Perovskite material and preparation method and application thereof

A perovskite material and reaction technology, which is applied in the direction of luminescent materials, preparation of amino compounds, chemical instruments and methods, etc., can solve the problems of poor stability and achieve good stability, good film-forming properties, and good UV anti-aging effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

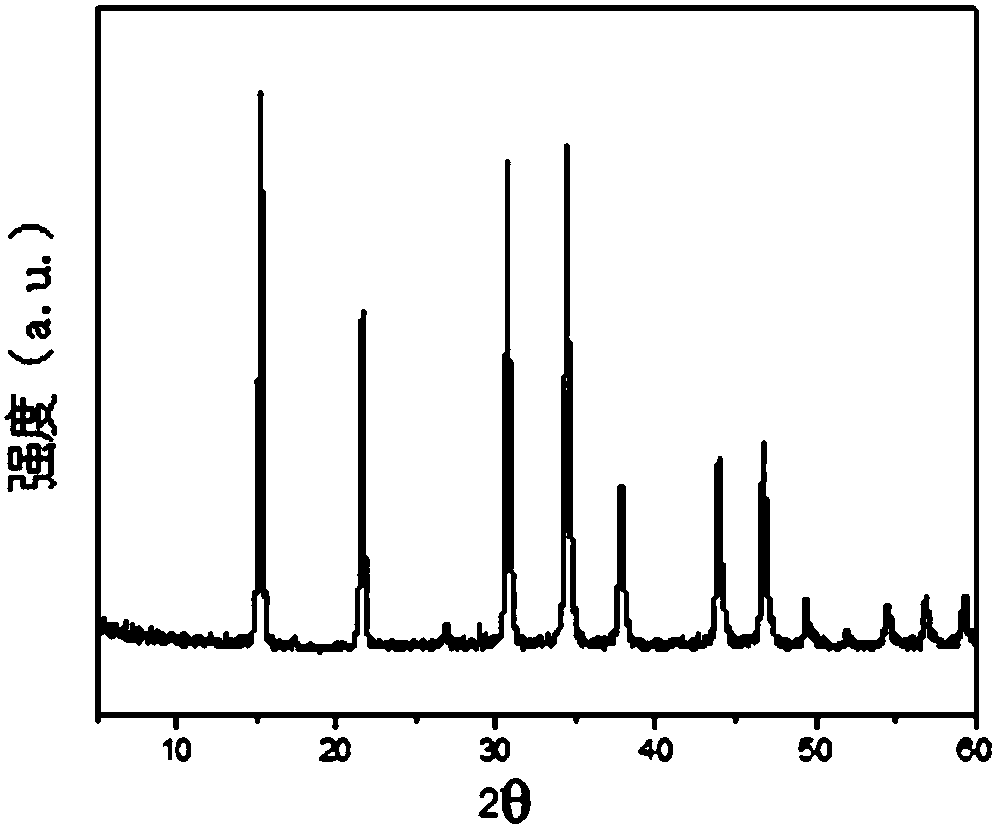

[0115] Embodiment 1 prepares perovskite material (CH 2 ClNH 3 )PbCl 3

[0116] S1, CH 2 ClNH 3 Preparation of Cl organic ammonium salt

[0117] Use a 10ml pipette to measure 5ml of 33% NH 3 Ethanol solution (purity>99.9%), placed in a 100ml round bottom flask, stirred for about 10 minutes until uniform. In an ice-water bath environment, add CH with a mass fraction of 98% to the above solution while stirring. 2 Cl 2 8ml, and kept stirring for 2 hours in an ice-water bath environment to obtain a clear solution, which was distilled under reduced pressure at 60°C and a pressure of -0.1MPa with a rotary evaporator to remove the solvent. The product left in the round-bottomed flask after rotary evaporation was washed three times with anhydrous ether, filtered with suction, and dried in a vacuum oven at 40°C under a pressure of -0.1MPa for 4 hours to obtain CH 2 ClNH 3 Cl organic ammonium salt powder.

[0118] S2, (CH 2 ClNH 3 )PbCl 3 Synthesis of perovskite materials ...

Embodiment 2

[0120] Embodiment 2 prepares perovskite material (CH 2 ClNH 3 )PbBr 2 Cl

[0121] S1. Preparation of CH 2 ClNH 3 Cl

[0122] Use a 10ml pipette to measure 5ml of 33% NH 3 Ethanol solution (purity>99.9%), placed in a 20ml glass bottle, stirred for about 10 minutes until uniform. Then add CH to the above solution 2 Cl 2 Solution (purity>98%) 5ml, to obtain a clear solution, heated at 60 ° C for 12 hours, until the solvent is completely evaporated to obtain CH 2 ClNH 3 Cl solid powder.

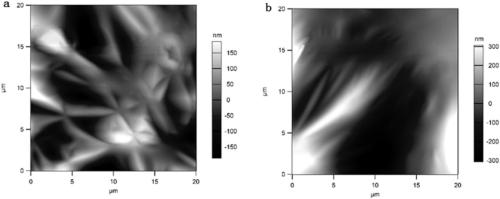

[0123] S2, Ligand-assisted reprecipitation method preparation (CH 2 ClNH 3 )PbBr 2 Cl

[0124] The metal halide component PbBr 2 1mmol, organic ammonium salt component CH 2 ClNH 3 Add 1mmol of Cl and 1ml of organic solvent component dimethylformamide into the glass bottle, then the ratio of perovskite component to organic solvent component is (1+1): 1mol / L, which is 2:1mol / L; Then add n-octylamine 0.4mmol, and use ultrasonic treatment to obtain a clear and transparent solution a...

