Patents

Literature

102results about How to "Hysteresis loss is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber mixtures

ActiveCN102731915AHysteresis loss is smallImproved Dynamic BehaviorThin material handlingPolyesterPolymer science

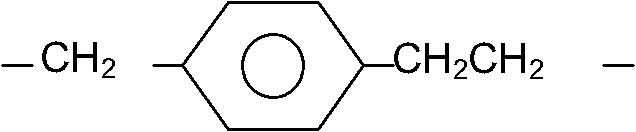

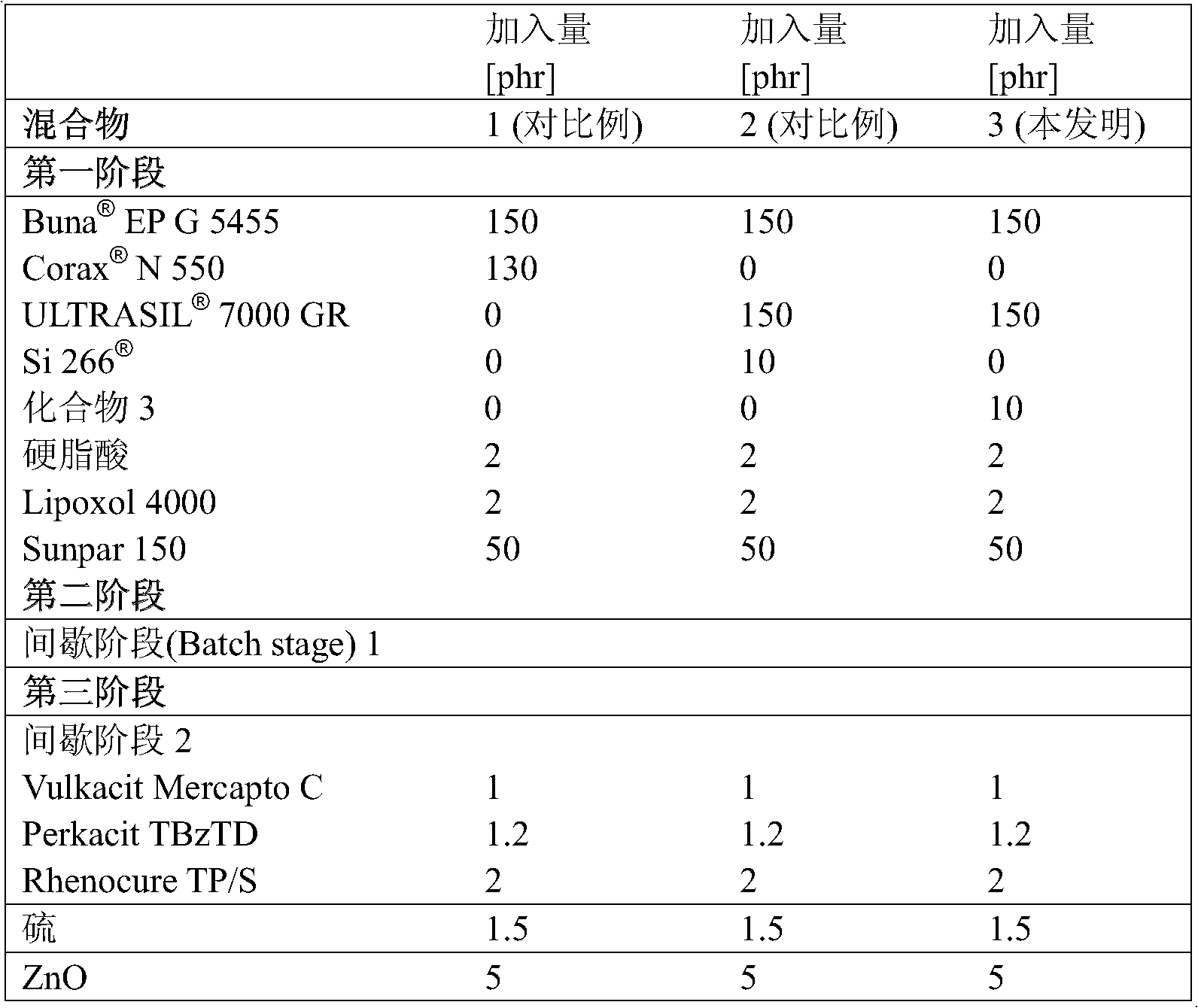

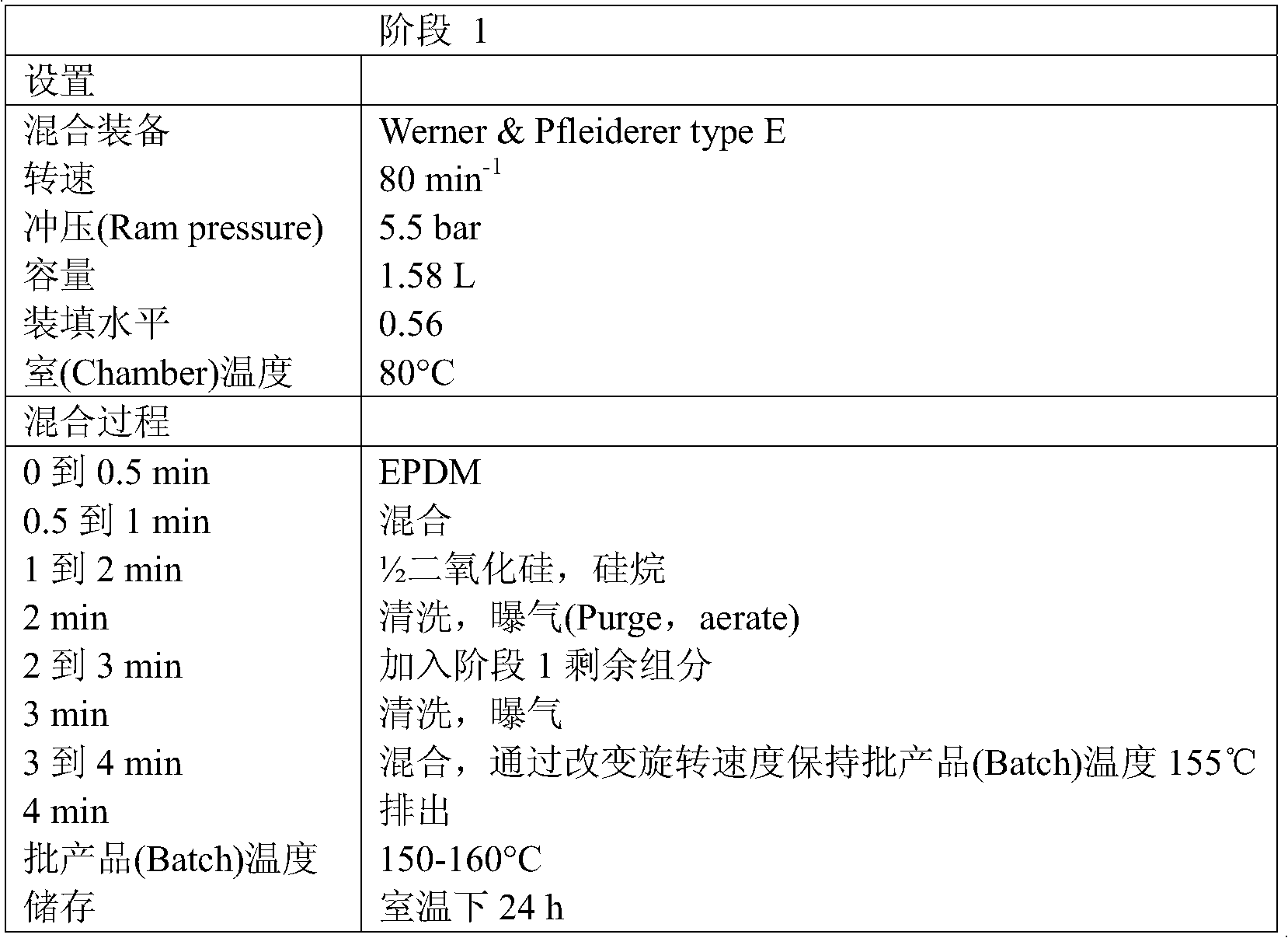

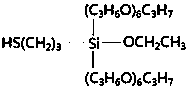

A rubber mixture, comprising (A) at least one rubber selected from the group of ethylene-propylene-diene copolymer (EPDM), ethylene-propylene copolymer (EPM), chloroprene rubber (CR), chloropolyethylene (CM), chloro-isobutene-isoprene (chlorobutyl) rubber (CIIR), chlorosulfonyl polyethylene (CSM), etylene-vinyl acetate copolymer (EAM), alkyl acrylate copolymer (ACM), polyester polyurethan (AU), polyether polyurethane (EU), bromo-isobutene-isoprene (bromobutyl)rubber (BIIR), polychlorotrifluoroethylene (CFM), isobutene-isoprene rubber (butyl rubber, IIR), isobutene rubber (IM), polyisoprene (IR), thermoplastic polyester polyurethane (YAU), thermoplastic polyether polyurethane (YEU), silicone rubber with methyl groups on the polymer chain (MQ), hydrogenated acrylonitrile-butadiene rubber (HNBR), acrylonitrile-butadiene rubber (NBR) or carboxylated acrylonitrile-butadiene rubber (XNBR), (B) at least one oxidic filler, and (C) at least one silicon containing azodicarbamide of the general formula I (R 1 ) 3-a (R 2 ) a Si-R I -NH-C(O) -N=N-C (O)-NH-R I -Si(R 1 ) 3-a (R 2 ) a (I) . The rubber mixture is produced by mixing at least one rubber, at least one oxidic filler, and at least one silicon containing azodicarbamide of the general formula I. It may be used for moldings.

Owner:EVONIK OPERATIONS GMBH

Formula of tread of low-rolling-resistance tire and preparation method thereof

ActiveCN103450508AHigh viscoelasticityReduce rolling resistanceTyresSpecial tyresPolymer scienceMicrocrystalline wax

The invention discloses a formula of a tread of a low-rolling-resistance tire and a preparation method thereof. The formula of the tread of the low-rolling-resistance tire comprises the following components: 10-20% of natural rubber, 10-20% of polybutadiene rubber, 20-40% of solution polymerized styrene butadiene rubber, 20-40% of high-dispersion white carbon black, 0.5-1% of a peptizer A-8, 1-2% of a chemical anti-aging agent 6PPD, 1-2% of a physical anti-aging agent microcrystalline wax, 1-3% of an active agent ZNO, 1-3% of an active agent SA, 1-3% of polyethylene glycol PEG, 1-3% of a vulcanizing agent S-325, 1-3% of an accelerant NS, 0.1-0.8% of a special accelerant CTP and 4-8% of a coupling agent SI69. The formula of the tread of the low-rolling-resistance tire has the beneficial effects that the rolling resistance of the tire is low and can reach an A level or a B level, various physical and mechanical properties of the tire are basically consistent to those of a tire having non-low rolling resistance, and the advantages of road holding of the tire on a wetland and a dry land are retained.

