SCR denitration device and method applied to high-dust-content smoke from kiln tail of cement clinker production line

A cement clinker and production line technology, applied in the direction of separation methods, chemical instruments and methods, climate sustainability, etc., can solve the problems of reduced catalyst activity, high power consumption, and difficult transformation, so as to achieve no impact on thermal insulation design and overcome The effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

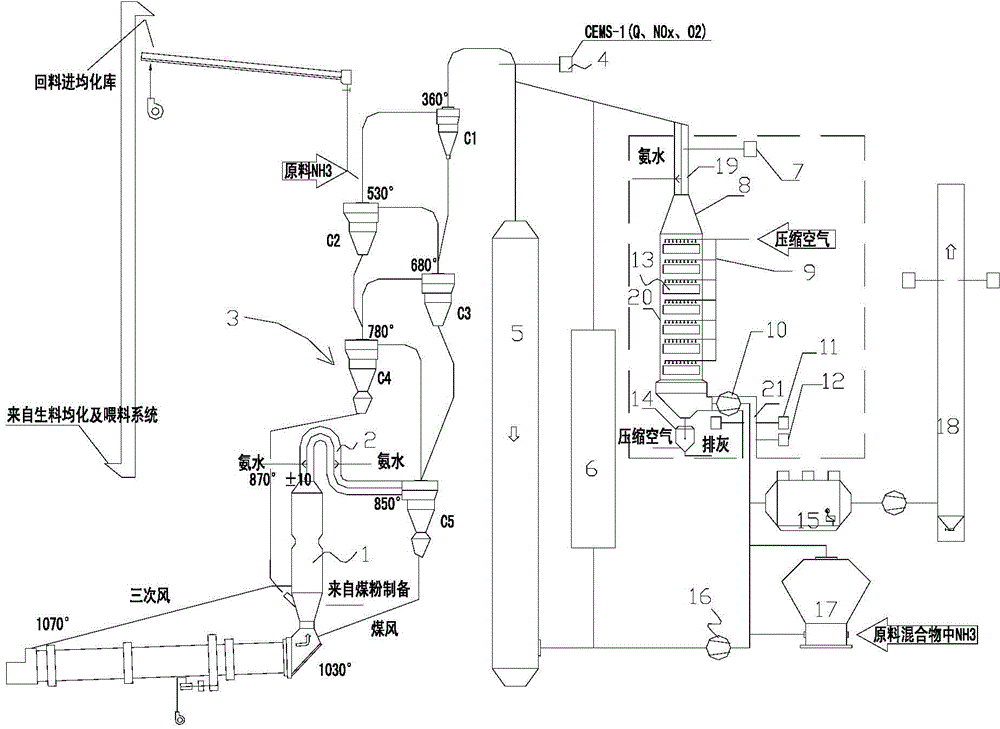

[0063] This embodiment follows as figure 1 The device and process shown. Cement kiln calciner 10000Nm 3 / h Bypass flue gas SCR denitrification test device, set up bypass at the front and back ends of the waste heat boiler to introduce actual flue gas, flue gas temperature 350℃±20℃, dust content 30-100g / m 3 , The initial concentration of NOx is 280-1200mg / m3 (the upstream of the SCR denitrification reactor has been equipped with SNCR denitrification device, if the upstream SNCR denitrification device is not put into operation, the initial concentration is as high as 700-1200mg / m 3 , After the upstream SNCR denitrification device is put into operation, the minimum NOx emission concentration can be controlled at 200mg / m 3 , Generally controlled at 320mg / m according to the standard 3 Below, therefore, the inlet NOx concentration can be adjusted within a wide range.

[0064] See attached for details figure 1 SCR denitration reactor is installed on the bypass flue at the front and back e...

Embodiment 2

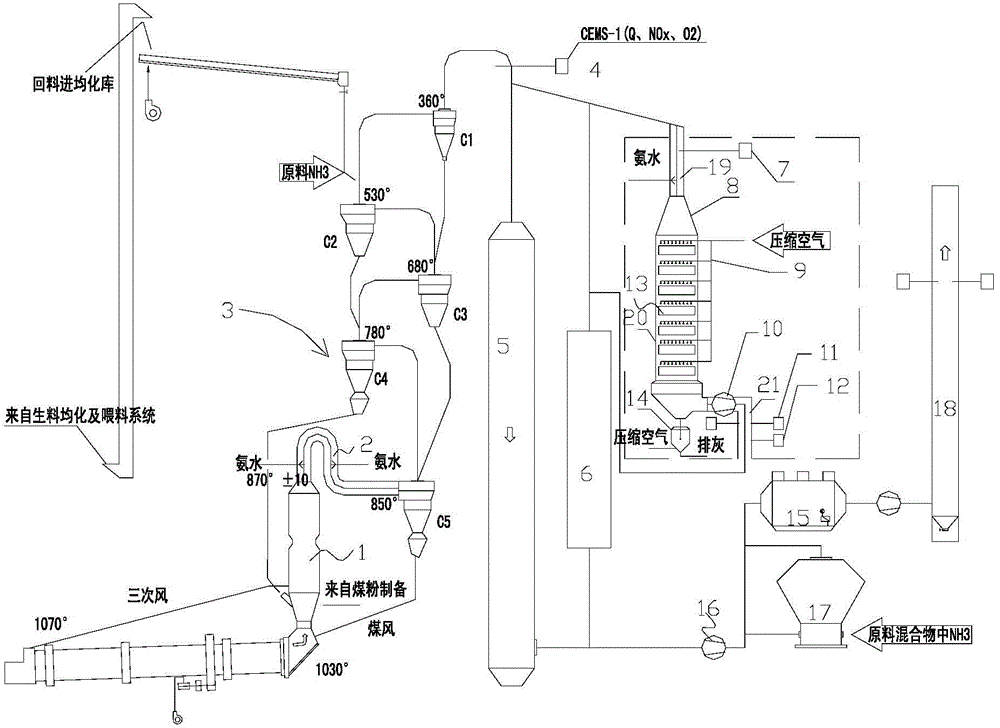

[0069] This embodiment follows as figure 2 The device and process shown. SCR denitration project of cement kiln calciner with daily output of 2500t clinker, deep denitration of flue gas, flue gas volume of 295000m 3 / h, flue gas temperature 350℃±20℃, dust content 30-100g / m 3 , The initial concentration of NOx is 280-1200mg / m 3 (The upstream of the SCR denitrification reactor has already been equipped with an SNCR denitrification device. If the upstream SNCR denitrification device is not put into operation, the initial concentration is as high as 700-1200mg / m 3 , After the upstream SNCR denitrification device is put into operation, the minimum NOx emission concentration can be controlled at 200mg / m 3 , Generally controlled at 320mg / m according to the standard 3 Below, therefore, the inlet NOx concentration can be adjusted within a wide range.

[0070] See attached for details figure 2 An SCR denitration reactor is added at the front end of the waste heat boiler. After denitratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com