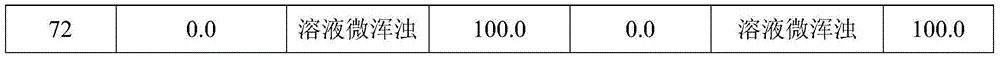

Patents

Literature

442results about How to "Good oil solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

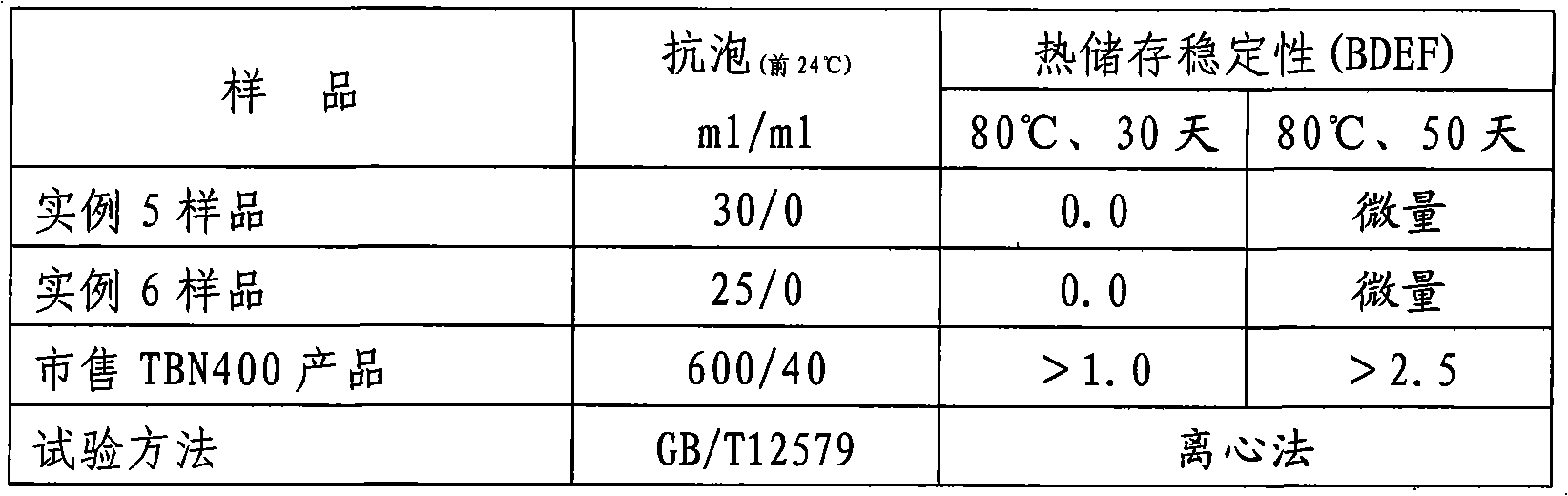

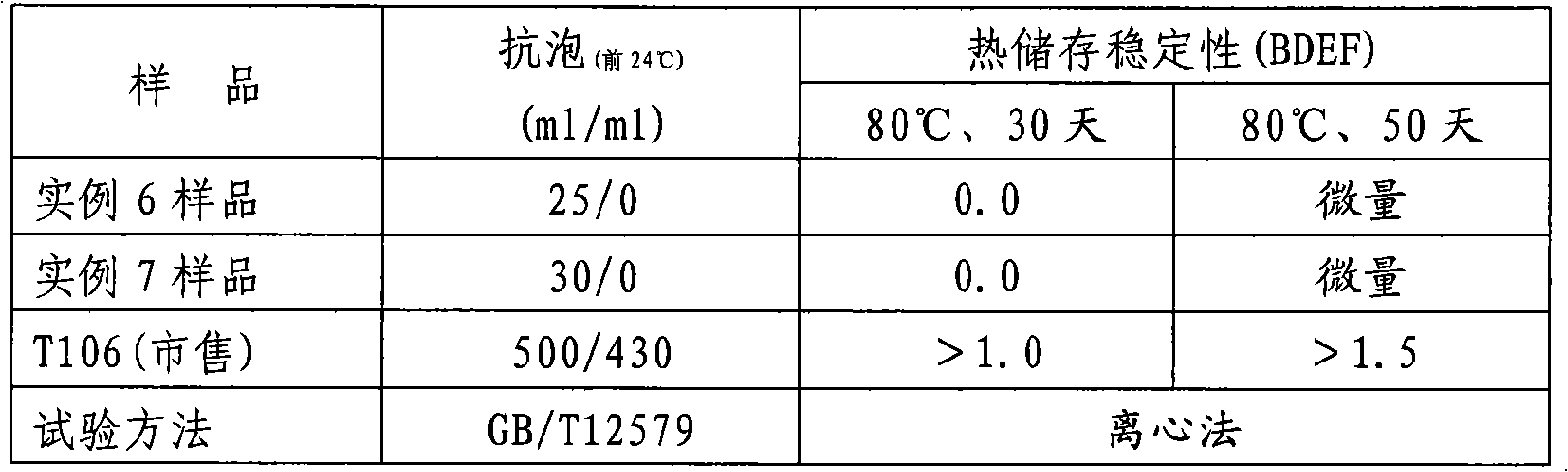

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

Temporary plugging diversion agent for refracturing of oil-water well and preparation method thereof

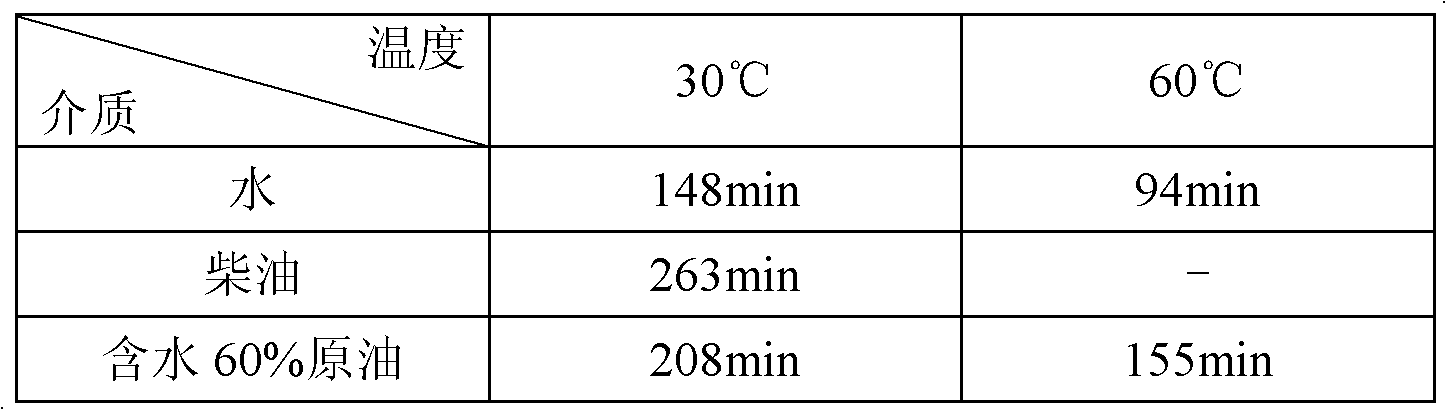

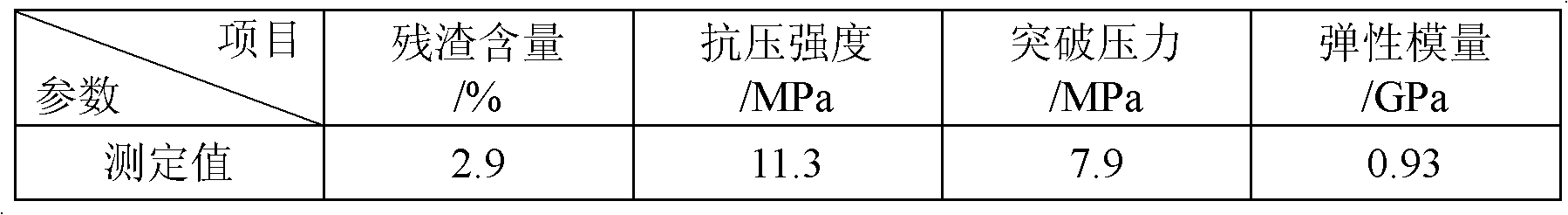

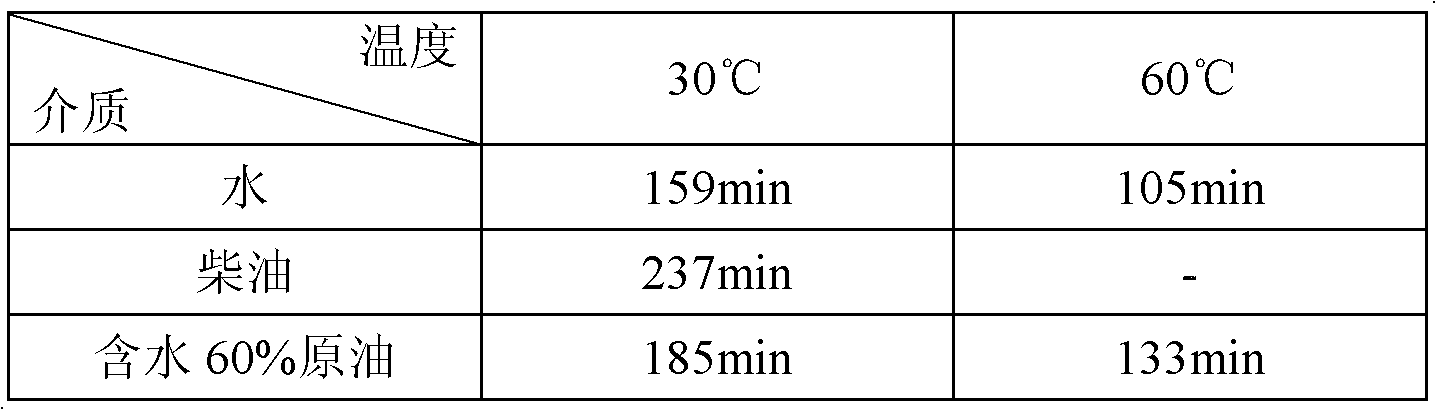

The invention relates to a temporary plugging diversion agent for refracturing of an oil-water well and a preparation method thereof. The temporary plugging diversion agent comprises the following raw materials: adhesive bonding agent 35-65%, plasticizer 15-25%, thickening agent 10-20%, and dispersant 10-20% calculated by the total weight of the temporary plugging diversion agent. The invention also provides the preparation method of the temporary plugging diversion agent, which comprises the following steps: preparing partial thickening agent into a thickening agent water solution; dissolving the adhesive bonding agent into the thickening agent water solution; holding constant temperature in a 25-35 DEG C water bath for 2-5 hours, and after the adhesive bonding agent is swollen completely, increasing the temperature to 45-55 DEG, and continuing holding constant temperature for 0.5-2 hours; after the adhesive bonding agent is completely dissolved, adding dispersant and stirring to be homogenous, and adding the plasticizer and the rest thickening agent while stirring to obtain viscous paste; and cutting the viscous paste to granules of side length 3-6 mm, and drying to obtain the temporary plugging diversion agent. The temporary plugging diversion agent provided by the invention has the advantages of good oil solubility and water solubility, low residue content, good elasticity, and on the like.

Owner:PETROCHINA CO LTD

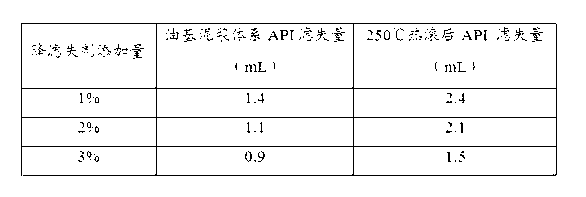

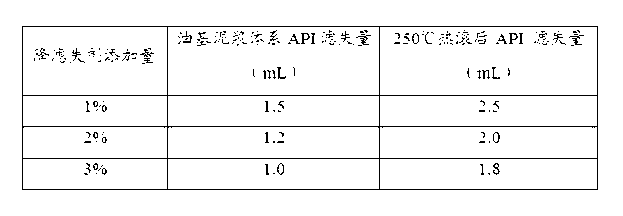

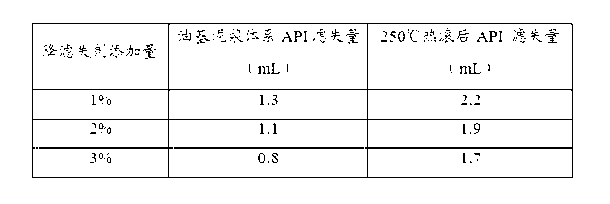

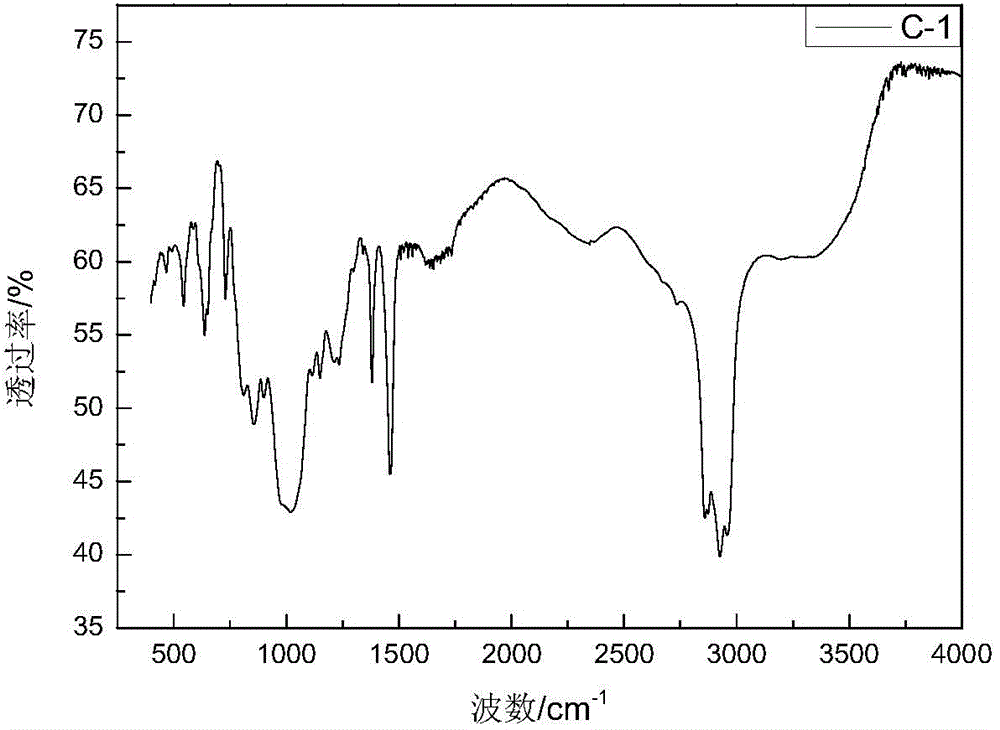

Oil base drilling fluid filtrate reducer as well as preparation method and application of oil base drilling fluid filtrate reducer

ActiveCN103013460ASatisfy the requirements of filtration volumeStrong oil solubilityDrilling compositionSolubilityWell drilling

The invention discloses an oil base drilling fluid filtrate reducer as well as a preparation method and application of the of oil base drilling fluid filtrate reducer. The oil base drilling fluid filtrate reducer comprises the following components in parts by weight: 70-90 parts of rubber powder and 10-30 parts of natural asphalt, wherein 2-8 parts of anti-sticking agent and calcium carbonate superfine powder is required to be added in the preparation process. The preparation method comprises the following steps of: simultaneously feeding three raw materials namely, the rubber powder, the natural asphalt and the calcium carbonate superfine powder to a winnowing crusher according to a weight ratio, controlling the material temperature to be 18-30 DEG C for mixing and crushing, and passing through a sieve with the particle size of 60 meshes, thereby obtaining the oil base drilling fluid filtrate reducer, wherein the oil base drilling fluid filtrate reducer accounts for 1-3 percent in the drilling fluid. The oil base drilling fluid filtrate reducer can resist high temperature of 250 DEG C, the filtrate reduction effect is good, the oil solubility is up to 98 percent, and the oil base drilling fluid filtrate reducer is easily biologically degraded and is harmless to the stratum.

