Patents

Literature

40results about How to "Does not reduce viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production for quick-freezing Chinese yam powder

InactiveCN1613365ADoes not reduce viscosityGuarantee the inner qualityFood shapingFruits/vegetable preservation by freezing/coolingQuick FreezeLarge intestine

A process for preparing the quickly frozen yam particles includes such steps as immersing raw yam in disinfecting liquid, peeling, cutting into segments, immersing in color protecting liquid and then in disinfecting liquid, granulating, loading in plastic bags and quick freezing.

Owner:胡传银 +2

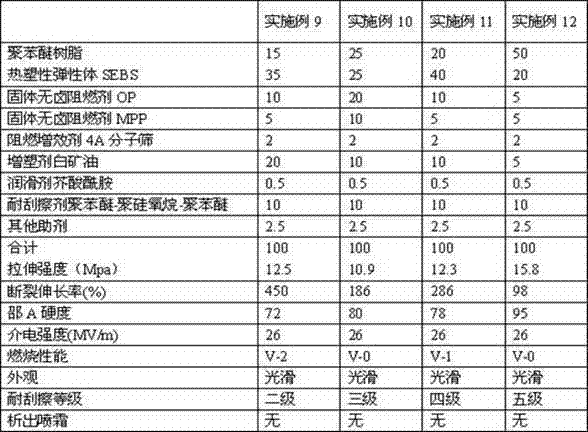

Scraping resistance halogen-free flame retardant thermoplastic elastomer composition and preparation method of composition

The invention discloses a scraping resistance halogen-free flame retardant thermoplastic elastomer composition, which comprises the following ingredients in percentage by weight: 15 to 50 percent of poly-phenylate resin, 20 to 40 percent of styrene thermoplastic elastomers, 10 to 30 percent of solid halogen-free flame retardants, 0.5 to 5 percent of flame retardant synergists, 5 to 20 percent of plasticizers and 5 to 20 percent of scraping resistance agents. The halogen-free flame retardant thermoplastic elastomer composition provided by the invention has the advantages that polysiloxane is added into the halogen-free flame retardant thermoplastic elastomer composition in a polymer form, the excellent scraping resistance is realized, the original mechanical property, the flame retardant performance, the appearance and the soft hand feeling are not damaged, on the basis, the viscosity of the composition in the extruding processing process can also be reduced, the energy consumption is reduced, and better low-carbon and environment-protection effects can be realized.

Owner:KINGFA SCI & TECH CO LTD +1

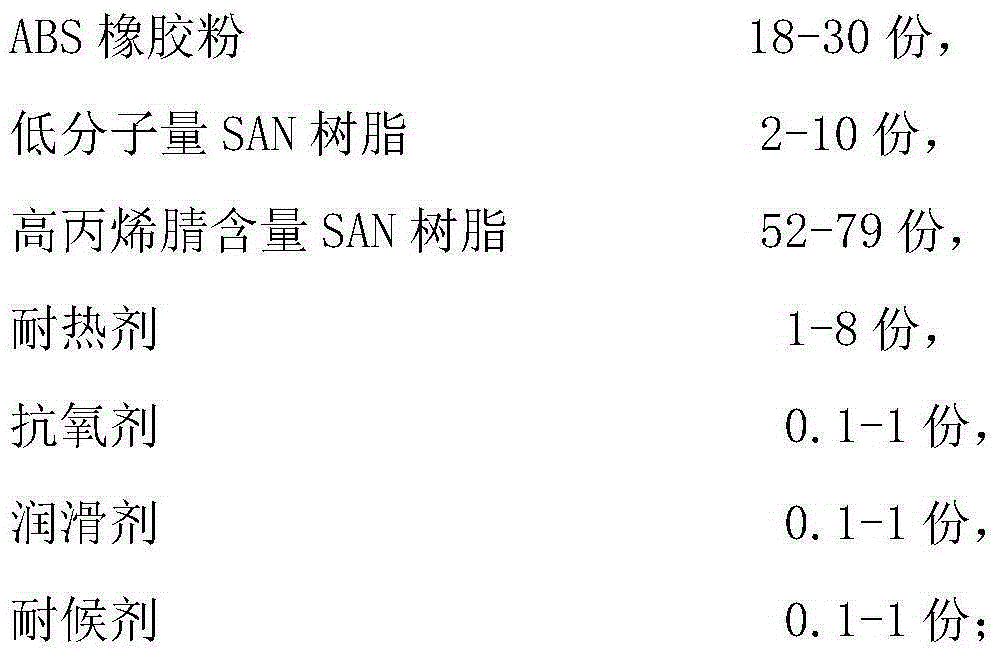

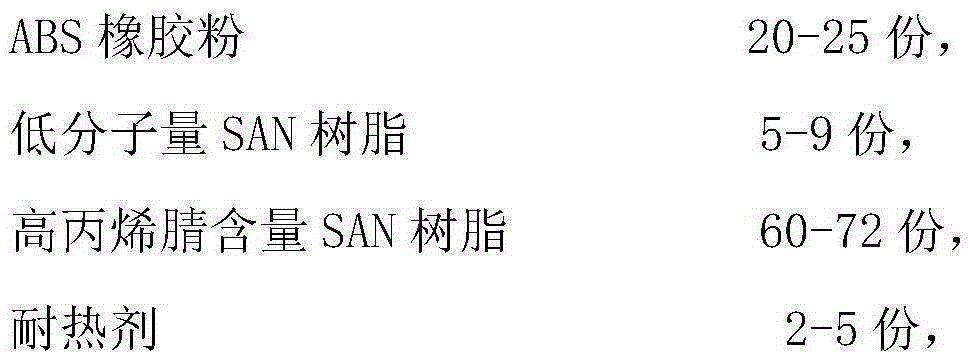

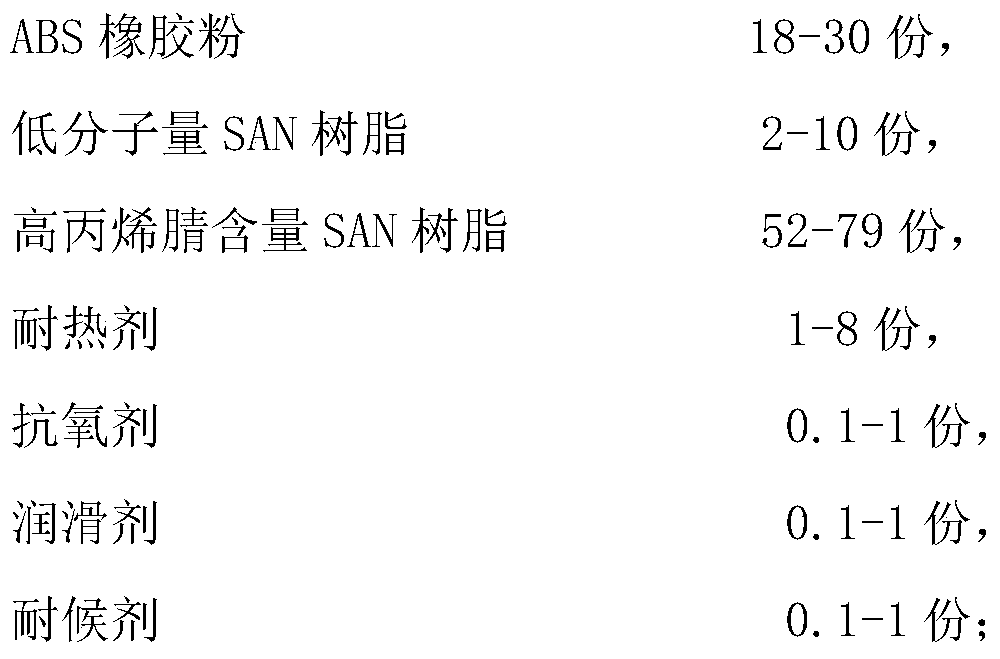

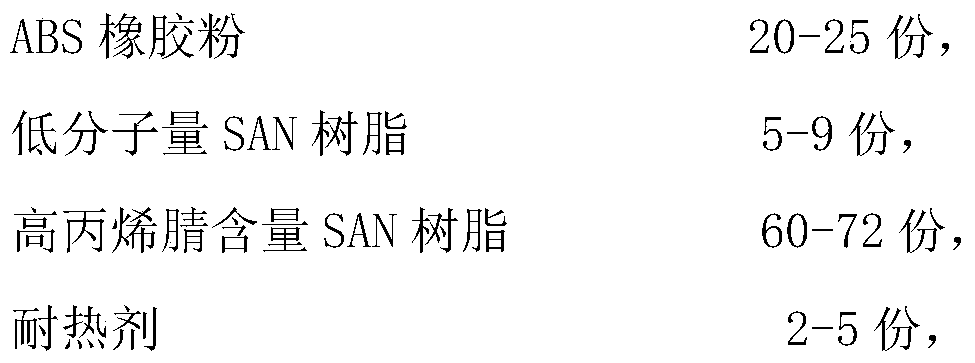

Low-internal-stress heat-resistant ABS resin and preparation method thereof

The invention provides low-internal-stress heat-resistant ABS resin and a preparation method and application thereof and belongs to the technical field of modified resin. The low-internal-stress heat-resistant ABS resin is prepared from, by weight, 20-40 parts of ABS rubber powder, 2-10 parts of low-molecular-weight SAN resin, 42-77 parts of high-acrylonitrile-content SAN resin, 1-8 parts of a heat resistant agent, 0.1-1 part of an antioxidant, 0.1-1 part of a lubricant and 0.1-1 part of a weather resistance agent according to a formula. Compared with the prior art, the prepared low-internal-stress heat-resistant ABS resin greatly improves the liquidity of a material on the basis that heat resistance and impact are guaranteed, can obviously reduces the internal gravity in the injection molding process and can be applied to interior decorative parts and exterior decorative painted parts of automobiles.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

