Patents

Literature

176results about How to "Good thermo-oxidative stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

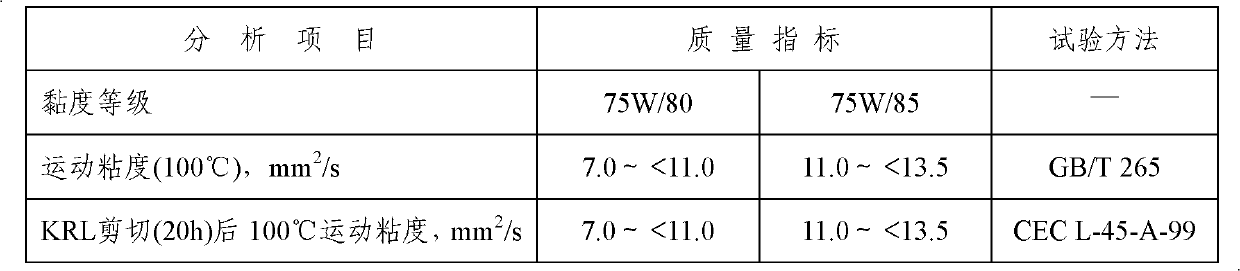

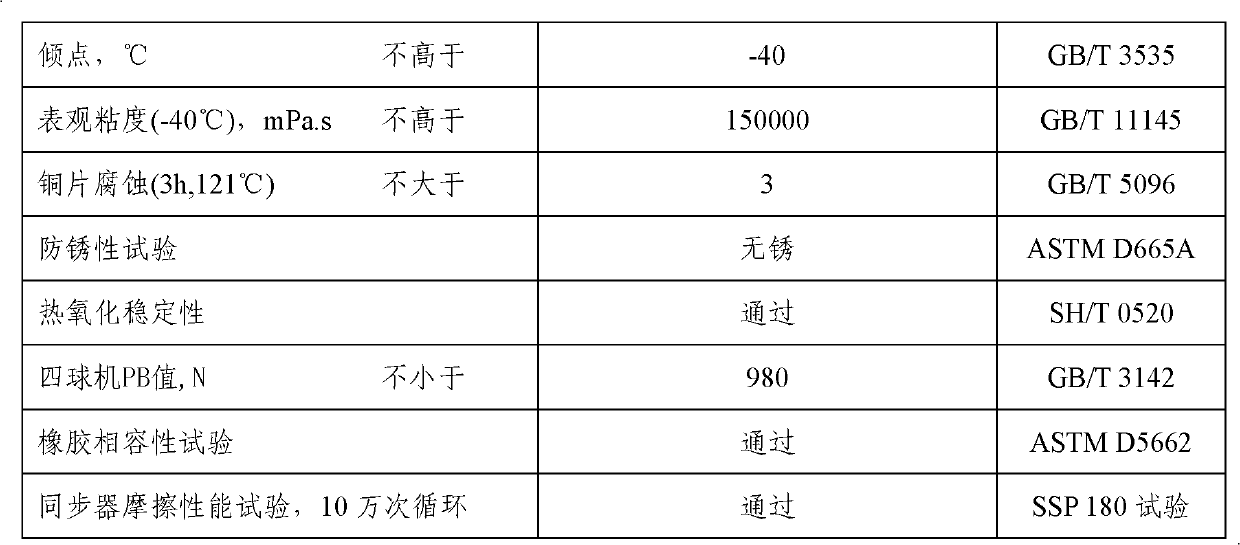

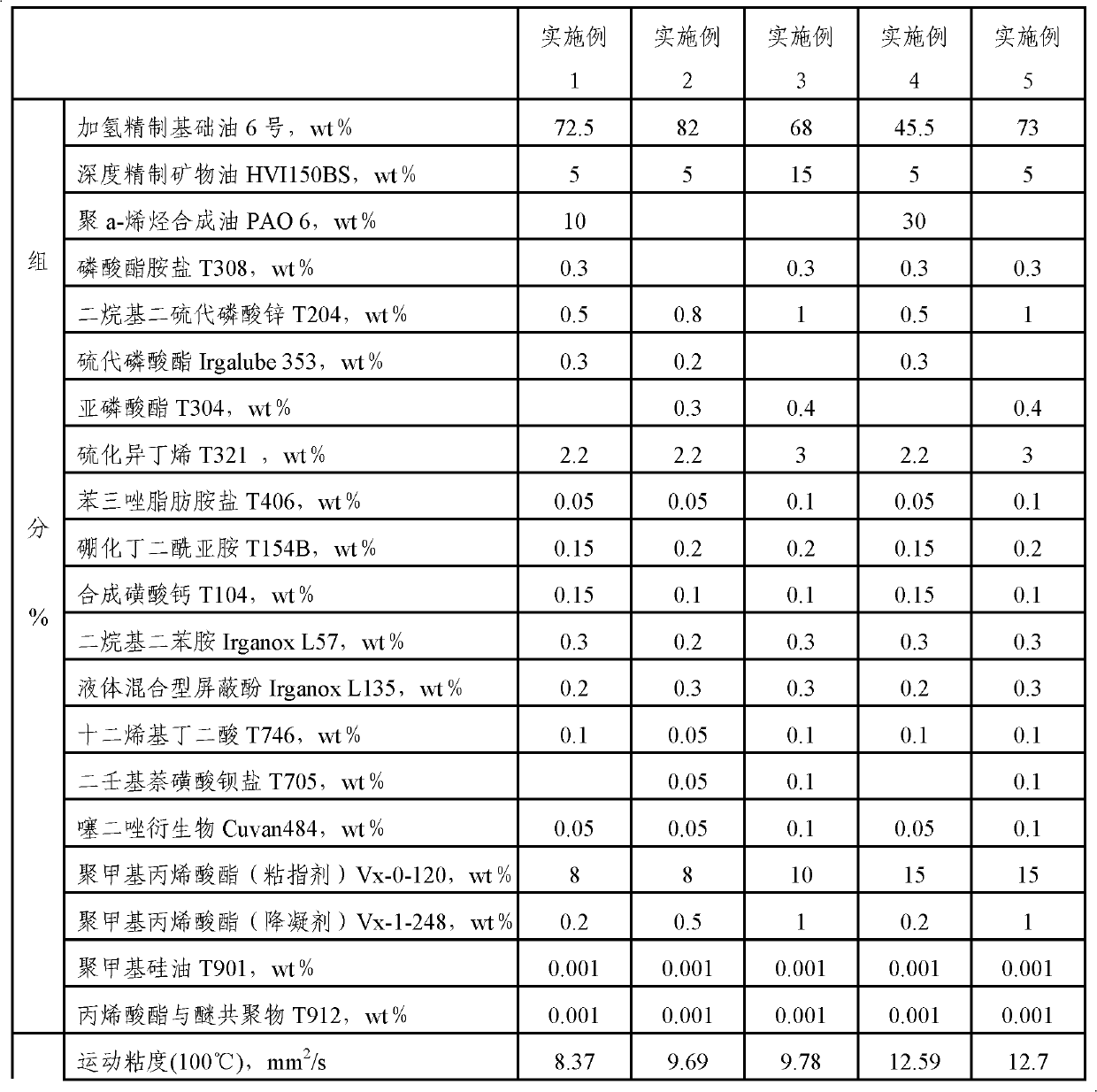

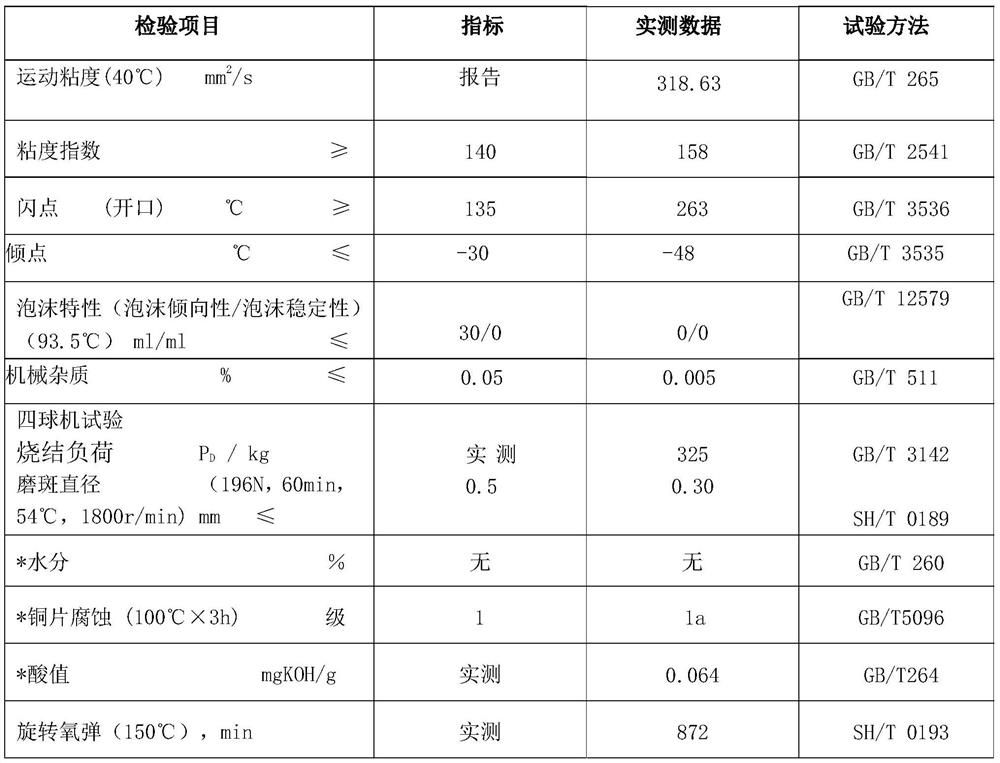

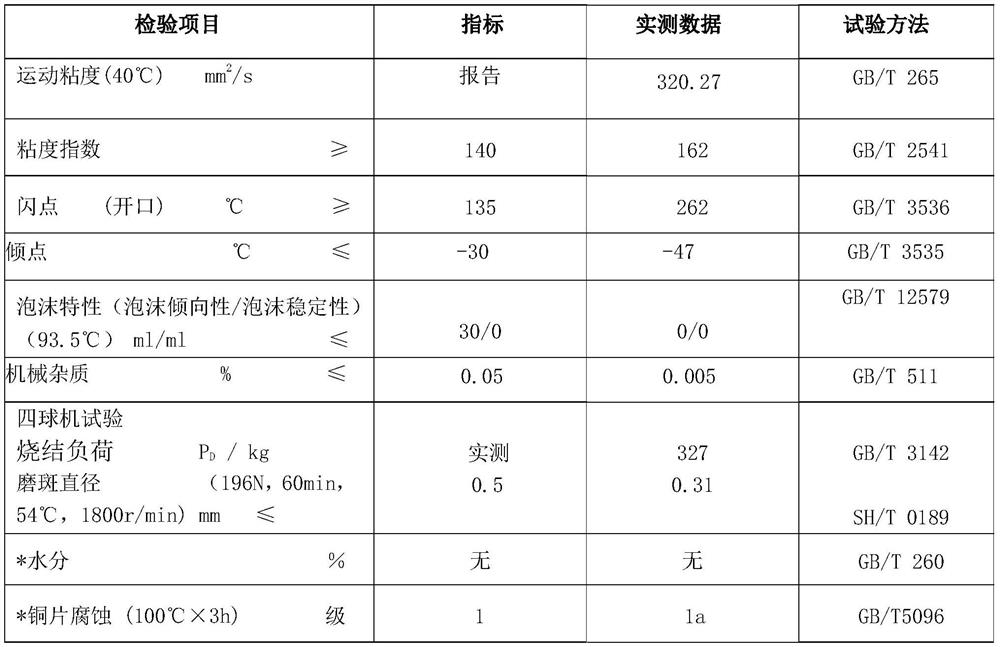

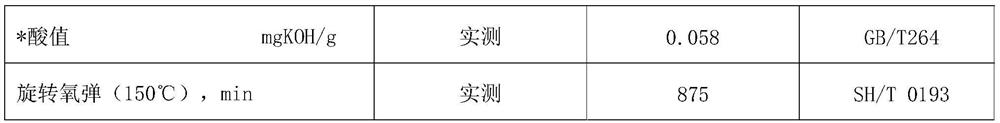

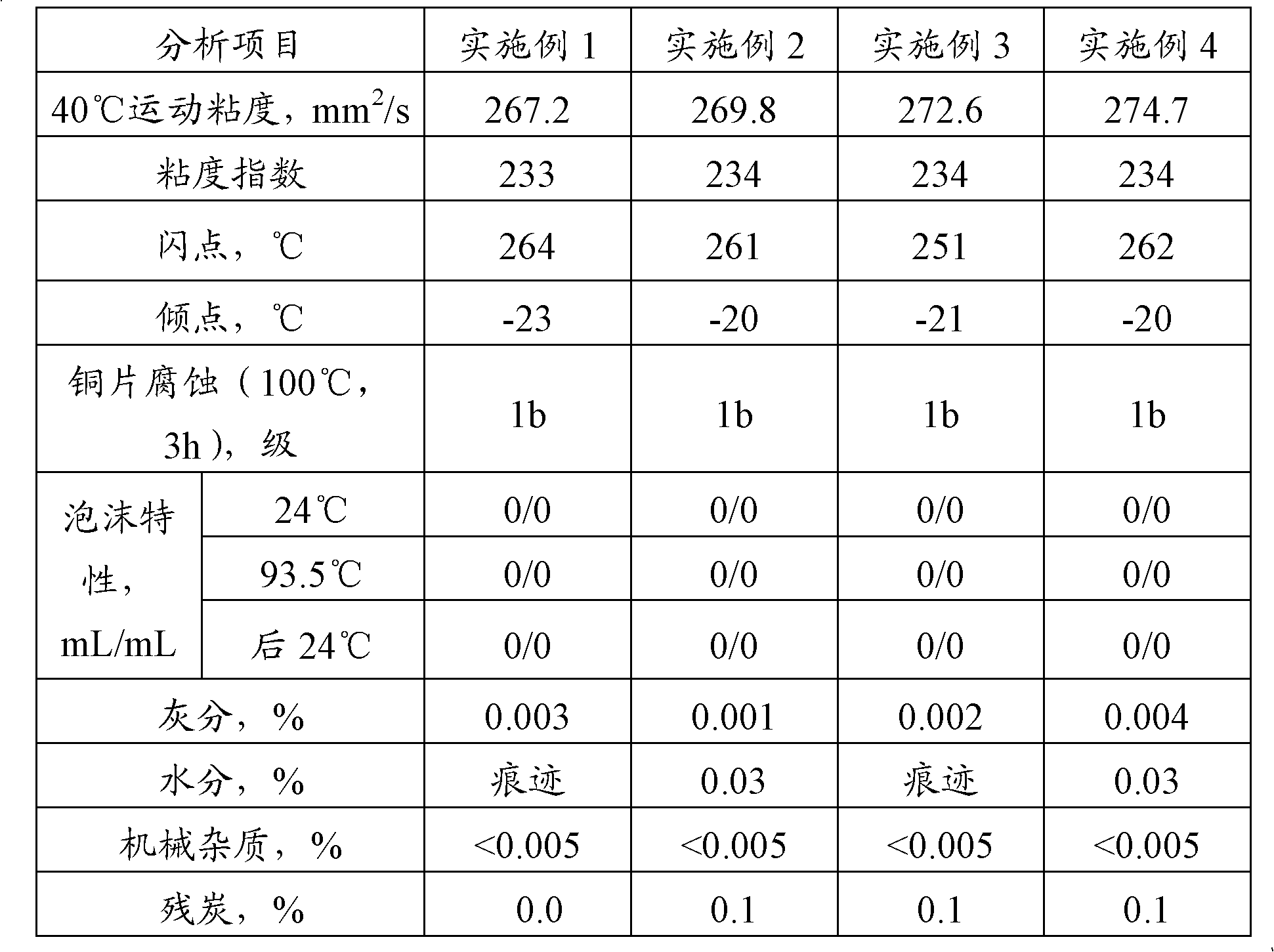

Manual transmission lubricating oil composition

ActiveCN103374452AGood high and low temperature performanceGood thermo-oxidative stabilityLubricant compositionManual transmissionViscosity index

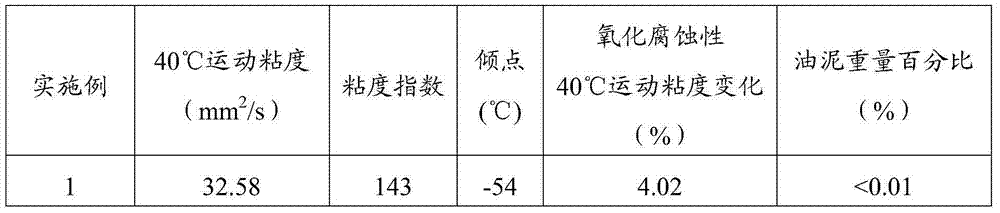

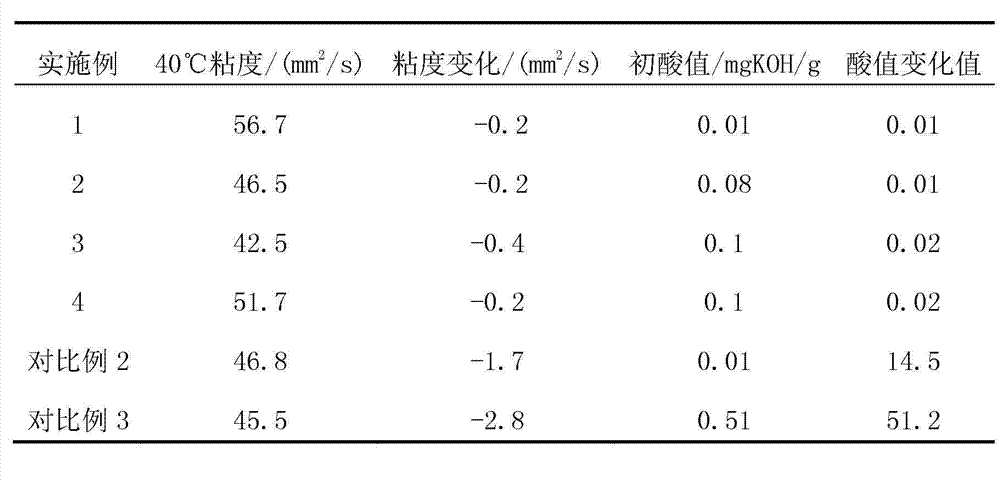

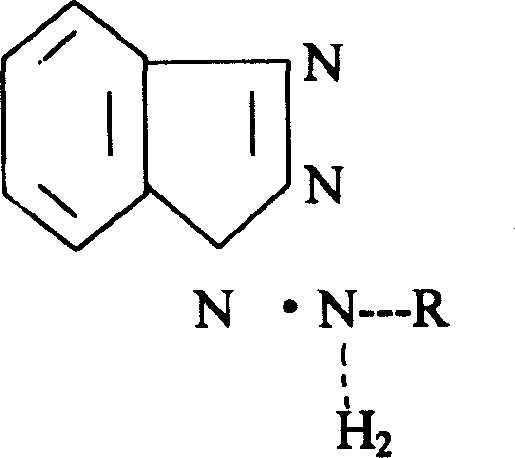

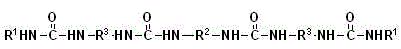

The invention provides a manual transmission lubricating oil composition. The manual transmission lubricating oil composition comprises (a) at least one mineral oil and / or synthetic oil with high viscosity index, (b) at least one viscosity index improving agent, (c) at least one pour point depressant, (d) at least one phosphorus-containing antiwear agent, (e) at least one sulfur-containing extreme pressure agent, (f) at least one friction improving agent, (g) at least one clean dispersion agent, (h) at least one antioxidant, (i) at least one antirust agent, (j) at least one metal deactivator and (k) at least one anti-foaming agent. The