Patents

Literature

63results about How to "Reduce the amount of resection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

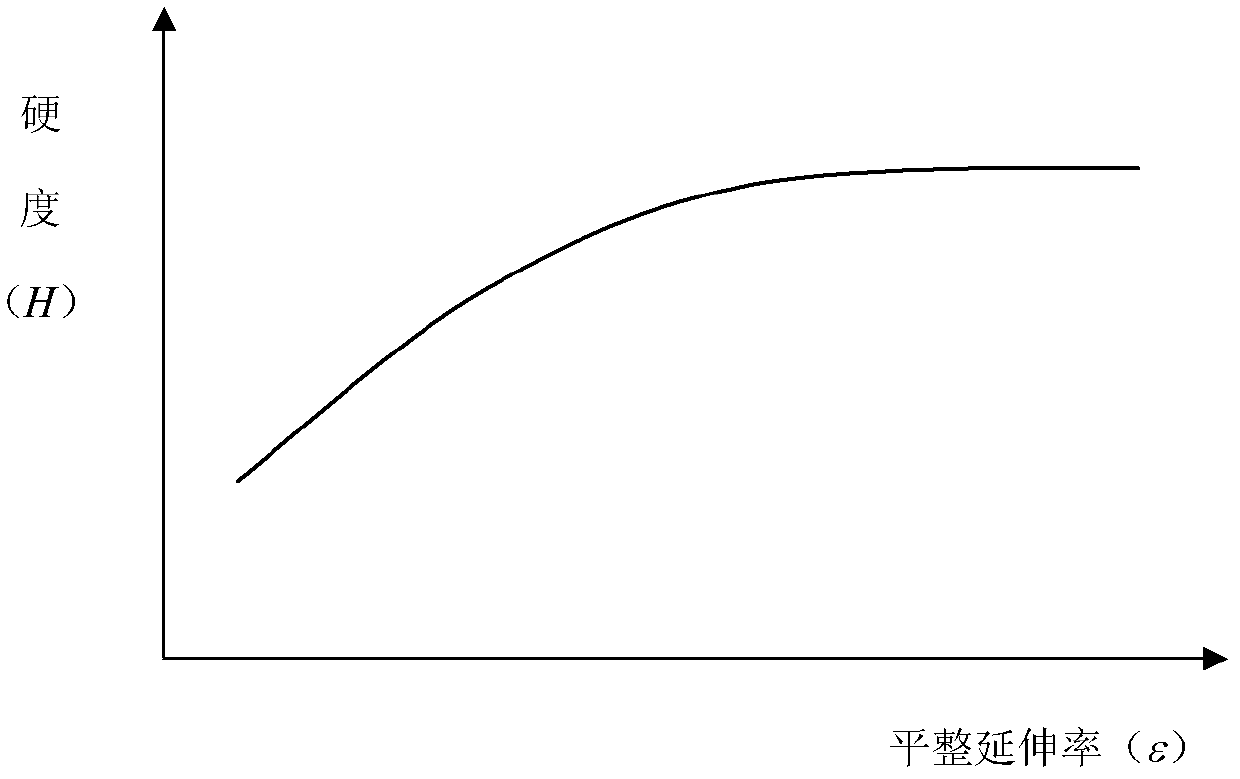

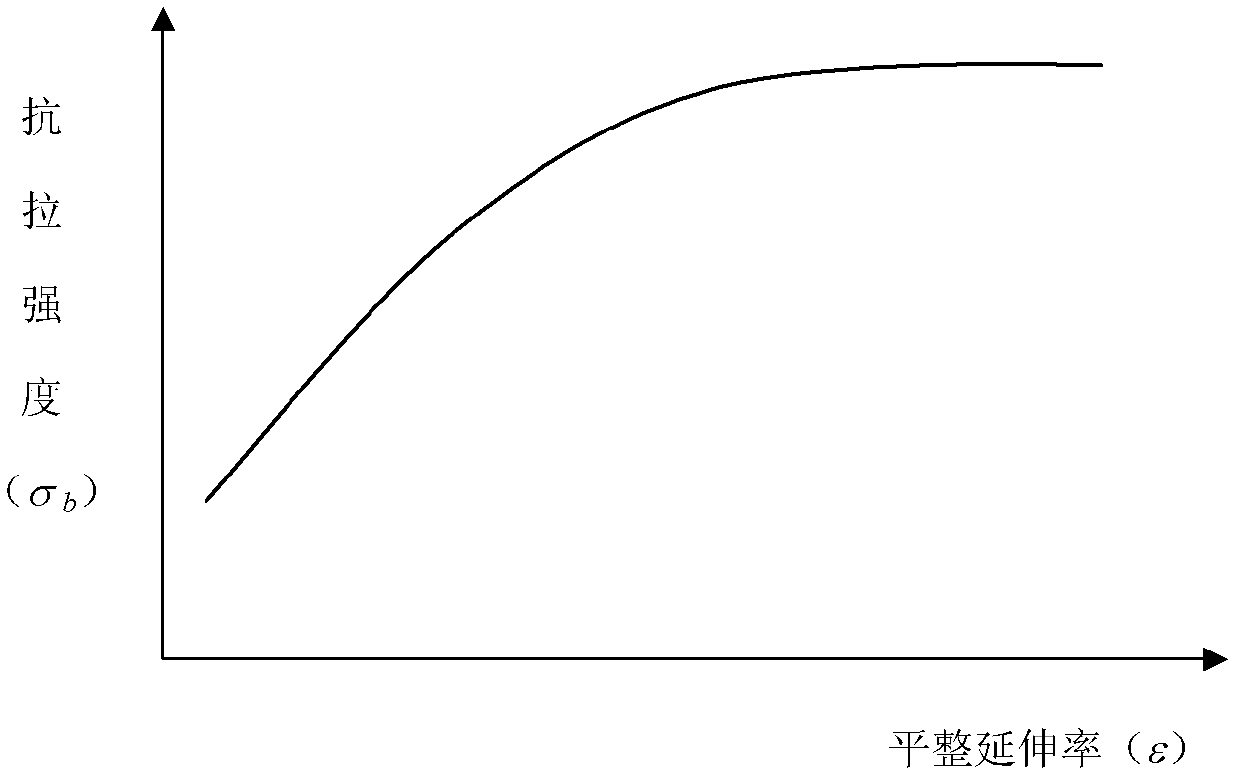

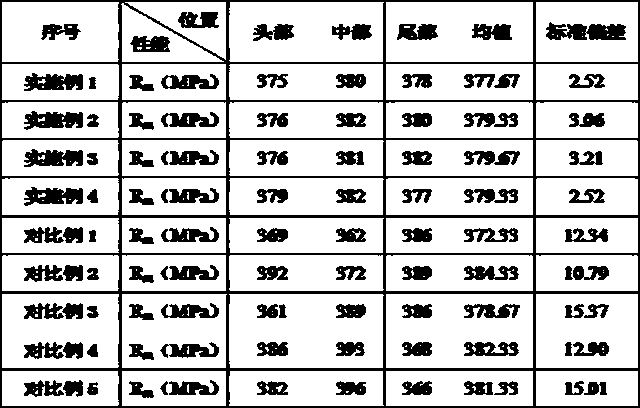

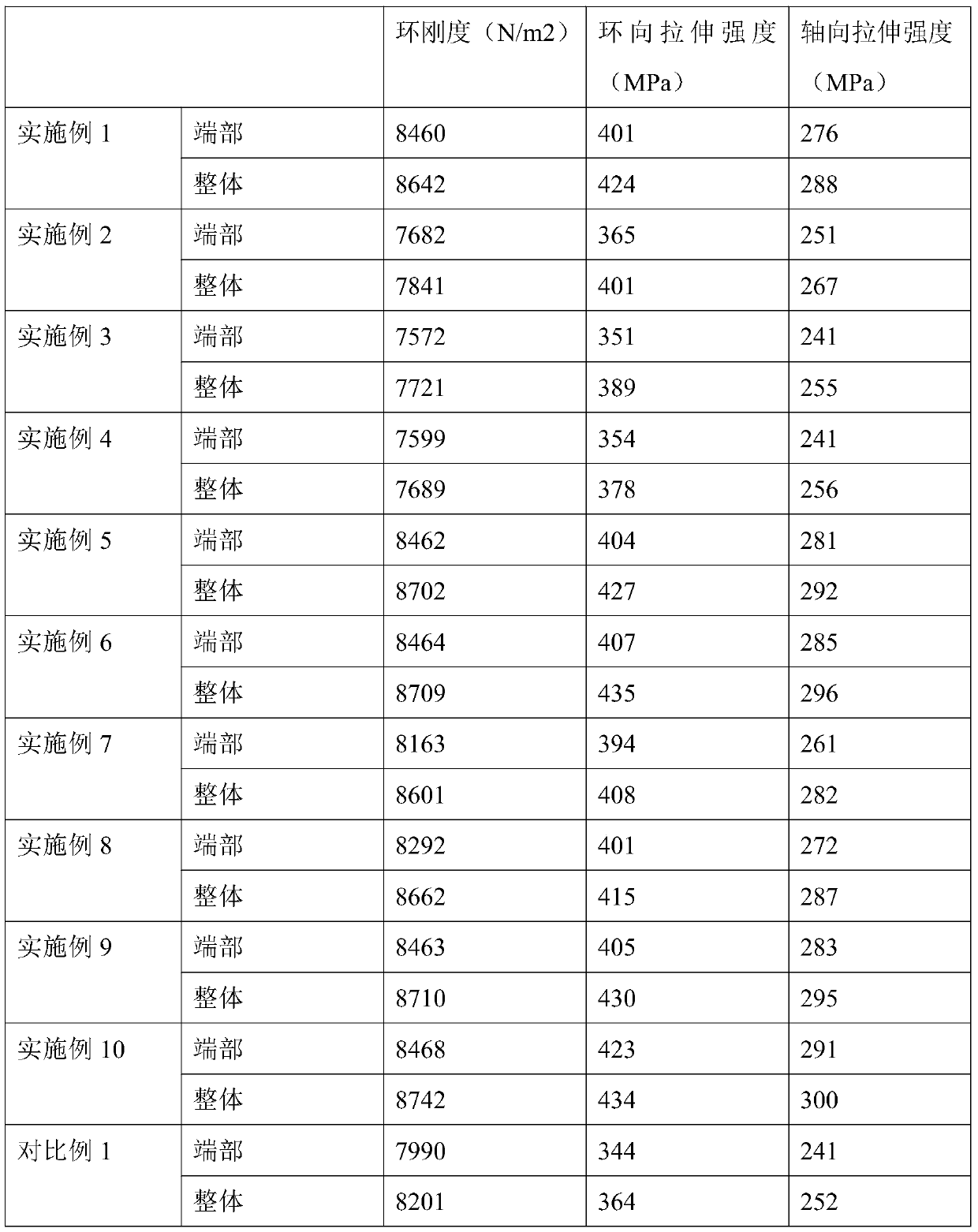

Method for controlling mechanical properties of cold-rolling strip steel in online manner

ActiveCN102886383AHigh control precisionRealize online detectionRoll force/gap control deviceTemperature control deviceCooling speedEconomic shortage

The invention relates to a method for controlling the mechanical properties of cold-rolling strip steel in an online manner. The method overcomes the shortage of the current conventional method for monitoring the mechanical properties of the strip steel by inspecting casually and sampling, analyzing and testing in an offline manner and adjusting the production process or material components in the online manner, and reduces the fluctuations of the mechanical properties of the strip steel. The method for controlling the mechanical properties of the strip steel in the online manner is based on a continuous hot dip galvanizing machine set or a continuous annealing machine set of the cold-rolling strip steel and is realized by testing the mechanical properties of the strip steel in the online manner and timely adjusting production process parameters such as flat elongation, annealing heating temperature or annealing cooling speed and the like according to a deviation between a mechanical property testing value and a target value. The method can improve the control accuracy of the mechanical properties of the cold-rolling strip steel and satisfy the requirements of downstream users in a better manner.

Owner:BAOSHAN IRON & STEEL CO LTD

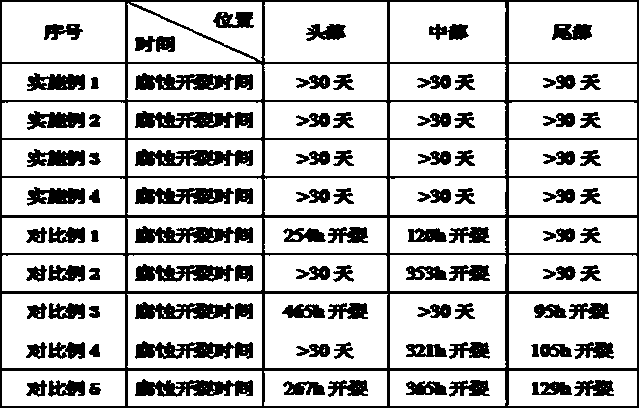

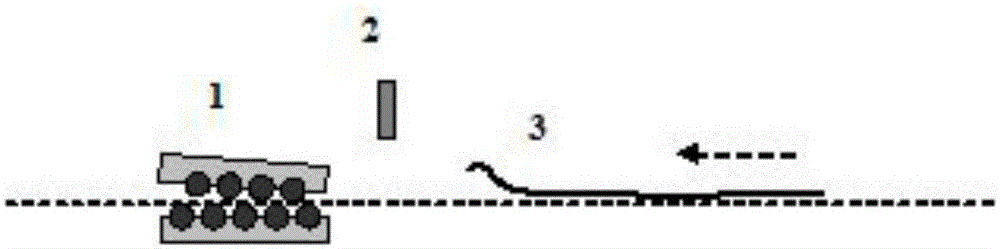

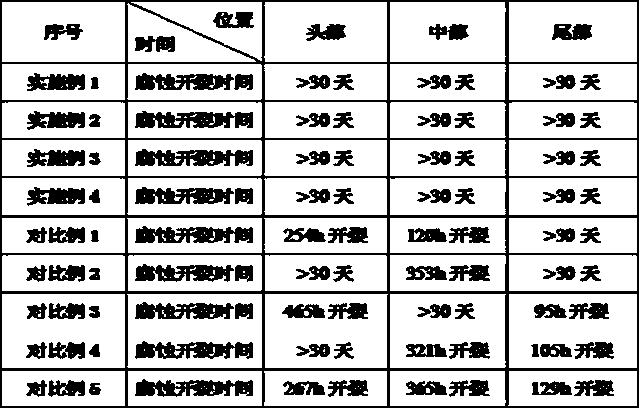

Al-Zn-Mn alloy profile for rail transit vehicle body and preparation method thereof

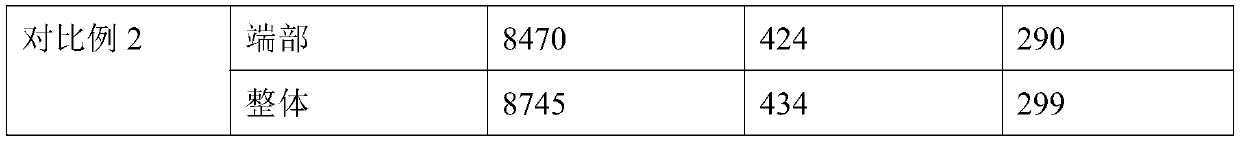

The invention belongs to the technical field of metal materials and machining thereof, discloses an Al-Zn-Mn alloy profile for a rail transit vehicle body and a preparation method thereof, and relatesto the technical field of aluminum alloy machining. The alloy comprises the following chemical components of, by mass, 4.4-4.6 % of Zn, 0.1-0.15% of Cu, 0.3-0.4% of Mn, 0.16-0.24% of Cr, 0.04-0.08% of Ti, 0.12-0.20 of Zr, less than or equal to 0.12% of Fe, less than or equal to 0.06% of Si, and the balance Al, wherein the ratio of the mass percentage of the Zn to the mass percentage of the Mg is3.2 to 3.5. The Al-Zn-Mn alloy material prepared through the preparation method has high toughness, corrosion resistance, anti-fatigue and weldable characteristics, and can meet the running requirements of the high-speed rail transit vehicle body.

Owner:广西南南铝加工有限公司

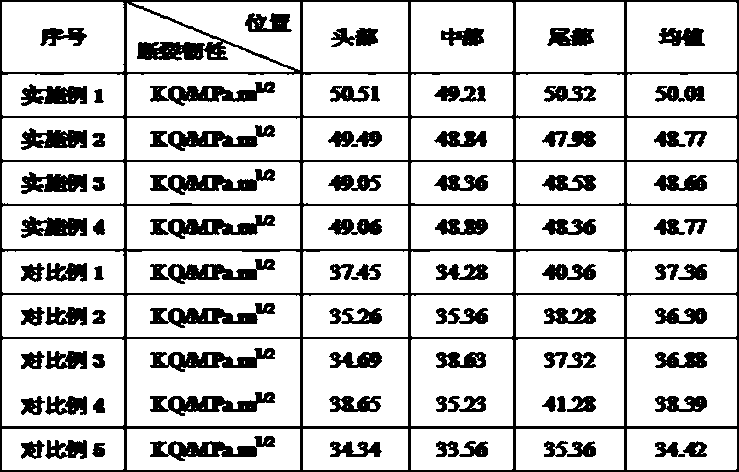

Wide and thick plate continuous casting machine dry capping method

The invention relates to a wide and thick plate continuous casting machine dry capping method, and belongs to the technical field of continuous casting technologies. The wide and thick plate continuous casting machine dry capping method particularly comprises the following steps and parameters that in the speed reduction stage, according to the actual measurement tundish tons, in cooperation the tundish measurement actual liquid level, the pull speed is reduced to 0.25 m / min; in the low-speed and constant-speed running stage, according to the tundish tons and the actual measurement liquid level, when the depth of the liquid face of molten steel in a tundish ranges from 100 mm to 300 mm, a plug bar is closed, meanwhile, the pull speed is reduced to 0.15 m / min to 0.2 m / min, and low-speed running is kept; and in the speed increasing process, the blank tail is pulled out of a crystallizer, and the pull speed is increased to a target pull speed. The wide and thick plate continuous casting machine dry capping method has the beneficial effects that slag is not wasted, slag fishing is avoided, low-speed weak-cold control is achieved, and therefore the effective improvement of the tail blank quality is achieved, the tail blank flaw detection yield is improved, the tail blank waste cutting amount is reduced, and the metal yield is improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Thick standard hot rolling nose plate thermal straightening process

InactiveCN104998927AAvoiding problems with colliding straightening rollersReduce warpageSheet steelNose parts

The invention discloses a thick standard hot rolling nose plate thermal straightening process, comprising the steps of: firstly, avoiding a steel plate nose part, and then straightening by small rolling reduction in a backward direction, thus avoiding the collision between the head of a nose plate and a straightening roll and reducing the buckling rate of the nose plate; then straightening by large rolling reduction in a forward direction to fully straighten the nose plate. The process adopts a method of firstly avoiding the steel plate and then straightening by small rolling reduction in the backward direction, the problem of collision of the head and the straightening roll in a conventional straightening process of the nose plate is solved, and the buckling rate of the nose plate is greatly reduced; through a method of straightening by large rolling reduction in the forward direction, the nose plate is fully straightened, the cutoff amount of the head of the steel plate is greatly reduced, and yield is improved.

