Patents

Literature

538results about How to "Fast vulcanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature resistance non halogen flame retardant cable sheath material and preparation method thereof

ActiveCN101613506AImprove temperature resistanceOvercome the problem of not being able to prepare high temperature resistant halogen-free flame retardant cable sheathing materialsRubber insulatorsPolymer scienceVulcanization

The invention discloses a high temperature resistance non halogen flame retardant cable sheath material and a preparation method thereof. The high temperature resistance non halogen flame retardant cable sheath material comprises the following components with the following parts by weight: 100 parts of ethylene-propylene-diene monomer (EPDM), 1.5-6 parts of vulcanizing agent, 1.5-6 parts of co-vulcanization agent, 0.5-5 parts of coupling agent, 4-20 parts of antiager, 4-30 parts of softener and 80-250 parts of inflaming retarding filling agent. In the invention, the halogen-free material is adopted, thick smoke, corrosive halogenide gas and other harmful substances are not generated in the process of burning; the cable sheath of the invention features excellent elasticity and tenacity, not only has obvious inflaming retarding effect, but also improves heat-resisting and anti-aging properties, can resist high temperature, and has high mechanical strength and wide application range; in addition, the production process is easy and is convenient for rubber-producing enterprises to achieve self-sufficiency.

Owner:SICHUAN MINGXING CABLE

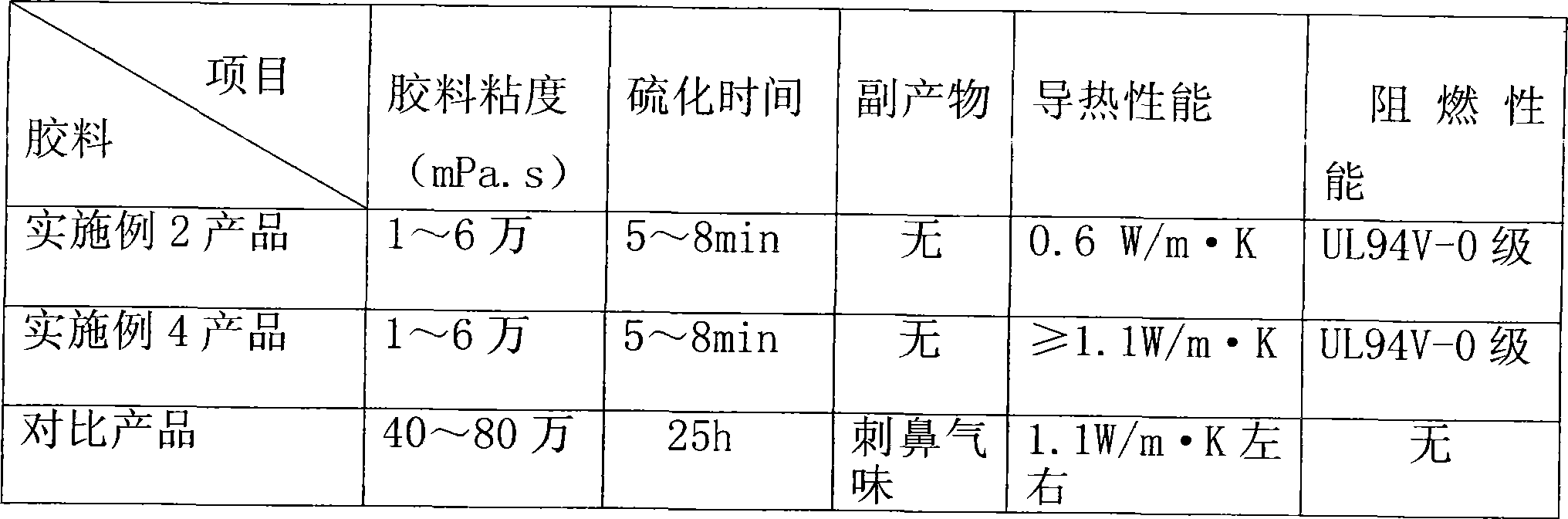

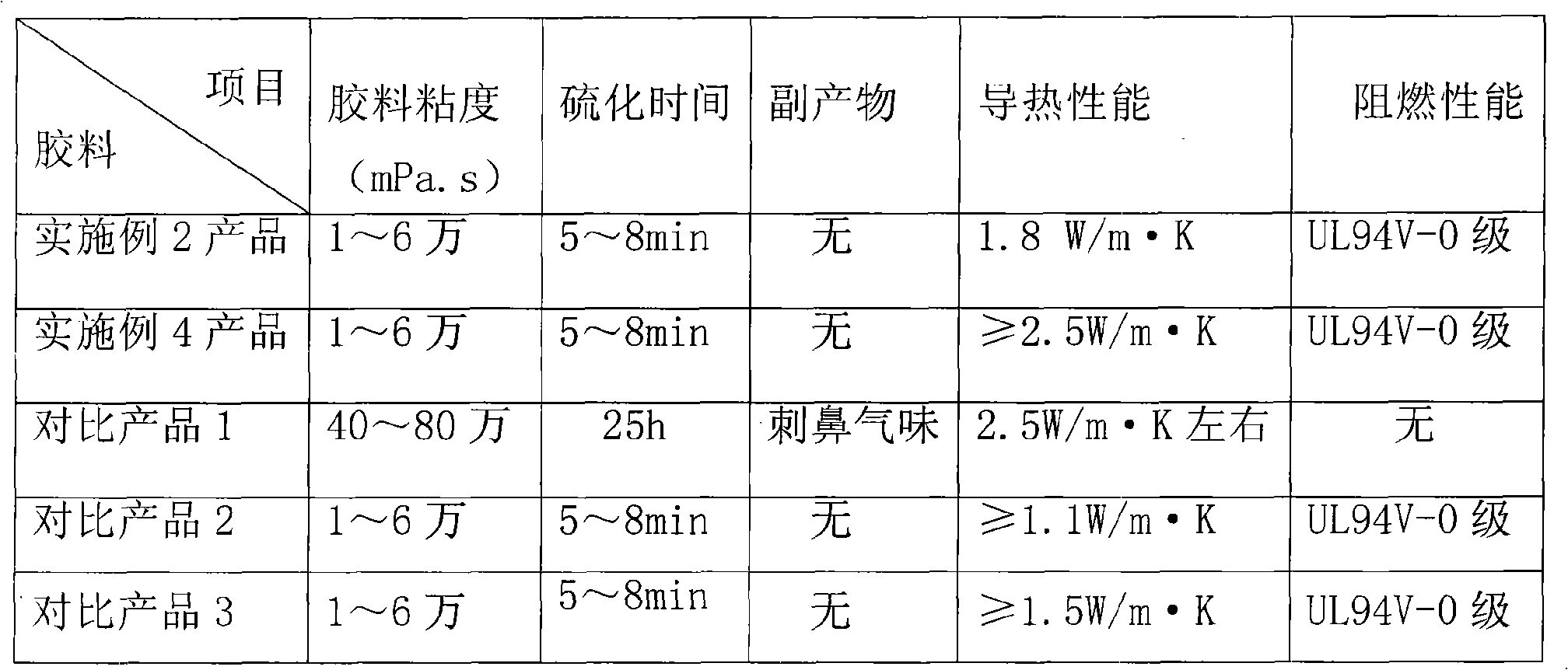

Heat-conducting anti-flaming liquid silicon rubber and preparation method thereof

InactiveCN101168620AReduce consumptionIncrease demandHeat-exchange elementsVulcanizationHeat conducting

The invention discloses heat conduction flame retardant liquid silica gel, which comprises components with the following parts by weight: 10 to 40 parts of vinyl end organopolysiloxane with 500 to 5000 mPa.s polymeric viscosity in 25 DEG C, 10 to 40 parts of vinyl end organopolysiloxane with 10000 to 50000 mPa.s in 25 DEG C, and 1 to 5 parts of hydrogen-containing polymethylsiloxane, 2 to 8 parts of alkyl disilazane, 20 to 50 parts of surface hydrophobicity Al2O3 powder with average particle diameter of 5 to 20 microns, 10 to 50 parts of Al(OH)3 powder with average particle diameter of 5 to 20 microns, 0.3 to 2 parts of addition solidification catalyst, 0.01 to 0.06 part of alkynol depressant and 0.5 to 2 parts of distilled water, wherein, R is methyl, ethyl, propyl or butyl. The invention is prepared by the way of addition type heat vulcanization, toxic substance or irritant gas is not produced in the production process, the vulcanization rate is quick, and the energy saving, the consumption decreasing and the environmental protection requirements are conformed. The storage stability of the product is good, the viscosity is moderate, the operability is good, the product integrates the heat conduction, insulation and flame retardant performances into a whole, and the performance-price ratio is high.