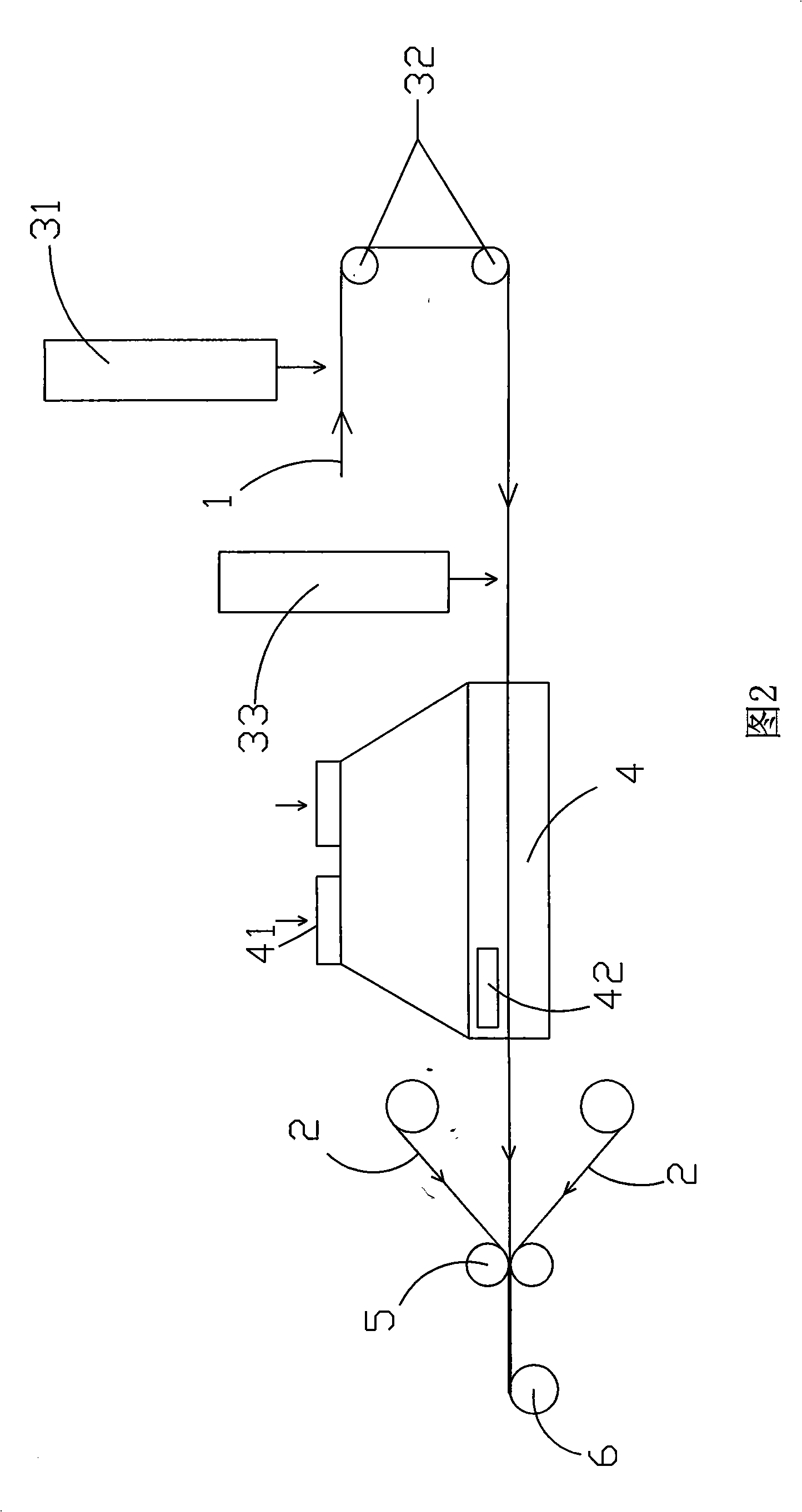

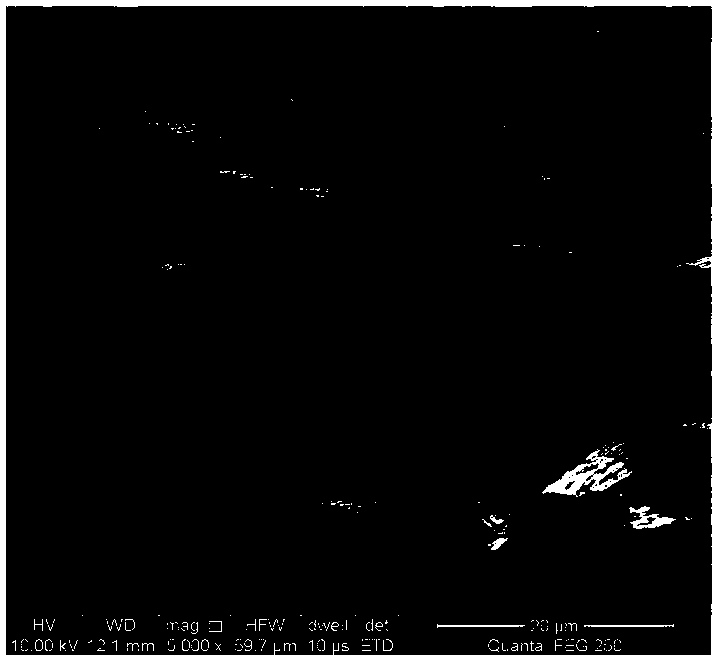

Method for producing regenerative heavy denier profiled polyester staple fibres

ActiveCN102094250AHigh fiber strengthAnd elasticFilament/thread formingMonocomponent polyesters artificial filamentMoistureSurface tension

The invention relates to a method for producing regenerative heavy denier profiled polyester staple fibres. The method comprises the following main procedures: selecting high-quality regenerative polyester bottle chips and spinning the bottle chips to form fibres with profiled sections through drying, melting spinning, cooling, drawing and setting. The method has the following main characteristics: A) after being dried, the moisture contents of the regenerative polyester bottle chips are below 80PPM; B) the melting temperature is controlled between 270 DEG C and 285 DEG C and the spin beam temperature is controlled between 275 DEG C and 278 DEG C; and C) a mist and recirculating air dual-purpose cooling device is adopted for cooling, the mist spray speed is 3.8-4.0m / s and the water temperature is not more than 30 DEG C. The method has the following positive effects: by adopting the cooling method and device combining mist spray cooling and recirculating air cooling for the fibres which are extruded, melted and spouted, the good setting property of the profiled sections of the fibres is ensured and the problem that the sections of the fibres tend to be round due to surface tension existing when the polymer melt is extruded from the spinneret orifice is solved, so that the fibres have multidimensional reflecting effects as the diamond shaped mirrors.

Owner:广东秋盛资源股份有限公司

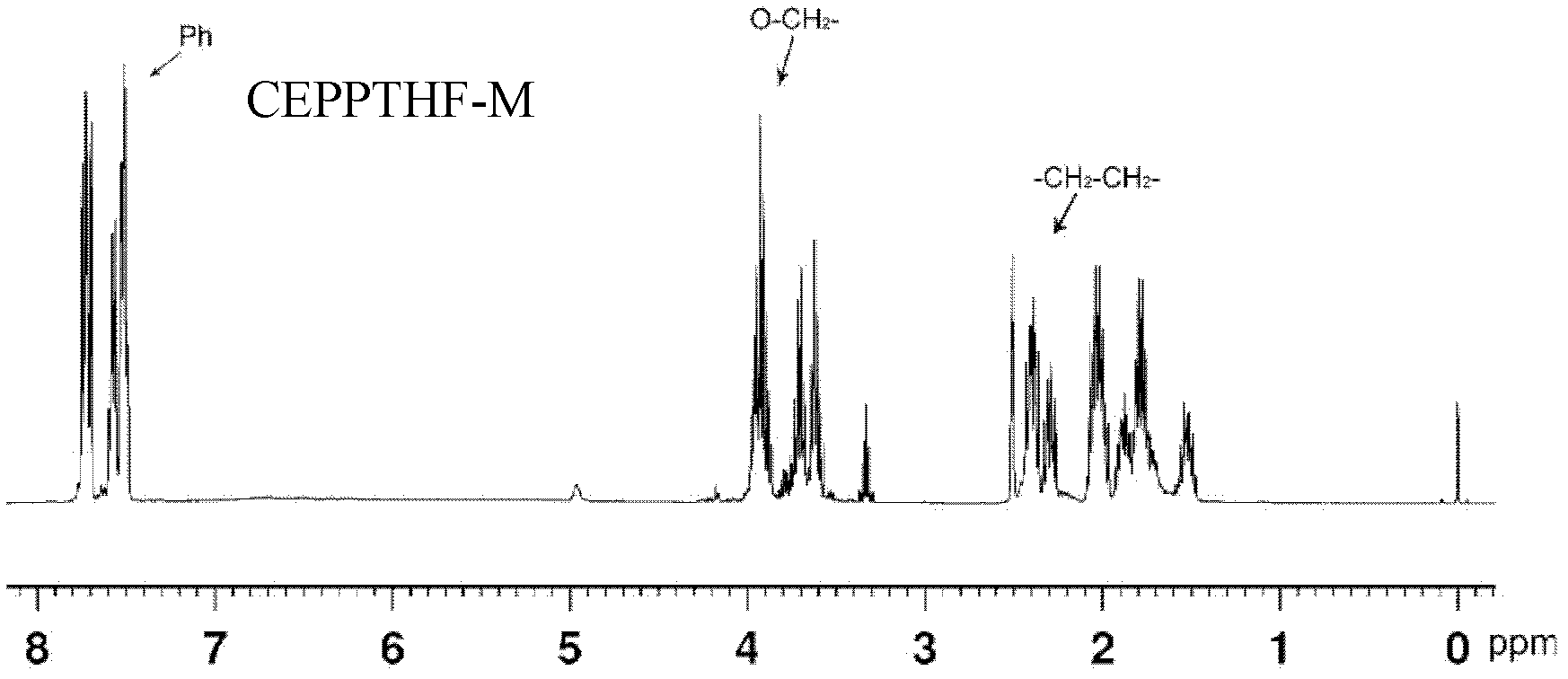

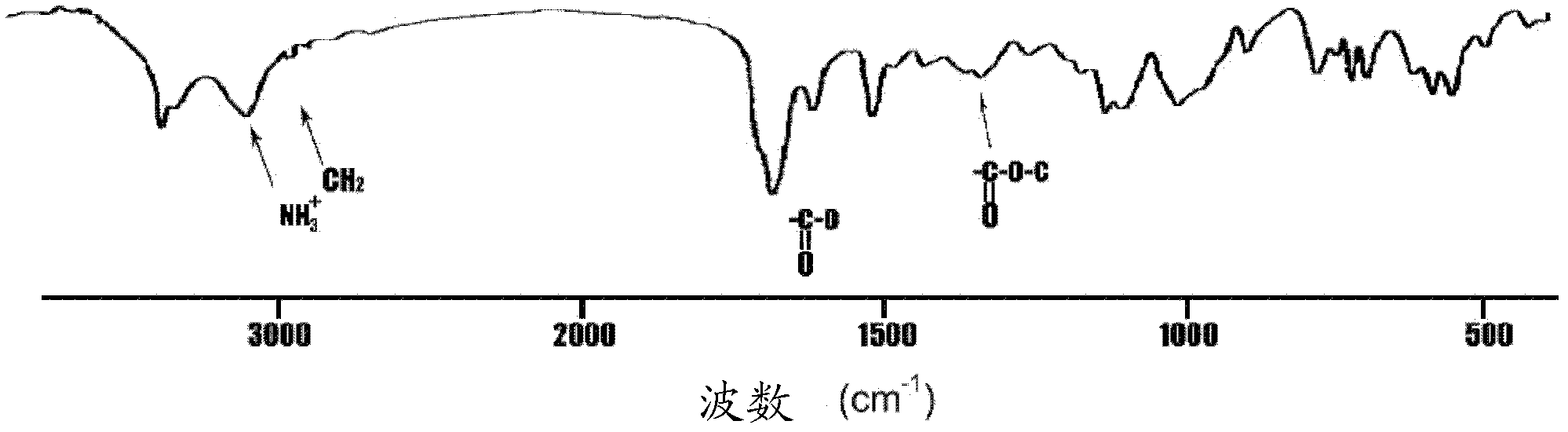

Melamine salt flame retardant, flame-retardant polyamide film and preparation method thereof

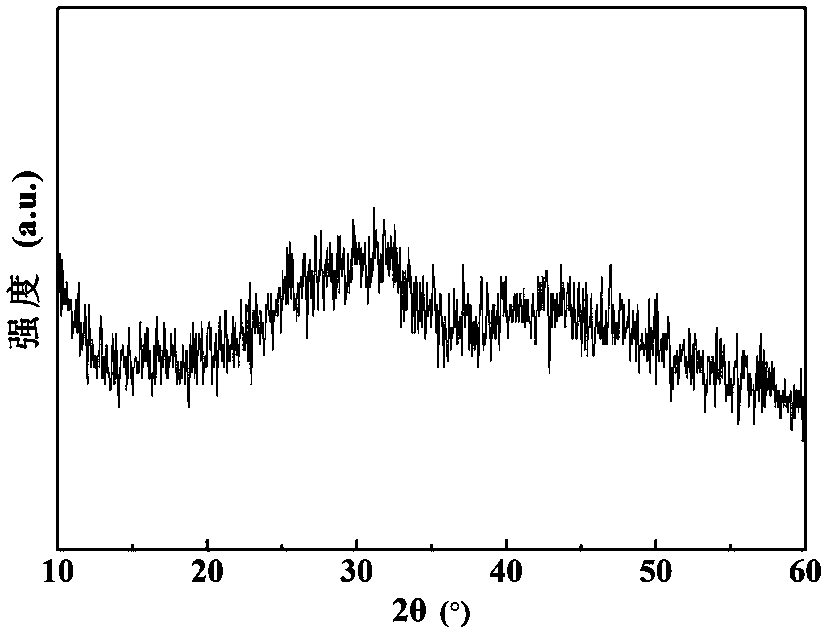

ActiveCN102532600ADoes not reduce viscosityPromote environmental protectionGroup 5/15 element organic compoundsPolymer scienceMelamine phosphate

The invention relates to the technical field of polyamide films, in particular to a melamine salt flame retardant, a flame-retardant polyamide film and the preparation method thereof, and aims to solve the problems in the prior art that the overall properties (including flame retardancy and mechanical property) of the flame-retardant polyamide film are poor. The invention provides the melamine salt flame retardant, the flame-retardant polyamide film containing the melamine salt flame retardant, and the preparation method thereof. The flame retardant is a melamine phosphate salt with the tetrahydrofuran ring structure. The addition of the melamine salt flame retardant does not reduce the viscosity of polyamide, the film product has excellent overall properties and is environment-friendly, and the preparation method is simple and favorable to industrial production.

