Patents

Literature

85results about "Food ingredient as anti-freezing agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frozen aerated product

InactiveUS20040161503A1Reduce the temperatureAvoid damageSugar food ingredientsFrozen sweetsGlycerolSweet food

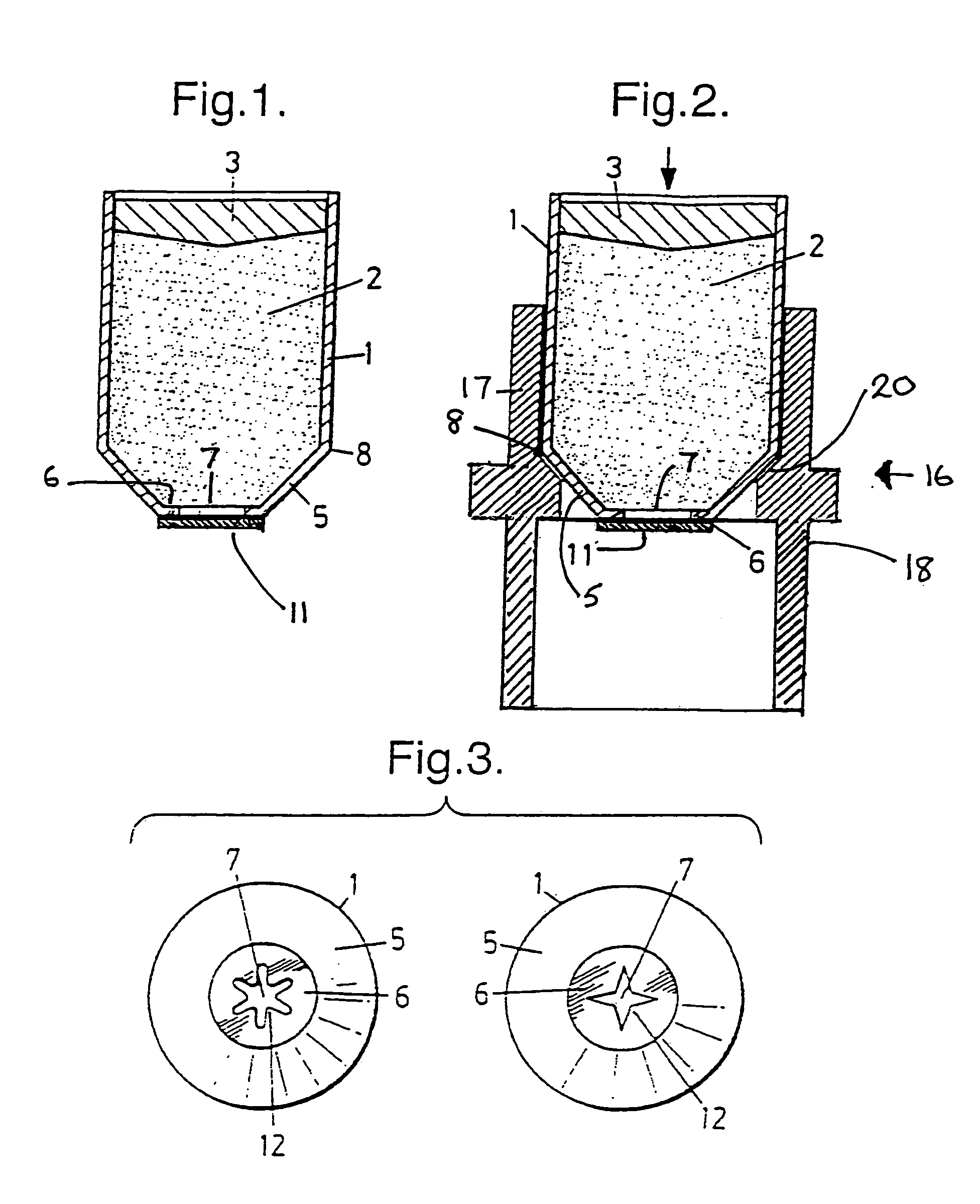

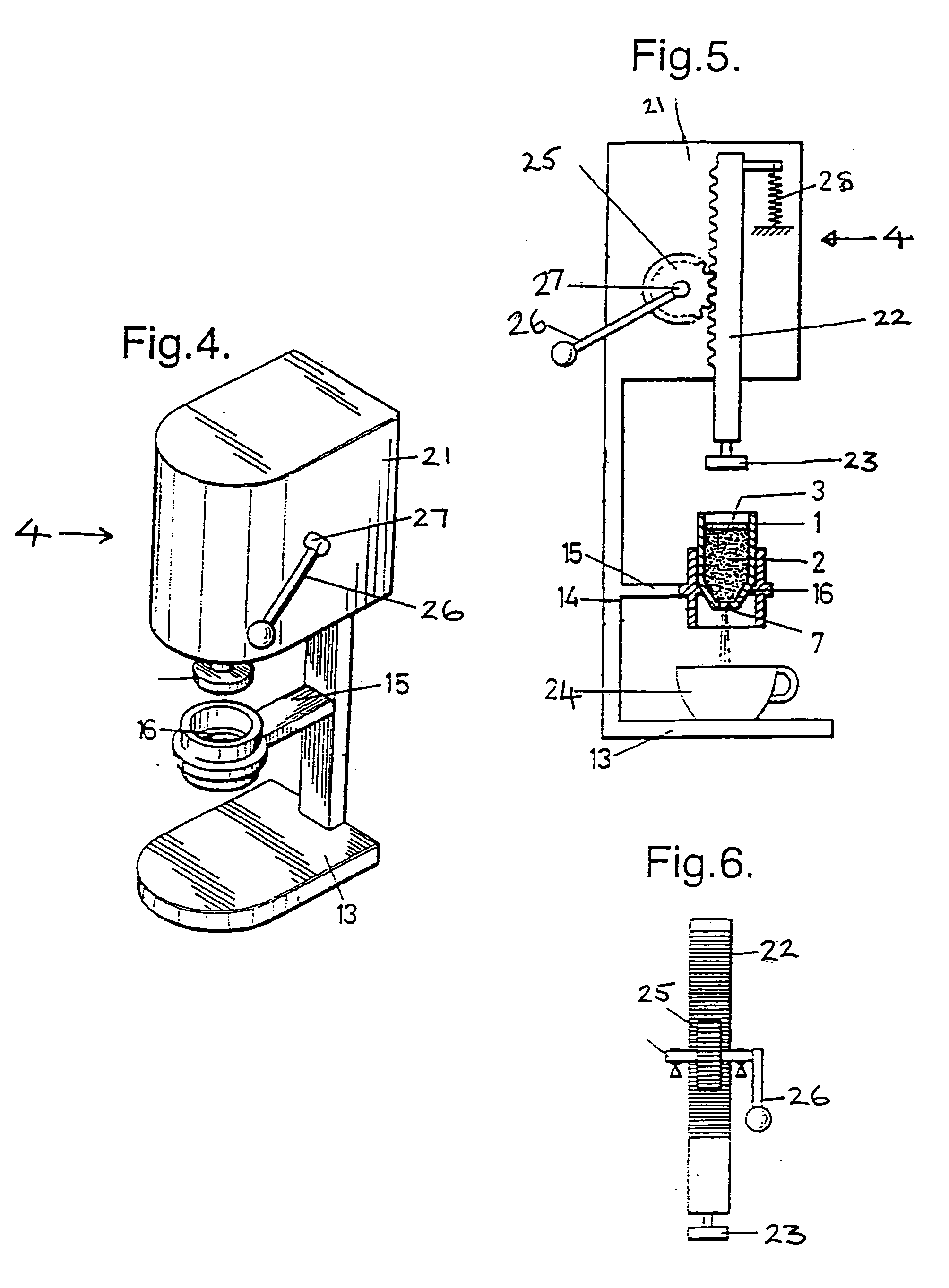

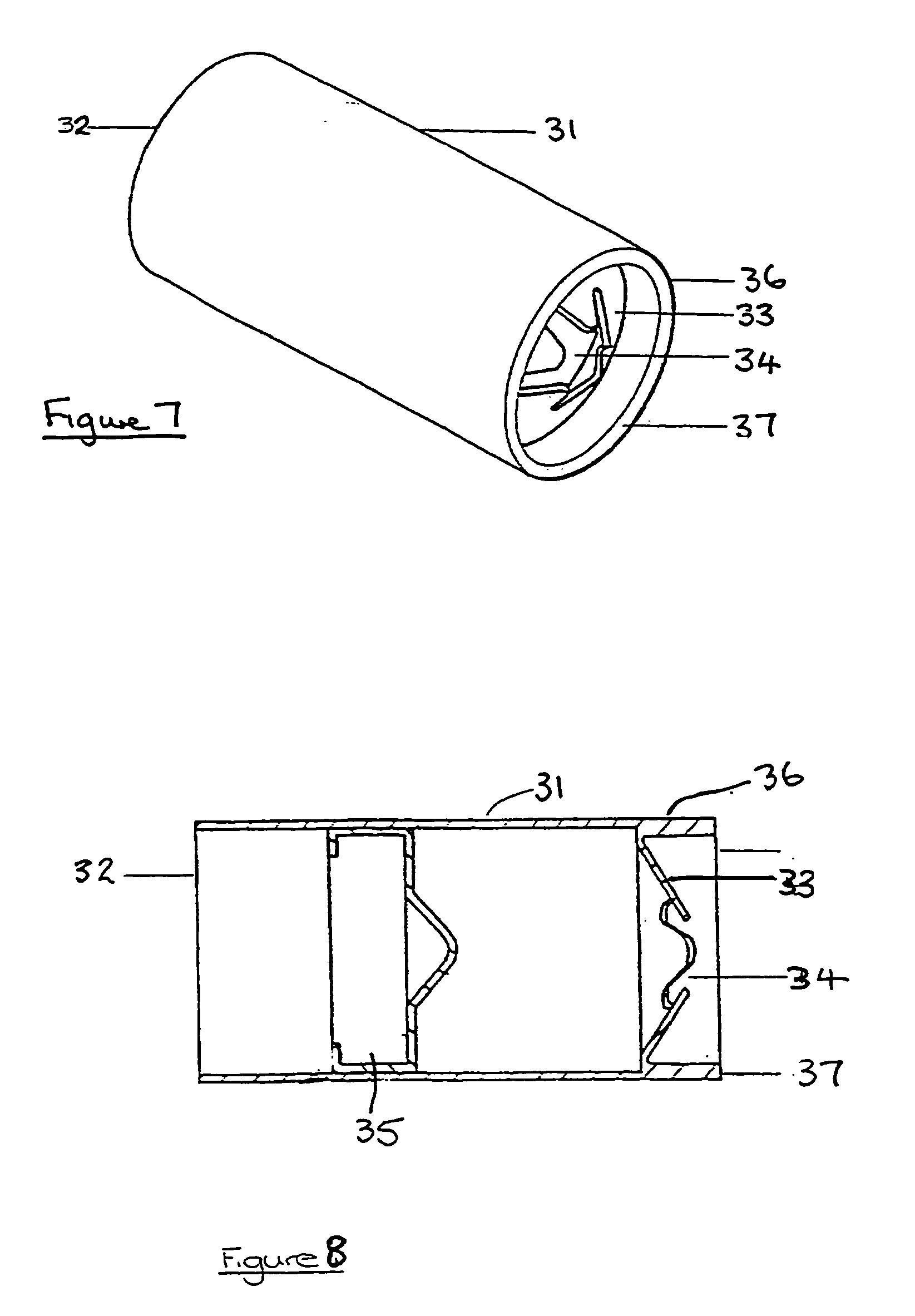

A frozen product comprises a cartridge containing a frozen aerated confection having an overrun of above 20% and below 100%, and containing less than 1.5% w / w glycerol, freezing point depressants in an amount of between 25% and 37% w / w, and between 2 and 12% fat, wherein the freezing point depressants have a number average molecular weight <M>n of less than 300. The frozen aerated confection has a soft structure and can be extruded from the cartridge at -18° C.

Owner:GOOD HUMOR BREYES ICE CREAM DIV OF CONOPCO

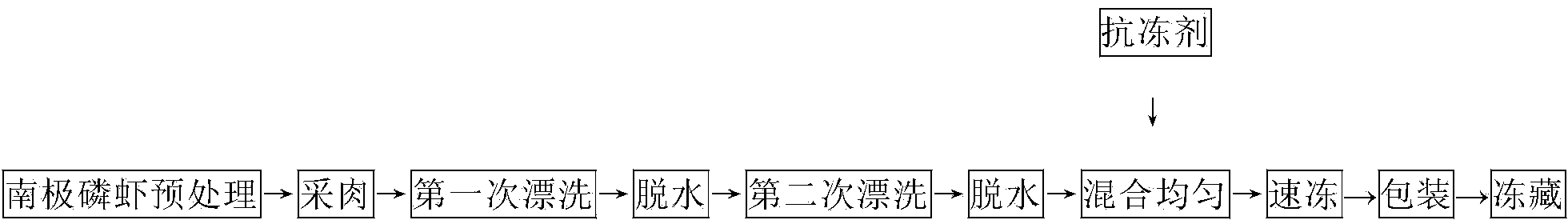

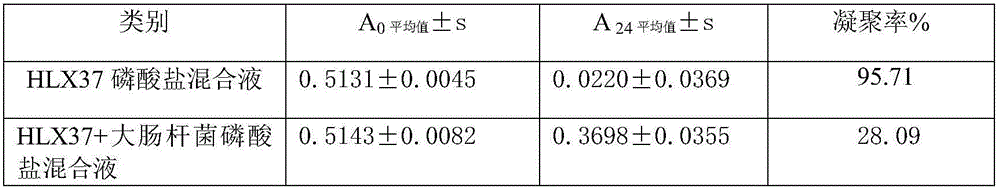

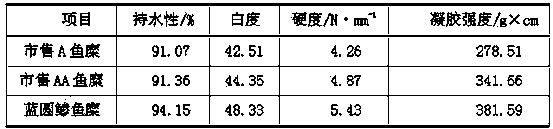

Production process of on-board euphausia superba mince

ActiveCN103549510AReduced fluorine and enzyme contentImprove qualityFood freezingFood ingredient as anti-freezing agentCarrageenanAdditive ingredient

The invention discloses a production process of on-board euphausia superba mince. The production process of on-board euphausia superba mince particularly comprises the following steps of rinsing euphausia superb twice after flesh extraction, dehydrating, adding an antifreeze agent, and storing frozen euphausia superb mince at minus 24 DEG C after quick-freezing; rinsing the euphausia superb mince by fresh water or seawater again which contains 0.1-0.3% of CaC12 for one time, and then rinsing the euphausia superb mince by fresh water or seawater for the second time, thus improving the jelly strength and the whiteness of the euphausia superba mince and reducing the loss of fluorine content and nutritional components; and adding 3-5% of saccharose, 3-5% of sorbitol, 0.2-0.3% of polyphosphates, 0.1-0.3% of sodium alginate tech grade as well as 0.2-0.4% of carrageenan, thus reducing the possibility of the protein denaturation of the euphausia superba mince during the freezing process, and improving the euphausia superba mince quality and yield.

