Patents

Literature

164results about How to "Optimize heat treatment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy material and heat treatment technique thereof

ActiveCN103131904AOptimize heat treatment processIntense organic combinationUltimate tensile strengthToughness

The invention discloses an aluminum alloy material and a heat treatment technique thereof. The aluminum alloy material comprises the following components in percentage by mass: 0.8-1.3% of Si, 0.3-0.7% of Cu, 0.20-0.60% of Mn, 0.8-1.4% of Mg, 0.05-0.25% of Cr, 0.05-0.2% of Zr, at most 0.5% of Fe, at most 0.2% of Zn, at most 0.1% of Ti, and the balance of Al and impurities. According to the aluminum alloy material aluminum alloy and the heat treatment technique thereof, on the basis of the traditional 6xxx alloy, microelements are added to optimize the content of principal elements; meanwhile, the heat treatment technique is optimized to further enhance the strength and toughness of the aluminum alloy material, thereby implementing organic combination of strength, toughness and corrosion resistance; and the aluminum alloy material can be used instead of 2xxx and 7xxx aluminum alloys in some fields. Thus, the product has favorable application prospects in the fields of aerospace, civil automobiles and the like.

Owner:佛山市三水凤铝铝业有限公司 +1

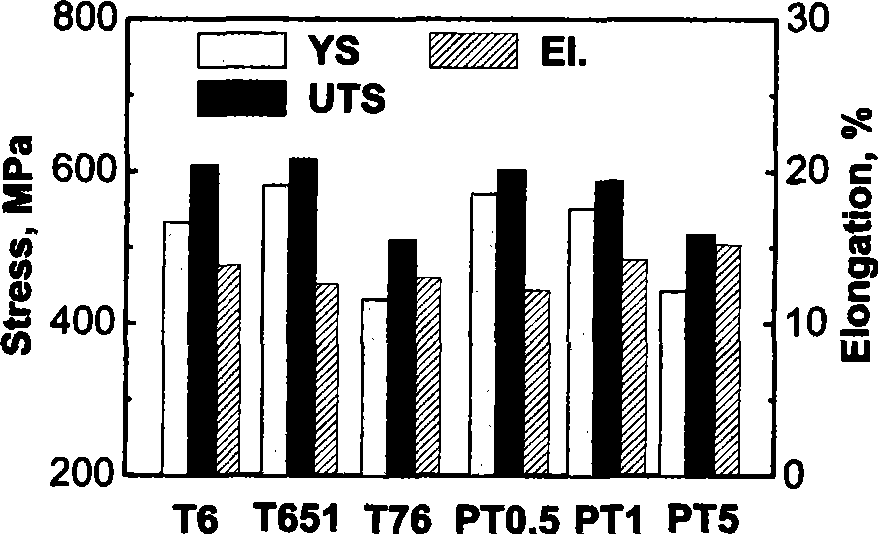

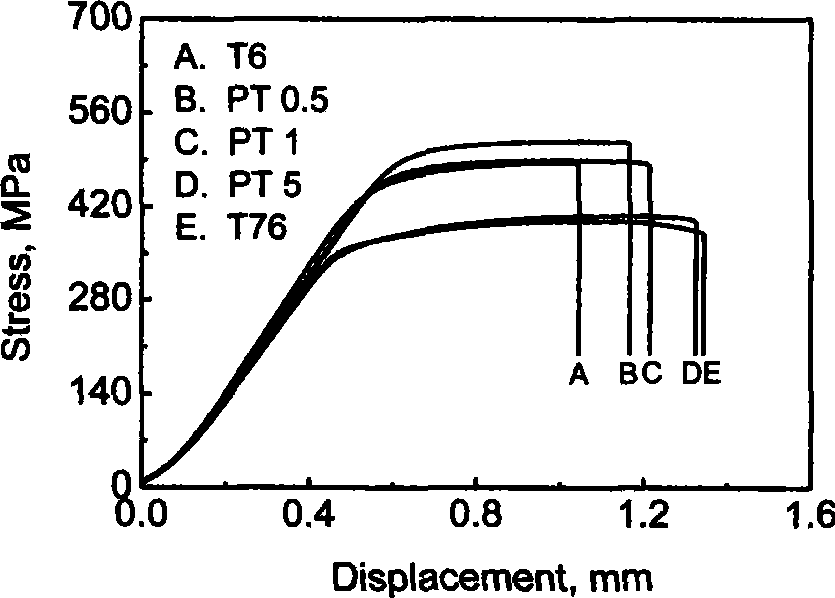

Thermal treatment process for improving high-strength aluminum alloy anti-stress corrosion performance

The invention relates to a heat treatment process for improving the stress corrosion resistance of a high-strength aluminum alloy, which comprises the following treatments on a heat-treatable high-strength aluminum alloy sequentially: solution treatment, primary quenching treatment, pre-stretching treatment, high-temperature and short-time aging treatment, secondary quenching treatment, and low-temperature aging treatment. The alloy treated by the process can achieve adequate strength and good stress corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for manufacturing wind power flange used in low-temperature environment

ActiveCN107058877ASolving the problem of low temperature impact performanceSimple processFurnace typesHeat treatment furnacesElectricityChemical composition

The invention discloses a method for manufacturing a wind power flange used in a low-temperature environment. Chemical components of Q345E is optimized further, so that a forging forming process and a heat treatment process of the wind power flange are optimized; and the technical problem that the impact property of an electric flange at the temperature of -60 DEG C is poor is solved.

Owner:SHANDONG IRAETA HEAVY IND

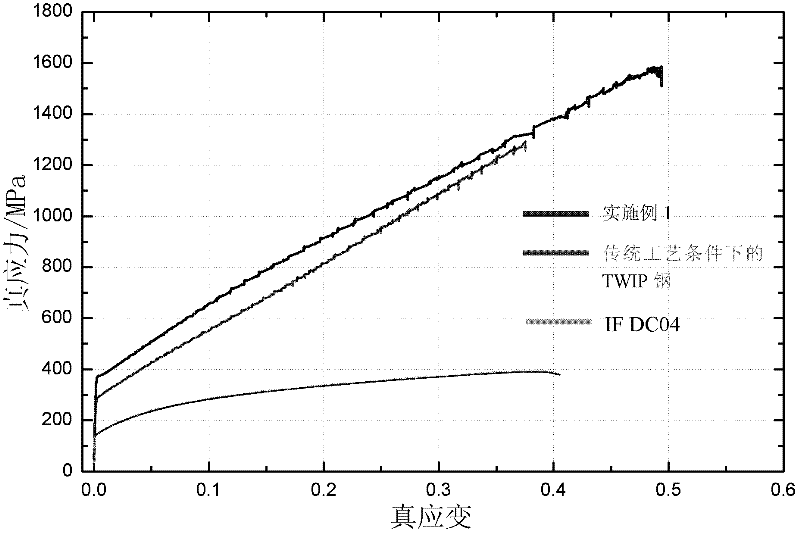

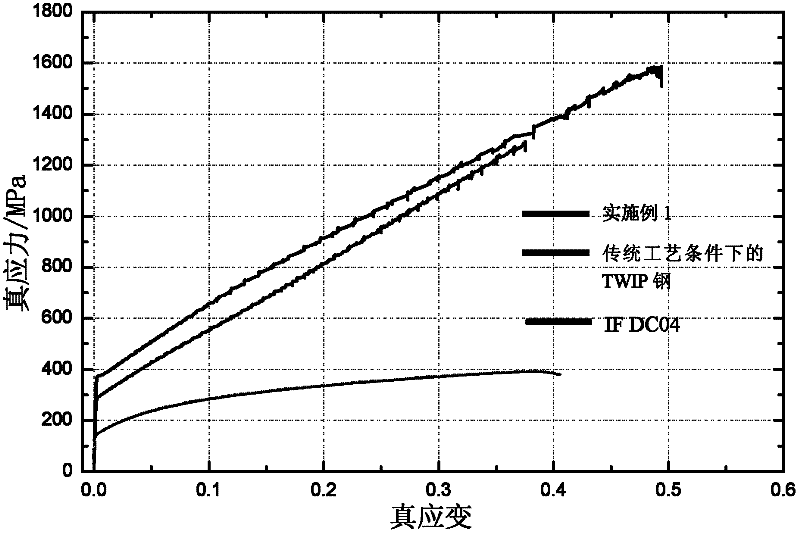

Annealing preparation process for enhancing product of strength and elongation of twinning-induced plasticity high-manganese steel board

The invention belongs to the field of metal material processing, and relates to an annealing preparation process for enhancing a product of strength and elongation of a twinning-induced plasticity (TWIP) high-manganese steel board. The high-manganese TWIP cold-rolled steel board comprises the following components in percentage by mass: 0.06-0.6% of C, not more than 3% of Si, not more than 3% of Al, 22-30% of Mn, not more than 0.1% of P, not more than 0.02% of S, and the balance of iron or inevitable impurities. The high-manganese TWIP cold-rolled steel board is prepared by the preparation steps of: smelting, carrying out die casting or continuous casting, hot rolling, cold rolling and heat treatment, carrying out heat insulation on the cold-rolled board in a heating furnace at 800-1000 DEG C for 0.1-0.5 hour, carrying out short-time heat treatment and rolling process multiple times, and carrying out air cooling to room temperature. According to the invention, by component and process control, the prepared material has superhigh strength and plasticity ratio, the tensile strength can reach 900-1020 MPa, the elongation can reach 70-80% and the strength and plasticity ratio can reach 80000 MPa.%; and the preparation process is simple and feasible as well as economical.

Owner:UNIV OF SCI & TECH BEIJING

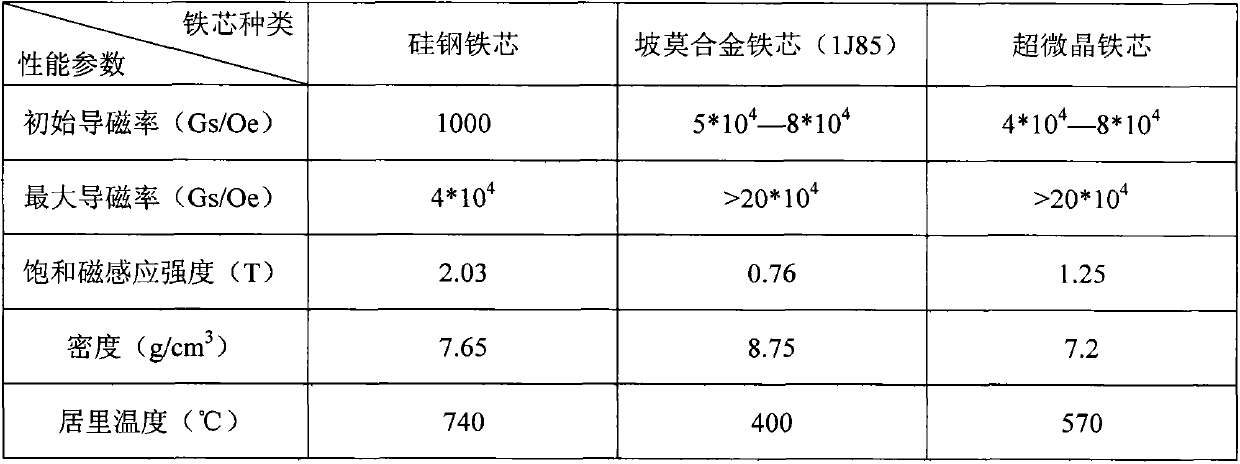

Production process of ultra-crystallite cutting iron core for split mutual inductor

ActiveCN103390492AThe process method is simpleLow costInductances/transformers/magnets manufactureCrystalliteInductor

The invention discloses a production process of an ultra-crystallite cutting iron core for a split mutual inductor. The production process comprises the following steps: a, placing an ultra-crystallite belt material iron core on a winding machine for winding into an iron core, and fixing by spot welding; b, thermally heating the iron core in a gradual temperature rising way, namely, heating to 380 DEG C and preserving heat for 10-50 minutes, heating to 450 DEG C and preserving heat for 10-50 minutes, and heating to 560-600 DEG C and preserving heat for 30-60 minutes; c, rapidly cooling by adopting air cooling till the temperature of the iron core is lowered to 300 DEG C, and controlling the time period from the end of the heat preservation to a moment when the temperature of the iron core falls below 300 DEG C to be within 45 minutes; d, reshaping the iron core, loading into a mold, putting into prepared paint together for soaking in vacuum, and hardening; e, cutting the cured iron core along a symmetrical center line, ensuring the flatness and smoothness of a notch, and eliminating scattering and burrs of the iron core; and f, testing and encapsulating. The process disclosed by the invention has the advantages that the method is simple, a thermal treatment process is improved, a paint soaking step is added, a low-cost and high-performance iron core can be realized, and a very remarkable effect is achieved.