Owner:NANJING IRON & STEEL CO LTD

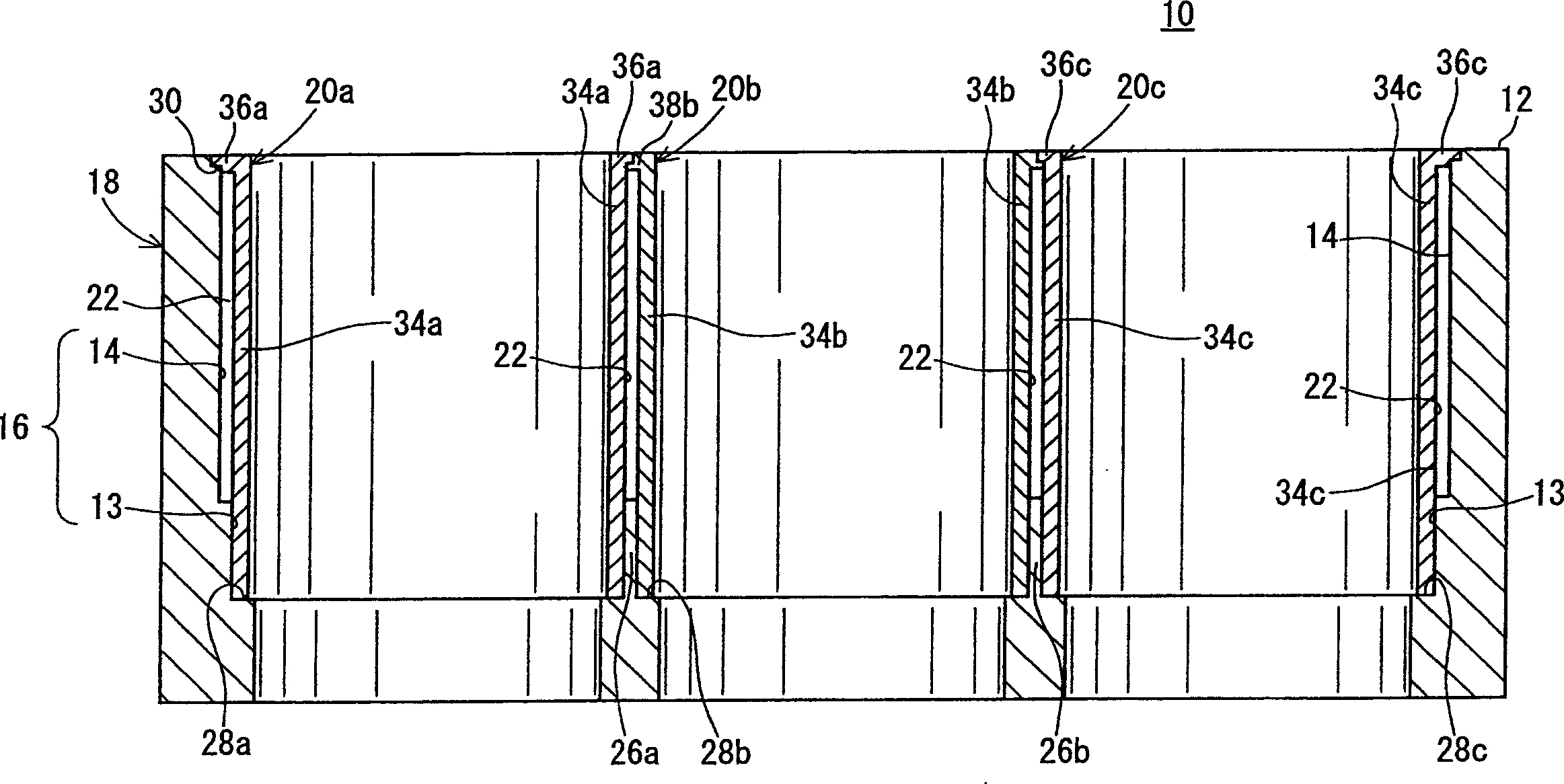

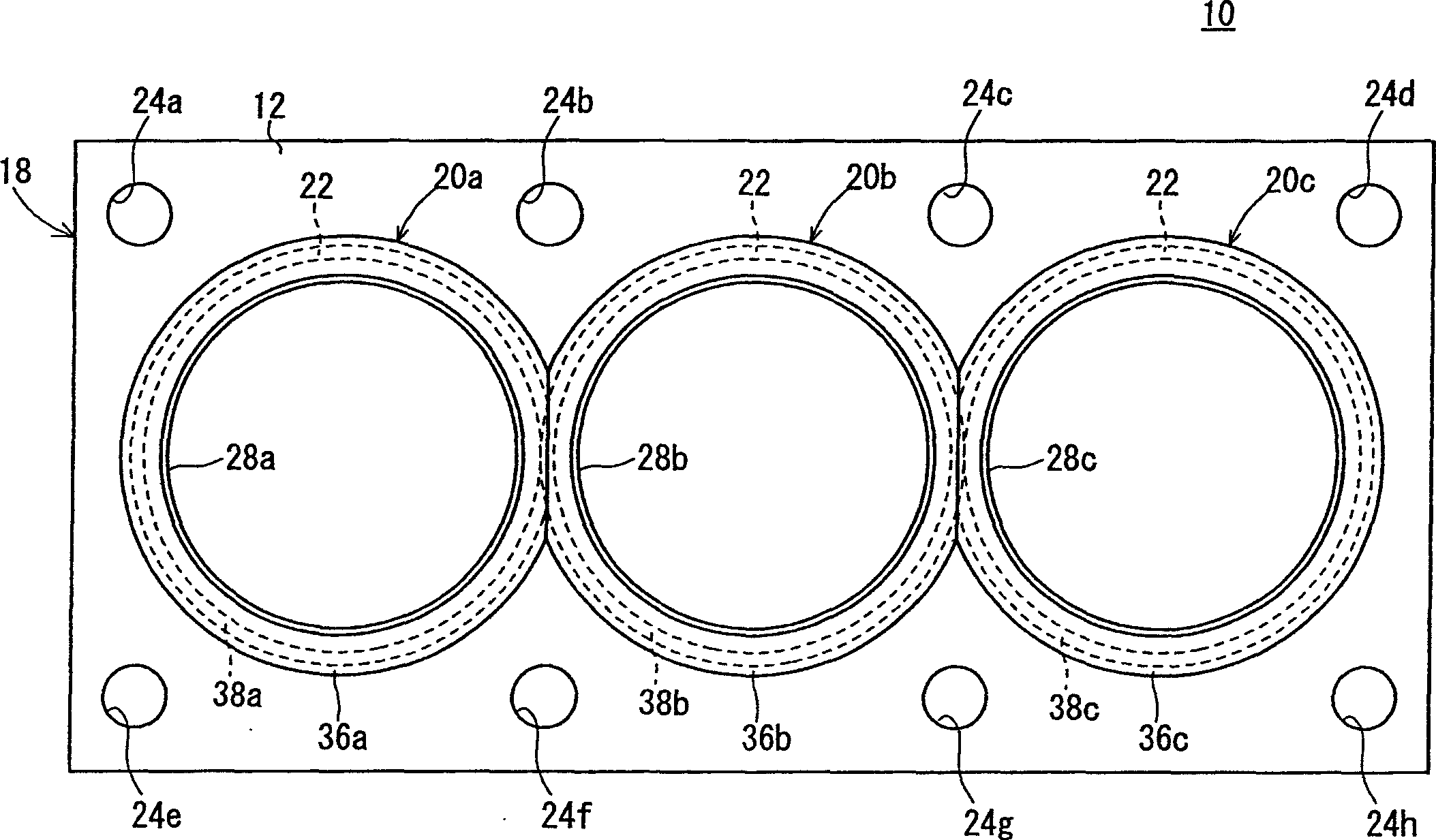

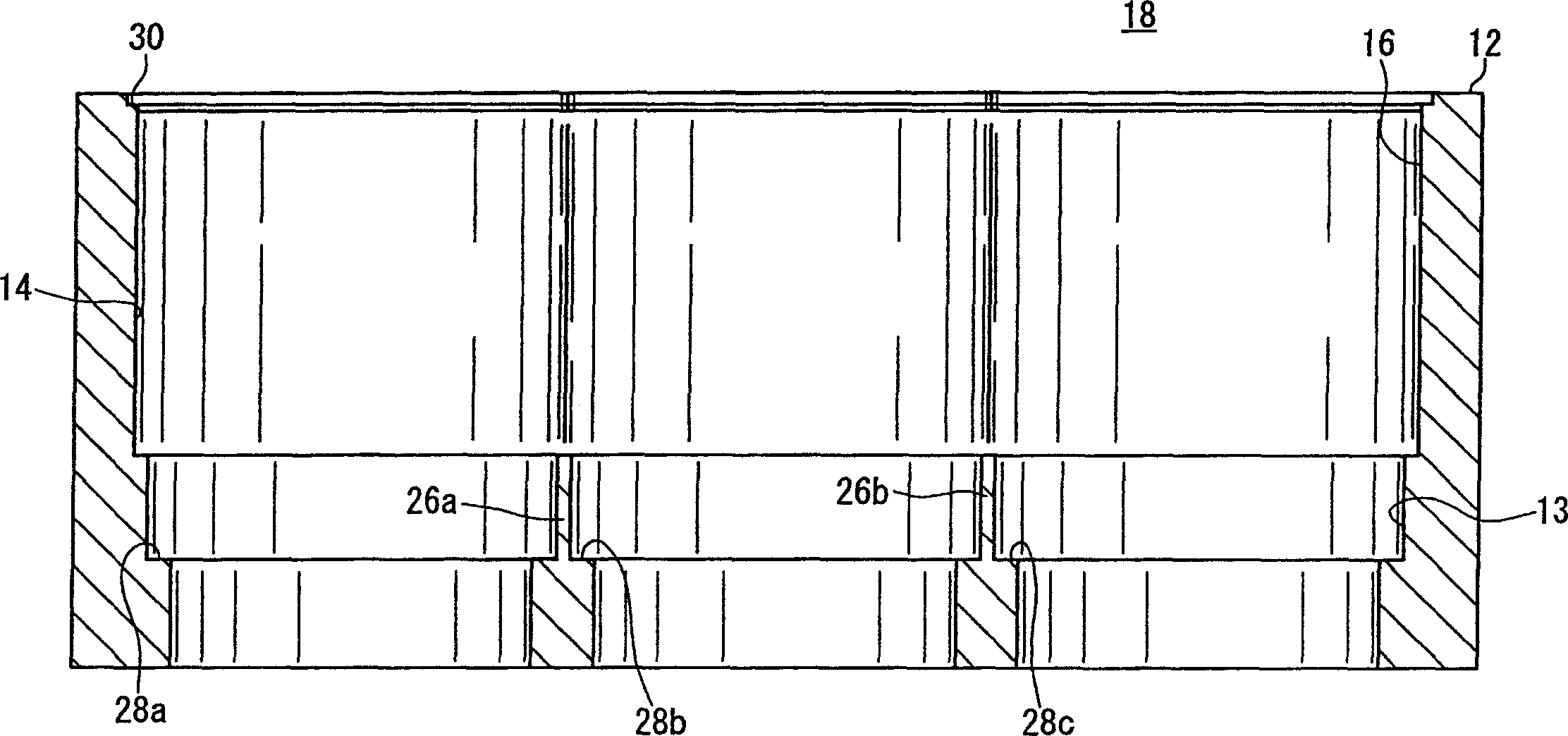

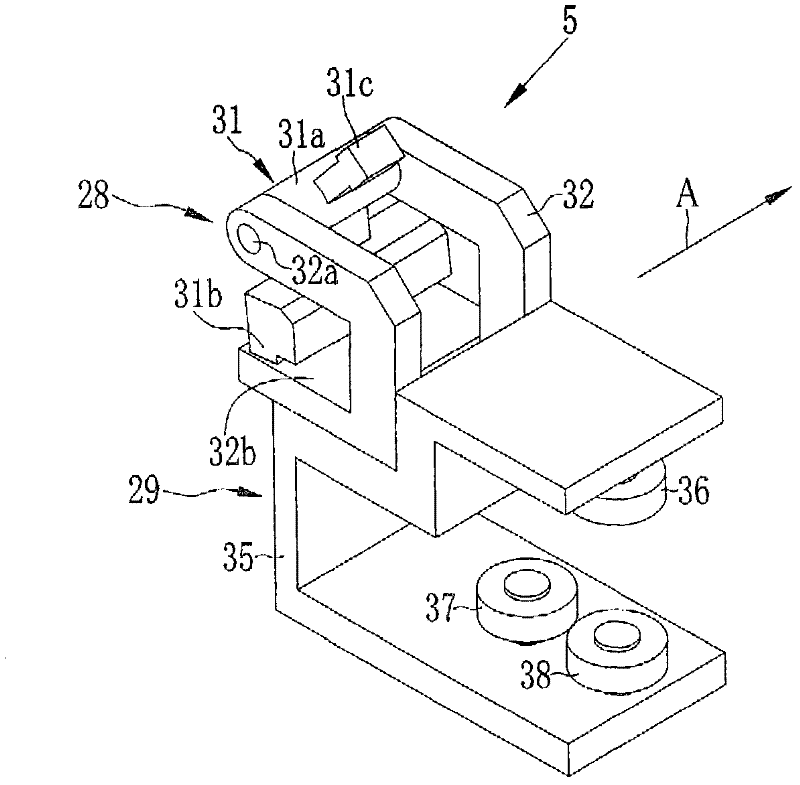

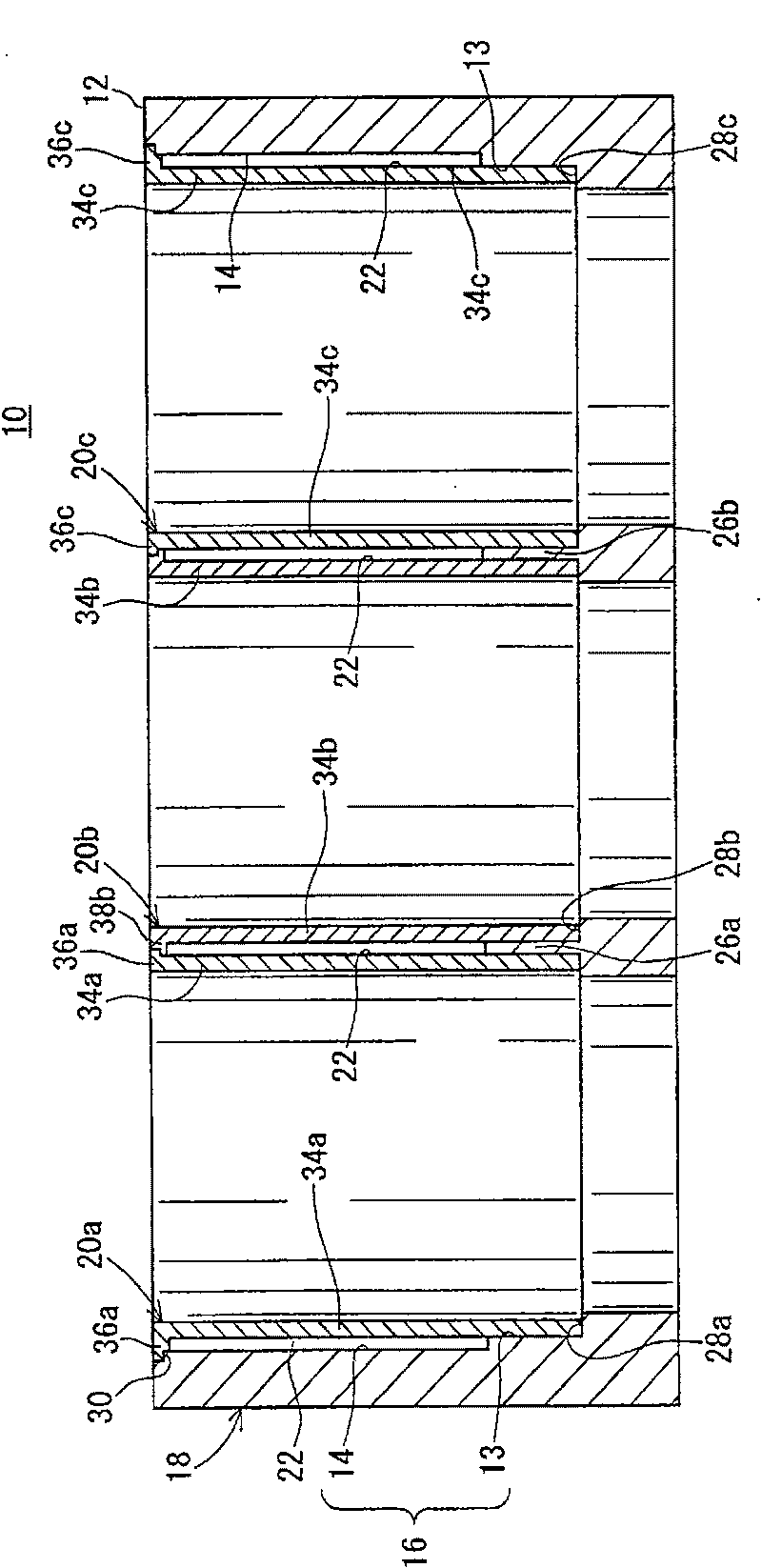

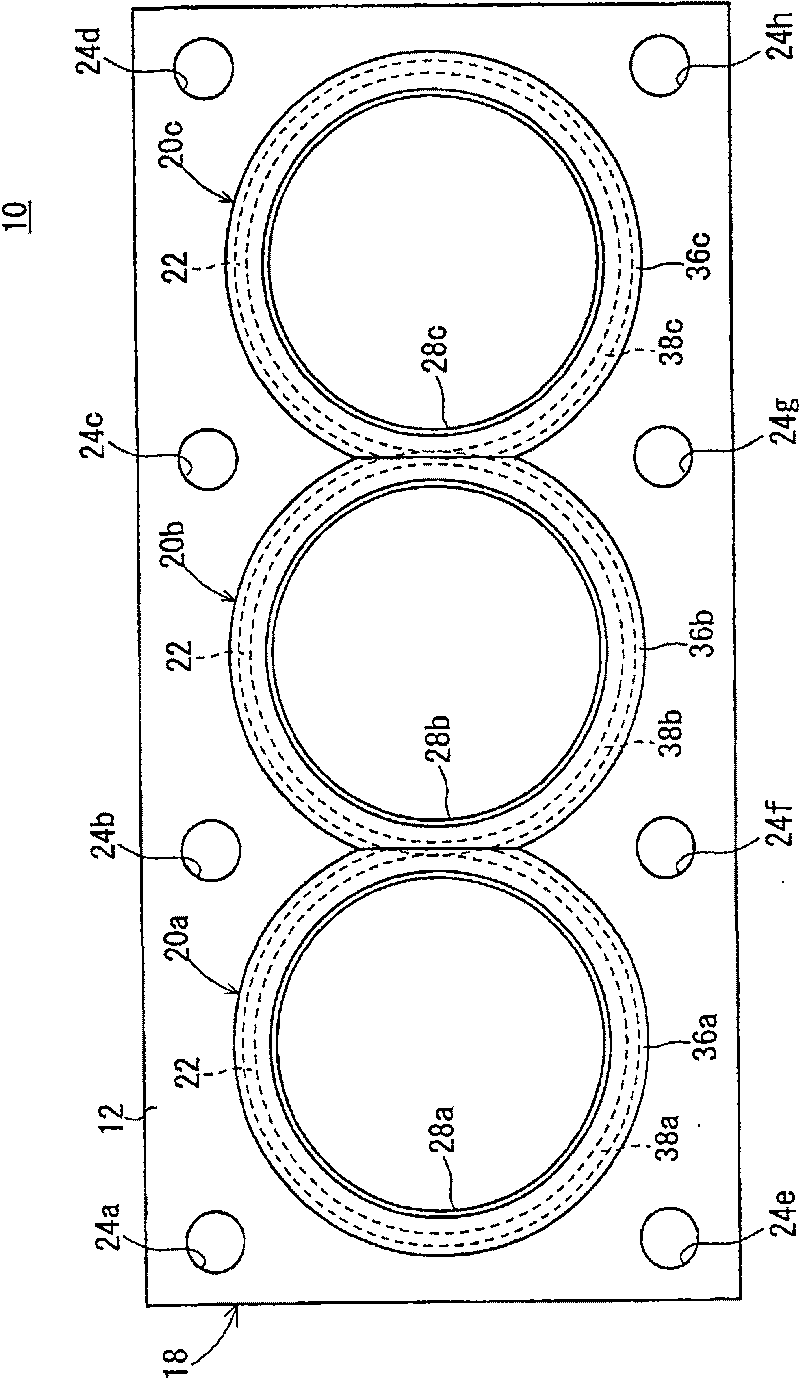

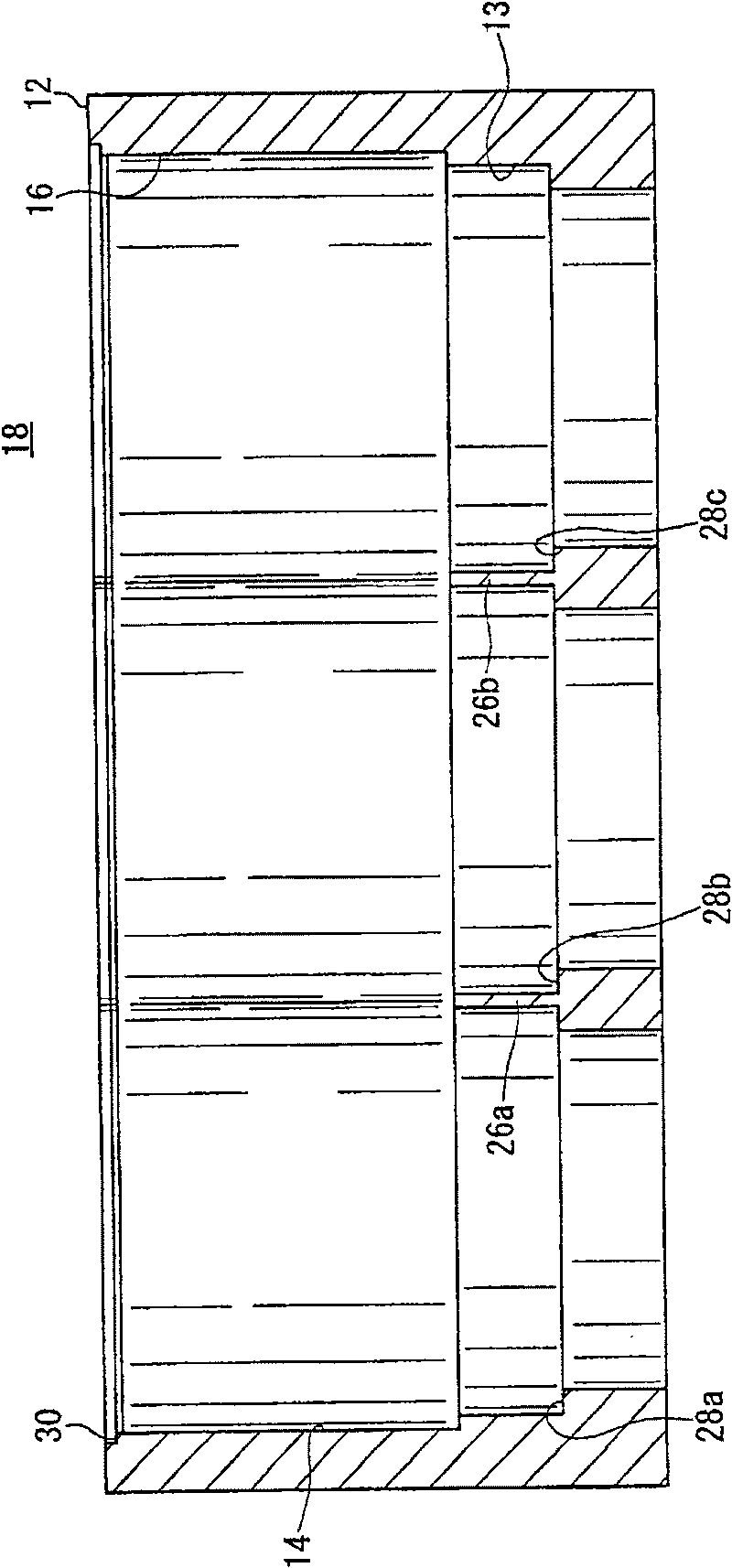

Cylinder block and cylinder sleeve, method of producing cylinder block and cylinder sleeve by friction stir welding, and friction stir welding method

InactiveCN1745238AGood lookingHigh mechanical strengthCylinder headsCylindersEngineeringCylinder block

A reduced-diameter portion (44) with a taper portion (46), a portion whose diameter is reduced in a tapered form, is provided on an inner peripheral wall of a cylinder sleeve (20a, 20b, 20c). On the outer peripheral wall of the top end of the cylinder sleeve (20a, 20b, 20c) is provided a large diameter portion (36a, 36b, 36c) projected outward along the diameter direction. Under the action of a friction stir welding tool (50), the cylinder sleeve (20a, 20b, 20c) inserted in a communication hole (16) of a block body (18) is joined to the block body (18) with the reduced-diameter portion (44) and the large-diameter portion (36a, 36b, 36c) in between. A closed deck-type cylinder block (10) is constructed with the process above. In the cylinder block (10), the gasket face (12) side of a water jacket (22) is closed by the large-diameter portion (36a, 36b, 36c).

