Low-fat and high-protein jam yogurt and preparation method of low-fat and high-protein jam yogurt

A high-protein, low-fat technology, applied in milk preparations, dairy products, applications, etc., can solve problems such as insufficient flavor, few varieties, and cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

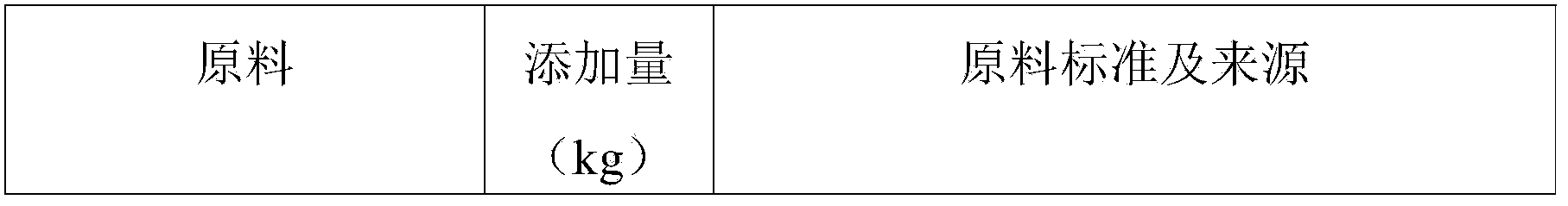

[0061] 1. Product formula (see Table 1).

[0062] Table 1. Raw materials, addition amount, standards and their sources (calculated on the basis of 1 ton of product)

[0063]

[0064]

[0065] 2. The preparation method is produced according to the following steps:

[0066] (a) Heat the low-fat milk in Table 1 to 50°C, dry mix the ingredients in Table 1 except low-fat milk, starter, jam and food flavor according to the corresponding addition amount in the table, and dissolve them In the heated low-fat milk, stir for 20 minutes until the ingredients are mixed.

[0067] (b) Enter the mixed material into the homogenization and sterilization stage, heat the material to 70°C, homogenize it under the pressure of 18MPa, and sterilize it at 95°C for 5 minutes;

[0068] (c) Pour the sterilized material into the milk buffer tank for cooling, and the cooling temperature is 42°C;

[0069] (d) cooling the obtained material to 40-44°C, adding a starter for heat preservation and ferme...

