Patents

Literature

177results about How to "Intrinsic Quality Guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

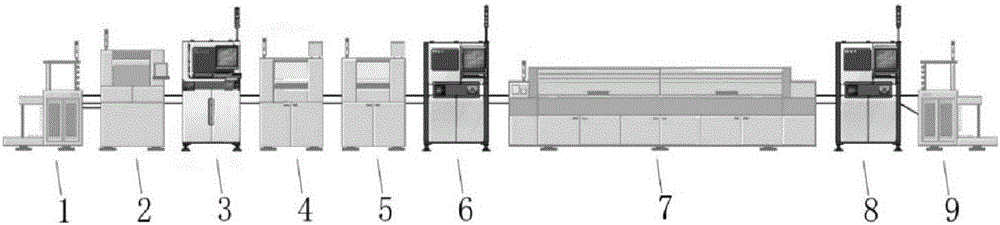

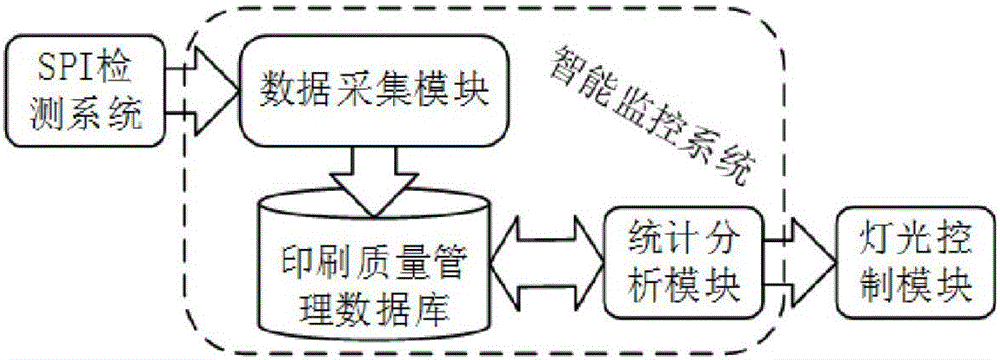

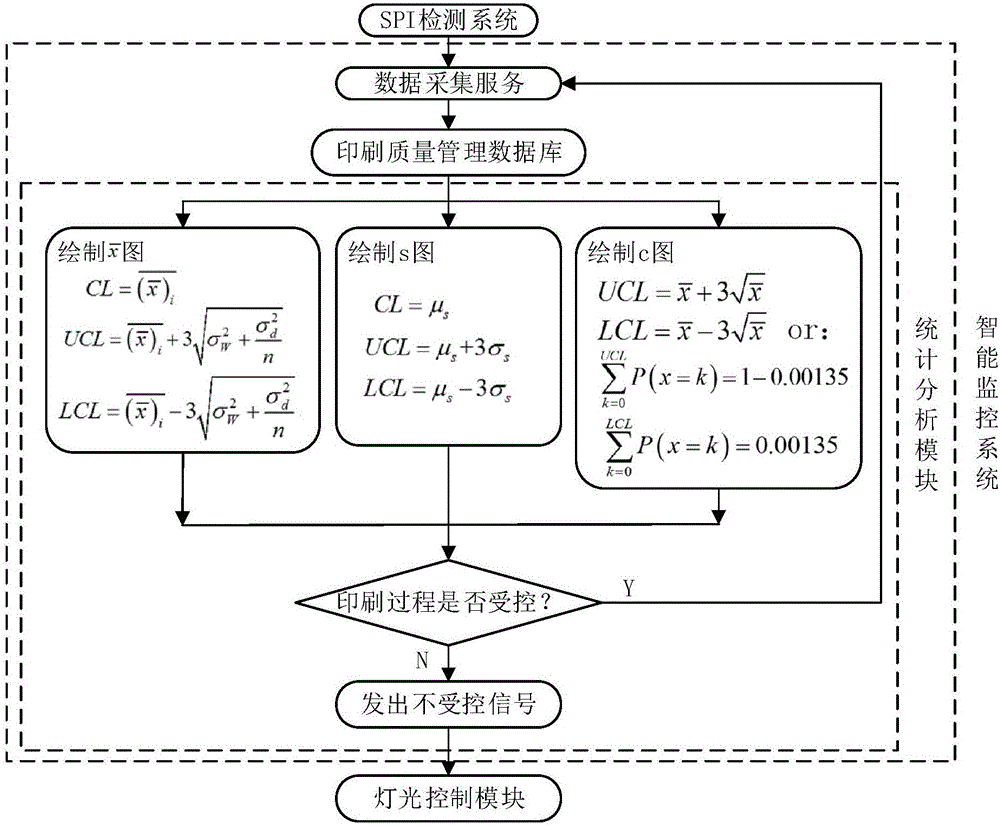

Intelligent monitoring system for quality of PCB solder paste printing process and method

InactiveCN106079892AReduce printing defectsSolve runnabilityTotal factory controlPrinting press partsIntelligent lightingData acquisition

The invention provides an intelligent monitoring system for the quality of a PCB solder paste printing process and a method. The system comprises a data acquisition module, a printing quality management database, a statistical analysis module and a light control module, wherein the data acquisition module is used for performing real-time acquisition of various parameter data of PCB printing solder paste, which is detected by an SPI detection system; the statistical analysis module is used for acquiring and analyzing the data acquired by the data acquisition module, judging whether the quality of the solder paste printing process is controlled or not according to an analysis result, and sending a signal representing that the quality of the printing process is out of control to the light control module when the quality of the solder paste printing process is out of control or tends to be out of control; and the light control module can control different warning lights to give a warning of specific out-of-control conditions. Through the system and the method, the defect that the quality of a printing process cannot be monitored in the prior art is overcome, the printing process can be monitored, and a warning can be given in time when that the printing process is out of control is found so as to reduce defects in solder paste printing.

Owner:CHONGQING UNIV

As-cast state high-carbon high-chromium cast iron and method for producing the same

InactiveCN101173340AIncrease productivitySimple processMolten metal pouring equipmentsWear resistantHigh carbon

The invention relates to an as-cast cast iron with high carbon and high chromium and a preparation method, which belongs to the technical field of metal wear-resistant material. The invention is characterized in that the composing components of the cast iron with high carbon and high chromium are (in weight percentage): 4.5 to 5.5 C, 22.5 to 30.8 Cr, 3.0 to 5.0 V, 0.7 to 1.2 Mn, 0.2 to 0.5 Nb, 0.5 to 1.0 Ti, 0.08 to 0.20 Mg, 0.05 to 0.20 Na, 0.05 to 0.20 RE, Si of less than 1.0 and Fe as well as unavoidable trace impurities for the rest, and Cr-to-C ratio is no less than 5.0 and no more than 5.6; the as-cast cast iron with high carbon and high chromium of the invention can be produced in an electric stove with the tapping temperature of 1440 to 1480 DEG C, and is inoculated with ferrovanadium particles after tapping; combined modification treatment is done with rare earth magnesium alloy and sodium salt; the casting temperature of hot metal is 1350 to 1380 DEG C; and the cast iron with high carbon and high chromium can be directly used after stress relief annealing treatment at the temperature of 200 to 280 DEG C. The invention has the advantages of no need of high-temperature heat treatment, low energy cost, short production period, good casting performance, high hardness and excellent abradability.

Owner:BEIJING UNIV OF TECH

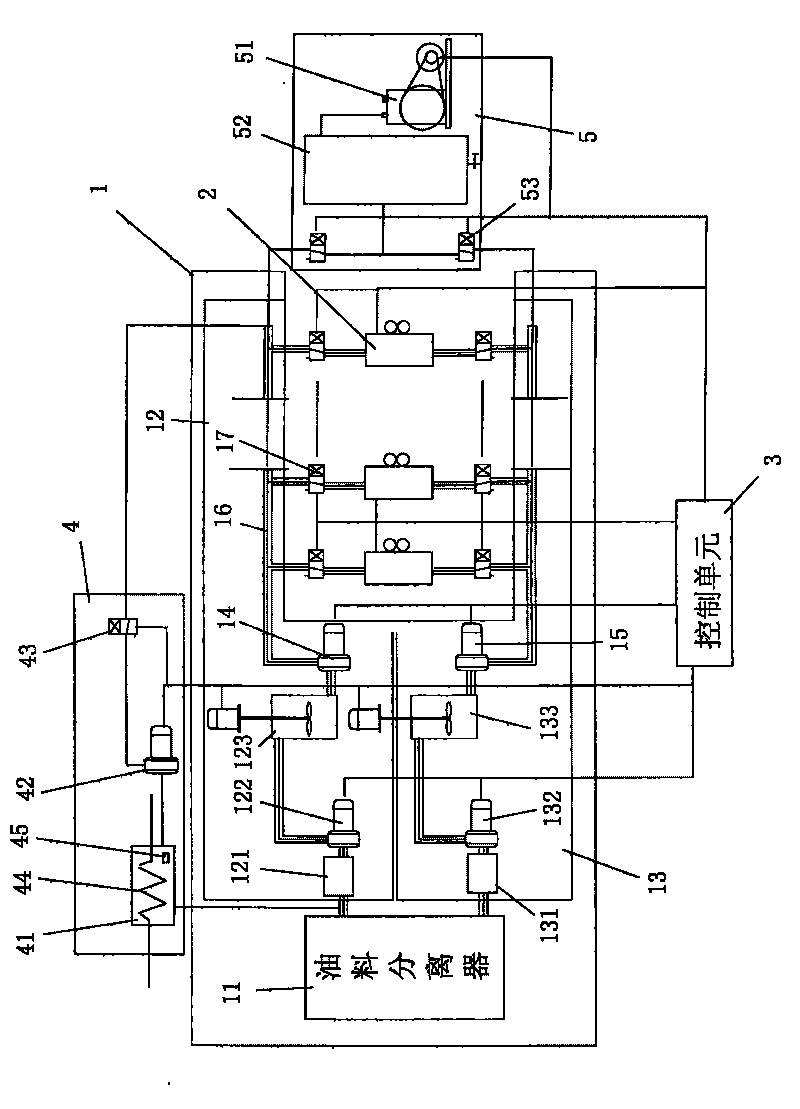

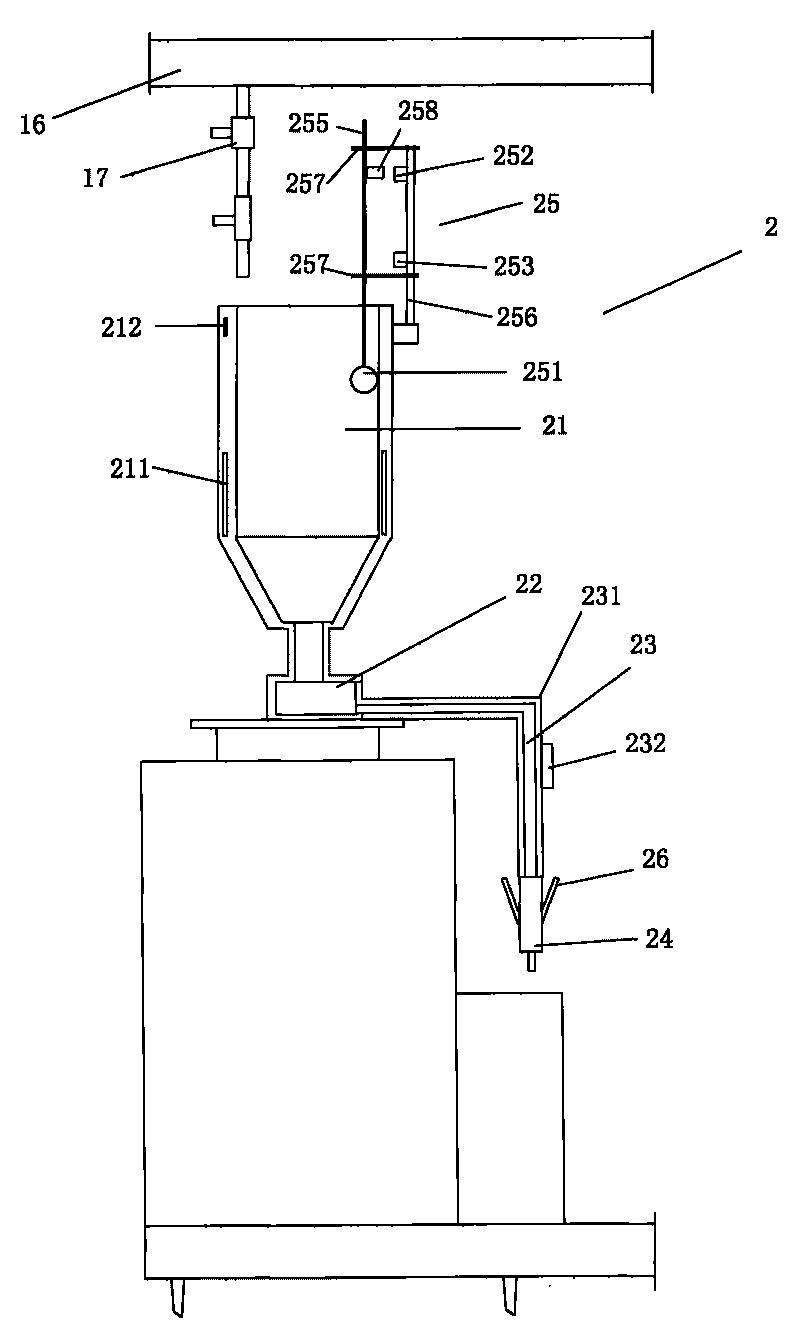

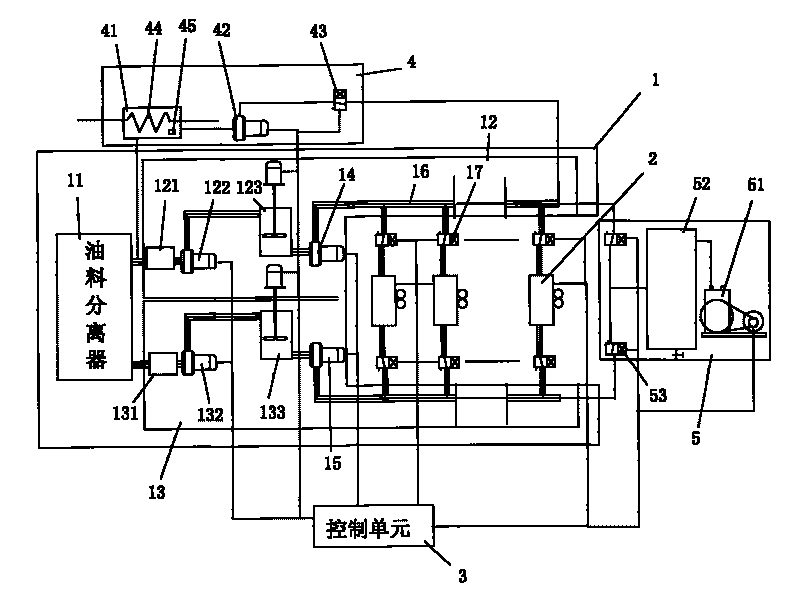

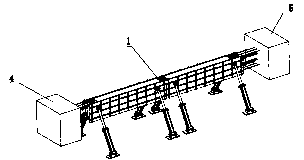

Fully-automatic packaging production line of beef tallow hot pot seasoning

ActiveCN101734382AAutomate the packaging processTake the time easilyPackaging automatic controlLiquid materialFully automaticBeef Tallow

The invention relates to an automatic packaging production line, in particular to a fully-automatic packaging production line of a beef tallow hot pot seasoning. The production line comprises a feeding and conveying device, a packaging machine and a control unit, wherein the packaging machine is a horizontal type fully-automatic constant temperature packaging machine; the feeding and conveying device comprises a tallow separator, a material feeding device and a tallow feeding device connected with the tallow separator, a booster pump respectively connected with the material feeding device and the tallow feeding device and an insulating conveying pipe provided with an insulating interlayer; the insulating conveying pipe is connected with the packaging machine through an electromagnetic valve; a heating device is arranged and connected with the feeding and conveying device; and the control unit is electrically connected with the horizontal type fully-automatic constant temperature packaging machine, the feeding and conveying device and the heating device so as to control the feed, the temperature, the quantitative loading and the packaging of materials and the cleanness of production line equipment. The production line realizes the packaging automation of the beef tallow hot pot seasoning, improves the productivity and avoids pollutions to products by manual operations.