Owner:HONDA MOTOR CO LTD

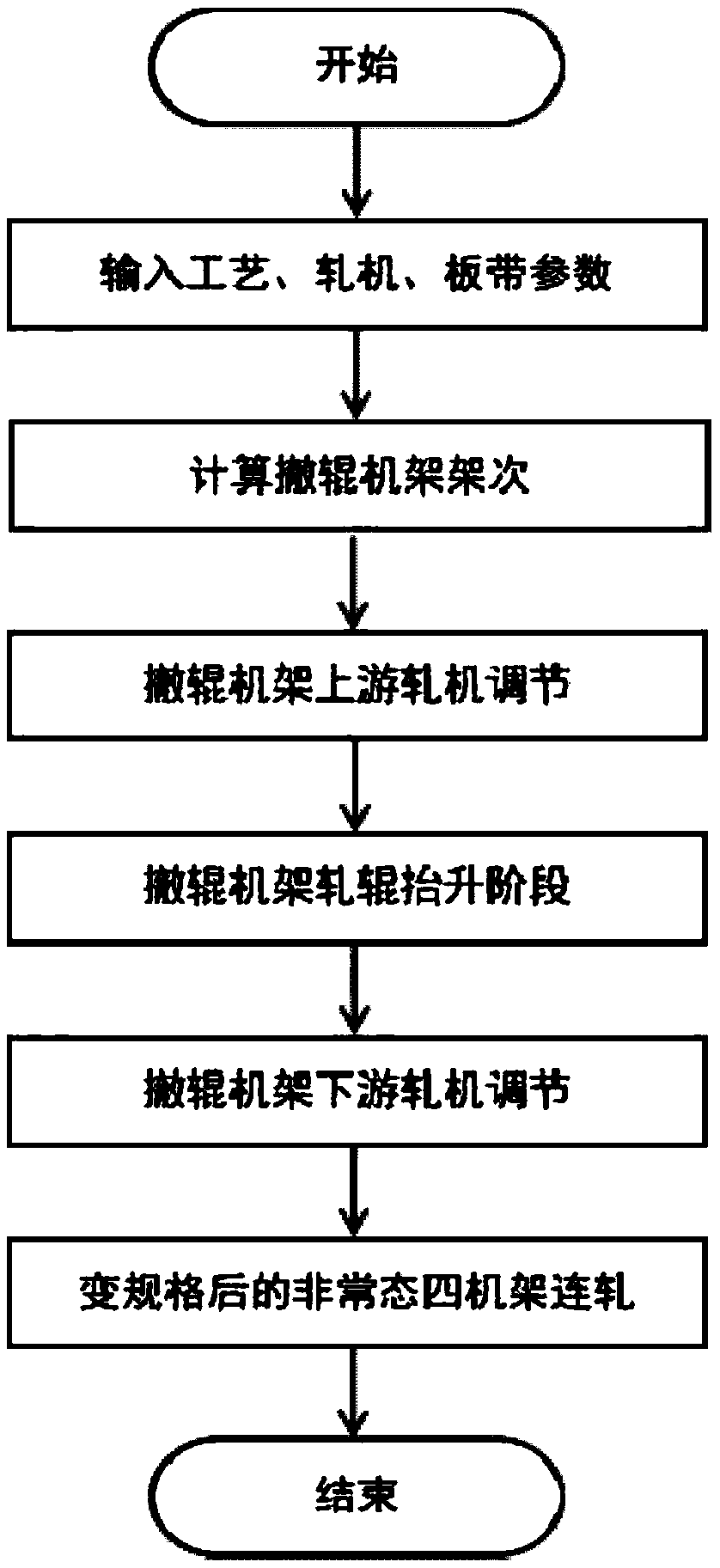

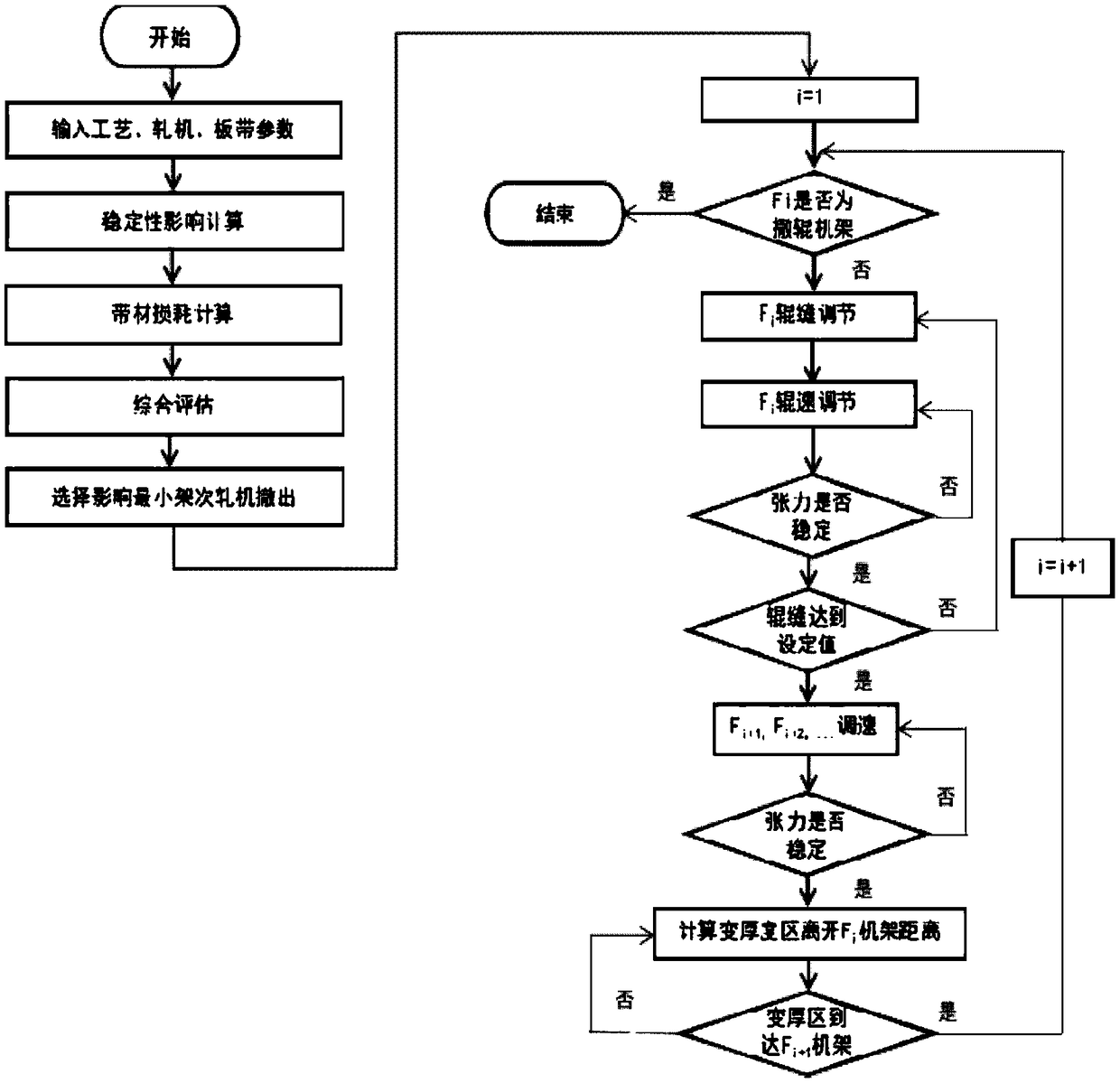

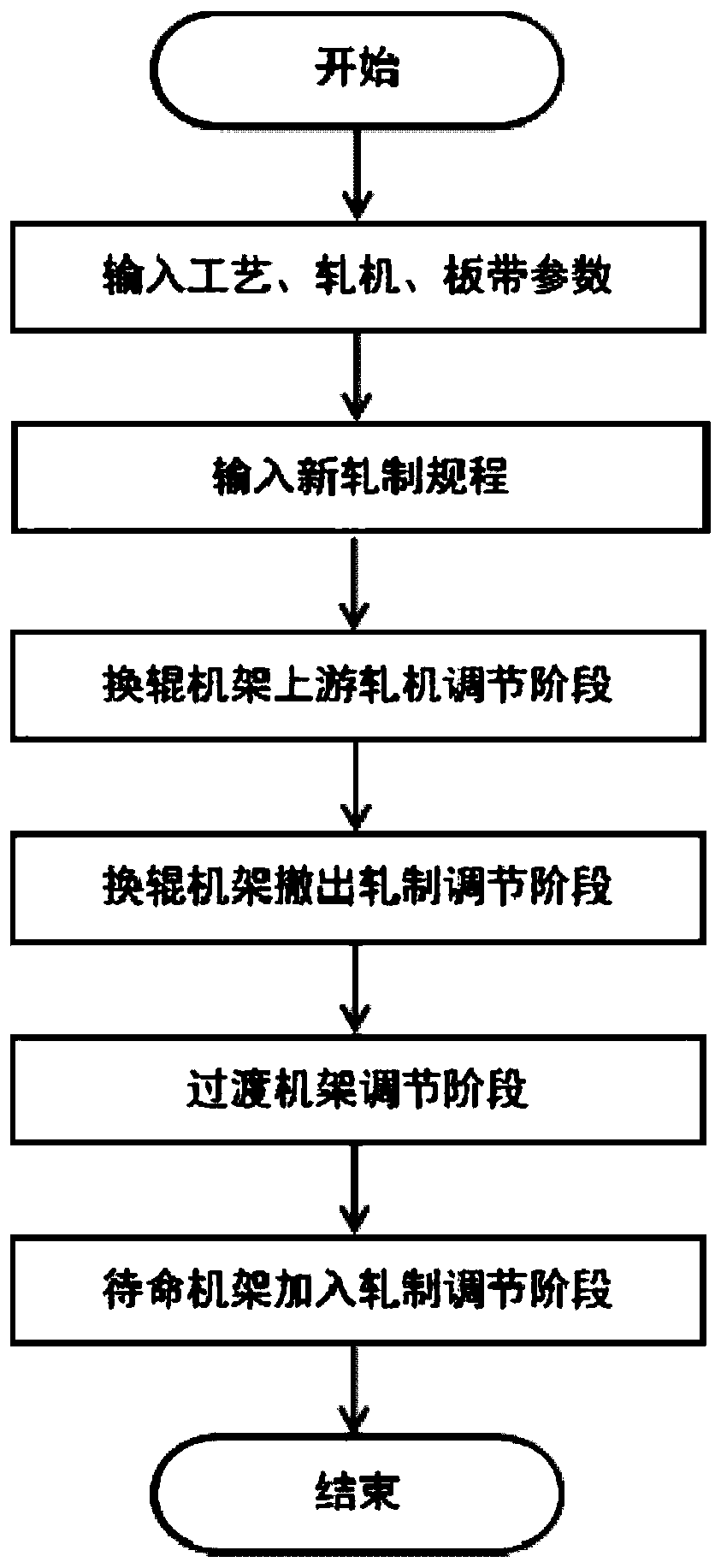

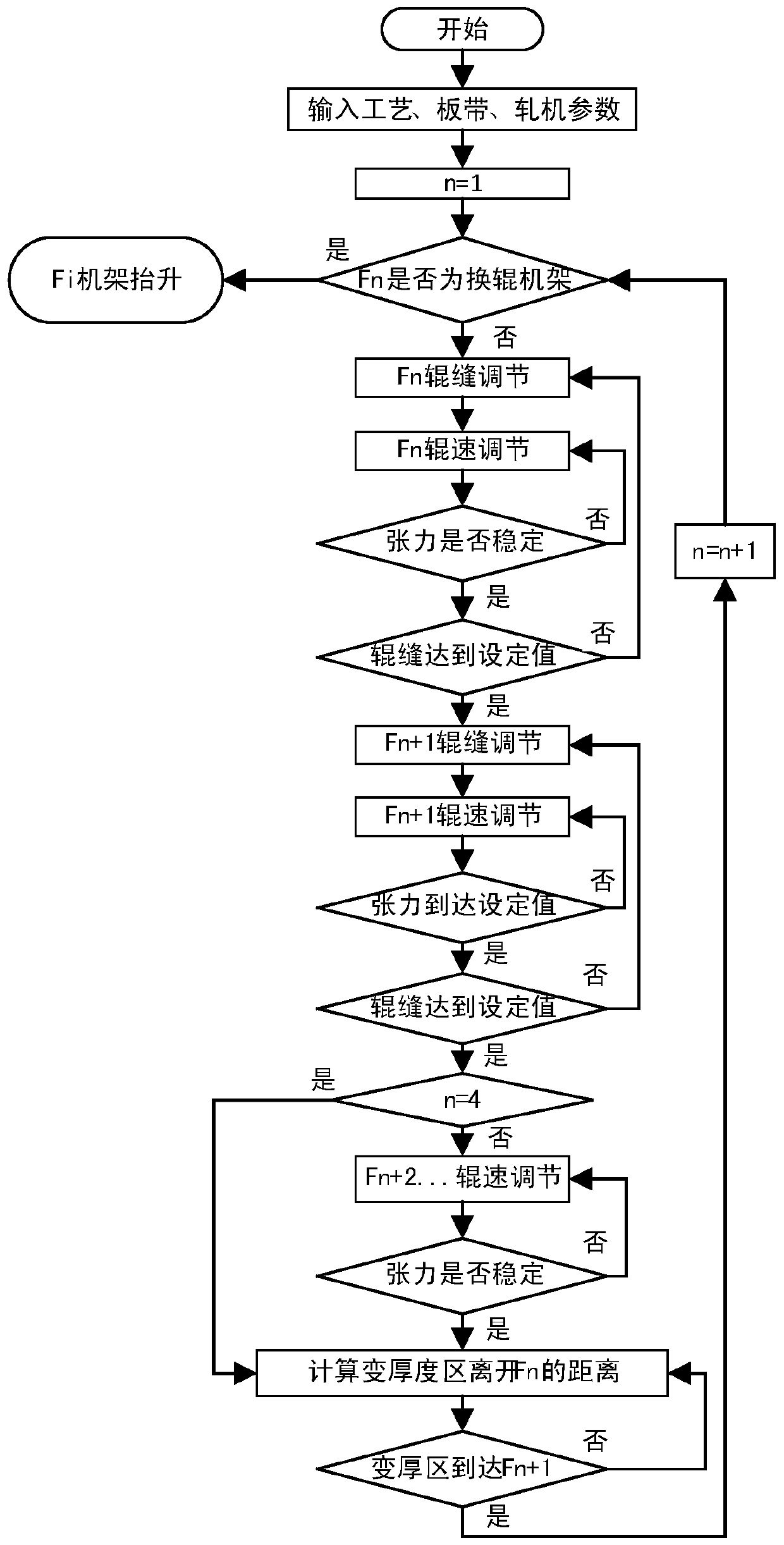

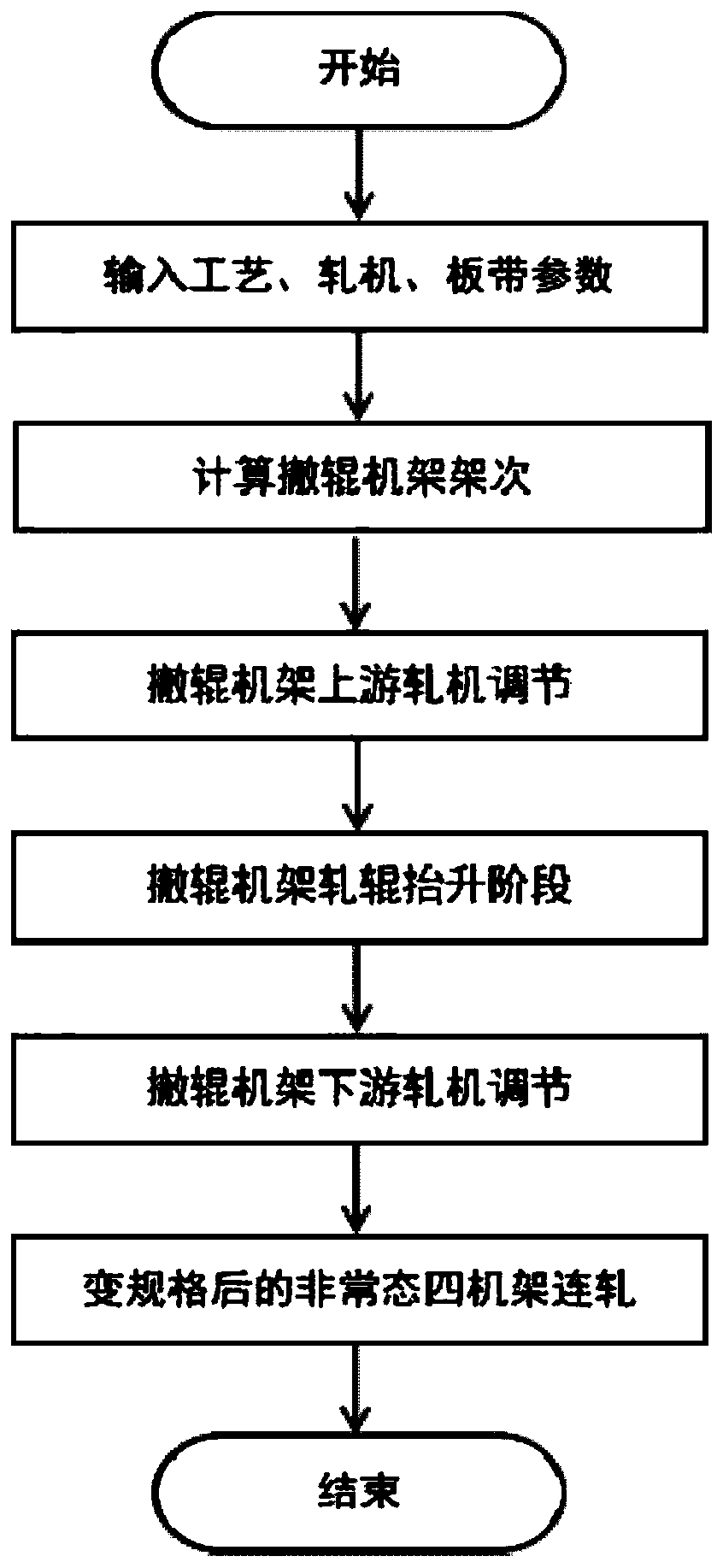

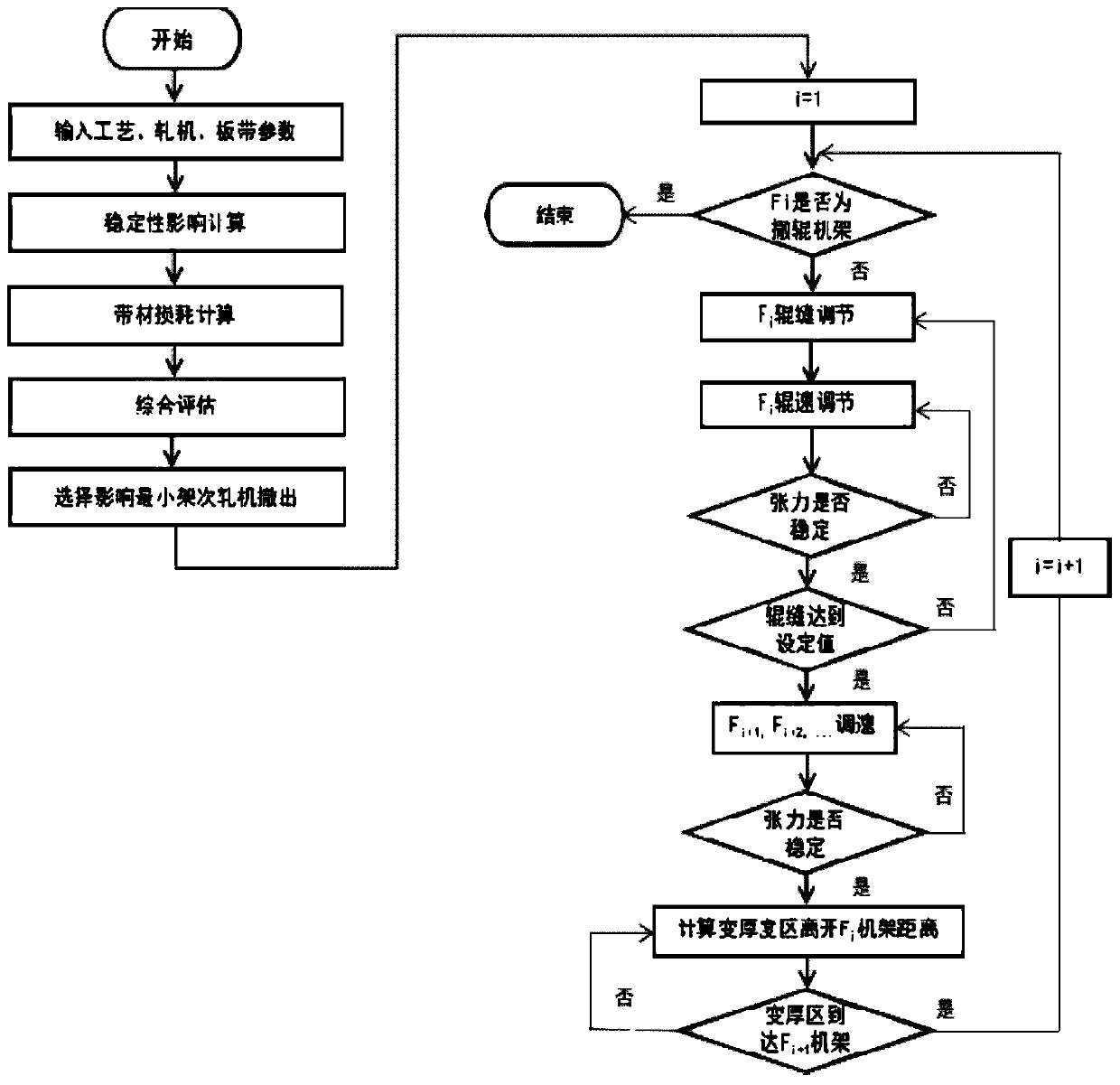

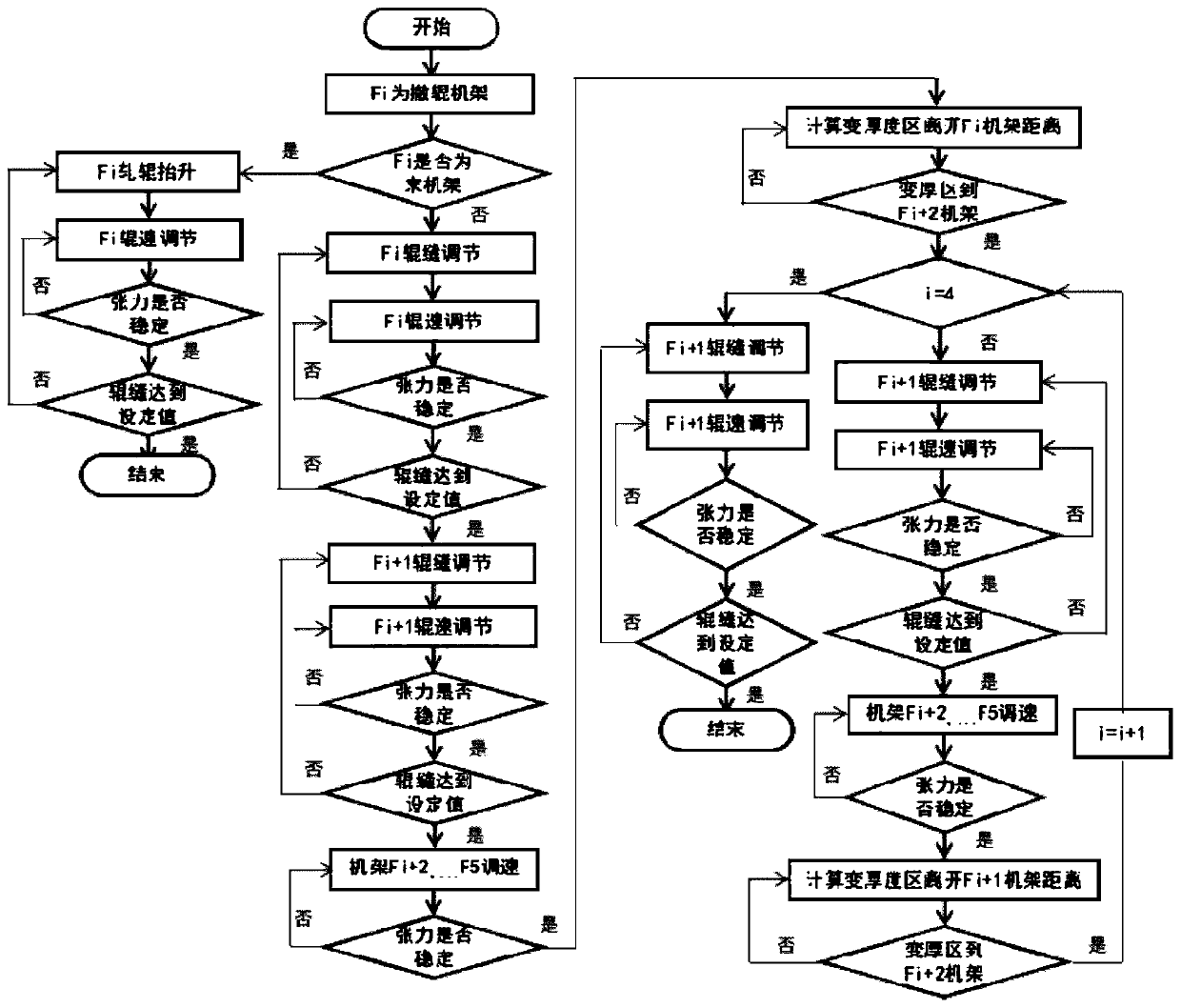

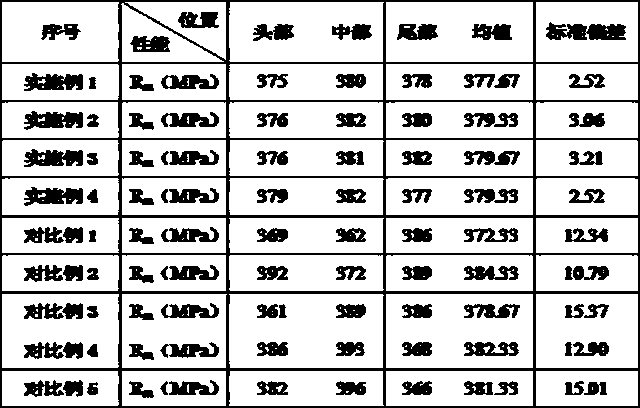

Dynamic variable regulation method based on ESP finishing mill group roll withdrawal

ActiveCN109351780AGuaranteed continuityReduce the amount of resectionRoll force/gap control deviceMetal rolling stand detailsProduction lineEngineering

The invention provides a dynamic variable regulation method based on ESP finishing mill group roll withdrawal. According to the input rolling process and rolling mill parameters, the sorties of roll withdrawal racks are calculated firstly. Then, each rack needs to be adjusted and each upstream rack of the roll withdrawal racks is adjusted. When a thickening point reaches the roll withdrawal racks,rolls of the roll withdrawal racks are lifted and adjusted. When the roll withdrawal racks Fi are removed from rolling, each downstream rack of the roll withdrawal racks is adjusted to complete the dynamic variable regulation by means of the rolls withdrawal. By calculating the sorties of the roll withdrawal racks and adjusting the rolls rotation speed and gaps in each stage of the roll changingprocess, the dynamic variable regulation method based on ESP finishing mill group roll withdrawal achieves that the dynamic variable regulation is completed by the non-stop roll withdrawal on the premise of ensuring the stable rolling of rolling mills, so that the continuity of an ESP production line is ensured, the energy loss caused by the shutdown is reduced, and the application value is high.

Owner:YANSHAN UNIV

Manufacturing method of bamboo laminated material

ActiveCN103144154AEasy to operateIncrease profitCane mechanical workingWood veneer joiningStructural engineeringMechanical engineering

Owner:熊晓晶

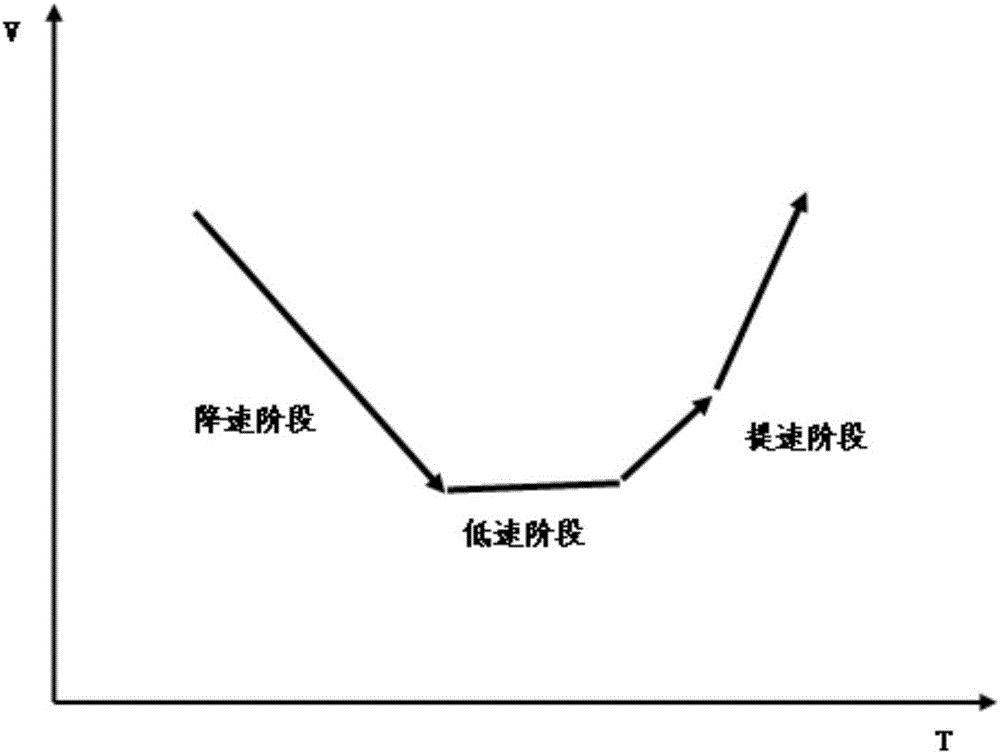

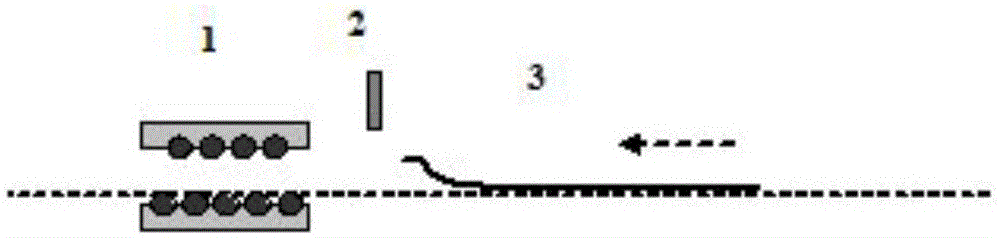

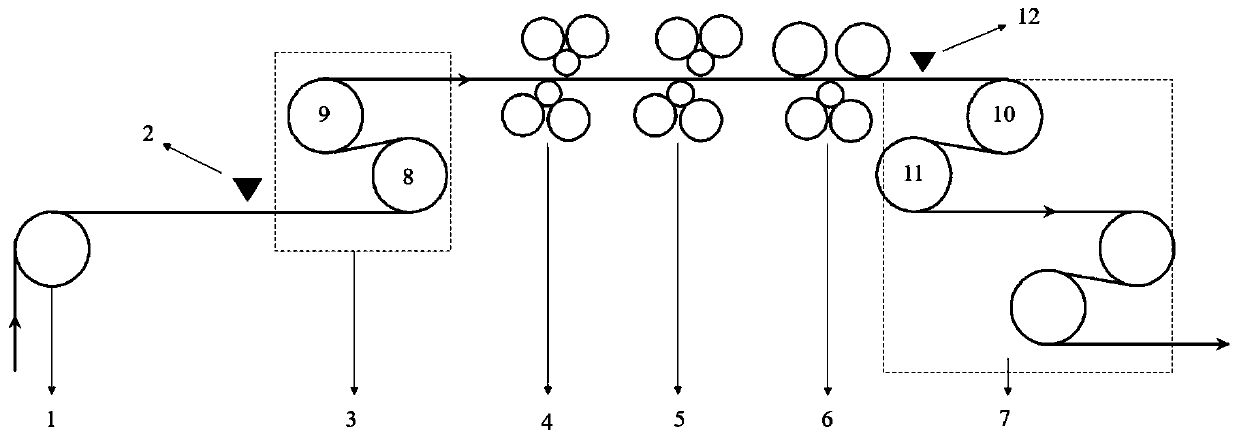

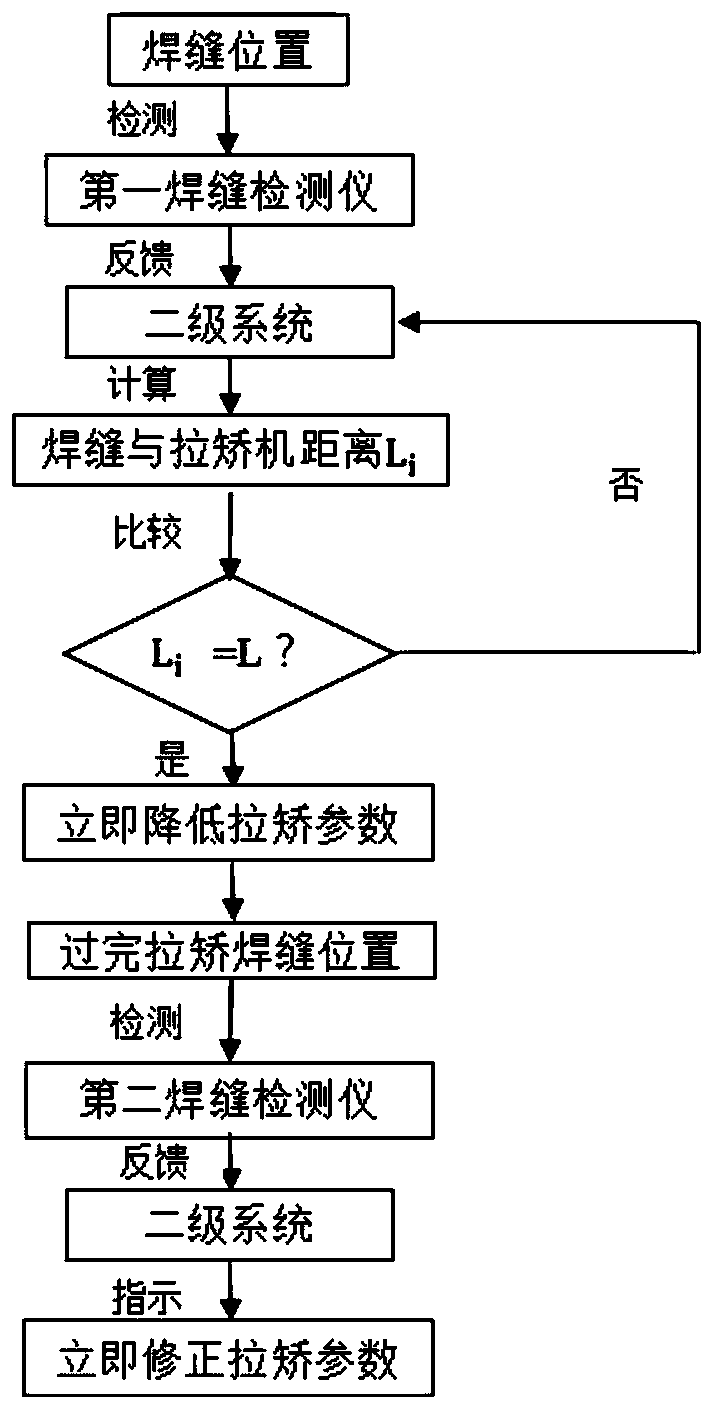

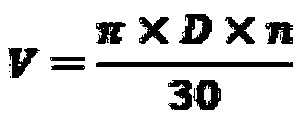

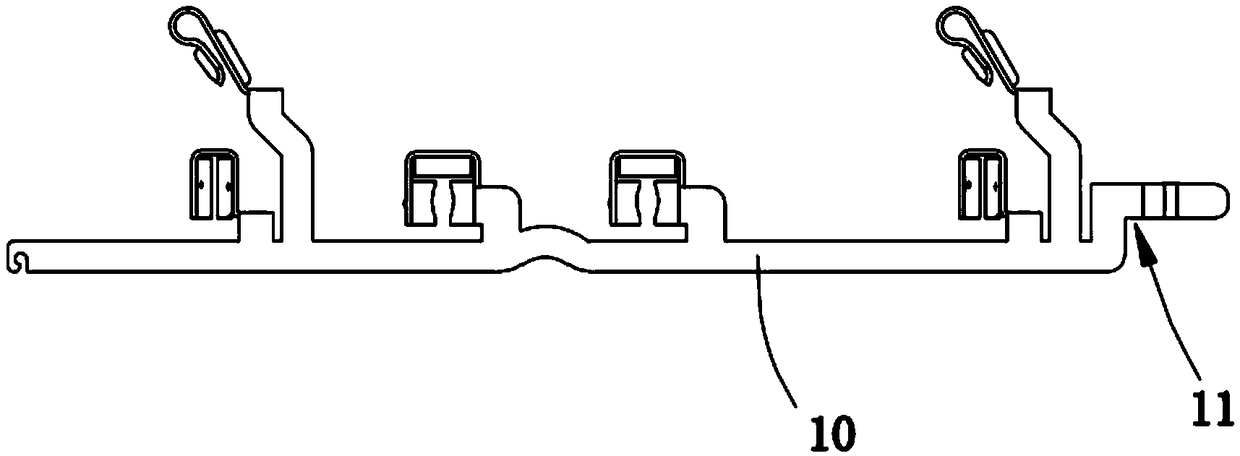

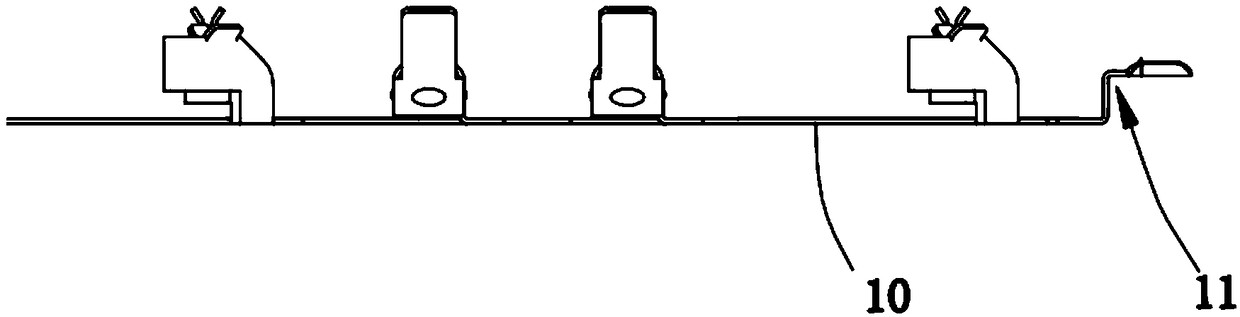

Stretching bending straightening mechanical system with self-adaptive function in case of pass through welding seam

