Patents

Literature

1935results about How to "No shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

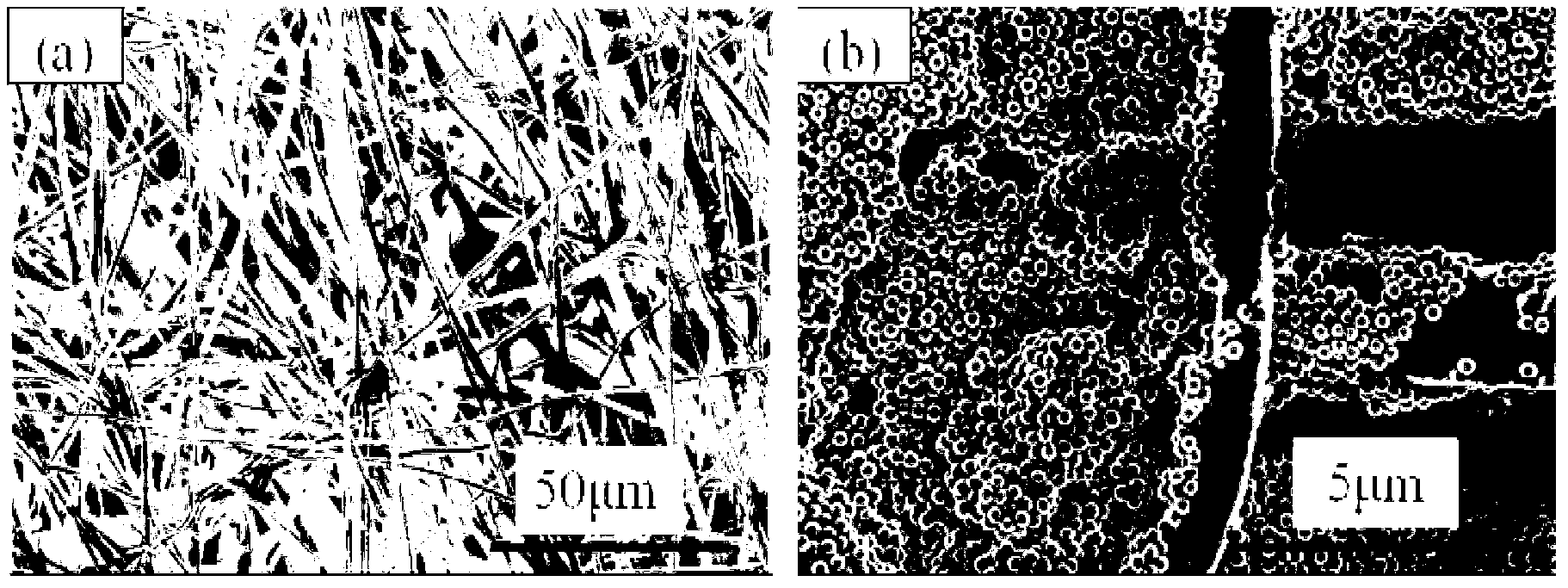

InactiveCN103474610AExcellent heat shrinkage resistanceIncrease fluid retentionCell component detailsNon-woven fabricsFiberOrganic solvent

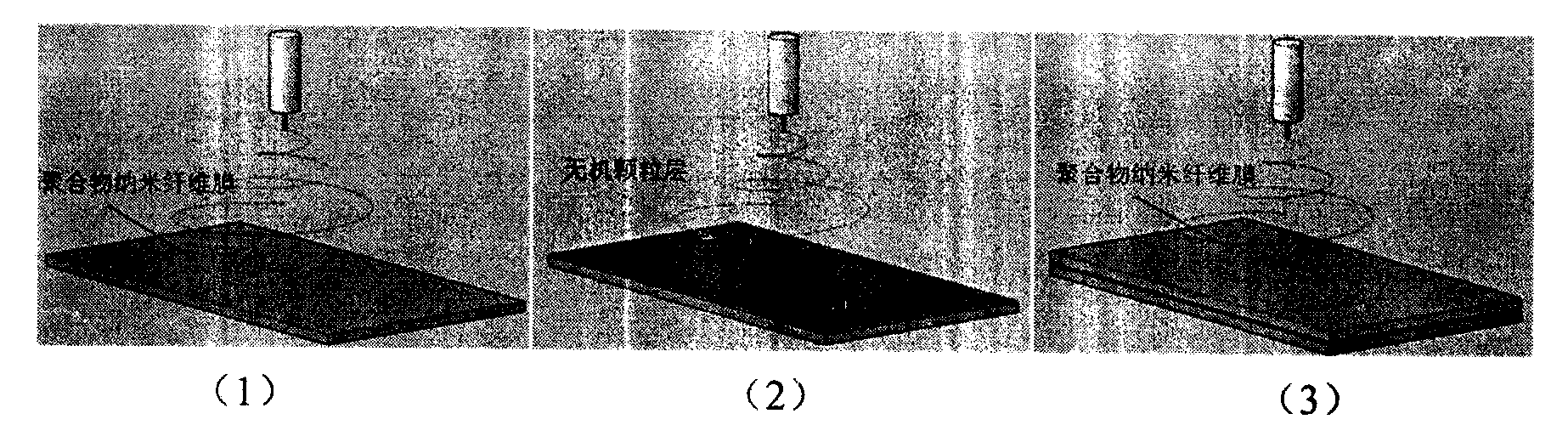

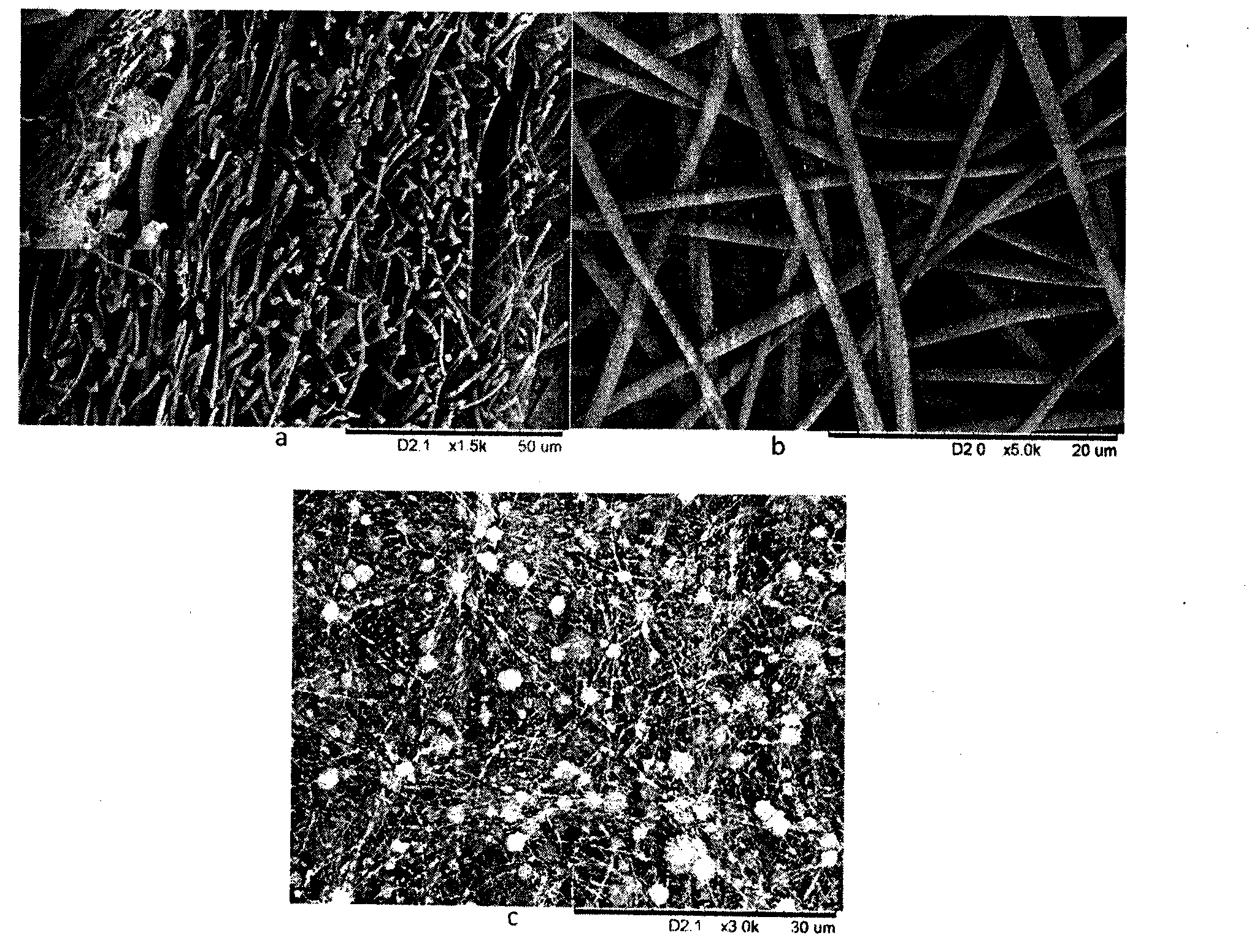

The invention relates to the field of lithium-ion batteries, in particular to a method for preparing a composite lithium-ion battery separator through electrostatic spinning / electrostatic spraying. The method specifically includes the steps of firstly, adding high molecular polymer into an organic solvent, dissolving the high molecular polymer through mechanical stirring to form a transparent solution, and obtaining an electrostatic spinning solution; secondly, mixing inorganic nanometer particles with the high molecular polymer and adding the mixture into the organic solvent, and conducting mechanical stirring to obtain inorganic nanometer particle suspension liquid; thirdly, conducting electrostatic spinning on the spinning solution prepared in the first step to prepare a lower layer nanometer fiber film, and enabling the inorganic nanometer particle suspension liquid prepared in the second step to be deposited on the lower layer nanometer fiber film through electrostatic spraying to obtain an interlayer; finally, receiving an electrostatic spun nanometer fiber layer on an inorganic particle layer to obtain the composite lithium-ion battery separator. The composite lithium-ion battery separator has the high imbibing rate and good electrochemical stability under the room temperature and has good heat shrinkage resistance performance at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

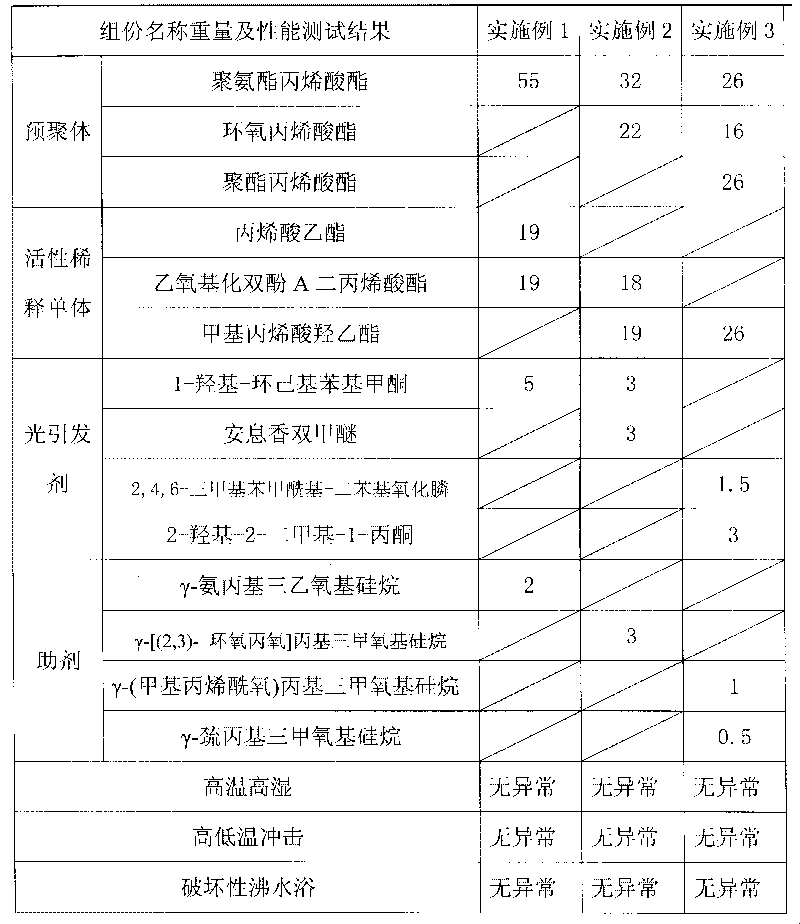

UV curing packaging adhesive for liquid crystal display

InactiveCN101724374AFast curingCuring shrinkage is smallOther chemical processesPolyureas/polyurethane adhesivesPrepolymerPhotoinitiator

The invention provides a UV curing packaging adhesive for a liquid crystal display. Based on 100 weight parts, the adhesive consists of following components: 40 to 70 parts of prepolymer, 20 to 50 parts of active diluent monomer, 1 to 8 parts of photoinitiator, and 0.1 to 5 parts of assistant. The prepolymer is one or a mixture of more of the urethane acrylate, epoxy acrylate and polyster acrylate. The UV curing packaging adhesive for the liquid crystal display has the characteristics of high curing speed, low shrinkage rate and excellent damp heat resistance.

Owner:BEIJING HYSTIC NEW MATERIALS

High-performance flexible composite nonwoven fabric membrane for lithium ion battery, as well as preparation method and application of membrane

InactiveCN103296240AGood flexibilityGood high current discharge performanceCell component detailsAdhesiveCharge discharge

The invention discloses a high-performance flexible composite nonwoven fabric membrane for a lithium ion battery, as well as a preparation method and an application of the membrane, which belongs to the technical field of a lithium-ion battery membrane material. The prepared composite nonwoven fabric membrane is formed by coating functional serous fluid with thermally curable or optically curable functional groups onto a substrate membrane containing an active functional group, thermally curing or optically curing the substrate membrane, removing a pore-forming agent, and hot pressing and drying the substrate. The prepared composite nonwoven fabric membrane is good in flexibility. The composite nonwoven fabric membrane has good ion electric conductivity and hot shrinkage resistance, can bear the large-current discharge, and also can improve the safety performance of the battery. Since no fluorine-containing adhesive is used in a preparation process, nano particles or nano optical fibers are connected with the substrate membrane through a chemical key, the nano particles or the nano fibers are bonded together through the chemical key and free from dropping off in the charging-discharging cycle, the stability of the coating is enhanced, and the cycling performance of the battery can be improved. The prepared flexible composite nonwoven fabric membrane is used as a membrane assembly of the lithium ion battery.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

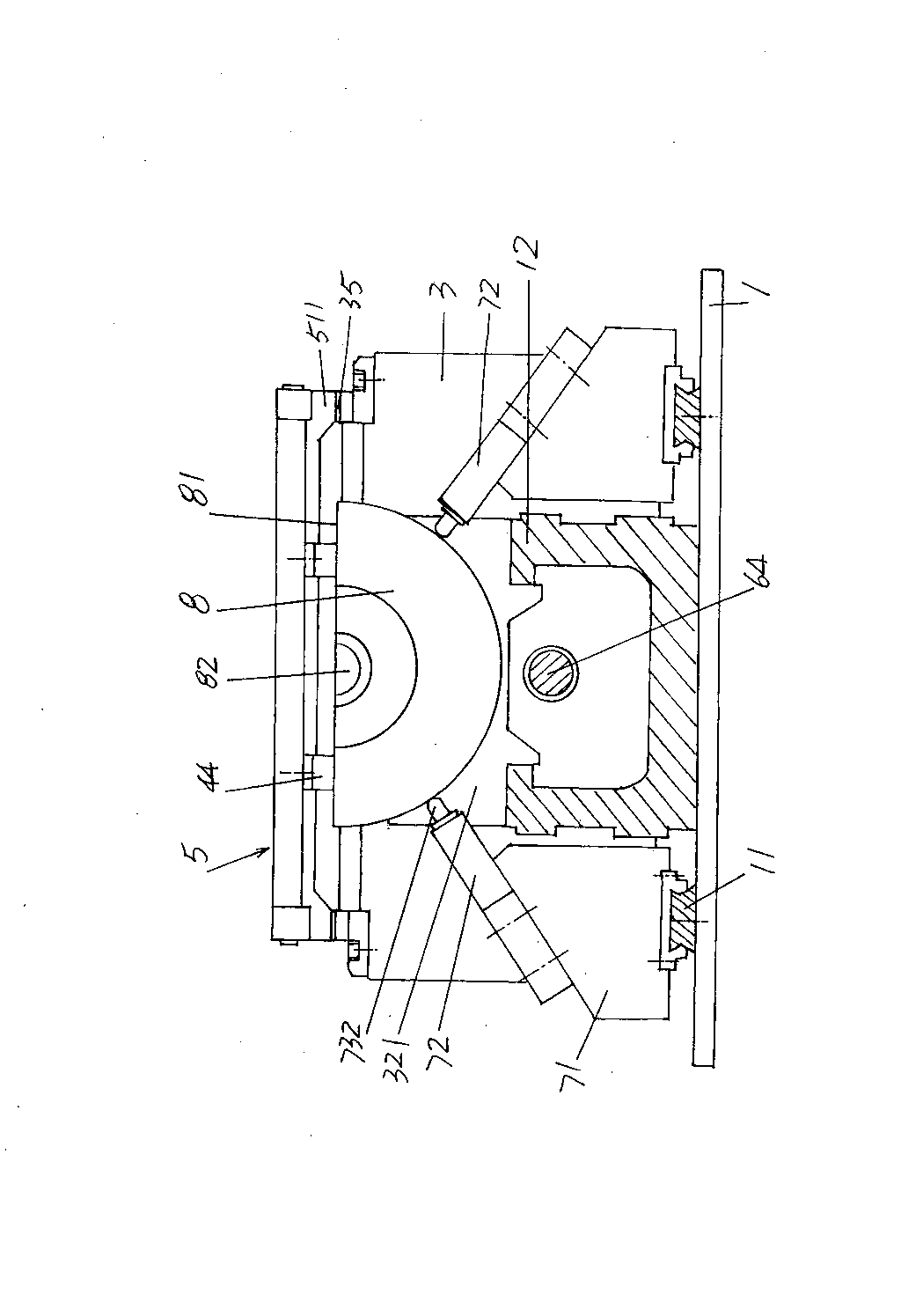

Clamp for processing glass mould

ActiveCN102350650BIdeal levelNo sheddingMetal working apparatusPositioning apparatusMechanical engineeringElectrical and Electronics engineering

Owner:CHANGSHU JIANHUA MOLD TECH

Aqueous emulsion type electromagnetic wave shielded coating and preparation process thereof

InactiveCN1450137AGood performance in physical environmentNo sheddingPolyurea/polyurethane coatingsEpoxy resin coatingsAdjuvantEmulsion

The composition of water emulsion electromagnetic wave shielding paint is composed of (by weight portion) 20-60 portions of water soluble film-forming resin, 20-60 portions of conducting filler, 30-100 portions of pure clean water, 1-5 portions of thickening agent and 1-5 portions of film-forming adjuvant, and its preparation process includes the following steps: (1) drying conducting filler, controlling temp. at 50-80 deg.C until the conducting filler is become into powder; (2). mixing the dried conducting filler together with film-forming adjuvant, film-forming resin and pure clean water orclean running water and grinding by using grinding machine; and (3) adding thickening agent and regulating the paint to make it have a certain viscosity.

