Patents

Literature

1572 results about "Polyprenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

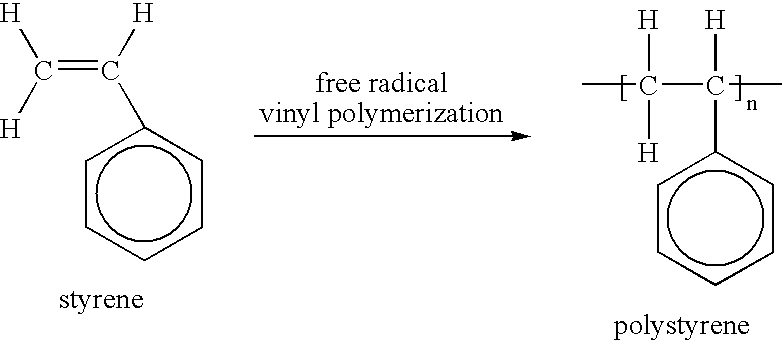

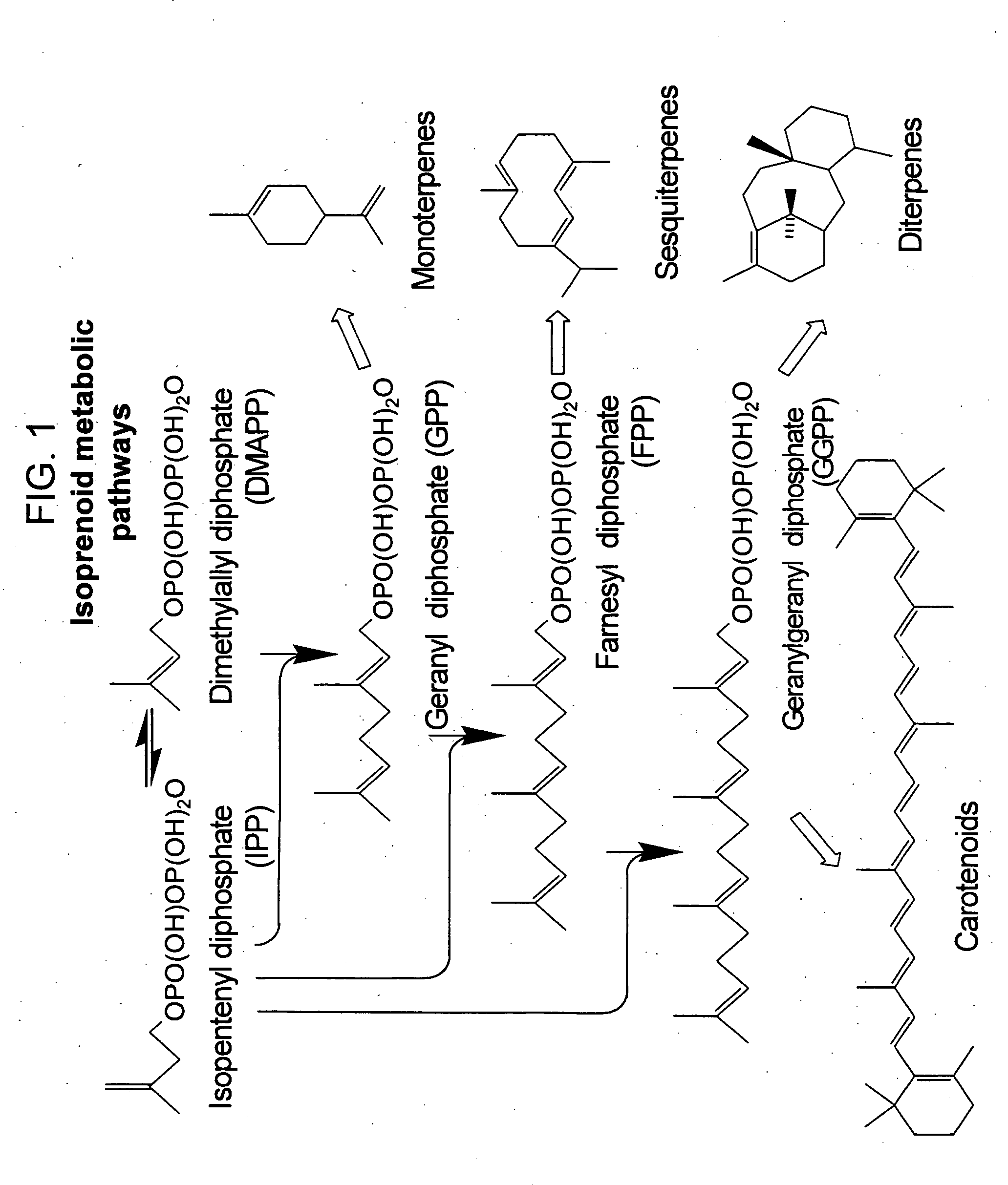

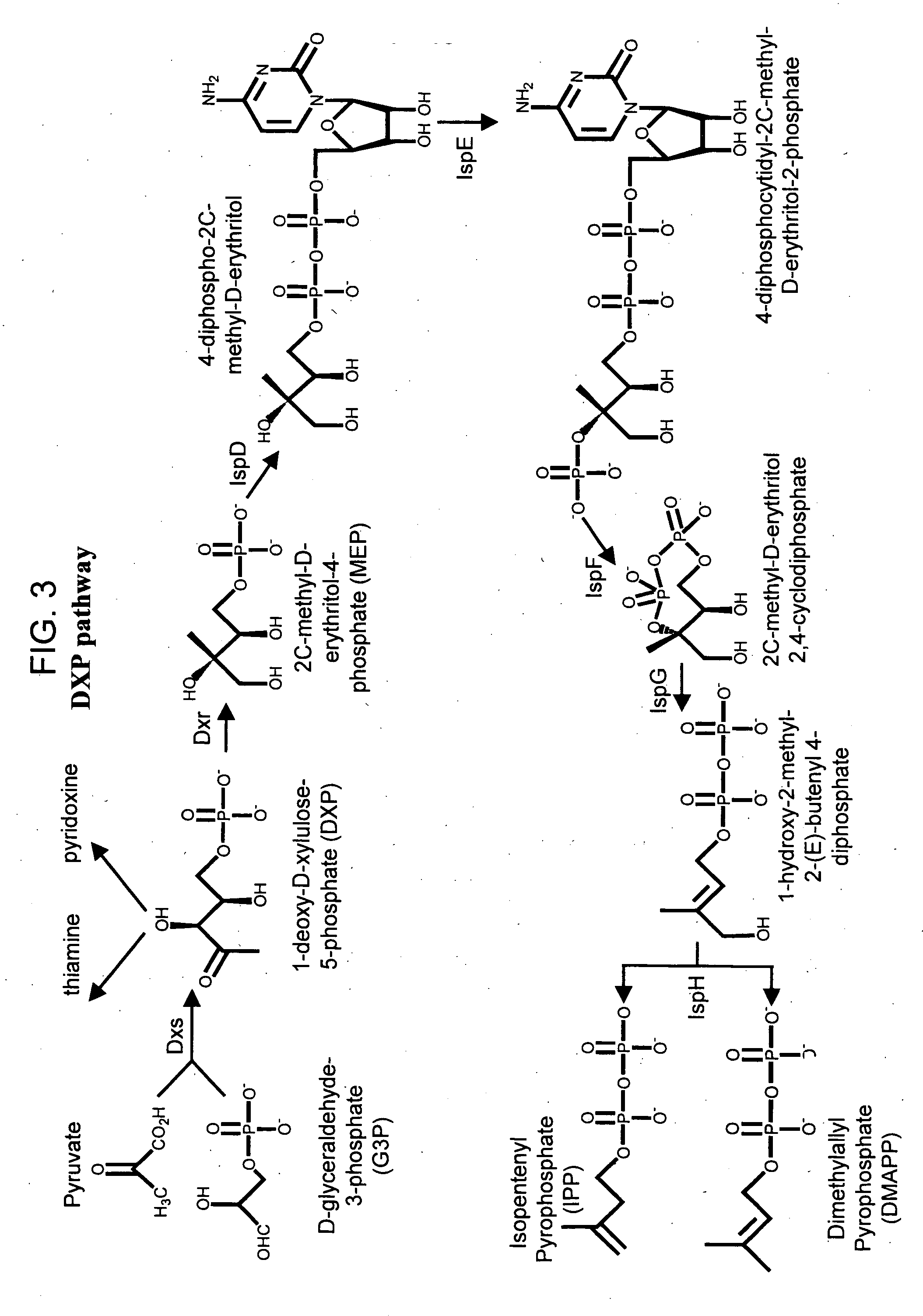

Polyprenols are natural long-chain isoprenoid alcohols of the general formula H-(C₅H₈)n-OH where n is the number of isoprene units. Any prenol with more than 4 isoprene units is a polyprenol. Polyprenols play an important function acting as natural bioregulators and are found in small quantities in various plant tissues. Dolichols, which are found in all living creatures, including humans, are their 2,3-dihydro derivatives.

