High intensity metallic core type seamless flux-cored wire

A seamless flux-cored welding wire and metal-cored technology, applied in metal processing equipment, welding media, welding equipment, etc., can solve the problems of low yield strength of deposited metal, difficult to meet high yield strength, etc., to reduce spatter and stabilize Arc, the effect of improving the strength of the weld metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

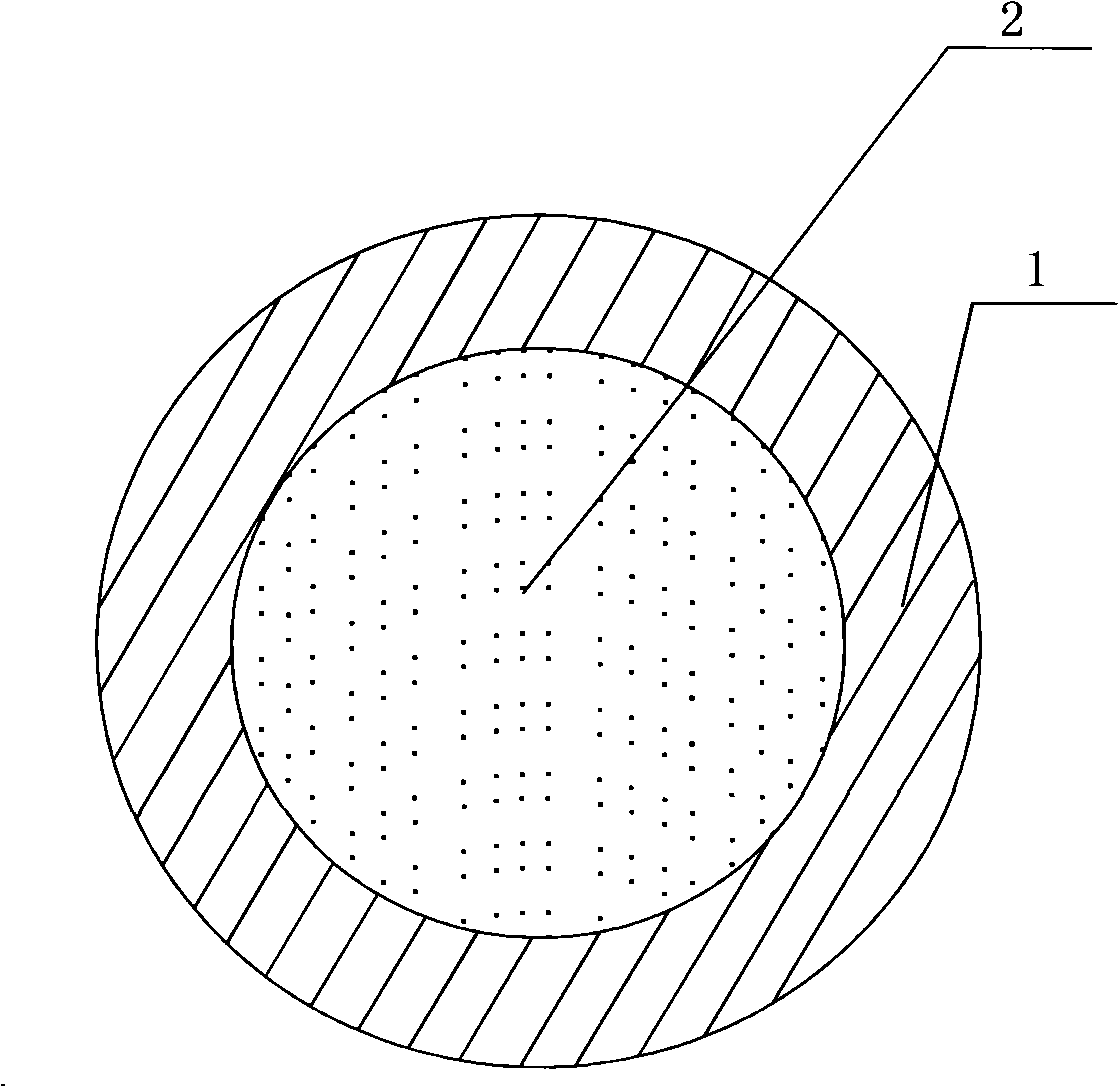

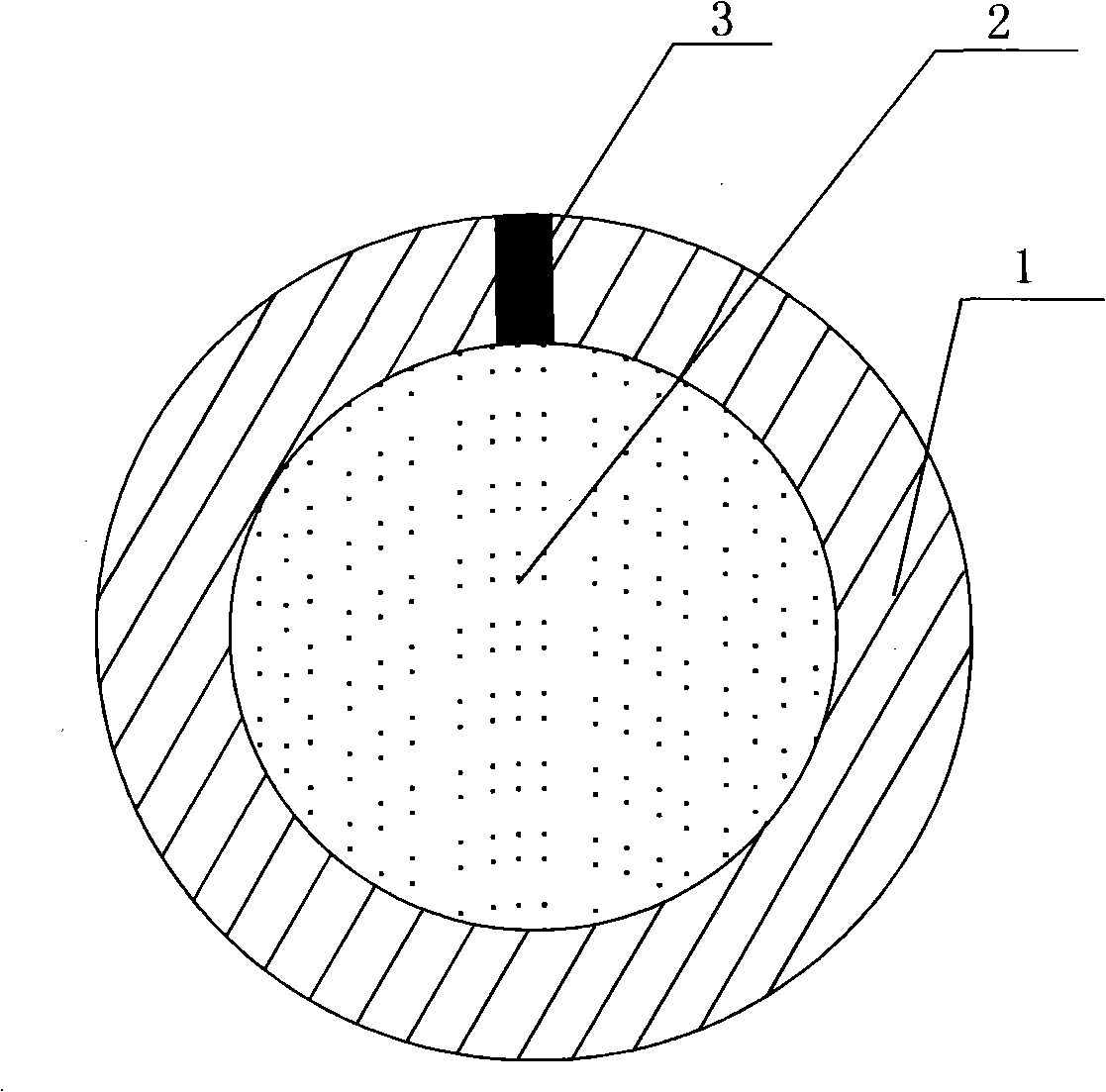

[0039] A high-strength metal-cored seamless flux-cored welding wire is filled with powdered steel in a steel sheath (1); the steel sheath (1) also contains steel with a mass percentage of 0.03% carbon (C), 0.02% silicon (Si), 0.5% manganese (Mn), 0.005% sulfur (S), 0.013% phosphorus (P); the powder filled into it contains 5.5% by mass % ferrosilicon powder (calculated as silicon Si), 11% metallic manganese powder, 1% titanium ferro powder (calculated as titanium Ti), 34% metallic nickel powder, 8% metallic chromium powder, 4% molybdenum Iron powder (calculated as molybdenum Mo), 4.5% titanium dioxide (TiO 2 ), 0.3% silicon dioxide (SiO 2 ), 0.2% manganese oxide (MnO), 1.8% sodium fluoride (NaF) (calculated as sodium Na), 0.6% potassium oxide (K 2 O), the rest is 29.1% iron powder. In this embodiment, the powder filling rate is 11%, and the diameter of the welding wire is 1.2mm.

Embodiment 2

