Patents

Literature

36results about How to "Improve as-cast structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and high-conductivity CuAg alloy material and preparation method thereof

InactiveCN101643866AImprove as-cast structureSemiconductor/solid-state device detailsSolid-state devicesElemental compositionFiber

The invention discloses a high-strength and high-conductivity CuAg alloy material with a continuous fiber tissue and a preparation method thereof. The material consists of Cu, Ag, etc. Cu and Ag alloyingot with a columnar structure is obtained by a directional solidification technology, and continuous fibrous tissue structure is obtained by the technologies of extruding, drawing, etc. The components of the alloy material are as follows: 5-10wt% of Ag and balance of Cu. The preparation method of the CuAg alloy comprises the following steps: (1) preparing chemical composition; (2) vacuumizing asmelting room and a directional solidification room; (3) smelting the alloy; (4) directionally solidifying; (5) hot extruding; (6) hot processing; and (7) drawing wire or rolling. The material is applicable to slide contact material such as a middle-load and low-load switch, a breaker, a contactor, a micromotor slip ring, a commutating sheet, and the like, high-pulse magnetic field conductor material, an integrated circuit lead wire frame, a fish torpedo lead wire, an electric conduction reed, etc.

Owner:KUNMING INST OF PRECIOUS METALS

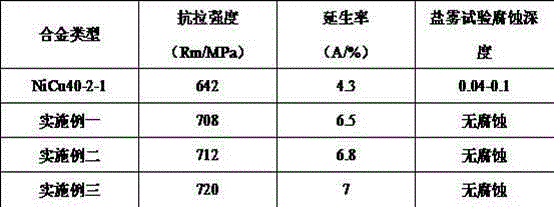

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

Preparation method of solar photovoltaic aluminum alloy profile

The invention discloses a preparation method of a solar photovoltaic aluminum alloy profile. The aluminum alloy profile is composed of the following elements, by weight, 0.2-0.5% of Si, 0.05-0.1% of Fe, 0.1-0.15% of Cu, 0.1-0.2% of Mn, 0.5-0.8% of Mg, 0.2-0.3% of Cr, 0.05-0.1% of Ti, 0.04-0.08% of Zn, 0.03-0.06% of Nb, 0.024-0.045% of Ta, 0.02-0.04% of Po, 0.004-0.008% of B, 0.03-0.05% of La, 0.02-0.03% of Eu, 0.01-0.02% of Tb and the balance Al. The aluminum alloy profile provided by the invention has excellent mechanical property, processability and corrosion resistance, and is durable in use.

Owner:淮北津奥铝业有限公司

High-temperature oxidation resistant wearproof Co-based alloy wire and preparation method thereof

ActiveCN106756257AGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodOxidation resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

Super advanced double-phase stainless steel smelting process method of CD3MWN material

ActiveCN108823348AIncrease contentReduce precipitationProcess efficiency improvementHydrogenDouble phase

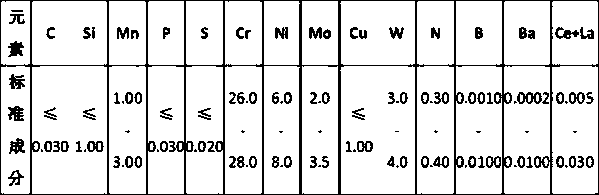

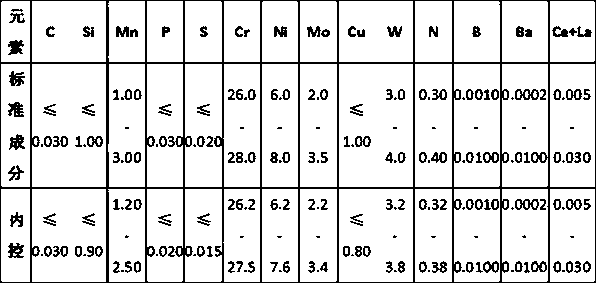

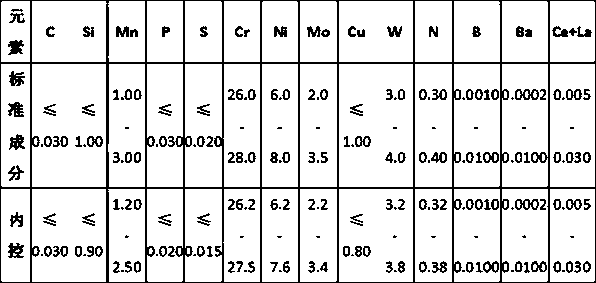

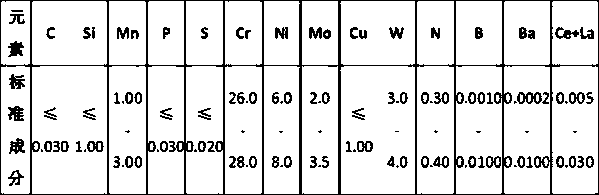

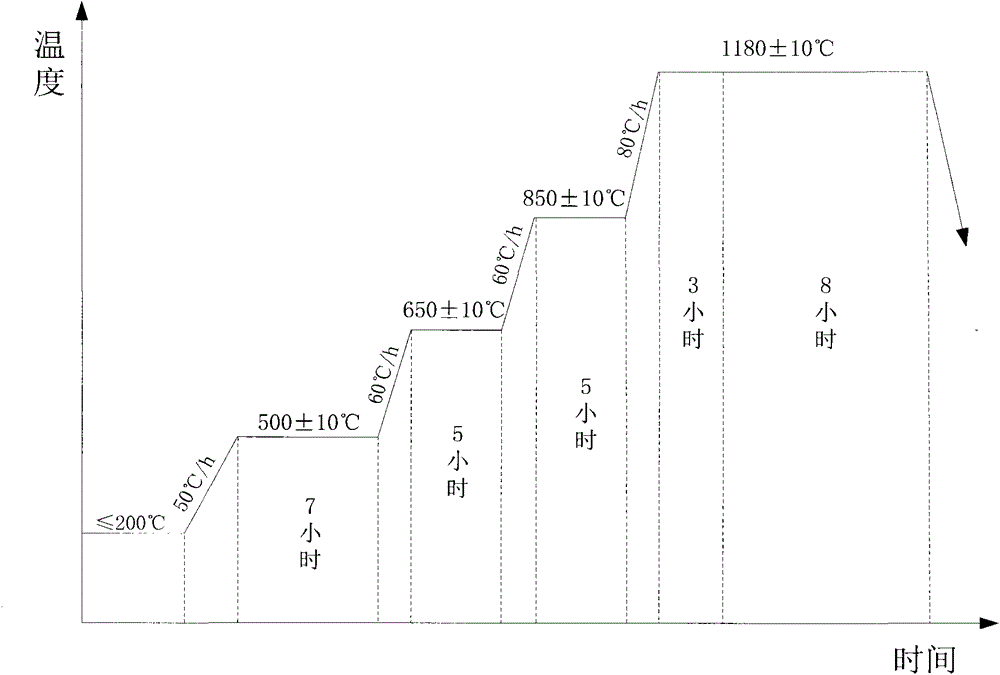

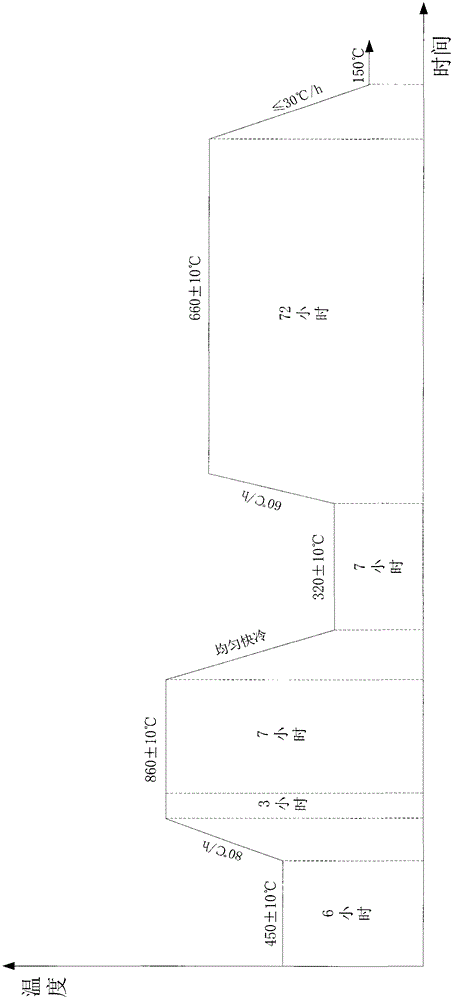

The invention relates to a super advanced double-phase stainless steel smelting process method of a CD3MWN material. According to the invention, internal control components during double-phase stainless steel smelting is designed, wherein C is less than or equal to 0.030 wt%, Si is less than or equal to 0.90 wt%, Mn is 1.20-2.50 wt%, P is less than or equal to 0.020 wt%, S is less than or equal to0.015 wt%, and Cr is 26.2-27.5 wt%, Ni is 6.2-7.6 wt%, Mo is 2.2-3.4 wt%, Cu is less than or equal to 0.80 wt%, W is less than or equal to 0.80 wt%, N is 0.32-0.38 wt%, B is 0.0010-0.0100 wt%, Ba is0.0002-0.0100 wt%, and Ce+La is 0.005- 0.030 wt%; and %Cr+3.3 (%Mo+0.5%W)+16%N is less than or equal to 45, the content of trace elements B, Ba, Ce, and La can be precisely controlled; the N content is increased to 0.30% or more, and at the same time, nitrogen holes in the casting can be avoided; and the content of harmful elements such as sulfur, oxygen, hydrogen and the like is minimized to improve the purity of the molten steel. The cast casting has high strength and excellent corrosion resistance. In the stainless steel, a ferrite phase and an austenite phase are close to 50%, the castinglife is prolonged. the production costs are greatly reduced, and purposes of energy saving and environmental protection can be realized.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Method for forging mold cavity (female mold) module

The invention discloses a method for forging a mold cavity (concavity) module. By means of hot machining, multi-heating-number and multi-direction forging is adopted, rolling reduction of different heating numbers and in different directions is controlled, and internal structures are improved. According to the mold cavity (concavity) forged through forging tools such as a wide anvil, a narrow anvil, a marking knife and a big platform, it is guaranteed that the dimension and appearance are qualified. Normalizing and tempering are adopted in heat treatment, so that structure hardness is uniform. Compared with the prior art, the method has the advantages that 1, the smelting steel tapping temperature is controlled, big ingot as-cast structures are improved, and composition segregation is reduced; 2, by means of the multi-heating-number and multi-direction forging mode, the mechanical properties of the large-cross-section module can meet standard requirements; 3, according to the mold cavity (concavity) forged through the forging tools such as the wide anvil, the narrow anvil, the marking knife and the big platform, the defect that billet iron smelting is nonuniform is overcome, and dimension and appearance requirements are met; and 4, the mold cavity (concavity) module which approximates to a mold in appearance is forged, machining procedures during mechanical mold machining can be simplified, time is saved, and waste of metal materials is reduced.