Owner:兆舜科技(广东)有限公司

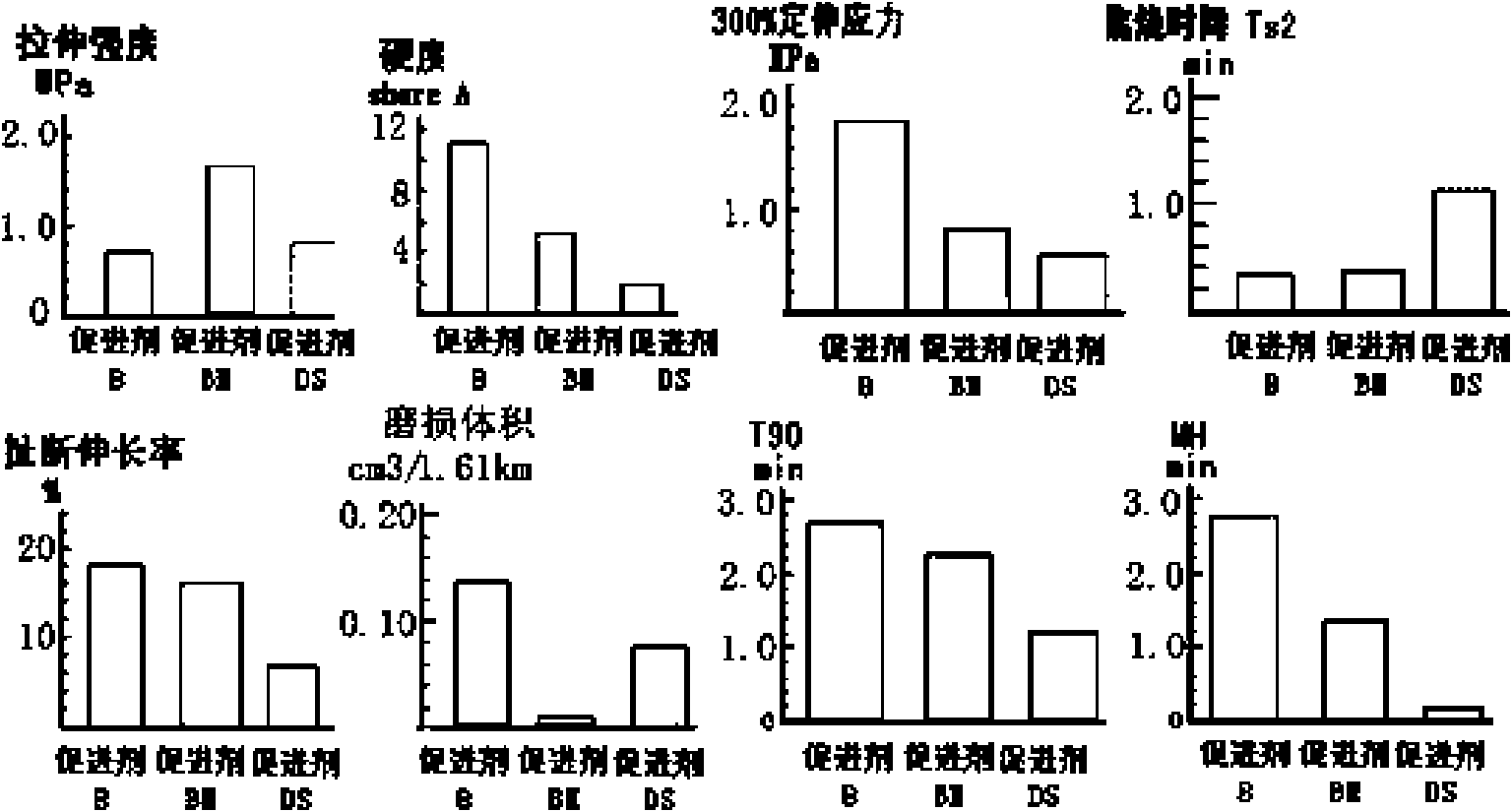

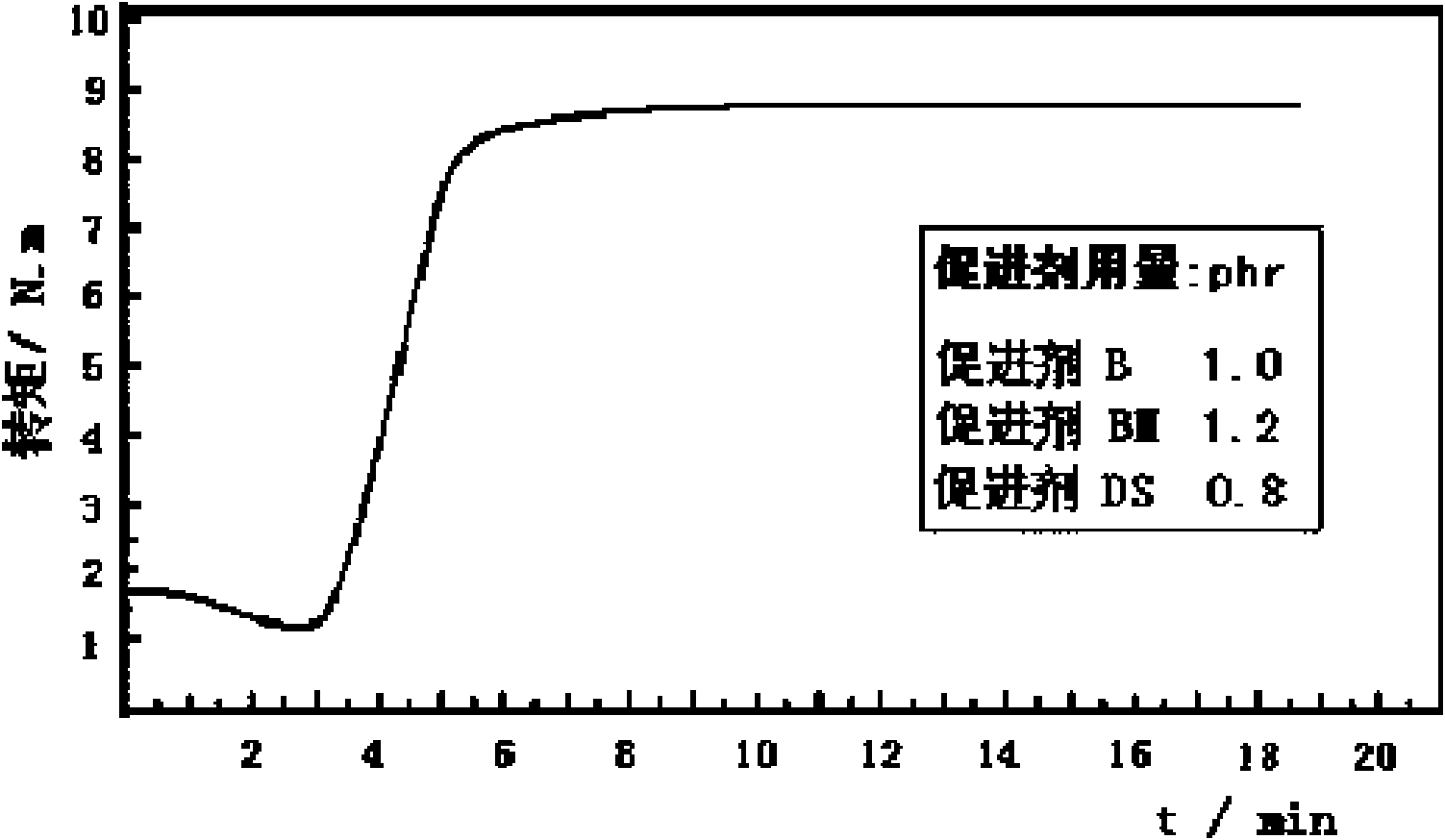

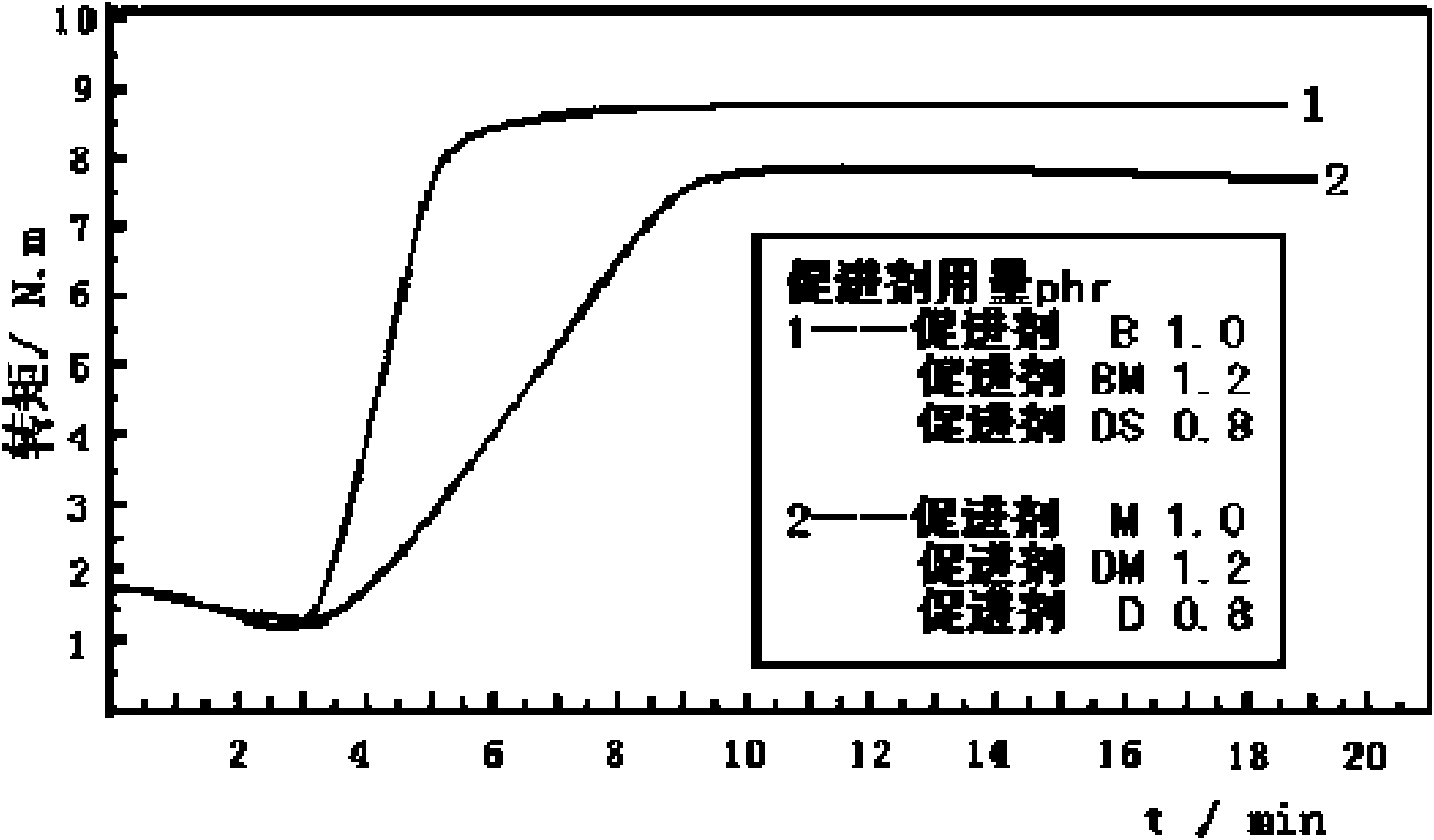

Vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and preparation method and vulcanization process thereof

The invention discloses a vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and a preparation method and a vulcanization process thereof. The vulcanized rubber isprepared from natural rubber, styrene-butadiene rubber, butadiene rubber, accelerator B, accelerator BM, accelerator DS, nanometer zinc oxide, rubber softening oil, sulphur, stearic acid, aging resister CD, carbon black N330, pine tar oil, solid coumarone, reclaimed rubber and pot clay. Compared with the prior art, the vulcanized rubber of the invention has suitable starting time of vulcanization,faster velocity of vulcanization and higher thermal oxidative aging property, the vulcanization efficiency is increased, and the heat-conducting property, processing safety and storage property of the rubber are increased in the vulcanization process; the provided vulcanization process can effectively shorten the vulcanization time, improve the vulcanization quality and increase the vulcanizationefficiency to 2-3 times of the original one.

Owner:JIHUA 3537 SHOE MAKING

Double-component addition-type liquid silicone rubber as well as preparation method of same

The invention belongs to the technical field of silicone rubber and particularly relates to double-component addition-type liquid silicone rubber as well as a preparation method of same. The liquid silicone rubber is prepared by mixing, curing and shaping a component A and a component B, wherein the component A includes 100 parts of basic rubber, 8-18 parts of vinyl-terminated silicone oil, 1-2 parts of a tackifier, and 0.5 parts of a platinum catalyst; the component B includes: 20-70 parts of vinyl-terminated silicone oil, 30-80 parts of hydrogen-containing silicone oil, and 0.3-0.5 parts ofan inhibitor; the basic rubber includes 100 parts of vinyl-terminated silicone oil, 5-10 parts of vinyl-terminated silicone oil having side-chain vinyl group, 40 parts of fumed silica, 10-15 parts ofa silazane processing agent, and 0-5 parts of a siloxane processing agent. In the liquid silicone rubber, the components are cooperated and are matched in reasonable ratio, so that firmness of the liquid silicone rubber on surfaces of fabrics is improved, and tensile strength and tearing strength of the silicone rubber are increased; the silicone rubber is high in vulcanization speed and high in production efficiency. The invention also provides a preparation method of the double-component addition-type liquid silicone rubber. The method is optimized in process and has simple operations.

Owner:佛山市天宝利硅工程科技有限公司

High heat resistant, fast setting, neutral deacetone type room temperature vulcanization silicon rubber and its preparation method

The present invention discloses one kind of heat resistant, fast cured, neutral acetone-eliminating room temperature vulcanized silicone rubber and its preparation process. The silicone rubber consists of alpha, omega-dihydroxy dimethyl siloxane 80-120 (in weight portions, the same below), hydroxyl radical terminated polydimethyl siloxane 10-20, silica 10-15, tackifier 0.5-1.5, heat resisting additive 5-15, organic guanidine catalyst 0.5-0.9, and acetone-eliminating siloxane cross-linking agent 5-8. The acetone-eliminating room temperature vulcanized silicone rubber has fast vulcanizing, easily completed cross-linking reaction, no need of using organic metal compound as catalyst, high heat resistance, high electrically insulating performance, high strength, high storing stability, wide adhering application range, and other advantages.

Owner:GUANGZHOU BAIYUN CHEM IND

Oil soluble molybdenum-based precursor of catalyst, preparation method and application thereof

InactiveCN103980320AGood oil solubilityReduce yieldPhysical/chemical process catalystsHydrocarbon oil crackingSlurry reactorDecomposition

The invention provides an oil soluble molybdenum-based precursor of a catalyst, a preparation method and application thereof, relating to the technical field of heavy oil hydrocracking catalysts and solving the problems of low catalytic hydrogenation activity and high cost of the existing catalysts. The preparation method for the precursor comprises the steps of (1) mixing a molybdenum source with water, reacting for 30-240 minutes at 70-90DEG C, and adding inorganic acid; (2) adding polycarbon alcohol into P2S5 in 5-15 minutes at 50-80DEG C, and reacting for 1-3 hours at 70-100DEG C; (3) adding the product of step (2) into the product of step (1), adding resin, and reacting for 4-8 hours at 70-110DEG C; (4) separating oil phase from the product of step (3) so as to obtain the target product. The precursor can form MoS2 active components through self sulfurization and in situ decomposition, is used in slurry reactor hydrocracking of poor heavy oil with high content of metal, carbon residue and sulfur, and can lower the yield of coke and keep a device to run for a long period.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Heat conduction flame-proof liquid silicon rubber for electron and method of producing the same

The invention discloses a heat-conductive anti-flaming liquid silicone rubber used for electrons, which comprises the components with the following parts by weight: ethylene group dead-end organic polysiloxane which has polymer viscosity of 500 to 5000mPa.s and 10000 to 50000mPa.s when reaching 25 DEG C and has a general formula R2SiO(SiRR'O)nSiR2; hydric polysiloxane which has a general formula R'R2SiO(SiR HO)nSiR2R'; alkyldisilazane which has a general formula R3SiNHSiR3; a mixed-powder of Al2O3 and MgO with the surface hydrophobic particle size being respectively 5 Mum and 2 Mum and with the ratio of 4:1between Al2O3 and MgO; an Al(OH)3 powder which has an average particle size of 2 to 10 Mum; an additive solidified catalyst; an alkynol solidified inhibitor; and distilled water. The silicone rubber generates no toxic substance or irritative gas and has no side product and high efficiency; the product obtained is characterized by high thermal conductivity, good storage stability, moderate viscosity and good operability, and can integrate heat conduction, insulation and anti-flaming properties together, thereby meeting higher requirements of electrical appliances industry and having high cost performance.