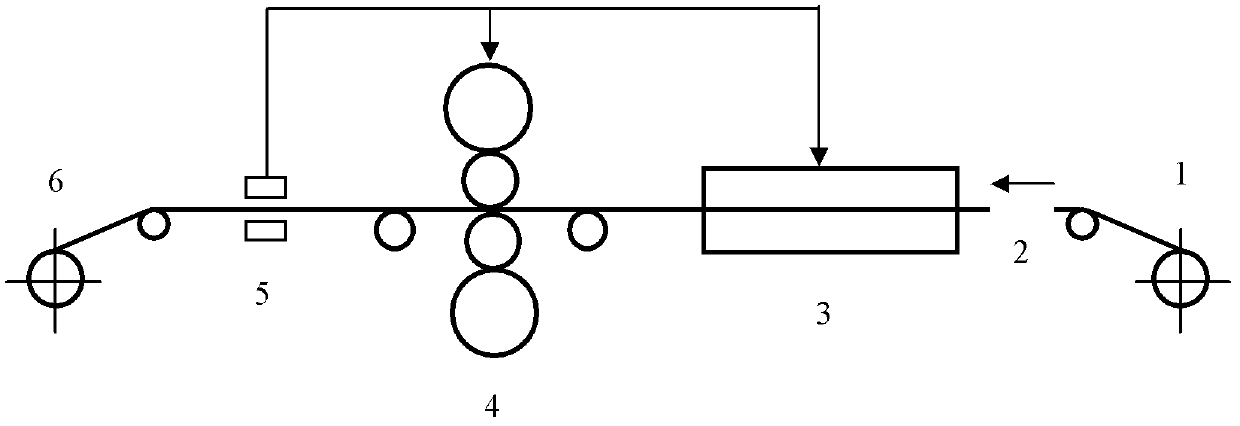

PendingCN111185482AImprove yieldReduce the amount of resectionWork treatment devicesMeasuring devicesStructural engineeringStrip steel

The invention provides a stretching bending straightening mechanical system with a self-adaptive function in the case of pass through a welding seam, and belongs to the technical field of cold rolling. The system involves a turning roller, a first welding seam detector, an inlet tensioning roller group, a 1# bending roller group, a 2# bending roller group, a straightening roller group, a second welding seam detector and an outlet tensioning roller group, wherein the first welding seam detector is arranged behind the turning roller, the second welding seam detector is arranged behind the straightening roller group, the inlet tensioning roller group is arranged behind the first welding seam detector, the outlet tensioning roller group is arranged behind the second welding seam detector, andthe 1# bending roller group, the 2# bending roller group and the straightening roller group are arranged between the inlet tensioning roller group and the outlet tensioning roller group in sequence. The system can adapt to welding seams, passing through a stretching straightening machine, of strip steel with various strength, width and thickness specifications, and can realize automatic switchingof stretching straightening process parameters of the welding seam with poor welding quality according to the detected welding seam position, thereby reducing the workload on workers and improving theautomatic working capacity of the equipment.

Owner:UNIV OF SCI & TECH BEIJING

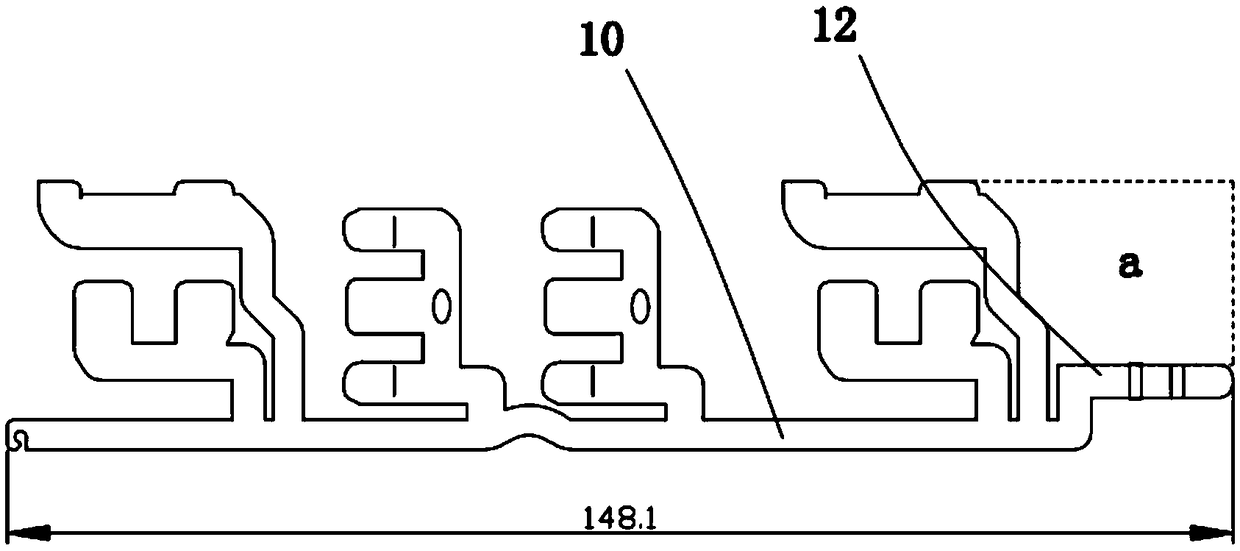

Copper bar for socket, socket and processing technology of copper bar for socket

PendingCN109037999AShorten the lengthReduce wasteContact member manufacturingCoupling contact membersCopper

The invention is applicable to the technical field of sockets, A copper bar for socket, a socket and processing technology of copper bar for socket are provided, The copper bar for socket comprises acopper bar main body and a plurality of insert sleeves connected with the copper bar main body, one end of the copper bar main body extends to form a molded part, the molded part is bent in the longitudinal direction of the copper bar main body or extends from one end of the copper bar main body to the other end of the copper bar main body, and the molded part is processed to form a bent structure, and the bent structure is connected with the terminal. The invention provides a copper bar for a socket, wherein a molded part of a bent structure which is molded and plugged into a terminal is folded with respect to the longitudinal direction of the main body of the copper bar, or the molded part extends from one end of the copper bar main body to the other end of the copper bar main body, thereby effectively shortening the length of the integral copper bar for manufacturing the copper bar for the socket, saving materials, reducing production cost, reducing waste cutting amount, greatly reducing waste of materials, and improving material utilization rate in the processing process of the copper bar for the socket.

Owner:BULL GRP CO LTD

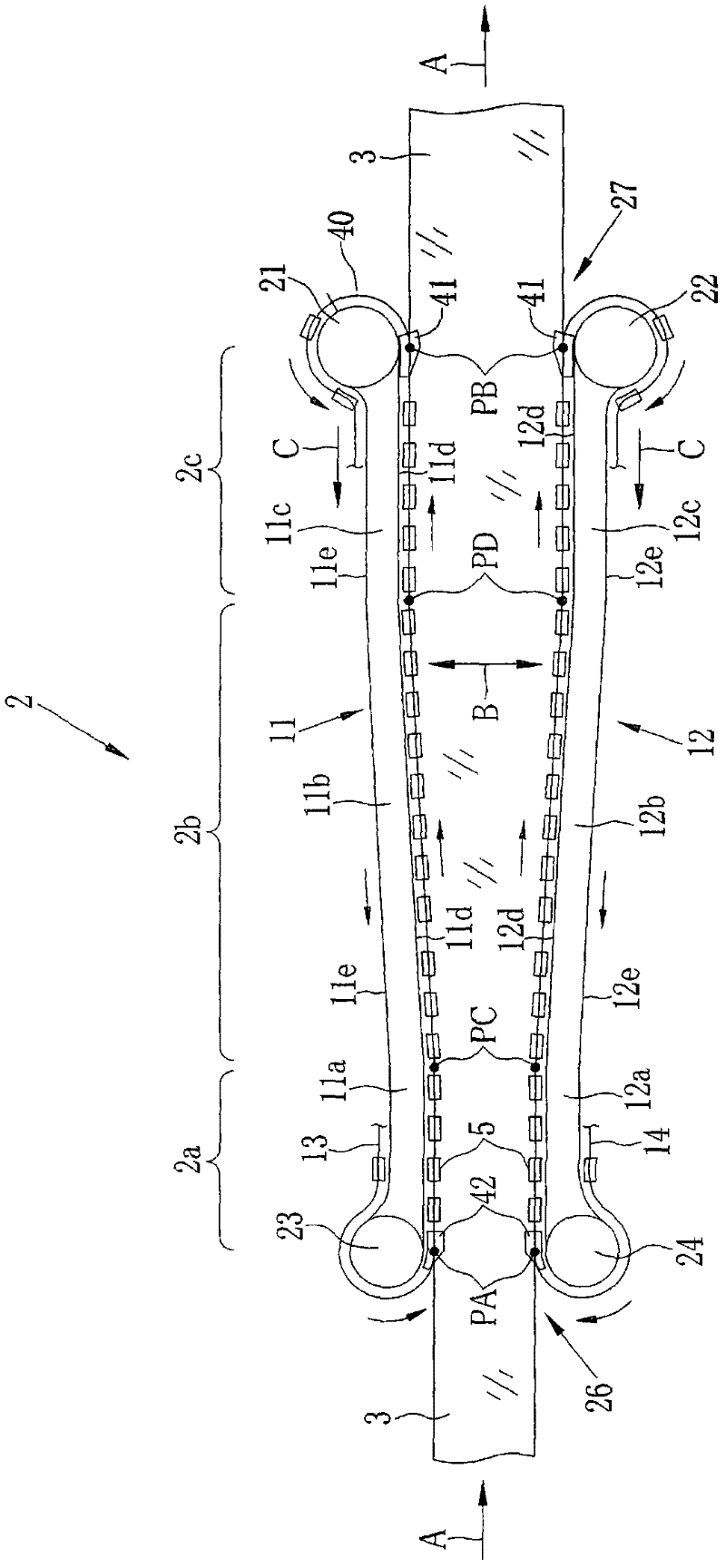

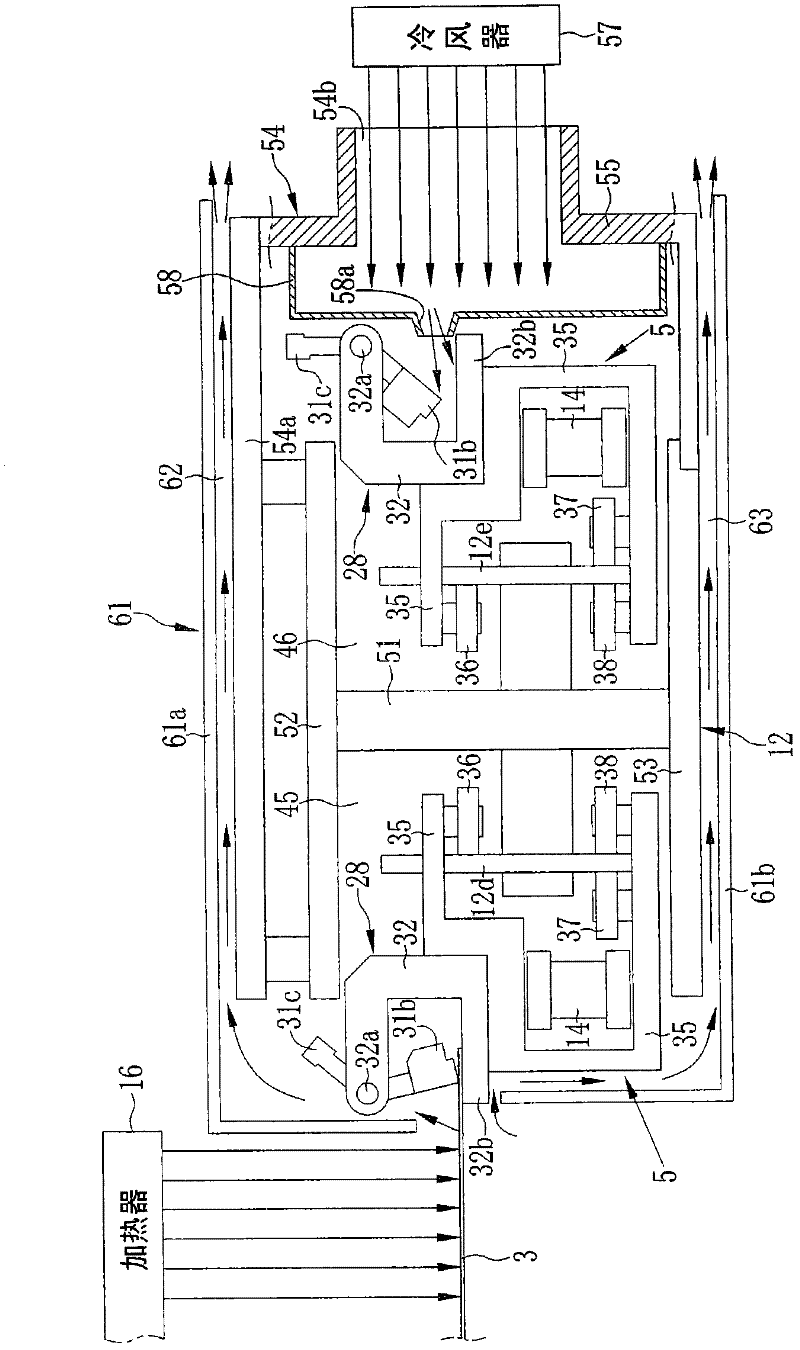

Film stretching device and method thereof

InactiveCN102189677AReduce the temperatureReduce the amount of resectionFlat articlesWebs handlingEngineeringGuide tube

The present invention provides a film stretching device and a method thereof. In the invention, a clamp (5) which moves along each outlet path (11d,12d) of each guide rail (11,12) is accommodated in an outlet chamber (45), and a clamp (5) which moves along each inlet path (11e,12e) is accommodated in an inlet chamber (46). The outlet chamber (45) and the inlet chamber (46) are provided through a mutually airtight mode. The cooling air which enters the inlet chamber for cooling the clamp is exhausted to one side of a pipe from an air outlet (54c) formed on the pipe. An upper exhaust channel (62) which exhausts the air in the outlet chamber to one side of an outer cover (61) is provided among an upper cover (61a), the outlet chamber and the inlet chamber. A lower exhaust channel which exhausts the air in the outlet path to one side of the outer cover is provided among a lower cover, the outlet chamber and the inlet chamber.

Owner:FUJIFILM CORP

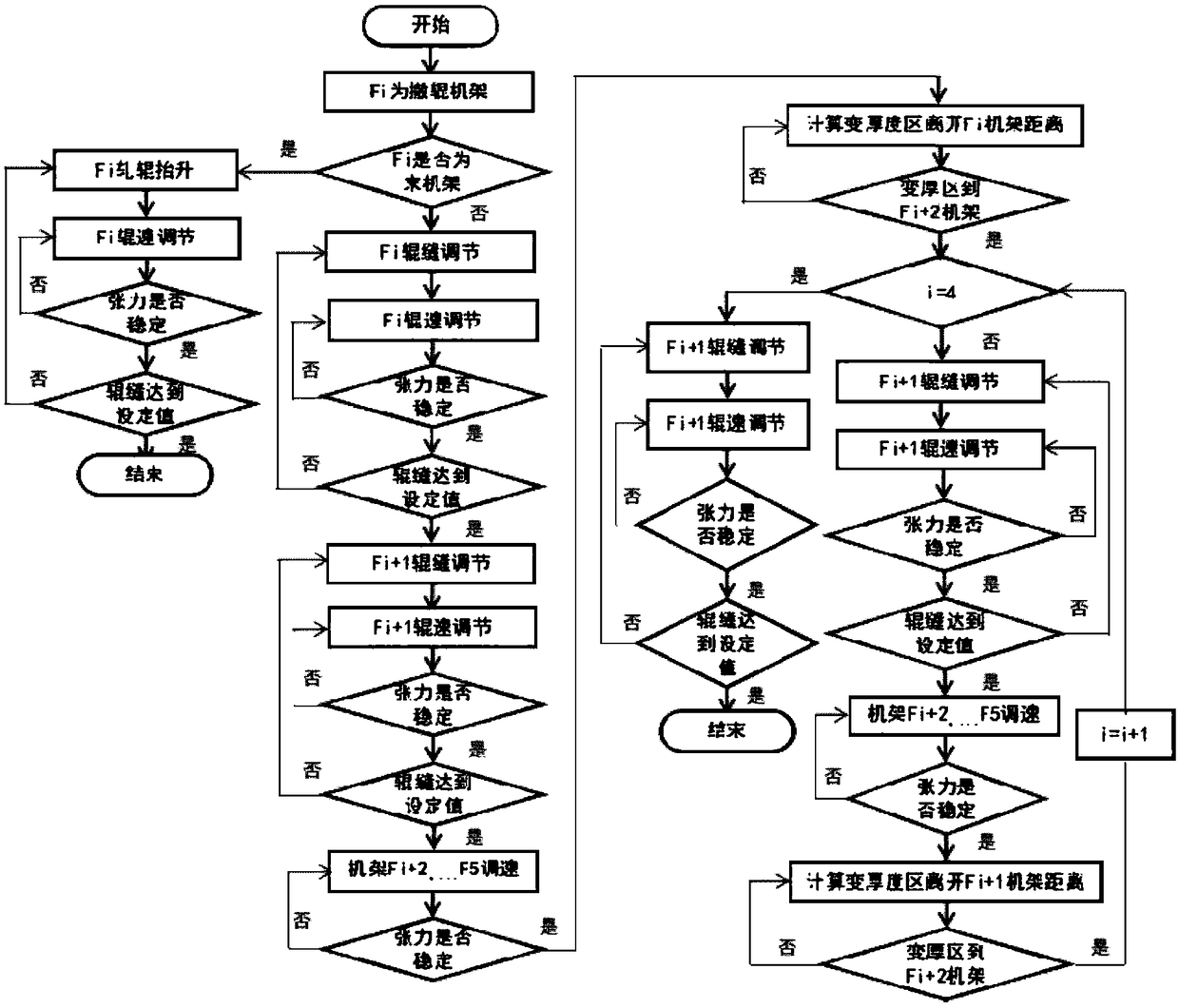

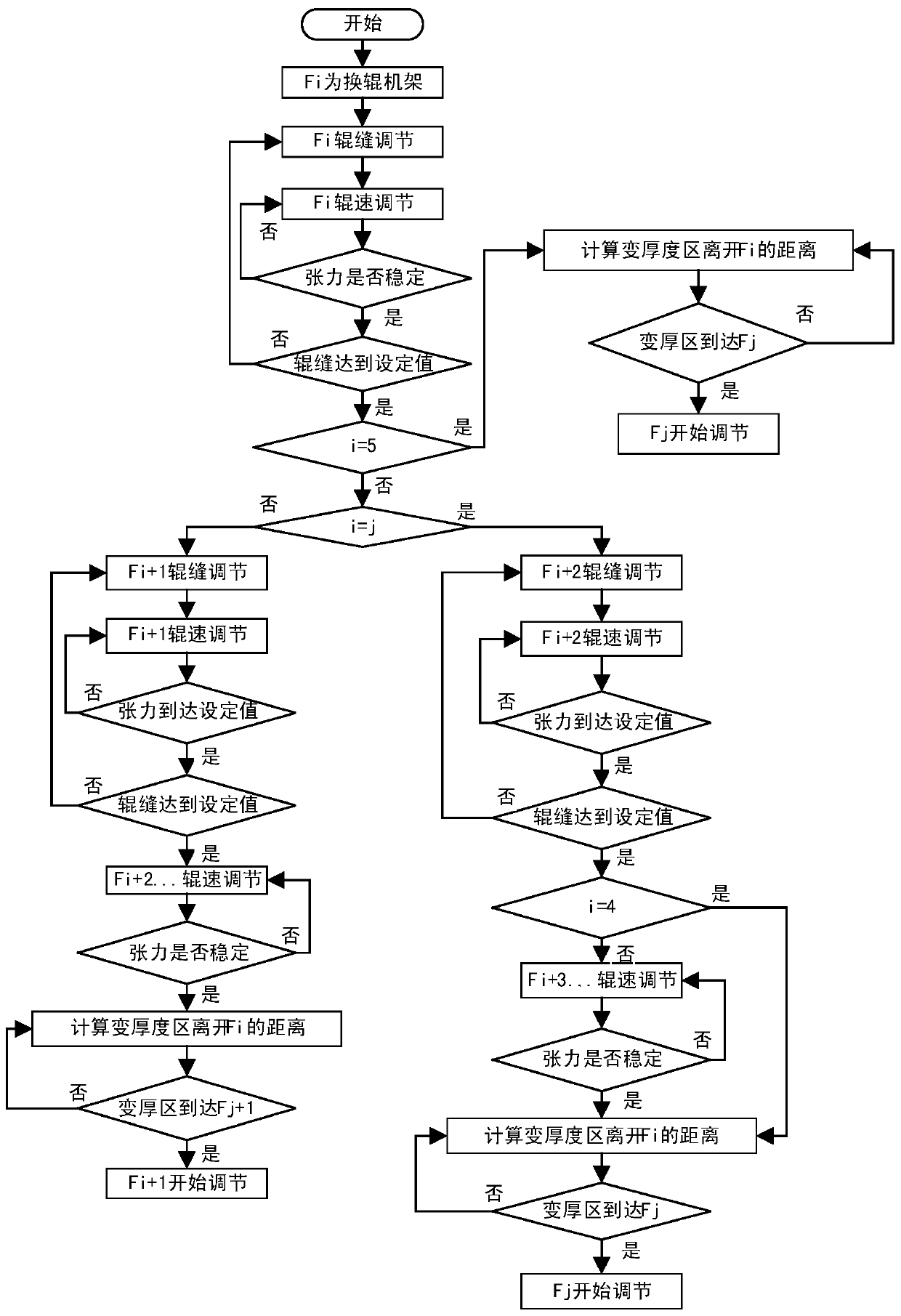

Simultaneous proceeding method of online countercurrent roller changing and dynamic procedure changing for ESP finishing mill group

ActiveCN109692874AGuaranteed continuityReduce lossesTension/compression control deviceMetal rolling arrangementsProduction linePulp and paper industry

The invention provides a simultaneous proceeding method of online countercurrent roller changing and dynamic procedure changing for an ESP finishing mill group. Racks over roller changing racks are adjusted according to input rolling technology and rolling mill parameters, the roller changing racks are raised and adjusted when thickened points reach the roller changing racks, racks below the roller changing racks are adjusted when a roller changing rack Fi is withdrawn from rolling, a standby rack roller is pressed down and adjusted when the thickened points reach a standby rack, and the racksbelow the standby rack are adjusted when a roller changing rack Fj is withdrawn from the rolling, the simultaneous proceeding of non-stop online roller changing and rolling procedure changing is realized. According to the simultaneous proceeding method, rotational speed and roller gap of each stage of roller changing are adjusted, product procedure is changed, the entering process of the standbyrack is achieved online under the premise that stable rolling of a rolling mill is ensured, non-stop online roller changing and rolling procedure changing are achieved, and continuity of an ESP production line is ensured.