Owner:SHANGHAI OCEAN UNIV

Preparation method of fruit and vegetable yoghourt balls

InactiveCN106879820AMake full use of nutritional functionsTake full advantage of health functionsFrozen sweetsFood ingredient as anti-freezing agentAdditive ingredientFreeze-drying

The invention discloses a preparation method of fruit and vegetable yoghourt balls. The preparation method comprises the following steps of A, making concentrated fruit and vegetable juice into restored fruit and vegetable juice; B, preparing raw milk; C, performing homogenizing: putting the raw milk obtained in the step B into a homogenizing machine, and performing homogenizing; D, performing sterilization and cooling: performing ultrahigh-temperature instantaneous sterilization on the raw milk homogenized in the step C; E, performing inoculation and fermentation: adding a yoghourt fermenting agent of which the mass percentage is 0.15-0.2% to the raw milk obtained in the step D, and then performing fermentation at 42-44 DEG C for 7-9h, wherein the yoghourt fermenting agent contains 50% of lactobacillus plantarum and 50% of other lactic acid bacteria; F, performing mixing and ageing; G, performing stirring and congelation; and H, after congelation, taking out materials, performing shaping, performing quick freezing, and then performing vacuum freeze drying. According to the preparation method disclosed by the invention, yoghourt, fruits and vegetables can be mutually merged, so that the fruit and vegetable yoghourt balls can have nutrient components of fruits and vegetables and nutrient components of the yoghourt at the same time, and have the fragrance of the fruits and the vegetables, and the fragrance of the yoghourt at the same time, and the appetite of human bodies is stimulated; and in addition, the fruit and vegetable yoghourt balls just melt in the mouth and are refreshing and smooth in mouth feel.

Owner:XUZHOU UNIV OF TECH

Frozen squid quality improver and preparation method and application thereof

InactiveCN105875798AImprove qualityThe formula is scientific and reasonableFood ingredient as anti-freezing agentMeat/fish preservation by freezing/coolingChemistryCarrageenan

The present invention discloses a frozen squid quality improver. The frozen squid quality improver is prepared from the following components in percentages by mass: 10-20% of potato flour, 0.05-0.1% of metallothionein, 5-10% of white sugar, 0.5-1% of trehalose, 1-3% of sodium lactate, 3-5% of sodium bicarbonate, 3-5% of glycerol, 0.05-0.1% of carrageenan, and the balanced being deionized water. The frozen squid quality improver is reasonable and scientific in recipe and good in use safety. Each component is in a synergic function, and the quality improver has effects of preventing freezing and inhibiting browning, retaining water, etc., can improve the quality of the frozen squids, and is suitable for promotion. The present invention also provides a preparation method of the frozen squid quality improver. The technology is simple in steps, and the preparation method is low in equipment requirement, low in preparation costs, strong in operation, and suitable for industrialized productions, and each of the components is good in dispersion uniformity.

Owner:ZHEJIANG OCEAN UNIV

Fermentation method for low-salt thick broad-bean sauce

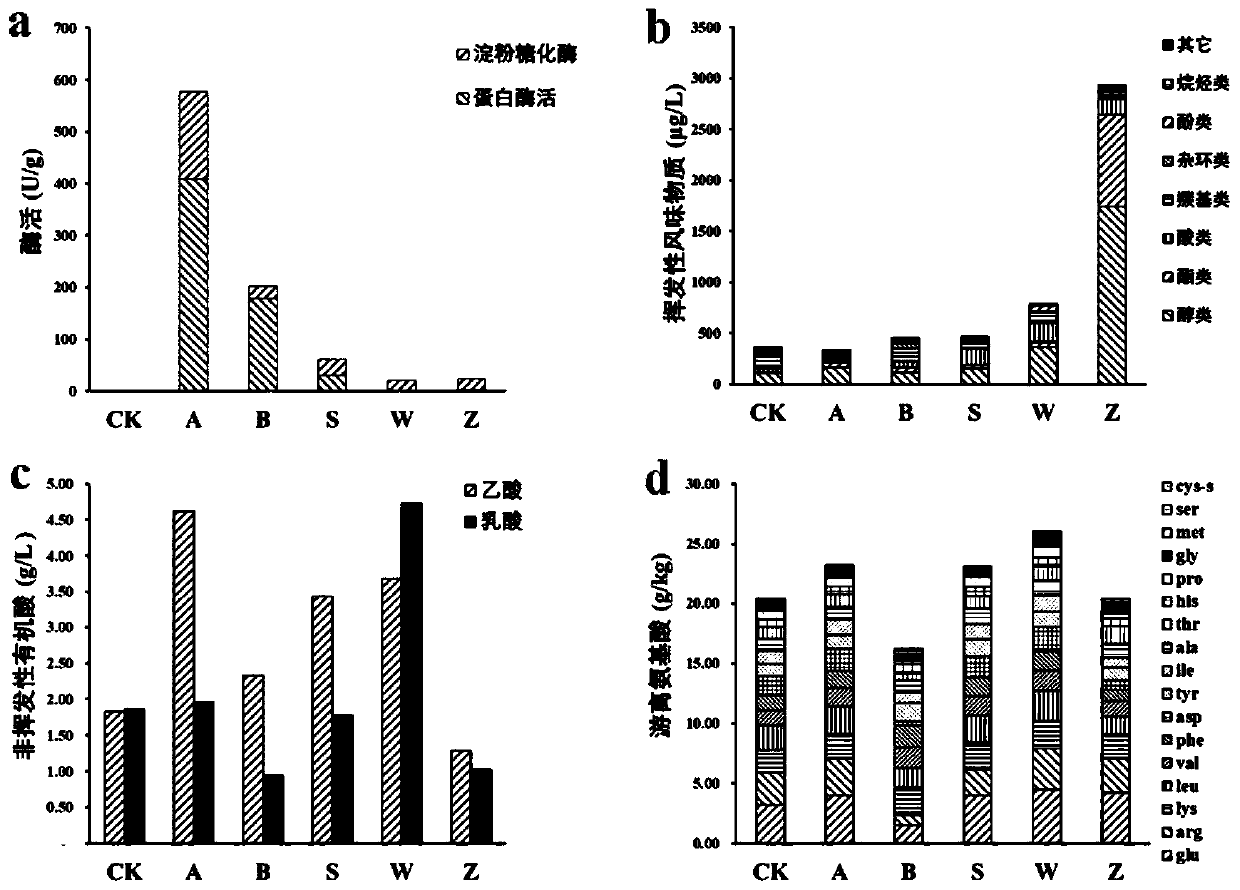

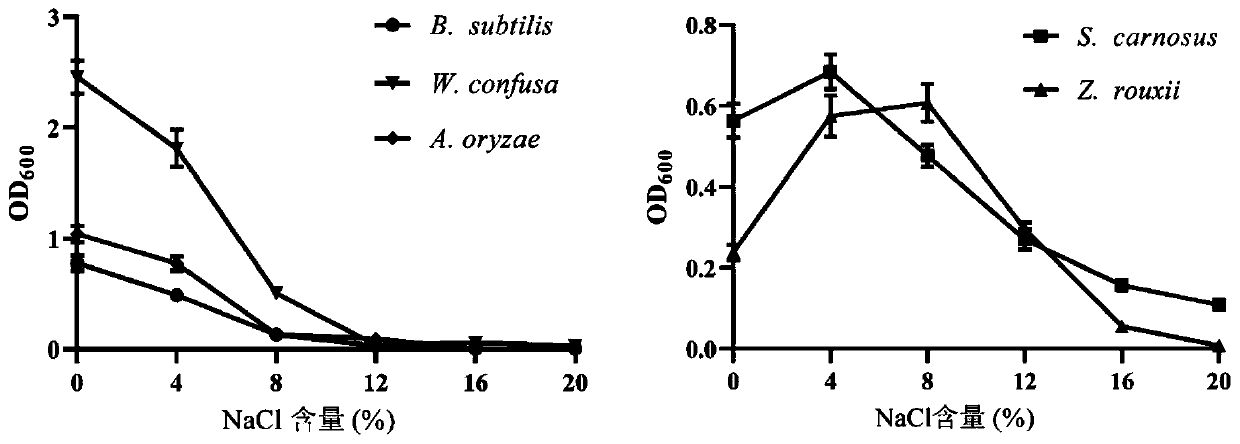

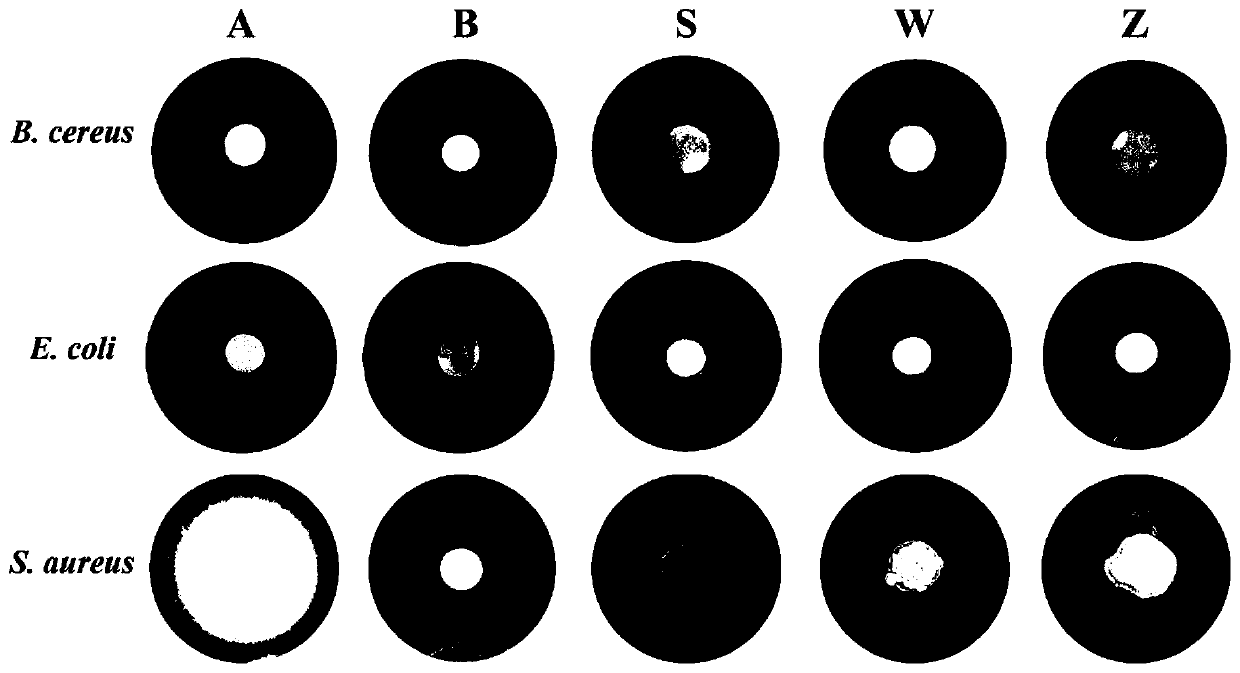

The invention relates to a fermentation method for low-salt thick broad-bean sauce. According to the multi-strain cooperative fermentation method and an application of the method in the thick broad-bean sauce provided by the invention, the low salinity of the product is realized, the total amount of flavor substances of the low-salt thick broad-bean sauce prepared by the method is increased by 50.4% and 111.1% respectively compared to those of thick broad-bean sauce prepared in a medium-concentration salt and thick broad-bean sauce prepared in a high-concentration salt, so that after fermentation is completed, the flavor of bean sauce mash with salinity of 6% is fuller, and the aroma is more mellow; the content of organic acids of the low-salt thick broad-bean sauce prepared by the methodis increased by 14.7% and 27.4% respectively compared to those of the thick broad-bean sauce prepared in the medium-concentration salt and the thick broad-bean sauce prepared in the high-concentrationsalt, so that the mouthfeel is softer, and a unique flavor is formed; and the method effectively improves the flavor and quality of the thick broad-bean sauce, thereby guiding the upgrading of traditional thick broad-bean sauce industry.

