Patents

Literature

47results about How to "Achieve continuous delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

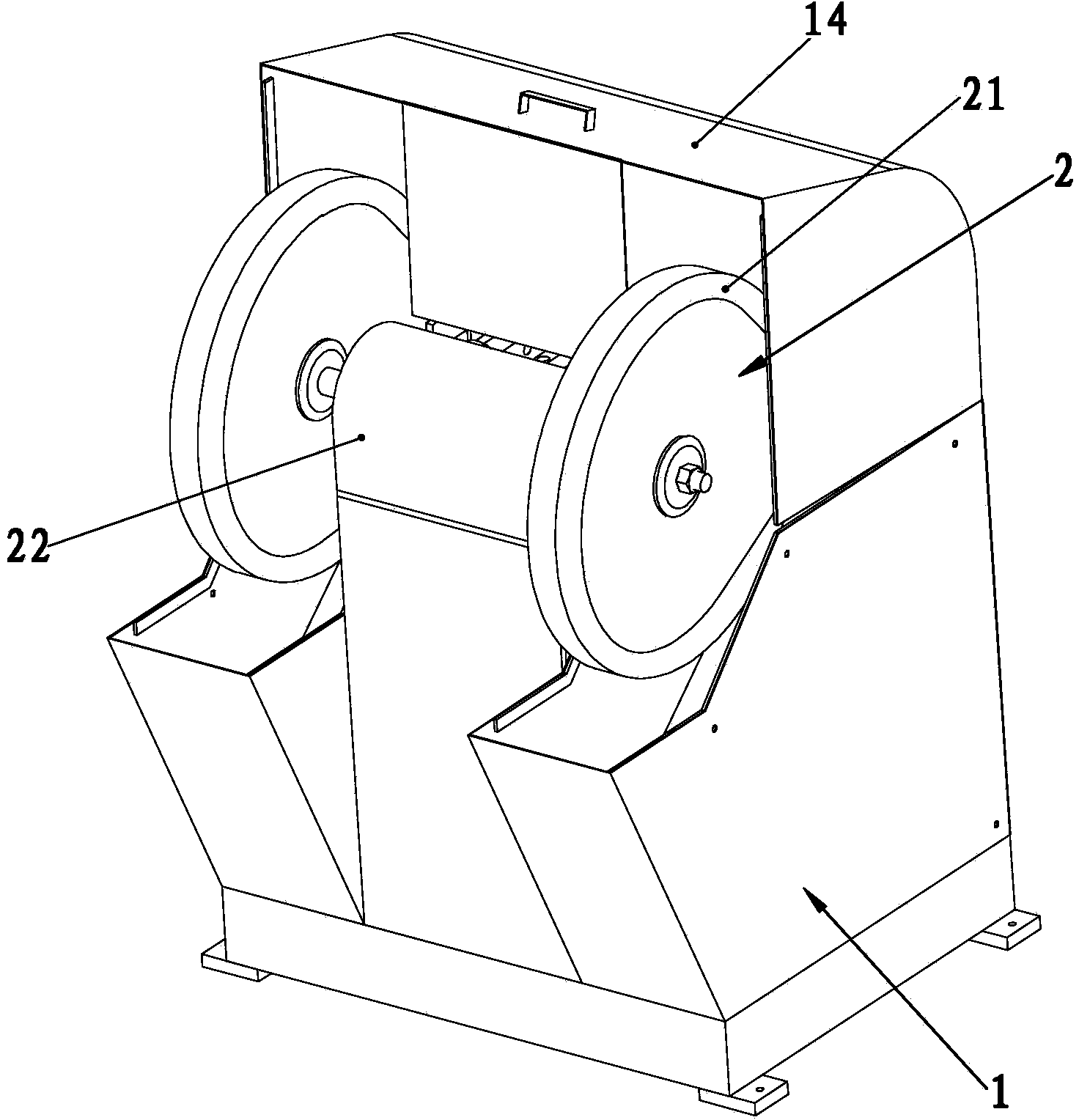

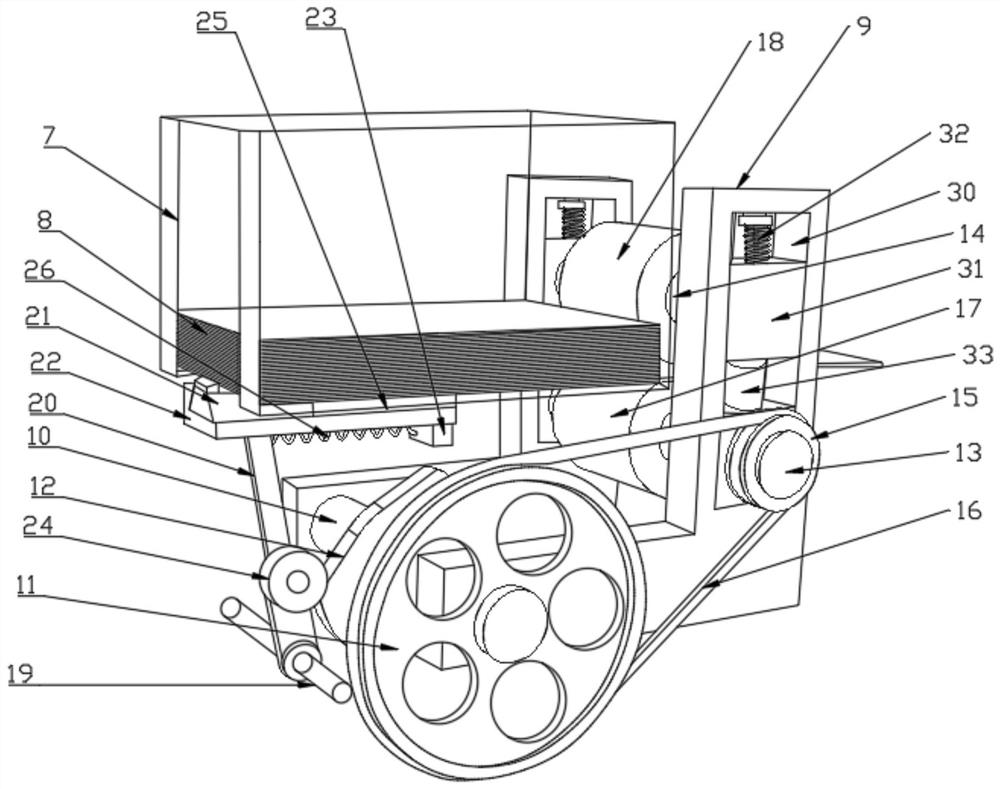

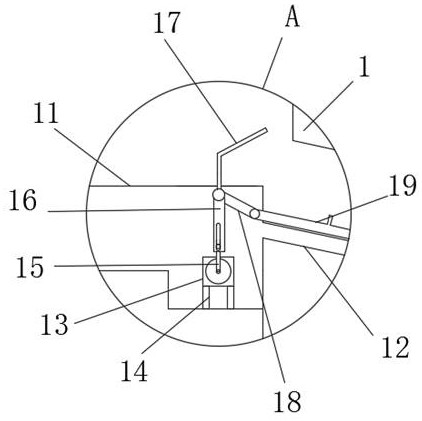

Polisher

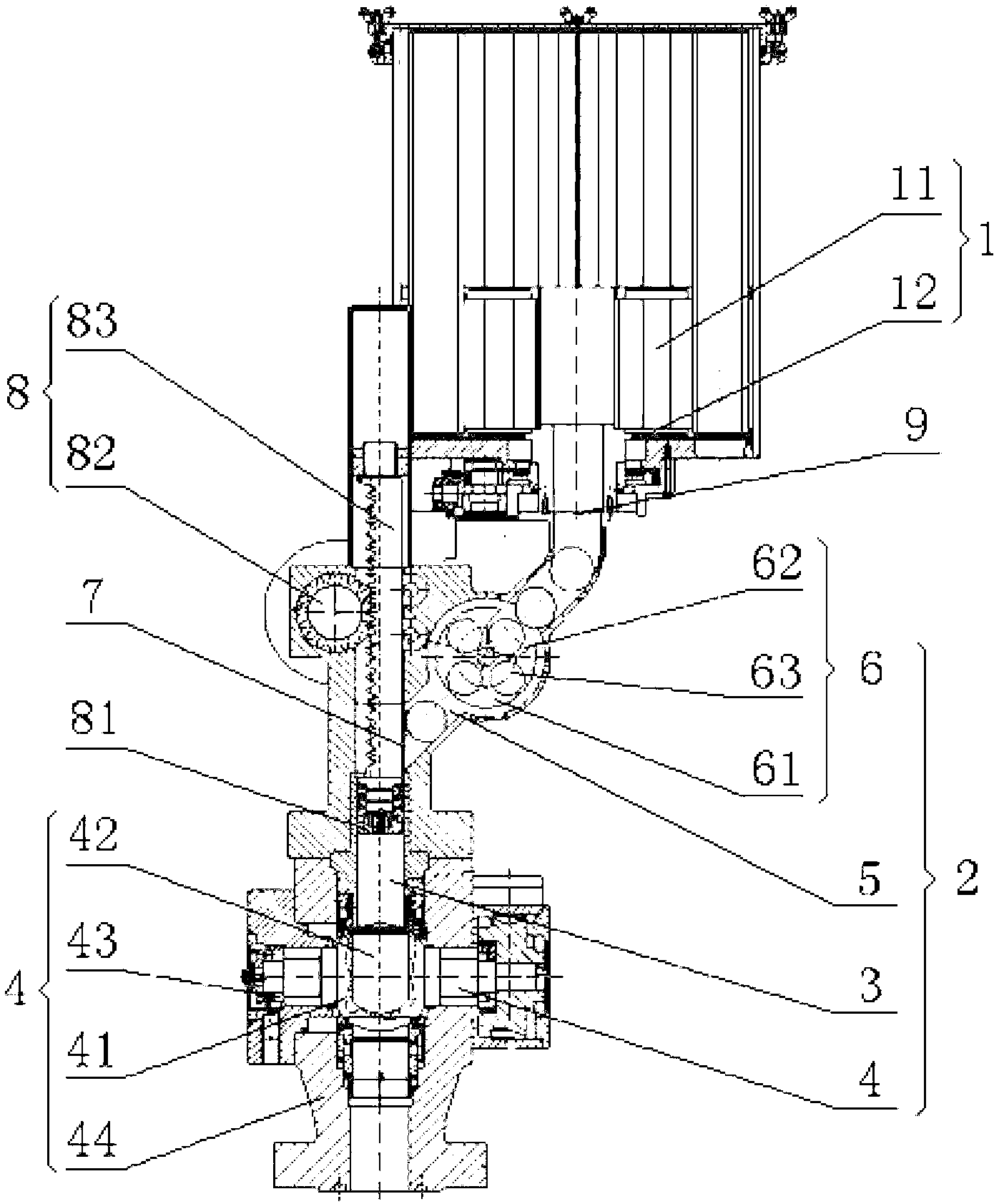

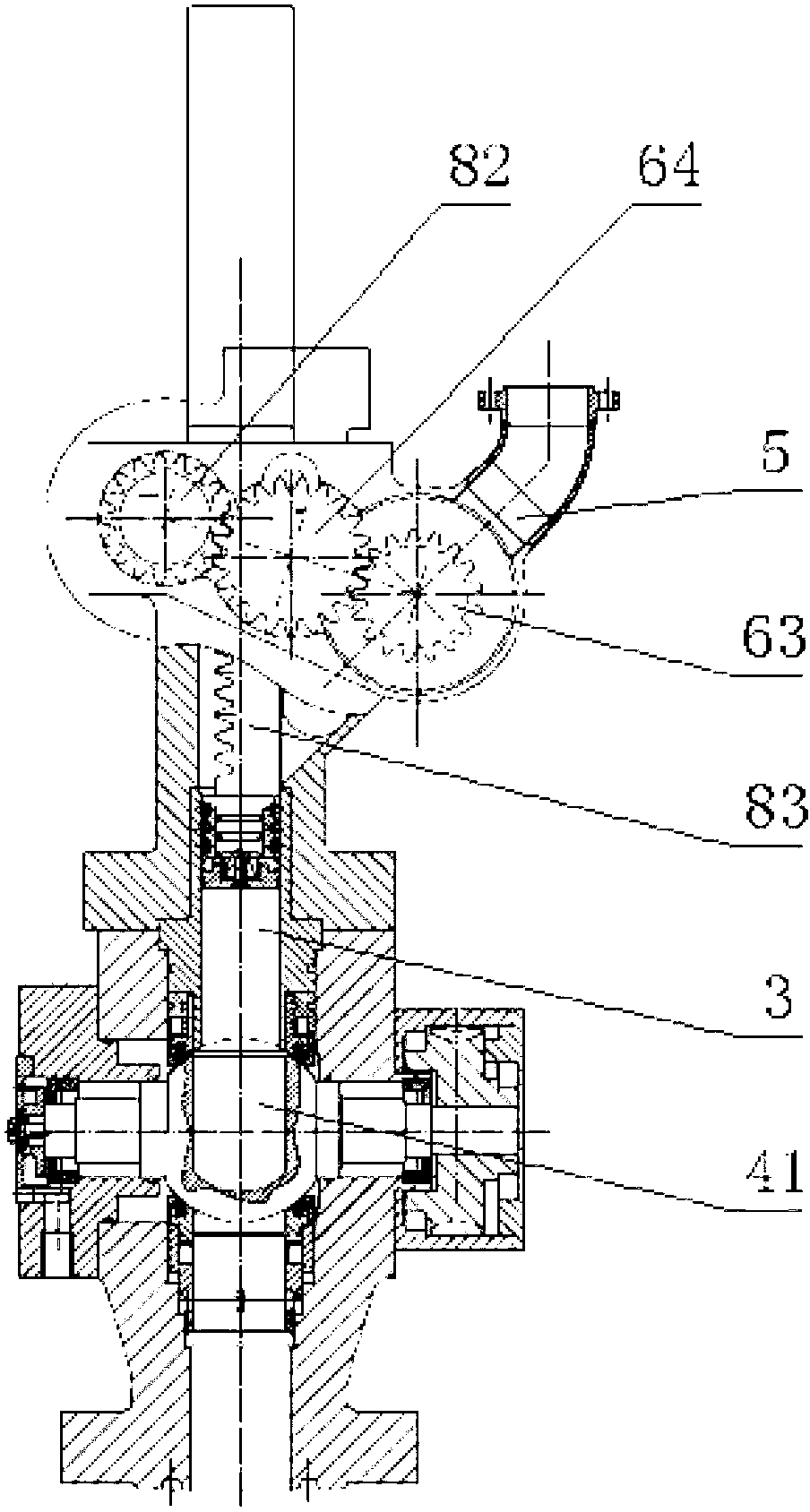

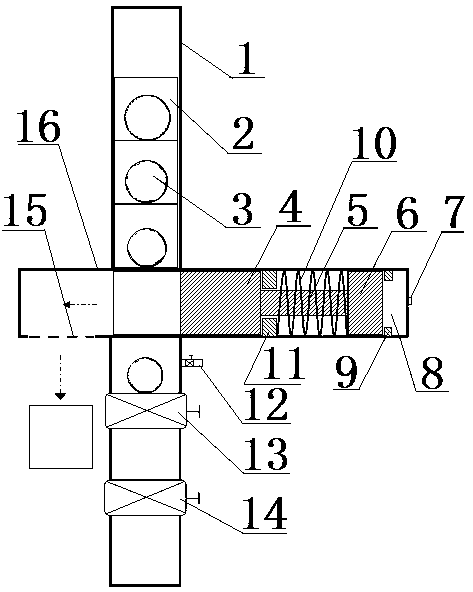

ActiveCN103934743AEasy to operateOperation time savingPolishing machinesGrinding/polishing safety devicesWaxEngineering

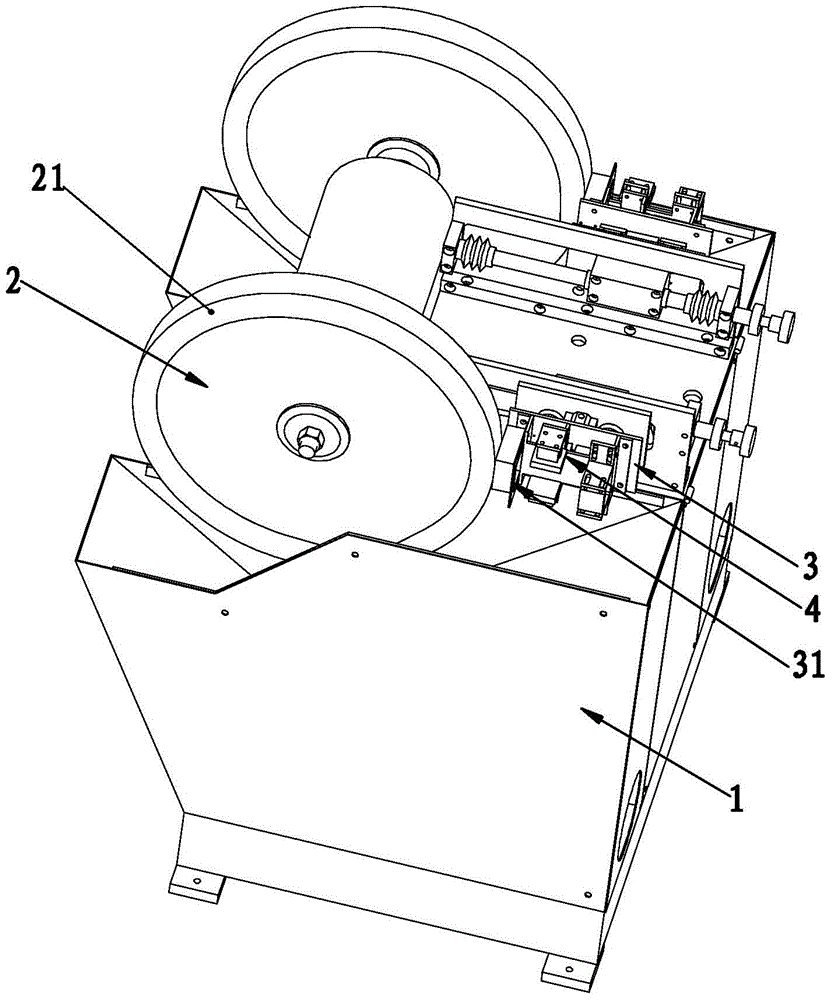

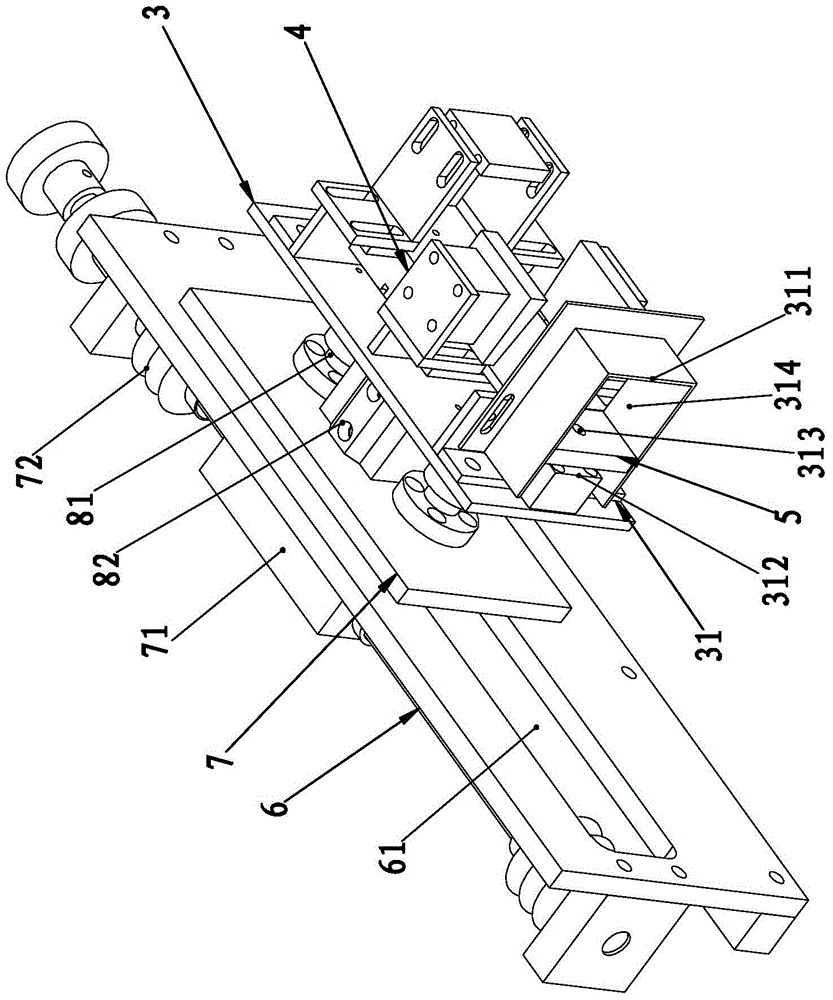

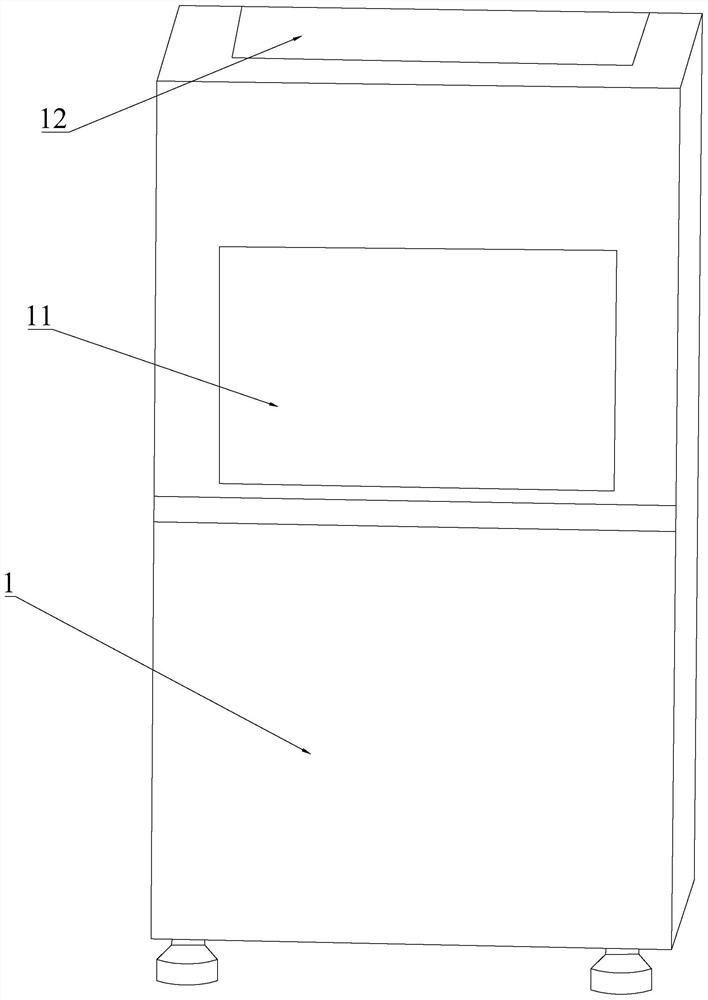

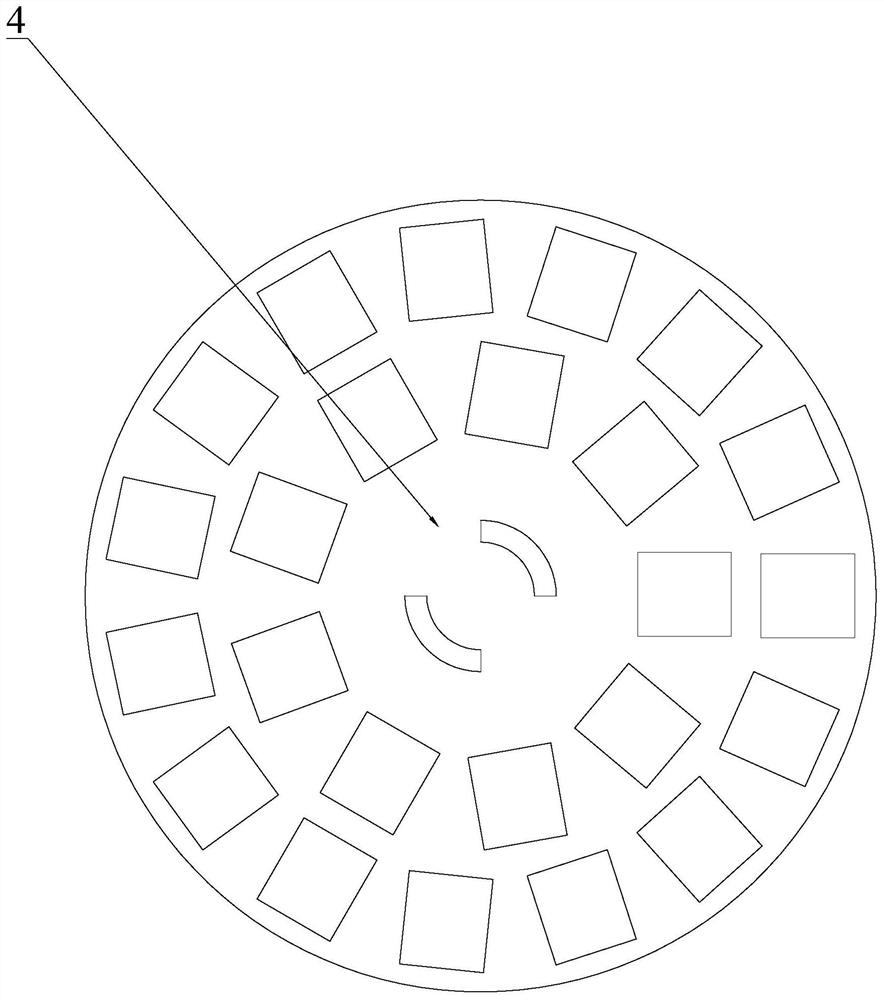

The invention relates to a polishing device, in particular to a polisher which comprises a machine frame, a polishing wheel arranged on the machine frame, a polishing textile arranged on the polishing wheel in a sleeved mode and a drive motor driving the polishing wheel. A wax stone clamping seat and a clamping mechanism arranged on the wax stone clamping seat are arranged on the machine frame and located at the polishing wheel. The wax stone clamping seat is provided with a wax stone continuous conveying mechanism matched with the clamping mechanism. The polisher is convenient to operate, saves time, and improves polishing quality.

