Patents

Literature

243results about How to "Improve stress corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

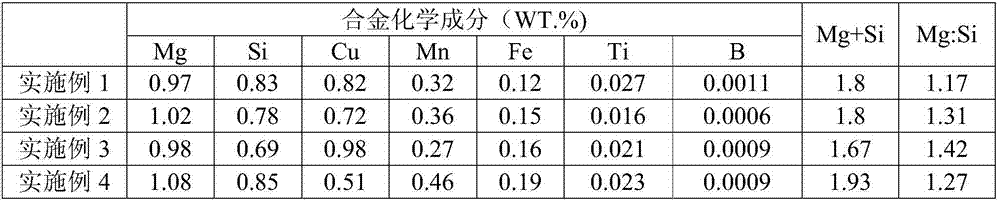

High-strength aluminum alloy with excellent oxidation effect and preparation method and application thereof

ActiveCN107385290AExcellent anode decoration effectAvoid problemsHigh intensityUltimate tensile strength

The invention discloses a high-strength aluminum alloy with an excellent oxidation effect and a preparation method and application thereof. The alloy comprises the following components in percentage by mass: 0.6-0.9% of Si, 0.8-1.1% of Mg, not more than 0.20% of Fe, 0.5-1.0% of Cu, 0.2-0.5% of Mn, 0.015-0.03% of Ti, 0.0006-0.0012% of B, less than 0.15% of the total quantity of other impurities, and the balance Al, wherein the mass ratio of Mg to Si is Mg / Si=1.15-1.45. The aluminum alloy is higher in strength and excellent in anodic oxidation performance, welding performance and stress corrosion resistance, and can be used for manufacturing high-strength and high-decorativeness industrial aluminum alloy materials, such as electronic structural parts and light vehicle parts.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

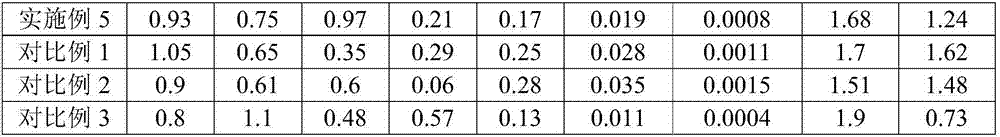

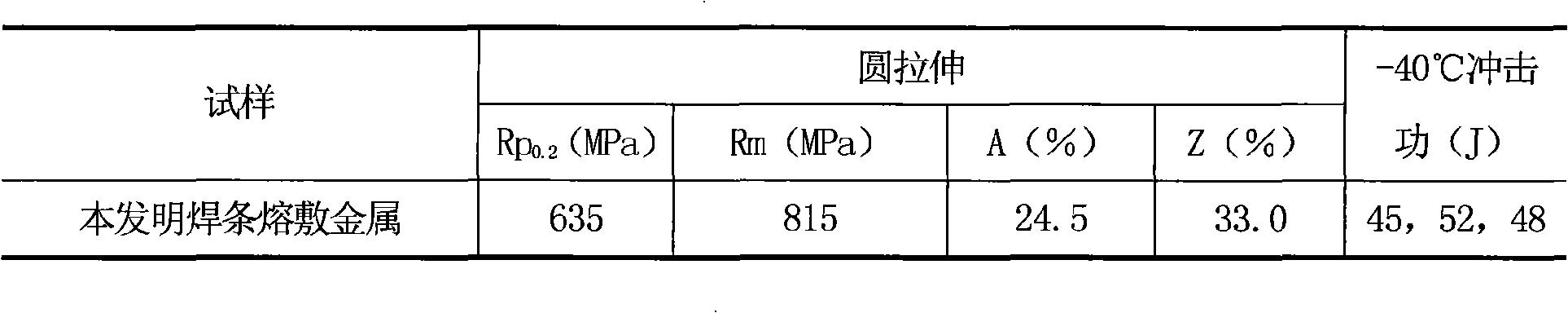

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

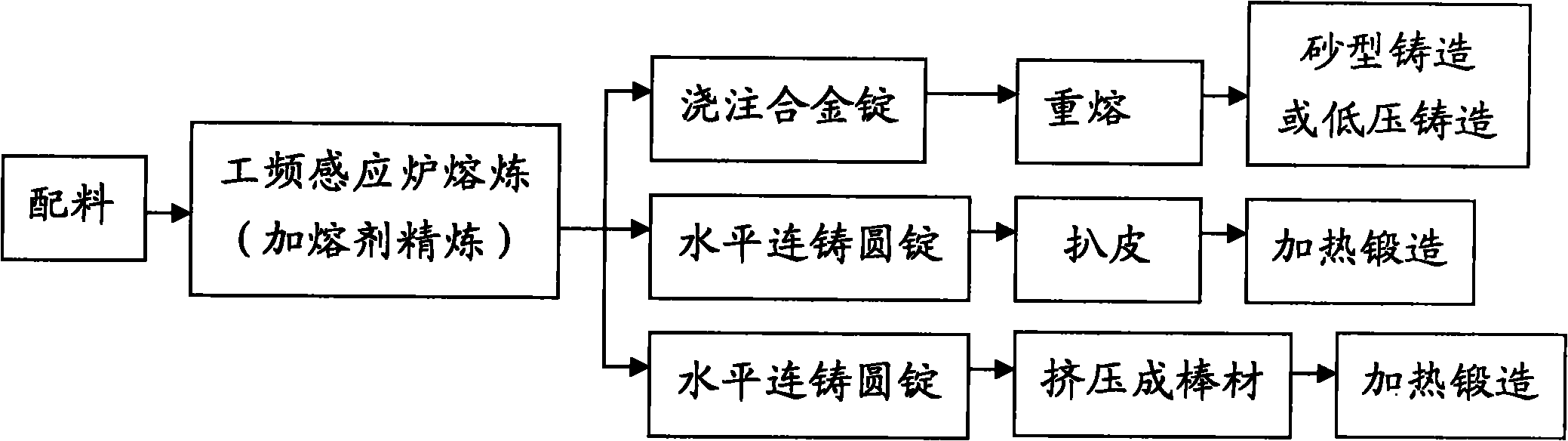

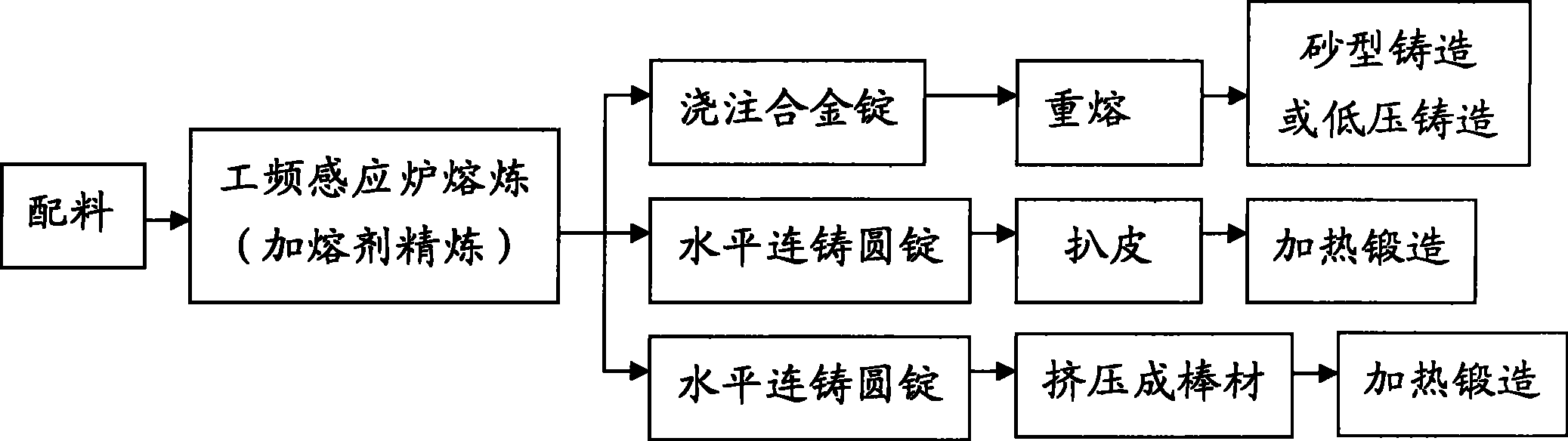

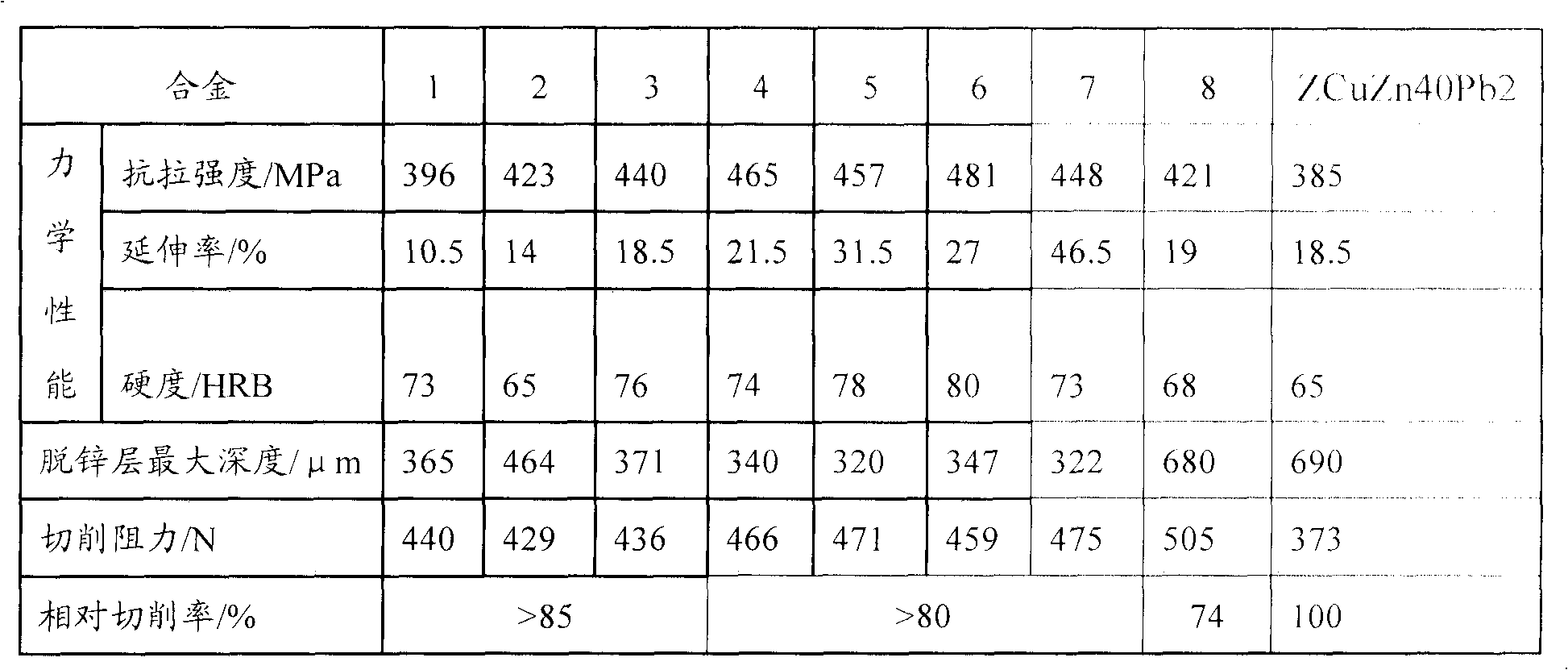

Environment-friendly manganese brass alloy and manufacturing method thereof

The invention provides an environment-friendly manganese brass alloy comprising 55-65 wt% of Cu, 1.0-6.5 wt% of Mn, 0.2-3.0 wt% of Al, 0-3.0 wt% of Fe, 0.3-2.0 wt% of Sn, 0.01-0.3 wt% of Mg, 0-0.3 wt% of Bi and / or 0-0.2 wt% of Pb, and the balance of Zn and other inevitable impurities. The alloy has favorable mechanical property, casting property, cutting property and corrosion resistance, particularly stress corrosion resistance, has the advantages of low manufacturing cost, simple production technology and the like, is suitable for parts processed by forging, casting, machining and other manufacturing methods, and is particularly suitable for a tap body and a valve processed by forging, casting and machining.

Owner:XIAMEN LOTA INT CO LTD

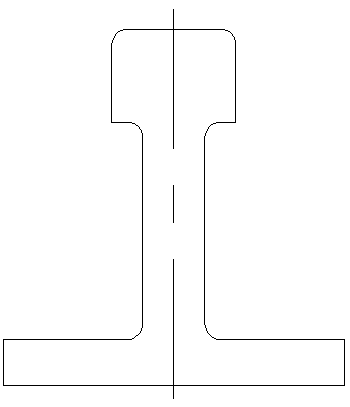

Production method of copper-steel composite plate

ActiveCN102671943AGood direct connectionHigh strengthWork treatment devicesCleaning using liquidsSurface cleaningSpray coating

The invention relates to a production method of a copper-steel composite plate. The production method comprises the following steps of: performing surface cleaning, performing texturing treatment, spraying a binding layer, rolling and annealing, wherein before rolling, alloy plating layers are respectively plated on the surfaces of a steel plate and a copper plate, which need to be compounded through an immersion plating or spray coating way, the thickness of each plating layer is 4-8 mu m, and each alloy plating layer contains the following components: 6-8 parts by weight of Zr, 25-50 parts by weight of Zn, 5-30 parts by weight of Al, 10-40 parts by weight of Fe, 0.5-1 part by weight of Si and 0.4-0.6 part by weight of Mo. The production method disclosed by the invention has the beneficial effects that as the bonding layers with the mixture ratio are adopted, the direct bonding property between the steel plate and the copper plate is good; in addition, the compounding temperature is lower, the rolling reduction is smaller and the working cost is saved; and the composite copper-steel material prepared by the method disclosed by the invention has the advantages of high strength, high plasticity and toughness and excellent stress and corrosion resistance.

