Patents

Literature

45results about How to "High temperature and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

Electrocatalytic reduction combined electrode and preparation method and application thereof

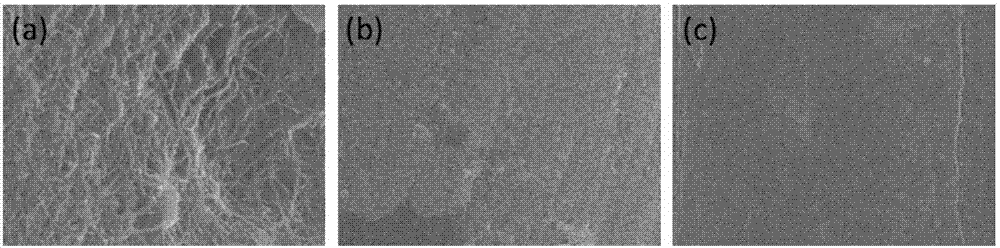

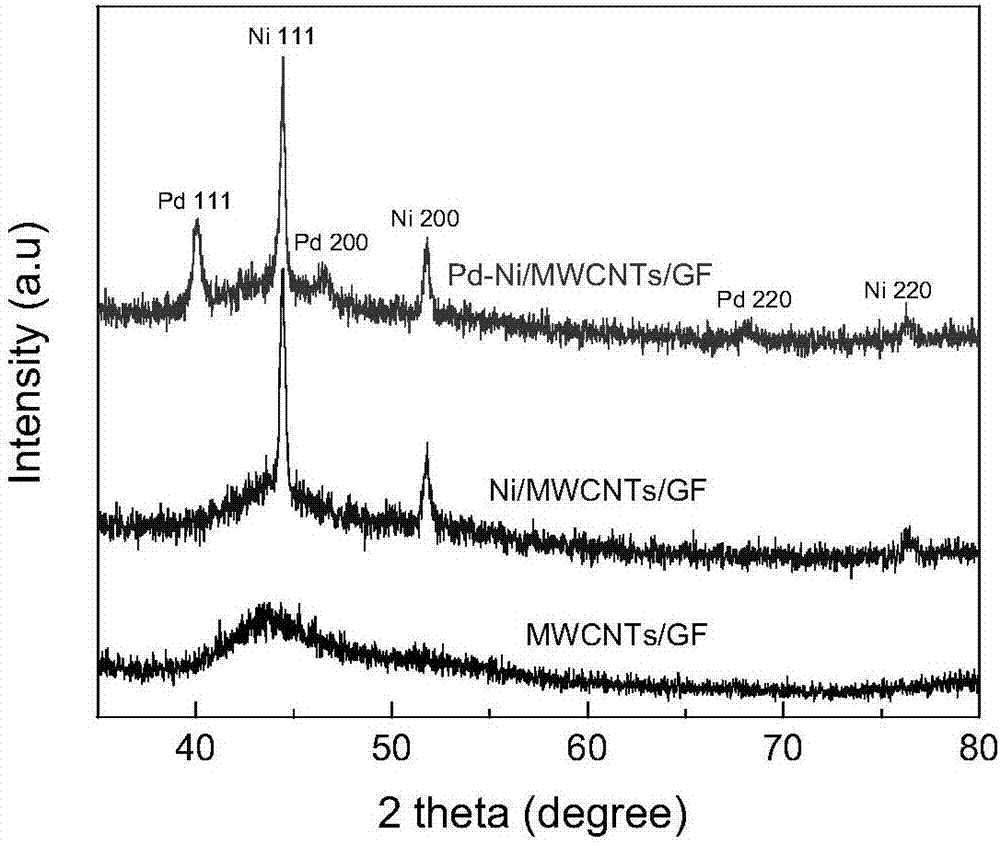

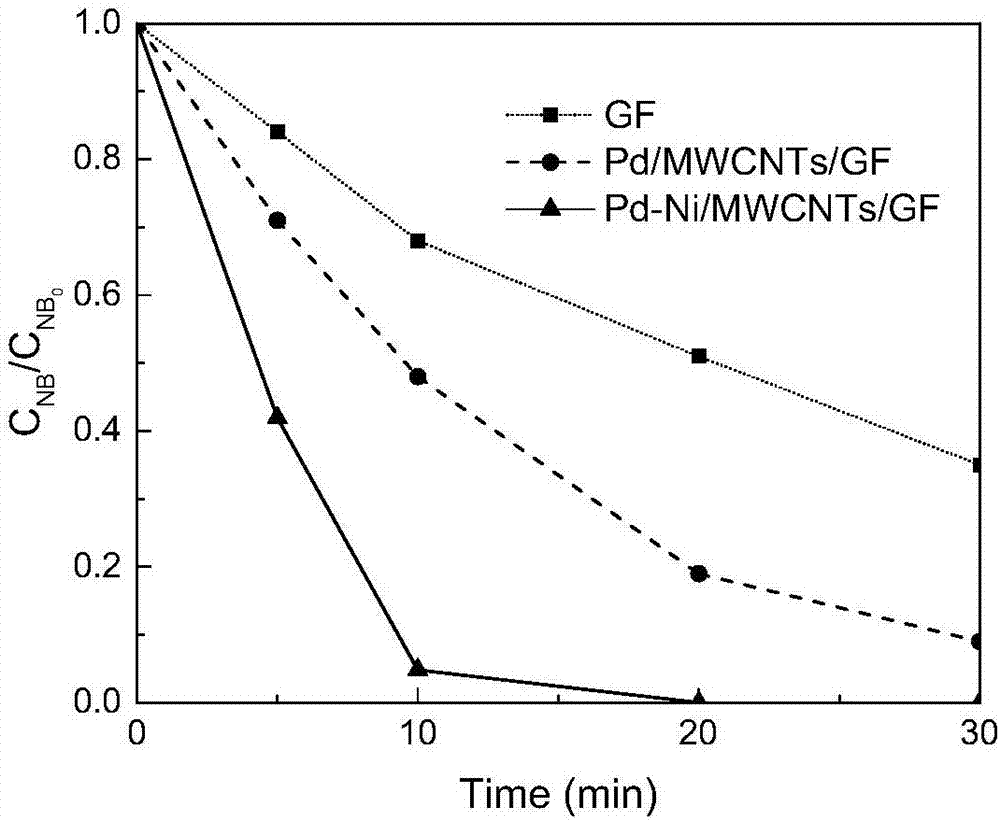

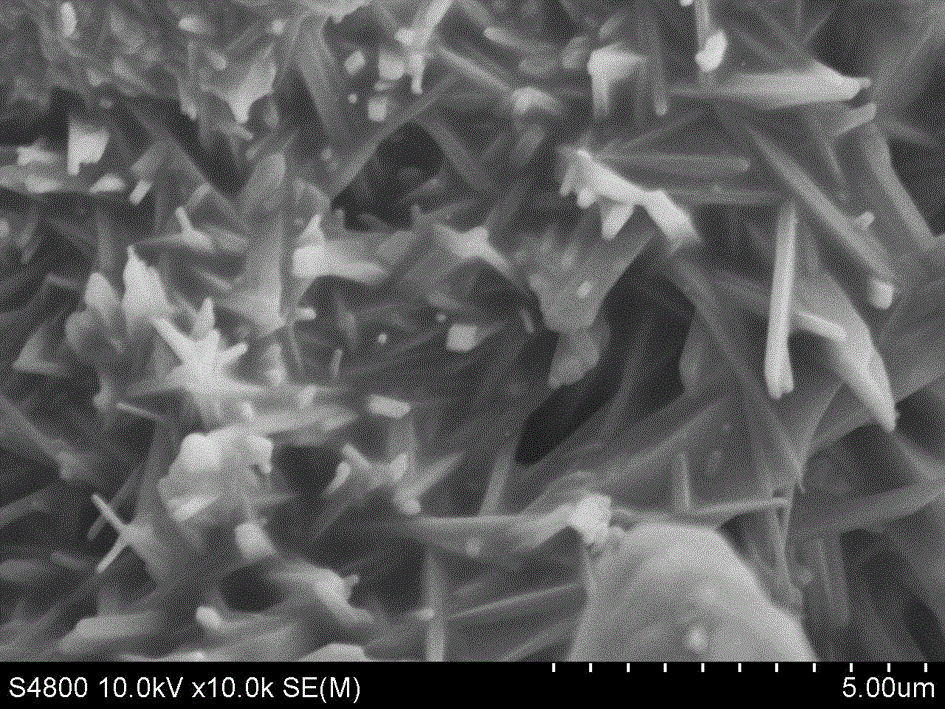

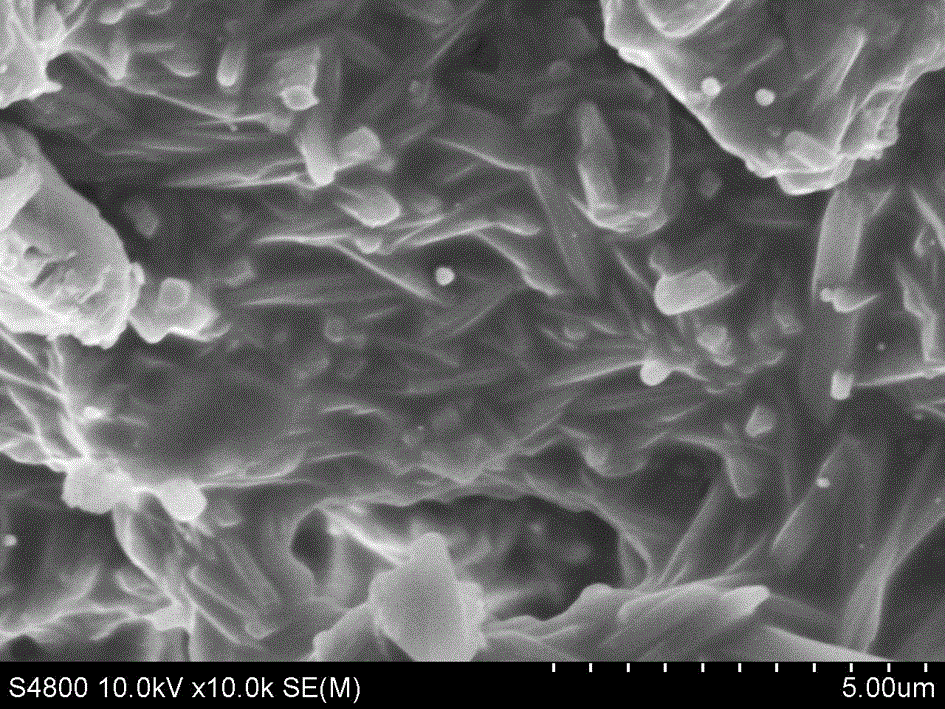

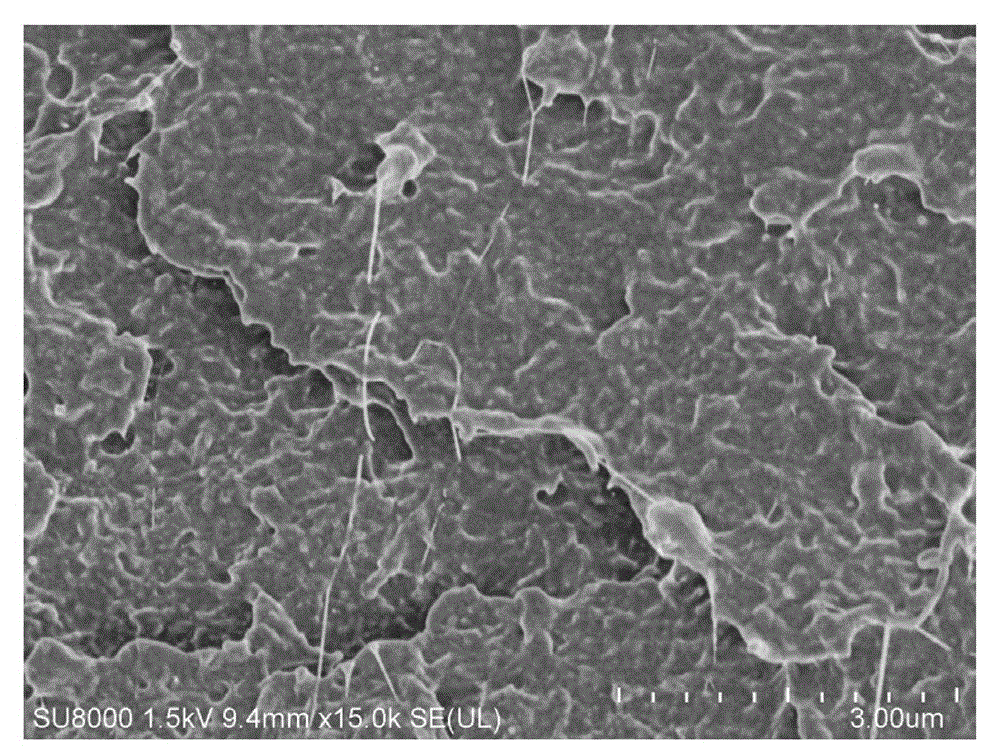

ActiveCN107364934ALarge specific surface areaHigh temperature and corrosion resistanceWater contaminantsWater/sewage treatment by reductionNickel saltMultiwalled carbon

The invention discloses an electrocatalytic reduction combined electrode and a preparation method and application thereof. The electrode is characterized in that a graphite felt is taken as a substrate, and a multiwalled carbon nanotube, a nickel metal layer and a palladium metal layer are deposited on the substrate sequentially. The method includes: firstly, preparing the multiwall carbon nanotube / graphite felt electrode; soaking the electrode in a nickel salt solution and forming the nickel metal layer on the surface of the electrode through high-temperature nitrogen reduction; forming the palladium metal layer through direct metal reduction in a palladium salt solution to obtain the nickel-palladium bimetal combined electrode. The combined electrode is high in catalytic activity and good in stability, and nitrobenzenes and chlorphenols in water can be subjected to electrocatalytic treatment rapidly and efficiently.

