Patents

Literature

33 results about "Fluorochemical industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The global market for chemicals from fluorine was about US$16 billion per year as of 2006. The industry was predicted to reach 2.6 million metric tons per year by 2015. The largest market is the United States. Western Europe is the second largest. Asia Pacific is the fastest growing region of production. China in particular has experienced significant growth as a fluorochemical market and is becoming a producer of them as well. Fluorite mining (the main source of fluorine) was estimated in 2003 to be a $550 million industry, extracting 4.5 million tons per year.

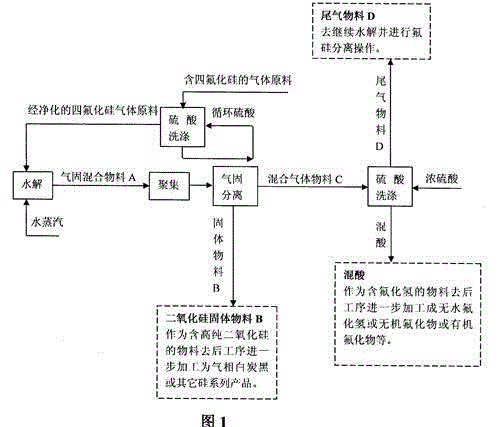

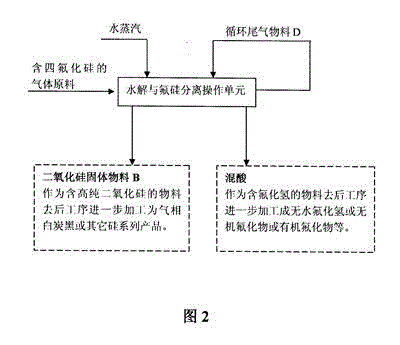

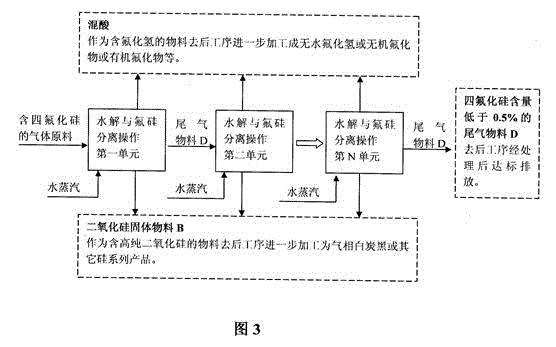

Gas phase hydrolysis and fluoride-silicon separation method of silicon tetrafluoride

InactiveCN103601195ASimple purification methodLow hydrolysis temperatureSilicaFluorine/hydrogen-fluorideChemical industrySilicon tetrafluoride

A two-step method is adopted to carry out low temperature gas phase hydrolysis and fluoride-silicon separation operations of silicon tetrafluoride. In a first step, a silicon tetrafluoride gas is hydrolyzed into a fluosilicic acid gas and silicon dioxide particles at a low temperature; in a second step, a hydrogen fluoride gas is dissolved by a washing operation of high concentrated sulfuric acid so as to promote complete decomposition of the fluosilicic acid into the hydrogen fluoride gas and a silicon tetrafluoride gas; decomposed and separated hydrogen fluoride gas is completely dissolved in high concentrated sulfuric acid; decomposed and separated silicon tetrafluoride can be continuously carried out hydrolysis and fluoride-silicon separation operations; and finally complete separation of the fluoride and silicon elements are realized. The method has the beneficial effects that a gas raw material containing relatively low silicon tetrafluoride content can be used; a method for purifying the raw material is simple; total conversion rate of silicon tetrafluoride introduced into a production apparatus system can reach over 98%; and hydrolysis temperature is relatively low, so that the method can realize industrial production relatively easily. The method is suitable for recovery and utilization of fluoride- and silicon-containing materials from industries such as phosphorus chemical industry, fluorine chemical industry, electron industry, glass processing industry and aluminium alloy processing industry.

Owner:班仁义

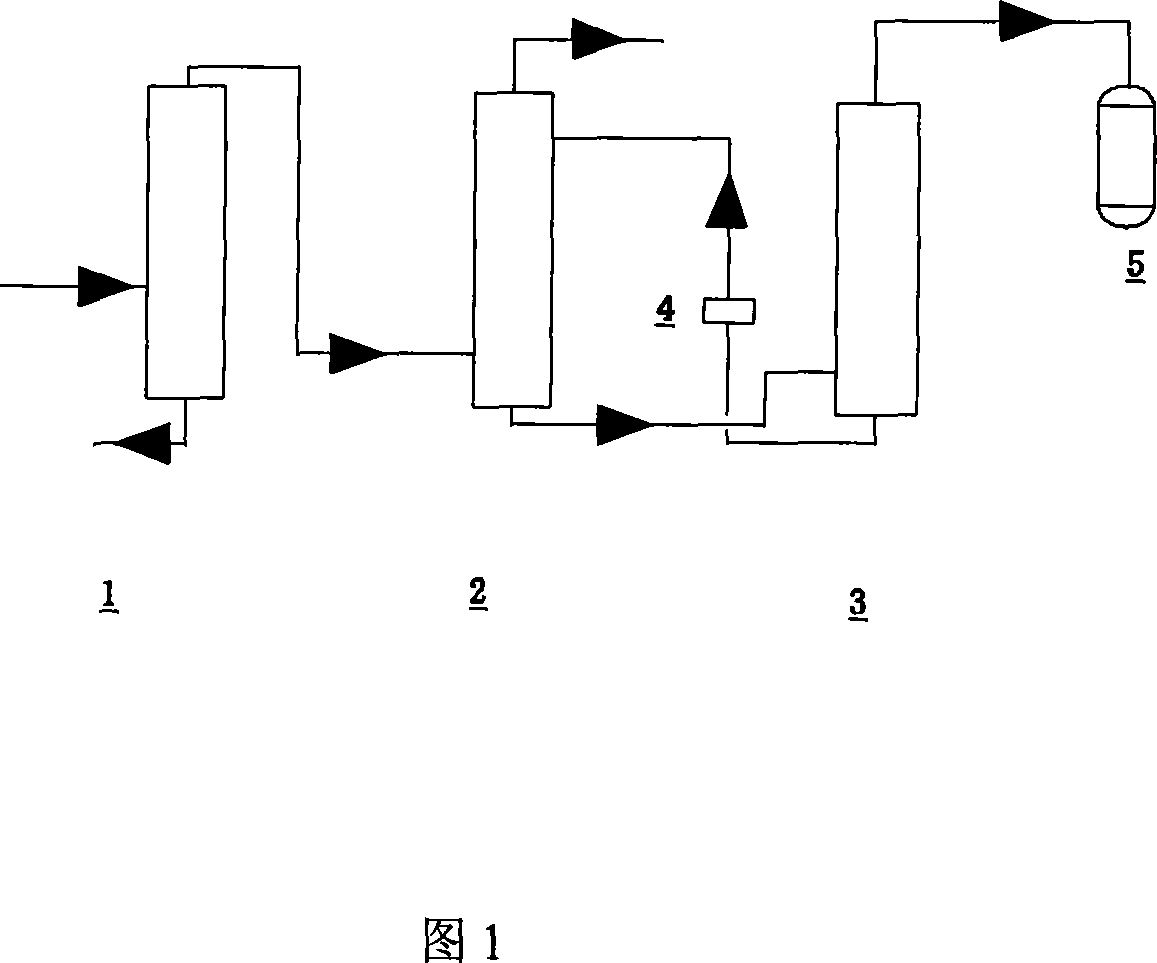

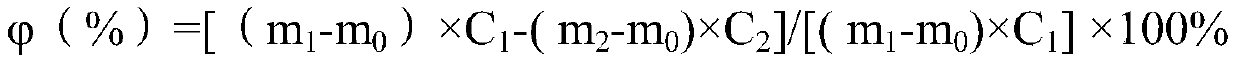

Method for separating trifluoroethylene in tetrafluoroethylene production

ActiveCN101219926AImprove the phenomenon of random discharge of trifluoroethyleneImprove controllabilityHalogenated hydrocarbon preparationTetrafluoroethyleneFluorochemical industry

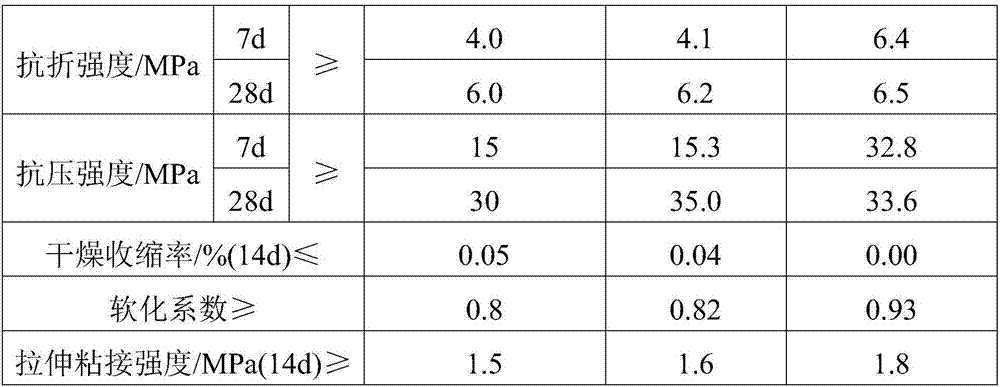

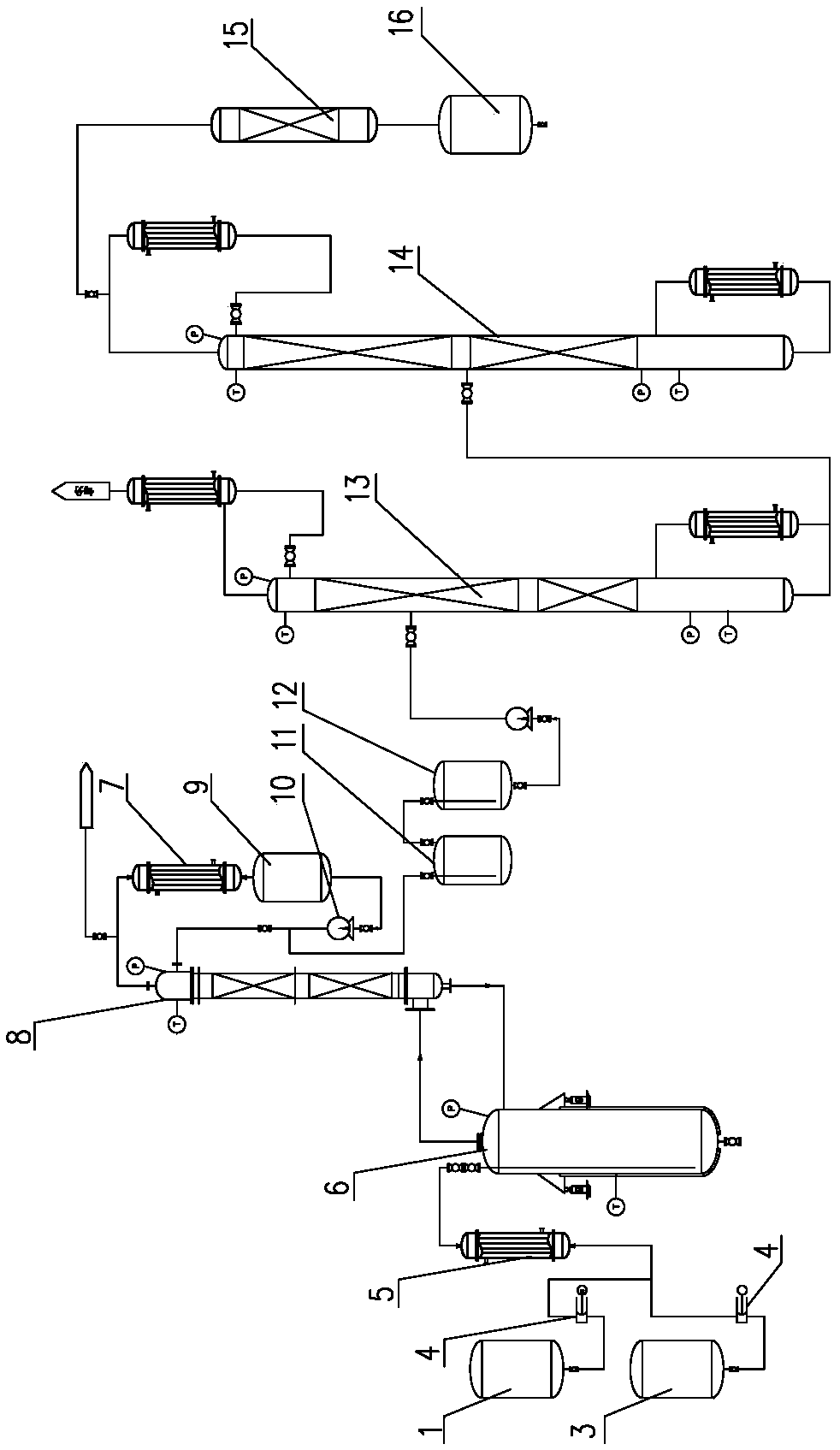

The invention belongs to the filed of fluorochemical industry and provides a method for separating a trifluoroethylene in the production of a tetrafluoroethylene. The specific technical steps are as follows: a material gas on the top of a recovery tower of the tetrafluoroethylene enters directly into a distillation column; the tetrafluoroethylene and the trifluoroethylene in the material gas are separated from other components; the tetrafluoroethylene and the trifluoroethylene in the material gas aggregate on the top of the column and the rest components return to a system after the recovery tower of the tetrafluoroethylene through the bottom column; a mixture of the tetrafluoroethylene and the trifluoroethylene enters into an extraction column and the trifluoroethylene is absorbed by utilizing an extracting agent; the trifluoroethylene enters into an absorption tower with the extracting agent and is separated from an extracting liquid by steam heating in the absorption tower; the trifluoroethylene aggregates on the top of the absorption tower and then enters into a trifluoroethylene tank. The invention realizes efficient separation on the trifluoroethylene, controllability on the quality of the tetrafluoroethylene and has great potentiality in the aspect of environmental protection.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