Owner:河北华运鸿业化工有限公司

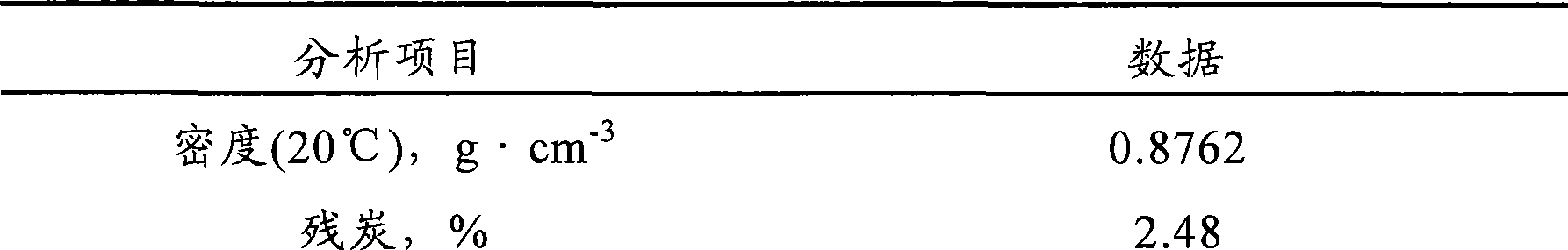

Oil soluble molybdenum-based precursor of catalyst, preparation method and application thereof

InactiveCN103980320AGood oil solubilityReduce yieldPhysical/chemical process catalystsHydrocarbon oil crackingSlurry reactorDecomposition

The invention provides an oil soluble molybdenum-based precursor of a catalyst, a preparation method and application thereof, relating to the technical field of heavy oil hydrocracking catalysts and solving the problems of low catalytic hydrogenation activity and high cost of the existing catalysts. The preparation method for the precursor comprises the steps of (1) mixing a molybdenum source with water, reacting for 30-240 minutes at 70-90DEG C, and adding inorganic acid; (2) adding polycarbon alcohol into P2S5 in 5-15 minutes at 50-80DEG C, and reacting for 1-3 hours at 70-100DEG C; (3) adding the product of step (2) into the product of step (1), adding resin, and reacting for 4-8 hours at 70-110DEG C; (4) separating oil phase from the product of step (3) so as to obtain the target product. The precursor can form MoS2 active components through self sulfurization and in situ decomposition, is used in slurry reactor hydrocracking of poor heavy oil with high content of metal, carbon residue and sulfur, and can lower the yield of coke and keep a device to run for a long period.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-temperature oil-soluble temporary plugging agent and preparation method thereof

The invention relates to a high-temperature oil-soluble temporary blocking agent. The high-temperature oil-soluble temporary blocking agent is characterized by comprising the following components in percent by weight: 10-40% of asphalt, 20-50% of C9 petroleum resin, 15-50% of coumarone resin, 5-15% of a surfactant, 2-15% of a polymer fiber and 1-10% of a softening-point additive. The preparation procedures of the high-temperature oil-soluble temporary blocking agent are as follows: firstly, adding the asphalt into a reactor, heating to melt the asphalt, adding the C9 petroleum resin and the coumarone resin into the reactor, stirring continuously until the substances in the reactor are fully melted, continuously adding the surfactant, the polymer fiber and the softening-point additive into the reactor, stirring for 30 minutes to mix uniformly, stopping heating a mixture, cooling, then collecting particles, washing, and screening to obtain the high-temperature oil-soluble temporary blocking agent with different particle sizes. The high-temperature oil-soluble temporary blocking agent provided by the invention overcomes the defect that the traditional oil-soluble temporary blocking agent can not resist high temperature. The high-temperature oil-soluble temporary blocking agent has good oil solubility, acid and salt resistance and high-temperature degradation resistance. The added softening-point additive is capable of regulating the range of the softening point, and thus an oil layer can be protected.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Long-acting emulsion-type antirust fluid

InactiveCN101608310AGood oil solubilityGood water solubilityDiethylene glycol monobutyl etherBarium salt

The invention relates to a long-acting emulsion-type antirust fluid used for metal rust prevention. Every 100 parts of the antirust fluid include the following components according to parts by weight: 3-15 oil soluble surfactant, 1-10 alcohol ether type couplant, 1-10 oily-type rust preventive and the balance base oil, wherein the oil soluble surfactant is any one of petroleum sodium sulfonate with molecular weight ranging from 300 to 800, sodium heavy alkylbenzene sulfonate and sodium sulfanilate, the alcohol ether type couplant is any one of ethyl alcohol, ethyl ether, butyl ether, diethylene glycol monobutyl ether, diethylene glycol propyl ether, butyl glycol ether and ethylene glycol propyl ether, the oily-type rust preventive is any one of barium petroleum sulfonate, dinonyl naphthalenesulfonic acid barium salt and barium soap of petroleum ester oxide, and the base oil is any one of cycloalkyl base oil and paraffin base oil. The long-acting emulsion-type antirust fluid has the advantages of meeting the demands of short-term rust prevention of metal and having lower using cost.

Owner:NANJING KERUN LUBRICANTS

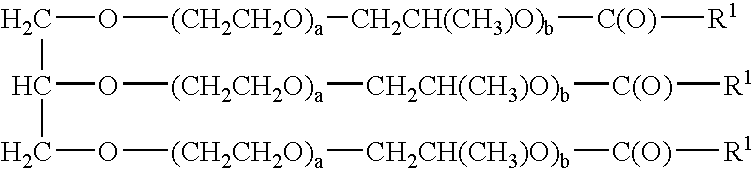

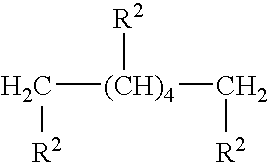

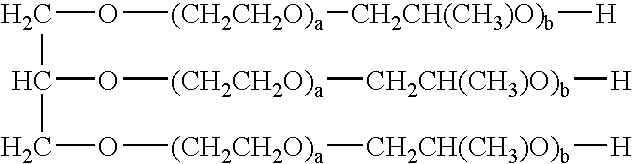

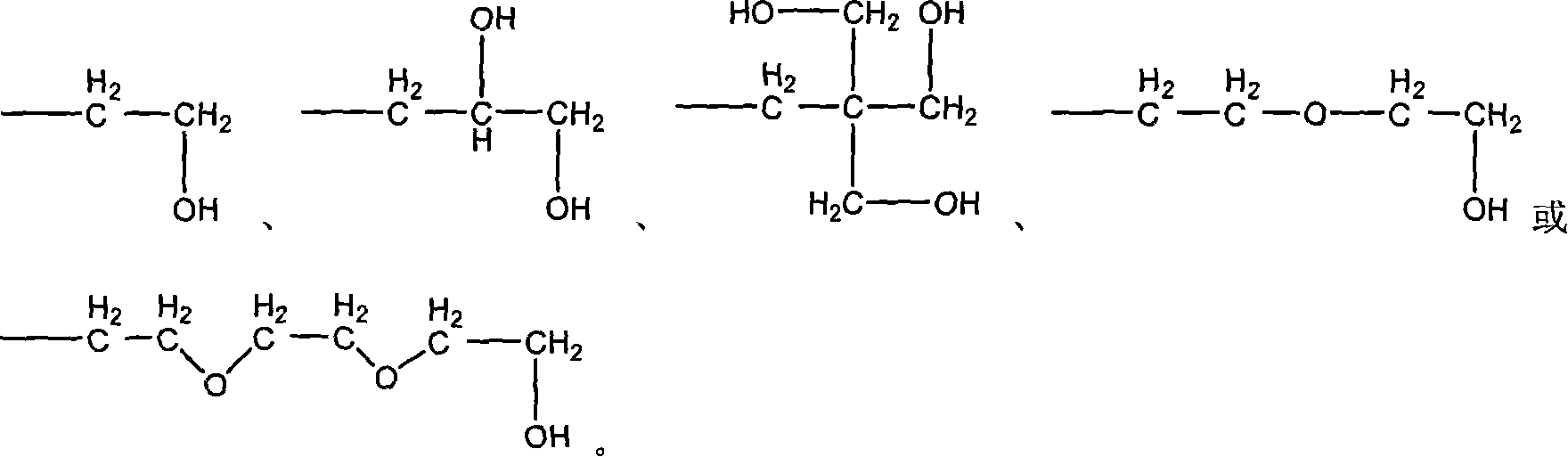

Spider esters in personal care applictions

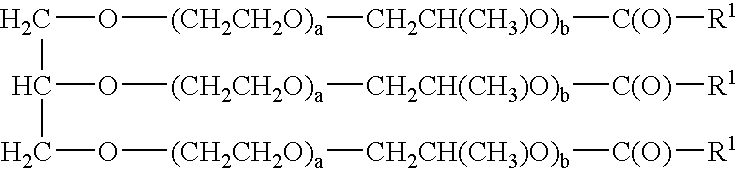

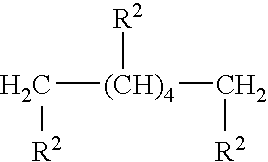

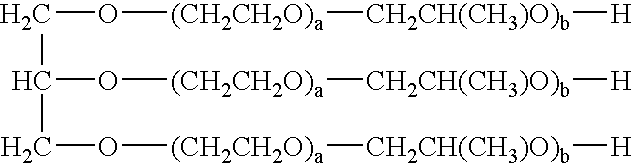

The present invention is drawn to a process for providing emolliency to the skin using a series so called “spider esters”. These esters are derived from poly-hydroxy functional compounds sequentially reacted with ethylene oxide or propylene oxide, followed by the reaction of the alkoxylate with fatty acid. The resulting products are called spider esters because they resemble the spider, wherein appendages are alkoxylated esters. The restrictions this orientation imposes on rotation allows for the preparation of polar esters that have little or no water solubility, and provide both moisturization to the skin and emolliency by reducing transepidermal water loss.

Owner:SURFATECH

Wear repairing lubricating agent composition containing sheet silicate mineral substances and preparation method thereof

