Patents

Literature

30results about How to "Less extractables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

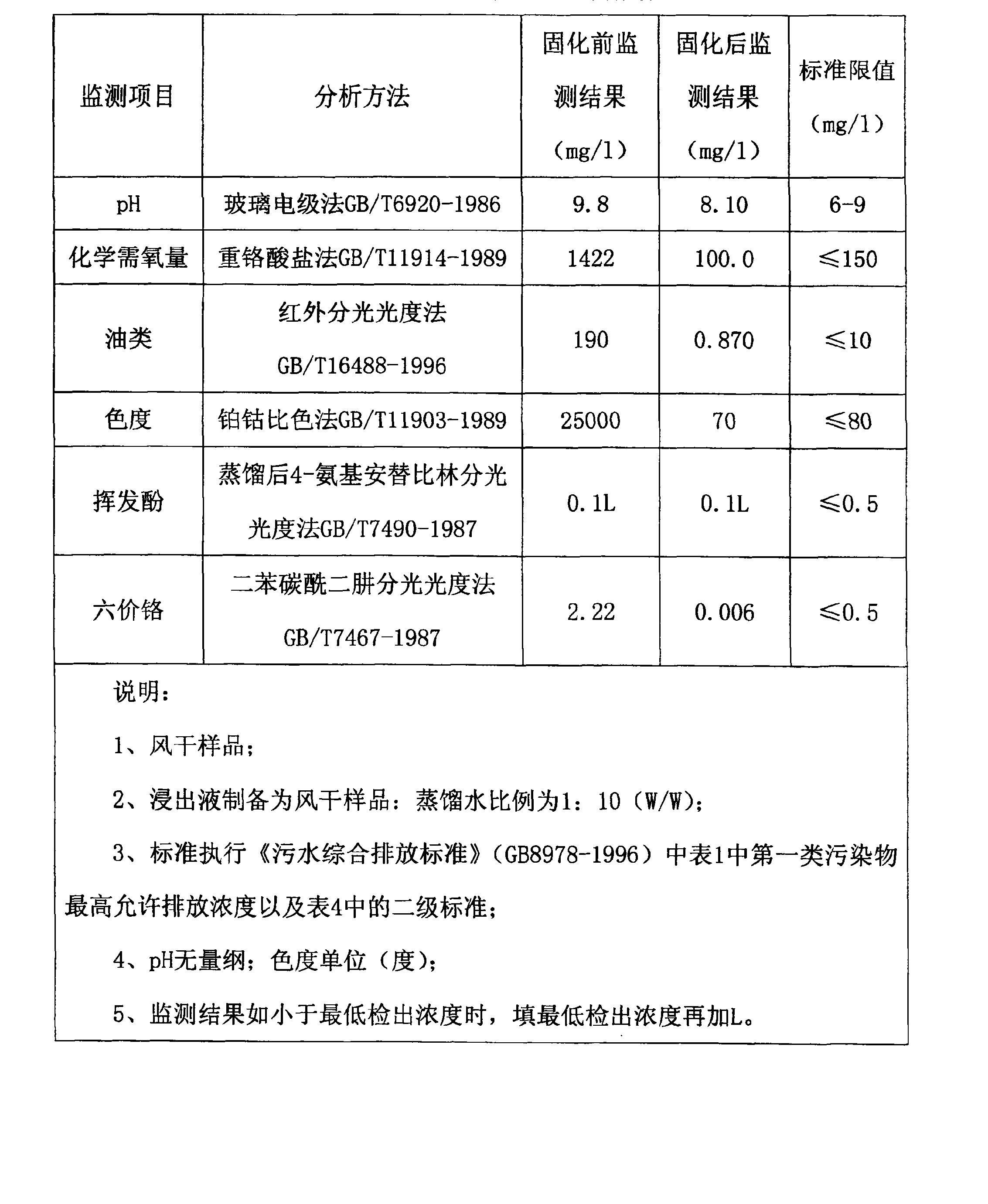

Solidified agent for drilling well waste mud

InactiveCN1792898APrevent seepageHigh strengthSludge treatment by de-watering/drying/thickeningSludgeWell drilling

Owner:刘茂平

Biological pulp and paper making wastewater zero discharge technique

InactiveCN101824766ALess extractablesReduce COD contentPulp liquor regenerationSludge treatment by de-watering/drying/thickeningFiberBlack liquor

The invention relates to a biological pulp and paper making wastewater zero discharge technique, which belongs to the technical field of paper making. The invention mainly improves the procedures of cooking and middle section water treatment. The cooking procedure adjusts the cooking technique, reduces the cooking pressure and shortens the cooking time, thereby effectively reducing the pulp extract and reducing the COD content in middle section water; and the middle section water treatment procedure modifies the rotary mixing type aerator in the bioaeration pool into a suspension-type aeration chain device, thereby enhancing the oxygen conversion efficiency by 5-10%, increasing the dissolved oxygen content in wastewater and enhancing the organic matter removal rate in wastewater on the premise of not increasing the power. The invention breaks through the normal procedure for the middle section water treatment, and treats the middle section water twice, so that all the treated water can be recycled. The invention realizes cyclic utilization of black liquor and zero discharge of middle section water, solves the problem of large amount of clear water of the paper machine, saves the water resources, reduces the environmental pollution and provides successful experience for non-xylogen paper making.