Embodiment 3

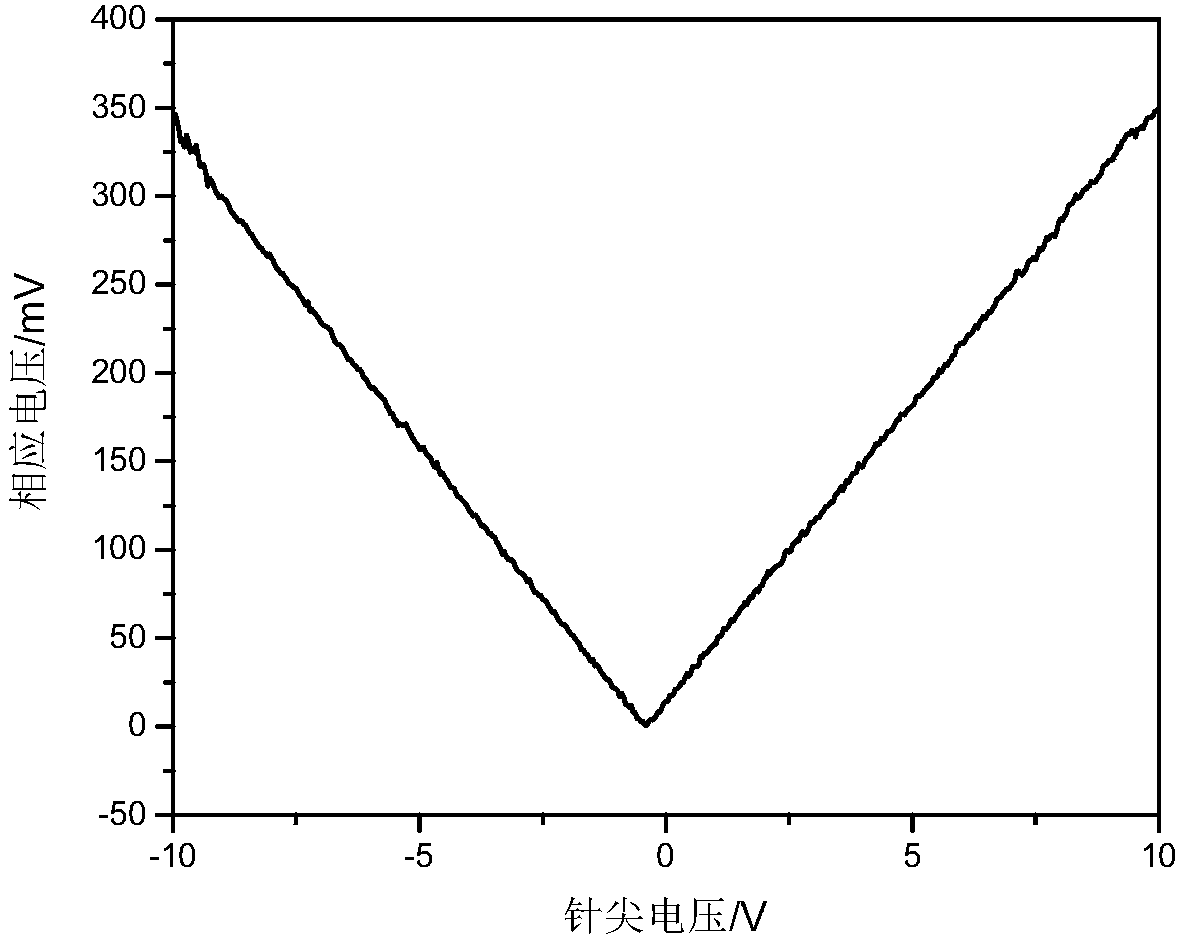

[0125] Embodiment 3 prepares perovskite material (CH 2 BrNH 3 )PbBr 3

[0126] S1, CH 2 BrNH 3 Preparation of Br

[0127] Use a 10ml pipette to measure 5ml of 33% NH 3 Ethanol solution (purity>99.9%), placed in a 20ml glass bottle, stirred for about 10 minutes until uniform. Then add CH to the above solution 2 Br 2 Solution (purity>98%) 8ml, to obtain a clear solution, heated at 60 ° C for 12 hours, until the solvent is completely evaporated to obtain CH 2 BrNH3 Br solid powder.

[0128] S2, using the emulsion method to synthesize (CH 2 BrNH 3 )PbBr 3 perovskite material

[0129] Weigh 1mmolCH 2 BrNH 3 The ammonium salt of Br was dissolved in 0.3ml of dimethylformamide and 1mmol of PbBr 2 Dissolve in 1ml of dimethylformamide, put them into two 5ml small centrifuge tubes and ultrasonically dissolve until clear and transparent; then weigh 10ml of toluene solution with a measuring cylinder, drop in 0.5ml of oleic acid, 20 microliters of dodecylamine, The toluene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com