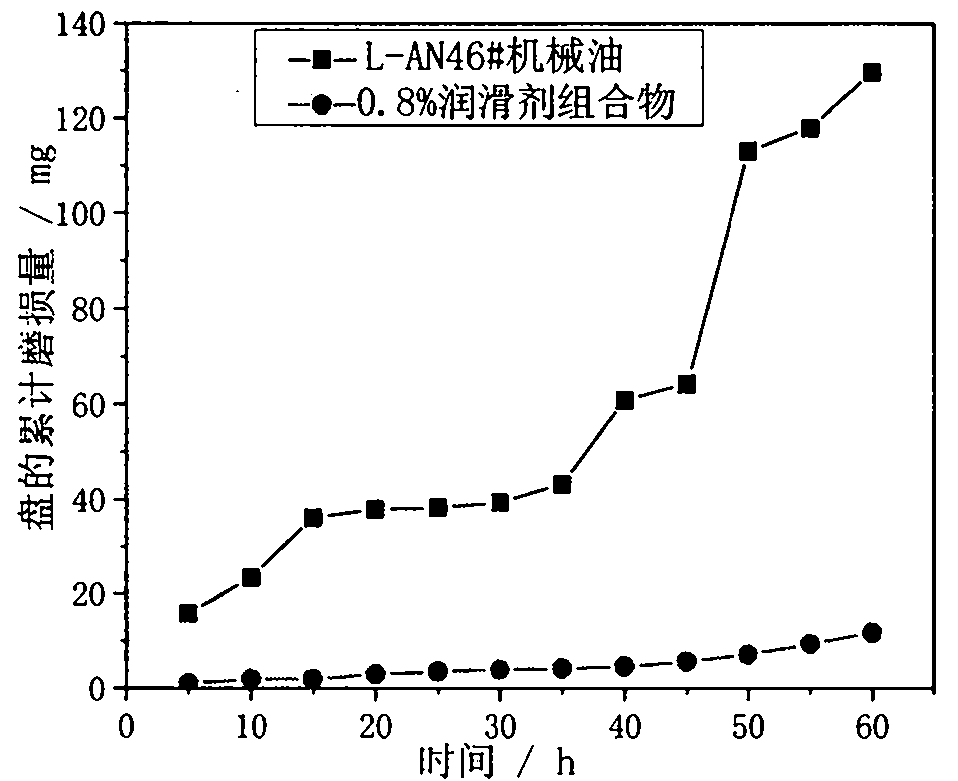

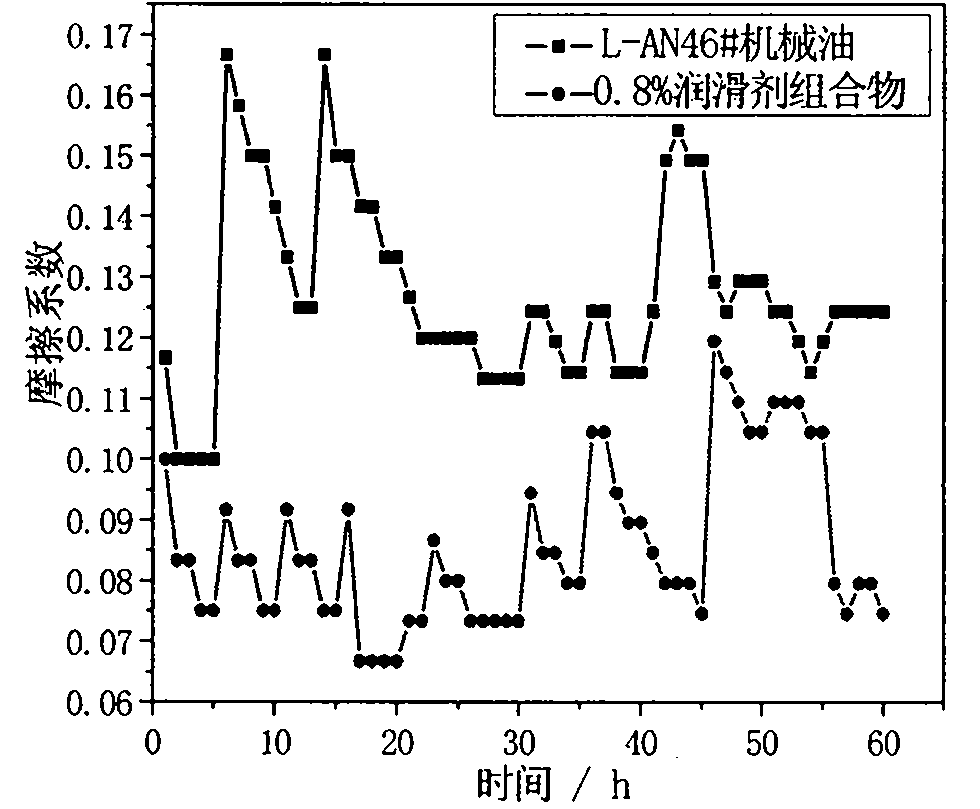

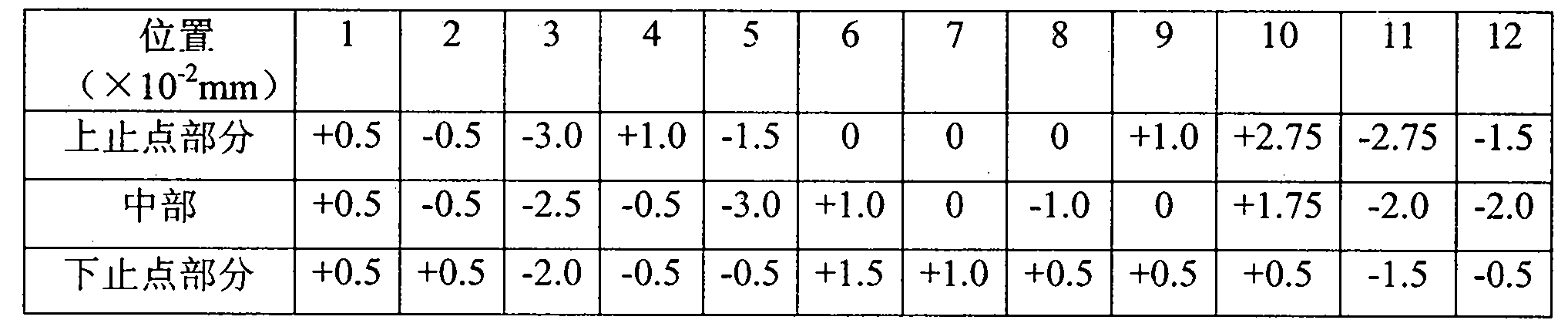

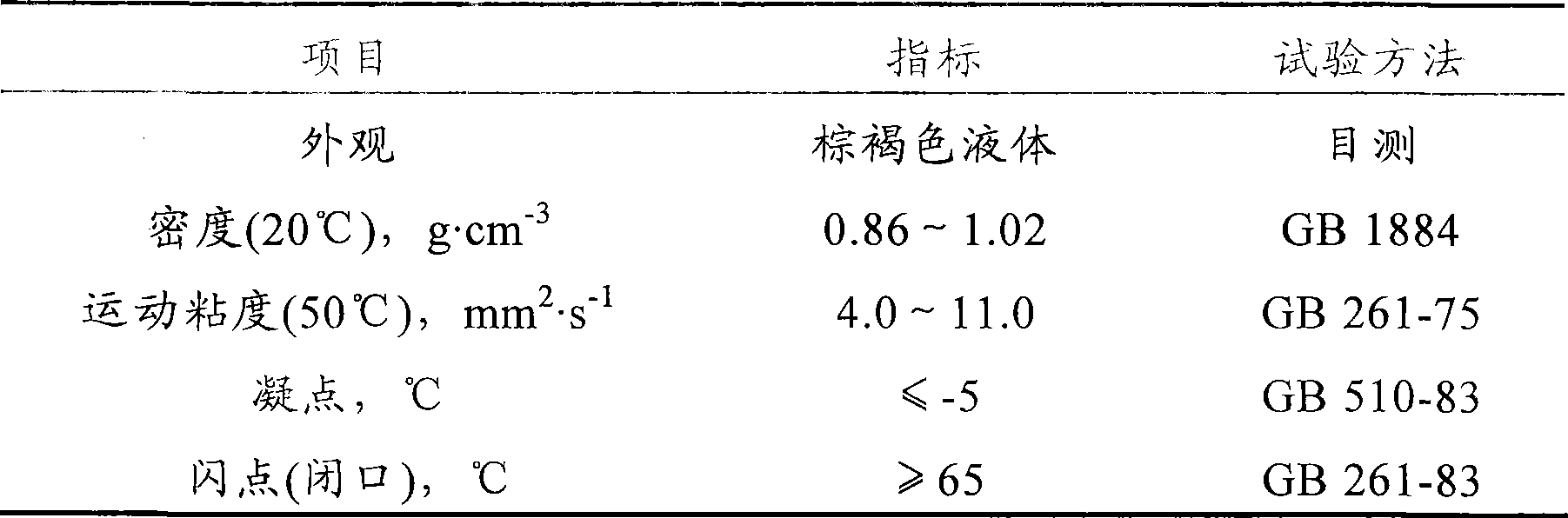

The invention relates to a wear repairing lubricating agent composition containing sheet silicate mineral substances and a preparation method thereof. The lubricating agent composition provided by the invention comprises the following components in percent by mass: 10-20 percent of sheet silicate mineral substances, 0.1-5 percent of surface modifying agent, 0.1-5 percent of metal catalytic object, 1-10 percent of performance regulating agent composition and 70-80 percent of base lubricating agent. The preparation method comprises the steps of: mixing and grinding the sheet silicate mineral substances according to the proportion, preferably, sheet silicate mineral substances with granularity D90 of not more than 3mu m; and then adding in a base lubricating agent prepared from a surfactant, the metal catalytic object and the performance regulating agent in different proportions, and grinding. The using method is as follows: 0.2-1 wt percent of the wear repairing lubricating agent composition is added in the traditional lubricating agent system of equipment. The lubricating agent composition provided by the invention has better self-repairing effect and remarkable energy-saving and consumption-reducing effect; and due to a repairing layer formed on the surface through friction, the hardness of a matrix is improved, and the roughness is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

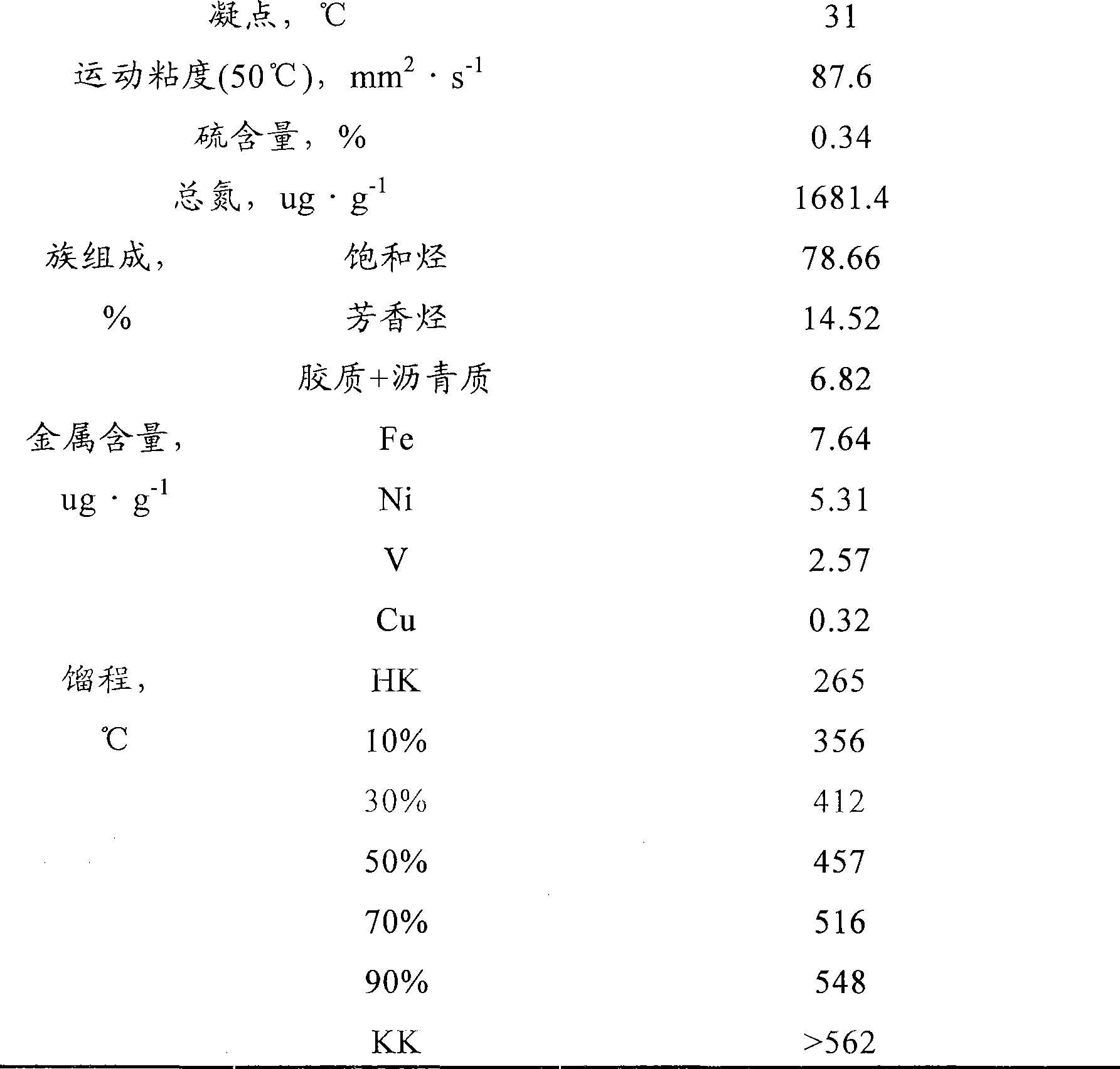

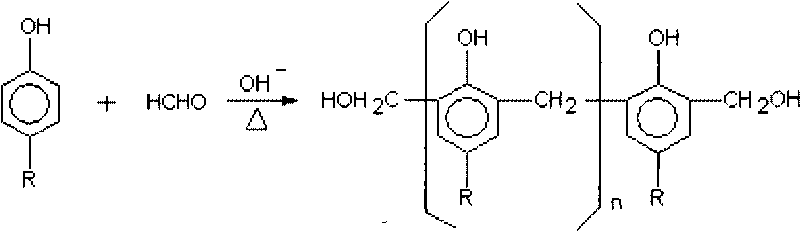

Vegetable oil modified rosin phenolic resin and preparation method thereof

The invention discloses vegetable oil modified rosin phenolic resin and a preparation method thereof. Alkyl phenol reacts with formaldehyde under an alkaline condition to obtain an alkyl phenol resin condensation compound; molten rosin and vegetable oil are firstly used to conduct a Diels-Alder addition reaction; then the alkyl phenol resin condensation compound is dripped into a reaction product of the molten rosin and the vegetable oil to conduct a Diels-Alder addition reaction; and finally, after a final reaction product is esterified, the vegetable oil modified rosin phenolic resin is prepared. The preparation method has the advantages that through the Diels-Alder reaction of the rosin and the vegetable oil, an aliphatic chain is led to a molecular structure, so that the solubility of the rosin phenolic resin in mineral oil is effectively improved, and a softening point of the resin is guaranteed at the same time; the n-heptane accommodation degree is larger than or equal to 20mL / 2g and the acid value is smaller than or equal to 25mgKOH / g, so that the vegetable oil modified rosin phenolic resin can serve as matrix resin of heat-set ink and satisfies the requirements of fast drying, high gloss, demulsibility, and the like of the heat-set ink.

Owner:山西省应用化学研究所

Catalytic cracking multifunctional strengthened additive

The invention provides multifunctional catalytic cracking strengthening additive which comprises a rare earth organic compound, heteropoly acid (and salt thereof), chemical inhibitor, solvent, and the like and has the functions of resisting oxidation and preventing from scorch, dispersing, increasing the acid center, passivating the metal, and the like. When being added into a catalytic cracking lifting pipe reactor, the multifunctional catalytic cracking strengthening additive can inhibit the generation of secondary reaction such as thermal cracking reaction, dehydrogenation condensation reaction, and the like, reduces the generation of side products of net gas, coke, hydrogen, and the like, and improves the yield coefficients of products with high added values, such as liquid gas (especially propylene), gasoline and diesel. The catalytic cracking strengthening additive has the function of metal deactivator and can replace the metal deactivator, therefore, the metal deactivator needs not to be added after the catalytic cracking strengthening additive is added. The invention has the function of resisting oxidation and preventing from scorch, can inhibit a lifting pipe and a settling vessel from being coked and prevent a reaction system from scale deposit, thereby being multifunctional catalytic cracking strengthening additive.