Owner:SICHUAN UNIV

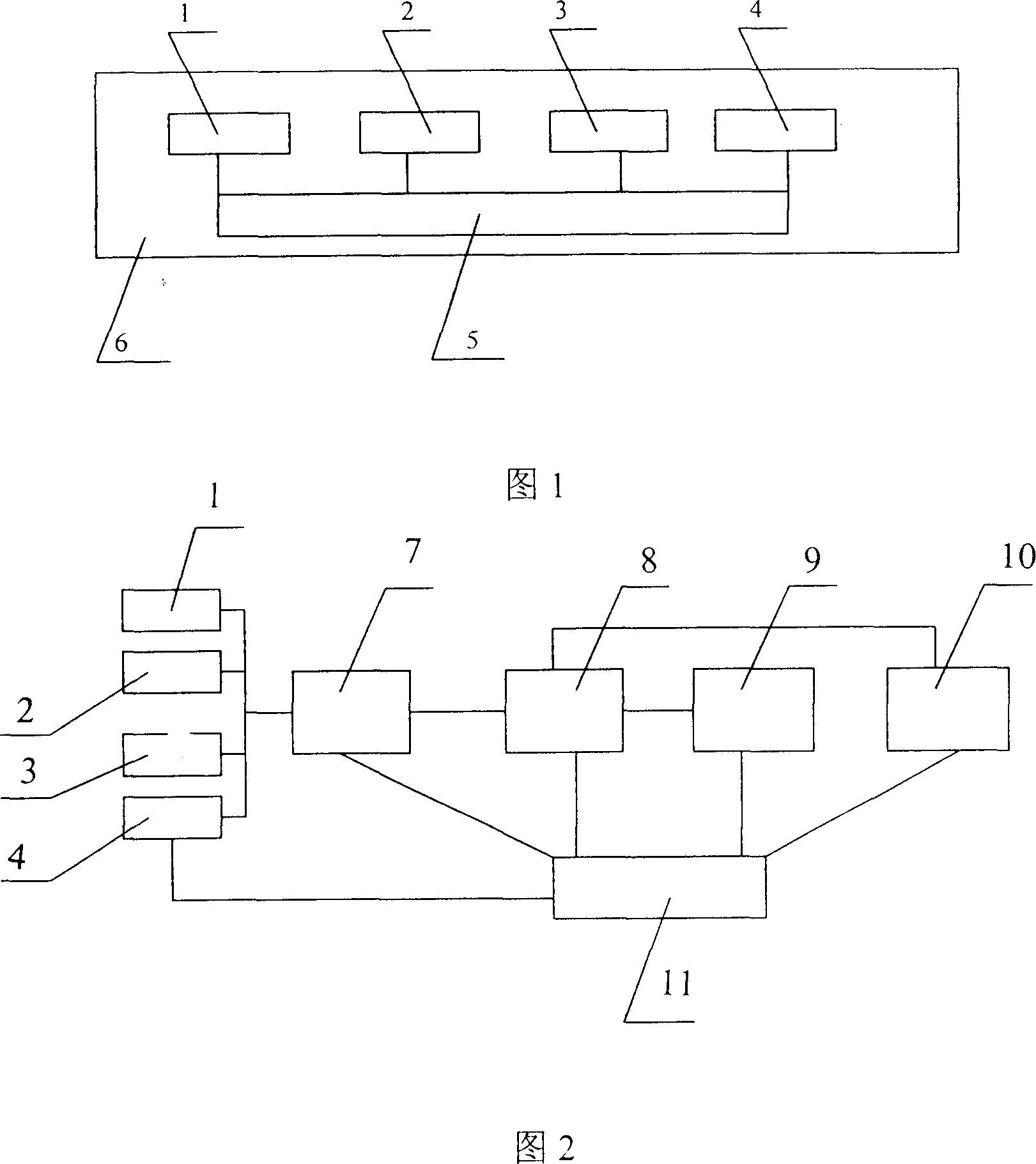

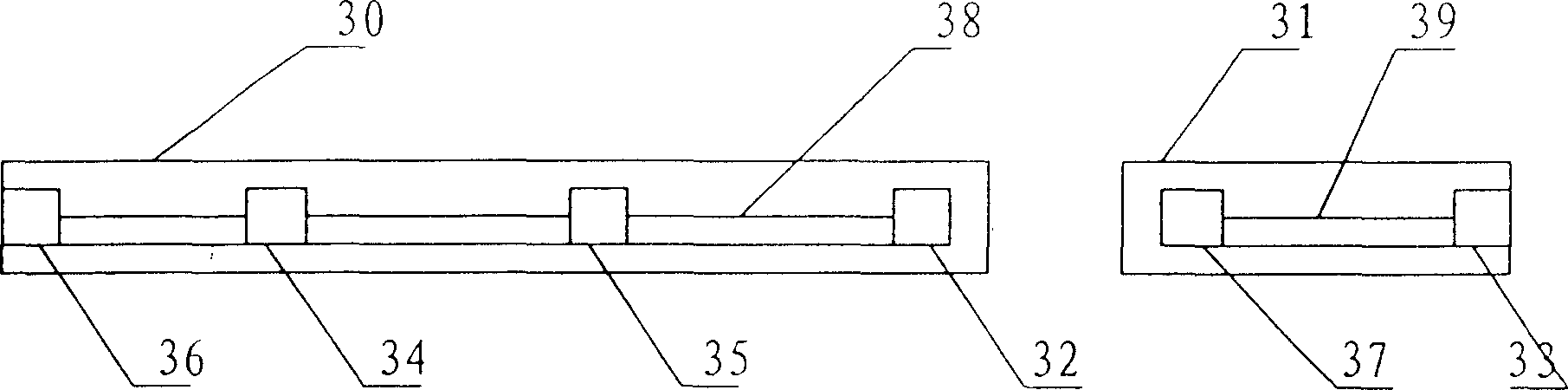

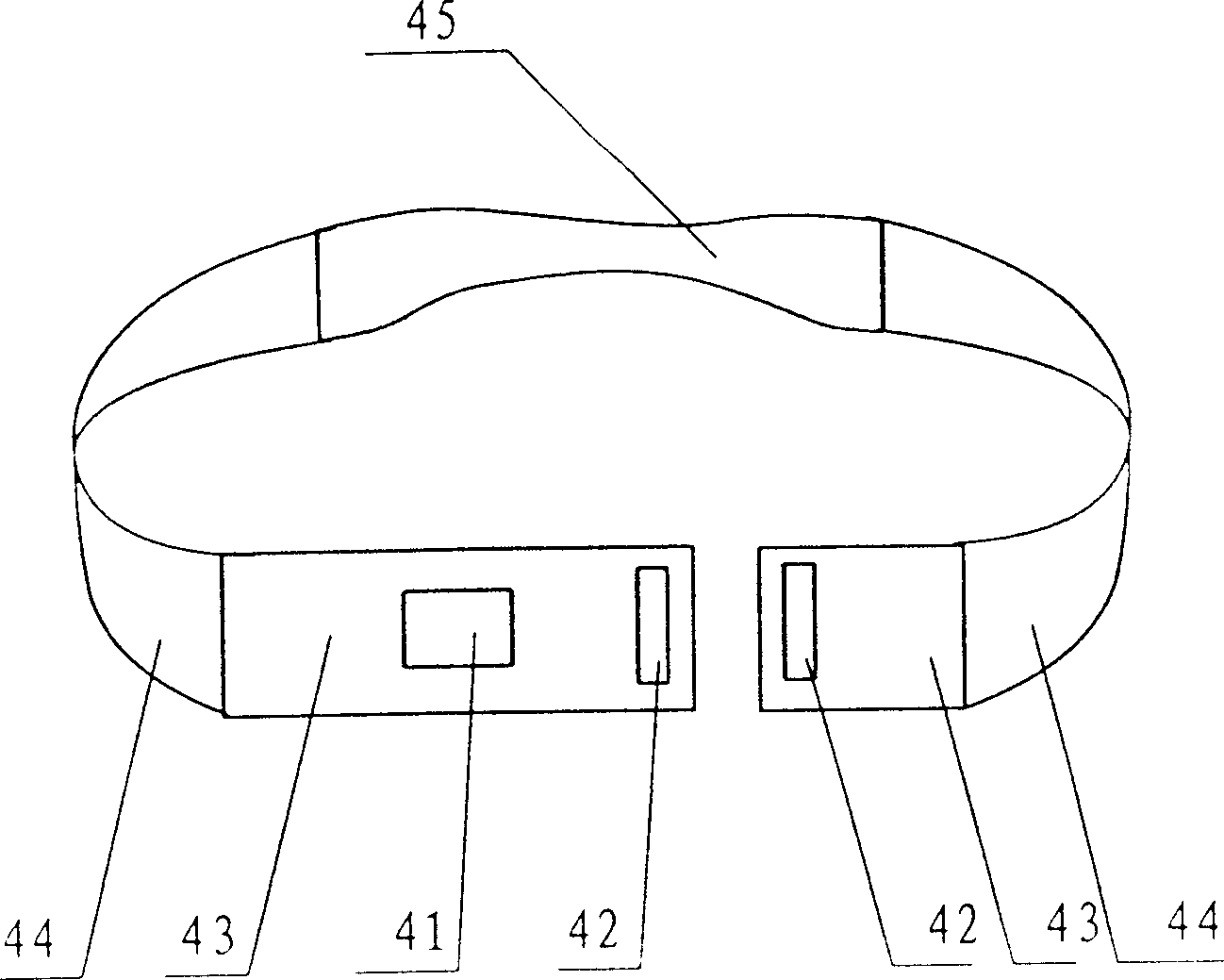

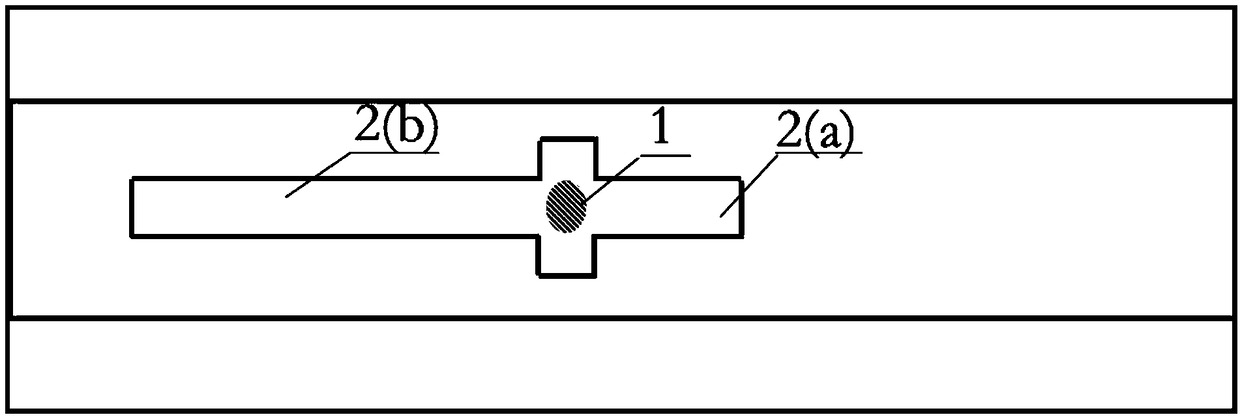

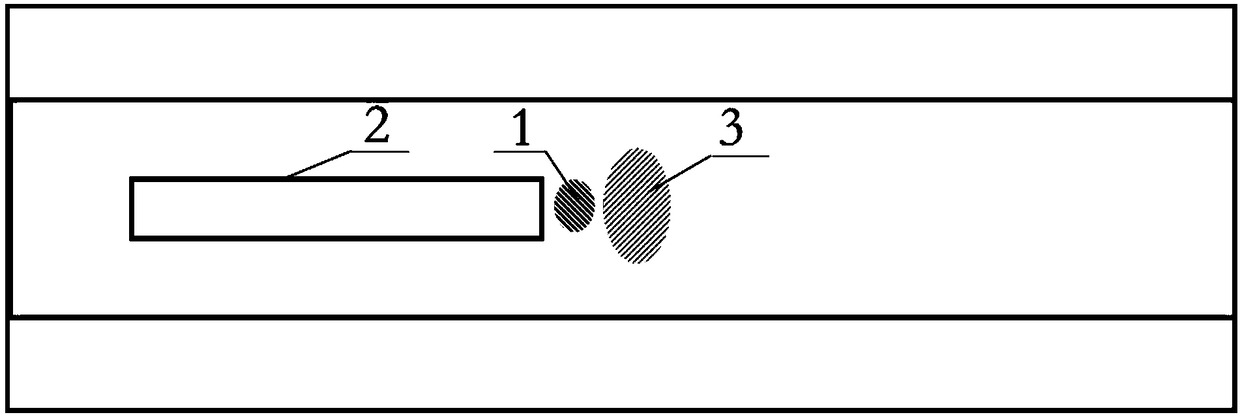

Integrated dynamic physiological parameter detecting and recording method and apparatus

InactiveCN1507833ANo sheddingThe activity has little impactDiagnostic recording/measuringSensorsAbdominal respirationContinuous use

The present invention relates to an integrated dynamic physiological parameter delection and recording method and equipment. It is characterized by that the sensors for detecting dynamic physiological parameters of human body, including multi-lead electrocardioelectrode, thoracico-abdominal respiration sensors, body surface and axially temperature sensors, infrared sensor, acceleration sensor and microphone, main circuit board connected with sensors and connecting wire for connecting them, are inlaid in the interior of base body made of insulating flexible material, and said base body cna be chest band, sleeveless vest, short-sleeve garment or long-sleeve shirt. Said invention also provides its application method and range.