Owner:兆舜科技(广东)有限公司

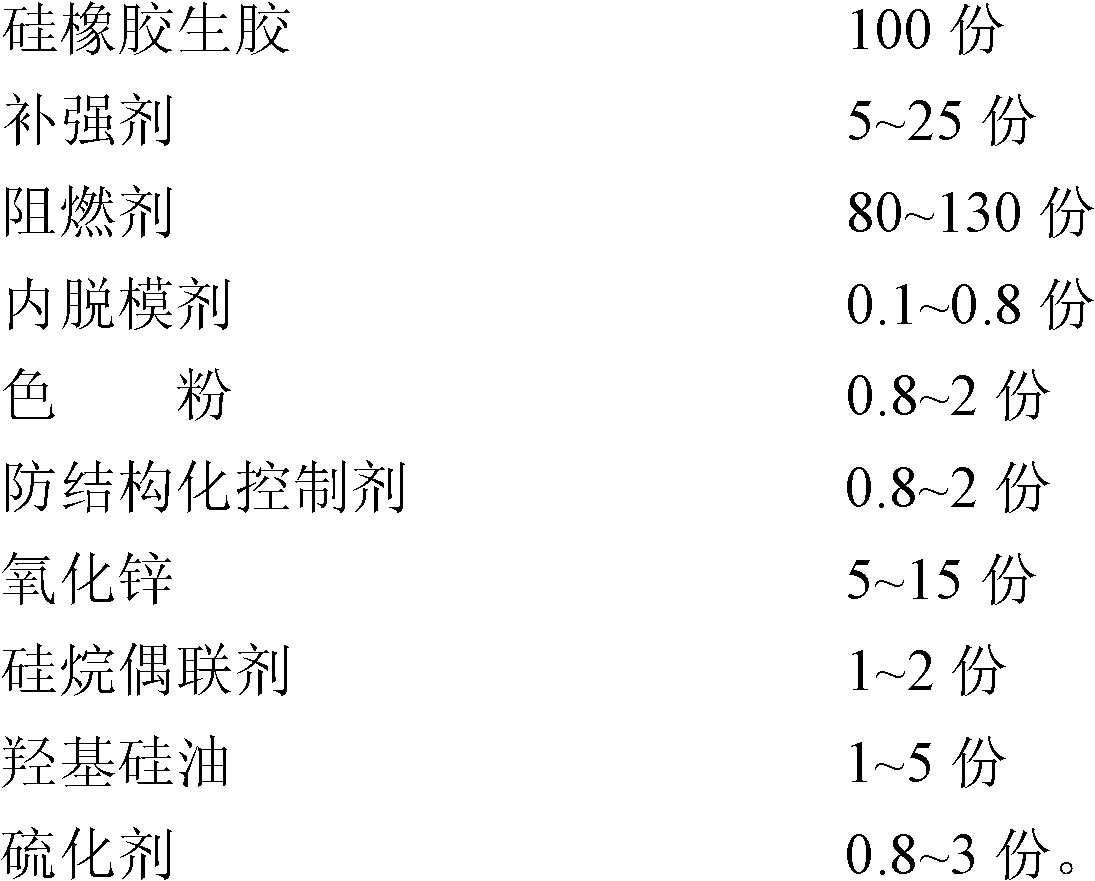

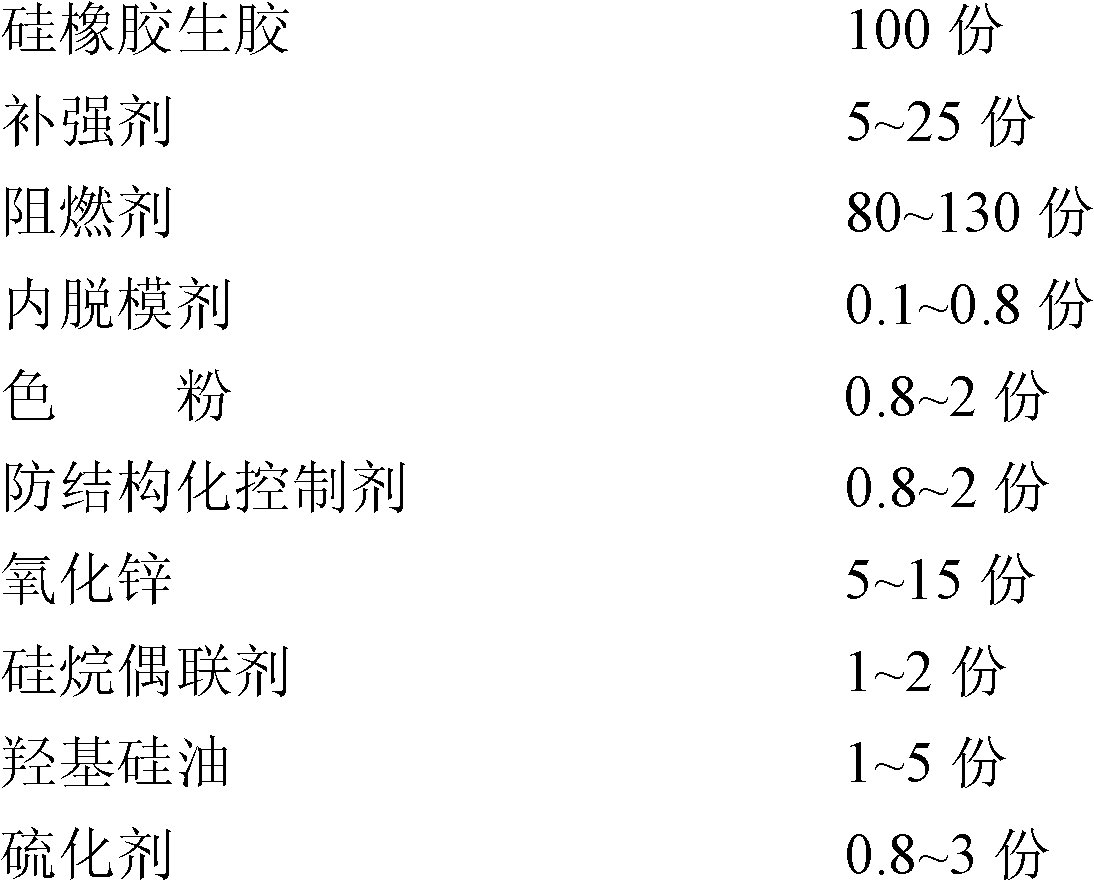

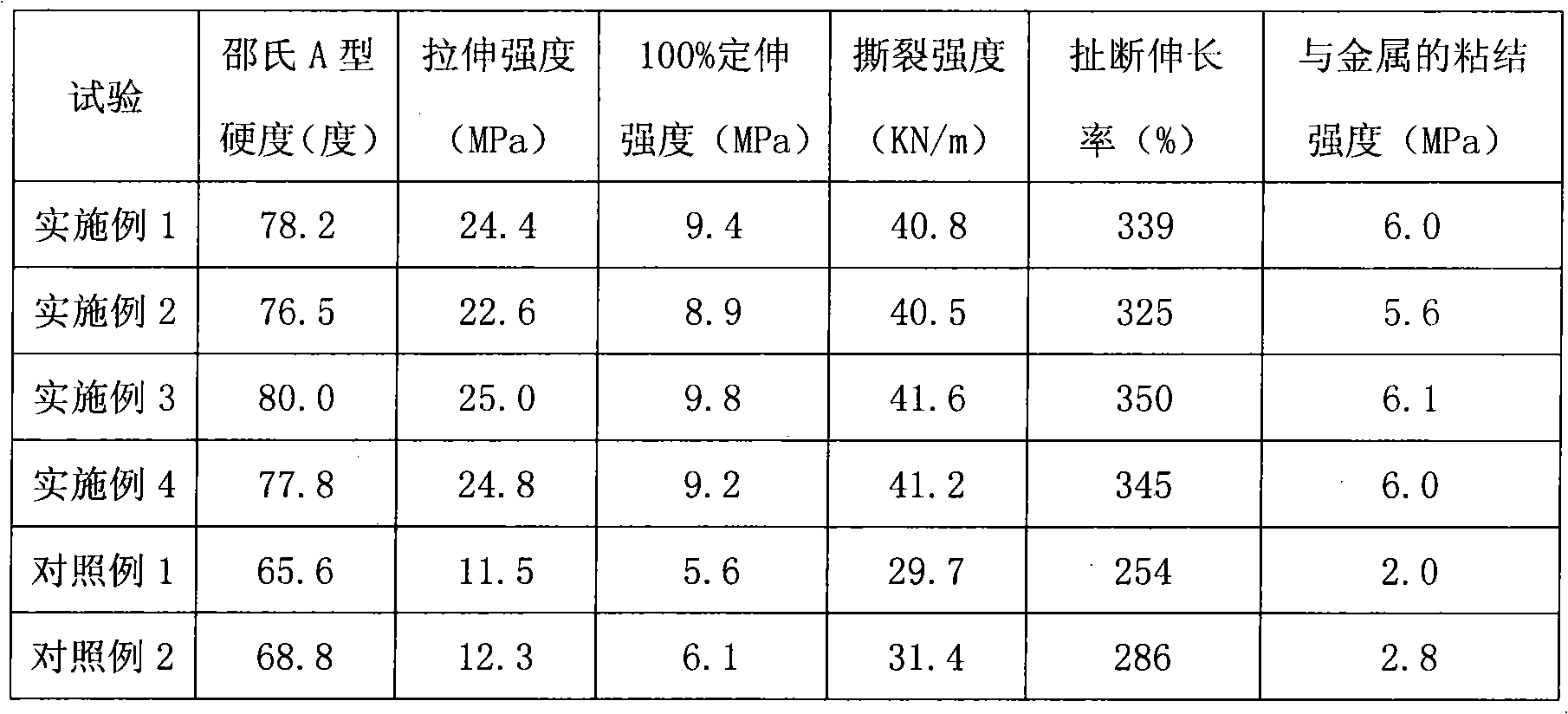

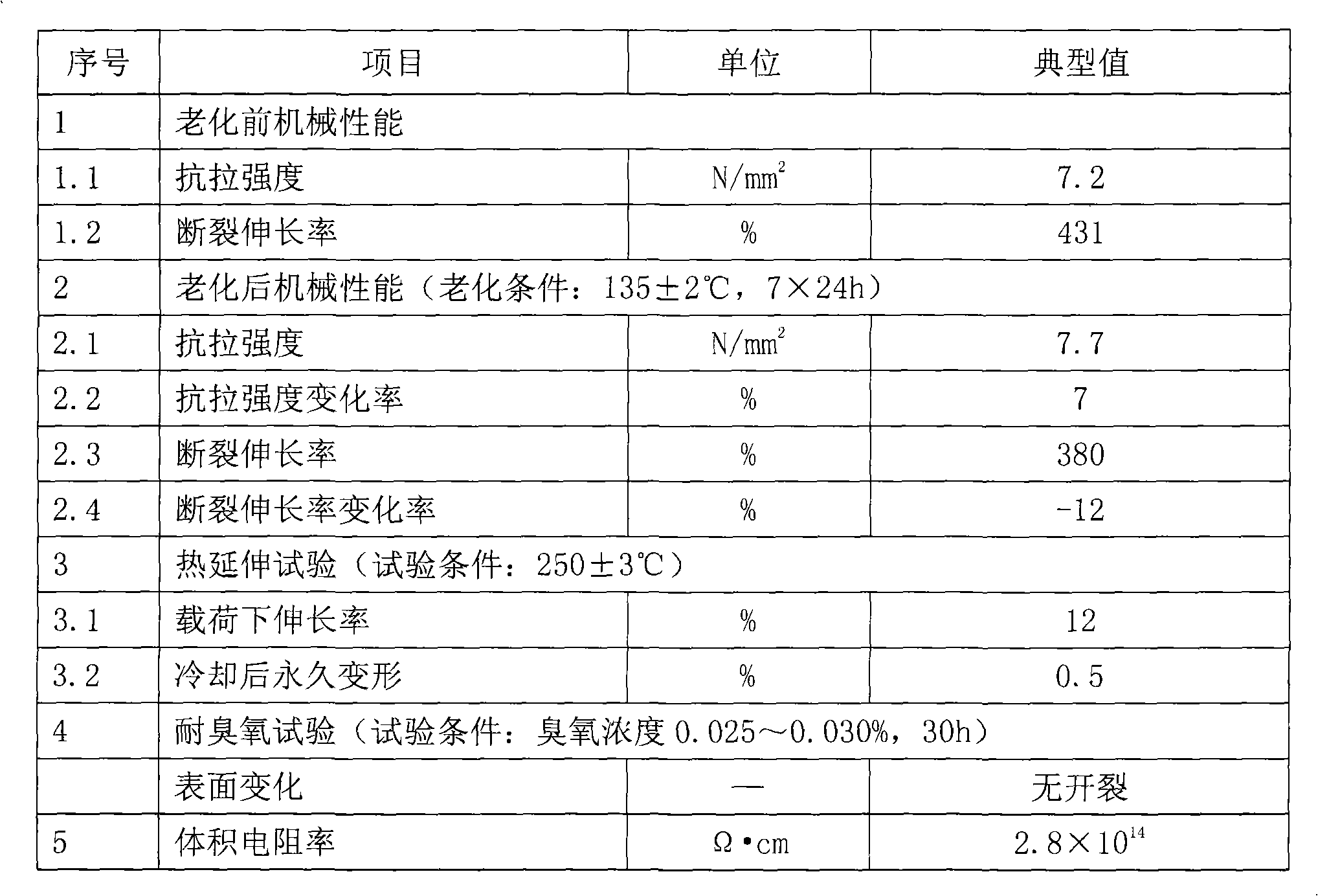

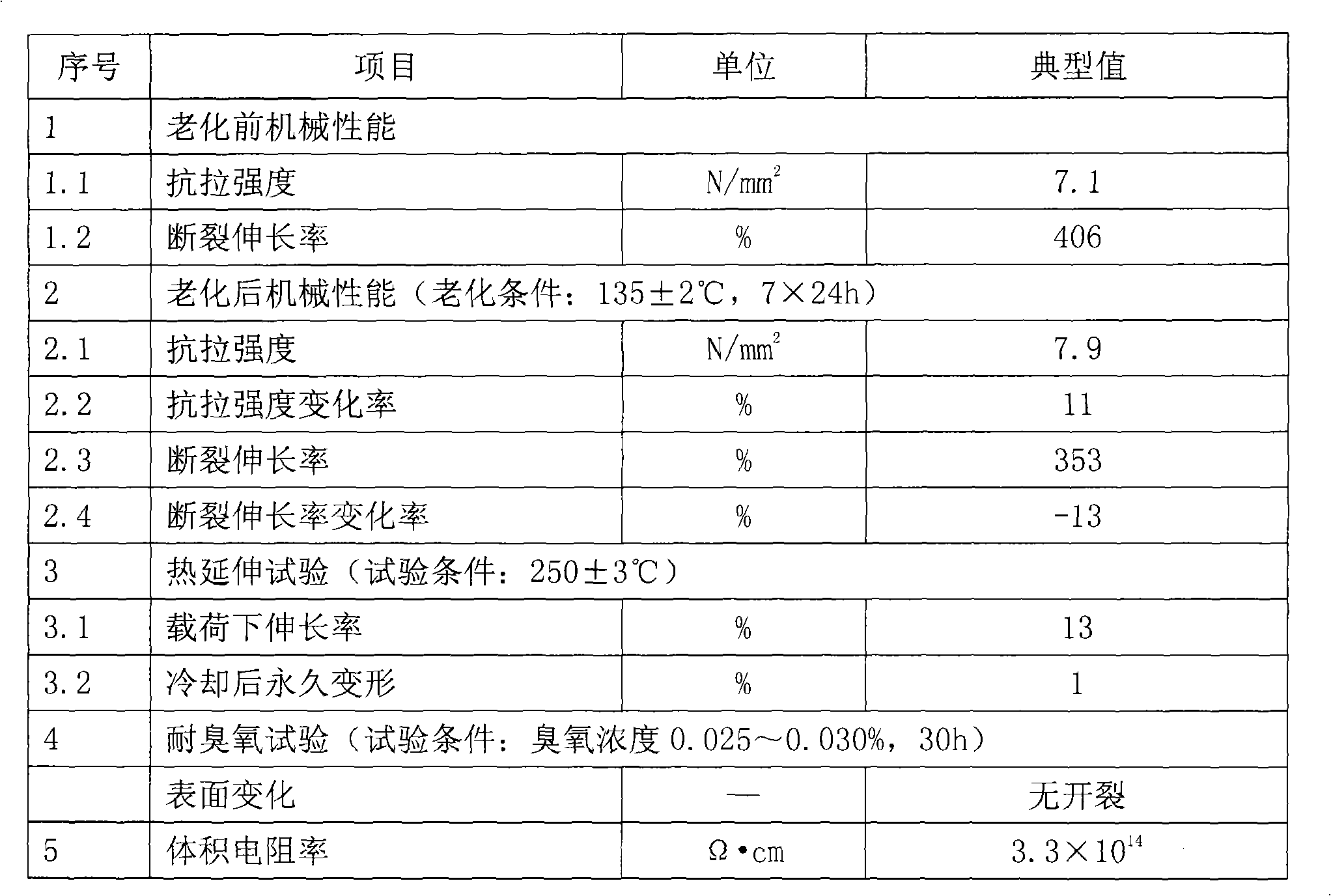

Silicone rubber insulation material applied to high voltage cable accessories in European series and preparation method for material

The invention belongs to the fields of special rubber technologies and medium and high voltage electrical equipment, is thorough improvement on the prior art, and in particular relates to a silicone rubber insulation material applied to high voltage cable accessories in European series and a preparation method for the material. The material comprises the following components in part by mass: 100 parts of crude silicone rubber, 5 to 25 parts of reinforcing agent, 80 to 130 parts of flame retardant, 0.1 to 0.8 part of internal release agent, 0.8 to 2 parts of masterbatch, 0.8 to 2 parts of anti-structuring control agent, 5 to 15 parts of zinc oxide, 1 to 2 parts of silane coupling agent, 1 to 5 parts of hydroxy silicone oil and 0.8 to 3 parts of vulcanizing agent. Compared with the conventional ethylene propylene diene monomer (EPDM) rubber, the material has the advantages that tracking resistance and electric corrosion loss can reach TMA4.5, and the material has lasting hydrophobicity and high dielectric constant, joint strength and wet electrical property, can be subjected to injection molding, avoids the phenomenon that an electric field is easily concentrated because EPDM is non-uniformly distributed, and is high in vulcanizing speed and efficiency, and cost is saved.

Owner:深圳市罗庚电气有限公司

Unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and preparation method thereof

ActiveCN103131088ANo pollution in the processSimple preparation processSuperoxideEthylene-propylene-diene-monomer

The invention discloses unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and a preparation method thereof. Carbon black, metallic compound, stearic acid, accelerant, inert filler, sulphur, superoxide and unsaturated carboxylic acid are added in the EPDM, then mixing treatment and sulfidizing are conducted, and therefore the unsaturated carboxylic acid metal salt modified EPDM is obtained. According to the unsaturated carboxylic acid metal salt modified EPDM and the preparation method thereof, unsaturated carboxylic acid metal salt in in-situ reaction is used for modifying the EPDM, preparation process is simple, modification effect is good, the prepared modified rubber has good physical mechanical performance and especially has good bonding strength with metal, and the application range is wide.