Owner:KENDA RUBBER CHINA

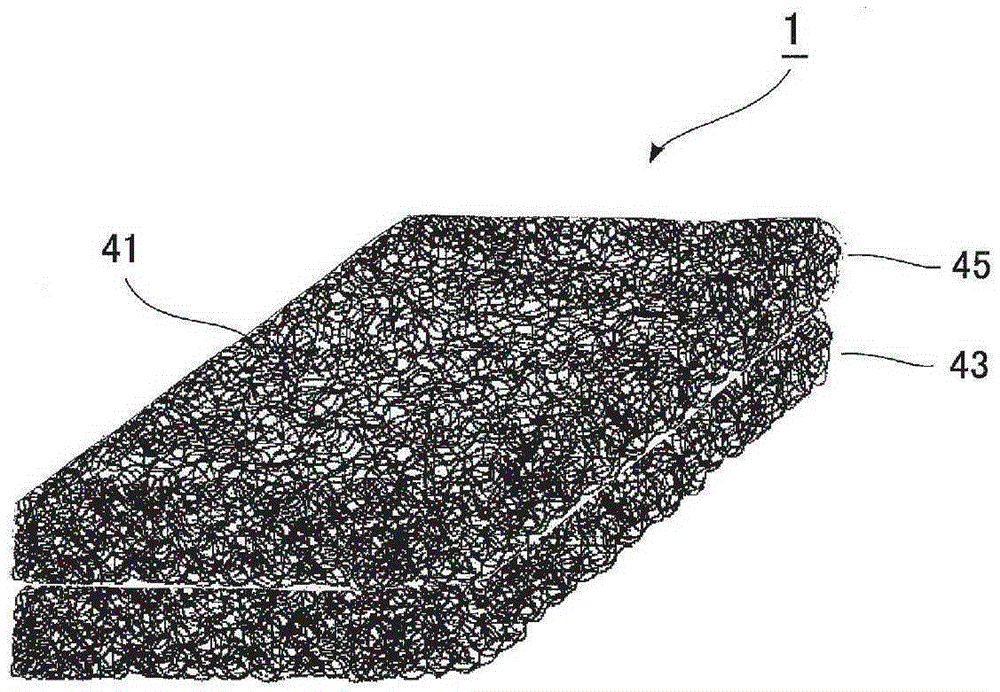

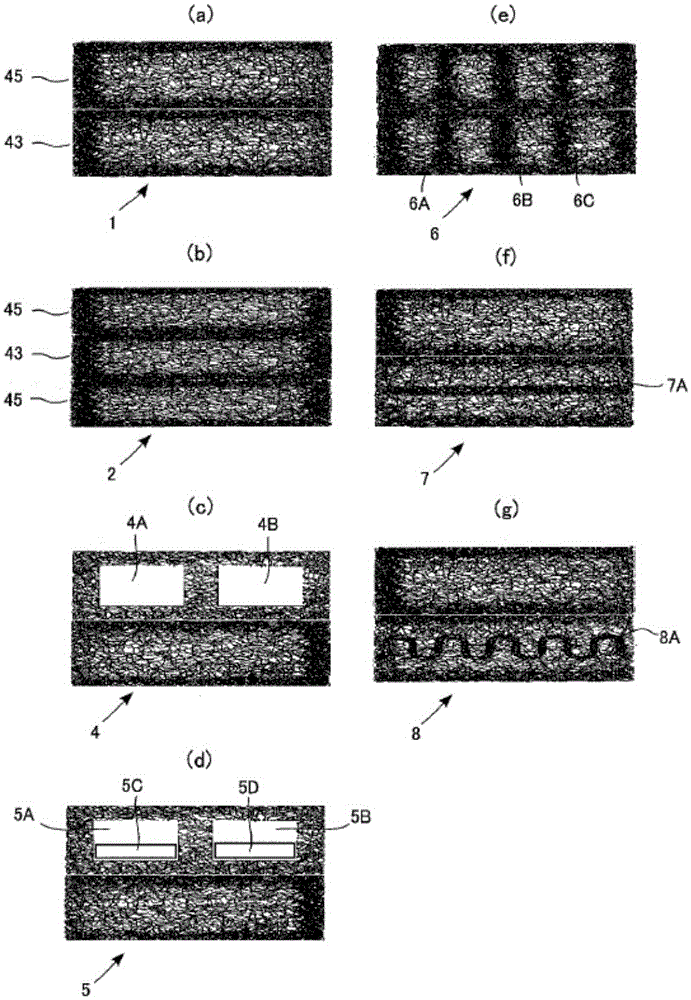

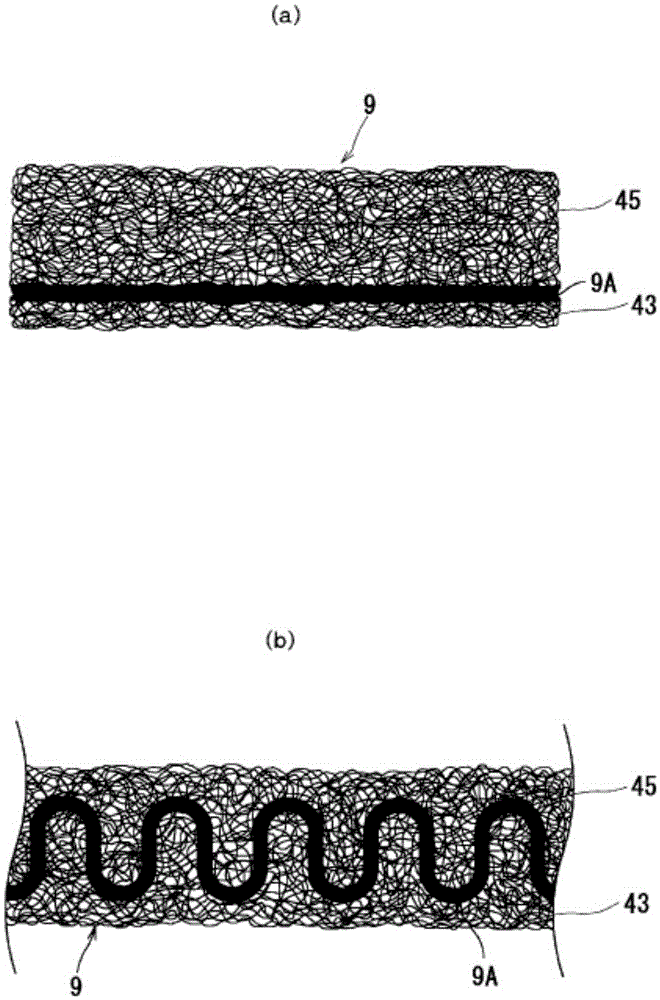

Core material for cushion, and cushion

ActiveCN105377083AInhibition of contractionHigh Thermal Expansion PropertiesStuffed mattressesDomestic upholsteryHysteresisPolyester

The present invention provides a hygienic cushion which can be washed in water, exhibits excellent air permeability, and is light while exhibiting body-shape retention and exerting a resiliency force no less than a given standard at an appropriate thickness. A core material (1) for a cushion, wherein: one surface or both surfaces of a first layer in a three-dimensional mesh structure, said first layer being formed from a polyethylene-based thermoplastic resin, a polyester-based thermoplastic elastomer, or a mixture of a polyethylene-based thermoplastic resin and a polyethylene-based thermoplastic elastomer, is / are laminated with a second layer containing a thermoplastic resin that is different from that of the first layer; the three-dimensional mesh structure has an impact resilience of 13cm or greater and a hysteresis loss of 13-34%; and the thermal elongation rate of the three-dimensional mesh structure in the lengthwise direction before and after a hot-air drying test is 0-8% after 30 minutes at 90 DEG C in the case of a polyethylene-based thermoplastic resin, after 30 minutes at 130 DEG C in the case of a polyester-based thermoplastic elastomer, or after 30 minutes at 90 DEG C in the case of a mixture of a polyethylene-based thermoplastic resin and a polyethylene-based thermoplastic elastomer.

Owner:C ENG CO LTD

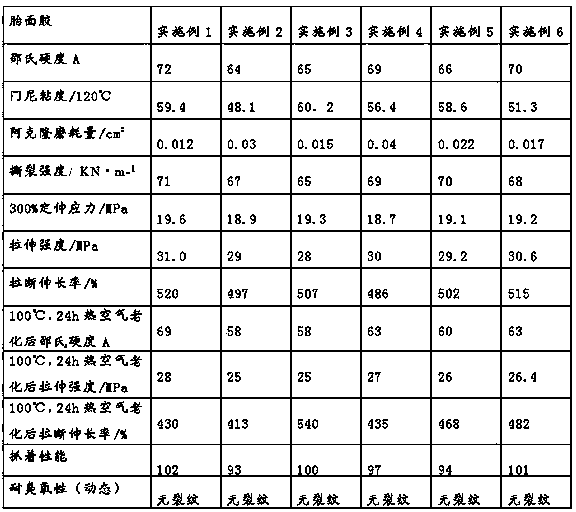

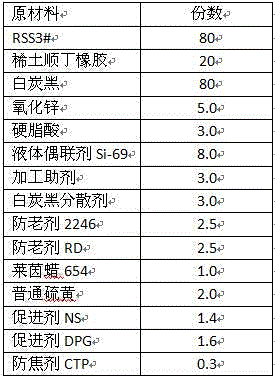

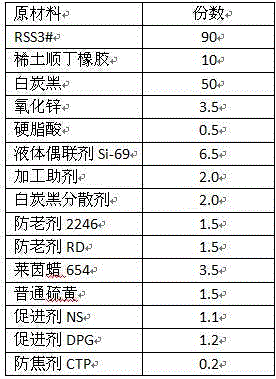

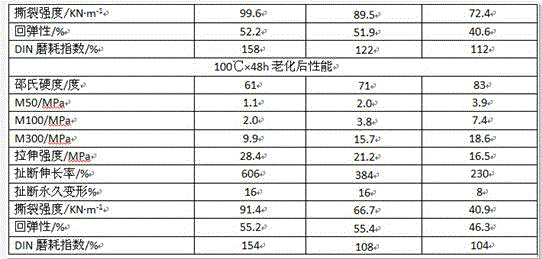

Solution-polymerized styrene-butadiene tread rubber and mixing process thereof

The invention discloses a solution-polymerized styrene-butadiene tread rubber and a mixing process thereof. The tread rubber comprises the components by weight: 40-220 parts of a solution-polymerized styrene-butadiene rubber, 10-60 parts of natural rubber, 5-20 parts of tread rubber powder, 1-4 parts of stearic acid, 1-2 parts of sulphur powder, 20-40 parts of white carbon black, 5-10 parts of carbon black, 2-30 parts of an aromatic hydrocarbon oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of a pine tar oil, 1-4 parts of an accelerant, 0.2-1 part of an anti-reversion agent and 2-5 parts of a bonding agent. A three-stage mixing process is employed. The tread rubber has good anti-aging performance and high wear-resistant property, can prolong service life of an automobile tyre, and has a high safety factor.

Owner:SHANDONG YONGTAI CHEM GROUP

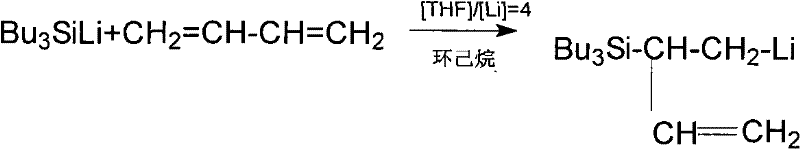

Preparation method of star-shaped solution polymerized butadiene styrene rubber with wide molecular weight distribution

The invention provides a preparation method of star-shaped solution polymerized butadiene styrene rubber (SSBR) with wide molecular weight distribution. The star-shaped SSBR is prepared through adopting a combined initiator system comprising an organic monolithium compound and a silicon lithium initiator, adding the initiator system in a multi-time dropwise mode, and carrying out a coupling reaction by adding a coupling agent in a multi-time adding mode after finishing polymerization. The star-shaped SSBR with wide molecular weight distribution, which can be processed under common conditions without adding low molecular weight polymers to improve the processing performance of the star-shaped SSBR and has the advantages of good tensile strength, balanced comprehensive mechanical property, good dynamic mechanical property, and combination of two properties of wet skid resistance and rolling resistance, is special rubber for tyres which has excellent properties. The star-shaped SSBR can be filled with carbon black, liquid rubber and the like, so the cost can be further saved, properties of rigidity, hardness and wear resistance of rubber products are improved, and the shrinkage of the rubber products is reduced, thereby the star-shaped SSBR can be widely applied to the shoemaking industry, the tyre industry and other industries.

Owner:PETROCHINA CO LTD

Method for producing polyurethane and use of polyurethane produced by the same

InactiveCN101484496AGood elasticityHigh elongation at breakMonocomponent polyurethanes artificial filamentFiberPolyurethane elastomer

Disclosed are a polyurethane and a polyurethaneurea which are extremely useful for polyurethane elastic fibers, synthetic / artificial leathers and highly functional polyurethane elastomers such as TPU. Specifically disclosed is a method for producing a polyurethane from a polyether polyol (a) obtained by a dehydration condensation reaction of a polyol and containing an 1,3-propanediol unit, a polyisocyanate compound (b) and a chain extender (c) in the co-presence of an aprotic polar solvent. Also specifically disclosed are a polyurethane produced by the method, and a film and a fiber composed of such a polyurethane.