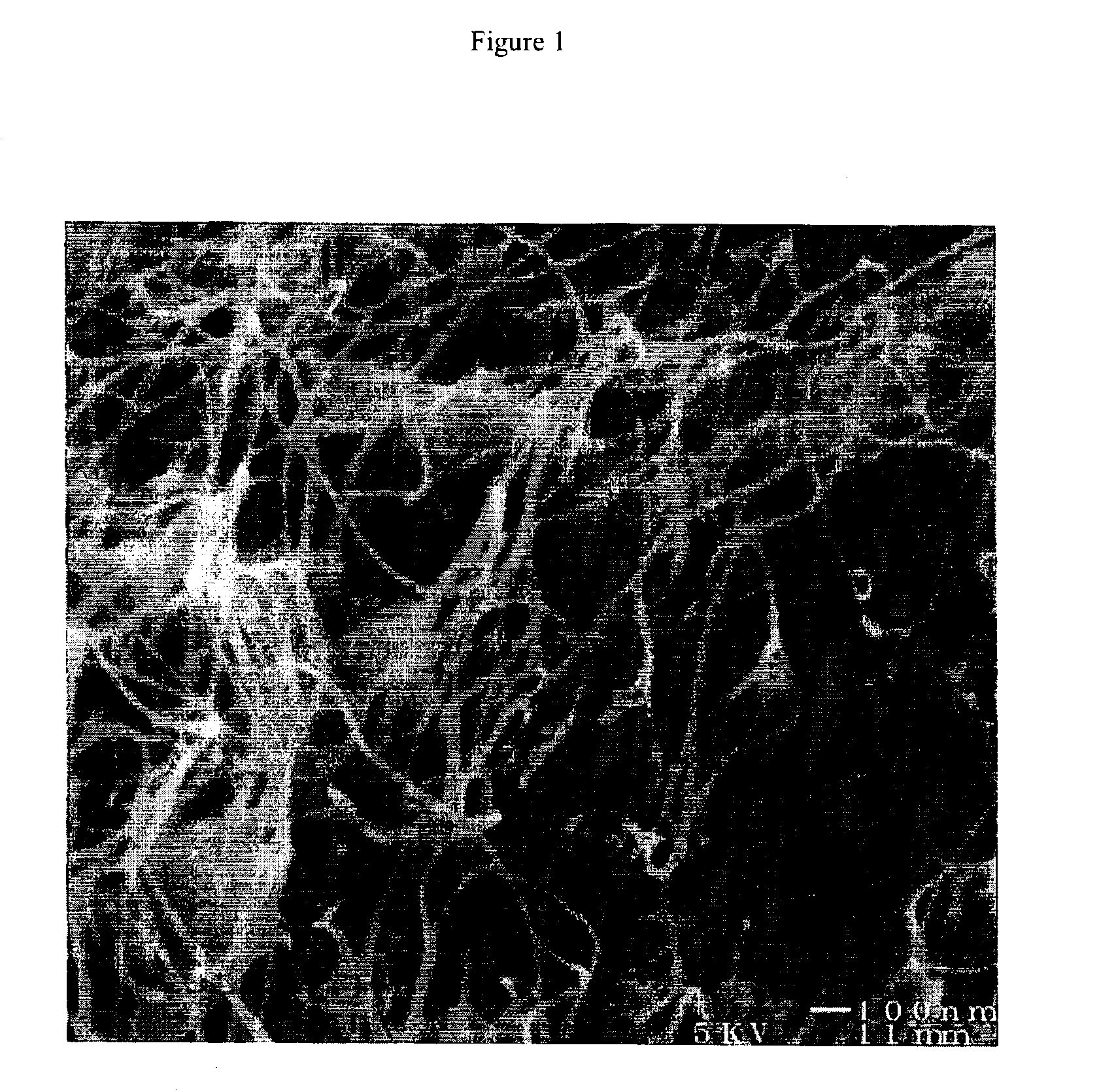

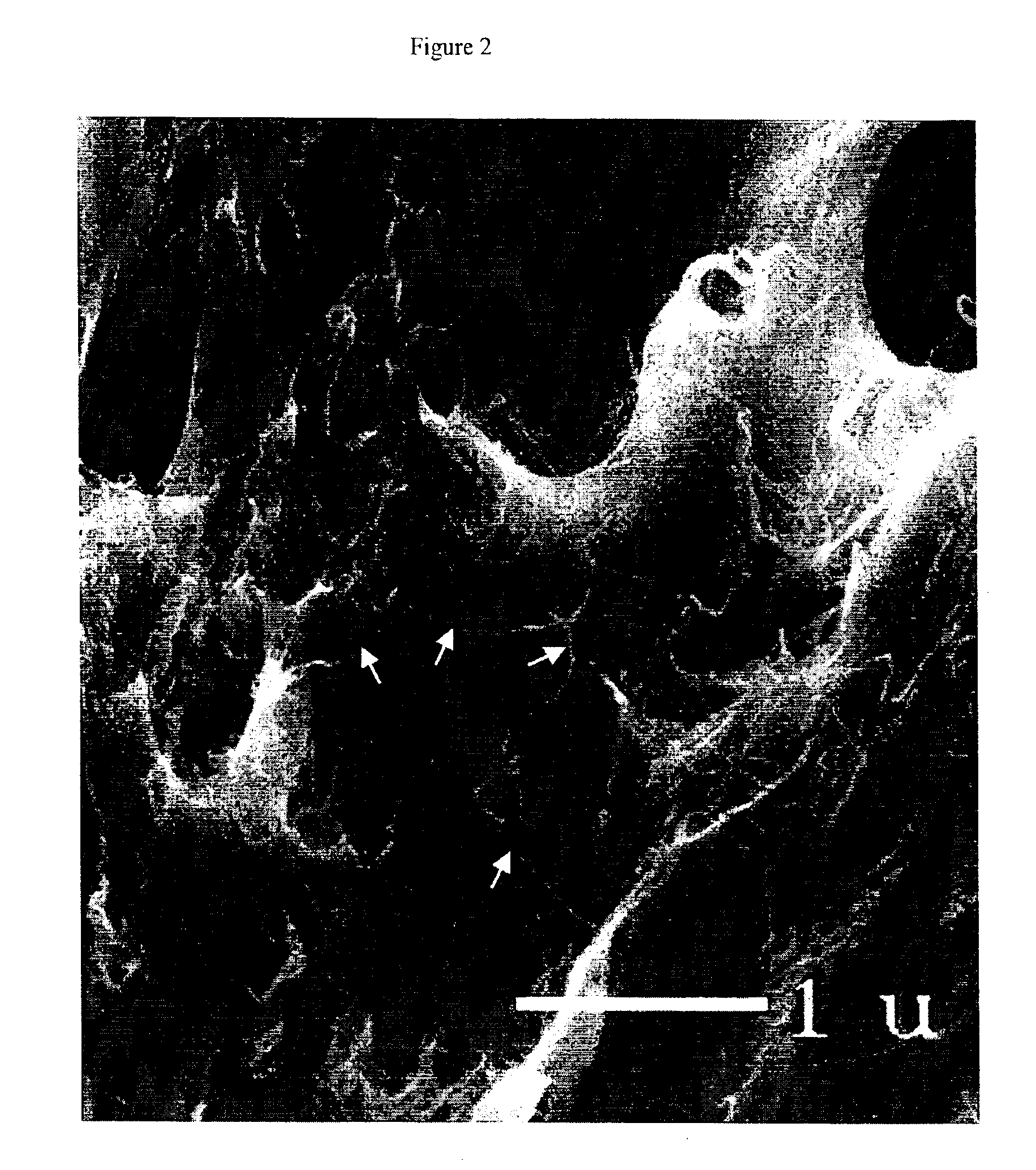

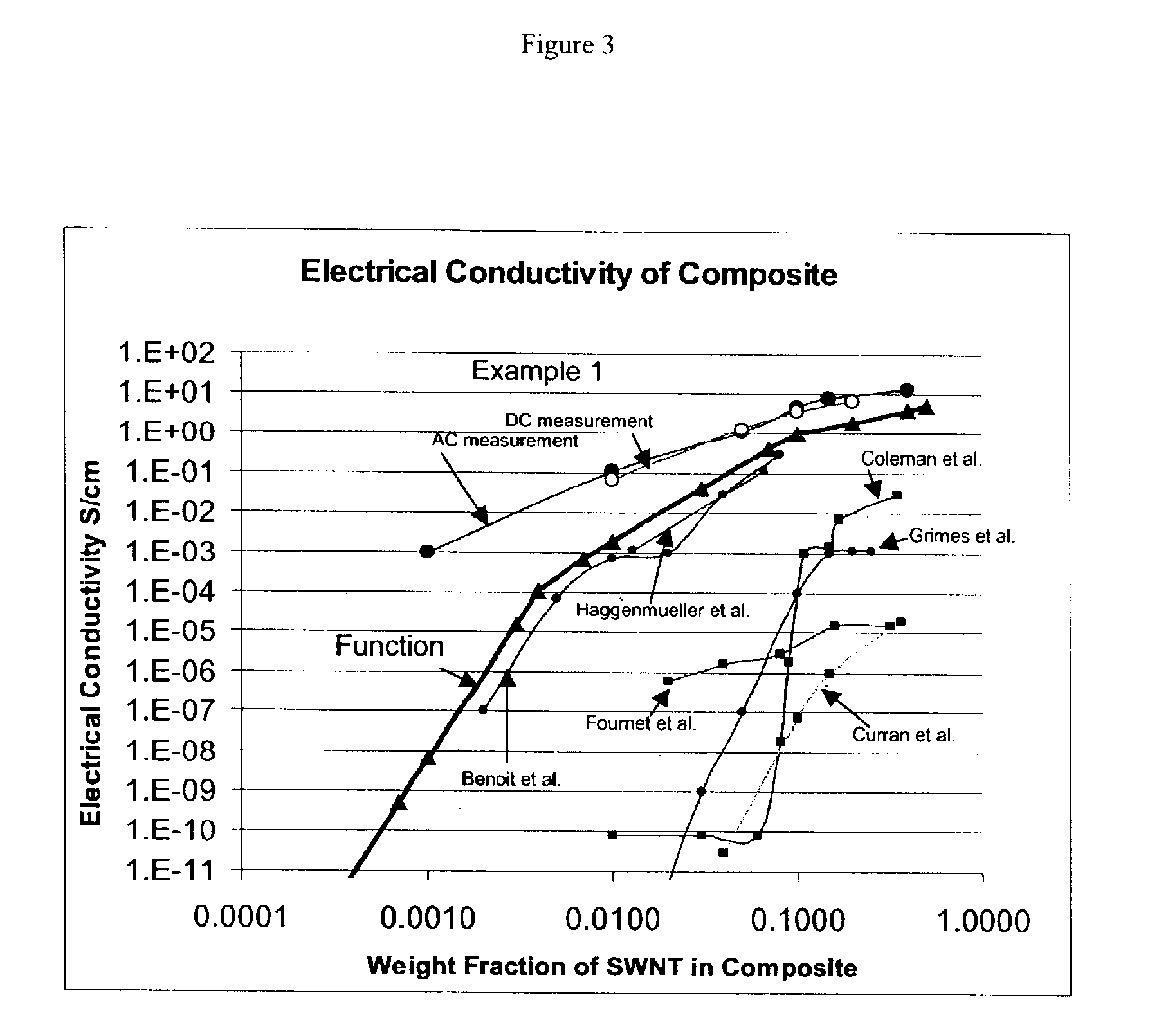

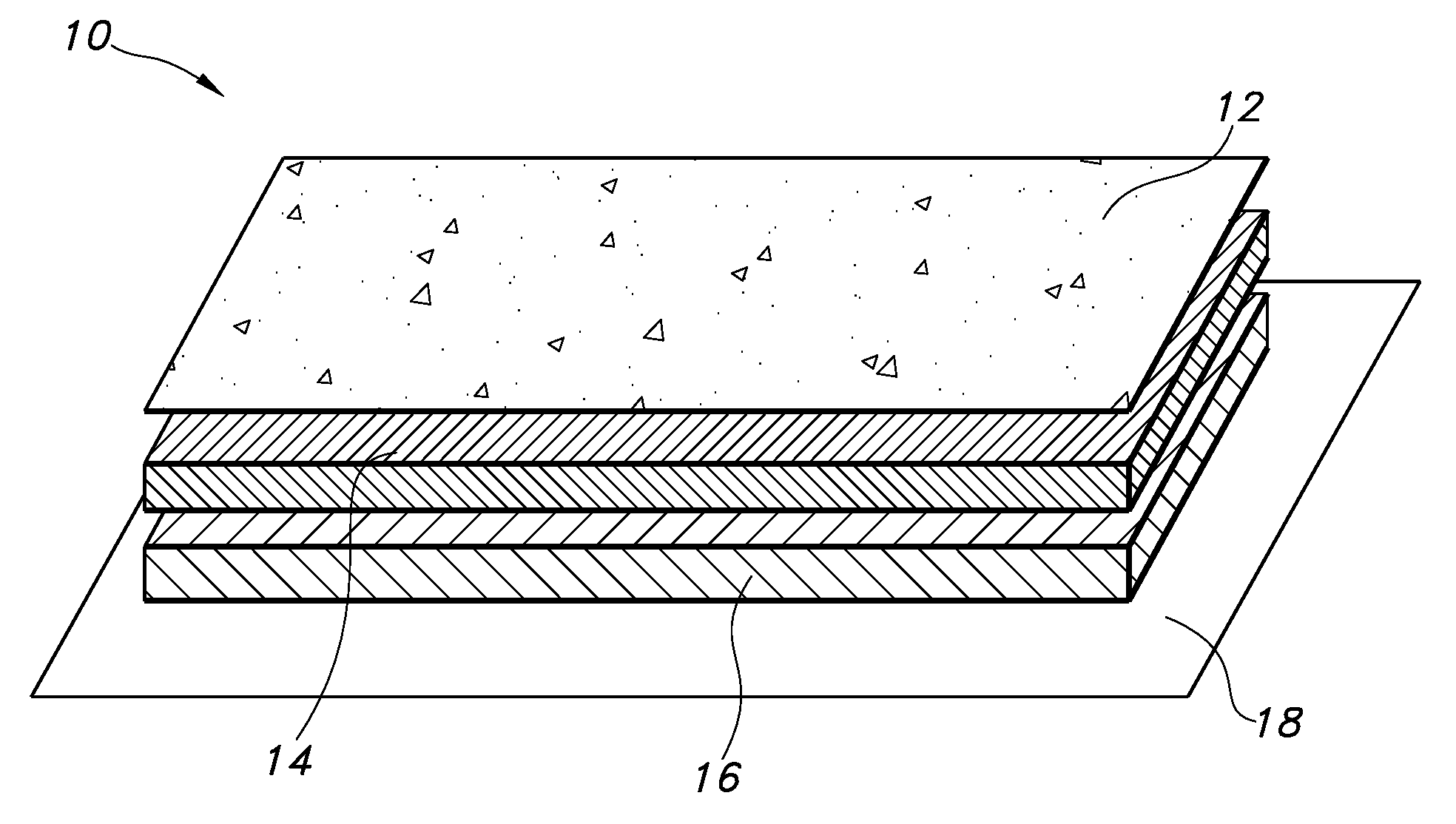

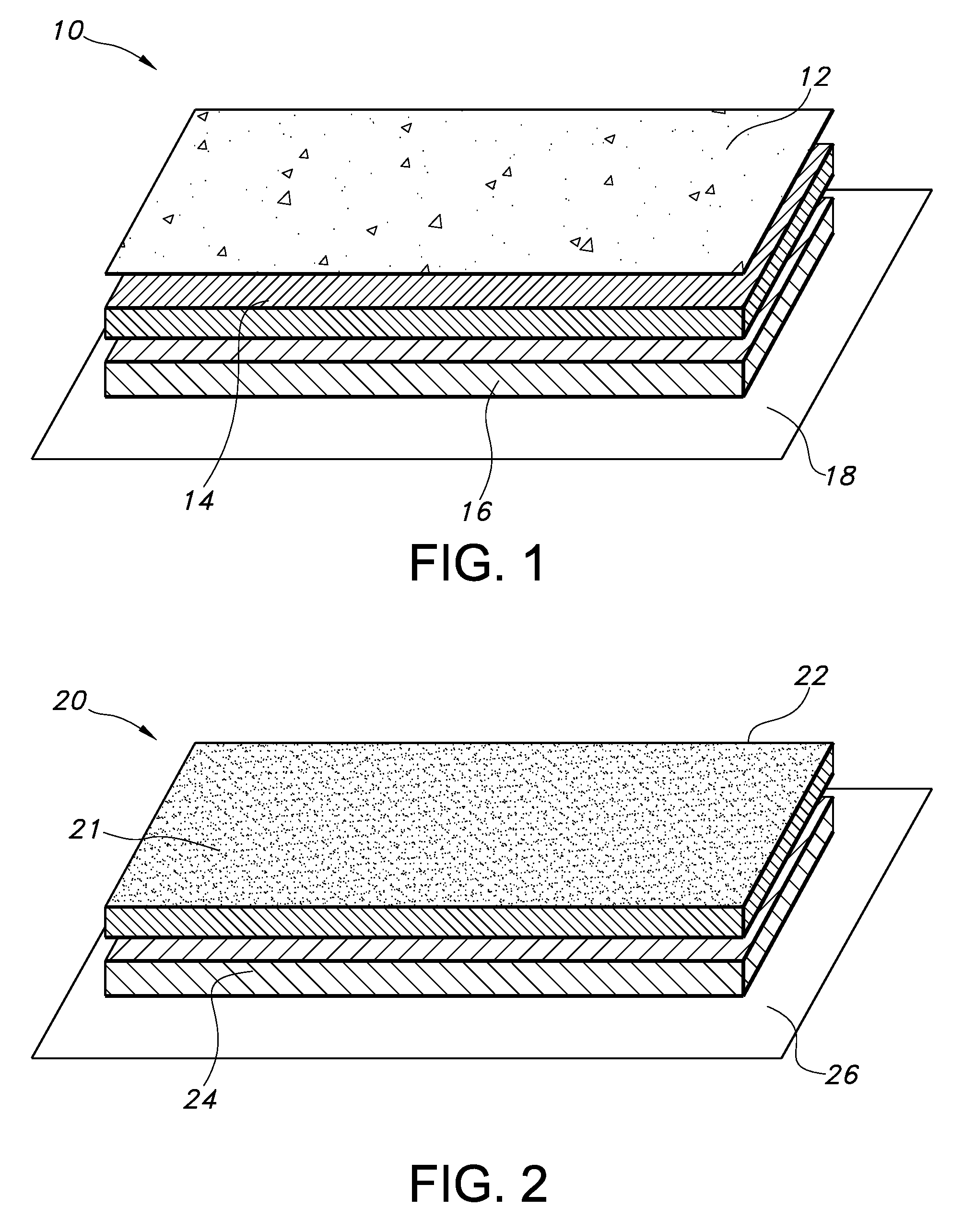

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

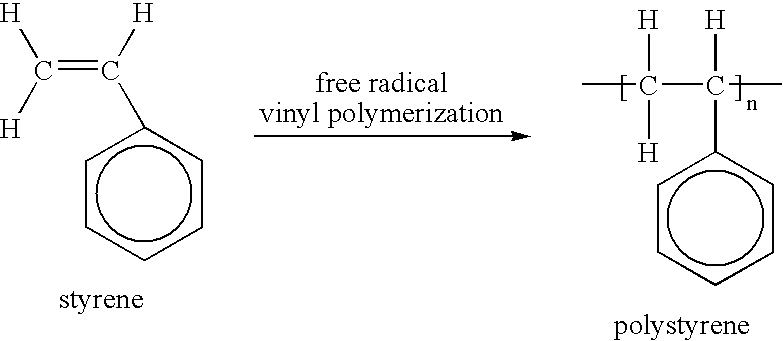

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

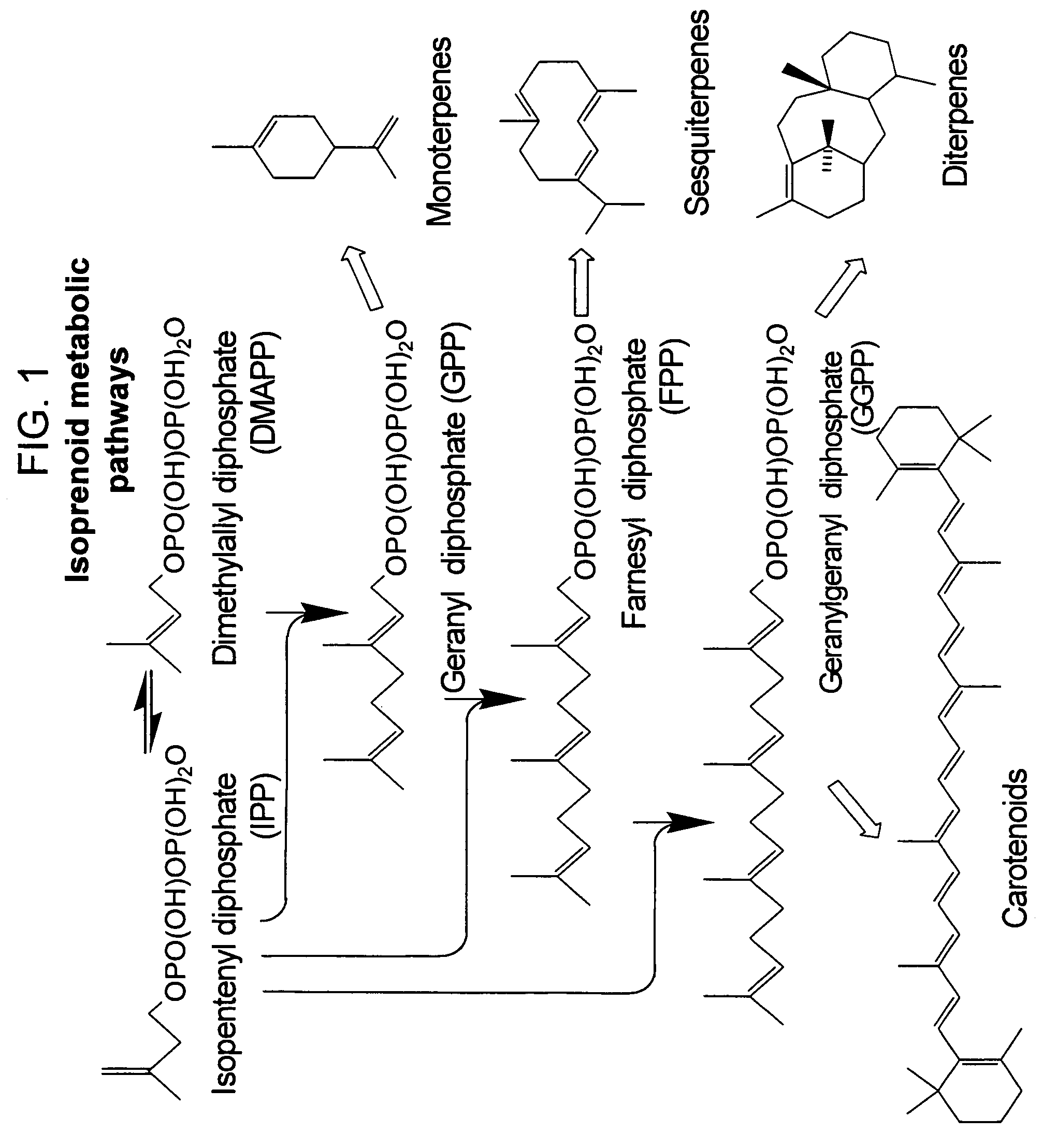

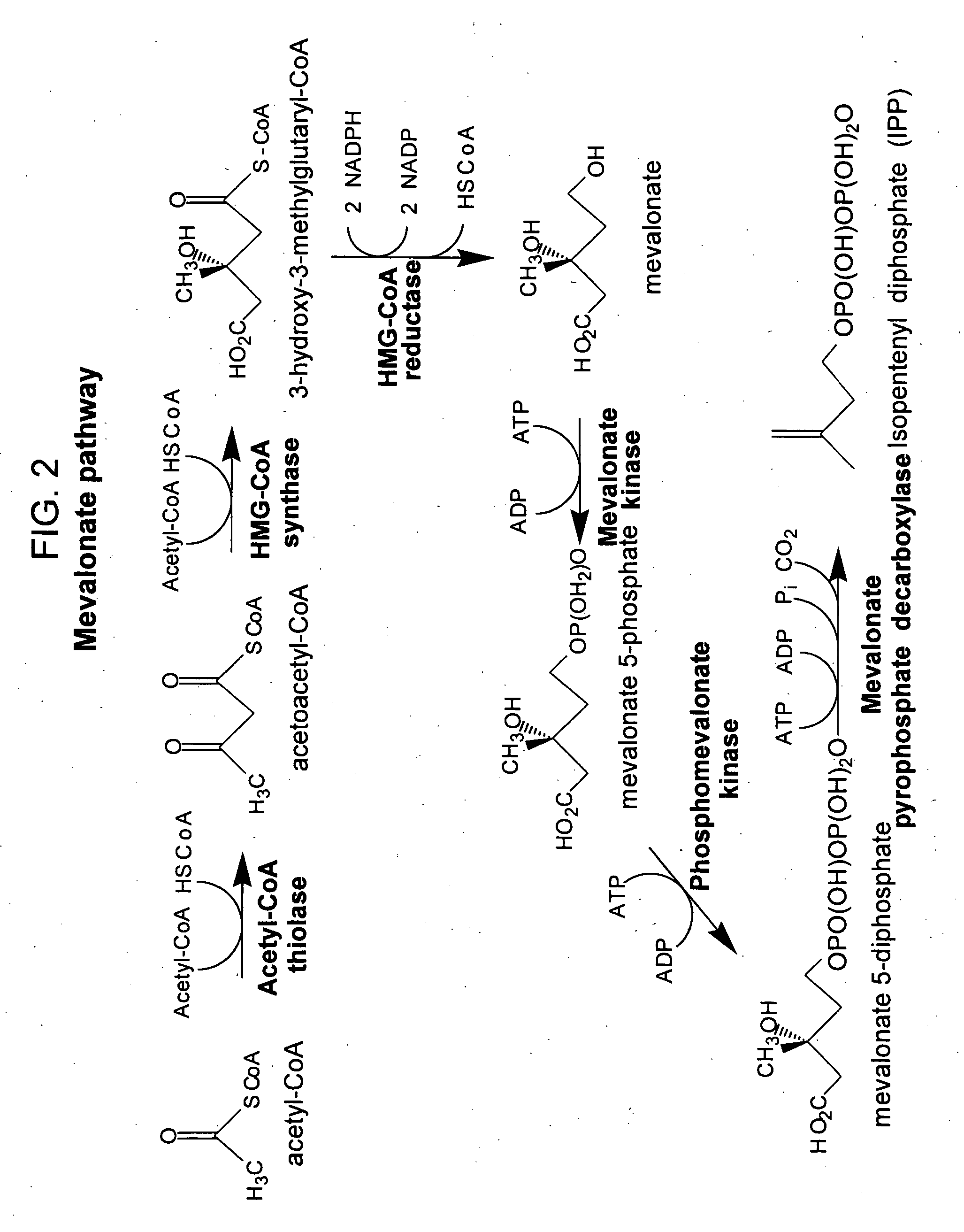

Method for enhancing production of isoprenoid compounds

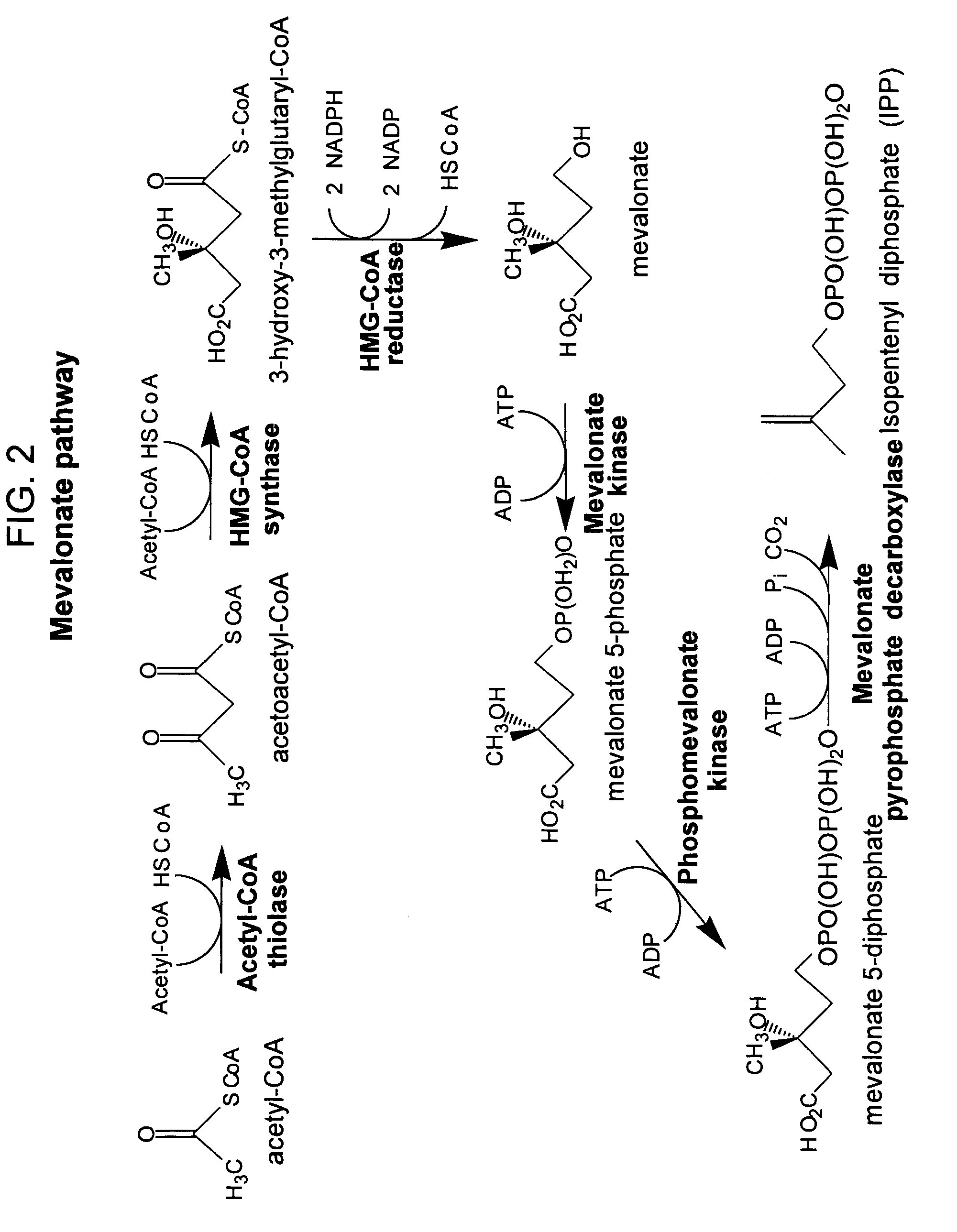

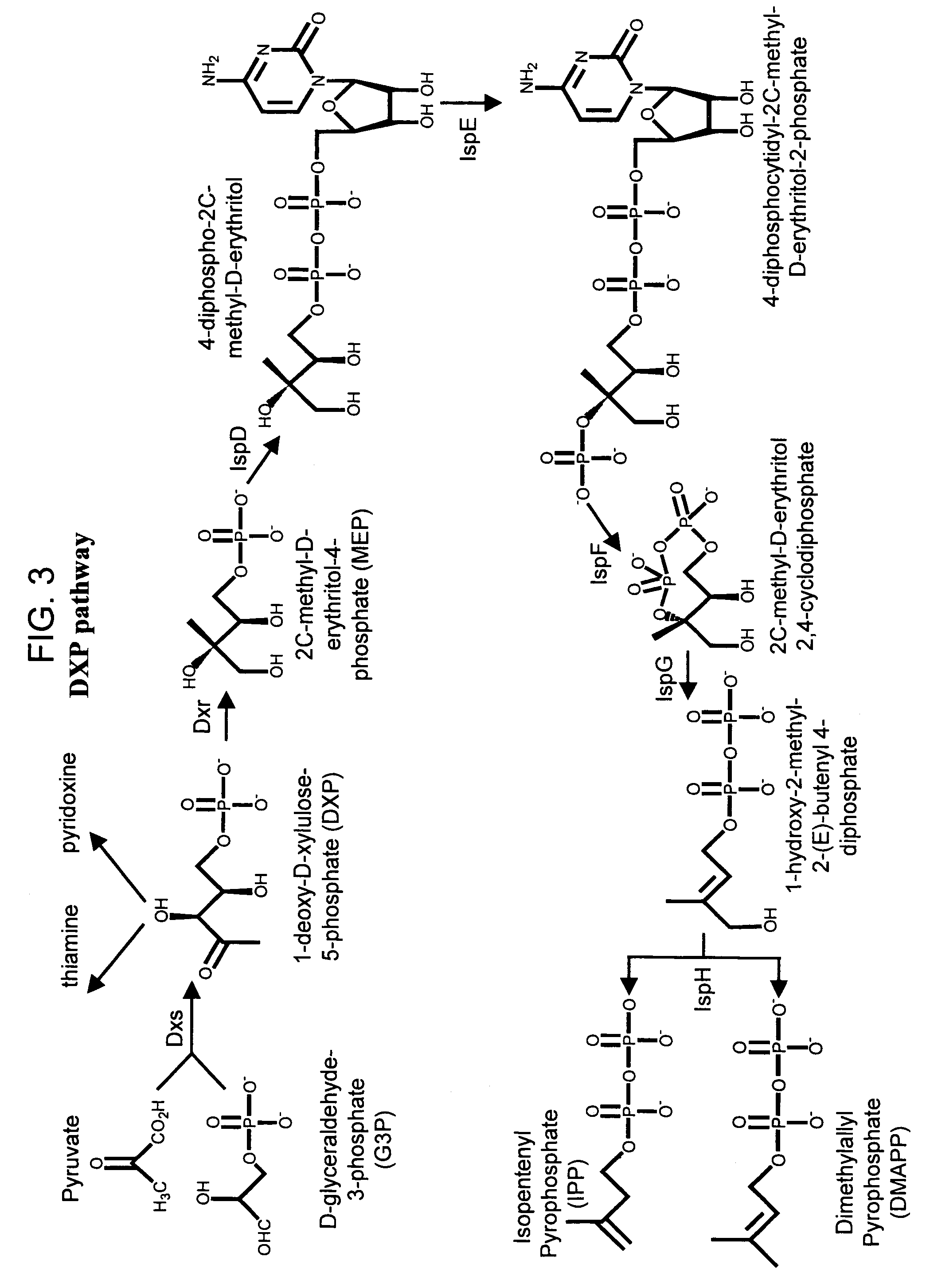

The present invention provides methods of producing an isoprenoid or an isoprenoid precursor in a genetically modified host cell. The methods generally involve modulating the level of hydroxymethylglutaryl-CoA (HMG-CoA) in the cell, such that the level of HMG-CoA is not toxic to the cell and / or does not substantially inhibit cell growth, but is maintained at a level that provides for high-level production of mevalonate, IPP, and other downstream products of an isoprenoid or isoprenoid pathway, e.g., polyprenyl diphosphates and isoprenoid compounds. The present invention further provides genetically modified host cells that are suitable for use in a subject method. The present invention further provides recombinant nucleic acid constructs for use in generating a subject genetically modified host cell, including recombinant nucleic acid constructs comprising nucleotide sequences encoding one or more mevalonate pathway enzymes, and recombinant vectors (e.g., recombinant expression vectors) comprising same. The present invention further provides methods for identifying nucleic acids that encode HMG-CoA reductase (HMGR) variants that provide for relief of HMG-CoA accumulation-induced toxicity. The present invention further provides methods for identifying agents that reduce intracellular accumulation of HMG-CoA.

Owner:RGT UNIV OF CALIFORNIA

Tire with silica reinforced tread and/or sidewall components

The present invention relates to the preparation of rubber compositions for tire tread and tire sidewall component applications. A tire is provided having tread of such composition designed for relatively heavy loads such as, for example, truck tires. A tire having a sidewall of such composition is also provided. Such tire component rubber compositions are of rubber compositions reinforced with precipitated silica and selected carbon black in specified amounts and prepared with a prescribed order of addition to the rubber composition and composed of elastomers as a specific combination of natural or synthetic cis 1,4-polyisoprene rubber together with cis 1,4-polybutadiene rubber or with a combination of cis 1,4-polybutadiene rubber and trans 1,4-polybutadiene rubber.