Owner:FUSHUN SPECIAL STEEL SHARES

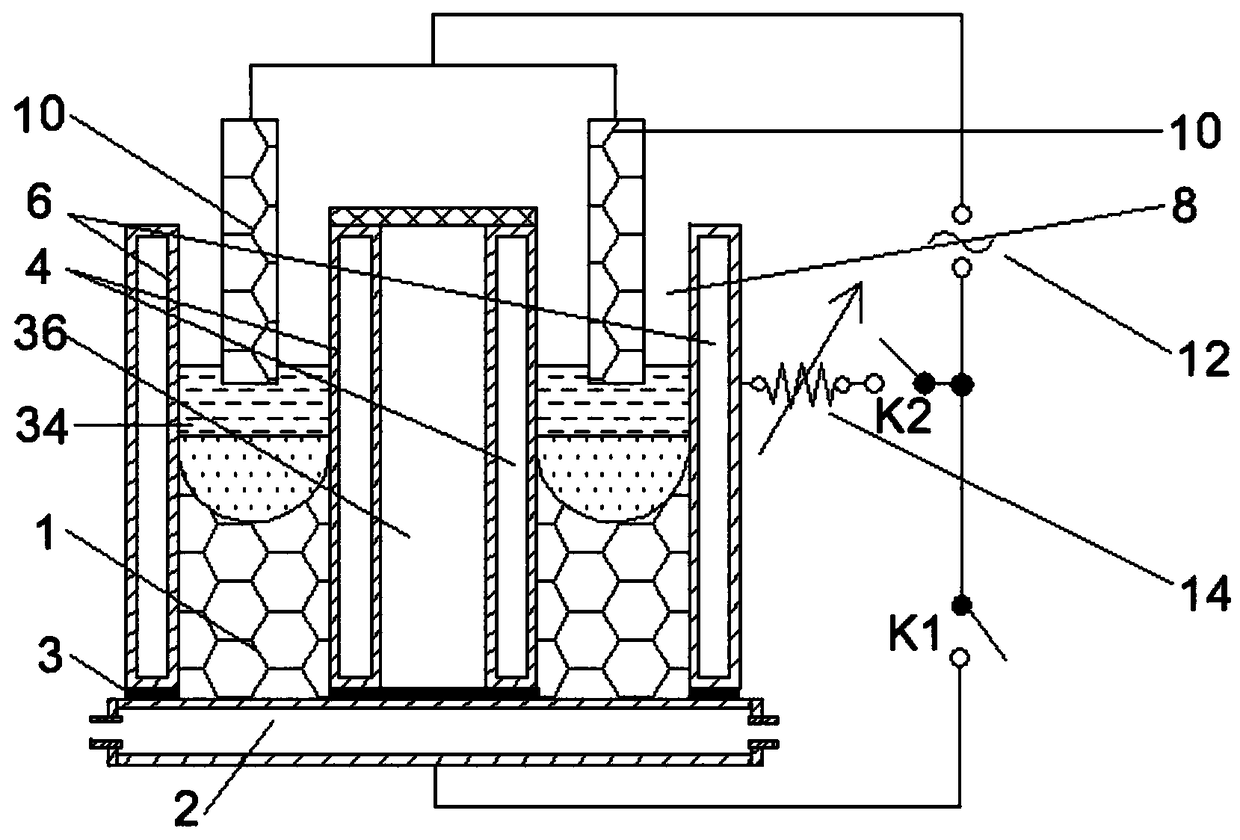

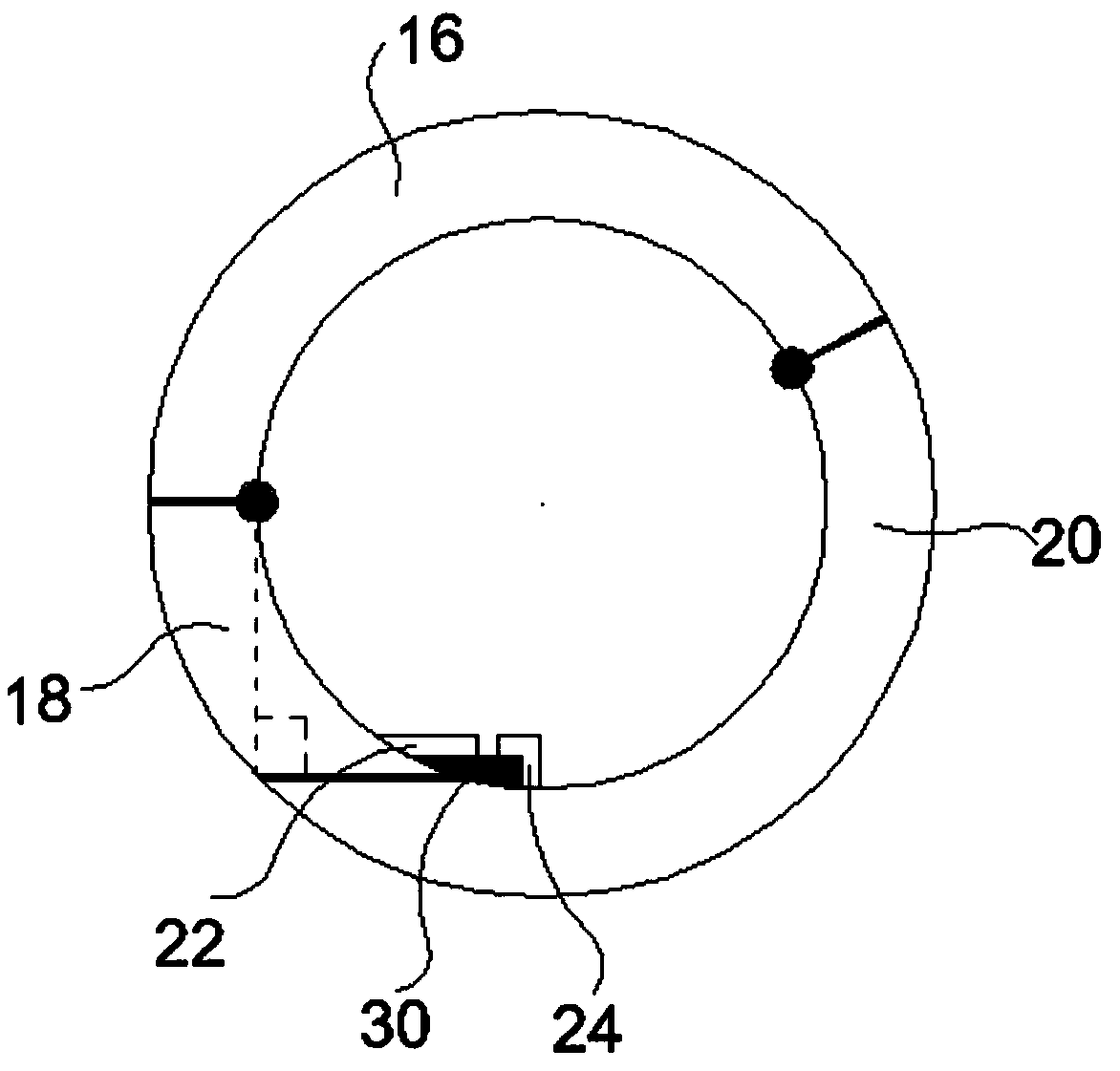

Device and method for preparing titanium-containing superalloy hollow steel ingot by electroslag remelting

The invention discloses a device for preparing a titanium-containing superalloy hollow steel ingot by electroslag remelting. The device comprises an electroslag remelting furnace, an inner crystallizer, an outer crystallizer and a power supply system, wherein an annular casting containing cavity is formed between the inner crystallizer and the outer crystallizer; after casting of slag in the annular casting containing cavity, a consumable electrode is heated, melted, cooled and crystallized to form a titanium-containing superalloy piece; and the slag comprises the following components including, by mass (59+ / -5)% of CaF2, (18+ / -2)% of CaO, (18+ / -2)% of Al2O3, (5+ / -3)% of TiO2 or (62+ / -5)% of CaF2, (8+ / -2)% of CaO, (15+ / -3)% of Al2O3, (7+ / -2)% of MgO and (8+ / -3)% of TiO2. The device for preparing a titanium-containing alloy by electroslag remelting eliminates the ingot drawing link (that is, a slag system containing no SiO2 can be adopted), and solves the technical problem of massive burning of titanium element massive burning caused by [Ti]+(SiO2)=(TiO2)+[Si], under the condition of ensuring the surface quality of the hollow steel ingot, the content of easily oxidizable elements meets the requirements of the alloy standard, and the elements are evenly distributed in the axial direction of the casting ingot.

Owner:SUZHOU UNIV

Low-density high-strength magnesium lithium alloy and preparing method thereof

The invention provides a low-density high-strength magnesium-lithium alloy and a preparation method thereof. The components and mass percentages of the magnesium-lithium alloy are: 11-15% Li, 0.5-4% Al, 0.05-0.5% Zr, 0.2~1.2%La, 0.1~0.6%Ce, the total amount of impurity elements Fe, Ni, Cu, Si≤0.2%, and the balance is Mg. The preparation method of the magnesium-lithium alloy involved in the present invention includes vacuum induction melting and plastic deformation treatment. The magnesium-lithium alloy processed by means of alloying, crystal grain refinement and deformation treatment in the present invention has high strength and plasticity under the premise of ensuring low density, and at the same time has excellent machining performance.

