Patents

Literature

8191 results about "Wire drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

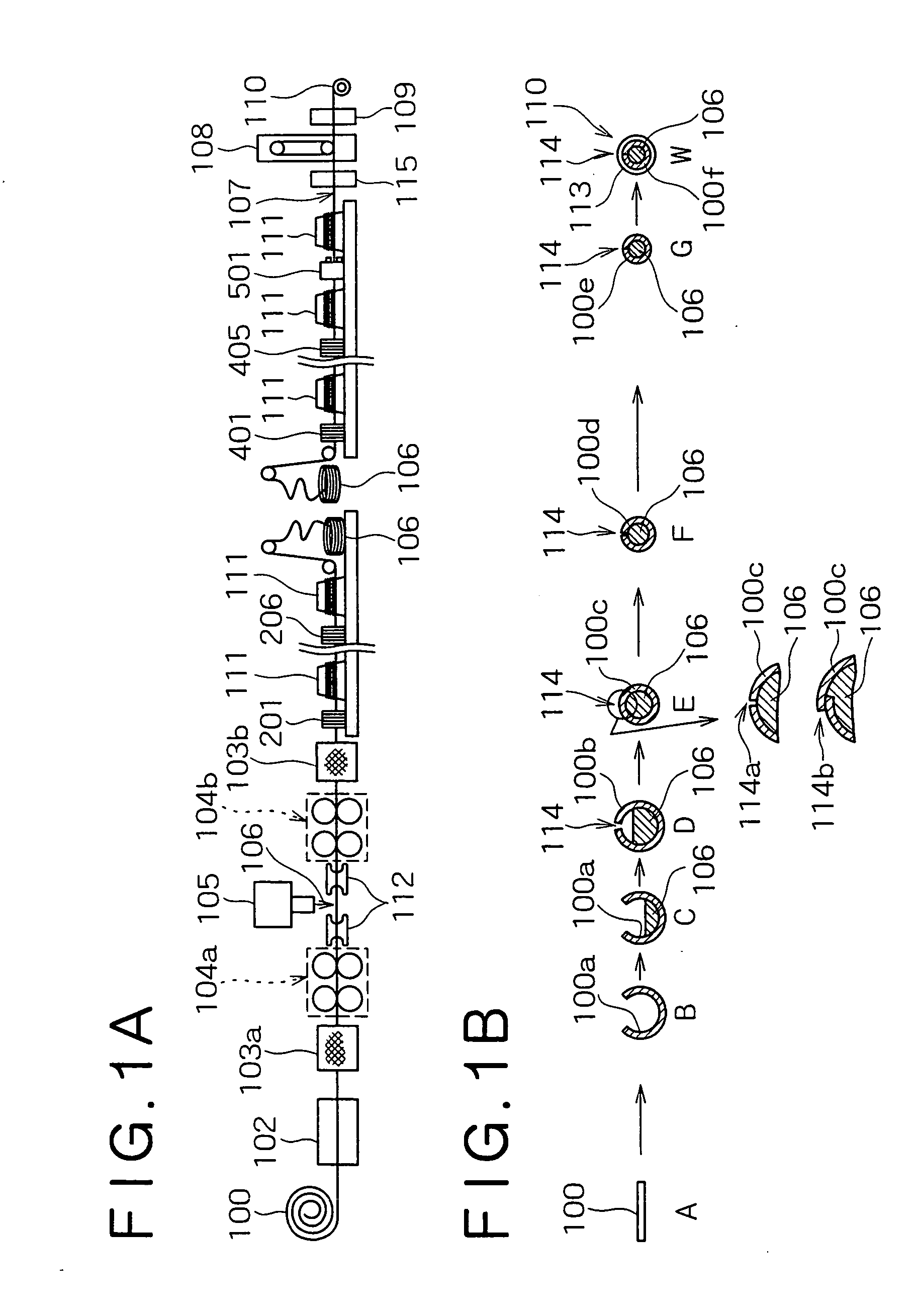

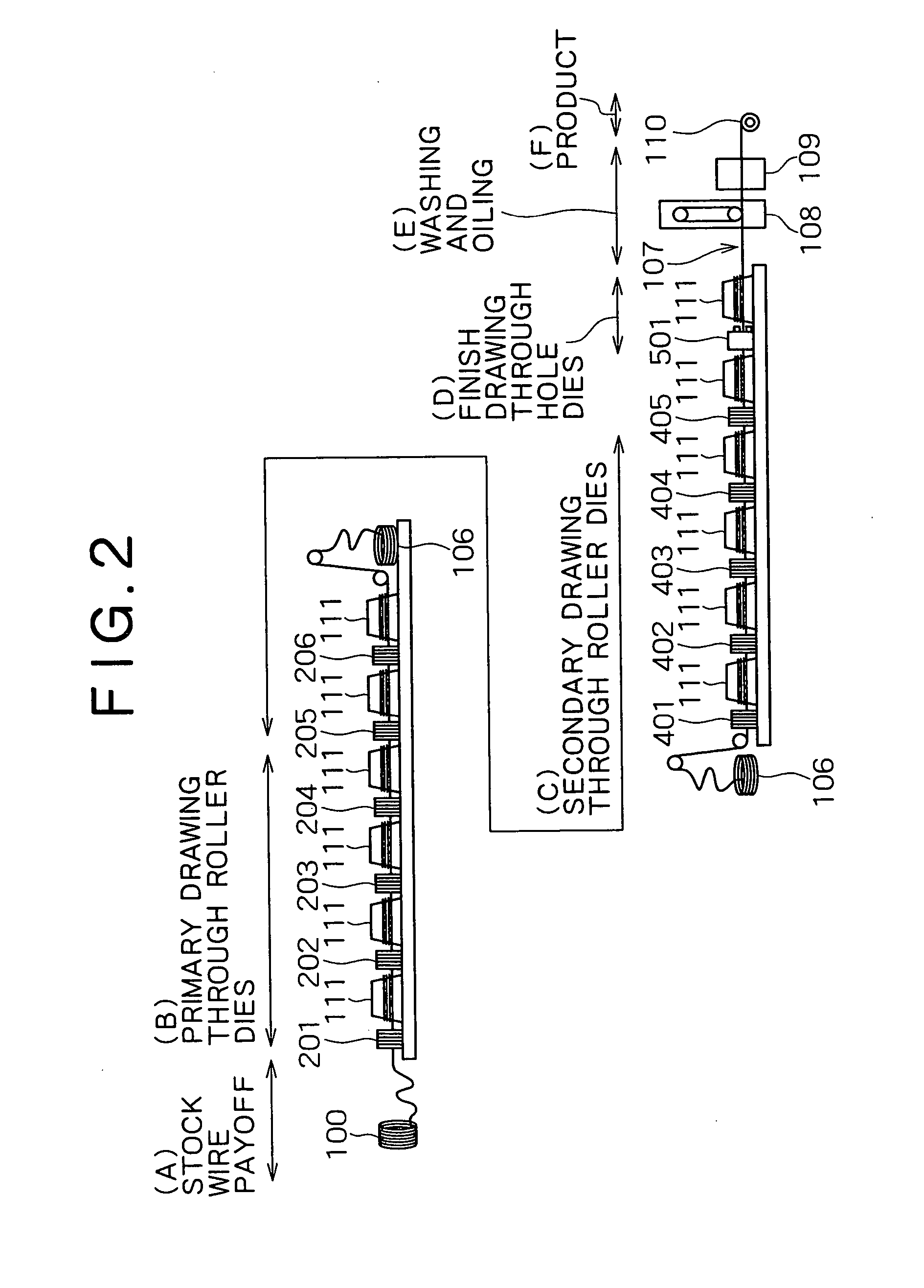

Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single, or series of, drawing die(s). There are many applications for wire drawing, including electrical wiring, cables, tension-loaded structural components, springs, paper clips, spokes for wheels, and stringed musical instruments. Although similar in process, drawing is different from extrusion, because in drawing the wire is pulled, rather than pushed, through the die. Drawing is usually performed at room temperature, thus classified as a cold working process, but it may be performed at elevated temperatures for large wires to reduce forces.

Process for drawing gel-spun polyethylene yarns

InactiveUS20050093200A1Domestic articlesMonocomponent polyolefin artificial filamentProduction rateForced convection

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

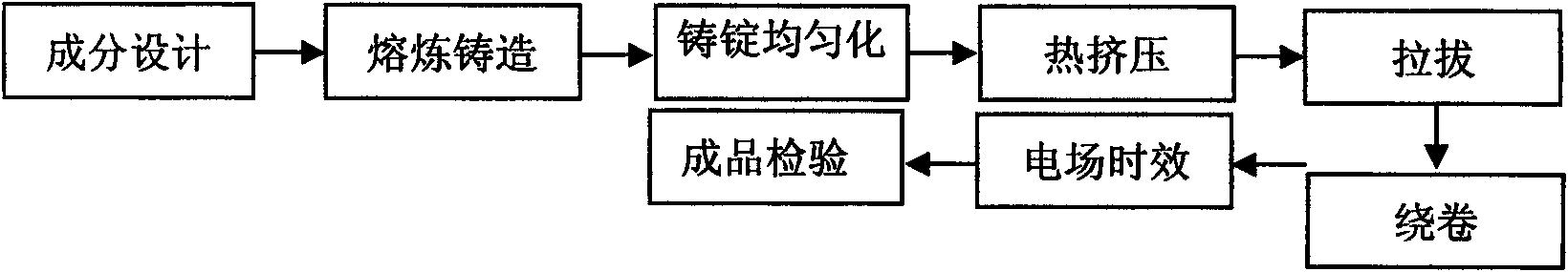

Aluminum alloy lead with lanthanon yttric and preparation method thereof

ActiveCN101587757AImprove conductivityHigh strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthTime effect

The invention discloses an aluminum alloy lead with lanthanon yttric and preparation method thereof. The specific component and weight percentage of the invention are Si0.5%-0.7%, Mg0.6%-0.9%, Fe 0.1%-0.2%, Y 0.2%-0.8%, Al residue. The preparation method is following: preparing the elements according to the alloy design to prepare aluminum alloy wire material via melting, casting, homogenization, extrusion and wire drawing, preparing the cables via winding to obtain the aluminum alloy lead with great intensity and conduction via the electric field time effect heat treatment. The aluminum alloy lead with high intensity of the invention adds the lanthanon yttric to purify the melting body and reduce the silicon quantity in the alloy further enhance the conductive rate of the melting on the one hand; on another hand to thin the crystal grain and enhance intensity of the alloy wire; the generatrix intending intensity is 260MPa and the conductive rate can achieve 57% IACS.

Owner:HUNAN XIANGNENG ELECTRIC WORKS

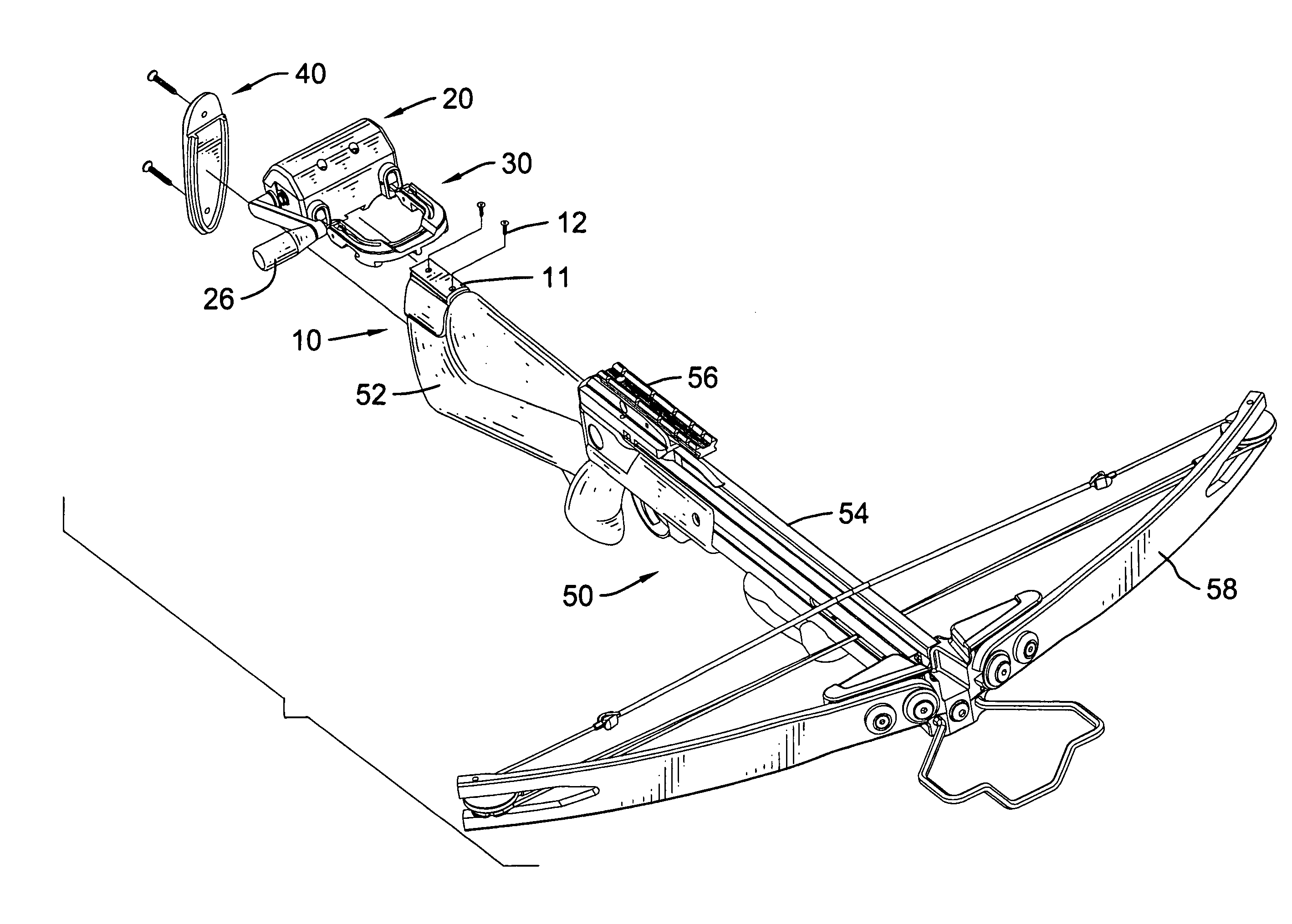

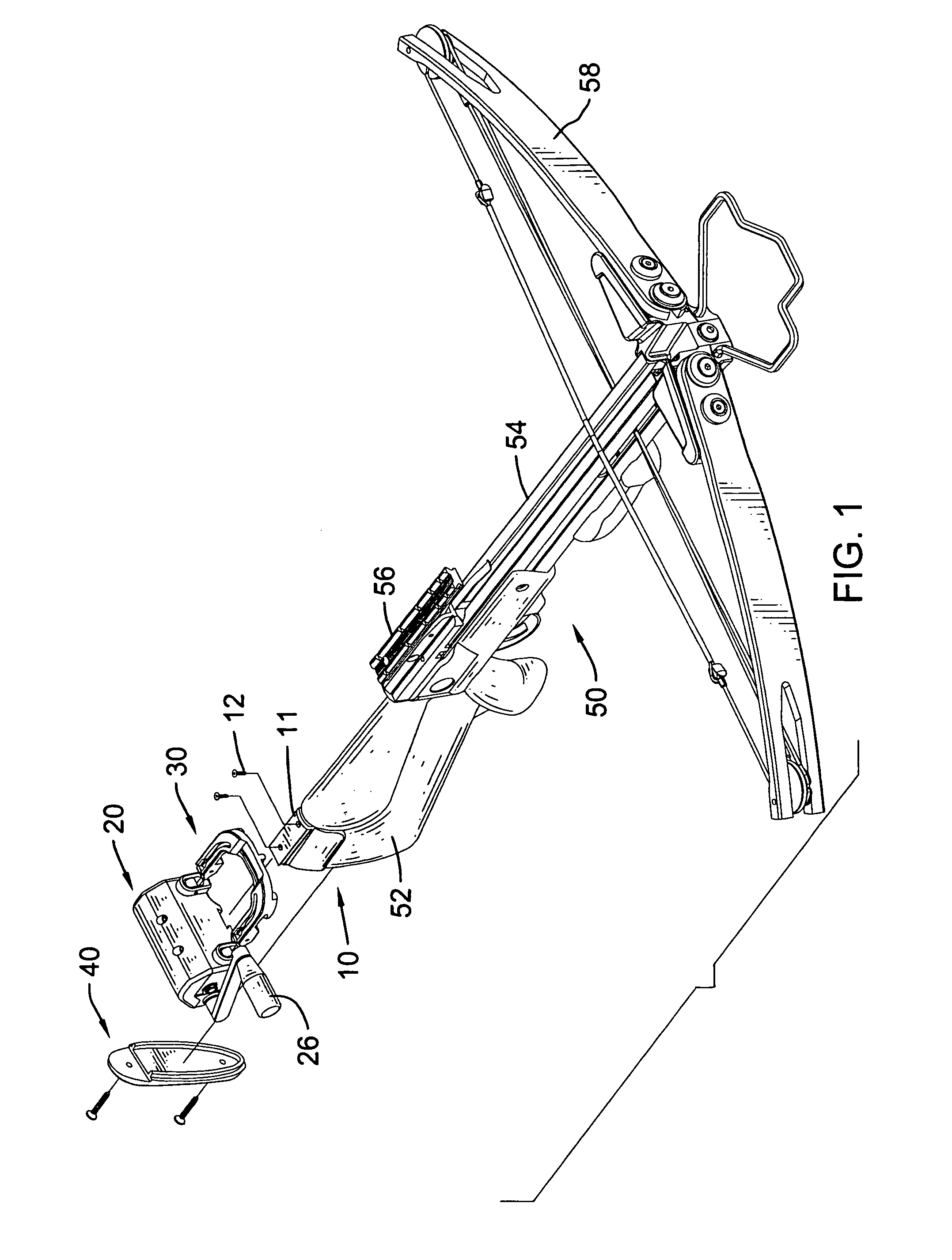

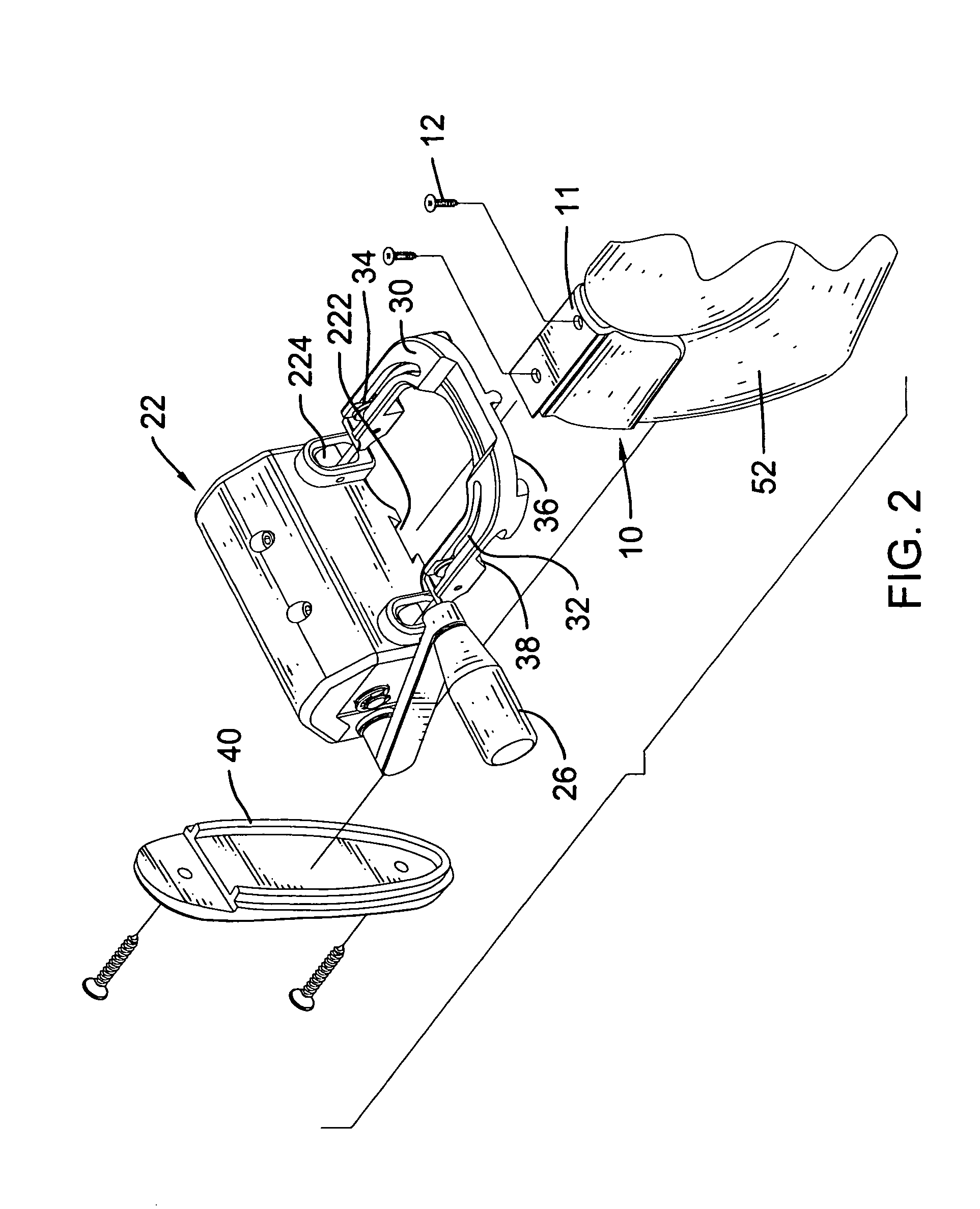

Bowstring drawing device for a crossbow

A bowstring drawing device for a crossbow has a mounting base, a reeling device and a hook. The mounting base has a rail. The reeling device has a casing with a bottom face and a rail recess defined in the bottom face of the casing to slidably engage with the rail of the mounting base. A wheel assembly is accommodated inside the casing and a crank arm connected to drive the wheel assembly. A clutch is operationally connected to the wheel assembly. The hook is retractably connected to the reeling device by a string. Because the reeling device and the mounting base are engaged with the rail and rail recess, detachment or engagement of the reeling device is convenient. Moreover, the crank arm and the wheel assembly also make the operation of the bowstring drawing device effort-saving.

