Process for preparing photocatalytic TiO2 film used to clean water and air

A photocatalytic thin film and titanium dioxide technology, applied in the field of photocatalysis, can solve the problems of high one-time investment and operating costs, difficulty in large-scale promotion and application, low catalyst activity, etc., to achieve easy oxidation and removal, good photocatalytic degradation, and maintenance no change in activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

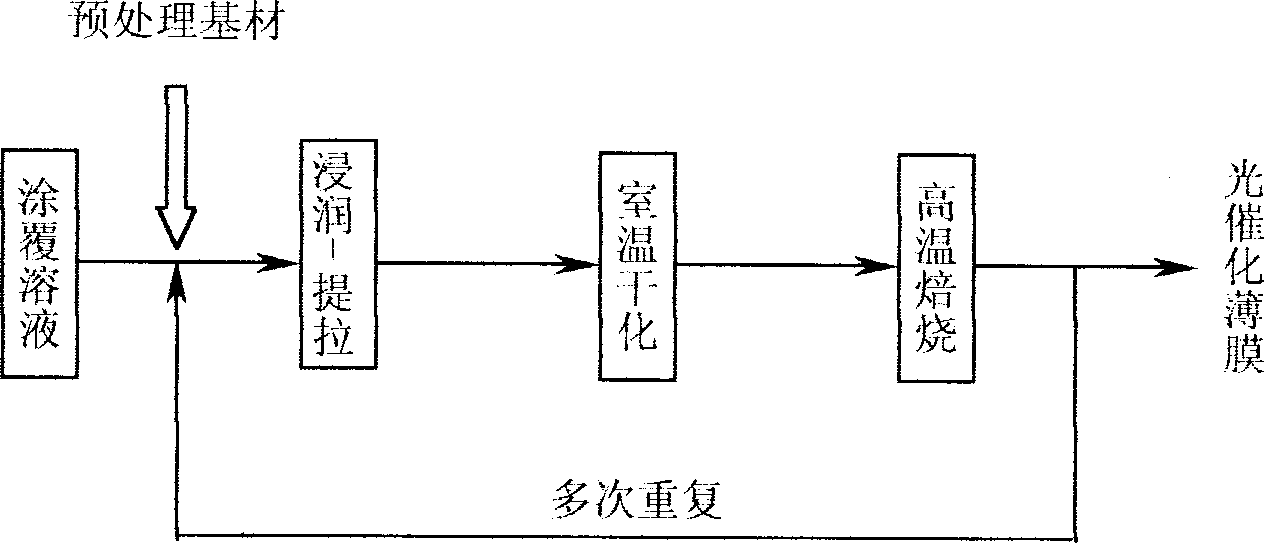

[0011] figure 1 Shown is the flow chart of the preparation of titania photocatalyst. The coating solution and substrate treatment can be carried out at the same time, and the finished product can be obtained after leaching coating, drying at room temperature, and repeated firing several times. For example, add 23.5mg of carbon black, 10ml of tetrabutyl titanate and 3ml of acetylacetone to 70ml of n-propanol in sequence, slowly add 4ml of deionized water dropwise after the liquid is evenly mixed, and disperse with ultrasonic wave for 10-20min to make the carbon black Disperse evenly, and keep it clean for more than 12 hours to prepare the coating solution for the catalyst; if the aluminum plate metal substrate is selected, it will be used as the substrate for catalyst coating after sanding, cleaning, and drying; the coating solution should be cleaned before each use Ultrasonic dispersion for 10 to 20 minutes, then soak the pretreated substrate in the coating solution, pull at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com