Patents

Literature

35results about How to "Enhanced mesh structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

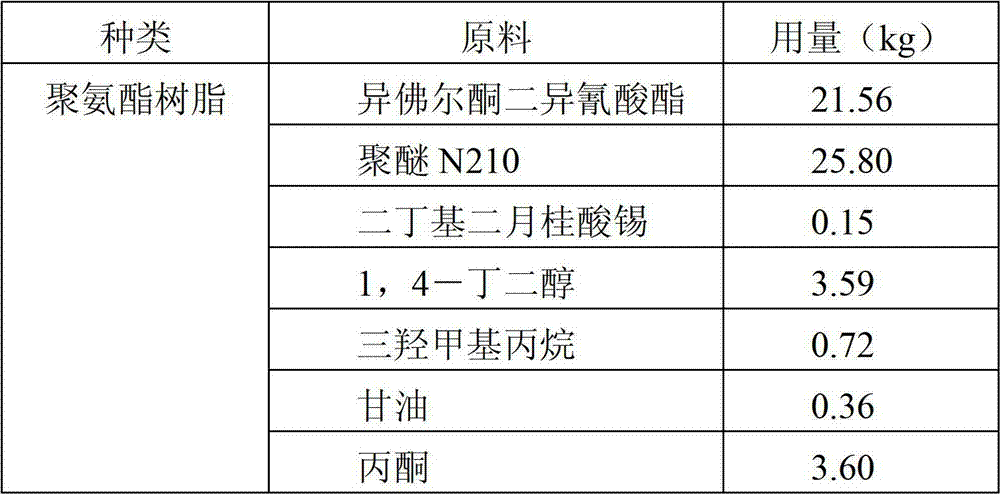

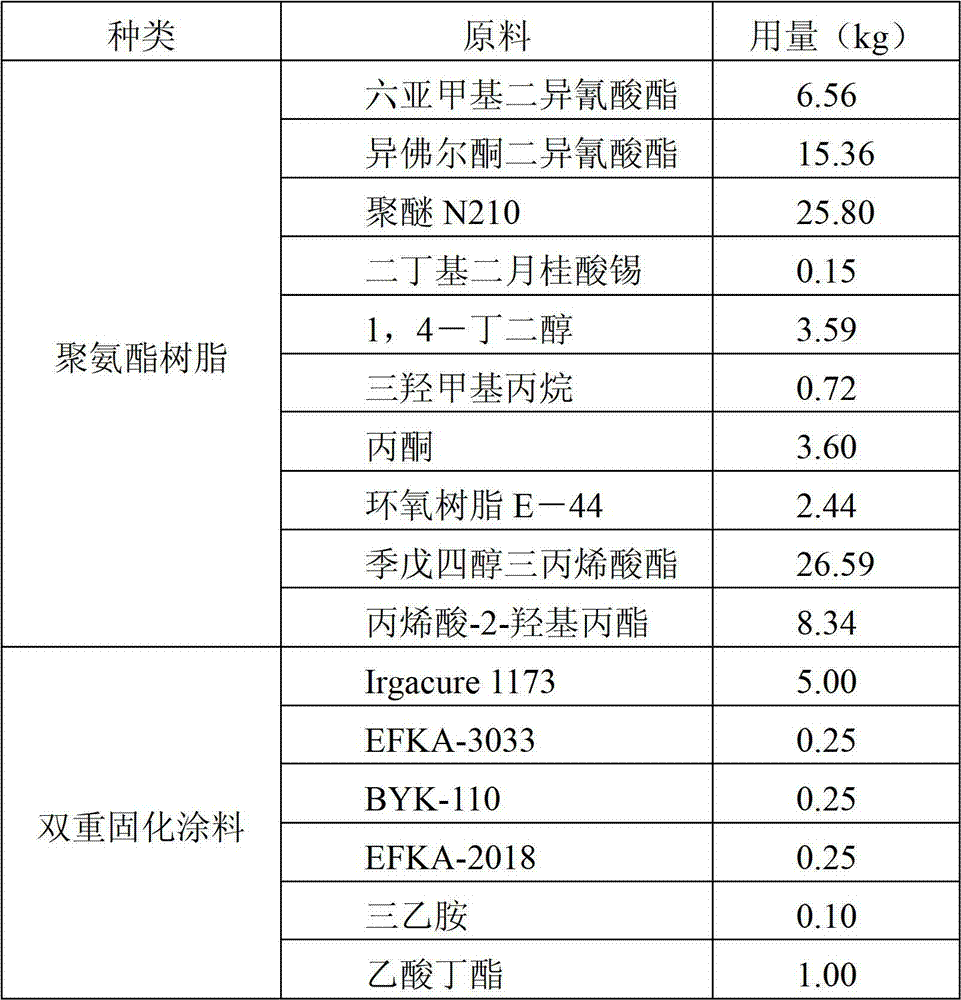

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

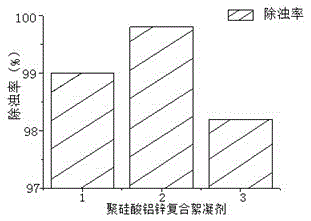

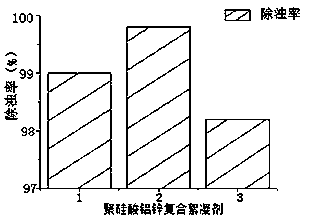

Aluminum-zinc polysilicate composite flocculating agent and application thereof

InactiveCN105984929AImprove adsorption bridging effectGood decolorization effectWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationTurbiditySODIUM SILICATE SOLN

The invention discloses an aluminum-zinc polysilicate composite flocculating agent and application thereof. Sodium silicate solution and excessive sulfuric acid are mixed with each other to prepare polysilicate solution, zinc sulfate and aluminum sulfate solution, polyacrylamide, calcium hydroxide and sodium hypochlorite are sequentially added into the polysilicate solution, and reaction is carried out to obtain the aluminum-zinc polysilicate composite flocculating agent. The aluminum-zinc polysilicate composite flocculating agent and the application have the advantages that the aluminum-zinc polysilicate composite flocculating agent can be applied to the field of water treatment, accordingly, excellent effects of removing colors, turbidity and carbon can be realized, coagulated floc particles are large, the aluminum-zinc polysilicate composite flocculating agent is high in floc settling velocity, excellent net capturing effects can be realized, and the excellent effects of removing the colors and the turbidity can be realized; raw materials for the aluminum-zinc polysilicate composite flocculating agent can come from wide sources, the aluminum-zinc polysilicate composite flocculating agent is easy to prepare and can be widely applied to the field of wastewater from dyeing and printing and papermaking industries and the like and the field of advanced municipal sewage treatment, and the like.

Owner:NANJING UNIV +1

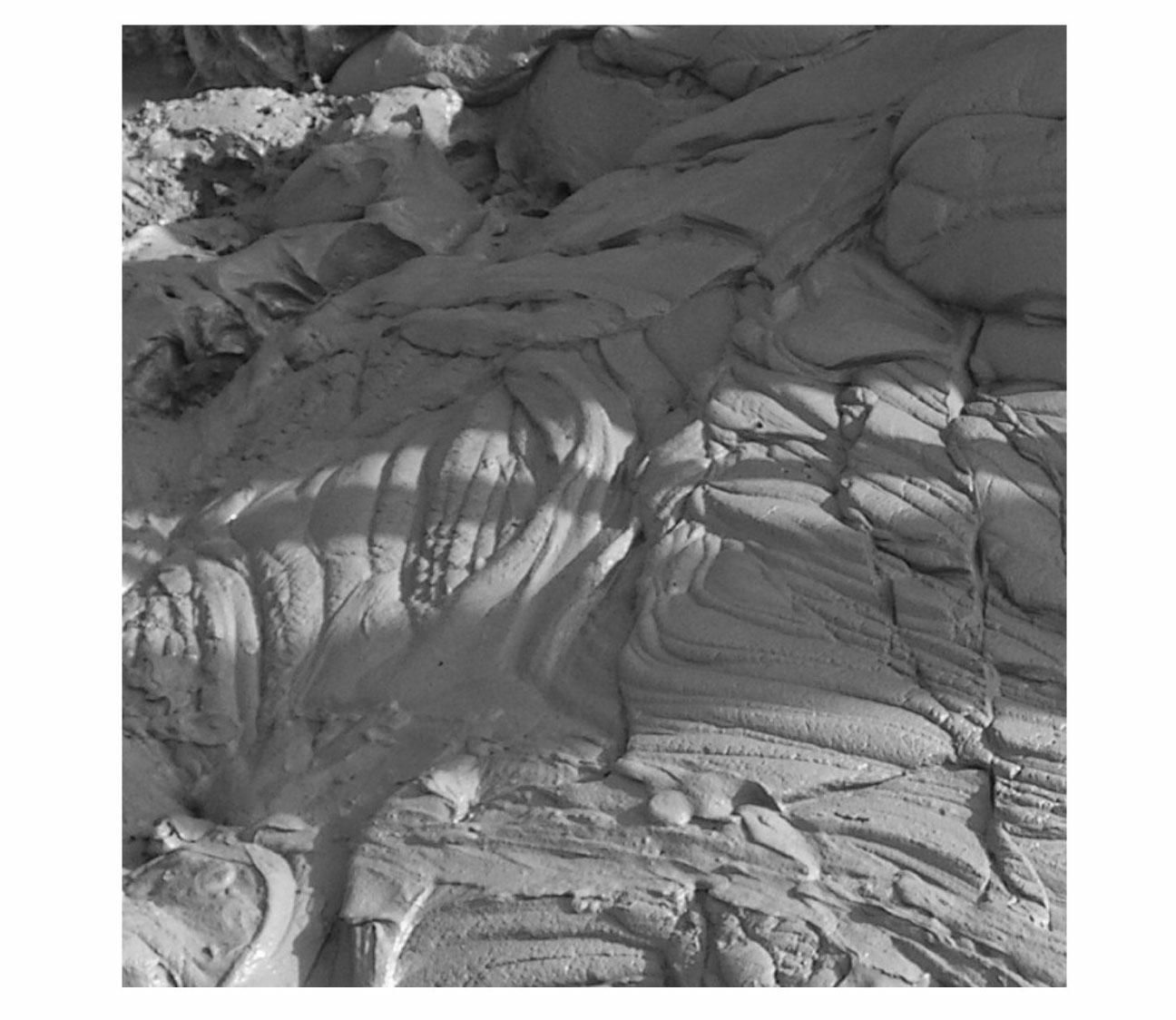

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Organic-resin-free inorganic zinc silicate shop primer

The invention discloses an organic-resin-free inorganic zinc silicate shop primer which is composed of a component A and a component B at a weight ratio of 2: 1. The component A comprises the following ingredients in parts by weight: 30 to 60 parts of zinc powder, 15 to 30 parts of ferro-phosphorus powder, 0.5 to 2 parts of gas phase silicon dioxide, 0.2 to 0.6 pat of liquid rheological agent, 5 to 15 part of isopropanol, 5 to 15 parts of methyl isobutyl ketone, and 2 to 8 parts of propylene glycol methyl ether. The component B comprises the following ingredients in parts by weight: 30 to 50 parts of ethyl silicate, 30 to 60 parts of anhydrous alcohol, and 3 to 6 parts of acidified water. The shop primer provided by the invention can improve the temperature tolerance and reduce the water absorptivity of varnish films, is compatible to ballast chamber paints, and meets the requirements listed in the PSPC (performance standard of protective coatings). The shop primer has good rheological effects, so as to prevent gelatination or sedimentation of the zinc slurry during 15-day storage at 50 DEG C. The steel plate coated with the shop primer produces less smoke during welding, so that the construction environment is improved.