Owner:NANJING UNIV

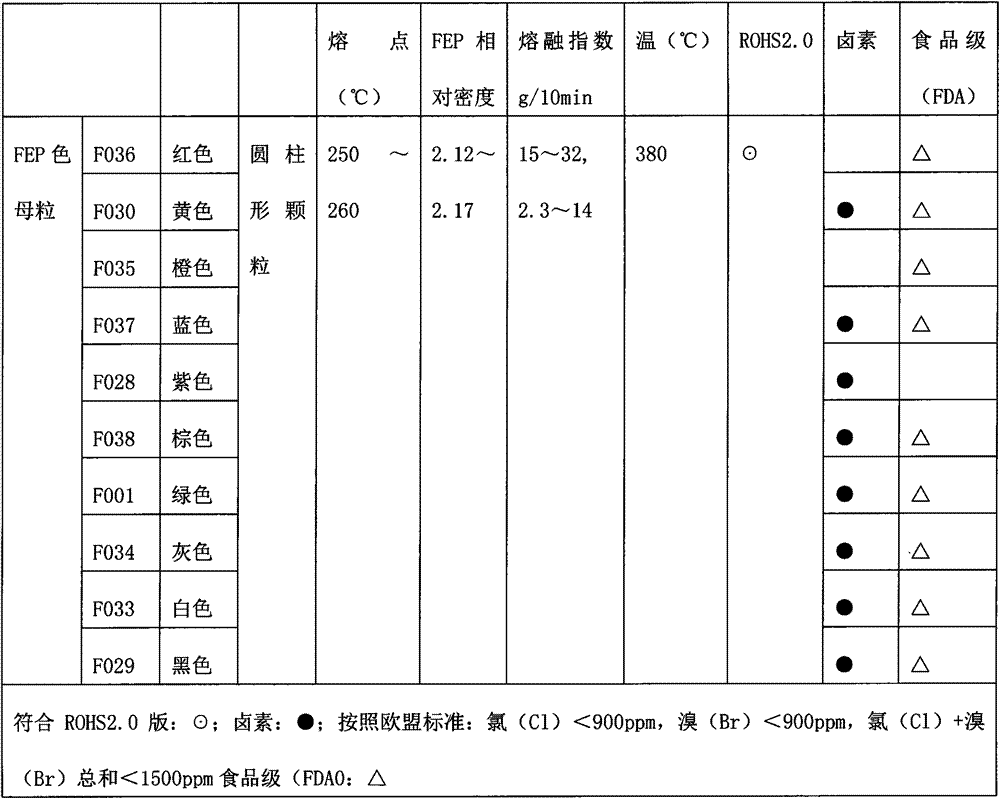

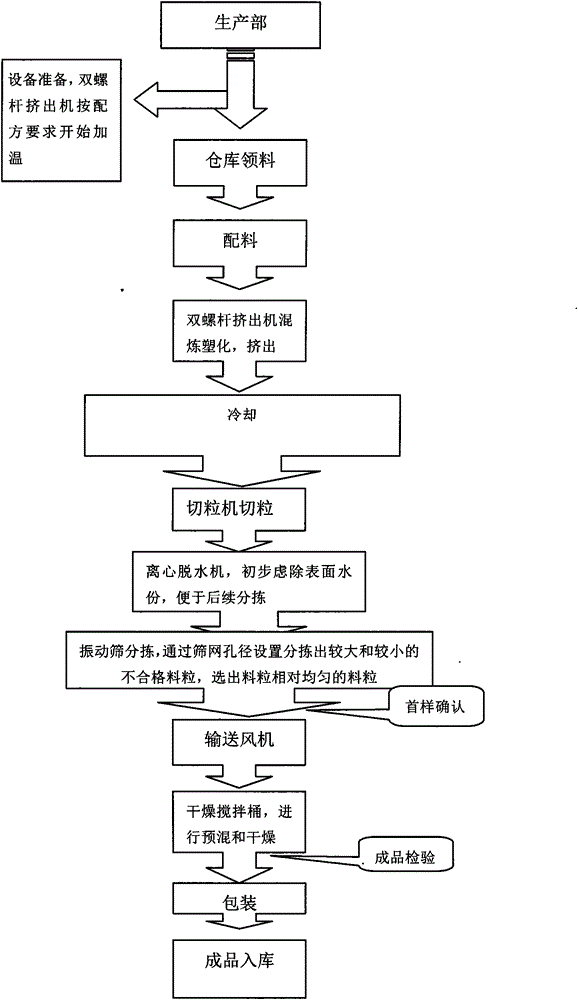

FEP fluorine color master batch and processing technique thereof

The invention discloses an FEP fluorine color master batch and a processing technique of the FEP fluorine color master batch. The FEP fluorine color master batch processed through the formula and the processing technique has better corrosion resistance, better electrical insulation property, longer service life and a lower price. The FEP fluorine color master batch comprises, by weight, 65%-85% FEP, 8%-25% high-temperature pigment, 3%-6% dispersing agents and 0.1-2% processing agents. The processing technique of the FEP fluorine color master batch comprises the steps of material allocation, extrusion molding, cooling, sized dicing, dewatering, sorting, drying and packaging for storage.

Owner:HUIZHOU WANLI IND

Negative ion ceramic product, and manufacturing method thereof

InactiveCN110194654AHigh temperature and corrosion resistanceImprove crack resistance and abrasion resistanceCeramic materials productionClaywaresCeramic glazePorous starch

The invention discloses a negative ion ceramic product, and a manufacturing method thereof, and belongs to the technical field of ceramic. The blank body raw materials of the negative ion ceramic product comprise, by mass, 30-40 parts of bone meal, 10-15 parts feldspar, 5-6 parts calcite, 20-30 parts kaolin, 10-15 parts clay, 3-5 parts water glass, 3-6 parts carbon fiber powder, 3-6 parts porous starch, 5-10 parts of tourmaline powder and 3-8 parts of Chongguang stone powder; a glaze raw material comprises following components, by mass, 10-20 parts agate stone, 10-50 parts feldspar, 5-10 partsquartz, 5-8 parts of sintered talc, 3-10 parts of zirconia, 5-15 parts of a fluxing agent, 3-8 parts of energy mineral powder, 5-10 parts of tourmaline powder and 2-5 parts of monazite powder. The negative ion ceramic product is excellent in negative ion release performance, flat in ceramic glaze surface, fine in texture, bright and smooth in glaze color, and high in strength and wear resistance.

Owner:DEHUA HENGHAN ARTS

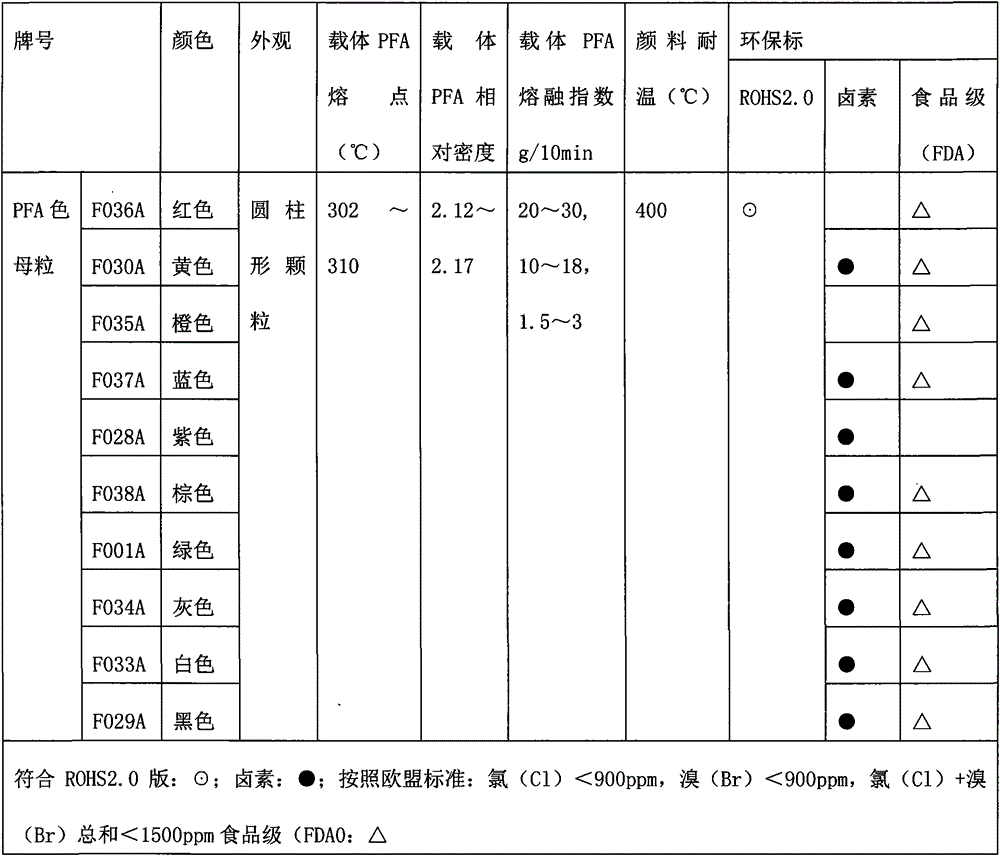

PFA fluorine color masterbatch and production process thereof

The invention discloses a PFA fluorine color masterbatch and a production process thereof. The PFA fluorine color masterbatch produced by virtue of a formula and the production process has excellent corrosion resistance and electrical insulation performance and is relatively long in service life and low in cost. The PFA fluorine color masterbatch is produced from the following raw materials in percentage by weight: 65%-85% of PFA, 8%-25% of a high-temperature pigment, 3%-6% of a dispersing agent and 0.1%-2% of a machining aid. The invention also discloses the production process of the PFA fluorine color masterbatch, comprising the following steps: (1) burdening; (2) molding by extrusion; (3) cooling; (4) granulating; (5) dehydrating; (6) sorting; (7) drying; and (8) packaging and warehousing.

Owner:WANLI SHENZHEN IND

High-temperature resistant coating for bridge and preparation method thereof

InactiveCN105219137ALow thermal expansion and contractionImprove surface strengthFireproof paintsAntifouling/underwater paintsEpoxyFiber

The invention discloses a high-temperature resistant coating for a bridge. The high-temperature resistant coating for the bridge comprises the raw materials of brown aluminium oxide, black silicon carbide, sodium silicate, melamine polyphosphate, pentaerythritol, 1,2-dimethyl-5-acetoxyl group-1H-indole-3-carboxylic acid ethyl ester, aluminum silicate fibers, hollow microspheres, silicon dioxide, antibacterial preservatives, film forming auxiliaries, water-based polyurethane resin, acrylic ester, tung oil, titanium dioxide, polyvinyl alcohol, light calcium carbonate, talcum powder, gypsum powder, titanium dioxide, silane compounds, guar gum, fluororesin, water-based epoxy modified resin, Ni, Zn, water and the like. Due to the fact that the high-temperature resistant coating for the bridge contains the components such as Ni and Zn, the high-temperature resistant coating for the bridge has the high-temperature resistant and anti-corrosion properties and meets the coating requirements of various occasions; in addition, the high-temperature resistant coating for the bridge does not contain toxic organic solvent, is free of pollution and has the advantages that the paint surface cannot crack, anti-aging is achieved, and the adhesive force is high.

Owner:江苏宇恒电气有限公司

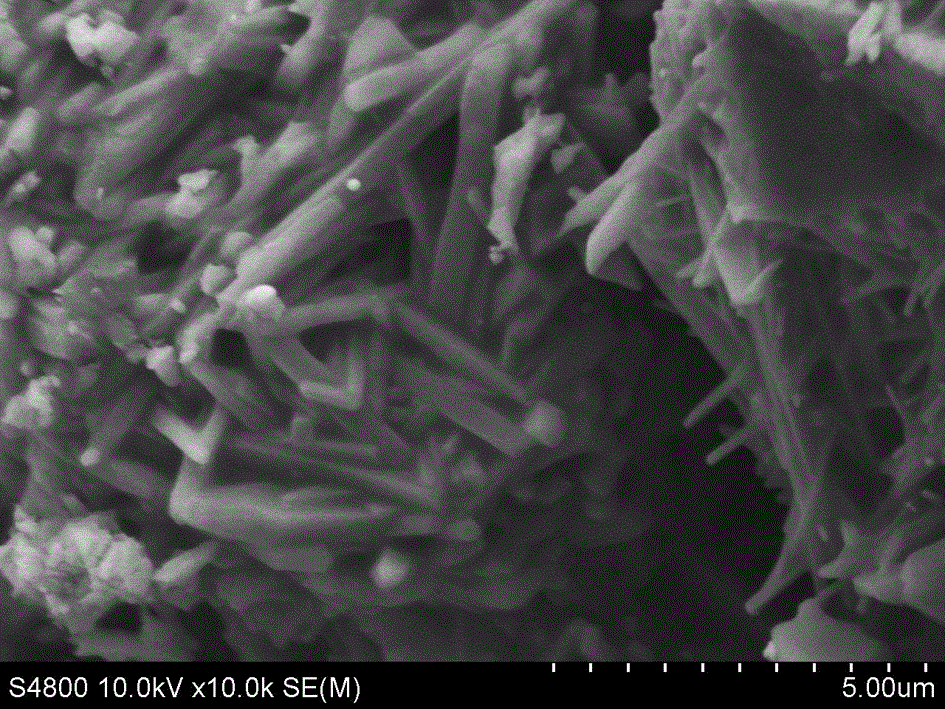

Preparation method of superfine polytetrafluoroethylene fiber

ActiveCN102168322AHigh purityHigh strengthFilament/thread formingArtificial filament heat treatmentHigh concentrationTetrafluoroethylene

The invention discloses a preparation method of a superfine polytetrafluoroethylene fiber. The preparation method includes the concrete steps as follows: preparing spinning solution 1 by using polytetrafluoroethylene high-concentration emulsion and adding water for dilution; preparing spinning solution 2 by polyvinyl alcohol with alcoholysis of 70%-80%; dissolving sodium sulfate by warm water at the temperature of 40-50 DEG C to form supersaturated solution with crystals being separated out, and adding caustic soda to adjust the pH value to 12-14 so as to prepare supersaturated coagulating bath; spinning the spinning solution 1 and the spinning solution 2 by a special spinneret plate to form a nascent fiber with a 'sheath core' structure; and sintering and highly stretching the nascent fiber to prepare the superfine polytetrafluoroethylene fiber. In the invention, the superfine polytetrafluoroethylene fiber is produced by a unique spinning process, the operation is convenient, simple and feasible; and the comprehensive performance of the obtained superfine polytetrafluoroethylene fiber is good.

