Patents

Literature

231results about How to "Good anti-foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

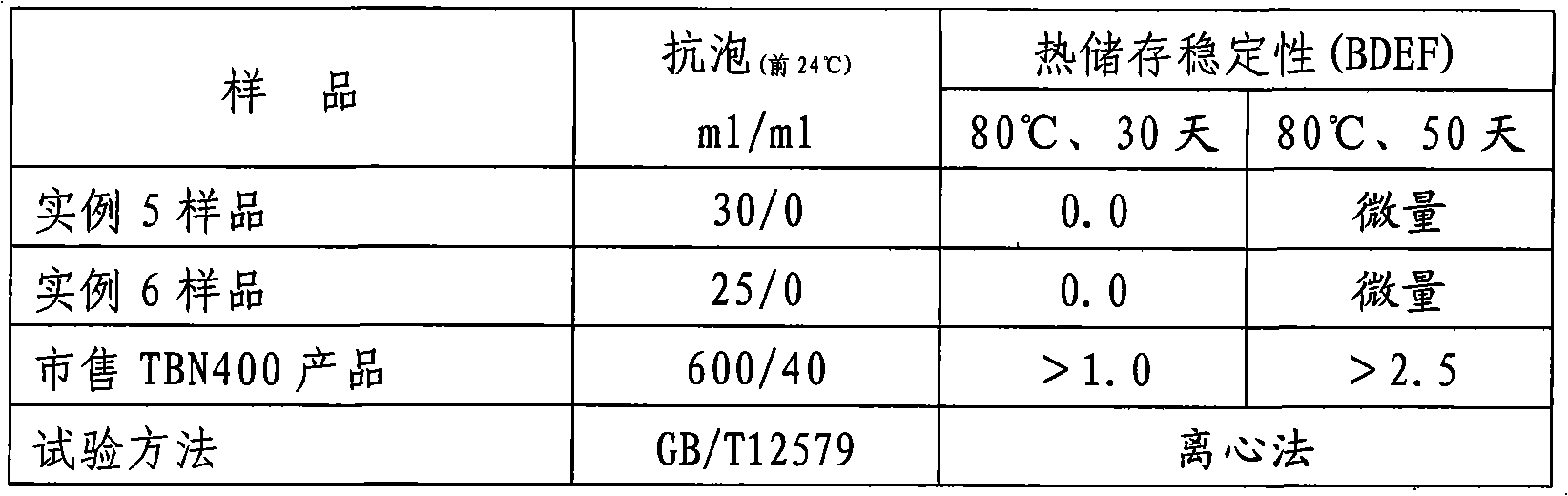

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

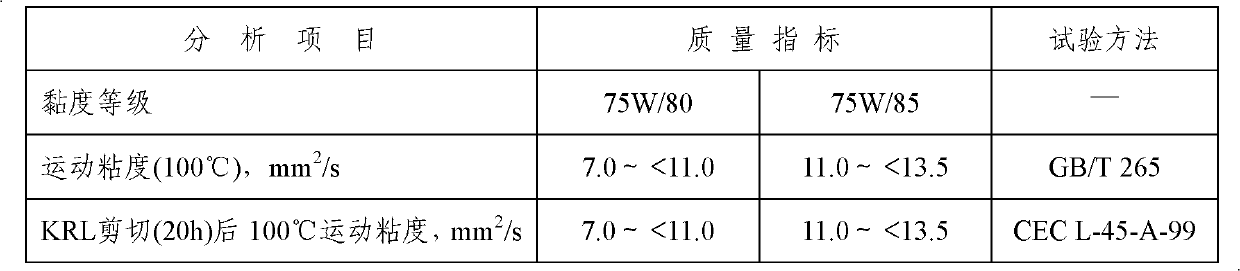

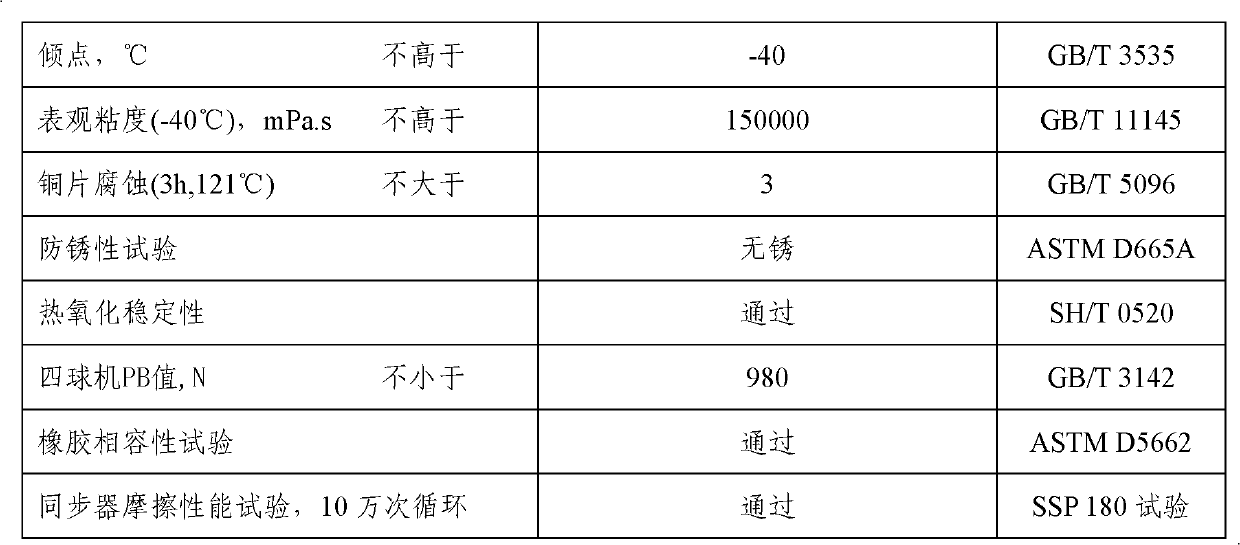

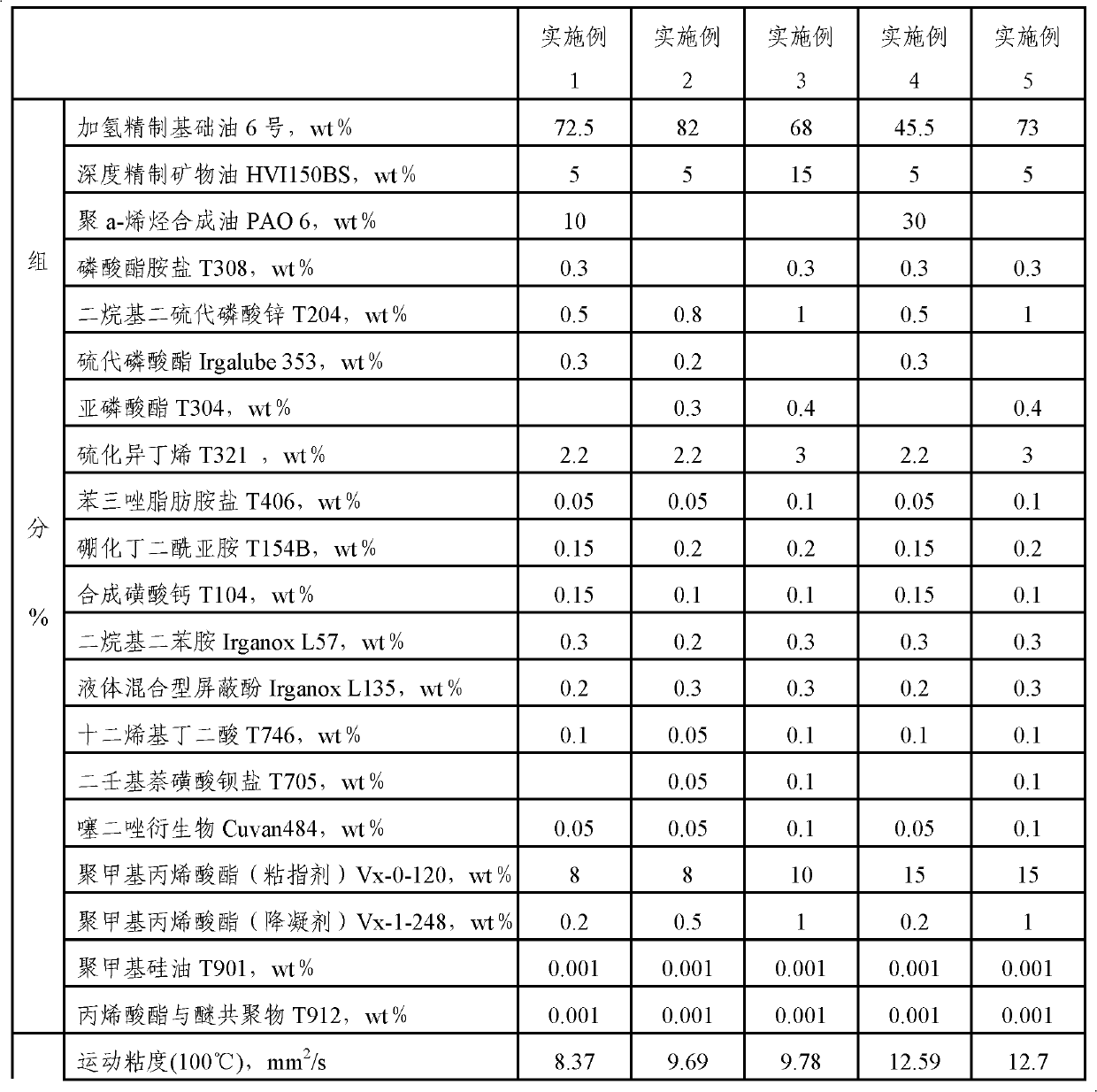

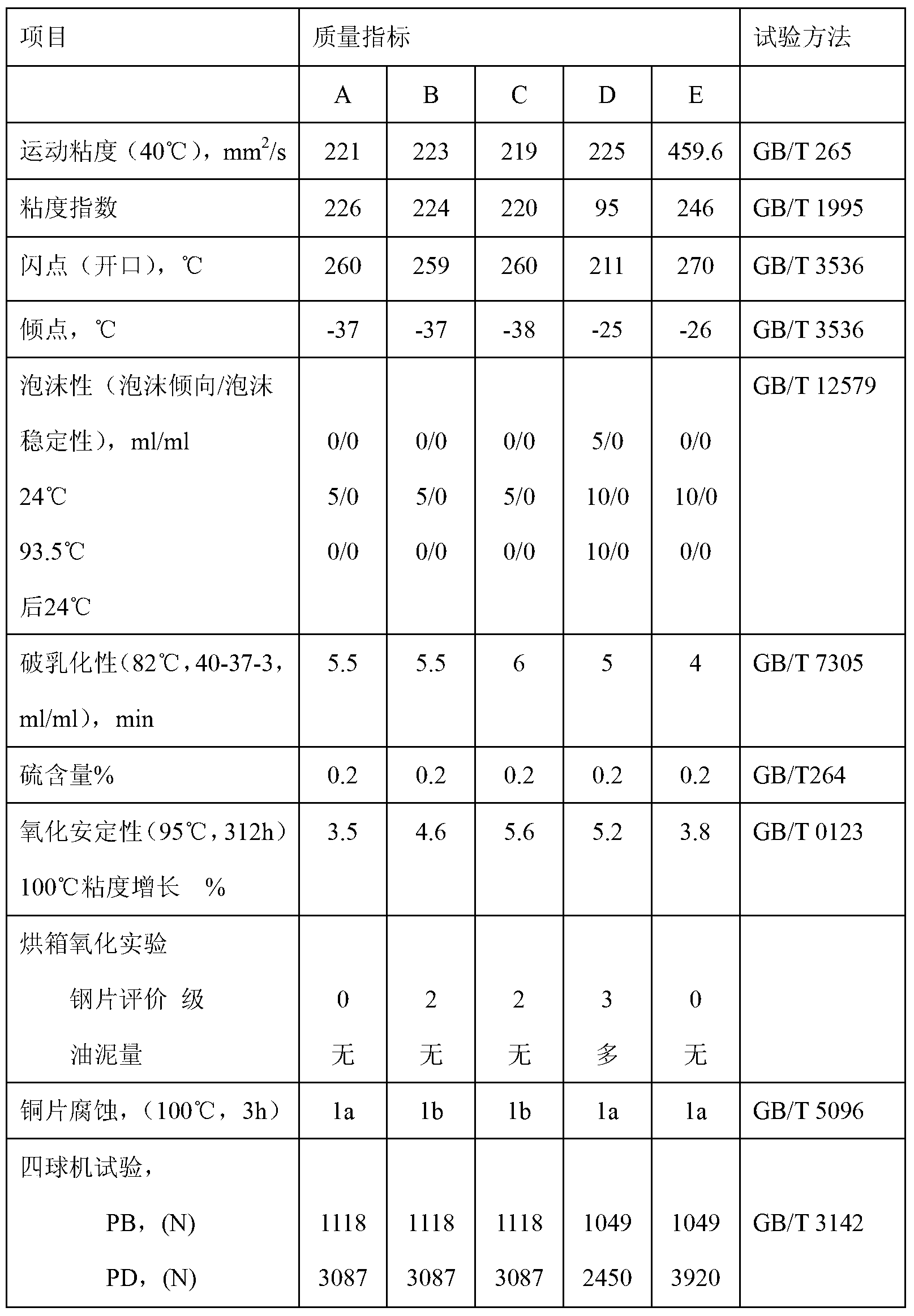

Manual transmission lubricating oil composition

ActiveCN103374452AGood high and low temperature performanceGood thermo-oxidative stabilityLubricant compositionManual transmissionViscosity index

The invention provides a manual transmission lubricating oil composition. The manual transmission lubricating oil composition comprises (a) at least one mineral oil and / or synthetic oil with high viscosity index, (b) at least one viscosity index improving agent, (c) at least one pour point depressant, (d) at least one phosphorus-containing antiwear agent, (e) at least one sulfur-containing extreme pressure agent, (f) at least one friction improving agent, (g) at least one clean dispersion agent, (h) at least one antioxidant, (i) at least one antirust agent, (j) at least one metal deactivator and (k) at least one anti-foaming agent. The manual transmission lubricating oil composition provided by the invention meets the vehicle gear oil viscosity level of 75W / 80 or 75W / 85, has excellent high-low temperature performances, anticorrosion performance, antirust performance and shearing-resistance performance, especially has excellent synchronizer friction performance, can be used for a manual transmission with a synchronizer, and can be completely suitable for the improvement of oil product performance requirement brought about by technique improvement of the manual transmission at present.

Owner:CHINA PETROLEUM & CHEM CORP

High-speed electroplating luminous tin-plating electroplating liquid as well as preparation method and application thereof

The invention discloses a high-speed electroplating luminous tin-plating electroplating liquid as well as a preparation method and application thereof. The high-speed electroplating luminous tin-plating electroplating liquid comprises the following raw materials calculated according to each liter of high-speed electroplating luminous tin-plating electroplating liquid: 120-200mL of tin methyl sulfonate, 100-175mL of 70 percent by weight methylsulfonic acid, 0.03-5g of brightening agent, 30-45g of conducting salt, 1-10g of grain refiner, 5-20g of antioxidant, 0.5-2g of wetting agent, 0.0005-0.001g of antifoaming agent and the balance water. The preparation method comprises the following steps of: dissolving the tin methyl sulfonate into the 70 percent by weight methylsulfonic acid; diluting the mixed solution with a proper amount of water; then adding the brightening agent, the conducting salt, the grain refiner, the antioxidant, the wetting agent and the antifoaming agent into the solution; and uniformly stirring and filtering to obtain filtrate, namely the high-speed electroplating luminous tin-plating electroplating liquid. The high-speed electroplating luminous tin-plating electroplating liquid disclosed by the invention has high coating speed, excellent dispersion capability and antifoaming capability and is suitable for a high-speed electroplating process.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Cleaning compositions