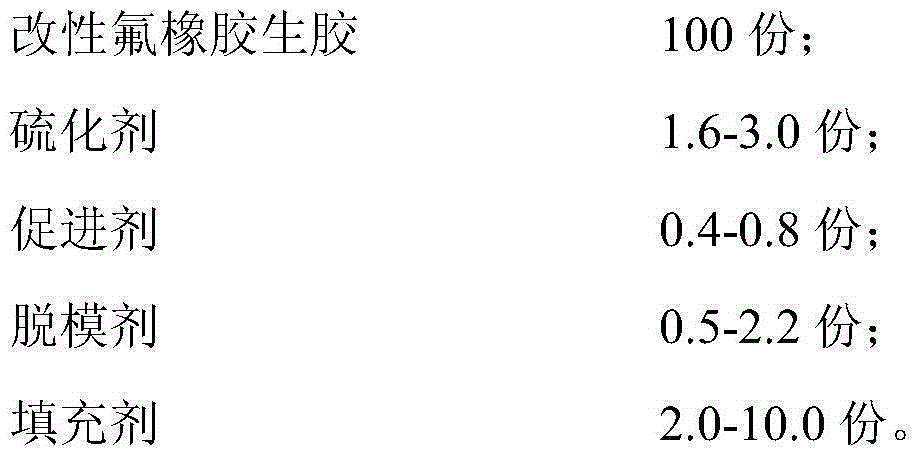

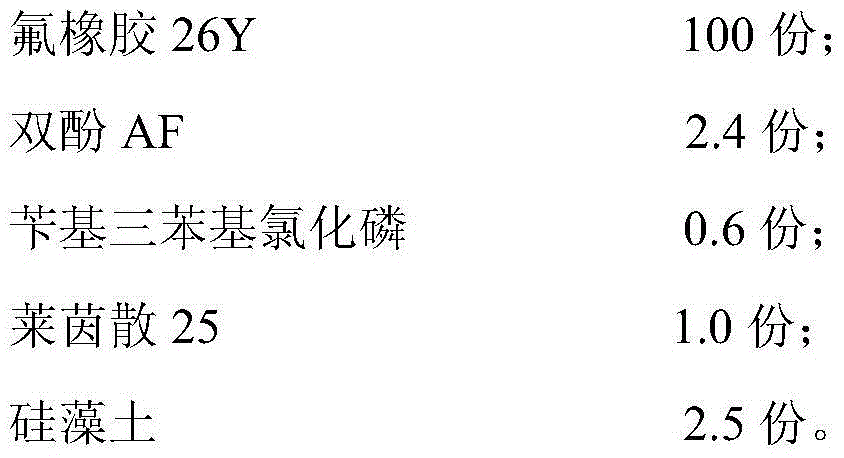

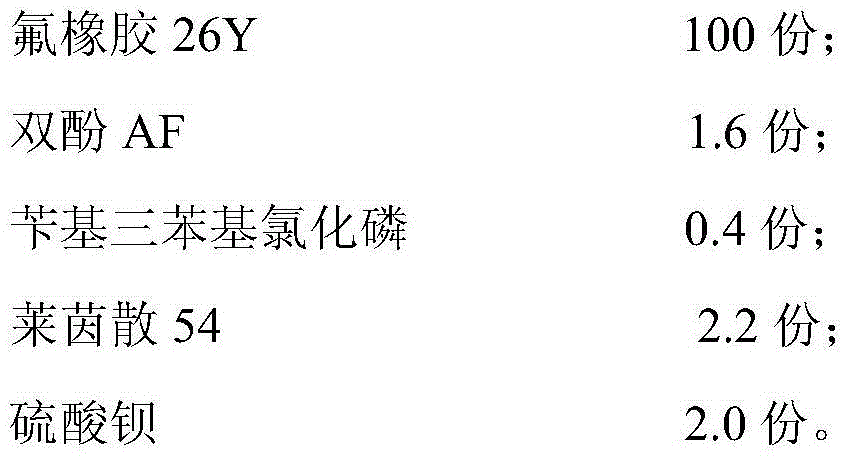

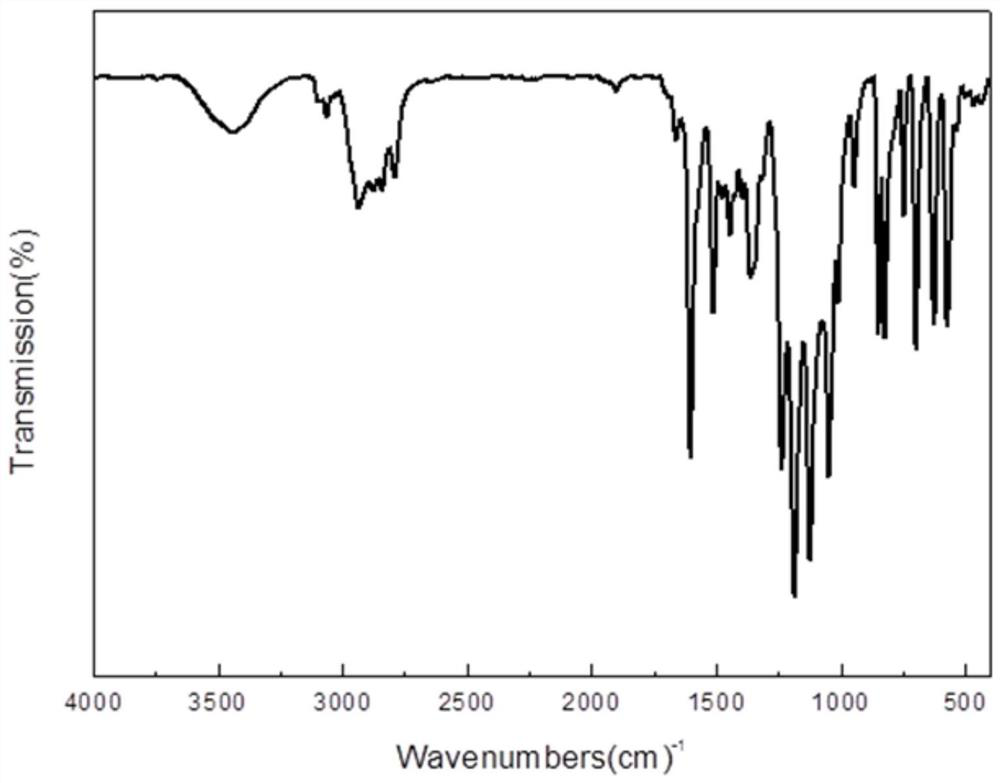

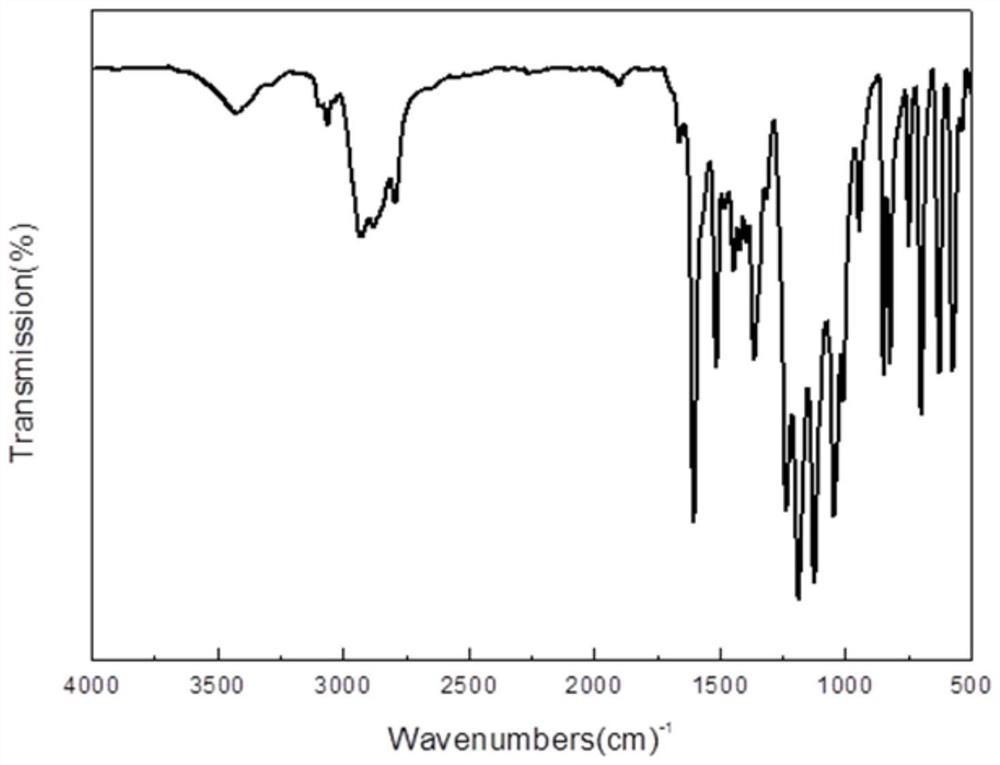

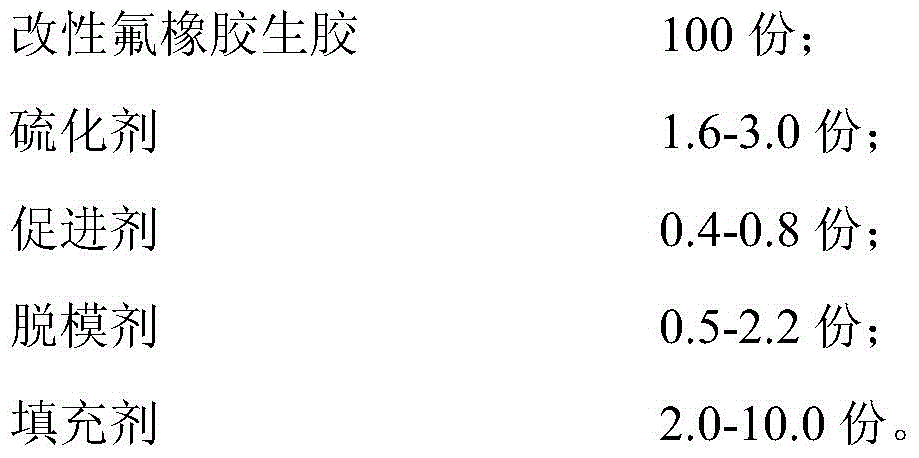

Low-compression-deformation fluororubber premix and preparation method thereof

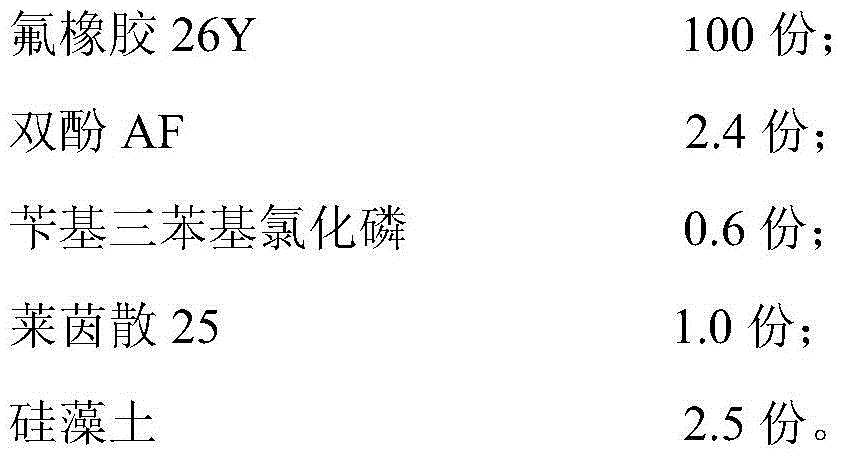

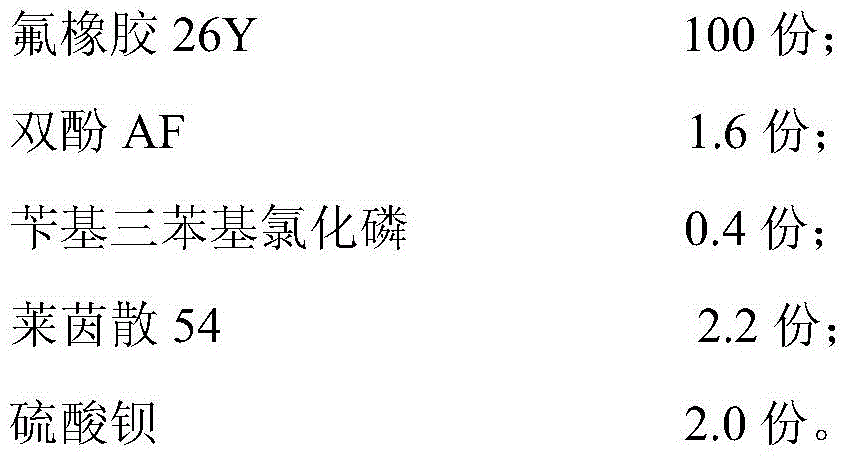

The invention belongs to the technical field of fluorochemical industry and particularly relates to a low-compression-deformation fluororubber premix and a preparation method thereof. The fluororubber premix is prepared from the following raw materials in parts by weight: 100 parts of modified crude fluororubber, 1.6-3.0 parts of a vulcanizing agent, 0.4-0.8 part of an accelerant, 0.5-2.2 parts of a release agent and 2.0-10.0 parts of a filling agent. A rubber compound prepared from the low-compression-deformation fluororubber premix is relatively low in permanent compression deformation rate and good in tensile strength. The preparation method is simple, feasible, and easy to realize.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

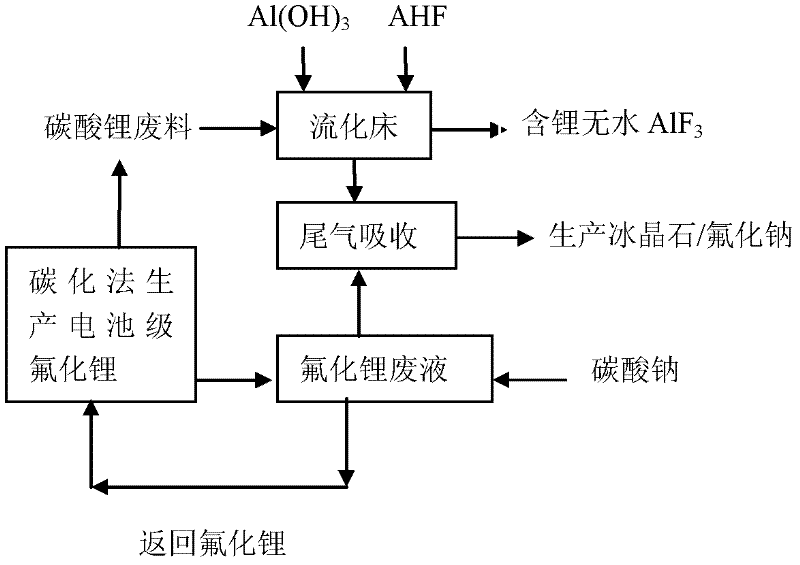

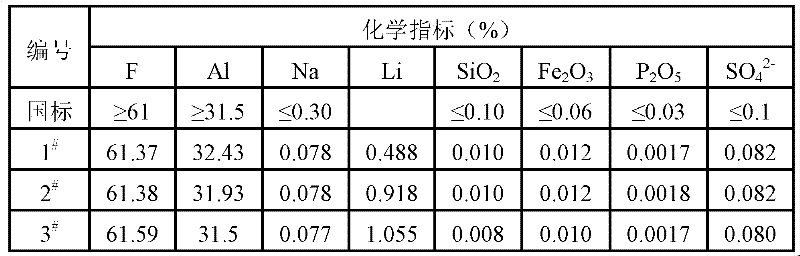

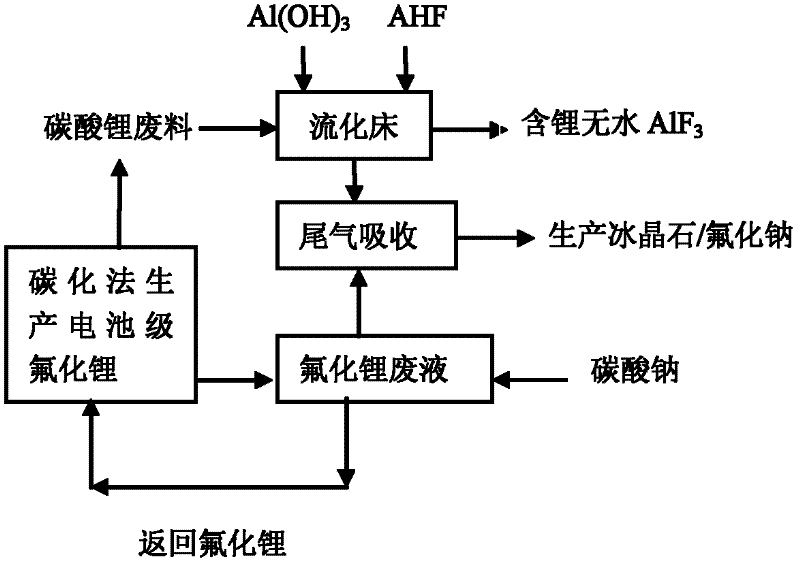

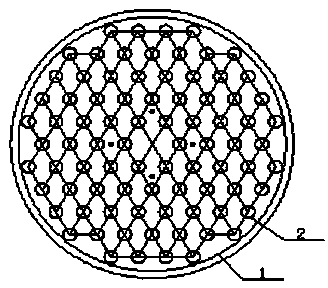

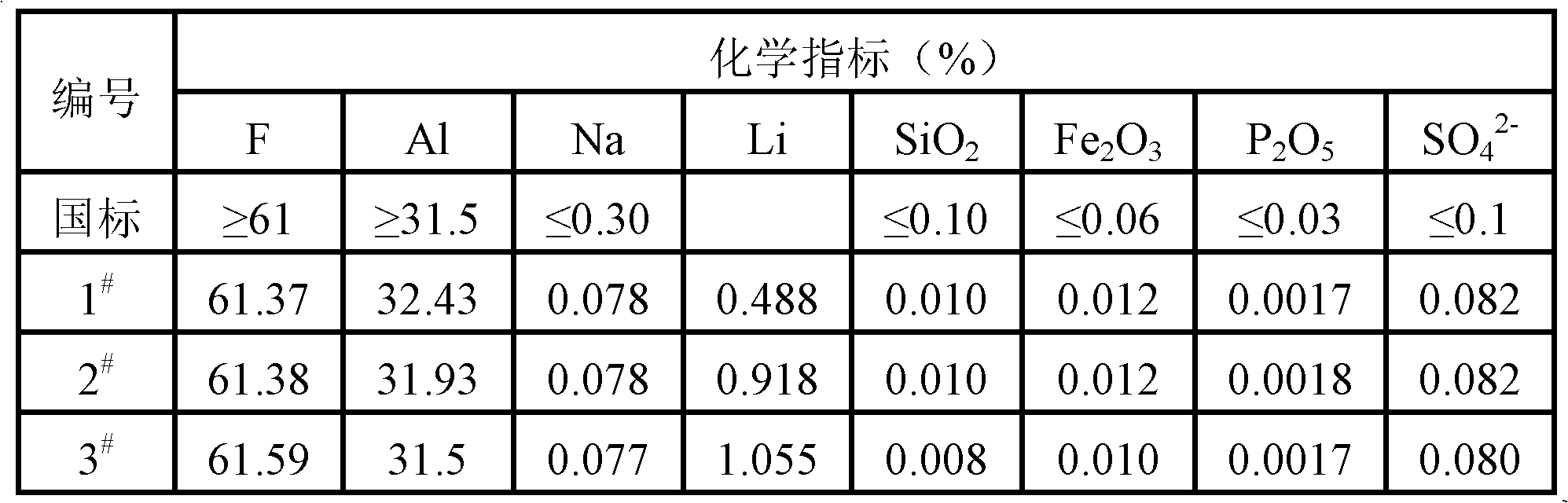

Processing method of wastes produced when battery grade lithium fluoride is manufactured by adopting carbonization method

ActiveCN102515203AImprove resource utilizationSolve environmental problemsAlkali metal fluoridesLithium carbonates/bicarbonatesChemical industryAluminium hydroxide

The invention discloses a processing method of wastes produced when battery grade lithium fluoride is manufactured by adopting a carbonization method, and the processing method comprises the steps that: A: excess sodium carbonate is added into a lithium fluoride waste liquor to react with the lithium fluoride waste liquor, a solid lithium carbonate paste is obtained after a reaction product is filtered, and a filter liquor is a spare mixed solution containing the left sodium carbonate; and B: a lithium carbonate waste material and aluminium hydroxide react with excess anhydrous hydrogen fluoride in a fluidized bed to obtain anhydrous aluminum fluoride containing lithium fluoride, and tail gas of the reacted anhydrous hydrogen fluoride is led into the mixed solution containing the left sodium carbonate in the step A so as to obtain a sodium fluoride solution. By adopting the processing method disclosed by the invention, two main wastes produced when the battery grade lithium fluoride is manufactured by adopting the carbonization method are both converted to useful substances capable of being used in downstream industries of inorganic fluorides, so the environmental protection problem to be solved in the fluoride chemical industry and the aluminum electrolysis industry is solved; and in addition, all raw materials are taken from production wastes of the battery grade lithium fluoride, secondary pollution cannot be produced, the resource utilization rates of fluorine and lithium are improved, and sustainable development of the inorganic fluoride chemical industry is urged.

Owner:DO FLUORIDE CHEM CO LTD

Production method of cryolite

InactiveCN102219249AAchieve recyclingSolve processing problemsAluminium fluoridesChemical industryWaste treatment

The invention discloses a production method of cryolite. With electrolytic aluminium fluorine-containing waste residues from flotation and single cryolite which is the byproduct of polysilicon material production as the raw material, and the method comprises the steps of: weighing the electrolytic aluminium fluorine-containing waste residues from flotation and the single cryolite as the byproduct of polysilicon material production; mixing the weighed electrolytic aluminium fluorine-containing waste residues from flotation and the single cryolite as a byproduct of polysilicon material production with a fluorine containing hydrochloric acid solution, then leaving the mixture reacting for 1-6 hours under stirring DEG C, filtering the mixture, washing a filter cake with water and drying the filter cake, thus obtaining the cryolite product. And the generated filtrate and washing liquid can be treated with lime so as to be discharged or used in calcium chloride production. By combining the current development situation of fluorine chemical industry, the invention makes fully use of low grade fluorine resources and makes the recycling of fluorine resources come true. In addition, the invention also provides a solution to the waste treatment problem that restricts the development of the fluorine chemical industry.