Owner:南京际华三五二一环保科技有限公司

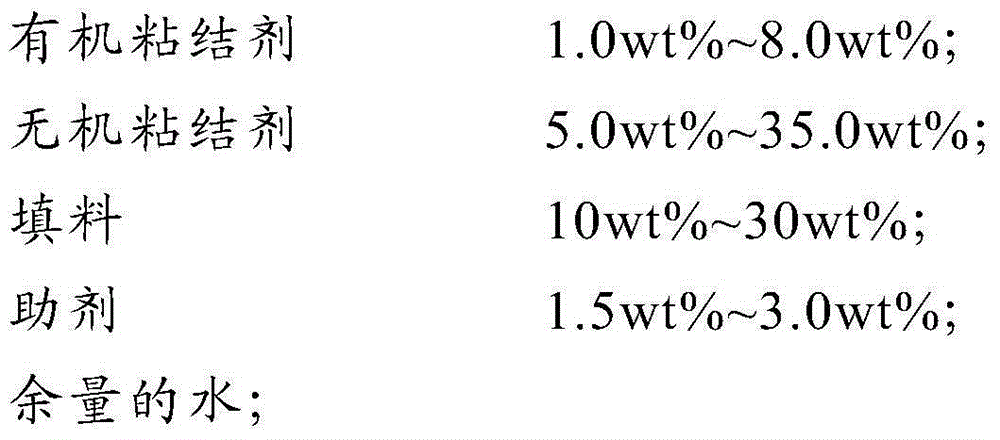

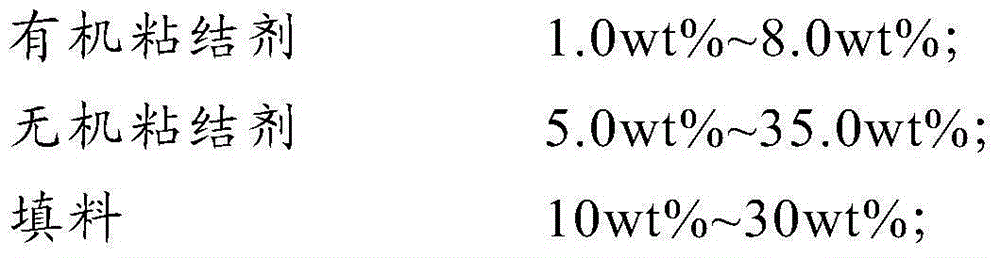

Ceramic paint and application thereof

The invention provides ceramic paint. The ceramic paint comprises 1.0wt%-8.0wt% of organic binders, 5.0wt%-35.0wt% of inorganic binders, 10wt%-30wt% of packing, 1.5wt%-3.0wt% of auxiliaries and the balance water. The organic binders are made of ethyl alcohol, the inorganic binders are made of aluminum dihydrogen phosphate, boehmite, phosphoric acid and nitric acid, and the packing comprises rare-earth oxide and zirconia. The invention further provides application of the ceramic paint to industrial furnaces. The ceramic paint and the application have the advantages that mutual synergistic effects are realized by components in the ceramic paint, and accordingly the ceramic paint is excellent in comprehensive performance when used as a ceramic coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

Waterborne coating and preparation method thereof

InactiveCN105219140AHigh temperature and corrosion resistanceStrong adhesionAnti-corrosive paintsEpoxySilane compounds

The invention discloses waterborne coating, which contains waterborne polyurethane resin, acrylic ester, tung oil, titanium dioxide, polyvinyl alcohol, light calcium carbonate, talcum powder, gypsum powder, titanium dioxide, silane compound, guar gum, fluororesin, waterborne epoxy modified resin, acrylate emulsion, Mn, Cr, Ni, Zn, Cu, Mo, Ti, Pd, Pt, Au, W, Ta, Nd, Ce, Eu, Lu and balance of water. As the waterborne coating contains the components like Ni, Zn and Ti, the waterborne coating has performance of high temperature resistance and corrosion resistance, and is adapted to the coating requirements of various occasions; moreover, the waterborne coating disclosed by the invention does not contain toxic organic solvent, is free of pollution and also has the advantages that the coating cannot be cracked, ageing resistance is high and adhesive force is powerful.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

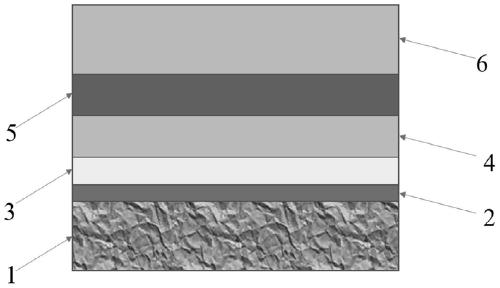

Pressure casting aluminum mold with nanocrystalline composite coating and preparing method

PendingCN110373632AImprove wear resistanceHigh temperature and corrosion resistanceVacuum evaporation coatingSputtering coatingAlloyTemperature resistance

The invention discloses a pressure casting aluminum mold with a nanocrystalline composite coating and a preparing method. A mold body and a coating on the mold surface are included; the coating comprises a binding layer, a transition layer, a supporting layer, a hardness increasing layer and a temperature-resisting corrosion-resisting layer which are distributed from inside to outside and have hardness gradient, the binding layer is a pure Cr layer, the transition layer is a CrN layer, the supporting layer is a CrN and AlCrSiN composite coating, the hardness increasing layer is an AlCrSiN andAlCrSiON alternative layer, and the temperature-resisting corrosion-resisting layer is an AlCrSiON and AlCrSiO alternative layer. The coating is a combination of multiple kinds of nanocrystalline complex nitride and oxide coating materials, the component has the gradual change characteristic, inner stress of the coating is reduced, coating toughness is improved, the defect that an existing pressure casting aluminum mold is insufficient in wear resistance, temperature resistance and corrosion resistance can be well overcome, the service life of the pressure casting aluminum mold can be greatlyprolonged, and adaptation of the pressure casting aluminum alloy can be greatly improved.

