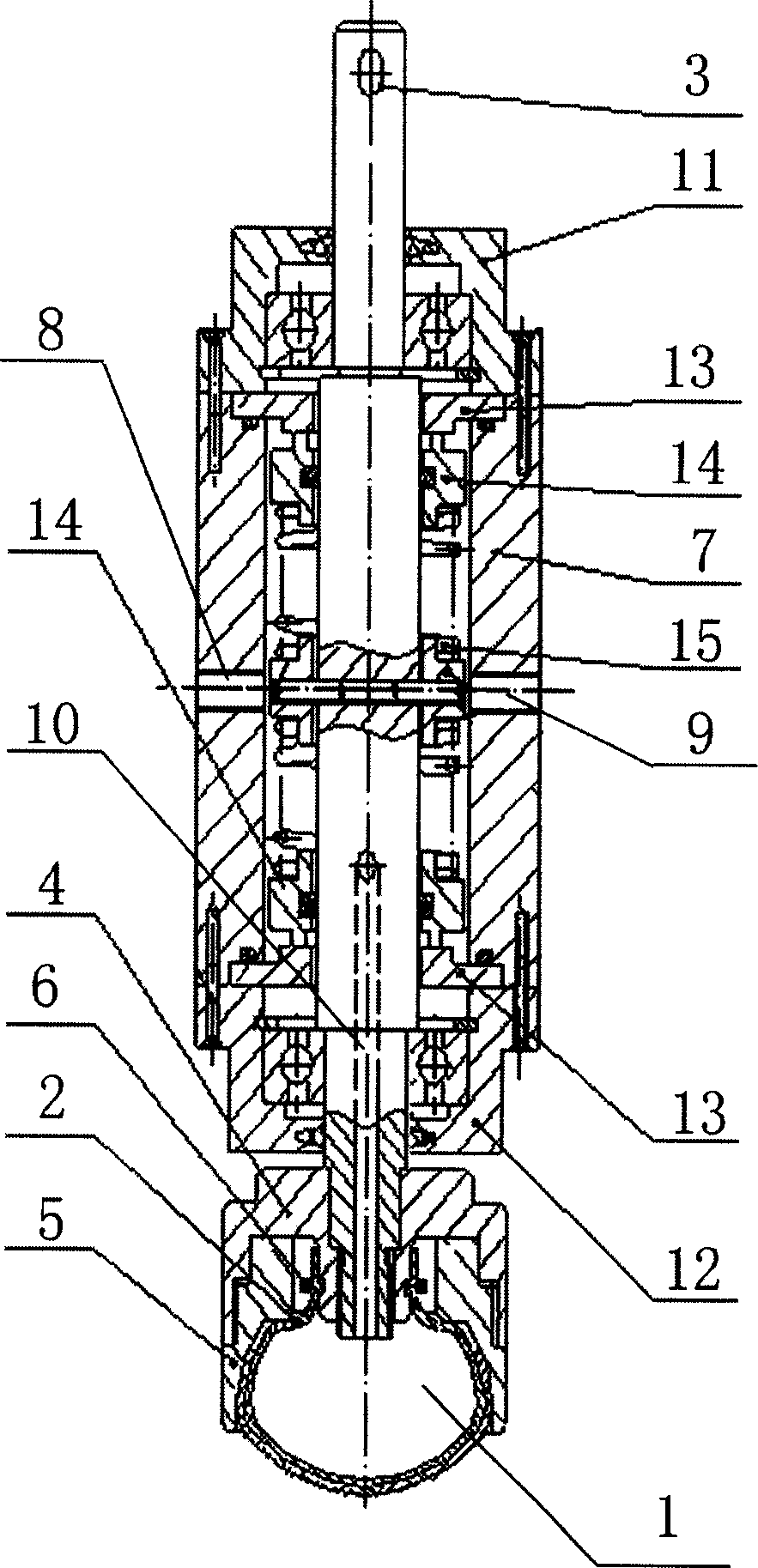

Polishing device of high-speed air flotation spindle airbag

ActiveCN109676507AHigh movement precisionReduce feverPolishing machinesGrinding drivesInternal pressureThrust bearing

The invention relates to a polishing device of a high-speed air flotation spindle airbag, and relates to airbag polishing devices. The polishing device is provided with an upper end cover, a lower endcover, an air flotation bearing mechanism, an air drive mechanism, an airbag pressure control mechanism and an airbag polishing head assembly. A shell of a cavity is formed by the upper end cover andthe lower end cover and is provided with a drive part air inlet hole, a drive part air outlet hole, four threaded holes, an air flotation bearing air inlet hole, a thrust bearing air outlet hole, a radial bearing air outlet hole, an air runner, a connecting threaded hole and the cavity. The air flotation bearing mechanism is provided with a radial bearing assembly and a thrust bearing assembly. The air drive mechanism is provided with a drive part and a fixed part and is mounted on a rotating shaft. The airbag pressure control mechanism is used for controlling the inner pressure of an airbaghead. The airbag pressure control mechanism is provided with an air pipe, a rapid joint, a sealing bearing and a locking nut. The airbag polishing head assembly is provided with a handle, a locking nut, two fixed parts, a 304 steel liner bottom part and a rubber part.