Owner:XIAMEN SUNRUI SHIP COATING

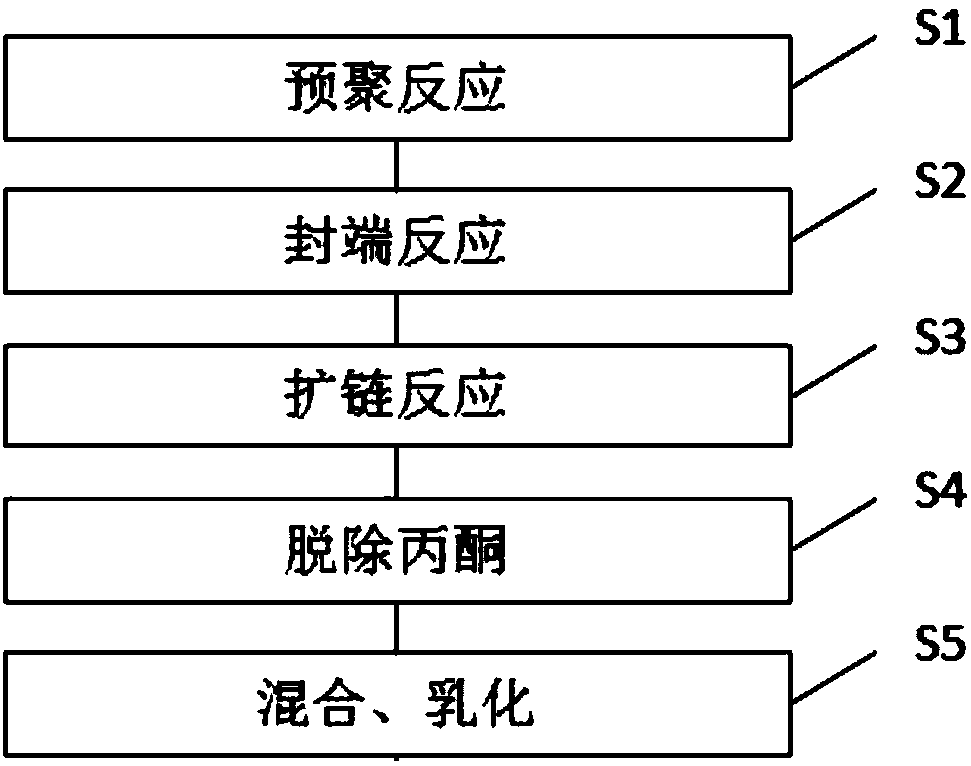

3D printing modified waterborne polyurethane and preparation method thereof

The embodiment of the invention discloses a 3D printing modified waterborne polyurethane and a preparation method thereof. The modified waterborne polyurethane comprises the following components in percent by mass: 60-94% of waterborne polyurethane, 5-10% of a silane coupling agent and 1-3% of nanometer silicon dioxide. The preparation method of the modified waterborne polyurethane comprises the following steps: dehydrating polyol, and then carrying out a prepolymerization reaction between the dehydrated polyol and isocyanate to obtain a polyurethane prepolymer; carrying out an end-capping reaction between the polyurethane prepolymer and small molecular diol, adding acetone for diluting and emulsifying, and then adding an amine chain extender for a chain extension reaction to obtain a polyurethane dispersion; removing the acetone in the polyurethane dispersion to obtain the waterborne polyurethane; putting the waterborne polyurethane, the silane coupling agent and the nanometer silicondioxide into a stirring kettle according to a mass ratio, sufficiently mixing, adding an emulsifier, and emulsifying to obtain the modified waterborne polyurethane. Through addition of the nanometersilicon dioxide for modifying the waterborne polyurethane, the pressure resistance is improved and a net structure is increased, so that the 3D printing effect can be enhanced and no collapse exists during 3D printing.

Owner:HUNAN XINLIHUA NANO TECH

Degradable modified soy protein plastic material

The invention discloses a degradable modified soy protein plastic material. The degradable modified soy protein plastic material comprises, by weight, 80-90 parts of low-density polyethylene, 20-30 parts of high-density polypropylene, 5-9 parts of low-density polypropylene, 3-8 parts of corn starch, 0.5-0.9 part of bacillus licheniformis, 3-12 parts of fire retardants (oligomeric ammonium phosphate), 5-10 parts of flexibilizer (ethylene-propylene- diene-terpolymer rubber), 2-5 parts of silane coupling agents, 0.5-1 part of antioxidant (phosphite ester) and 15-20 parts of modified soy protein. The technology for preparing the modified soy protein includes the following steps that 80-90 parts of soy isolate protein and 280-290 parts of tetrahydrofuran are weighed by weight, fed into a reactor and stirred, the mixture is heated in a water bath to 80 DEG C-85 DEG C, the water bath time is 20-30 min, the mixture is stirred for 10-15 min after adding 5-6 parts of zinc acetate and then evenly stirred after adding 18-20 parts of maleic anhydride, suction filtration is carried out after the reaction is completed, and the product is aired naturally to obtain the modified soy protein.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

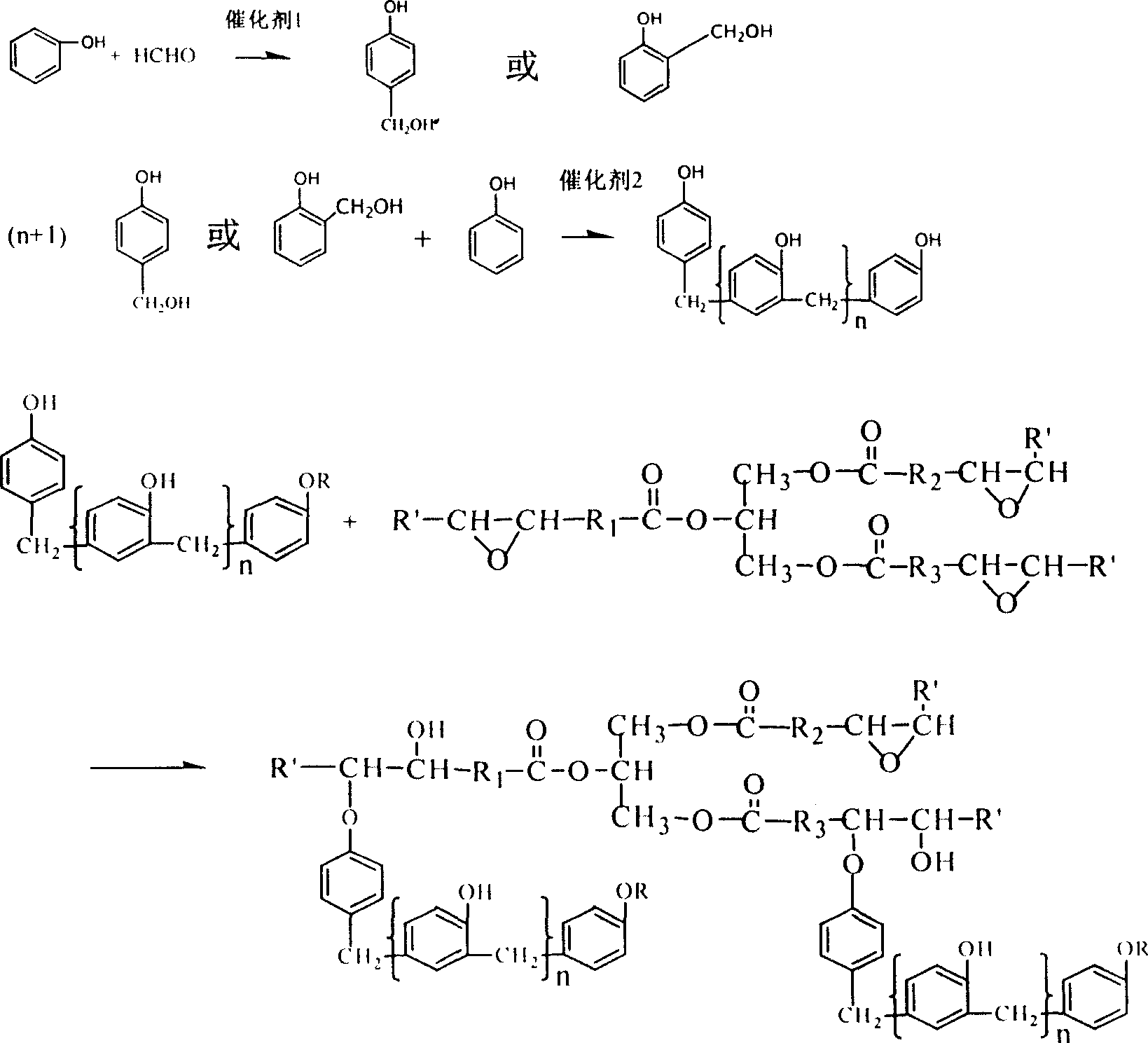

High-strength waterproof material for high-speed railways and preparation method thereof

InactiveCN106118431AHigh strengthGood physical and mechanical propertiesFireproof paintsPolyurea/polyurethane coatingsTemperature resistanceMechanical property

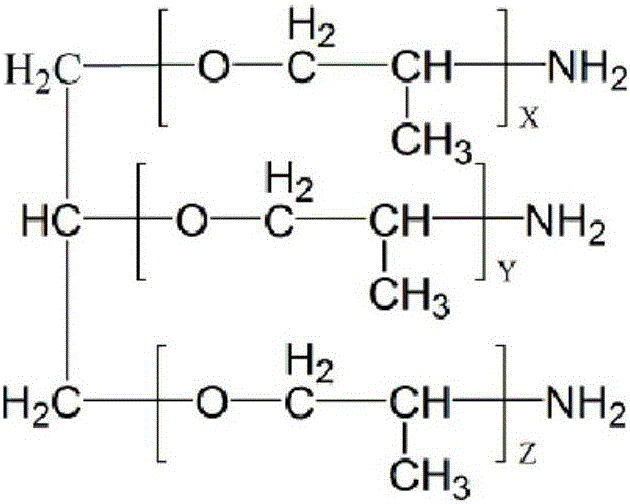

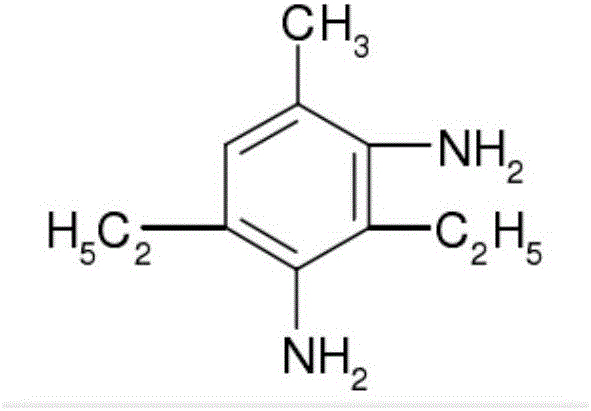

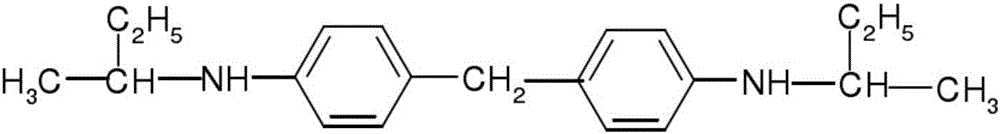

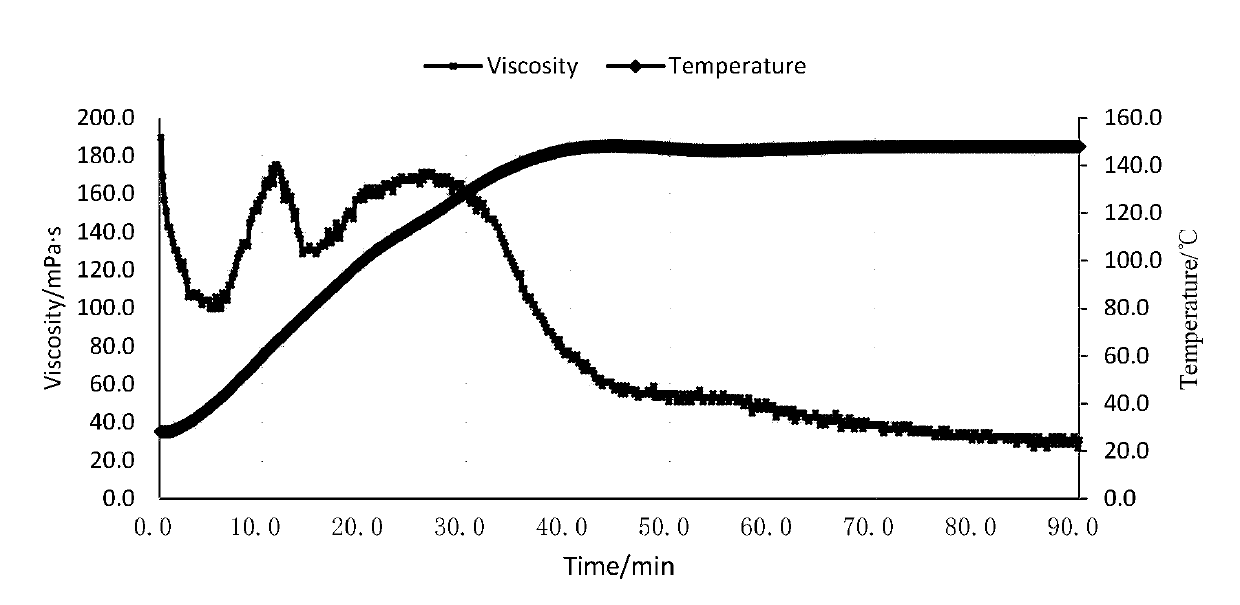

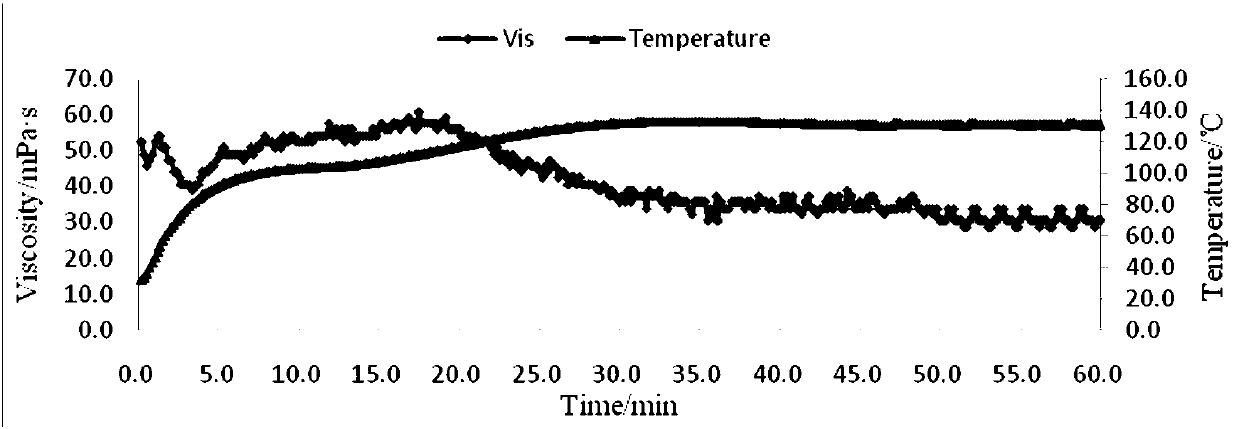

The invention discloses a high-strength high-speed iron waterproof material and a preparation method thereof. The high-strength high-speed iron waterproof material includes component A and component B, and component A is prepared from the following raw materials in parts by weight: polyether polyol 95‑105 parts, 1‑10 parts of plasticizer, 10‑20 parts of bis(4‑isocyanatophenyl) methane, 3‑30 parts of graphene / methanesulfonic acid solution, 5‑50 parts of additives; component B It is prepared from the following raw materials in parts by weight: 50-80 parts of amino-terminated polyether, and 20-40 parts of amine chain extender. The present invention optimizes the type and amount of amino-terminated polyether and amine chain extender suitable for high-strength high-speed iron waterproof materials through reasonable proportioning, and has excellent physical and mechanical properties, temperature resistance, weather resistance, chemical medium resistance and Outstanding wear resistance, convenient construction and high efficiency.