Owner:TIANJIN XINZHONGHE RUBBER IND

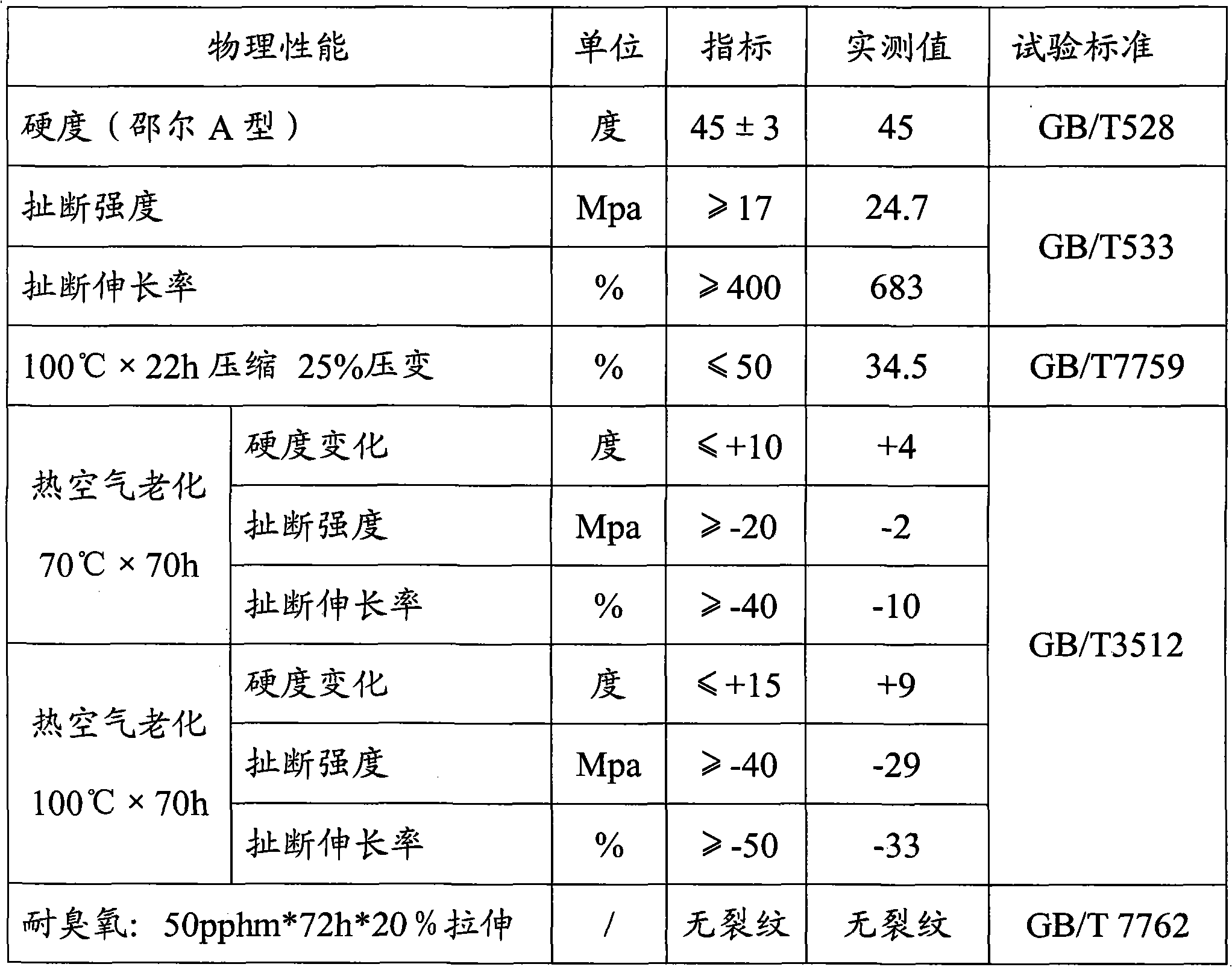

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

Super high wear resistance rubber sole and preparation thereof

ActiveCN101328288AImprove the ability to resist external forceHigh strengthSolesDomestic articlesWear resistantCarbon black

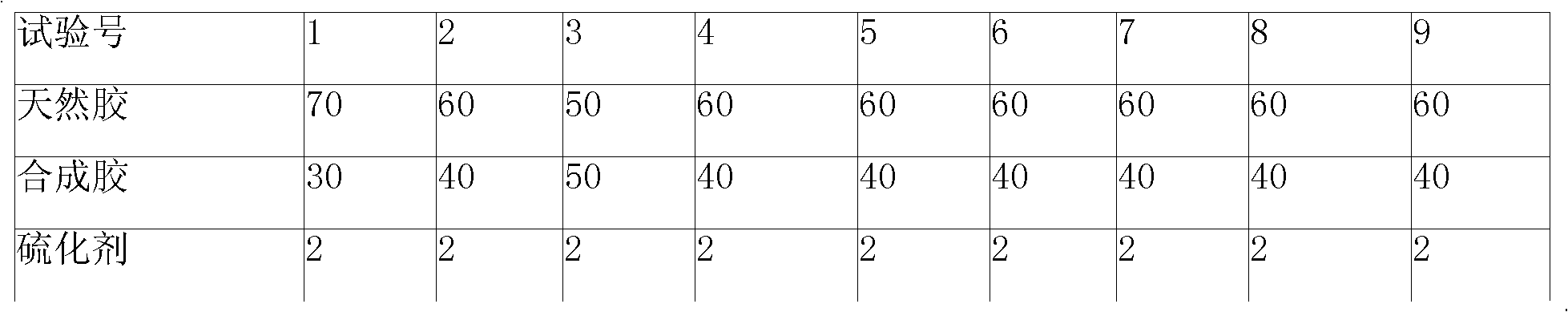

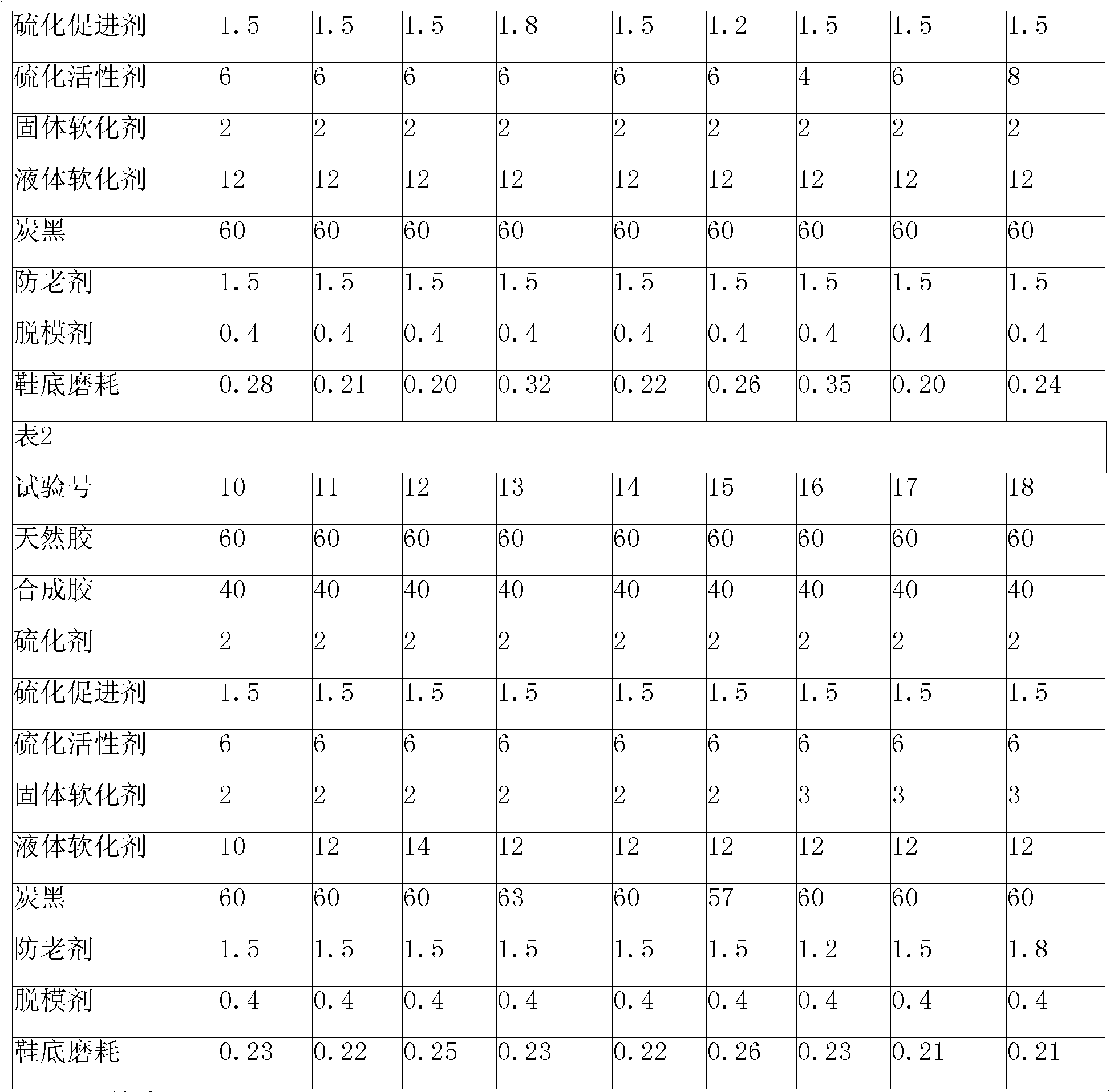

The invention discloses a highly wear resistant rubber sole and a preparation method thereof. The rubber sole is mainly made by plastication, masterbatching, mixing and remixing of natural rubber, synthetic rubber, sulfidizer, vulcanization accelerator, vulcanization activator, solid softener, liquid softener and carbon black. The rubber sole has the advantages of enhancing the outside force resistance of the rubber, improving the extension modulus and the tensile strength of the rubber, improving the resilience force of the outer bottom, lowering the Hardness HA of rubber materials and radically realizing the highly wear resistant performance; moreover, in the invention, the rubber materials for the highly wear resistant rubber sole are not mixed with plastic materials, and the weight of the synthetic rubber against the total weight of framework materials is not more than 40 percent, while the wear resistance of the sole reaches the Akron wear volume 0.15 to 0.30cm<3> / 1.61km, which is far higher than the wear resistance (0.5cm<3> / 1.61km) of the rubber for tires, so that the service life of the rubber sole is prolonged more than three times.

Owner:际华制鞋工业有限公司

Ultra-low-temperature fast-curing reinforcing glue for rubber shoes and preparation method thereof

ActiveCN101225194AIncrease the speed of cross-linking and settingSolve delaminationWeltsUpperPolymer scienceVulcanization

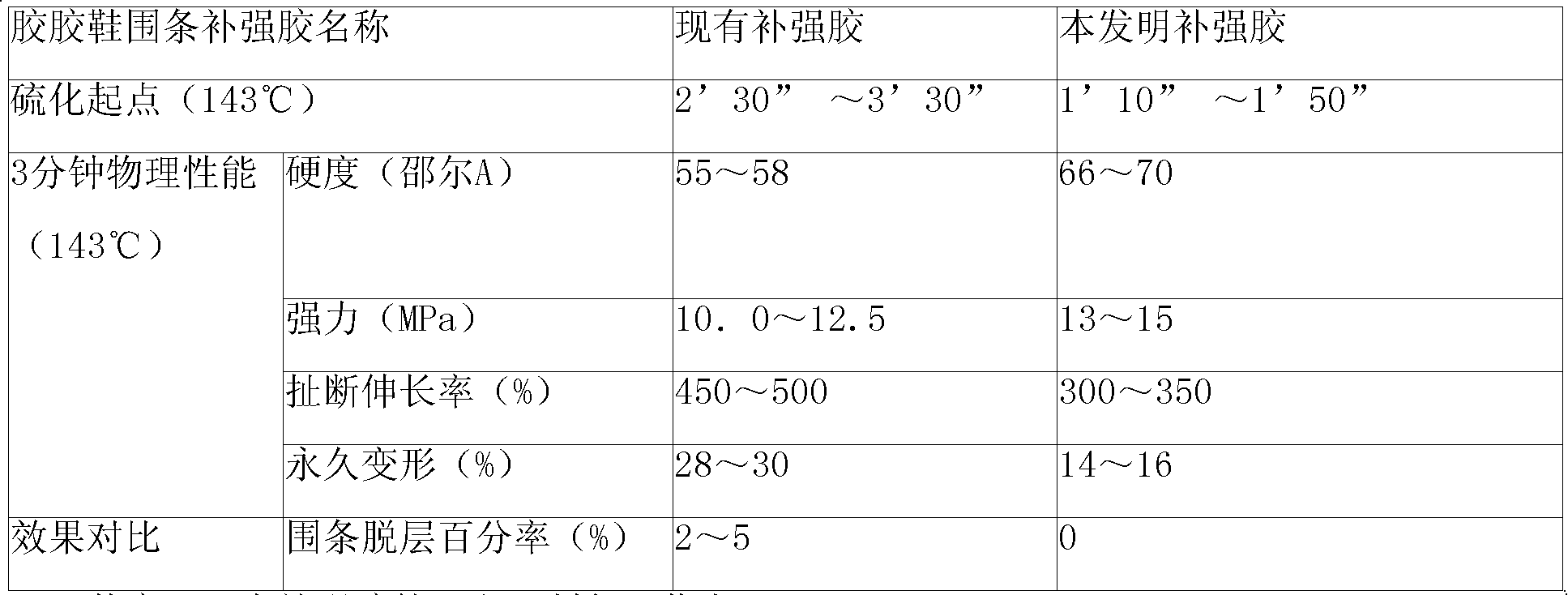

The invention discloses an ultra low temperature fast vulcanization strengthening adhesive used by rubber shoes and a preparation method of the strengthening adhesive, which is characterized in that: firstly, natural rubber is masticated to form masticated rubber, product A is obtained by mixing the masticated rubber and the synthetic rubber, the product B is obtained by mixing the polyethylene glycol and the silica, the product C is obtained by mixing the vulcanizing agent, the vulcanization accelerator and the vulcanization active agent; the product A is put into the rubber refiner to be refined for 0.5 to 1 minute, the product C is added into the rubber refined and keep on refining for 2 to 5 minutes, and then softener is added into the refiner to be refined homogenously, when the discharged material reaches the flattening machine, the supplementary re-processing is carried out to obtain the rubber compound, at last sulfur is added into the rubber compound to obtain the ultra low temperature fast vulcanization strengthening adhesive. The preparation method of the strengthening adhesive has the advantages that: the prescription of the strengthening adhesive materials are improved, the crosslinking stress of the strengthening adhesive is enhanced, thus, the crosslinking stress is ensured to be larger than the rebound force of the outsole plus the expansive force produced by the foaming sponge, and the crosslinking calibration speed is increased; meanwhile, the rubber foxing delamination problem is totally avoided.

Owner:JIHUA 3537 SHOE MAKING

Seal ring rubber material and mixing method thereof

InactiveCN102010553AAvoid bloomingPrevent blooming and scorching of rubberEngine sealsRubber materialCalcium hydroxide

The invention relates to a seal ring rubber material and a mixing method thereof. The mixing method comprises the following steps: carrying out crude rubber laminating and roller covering: adding 1-1.5 parts of aflux-42 serving as a processing agent and 1.5-2 parts of TM-80 serving as a mould release agent into 100 parts of fluororubber serving as crude rubber; mixing the above components of the rubber material for about 1 minute at the roller temperature of 40-45 DEG C, and adding 4-6 parts of activated magnesia serving as an acceptor; evenly mixing, adding 30-40 parts of a reinforcing agent which contains aramid pulp fiber; evenly mixing once again, adding 1-1.5 parts of bisphenol AF serving as a vulcanizing agent and 1-0.5 part of tert-butyl peroxypivalate (BPP) serving as an accelerator; and finally adding 5-7 parts of calcium hydroxide, packaging into a cornucopla for three or four times after all compounding ingredients are consumed up under the roller temperature of below 55 DEG C, adjusting the roller distance to be less than 0.55mm, rolling the dropped rubber for five or six times, and discharging. The seal ring rubber material has the advantages of rapid vulcanization speed of fluororubber, high production efficiency and low rejection rate.