Owner:YANSHAN UNIV

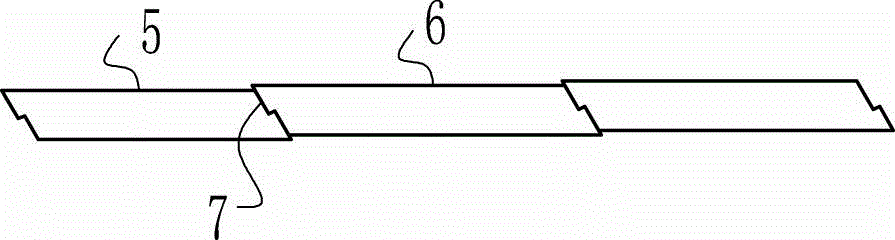

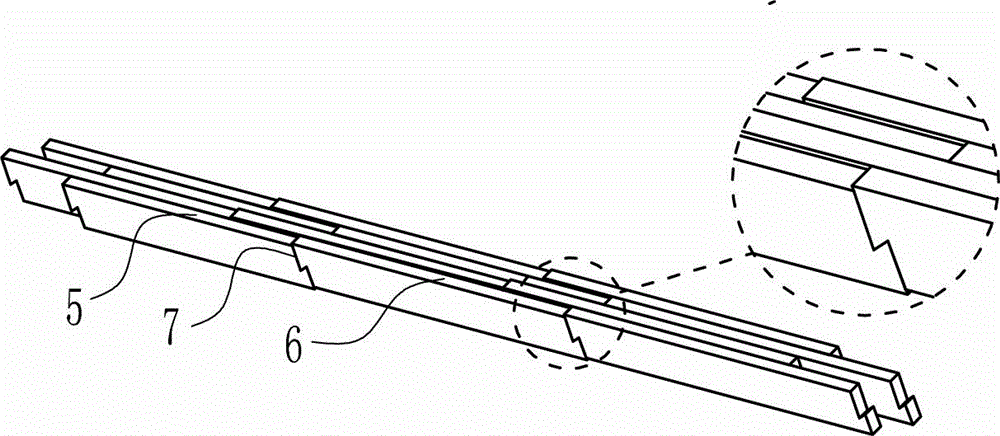

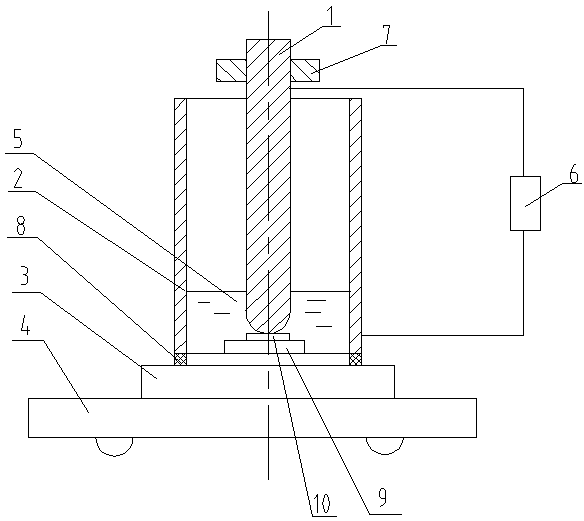

Fret bar for ingot slicing, ingot to which fret bar is stuck, and ingot cutting method using fret bar

InactiveCN102083598ALess lateral shakeAvoid lateral shakingMetal sawing devicesSemiconductor/solid-state device manufacturingWaferingIngot

The present invention provides a fret bar for ingot slicing, an ingot to which the fret bar is stuck, and an ingot cutting method using the fret bar. The object of the invention is to, in cutting an ingot by using a multi-wire saw, to improve material use efficiency by reducing variations in thickness among wafers to be obtained to thereby reduce material loss in cutting and improve working efficiency by shortening the time required for slicing. Means for solving problems is that in cutting an ingot by a multi-wire saw, a fret bar for ingot slicing is used in order to form notches at the start of the cutting. The fret bar for ingot slicing is characterized by being a columnar body stuck along the length direction of the ingot to a portion of the surface of the ingot.

Owner:SHINANO ELECTRIC REFINING

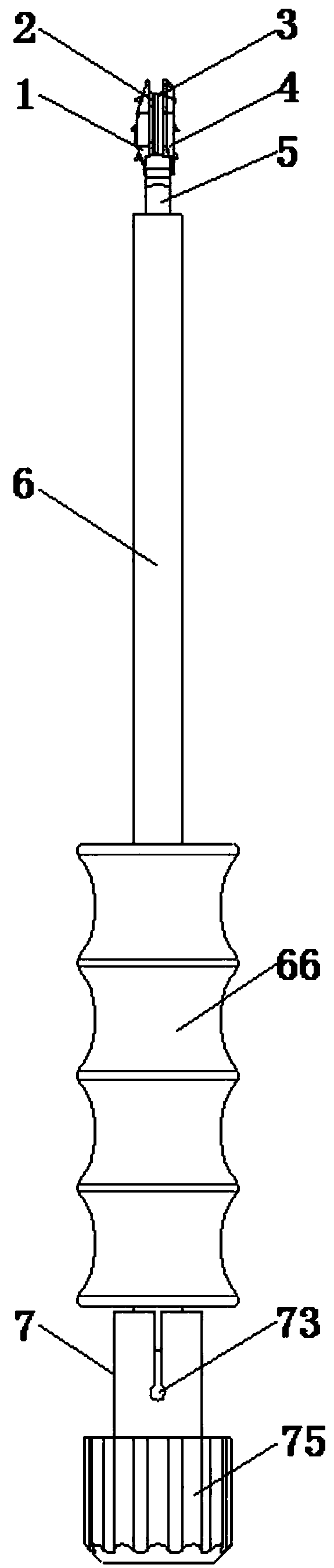

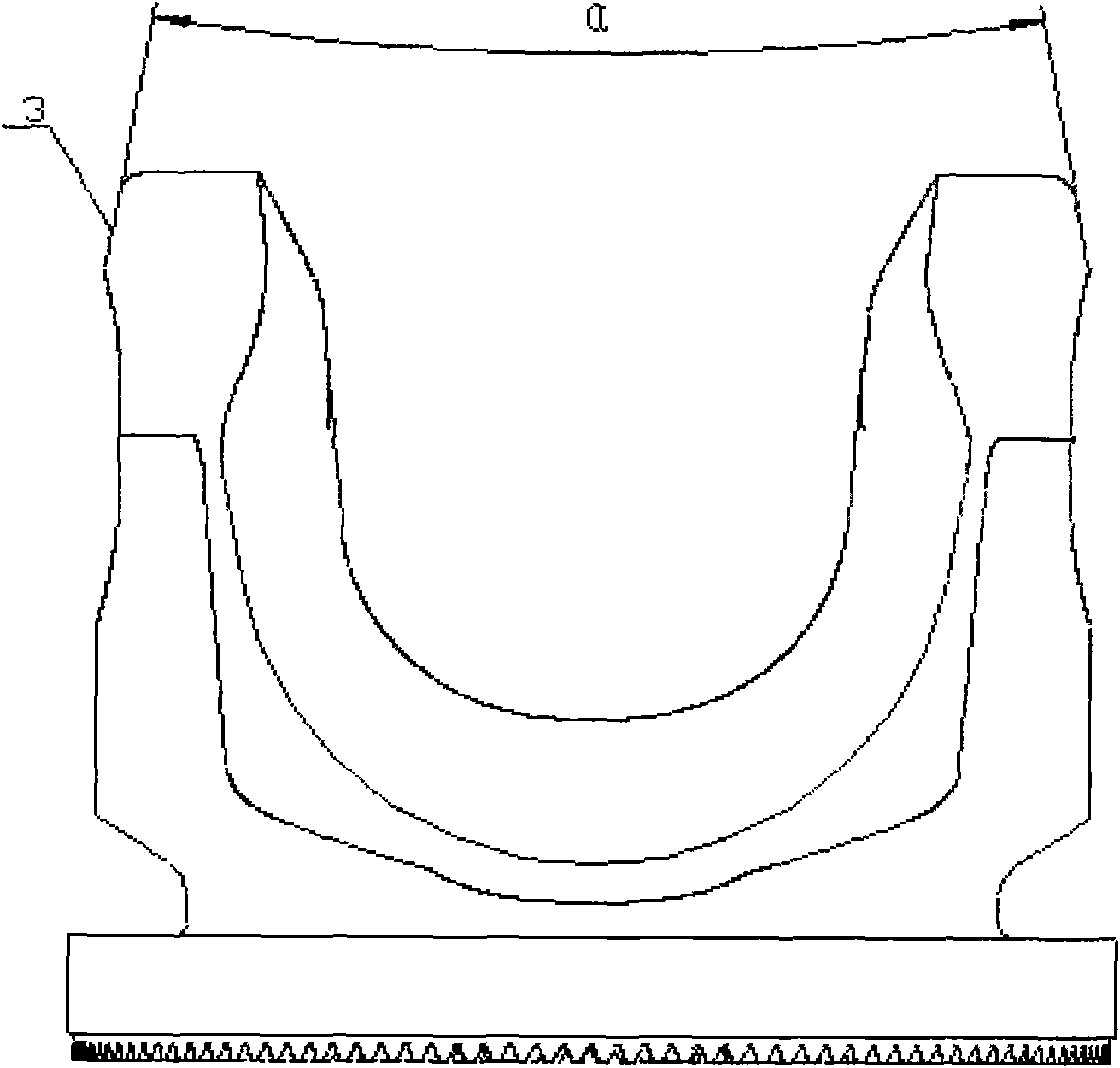

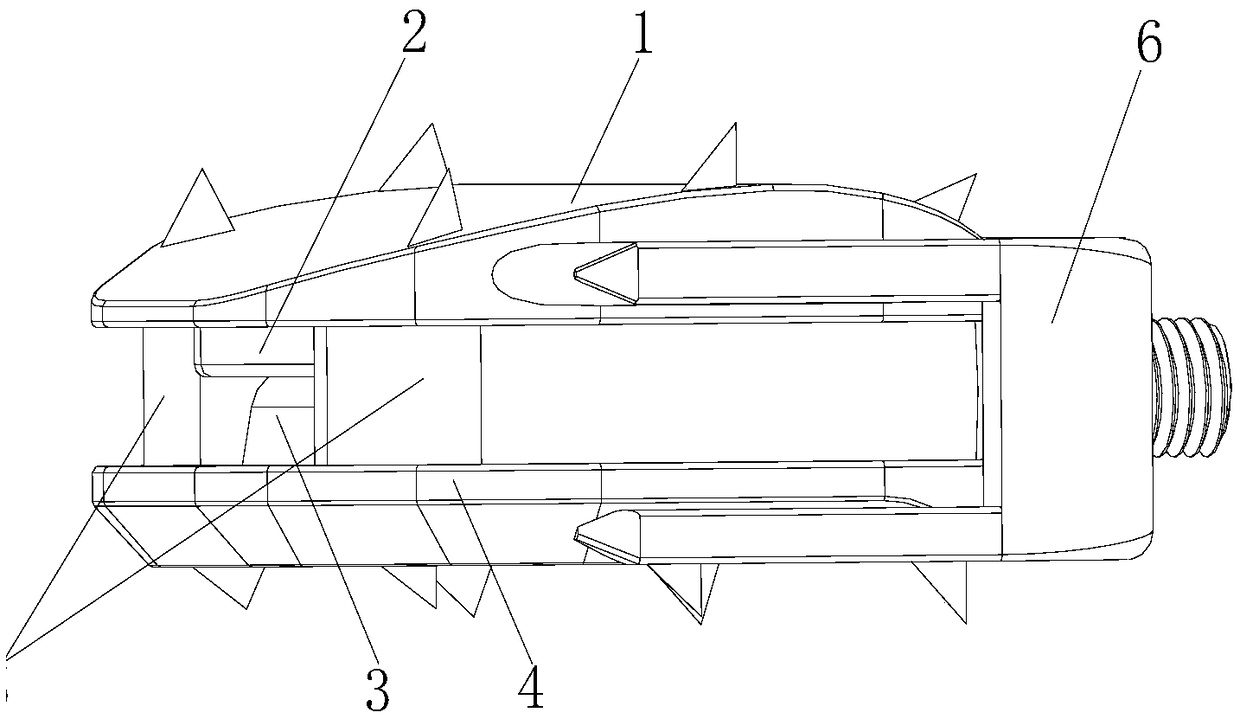

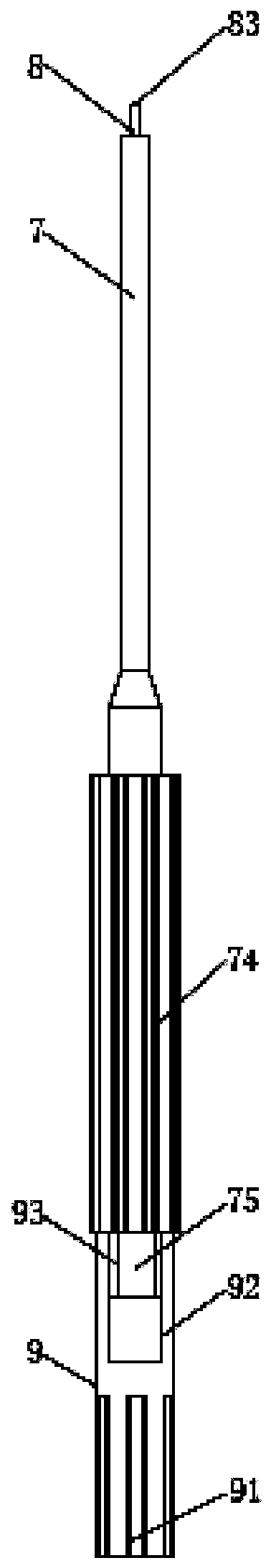

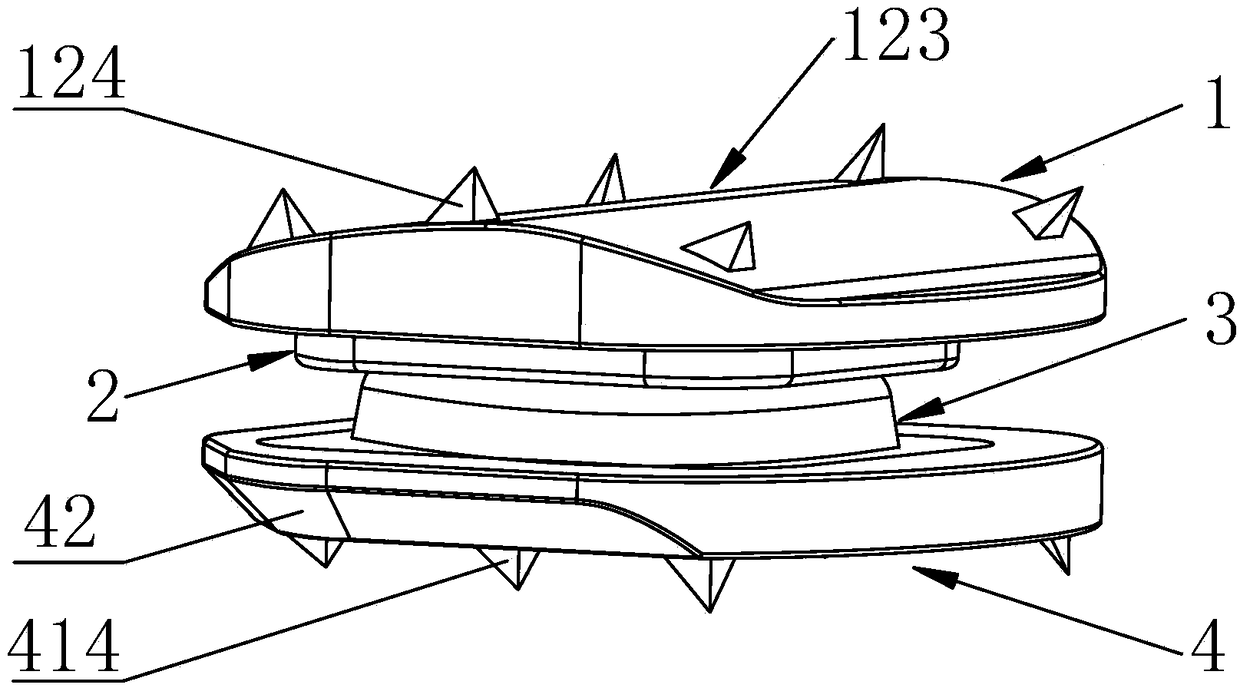

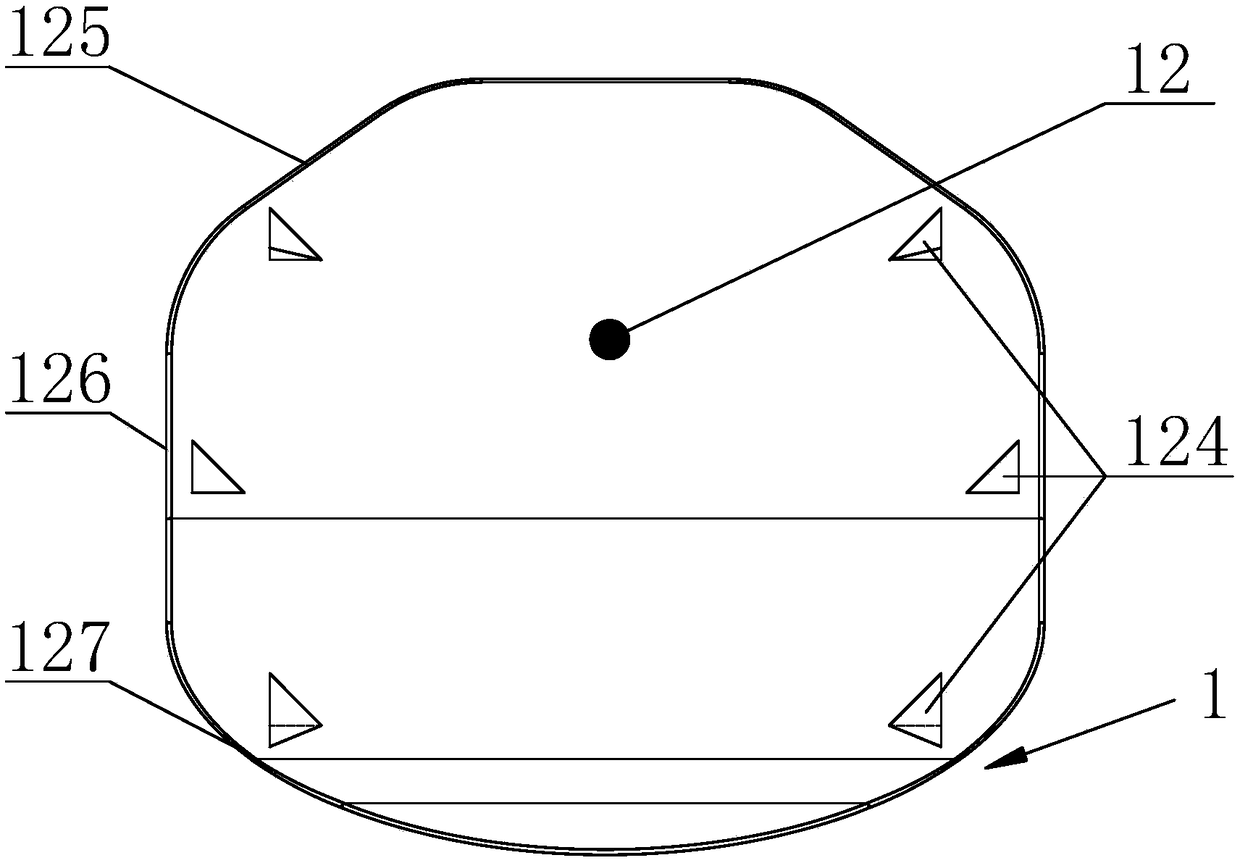

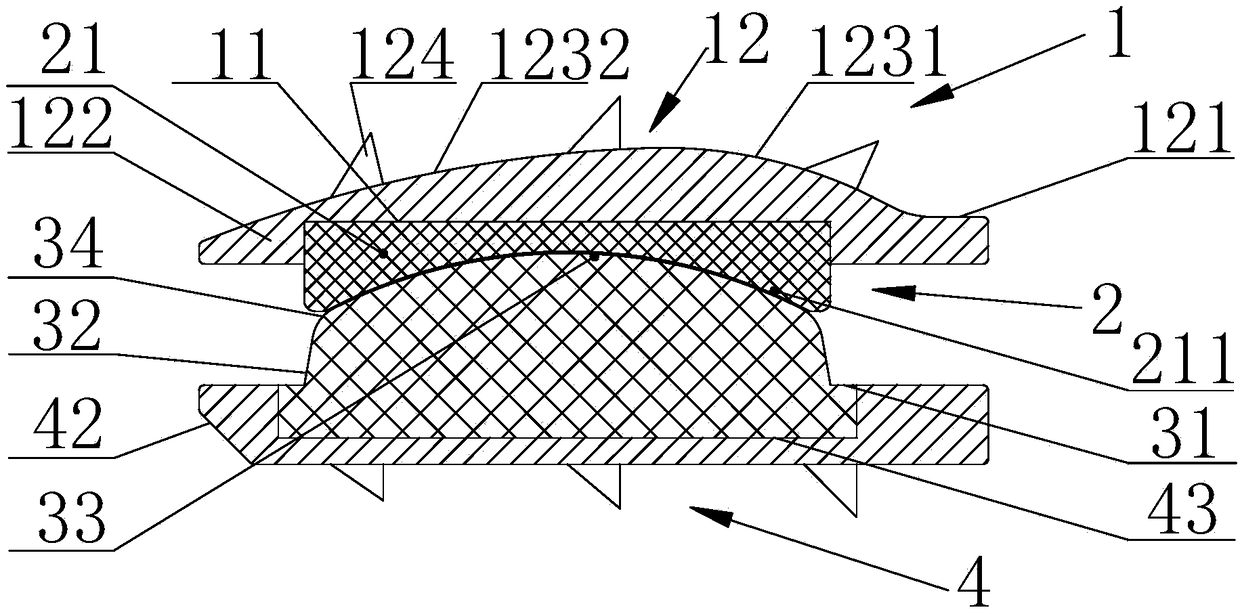

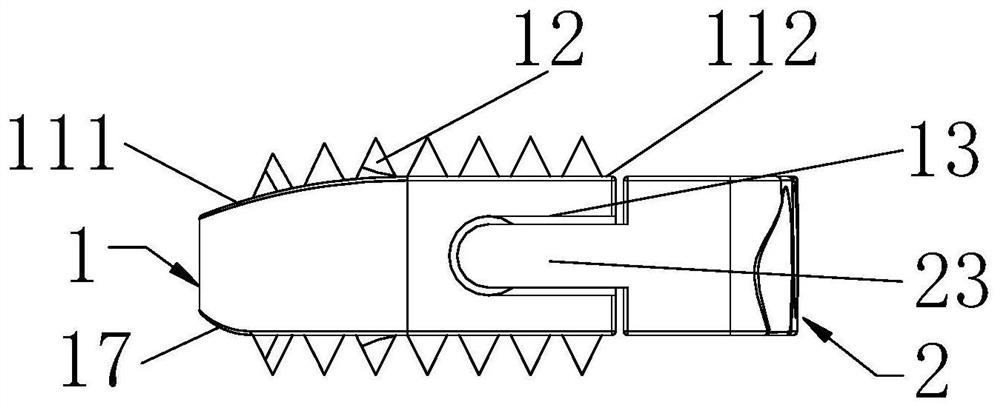

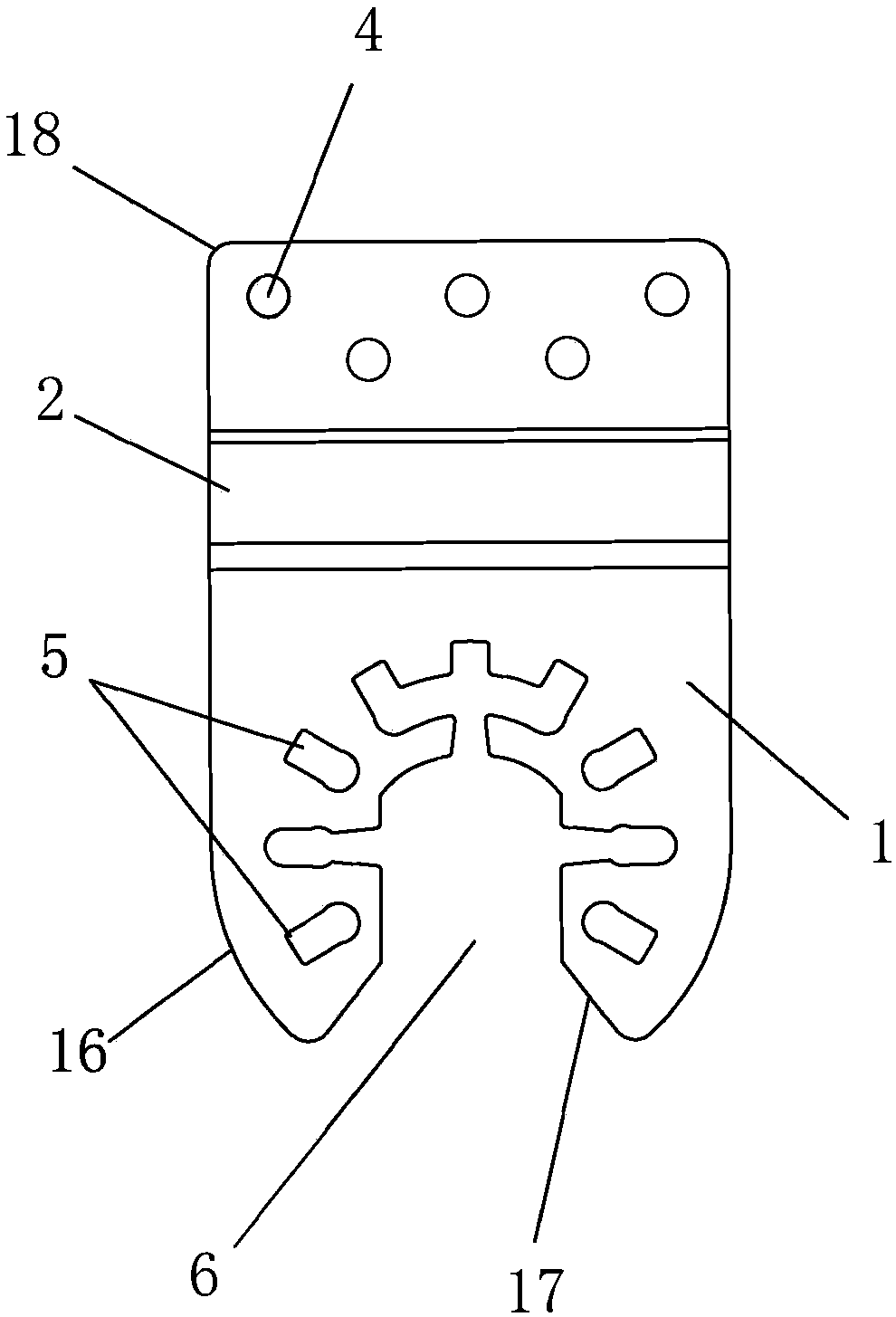

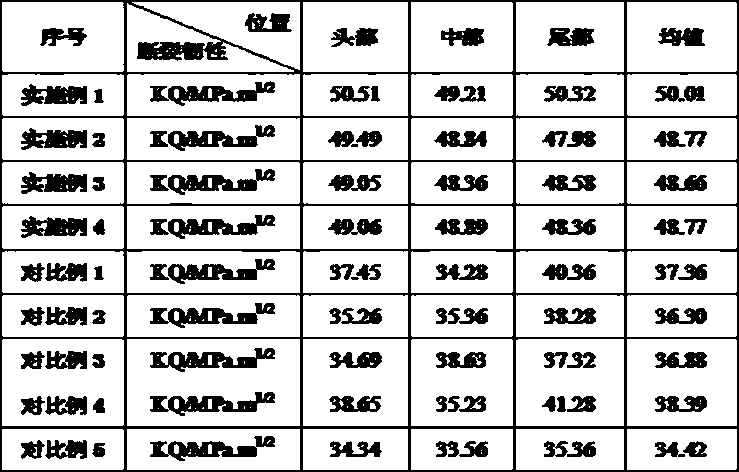

Intervertebral movable indwelling device and its integrated implanting apparatus and method