manual transmission lubricating oil composition provided by the invention meets the vehicle gear oil viscosity level of 75W / 80 or 75W / 85, has excellent high-low temperature performances, anticorrosion performance, antirust performance and shearing-resistance performance, especially has excellent synchronizer friction performance, can be used for a manual transmission with a synchronizer, and can be completely suitable for the improvement of oil product performance requirement brought about by technique improvement of the manual transmission at present.

Owner:CHINA PETROLEUM & CHEM CORP

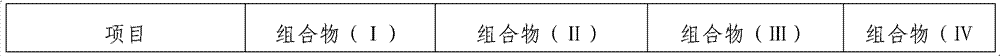

Combination of general gear oil

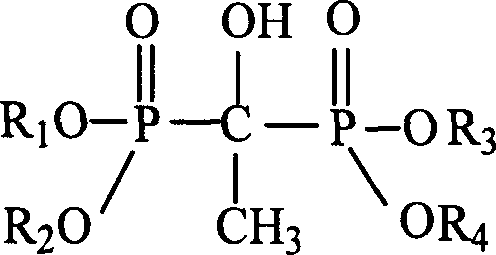

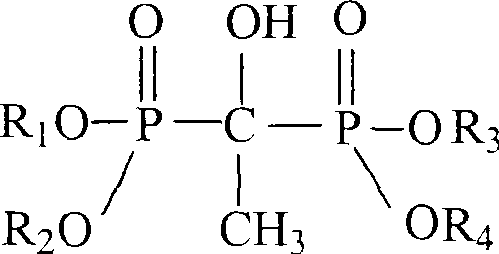

A universal oil composition for gear contains mineral lubricating oil or synthetic lubricating oil or their mixture, at least one viscosity index improver and / or pour depressor, at least one S-contained extreme-pressure agent, at least one P-contained antiwear agent, phosphate-type multi-effect agent, oil agent (1-hydroxyethylene-1, 1-biphosphonate), and at least one metallic deactivator and / or antirust agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating oil compound and preparation method thereof

InactiveCN103497818AImproved high temperature oxidation stabilityGood viscosity and temperatureLubricant compositionOxidation stabilityAlpha-olefin

