Graphene lubricating oil additive and preparation method thereof

A lubricating oil additive, graphene technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of complex additive process operation, emission of waste gas and pollutants, environmental pollution, etc., achieve excellent anti-oxidation stability, improve Power, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

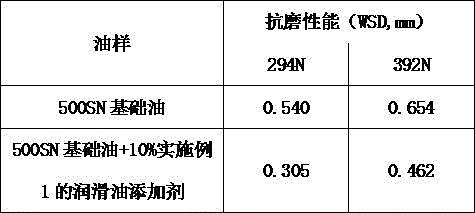

Embodiment 1

[0022] Graphene lubricating oil additive, gets raw material and comprises by weight percentage:

[0023] Graphene 0.1%, HSD (hydrogenated styrene-diene copolymer) 1%, borate 15%, oily solvent 83.9%;

[0024] Among them: the diameter of graphene is 1um-5um, the thickness is 1nm-10nm, and the specific surface area is 500-1000㎡ / g; HSD is Infineum's SV260; the borate ester component is 2-(4- Dodecylphenoxy) Hydroxyethylaminodiethoxyborate 40%, 2-(4-Dodecylphenoxy) Heptadecylaminodiethoxyborate 20% %, and 40% of 2-(4-dodecylphenoxy) oleate hydroxyethylamino diethoxy borate; the oily solvent is 500SN base oil.

[0025] The preparation method of graphene lubricating oil additive comprises the steps:

[0026] Add borate ester to oily solvent and stir fully at 50-60°C for 30 minutes, then add HSD electromagnetic stirring for 30 minutes, finally add graphene, and use a 55KW paint disperser to stir at high speed for 30 minutes to obtain a graphene lubricating oil additive. This product...

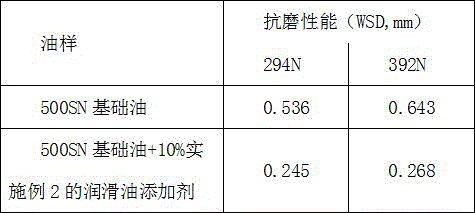

Embodiment 2

[0031] Graphene lubricating oil additive, gets raw material and comprises by weight percentage:

[0032] Graphene 0.4%, HSD (hydrogenated styrene-diene copolymer) 4%, borate 20%, oily solvent 75.6%;

[0033] Among them: the diameter of graphene is 1um-5um, the thickness is 1nm-10nm, and the specific surface area is 500-1000㎡ / g; HSD is Infineum's SV260; the borate ester component is: 2-(4-dodecane 40% hydroxyethylaminodiethoxy borate, 20% 2-(4-dodecylphenoxy) heptadecylaminodiethoxy borate, and 2-(4-dodecylphenoxy) oleate hydroxyethylaminodiethoxy borate 40%; oily solvent is 500SN base oil.

[0034] The preparation method of graphene lubricating oil additive comprises the steps:

[0035] Add borate ester to oily solvent and stir fully at 50-60°C for 30 minutes, then add HSD electromagnetic stirring for 30 minutes, finally add graphene, and use a 55KW paint disperser to stir at high speed for 30 minutes to obtain a graphene lubricating oil additive. This product is Black oil....

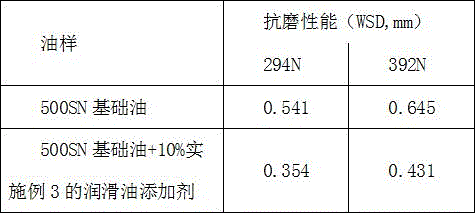

Embodiment 3

[0040] Graphene lubricating oil additive, gets raw material and comprises by weight percentage:

[0041] Graphene 0.5%, HSD5%, borate 20%, oily solvent 74.5%;

[0042] Among them: the diameter of graphene is 1um-5um, the thickness is 1nm-10nm, and the specific surface area is 500-1000㎡ / g; HSD is Infineum's SV260; the borate ester component is: 2-(4-dodecane 40% hydroxyethylaminodiethoxy borate, 20% 2-(4-dodecylphenoxy) heptadecylaminodiethoxy borate, and 2-(4-dodecylphenoxy) oleate hydroxyethylaminodiethoxy borate 40%; oily solvent is 500SN base oil.

[0043] The preparation method of graphene lubricating oil additive comprises the steps:

[0044] Add borate ester to oily solvent and stir fully at 50-60°C for 30 minutes, then add HSD electromagnetic stirring for 30 minutes, finally add graphene, and use a 55KW paint disperser to stir at high speed for 30 minutes to obtain a graphene lubricating oil additive. This product is Black oil.

[0045] Product anti-wear performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com