ActiveCN108969160AIncrease the difficulty of surgeryAvoid difficultyJoint implantsSpinal implantsSurgical operationIndwelling Device

The invention relates to the technical field of medicines, in particular to an intervertebral movable indwelling device and its integrated implanting apparatus and method. The intervertebral movable indwelling device comprises an upper bone plate, a liner, a vertebral core and a lower bone plate, wherein the liner is embedded in the upper bone plate, the vertebral core is inserted in the lower bone plate, and the liner and the vertebral core form a spherical friction pair in clearance fit. The integrated implanting apparatus comprises a clamp rod, a grip and a knob, wherein a taper joint at the tail of the grip is inserted in a rotary cavity at the end of the knob so that the grip and the knob can rotate freely, and the clamp rod penetrates the inner cavity of the grip and then is connected with internal thread of the knob. By the intervertebral movable indwelling device and its integrated implanting apparatus and method, doctors can complete multi-directional surgical operation without surgical reproduction instruments, and relative motion between the product and the implanting apparatus due to operations such as shifting and adjusting in different directions can be avoided.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

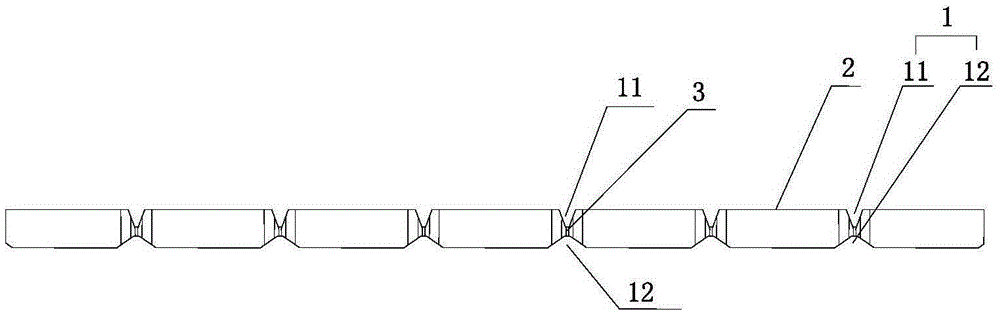

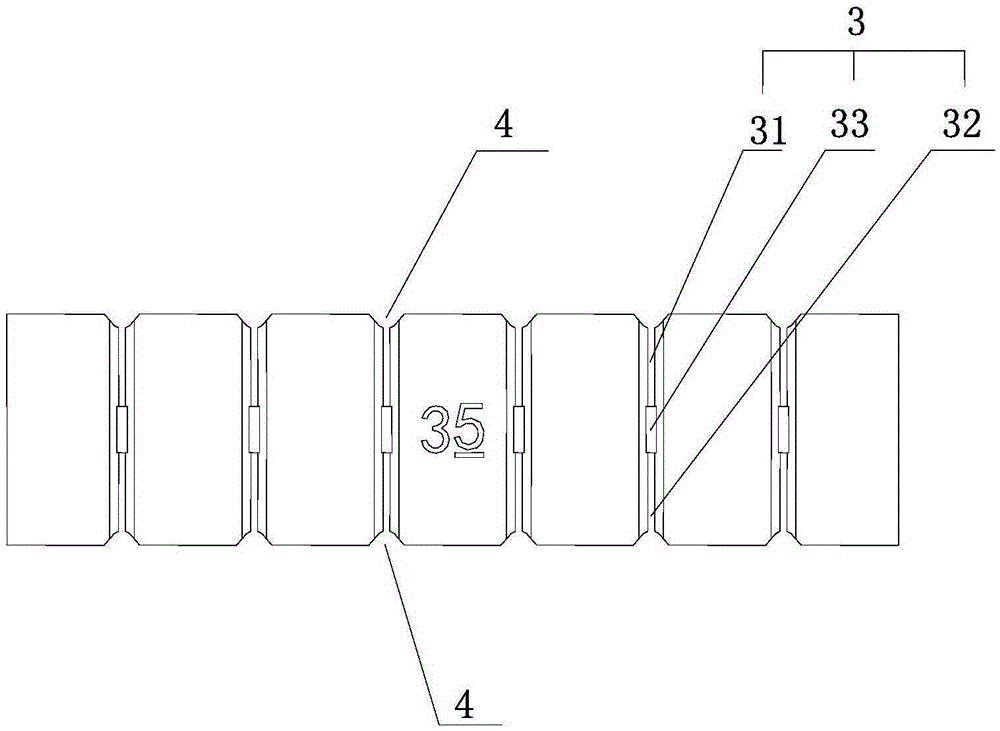

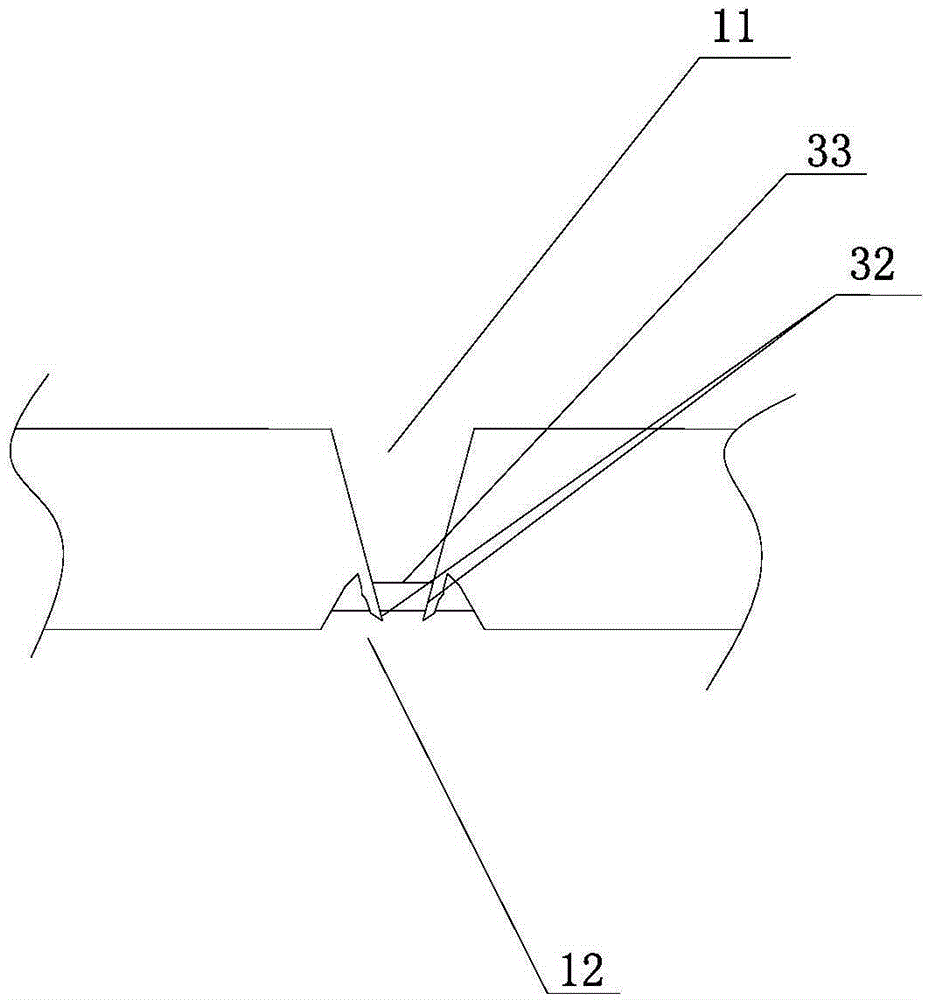

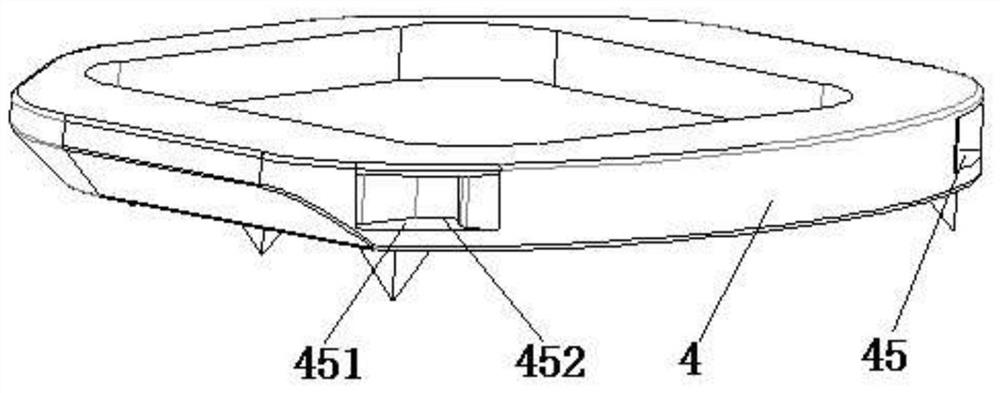

Integrated balance block and molding process thereof

ActiveCN105398284AReduce the amount of resectionIncrease profitWheel-ballasting weightsProcess operationScrap

The invention discloses an integrated balance block and a molding process thereof. The integrated balance block comprises a balance block body. The balance block body is provided with multiple pressing grooves and is cut into multiple connected sub-block bodies through the pressing grooves. Each pressing groove comprises an upper pressing groove body and a lower pressing groove body. The upper pressing groove bodies and the lower pressing groove bodies are oppositely arranged on the upper end face and the lower end face of the balance block body. The bottom faces of the upper pressing groove bodies and the bottom faces of the lower pressing groove bodies are stretched and extruded to form slice type connection belts. Each slice type connection belt comprises a first tearing belt, a second tearing belt and a connection belt body located between the first tearing belt and the second tearing belt. The portions, located at the two ends of each pressing groove, on the two sides of the balance block body are provided with avoiding grooves respectively. The molding process of the integrated balance block includes the steps of firstly, pressing groove molding, secondly, avoiding groove molding and thirdly, cutting off. By the adoption of the integrated structure design, the cut-off amount of waste is small, the material utilization rate is high, the appearance of the steel balance block can be improved, and following process operation convenience can be improved.

Owner:安徽拓扑思汽车零部件有限公司

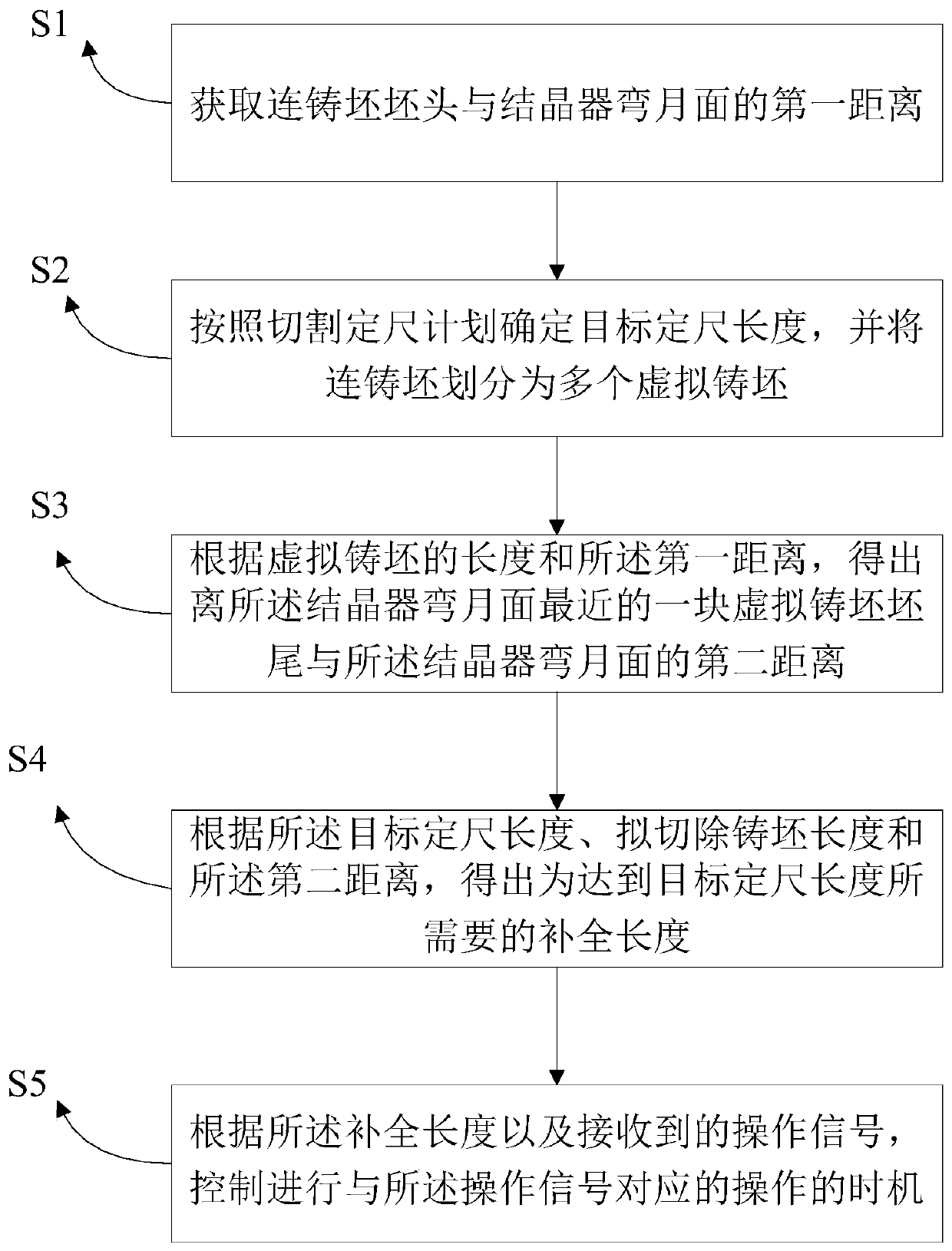

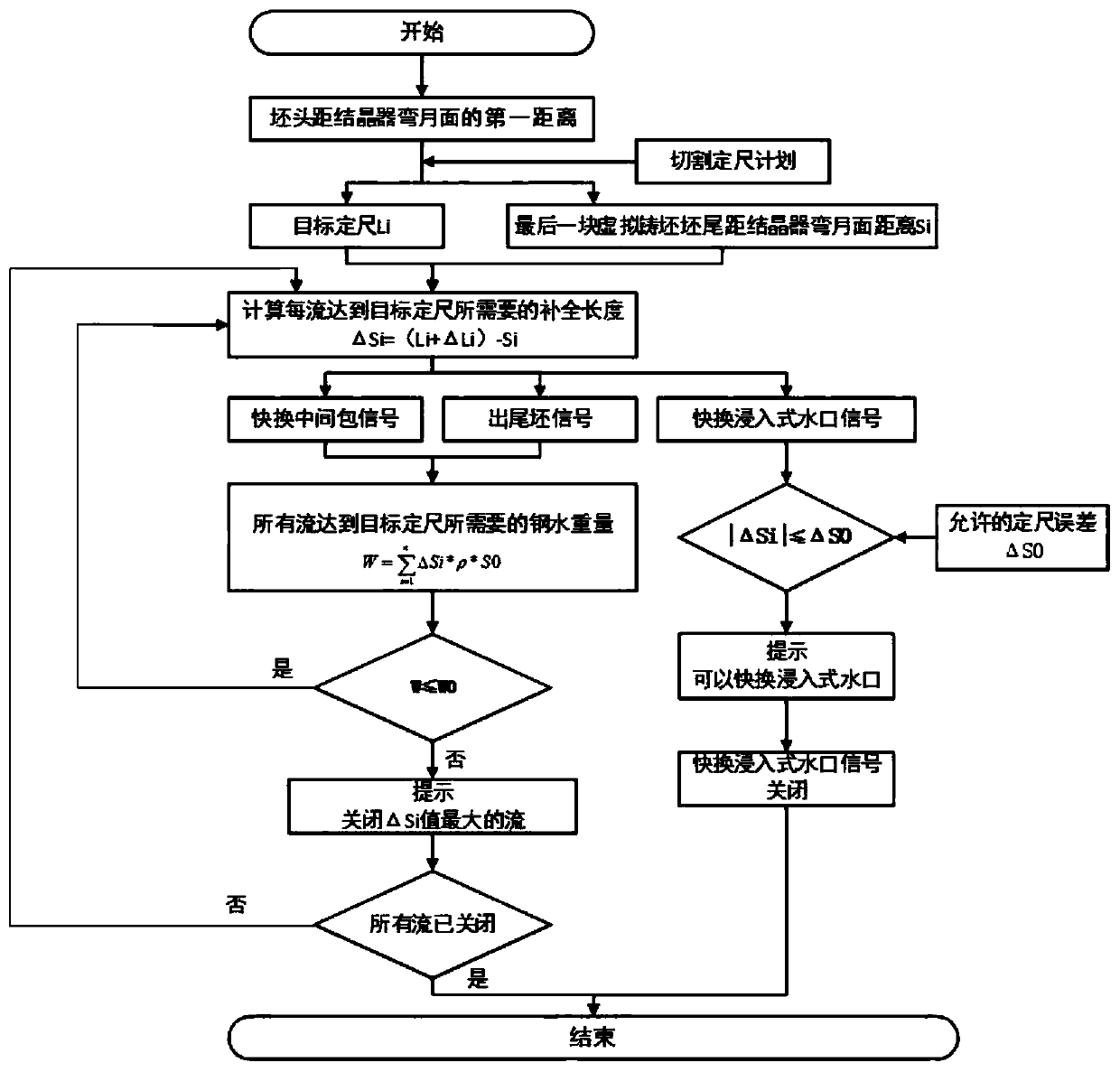

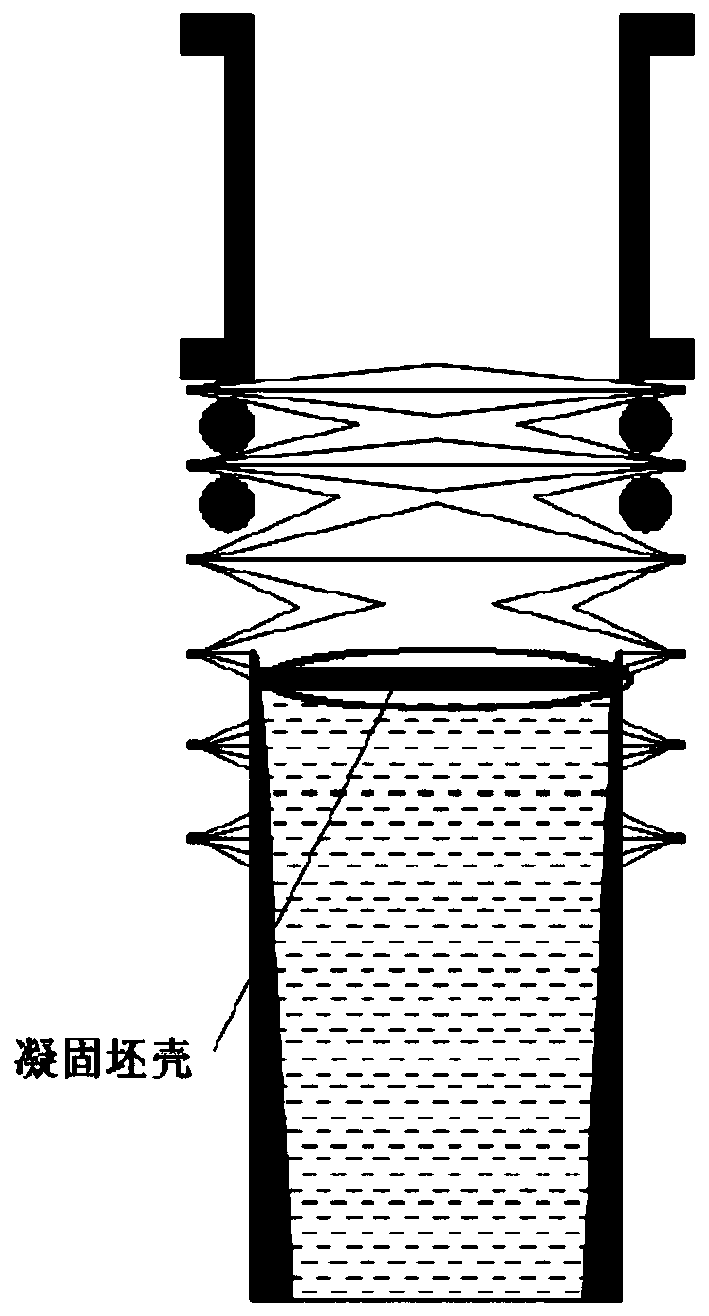

Fixed-length control method of continuous casting blank

ActiveCN110976804AEasy resectionReduce the amount of resectionMechanical engineeringIndustrial engineering

The invention discloses a fixed-length control method of a continuous casting blank. The method comprises the steps of obtaining a first distance between a continuous casting blank head and a crystallizer meniscus surface; according to a cutting fixed-length plan, determining a target fixed-length length, and dividing the continuous casting blank into multiple virtual casting blanks; according tothe length of the virtual casting blanks and the first distance, obtaining a second distance between one virtual casting blank tail closest to the crystallizer meniscus surface and the crystallizer meniscus surface; according to the tart fixed-length length, the planned-cutting casting blank length and the second distance, obtaining a complementing length needed for obtaining the target fixed-length length; and according to the complementing length and a received operation signal, controlling to carry out at the operation opportunity corresponding to the operation signal. The non-fixed-lengthcasting blank or waste blank caused by the casting blank quality during corresponding operation can be avoided, waste is avoided, and the casting blank yield can be improved.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

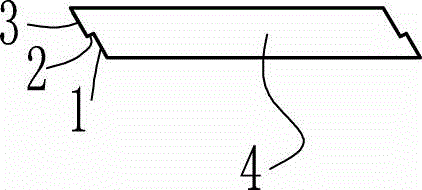

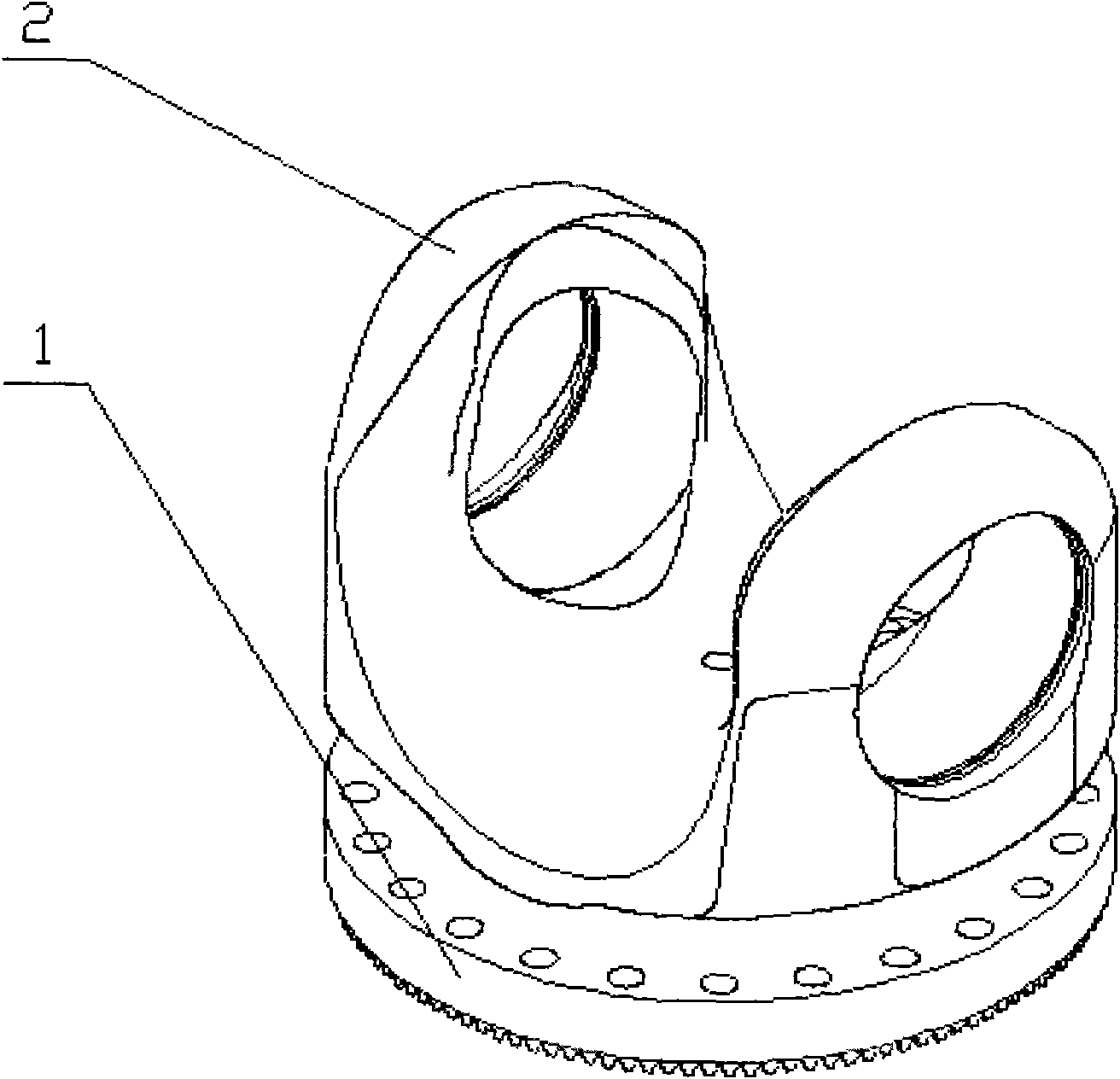

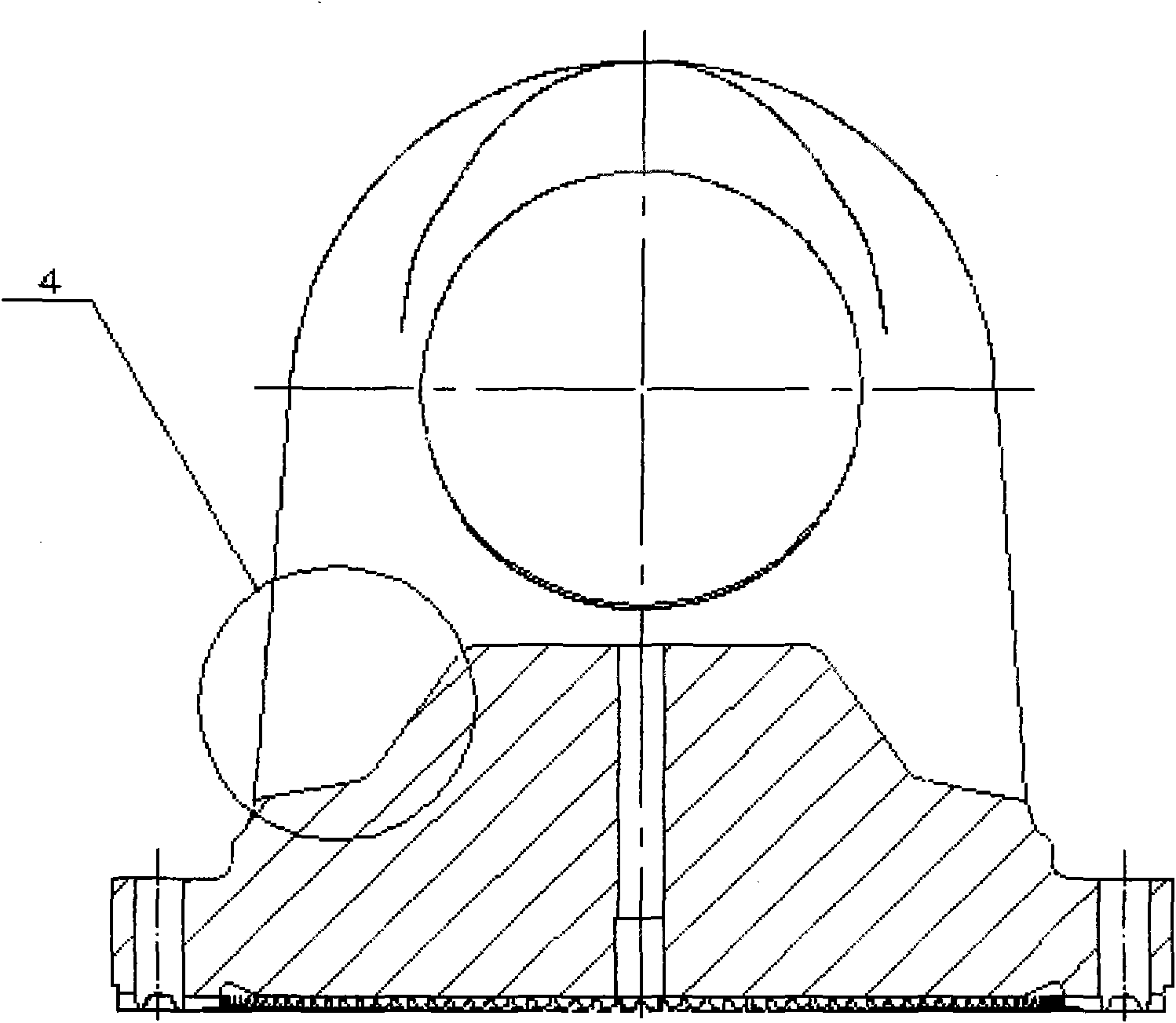

Forkhead of universal coupling

InactiveCN101639099AHigh strengthReduce the amount of resectionYielding couplingCouplings for rigid shaftsCouplingEngineering

The invention relates to a forkhead of a universal coupling, in particular to an integral forkhead of a SWC type cross-shaped universal coupling. The forkhead comprises a base part (1) used for fixinga shaft and a pair of parallel arms (2) extending from the base part. The top (3) of each arm (2) is a conical surface, the shape of the bottom (4) of the inner cavity of the forkhead is matched withthat of the top (3) of the arm. The cutting size of the bottom (4) of the inner cavity of the forkhead is determined by summing the relative size of the top (3) of the arm and a certain allowance. With the conical surface of the top of the pair of arms, the forkhead can meet the requirement that any part of the forkhead can not exceed the turning radius of the forkhead when the forkhead works atan inclination angle, so that the phenomenon of interference of the forkhead to a matched forkhead can not occur. Because the cutting size of the bottom (4) of the inner cavity of the forkhead is determined by summing the relative size of the top (3) of the arm and a certain allowance, the bottom has minimum cutting amount, i.e. highest strength when meeting the inclination angle and the forkheadof the universal coupling has higher strength.