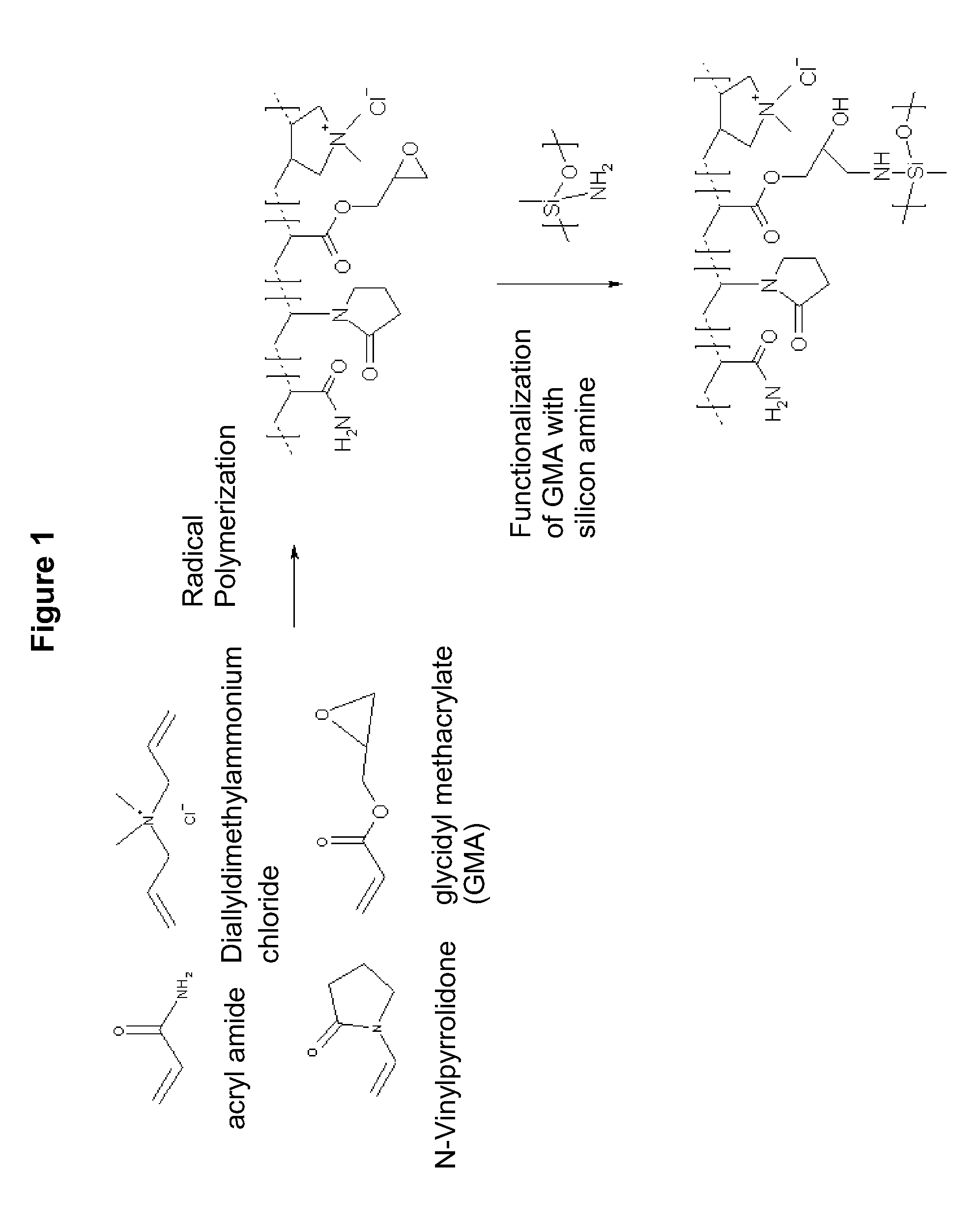

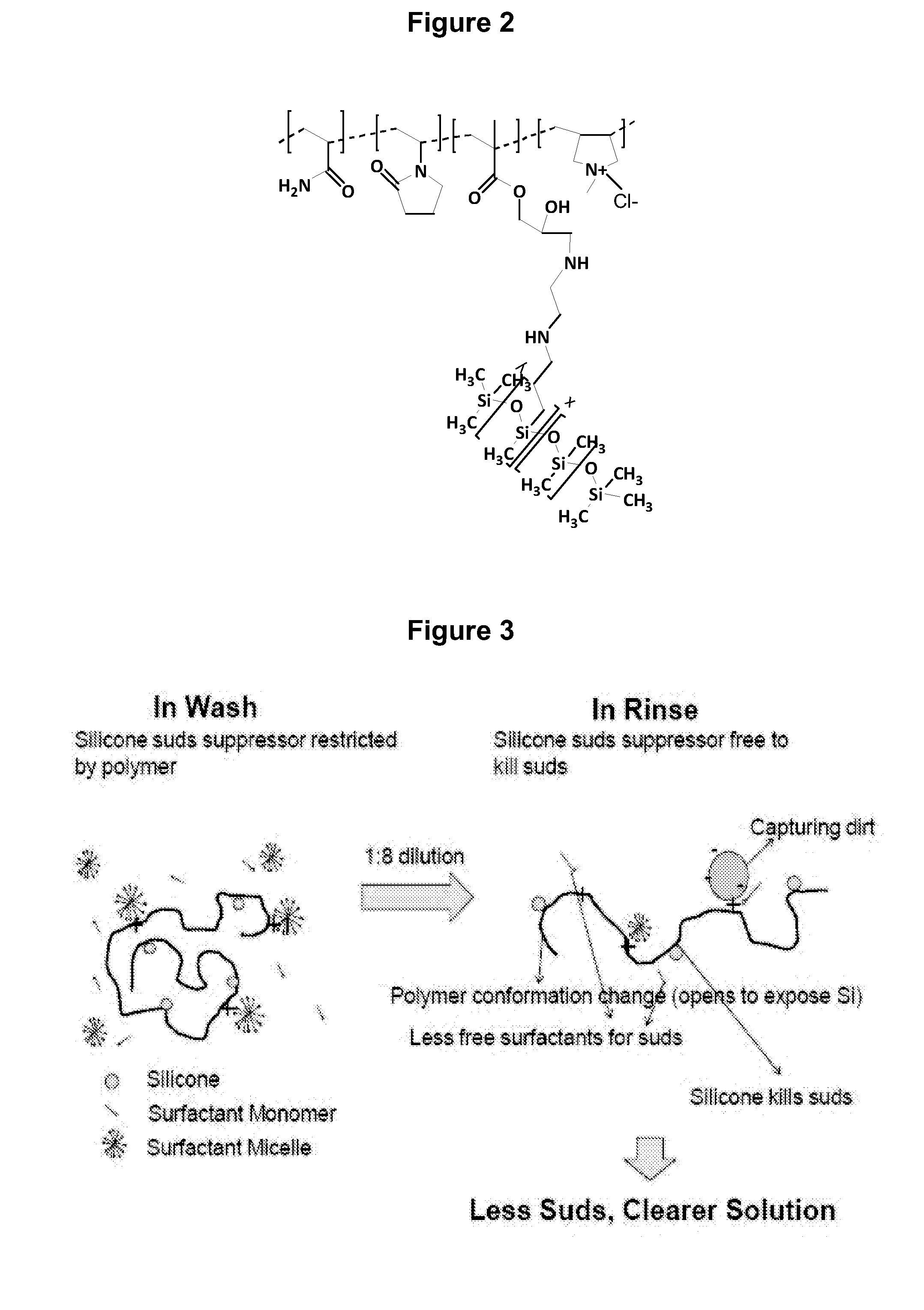

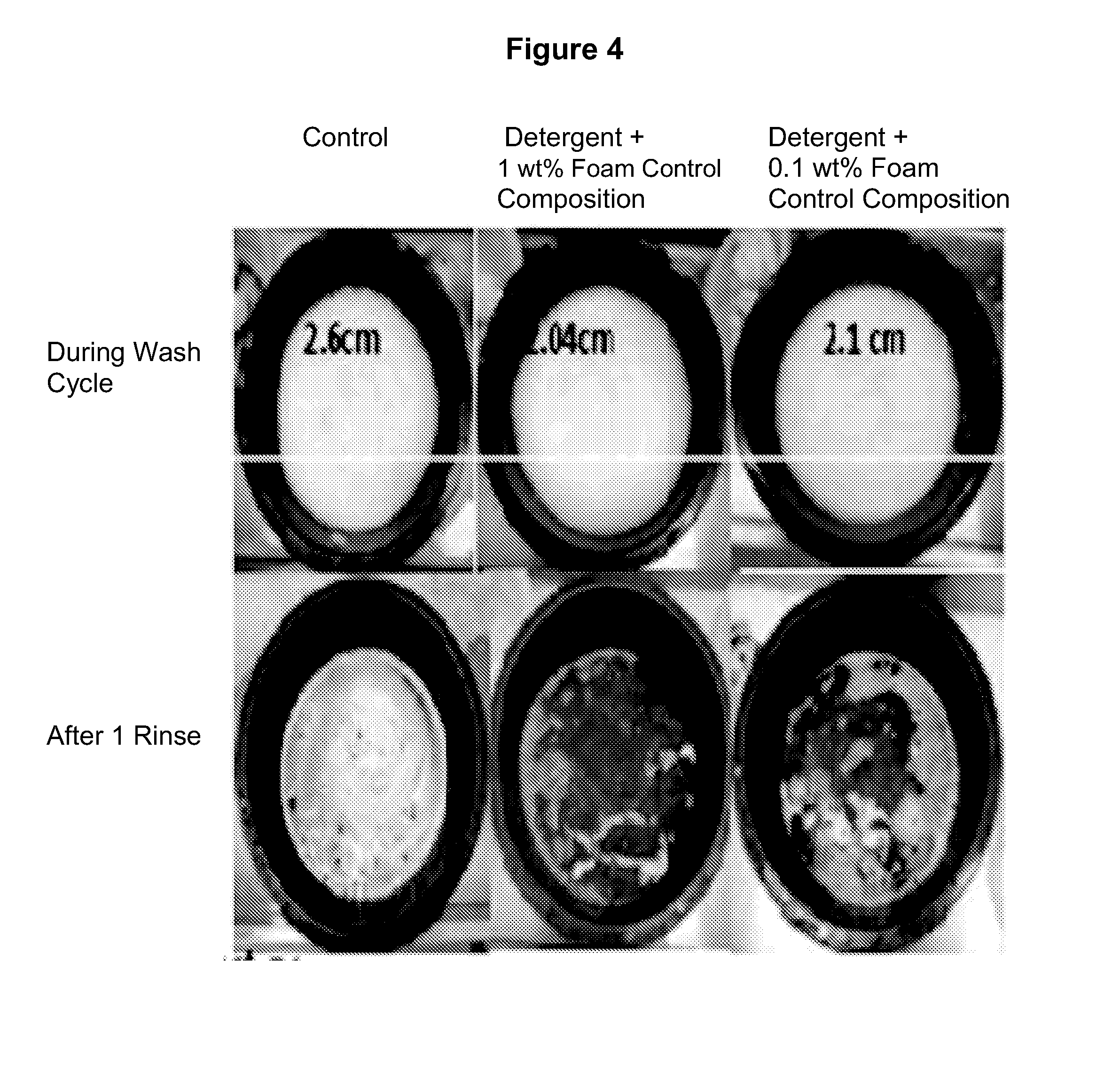

ActiveUS20140023609A1Improved suds removalNegatively impactingSynthetic polymeric active ingredientsFoam regulating compositionsFOAM CONTROLOrganic chemistry

The present invention relates to cleaning composition, preferably a laundry detergent composition, comprising a foam control composition comprising a hydrophobically modified cationic polymer, as well as processes for making and method of using such compositions. The composition of the present invention provides for enhanced suds removal during the rinse cycle with minimal or nil impact on suds volume during the wash cycle.

Owner:THE PROCTER & GAMBLE COMPANY

Concrete structure heavy-duty nano composite coating and protection method

The invention relates to a heavy anti-corrosion nano composite coating and a protection method for a concrete structure. The protection method belongs to a method for protecting the reinforced concrete structure. The heavy anti-corrosion nano composite coating for the concrete structure has a three-layer structure and comprises nano modified epoxy sealing coatings, a nano modified epoxy micaceous iron oxide intermediate paint and a nano modified fluorine-containing polyurethane finish or a fluorine-containing polysiloxane finish from inside to outside in turn. By adoption of the nano composite coating protection technology to perform anti-corrosion coating on the concrete structure, the anti-corrosion service life can reach more than 20 years, and the adhesion of the coating can be doubled compared with a common anti-corrosion coating; the coating has better impact resistance, sediment incrustation resistance, weathering resistance and flexibility; and the construction method is simple, and easy to popularize and apply, and has low cost.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

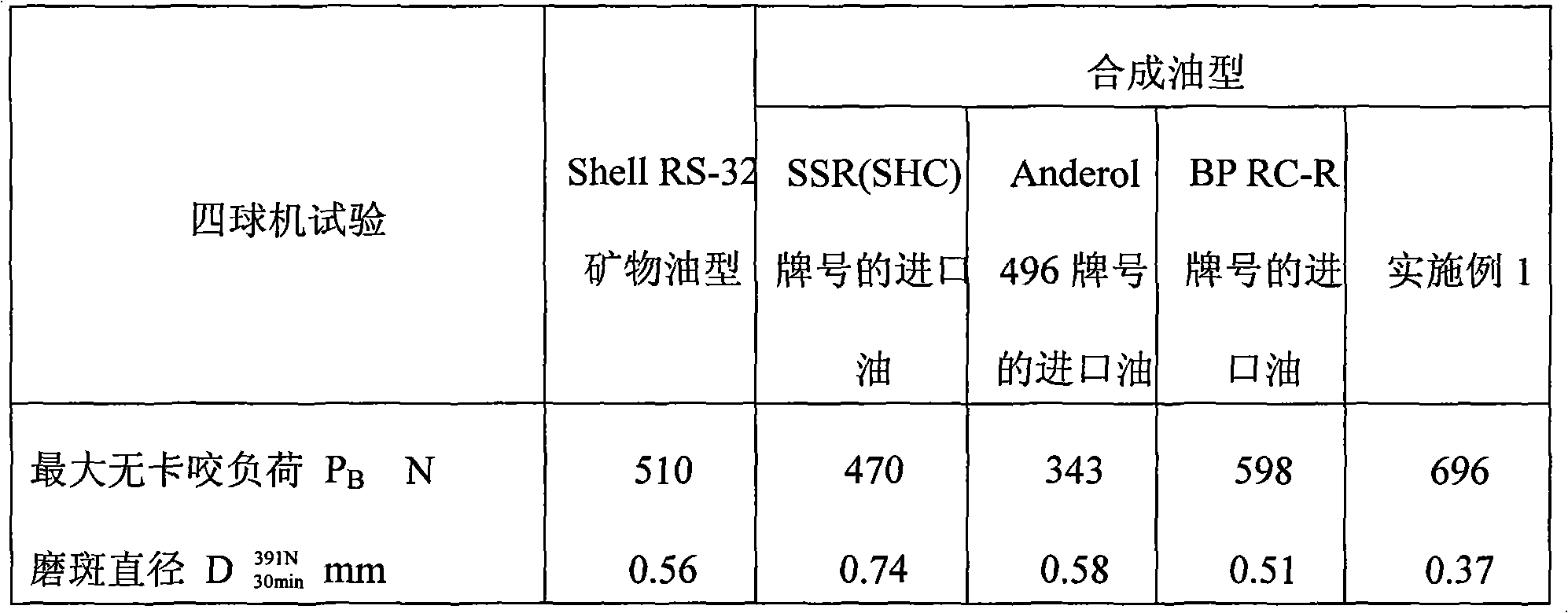

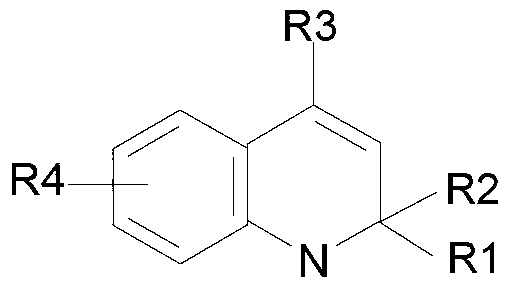

Air compressor oil composition and preparation method thereof

ActiveCN103194303AExtended service lifeImprove performanceHeat-exchange elementsLubricant compositionAntioxidantOxidation stability

The invention provides an air compressor oil composition and a preparation method thereof. The air compressor oil composition comprises polyether oil base oil or polyether oil and ester oil mixture base oil, a 2,2,4-trialkyl-1,2-dihydroquinoline antioxidant and a metal deactivator. Compared with the known air compressor oil composition, the air compressor oil composition has excellent oxidation stability, excellent comprehensive performance and a simple preparation method, and is particularly suitable for a screw air compressor.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Multi-station cold heading oil and preparation method thereof

InactiveCN104403738AExtended service lifeGood extreme pressure and anti-wear propertiesLubricant compositionVegetable oilFoaming agent

The invention relates to an oil product of a petroleum chemical product, and especially relates to multi-station cold heading oil and a preparation method thereof. According to the method, a deep refining mineral oil is taken as a base oil, an extreme pressure additive, an anti-rust agent, an oiliness additive, an anti-foaming agent, and animal and vegetable oil are added by blending, the cold heading oil comprises the following components by weight: 75% of base oil, 6% of extreme pressure additive, 3.7% of anti-rust agent, 8% of oiliness additive, 2.3% of anti-foaming agent and 5% of animal and vegetable oil. The cold heading oil is suitable for a cold heading machine, and has the advantages of good extreme pressure abrasion resistance, good antirust performance and anti-foaming performance, so that the usage life of the cold heading machine can be increased.

Owner:NINGBO BAORUN PETROCHEM

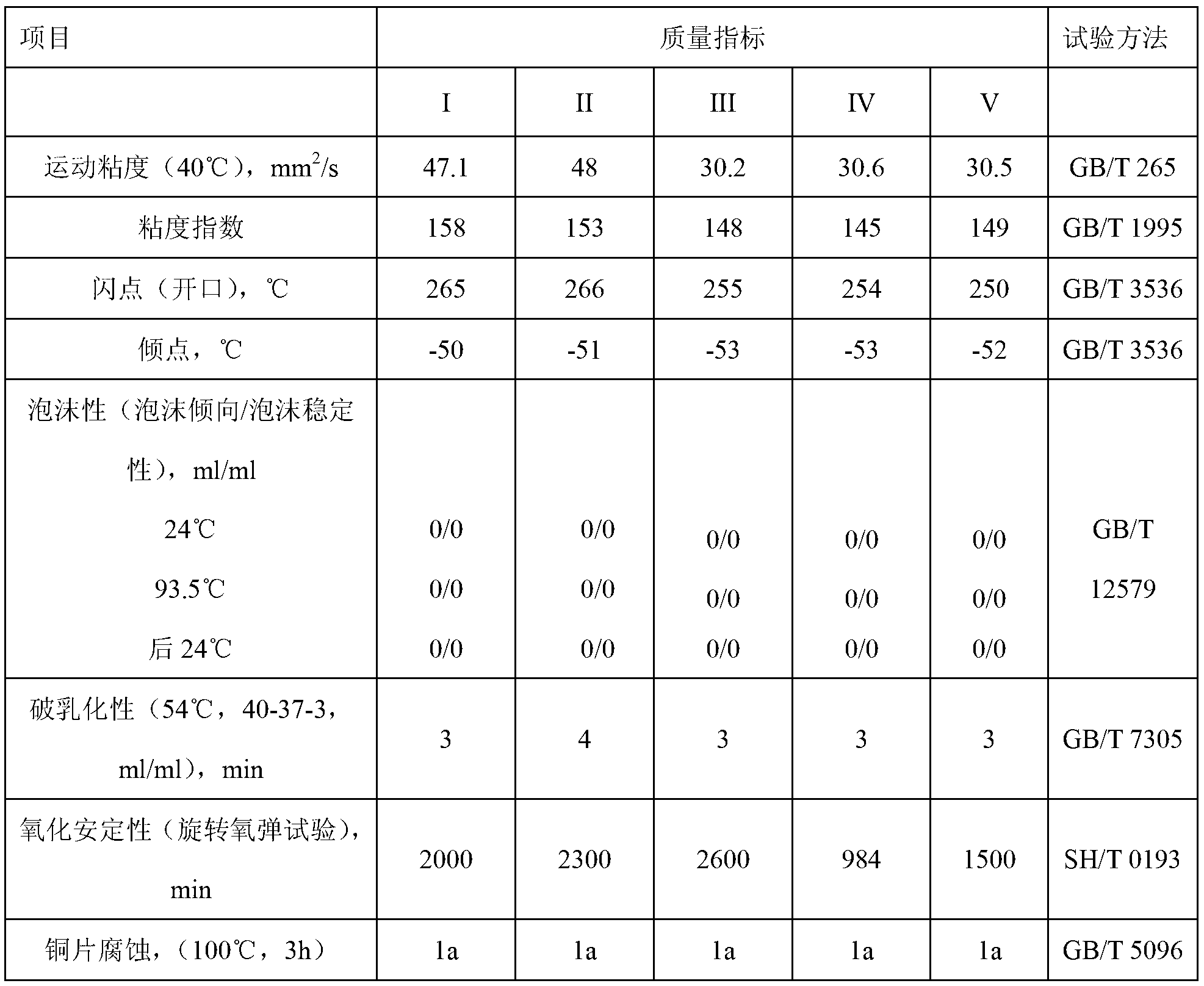

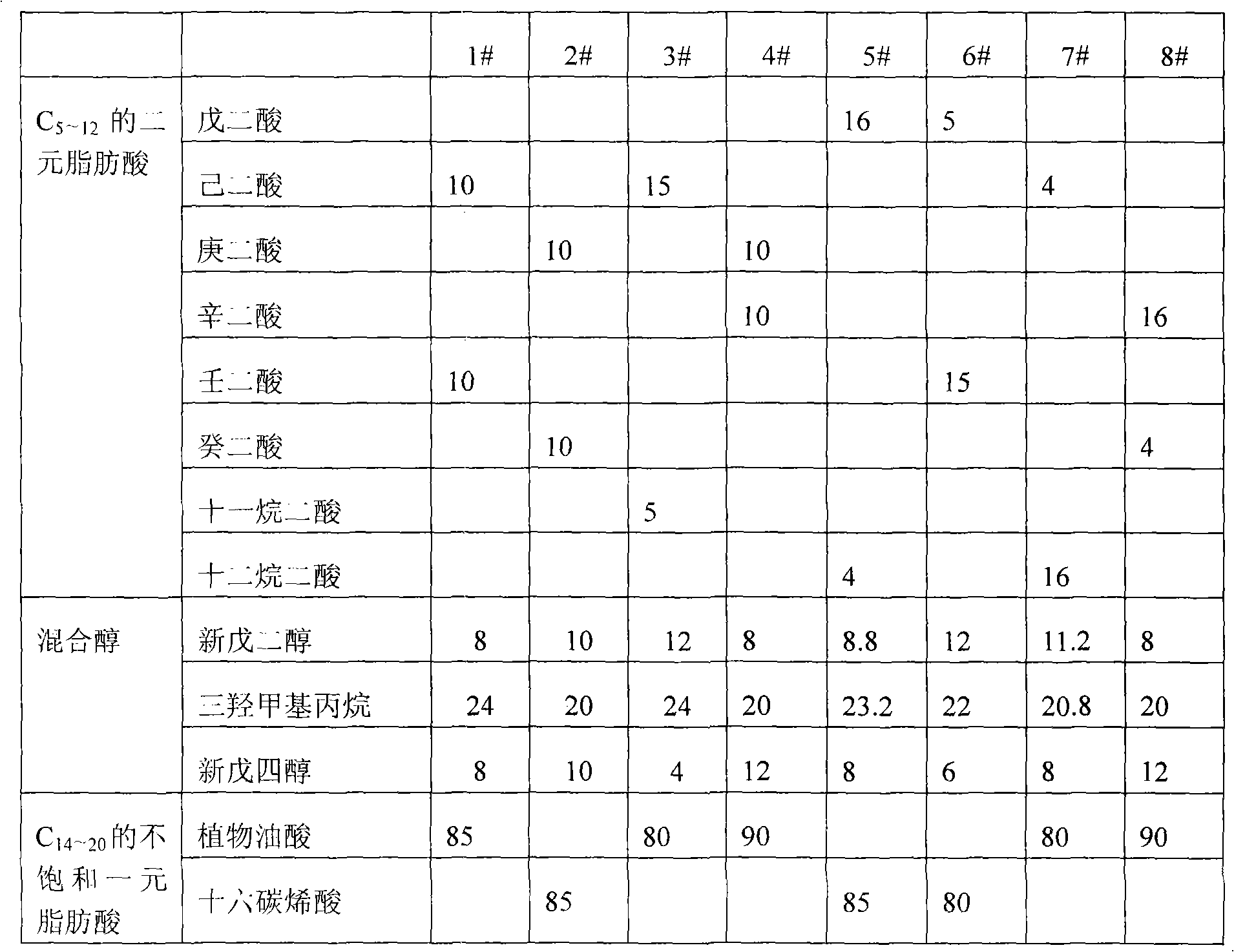

Flame-retardant hydraulic oil and preparation and application thereof

ActiveCN101831346AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceLubricant compositionAntioxidantHigh pressure

