Patents

Literature

63 results about "Excess sodium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Certain conditions may cause an excess of sodium in the blood. Specific causes of hypernatremia include: Dehydration or a loss of body fluids from prolonged vomiting, diarrhea, sweating or high fevers. Dehydration from not drinking enough water.

Titanium alloying milling solution and milling technique used for the same

The present invention discloses a titanium alloy chemical milling solution and its application milling process, which mainly contains nitric acid and hydrofluoric acid as the main components of mixed acid acidic corrosion solution, sodium lauryl sulfate, ethylene glycol n-butyl ether and / or or urea additives. The surface tension of the solution is maintained at a stable value by using the present invention. The adsorption of ethylene glycol n-butyl ether can reduce the interfacial tension and increase the chemical milling rate. Sodium lauryl sulfate, which improves the fluidity of the solution, can eliminate excessive corrosion of the metal at the root of the chemical milling fillet, and prevent the appearance of "grooves", "slopes" and "ripples". Sodium nitrate prevents the formation of scale of alloying elements on the surface of the chemical milling groove, improves the surface finish of the chemical milling surface and facilitates maintenance of the equipment. Urea can effectively absorb the nitrogen-containing gas produced in the chemical milling process, reduce the volatilization of acid liquid, and avoid pollution to the environment. The invention does not need heating equipment, the amount of hydrogen added is less than 9ppm, the service life of the solution is long, hydrogen embrittlement does not occur, and the process has little influence on the fatigue performance of the material.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

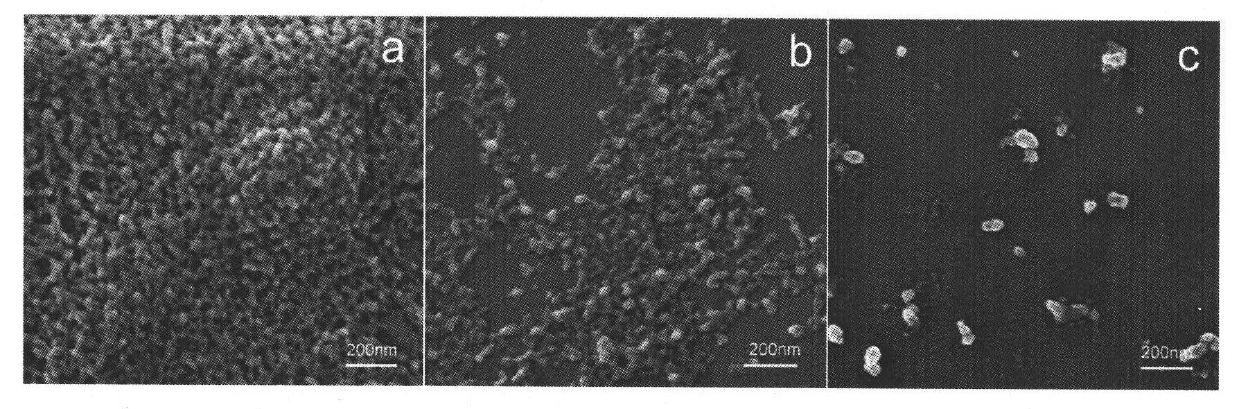

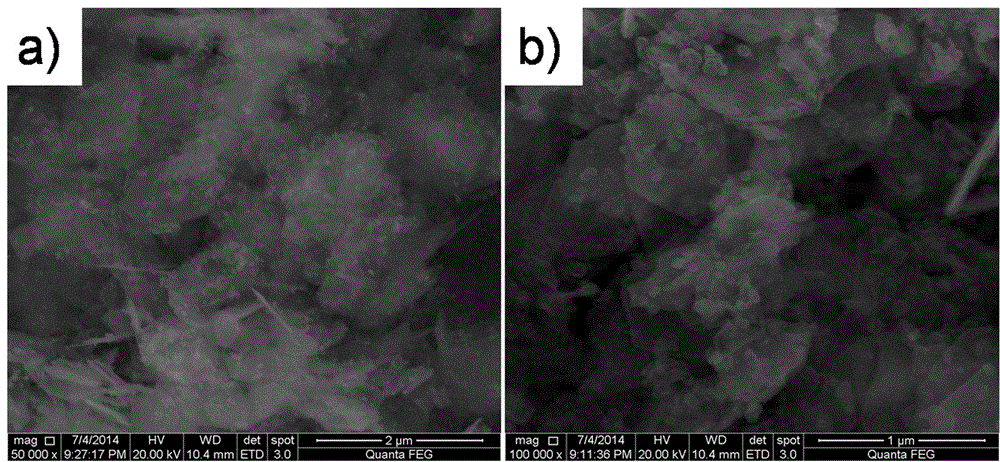

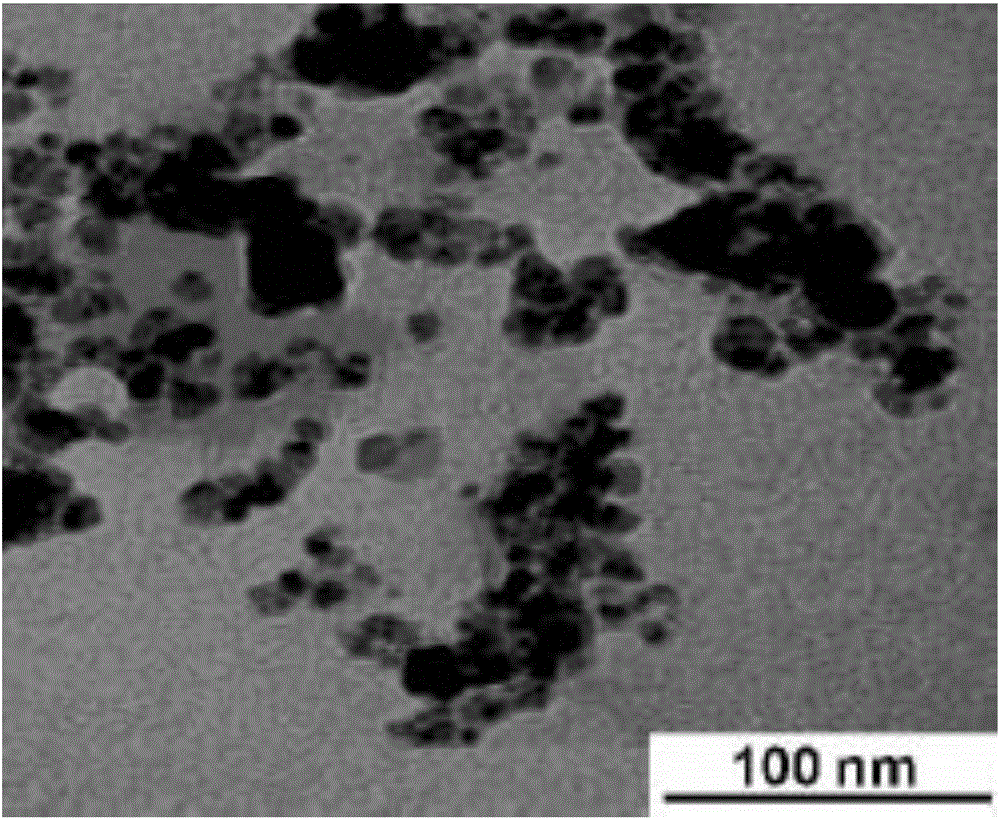

Novel method for preparation of chitosan nano carrier and functionalization thereof

InactiveCN101766820AParticle size controllableHigh mechanical strengthPharmaceutical non-active ingredientsChitosan nanoparticlesPhosphate

The invention discloses a novel method for preparation of a chitosan nano carrier and functionalization thereof, which relates to the chitosan nano carrier. The invention provides a novel method for preparation of the chitosan nano carrier and functionalization thereof. The chitosan is dissolved in acetic acid solution, meanwhile, pH is adjusted to 4.5-5.5 with NaOH solution, STPP (sodium tripolyphosphate) solution is added to the chitosan solution to obtain nanogels, then, crosslinking glutaraldehyde is provided for the chitosan, centrifugation is conducted after ending of reaction, reduction reaction is conducted with excess sodium borohydride, then centrifugation is conducted again, then, the obtained compound is dispersed in hydrochloric acid solution to remove the unreacted sodium borohydride, then dialysis is conducted, in order to wash STPP to obtain nanoparticles; the folic acid is weighed to be dissolved in the phosphate buffer solution, then the solution is added to chitosan nanoparticles water solution, after adding EDCI to the solution, folic acid modified nanoparticles are obtained through reaction; PEG succinimidyl propionate is weighed to be dissolved in the phosphate buffer solution, then is added to the chitosan nanoparticles water solution, after reaction, PEG modified nanoparticles are obtained.

Owner:XIAMEN UNIV

Method for recovering rare earth, aluminum and silicon from rare earth-containing aluminum and silicon wastes

ActiveCN106319218AReduce dosageEfficient separationRare earth metal oxides/hydroxidesRare earth metal chloridesAluminum IonAluminium hydroxide

The invention provides a method for recovering rare earth, aluminum and silicon from rare earth-containing aluminum and silicon wastes. The method comprises the following steps: 1, carrying out acid dipping on the rare earth-containing aluminum and silicon wastes by using an aqueous inorganic acid solution to obtain silicon-rich residues and an acid dipping solution containing rare earth ions and aluminum ions; 2, adding an alkaline substance to the acid dipping solution containing rare earth ions and aluminum ions to control the pH value of the acid dipping solution to be 3.5-5.2, and carrying out solid-liquid separation to obtain an aluminum hydroxide-containing precipitate and a rare earth-containing filtrate; and 3, reacting the aluminum hydroxide-containing precipitate with sodium hydroxide to obtain a sodium metaaluminate solution and aluminum and silicon residues, and using the rare earth-containing filtrate to prepare a rare earth compound product. Aluminum and rare earth are dissolved in the acid, segmented alkaline transfer is carried out, the aluminum ions are precipitated to obtain aluminum hydroxide and the rare earth ions which are separated from the aluminum hydroxide, and excess sodium hydroxide is added to convert aluminum hydroxide into the sodium metaaluminate solution, so simultaneous and high-efficiency recycling of the rare earth and aluminum is realized, the use amount of sodium hydroxide is greatly reduced, and the recovery cost is reduced.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Preparation method of dye-sensitized solar battery cobalt-nickel sulfide counter electrode

InactiveCN105719836AHigh mechanical strengthNo sheddingLight-sensitive devicesPhotovoltaic energy generationNickel saltSlurry

The invention discloses a method for preparing a cobalt-nickel sulfide counter electrode. The steps include: first step, hydrothermally reacting cobalt salt, nickel salt and excess sodium hydroxide or sodium carbonate at 120-200°C to generate hydrogen Oxycobalt nickel or basic cobalt nickel carbonate; the second step, mix the hydroxide cobalt nickel or basic cobalt nickel carbonate with a certain concentration of sulfur source aqueous solution, and heat it at 140-230 ° C; the third step is to generate the sulfur Cobalt nickel is made into a slurry and coated on a conductive substrate, and dried at room temperature. The electrode prepared by the invention does not need to be sintered under vacuum or protective atmosphere, and the preparation process is simple; the prepared cobalt-nickel sulfide counter electrode has high mechanical strength and no shedding phenomenon; Better electrocatalytic activity; Dye-sensitized solar cells assembled with cobalt-nickel sulfide electrodes obtained higher photoelectric conversion efficiency than dye-sensitized solar cells assembled with pyrolyzed Pt electrodes.

Owner:CHINA THREE GORGES UNIV

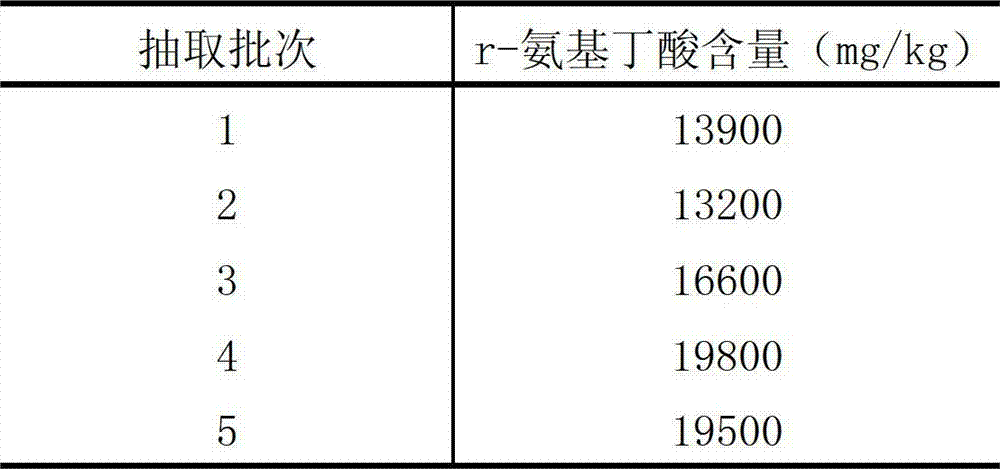

High-r-aminobutyric-acid-content highland-barley red yeast and preparation method thereof

ActiveCN102885303AIncrease contentIncreased r-aminobutyric acid contentFood preparationBiotechnologyGlutamate decarboxylase

The invention discloses a high-r-aminobutyric-acid-content highland-barley red yeast and a preparation method thereof, which belong to the field of biotechnical foods, and particularly relate to a highland-barley red yeast and a preparation method thereof. The highland-barley red yeast is prepared through the following steps of: preparing a slant medium, preparing a seed medium, preparing highland barley embryo buds, preparing a highland barley embryo bud medium, preparing a monascus fermentation seed liquid, inoculating, fermenting and drying. The high-r-aminobutyric-acid-content highland-barley red yeast and preparation method thereof disclosed by the invention have the beneficial effect that the natural r-aminobutyric acid content is improved through using a two-step method: the first step is implemented through catalyzing a glutamic acid or sodium glutamate to be converted into an r-aminobutyric-acid under the action of glutamic acid decarboxylase in the processes of highland barley sprouting and cultivating; and the second step is implemented through combing monascus with highland barley embryo buds, generating a metabolic product r-aminobutyric acid by using a characteristic that a starchiness part in highland barleys is taken as the nutrition metabolism energy of the monascus in the growth and metabolism processes of the monascus, and carrying out biological transformation on excess sodium glutamate, thereby improving the r-aminobutyric acid content.

