Anti-cracking method of quick-frozen sweet soup balls

A quick-frozen glutinous rice balls and anti-cracking technology, which is applied in the fields of food ingredients as antifreeze, food ingredients containing organic compounds, food science, etc., can solve the problems of water retention capacity reduction, glutinous rice balls cracking, water loss and other problems, and improve the freezing cracking rate and increase Viscosity, gluten strength, low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

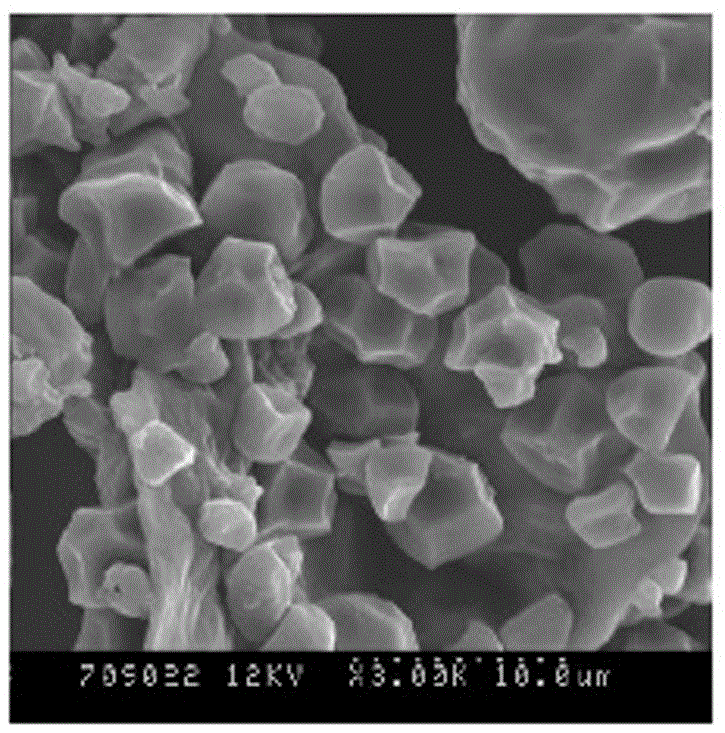

Image

Examples

Embodiment 1

[0022] Embodiment 1 of the present invention provides a kind of anti-cracking method of quick-frozen glutinous rice balls, comprising the following steps:

[0023] Step 1. Add glutinous rice flour 1% by weight of glutinous rice ball improving agent and mix evenly. The glutinous rice ball improving agent is composed of the following raw materials in parts by mass: 2 parts of monoglyceride, 4 parts of trehalose, sodium carboxymethyl cellulose 2 parts and 2 parts of sodium tripolyphosphate;

[0024] Step 2, making the mixed glutinous rice flour into glutinous rice dough;

[0025] Step 3, adding the stuffing and glutinous rice dough into the glutinous rice ball machine to make stuffing, and get glutinous rice balls;

[0026] Step 4. Quickly freeze the center temperature of the glutinous rice balls to -5°C within 30 minutes; then pack them and store them in a cold storage below -18°C. No cracks can be seen on the glutinous rice balls with the naked eye, and the glutinous rice ball...

Embodiment 2

[0029] Embodiment 2 of the present invention provides a kind of anti-cracking method of quick-frozen glutinous rice balls, and the difference between this embodiment and embodiment 1 mainly lies in:

[0030] Step 1. Add 3% by weight of glutinous rice ball improving agent to the glutinous rice flour and mix evenly. The glutinous rice ball improving agent is composed of the following raw materials in parts by mass: 2 parts of monoglyceride, 3.5 parts of trehalose, sodium carboxymethyl cellulose 4 parts and 1.8 parts of sodium tripolyphosphate;

[0031] Step 4. Quickly freeze the glutinous rice balls at the center temperature of the glutinous rice balls to -1°C within 30 minutes; then pack them and store them in a cold storage below -18°C. No cracks can be seen on the glutinous rice balls with the naked eye, and the glutinous rice balls will not crack.

[0032] Step 2 and Step 3 of this embodiment are basically the same as Step 2 and Step 3 in Embodiment 1.

Embodiment 3

[0034] Embodiment 3 of the present invention provides a kind of anti-cracking method of quick-frozen glutinous rice balls, and the difference between this embodiment and embodiment 1 mainly lies in:

[0035] Step 1. Add 4% of its weight glutinous rice ball improver to the glutinous rice flour and mix evenly. The glutinous rice ball improver is composed of the following raw materials in parts by mass: 1.5 parts of monoglyceride, 3 parts of trehalose, sodium carboxymethyl cellulose 3 parts and 1.5 parts of sodium tripolyphosphate;

[0036] Step 4. Quickly freeze the center temperature of the glutinous rice balls to -3°C within 30 minutes; then pack them and store them in a cold storage below -18°C. No cracks can be seen on the glutinous rice balls with the naked eye, and the glutinous rice balls will not crack.

[0037] Step 2 and Step 3 of this embodiment are basically the same as Step 2 and Step 3 in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com