Owner:上海基典防水科技有限公司

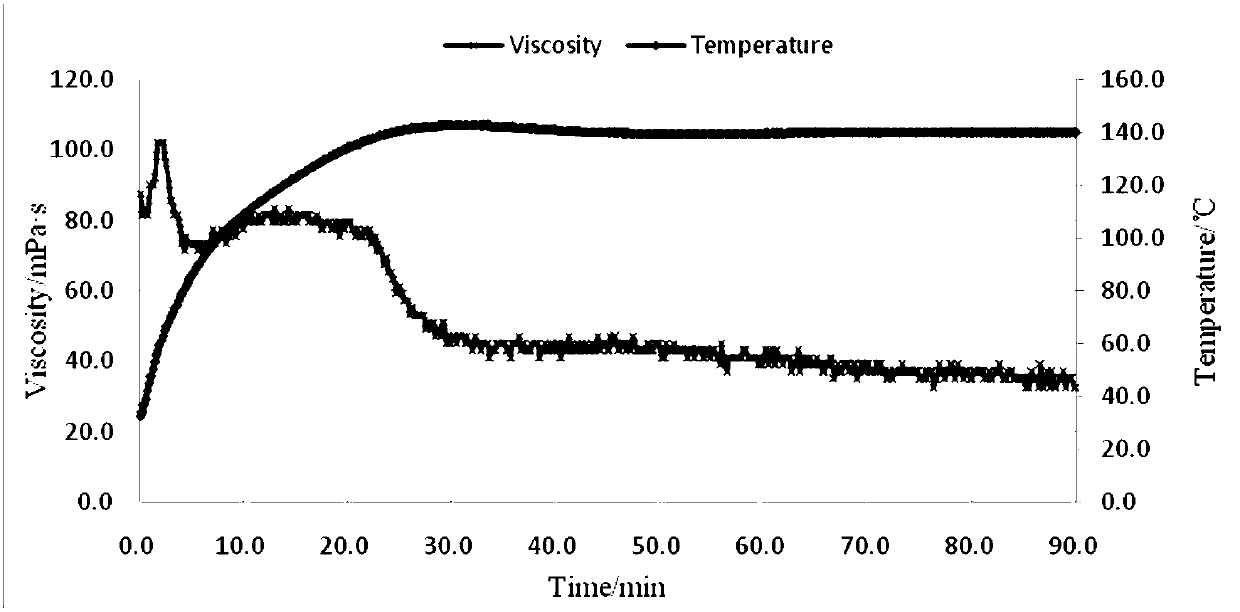

Clean high-temperature water-base fracturing fluid

InactiveCN107674668AViscoelasticImprove temperature resistanceDrilling compositionWater basedCross-link

The invention provides clean high-temperature water-base fracturing fluid. The clean high-temperature water-base fracturing fluid comprises components including, by weight, 0.5%-6% of clay stabilizers, 2%-6% of accelerators, 0.01%-0.1% of bactericides, 0.6%-3.0% of alcohol with a low molecular weight, 0.4%-2% of zwitterionic surfactants, 0%-0.5% of polysaccharide compounds and the balance water. The components are mixed with one another to obtain the clean high-temperature water-base fracturing fluid. The clean high-temperature water-base fracturing fluid has the advantages that as proved by indoor evaluation, the temperature resistance of the clean high-temperature water-base fracturing fluid can reach 150 DEG C at least, and accordingly the clean high-temperature water-base fracturing fluid is superior to general clean fracturing fluid systems; the dosage of betaine is 0.4%-2% (a weight ratio) and is far lower than the dosage (2%-5%) of amphoteric surfactants in formulas for conventional fracturing fluid; the clean high-temperature water-base fracturing fluid is convenient to use and operate, excellent in sand suspension ability and superior to common cross-link guar gum and quaternary ammonium salt systems, and cross-link can be omitted.

Owner:河北中大永迪生物科技有限公司

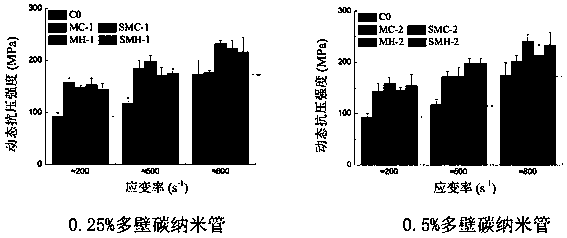

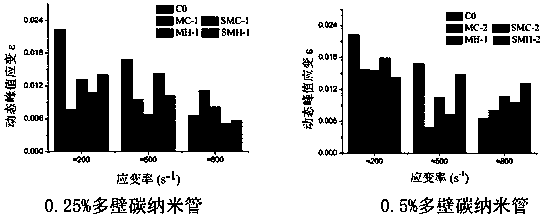

High-impact resistance surface functional group treated carbon nanotube modified reactive powder concrete

The invention discloses a high-impact resistance surface functional group treated carbon nanotube modified reactive powder concrete. The high-impact resistance surface functional group treated carbonnanotube modified reactive powder concrete is characterized in that the raw materials of the high-impact resistance surface functional group treated carbon nanotube modified reactive powder concrete comprise cement, functionalized multi-walled carbon nanotubes, silica fume, fly ash, sands, a water reducer and water; and the functionalized multi-walled carbon nanotubes are carboxylated multi-walledcarbon nanotubes or hydroxylated multi-walled carbon nanotubes. The functionalized multi-walled carbon nanotubes can significantly enhance the dynamic compressive strength, dynamic peak strain and impact toughness of the reactive powder concrete. When the strain rate is in a range of 200-800 / s and the dosage of the multi-wall carbon nanotubes is 0.25-0.5%, the dynamic compressive strength of concrete can be increased by 71.3%, the dynamic peak strain can be increased by 101. 1%, and the impact toughness can be increased by 100.8%.

Owner:DALIAN UNIV OF TECH

Polyurethane modified asphalt waterproof paint and preparation method thereof

InactiveCN108047948AEliminate coagulationEvenly dispersedFireproof paintsAntifouling/underwater paintsBituminous waterproofingGas phase

The invention relates to a polyurethane modified asphalt waterproof paint and a preparation method thereof. The paint is prepared from a polyurethane prepolymer, 90# petroleum asphalt, modified nano calcium carbonate, vinyl trichlorosilane, a tackifier, n-butyl acetate, citric acid, dibutyltin dilaurate, polyoxyethylene polyoxypropylene ether and fumed silica. The preparation method includes: modifying the 90# petroleum asphalt with the polyurethane prepolymer and modified nano calcium carbonate; then adding vinyl trichlorosilane, citric acid and n-butyl acetate into a reaction kettle, and stirring the substances evenly; then adding fumed silica, the tackifier and dibutyltin dilaurate, and stirring the substances evenly; then adding polyoxyethylene polyoxypropylene ether; further performing stirring till no powder flotation; shearing all the materials in the reaction kettle on a high speed shearing machine again until the 90# petroleum asphalt and other materials are evenly dispersed,thus obtaining the polyurethane modified asphalt waterproof paint. The product provided by the invention has the advantages of high bonding strength, high tensile strength and good dispersibility.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

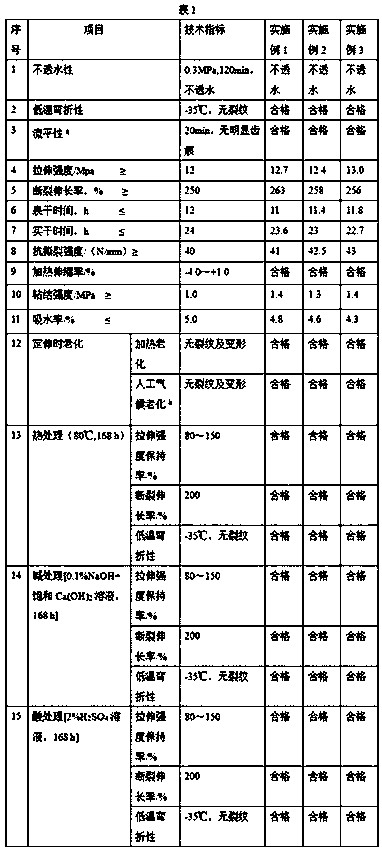

Epoxy plant oil modified phenol-formaldehyde resin, its preparation method and application

InactiveCN100347213CImprove punching effectImprove electrical performanceCircuit susbtrate materialsEpoxyVegetable oil

The preparation method for phenolic resin modified by epoxy vegetable oil comprises: putting thephenol, formaldehyde and nontoxic acid catalyst into a reactor; controlling temperature and holding for 1-8h; cooling to room temperature to obtain the coarse phenolic resin; transferring the coarse product into vacuum distillation kettle to dewater for refine; adding the epoxy vegetable oil, phenolic resin and faintly-alkaline catalyst into the reactor; heating and holding; reacting till the specified range of gelling time; cooling and adding solvent and additive to obtain the target with wide application. This invention has well security and quality with low cost and high efficiency.