Owner:西藏月王药诊生态藏药科技有限公司

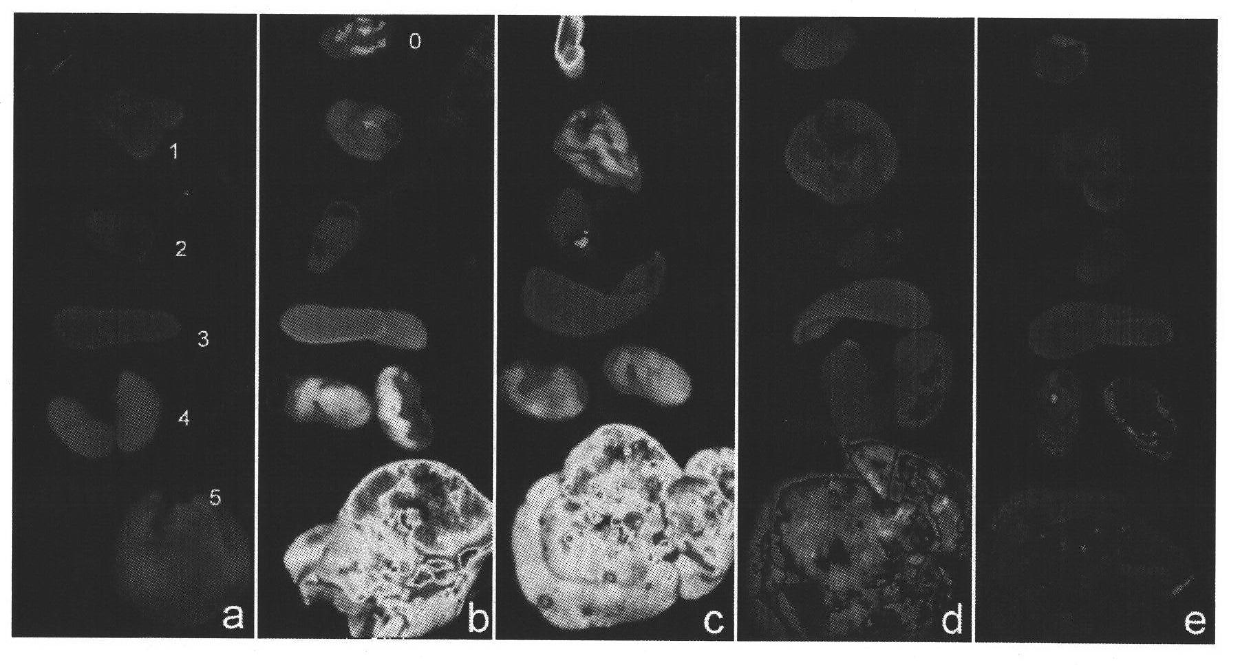

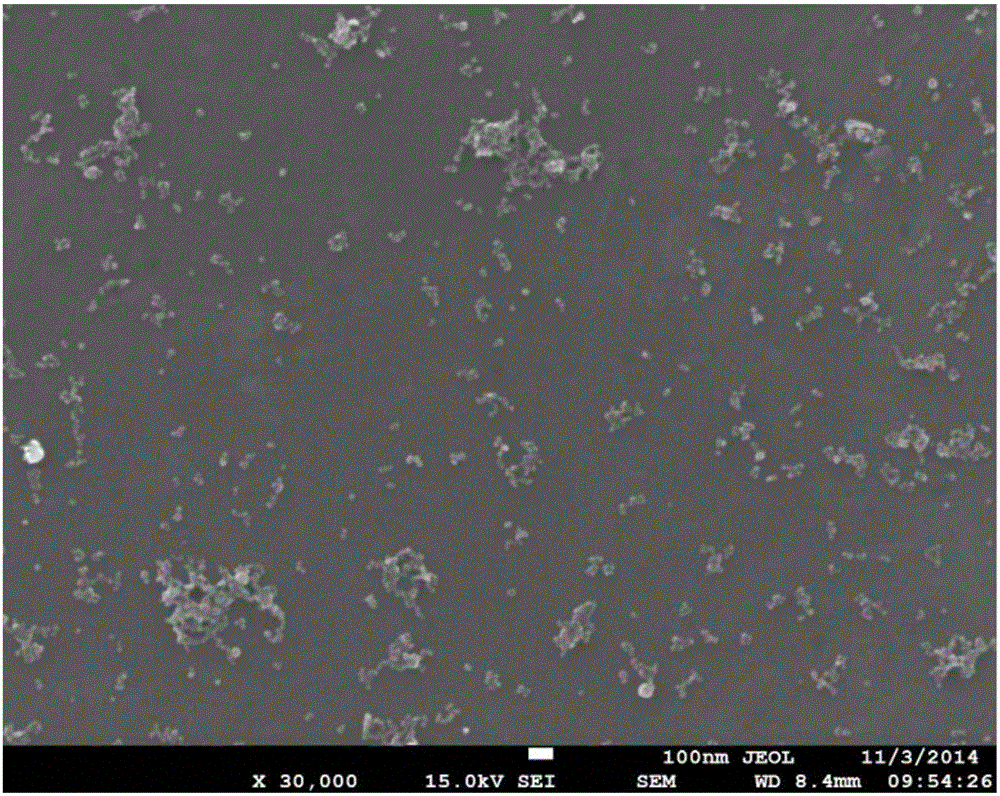

Nano silver-coated copper powder and preparation method and application thereof

InactiveCN105855538ASmall particle sizeParticle size controllableMaterial nanotechnologyTransportation and packagingCopper nitrateNitrogen gas

The invention discloses nano silver-coated copper powder and a preparation method and application thereof. A copper sulfate solution or a copper nitrate solution is mixed with a complexing agent to prepare a complexing copper solution, an alkaline solution is mixed with sodium borohydride and a dispersing agent to obtain a reducing solution, nitrogen is introduced to the reducing agent to remove air, and then the complexing copper solution is added to obtain nano-copper sol; a sulfuric acid solution is added to the nano-copper sol to react with excess sodium borohydride, then the pH is adjusted to 6-7.5 with the alkaline solution so as to obtain a nano-copper sol dispersing solution, then a silver nitrate solution is added to react to obtain a nano-silver coated copper dispersing solution, and after separation, the nano silver-coated copper powder is obtained. The nano silver-coated copper powder prepared according to the invention is core-shell structure nano particles with particle size conforming to ink-jet printing requirement, is low in cost and simple and easy in preparation method, can be used as a conducting material of conducting ink for ink jet printing, and has the advantages of being good in conducting performance and low in cost.

Owner:GUANGDONG UNIV OF TECH

A method for recovering waste lithium ion batteries

ActiveCN109103534APlay a conductive roleCalcination is preferredWaste accumulators reclaimingBattery recyclingRecovery methodPhysical chemistry

A method for recovering waste lithium ion batteries comprises the following steps: 1) discharging the waste lithium ion batteries and burying the waste lithium ion batteries in solid conductive powder; 2) pulverizing the waste lithium ion batteries, and then calcinating the pulverized waste lithium ion batteries at temperature of 400 DEG C- 600 DEG C without oxygen; 3) performing separation; 4) collecting powder sieved by a vibrating screen for standby use; 5) adding the powder of step 4) to excess NaOH; 6) adding the filter residue obtained in the step 5) into a mixed solution of sulfuric acid and H2O2, and filtering to obtain a solution; 7) adding excess sodium carbonate into the solution of the step 6), and washing and drying the precipitate obtained. The recovery method of the waste lithium ion batteries has high recovery efficiency; when discharging the waste lithium ion batteries, the method adopts the form of buried micro-discharge to be safe, high-efficient and pollution-free.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

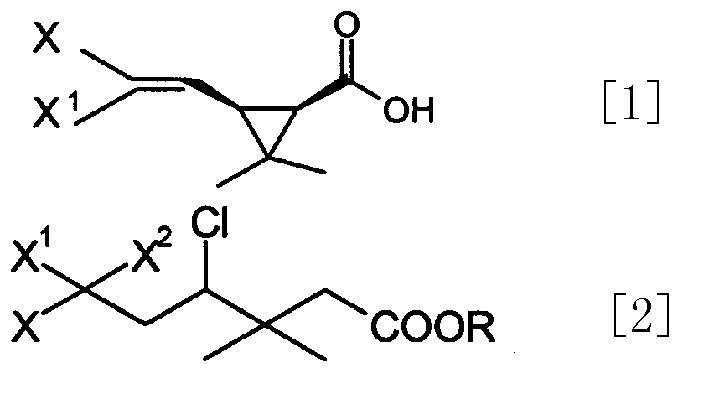

Process for preparing cis-halochrysanthemic acid

InactiveCN1390825AIncrease dosageReduce dosagePreparation from carboxylic acid esters/lactonesHexamethylphosphoramideTert butyl

A process for preparing cis-halochrysanthemic acid includes such steps as the addition reaction of raw material (sodium tert-butyl alkoxide), reaction for removing hydrogen chloride and hydrolysis, reflux with excess sodium hydroxide in the mixed solvent of methanol or ethanol and water to obtain cyclocompound, and acidation. Its advantages are simple process, high output rate, low cost and less pollution.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

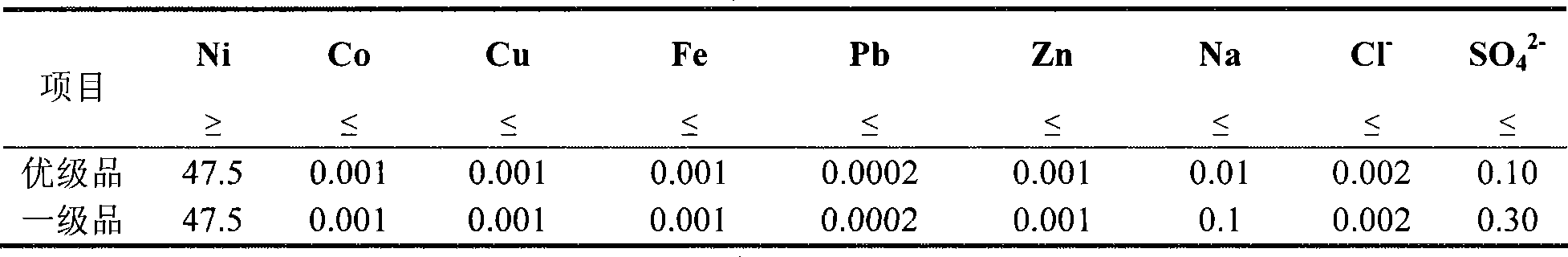

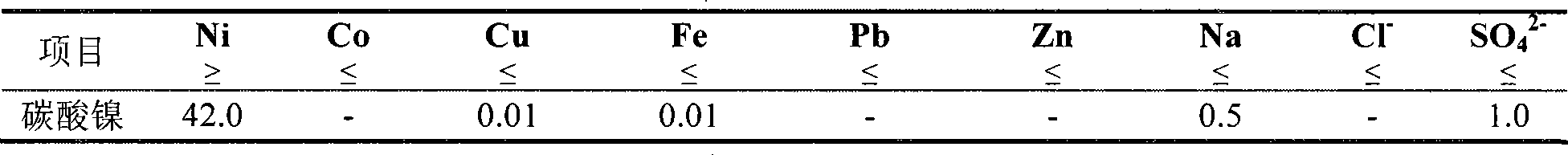

Method for continuously synthesizing nickel carbonate

InactiveCN101519229AImprove product qualityAvoid problems that are not easy to removeNickel carbonatesSulfateElectronic industry

The invention relates to a method for continuously synthesizing nickel carbonate, which is characterized by comprising the synthesizing processes: adding and combining a nickel sulfate solution with the concentration of nickel ions from 50 g / l to 55 g / l and a sodium carbonate solution with the concentration from 120 g / l to 125 g / l into a synthesizing kettle according to a flow rate of 1 to 1.2:1, and controlling the pH value of a synthesizing process to be 8.3-8.6 to synthesize the nickel carbonate. The method strictly controls the adding rate of the two raw solutions and the pH values, effectively solves the problems in the prior art that because the excess sodium carbonate solution is added, more local complex salts (Ni1-x / 2-y / 2Nax(CO3)1-a-b / 2(SO4)a(OH)b are generated, the impurity content of the prepared nickel carbonate is higher, the impurities, such as sodium, chlorine, and the like are not easy to be removed in a washing process, thereby effectively improving the product quality of the nickel carbonate, and meeting the requirements of electronic-grade nickel protoxide production and electronic industry.

Owner:JINCHUAN GROUP LIMITED

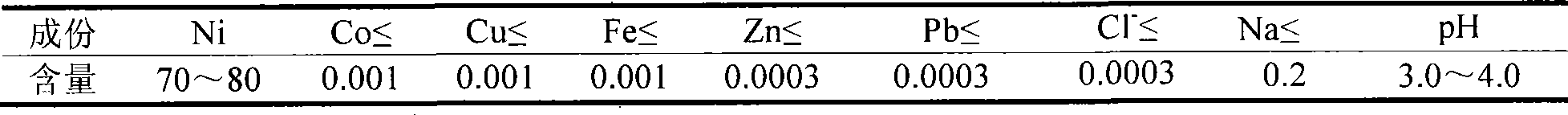

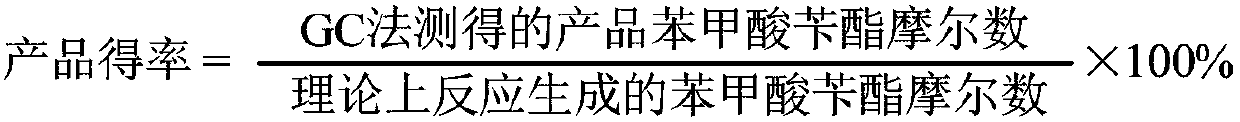

Synthetic method of benzyl benzoate

InactiveCN108047036AHigh reaction conversion rateHigh selectivityOrganic compound preparationCarboxylic acid esters separation/purificationOrganic synthesisDistillation

The invention discloses a synthetic method of benzyl benzoate and belongs to the field of organic synthesis. The synthetic method comprises the following steps of adding sodium benzoate, benzyl chloride and a solvent in a reaction vessel, and performing reaction under the environment with the temperature of 60-100 DEG C to produce the benzyl benzoate; after reaction is finished, performing cooling, filtering the cooled benzyl benzoate to remove sodium chloride solids which precipitate from a reaction solution; after removing the solvent from the reaction solution with steaming, filtering excess sodium benzoate; removing low-boiling substances and high-boiling substances in a product from a filtrate solution through distillation and rectification to obtain a finished product. By avoiding use of a catalyst, the method is short in reaction time, simple in reaction condition and high in product yield.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