Owner:四川天味食品集团股份有限公司

acidified straw

ActiveCN104128354BIntrinsic Quality GuaranteeAvoid chemical reactionsSolid waste disposalChemical reactionAdditive ingredient

The invention discloses an acidified straw. The main point of the technical scheme is that the acidified straw ingredients are composed of straw, attapulgite clay, magnesium oxide, sulfuric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methyl Composed of cellulose and sodium carbonate. The acidified straw ingredients are input into a mill for grinding, and the powder after grinding is the acidified straw. The production method of the acidified straw can avoid the chemical reaction between sulfuric acid and instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate; the straw is a new product that has been carbonized after being acidified and roasted. The utilization rate of the straw can be improved, not only can bring good economic benefits, environmental benefits and social benefits, but also can realize turning waste into wealth. It has the characteristics of good adsorption, thixotropy, thermal stability, plasticity, cohesiveness and high dry compressive strength. The acidified straw is suitable for the production of environmental protection materials, garden materials, building materials and foaming agent products.

Owner:江苏世澳非金属应用科技有限公司

Self-connecting type and high-strength seamless steel tube for rope coring drill rod, as well as manufacturing method thereof

InactiveCN103276297AIntrinsic Quality GuaranteeReduce surface cracksDrilling rodsMetallic material coating processesCoringSteel tube

The invention relates to a self-connecting type and high-strength seamless steel tube for a rope coring drill rod. The seamless steel tube is characterized by comprising components in percentage by weight as follows: 0.38%-0.43% of C, 0.17%-0.35% of Si, 0.70%-0.90% of Mn, P smaller than or equal to 0.015%, S smaller than or equal to 0.010%, 090%-1.10% of Cr, 0.15%-0.25% of Mo. Cu smaller than or equal to 0.10%. Ni smaller than or equal to 0.10%, AS smaller than or equal to 0.015%, Sn smaller than or equal to 0.015%, Sb smaller than or equal to 0.010%, Pb smaller than or equal to 0.008%, Bi smaller than or equal to 0.010%, and the balance of Fe. The seamless steel tube has high strength. The invention further relates to a manufacturing method of the seamless steel tube.

Owner:浙江新纪元管业科技有限公司

Making process of quick-frozen Chinese yam

InactiveCN1421153ADoes not lower mucusGuarantee the inner qualityFood preservationFood preparationDisinfectantLarge intestine

The making process of quick-frozen Chinese yam includes soaking in disinfectant liquid to kill bacteria, peeling, cutting into blocks, soaking in color protecting liquid for maintaining color, soaking in disinfectant liquid to kill bacteria again, quick freezing, coating with ice and further freezing. The present invention has the advantages of no decrease in Chinese yam grume viscosity, no change in color and high bactericidal effect.

Owner:徐州天马敬安食品有限公司

Preparation technology of non-oriented high grade silicon steel

InactiveCN101745794AReasonable chemical compositionIntrinsic Quality GuaranteeTemperature control deviceMetal rolling arrangementsReduction rateAcid washing

The invention relates to a preparation technology of non-oriented high grade silicon steel, in which a hot rolled steel coil without edge crack in full length is obtained via controlling the smelting ingredients and the hot rolling process of the steel; the cold-rolling uncoiling temperature is increased to keep the temperature of strip steel always above the brittle transition point thereof; and the acid washing--5 stand cold continuous rolling process is adopted to reasonably distribute the reduction rate of each cold rolling pass, and processing heat generated when the strip steel is rolled is utilized to realize the cold continuous rolling of the non-oriented high grade silicon steel. Compared with the conventional 5-pass rolling process of a single-stand reversing mill, the production efficiency of the cold rolling process is increased by nearly 20 times, the investment of equipment, personnel and raw materials is greatly reduced, the production cost is greatly reduced, the phenomenon of edge crack of a hot rolled plate is eliminated, and the surface quality and the product yield of the hot rolled plate are increased.

Owner:ANGANG STEEL CO LTD

Method for preparing extractive of dangshen polysaccharide as active ingredient, and preparation produced from the extractive

InactiveCN1696159ASufficient sources of medicineAdvanced quality standardOrganic active ingredientsCapsule deliveryMedicineBULK ACTIVE INGREDIENT

A process for extracting the codonopsinose used to prepare the codonopsinose medicines in the form of infusion, capsule, syrup, or oral liquid includes cutting the pilose asiabell root, decocting 2-3 times, collecting filtered decoction, vacuum concentrating, cooling, centrifugal separation, drying the deposit, and pulverizing.

Owner:叶美曾

Production for quick-freezing Chinese yam powder

InactiveCN1613365ADoes not reduce viscosityGuarantee the inner qualityFood shapingFruits/vegetable preservation by freezing/coolingQuick FreezeLarge intestine

A process for preparing the quickly frozen yam particles includes such steps as immersing raw yam in disinfecting liquid, peeling, cutting into segments, immersing in color protecting liquid and then in disinfecting liquid, granulating, loading in plastic bags and quick freezing.

Owner:胡传银 +2

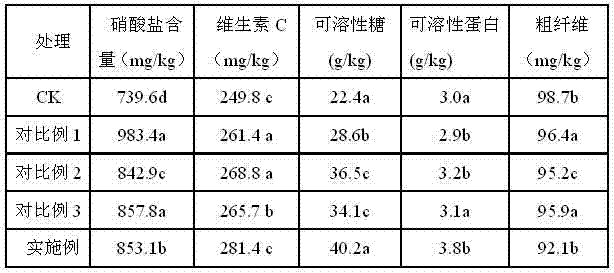

Polymorphic nitro-compound fertilizer and production method thereof

The invention discloses a polymorphic nitro-compound fertilizer, relating to the technical field of agricultural fertilizers. The polymorphic nitro-compound fertilizer comprises the following raw materials in parts by weight: 30-150 parts of urea, 160-600 parts of nitramine phosphorus, 0-120 parts of ammonium sulfate, 180-250 parts of potassium sulphate, 100-200 parts of monoammonium phosphate and 1-10 parts of medium and micro fertilizers. The polymorphic nitro-compound fertilizer is produced by mixing, granulating and cooling the raw materials. The polymorphic nitro-compound fertilizer adopts scientific proportion, has complete nutrition, can continuously nourish crops at gradient so as to be more beneficial to the full absorption of the vegetable crops, and can remarkably promote the growth and high and stable yield of the crops, thus having strong market competitiveness.

Owner:STANLEY AGRI GRP CO LTD

Method for preparing quick-freezing burdock

InactiveCN1640273AGuarantee the inner qualityIntrinsic Quality GuaranteeMeat/fish preservation by freezing/coolingFruits/vegetable preservation by freezing/coolingLarge intestineChemistry

The present invention relates to a preparation method of quick-frozen burdock. Said preparation method includes the following steps: soaking burdock in sterilizing liquor to make sterilization, peeling, cutting to obtain burdock block, soaking said burdock block in colour-protecting solution to make colour protection, then further soaking said burbock block in the sterilizing liquor to make sterilization, quickly freezing, ice-coating and further freezing so as to obtain said invented finished product burdock block.

Owner:胡传银 +2

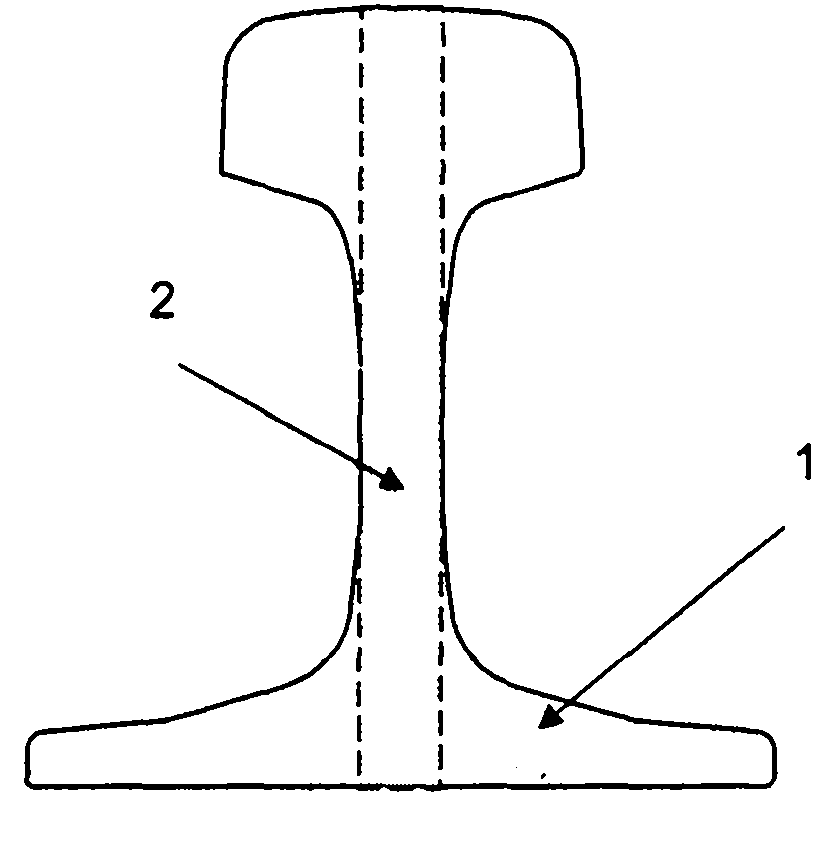

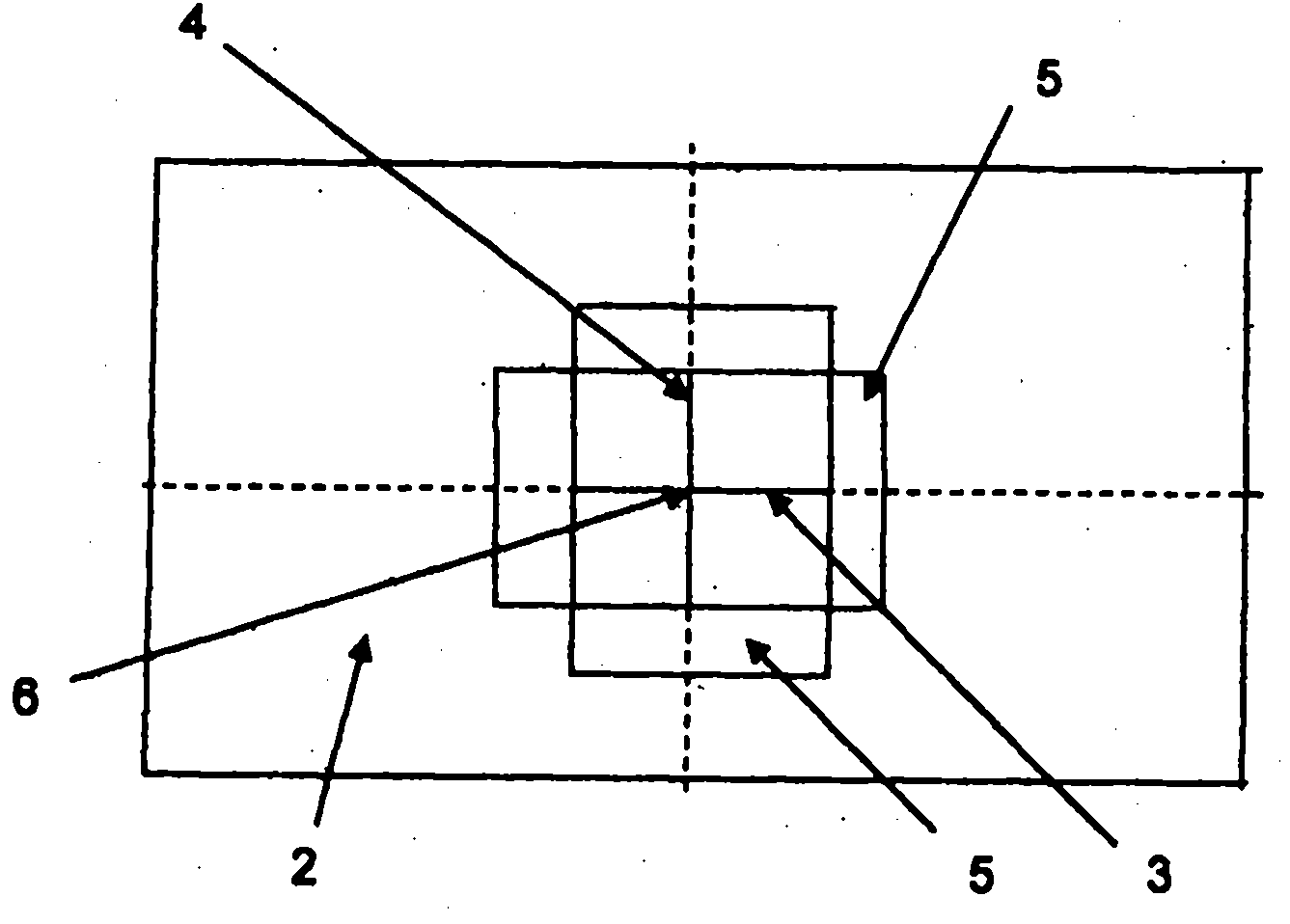

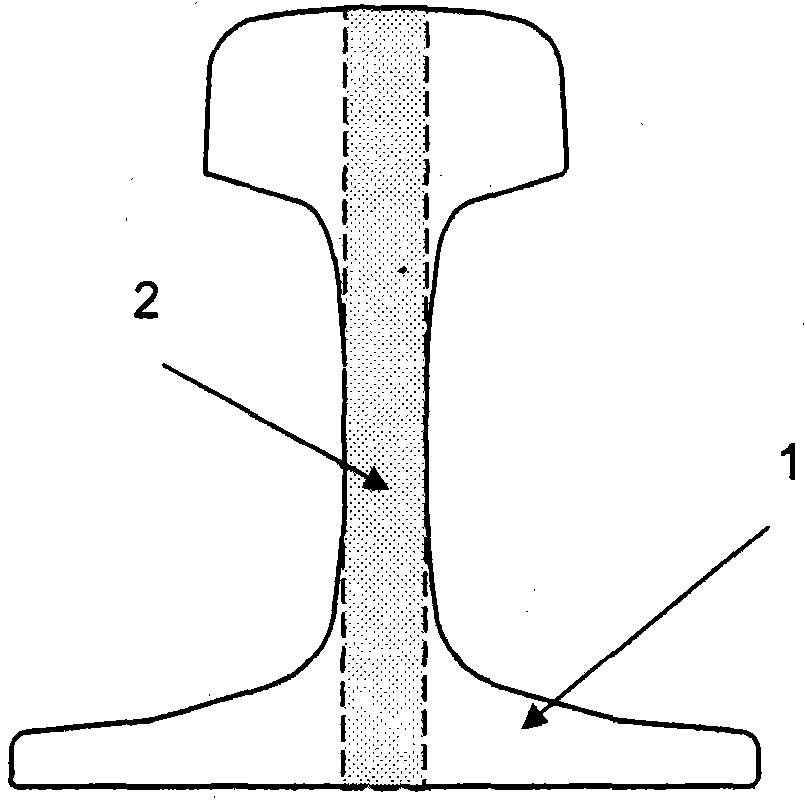

Flaw precise positioning method for steel rail ultrasonic flaw detection

ActiveCN101995434AReduce damage rateIntrinsic Quality GuaranteeAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationTest sampleEngineering

The invention discloses a flaw precise positioning method for steel rail ultrasonic flaw detection. In the method, a steel rail to be tested is processed into a plate sample of which the thickness is the same as that of the rail waist, a detection route in which the directions of two wheels are vertical is adopted, the central point of a flaw source of the steel rail is determined, and the flaw point is detected and analyzed by a linear cutting method; and thus, an ultrasound probe is in complete fit with the test sample, the detection accuracy is improved, the hit rate and accuracy of the positioning of the central point of the flaw source are increased, detection result offset caused by the offset of the central point is avoided. In addition, the linear cutting mode is used for dissecting the flaw source of the steel rail accurately and the data on the central point of the flaw source and the flaw type can be obtained by further detection and analysis, so an accurate detection basis is provided for improving the quality of the steel rail; and by corresponding control measures, the flaw rate of the steel rail is lowered effectively and the internal quality of the steel rail is assured.