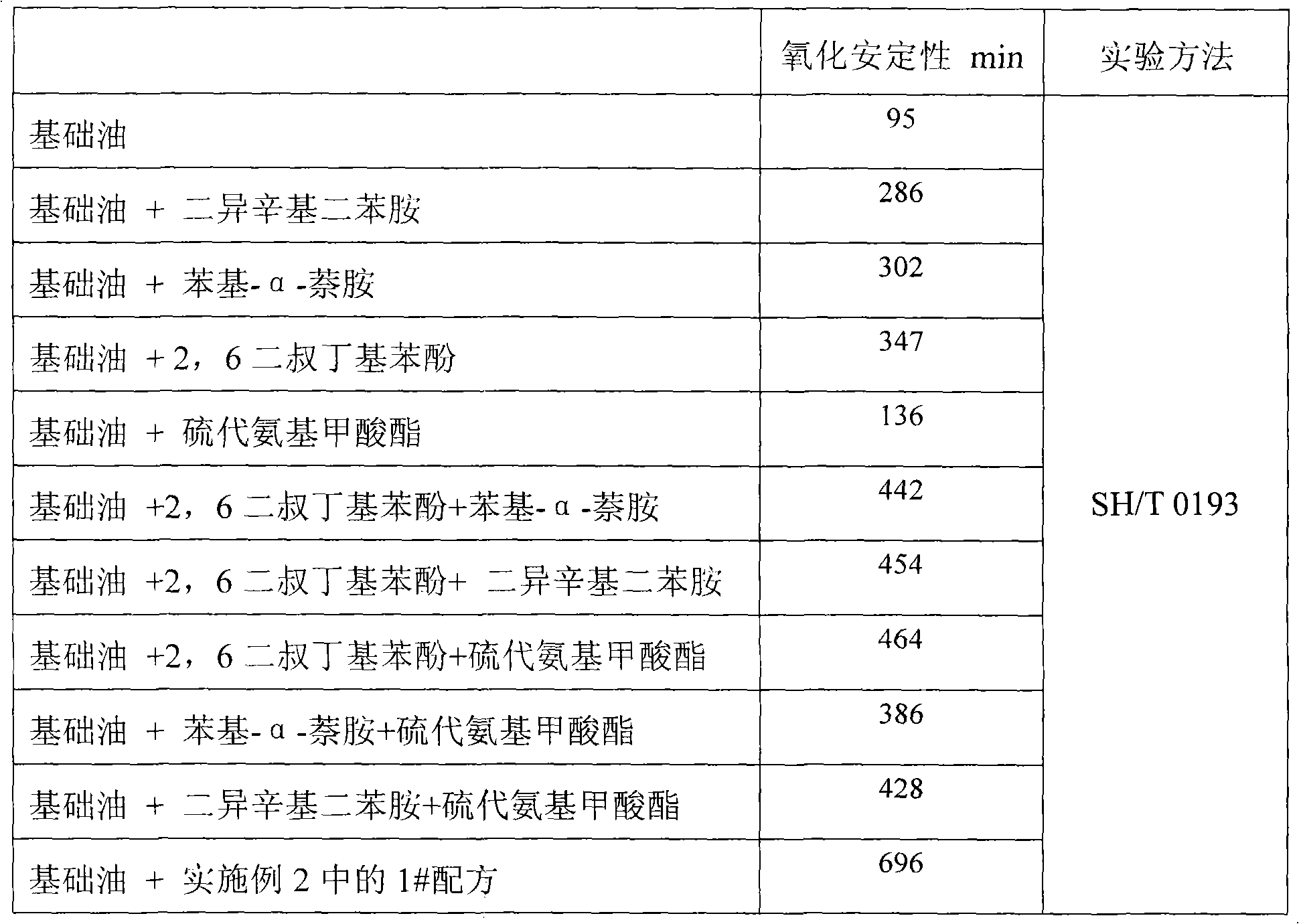

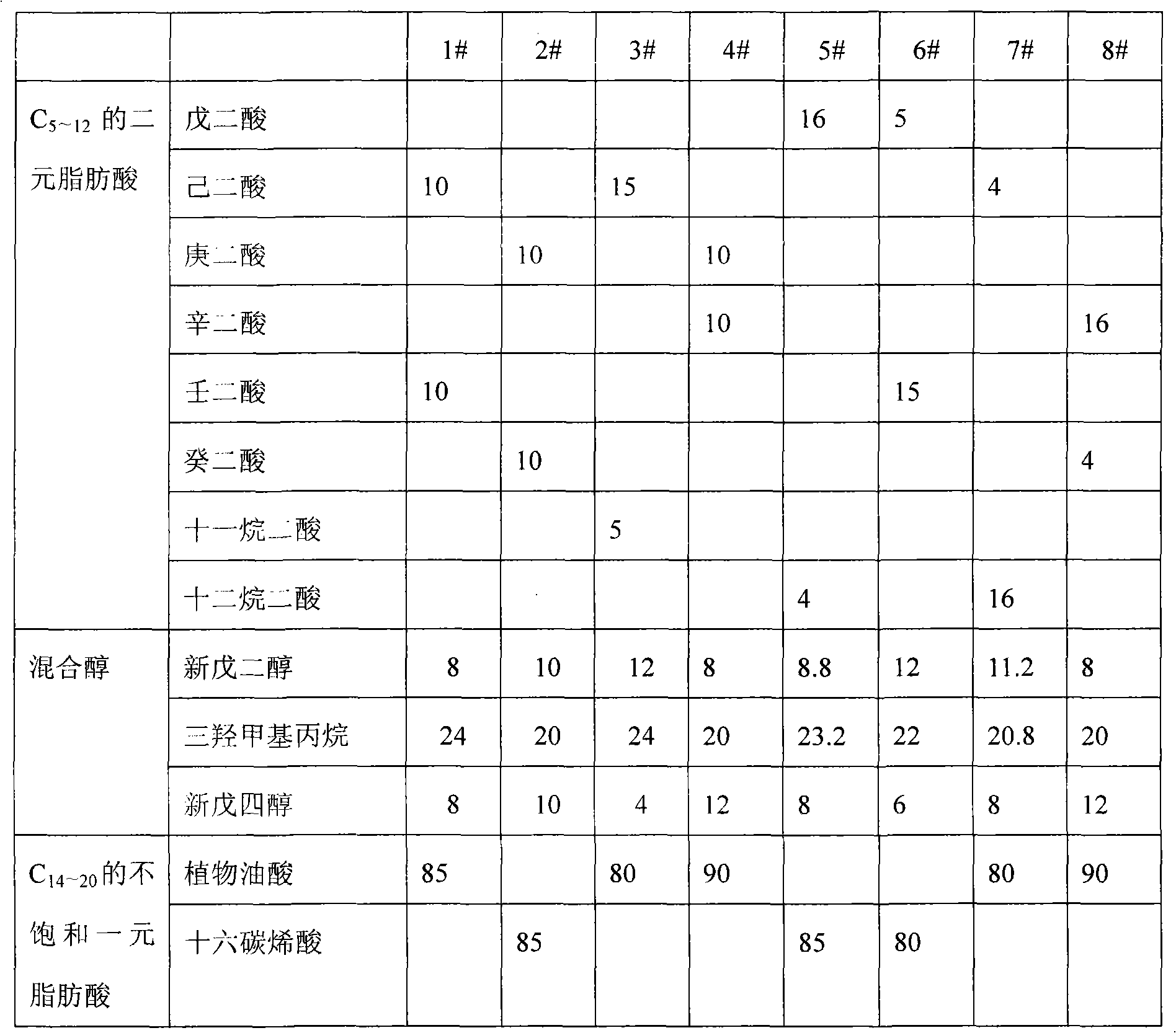

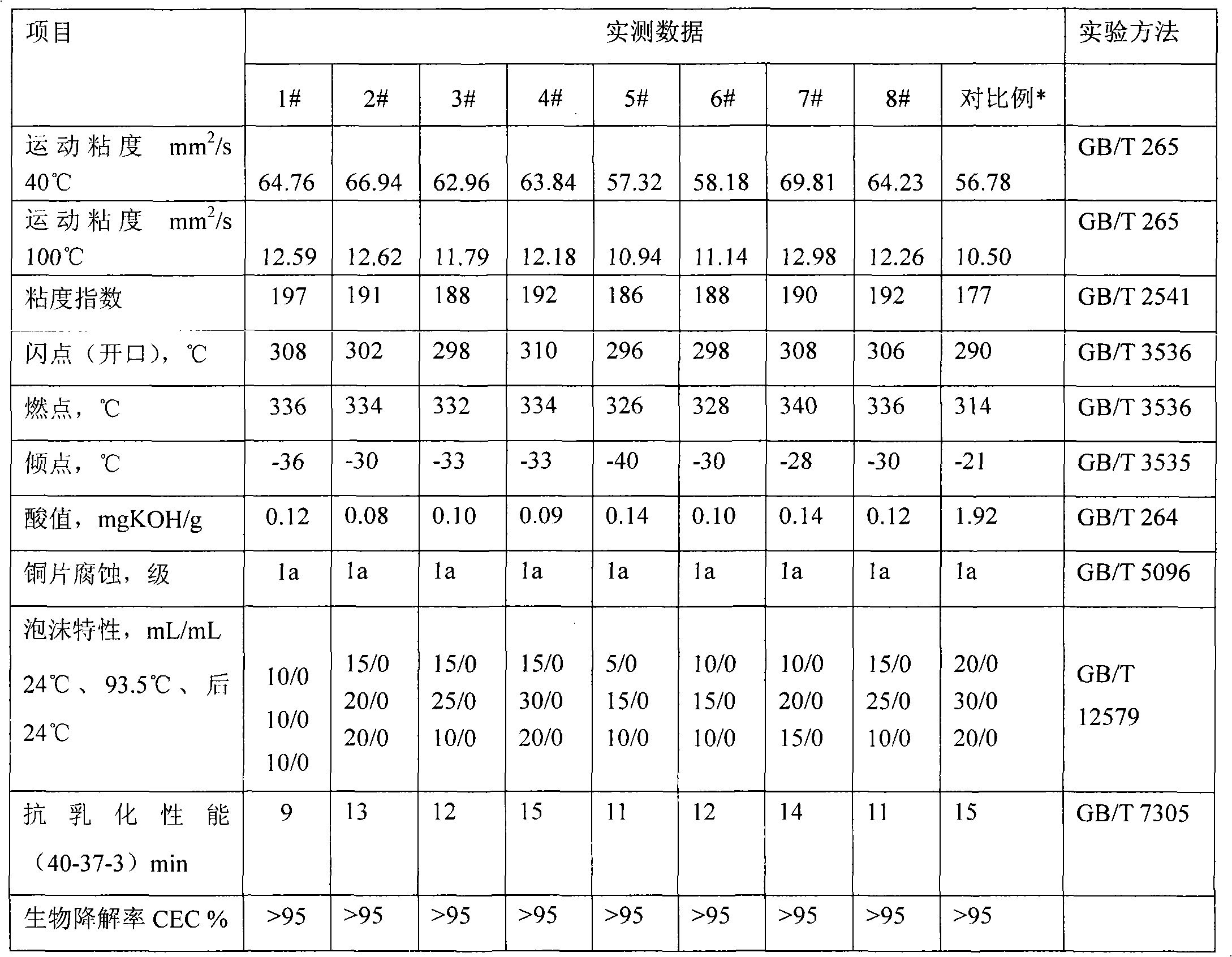

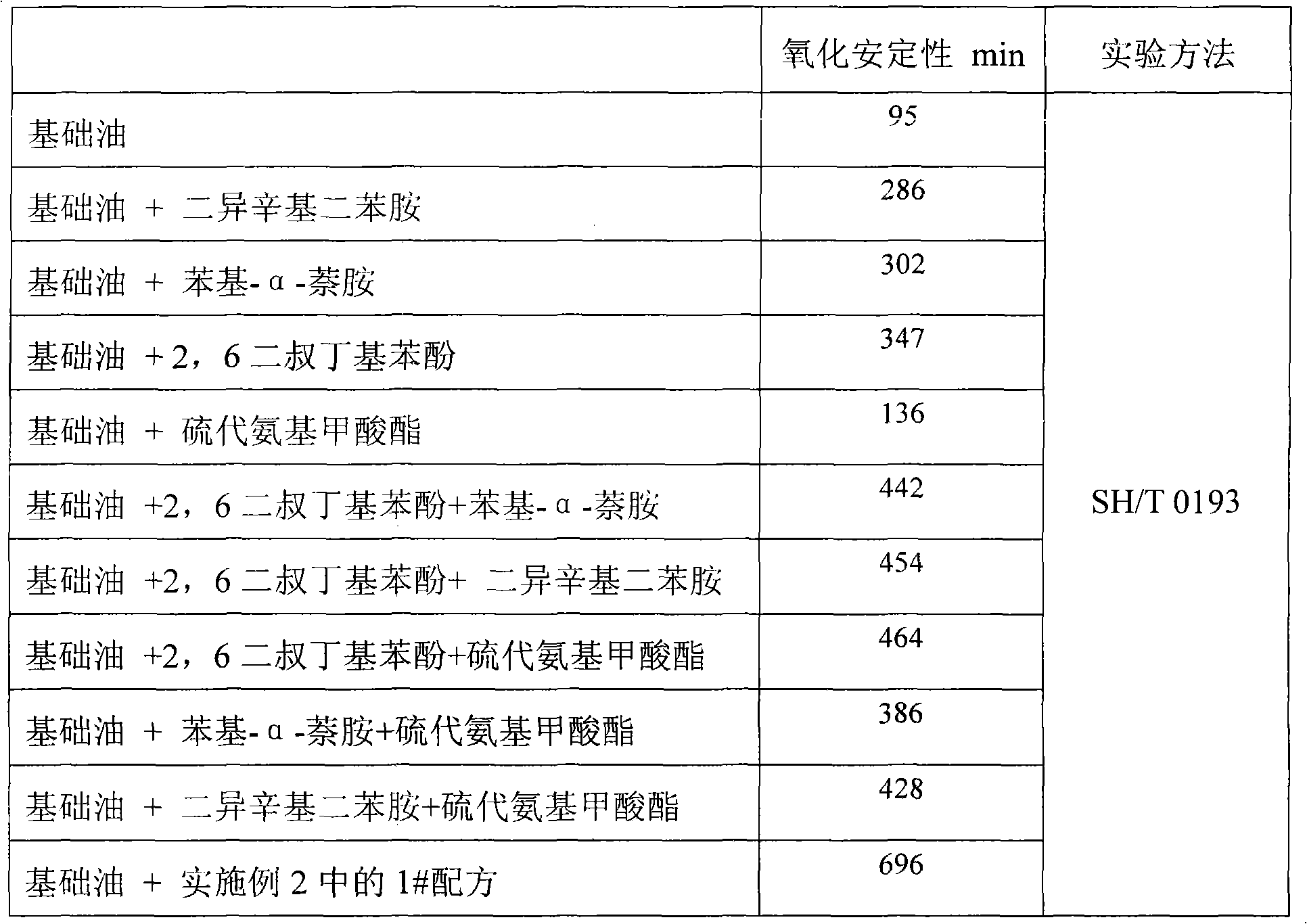

The invention provides flame-retardant hydraulic oil, which comprises the following components in percentage by weight: 1.9 to 4.5 percent of antioxidant, 1.5 to 3.5 percent of extreme-pressure abrasion resistant agent, 5 to 50ppm of antifoaming agent, 0.1 to 0.4 percent of anti-rusting agent and 92 to 97 percent of base oil, wherein the base oil is neopentyl polyol diacid composite ester which is prepared by fully esterifying carboxyl of aliphatic dibasic acid of C5-12 with mixed alcohol consisting of neopentyl glycol, trimethylolpropane and pentaerythritol and terminating the esterified product with unsaturated unitary fatty acid of C14-20. The flame-retardant hydraulic oil provided by the invention can be applied to various high-temperature and high-pressure hydraulic systems easy to contact naked flame. Compared with mineral-based (compressor) hydraulic oil, the flame-retardant hydraulic oil has the advantages of energy conservation, reduced oil consumption, reduced environmental pollution and prolonged service life, and can fully meet the working requirements of the high-temperature and high-pressure hydraulic systems easy to contact naked flame.

Owner:上海海都化学科技有限公司 +1

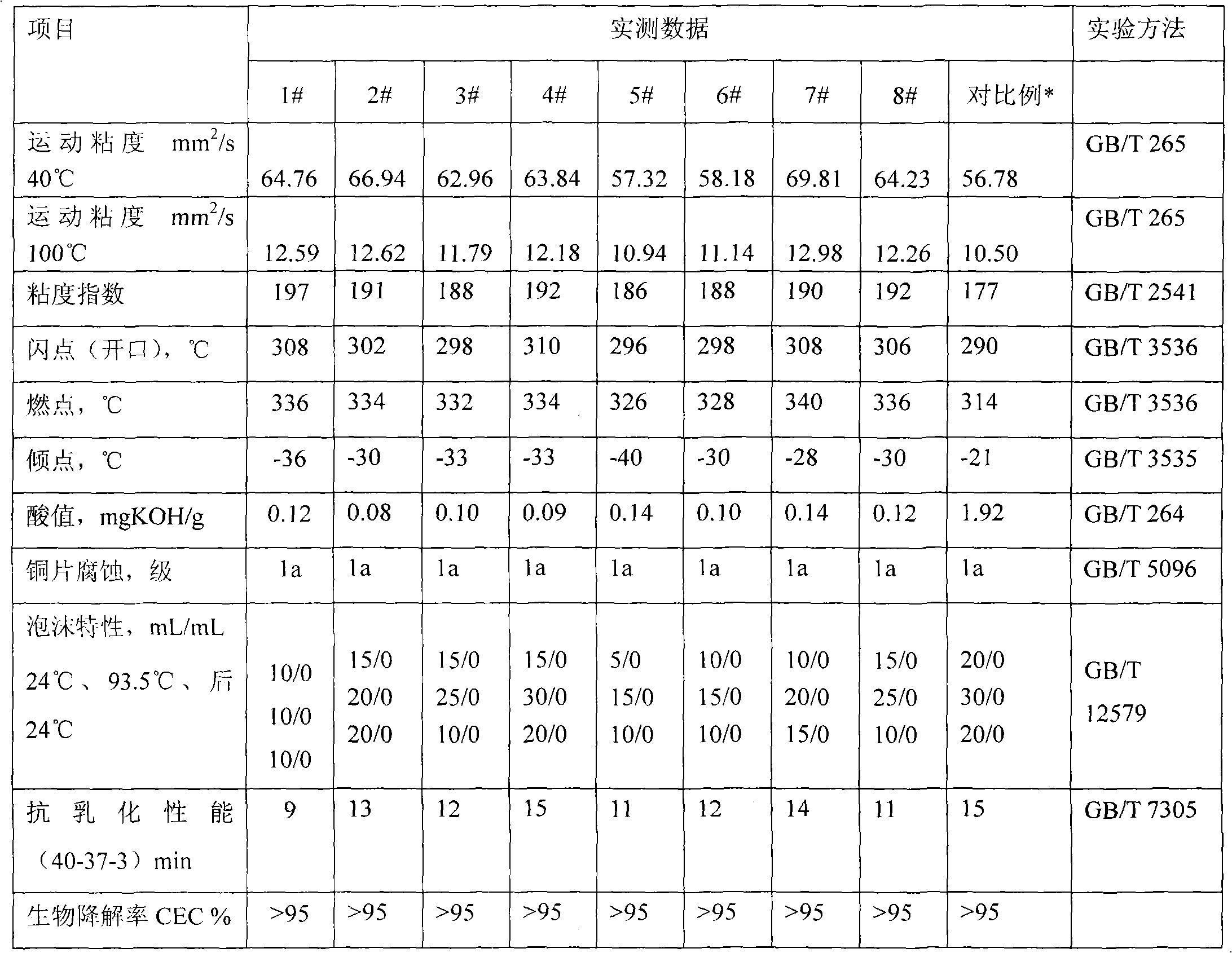

Lubricating oil and grease base oil, and preparation method and applications thereof

ActiveCN101812349AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceBase-materialsOil and greaseEvaporation

The invention provides base oil, in particular to a neopentyl polyalcohol dibasic acid complex ester. The neopentyl polyalcohol dibasic acid complex ester is prepared in a way that: completely esterifying C5-12 binary fatty acid carboxyl with the mixture of neopentyl glycol, trimethylolpropane and pentaerythritol, and blocking with C14-20 unsaturated monobasic fatty acid. The base oil provided bythe invention has the characteristics of high flash point, high flammability point, low pour point, high viscosity index, low evaporation loss, high thermal oxidation stability and high biodegradation rate. The invention can be used as syntholube and grease base oil, especially syntholube base oil used under the conditions of high temperature and high pressure. The invention is especially suitable to be used in fire resistant hydraulic fluid, high-temperature chain oil, high-temperature grease and the like in severe working spaces at which naked flame can is accessible under the conditions ofhigh temperature and high pressure.