Owner:合肥长阳新材料科技有限公司

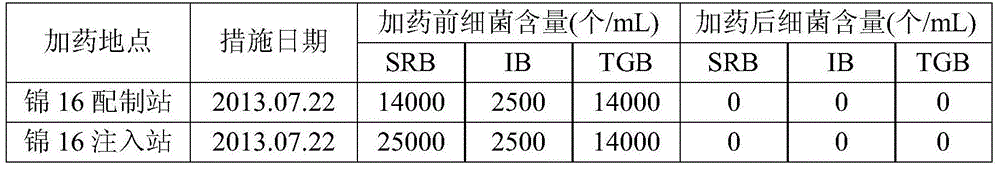

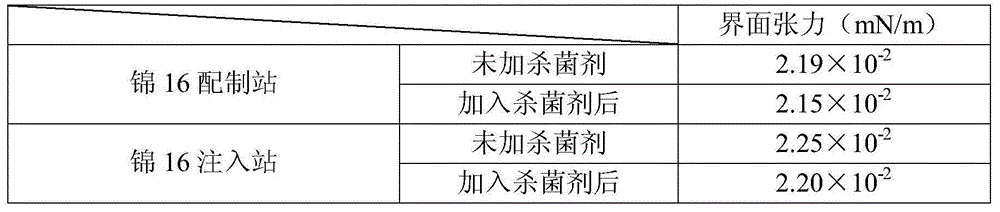

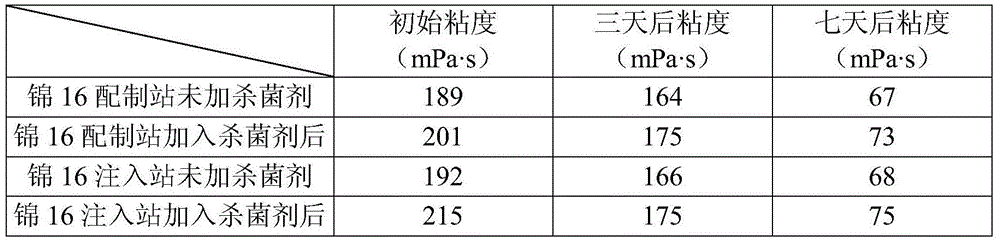

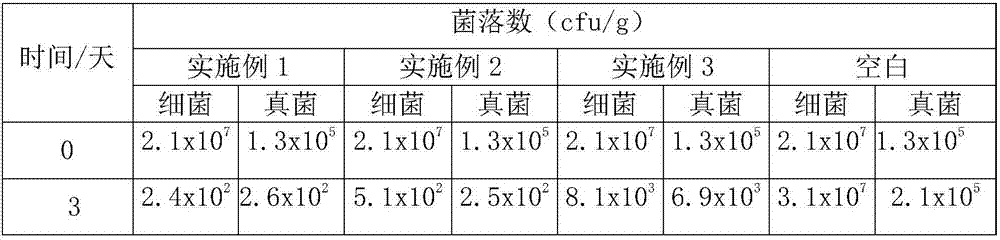

Bactericide for chemical flooding as well as preparation method and application of bactericide

InactiveCN104430494AGood application effect and application prospectIncrease productionBiocideDisinfectantsIron bacteriaSewage treatment

The invention provides a bactericide for chemical flooding as well as a preparation method and application of the bactericide. The bactericide is prepared from the following components in percentage by mass: 20-25 percent of tetrakis hydroxymethyl phosphonium sulfate, 0.3-0.5 percent of dithiocyano-methane, 3-5 percent of glutaraldehyde, 0.3-0.5 percent of xanthan gum, 0.3-0.5 percent of tween 80 and the balance of water. The preparation method of the bactericide comprises the following steps: adding water to mix tetrakis hydroxymethyl phosphonium sulfate and glutaraldehyde to obtain an insecticide A; adding water to mix dithiocyano-methane, xanthan gum and tween 80 to prepare an insecticide B; adding water to mix the insecticides A and B to prepare the bactericide. The invention further provides application of the bactericide in chemical flooding oilfield sewage treatment. The bactericide has good bacterium killing effect, can be used for completely killing sulfate reducing bacteria, iron bacteria and saprophytic bacteria without reducing viscosity of polymers or influencing the ultralow interfacial tension of the chemical blooding, and is a novel efficient bactericide for chemical flooding.

Owner:PETROCHINA CO LTD

Three-dimensional silicon carbide fiber reinforced aluminum oxide-zirconium oxide composite material and preparation method thereof

The invention discloses a three-dimensional silicon carbide fiber reinforced aluminum oxide-zirconium oxide composite material and a preparation method thereof. The preparation method comprises the following steps: (1) stabilizing aluminum oxide-zirconium oxide composite sol; (2) performing soaking, namely performing vacuum soaking on a three-dimensional silicon carbide fiber prefabricated part into the aluminum oxide-zirconium oxide composite sol; (3) drying the soaked three-dimensional silicon carbide fiber prefabricated part; (4) performing thermal treatment; (5) repeating the soaking-drying-thermal treatment process of steps (2) to (4) till the weight of a three-dimensional silicon carbide fiber reinforced aluminum oxide-zirconium oxide composite material intermittent is increased by less than 1% when being compared with that of a former soaking-drying-thermal treatment process, thereby obtaining the three-dimensional silicon carbide fiber reinforced aluminum oxide-zirconium oxidecomposite material. The three-dimensional silicon carbide fiber reinforced aluminum oxide-zirconium oxide composite material disclosed by the invention has the advantages of being good in high temperature resistance and oxidation resistance, excellent in mechanical property, and the like.

Owner:NAT UNIV OF DEFENSE TECH

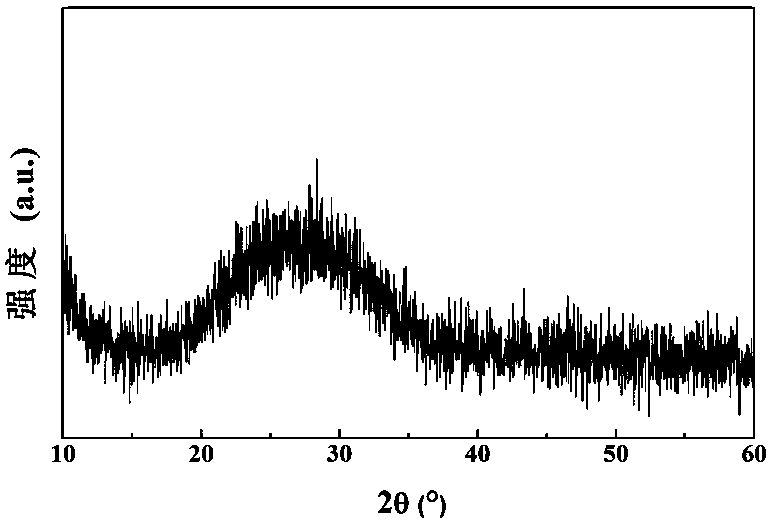

Three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material and preparation method thereof

The invention discloses a preparation method of a three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The preparation method ofthe three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material comprises the following steps of (1) stabilizing SiO2-ZrO2 composite sol;(2) impregnating three-dimensional silicon carbide fiber prefabricated members into the stabilized SiO2-ZrO2 composite sol; (3) drying the impregnated three-dimensional silicon carbide fiber prefabricated members; (4) performing thermal treatment; (5) repeating the impregnation-drying-thermal treatment process in the steps of (2) to (4) until the weight gain rate of a three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material intermediate in a current impregnation-drying-thermal treatment process relative to a previous impregnation-drying-thermal treatment process is smaller than 1% to obtain the three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The prepared three-dimensional silicon carbide fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material has the advantages of being high in high-temperature resistance and antioxidant and mechanical performance and the like.

Owner:NAT UNIV OF DEFENSE TECH

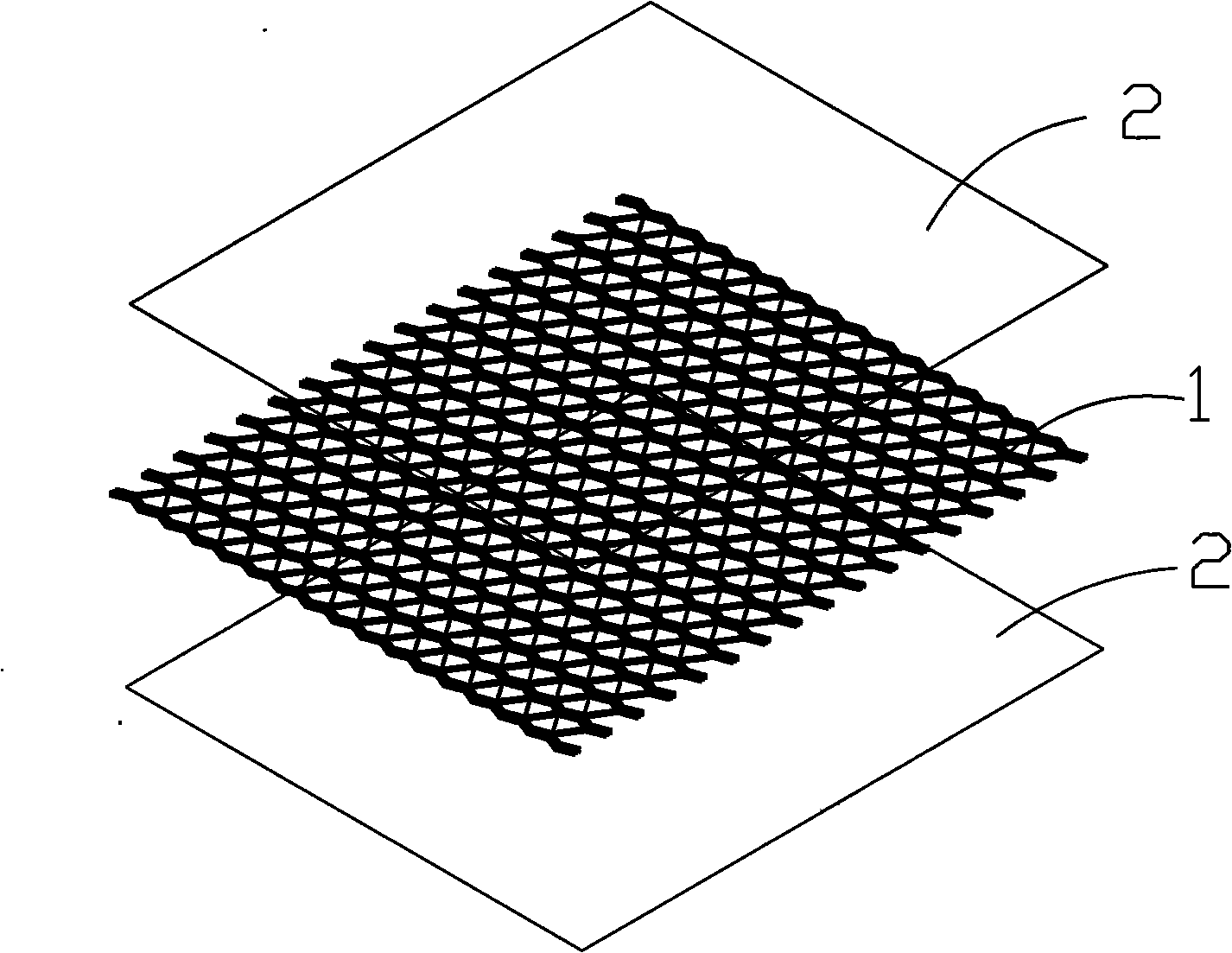

Antiskid connecting pad and fabrication technology thereof

InactiveCN101338178ALow densityLight densityOther chemical processesFilm/foil adhesivesPolyesterManufacturing technology

The invention relates to an antiskid connecting pad and the manufacturing process thereof. The antiskid connecting pad comprises knitting net gab at the middle and protective films which are respectively arranged on the two sides of the net gab. The knitting net gab is made of PET material or nylon or polyester. And sticky gel is coated on the two sides of the knitting net gab. The protective films on the two sides are adhered on the two sides of the knitting net gab through the sticky gel of the knitting net gab. The manufacturing process comprises that: A. the knitting net gab is set; B. the protective films are respectively adhered on the two sides of the knitting net gab. The antiskid connecting pad of the invention is provided with small density and light weight. The protective films can be stripped conveniently and no sticky gel is adhered. The viscosity of the knitting net gab can not be lowered. The protective films can be recycled and reused conveniently. Simultaneously, pasted matters such as carpets, floors, and the like can be stripped from the knitting net gab conveniently to guarantee the cleanness of the pasted matters.

Owner:DONGGUAN LIANYING NONWOVEN TECH

Three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material and preparation method thereof

The invention discloses a preparation method of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The preparation method of the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material comprises the following steps of (1) stabilizing SiO2-ZrO2 composite sol; (2) impregnatingthree-dimensional carbon fiber prefabricated members into the stabilized SiO2-ZrO2 composite sol; (3) drying the impregnated three-dimensional carbon fiber prefabricated members; (4) performing thermal treatment; (5) repeating the impregnation-drying-thermal treatment process in the steps of (2) to (4) until the weight gain rate of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material intermediate in a current impregnation-drying-thermal treatment process relative to a previous impregnation-drying-thermal treatment process is smaller than 1% to obtain the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The prepared three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material has the advantages of being high in high-temperature resistance and antioxidant and mechanical performance and the like.

Owner:NAT UNIV OF DEFENSE TECH

Polyolefin polymer modified binder material for organic electroluminescent device

ActiveCN103756615AReduce weight percentageIncrease dosageNon-macromolecular adhesive additivesSolid-state devicesOrganic electroluminescencePlasticizer

A composited binder material for packaging a electroluminescent device comprises 65.0-75.0% of organic silicon / epoxy resin matrix, 0.3-4.6% of ferroferric oxide fiber material, 2.0% of tetraethoxysilanecross-linking agent, 18.0-29.5% of the mixture of polyvinyl alcohol and polyethylene, and the balance of the assistant and a phthalic acid ester plasticizer, wherein the ratio of length to diameter of the fiber material is 4-6.