Owner:IKD CO LTD

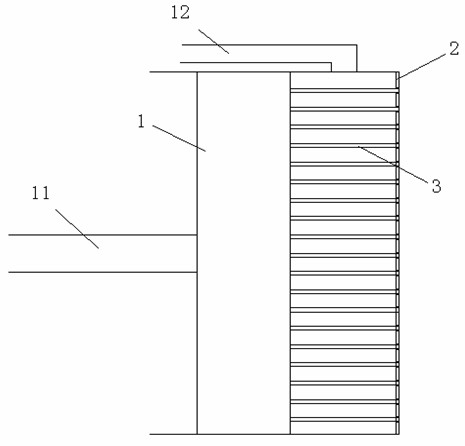

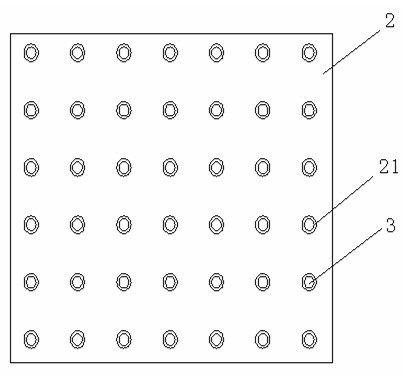

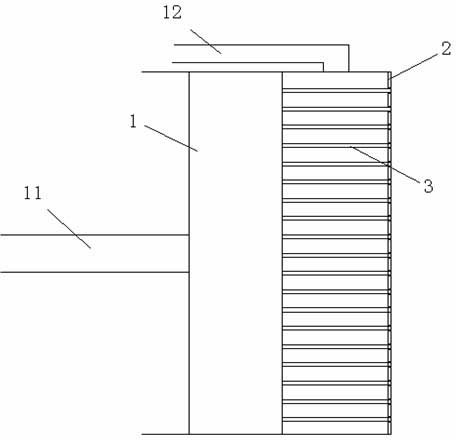

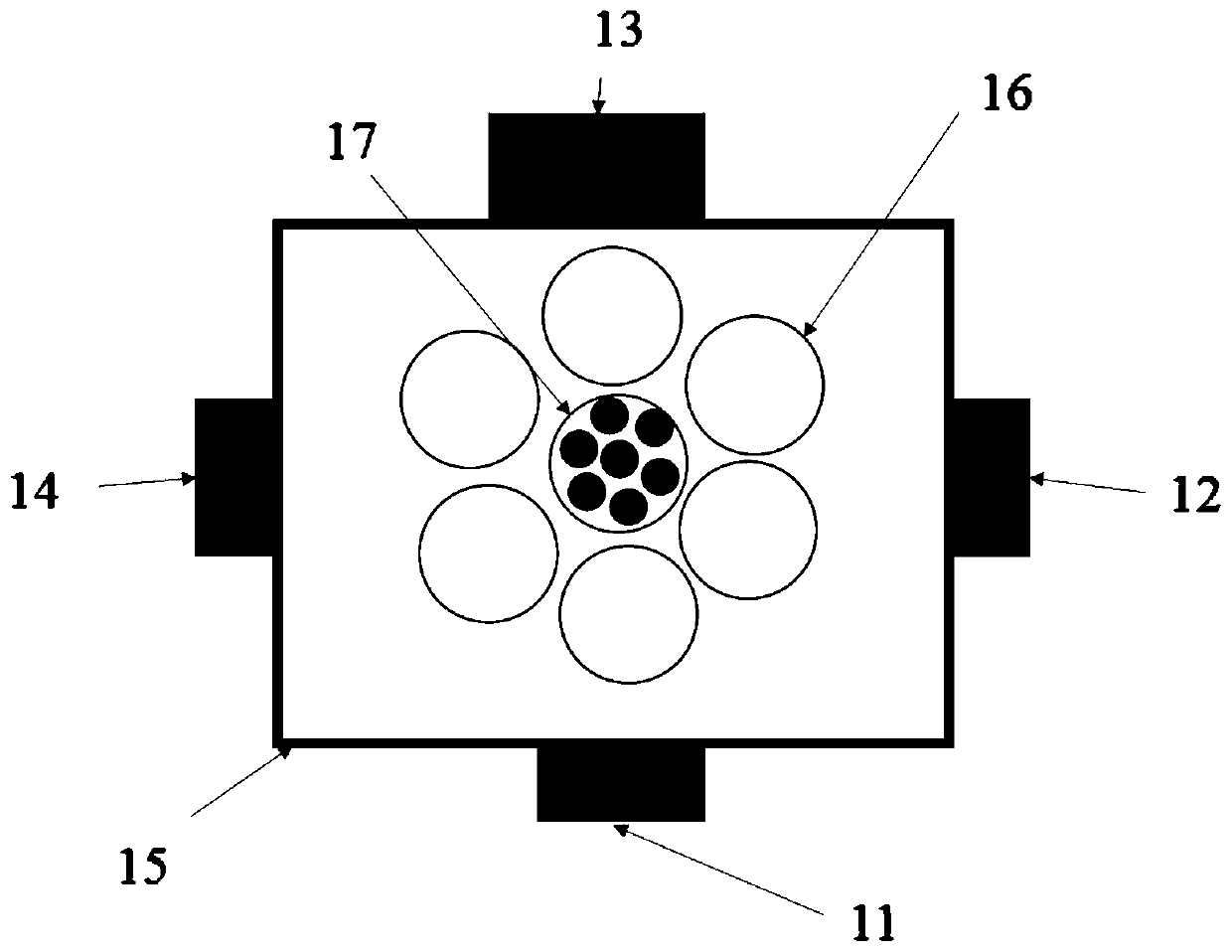

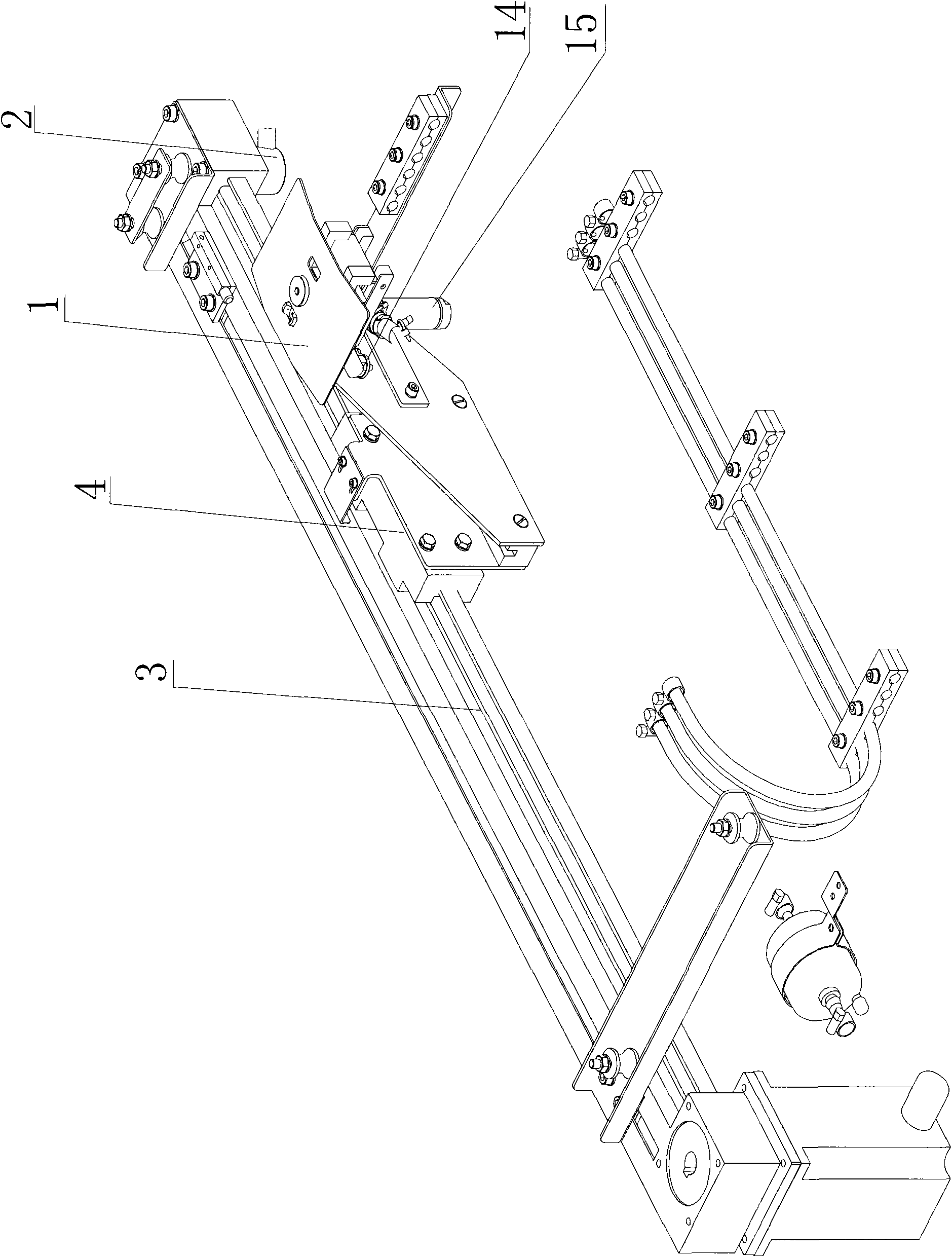

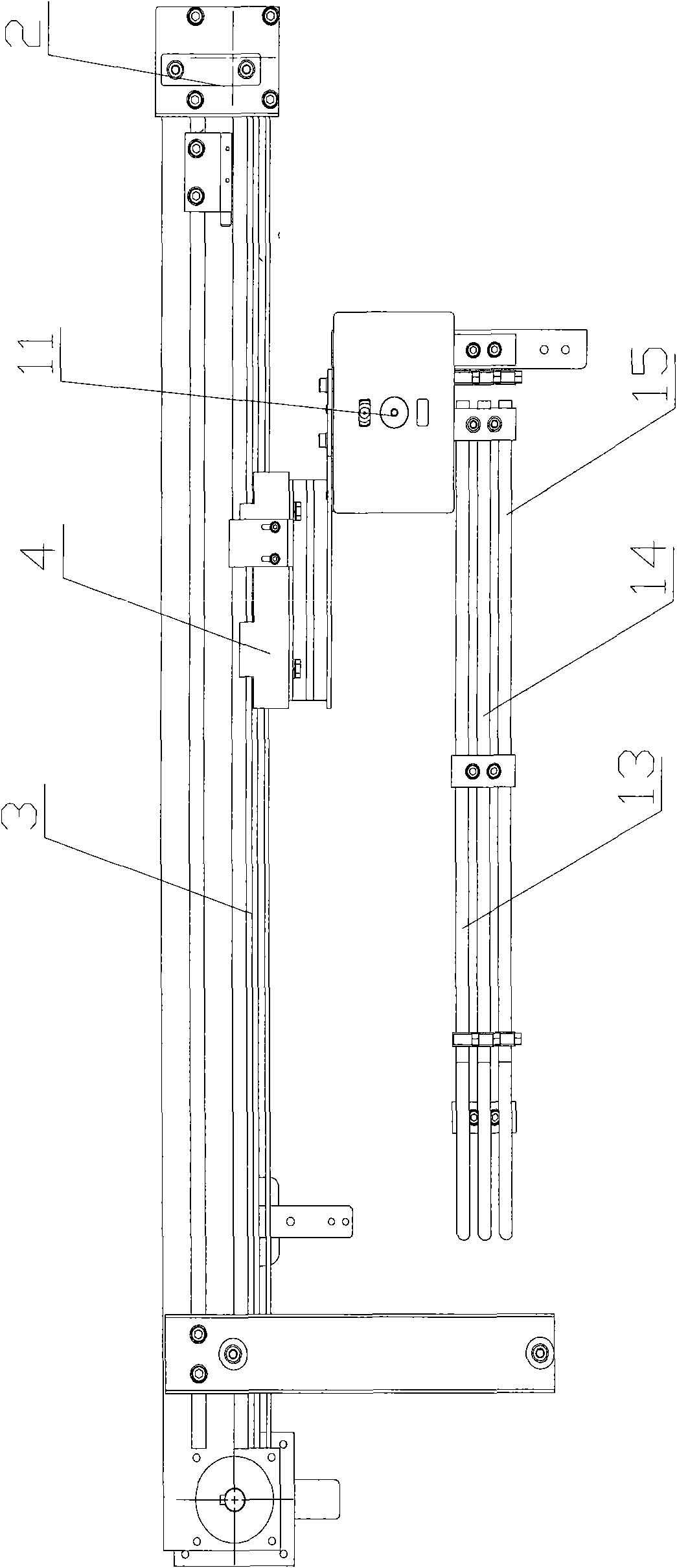

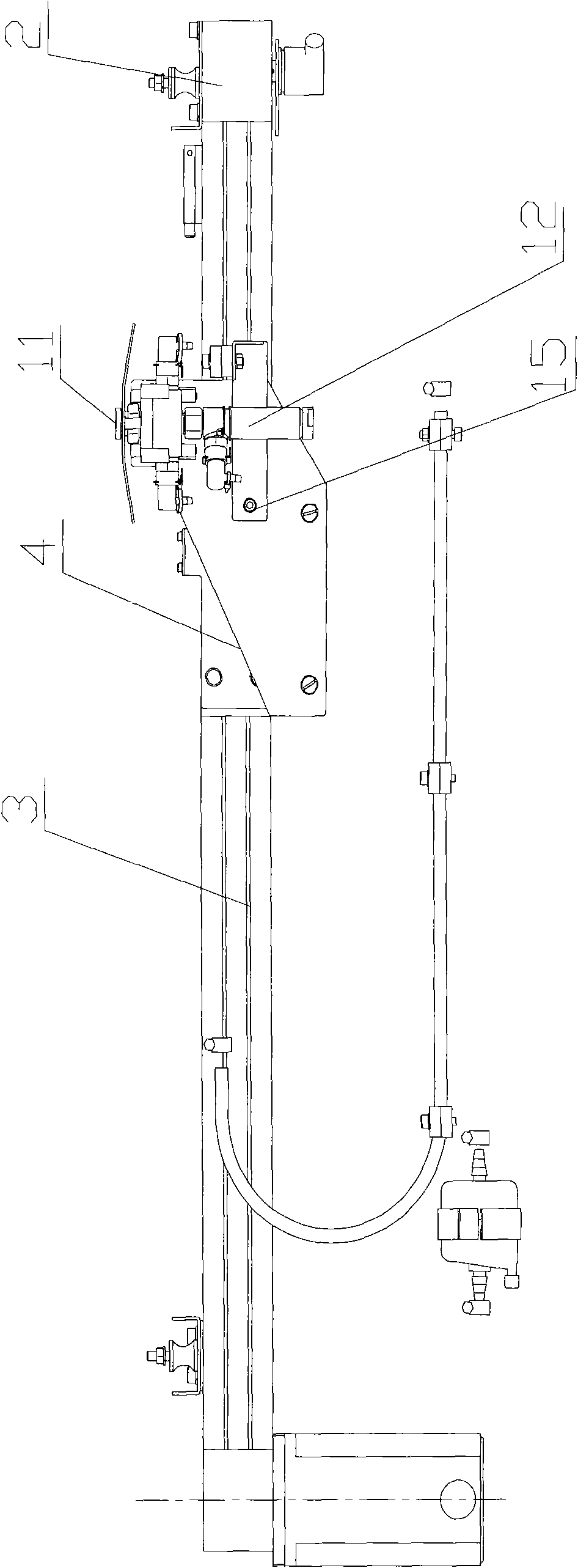

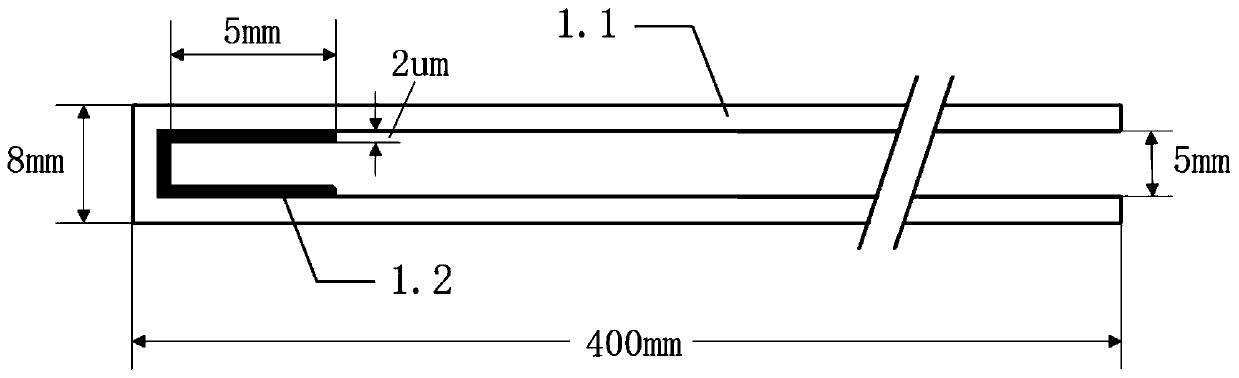

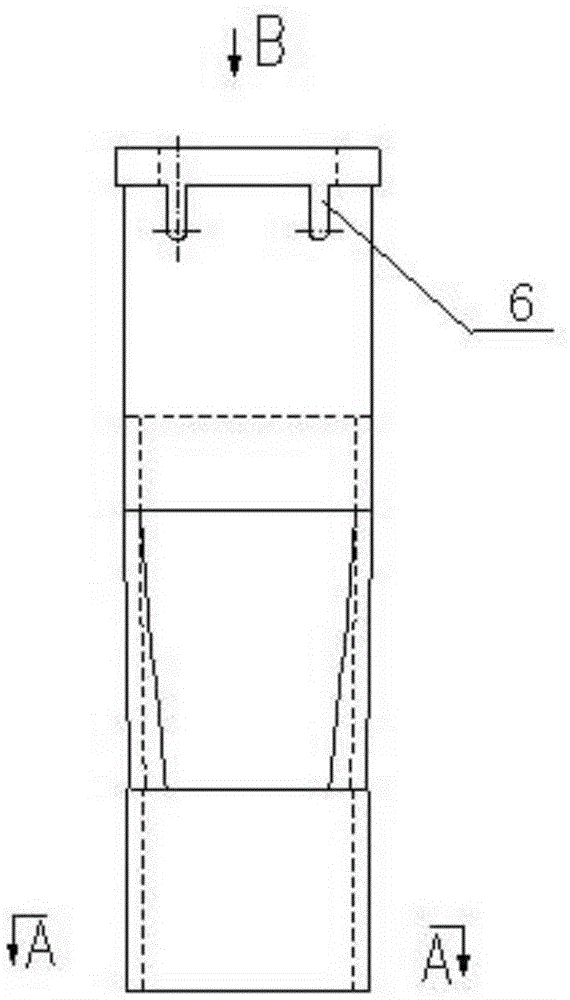

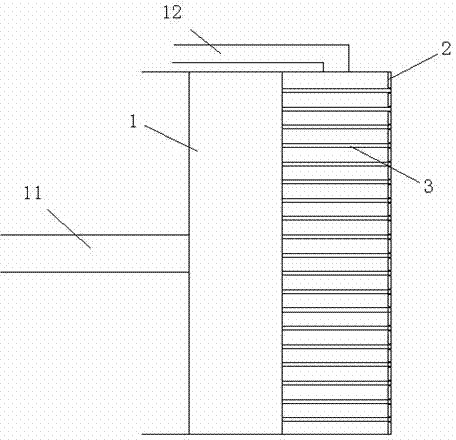

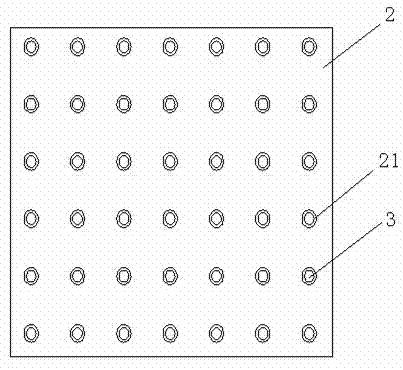

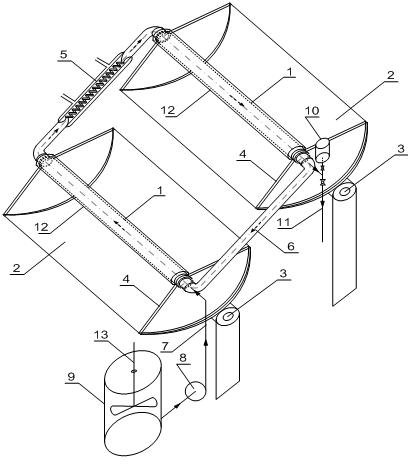

Soldering flux spraying system for wave soldering

ActiveCN101648309AUniform and stable spray effectGuaranteed uptimePrinted circuit assemblingSolder feeding devicesEngineeringPower unit

The invention discloses a soldering flux spraying system for wave soldering, which comprises a spraying unit (1). The system is characterized in that a power unit (2) is arranged on the outer side ofthe spraying unit, one end of the power unit is provided with a fixed guide rail (3), a slide block (4) of the fixed spraying unit (1) is arranged on the fixed guide rail (3), and the power unit and the block connected with a driving block slide along the fixed guide rail. The sliding of the spraying unit is realized by the arrangement of the fixed guide rail and the slide block of the fixed spraying unit, so the device has the advantages of small vibration and noise and stable operation in use; and the device has multiple types of sprayers with different diameters so as to realize the regulation on multiple flow rates, so that the atomization effect is more even.

Owner:依工电子设备(苏州)有限公司

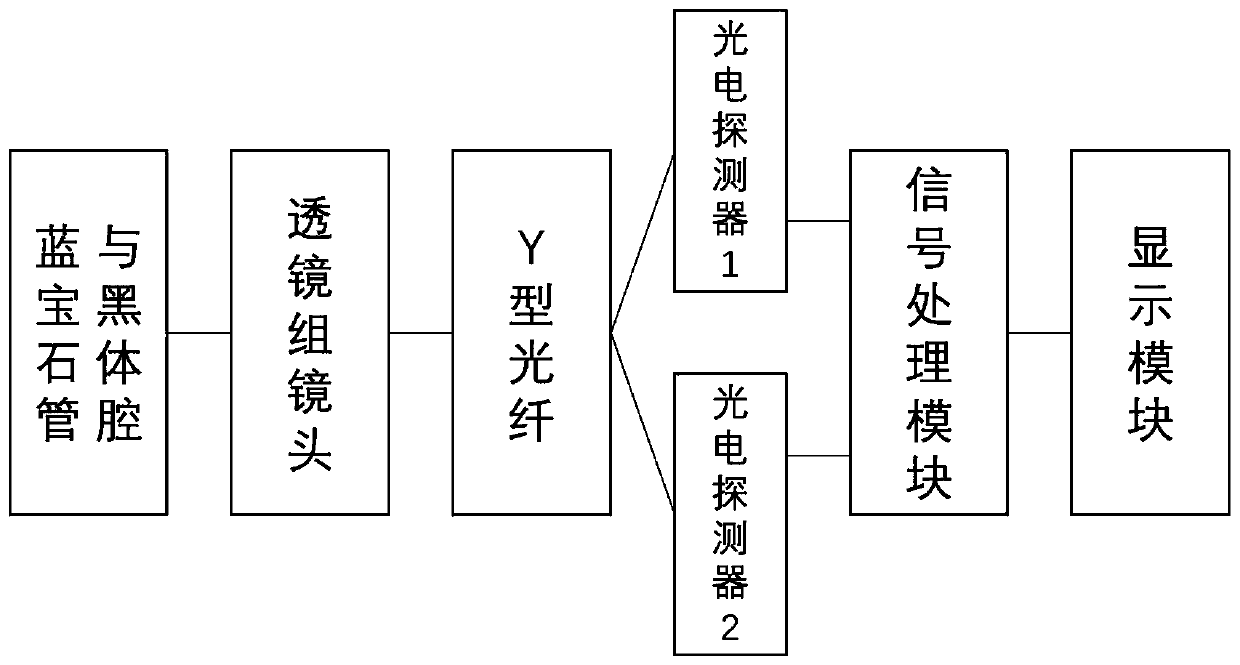

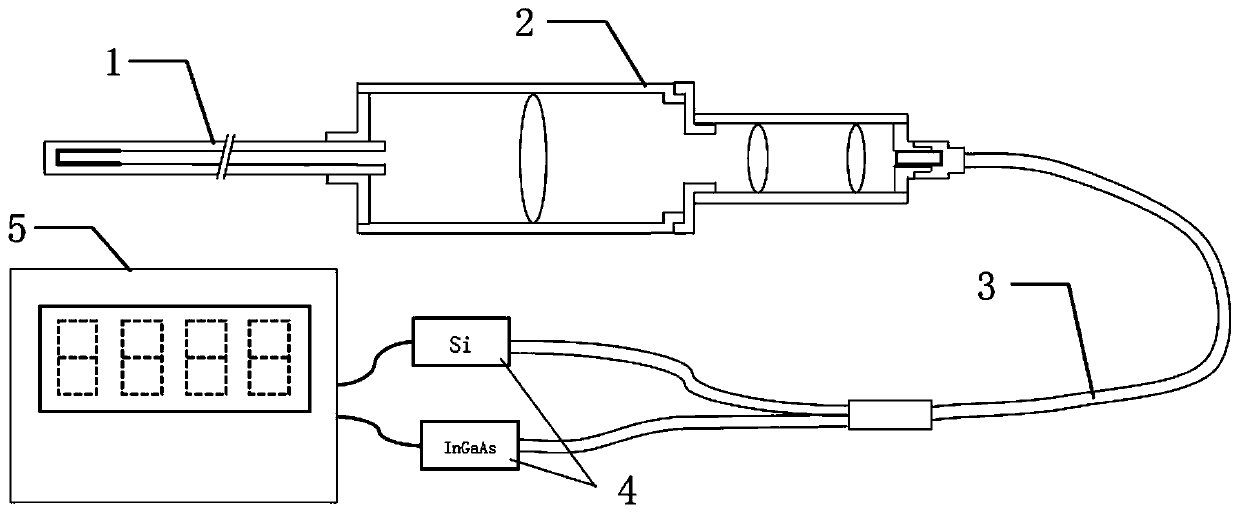

Sapphire tube black body cavity optical fiber temperature measurement device

InactiveCN110220613AReduce risk of deteriorationReduce distractionsThermometer detailsThermometers using physical/chemical changesTemperature measurementElectric signal