Owner:ZHEJIANG KINGSTONE HOUSEWARES

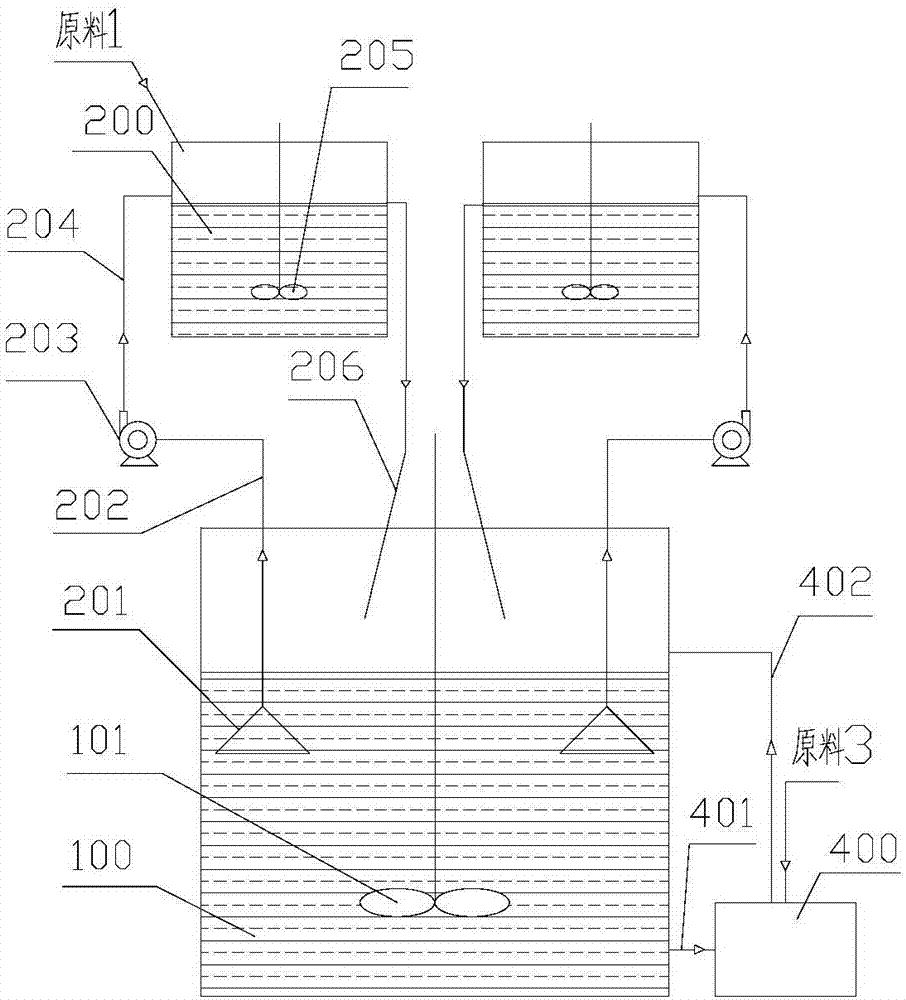

Non-manganese element-containing trimanganese tetraoxide complex, preparation method, used reaction system and uses thereof

ActiveCN107540021AImprove solubilityImprove dissolution rateHybrid capacitor electrodesCell electrodesGeneration rateReaction rate

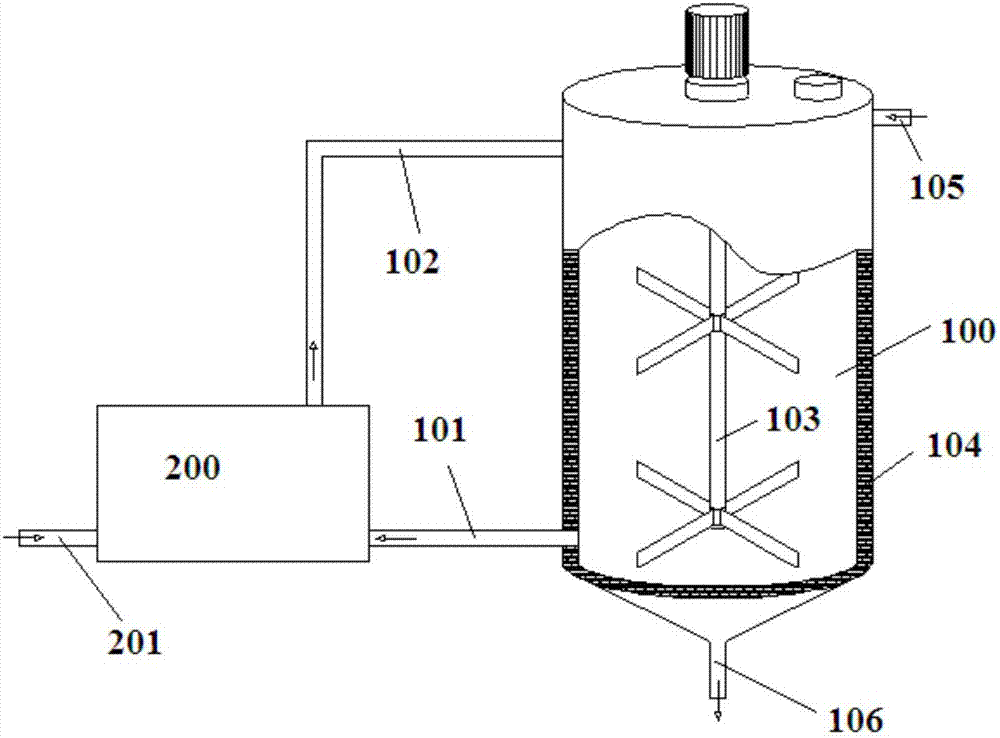

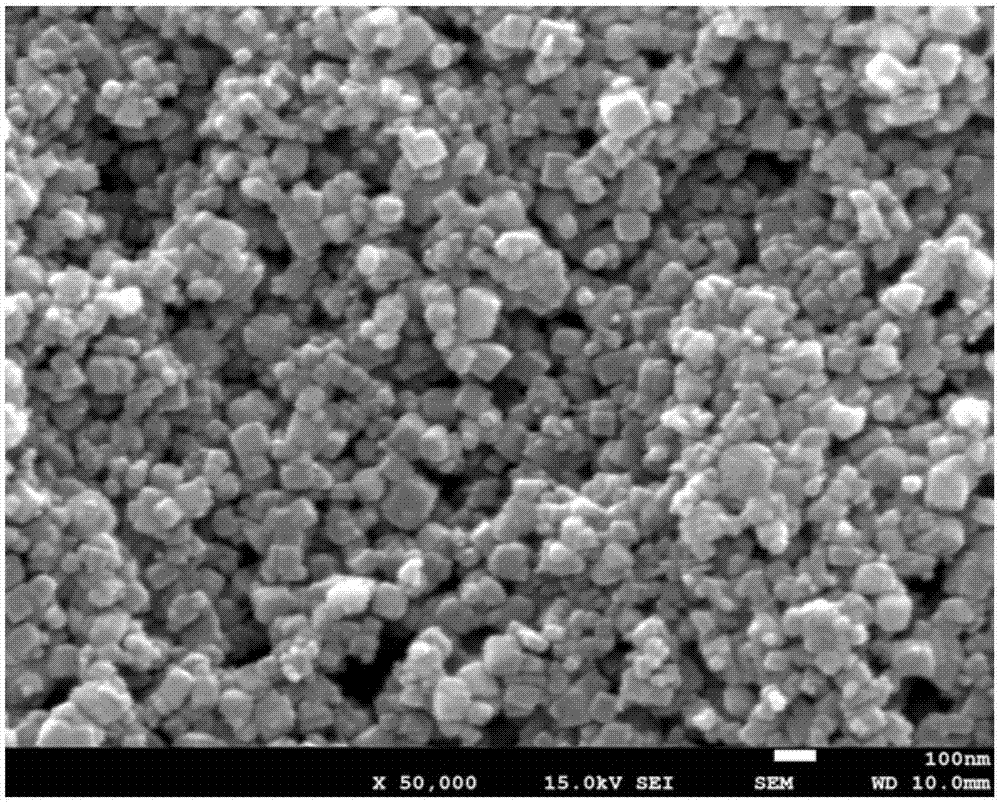

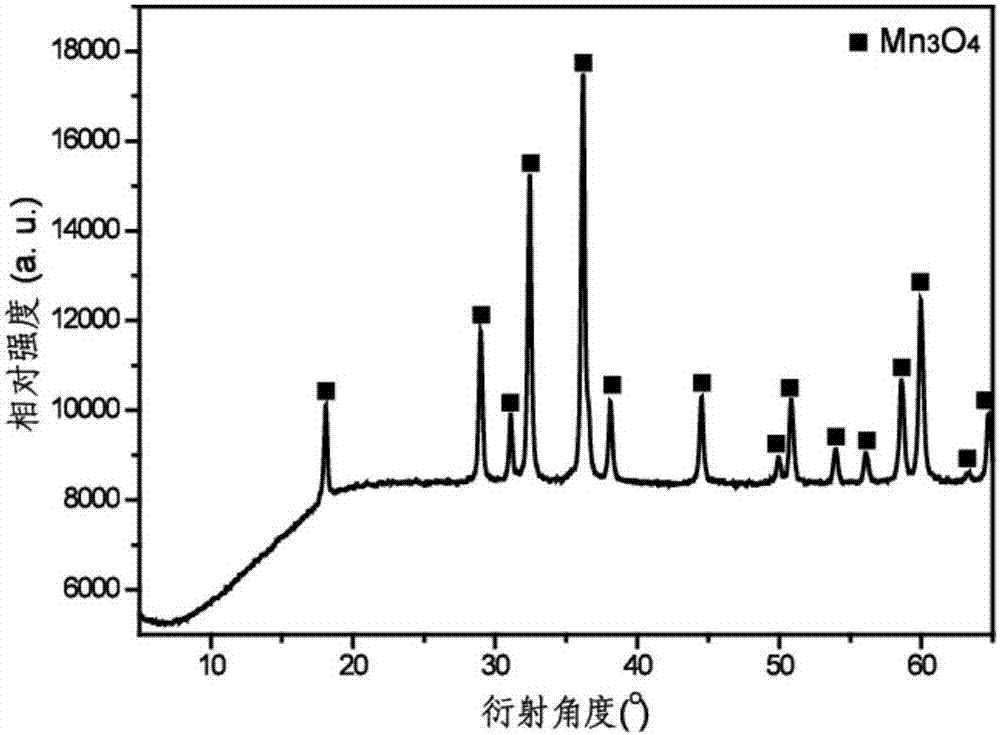

The present invention relates to a preparation method and a preparation system of a trimanganese tetraoxide complex. The preparation method comprises: introducing micro-nano gas bubbles into a reaction liquid mixture containing a manganese source and a non-manganese element-derived raw material to obtain a reaction liquid-gas mixture, and carrying out a reaction to obtain a non-manganese element-containing trimanganese tetraoxide complex, wherein the micro-nano gas bubbles contain oxidizing gas, can be introduced along with a solvent, can be directly introduced along with the reaction mixture,can be continuously introduced, and can further be introduced in one time. According to the present invention, by introducing the micro-nano gas bubbles containing the oxidizing gas into the reactionsystem containing the manganese source and the non-manganese element-derived raw material, the oxidation reaction rate is improved, and the oxidation reaction time is shortened; and the generation rate of the trimanganese tetraoxide complex is increased, the particle size of the trimanganese tetraoxide complex is reduced, and the develop integrity of the trimanganese tetraoxide complex crystal and the mixing uniformity of the complex are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method and used reaction system of trimanganese tetraoxide, and uses of used reaction system

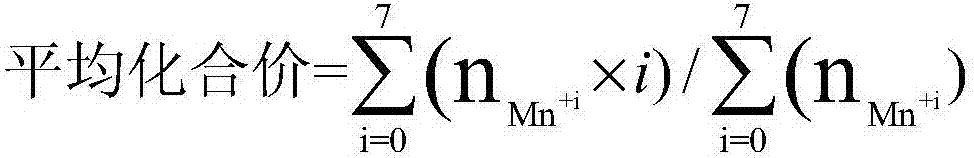

ActiveCN107540022AGuaranteed SolubilityGuaranteed dissolution rateManganese oxides/hydroxidesMicro nanoGeneration rate

The invention relates to a preparation method and a preparation system of trimanganese tetraoxide. The preparation method comprises: introducing micro-nano gas bubbles into a reaction liquid mixture containing a manganese source to obtain a liquid-gas mixture containing the micro-nano gas bubbles and the reaction liquid mixture, and carrying out a reaction to obtain trimanganese tetraoxide, wherein the micro-nano gas bubbles contain oxidizing gas, and the average valence of the manganese in the manganese source is less than 8 / 3. According to the present invention, by introducing the micro-nanogas bubbles containing the oxidizing gas into the reaction system containing the manganese source, the oxidation reaction rate is improved, and the oxidation reaction time is shortened; and the generation rate of the trimanganese tetraoxide is increased, the particle size of the trimanganese tetraoxide is reduced, the develop integrity of the trimanganese tetraoxide crystal is improved, and the defect of the crystal is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