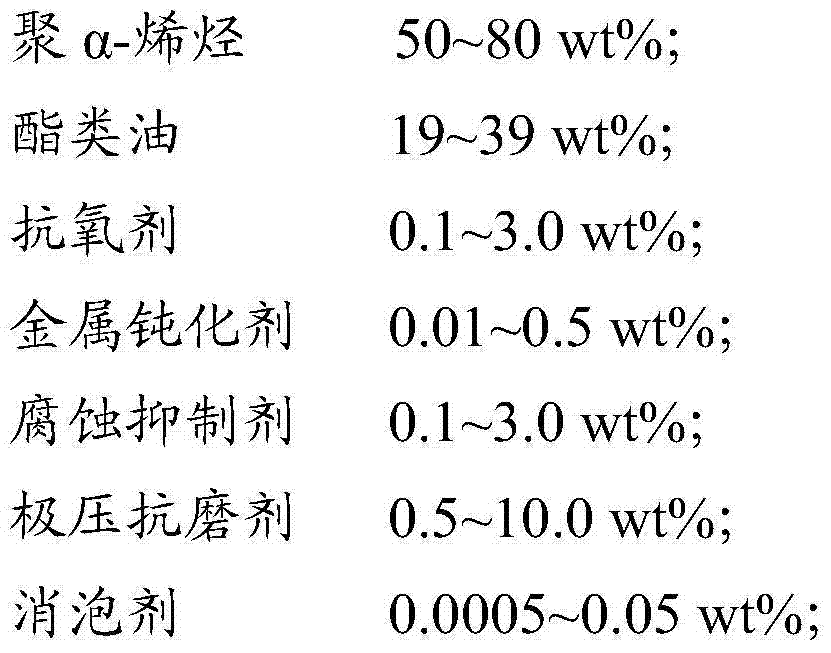

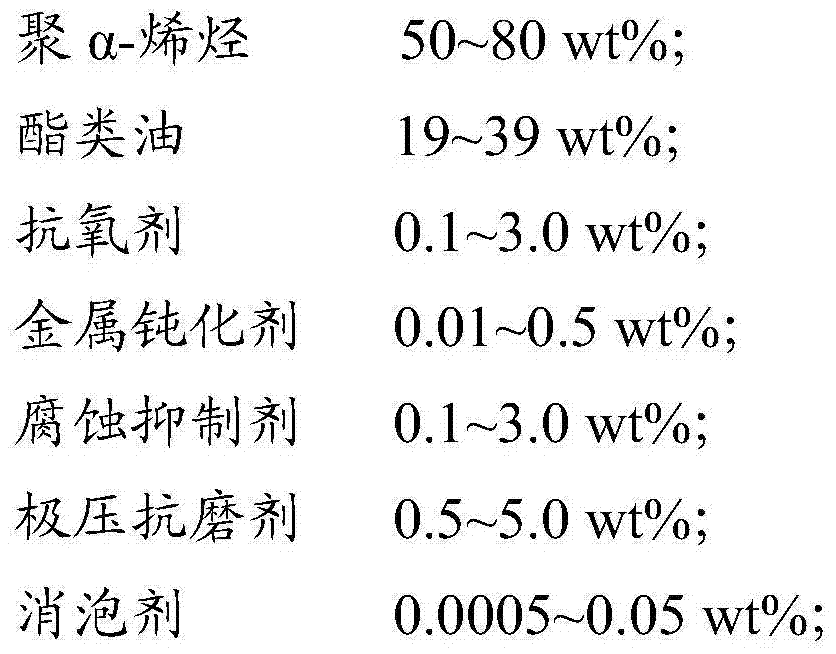

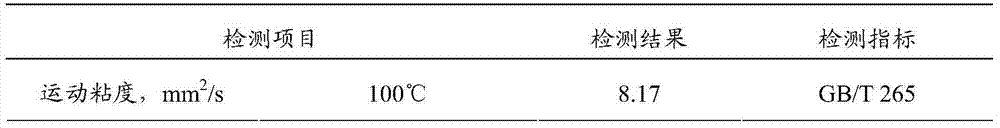

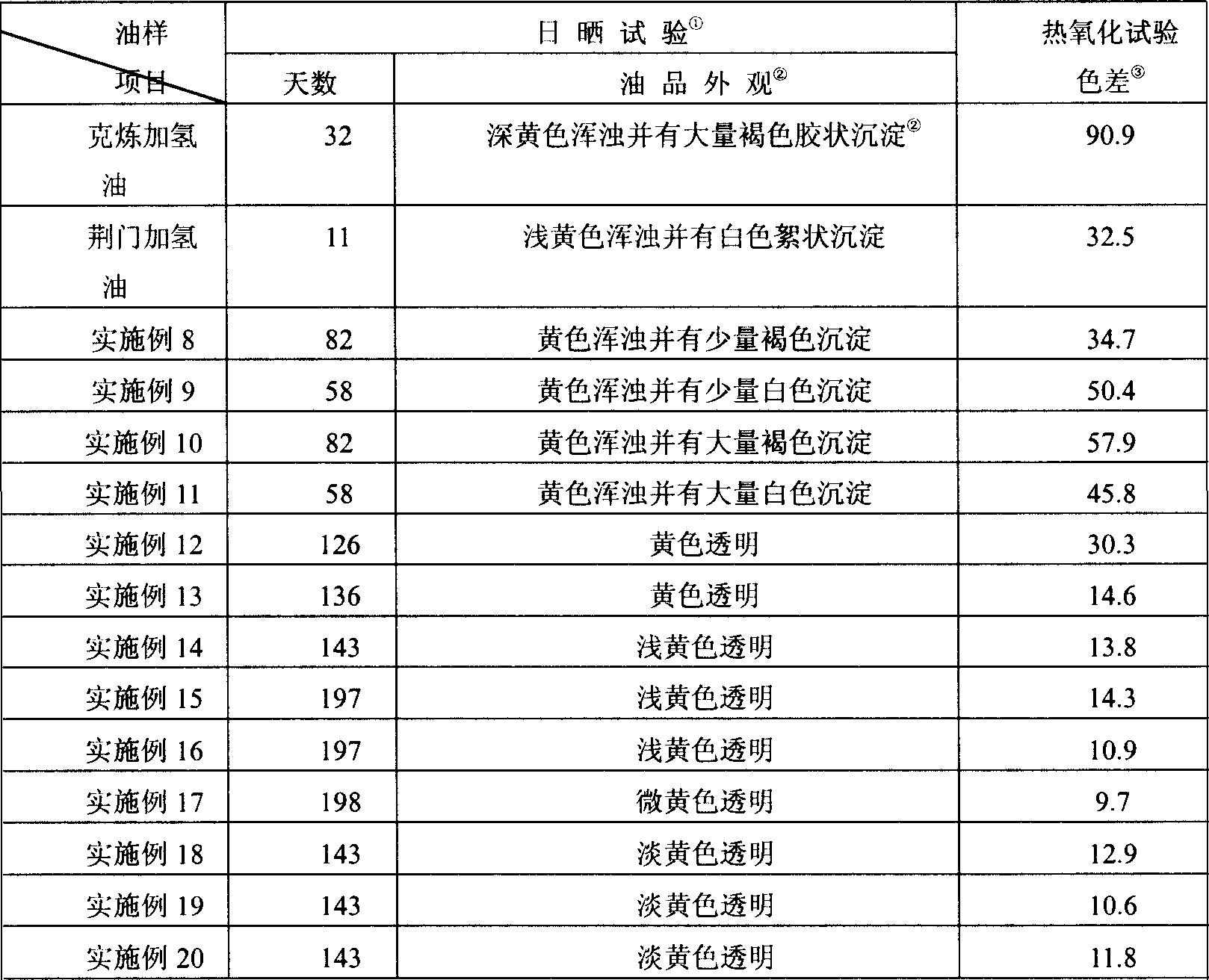

The invention provides lubricating oil compound and a preparation method thereof. The lubricating oil compound comprises 50-80wt% of poly alpha olefin, 19-39 wt% of ester oil, 0.1-3.0wt% of antioxidant, 0.01-0.5wt% of metal passivator, 0.1-3.0wt% of corrosion inhibitor, 0.5-5.0wt% of extreme pressure antiwear agent and 0.0005-0.05wt% defoaming agent. Compared with existing lubricating oil, the lubricating oil compound has the advantages that the poly alpha olefin in the lubricating oil is good in viscosity-temperature performance, low-temperature flowability and good in thermal oxidation stability; by the ester oil with good oxidation stability and high-temperature performance, high temperature oxidation performance of the lubricating oil compound can be increased; additives with good oxidation stability and extreme pressure antiwear performance are added to form a composite system, and the lubricating oil compound is good in extreme pressure lubricity and high-temperature oxidation stability under interaction of the additives.

Owner:CHINA PETROLEUM & CHEM CORP

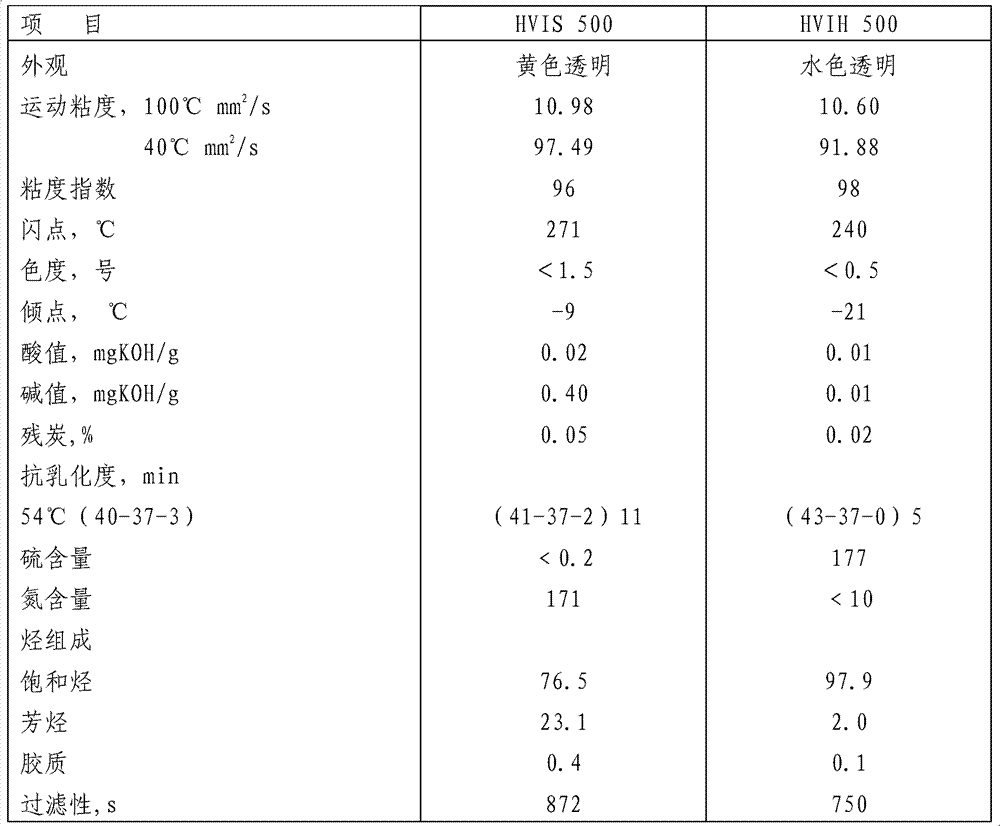

Lubricating oil composite stabilizer and stable hydrogenation lubricating oil composition

The composite lubricating oil stabilizer includes the following components: ultraviolet ray absorbent and light stabilizer of hindered amine in the weight ratio of 1-5 and total content inside the composite lubricating oil stabilizer of 40-80 wt%; antioxidant selected from the shielding phenol, aromatic amine, phenolic ester, metal phosphate-sulfate and carbamate sulfide in 15-45 wt%; and phenyl phosphite as chelating agent in 3-18 wt%. The composite lubricating oil stabilizer of the present invention may be added into the base oil of hydrogenated lubricating oil in the amount of 0.01-2.0 wt% to improve the light stability of the hydrogenated lubricating oil obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

Air compressor oil and preparation method thereof

InactiveCN104263481AGuaranteed safe operationAvoid cloggingLubricant compositionGas compressorAntioxidant

The invention provides air compressor oil which comprises the following components in parts by weight: 75-94 parts of synthetic hydrocarbon base oil, 5-20 parts of synthetic ester base oil and 1-5 parts of functional additive, wherein the functional additive comprises a purification dispersant, an antiwear agent, a metal deactivator, an antirust agent, an antioxidant, a pour point depressant, a demulsifying agent and an anti-foaming agent. The invention provides a preparation method of the air compressor oil. The preparation method comprises the step of mixing the synthetic hydrocarbon base oil, the synthetic ester base oil and the functional additive at the temperature of 60-80DEG C to obtain the air compressor oil. According to the air compressor oil provided by the invention, the synthetic oil is used as the base oil and the compound type functional additive is added, so that the air compressor oil provided by the invention has low oil sludge property. In addition, the air compressor oil provided by the invention also has the advantages of better thermal oxidation stability, low-temperature fluidity and higher viscosity index, and the use requirement of an air compressor is met.

Owner:CHINA PETROLEUM & CHEM CORP

Wide temperature range polyol ester lubricating oil composition suitable for aircraft engine

InactiveCN102807908ASatisfy the operabilityFulfil requirementsAdditivesPolyolesterChemical composition

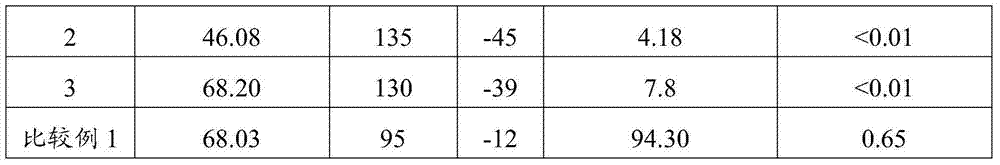

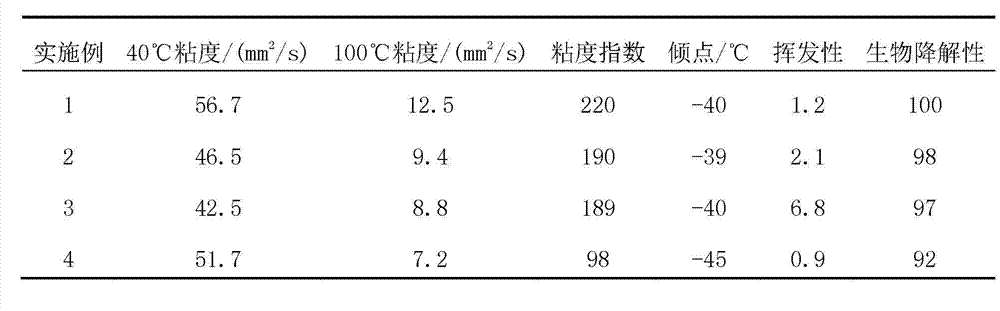

The invention relates to a wide temperature range polyol ester lubricating oil composition suitable for an aircraft engine. The wide temperature range polyol ester lubricating oil composition suitable for the aircraft engine consists of the following components in percentage by weight: 90-94 percent of polyol ester synthetic base oil, 2-5 percent of an organic polysulfide extreme-pressure wear-resisting agent, 0.5-1 percent of an antioxidant, 1-3 percent of a detergent dispersant and 0.5-1 percent of a corrosion inhibitor. Compared with traditional aircraft lubricating oil, the wide temperature range polyol ester lubricating oil composition has the advantages of excellent low-temperature starting performance, favorable thermal oxidation stability, strong hydrolytic stability, excellent lubricating performance, biodegradability and the like, and can meet the requirements of a modern aircraft engine on long-period rigorous working condition running and wide temperature range use.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Rotary jetting air-compressor lubricating oil and its production

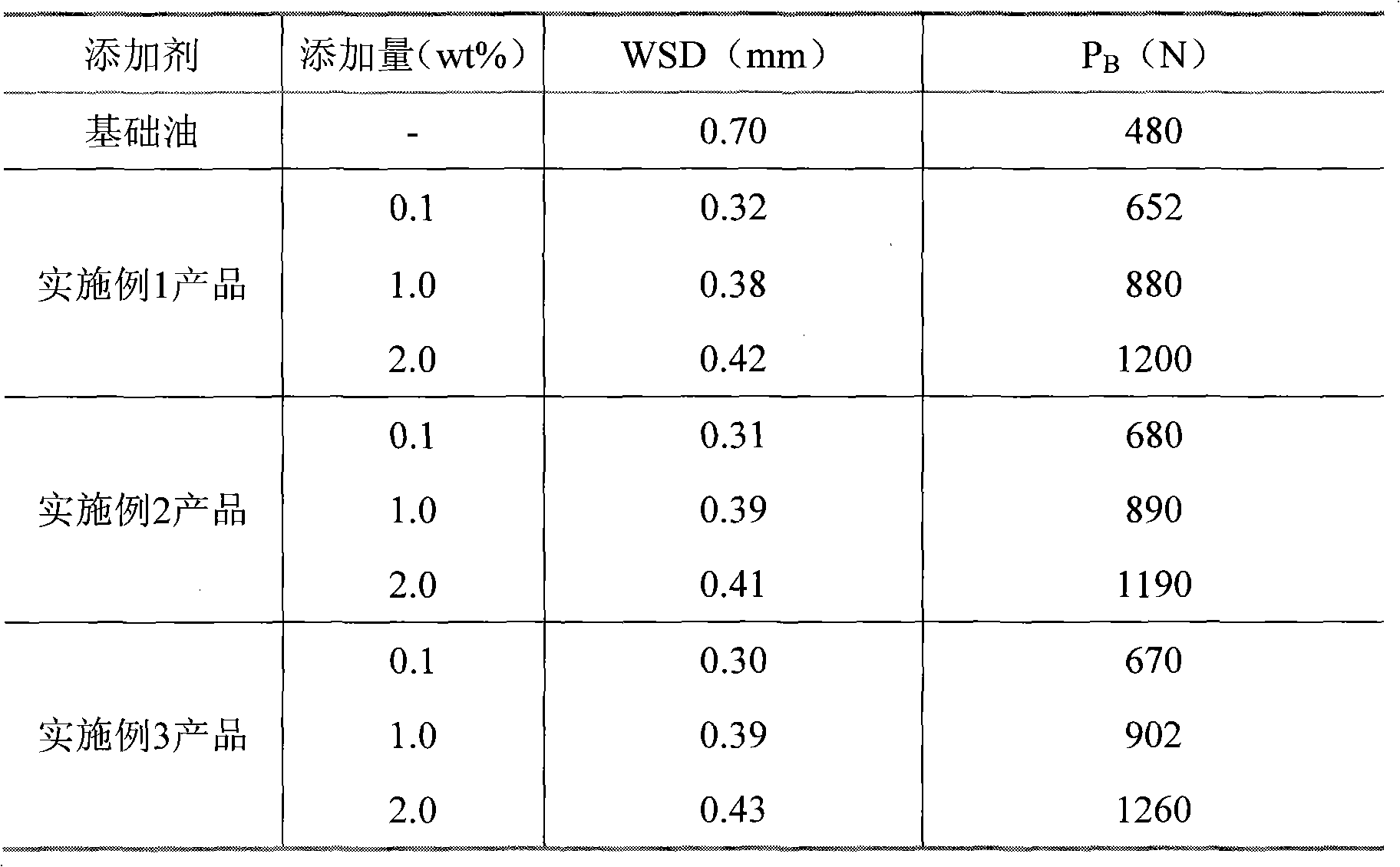

InactiveCN1982423AGood thermo-oxidative stabilityImprove rust resistanceAdditivesPhosphateDicarboxylic acid

Rotary oil-jet air compressor lube oil and its production are disclosed. The formula consists of aromatic amine high-temperature antioxidant 0.1-0.6wt%, phenol antioxidant 0.1-1.0wt%, organic phosphate oil solution 0.1-0.6wt%, tinuvin fatty salt synergistic 0.01-0.1wt%, alkenyl ethylene dicarboxylic acid antirust agent VO.01-0.1wt% and base oil residue. It can be used at 100-200degree and has long antioxidant life.

