Oil soluble molybdenum-based precursor of catalyst, preparation method and application thereof

A molybdenum-based catalyst and oil-soluble technology, applied in chemical instruments and methods, organic chemistry, hydrocarbon oil cracking, etc., can solve the problems of high production cost and low catalytic hydrogenation activity, and achieve short reaction time and high catalytic hydrogenation activity The effect of high and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A preparation method of an oil-soluble molybdenum-based catalyst precursor, comprising the following steps:

[0041] 1) Mix molybdenum source and water at a molar ratio of 1:10 to 2:1, react at 70 to 90°C for 30 to 240 minutes, cool to 30 to 50°C, add inorganic acid dropwise to make the solution neutral;

[0042] 2) According to the molar ratio of hydroxyl group in polycarbonate alcohol to phosphorus pentasulfide is 3:1~5:1, add polycarbonate alcohol into phosphorus pentasulfide, the addition temperature is 50~80℃, and the addition time is 5~15min. At a temperature of 70-100°C, react for 1-3 hours, and purge the hydrogen sulfide gas generated during the reaction with an inert gas;

[0043] 3) Add the product obtained in step 2) to the product obtained in step 1), and add an acidic cation exchange resin, the quality of the acidic cation exchange resin is 10-15% of the molybdenum mass in the molybdenum source, at 70-110 ° C, react 4~8h;

[0044] 4) Separating the produc...