Owner:XIAMEN UNIV

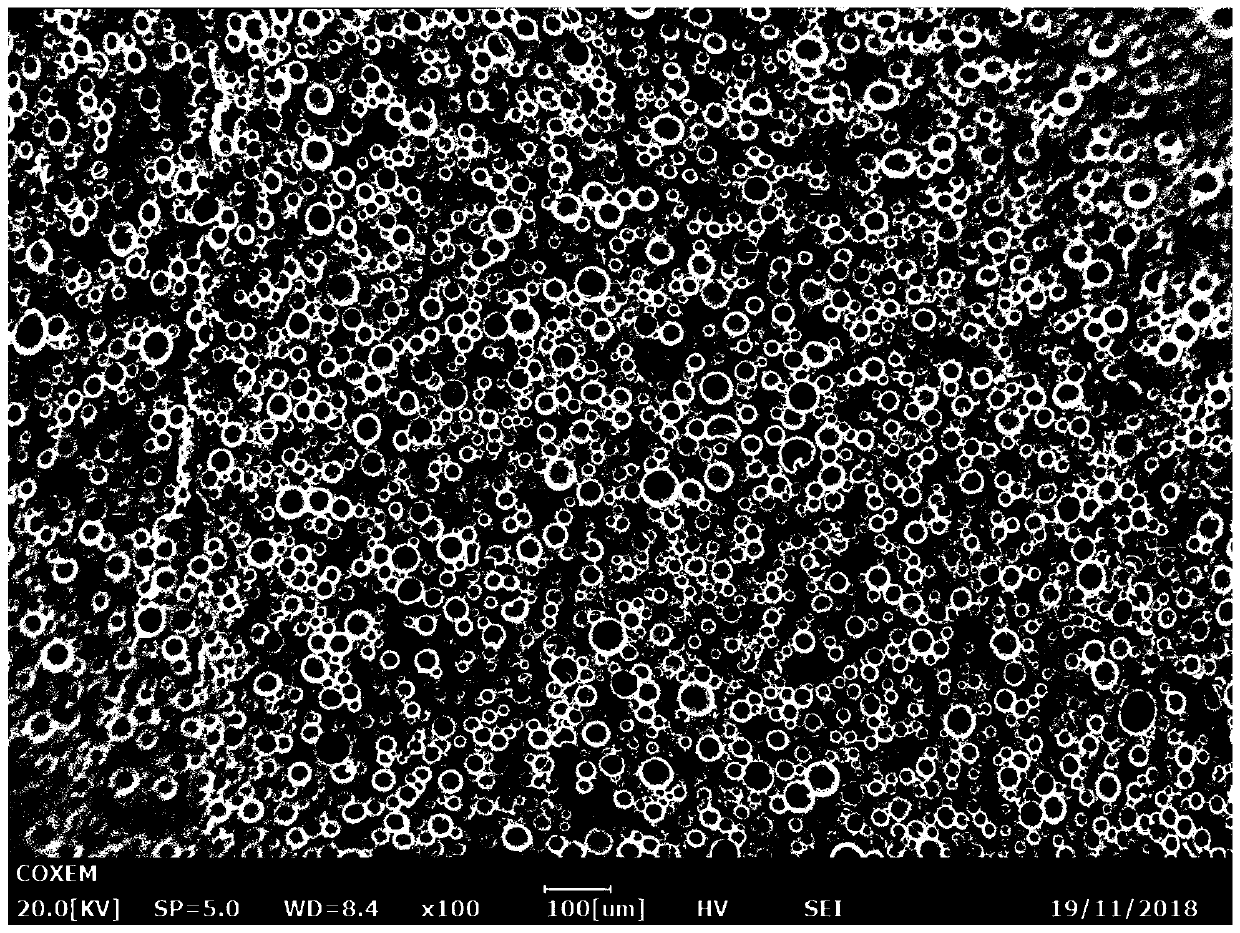

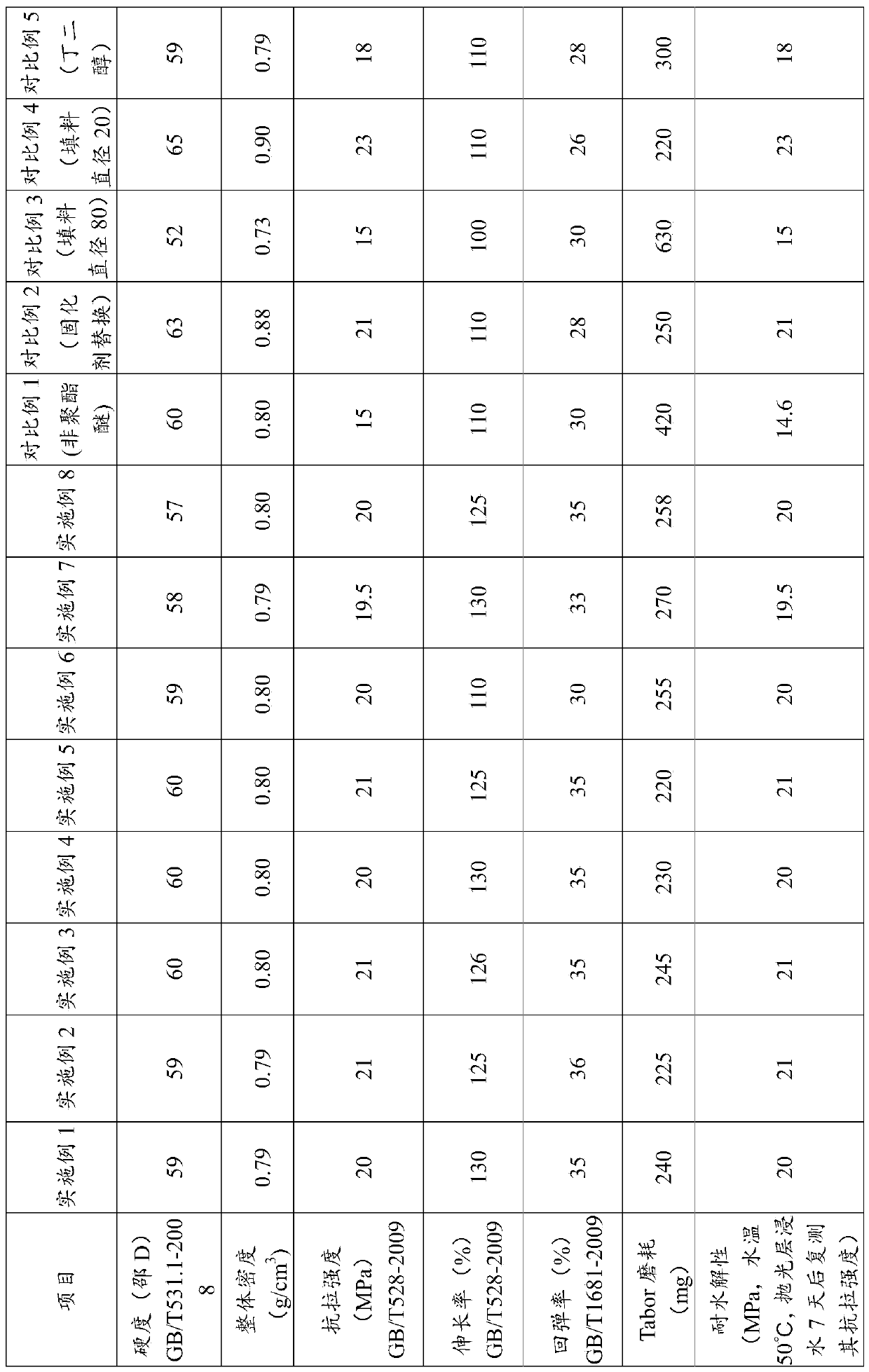

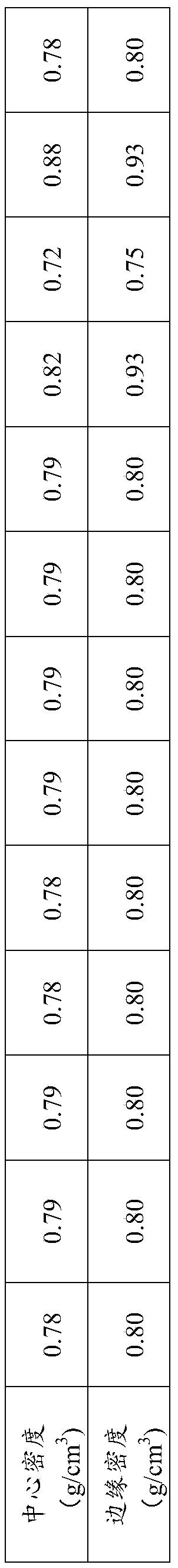

Polishing layer of chemical-mechanical polishing pad and application of polishing layer

ActiveCN110977756AImprove mechanical propertiesImprove wear resistanceSemiconductor/solid-state device manufacturingLapping toolsPolymer sciencePolyol

The invention provides a polishing layer of a chemical-mechanical polishing pad and application of the polishing layer. The polishing layer is prepared by the reaction of isocyanate prepolymer, a curing agent and functional filling; the isocyanate prepolymer is prepolymer prepared by the reaction of raw materials including diisocyanate, polyether ester polyol and optional small molecular polyol; the curing agent is dispersion liquid formed in dioctyl adipate by a complex of diamine compound and sodium chloride, wherein concentration of the complex is 40 wt%-50 wt%; and the functional filling is expanded polymer hollow microspheres. The polishing layer has higher mechanical strength and abrasive resistance while having high elasticity and hydrolysis resistance, so that the durability of thepolishing layer is good.

Owner:万华化学集团电子材料有限公司

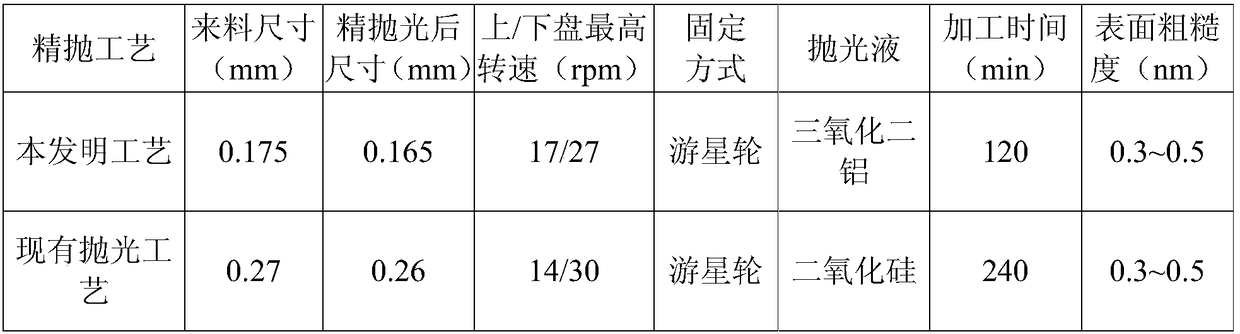

Polishing process for ultrathin sapphire wafers

ActiveCN108214260AEasy loading and unloadingReduce human and material resources inputPolishing machinesGrinding work supportsEngineeringSapphire wafer

The invention provides a polishing process for ultrathin sapphire wafers. The polishing process comprises the following steps of 1, grouping the sapphire wafers obtained after cutting according to thethickness; 2, providing an adsorption pad provided with multiple cavity holes used for containing the sapphire wafers, wetting the cavity holes with clear water, putting the sapphire wafers into thecavity holes, and making each sapphire wafer and the corresponding cavity hole be fixed relative to each other; 3, putting the adsorption pad on a copper disc of a polishing machine with openings of the cavity holes of the adsorption pad facing downwards, so that rough polishing is conducted on the sapphire wafers; and 4, putting the sapphire wafers obtained after rough polishing on a lower polishing disc of a double-face polishing machine for finish polishing. By means of the polishing process for the ultrathin sapphire wafers, the polishing time is greatly shortened, polishing efficiency isimproved, and production cost is lowered; the thickness of each sapphire wafer obtained after polishing is small and can reach 0.1-0.2 mm; polishing quality is stable and reliable; and the polishing process meets the trend that existing sapphire products develop to be lighter and thinner.