Owner:上海海都化学科技有限公司 +1

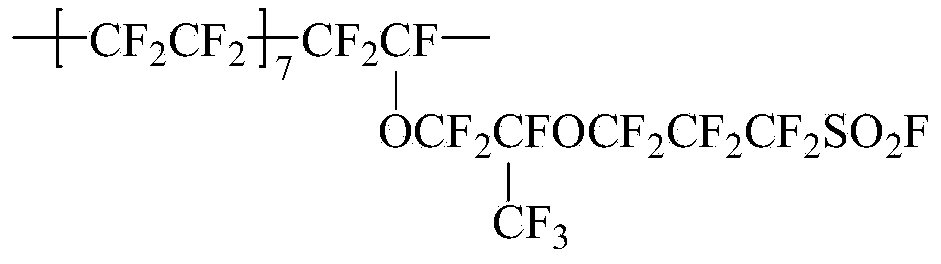

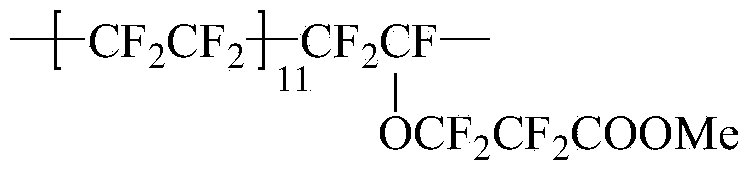

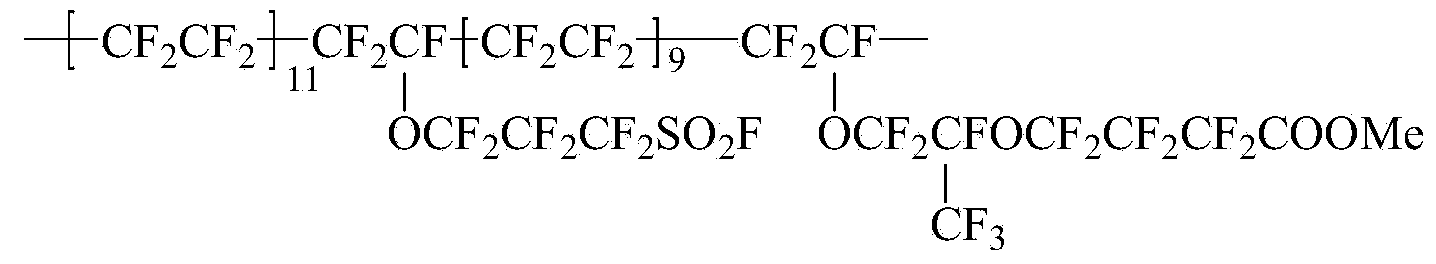

Zero-polar-distance ion exchange membrane and preparation method thereof

ActiveCN104018180AWith ion exchange functionReduce accumulationMembranesSemi-permeable membranesHigh current densityMicroparticle

The invention belongs to the technical field of ion membranes, which particularly relates to a zero-polar-distance ion exchange membrane. The ion exchange membrane is converted from a polymer membrane which is prepared by compounding a perfluorinated ion exchange resin and a reinforcement material, wherein a non-electrode porous gas releasing layer is arranged on at least one side of the ion exchange membrane and is formed by bonding a dispersion liquid on the surface of an ion exchange membrane layer and then drying; the dispersion liquid is formed by dispersing the broken microparticles of a perfluorinated sulfonic acid resin in an aqueous alcohol solution of the sulfonic acid resin. The prepared zero-polar-distance ion exchange membrane which is applied to the chlor-alkali industry can be used for stably and efficiently treating an alkali metal chloride solution with high impurity content and is more suitable for being applied in a zero-polar-distance electrolytic bath under a high current density condition as well as has an extremely low surface resistance. The invention further provides a preparation method of the zero-polar-distance ion exchange membrane. The method is reasonable in process and easy for industrial production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

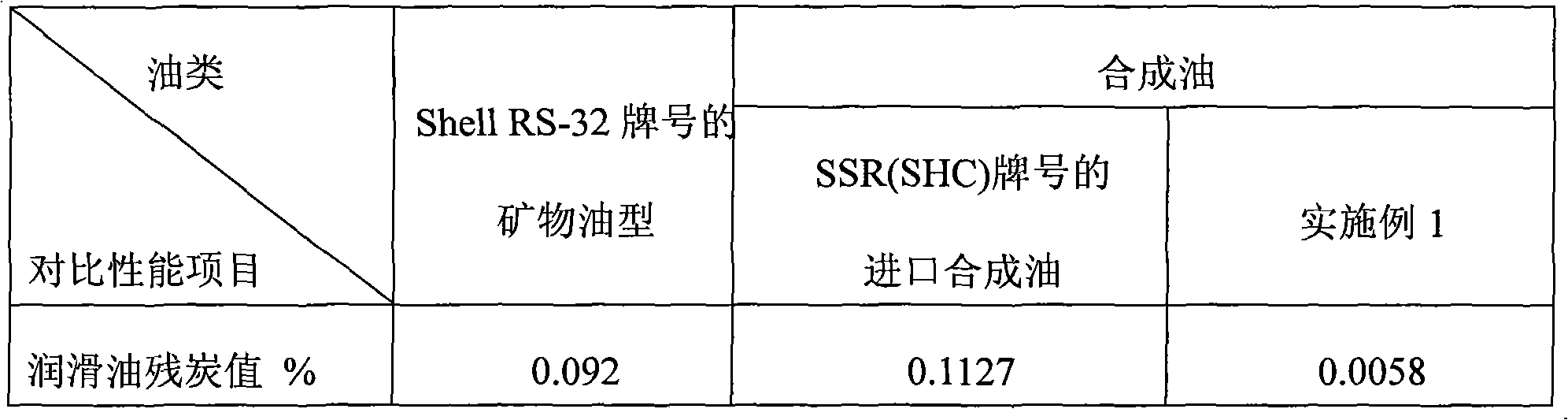

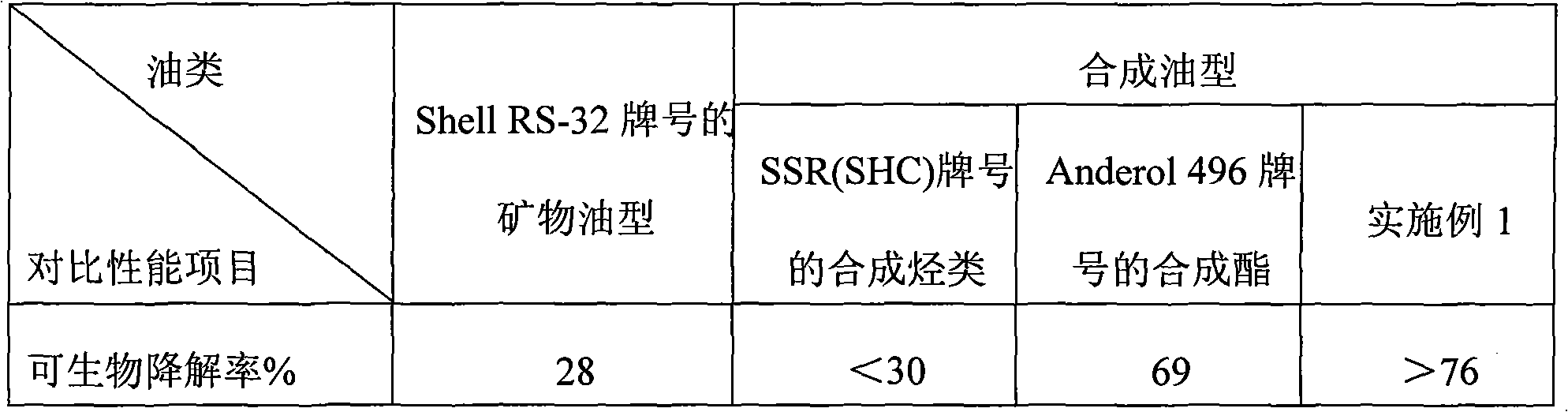

Composite synthetic air compressor oil

The invention discloses composite synthetic air compressor oil comprising the following components: a promoter, diisoalkyl (C8 to C13) linear dibasic ester, poly-alpha-olefin synthetic oil and diisoalkyl (C8 to C13) phthalate esters, wherein, the composite synthetic air compressor oil contains 15% to 20% of diisoalkyl (C8 to C13) linear dibasic ester by weight, 5% to 10% of poly-alpha-olefin synthetic oil by weight and 72% to 74% of diisoalkyl (C8 to C13) phthalate esters by weight. The composite synthetic air compressor oil of the invention can meet the requirements that the carbon residue value thereof is low and the biodegradation rate is higher than 70%; the composite synthetic air compressor oil has high high-temperature anti-oxidation stability, lubricating properties, rust-preventing properties, foam resistance and emulsion resistance; and the invention has the advantages that the energy is saved, the environmental pollution is reduced and the service life is prolonged, therefore, the invention can fully satisfy the operating requirements for rotary-type screw compressors.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Worm gear oil composition and preparation method thereof

ActiveCN103194302APrevent depolymerization and degradationGuaranteed long-life operationAdditivesOxidation stabilityViscosity

The invention provides a worm gear oil composition and a preparation method of the worm gear oil composition. The worm gear oil composition comprises a combination of polyether oil base oil, a 2, 2, 4-trialkyl-1, 2-dihydroquinolines antioxidant and a metal passivator. The worm gear oil composition provided by the invention has outstanding oxidation stability, high-temperature detergency, extreme pressure antiwear property, viscosity-temperature performance, anti-foaming performance and high comprehensive performance; and in addition, the preparation method is simple and wide in applicable scope.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

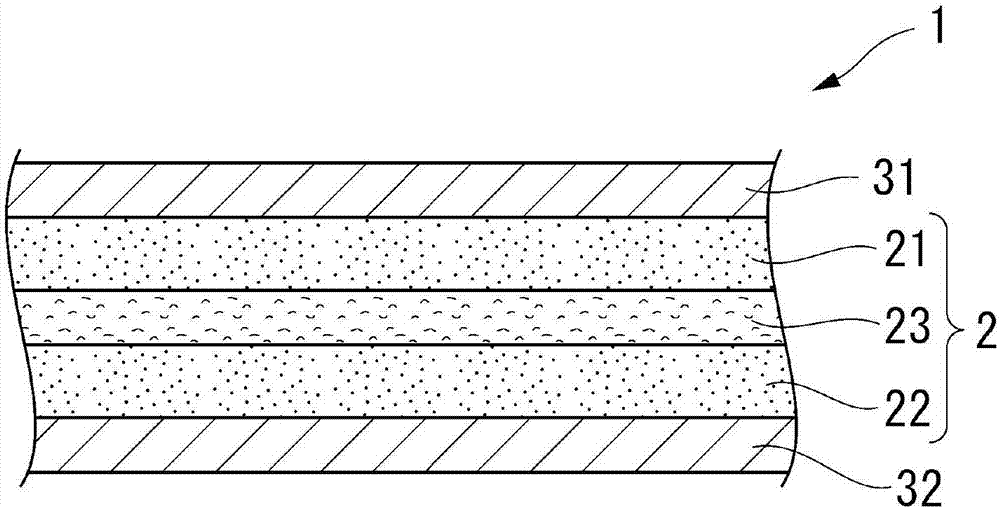

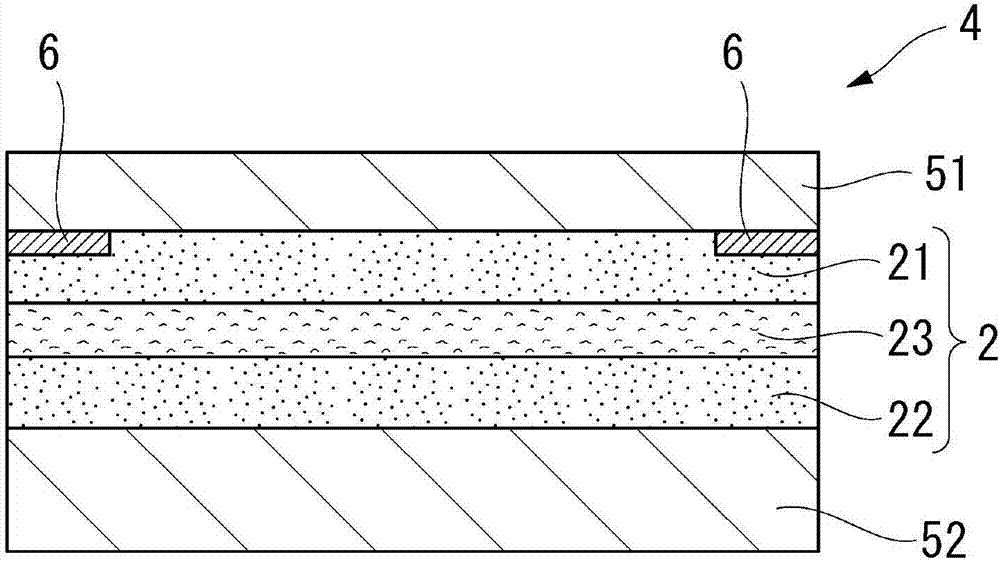

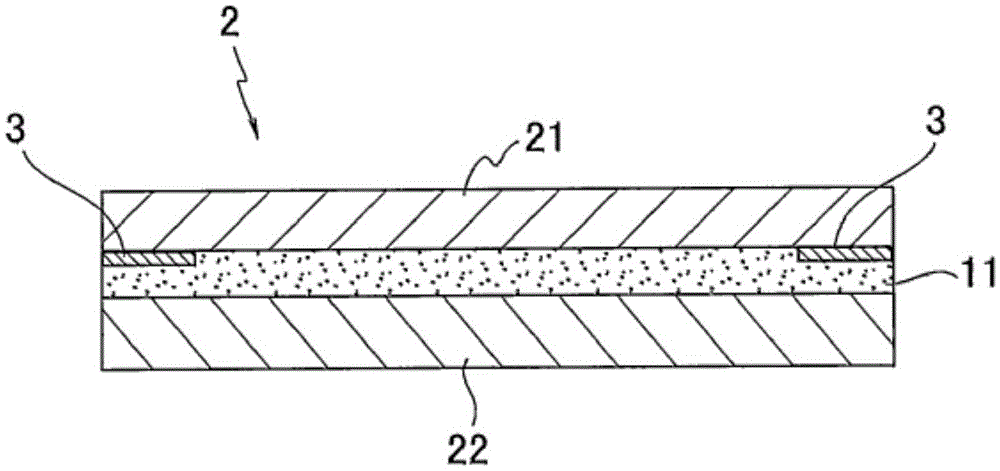

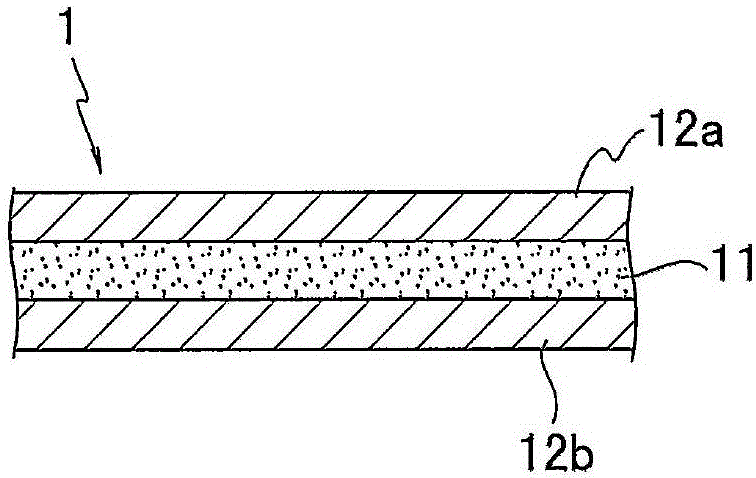

Adhesive Sheet And Display Body

ActiveCN106916540AExcellent step followabilityGood anti-foamNon-macromolecular adhesive additivesFilm/foil adhesivesPressure sensitiveChemistry

The present invention aims to provide an adhesive sheet and a display body. There is provided the adhesive sheet 1 having an adhesive layer 2, wherein the adhesive layer 2 comprises a first adhesive layer 21 as an outer layer on one surface side, a second adhesive layer 22 as an outer layer on the other surface side and a third adhesive layer 23 positioned as an intermediate layer between the first adhesive layer 21 and the second adhesive layer 22.An adhesive constituting the first adhesive layer 21 and an adhesive constituting the second adhesive layer 22 have a storage modulus (G') at 23 DEG C of 0.1 MPa or more, respectively. The third adhesive layer 23 is constituted of an active energy ray-curable pressure-sensitive adhesive. The storage modulus (G') at 23 DEG C of the active energy ray-curable pressure-sensitive adhesive before curing is lower than the storage modulus (G') at 23 DEG C of the adhesive constituting the first adhesive layer 21 and the storage modulus (G') at 23 DEG C of the adhesive constituting the second adhesive layer 22.

Owner:LINTEC CORP

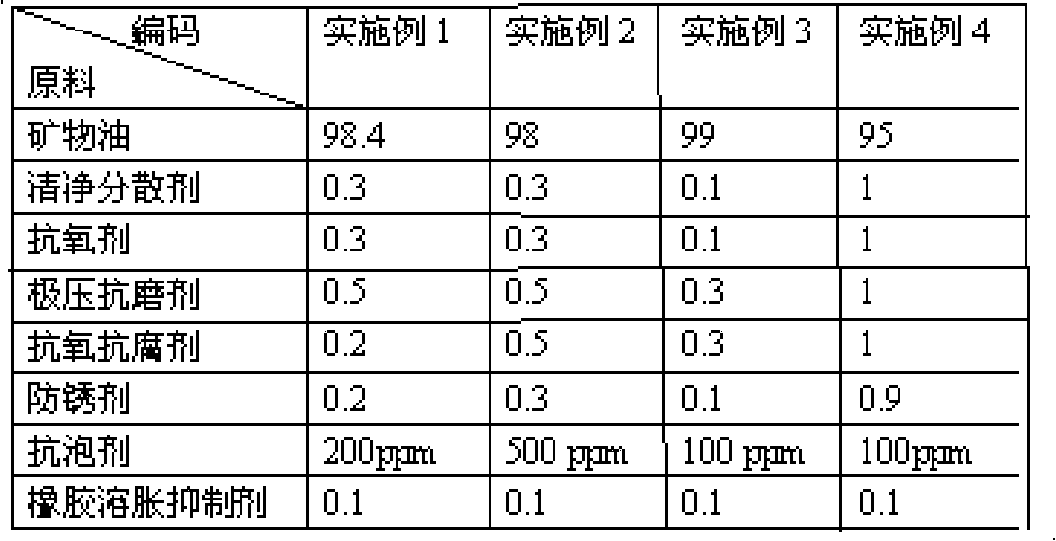

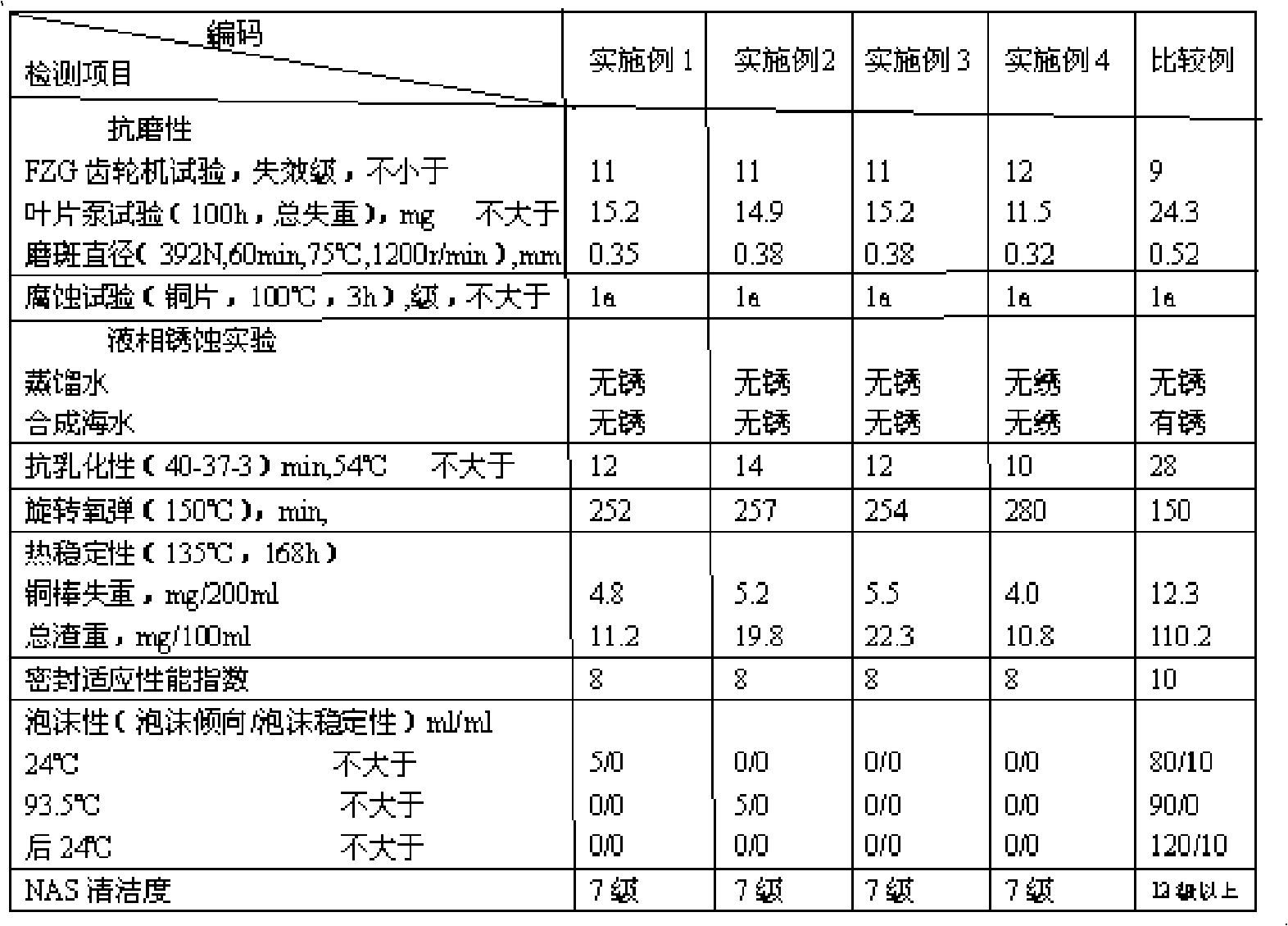

Antiwear hydraulic oil specially used for injection molding machine and preparation method thereof

InactiveCN101560435ALow costReduce manufacturing costAdditivesBase-materialsOxygenInjection molding machine

The invention discloses an antiwear hydraulic oil specially used for an injection molding machine, which is prepared by the following raw materials by weight percentage: 95-99% of mineral oil, 0.1-1.0% of detergent dispersant: high alkali synthesis calcium sulfonate, 0.1-1.0% of anti-oxidant: 2,6-di-tert-butyl-p-cresol and / or alkylated diphenylamine, 0.3-1.0% of extreme pressure antiwear additive, 0.2-1.0% of antioxidant and corrosion inhibitor, 0.1-0.9% of antirust: neutral dinonylnaphthalene sulfonic acid, 100-500ppm of defoaming agent and less than 0.1% of rubber swelling inhibitor. The invention also provides a method for preparing the hydraulic oil. The hydraulic oil has the advantages of excellent wearability, anti-rust performance, rotation oxygen bomb and thermal stability; simultaneously, the preparation method of the hydraulic oil is simple, is easy for industrial production and has low production cost.

