Multifunctional rubber chemicals and method for producing the same

A rubber additive and multi-functional technology, which is applied in the field of preparation of multi-functional rubber additives, can solve problems such as single function, and achieve the effects of high environmental protection, low cost, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Preparation process route of the present invention is:

[0023] 1. Preparation of starch xanthate

[0024] a. Under the condition of mechanical stirring, mix the starch and sodium chloride solution evenly, and the temperature rises to 45°C.

[0025] b. Under mechanical stirring conditions, add an appropriate amount of component A and a little component B and component C to the reaction solution in step a, react at 45°C for 2 to 10 hours, wash and filter, dry, and pulverize. Starch derivatives are produced.

[0026] 2. Component A is a strong alkali solution with a concentration of 15%.

[0027] 3. Component B is a halopropylene oxide.

[0028] 4. Component C is carbon disulfide.

[0029] 5. Use the starch xanthate prepared by the above method as the base material, and then add 18% to 15% reinforcing agent, 0.5% to 1% coupling agent, and 1% to 5% plasticizer to compound the multifunctional rubber Auxiliary.

[0030] 6. Pre-treat the starch sulfonate with a coupling...

Embodiment

[0035] The composition and proportion of the product are as follows:

[0036] 40 parts of natural rubber, 20 parts of butadiene rubber, 40 parts of styrene-butadiene rubber, 8 parts of multifunctional reinforcing agent, 50 parts of carbon black, 4 parts of zinc oxide, 2 parts of stearic acid, 2 parts of antioxidant 4010NA, 1.5 parts of sulfur, Accelerator NOBS 1 part, aromatic hydrocarbon process oil 6 parts.

[0037] Physical and Mechanical Properties Results:

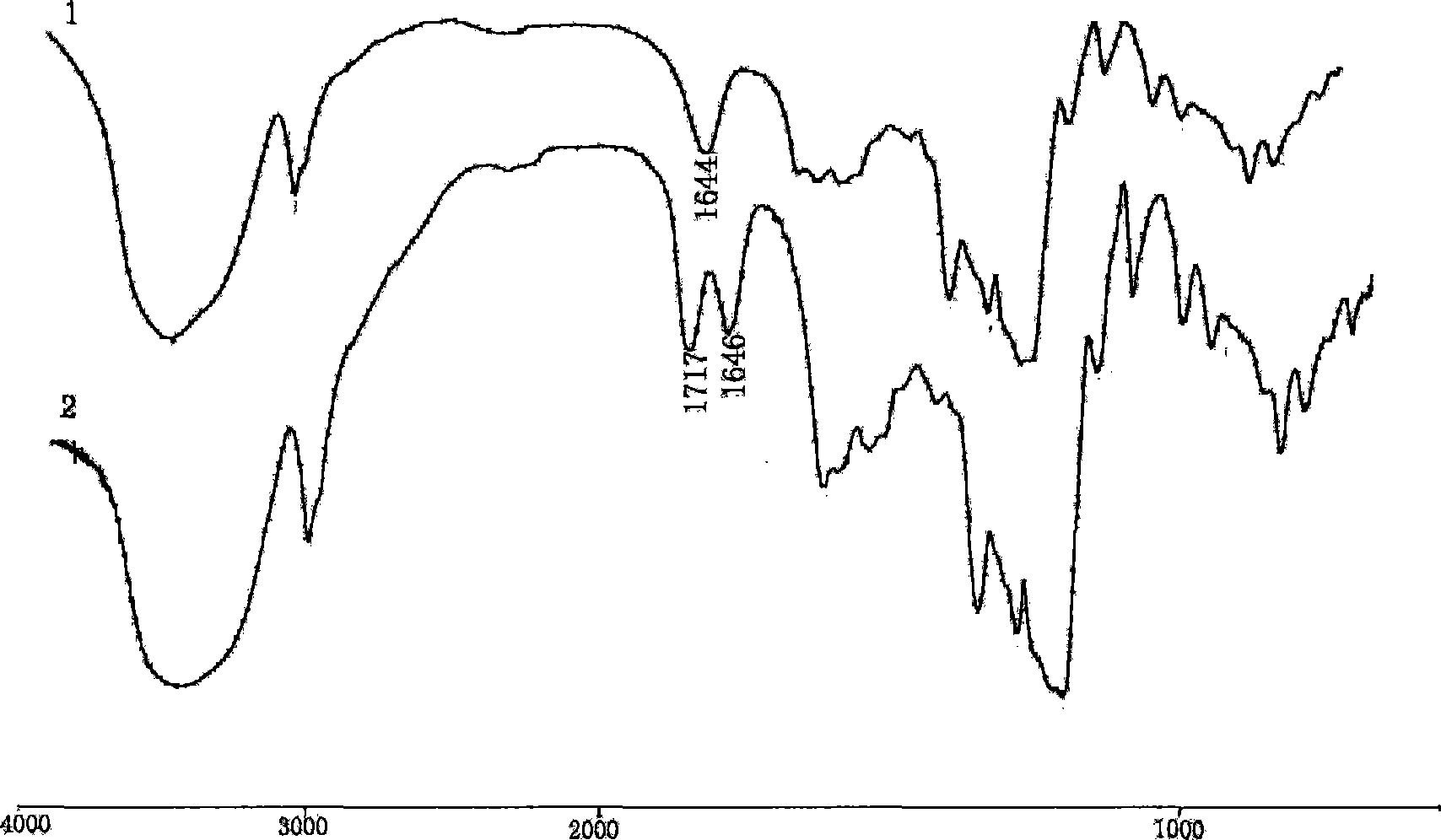

[0038] Figure 1 is the infrared image of starch xanthate (1 ordinary starch, 2 starch xanthate)

[0039] Performance name

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com