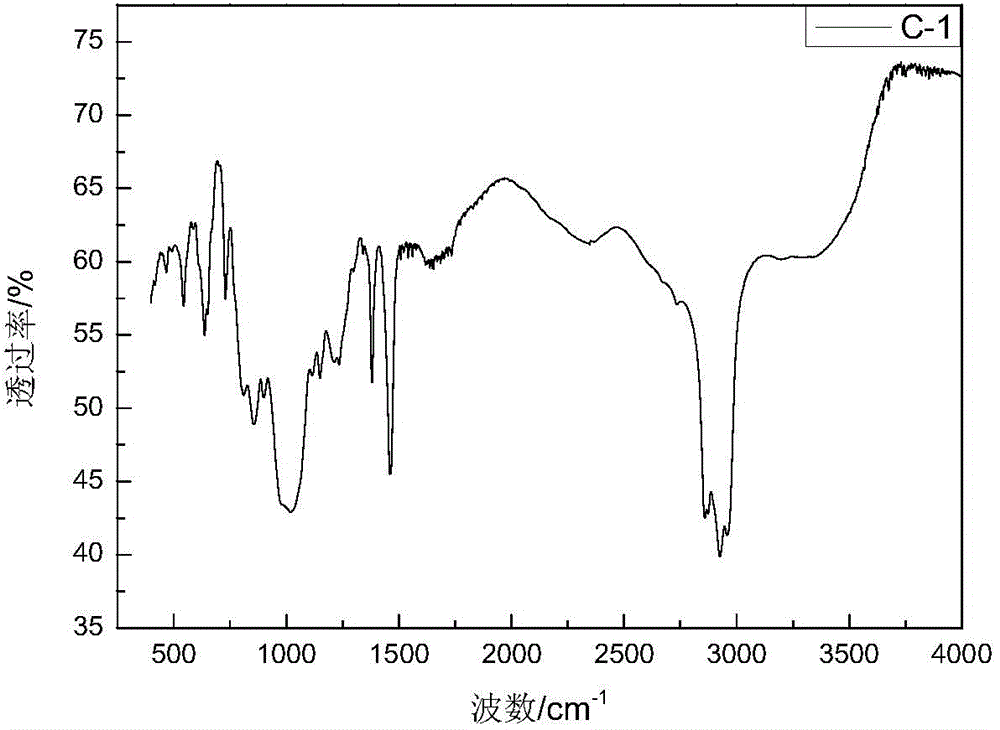

Embodiment 1

[0053] Take 0.5mol MoO 3 and 1.2mol NaOH, add 5mol water, in a 70°C water bath, stir and reflux for 240min, cool to 40°C, add 0.75mol concentrated H 2 SO 4 , make the solution neutral, and obtain the molybdenum source compound; take 3.0 mol of n-butanol and isooctyl alcohol mixed solution into the dropping funnel, dropwise add 1.0 mol of P 2 S 5 In a round-bottomed flask, the dropping temperature is 80°C, and the dropping time is 5 minutes. After the dropping is completed, react at 80°C for 3 hours. During the reaction, the solution is magnetically stirred and nitrogen gas is introduced, and the hydrogen sulfide gas is continuously purged to remove the generated hydrogen sulfide gas. ; Filtration, filter out the unreacted P 2 S 5 , transfer the filtrate into the dropping funnel, and add it dropwise to the above-mentioned molybdenum source compound, add 4.8g of acidic cation ion exchange resin to the mixed solution, stir and reflux at 95°C for 4h; filter, stand still, separ...

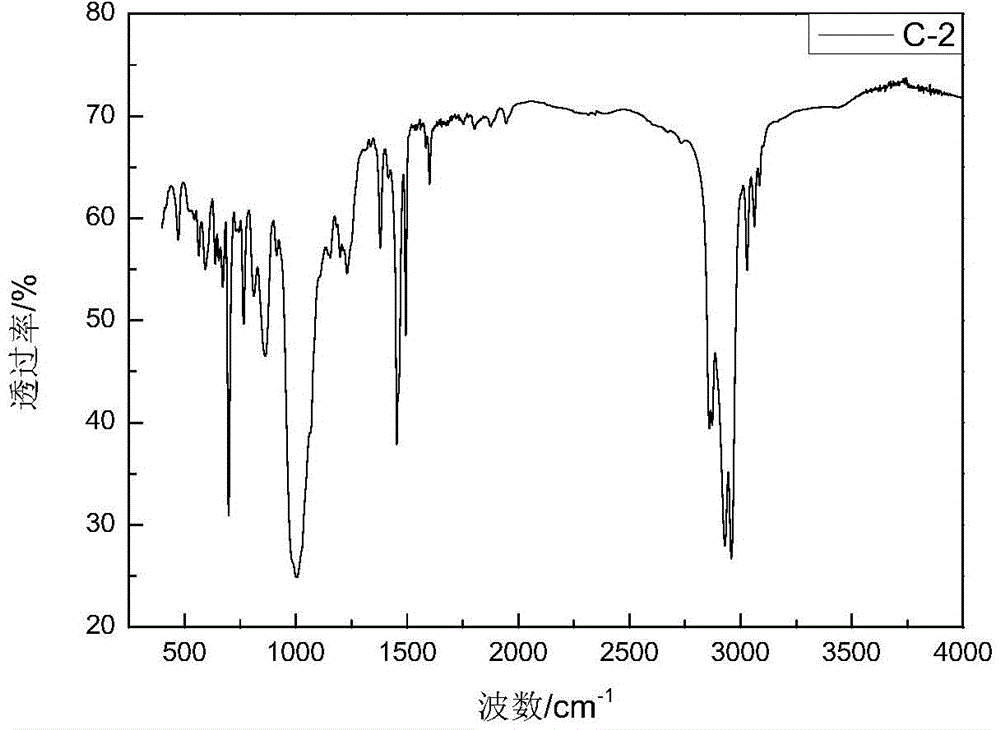

Embodiment 2

[0056] Take 0.5mol Na 2 MoO 4 2H 2 O, add 0.25mol water, stir and reflux for 30min in a water bath at 80°C, cool to 30°C, add 0.5mol concentrated H 2 SO 4 , acidified to obtain the molybdenum source compound; get 4.5mol of isooctyl alcohol and add it to the dropping funnel, and dropwise dropwise add 1.5mol of P 2 S 5 In the round-bottomed flask, the dropping temperature is 50°C, and the dropping time is 10 minutes. After the dropping is completed, the temperature is 90°C, and the reaction is carried out for 2 hours. During the reaction, magnetic stirring is used, and nitrogen gas is continuously purged to remove Generated hydrogen sulfide gas; cooling, filtering, filtering out unreacted P 2 S 5 , move the filtrate into the dropping funnel, and add it dropwise to the above-mentioned molybdenum source compound, and add 6g of acidic cation exchange resin, the acidic cation exchange resin is a sodium-type cation-exchange resin that is treated with sulfuric acid to be a hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com