Owner:AVIATION MEDICINE INST AIR FORCE PLA

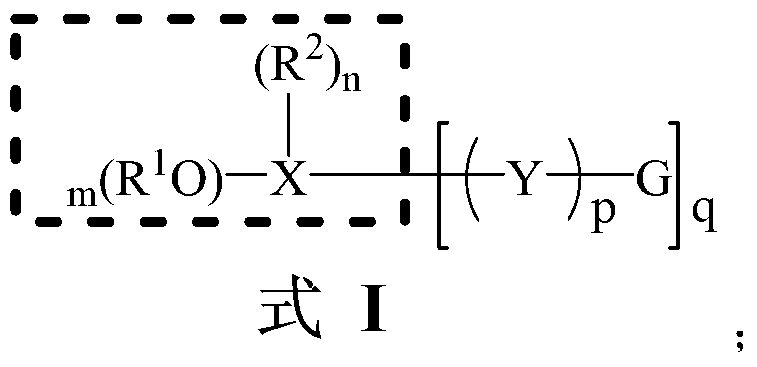

Multiple crosslinking ultraviolet light solidifying water polyurethane dispersoid and its preparation method and application

The invention discloses a multiple crosslink ultraviolet solidification aqueous polyurethane disperser, a relative preparation method and an application. The preparation method comprises synthesizing polyurethane initial polymerized compound I, synthesizing polyurethane prepolymer II, synthesizing polyurethane prepolymer III, synthesizing polyurethane acrylate oligomer and synthesizing ultraviolet solidification aqueous polyurethane disperser. The invention mainly utilizes aromatic diisocyanate, diatomic alcohol prepolymer, polyhydroxy carboxylic acid, epoxy resin and hydroxyl acrylate as raw materials, with better water dispersity and storage stability, which leads in light inducer, levelling agent, defoaming agent and thickener to prepare ultraviolet solidification aqueous wood paint better than solvent ultraviolet solidification photosensitive resin, with stable storage, low fineness, high rigidity, high brightness, better flow leveling property, better water resistance, better solvent resistance, excellent abrasion resistance, environment protection, easy process and fire hazard resistance.

Owner:SOUTH CHINA UNIV OF TECH

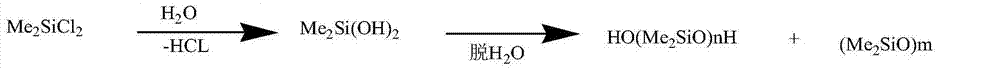

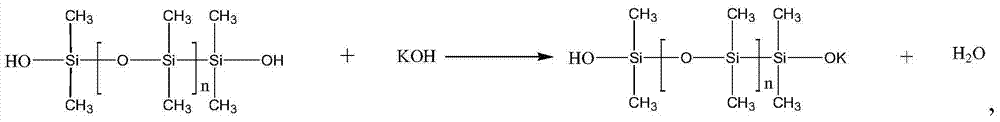

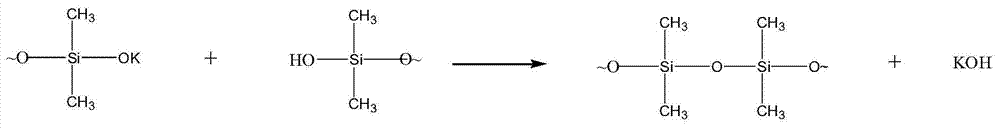

Bi-component condensed type organic silicon pouring sealant as well as preparation method and application thereof

InactiveCN104745141AMeet water resistanceFulfil requirementsNon-macromolecular adhesive additivesSemiconductor devicesPlasticizerCross linker

The invention discloses a bi-component condensed type organic silicon pouring sealant as well as a preparation method and an application thereof. The bi-component condensed type organic silicon pouring sealant consists of a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 350-500 parts of linear hydroxyl-terminated polydimethylsiloxane, 300-600 parts of filler, 50-150 parts of base gum and 0.1-5 parts of a deep curing agent; the component B comprises the following raw materials in parts by weight: 200-500 parts of a cross linker, 300-800 parts of a plasticizer, 50-100 parts of a coupling agent and 0.5-2 parts of a catalyst; and the weight ratio of the component A to the component B is (100:5) to (100:20). Under an airtight condition, the sealant, which is aged for 30d at 150 DEG C, is free from the abnormal phenomenons of peeling off, pores, failure, reduction and the like, and the sealant can completely meet the requirements of an LED driving power supply or a waterproof power supply on waterproofing and binding properties.

Owner:深圳广恒威科技有限公司

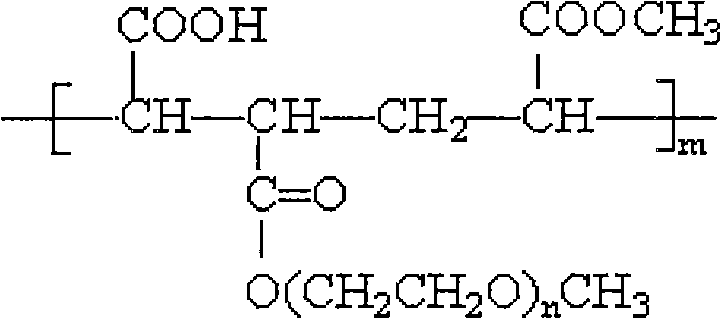

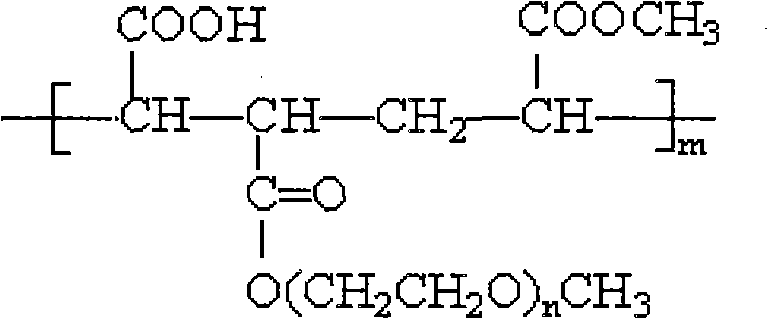

Preparation method of aqueous aluminum silver paste

InactiveCN102093761AEasy to useNo sheddingPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersitySolvent

The invention provides a preparation method of aqueous aluminum silver paste. The preparation method comprises the following steps of: 1, adding an aluminum powder pigment and acetone into a vessel, stirring and filtering to obtain washed aluminum powder; 2, adding the washed aluminum powder obtained in the step 1 into an alcohol solvent, ultrasonically dispersing, adding into a reaction vessel, adding organic silicon, stepwise adding ammonia water, abnd stirring to make the mixture react 3, filtering the product obtained in the step 2 and drying in a vacuum drying box; 4, adding the product obtained in the step 3 into an acetone solution of a comb-like polymer comprising an anchor group and a hydrophilic group and stirring; and 5, removing the acetone from the product obtained in the step 4 by decompressing and distilling to obtain the aqueous aluminum silver paste. According to the preparation method of the aqueous aluminum silver paste, coating completeness is enhanced, falling, dusting and agglomeration of a coating are prevented, and the coating has high dispersity, so that the using performance of the prepared aqueous aluminum silver paste is integrally enhanced.

Owner:SHENZHEN POLYTECHNIC

Electric heating film and preparation method thereof

ActiveCN101873729AStable powerImprove bindingNon-conductive material with dispersed conductive materialHeating element materialsGlass fiberGraphite

The invention discloses an electric heating film which comprises an adhesive agent and mixed powder mixed together as well as glass fiber cloth for bearing the adhesive agent and the mixed powder. The electric heating film is characterized by comprising the following components in parts by weight: 100 parts of polyimide resin as the adhesive agent, 4-30 parts of the mixed powder and 0-2 parts of stabilizer, wherein the mixed powder comprises conductive carbon black and graphite powder, and the weight ratio of the graphite powder to the conductive carbon black is 1: (0.8-1.25). A preparation method of the electric heating film comprises the following steps of: firstly, mixing the conductive carbon black with the graphite powder according to the weight ratio of 1: (0.8-1.25) to obtain the mixed powder, mixing the polyimide resin with the mixed powder according to the weight ratio of 1: (0.04-0.30), and adding a thinning agent for diluting; secondly, grinding for 10-60 minutes by using a grinding machine to obtain a colloidal mixture; and thirdly, coating the colloidal mixture on the glass fiber cloth by using a coating machine, roasting the colloidal mixture so that the colloidal mixture is immersed in and cured on the glass fiber cloth to form the electric heating film. The invention is mainly used for manufacturing the electric heating film.

Owner:刘忠耀

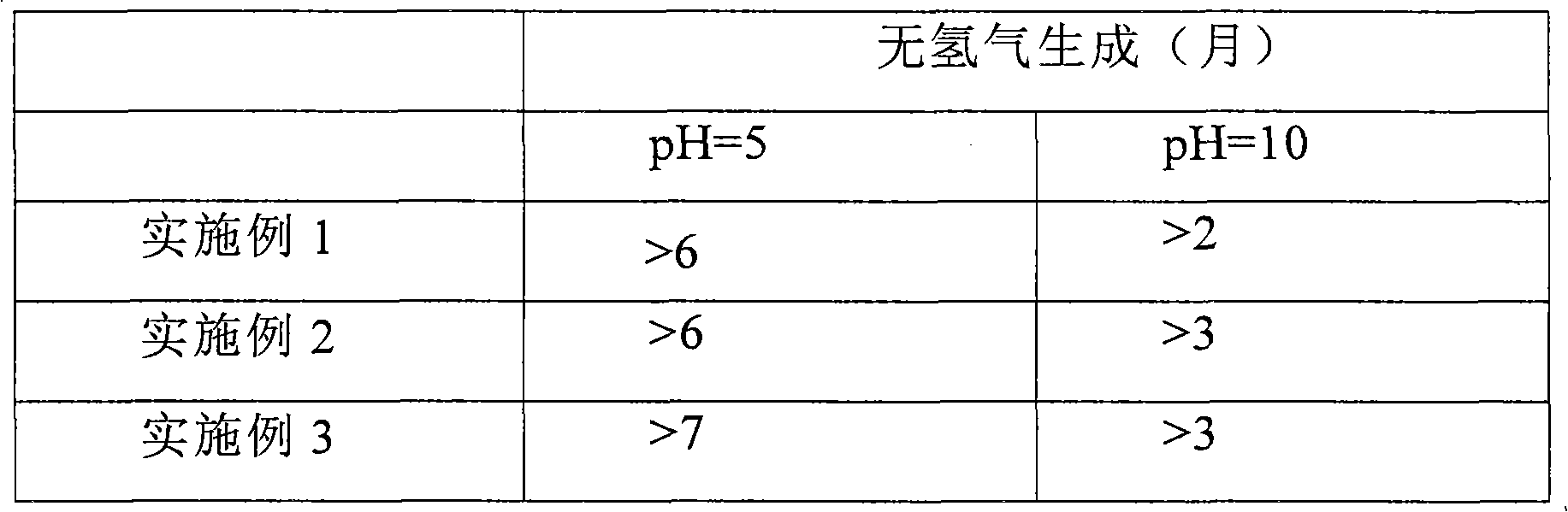

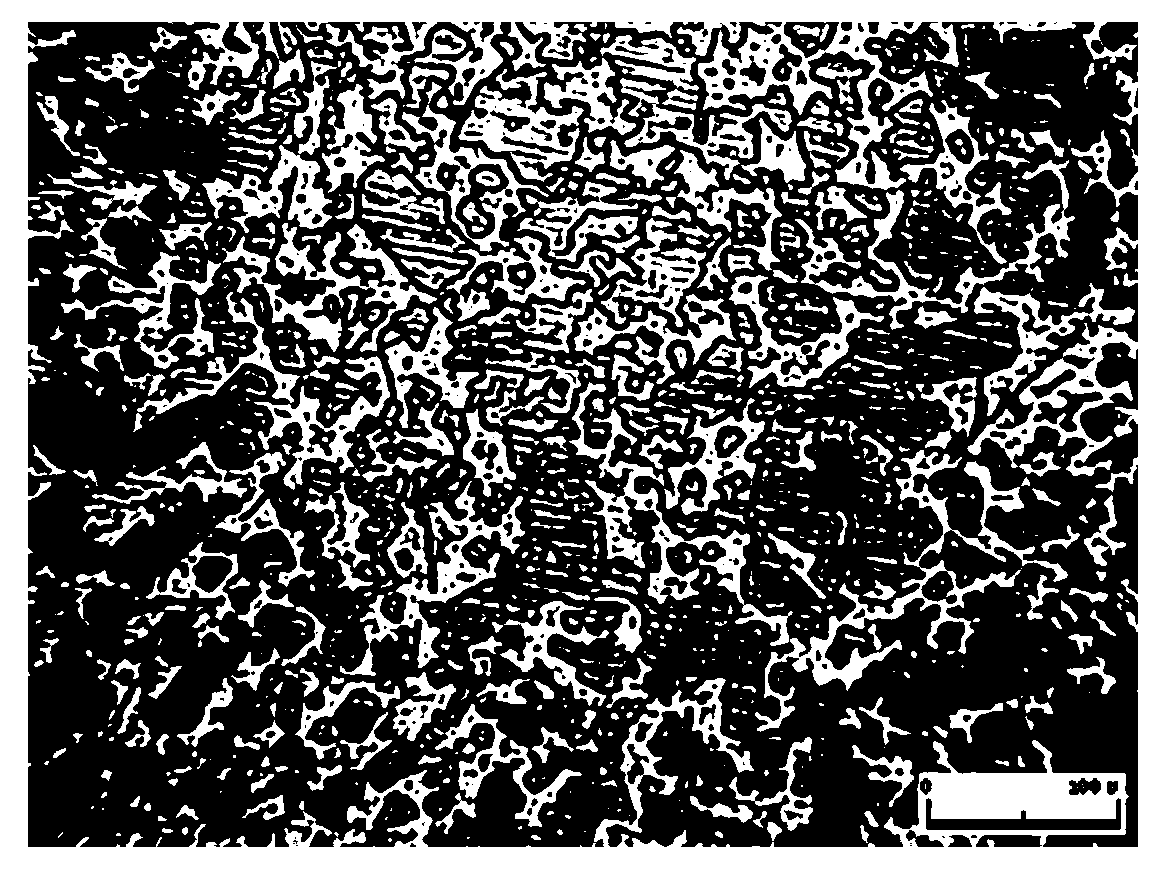

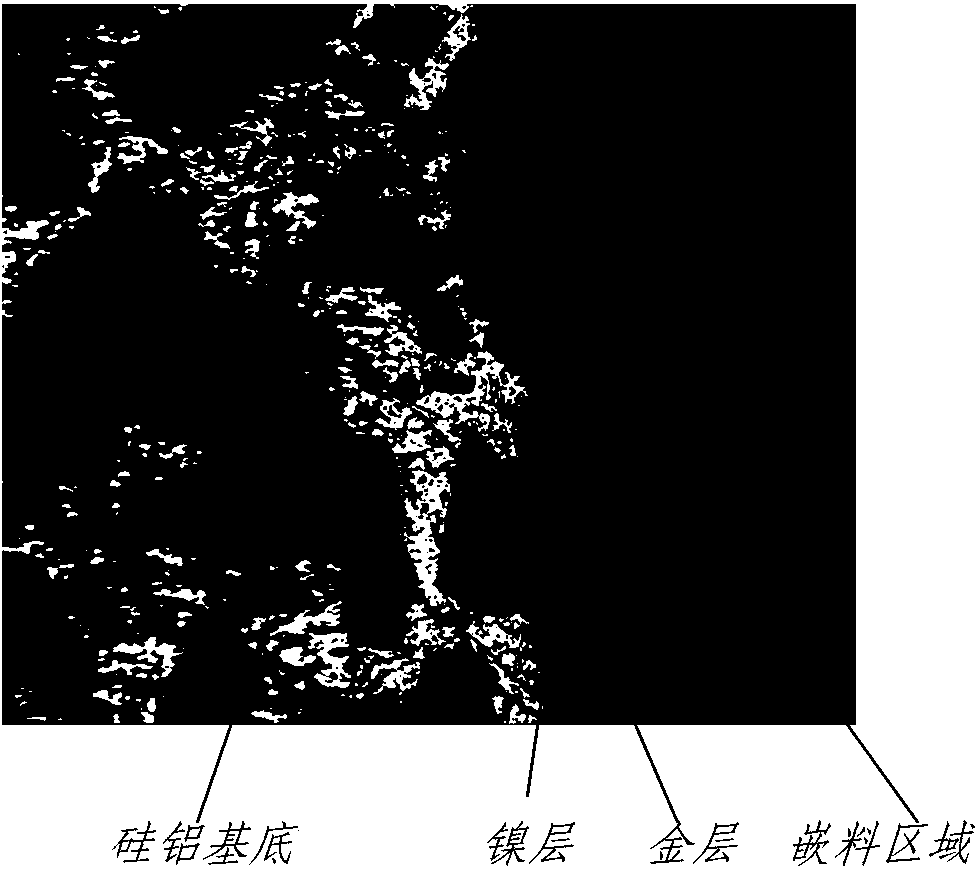

Gold-plating method of high silicon-aluminum composite material

ActiveCN103540935AImprove bindingNo foamingSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBinding forceAlkaline etching

The invention relates to a gold-plating method of a high silicon-aluminum composite material. According to a second zinc immersion treatment method of conventional aluminum alloy electroplating, pre-treatment of the method comprises the following six steps: cleaning and oil removing; alkaline etching; bright dipping; primary zinc immersion; zinc annealing; secondary zinc immersion. The gold-plating method subsequently comprises the following steps: I, preplating chemical nickel in a chemical nickel-plating liquid; II, plating nickel for the first time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; III, performing aging treatment; IV, performing activating treatment; V, plating nickel for the second time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; VI, taking a pure gold plate or a platinum titanium mesh as an anode and the high silicon-aluminum composite material as a cathode according to a conventional pure gold-plating method, wherein the gold layer is 2-3 microns thick; VII, detecting the binding force of the plating layer. The plating layer observed under tenfold amplifying glass is free from peeling and bubbling phenomena and good in binding force. The binding force of the gold-plating plating layer and a high silicon-aluminum base material adopted by the method provided by the invention is firm and reaches the standard of appendix A of GJB1420 General Specification of Semiconductor Integrated Circuit Shell.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

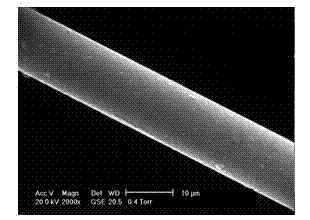

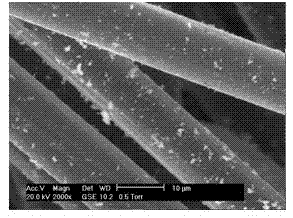

Aramid fiber surface metallization treatment method

The invention belongs to the field of fiber material surface metallization treatment and particularly relates to an aramid fiber surface metallization treatment method which takes hypophosphite as reductant and metal salt as the plating solution of the main salt to deposit a metal coating on the surface of aramid fiber through chemical plating. The surface metallization treatment process includes the steps of unoiling, coarsening, sensitizing, activating, carrying out preplating and carrying out chemical plating. Through the metallization treatment method disclosed by the invention, a uniform compact nonporous metal coating can be plated on the surface of the aramid fiber, and therefore the electrical conductivity and the corrosion resistance of the aramid fiber can be improved and the service life of the aramid fiber can be prolonged. The aramid fiber plated with the metal coating can also be used as reinforcement of metal matrix composite material so as to improve the mechanical property of the composite material.