Owner:HUIXIN BIOLOGICAL PULP PAPER

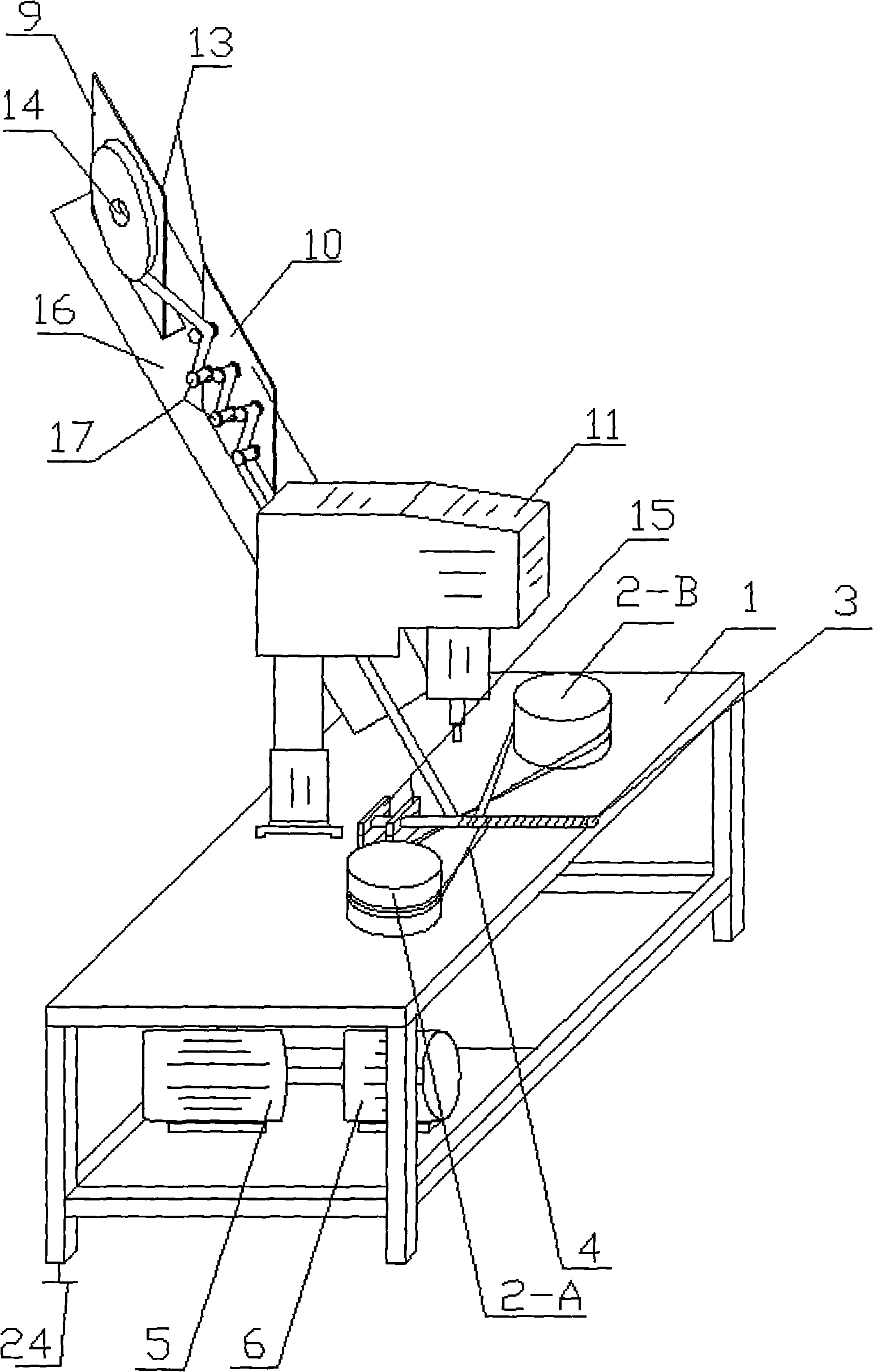

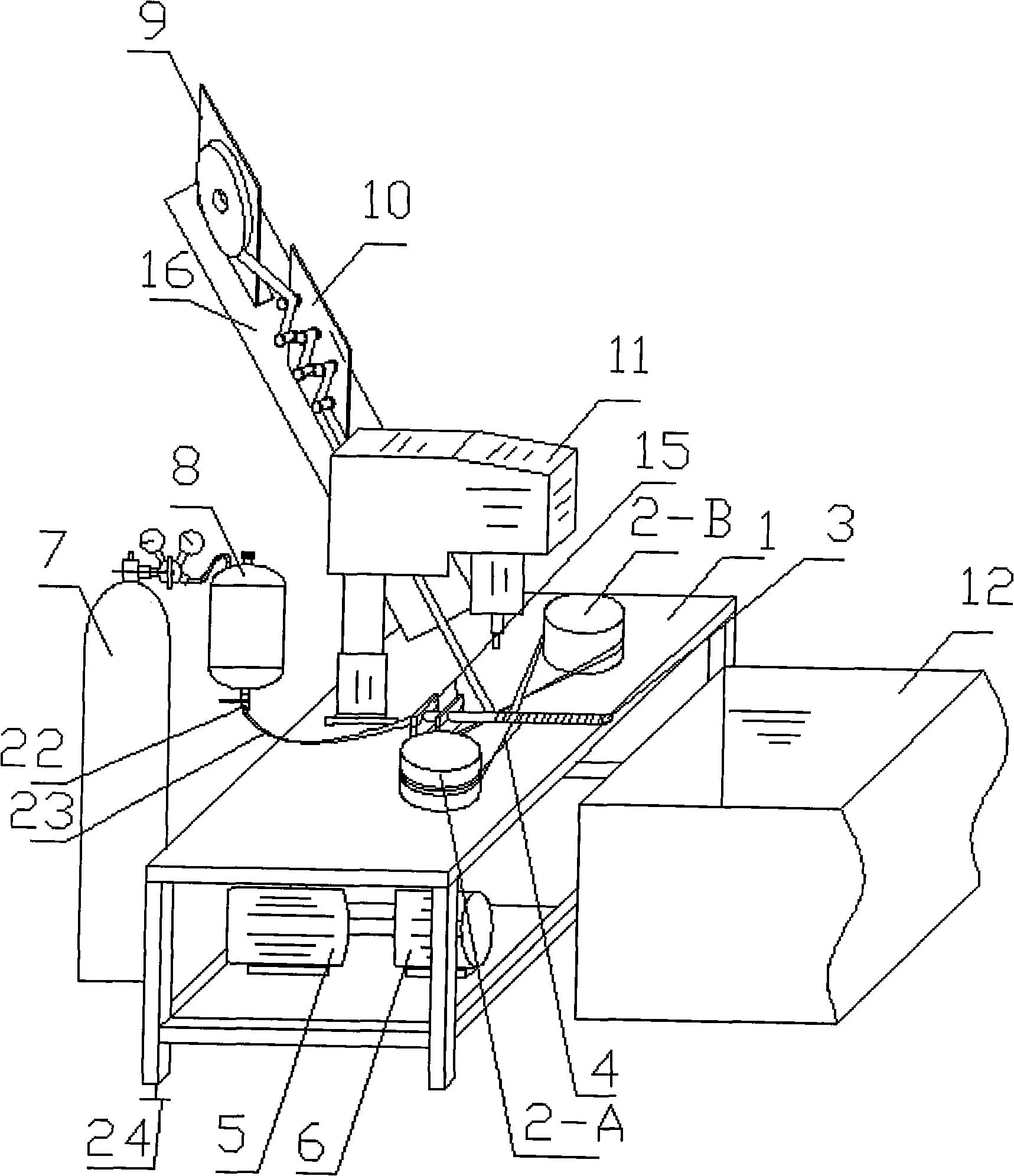

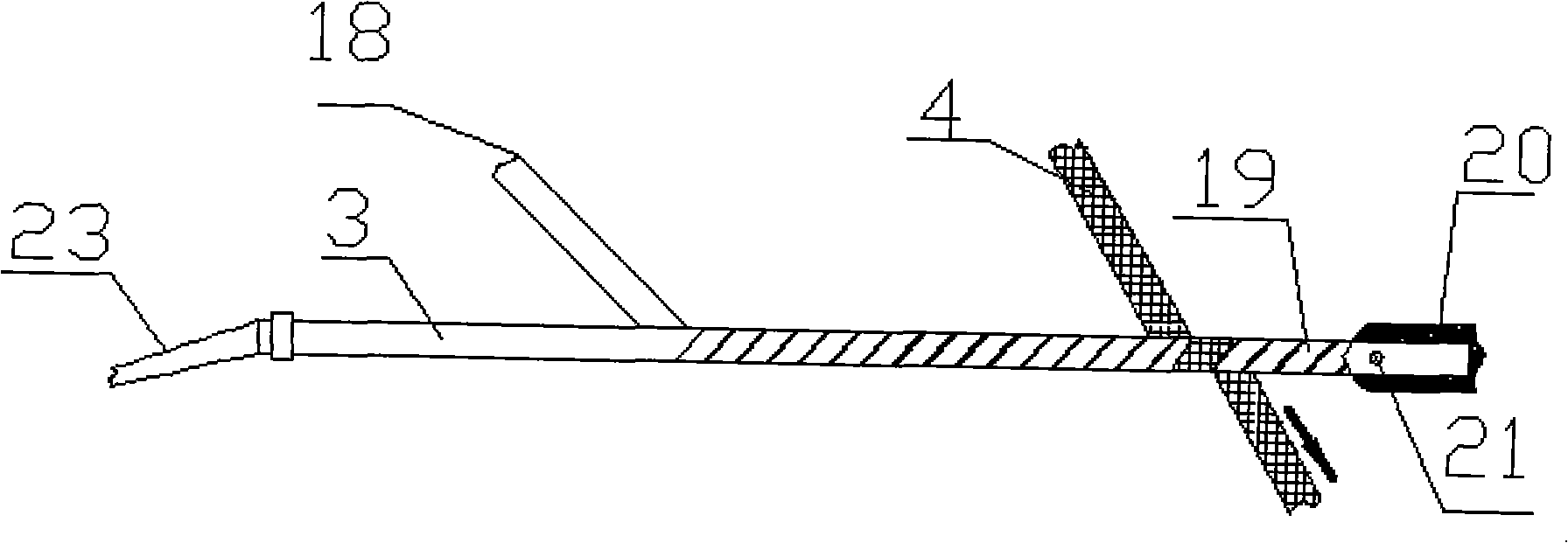

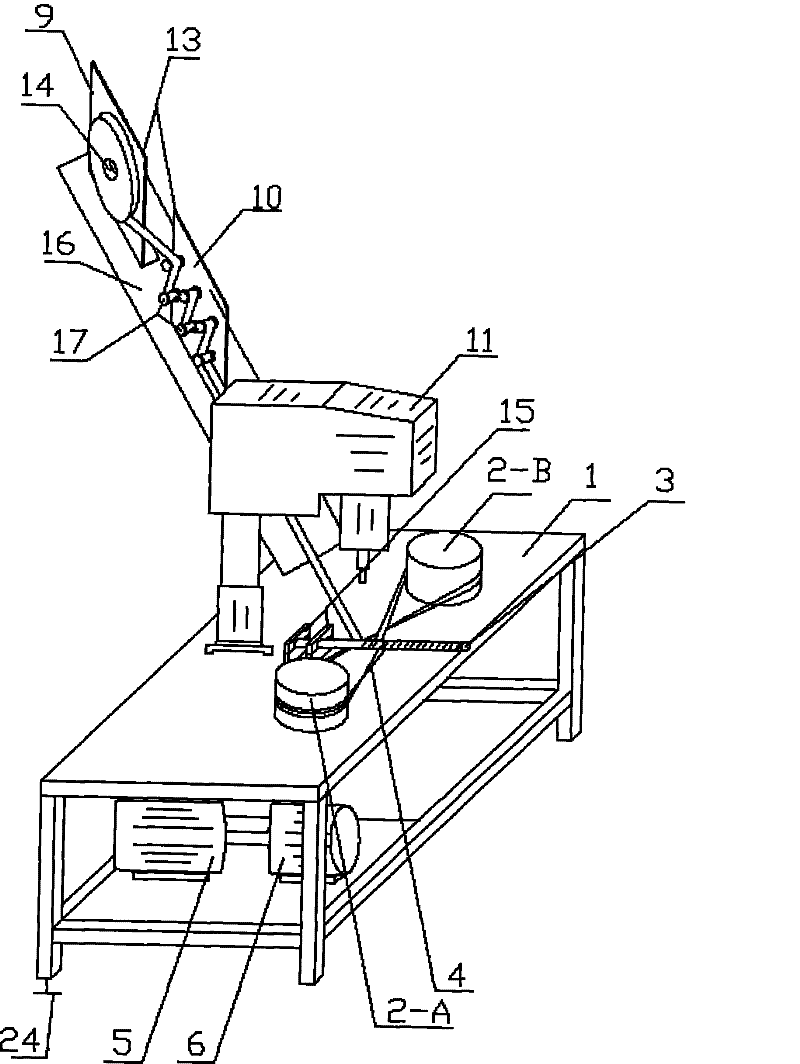

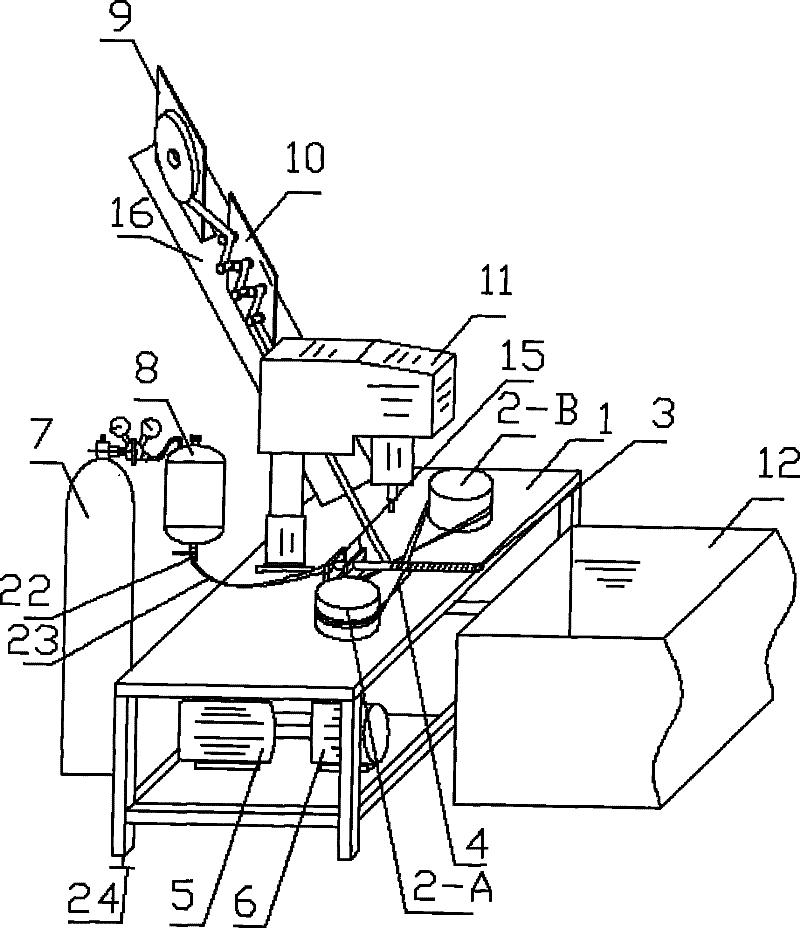

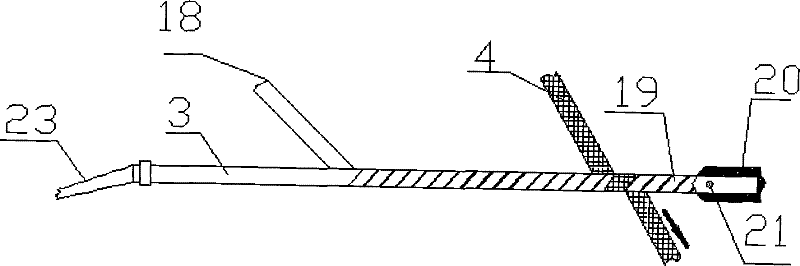

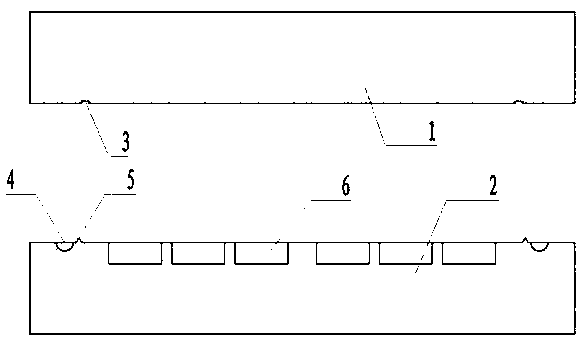

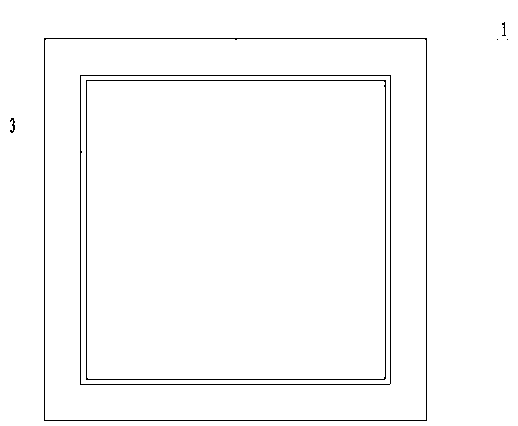

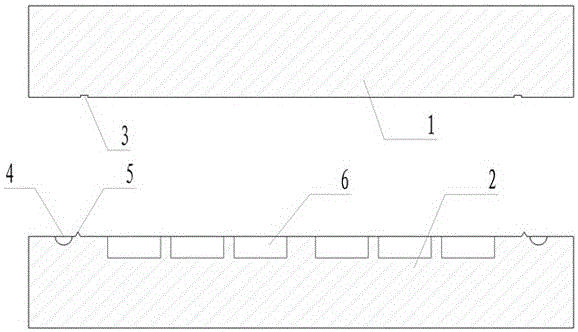

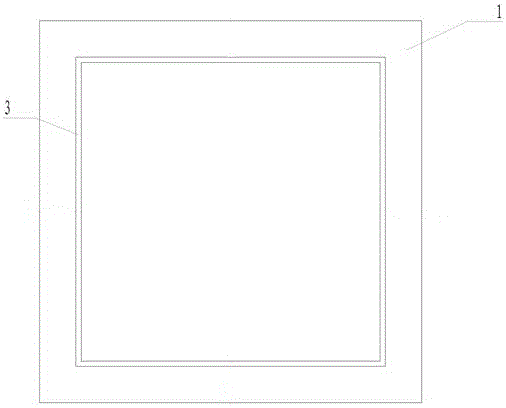

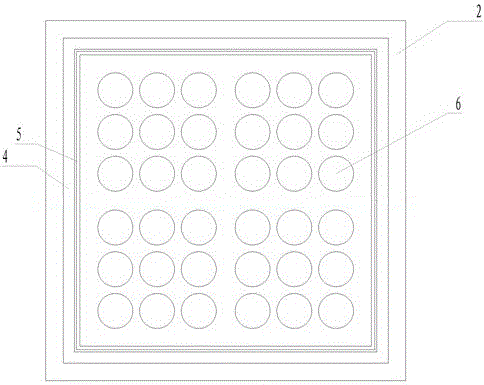

Tube winding machine and pipe membrane production equipment composed of the same

InactiveCN101269300AAvoid reducing extractablesLess extractablesSemi-permeable membranesWinding machineUltrasonic welding

The invention relates to a tube coiling machine and tubular type membrane producing equipment formed by the tube coiling machine. The tube coiling machine comprises a double-layer machine frame, a tube coiling mechanism, a non-woven fabric feeding mechanism and an ultrasonic welding machine, the tube coiling mechanism comprises an electrical motor which is arranged at the lower layer of the machine frame and a speed reducer which is mechanically connected with the tube coiling mechanism, the speed reducer is mechanically connected with a main driving roller which is arranged at the upper layer of the machine frame, the main driving roller is connected with an auxiliary driving roller which is arranged at the upper layer of the machine frame via a conveyor belt, a support bar is arranged between the main driving roller and the auxiliary driving roller via a small bracket which is fixedly arranged on the upper layer of the machine frame, and the conveyer belt coils around the support bar for one circuit before passing through; the non-woven fabric feeding mechanism is arranged at one side of the machine frame and the non-woven fabric feed mechanism forms an angle of 45 to 75 degrees with the axial line of the support bar of the tube coiling mechanism; the ultrasonic welding machine mainly comprises an ultrasonic generator which is arranged at the rear part of the support bar on the upper layer of the machine frame. The tubular type membrane production equipment takes the tube coiling machine of the invention as the main body, a delivering gear is arranged at one side of the feeding mechanism of the tube coiling machine, and a coagulating tank is arranged at one side of the output part of the tube coiling machine.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH

