Preparation method of dye-sensitized solar battery cobalt-nickel sulfide counter electrode

A solar cell and cobalt-nickel sulfide technology, which is applied in the field of electrode preparation, cobalt, and nickel sulfide preparation, can solve the problems of complex preparation process and inability to prepare a large area, and achieve simple preparation process, high mechanical strength, and good electrocatalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

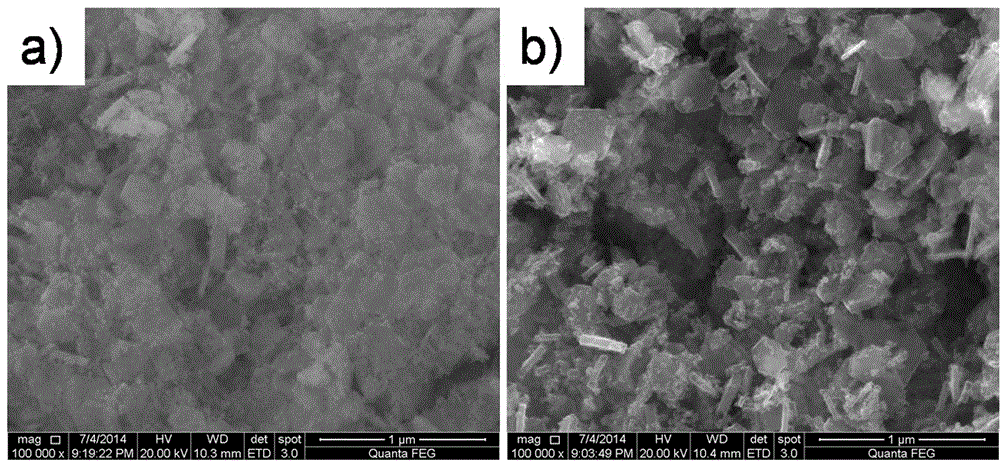

[0022] Step 1: Weigh 2.4mmol Ni(OAc) respectively 2 4H 2 O and 4.8 mmol CoCl 2 ·6H 2 O was put into 40 mL of deionized water, placed in a magnetic stirrer and stirred for 30 min to dissolve to prepare A solution. Weigh 24mmol NaOH into 40mL deionized water, place in a magnetic stirrer and stir to dissolve for 30min to prepare B solution. Under the condition of rapidly stirring solution B, slowly pour solution A into solution B, and continue stirring for 1 h after the addition. After that, transfer the mixed reaction suspension of A and B to a stainless steel reaction kettle with a polytetrafluoroethylene liner, seal it and put it in a hydrothermal furnace, slowly rise from room temperature to 160°C and react at 160°C for 10h . After the reaction, it was cooled to room temperature with the furnace and taken out, and the obtained brown-black cobalt-nickel precursor was centrifugally washed 3 times with deionized water.

[0023] Step 2: After washing, disperse it into 240mL...