Owner:NINGBO RUNBEI WANLING LUBRICANT

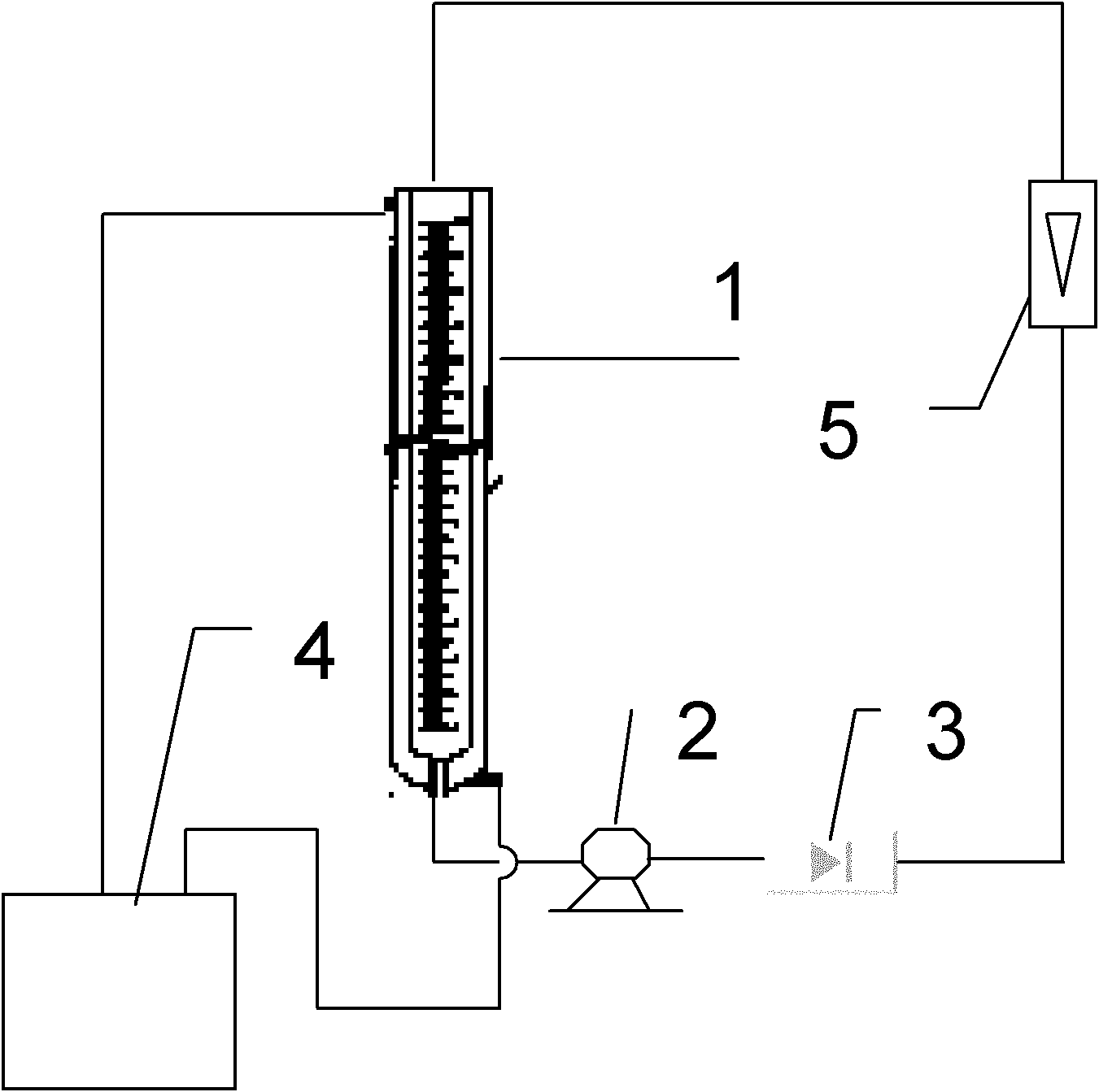

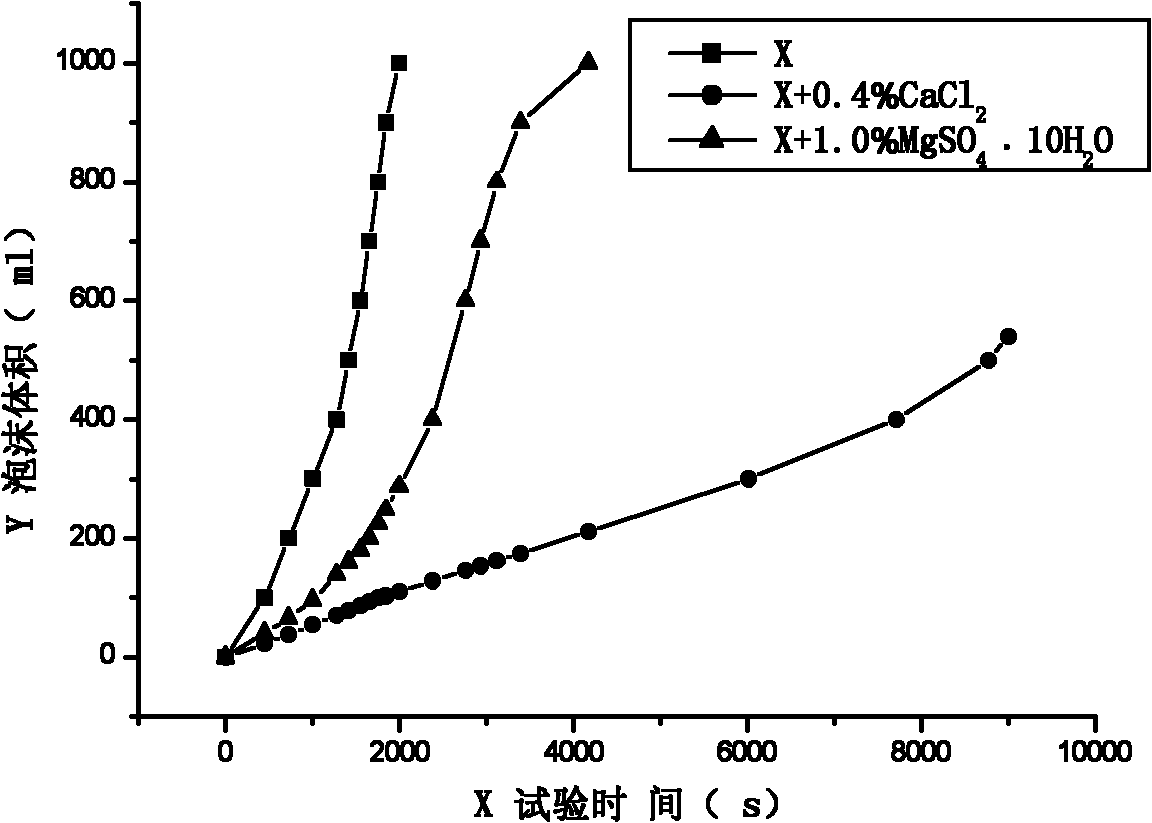

Method and device for testing foam properties

Owner:东莞太平洋博高润滑油有限公司

EP antiwear recombiner concentrate and its using method

InactiveCN1448494AImprove carrying capacityImprove the lubrication effectAdditivesGramSulfur containing

The concentrated composite extreme pressure anti-wear agent includes the following components: emulsifier in 20-80 wt%; at least one kind of sulfur-containing extreme pressure additive and at least one kind of phosphorus-containing extreme pressure additive with the gram atom S / P ratio 1-5000 in 10-80 wt%; oily agent in 0-60 wt% with the total content of extreme pressure additive and oily agent being 20-80 wt%; and diluent oil in 0-30 wt%. The emulsified liquid compounded with the concentrated agent has high lubricating effect, no toxicity, no bad smell, no bubble and other advantages, and may be used in metal cutting machining and metal deforming treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

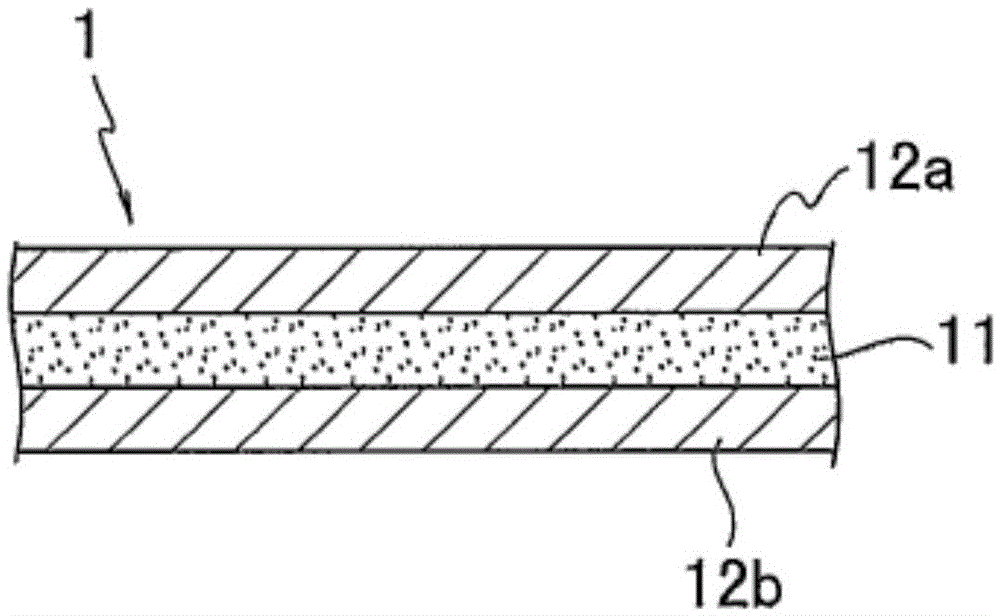

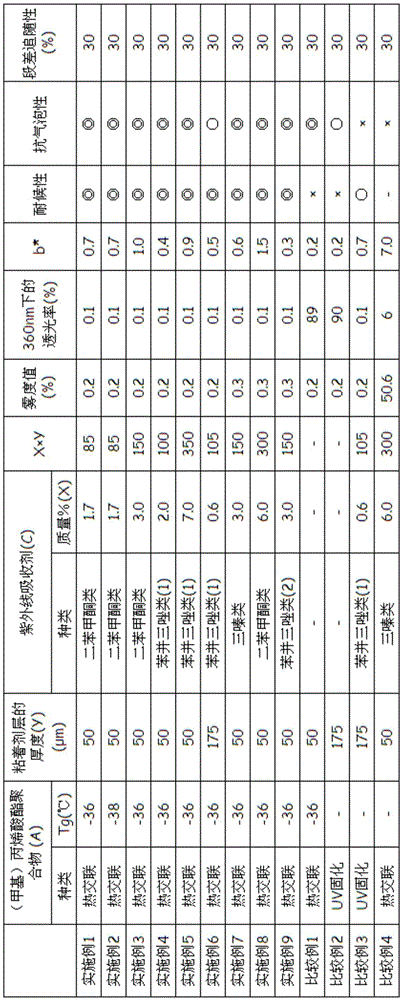

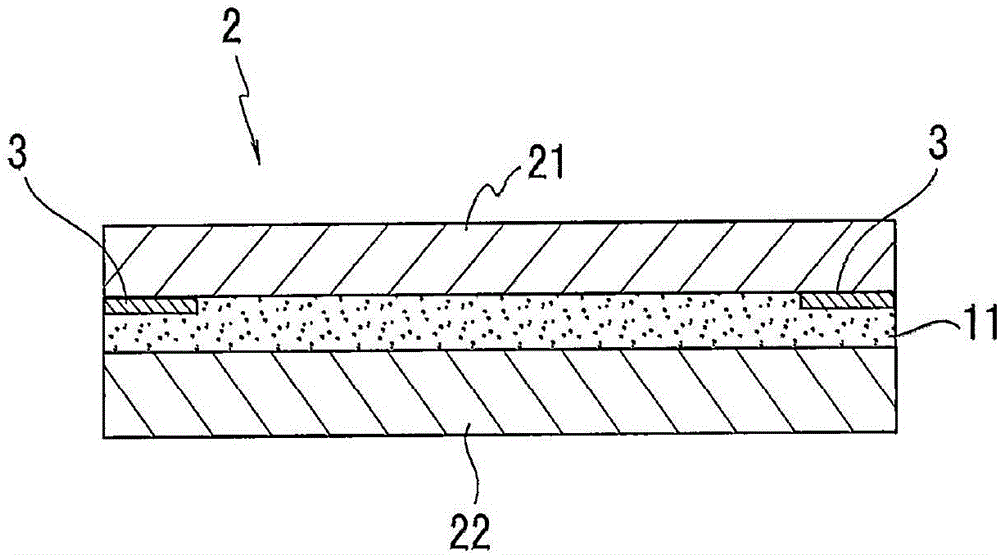

Adhesive sheet and display

PendingCN106010326AGood anti-foamNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

The invention provides an adhesive sheet and a display which are not liable to be subjected to adverse influence of UV light and have excellent anti-foaming performance. The adhesive sheet (1) has an adhesive layer (11) which bonds a display forming component (21) to another display forming component (22), which have section difference at least on to-be-laminated sides. The adhesive layer (11) is composed of an adhesive that is formed by thremal-crosslinking an adhesive composition including (methyl)acrylate polymer (a), a thermal-crosslinker (b) and a ultraviolet absrober (c). The adhesive layer (11) is lower than 2% in haze and is lower than 1% in light transmittance under wavelength of 360 nm.

Owner:LINTEC CORP

Process for forming multilayer coating film

ActiveCN104797350AImprove smoothnessImprove sharpnessLiquid surface applicatorsPolyurea/polyurethane coatingsCLARITYPolyester resin

The present invention addresses the problem of providing a process for forming a multilayer coating film which exhibits excellent smoothness, image clarity, water resistance, adhesiveness, and pinholing resistance, said process being capable of forming, even in a case where a coating material is stored and thereafter applied, a multilayer coating film which exhibits excellent water resistance and adhesiveness. A process for forming a multilayer coating film which includes applying successively a first aqueous pigmented coating material and a second aqueous pigmented coating material onto a substrate to be coated and simultaneously curing the first and second aqueous pigmented coating materials by heating, characterized in that the first aqueous pigmented coating material contains both an acryl-modified polyester resin and a blocked polyisocyanate compound which has a specific blocked isocyanate group.

Owner:KANSAI PAINT CO LTD

Heavy-duty antiemulsifying oil film bearing oil

InactiveCN1346874AGuaranteed normal operationImprove the lubrication effectAdditivesWire rodDemulsifier

A heavy-duty antiemulsifying oil film type bearing oil for high-speed wire rolling mill contains demulsifier, antiwear agent, antifoaming agent, alkylnaphthalene, antioxidant and mineral oil. Its advantages are excellent antiemulsifying, antiwear, anti-extreme-pressure, anticorrosion, antirust, antifoaming and antioxidizing performance, and better viscosity-temp characteristic.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