Owner:JIANGNAN UNIV

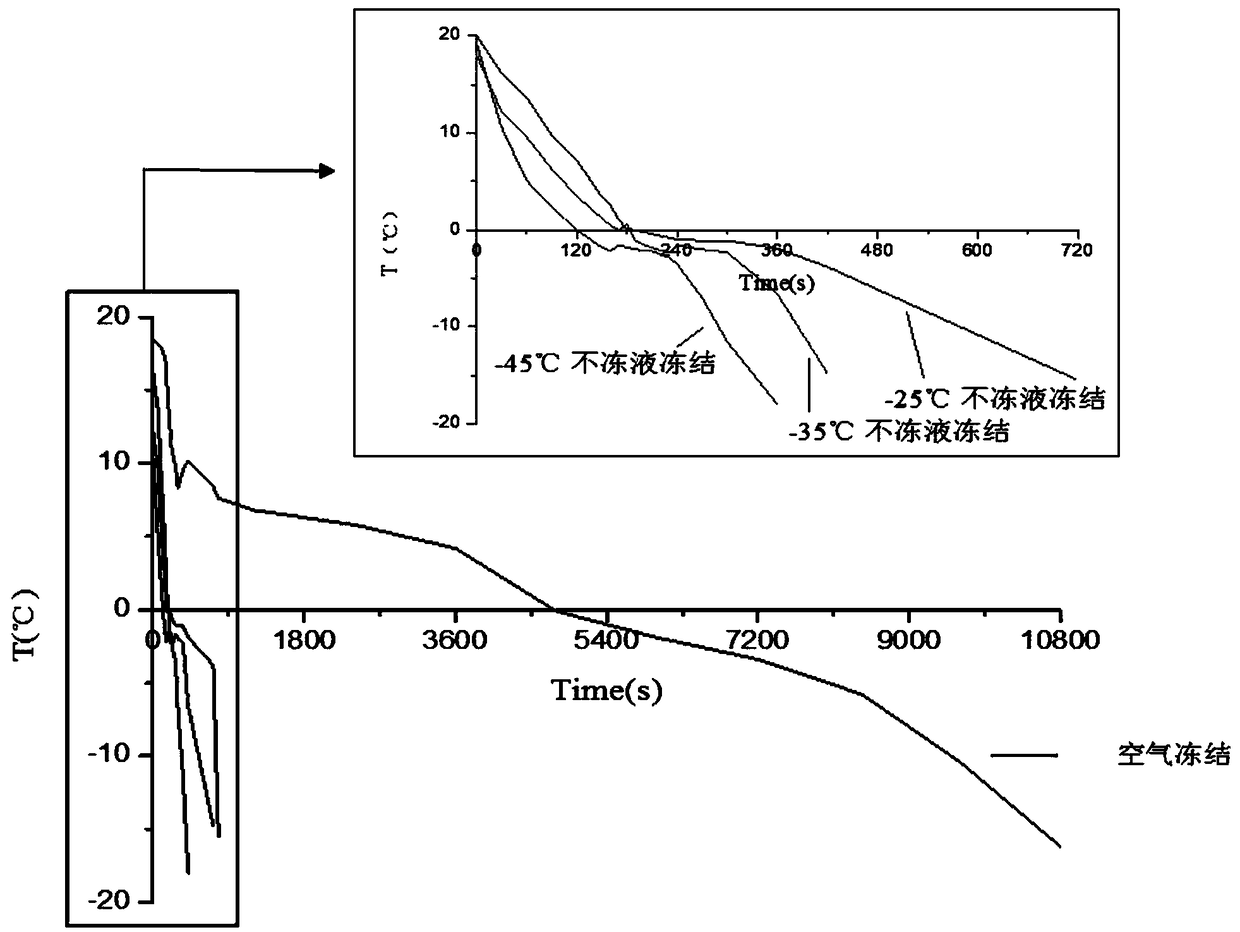

Non-freezing solution for food preservation

ActiveCN108795392AMeet food safety requirementsReduce contentFood processingFood ingredient as anti-freezing agentPhospholipidBalance water

The invention discloses a non-freezing solution for food preservation. The non-freezing solution contains, by mass, 15-30% of edible alcohol, 10-30% of propylene glycol, 2-15% of glycerin, 1-10% of calcium chloride, 3-10% of sodium chloride, 0.1-0.15% of amino acid, 0.01-0.3% of Antarctic krill protein hydrolysate with average molecular weight of 50-100 KDa, 0.005-0.5% of surfactant and the balance water, wherein the surfactant is one or more of phospholipid, twain-20, Twain-60 and Twain-80, and each component is of food-grade. The freezing point of the non-freezing solution can be reduced, the heat transfer efficiency can be improved, the crystallization phenomenon of the non-freezing solution in the low-temperature stirring process can be inhibited, and the stability of the non-freezingsolution can be improved.

Owner:ZHEJIANG UNIV OF TECH +1

Kelp active lactobacillus buccal tablet and preparation method thereof

InactiveCN103932273AGood dispersionImprove palatabilityFood freezingFood ingredient as anti-freezing agentBiotechnologySucrose

The invention relates to a kelp active lactobacillus buccal tablet and a preparation method of the kelp active lactobacillus buccal tablet, belonging to the field of food processing. The kelp active lactobacillus buccal tablet is prepared from the following main raw materials in percentage by weight: 40-60 percent of kelp lactic acid fermented ultrafine powder, 1-4 percent of beta-cyclodextrine, 10-20 percent of maltodextrin, 5-10 parts of xylitol, 10-20 percent of glucose powder, 5-20 parts of sugarcane powder, 0.5-2 percent of citric acid and 0.1-0.4 percent of peppermint oil. According to the preparation method provided by the invention, the kelp lactic acid fermented ultrafine powder is uniformly mixed with a filler, a flavor regulating agent and a lubricating agent, and a proper amount of water is taken as a wetting agent to prepare the kelp lactobacillus buccal tablet through steps such as granulation, drying, granulation regulation and tableting. A product prepared by the method provided by the invention contains a great quantity of active probiotics and functional components and has the advantages of being rich in nutrients, unique in flavor and convenient to carry and eat.

Owner:FUJIAN AGRI & FORESTRY UNIV

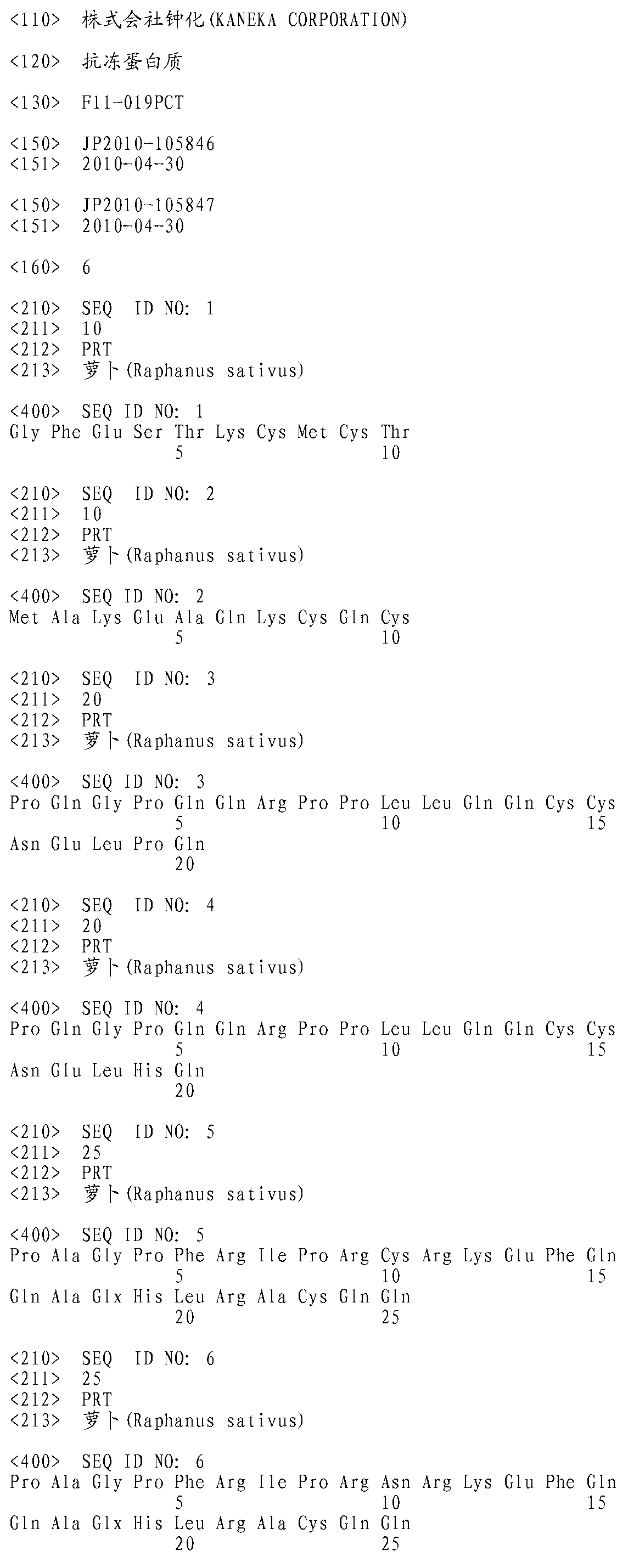

Antifreeze protein

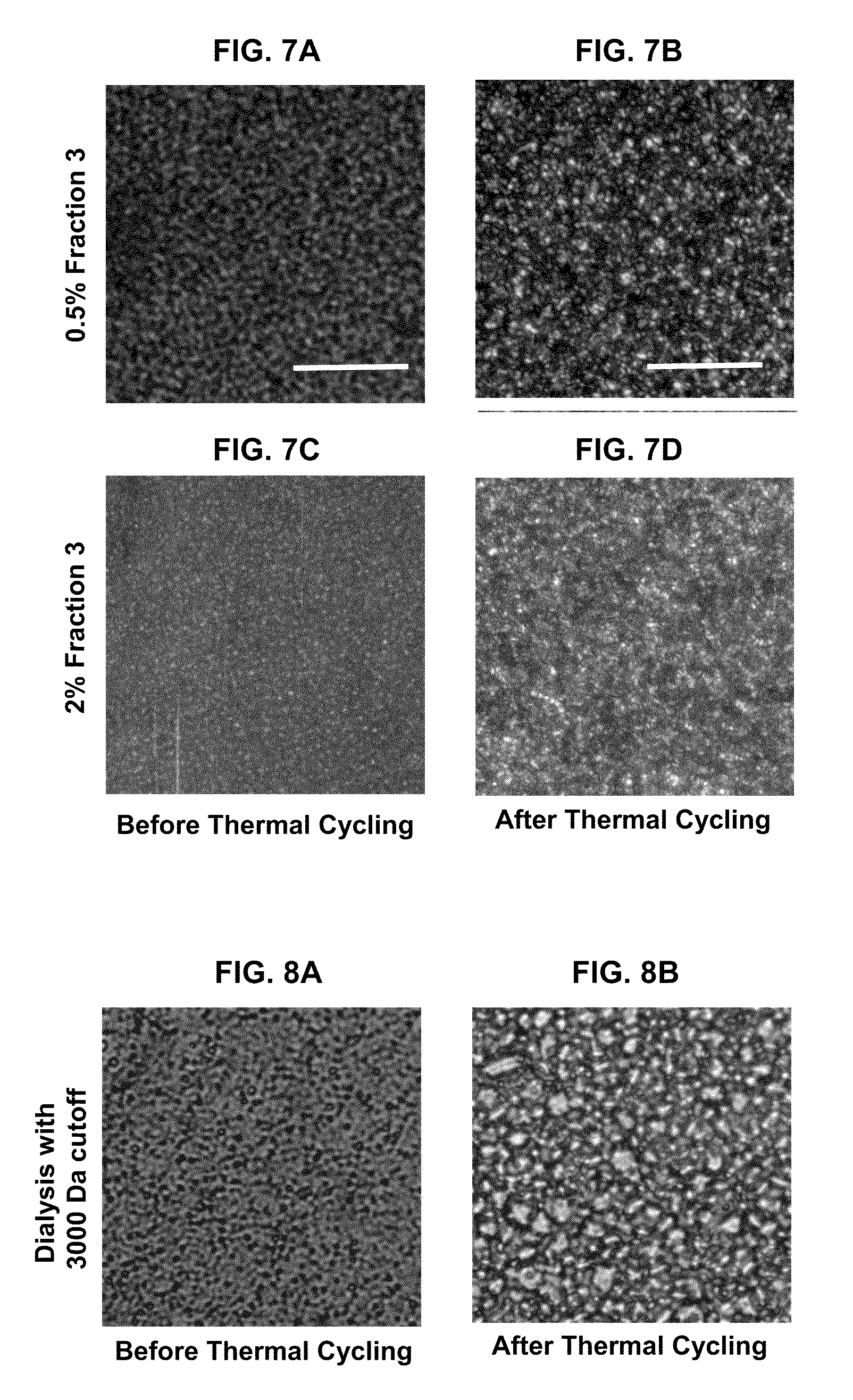

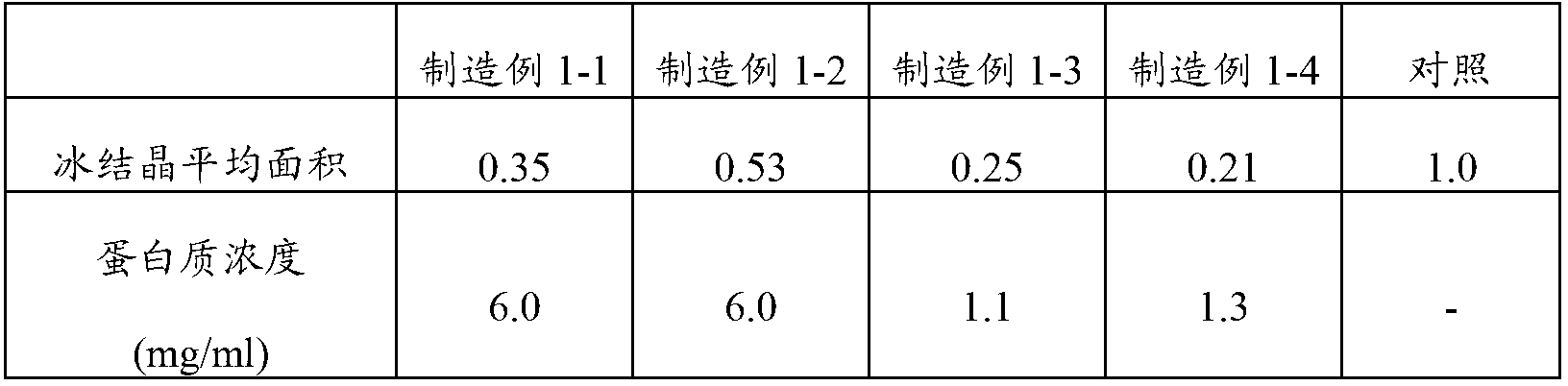

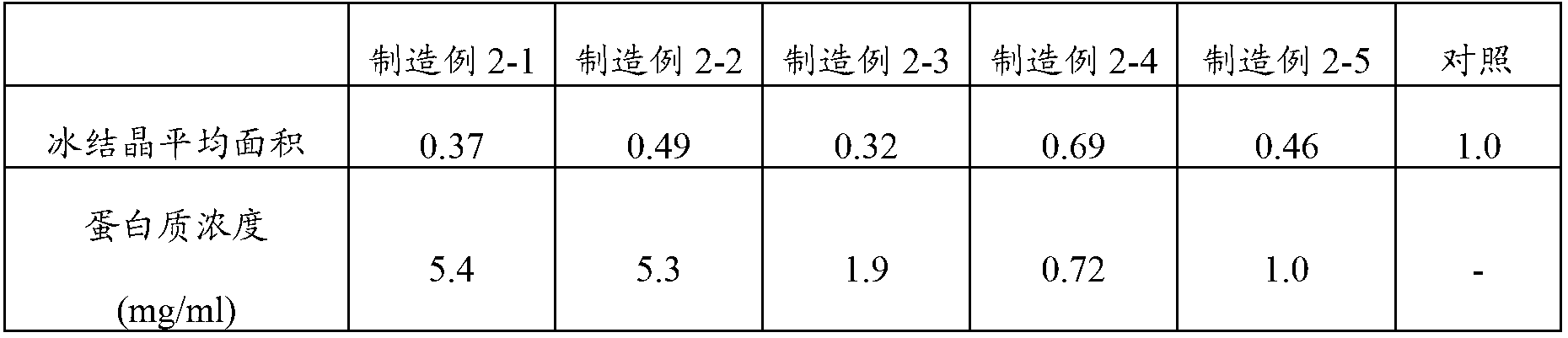

InactiveUS20130165626A1Efficient productionLow costCosmetic preparationsPeptide/protein ingredientsAntifreeze activityOrganism