Owner:MITSUBISHI RAYON CO LTD

Method for preparing activated rubber crumb by catalysis and activation reaction

InactiveCN101381476AImprove dynamic performanceEasy to usePlastic recyclingPolymer sciencePlasticizer

The invention provides a method for preparing activated rubber powder by catalytic reaction and activating reaction, and relates to a method for comprehensive utilization of waste and scrap rubber. Compared with the production of regenerated rubber, the method reduces processes of desulfurizing, kneading and refining, thereby avoiding secondary pollution to the environment. The prepared activated rubber powder has excellent compatibility with matrix rubber, and improves the physical and mechanical properties of the product. The formulation comprises the following compositions in weight portion: 100 portions of 30 to 40 meshes of waste rubber powder, 8 to 17 portions of plasticizer-dipentene, 5 to 8 portions of dusting agent-pottery clay, 0.2 to 0.5 portion of catalyst-cuprous chloride, 7 to 1.0 portion of promoting agent-polyalkylphenol disulfide, and 1 to 2.5 portions of dispersing agent-ethanol. The method comprises the following steps: placing the 30 to 40 meshes of waste rubber powder into a high-speed stirring reactor, and heating the waste rubber powder to the temperature of between 80 and 100 DEG C; adding the plasticizer, the dusting agent, the catalyst, the promoting agent and the dispersing agent into the reactor sequentially for reacting for 10 to 20 minutes at a temperature of between 80 and 120 DEG C, and cooling and discharging to produce the activated rubber powder. The prepared activated rubber powder can be used in rubber industry and building industry.

Owner:TIANJIN RUBBER IND RES INST

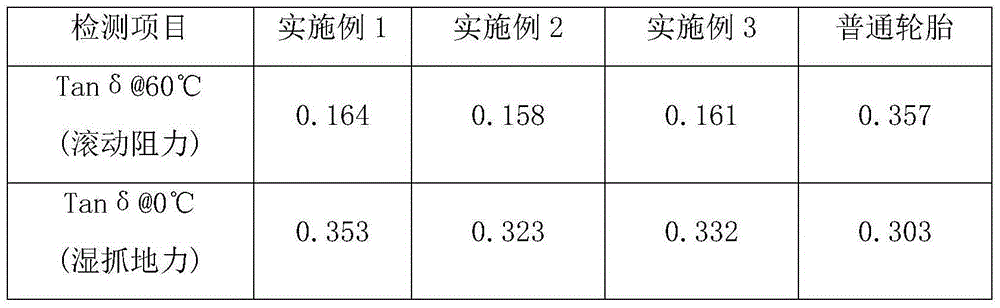

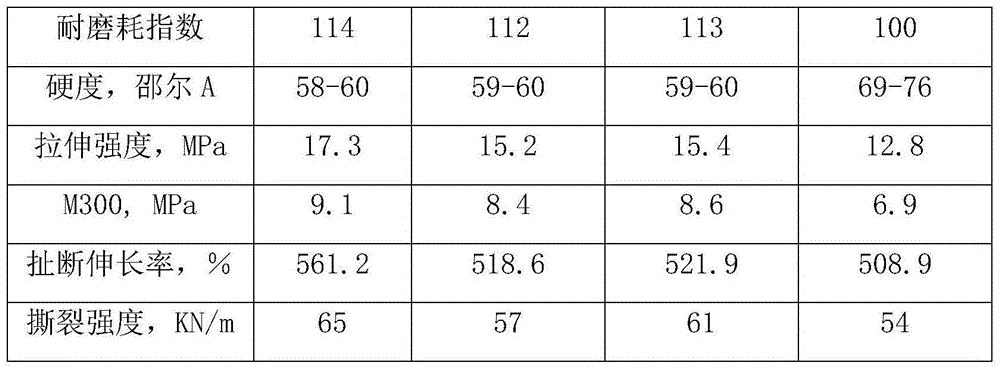

Low-rolling-resistance wet-skid-resistant abrasion-resistant tire tread formula and preparation method thereof

The invention discloses a low-rolling-resistance wet-skid-resistant abrasion-resistant tire tread formula. The low-rolling-resistance wet-skid-resistant abrasion-resistant tire tread formula comprises the following components: 10-20% of natural rubber, 0-20% of polybutadiene rubber, 20-60% of solution polymerized styrene butadiene rubber, 20-40% of high-dispersion white carbon black and 4-8% of a coupling agent SI69. The formula has the beneficial effects that: the hardness of a product is reduced, the wet-skid resistant performance is improved, so that a tire does not easily skid, and thus safety of the tire is improved; the abrasion resistant performance of the tire is excellent, and thus the service life of the tire is greatly increased; the rolling resistance of the tire is low and can reach an A level or a B level, various physical and mechanical properties of the tire are basically consistent to those of a tire having no low rolling resistance, and the advantages of the tire in road holding on a wet land and on a dry land are retained.

Owner:KENDA RUBBER CHINA

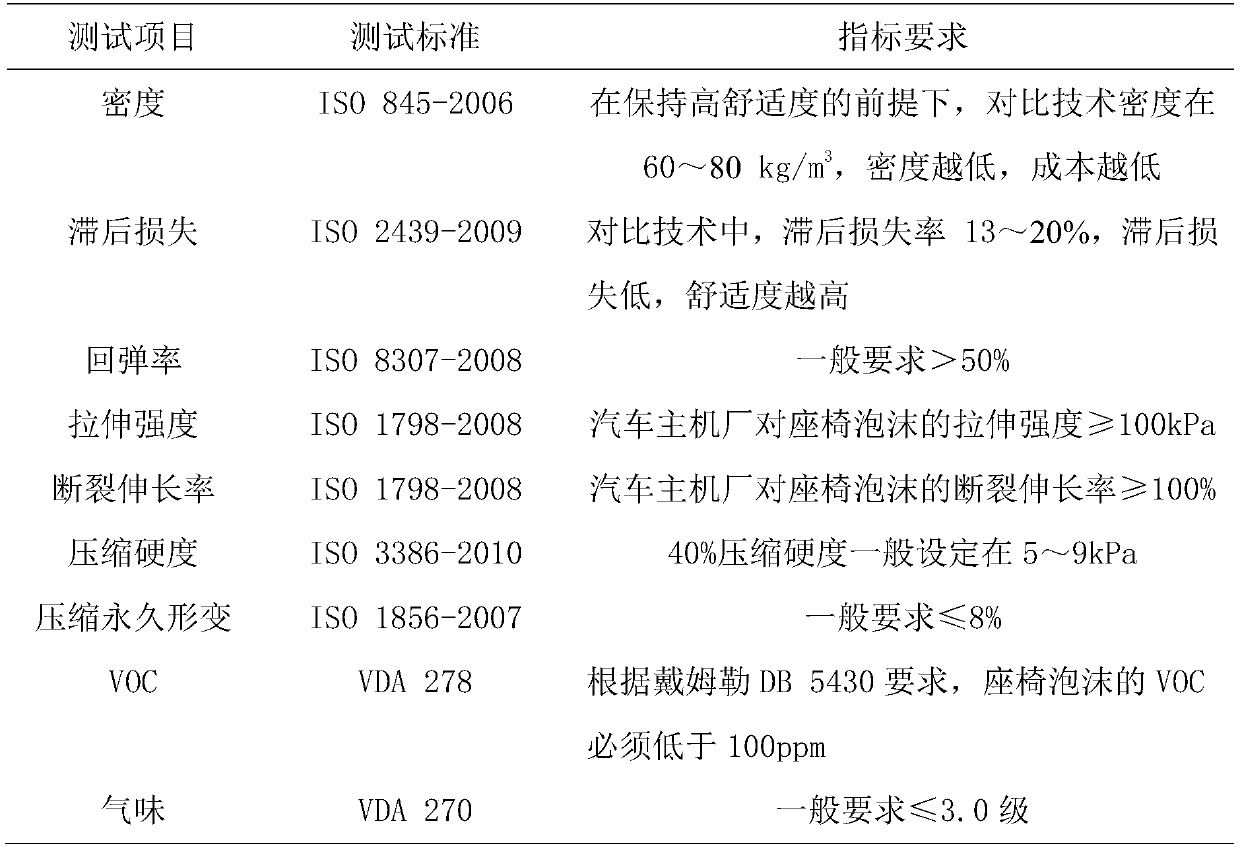

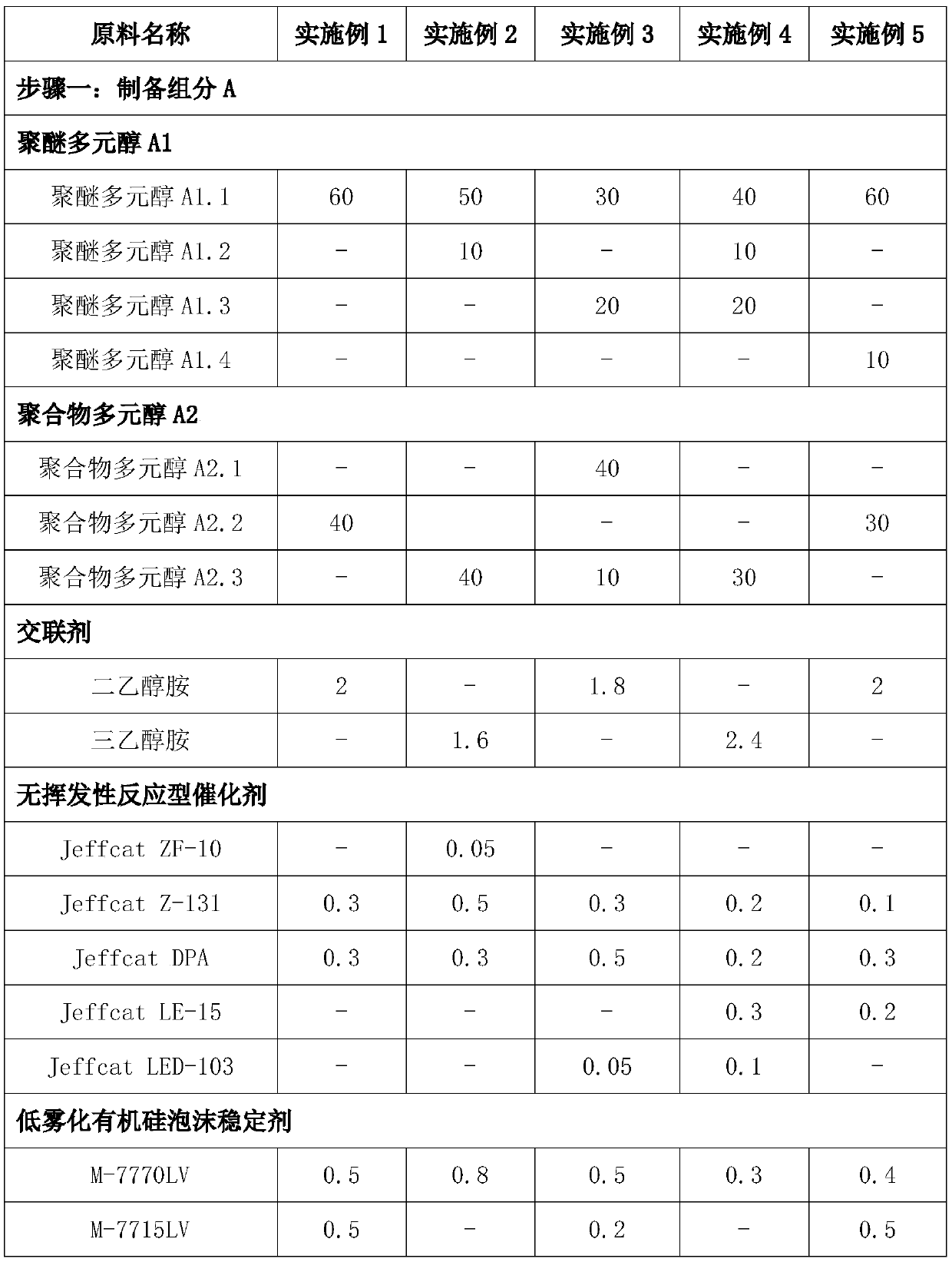

High-resilience polyurethane foam plastic with high comfort level, low hysteresis loss and low VOC, and preparation method and application thereof

The invention relates to a high-resilience polyurethane foam plastic with high comfort level, low hysteresis loss and low VOC, and a preparation method and an application thereof. The problems of lowcomfort level, high hysteresis loss and high VOC of polyurethane foam plastics in the prior art are mainly solved. The high-resilience polyurethane foam plastic is composed of a component A and a component B, and a weight ratio of the component A to the component B is 100:(30-55), wherein the component A comprises, by weight, 50-70 parts of polyether polyol A1, 30-50 parts of polymer polyol A2, 0.5-3 parts of a cross-linking agent, 0.5-2.5 parts of a non-volatile reactive catalyst, 0.3-1.5 parts of a low-atomization organic silicon foam stabilizer, 1.5-2.5 parts of water and 0.5-5 parts of anopening agent; and the component B is a mixture of toluene diisocynate and diphenylmethane diisocyanate. The polyurethane foam plastic prepared in the invention has the advantages of high comfort level, low hysteresis loss, low odor and low VOC, achieves good technical effects, and can be applied to vehicle seats and office furniture.