Owner:LENS TECH CHANGSHA

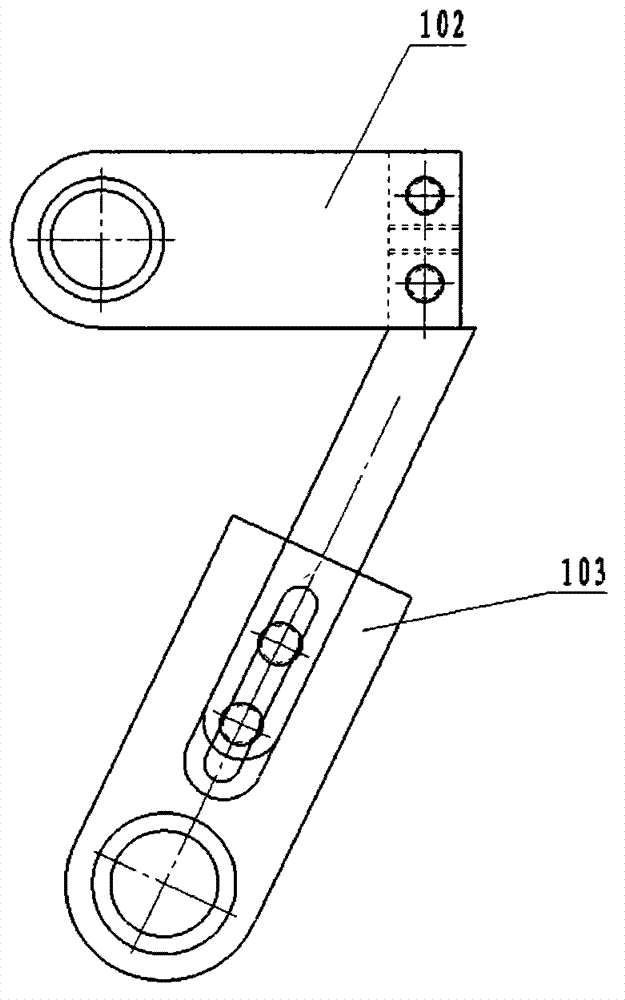

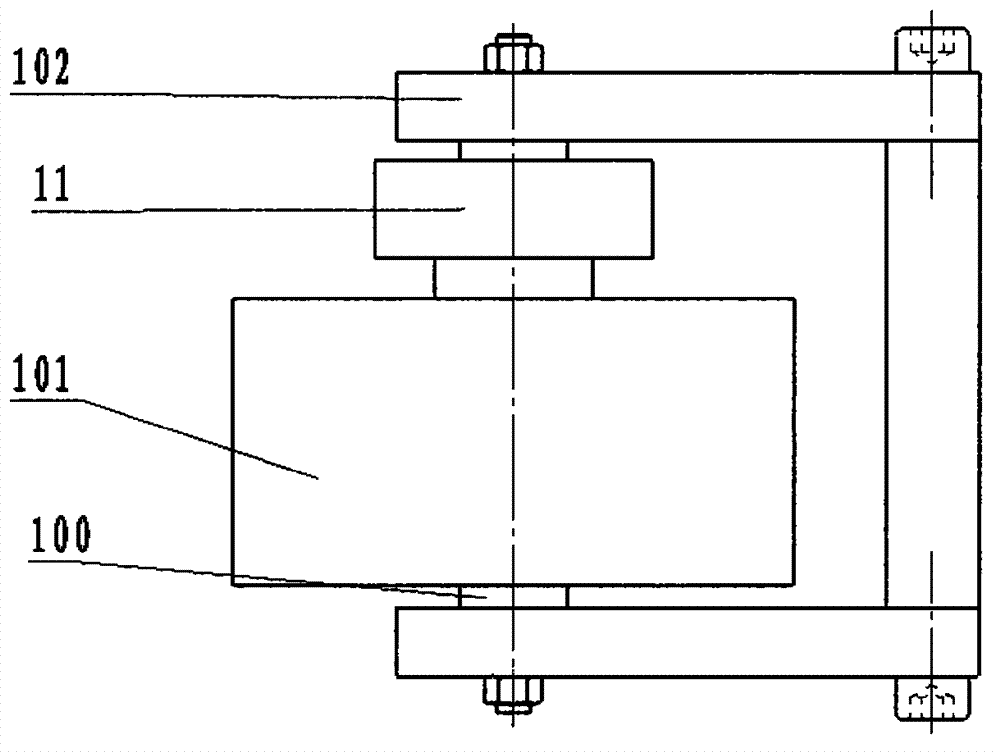

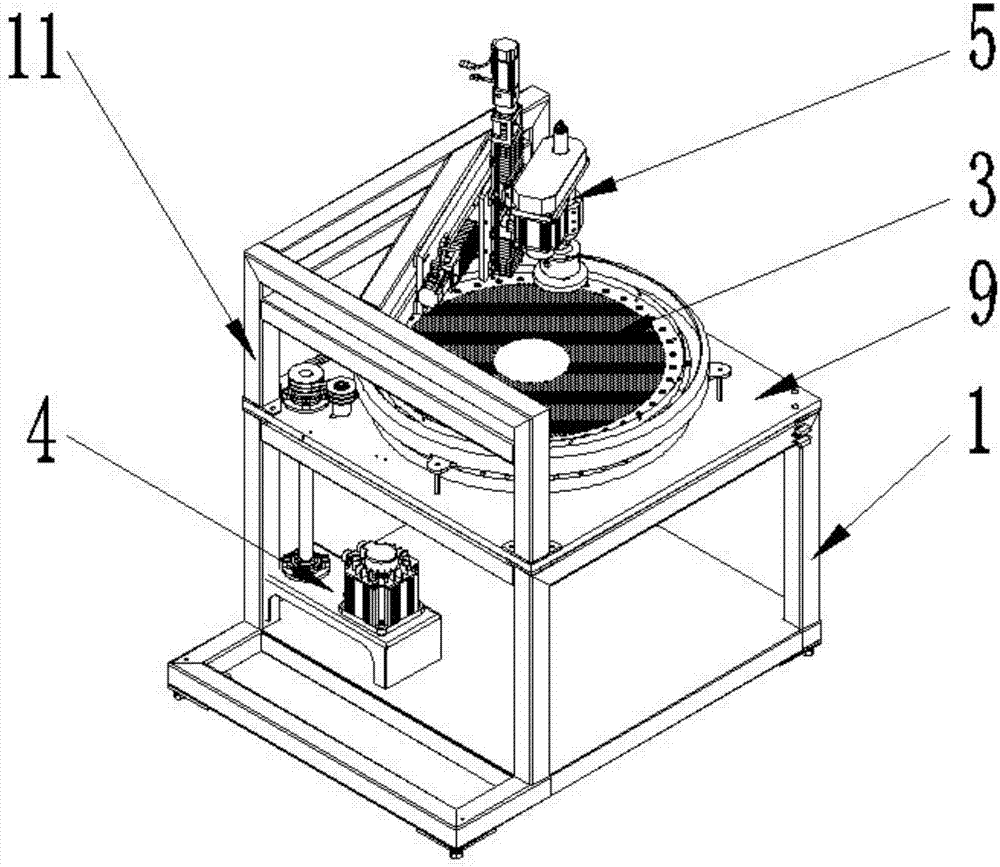

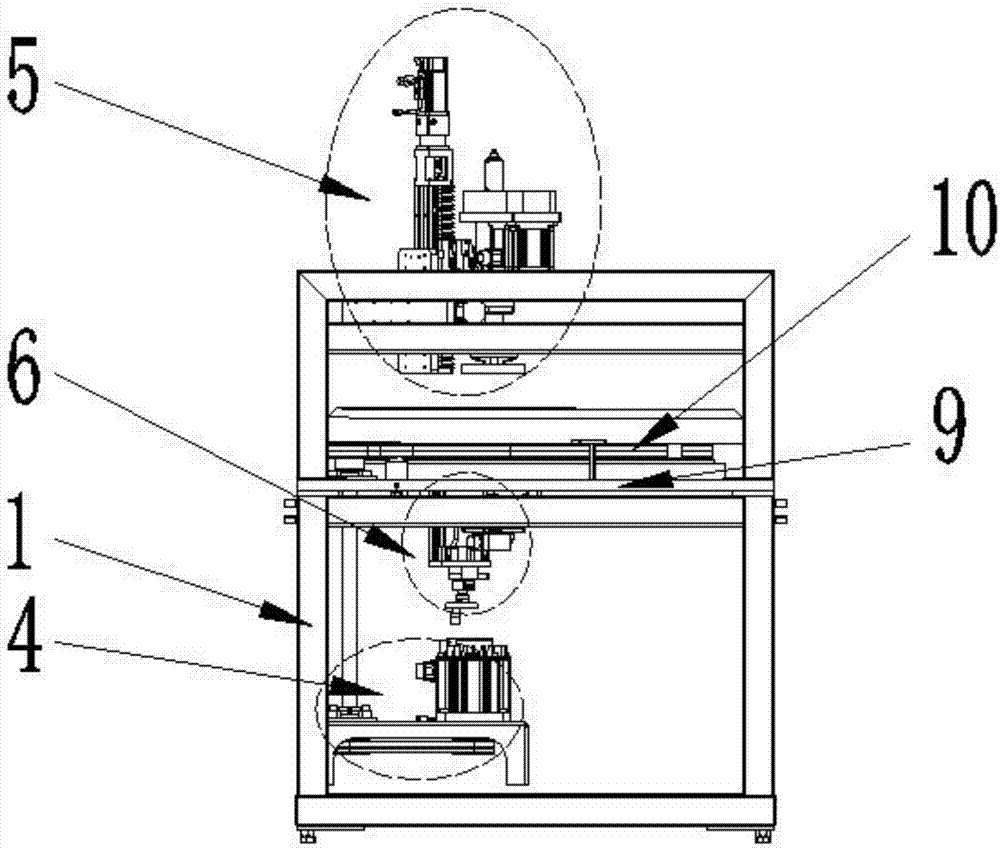

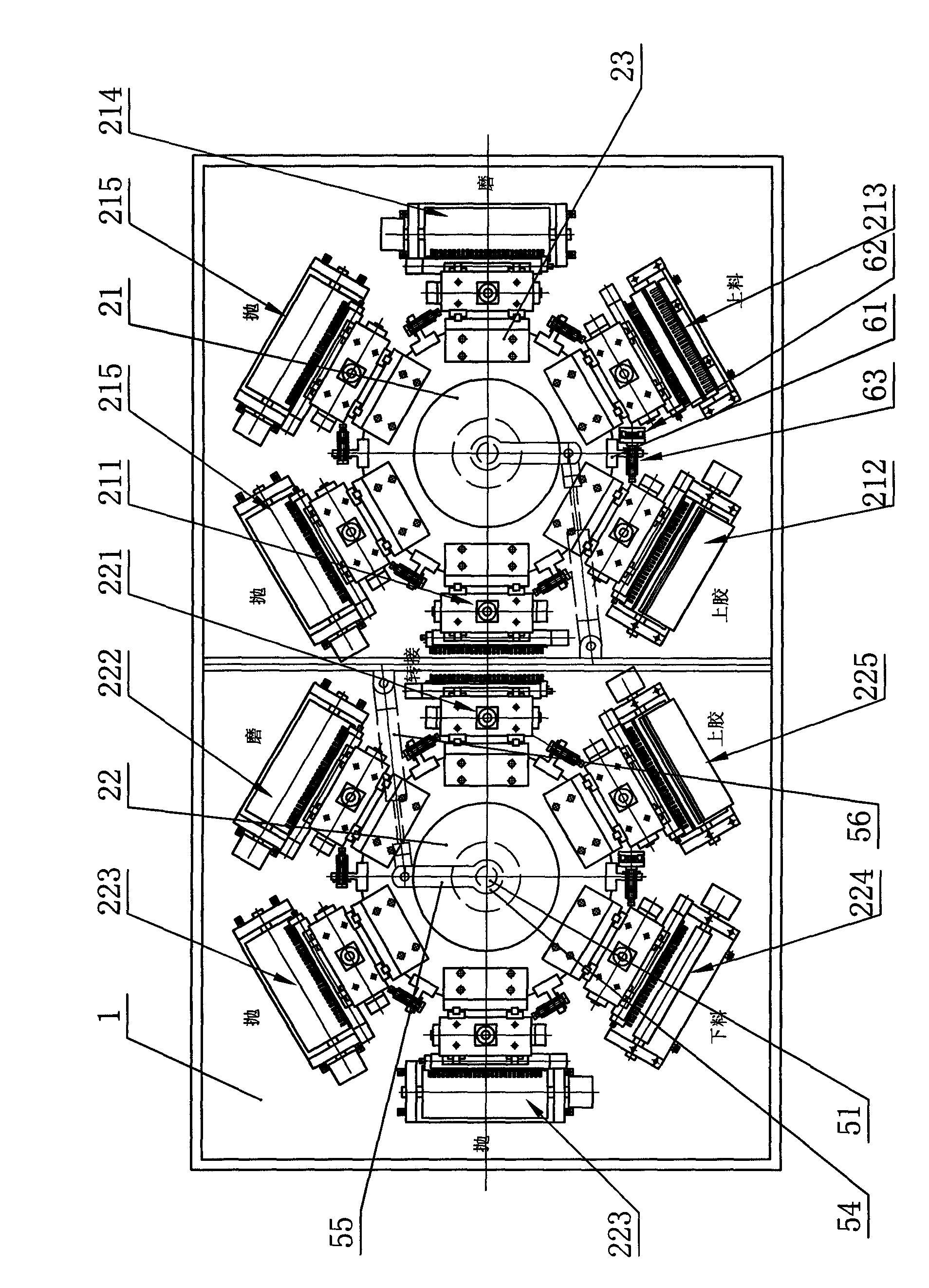