Embodiment 2

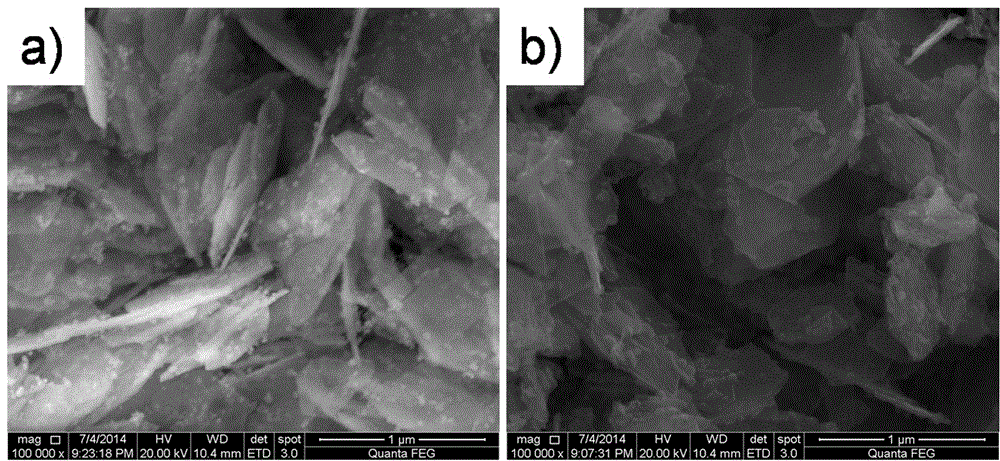

[0027] Step 1: Weigh 2.4mmol Ni(OAc) respectively 2 4H 2 O and 4.8 mmol CoCl 2 ·6H 2 O was put into 40 mL of deionized water, placed in a magnetic stirrer and stirred for 30 min to dissolve to prepare A solution. Weigh 24mmol NaOH into 40mL deionized water, place in a magnetic stirrer and stir to dissolve for 30min to prepare B solution. Under the condition of rapidly stirring solution B, slowly pour solution A into solution B, and continue stirring for 1 h after the addition. Afterwards, transfer the mixed reaction suspension of A and B to a stainless steel reaction kettle with a polytetrafluoroethylene liner, seal it and put it in a hydrothermal furnace, slowly rise from room temperature to 160°C and react at 160°C for 20h . After the reaction, it was cooled to room temperature with the furnace and taken out, and the obtained brown-black cobalt-nickel precursor was centrifugally washed 3 times with deionized water.

[0028] Step 2: After washing, disperse it into 240mL...

Embodiment 3

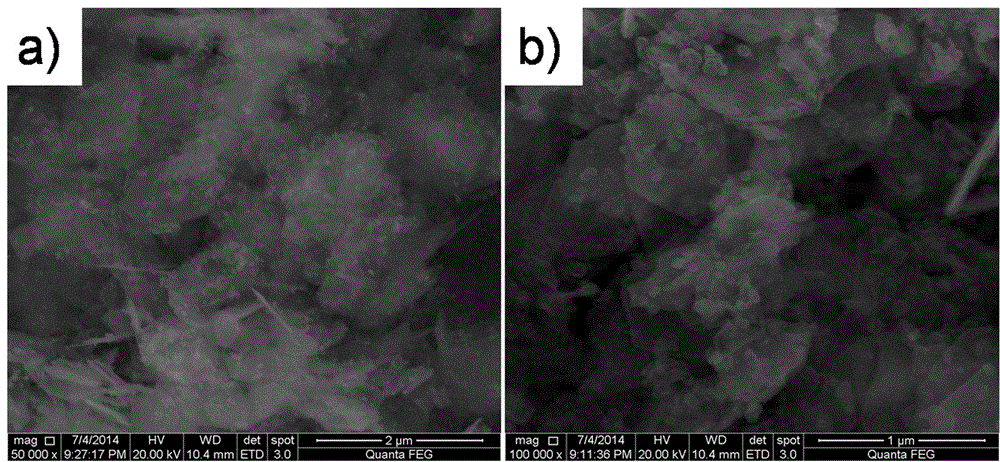

[0037] Step 1: Weigh 2.4mmol Ni(OAc) respectively 2 4H 2 O and 4.8 mmol CoCl 2 ·6H 2 O was put into 40 mL of deionized water, placed in a magnetic stirrer and stirred for 30 min to dissolve to prepare A solution. Weigh 16mmolNaOH and 8mmolNa 2 CO 3 Put it into 40mL of deionized water, place it in a magnetic stirrer and stir and dissolve for 30min to prepare B solution. Under the condition of rapidly stirring solution B, slowly pour solution A into solution B, and continue stirring for 1 h after the addition. After that, transfer the mixed reaction suspension of A and B to a stainless steel reaction kettle with a polytetrafluoroethylene liner, seal it and put it in a hydrothermal furnace, slowly rise from room temperature to 160°C and react at 160°C for 10h . After the reaction, it was cooled to room temperature with the furnace and taken out, and the obtained brown-black cobalt-nickel precursor was centrifugally washed 3 times with deionized water.

[0038] Step 2: Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com