Owner:JIANGSU CHANGHUA POLYURETHANE SCI & TECH

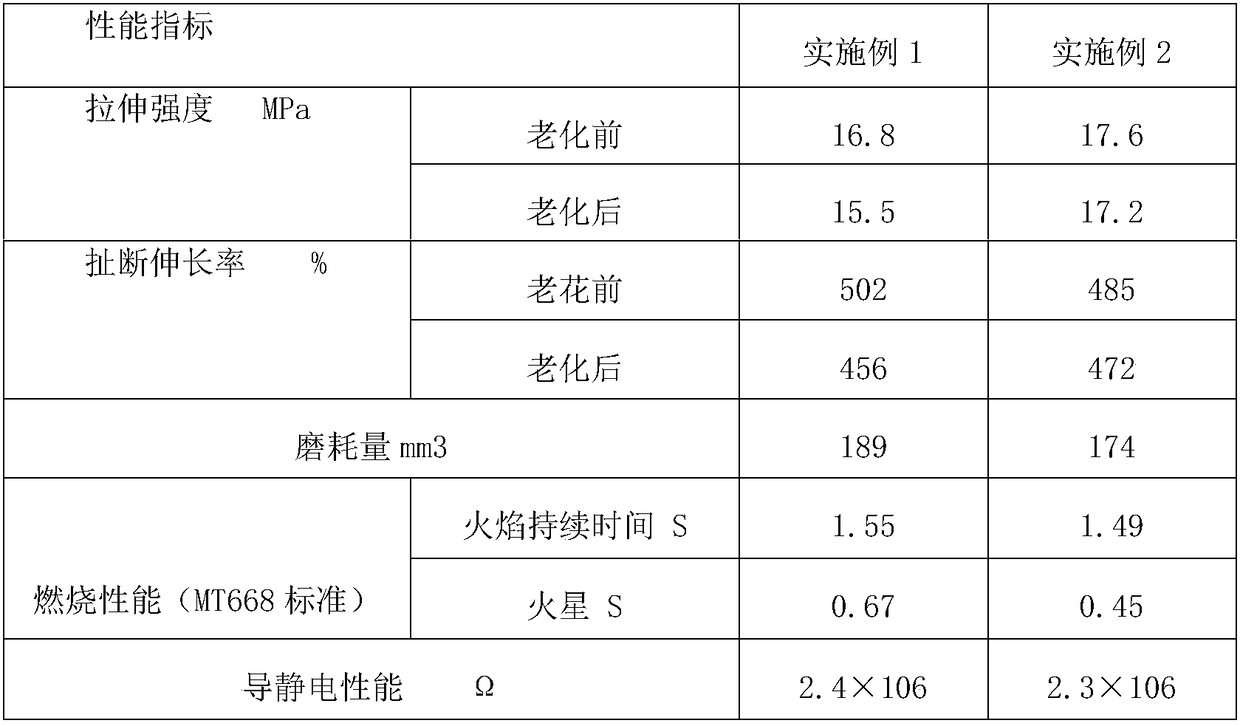

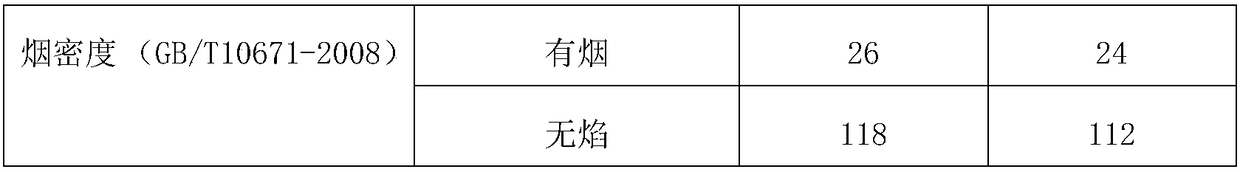

Low-smoke low-halogen flame-retardant conveyor belt covering glue for coal mine and preparation process thereof

InactiveCN108659285AHigh bromine contentImprove thermal stabilityConveyorsComposite ceramicEngineering

The invention discloses low-smoke low-halogen flame-retardant conveyor belt covering glue for a coal mine, and relates to the technical field of conveyor belt covering glue. The covering glue comprises the following chemical components: natural standard rubber, styrene-butadiene rubber SBR1502, cis-butyl BR9000 rubber, polyisobutylene PB1300, an anti-aging agent, zinc oxide, magnesium oxide, stearic acid, a flow release agent, N234 carbon black, nano-aluminum hydroxide, antimony trioxide, decabromodiphenylethane, composite ceramic powder, expanded halogen-free flame-retardant IFR, a multi-purpose synergistic halogen-free flame retardant PNA220, molybdenum salt used as a smoke suppressant, an accelerator and sulfur. The low-smoke low-halogen flame-retardant conveyor belt covering glue disclosed by the invention is used under a coal mine well to meet flame-retardant performance of the conveyor belt, has excellent wear resistance and flame retardancy, and is low in smoke amount and smoketoxicity.

Owner:江苏凯嘉橡胶科技股份有限公司

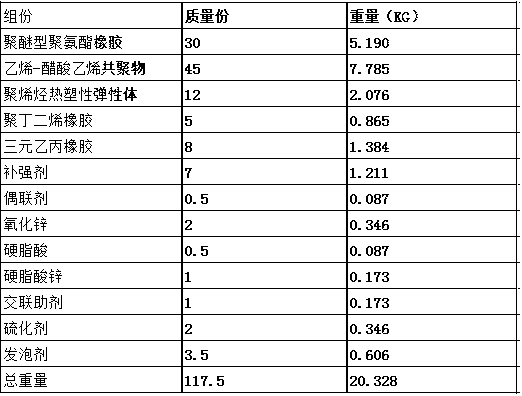

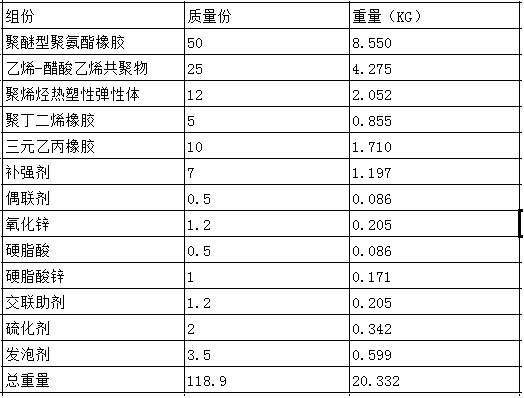

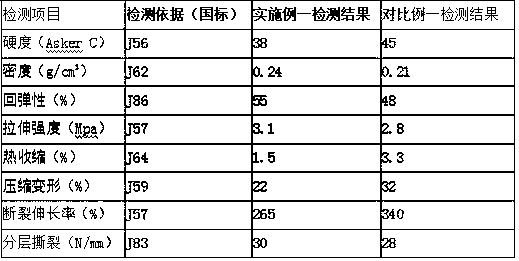

Composition and preparation method for preparing wear-resistant waterproof high-elasticity foaming materials

InactiveCN110256837AIdeal raw material function combinationIncrease elasticityPolymer sciencePolyolefin

The invention discloses a composition and a preparation method for high-elasticity wear-resistant foaming materials, wherein the composition comprises, by mass, 20-65 parts of a polyether type polyurethane rubber, 20-65 parts of an ethylene-vinyl acetate copolymer, 7-18 parts of a polyolefin thermoplastic elastomer, 3-8 parts of a polybutadiene rubber, 5-15 parts of ethylene propylene diene monomer, 5-10 parts of a reinforcing agent, 0.3-1 part of a coupling agent, 1.0-2.0 parts of zinc oxide, 0.5-1.0 part of stearic acid, 0.8-1.5 parts of zinc stearate, 0.5-1.5 parts of a cross-linking aid, 1.0-2.5 parts of a vulcanizing agent, and 1.5-3.5 parts of a foaming agent. The preparation method mainly comprises: two mixing, granulation, and foaming. According to the present invention, by adopting the technical scheme, the obtained foaming material product has advantages of small density, softness, wear resistance, excellent anti-cussion performance, good elasticity, compression resistance, small compression deformation and folding deformation resistance.

Owner:东莞华工佛塑新材料有限公司

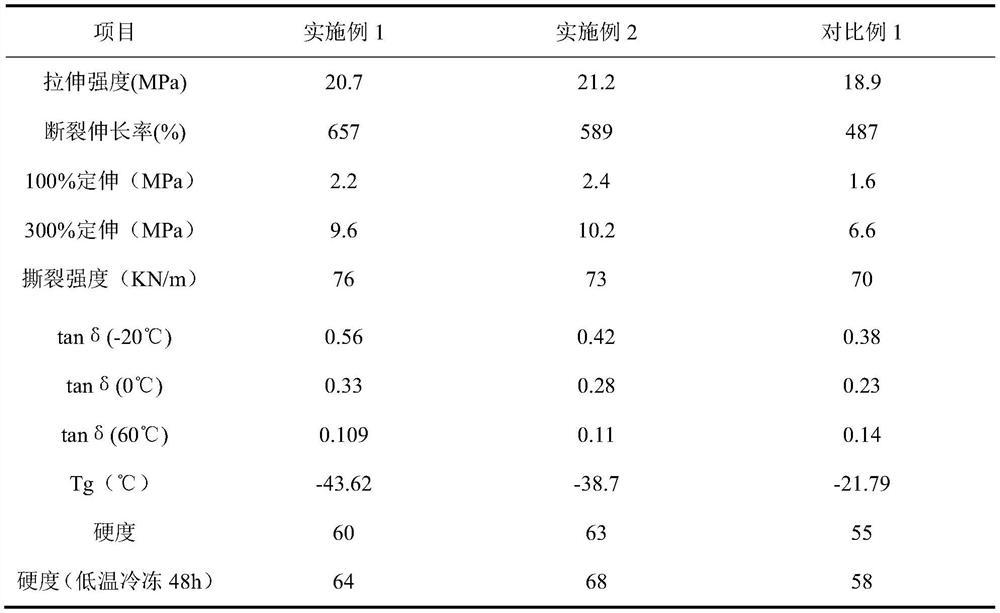

Low-temperature-resistant and high-wet-skid-resistant snow tire tread rubber and preparation method thereof

PendingCN112812388AGood dispersionReduce rolling resistanceRolling resistance optimizationRolling resistanceStearic acid

The invention relates to low-temperature-resistant and high-wet-skid-resistant snow tire tread rubber and a preparation method thereof. The tread rubber is prepared from the following raw materials in parts by mass: 40.0 to 60.0 parts of natural rubber, 20.0 to 60.0 parts of solution polymerized styrene-butadiene rubber, 10.0 to 40.0 parts of butadiene rubber, 5.0 to 20.0 parts of high-abrasion-resistance carbon black N234, 50.0 to 80.0 parts of high-dispersion white carbon black, 3.0 to 8.0 parts of a white carbon black dispersing agent, 4.0 to 8.0 parts of a silane coupling agent, 10.0 to 30.0 parts of paraffin-based oil, 1.0 to 3.0 parts of activated zinc oxide, 1.0 to 3.0 parts of tackifying resin, 1.0 to 3.0 parts of stearic acid, 2.0 to 5.0 parts of an anti-aging agent, 1.0 to 3.0 parts of an accelerant and 1.35 parts of sulfur. According to the invention, the rolling resistance of a tire is reduced, the wet grabbing of the tire is improved, and the tire tread formula with low rolling resistance and high wet grabbing performance is obtained.