Owner:河北申科电力股份有限公司 +5

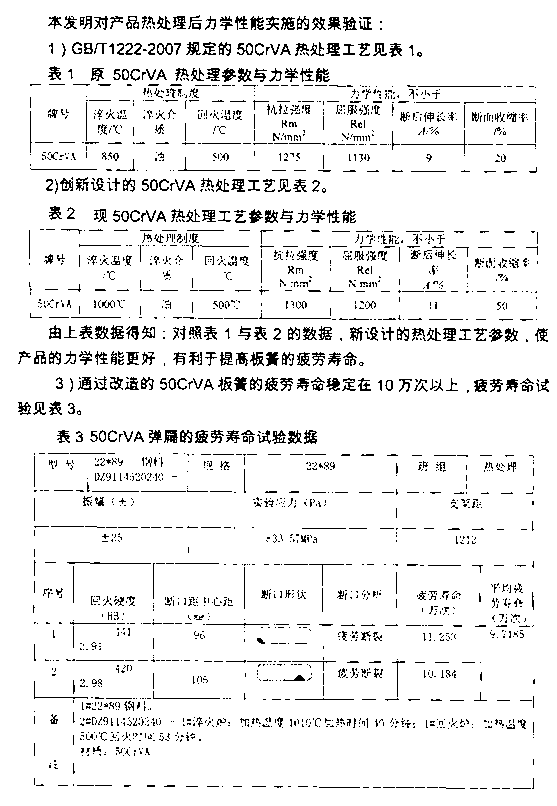

Technique for prolonging fatigue life of 50CrVA plate spring

ActiveCN103014533AGood deoxidation effectAvoid formingFurnace typesHeat treatment furnacesChemical compositionSlag

The invention provides a technique for prolonging the fatigue life of a 50CrVA plate spring. The technique includes the optimal design for the following chemical components of a 50CrVA flat spring steel: 0.49 to 0.53% of C, 0.20 to 0.30% of Si, 0.65 to 0.75% of Mn, 0.90 to 1.05% of Cr, 0.11 to 0.15% of V, 0.006 to 0.009% of Al, 0.018 to 0.020% of P, 0.016 to 0.020% of S, not greater than 0.25% of Ni, and not greater than 0.25% of Cu. The method for controlling and denaturating treatment on nonmetallic inclusion in steel comprises the following steps: (1) sealing a connector between a long nozzle of a large steel ladle and an intermediate submersed nozzle through an argon seal ring; controlling the amount of slag in tapping to 0 to 5kg / t; controlling the weight of the molten steel of the steel ladle to be not less than 7t; and controlling the molten steel level of a crystallizer to fluctuate within the scope of + / -2mm; and (2) carrying out denaturating treatment on inclusion; and adding SiCa wires at 2.1m / t through a wire feeder under a white slag condition, wherein the molten steel is at temperature of 1550 to 1580 DEG C; the parameters in heat treatment of the plate spring include quenching temperature of 1000 DEG C, tempering temperature of 500 DEG C, tensile strength of not less than 1300N / mm<2>, yield strength of not less than 1200N / mm<2>, percentage elongation after fracture of not less than 11%, and percentage reduction of area of not less than 50%.