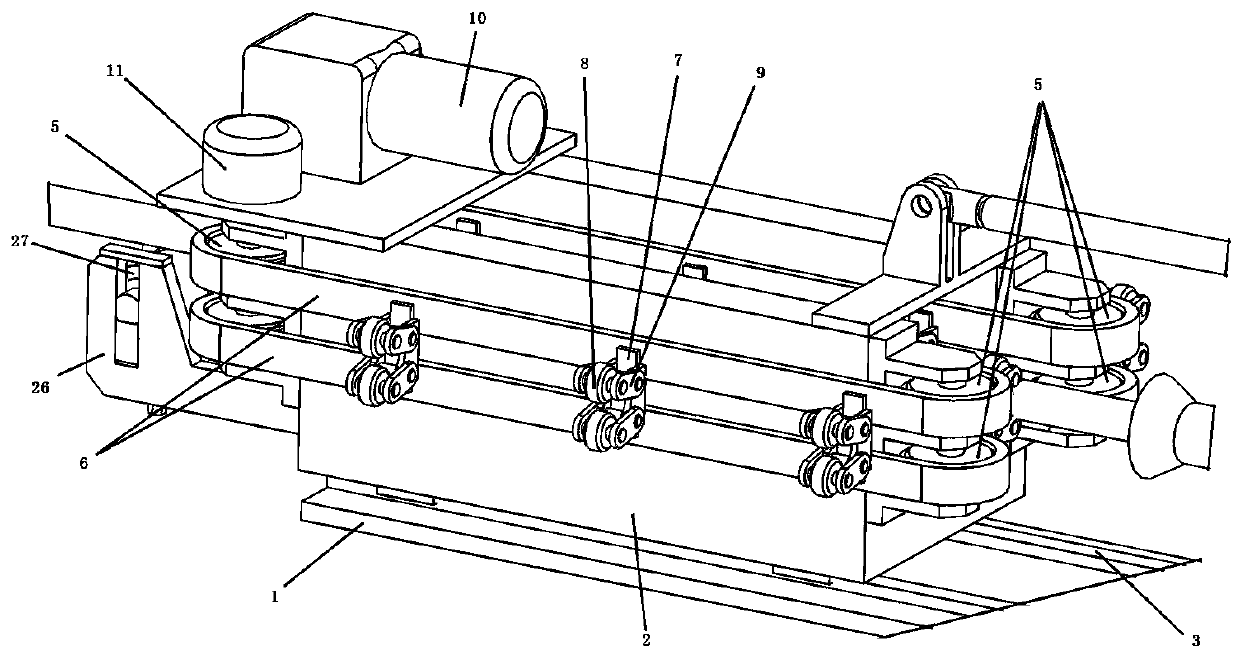

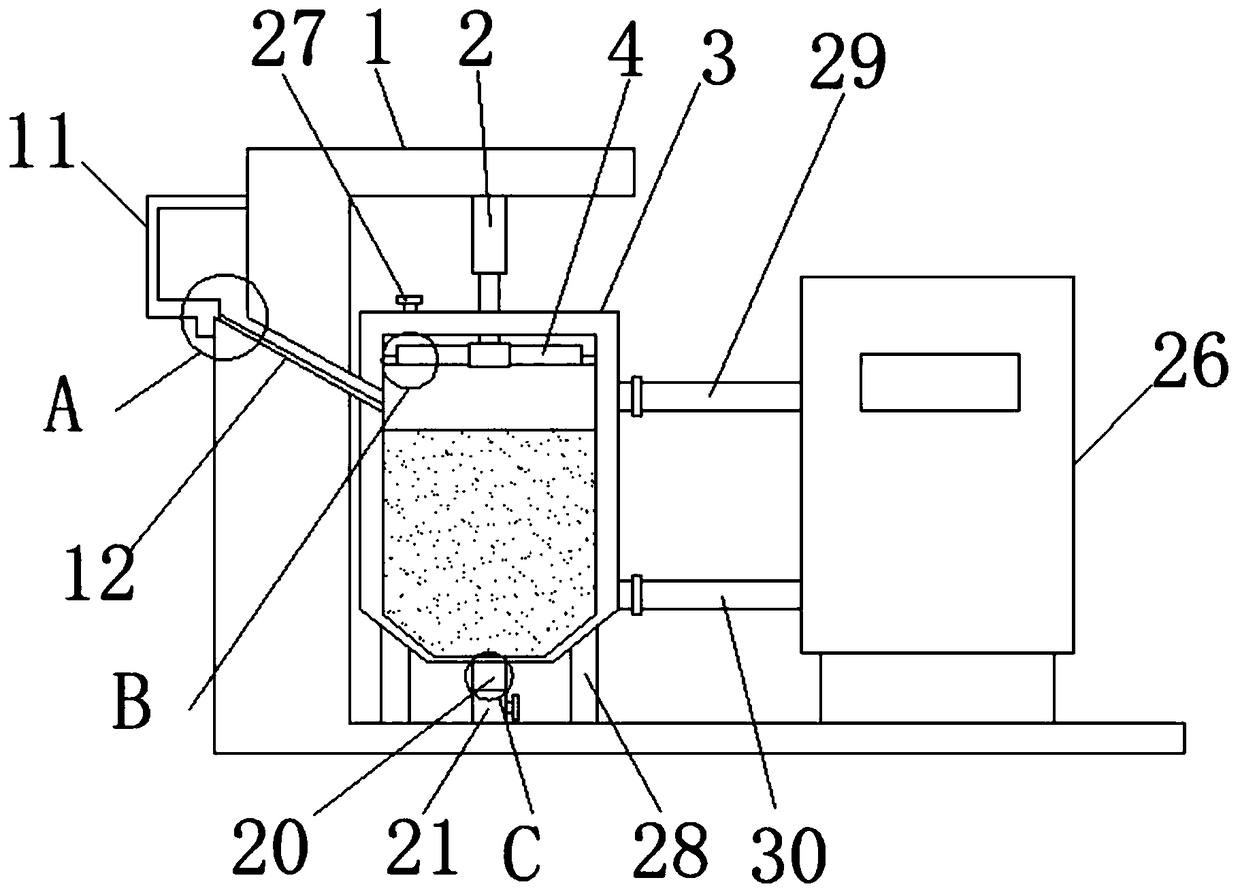

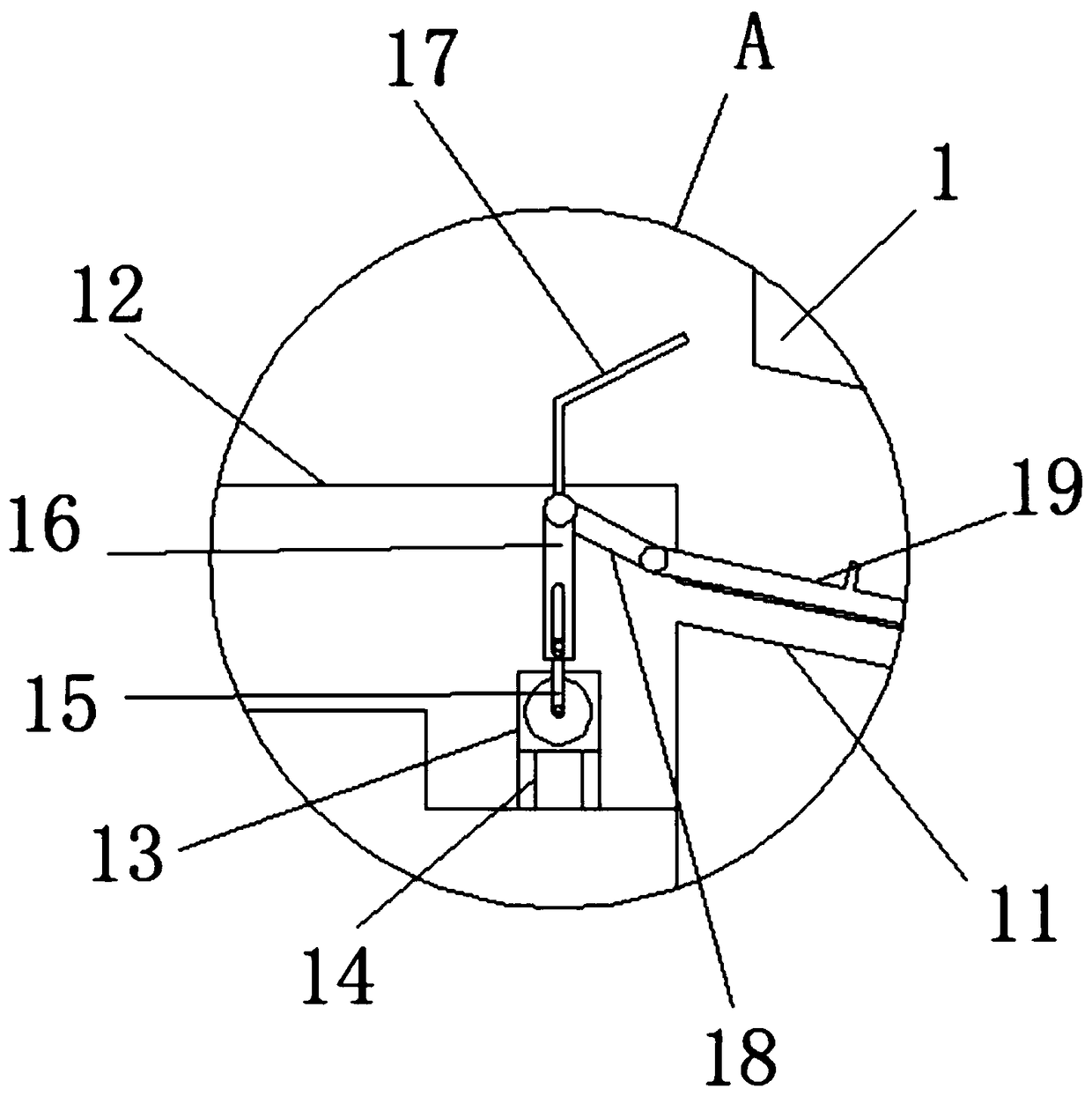

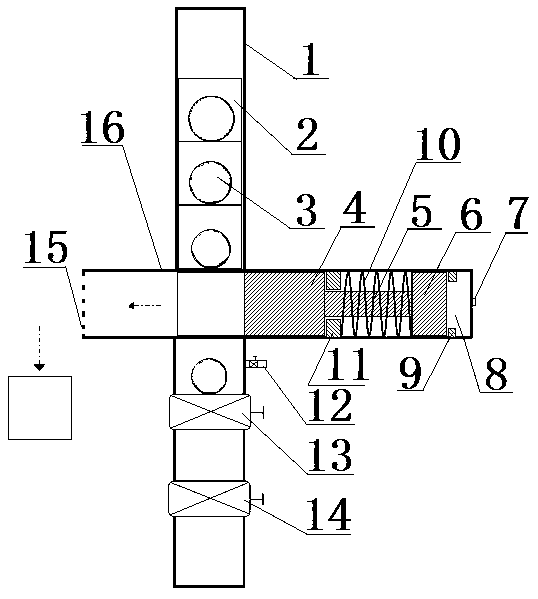

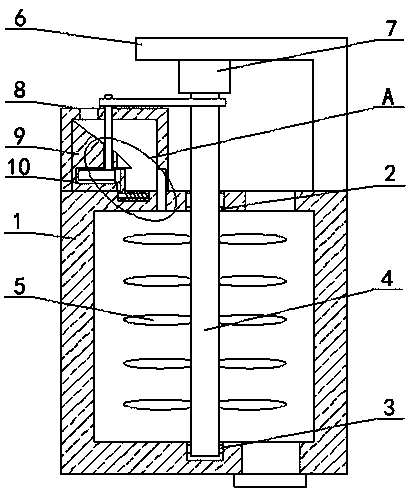

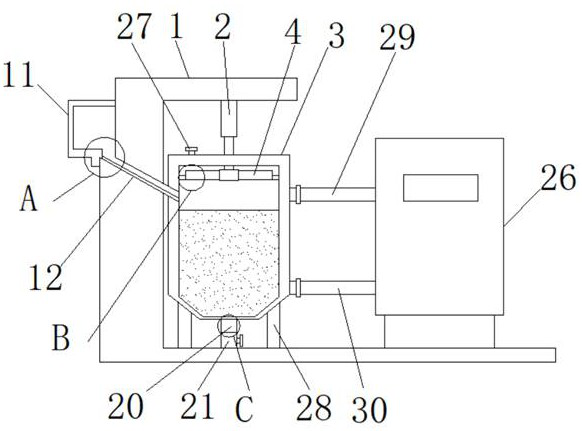

Automatic charging device of foam discharging ball

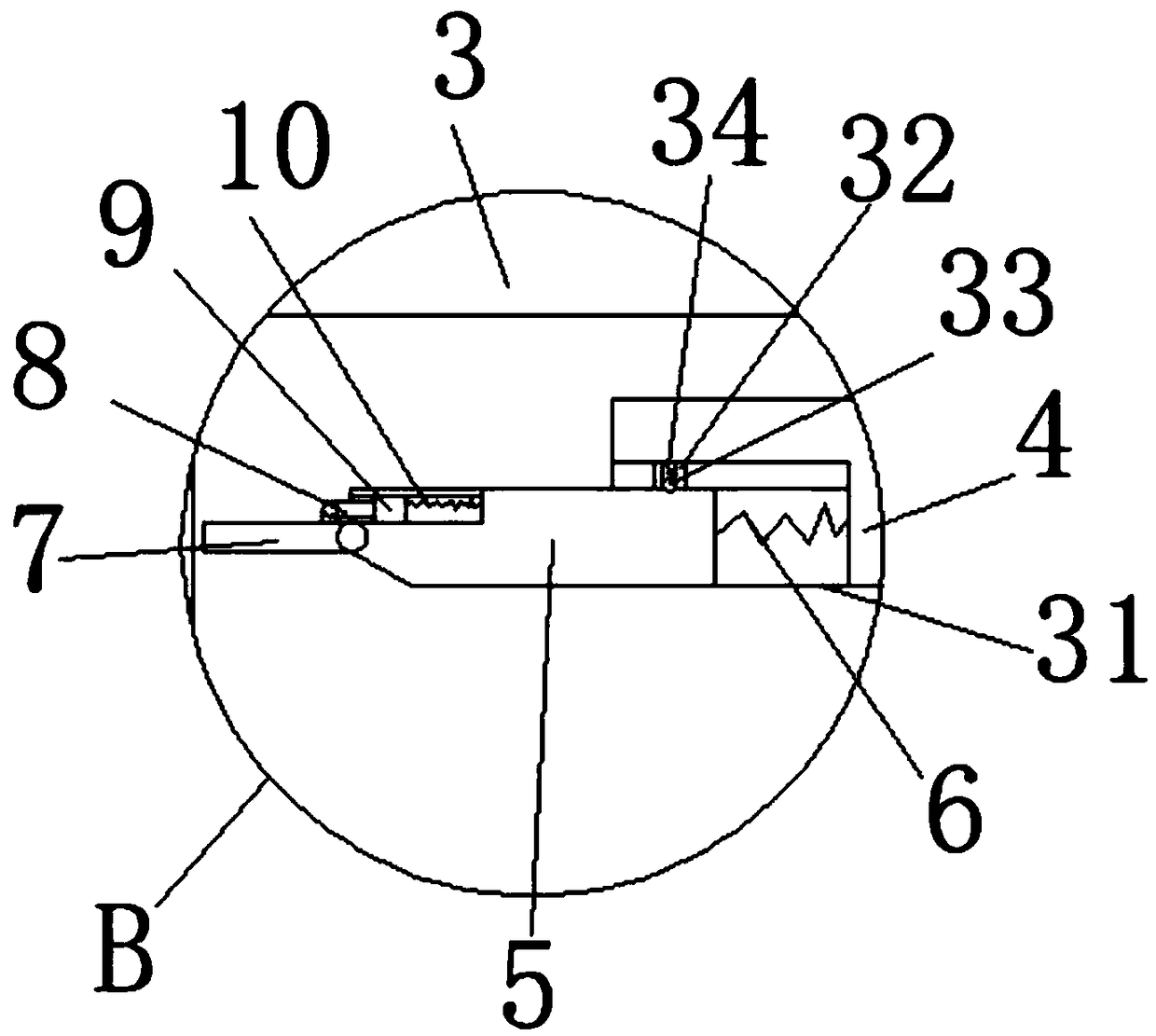

ActiveCN102797445AAchieve continuous deliveryIncrease delivery speedFluid removalEngineeringNatural gas

The invention discloses an automatic charging device of a foam discharging ball. The automatic charging device of the foam discharging ball comprises a storage mechanism and an adding mechanism, wherein the adding mechanism comprises a main path, a main path transporting mechanism, a by-path and a by-path transporting mechanism, the by-path is communicated with the main path and the storage mechanism; a communicating port of the by-path and the main path is provided with an opening and closing device; and when the main path transporting mechanism transports the foam discharging ball, the opening and closing device closes the communicating port. When the automatic charging device of the foam discharging ball works, the foam discharging ball inside the storage mechanism reaches the communicating port of the by-path and the main path through the by-path and the by-path transporting mechanism, the foam discharging ball enters the main path when the opening and closing device is opened, and the foam discharging ball is added to a wellhead through the main path transporting mechanism when the opening and closing device is closed; after the foam discharging ball is added, the opening and closing device is opened again, the foam discharging ball continuously enters the main path through the by-path, and the continuous adding of the foam discharging ball can be realized in such a repeated and sustained way so that the adding speed of the foam discharging ball is increased, and therefore, the exploitation efficiency of natural gases and the stability of the exploitation work of the natural gases are increased and the natural gases can be prevented from being wasted by being exhausted in the air.