Owner:山东兴鸿源轮胎有限公司

Cowhells color rubber composition for tire tread of load bearing radial tire

InactiveCN106279794AImprove aestheticsImprove developmentRolling resistance optimizationSilane couplingAutomotive engineering

The invention relates to a composition for a tire tread of a tire, in particular to the cowhells color rubber composition for a tire tread of a load bearing radial tire. The cowhells color rubber composition for the tire tread of the load bearing radial tire is characterized by being prepared from the following ingredients in parts by weight: 100 parts of base rubber, 4.0 to 8.0 parts of activating agents, 40 to 80 parts of white carbon black, 4.0 to 8.0 parts of silane coupling agents, 1.0 to 3.0 parts of carbon black dispersing agents, 1.5 to 3.0 parts of accelerants, 3.0 to 6.0 parts of anti-aging agents, 1.0 to 2.0 parts of vulcanizing agents, 0.1 to 0.3 part of scorch retarders and 1.0 to 3.0 parts of processing agents. The cowhells color rubber composition for the tire tread of the load bearing radial tire has the advantages that the attractive degree of the tire is improved; meanwhile, the tire rolling resistance is also reduced; the fuel saving and environment-friendly requirements can be met.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

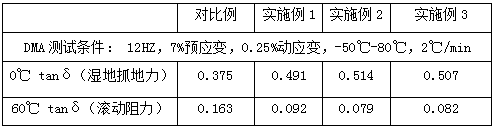

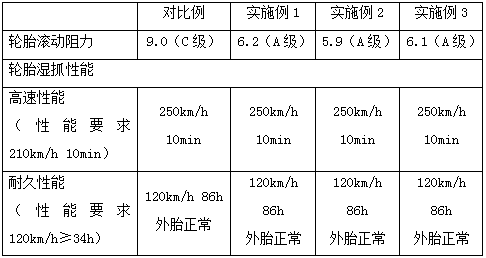

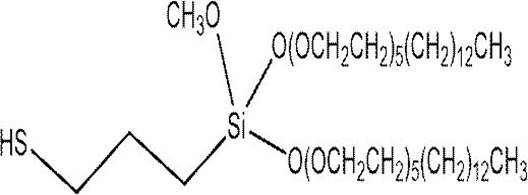

A kind of ultra-low rolling resistance and ultra-high wet grip tire tread compound and its preparation method and tire

ActiveCN106750668BGood dispersionReduce rolling resistanceSpecial tyresRolling resistance optimizationRolling resistanceEngineering

The invention belongs to the field of rubber tire manufacturing, and relates to tire tread rubber with ultra-low rolling resistance and ultra-high wet grapping performance and a preparation method thereof and a tire. The tire tread rubber with ultra-low rolling resistance and ultra-high wet grapping performance is prepared by smelting the following raw materials in parts by weight: 50.0-90.0 parts of solution-polymerized butadiene-styrene rubber I, 20.0-40.0 parts of solution-polymerized butadiene-styrene rubber II, 10.0-40.0 parts of solution-polymerized butadiene-styrene rubber III, 50.0-120.0 parts of highly dispersed white carbon black, 3.0-8.0 parts of a white carbon black dispersing agent, 5.0-30.0 parts of aromatic hydrocarbon oil, 8.0-15.0 parts of a silane coupling agent I, 2.0-8.0 parts of a silane coupling agent II, 6.0-18.0 parts of road grapping resin and 0.2-1.6 parts of an accelerant TOT-N. By using the tire tread rubber formula with ultra-low rolling resistance and ultra-high wet grapping performance, the rolling resistance of the tire can reach below 6.5 (A grade: RRC is smaller than or equal to 6.5), the wet grapping performance can reach over 1.55 (A grade: G is greater than or equal to 1.55), and meanwhile, various physical and mechanical properties of the rubber and the high-speed durability of the tire meet the normal operating requirements.

Owner:ZHONGCE RUBBER GRP CO LTD

Formula and preparation method of snow tire

The invention discloses a formula of a snow tire. The formula of the snow tire comprises the following components: 5-15% of natural rubber, 20-40% of solution polymerized styrene butadiene rubber, 15-30% of high abrasion proof carbon black N234, 10-20% of high dispersion white carbon black, 0.5-1% of a peptizer A-8, 0.5-1.5% of a chemical antioxidant 6PPD, 0.5-1.5% of a physical antioxidant microcrystalline wax, 1-3% of an active agent ZNO, 1-3% of an active agent SA, 0.5-1.5% of polyethylene glycol (PEG), 1-3% of a vulcanizing agent S-325, 0.5-1.5% of an accelerant CZ, 0.1-0.5% of a special agent CTP and 4-8% of a coupling agent SI69. The technical scheme provided by the invention has the beneficial effects of low hardness and good elasticity of tire surface glue, low vitrification point of rubber, high wear resistance, good road holding performance on ice and snow covered pavement; therefore, the snow tire can effectively avoid skidding on ice and snow covered pavement, and enhance road safety.

Owner:KENDA RUBBER CHINA

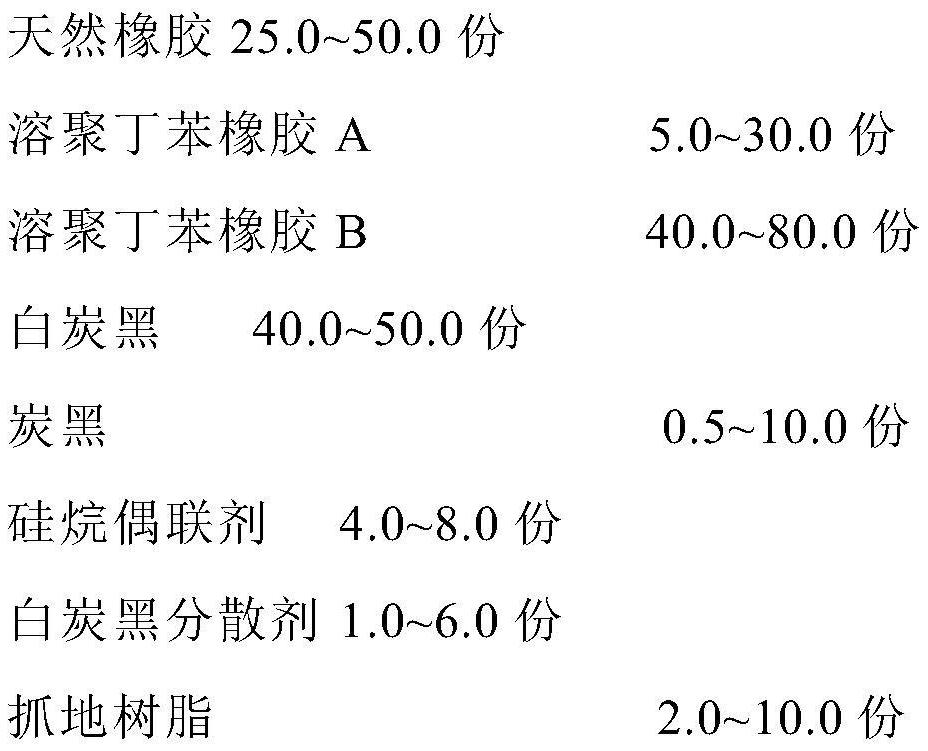

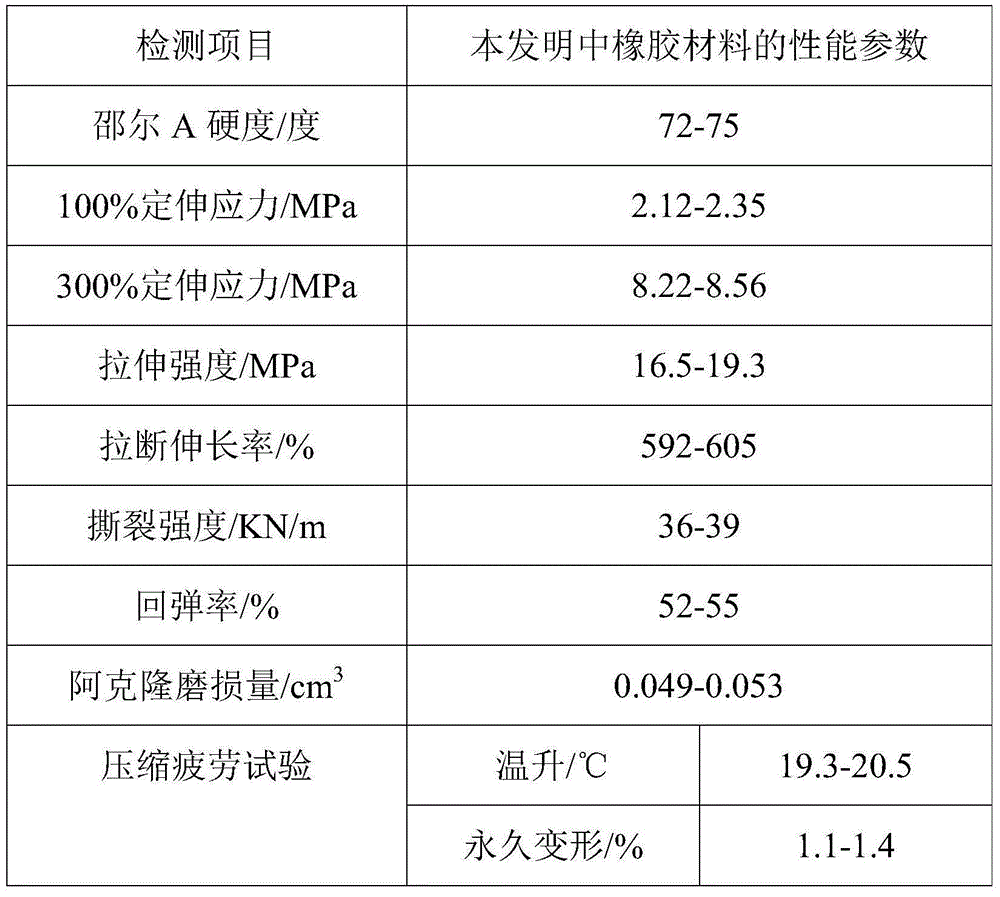

A kind of low filling high performance tire tread compound and tire

ActiveCN109251379BHigh strengthImprove thermal stabilitySpecial tyresRolling resistance optimizationRubber materialPolymer science

The invention belongs to the field of manufacturing of rubber tires, and relates to a low-filling high-performance tire tread rubber material and a tire, wherein the tire tread rubber material is formed by mixing the following raw materials by weight: 25.0-50.0 parts of natural rubber, 5.0-30.0 parts of a solution polymerized styrene-butadiene rubber A, 40.0-80.0 parts of a solution polymerized styrene-butadiene rubber B, 40.0-50.0 parts of white carbon black, 0.5-10.0 parts of carbon black, 4.0-10.0 parts of a silane coupling agent, 1.0-6.0 parts of a white carbon black dispersing agent, 2.0-10.0 parts of a road-holding resin, and 0.5-3.0 parts of an anti-reversion agent. According to the present invention, the tire tread rubber material uses a large amount of the natural rubber, is lessfilled with the filler, such that the high tensile strength and the high elongation at break can be achieved, the requirements of low rolling resistance and high wet gripping of the tire can be met, and the rolling resistance and the wet road-holding ability can meet the Class B stipulated by the EU Tire Labeling Regulation.