Owner:JIANGSU XINGHUA RUBBER BELT

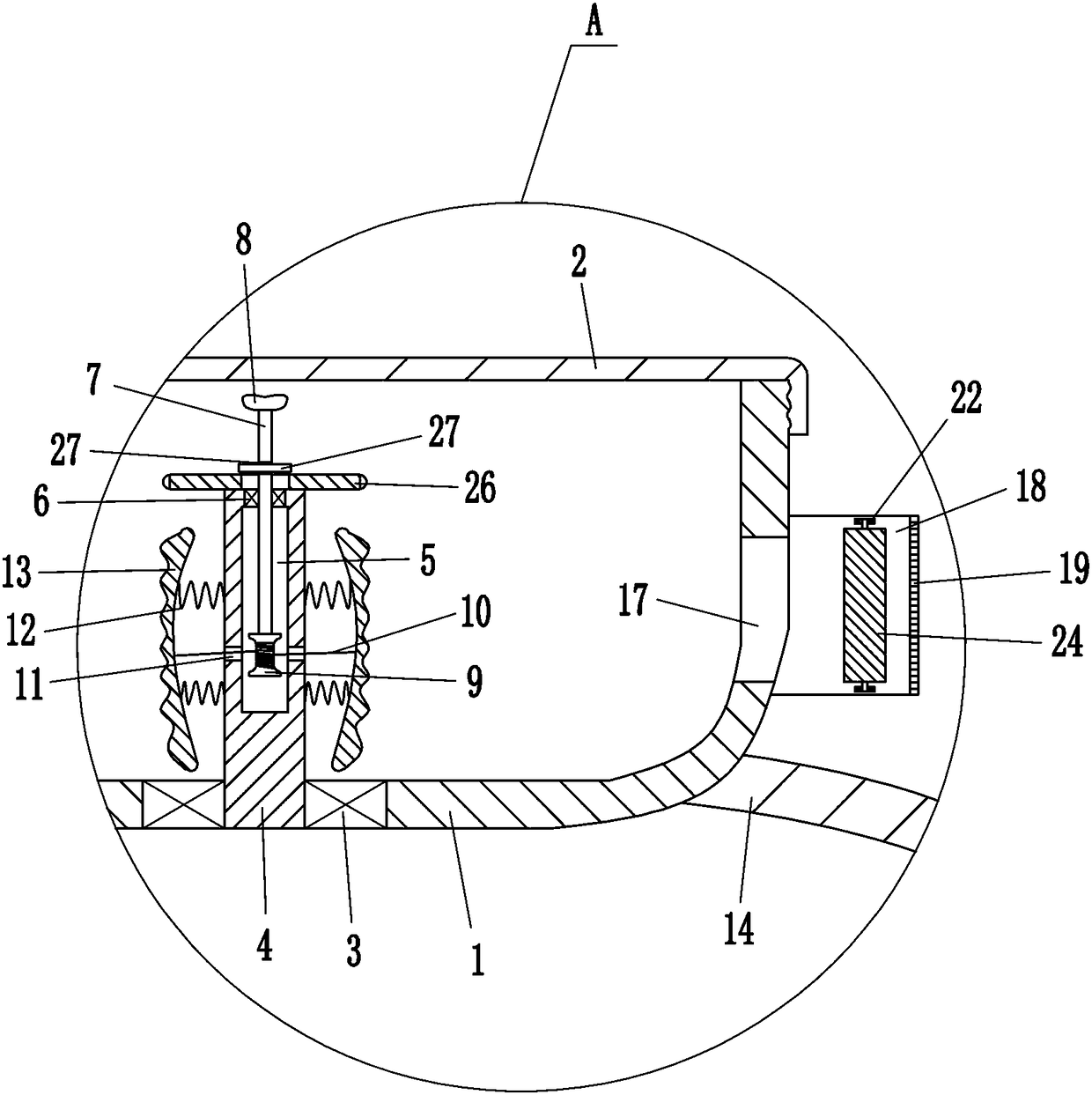

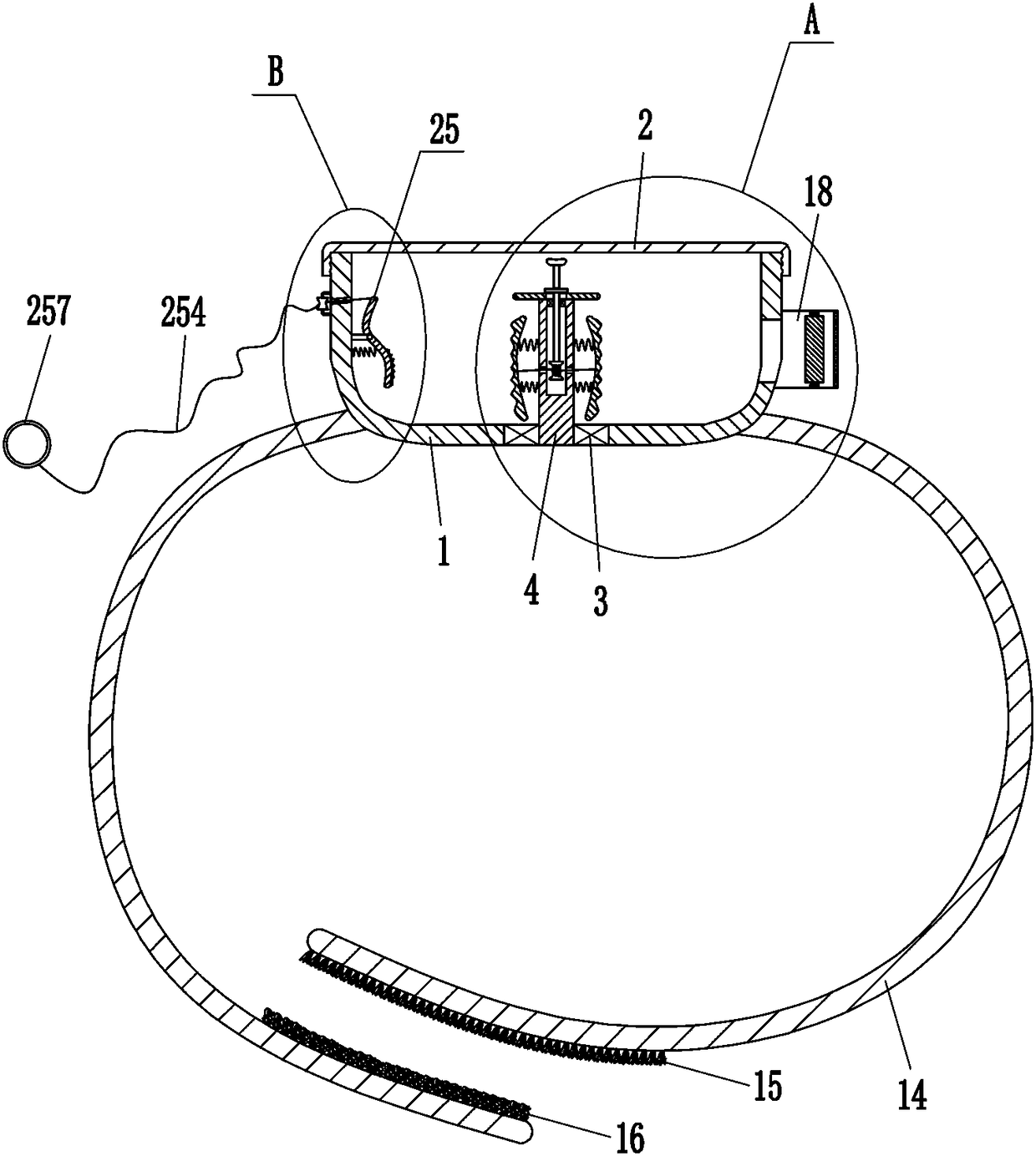

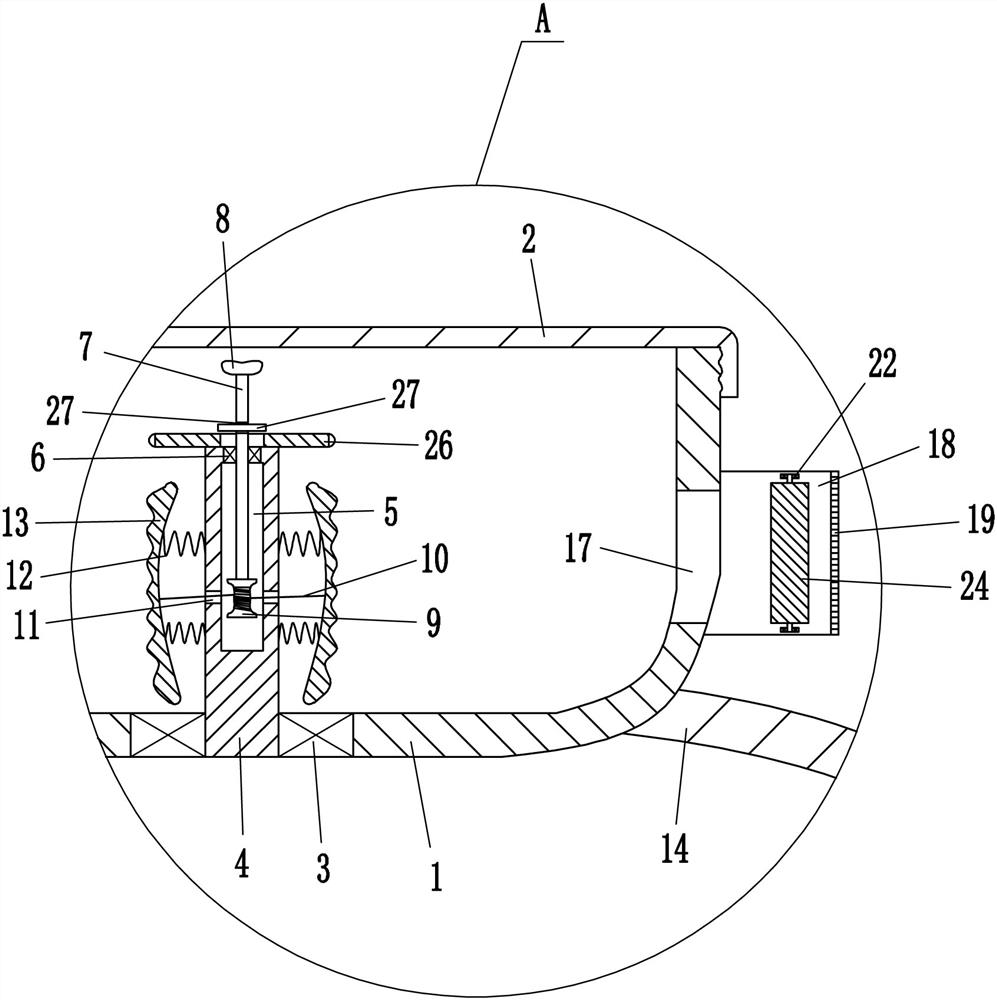

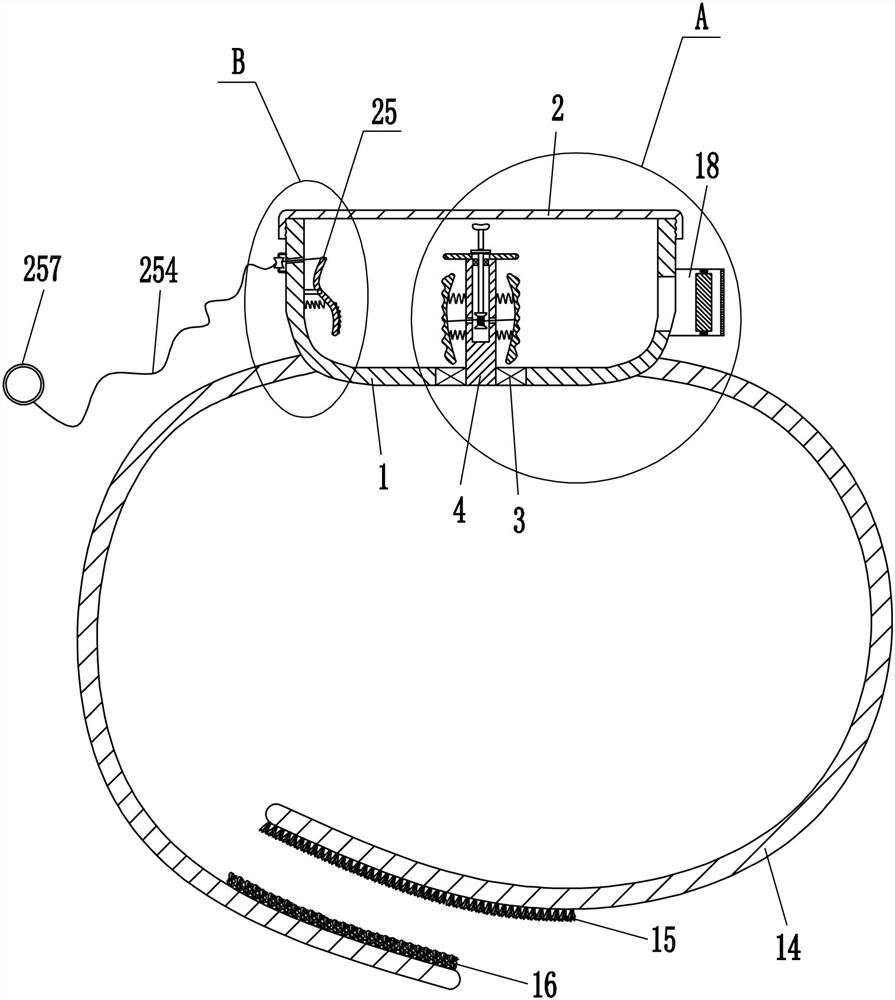

Worn medical adhesive tape pull-parting device

The invention relates to a pull-parting device, in particular to a worn medical adhesive tape pull-parting device. For solving the technical problem, the worn medical adhesive tape pull-parting devicesimple in operation and making the stickiness of an adhesive tape not prone to reduction. According to the technical scheme, the worn medical adhesive tape pull-parting device comprises a columnar box body, a cover, a first bearing seat, a rotary shaft, a second bearing seat, a rotary rod and the like. The top of the columnar box body is provided with the cover, the cover is matched with the columnar box body, the middle of the bottom of the columnar box body is provided with the first bearing seat in an embedded way, and the rotary shat is connected in the first bearing seat and is providedwith a cavity. Under the effect of the first bearing seat, the rotary shaft can rotate with an adhesive tape so that a medical worker can better pull out the adhesive tape and pull the adhesive tape apart through a toothed blade, the operation is simple, and the stickiness of the adhesive tape is not reduced; the adhesive tape can be compressed through a compressing mechanism, the phenomenon is avoided that the adhesive tape rotates when the toothed blade pulls the adhesive tape apart, and accordingly the tooth blade can better pull the adhesive tape apart.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