Owner:THE GOODYEAR TIRE & RUBBER CO

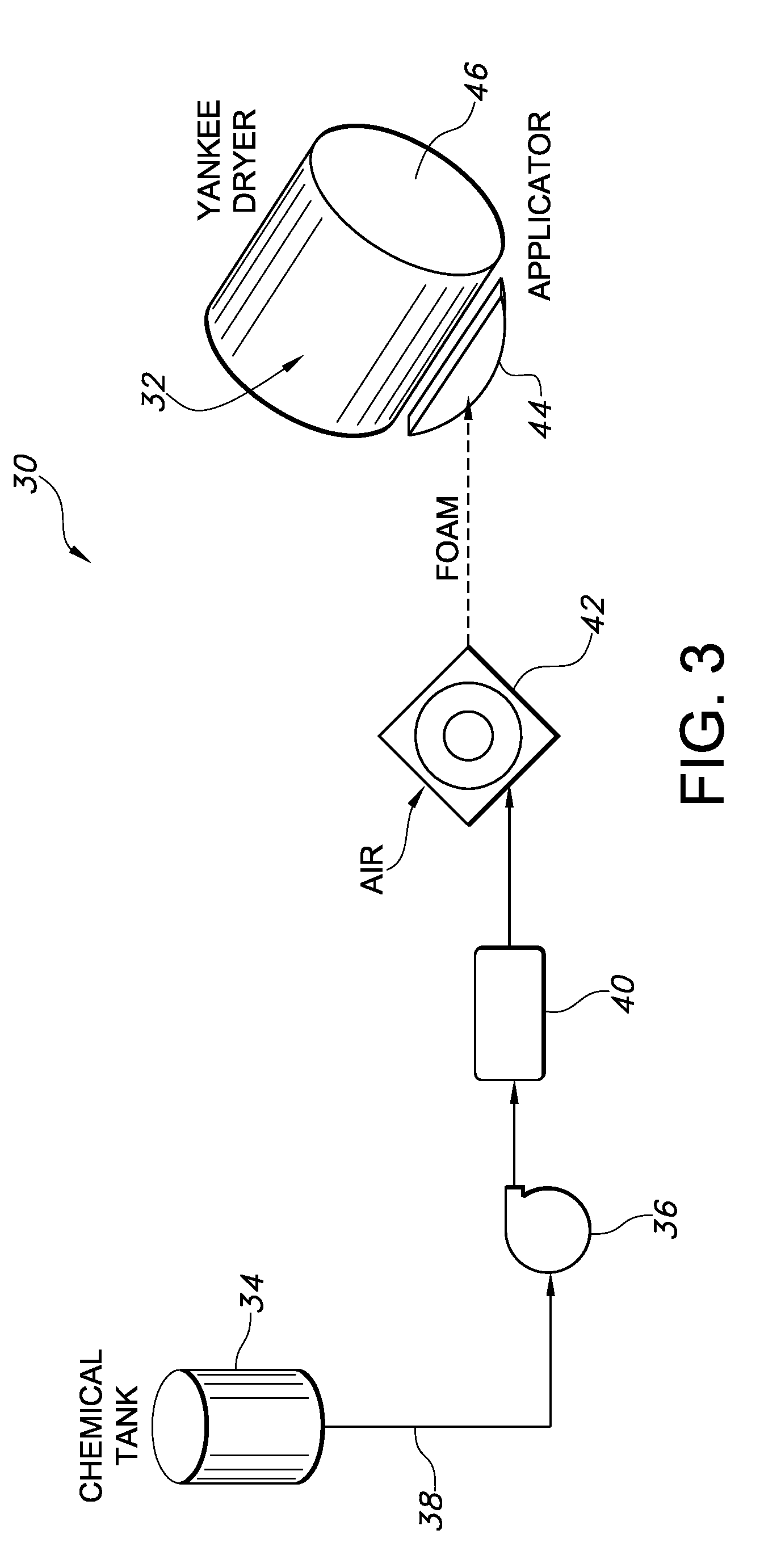

Enhanced personal care absorbent articles

The present invention relates to a personal care absorbent article comprising at least two substrates each having an internal and external surface, wherein at least one substrate is a fluid permeable bodyside substrate selected from spunbond, meltblown, coform, airlaid, bonded-carded web, spunlace materials and combinations thereof; at least one substrate is an impermeable backsheet; and an absorbent core disposed in between said substrates; wherein at least the external surface of at least one substrate has applied to it a benefit agent selected from an additive composition wherein said additive composition is a polymer dispersion selected from polyolefin dispersions, polyisoprene dispersions, polybutadiene-styrene block copolymer dispersions, latex dispersions, polyvinyl pyrrolidone-styrene copolymer dispersions, polyvinyl alcohol-ethylene copolymer dispersions, and combinations thereof; an enhancement component selected from microparticles, expandable microspheres, fibers, additional polymer dispersions, scents, anti-bacterials, moisturizers, medicaments, soothers and combinations thereof; and combinations thereof.

Owner:KIMBERLY-CLARK WORLDWIDE INC

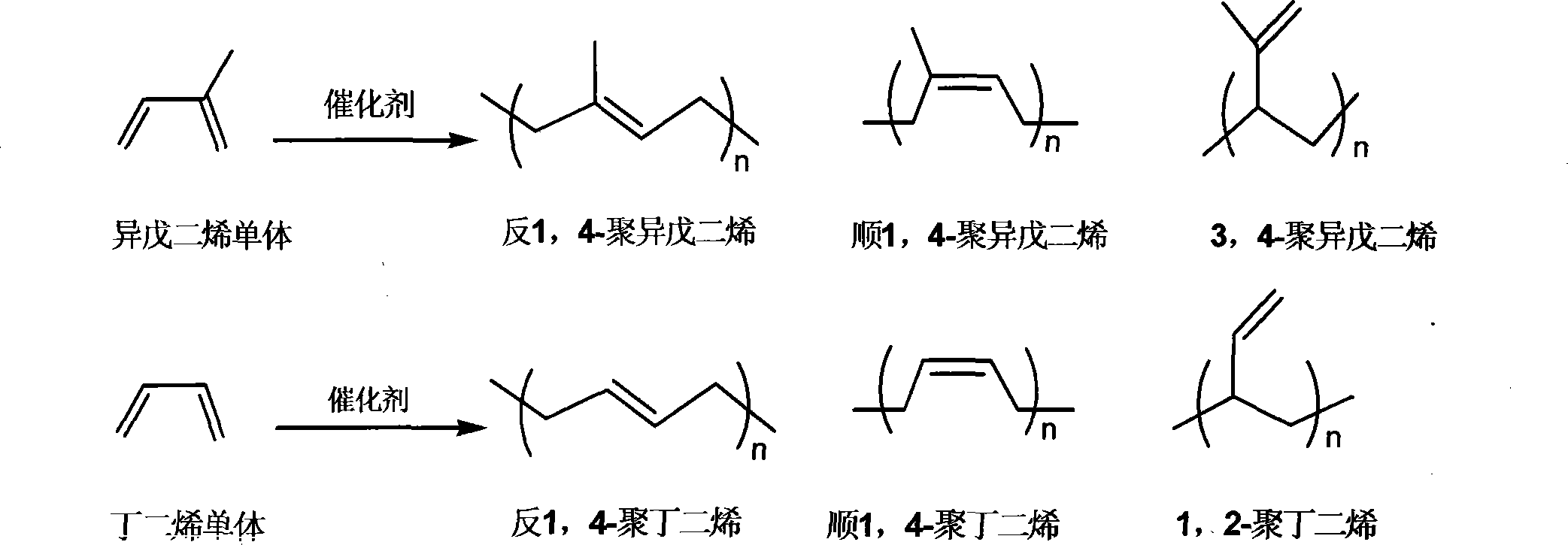

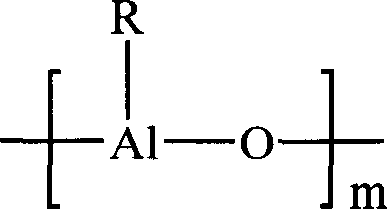

Rare earth catalyst for preparing polyisoprene and preparation method and method for preparing polyisoprene

This invention belongs to rare earth catalyzer for preparing polyisoprene, and its preparation method. This catalyzer is composed by carboxylic acid neodymium, aluminium alkyl, chloride, conjugated diolefine. Mixture ratio of aluminium alkyl, chloride, conjugated diolefine,and carboxylic acid neodymium is 5 - 30:1.0 -4.0:5 - 20:1. This invention could obtain homogeneous phase and stable rare earth catalyzer. This catalyzer possess higher catalytic activity, trigger off isoprene polymerization at higher polymerization temperature, obtain polyisoprene that has high content of syn- 1, 4 structure( not less than 96 percent) and narrow molecular weight distribution ( less than 3.0), and possess tensile crystallinity trait.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Pneumatic tire

The invention is directed to a pneumatic tire having a tread including a vulcanizable rubber composition including, expressed as parts by weight per 100 parts by weight of elastomer (phr),(A) 60 to 95 phr of solution-polymerized styrene-butadiene rubber with a bound styrene content of from 20 to 30 percent by weight, a vinyl 1,2 content of from 50 to 70 percent by weight based on the butadiene content, and a Tg of from about −40° C. to about −20° C.;(B) 5 to 15 phr of cis-1,4 polybutadiene having a Tg of from −95° C. to −105° C.;(C) 10 to 20 phr of 3,4-polyisoprene;(D) 30 to 70 phr of processing oil;(E) 10 to 30 phr of carbon black having an Iodine absorption ranging from 192 to 212 g / kg according to ASTM D-1510 and an oil absorption ranging from 126 to 142 cc / 100 g according to ASTM D-2414;(F) 90 to 110 phr of silica;(G) 0.5 to 20 phr of a sulfur containing organosilicon compound; and(H) 10 to 20 phr of resin.

Owner:THE GOODYEAR TIRE & RUBBER CO

Thermoplastic elastomer composition

InactiveUS20050288393A1Low costGood oil resistanceFilm/foil adhesivesCoatingsThermoplastic elastomerPolystyrene

A thermoplastic elastomer composition comprised of (a) a thermoplastic resin selected from the group consisting of polyphenylene ether, polypropylene, polyethylene, and polystyrene, (b) a block copolymer selected from the group consisting of styrene-ethylene butylene-styrene, styrene-ethylene propylene-styrene, hydrogenated polybutadiene, hydrogenated polyisoprene, hydrogenated styrene-isoprene random copolymer, styrene-ethylene propylene block copolymer, styrene-ethylene ethylene propylene-styrene and hydrogenated styrene-butadiene random copolymers, (c) a core-shell polymer comprised of a polymeric core and a polymeric shell with the proviso that the polymeric core and / or the polymeric shell may be crosslinked, and (d) an oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

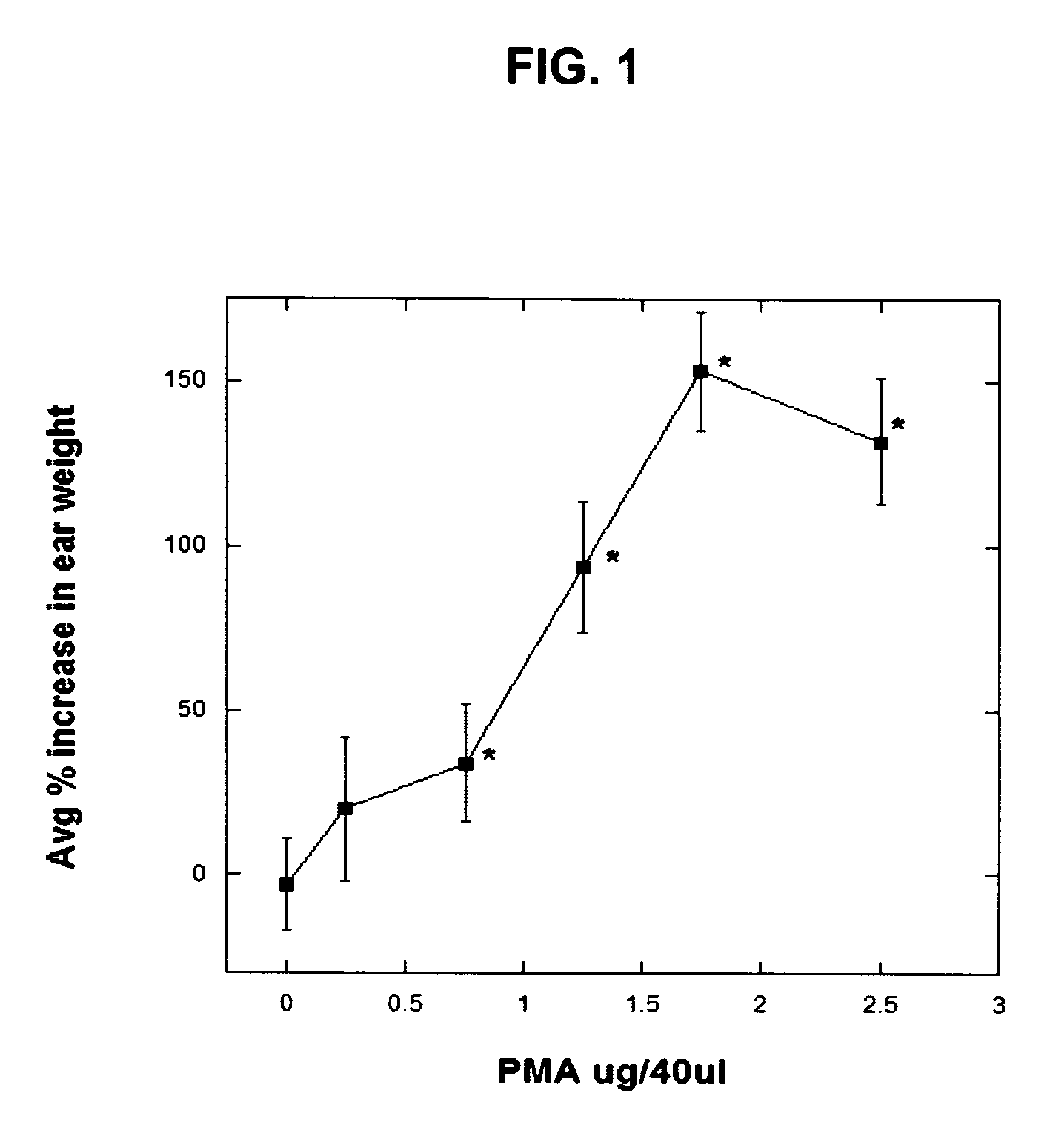

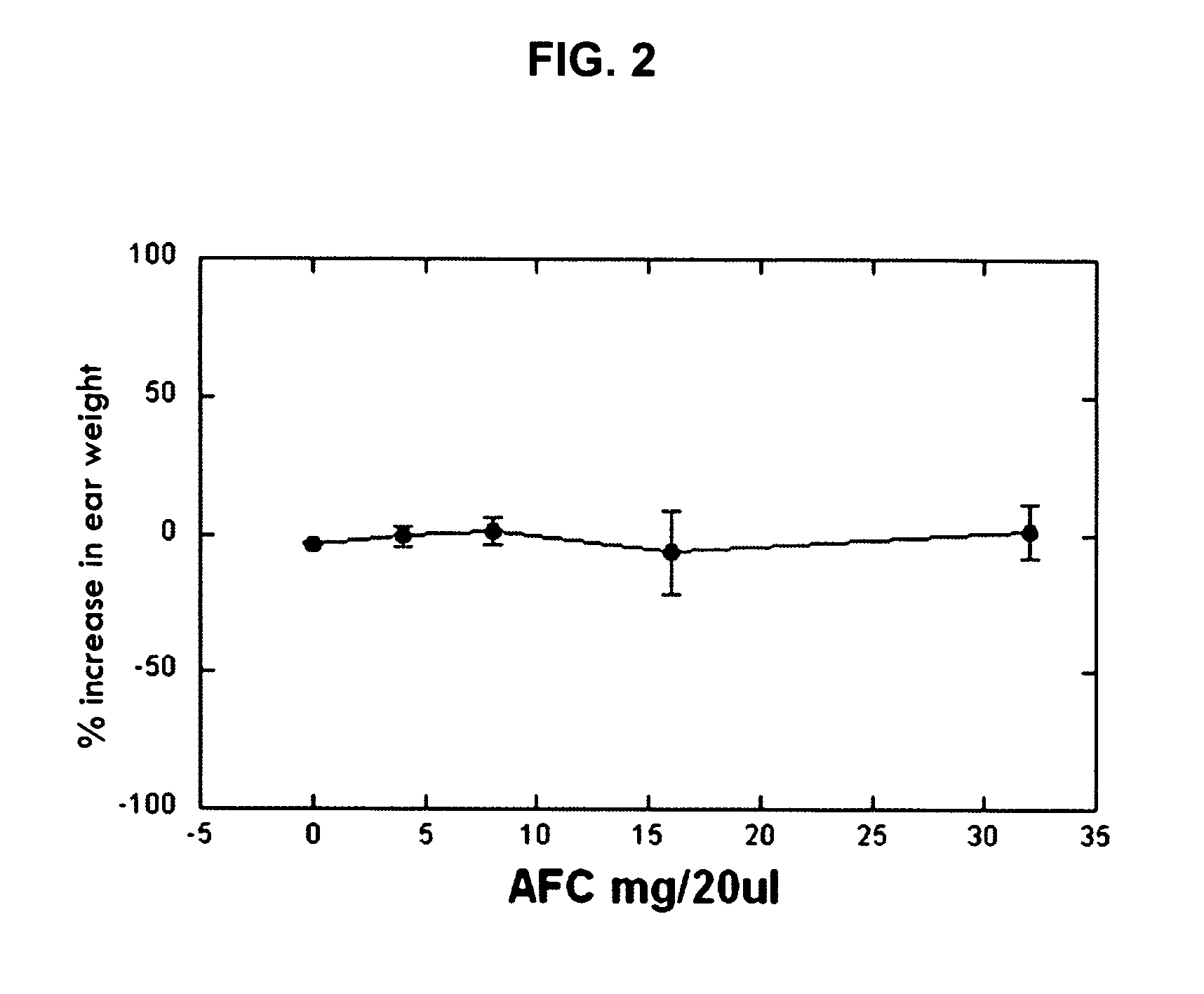

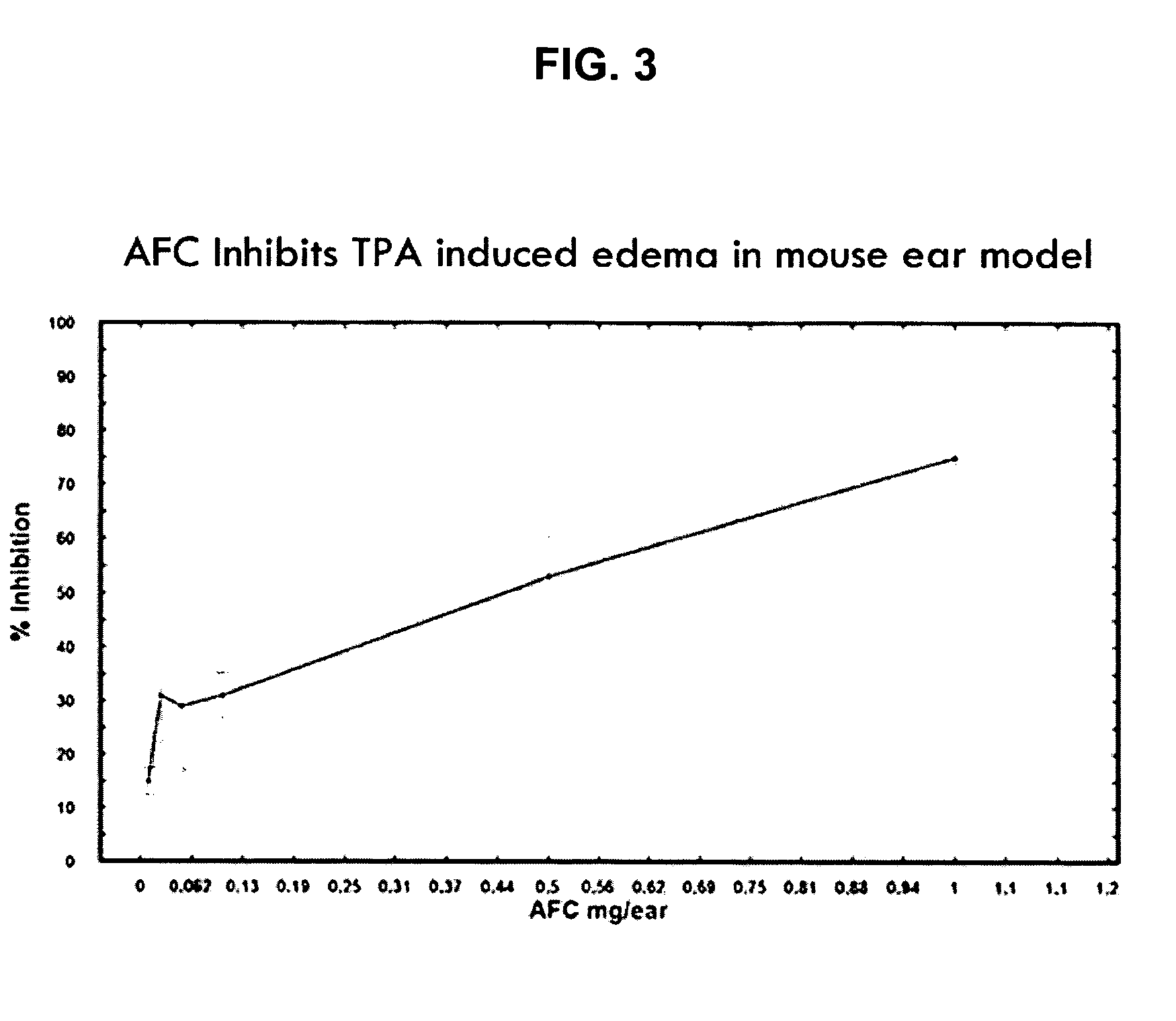

Topical compositions and methods for epithelial-related conditions

The present invention relates to pharmaceutical, cosmetic and cosmeceutical topical compositions containing polyisoprenyl-protein inhibitor compounds and methods useful in the promotion of healthy epithelium and the treatment of epithelial-related conditions

Owner:BRANDCO ELIZABETH ARDEN 2020 LLC

Pneumatic tire having built-in sealant layer and preparation thereof

This invention relates to a pneumatic tire having a built-in sealant layer and its preparation. The sealant layer precursor is a layer of a butyl rubber based composition which contains an organoperoxide. The butyl rubber of said precursor is a copolymer of isobutylene and isoprene containing from about 0.5 to about 5, alternately less than 1, mole percent isoprene. The precursor composition contains carbon black and / or coal dust and may contain a dispersion of liquid conjugated diene polymer (e.g. liquid cis 1,4-polyisoprene polymer), short fibers and / or hollow glass microspheres. A layer of the sealant precursor is built into the tire between a sulfur vulcanized halobutyl rubber innerliner and conjugated diene-based rubber of the tire carcass. The butyl rubber of the sealant precursor is partially depolymerized by the organoperoxide during the elevated temperature vulcanization of the tire to form the built-in sealant layer. In one aspect of the invention, said uncured butyl rubber sealant precursor layer composition has a storage modulus G′ (80° C.) in a range of about 100 to about 400 kPa and said partially depolymerized butyl rubber sealant layer composition has a storage modulus G′ (80° C.) in range of about 5 to about 50 kPa.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for enhancing production of isoprenoid compounds

ActiveUS20060079476A1Modulating levelToxic levelGenetic material ingredientsOxidoreductasesENCODEMevalonate pathway

The present invention provides methods of producing an isoprenoid or an isoprenoid precursor in a genetically modified host cell. The methods generally involve modulating the level of hydroxymethylglutaryl-CoA (HMG-CoA) in the cell, such that the level of HMG-CoA is not toxic to the cell and / or does not substantially inhibit cell growth, but is maintained at a level that provides for high-level production of mevalonate, IPP, and other downstream products of an isoprenoid or isoprenoid pathway, e.g., polyprenyl diphosphates and isoprenoid compounds. The present invention further provides genetically modified host cells that are suitable for use in a subject method. The present invention further provides recombinant nucleic acid constructs for use in generating a subject genetically modified host cell, including recombinant nucleic acid constructs comprising nucleotide sequences encoding one or more mevalonate pathway enzymes, and recombinant vectors (e.g., recombinant expression vectors) comprising same. The present invention further provides methods for identifying nucleic acids that encode HMG-CoA reductase (HMGR) variants that provide for relief of HMG-CoA accumulation-induced toxicity. The present invention further provides methods for identifying agents that reduce intracellular accumulation of HMG-CoA.