Owner:XINJIANG BAYI IRON & STEEL

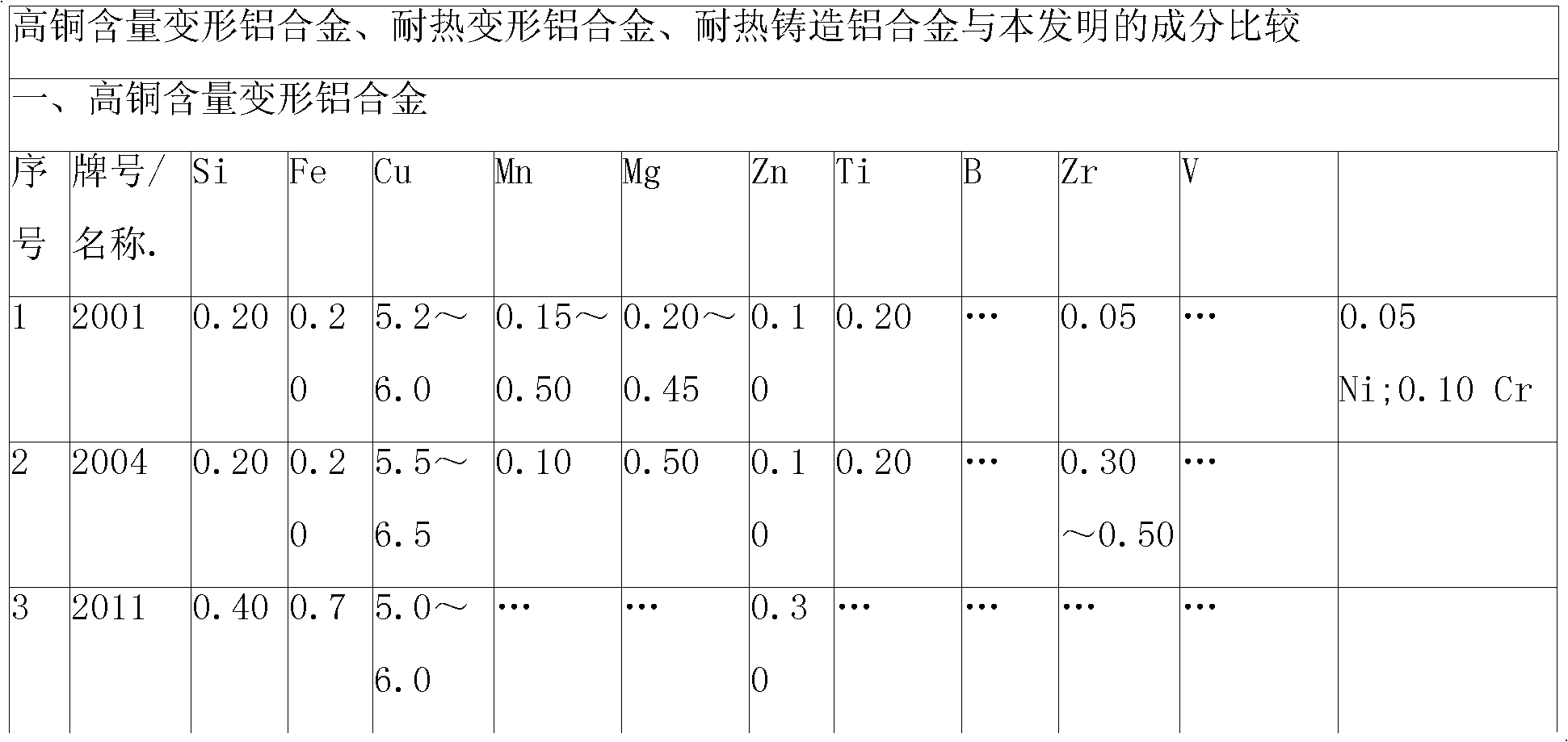

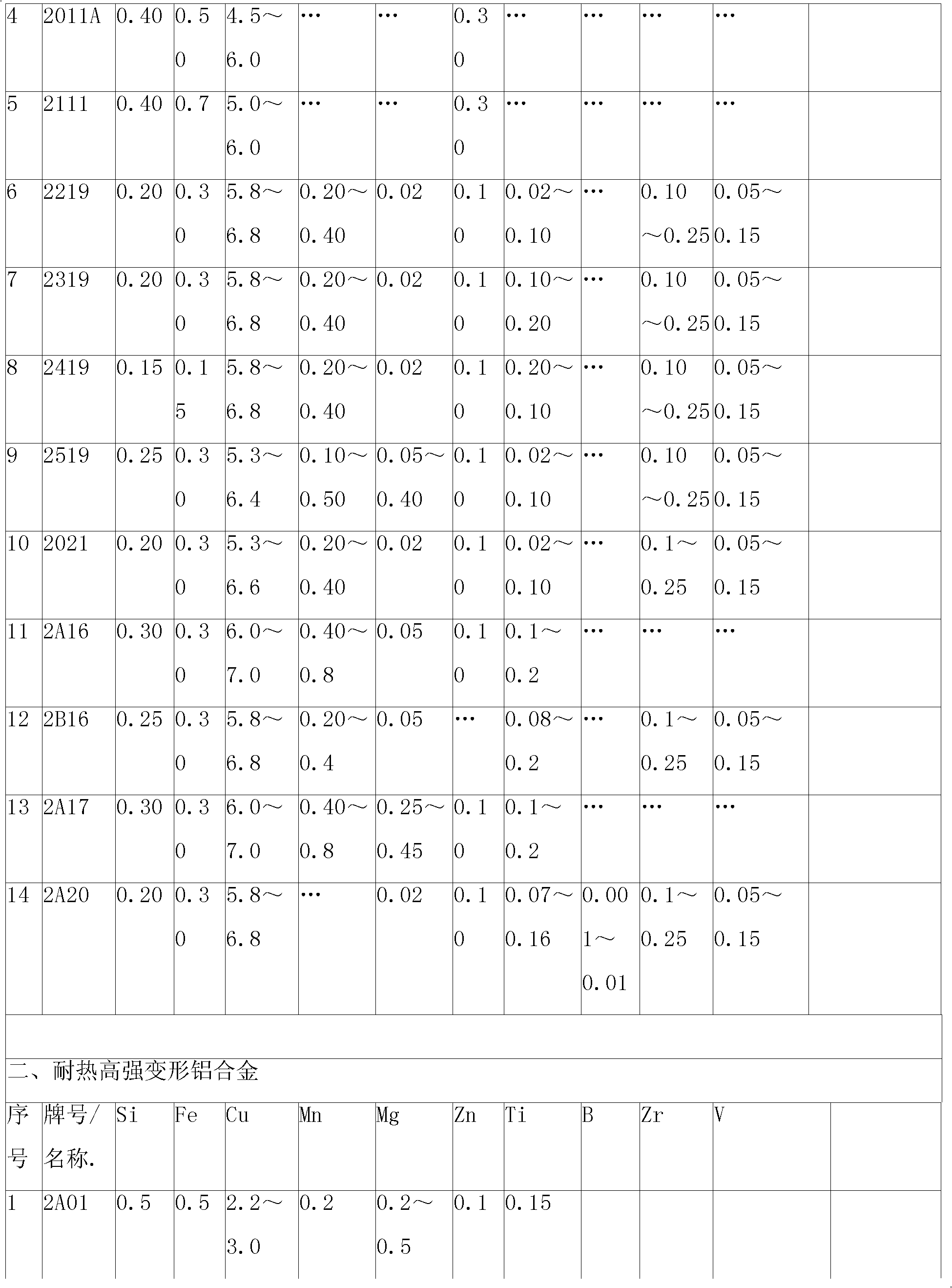

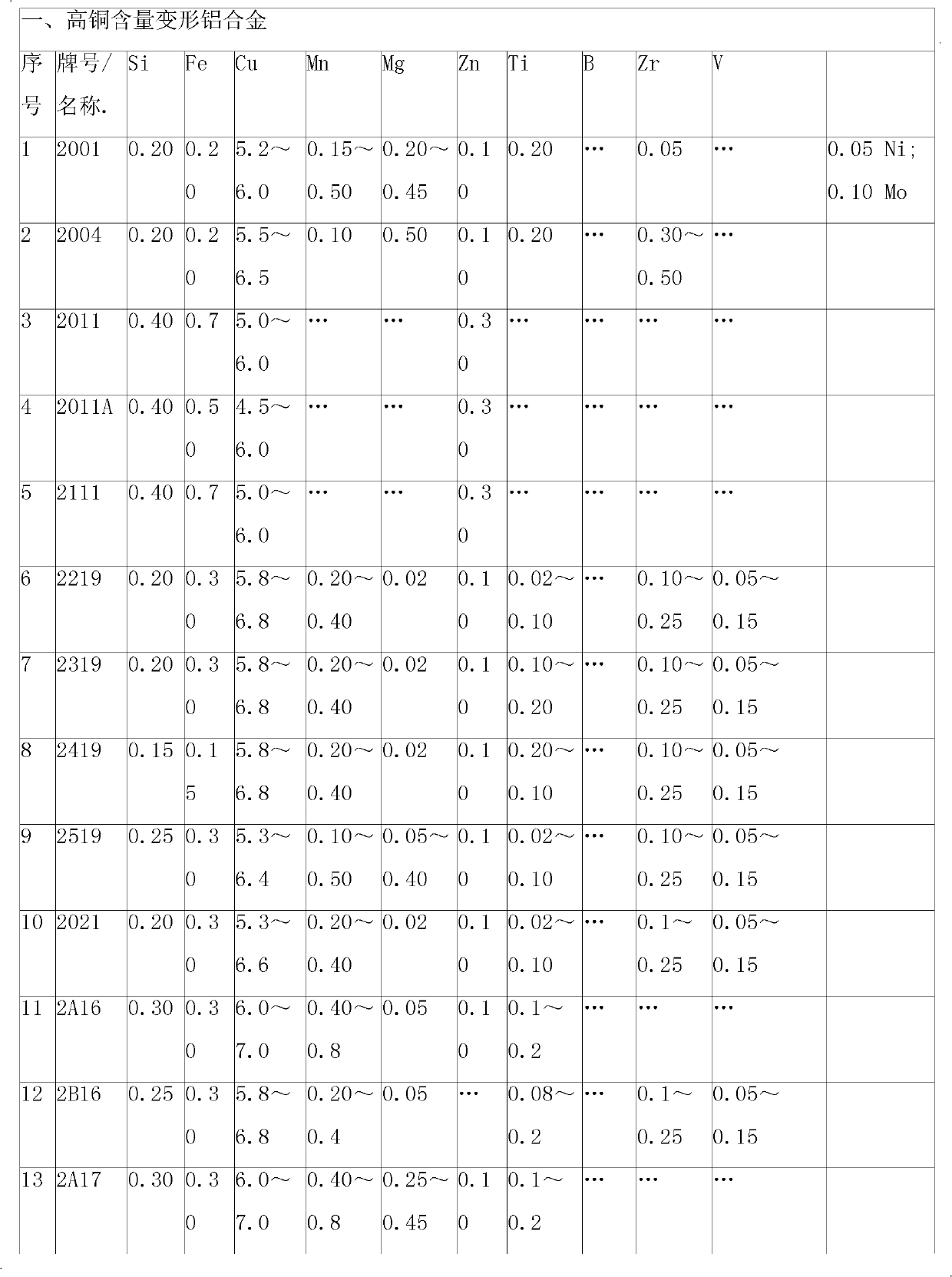

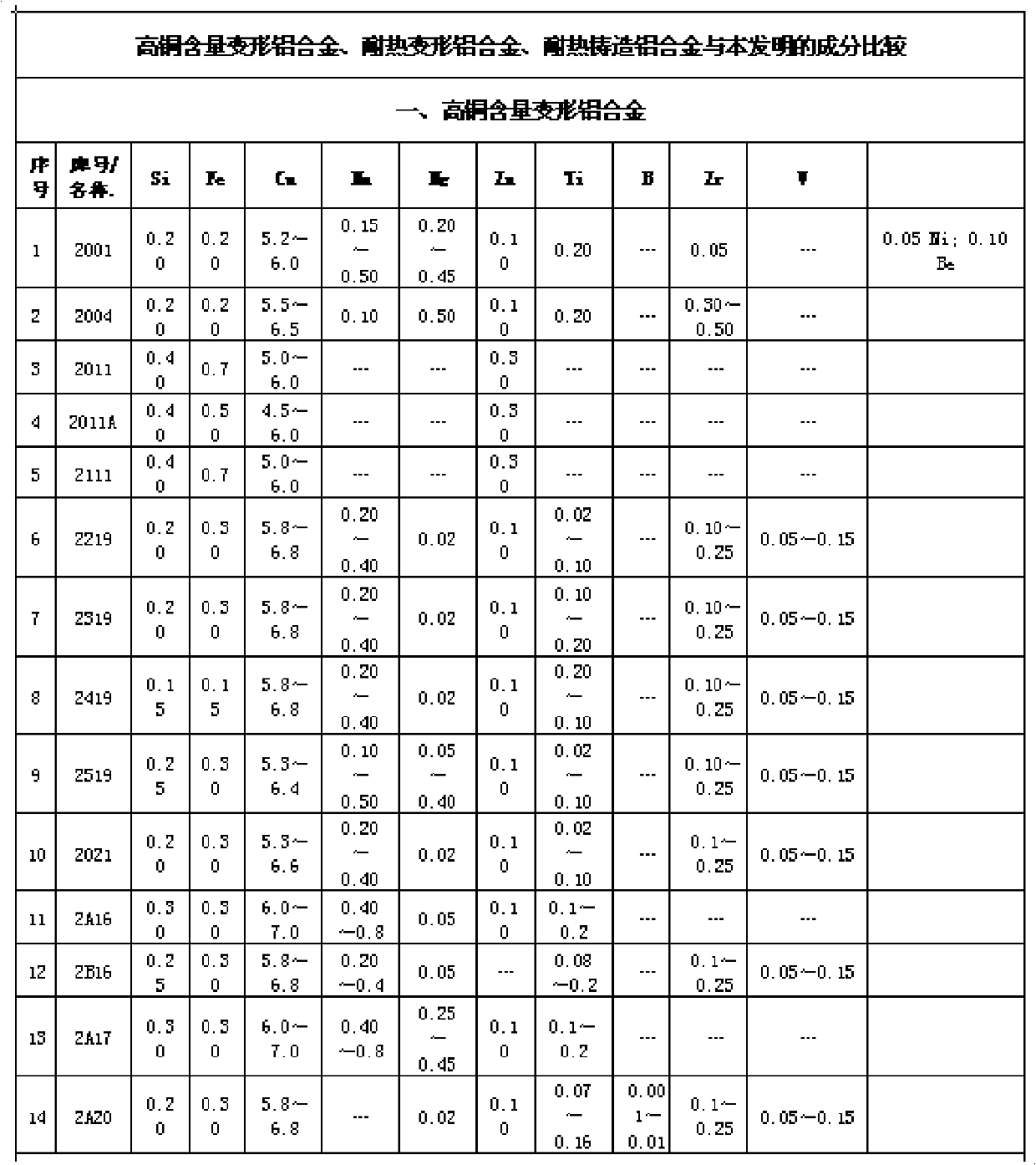

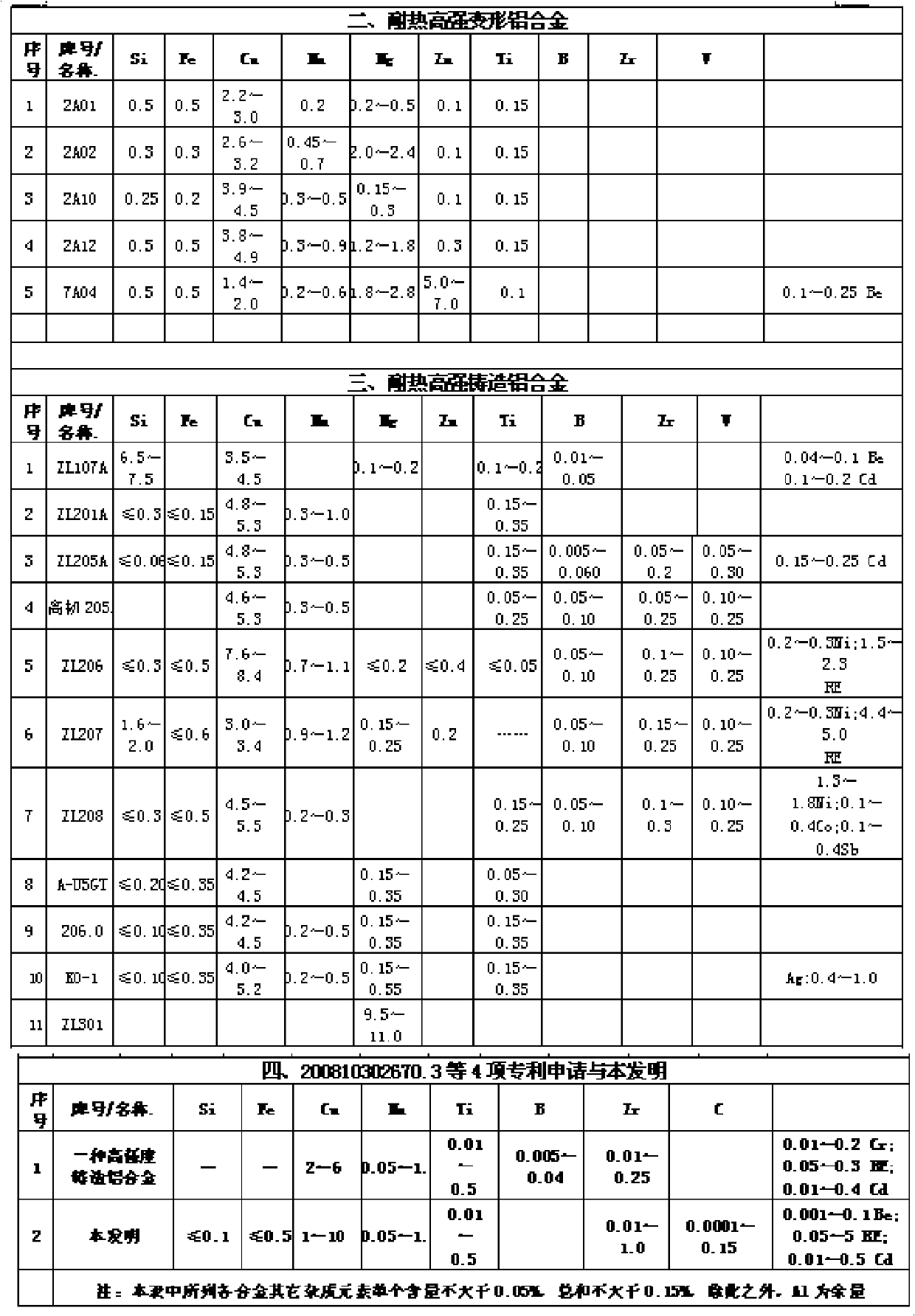

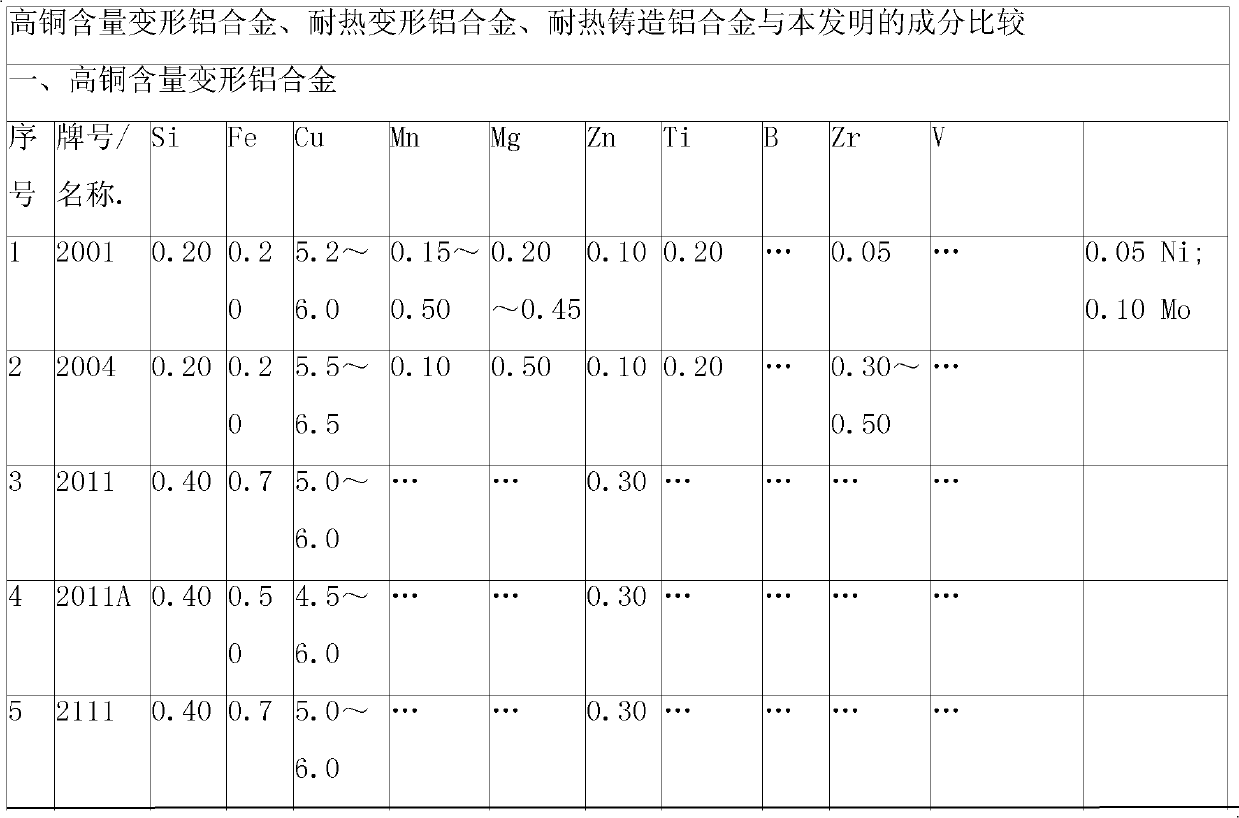

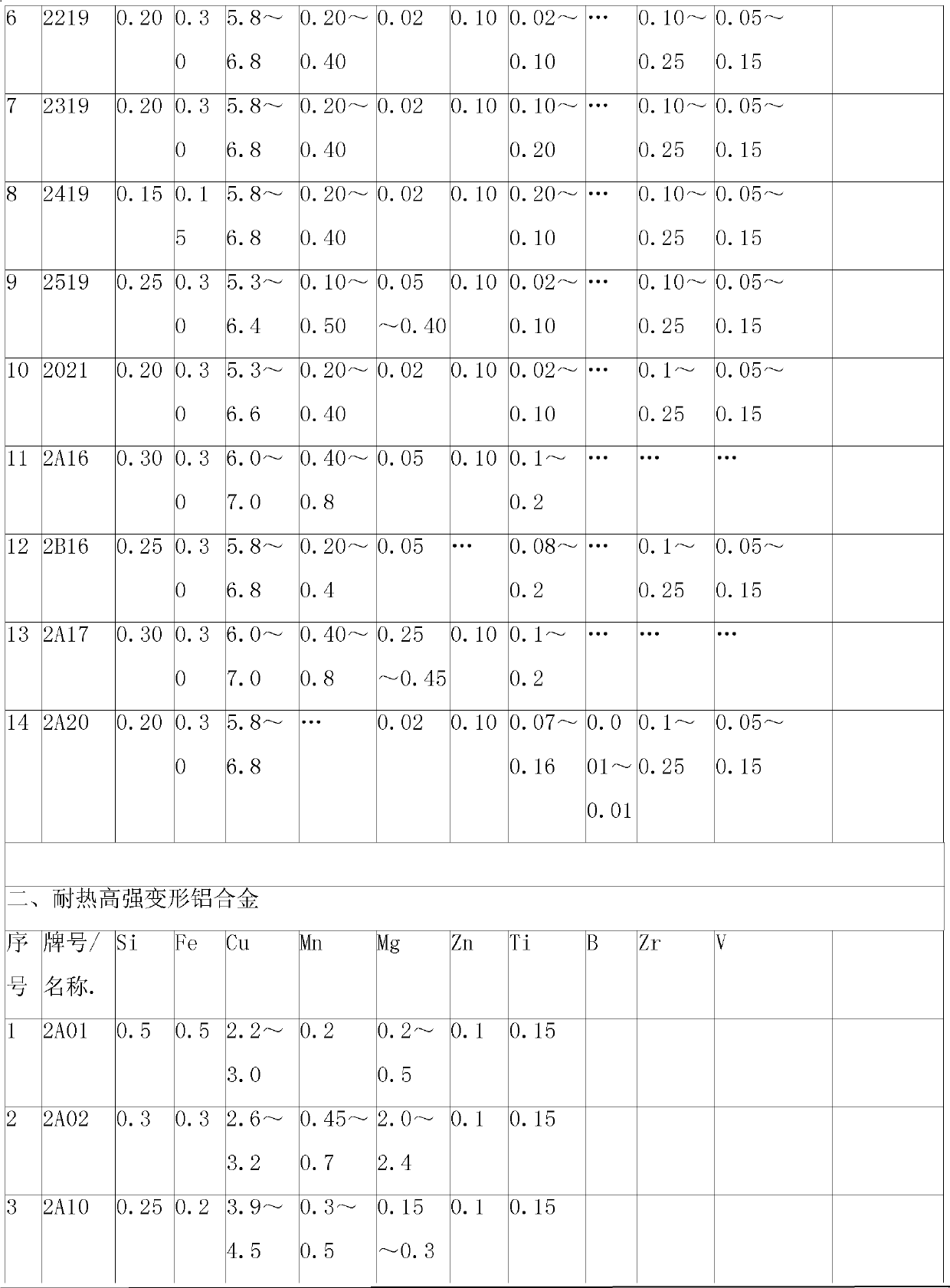

Li-W-RE high-strength heat resistant aluminum alloy material modified with C and preparation method thereof