Owner:抚顺远红润滑油制造有限公司

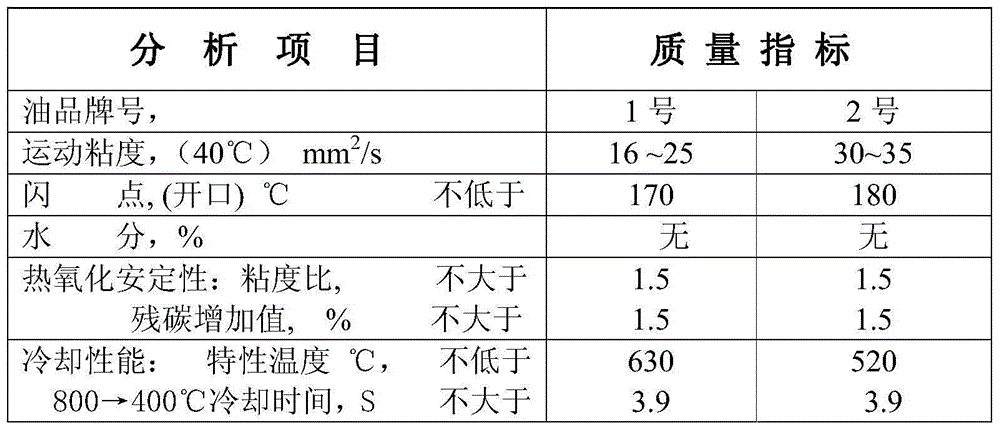

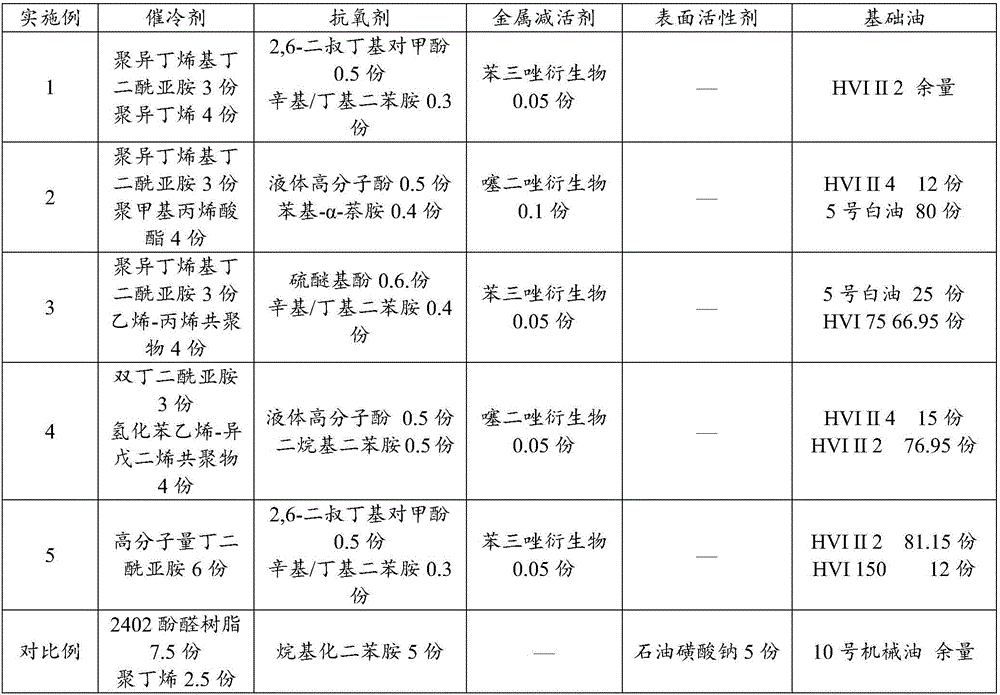

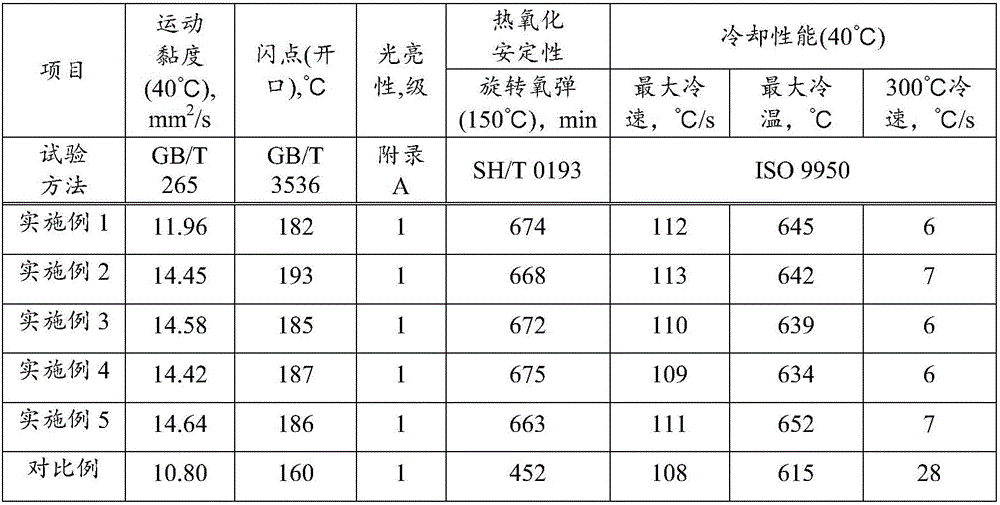

Rapid bright quenching oil and preparation method thereof

The invention relates to an oil product of a petrochemical product, and in particular relates to rapid bright quenching oil and a preparation method thereof. The rapid bright quenching oil is prepared from the following components in percentage by weight: 75% of deeply refined mineral oil as basic oil, 6% of a brightener, 3.7% of a refrigerant, 8% of an antioxidant, 2.3% of a cake-preventing agent and 5% of animal and plant oil. The rapid bright quenching oil is low in cost and good in cooling property, brightness and thermal oxidation stability, and the surface of a quenched workpiece is bright and free of crack.

Owner:QIDONG QINGQING VEGETABLE & FRUIT RURAL LAND STOCK PROFESSIONAL COOP

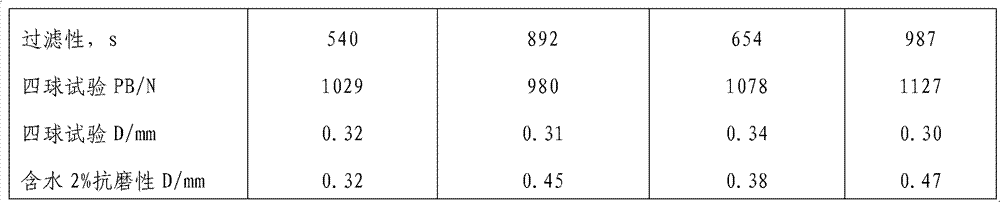

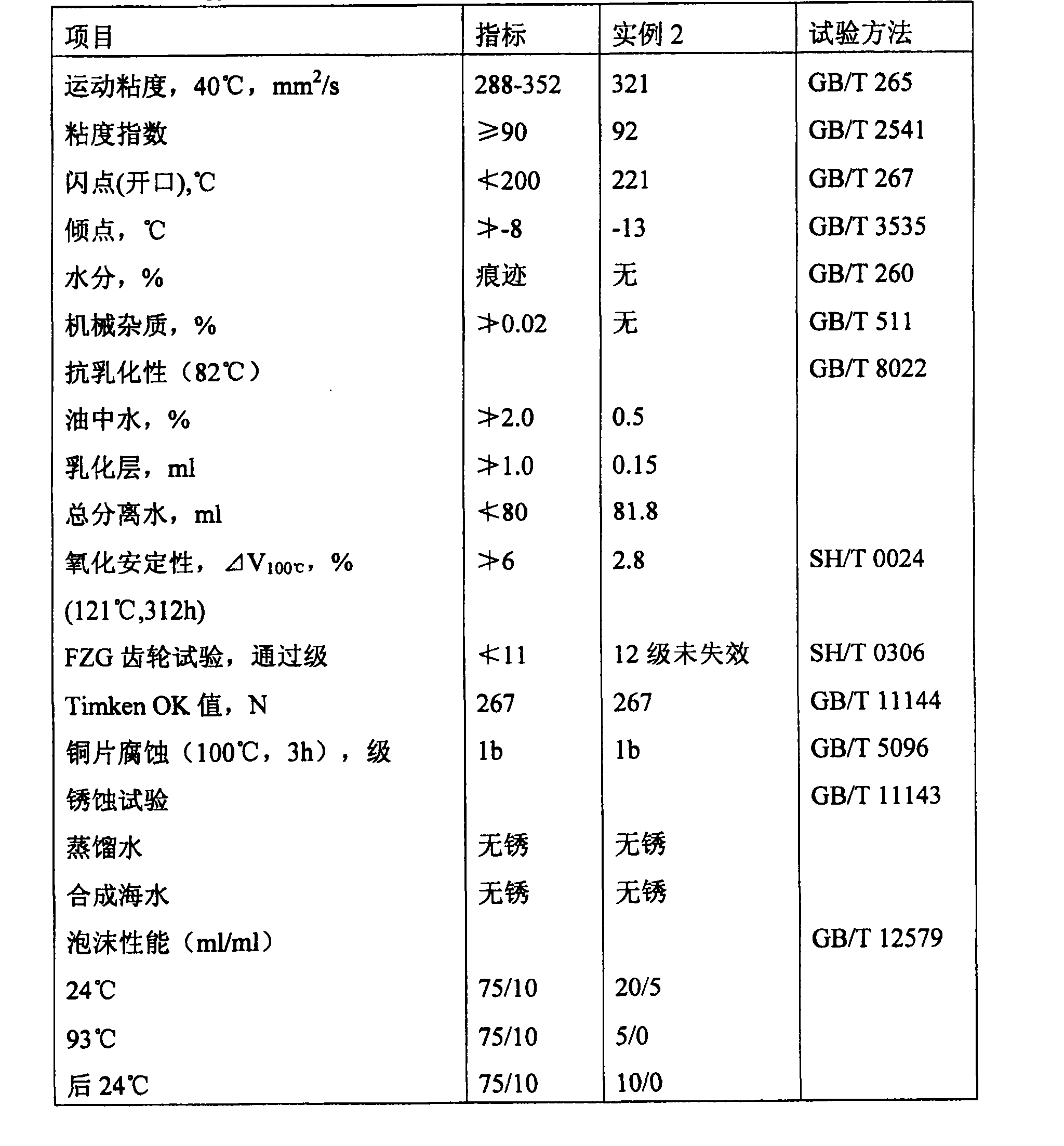

Ashless antiwear oil film bearing lubricant composition

ActiveCN102766505AImprove filtering effectGood demulsibilityLubricant compositionWire rodFoaming agent

The invention provides an ashless antiwear oil film bearing lubricant composition, which comprises: (A) at least a highly refined mineral oil with high viscosity index; (B) at least an emulsifier; (C) at least an anti-foaming agent; (D) at least an ashless phosphorus-containing antiwear additive; (E) at least an anti-oxidant; and (F) at least a metal passivator. The above lubricant component has excellent demulsibility, filterability, anti-foaming property, air release property, abrasion resistance and oxidation resistance, passes through FAG FE-8 bearing wear experiments, SKFEMCOR bearing corrosion experiments and FLENDER anti-foaming experiments, and is suitable for lubricating various bearings and industrial gears, especially lubricating highspeed wire rod oil film bearings.

Owner:PETROCHINA CO LTD

Synthesis method of calcium-magnesium salicylate composite detergent

InactiveCN104496786AImprove heat resistanceExcellent high temperature detergencyOrganic compound preparationAdditivesXylyleneSalicylic acid

The invention discloses a synthesis method of a calcium-magnesium salicylate composite detergent in the field of lubricant additives. The method comprises the following steps: adding alkyl salicylic acid and solvent xylene in a reaction container, adding calcium oxide, accelerant, auxiliary promoter and the like in a stirring state, and carrying out a neutralization reaction when a reaction temperature rises to the temperature needed by the neutralization reaction; after the neutralization reaction is ended, adding magnesium oxide, water, ammonia water, auxiliary promoter and the like, charging carbon dioxide and carrying out a carbonation reaction; after the carbonation reaction is ended, carrying out product post-treatment to obtain a lubricant detergent product. The method disclosed by the invention achieves the following beneficial effects: the alkali number of the calcium-magnesium salicylate composite detergent prepared by the method is greater than 400mg KOH / g, the thermal oxidation stability and the high-temperature detergency of lubricant oil are obviously improved, the dispersibility and the wear resistance of the lubricant oil are improved to a certain extent, and the product stability is great.

