Steel wire having excellent straightness quality and method for manufacturing same

A manufacturing method and steel wire technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as inability to provide linear steel wires, difficulty in meeting linear quality characteristics, and linearity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention relates to a steel wire with excellent linear quality and a manufacturing method thereof, which can improve the strain aging of the steel wire by heating the steel wire at a temperature above a certain temperature. The final straight line quality. Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

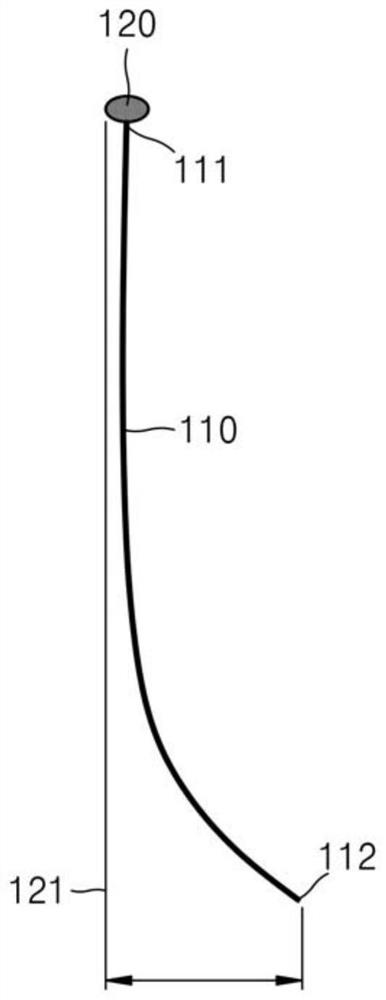

[0031] refer to figure 1 , the steel wire having excellent straightness quality according to an embodiment of the present invention is characterized by comprising a cable 110 which, after passing through the stretching step, undergoes a heating step of being heated under tension, and a cooling step, wherein, The cable 110 also has a straightness of 30 mm or less when the cable 110 is wound around the winding unit for a certain period of time or more.

[0032] refer to figure 1 , the linearity according to the embodiment of the present invention can be measured as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com