Owner:江苏立美航材科技有限公司

Manufacturing technique of nickel-copper alloy

The invention discloses a manufacturing technique of a nickel-copper alloy. The invention is characterized in that the nickel-copper alloy mainly comprises the following components in percentage by weight: 35-50% of copper, 8-15% of iron, 10-15% of chromium, 0.5-2% of rhenium, 1.25-2.25% of manganese, 0.15-0.2% of silicon, 0.05-0.1% of magnesium, 0.1-0.15% of titanium, at most 0.5% of other components and the balance of nickel. The manganese can improve the metallurgical structure of the material, improve the as-cast structure of the alloy, enhance the compactness of the material and promote the combination of the base, thereby effectively enhancing the high-temperature oxidation resistance and corrosion resistance, enhancing the strength, prolonging the service life of the material product and lowering the cost. The magnesium, which is used as a fluxing agent, can absorb abundant oxygen, hydrogen, nitrogen and other gases in the heating process, and thus, is an ideal degasser. The titanium has favorable corrosion resistance, and can further enhance the corrosion resistance of the material. The silicon is beneficial to enhancing and refining the grains by solid solution, thereby enhancing the metallic properties.

Owner:JIANGSU LEAP MACHINE

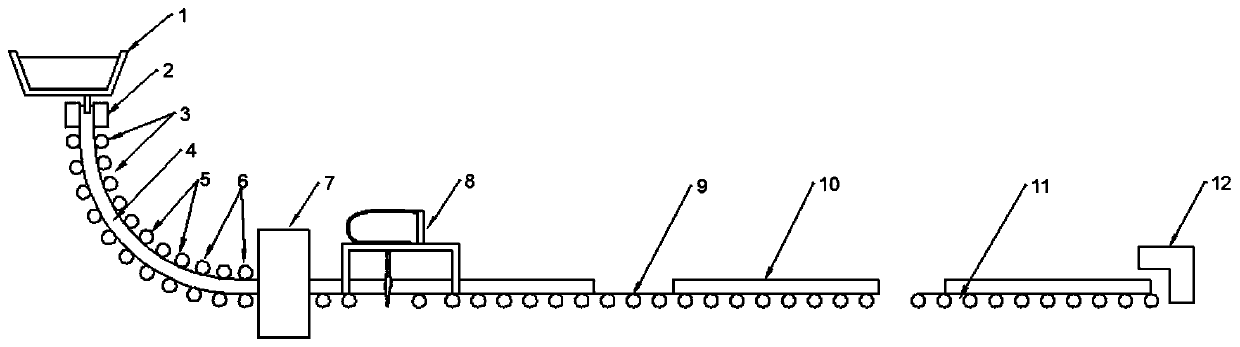

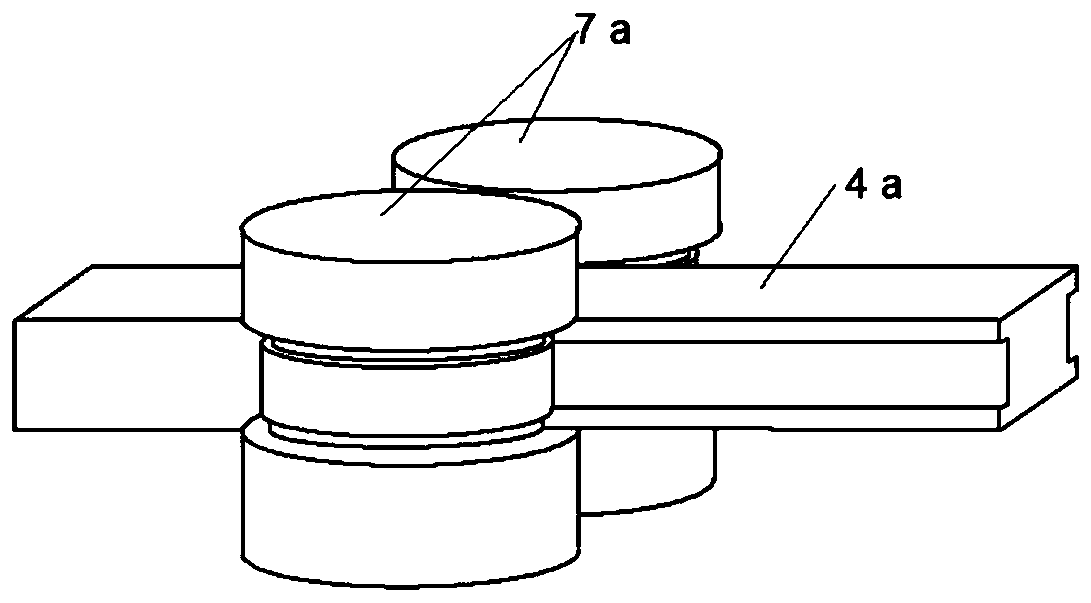

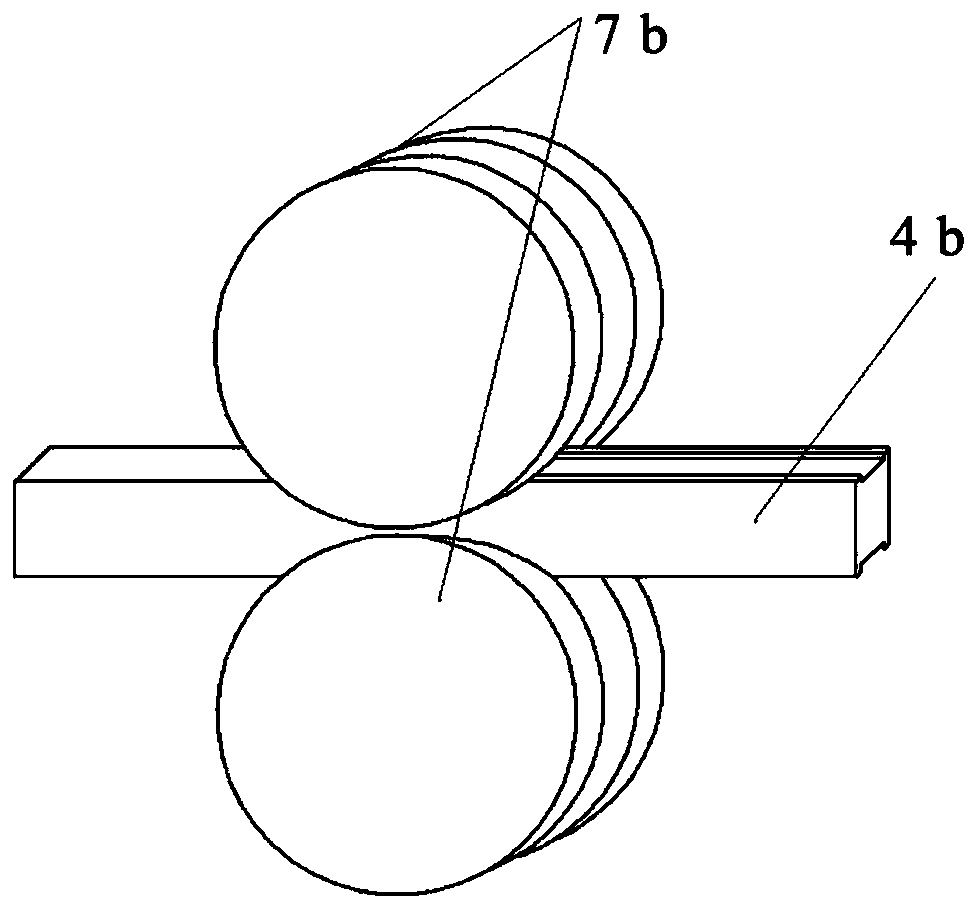

Square bloom continuous casting manufacturing method facilitating elimination of core defects

InactiveCN110508765AReduce riskHigh porosity removal capacityMetal rolling arrangementsPorosityRolling mill

The invention provides a square bloom continuous casting manufacturing method facilitating elimination of core defects and belongs to the field of large-section square bloom production. According to the square bloom continuous casting manufacturing method, the continuous casting blank soft reduction technology and the hot core high-temperature heavy reduction rolling technology are optimized and combined. The core macrosegregation defects are eliminated in the soft reduction process; heavy-reduction rolling mills are directly arranged behind a continuous casting straightening and withdrawing machine, the online opposite reduction rolling process is implemented by making full use of cold outside and hot inside temperature field features of a casting blank under the complete solidification state of the casting blank to eliminate the defects such as core shrinkage cavity porosity.

Owner:NORTHEASTERN UNIV

High-strength aluminum alloy for motor train unit gearbox and preparation method of high-strength aluminum alloy

The invention discloses high-strength aluminum alloy for a motor train unit gearbox and a preparation method of the high-strength aluminum alloy. The high-strength aluminum alloy comprises the following components in percentage by weight: Mg, Cu, Zn, Fe, Si, Ti, Cr, Te, Ge, Nb, Er, Mo, Ce, Sc, Zr, Sr and the balance of Al, wherein content of each of other impurity elements is equal to or less than 0.05%, and total content of other impurity elements is equal to or less than 0.2%. According to the invention, the alloy components are reasonable, the technology is optimized, and the obtained high-strength aluminum alloy has the advantages of light weight, high strength, corrosion resistance, low possibility of cracking and the like and can meet the performance requirements of the motor train unit gearbox.

Owner:LAIAN KELAIXING IND CO LTD

Process for producing die steel by utilizing converter continuous casting mode

ActiveCN103160635AHigh alloy contentImprove purityTemperature control deviceManufacturing convertersEconomic benefitsHigh pressure water

The invention discloses a process for producing die steel by utilizing a converter continuous casting mode. The process comprises a steel making continuous casting process and a steel rolling process. The steel making continuous casting process comprises the following process steps of: converter smelting, LF (Ladle Furnace) refining, continuous casting, slow cooling and other process steps; and the steel rolling process comprises the following process steps of: heating, scale removal by using high pressure water, rolling, straightening, stacking, slow cooling and other steps. By using the die steel produced by the invention, the contents of gas and occluded foreign substances in the die steel can be reduced, the thermal stress and the structural stress for slowing a steel blank down are eliminated, a thick and nonuniform cast structure inside the steel blank is improved, and the problems of flaw detection disqualification and finished product crack of the die steel are solved. By using the process, the aim of producing the die steel by using a converter is achieved, the production cost is reduced, and the economic benefit is increased.