Owner:河北鑫泰精细化工有限公司

Preparation method of rosin modified phenolic resin

The invention relates to a preparation method of a rosin modified phenolic resin. The method comprises the following three steps of reactions: 1. performing condensation of tert-butylphenol, bisphenol A, tung oil and solid formaldehyde under the action of catalyst magnesium acetate and lime to generate polymer of hydroxymethyl tert-butylphenol; 2. performing an addition reaction with rosin to generate an addition product; and 3. performing esterification of the addition product, pentaerythritol and glycerin under the action of catalyst zinc chloride to generate the rosin modified phenolic resin. The preparation method adopts proper raw material proportioning, reaction temperature, reaction time, catalyst and other technical conditions, thus during the production process, the resin viscosity can be effectively controlled, and the operation is simple and flexible and has good effect. The quality of the product is increased, the oil solubility of resin is good, the oil medium viscosity is high, the normal heptane capacity is 4.5ml / g or more; and the prepared paint film ink has good water resistance and alkali resistance, high hardness, excellent anti-after-binding performance, quick-drying performance, lightness and strong adhesive force. Therefore, the preparation method of the invention is applicable to industrial production.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

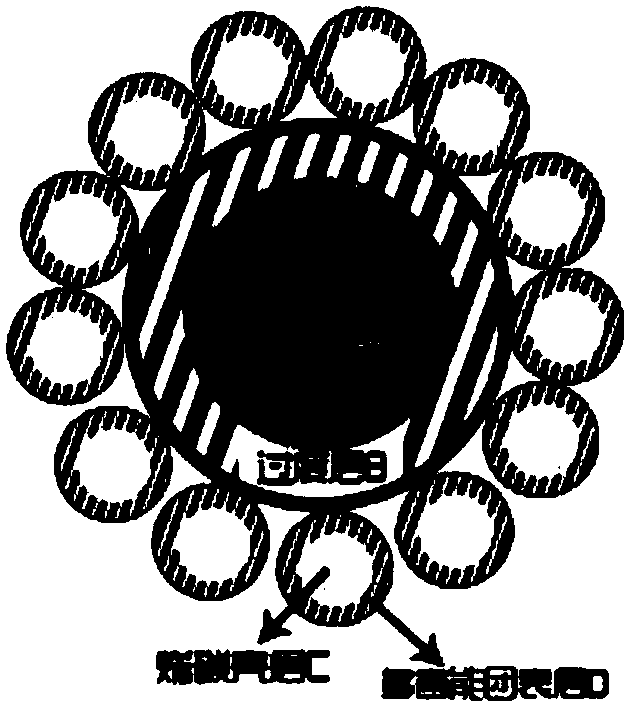

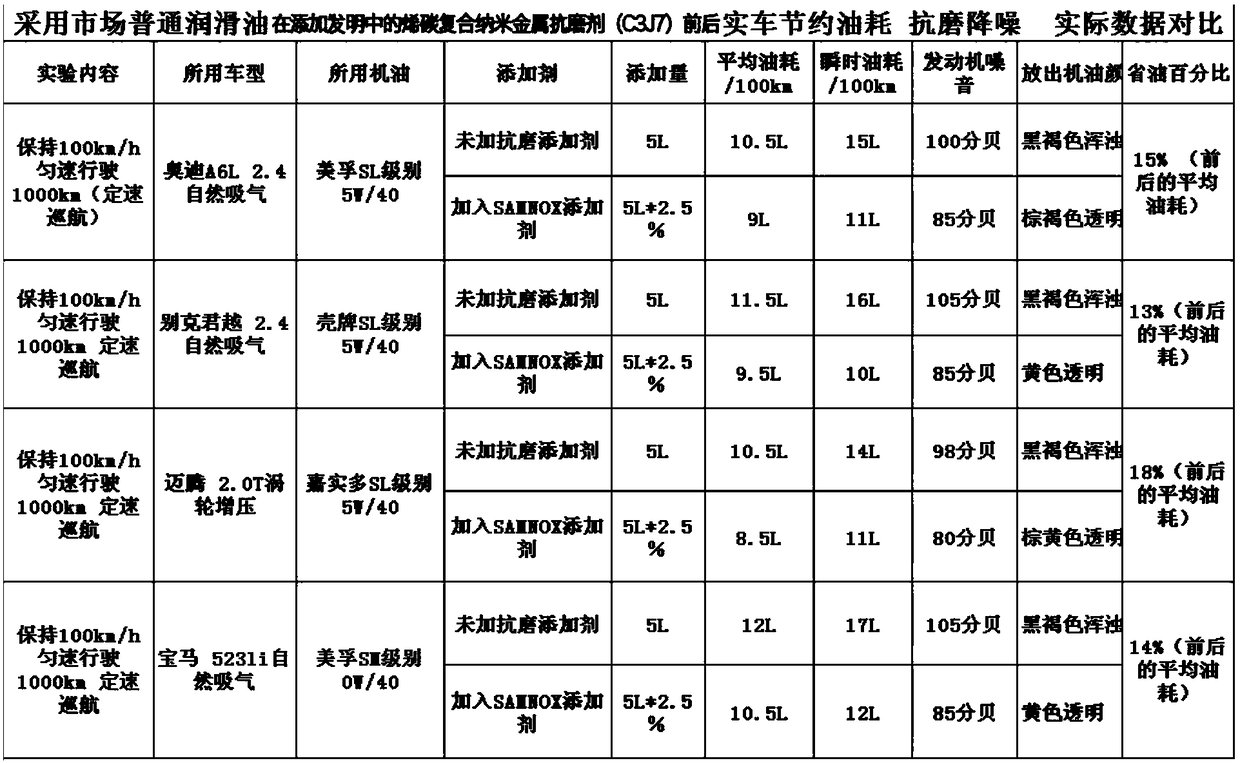

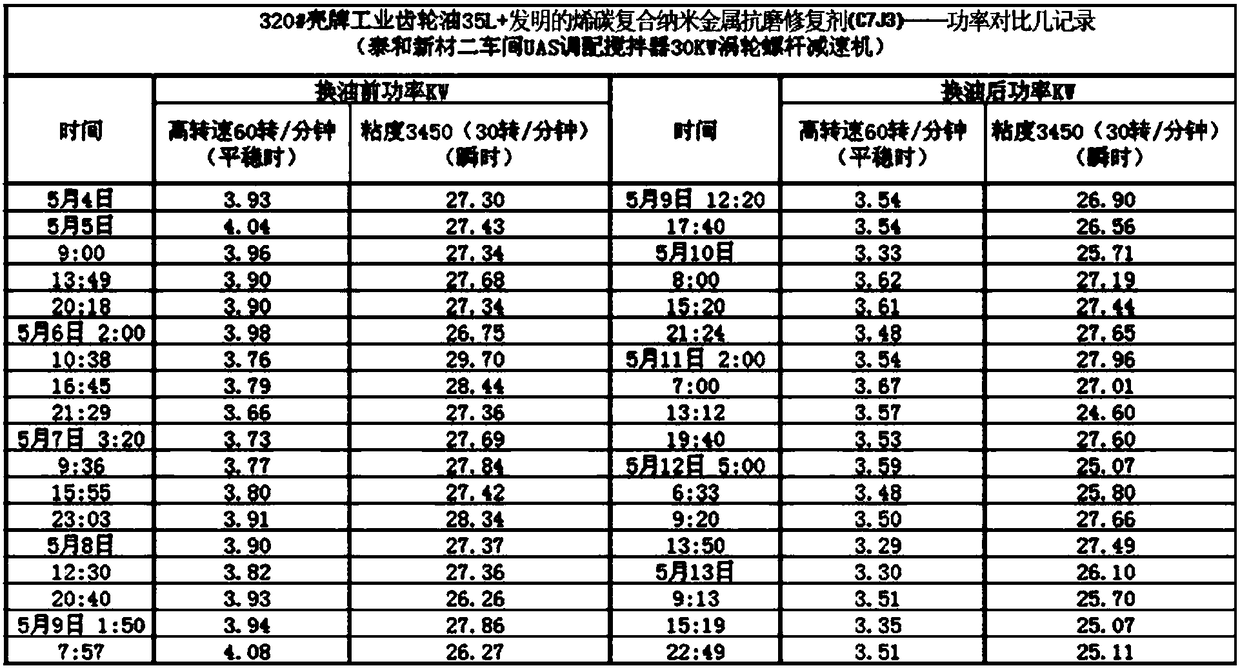

Olefinic carbon compound nanometer soft metal wear-resistant self-repairing material with surface modification, and preparation method thereof

ActiveCN108148652AImprove anti-wear performanceAchieve super lubricityAdditivesWear resistantLubrication

The invention relates to an olefinic carbon compound nanometer soft metal wear-resistant self-repairing material with surface modification, and a preparation method thereof. A nanometer olefinic carbon material with wear-resistant performance and a nanometer metal material with an abrasion repairing function are subjected to in-situ composite preparation with a sol-gel method, so that the materialhas dual functions of abrasion resistance and reduction and abrasion self-repairing, and the advantage complementation mechanism of the synergetic effect and the performance of different types of nanometer materials is performed. The olefinic carbon compound nanometer soft metal wear-resistant self-repairing material prepared with the preparation method can be used for realizing the breakthroughof 'exponential increase of wearing resistance under extreme pressure', 'zero abrasion of metal friction' under an extreme pressure situation is broken through, true super lubrication under the extreme pressure situation is realized, traditional sulfur-phosphorus-containing liquid lubrication performance and application technologies are subjected to revolutionary changes due to the occurrence of olefinic carbon compound wear-resistant energy-saving materials, the material does not contain caustic organic sulfur and phosphorus compound, wear-resistant performance is improved, and wear reductionenergy saving performance is also improved.

Owner:烟台华恒节能科技有限公司

Method for preparing high-alkali value (TBN300) synthesized calcium alkyl benzene sulfonate

ActiveCN101318916AThe overall performance of the product is goodSimple processAdditivesSulfonic acid preparationCarbonationSolvent

The invention provides a method for preparing high base number (TBN300) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture ofpolyisobutylene succinic anhydride and alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and refining the product to produce high base number synthetic alkyl-benzene sulfonate with a total base number (TBN) of 300mgKOH / g. The product is divided into high-base number (TBN300) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The method has the advantages of simple process, low cost, high yield and excellent economical efficiency; the product has the advantages of low viscosity, small turbidity, easy filtration, excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability; and when the product is used to prepare lubricant, the comprehensive performance of the lubricant can be improved, the service life of an engine can be prolonged, and environmental pollution can be reduced.

Owner:JINZHOU DPF TH CHEM CO LTD

Thick oil-soluble viscosity reducer and preparation method thereof

The invention relates to a thick oil-soluble viscosity reducer which is applied to viscosity reduction of crude oil in an oilfield and is characterized by comprising the following components in parts by mass: 15-25 parts of quaternary copolymer as a main agent, 2-3 parts of Span-80 and 1-2 parts of organic silicon surfactant serving as auxiliary agents, and 35-65 parts of petroleum solvent naphtha and 5-15 parts of benzene solvent serving as solvents, wherein the quaternary copolymer is a copolymer of long-chain alkyl methacrylate, styrene, N,N-bis(methacryloyl) diamine and maleic anhydride. The thick oil-soluble viscosity reducer has the effects of good viscosity reducing effect, no pollution and obvious economic benefit, and greatly saves the dosage of thin oil; and the viscosity reducing rate to thick oil with temperature of 50 DEG C and viscosity of 50000-600000 mPa s is more than 99% when the dosage of the viscosity reducer is 500-3000 ppm.

Owner:PETROCHINA CO LTD

Spider esters in personal care applications

The present invention is drawn to a process for providing emolliency to the skin using a series so called “spider esters”. These esters are derived from poly-hydroxy functional compounds sequentially reacted with ethylene oxide or propylene oxide, followed by the reaction of the alkoxylate with fatty acid. The resulting products are called spider esters because they resemble the spider, wherein appendages are alkoxylated esters. The restrictions this orientation imposes on rotation allows for the preparation of polar esters that have little or no water solubility, and provide both moisturization to the skin and emolliency by reducing transepidermal water loss.

Owner:SURFATECH

Sulfur-phosphor-free oil-soluble organic molybdenum additive

The invention relates to a sulfur-phosphor-free oil-soluble organic molybdenum additive. A technical scheme adopted in the invention is that a preparation method of the additive comprises the following steps: 1, placing castor oil and diethanolamine in a container, reacting for 4-5h under conditions that the temperature is 90-100DEG C and the pressure is a negative pressure, adding oleic acid, and reacting for 2-4h to obtain mixed castor oil amide and oleic acid amide; and 2, mixing the prepared mixed castor oil amide and oleic acid amide with ammonium molybdate, uniformly stirring, adding hydroxyethyl ethylenediamine, reducing the pressure to 13.33-20KPa at 70-80DEG C, reacting for 4-5h, adding polyethylene glycol to wash, separating out a transition layer, cooling the transition layer, and filtering to obtain the brown-red sulfur-phosphor-free oil-soluble organic molybdenum additive. In the additive, the molybdenum content is 7.5%, and the nitrogen content is 3.5%. The production method of the invention has the advantages of simplicity and low cost; and the product (the additive) has the advantages of stable molybdenum structure, good oil solubility, high yield and environmentalprotection.