Owner:RGT UNIV OF CALIFORNIA

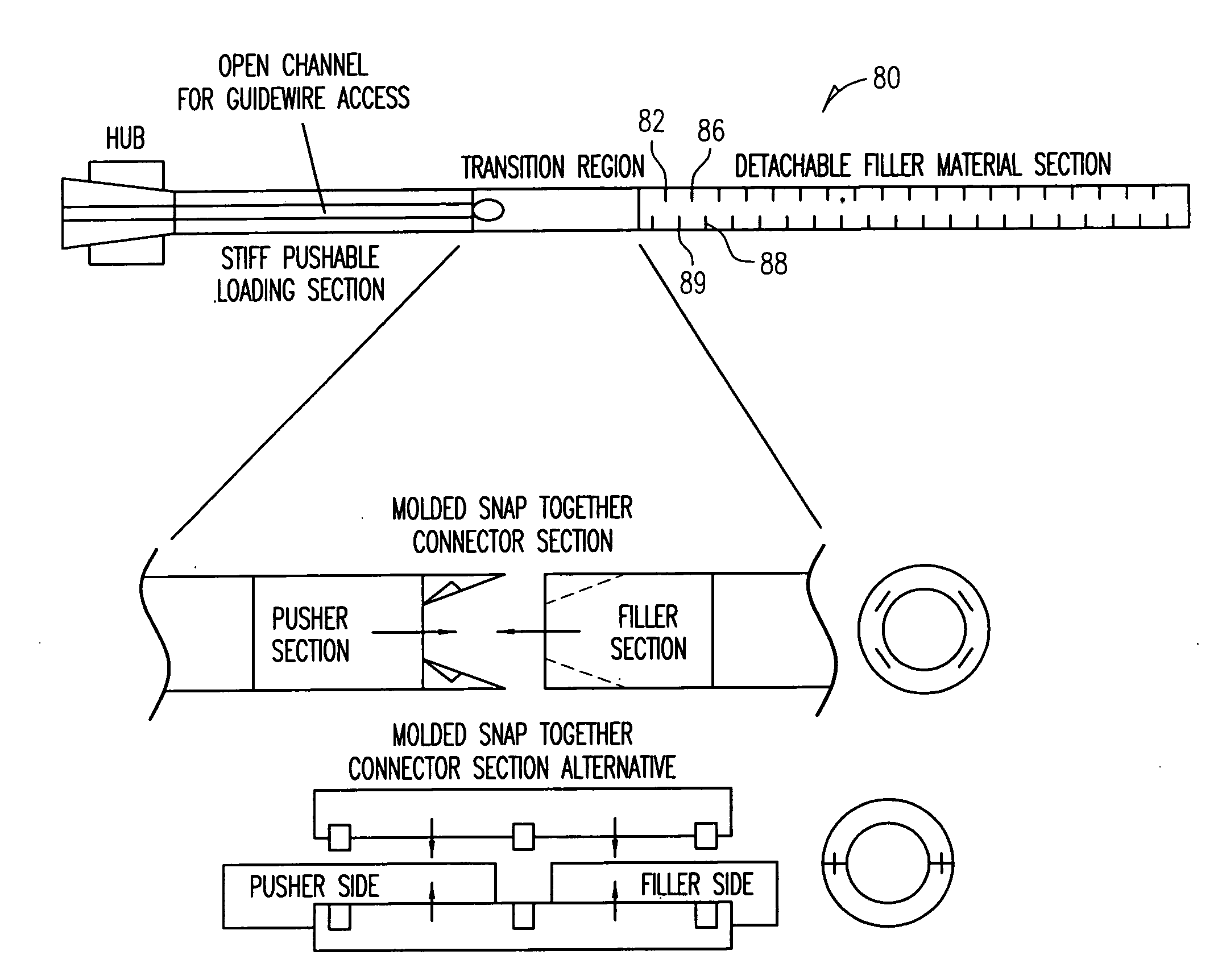

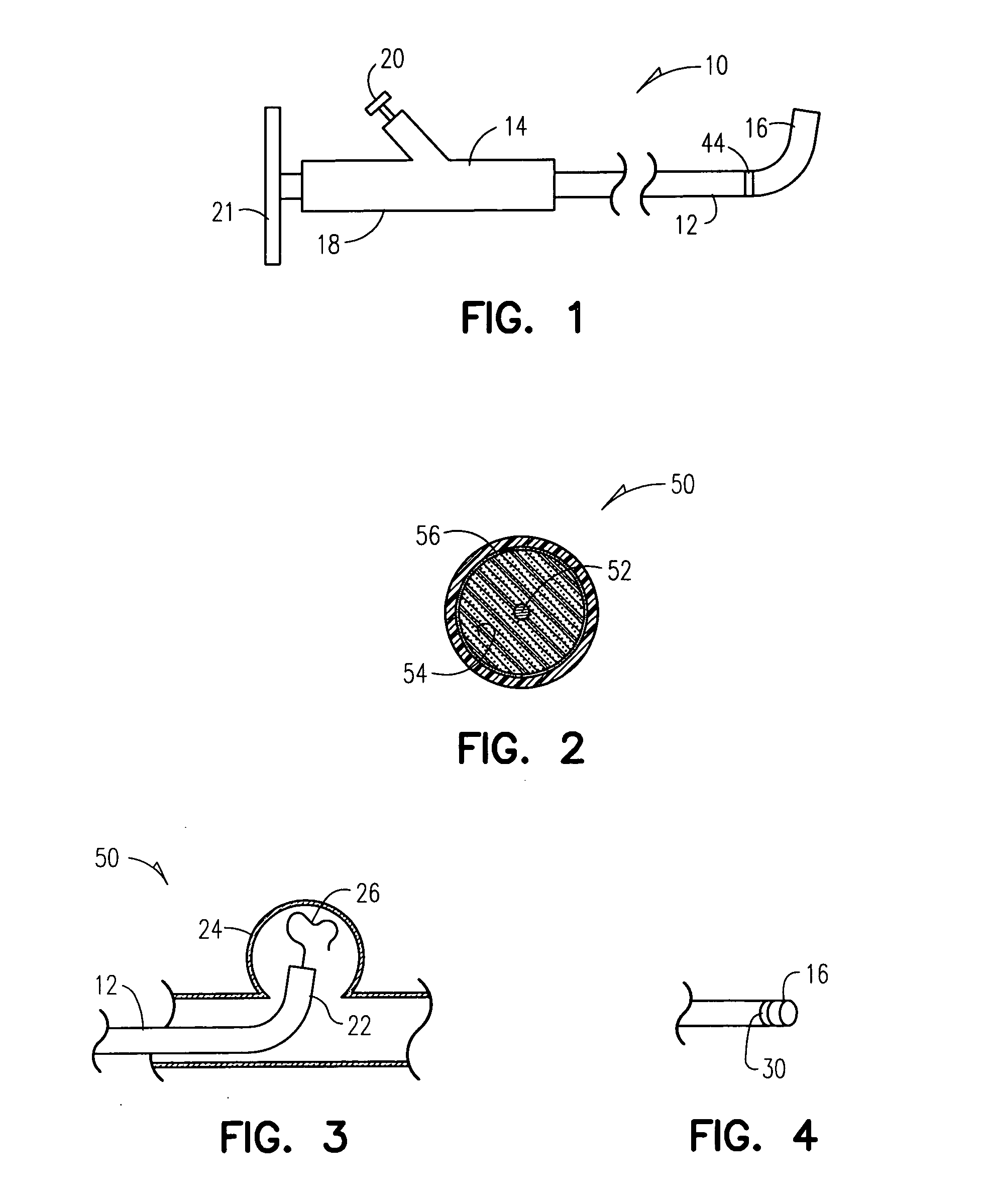

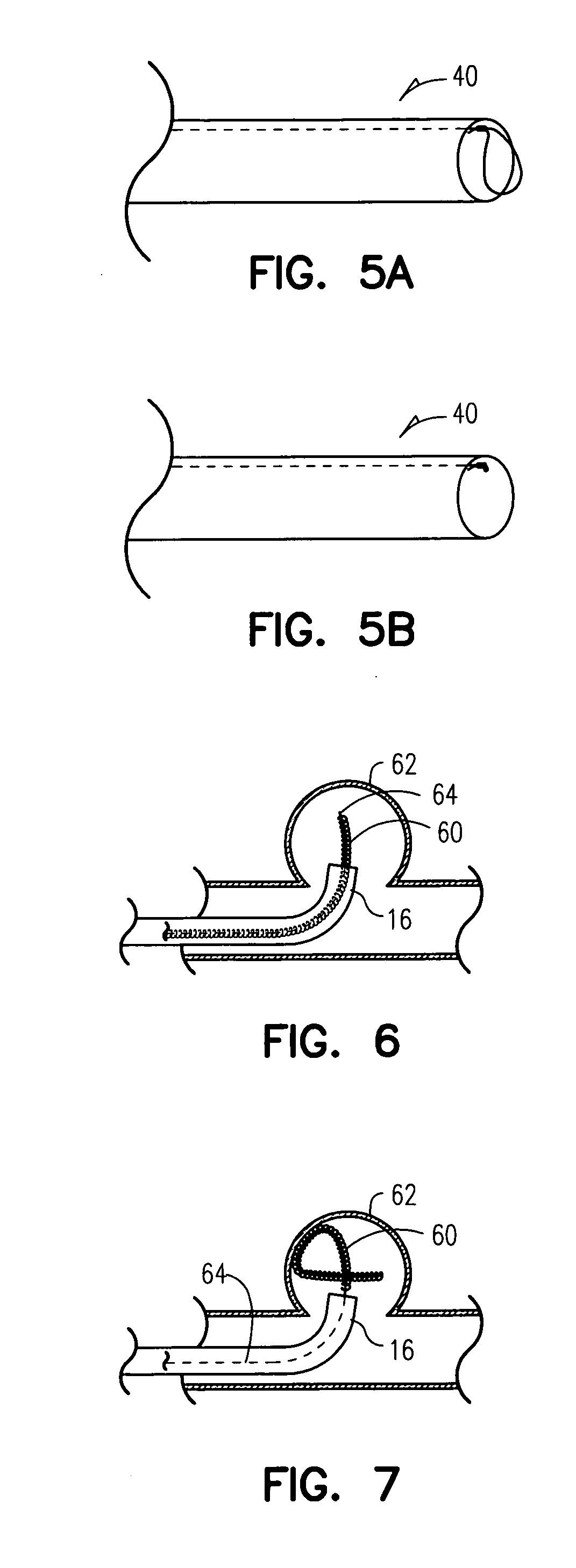

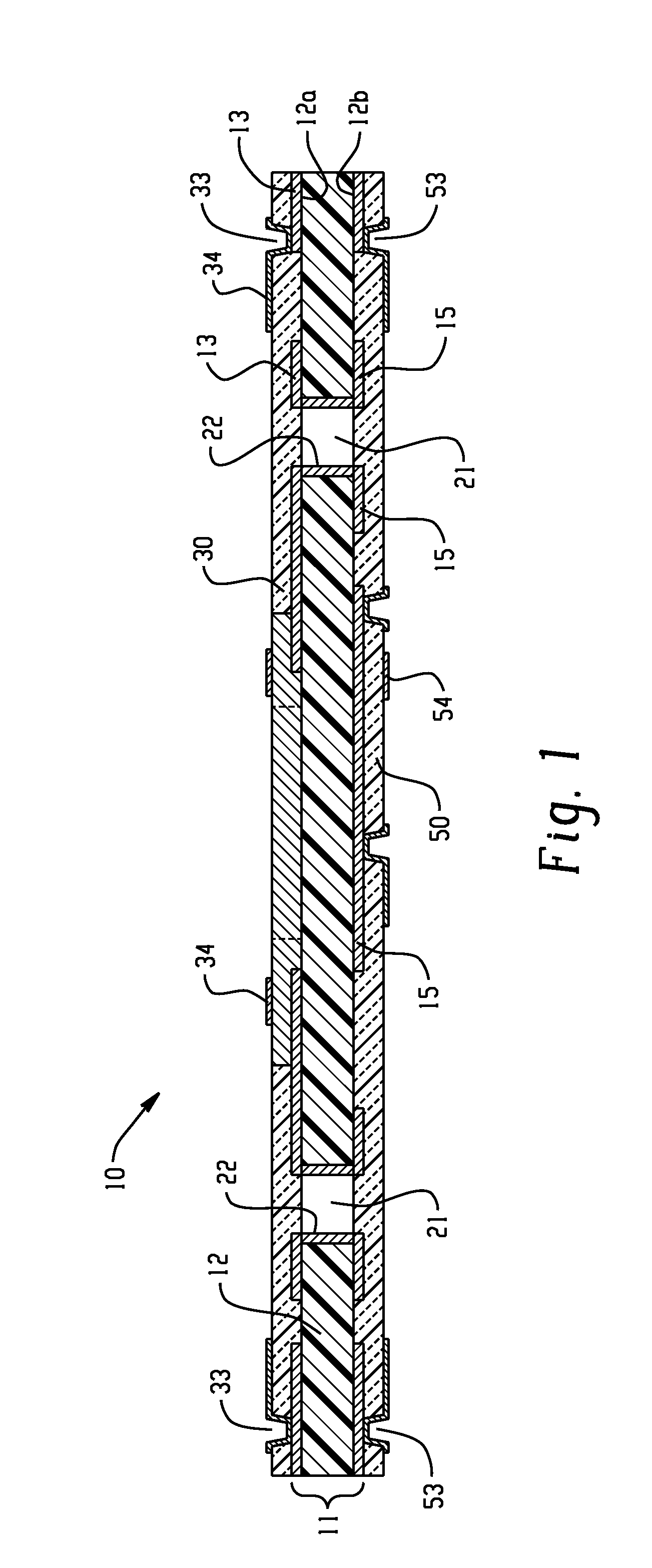

Multiple point detacher system

Embodiments of the invention include a method for treating an aneurysm, comprising: providing a biocompatible polymeric sleeve, string or coil or combination of sleeve, string or coil, made from a material selected from one or more of a group consisting of an acrylamide, a methacrylate, cyclodextran, synthetic elastin polymer, poly chelating amphiphilic polymers, hydrogels, hyaluronic acid conjugates, polyanhydrides, glycolipids, polysaccharides, and halamines, natural hydrogel, a synthetic hydrogel, silicone, polyurethane, polysulfone, cellulose, polyethylene, polypropylene, polyamide, polyimide, polyester, polytetrafluoroethylene, polyvinyl chloride, epoxy, phenolic, neoprene, polyisoprene, and a combination thereof; transporting the sleeve, string or coil to an aneurysm; filling the aneurysm with the sleeve, coil, or string; and detaching the sleeve, string or coil