Owner:RUGAO OUTONG MACHINERY FITTINGS

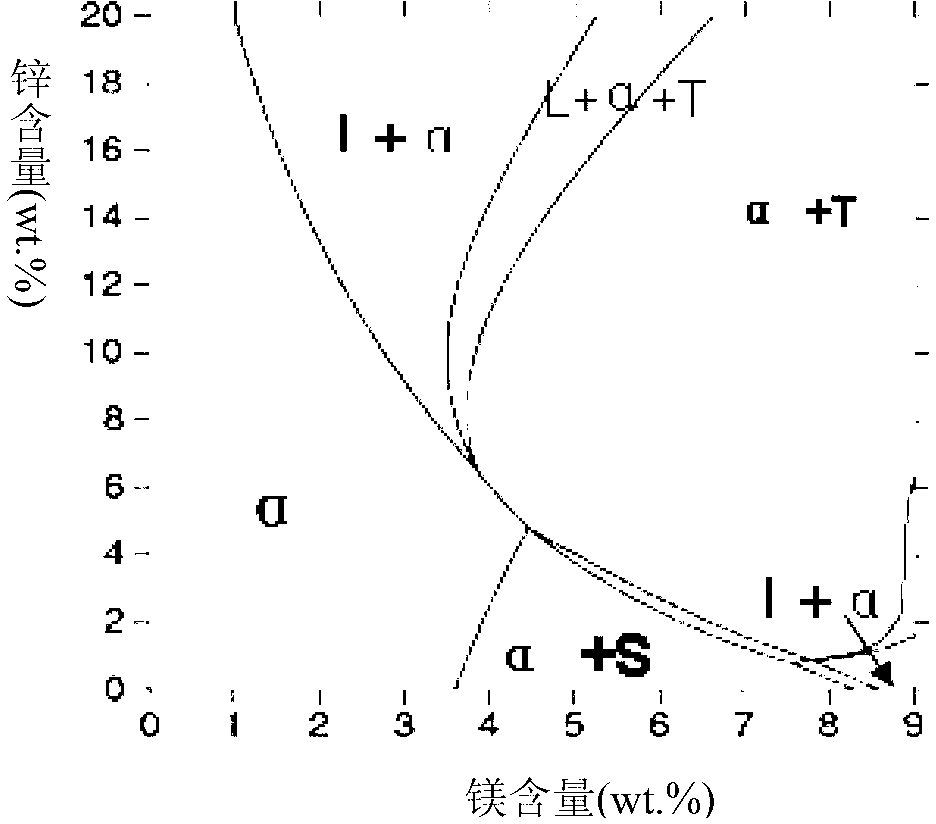

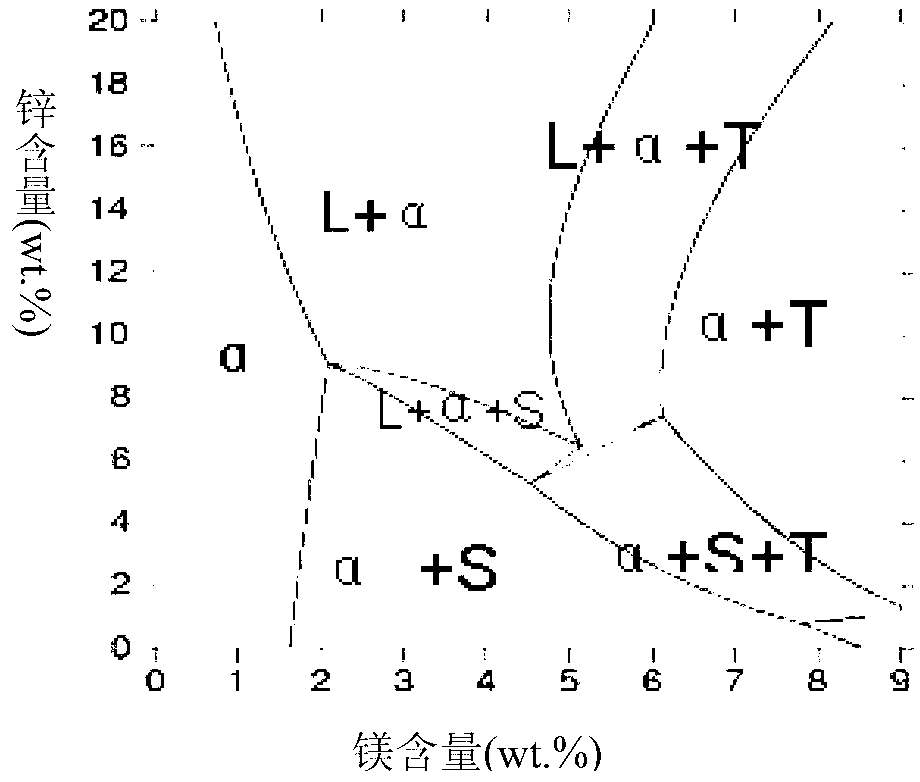

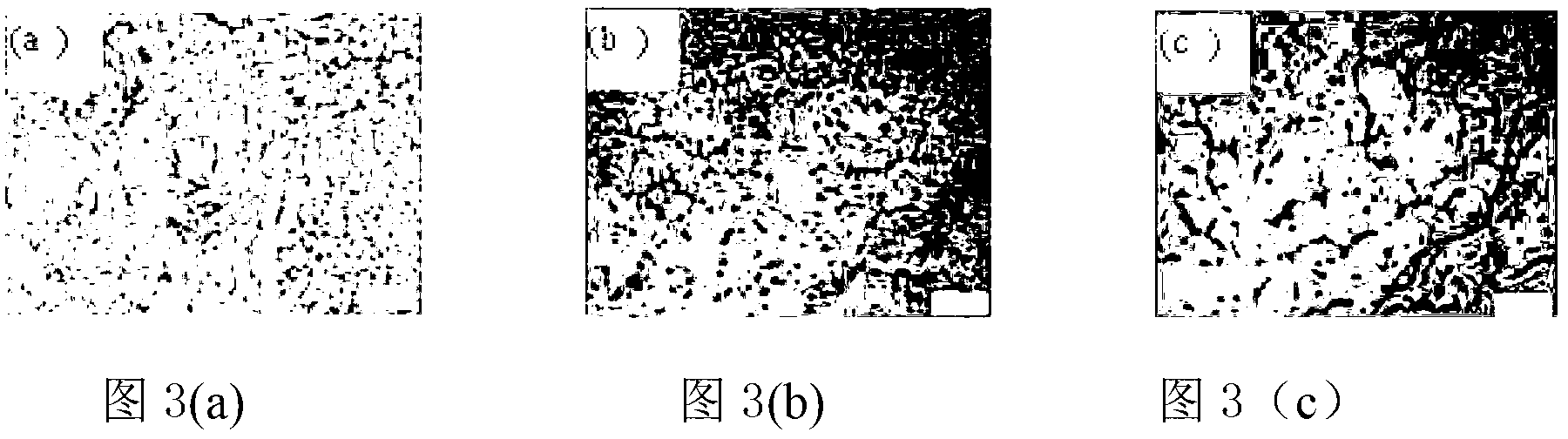

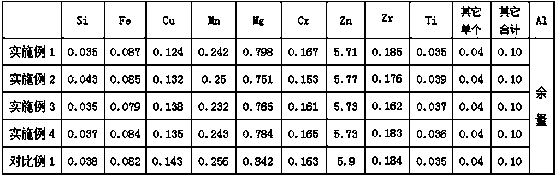

High-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and heat treatment method

The invention discloses a high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and a heat treatment method. The alloy comprises the following components by mass percentage: 6.5-8.3% of Zn, 2.3-3.0% of Mg, 0.8-1.2% of Cu, 0.1-0.2% of Zr, less than 0.15% of Fe, less than 0.1% of Si, and the balance of Al. A preparation method of the alloy comprises the steps of blending, smelting, semi-continuous casting, homogenizing, thermoplastic deformation, short time solid solution, and ageing heat treatment. For the high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy prepared with the method, the hardness (HV) is 185-209, the tensile strength sigma b is greater than or equal to 650Mpa, the percentage elongation delta is greater than or equal to 7%, the pitting resistance is high, the cast ingot yield is high, and the stress corrosion resistance is further improved while the mechanical property is kept after multiple regression reageing treatment. The alloy and the heat treatment method solve the problems that the cast ingot yield in the existing high-copper Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy is low, and the strength, toughness and corrosion resistance cannot be compromised. The heat treatment method is simple to operate, and the industrial production is facilitated.

Owner:CENT SOUTH UNIV

High strength low heat cracking aluminium copper serial alloy welding wire, its preparation method and application

InactiveCN1785580AHigh strengthImprove plasticityArc welding apparatusWelding/cutting media/materialsChemical compositionSlag

A welding Al-Cu alloy wire for MIG welding and AC TIG welding contains Cu (5.5-6.5 Wt%), Mn (0.2-0.6), Ti (0.15-0.30), Zr (0.15-0.35), V (0.05-0.20), Ag (0.2-0.5), Si (0-0.1), Fe (0-0.15) and Al (rest). Its preparing process includes such steps as smelting in graphite crucible, refining, removing slag, dehydrogenating, casting, soaking, removing scale, extruding, drawing and scraping. Its advantages are high strength, high plasticity and high cracking resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

7XXX aluminum alloy

The invention relates to 7XXX aluminum alloy. The 7XXX aluminum alloy comprises the following components by weight percent: 6.6 to 7.6 percent of zinc, 1.25 to 1.80 percent of magnesium, 0.18 to 0.44 percent of copper, less than or equal to 0.06 percent of silicon, less than or equal to 0.16 percent of iron, , less than or equal to 0.03 percent of manganese, less than or equal to 0.03 percent of chromium, less than or equal to 0.02 percent of germanium, less than or equal to 0.02 percent of vanadium, less than or equal to 0.03 percent of titanium, less than or equal to 0.02 percent of zirconium, and less than or equal to 0.03 percent of total weight of manganese and chromium, less than or equal to 0.03 percent of each rest impurity element, less than or equal to 0.10 percent of total weight of rest impurity elements, and the balance of aluminum. On the basis of experiment, the material strength is improved by re-designing the mass fraction and a ratio of Zn to Mg; by re-designing the mass fraction of Cu, the alloy has excellent corrosion resistance, and the oxidation different color problem of silver white can be solved. By strictly controlling the weight percent of the impurity elements such as Mn and Cr, the crystal grains of the alloy material are uniform. Compared with the existing disclosed Al-Zn alloy system, the alloy has better comprehensive performance, and an oxidized membrane formed by oxidizing the material by virtue of anode is more delicate and beautiful.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

Thermal treatment process for improving high-strength aluminum alloy anti-stress corrosion performance

The invention relates to a heat treatment process for improving the stress corrosion resistance of a high-strength aluminum alloy, which comprises the following treatments on a heat-treatable high-strength aluminum alloy sequentially: solution treatment, primary quenching treatment, pre-stretching treatment, high-temperature and short-time aging treatment, secondary quenching treatment, and low-temperature aging treatment. The alloy treated by the process can achieve adequate strength and good stress corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Anti-explosion material and manufacturing method thereof

The invention relates to an anti-explosion material, which is made of a cut and extended aluminum alloy foil mesh and has mesh-like or beehive-like porous structure, and is characterized in that: an aluminum alloy foil comprises the following chemical components in percentage by weight: 0.05 to 0.15 percent of silicon, 1.0 to 1.6 percent of copper, 0.2 to 0.5 percent of manganese, 1.0 to 3.0 percent of magnesium, 3.0 to 6.0 percent of zinc, 0.02 to 0.06 percent of titanium, 0.05 to 0.15 percent of zirconium, 0.1 to 0.3 percent of scandium and the balance of aluminum. Meanwhile, the invention also discloses a manufacturing method of the anti-explosion material. The material obtained by the method has the advantages of high electric and heat conductivities and large specific area and has the characteristics of corrosion resistance and high strength. When used as an anti-explosion material, the material is free from scraps and deformation. The material is particularly suitable for safe protection of containers for flammable and combustible liquid containers with high corrosivity as well as skid-mounted gasoline and gas filling station containers.