A kind of low internal stress heat-resistant ABS resin and preparation method thereof

The invention provides low-internal-stress heat-resistant ABS resin and a preparation method and application thereof and belongs to the technical field of modified resin. The low-internal-stress heat-resistant ABS resin is prepared from, by weight, 20-40 parts of ABS rubber powder, 2-10 parts of low-molecular-weight SAN resin, 42-77 parts of high-acrylonitrile-content SAN resin, 1-8 parts of a heat resistant agent, 0.1-1 part of an antioxidant, 0.1-1 part of a lubricant and 0.1-1 part of a weather resistance agent according to a formula. Compared with the prior art, the prepared low-internal-stress heat-resistant ABS resin greatly improves the liquidity of a material on the basis that heat resistance and impact are guaranteed, can obviously reduces the internal gravity in the injection molding process and can be applied to interior decorative parts and exterior decorative painted parts of automobiles.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

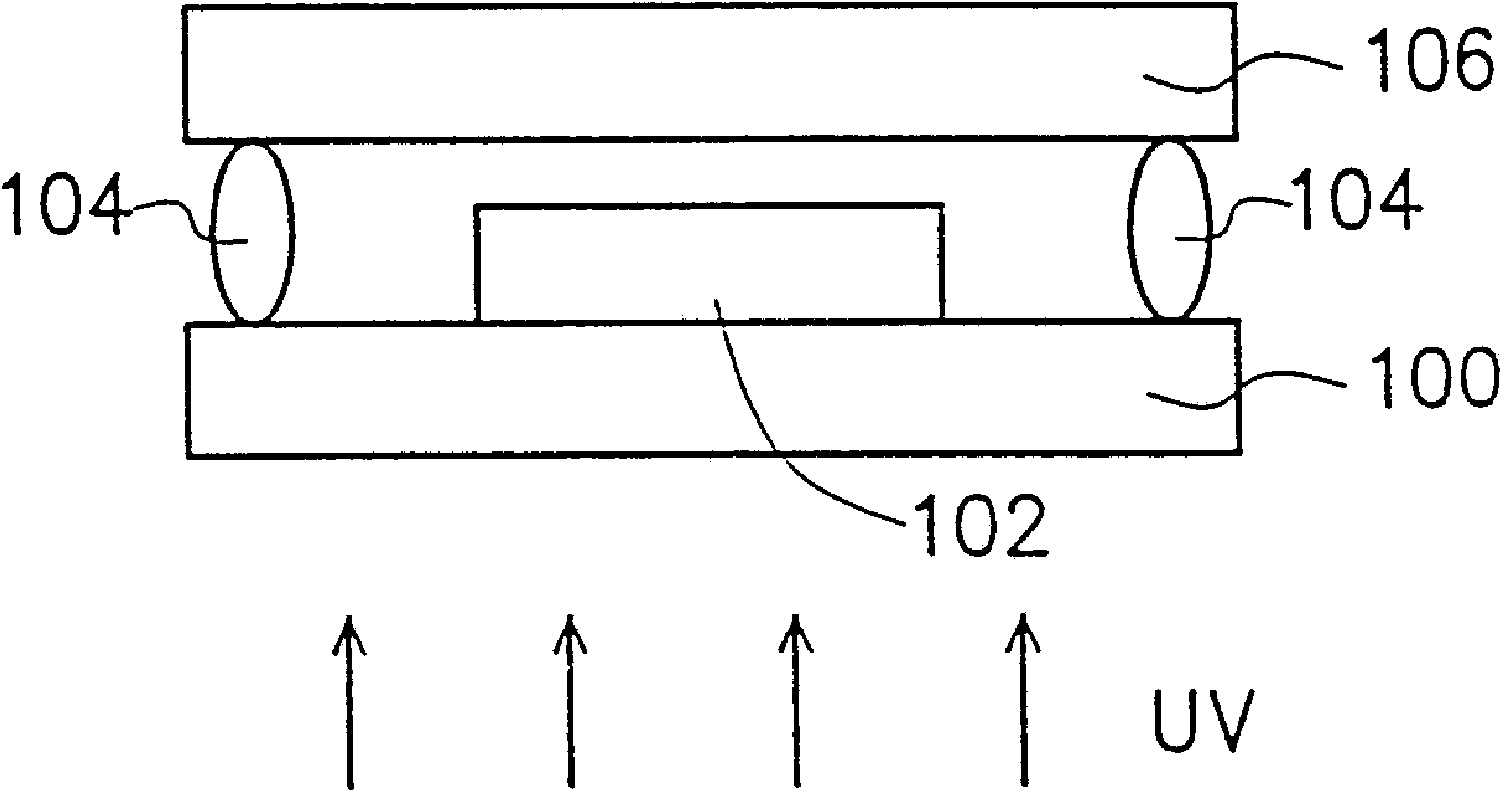

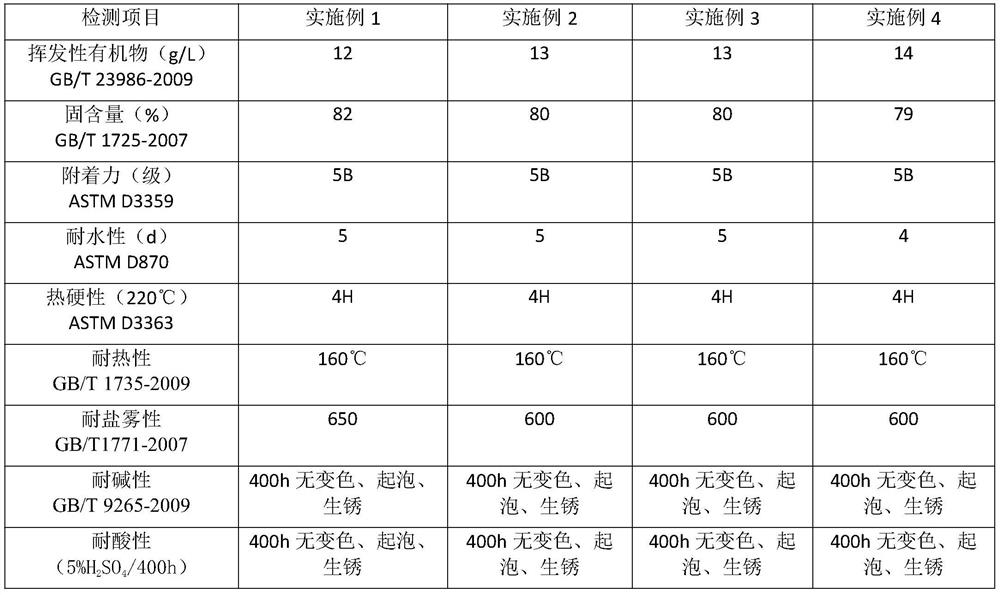

Low-VOC and high-solid-content water-based paint based on acrylic resin and preparation process thereof

ActiveCN112812647ANo reduction in physical propertiesReduce physical propertiesCoatingsPolymer scienceAcrylic resin

The invention discloses a low-VOC and high-solid-content water-based paint based on acrylic resin and a preparation method thereof, and the water-based paint prepared by adopting the formula provided by the invention still keeps excellent properties in the aspects of adhesive force, acid and alkali resistance and the like on the premise of reducing viscosity, increasing solid content and having relatively low VOC.

Owner:山东齐鲁漆业有限公司

Packaging method for electroluminescence devices

ActiveCN103840072AReduce weight percentageIncrease dosageNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyFiber

Disclosed is a packaging method for electroluminescence devices. The packaging method comprises the steps that firstly, a metal cover formed in a stamped mode is provided, a dispensing machine coats a binder to the edge of the metal cover, a moisture absorption layer is arranged in the metal cover, then the metal cover is located and corresponds to the position of a to-be-packaged electroluminescence light emitting diode on a glass substrate, the glass substrate with the electroluminescence light emitting diode covers the metal cover and is combined with the edge of the metal cover in a pressed mode through the binder, and the binder hardens naturally. The binder is composed of, by weight, 65.0-75.0% of organosilicone / epoxy resin matrixes, 0.3-4.6% of ferroferric oxide fiber materials, 2.0% of ethyl orthosilicate cross-linking agents, 18.0-29.5% of mixture of polyvinyl alcohol and polyethylene, and the balance addition agents and phthalic acid ester plasticizer, wherein the gross is one hundred percent, the ferroferric oxide fiber materials are fiber materials with the porous surface, the diameter of a ferroferric oxide fiber is about 100-150 nm, and the diameter of each hole in the surface is about 20-30 nm.

Owner:JIANGSU TIWIN OPTO ELECTRONICS TECH

Three-dimensional carbon fiber preform enhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material and preparation method thereof

ActiveCN107640975AImprove antioxidant capacityImprove high temperature resistanceCeramicwareFiberPorosity

The invention discloses a three-dimensional carbon fiber preform enhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material and a preparation method thereof. The composite materialcomprises a three-dimensional carbon fiber preform and yttrium oxide-aluminum oxide complex-phase ceramic, in the yttrium oxide-aluminum oxide complex-phase ceramic, the molar content of Al2O3 is 5%-95%, pores of a three-dimensional carbon fiber preform are uniformly filled with the yttrium oxide-aluminum oxide complex-phase ceramic, and the porosity of the three-dimensional carbon fiber preformenhanced yttrium oxide-aluminum oxide complex-phase ceramic composite material is 10%-15%. The preparation method comprises the following steps; (1) preparing yttrium oxide-aluminum oxide composite sol; (2) carrying out dipping; (3) drying; (4) carrying out heat treatment; and (5) repeating a dipping-drying-heat treatment process in the step (2)-step (4). The composite material has the advantagesof low porosity, high compactness, high temperature resistance, oxidation resistance, excellent mechanical property and the like. The preparation method is high in preparation efficiency, and the compactness and mechanical property of the prepared composite material are improved remarkably.

Owner:NAT UNIV OF DEFENSE TECH

Light-oil for releasing negative ions and preparation method thereof

The invention discloses light-oil for releasing negative ions and a preparation method thereof, the light-oil for releasing the negative ions is mainly composed of a mixture of 35 to 45 parts of negative ion powder and 95 to 105 parts of LED light-oil, the preparation method comprises the following steps: S1, preparing the negative ion powder and the LED light-oil; S2, heating the LED light-oil prepared in the step S1 in water bath for thermal insulating; S3, placing the negative ion powder S1 prepared in the step S1 in the LED light-oil in the S2, stirring, to fully mix the negative ion powder and the LED light-oil to obtain the light-oil with the negative ion powder. The light-oil is used to coat the surface of an object to radiate air. The air is ionized to release negative oxygen ionsto remove formaldehyde in a room, so that the indoor air is purified, the content of the formaldehyde in the air is reduced, and the negative oxygen ions are provided for the indoor environment, thereby creating a healthy environment for people.

Owner:成都韩尚艺术贴花有限公司

High-heat-resisting modified resin and preparation method thereof

InactiveCN108976825AImprove heat resistanceNo reduction in heat resistancePolymer scienceHeat resistance

The invention discloses a high-heat-resisting modified resin, comprising the following raw materials in parts by weight: 53-67 parts of rosin, 35-42 parts of sisal hemp fresh leaves, 13-24 parts of sepiolite, 11-19 parts of straw, 3-7 parts of paraffin and 2-6 parts of chitosan. The high-heat-resisting modified resin disclosed by the invention has superhigh heat resistance, can obviously reduce the viscosity of the material and improve the mobility of the material while the heat resistance and impact resistance of the material itself are reduced, and then the inner stress in the process of injection molding is reduced, and meanwhile adoption of a low-cost material can effectively reduce cost.