Owner:POE LANG ENTERPRISE

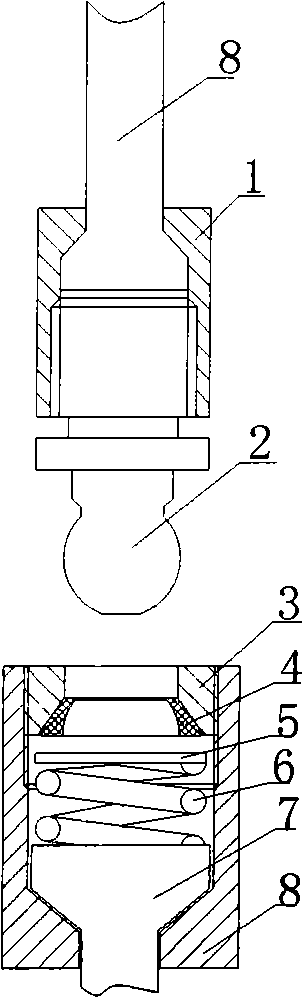

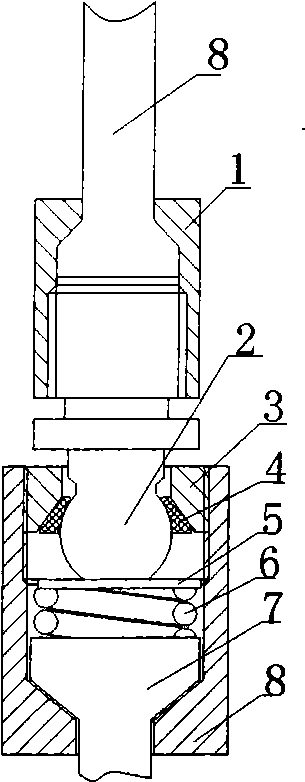

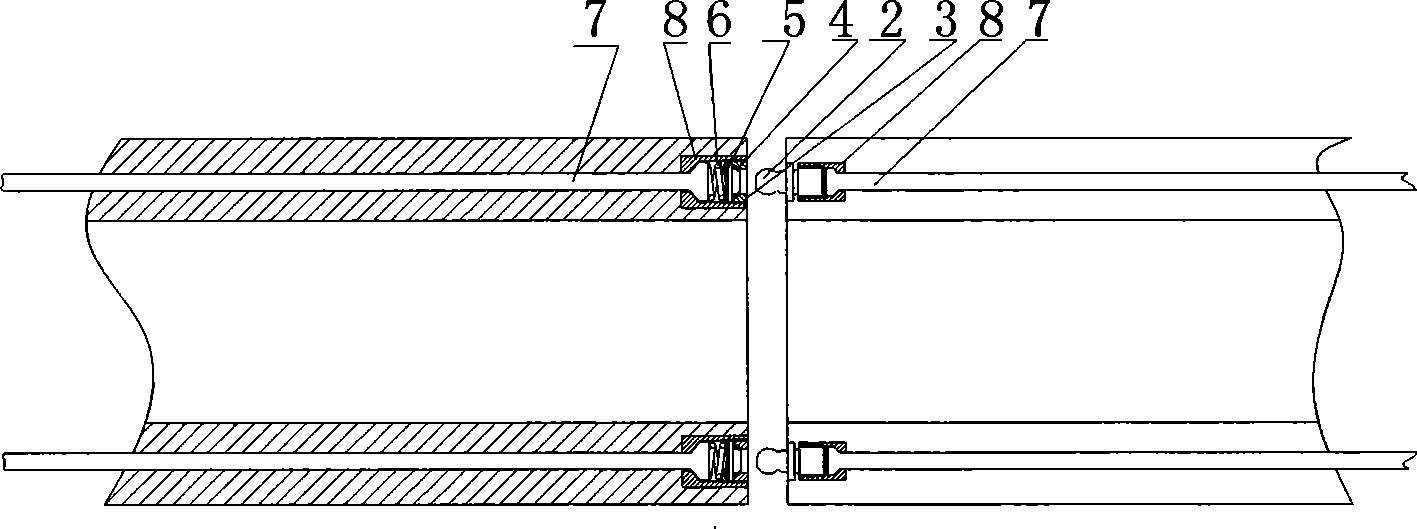

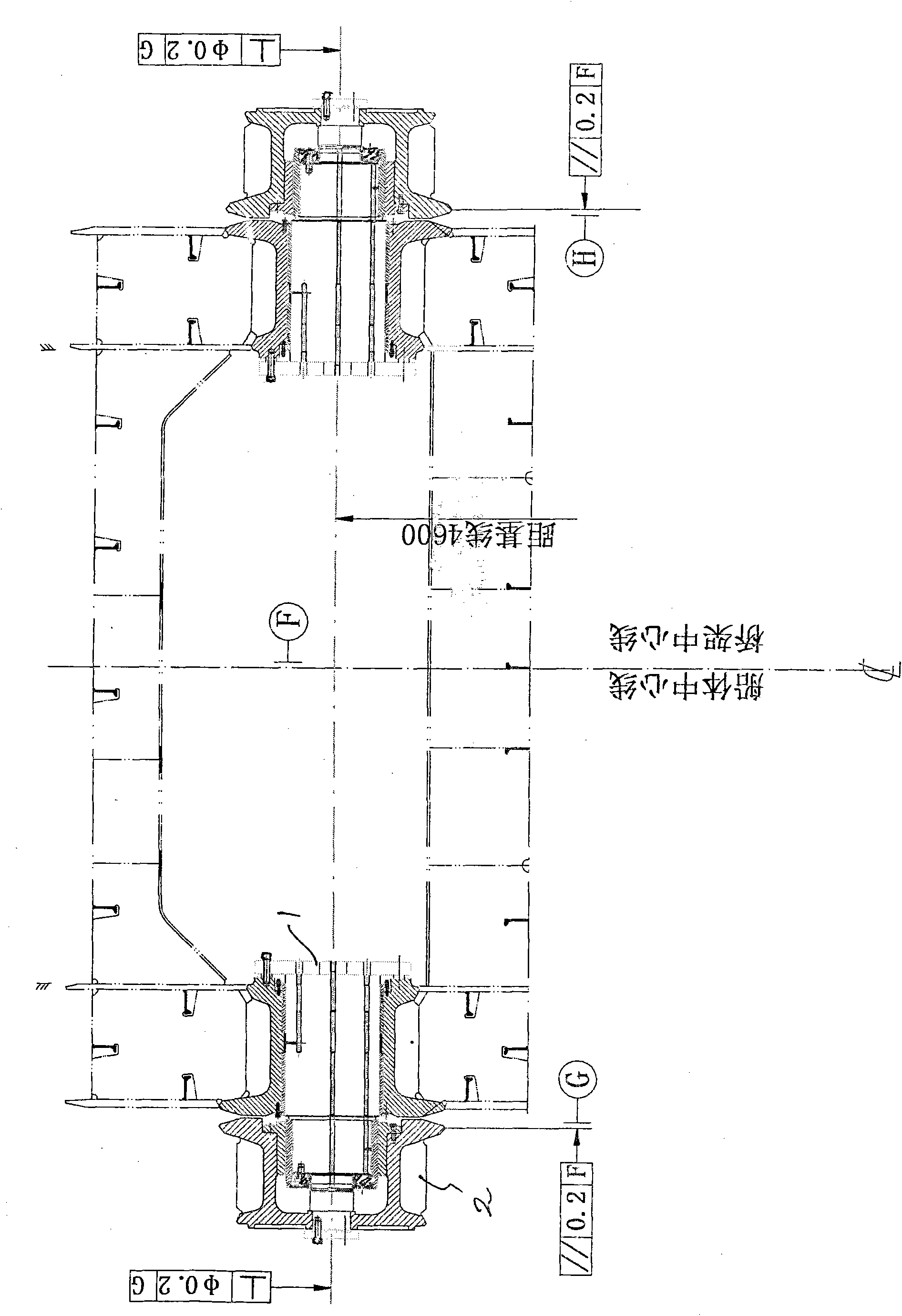

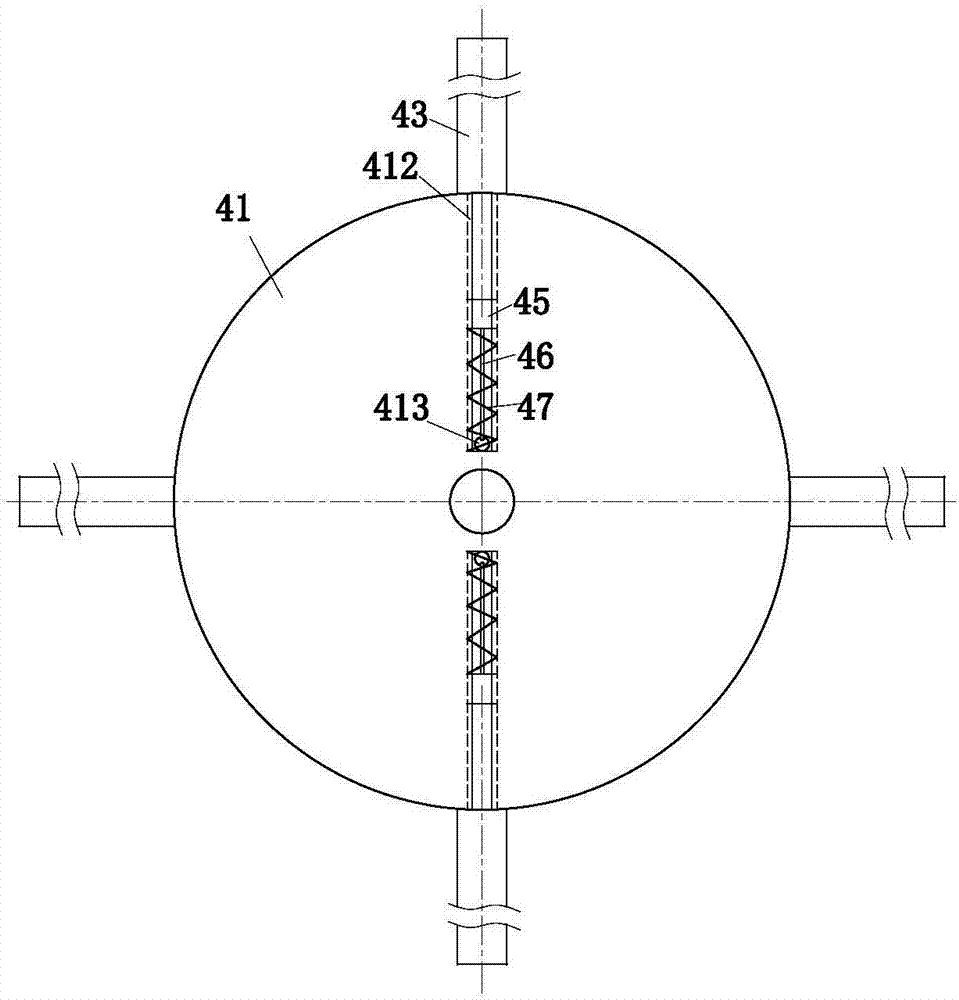

Cutting-free fast tearing butt coupler and butt joint piece

ActiveCN101519876AReliable dockingFirmly connectedCeramic shaping apparatusBulkheads/pilesButt jointSteel bar

The invention relates to a cutting-free fast tearing butt coupler and a butt joint piece, as well as a fabricated part formed by the cutting-free fast tearing butt coupler, a fabricated part formed by the cutting-free fast butt coupler, and butt joint structure between the fabricated parts, and the invention consists of a raising-pulling screw cap, a support-pulling screw cap and a fabricated part longitudinal bar which are positioned at the two ends of the fabricated parts, wherein the raising-pulling screw cap and the support-pulling screw cap have the internal thread structure, the internal thread is tearing screw thread, the center of the cap bottom is provided with a steel bar hole, the periphery of the steel bar hole is a steel bar upset head clamping table, the two ends of the fabricated part longitudinal bar are upset into the upset head which is clamped and connected on the upset head clamping table, a pressure spring is positioned inside the support-pulling screw cap, one end of the pressure spring is positioned on the steel bar upset head, the other end thereof is provided with a tapered sleeve formed by two or a plurality of pieces, a screw thread sleeve is rotatably connected inside the support-pulling screw cap and locates the displacement on the tampered sleeve, the tail part of a connection-peg is connected with the internal thread of the raising-pulling screw cap, and the head part of the connection-peg has the ball-lacking shape and is matched with the tampered sleeve in an elastic joint way.

Owner:周兆弟

Preparation method of recycled polyester chip microfilaments and usage thereof

InactiveCN101747596ASimple compositionNo smellFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterLinear low-density polyethylene

The invention relates to a preparation method of recycled polyester chip microfilaments and a usage thereof, belonging to the field of plastic modification and category of composite material / alloy promoter. The polyester chip microfilament is an ideal promoter which has excellent performance, environment-friendliness, high added value, wide application range and broad market prospect and can change the mechanical property of the composite material / alloy. Recycled blow molding polyester (RPET / RPBT) is taken as main raw material, and the following formula and process are adopted for preparing the microfilament according to parts by weight: 100 parts of recycled polyester (RPET / RPBT), 5-30 parts of wire-drawing high-density polyethylene (HDPE) / polypropylene (PP) / linear low-density polyethylene (LLDPE), 0.1-4 parts of crosslinking agent / chain extender / anchoring agent, 0.1-0.8 part of antioxidant, 0.5-6 parts of nucleating agent, and 1-5 parts of nucleate accelerant, and other processing aids (such as lubricant and plasticizer) / functional aids (such as fire retardant and ultraviolet absorber) can be additionally and appropriately added. The microfilament is prepared through extrusion, cooling, drawing and granulating by the reaction under 90-260 DEG C under the action of mechanical shear. The recycled polyester (RPET / RPBT) microfilament prepared in the invention can endow the composite material / alloy with excellent mechanical property.