Owner:王严绪

Resource recycling application of heavy metals in wastewater

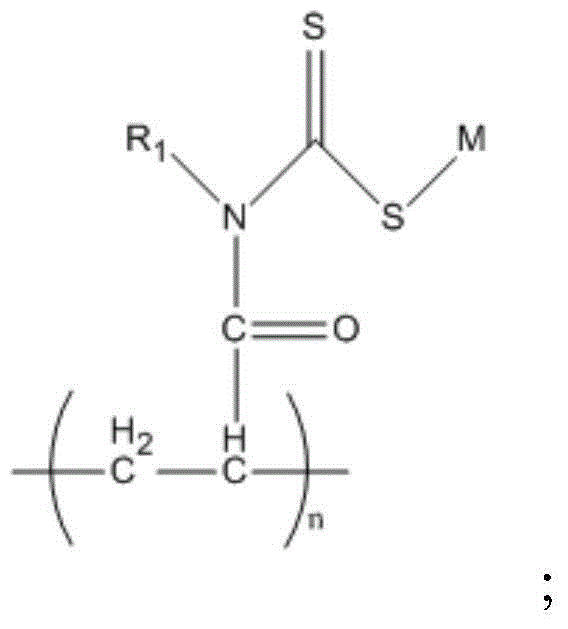

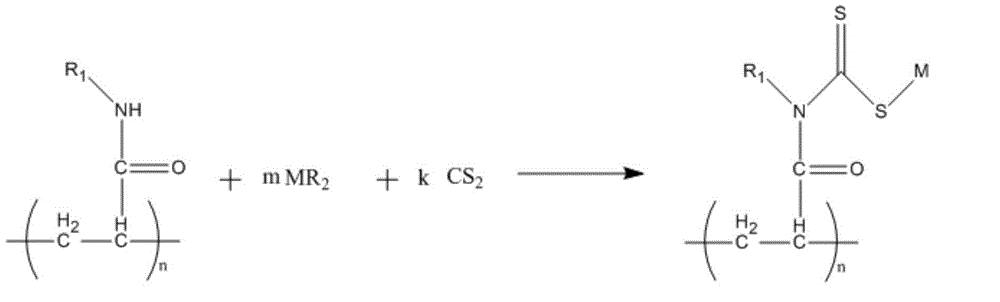

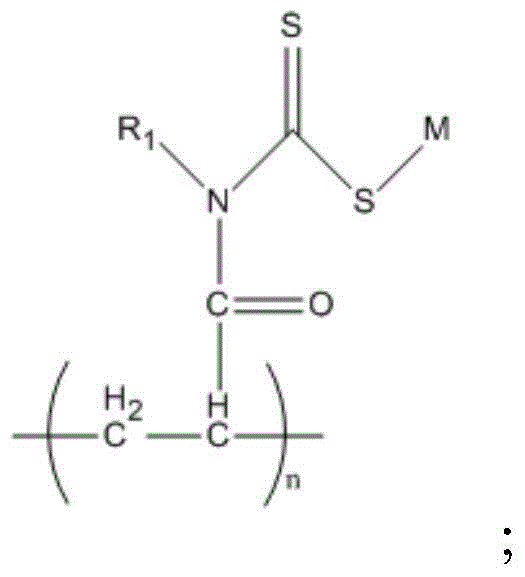

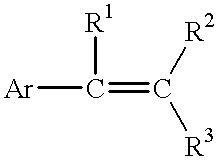

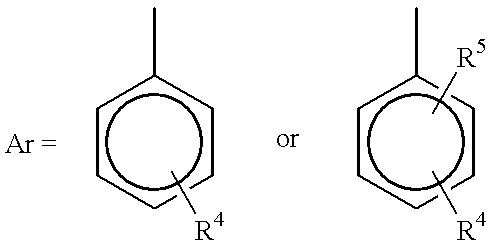

InactiveCN104558324AEasy to separate and recycleGood oil solubilityWater/sewage treatment by flocculation/precipitationCross-linkAryl

A heavy metal ion recycling agent is characterized by comprising a compound represented as a structural formula shown in the specification, wherein R1 is selected from an alkyl group, a derivative of the alkyl group, an amino group, a derivative of the amino group, an aryl group and a derivative of the aryl group, and the number of hydrogen atoms in the components and the number of carbon atoms in the components are smaller than 6; n is an integer larger than or equal to 50; M adopts K, Na, Li or NH4. The heavy metal ion recycling agent in water can form a stable heavy metal ion chelate in a cross-linked network shape with divalent and / or trivalent heavy metal ions, and flocculent precipitate is formed to facilitate separation and recycling, that is, the heavy metal ions in the wastewater can be recycled. Besides, the wastewater containing the heavy metal ions can be discharged up to the standard, and heavy metal can be recycled from the separated heavy metal ion chelate after reduction treatment.

Owner:上海源育节能环保科技有限公司

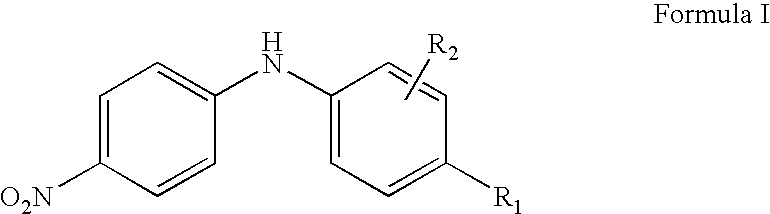

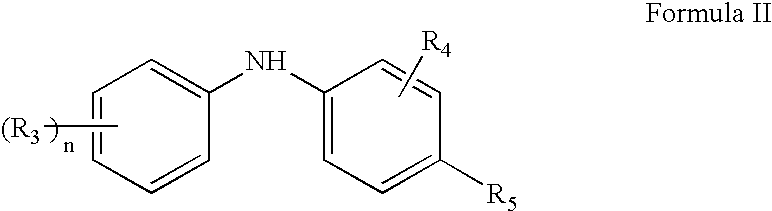

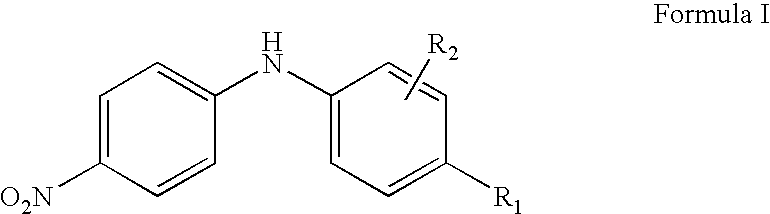

Synergistic lubricating oil composition containing a mixture of a nitro-substituted diarylamine and a dairylamine

ActiveUS20080318815A1Oxidative stability be improveImprove performanceOrganic chemistryProtective coatings for layersChemical compositionViscosity

Disclosed is a lubricating oil composition containing an oil of lubricating viscosity and a particularly effective mixture of a nitro-substituted diphenylamine and a diarylamine which together provide superior oxidation inhibition.