Owner:北京福吉长安防爆材料有限责任公司 +1

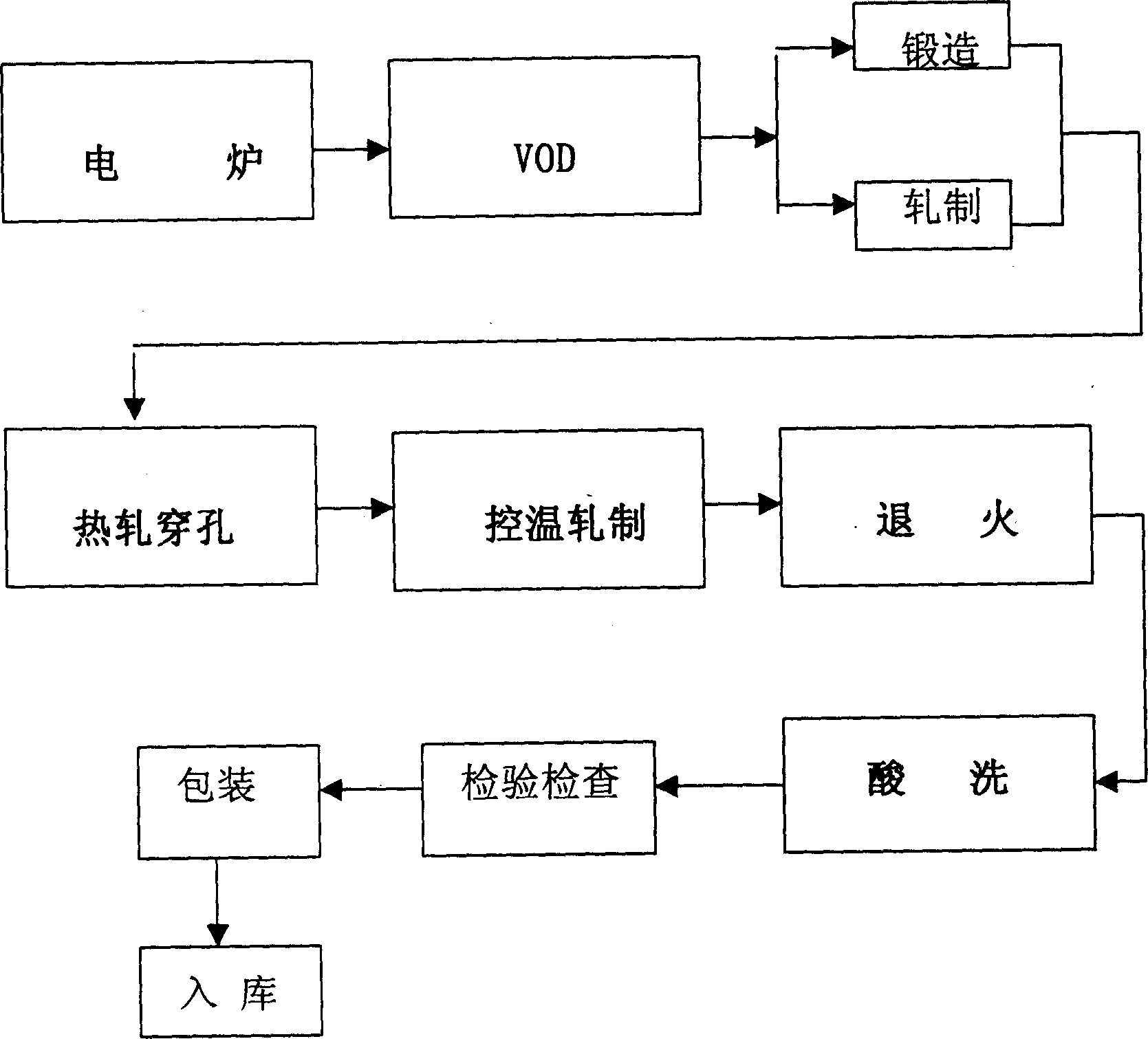

Production technology of high-strength 7-series aluminum alloy pipe

ActiveCN109355538AHigh strengthIncreased resistance to stress corrosion susceptibilityFurnace typesHeat treatment furnacesIngot castingMechanical property

The invention belongs to the technical field of heat treatment of aluminum alloy, and relates to a production technology of a high-strength 7-series aluminum alloy pipe. An aluminum alloy ingot casting is prepared from the following raw materials according to the mass percentage: 7.5-8.5% of Zn, 1.0-3.5% of Mg, 0.10-0.20% of Cu, 0.05-0.3% of Zr, 0.1-1.5% of Mn, 0.05-0.3% of Cr, 0 .05% of Ti, 0.05%of B, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of impurities in total and the balance Al. The two-stage homogenizing treatment and the two-stage aging heat treatment are adopted in the production technology of the aluminum alloy pipe, wherein according to the two-stage homogenizing system, the heat preservation is carried out for 24 hours at the temperature of 470 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 480 DEG C; and according to the two-stage aging system, the heat preservation is carried out for 7 hours at the temperature of 110 DEG C to 130 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 165 DEG C to 170 DEG C. The overall mechanical property of the high-strength 7-series aluminum alloy pipe is effectively improved.

Owner:CHINA ZHONGWANG

Machining method for 7-series aluminum alloy thick plates

The invention belongs to the technical field of aluminum alloy production, and relates to a machining method for 7-series aluminum alloy thick plates. Aluminum alloy ingots comprise the following components in percentage by mass: Si not more than 0.20%, Fe not more than 0.25%, 1.2-2.1% of Cu, 1.2-2.2% of Mg, 5.0-7.0% of Zn, 0.02-0.15% of Ti, 0.02-0.15% of Zr, Ti+Zr not more than 0.15%, single impurity not more than 0.05%, total impurity not more than 0.15%, and the balance of Al. The machining method for the aluminum alloy thick plates adopts a mode of multi-pass hot rolling, and adopts double-stage solid solution and double-stage aging to enable the finally prepared 7-series aluminum alloy thick plates to achieve excellent strength and rupture toughness.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