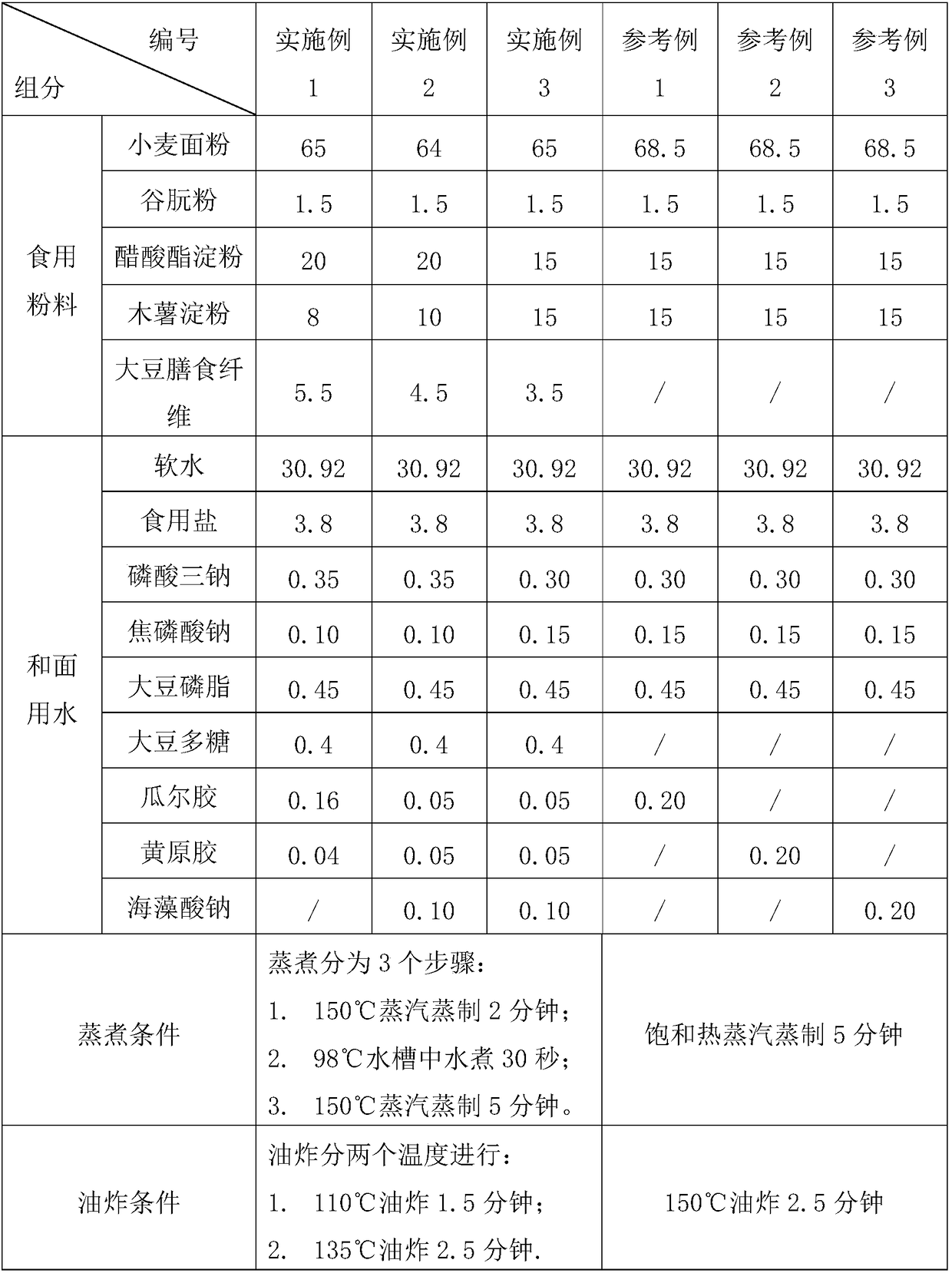

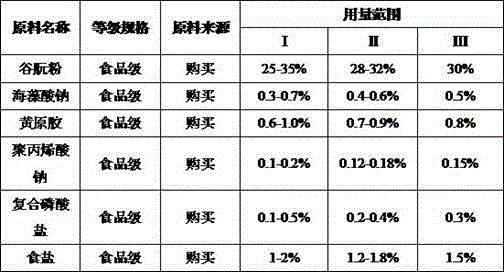

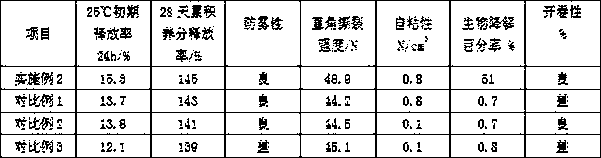

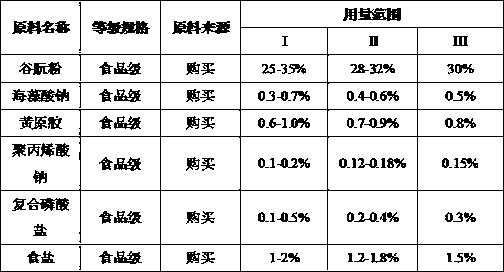

Oil-fried Udon noodles and processing method thereof

InactiveCN108208578AExcellent extension performanceExcellent pasting propertiesFood scienceWater solubleWater use

The invention discloses a processing method of oil-fried Udon noodles. The processing method of the oil-fried Udon noodles comprises the following steps of uniformly dissolving edible salt, compound phosphates, an emulsifier, a thickening agent and water-soluble soybean polysaccharides in weakly alkaline soft water so as to obtain water used for making dough; adding the water used for making doughinto edible flour, and carrying out vacuum stirring so as to make dough; performing 1-time compounding on the dough by utilizing a composite rolling machine so as to obtain a dough band, and performing curing treatment on the dough band; rolling the dough band by using a rolling machine so as to obtain dough sheet; cutting the dough sheet into stripes by using a cutter, and carrying out preliminary shaping by performing knurling by using a baffle so as to obtain noodles; sending the shaped dough noodles into a staged steaming box via a conveyor belt; stretching the steamed noodles, carrying out quantitative cutting, and carrying out oil-frying in a pan so as to carry out dewatering, and thus, oil-fried noodle blocks are prepared. The noodles are oil-fried by adopting two-stage oil-frying,wherein the first stage is low-temperature frying and the second stage is high-temperature frying. By optimizing raw material formula and processing method, the oil-fried Udon noodles prepared according to the processing method are chewy, soft and smooth in taste, as well as good in tenacity. And thus, a new idea and direction of noodle product industry is provided. The oil-fried Udon noodles andthe processing method thereof have wide market prospects and market benefits.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

Radiation curable hot melt composition and a process for the application thereof

InactiveUS20060083864A1High speedLess or no bad odourPolyurea/polyurethane coatingsNon-metallic protective coating applicationPhotoinitiatorOligomer

The invention relates to a radiation curable hot melt composition comprising: a) 20 to 100 wt. % of a radiation curable resin or a mixture of radiation curable resins having a viscosity in the range from 15 to 10,000 mPas in the temperature range from 40 to 150° C., b) 0 to 50 wt. % of a hydroxyfunctional resin or oligomer or a mixture of hydroxyfunctional resins or oligomers, c) 0 to 10 wt. % of a photoinitiator, d) 0 to 50 wt. % of fillers and / or additives, and e) 0 to 40 wt. % of pigment, wherein the total amount of components a) to e) adds up to 100 wt. %. The invention further relates to a process for the coating of a substrate with such radiation curable hot melt composition. In this process the composition is heated to a temperature in the range from 40 to 150° C., is applied to the substrate, and then the coated substrate is exposed to electromagnetic radiation having a wavelength λ≦500 nm.

Owner:AKZO NOBEL NV

Corn strengthening steamed bread and preparation method thereof

The invention relates to the technical field of corn steamed bread, in particular to corn strengthening steamed bread and a preparation method thereof. In the invention, the modified corn meal is used as major ingredient, and the accessories including wheat gluten, sodium alginate, xanthan gum, composite phosphate, sodium polyacrylate and table salt are added; the method comprises the following steps of: (1) preparation of the major ingredient; (2) preparation of the accessories; (3) mixing the materials and adding water; (4) kneading; (5) forming; (6) fermentation; (7) curing; and (8) cooling to obtain the corn strengthening steamed bread. The corn strengthening steamed bread is characterized in that the content of corn meal in the steamed bread reaches about 70%. The product has rich nutrition and is digestible; and moreover, the product has delicate and smooth mouthfeel and high elasticity, and is tasty and not stuck on teeth in chewing.

Owner:东莞市圣心食品有限公司

Anti-cracking method of quick-frozen sweet soup balls

InactiveCN105876769AMuscle strengtheningLess extractablesFood ingredient as anti-freezing agentOrganic compound food ingredientsQuick FreezeCarboxymethyl cellulose

The present invention provides an anti-cracking method of quick-frozen sweet soup balls. The anti-cracking method comprises the following steps: a sweet soup ball modifier at a weight of 1%-8% of glutinous rice flour is added into the glutinous rice flour, the mixture is mixed evenly, and the sweet soup ball modifier consists of the following raw materials in parts by mass: 1-2 parts of monoglycerides, 2-4 parts of trehalose, 2-4 parts of sodium carboxymethyl cellulose and 1-2 parts of sodium tripolyphosphate; the mixed well glutinous rice flour is prepared into glutinous rice balls; fillings and the glutinous rice balls are respectively added into a sweet soup ball machine to conduct filling wrapping to obtain the sweet soup balls; and the sweet soup balls are subjected to quick-freezing, the quick-frozen sweet soup balls are packaged, and the packaged sweet soup balls are put into a cold storage to conduct storage below -18 DEG C. The quick-frozen sweet soup balls prepared by the above provided method are prevented from cracks from naked eyes and do not crack.

Owner:HENAN HUANGGUO GRAIN COMPANY

Latex for coating drinking filter bag cotton paper and its preparing method

InactiveCN1294326CLess extractablesSimple processWater-repelling agents additionPaper coatingEmulsion polymerizationCotton paper

The latex for coating tissue paper of drink filtering bag is prepared through emulsion polymerization in the presence of emulsifier and initiator. The monomer mixture for the latex includes: vinylidene chloride in 60-85 wt%, acrylate in 5-30 wt%, and unsaturated fatty acid in 5-10 wt%. The latex makes the coated tissue paper possess high wet strength, high water penetrating capacity, no toxicity, no smell, few leached matter and high performance / cost ratio, and is especially suitable for coating tissue paper for coffee, tea and other drink extracting bag.

Owner:浙江森兰德包装科技有公司

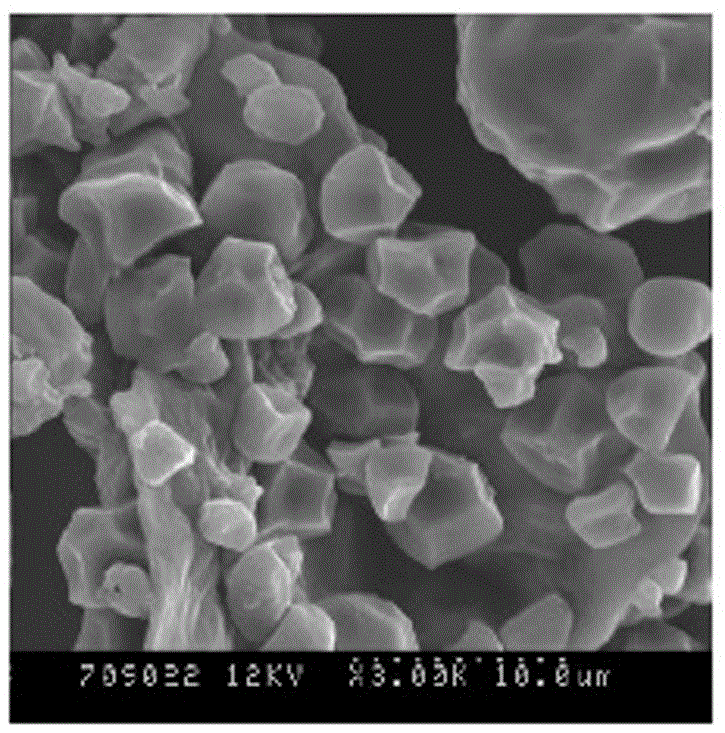

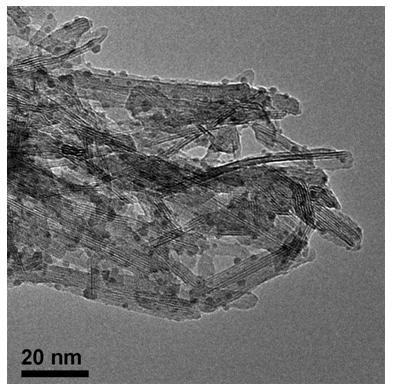

Preparation method of antibacterial and antiviral environment-friendly interior wall modification coating and product of antibacterial and antiviral environment-friendly interior wall modification coating

InactiveCN113652166AHigh broad spectrumSolve the problem of black spots caused by oxidation and discolorationAntifouling/underwater paintsPaints with biocidesH1n1 virusLarge intestine

The invention relates to a preparation method of an antibacterial and antiviral environment-friendly interior wall modification coating and a product thereof. The preparation method comprises the steps of preparation of nano inorganic antibacterial and antiviral powder, preparation of pure water-based polyurethane acrylate nano narrow-band emulsion and preparation of pure water-based nano antibacterial and antiviral coating. The pure water-based nano-scale dendritic copolyester is used as a base material to prepare the zero-VOC pure water-based antibacterial and antiviral interior wall modification coating, and the pure water-based nano-antibacterial and antiviral coating has the advantages of high coating fullness, good film coating effect, excellent water resistance, air permeability, water impermeability, excellent mildew-proof effect, dust is not prone to falling on the wall facing, stains are not prone to being attached, cleaning is easy, lasting antibacterial and antiviral capacity is achieved, the antibacterial rate of large intestines, golden yellow and the like reaches 99%, and the H1N1 virus killing rate reaches up to 92.3%.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Tube winding machine and pipe membrane production equipment composed of the same

InactiveCN101269300BAvoid reducing extractablesLess extractablesSemi-permeable membranesWinding machineUltrasonic welding

The invention relates to a tube coiling machine and tubular type membrane producing equipment formed by the tube coiling machine. The tube coiling machine comprises a double-layer machine frame, a tube coiling mechanism, a non-woven fabric feeding mechanism and an ultrasonic welding machine, the tube coiling mechanism comprises an electrical motor which is arranged at the lower layer of the machine frame and a speed reducer which is mechanically connected with the tube coiling mechanism, the speed reducer is mechanically connected with a main driving roller which is arranged at the upper layer of the machine frame, the main driving roller is connected with an auxiliary driving roller which is arranged at the upper layer of the machine frame via a conveyor belt, a support bar is arranged between the main driving roller and the auxiliary driving roller via a small bracket which is fixedly arranged on the upper layer of the machine frame, and the conveyer belt coils around the support bar for one circuit before passing through; the non-woven fabric feeding mechanism is arranged at one side of the machine frame and the non-woven fabric feed mechanism forms an angle of 45 to 75 degreeswith the axial line of the support bar of the tube coiling mechanism; the ultrasonic welding machine mainly comprises an ultrasonic generator which is arranged at the rear part of the support bar on the upper layer of the machine frame. The tubular type membrane production equipment takes the tube coiling machine of the invention as the main body, a delivering gear is arranged at one side of the feeding mechanism of the tube coiling machine, and a coagulating tank is arranged at one side of the output part of the tube coiling machine.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH

Transparent rubber pad of heparin cap for remaining needle and production method of transparent rubber pad

ActiveCN104387626ALow transparencyTo solve the chemical cleanliness needs to be improvedPolymer scienceThermoplastic elastomer

The invention discloses a transparent rubber pad of a heparin cap for a remaining needle. The transparent rubber pad mainly comprises 100 parts of polyisoprene rubber, 3-10 parts of a thermoplastic elastomer, 1-10 parts of alkali white carbon black and 0.3-1.5 parts of peroxide. The invention also discloses a production method of the transparent rubber pad of the heparin cap for the remaining needle. By using the production method, the problems that the existing transparent rubber pad of the heparin cap for the remaining needle is not high in transparency, the chemical cleanliness of the existing transparent rubber pad needs to be improved, and particularly, the pH change value and the ultraviolet absorbance of the transparent rubber pad easily exceed the standard are solved, the size of each curing burr are controlled within 0.03-0.10mm, and the cured transparent rubber pad of the heparin cap can be directly frozen and deburred; and meanwhile, the surface of a curing mould is treated by using a mirror polishing process, so that the transparent rubber pad of the heparin cap, which is provided with relatively thin curing burrs, is conveniently cured and demoulded. The transparent rubber pad of the heparin cap for the remaining needle, disclosed by the invention, is resistant to multiple punctures, excellent in cleaning performance and compatibility with tube sealing fluid of the heparin cap and low in extractable substance content.