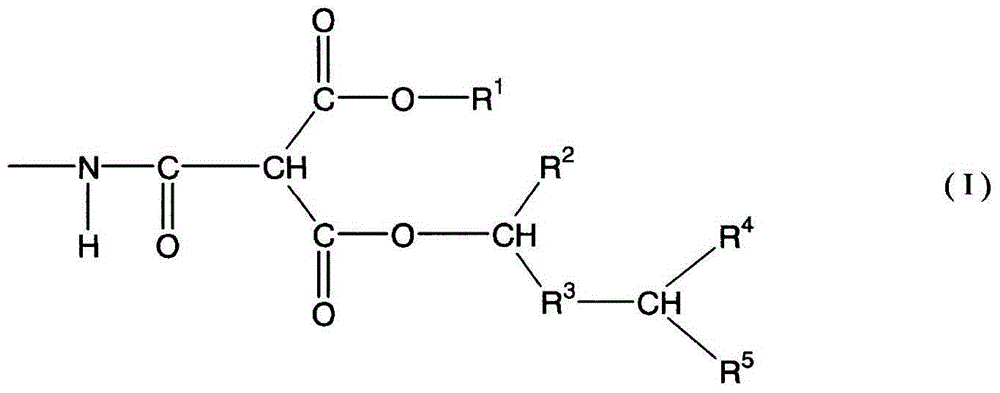

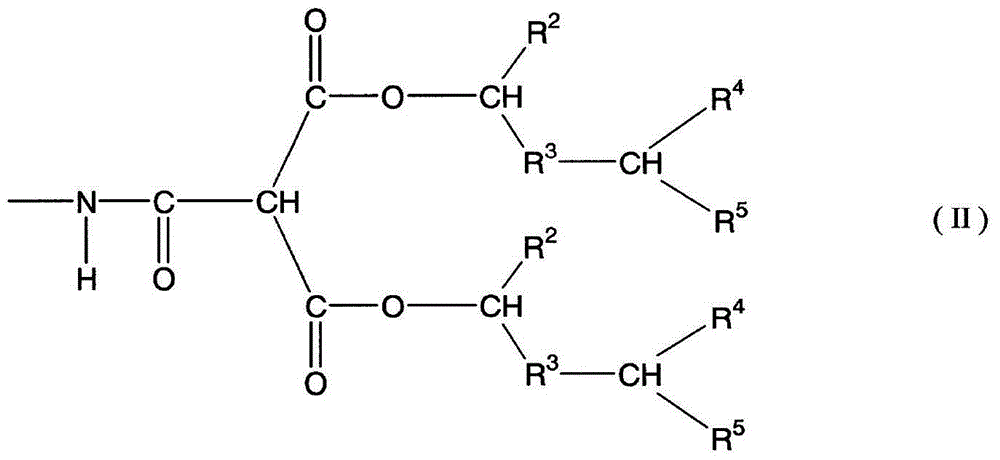

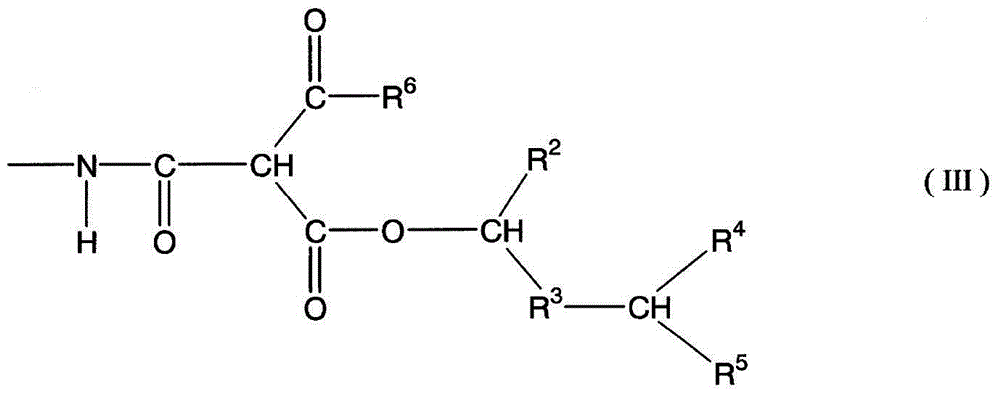

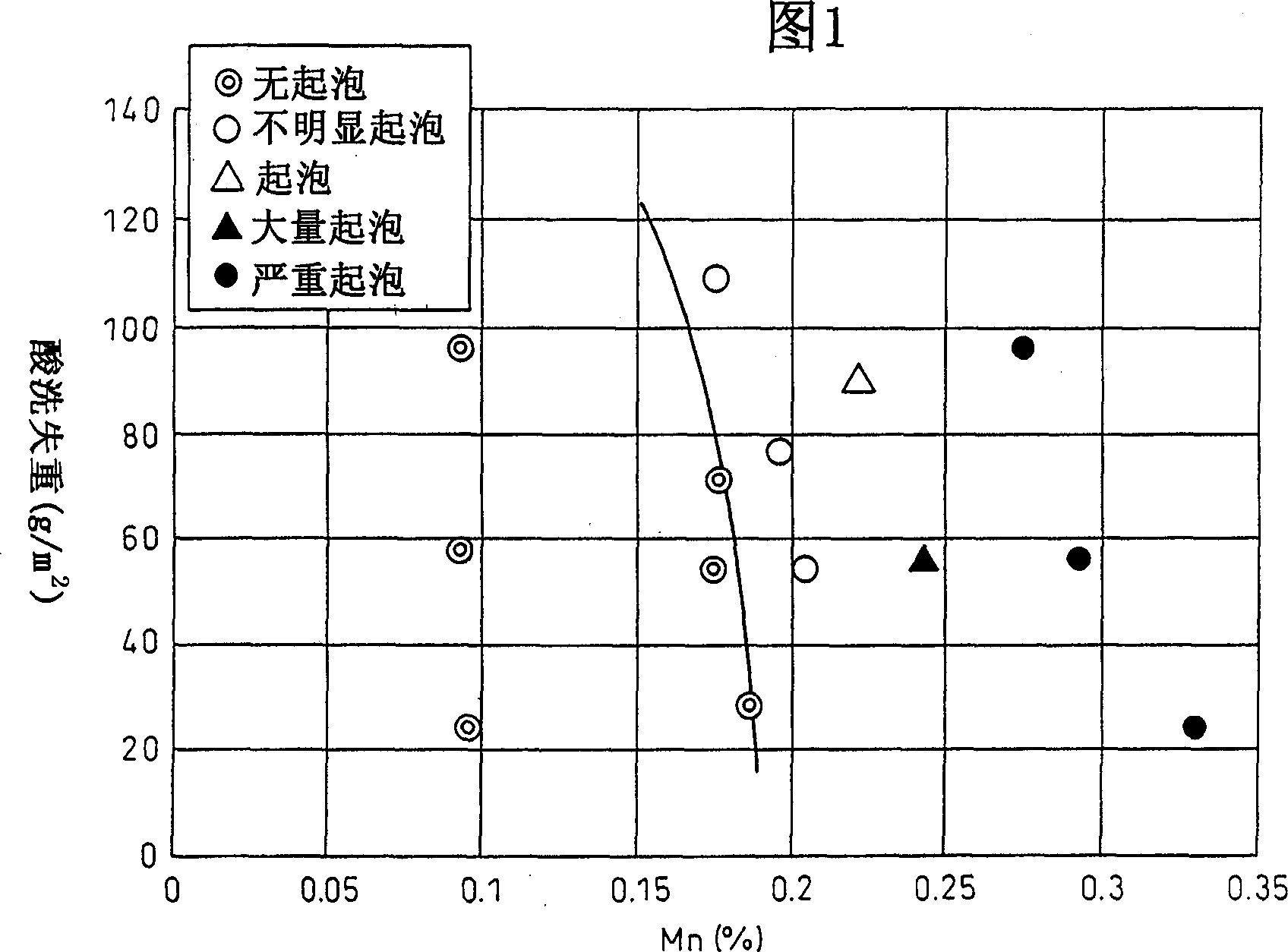

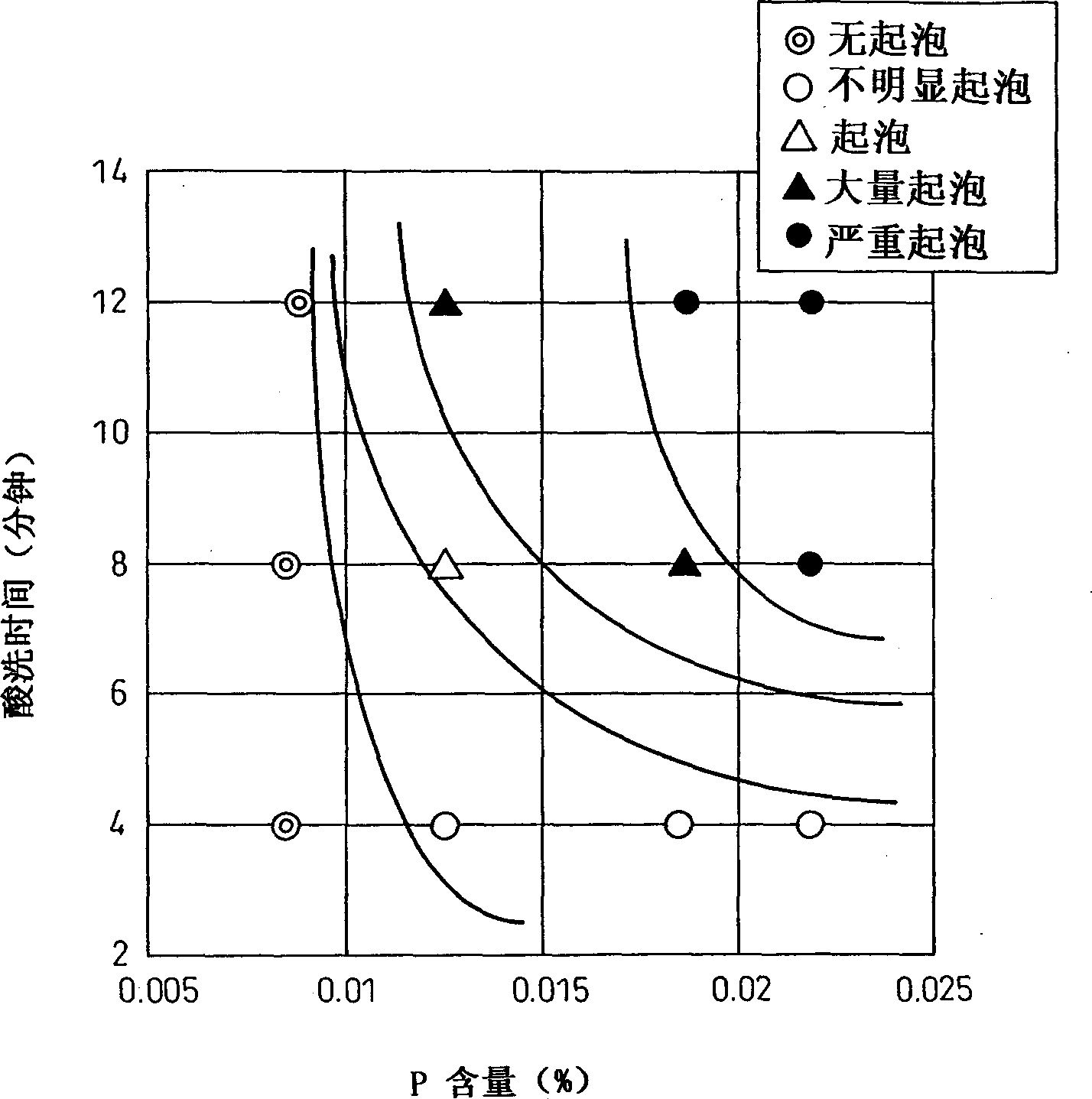

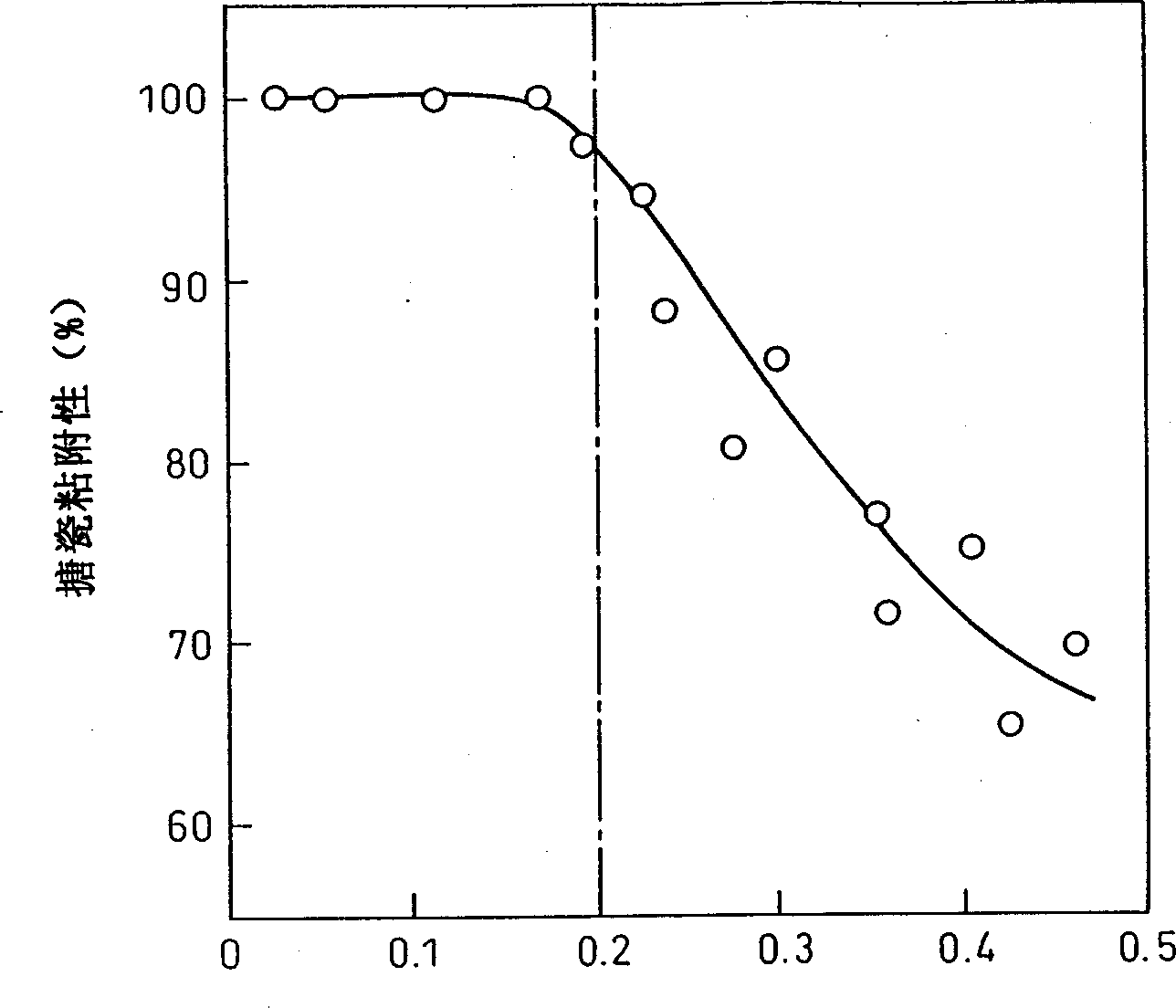

Continuous casting steel plate for porcelain enameling excellent in formability, resistance to occurrence of bubble or black point, and adhesion with porcelain enamel

InactiveCN1320171AGood formabilityGood anti-foamFurnace typesMetal rolling arrangementsBlack spotContinuous casting

A vitreous enamel steel sheet produced by a continuous casting, excellent in formability, bubbling and black spot resistance and adhesiveness, which comprises, in terms of mass %, 0.002% or less of C, 0.05 to 0.2% of Mn, 0.01% or less of Si, 0.004% or less of N, 0.015 to 0.05% of 0, less than 0.01% of P, 0.025% or less of S, 0.02 to 0.04% of Cu, 0.03 to 0.05% of Nb, and 0.03 to 0.07% of V, satisfying the inequality: 0.2>Mn (%)-2.0.O (%)+0.8.V (%)+0.5.Nb (%), and the balance consisting of Fe and unavoidable impurities, and a method for producing the same.

Owner:NIPPON STEEL CORP

Emulsion for modifying water emulsion asphalt coating, preparation method of emulsion and coating

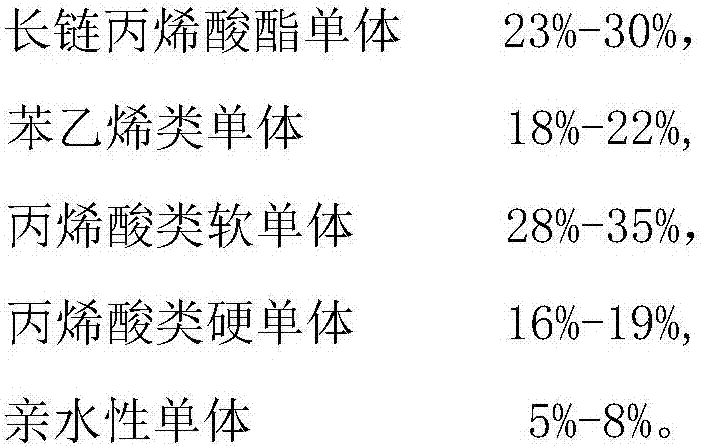

The invention discloses an emulsion for modifying a water emulsion asphalt coating, a preparation method of the emulsion, and the coating, relates to the field of building materials, and solves technical problems that the water emulsion asphalt coating cannot achieve high tensile strength, high elongation, high bonding strength and construction without blistering simultaneously. The emulsion of the invention comprises the following components by mass: 20%-30% of long chain acrylate monomers, 15%-25% of styrene monomers, 25%-35% of acrylic soft monomers, 15%-20% of acrylic hard monomers and 3%-8% hydrophilic monomers. The water emulsion asphalt coating prepared by adopted the emulsion provided by the invention has characteristics of high tensile strength, high elongation, high bonding strength and construction without blistering simultaneously.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

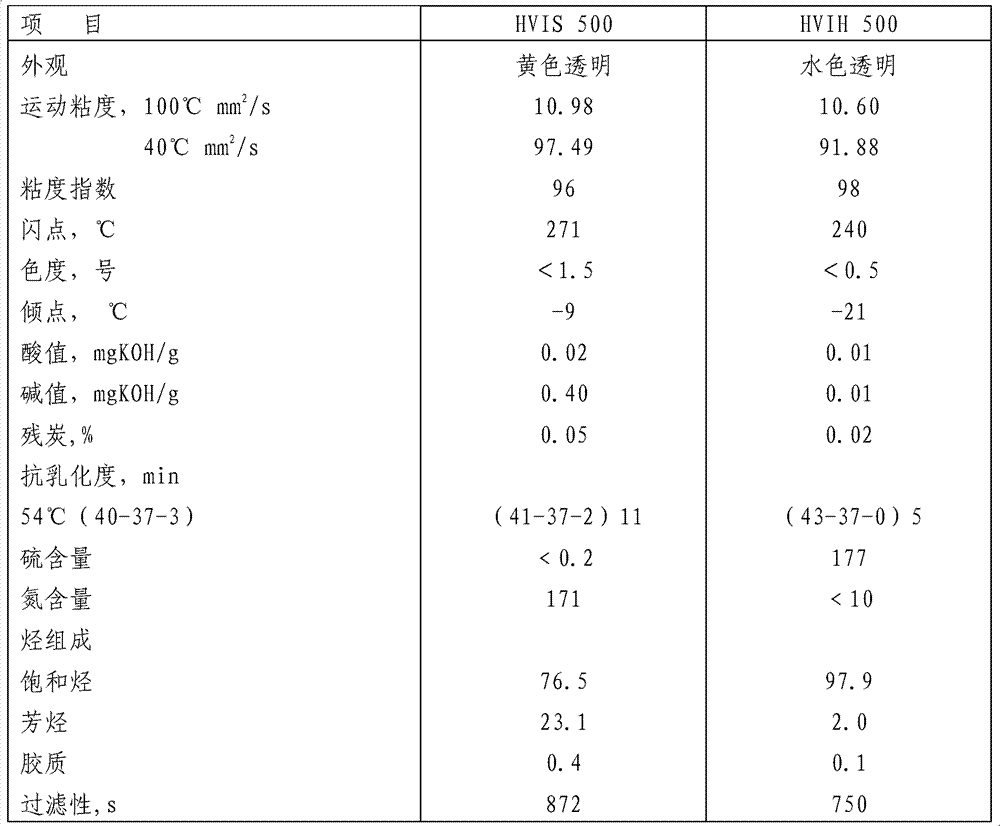

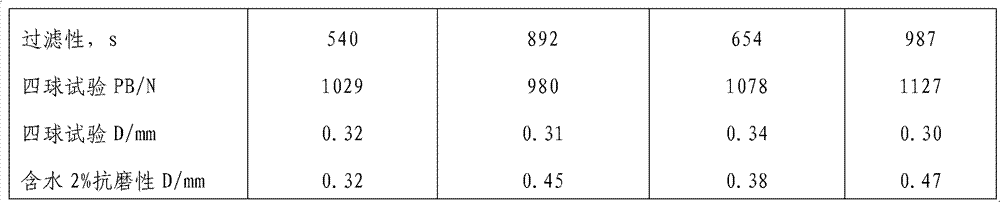

Ashless antiwear oil film bearing lubricant composition

ActiveCN102766505AImprove filtering effectGood demulsibilityLubricant compositionWire rodFoaming agent

The invention provides an ashless antiwear oil film bearing lubricant composition, which comprises: (A) at least a highly refined mineral oil with high viscosity index; (B) at least an emulsifier; (C) at least an anti-foaming agent; (D) at least an ashless phosphorus-containing antiwear additive; (E) at least an anti-oxidant; and (F) at least a metal passivator. The above lubricant component has excellent demulsibility, filterability, anti-foaming property, air release property, abrasion resistance and oxidation resistance, passes through FAG FE-8 bearing wear experiments, SKFEMCOR bearing corrosion experiments and FLENDER anti-foaming experiments, and is suitable for lubricating various bearings and industrial gears, especially lubricating highspeed wire rod oil film bearings.

Owner:PETROCHINA CO LTD

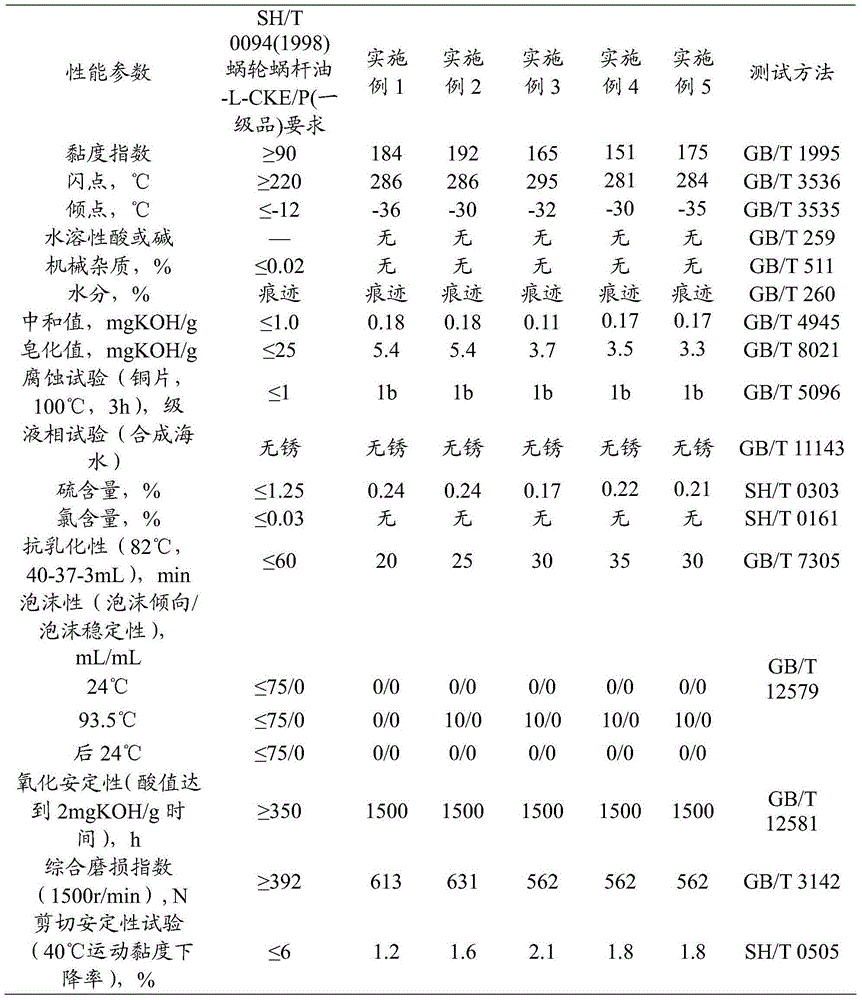

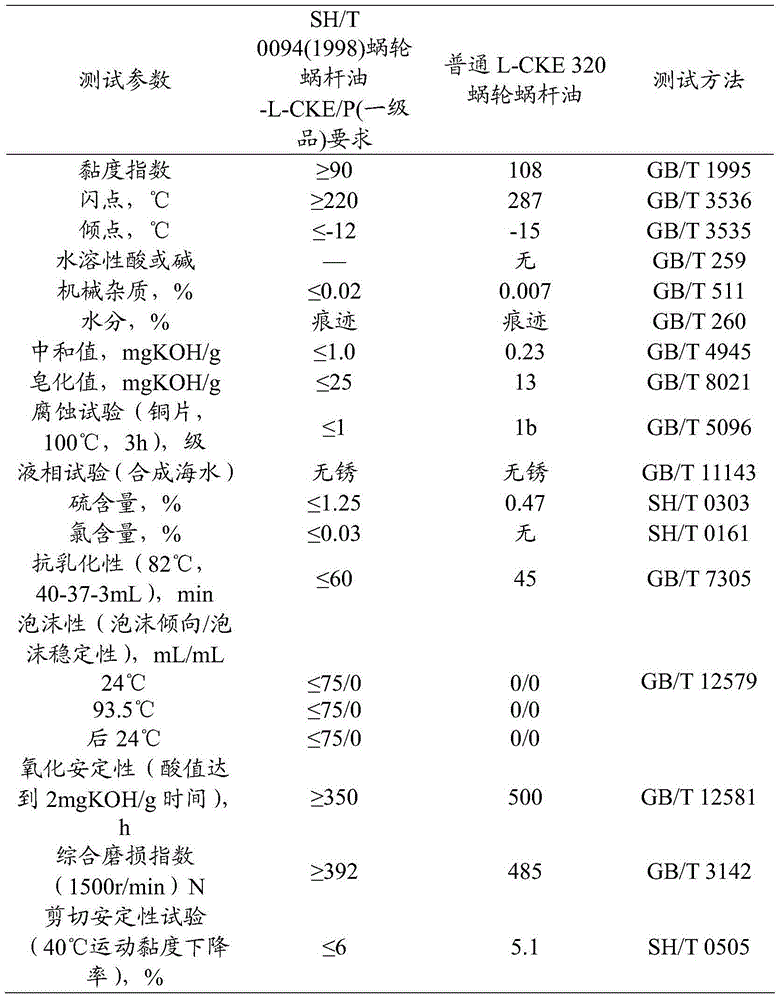

Worm wheel worm rod lubricating oil composition and preparation method thereof

ActiveCN104403741AImprove extreme pressure and anti-wear performanceImprove Oxidation StabilityLubricant compositionPolyolefinFoaming agent

The present invention provides a worm wheel worm rod lubricating oil composition and a preparation method thereof. The worm wheel worm rod lubricating oil composition comprises 45-75 wt% of poly[alpha]-olefin, 10-45 wt% of oil-soluble polyether, 0.1-5 wt% of an antioxidant, 0.01-0.5 wt% of a metal deactivator, 0.1-5 wt% of a corrosion inhibitor, 0.5-5 wt% of an extreme pressure anti-wear agent, and 0.0005-0.05 wt% of an anti-foaming agent. According to the present invention, the poly[alpha]-olefin and the oil-soluble polyether are adopted as the base oils, the antioxidant, the metal deactivator, the corrosion inhibitor, the extreme pressure anti-wear agent and the anti-foaming agent are adopted as the additives, and the contents of each component are controlled within the content range, such that the worm wheel worm rod lubricating oil composition has the good extreme pressure anti-wear property and the excellent oxidation stability; and the worm wheel worm rod lubricating oil composition further has characteristics of excellent corrosion resistance, excellent rust resistance, excellent shear stability, good oil-water separation property and good anti-foam property.