Owner:冀南钢铁集团有限公司

A kind of high-strength aluminum alloy for gear box of EMU and preparation method thereof

The invention discloses high-strength aluminum alloy for a motor train unit gearbox and a preparation method of the high-strength aluminum alloy. The high-strength aluminum alloy comprises the following components in percentage by weight: Mg, Cu, Zn, Fe, Si, Ti, Cr, Te, Ge, Nb, Er, Mo, Ce, Sc, Zr, Sr and the balance of Al, wherein content of each of other impurity elements is equal to or less than 0.05%, and total content of other impurity elements is equal to or less than 0.2%. According to the invention, the alloy components are reasonable, the technology is optimized, and the obtained high-strength aluminum alloy has the advantages of light weight, high strength, corrosion resistance, low possibility of cracking and the like and can meet the performance requirements of the motor train unit gearbox.

Owner:LAIAN KELAIXING IND CO LTD

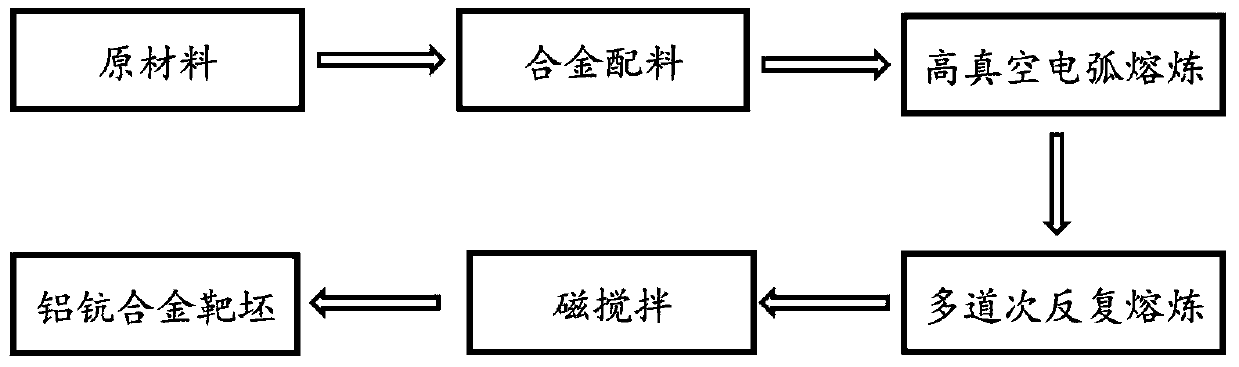

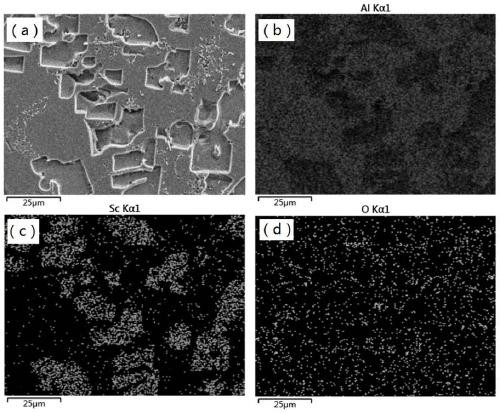

Aluminum-scandium alloy target blank and preparation method and application thereof

InactiveCN111500992AImprove tissue chemistryHomogeneous histochemical compositionVacuum evaporation coatingSputtering coatingAluminiumElectric arc

The invention provides an aluminum-scandium alloy target blank and a preparation method and application thereof, and relates to the technical field of aluminum-scandium alloys. The preparation methodof the aluminum-scandium alloy target blank comprises the following steps that an aluminum source and a scandium source are placed in a water cooling copper crucible, the water cooling copper crucibleis filled with inert gas after being vacuumized, electric arc melting is carried out repeatedly, and molten alloy liquid is obtained; the molten alloy liquid is condensed under inert gas shielding, and an aluminum-scandium alloy ingot is obtained; and the aluminum-scandium alloy ingot is sequentially subjected to electromagnetic stirring and repeated thermal mechanical treatment, and the aluminum-scandium alloy target blank is obtained. According to the aluminum-scandium alloy target blank and the preparation method and application thereof, electric arc melting is carried out under a vacuum and inert atmosphere, and the oxygen content in an aluminum-scandium alloy is reduced; by means of repeated electric arc melting, electromagnetic stirring and repeated thermal machining, the structureof the as-cast aluminum-scandium alloy is improved, and the defects of the as-cast aluminum-scandium alloy are repaired; the utilized water cooling copper crucible is high in cooling speed, segregation of scandium in the aluminum-scandium alloy is reduced, and the target blank is even in crystal particle, free of segregation, even in microstructure, high in density and good in film-forming property.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