Owner:SOUTH CHINA UNIV OF TECH

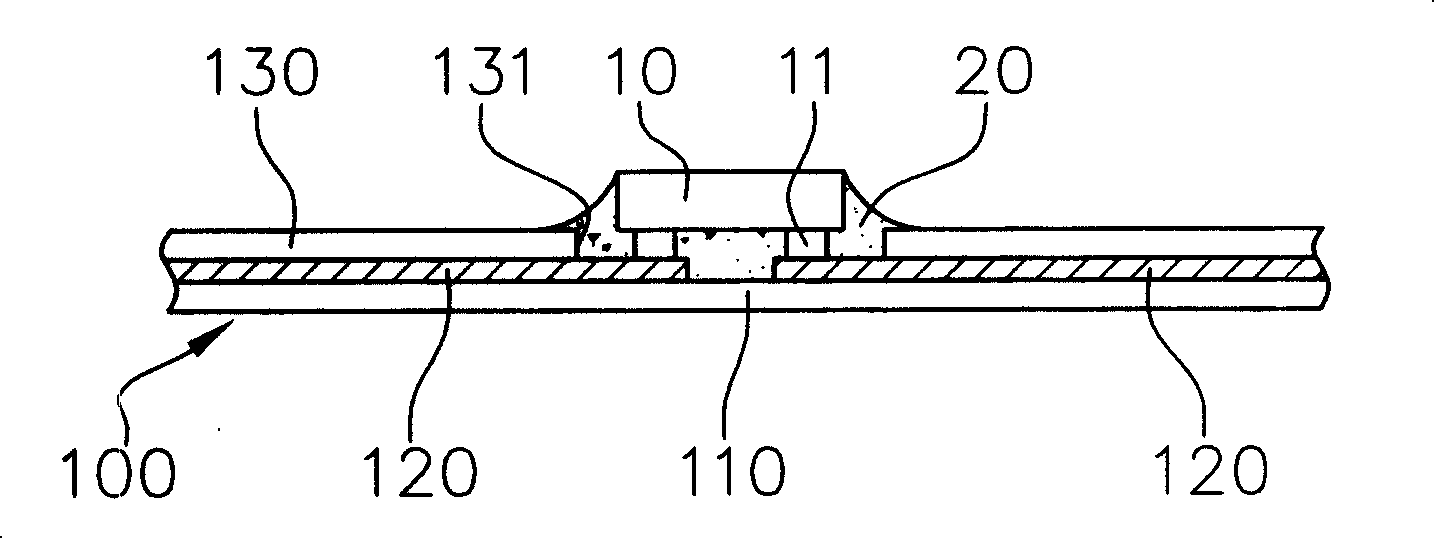

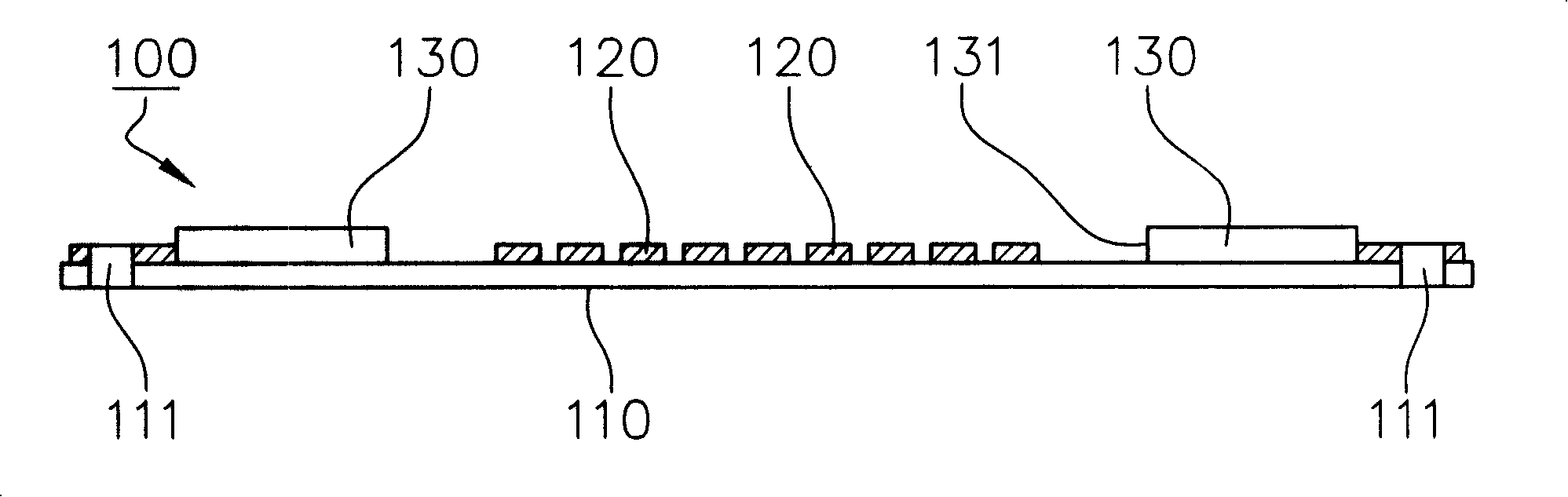

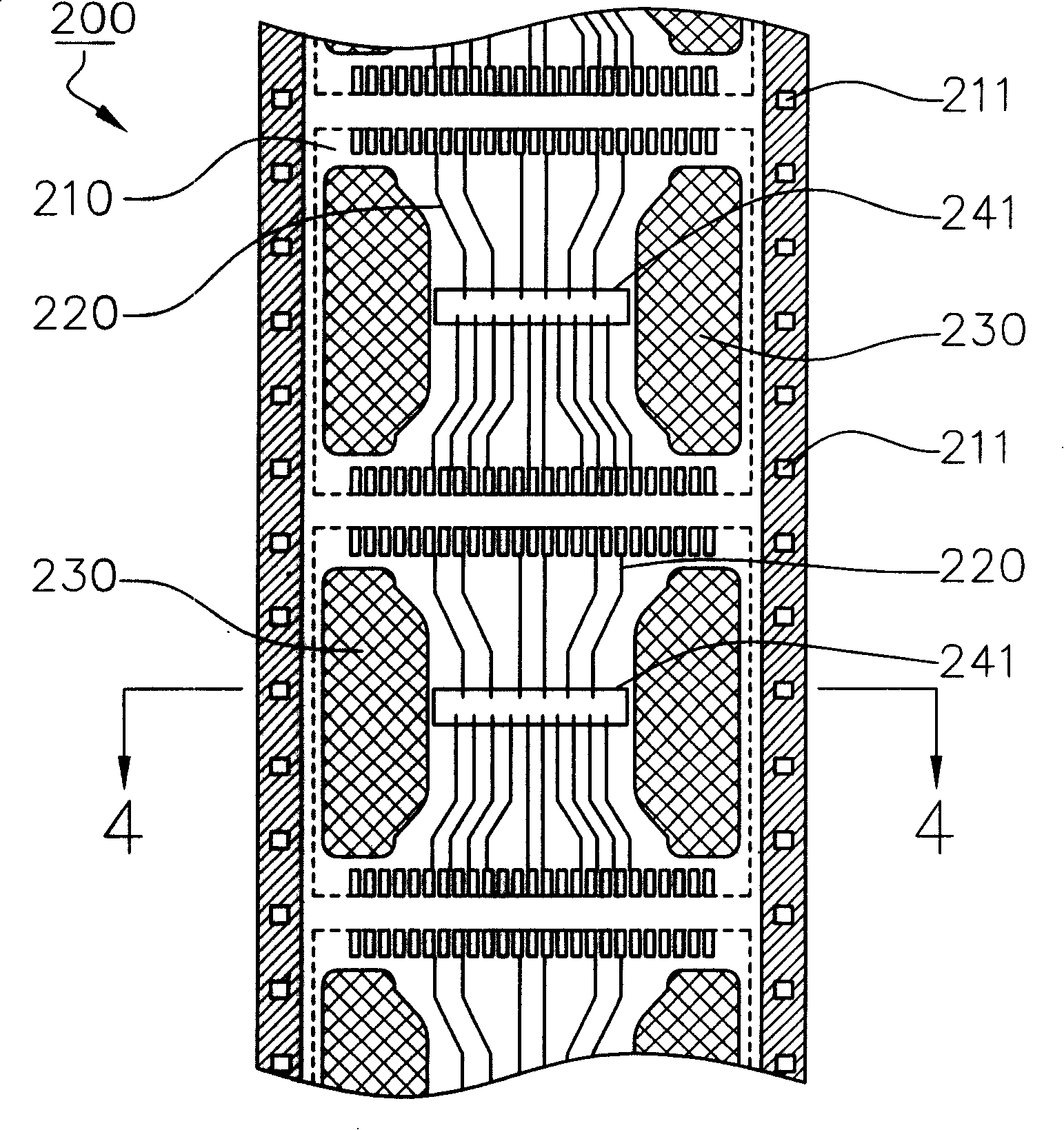

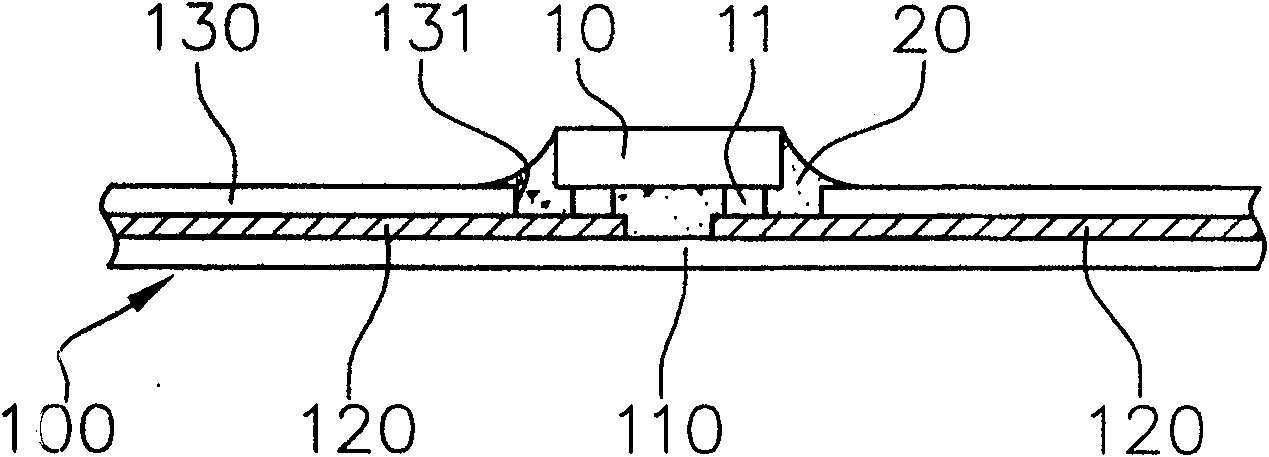

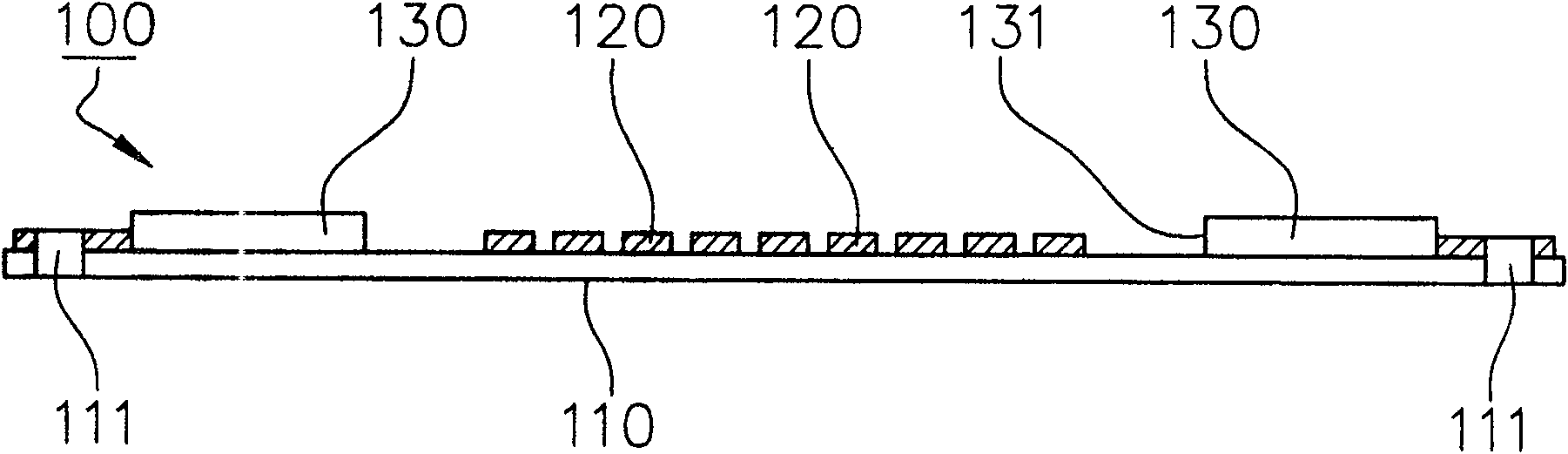

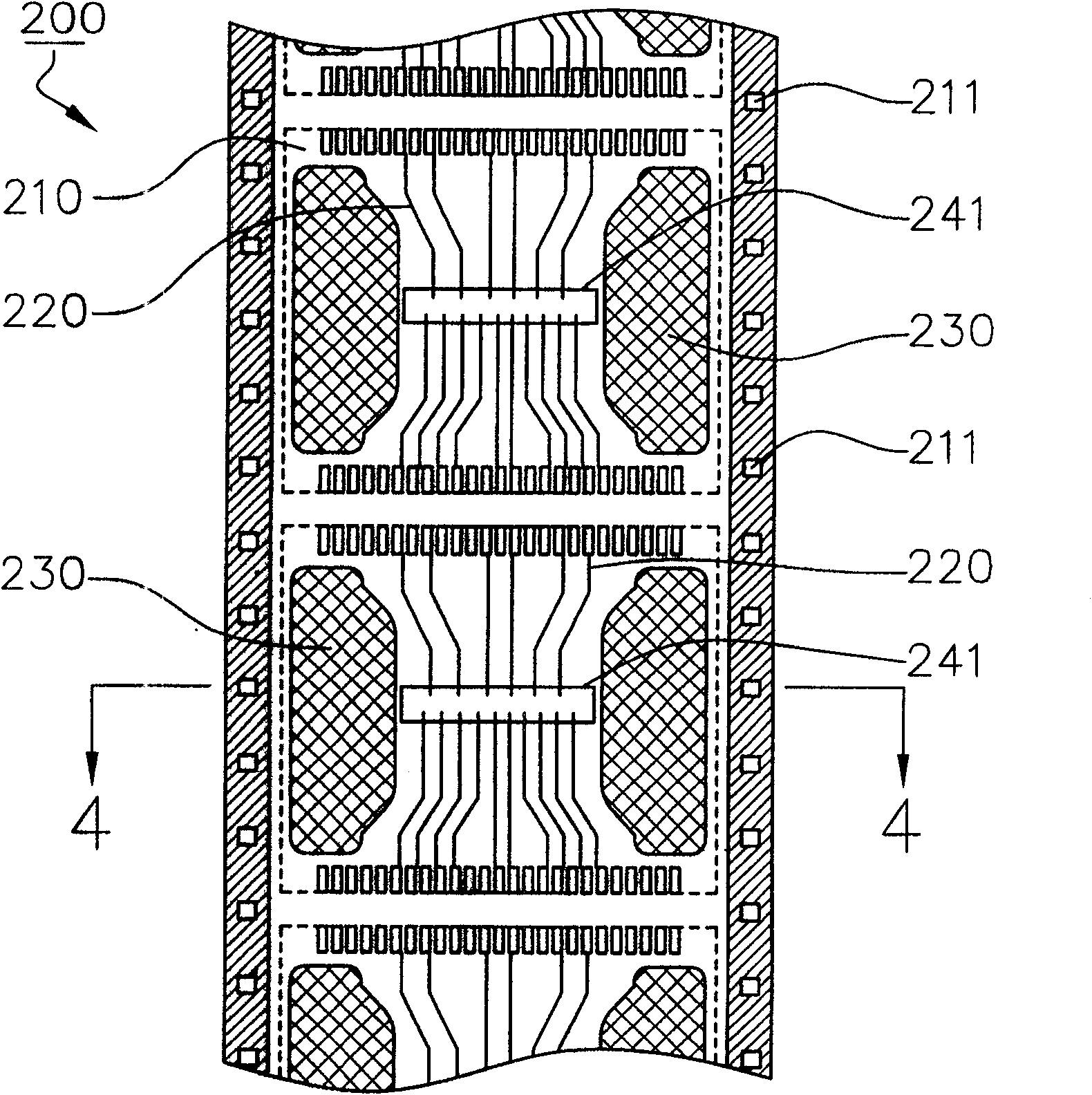

Semiconductor package substrate for improving deform

ActiveCN101231985AAvoid wrinklesAvoid deformationPrinted circuit detailsSemiconductor/solid-state device detailsSolder maskSemiconductor package

A semiconductor package substrate for preventing deformation mainly comprises a flexible dielectric layer, a plurality of pins, at least one reinforced metal pattern and a solder mask layer. All the pins and the reinforced metal pattern are formed on the same surface of the flexible dielectric layer, and the reinforced metal patterns are used for filling the pin blank section of the flexible dielectric layer. The solder mask layer is formed on the flexible dielectric layer to locally cover the pins and to cover or expose the reinforced metal patterns according to different application. The net-shaped formation positions of the reinforced metal patterns can prevent the flexible dielectric layer from crinkling or deforming.