Owner:DO FLUORIDE CHEM CO LTD

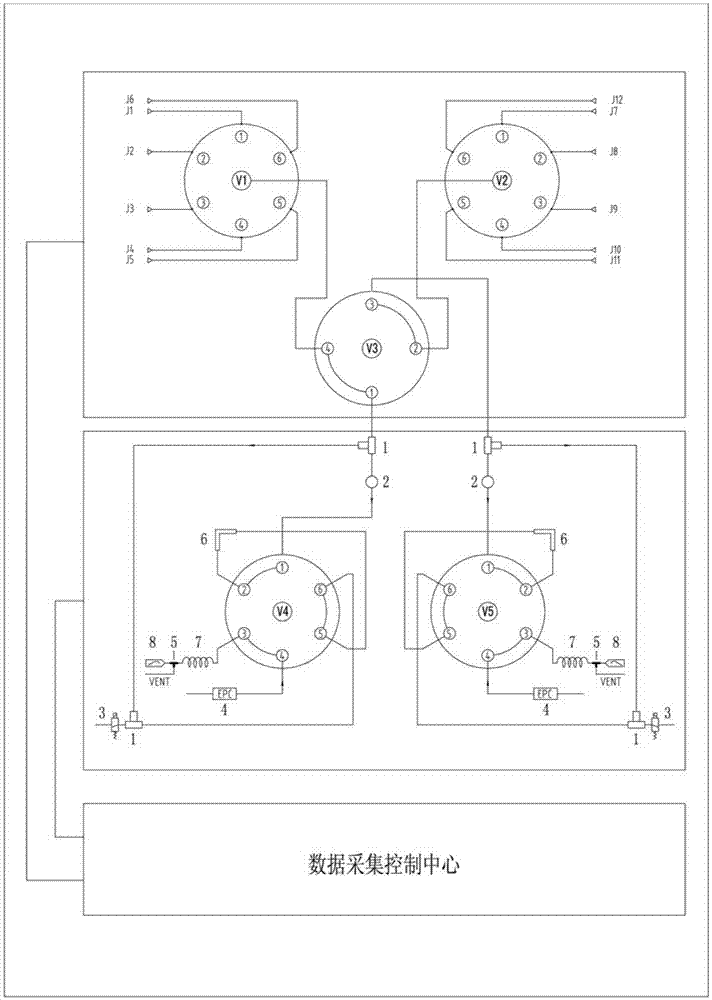

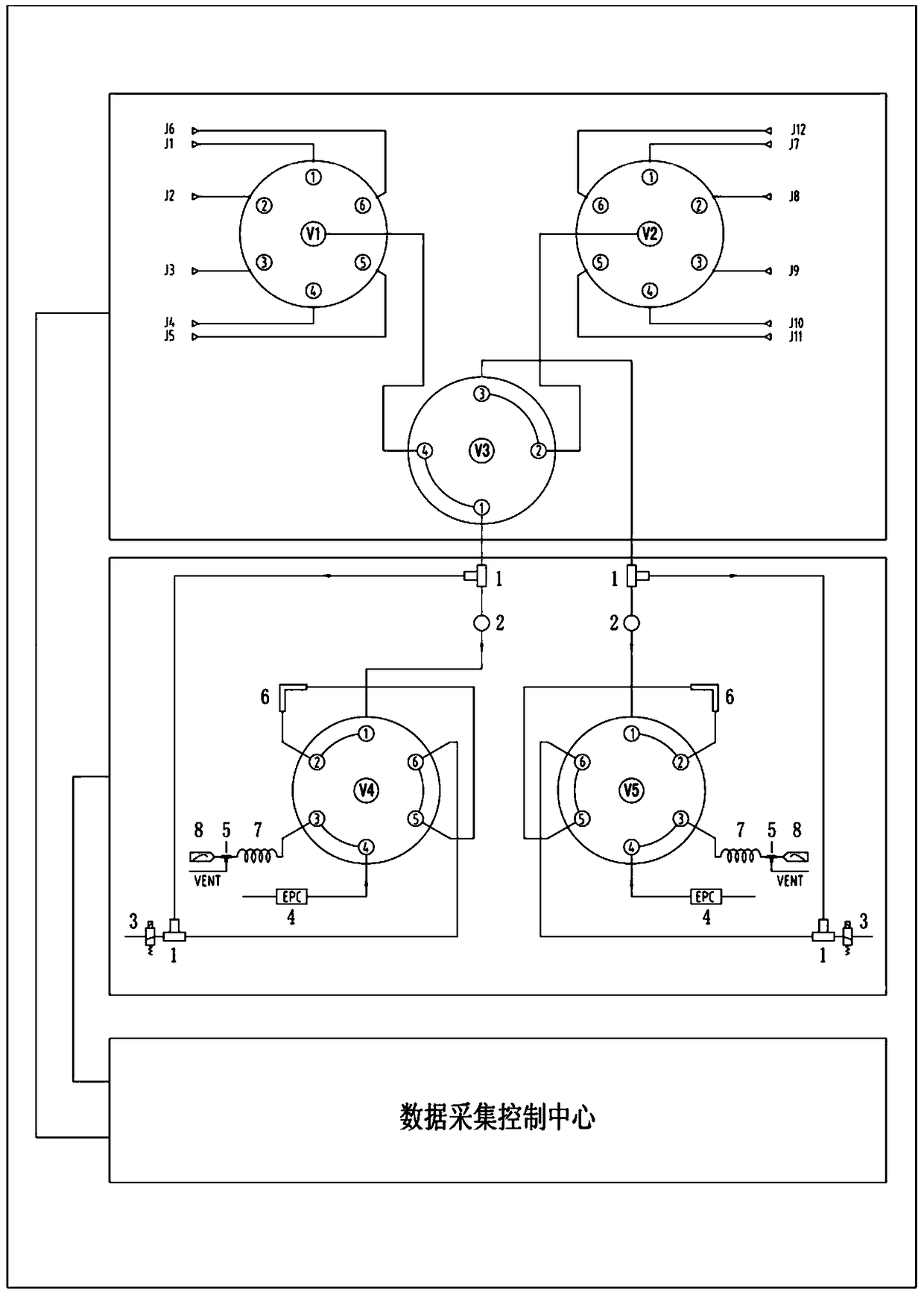

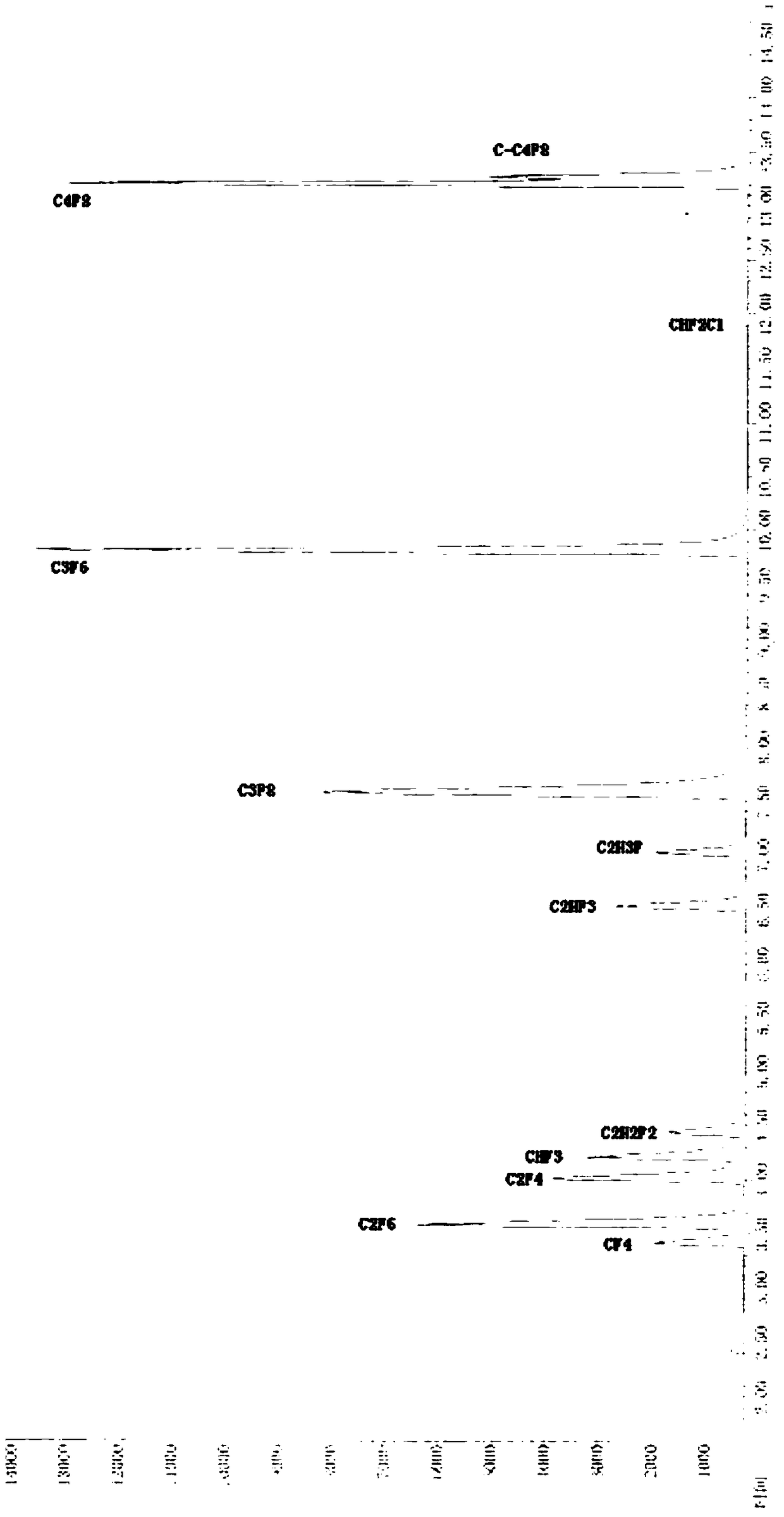

Online environment monitoring system and method in fluorine chemical industry

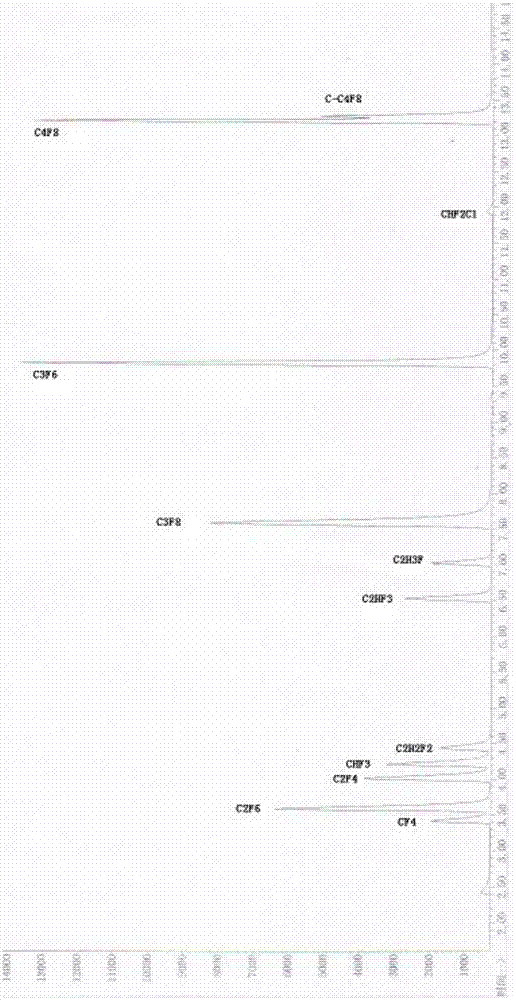

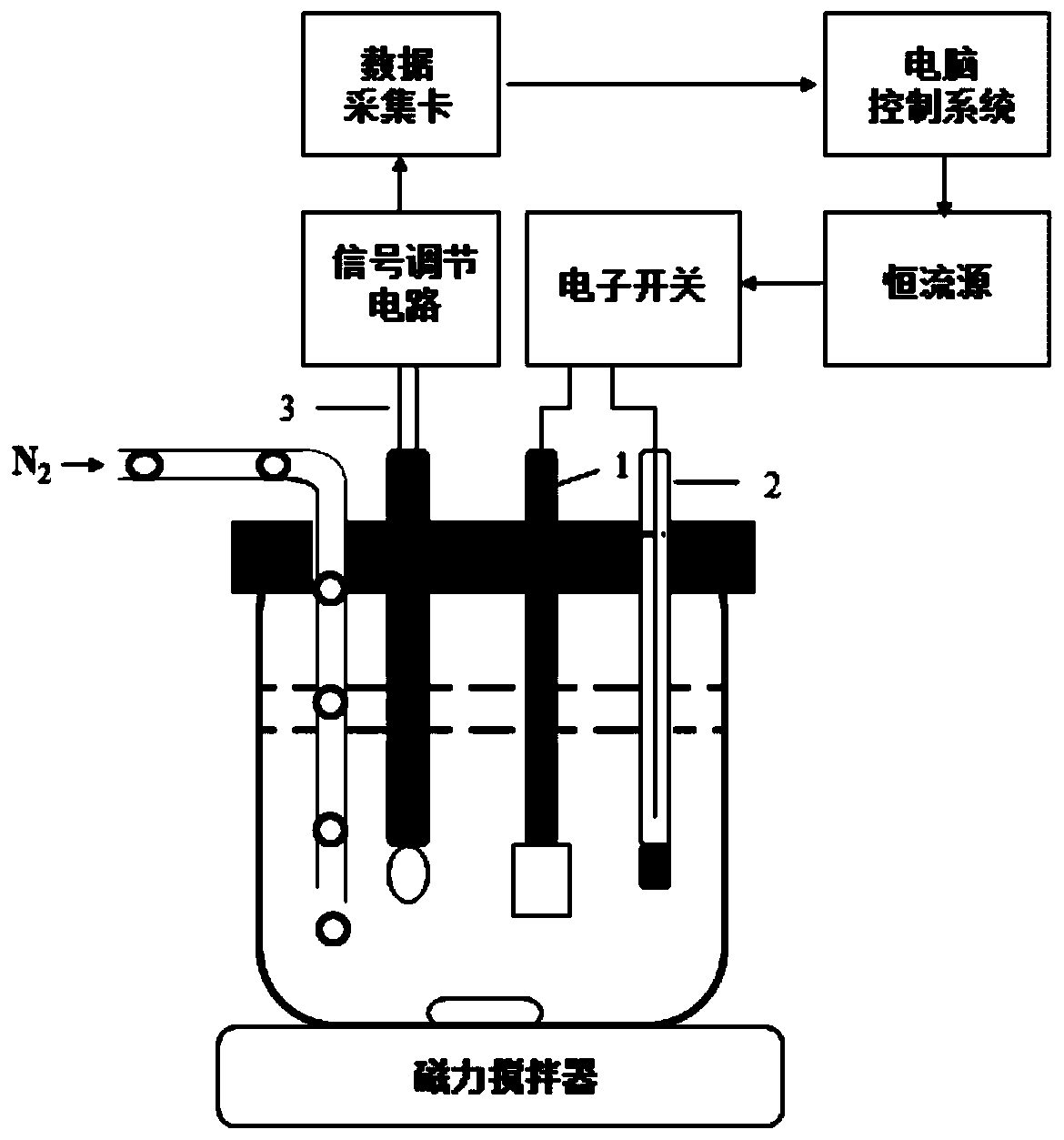

ActiveCN106896179AAccurate and intuitive reflectionAccurate and Intuitive KindComponent separationChemical industryCollection system

The invention provides an online environment monitoring system in a fluorine chemical industry. The system comprises a sample collection unit, a multi-channel comprehensive analysis unit and a data acquisition control center, wherein the sample collection unit is connected with the multi-channel comprehensive analysis unit through a pipeline; and the multi-channel comprehensive analysis unit is connected with the data acquisition control center. An online collection system comprises a collection port, bundle tubes and a multi-channel switching valve, wherein the multi-channel switching valve is arranged on a pipeline composed of the bundle tubes; and the multi-channel comprehensive analysis unit comprises an adjustable distributor electronic flow controller, an air pump and gas chromatography-mass spectrometric equipment. The monitoring system and the monitoring method disclosed by the invention overcome the defects in the prior art such as large labor amount, high dangerousness, inaccurate animal monitoring and the like, can be applied to online monitoring of fluorine chemical industry production sites, fluorine chemical industry raw product storage areas and the like, avoid direct contact between personnel and toxic substances, can intuitively reflect the varieties and contents of leaking substances and have excellent reproducibility and accuracy.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