Owner:ZHONGCE RUBBER GRP CO LTD

Antiskid wear-resistant tire composition and preparation method thereof

InactiveCN105086037AImprove wear resistanceGood physical and mechanical propertiesSpecial tyresDispersityWear resistant

The invention discloses an antiskid wear-resistant tire composition and a preparation method thereof. The antiskid wear-resistant tire composition is prepared from the following raw materials in parts by mass: 14-16 parts of silicon rubber, 12-18 parts of ethylene propylene diene monomer rubber, 4-8 parts of polyvinyl chloride, 2-5 parts of lead phosphite, 16-20 parts of hydrogenated butadiene-acrylonitrile rubber, 1-2 parts of rubber vulcanizer, 10-20 parts of high-dispersity white carbon black, 1-5 parts of nano zinc oxide, 5-7 parts of coupling agent, 4-6 parts of tackifying resin, 1-2 parts of accelerator NOBS, 0.5-1 part of accelerator CZ, 2-5 parts of aromatic oil and 1.3-2 parts of anti-aging agent H. The preparation method comprises the following steps of compounding, rubber sheet cooling, weight compounding and the like. The tire prepared from the composition has favorable wet grip ability, favorable dry grip ability and favorable wear resistance.

Owner:CHONGQING HONGQI JIEXUN WHEEL

Special highly-wear-resistant rubber material used for tire tread

InactiveCN105111517AImprove mechanical propertiesImprove heat resistanceSpecial tyresPolymer scienceWear resistant

The invention discloses a special highly-wear-resistant rubber material used for tire tread. The material comprises the following raw materials: natural rubber, polybutadiene rubber, modified kaolin, stearic acid modified ultrafine cerium oxide, nanometer calcium carbonate, nanometer titanium dioxide, zinc oxide, stearic acid, sulfur, 2-(4-morpholinyl dithio)benzothiazole, organic silicone-acrylate rubber particles, a methyl methacrylate-butadiene-styrene copolymer, lanthanum dioctyldith iocarbamate, cobaltic yttrium glycinemethane dithioate, N-cyclohexylthiophthalimide, an accelerator M, an accelerator CZ, an antiaging agent MB, lanthanum stearate, calcium stearate, trioctyl trimellitate and dimethyl 4-nitrophthalate. The special highly-wear-resistant rubber material used for the tire tread has the advantages of good mechanical property, high heat resistance and excellent wear resistance, and the material is used for the tire tread with good comprehensive performances and long service life.

Owner:合肥市再德高分子材料有限公司

Snow tire, snow tire tread rubber composition and rubber composition mixing method

The invention belongs to the field of rubber tire manufacturing, and discloses a snow tire, a snow tire tread rubber composition and a rubber composition mixing method. The snow tire tread rubber composition comprises in parts by weight: 100 parts of a rubber component, 35-55 parts of liquid polybutadiene rubber, and 70-90 parts of silica, wherein the mass percentage of the liquid polybutadiene rubber is 13% or more in the total composition. The liquid polybutadiene rubber is introduced into the composition, the plasticizing property of the liquid polybutadiene rubber is utilized, a part of environment-friendly oil is replaced by the liquid polybutadiene rubber, the oil content in tread rubber is reduced, and the liquid polybutadiene rubber has a relatively low glass transition temperature, so that effects of low hardness, low modulus, and low low-temperature hardening degree of the tread rubber can be achieved when a relatively large amount of the liquid polybutadiene rubber is used for filling.

Owner:ZHONGCE RUBBER GRP CO LTD

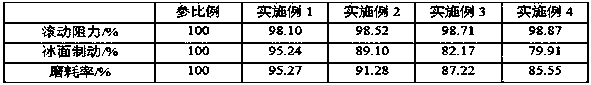

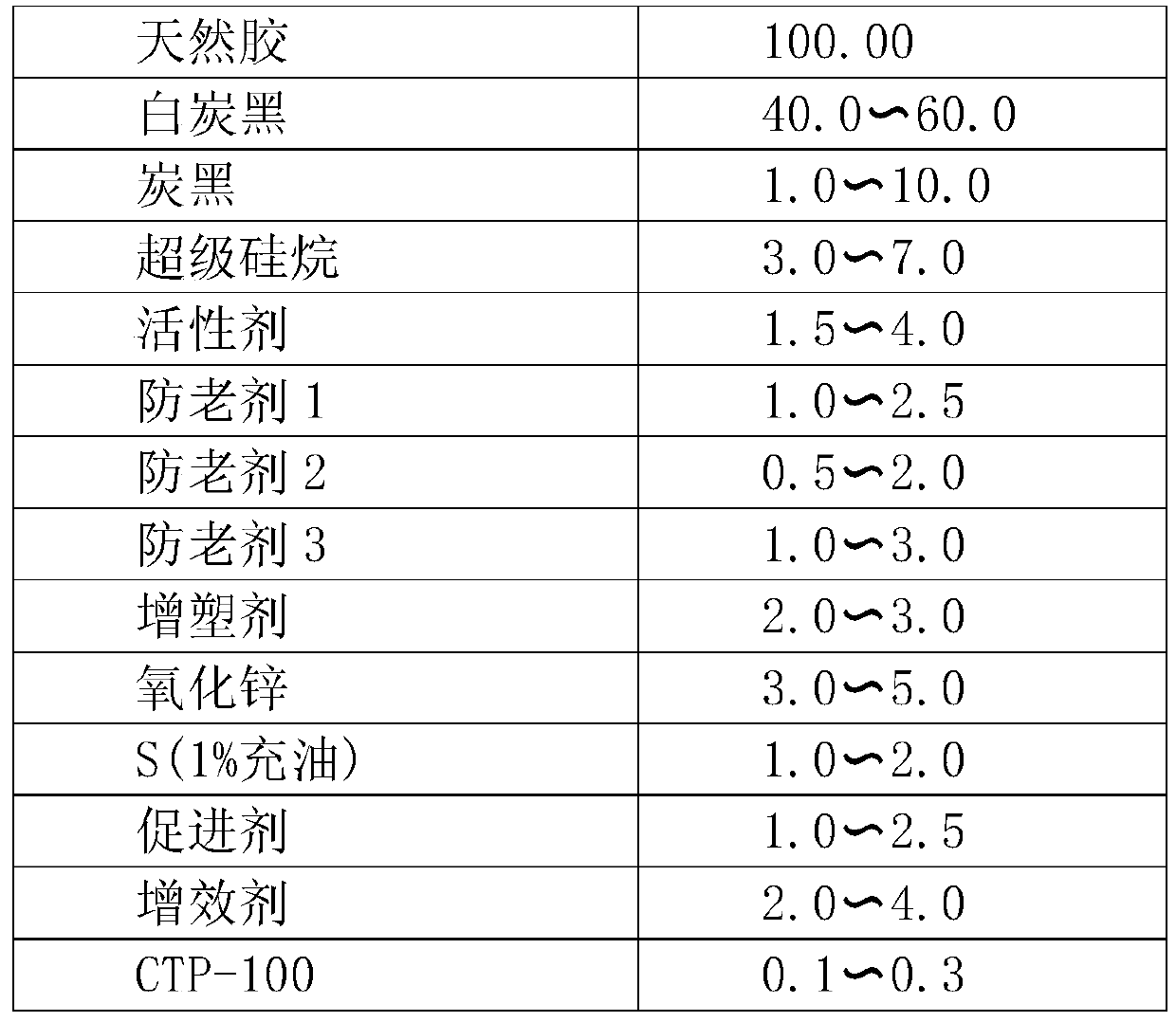

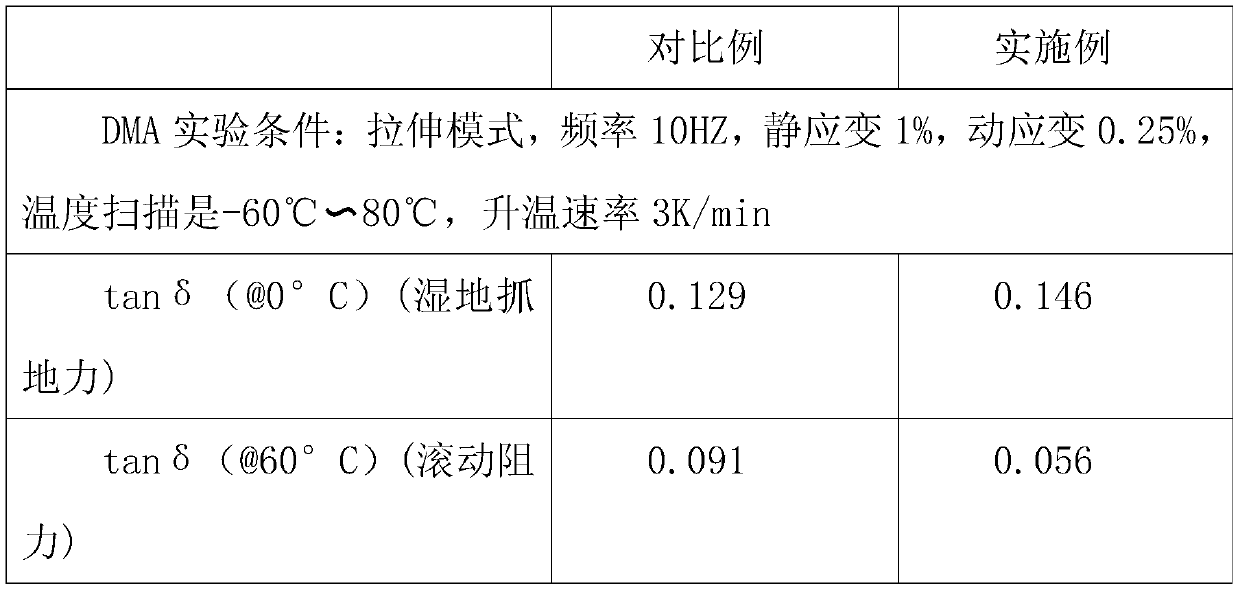

All-steel radial truck tire tread formula rubber compound, and preparation method and tire thereof

InactiveCN109836629ALow wear resistanceReduce rolling resistanceSpecial tyresRolling resistance optimizationRolling resistanceSilanes

The invention relates to an all-steel radial truck tire tread formula rubber compound and a preparation method and a tire thereof. The all-steel radial truck tire tread formula rubber compound comprises the following basic formula composition (by mass): 100 parts of natural rubber, 40.0-60.0 parts of high-dispersion white carbon black, 1.0-10.0 parts of high-structure wear-resistant carbon black,3.0-7.0 parts of super silane, 1.5-4.0 parts of an activator, 1.0-2.5 parts of an anti-aging agent 1, 0.5-2.0 parts of an anti-aging agent 2, 1.0-3.0 parts of an anti-aging agent 3, 2.0-3.0 parts of aplasticizer, 3.0-5.0 parts of an activator zinc oxide, 1.0-2.0 parts of a vulcanizing agent S, 1.0-2.5 parts of an accelerant, 2.0-4.0 parts of a synergist, and 0.1-0.3 part of an anti-scorching agent CTP. In comparison with the prior art, the invention has the following beneficial effects: by use of the tire thread formula, various physical and mechanical properties of the rubber compound and high speed and durability of the tire can meet the requirements of normal use; and the produced tire has excellent fuel consumption and controllability, and has good controllability, low rolling resistance, high mileage and long service life and is fuel-saving and environmentally-friendly in actual truck loading and use process.