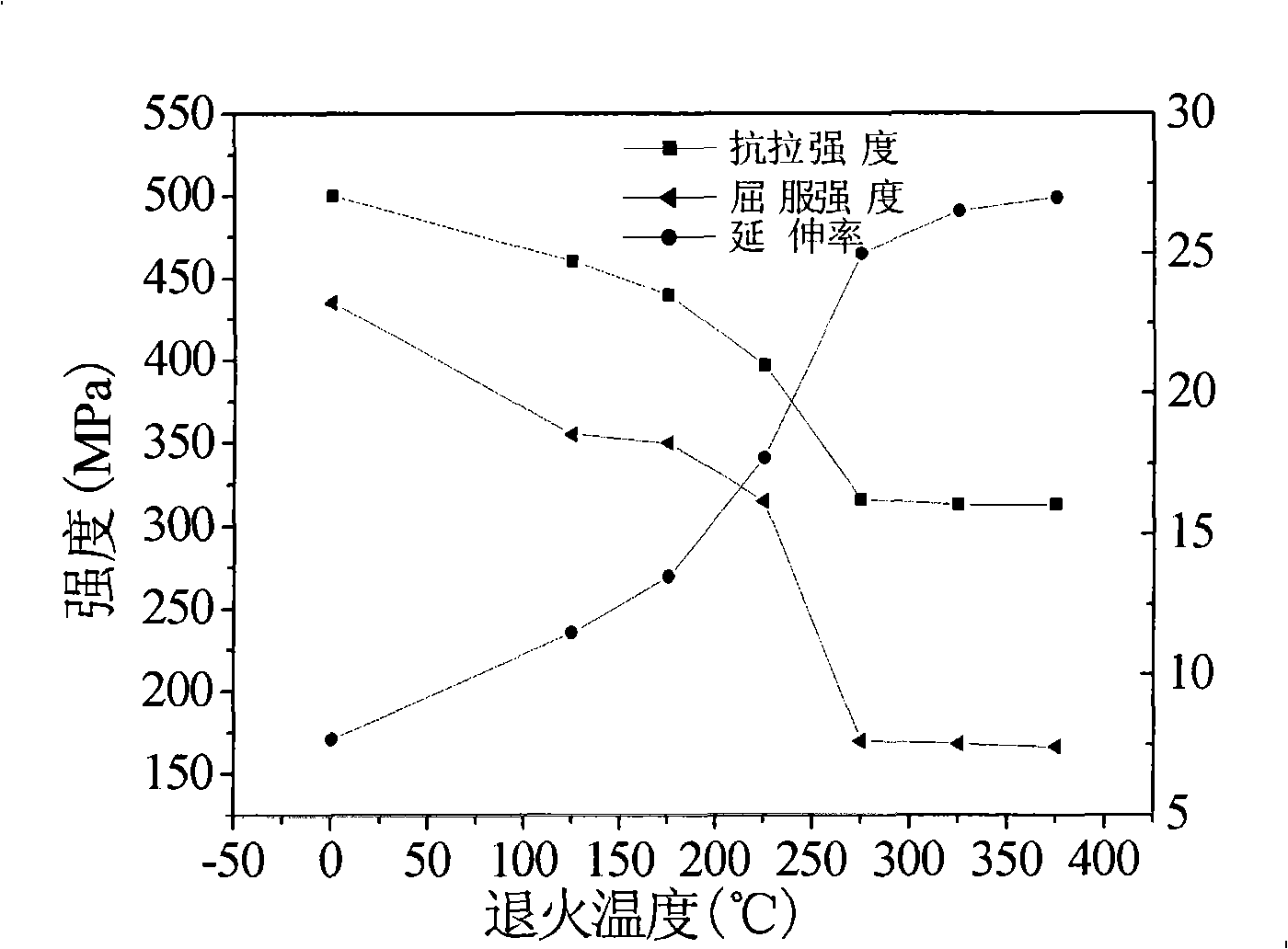

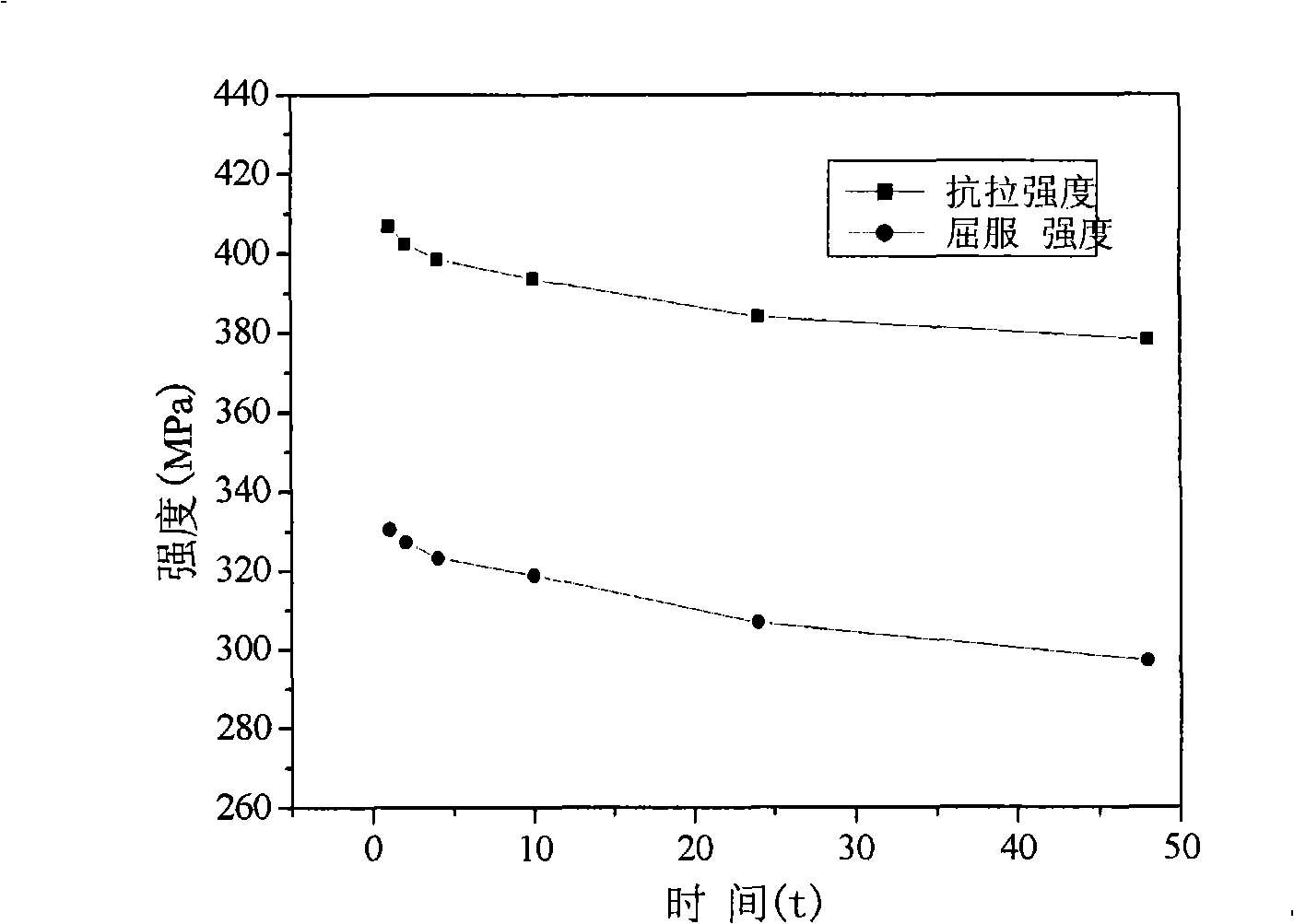

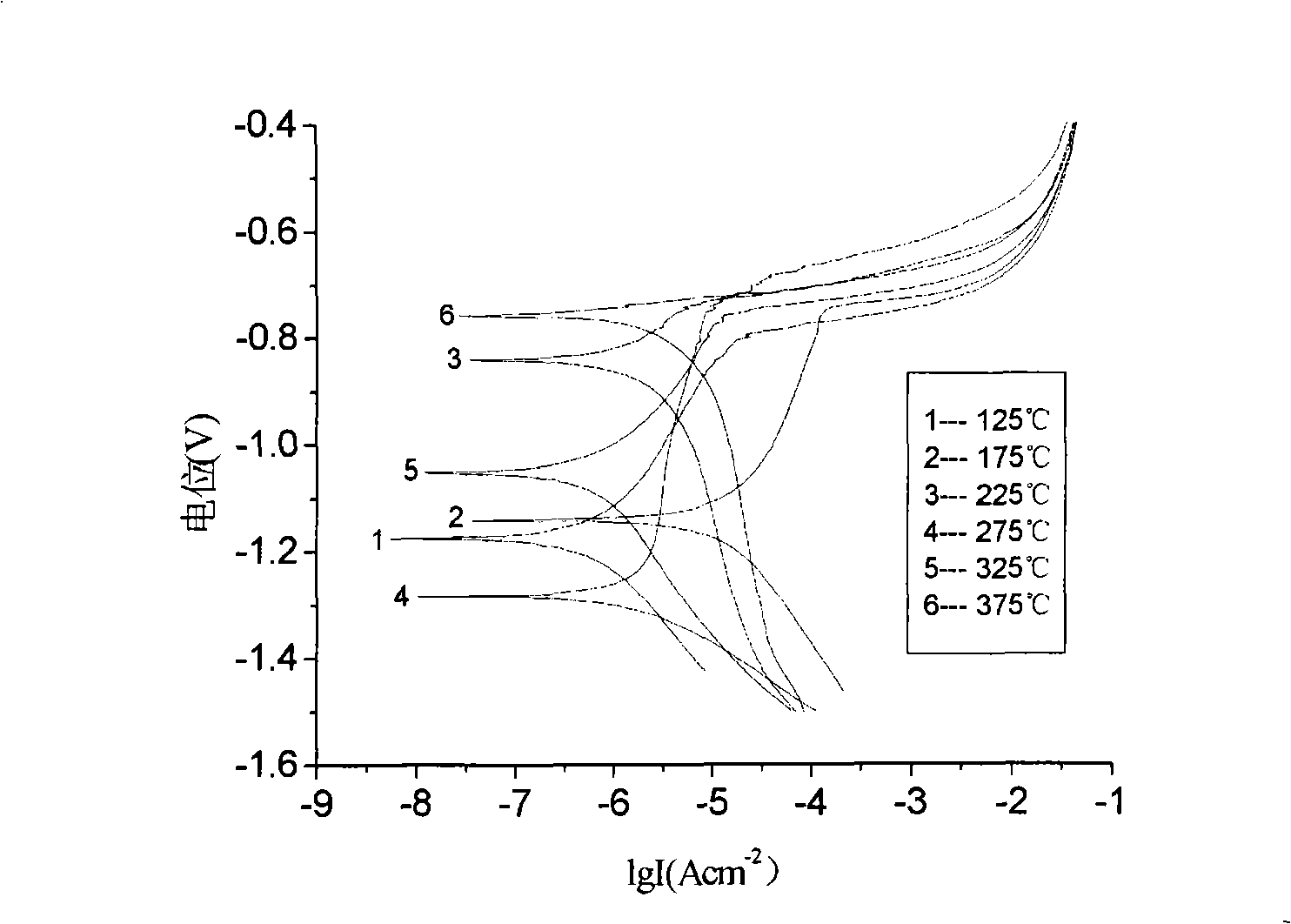

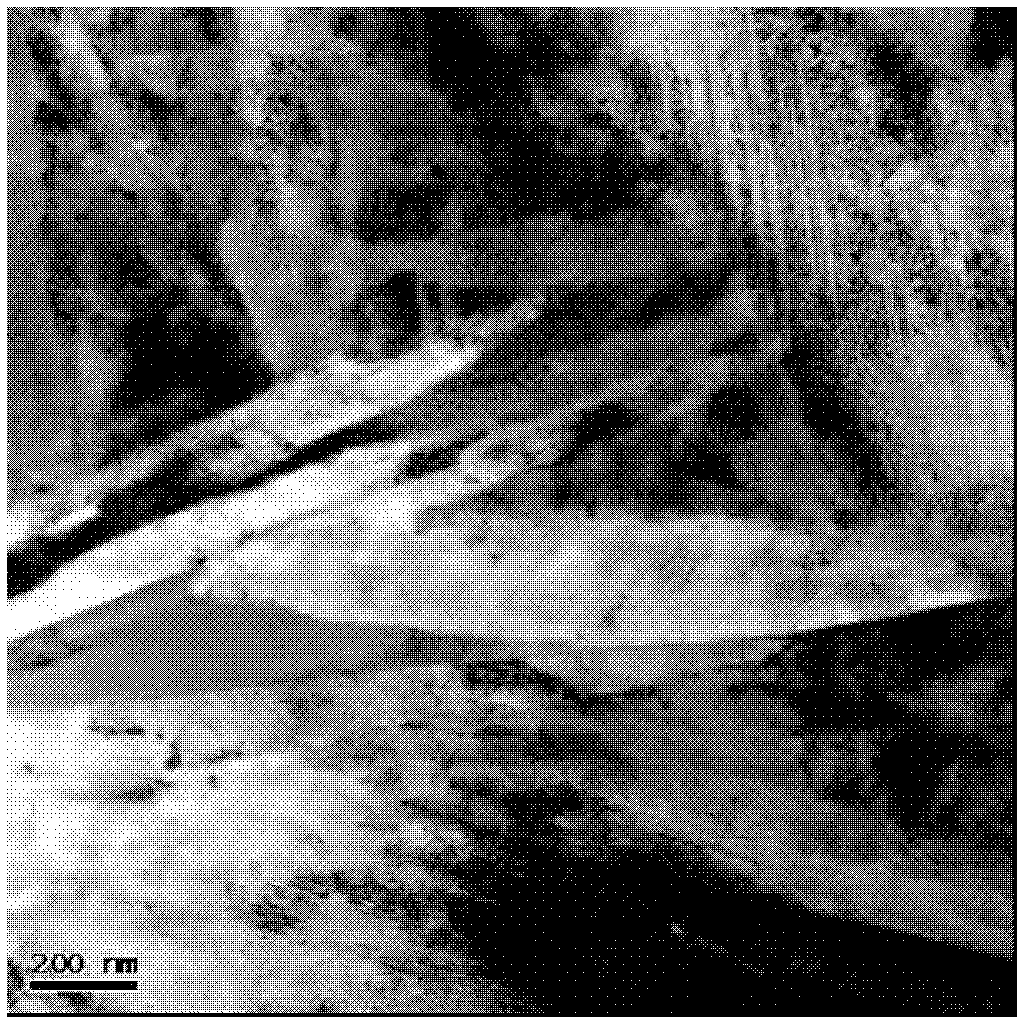

Thermal treatment process for erbium-containing aluminum-magnesium-manganese wrought aluminium alloy

The thermal treatment process for an aluminum-magnesium-manganese wrought aluminum alloy containing erbium belongs to the filed of metal alloys. The existing aluminum alloy thermal treatment process has the problems of strength reducing, corrosion resisting performance reducing after long term use, etc. The invention aims at providing the thermal treatment process for an aluminum-magnesium-manganese cold-rolled sheet containing erbium, which is realized by homogenizing annealing, hot rolling, cold rolling, stabilizing annealing and other process steps, wherein the stabilizing annealing process comprises the steps that, a cold-rolled sheet is annealed at the temperature of 100-400 DEG C and insulated for 1-48h; the annealing temperature and the insulating time are preferably 125-250 DEG C and 1-8h respectively. The thermal treatment process of the invention ensures the alloy to acquire excellent corrosion resisting performance under the condition that the high plasticity of the aluminum-magnesium-manganese cold-rolled sheet containing erbium is kept at a higher level; the treated alloy can be used for a long time with basically constant performance, and the service range of the alloy is wide.

Owner:BEIJING UNIV OF TECH

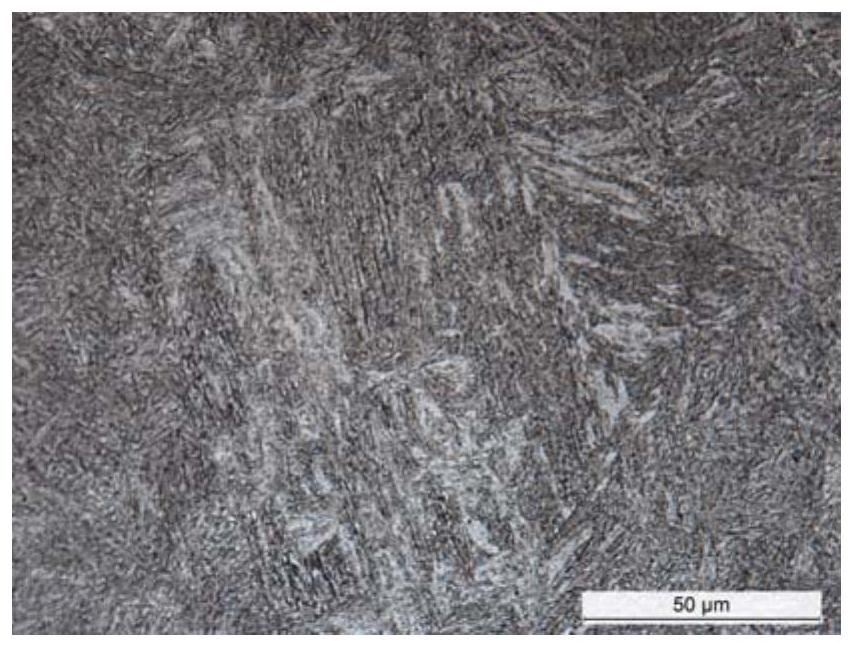

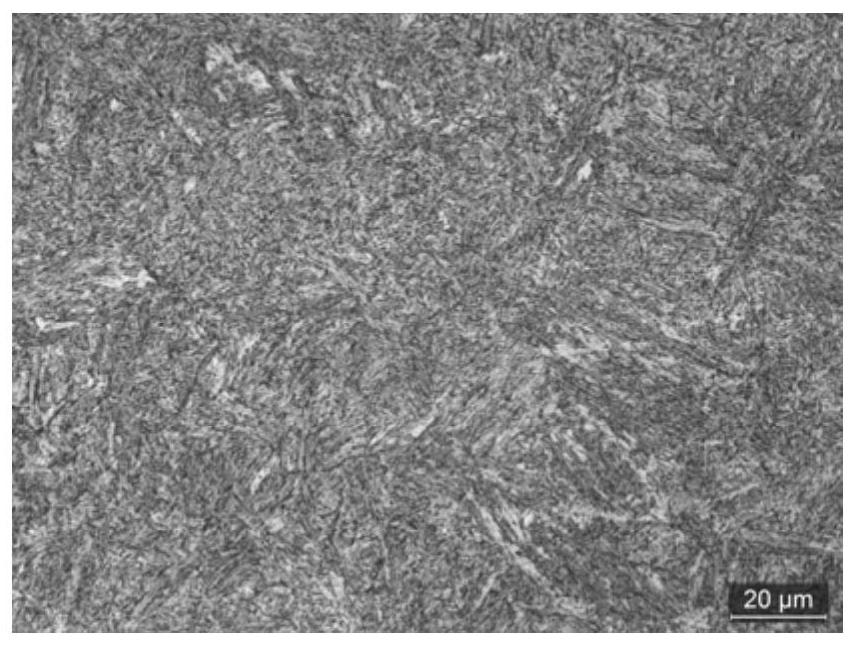

Quenching-partitioning thermal treatment method for high strength and toughness of medium carbon silicon-manganese low alloy steel

InactiveCN102534132AImprove plasticityCooperate wellHeat treatment process controlManganeseRoom temperature

The invention relates to a quenching-partitioning thermal treatment method for the high strength and toughness of medium carbon silicon-manganese low alloy steel and aims at solving the problems that the traditional medium carbon silicon-manganese low alloy steel has poor plasticity, toughness, and stress and corrosiveness resistance although having high strength. The quenching-partitioning thermal treatment method comprises the following steps of: carrying out austenization treatment on the medium carbon silicon-manganese low alloy steel, and then carrying out isothermal quenching in the martensite transition temperature range of the medium carbon silicon-manganese low alloy steel; and two. carrying out isothermal partitioning thermal treatment on the medium carbon silicon-manganese low alloy steel treated in the step one in a partitioning temperature from amartensite start (Ms) to 500 DEG C, and then quenching the medium carbon silicon-manganese low alloy steel to reach the room temperature, i.e. finishing the quenching-partitioning thermal treatment on the medium carbon silicon-manganese low alloy steel. After the medium carbon silicon-manganese low alloy steel is treated by the method, for the medium carbon silicon-manganese low alloy steel, the tensile strength reaches 1650MPa-2115MPa, the yield strength reaches 1490MPa-1950MPa, the coefficient of elongation is 5%-10%, and the reduction of area is 20%-50%.

Owner:HARBIN INST OF TECH

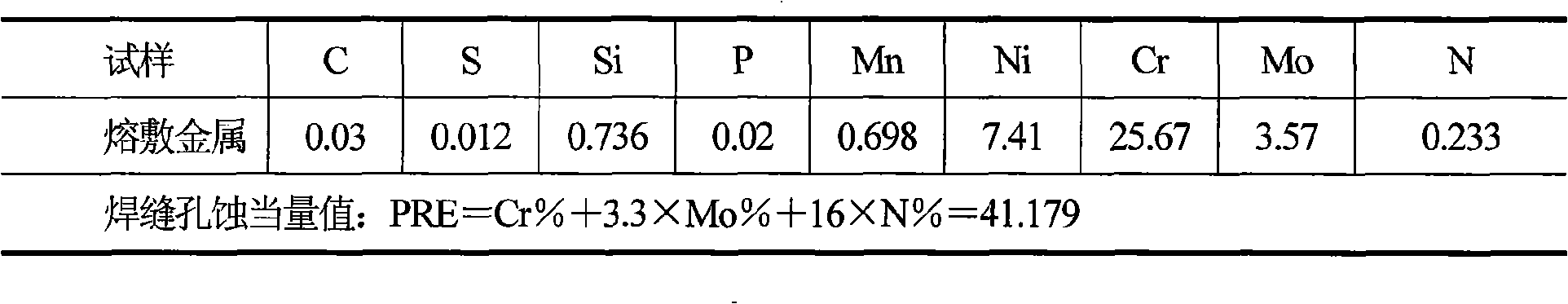

Low-hydrogen super diphasic stainless steel electrode

InactiveCN101367161AArc stabilizationWell formed weldWelding/cutting media/materialsSoldering mediaPotassium feldsparFerrosilicon