Owner:陕西航天泵阀科技集团有限公司

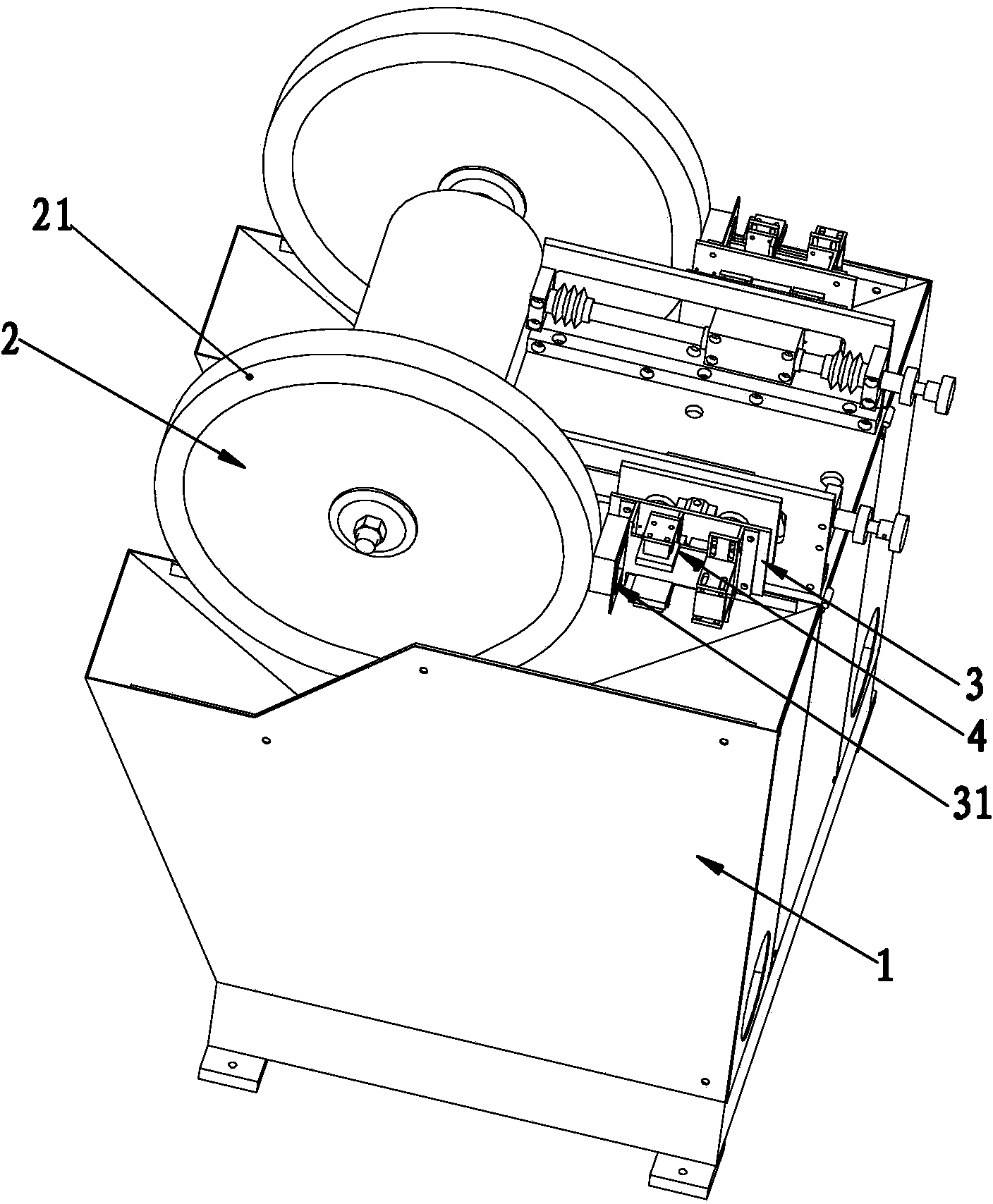

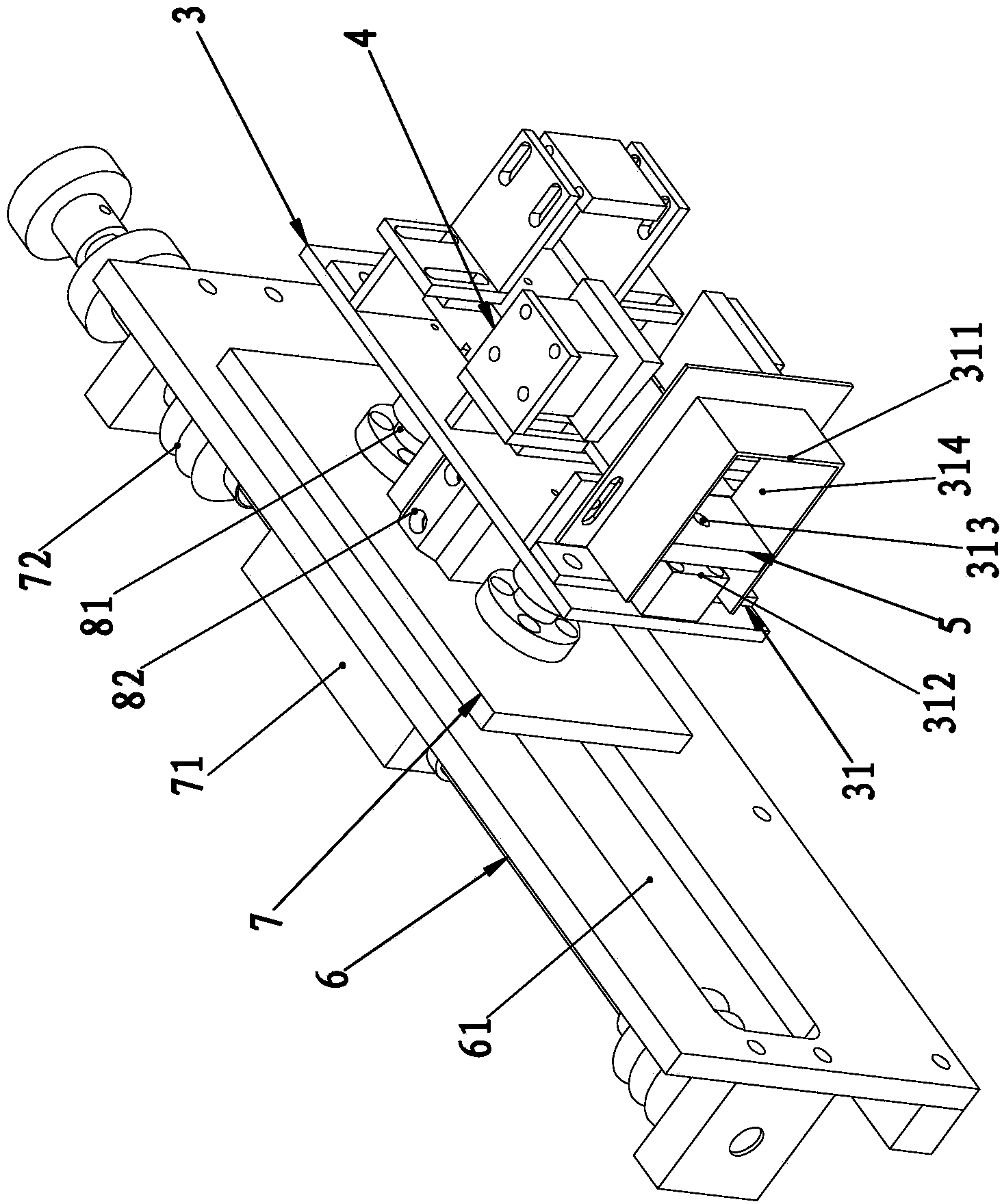

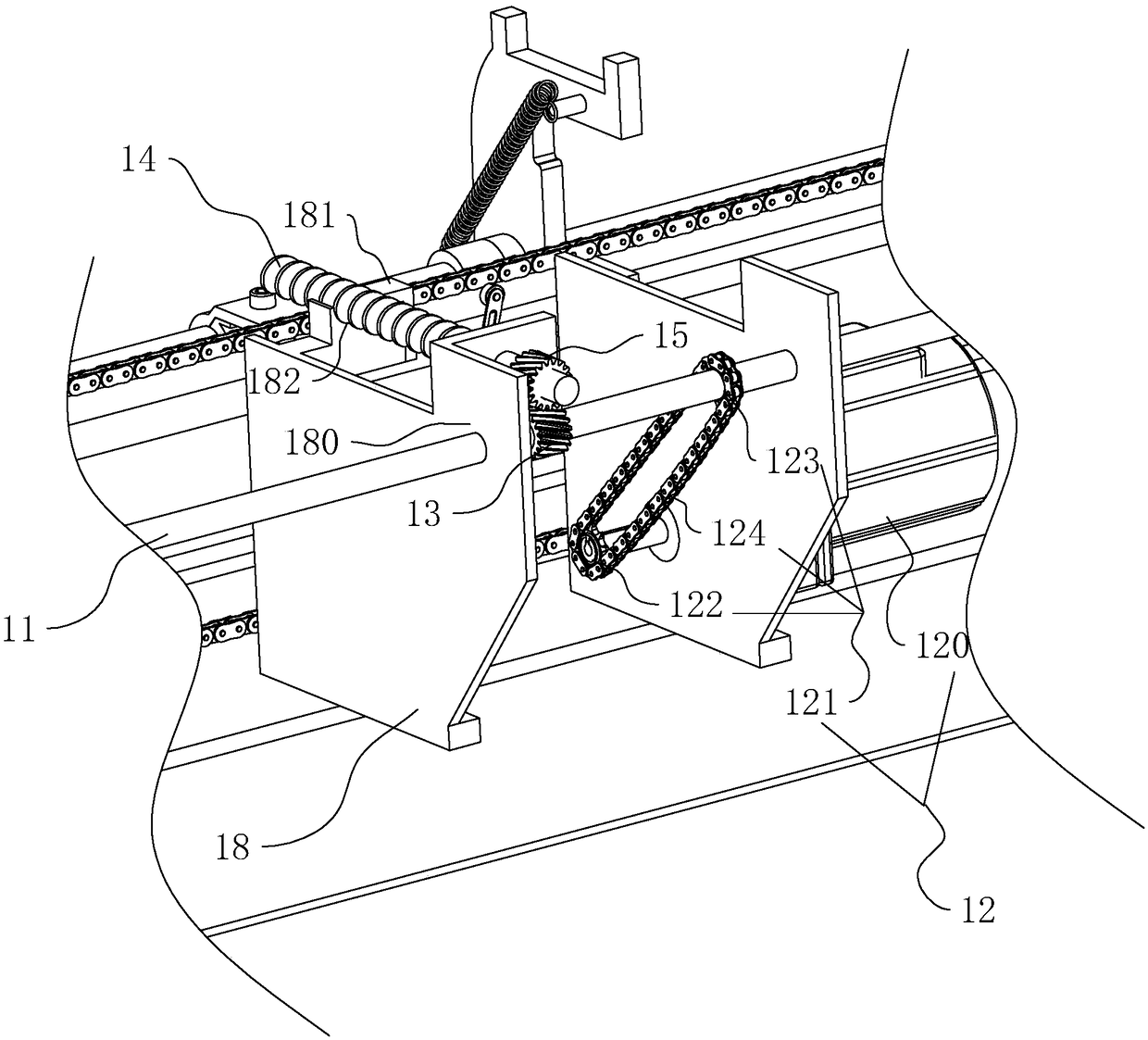

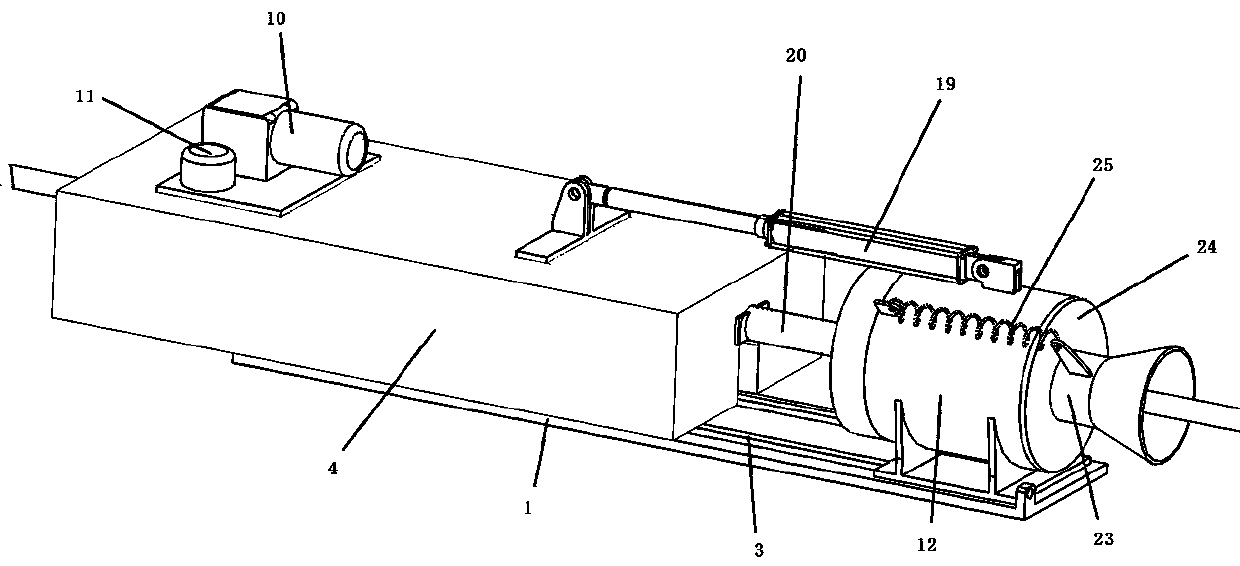

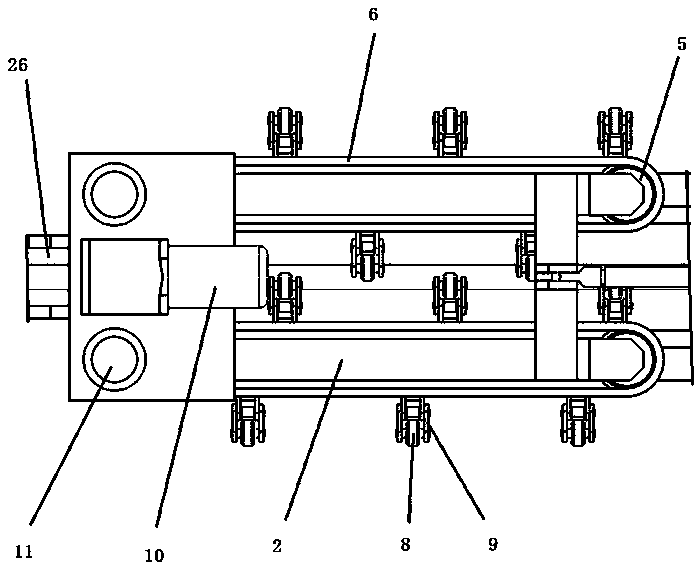

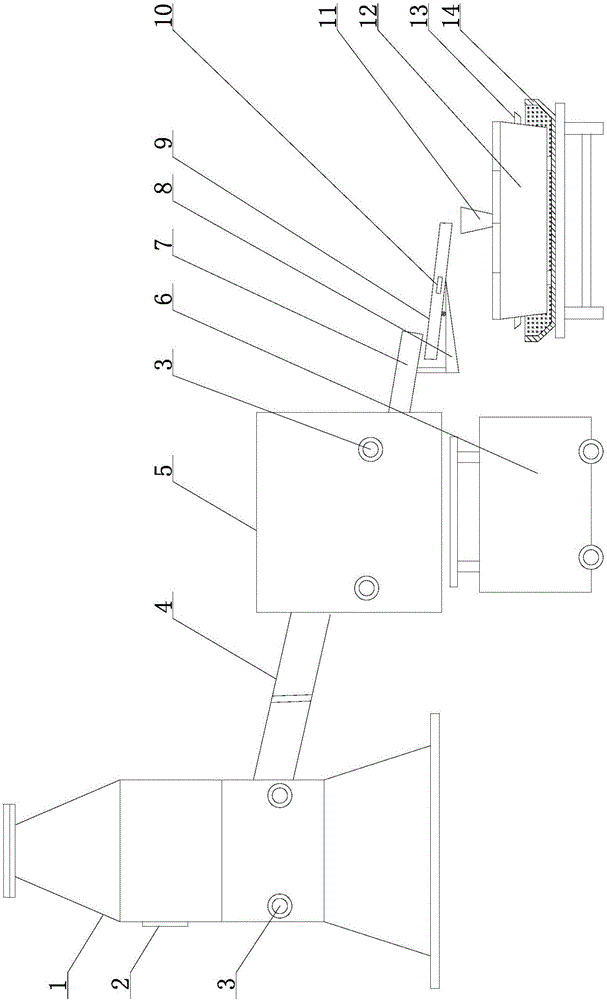

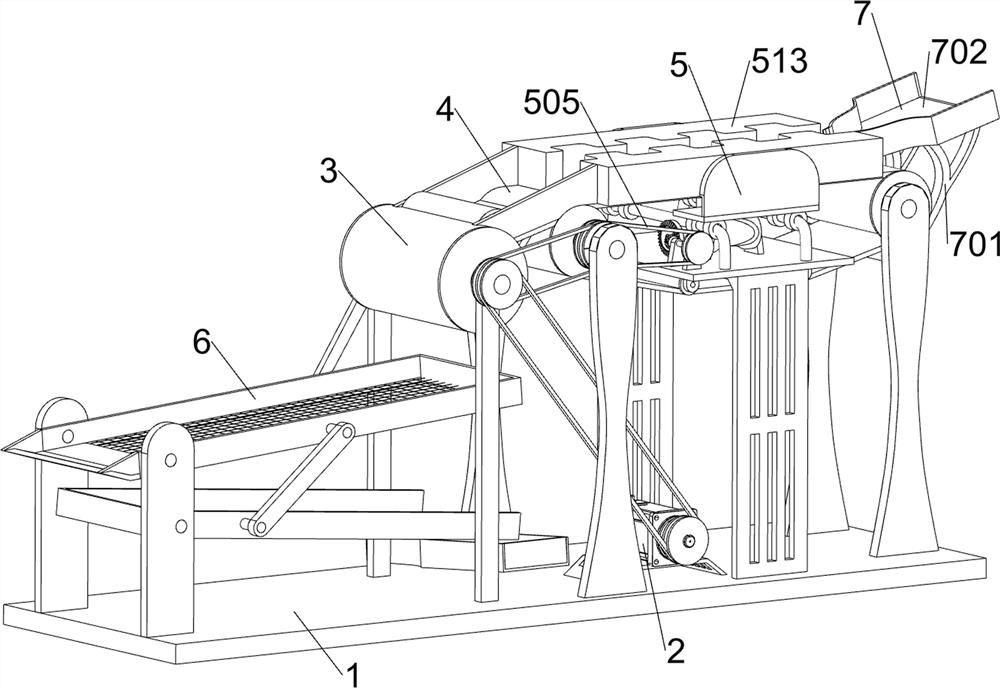

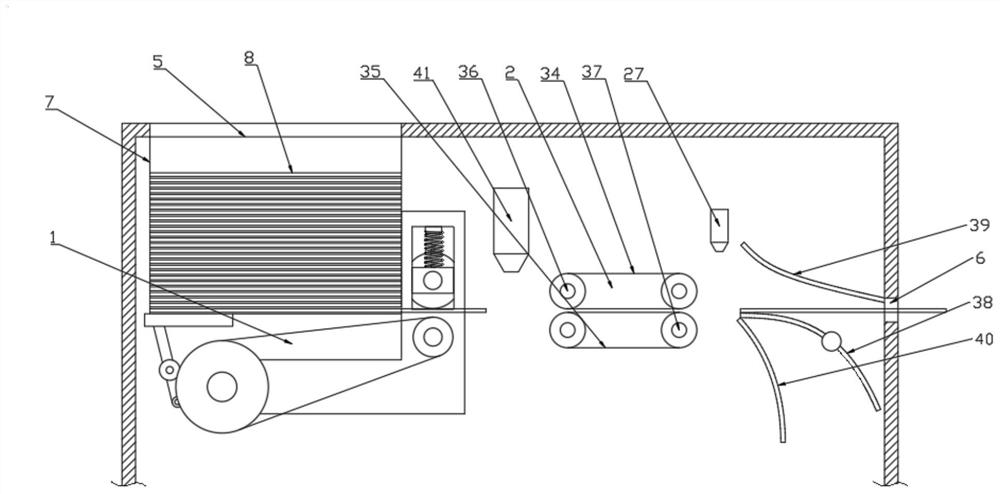

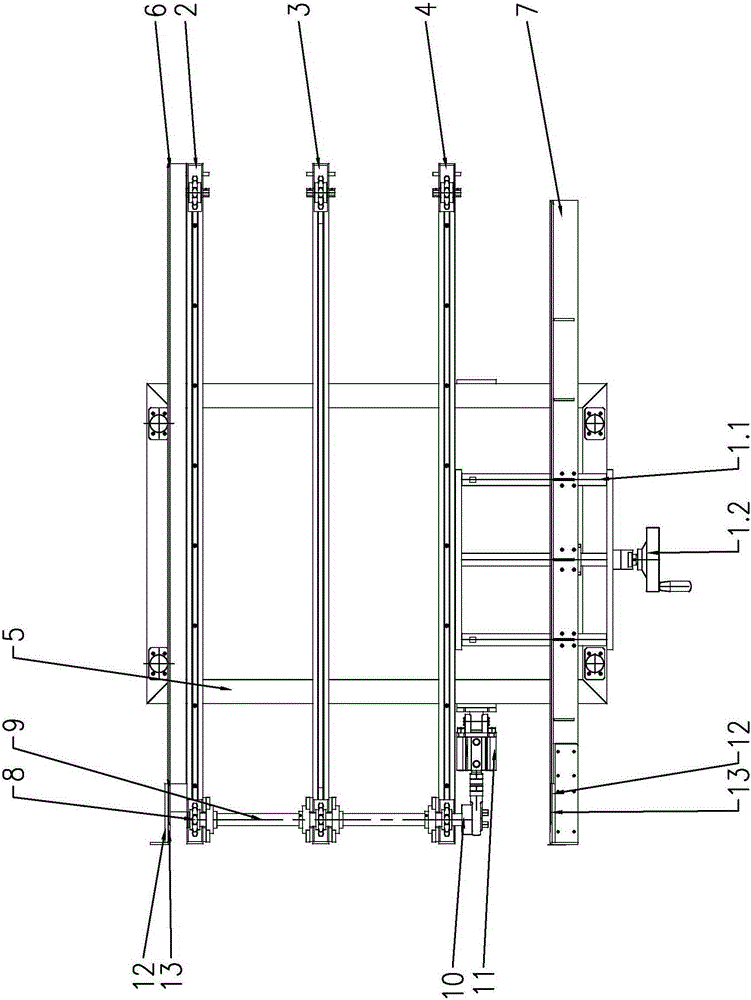

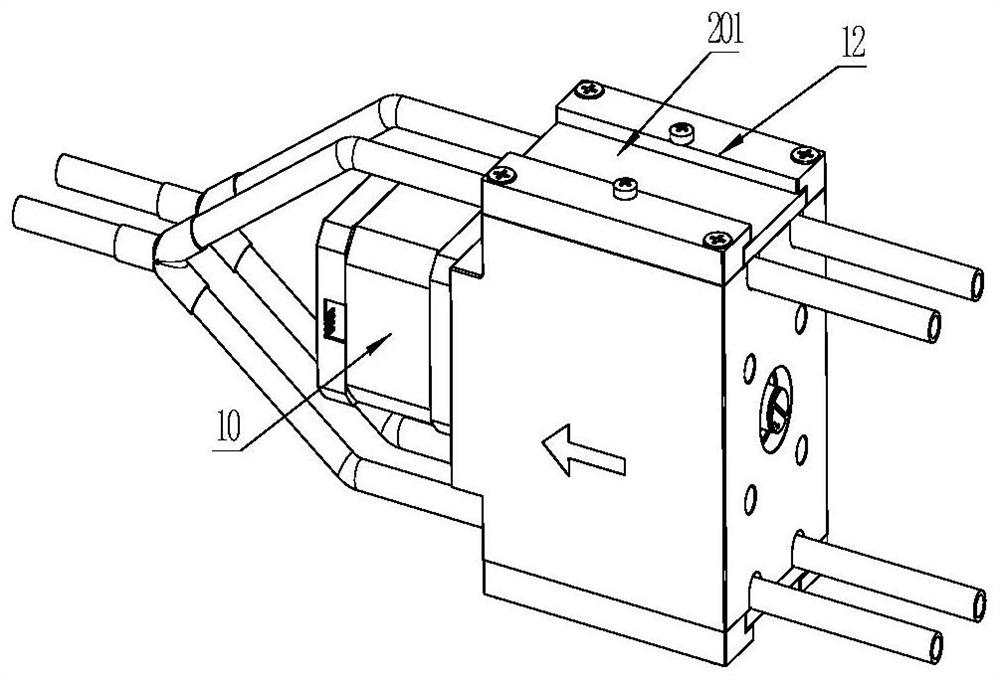

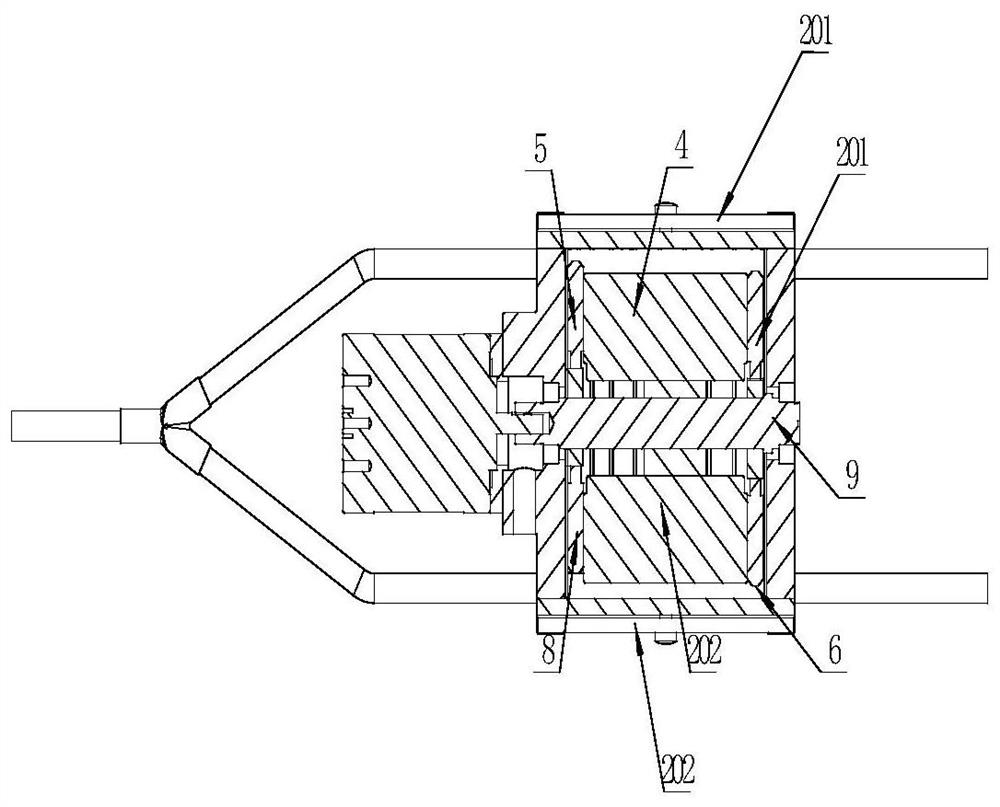

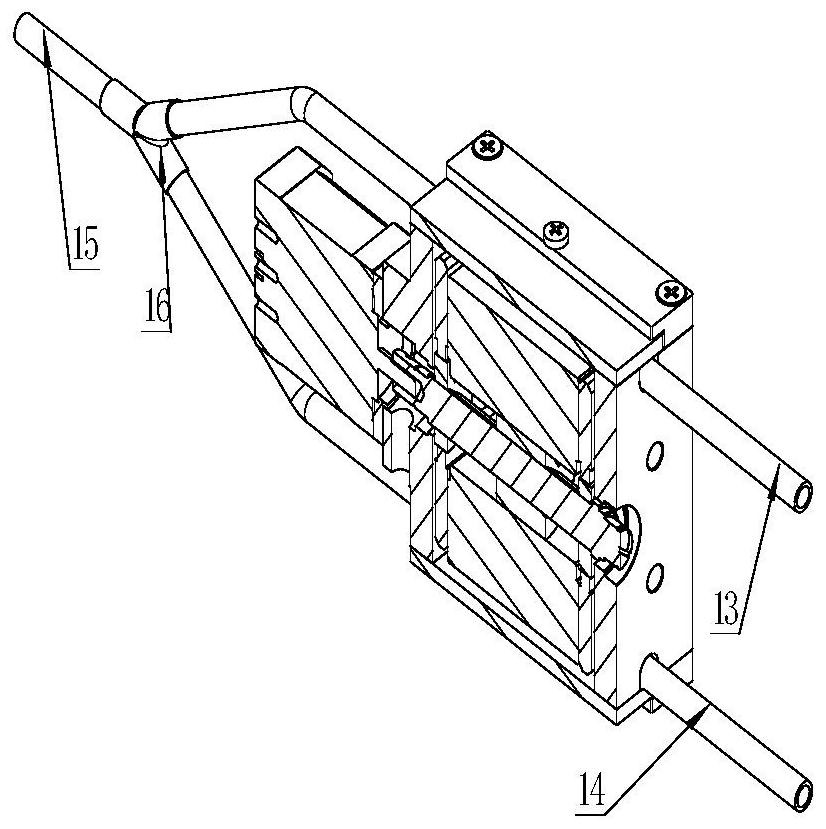

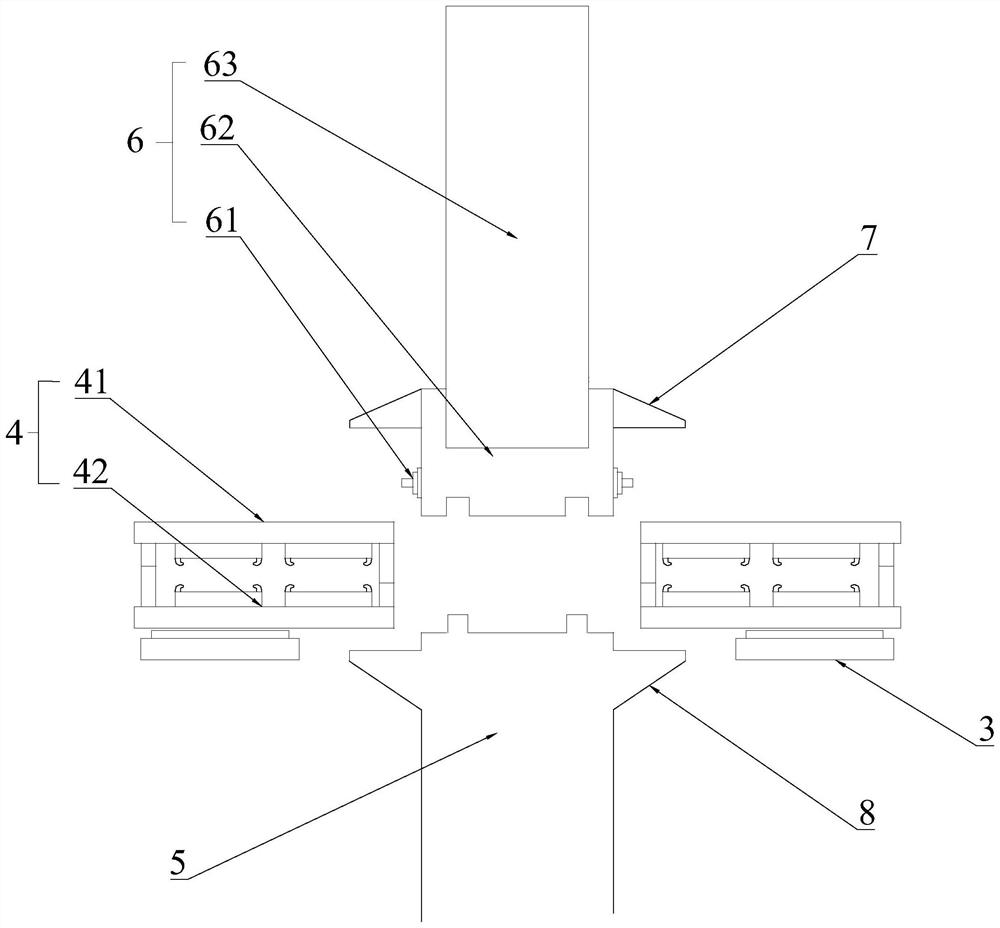

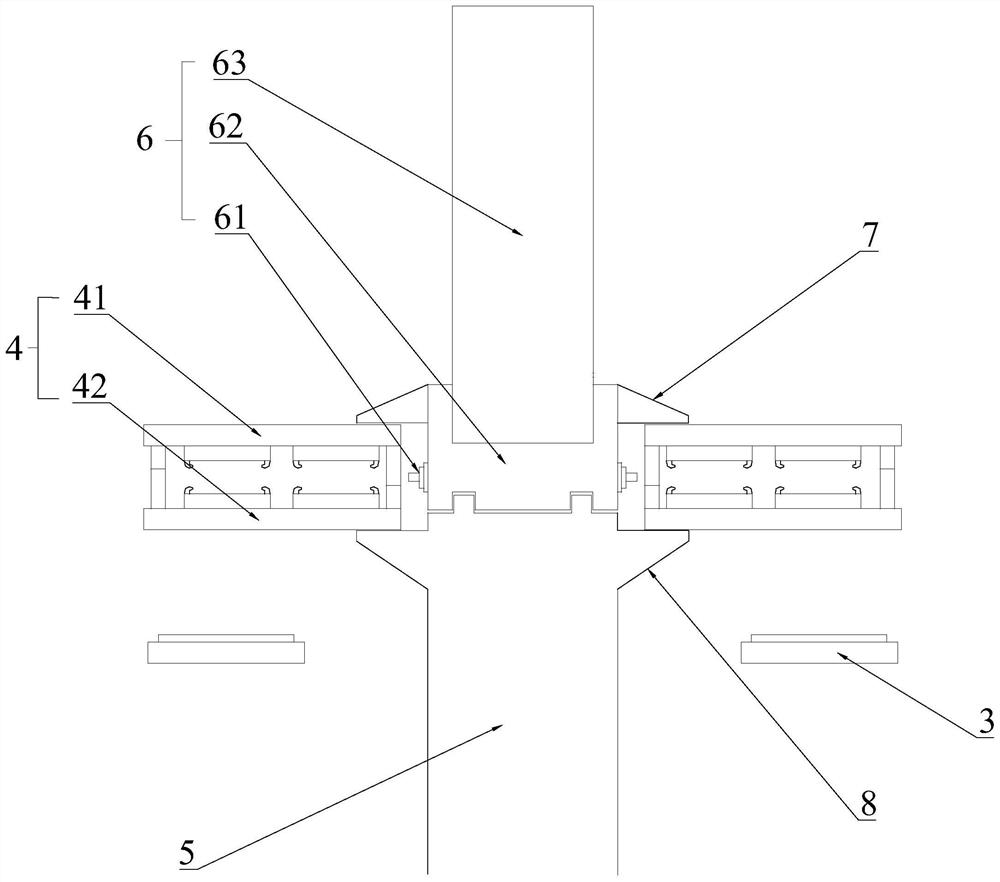

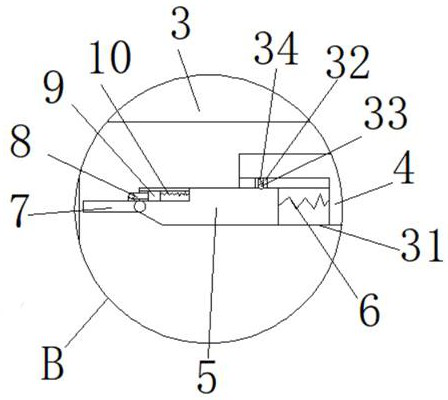

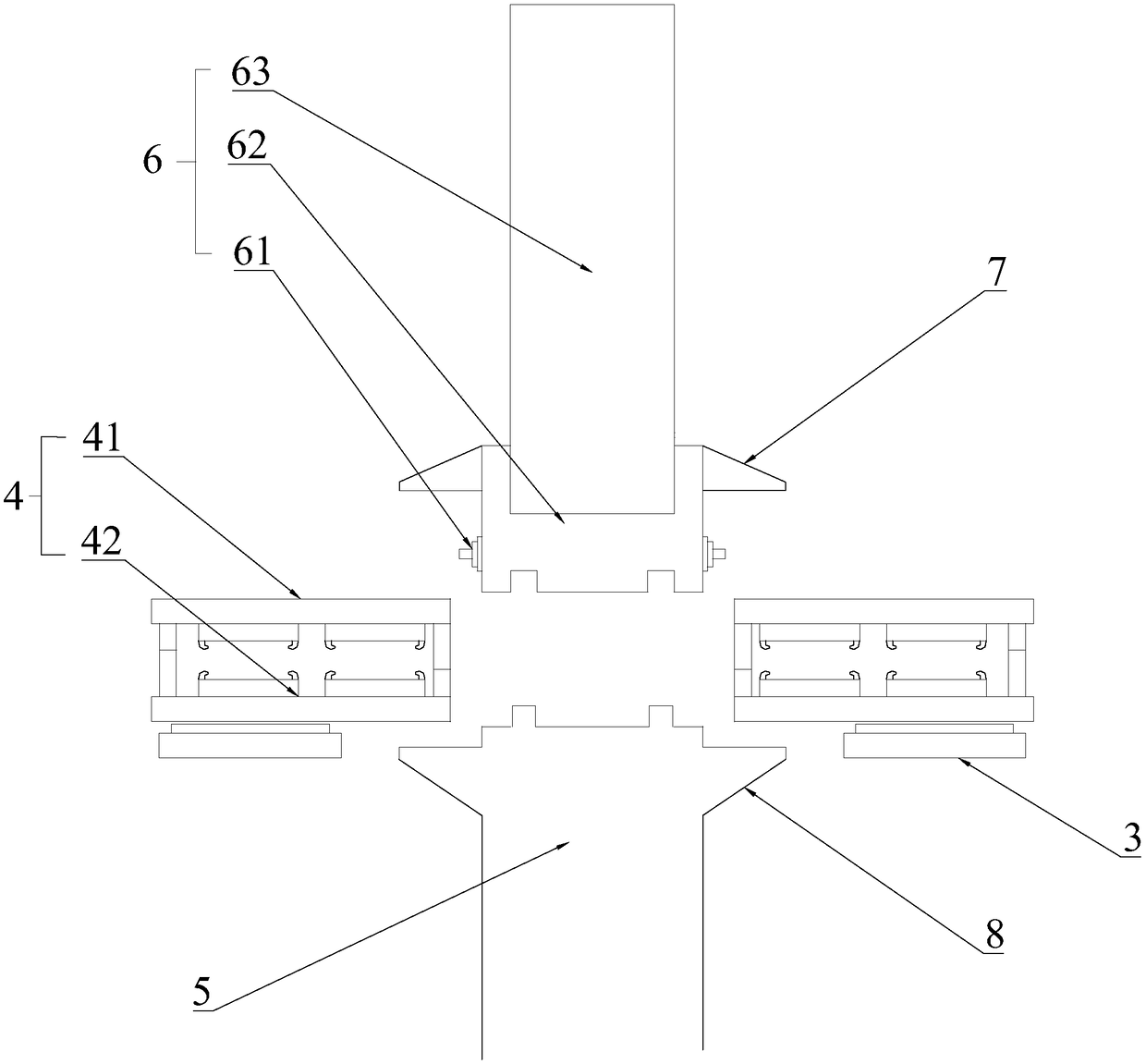

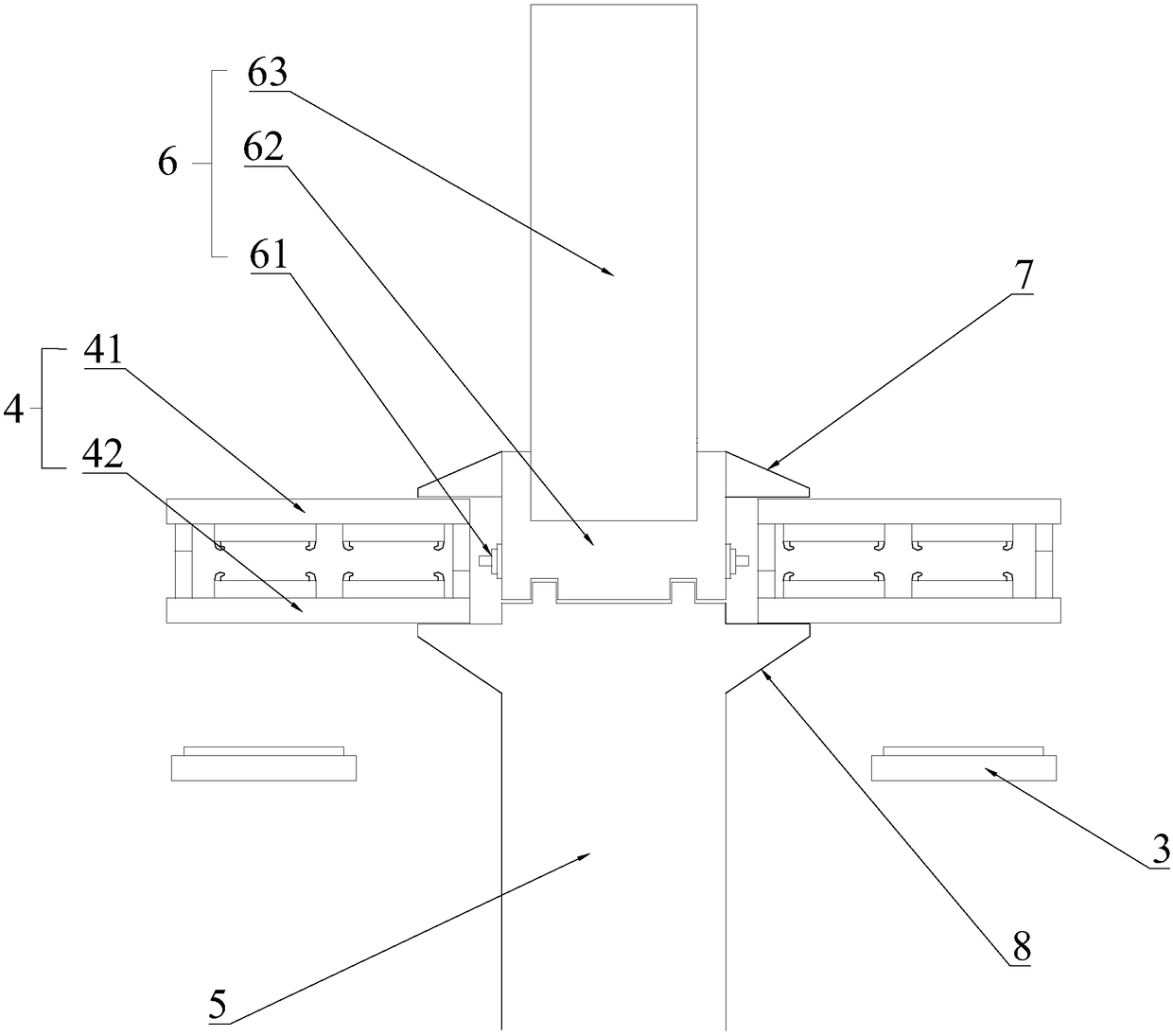

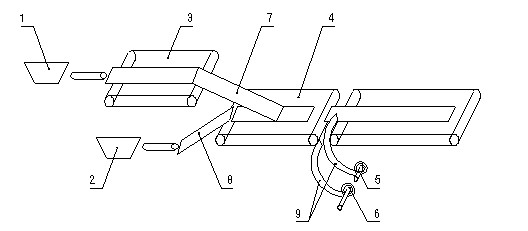

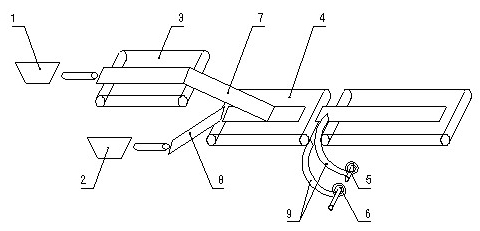

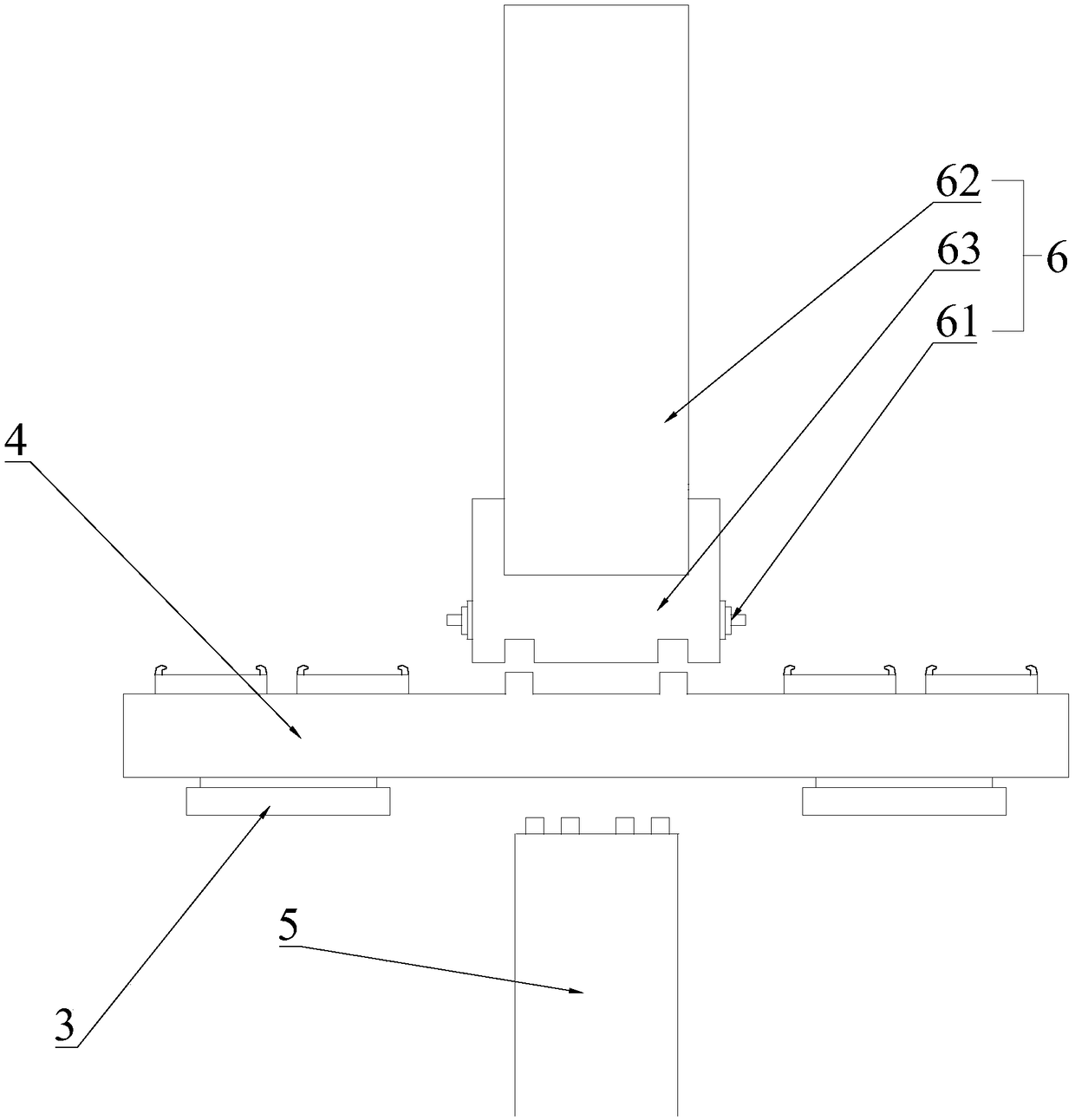

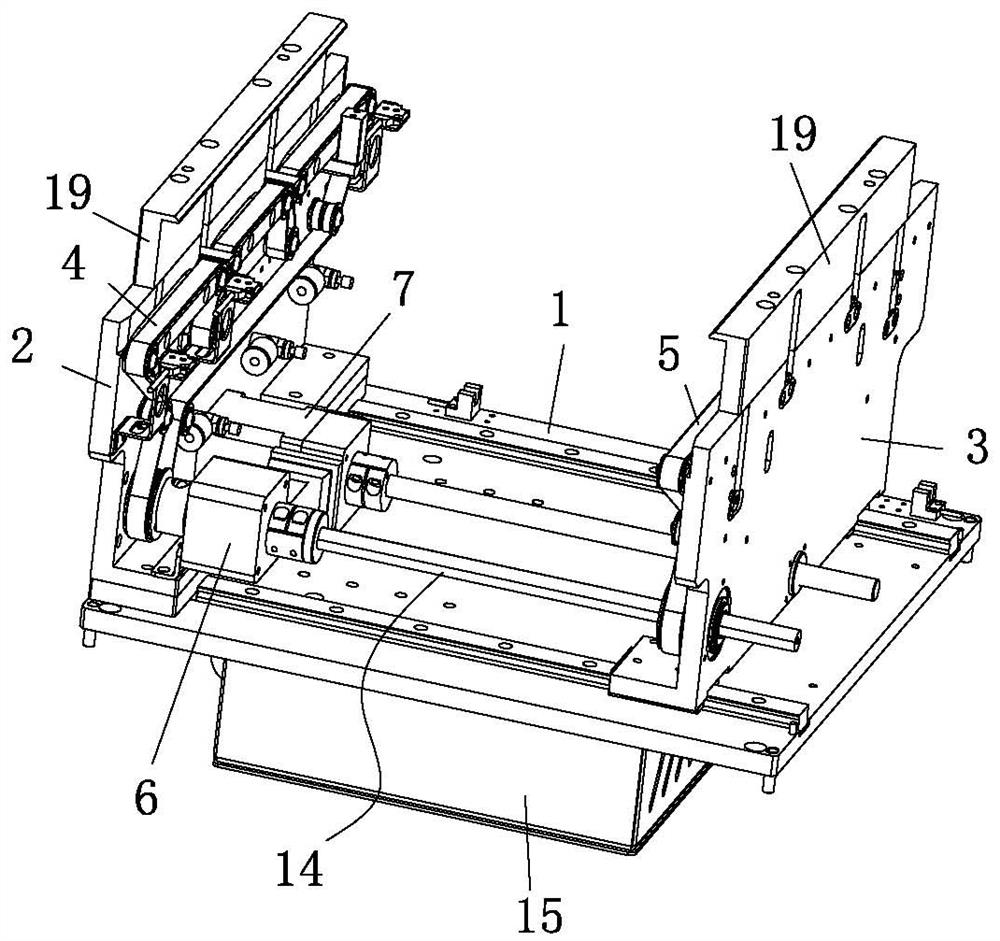

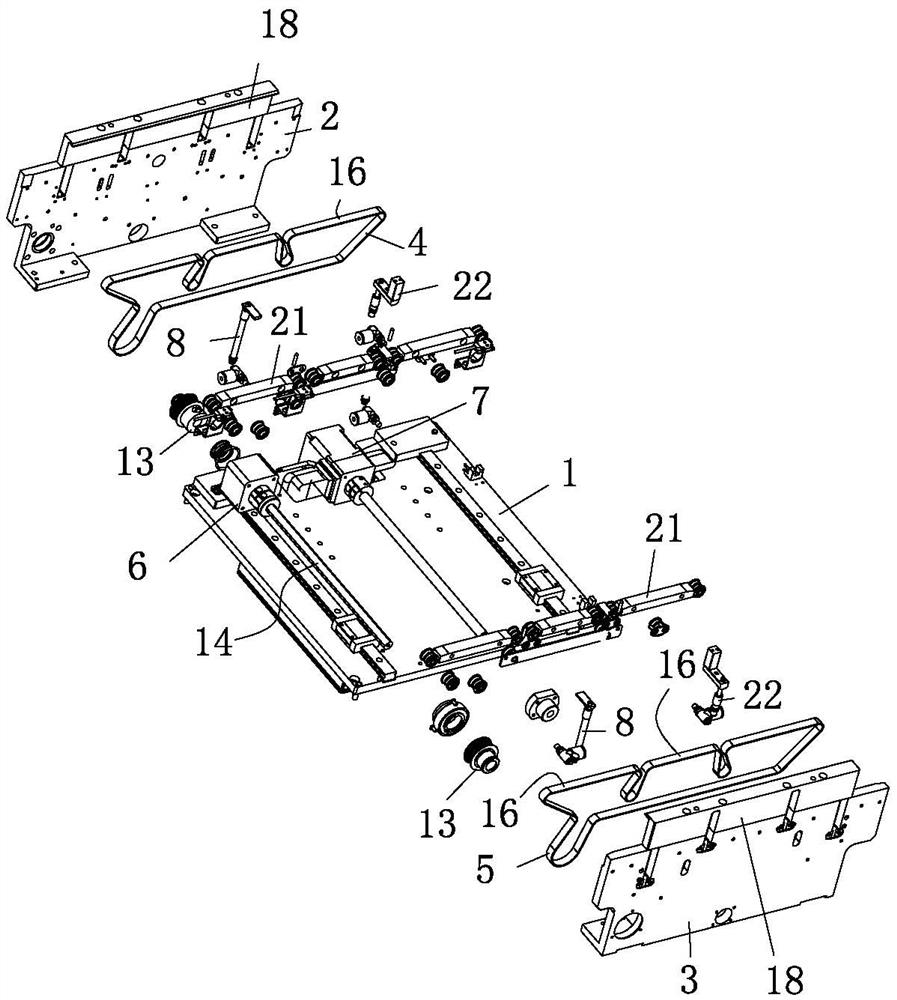

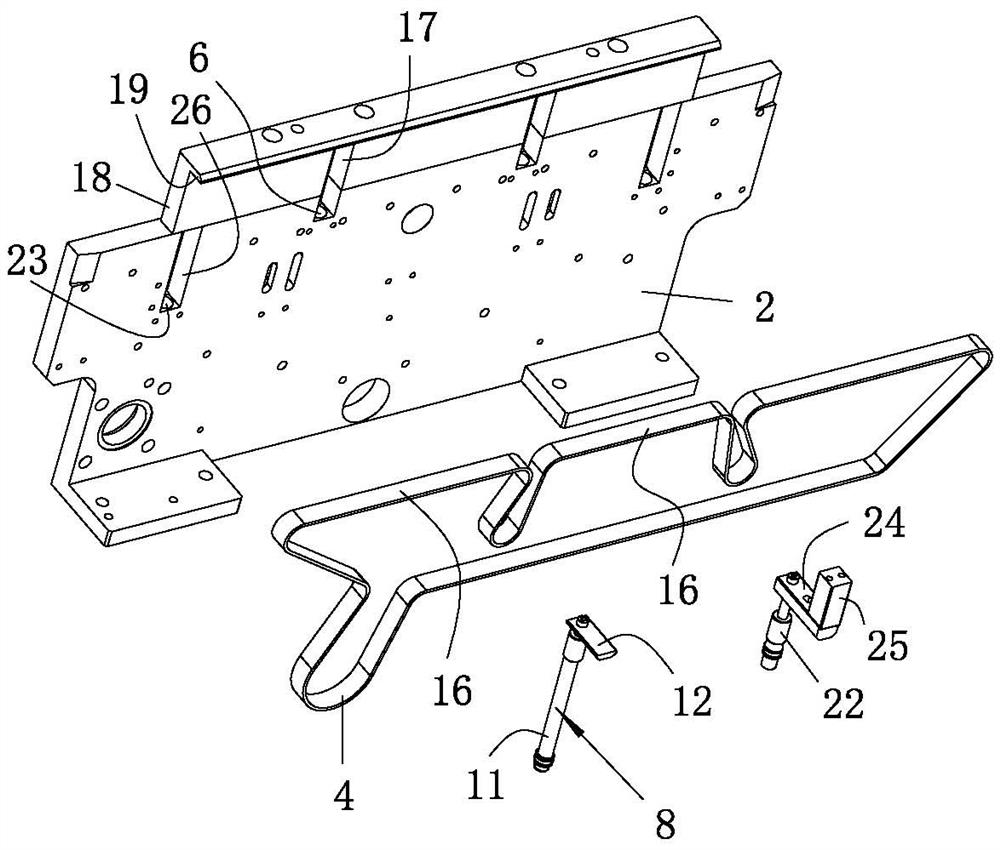

Lathe automatic feeding machine

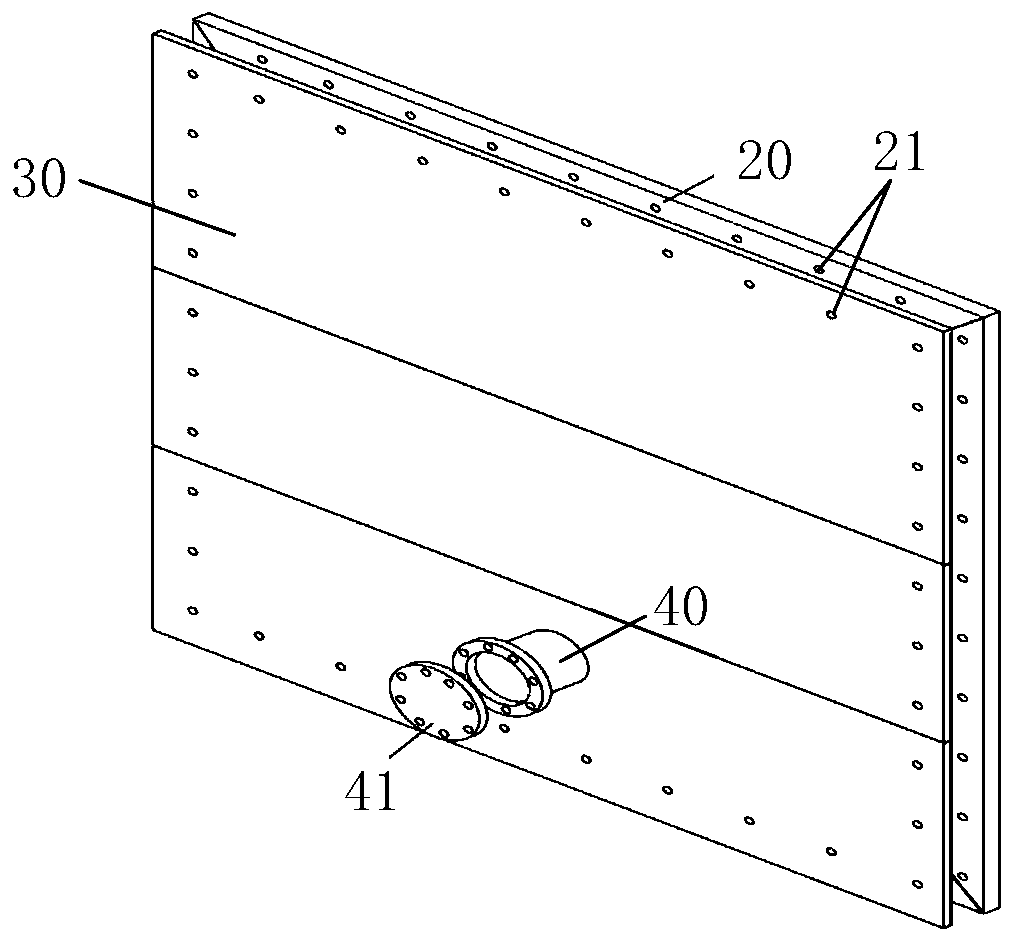

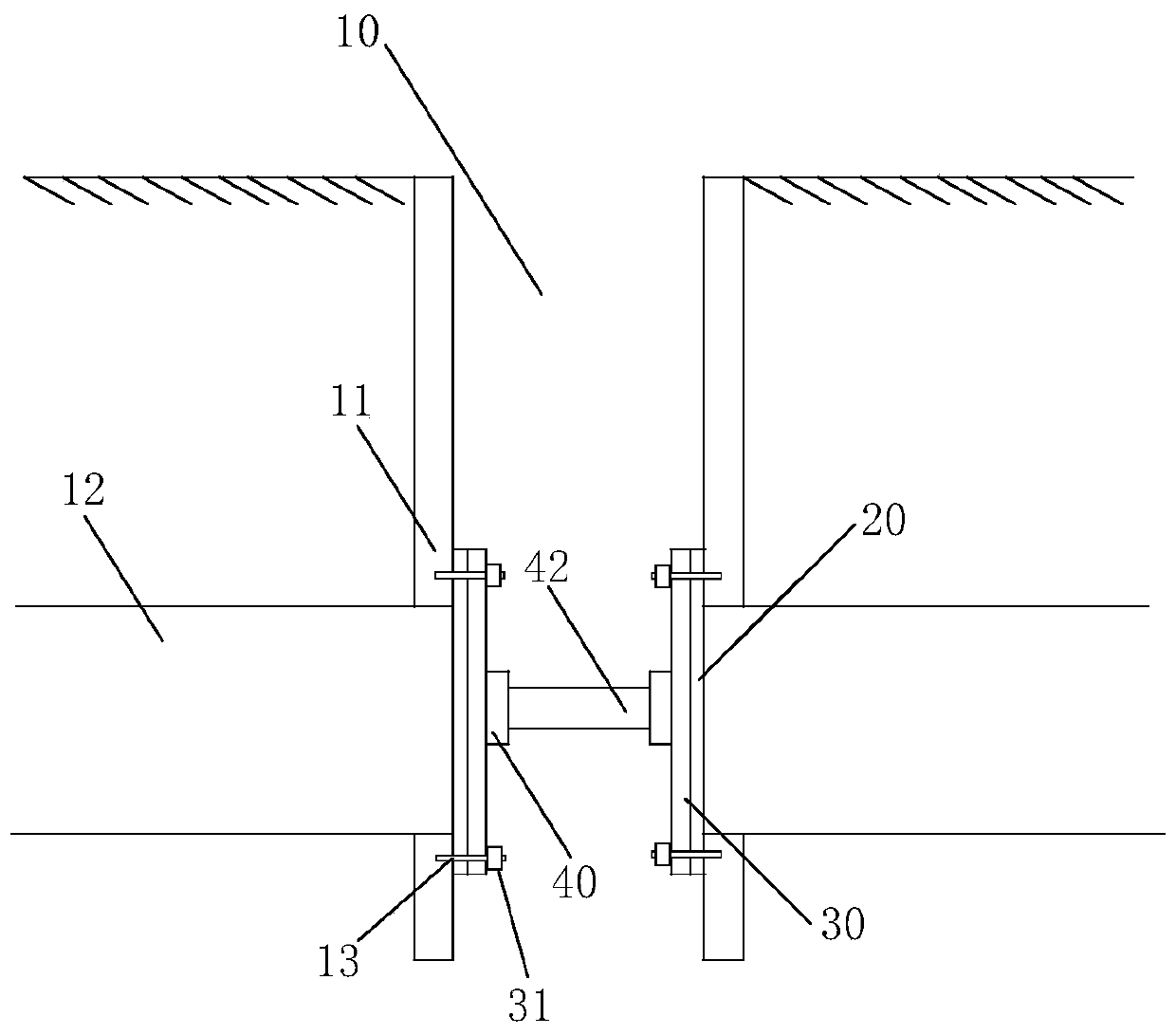

ActiveCN108608012AImprove securityImprove efficiencyAuxillary equipmentMetal working apparatusControl systemWaste management

The invention discloses a lathe automatic feeding machine. According to the technical scheme, the lathe automatic feeding machine comprises a machine body and further comprises a pressing device whichis arranged on the machine body and used for pressing and positioning bar materials, a spiral discharging device which is arranged on one side of the pressing device and used for conveying the bar materials onto the pressing device, and a pushing device which is parallel and right aligned to the pressing device and used for