The invention discloses a sapphire tube black body cavity optical fiber temperature measurement device, wherein an optical system comprises a sapphire tube black body cavity, a lens assembly shot anda Y-shaped energy transfer optical fiber; a circuit system comprises a photoelectric detector, a signal processing module and a display module; the sapphire tube black body cavity is formed by coatinga film inside the sealed end of a sapphire tube; the sapphire tube black body cavity, as a sensing part, is in contact with a to-be-measured environment, and converges thermal radiation energy at anenvironment temperature to the Y-shaped energy transfer optical fiber through the lens assembly shot; the Y-shaped energy transfer optical fiber divides thermal radiation energy into two paths of energy beams; the photoelectric detector converts two paths of energy beams into electric signals and transmits the electric signals to the signal processing module to carry out signal processing so as toobtain a digital signal; and the display module obtains a to-be-measured temperature value according to the digital signal and carries out display. According to the invention, the black body cavity and the lens assembly shot are combined so as to avoid continuous exposure of the optical system in a severe environment; and the sapphire tube black body cavity optical fiber temperature measurement device is applicable to the field of high-temperature industries with the long-time temperature measurement requirement.

Owner:NANJING NORMAL UNIVERSITY

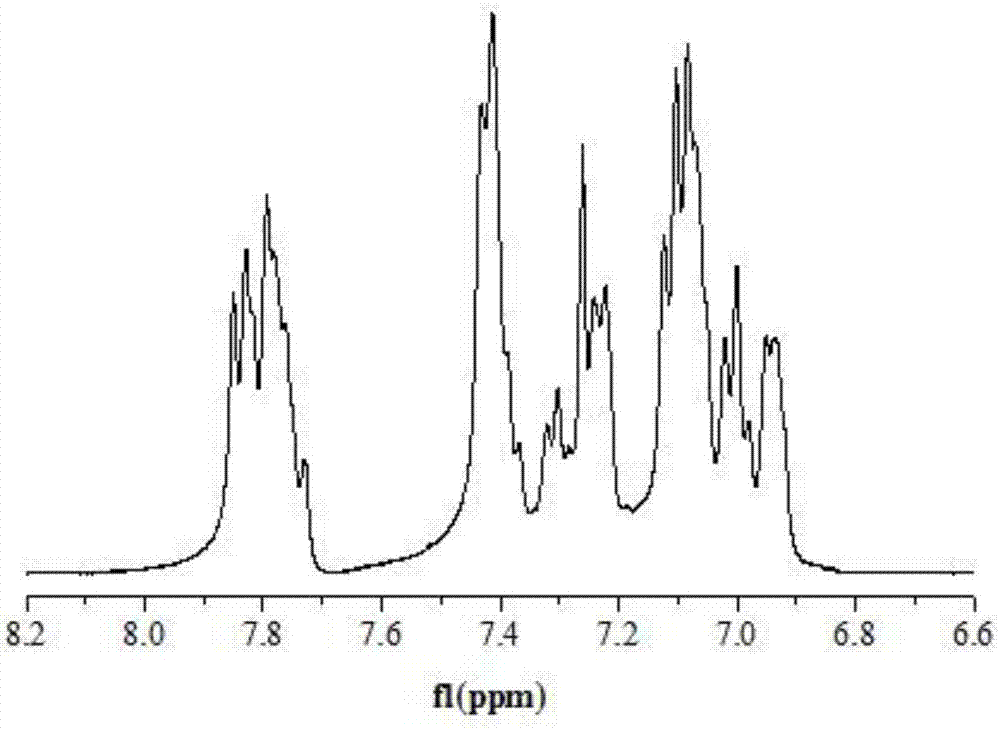

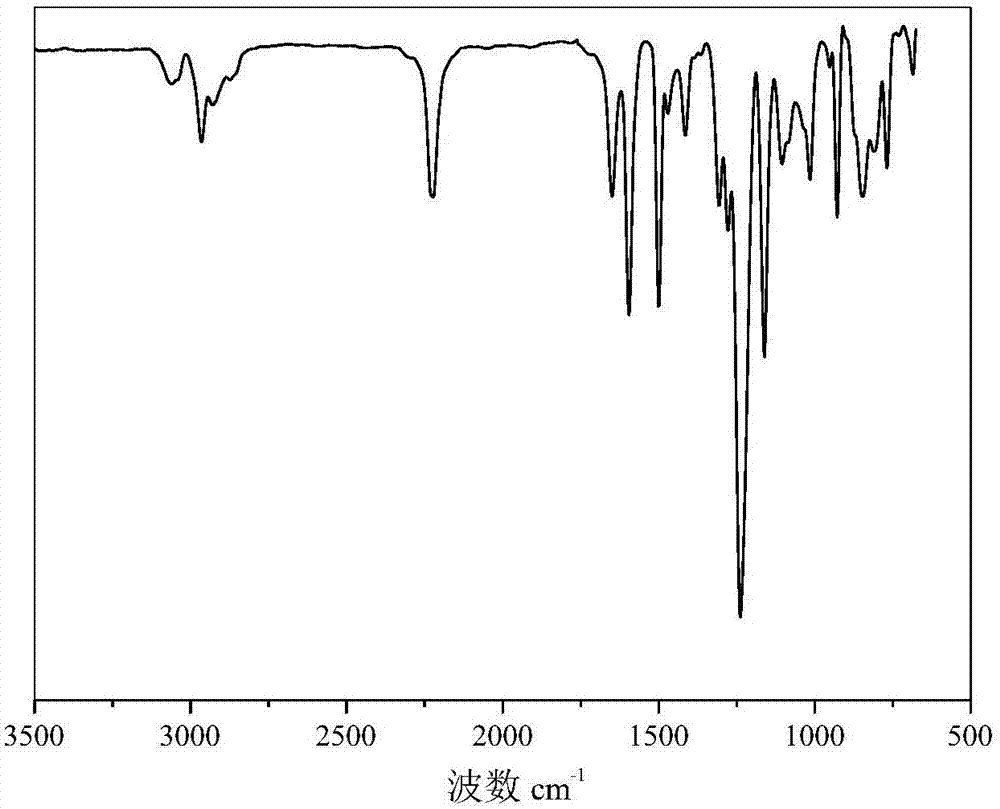

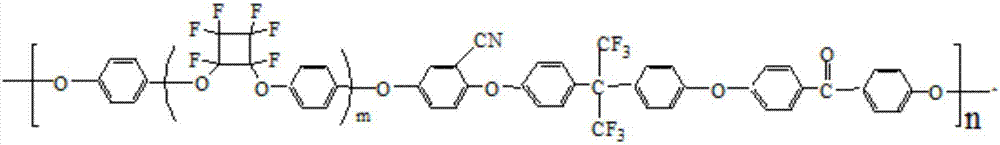

Poly(aryl ether ketone) cable material resin and synthesis method thereof

ActiveCN106947075AImproved and enhanced thermal stabilityLow dielectric constantSolubilityPolymer science

The invention discloses a poly(aryl ether ketone) cable material resin and a synthesis method thereof. According to the synthesis method, perfluorocyclobutylaryl ether-phenol polymer, hexafluorobisphenol A, dihalobenzonitrile / dihalo-para-phthalonitrile, and 4,4'-difluorobenzophenone are taken as the raw materials; and after two temperature controlled reactions in a nitrogen atmosphere in the presence of a catalyst, the reaction product is subjected to precipitation, filtration, washing, and centrifugal drying to obtain the poly(aryl ether ketone) cable material resin. The thermal stability, crystallinity, and dissolvability of the polymer are effectively improved; the polymer dielectric constant, polymer dielectric loss factor, and signal attenuation ratio of high speed transmission frequency band are reduced; at the same time, the excellent properties of poly(aryl ether ketone) material are preserved; and the poly(aryl ether ketone) material has the advantages of poly(arylene ether nitrile), polyether ether ketone, and a material having a fluorine containing structure.

Owner:福建超阳电线电缆有限公司

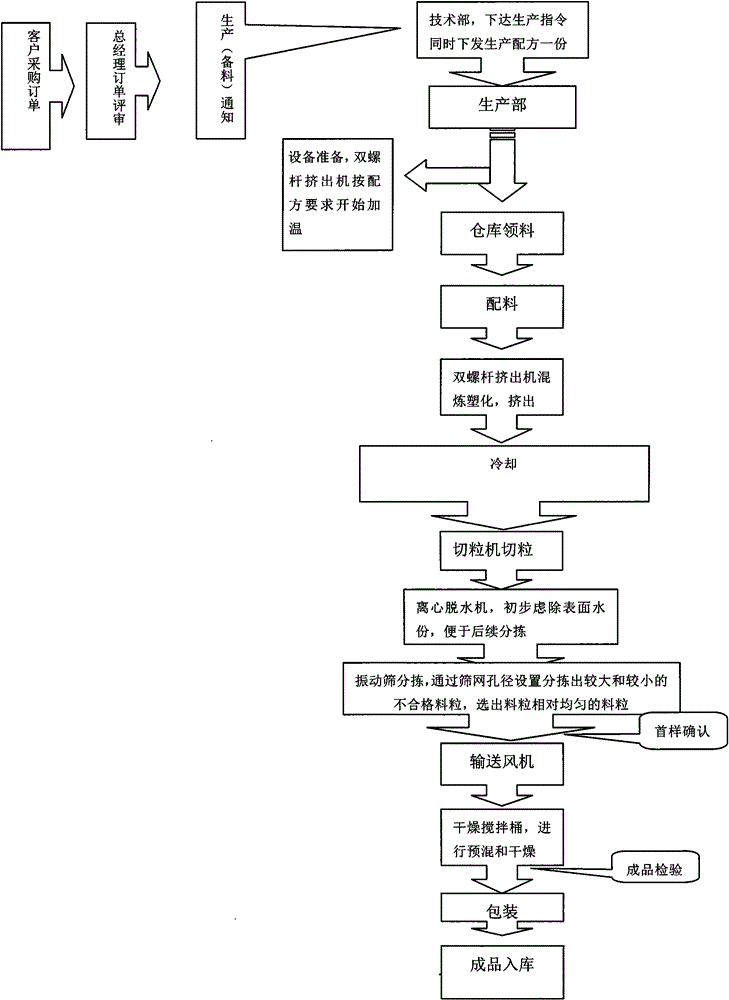

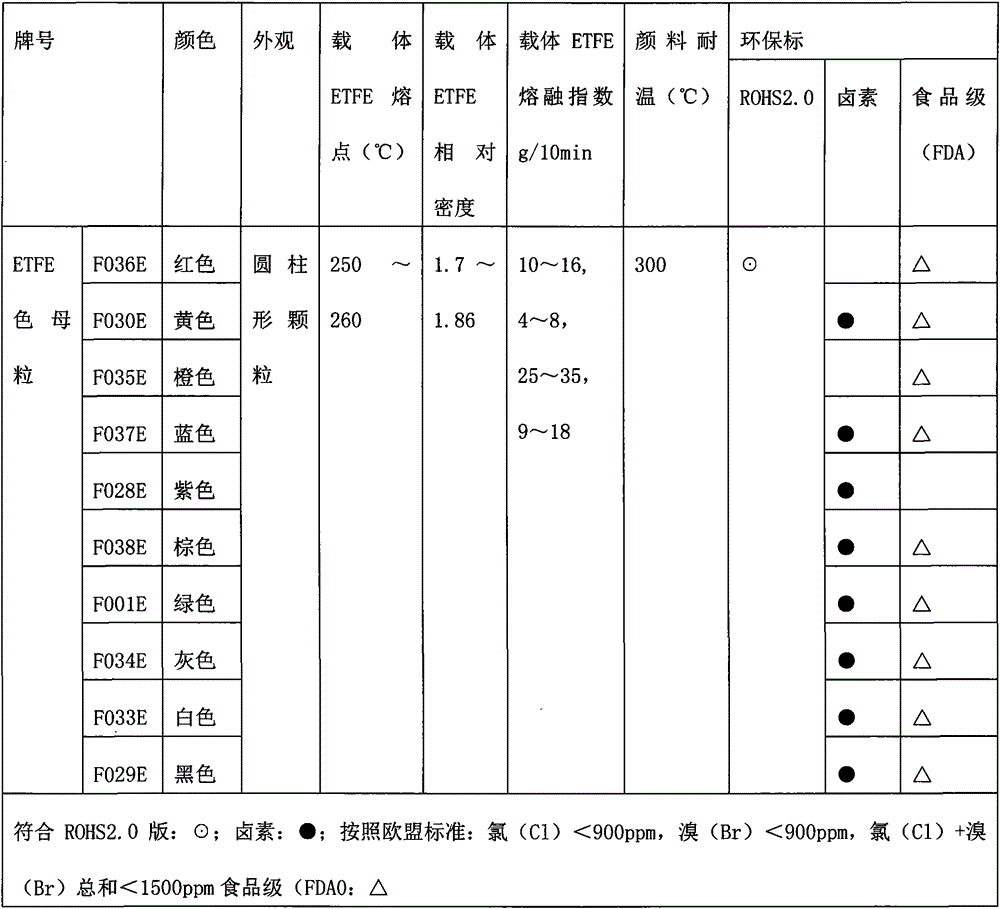

ETFE fluorine masterbatch and production flow thereof

InactiveCN104558790AHigh temperature and corrosion resistanceFill qualityMasterbatchProcedure Agents

The invention discloses an ETFE fluorine masterbatch and a production flow thereof. The ETFE fluorine masterbatch prepared by the formula and the production flow has the advantages of relatively good corrosion resistance and electric insulation property, relatively long service life, and low price. The ETFE fluorine masterbatch disclosed by the invention is prepared from the following raw materials in percentage by weight: 65%-85% of ETFE, 8%-25% of a high-temperature pigment, 3%-6% of a dispersing agent and 0.1%-1.5% of a processing agent. The invention further discloses a processing technology for preparing the ETFE fluorine masterbatch. The technology comprises the following steps: (1) burdening; (2) extruding and molding; (3) cooling; (4) dicing; (5) dewatering; (6) sorting; (7) drying; and (8) packaging and warehousing.