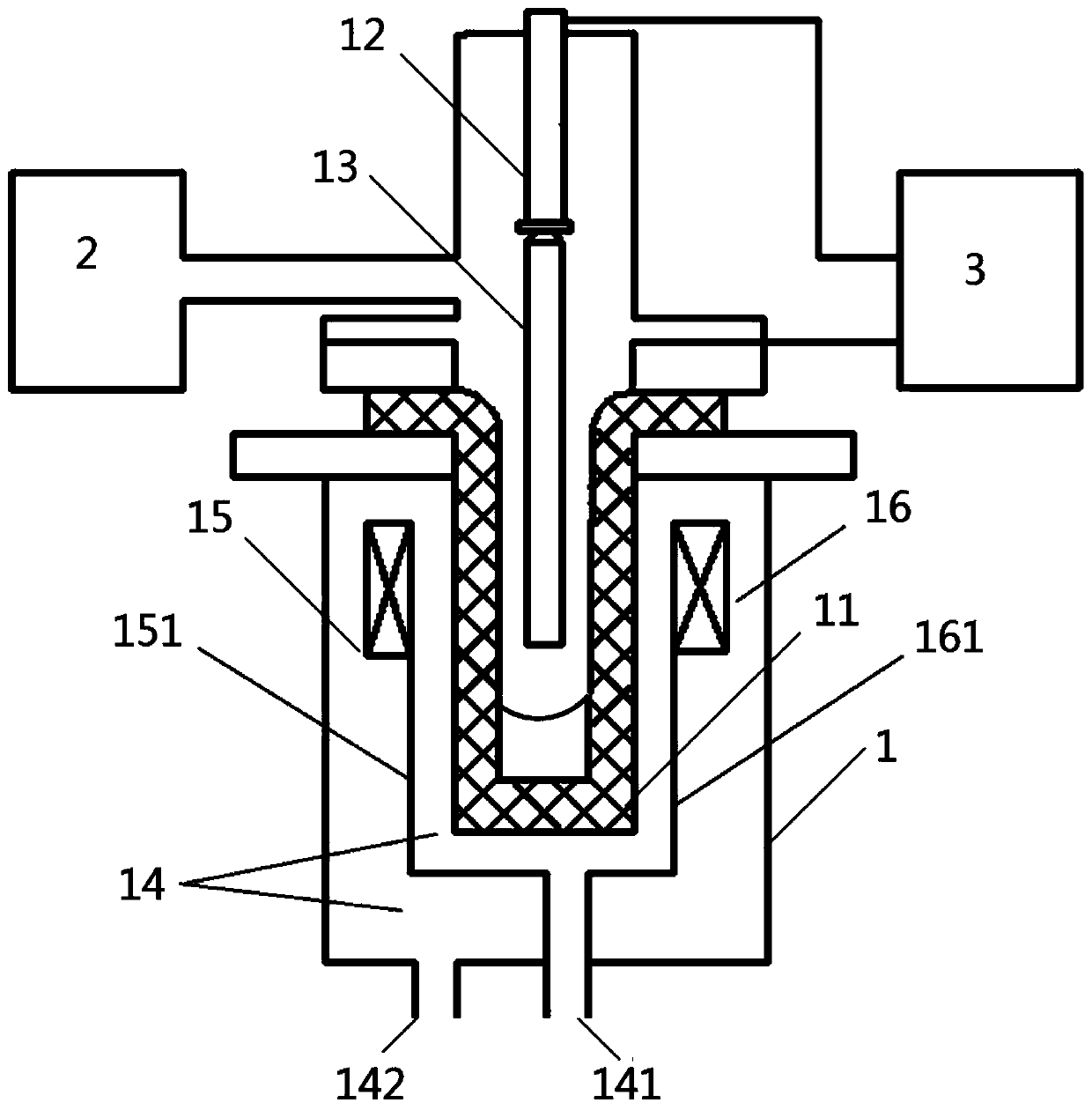

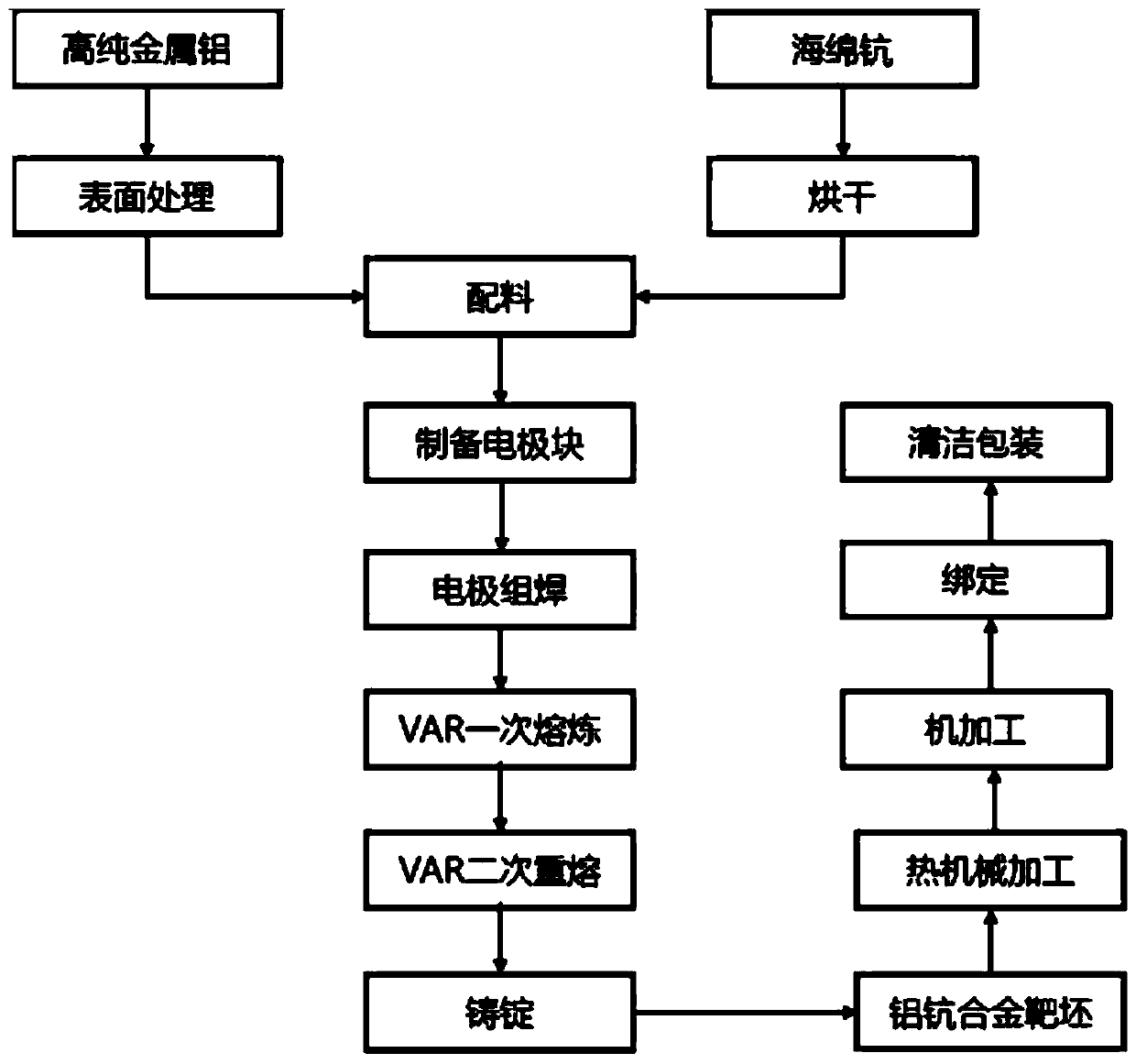

Aluminum-scandium alloy target material, preparation method and application thereof and vacuum consumable electro-arc furnace

InactiveCN111593216AImprove organization and fix defectsUniform microstructureLighting and heating apparatusVacuum evaporation coatingElectric arc furnaceCrucible

The invention provides an aluminum-scandium alloy target material, a preparation method and application thereof and a vacuum consumable electro-arc furnace, and relates to the technical field of target material preparation. The preparation method of the aluminum-scandium alloy target material comprises the following steps: after an aluminum source and a scandium source are mixed, a mixture is subjected to pressing and assembly welding, and an obtained assembly welding electrode is subjected to vacuum arc melting twice in a water-cooling copper crucible; and then repeated thermomechanical processing, machining and binding are carried out, the aluminum-scandium alloy target material is obtained, and the water-cooling copper crucible is provided with a water jacket and an arc-stabilizing coil. According to the aluminum-scandium alloy target material, the vacuum arc melting is carried out in the water-cooling copper crucible twice, pollution to scandium due to adoption of a refractory material in a traditional smelting furnace is avoided, the cleanliness is high, and the oxygen content is low; due to rapid cooling and subsequent thermomechanical processing in the water-cooling copper crucible, the structure of the aluminum-scandium alloy target material is improved, defects are overcome, the obtained aluminum-scandium alloy target material has a uniform microstructure and uniform average grain size and has no obvious defect of pores and segregation, and the density and the finished product rate of the aluminum-scandium alloy target material are high.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

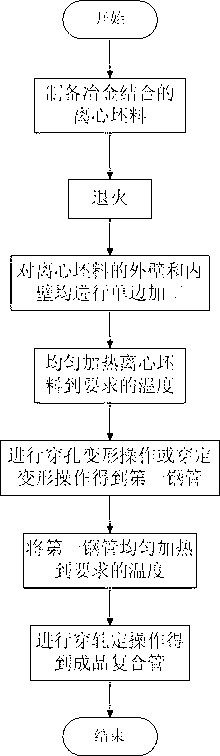

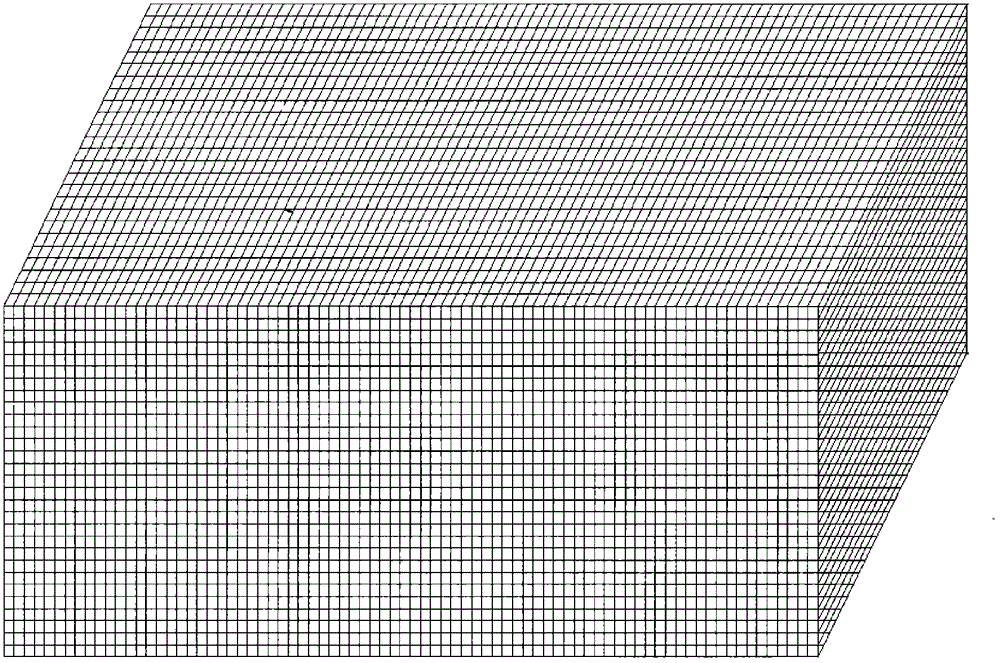

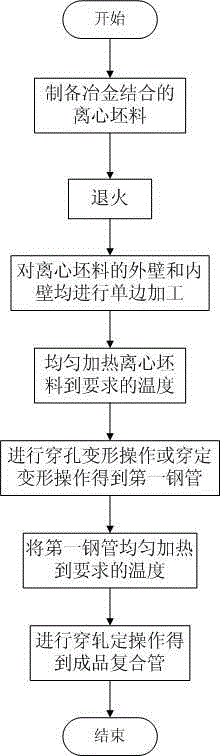

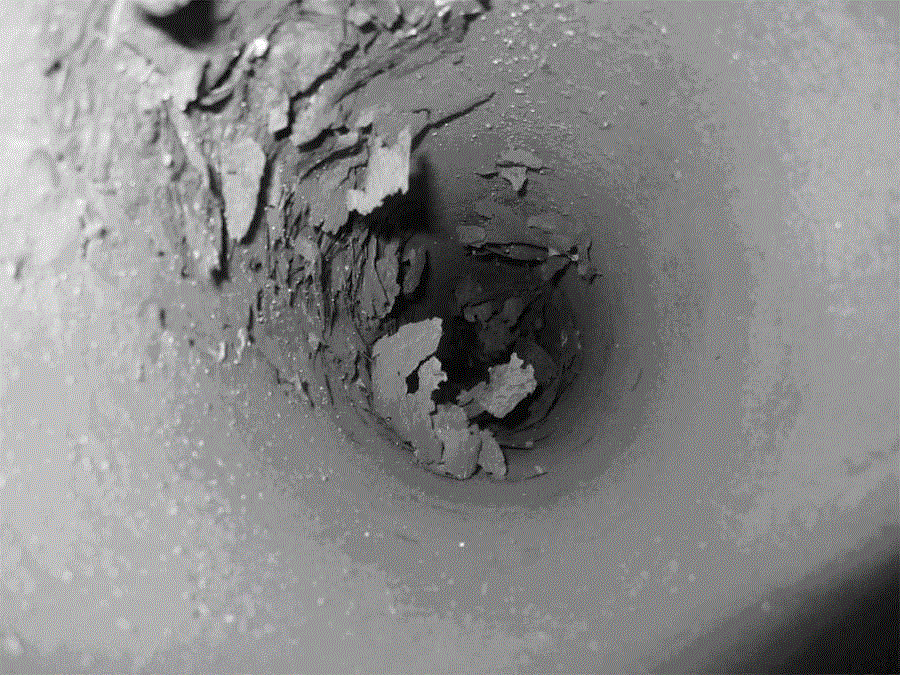

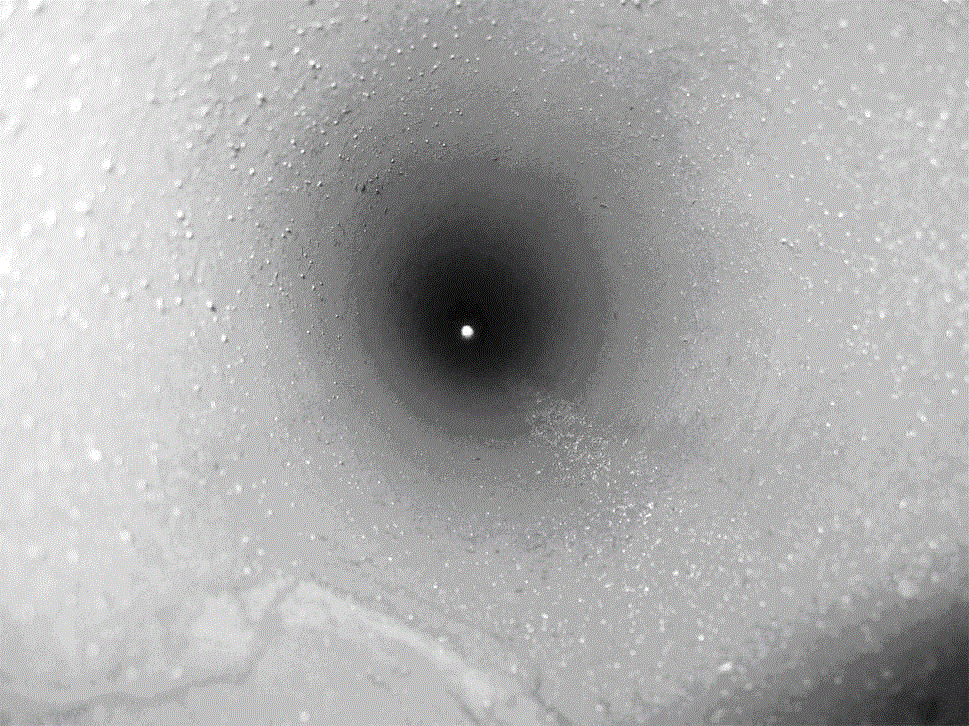

Hot rolling method of metallurgical bonding wear-resistant composite tube

InactiveCN103286157AImprove as-cast structureImprove plasticityEconomic benefitsMechanical engineering