An objective of the present invention is to provide an antifreeze protein which is capable of being efficiently produced on an industrial level at low cost and which is safe and has an excellent antifreezing activity for use on a practical level. Also, an objective of the present invention is to provide a polypeptide that corresponds to the active part of the antifreeze protein; a composition, a food, a biological sample protectant and a cosmetic containing the antifreeze protein or the polypeptide; and an antibody that specifically reacts with the antifreeze protein or the polypeptide. The antifreeze protein according to the present invention is characterized in being derived from a plant and having a specific amino acid sequence or being a plant seed protein.

Owner:KANEKA CORP

Frozen Confectionery Product Comprising Ice Structuring Proteins

Owner:CONOPCO INC D B A UNILEVER

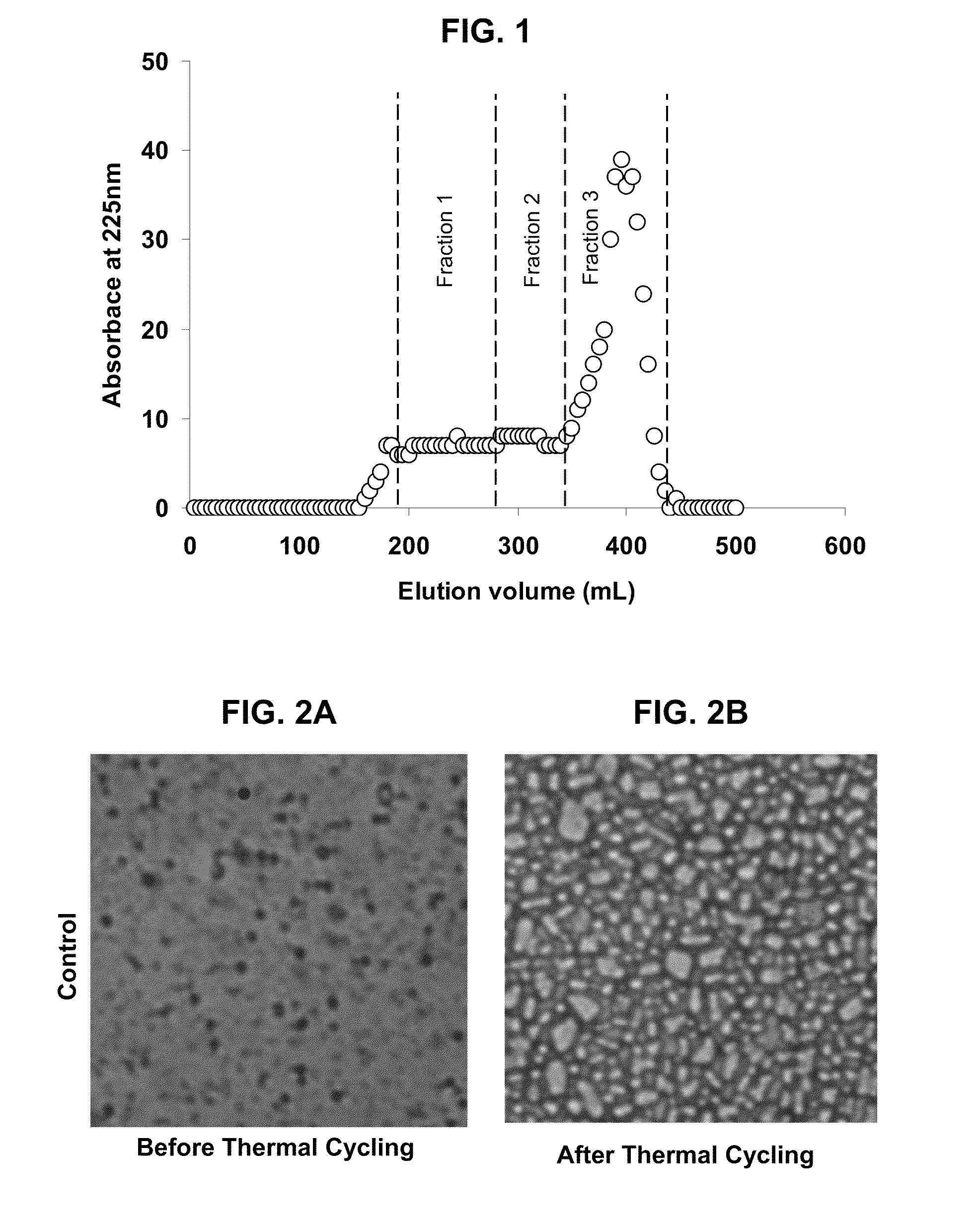

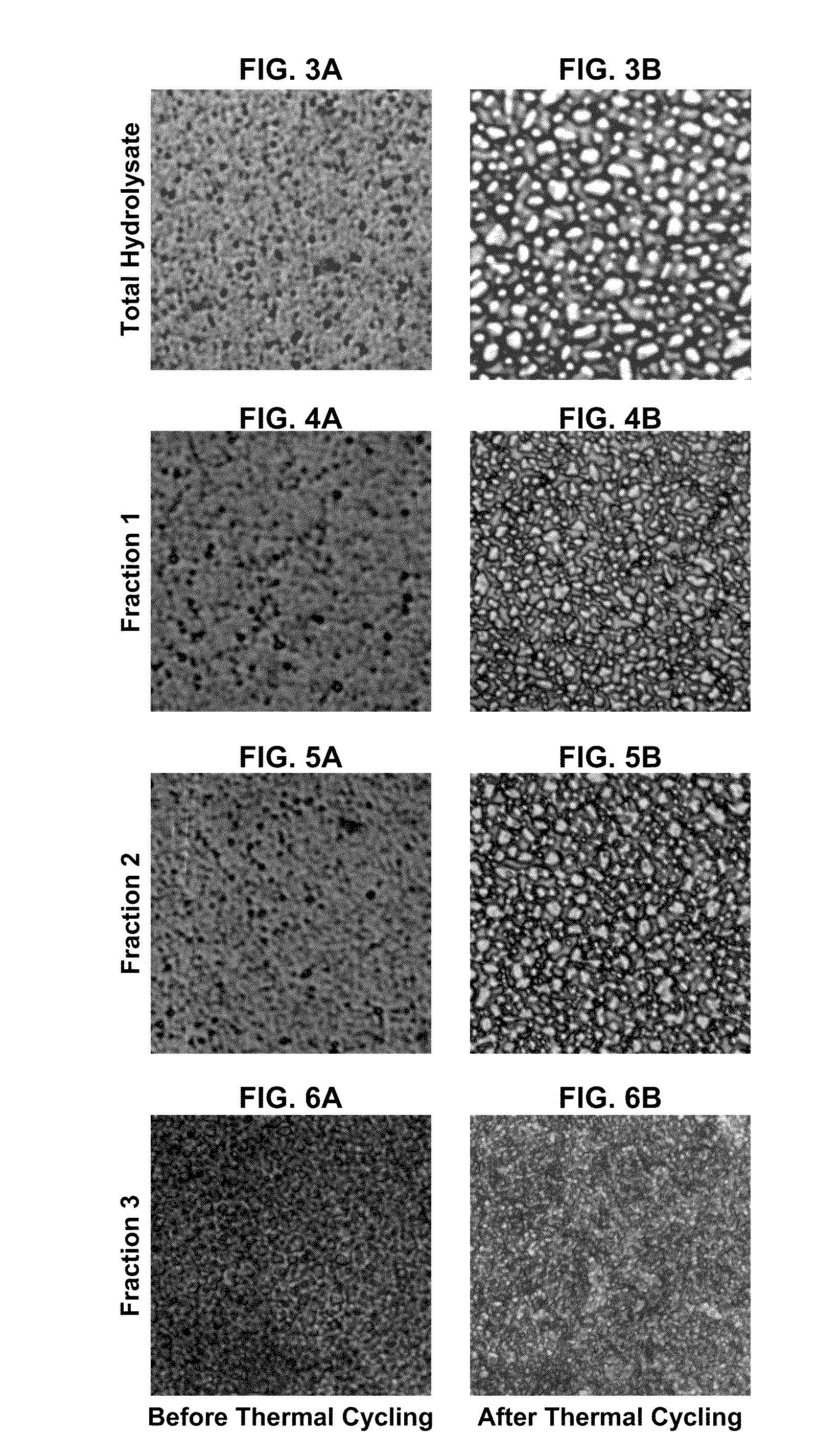

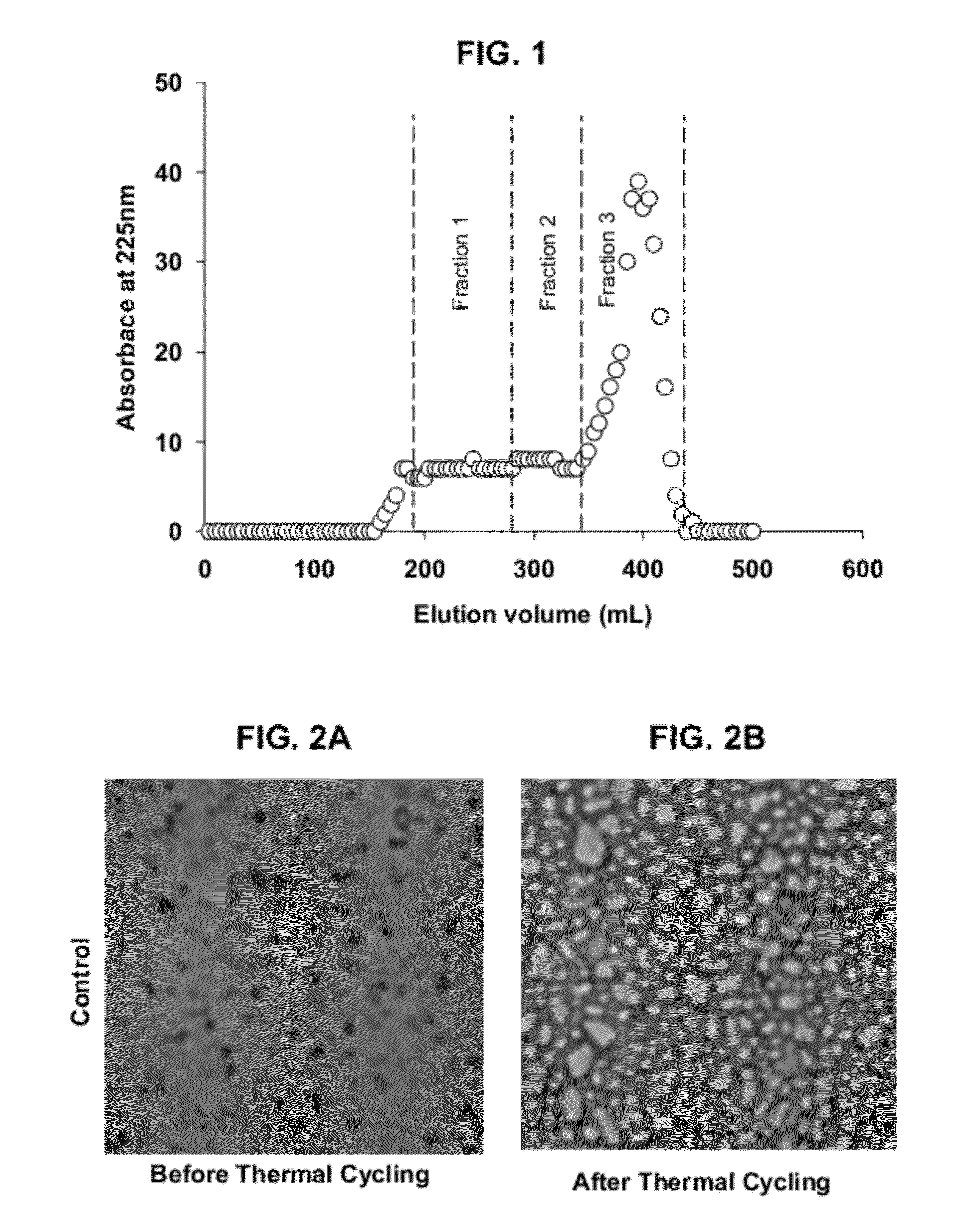

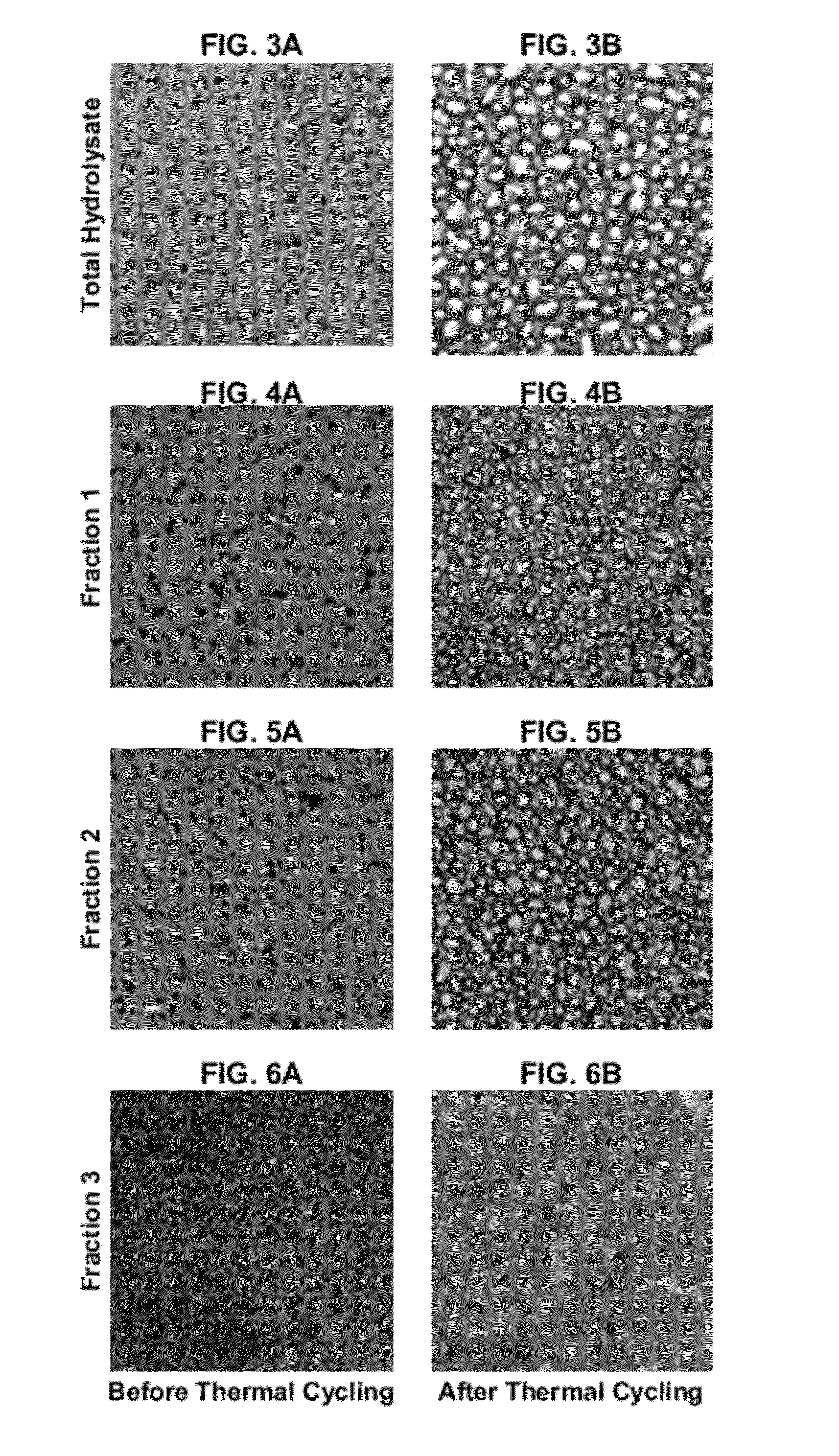

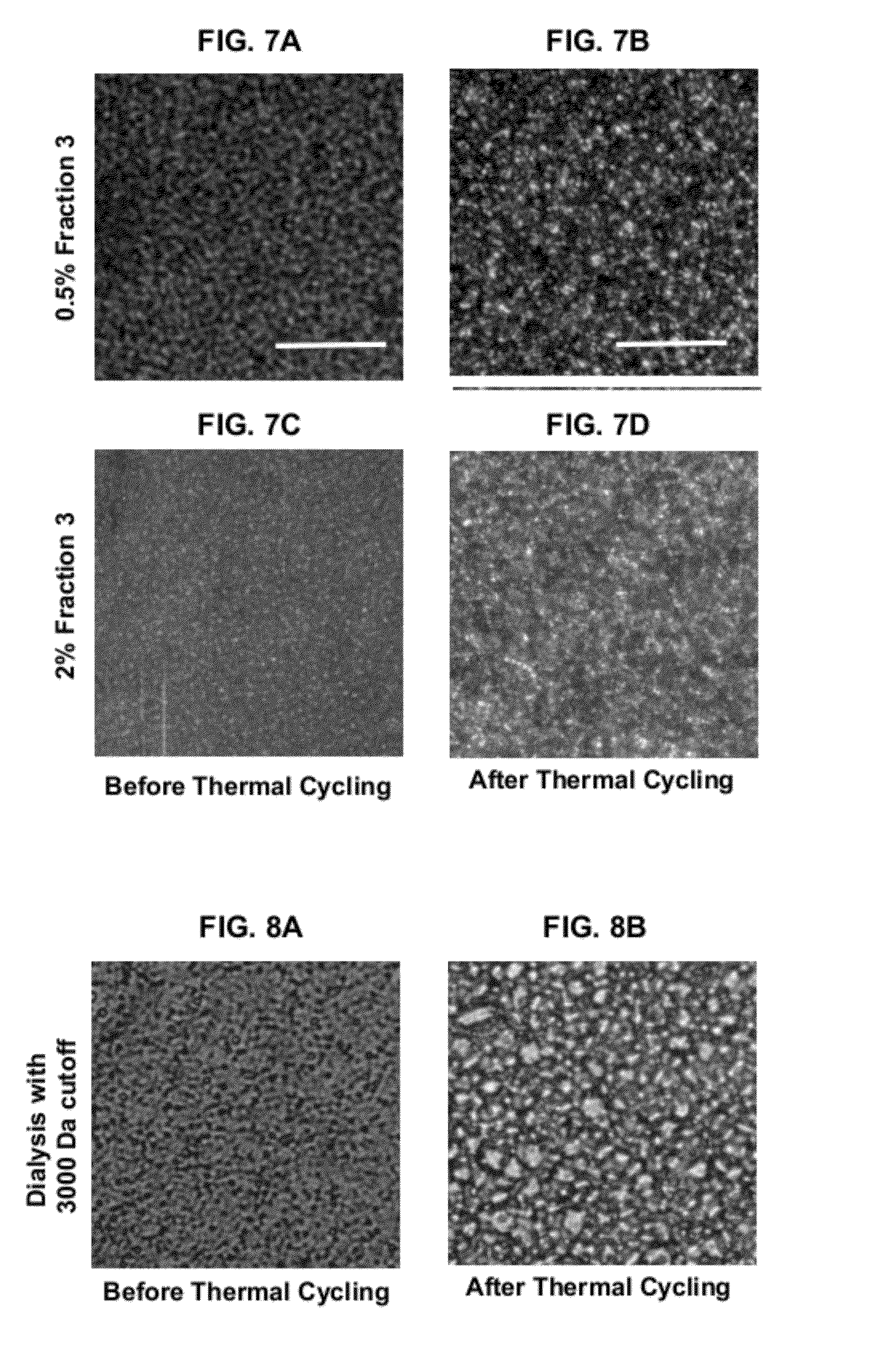

Inhibition of ice crystal growth

Antifreeze polypeptides, antifreeze compositions including the polypeptides, nucleotides encoding the antifreeze polypeptides, methods of making antifreeze compositions, and methods of inhibiting ice crystal growth are provided herein. The peptides are based on the primary sequence of collagen and include those having a molecular weight between about 500-7000 Da. The peptides preferably include cationic polypeptides. The methods of making antifreeze compositions include digesting collagen or gelatin into hydrolysates with peptides having molecular weights between about 500-7000 Da. The digestions are performed with proteases and / or non-enzymatic hydrolysis. The methods of inhibiting ice crystal growth include adding the antifreeze polypeptides or compositions described herein to a composition to be frozen. The methods may be used to inhibit ice crystal growth in frozen food products.

Owner:DAMODARAN SRINIVASAN

Antifreeze protein

InactiveCN102869673ACosmetic preparationsOther chemical processesAntiendomysial antibodiesPreservative

Provided is an antifreeze protein which is capable of being efficiently and inexpensively produced on an industrial level, is safe, and has excellent antifreeze activity for use on a practical level. Also provided are: a polypeptide that is the active segment of the antifreeze protein; a composition, food product, biological sample preservative and cosmetic comprising the antifreeze protein or polypeptide; and an antibody that specifically reacts with the antifreeze protein or polypeptide. The antifreeze protein is plant-derived and has a predetermined amino acid sequence, or is a plant seed protein.

Owner:KANEKA CORP

Cheese shrimp paste and processing method thereof

ActiveCN108497365ARich in nutrientsGreat tasteFood ingredient as anti-freezing agentFood ingredient as mouthfeel improving agentBiotechnologyWater Chestnuts

The invention discloses cheese shrimp paste. The cheese shrimp paste is prepared from the following raw materials in parts by mass: 50-80 parts of shrimp meat, 20-40 parts of fish meat, 5-10 parts ofhigh-melting point cheese, 2-5 parts of skimmed milk powder, 5-10 parts of water, 5-10 parts of frozen egg white, 1-2 parts of cassava flour, 1-2 parts of water chestnut starch, 0.5-1 part of soybeanmeal, 0.5-2 parts of corn starch, 0.5-2 parts of sweet potato starch, 0.5-1.5 parts of table salt, 0.5-1 part of soy sauce, 2-4 parts of sucrose, 1-2 parts of Shaoxing aged wine and 1-1.5 parts of chicken essence. A preparation method comprises the following steps: granulating live shrimps, granulating two kinds of sea fish, granulating the cheese, adding mixed starch and seasoning to the shrimp granules, fish meat granules and cheese granules according to certain parts by mass, performing uniform stirring and mixing, soaking the mixture in an anti-freezing agent for 3-10 seconds and taking out the mixture; and putting the mixture into plates, and performing freezing forming and packaging. The preparation method is simple and the prepared shrimp paste is smooth in taste, rich in nutrientsand easy to preserve.

