Preparation method of aqueous aluminum silver paste

An aluminum silver paste, water-based technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing low molecular organic compound treatment and other directions, can solve the problems of aluminum powder precipitation and aggregation, reduce surface tension, insufficient hydrophilicity, etc. No agglomeration, improved performance, excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

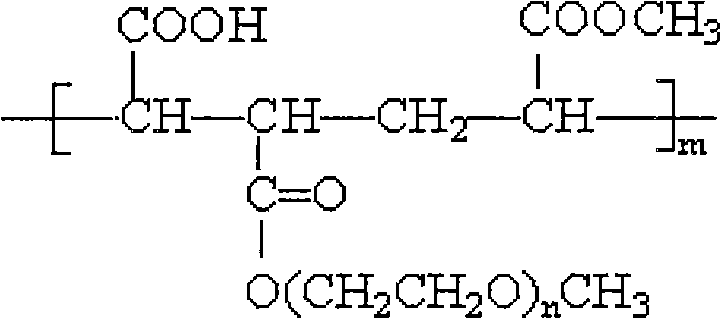

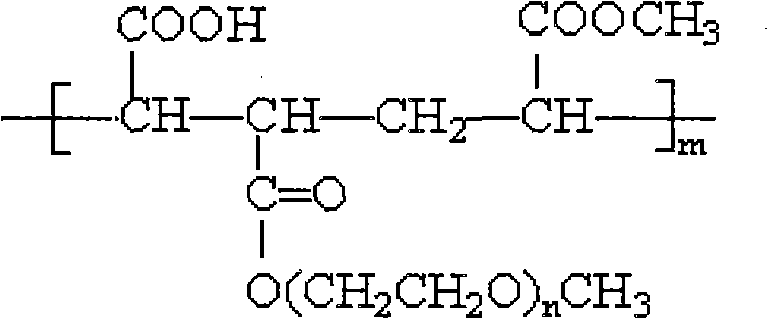

[0017] According to the technical idea of the preparation method of the water-based aluminum-silver paste of the present invention: firstly, a layer of silicon dioxide film (first coating) is coated on the surface of the flake aluminum powder particles, so that the surface of the aluminum powder changes from hydrophobicity to It is hydrophilic, and at the same time prevents the reaction of aluminum powder and water; secondly, synthesizes a comb-shaped polymer suitable for water-based systems. The surface of the aluminum powder forms a second layer of coating to further prevent the aluminum powder from reacting with water, and the other side of the comb polymer has a hydrophilic group, which can make the aluminum powder get stable dispersion in the water-based system, and Improve the compatibility of aluminum powder and resin, and solve the problem of "dropping powder".

[0018] Next, the preparation method of the water-based aluminum-silver paste according to the present inv...

Embodiment 1

[0040] 1. Add 1 part of aluminum powder pigment and 100 parts of acetone into the container, stir for 0.5 hours, and filter to obtain the washed aluminum powder; 2. Take the washed aluminum powder and add it to 80 parts of n-propanol, and after ultrasonic dispersion , into the reaction container, add 0.2 parts of tetraethyl orthosilicate and then gradually add 4 parts of ammonia water, react for 10 hours under stirring, and the reaction temperature is 40°C; 3. After filtering the aluminum powder, carry out in a vacuum oven at 80°C Drying, drying time is 2h, obtains the aluminum powder of silicon dioxide membrane coating; 4, add in the acetone solution of 40 parts of the comb polymer containing 0.1 part again, stir 0.5h; A part of acetone, the temperature does not exceed 50 ° C, that is, to obtain a water-based aluminum silver paste with a solid content of 90%.

[0041] Wherein, the preparation of the comb polymer is: after drying 1 part of polyethylene glycol monomethyl ether ...

Embodiment 2

[0043] 1. Add 10 parts of aluminum powder pigment and 100 parts of acetone into the container, stir for 1 hour, and filter to obtain the washed aluminum powder; 2. Take the washed aluminum powder and add it to 100 parts of isopropanol, and after ultrasonic dispersion, Put it into the reaction container, add 3 parts of methyl orthosilicate, then gradually add 18 parts of ammonia water, react for 2 hours under stirring, and the reaction temperature is 50°C; 3. After filtering the aluminum powder, carry out Drying, the drying time is 1h, to obtain aluminum powder coated with silicon dioxide film; 4. Then add it to 80 parts of acetone solution containing 2 parts of comb polymer, and stir for 2 hours; 5. Distill under reduced pressure to evaporate most of the Acetone, the temperature does not exceed 50 ° C, that is, to obtain a water-based aluminum silver paste with a solid content of 95%.

[0044] The preparation of the comb-shaped polymer is: after drying 1 part of polyethylene g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com