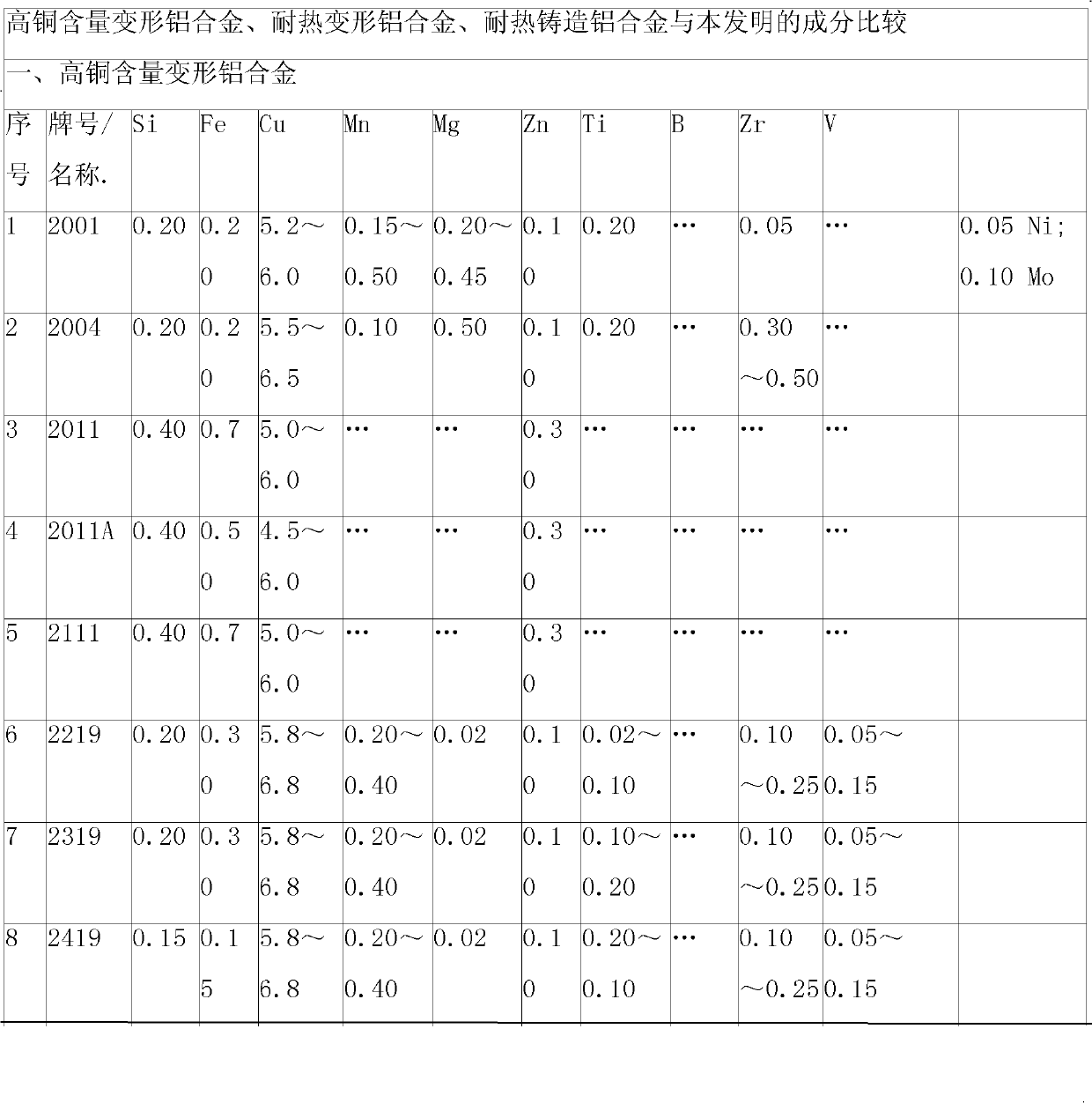

The invention discloses a Li-W-RE high-strength heat resistant aluminum alloy material modified with C. The alloy comprises the following components by weight percent: 1.0 to 10.0 percent of Cu, 0.05 to 1.5 percent of Mn, 0.01 to 0.5 percent of Cd, 0.01 to 0.5 percent of Ti, 0.0001 to 0.15 percent of C, 0.01 to 1.0 percent of Zr, 0.1 to 3.0 percent of Li, 0.01 to 1.0 percent of W, and 0.05 to 5 percent of rare earth element and the rest is Al. Through optimally choosing alloy host element Cu, Mn and RE prescription, the invention reduces alloy quasi-solid phase temperature range and solves the problems of large hot tear tend and low product high temperature strength in the casting process, guided by high quality melt, solid solution and phase diagram theory and taking a C element as modificator. The low cost multiple microalloyed element prescription is optimally choosen. Finally, a high-strength heat resistant aluminum alloy material is developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

12Cr2Mo1R heavy plate under critical hydrogen and heat treatment process thereof

The invention discloses a 12Cr2Mo1R heavy plate under critical hydrogen, which comprises, by weight, 0.12 to 0.15 percent of C, equal to less than 0.10 percent of Si, 0.50 to 0.60 percent of Mn, equal to or less than 0.008 percent of P, equal to or less than 0.005 percent of S, 2.35 to 2.50 percent of Cr, 0.95 to 1.05 percent of Mo, 0.020 to 0.045 percent of Al, 0.013 to 0.020 percent of Nb, equal to or less than 0.15 percent of Cu, equal to or less than 0.003 percent of Sb, equal to or less than 0.015 percent of Sn, equal to or less than 0.016 percent of As, equal to or less than 0.002 percent of O, equal to or less than 0.008 percent of N, equal to or less than 0.0002 percent of H, and the balance Fe as well as unavoidable impurities. The standard of 12Cr2Mo1R heavy plate under critical hydrogen defined by national standard GB 713-2008 has been improved. Constituent elements of 12Cr2Mo1R heavy plate under critical hydrogen and the proportion of the elements have also been optimized. The thickness of the obtained 12Cr2Mo1R heavy plate under critical hydrogen is within 155-170 mm, thereby increasing the thickness of the plate while ensuring the mechanical properties of the plate to be compatible with the standards for plates with a thickness of less than 150 mm defined by national standard 713-2008.

Owner:WUYANG IRON & STEEL +1

High-strength and high-modulus casting Mg-RE alloy and preparation method thereof

The invention provides a high-strength and high-modulus casting Mg-RE alloy and a preparation method thereof. The Mg-RE alloy comprises 2-4wt% of Nd, 1-3wt% of Li, 0.2-0.6wt% of Zn, 2-4wt% of Al, the balance of Mg and inevitable impurities, wherein the total content of Si, Fe, Cu and Ni in the impurities is smaller than 0.02wt%. The preparation method of the Mg-RE alloy includes the sequential steps of vacuum melting and heat treatment. Compared with the prior art, the preparation method has the advantages that the components of the alloy and the heat treatment process are optimized, the optimized alloy component proportion of the alloy is obtained by studying different component proportions of the alloy elements of Nd, Zn, Li and Al, and therefore compared with an existing alloy, the alloy has the better overall performance of room-temperature strength and elasticity modulus under the component proportion and the heat treatment process.