Owner:王世和

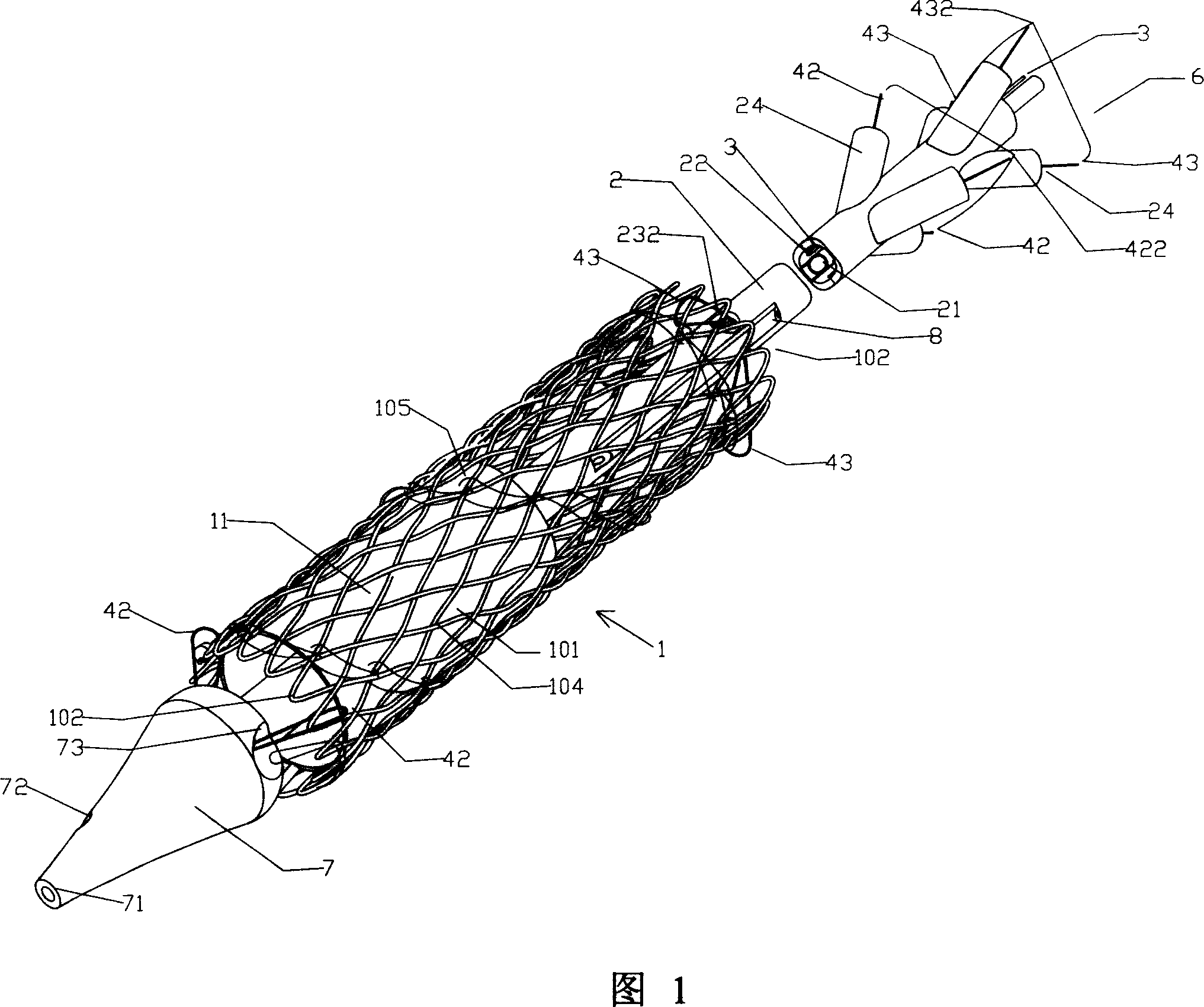

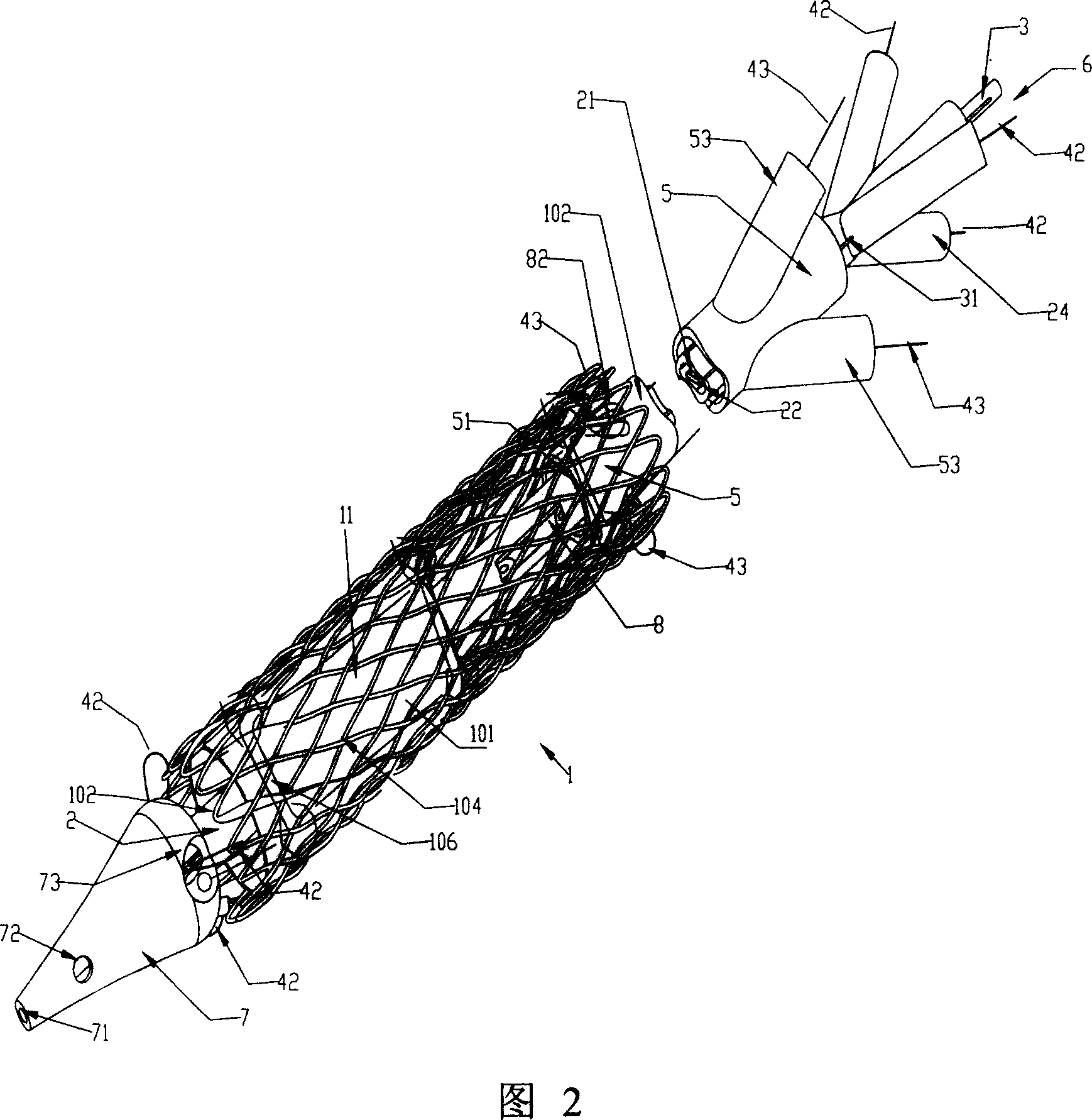

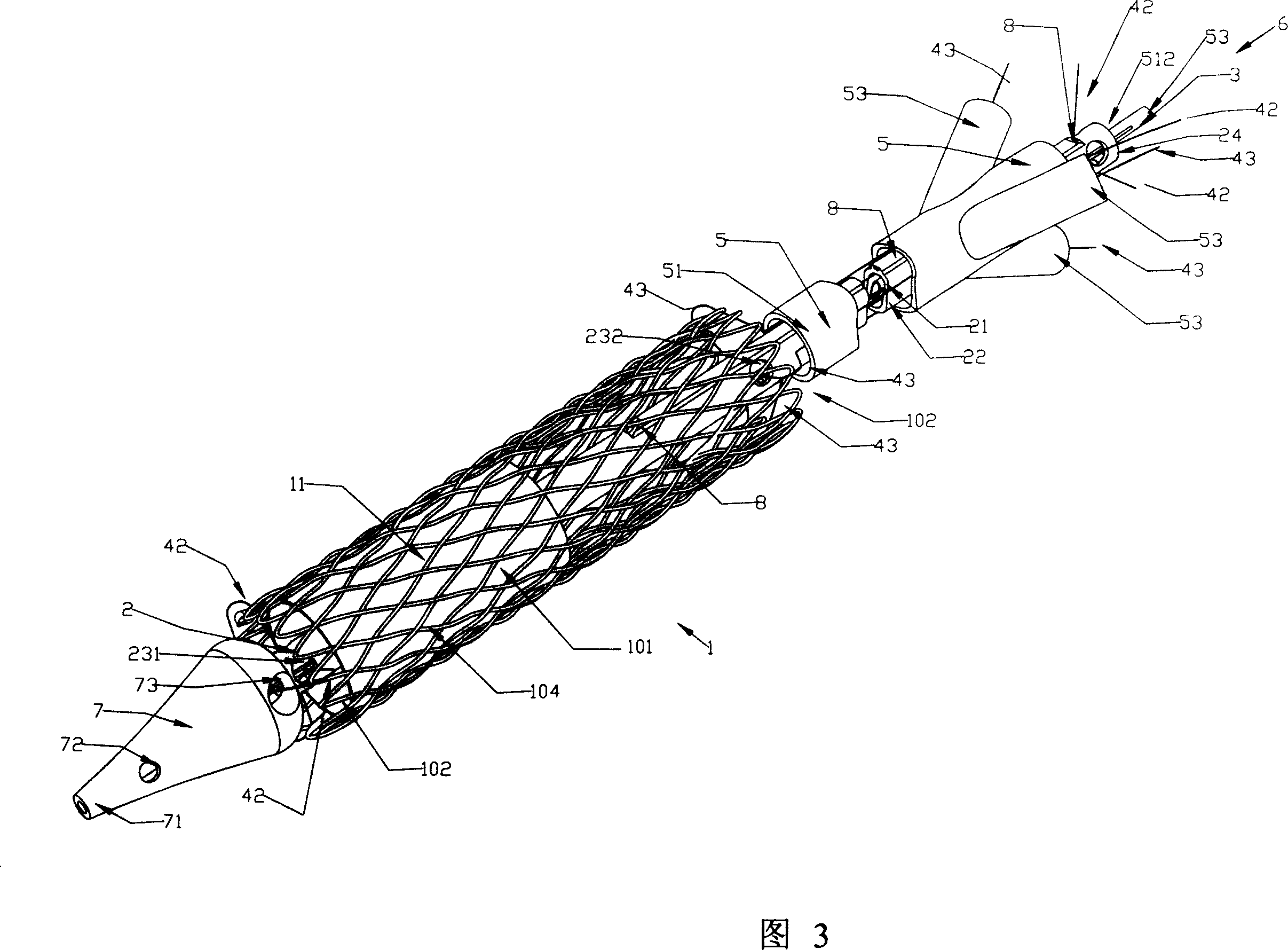

Self-expanding stent axial wire-drawing tensioning mechanism

An axially pulled stretch mechanism for a self-expanding stents is composed of an internal tube for the scaffold arranging system, an optional intermediate tube, a locking wire, at least one far-end and at least one near-end pull threads with respective pull rings at their far end, and the open fixers and / or closed thread pinholes at both ends of said scaffold. Its application is also disclosed.

Owner:BEIJING BALANCE MEDICAL

High intensity metallic core type seamless flux-cored wire

InactiveCN101323057AImprove impact toughnessReduce the ductile-brittle transition temperatureWelding/cutting media/materialsSoldering mediaManufacturing technologyHigh intensity

The invention discloses a high strength metal core type seamless flux-cored welding wire relating to the technical field of welding materials; the invention can be manufactured by adopting the existing steel tube drawing or in-service welding seamless flux-cored welding wire manufacturing technology; the diameter of a steel tube is reduced to the extent that the filling diameter of a specified filling rate can be acquired; by using the vibration filling pattern, filler is filled from one end of the steel tube; wire drawing processing is performed by using a roller group or a wire drawing die group, and during the period intermediate annealing is carried out (under 650 DEG C for two hours). The high strength metal core type seamless flux-cored welding wire of the invention has the advantage that yield strength is larger than 785MPa, and the requirements of high strength structure steel welding can be satisfied.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for manufacturing seamed flux-cored welding wire

ActiveUS20050044687A1Improve feeding effectReduce contentDrawing diesWelding/cutting media/materialsWire rodSulfur

Disclosed herein is a manufacturing method, excellent in wire drawability, of a seamed flux-cored welding wire having both favorable feedability and low hydrogen content characteristic. The method for manufacturing a seamed flux-cored wire, comprises the steps of: drawing a tube-like formed wire including a flux filled therein using a lubricant; removing the lubricant from the drawn wire by a physical means; and coating a lubricant (coating an oil) for wire feeding on the wire surface. The respective steps are carried out in an in-line manner. In the wire drawing step, a wire drawing lubricant containing a sulfur-bearing high-pressure lubricant is used, and the overall wire drawing from the tube-like formed wire to a roughly product-diameter wire is carried out by means of a roller die.

Owner:KOBE STEEL LTD

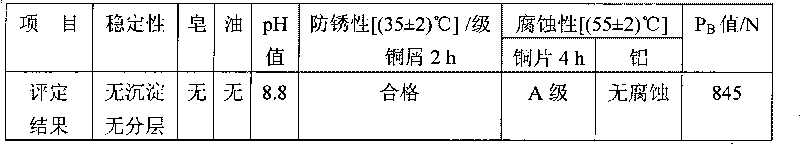

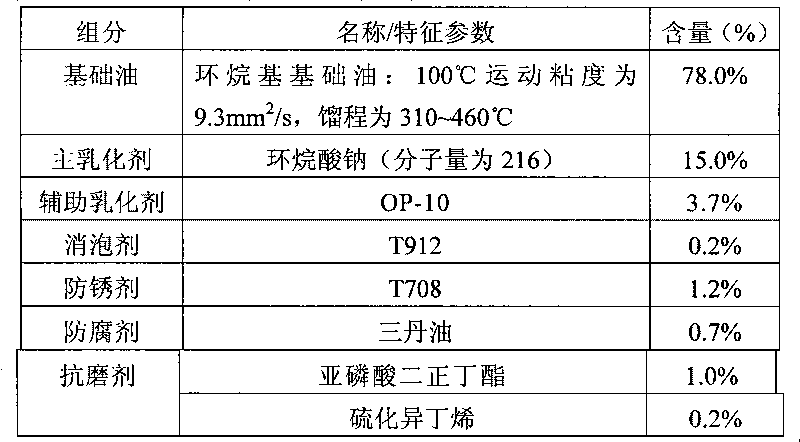

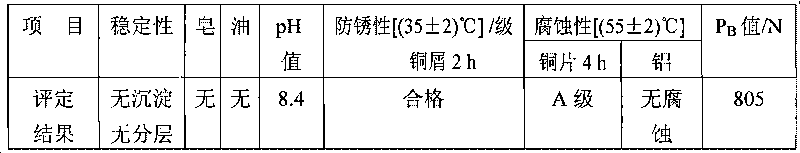

Copper and aluminum wire drawing oil and preparation method and use method thereof

The invention relates to the technical field of petroleum base lubricant composition and a preparation method thereof, which is copper and aluminum wire drawing oil and a preparation method thereof. The copper and aluminum wire drawing oil comprises base oil, an emulsifying agent, an auxiliary emulsifying agent, a defoaming agent, an antirusting agent, a preservative and an antiwear agent. The preparation method can be carried out by the following steps that: the copper and aluminum wire drawing oil is mixed into 3 percent to 45 percent of water-based emulsion according to the weight percentage. The water-based emulsion is showered into a wire drawing die cavity in the copper and aluminum wire drawing process. The product of the invention has good lubricating property, excellent light stability and storage stability, low cost, good cooling effect, fast heat-transfer speed, little temperature-rise amplitude, nonflammability and easy cleaning, thus guaranteeing safety of use environment. Copper wires and aluminum wires which are drawn by adopting the product have even line shapes, bright surfaces, and rustless property, and also have good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

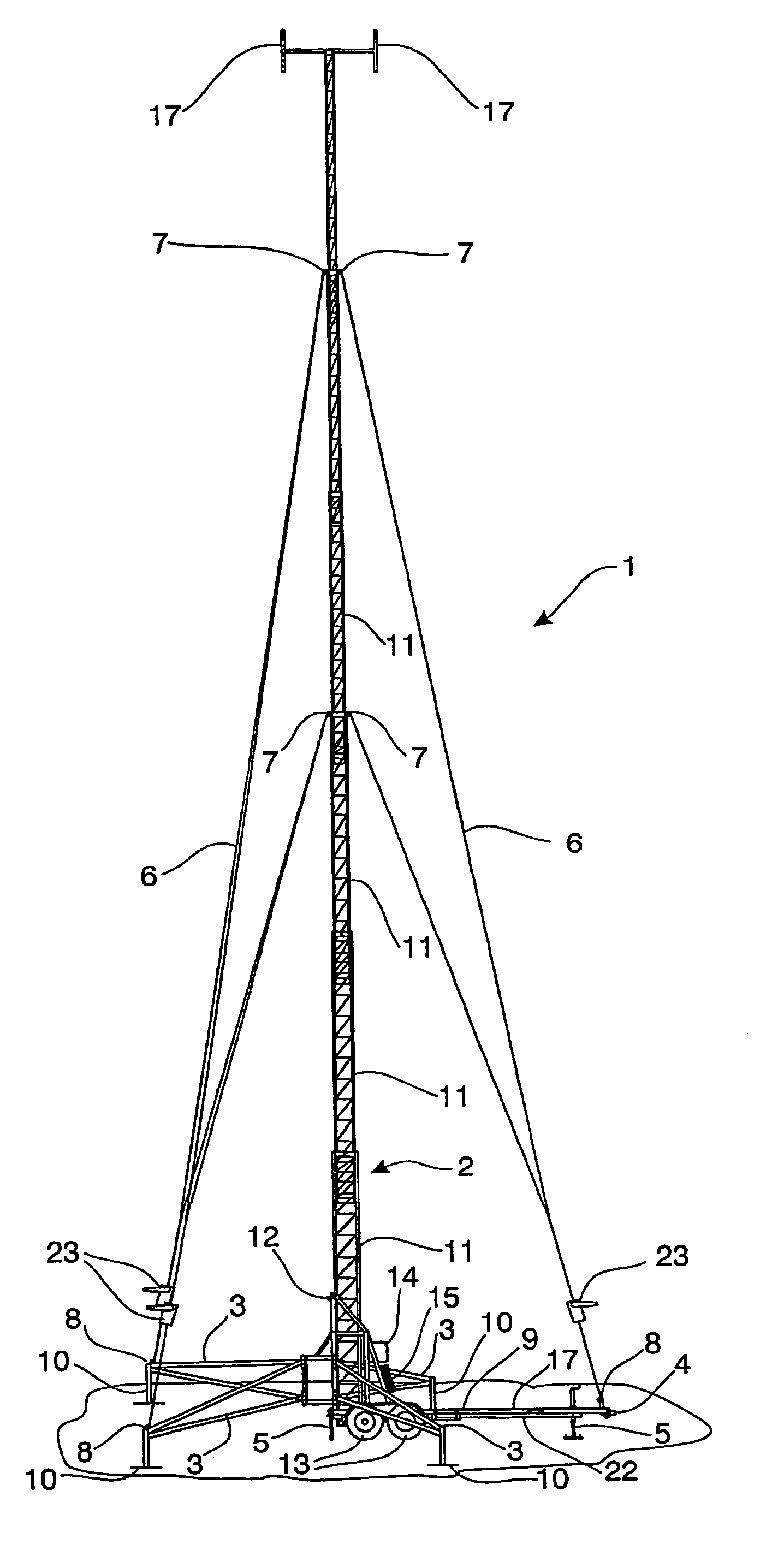

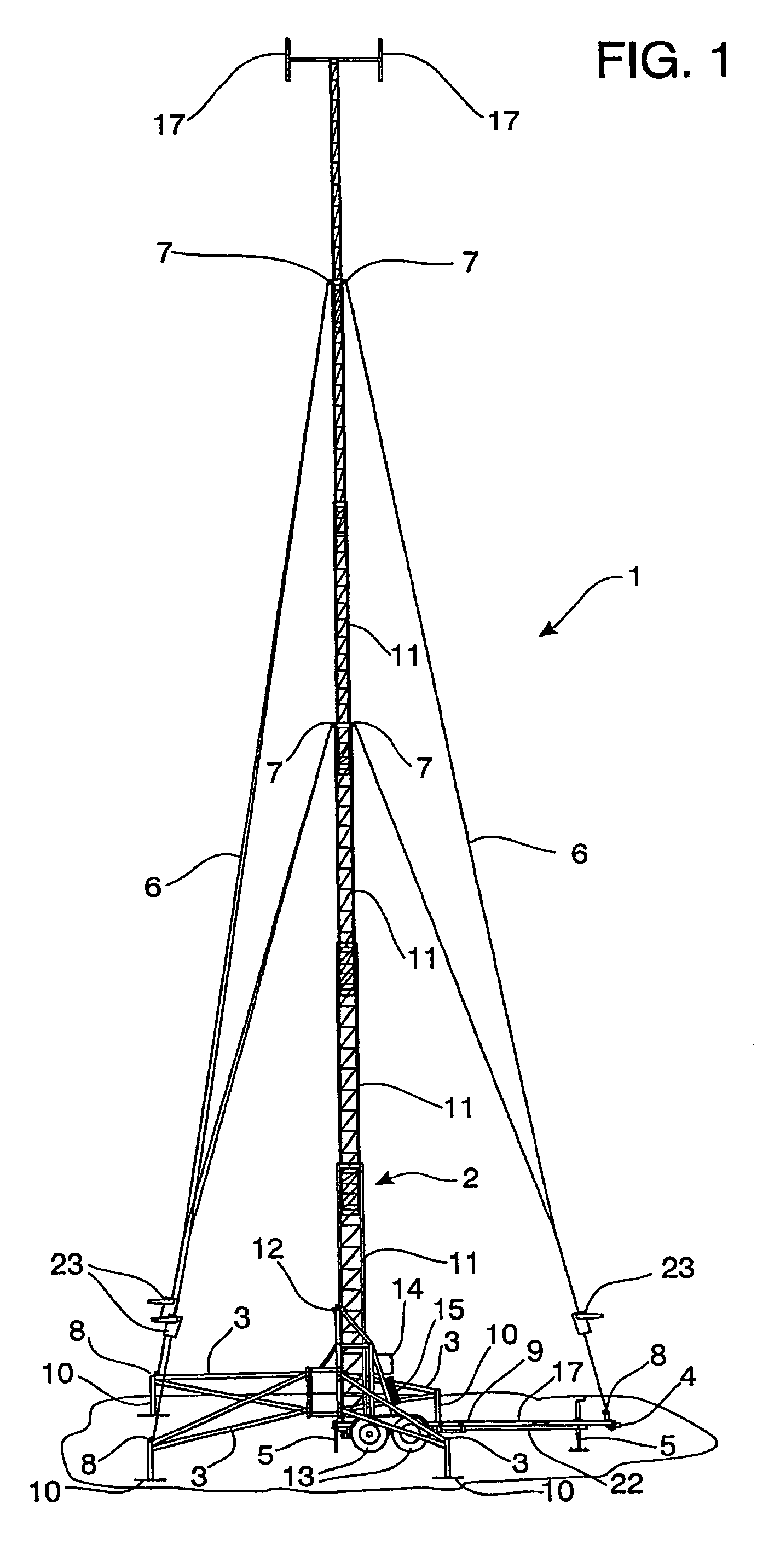

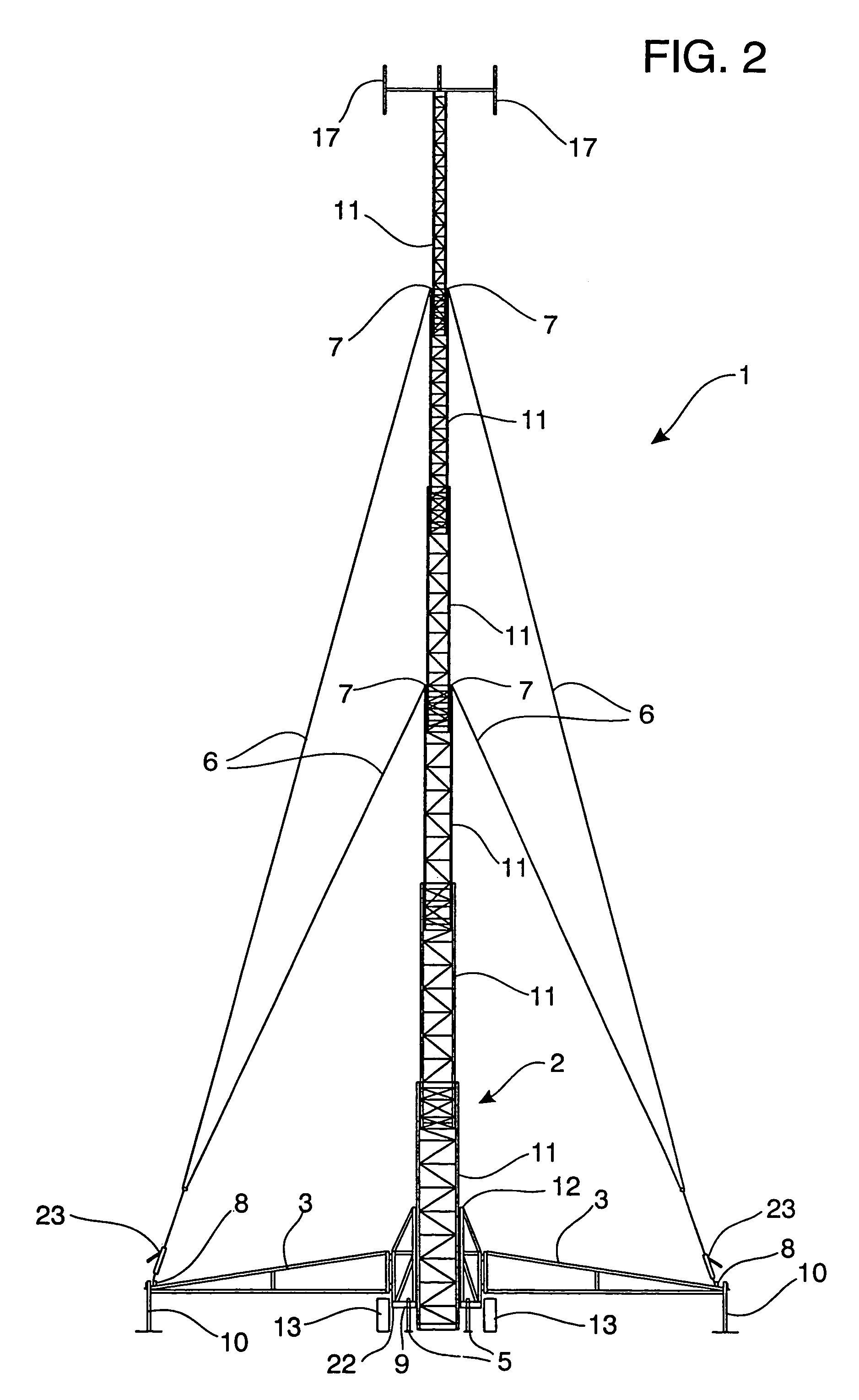

Self guying communication tower

A mobile communication tower comprising a trailer comprising a chassis, mounted on two or more wheels, a hitch, a plurality of chassis guy wire attachment points and a plurality of leveling mechanisms; a telescopic tower pivotally mounted on the trailer; a mechanism to raise and lower the tower; a plurality of tower guy wire attachment points located on the tower; and a plurality of guy wires each with an upper end attached to one of the tower guy wire attachment points and a lower end attached to one of the chassis guy wire attachment points.