Owner:ANGANG STEEL CO LTD

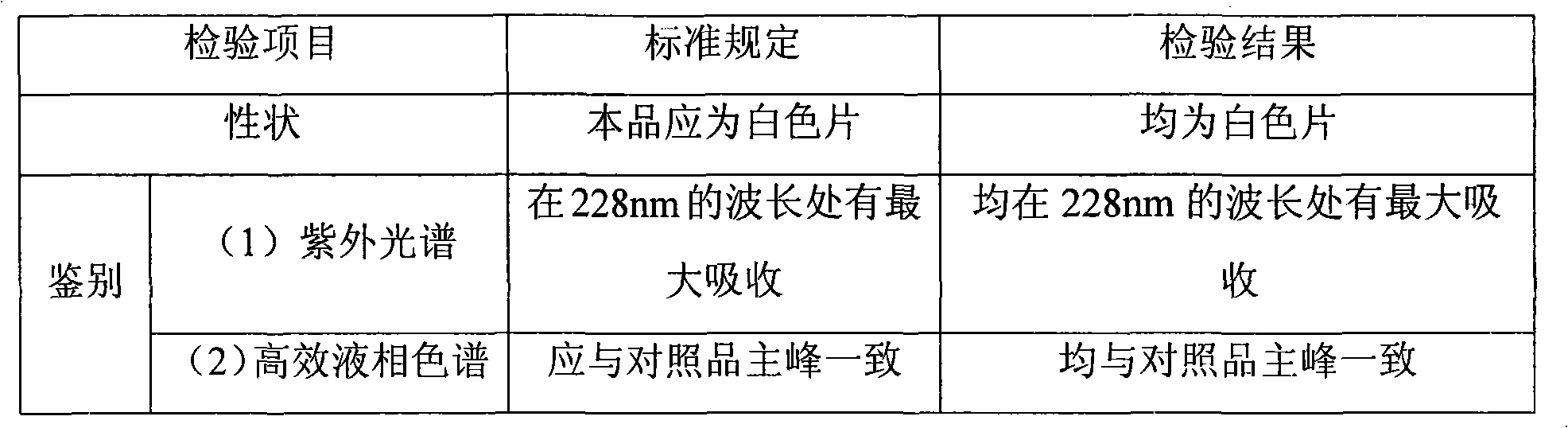

Preparation method of glimepiride tablet

InactiveCN101342146ASolve hydrophobicitySolve insolubleMetabolism disorderSulfonylurea active ingredientsDissolutionVolume concentration

The invention relates to a glimepinride tablet preparation method, which comprises 1) glimepinride and microposer silica gel are ground with a micronizaion method, and the mixture powder of micronized glimepinride and microposer silica gel is obtained after passing through a screen of 80 to 100 mesh; wherein, the weight ratio of the glimepinride and microposer silica gel is 1: 1; 2) the mixture powder obtained in the step 1) is mixed with filling agent, disintegrant, lubricant, bond and 30 percent to 40 percent by volume concentration of ethanol solution for 15 minutes to 20 minutes in normal temperature, and passes through a screen with 18 to 24 meshes to obtain the particles. The particles adopts micronization technique to increase the surface area of slightly soluble main drug to facilitate glimepinride pulverization so that the wettability of the surface of the powder particles is improved and the dissolution of the raw medicine in tablets and the quality stability of the product during storage time are improved.

Owner:上海天赐福生物工程有限公司

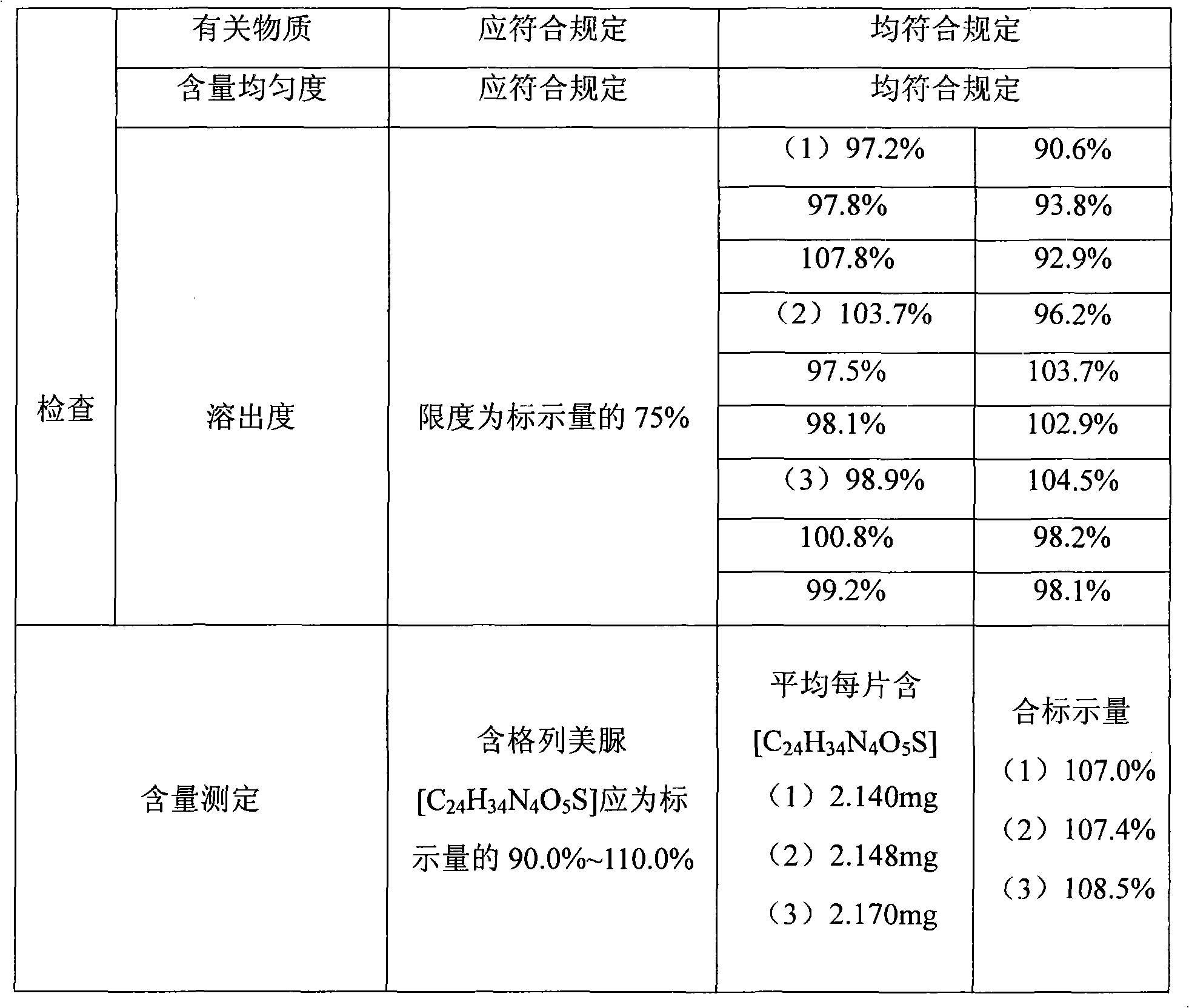

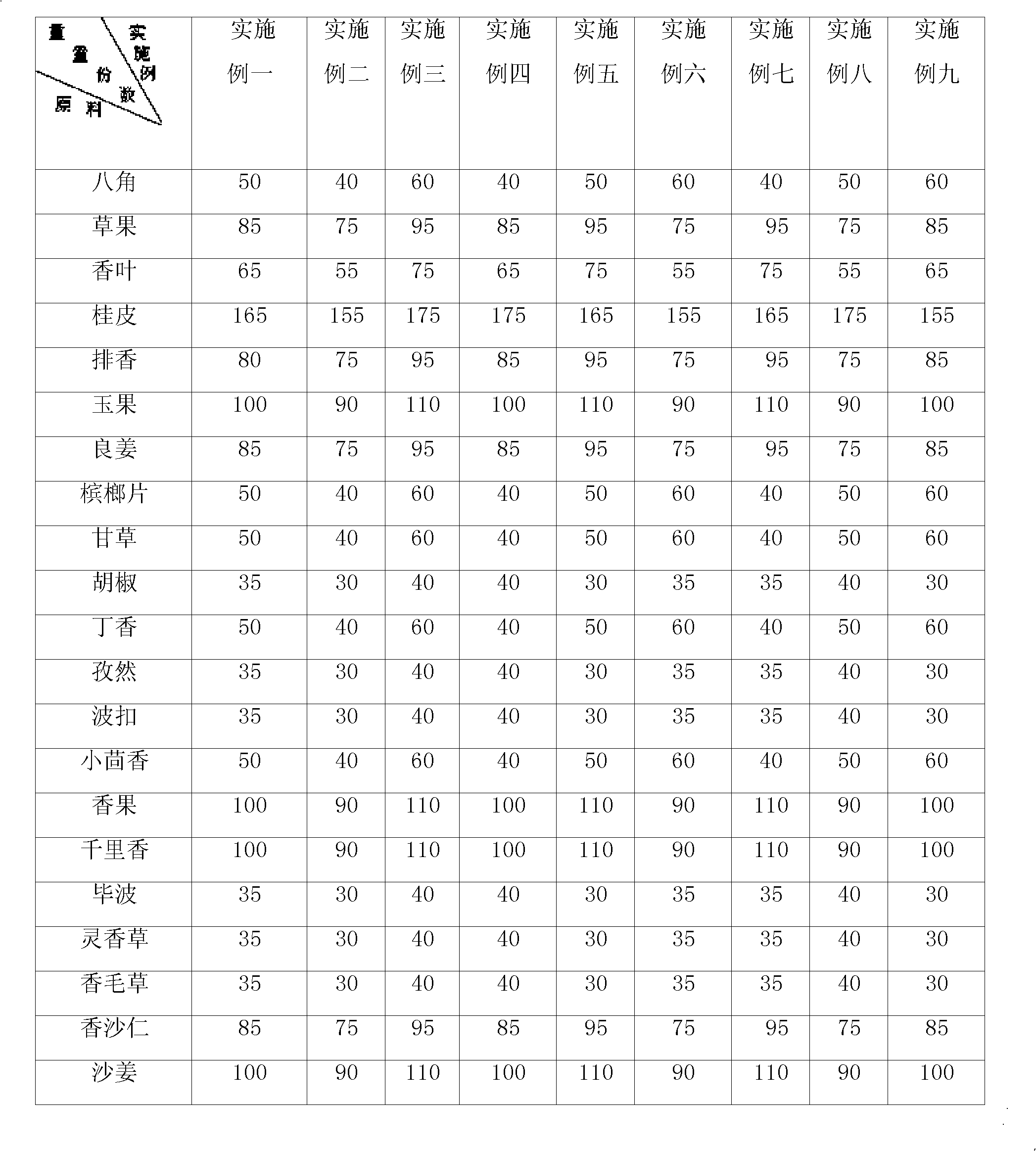

Edible brine and preparation method thereof

InactiveCN101536762AOvercome the disadvantages of storage intoleranceIncrease salesFood preparationCompound aFlavor

The invention discloses an edible brine and a preparation method thereof, which relates to a brine and a preparation method thereof. The edible brine is natural edible brine which is prepared by compounding a composition A and a composition B according to the weight proportion of 1:1.5-2.5, wherein the composition A is prepared by mixing and boiling chives oil and soycheese according to the weight proportion of 3-5:1, and the chives oil is prepared by mixing and boiling vegetable oil, chopped scallion pieces containing root and parsley; the composition B is spice sauce solution; the preparation method comprises the following steps: firstly the composition A is prepared, then the composition B is prepared, finally the composition A and the composition B are mixed according to the proportion, and the steps thereof are as follows: preparation of the composition A, preparation of the composition B, mixing and packaging. The edible brine can be stored and transported conveniently, and is clean, healthy and aromatic in flavor; the edible brine is an excellent seasoning being pure natural, nutritional and healthy, which not only is suitable for being used as a spice of rice stick, but also can be applicable to various soup blends, hot pot and the like, therefore, the edible brine has the advantages of large demands, low cost and very broad market prospect.