Owner:CHEVRON ORONITE CO LLC

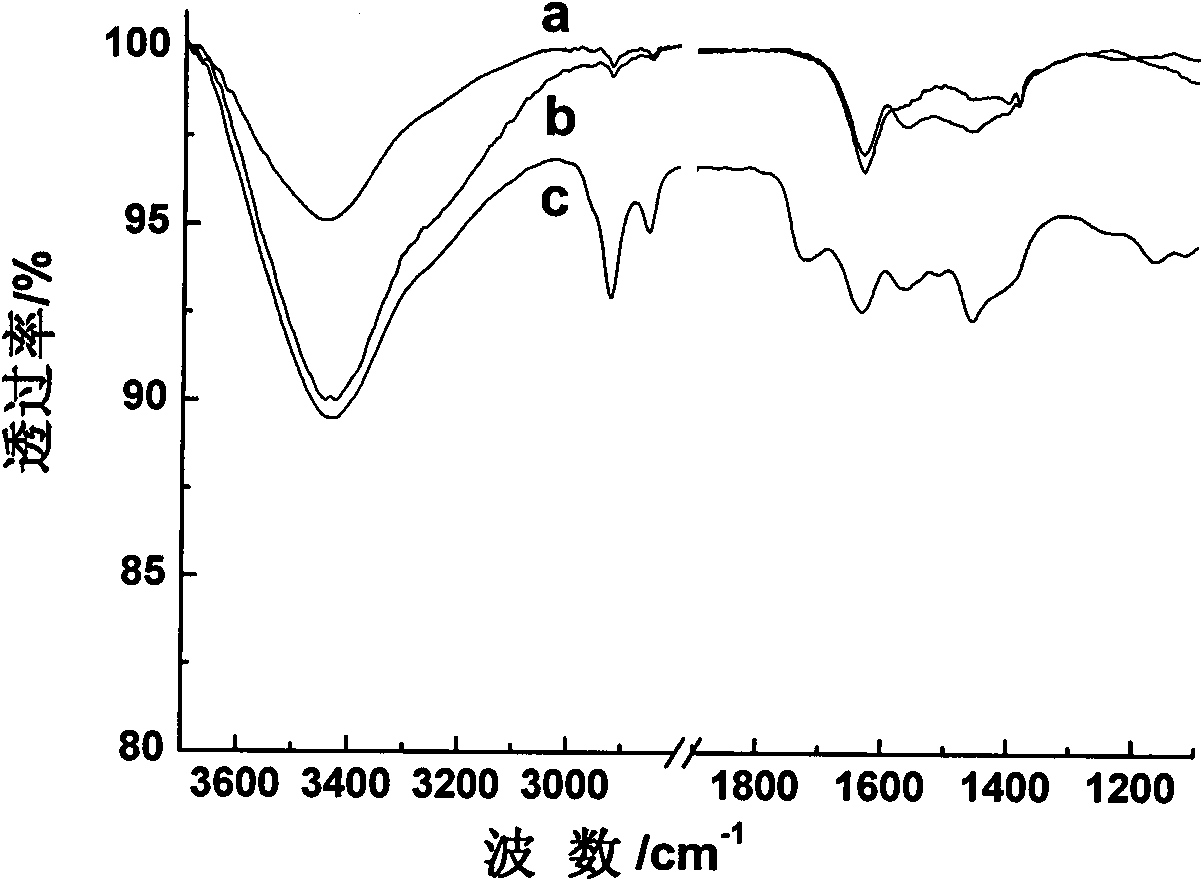

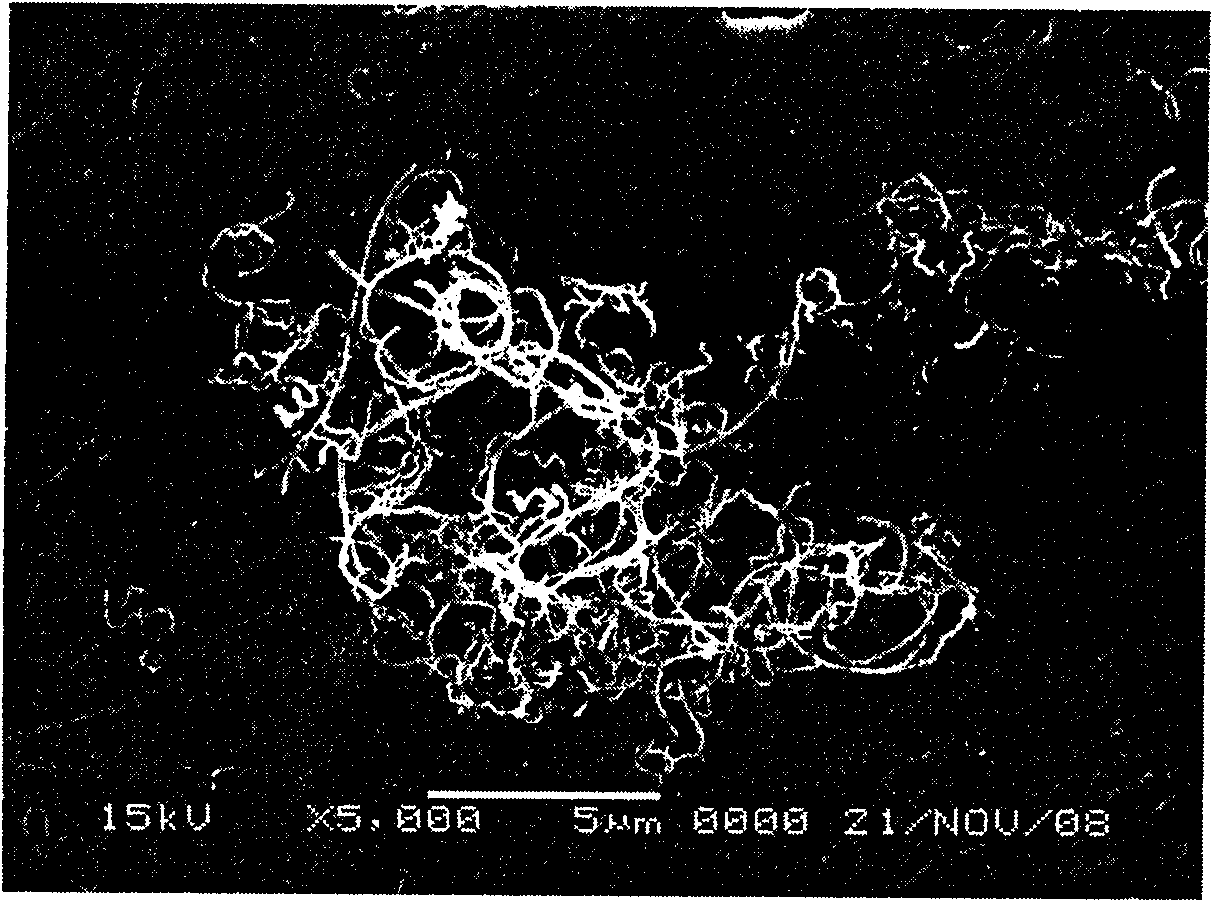

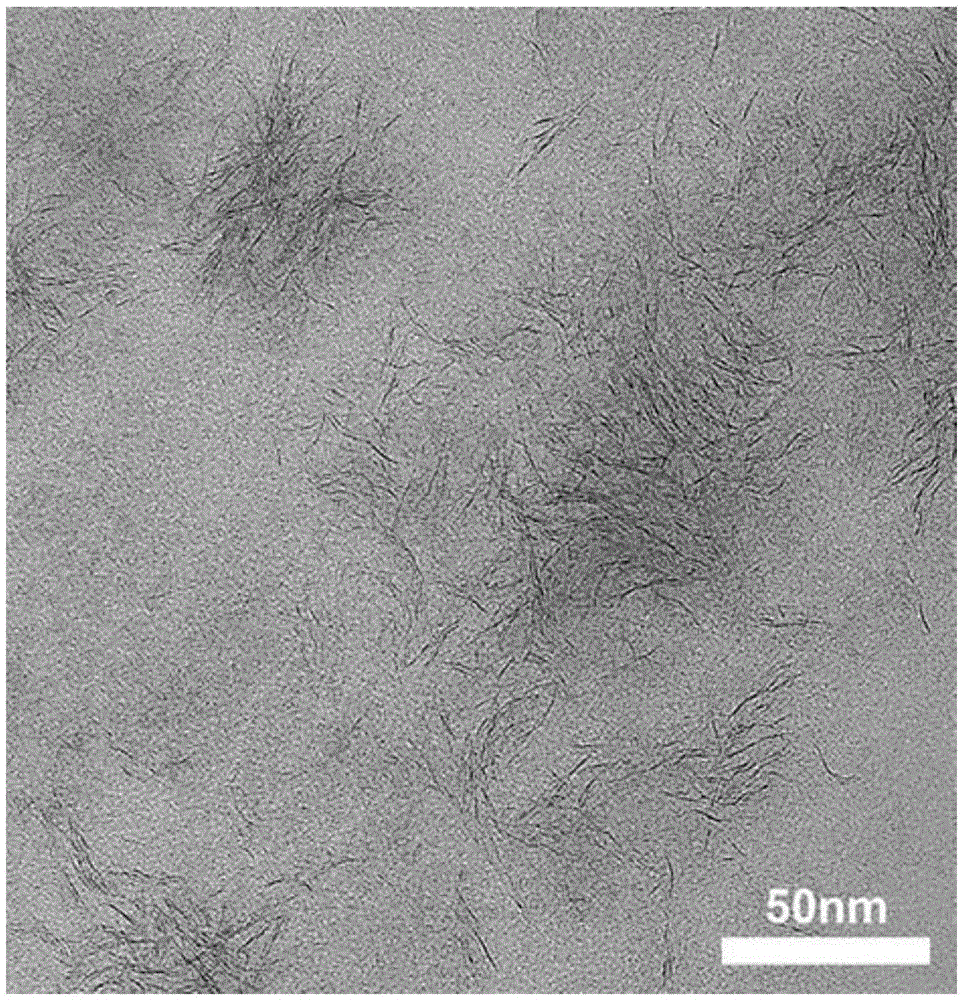

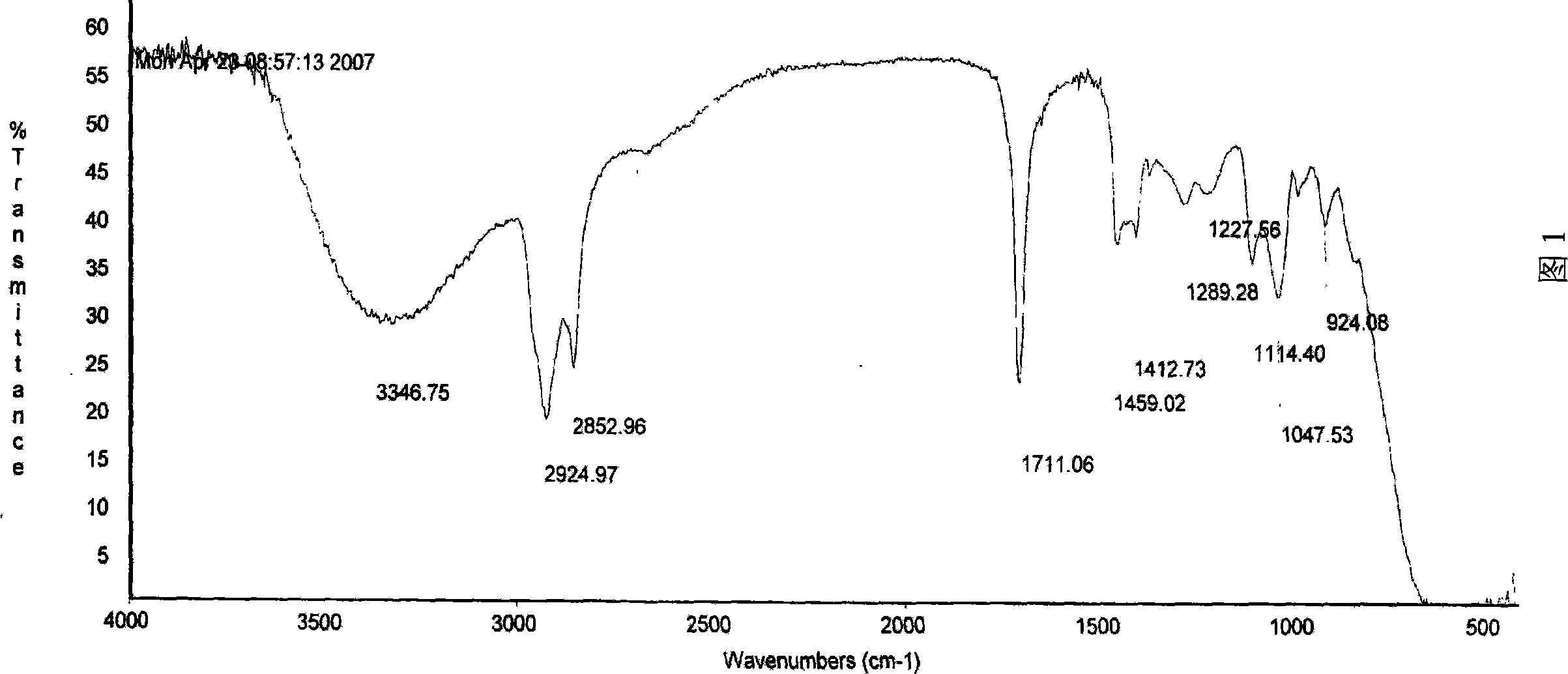

Method for preparing carbon nanotube grafted with vinyl macromolecular chain on the surface

The invention provides a method for preparing carbon nanotube grafted with vinyl macromolecular chain on the surface. The method is characterized in that carbon nanotube is processed by Fenton reagent formed by soluble ferrous salt and oxyful, so as to realize surface hydroxylation; a coupling agent containing unsaturated double bond functional groups is used for surface treatment; and the carbon nanotube of which the surface is provided with double bonds, and vinyl monomer are processed by graft polymerization reaction to obtain the carbon nanotube grafted with vinyl macromolecular chain on the surface. The method has the advantages of environmental protection, high efficiency, low cost and simple process, and is suitable for industrial production. The obtained functionalized carbon nanotube has excellent oil solubility or water solubility, vinyl monomer used for graft is adjusted to realize that the carbon nanotube can be endued with favorable dispersibility in a majority of polymer materials and higher interfacial function which mainly depends on chemical bonds can be formed by the carbon nanotube and the polymer materials, and therefore, the excellent performances of the carbon nanotube can be fully utilized to prepare high performance or functionalized polymer composite materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Natural antioxidant and preparation method natural antioxidant

InactiveCN103767042AGood oil solubilityGood application effectFood ingredient as antioxidantFood preservationSolubilityNatural product

The invention relates to the field of aseptic techniques of foods and particularly relates to a natural antioxidant used in grease and fat-rich foods and a preparation method of the natural antioxidant. The natural antioxidant comprises the following components in percentage by weight: 77.5%-85% of a natural product, 13.0%-17.5% of a solvent and 2.0%-8.0% of tea polyphenol. According to the preparation method, the tea polyphenol is compounded with one or more of lecithin or VE (vitamin E) or a rosemary extract when the primary biological activity of the tea polyphenol is maintained, and due to the integration of the formula, the oxidation resistance is enhanced; meanwhile, the oil solubility of the tea polyphenol is increased by virtue of the strong emulsifying capacity of the lecithin, so that the natural antioxidant reaches optimal dissolution and dispersing capacities in the grease and fat-rich foods, and the application effect of the tea polyphenol is improved.

Owner:GUANGDONG GUANGYI TECH IND

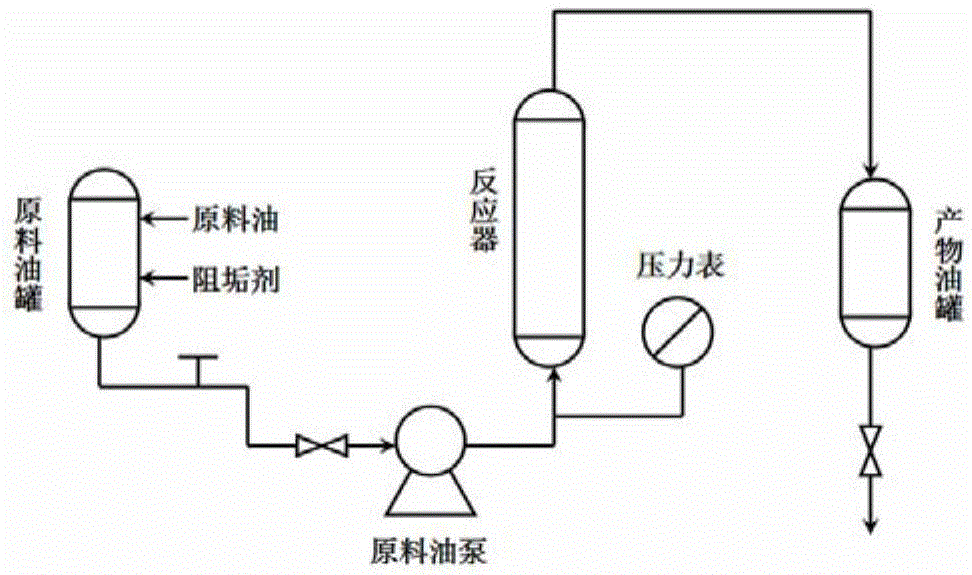

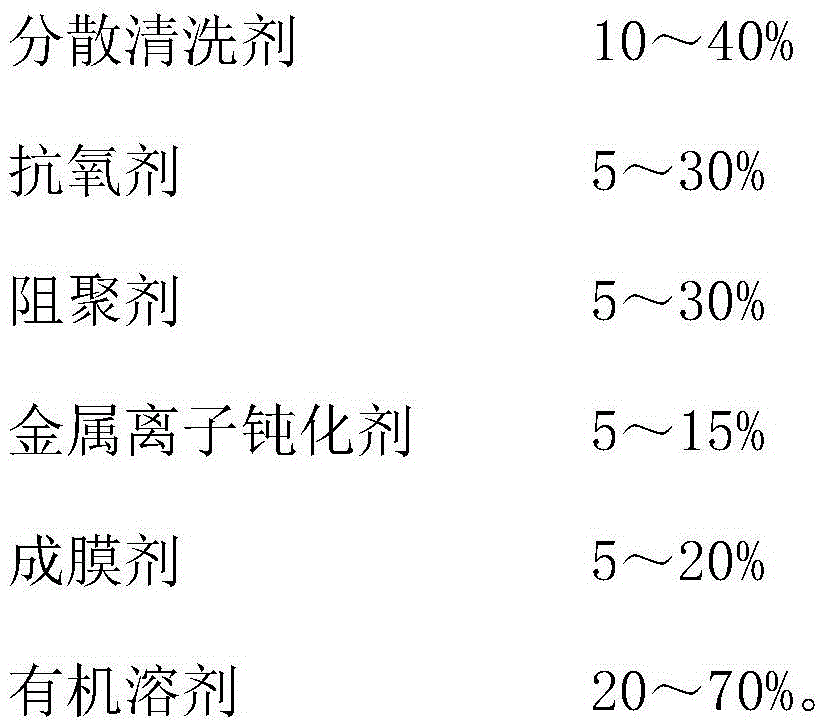

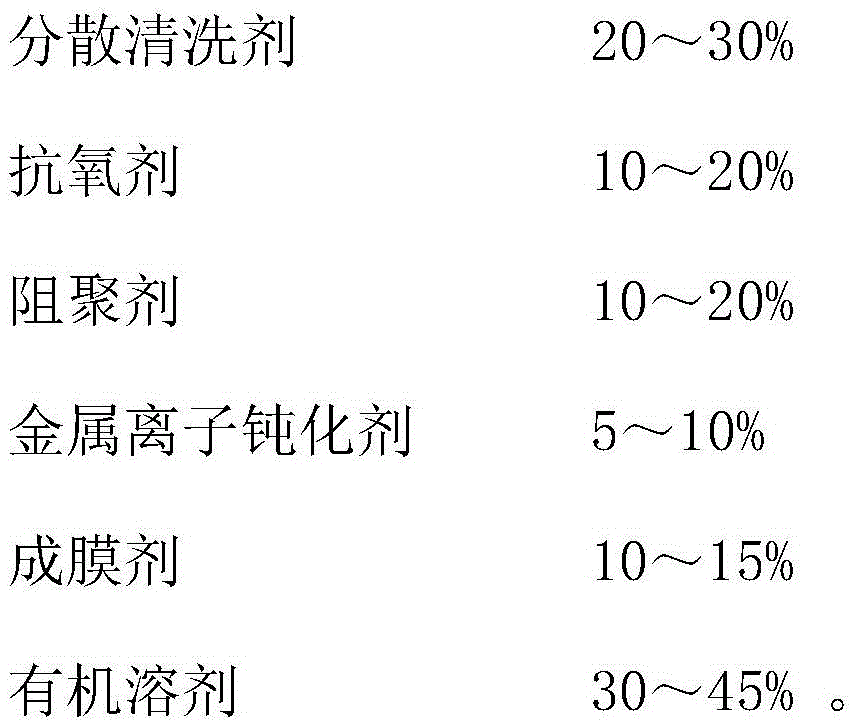

Scale inhibitor for oil refining technology process and preparation method thereof

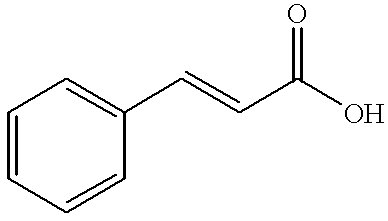

ActiveCN105482851AInhibition of polymeric foulingStrong scale resistanceTreatment apparatus corrosion/fouling inhibitionOrganic solventFuel oil

The invention relates to a scale inhibitor for the oil refining technology process. In order to provide an efficient environment-friendly scale inhibitor which is suitable for various oil refining technologies, the invention provides the scale inhibitor for the oil refining technology process. The scale inhibitor is characterized by being prepared from, by mass, 10%-40% of scattered detergent, 5%-30% of antioxygen, 5%-30% of polymerization inhibitor, 5%-15% of metal-ion passivator, 5%-20% of film-forming agent and 20%-70% of organic solvent, and the scale inhibitor is obtained by compounding all the substances. The scale inhibitor for the oil refining technology process has the advantages that the effect and the adaptability are strong, wherein the scattered detergent can scatter the scale inhibitor in the material, and the scale inhibitor is not prone to stick to and deposit on the surface of equipment; the stability is good, the scale inhibitor can still play a role under the high-temperature conditions such as heavy oil hydrogenation, therefore, polymerization and scaling of a hydrogenation system can be effectively inhibited, and long period operation of a device is guaranteed; elements of sulphur, phosphorus and the like are not contained, toxicity and undesirable odor do not exist, and pollution does not exist in the preparation and use process.