Owner:广东天诚密封件股份有限公司

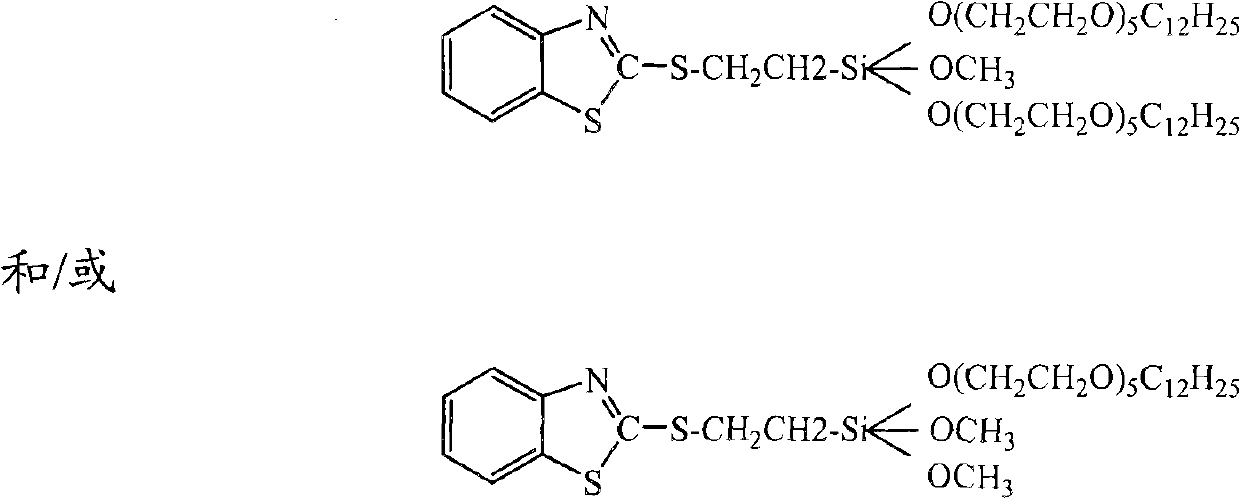

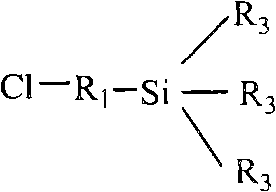

Low-volatility benzothiazolyl mercaptosilanes and preparation method thereof

ActiveCN102344462AImprove bindingImprove mechanical propertiesGroup 4/14 element organic compoundsRubber materialPolymer science

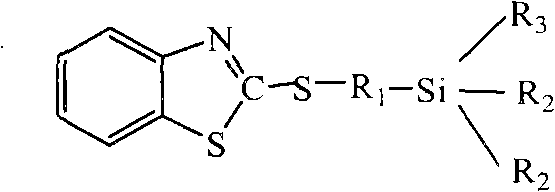

The invention discloses a low-volatility benzothiazolyl mercaptosilane and a preparation method thereof. A molecular structural formula of the low-volatility benzothiazolyl mercaptosilane is shown in the patent specification. The preparation method of the low-volatility benzothiazolyl mercaptosilane comprises the following steps that 1, a polyether and a chloroalkyl silane undergo a reaction at a temperature of 30 to 180 DEG C in the presence of one or more catalysts; and R3-H is separated from the reaction products so that a silane semi-finished product is obtained; and 2, 2-mercaptobenzothiazole is added into an organic solvent; and one or more alkalis and semi-finished silane are added into the 2-mercaptobenzothiazole solution to undergo a reaction with stirring at a temperature of 20 to 120 DEG C in a nitrogen atmosphere for 0.5 to 24 hours; the reaction products are subjected to filtration, washing and reduced pressure distillation to produce a brown-red liquid desired product. The low-volatility benzothiazolyl mercaptosilane can release a small quantity of alcohols, can improve reinforcing effects, mechanical properties and dynamic mechanical properties of vulcanized rubbers, and rolling resistance and wet skid resistance of tread rubber, has long scorch time and fast sulfuration speed, and can improve greatly sulfuration performances of rubber materials.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

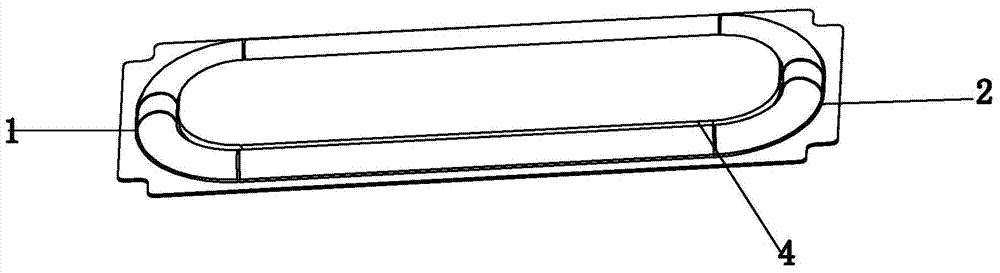

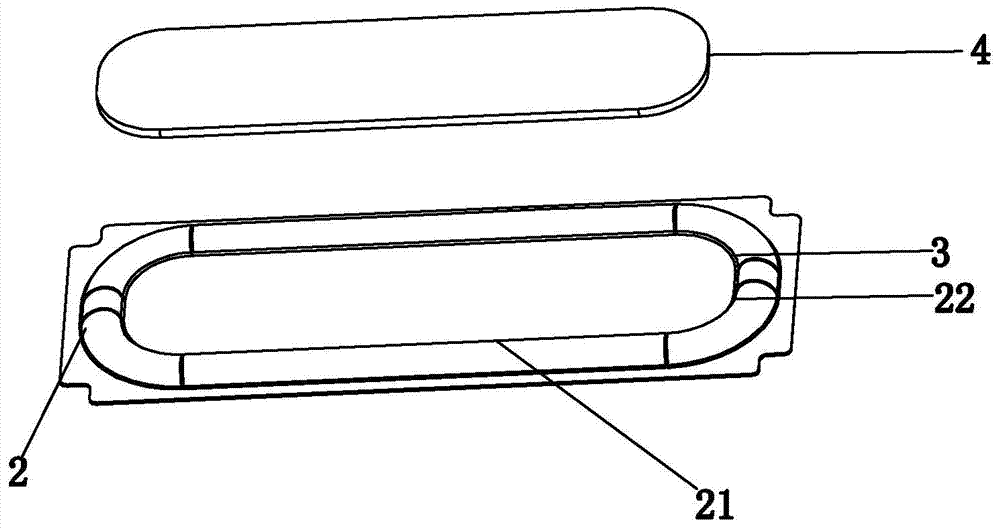

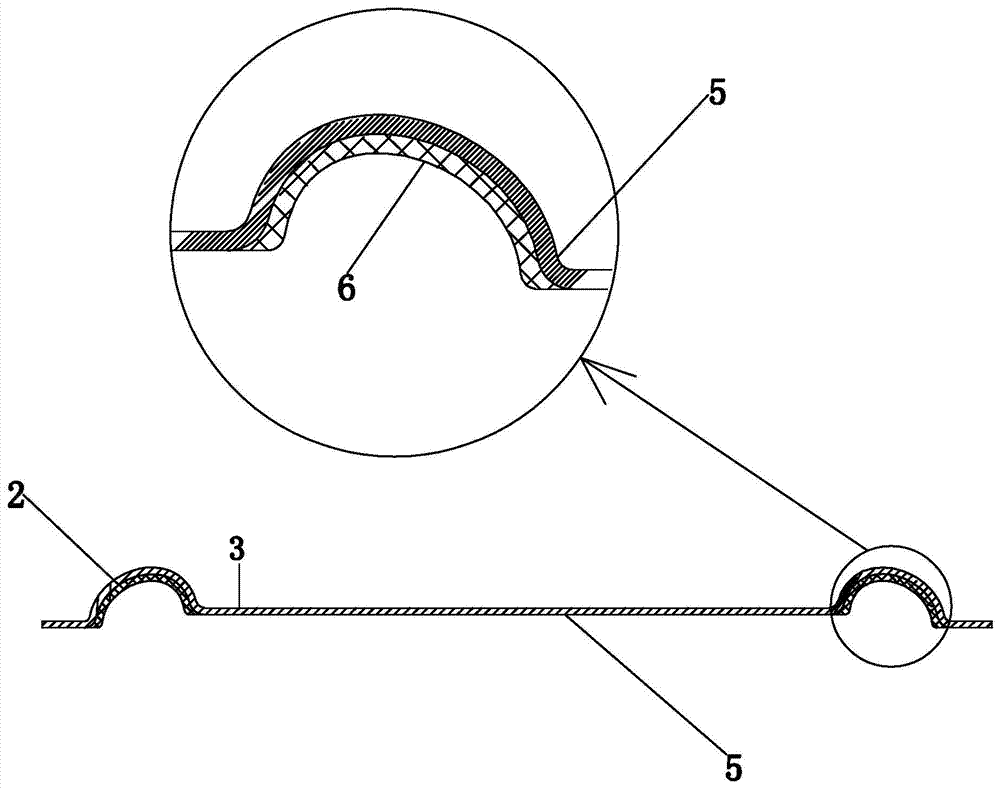

Vibration film component

InactiveCN104754472AStrong mechanical propertiesIncrease vibration amplitudePolymeric diaphragmsSynthetic resin layered productsFilm baseInjection moulding

The invention discloses a vibration film component, and relates to the technical field of electro acoustical products. The vibration film component comprises a vibration film, wherein the vibration film comprises a middle portion and a fold ring portion which wraps around the periphery of the middle portion. The vibration film furthermore comprises a vibration film base layer and a silica gel layer, wherein the silica gel layer is integrated in the vibration film base layer at least partially, the vibration film base layer is a polymer material layer, the silica gel layer is integrated in the surface of the fold ring portion, and the silica gel layer and the polymer material layer are injection molded. The vibrating film component achieves recombination of the silica gel layer and the polymer material layer by arranging the silica gel layer in the surface of the fold ring portion, and thereby improves compliance of the vibration film, enhances chemical stability and adaptability to temperature of the vibration film, optimizes acoustic performances, and improves products yield rate.

Owner:GOERTEK INC

Engine mounting heat-resisting material and preparation method thereof

The invention discloses an engine mounting heat-resisting material and a preparation method thereof. The engine mounting heat-resisting material comprises the following raw materials in parts by weight: 70 to 80 parts of standard natural rubbers, 10 to 20 parts of butadiene rubbers, 5 to 10 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of 2,2,4-trimethyl-1,2-dihydro-chinoline polymers, 1 to 2 parts of N-isopropyl-N-phenylene diamine, 1 to 3 parts of composite paraffin, 25 to 40 parts of carbon black, 3 to 6 parts of complex calcium salt, 5 to 8 parts of white carbon black, 1to 3 parts of silane coupling agent, 1 to 2 parts of sulphur, 1 to 3 parts of zinc diethyl dithiocarbamate, and 1 to 3 parts of N-Cyclohexyl-2-benzothiazole. In the invention, an engine mounting material with good heat-resisting performance is prepared through a special refining process, has long service life and saves the using cost.

Owner:ASIMCO NVH TECH CO LTD ANHUI

Composite insulation material for cable and preparation method thereof

InactiveCN101619148ALittle effect on insulation performanceEffective insulationRubber insulatorsPlasticizerActive agent

The invention discloses a composite insulation material for a cable and a preparation method thereof. The composite insulation material for a cable comprises the following materials by weight part: 30-60 parts of EPDM rubber, 70-40 parts of styrene-butadiene rubber, 1-4 parts of cross linker, 1-6 parts of cross linker addition agent, 4-16 parts of vulcanizing active agent, 1-4 parts of aging inhibitor, 10-40 parts of plasticizer, 1-3 parts of coupling agent and 100-200 parts of reinforcement filling material. The preparation method comprises the following steps: weighing the materials according to the weight parts; mixing; tabletting; cooling; and collecting. The composite insulation material is used for cable low-voltage insulation, has a temperature resistant level capable of reaching 90 DEG C, can resist heat, ozone and weathers and has high tensile strength, good electrical insulating property and mechanical property and cost being far lower than the cost of ethylene propylene rubber, and the preparation method is simple, applicable and easy to operate.

Owner:SICHUAN MINGXING CABLE

Ethylene-propylene-diene methylene using liquid-state oligomers of diolefin as third monomer and method for preparing same

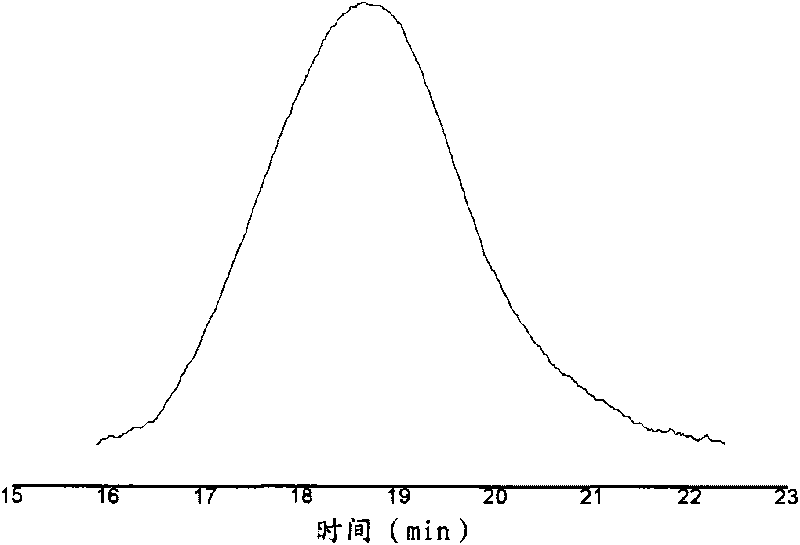

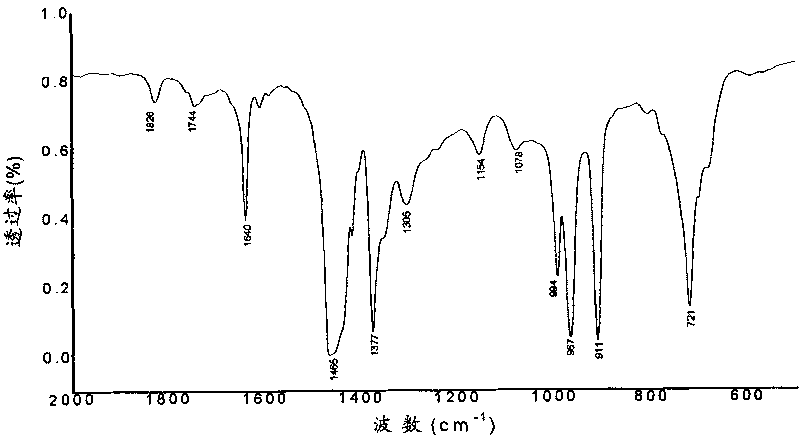

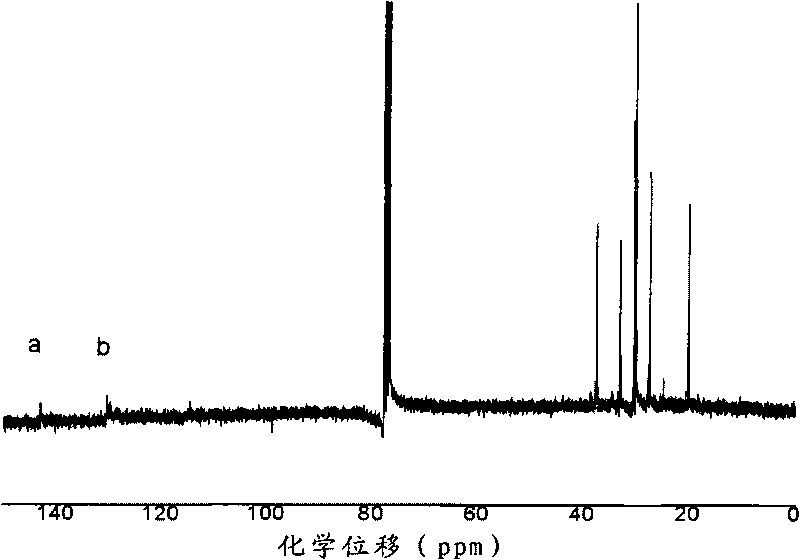

The invention provides ethylene-propylene-diene methylene taking liquid-state oligomers of diolefin as a third monomer and a method for preparing same. Combined propylene cells account for 20 to 45 molar percent of the ethylene-propylene-diene methylene, the third monomer which is a liquid-state oligomer of diolefin accounts for 0.5 to 15 molar percent of the ethylene-propylene-diene methylene, and the total molar percentage of the combined cells of ethylene, propylene and the third monomer is 100 percent; and the liquid-state oligomer of diolefin of the third monomer is selected from liquid-state oligomers with different double-bond structures and double-bond contents, including the liquid polybutadiene containing 20 to 80 percent of 1,2-strucutres and liquid polyisoprene containing over 90 percent of 1,4-strucutres. Because the side chains contain more double bonds, the ethylene-propylene-diene methylene has good curing and processing properties, and can vulcanize sulfur; the polymer has the molecular weight distribution indexes from 2 to 10; the ethylene-propylene-diene methylene can be used for manufacturing industrial rubber products of automobile parts, waterproof materials, telecom cables and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Novel platinum vulcanizing agent and preparation technology thereof