Owner:WANLI SHENZHEN IND

Low-density ceramsite propping agent made from flint clay clinker and dolomite and preparation method of low-density ceramsite propping agent

ActiveCN106190092AImprove uniformityHigh compressive strengthFluid removalDrilling compositionInstabilityExpanded clay aggregate

The invention discloses a low-density ceramsite propping agent made from flint clay clinker and dolomite and a preparation method of the low-density ceramsite propping agent, and belongs to the technical field of propping agents for hydrofracture construction and exploitation of oil and gas fields, solving the problems of product performance instability and incapability of mass production due to uneven blending and abnormal growth of crystalline grains during sintering in the prior art. The ceramsite propping agent is prepared through raw material ball-milling, pelleting, drying, sintering and sieving, and comprises, by mass, 86-98% of the flint clay clinker and 2-14% of the dolomite, wherein the total quantity of the flint clay clinker and the dolomite is 100%. The prepared ceramsite propping agent has the advantages of high uniformity of prepared ceramsites, high compressive strength, stable performance, low volume density, low apparent density, high anti-crushing capability, high surface smoothness and the like, has excellent performance such as high temperature resistance and corrosion resistance, and can be applied to high-temperature and high-corrosion underground environments for a long time, and performance of the low-density ceramsite propping agent meets technical standards of SY / T5108-2014.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

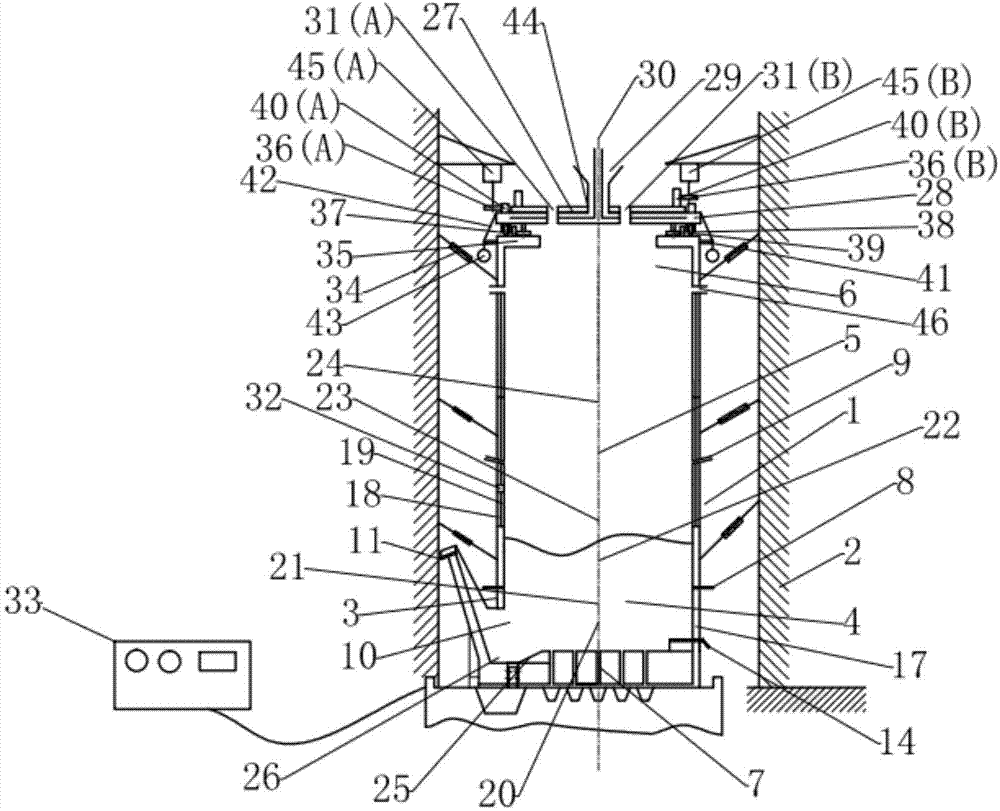

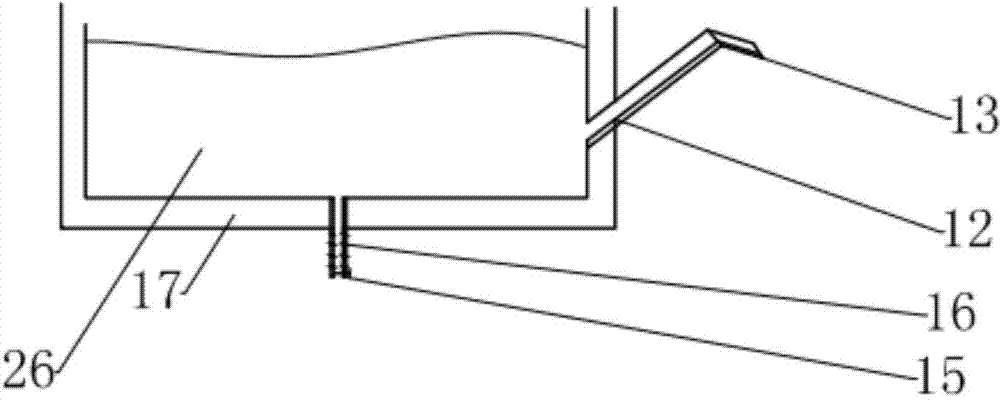

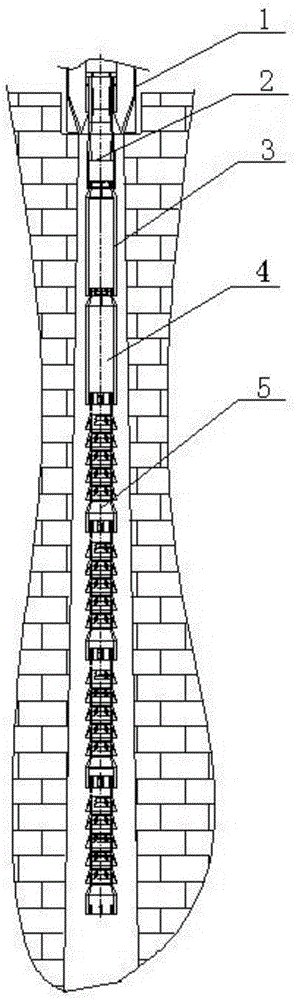

Combined regenerated lead oxygen-enriched three-blowing energy-saving smelting furnace

InactiveCN103834817AIncrease heightGuaranteed contactIncreasing energy efficiencyGas emission reductionSlagWater jacket

The invention discloses a combined regenerated lead oxygen-enriched three-blowing energy-saving smelting furnace. A furnace body 1 is arranged vertically, the whole furnace body 1 is divided into a lower section, a middle section and an upper section, the lower section is a smelting area 4 and comprises a stationary area 20, a bubbling area 21, and a reduction area 22 from bottom to top, the middle section is a waste heat utilization area 5, the lower half part of the waste heat utilization area is a secondary combustion area 23, the upper half part of the waste heat utilization area is a raw material preheating area 24, the upper section is a smoke discharging and feeding area 6. The vertical furnace body is more convenient to fully use the waste heat of the offgas for preheating the raw material, so that the energy-saving effect is remarkably improved, the dosage of the reducing agent is reduced, and the content of lead in the slag is lowered. The novel furnace body adopts a metal water jacket component and is combined by segmental hoisting, thus being convenient to maintain, and greatly lowering the maintenance cost.

Owner:ANHUI HUAXIN LEAD IND GROUP +1

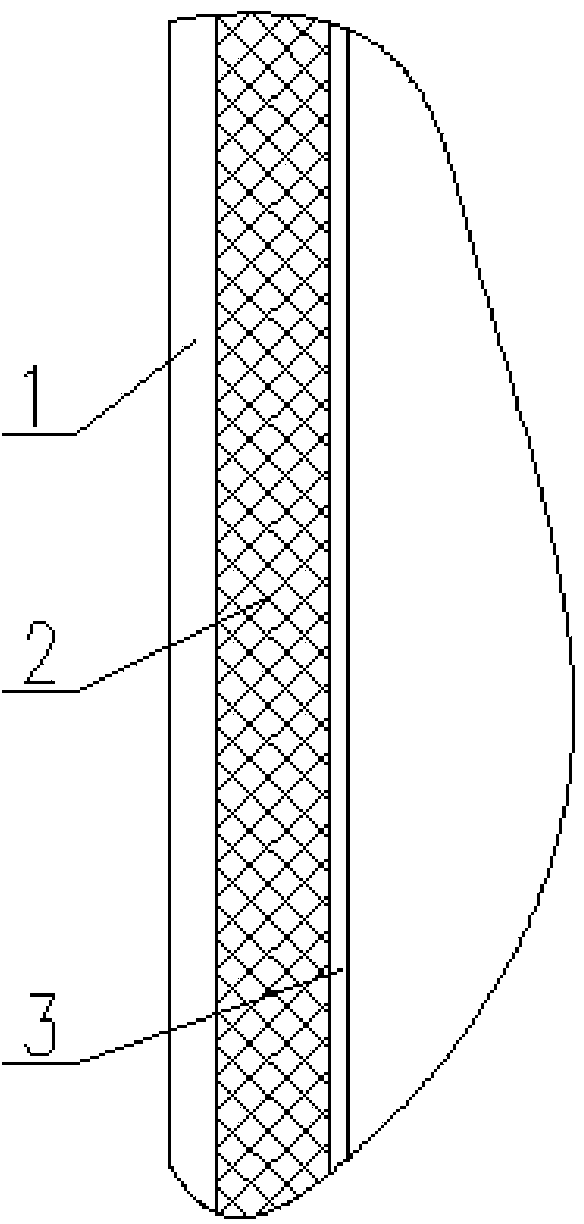

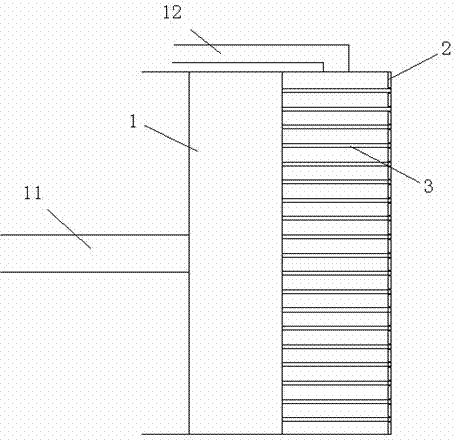

High-temperature storage tank body structure

InactiveCN103523404AIsolated contactHigh temperature and corrosion resistanceLarge containersTemperature resistanceCarbon steel

The invention relates to a high-temperature storage tank body structure. The storage tank body structure comprises a storage tank base material, a middle high-temperature-resistant material and a liner layer, wherein the storage tank base material is made of carbon steel, the middle high-temperature-resistant material is a layer of insulation refractory bricks, and the liner layer is a stainless steel liner protecting the refractory bricks. The high-temperature storage tank body structure can effectively isolate the storage tank base material from making contact with high-temperature liquid, greatly reduces amount of expensive stainless steel, meanwhile, meets the requirements for high temperature resistance and corrosion resistance and greatly reduces equipment investment.

Owner:JIANGSU SINOES EQUIP

Micro-expansive super early strength modifier for cement and using method thereof

InactiveCN102249585ALow costHigh temperature and corrosion resistanceBreaking strengthPortland cement

The invention relates to a micro-expansive super early strength modifier for cement and a using method thereof. The modifier comprises the following raw materials in part by mass: 30 to 40 parts of CaO, 10 to 20 parts of CaSO4, 45 to 65 parts of C4A3 and 25 to 35 parts of Al2O3. The micro-expansive super early strength modifier is combined with the ordinary portland cement, so that the cement has the advantages that: 'the breaking strength of 12 hours is more than 4.5 MPa; the compression strength of 12 hours is more than 20MPa; the breaking strength of 24 hours is more than 7.5 MPa; the compression strength of 24 hours is more than 30 MPa; the breaking strength of 7 days is more than 12 MPa; the compression strength of 7 days is more than 70 MPa; and the coefficient of linear expansion is more than 0.05 percent'. Compared with the common organic anchoring reinforcement material, the micro-expansive super early strength modifier has the advantage that: the cost of the material is reduced greatly, namely is reduced by over 50 percent on the premise of meeting the requirement of strength.