Owner:CHIPMOS TECH INC

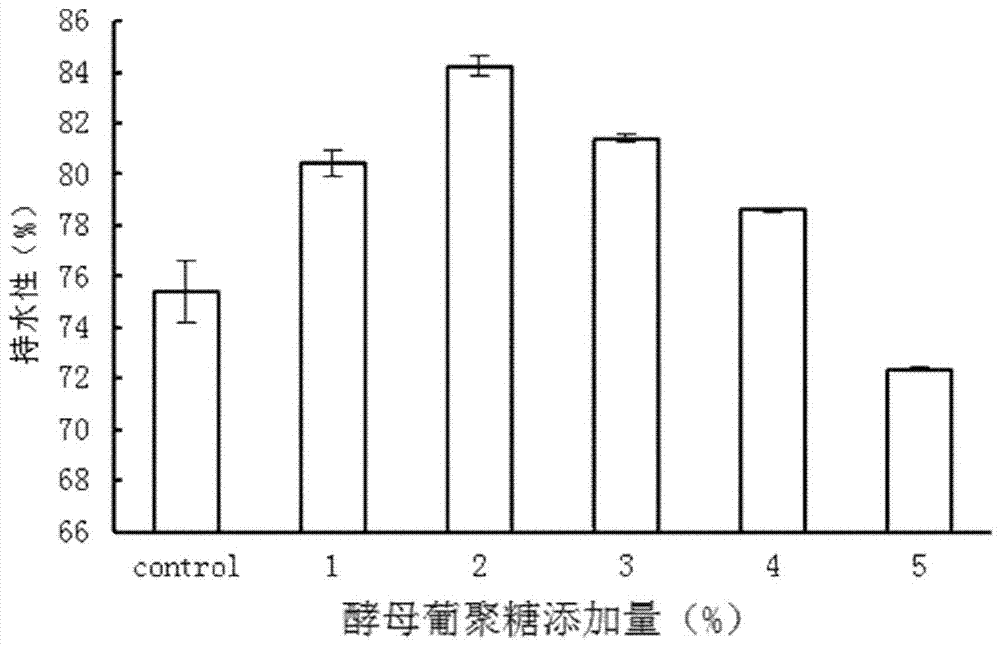

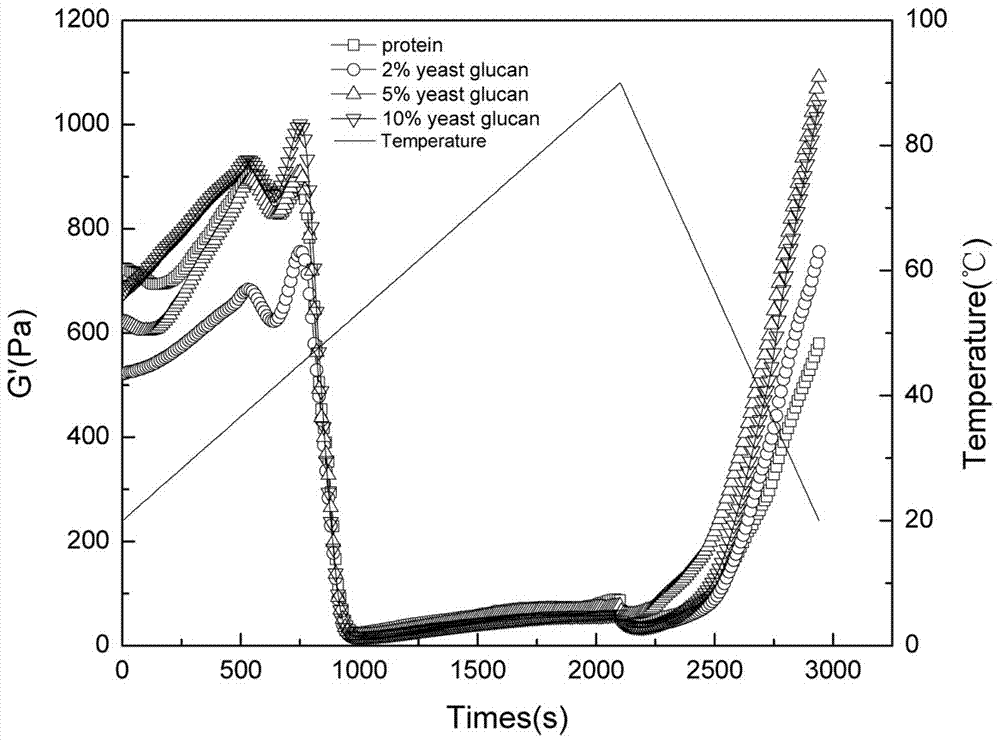

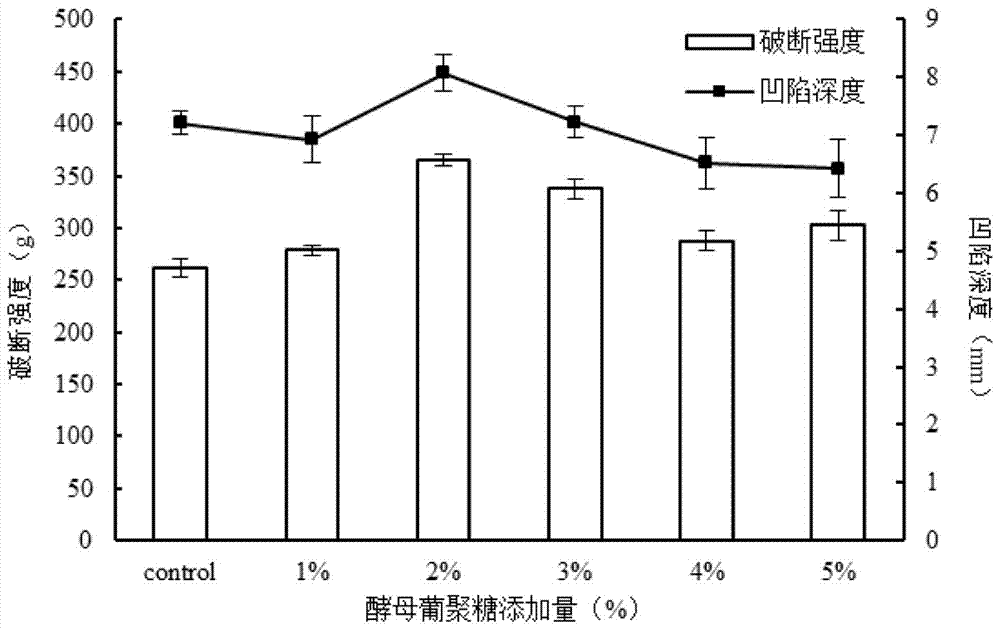

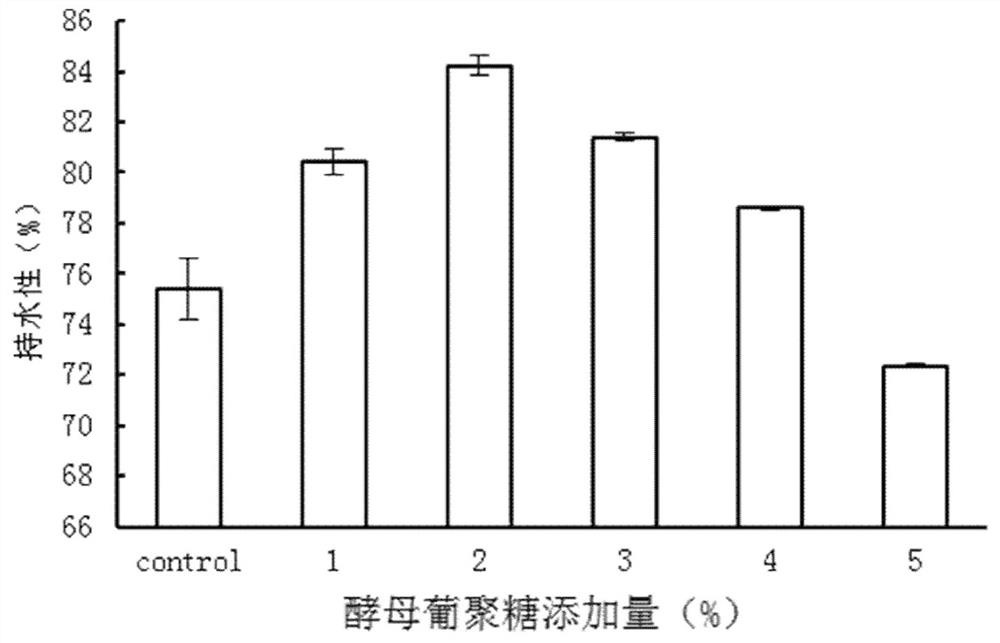

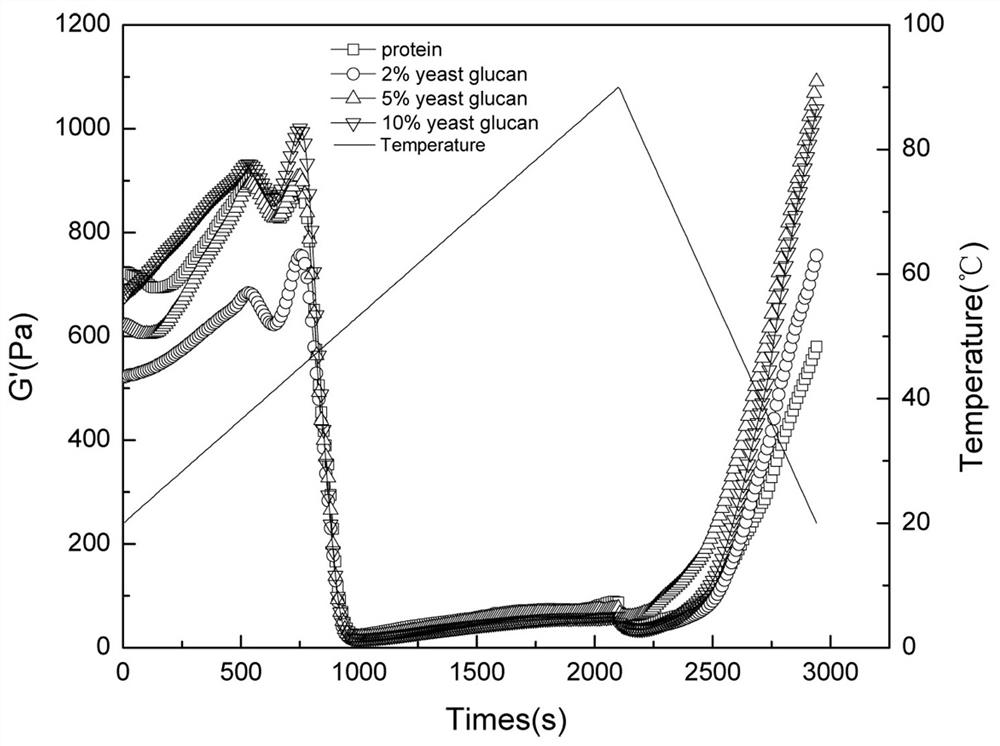

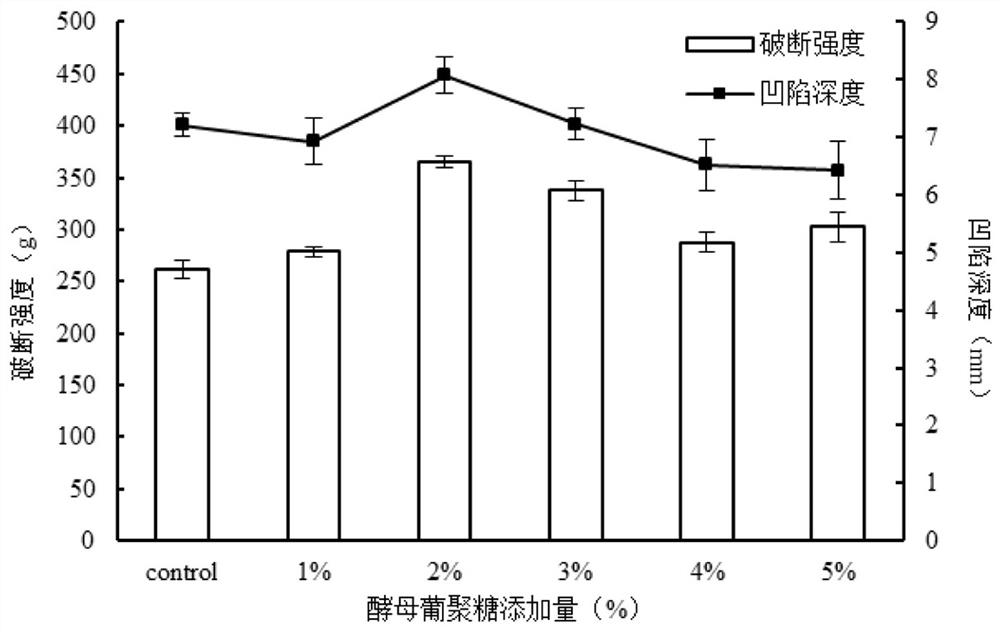

Method for producing health type yeast glucan/surimi composite product capable of removing fishlike smell and enhancing gel

ActiveCN106901244AIncrease elasticityHigh gel strengthFood thermal treatmentFood ingredient as gelling agentYeastBiotechnology

The invention belongs to the field of food processing and particularly relates to a method for producing a health type yeast glucan / surimi composite product capable of removing fishlike smell and enhancing gel. The method comprises the following steps: cleaning a fresh silver carp, removing a head, scales and internal organs, separating meat and then rinsing. The rinsed fish meat is centrifugally drained, chopped into minced fish meat in a food conditioning machine and blended with salt; yeast glucan which is 1-5 percent of the total mass of a compound is added in the minced fish meat; a minced fish meat product is prepared through molding and gelation. Compared with a traditional minced fish meat product, the minced fish meat product made by adopting the method provided by the invention is fine in mouth feeling, high in gel strength and low in fishlike smell, has special smell of the yeast glucan, can significantly increase the appetite and also has a health effect of the yeast glucan; therefore, the added value of the minced fish meat product can be significantly improved.