Owner:WENZHOU VOCATIONAL COLLEGE OF SCI & TECH +1

Anti-freeze fresh-keeping agent for frozen aquatic products

InactiveCN107744011AExtended shelf lifeReduce usageFood ingredient as anti-freezing agentMeat/fish preservation by coatingPhosphateArabinoxylan

The invention relates to an anti-freeze fresh-keeping agent for frozen aquatic products and belongs to the technical field of aquatic product processing. The anti-freeze fresh-keeping agent includes,by weight, 3.5-5.5 parts of araboxylan, 2.0-4.0 parts of alginate-derived oligosaccharides, 2.5-6.0 parts of modified soya bean protein powder, 0.15-0.3 parts of agar powder, 0.25-0.4 parts of alkaline phosphate, and 83.8-91.6 parts of water. The anti-freeze fresh-keeping agent is healthy and safe, has good fresh-keeping effect, can effectively alleviate defreezing loss of the frozen aquatic products, and improves texture properties and sensory quality of the frozen aquatic products.

Owner:舟山正品科技有限公司

Extract frozen-dried powder of fruit and vegetable medicine-food-homologous food and preparation method of frozen-dried powder

InactiveCN105747236ARetain natural colorNatural bright colorFood ingredient as anti-freezing agentNatural extract food ingredientsBiotechnologyNutritive values

The invention discloses extract frozen-dried powder of fruit and vegetable medicine-food-homologous food.The fruit and vegetable medicine-food-homologous food serves as the raw material, the low temperature extraction technology is adopted for the whole process, and obtained extract maintains natural color, lustre, flavor and mouthfeel of the food raw material to the maximum extent; in the vacuum freeze-drying process of the extract, an antifreeze agent which is prepared from natural plant raw materials and has a remarkable antifreezing effect replaces traditional and existing cryoprotectant, freezing losses caused by the freeze-drying technology are further greatly reduced, biological activity of the extract frozen-dried powder is effectively improved, nutritive value of the extract frozen-dried powder is effectively raised, the extract frozen-dried powder is scientifically compounded with functional dietary fiber powder, health-care factors and lactobacillus plantarum powder, medicine-food nutrition balance, functionality, dissolvability and health care performance of the extract frozen-dried powder are remarkably enhanced, the shelf life of a product is prolonged, and the extract frozen-dried powder of the fruit and vegetable medicine-food-homologous food is finally obtained, wherein the food is high in nutrient substance content, biologically active substance content, great in function, good in antifreezing effect and dissolvability and low in cost.

Owner:北京市绿友食品有限公司

Preparation method for high-quality decapterus maruadsi frozen surimi

InactiveCN104256724ASolve the problem of freeze denaturationImprove qualityFood ingredient as anti-freezing agentFood ultrasonic treatmentPolydextroseAnimal science

The invention belongs to the technical field of aquatic product processing, in particular relates to a preparation method for high-quality decapterus maruadsi frozen surimi. The preparation method comprises steps of raw material pretreatment, meat collection, rinsing, dehydration, antifreeze treatment, subpackaging, quick freezing and freeze preservation. During the rinsing process, an ultrasonic treatment is applied to assist the rinsing process; during the antifreeze treatment, compound phosphates, sorbitol, and polydextrose which are respectively 0.3%-0.5%, 3%-5% and 3%-5% of the mass of the fish meat are added. The present invention solves the problems of poor color, poor elasticity of the frozen surimi prepared from decapterus maruadsi by applying ultrasonic to the rinsing of the surimi, solves the problems of freeze denaturation of the decapterus maruadsi meat by using antifreeze agents, and develops a high-quality decapterus maruadsi frozen surimi.

