Thermal treatment process for improving high-strength aluminum alloy anti-stress corrosion performance

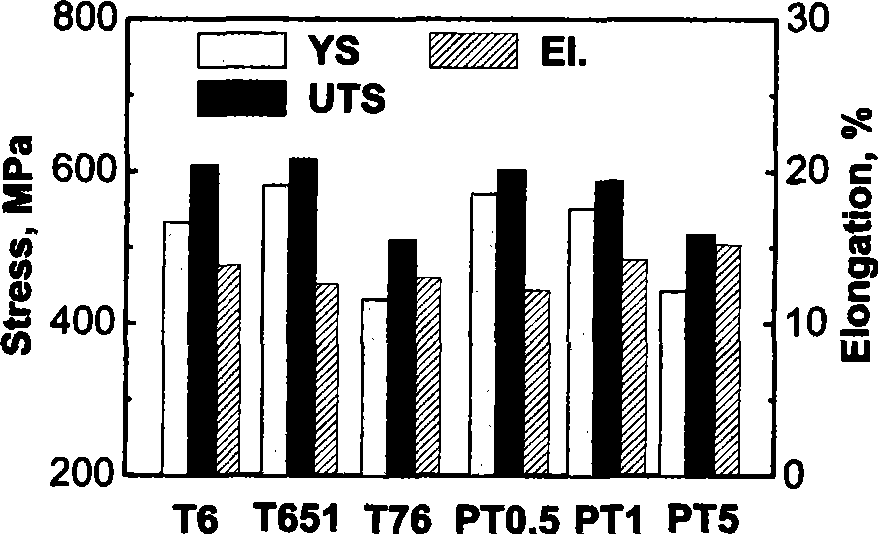

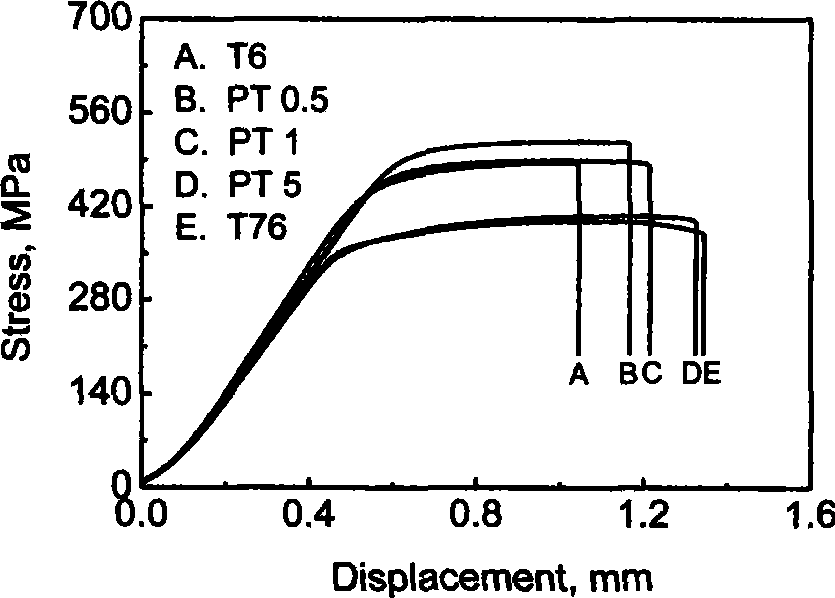

A corrosion performance, aluminum alloy technology, applied in the field of heat treatment technology, can solve the problems of high strength and poor stress corrosion resistance of aluminum alloys, and achieve good stress corrosion resistance, high strength, and improved stress corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Taking the hot-rolled 6mm thick 7050 plate as an example, the chemical composition (mass fraction, %) is Zn 6.18, Mg2.20, Cu 2.21, Zr 0.13, Si 0.11, Fe 0.10, and the balance of Al.

[0032] 1. Solution treatment: 7050 alloy is subjected to solution treatment, and the process parameters of solution treatment are 450°C, 120min.

[0033] 2. One-time quenching: Perform one-time quenching treatment on the alloy after solid solution treatment, that is, quench it with room temperature water to room temperature.

[0034] 3. Pre-stretching: After quenching, the alloy is pre-stretched and deformed by 3% in 2 hours, and dislocations are introduced into the alloy.

[0035] 4. Short-time aging at high temperature: aging the pre-stretched alloy at 200°C for 0.5min.

[0036] 5. Secondary quenching treatment: the alloy after high-temperature short-time aging treatment is quenched to room temperature with water at room temperature.

[0037] 6. Low-temperature aging: aging the alloy af...

Embodiment 2

[0039] Taking the hot-rolled 6mm thick 7050 plate as an example, the chemical composition (mass fraction, %) is Zn 6.18, Mg2.20, Cu 2.21, Zr 0.13, Si 0.11, Fe 0.10, and the balance of Al.

[0040] 1. Solution treatment: 7050 alloy is subjected to solution treatment, and the process parameters of solution treatment are 460°C, 90min.

[0041] 2. One-time quenching: Perform one-time quenching treatment on the alloy after solid solution treatment, that is, quench it with room temperature water to room temperature.

[0042] 3. Pre-stretching: After quenching, the alloy is pre-stretched and deformed by 5% in 3 hours, and dislocations are introduced into the alloy.

[0043] 4. Short-time aging at high temperature: aging the pre-stretched alloy at 220°C for 2.5 minutes.

[0044] 5. Secondary quenching treatment: the alloy after high-temperature short-time aging treatment is quenched to room temperature with water at room temperature, and then cooled.

[0045] 6. Low-temperature agin...

Embodiment 3

[0047] Taking the hot-rolled 6mm thick 7050 plate as an example, the chemical composition (mass fraction, %) is Zn 6.18, Mg2.20, Cu 2.21, Zr 0.13, Si 0.11, Fe 0.10, and the balance of Al.

[0048] 1. Solution treatment: 7050 alloy is subjected to solution treatment, and the process parameters of solution treatment are 470°C, 30min.

[0049] 2. One-time quenching: Perform one-time quenching treatment on the alloy after solid solution treatment, that is, quench it with room temperature water to room temperature.

[0050] 3. Pre-stretching: After quenching, the alloy is pre-stretched and deformed by 10% at 2 hours to introduce dislocations into the alloy.

[0051] 4. Short-term aging at high temperature: aging the pre-stretched alloy at 230°C for 5 minutes.

[0052] 5. Secondary quenching treatment: the alloy after high-temperature short-time aging treatment is quenched to room temperature with water at room temperature.

[0053] 6. Low-temperature aging: the alloy after the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com