Owner:KUNMING UNIV OF SCI & TECH

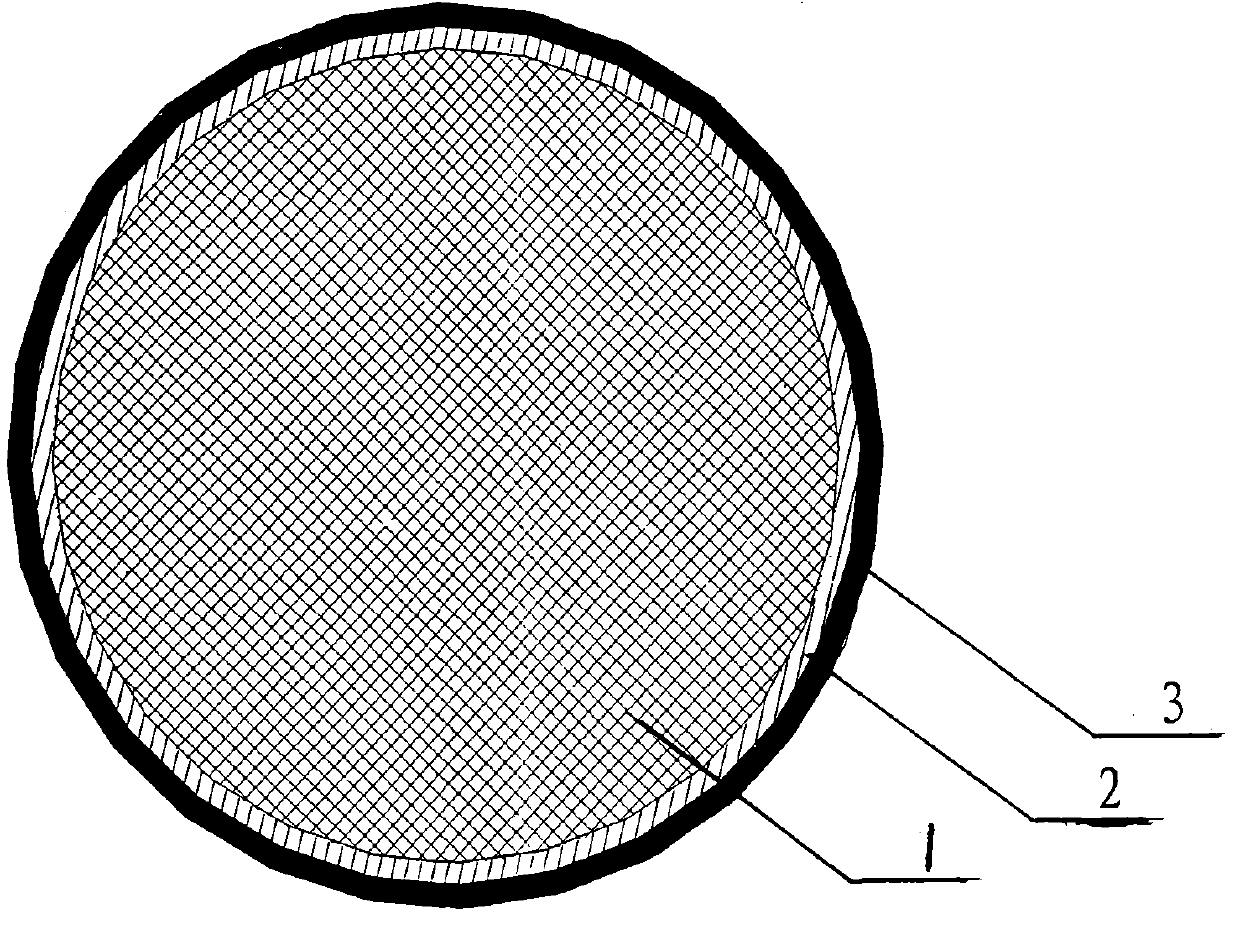

Electrode having titanium-based oxide composite coating and manufacturing method thereof

InactiveCN101275238ALow costImprove bindingWater/sewage treatmentElectrodesTitanium metalNon noble metal

The invention provides a Ti-based oxide composite coating electrode which is characterized in low cost, small power consumption and long service life, comprising titanium metal plate vector, an intermediate layer arranged on the surface of the vector and a surface active layer arranged outside of the intermediate layer. Wherein, the composition of the intermediate layer is Sn0<2> and Sb<2>0<3> and the molar ratio of Sn to Sb is 100: (5-15), and the composition of the surface active layer is Sn0<2>, Sb<2>0<3> and Ce0<2> and the molar ratio of Sn to Sb to Ce is 100: (5-15): (0.5-3). The electrode of the invention effectively makes use of non-noble metal electrode, reduces cost of electrode material. Because the intermediate layer is arranged, a bonding force between the surface active layer and the vector is greatly strengthened so as to extend service life. The electrode manufacturing method of the invention comprises steps of polishing the titanium metal plate vector, processing acid etch, coating the intermediate layer on the surface of the titanium metal plate, and coating the surface active layer.

Owner:CHINA MEAT RES CENT

Foamed high resilience polyurethane wave-absorbing material and preparation method thereof

InactiveCN101519487AThe shape of the material is regularThe size of the bottom surface is accurate and consistentPliabilityFire retardant

The invention relates to a foamed high resilience polyurethane wave-absorbing material and a preparation method thereof. In the foamed high resilience polyurethane wave-absorbing material, a foamed combining material takes 4,4'-diphenylmethane diisocyanate and polyether glycol as main reaction substances, and is added with a conventional blowing promoter. The foamed high resilience polyurethane wave-absorbing material is characterized in that the foamed combing material also comprises substances such as an absorbent, a flame retardant and the like. The material is applied to full-anechoic chambers and semi-anechoic chambers, not only can achieve the effect of absorbing electromagnetic waves, but also has the characteristics of good environmental protection, flexibility, and dimensional uniformity, good mounting matrix property, beautifulness and consistency, and is particularly suitable for clean experiment environment.

Owner:NANJING BOPING ELECTRONICS TECH CO LTD

Chromium-free Dyclo paint

InactiveCN101260252AGood effectNo pollution in the processLiquid surface applicatorsAnti-corrosive paintsChromium freeZinc

The invention relates to a non-chromate Dacromet paint belonging to the metal anticorrosion technical field. The non-chromate Dacromet paint is prepared by the following steps that: after mixing a component B with a component C based on the weight ratio of 3-5:1.5-2.4, mixing the mixture with a component A based on the weight ratio of 1:16-32, stirring evenly and controlling pH value between 3.5 and 5.5; the non-chromate Dacromet paint has the characteristics of non-environmental pollution and non-public nuisance, high permeability, high adhesion, high antifriction, high weatherability, high chemical stability and so on. And the anticorrosion of the non-chromate Dacromet paint improves 7-10 folds of zinc electroplating.

Owner:SHANDONG UNIV

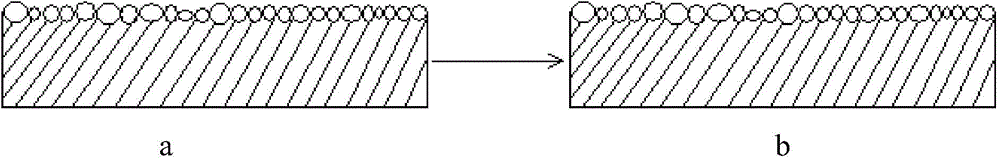

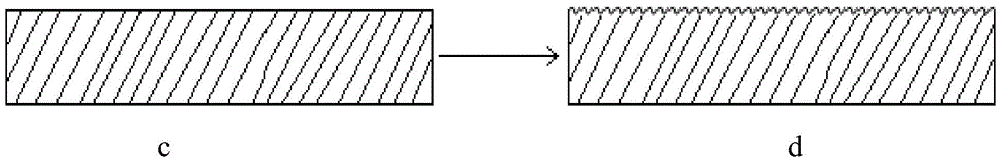

Super-hydrophobic/super-oleophilic oil-water separating net

Super hydrophobic / super oleophylic oil-water separation net has meshes 300-1500 covered thin perfluoroalkyl siloxane copolymer membrane with thickness 20~50nm, which can be metal fiber fabric of stainless steel or cupper, or fabric or terylene and nylon. Its preparation method is: 1. degrease, clean with acid and bath to the fabric net and dry; 2. for the weight share, mix the liquid with perfluoroalkyl siloxane 0.1-5%, water 1-10%, hydrochloric acid or 1N 0.1-2% and other is alcohol for 30-120 minutes, form gel-sol; 3. dip the net into gel-sol for 3-30 seconds, take out, dry naturally, repeat for 2-8 times; 4. take hot curing for the fabric net at 80-250Deg for 10-120 minutes, obtain the membrane and oil-water separation net.

Owner:NANJING UNIV

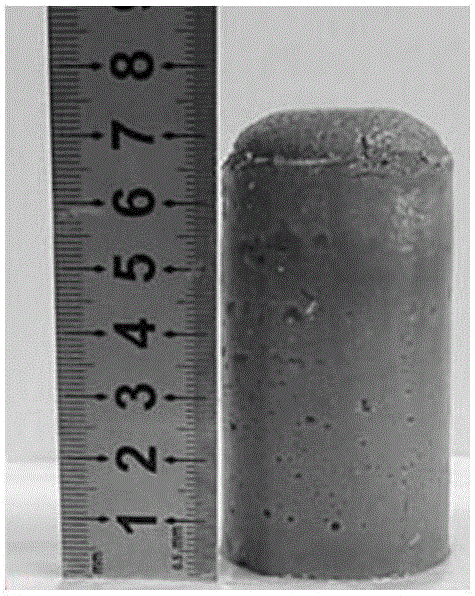

Phenolic resin/silicon dioxide composite aerogel materialand preparation method thereof

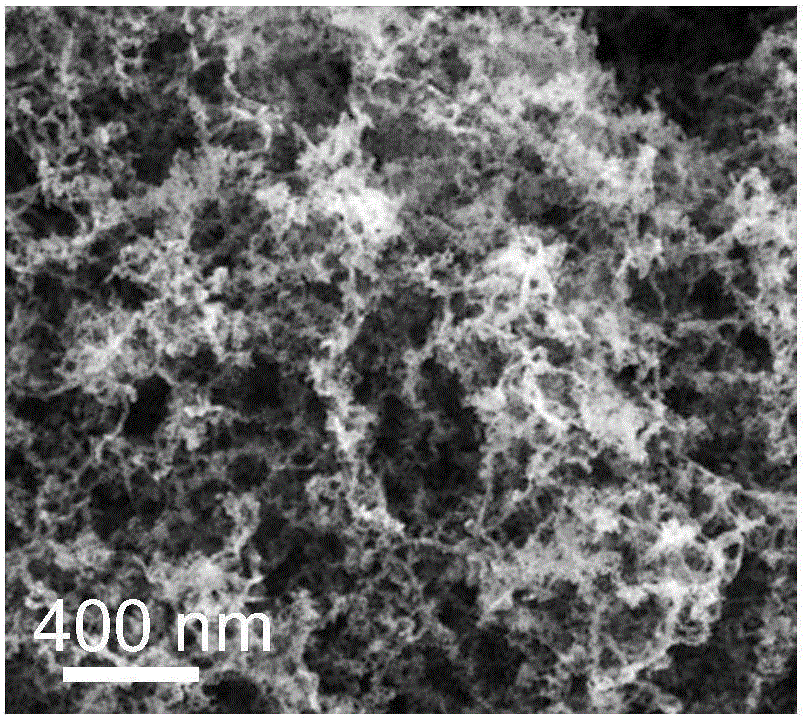

ActiveCN106189066ANo sheddingNo separabilityBulk chemical productionThermal insulationNanoscopic scale

The invention provides a phenolic resin / silicon dioxide compositeaerogel material and a preparation method thereof. The phenolic resin / silicon dioxide composite aerogel material has a nano-grid structure in which a silicon dioxide phase and a resin phase are mutually tangled. The phenolic resin / silicon dioxide composite aerogel material is prepared from a material containing an organic silicon precursor, a phenolic compound, an aldehyde compound and chitosan by virtue of a sol-gel method and supercritical carbon dioxide. According to the composite aerogel material, an organic phase and an inorganic phase are respectively continuous nano-scale tangle structures and are integrated with the mechanical property of organic aerogel and the thermal insulation property and fire resistance of silicon dioxide aerogel; and after the composite gel material with a thickness of 1cm is impacted by the 1300-DEG C flame of a blast burner for over 30 minutes, the falling and the separation of the inorganic phase are not caused, and meanwhile, the temperature of a protected side does not exceed 300 DEG C. The preparation method has the beneficial effects that the operation is simple, the reaction is safe and reliable, and the thermal insulation property and the fire resistance of the material can be regulated and controlled by simply changing the material proportion.