pushing the bar materials onto a lathe; a waste discharging system used for discharging bar material waste is arranged between the pushing device and the pressing device; the pressing device, the spiral discharging device, the pushing device and the waste discharging system are all electrically connected with a PLC control system; and a detection device which is electrically connected to the PLC control system and used for detecting whether the waste is discharged or not is arranged below the waste discharging system. The lathe automatic feeding machine has the effects that the bar materials are conveyed one by one, the machining safety and efficiency are improved,and the waste can be conveniently gathered and processed.

Owner:科德普(厦门)自动化科技有限公司

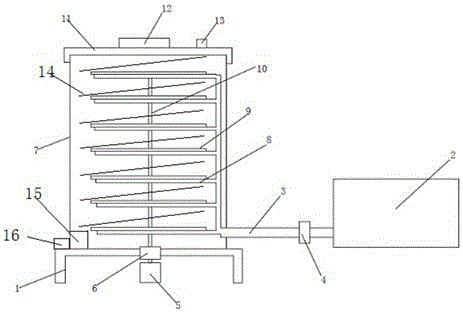

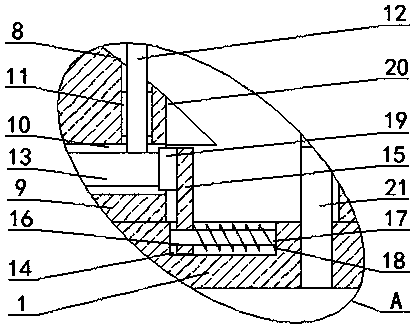

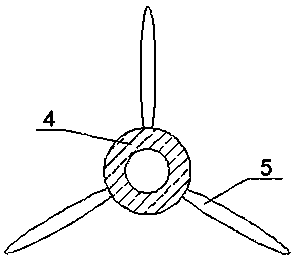

Pleurotus eryngii sterilization device

InactiveCN105724051AComprehensive sterilizationAvoid getting wetCultivating equipmentsMushroom cultivationEngineeringMechanical engineering

The invention discloses a pleurotus eryngii sterilization device, which comprises a steam sterilization tank, a high-temperature steam generator and a motor. The end is connected with a rotating shaft, the rotating shaft is vertically set, and the rotating shaft extends into the steam sterilization tank, and a plurality of grid plates are fixed on the rotating shaft. Bacteria bag, the present invention has simple and reasonable structure, convenient use and operation, high overall sterilization efficiency and good effect, so that each leaf can be fully sterilized, so the overall production efficiency is improved, and the overall operation of the equipment is stable and safe to use.