Owner:NEUROVASX

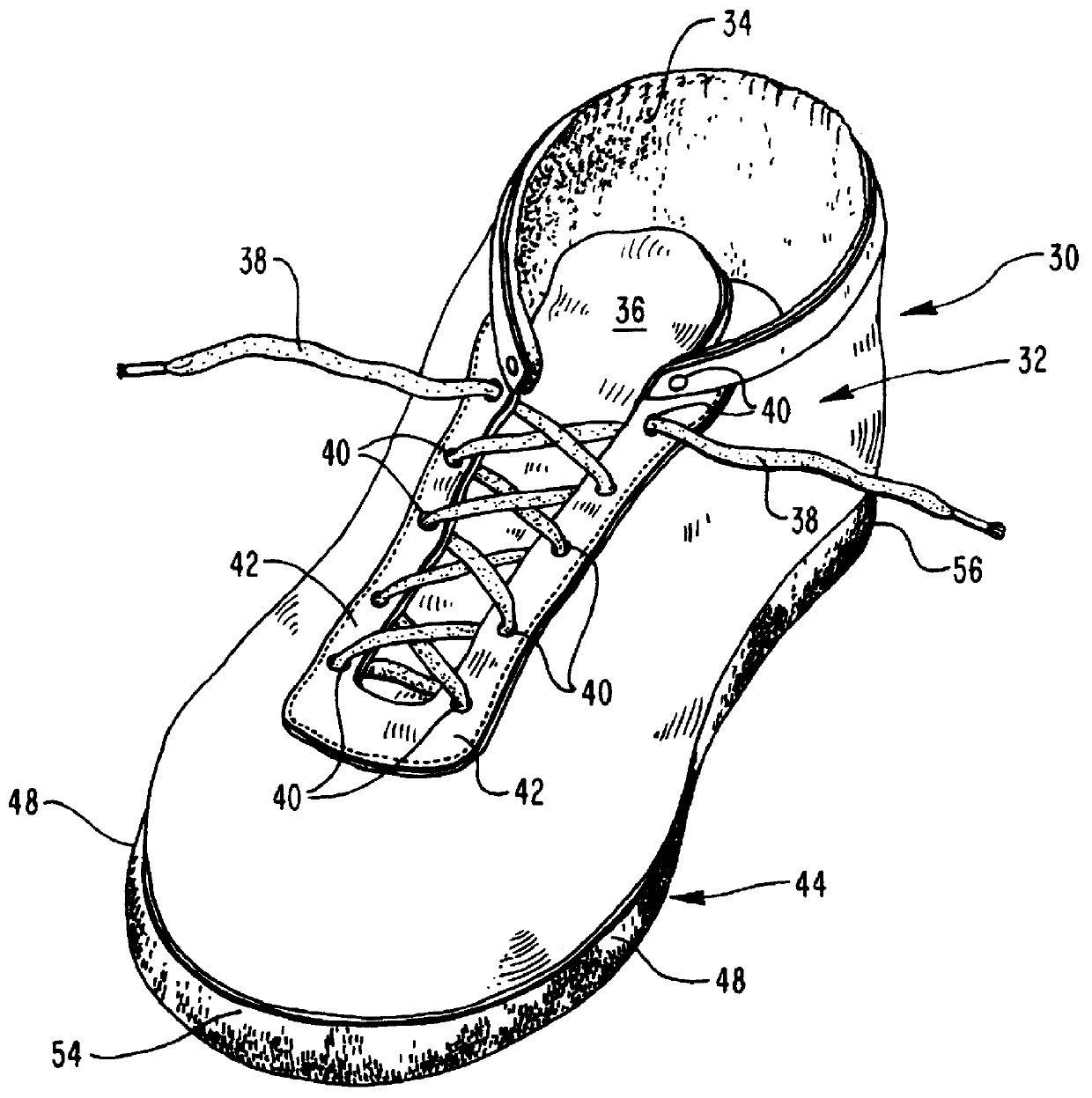

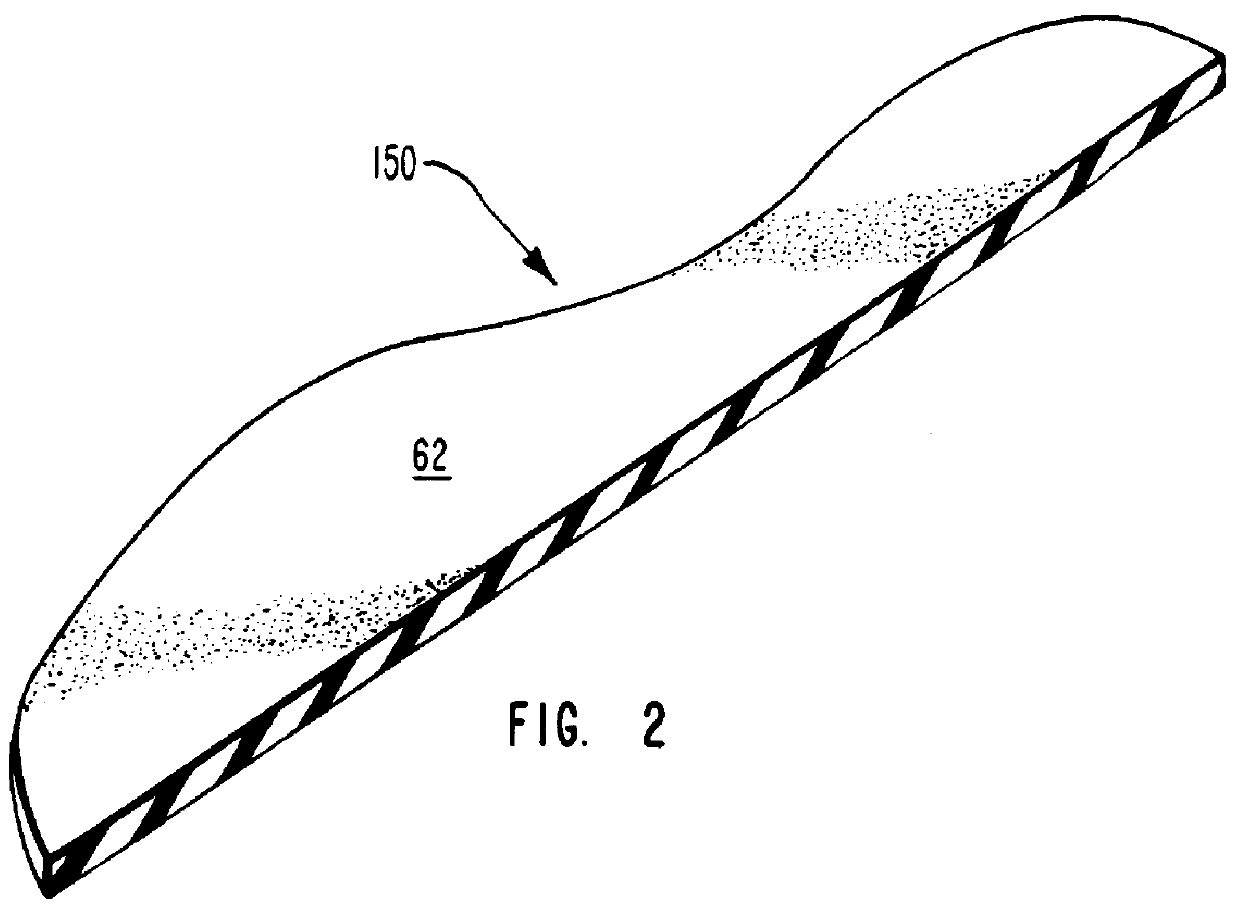

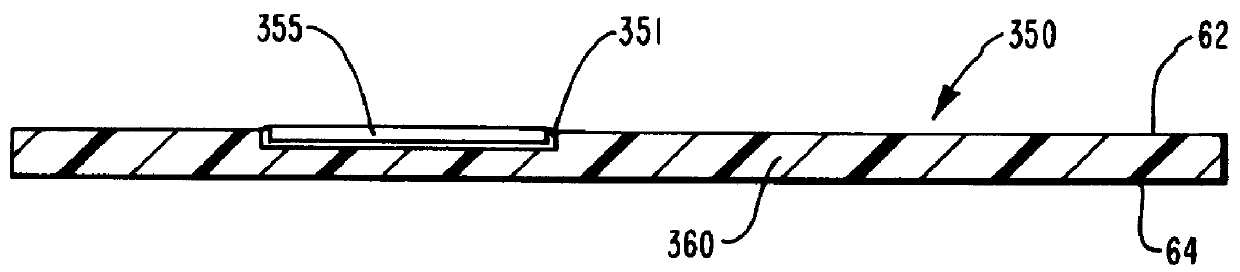

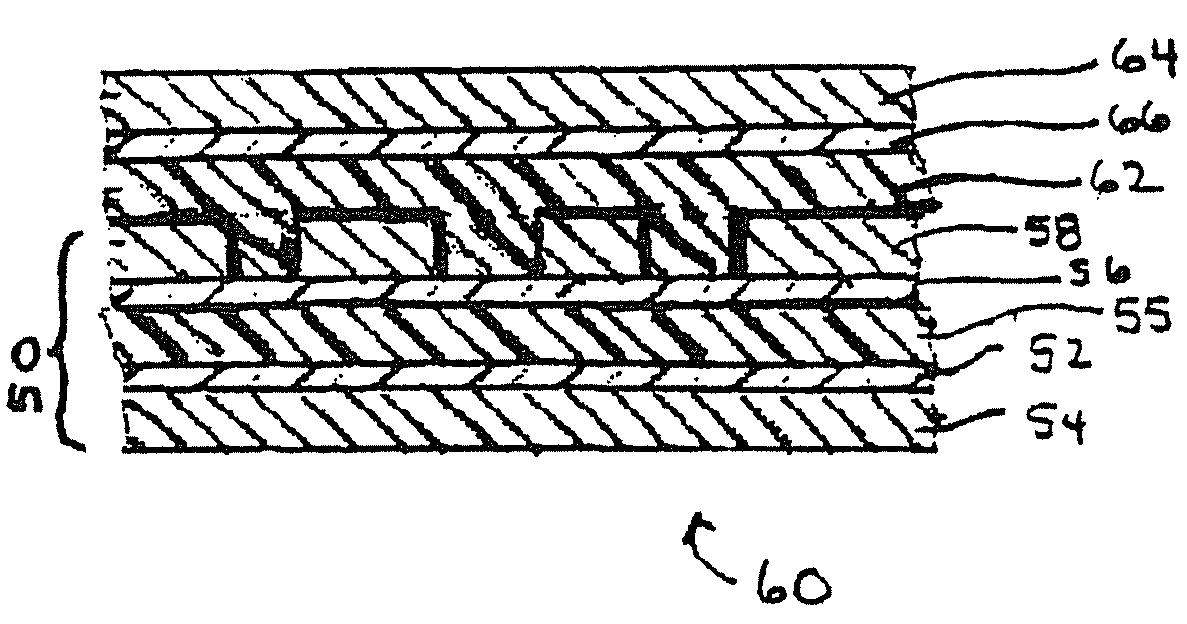

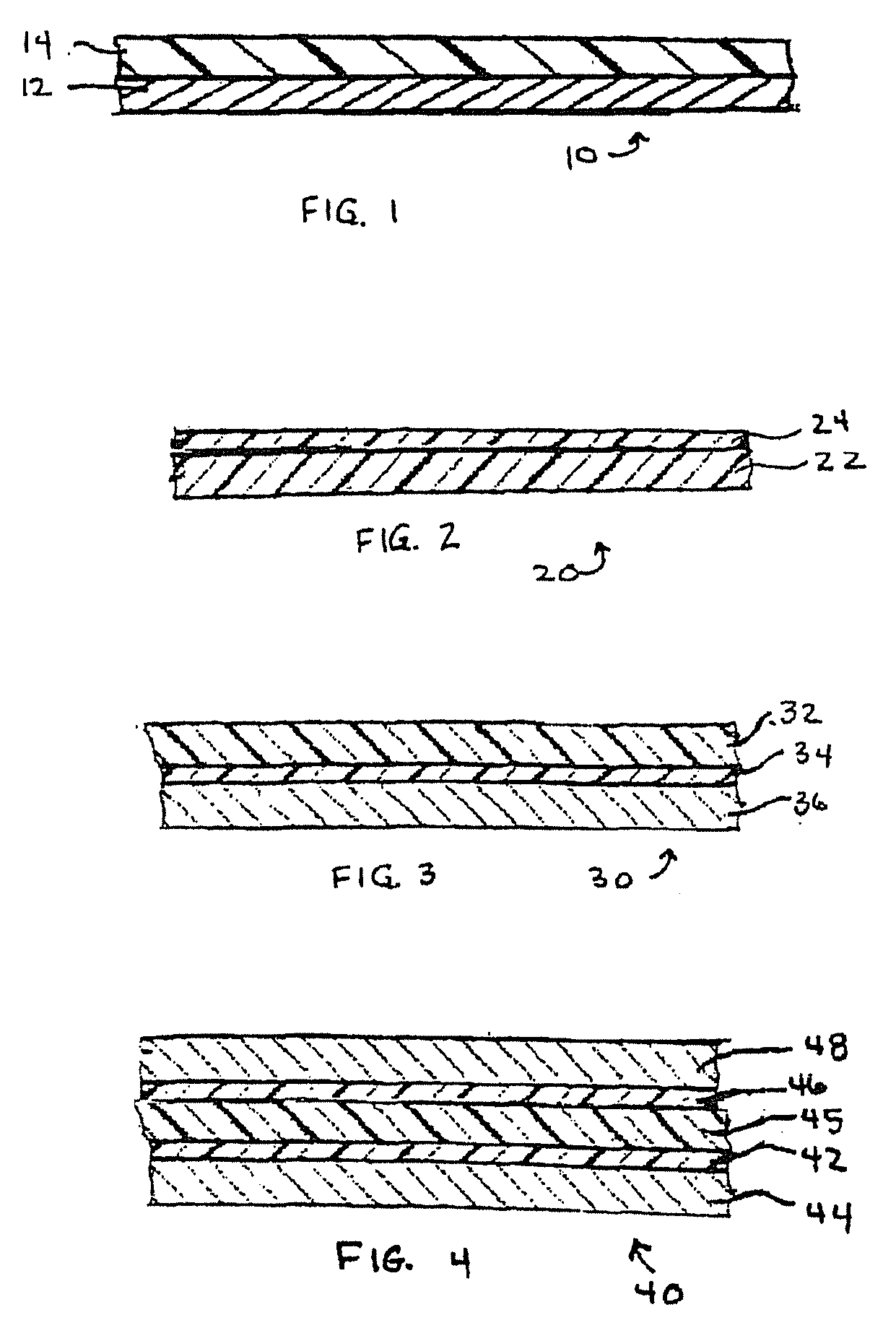

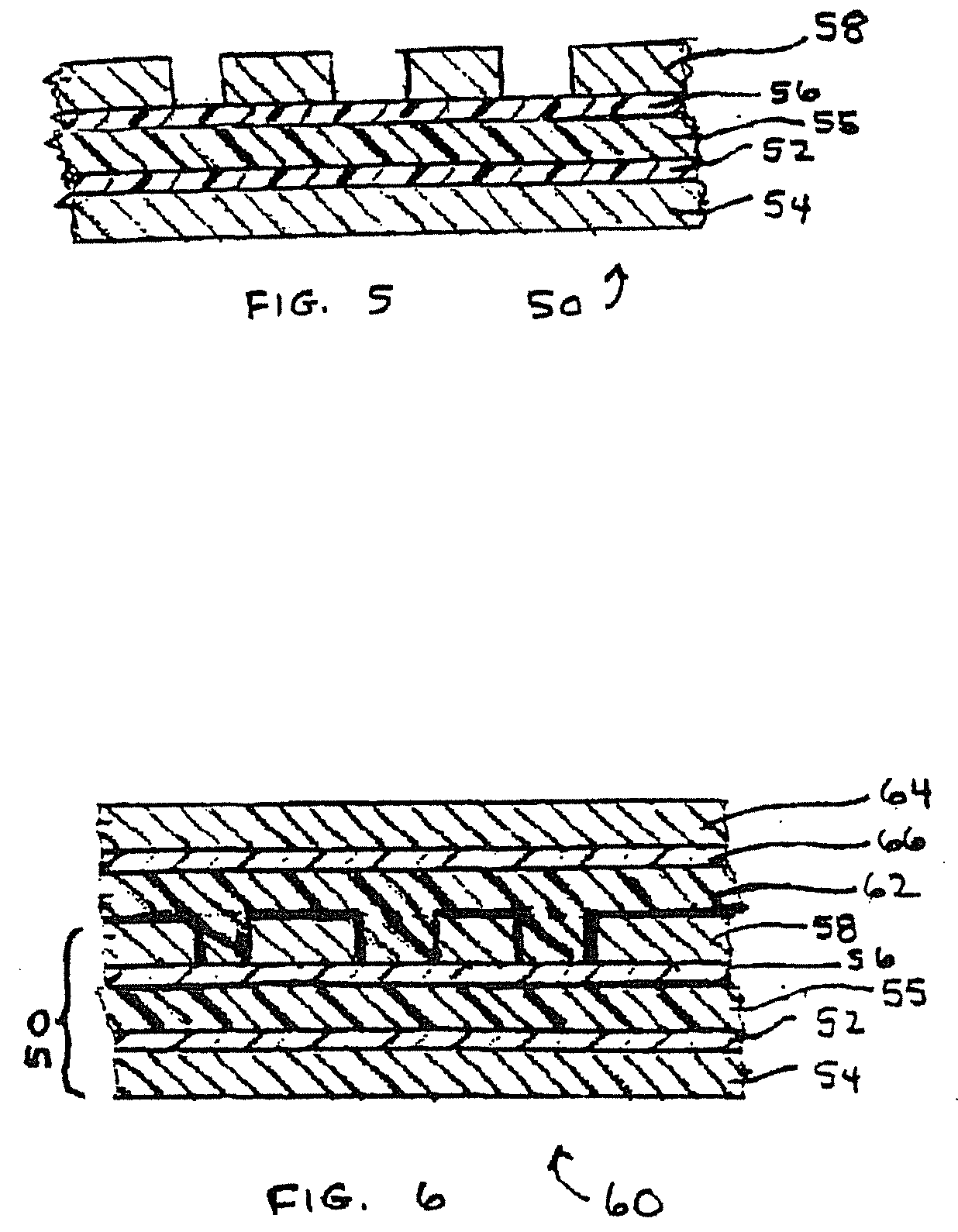

Performance enhancing athletic shoe components and methods

The present invention provides performance enhancing shoe components. The invented shoe component includes an upper layer of 1,4-polybutadiene and, optionally, a rubber such as natural rubber, synthetic isoprene rubber or polyisoprene. The first layer is attached to a resilient layer which extends substantially the length of the shoe. Optionally, a third layer or a coating may be attached to the resilient layer. The invented shoe components may be formed as shoe inserts, insoles, midsoles or shoe soles.

Owner:CROW WILLIAM R

Thermoplastic elastomer composition

InactiveUS7244783B2Low costReduce hardnessFilm/foil adhesivesCoatingsThermoplastic elastomerPolystyrene

A thermoplastic elastomer composition comprised of (a) a thermoplastic resin selected from the group consisting of polyphenylene ether, polypropylene, polyethylene, and polystyrene, (b) a block copolymer selected from the group consisting of styrene-ethylene butylene-styrene, styrene-ethylene propylene-styrene, hydrogenated polybutadiene, hydrogenated polyisoprene, hydrogenated styrene-isoprene random copolymer, styrene-ethylene propylene block copolymer, styrene-ethylene ethylene propylene-styrene and hydrogenated styrene-butadiene random copolymers, (c) a core-shell polymer comprised of a polymeric core and a polymeric shell with the proviso that the polymeric core and / or the polymeric shell may be crosslinked, and (d) an oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

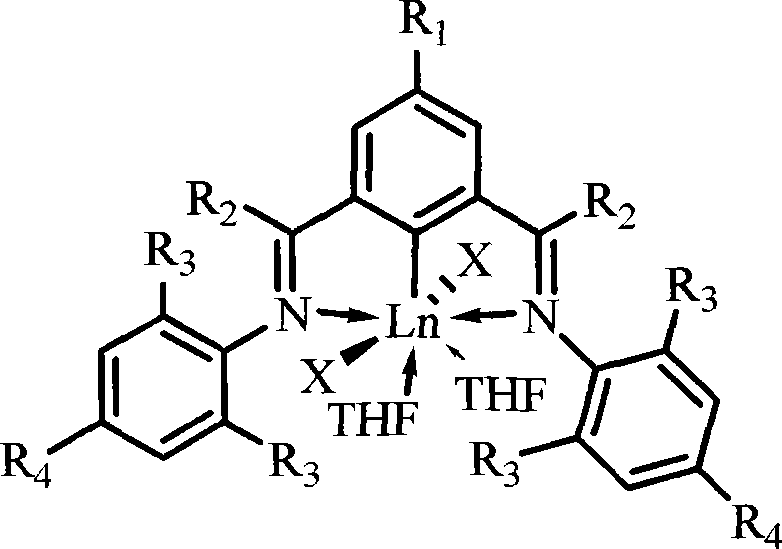

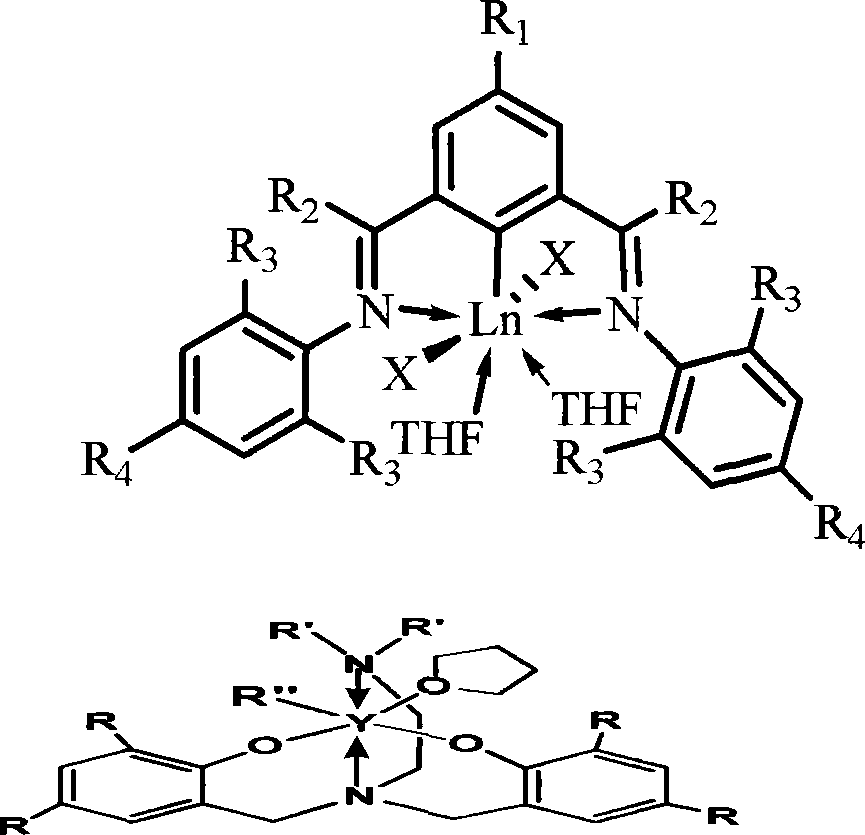

Rare earth catalyst for catalyzing syn form 1,4-selectivity polymerization of isoprene or butadiene

The invention relates to a rare-earth catalyst for catalyzing selective polymerization of isoprene or butadiene, while the catalyst system composed of the rare-earth catalyst can catalyze isoprene or butadiene to prepare polyisoprene or butadiene rubber with high cis-1, 4- structure. The rare-earth catalyst is composed of split-core type rare-earth complex, alkyl aluminium and organic boron salt. The solvent of polymerization is toluene or chlorobenzene. When catalyzes the polymerization of isoprene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organic boron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100% most, and the cis-1, 4 content of polymer is 55.0-98.8%, and when catalyzes the polymerization of butadiene, the alkyl aluminium and split-core type rare-earth complex are rationed at 10-40, the organic boron salt and split-core type rare-earth complex are rationed at 1-3, the polymerization temperature is -20-80DEG C, the polymerization time is 0.5-2h, the monomer conversation ratio can reach 100% most, and the cis-1, 4 content of polymer is 90.1-99.99%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Pneumatic tire having built-in sealant layer and preparation thereof

ActiveUS20040159386A1Improve abilitiesImprove efficiencyOther chemical processesSpecial tyresFiberVulcanization

This invention relates to a pneumatic tire having a built-in sealant layer and its preparation. The sealant layer precursor is a layer of a butyl rubber based composition which contains an organoperoxide. The butyl rubber of said precursor is a copolymer of isobutylene and isoprene containing from about 0.5 to about 5, alternately less than 1, mole percent isoprene. The precursor composition contains carbon black and / or coal dust and may contain a dispersion of liquid conjugated diene polymer (e.g. liquid cis 1,4-polyisoprene polymer), short fibers and / or hollow glass microspheres. A layer of the sealant precursor is built into the tire between a sulfur vulcanized halobutyl rubber innerliner and conjugated diene-based rubber of the tire carcass. The butyl rubber of the sealant precursor is partially depolymerized by the organoperoxide during the elevated temperature vulcanization of the tire to form the built-in sealant layer. In one aspect of the invention, said uncured butyl rubber sealant precursor layer composition has a storage modulus G'(80° C.) in a range of about 100 to about 400 kPa and said partially depolymerized butyl rubber sealant layer composition has a storage modulus G' (80° C.) in range of about 5 to about 50 kPa.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire with rubber component

ActiveUS20120029114A1Improve hysteresis loss characteristicPlastic/resin/waxes insulatorsSpecial tyresElastomerEngineering

Pneumatic rubber tire with a component comprised of a silica reinforced rubber composition comprised of specialized polybutadiene rubber, functionalized styrene / butadiene elastomer and cis 1,4-polyisoprene rubber.