Owner:QINGDAO BAIZHONG CHEM TECH

High-pressure anti-wear hydraulic oil

InactiveCN111363608AGood demulsibilityImprove rust resistanceLubricant compositionFoaming agentThermal stability

The invention discloses high-pressure anti-wear hydraulic oil, and belongs to the hydraulic oil field. The hydraulic oil comprises the following components in percentage by mass: 95-99% of base oil, 1.0%-1.5% of an extreme pressure anti-wear agent, 0.1-0.3% of a friction modifier; 0.4-1.0% of an antioxidant, 0.1-0.5% of an antirust agent, 0.1-0.5% of a metal deactivator, 0.02-0.1% of a detergent dispersant, 0.001-0.005% of an anti-foaming agent, and 0.1-0.5% of a demulsifying agent. Compared with the prior art, the hydraulic oil has the advantages of good viscosity-temperature performance, extreme pressure abrasion resistance, oxidation resistance stability, hydrolysis stability and thermal stability, and is not prone to aging and deterioration; the service life is prolonged, a friction pair can be normally lubricated under high-pressure and high-speed harsh conditions, and abrasion is reduced. The foam generated under the condition of violent mechanical stirring in the operation process can be quickly eliminated; air mixed in the oil can be released in a short time, and a static pressure can be accurately, sensitively and stably transmitted.

Owner:无锡中石油润滑脂有限责任公司

Heavy-load agricultural diesel engine special oil and production method thereof

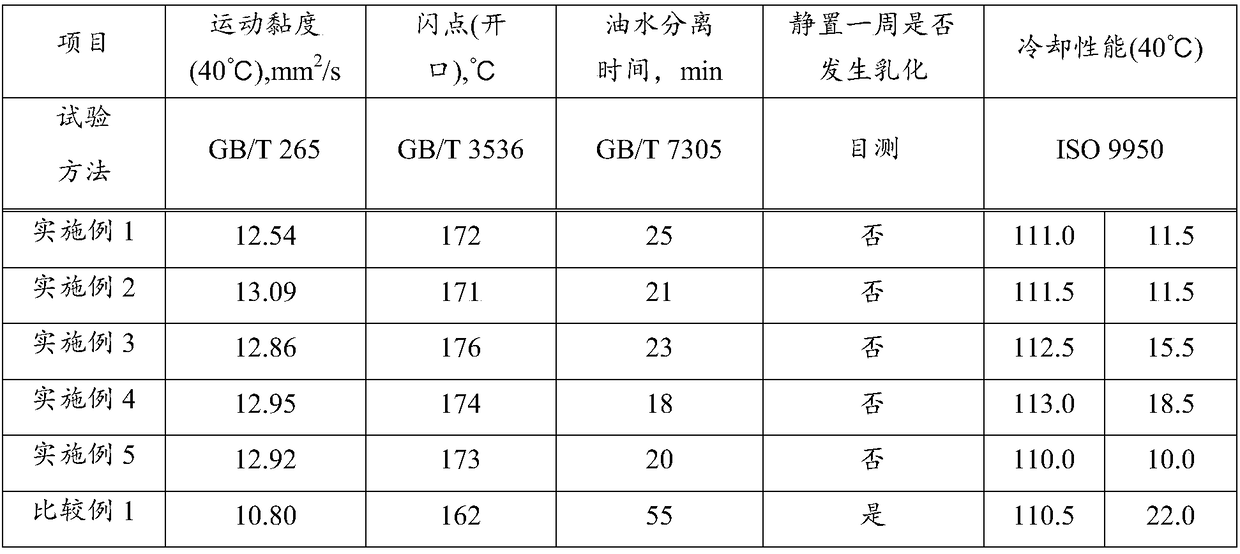

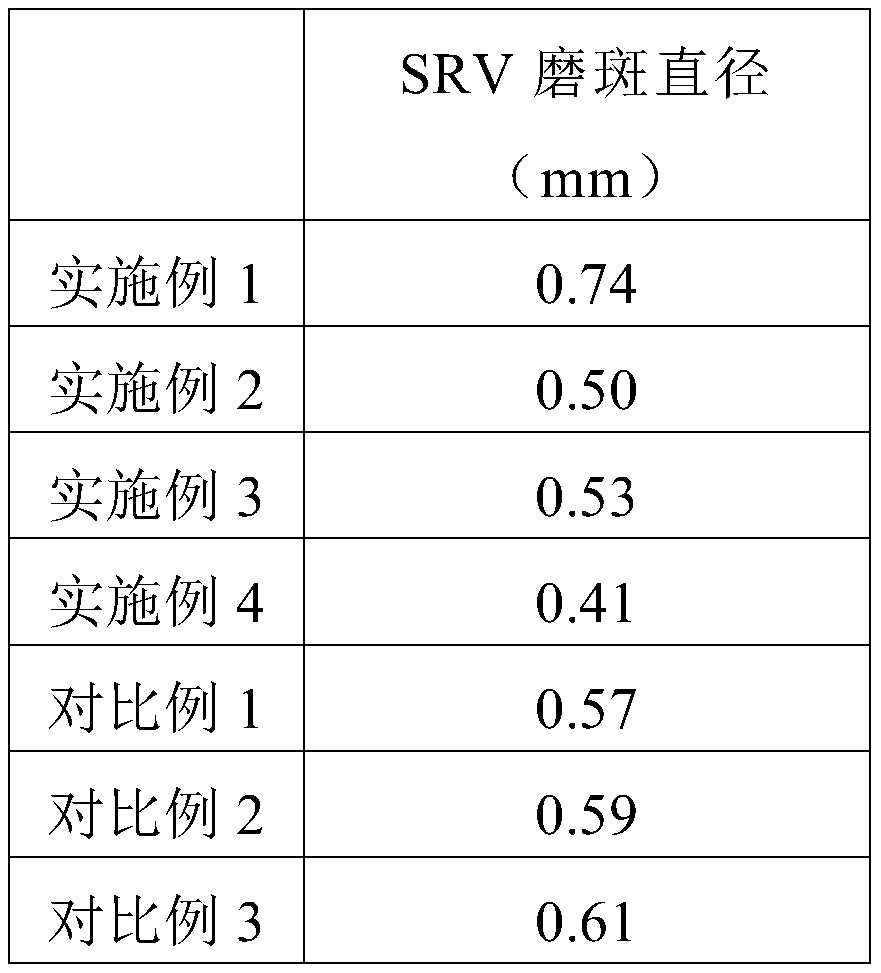

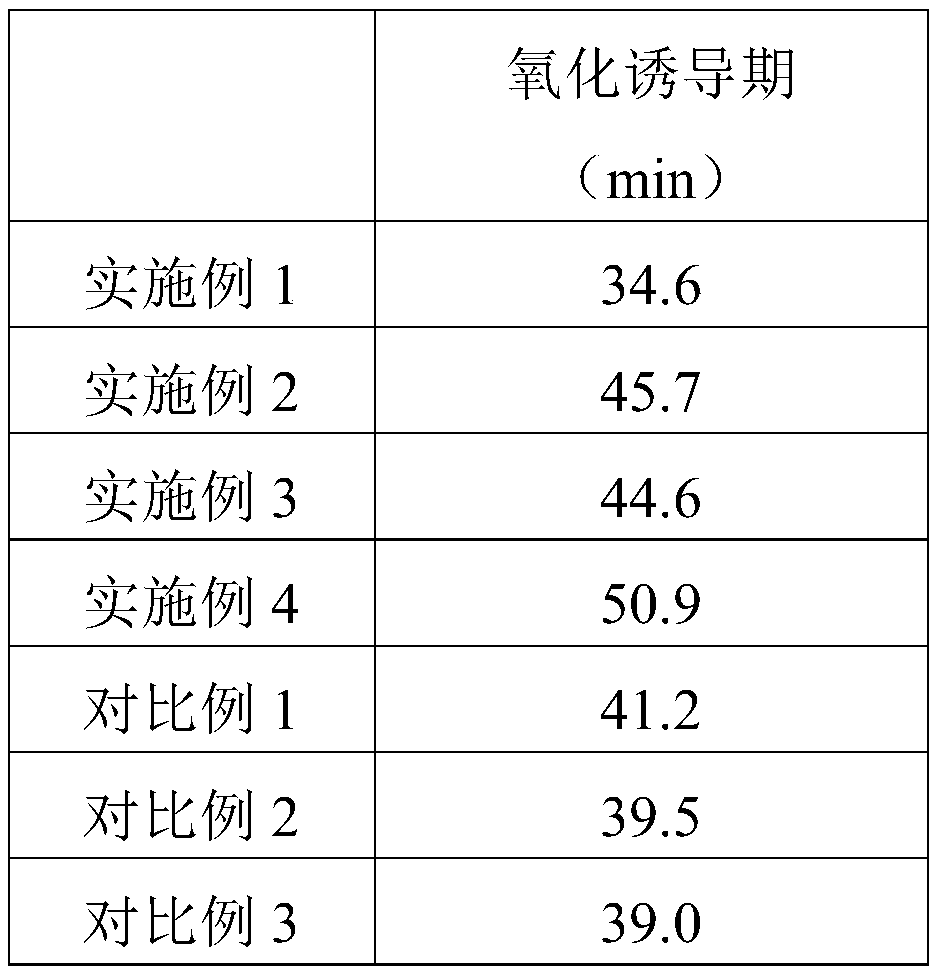

InactiveCN104862043AExcellent thermo-oxidative stability and oil-water separationImprove thermal and oxidative stabilityLubricant compositionLubricationViscosity index