Owner:ALLTECH COMM

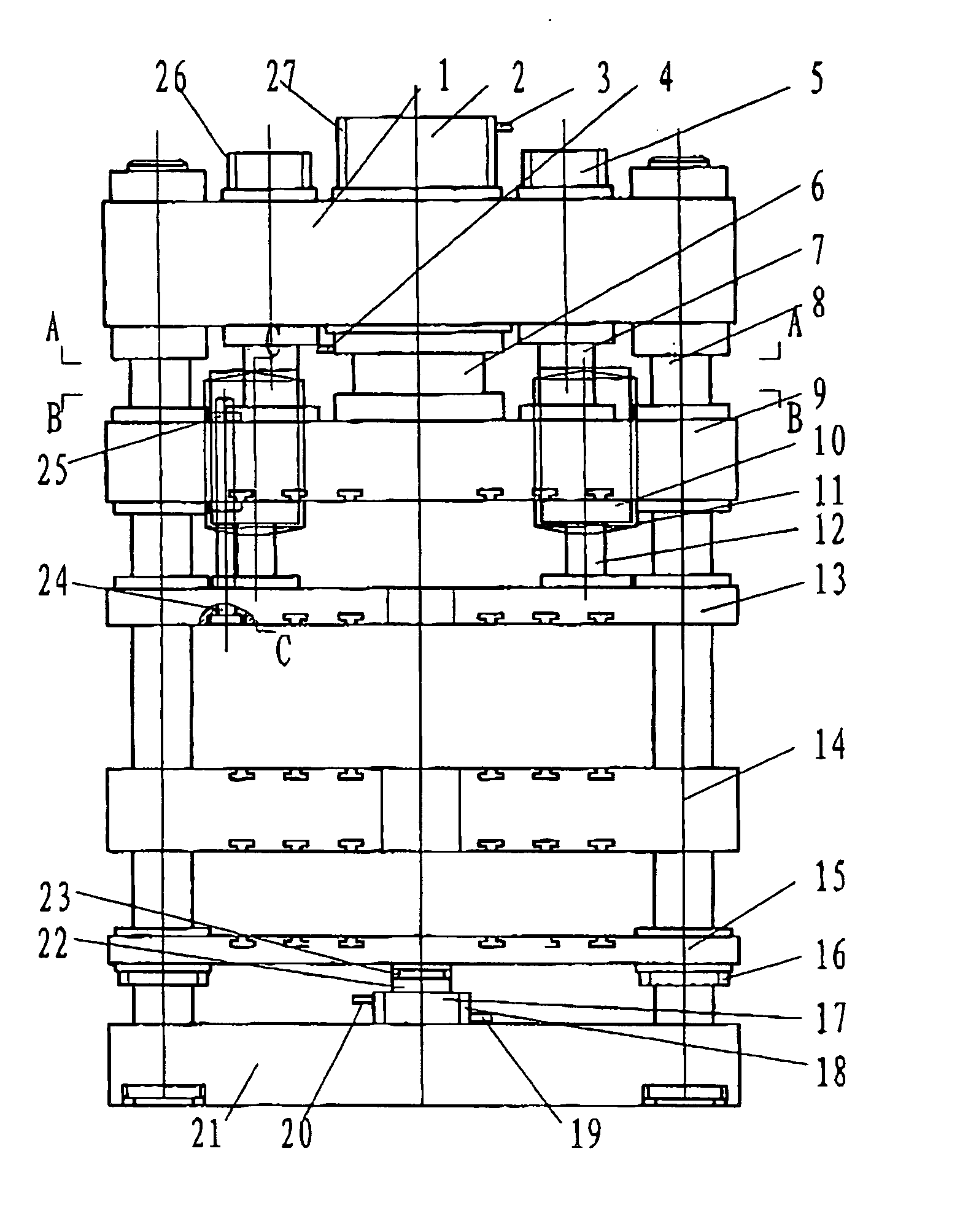

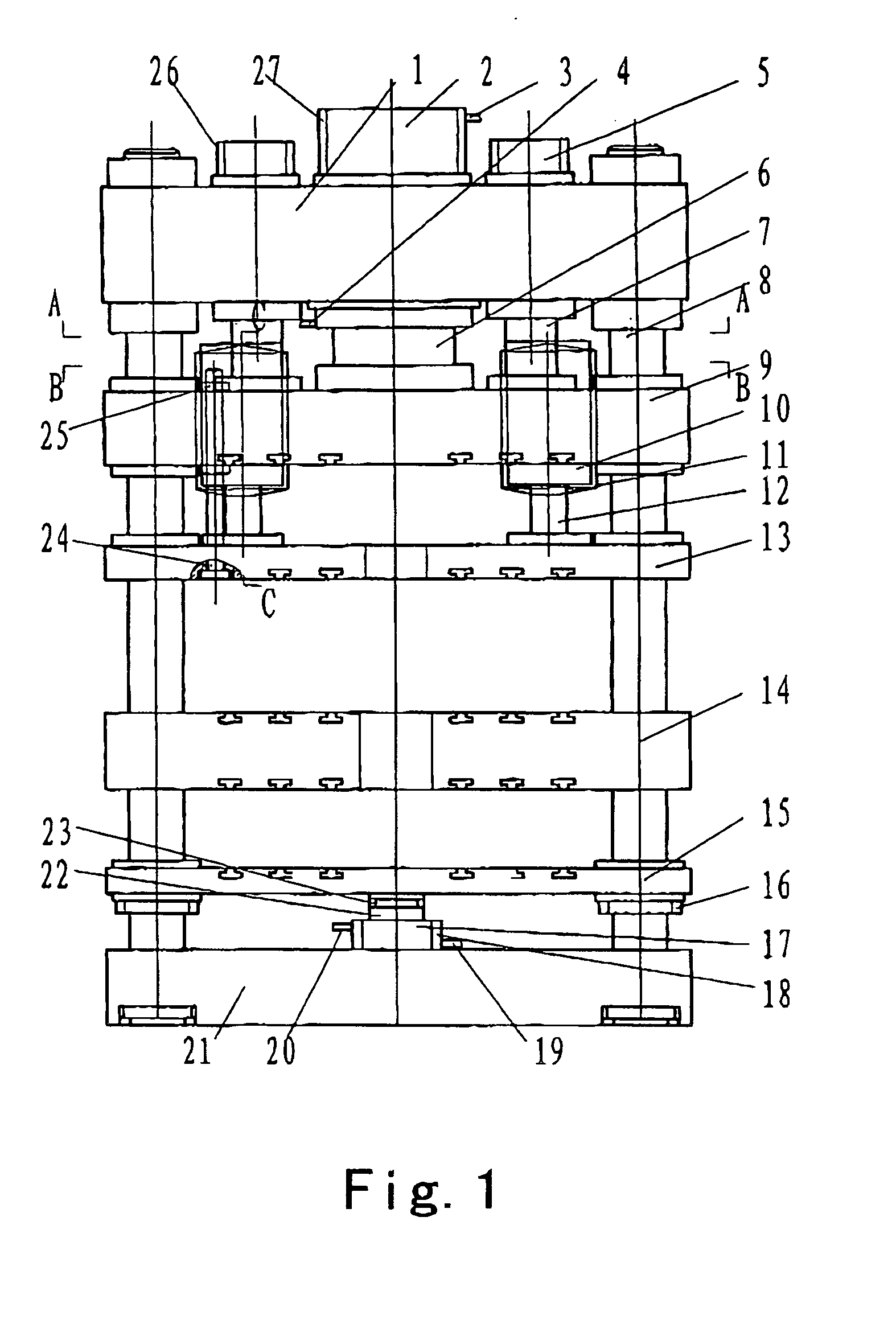

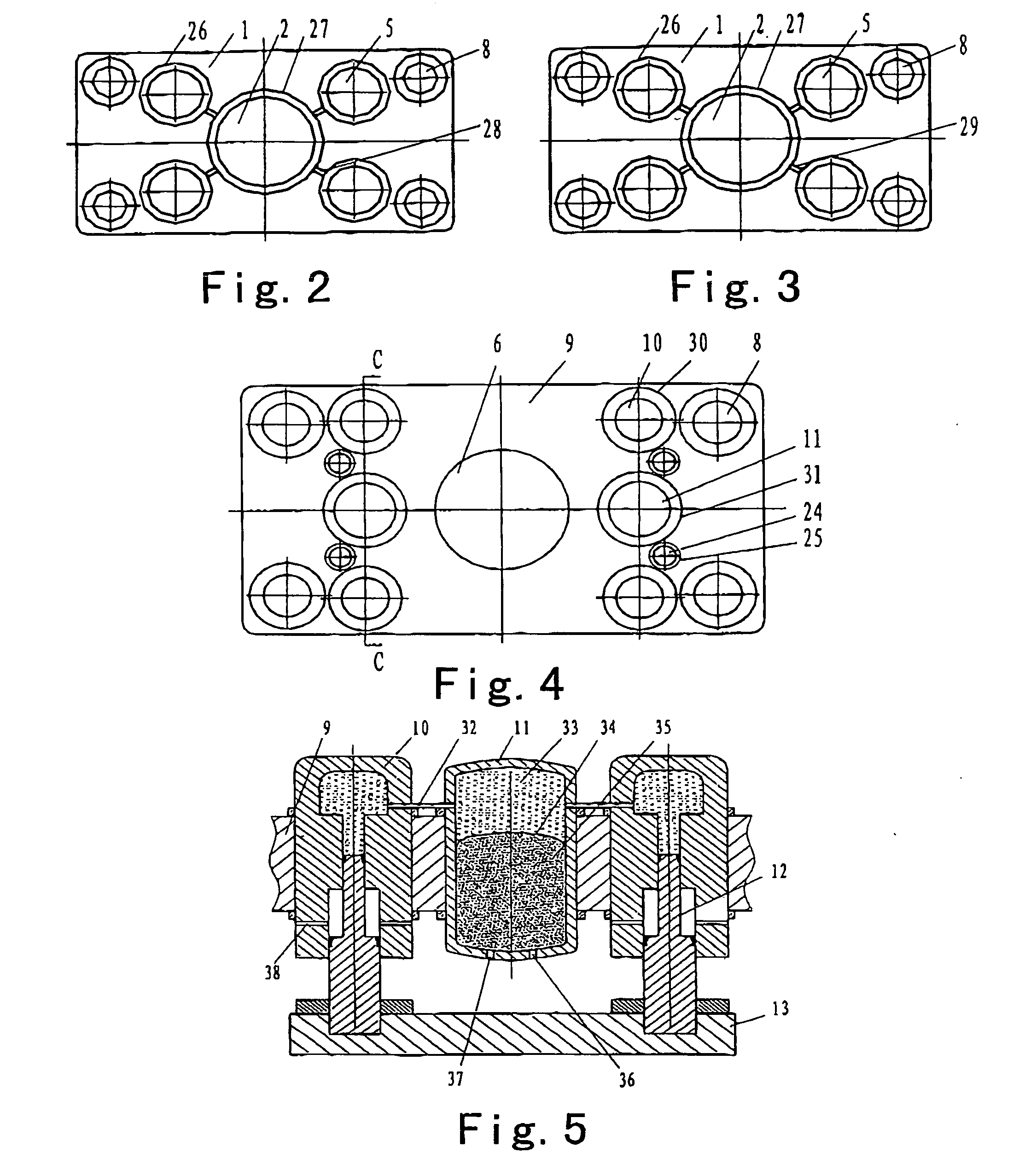

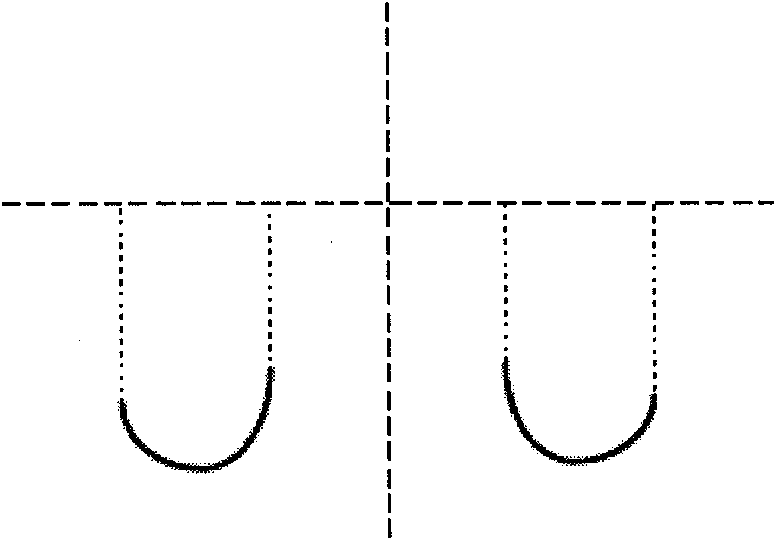

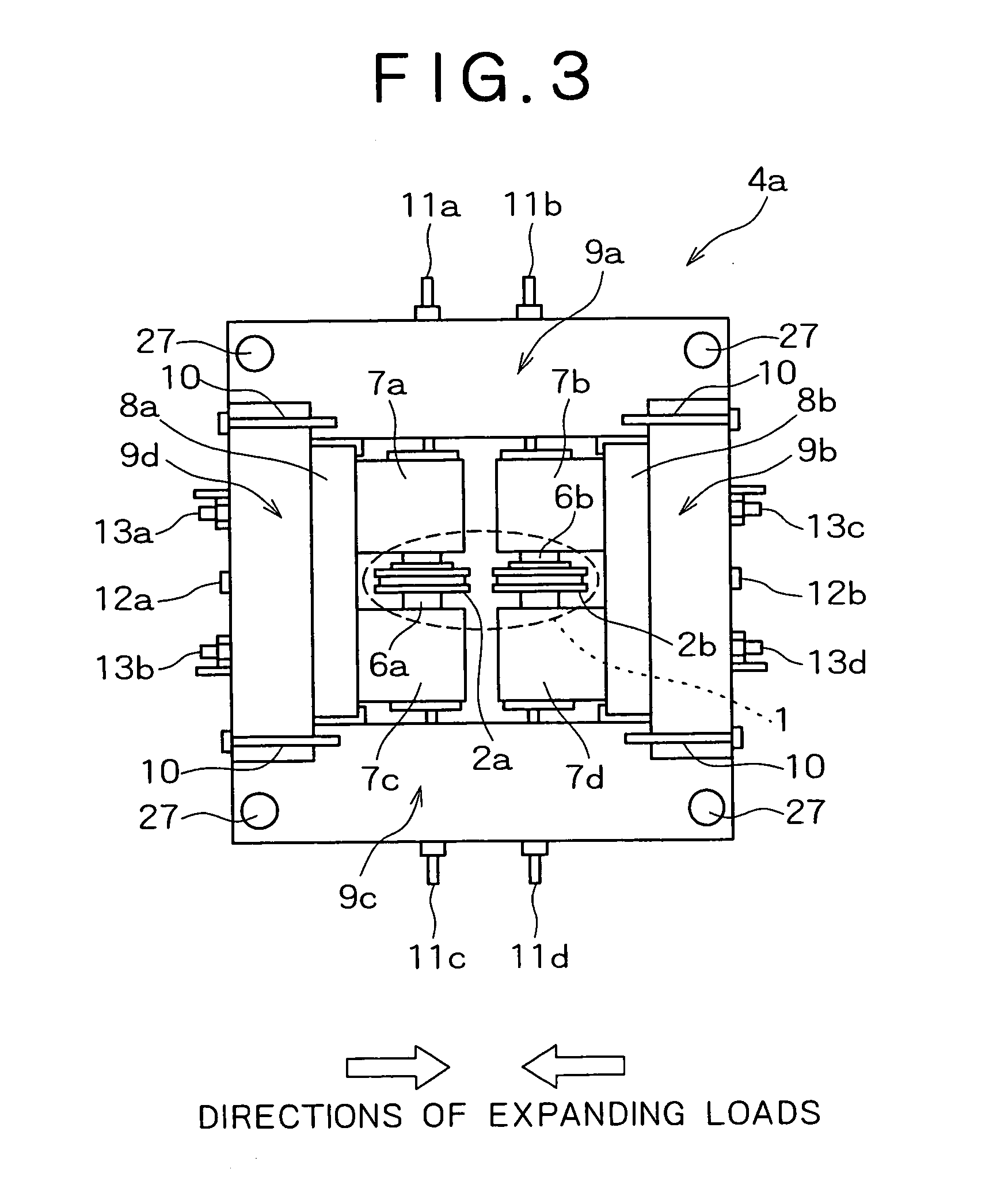

Adjustable Hydraulic Press With Both Upper And Lower Double Action

ActiveUS20080098908A1Innovative designSimple structureShaping toolsForging/hammering/pressing machinesMetal formingGear wheel

The present invention discloses an adjustable hydraulic press with both upper and lower double action, specially suitable for the cylindrical gear formed by stamping or expanding, closed forging and the metal cold forming or metal hot forming of punching, finishing, flanging and drawing of sheet materials. The press comprises four columns, an upper beam, a main slide block, a hold down slide block, a fixing worktable, a floating worktable and a lower beam. The hydraulic chamber of master cylinder fixed in the upper beam communicates to the hydraulic chamber of the auxiliary cylinder, the plunger of master cylinder is connected to the main slide block and drives it. The hydraulic chamber of gas-liquid power accumulator fixed in the main slide block communicates to the hydraulic chamber of hold down cylinder, the plunger of hold down cylinder is connected to the hold down slide block and drives it. The plunger of ejecting cylinder fixed in the lower beam is connected to the floating worktable and drives it. The hydraulic press of the invention simplifies the hydraulic system of the existing hydraulic, improves utilization rate of energy, production efficiency and working accuracy of workpiece.

Owner:JILIN UNIV

Regenerated wire drawing modified material of waste polypropylene woven bags and preparation method thereof

The invention provides a regenerated wire drawing modified material of waste polypropylene woven bags, comprising the following components in percentage by weight: 1-35 percent of polyolefin fresh material, 25-95 percent of waste polypropylene material, 1-55 percent of enhanced modifier, 1-30 percent of toughening modifier, 0.01-5 percent of activator, 0.1-3 percent of antioxidant, 0.01-6 percent of lubricant and 0.01-6 percent of dispersing agent. The invention also provides a preparation method of the regenerated wire drawing modified material of the waste polypropylene woven bags. In the preparation method, based on the arecovery treatment on the waste polypropylene woven bags, the new wire drawing modified material of woven bags are produced by adding proper amount of other raw materials and auxiliary materials and can be directly used for producing polyolefine flat fibers with stable performance. The performance of a new polypropylene woven tape produced from the prepared material and a small quantity of fresh material is equivalent to a woven bag wholly produced by carrying out granulation and wire drawing on the fresh material. The new polypropylene woven tape can completely satisfy the use performance requirements, dramatically lower the product production cost and provide a proper way for waste recycling utilization and environmental pollution reduction.

Owner:丁飞鹏 +1

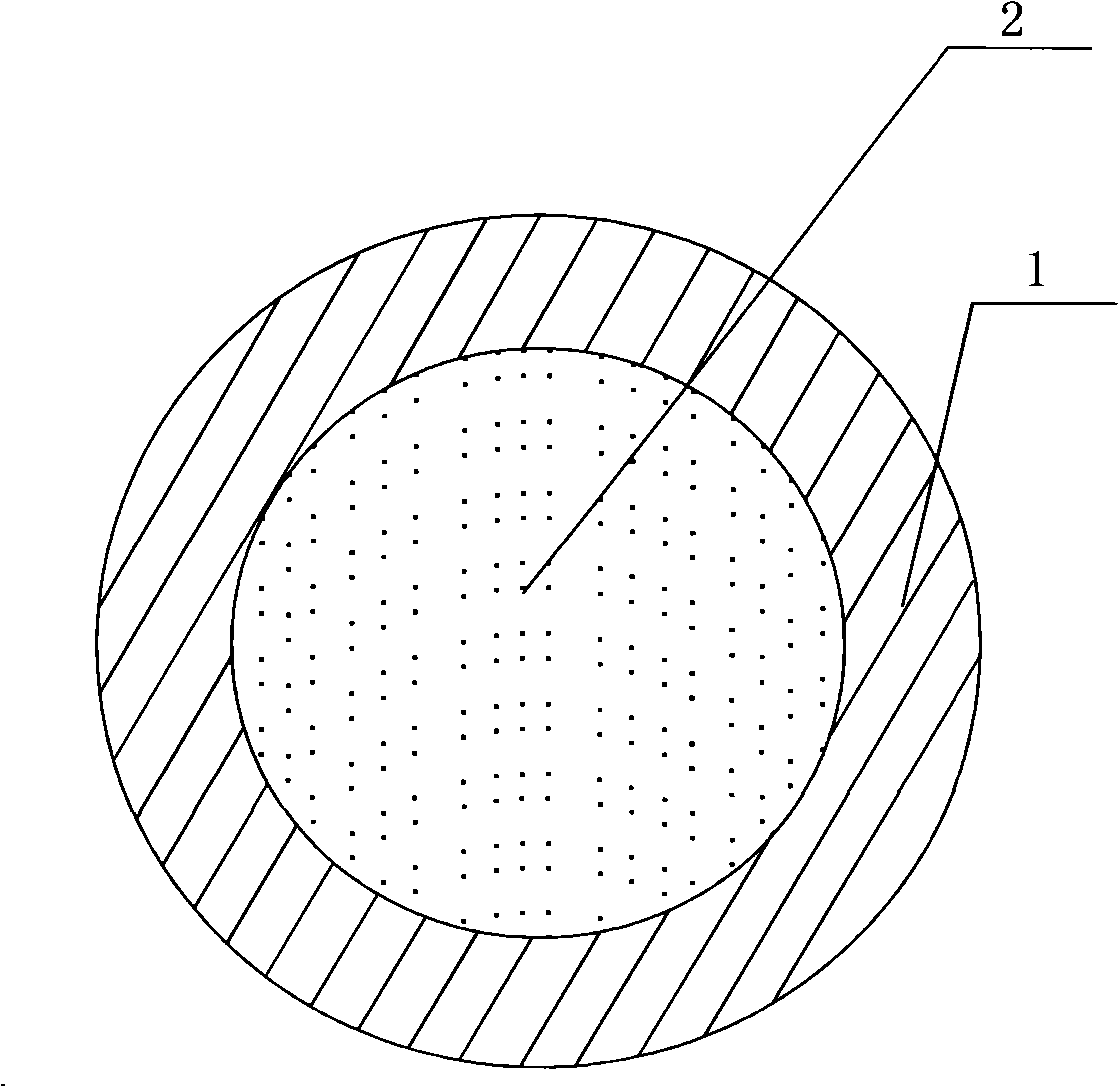

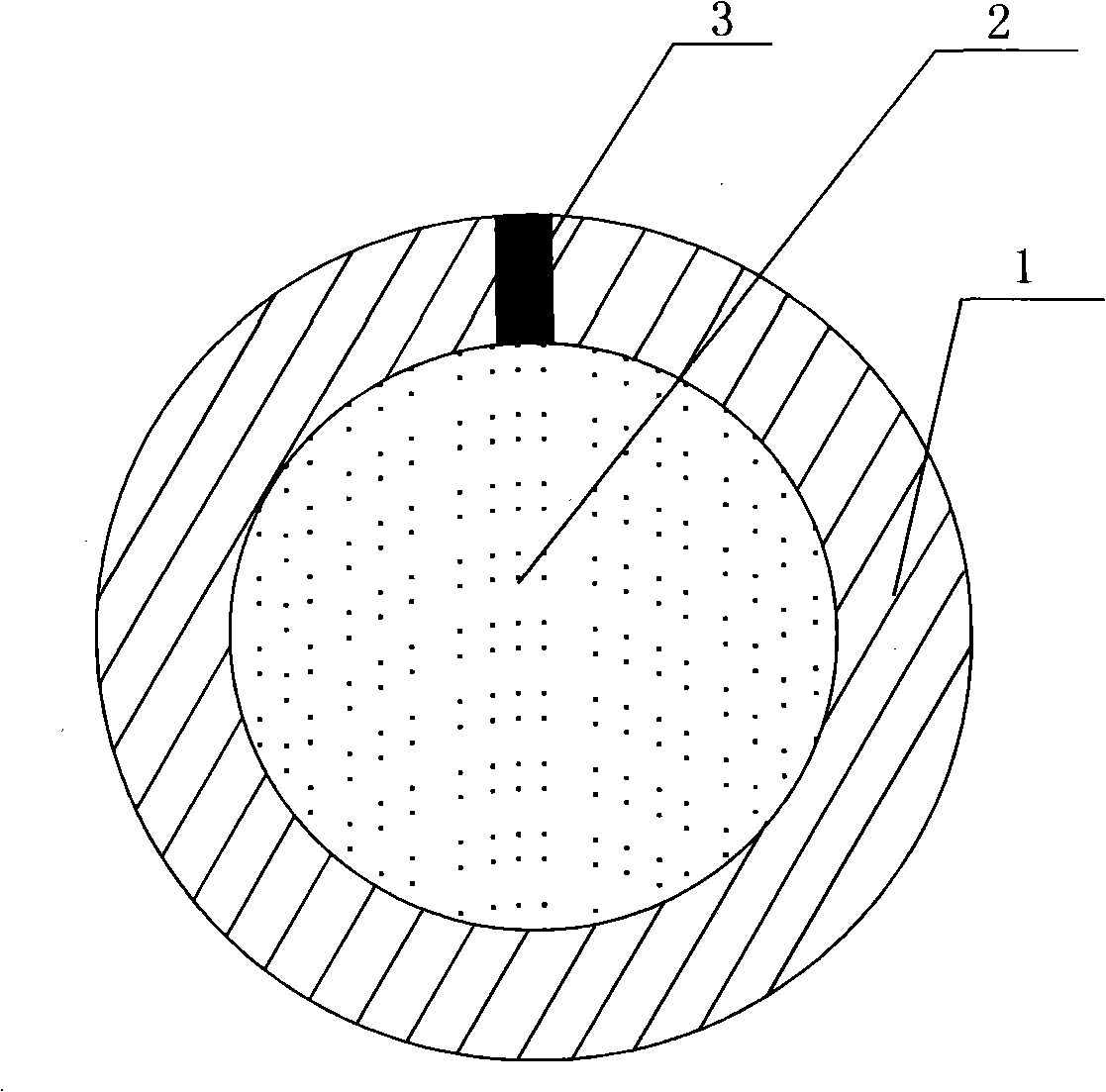

Large-size optical fiber preform and manufacturing method of optical fiber thereof