Owner:TAIER HEAVY IND

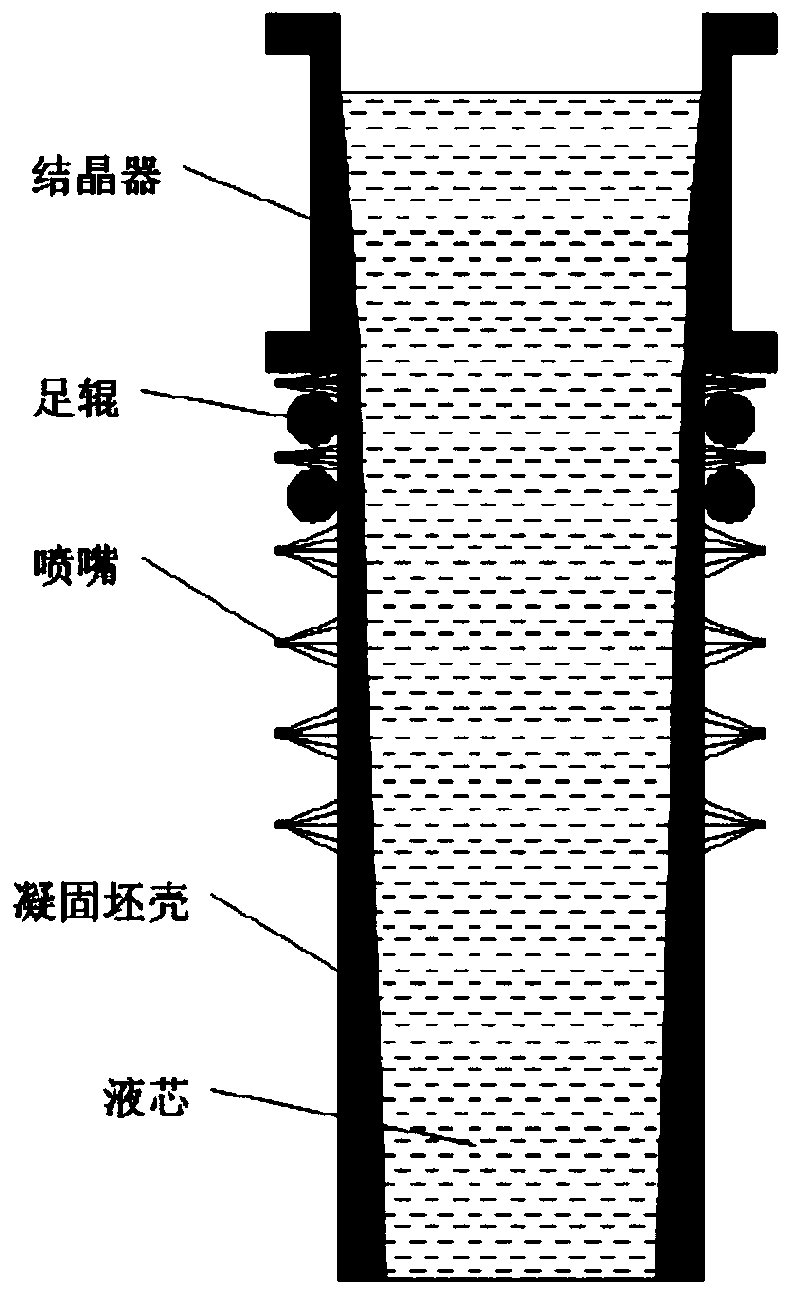

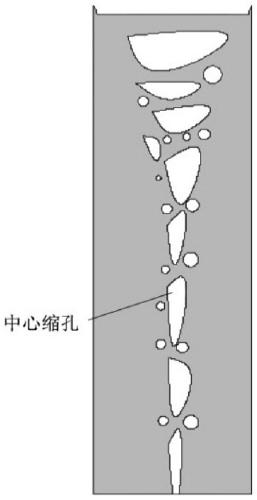

Process method for improving quality and yield of continuous casting tail billet

The invention discloses a process method for improving the quality and yield of continuous casting tail billet, and belongs to the technical field of metallurgical continuous casting. The process method includes the steps that when the tail billet is obtained after continuous casting, a special metallurgical heating agent is evenly sprinkled into a mold liquid level, and when the tail billet is about to be pulled out of a mold, the secondary cooling water is closed sequentially from top to bottom. The metallurgical heating agent can be in chemical reaction with liquid steel of the tail billet,heat is continuously released, and in the absence of the cooling effect of the secondary cooling water, the top of the tail billet remains in a high temperature liquid state, so that the solidification time of the tail billet is prolonged, the volume shrinkage of a liquid core is supplemented by metal iron generated by exothermic reaction and iron of the heating agent, and the purposes of improving the solidification structure quality of the tail billet and the yield rate of the molten steel of the tail billet are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Steel coil head-tail lap-joint and coil-separating method for re-coiling unit

The invention provides a steel coil head-tail lap-joint and coil-separating method for a re-coiling unit. The steel coil head-tail lap-joint and coil-separating method comprises the following steps: coiling a tape tail of the last steel coil into a coiling machine according to normal operation standards, and keeping a belt of a coiling assisting machine tight; when the coiling machine stops rotation, putting the tape tail of last steel coil to a position from 12 o 'clock to 2 o 'clock of a clock dial plate; inserting a tape head of a next steel coil into a position between the tape tail and a coil body of the last steel coil, keeping the belt of the coiling assisting machine tight, and starting operating; after the defect part of the tape head of the next steel coil is completely coiled into the last steel coil, carrying out shearing, coil-separating and coil-unloading by the unit. According to the steel coil head-tail lap-joint and coil-separating method, one coil-unloading operation process can be reduced, coil-separating time can be shortened, and operation efficiency of the re-coiling unit is improved; and moreover, head-tail cut-off amount of steel coils can be reduced, and shearing loss is reduced by 1 / 3, so that the yield of cold-rolled sheets is greatly increased, and economic benefits of enterprises are improved.

Owner:ANGANG STEEL CO LTD

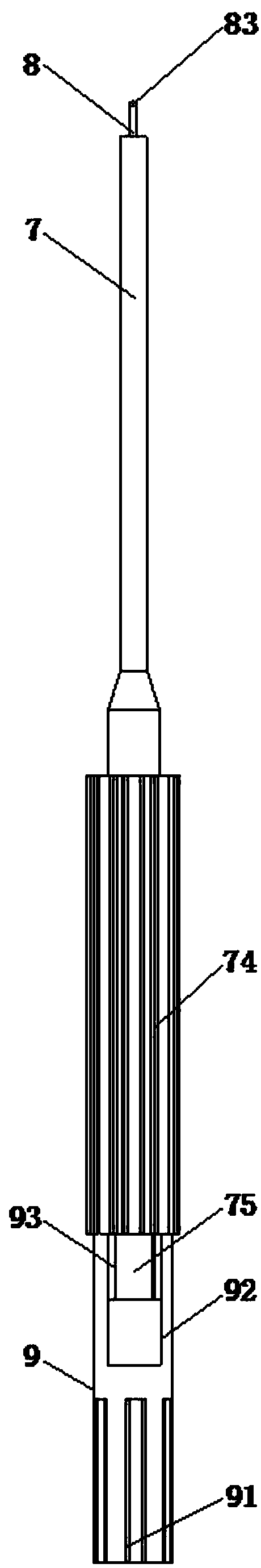

Intervertebral movable indwelling device and its assembled implanting apparatus and method

ActiveCN108969156AEasy to implantImplantation method is fast, safe and effectiveJoint implantsSpinal implantsSurgical operationIndwelling Device

The invention relates to the technical field of medicines, in particular to an intervertebral movable indwelling device and its assembled implanting apparatus and method, and discloses an intervertebral movable indwelling device and its corresponding assembled implanting apparatus. The intervertebral movable indwelling device comprises an upper bone plate, a liner, a vertebral core and a lower bone plate, wherein the liner is embedded in the upper bone plate, the vertebral core is inserted in the lower bone plate, and the liner and the vertebral core form a spherical friction pair in clearance fit. The assembled implanting apparatus comprises a holder, a retainer, a grip, a retracting rod and a knob, wherein the holder and the retainer form an assembled clamping member which is further assembled with the intervertebral movable indwelling device to be subjected to aseptic packaging, the grip, and the retracting rod and the knob form a clamp outer transmission member which is connectedwith the assembled clamp member packaged with the intervertebral movable indwelling device. During surgical operation, the clamp outer transmission member and the assembled intervertebral movable indwelling device in aseptic packaging are combined to complete clamping, thereby facilitating implanting.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

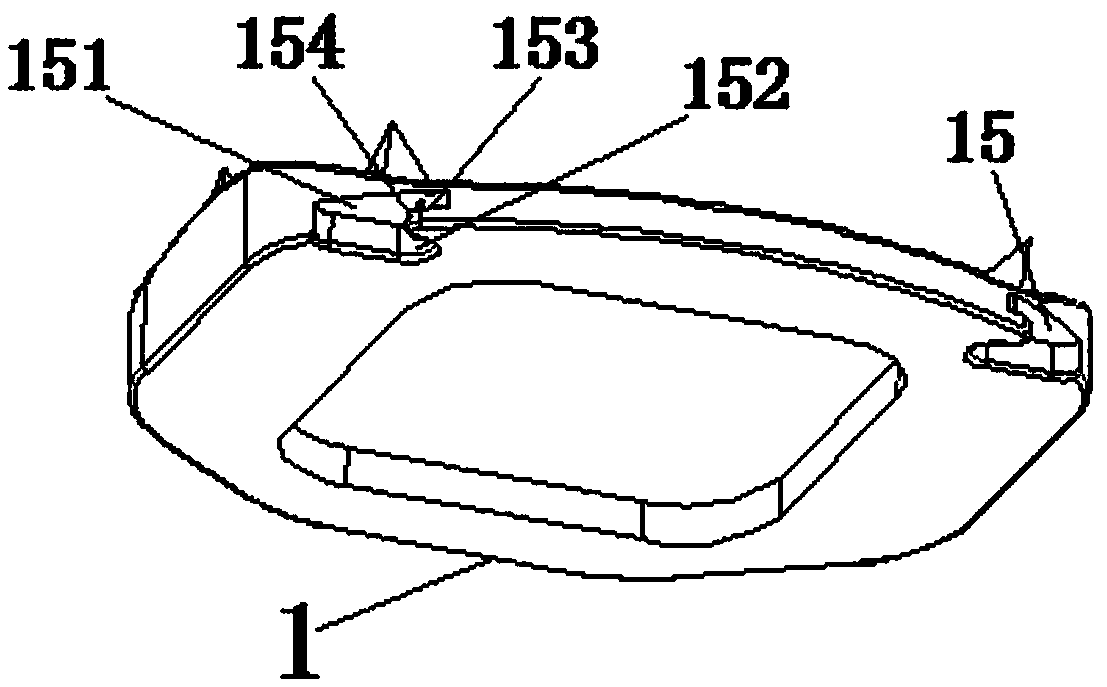

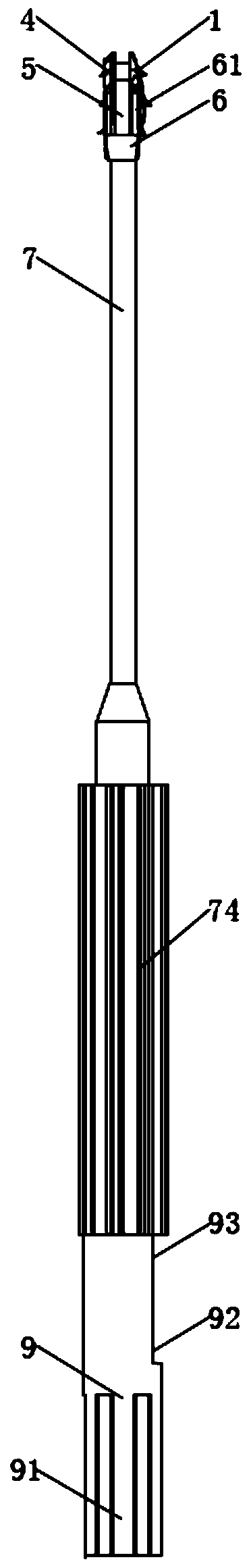

Intervertebral motion retaining device and preassembled implanting instrument and implanting method thereof

ActiveCN111467092AReduce the amount of resectionIncrease contact areaJoint implantsSpinal implantsAnatomyRetainer

The invention relates to the technical field of medicine, in particular to an intervertebral motion retaining device and a preassembled implanting instrument and implanting method thereof; the intervertebral motion retaining device comprises an intervertebral motion retaining device body and the preassembled implanting instrument corresponding to the intervertebral motion retaining device body, wherein the intervertebral motion retaining device body is composed of an upper bone fracture plate, a lining, a nucleus pulposus and a lower bone fracture plate; the lining is nested in the upper bonefracture plate; the nucleus pulposus is nested in the lower bone fracture plate, and the lining and the nucleus pulposus form a clearance fit type spherical friction pair; the preassembled implantinginstrument is composed of a clamping head, a retainer, a holding rod, an opening rod and a knob; the clamping head and the retainer form a preassembled clamping component, and the preassembled clamping component and the intervertebral motion retaining device body are preassembled together for aseptic packaging; the holding rod, the opening rod and the knob form a clamping instrument external transmission component; the clamping instrument external transmission component is connected with the preassembled clamping component packaged together with the intervertebral motion retaining device body;and during an operation, the clamping instrument external transmission component is combined with the preassembled clamping intervertebral motion retaining device body packaged aseptically, so that clamping and implantation can be completed.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Method of producing cylinder block and cylinder sleeve by friction stir welding

InactiveCN1745238BReduce the amount of resectionReduce material costsCylinder headsCylindersEngineeringCylinder block

A reduced-diameter portion (44) with a taper portion (46), a portion whose diameter is reduced in a tapered form, is provided on an inner peripheral wall of a cylinder sleeve (20a, 20b, 20c). On the outer peripheral wall of the top end of the cylinder sleeve (20a, 20b, 20c) is provided a large diameter portion (36a, 36b, 36c) projected outward along the diameter direction. Under the action of a friction stir welding tool (50), the cylinder sleeve (20a, 20b, 20c) inserted in a communication hole (16) of a block body (18) is joined to the block body (18) with the reduced-diameter portion (44) and the large-diameter portion (36a, 36b, 36c) in between. A closed deck-type cylinder block (10) is constructed with the process above. In the cylinder block (10), the gasket face (12) side of a waterjacket (22) is closed by the large-diameter portion (36a, 36b, 36c).

Owner:HONDA MOTOR CO LTD

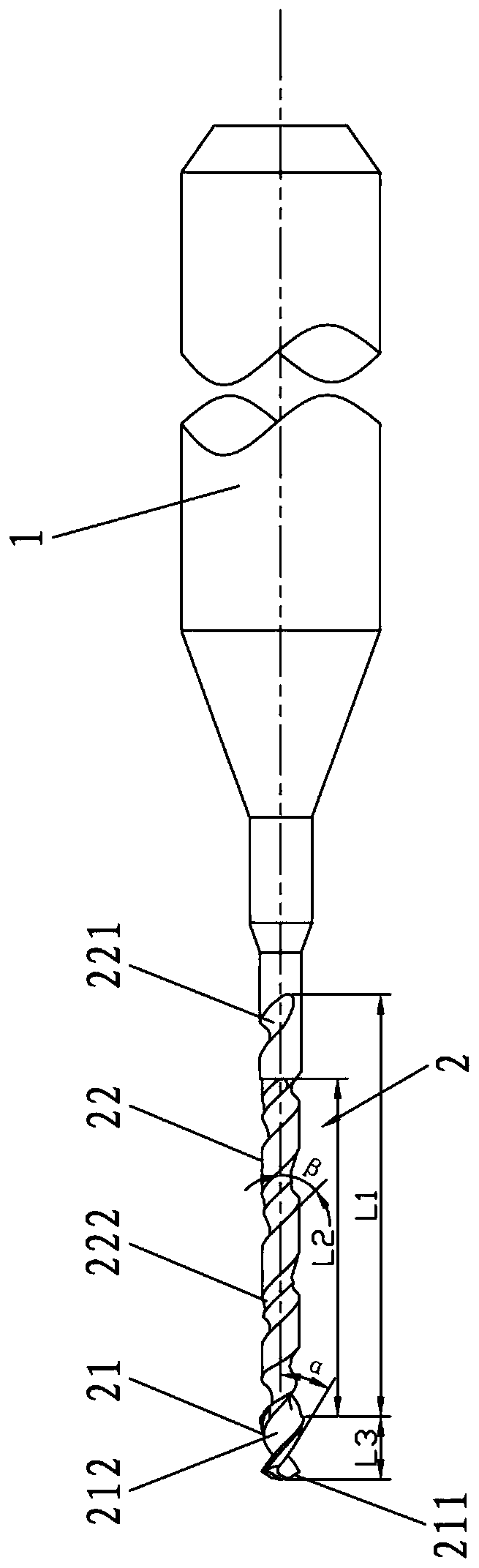

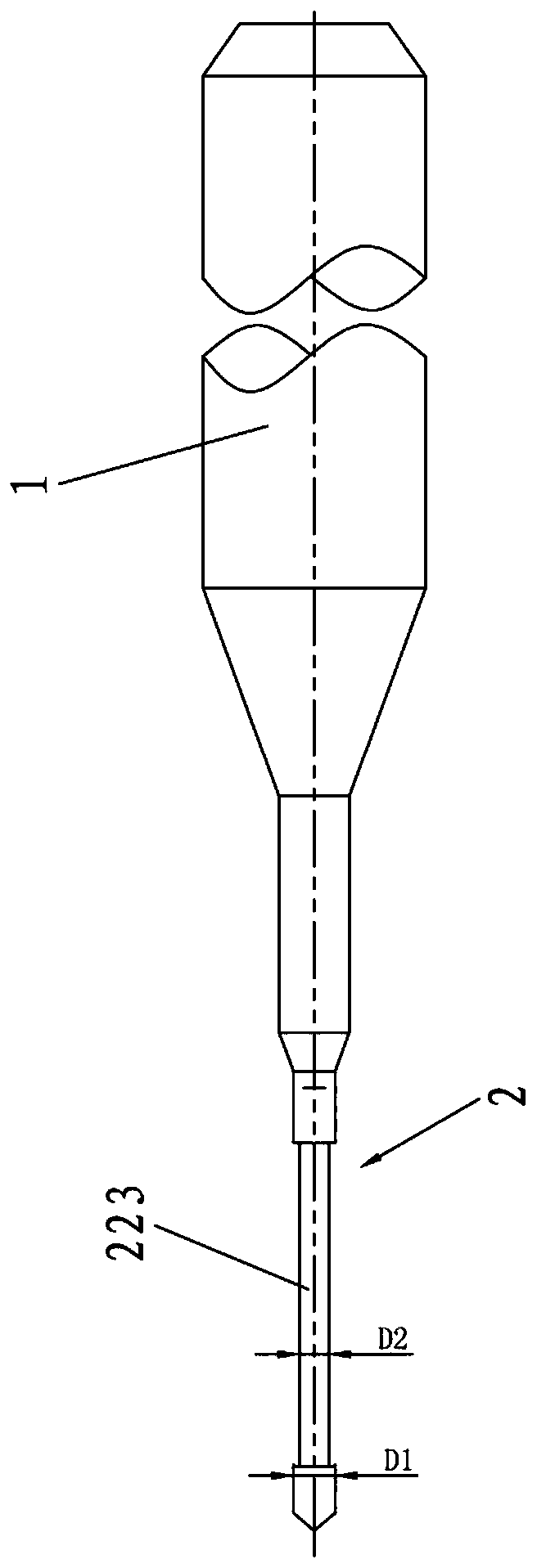

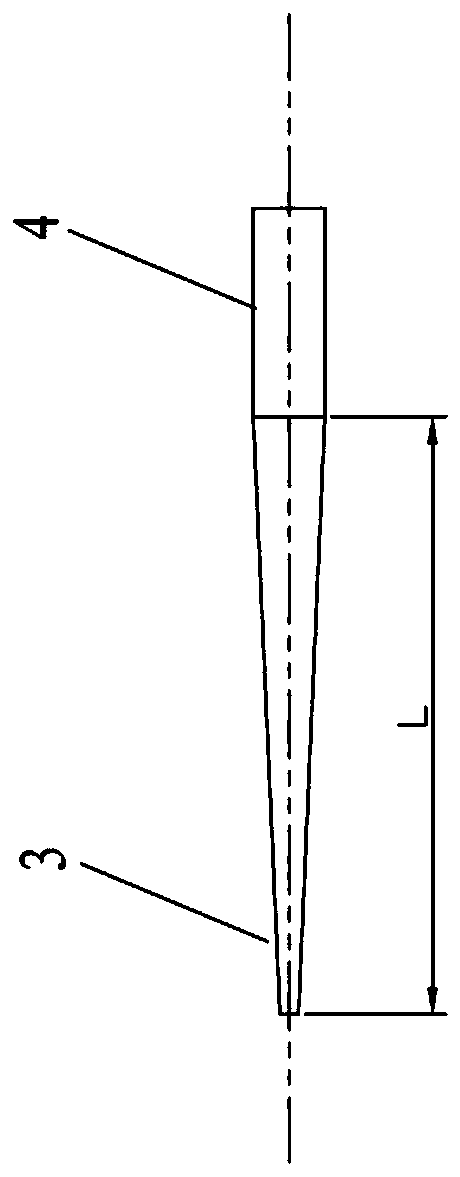

Miniature drill bit

PendingCN110170686AReduce the amount of resectionIncrease chip spaceTwist drillsDrill bitBiomedical engineering

The invention is applicable to the technical field of drill bit structures, and discloses a miniature drill bit. The miniature drill bit comprises a drillstock and a drill body arranged at one end ofthe drillstock, the drill body comprises a cutting part and a guide part, the guide part is arranged between the cutting part and the drillstock, the cutting part comprises two main cutting edges andspiral grooves corresponding to the two main cutting edges, the two main cutting edges are arranged on the end surface of the cutting part, the two spiral grooves spirally extend from the end surfaceof the cutting part to the direction of the guide part and intersect and stop at the front end of the guide part, a main chip removal groove and an auxiliary chip removal groove which extend spirallyfrom the front end of the guide part to the direction of the drillstock are formed in the guide part in parallel, and the front ends of the main chip removal groove and the auxiliary chip removal groove communicate with the intersection of the two spiral grooves. The miniature drill bit has the advantages that the overall rigidity of the drill bit can be improved, the problem that a cutting edge is broken in the drilling process of a PCB can be effectively solved, and the size precision of a machined hole site can be improved.