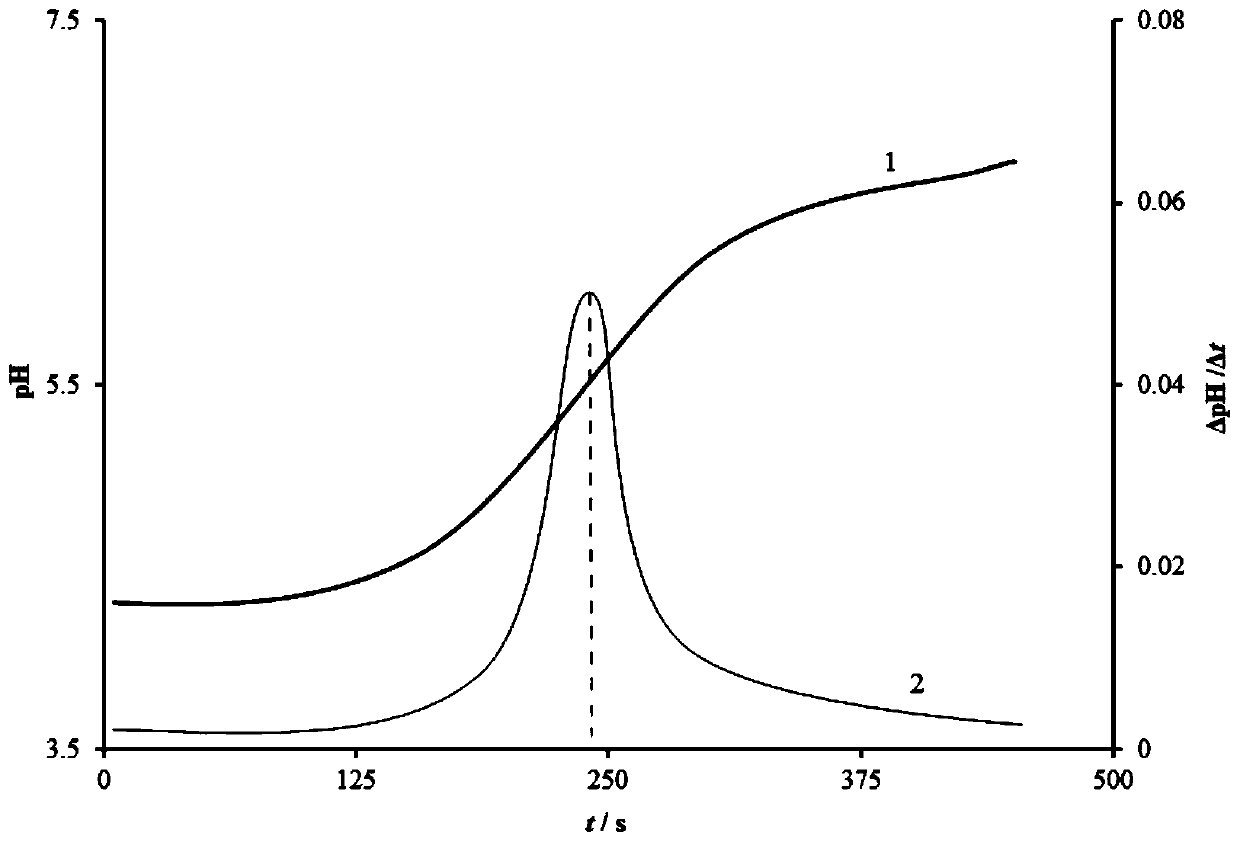

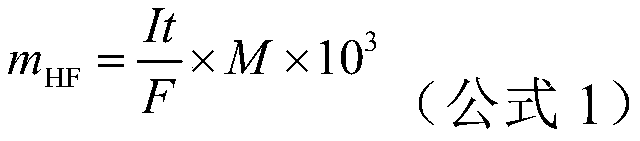

Method for rapidly determining content of free acid in lithium hexafluorophosphate product in non-aqueous system

InactiveCN110261464AMeet the densityMeet the accuracyChemical analysis using titrationMaterial electrochemical variablesChemical industrySupporting electrolyte

The invention relates to a method for rapidly determining the content of a free acid in a lithium hexafluorophosphate product in a non-aqueous system. According to the method, a water-free supporting electrolyte solution is used as an electrolytic solution; the free acid in the lithium hexafluorophosphate product is titrated with alkaline ions electrolyzed by the electrolytic solution; the content of the free acid in the sample is calculated according to the faraday's law; and the whole detection process can be finished within 5 minutes, and a result can be obtained. With the method of the invention adopted, three bottlenecks, namely, the poor thermal stability of the lithium hexafluorophosphate, interference caused by hydrofluoric acid generated by the reaction of the lithium hexafluorophosphate with water, and little possibility of accurately measuring trace free acids, can be broken; problems such as low precision, low accuracy and long detection time of acid-base titration methods, potentiometric titration methods and etching methods which are commonly used in current industrial production and scientific research can be overcome. The method can be applied to a wide range of samples, can practically promote the analysis and detection levels of fluorine chemical industries and lithium ion battery industries, and further improve the quality of related industrial products.

Owner:WUHAN UNIV OF TECH

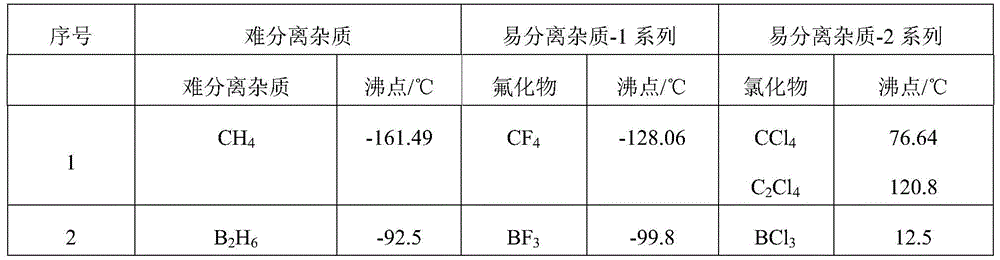

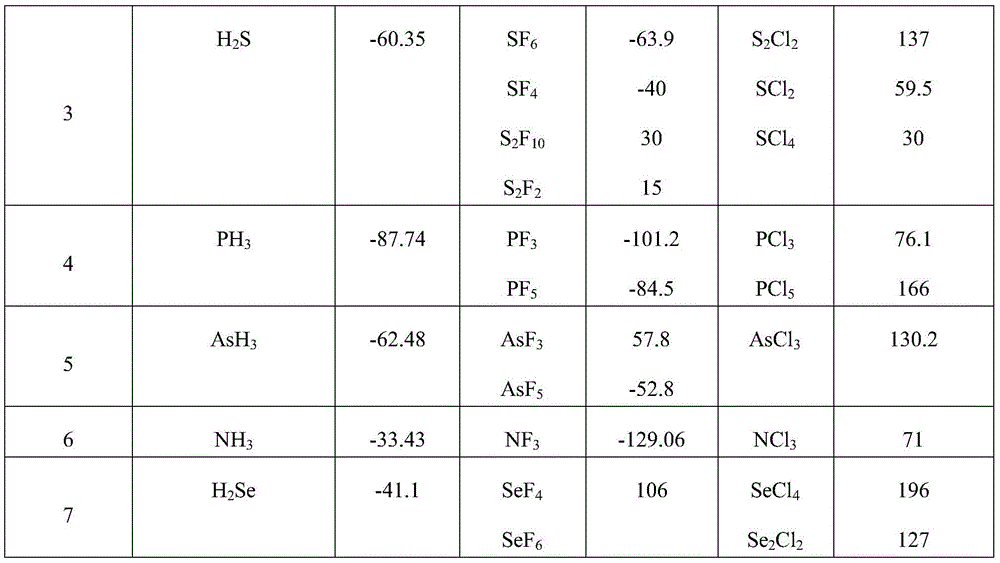

Silicon tetrafluoride purifying method

ActiveCN105565324ADegree of reductionReduce riskSpecific gas purification/separationHalogenated silanesFluorochemical industryProduct gas

The invention relates to a silicon tetrafluoride purifying method and belongs to the field of fluorochemical industry and electronic industry gas. The method includes: subjecting silicon tetrafluoride crude product gas and a purifying reactant 1 to purifying reaction to obtain purified silicon tetrafluoride gas, wherein the purifying reactant 1 is a substance containing fluorine atoms and / or chlorine atoms, temperature at which the purifying reaction occurs is minus 199-1999 DEG C, and when the purifying reactant 1 is F2, the temperature is minus 99-99 DEG C; pressure at which the purifying reaction occurs is minus 0.09-2MPa, and the silicon tetrafluoride crude product gas can be in purifying reaction with a purifying reactant 2 to obtain silicon tetrafluoride higher in purity. The silicon tetrafluoride purifying method is easy in obtaining high-purity silicon tetrafluoride, high in yield and safety and low in cost.

Owner:PERIC SPECIAL GASES CO LTD

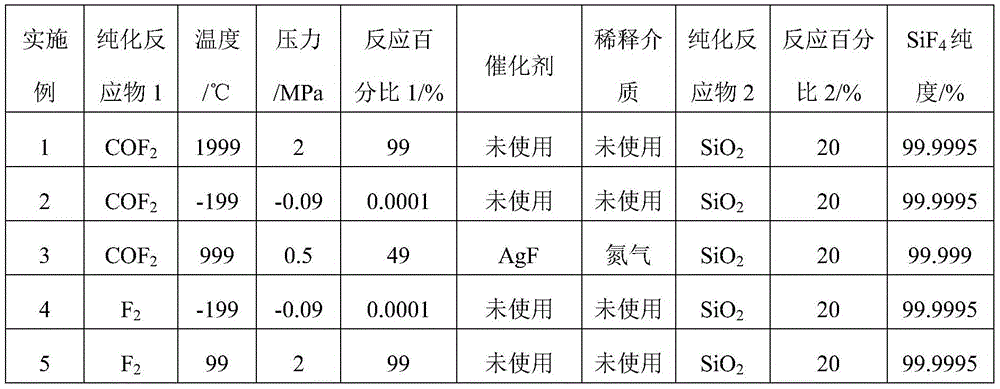

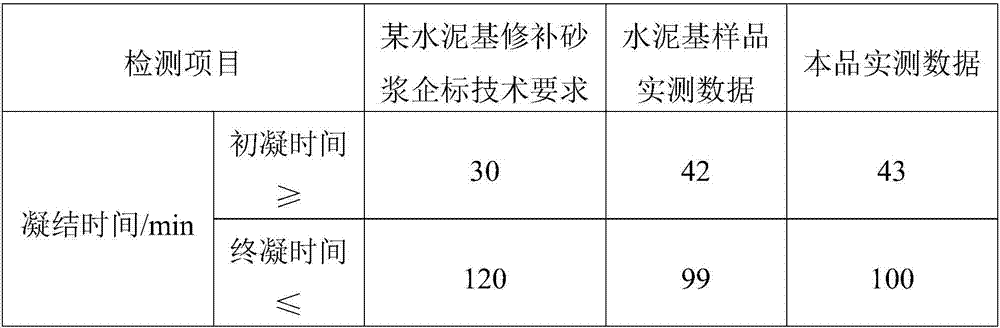

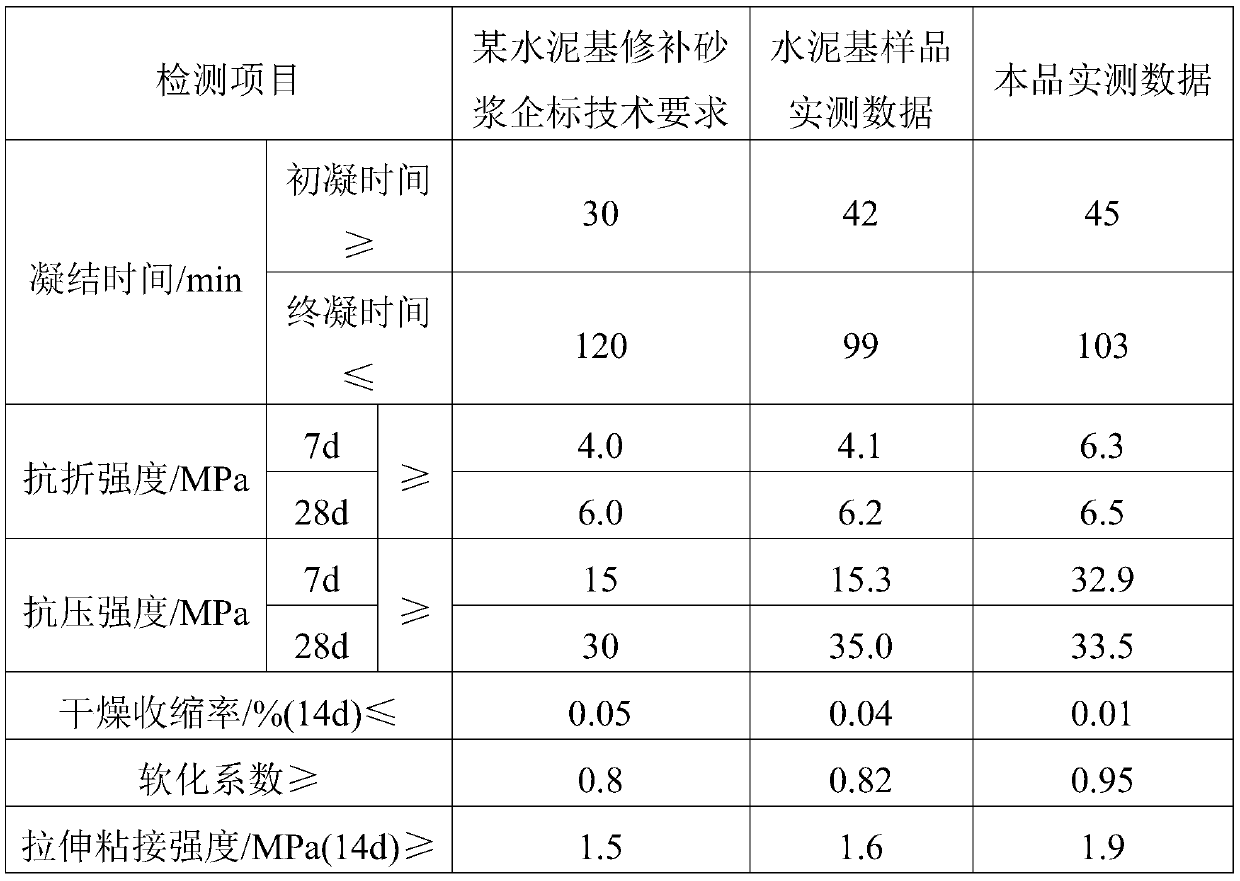

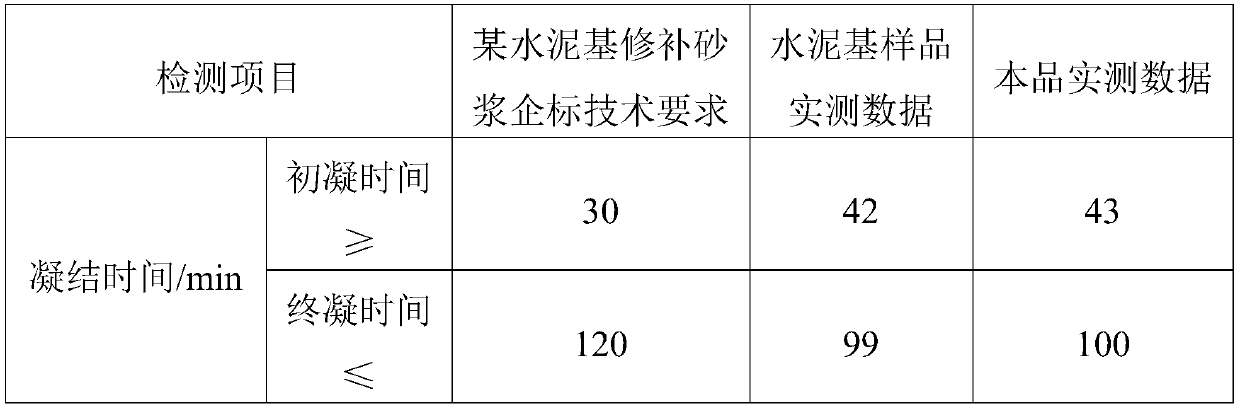

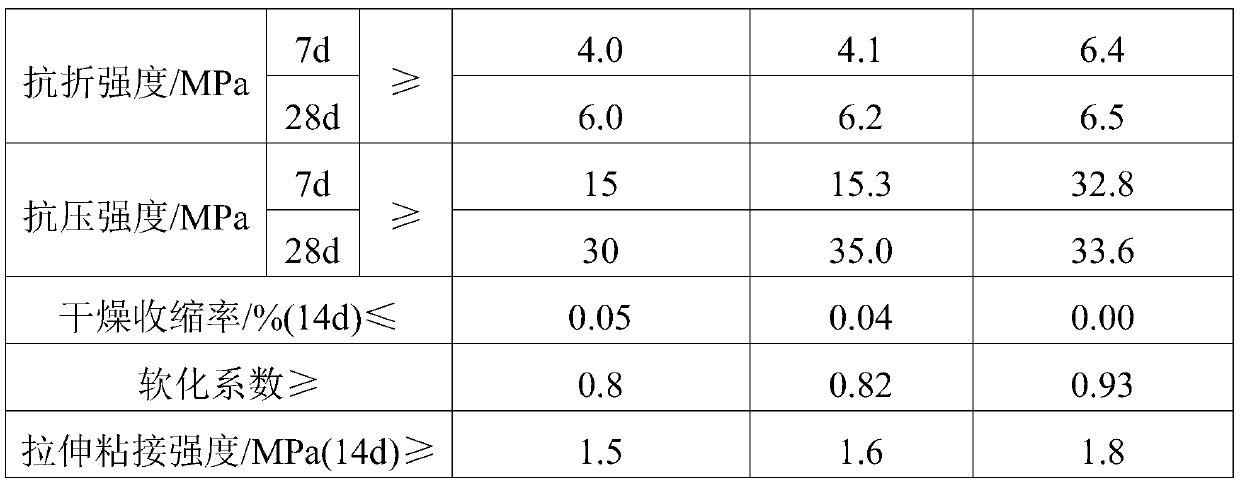

Fluorgypsum-based repair mortar

The invention discloses fluorgypsum-based repair mortar and belongs to the technical field of building materials. The fluorgypsum-based repair mortar is prepared from a main material and an admixture, wherein the main material is prepared from components in parts by mass as follows: 15-80 parts of fluorgypsum, 1-10 parts of an active mineral admixture and 20-75 parts of aggregate; the admixture is prepared from components in parts by mass as follows: 0.5-3 parts of an excitant, 0.5-3 parts of an adjusting admixture, 0.1-1 part of a water reducer, 0.05-0.5 parts of a water-retaining admixture, 0.1-1 part of a redispersible emulsion and 0.05-0.5 parts of a waterproof agent. The fluorgypsum-based repair mortar is formed by combining type-II anhydrous gypsum, the adjusting admixture and the active mineral admixture, and some compact aluminosilicate three-dimensional networks are added to gypsum crystals while the type-II anhydrous gypsum is rapidly and safely activated. The defects of low strength and poor water resistance of ordinary building gypsum materials are overcome while the advantages of good size stability, high stretching and bonding strength and the like of gypsum are reserved. Waste residues in the fluorine chemical industry are taken as main raw materials, environmental protection and waste utilization are realized, and the production cost of building materials is reduced.