InactiveCN104927363ATo achieve the purpose of cross-linking vulcanizationFast vulcanizationEnvironmental resistancePolymer science

The invention relates to the technical fields of a vulcanizing agent and a preparation technology of the vulcanizing agent, particularly to a novel platinum vulcanizing agent and a preparation technology thereof. The novel platinum vulcanizing agent comprises a component A and a component B which are respectively added while in use, wherein the component A is the mixture of methyl vinylsiloxane rubber and a 1,3-divinyltetramethyldisiloxane platinum complex compound; the component B is the mixture of methyl hydrogen polysiloxane, gas phase silicon dioxide and an inhibitor. Compared with the prior art, the novel platinum vulcanizing agent disclosed by the invention uses the methyl vinylsiloxane rubber as a carrier, and under the existence of a platinum catalyst, vinyl double bonds and the methyl hydrogen polysiloxane are liable to generate a silicon hydrogen addition reaction, so that the purpose of cross-linking vulcanization is realized; the gas phase silicon dioxide is added for adjusting the hardness of vulcanization products, the vulcanization speed is high and is 1 / 3-1 / 2 higher than the vulcanization speed of the conventional platinum vulcanizing agent, and the production efficiency is improved; the vulcanization temperature is 10%-30% lower than that of the conventional platinum vulcanizing agent, and the purposes of energy conversation and environmental protection are achieved; the addition proportion is 30%-50% lower than that of the conventional platinum vulcanizing agent, and the production cost is reduced; the inhibitor is used, the storage time is greatly prolonged, and the storage time can reach 20-48h; in addition, the hygiene grade and the environmental protection grade are high, and the preparation technology is simple.

Owner:东莞市圣力堡有机硅科技有限公司

Preparation method of transparent dealcoholized vulcanizing silicone rubber by quickly curing single components at room temperature

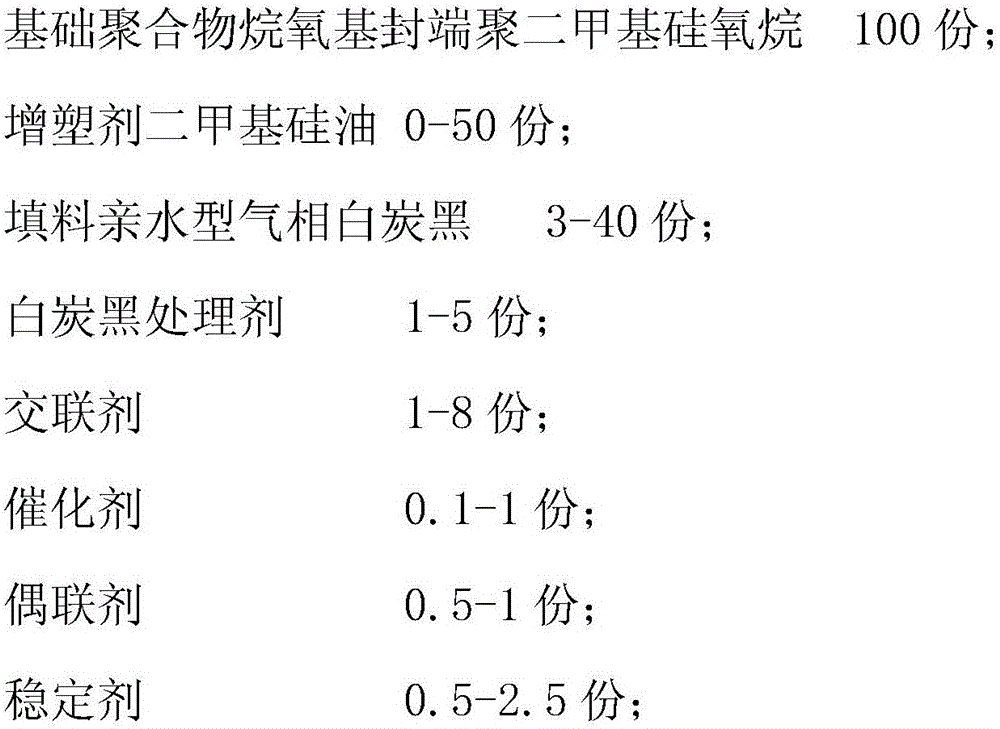

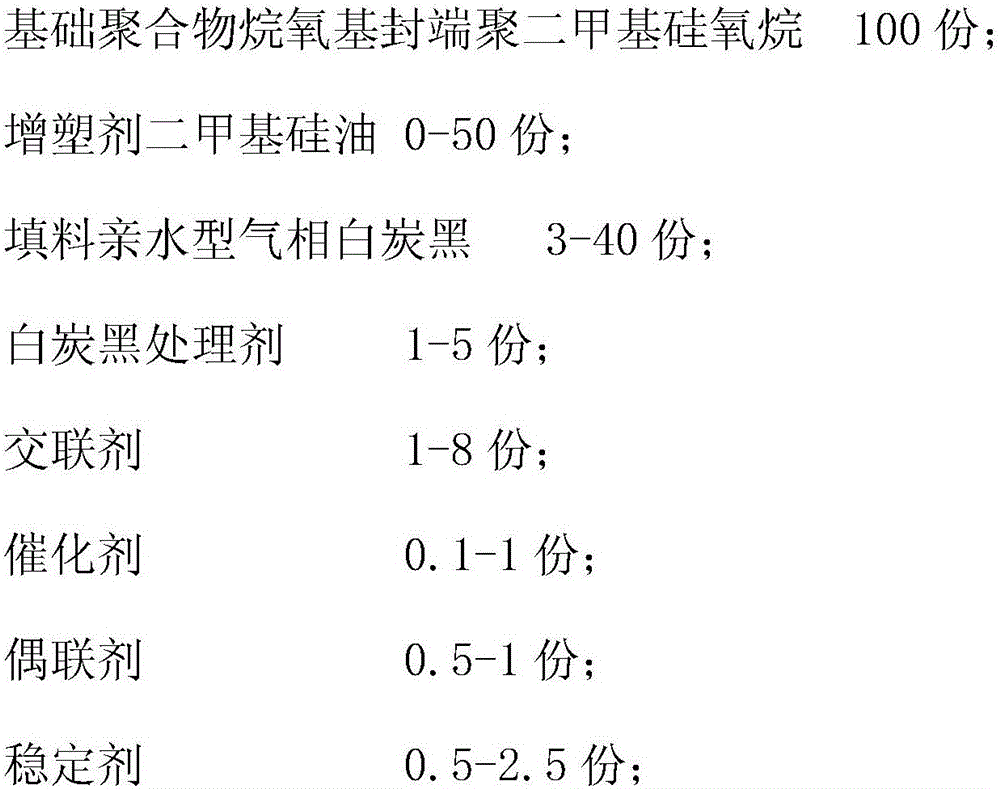

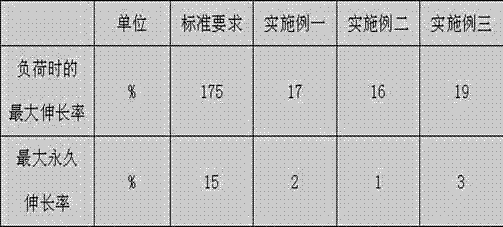

The invention provides a preparation method of transparent dealcoholized vulcanizing silicone rubber by quickly curing single components at room temperature. The preparation method comprises the following steps: under the protection of nitrogen, mixing dimethyl silicon oil serving as a plasticizer, white carbon black serving as a treating agent and alkoxy-terminated polydimethylsiloxane according to a mixture ratio of mass components by using a planetary mixer, then adding hydrophilic fumed silica serving as filler, uniformly dispersing and performing vacuum desorption on low-boiling-point substances; afterwards, sequentially adding a cross-linking agent, a catalyst, a coupling agent and a stabilizer, desorbing the low-boiling-point substances at the vacuum pressure of -0.097 to -0.092Mpa for 30 minutes, moving to an extrusion machine, extruding and filling, thus obtaining the transparent dealcoholized vulcanizing silicone rubber by quickly curing the single components at the room temperature. According to the preparation method provided by the invention, the hydrophilic fumed silica is adopted as the filler, the corresponding white carbon black is added as the treating agent, the defect that the hydrophobic fumed silica subjected to surface treatment is used as the filler in a traditional method is overcome, and the vulcanizing silicone rubber with the characteristics of low cost, high vulcanizing speed, stable viscosity and structure and excellent storage effect is obtained.

Owner:湖北环宇化工有限公司

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

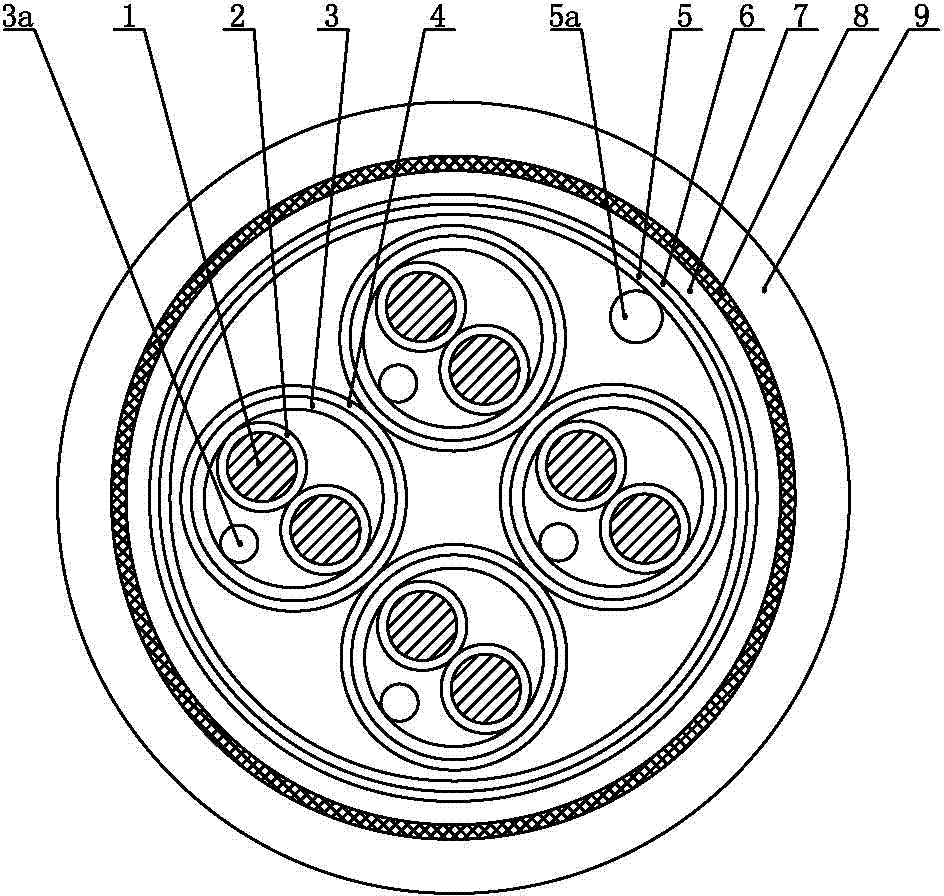

Whitening ultraviolet-proof double-shield instrument cable for ships and manufacturing method thereof

InactiveCN102969046AColor whiteGood physical and mechanical propertiesClimate change adaptationInsulated cablesCopper foilInsulation layer

The invention relates to a whitening ultraviolet-proof double-shield instrument cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs; each twisted wire pair is wrapped with a wire core copper foil polyester composite tape shielding layer at the periphery; the wire core copper foil polyester composite tape shielding layers are each wrapped with a wire core polyester tape at the periphery to form a pair-twist group; all the pair-twist groups are stranded to the right at 16-24 times of stranding lay ratio to form a cable core; the cable core is wrapped with a cable core copper foil polyester composite tape shielding layer at the periphery; the cable core copper foil polyester composite tape shielding layer is wrapped with a cable core polyester tape at the periphery; an inner sheath is extruded at the periphery of the cable core polyester tape; the inner sheath is coated with a copper alloy wire weaving armor layer at the periphery; and an outer sheath is extruded at the periphery of the copper alloy wire weaving armor layer. The insulation layer of the double-shield cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

High-strength and abrasion-proof cable sheath material

InactiveCN103788434AGood physical and mechanical propertiesImprove heat resistanceInsulated cablesInsulated conductorsAntimony trioxideTalc

The invention discloses a high-strength and abrasion-proof cable sheath material, which comprises the following components in parts by weight: 15 to 30 parts of nitrile rubber, 40 to 60 parts of chloroprene rubber, 10 to 15 parts of chlorinated polyethylene, 1.5 to 4 parts of zinc oxide, 1.5 to 4 parts of magnesium oxide, 0.8 to 1.5 parts of N,N'-m-phenylene dimaleimide, 0.5 to 2 parts of calcium stearate, 0.8 to 2.5 parts of accelerator 4010NA, 1.8 to 3 parts of paraffin, 35 to 44 parts of white carbon black, 20 to 25 parts of superfine talc powder, 12 to 14 parts of active kaolin, 2 to 4 parts of dicumyl peroxide, 0.7 to 1.4 parts of diallyl isocyanate, 2 to 4 parts of antimony trioxide and 4 to 6 parts of magnesium hydroxide. The high-strength and abrasion-proof cable sheath material is high in tear resistance and abrasion-proof performance and long in service life, and has good flame-retardant effects.