ActiveCN101891380AImprove the attenuation effectGuaranteed low water peak performanceGlass optical fibreGlass fibre drawing apparatusAccess networkCore (optical fiber)

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

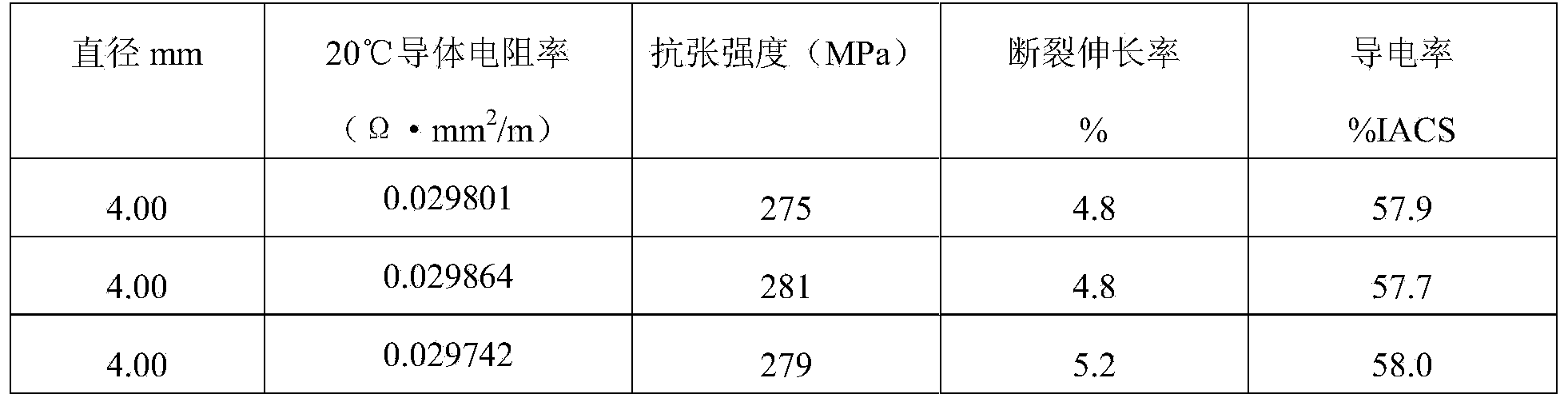

Intermediate-strength aluminum alloy wire and process for manufacturing same

ActiveCN104028961APurify gas impuritiesHigh strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsEddy currentSolid solution

The invention belongs to the field of overhead power transmission technologies, and discloses an intermediate-strength aluminum alloy wire and a process for manufacturing the same. The intermediate-strength aluminum alloy wire is used for an overhead conducting wire. The process includes adjusting components of alloy to a certain extent, and controlling an online deaeration purification system, rolling and an online solid-solution quenching system; performing wire drawing and ageing processing to ultimately obtain the single intermediate-strength aluminum alloy wire. The tensile strength of the single intermediate-strength aluminum alloy wire ranges from 260MPa to 300MPa, the elongation of the single intermediate-strength aluminum alloy wire is higher than or equal to 3.5%, and the single-wire conductivity of the single intermediate-strength aluminum alloy wire is higher than or equal to 57.5% IACS. The intermediate-strength aluminum alloy wire and the process have the advantages that the intermediate-strength aluminum alloy wire manufactured by the aid of the process is high in strength and elongation and good in conductivity, and an intermediate-strength aluminum alloy stranded wire which is formed after a plurality of intermediate-strength aluminum alloy wires are stranded with one another can be used for an overhead power transmission line and is high in tensile weight ratio, so that the running safety of the line can be improved; magnetic hysteresis loss and eddy current loss due to conventional steel-cored aluminum stranded wires can be prevented by the stranded wire which is completely formed after the intermediate-strength aluminum alloy wires are stranded with one another, and electric energy loss of the line can be greatly reduced.

Owner:FAR EAST CABLE +2

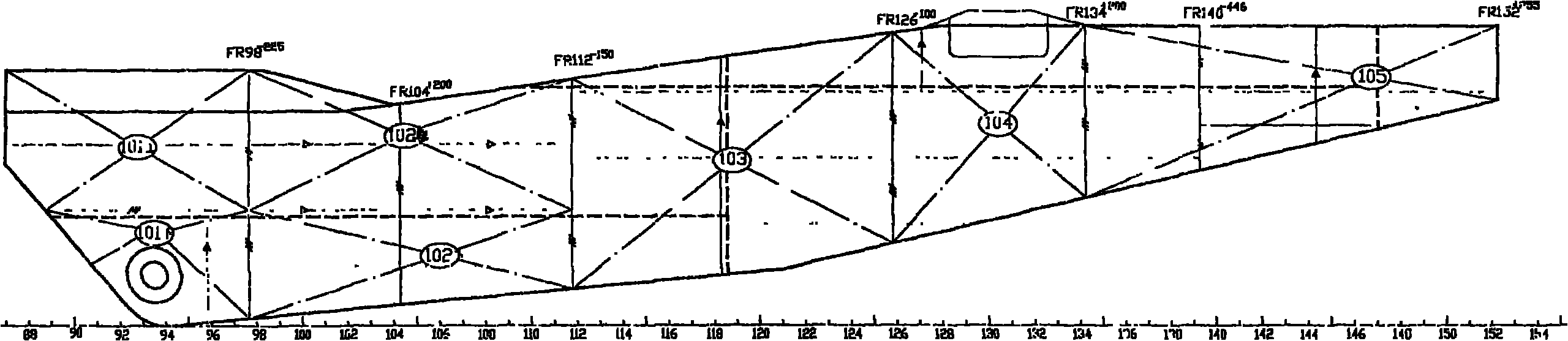

Preparation and on-board installation process of crane span of cutter suction dredger

InactiveCN101811553ASave installation timeShorten the manufacturing cycleVessel partsOn boardEngineering

The invention discloses a preparation and on-board installation process of crane span of cutter suction dredger. The process comprises the following steps: preparing the jig of a crane span, performing sectionalized assembly of the crane span, performing wire-drawing to the trunnion of the crane span, performing wire-drawing to the trunnion of a hull, closing shipways, fixing the crane span, installing bolts, etc. The process of the invention has the advantages of convenient construction and good construction effect; and the installation time of the crane span is fully reduced, and the total cycle time for the preparation of ships is shortened.

Owner:南通港闸船舶制造有限公司

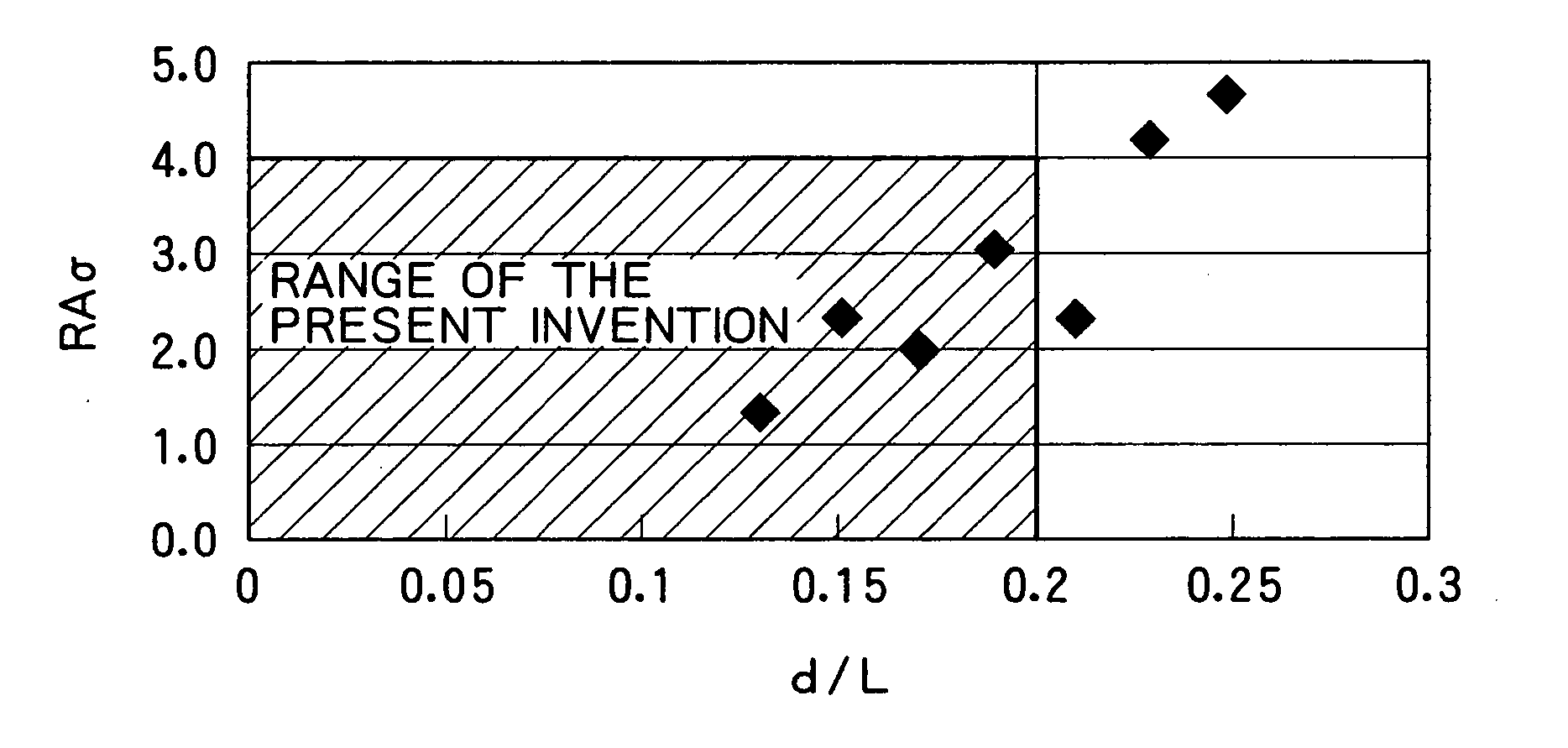

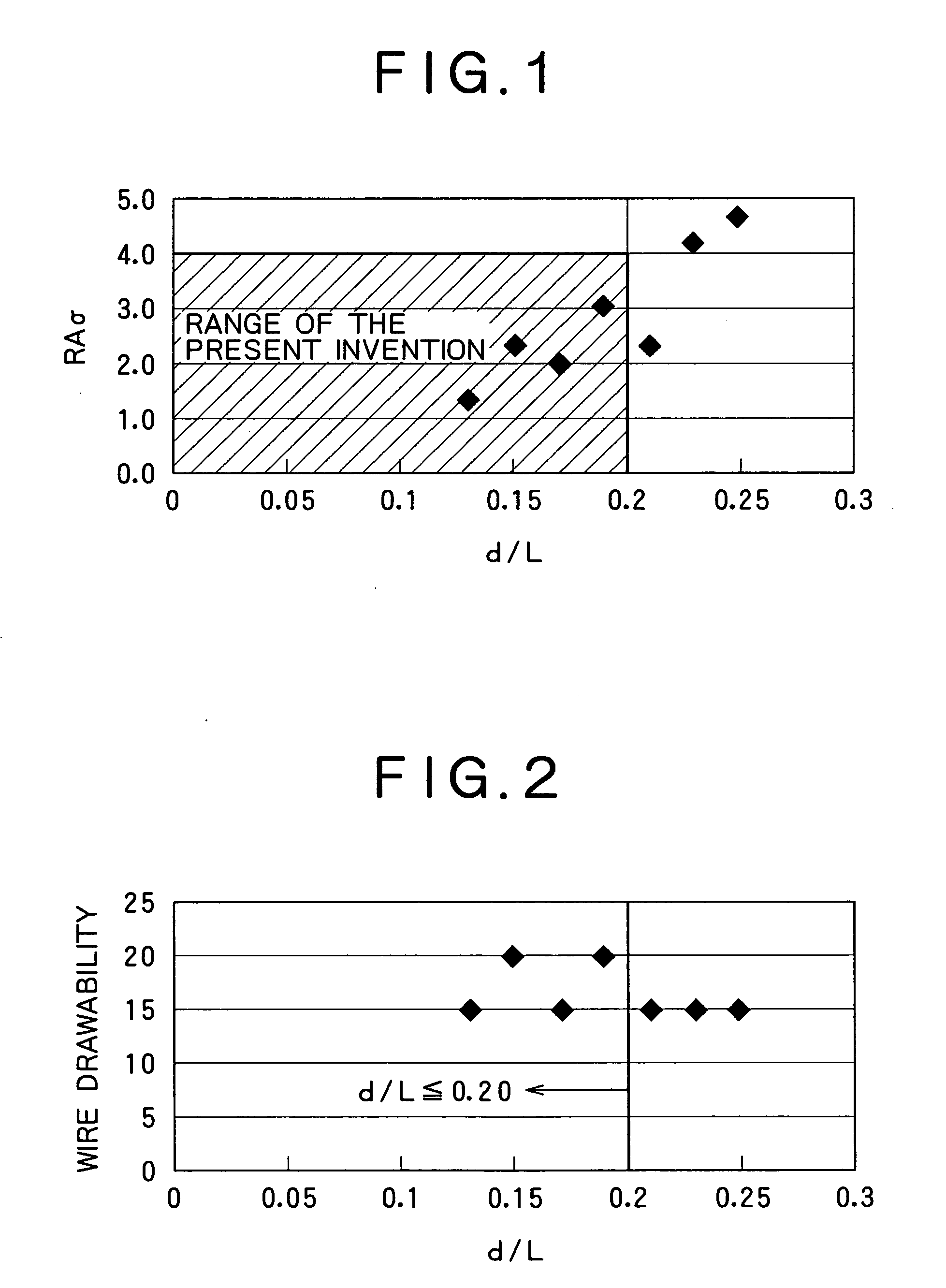

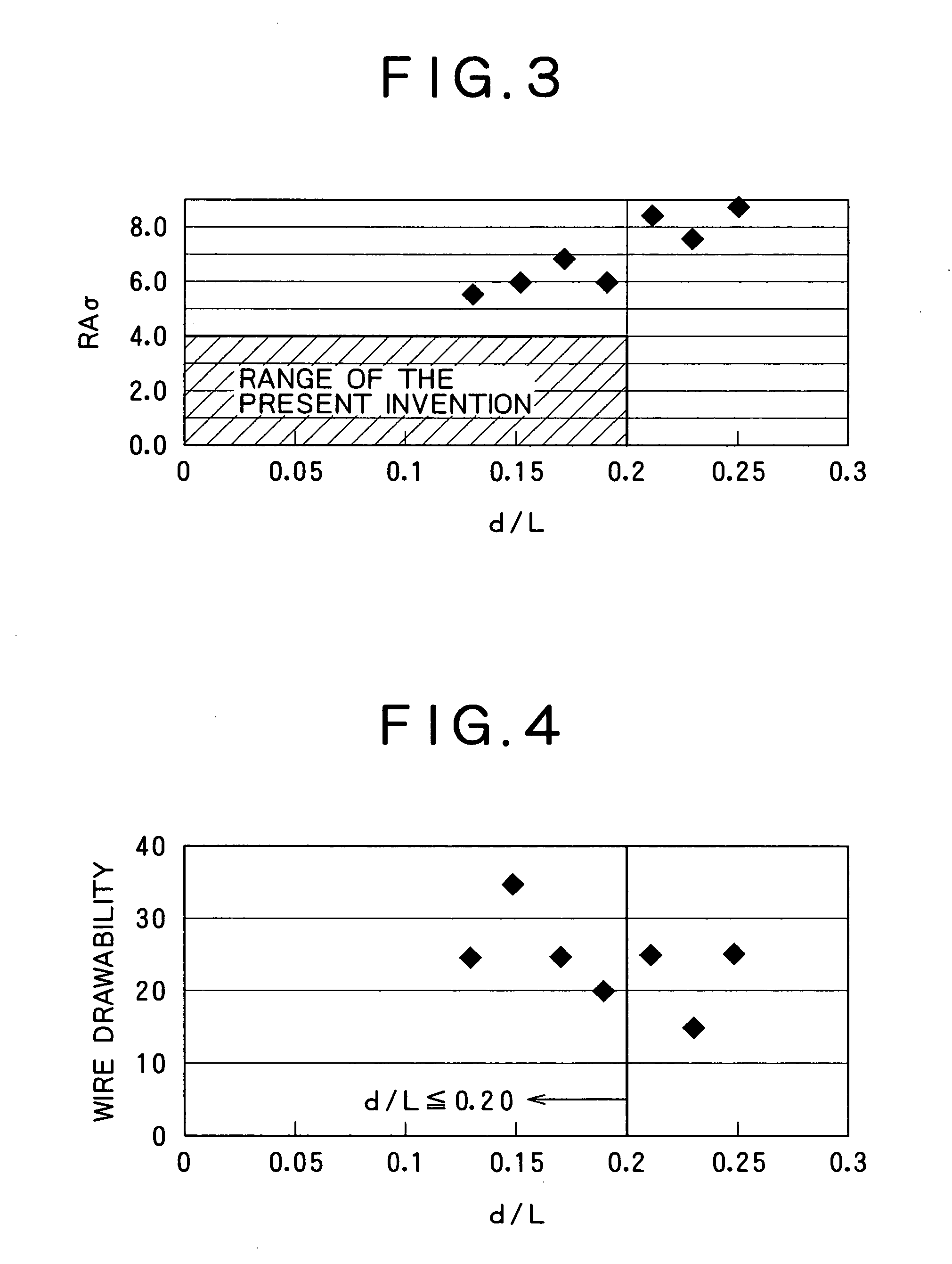

Hot milled wire rod excelling in wire drawability and enabling avoiding heat treatment before wire drawing

InactiveUS20060048864A1Good drawing effectSlow changeFurnace typesCooling bedsWire rodUltimate tensile strength

A hot-rolled wire rod: the wire rod being a hot-rolled wire rod 5.0 mm or more in diameter, containing in mass C: 0.6 to 1.0%, Si: 0.1 to 1.5%, Mn: 0.3 to 1.0%, P: 0.02% or less, and S: 0.02% or less; not less than 90% of the wire rod in area percentage being composed of a pearlite structure; and the mechanical properties of the wire rod 4 m in length satisfying the following expressions (1) to (4), (1) TS*−30≦Average value of tensile strength (TSAV in MPa)≦TS*+30, where, TS*=400×{[C]+([Mn]+[Si]) / 5}+670 and the elements in square brackets [ ] in the equality mean the contents of relevant elements in percentage, (2) Standard deviation of tensile strength (TSσ)≦30 MPa, (3) Average value of reduction of area (RAAV)>35%, (4) Standard deviation of reduction of area (RAσ) ≦4%. A hot-rolled wire rod according to the present invention is incomparably excellent in wire drawability and brakes less frequently than a conventional wire rod even when it is processed as hot-rolled with heat treatment such as patenting treatment omitted.

Owner:KOBE STEEL LTD

Technique for manufacturing frequency conversion varnished wire

InactiveCN101325102AImprove corona resistanceExtended service lifePlastic/resin/waxes insulatorsInsulating conductors/cablesPolyesterFrequency conversion

The invention discloses a production process of a frequency conversion lacquered wire. The process comprises the following steps: (1) paying off; (2) wire drawing; (3) cleaning; (4) annealing; (5) cooling; (6) varnishing, backing and cooling: firstly the surface of a norm wire is coated with 10 passes of the frequency conversion polyester paint, and then, 3 passes of polyamide-imide paint, after the surface is coated with each pass of paint, backing and cooling are performed, then the surface is coated with the next pass of the paint, the backing is performed from the lower layer to the upper layer during the process of backing, the temperature at the inlet of a baking oven is 220 DEG C, the temperature in the lower layer is 330 DEG C, the temperature is 330 DEG C before the primary catalyzing is performed, and the supplementary heat temperature is 430 DEG C after the catalyzing is performed; (7) lubricating; and (8) wire winding. By adopting the production process, the lacquered wire can be guaranteed to achieve the good corona resistance, thereby the insulation aging phenomena can be slowed down, and the service life of the motor can be prolonged.