The invention discloses a low-hydrogen type super duplex stainless steel welding rod. The prior duplex stainless steel wire is adopted as a welding core. The coating of the welding rod comprises the compositions in percentage by weight: 35 to 45 percent of marble, 20 to 33 percent of fluorite, 0 to 5 percent of titanium pigment, 2 to 5 percent of potassium feldspar, 0 to 2 percent of sodium carbonate, 5 to 15 percent of iron alloy, 10 to 20 percent of metal powder, and 0 to 2 percent of CrN iron, wherein the iron alloy consists of ferrosilicon and ferromolybdenum under the condition of constant total content, and the metal powder consists of manganese metal, chromium metal, and nickel powder under the condition of the constant total content. After raw materials of the compositions of the coating are mixed evenly, pure sodium water glass with certain Baume concentration is added, and the pressing of the welding rod is performed on welding rod production equipment. The use of the welding rod can satisfy the welding need of super duplex stainless steel in the national engineering construction, the welded welding seam has excellent mechanical property and good corrosion resistance, the tensile strength can reach 800MPa, and the welding rod has good low-temperature toughness.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

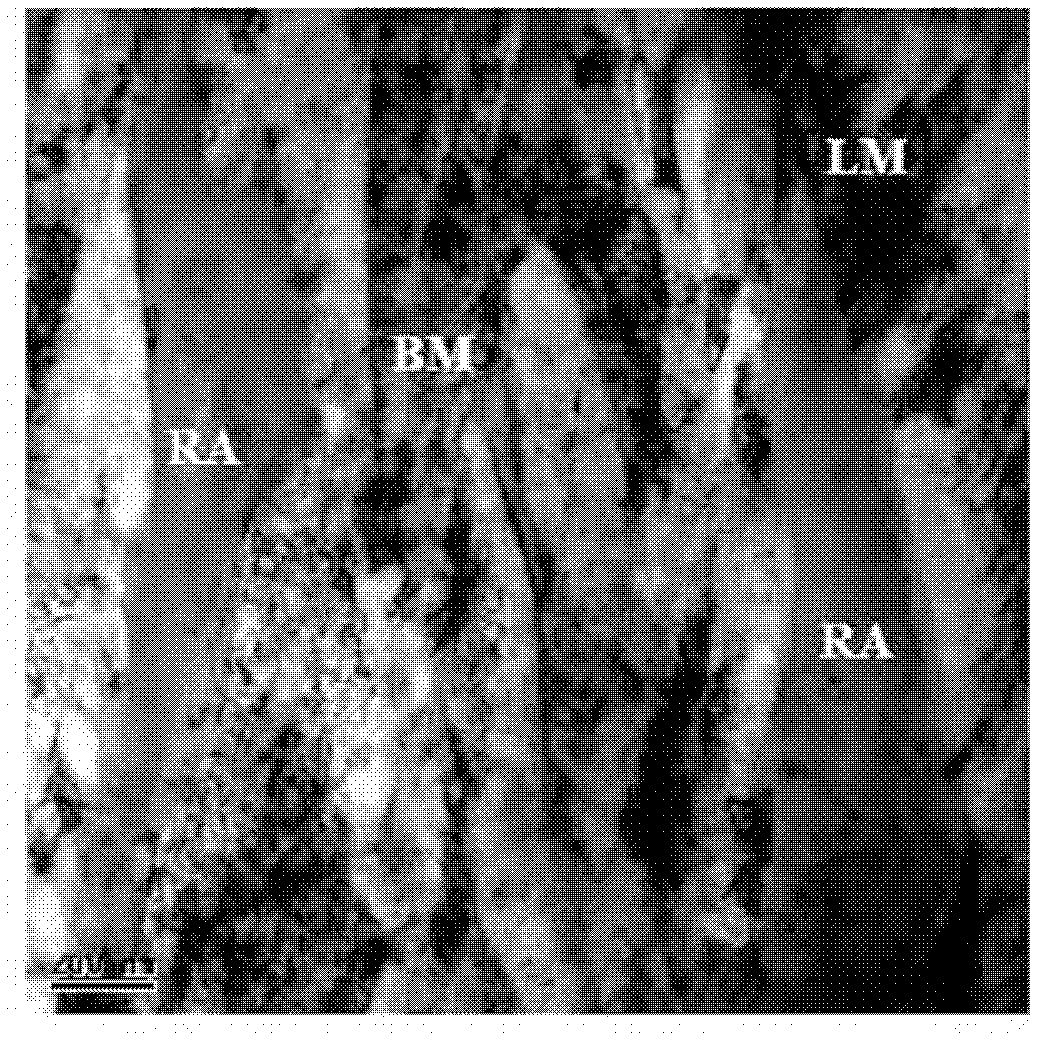

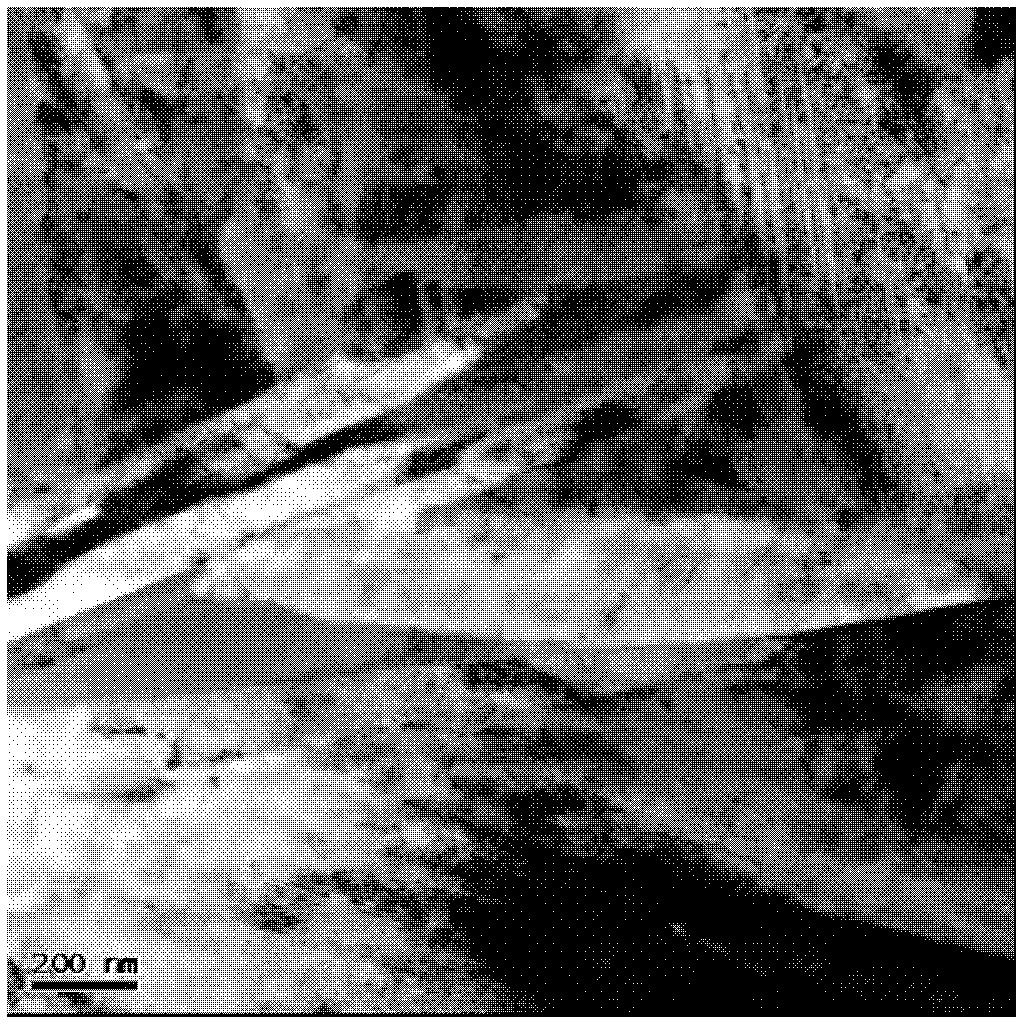

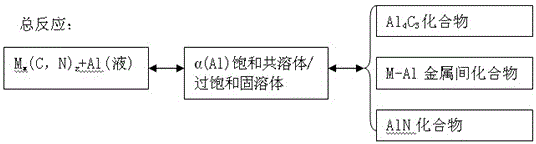

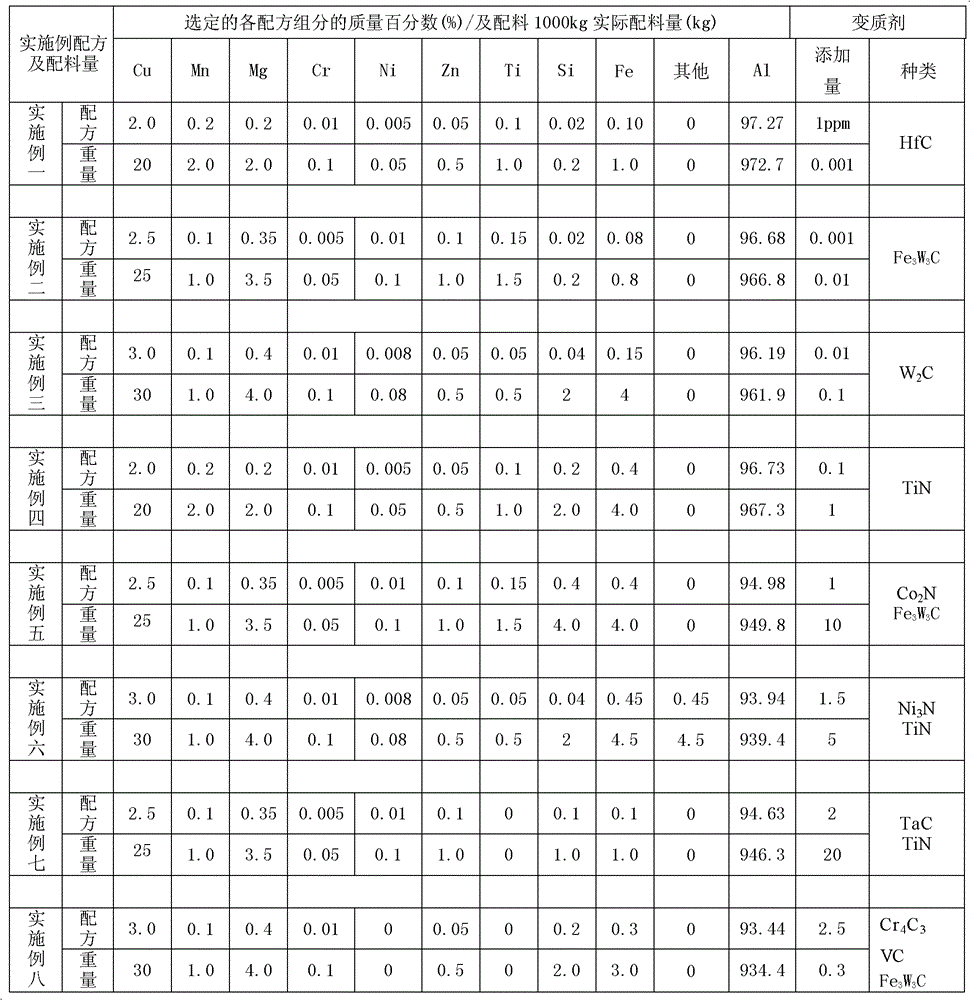

High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

The invention discloses a high-strength aluminum alloy subjected to carbonitride complex treatment and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.0-3.2 percent of Cu, less than or equal to 0.2 percent of Mn, 0.2-0.5 percent of Mg, less than or equal to 0.01 percent of Cr, less than or equal to 0.01 percent of Ni, less than or equal to 0.1 percent of Zn, less than or equal to 0.15 percent of Ti, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Fe, and the balance of Al and inevitable trace impurities, wherein the carbonitride MX(C,N)Y is 0.05-2.5 percent of total mass of the furnace burden. The aluminum alloy has the characteristics of high strength and good casting performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

High manganese easy cutting copper zinc alloy

The present invention relates to one kind of free machining high manganese Cu-Zn alloy, which consists of Cu 45- 70 wt%, Mn 7-30 wt%, Pb 0.2-4 wt%, X 0.0001-2 wt%, and Zn and inevitable impurity for the rest; where, X is at least one of elements Fe, As, P, B, Cr, Li, Ni, Sn, Al. The free machining high manganese Cu-Zn alloy has free machining performance similar to that of lead brass, lowered material cost and excellent plastic working performance, and may be used in producing plastic worked product and cast product.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy and preparation method thereof

The invention discloses Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy and a preparation method thereof. The alloy contains main alloying elements of Al-Zn-Mg or Al-Zn-Mg-Cu and microalloying elements of Zr, Ta, Fe and Si; moreover, a mass ratio of the microalloying elements satisfies the conditions that Ta is larger than or equal to 0.1Zr and less than or equal to 0.5Zr, Si is larger than or equal to 0.1Zr and less than or equal to 0.3Zr, and Fe / Si is larger than or equal to 0.7 and less than or equal to 1.5; according to the preparation method of the Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy, after an ingot metallurgy method is adopted for preparing the alloy, the alloy is subjected to homogenizing treatment, deformation treatment and solid solution waterquenching, and then artificial ageing is conducted. According to the Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy and the preparation method thereof, a multielement microalloying methodis adopted, cooperation of the multielement microalloying elements is strictly controlled to form a multielement coherent dispersed phase, recrystallization is completely inhibited, the microalloyingelements are used for improving the corrosion resistance effect of aluminium alloy passive film, high strength and good corrosion resistance performance are combined, and the problem that the strength and the corrosion resistance of existing Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy cannot be achieved at the same time is solved; the preparation method of the Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy is simple in technology, and the Ta-contained stress corrosion-resistant Al-Zn-Mg-(Cu) alloy is suitable for industrialized production.

