A kind of heparin cap transparent rubber pad for indwelling needle and preparation method thereof

A transparent rubber and heparin cap technology, which is applied in the field of heparin cap transparent rubber pads for indwelling needles, can solve the problems of product pH change value and ultraviolet absorbance easily exceeding the standard, transparent rubber pad transparency is not high, chemical cleanliness needs to be improved, etc., to achieve Less extractables, excellent compatibility, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

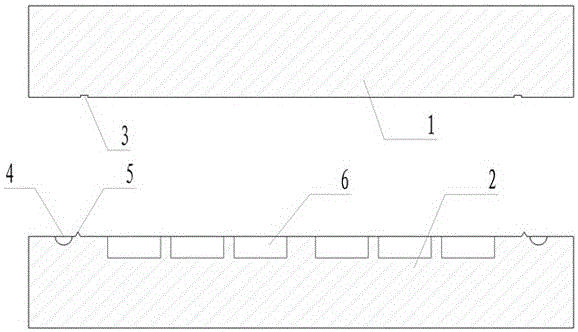

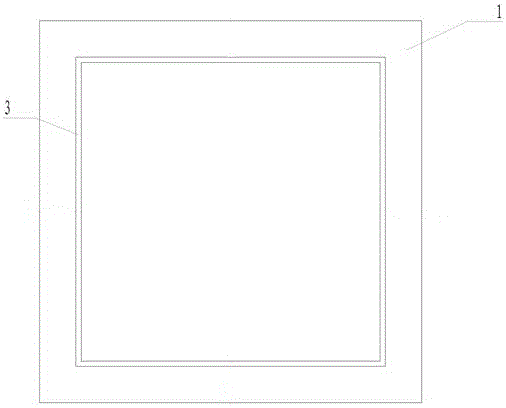

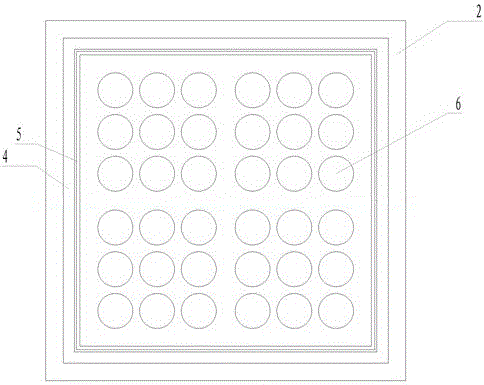

Image

Examples

Embodiment 1

[0024] The heparin cap transparent rubber pad for the indwelling needle of this embodiment is prepared from the following raw materials in parts by weight:

[0025] Polyisoprene rubber IR307 100 parts

[0026] 3 parts styrene-ethylene-butylene-styrene copolymer

[0027] Basic white carbon black MD1250 1 part

[0028] Dicumyl peroxide 1.5 parts

[0029] A preparation method of a heparin cap transparent rubber pad for indwelling needles, the steps are as follows:

[0030] (1) Accurately weigh the above-mentioned raw materials in parts by weight, formulate a suitable production formula for batching, and use a powerful pressurized internal mixer to mix the prepared raw materials evenly. The mixing cycle time is 6 minutes. The actual temperature is 90°C, and the mixed rubber is prepared for use;

[0031] (2) Cut the mixed rubber into strips on the open rubber mixer, park for 24 hours, and make mixed rubber strips for later use;

[0032] (3) Put the mixed rubber strip into the ...

Embodiment 2

[0036] The heparin cap transparent rubber pad for the indwelling needle of this embodiment is prepared from the following raw materials in parts by weight:

[0037] Polyisoprene rubber IR307 100 parts

[0038] Styrene-ethylene-butylene-styrene copolymer 10 parts

[0039] Basic white carbon black MD1250 10 parts

[0040] 2,5-Dimethyl-2,5-bis(tert-butyl peroxide) 0.3 parts

[0041] A preparation method of a heparin cap transparent rubber pad for indwelling needles, the steps are as follows:

[0042] (1) Accurately weigh the above-mentioned raw materials in parts by weight, formulate a suitable production formula for batching, and use a powerful pressurized internal mixer to mix the prepared raw materials evenly. The mixing cycle time is 8 minutes. The actual temperature is 110°C, and the mixed rubber is prepared for use;

[0043] (2) Cut the mixed rubber into strips on the open rubber mixer, park for 18 hours, and make mixed rubber strips for later use;

[0044](3) Put the ...

Embodiment 3

[0048] The heparin cap transparent rubber pad for the indwelling needle of this embodiment is prepared from the following raw materials in parts by weight:

[0049] Polyisoprene rubber IR307 100 parts

[0050] Styrene-ethylene-butylene-styrene copolymer 5 parts

[0051] Basic white carbon black MD1250 5 parts

[0052] 1 part cumene tert-butyl peroxide

[0053] A preparation method of a heparin cap transparent rubber pad for indwelling needles, the steps are as follows:

[0054] (1) Accurately weigh the above-mentioned raw materials in parts by weight, formulate a suitable production formula for batching, and use a powerful pressurized internal mixer to mix the prepared raw materials evenly. The mixing cycle time is 6 minutes. The actual temperature is 100°C, and the mixed rubber is prepared for use;

[0055] (2) Cut the mixed rubber into strips on the open rubber mixer, park for 12 hours, and make mixed rubber strips for later use;

[0056] (3) Put the mixed rubber strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com