Owner:UNIV OF SCI & TECH OF CHINA

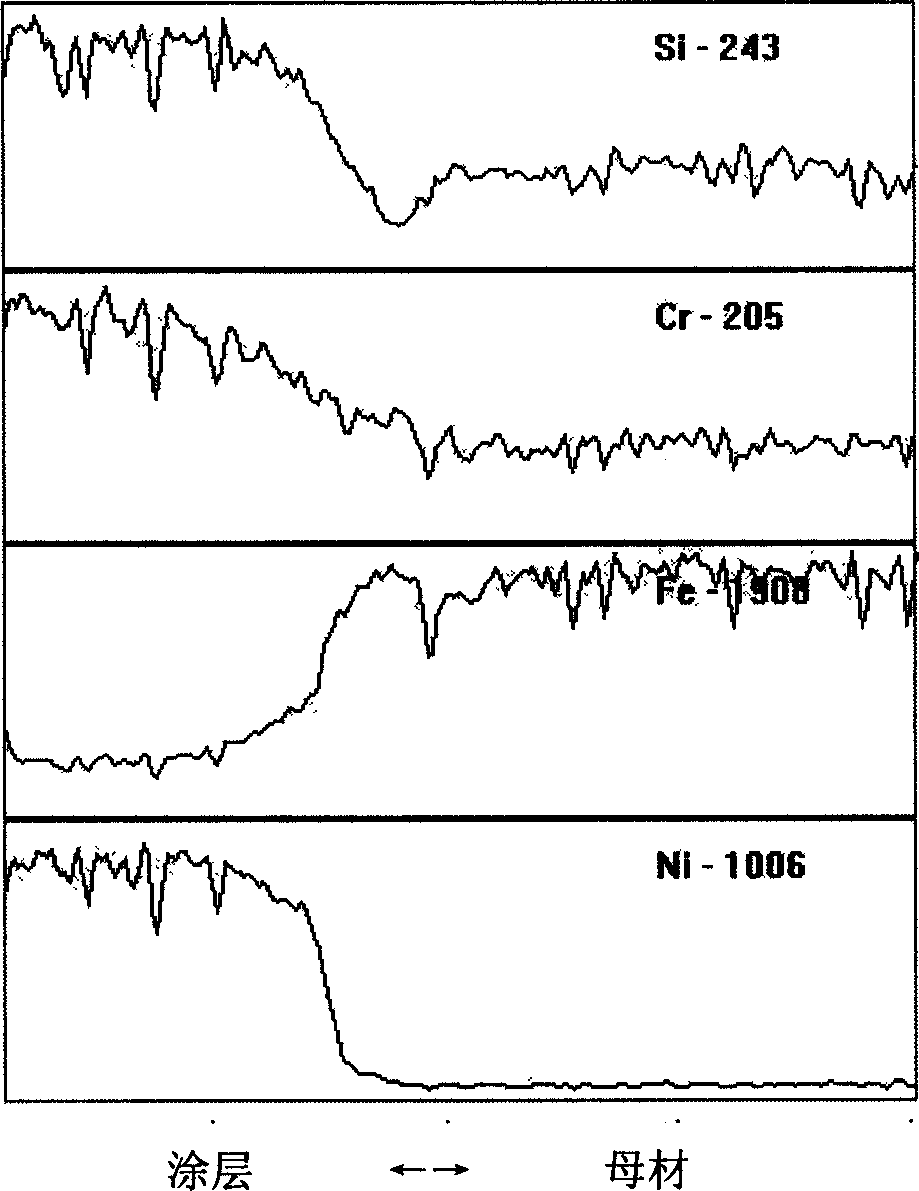

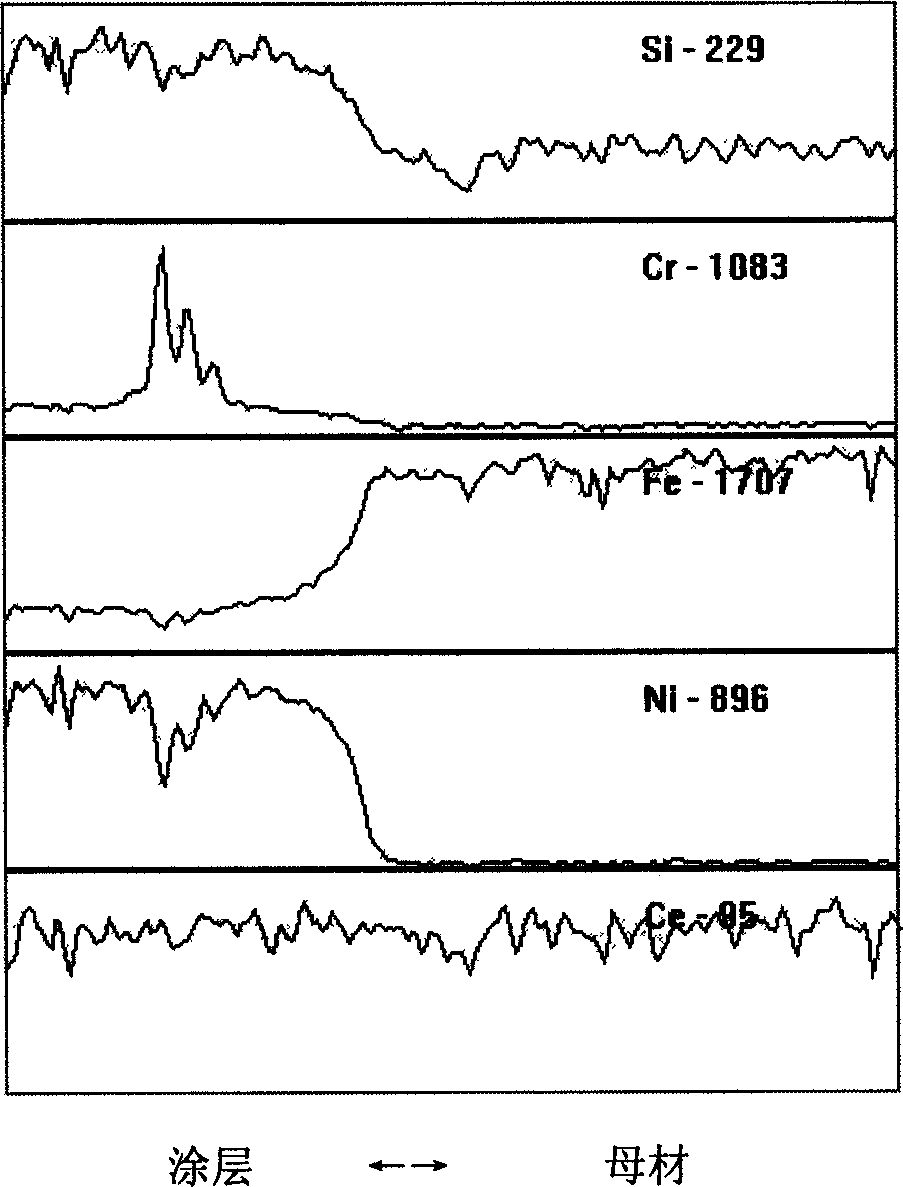

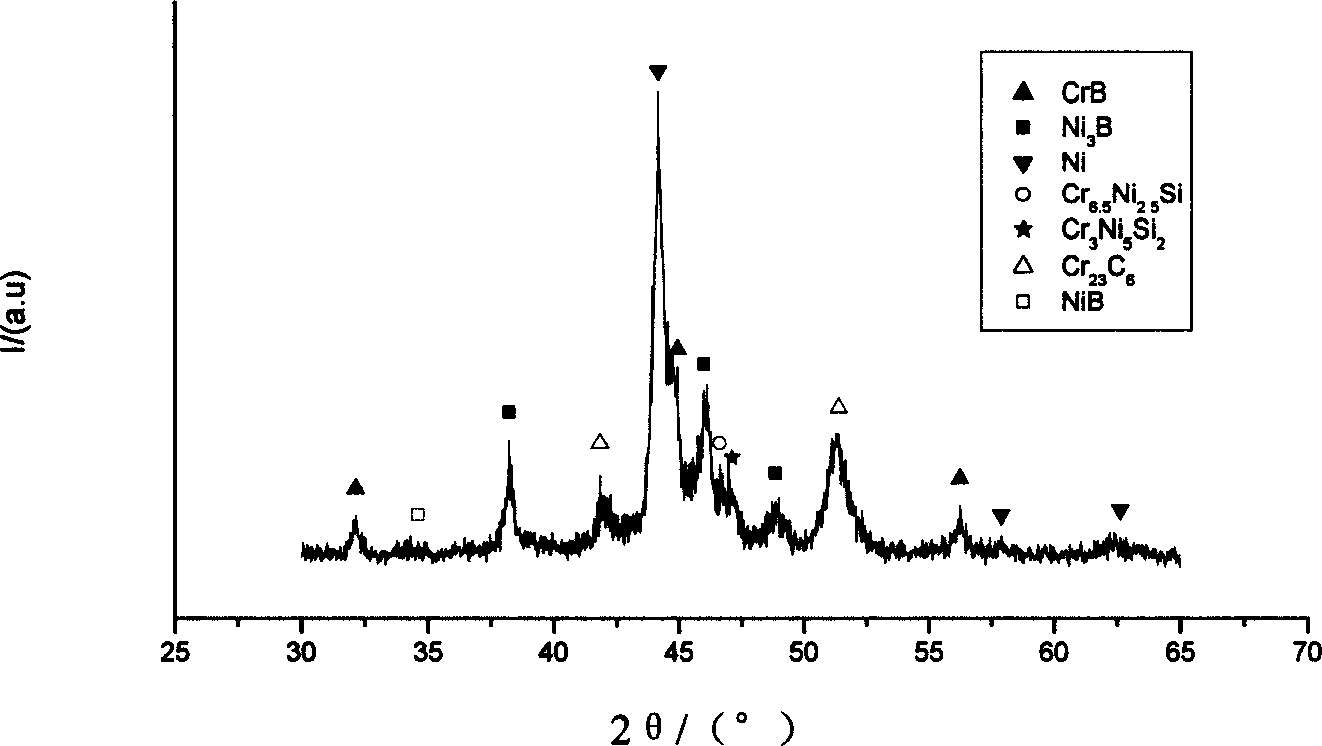

Nickel base self-fusible alloy-rare earth composite coating material and its preparing method

InactiveCN1580324AEasy to modifyImprove performanceMetallic material coating processesParticulatesSilanes

The invention is a nano-particulate demulsifying agent used in demulsification of trinary oil recovery produced fluid. The application of new technique of trinary oil recovery enhances the crude oil recovery, where the polymer injection oil-recovery technique increases the oil, obviously, but also causes the difficulty in demulsifying the produced fluid at the same time. Its character lies in that: the nano-particulate demulsifying agent is composed of particle nucleating material which processes the surface of nano silicon oxide material by silane coupler and fluorine compound and reacting solvent containing arenes as dimethylbenzene, as well as polyether demulsifying agent as multicomponent polyether, amine polyether and resin polyether. It effectively solve the problem about the demulsification of trinary oil recovery polymer injection produced fluid, field used quantity little, demulsifying speed rapid, dehydrating efficiency high and oil-water interface regular.

Owner:HEFEI UNIV OF TECH +1

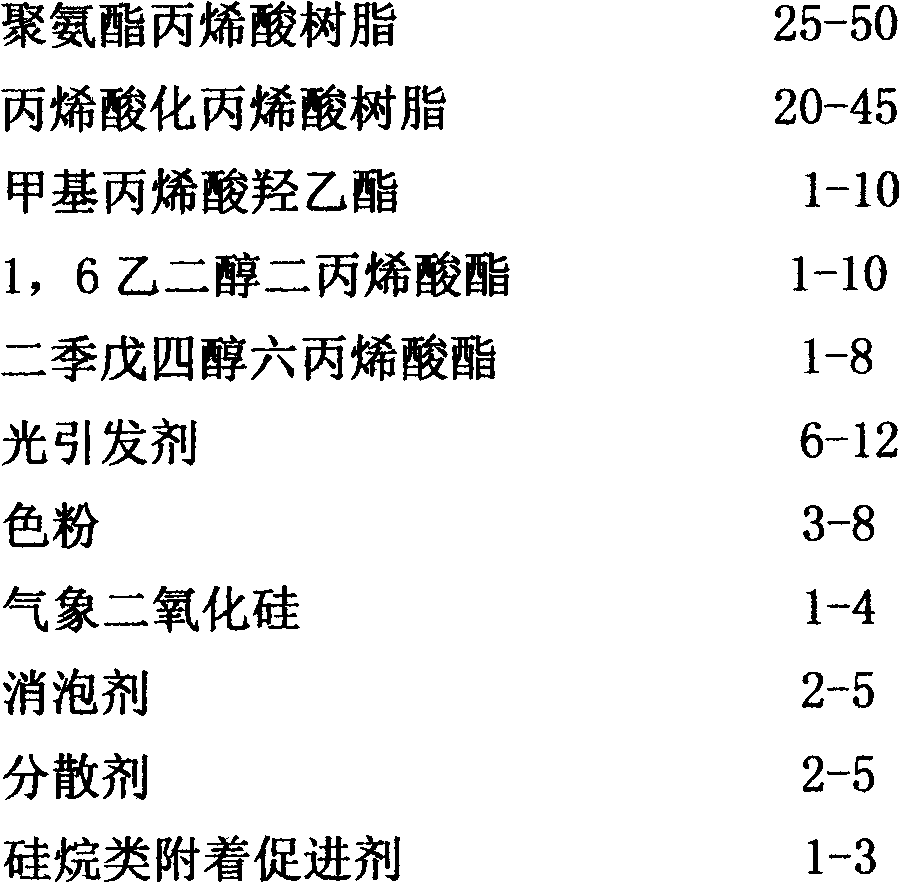

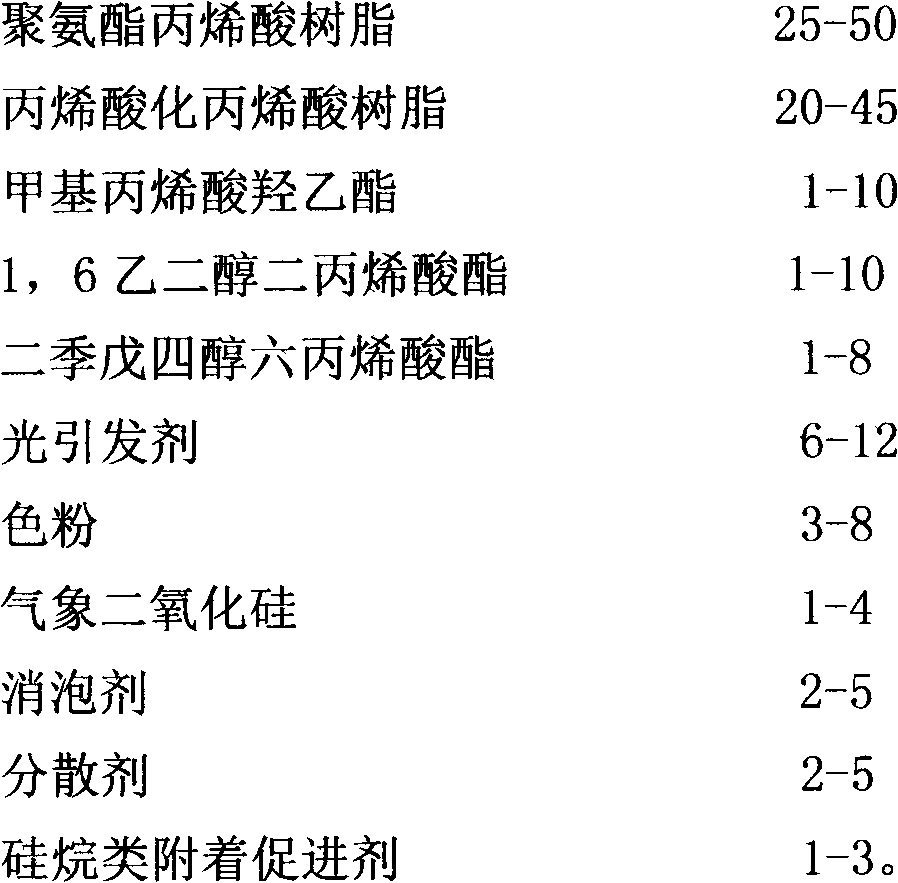

Ultraviolet (UV) glass protective printing ink

InactiveCN103160169AReduce waste of resourcesReduce enterprise manufacturing costsInksPhotoinitiatorChemistry

The invention discloses ultraviolet (UV) glass protective printing ink and a manufacturing method thereof. The printing ink comprises, by weight, 25-50 parts of urethane acrylate resin, 20-45 parts of acrylate crylic acid resin, 1-10 parts of hydroxyethyl methylacrylate, 1-10 parts of 1,6-ethylene acrylic acid ester, 1-8 parts of dipentaerythritol hexaacrylate, 6-12 parts of photoinitiators, 3-18 parts of toner, 1-4 parts of gas-phase silica, 2-5 parts of antifoaming agents, 2-5 parts of dispersing agents, and 1-3 parts of silane attaching accelerant. The components are added in sequence according to parts thereof, stirring is carried out at constant speed for full time, then grinding is carried out through a three-roller machine, and finally the printing ink can be obtained by filtering a solution. In a glass machining process of a touch screen, silk screen is carried out on the surface of glass for protection with the UV glass protective printing ink, final perfectness rate of glass products is improved by 27%-40% compared with the situation when a glass protective measurement is not taken, resource waste can be obviously reduced, enterprise manufacturing cost is lowered, and enterprise production capacity is improved.