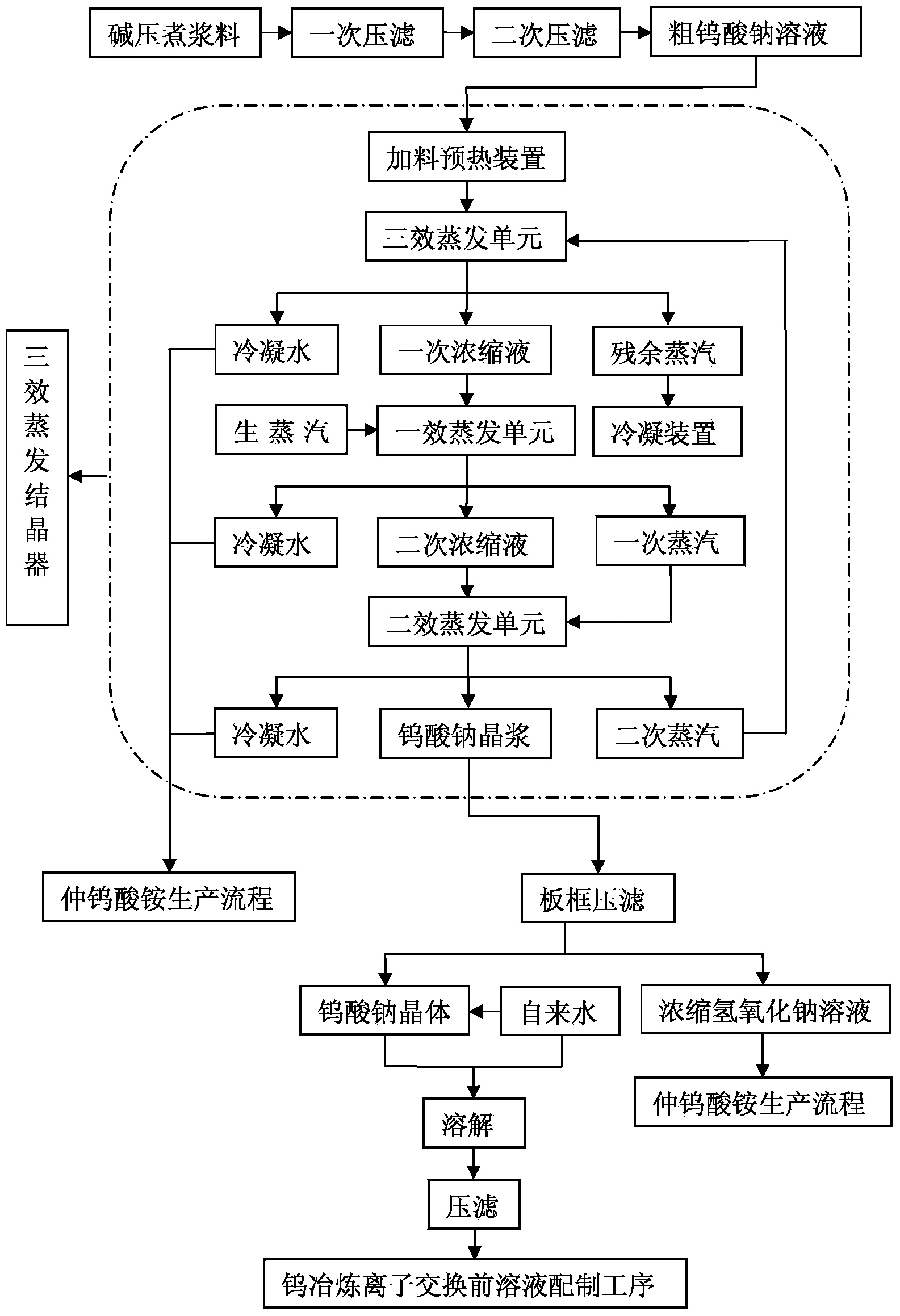

Method for recovering excess sodium hydroxide in tungsten smelting crude sodium tungstate solution

ActiveCN103523800AImprove recycling efficiencyPrevent crystallizationProcess efficiency improvementAlkali metal oxides/hydroxidesFiltrationEvaporation

Owner:CNMC GUANGXI PGMA

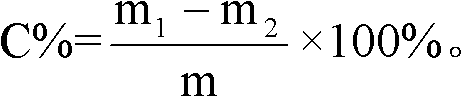

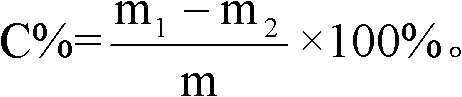

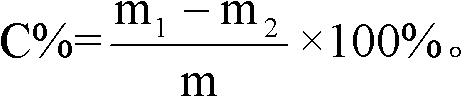

A method for analyzing free carbon

InactiveCN102288514ASimple and fast operationEasy to masterWeighing by removing componentPreparing sample for investigationMuffle furnaceSodium nitrite

The invention relates to a method for analyzing free carbon and belongs to the field of analytical chemistry. A pure chemical analysis method is established; by the method, a carbon sulfur determination instrument is not required; and the method is simple and convenient to operate, and easy to master. The invention adopts the technical scheme that: the method comprises the following steps of: weighting a sample of which mass is m for pre-processing; wetting the sample by using water, adding an acidic solution, and then adding a potassium permanganate solution and adding two drops more when the red color of the solution appears till the red color does not disappear in 3 minutes; adding a sodium nitrite solution, adding two drops more when the red color of the solution disappears, and removing the excess sodium nitrite by using urea; filtering, moving filter paper and residues into a porcelain crucible together, putting into a muffle furnace, firing at the temperature of 550 to 610 DEG C till constant weight, cooling to room temperature, and weighting mass m1; putting into the muffle furnace again, firing at the temperature of 850 to 950 DEG C till the constant weight, cooling to the room temperature, and weighting mass m2; and calculating the percentage content of the free carbon, namely C%=(m1-m2) / m*100%.

Owner:PANZHIHUA UNIV

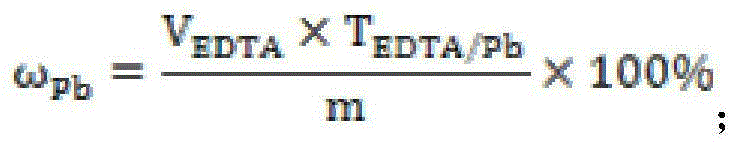

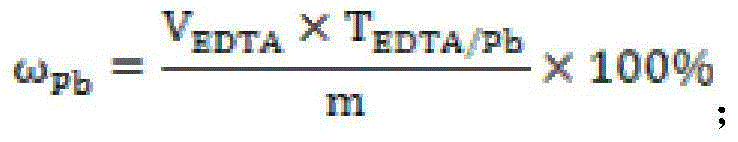

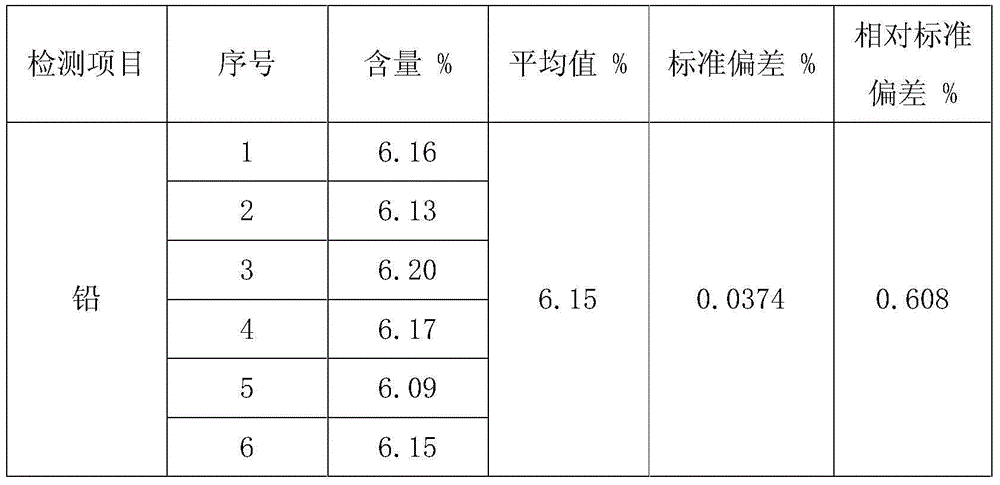

Rapid analysis method of lead in gold mud

ActiveCN105044097AFill vacancyEliminate distractionsMaterial analysis by observing effect on chemical indicatorSodium acetateSodium acetrizoate

The invention relates to a rapid analysis method of lead in gold mud. The method comprises the following steps: processing a sample by nitric acid, aqua regia, sulfuric acid, and a mixed acid of nitric acid and sulfuric acid in sequence, after the acid is smoked and evaporated, adding diluted sulfuric acid, boiling to dissolve the salts, adding excess sodium hyposulfite to reduce gold to zero valent and precipitate silver; allowing the system to stand still to carry out aging, filtering, washing the precipitate by diluted sulfuric acid and water; dissolving the precipitate by an acetic acid-sodium acetate buffer solution, filtering, recovering gold and silver, adding a xylenol orange indicator into the filtrate, dropwise adding EDTA until the color of the solution changes from purple-red to light yellow, wherein the color change shows that the titration end point is reached, and finally calculating the lead content. In the provided method, sodium hyposulfite is used to reduce gold and precipitate silver so as to effectively separated gold and silver from lead, thus the interference of gold and silver on the end point is avoided, moreover, the operation is largely simplified, and precise and stable analysis results can be obtained by the provided method.

Owner:山东黄金冶炼有限公司

Regeneration utilization method of germanium in infrared chalcogenide glass waste material

PendingCN109385540AAchieve recyclingRealize recyclingProcess efficiency improvementDistillationZone melting

The invention more specifically relates to a regeneration utilization method of germanium in infrared chalcogenide glass waste material. According to the regeneration utilization method of germanium in infrared chalcogenide glass waste material, germanium is extracted from infrared chalcogenide glass waste material, and the method principles are that: the oxidation performance of H2O2 is adopted to destroy Ge-Se, Ge-As, Ge-Sb bonds in infrared chalcogenide glass waste material, germanium is oxidized into GeO, a single GeO layer is formed on the surface, GeO is oxidized into GeO2, GeO2 is dissolved in water to form germanic acid; when an obtained solution contains an alkali, germanic acid is reacted with the alkali to produce sodium germinate, so that germanium dissolving is accelerated; concentrated sulfuric acid is adopted to neutralize excess sodium hydroxide solution and adjust and control the concentration of hydrogen ions in the solution; FeCl3 is adopted to oxidize As<3+> into As<6+>, and sufficienct chloride ions are provided; concentrated hydrochloric acid is adopted for distillation of germanium tetrachloride from the solution, and AsCl6 is left in a distillation raffinate; the germanium tetrachloride obtained through distillation is subjected to traditional technology including secondary distillation, rectification, hydrolysis, reduction, and zone melting so as to obtain high purity zone-refined germanium ingot.

Owner:YUNNAN KIRO CH PHOTONICS

Eluting agent for removing heavy metals in agricultural solid organic compost and removal method using the same

InactiveCN103980041ALow costReduce churnFertilizer mixturesAlkyl polyglycosidePhosphatidylethanolamine

The invention discloses an eluting agent for removing heavy metals in agricultural solid organic compost and a removal method using the same. The eluting agent is prepared from 2-4wt% of alkyl polyglycoside, 1-2wt% of phosphatidylethanolamine (phosphatidylcholine or phosphatidic acid), 1wt% of mannoprotein and the balance water. The removal method comprises the following steps of putting decomposed organic compost into a cement pool, eluting the decomposed organic compost by an eluant of which the volume is 4-6 times that of the organic compost from a position above the organic compost, carrying out re-eluting by the eluant once after 12-24h after the eluting, carrying out eluting again by water, collecting the eluting solution, and adding excess sodium hydroxide into the eluting solution so that heavy metals in the filtrate are precipitated. The biochemical eluting agent has a simple formula, substantial effects, good removal effects on copper, zinc, arsenic and selenium in the compost and characteristics of low cost and high restoration efficiency.