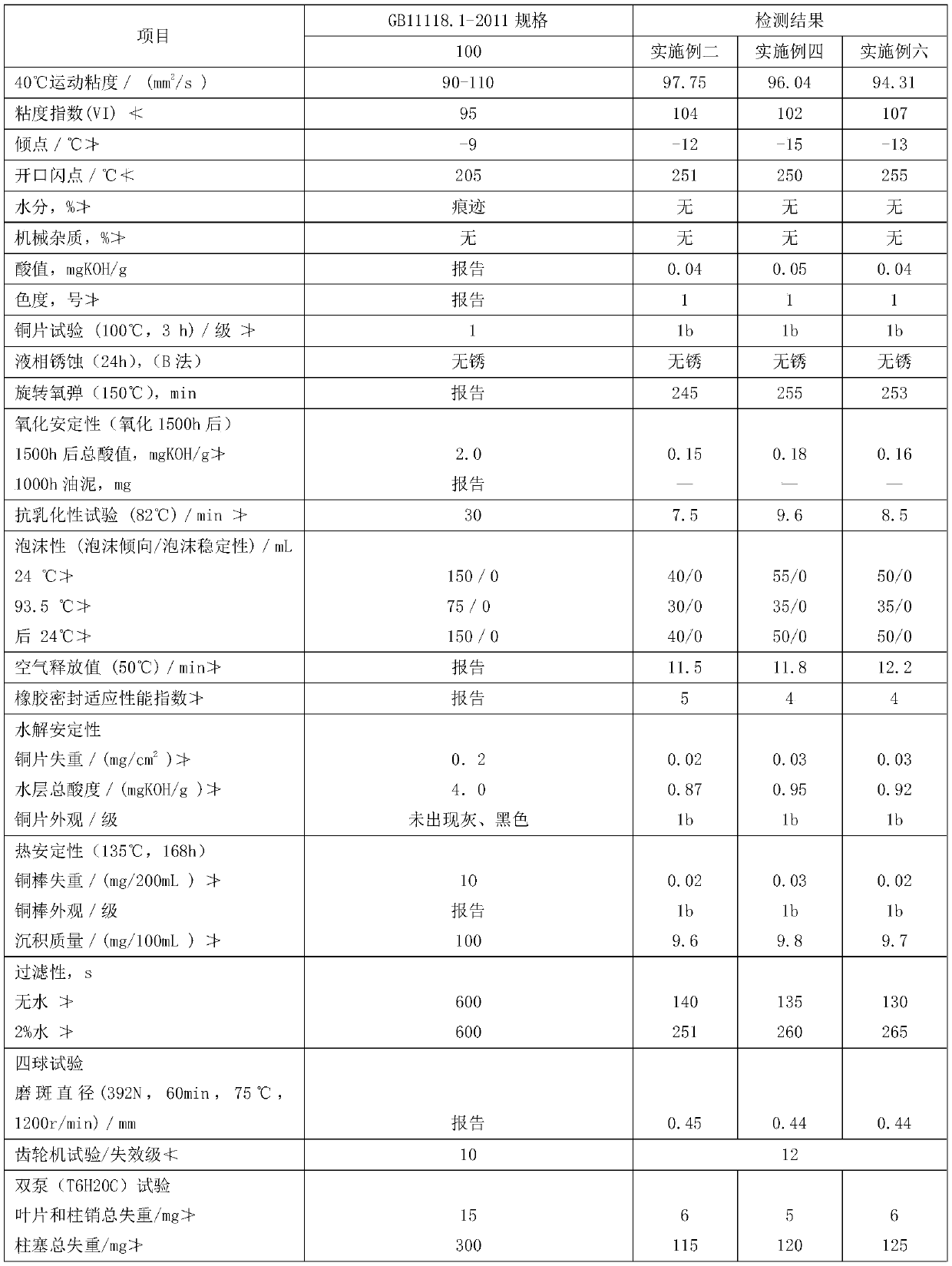

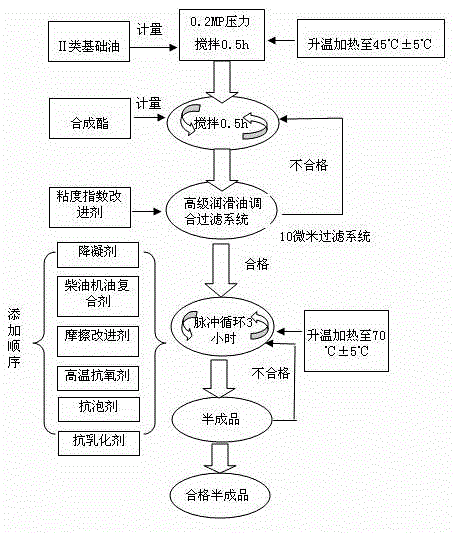

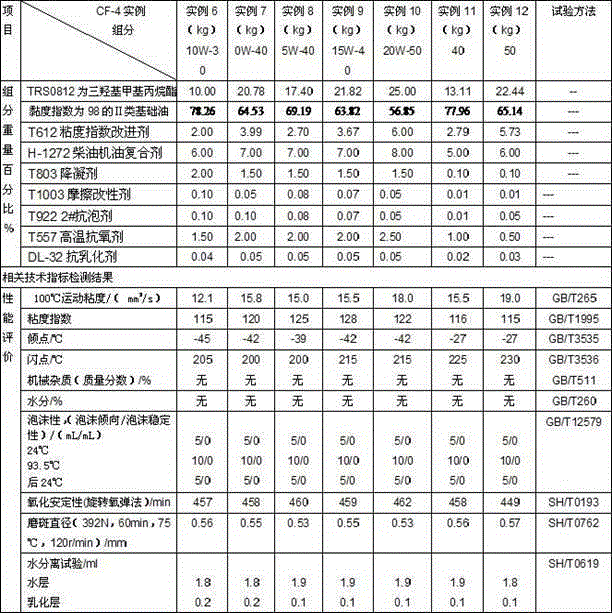

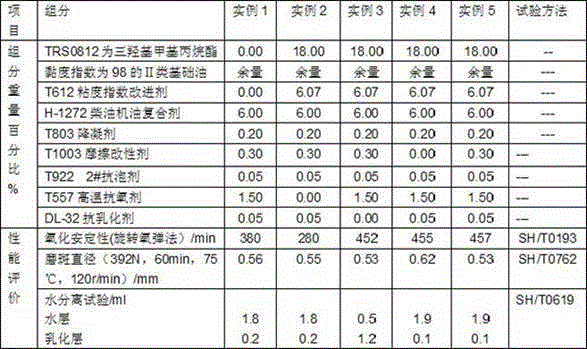

The invention provides heavy-load agricultural diesel engine special oil and a production method thereof, synthetic ester, II type base oil, a viscosity index improver, a diesel engine oil compound agent, a pour point reducer, an antifoaming agent, a friction modifier, a high antioxidant and other components are used, most excellent technical parameters are screened by orthogonal experiment method and component ratio and dosage to use as technical formula parameters of the heavy-load agricultural diesel engine special oil, the heavy-load agricultural diesel engine special oil meets specification requirements of high-grade diesel engine oil of the level of API CF-4 or above, and has excellent thermal oxidation stability and oil / water separation property. The method improves the thermal oxidation stability, lubricity and oil / water separation properties of oil products, shortens the time of oil-water separation, prolongs lubrication protection ability and the service life of the oil products, saves resources, and the heavy-load agricultural diesel engine special oil can completely meet the oil requirements of 25-80 p heavy-load agricultural diesel engines.

Owner:广西飞日能源集团有限公司

Quenching oil composition and application thereof

InactiveCN106435110AHigh hardnessImprove cooling effectQuenching agentsChemical compositionAntioxidant

The invention relates to a quenching oil composition and application thereof. The problems that in the prior art, the cooling performance of a high-medium-temperature zone of super-speed quenching oil is insufficient, and the cooling speed of a low-temperature zone of the super-speed quenching oil is too high are mainly solved. The quenching oil composition comprises, by weight, (a) 0.5-10 parts of a cooling accelerant, (b) 0.1-3 parts of an antioxidant, (c) 0.01-1 part of a metal deactivator, and (d) 75-95 parts of base oil. By means of the technical scheme, the problems are well solved, and the quenching oil composition can be used for quenching automobile plate spring parts.

Owner:CHINA PETROLEUM & CHEM CORP

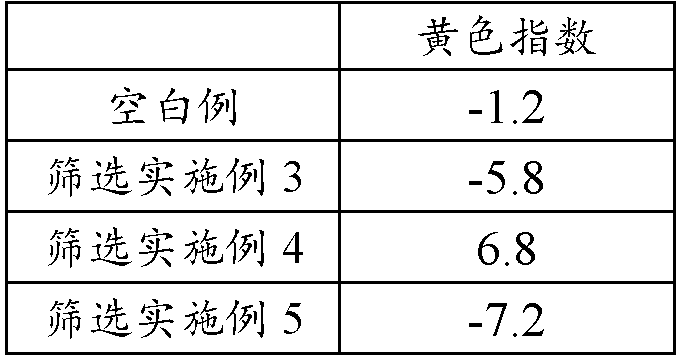

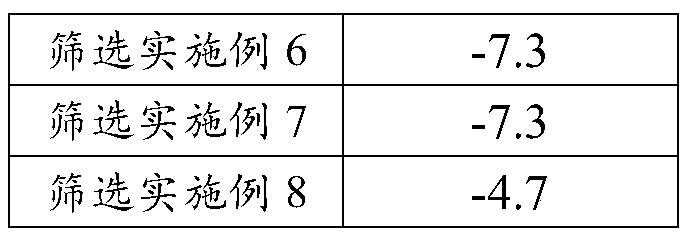

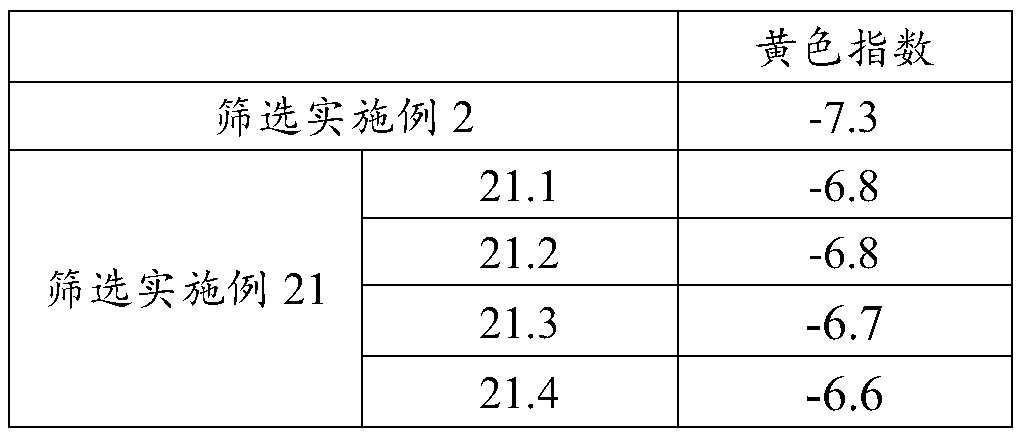

Preparation method of composite antioxidant for better improving yellowing of polymer caused by processing and long-term aging

InactiveCN110272563APrevents settling and agglomerationUniform pigment contentChemistryUltrasonic technology

The invention discloses a preparation method of a composite antioxidant for better improving yellowing of a polymer caused by processing and long-term aging. The composite antioxidant adopts a main antioxidant, an auxiliary antioxidant, a dispersant, an organic pigment, an inorganic pigment as main raw materials for preparation; and the method comprises the following steps: mixing the main antioxidant and the auxiliary antioxidant, performing melting to form a molten liquid, adding the dispersant, performing uniform mixing, performing ultrasonic treatment under ultrasonic waves, adding the organic pigment powder and the inorganic pigment powder, performing uniform dispersion, and finally performing extrusion granulation by using a twin-screw extruder to obtain the composite antioxidant particles. According to the method provided by the invention, the molten liquid of the main and auxiliary antioxidants is compounded with the pigments, the function of the dispersant and the ultrasonic technology are combined, so that the pigment powder is more uniformly dispersed into the molten liquid of the antioxidants, and the content of the pigments in a single composite antioxidant particle is uniform; and the composite antioxidant is compounded with the polymer, so that a color complementary effect of the pigments on coloring of the polymer is improved, and yellowing of the polymer caused by the processing and the long-term aging is effectively improved.

Owner:JIANGSU JIYI NEW MATERIAL CO LTD

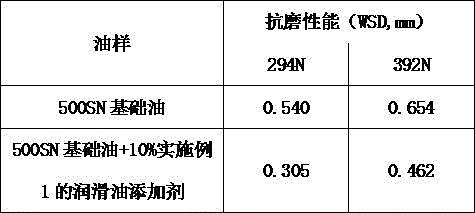

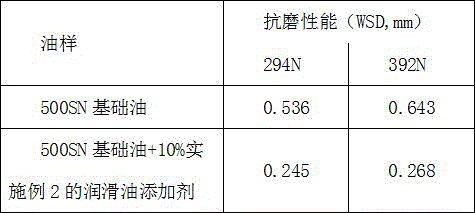

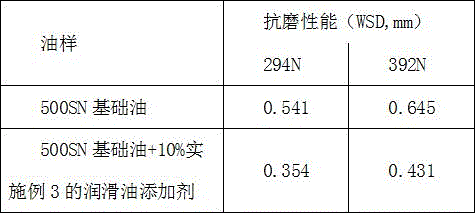

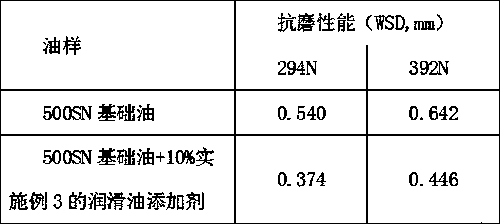

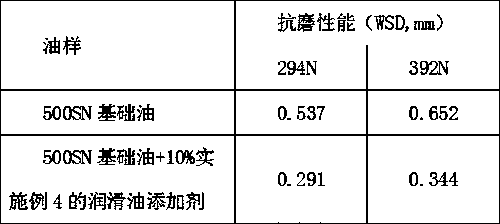

Graphene lubricating oil additive and preparation method thereof

InactiveCN105602654AReduce ultrasonic dispersionSolve corrosiveAdditivesOil additiveMechanical equipment

The invention discloses a graphene lubricating oil additive and a preparation method thereof. The graphene lubricating oil additive is prepared from proper amounts of graphene, a hydrogenated styrene-diolefin copolymer, a borate and an oil-based solvent. The graphene lubricating oil additive disclosed by the invention solves the problem of corrosivity and selectivity in the traditional lubricating oil additive. The nano material additive technique is complex to operate, can discharge waste gas and pollutants, and can pollute the environment. The graphene lubricating oil additive can implement self-repair on the worn part, performs the functions of oil saving, wear resistance, noise reduction, power enhancement and the like, can be well dispersed in many types of lubricating oil base oil, has favorable oxidation stability, can exist stably for a long time, and is suitable for solving the problems of friction, wear and maintenance of different kinds of mechanical equipment under multiple working conditions.

Owner:SICHUAN CARBON WORLD TECH CO LTD

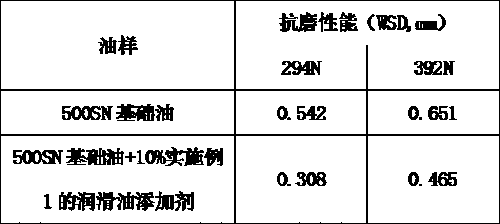

Additive for wear resistance of lubricating oil

ActiveCN101812354AExcellent extreme pressure anti-wear and anti-friction propertiesNot corrosiveAdditivesParaffin waxPolybutene

The invention discloses an additive for wear resistance of lubricating oil, which comprises the following components in part by weight: 15 to 35 parts of antiwear agent, 6 to 29 parts of detergent dispersant and 12 to 26 parts of antioxidant preservative, wherein the antiwear agent consists of boric acid tributylester, phosphonic acid dibutyl ester, copper isooctoxyborate and cupric cyclohexoxylborate; the detergent dispersant consists of polybutene amine, polyisobutene carbamic acid ester and 2-aminopyridine; and the antioxidant preservative is boronized butanimide. The additive has wide use range, can be used in paraffin, naphthene and intermediate base oil, and also can be used in synthetic and semi-synthetic base oil. The additive has the advantages of effectively improving the wear resistance of the lubricating oil, strengthening the bearing capacity of the lubricating oil, making the lubricating oil have long service life, and having small dosage in the lubricating oil and simple and convenient preparation process.

Owner:山东星火知识产权服务有限公司

Synthetic compressor lubricating oil composition and production method thereof

InactiveCN102952615AReduce vibrationImprove the lubrication effectLubricant compositionSocial benefitsFoaming agent

The present invention relates to a synthetic compressor lubricating oil composition and a production method thereof. The synthetic compressor lubricating oil composition is prepared by mixing the following raw materials, by weight, 80-90 parts of a liquid A and 10-20 parts of a liquid B, wherein the liquid A is prepared by mixing one or a plurality of poly alpha-olefin synthetic base oil with different viscosities, and the liquid B is prepared by mixing the following additives, by weight, 5.0-15.0 parts of an ester, 0.05-2 parts of an antioxidant, 0.01-2 parts of a rust inhibitor, 0.01-0.5 part of a metal deactivator, 0.5-3 parts of an extreme pressure wear resistance agent, 0.005-0.05 part of anti-emulsification agent, and 0.003-0.01 part of an anti-foaming agent. According to the present invention, stability is high, an oil change period is long, compressor energy consumption can be substantially reduced, a service life of the compressor can be prolonged, significant economic and social benefits are provided, and environmental pollution can not be caused.