Owner:THE GOODYEAR TIRE & RUBBER CO

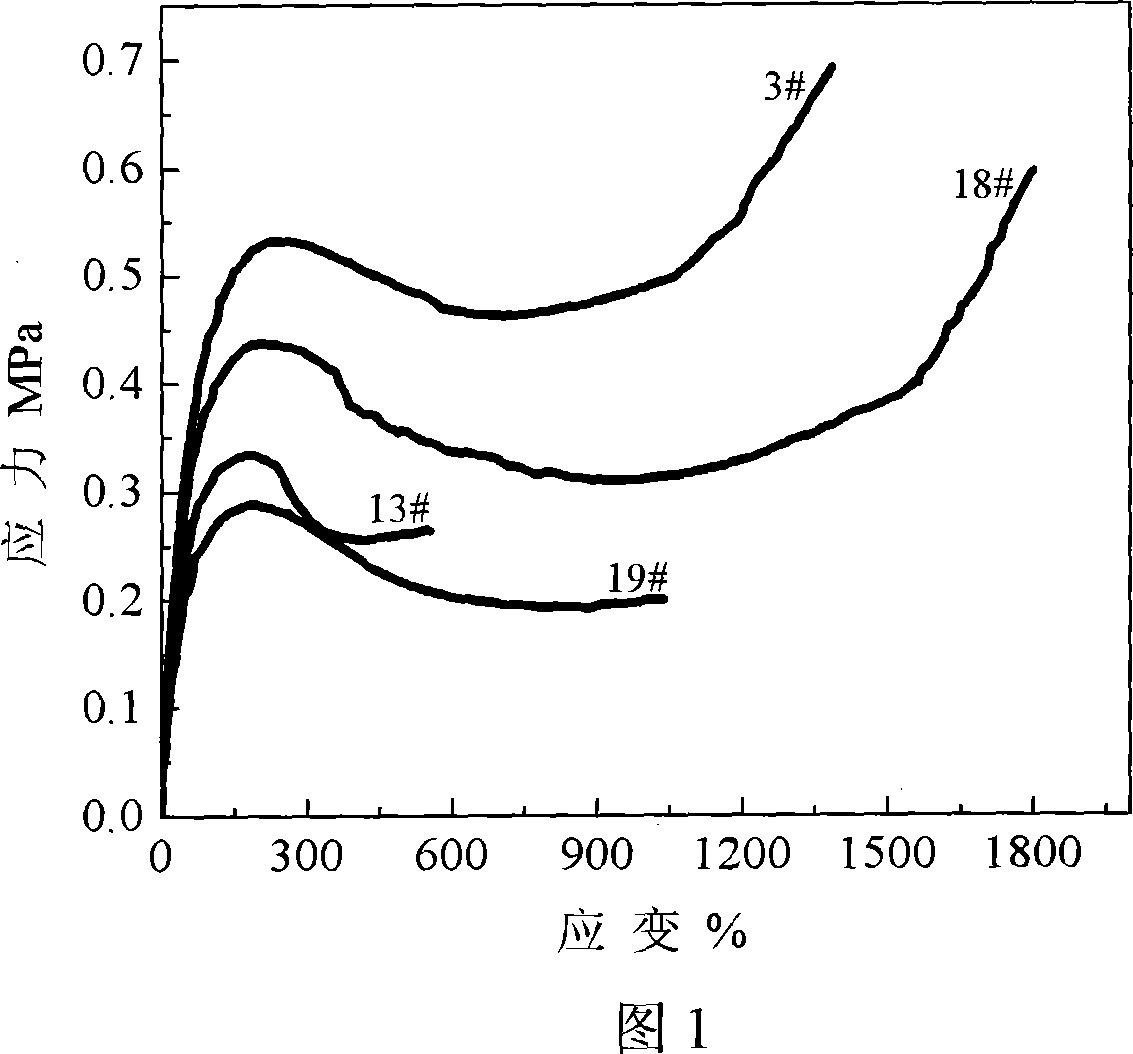

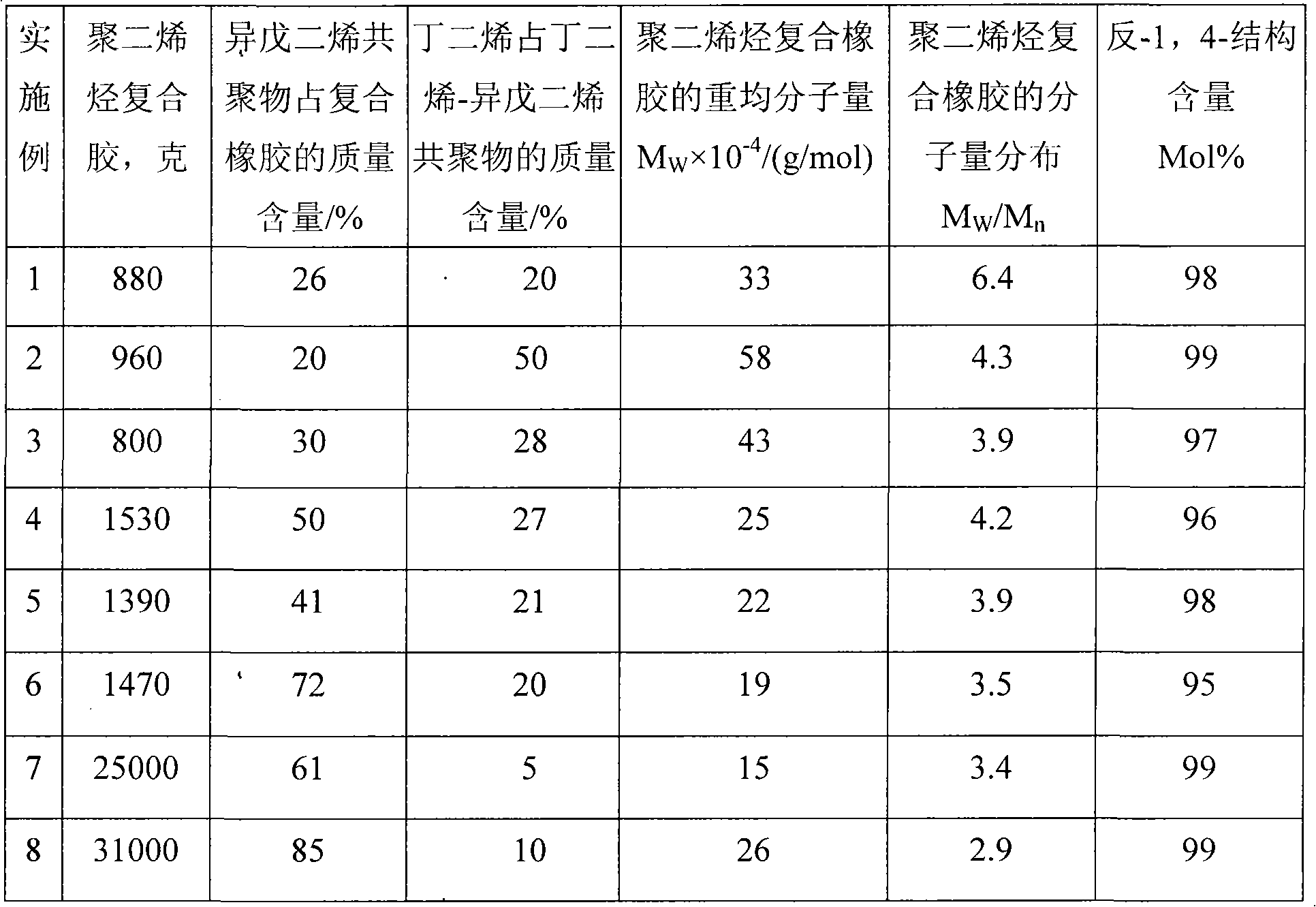

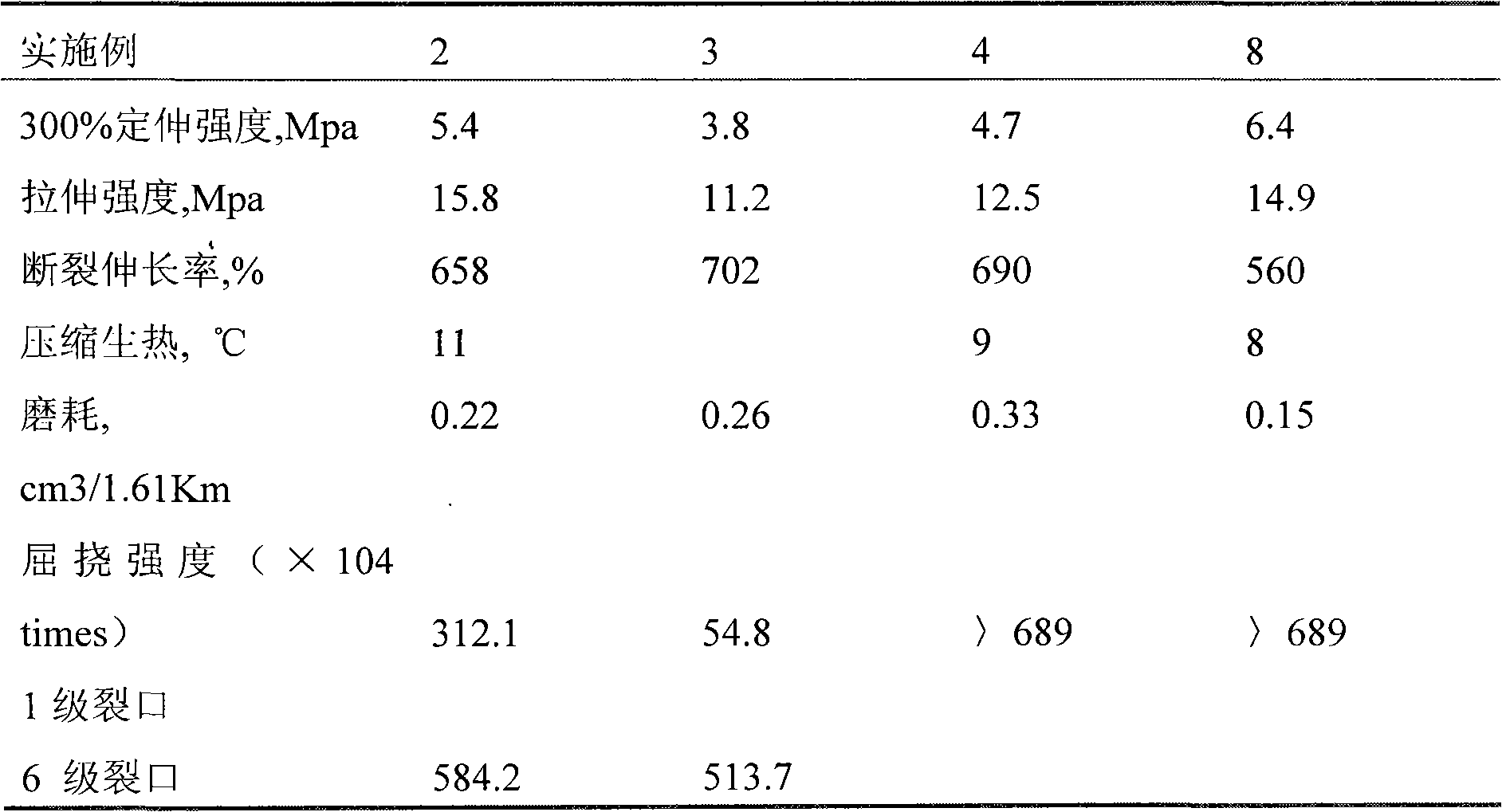

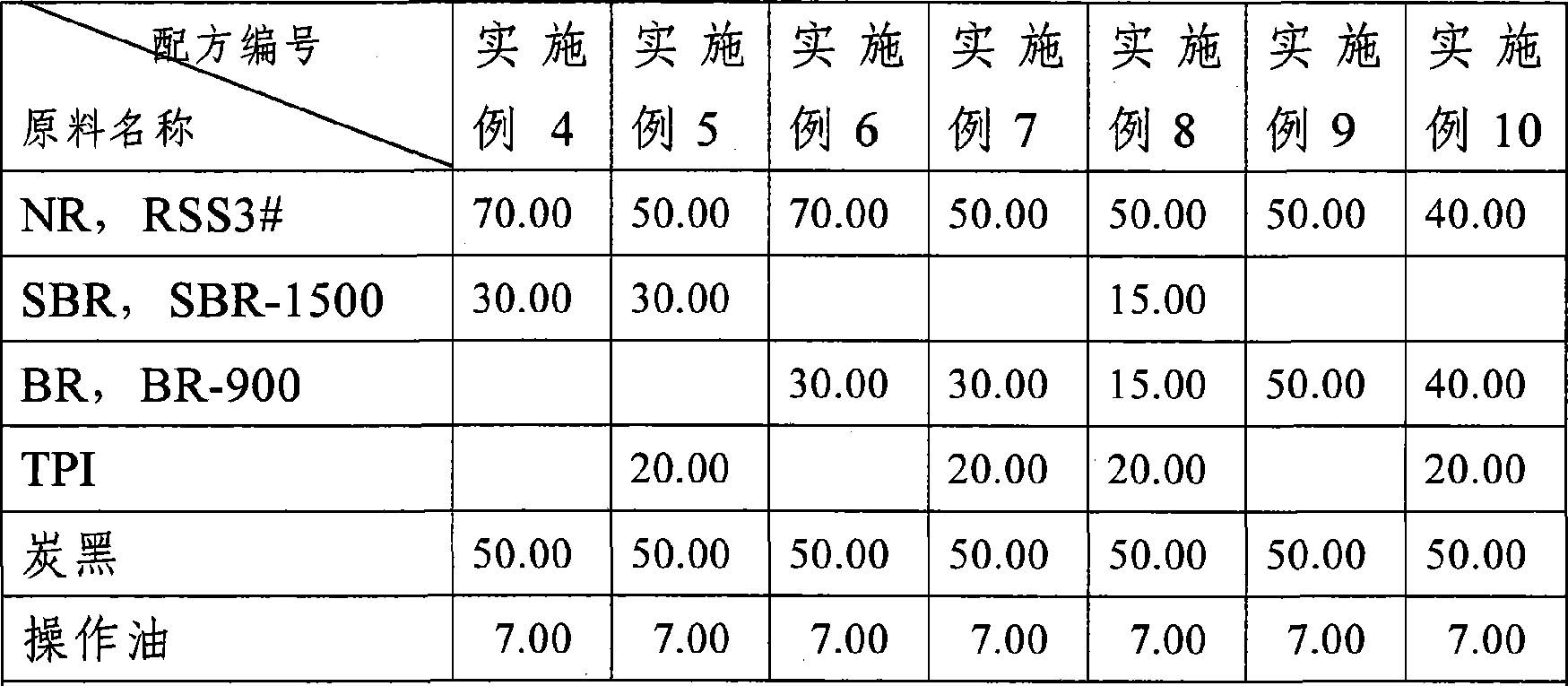

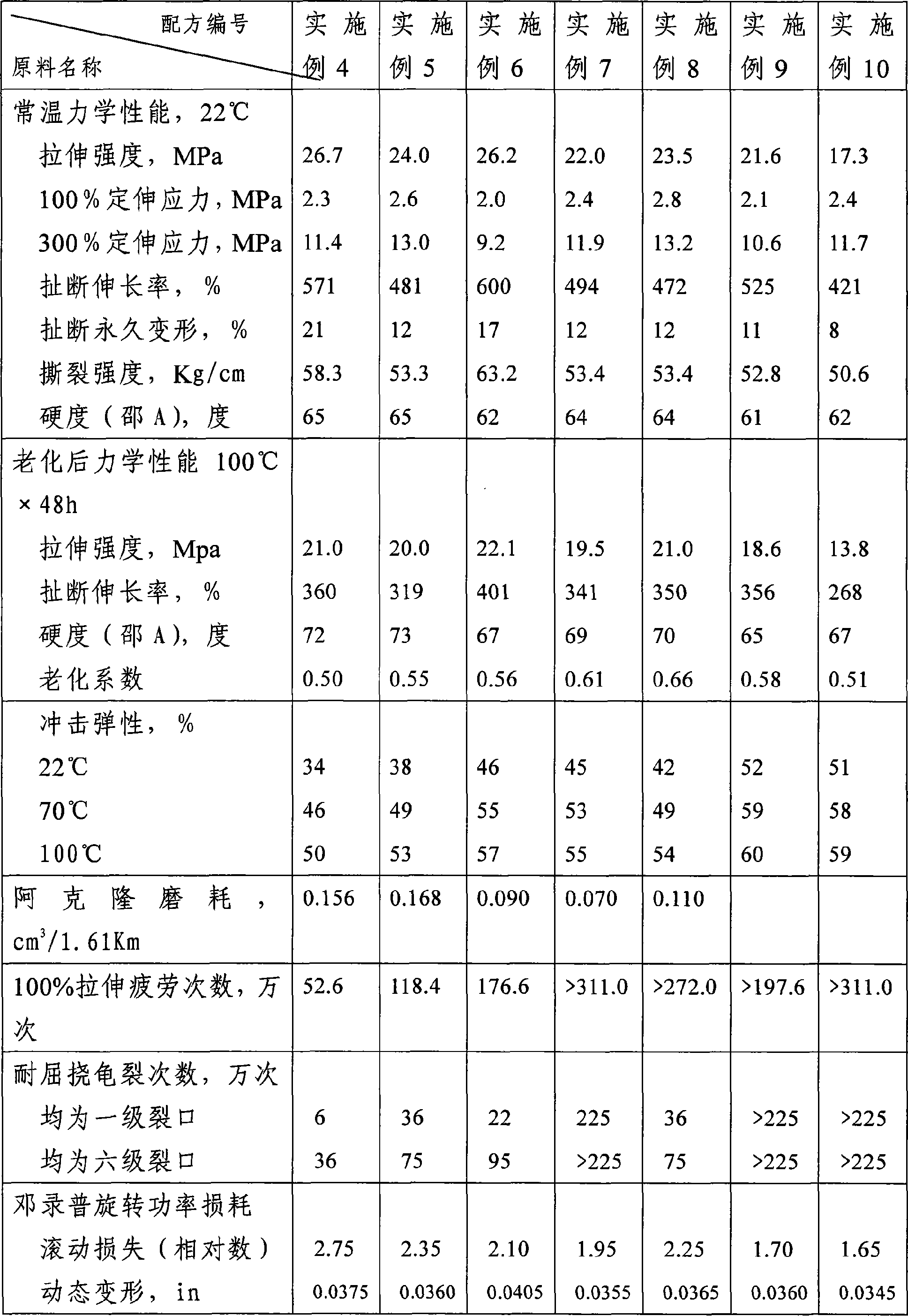

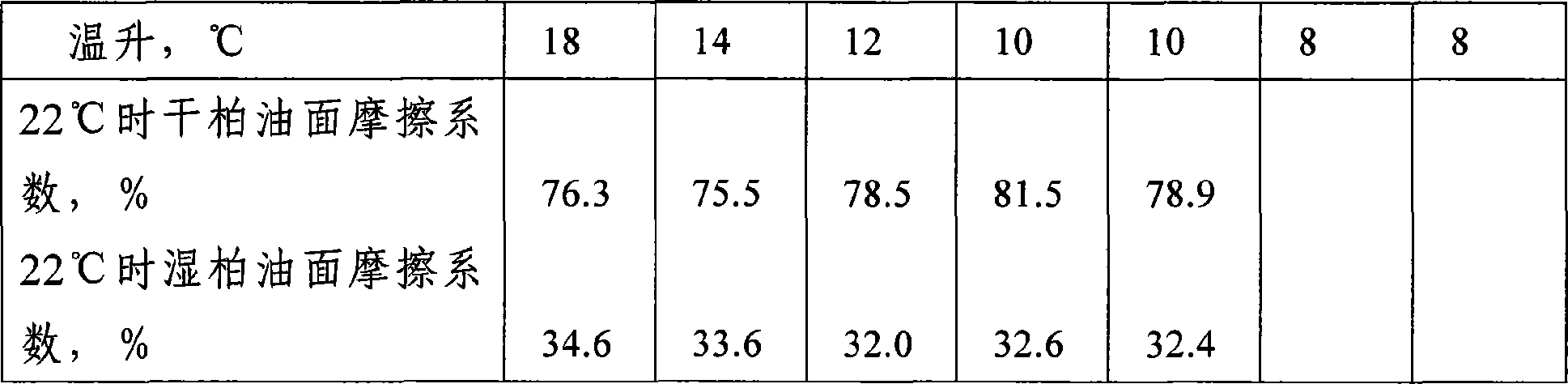

Trans-1,4-polydialkene composite rubber and preparation methods thereof

The invention relates to a polydialkene composite rubber of trans-1,4- structure and preparation methods thereof. The composite rubber consists of 10 to 80 mass percent of trans-1,4-polyisoprene and 20 to 90 mass percent of trans-1,4-butadiene-isoprene copolymer, wherein over 90 percent of structural units of all dialkenes in the composite rubber have trans-1,4-structures. The first preparation method comprises the following steps of: homopolymerizing isoprene to obtain trans-1,4-polyisoprene by adopting a Ziegler-Natta catalysis system consisting of MgCl2 supported titanium and organic aluminum compound, and then adding butadiene to synthesize the trans-butadiene-isoprene copolymer. The second preparation method comprises the following steps of: adding mixed monomers of butadiene and isoprene into a polymerization device at the same time, performing copolymerization to obtain the butadiene-isoprene copolymer of the trans-1,4-structure, and continuously polymerizing the isoprene to obtain the trans-1,4-polyisoprene after the butadiene with high polymerization speed is completely consumed. The used polymerization device is a stirring reaction kettle or a screw extruder. The composite rubber has excellent performance such as low rolling resistance, low generated heat, abrasion resistance, particularly fatigue break increment resistance and the like, and is suitable for dynamically used rubber products such as tyres, vibration absorption materials and the like.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

Preparation of silica reinforced polyisoprene-rich rubber composition and tire with component thereof

This invention relates to the preparation of a cis 1,4-polyisoprene rubber-rich rubber composition containing precipitated silica which has been pre-treated with a fatty alcohol and / or epoxidized soybean oil together with an organosilane containing polysulfide coupling agent and to tires having at least one component comprised of such rubber composition. The invention particularly relates to a process of (a) preparing a natural rubber-rich rubber composition comprised of pre-treating precipitated silica aggregates prior to blending with, or in the presence of, dry natural rubber with a fatty alcohol and / or epoxidized soybean oil to the exclusion of sulfur curative for the natural rubber, mixing an organalkoxysiloxane based polysulfide coupling agent with said dry natural rubber coincidentally with or subsequent to said precipitated silica aggregate fatty alcohol and / or epoxidized soybean oil pre-treatment to form a composite thereof, to the exclusion of sulfur curative, followed by (b) mixing the resulting rubber mixture with sulfur curative and (c) curing the resulting rubber composition.

Owner:THE GOODYEAR TIRE & RUBBER CO

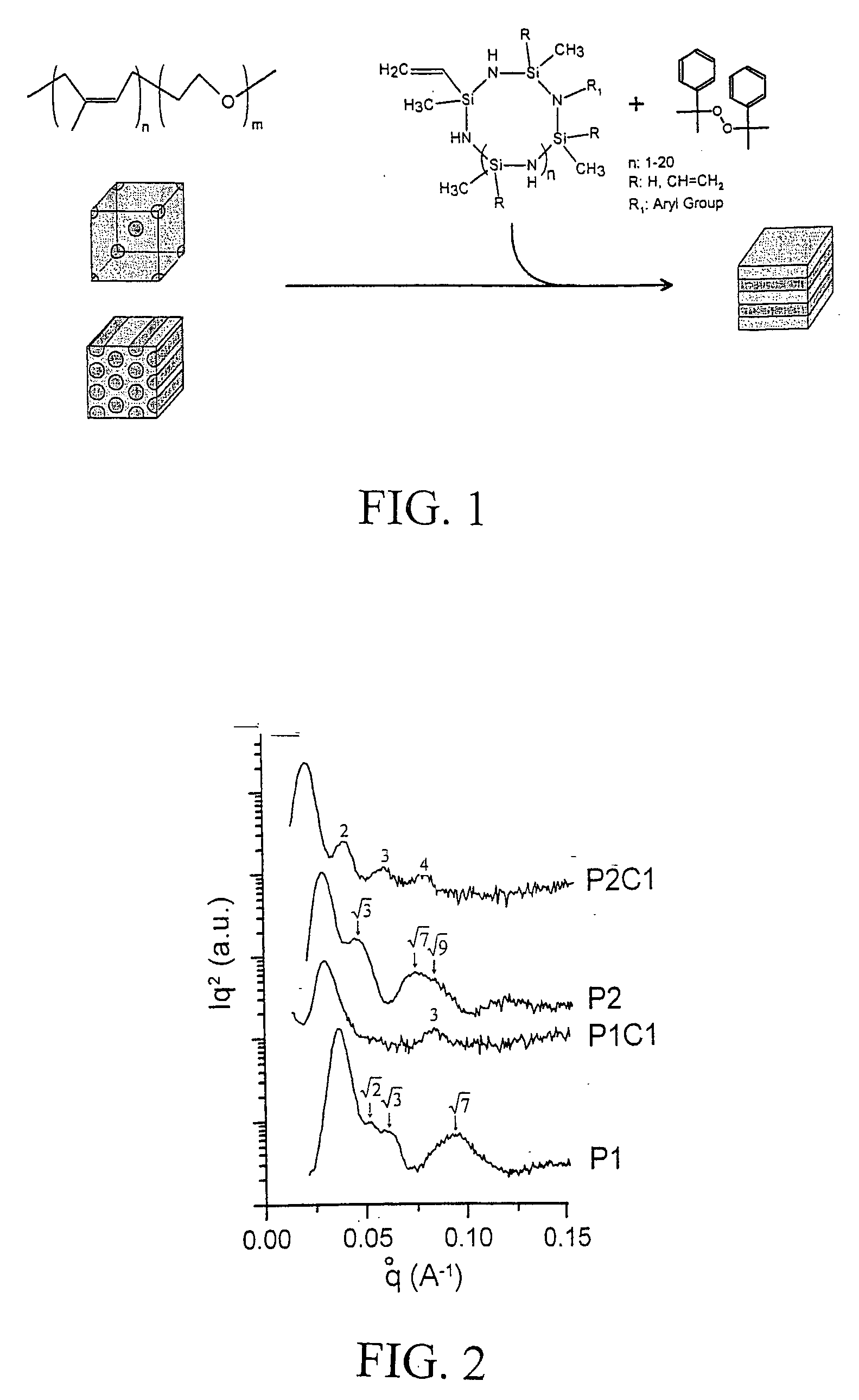

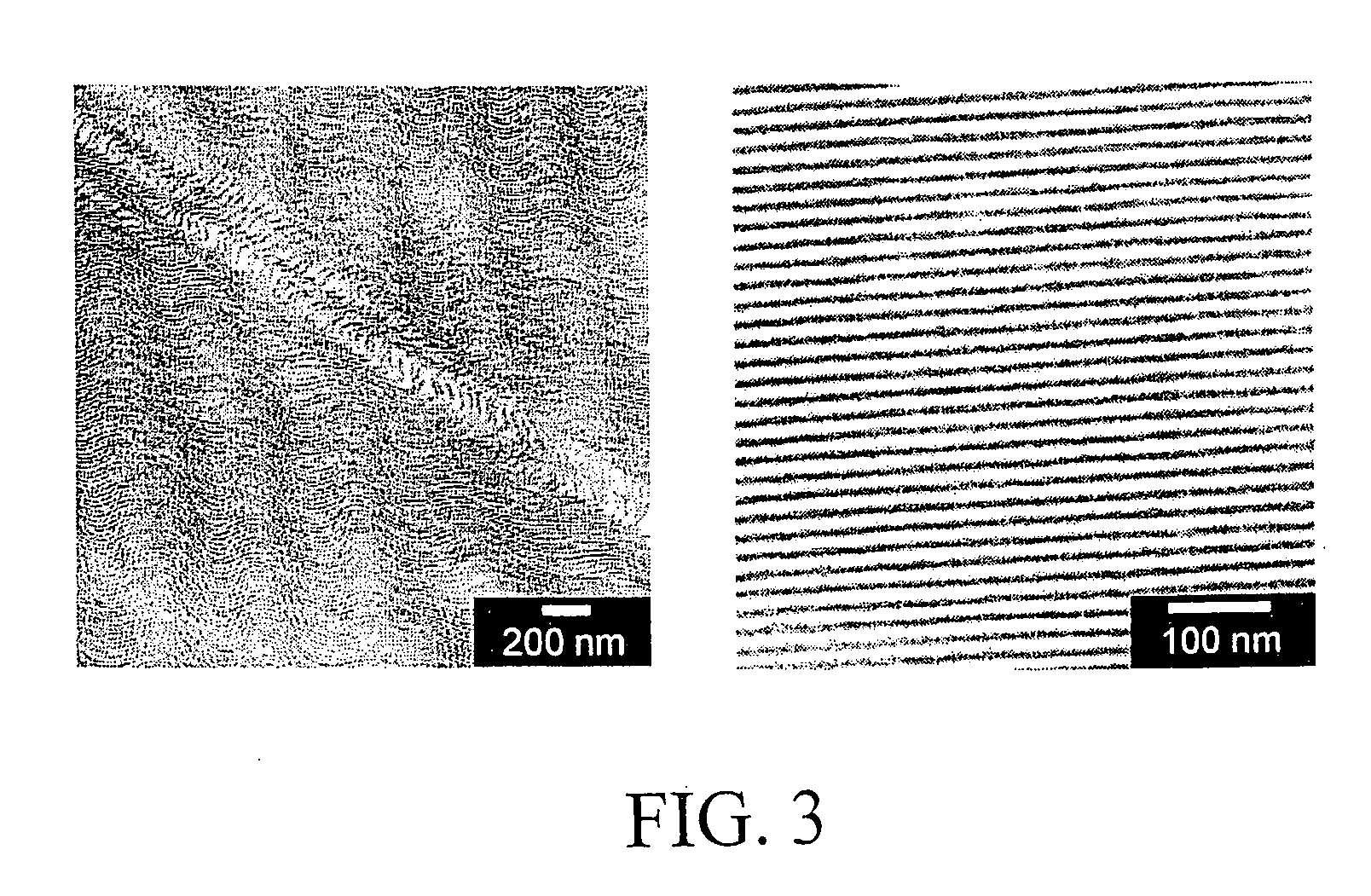

High temperature SiCN and SiC-type nanostructured ceramic material from block copolymer mesophases

InactiveUS20050036931A1Simple and easily controlled pathwayCarbon compoundsNitrogen and non-metal compoundsNon oxide ceramicsPolymer science

A block copolymer, preferably a block copolymer such as poly(isoprene-block-ethylene oxide), PI-b-PEO, is used as a structure directing agent for a polymer derived ceramic (PDC) precursor, preferably a silazane, most preferably a silazane commercially known as Ceraset. The PDC precursor is preferably polymerized after mixing with the block copolymer to form a nanostructured composite material. Through further heating steps, the nanostructured composite material can be transformed into a nanostructured non-oxide ceramic material, preferably a high temperature SiCN or SiC material.