Owner:岑思

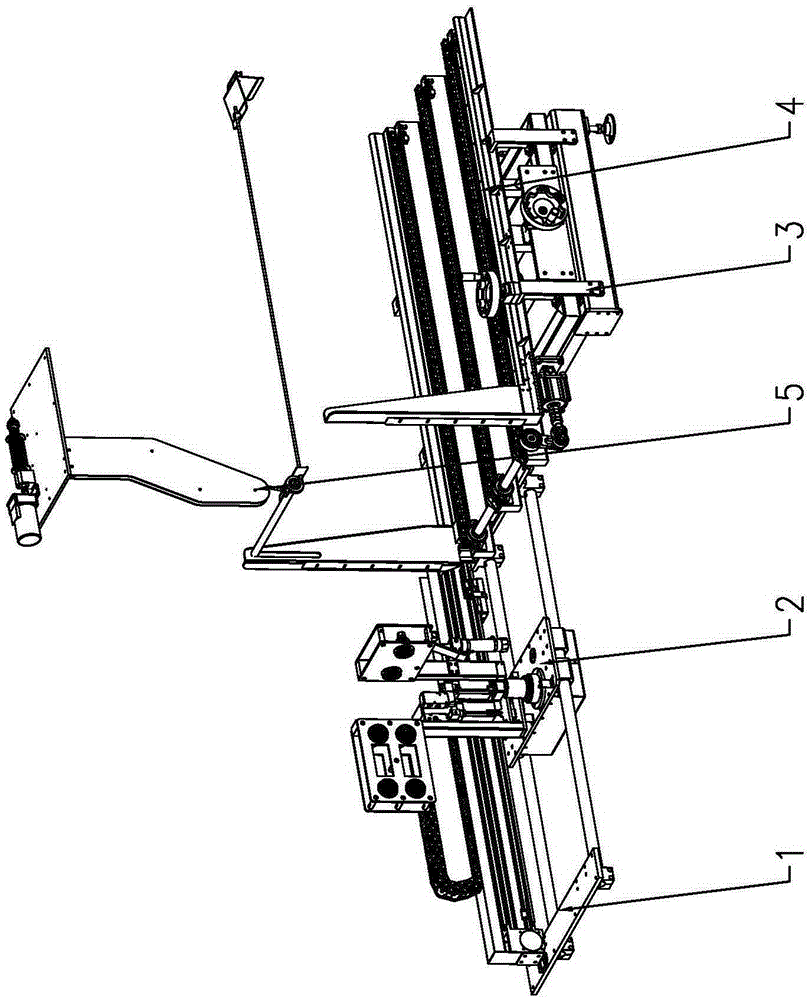

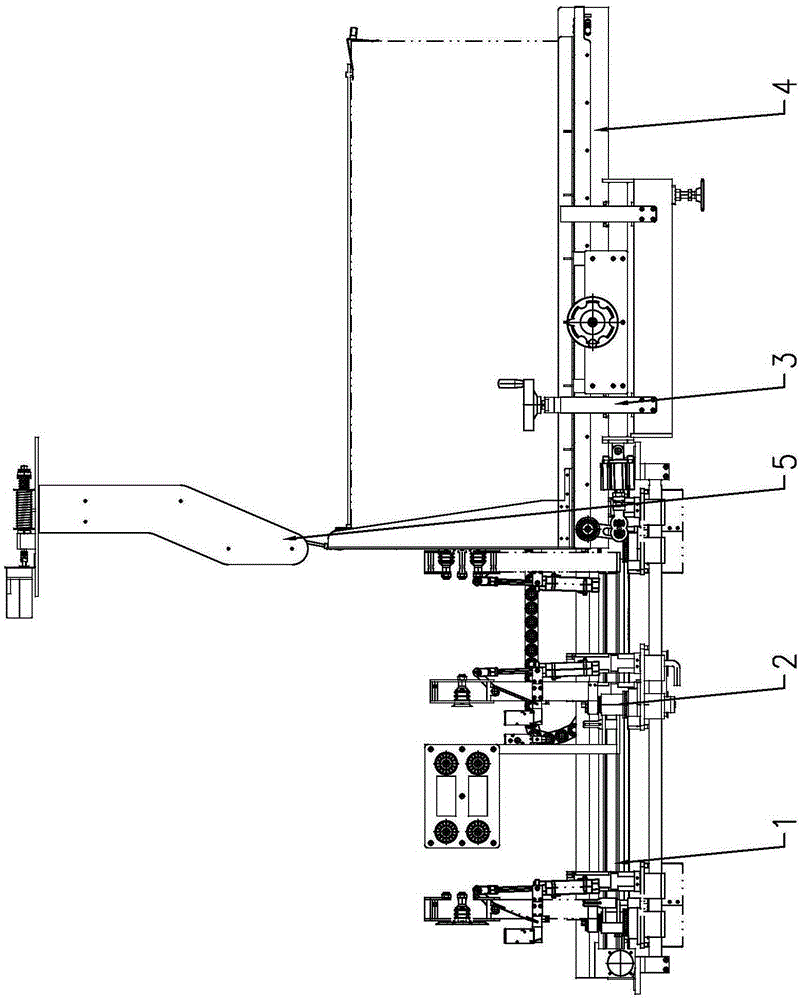

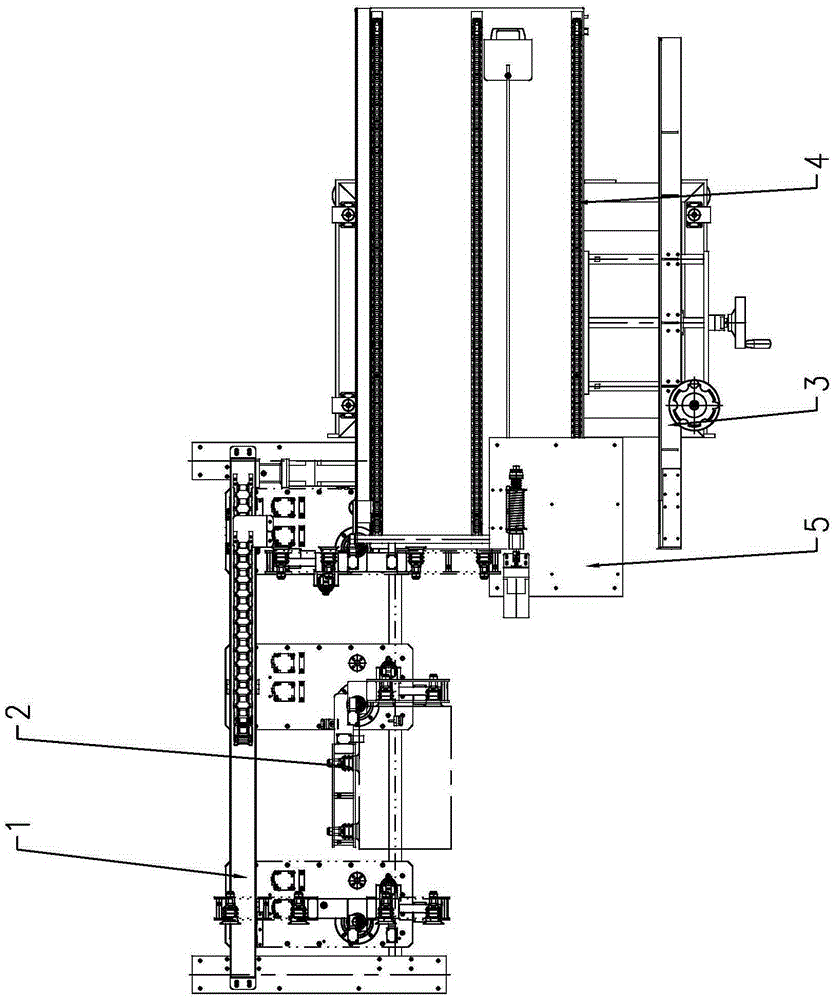

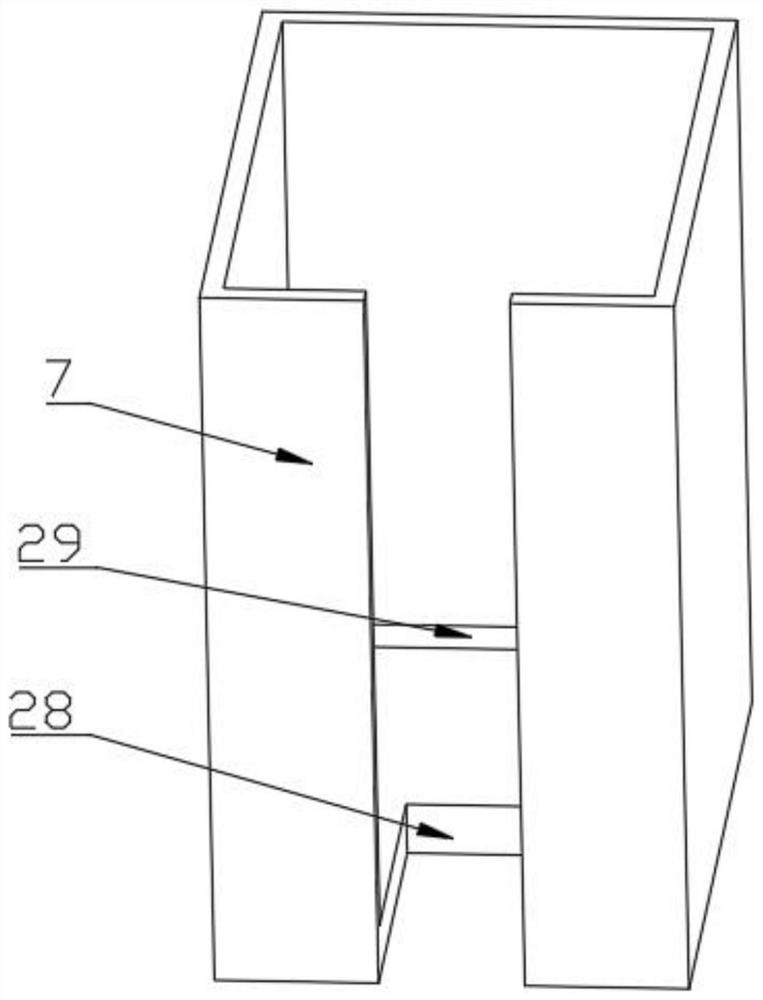

Servo box supplying and opening device

ActiveCN105292602APrevent collapseImprove quality and efficiencyPackagingMedical equipmentEngineering

The invention relates to a servo box supplying and opening device for automatic boxing of transfusion products and belongs to the technical field of medical equipment. The servo box supplying and opening device comprises a linear sliding assembly, a servo box opening assembly, a supporting and jacking assembly, a chain box supply assembly and a tensioning anti-collapse assembly, wherein the lower end of the chain box supply assembly is connected with the supporting and jacking assembly; the supporting and jacking assembly can drive the chain box supply assembly to ascend and descend; the tensioning anti-collapse assembly is disposed at the upper end of the chain box supply assembly; the linear sliding assembly is disposed on one side of the chain box supply assembly; the linear sliding assembly is in sliding connection with the servo box opening assembly. The servo box supplying and opening device can take away paper boxes on a box supply platform and deliver the paper boxes to a packaging line, the production efficiency is improved, and the operation is stable and efficient.

Owner:无锡众创自动化科技有限公司

Thin-walled tube penetrating and conveying device

PendingCN109665254AAvoid damageTo achieve continuous inputConveyorsRoller-waysWorking environmentEngineering

Owner:郑州科慧科技股份有限公司

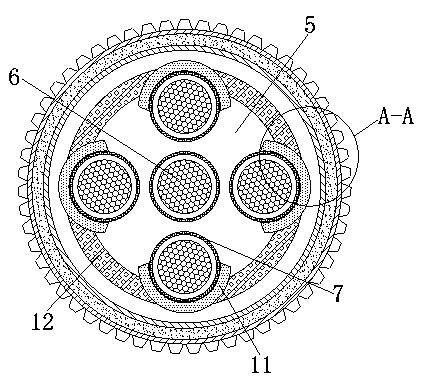

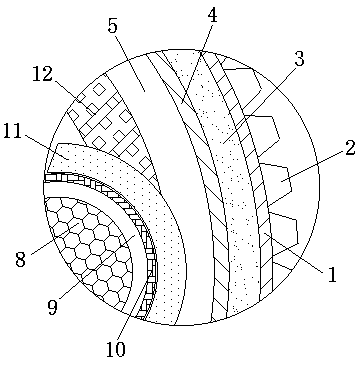

A waterproof and twist-proof cable for wind power generation

ActiveCN108962466AImprove insulation performanceEffective waterproof protectionInsulated cablesPower cablesCopper wireEngineering

The invention discloses a waterproof and twist-proof cable for wind power generation. The cable comprises an outer insulating layer; the surface of the outer insulating layer is fixedly connected withrubber protrusions; and an outer waterproof layer is adhered to the inner wall of the outer insulating layer; a silicone layer is adhered to the inner wall of the outer waterproof layer; and a filling layer is adhered to the inner wall of the silicone layer; a main conductive wire is arranged at the center of the inside portion of the filling layer; secondary conductive wires are arranged in portions, at the top and left and right sides of the main conductive, inside the filling layer; and the four secondary conductive wires are arranged to encircle the main conductive wire at the center. Themain conductive and the secondary conductive wires each comprise a copper core, wherein the copper core is formed by twisting 23 bundles of wires, and each bundle is formed by twisting 102 copper wires with a diameter of 0.2 mm. The waterproof and twist-proof cable for wind power generation is simple in structure, low in cost, effectively avoids occurrence of cable twisting-off or water seepage,can realize continuous conveying of electric energy, reduces cost of circuit setting and completely satisfies demands of usage.

Owner:宝胜(宁夏)线缆科技有限公司

Cotton degreasing device

ActiveCN109092780AEasy to stackNot easy to damageTreatment involving filtrationMultistage water/sewage treatmentWater flowPulp and paper industry

The invention provides a cotton degreasing device and relates to the technical field of cotton degreasing. The cotton degreasing device comprises a mounting base. An electric telescopic rod is arranged at the top of the mounting base, and a boiling-off barrel is arranged inside the mounting base; and a stirring disc is movably mounted at the end, away from the top of the mounting base, of the electric telescopic rod, a first sliding block is arranged inside the stirring disc and movably connected with the stirring disc through a first spring, and a stirring rod is movably mounted at the end, away from the first spring, of the first sliding block. According to the cotton degreasing device, the bottom section of the boiling-off barrel is in a trapezoidal shape, and thus cotton is accumulatedat the bottom of the boiling-off barrel advantageously; the stirring rod can be changed with changing of the bottom barrel diameter of the boiling-off barrel, and with discharging of sewage, the cotton is further gathered to the bottom through the action of a water flow, so that the cotton is dehydrated more thoroughly; and meanwhile, the stirring rod is not liable to be damaged and can further recover to the original shape easily.

Owner:MEDWELL MEDICAL PROD

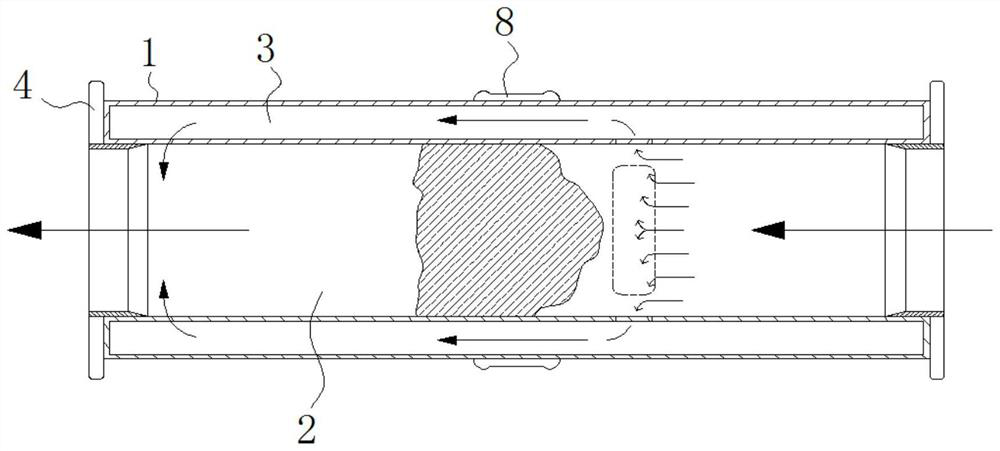

Sewage pipeline blocking device and construction method thereof

PendingCN110185118AEnsure construction safetyImprove the blocking effectSewer pipelinesPipeflowArchitectural engineering

The invention relates to a sewage pipeline blocking device and a construction method thereof. The sewage pipeline blocking device is arranged on the wall of a working well and is used for sealing a pipeline. The sewage pipeline blocking device comprises a rubber plate, a water retaining steel plate and a reserved hole pipe which are arranged in sequence, wherein the rubber plate is attached to thewell wall; first preserved holes which are corresponding in positions are respectively formed in the water retaining steel plate and the rubber plate; and the reserved hole pipe communicates with thefirst preserved holes. According to the sewage pipeline blocking device, the water retaining steel plate is used for main blocking, performs sealing water stop in combination with the rubber plate, has a relatively good blocking effect, and can ensure the construction safety in an operation area; the reserved hole pipe can realize the continuous sewage transportation, and the transportation of intake sewage of sewage treatment plants does not need to be completely stopped; the dismantling workload in later period is small; the workload of underwater frogmen is effectively reduced; and the operating risk is reduced.

Owner:SHANGHAI MUNICIPAL CONSTR

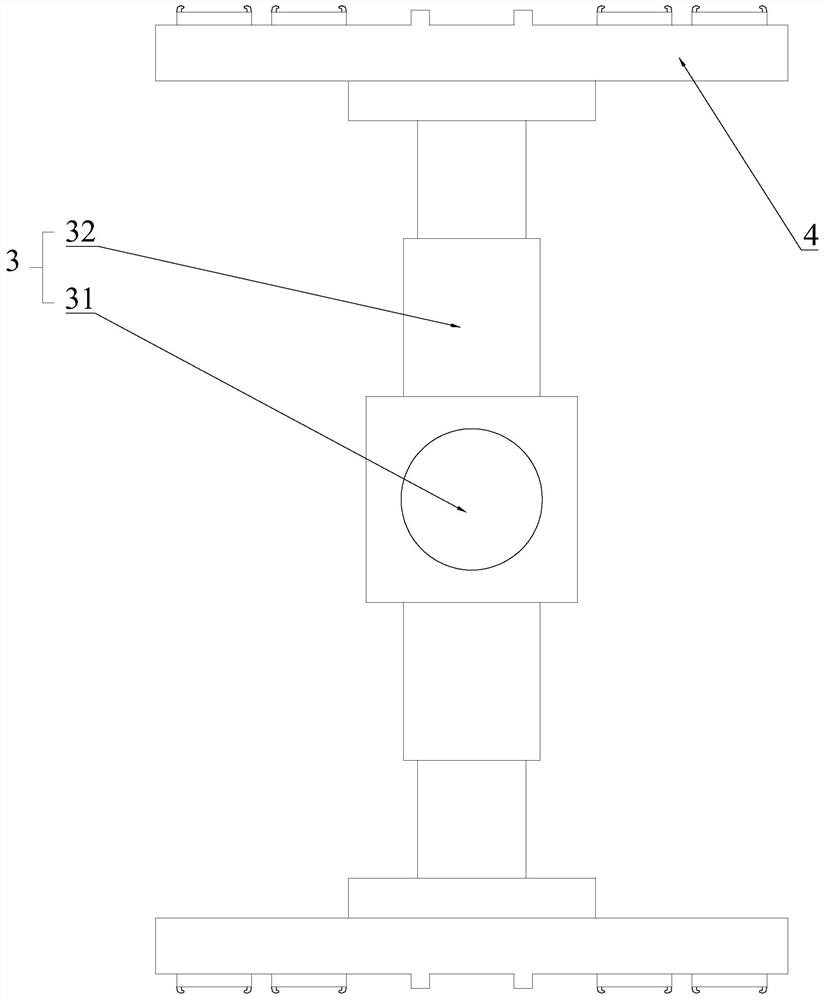

Continuous pitching device

ActiveCN108775238AGuaranteed continuityImprove construction efficiencyFluid removalWell/borehole valve arrangementsEngineeringHigh pressure

The invention relates to a continuous pitching device. The continuous pitching device comprises a pitching pipeline which is internally provided with multiple ball storing barrels continuously, support structures used for supporting fracturing balls are arranged on the tops of the ball storing barrels, through holes allowing the fracturing balls to pass through are formed in the lower ends of theball storing barrels, stop structures which are in stop cooperation with the ball storing barrels in the axial direction are arranged on the portions, below the multiple ball storing barrels, in the pitching pipeline, avoidance holes avoiding the fracturing balls are formed in the portion where the stop structures are located, and an opening allowing the ball storing barrels to leave the pitchingpipeline is formed in the side wall of the pitching pipeline; the continuous pitching device further comprises a reciprocating pushing mechanism used for pushing the ball storing barrels out of the opening, the reciprocating pushing mechanism of the continuous pitching device can push the pushing the ball storing barrels away from the pitching pipeline in the reciprocating movement process, then continuous pitching of the fracturing balls can be achieved, continuity of construction is ensured, and the construction efficiency is improved; the phenomenon that constructors enter a high pressure area can be avoided, and the safety risks are lowered to the maximum extent.

Owner:SINOPEC SSC +1

Continuous sacrificial anode casting technology

InactiveCN106756155AIntrinsic Quality GuaranteeAvoid enteringMolten metal conveying equipmentsCasting moldContinuous casting

The invention belongs to the field of sacrificial anode casting, and particularly relates to a continuous sacrificial anode casting technology. The technology comprises following steps: before-furnace preparing is carried out; base stocks are continuously put in a continuous casting furnace, casting is carried out, and a base stock melt is obtained; when the weight of the base stock melt entering a heat preservation furnace reaches the set value, melt supply is stopped; an alloy element and an aluminum beryllium alloy are added in the base stock melt successively, permanent magnet stirring is carried out, and molten alloy is obtained; standing and sampling are carried out, after it is analyzed that qualification is achieved, the molten alloy is poured into a casting mold, cooling is carried out, and a finished product is obtained. Continuous putting of the base stocks can be achieved, meanwhile, the amount of the base stock melt needed by casting of one sacrificial anode in the heat preservation furnace can be effectively controlled, and therefore continuous production is achieved, and the traditional sacrificial anode casting efficiency is improved; through the manner that the alloy is element is firstly added, and after the alloy element and the base stock melt are melted, the aluminum beryllium alloy is added, crystalline grains are refined, and the produced sacrificial anode is uniform in component and free of cracks.

Owner:SHANDONG DERUI ANTI-CORROSION MATERIAL CO LTD

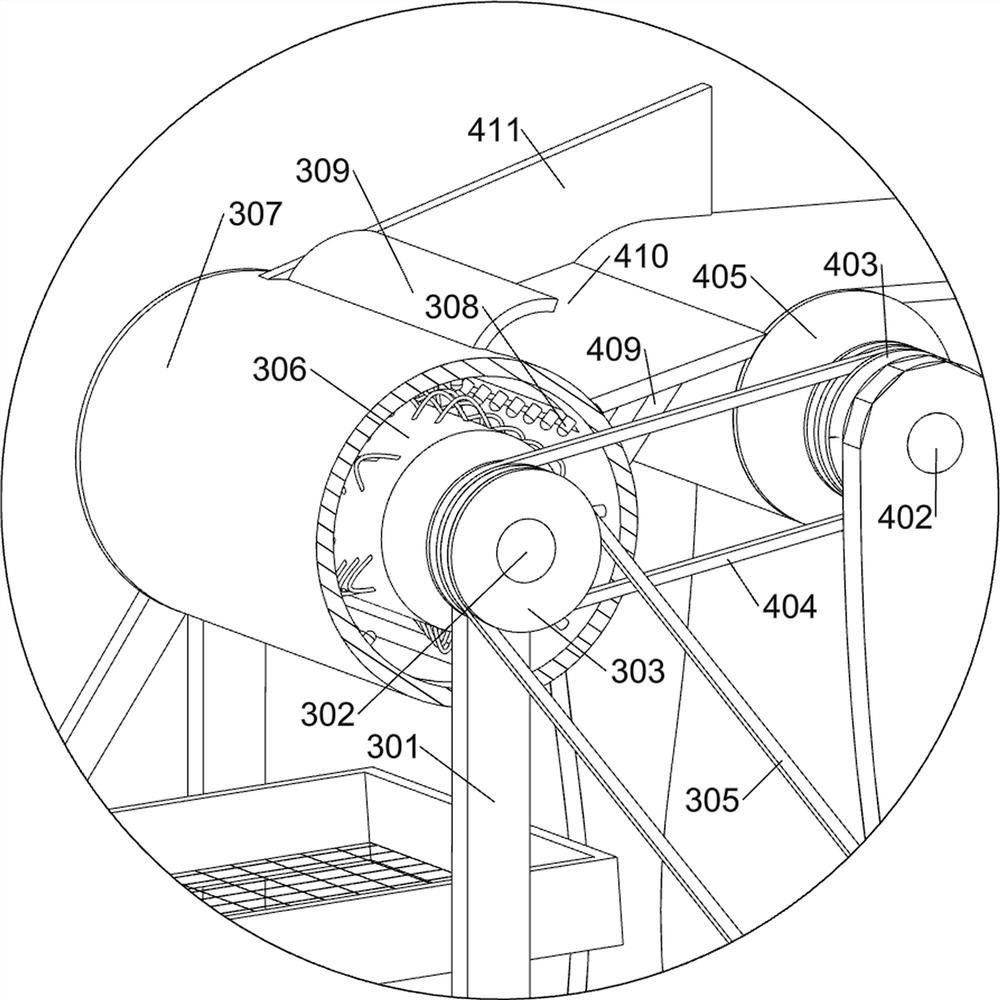

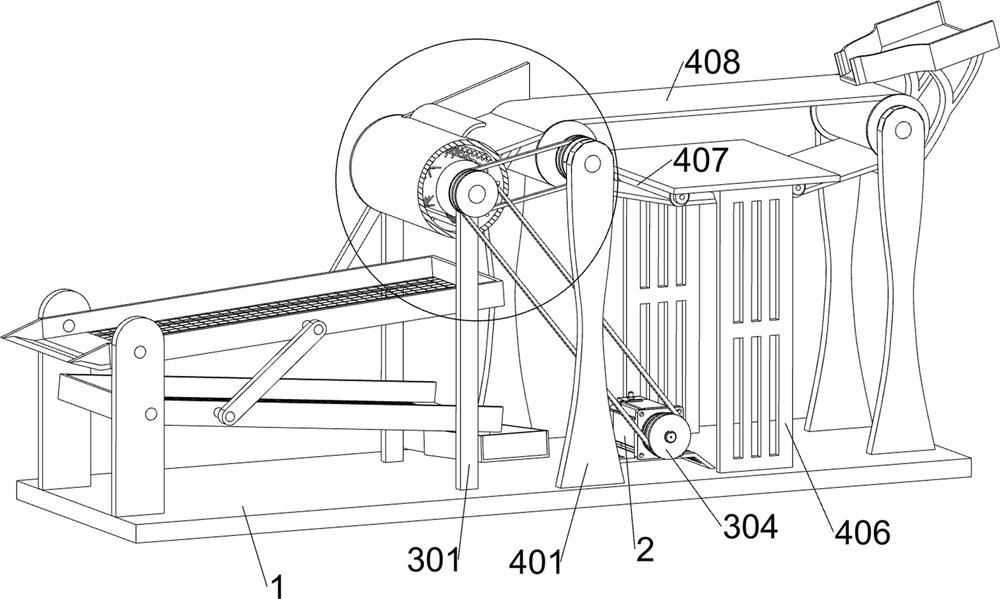

Gorgon fruit shelling device for agricultural production

The invention relates to a shelling device, and especially relates to a gorgon fruit shelling device for agricultural production. The provided can completely squeeze fruits and can also guarantee thecompleteness of the fruits. The shelling device includes a base plate, a servo motor, a shedding assembly, a transmission assembly and a squeezing assembly; the base plate is used for supporting the whole device; the servo motor is arranged on one side on the top of the base plate; the shedding assembly is arranged in the middle part on the top of the base plate; the transmission assembly is arranged on one side on the top of the base plate; and the squeezing assembly is arranged at the upper part of the transmission assembly. Workers firstly put gorgon fruits in a feeding basket, and then start the servo motor, so that the servo motor can drive a sketch plate and a pressing plate to continuously squeeze the gorgon fruits.