The invention discloses a hot rolling method of a metallurgical bonding wear-resistant composite tube, belonging to the field of tube rolling methods. The hot rolling method comprises the following steps of: producing a centrifugal blank of bearing steel with external low-carbon steel and internal high-carbon chromium by a centrifugal pouring technology; performing a perforation deformation operation or piercing constant-deformation operation, wherein a small elongation coefficient is adopted in the operation; and finally, performing a roll-piercing constant-deformation operation again to obtain a target composite tube, wherein a large elongation coefficient is adopted in the operation. The method disclosed by the invention adopts two deformation processes; the first perforation deformation operation or piercing constant-deformation operation improves the as-cast structure of the centrifugal blank, refines the crystal grains and improves the plasticity of the centrifugal blank; and the second piercing constant-deformation operation is used for producing a finished product of composite tube with the required specification. The method disclosed by the invention effectively avoids the defects of rolling crease, internal warp and the like on the inner wall in the production of a metallurgical bonding wear-resistant composite tube of bearing steel with external low-carbon steel and internal high-carbon chromium, and greatly improves the yield and economic benefits, wherein the yield reaches 90%.

Owner:XINXING DUCTILE IRON PIPES CO LTD

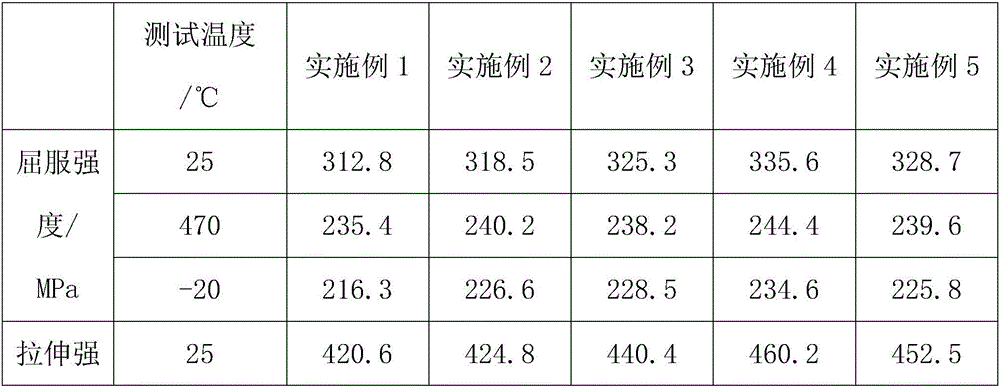

High- and low-temperature-resistant aluminum alloy for gear box of motor train unit and preparation method therefor

ActiveCN106367637AImprove low temperature performanceImprove performanceUltimate tensile strengthImpurity

The invention discloses a high- and low-temperature-resistant aluminum alloy for a gear box of a motor train unit and a preparation method therefor. The aluminum alloy comprises the following components in percentages by weight: Mg, Cu, Zn, Si, B, Ti, Ni, Nd, Mn, Pt, Cd, Sn, Cr, Ge, Nb, Mo, Hf, and the balance of Al, wherein the single content of other impurity elements is less than or equal to 0.05% and the total content of the other impurity elements is less than or equal to 0.15%. According to the alloy disclosed by the invention, the alloy components are reasonable, the process is optimized, and the obtained aluminum alloy has the advantages of being light in weight, high in strength, corrosion-resistant, high- and low-temperature-resistant, is unlikely to crack and the like, and can satisfy the performance requirements of the gear box of the motor train unit.

Owner:LAIAN KELAIXING IND CO LTD

Heat-resistant alloy resisting to sulfur corrosion and rod production method thereof

The invention discloses a heat-resistant alloy resisting sulfur corrosion. The heat-resistant alloy is prepared from the following components in percentage by weight: 0.025-0.25 percent of C, 1.30-2.50 percent of Si, 1.00-2.50 percent of Mn, 20-30 percent of Cr, 17-27 percent of Ni, 0.75-2.50 percent of Nb, 0.6-1.50 percent of Mo, 1.0-2.5 percent of Al, 0.6-1.5 percent of V, 0.001-0.050 percent of Ce+La, at most 0.035 percent of P, at most 0.030 percent of S and the rest being Fe. The invention further discloses a rod production method of the heat-resistant alloy resisting sulfur corrosion. According to the heat-resistant alloy and the rod production method, the alloy rod has relativley high strength and good high-temperature sulfur corrosion resistance.

Owner:广东华鳌合金新材料有限公司

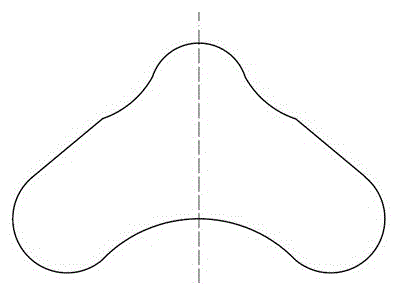

Forming process of a medium-strength heat-resistant magnesium alloy triangular profile

InactiveCN103774015BGrain refinementGuaranteed high temperature plasticityHeat resistanceUltimate tensile strength