Owner:CORNELL RES FOUNDATION INC

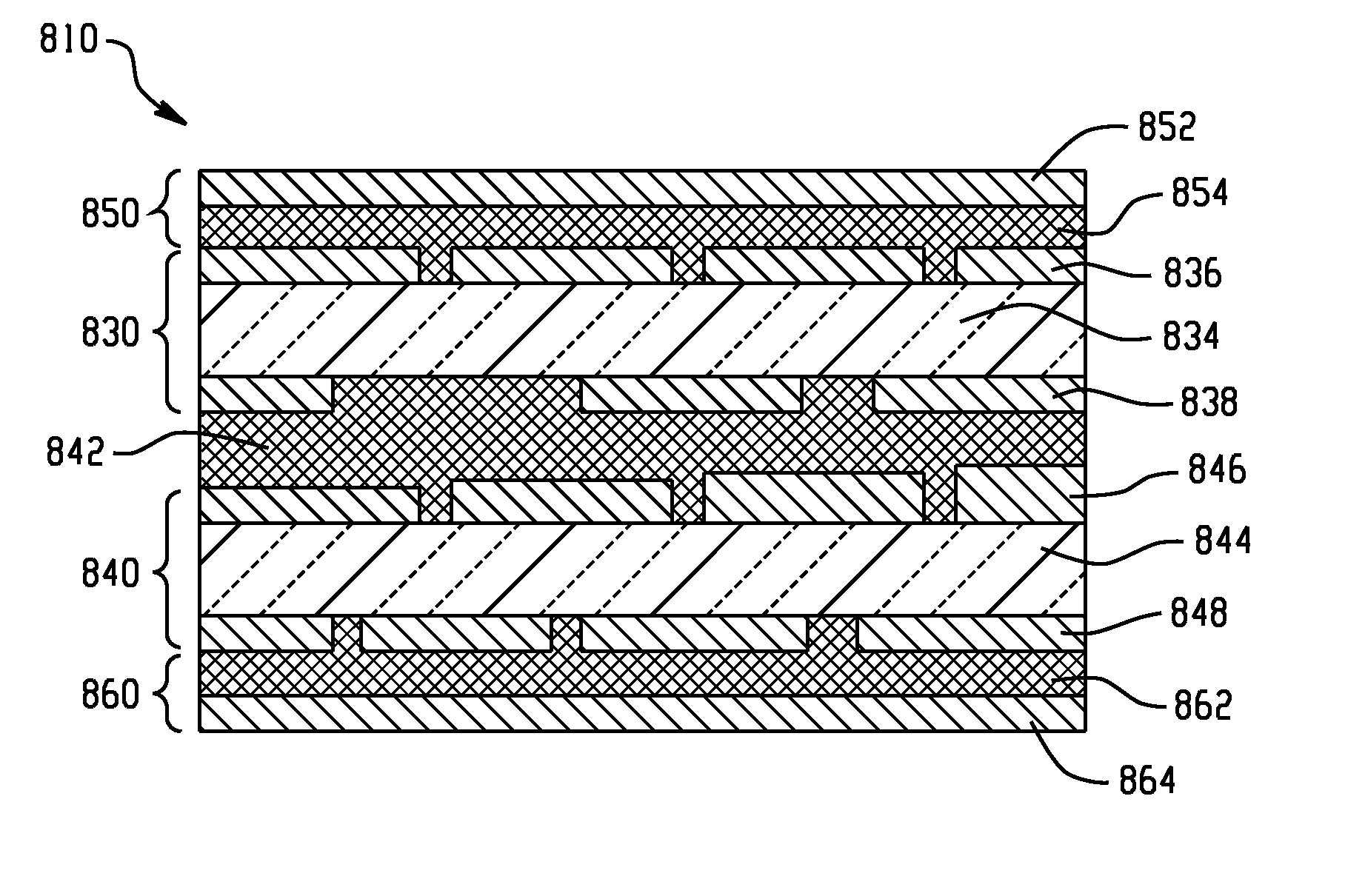

Circuit materials with improved bond, method of manufacture thereof, and articles formed therefrom

A circuit material, comprising a conductive metal layer or a dielectric circuit substrate layer and an adhesive layer disposed on the conductive metal layer or the dielectric substrate layer, wherein the adhesive comprises a poly(arylene ether) and a polybutadiene or polyisoprene polymer.

Owner:WORLD PROPERTIES

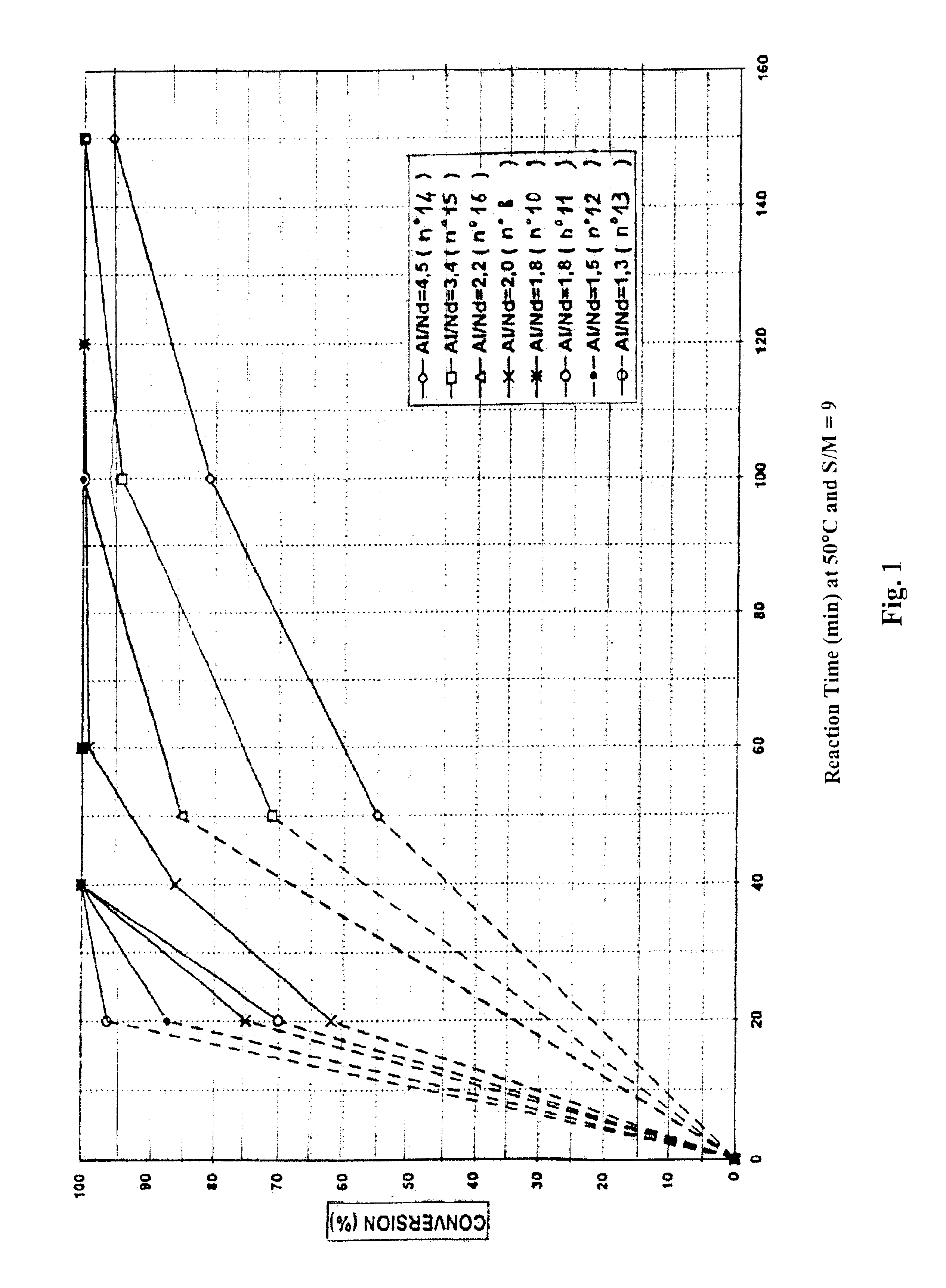

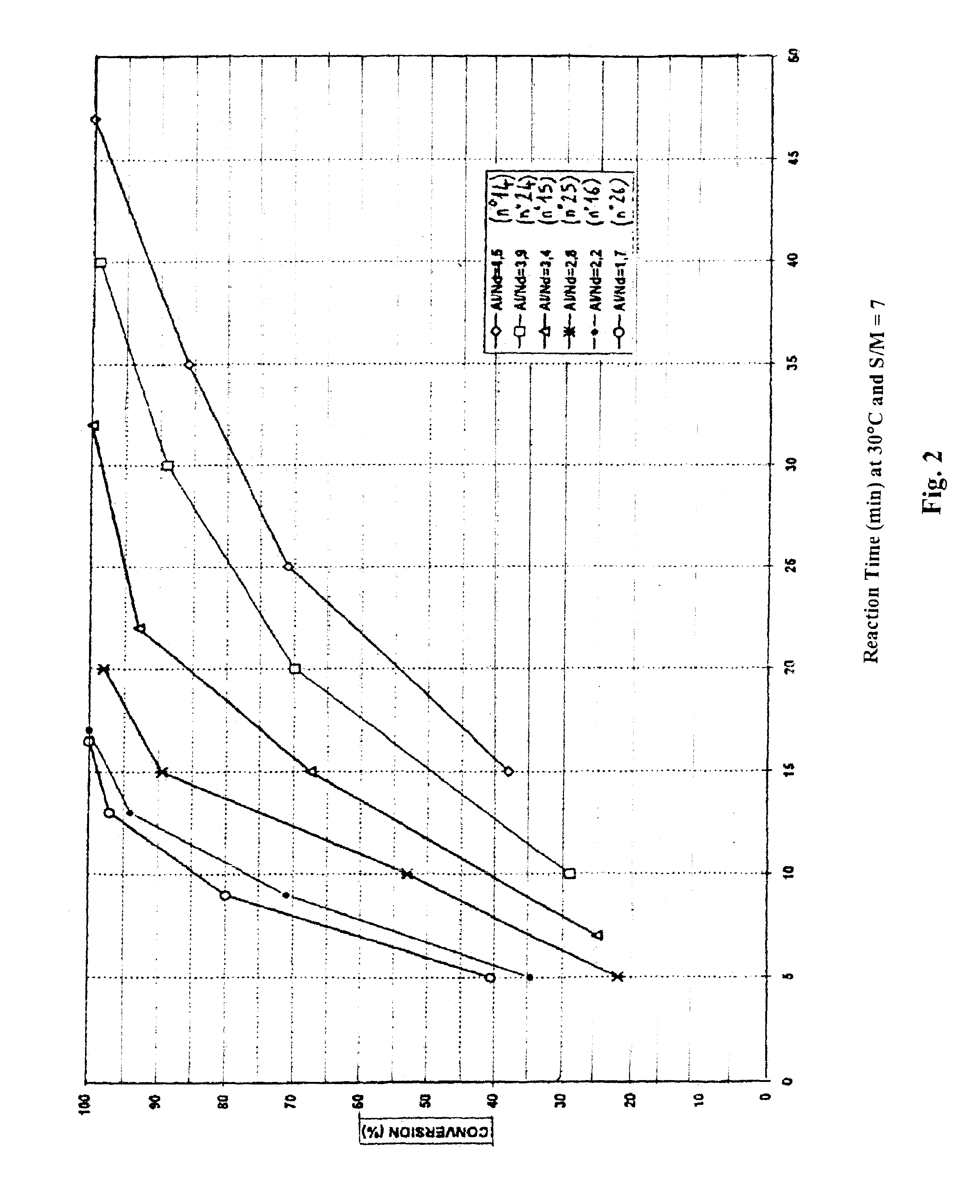

Catalytic system and process for the preparation of elastomers by means of this system

InactiveUS6838534B2High catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElastomerPhosphoric acid

The present invention provides a catalytic system that can be used to prepare by polymerization diene elastomers comprising polyisoprenes and polybutadienes. The invention also provides a process for the preparation of the catalytic system and to a process using the catalytic system to prepare diene elastomers comprising polyisoprenes having a high cis-1,4 linkage content and polybutadienes. The catalytic system according to the invention is based on (a) a conjugated diene monomer, (b) an organic phosphoric acid salt of a rare earth metal, (c) an alkylating agent consisting of an alkylaluminium of the formula AlR3 or HAlR2, and (d) a halogen donor consisting of an alkylaluminium halide, and is such that said salt is suspended in at least one inert and saturated aliphatic or alicyclic hydrocarbon solvent and, the “alkylating agent:rare earth salt” molar ratio ranges from 1 to 5.

Owner:MICHELIN RECH & TECH SA

Dielectric materials, methods of forming subassemblies therefrom, and the subassemblies formed therewith

A circuit subassembly, comprising a dielectric layer formed from a dielectric composition comprising, based on the total volume of the composition: about 15 to about 65 volume percent of a dielectric filler; and about 35 to about 85 volume percent of a thermosetting composition comprising: a poly(arylene ether), and a carboxy-functionalized polybutadiene or polyisoprene polymer.

Owner:ROGERS CORP

Rubber composition and pneumatic tire using the same

InactiveUS20070167555A1Reduce fuel consumptionReduce consumptionSpecial tyresTyre beadsSilicon dioxidePolybutadiene

A rubber composition containing (i) a conjugated diene-based rubber gel having a toluene swelling index of 16 to 70, (ii) a diene-based rubber such as natural rubber, polyisoprene rubber, aromatic vinyl-conjugated diene copolymer rubber and / or polybutadiene rubber, and (iii) an optional carbon black and / or silica and (a) a pneumatic tire using this composition as a high hardness reinforcing layer extending from a bead along a tire sidewalls, in which the fluidity and dimensional stability at the time of extrusion are improved, while maintaining a sufficient hardness of a high hardness reinforced rubber, (b) a pneumatic tire using this composition as two ends of a tire tread extrudate, maintaining a flex fatigue of the two ends of the tread, in which the extrudability and extrusion dimensional stability are improved and (c) a pneumatic tire using the composition as a 1.5 mm to 6 mm thick undertread, in which a high elasticity and relatively thick gauge undertread, and excellent processability and steering stability are provided.

Owner:THE YOKOHAMA RUBBER CO LTD +1

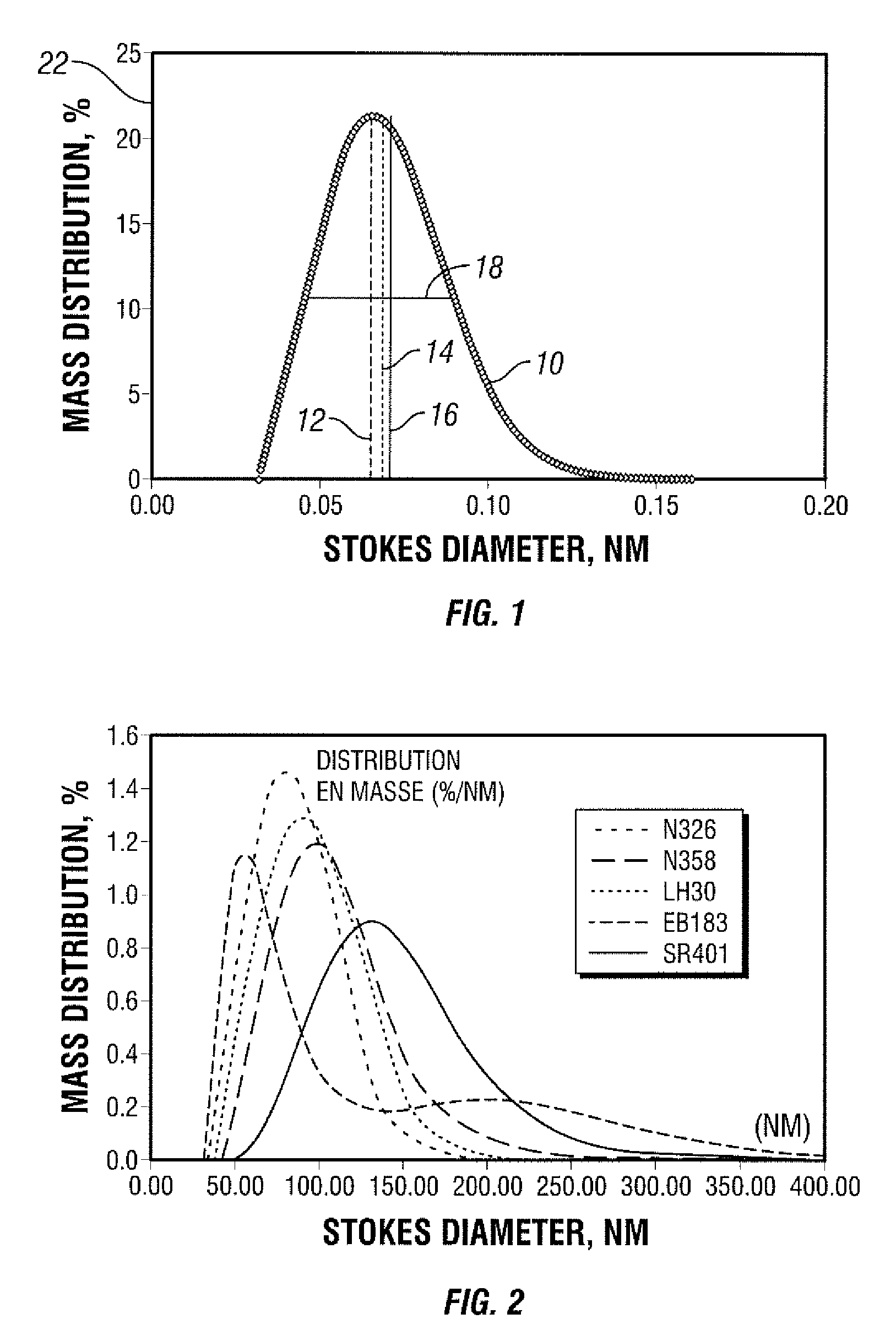

Elastomer compositions with carbon black

An elastomer composition includes an elastomer and a carbon black, wherein the carbon black is characterized as having a COAN of between about 90 and 150 ml / 100 g, a BET of between 50 and 69 m2 / g and a distribution index DI that is greater than 1.15, wherein the DI is a ratio of dw to dmode. In particular embodiments, the elastomer may be selected from one or more natural rubbers, one or more synthetic rubbers or combinations thereof For example, the one or more synthetic rubbers may be selected from styrene butadiene rubber, butadiene rubber, polyisoprene rubber, butyl rubber or combinations thereof. Products made from the elastomer composition include tires and other products, particularly tires that include a sidewall, a carcass, a carcass reinforcement, tread and / or an undertread comprising the elastomeric composition.

Owner:MICHELIN RECH & TECH SA +1

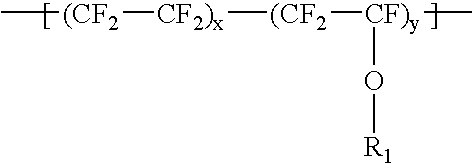

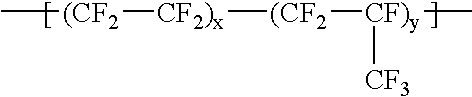

Compositions useful in electronic circuitry type applications, patternable using amplified light, and methods and compositions relating thereto

InactiveUS20060286365A1Synthetic resin layered productsLiquid/solution decomposition chemical coatingPolyesterPolyamide

A light-activatable polymer composition and polymer composite includes a polymer binder selected from epoxy resins, silica filled epoxy, bismaleimide resins, bismaleimide triazines, fluoropolymers, polyesters, polyphenylene oxide / polyphenylene ether resins, polybutadiene / polyisoprene crosslinkable resins (and copolymers), liquid crystal polymers, polyamides, cyanate esters, or combinations thereof, the polymer binder being present in an amount from 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 96, or 97 weight-percent of the total weight of the polymer composition; a spinel crystal filler present in an amount from 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 20, 25, 30, 35, 40, 45, 50, 55 and 60 weight-percent of the total weight of the polymer composition, and methods for making same are provided.