Owner:ANHUI SCI & TECH UNIV

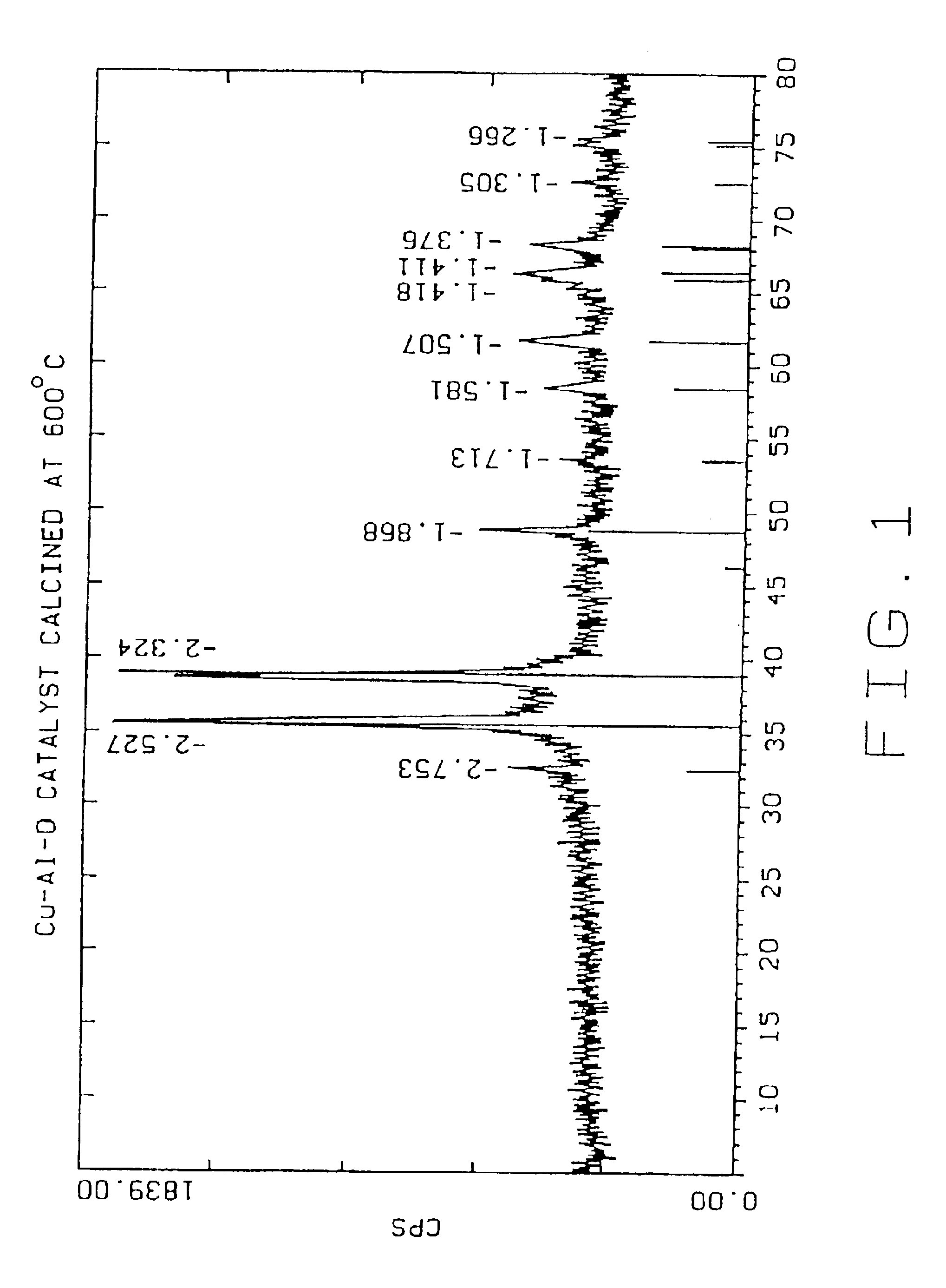

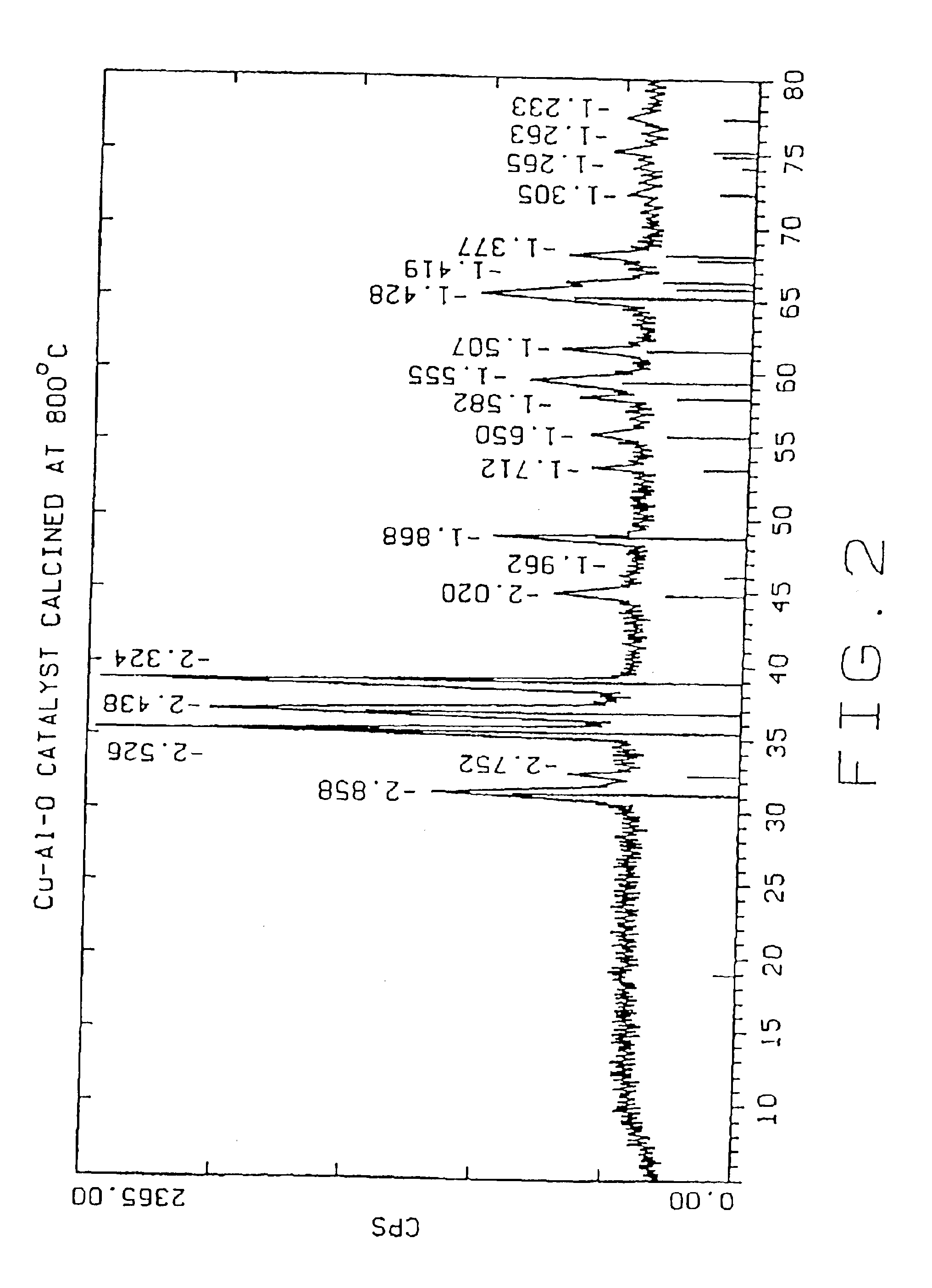

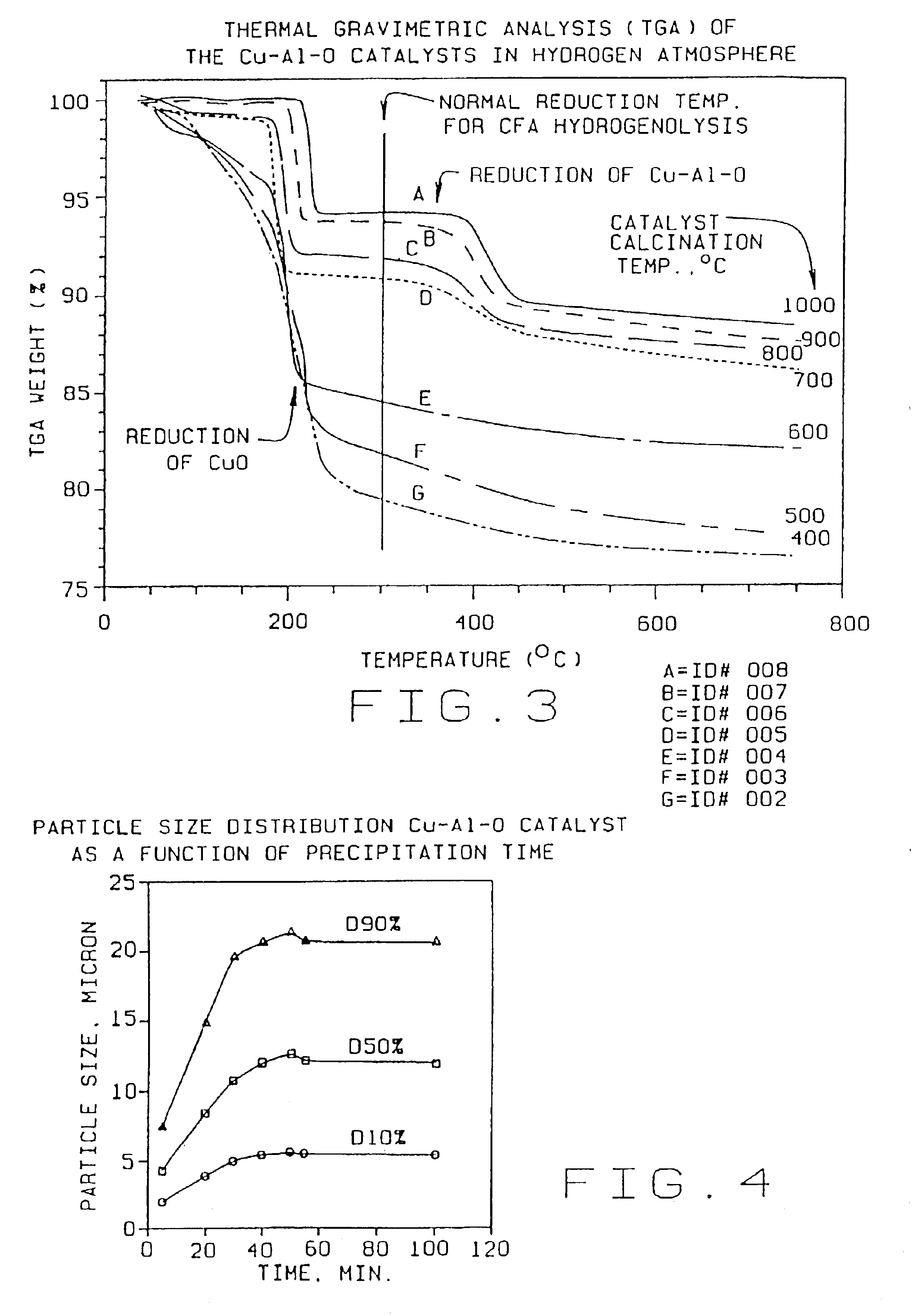

Preparation and use of non-chrome catalysts for Cu/Cr catalyst applications

InactiveUS6916457B2Comparable and superior activity and selectivityEliminate environmental problemsPreparation by oxidation reactionsSulfur compoundsHydrogenSodium aluminate

A non-chrome, copper-containing catalyst, Cu—Al—O and method of preparing the same are provided wherein the Cu—Al—O catalyst is prepared by the co-precipitation of copper nitrate (Cu(NO3)2) and sodium aluminate (Na2Al2O4) solutions using sodium carbonate (Na2CO3) as a precipitant. The precipitate is filtered, washed to removed excess sodium, and dried. The dried product, to be used in a powder form, is calcined at a preferred temperature of approximately 700° to 900° C. for approximately 1 to 4 hours. The dry powder, to be tableted or extruded, is calcined at a temperature of approximately 400° to 700° C. The activity of the Cu—Al—O catalyst can be promoted in hydrogenolysis applications by the addition of various agents. The Cu—Al—O catalyst can be employed in applications in place of Cu / Cr, or other copper based catalysts.

Owner:ENGELHARD CORP

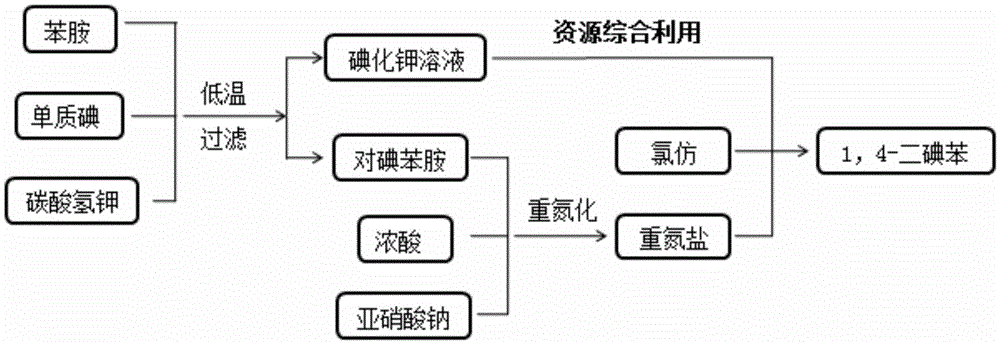

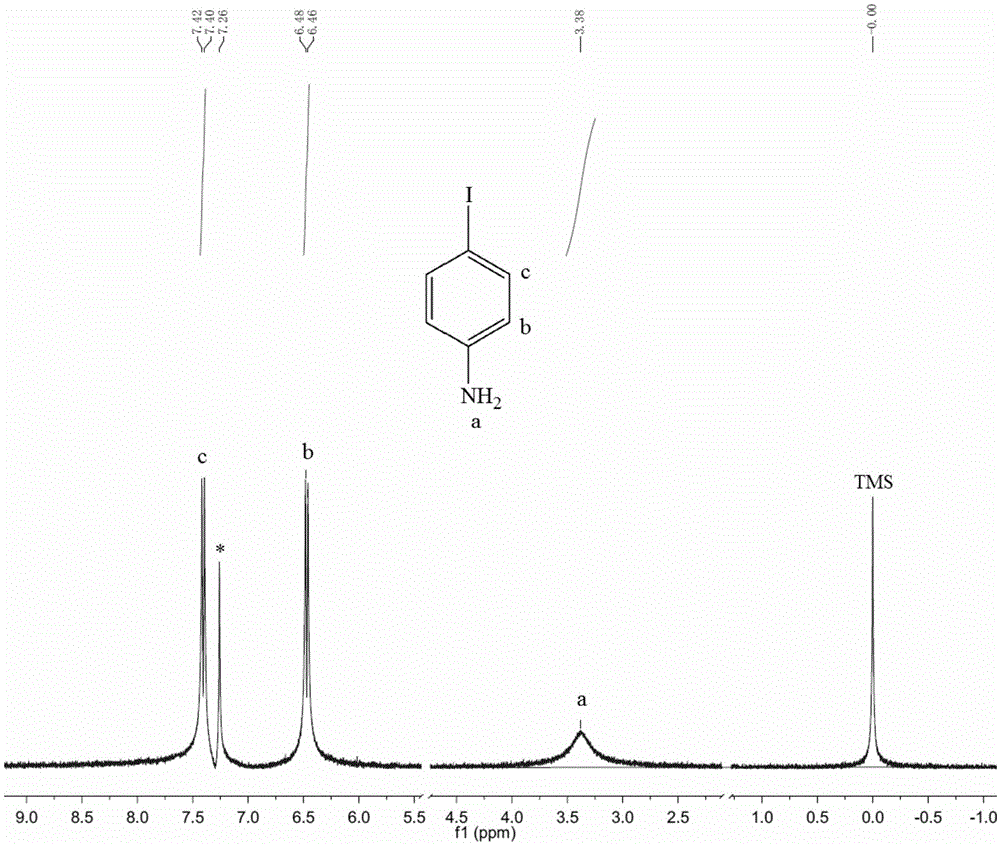

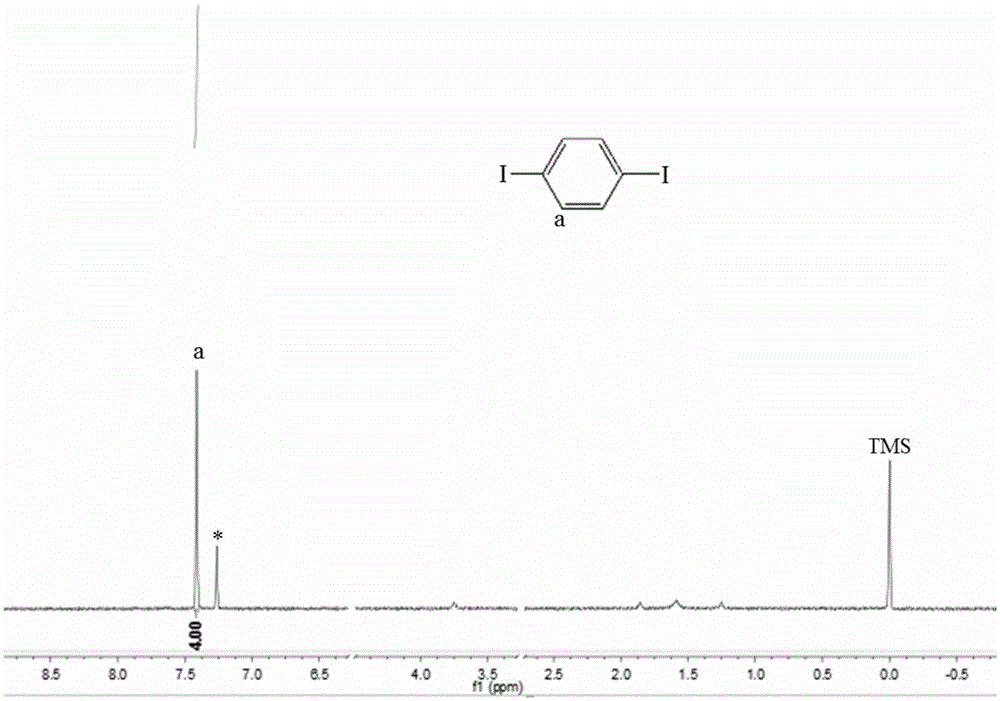

Green preparation technique of 1,4-diiodo-benzene

ActiveCN105669357AHigh purityReduce manufacturing costOrganic compound preparationAmino compound preparationAnilinePotassium iodine