Owner:ANHUI FUXING CABLE GRP

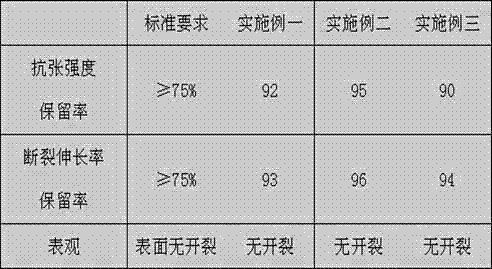

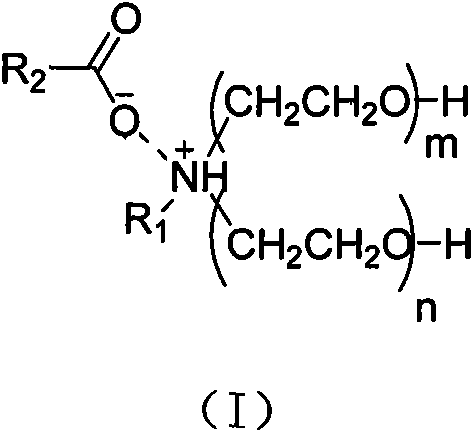

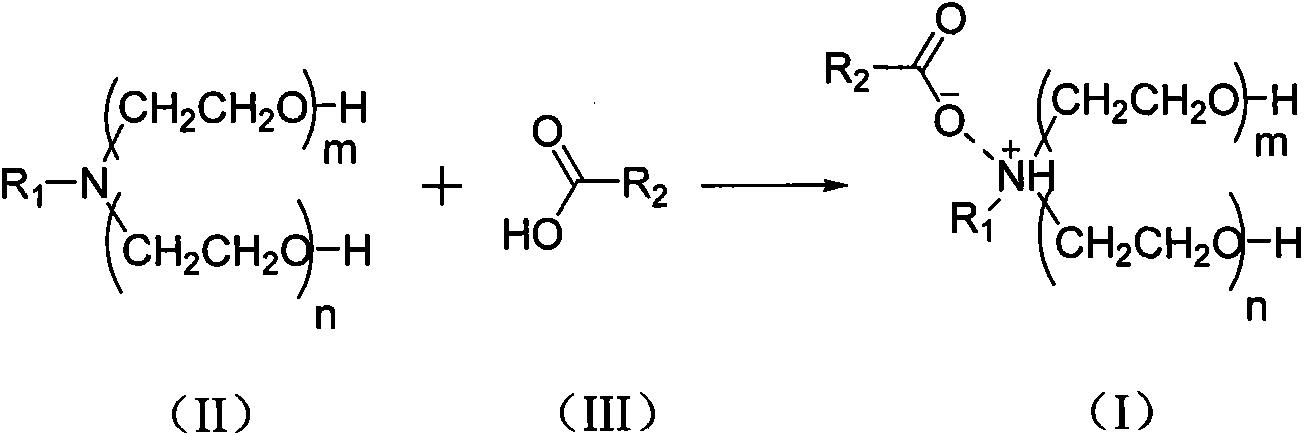

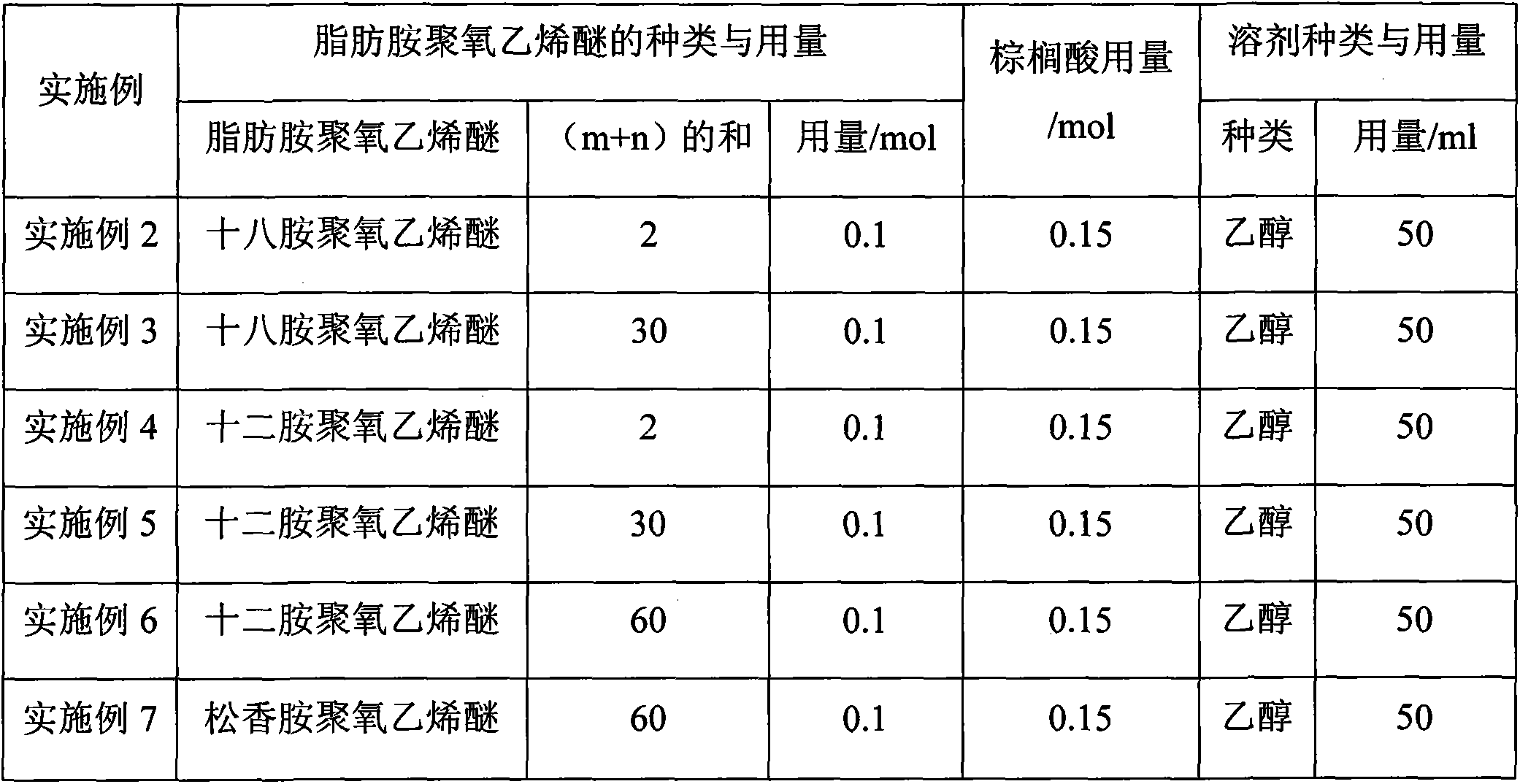

White carbon black dispersant, preparation method and applications

ActiveCN103525068ASimple processMild reaction conditionsOrganic compound preparationThiol preparationOrganic acidPhysical property

The invention relates to a white carbon black dispersant. The dispersant is prepared through reaction of organic amine substances and organic acid substances, the dispersant can be loaded in different carriers The white carbon black dispersant has a simple preparation method, can raise dispersion of white carbon black in rubber effectively, and raises the processing properties and various physical properties of the rubber.

Owner:BEIJING RED AVENUE INNOVA

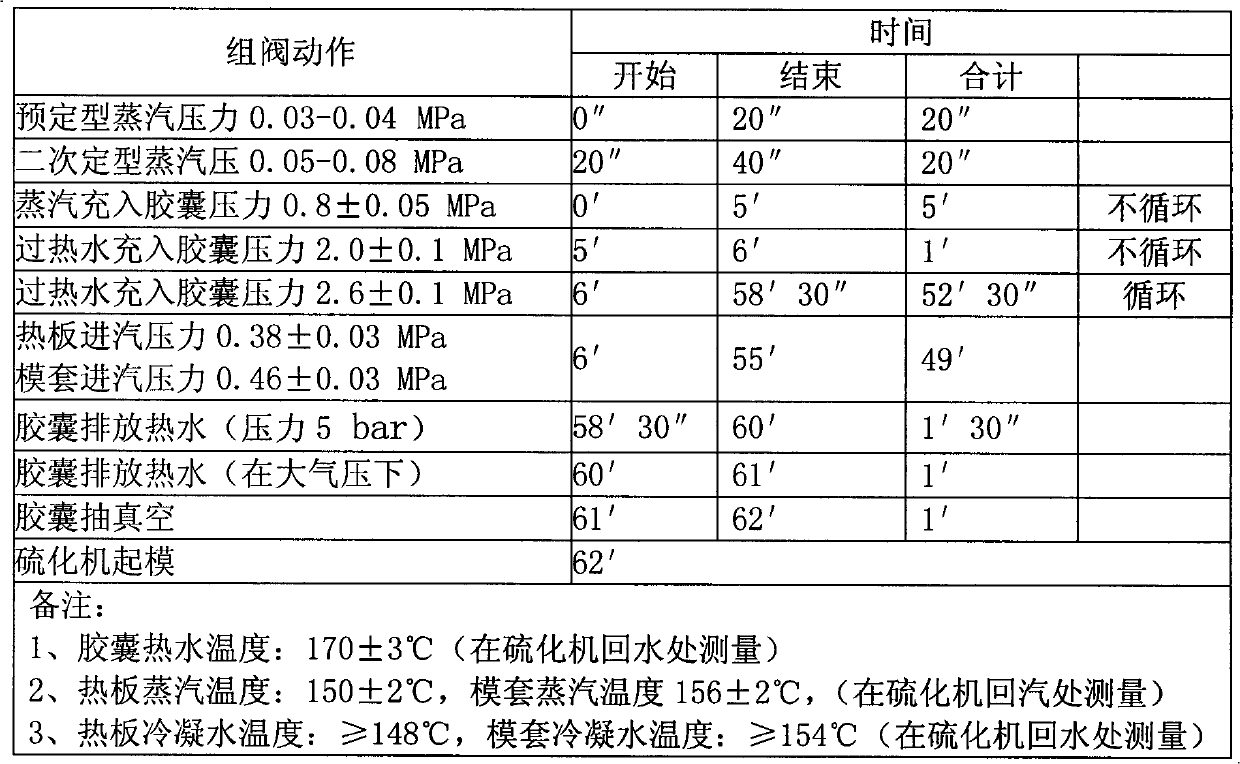

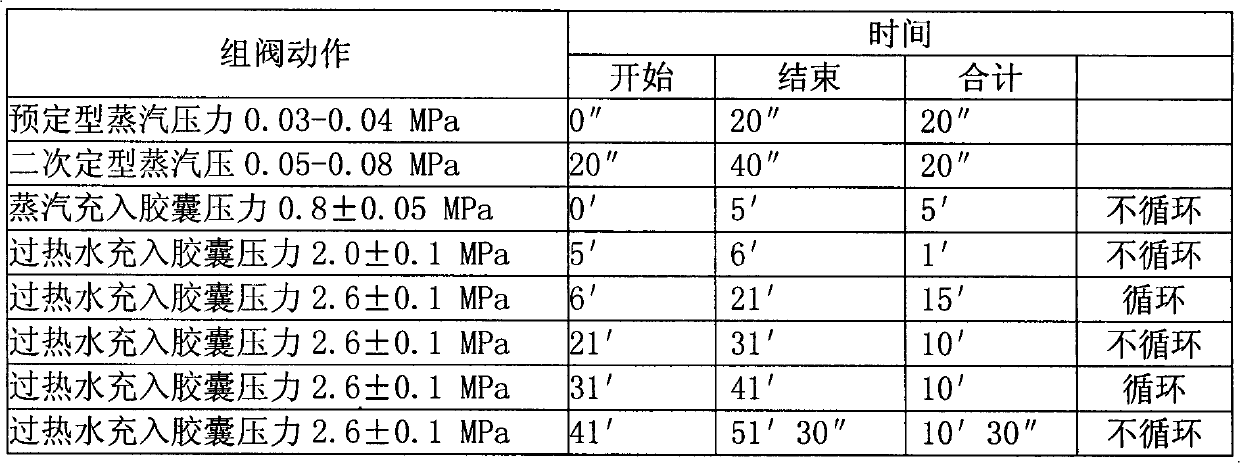

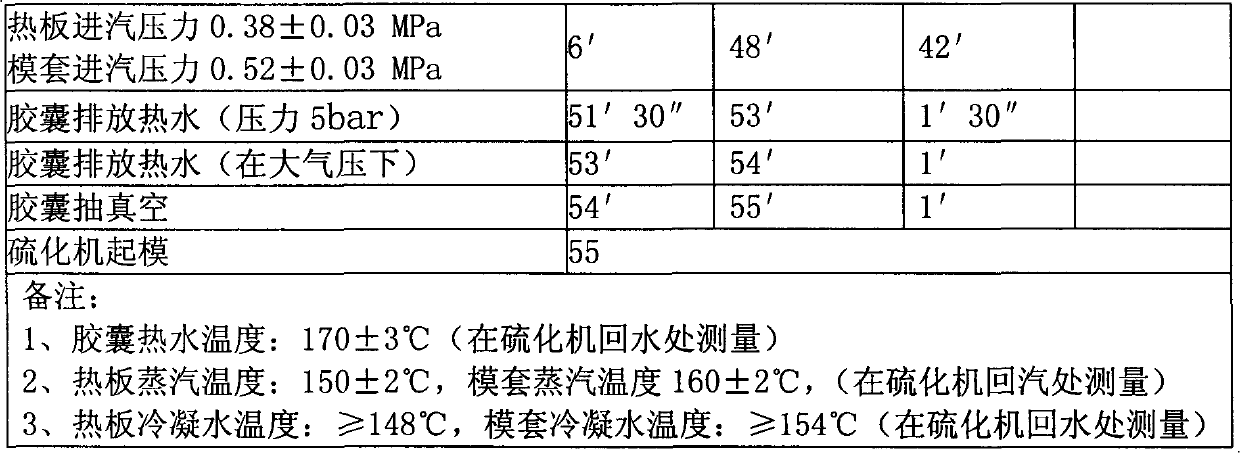

Intermittent hot water circulation pressure stabilization insulation tyre vulcanization technology

The invention discloses an intermittent hot water circulation pressure stabilization insulation tyre vulcanization technology, comprising the following steps: injecting saturated superheated steam to a vulcanizing machine after spotting, injecting primary superheated water without backing, providing internal pressure rapidly to enable a tread rubber material to fill patterns, injecting secondary superheated water and circulating as external pressure steam is entered to heat a green tyre, starting positive vulcanization, stopping the circulation of the secondary superheated water, feeding external pressure steam continuously, carrying out positive vulcanization for a tyre continuously, cycling the secondary superheated water again, feeding external pressure steam continuously, stopping the circulation of the secondary superheated water, keeping the pressure until the vulcanization is finished, stopping the external pressure steam, discharging the external pressure to atmospheric pressure, discharging hot water in capsules and vacuumizing, completing the vulcanization finally and taking the tire out of a mould. The overcure phenomena of carcass and the belt layer are effectively prevented according to the invention. The durability of the tire is enhanced from original 90 hr to over 110 hr. The service life of the tire is prolonged.

Owner:WEIFANG YUELONG RUBBER

Hydrogenation catalyst presulfurizing method

InactiveCN101024204AOvercome lossOvercome CorrosivityCatalyst activation/preparationOil processingVulcanization

This invention discloses a hydrogenation catalyst pre-curing method. The method used the by-products of the oil and gas industry processing acidic gas as medium sulfide, pretreatment the hydrogenation catalyst, the main component of acid gas is hydrogen sulfide and carbon dioxide, the invention can be used inside or outside of pre-vulcanization mode, put the oxidation states catalyst into vulcanization reactor, heated to200-500degree centigrade in an inert atmosphere, and then conducted hydrogen and acid gas to sulphate under 0.1-10MPa pressure, the reaction time is 0.5 to 30 hours, of which an acid gas occupy 1-40%. The invention method not only overcome the presence of sulfide wet curing agent losses, metal tube surface corrosion defects, also have fast curing process, even curing, can greatly improve the activity and stability of catalysts, extended catalyst life and other advantages, and wide sulfide-media sources, easy to get, significantly lower sulfide cost.