Owner:EI DU PONT DE NEMOURS & CO

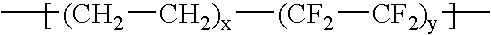

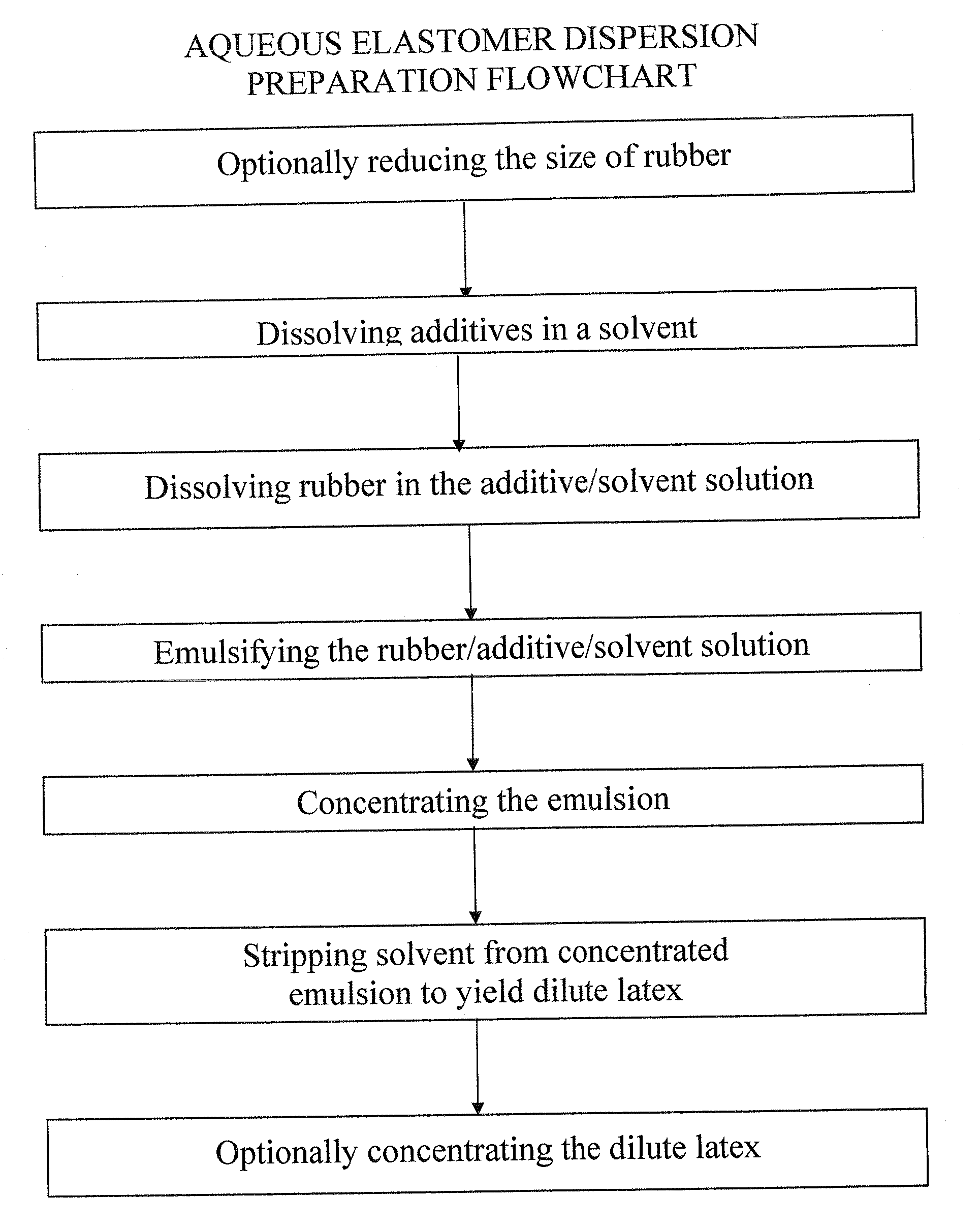

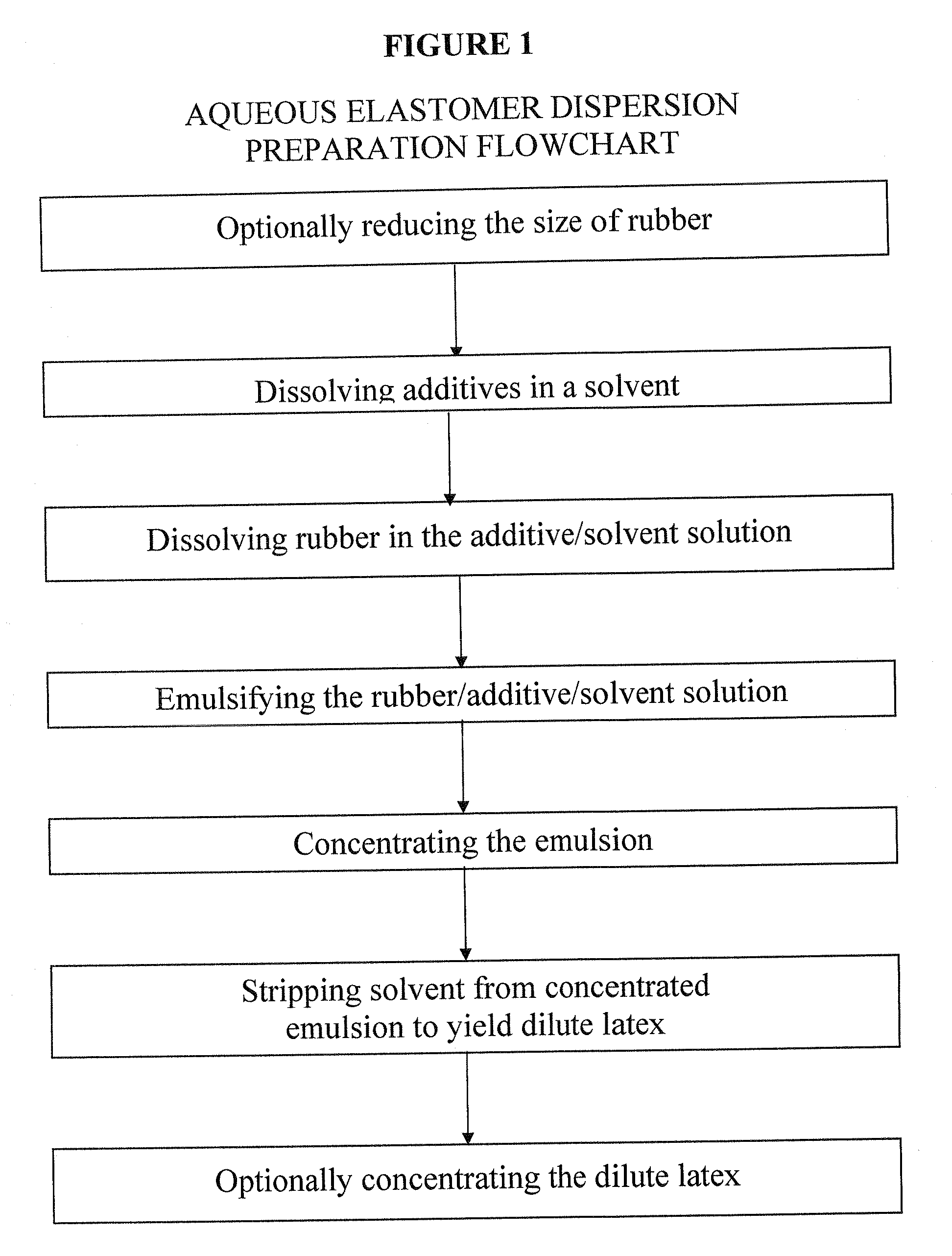

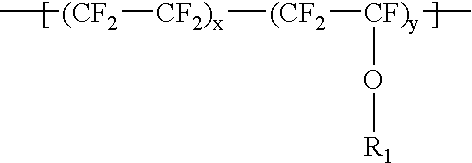

Water-based resin composition and articles made therefrom

InactiveUS20090234064A1Well formedLess surfactant/emulsifierGroup 4/14 element organic compoundsSpecial tyresElastomerWater based

An aqueous elastomer dispersion includes a dispersed phase and an aqueous phase. The dispersed phase includes an elastomer including curable aliphatic conjugated-diene elastomers, such as polyisoprene, and a minor amount of at least one additive. The aqueous phase includes water and other optional components in either a soluble state or a dispersion state. The aqueous elastomer dispersion may be prepared by dissolving an elastomer, such as rubber, and additives in a solvent mixture and then converting the resulting solution into an aqueous emulsion. The aqueous emulsion is concentrated and the solvent is stripped from it to yield a dilute latex. The dilute latex that is obtained is concentrated again. Articles made from the aqueous elastomer dispersion include medical gloves, condoms, probe covers, dental dams, finger cots, catheters and the like.

Owner:ALLEGIANCE CORP

Compositions useful in electronic circuitry type applications, patternable using amplified light, and methods and compositions relating thereto

A light-activatable polymer composition and polymer composite includes a polymer binder selected from epoxy resins, silica filled epoxy, bismaleimide resins, bismaleimide triazines, fluoropolymers, polyesters, polyphenylene oxide / polyphenylene ether resins, polybutadiene / polyisoprene crosslinkable resins (and copolymers), liquid crystal polymers, polyamides, cyanate esters, or combinations thereof, the polymer binder being present in an amount from 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 96, or 97 weight-percent of the total weight of the polymer composition; a spinel crystal filler present in an amount from 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 20, 25, 30, 35, 40, 45, 50, 55 and 60 weight-percent of the total weight of the polymer composition, and methods for making same are provided.

Owner:EI DU PONT DE NEMOURS & CO

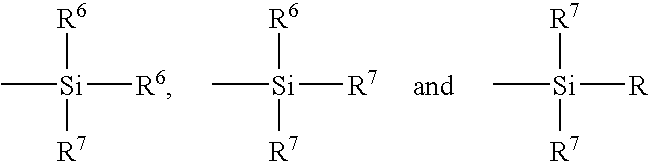

Rubber mixtures

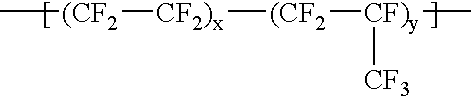

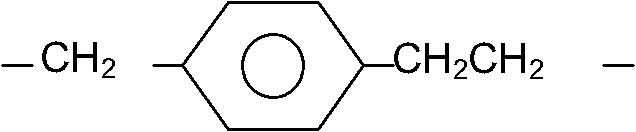

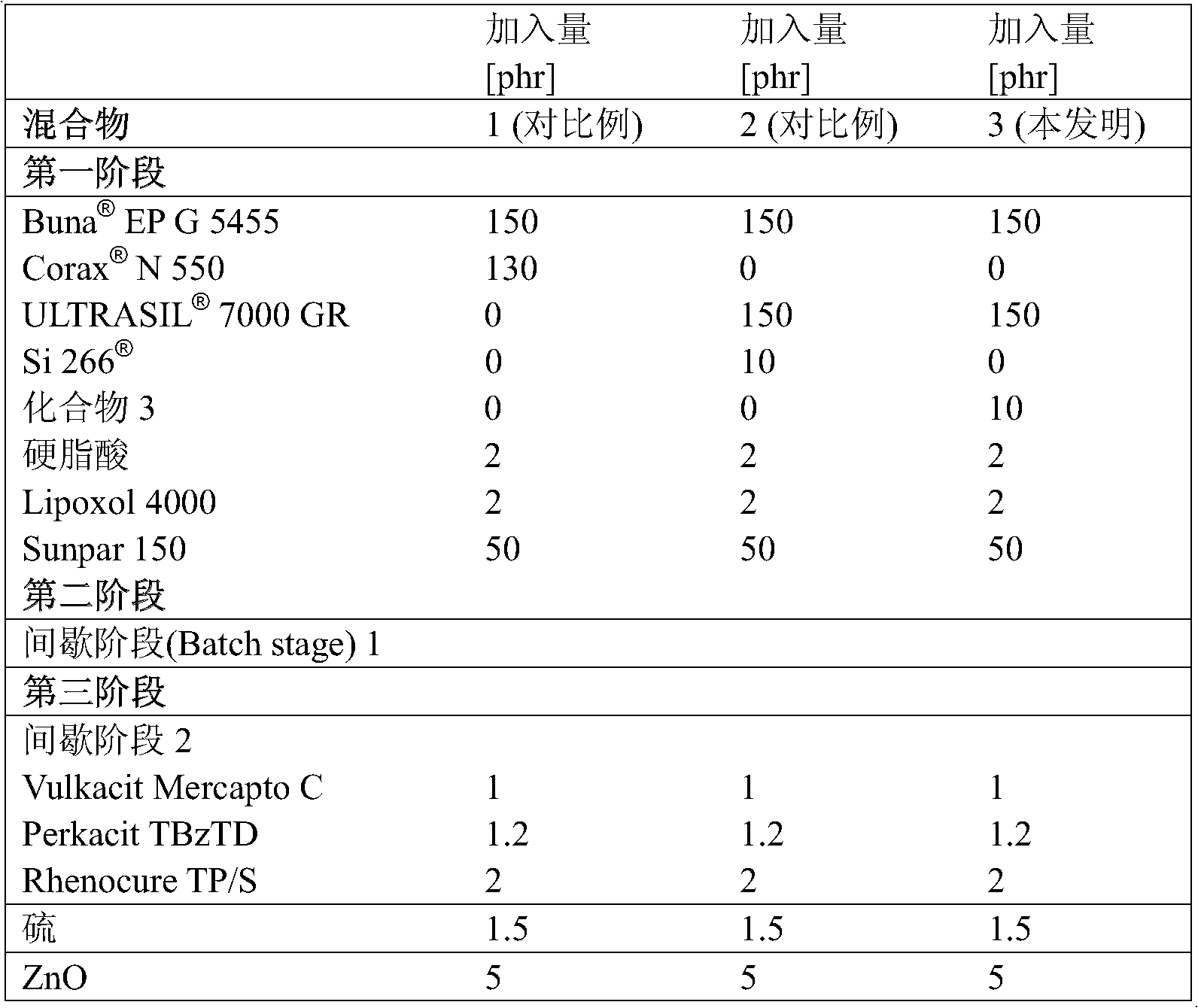

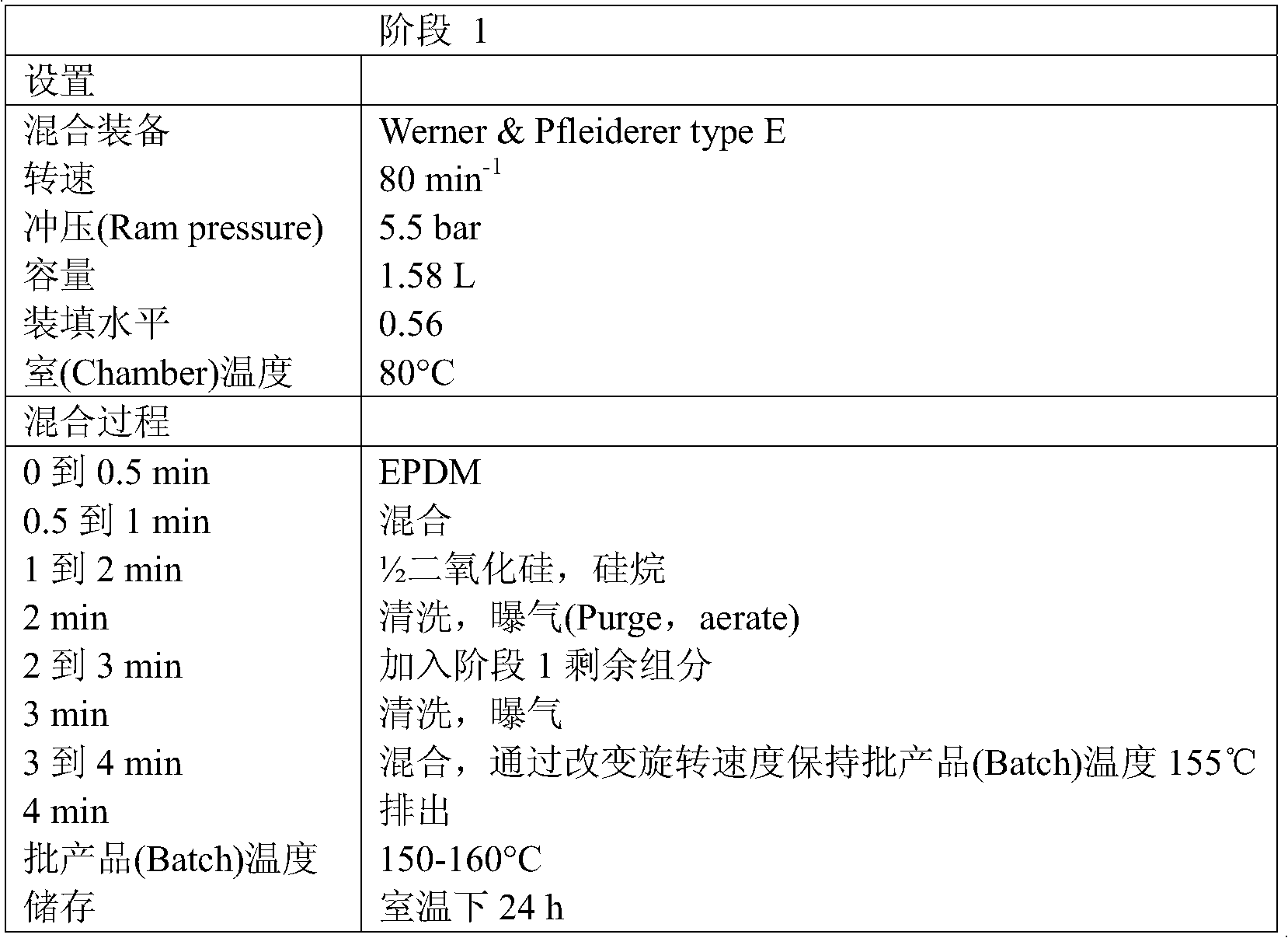

ActiveCN102731915AHysteresis loss is smallImproved Dynamic BehaviorThin material handlingPolyesterPolymer science

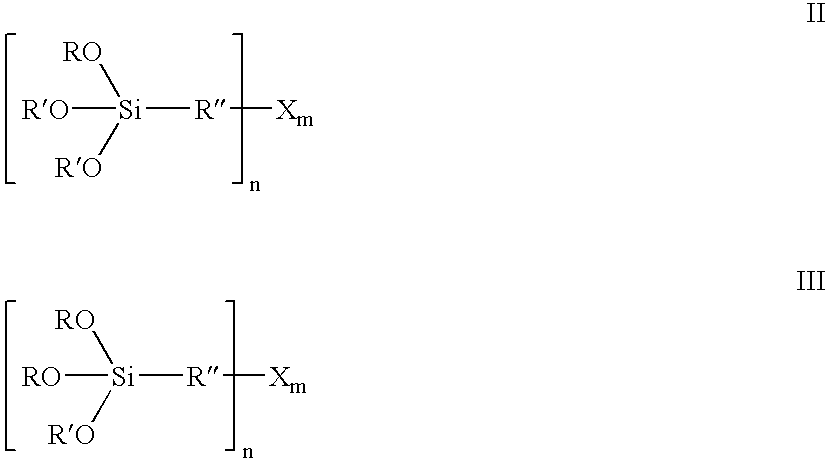

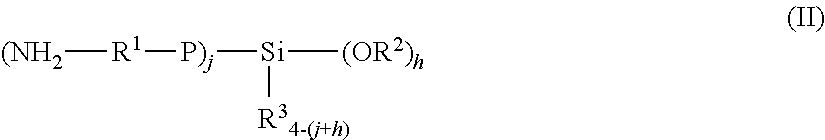

A rubber mixture, comprising (A) at least one rubber selected from the group of ethylene-propylene-diene copolymer (EPDM), ethylene-propylene copolymer (EPM), chloroprene rubber (CR), chloropolyethylene (CM), chloro-isobutene-isoprene (chlorobutyl) rubber (CIIR), chlorosulfonyl polyethylene (CSM), etylene-vinyl acetate copolymer (EAM), alkyl acrylate copolymer (ACM), polyester polyurethan (AU), polyether polyurethane (EU), bromo-isobutene-isoprene (bromobutyl)rubber (BIIR), polychlorotrifluoroethylene (CFM), isobutene-isoprene rubber (butyl rubber, IIR), isobutene rubber (IM), polyisoprene (IR), thermoplastic polyester polyurethane (YAU), thermoplastic polyether polyurethane (YEU), silicone rubber with methyl groups on the polymer chain (MQ), hydrogenated acrylonitrile-butadiene rubber (HNBR), acrylonitrile-butadiene rubber (NBR) or carboxylated acrylonitrile-butadiene rubber (XNBR), (B) at least one oxidic filler, and (C) at least one silicon containing azodicarbamide of the general formula I (R 1 ) 3-a (R 2 ) a Si-R I -NH-C(O) -N=N-C (O)-NH-R I -Si(R 1 ) 3-a (R 2 ) a (I) . The rubber mixture is produced by mixing at least one rubber, at least one oxidic filler, and at least one silicon containing azodicarbamide of the general formula I. It may be used for moldings.

Owner:EVONIK OPERATIONS GMBH

Rare-earth catalyst for diolefin polymerization and its prepn.

This invention is attributed to the rare earth catalyst for diene polymerization and its preparation method. The catalyst is composed of neodymium chloride electron donor complex and organic methylaluminoxane with a molar ratio of 1:20~200. Monomers can be also added, with a neodymium chloride electron donor complex / monomer molar ratio of 1:5~40. The preparation method is simple and the obtained rare earth catalyst has high catalytic activity. With this catalyst, polybutadiene with a cis-1, 4-butadiene content of over 95%, polyisopentadiene and butadiene / isopentadiene copolymer can be obtained and the polymers uniquely have narrow molecular weight distributions, i.e., the ratio of weight-average molecular weight to number-average molecular weight is not larger than 2.0.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing trans-isoprene complexes and its products and use

InactiveCN101121803AImprove appearance qualityStrong mold filling abilityPolymer scienceVulcanization

The present invention is a preparation method of the trans-isoamyl rubber complex, the product and the application. The trans-isoamyl rubber complex is made by doing the binary, ternary, quaternary or multi-blend and total vulcanization with the synthetic reversing formula 1, 4-polyisoprene and the general rubber such as the natural rubber, the styrene-butadiene rubber, the polybutadiene rubber, the cis-polyisoprene rubber, the ethylene propylene rubber, the nitrile rubber, the chloroprene rubber and so on, or with the special rubber. The TPI is used to load the titanium catalyst to catalyze the synthesis of the polyisoprene body through the methods of deposition and polymerization. The structural content of the formula-1, 4 is equal to or more than 90 percent. The present invention makes a rubber complex containing the TPI to overcome the insufficiency of the existing rubber complex in the dynamic performance and to reach the balance between the rolling resistance, the traction performance and the wear performance; the trans-isoamyl rubber complex of the present invention is suitable for the rubber products used in the tire surface and side, the shock absorber product for trains and vehicles, the V-belt, the conveyor belt and in other dynamic uses.

Owner:TSINDAO TSJUJST FANTAJ MATIRIAL EHNDZHINIRING KO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com