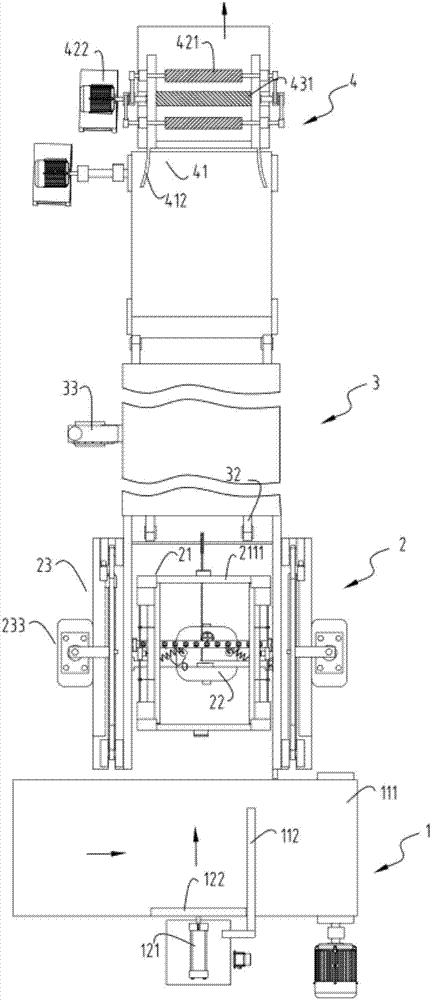

Full-automatic diamond abrading and polishing machine

InactiveCN101648356AImprove polishing qualityImprove efficiencyEdge grinding machinesComputer scienceAutomation