Owner:HUAZHONG AGRI UNIV

Preparation method for chewy sausage bars

InactiveCN108260774AHigh extraction rateReduce intensityFood ingredient as anti-freezing agentAcidic food ingredientsThree stageAdditive ingredient

The invention discloses a preparation method for chewy sausage bars. The preparation method comprises the following steps: bleaching, adding additives, performing frequency-conversion chopping, performing three-stage gelating, and performing enteroclysis. Low-concentration calcium chloride is adopted to bleach fish, so that not only can colored substances and fishy ingredients in the fish be eliminated, but also water-soluble protein (such as myogen) in the fish can be eliminated. 15-30 parts of an antifreezing agent, 10-20 parts of soy protein, 1-3 parts of a gel intensifier and 2-4 parts ofNaCl are added into 100 parts of the bleached fish. Frequency-conversion chopping and emusification are performed on the fish, and three-stage gelating is performed so as to cause no plasticity of collosol in the chopped fish, so that elastic gel is formed. The preparation method has the beneficial effects that the salt-soluble protein-myofibrilar protein extraction rate of the minced fillet prepared by the method is high, the gelating effect is good, and the nutritional value, elasticity, whiteness and water holding capcity of the minced fillet can be kept for a long time under a freezing condition.

Owner:兰溪市捷喜食品加工技术有限公司

Degradable environment-friendly plastic material

The invention discloses a degradable environment-friendly plastic material. The degradable environment-friendly plastic material comprises, by weight, 60-70 parts of low-density polyethylene, 50-60 parts of high-density polyethylene, 10-13 parts of polypropylene, 3-5 parts of nano calcium carbonate, 1-3 parts of organosilicon materials, 5-8 parts of fire retardants (ammonium phosphate), 4-7 parts of flexibilizer (ethylene-propylene rubber), 3-5 parts of aluminic acid ester coupling agents, 1-1.5 parts of antioxidants 168 and 25-30 parts of modified soy protein. The technology for preparing the modified soy protein includes the following steps that 100 parts of soy isolate protein and 200-220 parts of tetrahydrofuran are weighed by weight, fed into a reactor and stirred, the mixture is heated in a water bath to 82 DEG C-89 DEG C, the water bath time is 25-30 min, the mixture is stirred for 10-15 min after adding 5-6 parts of zinc acetate and then evenly stirred after adding 18-20 parts of maleic anhydride, suction filtration is carried out after the reaction is completed, and the product is aired naturally to obtain the modified soy protein.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

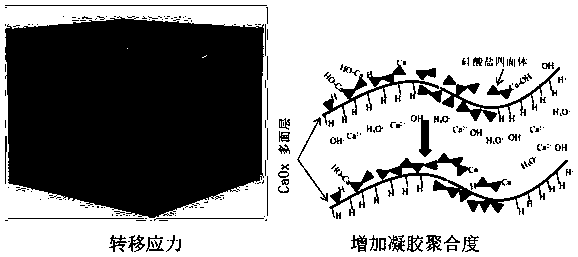

Preparation method of magnetic hydrogel

InactiveCN110064345AAvoid decompositionPlay a pore-forming roleGel preparationColloidal chemistry detailsIron(II) chloridePolyacrylamide

The invention belongs to the technical field of hydrogel, and particularly relates to a preparation method of magnetic hydrogel. In the preparation process, calcium oxide is taken as a raw material, firstly, the raw material and nanometer titania are heated, then the effect of carbon dioxide is utilized, nano calcium carbonate is formed, and under the effect of an auxiliary agent, the nano calciumcarbonate is continuously combined with the nanometer titania; dispersion performance is added for polyvinylpyrrolidone, then the polyvinylpyrrolidone, ferric chloride and ferrous chloride are mixed,magnetic particles are formed and uniformly distributed on the surfaces of mixed particles at the same time, the crystal form is improved through a guiding agent, and finally, polyacrylamide is formed for wrapping; groups on the surfaces of the particles can be combined with polyacrylamide well, the effect is utilized that the nano calcium carbonate is combined with the nanometer titania, gaps can be formed well for loading the magnetic particles, and by utilizing formation of a nano-substance, the mechanical performance and magnetic performance of the hydrogel can be effectively improved.

Owner:龙升

Method for preparing medium-density, high-strength and multi-purpose zirconium silicate composite micro-bead by using surplus materials

The invention relates to the field of preparation of micro-beads, in particular to a method for preparing a medium-density, high-strength and multi-purpose zirconium silicate composite micro-bead by using surplus materials. The formula comprises the raw materials in mass percentage: 48%-88% of zirconium silicate micro-powder surplus material having D50 of smaller than 7 microns discarded in the process of preparing zirconium silicate polishing micro-powder, 9%-49% of aluminum sesquioxide micro-powder surplus material having D50 of smaller than 7 microns discarded in the process of preparing aluminum sesquioxide polishing micro-powder and 3% of lignin. The method comprises the preparation steps of proportioning materials, drily mixing the materials, wetly mixing the materials, ageing the mixture, tightly compacting the mixture, crushing the mixture, screening the mixture, pelletizing the mixture, tightly molding the pelletized balls, selecting balls, drying the balls, screening the balls, sintering the balls, carefully selecting the sintered balls, polishing the balls, cleaning the balls and drying the balls. The prepared micro-bead has a particle size of 63-600 microns and a density of 3.8-4.0 g / cm3 and a sphericity of more than 95%. According to the method for preparing the medium-density, high-strength and multi-purpose zirconium silicate composite micro-bead by using the surplus materials, the industrial residual materials are utilized, the cost is low, the product application is wide, the process is simple, and the method is an innovation in the preparation method of the zirconium silicate composite microbead.

Owner:郑州可塑金新材料有限公司

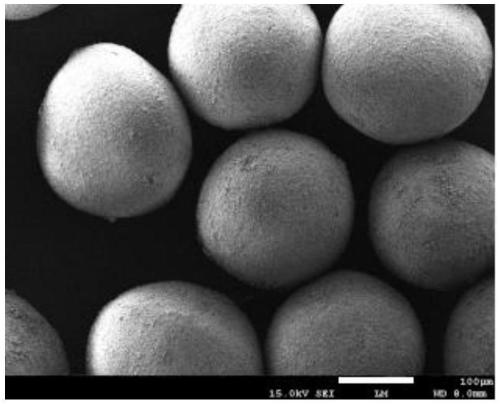

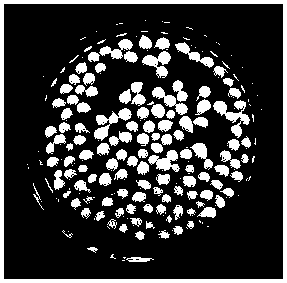

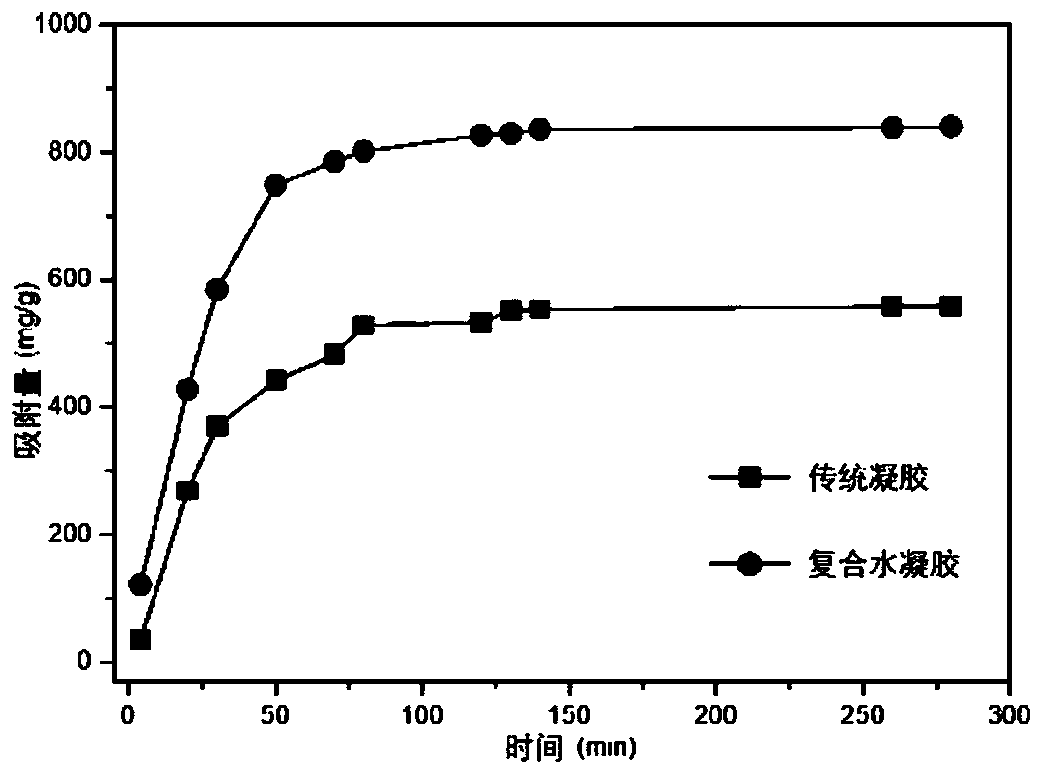

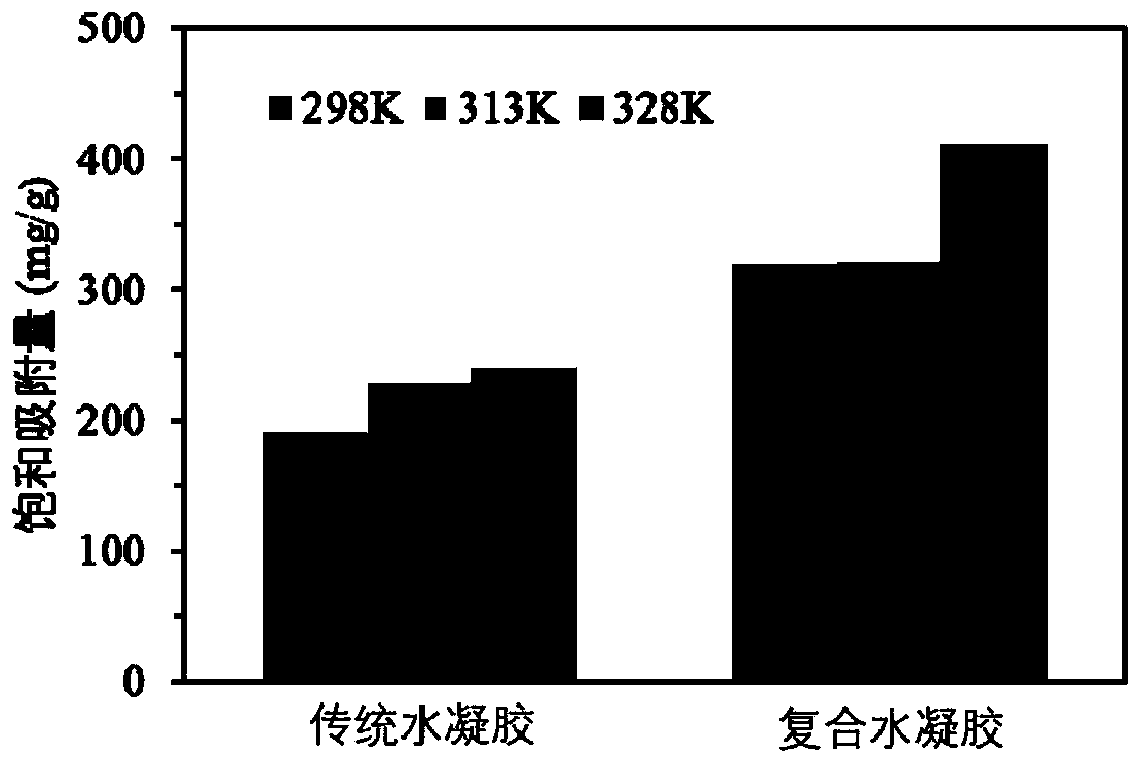

Dye-adsorbing composite hydrogel microspores and preparation method thereof

InactiveCN109894096AHigh strengthEnhanced mesh structureOther chemical processesWater contaminantsPhosphoric acidHydrogel microspheres