The invention relates to a green preparation technique of 1,4-diiodo-benzene. The technique comprises the following steps: carrying out electrophilic substitution reaction on a simple substance iodine and aniline in a weakly alkaline medium solution, separating, and drying to obtain a paraiodoaniline crude product; carrying out diazo-reaction on the paraiodoaniline crude product and a sodium nitrate solution to prepare a diazonium salt, and removing excess sodium nitrate in the system; adding chloroform and a potassium iodide solution into the reaction system, reacting for 3-6 hours while keeping the temperature at -5 to -10 DEG C, slowly heating to room temperature, continuing reacting for 2-6 hours, and carrying out separation and purification on the reaction product to obtain the 1,4-diiodo-benzene. The technique has the advantage of high product purity, and obviously lowers the production cost. The technique implements comprehensive utilization of the potassium iodide waste solution resources, thereby lowering the production cost. The technique simplifies the operation engineering, and enhances the yield of the product.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

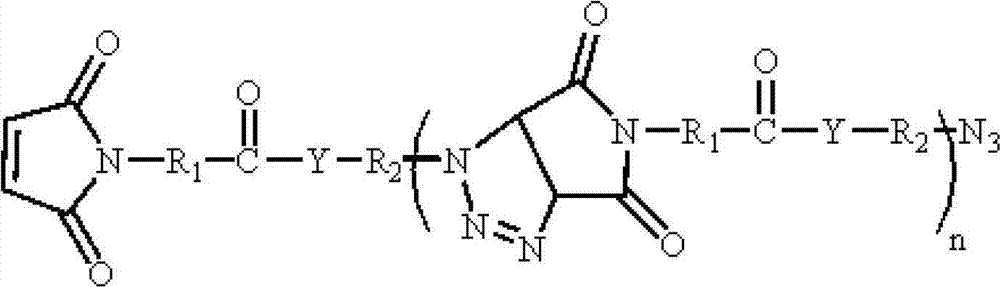

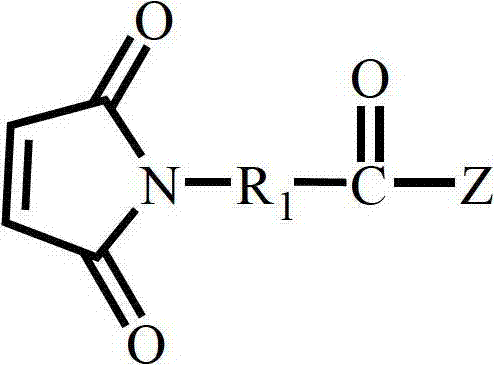

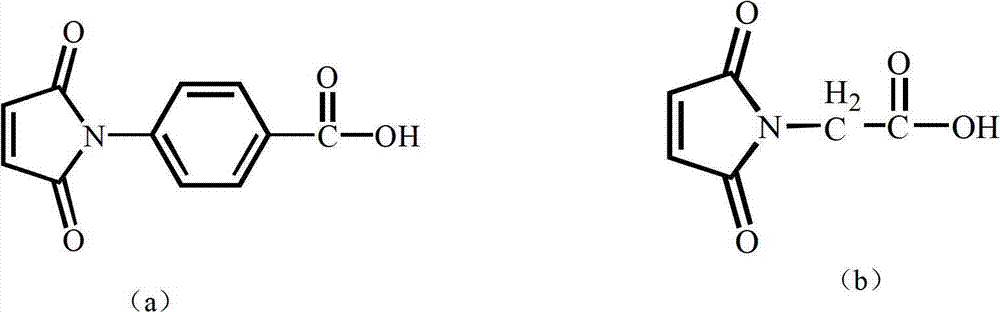

Polymaleimide polymer as well as preparation method and application of polymaleimide polymer

The invention discloses a polymaleimide polymer as well as a preparation method and an application of the polymaleimide polymer. In the preparation method, sodium azide and maleimide substance of which the tail end is halogen are used as raw materials for the first time, and the polymaleimide polymer is prepared by the cycloaddition reaction of the nitrine and the maleimide. The cycloaddition reaction of the nitrine and the maleimide is a click chemical reaction, a catalyst is not needed, and the purification technology is simple, moreover, the maleimide substance can be dissolved in most organic solvents, and the nitrine is almost insoluble in the organic solvent, thus, the reaction of the nitrine and the maleimide is a two-phase reaction; based on the advantages of the two-phase reaction, excess sodium azide is separated, and the synthesis technology is simplified. In the preparation method, the reaction temperature is lower, isomers cannot be generated, the simplicity of the product structure is guaranteed, and the prepared polymaleimide polymer is excellent in heat resistance and bonding performance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

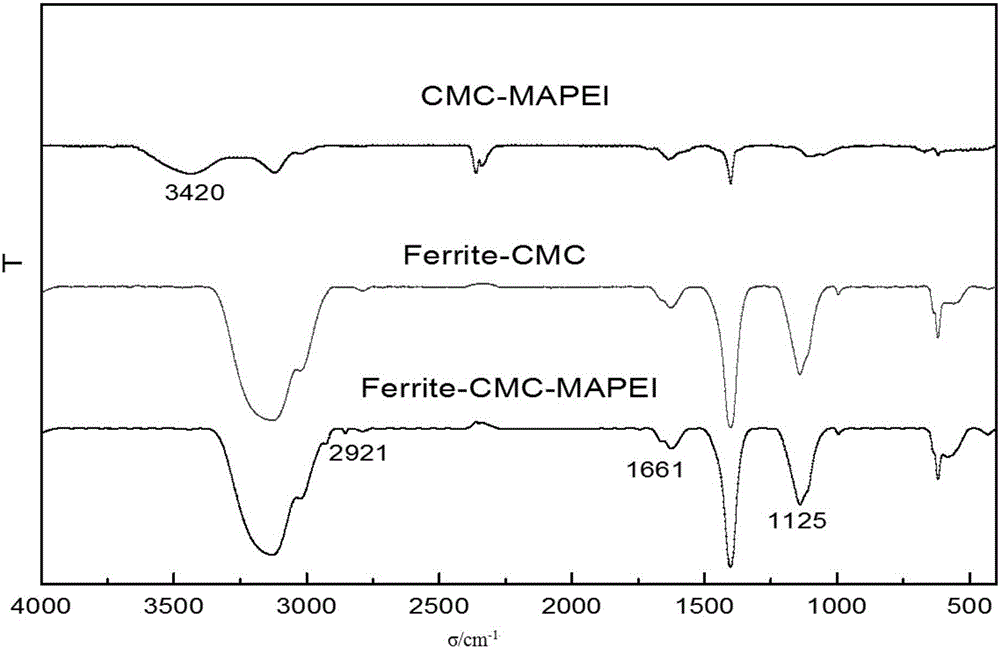

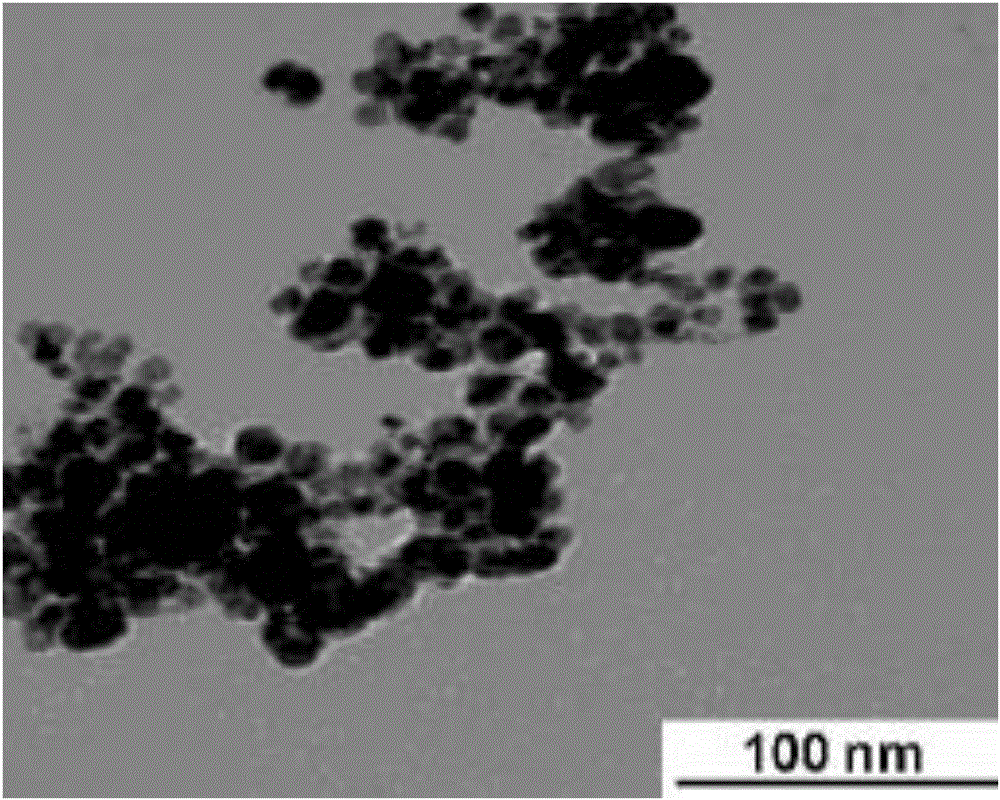

Composite flocculant preparation and heavy metal organic matter-containing tailings wastewater treatment method

InactiveCN106542625AEasy to handleImprove performanceWater contaminantsWater/sewage treatment by flocculation/precipitationPollutionThiol group

The invention provides composite flocculant preparation and a heavy metal organic matter-containing tailings wastewater treatment method. The composite flocculant preparation comprises: mixing a magnesium-copper-zinc ferrite and distilled water, carrying out ultrasonic dispersing, adding an excess sodium carboxymethyl cellulose aqueous solution in a dropwise manner, carrying out a stirring reaction to generate magnesium-copper-zinc ferrite-carboxymethyl cellulose, adding excess thioglycolic acid, carrying out an amidation reaction by using polyethylene imine as a precursor and using a polypeptide reagent as an initiator to prepare mercaptoacetyl polyethylene imine, adding the excess mercaptoacetyl polyethylene imine aqueous solution to the magnesium-copper-zinc ferrite-carboxymethyl cellulose, uniformly stirring, adding an excess glutaraldehyde aqueous solution in a dropwise manner, carrying out a stirring reaction, washing, and drying to obtain the composite flocculant. According to the present invention, the net capturing sweeping effect and the chelating effect of the sulfur terminal having the heavy metal affinity and the amphoteric groups such as carbonyl and amino in the thiol group of the novel polymer composite flocculant are used, such that the low concentration heavy metal and the organic pollution in composite wastewater are effectively treated, and the performance is stable.

Owner:SHANGLUO UNIV +1

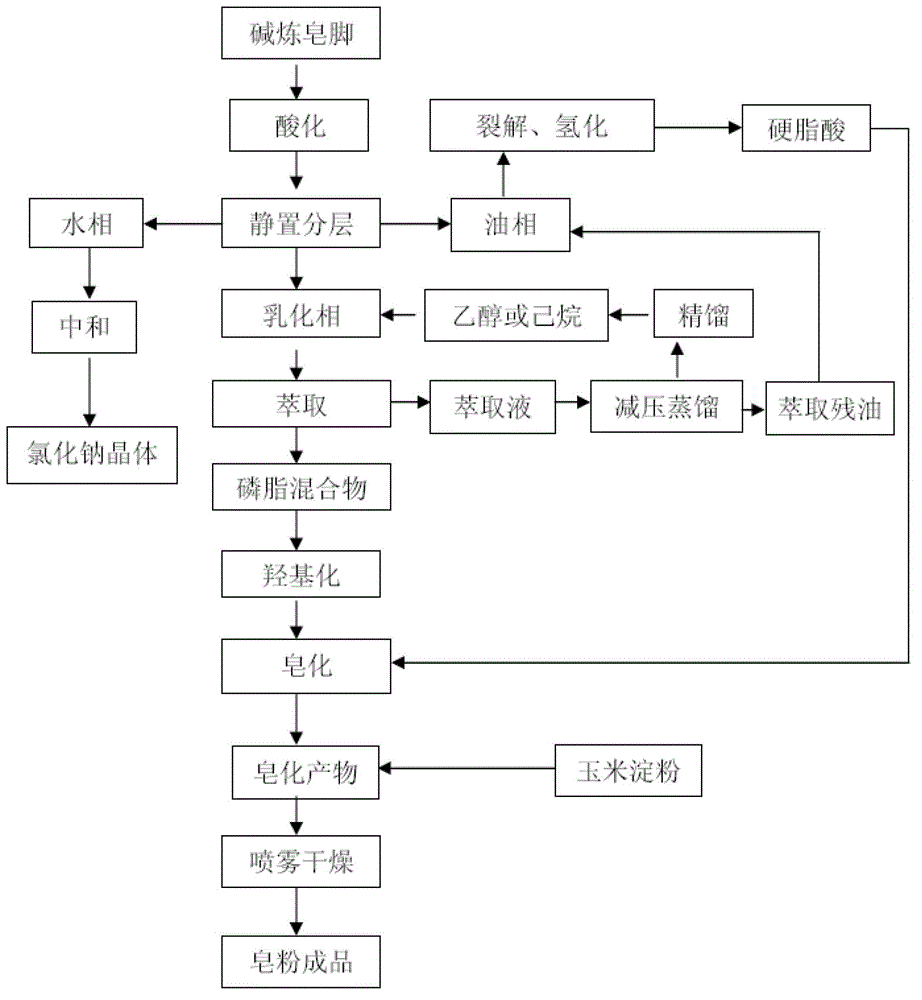

Method of producing powdered soap by using vegetable oil alkali refining nigre containing phospholipid

ActiveCN103333751AEfficient recyclingSolve pollutionAlkali/ammonium soap compositionsVegetable oilOil phase

The invention relates to a method of producing powdered soap by using vegetable oil alkali refining nigre containing phospholipid. The method comprises a step of mixing and stirring the vegetable oil alkali refining nigre with hydrochloric acid for acidification, and separating a water phase, an emulsification phase and an oil phase after the mixture is layered; a step of mixing the emulsification phase with an organic solvent and extracting to obtain a phospholipid mixture; a step of adding lactic acid or acetic acid into the phospholipid mixture obtained after extraction that is performed to remove oil, adding hydrogen peroxide, and mixing, stirring and performing a hydroxylation reaction at 40-70 DEG C; a step of adding excess sodium hydroxide into the product of the hydroxylation reaction after the hydroxylation reaction is finished, and mixing, stirring and performing a saponification reaction at 50 DEG C; and a step of mixing the product of the saponification reaction with corn starch, and performing spray drying to obtain the powdered soap. According to the method provided by the invention, nigre produced by vegetable oil alkali refining can be made full use of, phospholipid contained in the nigre can be effectively recycled, and therefore problems of material waste and environmental pollution, which are caused by inadequate utilization of the vegetable oil alkali refining nigre, are prevented.