Owner:CHAOYANG LONG MARCH TIRE

Abrasion-resistant base compound for solid tyres of crane cars

The invention belongs to the technical field of rubber production, and particularly relates to an abrasion-resistant base compound for solid tyres of crane cars. The abrasion-resistant base compound for the solid tyres of the crane cars comprises raw materials in parts by weight as follows: natural rubber, liquid polybutadiene rubber, carbon black N234, white carbon black, a silicon coupling agent, poly-2,3,4-trimethyl-1,2-dihydroquinoline, N-(1,3-dimethyl)-N'-phenyl-p-phenylenediamine, zinc oxide, zinc stearate, N-tert-butylbenzothiazole-2-sulfenamide, tetramethyl-thiuram sulfide, sulfur, N-cyclohexylthiophthalimide and polyamide fibers. The base compound has the higher modulus and the good abrasion resistance, and meanwhile, the base compound is better in reversion resistance and low in hysteresis loss.

Owner:SHANDONG YONGTAI CHEM GROUP

Multifunctional rubber chemicals and method for producing the same

A multi-functional rubber ingredient and a preparation method thereof relate to the chemical engineering accessory ingredient and the preparation method thereof. Starch derivate is prepared by adding a strong alkaline solution component A with 15 percent of concentration, a halogenating epihydrin component B and a carbon bisulfide component C to the mixed solution of starch and sodium chloride, and then the multi-functional rubber ingredient is obtained by adding a strengthening agent, a coupling agent and a plasticizer. Firstly the starch xanthate is prepared, and then 100 parts of prepared starch xanthate are used as base stock, then the multi-functional rubber ingredient is obtained by adding 20 to 25 parts of strengthening agent, 0.1 to 1 part of coupling agent and 3 to 10 parts of plasticizer. Using the method to prepare the multi-functional strengthening agent has the simple technique and high grafting ratio, so the multi-functional strengthening agent has good effect when being used as a tyre rubber ingredient and processing an accelerating agent.

Owner:DALIAN TIANBAO CHEM IND

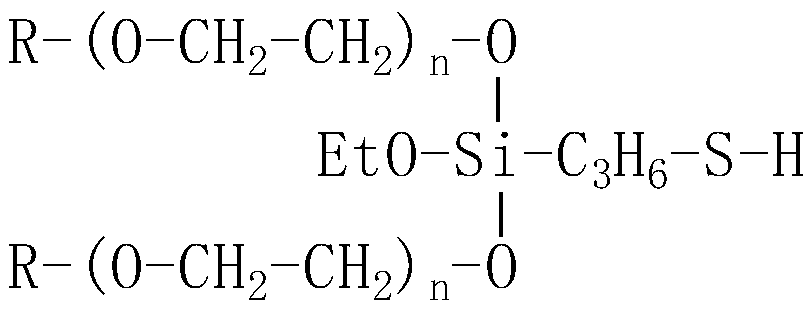

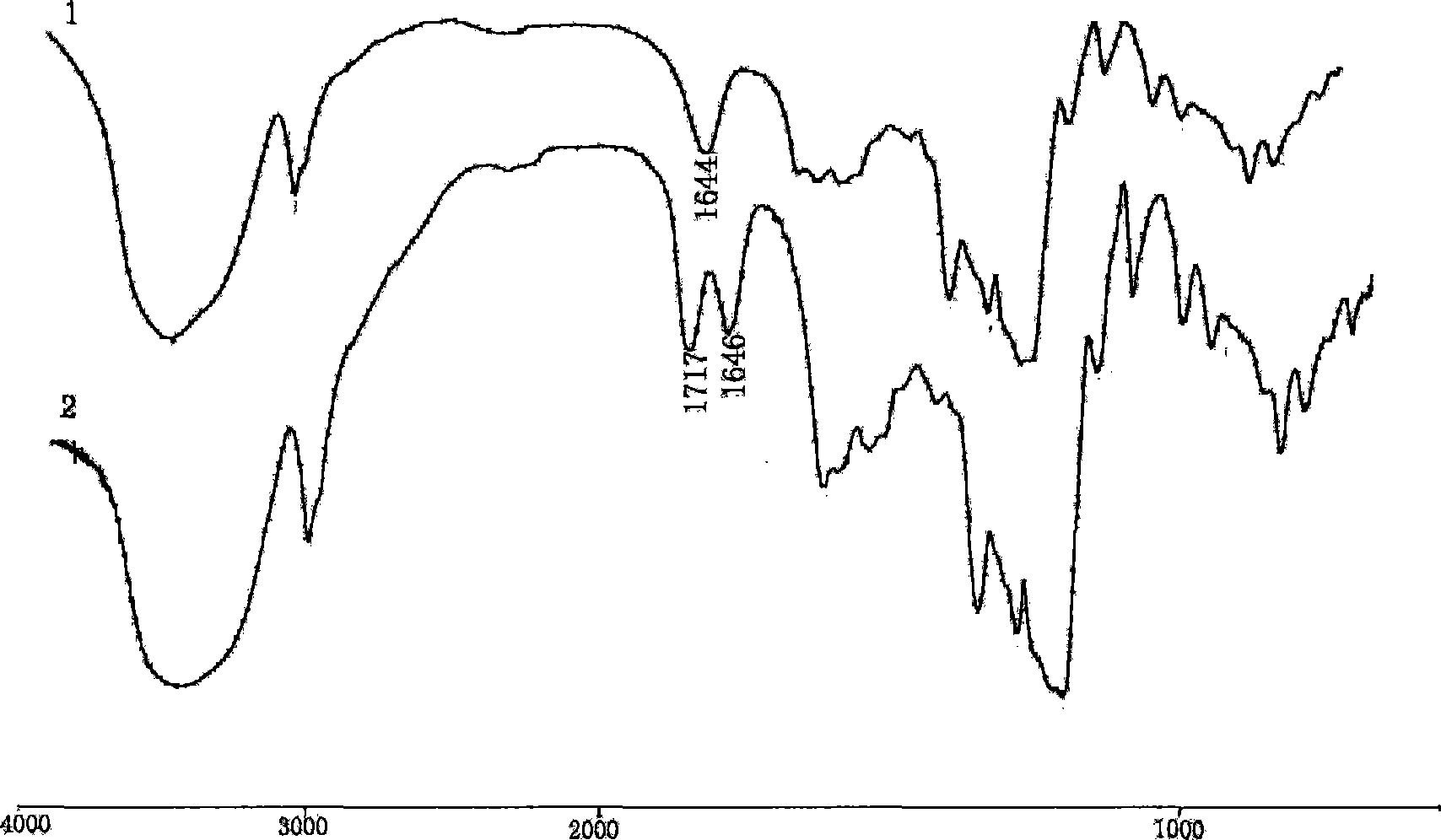

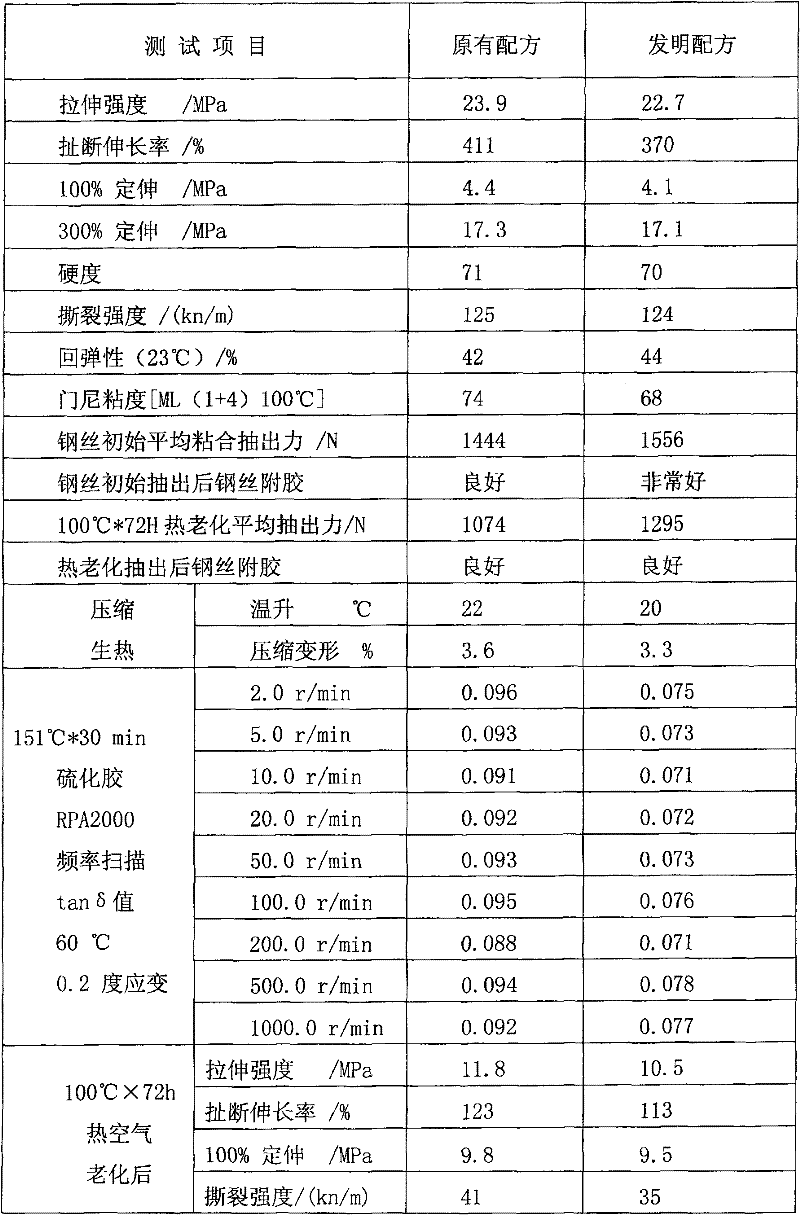

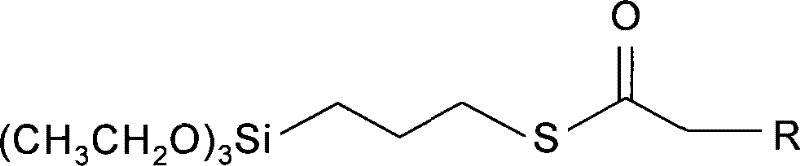

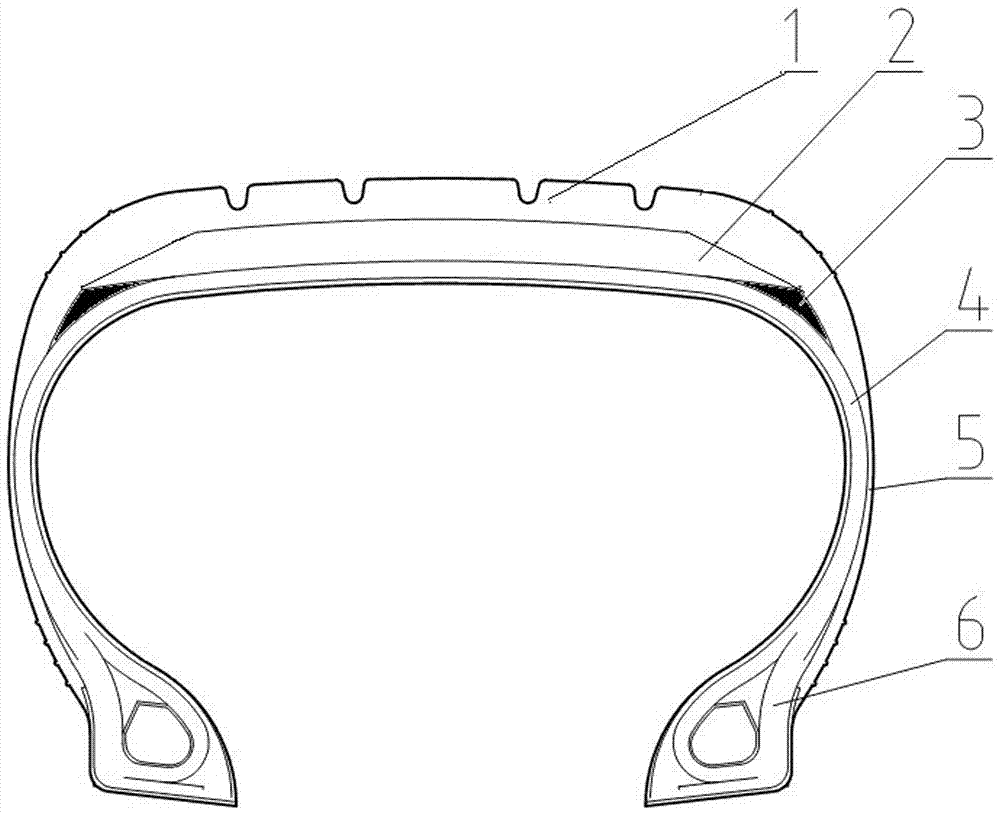

Belt steel wire cord adhesive gum

ActiveCN101492593BLower Mooney ViscosityHysteresis loss is smallNatural rubber adhesivesNon-macromolecular adhesive additivesHysteresisEther

The invention relates to a belted layer steel wire cord seam gum. A certain quantity of special silane coupling agent is added into the formulation of the seam gum which uses a great deal of white carbon black, so that the mooney viscosity of glue stock can be effectively reduced, thus reducing the segments of mixing, decreasing the hysteresis loss of glue stock and improving the bonding performance between the glue stock and steel wires. The belted layer steel wire cord seam gum comprises the components with the mass proportion: 100 parts of natural rubber, 40-50 parts of carbon black, 10-15parts of white carbon black, 8-12 parts of zinc oxide, 1.2 parts of decanoate cobalt, 2.5 parts of age inhibitor, 1.5 parts of hydroxyphenol, 5 parts of insoluble brimstone, 5 parts of adhesion promoter and 1.2 parts of sulfonamides accelerant; and 1-2.5 parts of sulpho-carboxylic ethers silane coupling agent is added into the formulation.