The invention relates to dye-adsorbing composite hydrogel microspores and a preparation method thereof. The dye-adsorbing composite hydrogel microspores are prepared from sodium alginate, magnesium biphosphate, alumina, attapulgite, calcium nitrate, ammonia water and phosphoric acid. The preparation method comprises (1) preparing sodium alginate solution and magnesium biphosphate solution sequentially with deionized water; (2) mixing the solutions of the step (1), heating to 50 DEG C, and stirring with a magnetic stirrer for 1.5 hours; (3) adding 0.5-1 g of alumina into the mixed liquid of thestep (2) under stirring; (4) adding 1-10 g of attapulgite in an oven with 102 DEG C, drying for 2 hours, adding into the mixed liquid of the step (3) under quick stirring, and continuing to stir for0.5 hour; (5) preparing calcium nitrate solution having the mass concentration of 0.02-0.06 g / ml, dropwise adding the mixed liquid of the step (4) into the calcium nitrate solution through an injectorunder stirring, and continuing to stir the formed hydrogel microspheres in the calcium nitrate solution overnight; (6), filtering the gel of the step (5) through a screen, and washing with deionizedwater 5 times to obtain the composite hydrogel microspheres.

Owner:SHENZHEN QINGYAN ENVIRONMENTAL TECH CO LTD

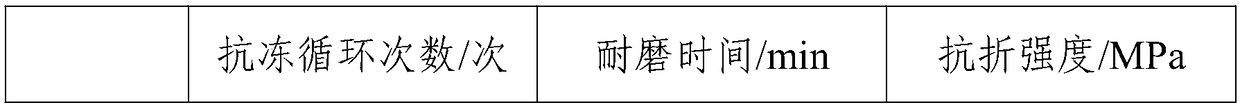

Highly wear-resistant anti-freezing glass ware and preparation process thereof

The invention relates to the field of manufacturing of glass ware and in particular relates to highly wear-resistant anti-freezing glass ware and a preparation process thereof. The glass ware is prepared from the following raw materials in parts by weight: 60-75 parts of silica powder, 10-20 parts of sodium carbonate, 3-10 parts of potassium carbonate, 2-6 parts of calcium oxide powder, 15-25 parts of fly ash, 4-8 parts of powdered titanium dioxide, 3-7 parts of boric oxide powder, 4-9 parts of phosphoric acid and 1-6 parts of powdered aluminium. The preparation method comprises the followingsteps: heating, melting, extrusion forming, annealing and tempering, thereby obtaining the highly wear-resistant anti-freezing glass ware. According to the technical scheme provided by the invention,the defects in the prior art that the made glass ware has poor freezing resistance and poor wear resistance can be effectively overcome, and the highly wear-resistant anti-freezing glass ware is worthy of popularization.

Owner:安徽钦同瓶业有限公司

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Semiconductor package substrate for improving deform

ActiveCN100580919CAvoid wrinklesAvoid deformationPrinted circuit detailsSemiconductor/solid-state device detailsSolder maskSemiconductor package

A semiconductor package substrate for preventing deformation mainly comprises a flexible dielectric layer, a plurality of pins, at least one reinforced metal pattern and a solder mask layer. All the pins and the reinforced metal pattern are formed on the same surface of the flexible dielectric layer, and the reinforced metal patterns are used for filling the pin blank section of the flexible dielectric layer. The solder mask layer is formed on the flexible dielectric layer to locally cover the pins and to cover or expose the reinforced metal patterns according to different application. The net-shaped formation positions of the reinforced metal patterns can prevent the flexible dielectric layer from crinkling or deforming.

Owner:CHIPMOS TECH INC

A production method of a health-care yeast glucan/surimi composite product that removes fishy smell and strengthens the gel

ActiveCN106901244BIncrease elasticityFine granularityFood thermal treatmentFood ingredient as gelling agentBiotechnologyFish surimi

The invention belongs to the field of food processing, and relates to a production method of a health-care yeast glucan / surimi composite product that removes fishy smell and strengthens the gel. The method includes the following steps: fresh silver carp is cleaned and then "three removals" (removing the head, scales and viscera), and rinsing after the meat is harvested. Centrifuge and drain the fish after rinsing, and chop it into mince in a food conditioner. Forming and gelling are prepared into surimi products. Compared with traditional surimi products, the surimi products produced by the method for making surimi products provided by the present invention have delicate taste, high gel strength, low fishy smell, special smell of yeast glucan, and can significantly It can improve appetite, and also has the health care function of yeast glucan, which can significantly increase the added value of surimi products.

Owner:HUAZHONG AGRI UNIV

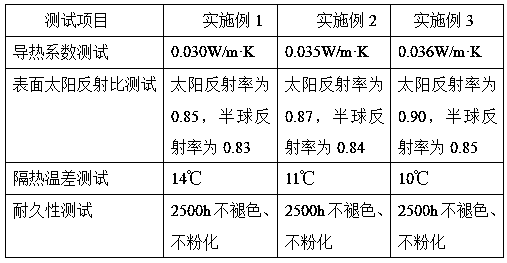

Roofing polyurethane modified asphalt waterproof paint and preparation method thereof

InactiveCN108047953ALow shrinkageHigh bonding strengthFireproof paintsAntifouling/underwater paintsPolymer scienceBituminous waterproofing

The invention relates to a roofing polyurethane modified asphalt waterproof paint and a preparation method thereof. The paint is prepared from a polyurethane prepolymer, 90# petroleum asphalt, modified nano calcium carbonate, vinyl trichloro silane, a tackifier, n-butyl acetate, citric acid, dibutyltin dilaurate, polyoxyethylene polyoxypropylene ether, fumed silica and a heat insulation material.The preparation method includes: using the polyurethane prepolymer and modified nano calcium carbonate to modify 90# petroleum asphalt; then adding vinyl trichloro silane, citric acid and n-butyl acetate, and stirring the substances evenly; then adding fumed silica, the tackifier, dibutyltin dilaurate and the heat insulation material, and stirring the substances evenly; then adding polyoxyethylenepolyoxypropylene ether and performing further stirring till no powder flotation; subjecting all the materials to shearing again on a high speed shearing machine until the 90# petroleum asphalt and the other materials are evenly dispersed, thus obtaining the product. The product has the advantages of good weather resistance, good heat insulation effect and good dispersibility.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Low compression and deformation rubber part

InactiveCN103122084AImprove vulcanization efficiencyEnhanced mesh structurePolymer scienceVulcanization

The invention provides a low compression and deformation rubber part. The rubber part comprises the following rubber raw material ingredients in weight ratio: 120-140 parts of No.18 butadiene rubber, 2-3 parts of antioxidant (Chinese name: N, N-dibutyldithiocarbamate), 30-50 parts of fast extruding furnace (FEF) 330 carbon black (Chinese name: fast extruding furnace carbon black), 6-8 parts of zinc oxide, 9-10 parts of magnesium oxide, 1-1.2 parts of sulfur, 30-40 parts of spray carbon black, 20-30 parts of dibutyl phthalate, 10-15 parts of transformer oil and 1-1.2 parts of accelerant DM (Chinese name: 2, 2'-dithio-dibenzo thiazole). The rubber formula takes the No.18 butadiene rubber with good compression resistance as a main material, so that the vulcanization efficiency is increased, a three-dimensional network structure is improved, and the rubber part has good elasticity under compression.

Owner:XIAN ZHITAI RUBBER & PLASTIC IND

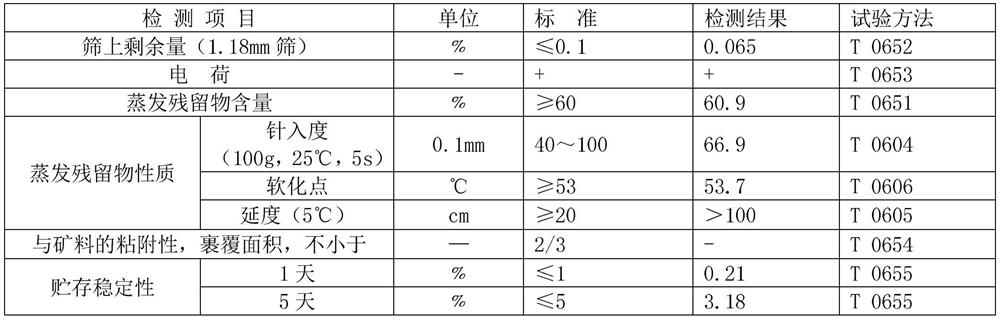

Cationic asphalt emulsifier, preparation method thereof and preparation method of asphalt emulsion

ActiveCN113698596AHigh molecular weightIncrease the range of HLB valuesClimate change adaptationBuilding insulationsPolymer scienceDimer acid

The invention discloses a cationic asphalt emulsifier and a preparation method thereof, and a method for preparing an asphalt emulsion by using the cationic asphalt emulsifier. The cationic asphalt emulsifier is formed by taking dimer acid, polyamine, a cationic etherifying agent CHPTAC and paraformaldehyde as raw materials, according to corresponding weight components. The cationic asphalt emulsifier is obtained through amidation reaction and quaternization reaction, the net structure of the asphalt emulsifier is increased through addition of paraformaldehyde, and the bonding strength of asphalt and stone is enhanced. The asphalt emulsifier has excellent emulsifying performance aiming at different types of asphalt, can be widely compatible with various aggregates, is good in wrapping performance, and can adapt to micro-surfacing construction of high-activity stones and high-temperature weather.