Owner:SHANGHAI JIAO TONG UNIV

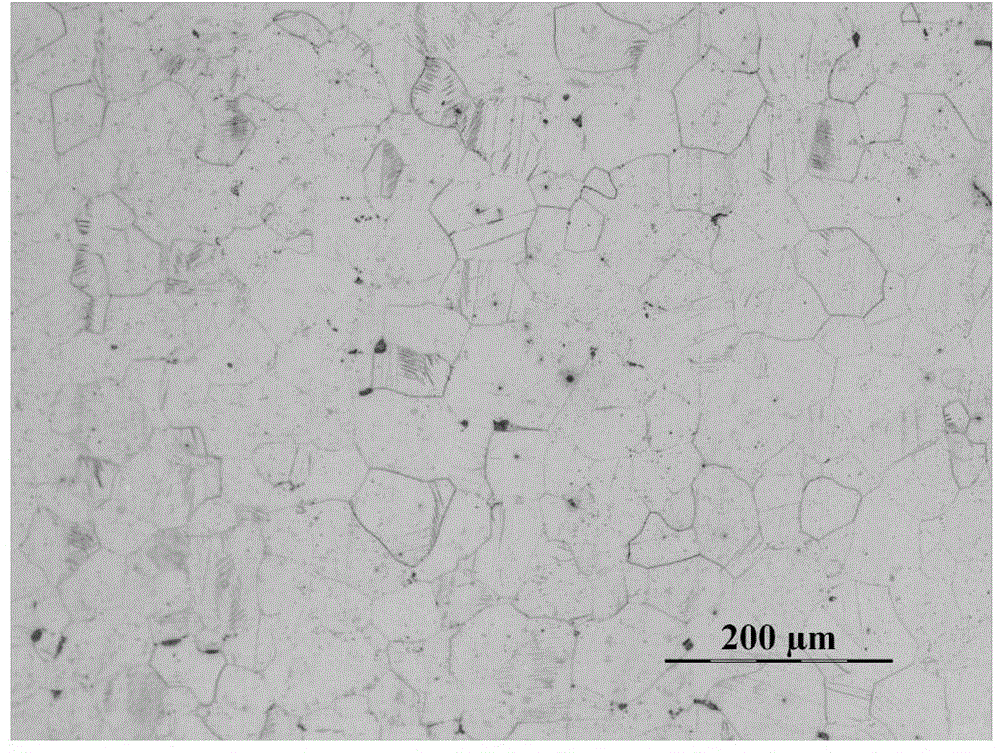

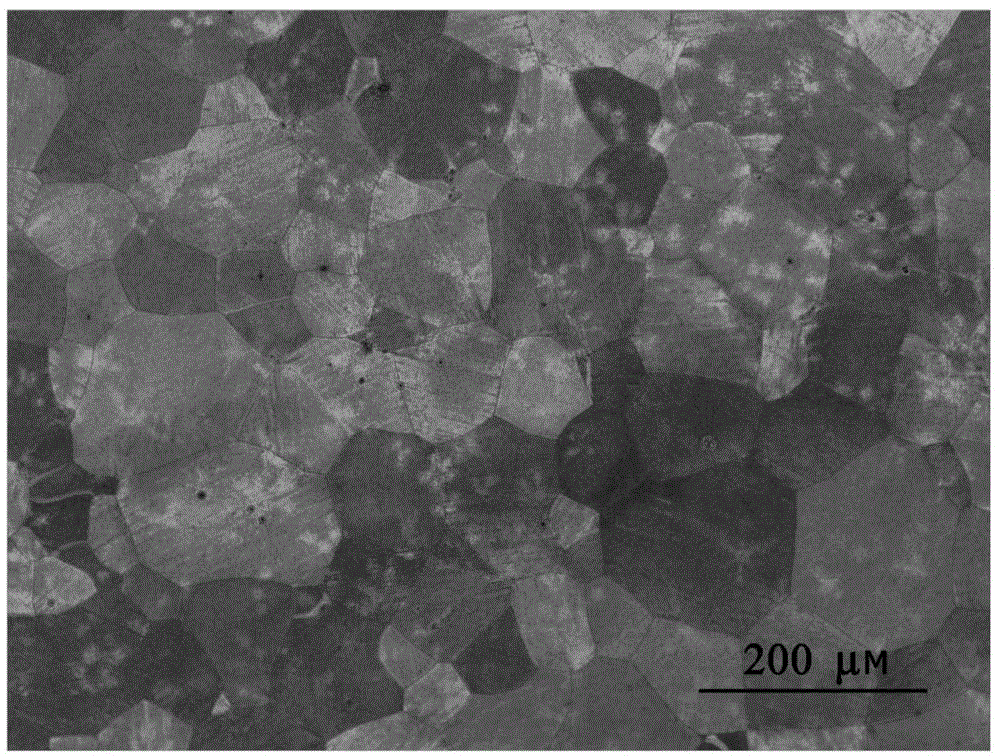

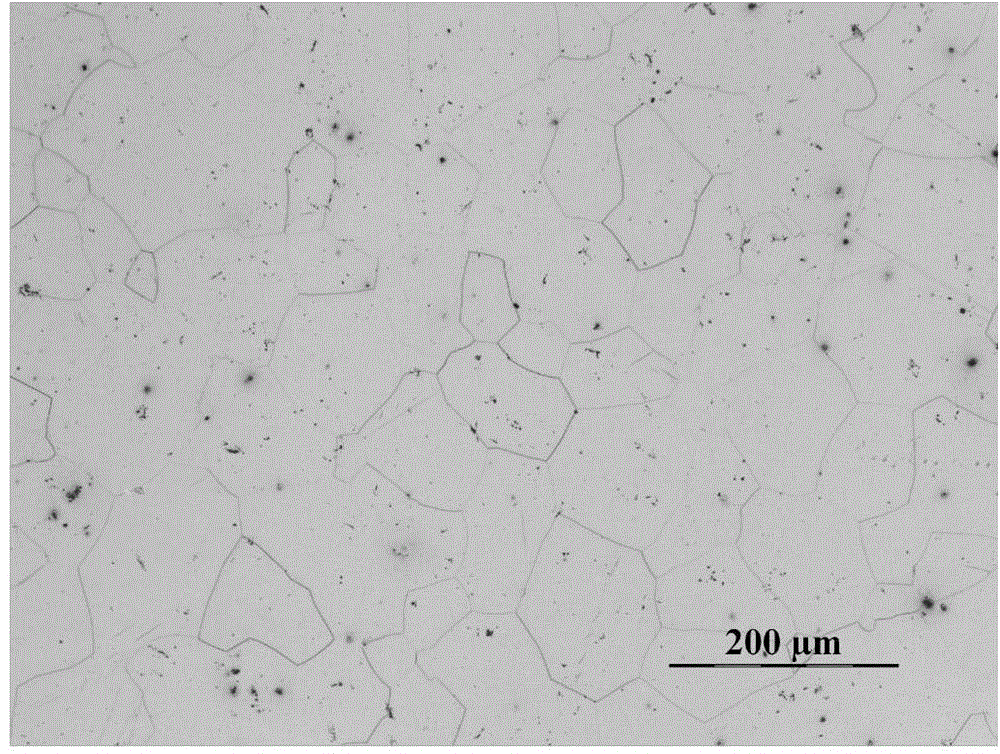

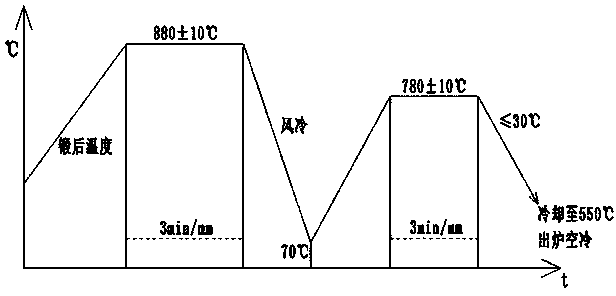

Pre-hardening plastic die steel

ActiveCN103774059AImprove corrosion resistanceImprove anti-corrosion performanceMetallurgyAir cooling

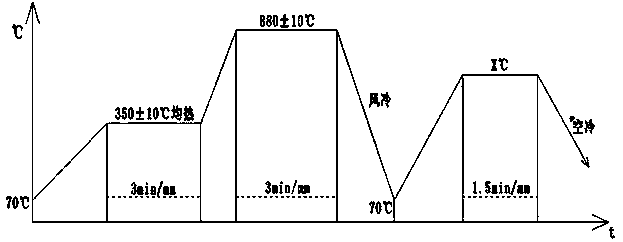

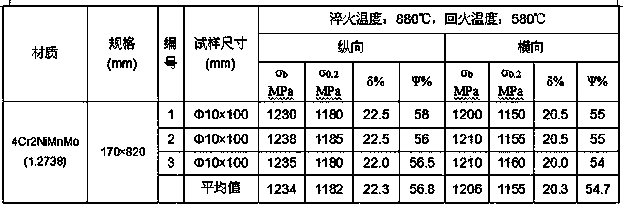

The invention relates to pre-hardening plastic die steel. The preparation method comprises the following steps: adding 0.05-0.15%V of microalloying elements into 4Cr2NiMnMo; after pleiotropic deformation, carrying out fine treatment and pre-hardening treatment, wherein the pleiotropic deformation comprises radial and axial forging deformation of the die steel and transverse and vertical pleiotropic deformation with the forging ratio greater than or equal to 8; the fine treatment comprises the following step: by taking the temperature of the forged die steel with the product thickness as a starting point, heating to 880+ / -10 DEG C; and after insulating at a speed of 3min / mm, discharging and air-cooling to 70 DEG C for spheroidizing annealing, wherein the specific process comprises the following steps: quickly heating to 780+ / -10 DEG C*3min / mm; and then cooling to 550 DEG C for discharging and air cooling at a speed less than or equal to 30 DEG C / h; the pre-hardening treatment comprises the following steps: heating the die steel with the product thickness from 70 DEG C to 350+ / -10 DEG C; insulating at the speed of 3min / mm; then heating to 880+ / -10 DEG C; then, insulating at the speed of 3min / mm; and then air-cooling to 70 DEG C and tempering.

Owner:胡财基

Corrosion-resistant aluminum alloy section bar and preparation method thereof

The invention relates to a corrosion-resistant aluminum alloy section bar and a preparation method thereof. The section bar comprises the components of, by weight, 0.5-0.55% of silicon, 0.5-0.7% of magnesium, 0.05-0.07% of zirconium, 0.2-0.3% of nickel, 0.5-0.9% of copper, 0.6-0.75% of zinc, 0.25-0.35% of boron, 0.1-0.2% of antimony, 0.016-0.026% of lanthanum, 0.35-0.45% of chromium, and balance aluminum. According to the invention, rear earth elements are added into aluminum liquid, such that corrosion resistance and extrusion speed are greatly improved, surface smoothness is improved, material strength is improved, and finished product rate is improved. According to the invention, through preparing silicon alloy blocks and zirconium alloy blocks, aluminum alloy grain structure is improved, the structure of various components of an aluminum alloy ingot is more compact, and aluminum alloy section bar strength and corrosion resistance are improved. Also, a heat treatment process is improved, such that aluminum alloy section bar strength, hardness, wear resistance, and elongation rate are improved. According to testing, the yield strength reaches 240MPa, a tensile strength reaches 294MPa, and an elongation rate is 14%.

Owner:安徽家园铝业有限公司

Ag-RE high-strength high-toughness aluminum alloy material and preparation method thereof

The invention discloses an Ag-RE high-strength high-toughness aluminum alloy material and a preparation method thereof. The alloy comprises the following components in percentage by weight: 1.0 to 10.0 percent of Cu, 0.05 to 1.5 percent of Mn, 0.01 to 0.5 percent of Cd, 0.01 to 0.5 percent of Ti, 0.01 to 0.2 percent of B, 0.01 to 1.0 percent of Zr, 0.01 to 1.0 percent of Ag, 0.05 to 5 percent of RE, and the balance of Al. High-quality melt, solid solution and a phase diagram theory are taken as guidance, and by using a preferable alloy main element formula of Cu, Mn and RE, the quasi solid temperature range of the alloy is reduced, and the problems of large hot tearing tendency in the casting process, low high-temperature strength of products and the like are solved; by using a preferable multielement microalloying element formula, material foundation conditions are created for the cultivation of a strengthening phase in the solid solution and grain refining effect; and the high-strength high-toughness aluminum alloy material is finally manufactured by optimizing smelting and thermal treatment process technology.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

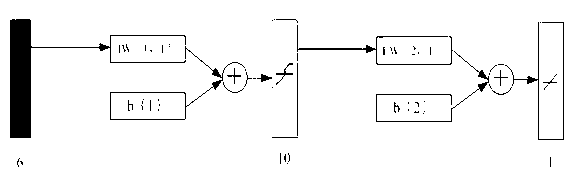

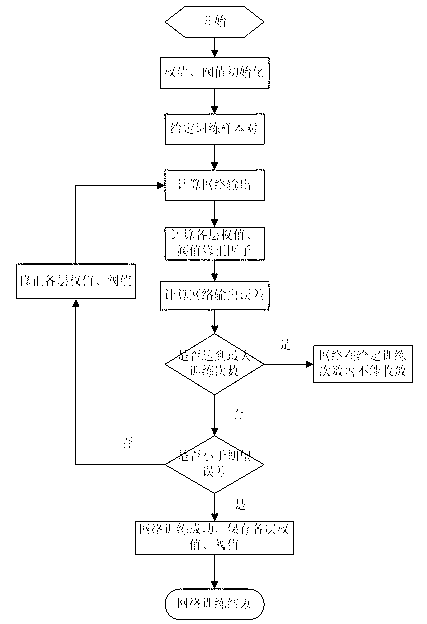

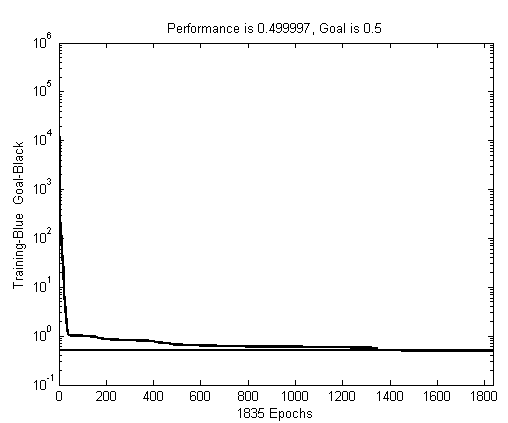

Forecasting method of inner and outer wall temperature difference of 9% Cr martensitic steel thick wall pipeline in heat treatment

ActiveCN102719644AGuarantee the quality of heat treatmentImprove heat treatment efficiencyFurnace typesHeat treatment process controlTemperature controlProcess engineering

The invention relates to a forecasting method of inner and outer wall temperature difference of a 9% Cr martensitic steel thick wall pipeline in heat treatment. The method comprises the following steps of: calculating to obtain inner and outer wall temperature difference data of T groups of pipelines with different dimensions in postweld heat treatment under the conditions of different heating widths, different temperature preservation widths, and different heat treatment environment temperatures and different temperature control temperatures; establishing a neural network based on an error back propagation by comprehensively considering the influence of the pipeline dimensions, the heating widths, the temperature preservation widths, the heat treatment environment temperatures and the temperature control temperatures on the inner and outer temperature difference in postweld heat treatment and training and testing the neural network; and finally, amending by combining the actual tested data to obtain a method for forecasting the inner and outer wall temperature difference of the 9% Cr novel martensitic heat-resistant steel thick wall pipeline in postweld heat treatment. The forecasting method can rapidly calculate the inner and outer wall temperature difference, can help for instructing and optimizing the heat treatment technology, and can improve the heat treatment quality.

Owner:WUHAN UNIV

Ni-RE high-strength heat-resistance aluminum alloy material and preparation method thereof

The invention discloses a high-strength heat-resistance aluminum alloy material and a preparation method thereof. The alloy material comprises the components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.01-2.3% of Ni, 0.05-5% of RE and the balance of Al. By adopting high-quality melt and solid solution and phase diagram principle as guide and preferably choosing alloy main elements Cu, Mn and RE formula, the invention reduces alloy standard solid phase temperature range and solves the problems of large hot crack tendency, low high-temperature strength of products and the like in casting; in addition, by preferably choosing low-cost multielement microalloying element formula, the invention creates material condition for culturing and grain refining of medium-high and strengthening phases of the solid solution; and moreover, by optimizing the melting and heating processing technology, the invention realize sufficient culturing and full play of grain refining of the medium-high and strengthening phases of the solid solution so as to finally prepare the high-strength heat-resistance aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

High-temperature resisting anti-corrosion aluminum alloy section for automobile engine and preparation method of high-temperature resisting anti-corrosion aluminum alloy section

InactiveCN108642354AImprove mechanical propertiesImprove high temperature resistanceMetallic material coating processesImpurityMaterials science

The invention discloses a high-temperature resisting anti-corrosion aluminum alloy section for an automobile engine and a preparation method of the high-temperature resisting anti-corrosion aluminum alloy section. An aluminum alloy base body comprises the following components: Cu, Mn, Cr, Zr, B, Be, Mg, Zn, Si, Fe, Ti, Ni, V, La, Eu and Er and the balance Al and unavoidable impurities. Raw materials of a coating include, by weight, 25-40 parts of TiC, 15-25 parts of NiO and 10-20 parts of TiO2. According to the high-temperature resisting anti-corrosion aluminum alloy section for the automobileengine and the preparation method of the high-temperature resisting anti-corrosion aluminum alloy section, the aluminum alloy section has good mechanical performance and excellent high-temperature resistance and anti-corrosion performance and is long in service life, and the performance of the automobile engine is effectively improved.

Owner:铜陵康达铝合金制品有限责任公司

Large-thickness 14Cr1MoR steel plate and production method thereof

The invention discloses a large-thickness 14Cr1MoR steel plate and a production method thereof. The large-thickness 14Cr1MoR steel plate comprises the following chemical components in percentage by mass: 0.12-0.14% of C, 0.5-0.6% of Si, 0.40-0.50% of Mn, 0.006-0.007% of P, equal to or less than 0.005% of S, 1.3-1.5% of Cr, 0.58-0.60% of Mo, 0.10-0.20% of Ni, equal to or less than 0.05% of Nb, equal to or less than 0.20% of Cu, equal to or less than 0.003% of Sb, equal to or less than 0.010% of Sn, equal to or less than 0.010% of As and the balance of Fe and unavoidable impurities. The production method comprises the procedures of smelting, continuous casting, heating, rolling and thermal treatment. According to the production method, the two-stage rolling control technology and the thermaltreatment technology of normalizing and tempering are adopted to solve the problems that the crystal particles are thick, non-uniform, lower in impact toughness and higher in hardness, and the head performance and the tail performance of the steel plate differ widely.