Owner:BEIJING ALLUBE PETROCHEM

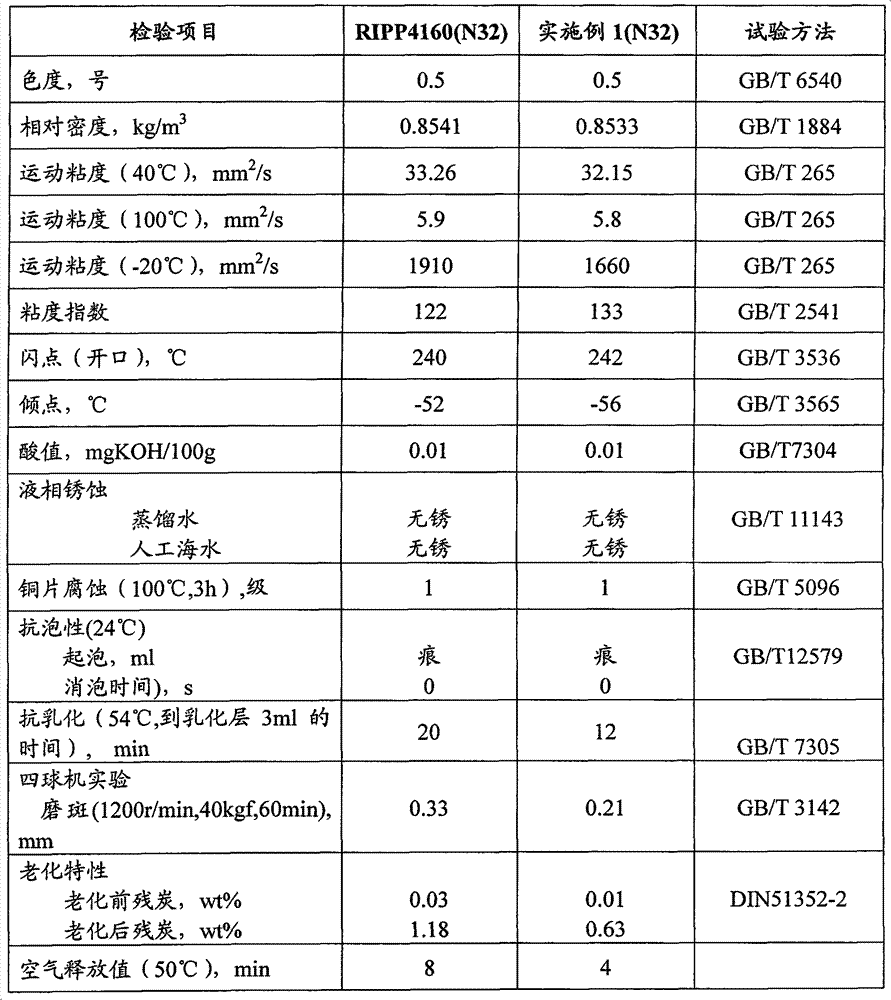

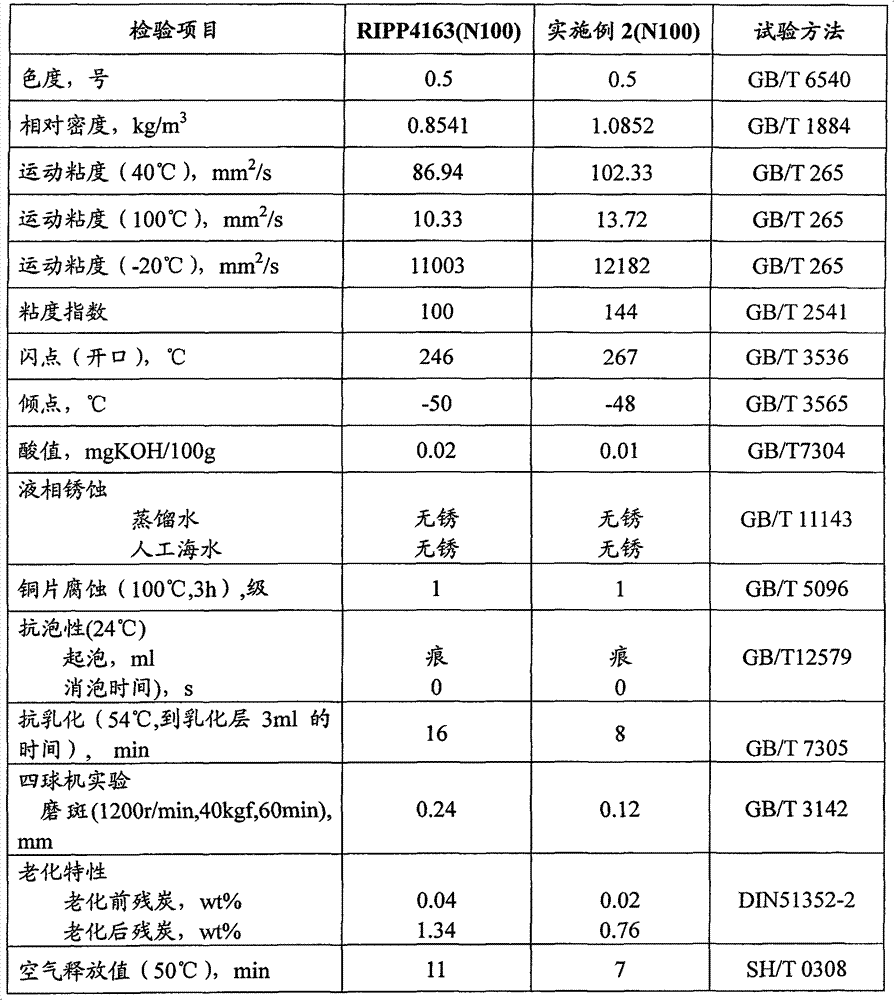

Synthetic lubricating oil composition for air compressor and preparation method thereof

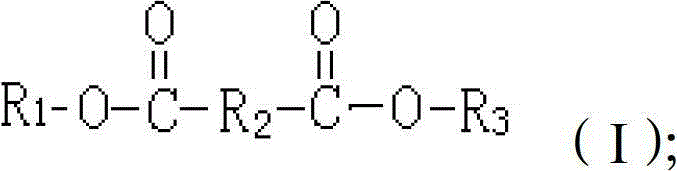

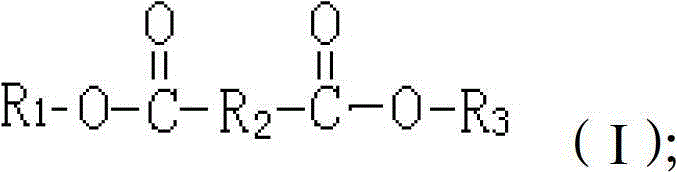

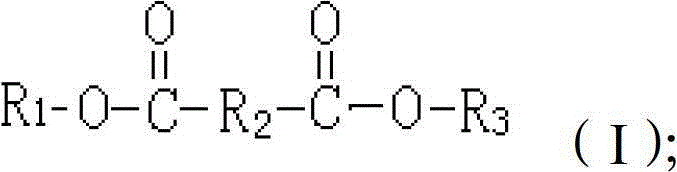

ActiveCN102911766AMeet the use requirementsExcellent coke cleaning functionAdditivesTO-18Chemical composition

The invention provides a synthetic lubricating oil composition for an air compressor. The synthetic lubricating oil composition comprises 0.1 to 10wt% of tackifier, 2 to 7wt% of antioxygen, 0.05 to 1wt% of corrosion inhibitor, 1 to 8wt% of extreme pressure anti-wear agent, 0.0001 to 0.05wt% of antifoaming agent, and the balance of ester oil. The ester oil is provided with a structure shown as formula (I), wherein R1 and R3 are independently selected from alkyl with 5 to 20 carbon atoms; and R2 is the alkylene with 5 to 18 carbon atoms. The ester oil is provided with a special molecular structure, so that the synthetic lubricating oil composition for the air compressor is excellent in function of cleaning the coking material, and original oil sludge and coking matter of the compressor system can be cleaned and carried out; and the synthetic lubricating oil composition for the air compressor is higher in coking resistance. The invention also provides a preparation method of the synthetic lubricating oil composition for the air compressor.

Owner:CHINA PETROLEUM & CHEM CORP

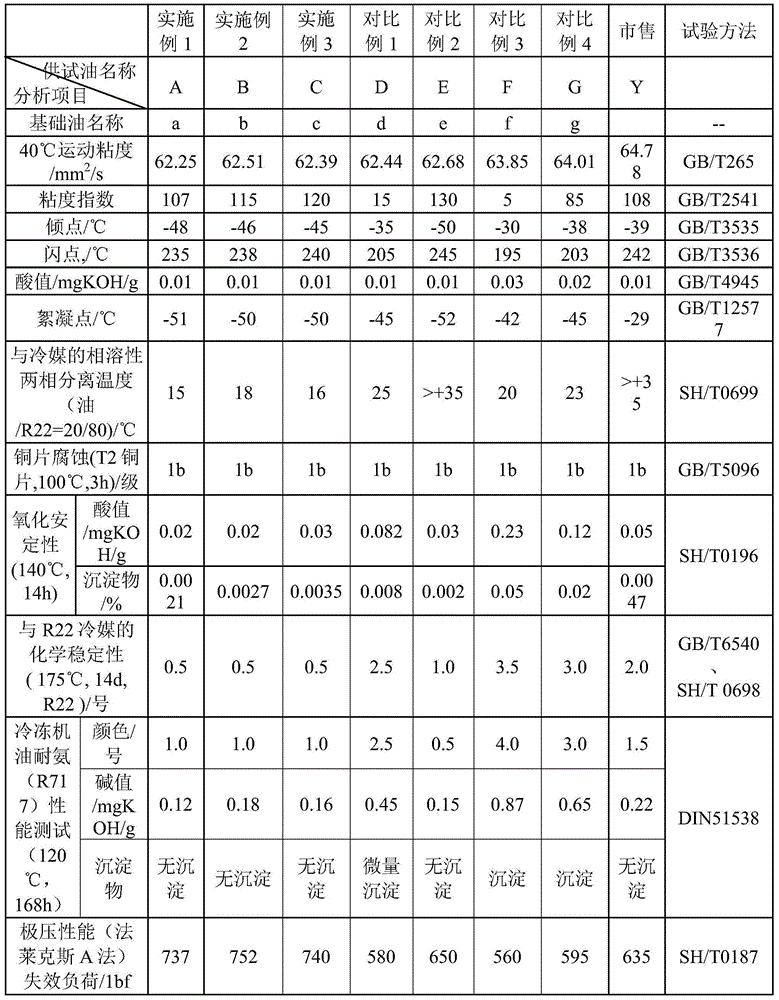

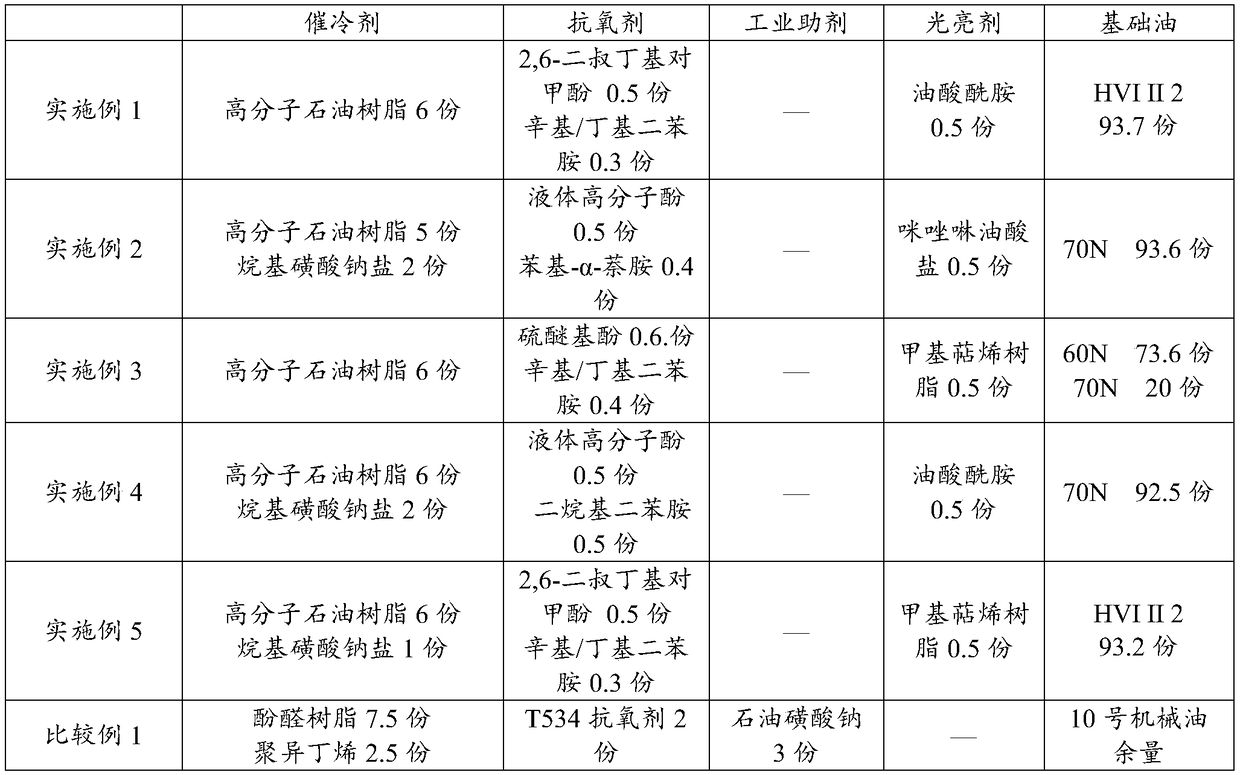

Refrigeration machine oil composition and application thereof

ActiveCN106147925AGood chemical stabilityHigh viscosity indexBase-materialsHigh pressureChemical stability

The invention provides a refrigerating machine oil composition and its application, which comprises the following components based on the weight of the base oil: (1) 35-75wt% polyalphaolefin synthetic lubricating oil base oil; (2) 20-60wt% naphthene Base mineral lubricating oil base oil, the naphthenic mineral lubricating oil base oil is obtained by adopting "hydrodemetallization-hydrotreating-hydrogen decondensation-supplementary refining" high-pressure series all-hydrogen process technology; (3) 1-5 wt% alkylbenzene synthetic lubricant base oil; (4) additives. The refrigerating machine oil provided by the invention has good chemical stability with ammonia refrigerant (such as R717), and has a higher viscosity index, lower flocculation point and good thermal oxidation stability, and is especially suitable for ammonia refrigerant Refrigeration machine oil can also be used for refrigeration machine oil with fluorocarbons, hydrochlorofluorocarbons, and isobutane as refrigerants, which can achieve the purpose of reducing low-temperature viscosity, improving energy saving, and has excellent anti-wear performance.