Owner:武汉中智德远科技开发有限公司

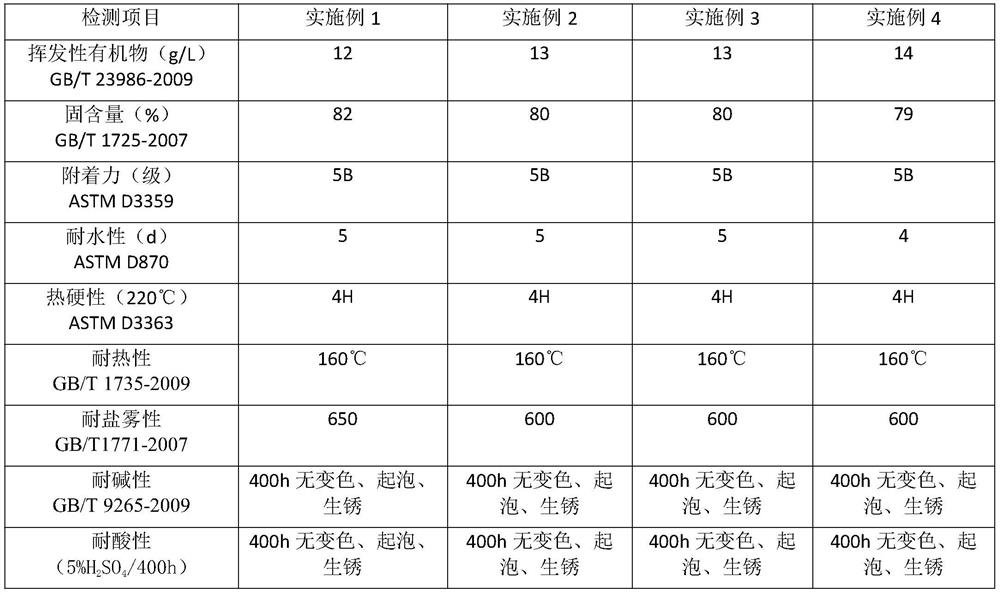

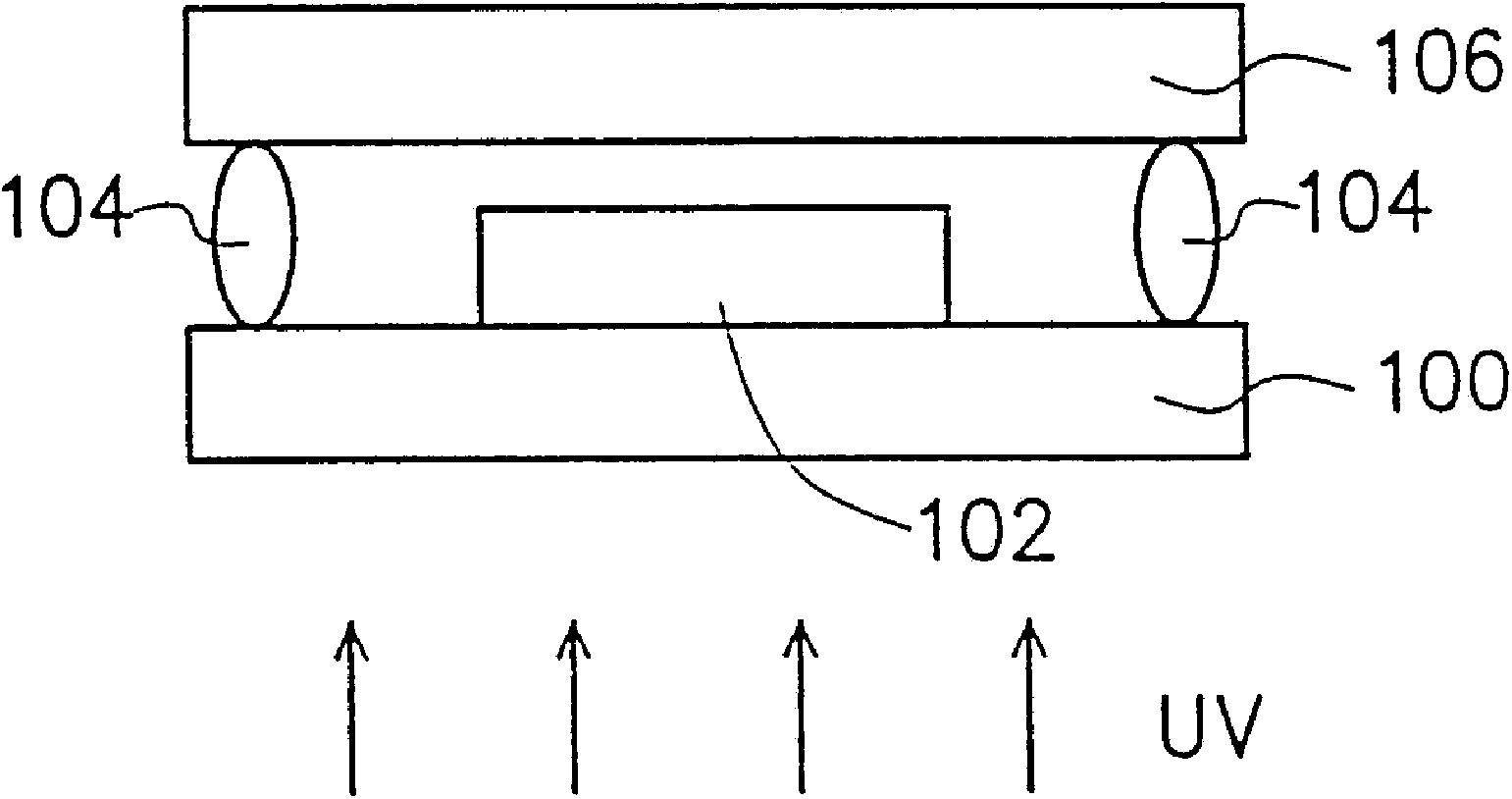

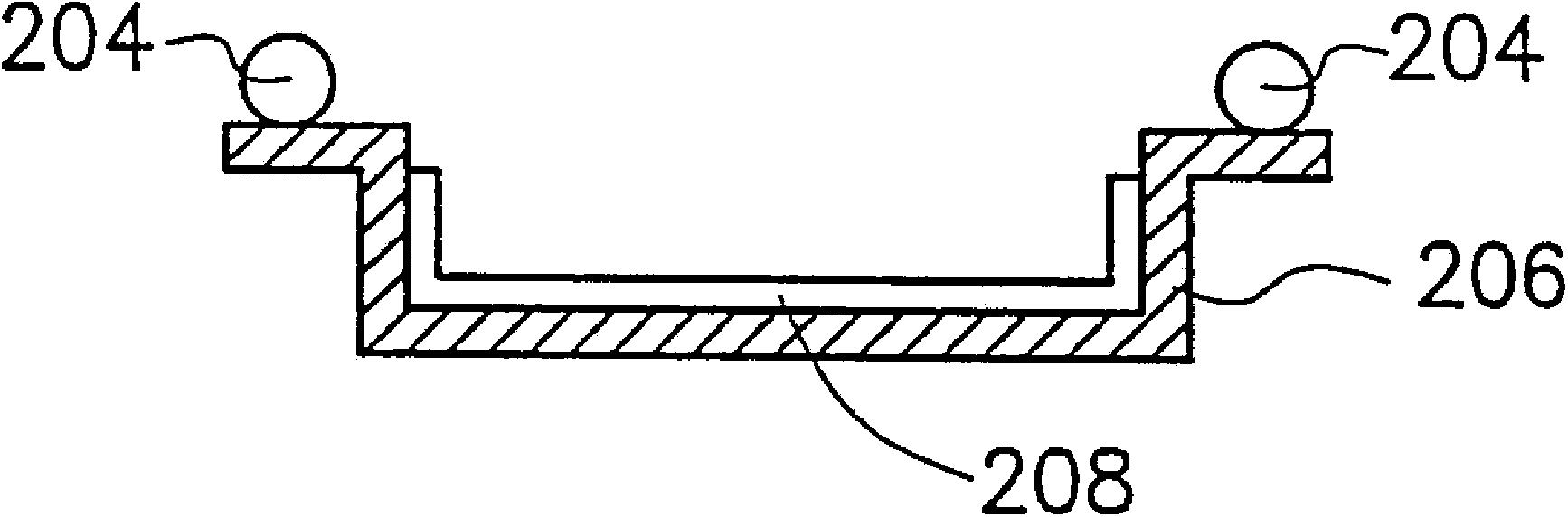

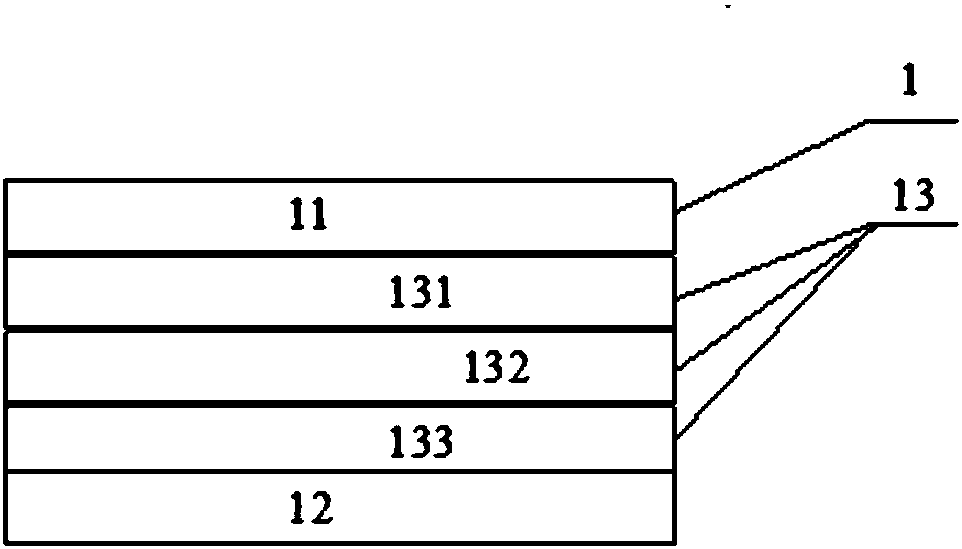

Double-sided adhesive film and supporting method for forming touch control structure on film

ActiveCN109233662ASticky releaseDoes not reduce viscosityAdhesive processesFilm/foil adhesivesAdhesiveStrong acids

The invention firstly provides a double-sided adhesive film. The double-sided adhesive film comprises a release film I, a first adhesive layer, a UV light isolation film, a second adhesive layer and arelease film II in the thickness direction sequentially, wherein the first adhesive layer, the UV light isolation film and the second adhesive layer jointly form a double-sided adhesive layer of thedouble-sided adhesive film, and the double-sided adhesive layer can withstand high temperature, strong acid and strong alkali environments in the process of developing and etching an ITO layer on thefilm; viscosity of the first adhesive layer and the second adhesive layer does not decrease significantly under the conditions of high temperature, strong acid and strong alkali, and the adhesive in the second adhesive layer is UV subtractive adhesive whose viscosity can be significantly decreased or lost after irradiation by UV light. The invention further provides a supporting method for forminga touch control structure on the film. According to the double-sided adhesive film and the Film supporting method, an expensive substrate can be fully reused, and the cost is saved.

Owner:LENS TECH CHANGSHA

Production for quick-freezing Chinese yam powder

InactiveCN1284477CDoes not reduce viscosityGuarantee the inner qualityFood shapingFruits/vegetable preservation by freezing/coolingQuick FreezeBacteria coliforms

A process for producing quick-frozen Chinese yam includes soaking in disinfectant liquid to kill bacteria, peeling, cutting into blocks, soaking in color protecting liquid for maintaining color, soaking in disinfectant liquid to kill bacteria again, milling into particles, filling in plastic bag, quick freezing and further freezing. The present invention has the advantages of keeping its original color, no change in its surface color and gloss, as well as bactericidal effect superior to heat sterilization. Total count of bacteria colonies per 1 g sample is less than 1000, and total count of Coliform bacteria per 100 g sample is less than 3.

Owner:胡传银 +2

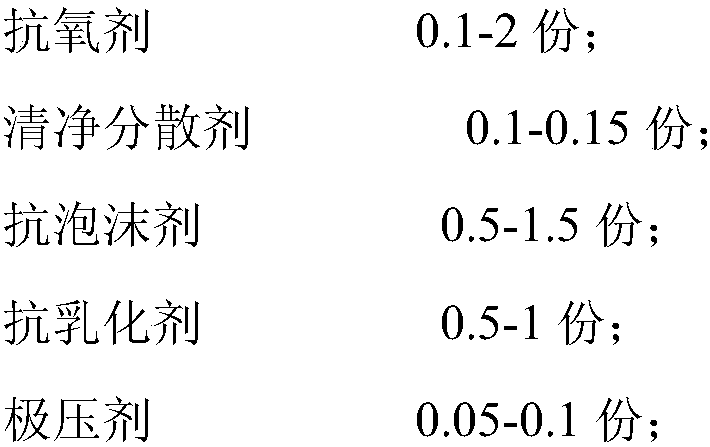

A kind of environment-friendly and easily decomposable vegetable oil-based lubricating oil and its production process

ActiveCN104745280BMeet actual use needsProduce pollutionLubricant compositionVegetable oilSunflower oil

The invention discloses an environmentally friendly and easily decomposable vegetable oil-based lubricating oil and a production process thereof, belonging to the field of lubricating oil. The lubricating oil of the present invention adopts vegetable oil as the base oil, and the mass ratio of the base oil and the additive is 7:3, wherein the base oil includes high oleic sunflower oil and castor oil, and the quality of the high oleic sunflower oil and castor oil is The ratio is 6:4. Among them, high oleic sunflower oil, with an oleic acid content of up to 90%, has extremely high antioxidant properties, while castor oil has an ideal viscosity. The two are used in a ratio. As an ideal vegetable oil, no special processing is required. Advantageous characteristics of conventional mineral oils as base oils. In addition, through the auxiliary modification of additives, no special processing is required, and it can be put into use after simple proportioning and high-temperature smelting. The production cost is low and it is easy to popularize.