[0041] A high-strength metal-cored seamless flux-cored welding wire is filled with powdered steel in a steel sheath (1); the steel sheath contains steel with a mass percentage of 0.03% of carbon (C), 0.02% of silicon (Si), 0.5% of manganese (Mn), 0.005% of sulfur (S), 0.013% of phosphorus (P); the powder filled into it contains a mass percentage of 2 % ferrosilicon powder (calculated as silicon Si), 26% metal manganese powder, 2.5% ferro-titanium powder (calculated as titanium Ti), 28% metal nickel powder, 8.5% molybdenum iron powder (calculated as molybdenum Mo ), 1.2% titanium dioxide (TiO 2 ), 0.2% silicon dioxide (SiO 2 ), 0.5% aluminum oxide (AL 2 o 3 ), 0.2% manganese oxide (MnO), 0.5% sodium fluoride (NaF) (calculated as sodium Na), 2.7% potassium oxide (K 2 O), the rest is 27.7% iron powder. In this embodiment, the powder filling rate is 11%, and the diameter of the welding wire is 1.2mm.

Embodiment 3

[0043] A high-strength metal-cored seamless flux-cored welding wire is filled with powdered steel in a steel sheath (1); the steel sheath (1) also contains steel with a mass percentage of 0.04% carbon (C), 0.02% silicon (Si), 0.4% manganese (Mn), 0.25% yttrium (Y), 0.006% sulfur (S), 0.013% phosphorus (P); filled into The powder contains 4.5% ferrosilicon powder (calculated as silicon Si), 15% metal manganese powder, 1.5% ferro-titanium powder (calculated as titanium Ti), 26% metal nickel powder, 6% Metal chromium powder, 3% ferromolybdenum powder (calculated as molybdenum Mo), 3% titanium dioxide (TiO 2 ), 0.2% silicon dioxide (SiO 2 ), 0.1% aluminum oxide (AL 2 o 3 ), 0.6% of manganese oxide (MnO), 1.6% of sodium fluoride (NaF) (calculated as sodium Na), 1.5% of potassium oxide (K 2 O), and the rest are 37% iron powder. In this embodiment, the powder filling rate is 14%, and the diameter of the welding wire is 1.4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com