Polisher

A polishing machine and polishing wheel technology, applied in the field of polishing machines, can solve the problems of uneven wax coating, time-consuming, poor polishing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

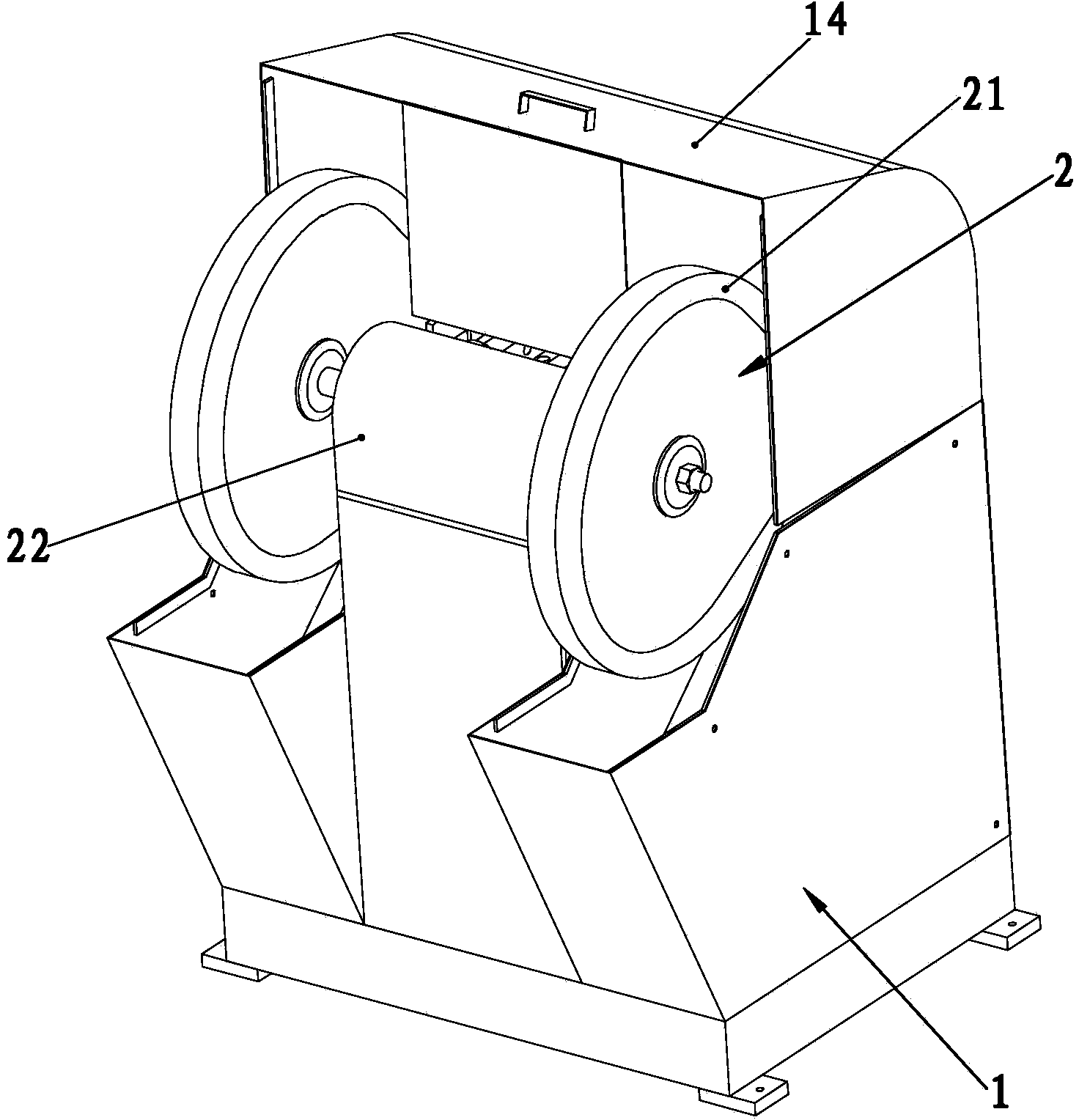

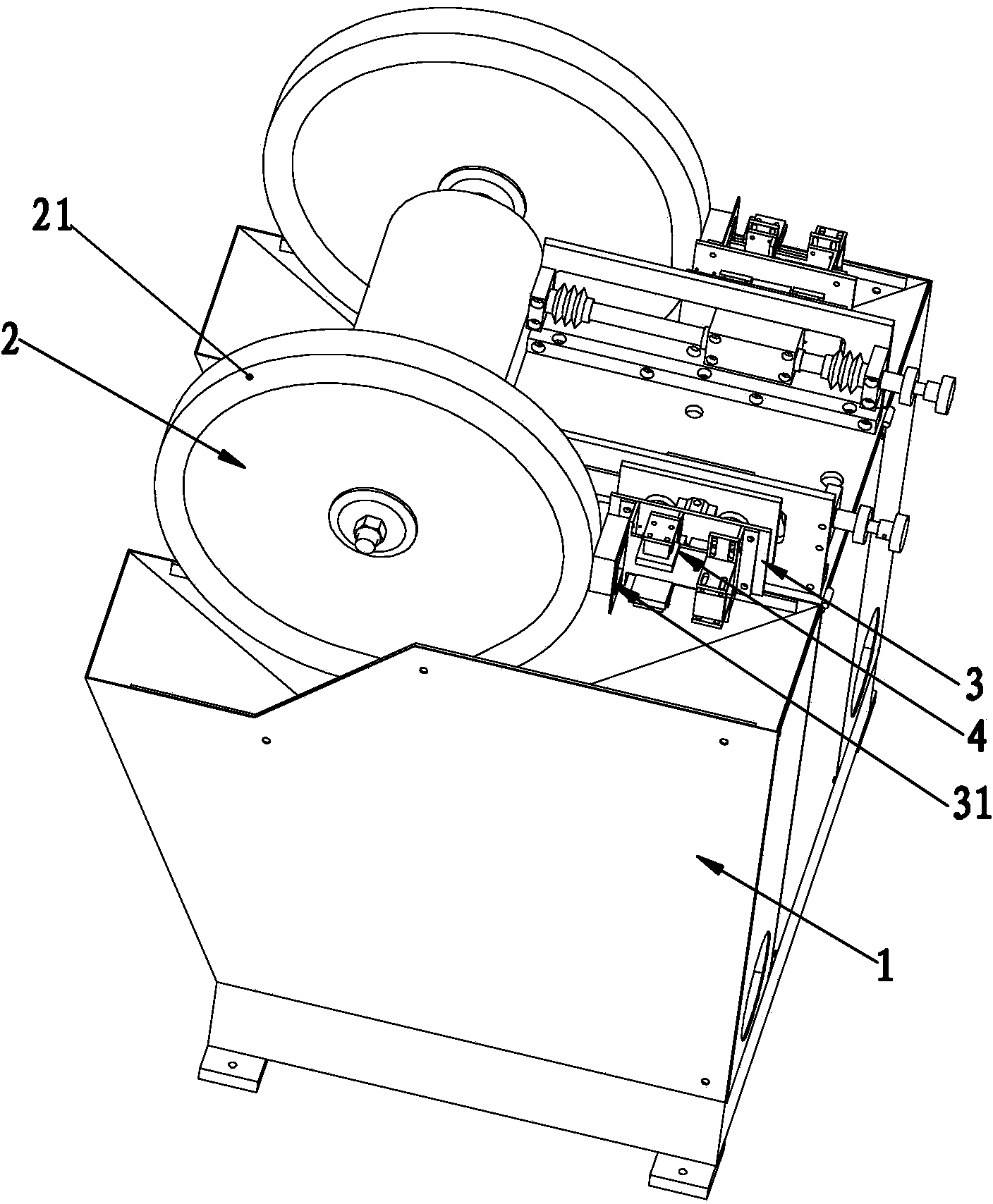

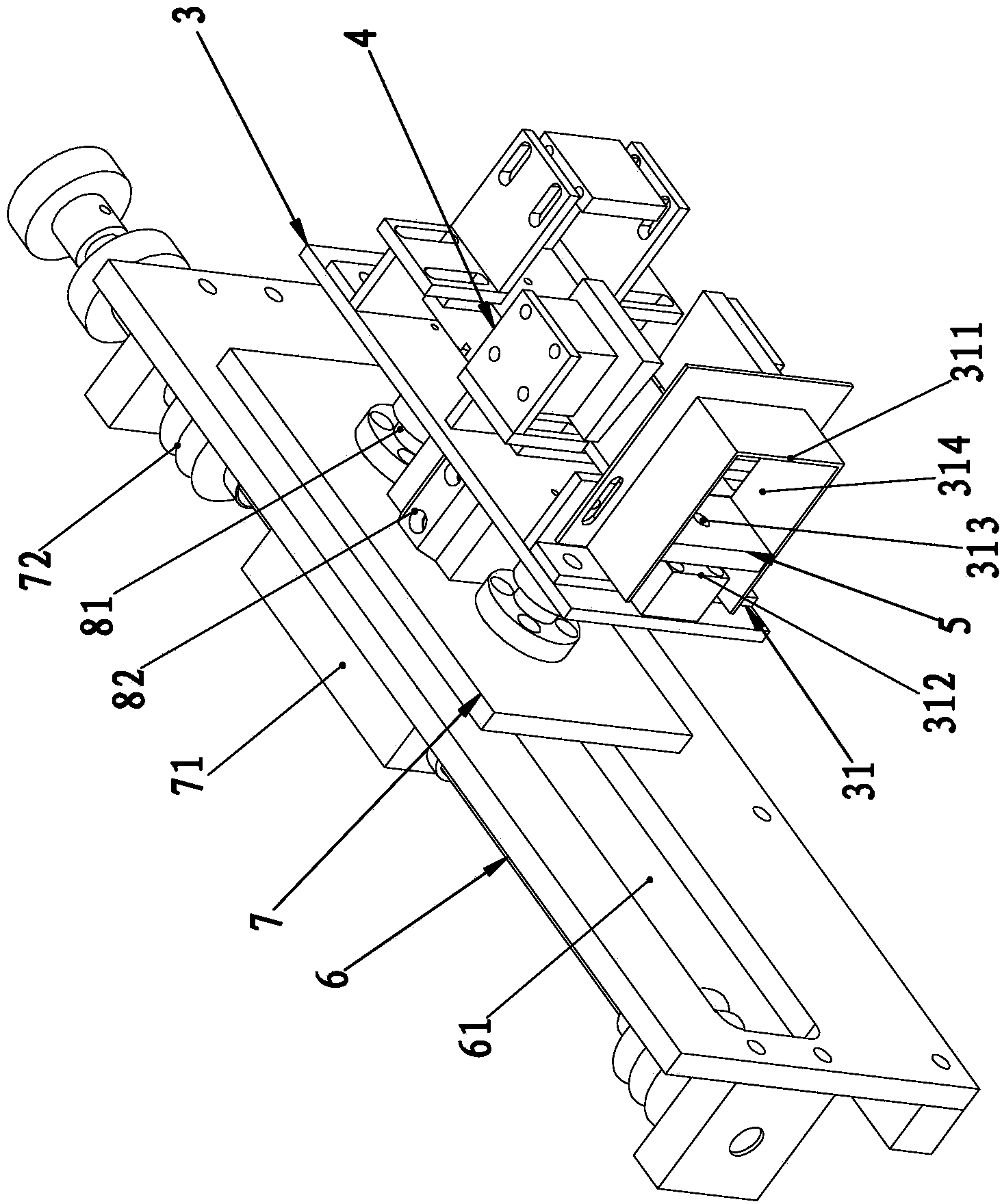

[0023] Such as figure 1 — Figure 6 A kind of polishing machine shown, comprises frame 1, is located at the buffing wheel 2 on the frame 1, is sleeved on the buffing fabric 21 on the buffing wheel 2 and drives the driving motor 22 of buffing wheel 2, on the frame 1 The wax block holding seat 3 and the holding mechanism 31 arranged on the wax block holding seat 3 are erected at the buffing wheel 2, and the wax block holding seat 3 is provided with a wax block continuous conveying mechanism that cooperates with the holding mechanism 31 4. In the above scheme, by setting the wax block holding seat 3 and the holding mechanism 31 on the wax block holding seat 3 on the frame 1, the wax block can be placed on the frame 1 at the installation place of the polishing wheel 2, During the rotation of the polishing wheel 2, the wax block can directly contact the polishing fabric 21 on the polishing wheel 2, so that the polishing fabric 21 can be continuously coated with wax, without manua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com