Owner:李成宏 +3

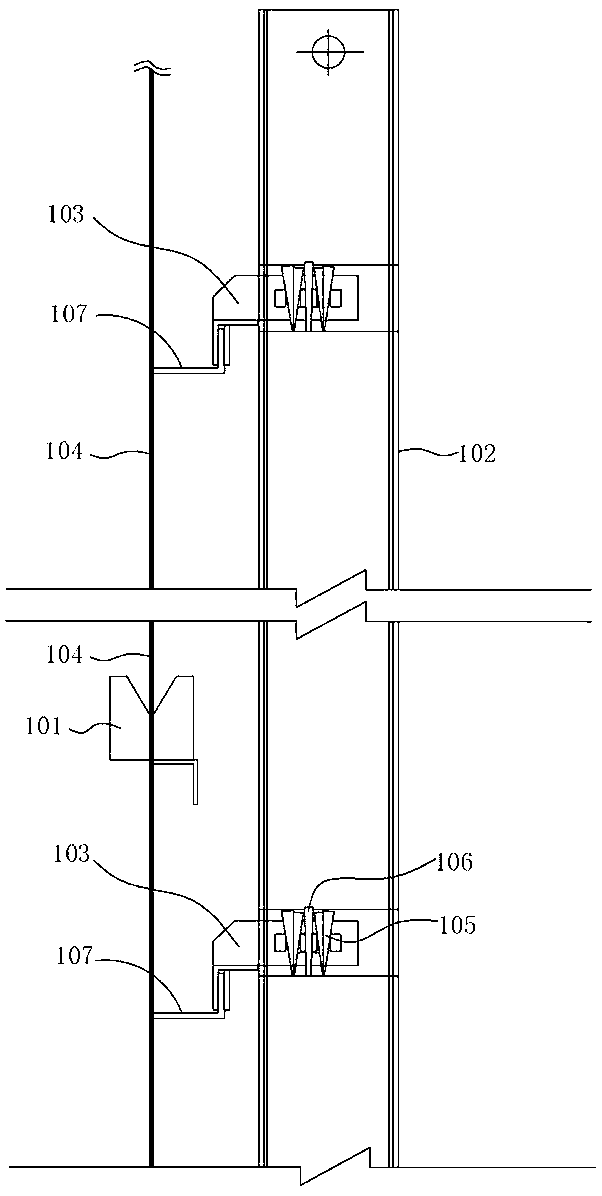

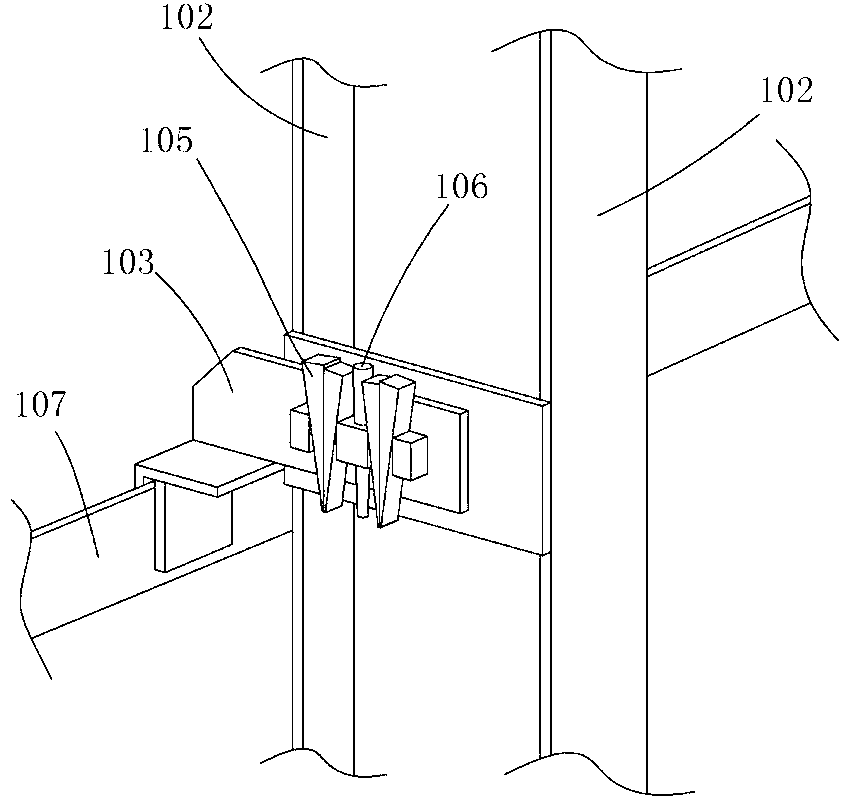

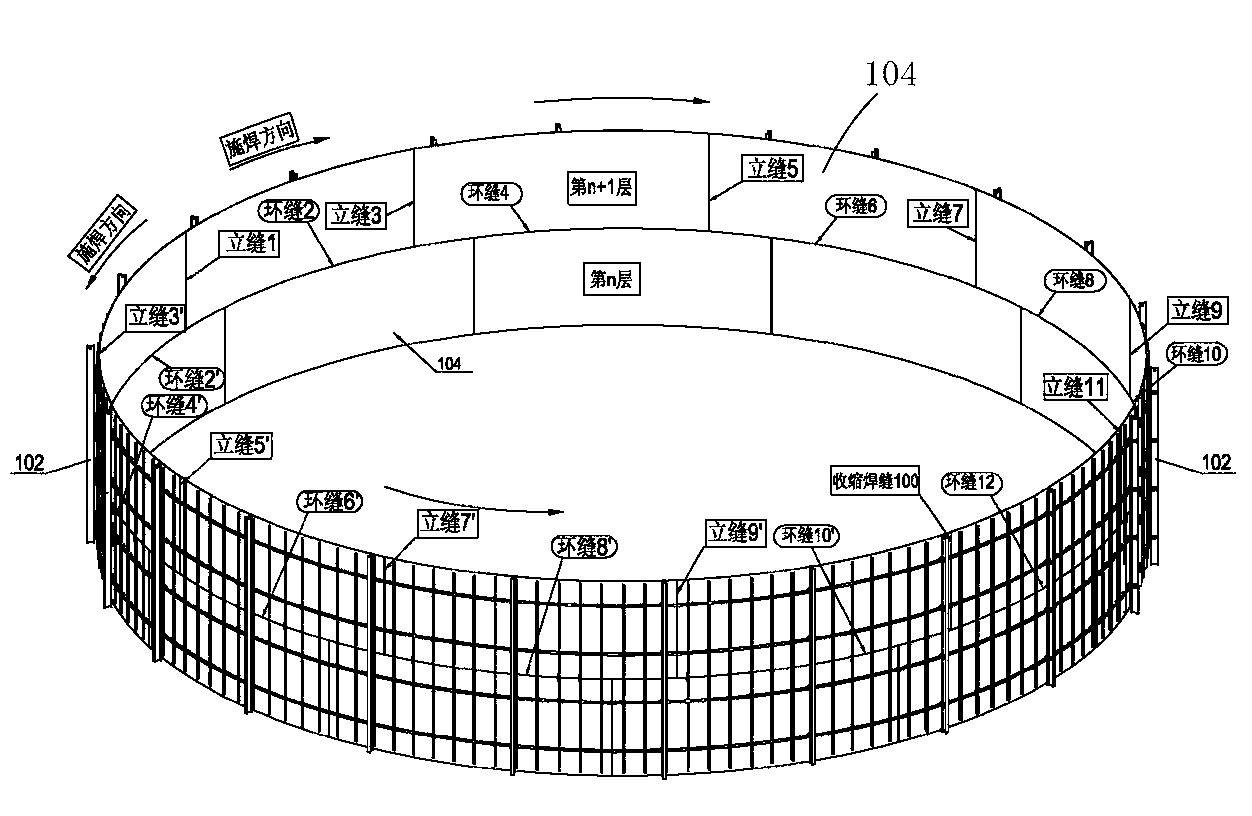

Field welding method for wall boards of steel lining of nuclear power plant

ActiveCN102848056AStable welding parametersAlleviate bottleneck constraintsArc welding apparatusNuclear power plantStructural engineering

The invention relates to a field welding method for wall boards of a steel lining of a nuclear power plant, belonging to the technical field of building decoration of the nuclear power plant. The method comprises the following steps of: assembling the wall boards of the steel lining in place through a tool and randomly selecting a vertical seam between the wall boards of the steel lining as a shrinkage vertical seam for field final welding; performing spot welding on a vertical seam opposite to the shrinkage vertical seam, next performing spot welding on two circular seams adjacent to the left and right sides of the first vertical seam, then continuously performing spot welding on the two vertical seams adjacent to two first circular seams along the clockwise direction and the anticlockwise direction respectively, performing spot welding on all vertical seams and circular seams at spaced locations along the clockwise direction and the anticlockwise direction respectively from the first vertical seam by analogy, until the final manual spot welding is performed on the shrinkage vertical seam; and repeating the steps to perform automatic full-length welding on all vertical seams and circular seams from the first vertical seam which is subjected to spot welding, until the final automatic full-length welding is performed on the shrinkage vertical seam. According to the method, field mounting of the wall boards of the steel lining of the nuclear power plant is performed by using a tungsten electrode argon arc automatic welding machine, the welding deformation is reduced, and the mounting working efficiency and the quality are improved.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

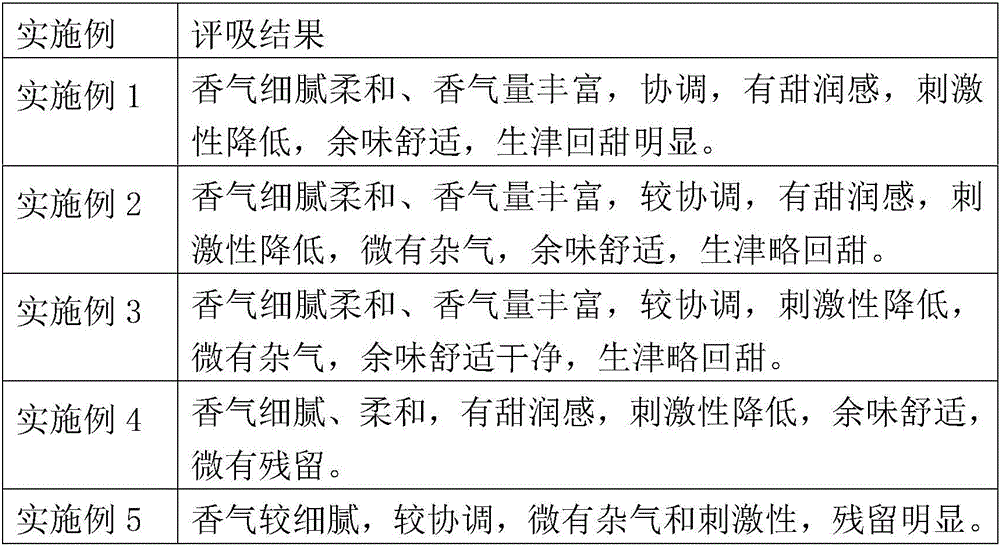

Preparation method of composite fruity tobacco essence

InactiveCN105969525AIntrinsic Quality GuaranteeReduce stimulationTobacco preparationTobacco treatmentEnzymatic hydrolysisAdipic acid

The invention provides a preparation method of a composite fruity tobacco essence. The preparation method comprises the following steps: respectively crushing 20-30g of apple skins, 100-120g of grape skins, 80-110g of watermelon peel, 12-20g of orange peel, 50-70g of banana skins, 5-10g of mango skins and 20-40g of shaddock peel to form residues, mixing above residues, adding compound enzyme and 800-1000g of water, adjusting the pH value of the above obtained liquid to 5.0-5.3, carrying out enzymatic hydrolysis at 45-50DEG C for 40-60min, heating the obtained liquid to 100DEG C in order to inactivate enzyme, adding 1.2-1.8g of sodium benzoate, 0.2-0.6g of titanium dioxide, 8.5-11.2g of riboflavin, 1-3g of adipic acid, 15-23g of sodium sulfate and 20-25ml of n-butaonl, continuously decocting the obtained liquid at 100DEG C for 1.5-2h, filtering the decocted liquid, and concentrating the obtained filtrate. The essence prepared in the invention has the advantages of high aroma intensity, abundant fruit aromas, and satisfactory improvement of the quality of tobacco.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Production technology of sweet potato vermicelli

ActiveCN103734580AGuaranteed colorIntrinsic Quality GuaranteeFood freezingFood shearingWarm waterInternal quality

The invention relates to a production technology of sweet potato vermicelli, which comprises the processes of starchy sauce preparation, dough preparation, vermicelli preparation, cooling and drying, wherein the processes of starchy sauce preparation and dough preparation comprise the following steps: 1) starchy sauce preparation: pouring a fixed quantity of starch into a starchy sauce jar, adding 35-45 DEG C warm water of which the weight is 1.5-2 times the weight of the starch, and stirring uniformly; and adding 94-97 DEG C hot water of which the weigh is 4.5-5.5 times the weight of the starch in weight, stirring uniformly into a paste, and cooling to 68-70 DEG C; and 2) dough preparation: based on 100kg of starch with over 99% of fineness, adding 20-24kg of prepared starchy sauce paste and 52-55kg of 35-45 DEG C warm water, and stirring for 10-12 minutes while ensuring that the temperature in dough preparation is 40-45 DEG C; and pouring the prepared dough into a vacuum machine, and performing vacuumizing treatment through a vacuumizing machine to finish the dough preparation process. In the production technology of sweet potato vermicelli provided by the invention, no additive is added in the starchy sauce preparation process, the color and internal quality of the vermicelli are guaranteed, and the mouthfeel and toughness of the vermicelli are increased by the vacuumizing treatment.