Owner:SANHE HOPEFULL BIOTECH

Novel method for preparation of chitosan nano carrier and functionalization thereof

InactiveCN101766820BParticle size controllableHigh mechanical strengthPharmaceutical non-active ingredientsChitosan nanoparticlesPhosphate

The invention discloses a novel method for preparation of a chitosan nano carrier and functionalization thereof, which relates to the chitosan nano carrier. The invention provides a novel method for preparation of the chitosan nano carrier and functionalization thereof. The chitosan is dissolved in acetic acid solution, meanwhile, pH is adjusted to 4.5-5.5 with NaOH solution, STPP (sodium tripolyphosphate) solution is added to the chitosan solution to obtain nanogels, then, crosslinking glutaraldehyde is provided for the chitosan, centrifugation is conducted after ending of reaction, reduction reaction is conducted with excess sodium borohydride, then centrifugation is conducted again, then, the obtained compound is dispersed in hydrochloric acid solution to remove the unreacted sodium borohydride, then dialysis is conducted, in order to wash STPP to obtain nanoparticles; the folic acid is weighed to be dissolved in the phosphate buffer solution, then the solution is added to chitosannanoparticles water solution, after adding EDCI to the solution, folic acid modified nanoparticles are obtained through reaction; PEG succinimidyl propionate is weighed to be dissolved in the phosphate buffer solution, then is added to the chitosan nanoparticles water solution, after reaction, PEG modified nanoparticles are obtained.

Owner:XIAMEN UNIV

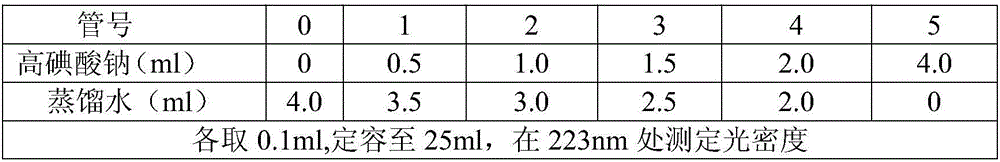

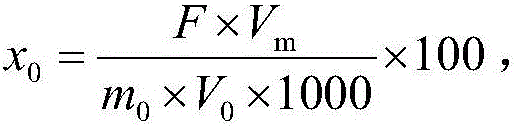

Structural analysis method of beta-glucan

InactiveCN106323895AReduce solubilityImprove accuracyMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsHelicaseStructural analysis

The invention provides a structural analysis method of beta-glucan. The structural analysis method comprises the following steps: (1) measuring the reducing sugar quantity x0 by using an alkaline cupric tartrate solution titration method; (2) measuring the reducing sugar quantity x1 of a sample treated by using amylase by the alkaline cupric tartrate solution titration method; (3) measuring the reducing sugar quantity x2 of a sample treated by helicase by using the alkaline cupric tartrate solution titration method; (4) dissolving a to-be-measured sample in water, and adding enough sodium periodate for reacting; after complete reaction, adding ethylene glycol to break excess sodium periodate; measuring the optical density of the solution at a wavelength of 223nm; and calculating the consumption amount n1 mole of periodic acid; and (5) taking the solution obtained by the step (4), performing titration with a sodium hydroxide solution, and calculating the formic acid release amount n2 mole. Through calculation, the beta-glucan linked by 1,3- and 1,6-glucosidic bonds and 1,3- and 1,4-glucosidic bonds can be identified by a chemical analysis method.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

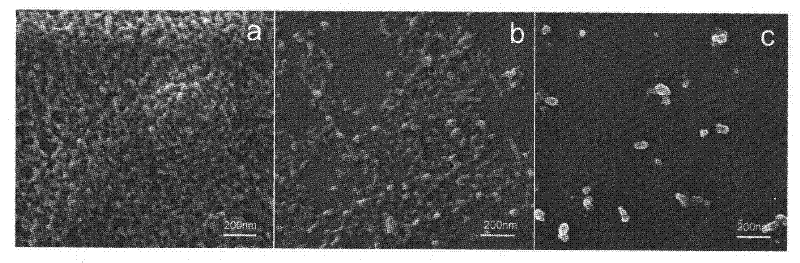

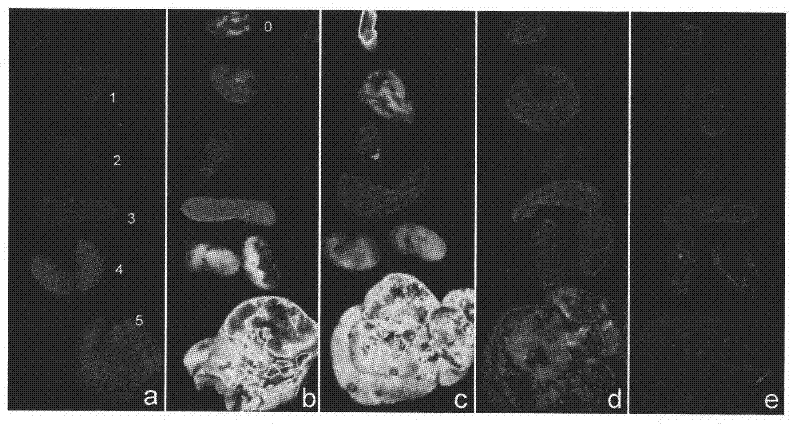

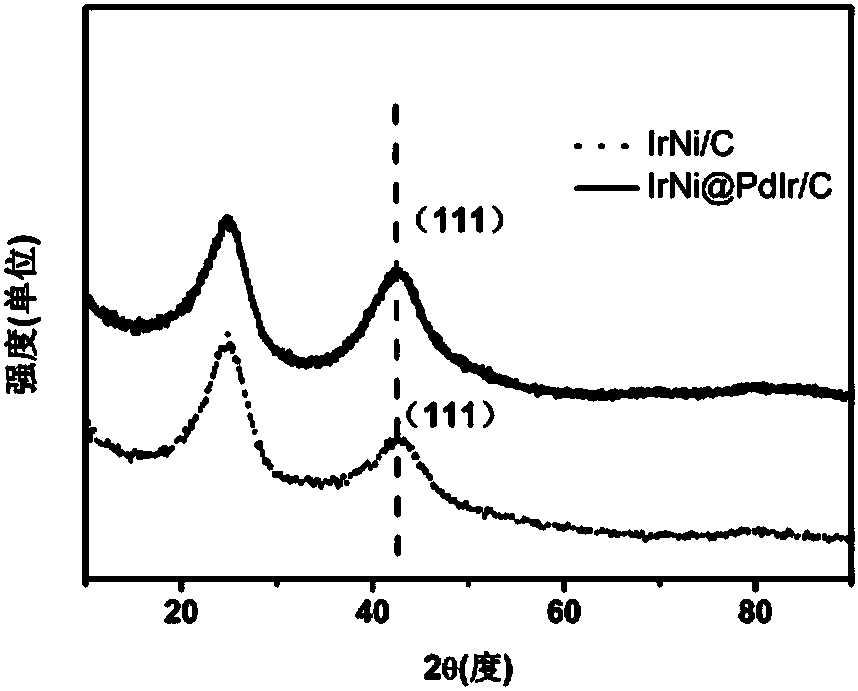

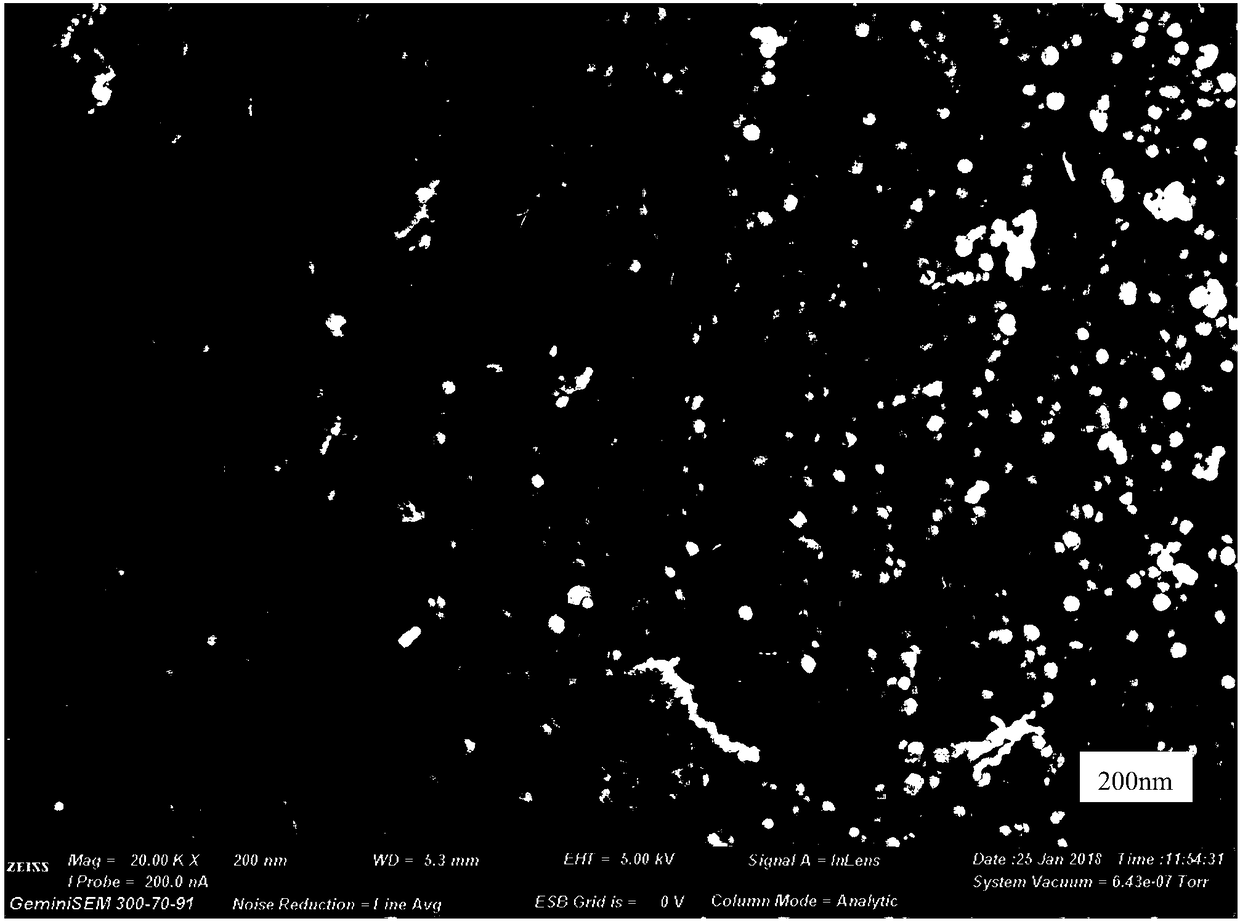

Hydroxide IrNi@PdIr/C core-shell catalyst for alkaline anion exchange film fuse cell and application thereof

The invention relates to a hydroxide IrNi@PdIr / C core-shell catalyst for an alkaline anion exchange film fuse cell and application thereof. The method specifically comprises a step of dissolving an appropriate amount of carbon carriers and a stabilizer in ethylene glycol with chloroantimonic acid and nickel chloride as metal precursor salts, ultrasonically stirring, adjusting pH to be alkaline byusing NaOH, introducing nitrogen gas for protection, adding an excess sodium borohydride reducing agent, and after reaction is completed, preparing IrNi nano particles with the average diameter of 2-4nm through centrifugation, washing and drying, and a step of weighing an appropriate amount of IrNi nanoparticles, placing the appropriate amount of IrNi nanoparticles into deionized water and isopropanol, mixing evenly, adding a PdCl2 solution, and after a replacement reaction for a period of time, obtaining IrNi@PdIr / C core-shell catalyst through centrifugal washing, vacuum drying and heat treatment under a hydrogen atmosphere. The particle size of the catalyst is distributed between 2 and 13 nanometers, and the catalyst is uniformly dispersed without agglomeration. The mass specific activity of the catalyst at 50mV overpotential is 1.78 times of that of commercial Pt / C, 3.06 times of that of Ir / C and 10.8 times of that of Pd / C, and the catalyst has an application value in the hydroxideof the anion exchange film fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