Owner:福建省交通科学技术研究所

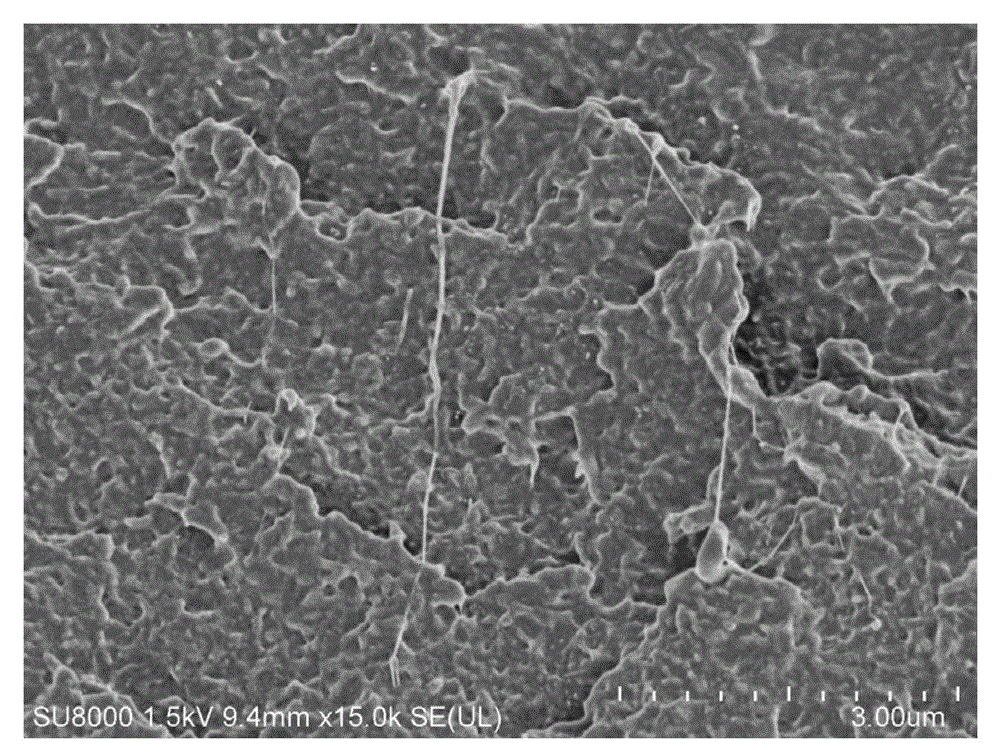

Foam ceramic and preparation method thereof

PendingCN110092666ALight weightWith thermal insulationCeramic materials productionCeramicwarePorosityRed mud

The invention relates to the technical field of solid waste utilization, in particular to foam ceramic and a preparation method thereof. The foam ceramic is prepared from following raw materials, by weight, 50-70 parts of semi-coke, 20-40 parts of red mud, 3-15 parts of feldspar, and 2-10 parts of a dispersing agent. The semi-coke and the red mud are adopted as raw materials, so that the semi-cokeand the red mud are fully utilized, and resource utilization of waste is realized. According to embodiments, the foam ceramic has a bulk density of 300-700 kg / m<3>, a porosity of 50-80%, and a compressive strength of 7-10 MPa. The preparation method has the advantages of low cost, easy operation, low energy consumption and environmental protection, and is beneficial to industrial production.

Owner:广西中添新型材料有限公司

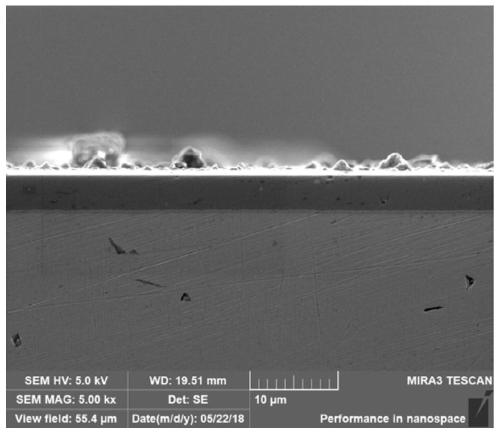

A polyether ether ketone antistatic high temperature resistant coating and preparation method thereof

ActiveCN103194142BEasy to prepareImprove conductivityPretreated surfacesPolyether coatingsPoly ether ether ketoneCarbon nanotube

Owner:吉林省奕彤新材料有限公司

Bright red glaze and preparation method thereof

The invention provides a bright red glaze. The glaze comprises the following raw materials: feldspar, clay, high-boron frit, Mg-Al hydrotalcite, kojic acid dipalmitate, nano zinc oxide, nano copper oxide, manganese carbonate and aluminum hydroxide. A preparation method of the above bright red glaze comprises the following steps: putting the raw materials into a glaze mill according to a ratio, performing grinding, and performing filtering through a 120-140-mesh sieve to obtain a mixed base material; and putting the mixed base material into a glaze mill, performing grinding at 45 r / min for 4-8h, and performing filtering through a 120-140-mesh sieve to obtain the bright red glaze. The bright red glaze prepared by adopting the raw material ratio and the preparation method provided by the present application has a bright and stable color, good gloss, fine texture and good adhesion, a glaze layer prepared by adopting the above glaze has very strong adhesion, and a fired ceramic has a smooth glaze surface, fine texture and a bright and smooth glaze color, and has stronger strength, wear resistance, thermal stability and high-temperature resistance.

Owner:福建省德化县鹏欣陶瓷有限公司

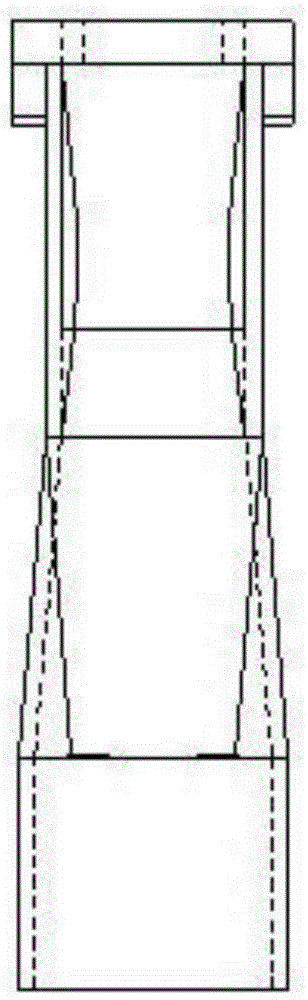

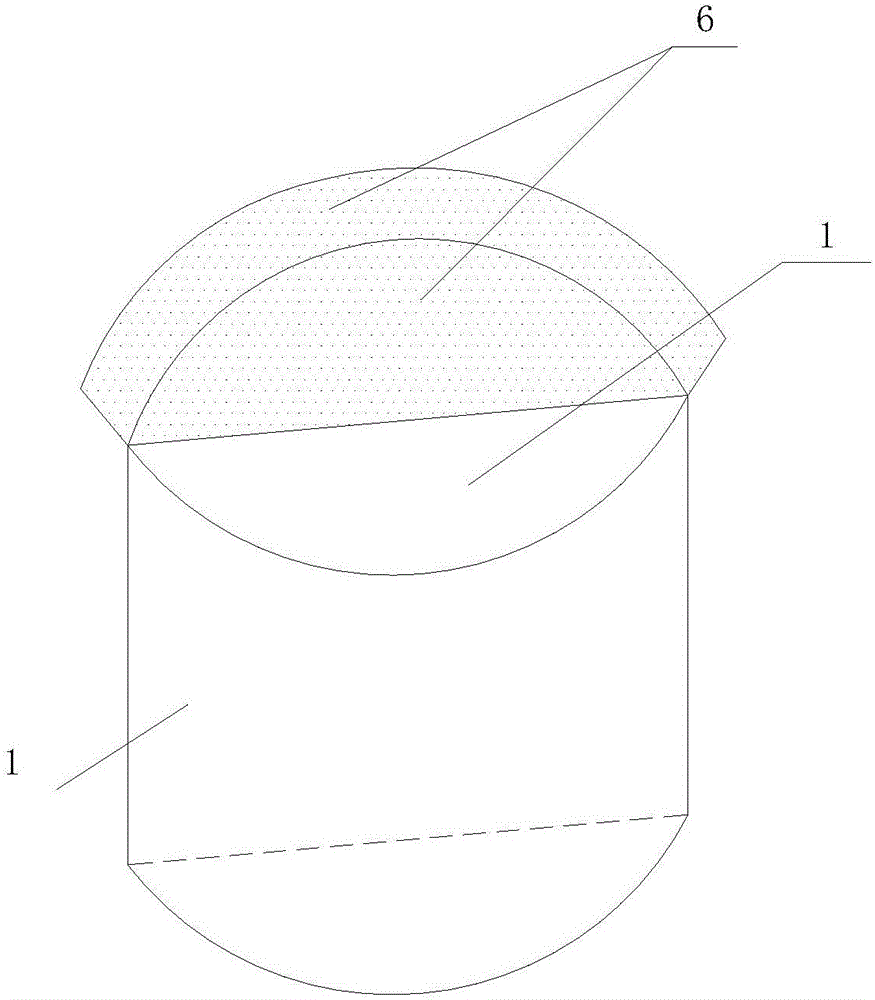

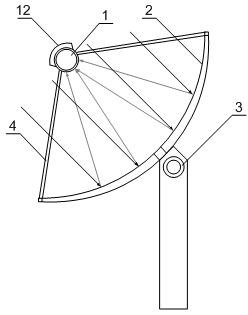

Umbrella-shaped gas collecting structure

ActiveCN105670652AReasonable structureIncrease the conductive areaSpecial form destructive distillationDistillation gas withdrawalCouplingMulti segment

The invention relates to an umbrella-shaped gas collecting structure. The umbrella-shaped gas collecting structure comprises an upper-section tubular structure and a lower-section umbrella-shaped structure, wherein the upper-section tubular structure consists of a first section, an intermediate section and a tail section which are sequentially connected from top to bottom; the first section is hung on a deep coal box; the first section, the intermediate section and the tail section are connected by a clamping groove quick coupling; the tail section is connected with a lifting hook at the upper part of the lower-section umbrella-shaped structure through a lifting lug; the lower-section umbrella-shaped structure consists of multiple sections of gas collecting umbrellas; a plurality of umbrella skirts expanding towards the lateral lower direction are arranged on each section of gas collecting umbrella along the axial direction; annular clearances are formed between the umbrella skirts and the corresponding gas collecting umbrella main body; the gas collecting umbrellas of all sections are connected by the lifting lugs and the lifting hooks. According to the umbrella-shaped gas collecting structure disclosed by the invention, the structure is reasonable, the conduction area of gas is large, raw coal gas generated by a dry distillation section can be timely exported, and pulverized coal can be prevented from entering into a gas collecting channel; the umbrella-shaped gas collecting structure is of a multi-segment and multi-section structure, is quick and reliable in connection and is very convenient in manufacturing, mounting and replacing; in addition, the umbrella-shaped gas collecting structure also has the characteristics of high temperature resistance and corrosion resistance, and sufficiently meets the demand of exporting of the raw coal gas.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

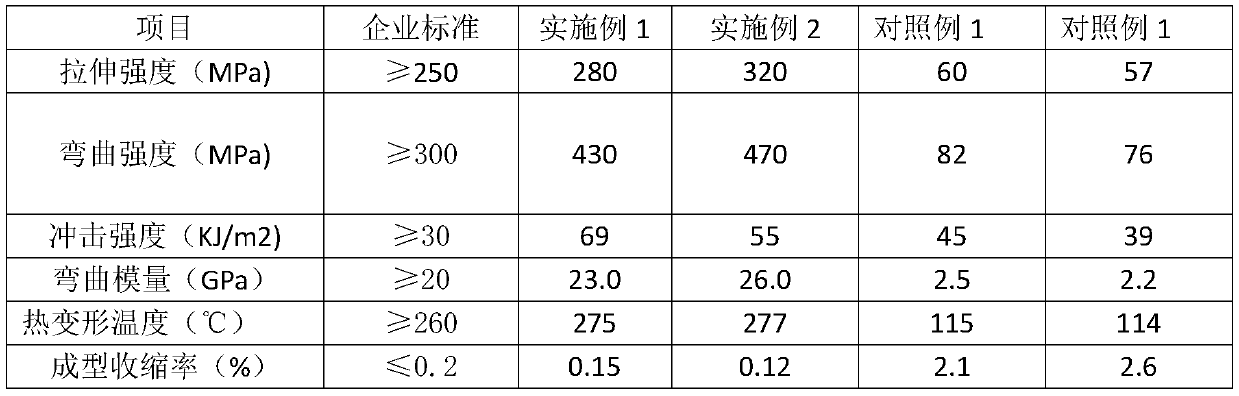

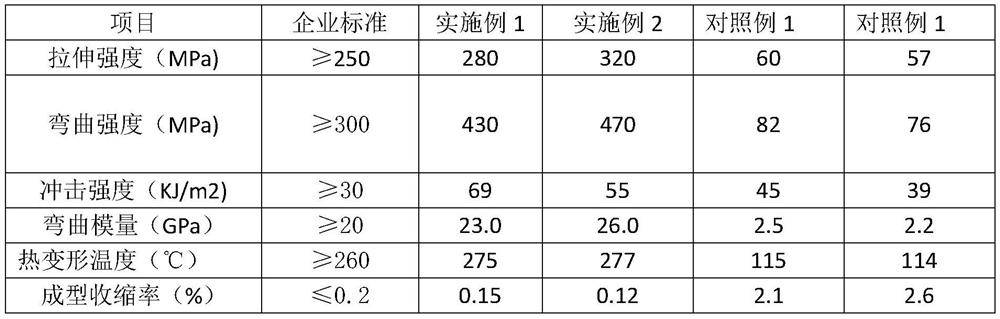

Special thermoplastic composite material applicable to 3D printing and preparation method thereof

ActiveCN109705570ASimple recipeEasy to manufactureAdditive manufacturing apparatusGlycidyl methacrylateAntioxidant

The invention discloses a special thermoplastic composite material applicable to 3D printing and a preparation method thereof. The special thermoplastic composite material applicable to 3D printing isprepared from the following main components by weight: 45 to 85 parts of polyphthalamide (PPA), 5 to 35 parts of Surlyn resin (Surlyn), 5 to 20 parts of an ethylene-glycidyl methacrylate copolymer (E-GMA), 1 to 20 parts of nanometer titanium dioxide, 1 to 15 parts of graphene, 0.2 to 1.5 parts of a nucleating agent, 0.1 to 1.5 parts of a dispersant and 0.5 to 1 part of an antioxidant. The specialthermoplastic composite material applicable to 3D printing provided by the invention is simple in formula, convenient in preparation, rapid in molding and cooling speed and strong in melt viscosity,has the characteristics of high-temperature resistance and corrosion resistance, and is applicable to molding of special high-temperature-resistant 3D-printed products or components and parts; and a 3D-printed product can be directly used as a final product, so the disadvantages of long period and high cost for mold manufacturing are overcome, and rapid 3D printing of a complicated product can beeasily realized at the same time.