Owner:商爱英

Food waste treatment system

InactiveCN111410258AWell mixedAchieve continuous deliveryWater/sewage treatment by sorptionActivated carbonElectric machinery

The invention belongs to the field of garbage treatment, and especially relates to a food waste treatment system. Aiming at the existing sewage in garbage, sewage is purified by adopting a mode of manually putting activated carbon for adsorption, the method is time-consuming and labor-consuming, delivery efficiency, slow sewage purification, the use requirements cannot be met. Proposed now is thefollowing scheme, the system comprises a treatment box of a hollow structure, a rotating hole, a rotating groove, a rotating column, stirring blades, an L-shaped plate, a motor, a feeding box, a rectangular plate, a limiting groove, a mounting hole, a mounting rod, a cam, a chute and a sliding block. The food waste treatment system has the advantages that the sewage treatment device is simple in structure and convenient to operate, activated carbon can be quickly and conveniently fed into sewage in the treatment box, the sewage and the activated carbon can be uniformly stirred, the purification efficiency can be improved, and the automation can be realized.

Owner:人与自然环保生物科技(南京)有限公司

Lathe automatic feeder

ActiveCN108608012BImprove securityImprove efficiencyAuxillary equipmentMetal working apparatusControl systemWaste management

The invention discloses a lathe automatic feeding machine. According to the technical scheme, the lathe automatic feeding machine comprises a machine body and further comprises a pressing device whichis arranged on the machine body and used for pressing and positioning bar materials, a spiral discharging device which is arranged on one side of the pressing device and used for conveying the bar materials onto the pressing device, and a pushing device which is parallel and right aligned to the pressing device and used for pushing the bar materials onto a lathe; a waste discharging system used for discharging bar material waste is arranged between the pushing device and the pressing device; the pressing device, the spiral discharging device, the pushing device and the waste discharging system are all electrically connected with a PLC control system; and a detection device which is electrically connected to the PLC control system and used for detecting whether the waste is discharged or not is arranged below the waste discharging system. The lathe automatic feeding machine has the effects that the bar materials are conveyed one by one, the machining safety and efficiency are improved,and the waste can be conveniently gathered and processed.

Owner:科德普(厦门)自动化科技有限公司

Ticket card conveying mechanism of entrance ticket selling equipment

InactiveCN112419513AWill not bend and wearAchieve continuous deliveryArticle feedersMachines for printing and issuing ticketsTicketSoftware engineering

The invention discloses a ticket card conveying mechanism of entrance ticket selling equipment, which comprises a ticket card taking-out mechanism, a conveying mechanism, a shunting mechanism and a read-write mechanism, and is characterized in that the ticket card taking-out mechanism is arranged to realize continuous conveying of a single ticket card, so that the phenomenon of blockage of the existing ticket card conveying mechanism is avoided; due to the arrangement of the conveying mechanism, the ticket cards are prevented from being bent and abraded in the conveying process; by arranging asliding block and a first spring, when the ticket card taking-out mechanism conveys the ticket card, a driving roller and a driven roller can be in good friction contact with the ticket card, and theticket card can be smoothly guided out of the ticket guide opening on the premise that it is guaranteed that the ticket card is not bent or abraded. Through arrangement of the shunting mechanism, theclassification processing of the ticket cards is realized.

Owner:王野

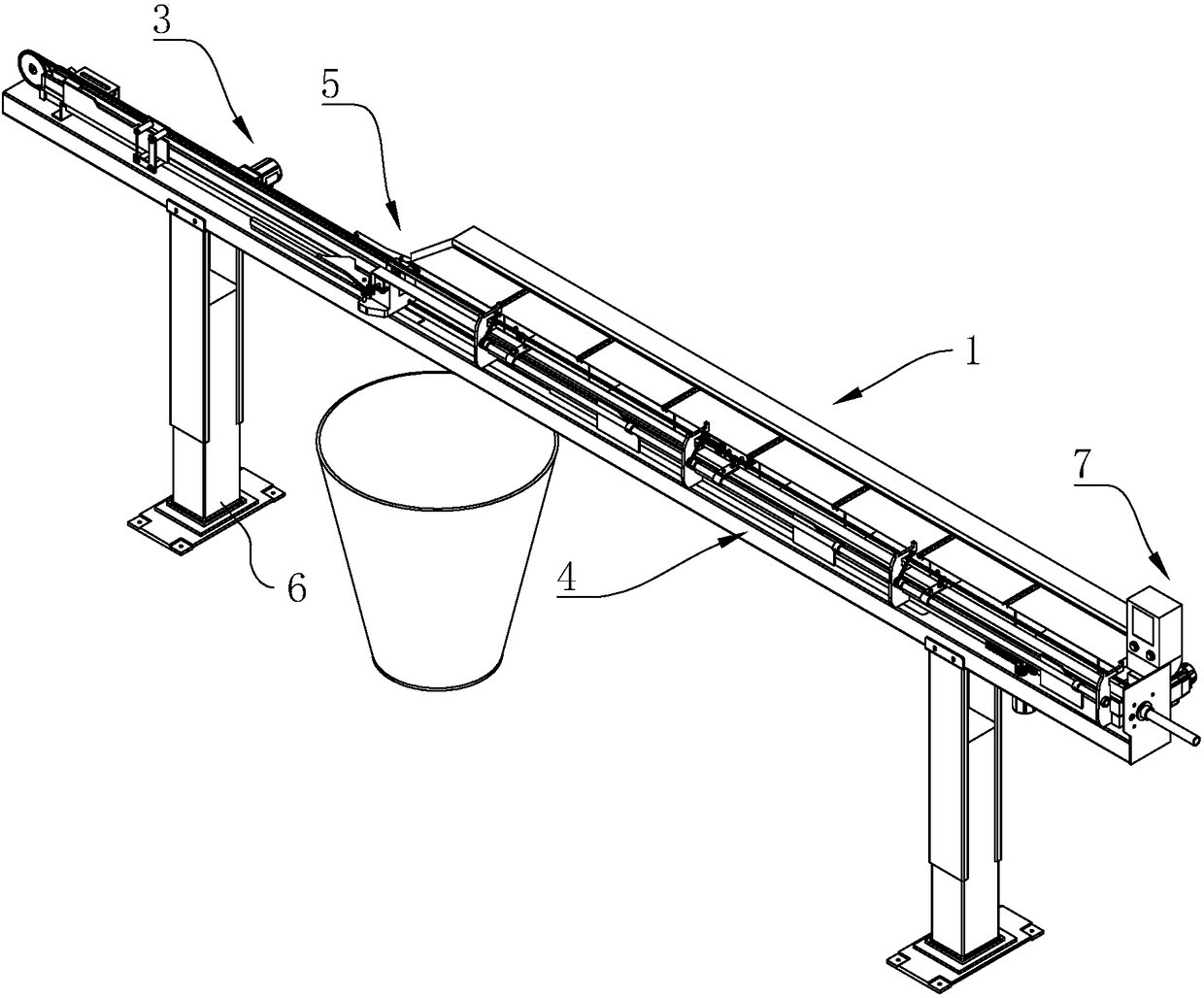

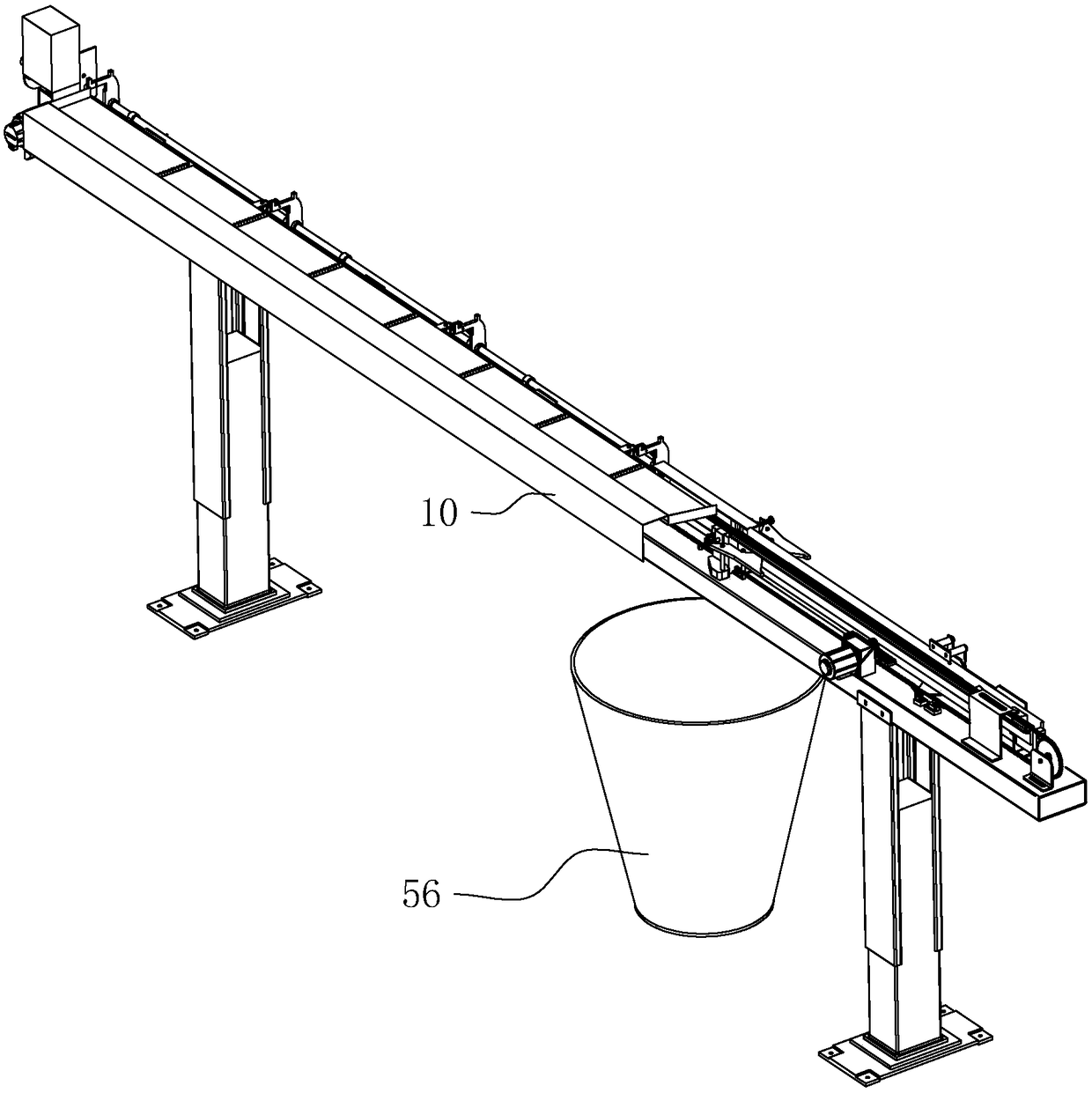

Chain box-supplying component

InactiveCN105197304AAchieve continuous deliveryContinuous Packaging ProductionPackagingDrive shaftCarton

The invention relates to a box-supplying component, in particular to a chain box-supplying component and belongs to the technical field of medicine equipment. The chain box-supplying component comprises a base, a first side plate, a second side plate and a third side plate are fixed to the base at intervals, the first side plate, the second side plate and the third side plate are each provided with a chain wheel chain conveying component, the three chain wheel chain conveying components are jointly connected to a transmission shaft, and the transmission shaft drives the three chain wheel chain conveying components to rotate synchronously. One end of the transmission shaft is connected with a push rod of a driving air cylinder through a one-way bearing, and the driving air cylinder is fixed to the base; a movable guardrail is arranged at the outer side of the third side plate, and the movable guardrail is connected with the base through a width adjusting component. By means of the chain box-supplying component, box bodies can be conveyed continuously, packaging production of large infusion products can be conducted continuously, and production efficiency is improved; a guide plate plays the role of guiding for advancing of carton boxes, and reaching-in-place accuracy of the carton boxes is improved.

Owner:无锡众创自动化科技有限公司

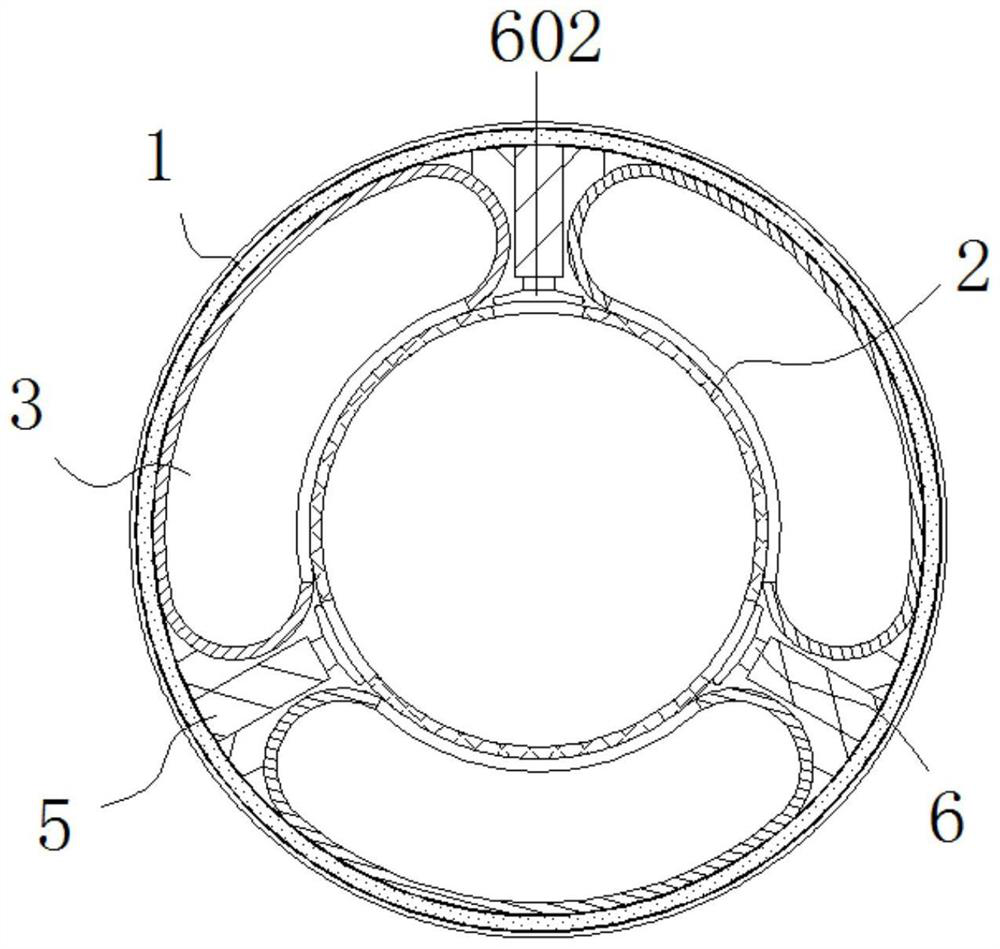

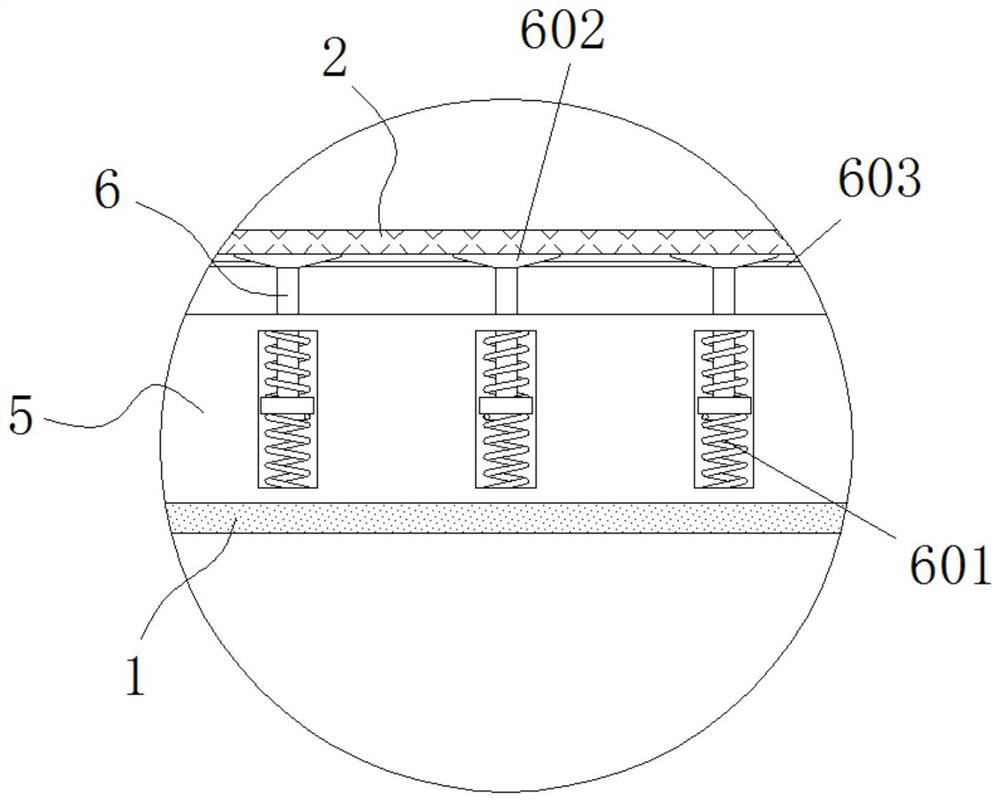

Squeezing type peristaltic pump

PendingCN114658638AReduce axial frictionReduce fatigue damagePositive displacement pump componentsFlexible member pumpsPeristaltic pumpReciprocating motion

The extrusion type peristaltic pump comprises a body, a transmission part, a first pressing unit, a second pressing unit, a limiting plate and a hose, the limiting plate is fixedly connected with the body, and the hose comprises a first branch pipe and a second branch pipe; the first branch pipe is arranged between the limiting plate and the first pressing unit, and the first pressing unit is driven by the transmission part to do reciprocating motion and used for pressing the first branch pipe; the second branch pipe is arranged between the limiting plate and the second pressing unit; the second pressing unit is driven by the transmission part to reciprocate and used for pressing the second branch pipe, the first branch pipe and the second branch pipe are alternately pressed, and the hose continuously discharges liquid. According to the scheme, the first branch pipe and the second branch pipe alternately extrude and convey the fluid to the gathering pipe, finally continuous conveying of the fluid in the gathering pipe is achieved, fluid cutoff is avoided, the flow stability in the fluid conveying process is improved, and pulsation is reduced.

Owner:BAODING LEAD FLUID TECH

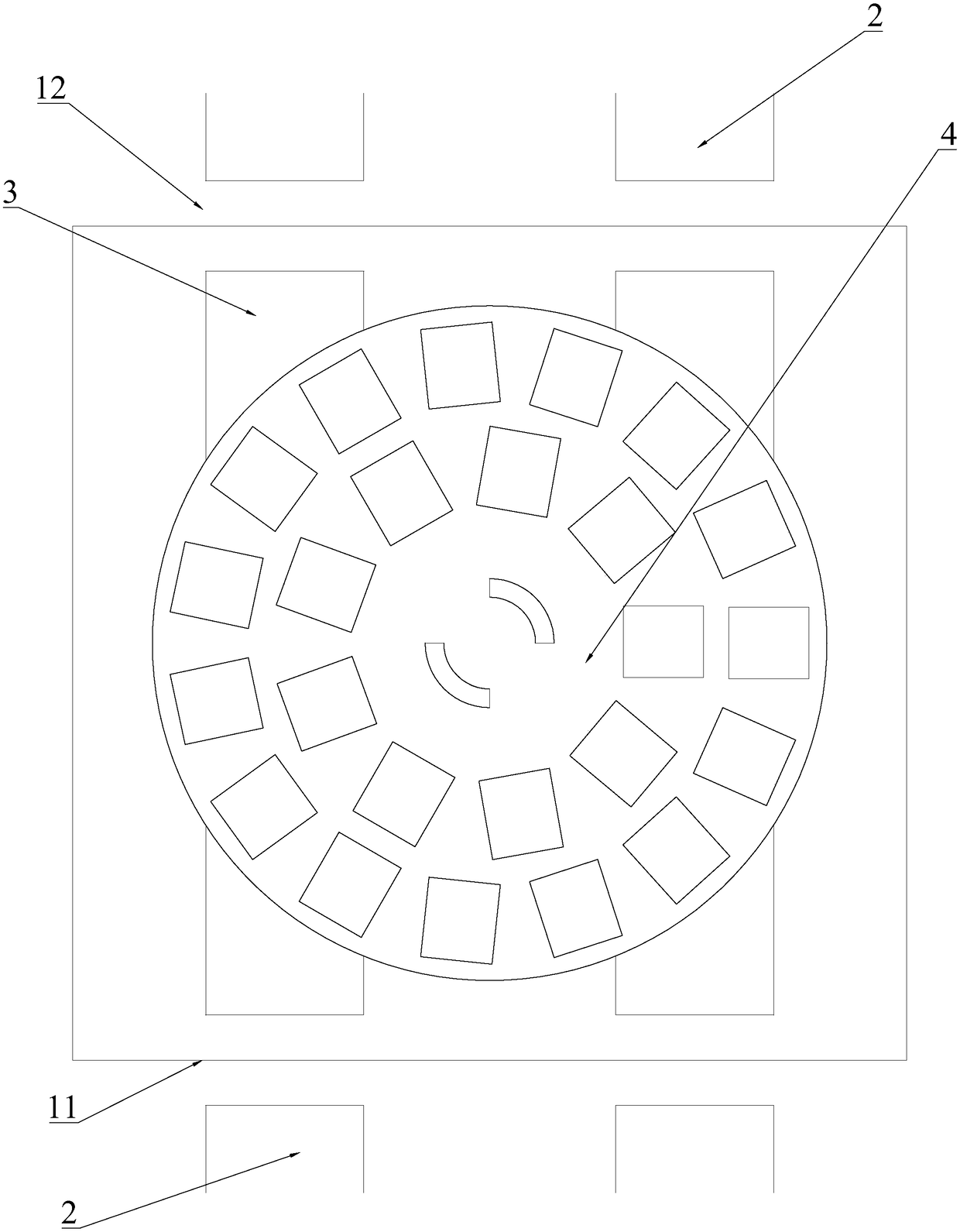

Optical lens centrifugal cleaning equipment

ActiveCN108889698BAchieve continuous deliveryImprove efficiencyFlexible article cleaningCleaning using liquidsEngineeringOptic lens

The invention discloses a centrifugal cleaning device for optical lenses. The key point of the technical solution is that it includes a casing, an inlet and an outlet are arranged on the casing, and two conveying conveyors arranged in parallel are arranged at the inlet and the outlet. Rails, the housing is provided with auxiliary rails, and also includes a loading carousel arranged in the housing, the loading carousel includes an upper disc body and a lower disc body, the lower part of the upper disc body and the upper part of the lower disc body It is the storage surface, and it also includes a rotating shaft located on the lower side of the loading turntable, and a spray assembly located on the upper side of the loading turntable. The track is disengaged, after the rotating shaft rises, the rotating shaft passes through the lower plate body and the spray assembly passes through the upper plate body. The rotating shaft is connected with the spray assembly and is limited in the circumferential direction. The spray assembly is provided with several nozzles. The nozzles are arranged radially along the loading carousel.