Owner:CHINA PETROLEUM & CHEM CORP

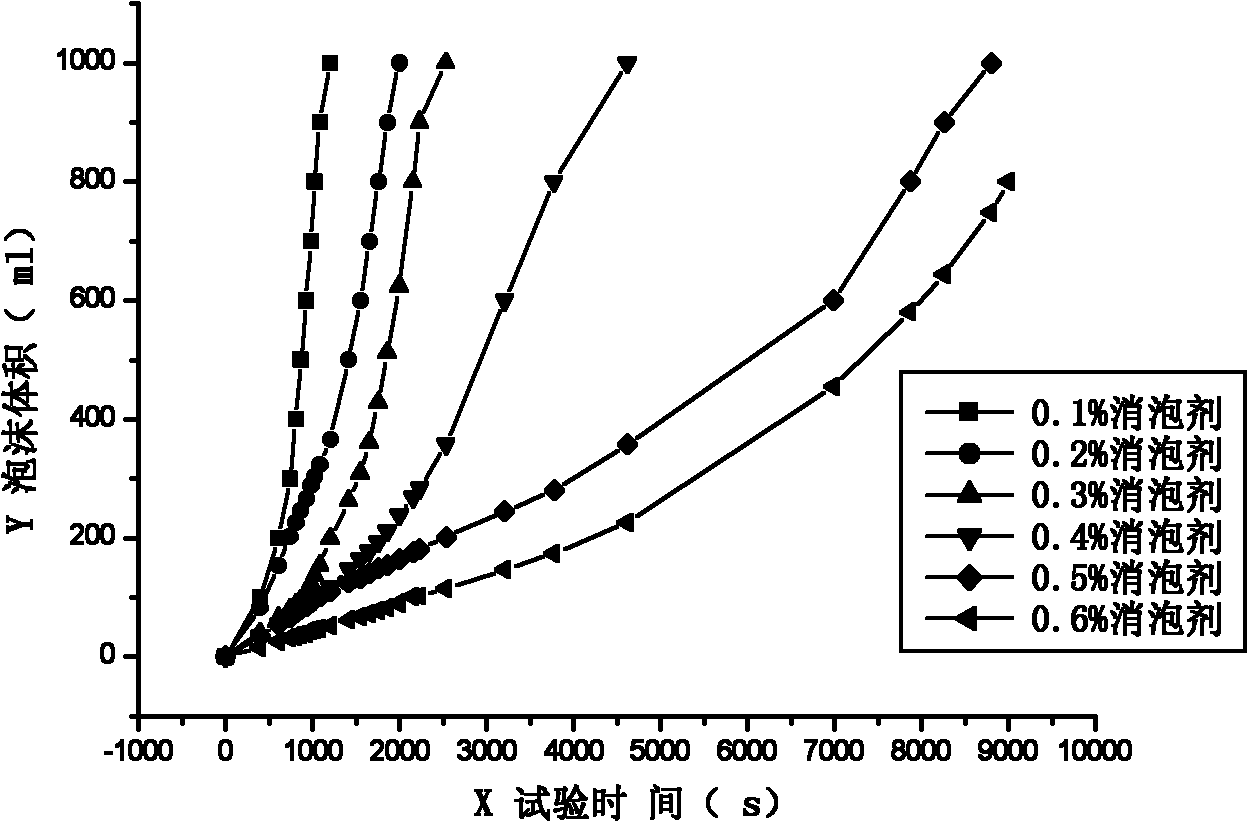

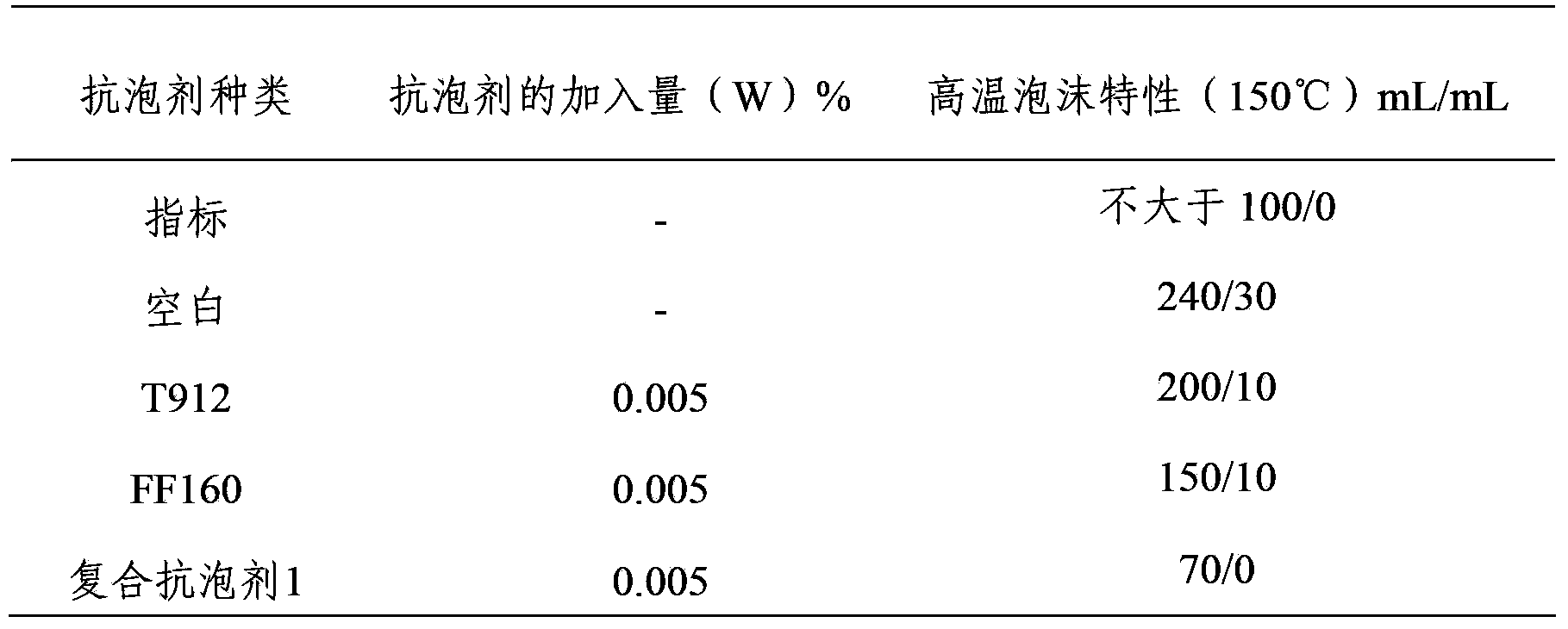

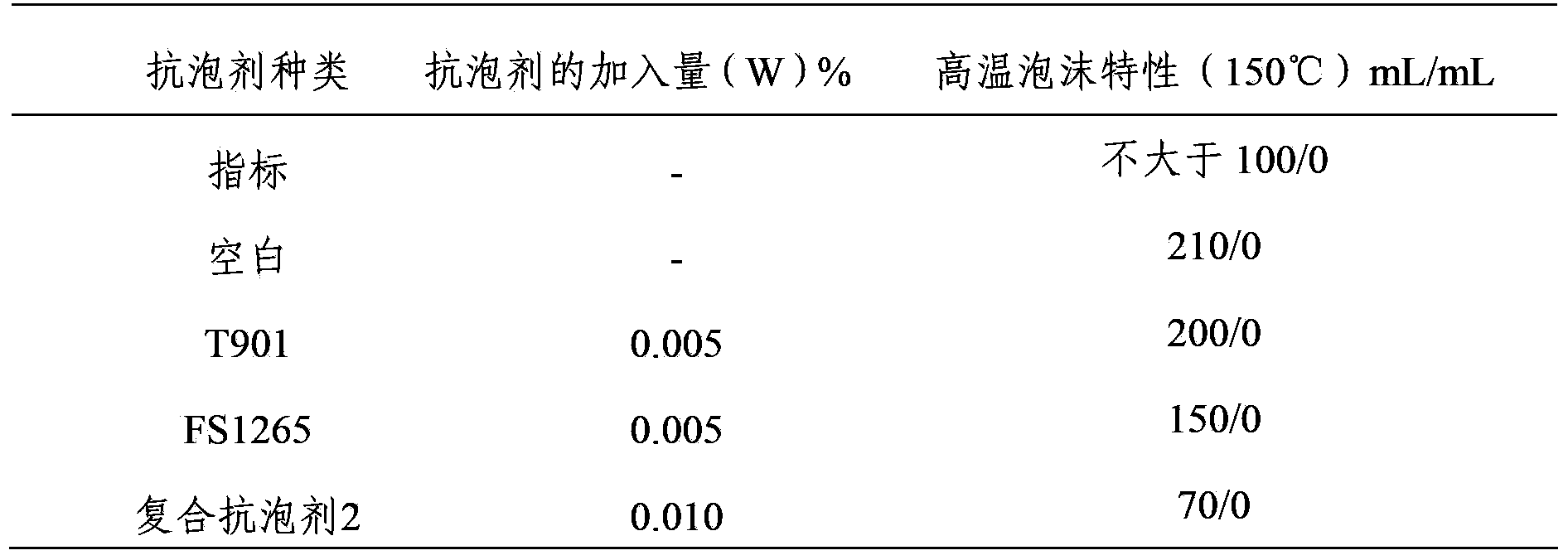

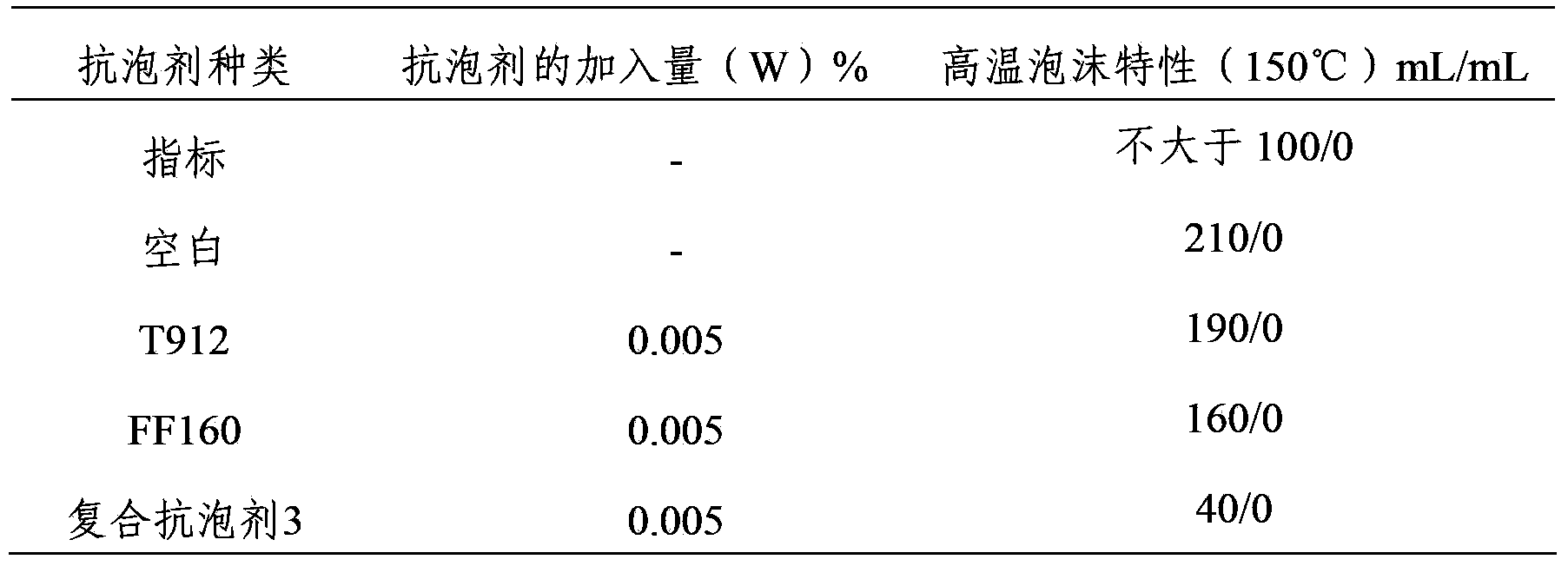

Lubricating oil composite type antifoaming agent and application thereof

The invention provides a lubricating oil composite type antifoaming agent. With composite of two or more antifoaming agents comprising silicone oil, fluorine-containing silicone oil and an acrylate copolymer and with cooperative use of two or more solvents comprising paint industry solvent oil, aviation kerosene and pentanone, the antifoaming agent is used in lubricating oil products, and improves the high-temperature antifoaming property of the oil products.

Owner:CHINA PETROLEUM & CHEM CORP

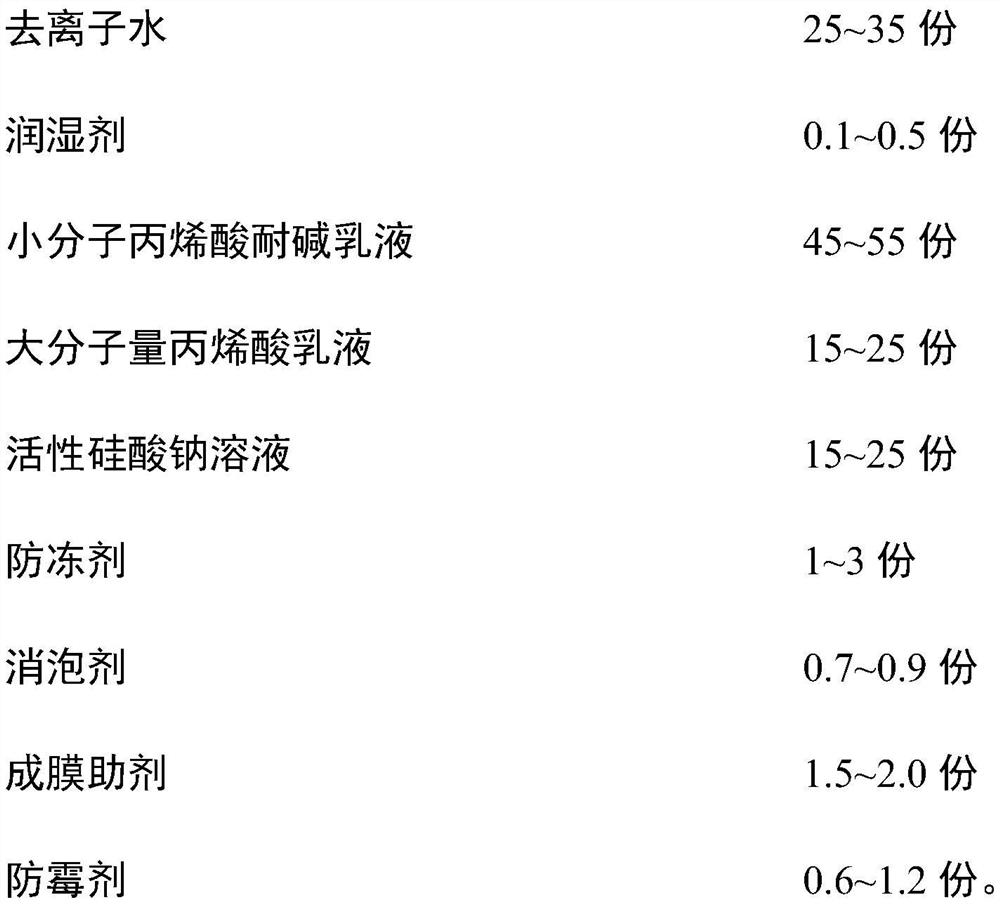

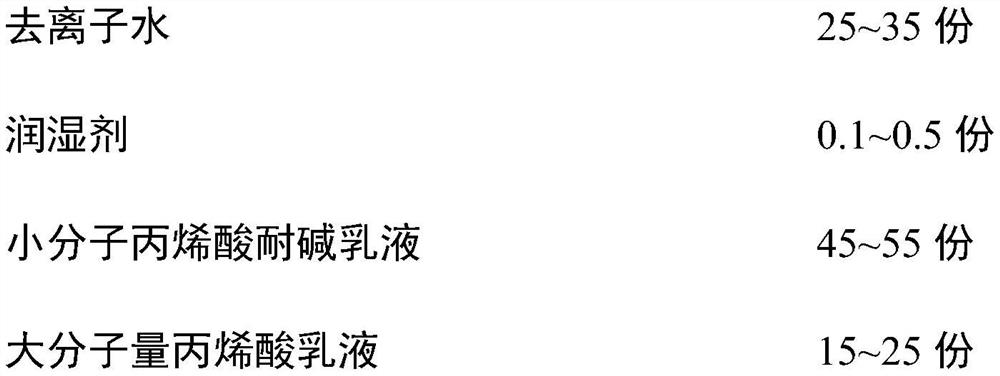

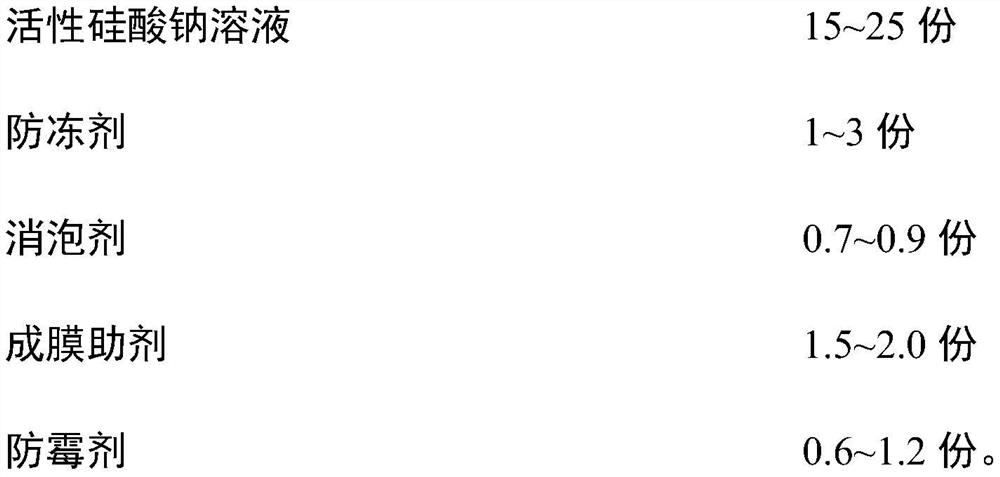

Formula and preparation method of special high-performance concrete substrate seal primer for heat-insulating waterproof coating

The invention discloses a formula of a special high-performance concrete substrate seal primer for a heat-insulating waterproof coating. The formula comprises the following components in parts by weight: 25-35 parts of deionized water; 0.1 to 0.5 part of a wetting agent; 45-55 parts of small molecular acrylic acid alkali-resistant emulsion; 15-25 parts of high molecular weight acrylic emulsion; 15to 25 parts of an active solution; 1-3 parts of an anti-freezing agent; 0.7 to 0.9 part of a defoaming agent; 1.5 to 2.0 parts of a coalescing agent; and 0.6-1.2 parts of a mildew inhibitor. The invention further discloses a preparation method of the formula. The seal primer has an excellent anti-foaming performance in a long-term soaking environment, and does not lose the sealing effect due to soaking and foaming within 3-5 years. The seal primer has good permeability to a concrete substrate, and can be easily combined with fine cracks and capillary gaps in a concrete roof to form a firm waterproof layer.

Owner:哈尔滨猎客科技有限公司

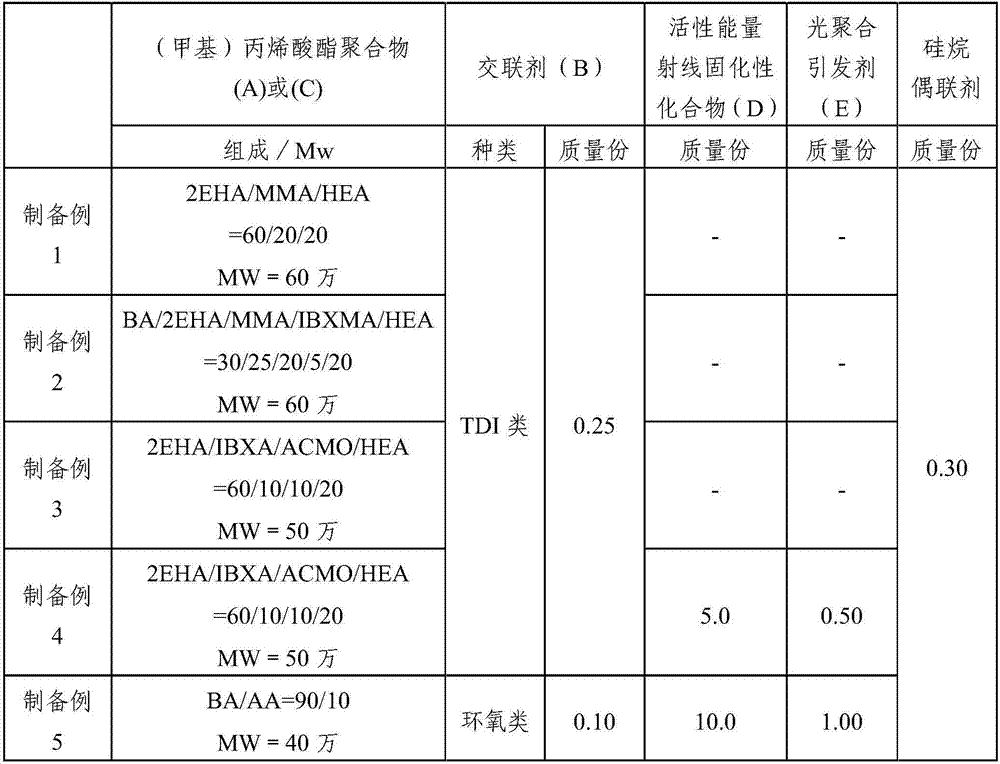

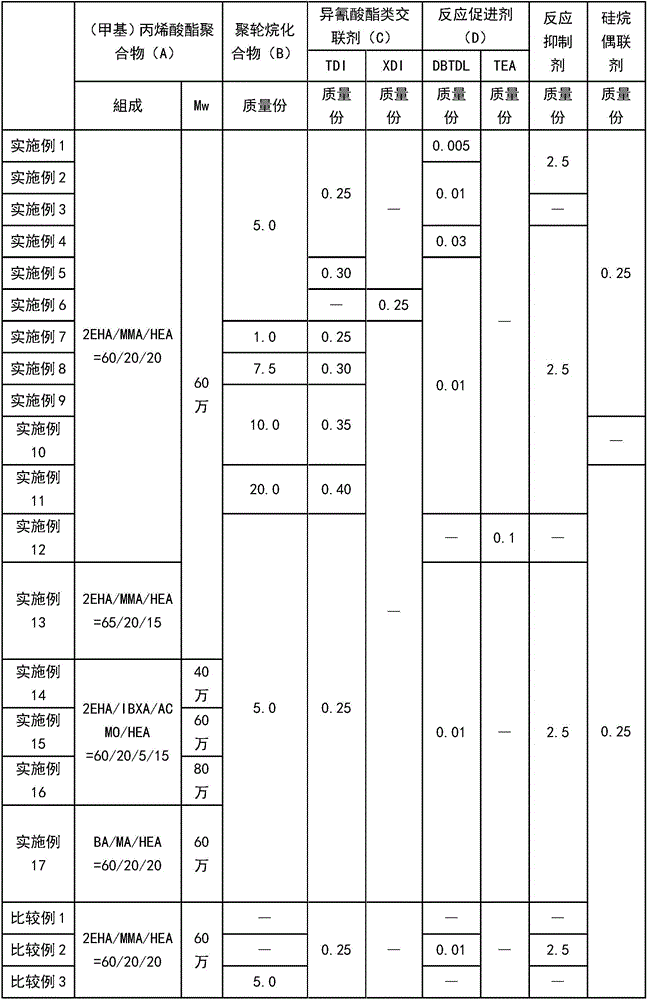

Adhesive composition, adhesive, adhesive sheet, and display body

PendingCN106433523AExcellent step followabilityGood anti-foamNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyrotaxaneMeth-

The invention provides an adhesive composition, an adhesive, an adhesive sheet, and a display body. The adhesive composition has an excellent performance on preventing foaming. The adhesive composition comprises (meth)acrylate polymer (A), which comprises a monomer unit composed of hydroxyl monomers; polyrotaxane (B), which comprises hydroxyl taken as the reactive groups and cyclic oligosaccharide as the cyclic molecules; an isocyanate crosslinking agent (C); and a reaction promoter (D), which promotes the carbamate reactions.