The invention discloses a full-automation diamond abrading and polishing machine which comprises a frame and a rotating disk, wherein the rotating disk comprises two kinds which are respectively a first rotating disk and a second rotating disk. The full-automatic diamond grinding and polishing machine also comprises a rotating disk rotating mechanism, wherein the two rotating disks are arranged ina synchronous and homodromous rotary matching way by the rotating disk rotating mechanism; a switching station, a gluing station, a blank feed station, an abrading station and at least one polishingstation alternately distributed on the periphery of the rotating disk uniformly according to the rotating direction are arranged on the first rotating disk; the second rotating disk is arranged at theside of the first rotating disk, a switching station, an abrading station, at least one polishing station, a feed station and a gluing station having an equal interval with the adjacent station of the first rotating disk according to the rotating direction are arranged on the second rotating disk, and the switching stations on the two rotating disks are arranged in an opposite matching way afterrespectively finishing a circle of stations at the two rotating disks. The invention has the advantages of full-automation integration, two-end abrading and polishing function, high abrading and polishing quality and efficiency, and the like.

Owner:张岳恩

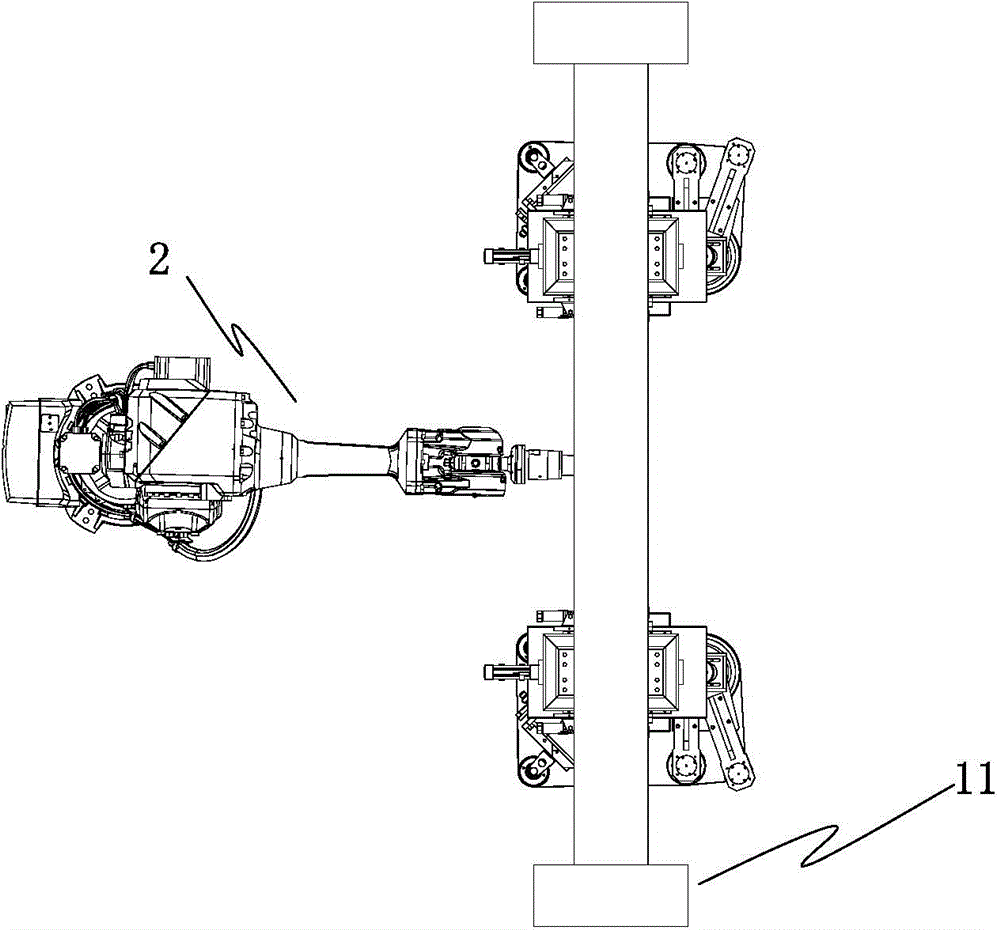

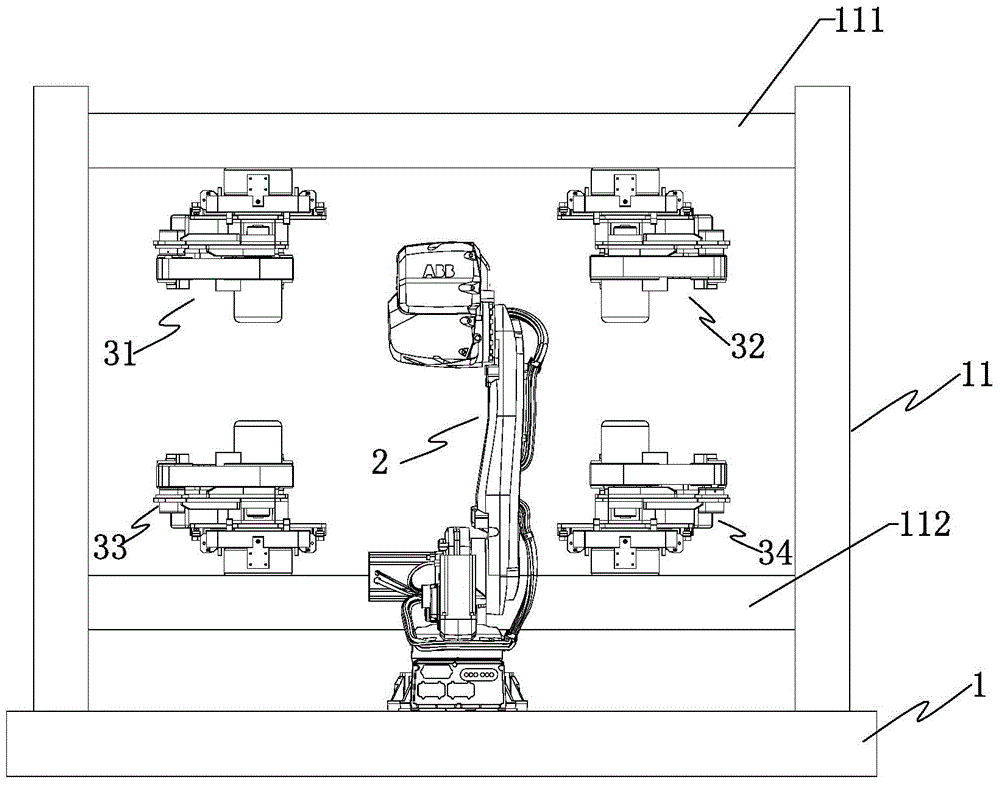

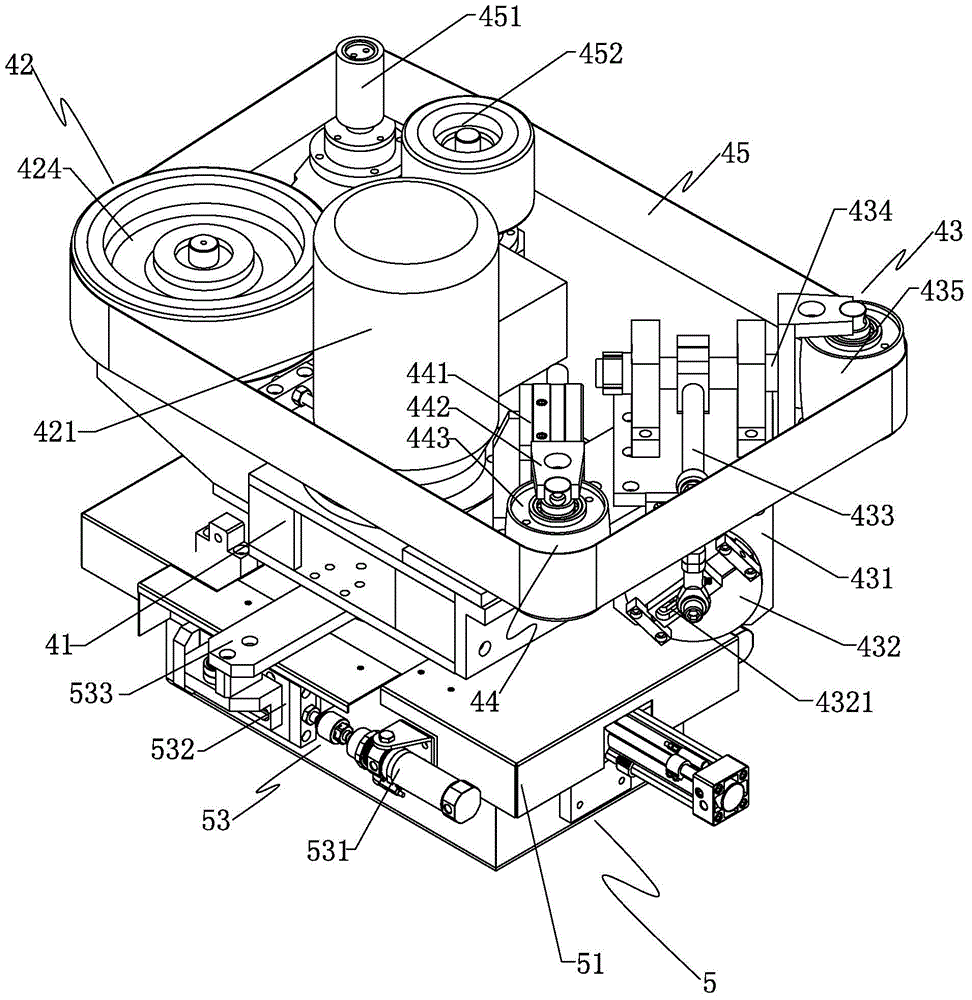

Multi-workstation single-robot abrasive-belt-type polishing machine