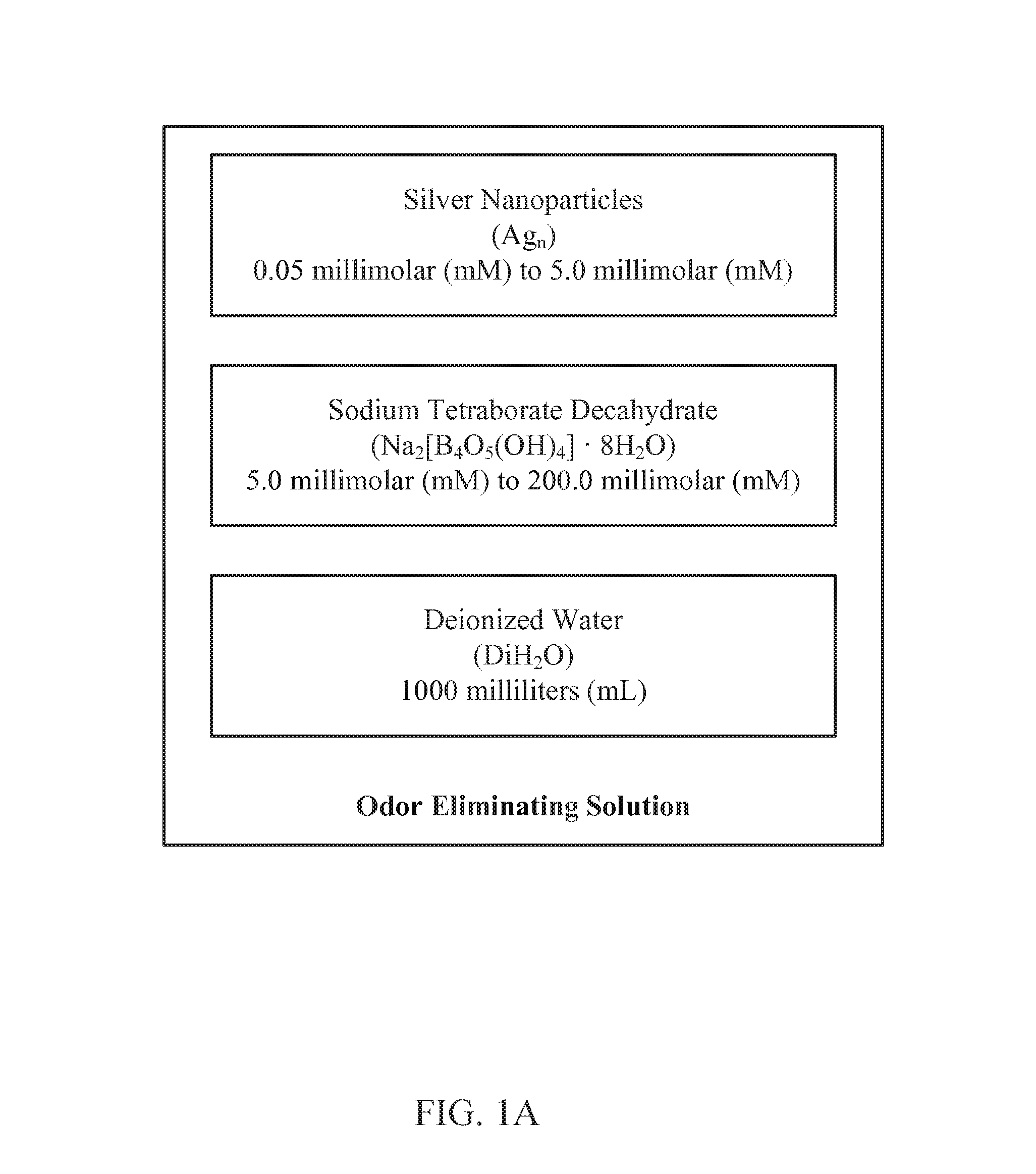

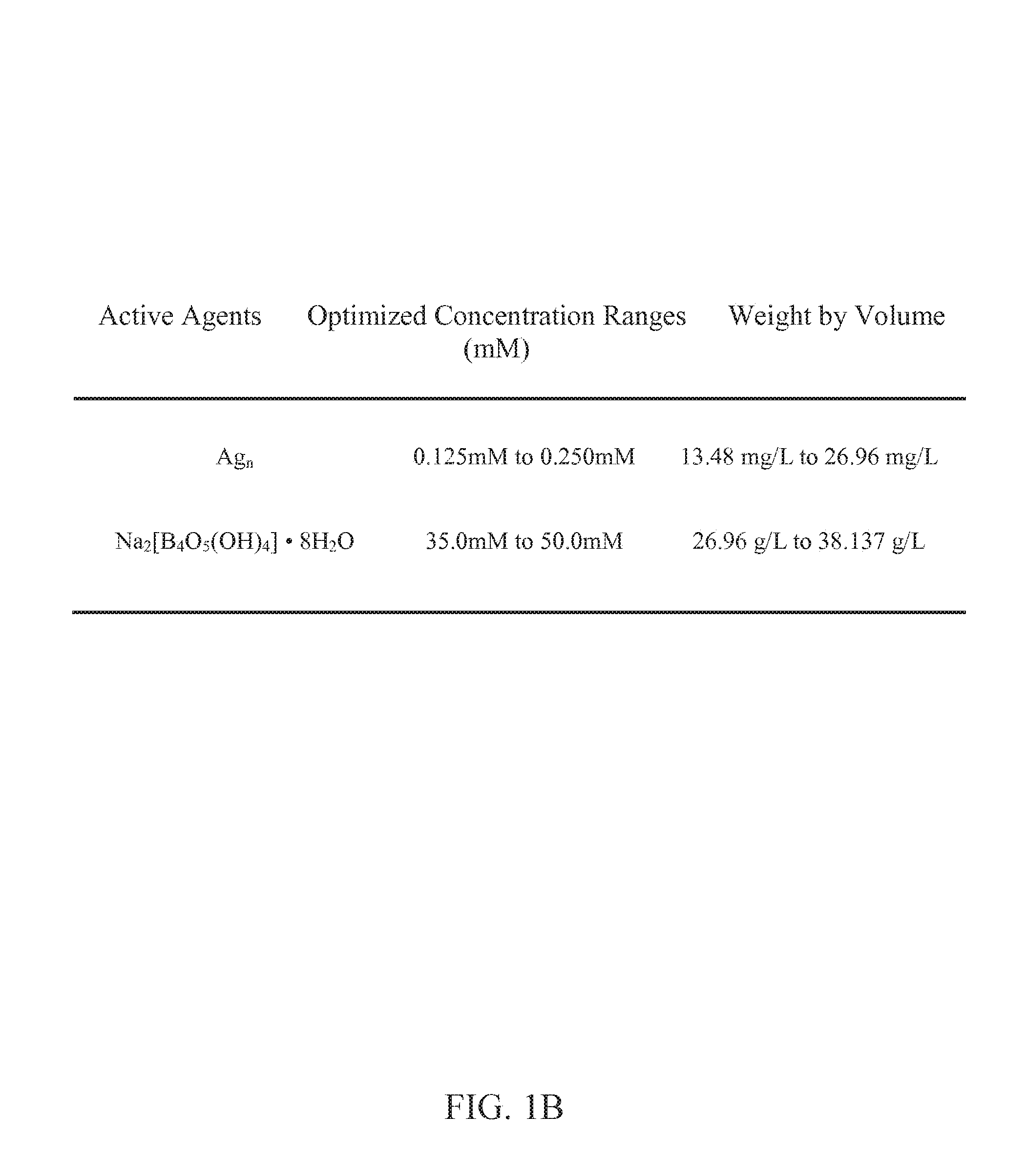

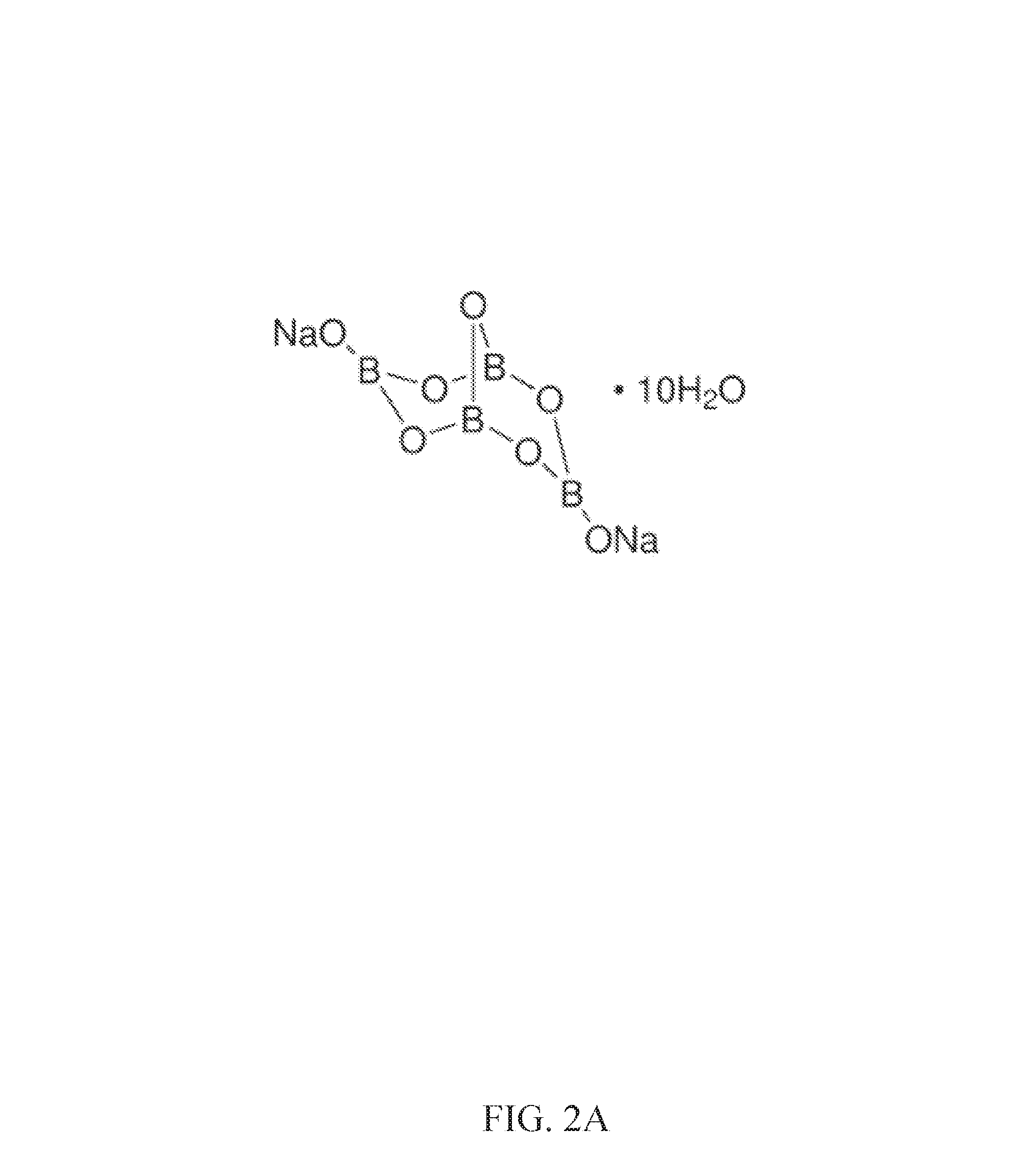

Odor eliminating solution

An odor eliminating solution comprises the active deodorizing and antimicrobial agents of silver nanoparticles dispersed in colloidal suspension in a solution containing excess sodium tetraborate decahydrate, commonly referred to as borax. The silver nanoparticles provide deodorizing and antimicrobial properties through the colloidal dispersion which provides a high surface area to volume ratio for the suspension. The sodium tetraborate decahydrate provides deodorizing and antimicrobial properties through its co-complexing ability with various substances. The combination of both provides the present invention with long term stability and deodorizing and antimicrobial activity. Furthermore, the present invention include the method for formulating the odor eliminating solution through the combination of a silver nanoparticle source solution and an aqueous sodium tetraborate solution which results in a chemical reaction that synthesizes the silver nanoparticles from the silver cations. The resulting odor eliminating solution can be utilized independently or combined with existing odor management products.

Owner:WIZARD LABS

Nanometer zero-valent iron loaded fiber and preparation method and application thereof

InactiveCN108479717AOptimized areaImprove the problem of reducing reductionOther chemical processesWater/sewage treatment by sorptionFiberBorohydride

The invention relates to nanometer zero-valent iron loaded fiber and a preparation method and application thereof. The preparation method comprises the following steps: under the protection of inert gas, mixing a pulp with the beating degree of 10-50 degree SR and a ferrous sulfate solution in proportion, and stirring for reaction; adding an excess sodium borohydride solution into the completely reacted pulp, and continuing to stirring for the reaction; washing the completely reacted pulp by using water, filtering and then lyophilizing to obtain the nanometer zero-valent iron loaded fiber. Byan in-situ reduction method, firstly divalent iron ions are mixed with the pulp to penetrate the divalent iron ions into a cell cavity of the fiber, and then the divalent iron ions in the cell cavityare reduced by sodium borohydride to obtain a zero-valent iron precipitate. Relatively strong adsorbing and reducing effects of nanometer zero-valent iron in wastewater treatment process can be played, the problem that the powdered nanometer zero-valent iron is difficult to recycle after wastewater treatment can be solved, and the problem of reduction in reductibility caused by reduction in the specific surface area of the nanometer zero-valent iron due to agglomeration can be alleviated.

Owner:SOUTH CHINA UNIV OF TECH

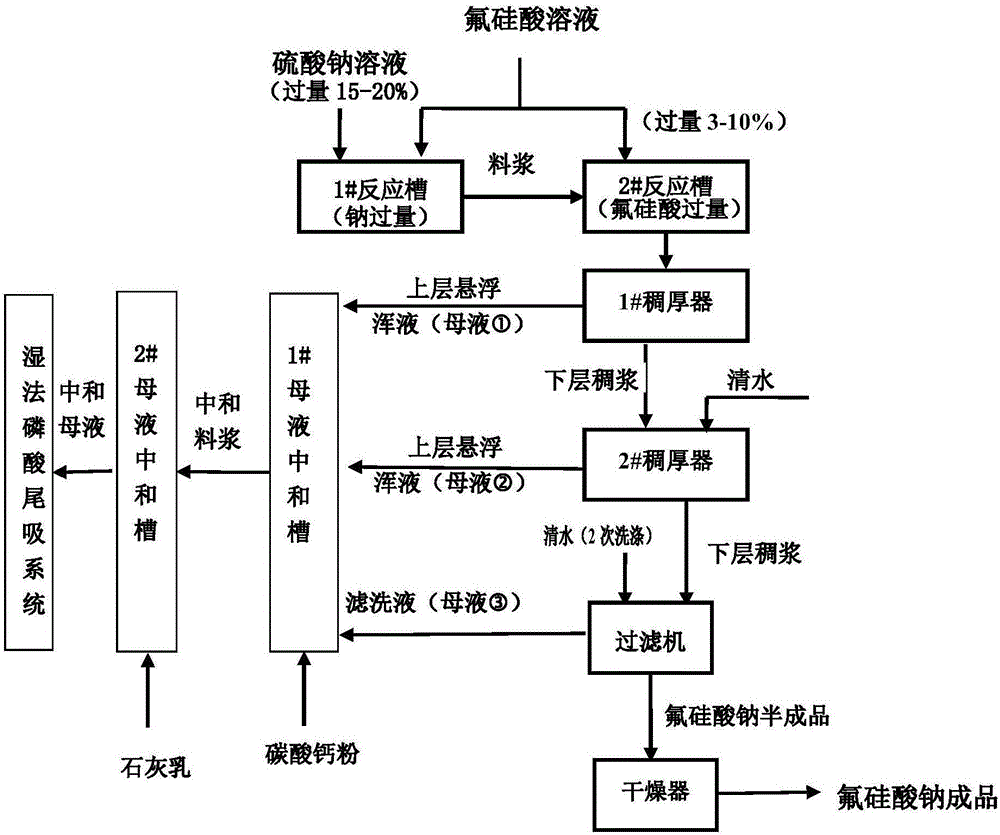

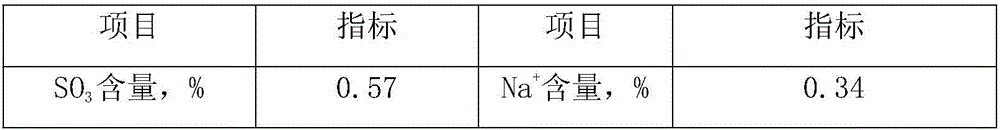

Double-tank method for production of sodium fluorosilicate

The invention relates to a double-tank method for production of sodium fluorosilicate. The method mainly includes the steps of adding fluosilicic acid into two reaction tanks in two times, carrying out synthesis reactions, maintaining excess sodium sulfate in a slurry in the 1# reaction tank, keeping excess fluorosilicic acid in a slurry in the 2# reaction tank, conducting sedimentation and thickening twice on the sodium fluorosilicate slurry coming out from the 2# reaction tank, filtering and washing the separated thick slurry in a lower layer to obtain a wet sodium fluorosilicate semi-finished product, and conducting drying to obtain a sodium fluorosilicate finished product; adding calcium carbonate powder and lime milk into the supernatant and washing liquid separated by the two times of sedimentation and thickening to conduct neutralizing treatment, and returning the obtained neutral mother liquor with about 0.3% of a sodium ion content to a wet process phosphoric acid tail gas absorption system to recover sodium ions. The production method provided by the invention has lower raw material consumption, and realizes real circulation of sewage in sodium fluorosilicate production.