Owner:青岛科凯达橡塑有限公司

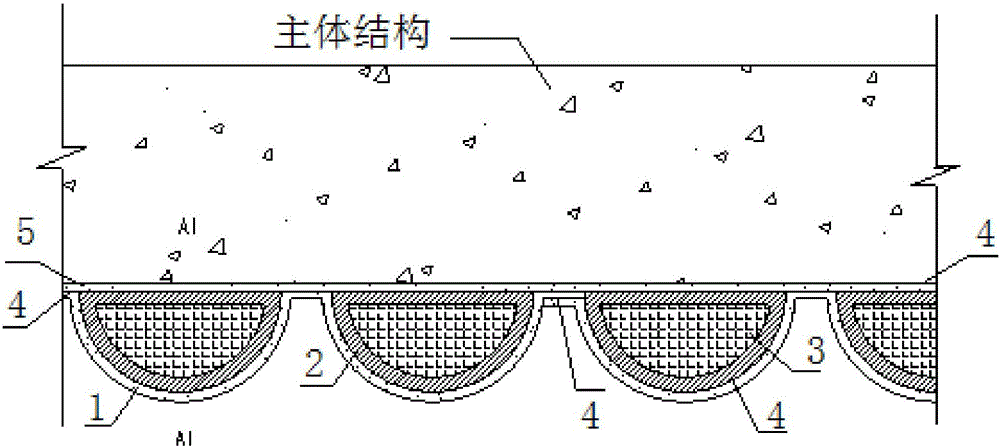

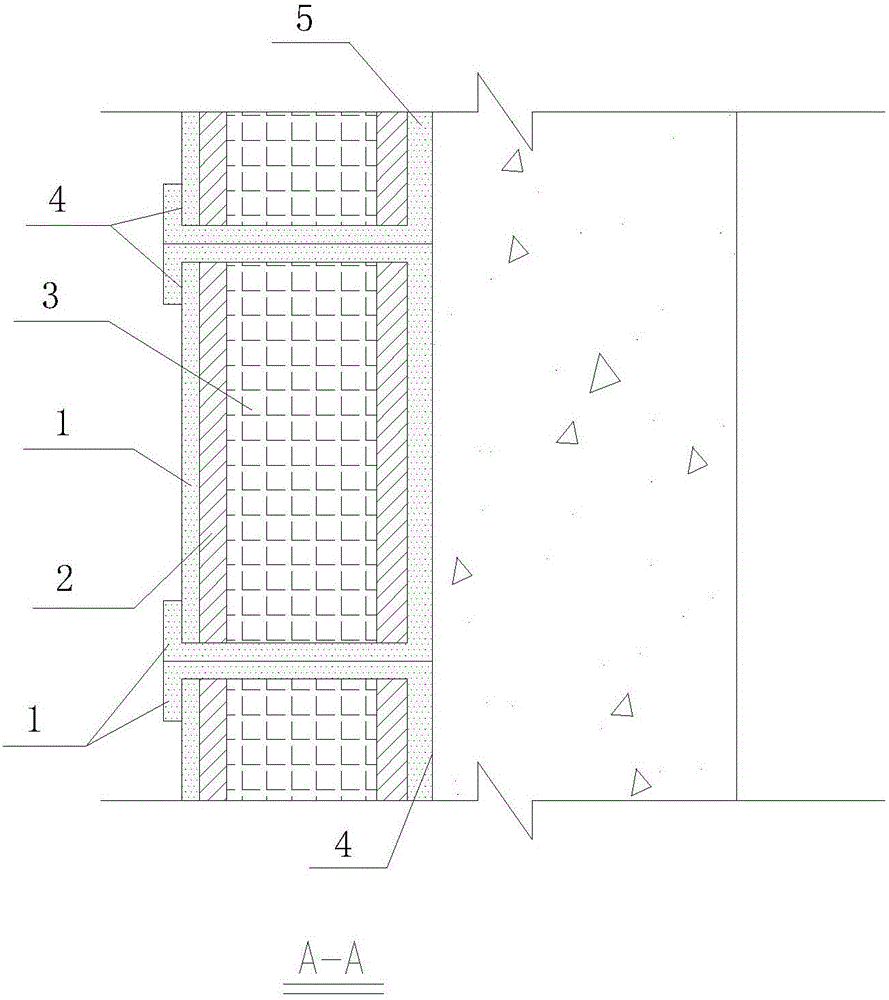

Shear thickening fluid protective armor device wrapped with high-performance fiber cloth

InactiveCN105908929AIncrease Section ThicknessGood impact protectionCovering/liningsProtective buildings/sheltersFiberThickened fluids

The invention provides a shear thickening fluid protective armor device wrapped with high-performance fiber cloth. The shear thickening fluid protective armor device wrapped with the high-performance fiber cloth comprises the outer high-performance fiber cloth layer and the inner high-performance fiber cloth layer. The outer high-performance fiber cloth layer and the inner high-performance fiber cloth layer are processed into a row of continuous structures with semi-columnar spaces through allocation. Semi-columnar plastic containers filled with shear thickening fluid are arranged in the semi-columnar spaces. Compared with the mode of increasing the thickness of the section of a building body structure, the shear thickening fluid protective armor device wrapped with the high-performance fiber cloth has a better effect in preventing impact of flying matter, and is free of modifying layout of the body structure too much.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

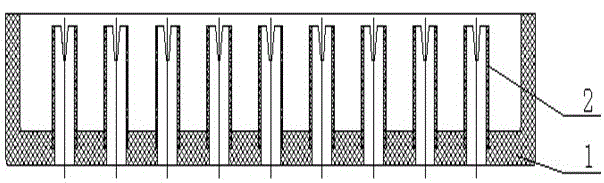

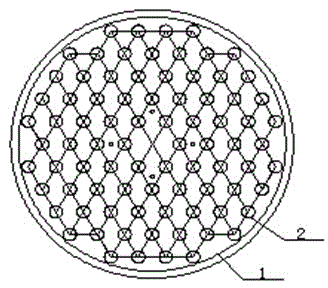

A method for manufacturing a high-temperature and corrosion-resistant graphitic acid distributor

ActiveCN103752141BIncrease stiffnessEasy to separateDispersed particle separationChemical industryPetrochemical

The invention discloses a high-temperature-resistant corrosion-resistant graphitic acid distributor and a manufacturing method thereof. The graphitic acid distributor comprises an acid disc, wherein overflow pipes are uniformly distributed inside the acid disc; both the acid disc and the overflow pipes are made of graphite material. The acid distributor is made of the graphite material, the graphite has high-temperature resistance and corrosion resistance, the influence of temperature on the graphite material is slight, the deformation amount is small, the distribution uniformity of materials in tower equipment in chemical production is guaranteed, and bias of the materials in the tower equipment is reduced. Compared with the conventional acid distributor made of a polytetrafluoroethene material, the graphitic acid distributor manufactured by adopting the manufacturing method has the advantages that the temperature resistance and corrosion resistance are improved by 30 percent, the strength is improved by 5-10 times, the bias is reduced, the production consumption is lowered, the service life is prolonged by two times, the problem that the high-temperature highly corrosive materials are easily biased in the tower equipment is solved, and great contribution is made to the development of fluorine chemical industry and other petrochemical industries.

Owner:龚孝祥

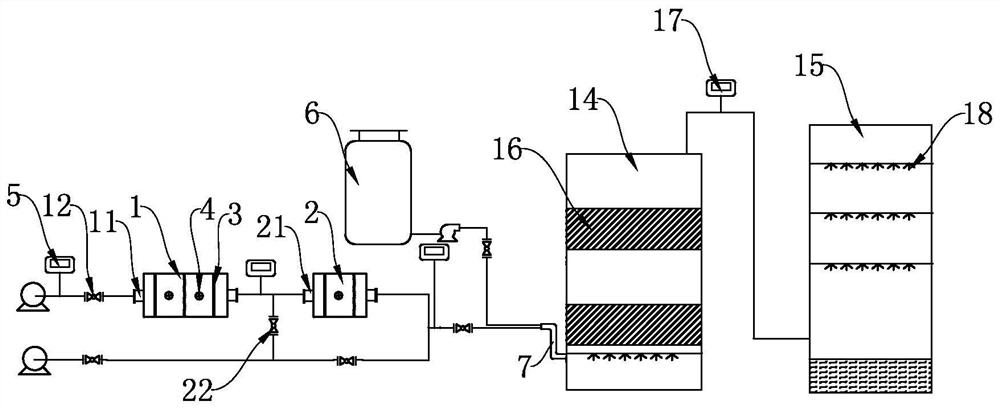

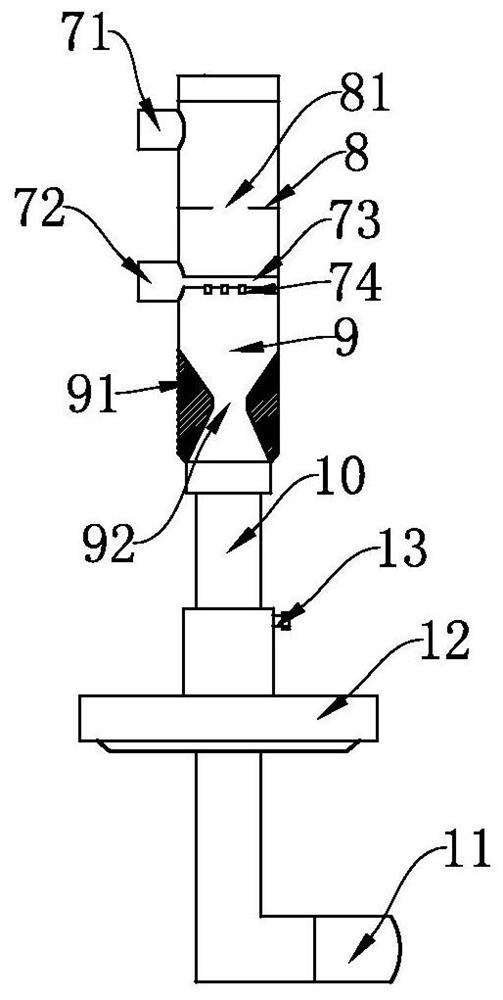

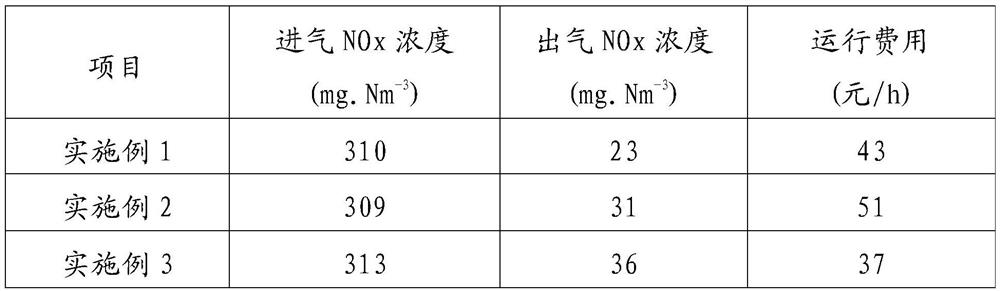

No in boiler flue gas x Partial redox removal method and removal device

ActiveCN109999635BReduce concentrationShorten speedGas treatmentDispersed particle separationPhoto catalyticPartial oxidation

The invention discloses a method for reducing NO in boiler flue gas X The partial redox removal method and removal device include the following steps: (1) respectively enter the boiler flue gas into at least two photocatalytic oxidation devices connected in series, and perform photocatalytic oxidation in sequence, and the flue gas after the photocatalytic oxidation is completed NO X The degree of oxidation is 45-50%. (2) The flue gas and reducing liquid after the catalytic oxidation are completed are instantly pressurized and the flue gas is atomized in the mixing feeder to become atomized flue gas. (3) The atomized flue gas enters the reduction and denitration tower, and is discharged from the top after being reduced and denitrated by the denitration catalytic packing. (4) The flue gas from the top of the reduction denitrification tower enters the desulfurization tower, and is discharged after being desulfurized by spraying desulfurization liquid. In the present invention, the boiler flue gas enters at least two stages of photocatalytic oxidation devices connected in series, and the photocatalytic oxidation is carried out sequentially, thereby improving the photocatalytic oxidation speed, controlling the oxidation degree of each stage accurately, and ensuring a good reduction and denitrification effect.

Owner:山东默锐环境产业股份有限公司

A kind of preparation method of wear-resistant and anti-corrosion nickel base alloy wire

Owner:江苏鑫信润科技股份有限公司

A special thermoplastic composite material suitable for 3D printing and its preparation method

ActiveCN109705570BSimple recipeEasy to manufactureAdditive manufacturing apparatusAntioxidantThermoplastic composites

The invention discloses a special thermoplastic composite material suitable for 3D printing and a preparation method thereof. The special thermoplastic composite material suitable for 3D printing is mainly prepared from the following components in parts by weight: polyphthalamide ( PPA) 45-85 parts, Surlyn 5-35 parts, ethylene-glycidyl methacrylate copolymer (E-GMA) 5-20 parts, nano-titanium dioxide 1-20 parts, graphene 1-15 parts 0.2-1.5 parts of nucleating agent, 0.1-1.5 parts of dispersant, 0.5-1 part of antioxidant. The special thermoplastic composite material suitable for 3D printing has simple formula, convenient preparation, fast forming and cooling speed, strong melt viscosity, high temperature resistance and corrosion resistance, and is suitable for forming special high temperature resistant 3D printing products or parts. 3D printing products can It can be directly used in the final product to overcome the weakness of long mold production cycle and high cost, and at the same time facilitate the rapid 3D printing of complex products.

Owner:青岛科凯达橡塑有限公司

Preparation method of superfine polytetrafluoroethylene fiber

ActiveCN102168322BHigh purityHigh strengthFilament/thread formingArtificial filament heat treatmentHigh concentrationTetrafluoroethylene

The invention discloses a preparation method of a superfine polytetrafluoroethylene fiber. The preparation method includes the concrete steps as follows: preparing spinning solution 1 by using polytetrafluoroethylene high-concentration emulsion and adding water for dilution; preparing spinning solution 2 by polyvinyl alcohol with alcoholysis of 70%-80%; dissolving sodium sulfate by warm water at the temperature of 40-50 DEG C to form supersaturated solution with crystals being separated out, and adding caustic soda to adjust the PH value to 12-14 so as to prepare supersaturated coagulating bath; spinning the spinning solution 1 and the spinning solution 2 by a special spinneret plate to form a nascent fiber with a 'sheath core' structure; and sintering and highly stretching the nascent fiber to prepare the superfine polytetrafluoroethylene fiber. In the invention, the superfine polytetrafluoroethylene fiber is produced by a unique spinning process, the operation is convenient, simple and feasible; and the comprehensive performance of the obtained superfine polytetrafluoroethylene fiber is good.

Owner:南京际华三五二一环保科技有限公司

A Concentrating Enhanced Solar Photocatalytic Reactor

ActiveCN106830171BGood light transmissionHigh temperature and corrosion resistanceWater/sewage treatment by irradiationWater contaminantsPhotocatalytic reactionHeliostat

The invention discloses a condensation intensified type solar photocatalytic reactor. The reactor comprises two parallel trough type condensation reaction devices which form the height head, a quartz glass reaction tube in each trough type condensation reaction device is placed in the focusing position of a trough type condenser and is supported by a support; heliostat tracking systems are connected with and support the trough type condensers; the two trough type condensation reaction devices are connected through a cooling tube and a circulating tube to form a closed circulating passage; the lower end of the circulating tube is open and connected with a feeding pipe, and the feeding pipe is sequentially connected with a feeding pump and a reaction solution container; the upper end of the circulating tube is open and connected with a T-joint, and the other two ends of the T-joint are connected with a buffer surge tank and a sampling tube respectively. By using the excellent light transmission of the quartz glass reaction tubes, the characteristics of the heliostat tracking systems, the condensing effect of the trough type condensers as well as the secondary light compensation effect of reflectors, the comprehensive utilization efficiency of sunlight is improved, and sufficient sunlight illumination intensity is provided for photocatalytic reactions.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com