ActiveCN104440470AShorten the transfer journeySmall footprintBelt grinding machinesGrinding/polishing safety devicesEconomic benefitsEngineering

The invention discloses a multi-workstation single-robot abrasive-belt-type polishing machine. The multi-workstation single-robot abrasive-belt-type polishing machine comprises a pedestal and a machine head bracket arranged on the pedestal, wherein at least two polishing machine heads are arranged on the machine head bracket; a clamp robot is arranged on one side of the machine head bracket; each polishing machine head comprises an abrasive belt driving assembly, an abrasive belt oscillating assembly and an abrasive belt tensioning assembly, which are integrated on the same machine head base. The multi-workstation single-robot abrasive-belt-type polishing machine adopts a compact cascading arrangement structure for replacing a fan-shaped arrangement structure which occupies a large area, the stroke for the robot to transfer among workstations is reduced, the production efficiency is improved and the occupied area of the robot is reduced; through the novel polishing machine heads, the polishing quality is improved, the operating difficulty is reduced and the investment recovery of equipment is accelerated, so that the production cost is reduced and economic benefits are increased.

Owner:广东博科数控机械有限公司

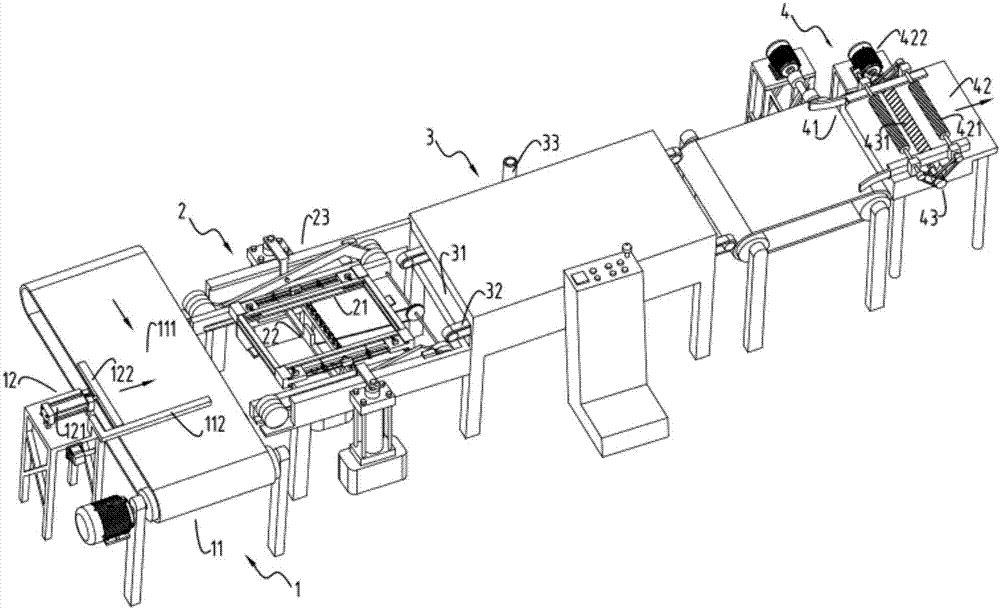

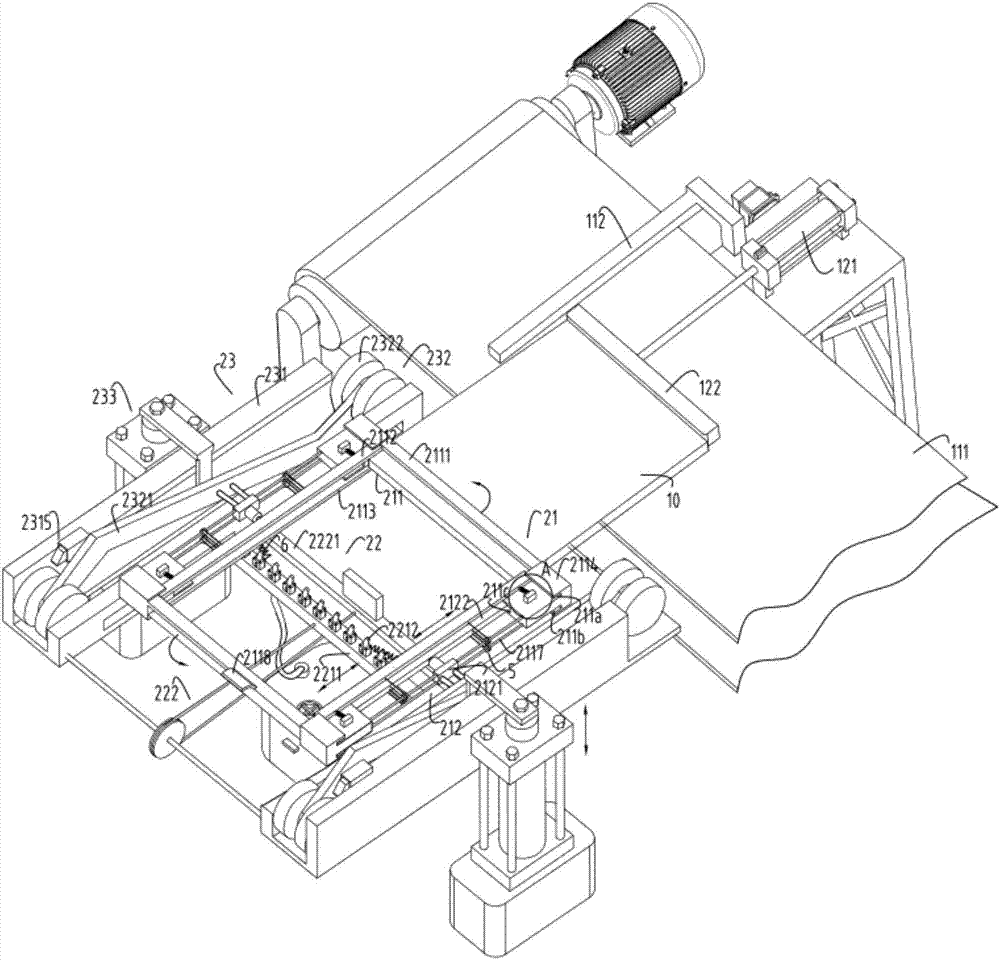

Ceramic tile surface waxing treatment production line

InactiveCN106938227AWaxes quickly and evenlyDry fastSpraying apparatusPretreated surfacesProduction lineWax treatment