Owner:湖南昌迅科技环保股份有限公司

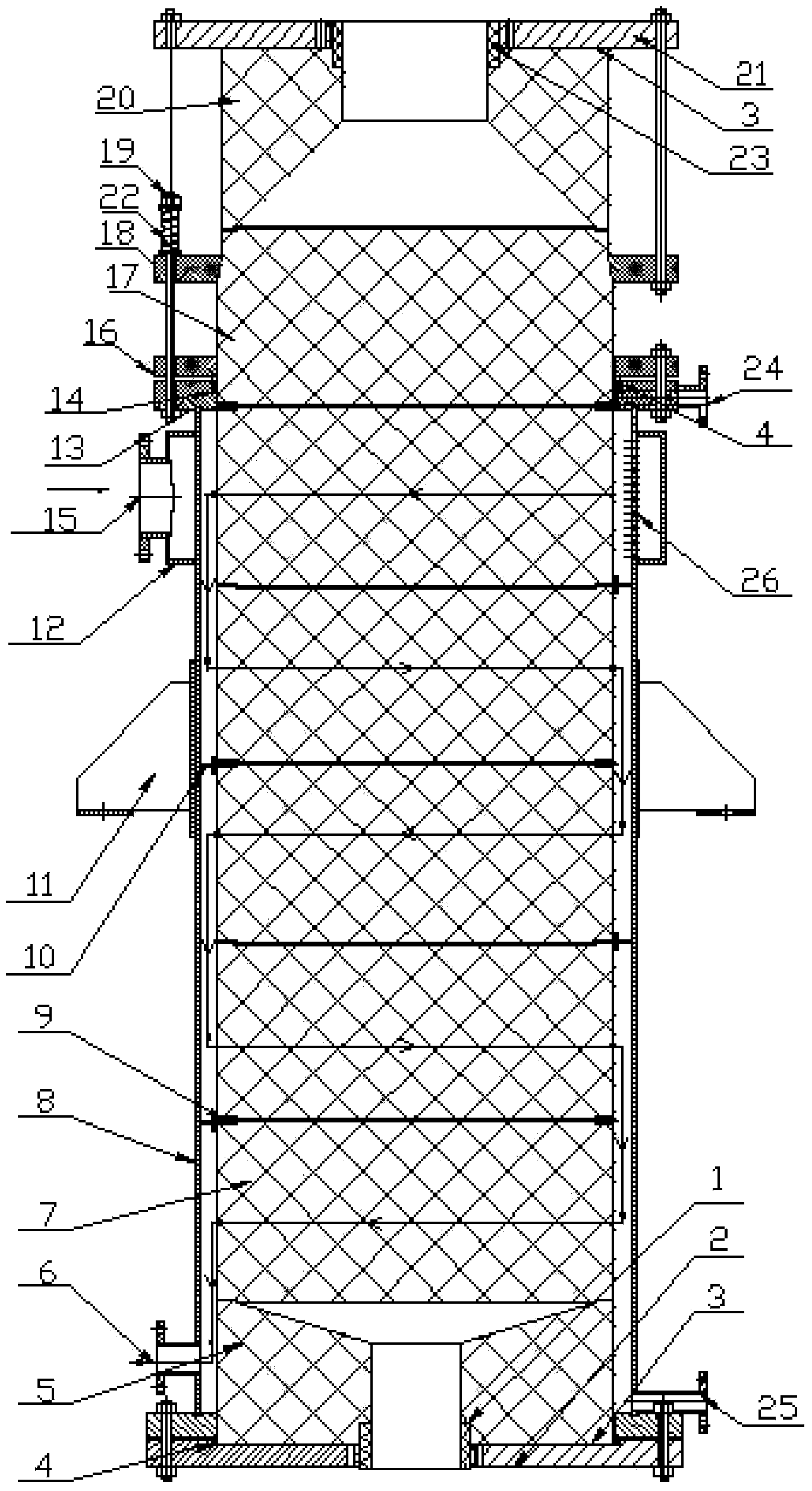

Device used for treating unstable terminal group of fluorine-containing polymer and a process for treating same

The invention relates to a device used for treating an unstable terminal group of a fluorine-containing polymer. The device comprises a fluorine-preparing electrolyzer, a hydrogen fluoride freezing remover, a fluorine gas collecting tank, a diaphragm compressor, a fluorine and nitrogen mixed gas high-pressure storage tank and a high-pressure reaction tank, wherein the gas outlet of the high-pressure reaction tank is connected with one gas outlet pipeline of the fluorine gas collecting tank. A process for treating the unstable terminal group of the fluorine-containing polymer concretely comprises the following steps: (1) refinement and collection of fluorine gas; (2) preparation and pressurization of fluorine and nitrogen mixed gas; and (3) fluorination of the unstable terminal group of the fluorine-containing polymer. The device and process for fluorination provided by the invention can realize fluorination directing at different fluorine-containing polymers (like polytetrafluoroethylene PTFE, fluorinated ethylene propylene FEP and a tetrafluoroethylene and heptafluoropropyl trifluorovinyl ether copolymer PFA), has extremely extensive applicability and good fluorination effects, and is applicable to great popularization in the fluorine chemical industry.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

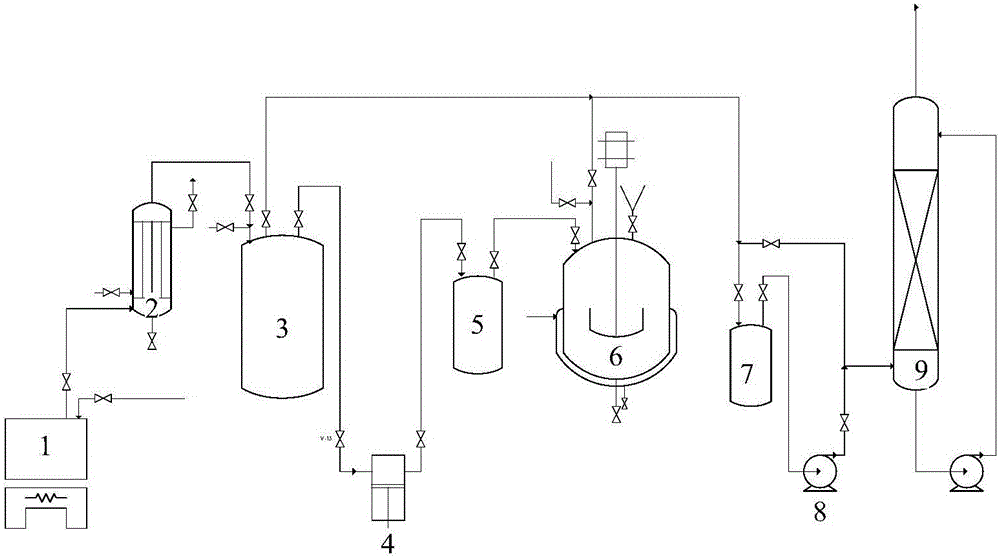

Preparation method for high heat resistance polyvinylidene fluoride

ActiveCN102336854BReduced stickinessImprove high temperature resistanceSlurrySuspension polymerization

Provided is a preparation method for high heat resistance polyvinylidene fluoride, which belongs to the technical field of fluorochemical industry. The method is characterized by comprising the following steps: 1) blowing nitrogen into an enclosed polymerization kettle to remove oxygen and adding deionized water, magnesium hydroxide, diisopropyl peroxydicarbonate, diethyl malonate and vinylidene fluoride; 2) under the conditions that reaction pressure is 3.0 to 7.0 MPa and reaction temperature is 45 to 120 DEG C, starting a stirring paddle, with a rotating speed being 350 to 750 r / min, and allowing an obtained mixture to react for 4 to 6 hours so as to prepare a polyvinylidene fluoride slurry; 3) rinsing the polyvinylidene fluoride slurry with deionized water until foams disappear, allowing the conductivity of rinsing liquid to decrease to less than 1 mu s / cm, and carrying out vacuum drying at a temperature of 90 to 100 DEG C for 15 to 20 hours so as to prepare a finished product. According to the invention, suspension polymerization is employed in the preparation method; a finally prepared polyvinylidene fluoride resin is loose and has greatly reduced possibility of adhering to the kettle and excellent high temperature resistance

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

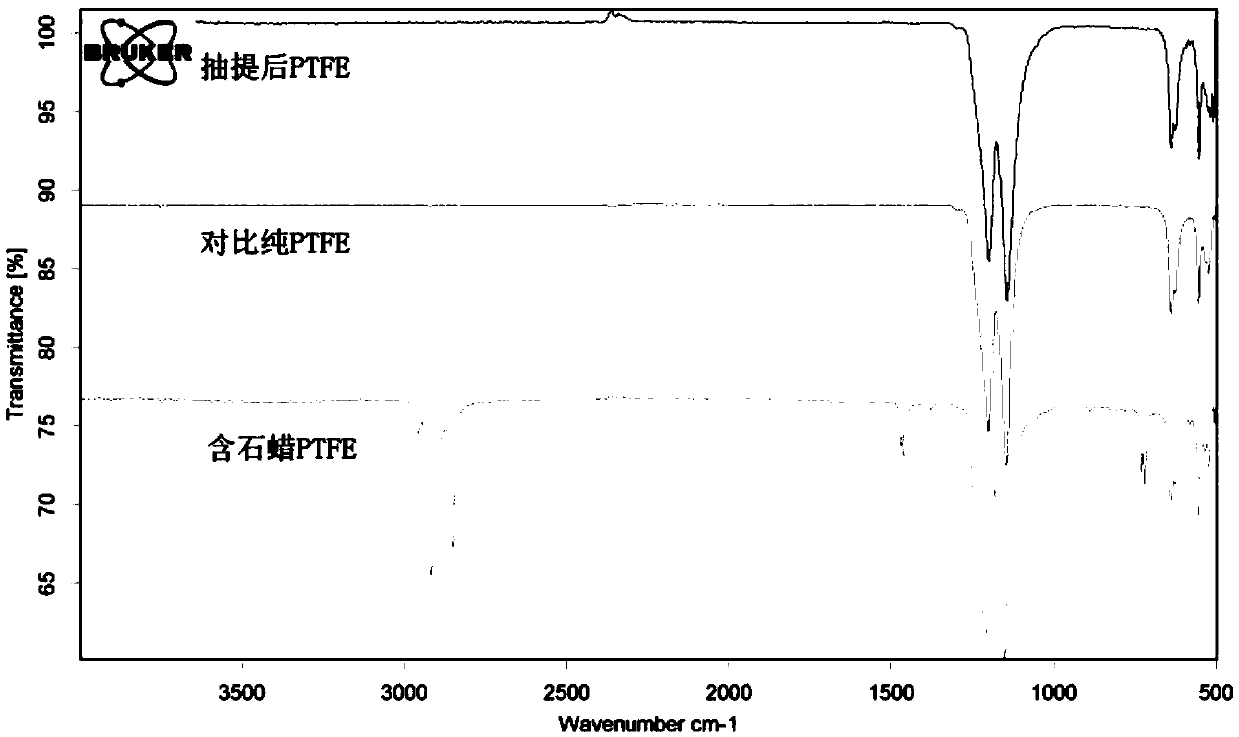

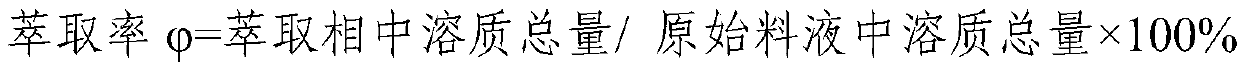

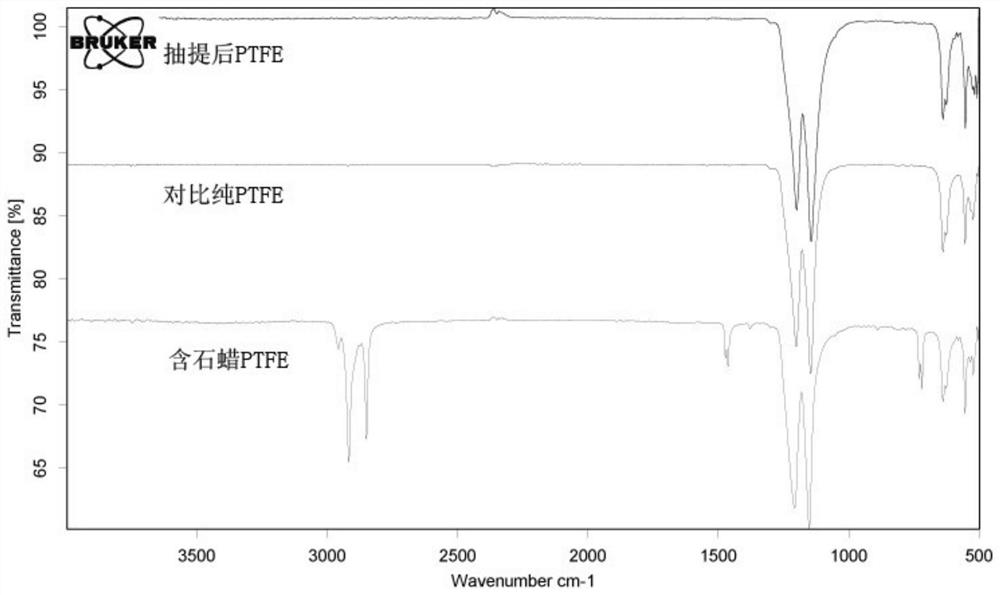

Method for continuously extracting and recovering polytetrafluoroethylene dispersion resin

ActiveCN111073034AChange the status quo of landfillEfficient reusePlastic recyclingChemical industryParaffin wax

The invention relates to a method for continuously extracting and recovering polytetrafluoroethylene dispersion resin, which specifically comprises the following steps: putting paraffin-containing PTFE waste residues with the moisture content not higher than 10% into an extractor, and carrying out extraction treatment. The method disclosed by the invention has the characteristics of mild operationconditions, low cost, high yield, practicability and easiness in operation. The current situation of wax-containing PTFE waste residue landfill in the fluorine chemical industry is changed, effectivereutilization of resources is achieved, and good social benefits and economic benefits are achieved. Through continuous extraction, the content of paraffin in the finally dispersed PTFE reclaimed material is less than or equal to 5%, and the recovery rate of the paraffin is greater than or equal to 90%.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Method for separating trifluoroethylene in tetrafluoroethylene production

ActiveCN100540517CImprove the phenomenon of random discharge of trifluoroethyleneImprove controllabilityHalogenated hydrocarbon preparationTetrafluoroethyleneFluorochemical industry

The invention belongs to the filed of fluorochemical industry and provides a method for separating a trifluoroethylene in the production of a tetrafluoroethylene. The specific technical steps are as follows: a material gas on the top of a recovery tower of the tetrafluoroethylene enters directly into a distillation column; the tetrafluoroethylene and the trifluoroethylene in the material gas are separated from other components; the tetrafluoroethylene and the trifluoroethylene in the material gas aggregate on the top of the column and the rest components return to a system after the recovery tower of the tetrafluoroethylene through the bottom column; a mixture of the tetrafluoroethylene and the trifluoroethylene enters into an extraction column and the trifluoroethylene is absorbed by utilizing an extracting agent; the trifluoroethylene enters into an absorption tower with the extracting agent and is separated from an extracting liquid by steam heating in the absorption tower; the trifluoroethylene aggregates on the top of the absorption tower and then enters into a trifluoroethylene tank. The invention realizes efficient separation on the trifluoroethylene, controllability on the quality of the tetrafluoroethylene and has great potentiality in the aspect of environmental protection.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method for preparing high-quality ammonium bifluoride from fluorine silicon compound

InactiveCN107867701AImprove qualityLow impurity contentAmmonium halidesChemical industrySilicic acid

The invention discloses a method for preparing high-quality ammonium bifluoride from a fluorosilicon compound, and relates to the preparation technology of inorganic fluorine salts in the fluorine chemical industry in the chemical industry. In the present invention, solid fluorosilicic acid or silicon tetrafluoride gas is added to a saturated ammonium fluoride solution, and excess ammonia is passed through at the same time for ammonolysis reaction. After the reaction is complete, ammonium fluoride crystal slurry and silicon dioxide are respectively obtained. Suspension, the following six steps are followed in turn, and finally high-quality ammonium bifluoride products are obtained, and the reaction solution is returned to the system for recycling. The technology of the invention makes the impurities brought in by the raw materials mainly stay in the silicon dioxide, making it easier to produce high-quality ammonium bifluoride products. At the same time, it solves the problem of fluorine pollution in the production of phosphate fertilizer enterprises, so that fluorine resources can be recycled, and the system cycle operation does not add three wastes.

Owner:青岛九洲千和机械有限公司

Method used for preparing high quality ammonium bifluoride from fluorine silicon compound

The invention discloses a method used for preparing high quality ammonium bifluoride from a fluorine silicon compound, and belongs to the field of inorganic fluoride salt preparation in fluorine chemical industry. According to the method, solid fluosilicic acid or silicon tetrafluoride gas are added into a saturated ammonium fluoride solution, and excess ammonia is introduced at the same time for ammonolysis reaction; after reaction, an ammonium fluoride crystal slurry and a silicon dioxide suspension are obtained respectively; and six steps of treatment disclosed in the invention are carried out successively so as to obtain a high quality ammonium bifluoride product, and a reaction liquid is recycled back to a system circulation for recycling. Impurities introduced by the raw materials are mainly retained in silicon dioxide, so that the high quality ammonium bifluoride product can be produced easily. The method is capable of solving a fluorine pollution problem in phosphate fertilizer enterprise production, and realizing recycling of fluorine resource; and no three wastes is generated in system recycling operation.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

Preparation device and preparation method for 2,3,3,3-tetrafluoropropene

ActiveCN109384640ASimple structureEasy to operatePreparation by hydrogen halide split-offPreparation by halogen replacementAluminium chlorideTitanium fluoride

The invention relates to a preparation device and a preparation method for 2,3,3,3-tetrafluoropropene and belongs to the technical field of fluorochemical industry. The preparation device for 2,3,3,3-tetrafluoropropene is simple in structure, easy to operate, low in energy consumption and suitable for industrial production. According to the preparation method for 2,3,3,3-tetrafluoropropene, 1,1,1,2,3-pentachloropropane or 1,1,2,3-tetrachloropropene and hydrogen fluoride are taken as raw materials, any one or a combination of tin tetrachloride, stannous fluoride, antimony chloride, titanium tetrachloride, titanium fluoride, aluminium chloride and aluminum fluoride is taken as a catalyst, and 2,3,3,3-tetrafluoropropene is synthesized with a one-step liquid phase method with high catalyst contact rate. The process is simple, and the technological flow is simplified greatly; equipment investment is reduced remarkably due to less equipment, and 99.9% 2,3,3,3-tetrafluoropropene can be obtained. The product selectivity is high, reaction is completed by one step, the flow is short, the conversion rate is high, few byproducts are produced, and energy consumption is low.