Owner:河南新天豫食品有限公司

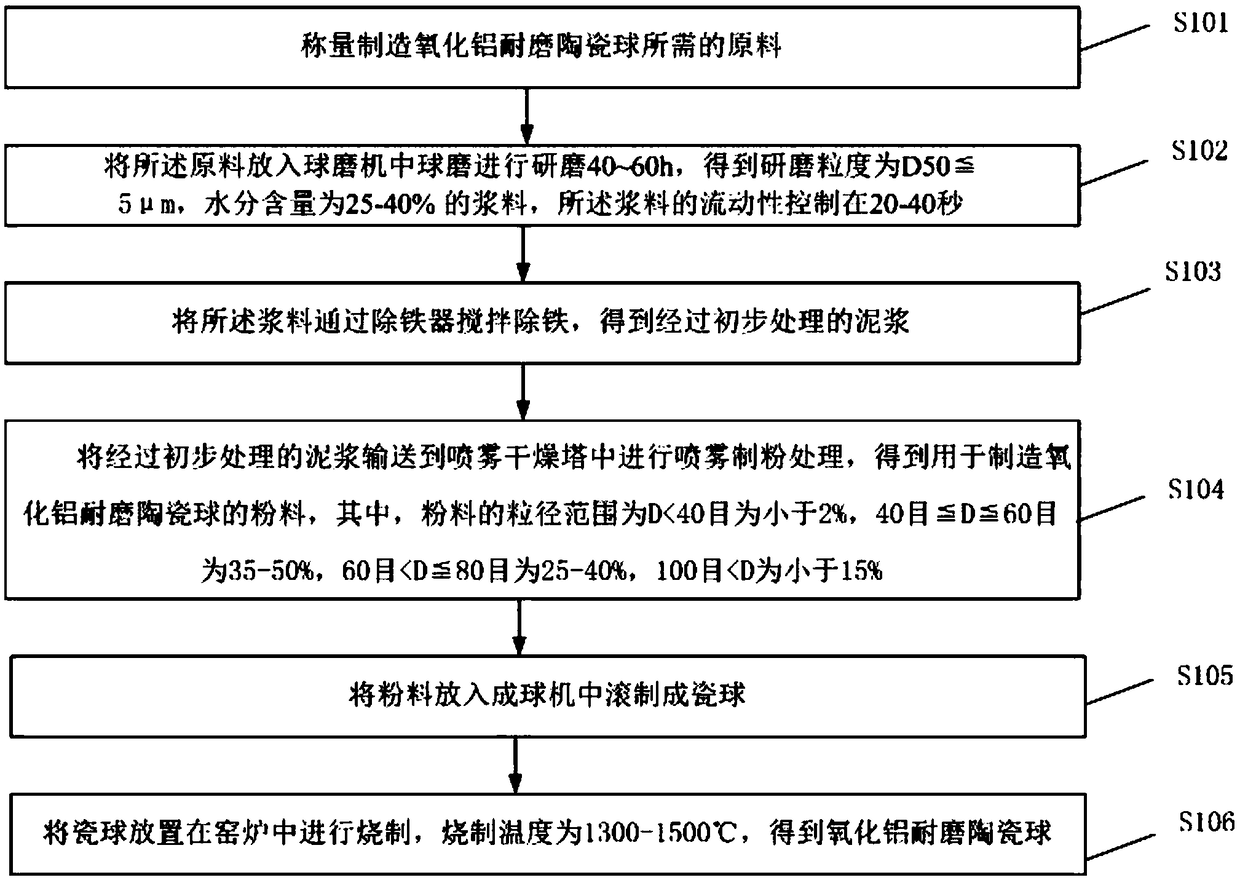

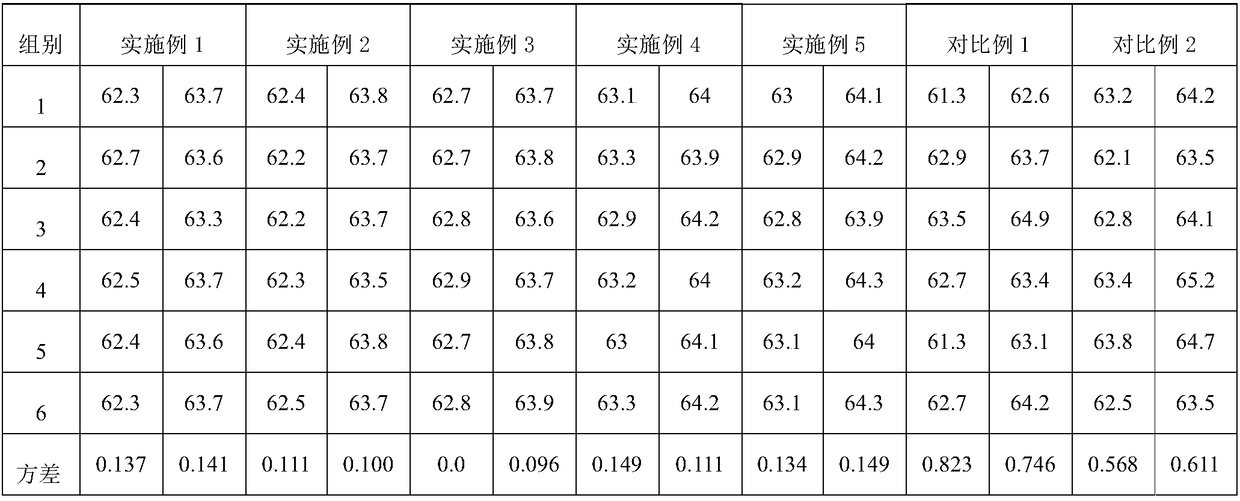

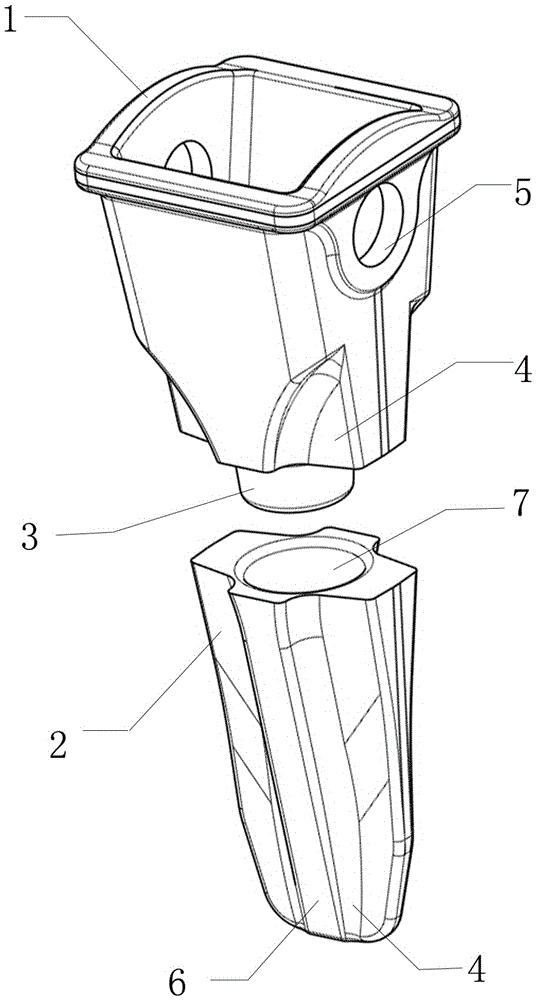

Preparation method for alumina wear-resistant ceramic ball

ActiveCN109279869AHigh bulk densitySmall differenceCeramic materials productionClaywaresWear resistantSlurry

The invention discloses a preparation method for an alumina wear-resistant ceramic ball. The preparation method comprises the following steps: weighing raw materials needed for preparation of the alumina wear-resistant ceramic ball; grinding the raw materials in a ball mill through ball milling to obtain slurry, and controlling the fluidity of the slurry to be 20-40 seconds; subjecting the slurryto stirring and iron removal via an iron separator to obtain preliminarily-treated mud; conveying the preliminarily-treated mud to a spray drying tower for spraying powdering treatment so as to obtainpowder used for the preparation of the alumina wear-resistant ceramic ball, wherein the particle diameter ranges of the powder are that less than 2% of the powder has a particle diameter D of less than 40 meshes, 35-50% of the powder has a particle diameter D of no less than 40 meshes and no more than 60 meshes, 25-40% of the powder has a particle diameter D of more than 60 meshes and no more than 80 meshes, and 15% of the powder has a particle diameter D of more than 100 meshes; putting the powder into a ball forming mill for rolling to obtain a porcelain ball; and sintering the porcelain ball in a kiln at a sintering temperature of 1,200-1,500 DEG C so as to obtain the alumina wear-resistant ceramic ball. By controlling the particle diameter ratio of the powder, the produced alumina wear-resistant ceramic ball has a smooth surface, good sphericity and high dimensional precision, and difference between different balls is extremely small.

Owner:FOSHAN CERAMICS RES INST GRP CO LTD +1

Acidified fly ash

ActiveCN104128352AIntrinsic Quality GuaranteeAvoid chemical reactionsSolid waste disposalChemical reactionAdditive ingredient

The invention discloses acidified fly ash. The main point of a technical scheme provided by the invention is that acidified fly ash ingredients comprise fly ash, attapulgite clay, magnesium oxide, sulfuric acid, fast-dissolving sodium silicate, polyvinyl alcohol, hydroxypropyl methyl cellulose and sodium carbonate. The acidified fly ash ingredients are input into a mill for milling, and powder obtained after milling is the acidified fly ash. A production method for the acidified fly ash can prevent a chemical reaction of sulfuric acid with fast-dissolving sodium silicate, polyvinyl alcohol, hydroxypropyl methyl cellulose and sodium carbonate; after acidification of fly ash, the utilization rate of fly ash can be increased, good economic benefits, environmental benefits and social benefits are obtained, and the waste is turned into the valuable. The acidified fly ash has the characteristics of good adsorptivity, thixotropy, heat stability, plasticity, caking performance and high dry-pressing strength and is applicable to production of environmental protection materials, garden materials, building materials, foaming agents and fire-fighting products.

Owner:江苏世澳非金属应用科技有限公司

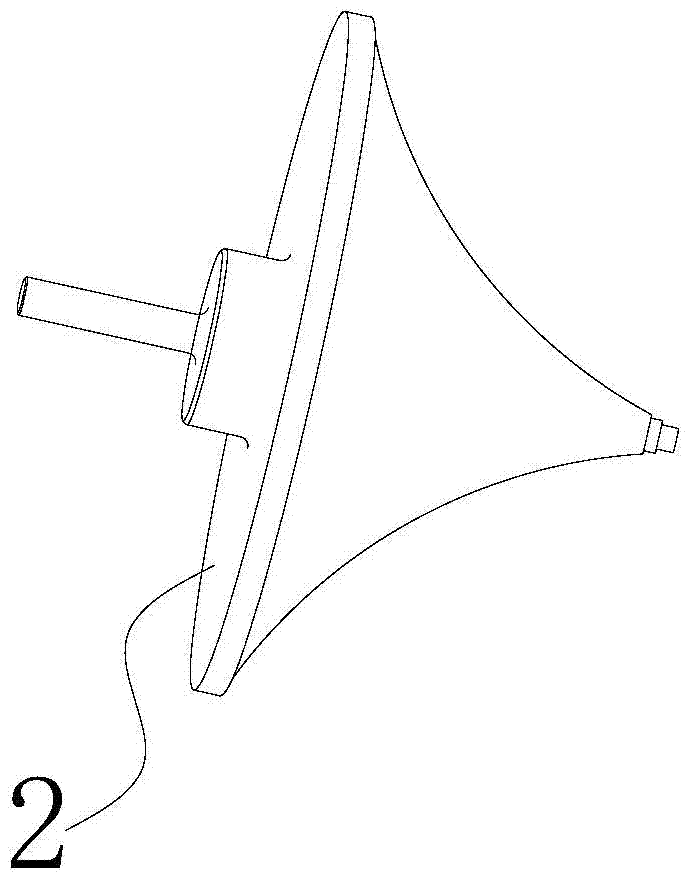

Split bucket tooth for buckets of excavators and manufacturing method thereof

ActiveCN105714075AImprove wear resistanceExtend your lifeSoil-shifting machines/dredgersSolid state diffusion coatingWear resistantEngineering

The invention discloses a split bucket tooth for buckets of excavators and a manufacturing method thereof. The split bucket tooth for buckets of excavators is manufactured by three steps: manufacturing of tooth roots, manufacturing of tooth tops and assembling. The split bucket tooth for buckets of excavators is divided into a tooth root and a tooth top, wherein the tooth root and the tooth top are separately forged from different materials; the tooth top adopts materials, the wear resistance of which is superior to that of the materials of the tooth root; the tooth root is made from common materials such as 40Cr and 42CrMo through a common heat treatment method; the tooth top is made from wear-resistant materials such as 20CrMnTi, 38CrMoLA and GCr15 through a wear-resistant heat treatment method; the tooth root manufactured through the manufacturing method can be repeatedly used, so that the process requirement is reduced, the cost is greatly reduced and both the inner quality and surface quality can be ensured; the tooth top is light in weight (about 1 / 3 of the total weight) and the tooth top selects the wear-resistant materials and a heat treatment process capable of enhancing the wear resistance, so that the wear resistance of the tooth top is greatly improved.

Owner:李令禹

Blood replacing base liquid for blood purification treatment

ActiveCN1857311AIntrinsic Quality GuaranteeStandardized mass production preparationOrganic active ingredientsInorganic phosphorous active ingredientsPotassiumPhosphoric acid

Owner:CHENGDU QINGSHAN LIKANG PHARMA CO LTD

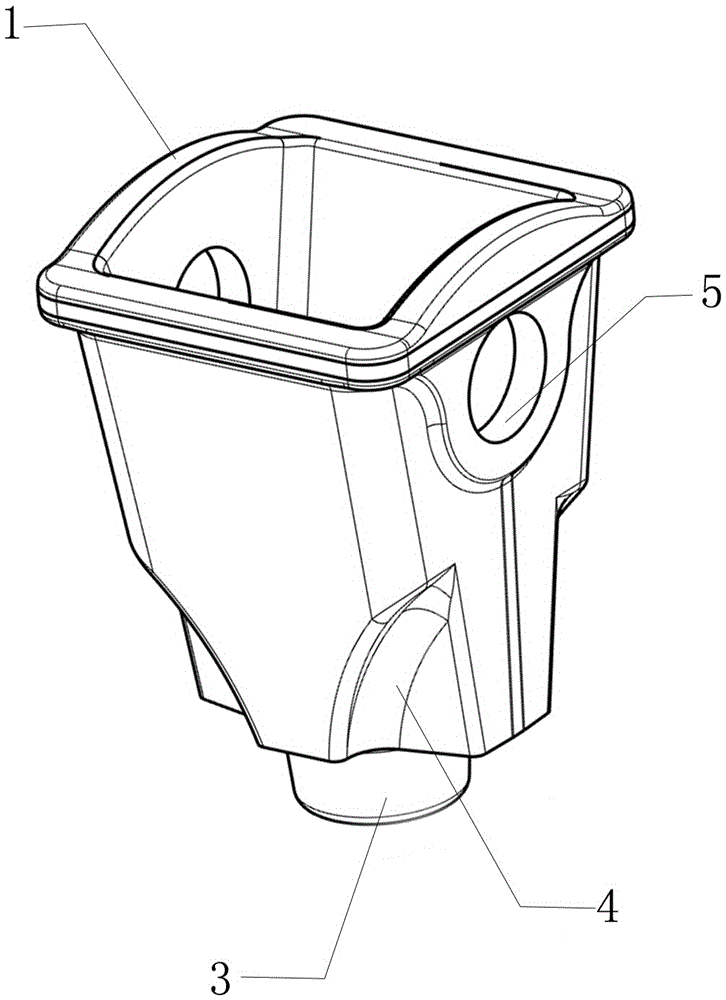

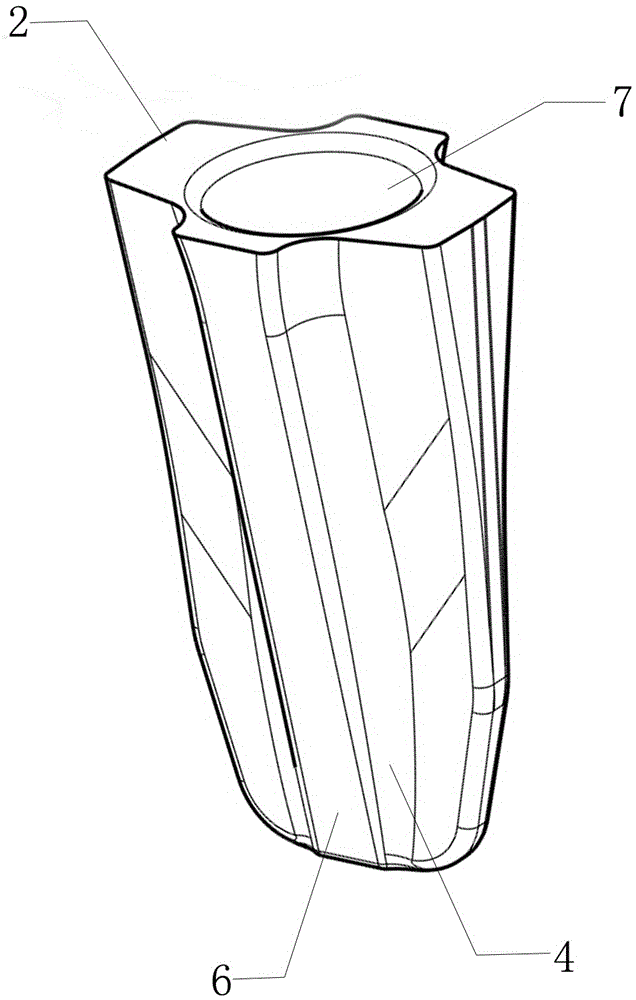

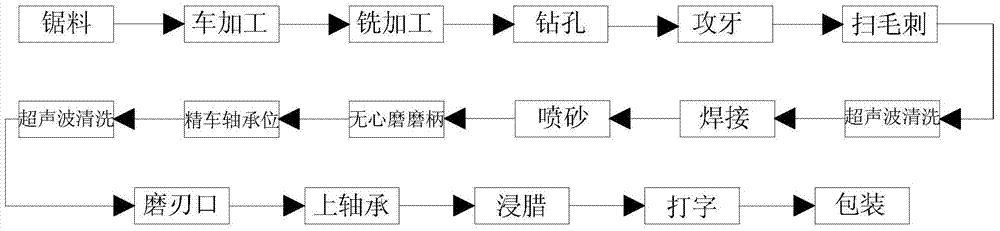

Woodworking cutting tool machining method

The invention discloses a woodworking cutting tool machining method and belongs to the cutting tool machining filed. The woodworking cutting tool machining method comprises the following steps of (1) bar sawing; (2) lathing; (3) milling; (3) drilling; (5) tapping; (6) burr sweeping; (7) ultrasonic cleaning; (8) blade welding; (9) sand blasting; (10) handle grinding through centreless grinding; (11) finish lathing bearing position; (12) ultrasonic cleaning; (13) cutting edge grinding; (14) ultrasonic cleaning; (15) bearing placing. The woodworking cutting tool machining method which aims at providing a cutting tool which is stable in quality, safe in utilization is applied to non-metallic machining.