Owner:金甲化工企业(中山)有限公司

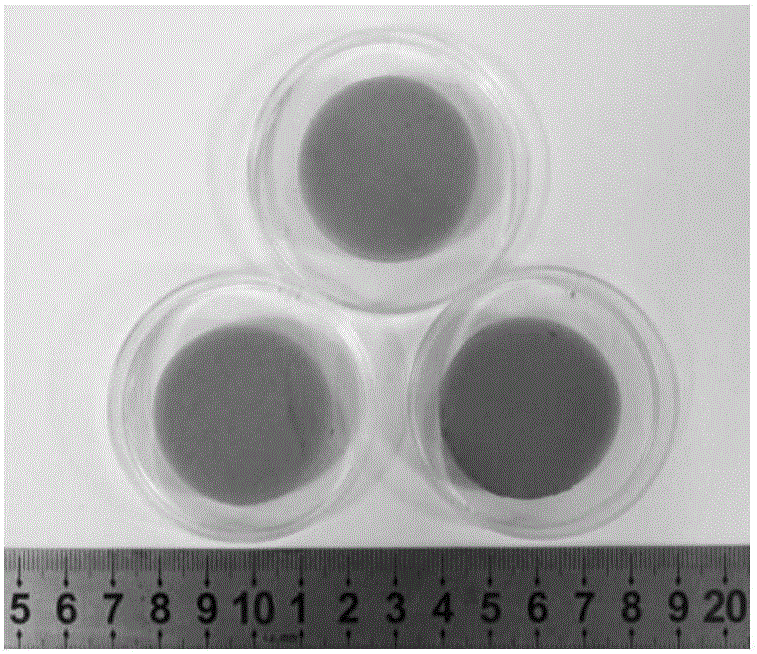

Brightly colorful contact lens and preparation method thereof

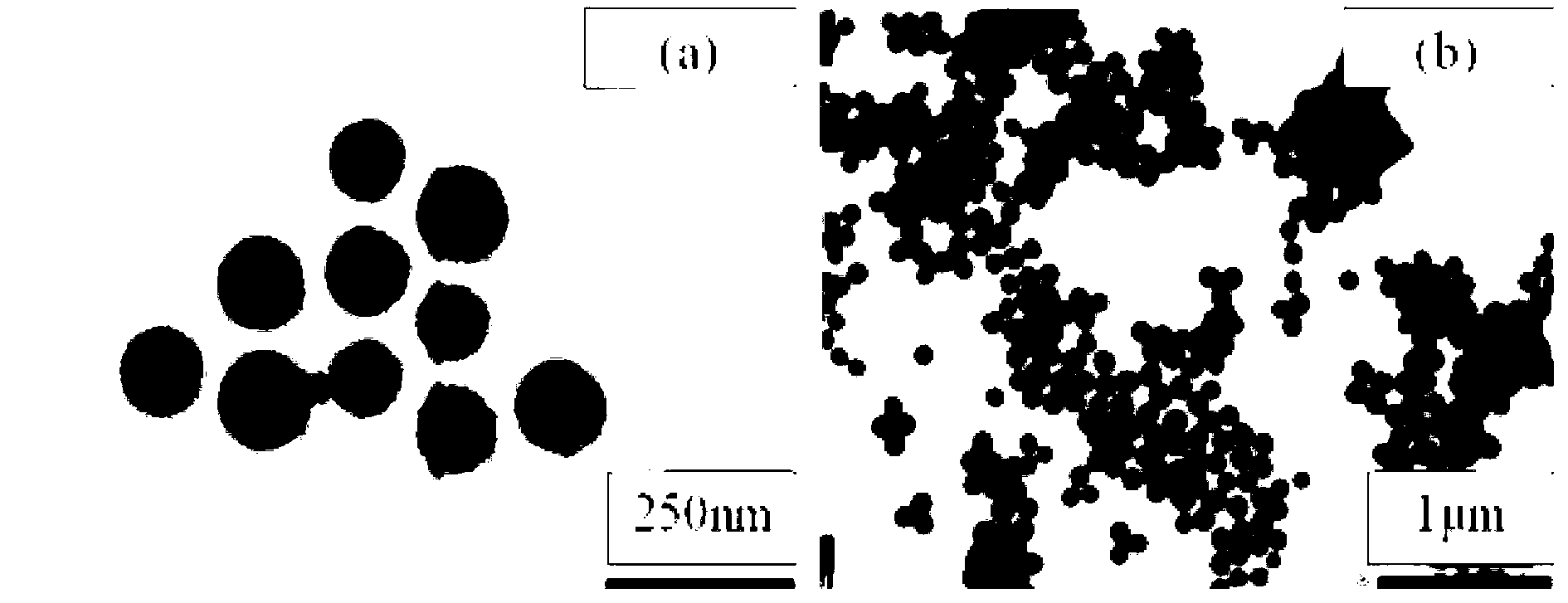

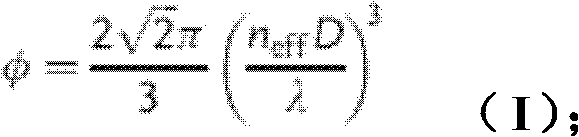

InactiveCN102193213ANo sheddingNo problems such as damage to the corneaOptical articlesOptical partsSaline waterPhotonic crystal structure

The invention discloses a brightly colorful contact lens which is characterized by being prepared by using a method comprising the following steps of: (1) preparing structural color hydrogel with an inverse opal photon crystal structure by using a sequenced colloid nano particle photon crystal structure as a template through a colloid crystal template method; (2) paving the structural color hydrogel with the inverse opal photon crystal structure in a PV (polyvinyl) mould of the contact lens; adding the contact lens standard hot-solid liquid to completely permeate into the network structure ofthe hydrogel; processing the thermal solidification sequence to form the initial film of the contact lens; immersing the initial film of the contact lens in a standard saline water solution to process hydration treatment until swelling is in equilibrium. Compared with other colored contact lenses, the brightly colorful contact lens is beautiful in appearance, good in biological compatibility and good in practicability.