Owner:JIANGSU DAZHONG ELECTRIC MOTOR

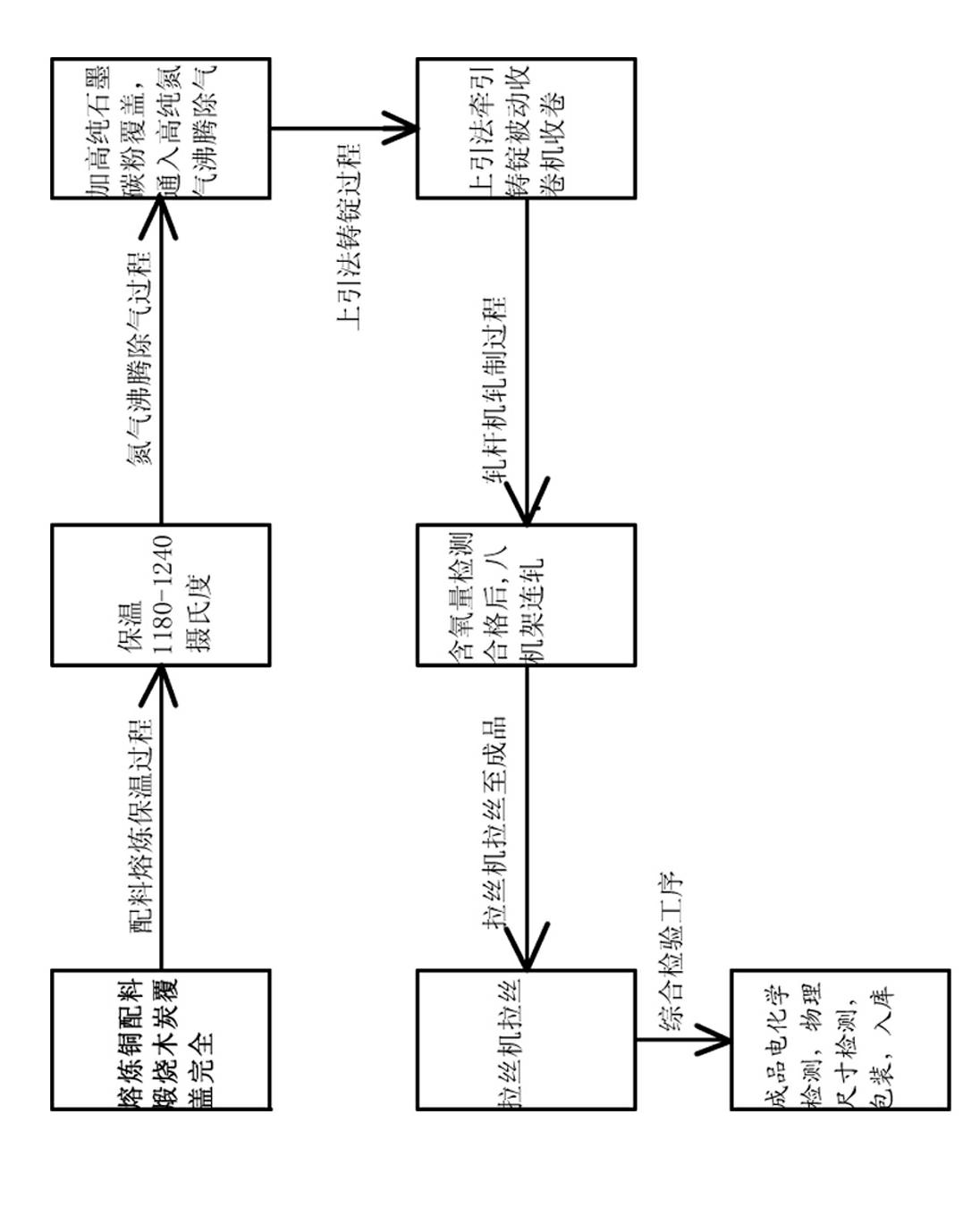

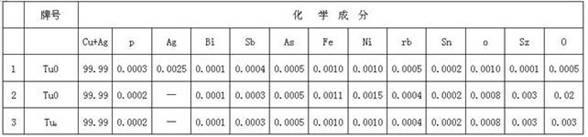

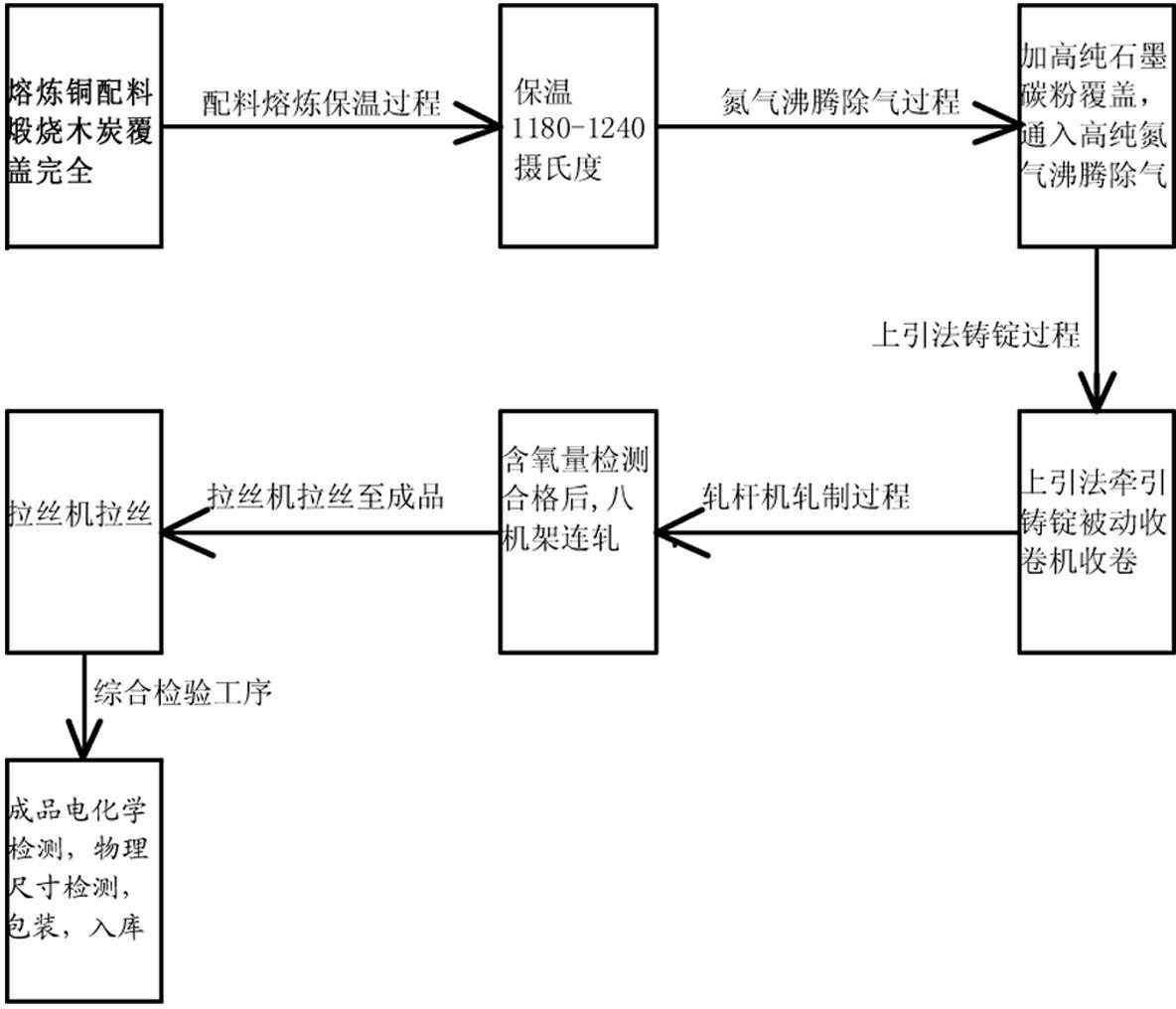

Upcast method for producing high-purity bright copper rod

ActiveCN102168180ALight weightFull reduction reactionProcess efficiency improvementGraphite carbonWinding machine

The invention relates to an upcast method for producing a high-purity bright copper rod. The method comprises the following steps of: drying smelting copper raw materials needed by smelting, mixing, adding the mixture into a smelting furnace, and covering firing charcoal with the thickness of between 100 and 150mm on starting molten copper until red copper is entirely molten, wherein molten copper constantly flows toward a heat preservation furnace under the action of fluid force; boiling the high-temperature molten copper and degassing before ingot guiding, adding prepared high-purity graphite carbon powder onto the liquid level of the molten red copper in the heat preservation furnace, and aerating high-purity nitrogen at the position which is 50 to 100mm lower than the liquid level of the heat preservation furnace; covering the firing charcoal after boiling and degassing, covering a furnace cover, performing draw casting operation, drawing a draw casting machine for draw casting bythe upcast method, cooling in a graphite crystallizer by the upcast method to obtain a qualified high-purity oxygen-free copper rod blank, and winding on a drawn cast ingot passive winding machine; and performing multi-pass rolling and fine-drawing on the high-purity oxygen-free high-brightness copper rod blank by an eight-rack rod cold rolling mill, and drawing the blank until the copper rod is obtained by a wire drawing machine, namely obtaining a finished product after the copper rod passes the inspection.

Owner:ZHONGTIAN ALLOY TECH

Continuous pickling and wiredrawing process of brass wire

ActiveCN101961736AImprove surface qualityReduce labor intensityDrawing diesCompression injuryProduction line

The invention relates to a continuous pickling and wiredrawing process of a brass wire, which is characterized in that: after being drawn out of a wire releasing disc, a brass wire blank is subjected to continuous processes of pickling, neutralizing, brushing, cleaning and wiredrawing. A continuous producing mode is used for connecting the pickling process and the drawing process of the brass wire together, namely that after an annealed brass wire blank is arranged on a wire releasing frame by one end of a production line, a finished product of the fine-drawn brass wire can be generated from the other end, therefore, the continuous producing mode has few processing and flowing processes and stops scrapes and compression injuries in the flowing process; pickled products are wiredrawn in a shorter period to ensure better brightness and consistency of product appearance and obviously increase the surface quality of the finished product of the brass wire; the processing process has high automation degree, reduces labor intensity of staffs and increases production efficiency; when the brass wire is in the pickling process, an oxide layer on the surface of the brass wire only needs to be loosened; and therefore, when the brass wire is pickled, nitric acid does not need to be added, the usage amount of acid liquor is greatly reduced, and the production cost is reduced.

Owner:JINTIAN COPPER GROUP CORP NINGBO

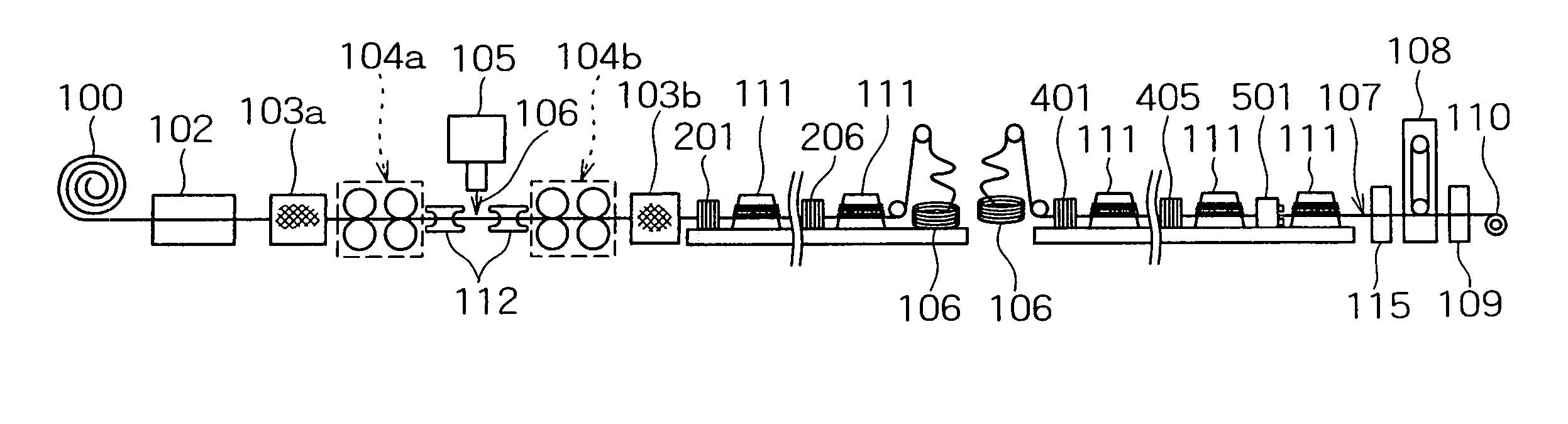

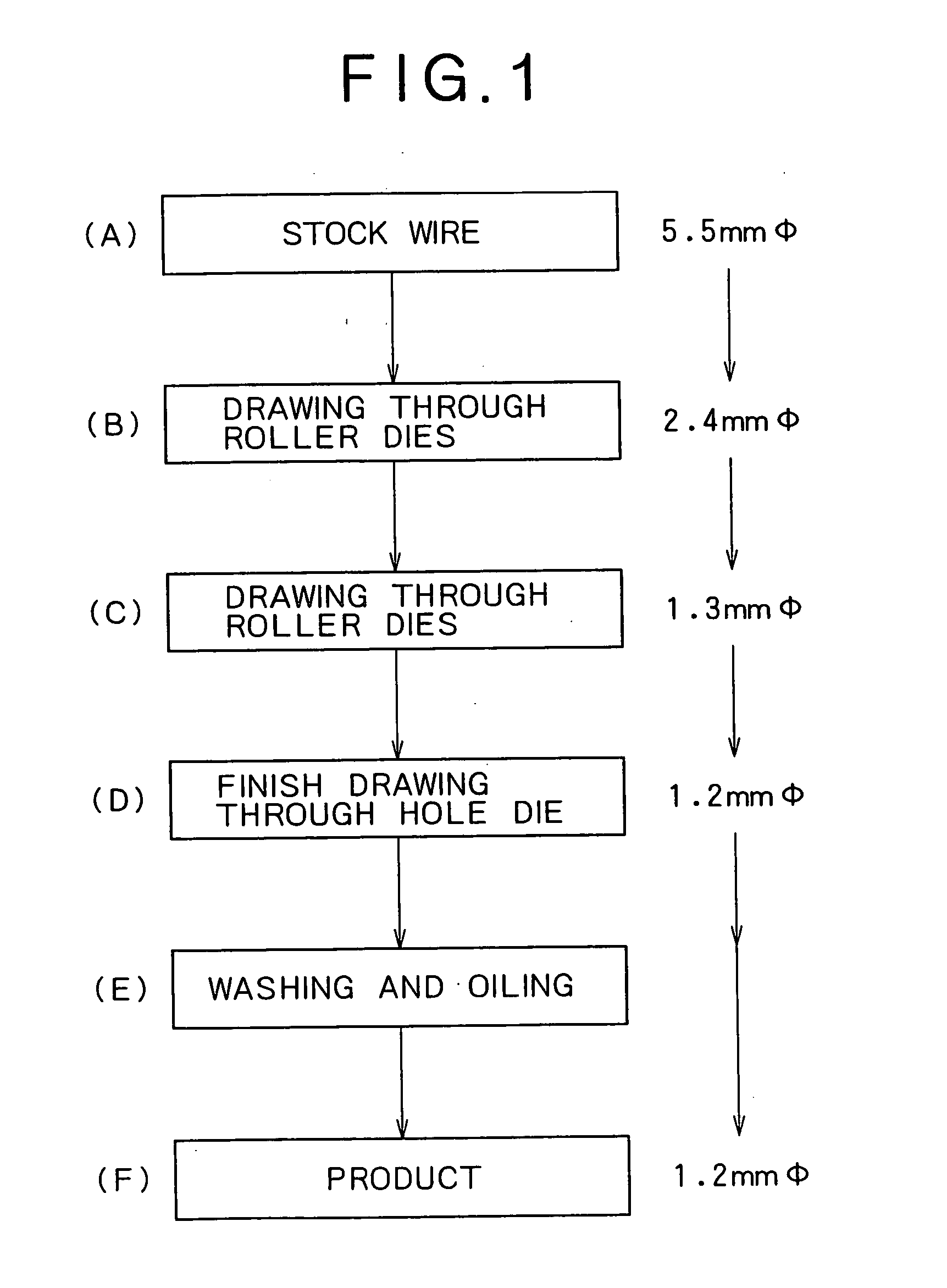

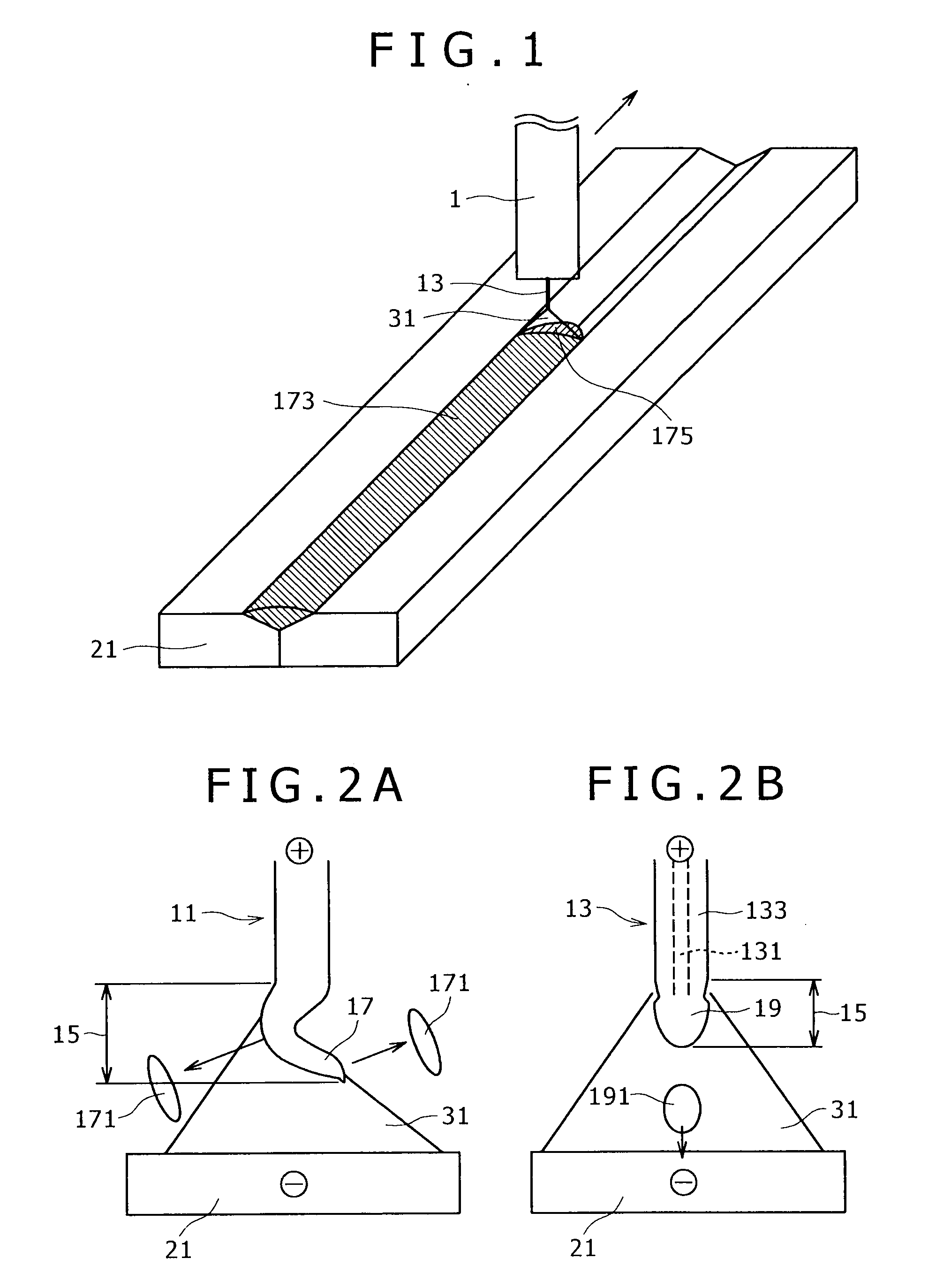

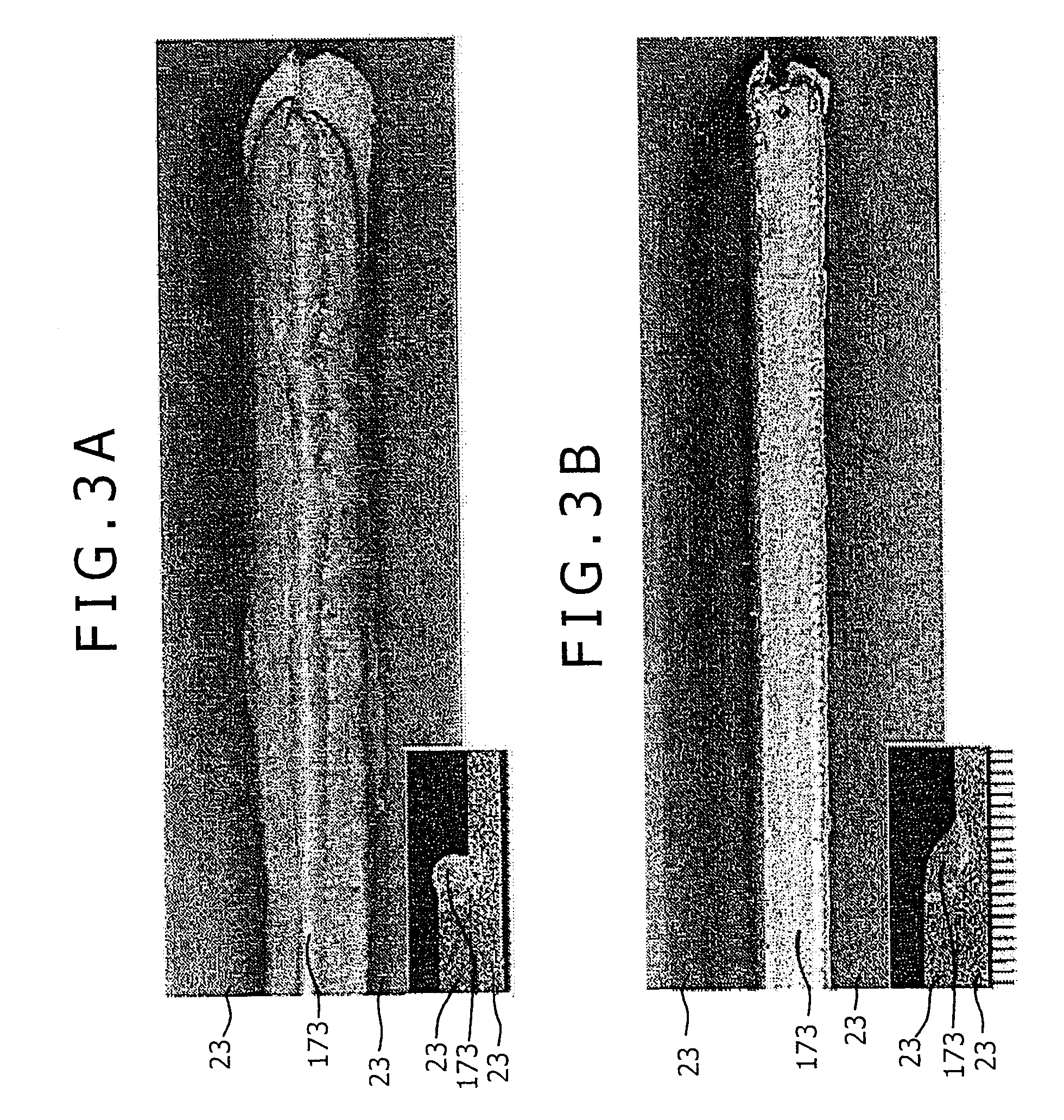

Method of producing solid wire for welding

ActiveUS20050045699A1Uniform applicationEfficient weldingDrawing diesArc welding apparatusCopper platingSodium stearate