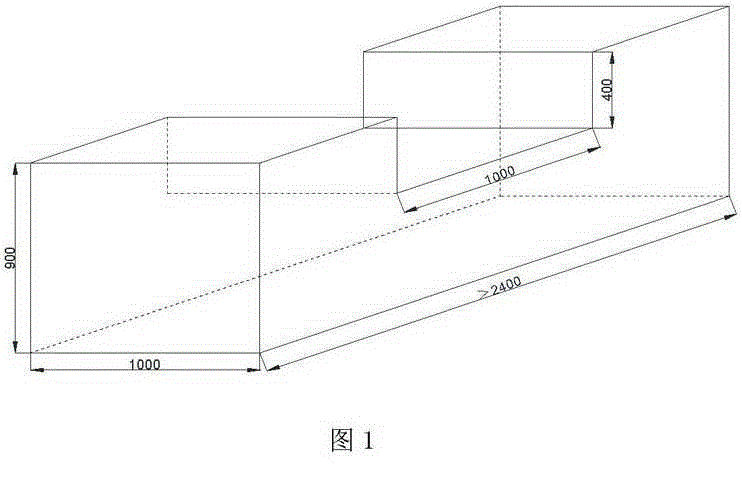

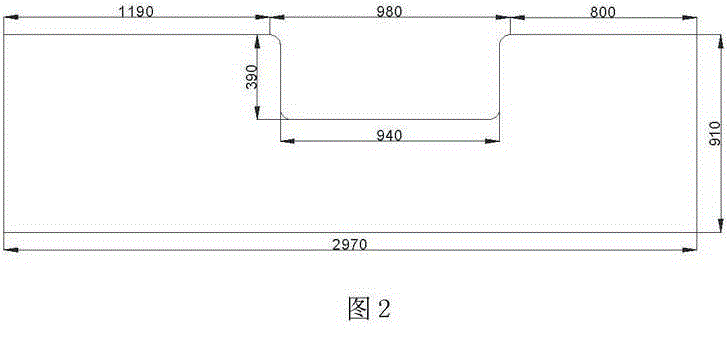

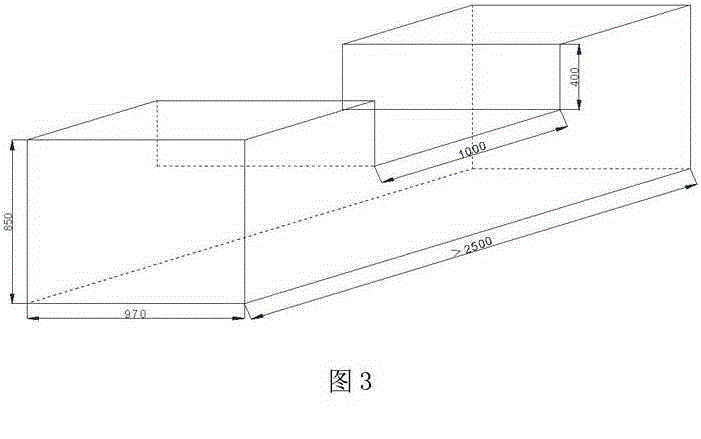

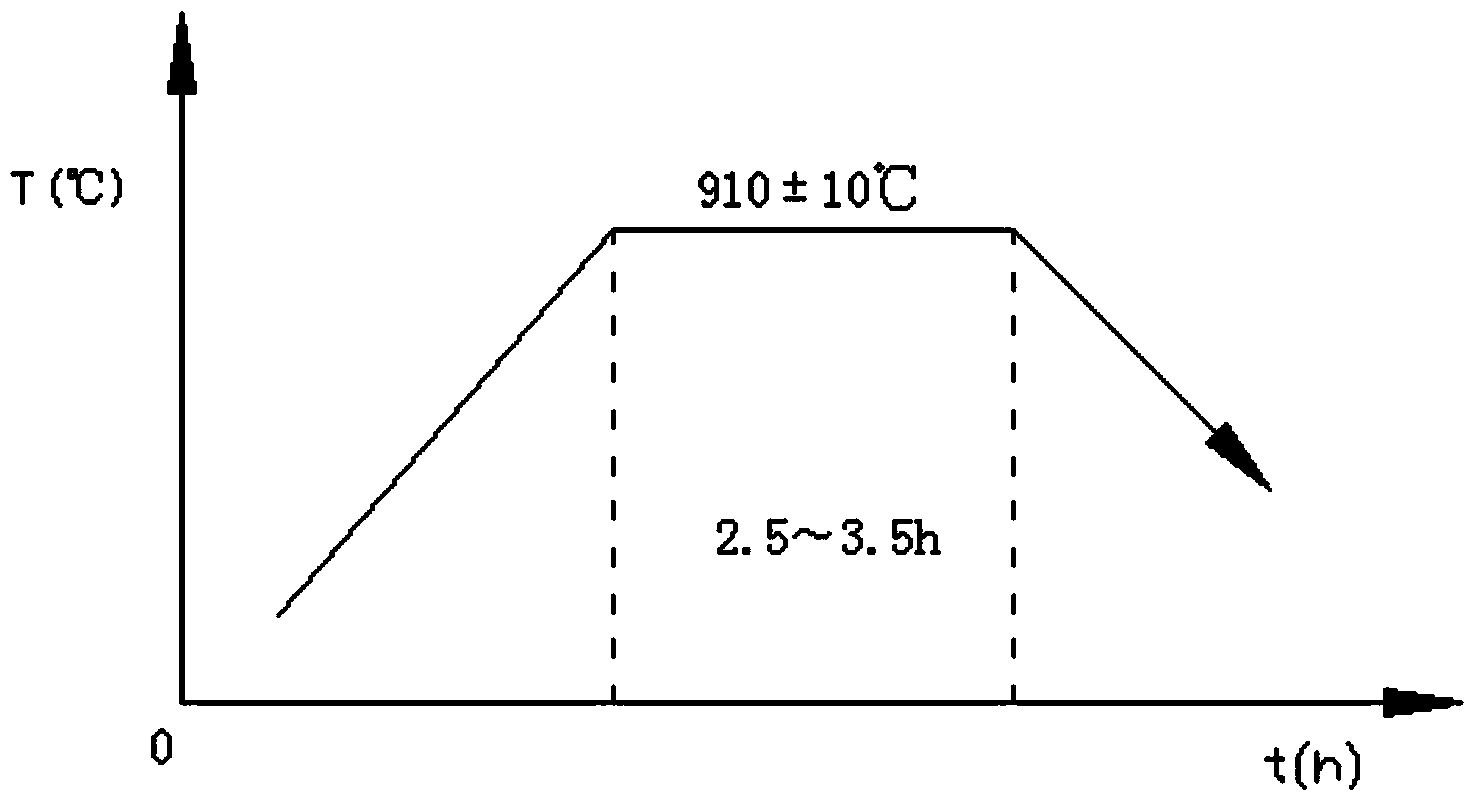

The invention discloses a forming process of a medium-strength heat-resistant magnesium alloy triangular profile. The process steps include: large furnace melting, semi-continuous casting, homogenizing annealing, multi-directional forging, extrusion forming and heat treatment after forming. Among them, the multi-directional forging is carried out on a hydraulic press. Before forging, the blank is kept at 370-400°C for 2-4 hours and subjected to three times of upsetting. Extrusion is carried out on a horizontal extruder, with an extrusion ratio of 10-14, and a triangular profile with a length ≥ 1000mm is extruded. The profile has high strength and good heat resistance, which can meet the performance requirements of structural parts in the aerospace field. After heat treatment, the yield strength at room temperature along the extrusion direction is ≥265MPa, the tensile strength is ≥375MPa, and the elongation is ≥9%.

Owner:CENT SOUTH UNIV +1

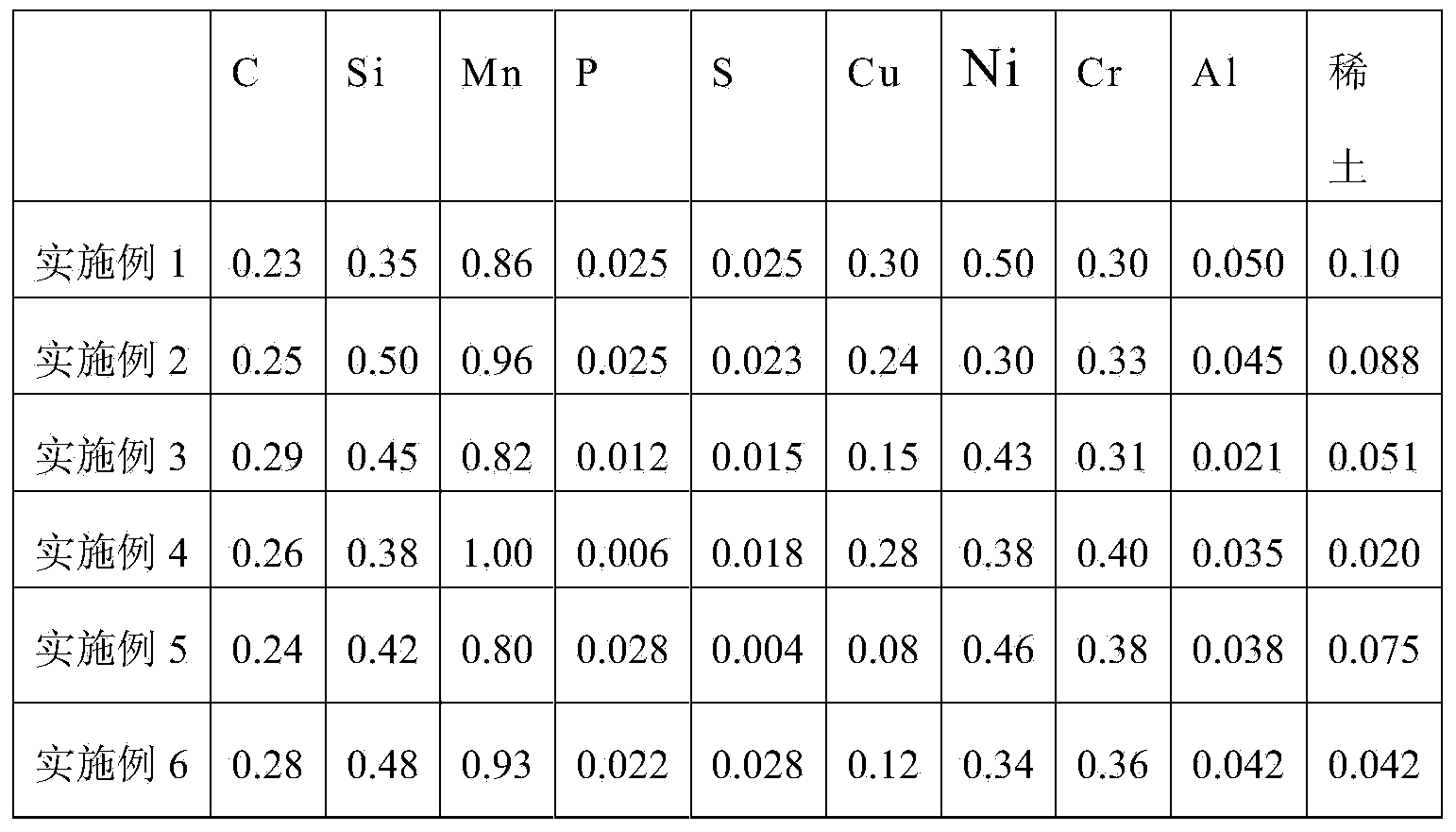

Casting piece steel for railway vehicle swing bolster side frame and preparation method thereof

The invention discloses casting piece steel for railway vehicle swing bolster side frame and a preparation method thereof. The casting piece steel comprises the following chemical components in percentage by weight: 0.23%-0.29% of C, 0.30%-0.50% of Si, 0.80%-1.00% of Mn, not greater than 0.030% of P, not greater than 0.030% of S, not greater than 0.30% of Cu, 0.20%-0.50% of Ni, 0.30%-0.40% of Cr, 0.020%-0.050% of Al, not greater than 0.10% of rear earth, and the balance of Fe and inevitable impurities. The preparation method of the casting piece steel comprises the following steps: firstly, adding materials corresponding to C, P, S, Cu and Ni into an eccentric-bottom electric arc furnace, melting the materials into molten steel, and controlling the carbon content in the molten steel to not less than 0.50%; carrying out oxidation and decarbonization by using oxygen gas, discharging steel when the temperature of the molten steel is not less than 1630 DEG C, adding refining slag, lime, a deoxidizing agent, manganese-iron alloy, silicon-iron alloy and chromium-iron alloy into every ton of steel ladles while the steel is discharged to the steel ladles, and then, carrying out molten steel refining; after casting a casting piece, feeding the casting piece steel into a gathering-releasing chain type thermal treatment line for carrying out normalizing to obtain the casting piece steel for manufacturing the swing bolster side frame. The casting piece steel disclosed by the invention has the effects of purifying steel, improving a cast structure, reducing component segregation, carrying out microalloying in steel and deteriorating impurities.