Owner:WUYANG IRON & STEEL

Sc-Ni-RE high-strength heat-resistant aluminium alloy material and preparation method thereof

InactiveCN102021429AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a Sc-Ni-RE high-strength heat-resistant aluminium alloy material and a preparation method thereof. The Sc-Ni-RE high-strength heat-resistant aluminium alloy material comprises the components in percent by weight: 1.0-10.0 percent of Cu, 0.05-1.5 percent of Mn, 0.01-0.5 percent of Cd, 0.01-0.5 percent of Ti, 0.01-0.2 percent of B, 0.01-1.0 percent of Zr, 0.01-1.0 percent ofNi, 0.01-1.0 percent of Sc, 0.05-5 percent of RE and the balance of Al. With an excellent-quality melt, a solid solution and a phase diagram theory as guidance and through preferably selecting alloy principal elements of Cu, Mn and RE, the invention reduces the alloy quasi solid phase temperature range and solves the problems of large heat cracking tendency, low high-temperature strength of the product, and the like during the casting; and preferably, a multielement microalloying element formula is selected, the material base condition is created for carrying out culturing and grain refining on a high-temperature phase and a strengthening phase in the solid solution, and a high-strength heat-resistant aluminium alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Silicon carbide-enhanced iron/aluminum composite material and preparation method thereof

The invention relates to a composite material, and particularly relates to a silicon carbide-enhanced iron / aluminum composite material and a preparation method thereof. The composite material comprises a silicon carbide reinforcement and an iron / aluminum alloy matrix, wherein the reinforcement accounts for 0.1-1% of total mass; the balance is the iron / aluminum alloy matrix; and the silicon carbide reinforcement is SiC particle and is 1-5nm in particle size. The preparation method comprises the following processes: burdening; preprocessing the silicon carbide reinforcement; smelting; homogenizing annealing; forging; carrying out hot rolling; carrying out wire drawing; and carrying out thermal treatment. The material product prepared by the method has good high-temperature strength and inoxidizability, and low coefficient of thermal expansion, the defects in the prior art are overcome, and the composite material has a good industrial application prospect.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

Boron-carbide-reinforced wear-resistant bainite ductile iron grinding ball and manufacturing method thereof

InactiveCN103225036AReduce manufacturing costOptimize heat treatment processGrain treatmentsWear resistantBoron carbide

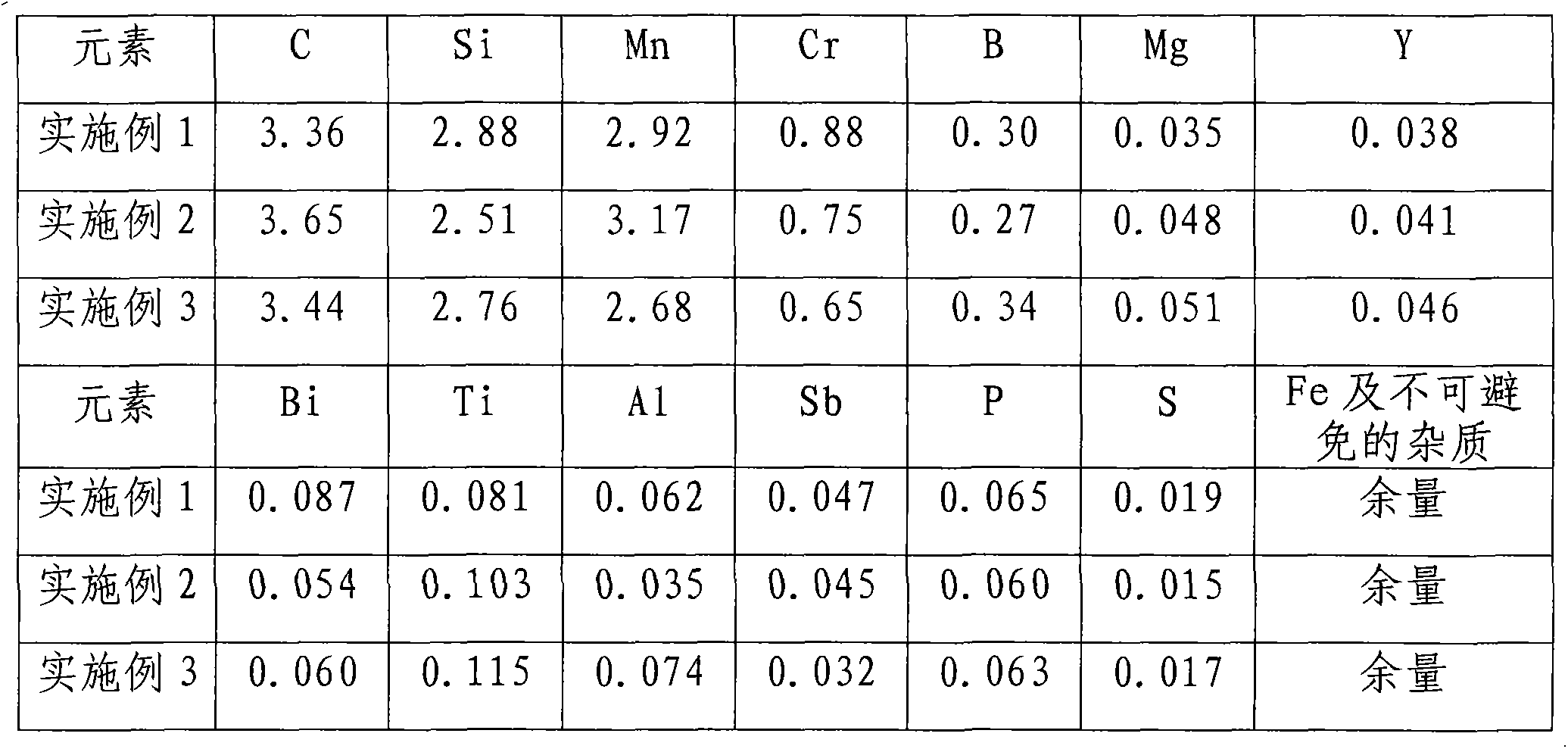

The invention relates to a boron-carbide-reinforced wear-resistant bainite ductile iron grinding ball and a manufacturing method thereof. The invention is characterized in that the grinding ball comprises the following chemical components in percentage by mass: 3.35-3.65% of C, 2.50-2.90 of Si, 2.65-3.20 of Mn, 0.65-0.90 of Cr, 0.25-0.35 of B, 0.03-0.06 of Mg, 0.03-0.05 of Y, 0.05-0.09 of Bi, 0.08-0.12 of Ti, 0.03-0.08 of Al, 0.03-0.05 of Sb, at most 0.08 of P, at most 0.025 of S, and the balance of Fe and inevitable impurities. After being subjected to electric-furnace smelting, metal mold casting and water glass water solution quenching, the grinding ball has the characteristics of high hardness, favorable toughness, low crashing ratio, low abrasion and the like.

Owner:LIAOYUAN JINCHENG HEAVY MINERAL PROCESSING MACHINERY CO LTD

Wear-resistant vanadium-titanium gear and preparation method thereof

InactiveCN105154786AStrong oxidation and corrosion resistanceHigh bending strength and fatigue strengthSolid state diffusion coatingFurnace typesTungstenIsothermal annealing

The invention discloses a wear-resistant vanadium-titanium gear and a preparation method thereof. The wear-resistant vanadium-titanium gear is composed of the following components in percentage by weight: 0.18-0.33% of carbon, 2.3-3.8% of chromium, 0.3-0.5% of manganese, 0.17-0.25% of silicon, 3.8-4.2% of nickel, 1.0-1.8% of tungsten, 1.10-2.15% of vanadium, 1.48-2.57% of titanium, 0.21-0.34% of copper, 1.3-2.1% of molybdenum, 0.18-0.32% of rare earth, 0.0018-0.0041% of boron, at most 0.035% of sulfur and phosphorus, and the balance of iron and inevitable impurities. The method comprises the following steps: preheating treatment, isothermal annealing treatment, primary quenching, primary tempering, carburizing treatment, high-temperature tempering, secondary quenching, secondary tempering and shot blasting. The finally obtained gear has the advantages of high mechanical properties (wear resistance, fatigue resistance, hardness and the like), favorable comprehensive properties and longer service life, and is especially suitable for the high-speed heavy-load high-impact-force occasions with the gear module of greater than 6.

Owner:何鹏

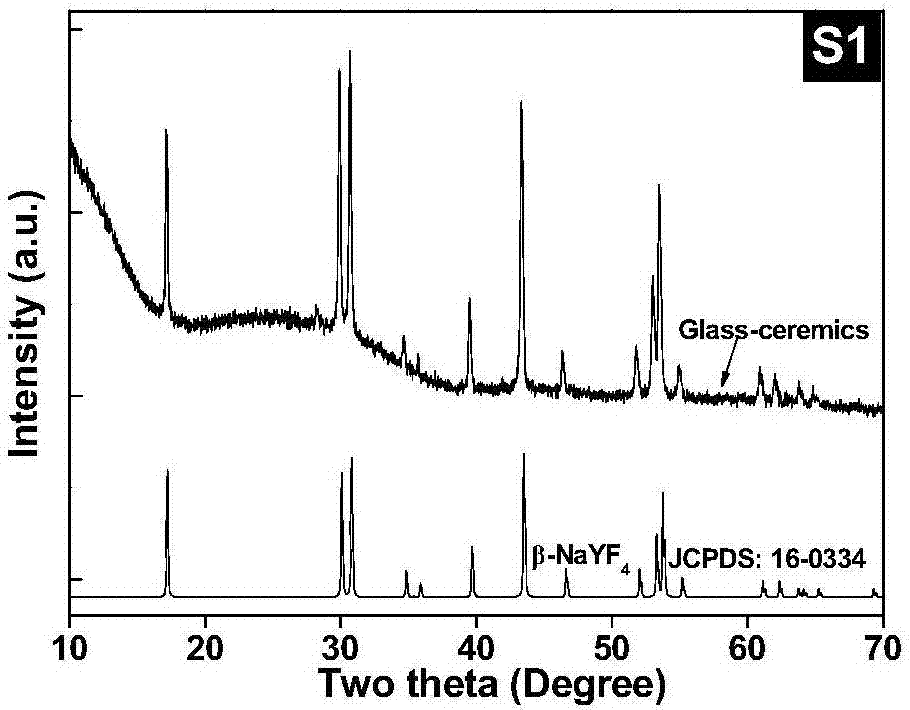

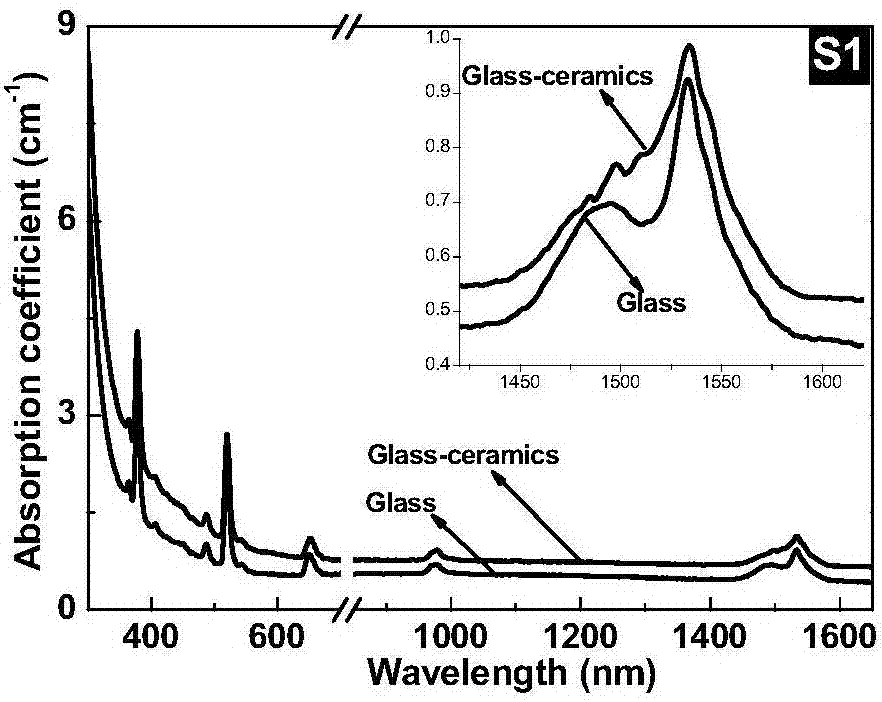

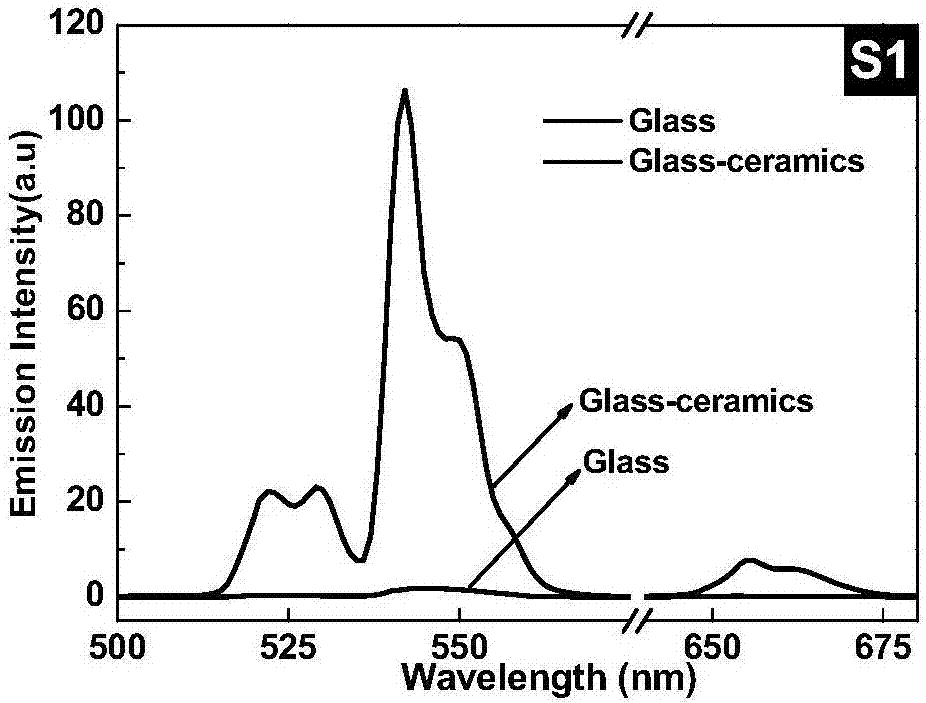

Transparent rare earth ion-doped hexagonal sodium yttrium fluoride oxyfluoride glass-ceramics and preparation method thereof