Owner:江西省长益光电有限公司

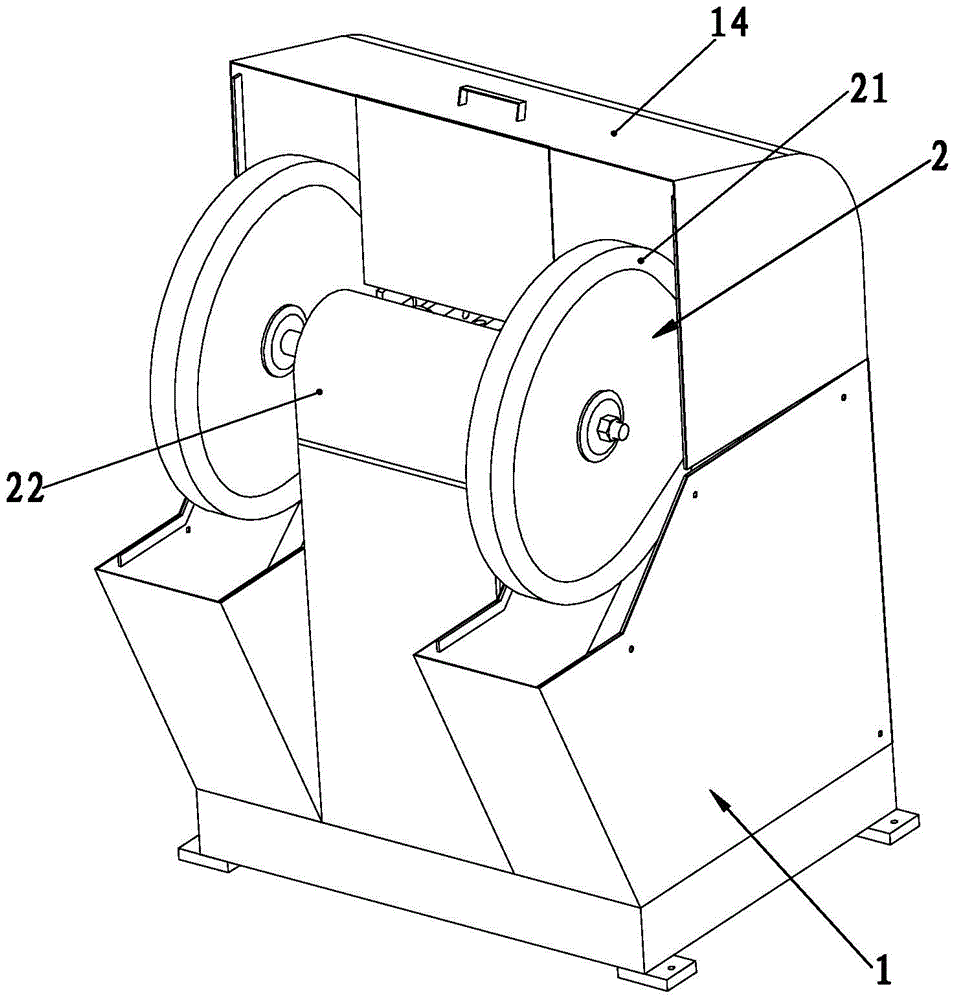

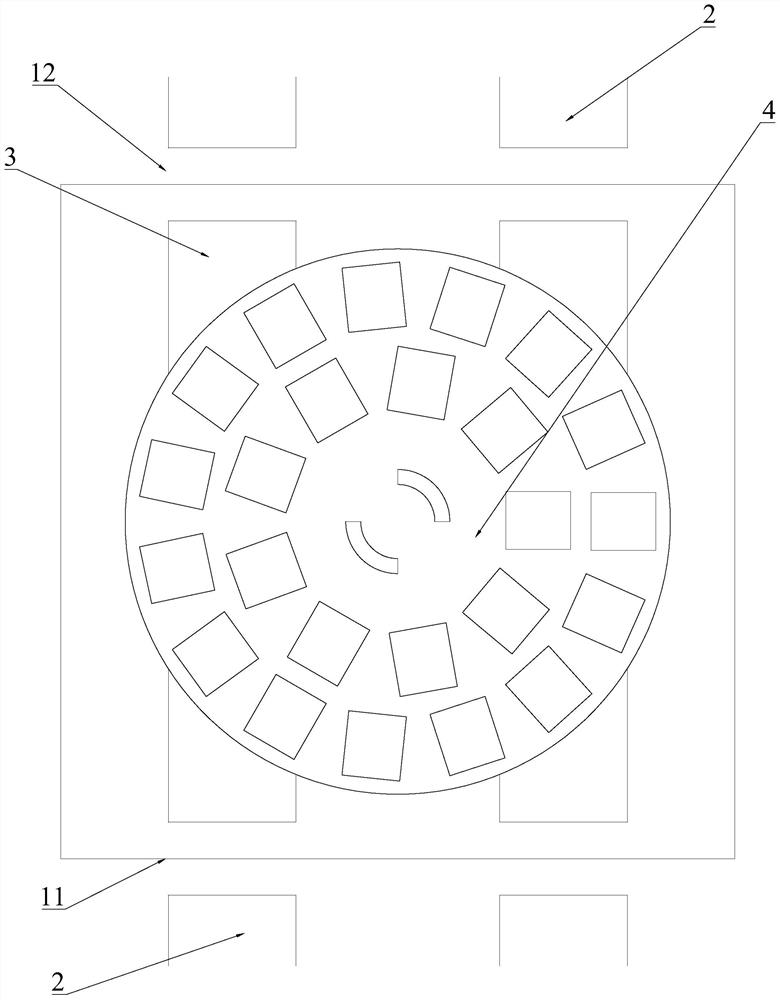

polisher

ActiveCN103934743BEasy to operateOperation time savingPolishing machinesGrinding/polishing safety devicesWaxDrive motor

The invention relates to a polishing device, in particular to a polisher which comprises a machine frame, a polishing wheel arranged on the machine frame, a polishing textile arranged on the polishing wheel in a sleeved mode and a drive motor driving the polishing wheel. A wax stone clamping seat and a clamping mechanism arranged on the wax stone clamping seat are arranged on the machine frame and located at the polishing wheel. The wax stone clamping seat is provided with a wax stone continuous conveying mechanism matched with the clamping mechanism. The polisher is convenient to operate, saves time, and improves polishing quality.

Owner:ZHEJIANG KINGSTONE HOUSEWARES

Optical lens centrifugal cleaning machine

ActiveCN108889697BAchieve continuous deliverySpraying does not directly affectFlexible article cleaningCleaning using liquidsEngineeringOptic lens

The invention discloses a centrifugal cleaning machine for optical lenses, which can not only ensure comprehensive cleaning on the surface of the lens, but also reduce the possibility of scratches, and does not require manual loading and unloading. The housing is provided with an inlet and an outlet, and the inlet and outlet are provided with conveying tracks, and also includes a loading carousel and a rotating mechanical arm arranged in the housing, and also includes a rotating shaft located on the lower side of the loading carousel. A spray assembly is fixedly connected to the rotating shaft, and the spray assembly includes a spray body fixedly connected to the shaft and nozzles arranged along the circumference of the spray body, and the spray body is detachably connected to the loading carousel. The spraying body and the carrying carousel are circumferentially limited, and the rotating mechanical arm is used to grab the carrying carousel so that it is located on the conveying track or the spraying body.

Owner:江西省长益光电有限公司

A cotton degreasing device

ActiveCN109092780BEasy to stackNot easy to damageTreatment involving filtrationMultistage water/sewage treatmentWater flowSewage

The invention provides a cotton degreasing device and relates to the technical field of cotton degreasing. The cotton degreasing device comprises a mounting base. An electric telescopic rod is arranged at the top of the mounting base, and a boiling-off barrel is arranged inside the mounting base; and a stirring disc is movably mounted at the end, away from the top of the mounting base, of the electric telescopic rod, a first sliding block is arranged inside the stirring disc and movably connected with the stirring disc through a first spring, and a stirring rod is movably mounted at the end, away from the first spring, of the first sliding block. According to the cotton degreasing device, the bottom section of the boiling-off barrel is in a trapezoidal shape, and thus cotton is accumulatedat the bottom of the boiling-off barrel advantageously; the stirring rod can be changed with changing of the bottom barrel diameter of the boiling-off barrel, and with discharging of sewage, the cotton is further gathered to the bottom through the action of a water flow, so that the cotton is dehydrated more thoroughly; and meanwhile, the stirring rod is not liable to be damaged and can further recover to the original shape easily.

Owner:MEDWELL MEDICAL PROD

Optical lens centrifugal cleaning device

ActiveCN108889698AAchieve continuous deliveryImprove efficiencyFlexible article cleaningCleaning using liquidsEngineeringLens plate

The invention discloses an optical lens centrifugal cleaning device. The technical scheme of the optical lens centrifugal cleaning device is that the optical lens centrifugal cleaning device comprisesa shell; an inlet and an outlet are arranged on the shell; both the inlet and outlet are provided with two conveying tracks in parallel arrangement; the shell is internally provided with an auxiliarytrack, a carrier turntable comprising an upper disc body and a lower disc body, a rotating shaft located on the lower side of the carrier turntable, and a spray assembly positioned on the upper sideof the carrier turntable; the lower portion of the upper disc body and the upper portion of the lower disc body are a storage surface; the rotating shaft moves up and down along the axial direction; when the rotating shaft rises and drags the carrier turntable, the carrier turntable is separated from the auxiliary track; after the rotating shaft rises, the rotating shaft passes through the lower disc body, and the spray assembly passes through the upper disc body; the rotating shaft and the spray assembly are connected and conduct circumferential limit; the spray assembly is provided with multiple nozzles which are in radial setting along the carrier turntable.

Owner:江西省长益光电有限公司

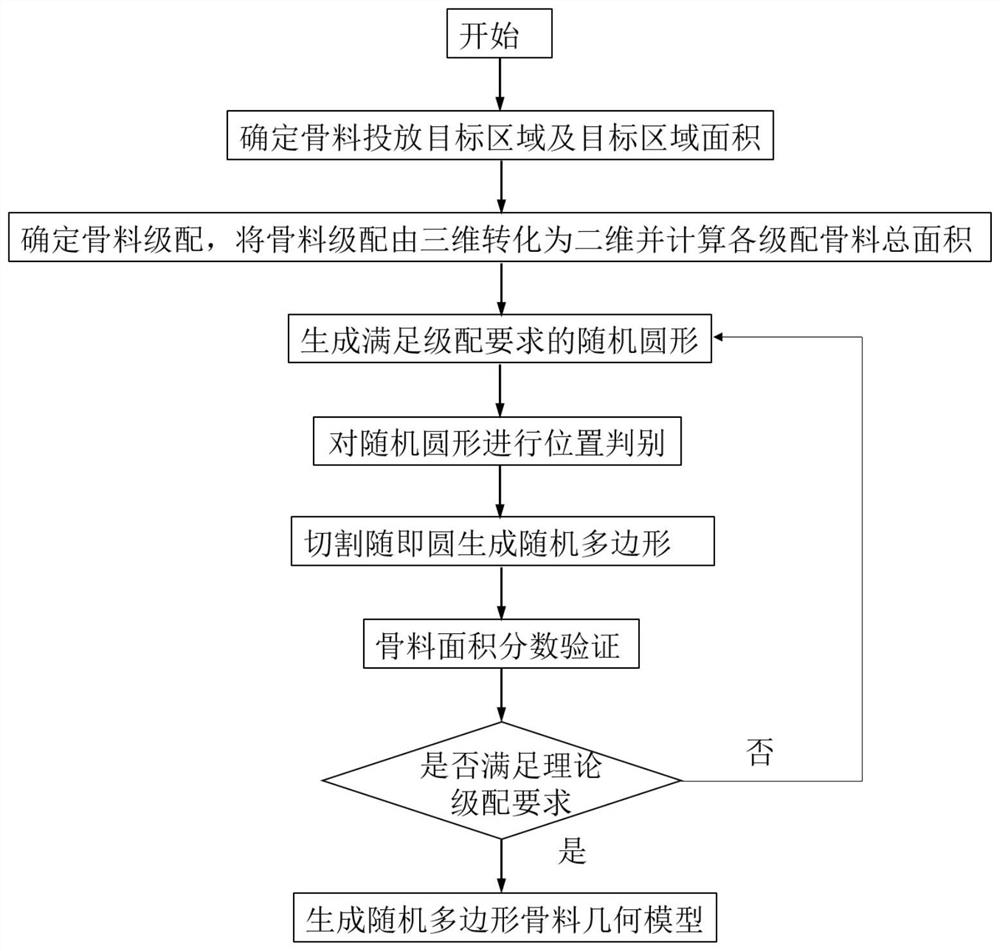

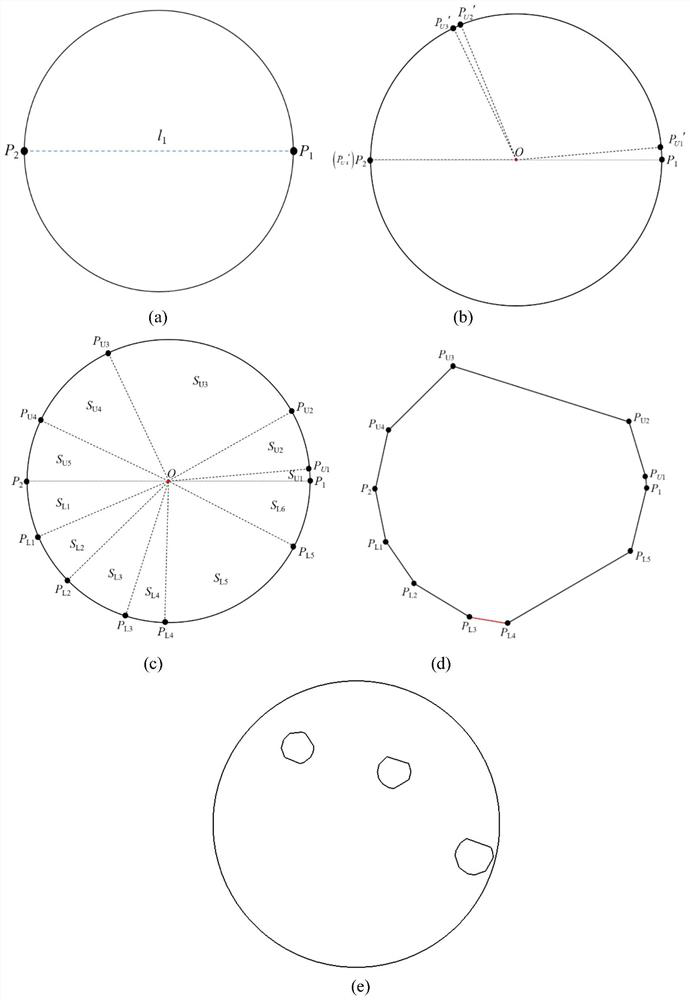

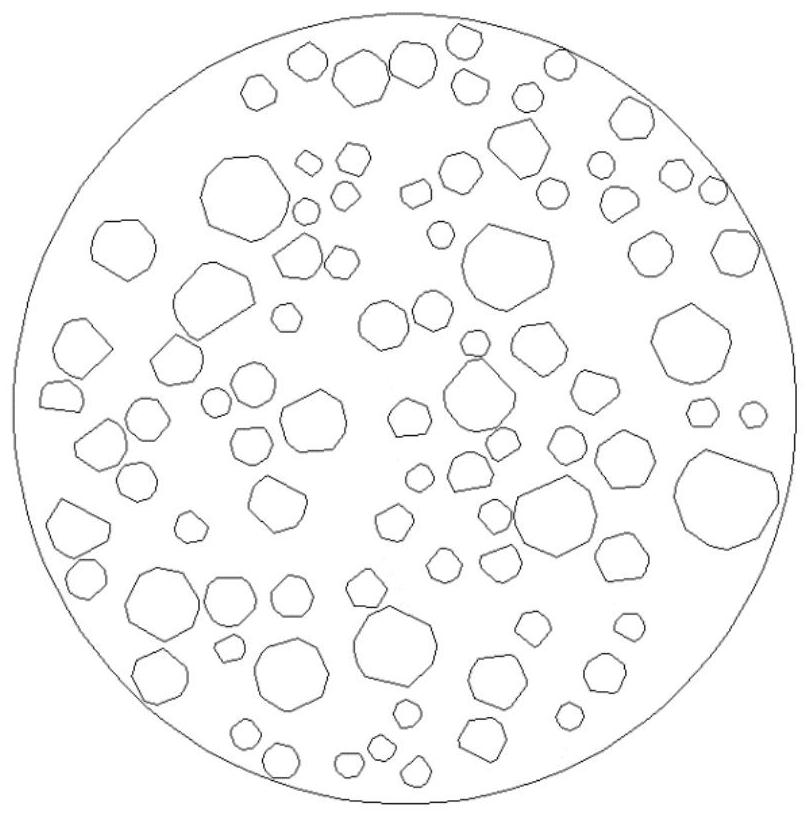

A stochastic generation method for graded distribution of two-dimensional concrete aggregates

ActiveCN113158454BAchieve continuous deliveryAchieve accurate generation of graded allocationsGeometric CADSolid waste managementClassical mechanicsGeometric modeling

The invention is a random generation method of a multi-gradation two-dimensional concrete aggregate model. The steps are as follows: 1. Determine the two-dimensional target area for aggregate delivery and the area of the target area; Step 2. Determine the three-dimensional gradation of aggregates, and calculate the appearance of aggregates with different gradations on the two-dimensional delivery target area according to the Lavalvin formula. The probability of , as the two-dimensional gradation of aggregates, combined with the total area of the target area determined in step 1, calculate the theoretical value of the aggregate area at all levels; step 3, in the target area, according to the gradation from large to small In the order of grading, random polygons that meet the requirements of two-dimensional grading are generated as aggregate geometric models. Using this method to generate random polygonal concrete aggregates can ensure that the aggregate particle size is within the design gradation range. The difference between the content of the aggregates at all levels and the theoretical calculation value is no more than 4%, and the accurate generation of the polygonal random aggregates can be realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Optical lens centrifugal cleaning machine

ActiveCN108889699BAchieve continuous deliveryPrecise and exquisite structureFlexible article cleaningCleaning using liquidsEngineeringOptic lens

Owner:江西省长益光电有限公司

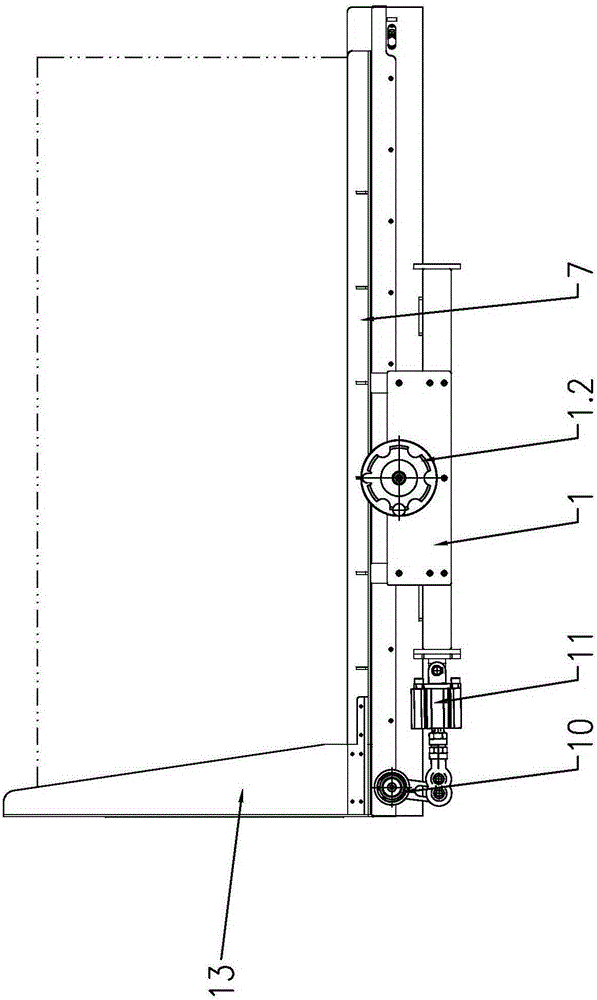

Release paper emptying device in multilayer adhesive tape production line

InactiveCN101992537AAchieve continuous deliveryGuaranteed continuityOther domestic articlesProduction linePulp and paper industry

The invention discloses a release paper emptying device in a multilayer adhesive tape production line, which is capable of emptying release paper continuously and comprises a production line bracket and a synthesized conveyor belt arranged on the production line bracket, and at least one pair of release paper cradles are arranged below the synthesized conveyor belt by the production line bracket. In the invention, by arranging at least one pair of release paper cradles, continuous emptying of release paper can be realized by alternatively emptying, thus preventing the shockproof tape production line from shutdown due to release paper replacement, and ensuring continuous production.

Owner:张家港爱科思汽车配件有限公司

Anti-blocking and anti-explosion rubber oil conveying pipe

InactiveCN114658931ATo achieve the purpose of diversion transportationAvoid cloggingPipe elementsRigid pipesMechanical engineeringOil pressure

The invention discloses an anti-blocking and anti-explosion rubber oil conveying pipe which comprises an outer pipe, an inner pipe and an inner pipe. The supporting plates are distributed on the inner side wall of the outer pipe at equal angles, and the outer pipe is located between the adjacent secondary pipes; the secondary pipe is of an arc-shaped structure, the outer wall of the secondary pipe is fixedly connected with the outer pipe and the lining rubber pipe, and a hole channel is formed in the side, close to the lining rubber pipe, of the secondary pipe; the observation windows are installed in the middle of the outer wall of the outer pipe in an embedded mode, the observation windows correspond to the secondary pipes one to one, and oil liquid discharging assemblies are arranged at the connecting tail ends of the secondary pipes and the connector and the connecting tail ends of the lining rubber pipe and the connector. According to the anti-blocking and anti-explosion rubber oil conveying pipe, the auxiliary oil liquid discharging channel is arranged, when local blocking occurs in the pipe, the auxiliary oil liquid discharging channel can be opened by pushing and bypassing the blocking position through oil pressure, the purpose of guiding and conveying oil liquid is achieved, and the oil liquid pipe is prevented from being blocked and exploded.

Owner:刘阳

Optical lens centrifugal cleaning machine

ActiveCN108889699AAchieve continuous deliveryPrecise and exquisite structureFlexible article cleaningCleaning using liquidsEngineeringLens plate

The invention discloses an optical lens centrifugal cleaning machine which not only ensures that a lens surface is completely cleaned and has a small possibility of scratches but also needs no manualloading and unloading. The technical scheme of the optical lens centrifugal cleaning machine is that the optical lens centrifugal cleaning machine comprises a shell; an outlet and an inlet are disposed on the shell; both the outlet and the inlet are provided with two conveying tracks which are disposed in parallel; the shell is internally provided with an auxiliary track, a carrier turntable, a rotating shaft and a spray assembly, wherein the rotating shaft is located on the lower side of the carrier turntable, and the spray assembly is positioned on the upper side of the carrier turntable; the rotating shaft moves up and down along the axial direction; when the rotating shaft rises, the carrier turntable is separated from the auxiliary track to be in contact with the spray assembly, the rotating shaft and the carrier turntable conduct circumferential limit, and the rotating shaft or the carrier turntable drives the spray assembly to rotate; the spray assembly is provided with multiplenozzles which are in radial setting along the carrier turntable.

Owner:江西省长益光电有限公司

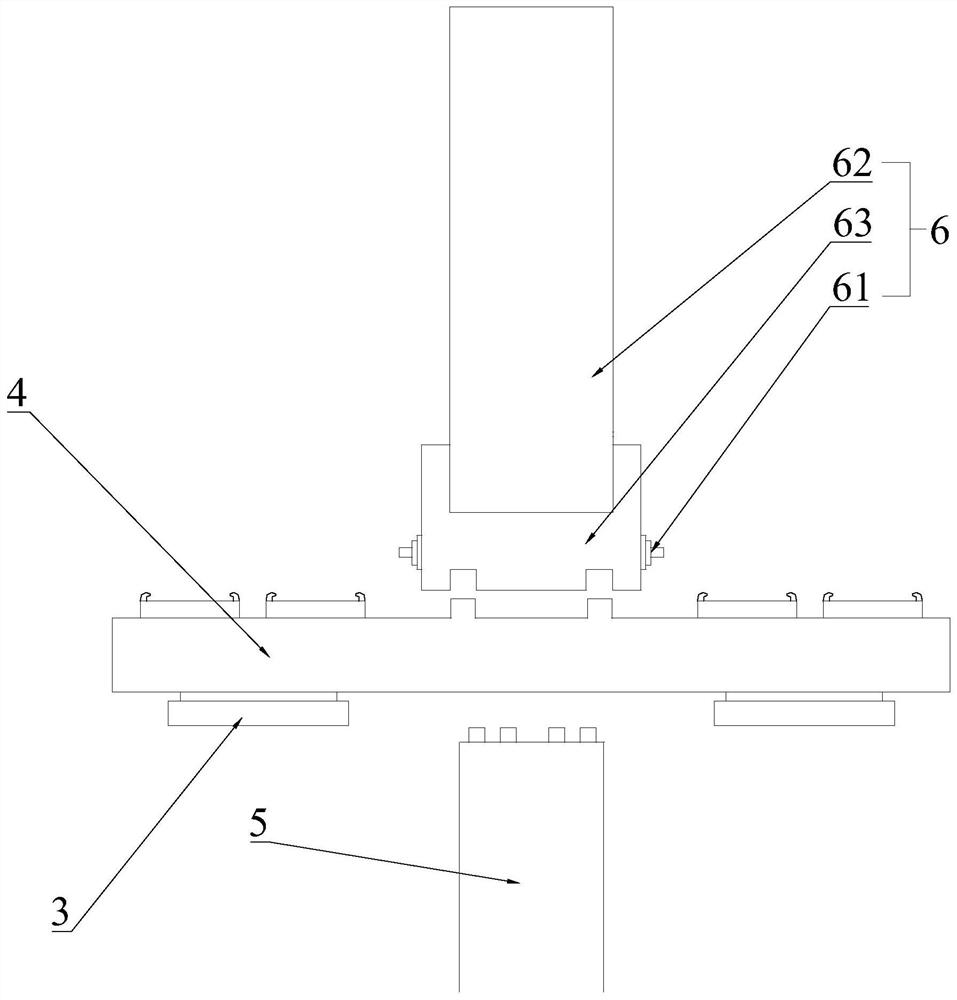

Ultra-thin jacking conveying driving control system

PendingCN113023296AAchieve continuous deliveryImprove delivery efficiencyConveyorsControl devices for conveyorsControl systemClassical mechanics

The invention relates to the technical field of object transfer, and particularly discloses an ultra-thin jacking conveying driving control system. The ultra-thin jacking conveying driving control system comprises a base plate, a first supporting plate, a second supporting plate, a first annular belt, a second annular belt and a first driving part, wherein the first supporting plate and the second supporting plate are arranged on the base plate and are parallel used; the first annular belt and the second annular belt are correspondingly and rotatably arranged on the first supporting plate and the second supporting plate; and the first driving part is used for driving the annular belts to rotate. The first supporting plate is fixedly arranged on the base plate, and a second driving part is used for driving the second supporting plate to get close to or away from the first supporting plate. Two jacking units are correspondingly arranged on the two supporting plates, each supporting plate is provided with a first accommodating hole, each jacking unit comprises a third driving part located in the corresponding first accommodating hole and a supporting plate connected with the output end of the third driving part, and the supporting plates of the two jacking units correspondingly abut against the two ends of supporting objects. The third driving parts are mounted in the first accommodating holes, so that the thickness is reduced, the structural design is simplified, and the miniaturization development trend is met; and the jacking units jack up the objects, the annular belts continuously convey the objects, and the object conveying efficiency is improved.

Owner:DONGGUAN ANDA AUTOMATIC EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com