Owner:CENT SOUTH UNIV

Heat treatment method capable of reducing stress of spray-formed 7000 series aluminum alloy products

The invention relates to 7000 series aluminum alloys, in particular to a heat treatment method capable of reducing stress of spray-formed 7000 series aluminum alloy products. The heat treatment method comprises a two-stage solid solution treatment step and an artificial ageing treatment step sequentially and is characterized in that after the artificial ageing treatment step and before rough machining or after the rough machining and before finish machining, high-temperature stress-relieving aging is performed, that is, heat preservation is performed at the temperature of 125-155 DEG C for 8-32 h. The heat treatment method can maintain the higher strength level of the spray-formed 7000 series aluminum alloy products, reduce residual stress efficiently and improve the comprehensive performance of the products, the problem of cracking of the products in follow-up machining process is solved, machining deformation of the products is reduced, the machining efficiency is improved, and the dimensional precision is improved.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

Duplex stainless steel and production process thereof

The invention discloses duplex stainless steel which comprises the following components by weight percent (wt%): not more than 0.03 wt% of C (carbon), 0.4-0.7 wt% of Si (silicon), 1.4-1.7 wt% of Mn (manganese), not more than 0.03 wt% of P (phosphorus), not more than 0.001 wt% of S (sulfur), 22.3-22.7 wt% of Cr (chromium), 5.6-5.9 wt% of Ni (nickel), 3.0-3.2 wt% of Mo (molybdenum), not more than 0.5 wt% of Cu (copper), not more than 0.15 wt% of Al (aluminum), 0.0028-0.0043 wt% of B (boron), 0.145-0.175 wt% of N (nitrogen), not more than 0.005 wt% of Ti (titanium), not more than 0.99 wt% of Pb (plumbum) and the balance of Fe (ferrum). The invention further provides a production process of the duplex stainless steel with strong corrosion resistance, and the duplex stainless steel has the advantages of higher strength, more excellent chloridion pitting corrosion resistance and stress corrosion resistance; simultaneously, the production process is conductive to better product quality.

Owner:何建

High-silicon high-aluminium ferrite stainless steel and its application in preparation of heat-resisting steel pipe

InactiveCN1542156AHigh temperature oxidation resistanceResistant to chloride ionsTemperature control modeSS - Stainless steel

The present invention relates to ferrite stainless steel and its application in rolling heat resistant steel pipe. The ferrite stainless steel contains: C not more than 0.06 wt%, Cu not more than 0.30 wt%, Si 0.5-2.0 wt%, S not more than 0.030 wt%, Mn not more than 0.6 wt%, P not more than 0.030 wt%, Cr 16.0-25.0 wt%, Ti not more than 0.3wt%, Al 0.5-2.0 wt%, Ni not more than 0.60 wt%, N not more than 0.030 wt%, except Fe. During making heat resistant steel pipe with the ferrite stainless steel, temperature control mode in 100-1050 deg.c is adopted.

Owner:王光煌

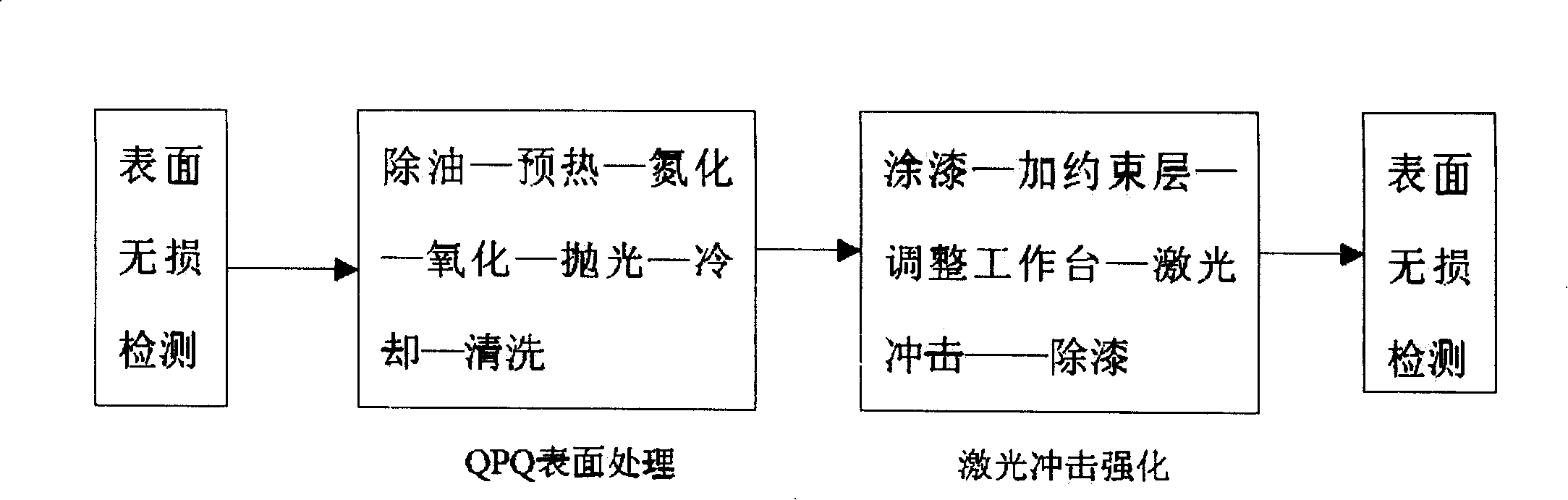

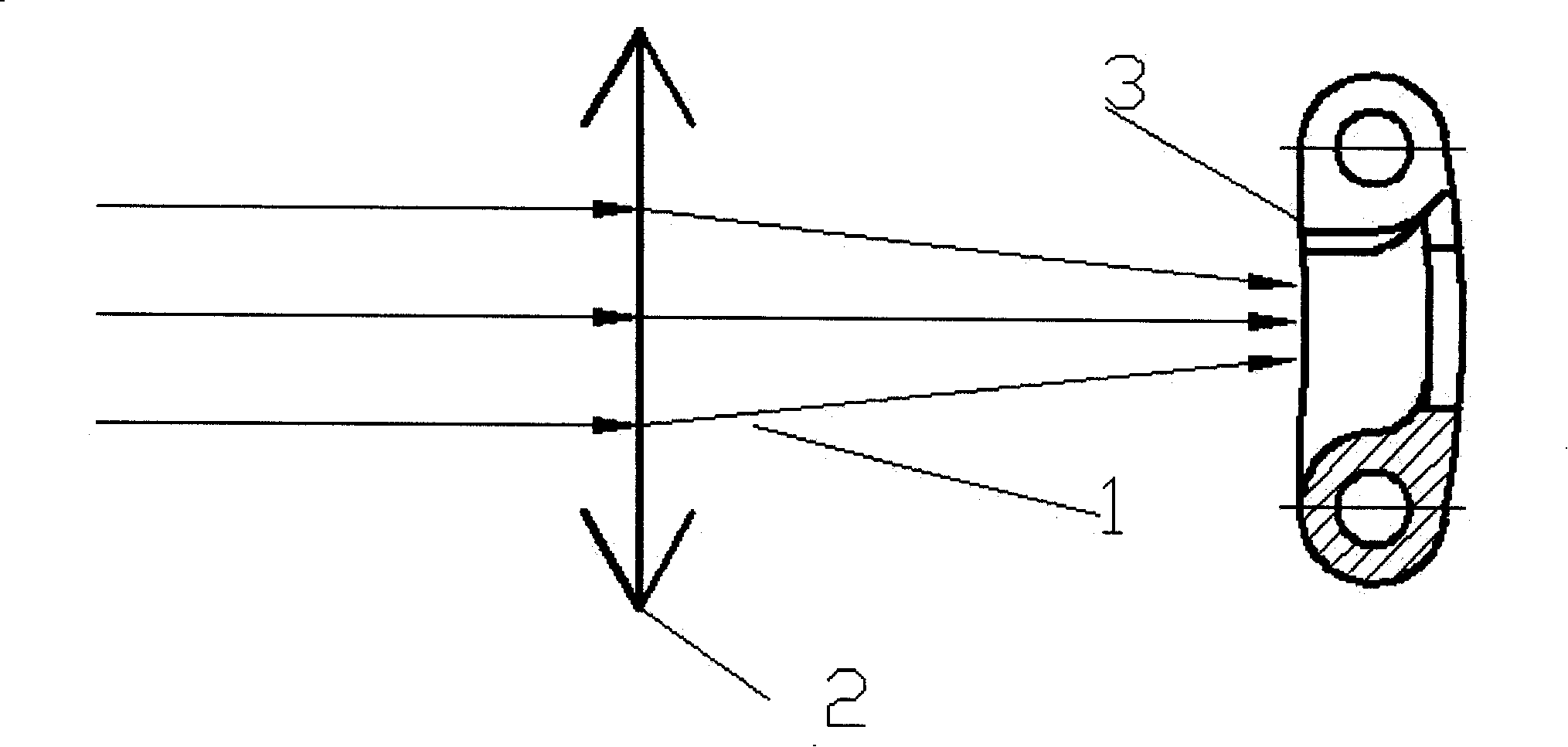

Composite treating method for prolonging life of grating machine key components

ActiveCN101225456APrecise positioningSave resourcesSolid state diffusion coatingHeat treatment process controlStress concentrationMolten salt

The invention relates to a complex processing method for prolonging the service lift of chain grate key parts, belonging to mechanical manufacturing and material processing and application technical field, which comprises: firstly, surface nondestructive testing is carried out on the key parts of the chain grate of process; molten salt complex processing are carried out in parts of the surface according to the surface drawbacks tested by surface nondestructive testing; before the laser shocks, the workpiece surface is coated with black coating layer and use water as protective layer, and the laser shock processes the area which is easy to fatigue and fracture and has concentrated stress. The molten iron pretreatment spray-feeding device before iron-making blast furnace has the advantages of simple shortcut, high efficiency, low maintenance cost, short processing time (30 minutes to 5 hours), and the continuous operation can be realized, thus, high efficiency of production is ensured.