Owner:郑州翱翔医药科技股份有限公司

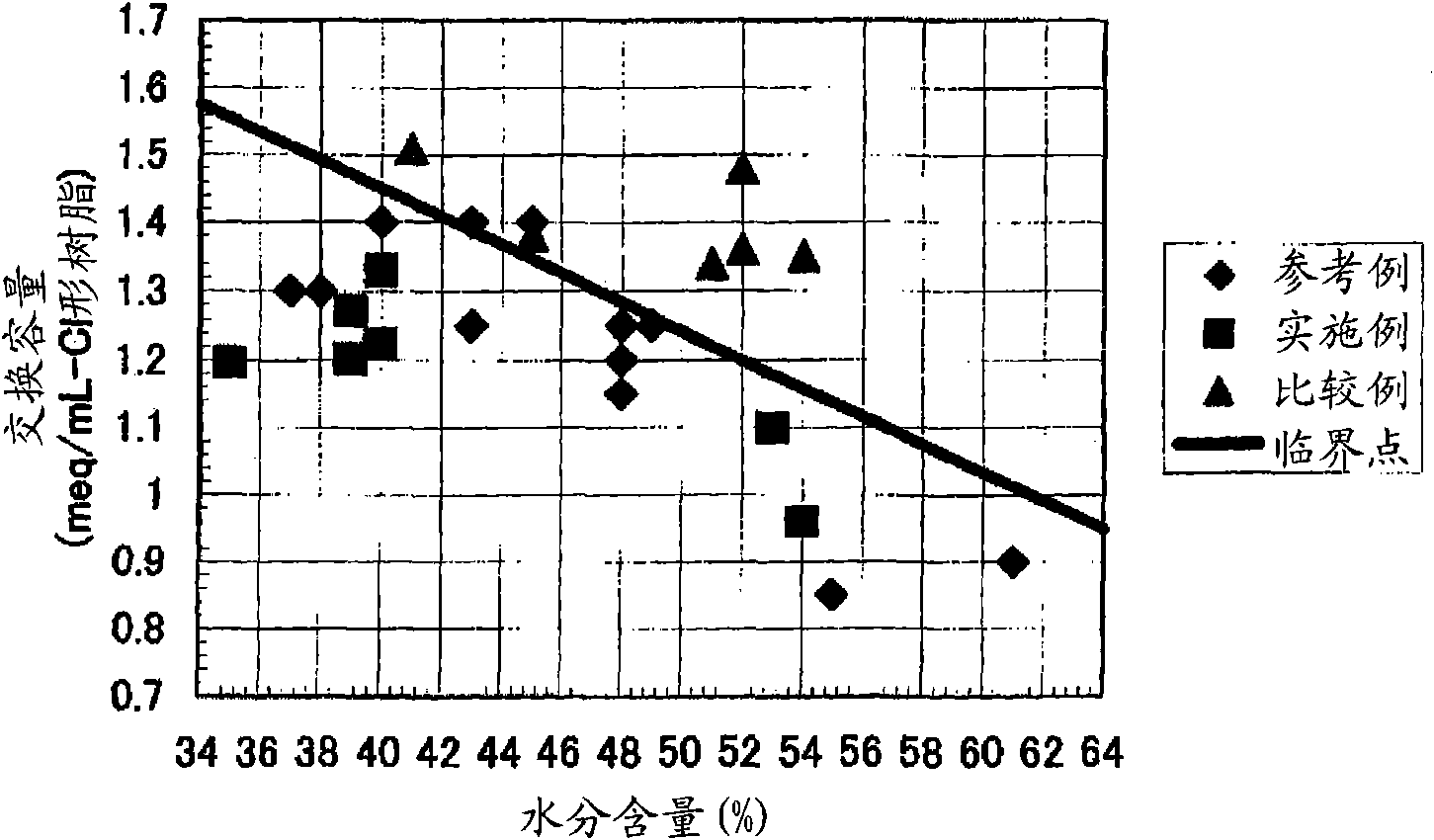

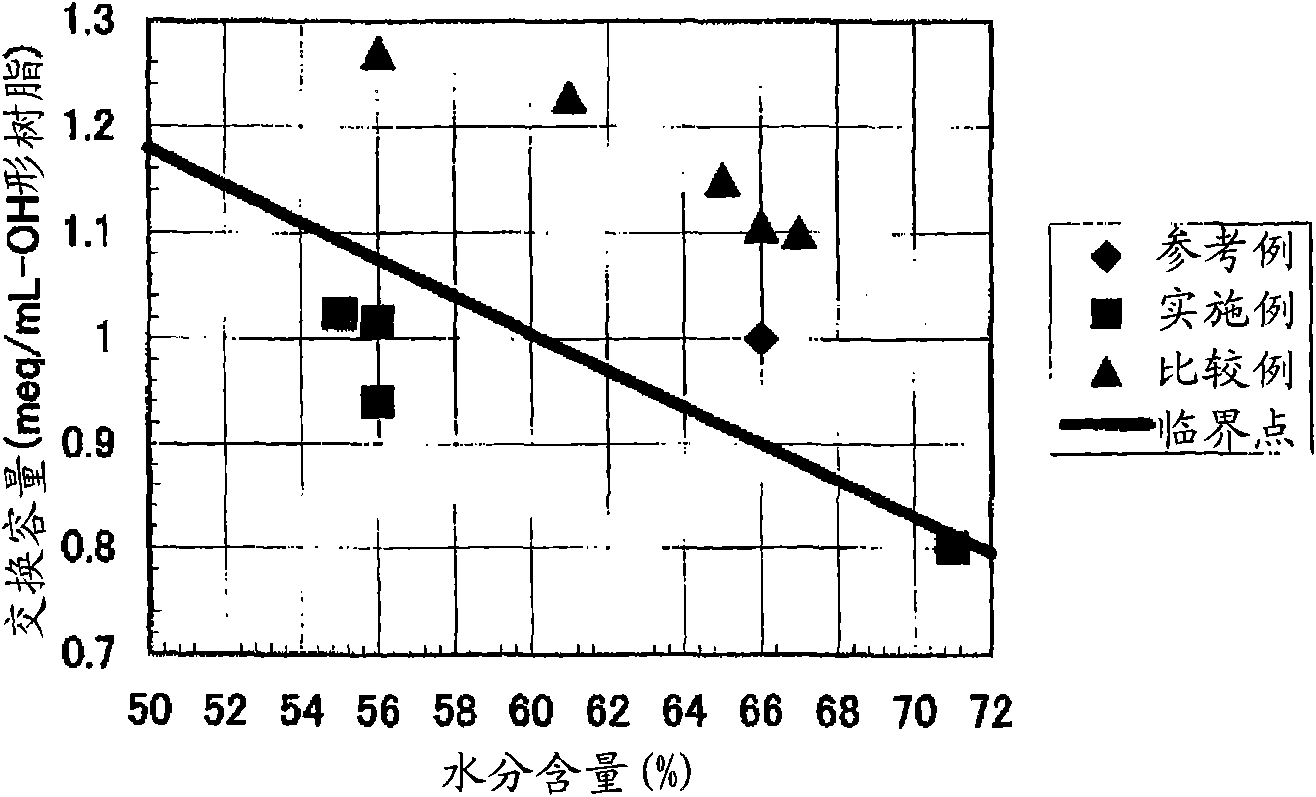

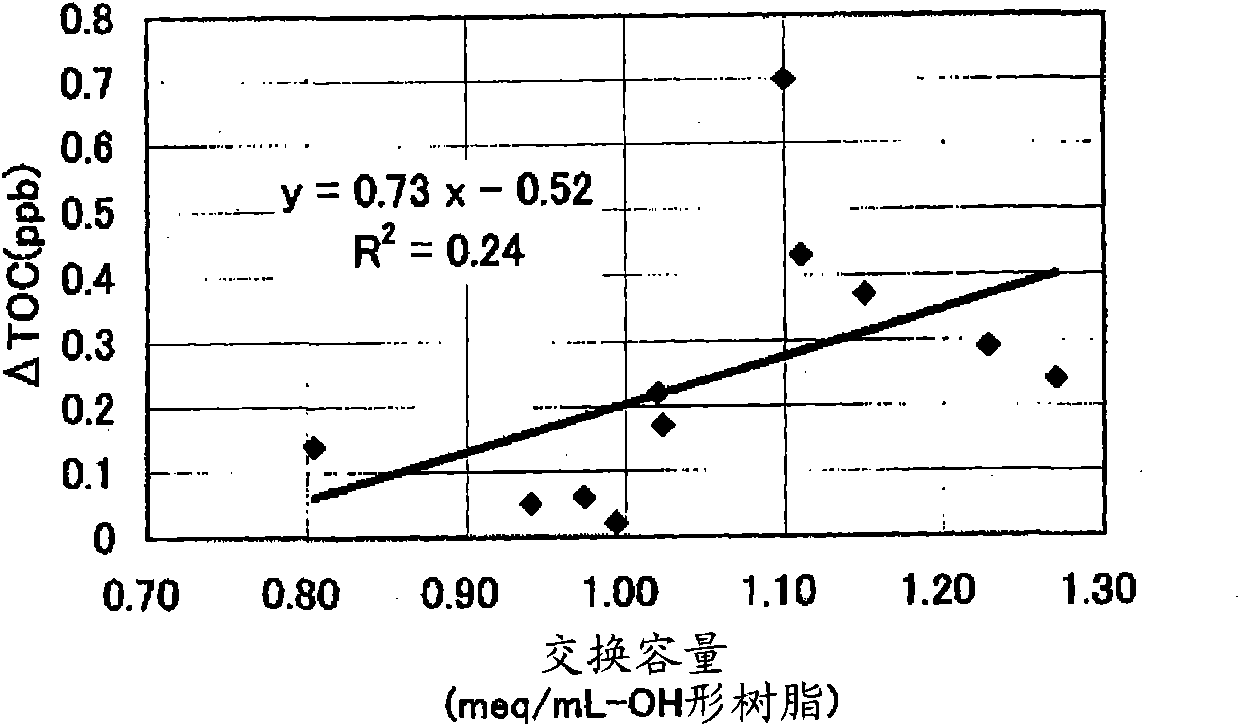

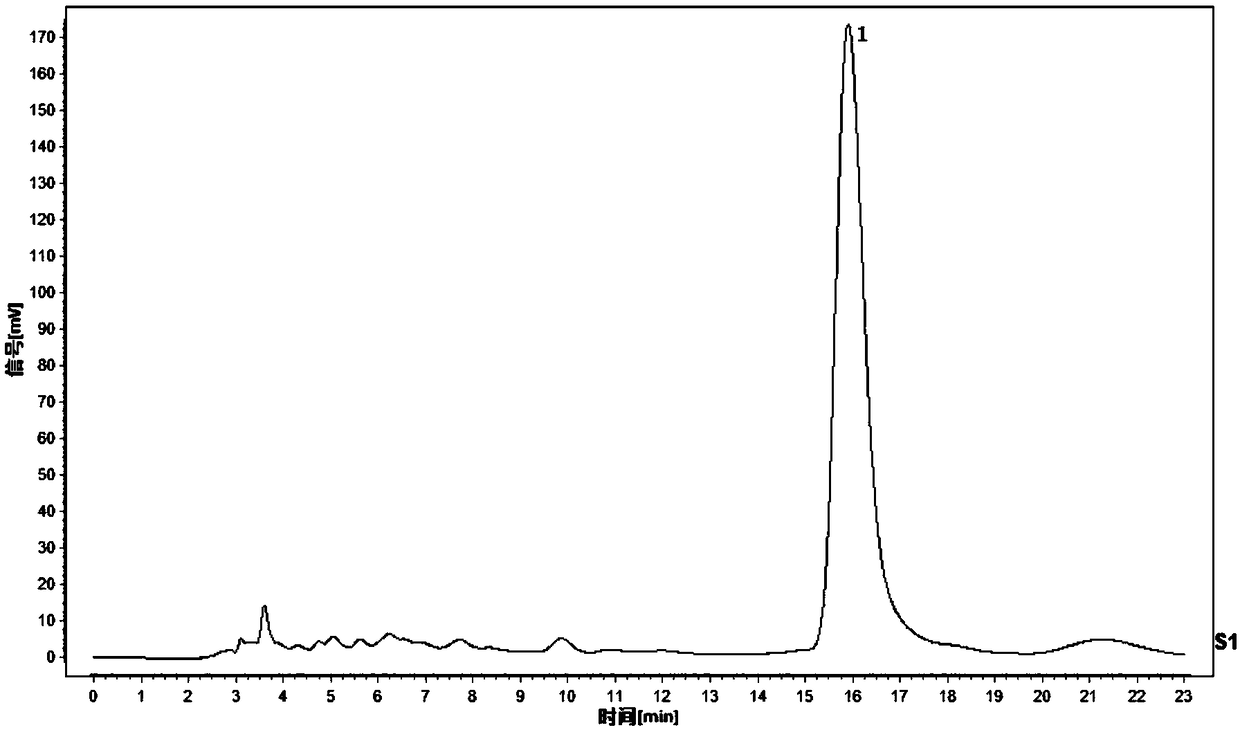

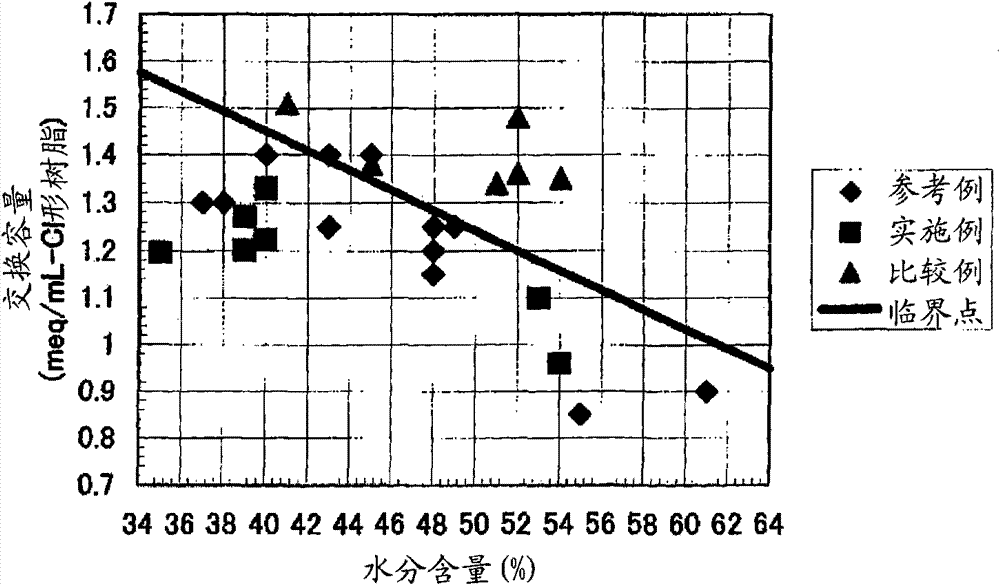

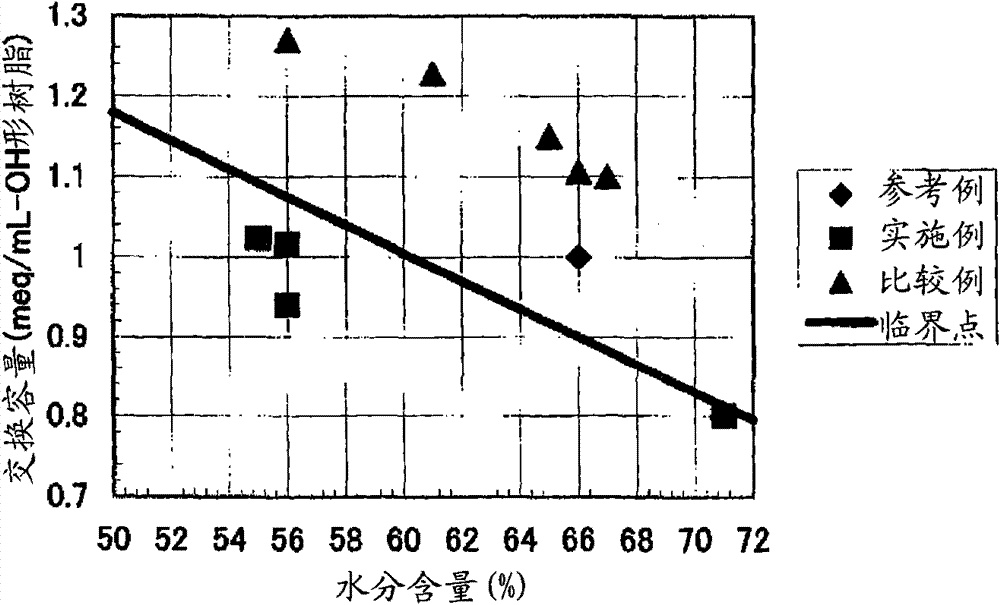

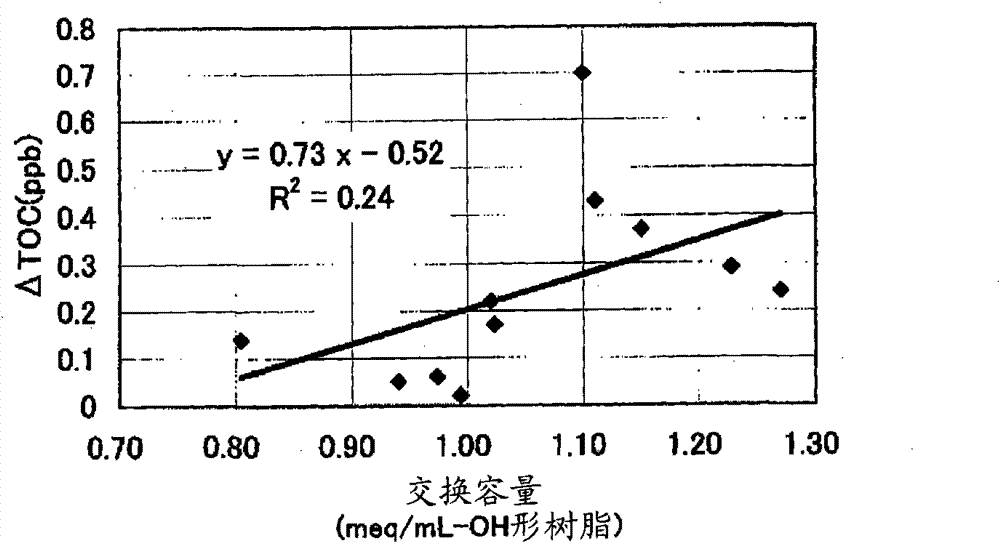

Method for producing anion exchange resin, anion exchange resin, method for producing cation exchange resin, cation exchange resin, mixed bed resin, and method for producing ultra-pure water for clean

ActiveCN101663094AHigh purityInhibitionCation exchanger materialsWater/sewage treatment by ion-exchangeDissolutionIon-exchange resin

Disclosed is a method for producing an anion exchange resin comprising the steps (1-a)-(1-e) below, wherein residual impurities and formation of decomposed products are suppressed and dissolution of a material is also suppressed. (1-a) a step for obtaining a crosslinked copolymer by copolymerizing a monovinyl aromatic monomer and a crosslinkable aromatic monomer (1-b) a step for setting the content of a specific dissolvable compound to 400 [mu]g or less per 1 g of the crosslinked copolymer (1-c) a step for introducing 80% by mole or less of a haloalkyl group relative to the monovinyl aromaticmonomer by haloalkylating the crosslinked copolymer (1-d) a step for removing the specific dissolvable compound from the haloalkylated crosslinked copolymer (1-e) a step for reacting the haloalkylated crosslinked copolymer with an amine compound. The present invention also relates to a method of producing an anion exchange resin, an cation exchange resin and a method of producing an cation exchange resin, a mixed bed resin and ultra-pure water for cleaning electronic device and / or material.