The invention relates to a tile surface waxing treatment production line, which includes a positioning feeding part, the positioning feeding part is used to position and push the delivered tiles backward; a turning waxing part is arranged on the Positioning the rear end of the feeding part, the turning waxing part is used to wax the tiles pushed by the positioning feeding part; the drying part, the drying part is arranged at the rear end of the turning waxing part, and the drying part is used for It is used to dry the ceramic tiles output after being waxed by the turned waxing part; the polishing part is arranged at the rear end of the drying part, and the polishing part is used to perform surface waxing on the ceramic tiles output after the drying process of the drying part Polishing of the first layer; it overcomes the problems of tile waxing and wax surface polishing that do not have the function of integrated continuous processing, low efficiency and labor-intensive waxing process and uneven waxing.

Owner:湖州裕尚卫浴有限公司

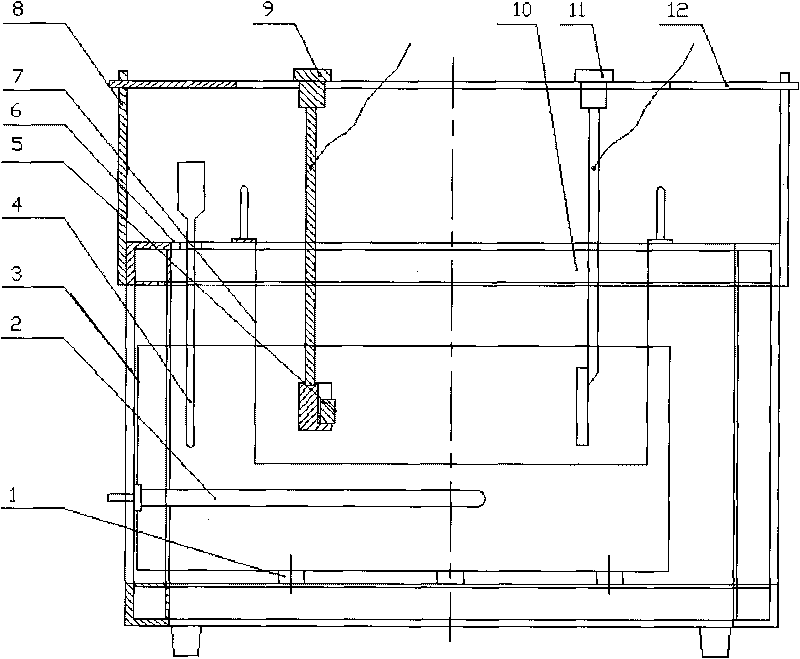

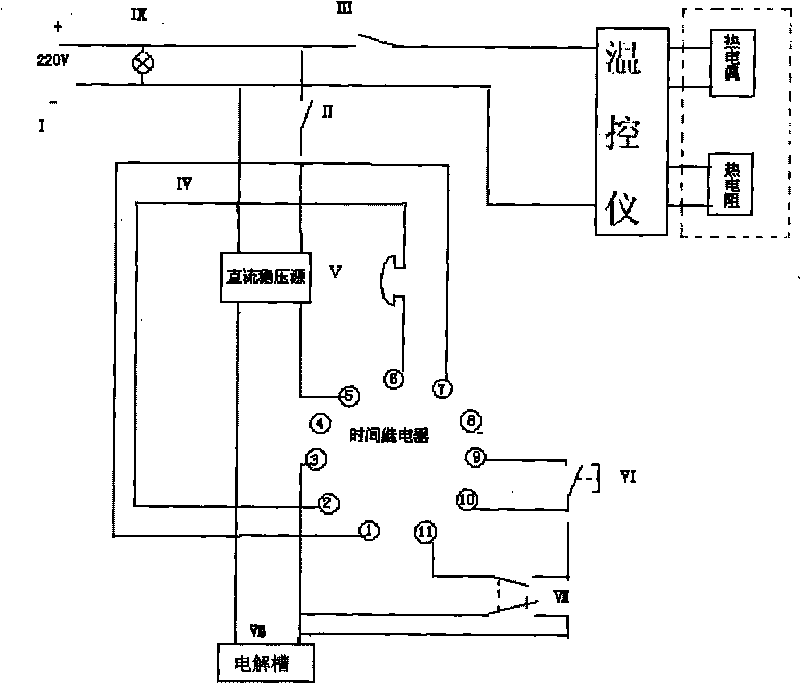

Metallographical sample electrolytic polishing device applied to laboratory

InactiveCN101718648AAvoid temperatureAvoid timePreparing sample for investigationElectrolysisAutomatic control

The invention discloses a metallographic sample electrolytic polishing device applied to a laboratory, comprising a working voltage and current density regulating system, an electrolyte constant temperature system, an electrolytic time automatic control and automatic alarm system, an electrolytic bath, two supports and a crossbeam, wherein, the working voltage and current density regulating system is formed by a DC voltage-stabilized source and a mobile electrode which are connected in series; the electrolyte constant temperature system is formed by a temperature control device, a heating element, a shell, a heating groove and a thermocouple; the electrolytic time automatic control and automatic alarm system is formed by a time relay and a buzzer; the electrolytic bath is formed by an electrolytic bath frame, an anode electrode and a cathode electrode. The working voltage and current density of the invention can be controlled independently, and the device has good polishing effect and high speed.