Owner:SHANDONG HUAAN NEW MATERIAL

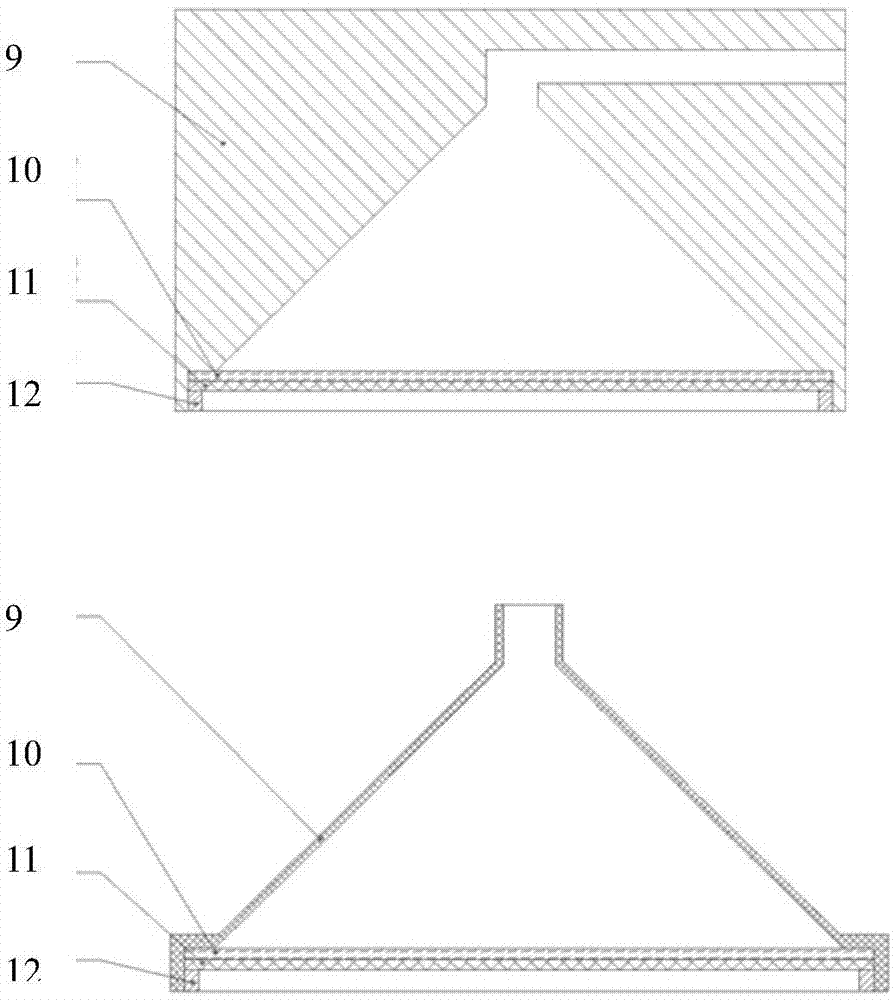

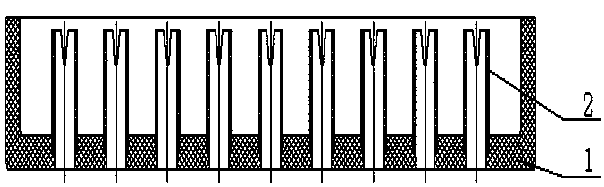

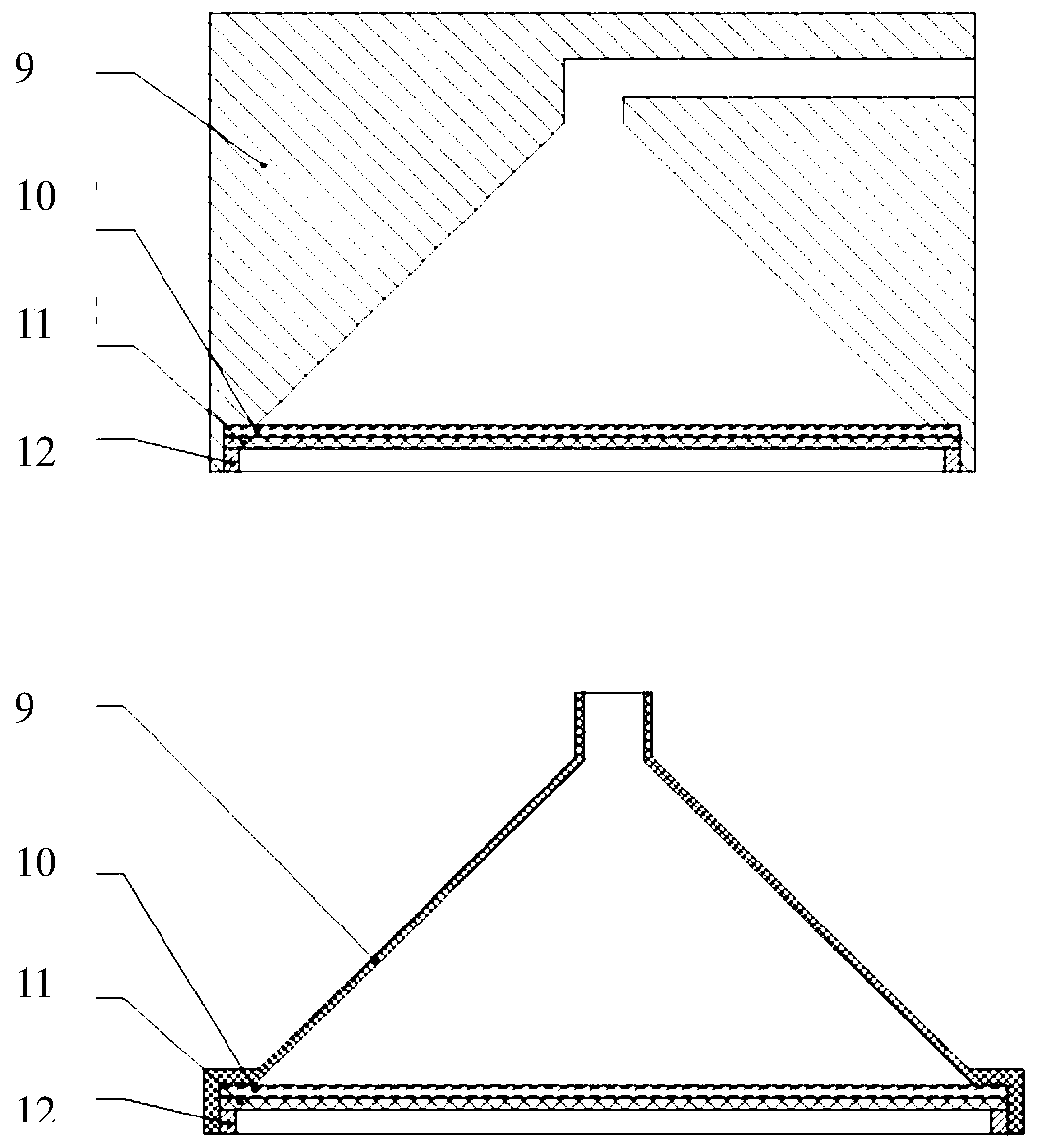

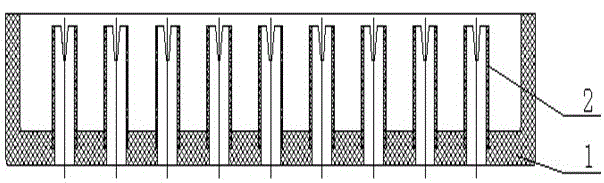

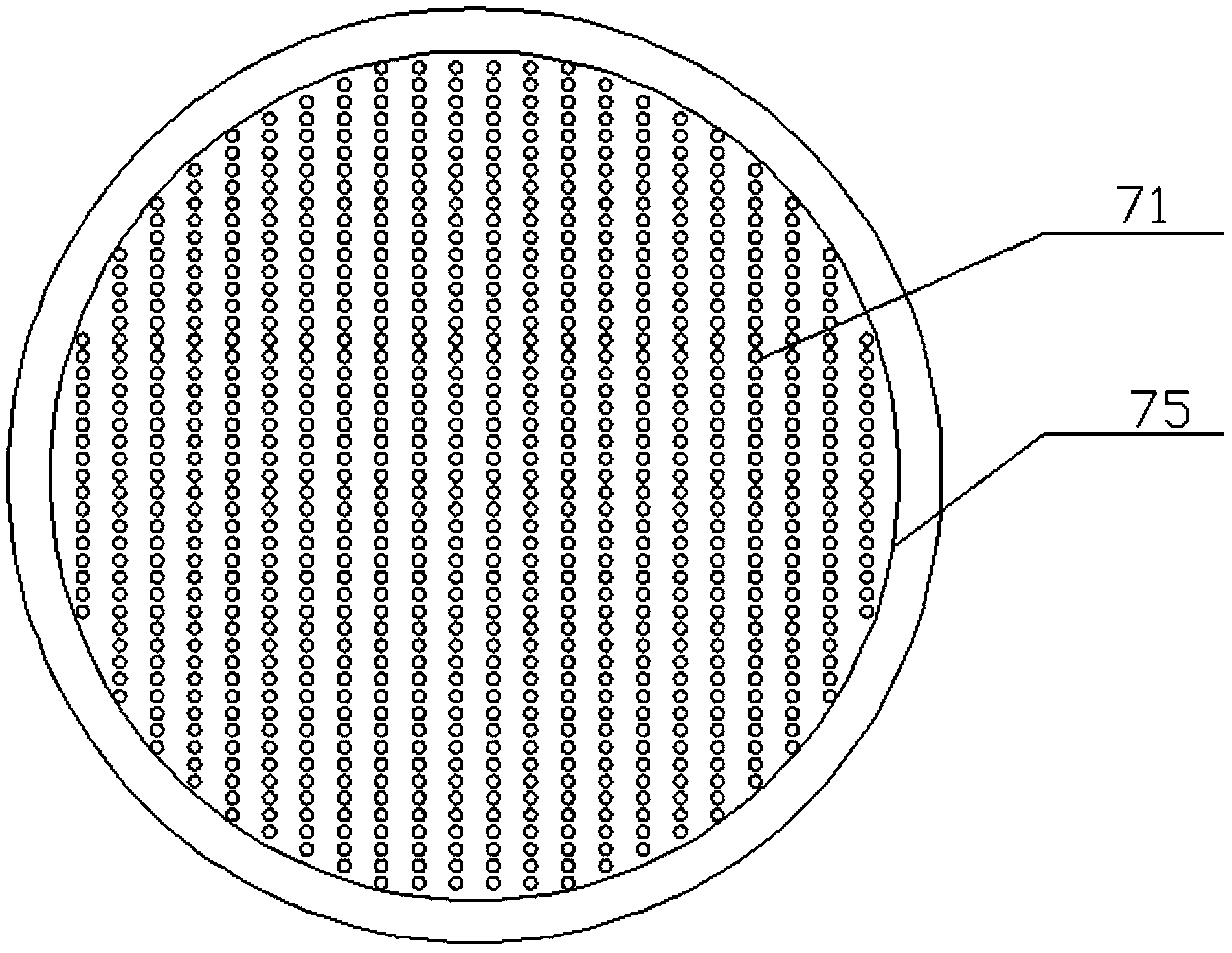

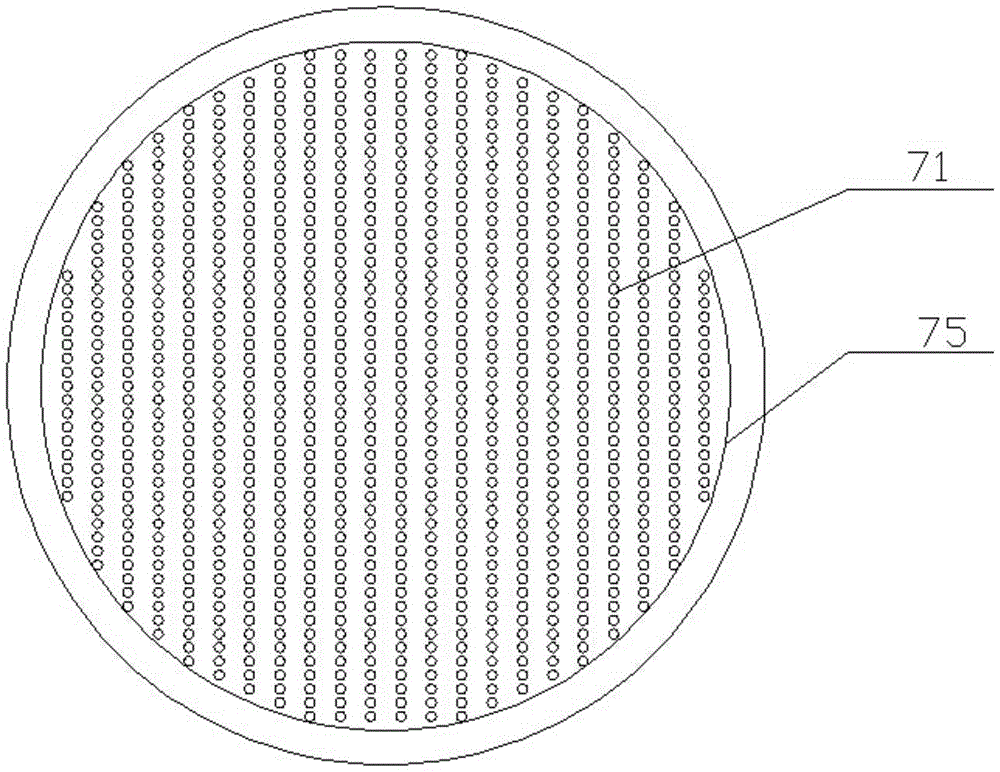

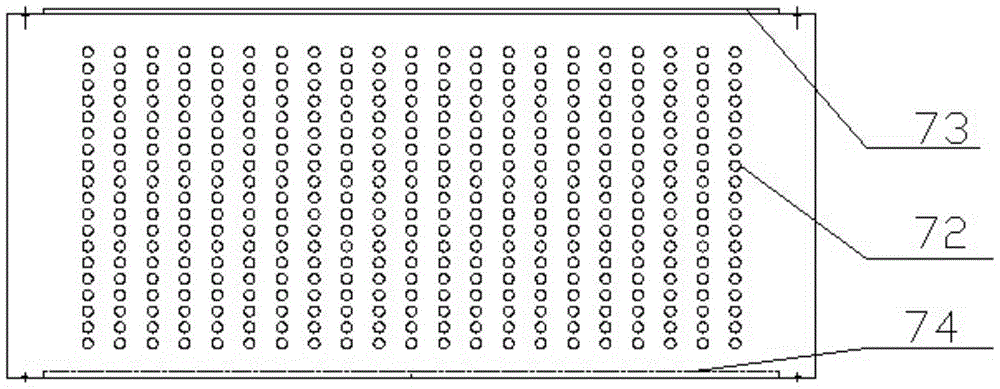

High-temperature-resistant corrosion-resistant graphitic acid distributor and manufacturing method thereof

ActiveCN103752141AIncrease stiffnessEasy to separateDispersed particle separationChemical industryFluorochemical industry

The invention discloses a high-temperature-resistant corrosion-resistant graphitic acid distributor and a manufacturing method thereof. The graphitic acid distributor comprises an acid disc, wherein overflow pipes are uniformly distributed inside the acid disc; both the acid disc and the overflow pipes are made of graphite material. The acid distributor is made of the graphite material, the graphite has high-temperature resistance and corrosion resistance, the influence of temperature on the graphite material is slight, the deformation amount is small, the distribution uniformity of materials in tower equipment in chemical production is guaranteed, and bias of the materials in the tower equipment is reduced. Compared with the conventional acid distributor made of a polytetrafluoroethene material, the graphitic acid distributor manufactured by adopting the manufacturing method has the advantages that the temperature resistance and corrosion resistance are improved by 30 percent, the strength is improved by 5-10 times, the bias is reduced, the production consumption is lowered, the service life is prolonged by two times, the problem that the high-temperature highly corrosive materials are easily biased in the tower equipment is solved, and great contribution is made to the development of fluorine chemical industry and other petrochemical industries.

Owner:龚孝祥

Processing method of wastes produced when battery grade lithium fluoride is manufactured by adopting carbonization method

ActiveCN102515203BImprove resource utilizationSolve environmental problemsAlkali metal fluoridesLithium carbonates/bicarbonatesChemical industryAluminium hydroxide

The invention discloses a processing method of wastes produced when battery grade lithium fluoride is manufactured by adopting a carbonization method, and the processing method comprises the steps that: A: excess sodium carbonate is added into a lithium fluoride waste liquor to react with the lithium fluoride waste liquor, a solid lithium carbonate paste is obtained after a reaction product is filtered, and a filter liquor is a spare mixed solution containing the left sodium carbonate; and B: a lithium carbonate waste material and aluminium hydroxide react with excess anhydrous hydrogen fluoride in a fluidized bed to obtain anhydrous aluminum fluoride containing lithium fluoride, and tail gas of the reacted anhydrous hydrogen fluoride is led into the mixed solution containing the left sodium carbonate in the step A so as to obtain a sodium fluoride solution. By adopting the processing method disclosed by the invention, two main wastes produced when the battery grade lithium fluoride is manufactured by adopting the carbonization method are both converted to useful substances capable of being used in downstream industries of inorganic fluorides, so the environmental protection problem to be solved in the fluoride chemical industry and the aluminum electrolysis industry is solved; and in addition, all raw materials are taken from production wastes of the battery grade lithium fluoride, secondary pollution cannot be produced, the resource utilization rates of fluorine and lithium are improved, and sustainable development of the inorganic fluoride chemical industry is urged.