Owner:梧州市三禾添佰利五金加工有限公司

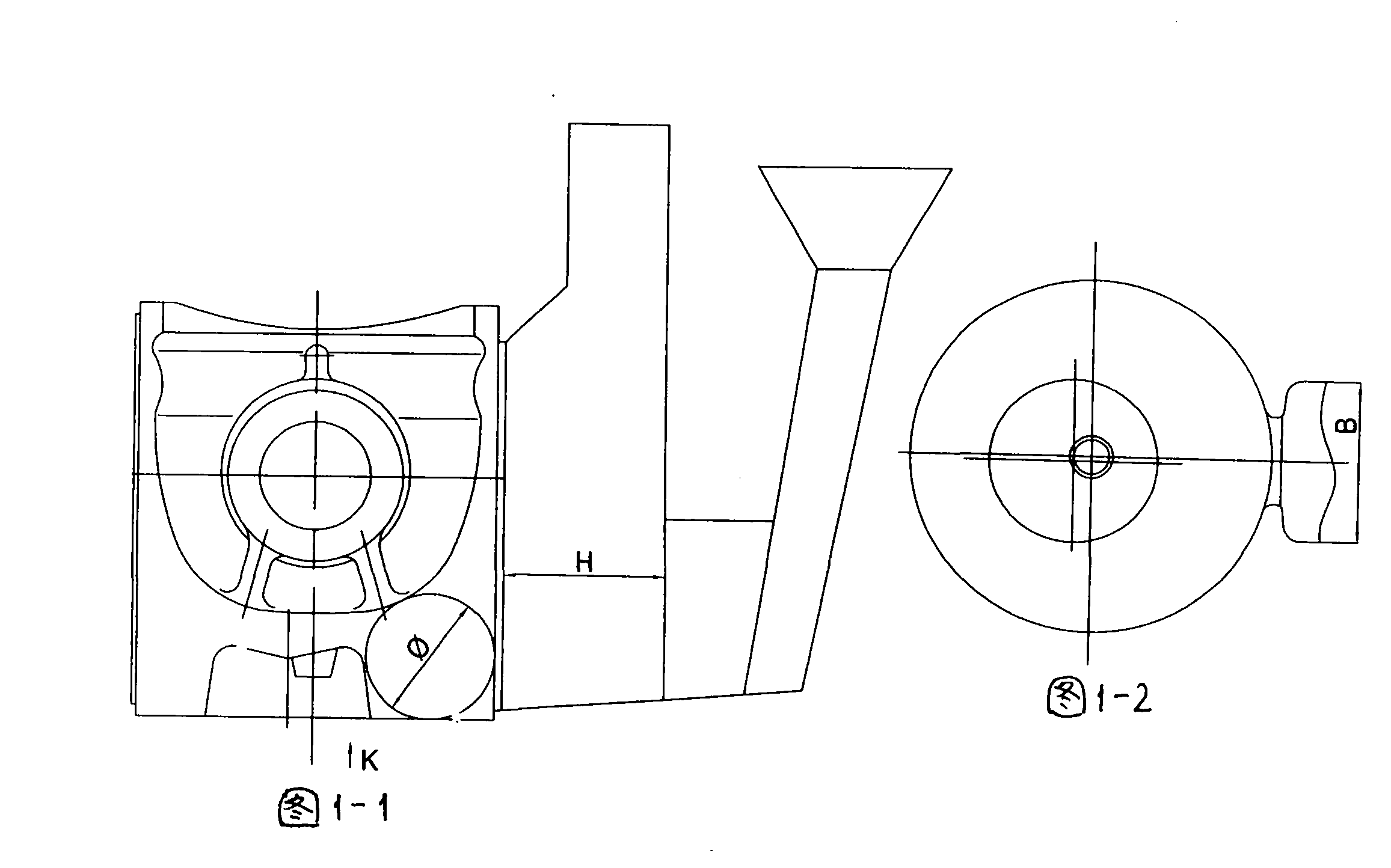

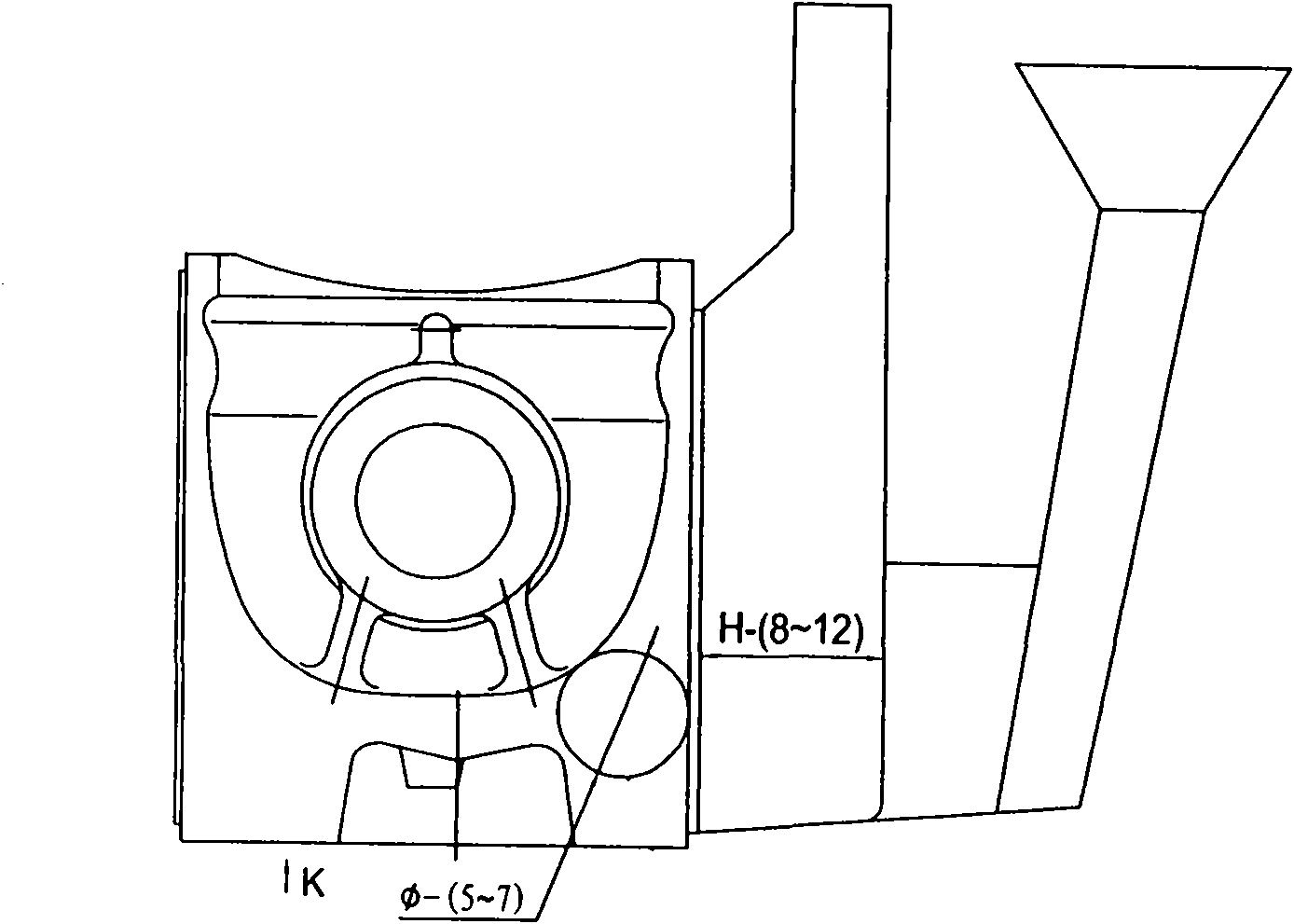

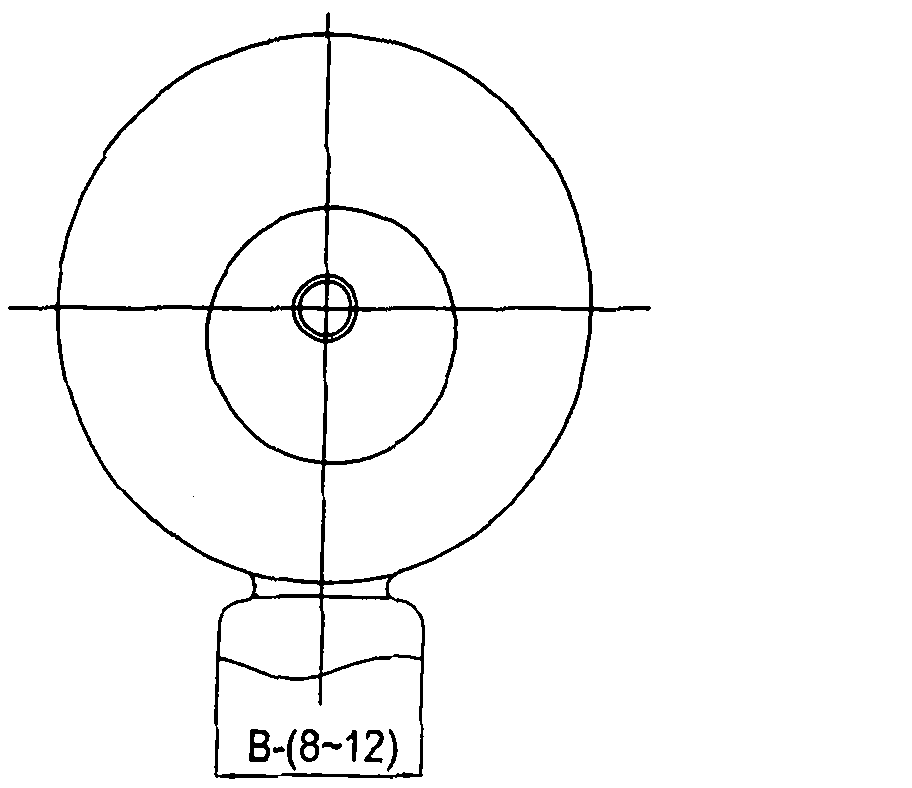

Process for improving metallographic structure of piston head and increasing casting production efficiency

ActiveCN101829763AReduced packing timeImprove cooling effectFoundry mouldsFoundry coresPistonMechanical engineering

The invention provides a process for improving the metallographic structure of a piston head and increasing casting production efficiency. The process comprises the steps of: (1) eliminating an exhaust hole and an exhaust nail on a bottom die, and meanwhile reducing the thickness of a wall between the bottom die and a cooling water cavity, respectively subtracting 10mm from the length and the width of a casting head on an outer die, wherein the specifications of the length and the width are respectively 48mm-55mm and 48mm-54mm; and meanwhile, adding 10mm-12mm to the length L2 of the rear part of the outer die, and adding 5mm-8mm to the width D of the rear part of the outer die, wherein the specifications of the length L2 and the width D are respectively 176-mm-195mm and 78mm-85mm; (2) processing a tooling die; (3) preparing for the smelting of an aluminum liquid; (4) assembling and debugging the tooling die; (5) casting in field production; (6) hot treating a piston blank; and (7) detecting the quality of the piston. The invention can refine the metallographic structure of the piston head by 1-2 levels and improve casting efficiency by more than 15%.