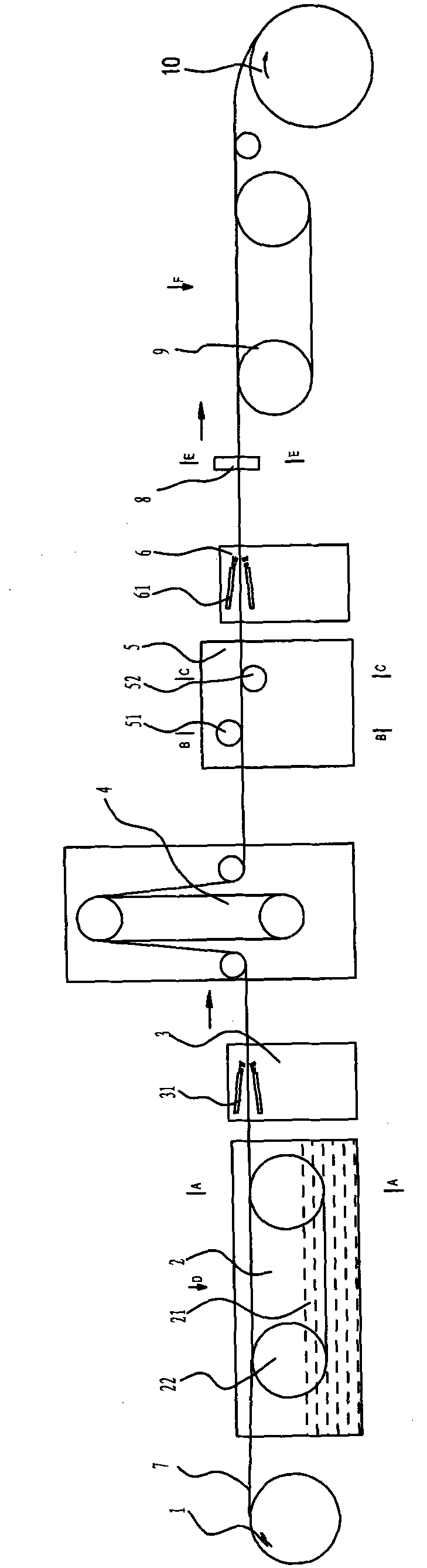

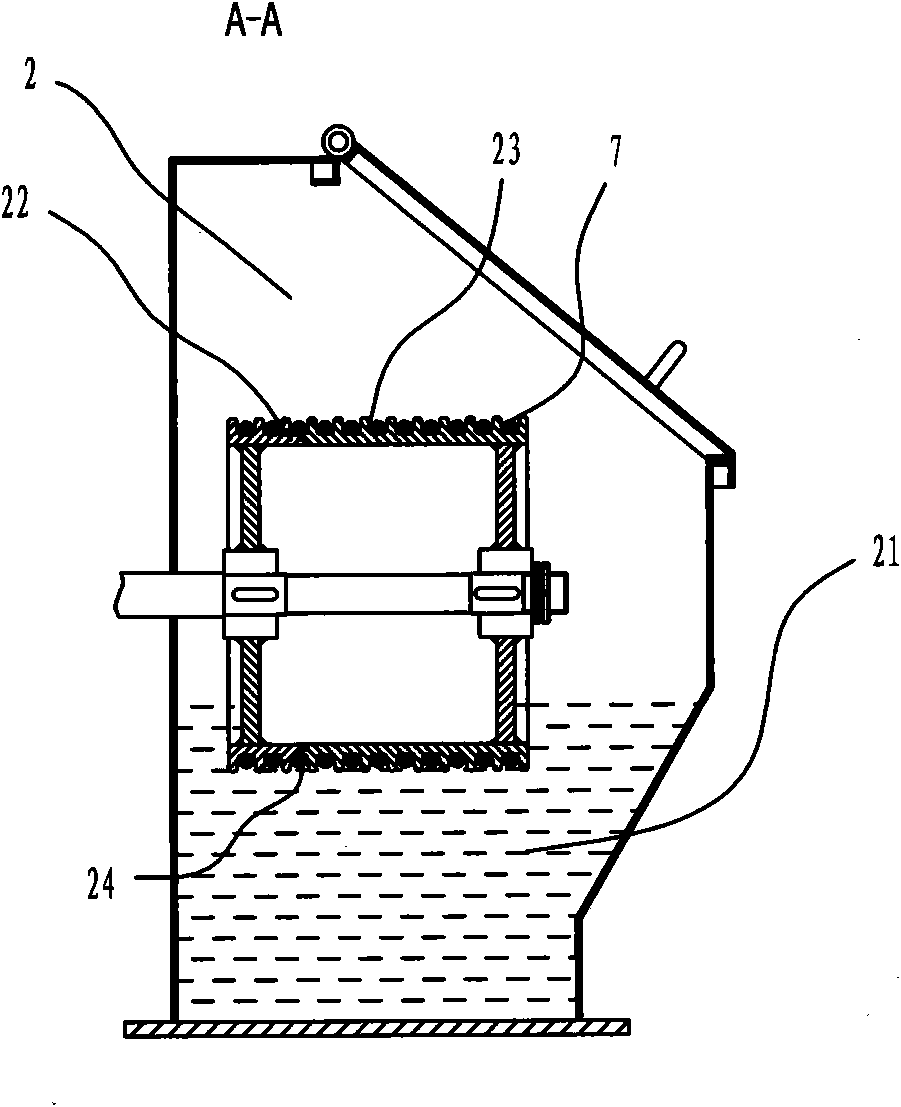

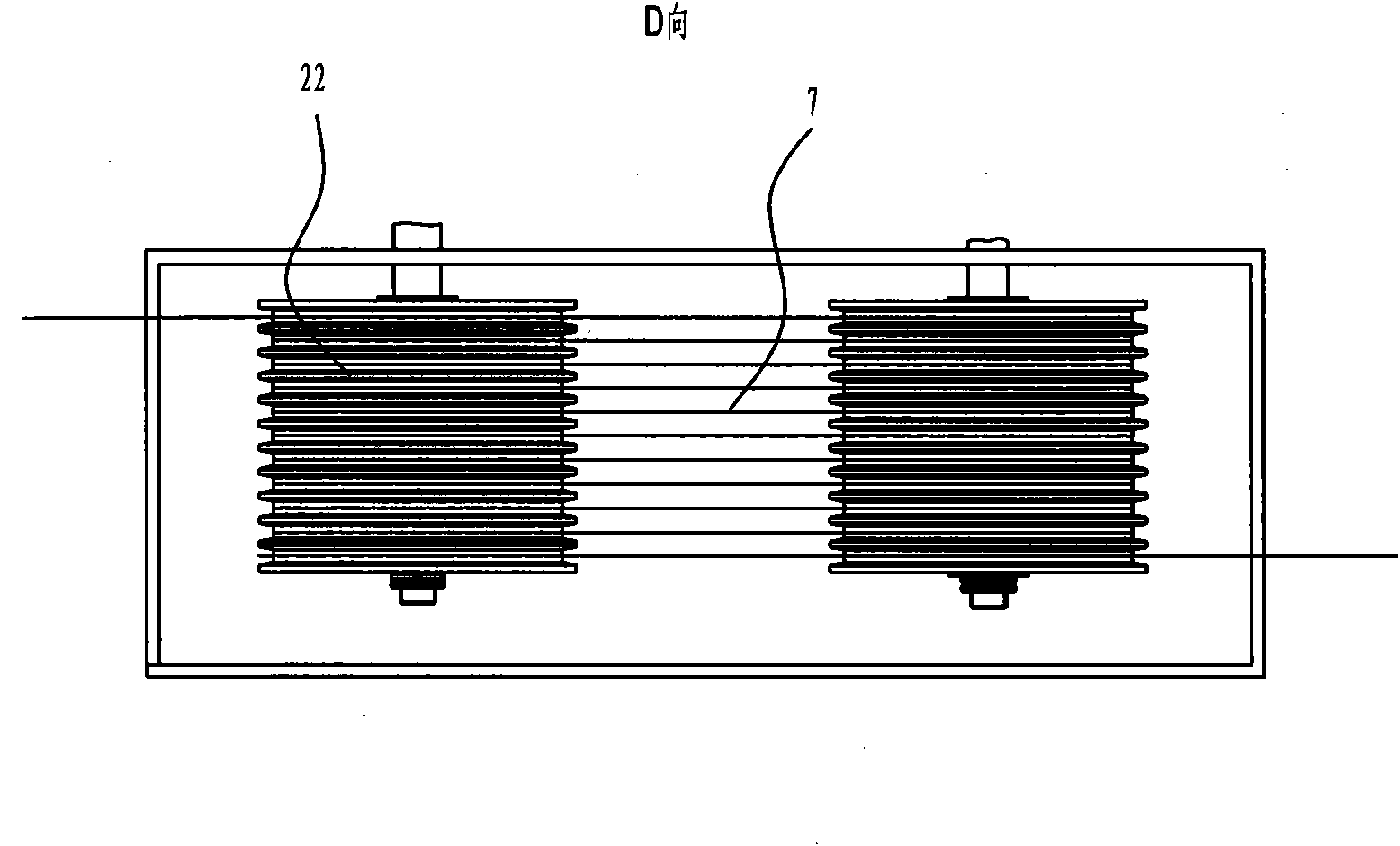

A method for efficient production of a welding solid wire free of copper plating. The method consists of drawing by means of roller dies with the help of a dry solid lubricant for drawing which is at least either of sodium stearate or potassium stearate, removing the lubricant from the wire surface by means of a washing device, and applying a lubricant for wire feeding to the surface of the drawn wire by means of an oiling device. High-speed drawing by means of roller dies makes a stock wire into a welding solid wire having the diameter of the finished wire or nearly finished wire. The drawing step is followed by the washing step and the lubricant applying step, which are all accomplished in-line.

Owner:KOBE STEEL LTD

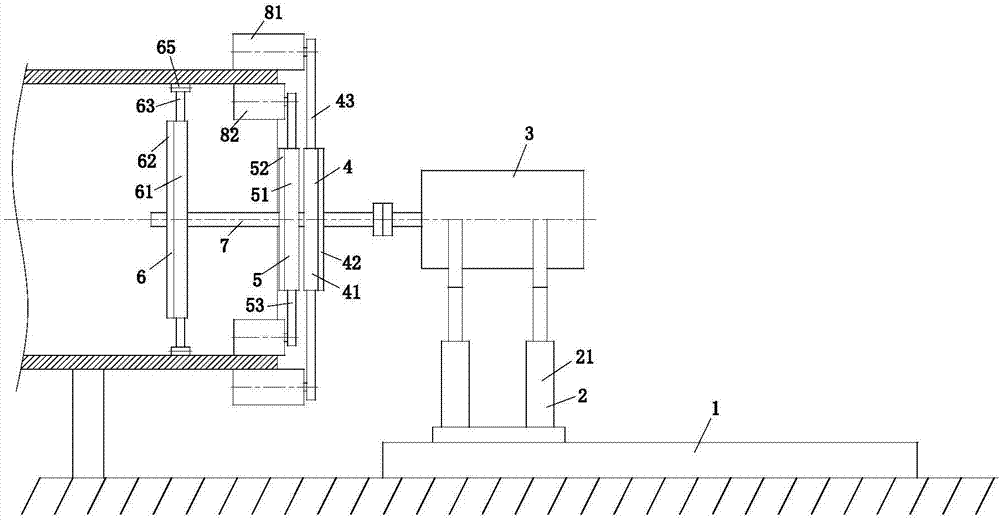

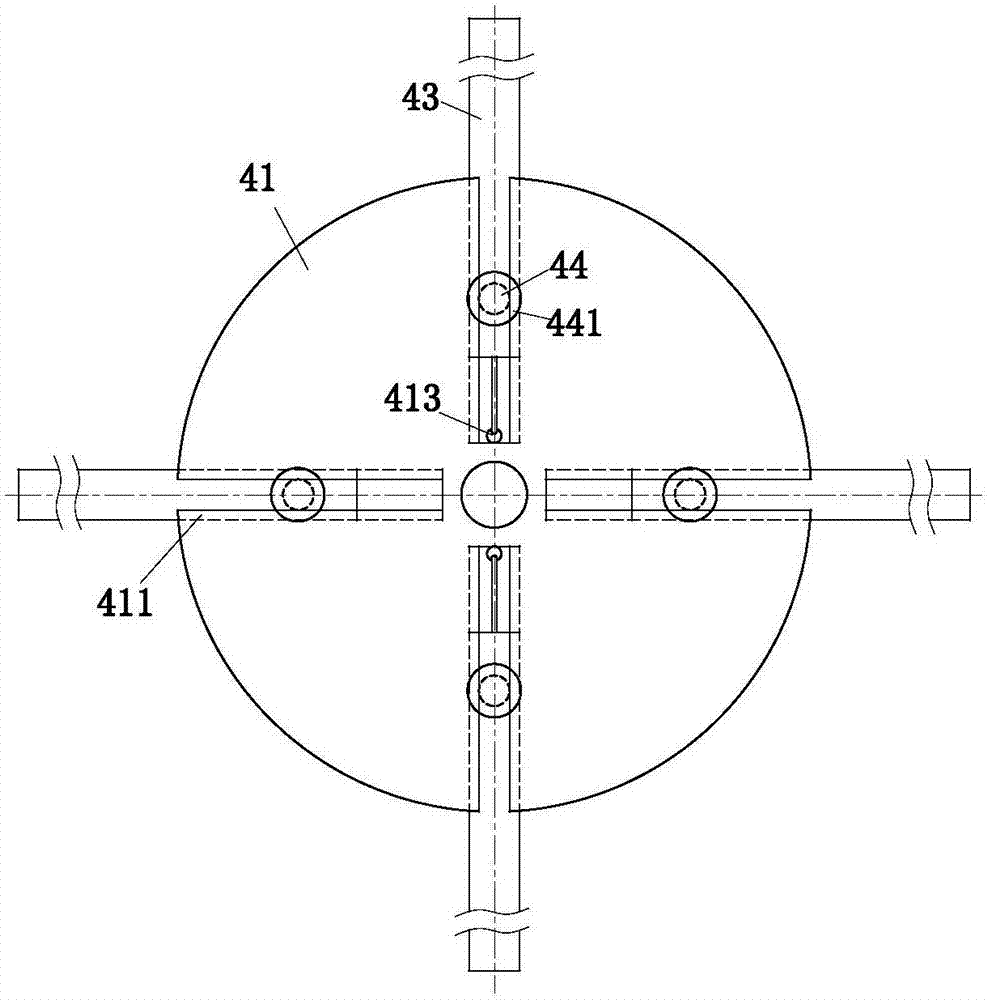

Stainless steel cylinder polishing wire-drawing treatment equipment

ActiveCN107363695ARealize automatic shrinkage adjustmentImprove production efficiencyGrinding carriagesRevolution surface grinding machinesEngineeringDrive motor

The invention belongs to the field of mechanical processing equipment, and in particular discloses stainless steel cylinder polishing wire-drawing treatment equipment which comprises a bottom plate, an adjusting module, a driving motor, an outer cylinder grinding disc, an inner cylinder grinding disc, a centering support and a connecting rotating shaft, wherein the bottom plate is placed on the ground; an adjusting module is arranged on the upper surface of the bottom plate; the driving motor is mounted on the adjusting module; the inclination angle of an axis of the driving motor can be adjusted through the adjusting module; and the outer cylinder grinding disc, the inner cylinder grinding disc and the centering support are detachably mounted on the connecting rotating shaft coaxially. By adopting the equipment, automatic shrinkage adjustment on a polishing wire-drawing radius is achieved under the centrifugal action of the outer cylinder grinding disc and the inner cylinder grinding disc, then operation of polishing and wire-drawing is completed at one time, and the generation efficiency is improved.

Owner:南京拓创精密金属材料有限公司

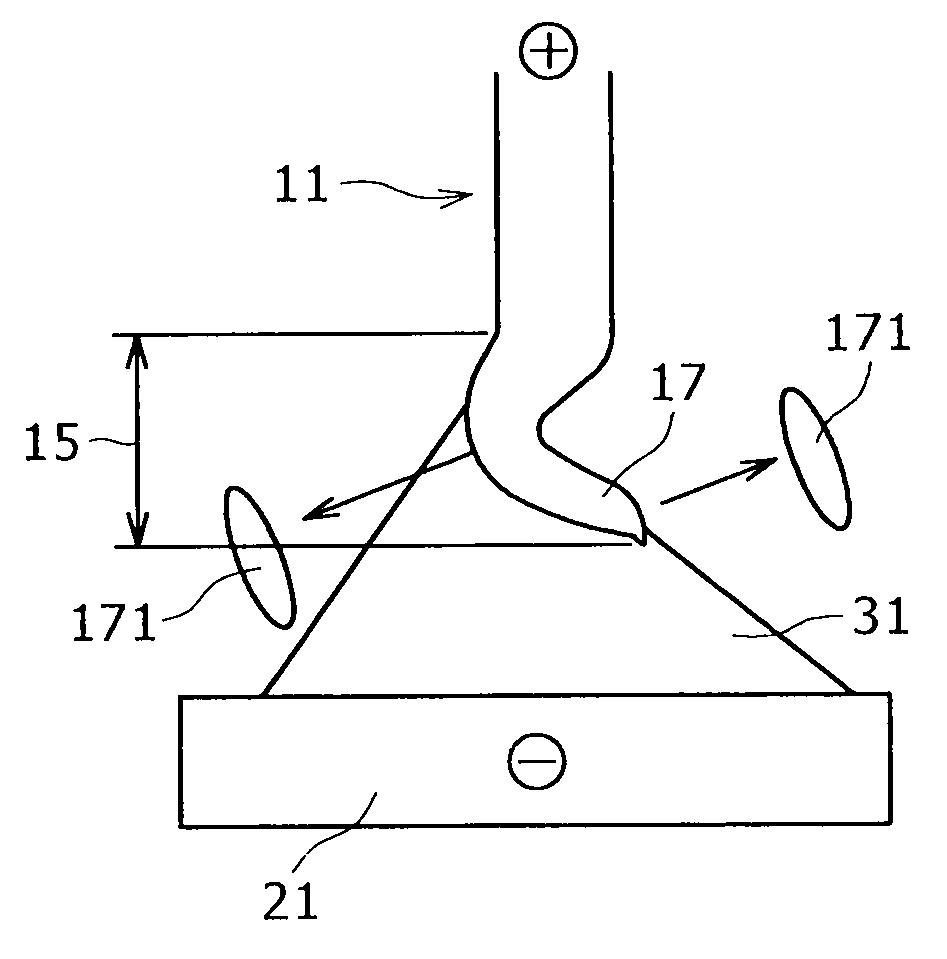

Pure ar gas shielded welding mig flux-cored wire and mig arc welding method

InactiveUS20090261085A1High static tensile strengthLow-cost and stable pure Ar-MIG weldingArc welding apparatusWelding/cutting media/materialsSlagGreenhouse effect

A pure Ar-MIG welding wire for welding steel according to the present invention is formed of a flux-cored wire. The flux-cored wire is formed in the manner that a formation formed by welding a carbon steel hoop into a pipe shape or a seamless pipe is used as an outer sheath, the outer sheath is filled with a flux, and a wire drawing process is performed. The flux accounts for 7 to 27 mass % of the total wire mass. The wire contains graphite in the amount of 0.16 to 2.00 mass % on the basis of the total wire mass and iron powder in the amount of 20 mass % on the basis of the total flux mass. According to the construction, neither expensive metal resource nor a greenhouse effect gas is used, slag and fume generation is inhibited, and a weld joint having a high static tensile strength and fatigue strength can be obtained.