Owner:FUJIAN AGRI & FORESTRY UNIV

Anti-cracking method of quick-frozen sweet soup balls

InactiveCN105876769AMuscle strengtheningLess extractablesFood ingredient as anti-freezing agentOrganic compound food ingredientsQuick FreezeCarboxymethyl cellulose

The present invention provides an anti-cracking method of quick-frozen sweet soup balls. The anti-cracking method comprises the following steps: a sweet soup ball modifier at a weight of 1%-8% of glutinous rice flour is added into the glutinous rice flour, the mixture is mixed evenly, and the sweet soup ball modifier consists of the following raw materials in parts by mass: 1-2 parts of monoglycerides, 2-4 parts of trehalose, 2-4 parts of sodium carboxymethyl cellulose and 1-2 parts of sodium tripolyphosphate; the mixed well glutinous rice flour is prepared into glutinous rice balls; fillings and the glutinous rice balls are respectively added into a sweet soup ball machine to conduct filling wrapping to obtain the sweet soup balls; and the sweet soup balls are subjected to quick-freezing, the quick-frozen sweet soup balls are packaged, and the packaged sweet soup balls are put into a cold storage to conduct storage below -18 DEG C. The quick-frozen sweet soup balls prepared by the above provided method are prevented from cracks from naked eyes and do not crack.

Owner:HENAN HUANGGUO GRAIN COMPANY

Frozen confectionery product comprising ice structuring proteins

InactiveCN1889851AFrozen sweetsFood ingredient as anti-freezing agentProcess engineeringStructural protein

A frozen confectionery product is provided comprising a plurality of discrete unaerated dairy frozen confections, each discrete frozen confection being able to contact directly other discrete frozen confections in the product, which frozen confections comprise an ice structuring protein (ISP) and have an average volume of less than 1 ml.

Owner:UNILEVER NV

Method for preventing instant frozen glue pudding from cracking

InactiveCN105852052AAvoid crackingTight and soft tissueFood ingredient as anti-freezing agentRice flourSodium carboxymethylcellulose

The invention provides a method for preventing instant frozen glue pudding from cracking. The method includes the following steps that a glue pudding modifying agent accounting for 1-8% of the weight of sweet rice flour is added into the sweet rice flour and mixed uniformly, wherein the glue pudding modifying agent is prepared from, by mass, 1-2 parts of monoglyceride, 3-6 parts of trehalose and 2-4 parts of sodium carboxymethylcellulose; the mixed sweet rice flour is manufactured into sweet rice flour dough; stuffing and the sweet rice flour dough are put into a glue pudding machine to wrap the stuffing so as to obtain the glue pudding; the glue pudding is instantly frozen, packaged and put into a refrigeration storage with the temperature below minus 18 DEG C to be stored. People can see cracks in the instant frozen glue pudding manufactured through the method, and the instant frozen glue pudding will not crack.

Owner:HENAN HUANGGUO GRAIN COMPANY

Method for the conservation of a plant material

ActiveUS20100227030A1Pleasant tastePleasant textureMilk preparationDough treatmentRest periodCryoprotective Agent

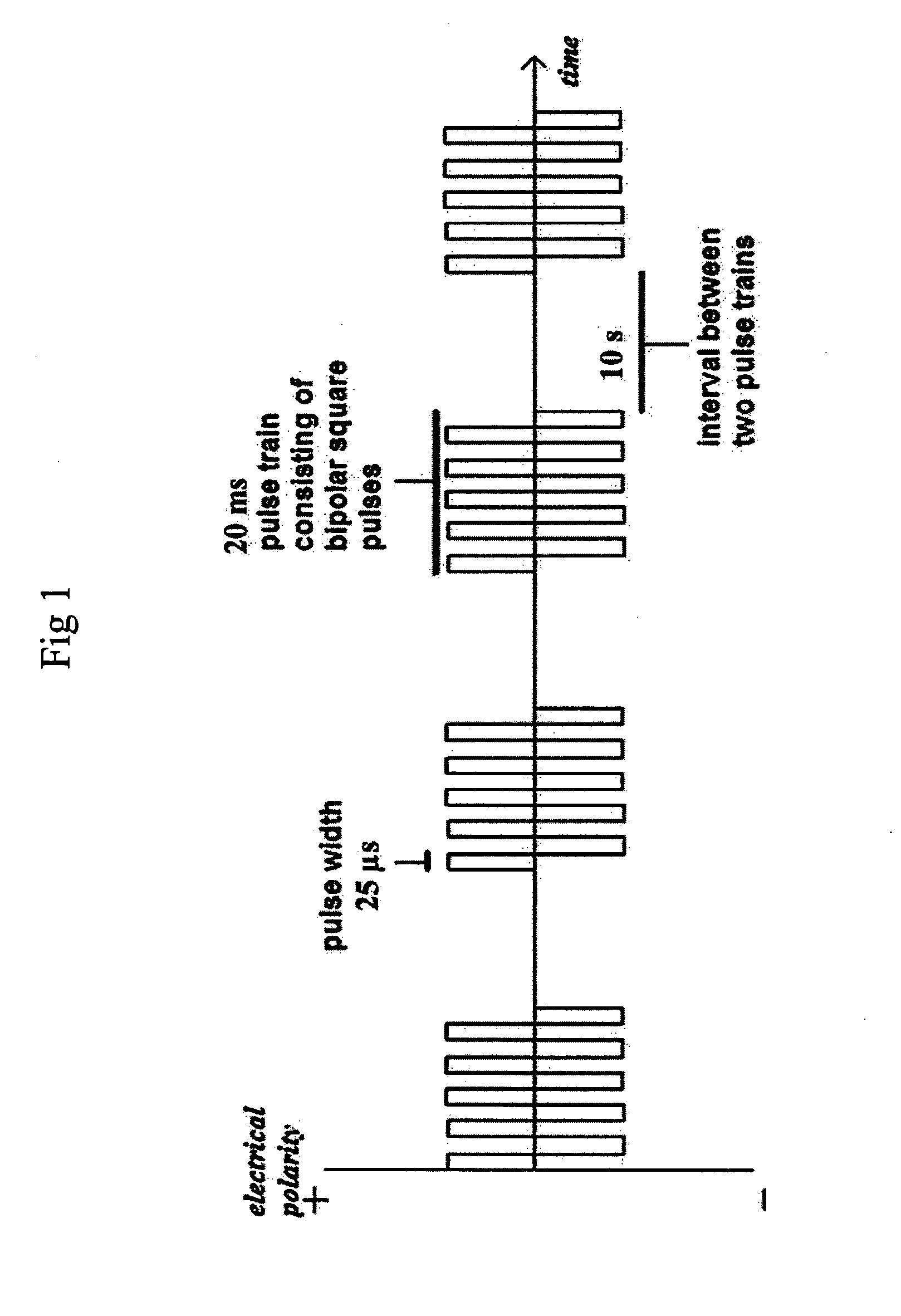

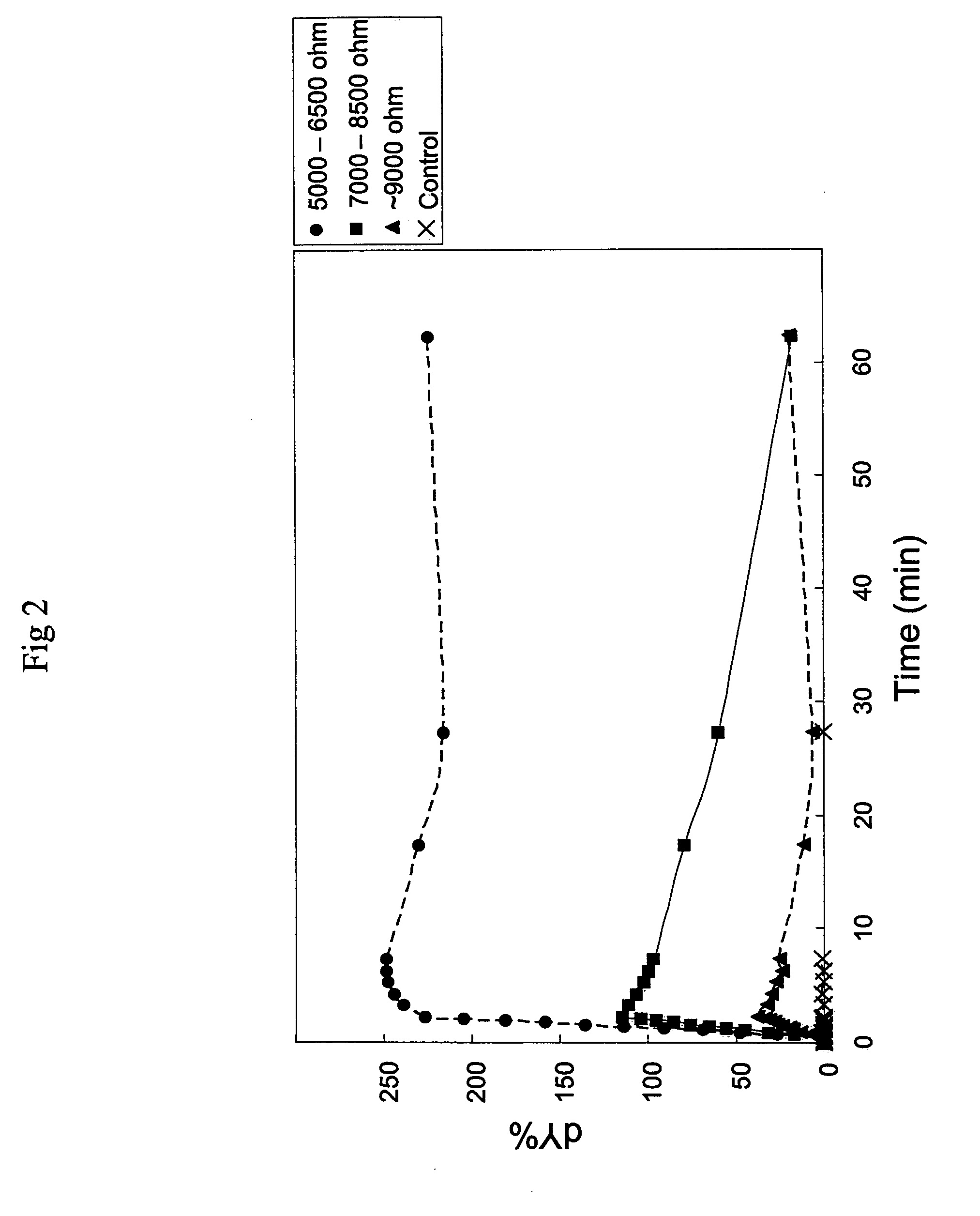

The invention relates to a plant food material comprising at least one cryoprotective agent present in the intracellular space of the cells of said plant. The invention also relates to a freezing method for a plant food product comprising the steps of; providing a plant food material comprising at least 70% water, applying a pulsed electrical field to said plant food material, adding a cryoprotective agent to said plant food material, applying a pressure to said plant food material followed by, a resting period of at least 30 minutes and freezing said plant food material. Thereby it is for the first time possible to conserve a plant food material and maintaining the texture as well as the taste of the plant food material

Owner:DEJMEK PETR +3

Health and safe preservation technology of tomatoes

ActiveCN108651613AEasy to operateExtend freshnessFruits/vegetable preservation by irradiation/electric treatmentFood thermal treatmentPre treatmentRefrigeration

The present invention discloses a health and safe preservation technology of tomatoes. The health and safe preservation technology comprises the following steps: I, pretreatment; II, pre-cooling; III,preservation treatment; IV, sterilization; and V, refrigeration. The health and safe preservation technology of the tomatoes is simple in process steps, environmentally protective and safe, can effectively reduce the nutrient loss of the tomatoes, delays occurrence of cold damage symptoms of the post-harvested tomato fruits, inhibits the decay and deterioration of the tomato fruits, and prolongsthe shelf life of the tomatoes.