Owner:SHENZHEN JINZHOU PRECISION TECH

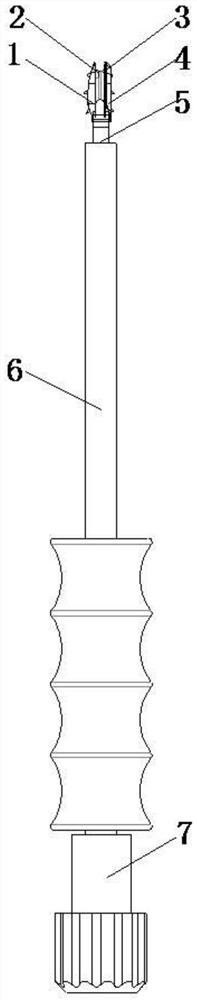

High bionic intervertebral motion retention device

ActiveCN108969157AReduce the amount of resectionAvoid the problem of not being in the motion area of the actual rotation center of the human bodySpinal implantsPhysical medicine and rehabilitationBone plate

The invention relates to a high bionic intervertebral motion retention device. The high bionic intervertebral motion retention device comprising an upper bone plate and a lower bone plate is characterized in that a spherical friction pair composed of a lining and a nucleus pulposus and in clearance fit is embedded between the upper bone plate and the lower bone plate; the spherical radius of a concave spherical crown friction spherical groove in the lining is larger than that of an external convex friction ball top friction spherical surface of the nucleus pulposus; relative to the upper boneplate, the lining is stationary or rotates or translates; relative to the lower bone plate, the nucleus pulposus is stationary or rotates or translates; the rotation center of the spherical friction pair formed by the lining and the nucleus pulposus realizes movement without axis or free movement in front, back, left and right directions.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

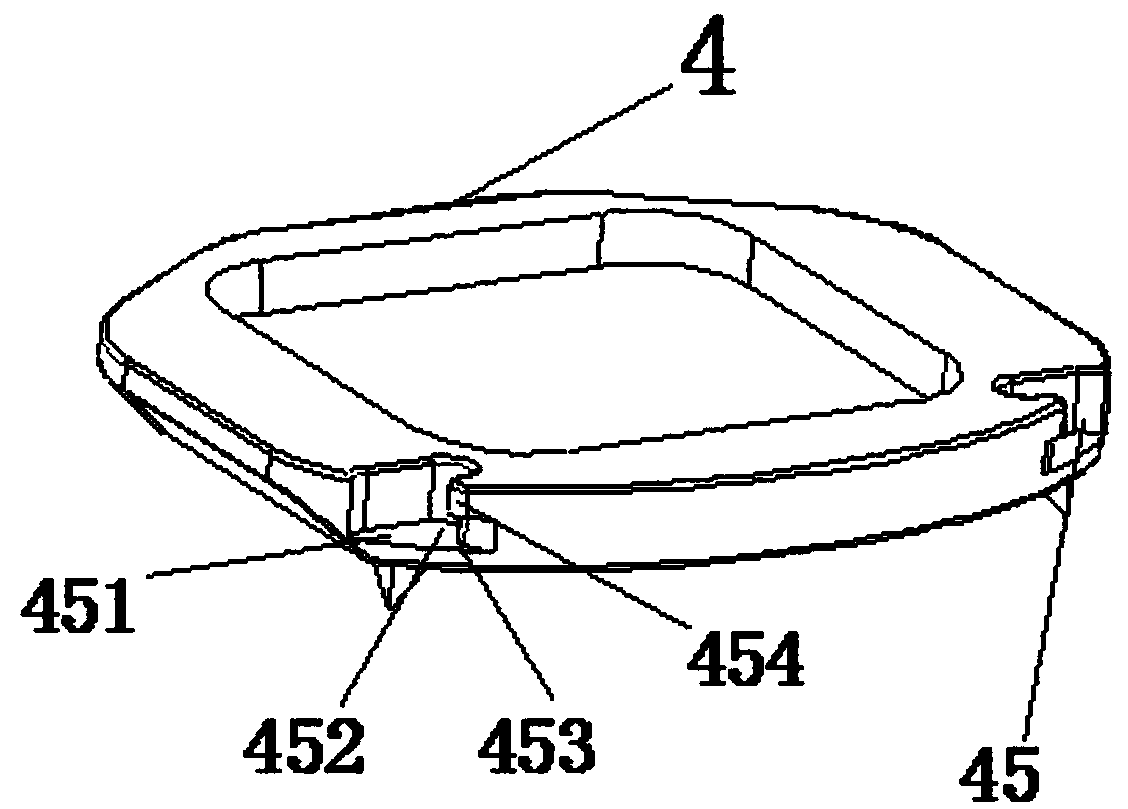

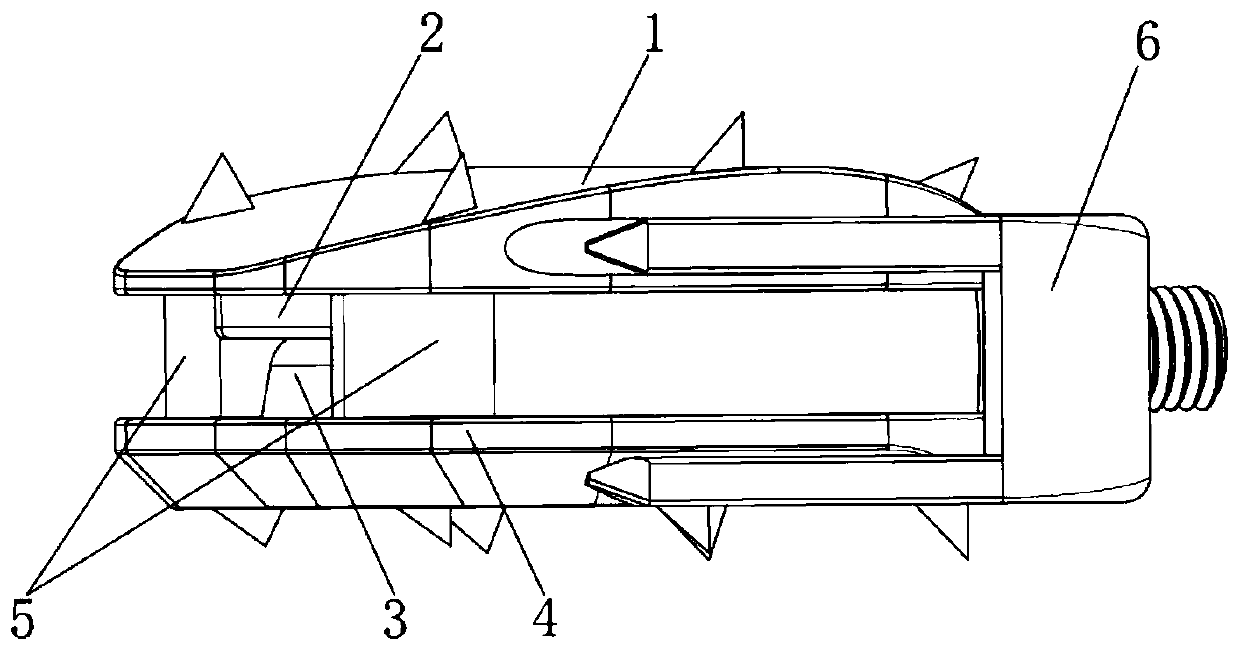

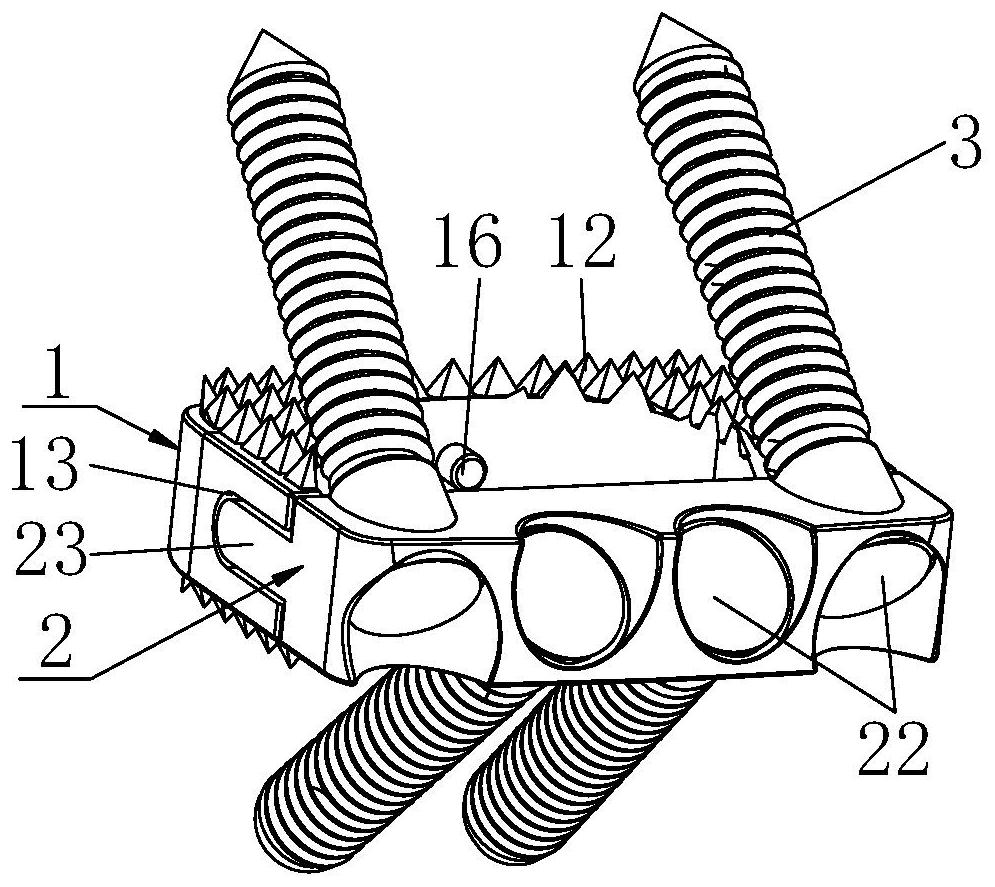

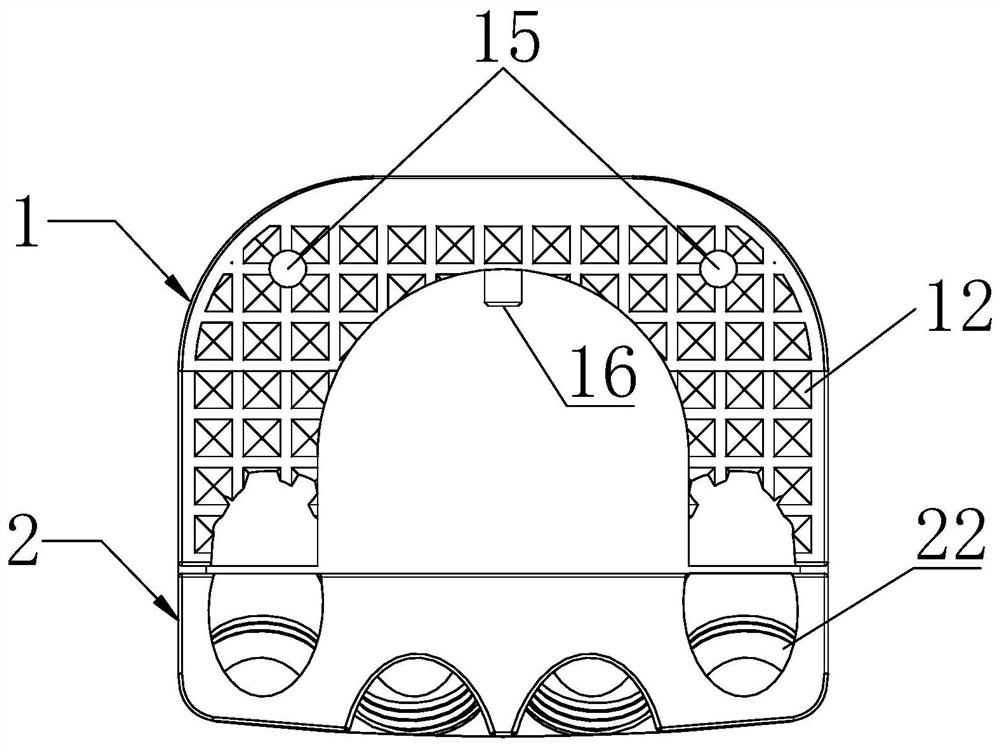

Anterior cervical zero-profile intervertebral fusion

The invention relates to a zero-incisure interbody fusion cage for the anterior cervical vertebra. The interbody fusion cage comprises a fusion cage body and a fixing component, wherein the fusion cage body and the fixing component form micromotion gap buckling connection. The fixing component is composed of a massive body, screw holes, clamping arms and clamping hook parts, wherein the screw holes are formed in the massive body, form a reverse inclination angle and are arrayed through staggering; the two ends of the massive body separately extend perpendicularly to form the clamping arms, andthe ends of the clamping arms separately extend inwards and perpendicularly to form the clamping hook parts; the fuse cage body is composed of a U-shaped frame, saw teeth, inclined sliding grooves, half screw holes and fastening screws, wherein the saw teeth are arranged on the two end faces of the U-shaped frame respectively through protruding, the inclined sliding grooves are symmetrically formed in the outer side face of the waist of the U-shaped frame and extend inwards separately from the outer end wall, the half screw holes which are in butt joint with half screw holes of the fixing component are formed in the two ends of one end face and incline toward the direction of the saw teeth separately, and the fastening screws fasten the fixing component on the upper and lower vertebral bodies of a human body through the screw holes.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Electroslag arc-starting smelting method by multiple granular reducing slag by electroslag furnace

Owner:张家港市欧微自动化研发有限公司

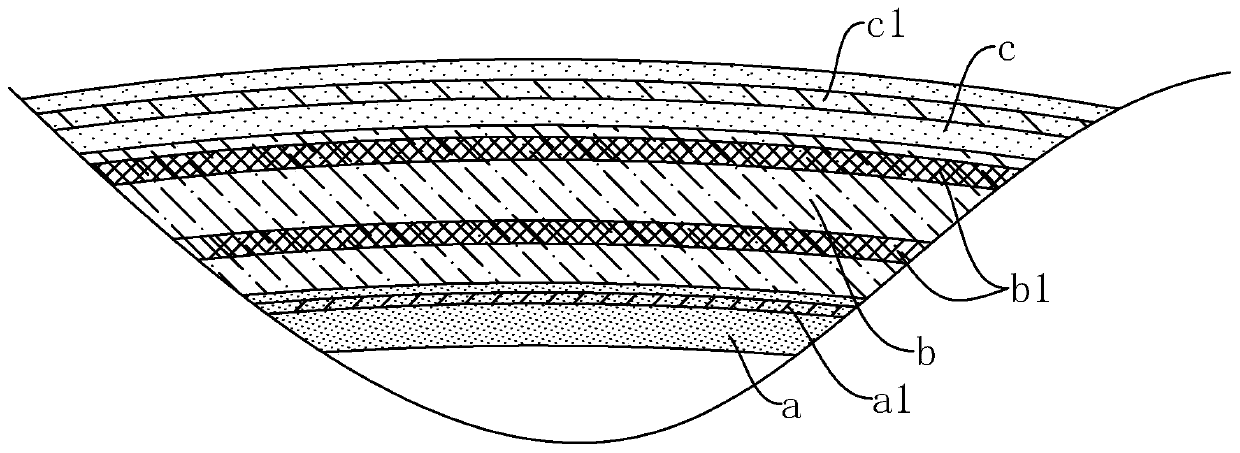

Glass fiber reinforced plastic pipe and manufacturing method thereof

InactiveCN110274098AHigh strengthReduce the amount of resectionRigid pipesTubular articlesGlass fiberCompound a

The invention relates to a glass fiber reinforced plastic pipe and a manufacturing method thereof. The glass fiber reinforced plastic pipe sequentially comprises a lining layer, a structural layer and a protective layer from inside to outside; the lining layer is formed by compounding a polytetrafluoroethylene film with the thickness of 0.1-0.15 mm and lining slurry; the structural layer is formed by compounding glass fiber cloth with the thickness of 0.2-0.3 mm and structural slurry; and the protective layer is formed by compounding 100# aramid fiber untwisted plain cloth with the thickness of 0.1-0.15 mm and protective slurry. Each layer of the glass fiber reinforced plastic pipe is formed by compounding the corresponding fiber cloth and the slurry respectively and a weak area at the end part caused by spiral winding is avoided; the cutting amount of the two ends of the pipe is controllable and small, and the waste of materials and the generation of industrial garbage are reduced; and the layers are connected through a resin curing forming process, the interface connection is firm, the integral strength of the glass fiber reinforced plastic pipe is high, and the lining and the protective layer have corrosion resistance.

Owner:深圳市深捷通管业发展有限公司

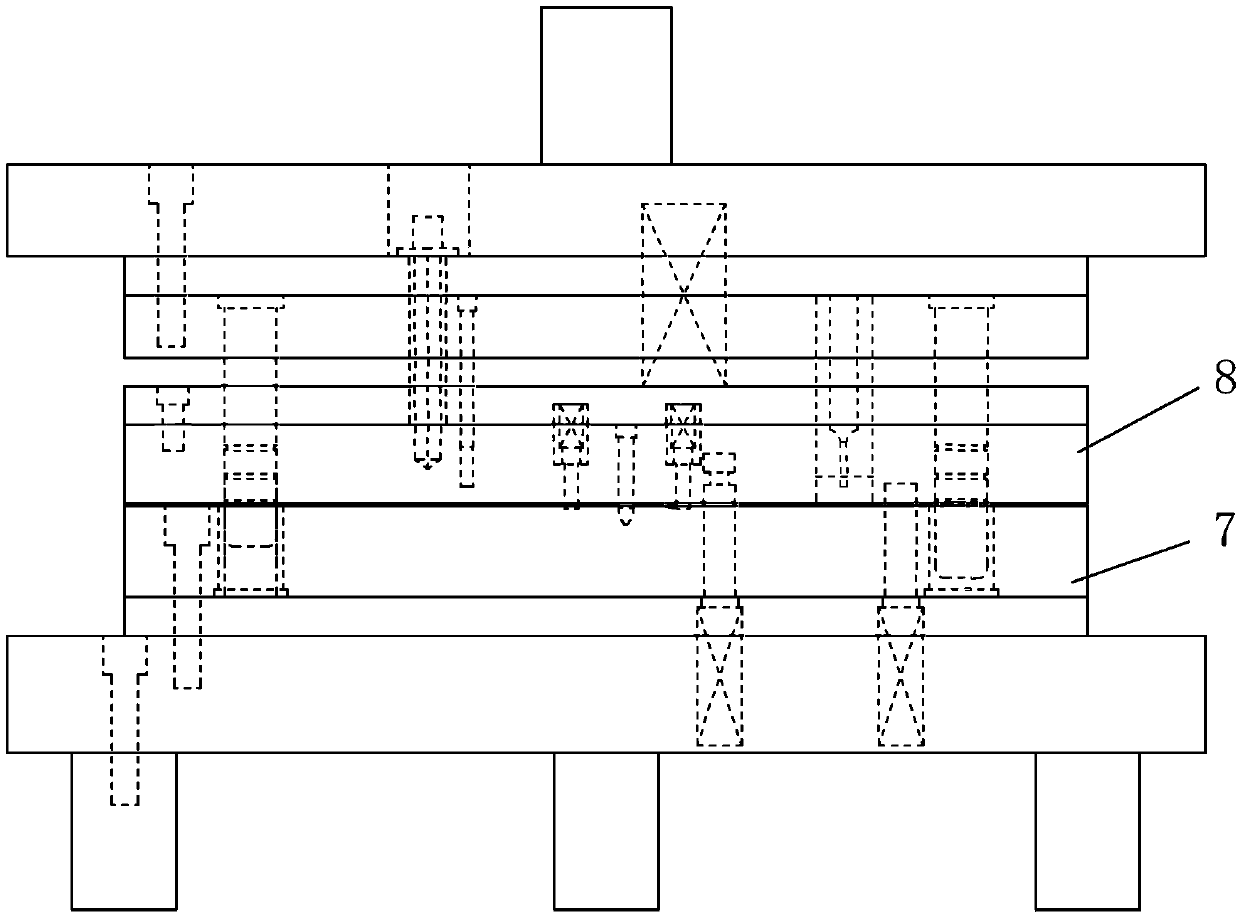

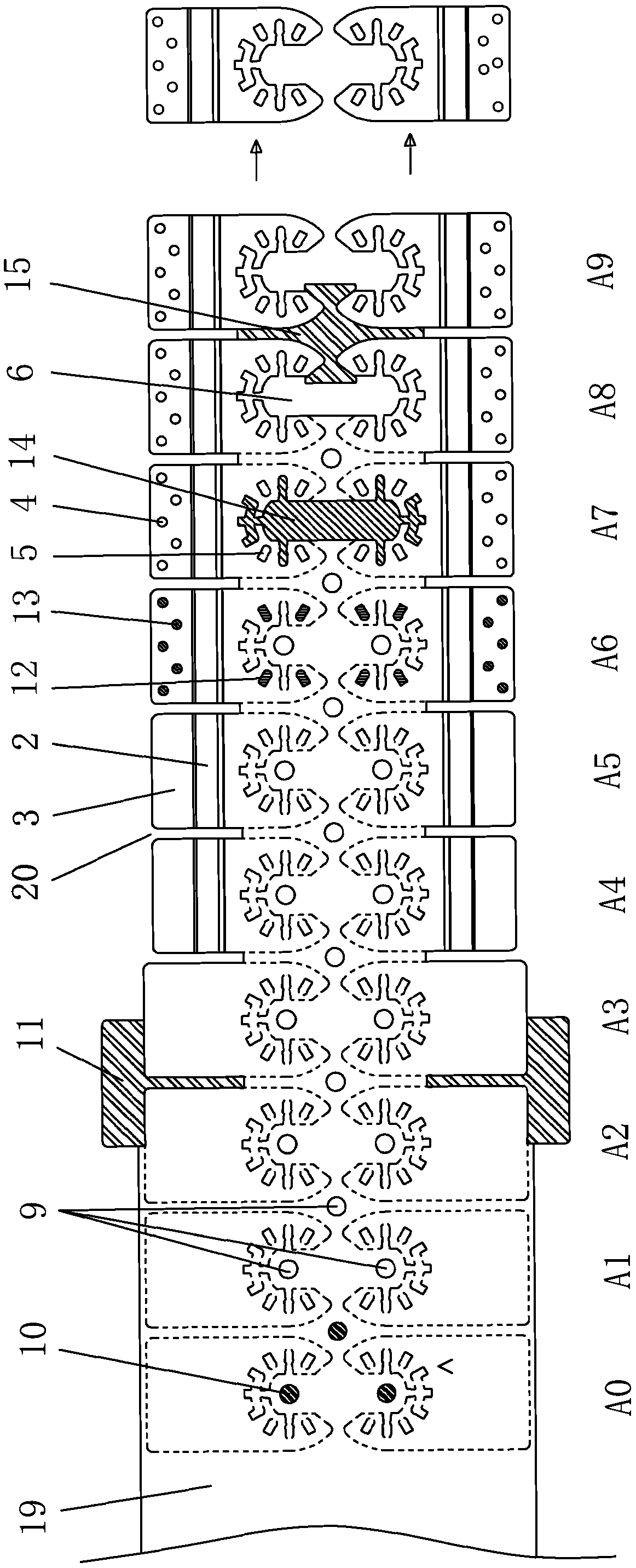

Process method of stamping forming of saw arm of swing saw

InactiveCN109590379AImprove forming qualityReduce the amount of resectionShaping toolsPerforating toolsPunchingEngineering

The invention relates to a process method of stamping forming of a saw arm of a swing saw. the method comprises the steps that opening parts of middle holes of opening parts of two swing saw arm middle holes are opposite; an A0 pre-entering position and A1 to A9 grading positions are arranged in a mold cavity in sequence; firstly the A0 pre-entering position is used for stamping a guide hole; secondly, on the A2 grading position and the A3 grading position, the board side is cut off, and a top side of a base plate is formed, the A2 grading position punches and cuts off the right side part, theA3 grading position punches and cuts off the left part, the A2 grading position and the A3 grading position cut out the side upper edge connected with the top side, and an upper middle groove and a lower middle groove are formed in a board; 3, the A4 grading position bends the inclined part and a front end flat plate; 4, the A6 grading position punches the convex point of the middle and an inclined hole in the outer side at the same time; 5, the A7 grading position punches a middle hole; 6, the A8 grading position and the A9 grading position enable a punching part of the A9 grading position to be broken away from a board (19), and the two swing saw arms are broken, so that an outer lip side and an inner lip side are formed, wherein the A8 grading position forms the outer lip side and theinner lip side on the right side, and the A9 grading position forms an outer lip side and an inner lip side on the left side.

Owner:HANGZHOU XIAOSHAN CHANGYU METAL MACHINERY

A dynamic variable procedure method for roll removal based on esp finishing mill

ActiveCN109351780BGuaranteed continuityReduce the amount of resectionRoll force/gap control deviceMetal rolling stand detailsProduction lineEngineering

The invention provides a dynamic variable regulation method based on ESP finishing mill group roll withdrawal. According to the input rolling process and rolling mill parameters, the sorties of roll withdrawal racks are calculated firstly. Then, each rack needs to be adjusted and each upstream rack of the roll withdrawal racks is adjusted. When a thickening point reaches the roll withdrawal racks,rolls of the roll withdrawal racks are lifted and adjusted. When the roll withdrawal racks Fi are removed from rolling, each downstream rack of the roll withdrawal racks is adjusted to complete the dynamic variable regulation by means of the rolls withdrawal. By calculating the sorties of the roll withdrawal racks and adjusting the rolls rotation speed and gaps in each stage of the roll changingprocess, the dynamic variable regulation method based on ESP finishing mill group roll withdrawal achieves that the dynamic variable regulation is completed by the non-stop roll withdrawal on the premise of ensuring the stable rolling of rolling mills, so that the continuity of an ESP production line is ensured, the energy loss caused by the shutdown is reduced, and the application value is high.

Owner:YANSHAN UNIV

A kind of al-zn-mg alloy profile for rail transit car body and preparation method thereof

ActiveCN108251723BHigh tensile strengthImprove stress corrosion resistanceMetallic materialsToughness

The invention belongs to the technical field of metal materials and machining thereof, discloses an Al-Zn-Mn alloy profile for a rail transit vehicle body and a preparation method thereof, and relatesto the technical field of aluminum alloy machining. The alloy comprises the following chemical components of, by mass, 4.4-4.6 % of Zn, 0.1-0.15% of Cu, 0.3-0.4% of Mn, 0.16-0.24% of Cr, 0.04-0.08% of Ti, 0.12-0.20 of Zr, less than or equal to 0.12% of Fe, less than or equal to 0.06% of Si, and the balance Al, wherein the ratio of the mass percentage of the Zn to the mass percentage of the Mg is3.2 to 3.5. The Al-Zn-Mn alloy material prepared through the preparation method has high toughness, corrosion resistance, anti-fatigue and weldable characteristics, and can meet the running requirements of the high-speed rail transit vehicle body.

Owner:广西南南铝加工有限公司

A kind of intervertebral movement preserving device and its guided implantation instrument and implantation method

ActiveCN108969158BReduce the amount of resectionIncrease contact areaJoint implantsSpinal implantsAnatomyReoperative surgery

The invention relates to the field of medical technology, in particular to an intervertebral motion preservation device and its guided implantation instrument and implantation method. The intervertebral motion preservation device consists of an upper bone plate, an inner lining, a nucleus pulposus and a lower bone plate. The lining is nested in the upper bone plate, and the nucleus pulposus is nested in the lower bone plate. The inner lining and the nucleus pulposus form a spherical friction pair with clearance fit. The embedded clamping groove is composed of an open area and a concave clamping area. The open area and the clamping area are connected together. There is a gap between the clamping groove and the upper bone plate and the lower surface There is a certain thickness, and the same embedded clamping groove is symmetrically provided at the corresponding position of the lower bone plate. The clamping process is in place in one step, fast and simple, and can avoid centering and direction correction during the product clamping process, which can effectively reduce the difficulty of the operation and reduce the operation time.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com