Owner:天津康泽威科技有限公司

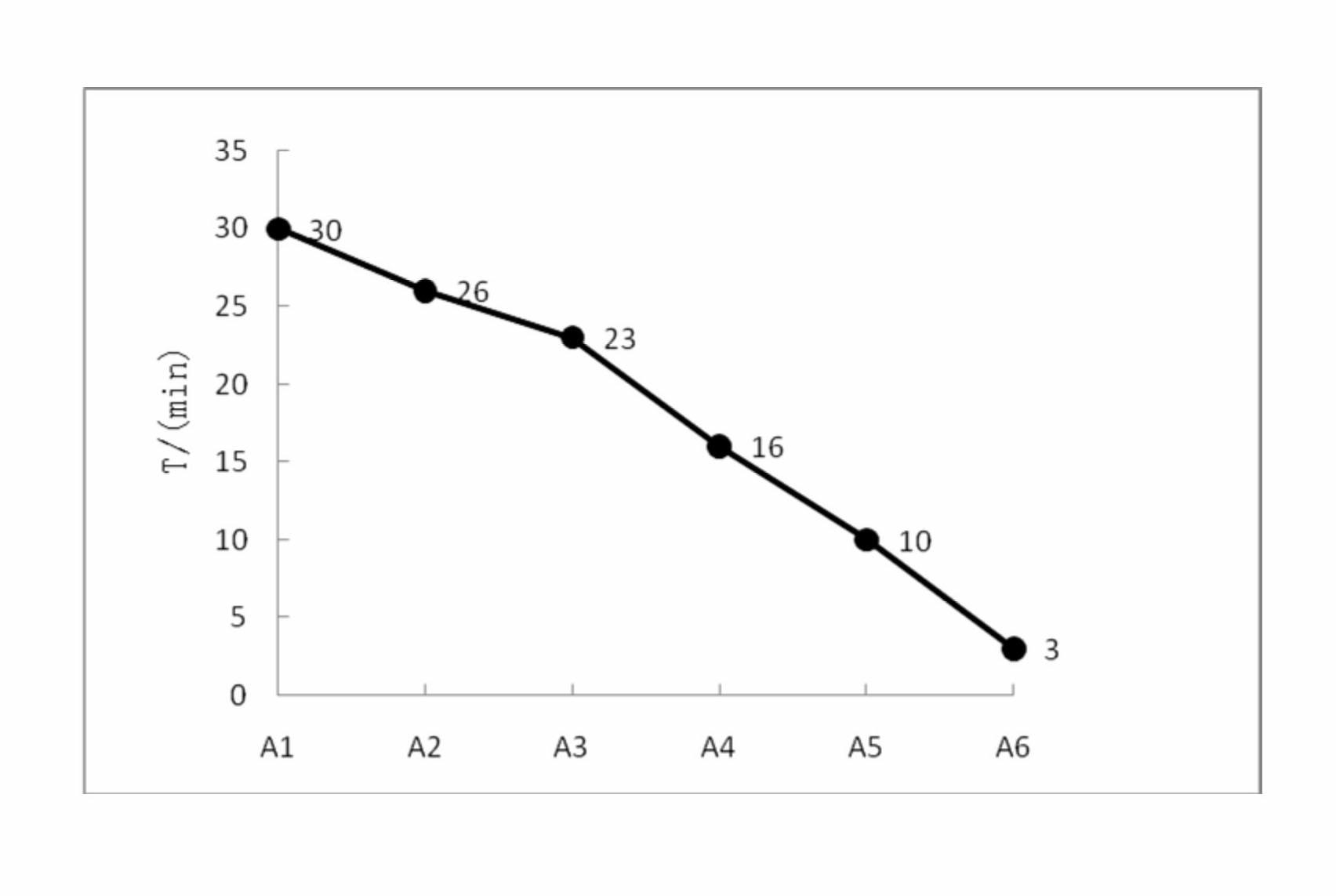

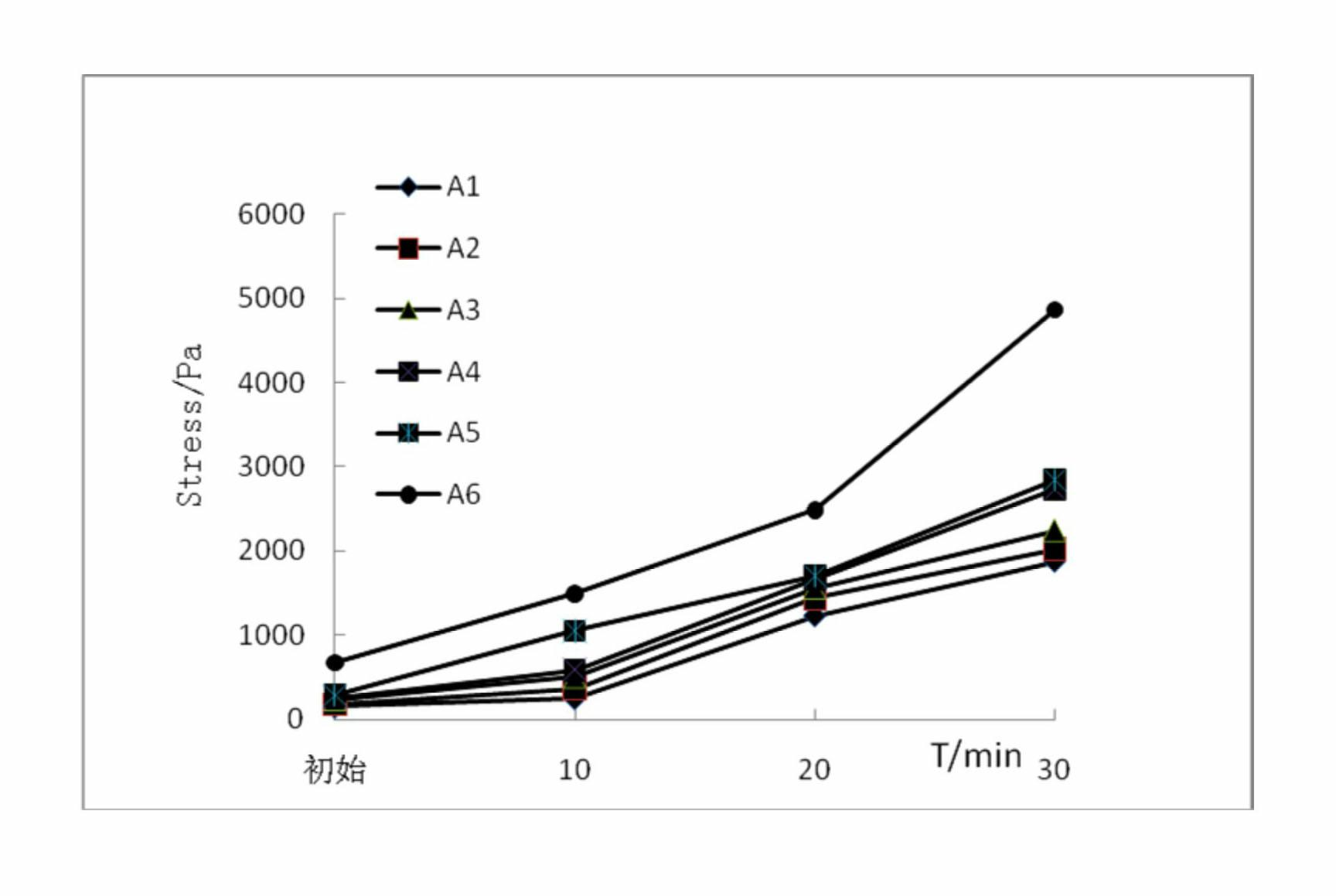

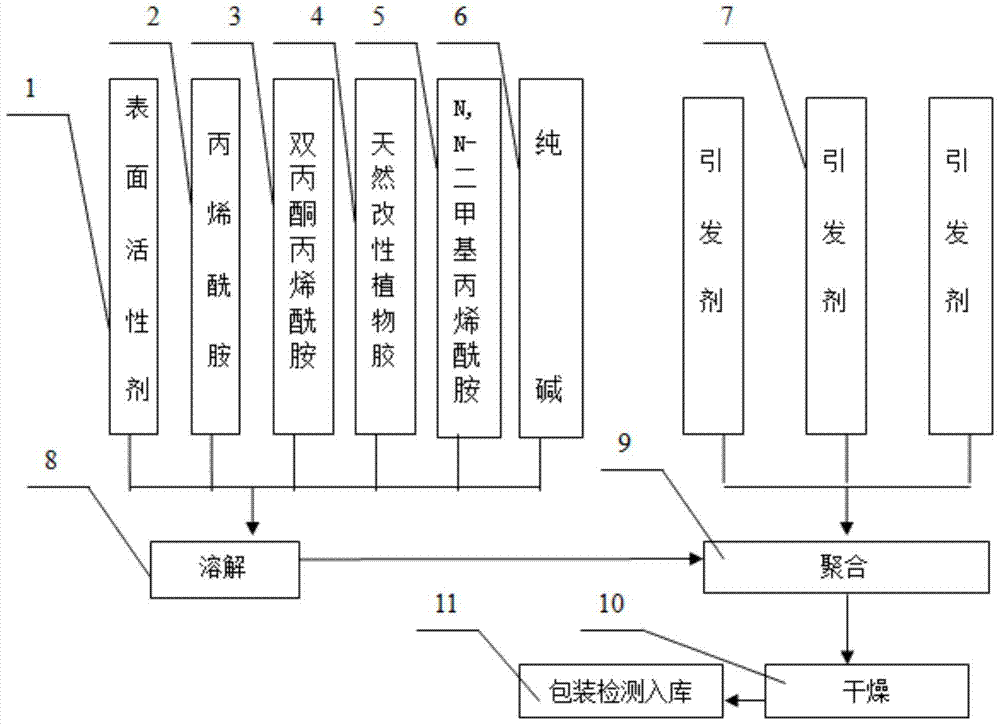

A kind of weak gelling agent for drilling fluid and preparation method thereof

ActiveCN104559961BIncrease shear forceGood ability to carry cuttingsDrilling compositionUltraviolet lightsSlurry

The invention provides a weak gel for a drilling fluid and a preparation method of the weak gel. The weak gel is characterized by being prepared by sequentially adding natural modified plant gel, acrylamide, N,N-dimethacrylamide, a nonionic fluorocarbon surfactant, diacetone-acryloamide and sodium carbonate under normal temperature conditions, adjusting the pH value to be 8-9, introducing nitrogen to deoxidize, adding an initiator, implementing polymerization reaction under radiation of ultraviolet light, and drying, thereby preparing a finished product. The weak gel provided by the invention is good in temperature resistance property and tackification and lifting cutting effect, can be used in a horizontal well to improve the property of the drilling fluid in carrying rock debris, can solve the problem of static sand suspension and dynamic sand carrying in a horizontal well section, is additionally good in computability and is applicable to light slurry and salt water slurry, and a reservoir stratum can be protected and is slightly damaged.

Owner:BEIJING SHIDABOCHENG TECH

A kind of polyaluminum-zinc composite flocculant and its application

InactiveCN105984929BImprove adsorption bridging effectGood decolorization effectWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationTurbiditySODIUM SILICATE SOLN

Owner:NANJING UNIV +1

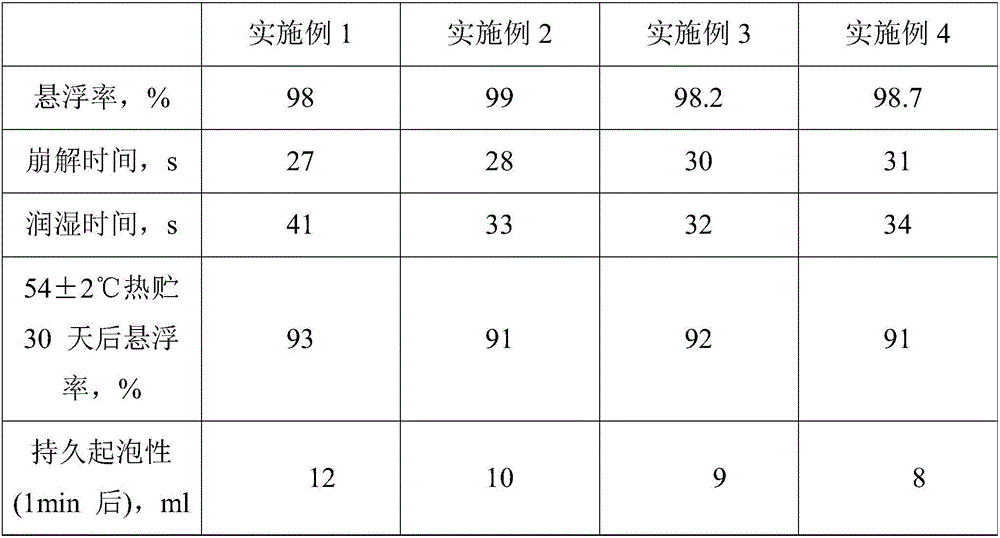

Metamifop water dispersible granule

InactiveCN106332879AImprove stabilityImprove rain resistanceBiocideDead animal preservationSodium bicarbonateWater dispersible

The invention provides a metamifop water dispersible granule. The granule is prepared from, by weight, 10-30% of metamifop, 2-10% of wetting agent, 2-8% of dispersing agent, 3-6% of organosilicone surface active agent, 0.5-6% of adhesive and the balance filler. The adhesive is a mixture of corn starch and gas-phase silicon dioxide. Metamifop is washed through a sodium bicarbonate solution with concentration of 0.1-0.5 wt% in advance. The water dispersible granule is high in suspension stability, meets the requirements of high-altitude low-temperature regions, and reduces the influences of organic solvent on the environment.

Owner:HEFEI JIUYI AGRI DEV

Preparation method of waterproof roll

PendingCN111605272AImprove radiation resistanceReduce thermo-oxygenationProtein adhesivesSynthetic resin layered productsEpoxyPolystyrene

The invention belongs to the technical field of building waterproof materials, and particularly relates to a preparation method of a waterproof roll. The preparation method comprises the following steps: heating, stirring and mixing asphalt and turpentine, adding rubber powder to obtain modified asphalt, acidifying the other part of industrial protein powder with acetic acid, dispersing with cornstarch at a high speed to obtain a biomass waterproof adhesive, uniformly mixing polyimide, acrylic fiber waste sweater threads, polystyrene, dioctyl adipate, asphalt latex, epoxy fatty acid butyl ester and other raw materials, extruding and molding the uniformly mixed raw materials, stretching, cooling, and rolling to obtain an anti-aging isolation layer, compounding the anti-aging isolation layer, a waterproof roll base and an isolation film layer from top to bottom, bonding layers by using the biomass waterproof adhesive to form bonding layers, and performing roller pressing rolling after compounding to obtain the waterproof roll. The waterproof roll prepared in the preparation method disclosed by the invention is relatively good in weather resistance, relatively long in use durability,relatively good in anti-leakage effect, not easy to leak water due to water mixing, and wide in application prospect.

Owner:泉州市鼎鑫丰泰建筑材料科技有限公司

Preparation method of acrylamide cross-linked urea glyoxal resin wet strength agent

ActiveCN103044629BEliminate the source of the hazardHigh cross-linking activityReinforcing agents additionPolymer scienceHuman health

The invention relates to a preparation method of acrylamide cross-linked urea glyoxal resin wet strength agent. The preparation method is characterized by comprising the following steps: mixing glyoxal and urea as per mole ratio of 1 to 2: 0.3 to 1, regulating pH value to be 1.5 to 3 with acid, reacting for 2.5 to 6 h under the temperature of 35 DEG C to 75 DEG C, cooling, regulating pH value to be neutral with alkali after adding the glyoxal with the adding amount of moles of 15% to 40 % of first glyoxal weight, reacting for 1 to 2 h under the temperature of 20 DEG C to 35 DEG C, regulating pH value to be neutral so as to obtain urea resin, adding cross-linking monomers and cation monomers into the urea resin (the mole ratio of the cross-linking monomers, the cation monomers and the urea is 0.5 to 3.5:0.2 to 2:5, reacting for 1 to 2 h under the temperature of 50 DEG C to 80 DEG C, and adding deionized water for dilution until the solid content occupies 12% of total content so as to obtain acrylamide cross-linked urea glyoxal resin wet strength agent. The invention has the benefits that formaldehyde and organic halide are not added during preparation process, so that damage to environment and human health is eliminated.

Owner:西安绿野环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com