Owner:SHENZHEN GCD PETROLEUM ADDITIVE CO +1

Preparation of rosen modified mixed alkyl phenolic resin

The present invention belongs to the field of resin preparation technology that is a kind of connecting material to printing ink. It is obtained with processed by the following steps: arbitrarily mixing p-methyl hydroxybenzene, p-tert-butylphenol, p-tex-octylphenol and p-nonylphenol, making them produce reaction with formaldehyde to synthesize A-stage mixed alkyl phenolic resin, then using rosin to make modification and using polyhydric alcohol to make esterification. Said invention is easy to operate, safe, and its resin oil-solubility and fatty hydrocarbon solubility are good. Its colour islight and softening point is high. The printing ink made up by using said invented product does not skin, and possesses good printing property.

Owner:山西省应用化学研究所

Preparation method of diesel oil pour point depressant

InactiveCN106279514ALower condensation pointImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesMaleic anhydrideSolvent

The invention discloses a preparation method of a diesel oil pour point depressant. The method includes the following steps of firstly, weighing high alcohols, catalyst, polymerization inhibitor and solvent to be sequentially added into a reactor and stirred till solids are completely dissolved, then adding methacrylic acid, and conducting reduced pressure distillation, alkali washing and water washing on the product after reaction ends to obtain methylacrylic acid high-carbon ester; secondly, weighing methylacrylic acid high-carbon ester, maleic anhydride, initiator and solvent to be evenly mixed, conducting reacting at a certain reaction temperature under the protection of nitrogen, adding aromatic amine and catalyst after reaction, changing the reaction temperature for reaction for a certain period of time, conducting reduced pressure distillation on the reaction liquid after reaction ends, then adding an excessive amount of methyl alcohol to generate white precipitates, removing supernate, and conducting washing and vacuum drying on the obtained white precipitates through methyl alcohol to obtain the diesel oil pour point depressant. The prepared diesel oil pour point depressant can remarkably reduce the condensation point of diesel oil and improve the low-temperature flowability of diesel oil; the raw materials are easy to obtain, the synthesis method is simple, and the additive dosage is small.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

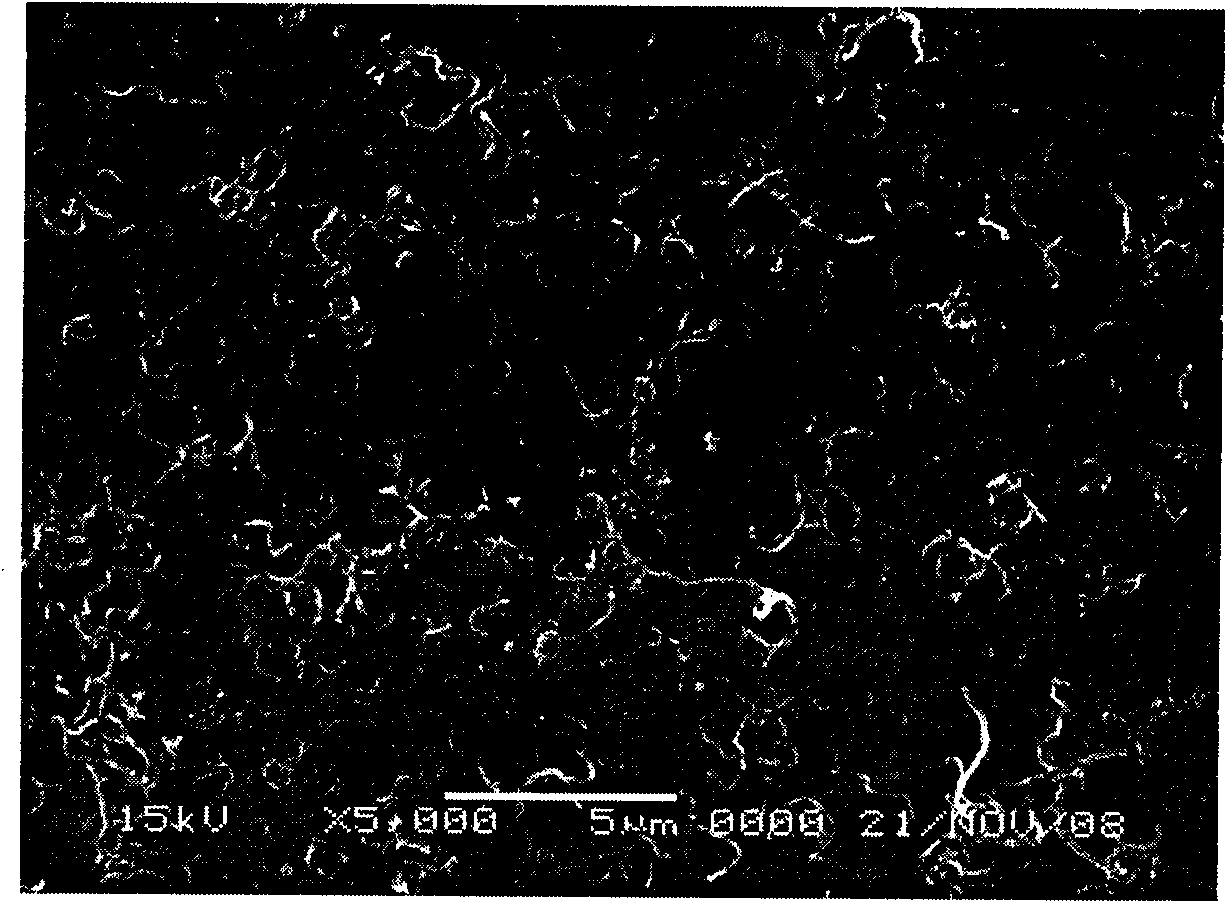

Oil-soluble temporary blocking agent and preparation method thereof

InactiveCN104831401AAdjustable lengthWidely distributedDrilling compositionMonocomponent polyolefin artificial filamentSolubilityAntioxidant

The present invention discloses an oil-soluble temporary blocking agent and a preparation method thereof, wherein a thermoplastic polymer or a mixture comprising a thermoplastic polymer and one or a plurality of materials selected from a surfactant, an antioxidant and a coupling agent is adopted as a spinning raw material and is subjected to melt electrospinning to prepare the oil-soluble temporary blocking agent. According to the present invention, the oil-soluble temporary blocking agent can be adopted as the temporary blocking agent so as to be applied in the petroleum extraction field, such that the purposes of low cost and complete petroleum extraction and no pollution are achieved; the average diameter of the obtained temporary blocking agent of the present invention is a few microns to tens of microns, even achieves the nano-scale, the distribution is wide, and the oil-soluble temporary blocking agent is suitable for various types of oil wells with complex structures, particularly the temporary blocking operation on the core with the small crack width; the oil-soluble temporary blocking agent has characteristics of high oil dissolution rate, water insolubility, acid insolubility, low residual pollution on stratum, high solubility in diesel fuel, and easy blocking releasing; and the preparation method has characteristics of easily available raw materials, simple preparation process, low cost, and good applicability.

Owner:BEIJING UNIV OF CHEM TECH

Process for reducing mono-functional and non-functional by-products during aralkylation of phenolics

Phenol aralkyistion polymers can be prepared by reaction among a phenolic monomer, at least one styrenic monomer and an aryl diolefin. A phenolic monomer can be initially aralkylated in the presence of an acid catalyst with a first portion of at least one styrenic monomer to obtain an aralkylated phenol. The aralkylated phenol thereafter can be reacted with an aryl diolefin to obtain a phenol aralkylation polymer. Optionally, (though preferably) the phenol aralkylation polymer is further aralkylated with a second portion of at least one styrenic monomer. By employing specific catalyst concentrations, reactant concentrations, reaction temperatures, and reaction times, the formation of mono-functional and non-functional by-products is substantially reduced.

Owner:GEORGIA PACIFIC CHEM LLC

Hydration degumming method for hot pepper extract

ActiveCN102492307ADegumming completelyEfficient removalNatural dyesFood preparationCapsicum extractHot peppers

The invention discloses a hydration degumming method for a hot pepper extract. The method comprises the following process steps of: (1) extracting hot pepper particles with solvent oil, and concentrating obtained mixed oil to obtain a crude hot pepper extract; (2) adding an ester solvent into the crude hot pepper extract, stirring, standing and separating to obtain an ester solvent layer, concentrating the ester solvent layer, and removing solvent residues to obtain a crude degreased hot pepper extract; (3) acidifying the crude degreased hot pepper extract with edible phosphoric acid or citric acid; and (4) degumming the acidified crude degreased hot pepper extract with a saline solution, and separating a lower layer colloid to obtain a degummed crude hot pepper extract. In the method, the hot pepper extract is treated with the ester solvent, and is acidified and degummed, so that the colloid in the hot pepper extract can be removed effectively.

Owner:CHENGUANG BIOTECH GRP CO LTD

Method for synthesizing ultrathin molybdenum disulfide nanocrystals

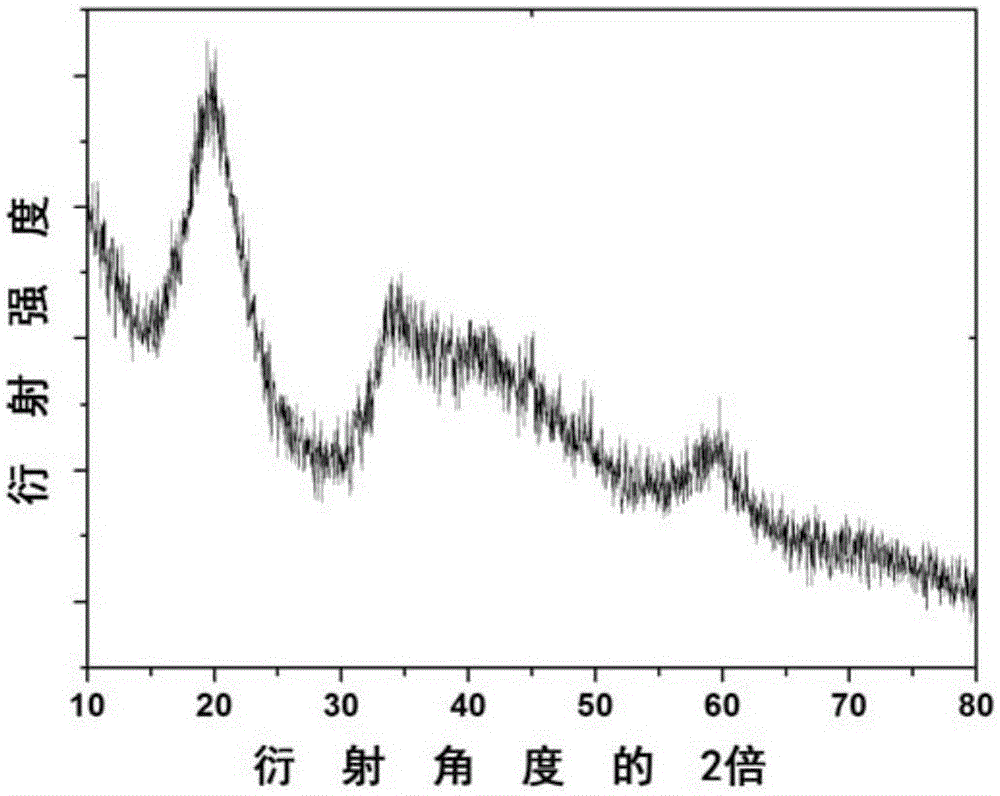

ActiveCN105060347ASimple processSmall sizeMaterial nanotechnologyMolybdenum sulfidesReaction temperatureSulfur containing

The invention discloses a method for synthesizing ultrathin molybdenum disulfide nanocrystals and belongs to the technical field of inorganic material preparation processes. According to the method, a molybdenum-containing inorganic salt and a sulfur-containing compound or sulfur powder are used as raw materials and have a reaction at the temperature of 160-300 DEG C for 30-120 min in a long-chain amine solvent and a long-chain fatty acid surfactant, experiment parameters such as the reactant molar ratio, the reactant concentration, the reaction temperature, the reaction time and the like are controlled, molybdenum disulfide nanocrystals which are well crystallized and have a few atomic layers (1-5 layers) are formed and can be well dispersed in a nonpolar solvent or base oil, and stable lubricating oil is formed. According to the method, raw materials are cheap and easy to obtain, the reaction time is short, the yield is high, instruments and equipment are simple, operation is convenient, safe and reliable, process repeatability is good, product quality is stable, and the method is suitable for industrial enlarged production.

Owner:TSINGHUA UNIV

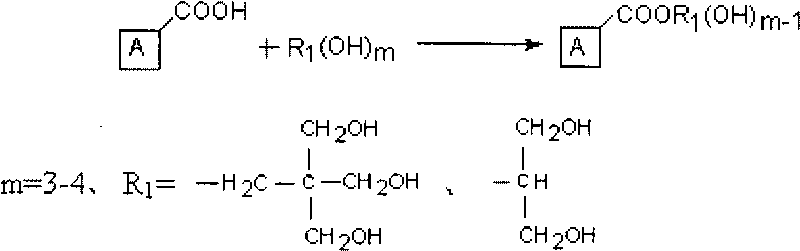

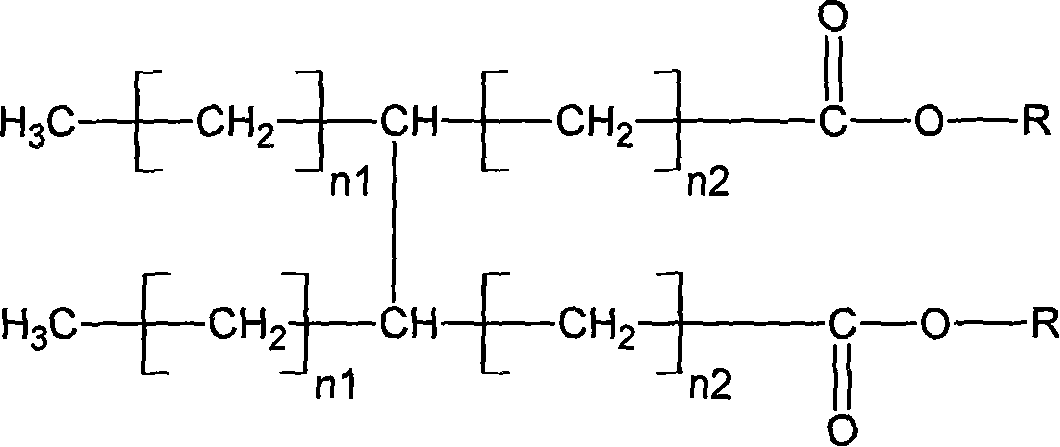

Fatty polyol dimer and its prepn process and application in foamed polyurethane plastic

InactiveCN101066920AGood heat resistanceImprove oil solubilityOrganic compound preparationCarboxylic acid esters preparationBiomassPolymer chemistry

The present invention relates to organic high molecular compound and its preparation, chemical preparing and complex. The present invention provides one kind of fatty polyol dimer originated from biomass resource and its preparation process in polyurethane foam for raising the heat resistance, strength and tearing resistance.