Owner:海南农佳佳科技发展有限公司

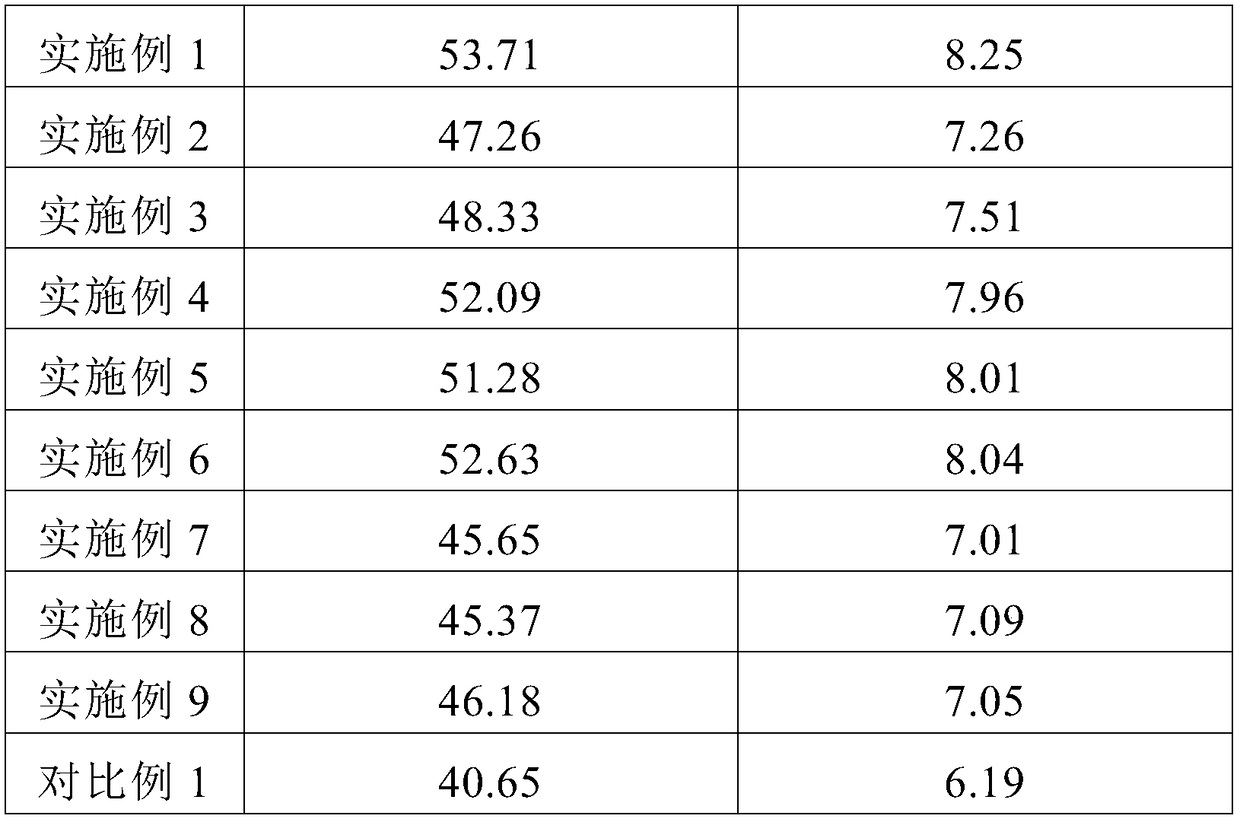

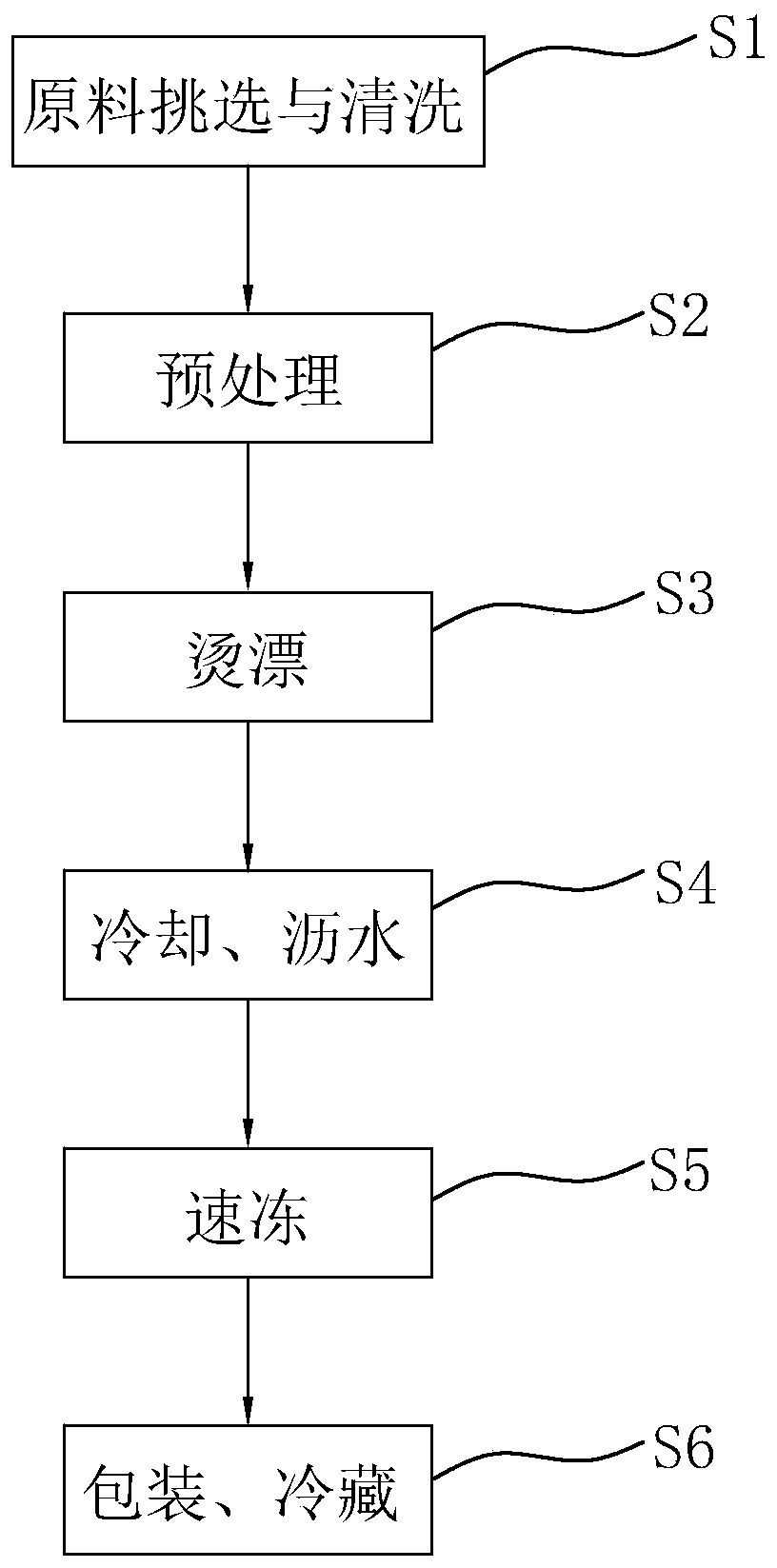

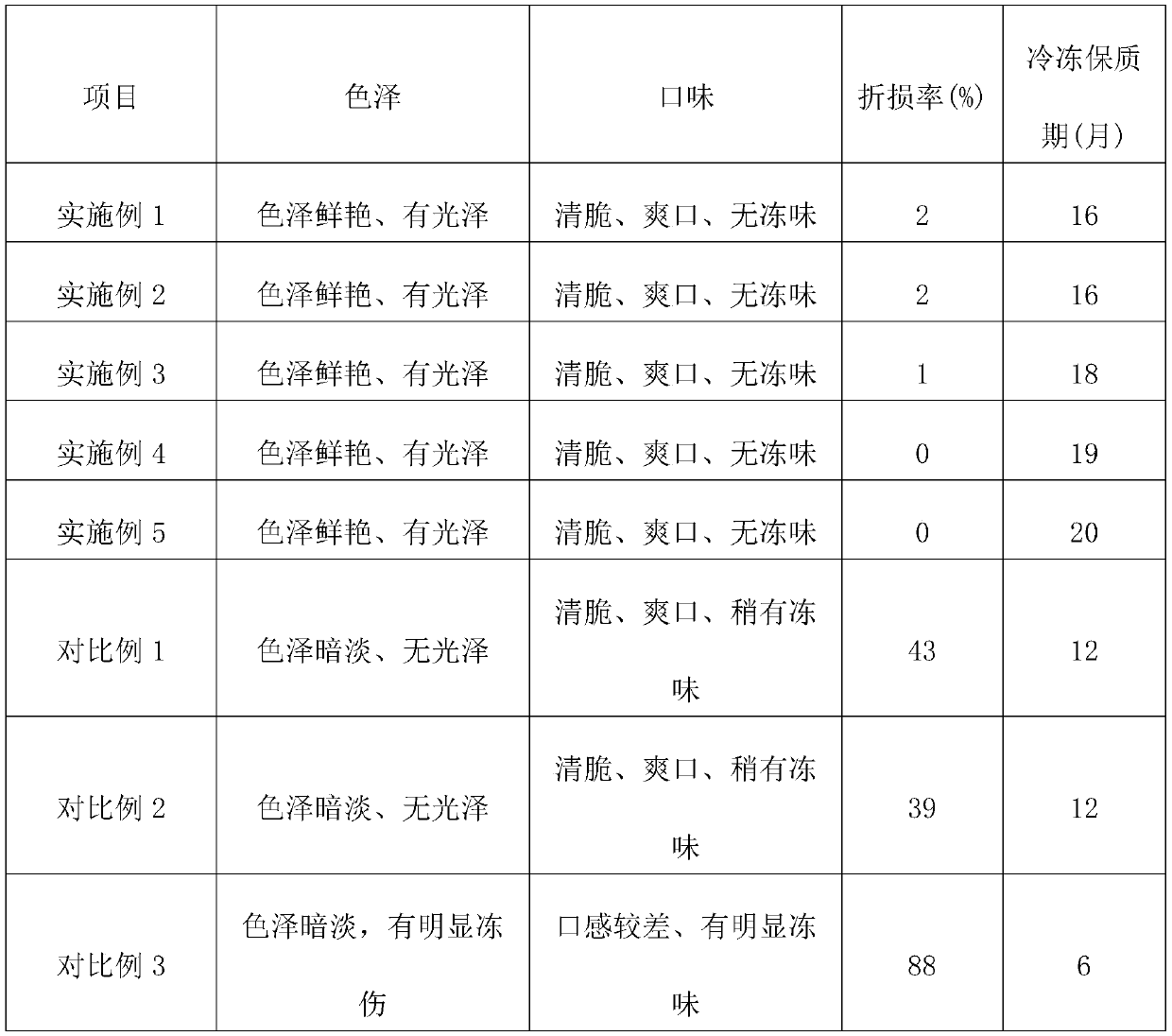

Processing technology of quick-frozen Chinese cabbages

PendingCN111011472ABright colorReduce frost damage rateFruits/vegetable preservation by heatingFood ingredient as anti-freezing agentBiotechnologyCellulose

The invention discloses a processing technology of quick-frozen Chinese cabbages, which relates to the technical field of vegetable processing. The processing method comprises the following operationsteps: S1, selecting and cleaning raw materials; S2, performing pretreatment; S3, performing blanching; S4, cooling and draining; S5, quick freezing; and S6, packaging and refrigerating. Wherein in the step 2, an anti-freezing agent used for pretreatment is prepared from the following components in parts by weight: 2.5 to 10 parts of modified starch; 0.01 to 0.1 part of sodium lactate; 0.01 to 0.1part of sodium sorbate; 0.1 to 0.2 part of hydroxymethyl cellulose; 0.1 to 0.5 part of chitosan; 0.2 to 0.5 part of tea polyphenol; and 0.2 to 0.5 part of an orange peel extract. The Chinese cabbagesare pretreated and blanched before quick freezing, so that the unfrozen Chinese cabbages are free of frozen taste and bright in color and luster.

Owner:余姚市鸿基食品有限公司

Processing method of squid skewer

InactiveCN107259423AReduce degradationReduce oxidationFood ingredient as anti-freezing agentFood ingredient as humectantDigestionFish Proteins

In order to improve the utilization rate of squid resources, effectively extends squid deep processing, and enhance the economic value added of products, the invention relates to a processing method of a squid skewer. The method is characterized by adding whey protein, calcium chloride and modified starch to improve the surimi gel strength and water holding capacity. Papain is inoculated for enzymolysis of fish protein to reduce the fishy smell and bitterness. And small peptides with bioactivity are generated to promote human body digestion and absorption.

Owner:必斐艾食品有限公司

Bactericide composition

ActiveCN105454273AImprove securityReduce dosageBiocideFood ingredient as thickening agentMicroorganismPyrazine

The invention relates to a bactericide composition which is used for keeping fruits and vegetables fresh after harvest and used for preventing and treating microorganism diseases. The bactericide composition is prepared from prochloraz A and effective component B which have the synergistic effect. The effective component B is one or more of n-heptyl methyl ketone, 2-methyl pyrazine and methyl octyl ketone, the mass ratio of A to B is 10:(0.5-5), and the effective component A and B account for 10-52.5% of the mass of the composition. By means of the bactericide composition, the bactericide effect is remarkably improved, the consumption of chemical preservatives is lowered, the environment pollution and bactericide residual are reduced, and safety is higher.

Owner:SHANDONG XIANZHIYUAN BIOTECH CO LTD

Production process of fine-point round-toe crab meat recombined product

ActiveCN110050967AImprove qualityHigh economic valueFood ingredient as antioxidantFood ingredient as thickening agentFlavorOperability

The invention discloses a production process of a fine-point round-toe crab meat recombinant product. The production process comprises the following steps: (1) collecting meat; (2) protecting color; (3) executing coarse rolling; (4) executing salt rolling and ultrasonic treatment; (5) executing seasoning and grinding; (6) executing gelling; (7) executing cooking; (8) executing packaging and refrigeration. The fine-point round crab meat recombinant product production process is developed and designed by taking fine-point round crabs as a main raw material and is simple in process steps, strongin operability, low in equipment requirement and suitable for industrial production, the produced fine-point round-toe crab meat recombinant product is compact and uniform in structure, rich in elasticity, good in flavor and taste and good in product quality, provides a feasible new way for deep processing of the fine-point round toe crabs, and is beneficial to improvement of the economic value ofthe fine-point round toe crabs.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Preparation method of passion fruit peel fermented freeze-dried enzyme powder containing high active probiotics

InactiveCN108450942AAvoid damageStrong prebiotic effectFood freezingYeast food ingredientsFreeze-dryingPassion fruit

The present invention discloses a preparation method of passion fruit peel fermented freeze-dried enzyme powder containing high active probiotics. Firstly, passion fruit peels are beaten; blending, grinding and sterilizing are conducted; yeasts and lactic acid bacteria are sequentially added for fermentation; then the obtained passion fruit peel pulp fermentation liquid is used as a main raw material; trehalose and maltodextrin are supplemented; and the freeze-dried enzyme powder is prepared using a freeze-drying method. The method uses the passion fruit peels as the main material; the "two-step fermentation" technology of first yeast fermentation and then lactic acid bacterium fermentation is used; functions of the trehalose and maltodextrin are used; the vacuum freeze-drying method is combined; and the fermentation of the microorganisms is fully utilized, so that the prepared freeze-dried enzyme powder is unique in aroma, has high probiotic activity, is rich in lactic acid, antioxidant components and other beneficial components, provides a basis for solving the problems that the existing passion fruit peels are low in utilization rate, not high in application value, etc., and have very good application prospects.