Owner:SOUTHEAST UNIV

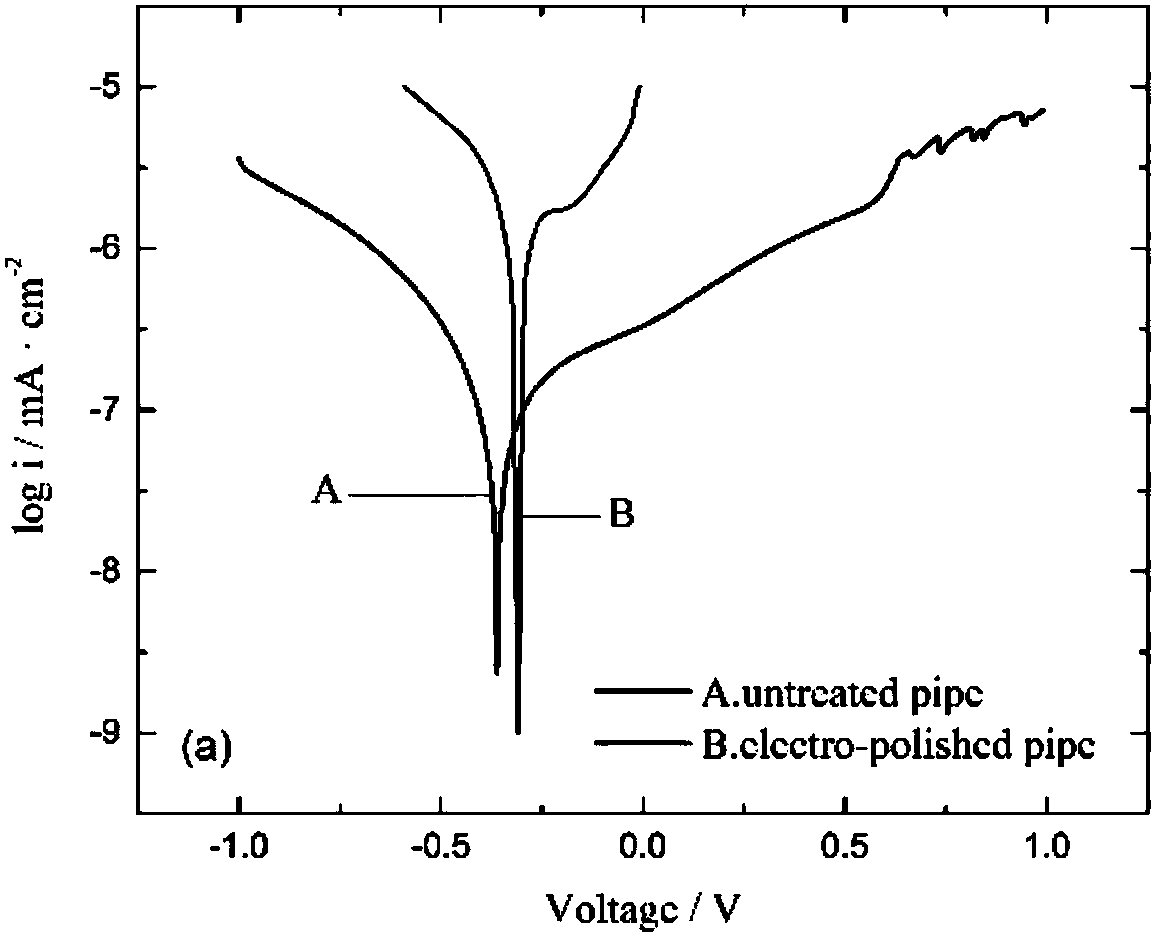

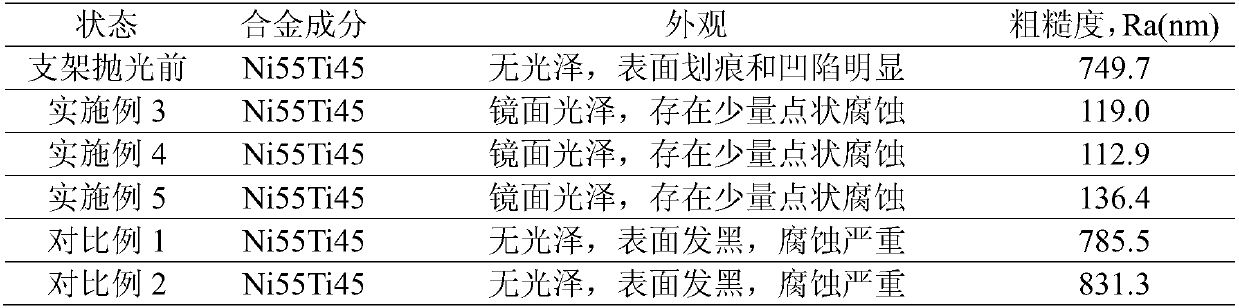

Polishing solution for electrochemical polishing of nickel-titanium alloy and application

InactiveCN107675244AGood corrosion inhibition effectImprove the leveling effectElectrochemistryTitanium alloy

The invention provides a polishing solution for electrochemical polishing of a nickel-titanium alloy, and belongs to the field of nickel-titanium alloy surface treatment. The polishing solution is composed of the following matter of, by volume, 22%-43% of concentrated sulfuric acid, 37%-50% of ethylene glycol, 5%-10% of an additive agent and the balance water. The invention further discloses a method for electrochemical polishing of the nickel-titanium alloy, the nickel-titanium alloy is treated as the anode, a stainless steel plate is treated as the cathode, the anode and the cathode are placed into the electrical polishing solution, and electrochemical polishing is conducted. The electrochemical polishing solution and the polishing method can be used for polishing a medical nickel-titanium alloy, the nickel-titanium alloy which is subjected to polishing treatment is good in corrosion resistance. The formula of the nickel-titanium alloy electrochemical polishing solution is not proneto volatilizing, stable and environmentally friendly, low in cost and good in operating environment.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Cup rabbet polishing device

PendingCN107900837AImprove stabilityImprove user experienceEdge grinding machinesPolishing machinesDrive motorConveyor belt

The invention belongs to the technical field of cup rabbet processing equipment and particularly relates to a cup rabbet polishing device. The cup rabbet polishing device comprises a conveyor belt device. A guide rail and a first cylinder are vertically mounted on a rack on one side of the conveyor belt device. A motor is connected with the guide rail through a motor mounting plate. The motor is driven by the first cylinder to move up and down along the guide rail. A polishing cutting head is arranged on a rotary shaft of the motor. A clamping device for clamping cups conveyed on a conveyor belt is arranged on the conveyor belt located below the polishing cutting head. The polishing cutting head can conduct polishing on cup rabbets of the cups clamped by the clamping device. The cup rabbetpolishing device conducts clamping on the cups through the clamping device, corrects the polishing positions of the cups and can place a cutting edge onto one cup rabbet and improve the device stability and the polishing efficiency and quality of the cup rabbets.

Owner:TAIZHOU SHUOXIANG COMMODITY CO LTD

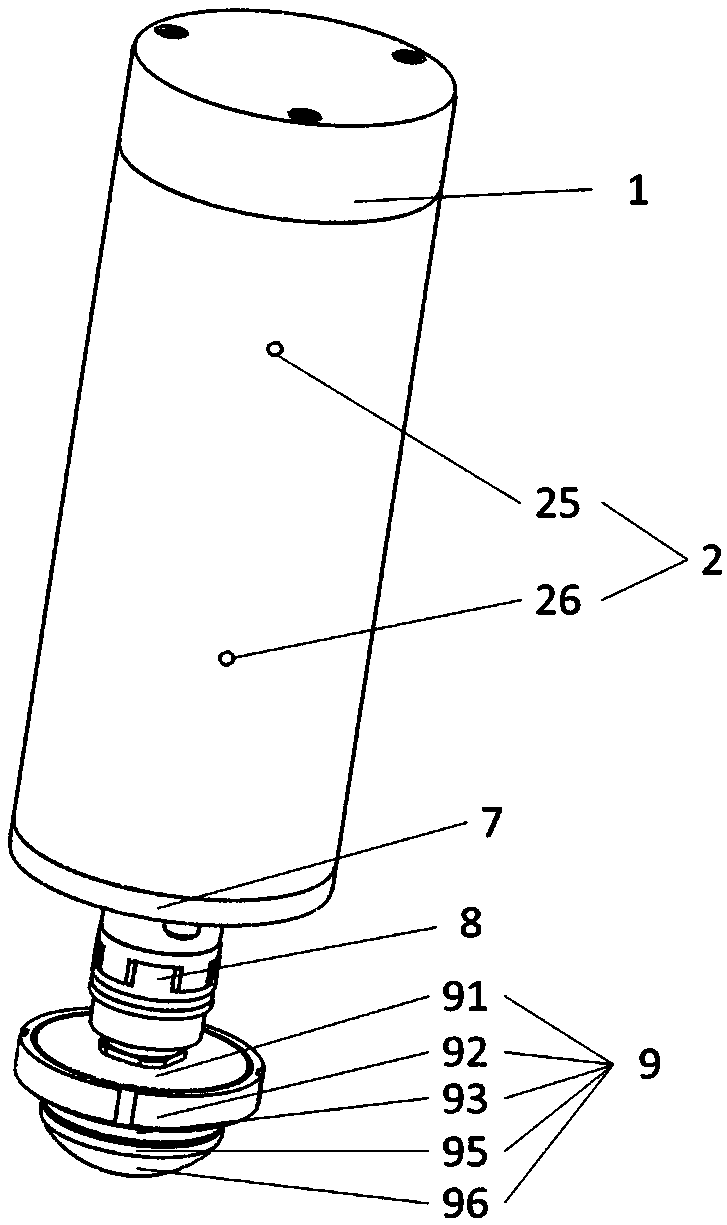

Passive air sac pressure controlled flexible furbisher

InactiveCN1754659AReduce weightSmall driving forceGrinding machinesMetal working apparatusGas chamberAirbag deployment

This invention relates to passive gas chamber pressure flexible polishing tool, which comprises the following parts: one gas chamber with polishing math as work surface on front end installed in one sustaining rack; the said sustaining rack is installed on one rotation axis connected with one cover tube; the said cover tube is connected to the drive axis with outer source entrance and overflow valve; the cover tube drive axis is opened with gas channel connected to the gas chamber. The invention provides one mode curve polishing tool with high efficiency and quality.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com