Owner:SOUTHEAST UNIV

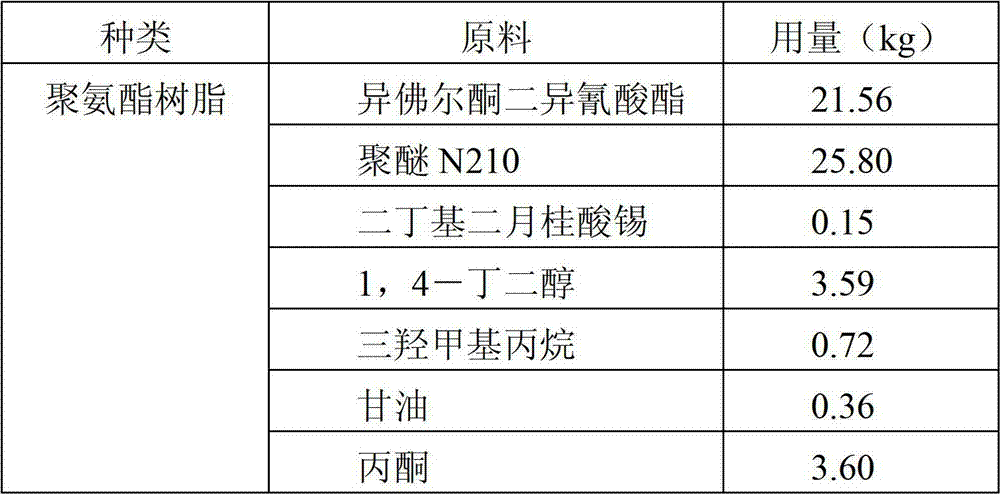

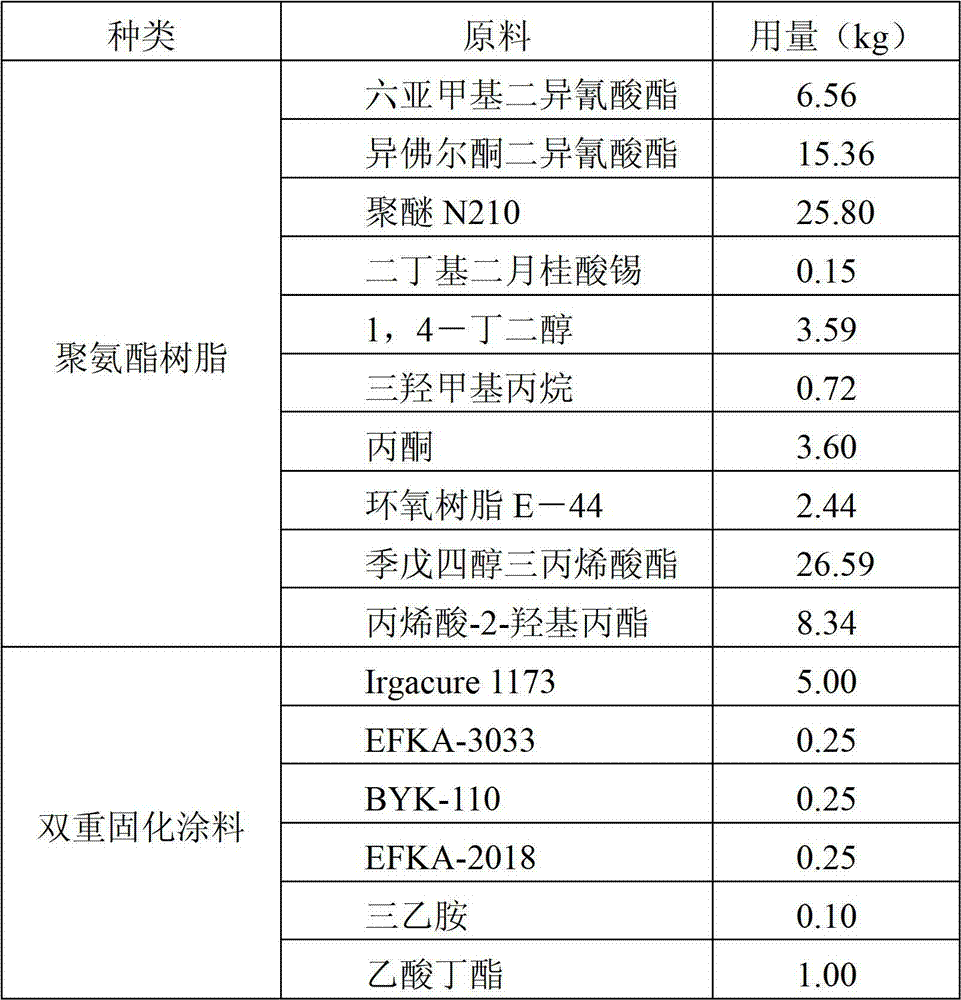

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

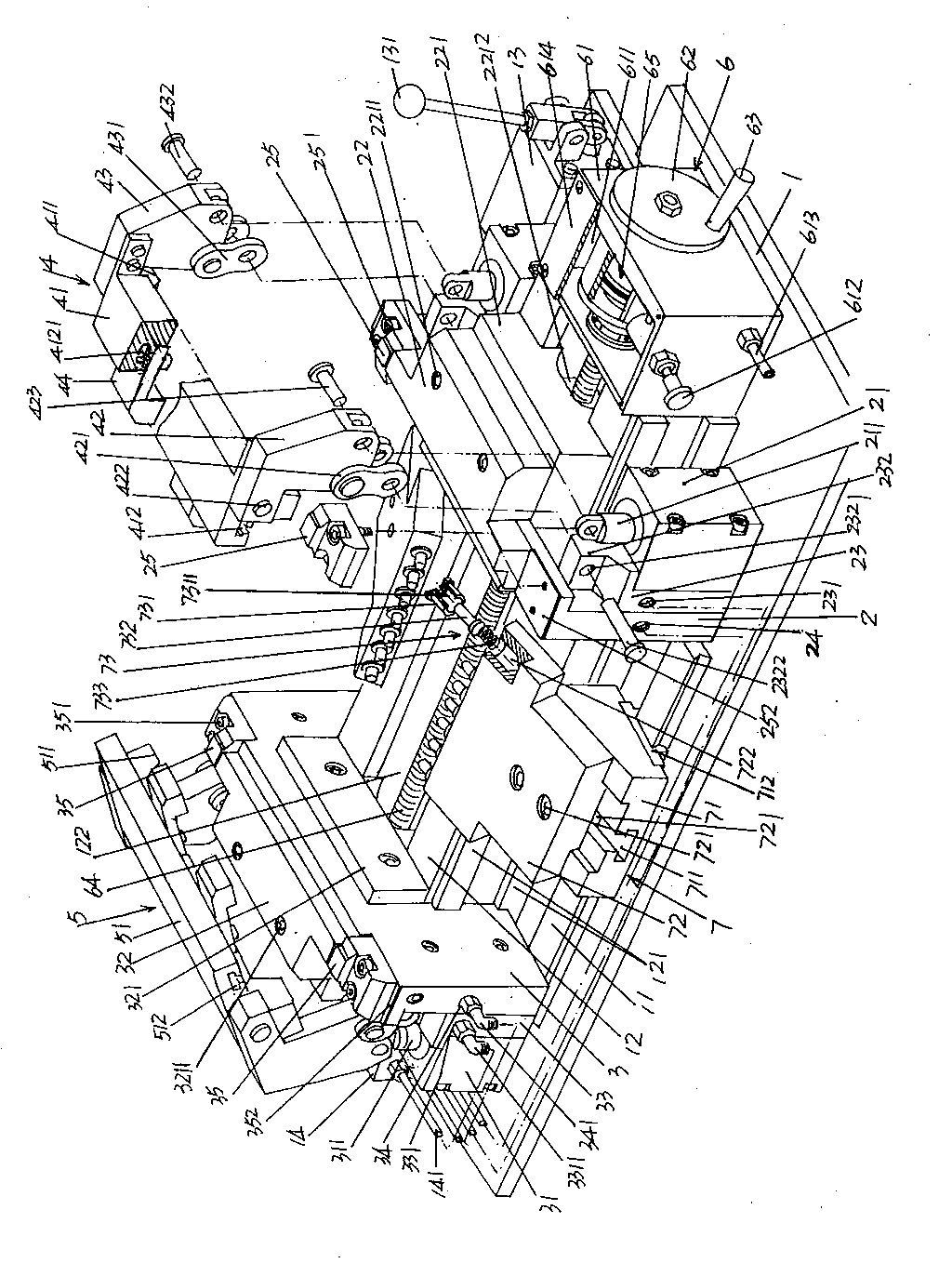

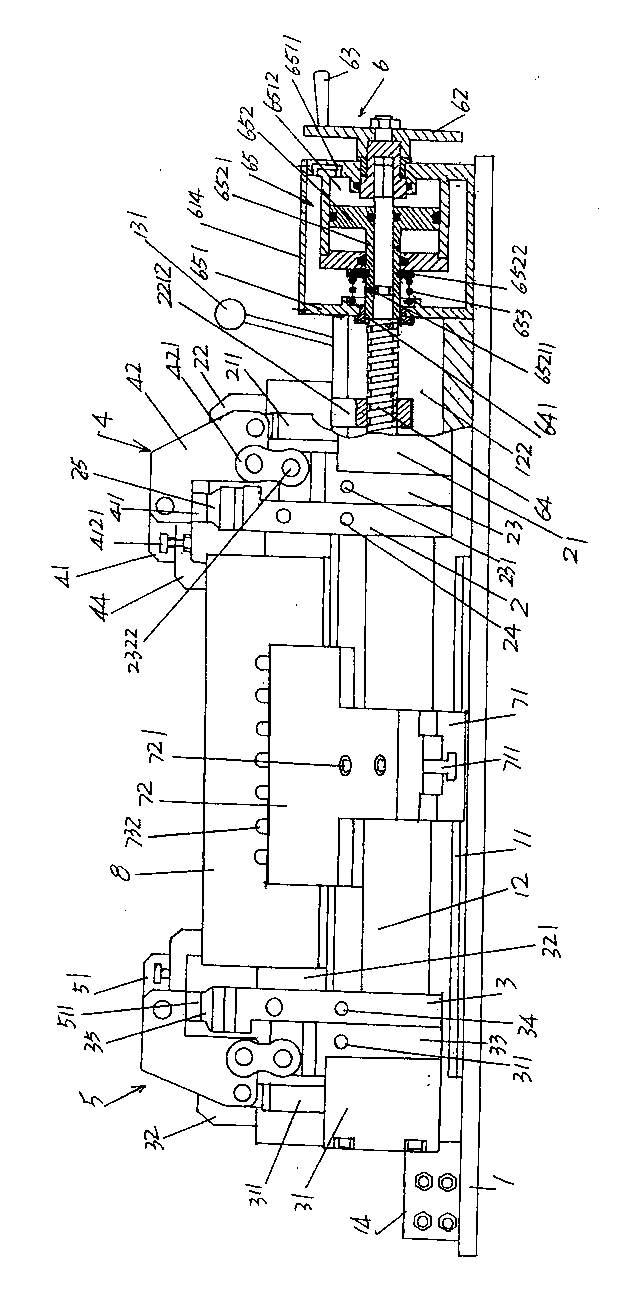

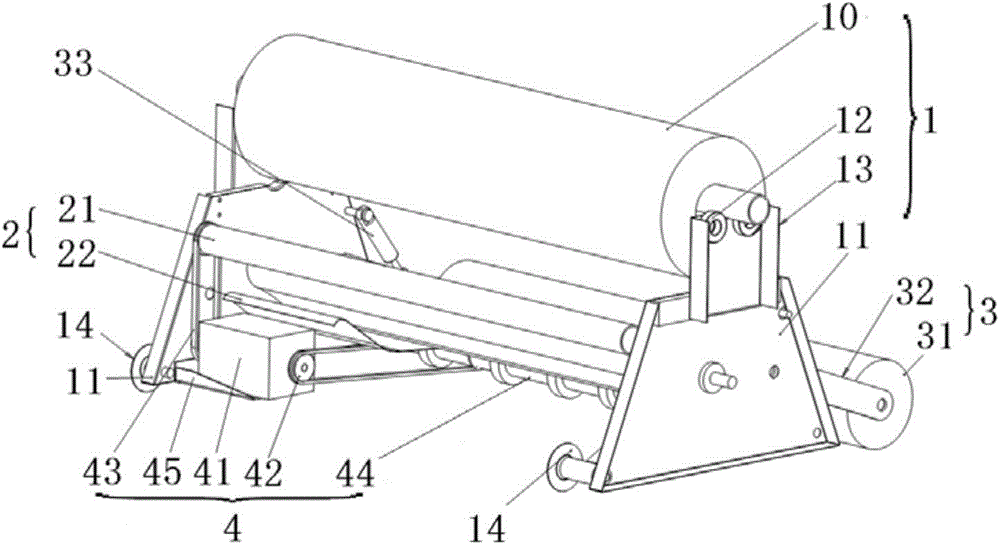

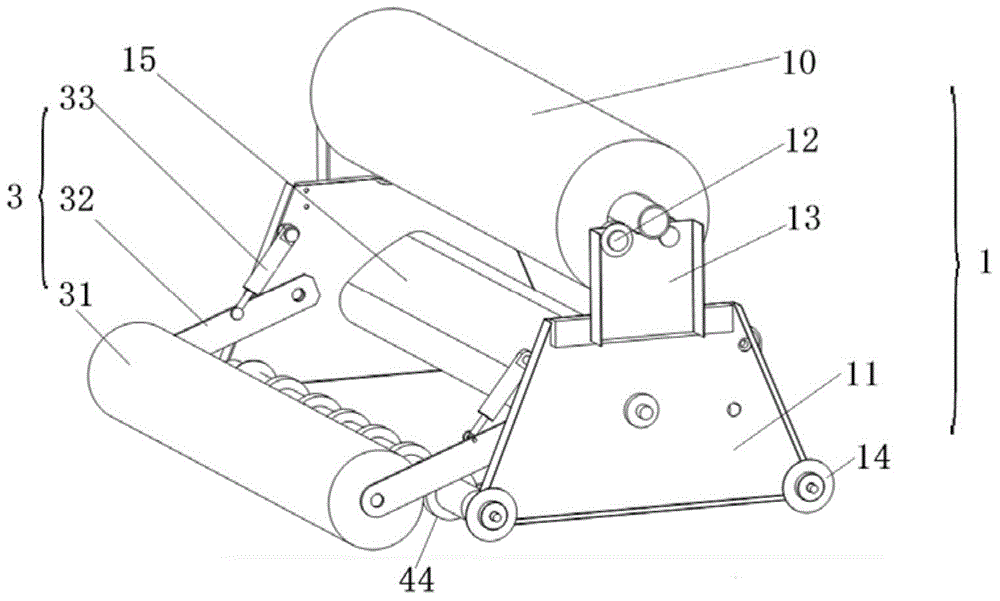

Waterproof roll paver and paving method

The invention provides a waterproof roll paver and a paving method, belongs to the technical field of waterproof rolls, and can solve the problems of easy pollution and easy fall of overlap edges of traditional wet paved rolls. The waterproof roll paver comprises a support device for supporting and sending out the waterproof rolls, a guide device for tensioning the waterproof rolls sent out from the support device, a driving device for towing the waterproof rolls guided out from the guide device to pave on a basal surface and driving the paver to move, and a pressing device for compacting the paved waterproof rolls. The waterproof roll paver can enable the overlap widths of the overlap edges of the waterproof rolls to be consistent, is free of leaking points, fall and pollution on the overlap edges, can realize continuous paving, can save the labor, improves the working efficiency, and greatly enhances the waterproof quality. The waterproof roll paver is suitable for paving various waterproof rolls, and specifically for wetly paving asphalt rolls.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

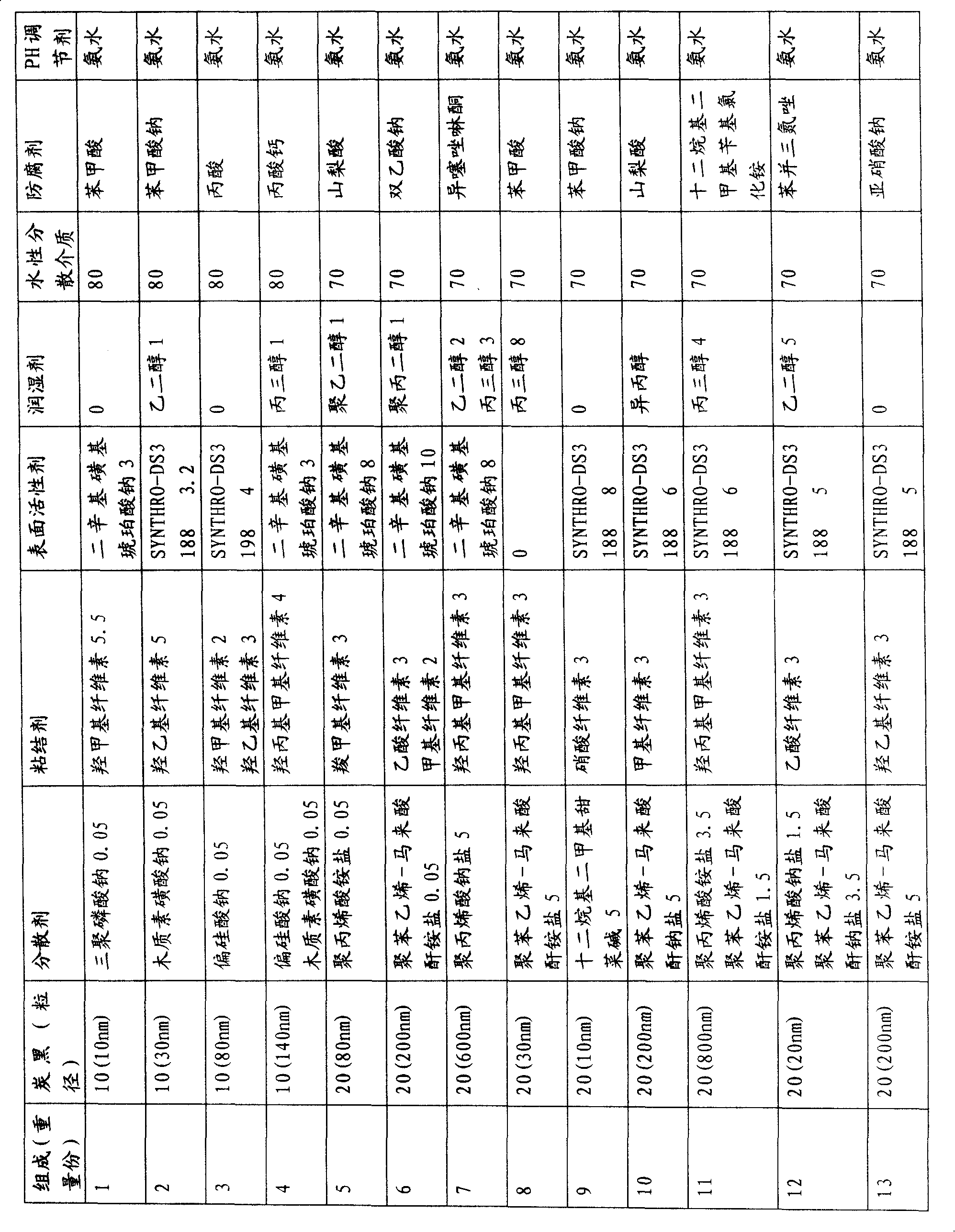

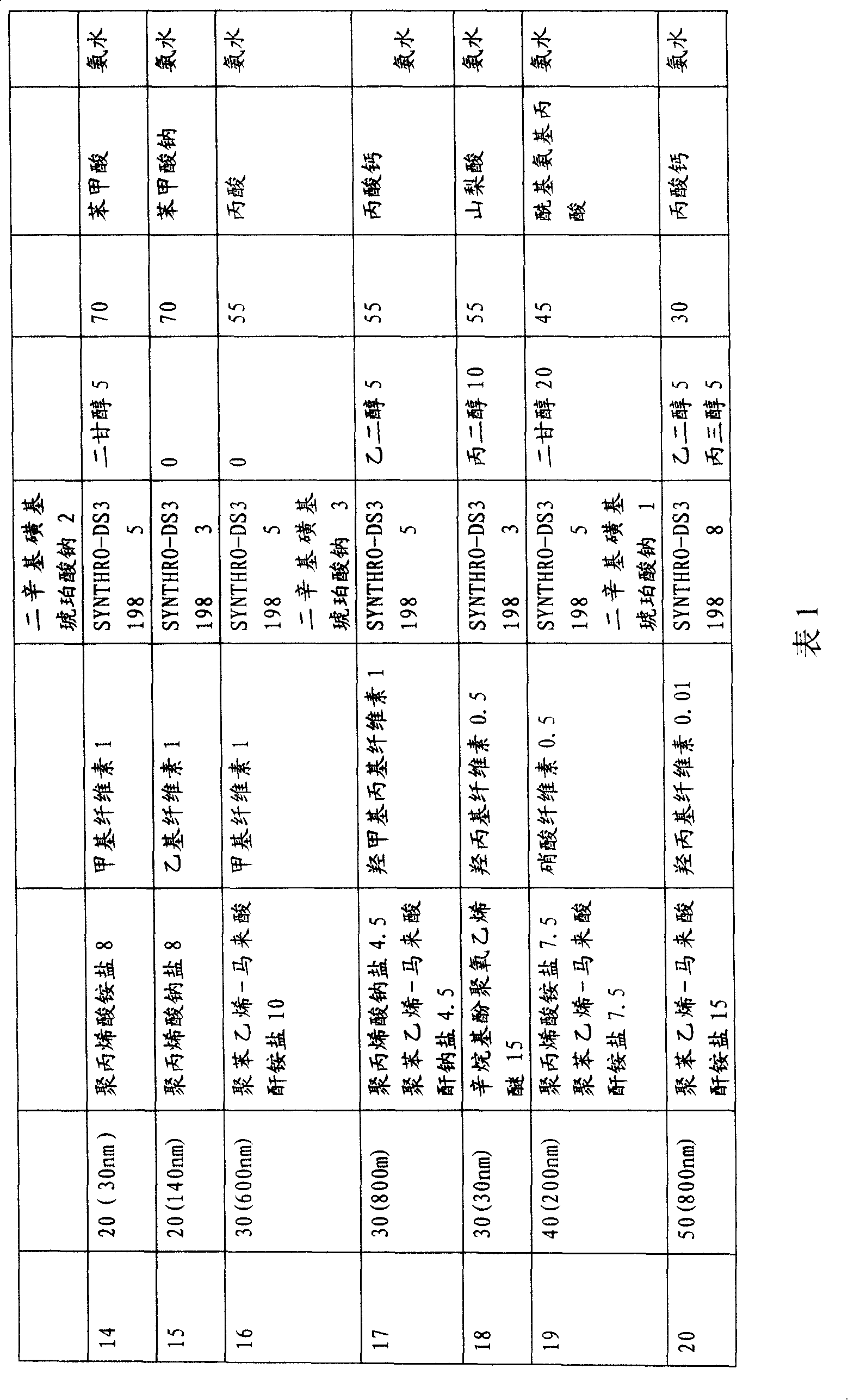

Carbon black conductive fluid

InactiveCN101165820AImprove wettabilityWill not cause accumulationNon-conductive material with dispersed conductive materialPrinted circuit manufacturePolyesterDisperser

The invention comprises (based on unit weight percent): carbon black 0.1-50, disperser 0.01-15; binder 0.01-15; aquosity dispersion medium 50-99.

Owner:深圳市合力泰光电有限公司

Method for efficiently compounding fusion-covering reinforced steel rail through laser and auxiliary heat source

ActiveCN108456879AReduce temperature gradientAvoid crackingFurnace typesMetallic material coating processesMelting tankHeat-affected zone

The invention discloses a method for efficiently compounding a fusion-covering reinforced steel rail through laser and an auxiliary heat source. The laser and the auxiliary heat source act on a to-be-fusion-covered area on the surface of the steel rail simultaneously, as a main heat source, the laser makes the material of a fusion-covering layer and the material on part of the base of the surfaceof the steel rail quickly fused simultaneously to form a fusion pool, the auxiliary heat source and the laser heat source move in the same direction at the same speed and preheat and / or postheat the laser fusion pool, a heat influence area and the surface layer of the base of the steel rail, the temperature gradient of the steel rail is lowered, thus the cooling speed of the steel rail is lowered,and the phenomena of transforming of a martensite in a heat influence area and cracking are avoided. Through the compounding effect, the critical cooling time for transforming an austenite to a pearlite is shortened in the heat influence area wherein the cooling time is larger than a CCT curve or a TTT curve, so that the mechanical performance among the fusion-covering layer, the heat influence area and the base is reasonably matched, the rigidity curve is smooth in distribution, and the overall fatigue performance is good. The method can fuse-cover a metal layer on the surface of a field ofa railway steel rail on line and can also achieve fuse-covering machining on the surface of the steel rail in a production workshop.

Owner:HUAZHONG UNIV OF SCI & TECH +1

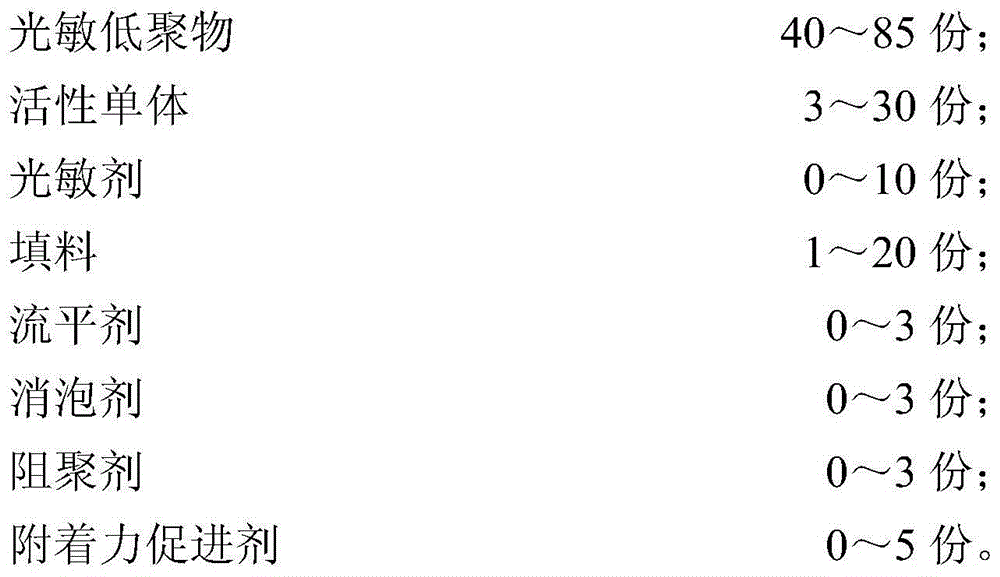

Endogenous frosting-effect glass ink and method for producing frosting-effect product by utilizing same

The invention discloses endogenous frosting-effect ink and a method for producing a frosting-effect product in a two-stage UV curing method. The ink consists of the following components in parts by weight: 40 to 85 parts of photosensitive oligomer, 3 to 30 parts of active monomer, 0 to 10 parts of photosensitive agent, 1 to 20 parts of stuffing, 0 to 3 parts of flatting agent, 0 to 3 parts of defoaming agent, 0 to 3 parts of polymerization inhibitor and 0 to 5 parts of adhesion promoter. The two-stage UV curing process comprises a low-energy UV light curing step and a high-energy UV light curing step. The ink is good in mobility, excellent in printing property, high in production efficiency and true in UV curing layer frosting effect, and no waste water and no waste gas are produced; and the endogenous frosting-effect glass ink has the characteristics of high hardness, scratch resistance, excellent adhesion force, excellent water resistance, excellent acid-alkali resistance and the like.

Owner:HANGZHOU KEWANG SPECIAL INK CO LTD

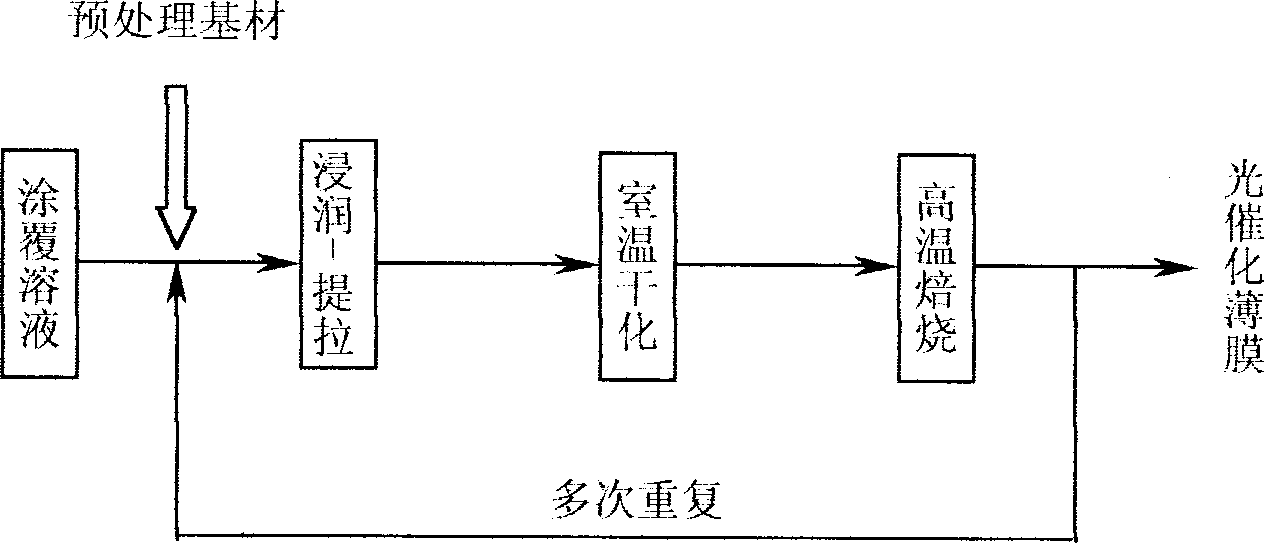

Process for preparing photocatalytic TiO2 film used to clean water and air

InactiveCN1397377AImprove firmnessImprove photocatalytic degradation performanceDispersed particle separationVacuum evaporation coatingAir cleaningSlurry

A photocatalytic TiO2 film for cleaning water and air is prepared through dissolving the titanium alkoxiode in alcohol solvent, adding water and carbon black to obtain slurry, dipping substrate in it, and gradient calcining several times. It has high catalytic degradation rate to organic pollutant (83-93%).