InactiveCN106946462ARealize precipitationImprove up-conversion luminous efficiencyUpconversion luminescenceRare earth ions

The invention provides a transparent rare earth ion-doped hexagonal sodium yttrium fluoride oxyfluoride glass-ceramics and a preparation method thereof. The glass is prepared from the following compositions: 50-70mol% of SiO2, 3-12mol% of Al2O3, 15-20mol% of Na2O, 5-12mol% of NaF and 5-12mol% of YF3, and a sum of the compositions is 100 percent; and the glass also is prepared from ErF3 which accounts for 0.1-1mol% of the sum of the compositions, wherein the molar content ratio of SiO2 to Al2O3 is larger than 6.5. Compared with silicate glass, the hexagonal sodium yttrium fluoride oxyfluoride glass-ceramics has lower phonon energy (as low as 230cm<-1>), lowers the multi-phonon nonradiative relaxation rate of rare earth ions, and thus enabling the up-conversion luminescence efficiency of the rare earth ions in the glass-ceramics to be obviously improved.

Owner:WUHAN UNIV OF TECH

Heat treatment technique for additive component

InactiveCN107470629AOptimize heat treatment processHigh elongationAdditive manufacturing apparatusPerformance indexQuenching

The invention discloses a heat treatment technique for an additive component. The heat treatment technique for the additive component is used for improving the overall mechanical performance index of the additive component. The heat treatment technique for the additive component comprises the following steps of annealing, specifically, annealing treatment is conducted on the additive component; and quenching, specifically, quenching treatment is conducted on the annealed additive component twice, low-temperature quenching is conducted on the additive component firstly, and then high-temperature quenching is conducted on the additive component. By adoption of the heat treatment technique, the overall mechanical performance index of the additive component can be improved, and the using requirements in the aviation field are met.

Owner:ADVANCED FOR MATERIALS & EQUIP

Ag-Mo-RE high-strength heat-resisting aluminum alloy material and preparation method thereof

InactiveCN102021410AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses an Ag-Mo-RE high-strength heat-resisting aluminum alloy material and a preparation method thereof. The Ag-Mo-RE high-strength heat-resisting aluminum alloy material comprises the following components in percent by weight: 1.0-10.0 percent of Cu, 0.05-1.5 percent of Mn, 0.01-0.5 percent of Cd, 0.01-0.5 percent of Ti, 0.01-0.2 percent of B, 0.01-1.0 percent of Zr, 0.01-1.0 percent of Mo, 0.01-1.0 percent of Ag, 0.05-5 percent of RE and the balance of Al. With an excellent-quality melt, a solid solution and a phase diagram theory as guidance and through preferably selecting alloy principal elements of Cu, Mn and RE, the invention reduces the alloy quasi solid phase temperature range and solves the problems of large heat cracking tendency, low high-temperature strength of the product, and the like during the casting; and preferably, a multielement microalloying element formula is selected, the material base condition is created for carrying out culturing and grain refining on a high-temperature phase and a strengthening phase in the solid solution, and a high-strength heat-resistant aluminium alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Processing method for increasing bamboo durability

InactiveCN107379187AIncreased durabilityGood flexibilityRadiation/waves wood treatmentWood treatment detailsSaline waterMicrowave

The invention discloses a processing method for increasing the bamboo durability. The processing method comprises the following steps of (S1) putting bamboos in saline water so as to be cooked, and taking out so as to clean and air; (S2) performing microwave treatment on materials obtained in the step (S1); (S3) dipping materials obtained in the step (S2) in impregnation liquid, and draining off so as to obtain a material A; and (S4) performing heat treatment on the material A, and then cleaning. According to the processing method for increasing the bamboo durability, the processing technique is optimized, so that the anti-cracking and mothproof performance of bamboo products is effectively improved, and the service life of the bamboo products is effectively prolonged.

Owner:宿松县先盛竹业有限公司

Be-RE high-strength heat-resistant aluminium alloy material with C as modifier and preparation method thereof

ActiveCN102021448AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat-resistant aluminium alloy material and a preparation method thereof. The aluminium alloy material comprises the following components by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.0001-0.15% of C, 0.01-1.0% of Zr, 0.001-0.1% of Be, 0.05-5% of RE and the balance Al. The invention finally develops the high-strength heat-resistant aluminium alloy material by taking the high-quality melt, solid solution and phase diagram theory as the guidance, taking C as the efficient modifier, giving preference to the main alloying elements Cu, Mn and RE as formulas, reducing the temperature range of the quasi-solid phase of the alloys, solving the problems of great hot cracking tendency, low high temperature strength of the products and the like during casting and giving preference to multiple microalloying elements with low cost as formulas to create basic material conditions for cultivation and grain refining functions ofthe high temperature phase and strengthening phase in the solid solution.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

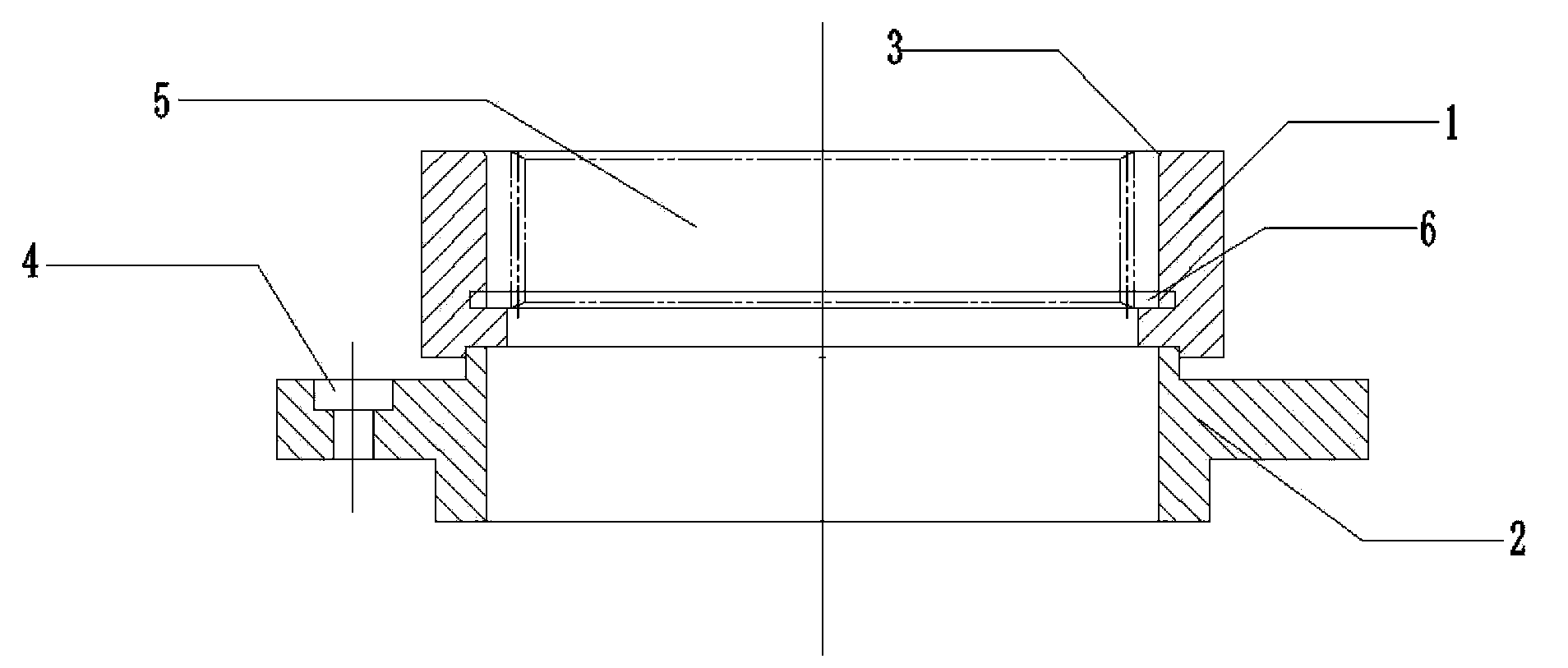

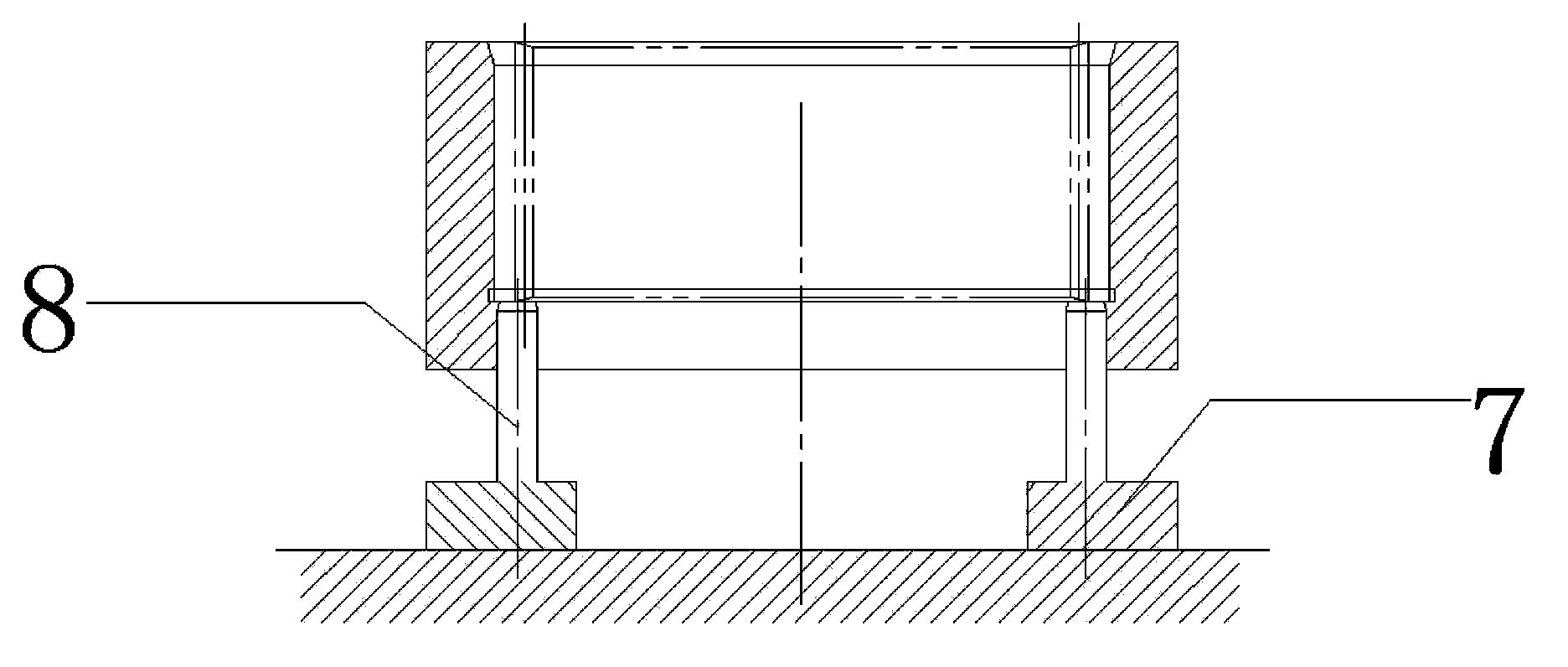

Device for machining thin-walled gear ring broaching

InactiveCN103659352AControl Broaching Stress Deformation and TaperSimple heat treatment processMetal working apparatusPositioning apparatusThin walledHeat processing

The invention provides a device for machining thin-walled gear ring broaching. The device for machining the thin-walled gear ring broaching comprises a thin-walled gear ring fixation part and a connection fixation block which connects a thin-walled gear ring fixation device and an operation platform. The thin-walled gear ring fixation part is of a cylindrical structure and an upper groove matched with a thin-walled gear ring is formed in the thin-walled gear ring fixation part. The depth of the upper groove is larger than the thickness of the thin-walled gear ring to be machined. A groove is formed in the bottom. The upper portion of the connection fixation block of the operation platform is provided with a protruding portion matched with the bottom of the thin-walled gear ring fixation part. The connection fixation block further comprises a through hole. By means of the technical scheme, the problems of the thin-walled gear ring that deformation is excessively large in a broaching process, plastic deformation is caused and broaching taper is caused by plastic deformation are solved, broaching stress and production of taper can be effectively controlled, and the subsequent heat processing technology is more convenient to perform. Meanwhile, the device for machining the thin-walled gear ring broaching has the advantages of being simple in structure, convenient to maintain, low in machining cost and the like.

