A method for manufacturing a high-temperature and corrosion-resistant graphitic acid distributor

A manufacturing method and technology of graphitic acid, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of biased flow of acid distribution in tower equipment, easy deformation of acid distributors, etc., and achieve uniform acid distribution, gas-liquid distribution, etc. Good separation or absorption effect, reducing the effect of bias flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

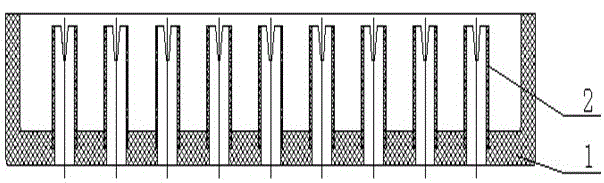

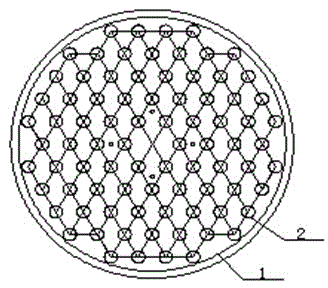

[0018] Embodiment 1 of the present invention: a manufacturing method of a high-temperature and corrosion-resistant graphitic acid distributor, the graphitic acid distributor is as attached Figure 1-2 As shown, it includes an acid pan 1, and a plurality of overflow pipes 2 are evenly distributed inside the acid pan 1, and the acid pan 1 and the overflow pipe 2 are all made of graphite materials.

[0019] The manufacturing method of acid pan 1, overflow pipe 2 comprises:

[0020] A. Selection of graphite raw materials: Choose graphite raw materials with 0.8mm or 2.0mm particles according to different media. If the medium is sulfuric acid with more than 70% and the temperature is above 100°C, choose graphite materials with 0.8mm particles, and the medium is fluorosilicon For non-oxidizing acids such as acids, graphite materials with 2.0mm particles should be used for media whose temperature is below 100°C.

[0021] B. Design acid tray 1 and overflow pipe 2 of corresponding size...

Embodiment 2

[0028] Embodiment 2 of the present invention: after the selected graphite material is processed into acid pan 1 and overflow pipe 2 through lathe and drilling machine, acid pan 1 and overflow pipe 2 are put into phenolic resin for impregnation treatment, and the treatment time is 10 Hours, after the dipping treatment is completed, put the acid tray 1 and the overflow pipe 2 into a heat treatment kettle at 160°C for heat treatment, the heat treatment time is 10 hours, and after the heat treatment is completed, the components by weight are: 1800 parts of graphite powder, 1200 parts of phenolic resin and 3.5-4 parts of graphite resin cement of benzenesulfonyl chloride bond the acid tray 1 and the overflow pipe 2, and then spontaneously ignite the bonded acid tray 1 and overflow pipe 2 at a temperature of 35°C After curing for 20 hours, remove the excess graphite resin cement, and finally put the prepared high-temperature and corrosion-resistant graphite acid distributor on the wat...

Embodiment 3

[0030] Embodiment 3 of the present invention: after the selected graphite material is processed into acid pan 1 and overflow pipe 2 through lathe and drilling machine, acid pan 1 and overflow pipe 2 are put into phenolic resin for impregnation treatment, and the treatment time is 12 Hours, after the dipping treatment is completed, put the acid pan 1 and the overflow pipe 2 into a heat treatment kettle at 180°C for heat treatment, the heat treatment time is 10 hours, and after the heat treatment is completed, the components by weight are: 1800 parts of graphite powder, 1200 phenolic resin and 3.5-4 parts of graphite resin cement of benzenesulfonyl chloride to bond the acid pan 1 and the overflow pipe 2, and then spontaneously ignite and solidify the bonded acid pan 1 and overflow pipe 2 at a temperature of 40°C After 20 hours, remove the excess graphite resin cement, and finally put the prepared high-temperature and corrosion-resistant graphite acid distributor on the water plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com