Owner:江苏宏大特种钢机械厂有限公司

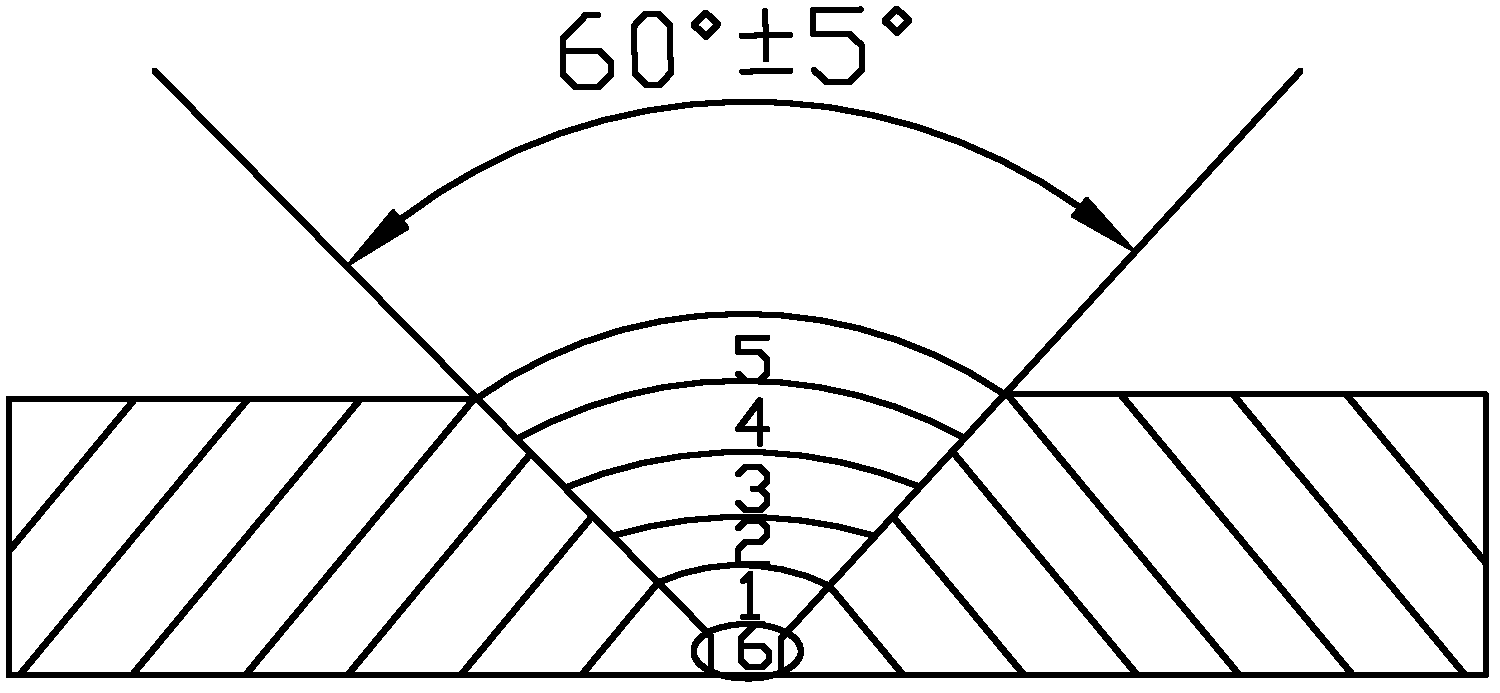

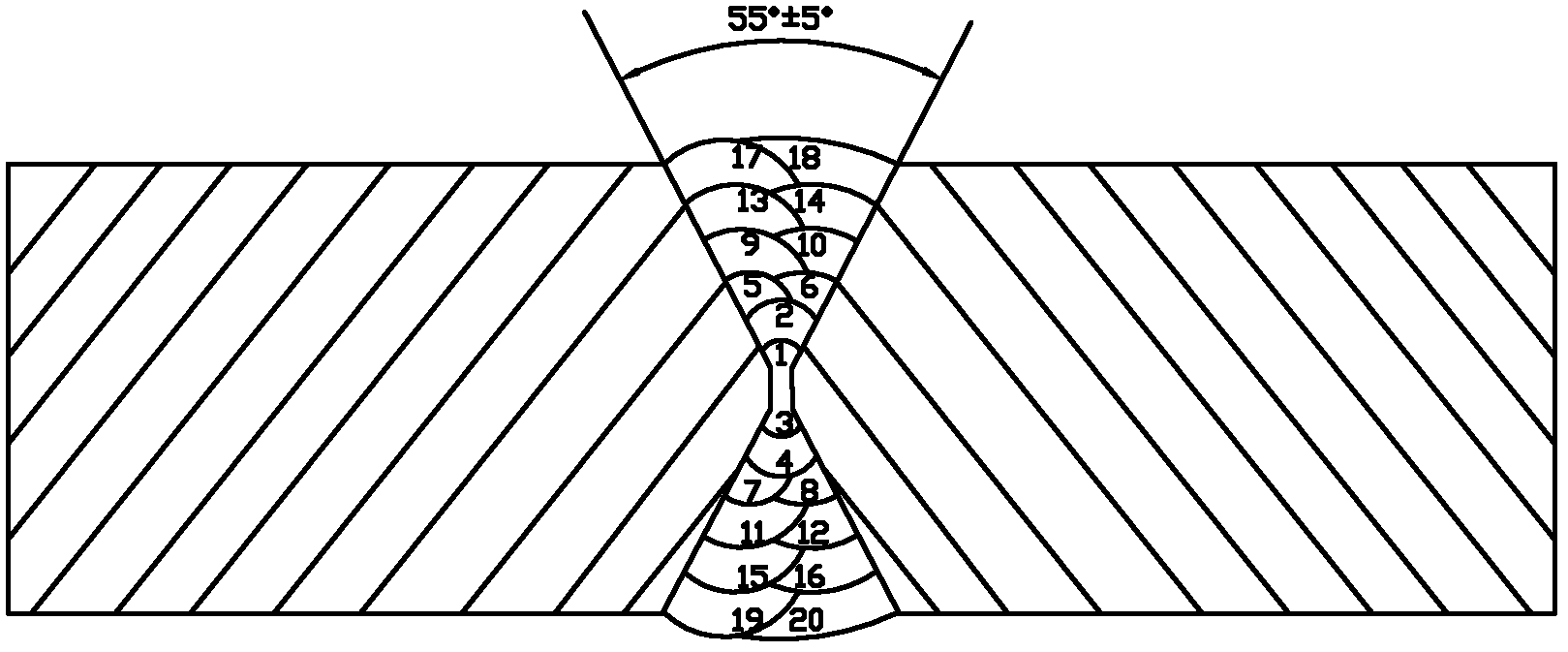

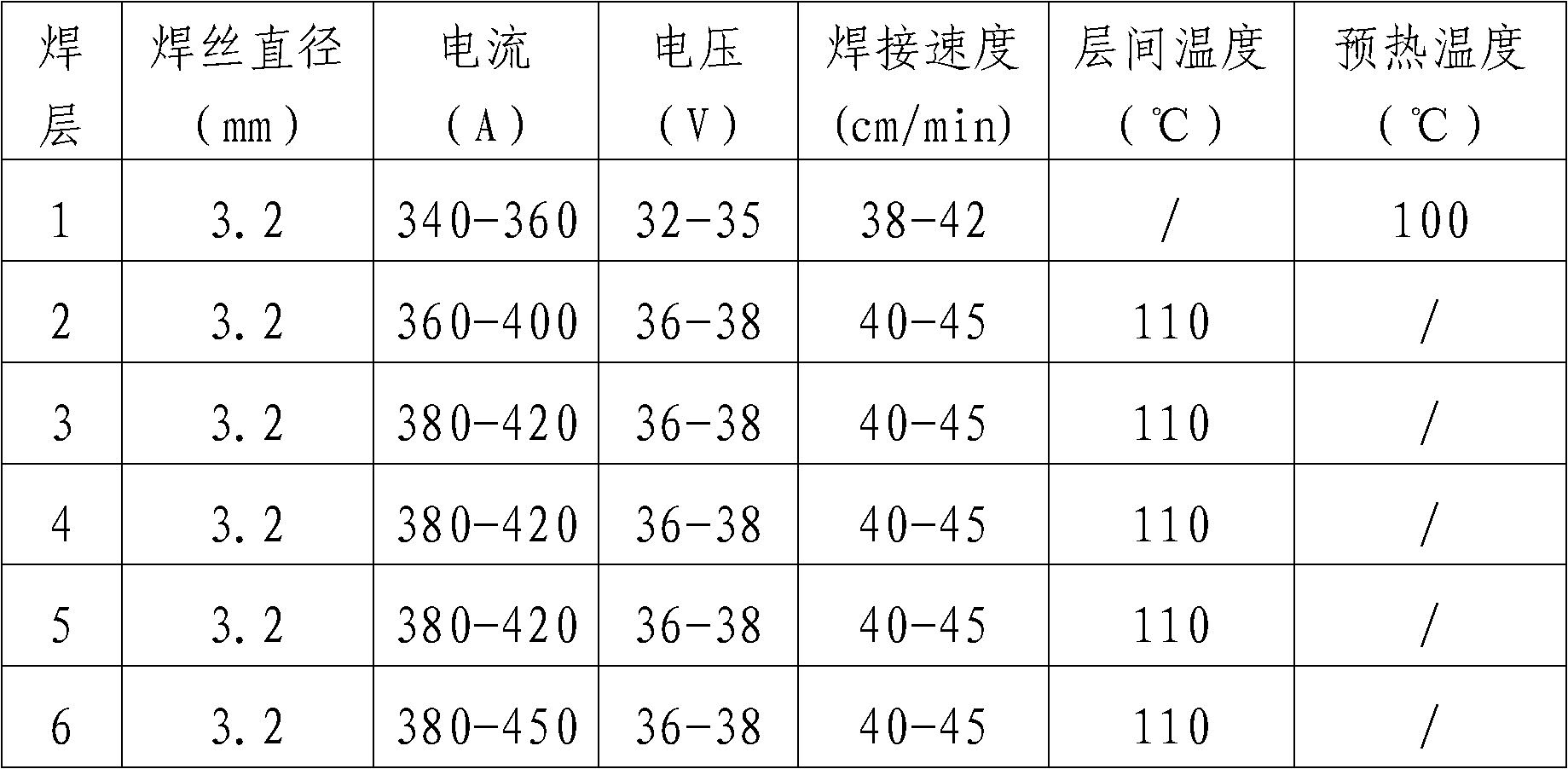

Domestic 08Ni3DR steel thin multi-pass welding process

ActiveCN102806405ARealize technological innovationAchieve upgradeArc welding apparatusFurnace typesCo2 absorptionDehydrogenation

The invention discloses a domestic 08Ni3DR steel thin multi-pass welding process, which is characterized by comprising the following steps of: machining a welding part into a single V-shaped or symmetrical double V-shaped groove, employing thin layer multi-pass welding, wherein on each layer, the weld pass thickness is less than 3mm, the diameter of a welding wire is 3.2mm, the welding current is 350 to 380A, the welding voltage is 34 to 38V and the welding speed is 36 to 45cm per minute, and controlling the interlayer and inter-pass temperature to be less than or equal to 150 DEG C; and performing dehydrogenation treatment and overall stress relief heat treatment after welding, and manufacturing a pressure container with the temperature level of 100 DEG C below zero such as main low temperature methanol wash equipment H2S and a CO2 absorption tower by employing the process, wherein the impact work kv2 of the welding joint of the equipment at the temperature of 101 DEG C below zero is more than or equal to 47J, and the mean value of the technical index and physical level is higher than American society of mechanical engineers (ASME) standard technical index.

Owner:WUHAN EAST PETROCHEM HEAVY EQUIP

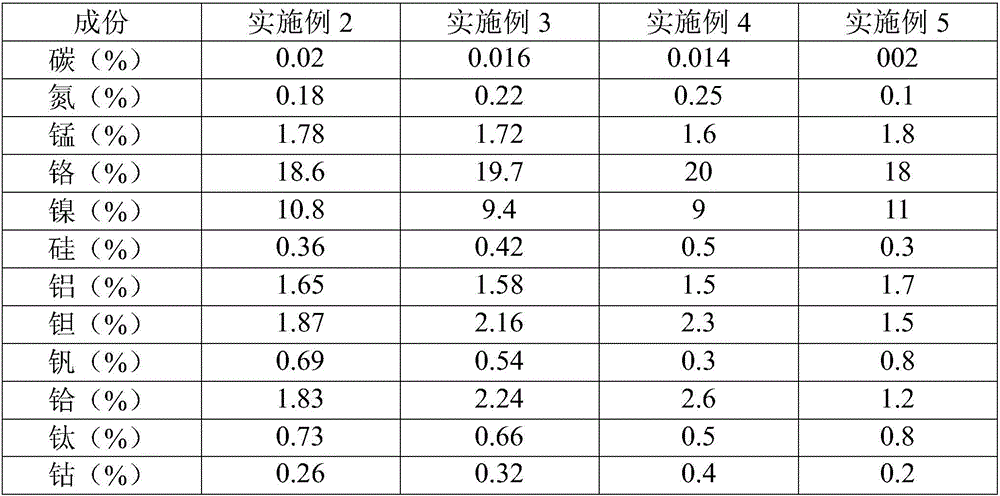

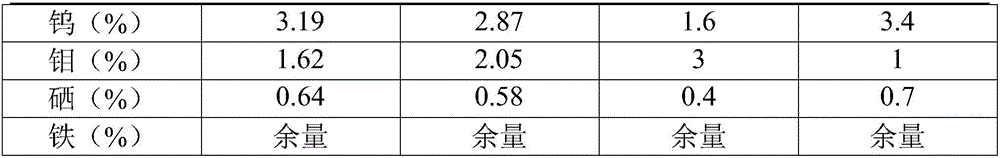

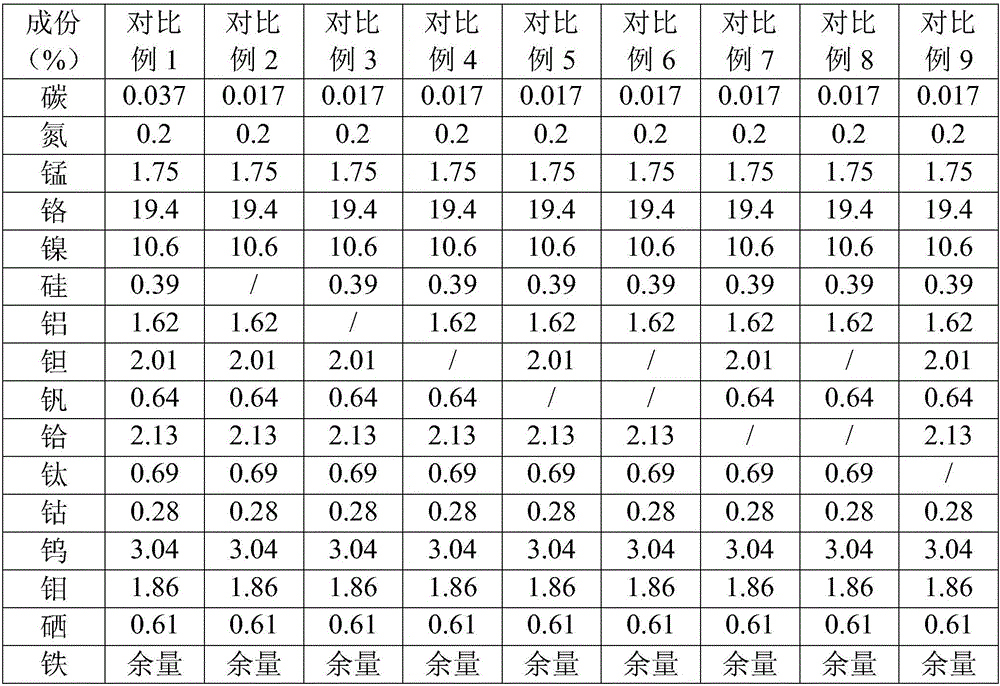

Corrosion-resistance seamless stainless steel pipe and preparation method thereof

InactiveCN106282845AMake up for the lack of strengthImprove corrosion resistanceFurnace typesHeat treatment furnacesManganeseHafnium

The invention discloses a corrosion-resistance seamless stainless steel pipe and a preparation method thereof. The corrosion-resistance seamless stainless steel pipe comprises the following chemical components in percentage by mass: carbon not more than 0.02%, 0.1-0.25% of nitrogen, 1.6-1.8% of manganese, 18-20% of chromium, 9-11% of nickel, 0.3-0.5% of silicon, 1.5-1.7% of aluminum, 1.5-2.3% of tantalum, 0.3-0.8% of vanadium, 1.2-2.6% of hafnium, 0.5-0.8% of titanium, 0.2-0.4% of cobalt, 1.6-3.4% of tungsten, 1-3% of molybdenum, 0.4-0.7% of selenium, and the balance of iron. Tantalum, hafnium and tungsten are added in austenitic stainless steel, and the chemical components can improve the performances of corrosion resistance, hardness, strength and high-temperature resistance of the austenitic stainless steel, so that the austenitic stainless steel is rich in high ductility and toughness.

Owner:ZHEJIANG HENGYUAN STEEL CO LTD

High-corrosion resistant high-strength dual-phase hot-rolled stainless steel strip and hot rolling process thereof

InactiveCN101748343AImprove flatnessIncrease volumeTemperature control deviceMetal rolling arrangementsSS - Stainless steelUltimate tensile strength

The invention discloses a high-corrosion resistant high-strength dual-phase hot-rolled stainless steel strip, which comprises the following components in percentage by weight: less than or equal to 0.03 percent of C; 0.4 to 0.7 percent of Si; 1.4 to 1.7 percent of Mn; less than or equal to 0.03 percent of P; less than or equal to 0.001 of S; 22.3 to 22.7 percent of Cr; 5.6 to 5.9 percent of Ni; 3.0 to 3.2 percent of Mo; less than or equal to 0.5 percent of Cu; less than or equal to 0.15 percent of Al; 0.0028 to 0.0043 percent of B; 0.145 to 0.175 percent of N; less than or equal to 0.005 percent of Ti; less than or equal to 0.99 percent of Pb; and the balance of Fe. The invention also provides a hot rolling process for the high-corrosion resistant high-strength dual-phase hot-rolled stainless steel strip. The stainless steel strip and the hot rolling process have the advantages that: the stainless steel strip has higher strength and more superior chloridion pitting resistance and stress corrosion resistance; and at the same time, the hot rolling process improves the planeness and the scrolling quality of the steel strip.