Owner:PETROCHINA CO LTD

High-property modified nitrile butadiene rubber cable material used for ships

InactiveCN105153497AImprove thermo-oxidative stabilityGood mechanical propertiesRubber insulatorsAlkaneFiber

The invention discloses a high-property modified nitrile butadiene rubber cable material used for ships. The cable material comprises the following raw materials in parts by weight: 20-40 parts of nitrile butadiene rubber, 5-10 parts of modified polyurethane composite material, 12-18 parts of styrene butadiene rubber, 5-15 parts of butadiene rubber, 1-2 parts of oleic acid, 0.5-1.5 parts of stearic acid, 1-2 parts of ammonium dichromate, 0.8-1.4 parts of dibenzothiazyl disulfide, 15-30 parts of kaolin, 8-12 parts of pottery clay powder, 42-55 parts of white carbon black, 5-10 parts of graphite, 1-3 parts of octyl-phenolic tackifying resin, 10-30 parts of ceramic fibers, 20-40 parts of modified active fibers, 0.5-1.5 parts of diisooctyl phthalate, 1-1.4 parts of aromatic hydrocarbon oil, 0.4-0.8 part of naphthenic hydrocarbon oil, 0.5-1.4 parts of antioxidant AT-215, 1-3 parts of ultraviolet absorber UV-531 and 1-2 parts of ultraviolet absorber TB75. The cable material has good thermal oxidative stability and excellent mechanical properties and is resistant to aging.

Owner:安徽华润仪表线缆有限公司

Jet fuels having superior thermal stability

ActiveUS20120211399A1Good thermo-oxidative stabilityAcceptable swell propertyMolecular sieve catalystsRefining to change hydrocarbon structural skeletonBoiling pointThermal stability

Disclosed herein are jet fuel compositions containing (a) a total aromatics content of from 2 vol. % to no more than about 25 vol. %; (b) a net heat of combustion of at least about 125,000 Btu / gal; (c) a concentration of less than about 5 vol. % of hydrocarbons having a boiling point greater than or equal to about 550° F., as determined by ASTM D 2887; and (d) a Jet Fuel Thermal Oxidation Test (JFTOT) thermal stability characterized by a filter pressure drop of no more than 25 mm Hg, a breakpoint temperature greater than or equal to about 300° C., and an overall tube deposit rating less than 3, as determined by ASTM D 3241. Methods for their preparation are also disclosed.

Owner:CHEVROU USA INC

Anti-emulsification type overspeed quenching oil composition and application thereof

The invention relates to an anti-emulsification type overspeed quenching oil composition and application thereof, and mainly relates to overspeed quenching oil with good oil-water separation and excellent cooling performance. The anti-emulsification performance of the overspeed quenching oil in the prior art is improved, and the oil-water separation performance is enhanced so as to solve the problem of emulsification of the overspeed quenching oil in the cleaning process of quench workpieces in the prior art. The anti-emulsification type overspeed quenching oil composition comprises, by weight, (a) 0.5-10 parts of cooling agents, (b) 0.1-3 parts of antioxidants, (c) 0.05-1 part of brightener and (d) 75-95 parts of base oil. The anti-emulsification type overspeed quenching oil composition can be used for quenching workpieces which require high emulsifying performance and have high thickness, large cross section and low hardenability, such as automobile fasteners, gears, bearings and seamless steel pipes.

Owner:CHINA PETROLEUM & CHEM CORP

Biodegradable lubricating oil, and preparation method thereof

ActiveCN110157531AImprove the lubrication effectImprove anti-wear performanceBase-materialsPolymer scienceCottonseed oil

The invention discloses a biodegradable lubricating oil, and a preparation method thereof. The preparation method comprises following steps: 1, raw materials are prepared, wherein the raw materials comprise cotton seed oil, bis(2-ethylhexyl) sebacate, a dispersant, an extreme pressure antiwear agent, an antioxidant, potassium sorbate, dodecenyl succinic acid, a viscosity index improver, an a defoaming agent; 2, an obtained cotton seed oil mixture is introduced into a blending vessel for stirring, and is discharged through a 2-10<mu>m filter so as to obtain a finished product. The biodegradablelubricating oil is scientific and reasonable in formula, is friendly to the environment, is nontoxic, is prepared taking cotton seed oil as a base oil, is cheap, and is biodegradable; cotton seed oilis subjected to functional treatment, so that the lubricating performance and anti-wearing performance of the lubricating oil are improved greatly; the preparation method is simple and convenient, and is convenient for industrialized production. The biodegradable lubricating oil is excellent in wear resistance, lubricating performance, low temperature performance, high temperature performance, and heat oxidation stability, and the bio-degradability and the economical performance are better than those of fully synthetic oil.

Owner:深圳市超美化工科技有限公司

Environment-friendly and energy-saving hydraulic oil and preparation method thereof

InactiveCN111139118AGood thermo-oxidative stabilityImprove anti-friction and anti-wear effectLubricant compositionInorganic saltsActive agent

The invention discloses an environment-friendly and energy-saving hydraulic oil. The hydraulic oil comprises, by weight, 60 to 80 parts of a binding agent, 60-90 parts of medium oil, 0.1-0.5 part of an anti-aging agent, 0.1-0.5 part of a rust loosening agent, 0.1-0.5 part of a pour point depressant, 0.8-3 parts of a defoaming agent, 50-80 parts of a heat stabilizer, 50-80 parts of an expanding agent, 40-70 parts of a thickening agent, 50-90 parts of a vulcanizing agent, 0.1-0.9 part of an extreme pressure anti-wear agent and 0.8-3 parts of an activator. The invention also discloses a preparation method of the environment-friendly and energy-saving hydraulic oil. By utilizing the excellent thermal oxidation stability of an ionic liquid, the proper viscosity index is adjusted, the dissolvingcapacity is changed, and the anti-wear and anti-friction effects are good, and the energy-saving and environment-friendly hydraulic oil is prepared; and the ionic liquid with excellent thermal oxidation stability, high viscosity index, good dissolving capacity for inorganic salt and organic matter and good anti-wear and anti-friction effects is synthesized, the ionic liquid is used as a base liquid, and an additive with an excellent extreme pressure anti-wear effect is added to prepare the green, environment-friendly and energy-saving hydraulic oil.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

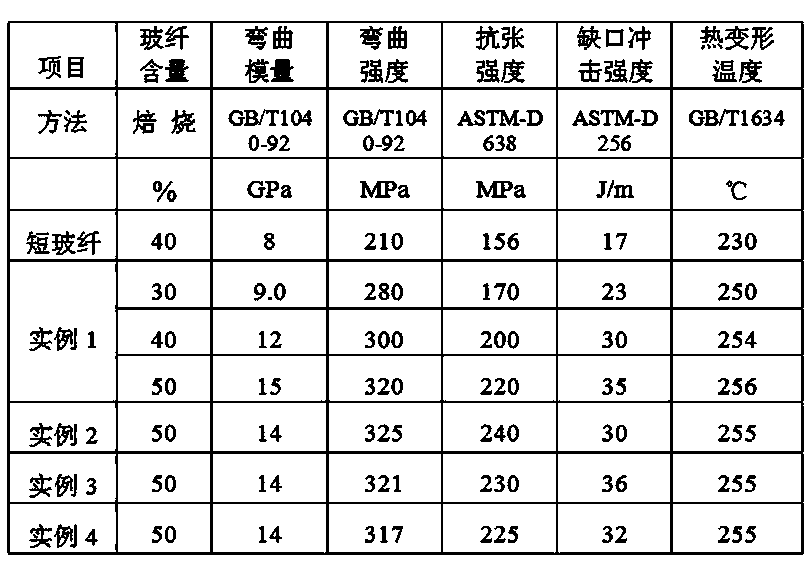

Nylon 66 impregnated ingredient and method of producing long glass fiber reinforced nylon 66 aggregate by utilizing ingredient

The invention discloses a nylon 66 impregnated ingredient and a method of producing long glass fiber reinforced nylon 66 aggregate by utilizing the ingredient. The nylon 66 impregnated ingredient consists of the following components in parts by weight: 100 parts of nylon 66, 2-8 parts of a compatilizer, 0.3-1.5 parts of coupling agent, 0.3-1.5 parts of impregnating compound and 0.5-2 parts of antioxidant. The impregnated ingredient disclosed by the invention is low in melt viscosity, good in wettability with glass fiber, good in thermal oxidation change resistance and suitable for producing the long glass fiber reinforced nylon 66 aggregate by melting an impregnated glass fiber tow at a high speed under a temperature lower than 320 DEG C in a wire guide roller-combined impregnation mould head.

Owner:SOUTH CHINA UNIV OF TECH +1

High-performance fully-synthetic wind-power gear oil and preparation method thereof

InactiveCN112011392AGood chemical stabilityImprove the lubrication effectLubricant compositionPolyolesterAntioxidant

The invention discloses high-performance fully-synthetic wind power gear oil. The wind power gear oil comprises base oil and additives, wherein the base oil is polyol ester, and the additives comprisean antioxidant, a demulsifying agent, a pour point depressant, an antirust agent, an extreme-pressure anti-wear agent, a detergent dispersant, a defoaming agent and a metal deactivator. The inventionalso provides a preparation method of the wind power gear oil. The preparation method comprises the following steps: carrying out an esterification reaction on polyol monoester and fatty acid to synthesize polyol ester, blending the polyol ester to obtain the base oil, adding the additives into the base oil, and conducting mixing to obtain the environment-friendly fully-synthetic wind power gearoil. According to the invention, the wind power gear oil has good compatibility with various additives and can be widely applied to a wind power gear oil tank; the gear oil has very long service lifeeven under severe working conditions; the high viscosity index and good shear stability of the gear oil are guaranteed; the lubricating requirement of a gear box used in a very wide viscosity range ismet; pitting corrosion can be effectively avoided or inhibited; and normal operation of a large heavy-duty mechanical gear transmission device is guaranteed.

Owner:上海中孚油品集团有限公司

Super-high-pressure ethylene compressor oil and preparation method thereof

ActiveCN102311848AKeep healthyMeet the special requirements of oilLubricant compositionUltra high pressureAntioxidant

The invention provides super-high-pressure ethylene compressor oil, which contains the following components in percentage by weight: 93-99% of polyethers synthetic oil, 0.1-2% of antioxidant and 0-5% of anti-rusting agent. The super-high-pressure ethylene compressor oil provided by the invention takes the polyethers synthetic oil as the base oil and special additive compositions are added, so that the product can resist the dilution of ethylene gas and also can control the rise of viscosity under the extremely-high pressure to realize good lubrication; and the oil has good thermal oxidation stability and lubricity, low carbon deposition tendency and low biological toxin, so that the physical health of operators and safety and sanitation of mixing extremely little amount composition with polyethylene products can be guaranteed, and special requirements on the oil for a super-high-pressure compressor system can be satisfied.

Owner:CHINA PETROLEUM & CHEM CORP

Polytetraurea lubricant grease

InactiveCN105779083AStrong viscosity retention at high temperatureLow pour pointLubricant compositionFood industryAntioxidant

The invention discloses polytetraurea lubricant grease. The polyurea lubricant grease disclosed by the invention is obtained through taking low-viscosity lubricating oil prepared from ester oil and poly alpha olefin as base oil, taking synthesized polytetraurea as a thickener and adding a friction modifier and an antioxidant. According to the ureido-based lubricant grease disclosed by the invention, the thickening effect is greatly increased without increasing the cost, the comprehensive performance is good, and the lubricant grease can be applied to machinery in the fields of electrical appliance industry, metallurgical industry, food industry, paper-making industry, automobile industry, airplane industry and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Combination of general gear oil

A universal oil composition for gear contains mineral lubricating oil or synthetic lubricating oil or their mixture, at least one viscosity index improver and / or pour depressor, at least one S-contained extreme-pressure agent, at least one P-contained antiwear agent, phosphate-type multi-effect agent, oil agent (1-hydroxyethylene-1, 1-biphosphonate), and at least one metallic deactivator and / or antirust agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Graphene lubricating oil additive and preparation method thereof

The invention relates to a partial component of a combine harvester, and more particularly relates to a graphene lubricating oil additive. The graphene lubricating oil additive comprises the followingcomponents in percentages by weight: 0.1-1% of graphene, 1-10% of a hydrogenated styrene-diene copolymer, 1-10% of oleic acid, 10-25% of boric acid ester and 70-90% of an oil-based solvent. The additive provided by the invention has the beneficial effects that the process is simple, the production process is simplified, and the production costs are reduced.

Owner:山东沾化莱斯特石油化工有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com