Owner:SOUTH CHINA AGRI UNIV

Production method of frozen skinless shrimp

ActiveCN106615039AImprove frost resistanceKeep freshFood ingredient as anti-freezing agentMeat/fish preservation by freezing/coolingFlavorAquatic product

The invention provides a production method of a frozen skinless shrimp. The method comprises the following steps of (S1) pretreatment of the shrimp, namely removing the head of the shrimp, carrying out first cleaning, carrying out shelling and enteraden removal treatment, carrying out second cleaning and draining to obtain the skinless shrimp; (S2) infiltration of the skinless shrimp, namely infiltrating the skinless shrimp in a water solution of an antifreeze agent for 1-2 hours, wherein the antifreeze agent comprises the following components in parts by weight: 2-8 parts of konjac powder, 1-4 parts of sodium polyacrylate, 0.5-2 parts of mannitol and 1-5 parts of sodium chloride; and (S3) freezing of the skinless shrimp, namely quickly cleaning, draining and pre-freezing the infiltrated skinless shrimp and then quickly freezing the skinless shrimp to obtain the frozen skinless shrimp. The production method belongs to the technical field of aquatic product processing. According to the production method provided by the invention, the storage performance of the frozen skinless shrimp can be significantly improved, the loss of nutrient and flavor substances in the freezing and storage processes is reduced and the freshness of the frozen skinless shrimp is relatively well kept.

Owner:广东环球水产食品有限公司

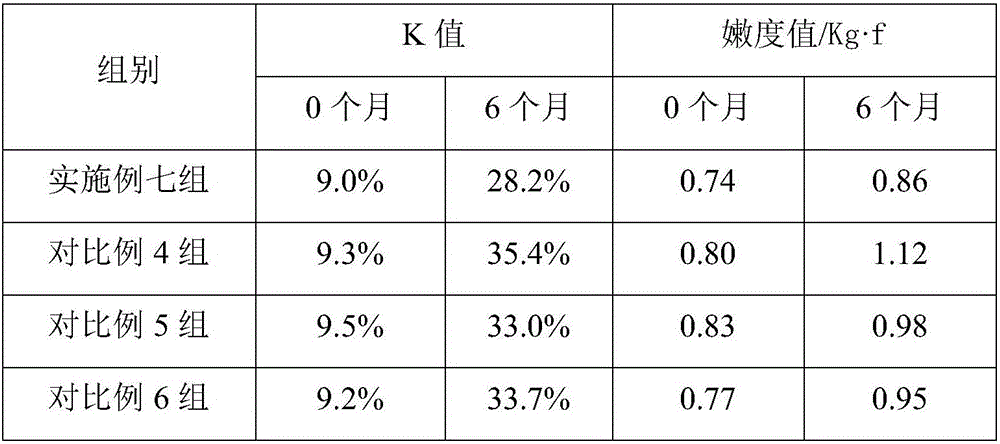

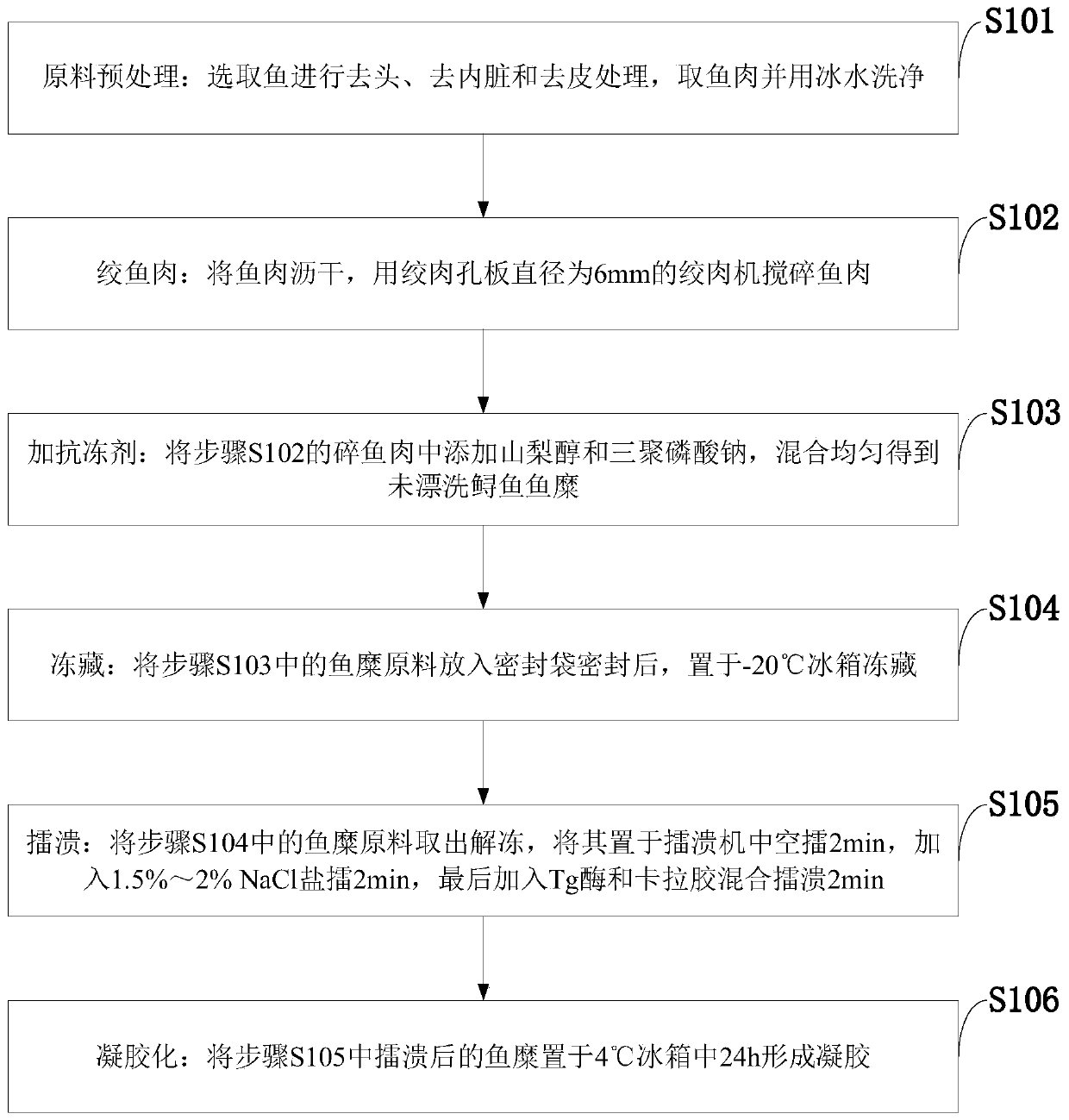

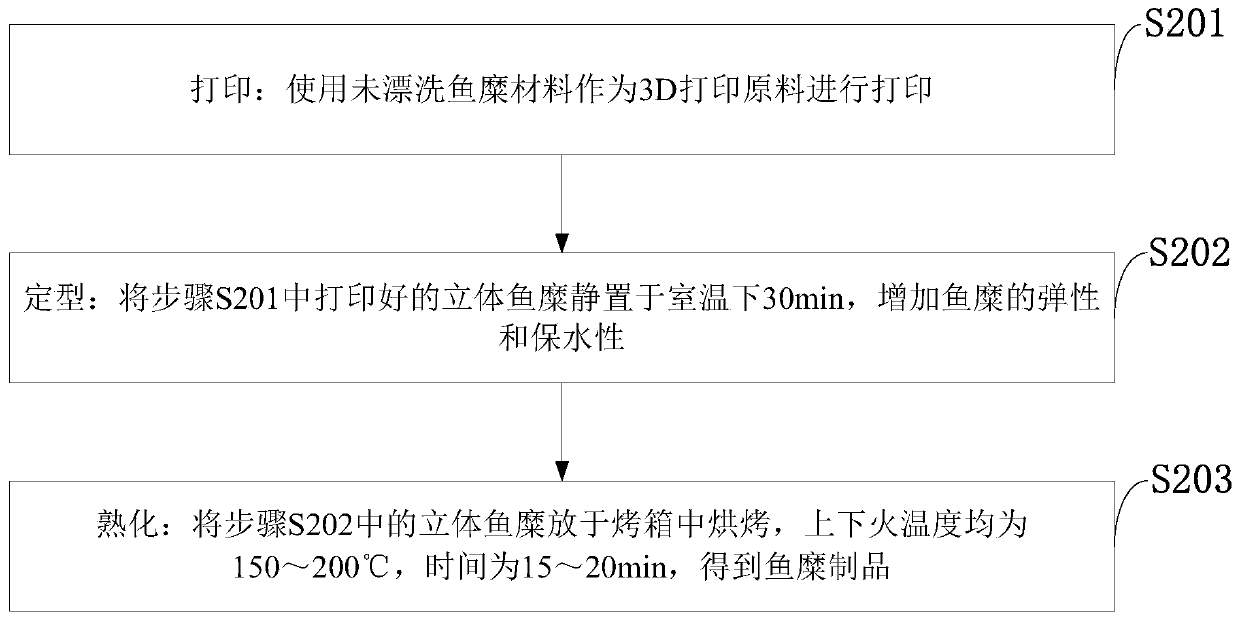

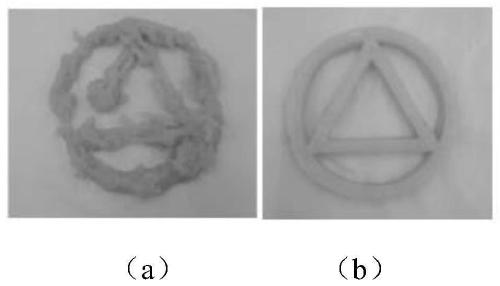

Preparation method of non-washed surimi material suitable for 3D printing and application of preparation method

PendingCN111357950AEasy to manufactureGuaranteed gel strengthAdditive manufacturing apparatusFood ingredient as anti-freezing agentCarrageenanIce water

The invention belongs to the technical field of 3D printing, and discloses a preparation method of a non-washed surimi material suitable for 3D printing and application of the preparation method. Thepreparation method comprises the steps: taking fish, washing the fish with ice water, draining the fish, grinding the fish with a meat grinder, adding sorbitol and sodium tripolyphosphate to the ground fish, performing mixing so as to obtain non-washed surimi, putting the surimi raw material into a sealing bag, performing sealing, putting the sealing bag in a refrigerator, performing frozen storage, taking the surimi raw material out, performing thawing, putting the thawed surimi in a blending machine, performing empty blending, adding NaCl, performing salt blending, adding a Tg enzyme and carrageenan, performing mixing and blending, and putting the blended surimi in the refrigerator so as to form gel. A production process of surimi is simplified, rinsing and other steps are eliminated, time and effort are saved, waste of resources and loss of nutrients are reduced, the production cycle is shortened, and the cost is saved greatly; and on the basis of the non-washed surimi, the Tg enzyme and carrageenan are added, so that the jelly strength and whiteness of the surimi are ensured.

Owner:OCEAN UNIV OF CHINA

Method for treating preserved goose eggs

InactiveCN107183147AAvoid breakingAvoid destructionEggs preservation by coatingEggs preservation by irradiation/electric treatmentUltraviolet lightsZoology

The invention provides a method for treating preserved goose eggs. The method comprises the following steps: 1) cleaning goose eggs just laid by geese with light salt brine, and drying; 2) performing primary sterilization on the dried goose eggs in ultraviolet light; 3) soaking the sterilized goose eggs in a sterilizing solution for performing secondary sterilization; 4) drying the goose eggs subjected to secondary sterilization, and coating an antifreeze agent layer on the surface of the dried goose eggs; 5) coating the coated goose eggs with plant ash, and airing; 6) spraying a peelable liquid protective film layer on the outer surface of the coated goose eggs. According to the method disclosed by the invention, the sterilization is safe and environmentally friendly, and the sterilization efficiency is improved due to the secondary sterilization. Meanwhile, a protective layer can be formed on the goose eggs, and after the antifreeze agent is unfrozen, damage of inner surface and internal cells of the goose eggs can be avoided.

Owner:SHOUXIAN TIANGE GOOSE DEV CO LTD

Inhibition of ice crystal growth

Antifreeze polypeptides, antifreeze compositions including the polypeptides, nucleotides encoding the antifreeze polypeptides, methods of making antifreeze compositions, and methods of inhibiting ice crystal growth are provided herein. The peptides are based on the primary sequence of collagen and include those having a molecular weight between about 500-7000 Da. The peptides preferably include cationic polypeptides. The methods of making antifreeze compositions include digesting collagen or gelatin into hydrolysates with peptides having molecular weights between about 500-7000 Da. The digestions are performed with proteases and / or non-enzymatic hydrolysis. The methods of inhibiting ice crystal growth include adding the antifreeze polypeptides or compositions described herein to a composition to be frozen. The methods may be used to inhibit ice crystal growth in frozen food products.

Owner:DAMODARAN SRINIVASAN

Sleeve-fish freeze-drying method

InactiveCN107361119AProtect umamiKeep the lookFood ingredient as anti-freezing agentMeat/fish preservation using chemicalsQuick FreezePropolis

The invention discloses a sleeve-fish freeze-drying method, which includes steps of (1), flushing a sleeve-fish by clean water, and then putting in a spot to cook; slicing and draining the sleeve-fish after cooking thoroughly to obtain sleeve-fish blocks; (3), placing the sleeve-fish blocks in step (2) in antifreeze agent solution to soak for 30-45 minutes, wherein the temperature of the antifreeze agent solution is 2-5 DEG C, and the antifreeze agent is prepared from, by weight, 3-6 parts of Konjac powder, 2-5 parts of lactitol, 5-9 parts of glycerinum, 1-3 parts of chitosan, 3-8 parts of glycine, 3-5 parts of sodium alga acid, 1-5 parts of sodium citrate, 3-6 parts of propolis, and 2-4 parts of tea polyphenol; (4) placing the sleeve-fish after the treatment of antifreeze agent in a quick-freeze library at -30 to -35 DEF C to quickly freeze and pretreat; (5) performing vacuum freezing and drying under the condition of 30 to 33 Pa and -36 to -40 DEG C; finally, filling in a moistureproof bag. The sleeve-fish freeze-drying method can effectively reduce the nutrition loss of the sleeve-fish while well protect the freshness of water products.

Owner:程翀宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com