Embodiment 2

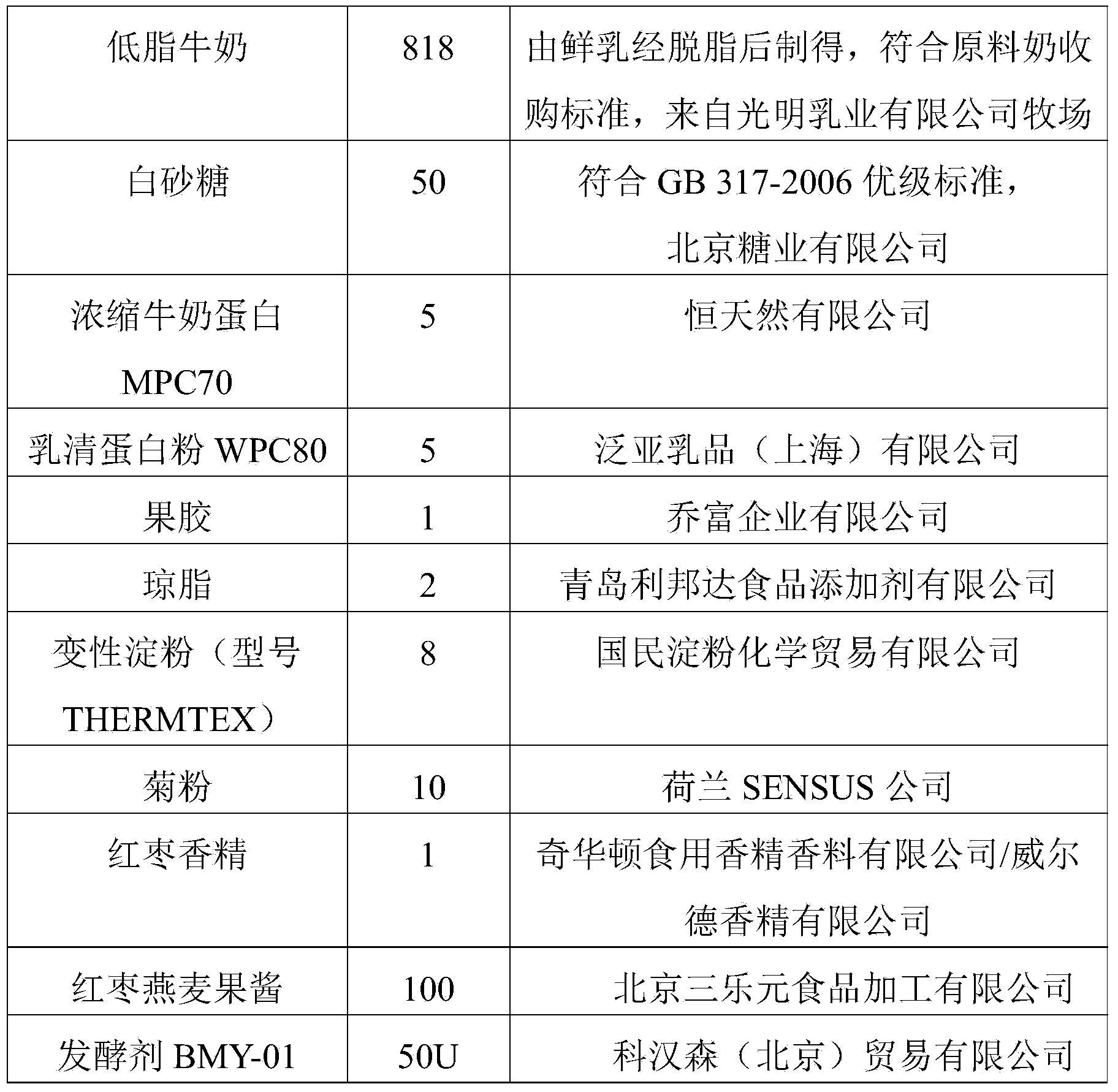

[0073] 1. Product formula (see Table 2).

[0074] Table 2. Raw materials, additive amounts, standards and their sources (calculated on the basis of 1 ton of product)

[0075]

[0076] 2. The preparation method is produced according to the preparation method in Example 1.

Embodiment 3

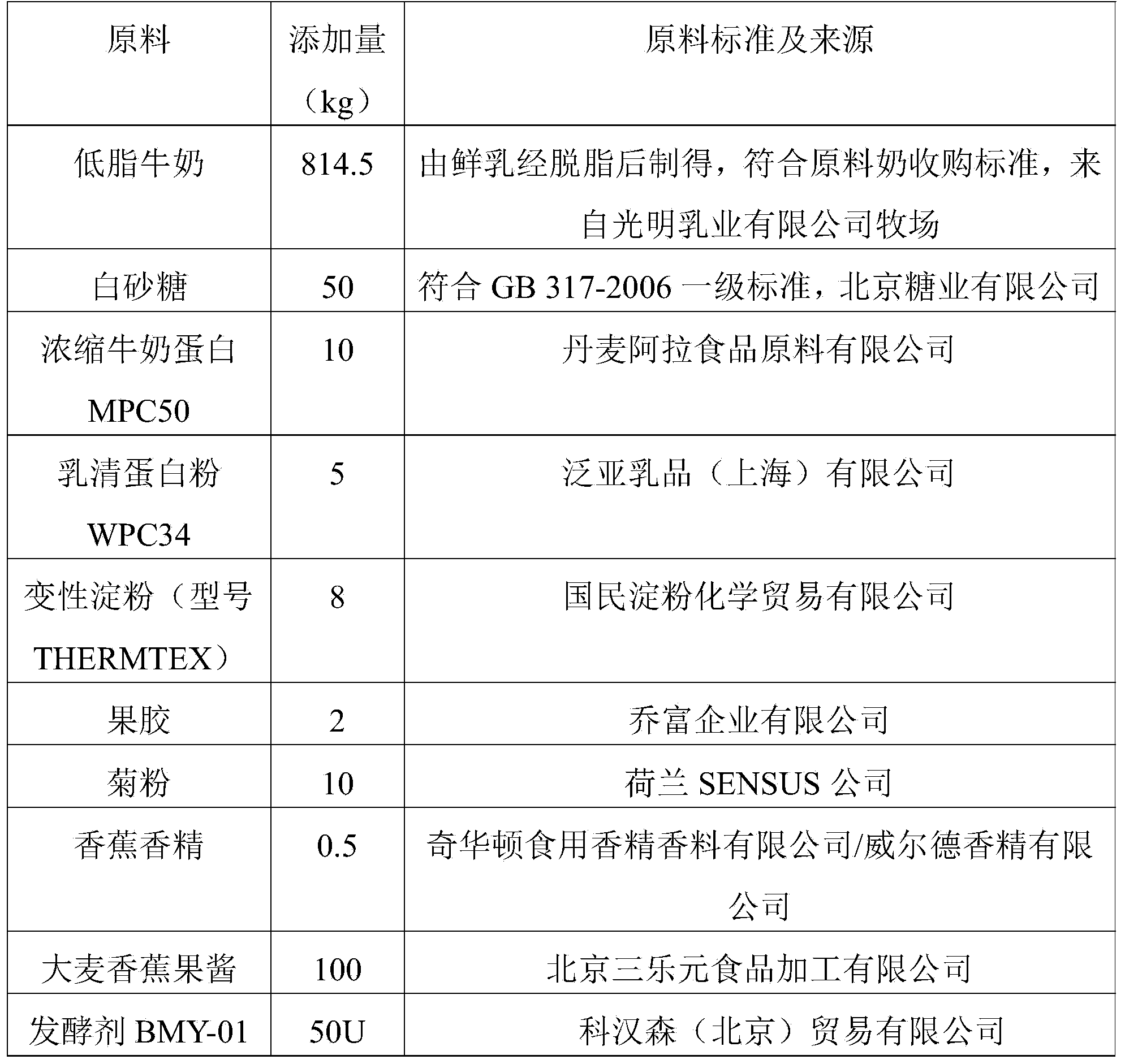

[0078] 1. Product formula (see Table 3).

[0079] Table 3. Raw materials, additive amounts, standards and their sources (calculated on the basis of 1 ton of product)

[0080]

[0081] 2. The preparation method is produced according to the preparation method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com