Owner:KURITA WATER INDUSTRIES LTD

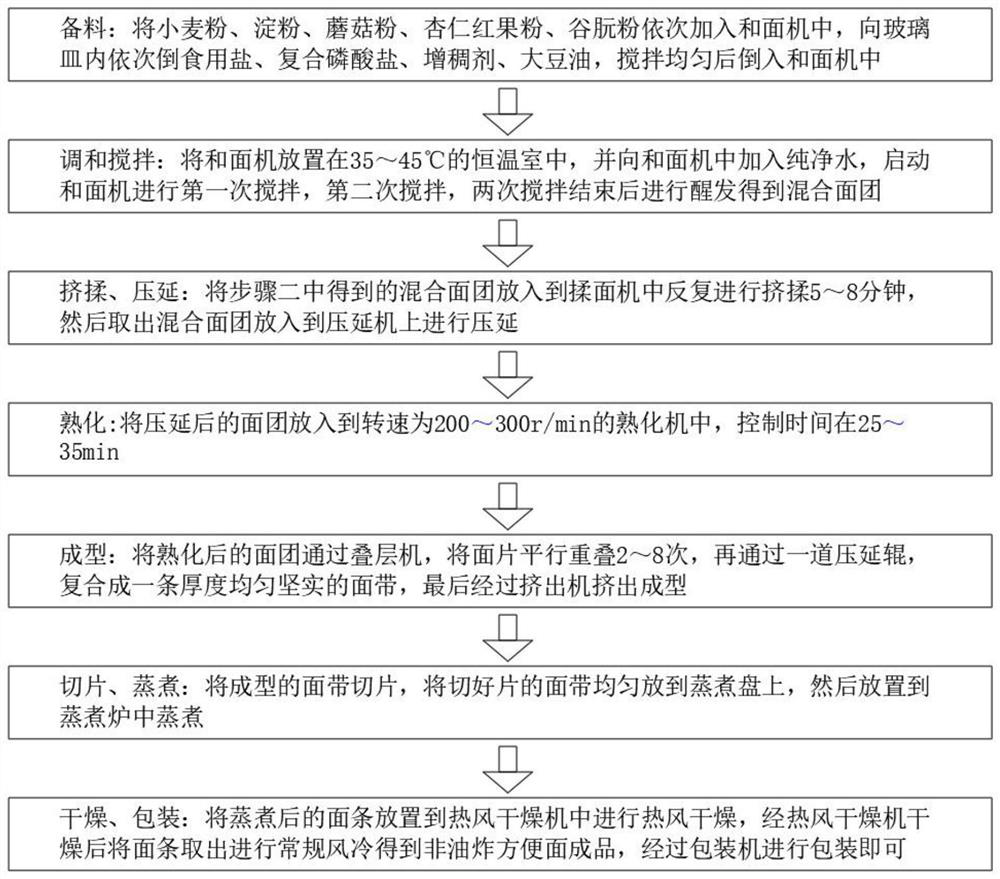

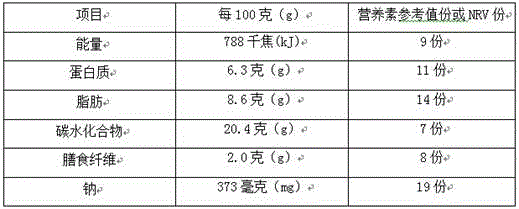

Low-oil-content healthy instant noodles and making method thereof

PendingCN112293659AConvenient supplementNutritional diversityFood ingredient as thickening agentFood ingredient as mouthfeel improving agentNutritive valuesProcess engineering

The invention discloses low-oil-content healthy instant noodles and a making method thereof. The low-oil-content healthy instant noodles are made from the following raw materials in parts by weight: 60-80 parts of wheat flour, 20-40 parts of starch, 4-6 parts of mushroom powder, 2-4 parts of apricot kernel and haw powder, 1-3 parts of vital gluten, 38-42 parts of purified water, 1.2-2.0 parts of edible salt, 0.1-0.5 part of composite phosphate, 0.02-0.04 part of a thickener and 0.01-0.03 part of soybean oil. According to the low-oil-content healthy instant noodles and the making method thereof, the mushroom powder, the apricot kernel and haw powder and the vital gluten are added, so that the nutrition of the instant noodles is diversified, the requirement of supplementing nutrition to human bodies is met, the nutritional value is increased, and the noodles are improved by adding the composite phosphate. Compared with a traditional making method, the making method of the instant noodlesis lower in content, more sanitary, shorter in rehydration time, better in taste, simpler in processing technology and wider in application prospect through cooking processing and high-temperature hot air drying.