Owner:天津天海同步科技有限公司

Ag-Cr-RE high-strength heat-resistant aluminium alloy material with C as modifier and preparation method thereof

InactiveCN102021384AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses an Ag-Cr-RE high-strength heat-resistant aluminium alloy material with C as a modifier and a preparation method thereof. The aluminium alloy material comprises the following components by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.0001-0.15% of C, 0.01-1.0% of Zr, 0.01-1.0% of Ag, 0.01-1.0% of Cr, 0.05-5% of RE and the balance Al. The invention finally develops the high-strength heat-resistant aluminium alloy material by taking the high-quality melt, solid solution and phase diagram theory as the guidance, giving preference to the main alloying elements Cu, Mn and RE as formulas, reducing the temperature range of the quasi-solid phase of the alloys, taking C as the efficient modifier, solving the problems of great hot cracking tendency, low high temperature strength of the products and the like during casting and giving preference to multiple microalloying elements as formulas.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

High-strength low-abrasion abrasion-resisting ball used for ball mill and preparation method of high-strength low-abrasion abrasion-resisting ball

InactiveCN107739994AGood toughening effectStrengthen the toughening effect, effectively improve the wear resistance of wear-resistant ballsMetallic material coating processesHigh intensityBall mill

The invention discloses a high-strength low-abrasion abrasion-resisting ball used for a ball mill and a preparation method of the high-strength low-abrasion abrasion-resisting ball. The high-strengthlow-abrasion abrasion-resisting ball used for the ball mill comprises a cladding layer and an abrasion-resisting ball base body, and the abrasion-resisting ball base body comprises the following components of C, B, Ti, Mg, Si, W, Cr, Mn, Ni, V, Zr, Nb, Mo, Ce, Nd, Sm, Er and the balance Fe and inevitable impurities. According to the high-strength low-abrasion abrasion-resisting ball used for the ball mill and the preparation method of the high-strength low-abrasion abrasion-resisting ball, through optimization of the matching ratio and a preparation technology, the high-strength low-abrasion abrasion-resisting ball has the advantages of being large in impact toughness, good in corrosion resistance, large in strength, small in abrasion and the like, and the working efficiency of the abrasion-resisting ball is effectively improved.

Owner:蚌埠市光辉金属加工厂

Corrosion resisting low-abrasion coating abrasion-resisting ball for ball mill and preparation method of corrosion resisting low-abrasion coating abrasion-resisting ball

InactiveCN109023086AReduce wearAccelerated corrosionMetallic material coating processesProcess efficiency improvementManganeseBall mill

The invention discloses a corrosion resisting low-abrasion coating abrasion-resisting ball for a ball mill and a preparation method of the corrosion resisting low-abrasion coating abrasion-resisting ball. The corrosion resisting low-abrasion coating abrasion-resisting ball for the ball mill is composed of an abrasion-resisting ball base body and a coating wrapping the surface of the abrasion-resisting ball base body. The abrasion-resisting ball base body comprises the following components: C, B, Mg, Al, Si, Mn, Cr, Zr, Mo, Ni, V, Ti, Nb, Ce, Y and the balance Fe and unavoidable impurities. Coating raw materials include nano ceramic powder, nickel powder and manganese powder. According to the corrosion resisting low-abrasion coating abrasion-resisting ball for the ball mill and the preparation method of the corrosion resisting low-abrasion coating abrasion-resisting ball, by optimizing a formula and a preparation process, the obtained product is good in corrosion resistance and mechanical performance, low in abrasion and long in service life.

Owner:ANHUI NINGGUO NINGHU STEEL BALL

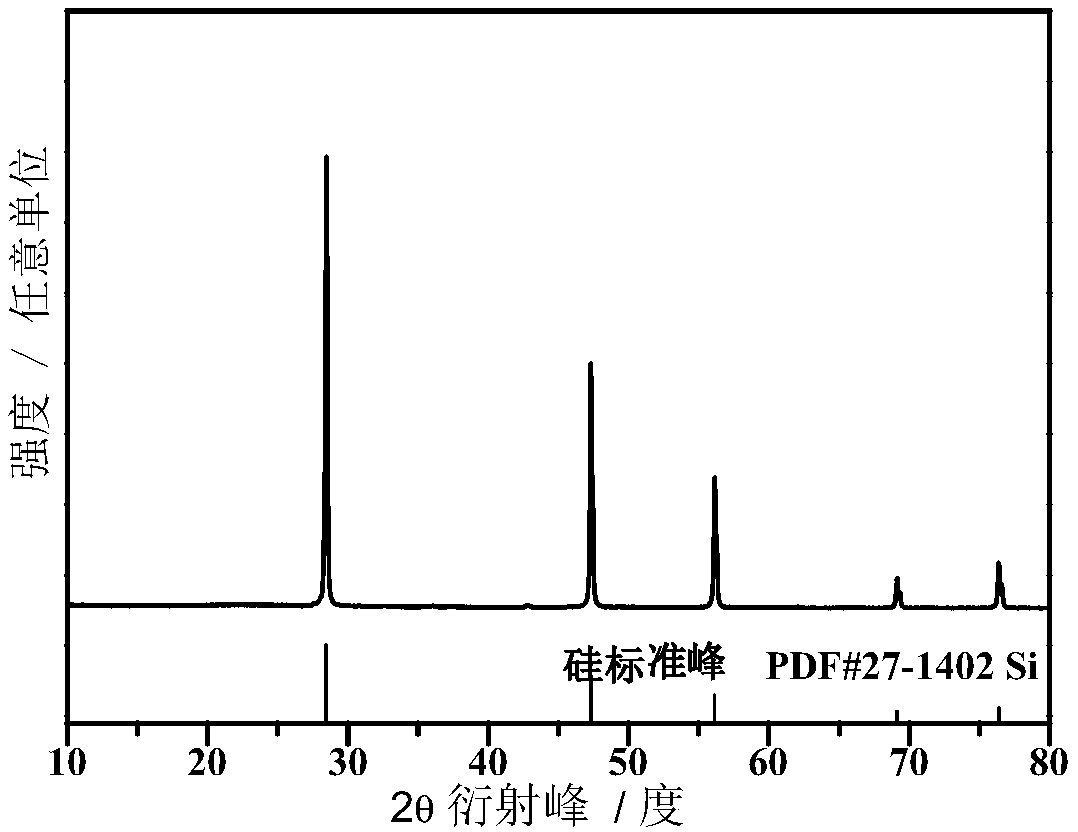

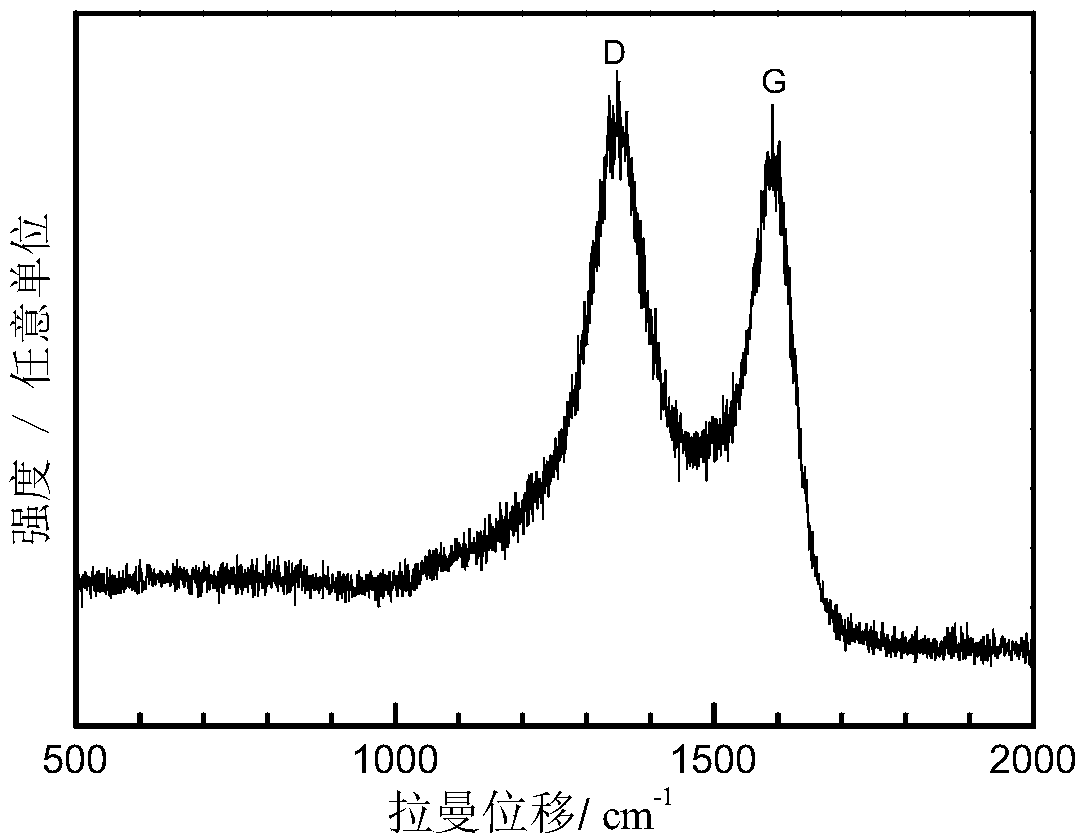

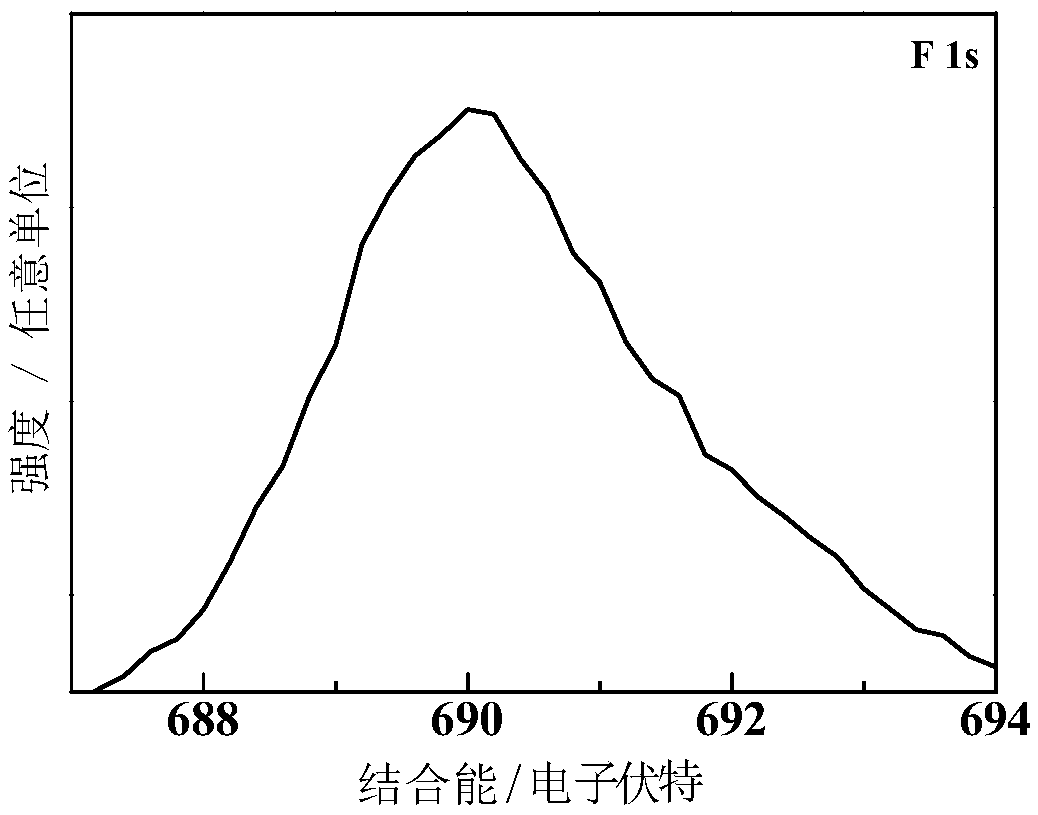

Surface-modified silicon-carbon composite material and preparation method and application thereof

InactiveCN109546122AImprove conductivityAvoid contactCell electrodesSecondary cellsCarbon compositesCarbon coating

The invention discloses a surface-modified silicon-carbon composite material and a preparation method and application thereof. The preparation method comprises the following steps: purifying commercial coarse silicon, enabling the purified commercial coarse silicon to react with magnesium to obtain a magnesium-silicon alloy, carrying out thermal decomposition of the magnesium-silicon alloy to obtain nano-silicon, carrying out in-situ carbon coating to obtain a silicon-carbon nano-material, and compounding the nano-silicon carbon with fluoride through ball milling to obtain a silicon-based composite material. Compared with the prior art, the method provided by the invention is low in energy consumption, low in cost, short in period and beneficial to large-scale production. According to themethod, the volume change of silicon in the lithiation / delithiation process can be buffered, and the contact between silicon particles and the electrolyte can be prevented, so that the silicon is prevented from being corroded by the electrolyte, and the diffusion of lithium ions from the liquid electrolyte to the silicon particles is not influenced. The prepared surface fluoride modified silicon-carbon composite material is high in capacity, is high in initial coulombic efficiency, and is excellent in cycle performance.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com