Owner:KUNMING CHUAN JINNUO CHEM IND

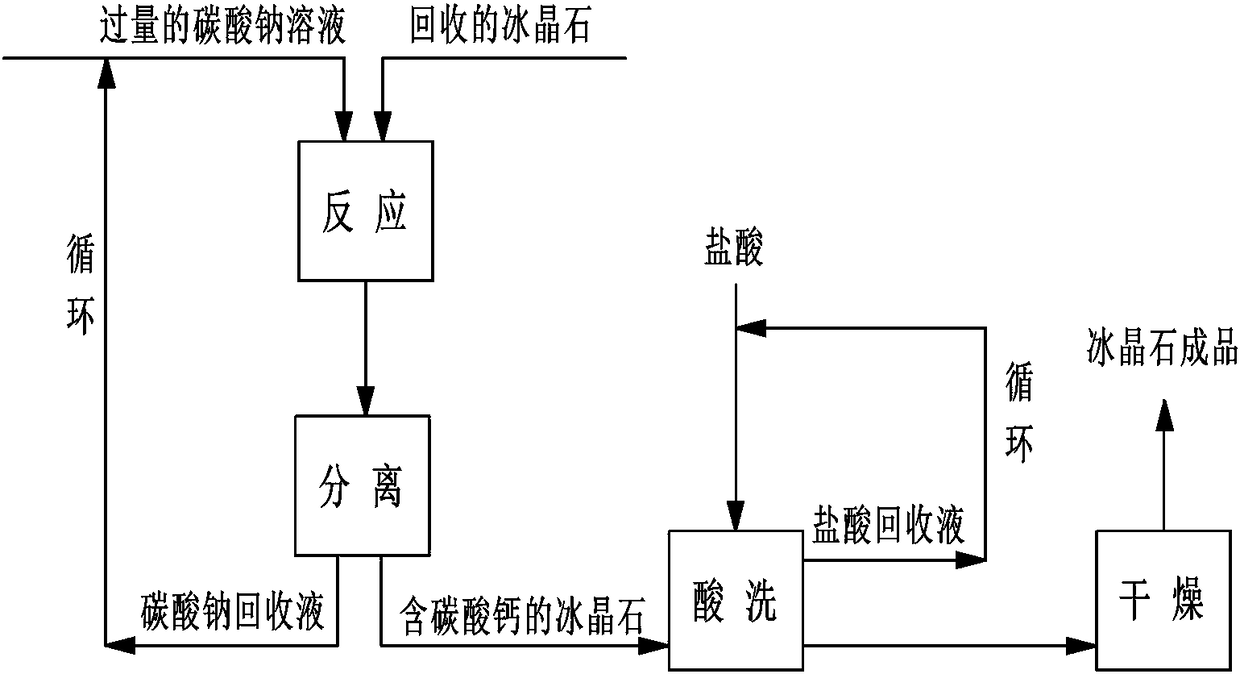

Method of lowering content of calcium in recovered cryolite

The invention provides a method of lowering the content of calcium in recovered cryolite. The method comprises the following steps of providing a kind of cryolite recovered from electrolytic aluminiumwaste slag, wherein the recovered cryolite contains calcium fluoride; adding an excess sodium carbonate solution into the recovered cryolite according to the content of the calcium fluoride in the recovered cryolite, and performing reaction on the calcium fluoride in the recovered cryolite with the sodium carbonate solution to obtain cryolite containing calcium carbonate; and sequentially performing acid pickling, washing and drying treatments on the cryolite containing calcium carbonate to remove calcium carbonate to obtain a finished cryolite product. The method can effectively remove the calcium fluoride in the recovered cryolite; and the content of the calcium in the recovered cryolite treated with the method can be lowered by 90 percent or above.

Owner:河南宏氟环保科技有限公司

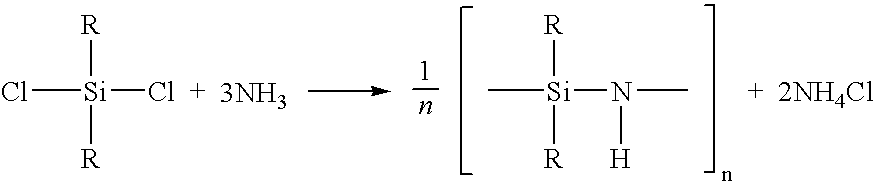

Application of photocurable pre-ceramic polymers

A process for synthesizing photocurable poly(ethynyl) carbosilane includes the steps of mixing dichlorosilane and trichlorosilane reagents, adding sub-stoichiometric amounts of alkali metal and adding excess sodium acetylide.

Owner:GLOBAL STRATEGIC MATERIALS

Method for producing silicon dioxide and calcium silicate by phosphorus residue

The invention relates to a method for producing silicon dioxide and calcium silicate by phosphorus residue, which comprises the steps of: grinding the phosphorus residue into coarse powder with 80-100 meshes, fully mixing the coarse powder with water and then reacting with excess hydrochloric acid, and obtaining mixture containing silicon dioxide precipitate and chloride; filtering the mixture, and obtaining mixed filtrate of chloride mainly containing calcium chloride as well as a silicon dioxide filter cake; washing, drying and grinding the silicon dioxide filter cake, and obtaining an industrial silicon dioxide product; putting the mixed filtrate of the chloride mainly containing the calcium chloride into a reactor and reacting with excess sodium silicate solution, and leading calcium ions to be combined with silicate for generating calcium silicate for precipitation; filtering and separating the obtained precipitate, and obtaining a calcium silicate filter cake and clear filtrate; and finally, washing, drying and grinding the calcium silicate filter cake, and obtaining the industrial calcium silicate.

Owner:张胜勇

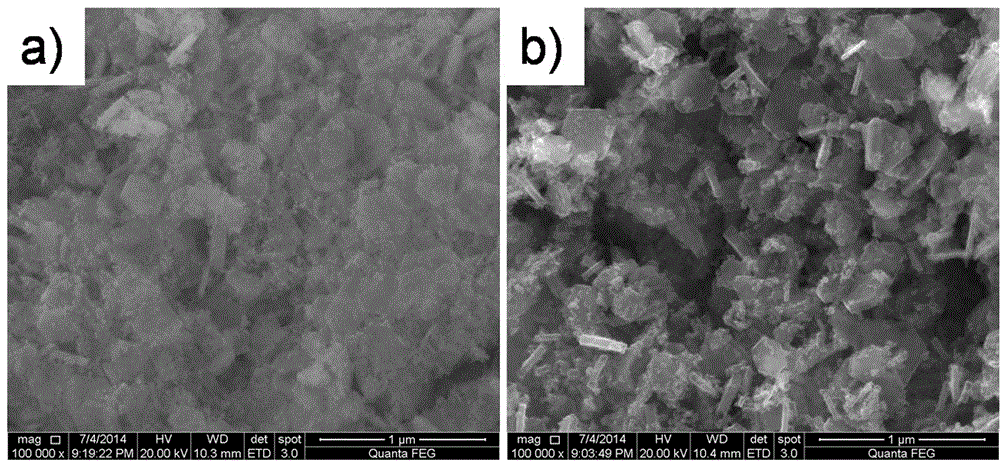

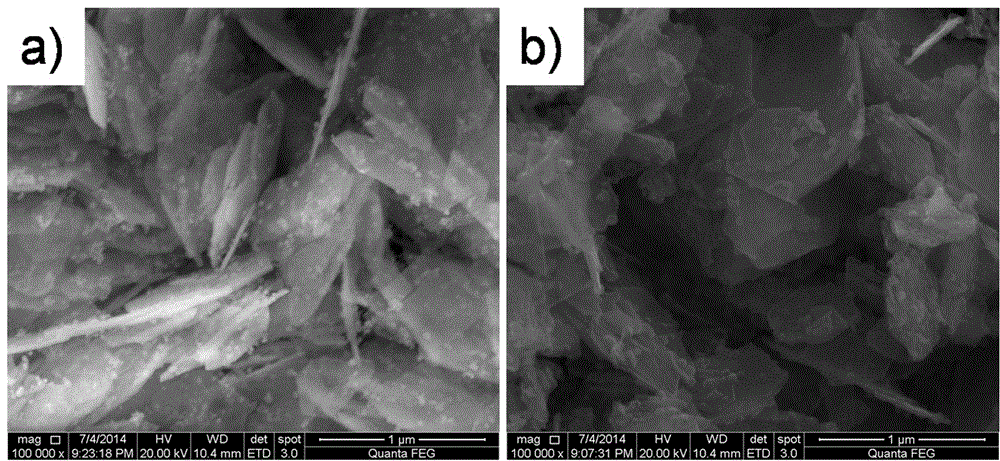

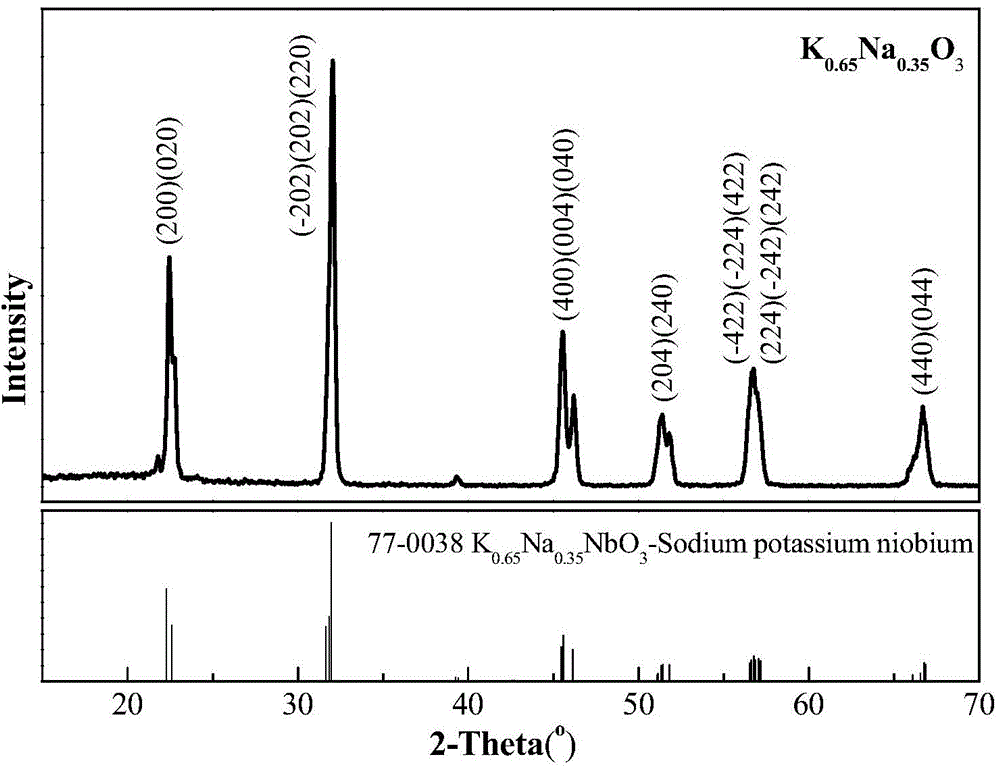

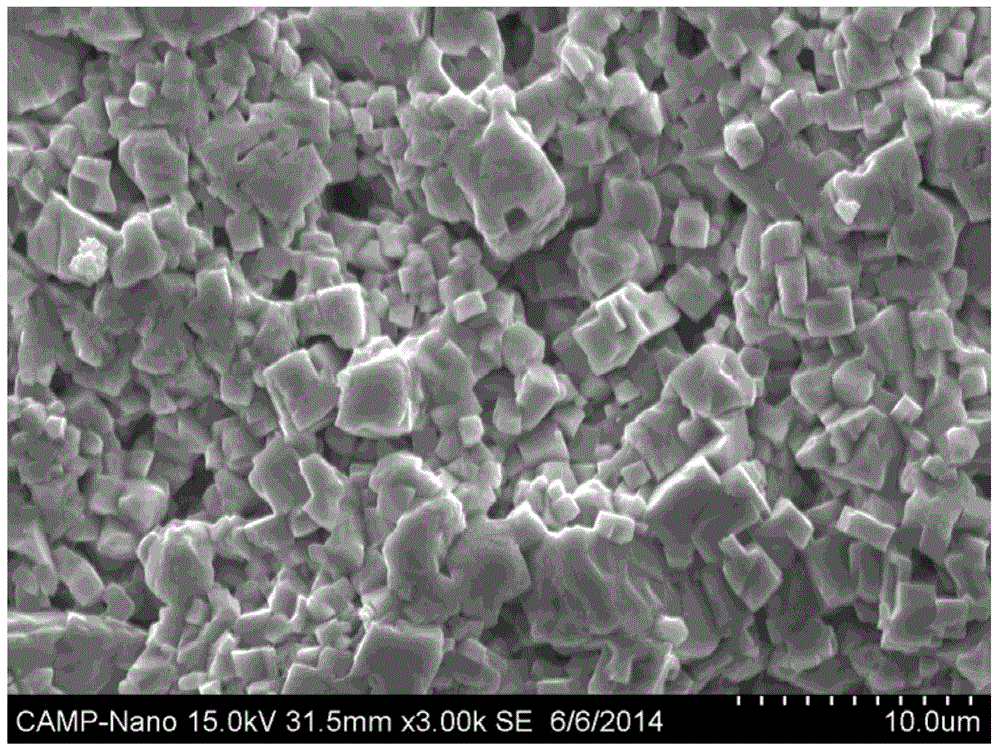

Method for synthetizing leadless piezoelectric ceramic K0.65Na0.35NbO3 powder adopting two-step hydrothermal method

The invention provides a method for synthetizing leadless piezoelectric ceramic K0.65Na0.35NbO3 powder adopting a two-step hydrothermal method. Excess potassium hydroxide and excess sodium hydroxide are taken as a potassium source and a sodium source respectively and dissolved in deionized water; then niobium pentoxide is added into the solution respectively, and precursor solutions of KNbO3 and NaNbO3 can be synthesized respectively after even stirring; the precursor solutions are sealed in a hydrothermal kettle respectively, the hydrothermal kettle is placed in a thermostat for hydrothermal synthesis at a certain temperature, cooling to the room temperature is performed after the reaction, and powder obtained through the reaction is washed with deionized water for several times and dried finally. After a grinding process, KNbO3 powder and NaNbO3 powder are accurately weighed and mixed in the deionized water; microwave oscillation is performed after stirring; the mixture is poured into a hydrothermal reaction kettle and sealed for hydrothermal synthesis, cooling to the room temperature is performed after the reaction, and a mixed liquid obtained through the reaction is fully dried to obtain the powder. According to the method, the two-step hydrothermal method is adopted to synthetize the K0.65Na0.35NbO3 powder, the preparation technology is good in repeatability, the material component proportion is accurate, the powder is good in uniformity and high in purity, and crystal grains are complete in development and even in distribution.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com