Owner:安徽佳康食品有限公司

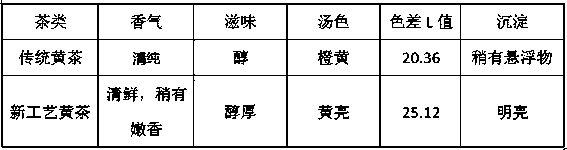

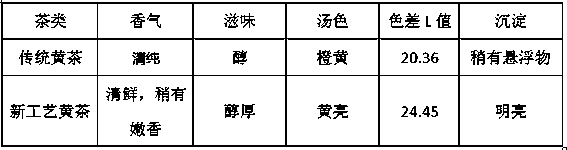

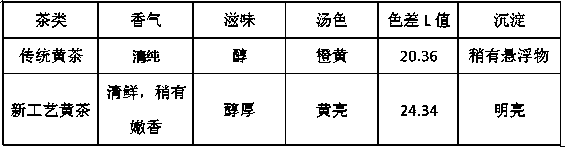

Processing method of special yellow tea for beverages

InactiveCN108740078AThe soup is bright yellow and stableExtended shelf lifePre-extraction tea treatmentFluidized bed dryingBlack tea

The invention discloses a processing method of special yellow tea for beverages, and belongs to the technical field of tea processing. The processing method of the special yellow tea for beverages comprises the following steps: performing withering treatment on tea leaves; carrying out fixation treatment; carrying out heap-yellowing treatment; carrying out rolling and cutting treatment by using arotor-type rolling and cutting machine; carrying out rolling and cutting treatment by using a CTC tea rolling and cutting machine; carrying out drying treatment by using a vibrating fluidized bed drying machine; carrying out alcoholization treatment; and carrying out drying treatment by using the vibrating fluidized bed drying machine. The processing method of the special yellow tea for beveragestakes tender tips of tea trees with medium-sized leaves which are rich in contents and mellow in flavor as a raw material; and innovations are made on yellow tea processing technology so as to preparefresh tea leaves into yellow tea that is yellow, bright and stable in soup color, mellow in flavor as well as convenient for extracting or mechanical packaging instead of bag-packaging in the beverage industry. Thus, the problems of tea soup stability of traditional yellow tea, green tea and black tea in the tea beverage industry are solved; moreover, the fluidized bed drying process is adopted,so that the phenomena of tea leakage through air holes of linking boards of common chain-plate automatic drying machines and blowing of tea granules out of the drying machines by hot air are avoided.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Preparation method of self-adhesive and degradable disposable tablecloth

InactiveCN108903542AImprove self-adhesivenessGood self-adhesiveFilm/foil adhesivesMacromolecular adhesive additivesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a preparation method of a self-adhesive and degradable disposable tablecloth. The self-adhesive and degradable disposable tablecloth comprises an adhesive layer, an inner layer and an outer layer and is composed of components including C6LLDPE (carbon 6 linear low-density polyethylene), mLLDPE (metallocene linear low-density polyethylene), PIB (polyisobutylene), starch, polylactic acid, glycerinum, bulking agent, soy protein, C8LLDPE, LDPE (low-density polyethylene), cycloolefin, anti-blocking agent and calcium carbonate. The self-adhesive and degradable disposable tablecloth prepared through the preparation method has the advantages of being non-toxic, environmentally friendly, pollution-free, light in weight, low in water absorption, high in breaking elongation,biologically degradable and free from recycling.

Owner:安徽永豪日用品有限公司

Sugar-controlled quick-frozen dumplings and preparation method thereof

InactiveCN106107428AImprove qualityIncrease elasticityFood ingredient as thickening agentFood preservationQuick FreezeCholesterol

The invention belongs to the field of food processing, and in particular relates to sugar-controlled quick-frozen dumplings and a preparation method thereof. The sugar-controlled quick-frozen dumplings are characterized by comprising the following components in parts by mass: 55-85 parts of high-gluten wheat flour and 15-50 parts of tartary buckwheat flour, and then adding 0.3-2.5 parts of modified starch, 0.2-1.5 parts of a quick-frozen dumpling improver and 30-60 parts of water by total mass of high-gluten wheat flour and tartary buckwheat flour. According to the formula of the improved dumpling wrapper, tartary buckwheat flour and modified starch are added on the basis of the traditional formula, the sugar rising index of the dumplings is reduced, and diabetic patients can be helped to effectively control the postprandial blood sugar fluctuation; in addition, the sugar-controlled tartary buckwheat dumplings are rich in dietary fiber, can enhance satiety and inhibit the absorption of intestinal tract in glucose and cholesterol. The quick-freezing technology is adopted, the nutritional ingredients in the dumplings are retained to the maximum extent, and the dumplings are convenient and fast to eat.

Owner:CHENGDU BAOWEI CONTROL SUGAR FOOD CO LTD

Extruded grain granules in liquid granule mixed sterilization product and preparation method thereof

The invention discloses extruded cereal particles in a liquid particle mixed sterilization product and a preparation method of the extruded cereal particles. The extruded cereal particles are prepared by extruding the following raw materials in parts by weight through a screw rod extruder: 100 parts of cereals, 1.6-50 parts of hydrophilic colloid and 0-25 parts of a food ingredient, wherein the hydrophilic colloid comprises 0.4-1.4 parts of xanthan gum, 1-2.5 parts of sodium carboxymethylcellulose, 0.2-1.2 parts of gellan gum and 0-44.9 parts of selective hydrophilic colloid; and the selective hydrophilic colloid is one or any match of more of artamisia sphaerocephala krasch gum, sodium alginate, curdlan gum, fenugreek gum, locust bean gum, guar gum, gelatin, carrageenan, Arabic gum, konjac glucomannan, sodium polyacrylate, propylene glycol alginate, modified starch and plant protein powder. The extruded cereal particles can bear sterilization, and are not scattered and excessively gelatinized after being immersed for a long time; and the production period is short and the production cost is low, and the food ingredient can be added in a relatively wide range.

Owner:GUIZHOU UNIV

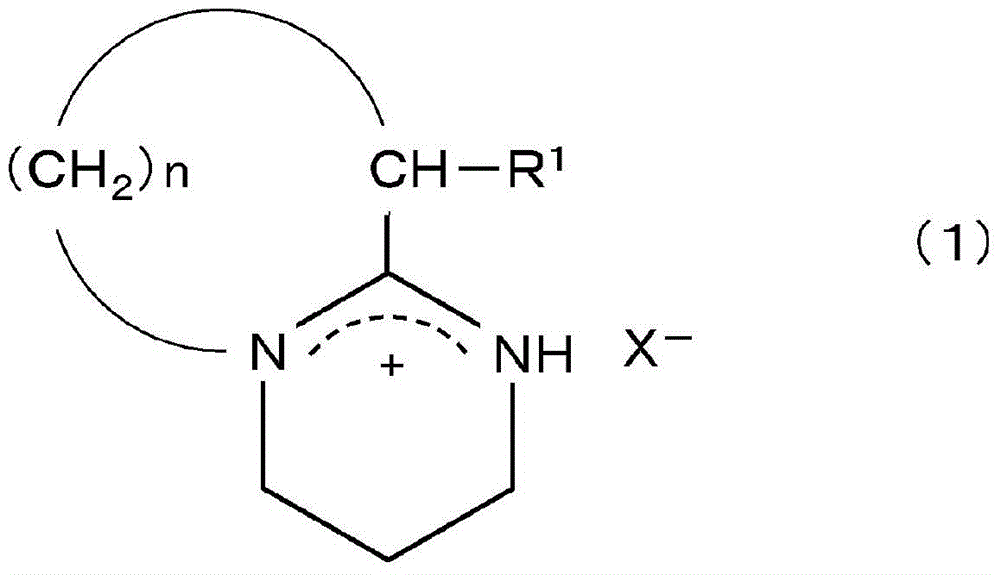

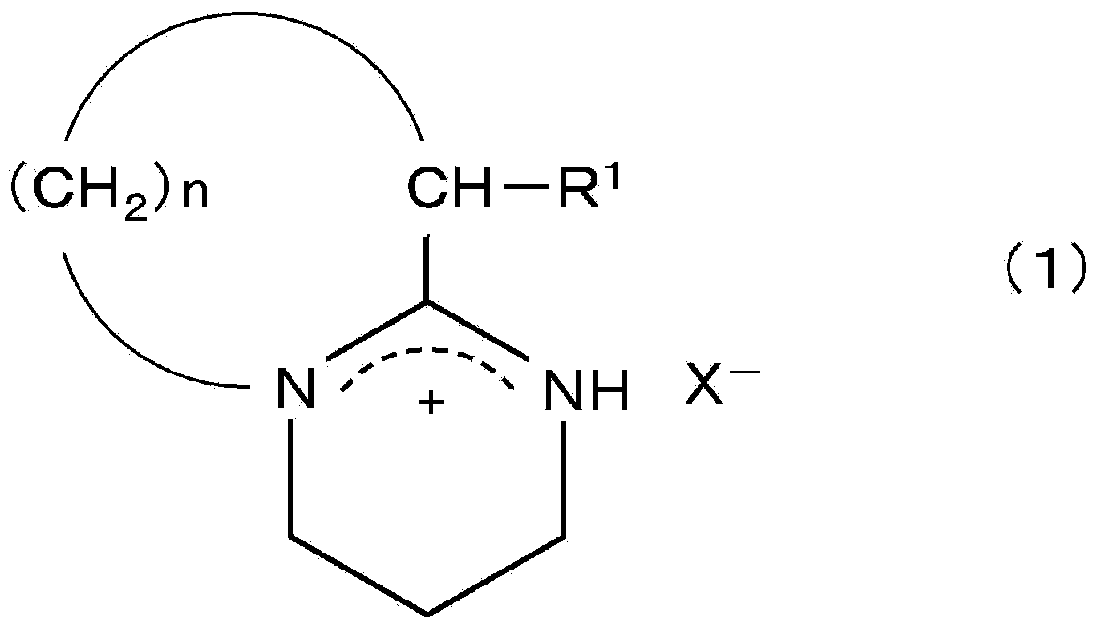

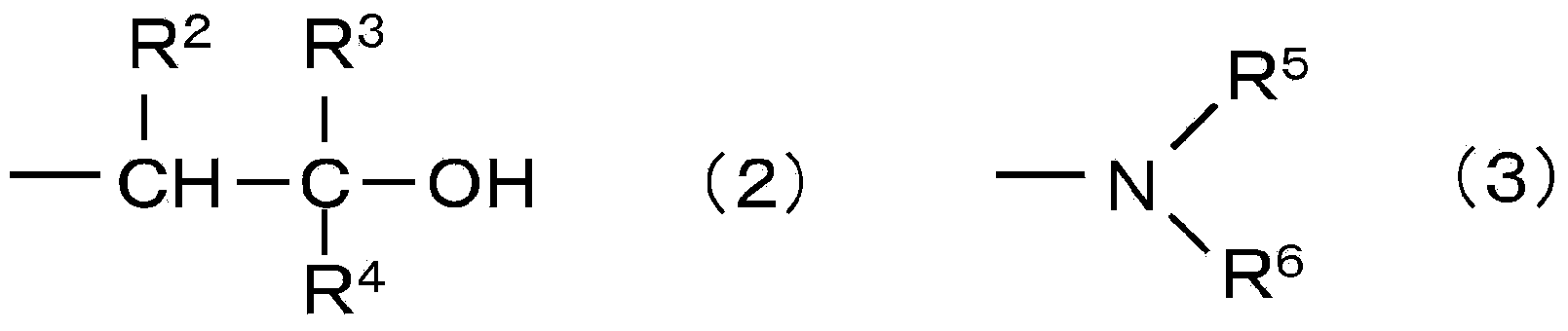

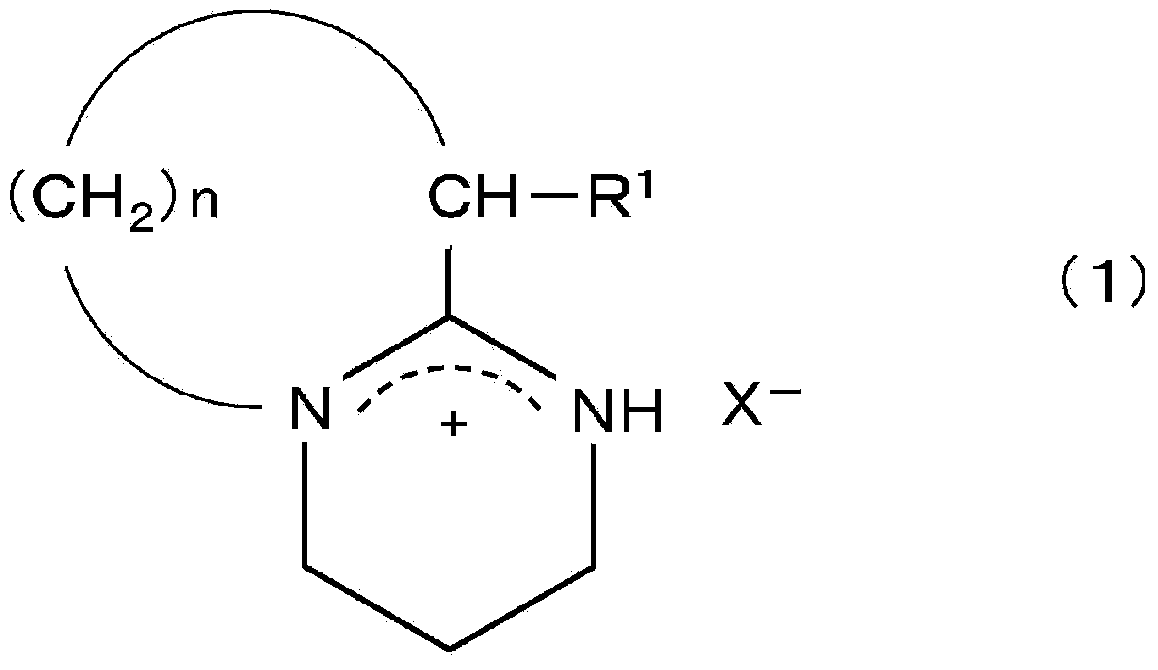

Urethane resin-forming composition for sealing material of membrane module

ActiveCN104114262BReactiveHigh hardnessSemi-permeable membranesOther chemical processesPolyolAmidine

Owner:SANYO CHEM IND LTD

A kind of heparin cap transparent rubber pad for indwelling needle and preparation method thereof

ActiveCN104387626BAvoid yellowingSolve the problem of not easy punching positioningUv absorbanceVulcanization

