A kind of low voc based on acrylic resin, high solid content water-based paint and its preparation process

An acrylic resin, high solid content technology, applied in coatings and other directions, can solve the problems of poor coating construction performance, unsatisfactory coating film fullness, low solid content, etc., and achieve low VOC content, reduced viscosity, and high solid content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

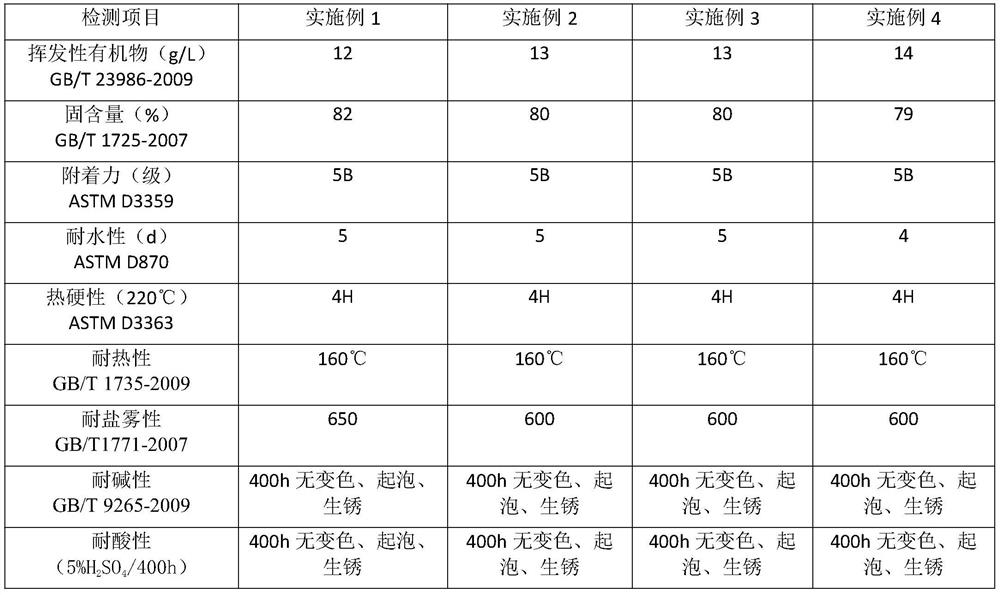

Examples

Embodiment 1

[0033] (1) Add 50 parts of isophorone diisocyanate, 40 parts of hydroxypropyl acrylate, 0.2 part of hydroquinone, 0.1 part of dibutyltin dilaurate in a four-necked flask equipped with a condenser tube, a thermometer and a stirrer, Stir at 25°C for 2 hours, raise the temperature to 50°C, continue the reaction for 5 hours, titrate the content of isocyanate group with di-n-butylamine method, when the content of -NCO group reaches the theoretical end point, an intermediate product is obtained;

[0034] (2) Add 20 parts of hydroxypolypropylene glycol to the intermediate product, stir and react at 70°C for 3h, cool down to 50°C, add 10 parts of hyperbranched polyester acetone solution, react at 50°C for 4h, dioxane as solvent Add 15 parts of perfluoropropionic anhydride and raise the temperature to 100°C to react for 5 hours, remove the solvent under reduced pressure, cool down to 40°C and add 3 parts of triethylamine to neutralize and form a salt to obtain hyperbranched polyurethane...

Embodiment 2

[0040] (1) Add 20 parts of toluene diisocyanate, 20 parts of hydroxypropyl acrylate, 0.1 part of 4-hydroxypiperidinol oxygen free radical, 1 part of dilauric acid di Butyl tin, stirred at 25°C for 2h, heated to 50°C, continued to react for 5h, titrated the content of isocyanate group with di-n-butylamine method, when the content of -NCO group reached the theoretical end point, an intermediate product was obtained;

[0041] (2) Add 10 parts of hydroxy polypropylene glycol to the intermediate product, stir and react at 70°C for 3h, cool down to 50°C, add acetone solution containing 1 part of hyperbranched polyester, react at 50°C for 4h, dioxane as solvent Add 5 parts of phthalic anhydride and raise the temperature to 100°C to react for 5 hours, remove the solvent under reduced pressure, cool down to 40°C and add 1 part of dimethylethanolamine to neutralize and form a salt to obtain hyperbranched urethane acrylate;

[0042] (3) Add 12 parts of acetoacetoxyethyl methacrylate, 10 ...

Embodiment 3

[0047] (1) Add 100 parts of isophorone diisocyanate, 50 parts of hydroxypropyl acrylate, 1 part of p-hydroxyanisole, and 1 part of dibutyltin dilaurate into a four-necked flask equipped with a condenser tube, a thermometer and a stirrer , Stir at 25°C for 2h, raise the temperature to 50°C, continue the reaction for 5h, titrate the content of isocyanate group with di-n-butylamine method, when the content of -NCO group reaches the theoretical end point, an intermediate product is obtained;

[0048] (2) Add 50 parts of hydroxypolypropylene glycol to the intermediate product, stir and react at 70°C for 3h, cool down to 50°C, add acetone solution containing 20 parts of hyperbranched polyester, react at 50°C for 4h, dioxane as solvent Add 20 parts of mellitic acid trianhydride and raise the temperature to 100°C to react for 5 hours, remove the solvent under reduced pressure, cool down to 40°C and add 5 parts of triethanolamine to neutralize and form a salt to obtain hyperbranched ure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com