Owner:SHENYANG HEPING ZIWUXIAN TIRE MFG CO LTD

Carcass layer tread rubber of aviation radial tire

The invention discloses a carcass layer tread rubber of an aviation radial tire. A crude rubber system of the carcass layer tread rubber jointly adopts natural rubber and butadiene rubber; a reinforcement system adopts STERLIN V (SV) carbon black and adopts parts of white carbon black; accessory ingredients, including silane coupling agent KH-560, binding agent SL-3090, adhesion promoter AIR-201, adhesion promoter AIR-1 and the like, are added into a formula. The carcass layer tread rubber disclosed by the invention has the advantages of low hardness and stress at definite elongation, soft rubber material and small possibility of generating gaps during repeated deformation; the carcass layer tread rubber can be suitable for the performance requirements of high speed, high load and high refurbishment frequency of a novel tire in the future; before and after ageing, the carcass layer tread rubber has the advantages of high bonding strength of the rubber material and a nylon cord, good fatigue durability, low heat generation, high rebound value and small hysteresis loss; a carcass layer of the tire can be protected from delamination, swelling and tire side puncturing, and the service life and the safe performance of the aviation radial tire are improved.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Rubber composition where wet method mixed master batches are used together with filler or aster batches and preparation method

InactiveCN105237832AHysteresis loss is smallImprove wear resistanceRolling resistance optimizationPolymer scienceRolling resistance

The invention discloses a rubber composition. The rubber composition comprises rubber, the first filler and the second filler. The first master batches are prepared from the first filler through wet method mixing. The second filler is added to the master batches in the form of powder or the second master batches. The rubber composition can be used for manufacturing tires, and can reduce rolling resistance of tires, improve the slip-resistant performance and improve the wear-resistant performance.

Owner:EVE RUBBER RES INST

Abrasion-resistant base compound for solid tyres of heavy trucks

The invention belongs to the technical field of rubber production, and particularly relates to an abrasion-resistant base compound for solid tyres of heavy trucks. The abrasion-resistant base compound for the solid tyres of the heavy trucks comprises raw materials in parts by weight as follows: natural rubber, carbon black N339, aromatic oil, poly-2,3,4-trimethyl-1,2-dihydroquinoline, N-(1,3-dimethyl)-N'-phenyl-p-phenylenediamine, zinc stearate, N-tert-butylbenzothiazole-2-sulfenamide, tetramethyl-thiuram sulfide, sulfur, an anti-scorching agent and P-tert-butylphenol formaldehyde resin. The base compound has the higher modulus and the good abrasion resistance, and meanwhile, the base compound is better in reversion resistance and low in hysteresis loss.

Owner:盐城易宝路轮胎有限公司

Formula and preparation method of snow tire with high tensile strength

A formula of a snow tire with high tensile strength disclosed by the invention comprises the following components: 5-20% of natural rubber, 40-60% of solution polymerized styrene butadiene rubber, 10-40% of high-dispersion white carbon black, 1-3% of polyethylene glycol (PEG) and 4-8% of a coupling agent SI69. The technical scheme provided by the invention has the beneficial effects that the tire has high tensile strength and low hardness and good elasticity of tread rubber; the rubber has low vitrification point, can maintain soft under low ambient temperature, has good road holding performance, and reduces lag loss and rolling resistance. Meanwhile, the snow tire has physical mechanical properties basically consistent to those of a common tyre, and maintains the advantage in road holding on wet road and dry road.

Owner:KENDA RUBBER CHINA

Polyurethane elastomeric fiber and process for making the fiber

InactiveCN1818162AImprove heat resistanceHysteresis loss is smallMonocomponent polyurethanes artificial filamentThin material handlingPolyesterPolyurethane elastomer

This invention is comprised of a thermoplastic polyurethane elastomer fiber obtained by melt spinning a polyurethane having a rebound of 60% or greater and a isocyanate-terminated polyether or polyester additive. The elastic fibers have low shrinkage, high heat resistance, low tensile set, and high elongation.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Rubber composition for side rubber and pneumatic radial tire for heavy load using the same

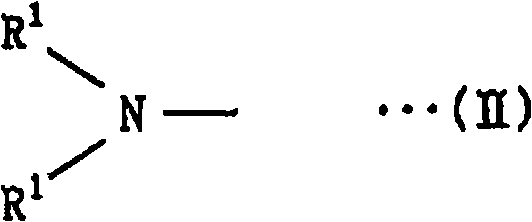

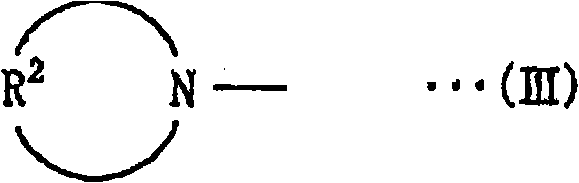

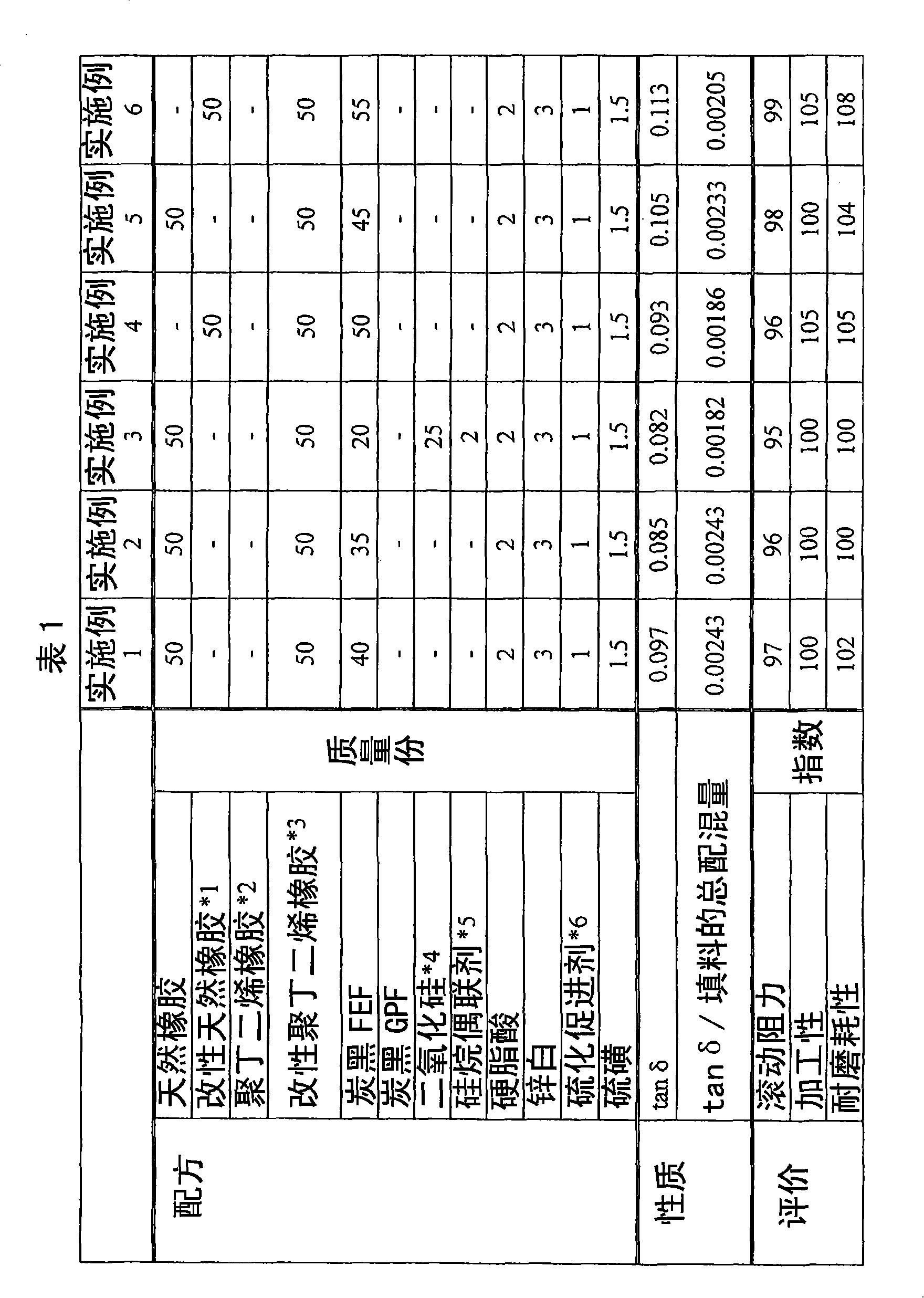

InactiveCN101516984AEasy to processHysteresis loss is smallSpecial tyresTyre sidewallsHysteresisPolymer science

The invention discloses a rubber composition for side rubbers, which has good workability and reduced hysteresis loss without decreasing durability of side rubbers. Specifically disclosed is a rubber composition for side rubbers, which is obtained by blending 35-55 parts by mass of a filler containing a carbon black of at least FEF-grade per 100 parts by mass of a rubber component which is composed of at least one of a natural rubber and a synthetic polyisoprene rubber, and another synthetic diene rubber. This rubber composition for side rubbers is characterized in that the blending amount of the carbon black of at least FEF-grade is 15-55 parts by mass, and tan delta and the total blending amount of the filler at 25 DEG C satisfy the following formula (I). tan delta / (total blending amount of filler) = 0.0025 (I).

Owner:BRIDGESTONE CORP

Method for preparing tread rubber through carbon black wet-process masterbatch together with white carbon black and application thereof

InactiveCN105237833AImprove performanceReduce rolling resistanceSpecial tyresRolling resistance optimizationRubber materialMasterbatch

The invention relates to a method for preparing a tread rubber material through wet-process mixing carbon black masterbatch together with white carbon black. The method includes the following steps that a, the wet-process mixing carbon black masterbatch and the white carbon black are added into an internal mixer; then additives including a coupling agent, an anti-ageing agent, an active agent, oil and one or more of other processing agents are added; afterwards, a vulcanizing agent and an accelerator are added to be evenly mixed and then a rubber compound of tread rubber is obtained; b, the rubber compound is vulcanized, so that vulcanized rubber of the tread rubber is obtained. By the adoption of the vulcanized rubber of the tread rubber, due to the fact that the white carbon black is used at the same time, the rolling resistance of tires is lowered on the premise that the abrasion resistance of the tires is guaranteed, and the wet-skid resistance of the tires is improved.

Owner:EVE RUBBER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com