Owner:郑州翱翔医药科技股份有限公司

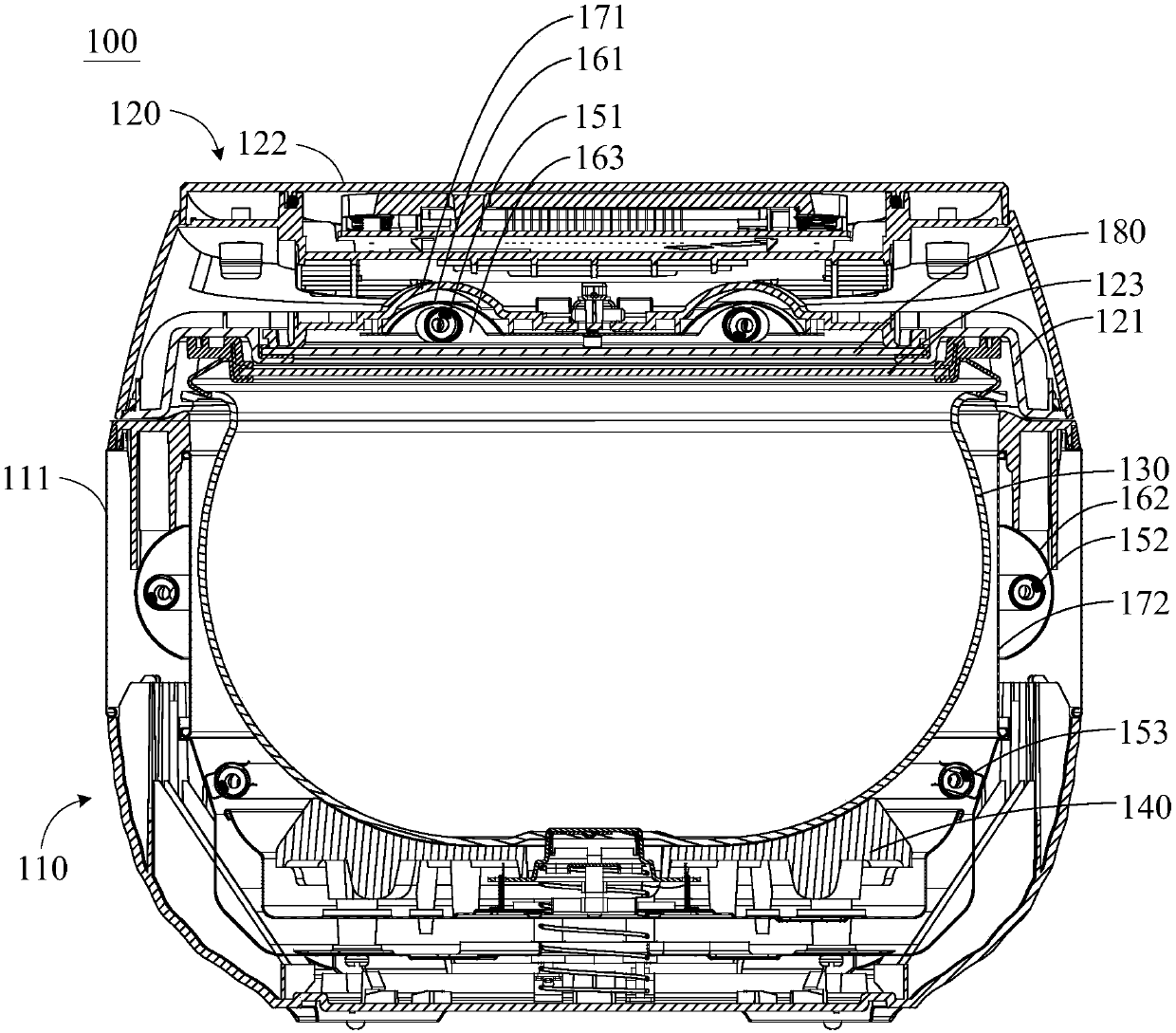

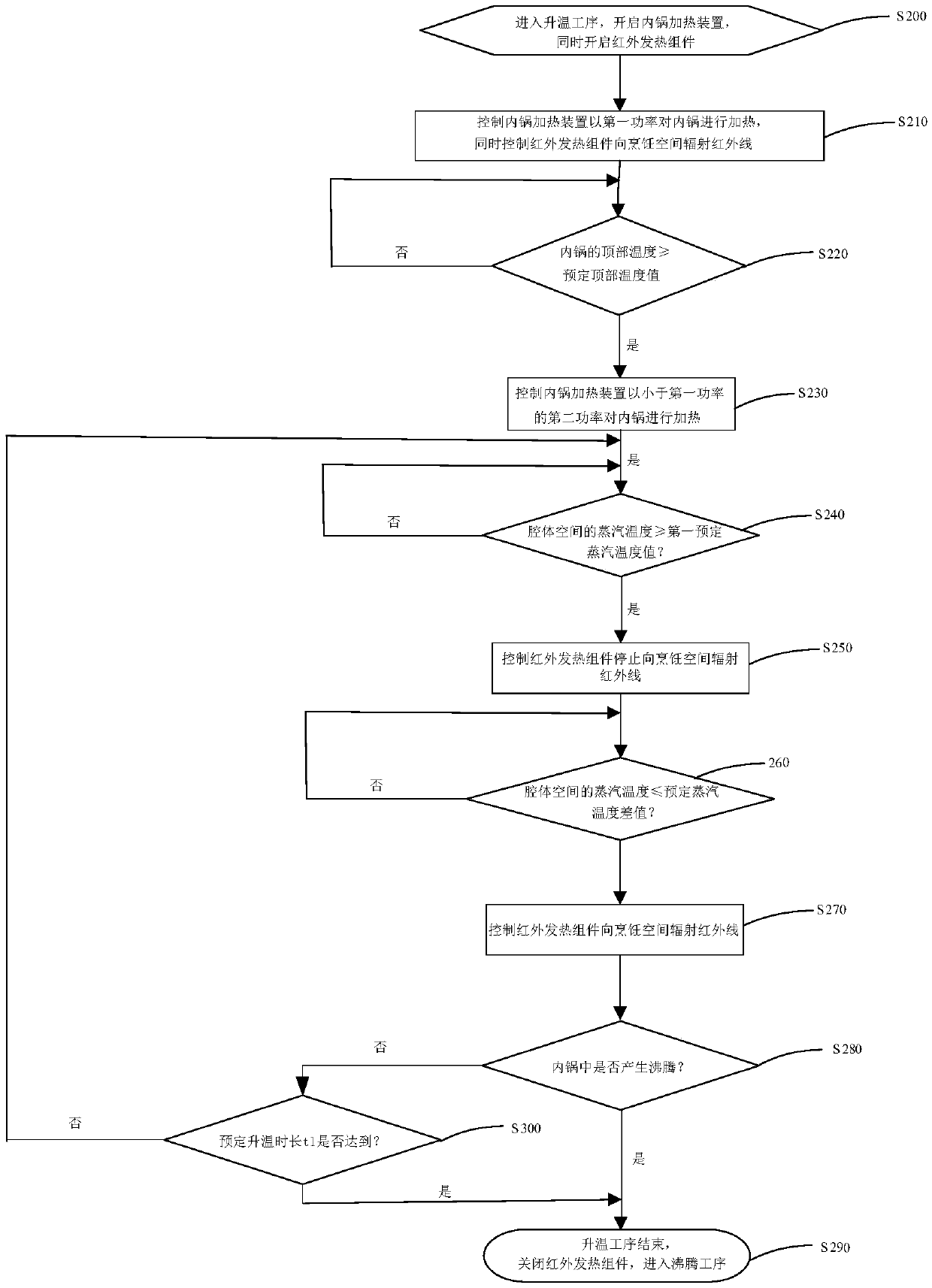

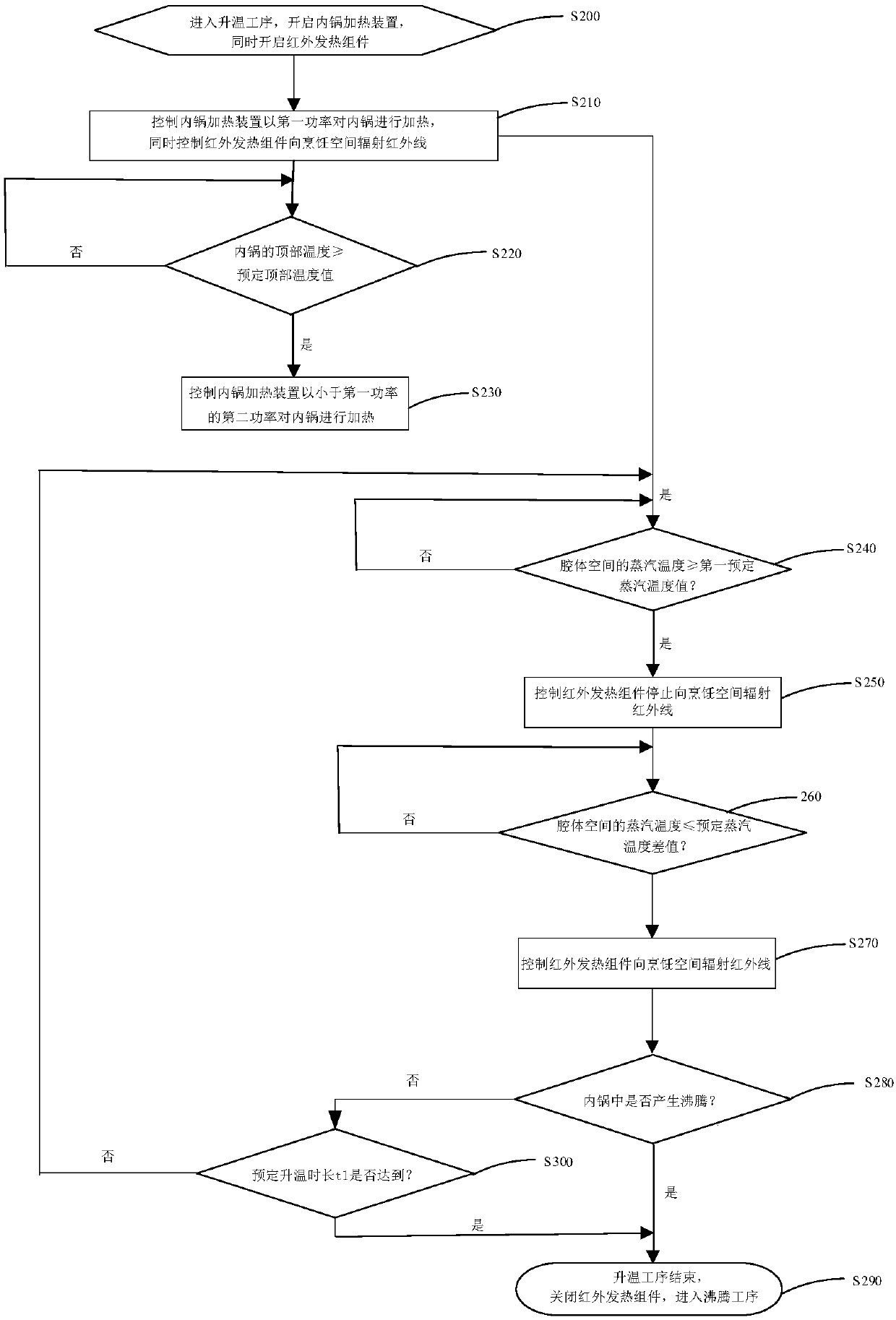

Cooking method for cooking utensil and cooking utensil

ActiveCN111281116AImprove gelatinizationSmall deformation of outer wallSteam cooking vesselsVessels with intergral heatingRice dishesProcess engineering

The invention provides a cooking method for a cooking utensil and the cooking utensil. The cooking utensil comprises a pot body, a cover body, an inner pot heating device, an infrared heating assemblyand a controller. An inner pot is arranged in the pot body. The cover body is arranged on the pot body in an openable and closable mode. When the pot body is covered with the cover body, a cooking space is formed between the cover body and the inner pot. The inner pot heating device is used for heating the inner pot. The infrared heating assembly is used for radiating infrared rays to the cookingspace. The cooking method comprises a water absorption process, a heating process, a boiling process and a rice braising process. The infrared heating assembly is started when the temperature risingprocess is started and is closed when the temperature rising process is finished. According to the cooking method, the cooked rice is good in taste, the fragrance of the rice can be stimulated, and the fragrance can overflow in the cooking process and after cooking is finished. In addition, the surface of the cooked rice is complete.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

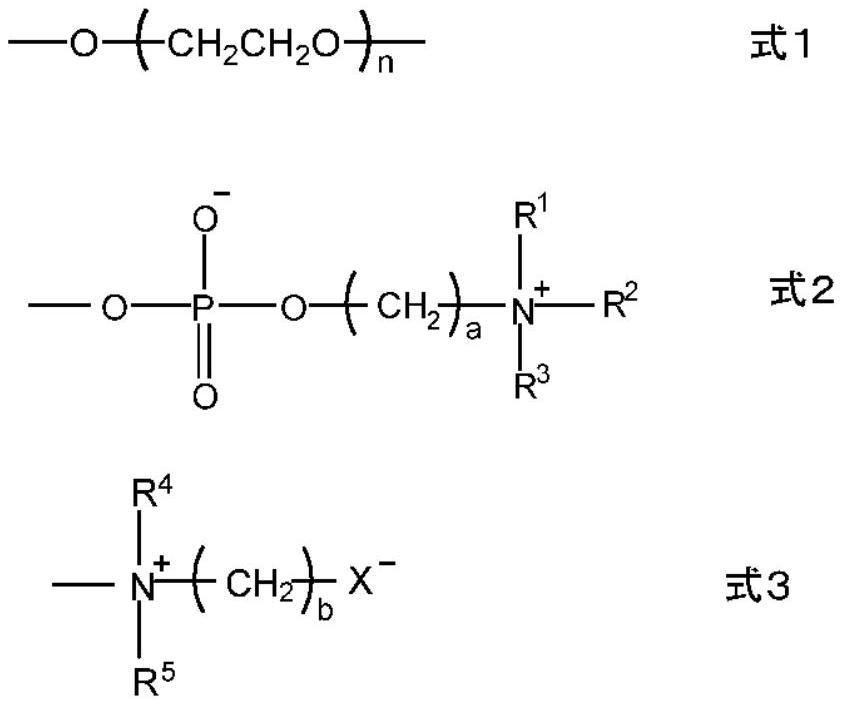

Medical device

InactiveCN111936855AReduced non-specific adsorptionIncreased durabilityBioreactor/fermenter combinationsBiological substance pretreatmentsSurgeryInorganic materials

Provided is a medical device which has a reduced non-specific absorption amount, which has excellent durability of said reduction, and which has reduced eluates from the surface layer. The medical device has a device substrate, and a surface layer positioned on at least part of the surface of the device substrate that comes into contact with water. At least part of the surface of the device substrate is made from an inorganic material, and the surface layer is made from a cured product of a compound having a biocompatible group and an alkoxy silyl group. The content of the biocompatible groupin the compound falls within the range of 25 to 83% by mass, inclusive, and the content of the alkoxy silyl group falls within the range of 2 to 70% by mass, inclusive.