Owner:朱浩锋

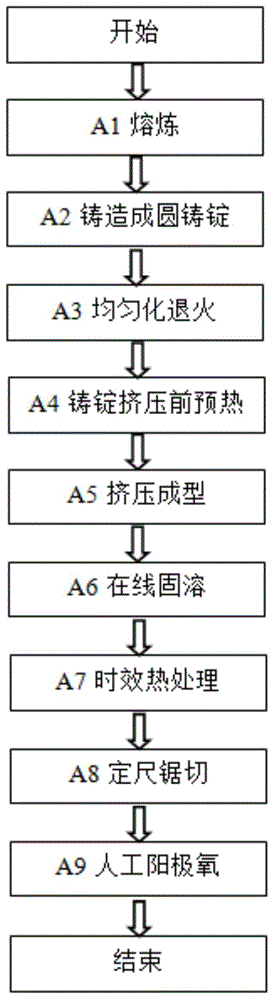

Al-Zn-Mg-Cu aluminum alloy profile with high stress corrosion resistance and preparation method thereof

ActiveCN110184513AImprove mechanical propertiesAccelerated corrosionStress relievingUltimate tensile strength

The invention aims to provide an Al-Zn-Mg-Cu aluminum alloy profile with high stress corrosion resistance and a preparation method thereof. The aluminum alloy material is prepared from, by mass, smaller than or equal to 0.1% of Si, smaller than or equal to 0.1% of Fe, 0.12%-0.14% of Cu, 0.23%-0.25% of Mn, 0.75%-0.8% of Mg, 0.15%-0.17% of Cr, 5.7%-5.8% of Zn, 0.16%-0.19% of Zr, 0.02%-0.04% of Ti, wherein the ratio of Fe to Si ranges from 1.8 to 2.5, and the ratio of Zn to Mg is controlled to range from 7.1 to 7.7. The preparation method comprises the steps of smelting, refining, essence melting, casting, homogenization annealing, extruding, solid solution quenching, stress relieving and aging treatment. According to the Al-Zn-Mg-Cu aluminum alloy profile with the high stress corrosion resistance and the preparation method thereof, the material shows good mechanical strength and stress corrosion resistance, and the material is especially suitable for aluminum alloy structural members which are prone to stress corrosion and failure, in particular to aluminum alloy structural members subjected to tensile stress at the bottom of a rail transit or a vehicle body.

Owner:广西南南铝加工有限公司

High-toughness mining chain steel and manufacturing method thereof

ActiveCN113322409AEasy to rollReasonable ingredientsFurnace typesForging press detailsTemperingWeather resistance

The invention discloses high-toughness mining chain steel and a manufacturing method thereof. The high-toughness mining chain steel comprises the following components in percentage by weight: 0.20-0.28% of C, 0.01-0.40% of Si, 0.50-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.30-2.00% of Cr, 0.50-2.00% of Ni, 0.10-0.80% of Mo, 0.01-0.30% of Cu, 0.01-0.05% of Al, 0.001-0.10% of Nb, 0.001-0.10% of V, less than or equal to 0.00018% of H, less than or equal to 0.0150% of N, less than or equal to 0.0020% of O and the balance of Fe and inevitable impurities. The manufacturing process comprises the working procedures of smelting, refining, vacuum treatment, casting, heating, forging or rolling, quenching and tempering heat treatment and the like. The chain steel has high strength and good impact toughness, ductility and percentage reduction of area, can resist stress corrosion cracking, has good weather resistance, wear resistance and fatigue resistance, and can be used for engineering machinery, ocean engineering and other occasions needing high-strength and high-toughness steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Duplex stainless steel with high corrosion resistance and production technology thereof

InactiveCN102102166AHigh strengthExcellent resistance to chloride ion pittingTemperature control deviceChlorideUltimate tensile strength

The invention discloses duplex stainless steel with high corrosion resistance. The duplex stainless steel comprises the following components by weight percent: 0.03% or less of C, 0.4-0.7% of Si, 1.4-1.7% of Mn, 0.03% or less of P, 0.001% or less of S, 22.3-22.7% of Cr, 5.6-5.9% of Ni, 3.0-3.2% of Mo, 0.5% or less of Cu, 0.15% or less of Al, 0.0028-0.0043% of B, 0.145-0.175% of N, 0.005% or less of Ti, 0.99% or less of Pb and the balance Fe. The invention also provides a production technology of the duplex stainless steel with high corrosion resistance. The invention has the following advantages: the stainless steel has higher strength and better chloride ion pitting resistance and stress corrosion resistance; and by adopting the production technology, higher product quality can be obtained.

Owner:李锦峰

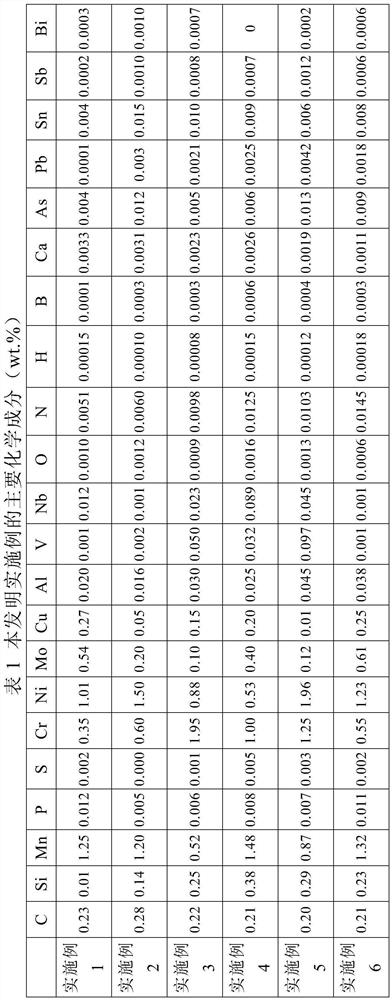

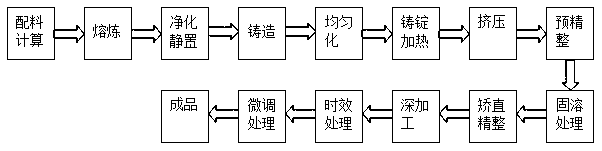

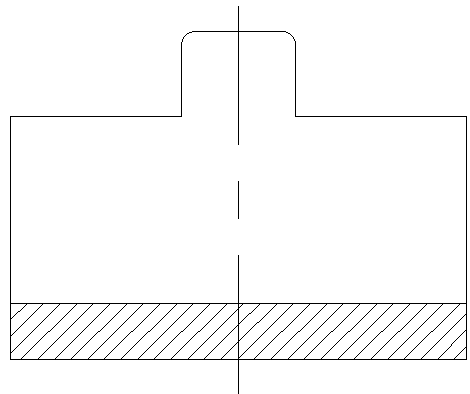

Aluminum alloy variable section extruded profile for spaceflight and preparation method of aluminum alloy variable section extruded profile

The invention discloses an aluminum alloy variable section extruded profile for spaceflight and a preparation method of the aluminum alloy variable section extruded profile. The profile consists of the following elements of, in percentage by weight, 5.0%-6.0% of Zn, 1.0%-2.0% of Cu, 0.04%-0.1% of Mn, 2.0%-3.0% of Mg, 0.15%-0.25% of Cr, 0.35%-0.42% of Fe, less than or equal to 0.25% of Si, and thebalance Al. During preparation, a finished product is obtained after being subjected to smelting, purifying, standing, casting, homogenizing treatment, ingot heating, extrusion, pre-finishing, solution treatment, straightening finishing, deep machining, aging treatment and fine adjustment treatment. According to the method, by setting specific alloy composition and the preparation process, the aluminum alloy variable section extruded profile formed by once is obtained, the strength, fatigue resistance, corrosion resistance and stress corrosion resistance of the aluminum alloy profile are greatly improved, comprehensive performance requirements of a carrier rocket launcher on the variable section aluminum alloy profile can be met, the bottleneck of extrusion forming of the variable sectionprofile at present is broken, various indexes of the aluminum alloy profile are ensured to meet standards and use requirements, and material guarantee is provided for research of new carrier rockets in China.

Owner:西北铝业有限责任公司

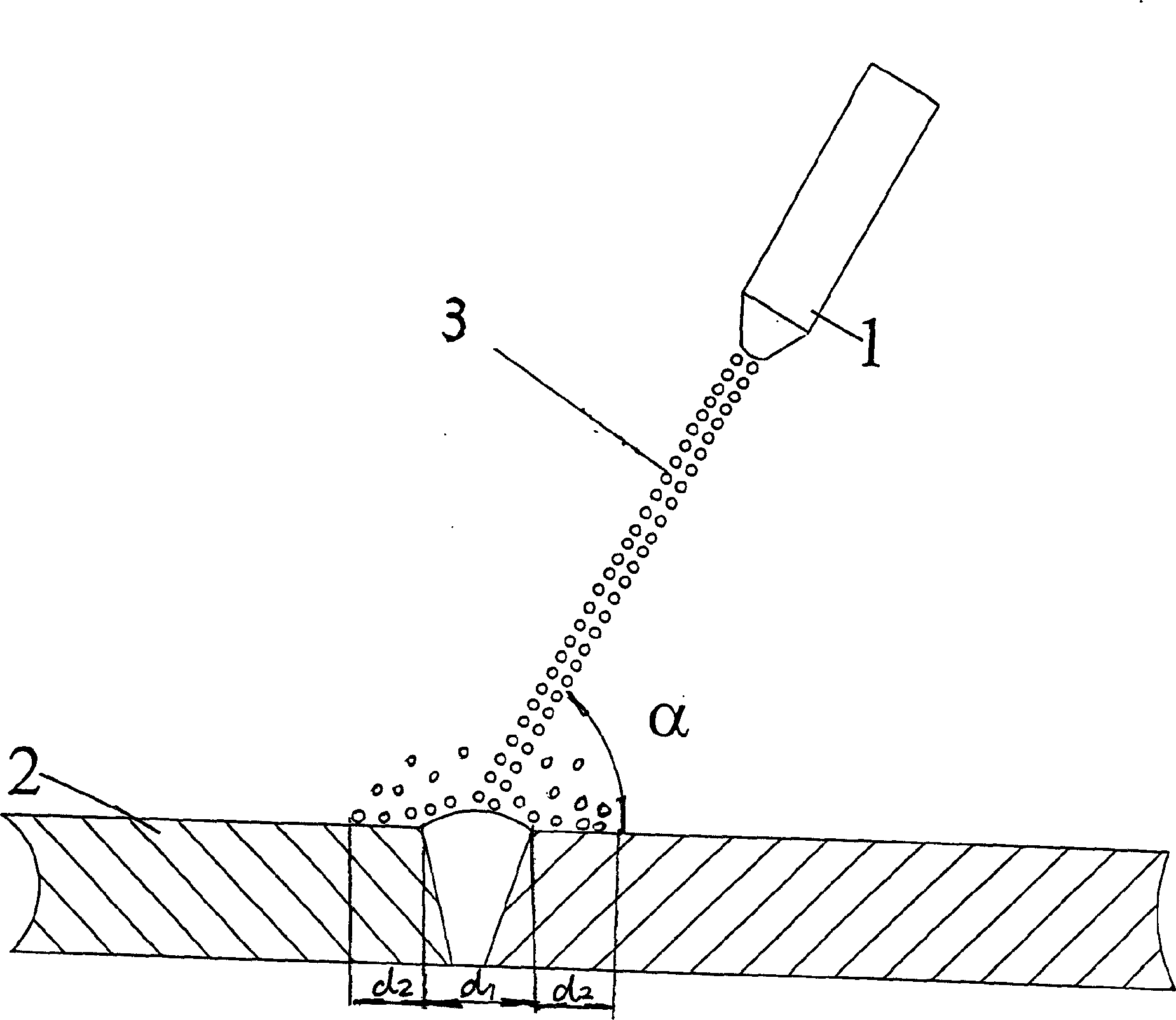

Glass cloudburst treatment art for improving anti-stress corrosion performance of welding joint of stainless steel

ActiveCN1757484AImprove stress corrosion resistanceStress Corrosion Resistant StrengtheningAnti stressCloudburst

A glass grit blasting technology for increasing the stress corrosion resistance of the welded seam between stainless steels includes such steps as cleaning the surface of the welded seam, blasting the glass grits onto the welded seam by a blasting gun driven by compressed air and with an inclination by 70-100 deg.C, cleaning the surface of welded workpiece, and detecting the residual stress by X-ray diffractometer.

Owner:NANJING UNIV OF TECH

Forging and heat treating technology of 7085 aluminum alloy

The invention relates to a forging and heat treating technology of 7085 aluminum alloy. The forging and heat treating technology comprises the following operation steps of blank material purchasing, blank material cutting and discharging, forging and heating, blank making, inner bore machining, heating, mandrel supporter bore broadening, remelting and heating, ring rolling, cooling, solid solution, cold deformation, aging and machining to the required size. According to the forging and heat treating technology, operation is convenient, transgranular precipitates and grain boundary precipitates are regulated and controlled through a multi-step aging technique under the condition of ensuring the strength, and the stress resistance and the corrosion resistance are promoted.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com