Owner:CRRC YANGTZE TONGLING CO LTD

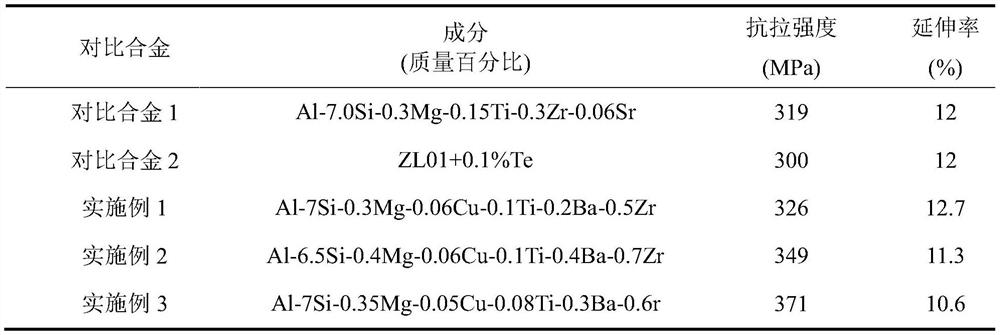

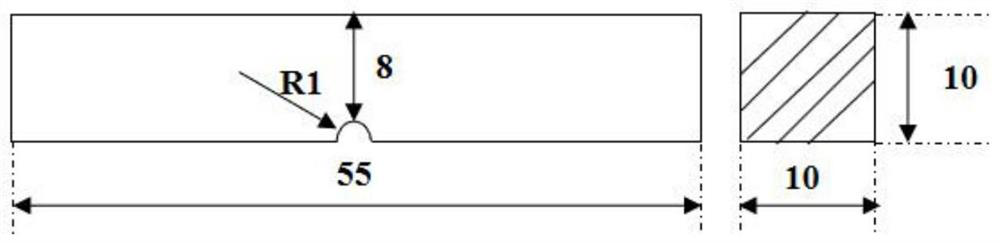

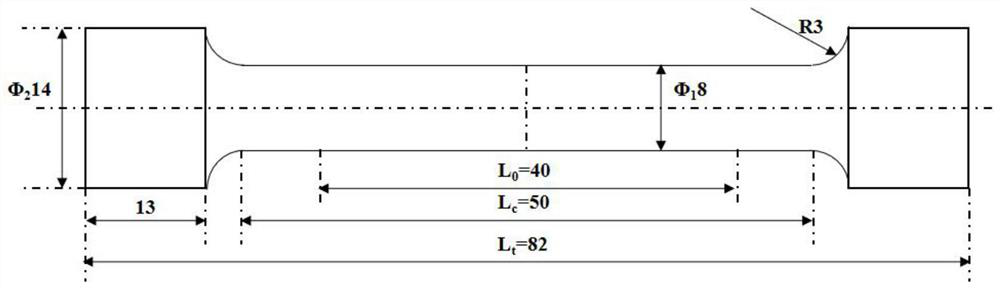

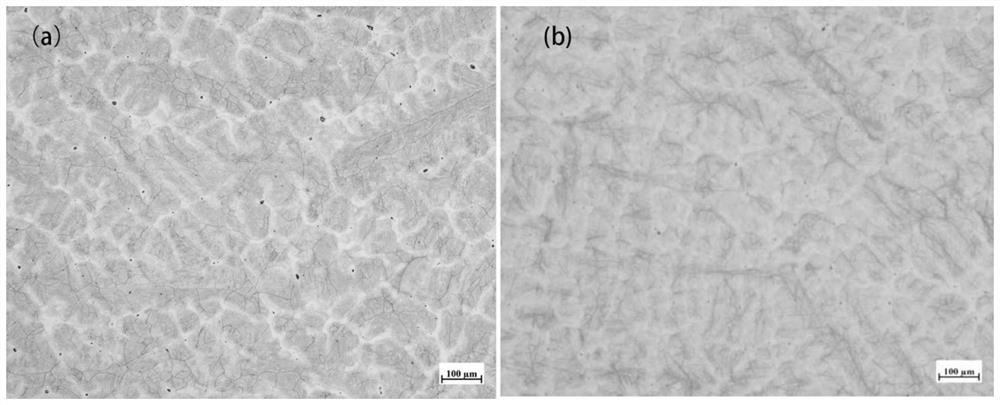

A kind of preparation method of high-strength a356 alloy

ActiveCN109778027BImprove as-cast structureFine grainSolid solution strengtheningUltimate tensile strength

The invention discloses a method for preparing a high-strength A356 alloy. A novel low-cost, high-strength A356 alloy is prepared by means of modification treatment, solid solution strengthening, fine-grain strengthening and second phase strengthening. (1) Improve the as-cast structure of the alloy by adding modifiers Ba and Zr; (2) Use high-pressure solidification technology to prepare high-pressure solidified A356 with finer grains and higher supersaturated solubility of Mg, Si and other elements in the matrix (3) Further enhance the strength of the high-pressure solidified A356 alloy through aging strengthening.

Owner:CITIC DICASTAL

A kind of modified 4cr5mosiv1 hot work die steel and preparation method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH

A preparation method of high corrosion resistance and high wear resistance engine cylinder head aluminum alloy profile

The invention discloses a preparation method of a high corrosion resistant and high wear resistant aluminium alloy profile for an engine cylinder cover. the aluminium alloy profile is composed of the following elements, by weight, 9.4-10.8% of Si, 0.7-1.4% of Cu, 0.4-0.8% of Mg, 0.15-0.25% of Fe, 0.3-0.6% of Cr, 0.05-0.1% of Mn, 0.02-0.04% of Zn, 0.01-0.02% of Ni, 0.03-0.05% of As, 0.025-0.045% of Sn, 0.02-0.03% of Cd, 0.015-0.025% of Hf, 0.005-0.01% of B, 0.02-0.04% of Ce, 0.01-0.03% of Yb and the balance Al. The aluminium alloy profile prepared by the above method has excellent comprehensive properties and high high-temperature strength, can operate at 250-300 DEG C for a long time, has excellent corrosion resistance and wear resistance, and has a wide application prospect.

Owner:HUAIBEI YINFENG ALUMINUM

Process for producing die steel by utilizing converter continuous casting mode

ActiveCN103160635BHigh alloy contentImprove purityTemperature control deviceManufacturing convertersEconomic benefitsHigh pressure water

The invention discloses a process for producing die steel by utilizing a converter continuous casting mode. The process comprises a steel making continuous casting process and a steel rolling process. The steel making continuous casting process comprises the following process steps of: converter smelting, LF (Ladle Furnace) refining, continuous casting, slow cooling and other process steps; and the steel rolling process comprises the following process steps of: heating, scale removal by using high pressure water, rolling, straightening, stacking, slow cooling and other steps. By using the die steel produced by the invention, the contents of gas and occluded foreign substances in the die steel can be reduced, the thermal stress and the structural stress for slowing a steel blank down are eliminated, a thick and nonuniform cast structure inside the steel blank is improved, and the problems of flaw detection disqualification and finished product crack of the die steel are solved. By using the process, the aim of producing the die steel by using a converter is achieved, the production cost is reduced, and the economic benefit is increased.

Owner:冀南钢铁集团有限公司

A method for smelting ultra-advanced duplex stainless steel made of cd3mwn

ActiveCN108823348BIncrease contentReduce precipitationProcess efficiency improvementSmelting processSS - Stainless steel

Owner:LUOYANG SUNRUI SPECIAL EQUIP

A kind of preparation method of aluminum alloy profiles for solar photovoltaic

The invention discloses a preparation method of a solar photovoltaic aluminum alloy profile. The aluminum alloy profile is composed of the following elements, by weight, 0.2-0.5% of Si, 0.05-0.1% of Fe, 0.1-0.15% of Cu, 0.1-0.2% of Mn, 0.5-0.8% of Mg, 0.2-0.3% of Cr, 0.05-0.1% of Ti, 0.04-0.08% of Zn, 0.03-0.06% of Nb, 0.024-0.045% of Ta, 0.02-0.04% of Po, 0.004-0.008% of B, 0.03-0.05% of La, 0.02-0.03% of Eu, 0.01-0.02% of Tb and the balance Al. The aluminum alloy profile provided by the invention has excellent mechanical property, processability and corrosion resistance, and is durable in use.

Owner:淮北津奥铝业有限公司

A kind of preparation method of wear-resistant and anti-corrosion nickel base alloy wire

Owner:江苏鑫信润科技股份有限公司

Ultra-high-strength, ultra-high and low-temperature impact fracturing pump valve box steel forgings and manufacturing method thereof

The invention relates to a steel forging with an ultra-high strength and an ultra-high low-temperature impact on the box body of a fracturing pump valve and a manufacturing method of the steel forging. The steel forging is used for solving the technical problems of low mechanical performance, bad corrosion resistance, short service life, and high cost of the existing steel materials. The steel forging comprises the following chemical ingredients in percentage by weight: 0.25-0.3% of C, 0.15-0.35% of Si, 0.6-0.9% of Mn, 1.8-2.2% of Cr, 4.05-4.25% of Ni, 0.46-0.6% of Mo, 0.12-0.18% of V, not greater than 0.01% of P, not greater than 0.01% of S, not greater than 0.12% of Nb, not greater than 0.12% of Re, not greater than 0.2% of Cu, not greater than 0.00016% of H, not greater than 0.0035% of O, not greater than 0.0065% of N, and the balance of Fe and inevitable impurities. The steel forging disclosed by the invention can be used in the fields of petroleum exploitation and shale gas exploitation.

Owner:陕西华威科技股份有限公司

A kind of anti-high temperature oxidation and wear-resistant cobalt-based alloy wire and its preparation method

ActiveCN106756257BGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodWear resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

Hot rolling method of metallurgical bonding wear-resistant composite tube

InactiveCN103286157BImprove as-cast structureImprove plasticityEconomic benefitsMechanical engineering

The invention discloses a hot rolling method of a metallurgical bonding wear-resistant composite tube, belonging to the field of tube rolling methods. The hot rolling method comprises the following steps of: producing a centrifugal blank of bearing steel with external low-carbon steel and internal high-carbon chromium by a centrifugal pouring technology; performing a perforation deformation operation or piercing constant-deformation operation, wherein a small elongation coefficient is adopted in the operation; and finally, performing a roll-piercing constant-deformation operation again to obtain a target composite tube, wherein a large elongation coefficient is adopted in the operation. The method disclosed by the invention adopts two deformation processes; the first perforation deformation operation or piercing constant-deformation operation improves the as-cast structure of the centrifugal blank, refines the crystal grains and improves the plasticity of the centrifugal blank; and the second piercing constant-deformation operation is used for producing a finished product of composite tube with the required specification. The method disclosed by the invention effectively avoids the defects of rolling crease, internal warp and the like on the inner wall in the production of a metallurgical bonding wear-resistant composite tube of bearing steel with external low-carbon steel and internal high-carbon chromium, and greatly improves the yield and economic benefits, wherein the yield reaches 90%.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com