Owner:CHENGDU GALAXY POWER CO LTD

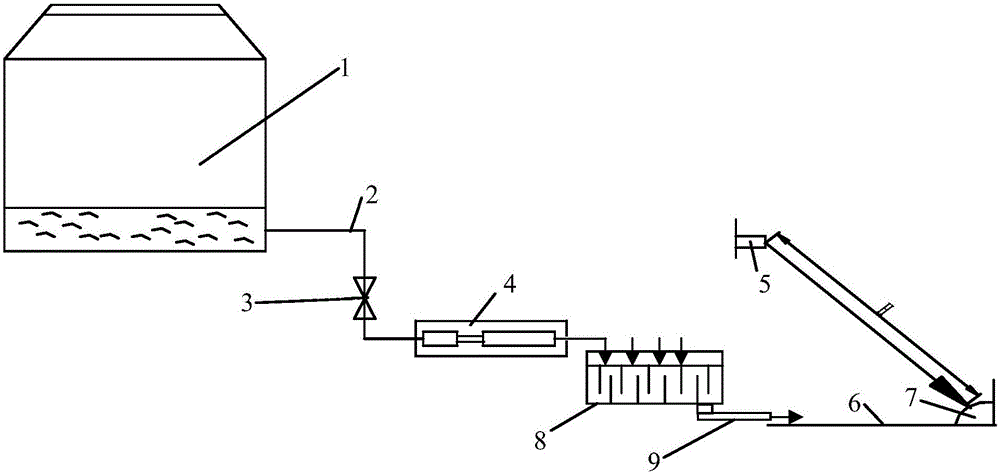

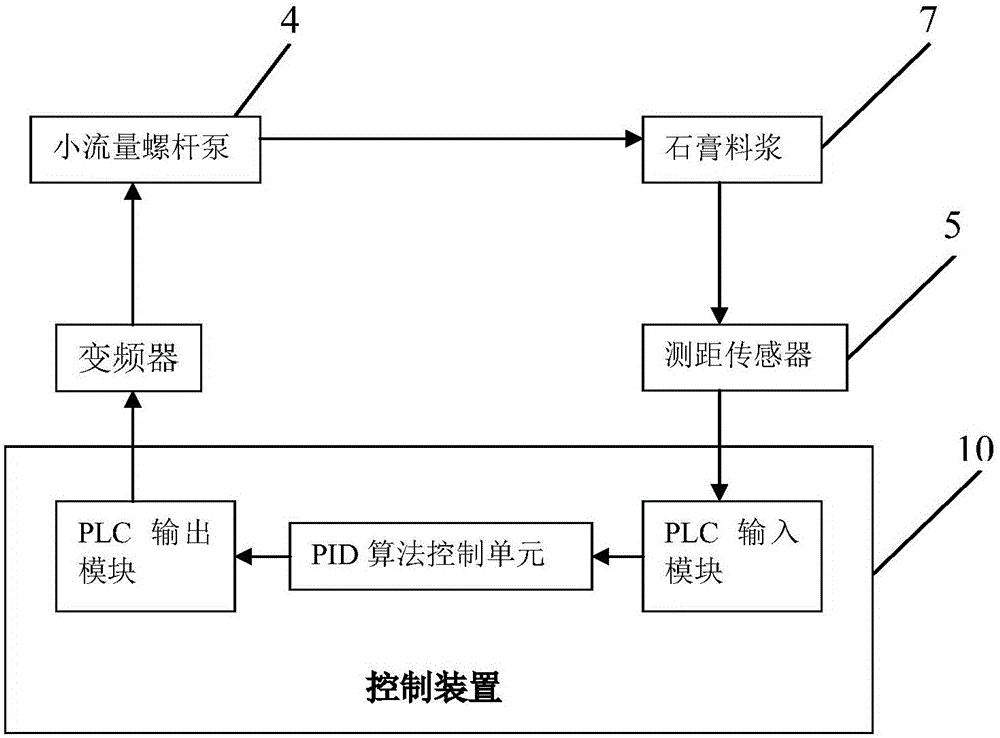

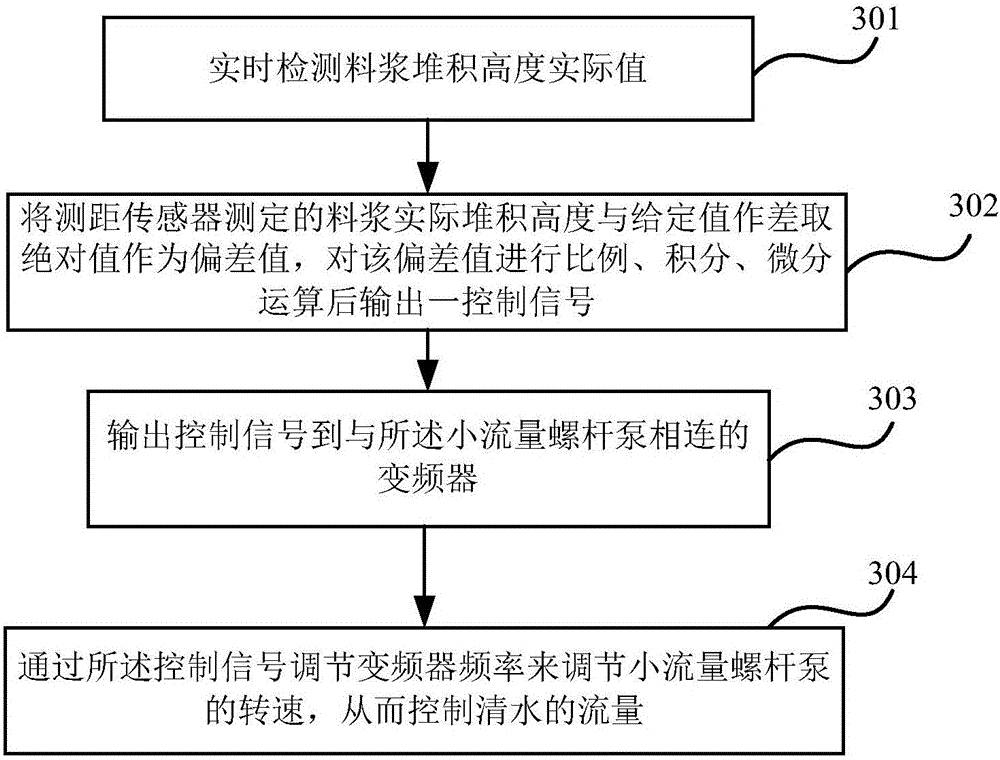

Gypsum slurry thickness fine regulation system and method

InactiveCN106003400AControl pile heightThe output of the control device controls the pile heightMixing operation control apparatusFeeding arrangmentsProduction lineFrequency changer

The present invention provides a system and method for fine-tuning the thickness of gypsum slurry. The method includes: detecting the actual value of the slurry accumulation height in real time; taking the absolute value as the difference between the actual accumulation height of the slurry measured by the ranging sensor and a given value. Deviation value, output a control signal after performing proportional, integral and differential operations on the deviation value; output the control signal to the frequency converter connected with the small flow screw pump; adjust the frequency converter frequency through the control signal to adjust the small flow screw pump The speed of the pump controls the flow of clean water. The technical solution of the present invention is a dynamic adjustment method, the system is stable, and the control accuracy is much higher than that of the pulp pump controlled in the past, which can reach 0.5%, which improves the quality of gypsum molding, the surface density of the board is uniform, the strength is uniformly increased, and the inner quality of the finished product is guaranteed. . The adjustment of the slurry does not require the operator to track and adjust all the time, which reduces the human labor, improves the automation level of the production line, and achieves better expected results.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Quality control method of Chinese herbal preparation-cannabis fruit spleen-enriching pill for treating constipation

ActiveCN102038789AImprove controllabilityIntrinsic Quality GuaranteeComponent separationDigestive systemThin-layer chromatographyHerbal preparations

The invention relates to a quality control method of Chinese herbal preparation-cannabis fruit spleen-enriching pill for treating constipation, comprising the following steps of: (1) identifying characters; (2) identifying dried immature fruit of citron orange, angelica and magnolia officinalis by the thin-layer chromatography; (3) identifying white paeony root by the thin-layer chromatography; and (4) determining rheum officinale by the high performance liquid chromatography. The quality control method improves and perfects the quality standard of the Maren Zipi pill, revises the character and the microscopical characters of the Maren Zipi pill on the basis of the original standard, and adds the thin-layer identification detection method of angelica, magnolia officinalis dried immature fruit of citron orange and white paeony root in the prescription; the quality control method also formulates to determine the content of rheum officinale in the prescription by the high performance liquid chromatograph by taking rheumemodin and chrysophanol as reference substances; the revised quality standard improves the controllability of the quality standard of the Maren Zipi pill, further guarantees the inherent quality and the curative effect of the product, and has an important meaning for accelerating product sales, increasing the competitiveness of the product in the market and guaranteeing pharmacy safety for patients.

Owner:津药达仁堂集团股份有限公司达仁堂制药厂

Method for producing H-shaped support piles

The invention provides a method for producing H-shaped support piles which are low in cost, bending resistant, shearing resistant and high in intensity. The technical scheme includes that the method specifically includes: (1) placing stop plates on the baseplate of an H-shaped support pile die or at two ends of the baseplate, serially connecting the stop plates on prestressed steel via holes on the stop plates, serially connecting a plurality of stirrups on the prestressed steel, connecting one end of the prestressed steel on a first tensioning device, and connecting the other end of the prestressed steel on a second tensioning device; and (2) adjusting distributing distance of the stop plates and the stirrups, closing the H-shaped support pile die to tension the prestressed steel, and the like.

Owner:俞晓东 +2

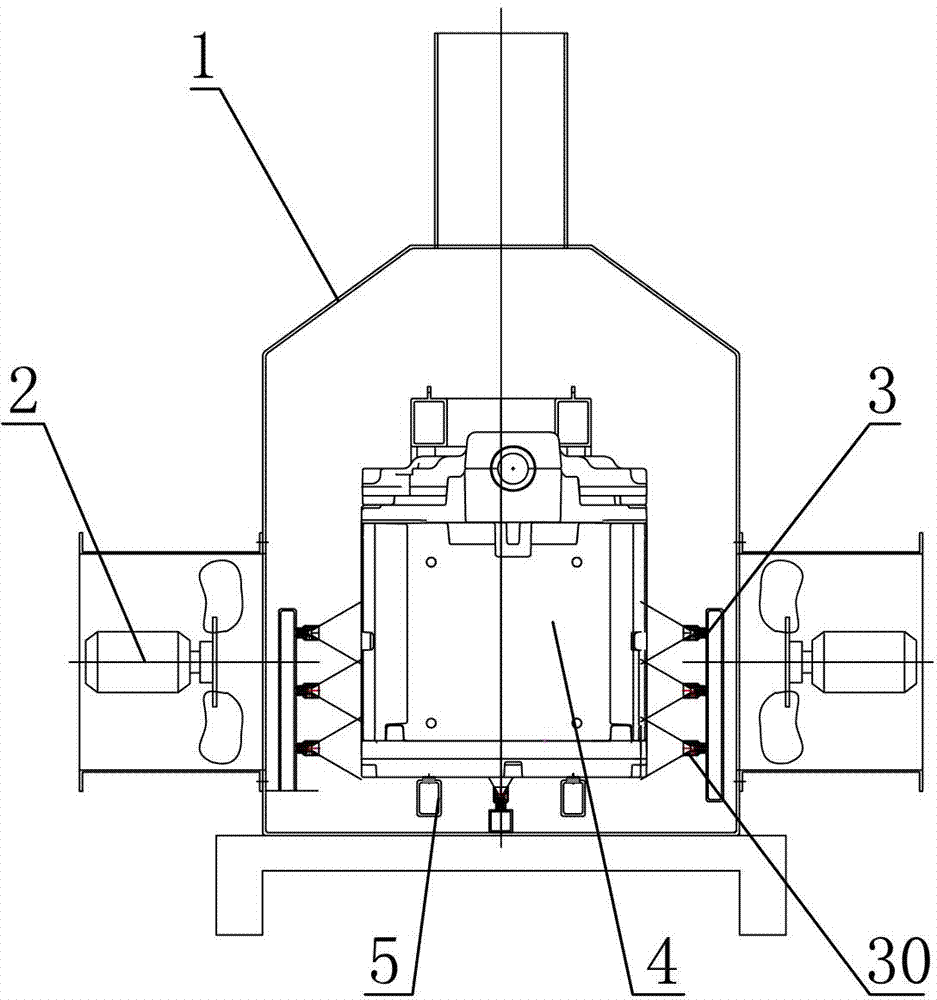

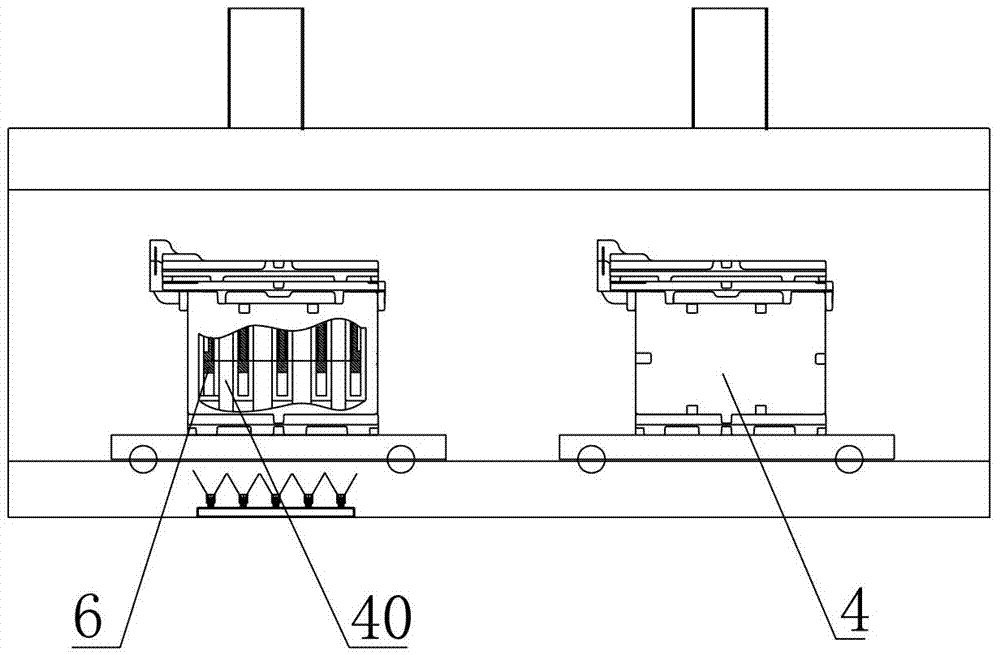

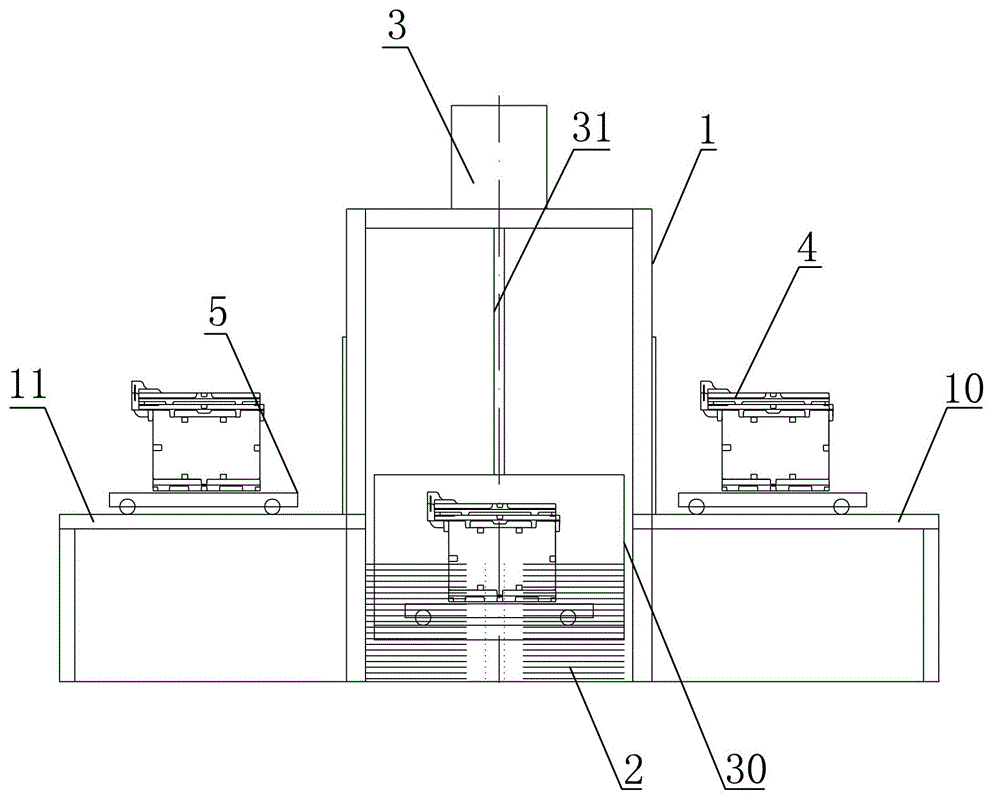

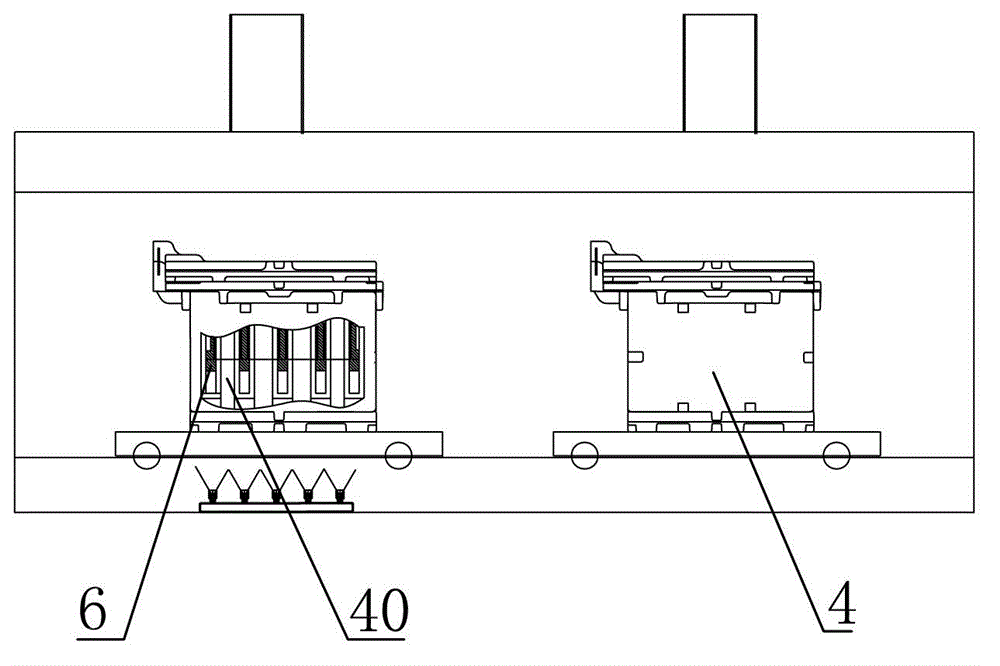

Method and device for controlling cooling speed of core assembly casting

InactiveCN102962435AIntrinsic Quality GuaranteeRapid coolingFoundry mouldsFoundry coresHigh volume manufacturingCylinder block

The invention relates to a method for controlling the cooling speed of core assembly casting, which is characterized in that molten metal is poured in a sand mold, and airflow or water mist is sprayed onto a part of the sand mold, which is corresponding to the local thick part of a cast, so that cooling and solidification of the cast inside the sand mold can be accelerated. An airflow or water mist spraying device for controlling the cooling speed of core assembly casting comprises a framework, an airflow or water mist generating device and a spraying device; the airflow or water mist generating device is communicated with the spraying device; and the spraying device can spray the sand mold placed in the framework. According to the invention, an external physical cooling measure, namely airflow or water mist spraying, and the device are used for controlling the cooling speeds of different positions of core assembly casting, so as to realize rapid cooling or local rapid cooling and ensure the inner quality of the cast; and therefore, the core assembly casting process can be used for mass production of casts with high quality requirements, complicated shapes and local thermal centers, such as aluminium alloy cylinder bodies and cylinder covers in the industry of automobiles.