Owner:DO FLUORIDE CHEM CO LTD

Method for preparing high-quality ammonium bifluoride from fluorine-silicone compound

InactiveCN108203107AImprove qualityLow impurity contentAmmonium fluorideSilicon tetrafluorideSilicon dioxide

The invention provides a method for preparing high-quality ammonium bifluoride from a fluorine-silicone compound, and relates to an inorganic villiaumite preparation technology in a fluorine chemicalindustry of the chemical industry field. The method provided by the invention comprises the following steps: adding solid fluorosilicic acid or silicon tetrafluoride gas into a saturated ammonium fluoride solution, introducing excess ammonia at the same time, carrying out an ammonolysis reaction so as to respectively obtain an ammonium fluoride crystal mush and a silicon dioxide suspension after completion of the reaction, and successively carrying out six steps as described in the specification so as to obtain a high-quality ammonium bifluoride product, wherein a reaction solution returns a system for cyclic utilization. With the process technology of the invention, impurities contained in raw materials are mainly reserved in silicon dioxide, so the high-quality ammonium bifluoride product can be easier to be produced. Meanwhile, the problem of fluorine pollution from production in phosphorus fertilizer enterprises is solved; fluorine resources are recycled; and three wastes are not additionally generated in cyclic operation of the system.

Owner:QINGDAO XIANGZHI ELECTRONICS TECH CO LTD

Fluorogypsum-based repair mortar

The invention discloses a fluorogypsum-based repair mortar, which belongs to the technical field of building materials. The fluorogypsum-based repair mortar includes main ingredients and admixtures, and the main ingredients include the following components in parts by mass: 15-80 parts of fluorogypsum, 1-10 parts of active mineral admixtures, 20-75 parts of aggregates The admixture includes the following components: 0.5 to 3 parts of activator, 0.5 to 3 parts of coagulation regulator, 0.1 to 1 part of water reducer, 0.05 to 0.5 part of water-retaining thickener, and 0.1 to 0.5 part of redispersible emulsion 1 part, 0.05-0.5 parts of waterproofing agent. The fluorogypsum-based repair mortar uses a combination of type II anhydrite, coagulant and active mineral admixture, while quickly and safely stimulating type II anhydrite, some dense aluminosilicate three-dimensional network. While retaining the advantages of good volume stability and high tensile bond strength of gypsum, it also overcomes the disadvantages of low strength and poor water resistance of ordinary building gypsum materials. It uses waste residue from the fluorine chemical industry as the main raw material, which not only protects the environment, but also reduces the production cost of building materials.

Owner:湖南昌迅科技环保股份有限公司

An online environmental monitoring system and online monitoring method for fluorine chemical industry

ActiveCN106896179BAccurate and intuitive reflectionMeet monitoring needsComponent separationChemical industryCollection system

The invention provides an online environment monitoring system in a fluorine chemical industry. The system comprises a sample collection unit, a multi-channel comprehensive analysis unit and a data acquisition control center, wherein the sample collection unit is connected with the multi-channel comprehensive analysis unit through a pipeline; and the multi-channel comprehensive analysis unit is connected with the data acquisition control center. An online collection system comprises a collection port, bundle tubes and a multi-channel switching valve, wherein the multi-channel switching valve is arranged on a pipeline composed of the bundle tubes; and the multi-channel comprehensive analysis unit comprises an adjustable distributor electronic flow controller, an air pump and gas chromatography-mass spectrometric equipment. The monitoring system and the monitoring method disclosed by the invention overcome the defects in the prior art such as large labor amount, high dangerousness, inaccurate animal monitoring and the like, can be applied to online monitoring of fluorine chemical industry production sites, fluorine chemical industry raw product storage areas and the like, avoid direct contact between personnel and toxic substances, can intuitively reflect the varieties and contents of leaking substances and have excellent reproducibility and accuracy.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

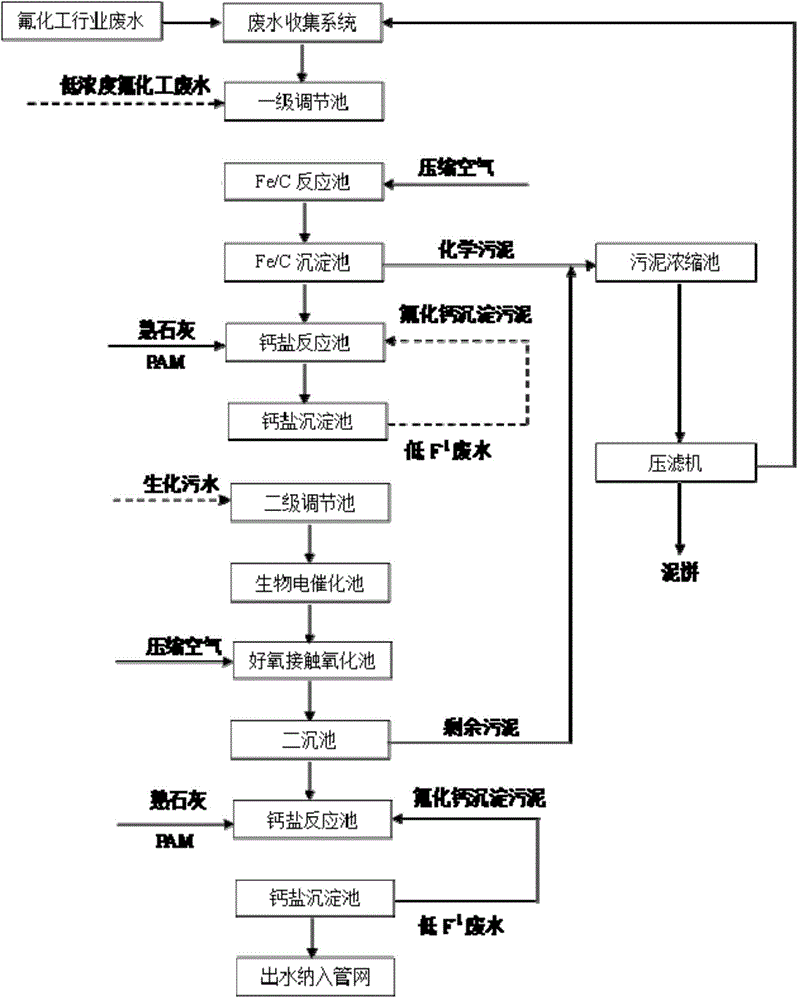

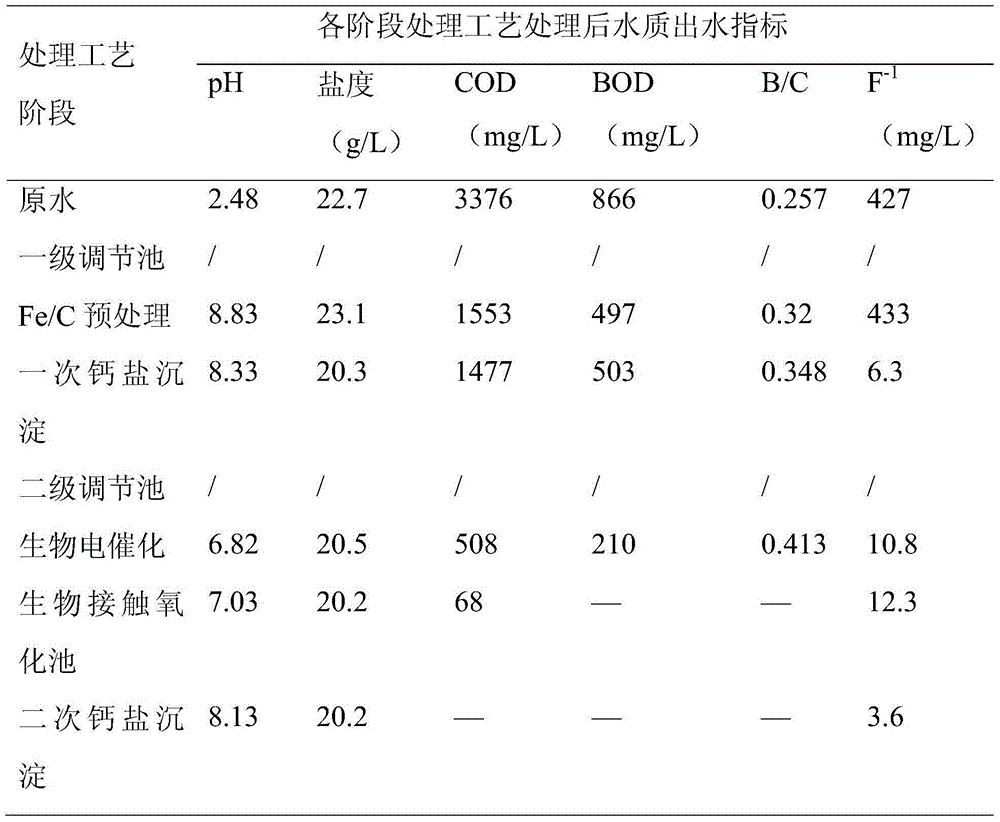

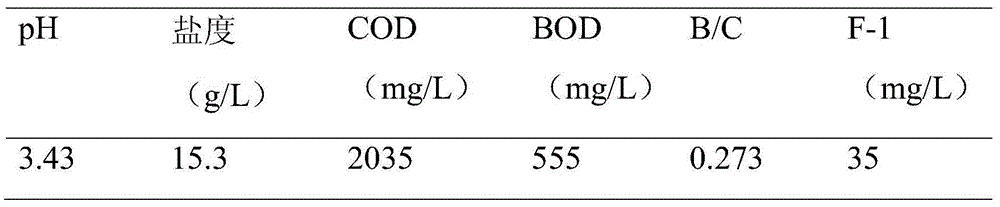

Treatment process for fluorine chemical wastewater

ActiveCN103708679BReduced settling timeEasy to handleWater contaminantsMultistage water/sewage treatmentPrimary standardFluorochemical industry

The invention discloses a treatment process for fluorine chemical wastewater. The process comprises the following steps: sequentially carrying out one-time regulating, carrying out iron-carbon reaction pre-treatment, carrying out iron-carbon precipitation, carrying out one-time calcium salt reaction, carrying out one-time calcium salt precipitation, adjusting for the second time, carrying out bioelectrocatalysis, carrying out an aerobic contact oxidation, carrying out second-time calcium salt reaction, second-time precipitation and discharging water. The process provided by the invention is used for treating the fluorine chemical wastewater; the wastewater treated by the process can achieve primary standards of Integrated Wastewater Discharge Standard (GB8978-1996) and the operation cost of wastewater treatment is low.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