Owner:ASAHI GLASS CO LTD

Extraction method suitable for water-soluble heat-sensitive ingredients of traditional Chinese medicines

InactiveCN109331053AReduce lossesReduce the risk of non-conformityPlant ingredientsMicroorganismMedicinal herbs

Owner:SHINEWAY PHARMA GRP LTD

Preparation method of modified coconut shred material for artificial fish nest

ActiveCN114128658AGood adhesionImprove kneading and grinding modificationClimate change adaptationPisciculture and aquariaFiberFishery

The invention discloses a preparation method of a modified coconut shred material for an artificial fish nest, and relates to material modification of the artificial fish nest. The problems that an existing artificial fish nest material is poor in artificial material hydrophilicity, and a natural plant material is odorous, small in specific surface area and prone to decay are solved. The method comprises the following steps: 1, washing coconut shreds and dehydrating; and 2, sequentially carrying out organic extraction, dehydration, alkali extraction, dehydration and kneading and grinding on the dehydrated coconut shreds to obtain the modified coconut shreds. According to the modified coconut shred material for the artificial fish nest, the fish egg attachment effect is good, and the attachment amount of fish eggs per mu is increased by 25%-35%; the aquatic environment is effectively improved, and the CODMn of the water body is reduced by 12% 10 days after the artificial fish nest is hung; and the service life is long, and the service cycle is prolonged from 2-3 years to 4-10 years. The preparation process is simple and stable, the process is green and environment-friendly, the cost is low, resource utilization of the coconut shred fibers is achieved, and the method is suitable for application and popularization. The modified coconut shred material is suitable for manufacturing the artificial fish nest.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

Solidified agent for drilling well waste mud

InactiveCN100358816CPrevent seepageHigh strengthSludge treatment by de-watering/drying/thickeningSludgeWell drilling

Owner:刘茂平

Method for producing anion exchange resin, anion exchange resin, method for producing cation exchange resin, cation exchange resin, mixed bed resin, and method for producing ultra-pure water for cleaning electronic parts/or materials

ActiveCN101663094BHigh purityInhibitionCation exchanger materialsWater/sewage treatment by ion-exchangeDissolutionIon-exchange resin

Disclosed is a method for producing an anion exchange resin comprising the steps (1-a)-(1-e) below, wherein residual impurities and formation of decomposed products are suppressed and dissolution of amaterial is also suppressed. (1-a) a step for obtaining a crosslinked copolymer by copolymerizing a monovinyl aromatic monomer and a crosslinkable aromatic monomer (1-b) a step for setting the content of a specific dissolvable compound to 400 ¢mu!g or less per 1 g of the crosslinked copolymer (1-c) a step for introducing 80% by mole or less of a haloalkyl group relative to the monovinyl aromaticmonomer by haloalkylating the crosslinked copolymer (1-d) a step for removing the specific dissolvable compound from the haloalkylated crosslinked copolymer (1-e) a step for reacting the haloalkylatedcrosslinked copolymer with an amine compound. The present invention also relates to a method of producing an anion exchange resin, an cation exchange resin and a method of producing an cation exchange resin, a mixed bed resin and ultra-pure water for cleaning electronic device and / or material.

Owner:KURITA WATER INDUSTRIES LTD

Corn strengthening steamed bread and preparation method thereof

The invention relates to the technical field of corn steamed bread, in particular to corn strengthening steamed bread and a preparation method thereof. In the invention, the modified corn meal is used as major ingredient, and the accessories including wheat gluten, sodium alginate, xanthan gum, composite phosphate, sodium polyacrylate and table salt are added; the method comprises the following steps of: (1) preparation of the major ingredient; (2) preparation of the accessories; (3) mixing the materials and adding water; (4) kneading; (5) forming; (6) fermentation; (7) curing; and (8) cooling to obtain the corn strengthening steamed bread. The corn strengthening steamed bread is characterized in that the content of corn meal in the steamed bread reaches about 70%. The product has rich nutrition and is digestible; and moreover, the product has delicate and smooth mouthfeel and high elasticity, and is tasty and not stuck on teeth in chewing.

Owner:东莞市圣心食品有限公司

High efficiency solidifying processing agent for waste sludge in oil area and its solidifying treating process

InactiveCN100503487CFacilitate chemical reactionsHigh strengthSludge treatment by de-watering/drying/thickeningWastewaterOil sludge

The invention relates to the treatment of waste drilling mud in oil fields in the technical field of environmental protection. The technical scheme of the present invention comprises two major parts. 1. High-efficiency solidification treatment agent for waste mud in the oil area: one part is composed of 1-3% ion precipitant, 1-2% gel breaker, and 2-8% adsorbent, which account for the weight of waste mud; the other part is composed of sedimentation It is composed of 5-20% of sulfoaluminate hardening agent, 2-4% of loosening agent and 2-8% of gypsum powder in the percentage of solid weight. 2. The treatment process of using the high-efficiency solidification treatment agent for waste mud in the oil area: first, mix the waste mud with the mixed ion precipitant and gel breaker in proportion and mix them evenly, and then add the adsorbent to the waste water after standing still for 1-3 hours Finally, stir, and then mix the separated settled solid with the mixed sulphoaluminate hardener, loosening agent, and gypsum powder in proportion and mix evenly, and then stop for 3-7 days until it is qualified. The invention has good water stability, the cured product meets the requirements of the planting soil, the raw materials are easy to purchase, the use is convenient, and the curing effect is good.

Owner:俞然刚

Rubber material for sealing cover of automatic injector and preparation process thereof

The invention relates to a rubber material for a sealing cover of an automatic injector and a preparation process thereof. The rubber material comprises a sealing plug and a sealing sleeve, wherein the sealing plug is prepared from the following components in parts by weight: 45 to 55 parts of silica gel C6-235, 45 to 55 parts of silica gel C6-265, 0.8 to 1.2 parts of 2,5-dimethyl-2,5-bis-(tert-butyl peroxide) hexane and 0.8 to 1.2 parts of carbon black; and the sealing sleeve is prepared from the following components in parts by weight: 95 to 105 parts of silica gel C6-235, 0.5 to 1.5 parts of 2,5-dimethyl-2,5-bis-(tert-butyl peroxide) hexane and 0.5 to 1.5 parts of carbon black. The process is simple, environmental pollution is avoided, production conditions are easy to control, the product quality is good, a small amount of dissolved substances are generated, the sealing sleeve does not need to be opened and directly enters the blood vessels of the human body together with the injection, and no harm is caused to the human body.

Owner:湖北华强药用制盖有限公司

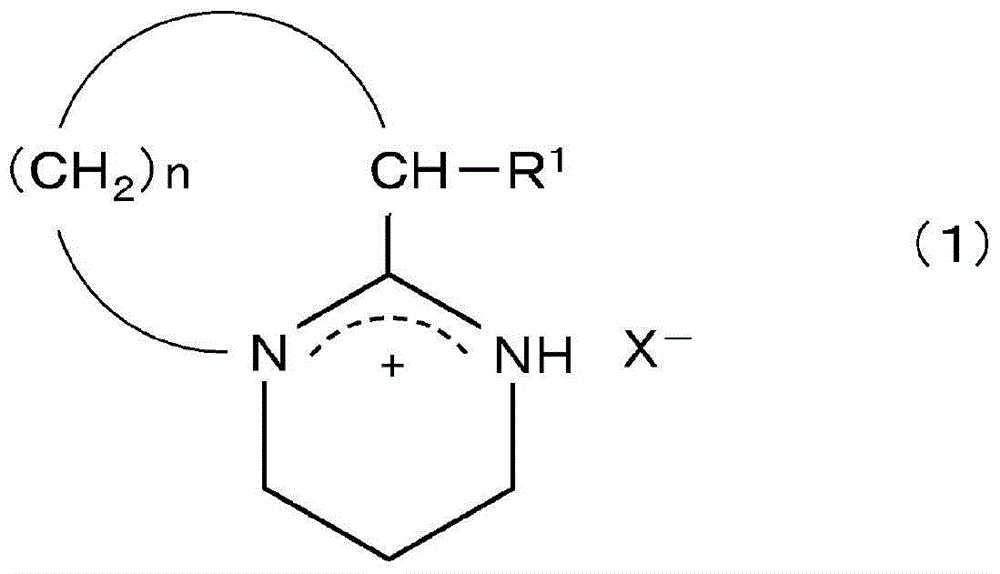

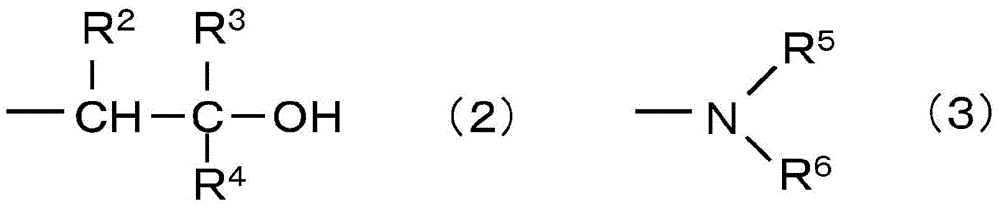

Polyurethane resin forming compositions for use in sealing membrane module

ActiveCN104114262ALow viscosityImprove injection effectSemi-permeable membranesOther chemical processesPolyolTurbidity

The purpose of the present invention is to provide polyurethane resin forming compositions which are for use in sealing a membrane module and exhibit excellent curability and castability and low turbidity and which can ensure excellent flatness of a cut section when used as a sealing material for a membrane module and which can form a polyurethane resin that is less susceptible to elution. The present invention provides two polyurethane resin forming compositions which are for use in sealing a membrane module, namely, a polyurethane resin forming composition which comprises a chief material that contains (A) an organic polyisocyanate component and a curing agent that contains (B) a polyol component and which is characterized in that the chief material and / or the curing agent contains (C) a bicyclic amidinium salt represented by general formula (1), and a polyurethane resin forming composition which is characterized by comprising a chief material that comprises (A) an organic polyisocyanate component, a curing agent that comprises (B) a polyol component, and (C) a bicyclic amidinium salt represented by general formula (1).

Owner:SANYO CHEM IND LTD

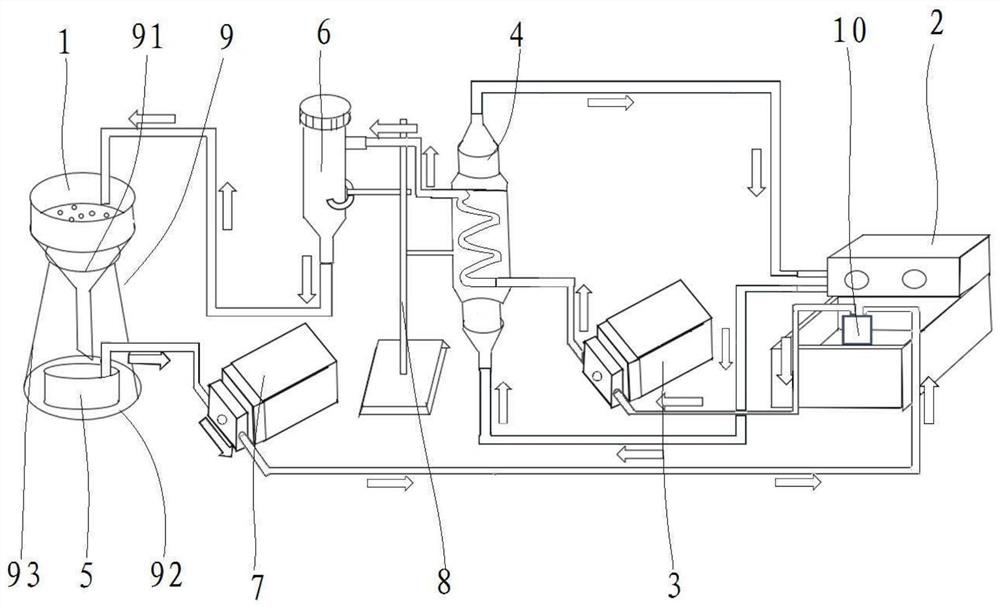

Organ perfusion equipment

PendingCN111925908ASmooth control of flow rateStable and precise flow rate controlBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpVena porta

The invention relates to the technical field of biomedicine, in particular to organ perfusion equipment which is characterized in that a water outlet of a thermostat water bath is communicated with awater inlet of a serpentine condenser pipe through a pipeline, and a water outlet of the serpentine condenser pipe is communicated with a constant-temperature water inlet of the thermostat water baththrough a pipeline; a perfusion bottle is arranged in the thermostat water bath, the perfusion bottle is sequentially communicated with a first peristaltic pump and the serpentine condenser pipe through a pipeline, a water outlet in the upper end of an inner pipe of the serpentine condenser pipe is used for being communicated with an inferior vena cava or a portal vena cava of a liver arranged atthe upper end of the Buchner funnel through a pipeline; and a liquid receiving cup is arranged vertically below the Buchner funnel. The equipment has the beneficial effects that the thermostat water bath is connected with the serpentine condenser pipe to maintain the constant temperature of a perfusate flowing in the pipeline; the peristaltic pump replaces manual operation to propel the perfusate,so that the flow velocity of the perfusate can be stably and accurately controlled, and the perfusion operation can be stably and continuously operated for a long time; a perfused enzyme liquid can be recycled, so that the perfusion operation cost is reduced.

Owner:立沃生物科技(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com