Owner:HANERGY (QINGDAO) LUBRICATION TECH CO LTD

Method for producing regenerative heavy denier profiled polyester staple fibres

ActiveCN102094250BSolve the problem of aqueous high viscosity degradationHigh strengthFilament/thread formingMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a method for producing regenerative heavy denier profiled polyester staple fibres. The method comprises the following main procedures: selecting high-quality regenerative polyester bottle chips and spinning the bottle chips to form fibres with profiled sections through drying, melting spinning, cooling, drawing and setting. The method has the following main characteristics: A) after being dried, the moisture contents of the regenerative polyester bottle chips are below 80PPM; B) the melting temperature is controlled between 270 DEG C and 285 DEG C and the spin beam temperature is controlled between 275 DEG C and 278 DEG C; and C) a mist and recirculating air dual-purpose cooling device is adopted for cooling, the mist spray speed is 3.8-4.0m / s and the water temperature is not more than 30 DEG C. The method has the following positive effects: by adopting the cooling method and device combining mist spray cooling and recirculating air cooling for the fibres which are extruded, melted and spouted, the good setting property of the profiled sections of the fibres is ensured and the problem that the sections of the fibres tend to be round due to surface tension existing when the polymer melt is extruded from the spinneret orifice is solved, so that the fibres have multidimensional reflecting effects as the diamond shaped mirrors.

Owner:广东秋盛资源股份有限公司

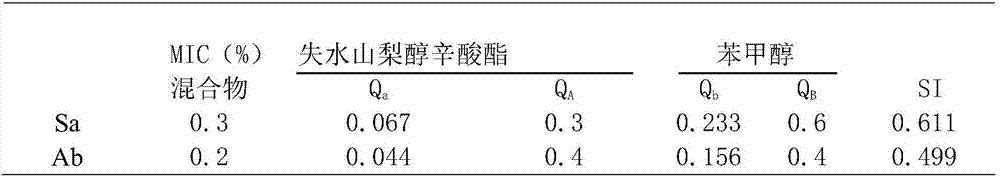

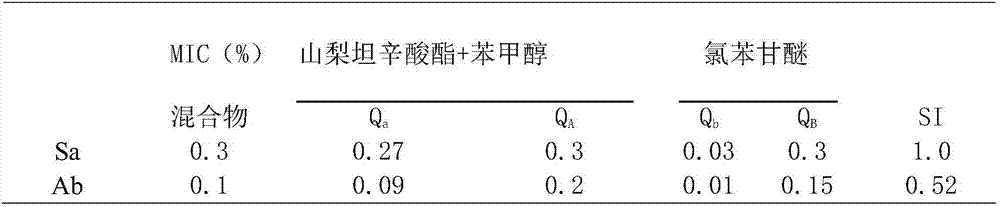

Preservative and bactericidal agent for broad-spectrum daily chemicals

ActiveCN107535495AHigh activityBroad-spectrum anti-corrosion and anti-mildew abilityBiocideFungicidesBENZYL ALCOHOL/WATERBroad spectrum

The invention relates to a preservative and bactericidal agent for broad-spectrum daily chemicals, which is prepared from the following substances in percentage by weight: 8 to 16 percent of chlorphenesin, 55 to 75 percent of benzyl alcohol, 15 to 30 percent of sorbitan caprylate and 0.1 to 0.5 percent of additive. The preservative and bactericidal agent is compounded by adopting a variety of zero-added preservatives with different bactericidal mechanisms and antibacterial spectra complementing one another and a conventional preservative, and has the advantages of reasonable concerted application, full protection, strong synergism, toxicological safety, good bactericidal and preservative effects and the like. Practice proves that the effect of use in the daily chemicals is good.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Polyolefin polymer modified binder material for organic electroluminescent device

ActiveCN103756615BReduce weight percentageIncrease dosageNon-macromolecular adhesive additivesSolid-state devicesFiberEpoxy

A composited binder material for packaging a electroluminescent device comprises 65.0-75.0% of organic silicon / epoxy resin matrix, 0.3-4.6% of ferroferric oxide fiber material, 2.0% of tetraethoxysilanecross-linking agent, 18.0-29.5% of the mixture of polyvinyl alcohol and polyethylene, and the balance of the assistant and a phthalic acid ester plasticizer, wherein the ratio of length to diameter of the fiber material is 4-6.

Owner:JIANGSU XINGHUA RUBBER BELT

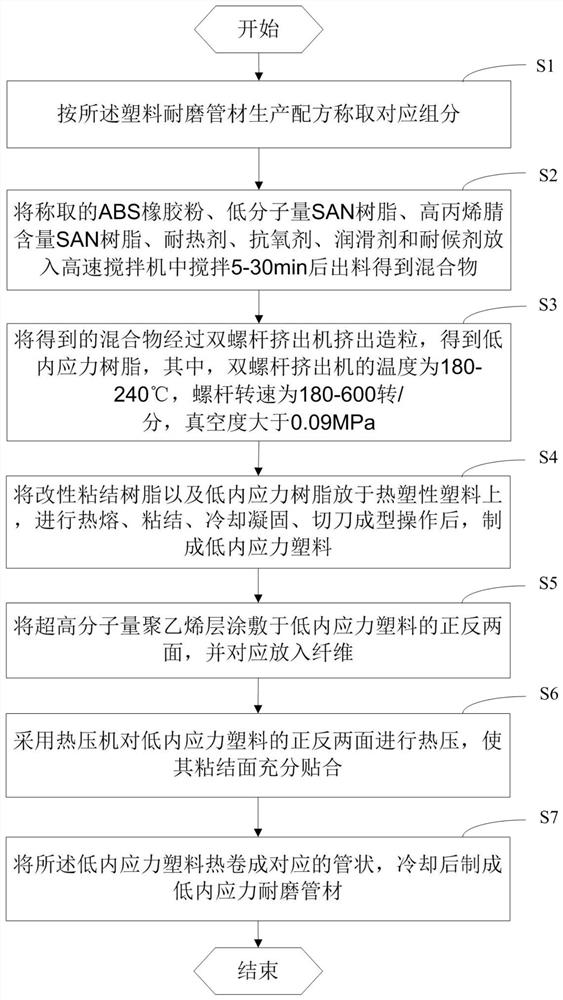

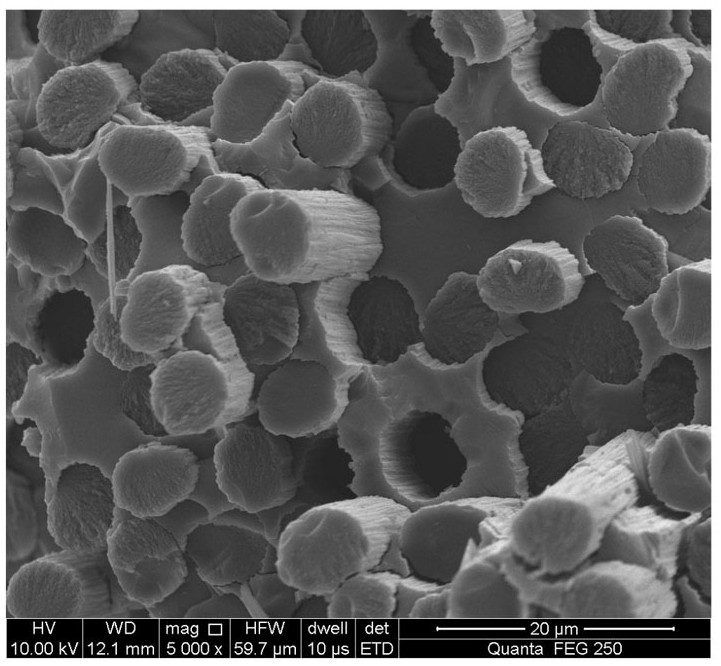

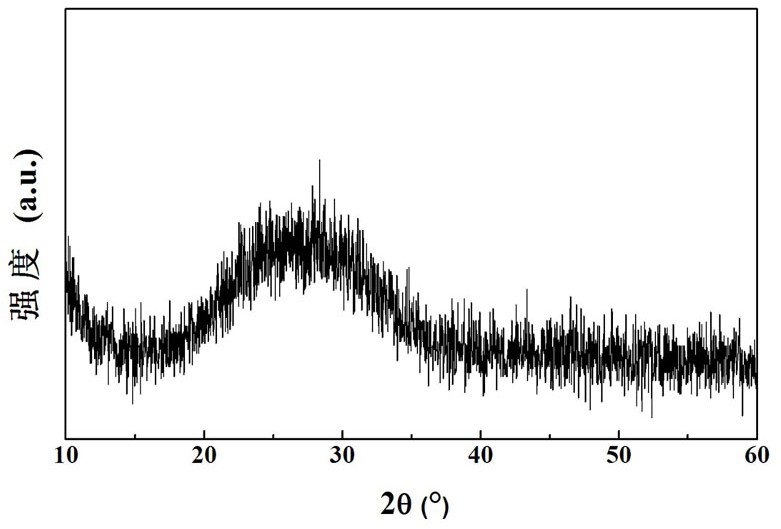

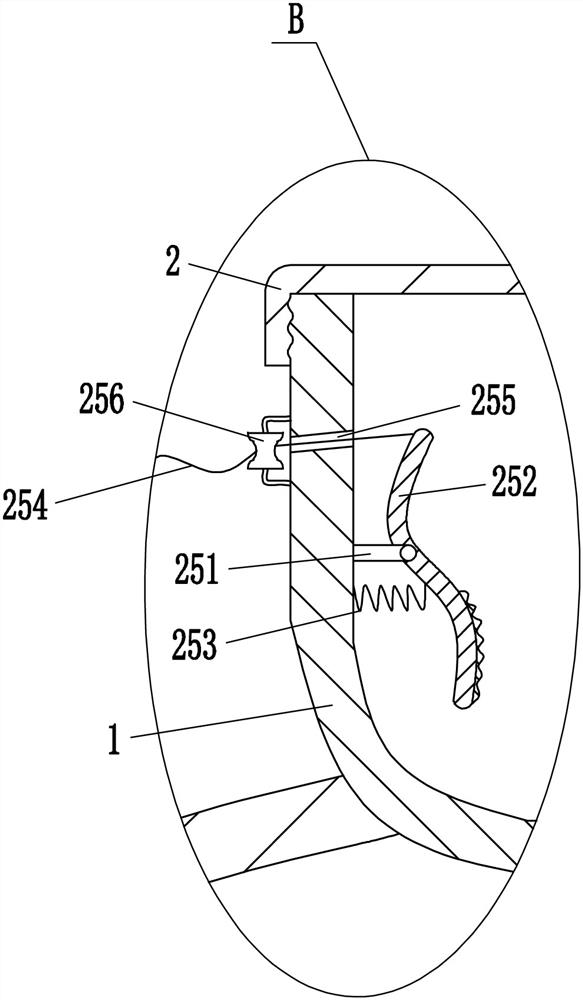

Plastic wear-resistant pipe production formula and process

The invention provides a plastic wear-resistant pipe production formula and a process, which are applied to the technical field of plastic manufacturing, and the production formula comprises thermoplastic plastic, a matrix, modified adhesive resin and fibers, and also comprises ABS rubber powder, low molecular weight SAN resin, high acrylonitrile SAN resin, a heat-resistant agent, an antioxidant,a lubricant and a weather-resistant agent. In the production formula, the plastic wear-resistant pipe is prepared from the following components in percentage by mass: 5-10% of an ultra-high molecularweight polyethylene layer of the matrix; 60-80% of thermoplastic plastic; 2-3% of modified adhesive resin; 0.1-1 percent of fibers; 4%-6% of ABS rubber powder, 0.5%-3% of low molecular weight SAN resin and 7%-10% of high acrylonitrile SAN resin; 0.2-0.8% of the heat-resistant agent; 0.1-0.5 percent of the antioxidant; 0.1-0.5% of the lubricant; and 0.1-0.5% of the weather-resistant agent. The ultra-high molecular weight polyethylene / continuous fiber reinforced thermoplastic plastic is used for manufacturing the wear-resistant pipe, and meanwhile, the effect of solving the problem of internal stress is achieved.