Owner:SUZHOU MINGZHI TECH

Slice control method of vertical slice cutter

ActiveCN101632488AAvoid volatilityIntrinsic quality is stableTobacco treatmentProgramme control in sequence/logic controllersProduction lineAutomatic control

The invention discloses a slice control method of a vertical slice cutter, comprising the steps: firstly, making corresponding slice control modes of the prior cigarette packets of various specifications and dimensions according to production requirements; inputting the slice control modes into an automatic control system; automatically identifying the slice control modes of the cigarette packetsafter the cigarette packets of certain specifications enter a production line; and slicing and processing the cigarette packets according to the identified specifications and dimensions by the automatic control system in the corresponding slice control modes. If the cigarette packets of new specifications and dimensions are brought into a factory, the corresponding slice control modes of the cigarette packets of the new specifications and dimensions are made according to the production requirements and are inputted into the automatic control system for realizing the automatic control over thecigarette packets of the new specifications and dimensions. The invention achieves the consistency between slice times and flow rate, avoids the fluctuation of the flow rate and water due to different specifications and dimensions of the cigarette packets, solves the single control mode of processing slices, stabilizes the internal quality of cigarette products, promotes the stable enhancement ofslice processing quality, ensures the internal quality of tobacco in the process of making the tobacco and is suitable for making the slices of the cigarette packets with different tobacco specifications and dimensions.

Owner:HONGTA TOBACCO GRP

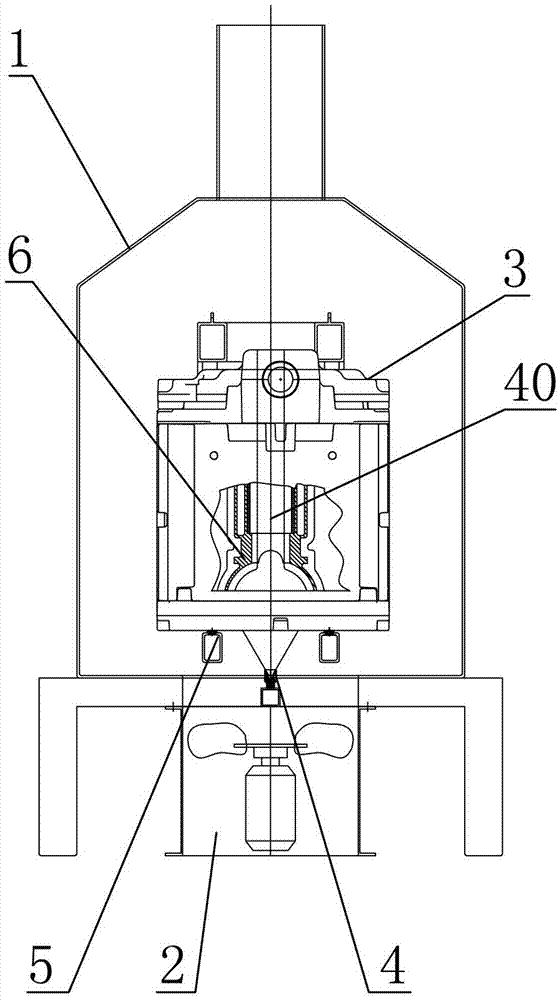

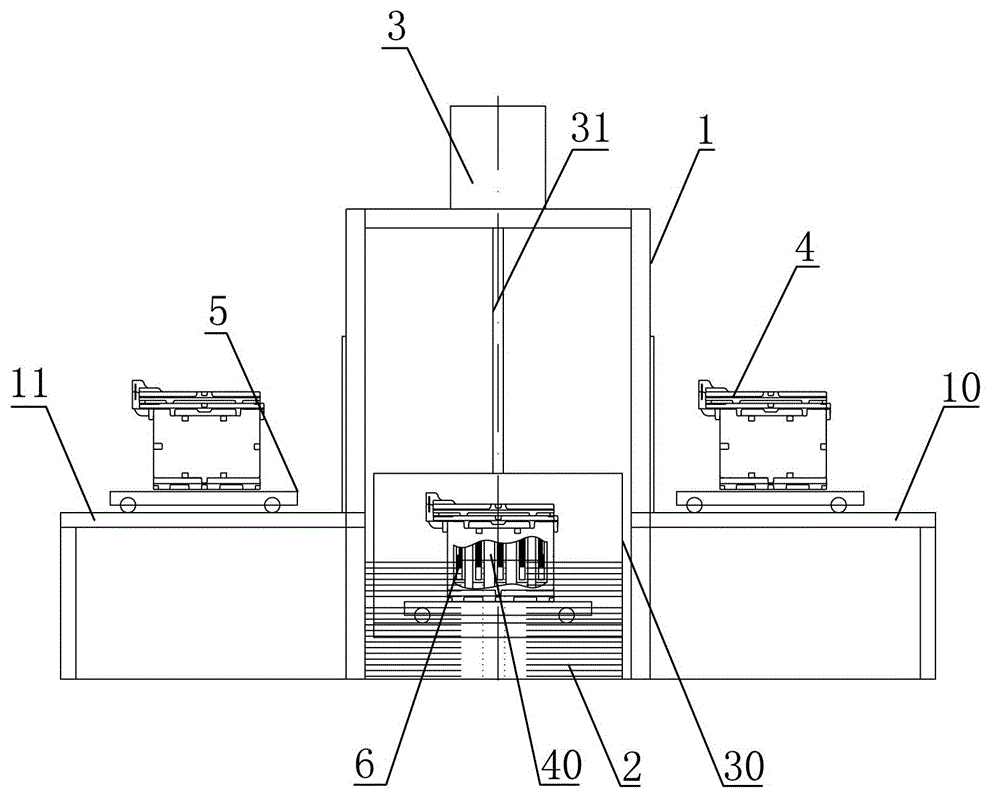

Method and device for controlling cooling speed of core assembling casting

ActiveCN102941338AIntrinsic Quality GuaranteeRapid coolingFoundry mouldsFoundry coresEngineeringWater cooling

The invention relates to a method for controlling the cooling speed of core assembling casting. A metal solution is poured into a sand mold; and the poured sand mold is put into water, so that a cast inside the sand mold can be cooled and solidified in water. A water-cooling device for controlling the cooling speed of the core assembling casting comprises a stander, a cooling water tank which is arranged on the stander and is used for storing water; and a lifting device is arranged above the cooling water tank and can drive the sand mold into the cooling water tank to be cooled. The cooling speed of different positions of the core assembling casting can be controlled by an external physical cooling measure, namely water cooling, and the device for water cooling, so that quick cooling and partial quick cooling can be realized, and internal quality of the cast is guaranteed; therefore, the core assembling casting process can be used for producing a batch of casts, such as an aluminum alloy cylinder cover in the automobile industry, which have high quality requirement, complicated shapes and partial hot joints.

Owner:SUZHOU MINGZHI TECH

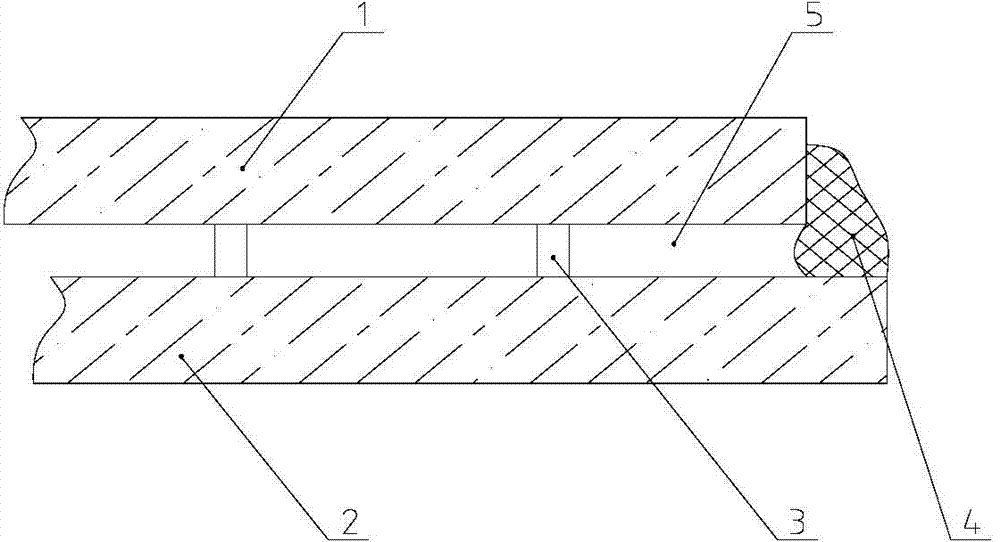

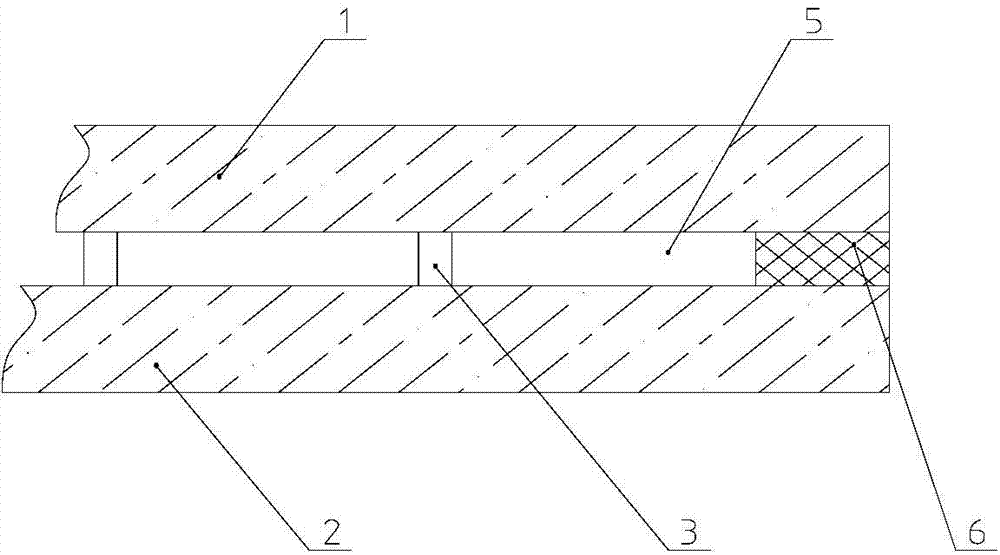

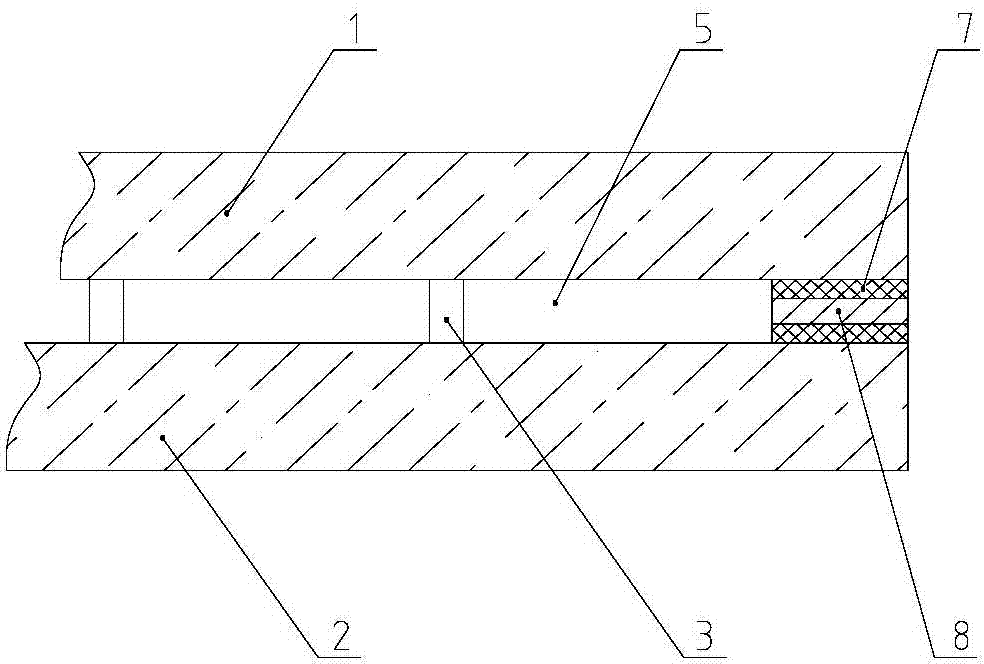

Vacuum glass sealing and connecting structure, semi-finished product of vacuum glass sealing and connecting structure, and sealing and connecting method of vacuum glass sealing and connecting structure

The invention provides a vacuum glass sealing and connecting structure, a semi-finished product of the vacuum glass sealing and connecting structure, and a sealing and connecting method of the vacuum glass sealing and connecting structure. According to the sealing and connecting method, one surface of a metal strap material is coated with a glass powder slurry, and the surface is bonded with the peripheral surface, to be sealed and connected, of each glass plate; connection as a whole body is realized via heating melting; and the metal strap material on the adjacent glass plates is laminated, and is connected as a whole body via connection and airtight welding. According to the vacuum glass sealing and connecting structure, the periphery surface, to be sealed and connected, of each glass plate is connected with the metal strap material via glass powder slurry heating melting, so that the metal strap material on the adjacent glass plates is laminated, and is connected and subjected to airtight welding According to the vacuum glass sealing and connecting structure, infiltrating characteristics of the glass powder slurry and bonding performance under fusion states are used fully; easy welding characteristics of metal material is used fully; and flow line production of vacuum glass with tempered glass and semi-tempered glass is realized.

Owner:LUOYANG NORTHGLASS TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com