Owner:LINTEC CORP

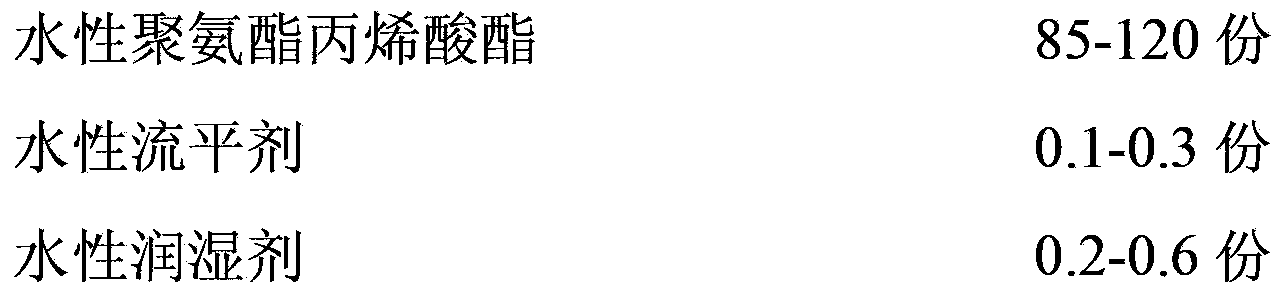

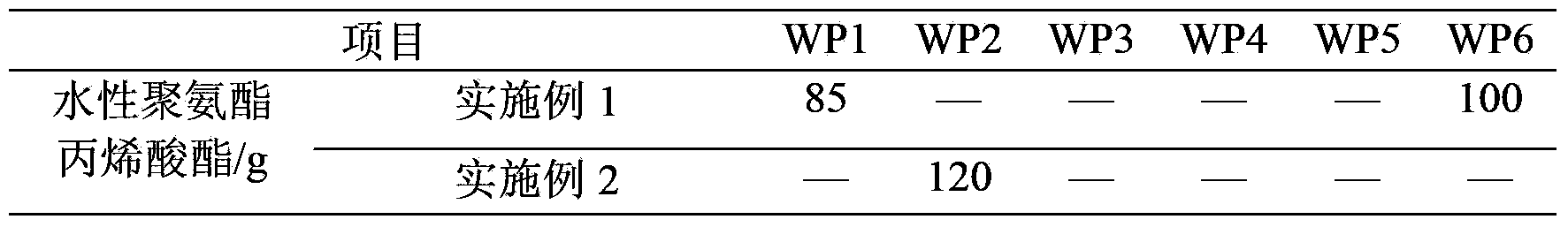

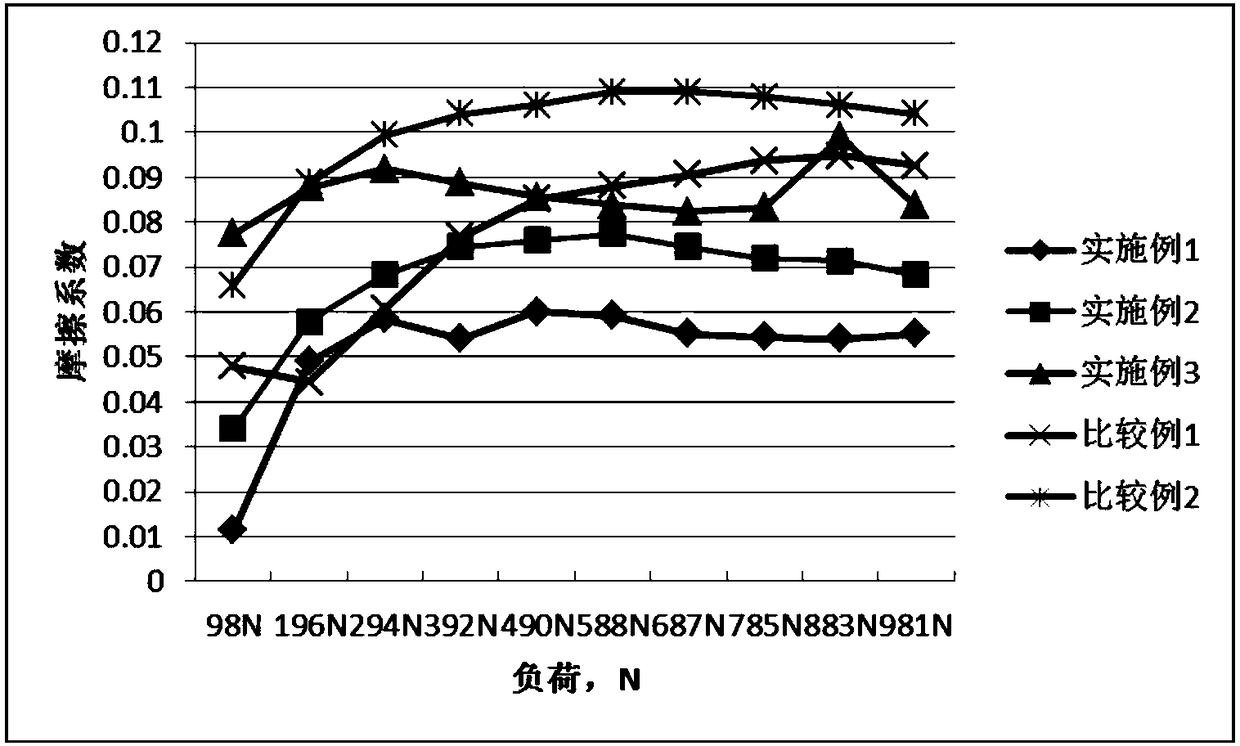

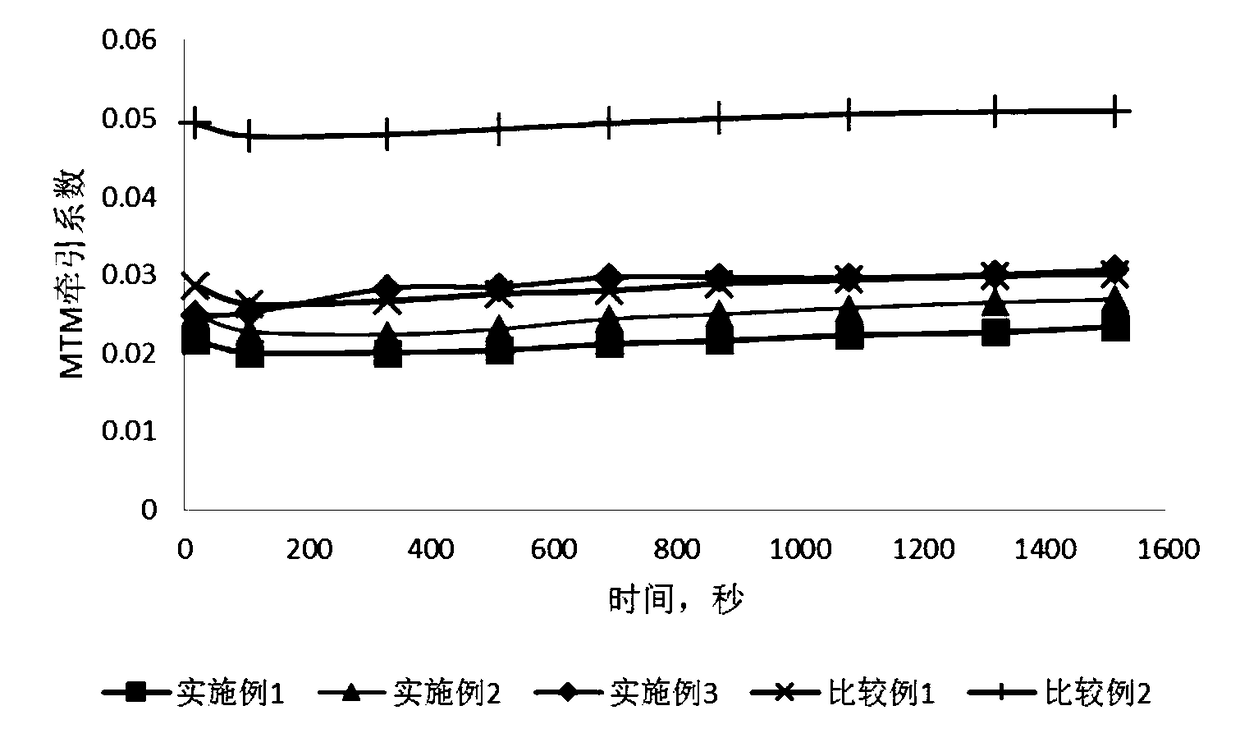

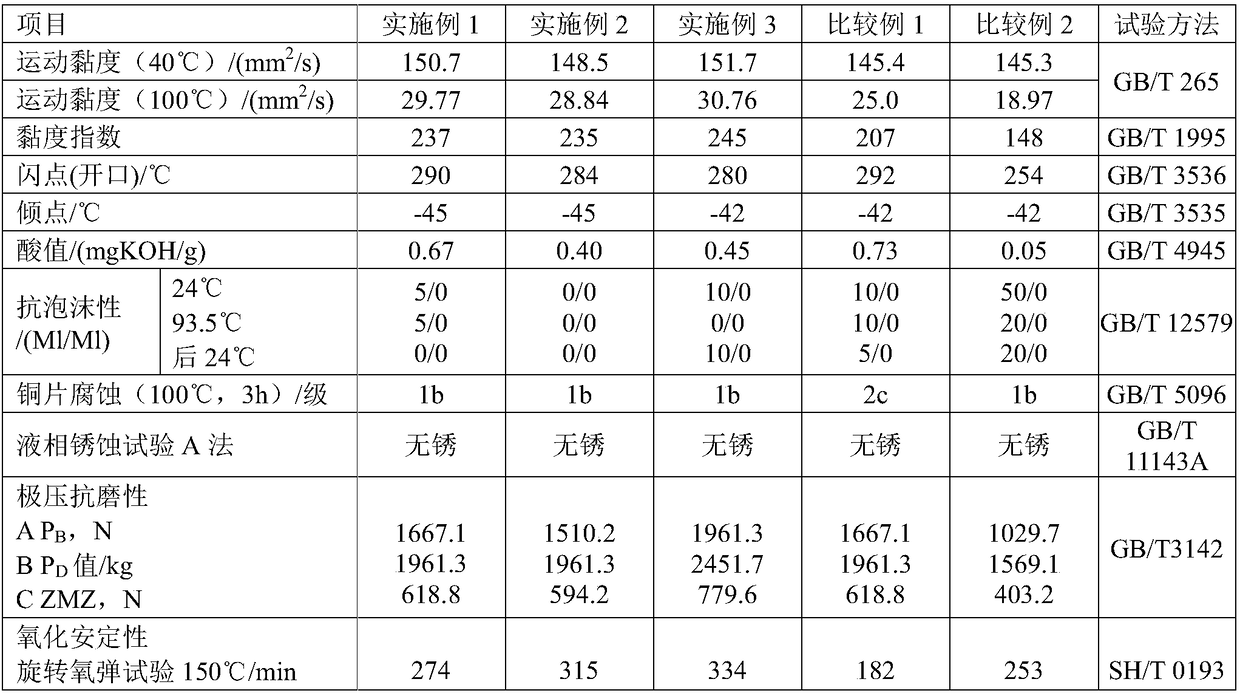

Water-based ultraviolet-thermal dual-curing coating and preparation method thereof

ActiveCN103409060AImprove water resistanceGood anti-foamPolyurea/polyurethane coatingsWater basedUrethane acrylate

The invention provides a water-based ultraviolet-thermal dual-curing coating and a preparation method thereof, belongs to the technical field of water-based coatings and solves the problem that a conventional water-based ultraviolet-thermal dual-curing coating has poor waterproof and anti-foaming properties. The coating provided by the invention comprises 85-120 parts of water-based urethane acrylate, 0.1-0.3 part of water-based flatting agent, 0.2-0.6 part of water-based wetting agent, 1.2-2.6 parts of photoinitiator, 8-12 parts of water-based cosolvent and 4.5-8 parts of water-based curing agent. The water-based urethane acrylate is nonionic water-based urethane acrylate modified by silicone. The invention further provides the preparation method of the water-based ultraviolet-thermal dual-curing coating. After being soaked in indoor-temperature water for 24 hours, the water-based ultraviolet-thermal dual-curing coating doesn't foam, wrinkle or flake off, which proves that the water-based ultraviolet-thermal dual-curing coating has excellent waterproof and anti-foaming properties.

Owner:CHANGCHUN SANHUA IND

Lubricating oil composition for industrial robot speed reducer

InactiveCN109401820AImprove performanceTechnically difficultLubricant compositionLinear polymerDefoaming Agents

The invention discloses a lubricating oil composition for an industrial robot speed reducer. The lubricating oil composition comprises 84.0-95.91wt% of polyalkylene glycol, 3-10wt% of a sealing applicability improver, 0.1-2.0wt% of an extreme pressure anti-wearing additive, 0.01-1.0wt% of a metallic deactivator, 0.05-1.0wt% of an anti-rusting corrosion inhibitor, 0.5-3.0wt% of an anti-oxidation additive and 10-20mu g / g of a defoaming agent, wherein the polyalkylene glycol is a linear polymer taking ethylene oxide and propylene oxide as main raw materials; the polymer comprises 50-70% of an EO(Ethylene Oxide) unit and 30-50% of a PO (Propylene Oxide) unit; the sealing applicability improver is a saturated polyol ester or diester. The lubricating oil composition has excellent viscosity-temperature performance and low-temperature performance, excellent oxidation stability and good extreme pressure wearing resistance, anti-rusting corrosion resistance and foam resistance, an oil film canbe rapidly formed, operation temperatures can be reduced, energy consumption can be reduced, the transmission efficiency of a speed reducer is degraded, the wearing of tooth surfaces can be reduced, and lubricating requirements of multi-stage speed reducers of multi-axis industrial robots can be met.

Owner:PETROCHINA CO LTD

Graphene-containing vegetable lubricant and preparation method thereof

InactiveCN106350167AReduce friction lossGood friction and lubrication propertiesLubricant compositionSucrosePolymethyl methacrylate

The invention discloses a graphene-containing vegetable lubricant. The graphene-containing vegetable lubricant is prepared from the following raw materials: castor oil, modified castor oil, liquid graphene, trimethyl citrate, N,N-dimethylacetamide, modified nano cerium vanadium oxide, modified sodium carboxymethylcellulose, sucrose ester, an organic molybdenum compound, dodecyl selenium, 4-hydroxy-4-methyl-2-pentanone, benzotriazole, polymethyl methacrylate, 1-butyl-3-vinyl imidazole hexafluoroantimonate, polyurethane, cyclohexane and an organic anti-aging agent. The graphene-containing vegetable lubricant disclosed by the invention has the advantages that the castor oil and other additives are combined, an environment-friendly vegetable lubricant is prepared, the balance of properties is achieved by controlling the types and quantity of the additives, the vegetable lubricant has better oxidation resistance and self-cleaning capability and also has good lubricating property, viscosity-temperature characteristic, low temperature fluidity, low volatility, corrosion resistance, anti-foam property and anti-emulsifying property, and the overall performance is good.

Owner:梁海东

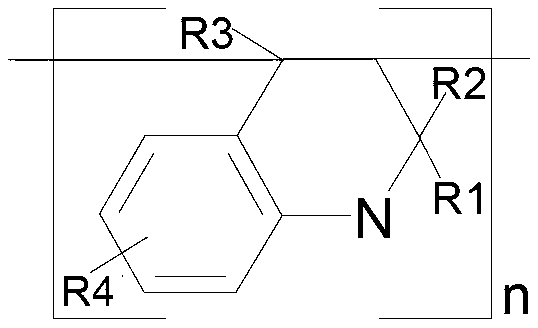

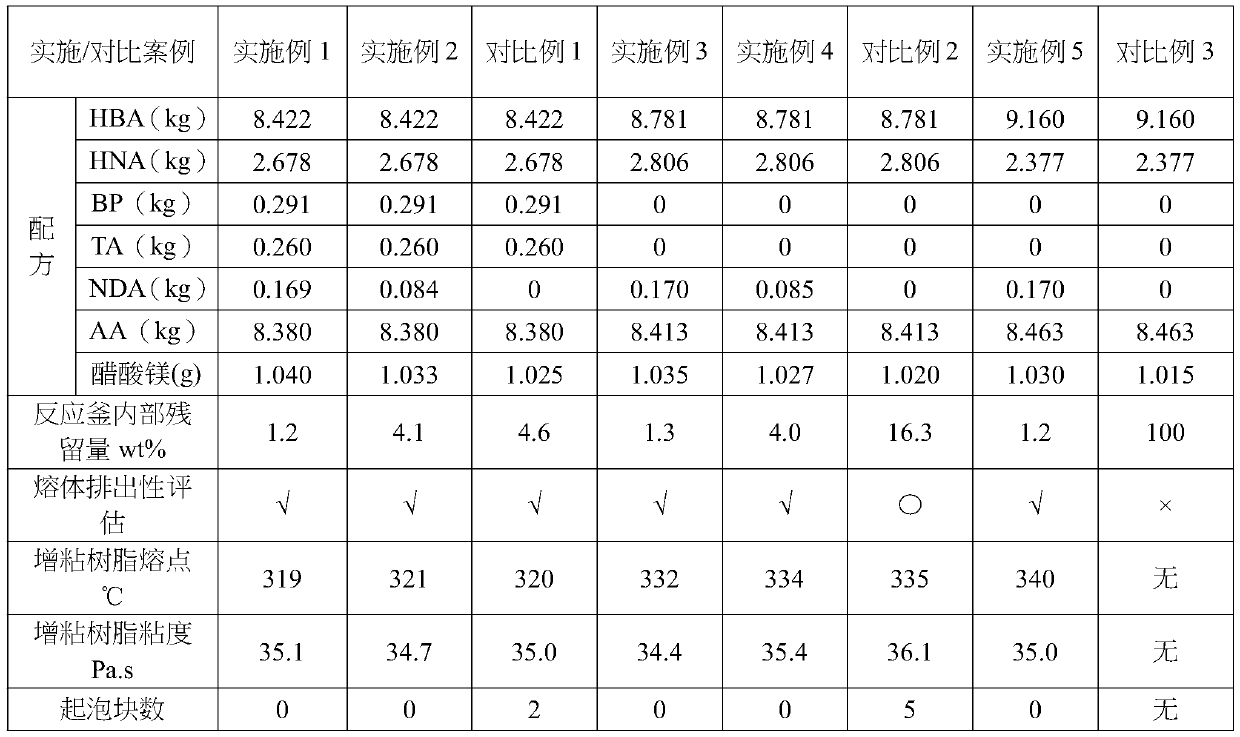

Liquid crystal polyester, liquid crystal polyester composition and products prepared from liquid crystal polyester composition

The invention provides a liquid crystal polyester and a liquid crystal polyester composition and products prepared from the liquid crystal polyester composition. The liquid crystal polyester comprisesaromatic-derived oxy and carbonyl repetitive units (I) and a small amount of aromatic dicarboxylic acid (IV) and can also comprise aromatic-derived dioxy repetitive units (II) and aromatic-derived dicarbonyl repetitive units (III); the composition molar ratio of the repetitive units meets the following conditions: the molar sum of the aromatic-derived oxy and carbonyl repetitive units (I), the aromatic-derived dioxy repetitive units (II) and the aromatic-derived dicarbonyl repetitive units (III) is 100 mol%, and by introducing the small amount of aromatic dicarboxylic acid into the liquid crystal polyester, the excessive molar ratio of carboxylic groups in the liquid crystal polyester is 0.1-5%, which is calculated through (carboxylic groups / hydroxyl groups) / hydroxyl groups*100 mol%. By introducing the small amount of aromatic dicarboxylic acid into preparation of the liquid crystal polyester, the prepared liquid crystal polyester can achieve excellent anti-foaming performance and good melt drainability.

Owner:KINGFA SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com