Owner:吴红侠

Three-dimensional carbon fiber reinforced silica-zirconia composite ceramic composite material and preparation method thereof

The invention discloses a preparation method of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The preparation method of the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material comprises the following steps of (1) stabilizing SiO2-ZrO2 composite sol; (2) impregnatingthree-dimensional carbon fiber prefabricated members into the stabilized SiO2-ZrO2 composite sol; (3) drying the impregnated three-dimensional carbon fiber prefabricated members; (4) performing thermal treatment; (5) repeating the impregnation-drying-thermal treatment process in the steps of (2) to (4) until the weight gain rate of a three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material intermediate in a current impregnation-drying-thermal treatment process relative to a previous impregnation-drying-thermal treatment process is smaller than 1% to obtain the three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material. The prepared three-dimensional carbon fiber-reinforced silicon dioxide-zirconium dioxide multiphase ceramic composite material has the advantages of being high in high-temperature resistance and antioxidant and mechanical performance and the like.

Owner:NAT UNIV OF DEFENSE TECH

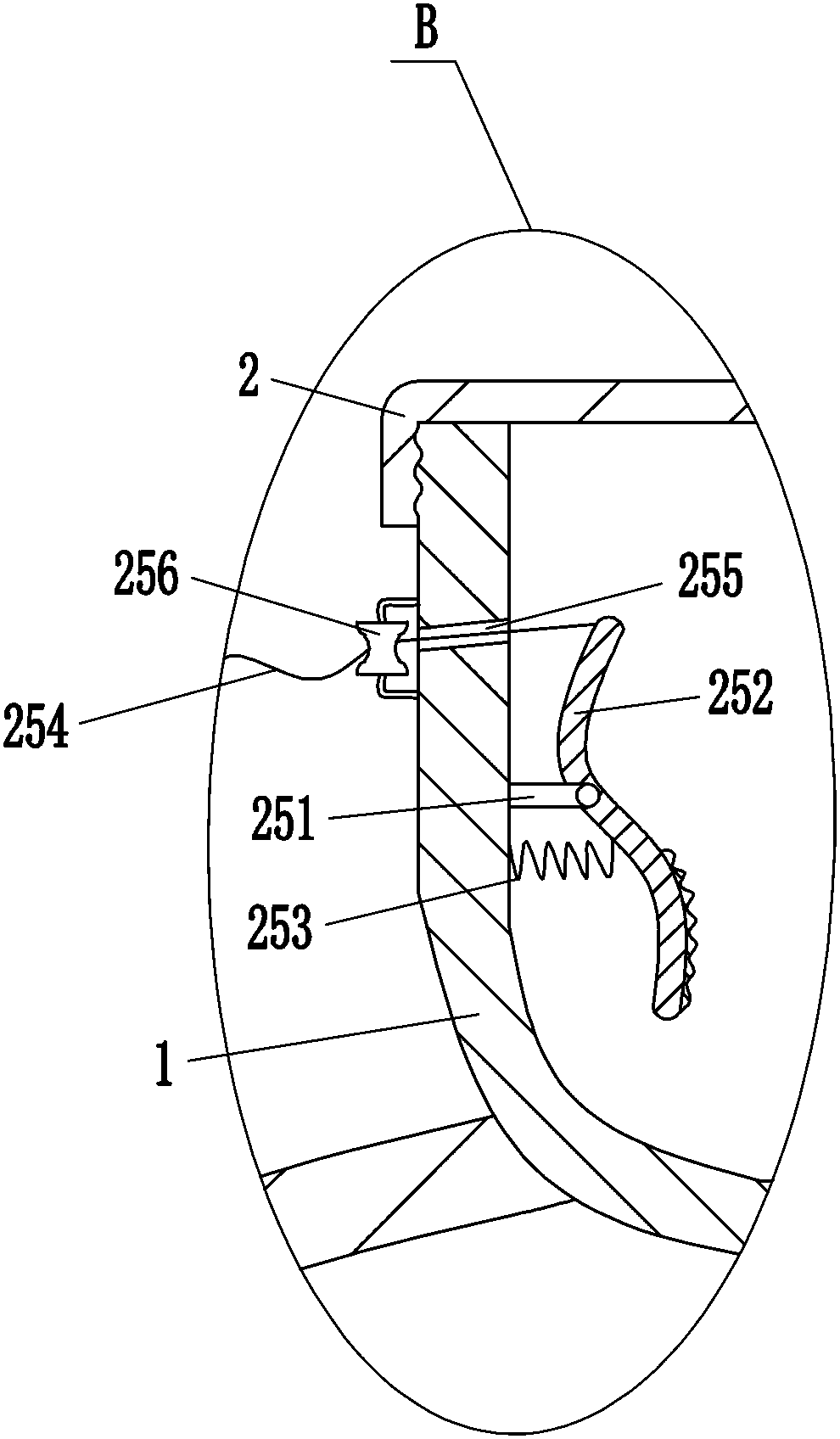

A wearable medical tape tearing device

The invention relates to a tearing device, in particular to a wearable medical adhesive tape tearing device. Technical problem: To provide a wearable medical tape tearing device that is easy to operate and not easy to reduce the adhesiveness of the tape. The technical solution is: a wearable medical tape tearing device, including a cylindrical box, a cover, a first bearing seat, a rotating shaft, a second bearing seat, a rotating rod, etc.; the top of the cylindrical box is provided with a cover, and the cover is connected with The cylindrical box is matched, and a first bearing seat is embedded in the middle of the bottom of the cylindrical box. The first bearing seat is connected with a rotating shaft, and a cavity is opened on the rotating shaft. Through the function of the first bearing seat, the present invention can allow the rotating shaft to rotate with the tape, so that the medical staff can pull out the tape better, and the tape can be torn off by the toothed blade, which is easy to operate and does not reduce the stickiness of the tape; The adhesive tape can be pressed by the pressing mechanism to prevent the adhesive tape from rotating when the toothed blade is tearing off the adhesive tape, so that the toothed blade can better tear off the adhesive tape.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

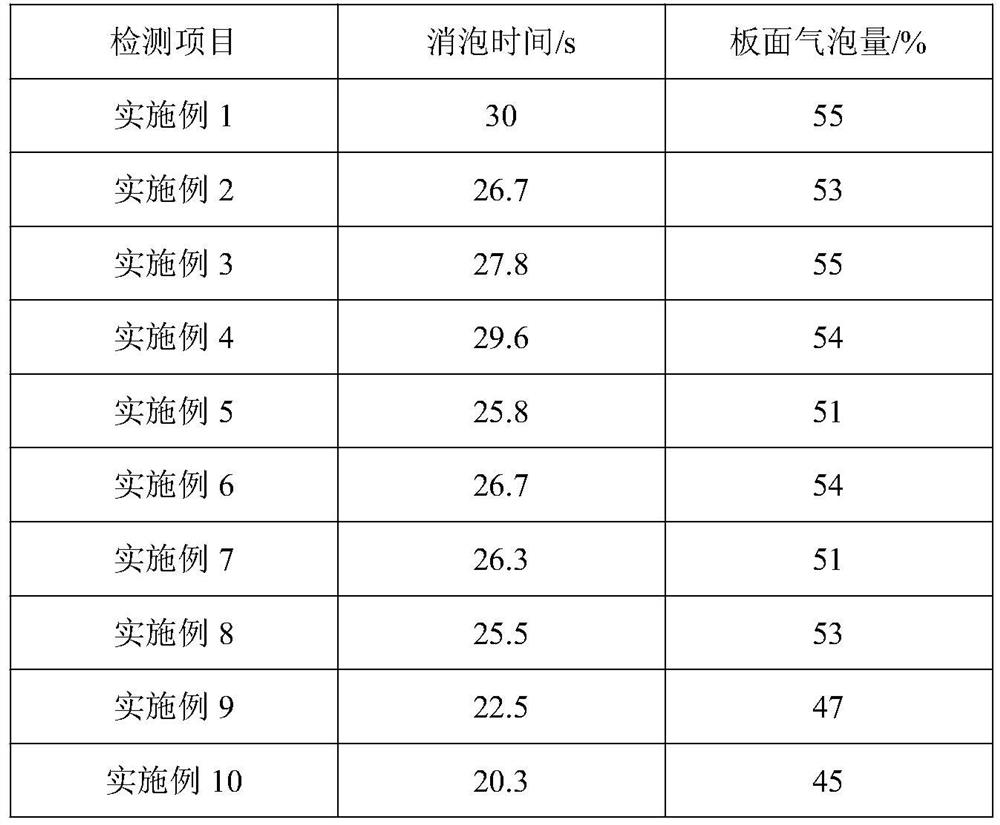

Defoaming agent suitable for curtain coating of mirror back coating, preparation method of defoaming agent and mirror back coating

ActiveCN114213578AGood anti-foam performanceShort defoaming timeCoatingsSolar thermal energy generationXylylenePolymer science

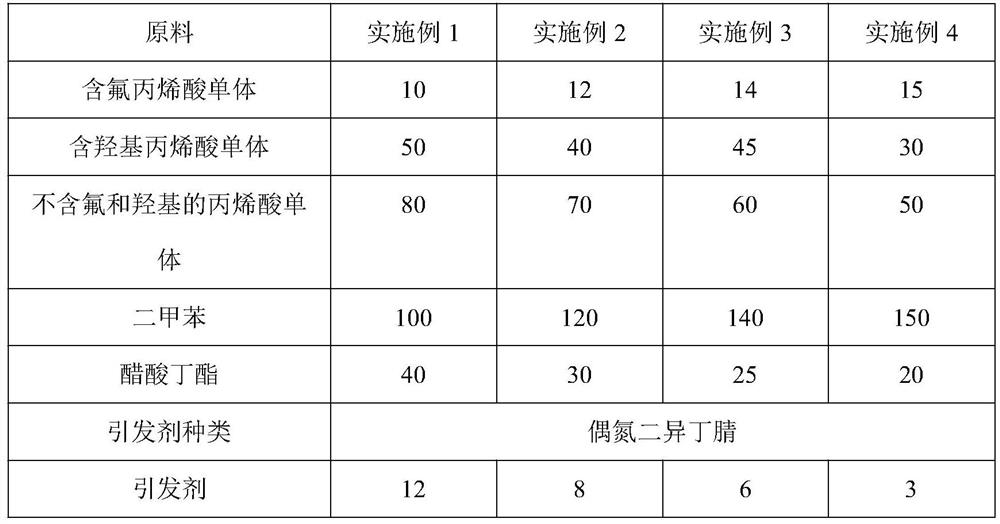

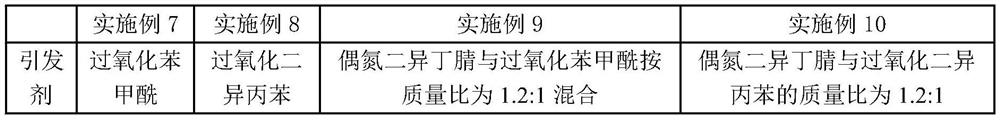

The invention relates to the technical field of defoaming agents, and particularly discloses a defoaming agent suitable for curtain coating of a mirror back coating, a preparation method of the defoaming agent and the mirror back coating. The defoaming agent suitable for curtain coating of the mirror back coating comprises the following raw materials: a fluorine-containing acrylic monomer, a hydroxyl-containing acrylic monomer, an acrylic monomer without fluorine and hydroxyl, xylene, butyl acetate, an initiator and a silane coupling agent, wherein the initiator is one or more of dicumyl peroxide, benzoyl peroxide and azodiisobutyronitrile; the defoaming agent prepared in the invention has high defoaming performance and foam inhibition performance, hydroxyl in the hydroxyl-containing acrylic monomer is crosslinked with amino in the coating, CASS of a mirror back coating product is also protected to a certain extent, and meanwhile, the initiator is compounded to ensure that the prepared polymer does not cause a broken screen phenomenon, so that the defoaming agent has high defoaming performance and foam inhibition performance. And the coating has good compatibility with a mirror back coating, and meets the market demand.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

A varnish for releasing negative ions

The invention discloses a varnish for releasing negative ions and a preparation method thereof. The varnish for releasing negative ions is mainly composed of negative ion powder mixed with LED varnish, and the negative ion powder is 35-45 parts , 95-105 parts of LED varnish; the preparation method includes the following steps: S1: prepare anion powder and LED varnish; S2: heat the LED varnish prepared in step S1 in a water bath; S3: heat the LED varnish produced in step S1; The prepared negative ion powder is added to the LED varnish in S2 and stirred, and the negative ion powder is fully mixed with the LED varnish to obtain a varnish with negative ion powder. The varnish coated on the surface of the object can radiate air The air is ionized to release negative oxygen ions, remove the formaldehyde in the room, purify the indoor air, reduce the content of formaldehyde in the air, and at the same time provide negative oxygen ions for the room to create a healthy environment for people.

Owner:成都韩尚艺术贴花有限公司

A kind of low voc based on acrylic resin, high solid content water-based paint and its preparation process

ActiveCN112812647BNo reduction in physical propertiesReduce physical propertiesCoatingsPolymer scienceAcrylic resin

The invention discloses a low-VOC, high-solid-content water-based paint based on acrylic resin and a preparation method thereof. The water-based paint prepared by using the formula of the invention can reduce viscosity, increase solid content and have relatively low VOC. It still maintains excellent performance in terms of adhesion, acid and alkali resistance.

Owner:山东齐鲁漆业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com