Owner:KOBE STEEL LTD

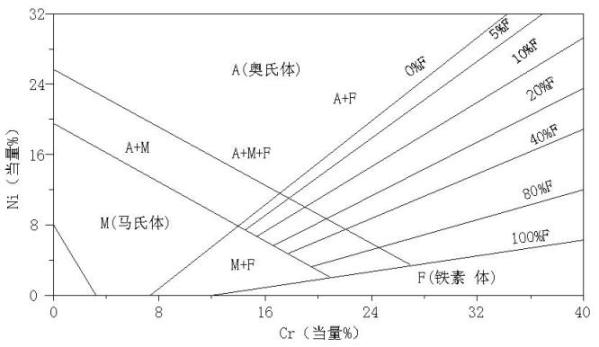

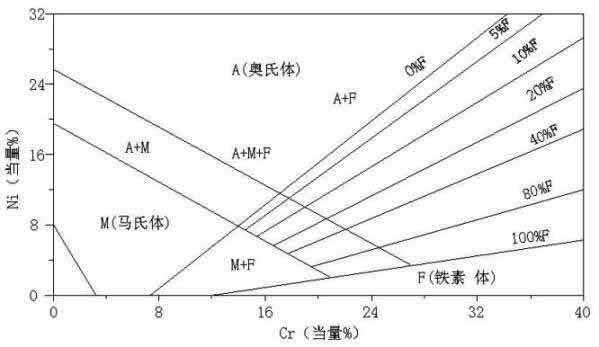

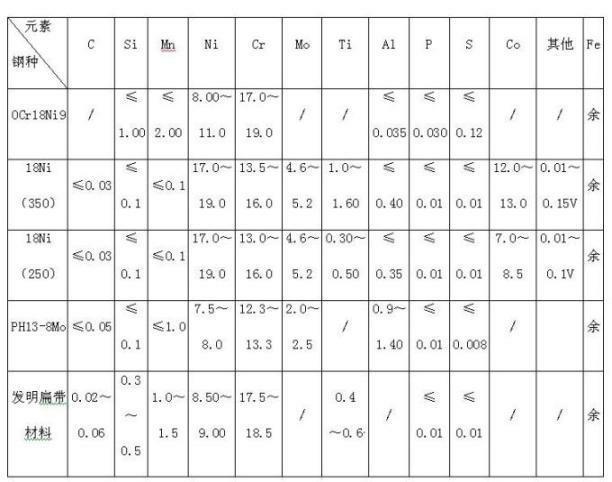

Martensite stainless steel and preparation method for flat strip of martensite stainless steel

ActiveCN102251191AHigh strengthHigh hardnessIncreasing energy efficiencySolution treatmentMartensitic stainless steel

The invention discloses martensite stainless steel and preparation method for flat strips of martensite stainless steel. The martensite stainless steel comprises following chemical components by weight percentage: C 0.02 to 0.06%, Si 0.3 to 0.5%, Mn 1.0 to 1.5%, Ni 8.5 to 9.0%, Cr 17.5 to 18.5%, Ti 0.4 to 0.6%, P no more than 0.009% and S no more than 0.009%, with the balance being Fe. The preparation method for flat strips of the martensite stainless steel comprises the following steps: a) weighing above-mentioned chemical components at desired weight percentage; b) carrying out vacuum induction melting; c) carrying out casting to obtain remelt electrode bars; d) carrying out electroslag remelting to obtain steel ingots; e) forging steel ingots into billets; f) processing billets into round strips; g) carrying out solid solution treatment; h) drawing treated blanks into wires; i) preparing flat strips. According to the invention, equivalents of nickel and chromium are strictly controlled, the ratio of C to Ti and alloy elements are optimized, EVR smelting is carried out and such alloying elements as C, Si, Mn and Ti are added, thereby enabling formation of a metastable austenite structure; a predeformed phase-changed martensite wire material is obtained by wire drawing; and the ultra high strength deformed flat strips of martensite stainless steel are obtained by flat strip rolling.

Owner:CHONGQING MATERIALS RES INST

3D printing wood-plastic composite material and preparation method thereof

The invention relates to a 3D printing wood-plastic composite material and a preparation method thereof. The 3D printing material is composed of the following components in parts by weight: 100-150 parts of natural plant fiber, 125-175 parts of polyolefin plastic, 20-30 parts of mineral filler, 1-5 parts of coupling agent, 10-15 parts of dispersant, 5-10 parts of lubricant and 15-20 parts of toughener. The preparation method comprises the following steps: pulverizing the plant fibers, drying, modifying with the processing assistants, blending with the polyolefin granules, extruding the mixture with a double screw granulator to obtain a master batch, mixing the master batch and polyolefin in a certain mass ratio, extruding with a double screw extruder, carrying out wire drawing, and reeling. The 3D printing material has the appearance of the wood product and the processing characteristics of the wood-plastic material, has wide application range, and provides a more diversified environment-friendly material for 3D printing.

Owner:JIANGSU JINHE HI TECH

High-strength and high-conductivity CuAg alloy material and preparation method thereof

InactiveCN101643866AImprove as-cast structureSemiconductor/solid-state device detailsSolid-state devicesElemental compositionFiber

The invention discloses a high-strength and high-conductivity CuAg alloy material with a continuous fiber tissue and a preparation method thereof. The material consists of Cu, Ag, etc. Cu and Ag alloyingot with a columnar structure is obtained by a directional solidification technology, and continuous fibrous tissue structure is obtained by the technologies of extruding, drawing, etc. The components of the alloy material are as follows: 5-10wt% of Ag and balance of Cu. The preparation method of the CuAg alloy comprises the following steps: (1) preparing chemical composition; (2) vacuumizing asmelting room and a directional solidification room; (3) smelting the alloy; (4) directionally solidifying; (5) hot extruding; (6) hot processing; and (7) drawing wire or rolling. The material is applicable to slide contact material such as a middle-load and low-load switch, a breaker, a contactor, a micromotor slip ring, a commutating sheet, and the like, high-pulse magnetic field conductor material, an integrated circuit lead wire frame, a fish torpedo lead wire, an electric conduction reed, etc.

Owner:KUNMING INST OF PRECIOUS METALS

Stainless steel wire drawing liquid composition

The invention relates to stainless steel wire drawing liquid, the formula thereof comprises the following components: 10 to 30 percent of base oil, 10 to 30 percent of petroleum sodium sulfonate, 5 to 20 percent of mixed alcohol amine, 15 to 30 percent of turkey red oil and turkey red oil ammonium salt, 1 to 3 percent of bactericide, 0.1 to 1 percent of copper corrosion inhibitor, 10 to 20 percent of ester oil and the balance of water. The stainless steel wire drawing liquid is characterized by having excellent lubricating performance and stainless steel rust-preventing performance. In addition, the stainless steel wire drawing liquid related by the invention has an excellent defoaming function and can greatly improve the environmental hygiene of wire drawing processing enterprises.

Owner:河北九熙新材料科技有限公司

Copper imitation wire drawing process

InactiveCN101607501AStrong textureSimple processLiquid spraying plantsNatural patternsMetallic materialsHeat sensitive

The invention relates to a metal material surface coating process, in particular to a metal material surface copper imitation wire drawing process. The technical problem to be solved by the invention is to overcome the defects of the prior art and provide the metal material surface copper imitation wire drawing process with good copper imitation effect, strong copper metal texture, long light-keeping and color-keeping time and easy scale production. The technical proposal is as follows: the copper imitation wire drawing process comprises the following steps of: 1) carrying out conventional chemical pretreatment on the surface of a metal material and leading the metal surface to be clean, smooth and flat; 2) electrostatic spraying a transparent red outdoor powder coating or a pure transparent outdoor powder coating containing pigments; and 3) using a thermal-sensitive transfer paper with copper imitation bottom color of deep sky blue or black straight stripes for carrying out thermal transfer and obtaining the copper imitation wire drawing effect, wherein the straight-silkiness stripes with the color phase of deep sky blue or black silkiness straight textures are printed on the thermal-sensitive transfer paper with the copper imitation bottom color of deep sky blue or black straight stripes, the bottom color of the copper imitation color is light red purple or red purple or light yellow. In addition to the advantages, the copper imitation wire drawing process is more conductive to environmental protection.

Owner:李宗炳

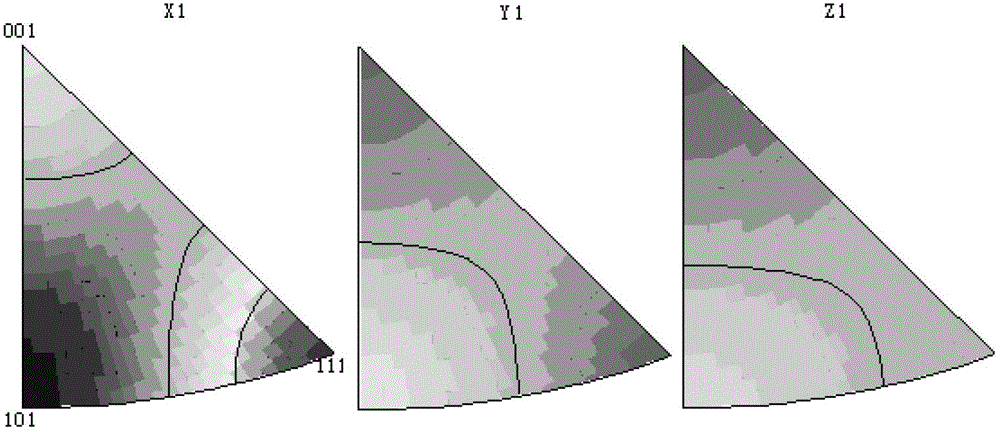

Aluminium alloy wire with high strength and high electrical conductivity, and preparation method thereof

InactiveCN102719709AHigh strengthImprove conductivityMetal/alloy conductorsCable/conductor manufactureFiberRoom temperature

The invention relates to a wire material of an aluminium alloy wire, and a preparation method thereof. An aluminium alloy wire with high strength and high electrical conductivity which has a high fiber texture degree is obtained through an ultra-low temperature rapid drawing process, and the aluminium alloy wire has a fiber texture degree of more than 60%, a tensile strength of more than 130Mpa, and an electrical conductivity of more than 63% IACS. According to the invention, a micro alloying design is performed by using composites of ferrum, scandium and the like which can form Al3Me type eutectic compound particles; a certain fiber texture is obtained through a drawing process by controlling a continuous casting and rolling process; the fiber texture degree is greatly increased and the distortion caused by room temperature deformation is reduced through the ultra-low temperature rapid drawing process; and the texture orientation and the texture degree of the aluminium wire after the drawing process are adjusted through an annealing treatment, the drawing stress is relaxed, the plasticity of the wire is recovered, the resistance of the wire is reduced and the electrical conductivity of the wire is increased. Compared with the prior art, the aluminium alloy wire and the preparation method of the invention can control the deformation process in micro alloying conditions to greatly increase the strength and the electrical conductivity of the wire.

Owner:SHENZHEN ZHAOFANG VENTURE TECH

Production method of high-strength steel rope

InactiveCN103352381AMeet the standard requirementsUniform tissueFurnace typesQuenching agentsWater bathsQuenching

The invention provides a production method of a high-strength steel rope. The production method of the high-strength steel rope is characterized that low carbon is selected and used as raw materials of the steel rope, and the production technology comprises a first step of surface processing, wherein wire materials are placed on a pay-off rack, the diameter of the wire materials is 5.5mm, hot-rolled oxide-scale is eliminated through mechanical dephophorization equipment, high-power ultrasonic cleaning is conducted on the wire materials, the wire materials enter phosphating equipment, phosphating is conducted on the wire materials, the wire materials enter drying equipment and are dried finally, and preprocessed wire materials are obtained; a second step of drawing, wherein the preprocessed wire materials obtained from the first step are placed on a drawing machine, multi-pass drawing is conducted on the preprocessed wire materials, semi-finished wire materials are obtained, and winding up is conducted through a spool; a third step of water bath heat treatment and galvanization, wherein the semi-finished wire materials obtained in the second step are placed on the pay-off rack, the semi-finished wire materials are heated in a four-section form heat treatment furnace, quenching, drying, galvanization and cooling are conducted on the semi-finished wire materials, semi-finished wire materials are obtained, and winding up is conducted; a fourth step of wet type drawing, wherein the semi-finished wire materials obtained in the third step are placed on the drawing machine, multi-pass drawing is conducted on the semi-finished wire materials, the compression angle of a wire-drawing die of each pass is 13-14 degrees, dedicated lubricating agent is used as lubricating agent, the concentration of the dedicated lubricating agent is 2%-3%, finished wire materials are obtained, and winding up is conducted through a spool; a fifth step of stranding and rope forming, wherein the finished wire materials are placed on a stranding machine, stranding and laying-up are conducted, and the finished steel stranded rope is obtained.

Owner:ZHANGJIAGANG SHENGDA STEEL ROPE

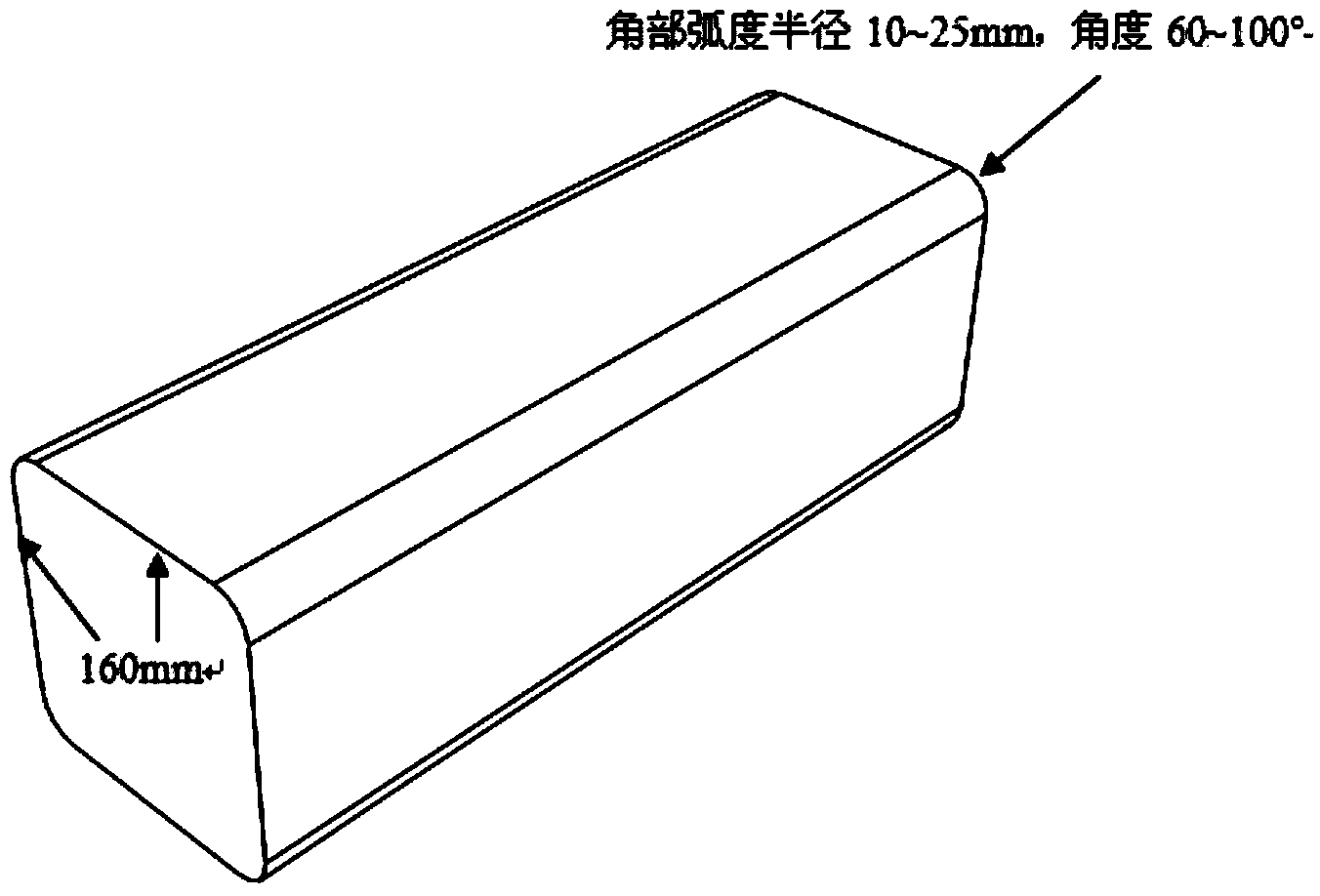

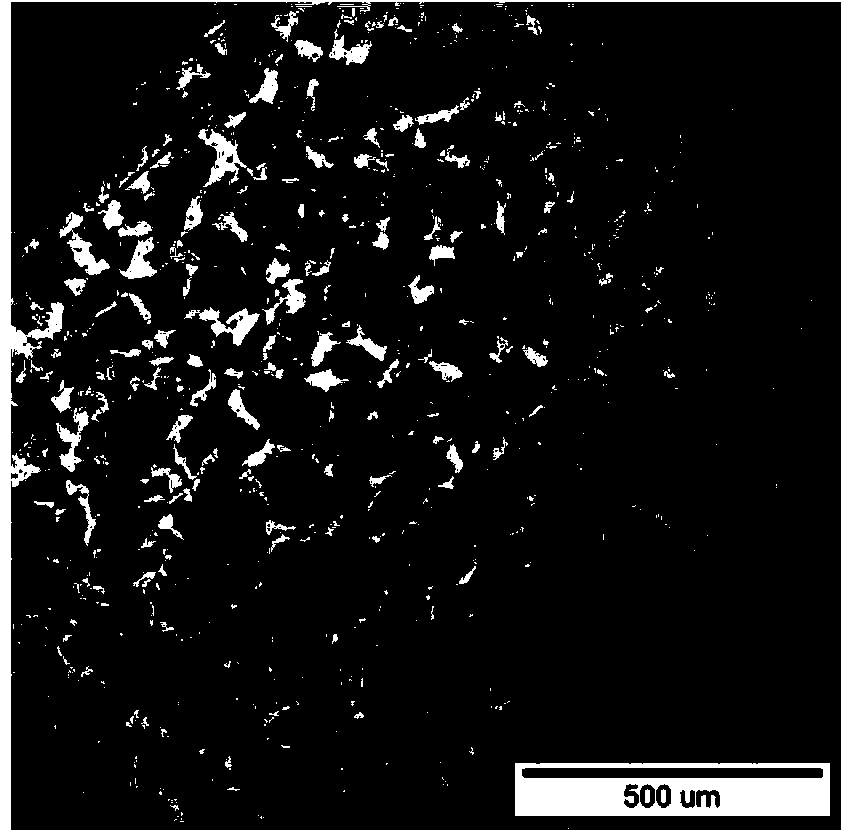

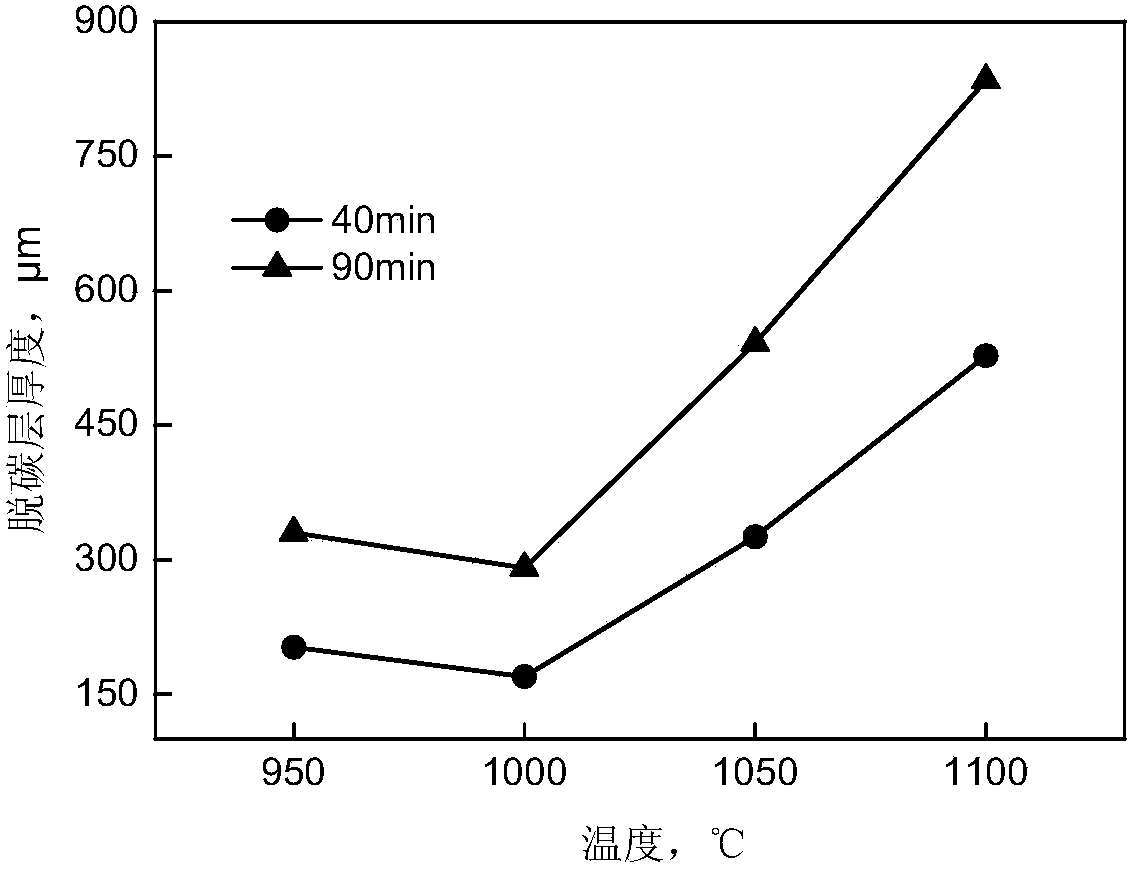

Rolling technology for controlling decarbonization of 42CrMo steel bloom hot-rolled wire rod

ActiveCN104141039AReduce segregationLow heating temperatureTemperature control deviceHeat treatment process controlWire rodRetention time

The invention discloses a rolling technology for controlling the decarbonization of a 42CrMo steel bloom hot-rolled wire rod, belonging to the field of metallurgy technology. The rolling technology comprises the following steps: blooming a 42CrMo steel bloom, wherein the temperature, time and remaining oxygen of a blooming heating furnace are all under control; polishing the surface and corners of the bloomed steel bloom; then rolling, wherein the temperature, time, remaining oxygen of a rolling heating furnace, as well as the retention time of each steel bloom are all under control, and in rolling, the rough rolling temperature is 980-1020DEG C, the finish rolling temperature is 900DEG C, and the wire drawing temperature is 850DEG C; rapidly cooling to 600DEG C-650DEG C at the cooling speed of 5-15DEG C / S after rolling, reeling after the temperature is held to about 300-350DEG C, wherein the speed of a roller bed is controlled to be 0.4-0.5m / s. According to the rolling technology, the decarbonization layer of the 42CrMo steel bloom hot-rolled wire rod is basically eliminated, and the thickness of the decarbonization layer is controlled to be no more than 0.5%D, and the thickness of more than 95% of decarbonization layer reaches or is close to 0.

Owner:武安市裕华钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com