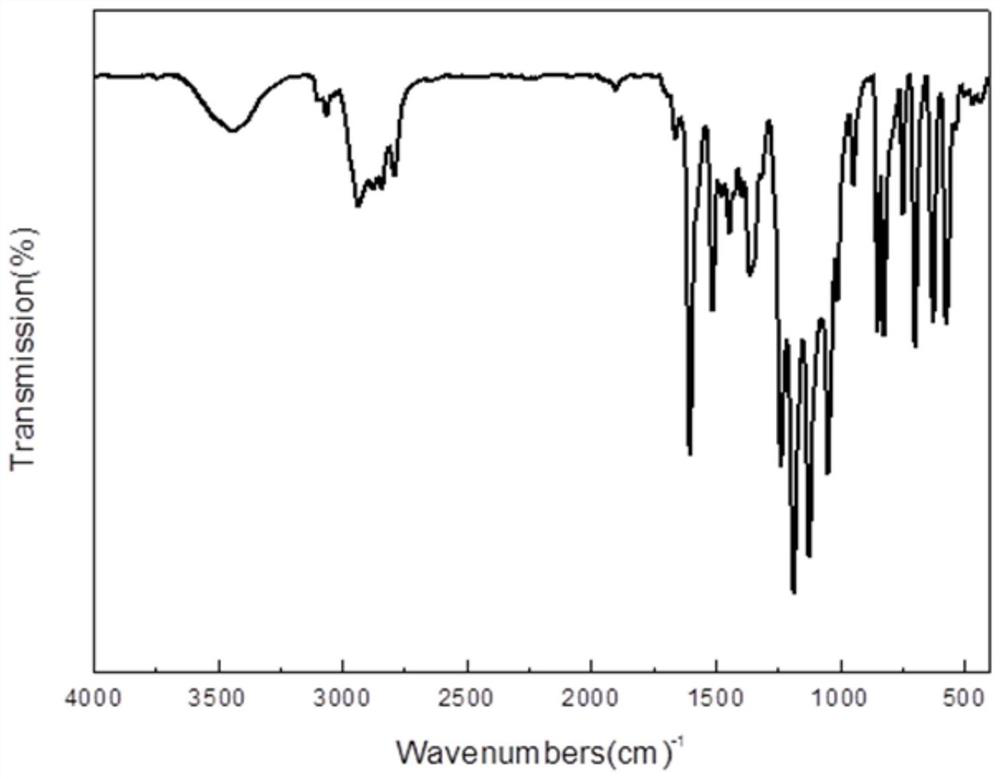

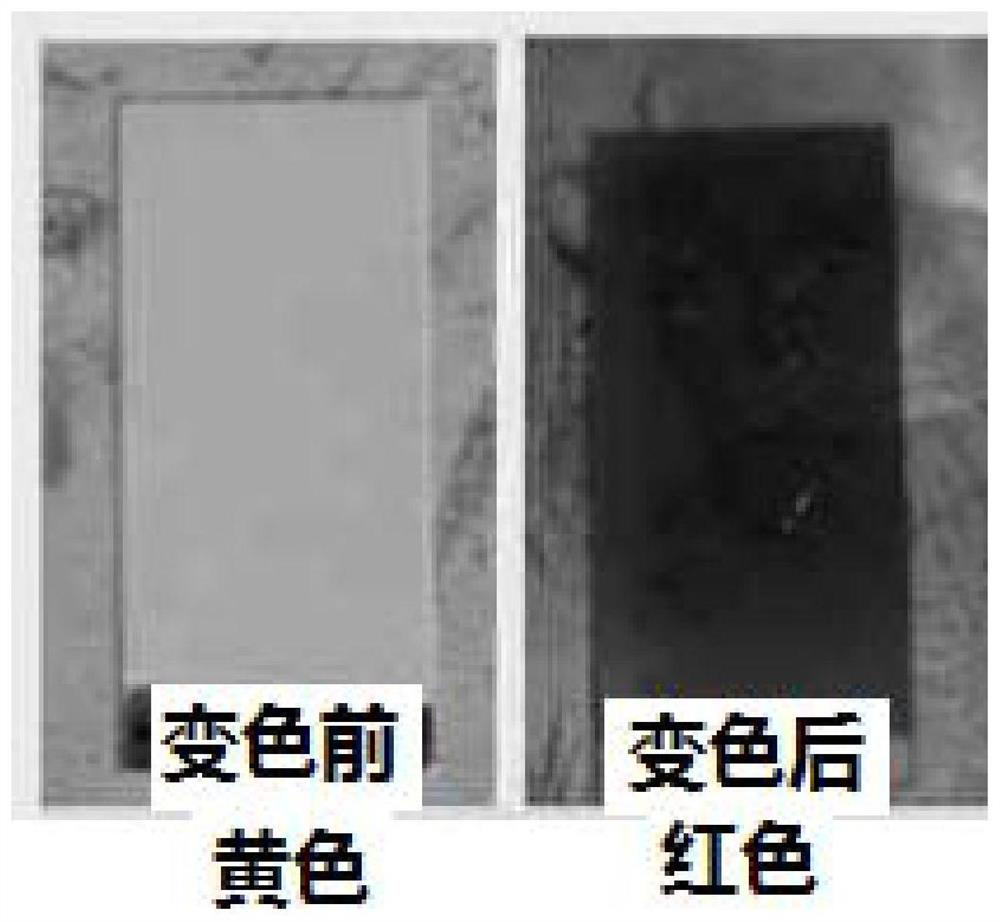

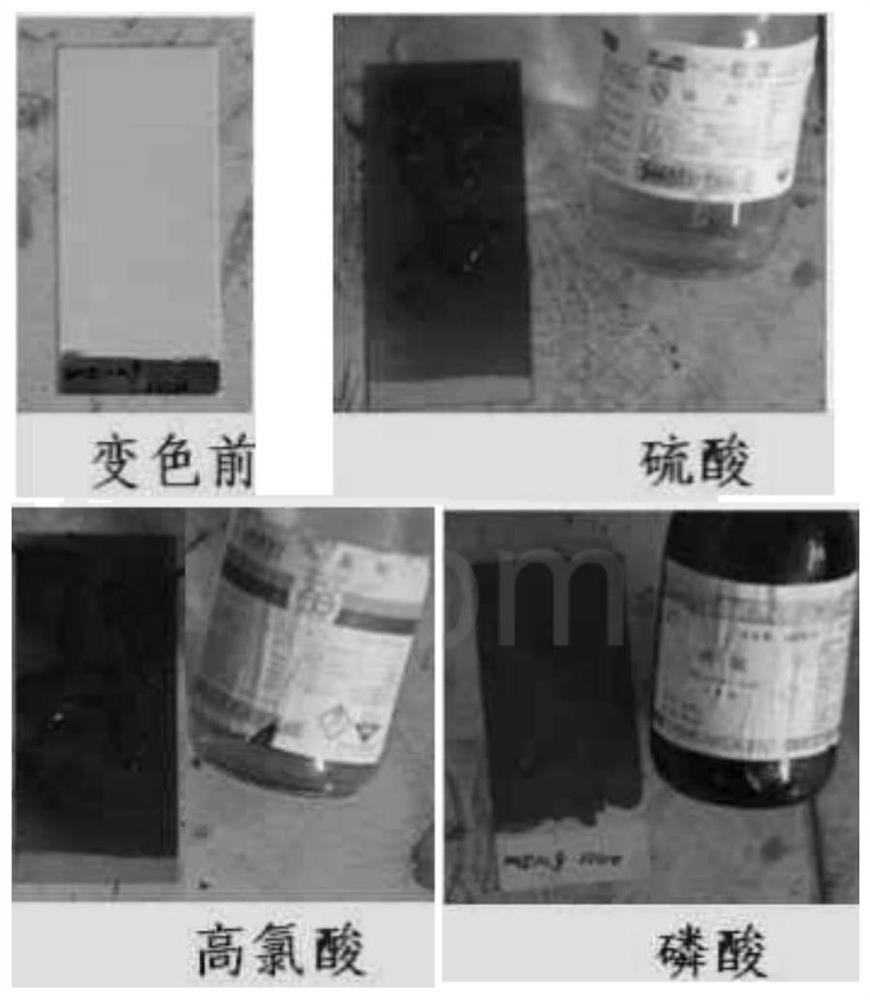

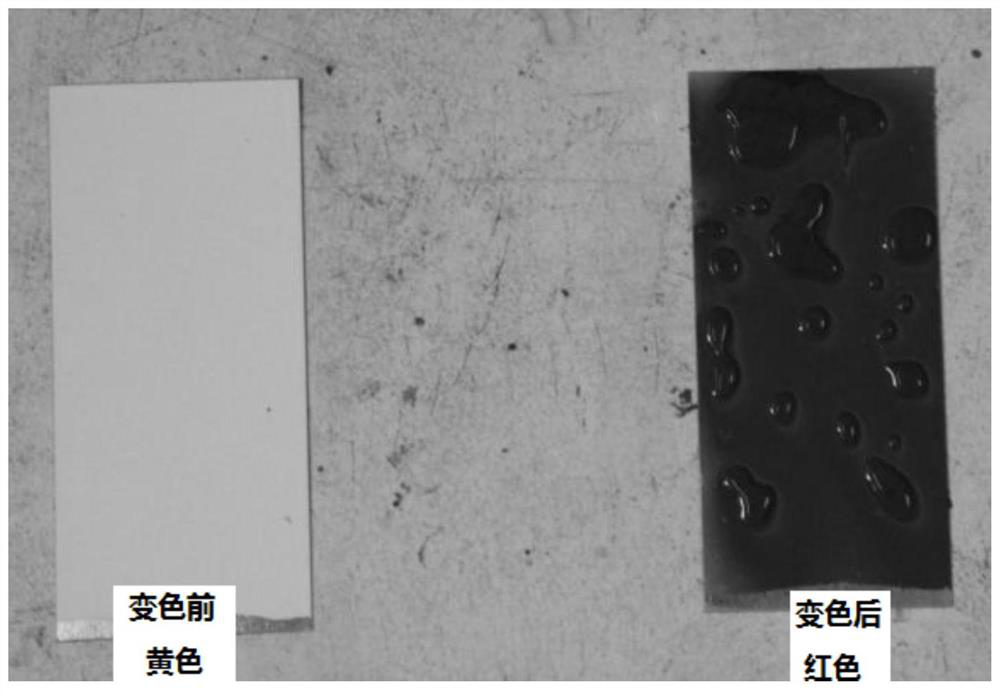

A kind of acid color changing warning paint and preparation method thereof

ActiveCN110804350BChange color quicklyDiscoloration reversibleRubber derivative coatingsPolyurea/polyurethane coatingsChemical industryFluorochemical industry

The present invention relates to a color-changing warning paint in case of acid and a preparation method thereof. 0-20 parts, 0-20 parts of additives, 0-300 parts of solvents. The acid-encounter warning paint for strong acid, obvious and rapid discoloration and reversible discoloration of the present invention. Using single-component strong acid-resistant resin as the base resin, adding special color-changing agent A, auxiliary color-changing components, pigments and fillers, etc., the acid-encountered warning paint has the characteristics of obvious color change, rapid color change, reversible color change, and good matching. Suitable for manufacturing, storage, transportation and device surfaces where strong acids are used. The market demand prospects of petroleum alkylation, fluorine chemical industry, ore flotation, pulp and paper industry, semiconductor industry and other manufacturing industries are good.

Owner:SHANDONG UNIV

A method for manufacturing a high-temperature and corrosion-resistant graphitic acid distributor

ActiveCN103752141BIncrease stiffnessEasy to separateDispersed particle separationChemical industryPetrochemical

The invention discloses a high-temperature-resistant corrosion-resistant graphitic acid distributor and a manufacturing method thereof. The graphitic acid distributor comprises an acid disc, wherein overflow pipes are uniformly distributed inside the acid disc; both the acid disc and the overflow pipes are made of graphite material. The acid distributor is made of the graphite material, the graphite has high-temperature resistance and corrosion resistance, the influence of temperature on the graphite material is slight, the deformation amount is small, the distribution uniformity of materials in tower equipment in chemical production is guaranteed, and bias of the materials in the tower equipment is reduced. Compared with the conventional acid distributor made of a polytetrafluoroethene material, the graphitic acid distributor manufactured by adopting the manufacturing method has the advantages that the temperature resistance and corrosion resistance are improved by 30 percent, the strength is improved by 5-10 times, the bias is reduced, the production consumption is lowered, the service life is prolonged by two times, the problem that the high-temperature highly corrosive materials are easily biased in the tower equipment is solved, and great contribution is made to the development of fluorine chemical industry and other petrochemical industries.

Owner:龚孝祥

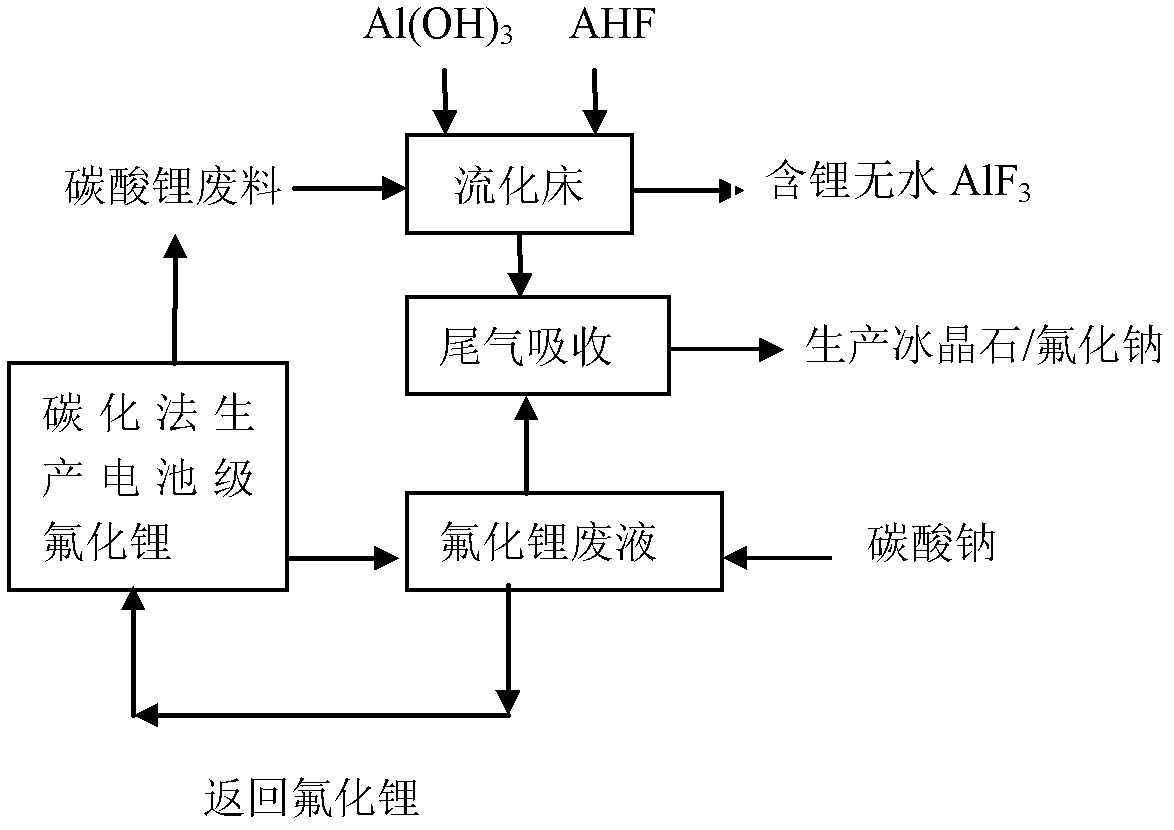

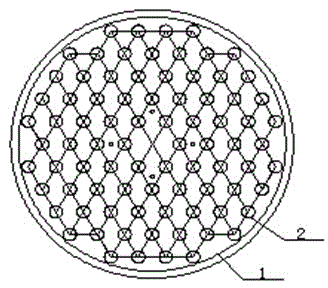

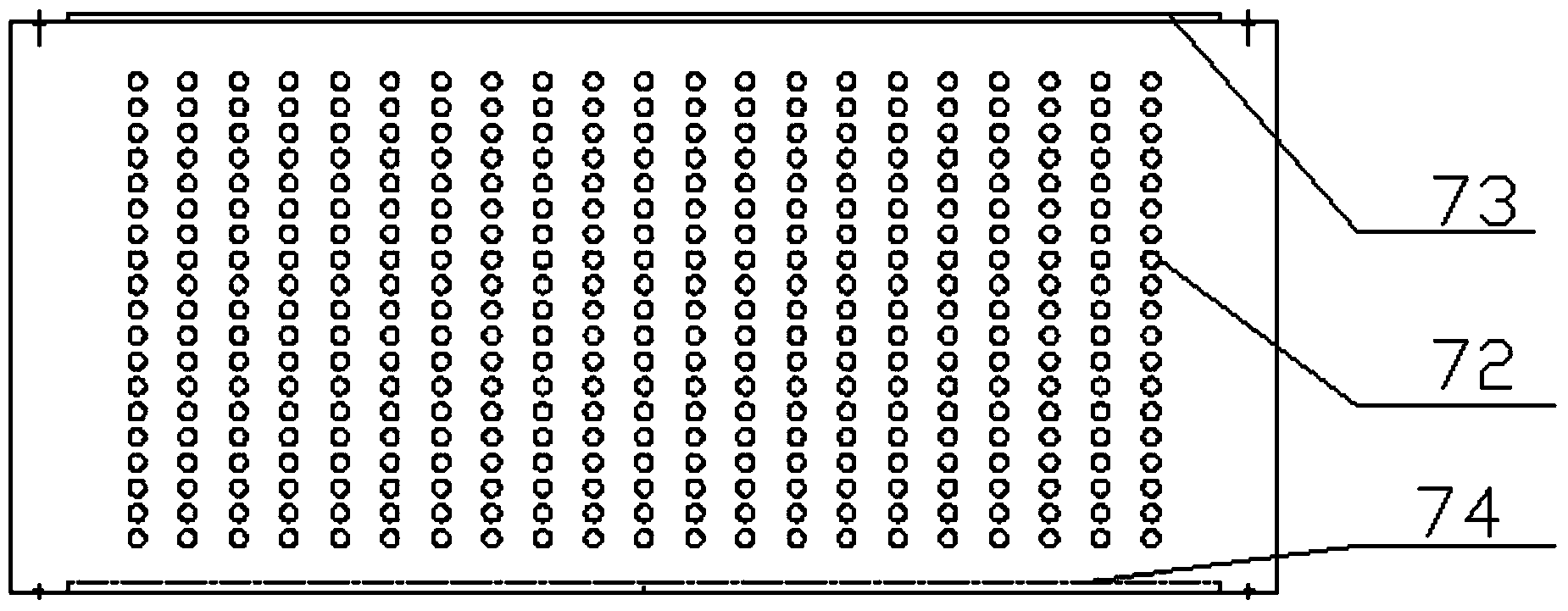

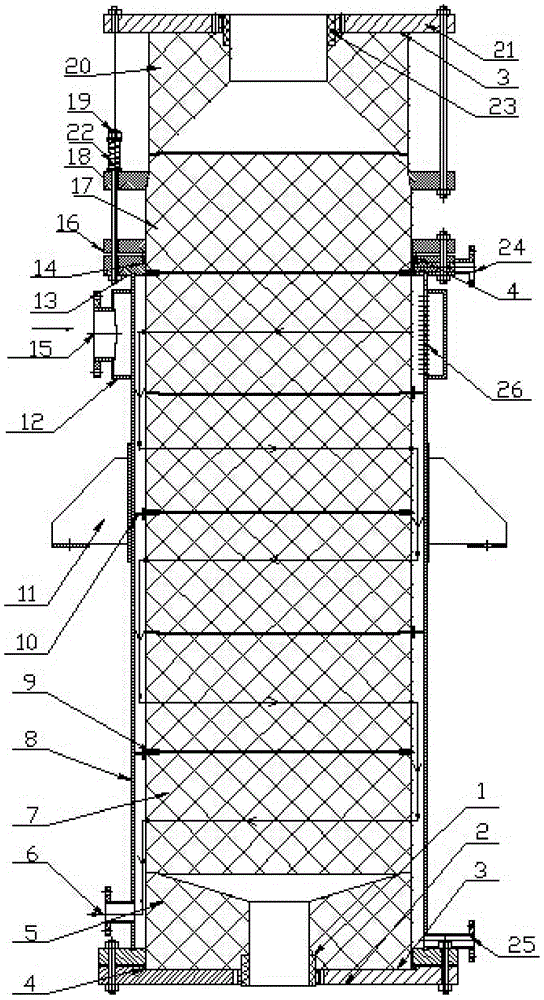

Block-hole-type graphite reboiler and manufacturing method thereof

ActiveCN104058394AImprove penetration resistanceAccelerated corrosionFluorochemical industryReboiler

The invention discloses a block-hole-type graphite reboiler. The block-hole-type graphite reboiler comprises a graphite block, through material holes are formed in the graphite block from top to bottom, through steam holes are formed in the graphite block from left to right, the material holes and the steam holes are arranged in a staggered mode, and the material holes are not communicated with the steam holes. The material holes and the steam holes are formed in the graphite block in an integrally-formed mode, the material holes and the steam holes are arranged in a staggered mode, the material holes are not communicated with the steam holes, the material holes are spaced from the steam holes by certain distances, and therefore the graphite block is free from leakage between the material holes and the steam holes. The block-hole-type graphite reboiler is good in temperature resistance and corrosion resistant performance, high in strength, good in sealing performance, long in service life, and capable of solving the problem that a conventional block-hole-type graphite reboiler is prone to breakage and leakage and making great contributions to development of the fluorine chemical industry and other petrochemical industries.

Owner:龚孝祥

A kind of preparation method of bis(fluorosulfonyl)imide and alkali metal salt thereof

ActiveCN106219503BEasy to operateEase of industrial productionNitrosyl chlorideSulfonic acid amide preparationImideDistillation

Owner:武汉松石科技股份有限公司

A kind of environment-friendly gas-sensitive coating for volatile acid and preparation method thereof

ActiveCN110922860BObvious discolorationChange color quicklyGroup 4/14 element organic compoundsPigmenting treatmentChemical industryFluorochemical industry

The invention relates to an environment-friendly gas-sensitive paint for volatile acids and a preparation method thereof, comprising the following components by mass: 50-100 parts of strong acid-resistant resin, 1-30 parts of special color-changing agent A, and auxiliary color-changing components 0.5-5 parts, 0-20 parts of filler, 0-20 parts of auxiliary agent, 0-300 parts of solvent; the special discoloration agent A is the substance obtained after compound B is treated with white carbon black. The invention utilizes the discoloration performance of the special color-changing agent A when it encounters acid gas, strengthens the color change through auxiliary color-changing components, and combines the reasonable compatibility of pigments, fillers, auxiliary agents, etc., to realize the preparation of gas-sensitive coatings for volatile acids. The invention has the characteristics of obvious discoloration, rapid discoloration, reversible discoloration and good compatibility, and is suitable for manufacturing, storing, transporting and the surface of devices using strong acids. Petroleum alkylation, fluorine chemical industry, ore flotation, pulp and paper industry, semiconductor industry and other manufacturing industries have good market demand prospects.

Owner:SHANDONG UNIV

A method for continuous extraction and recovery of polytetrafluoroethylene dispersed resin

ActiveCN111073034BChange the status quo of landfillEfficient reusePlastic recyclingParaffin waxChemical industry

The invention relates to a method for continuously extracting and recovering polytetrafluoroethylene dispersed resin, which specifically comprises: placing PTFE waste residue containing paraffin wax with a water content not higher than 10% in an extractor for extraction treatment. The method of the invention has the characteristics of mild operating conditions, low cost, high yield, practicality and easy operation. It changes the current situation of waxy PTFE waste residue landfill faced by the fluorine chemical industry, realizes the effective reuse of resources, and has good social and economic benefits. After continuous extraction, the paraffin content in the final dispersed PTFE recycled material is ≦5%, and the paraffin recovery rate is ≧90%.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

A block hole type graphite reboiler and its manufacturing method

ActiveCN104058394BImprove penetration resistanceAccelerated corrosionEffective solutionChemical industry

The invention discloses a block hole type graphite reboiler, which comprises a graphite block. A through material hole is arranged inside the graphite block from top to bottom, and a through steam hole is arranged inside the graphite block from left to right. The material hole and the steam The holes are arranged in a staggered manner and are not connected to each other. The graphite block is provided with a material hole and a steam hole formed in one body, and the two are arranged at staggered intervals and are not connected to each other, and there is a certain distance between them, so that the graphite block will not produce leakage between the material hole and the steam hole The block hole type graphite reboiler of the present invention has good temperature resistance and corrosion resistance, high strength, good sealing performance and long service life, effectively solving the problem of easy damage and leakage of the usual block hole type graphite reboiler , has made great contributions to the development of fluorine chemical industry and other petrochemical industries.

Owner:龚孝祥

Low compression deformation fluororubber premix and preparation method thereof

The invention belongs to the technical field of fluorochemical industry and particularly relates to a low-compression-deformation fluororubber premix and a preparation method thereof. The fluororubber premix is prepared from the following raw materials in parts by weight: 100 parts of modified crude fluororubber, 1.6-3.0 parts of a vulcanizing agent, 0.4-0.8 part of an accelerant, 0.5-2.2 parts of a release agent and 2.0-10.0 parts of a filling agent. A rubber compound prepared from the low-compression-deformation fluororubber premix is relatively low in permanent compression deformation rate and good in tensile strength. The preparation method is simple, feasible, and easy to realize.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com