Owner:DAQING GASOLINEEUM INST

High-performance modified carboxylated nitrile rubber material and preparation method thereof

The invention discloses a high-performance modified carboxylated nitrile rubber material. The material comprises the following raw materials by weight: 90 to 130 parts of modified carboxylated nitrile rubber, 15 to 30 parts of natural rubber, 20 to 40 parts of carbon black N-774, 5 to 10 parts of carbon black N-990, 5 to 10 parts of antimony trioxide, 3 to 5 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of sulfur, 0.5 to 3 parts of tetrabenzylthiuramdisulfide, 1 to 3 parts of N-tert-butyl-2-benzothiazole sulfonamide, 2 to 6 parts of dioctyl sebacate and 4 to 8 parts of an auxiliary. The modified carboxylated nitrile rubber blending material provided by the invention has higher comprehensive mechanical property, and heat and ageing resistant properties, high-temperature and oil resistant properties and low-compression and permanent-deformation properties.

Owner:合肥市再德高分子材料有限公司

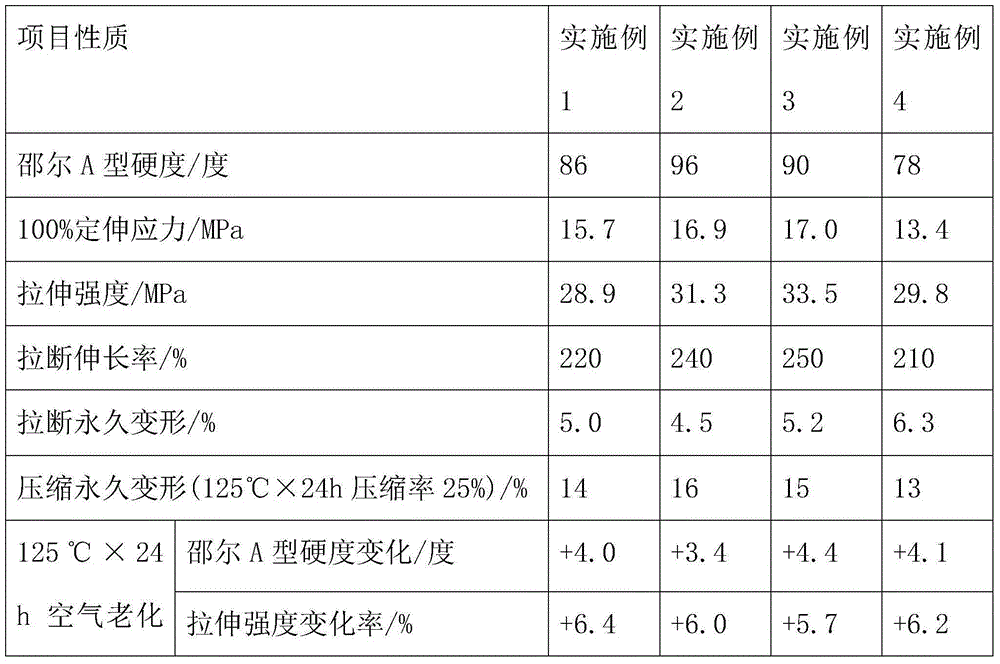

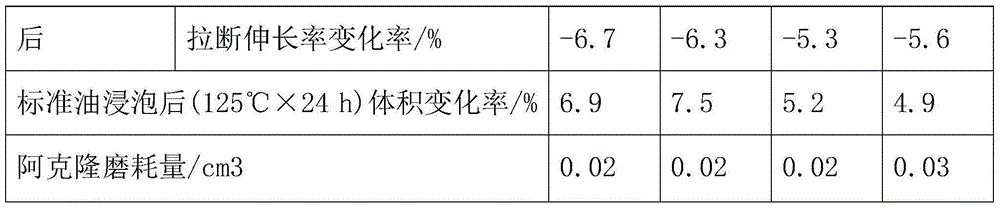

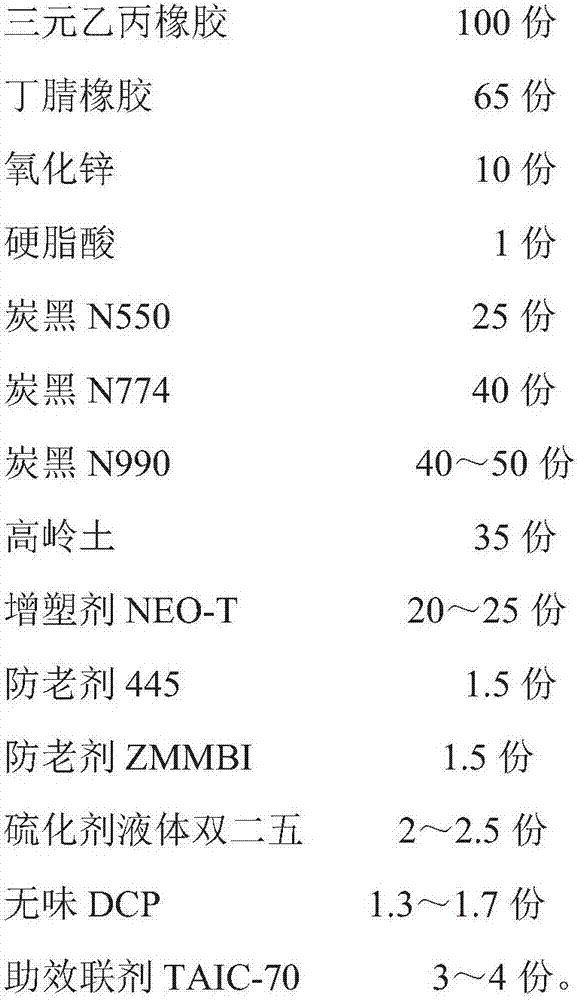

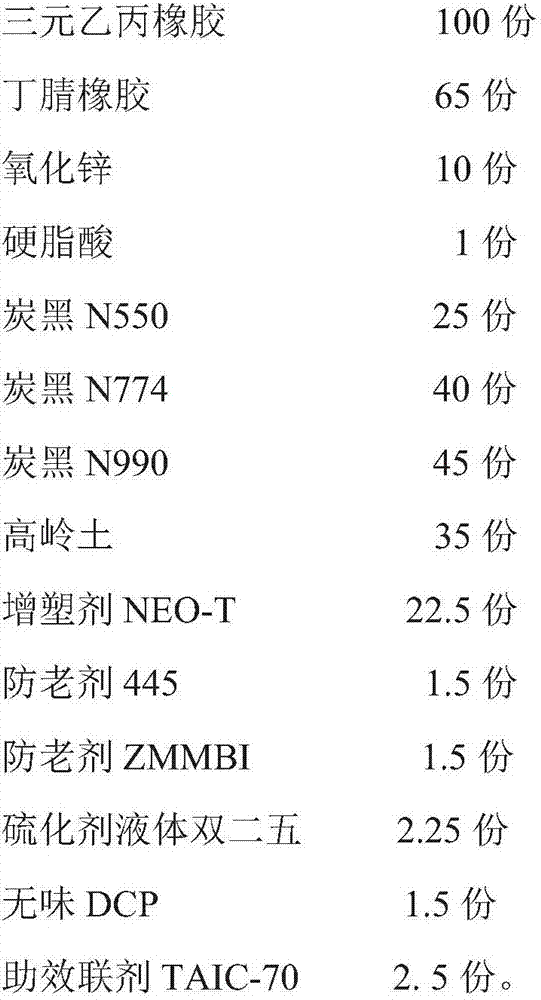

Oil-proof ethylene propylene diene monomer material and preparation method thereof

InactiveCN107141617AGood oil resistanceImprove high temperature resistancePolymer scienceStearic acid

The invention discloses an oil-proof ethylene propylene diene monomer material and a preparation method thereof and belongs to the technical field of rubber preparation. The material is prepared from the following components in parts by weight: 100 parts of ethylene propylene diene monomer, 65 parts of nitrile butadiene rubber, 10 parts of zinc oxide, 1 part of stearic acid, 25 parts of carbon black N550, 40 parts of carbon black N774, 40-50 parts of carbon black N990, 35 parts of kaolin, 20-25 parts of plasticizer NEO-T, 1.5 parts of anti-aging agent 445, 1.5 parts of anti-aging agent ZMMBI, 2-2.5 parts of vulcanizing agent liquid 2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane, 1.3-1.7 parts of odorless DCP and 3-4 parts of synergistic agent. According to the oil-proof ethylene propylene diene monomer material disclosed by the invention, after the material is soaked for 70 hours in 5W30 engine oil at 150 DEG C, the hardness change is -2 Shore A, the elongation change is 0-(-15%), the tensile strength change is 0-(-17%), the volume change is less than or equal to 25%, and the high temperature resistance, oil-proof property and compression set property are excellent.

Owner:南京金三力高分子科技有限公司

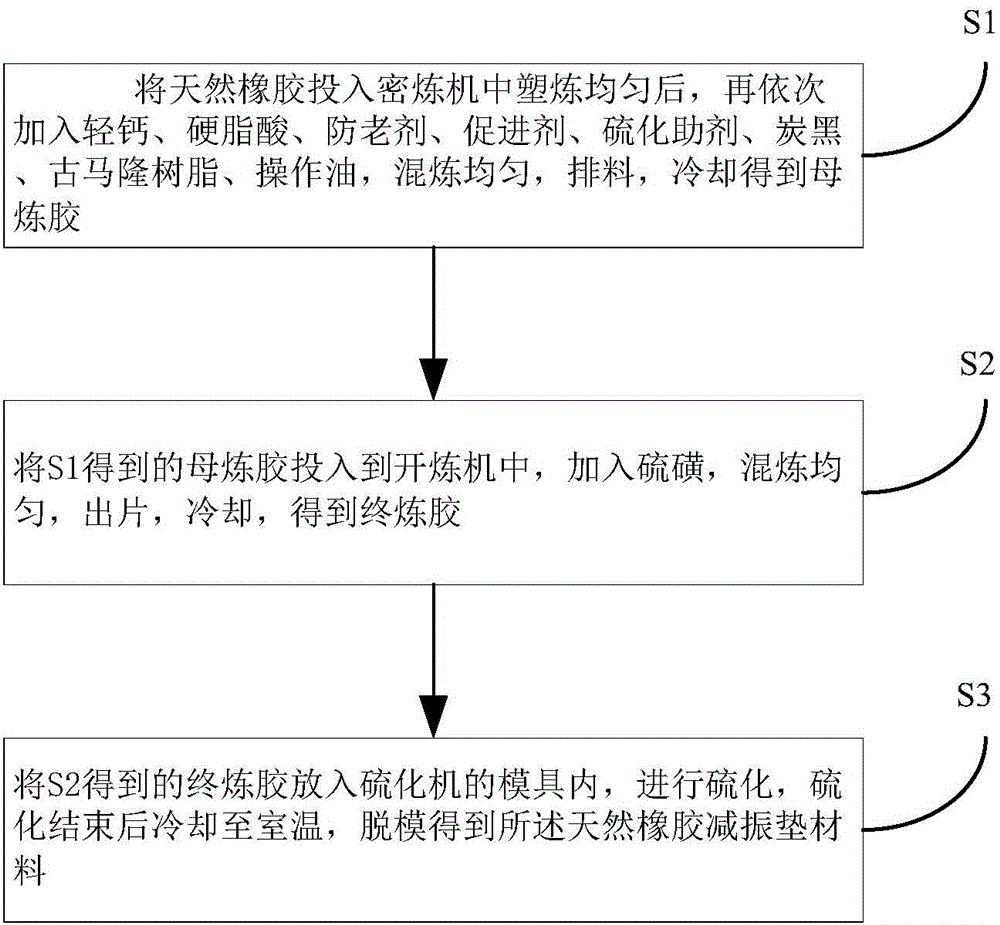

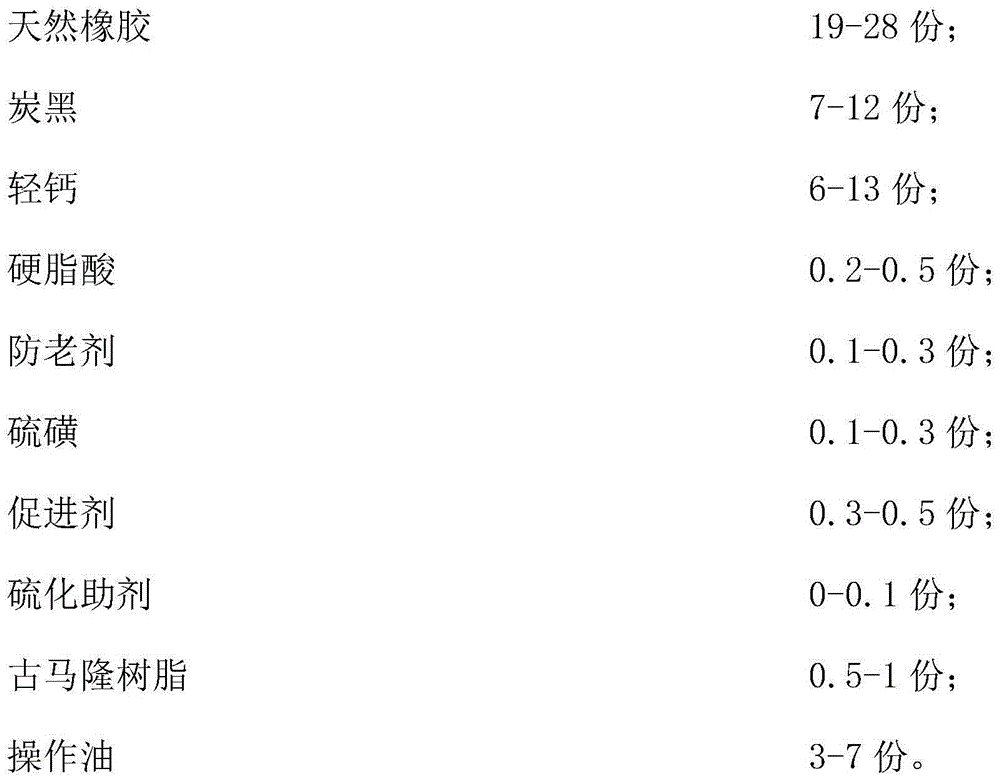

Natural rubber anti-vibration pad material and preparation method thereof

The invention discloses a natural rubber vibration damping pad material. The raw materials include: natural rubber, 19-28 parts; carbon black, 7-12 parts; light calcium, 6-13 parts; stearic acid, 0.2-13 parts by weight. 0.5 part; anti-aging agent, 0.1‑0.3 part; sulfur, 0.1‑0.3 part; accelerator, 0.3‑0.5 part; vulcanization aid, 0‑0.1 part; coumarone resin, 0.5‑1 part; process oil, 3‑ 7 servings. The natural rubber vibration-damping pad material has good vibration-damping effect and excellent weather resistance, and at the same time has high radial strength, moderate hardness, good elasticity and long service life. The invention also discloses a preparation method of the natural rubber damping pad material.

Owner:安徽华润仪表线缆有限公司

Preparation method for novel rubber strip for sealing of automobile doors and windows and product

The invention relates to a preparation method for a novel rubber strip for sealing of automobile doors and windows and a product. The preparation method employs ethylene propylene diene monomers as basic materials with cooperation of certain amounts of carbon black, calcium carbonate, paraffin oil, zinc oxide, stearic acid, polyvinyl alcohol, high-molecular wax, compound antioxidants, dispersants, compound accelerants, vulcanizing agents, fire retardants and the like. The above materials are subjected to mixing, open milling and vulcanization technologies to obtain the rubber strip. The preparation method has advantages of simple formula, simple production technology, short vulcanizing time, high production efficiency, relatively low production cost, easy industrialization enforcement and the like. The rubber product for sealing is advantaged by good sealing performance, uniform structure, resistance to corrosion, resistance to high and low temperature, flame resistance, environment protection and comfort.

Owner:天津滨海新区大港汇丰汽车装饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com