Owner:JIANGSU QIANGLIN BIO ENERGY

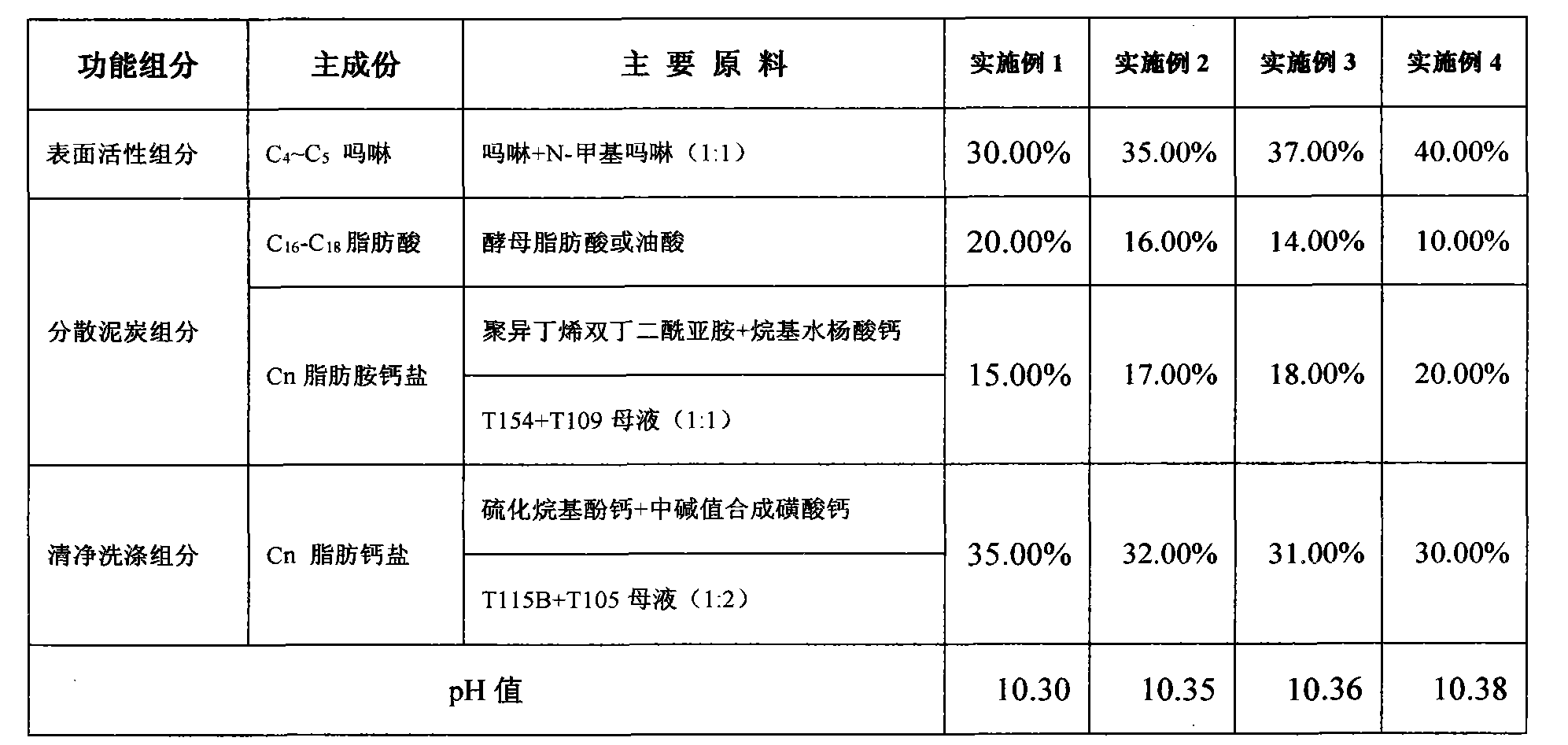

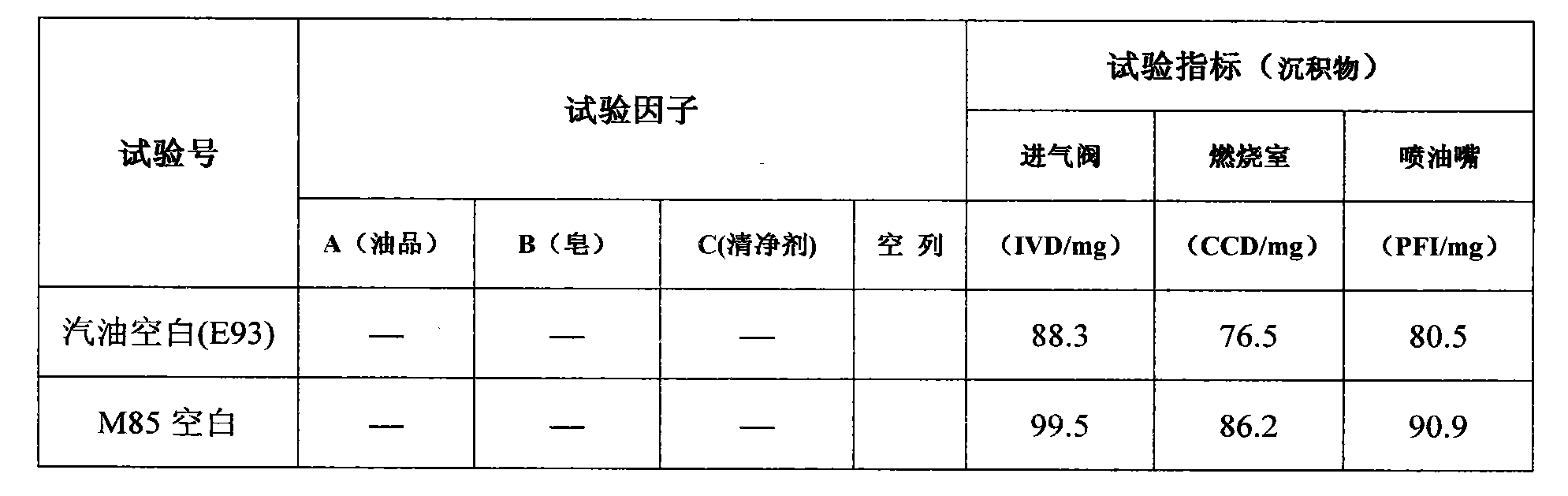

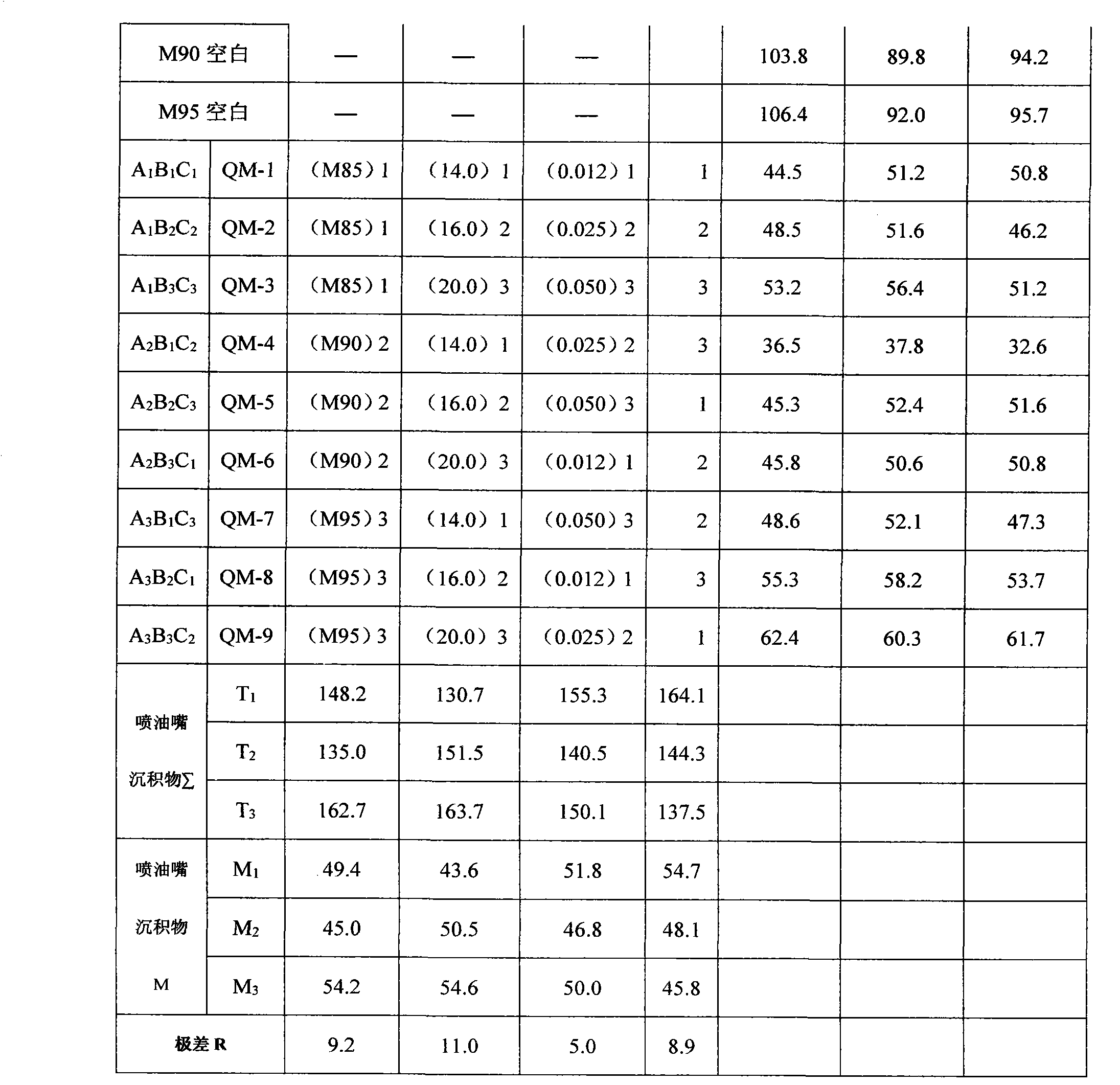

Cleaning and dispersing agent for bio-based methanol gasoline and preparation method of cleaning and dispersing agent

ActiveCN103320183ATurn waste into treasureTurn waste into energyLiquid carbonaceous fuelsCombustion chamberMorpholine

The invention discloses a cleaning and dispersing agent for bio-based methanol gasoline and a preparation method of the cleaning and dispersing agent. The cleaning and dispersing agent consists of 30-40% of surfactant ingredient, 32-35% of dispersing peat ingredient and 30-35% of cleaning and washing ingredient; and the cleaning and dispersing agent product is prepared through uniformly mixing the three functional ingredients at normal temperature. According to the cleaning and dispersing agent and the preparation method of the cleaning and dispersing agent, cleanable, environmental-friendly, reproducible and degradable petroleum yeast fatty acid is selected as a cheap additive, so that the energy is saved and the emission is reduced; and compared with the prior art, the cleaning and dispersing agent is low in cost, non-toxic, free of pollution, low in dosage and remarkable in cleaning and dispersing effect and cannot cause secondary pollution to the environment. According to the cleaning and dispersing agent and the preparation method of the cleaning and dispersing agent, organic modification is carried out by using substances such as the yeast fatty acid, morpholine and fatty-amine calcium salts, so that the special cleaning and dispersing agent for the methanol gasoline is synthesized; and the cleaning and dispersing agent disclosed by the invention has the advantages that the formation of carbon deposit can be prevented effectively, formed carbon deposit is removed, a fuel injection nozzle, an air inlet valve and a combustion chamber of a gasoline engine are effectively prevented from emergence and production of carbon deposit, and the removal ratio is up to 32.12-64.14%.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Process for preparing vegetable oil fractions rich in non-tocolic, high-melting, unsaponifiable matter

InactiveUS20040047970A1Prevent precipitationGood oil solubilityBiocideEdible oils/fats ingredientsBiotechnologyVegetable oil

A vegtable oil fraction rich in non-tocolic, high-melting, unsaponifiable matter is prepared by the following steps: A vegetable oil having a slip melting point of not more thatn 30° C. and a content of unsaponifiable matter of at least 0.5% by weight is hydrongenated to fully saturate the fatty acids of the glycerides and to reach a slip melting point of at least 57° C. To the hydrongenated oil is added from 1 to 75% by weight of the unhydrogenated starting oil or another oil having a slip melting poing of not more than 30° C. in order to act as a carrier and vehicle for the unsaponifiable matter. Then, a solvent is added to the oil mixture in a ratio between oil and solvent from 1:2 to 1:20, and the mixture is heated to transparency. The oil / -solvent-mixture is cooled in one or more steps to a final temperature in the range from -35 to +30° C., and the precipitated high-melting fraction(s) is (are) filtered off. The filtrate is desolventised, leaving a fraction rich in unsaponifiable matter. By this process very high concentrations of in particular the non-tocolic, higher melting unsaponifiables can be achieved, and the composition of the glyceridic part of the enriched fraction can betailored to specific applications. Also, a novel blood cholesterol-lowering effect of the unsaponifiable constituents from shea butter has been found.

Owner:AAK DENMARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com