Owner:TSINGHUA UNIV

Method for preparing high-thermal conductivity graphite radiating fins

InactiveCN101951751ANo pollution in the processNo sheddingCooling/ventilation/heating modificationsStrong acidsPhysical chemistry

The invention provides a method for preparing high-thermal conductivity graphite radiating fins. The method comprises the following steps of: a, soaking graphite powder serving as a raw material in acid treatment solution obtained by mixing sulfuric acid and hydrogen peroxide at the temperature of between 20 and 100 DEG C for 20 to 120 minutes; or treating the graphite powder by a high-temperature purification method; or soaking the graphite powder in mixed solution obtained by mixing fluorides and strong acid for 20 to 150 minutes; b, washing the treated graphite powder until the pH value is 5 to 6.5; c, putting the washed graphite powder into a graphite expansion furnace for expansion at the temperature of between 800 and 1,000 DEG C for 3 to 20 hours, and slowly cooling the graphite powder to room temperature; and d, in the mass ratio of the graphite powder to compound particles of 2-8:1, preparing the graphite radiating fins with the thickness of 0.05 to 5mm by using graphite coiled material manufacturing equipment.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

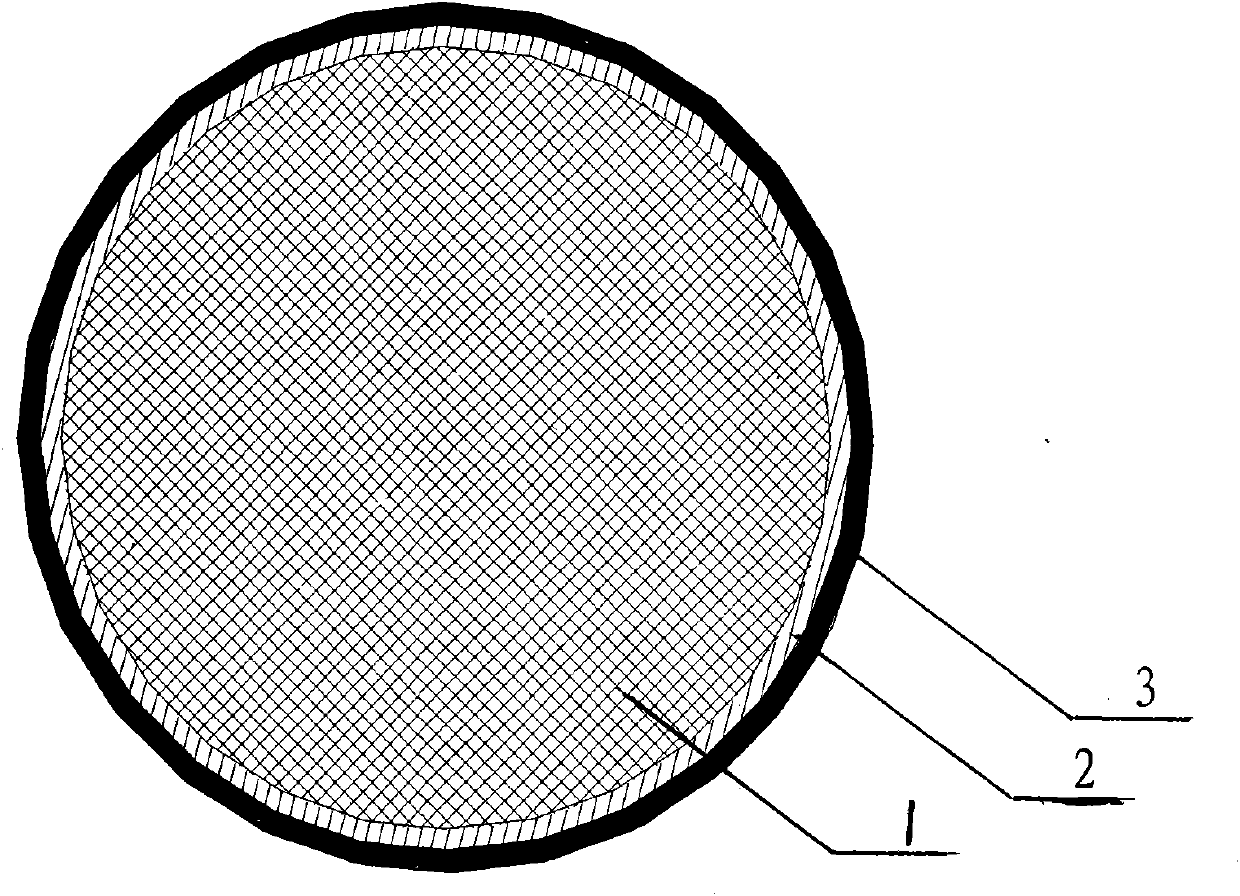

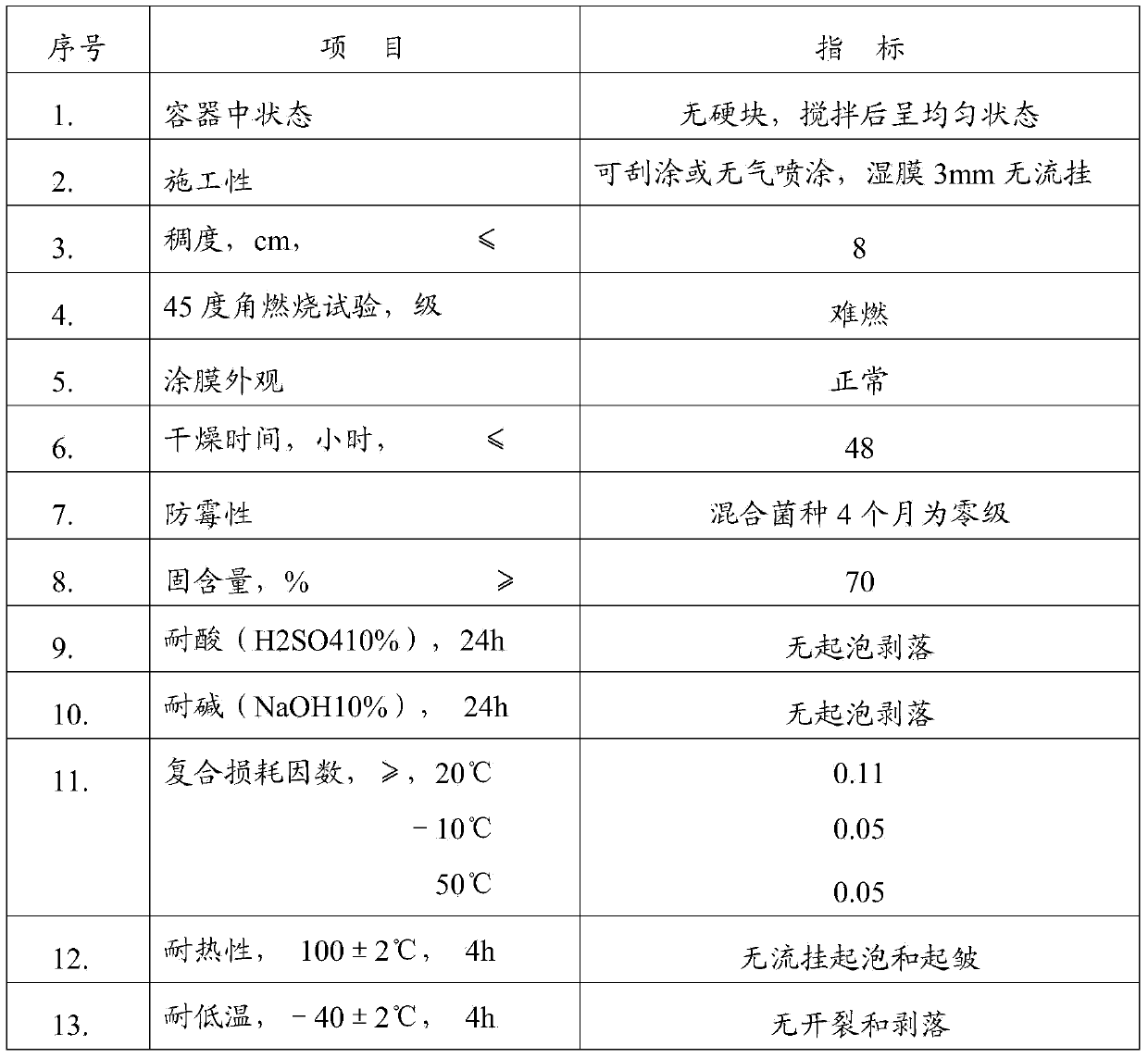

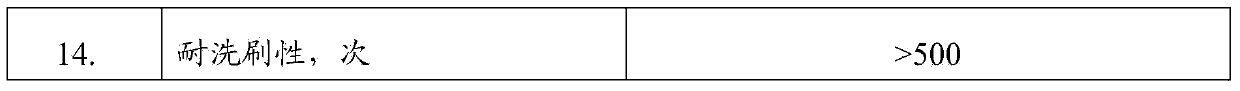

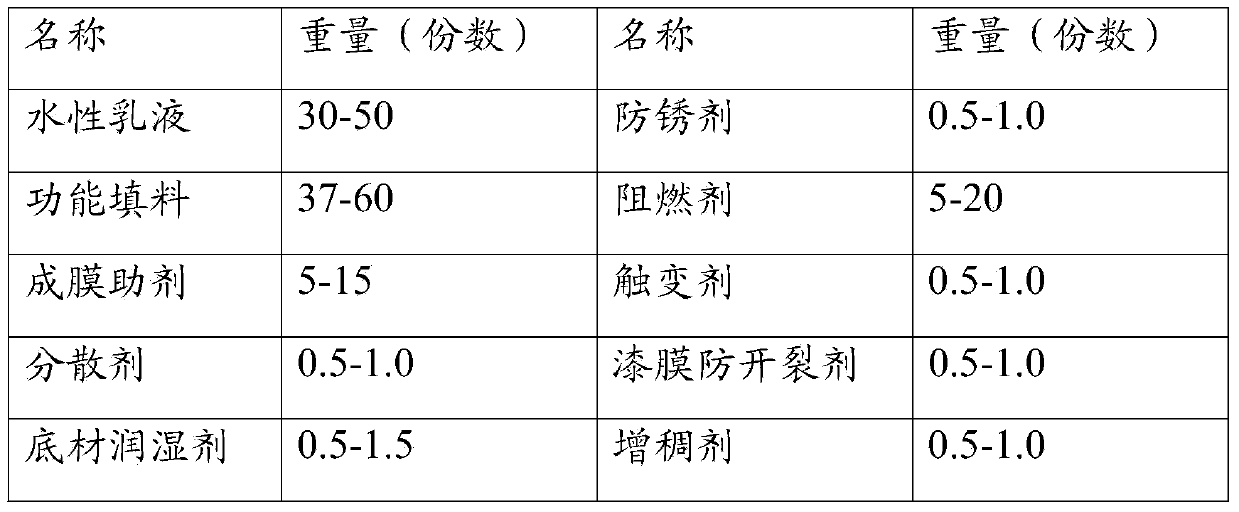

Chassis armored coating and preparation method thereof

ActiveCN103805012AImprove adhesionLow thermal conductivityAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionThermal insulation

The invention discloses a chassis armored coating. The chassis armored coating comprises the following main components in parts by weight: 30-50 parts of waterborne emulsion, 37-60 parts of functional filler, 5-15 parts of coalescing agent, 0.5-1.0 part of dispersant, 0.5-1.5 parts of wetting agent, 0.5-1.0 part of antiseptic mildewproof agent, 0.5-1.0 part of defoaming agent, 0.5-1.0 part of anti-rust agent, 5-20 parts of flame retardant, 0.5-1.0 part of thixotropic agent, 0.5-1.0 of anti-cracking agent, 0.5-1.0 part of thickening agent, 2.0-5.0 parts of antifreeze and 5-15 parts of water. The invention aslo discloses a preparation method of the chassis armored coating. The chassis armored coating uses the water as a dispersion medium, is safe and environmentally-friendly and has excellent corrosion resistance and good solvent resistance and machine oil resistance; a paint film formed by the chassis armored coating has low coefficient of heat conductivity and good thermal insulation property; when the dry film is 2mm, the sound insulation property can reach 30dB.

Owner:QINGDAO AIR NEW MATERIALS

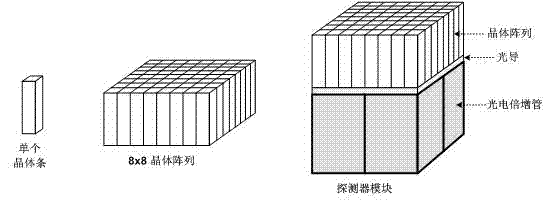

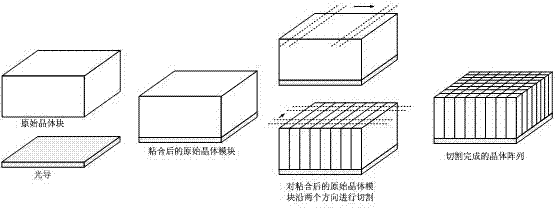

Method for manufacturing crystal array of gamma-ray detector

InactiveCN102176335ANo sheddingHigh mechanical stabilityX-ray/infra-red processesFine working devicesDislocationGamma ray detectors

The invention provides a method for manufacturing a crystal array of a gamma-ray detector, relating to the technical field of gamma-ray detection imaging. The method comprises the following steps of: firstly, cutting an original crystal material into a one-piece original rectangular crystal block, and carrying out mechanical surface treatment on the original rectangular crystal block; then, bonding a light-guide medium on the lower surface of the original crystal block by using a bonding agent; cutting the original crystal block to form a crystal strip array; carrying out surface polishing treatment on each crystal strip arranged in an array; then plating or filling reflective materials in clearances among all the crystal strips; and finally, plating or wrapping the reflective materials on the upper surface and peripheral surfaces of the crystal strip array. By means of the method provided by the invention, the processing difficulty is reduced, the yield is increased, artificially made components in the traditional process are reduced, and the crystal arrays with complex structures, such as a crystal array with a multilayer dislocation structure with response depth information, and the like, are realized more conveniently.

Owner:JIANGSU SINOWAYS (ZHONGHUI) MEDICAL TECH CO LTD

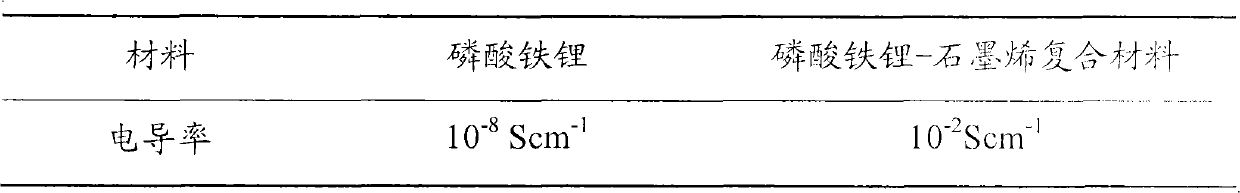

Lithium salt and graphene composite material as well as preparation method and application thereof

ActiveCN102201275AImprove stabilityImprove conductivityElectrolytic capacitorsNon-conductive material with dispersed conductive materialLithiumCvd graphene

The invention discloses a lithium salt and graphene composite material which is crystal formed by lithium salt and graphene, wherein the mass of the graphne accounts for 1-99% of the total mass of the composite material, and the mass of the lithium salt accounts for 1-99% of the total mass of the composite material. The invention also discloses a preparation method of the composite material, comprising the following process steps: preparation of a graphite oxide system, preparation of a mixing system of the lithium salt and the graphite oxide, formation of mixed powder of the lithium salt and the graphite oxide, reduction and crystallization. In the lithium salt and graphene composite material, the stability and the conductivity are high, and the composition of the graphene and the lithium salt is more uniform and more compact without generating falling. The composite material can be prepared only by mixing oxidized natural graphite with the lithium salt and then carrying out reduction and crystallization, so that the preparation method is simple in process, low in cost and suitable for entrepreneurial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com